Patents

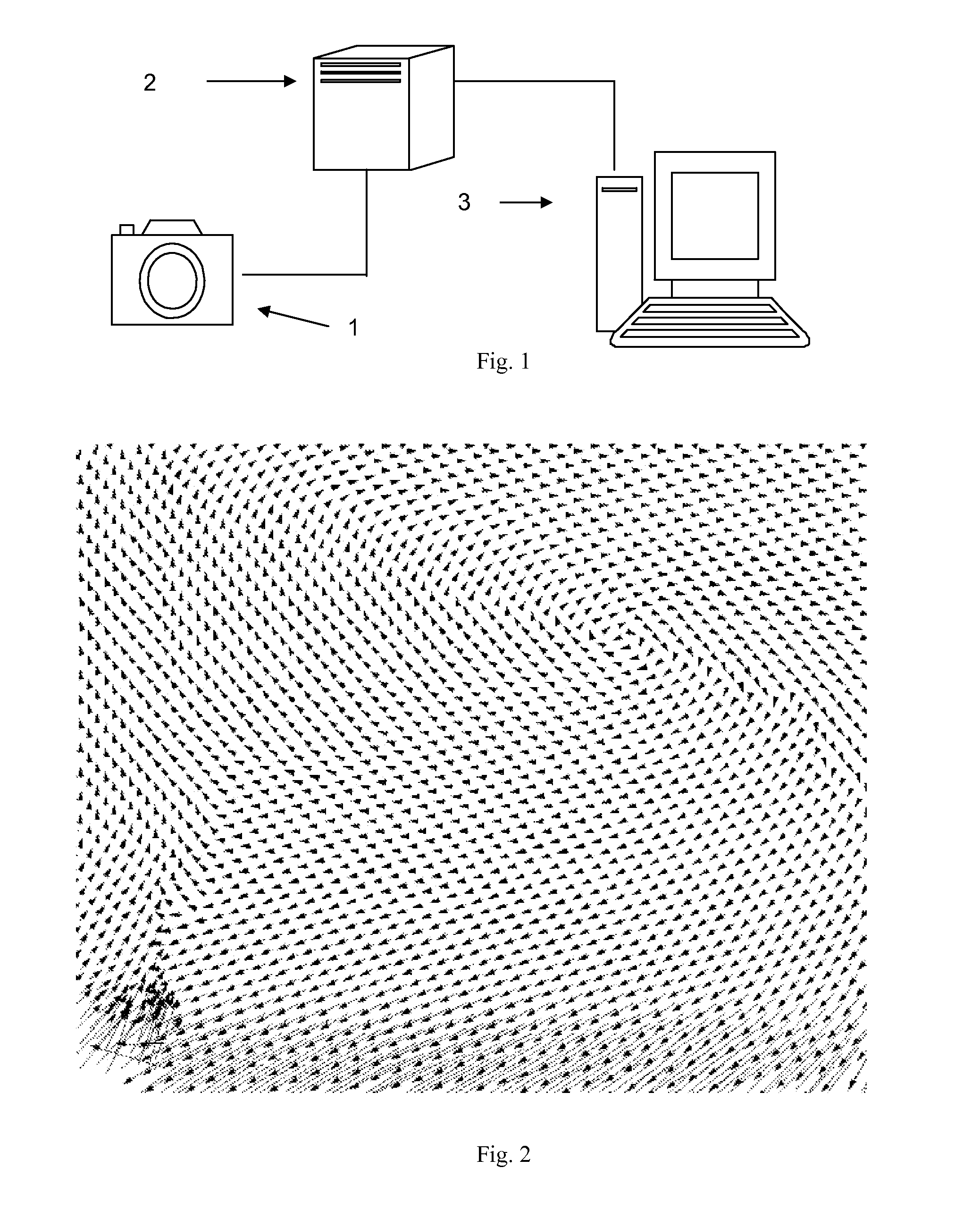

Literature

64 results about "Speckle correlation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

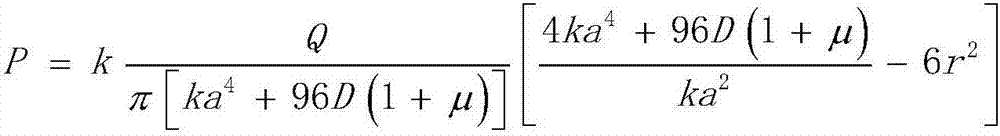

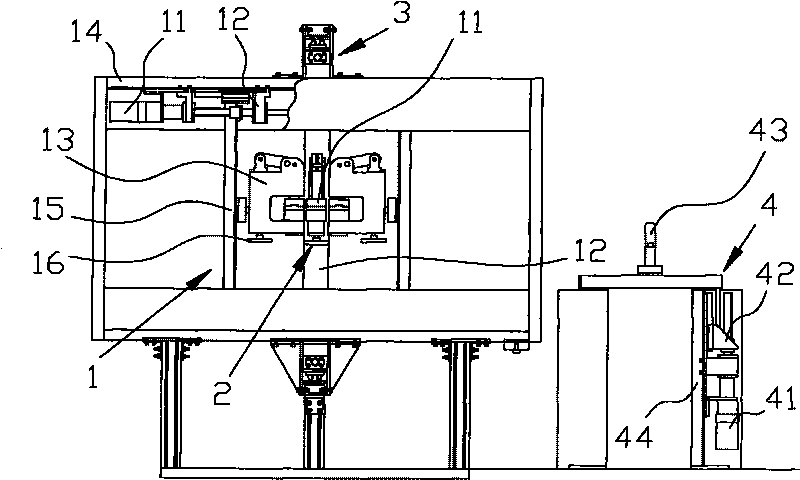

Device for detecting mechanical property of multifunctional film

ActiveCN101788427AHigh measurement accuracyMeasuring field of view can be adjustedMaterial strength using tensile/compressive forcesUsing optical meansElastic plasticSpeckle correlation

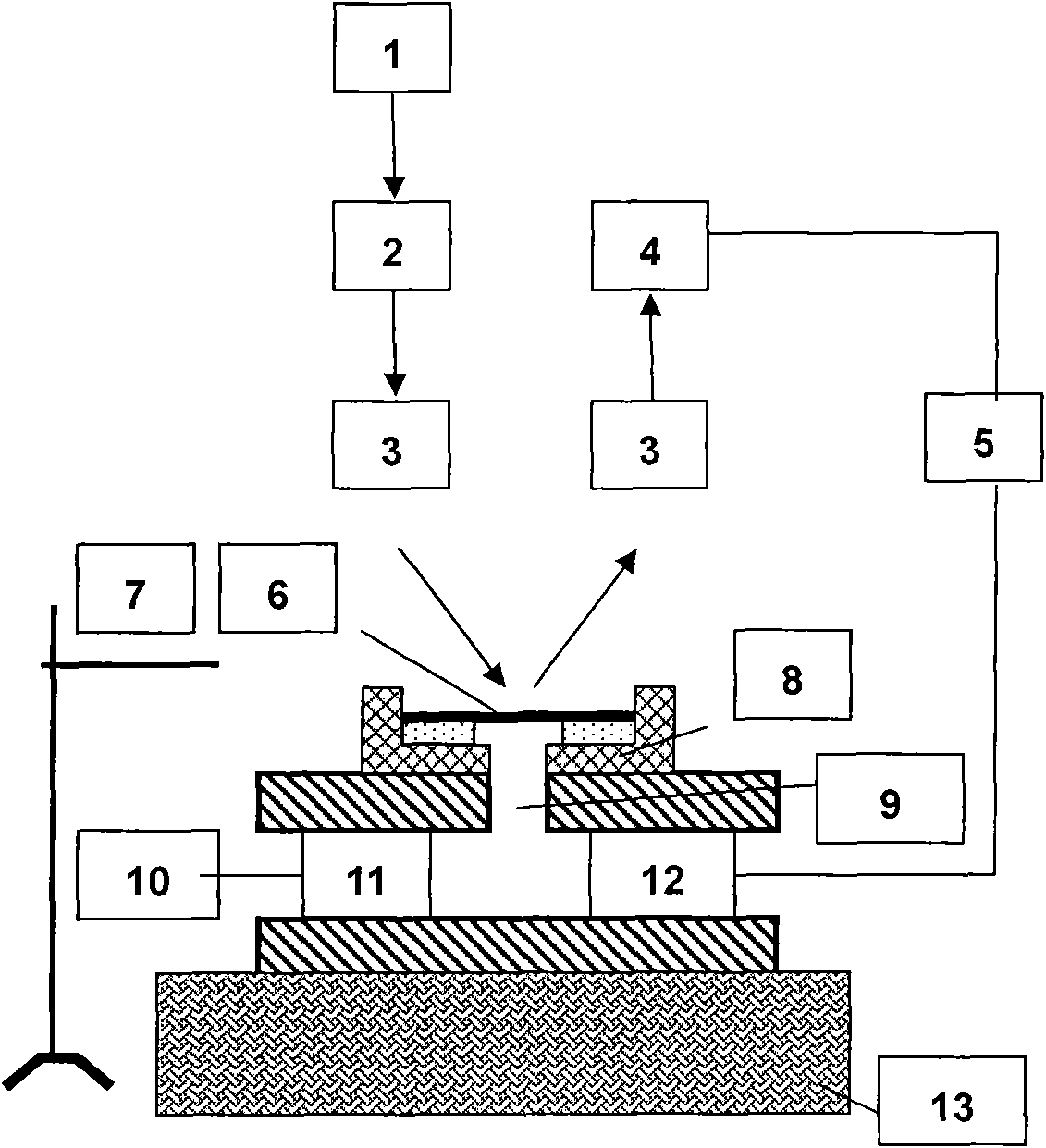

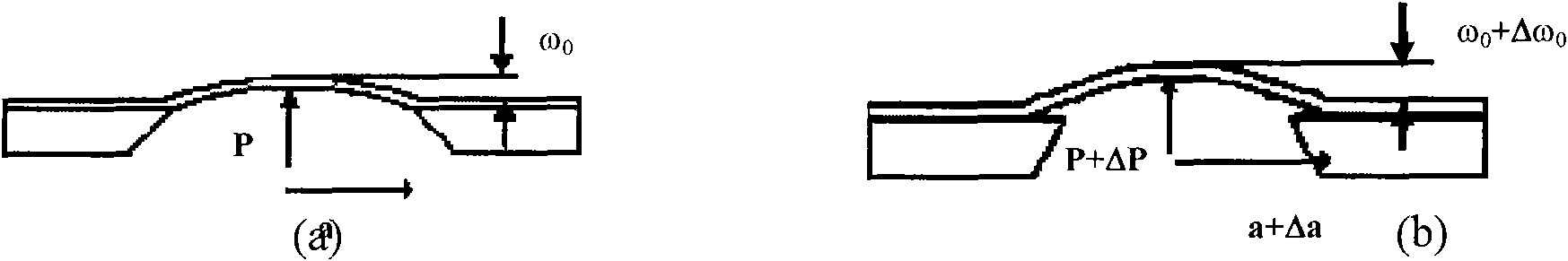

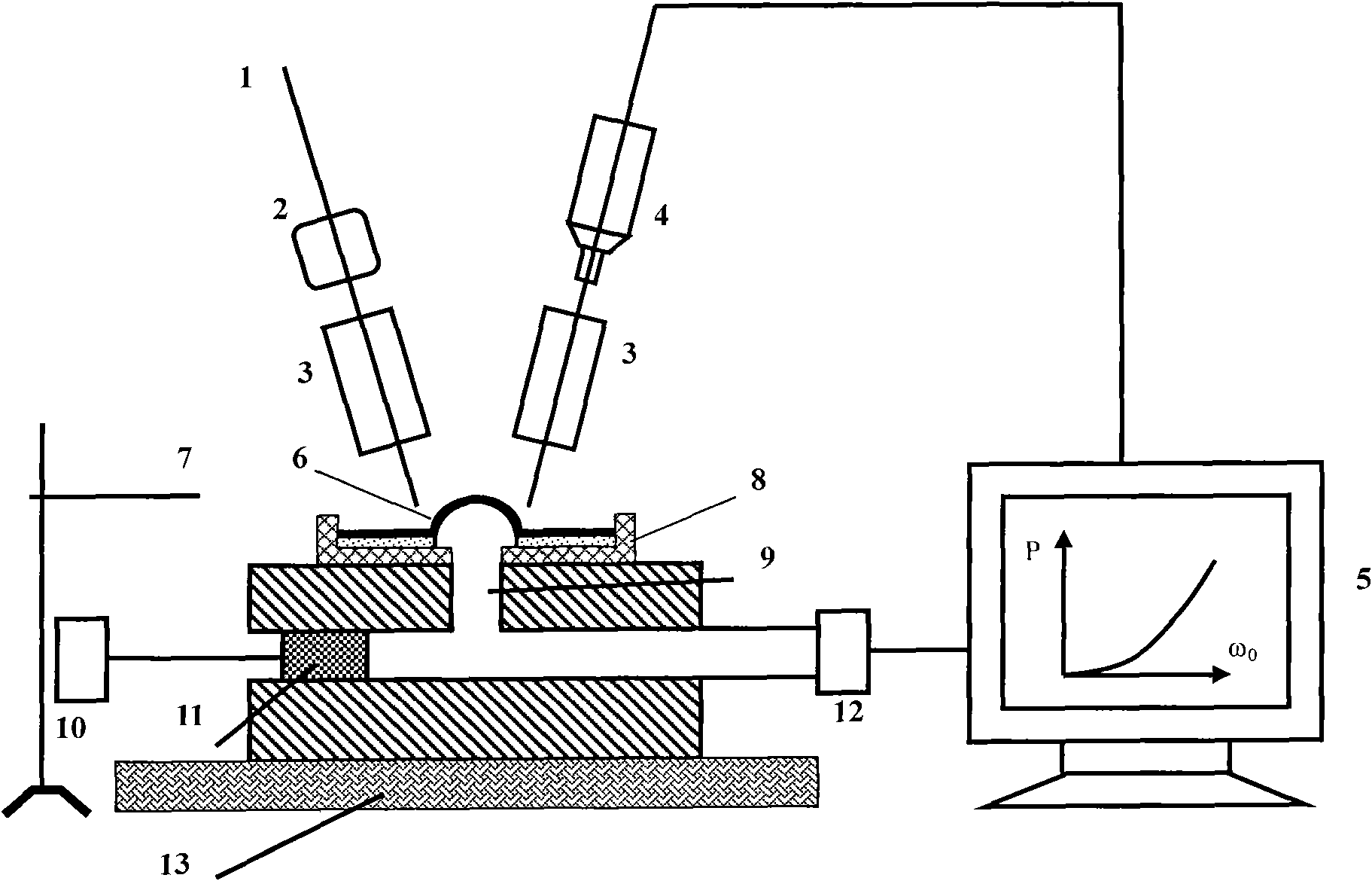

The invention discloses a device for detecting the mechanical property of a multifunctional film, comprising a sample stage, a loading mechanism for applying pressure on a film sample, a measuring mechanism for detecting the pressure applied on the film sample and deformation and a computer. The invention uses a digital speckle correlation method (DSCM) to measure film deformation, and combines two mechanical test methods of a bubbling method and a modified layer removal method, thus conveniently, rapidly and accurately measuring a pressure-deformation curve or a corrosion thickness-deformation curve; and mechanical properties of a film and a coating are extracted in terms of a corresponding theoretical model, thus being suitable for detecting the mechanical properties of tool films, decorative films, polymeric films and films of other types in various elastic-plastic systems.

Owner:XIANGTAN UNIV

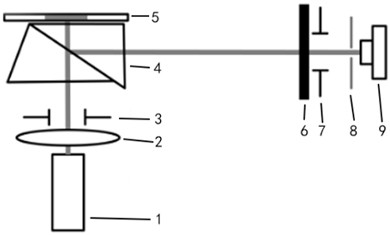

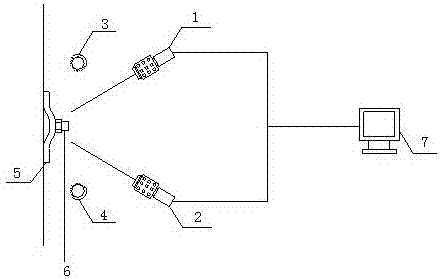

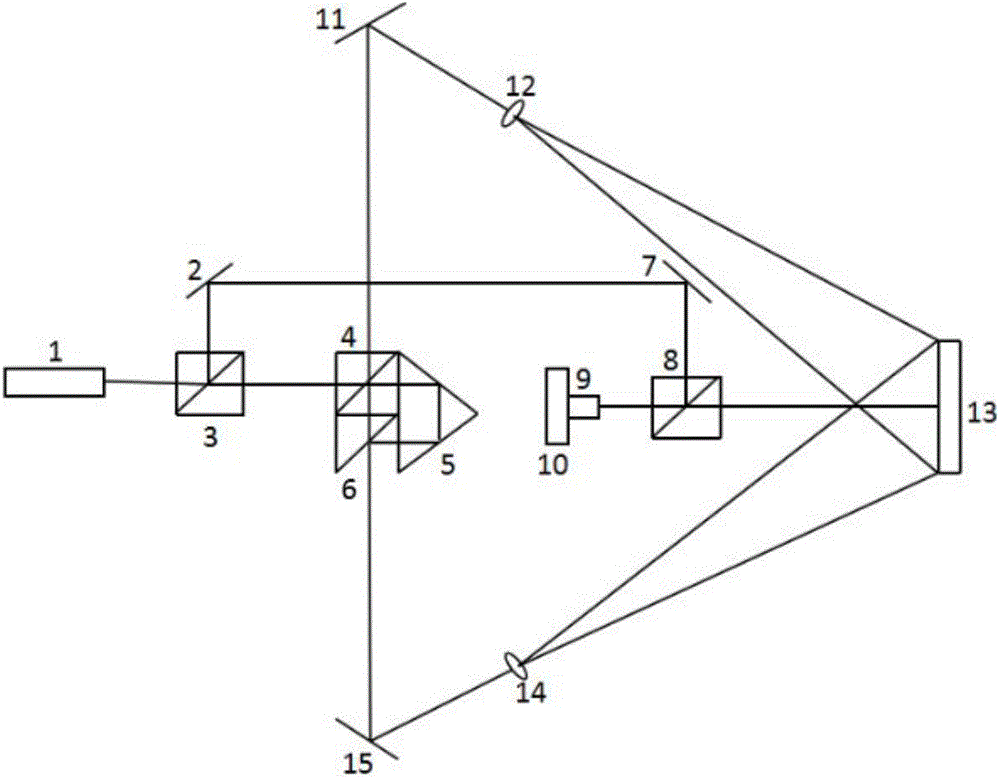

Three-dimensional deformation measuring system and three-dimensional deformation measuring method combining speckle correlation and speckle interference

InactiveCN102788558ARealize three-dimensional displacement measurementEasy to operateUsing optical meansIn planeSpeckle correlation

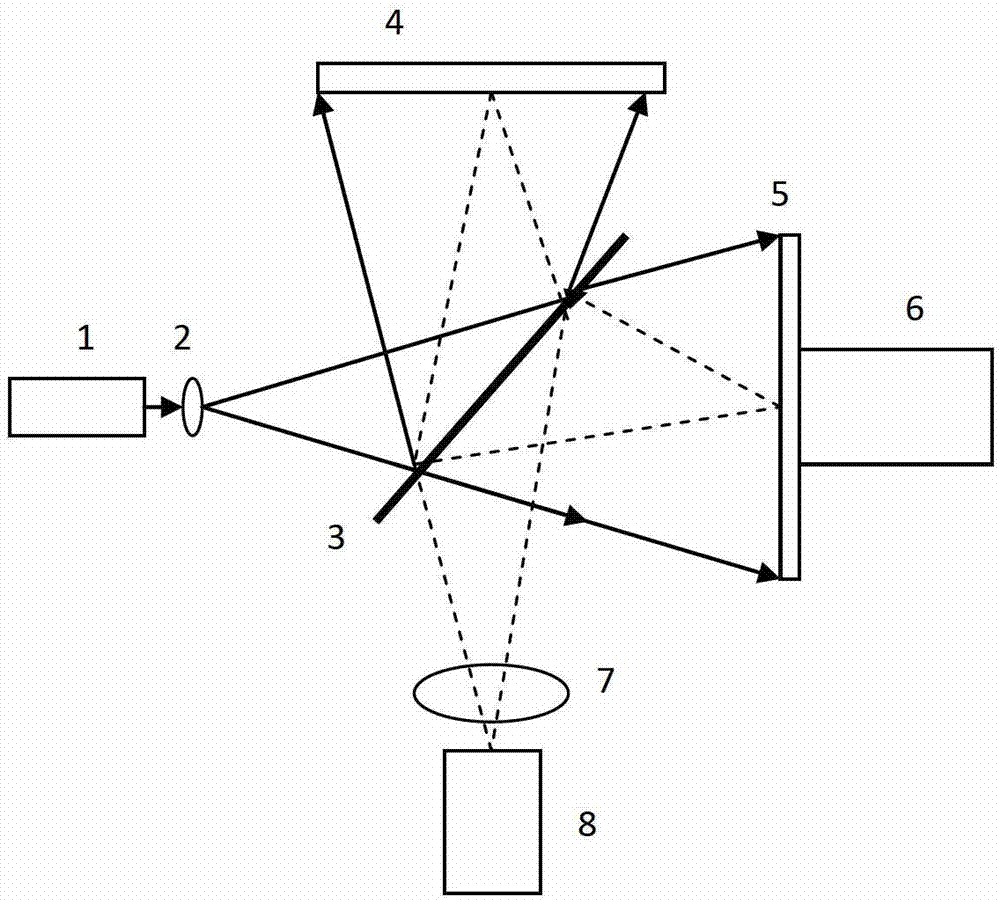

The invention relates to a three-dimensional deformation measuring system and a three-dimensional deformation measuring method combining speckle correlation and speckle interference. The system comprises a laser, wherein laser light emitted by the laser passes through a semi-permeable and semi-reflective mirror after being expanded for illuminating a tested object and a reference object surface respectively; the tested object surface and the reference object surface are imaged simultaneously on the target surface of a CCD (Charge Coupled Device) camera through an imaging lens by means of the semi-permeable and semi-reflective mirror; the semi-permeable and semi-reflective mirror is arranged obliquely at an angle of 45 degrees relative to incident rays; and when a reference path exists, object surface speckles and reference surface speckles are interfered with mutually on the target surface of the CCD camera to form an interference speckle image for measuring an off-plane displacement component. A reference substance light path is removed, a speckle image on the object surface is acquired, and two components of in-plane displacement are calculated by using two speckle images acquired before and after deformation. A typical digital speckle light path which is sensitive to the off-plane displacement is utilized, so that the in-plane displacement and speckle interference off-plane displacement of a speckle relevance measuring object are realized, and three-dimensional displacement measurement is realized; and and the system and the method have the advantages of simple light path, and easiness and rapidness for operating and processing data.

Owner:SHANDONG NORMAL UNIV

Test device and test method for measuring residual stress of bent pipe

InactiveCN102052981AReduce cumbersome proceduresThe result is accurateForce measurement by measuring optical property variationPrincipal stressSpeckle correlation

The invention relates to a test device and test method for measuring residual stress of a bent pipe and belongs to the technical field of experimental mechanics and residual stress measurement. In the method provided by the invention, the digital speckle correlation technique is combined with the drilling technique, and the method comprises the following steps: using a CCD (charge coupled device) camera to take photos of the bent pipe before and after the bent pipe is drilled; utilizing the digital speckle technique to measure the stretched displacement of two ends of the front and back drilled round holes; and measuring the residual stress of the bent test piece with a confirmed principal stress direction, so as to acquire the residual stress. The digital speckle correlation technique used in the method refers to non-contact measurement. Compared with the traditional electrical testing method, the method has the advantage that the complex process of sticking a foil gauge each time is omitted, thereby being more convenient and simpler. For the measurement of the residual stress of the bent pipe, a column correcting process is added in the method provided by the invention as compared with the traditional method, thus the acquired result is more accurate.

Owner:TSINGHUA UNIV

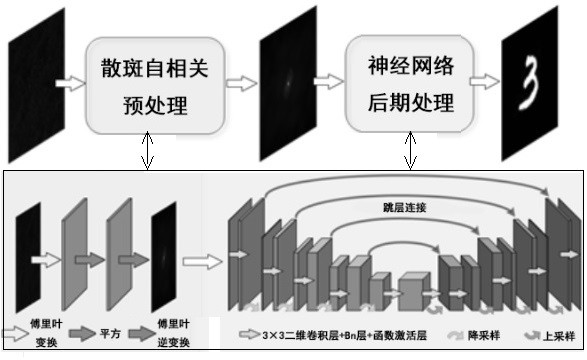

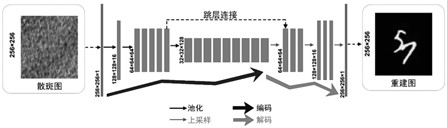

Scattering generalization imaging method and experimental method based on physical driving

ActiveCN112287571AImprove robustnessImprove efficiencyDesign optimisation/simulationNeural architecturesPhysical modelSpeckle correlation

The invention relates to a scattering generalization imaging method and experiment method based on physical driving, and belongs to the technical field of imaging analysis, and the method comprises the steps: building a physical / data model, and employing a speckle pattern collected by a camera for imaging the speckle pattern; and taking the speckle correlation theory as a universal physical principle to constrain and guide the neural network to carry out generalized imaging in different scattering scenes. The experimental method comprises theoretical analysis and a system experiment, and the method is systematically discussed by establishing a specific system experiment. And the generalization ability and the generalization quality are improved, and more complex targets are generalized. Aphysical model based on speckle correlation and a data model based on deep learning are organically combined, so that the scattering generalization imaging effect and the imaging range of the neural network model are greatly improved.

Owner:NANJING UNIV OF SCI & TECH

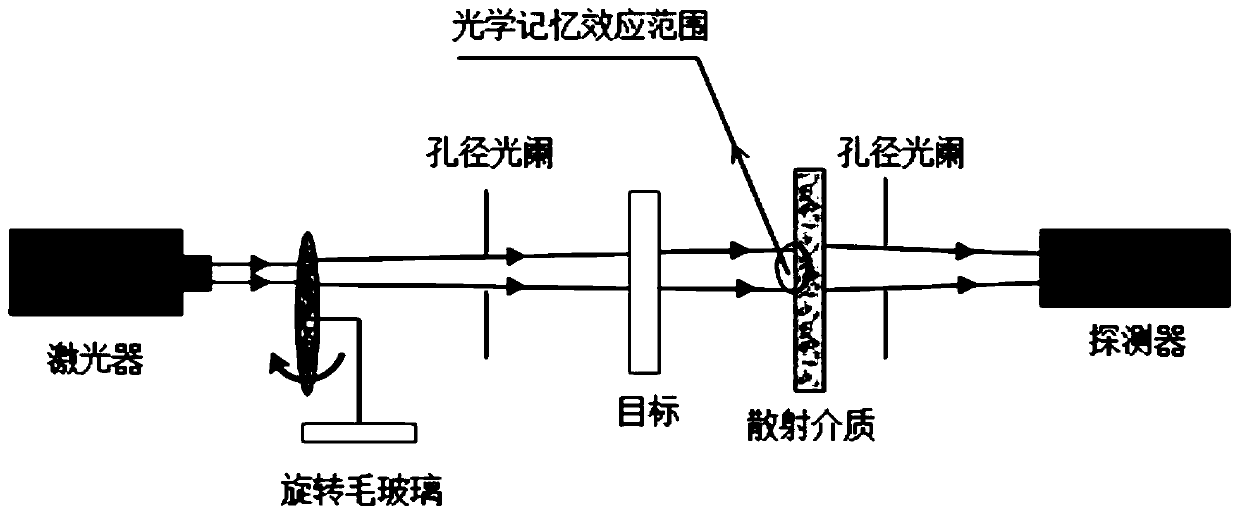

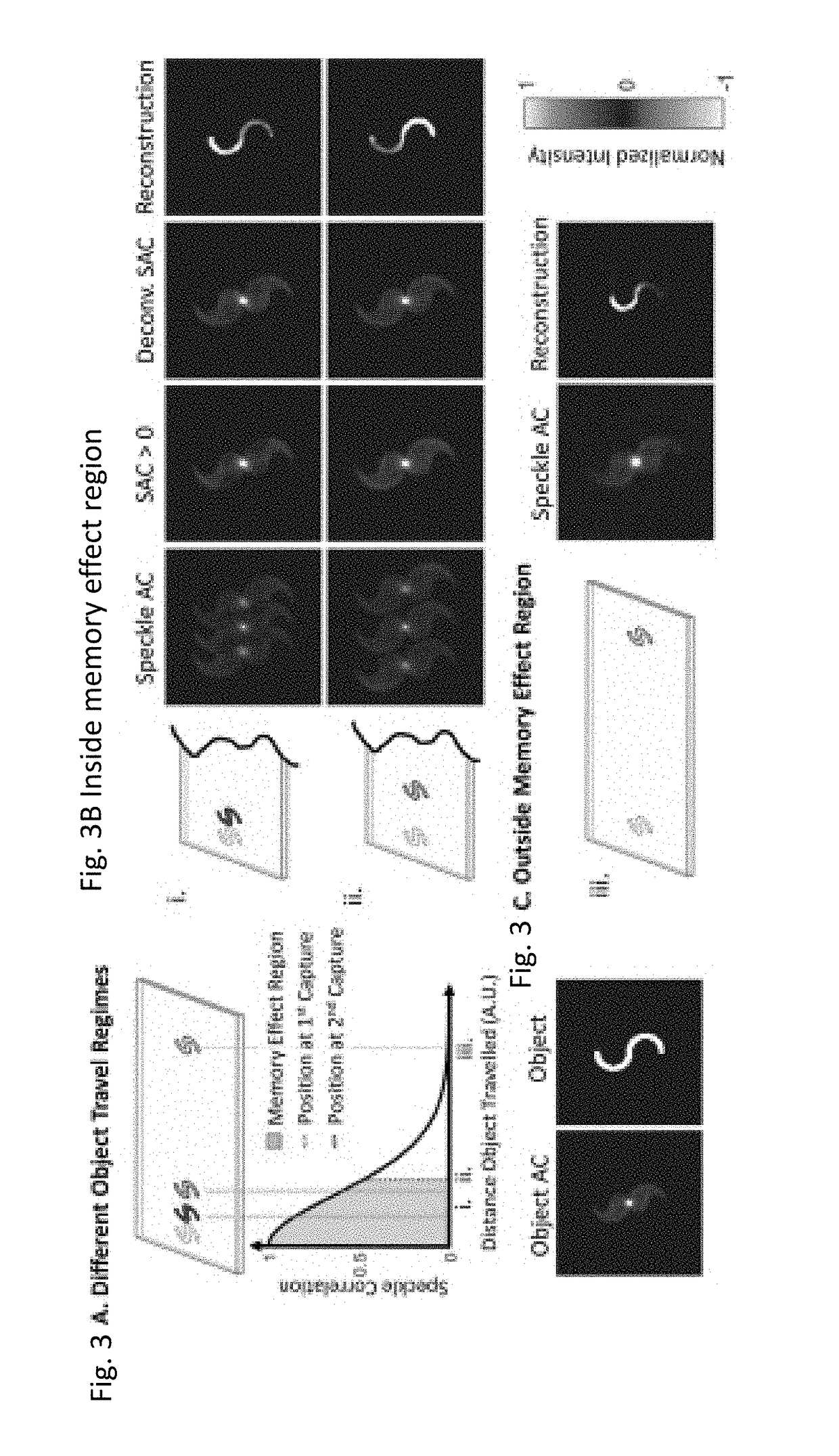

Method for imaging object passing behind scattering medium based on convolutional neural network

InactiveCN111739117ASuccessfully rebuiltOptical memory effect range extensionReconstruction from projectionCharacter and pattern recognitionAlgorithmSpeckle correlation

The invention discloses a method for imaging an object behind a scattering medium based on a convolutional neural network PDSNet. According to the method, the traditional speckle correlation imaging algorithm principles are combined, the design and optimization of the network are guided, and the limitation of the optical memory effect OME on the imaging field angle FOV is eliminated in a data driving mode. The convolutional neural network PDSNet is a neural network structure suitable for a random scale and a complex target. The hidden object recovery capability of the convolutional neural network PDSNet is experimentally tested, and at least 40 times of optical memory effect range expansion is realized on the premise that the average PSNR is kept above 24dB. And meanwhile, under an untrained scale, the average PSNR of the recovered image is more than 22dB, and complex targets such as a human face are successfully reconstructed. Experimental results given in the invention verify the accuracy and effectiveness of the method.

Owner:NANJING UNIV OF SCI & TECH

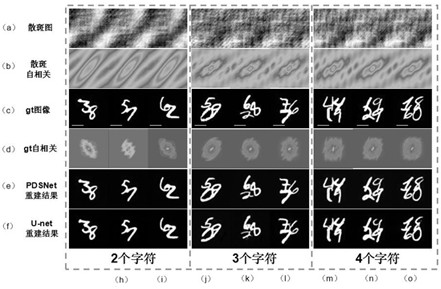

Wing vibration detection device and method based on three-dimensional digital speckle correlation method

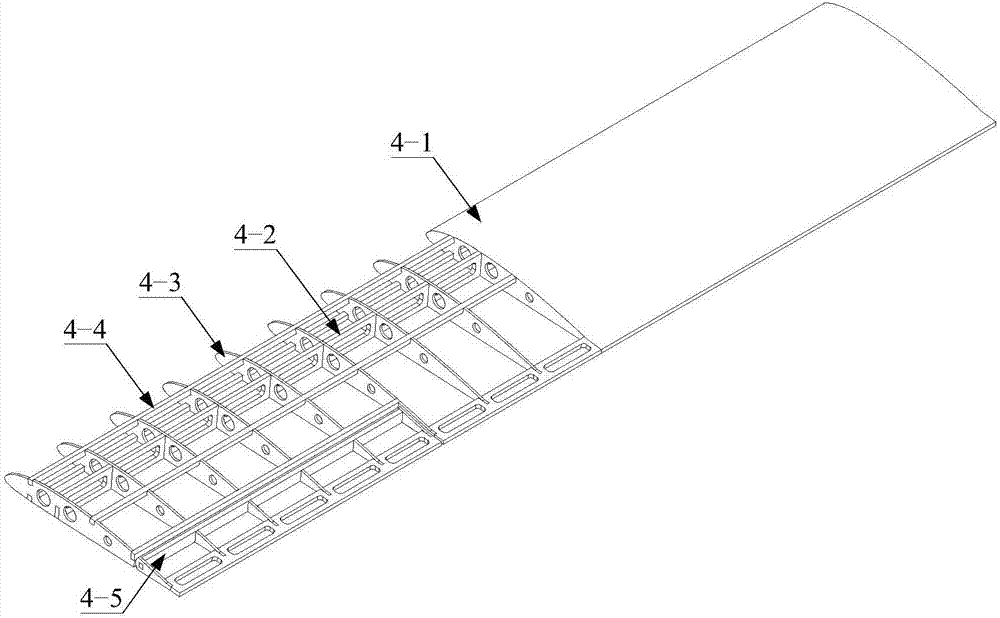

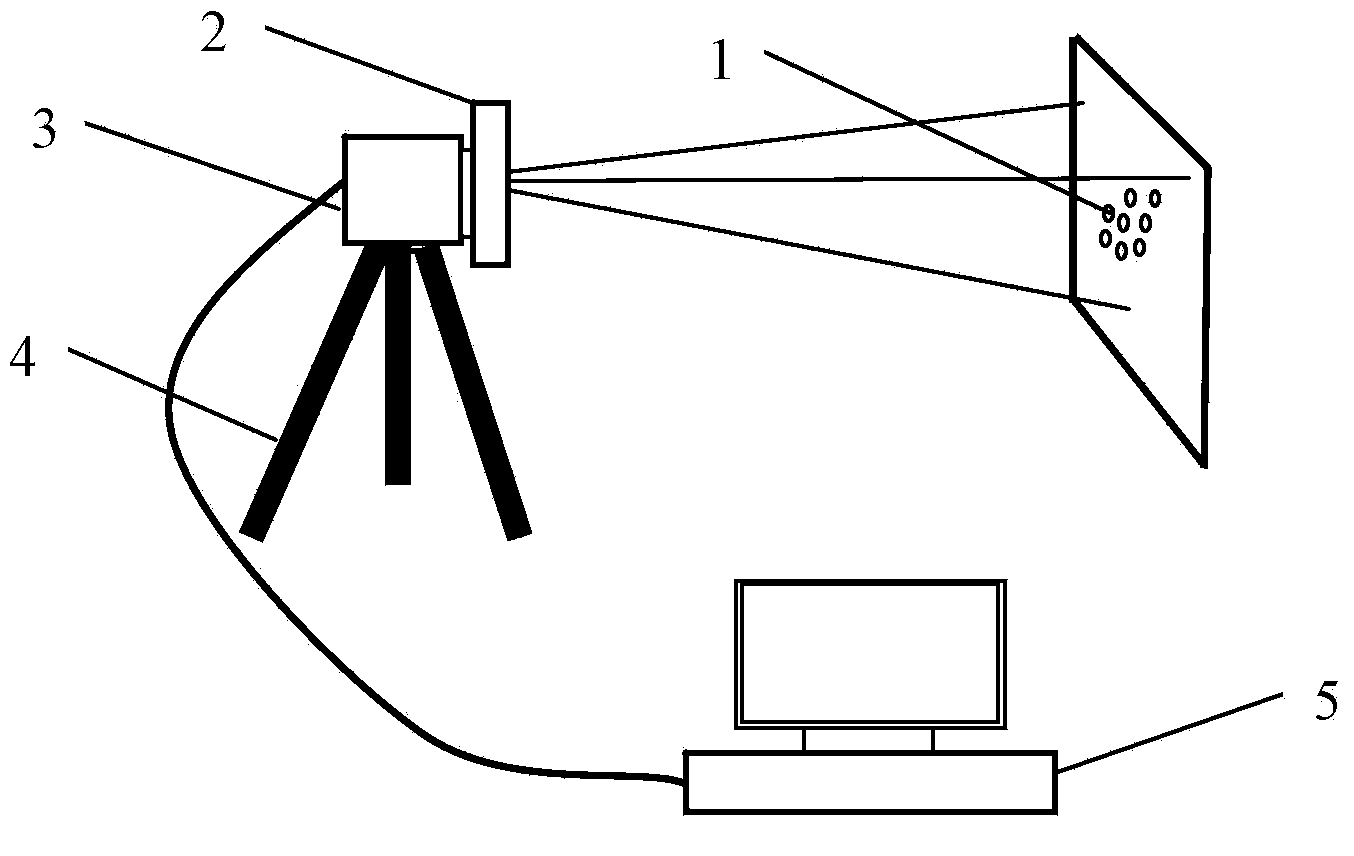

ActiveCN107228708ARestoring vibrationRestore deformationSubsonic/sonic/ultrasonic wave measurementSustainable transportationEngineeringSpeckle correlation

The invention discloses a wing vibration detection device and a wing vibration detection method based on a three-dimensional digital speckle correlation method. The wing vibration detection device comprises a wing body part, a vibration detection part, a vibration excitation part and a computer, wherein the wing body part comprises a wing and a thin film painted with dense spots; the vibration detection part comprises two high-speed cameras and a camera bracket; the vibration excitation part comprises an exciter, a power amplifier and a signal generator; the vibration excitation part conducts vibration excitation on the wing body part, so that the surfaces of the wing deform accordingly; the vibration detection part performs synchronous and continuous image acquisition in the wing surface scope displaying the dense spots; the acquired images are transmitted to the computer, displacement information data obtained through corresponding image registration and by adopting the three-dimensional digital speckle correlation method is imported into relevant processing software, three-dimensional curved surface fitting operation is conducted on the displacement information data, so as to display the morphology during wing vibration or deformation, thereby realizing visualized operation.

Owner:SOUTH CHINA UNIV OF TECH

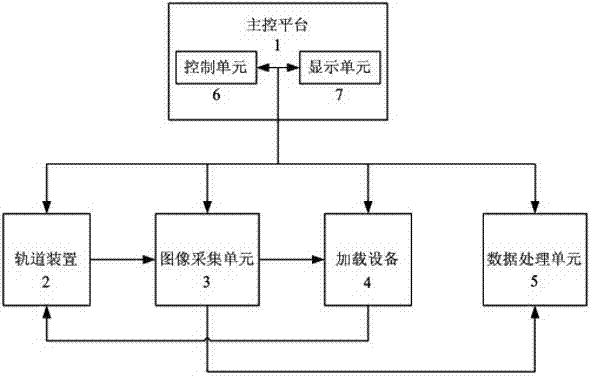

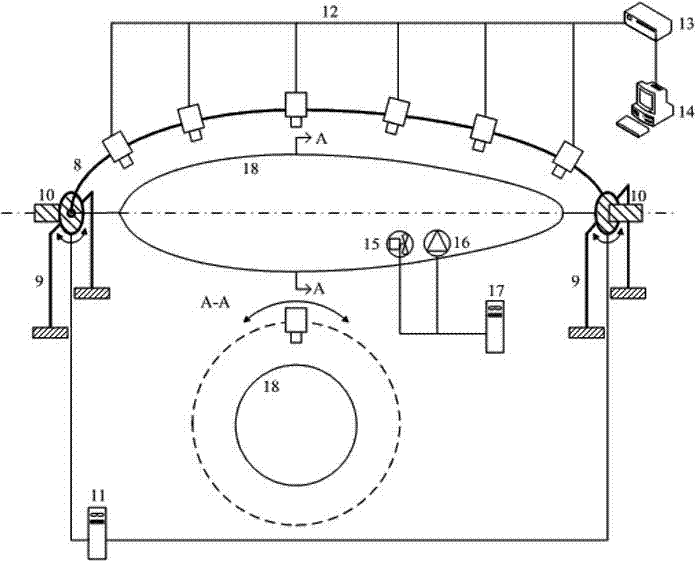

Aerostat airbag detection system based on digital speckle correlation method

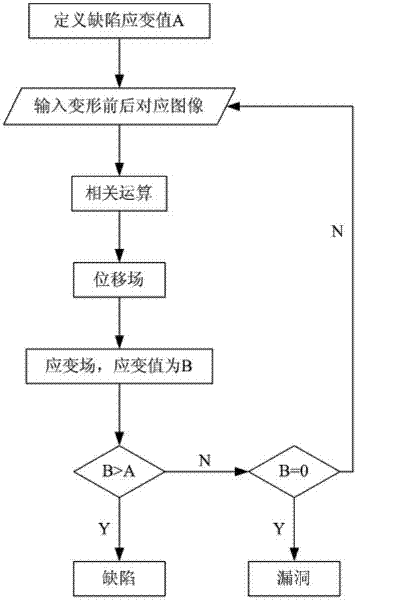

InactiveCN102313746AWith NDTWith full field measurementOptically investigating flaws/contaminationFluid-tightness measurement using lightNon destructiveSpeckle correlation

The present invention discloses an aerostat airbag detection system based on a digital speckle correlation method, and belongs to the technical field of the aircraft detection, wherein the aerostat airbag detection system is applicable for detecting defects and leaks on the aerostat airbag surface. The detection system comprises a main control platform, a track apparatus, an image acquisition unit, a loading device and a data processing unit. According to the present invention, during detecting, the track apparatus providing with a camera is provided for carrying out overall shooting for the aerostat airbag; then the pressure difference between the inner and the outer of the airbag is changed through controlling the loading device on the airbag to enable the airbag to be deformed; then the overall shooting is performed again for the deformed airbag; finally, the digital speckle correlation technology is adopted for processing the two shot images to obtain the displacement and the strain distribution of the airbag surface so as to realize the detections of the defects and the leaks on the airbag. The system has characteristics of non-destructive detection, full field detection, high precision, quantification and automation, and provides a new solution scheme for detection of the aerostat airbag performance.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

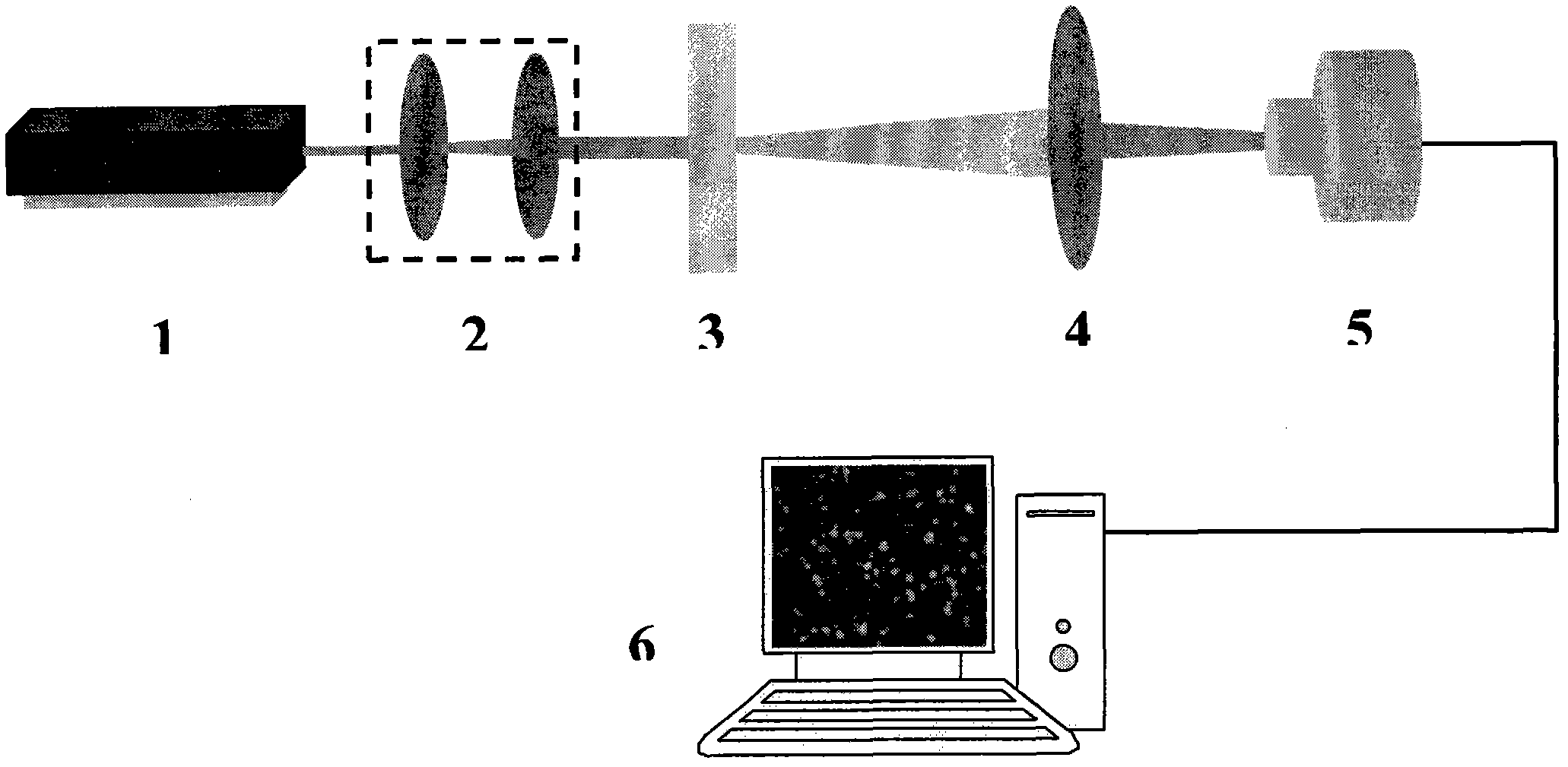

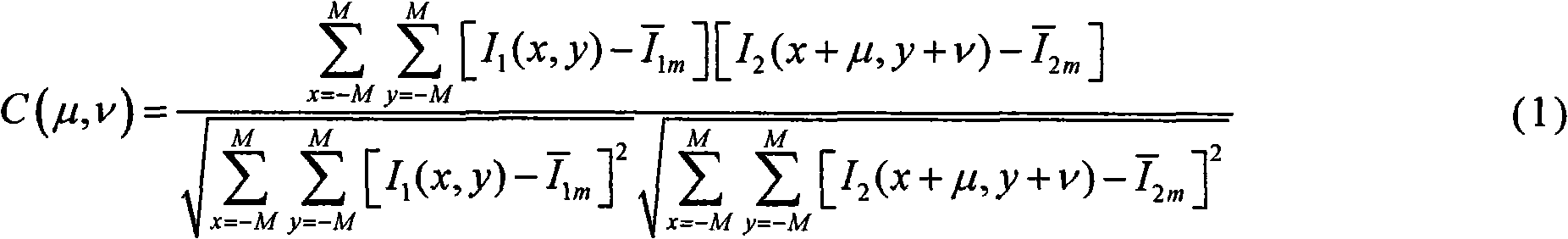

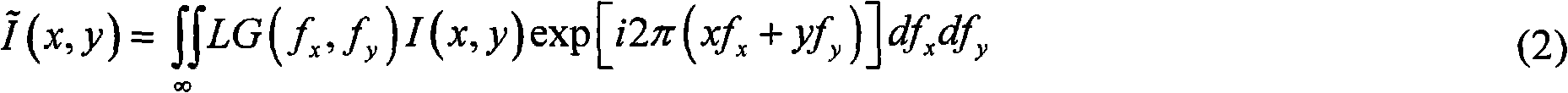

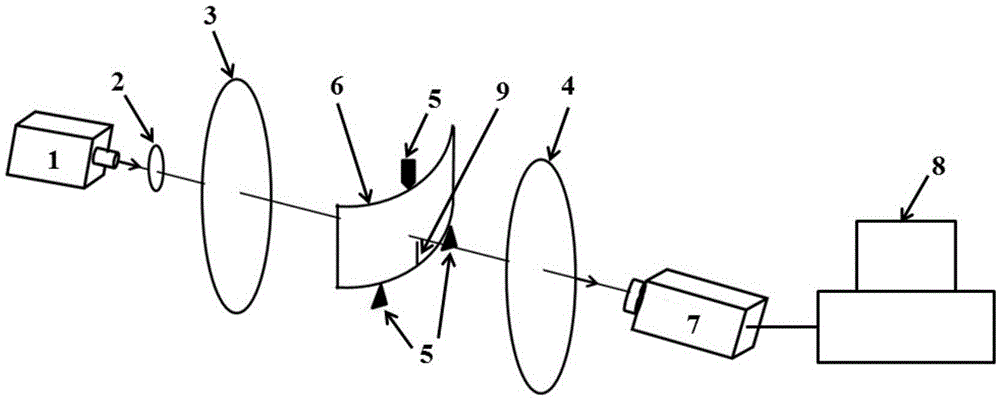

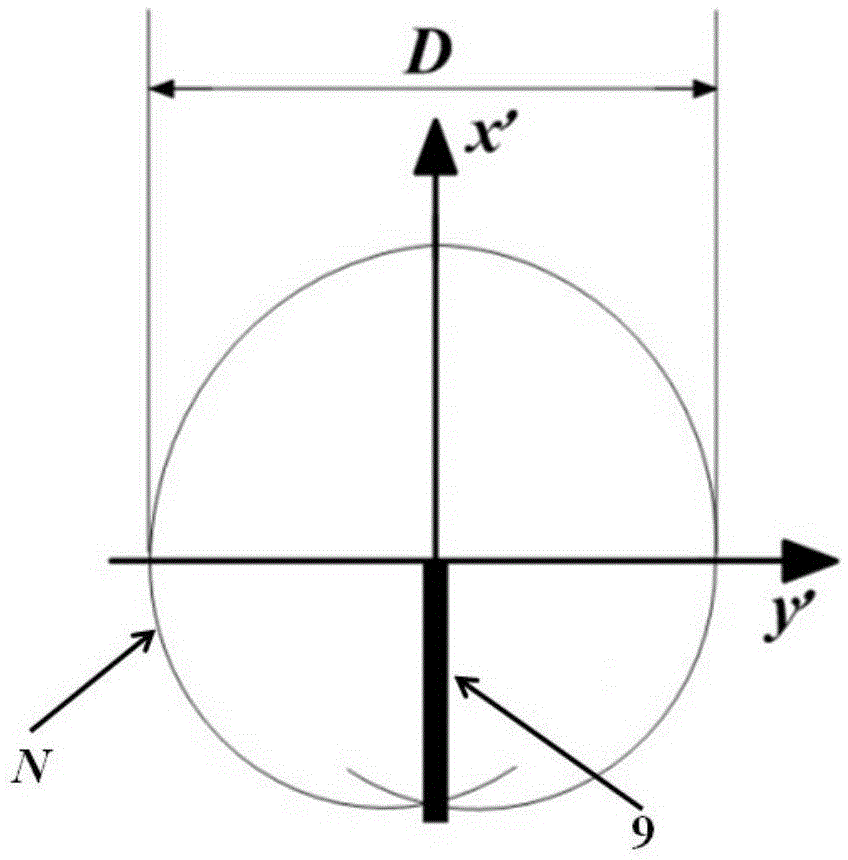

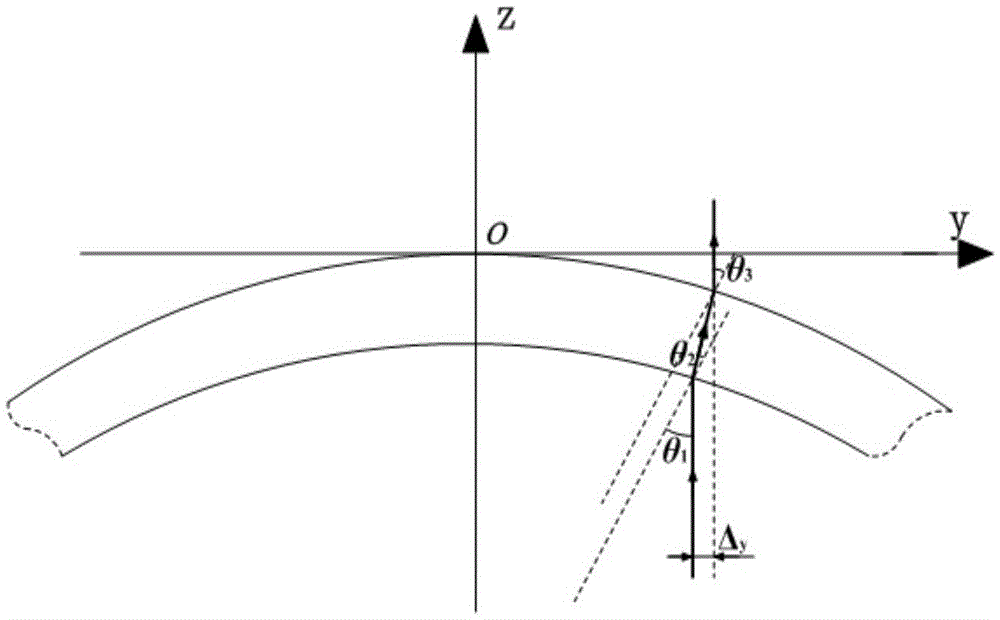

Phase vortex based digital speckle correlation measurement method

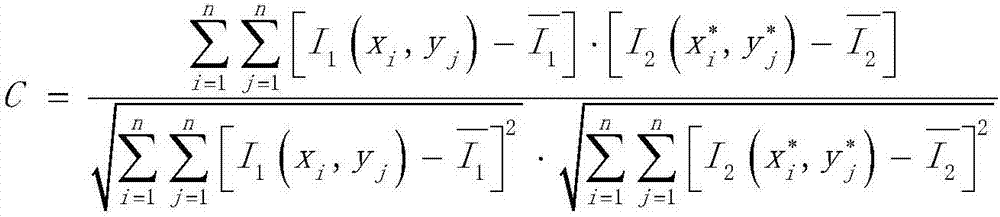

The invention discloses a phase vortex based digital speckle correlation measurement method. The method comprises the following steps of: acquiring speckle light intensity images of two states before and after movement of a measured object by using a digital speckle correlation measurement light path; filtering the two images by using a Laguerre-Gaussian complex filter to acquire light intensity complex signals; extracting cross points of real part zero lines and imaginary part zero lines of the signals to acquire phase vortex distribution of the two states before and after the movement of the measured object respectively; calculating corresponding topological charge distribution data matrixes; and finally performing correlation operation on the two data matrixes to acquire displacement information of the measured object. By adopting the method, the influence of background noise and high frequency noise on reliability of correlation measurement can be effectively eliminated, the measurement accuracy can reach a subpixel level; and the method is simple, practicable, quick and accurate and can be widely applied to the fields of nondestructive examination and the like.

Owner:HENAN UNIV OF SCI & TECH

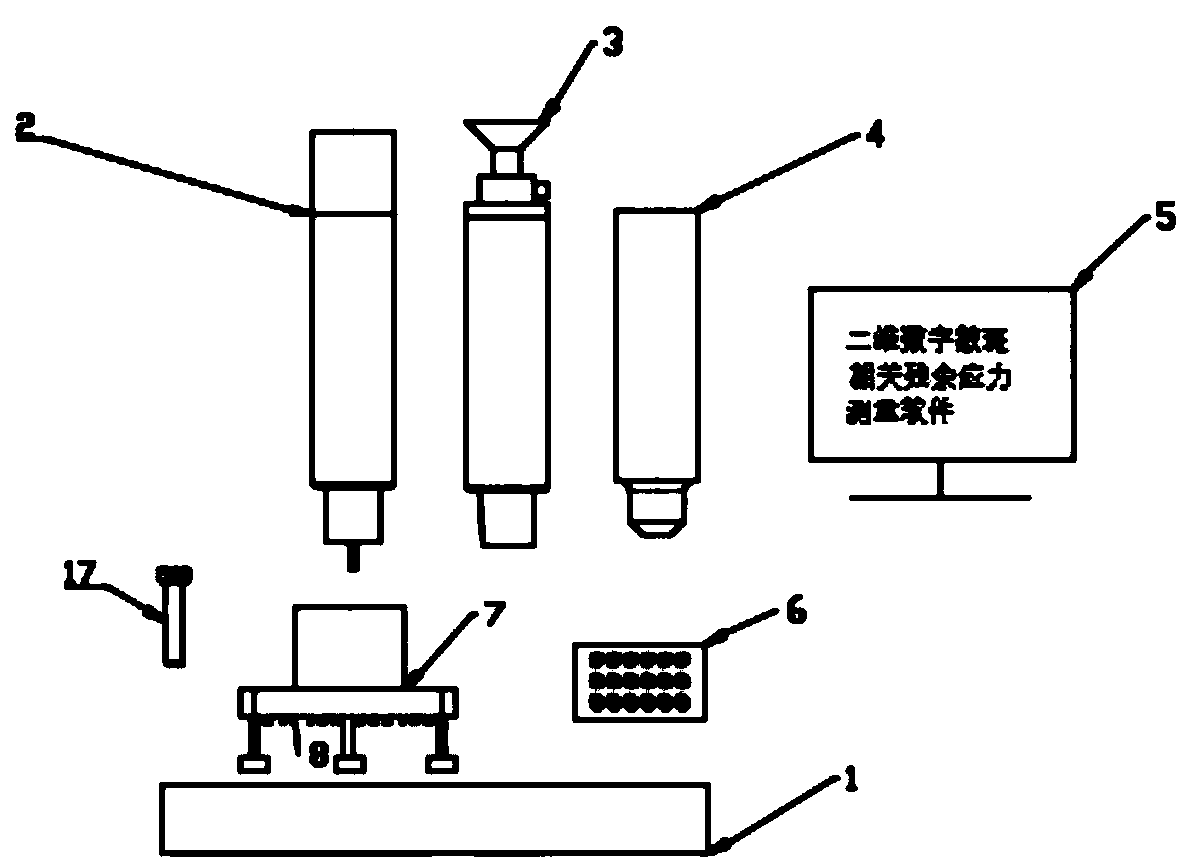

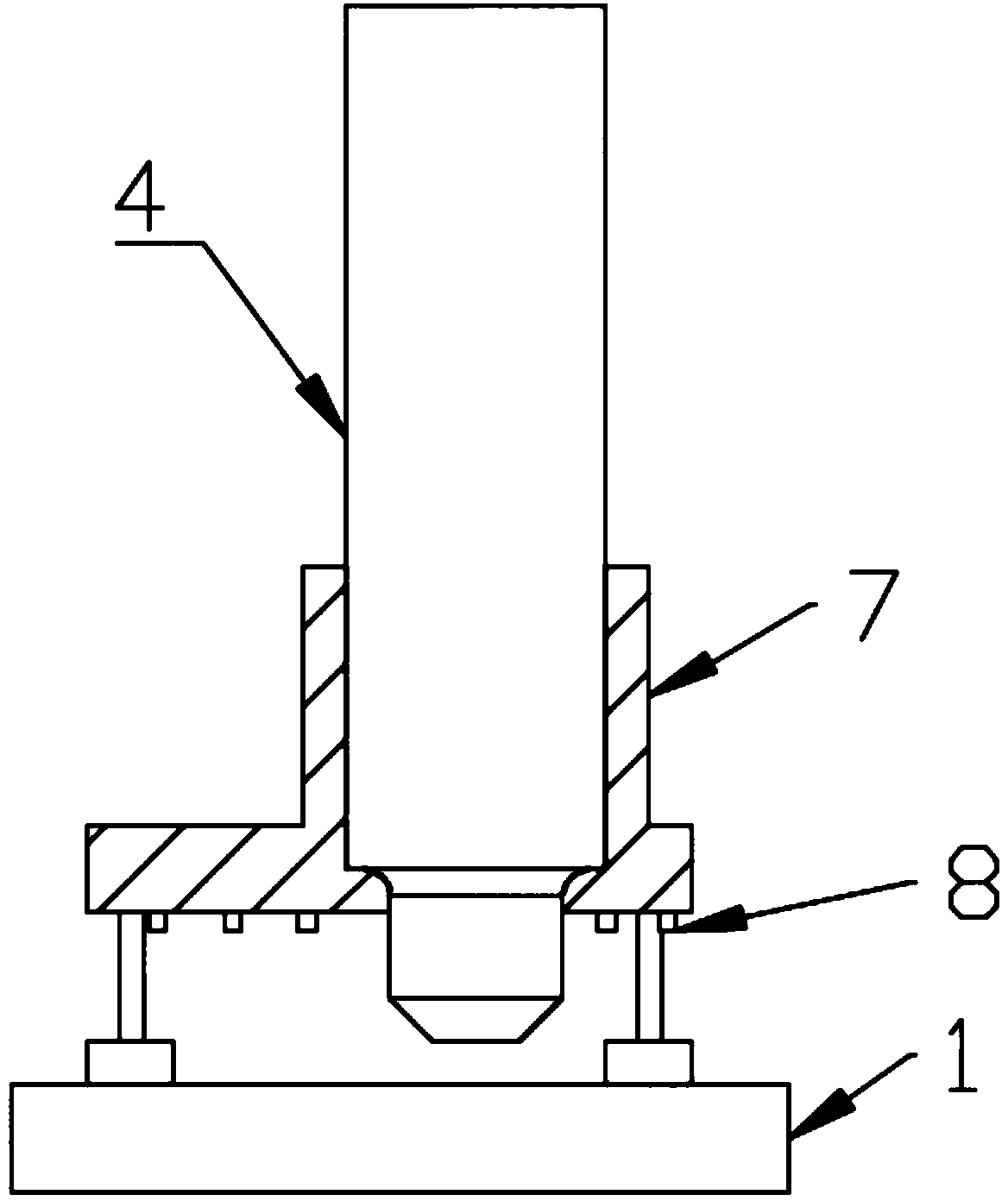

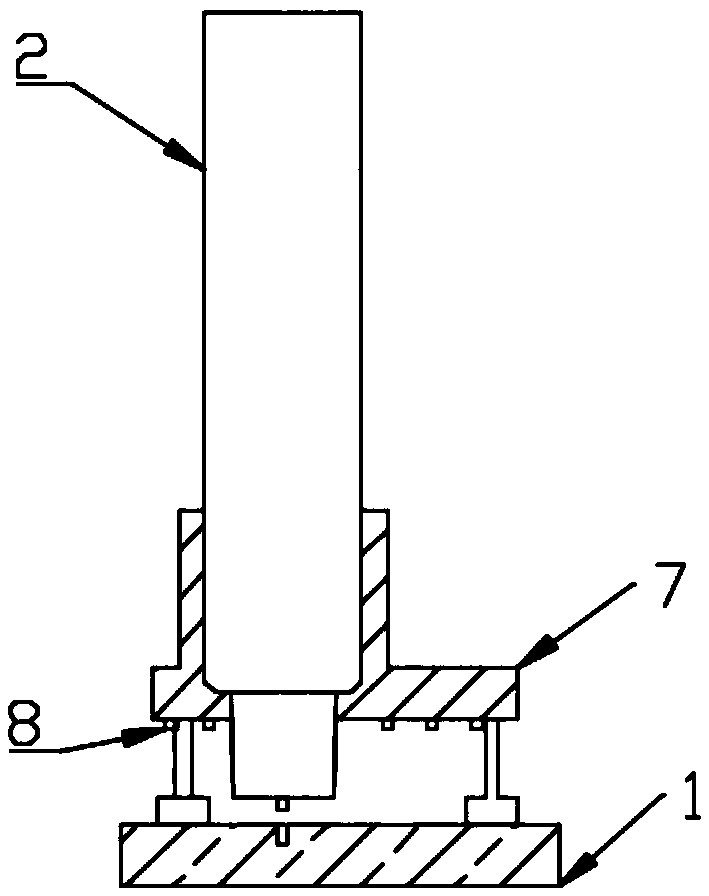

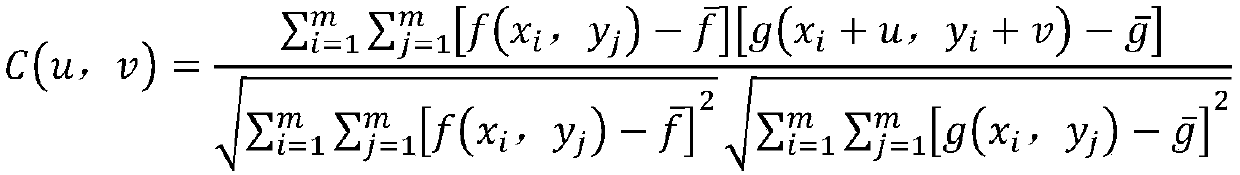

Portable residual stress measurement device and method

InactiveCN104236759AEnables residual stress measurementSimple and fast operationForce measurementMeasurement deviceSpeckle correlation

The invention relates to a portable residual stress measurement device and a method. A two-dimensional digital speckle correlation method is used for conducting correlation calculation on speckle images obtained before and after the residual stress of a planar test piece is released, so regional strain fields formed before and after the residual stress of the planar test piece is released are obtained. The stress of the test piece can be released through a drilling device or an impacting indentation device. According to the theoretical equation, used in the drilling method or the impacting indentation method, for the residual stress, the intensity of the residual stress of the test piece is worked out. According to the portable residual stress measurement device, the method for releasing the stress can be flexibly selected according to different needs, and meanwhile the portable residual stress measurement device has the advantages of being high in precision, contactless, convenient and rapid to operate and the like.

Owner:BEIHANG UNIV

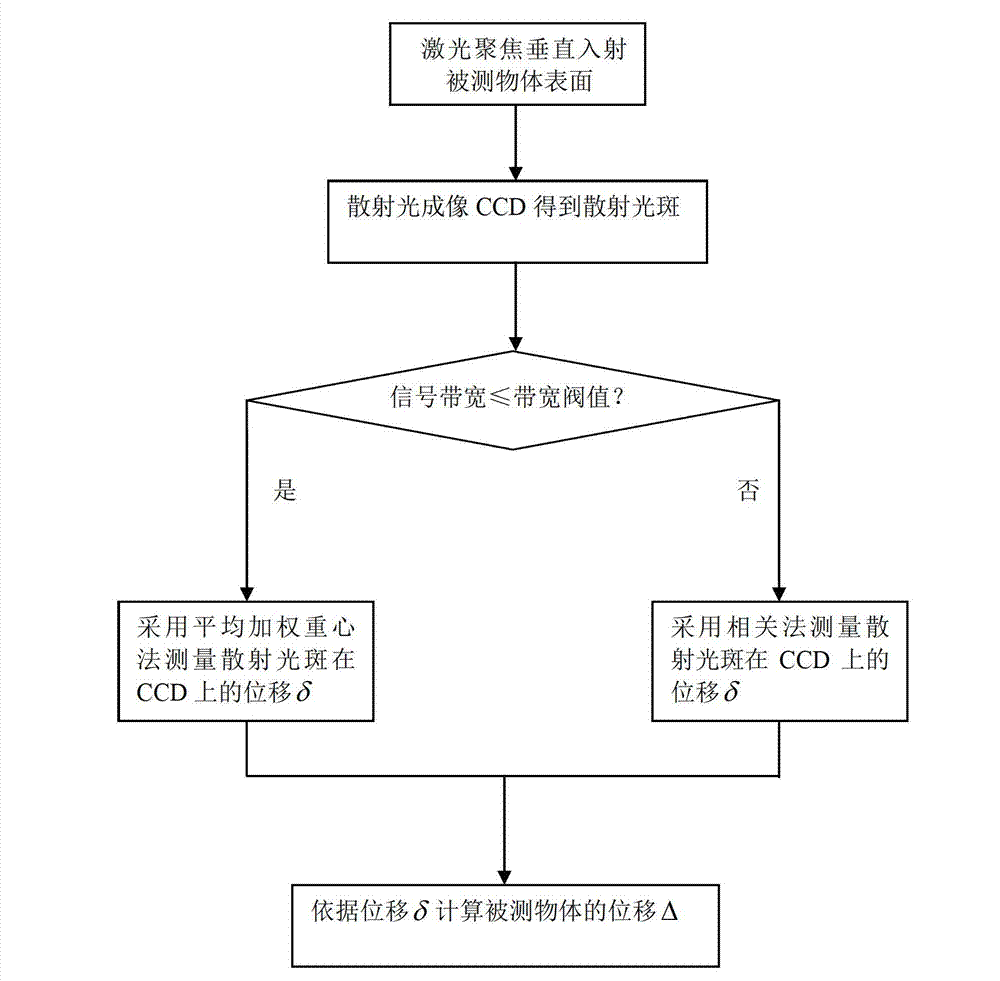

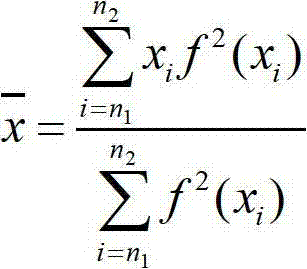

Laser displacement measuring method based on digital speckle correlation method (DSCM)

InactiveCN102967261AMake up for the defect of large error in measurement resultsAccurate measurementUsing optical meansScattering cross-sectionImaging lens

The invention discloses a laser displacement measuring method based on a DSCM. The method includes that lasers are vertically shot into a moving measured object surface through focusing; scattered light at incident spots on the measured object surface is received and is imaged on the sensitive surface of a charge coupled device (CCD) through an imaging lens to obtain scattering spots; when the signal bandwidth of the scattering spots is smaller than or equal to a bandwidth threshold, the measured object surface is indicated to be a weak scattering interface, and displacements of the scattering spots on the CCD are measured by using an average weighted centroid method; when the signal bandwidth of the scattering spots is larger than the bandwidth threshold, the measured object surface is indicated to be a strong scattering interface, and displacements of the scattering spots on the CCD are measured by using a correlation method; and the displacement of the measured object is calculated according to the displacements of the scattering spots on the CCD. According to the method, accurate measurement of displacements of various roughness object surfaces is achieved, and the measurement is rapid and accurate.

Owner:HUAZHONG UNIV OF SCI & TECH

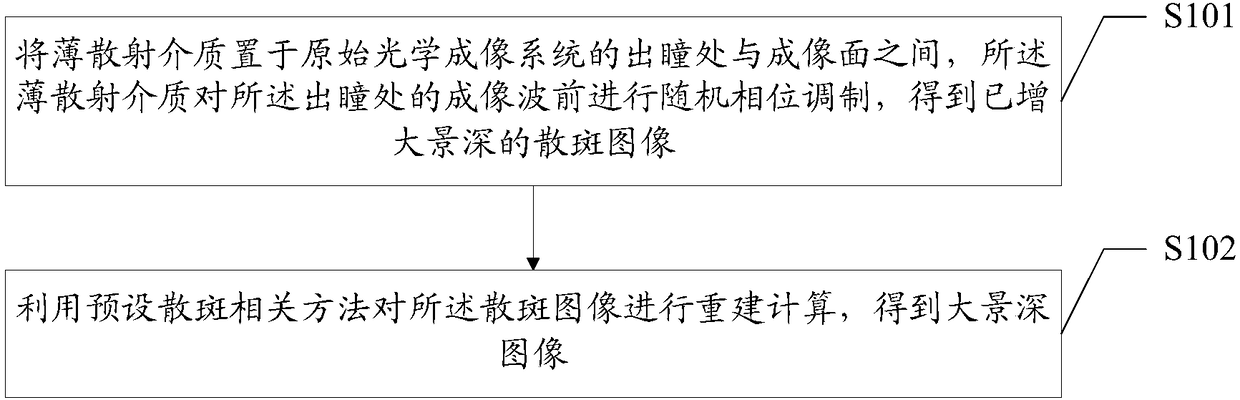

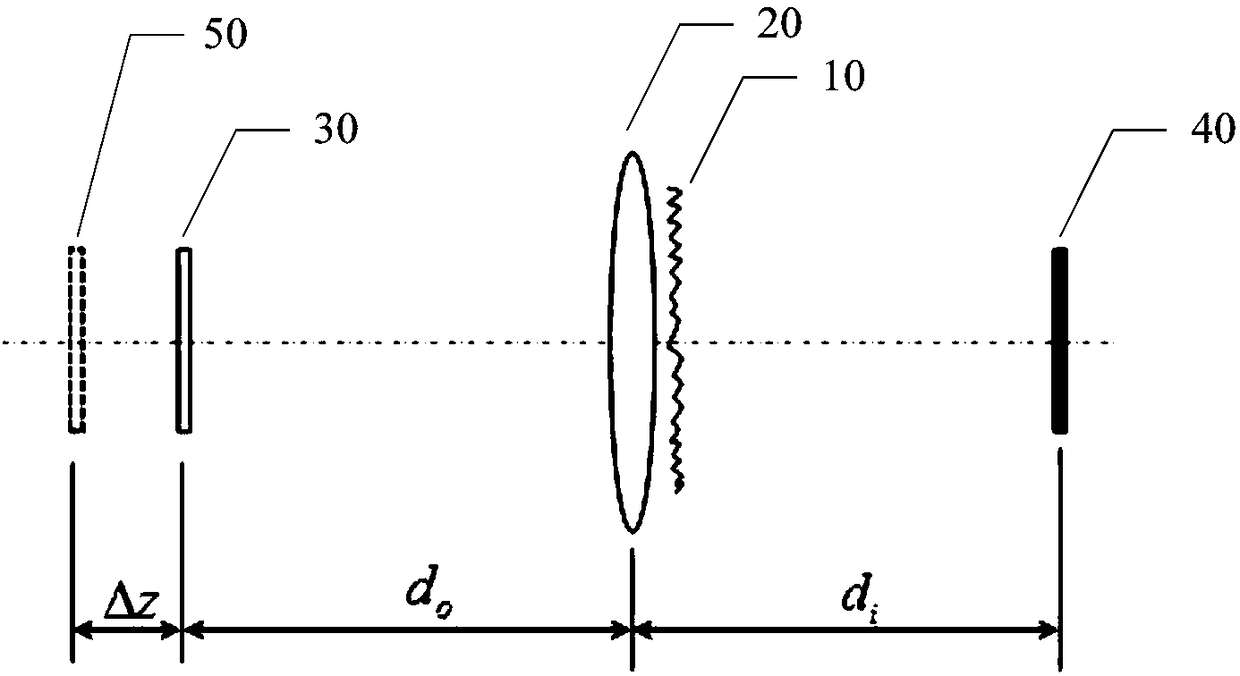

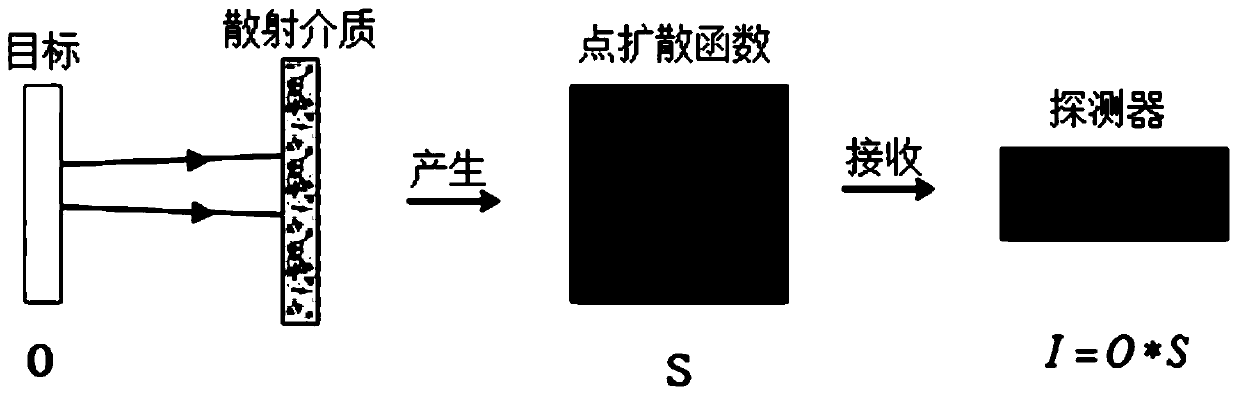

Method and system for extending depth of field in optical imaging

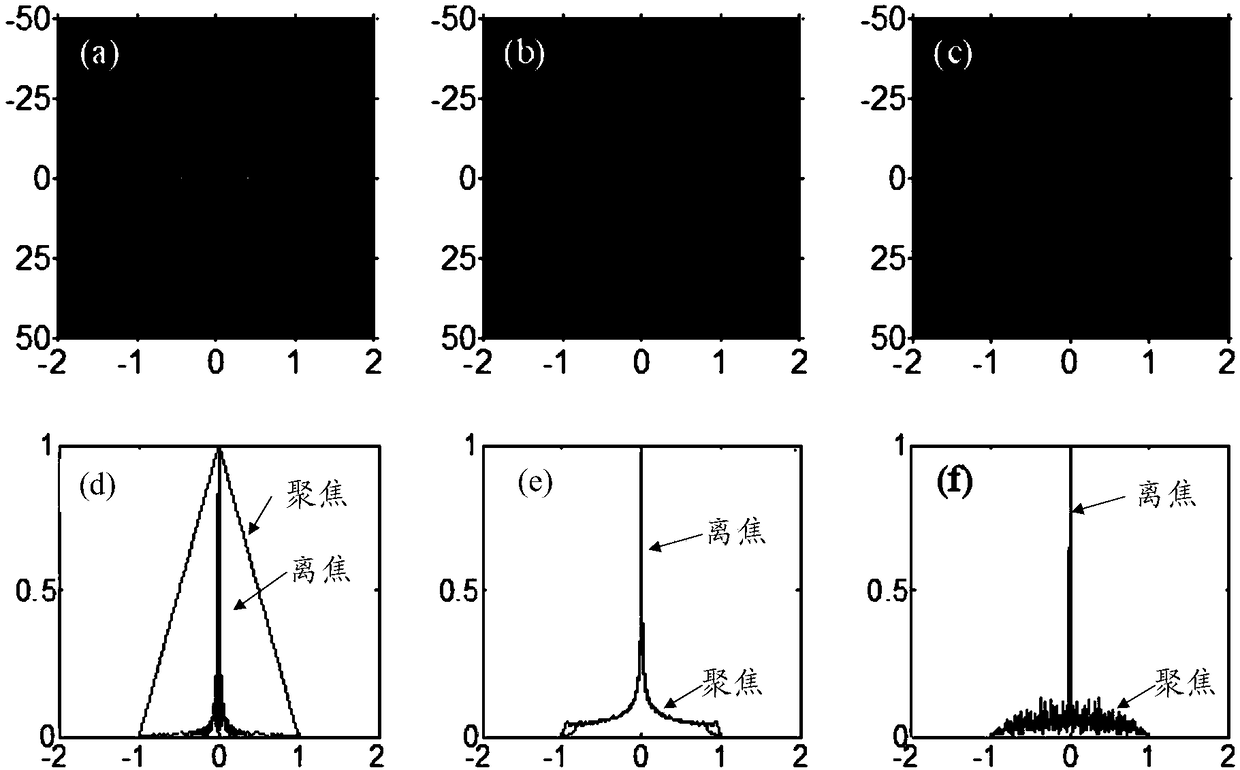

The invention belongs to the field of computational optical imaging, and particularly relates to a method and a system for extending the depth of field of optical imaging. According to the method, only a thin scattering medium needs to be placed between an exit pupil portion and an imaging plane of an original optical imaging system, imaging waves at the exit pupil portion are subjected to randomphase modulation by the thin scattering medium, speckle images are obtained by an image detector, the speckle images are reconstructed by a preset speckle correlation method, and a large image of thedepth of the field is obtained. Therefore, the method does not need a complex process precision design, is simple, and greatly reduces the process cost.

Owner:SHENZHEN UNIV

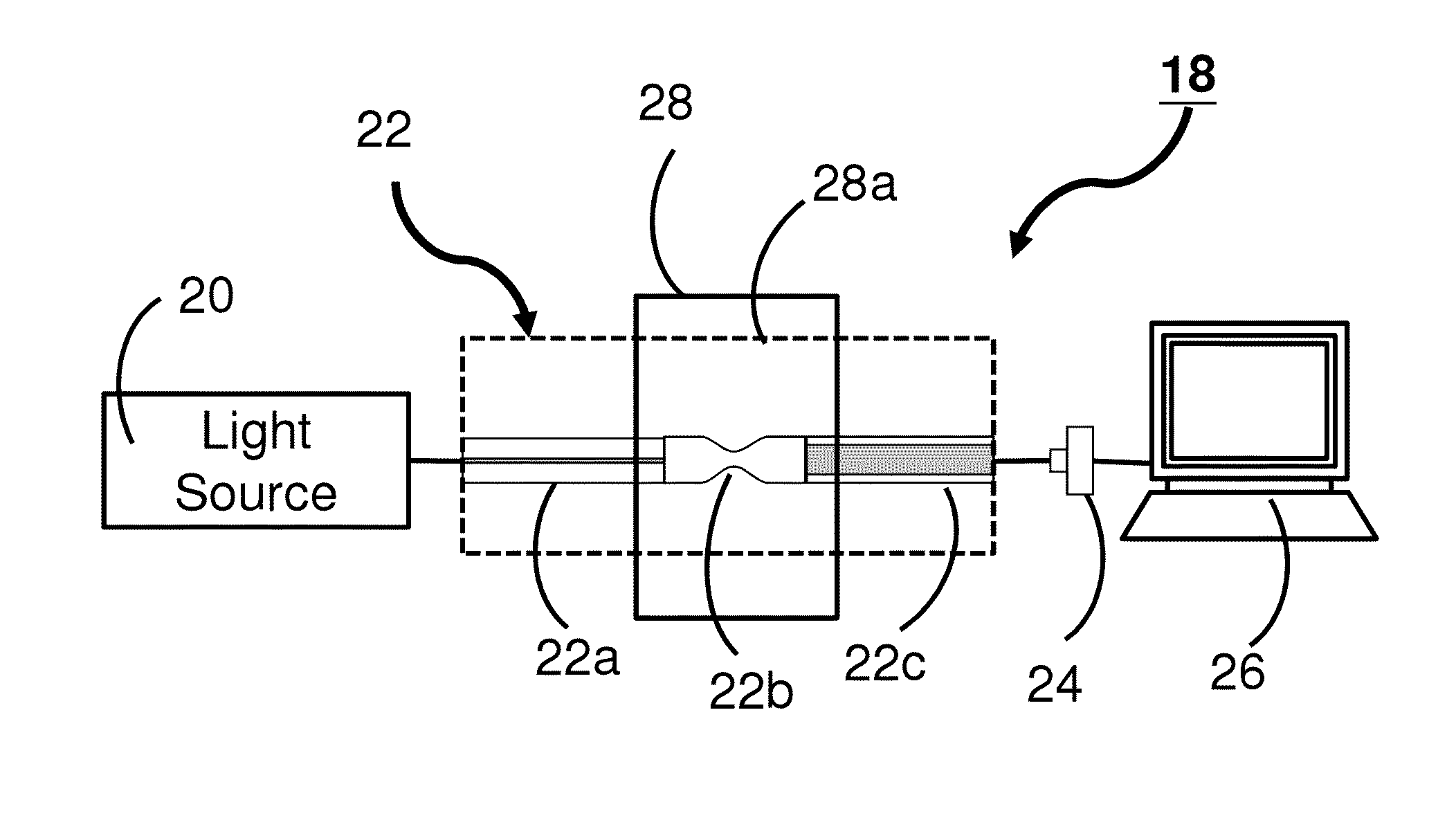

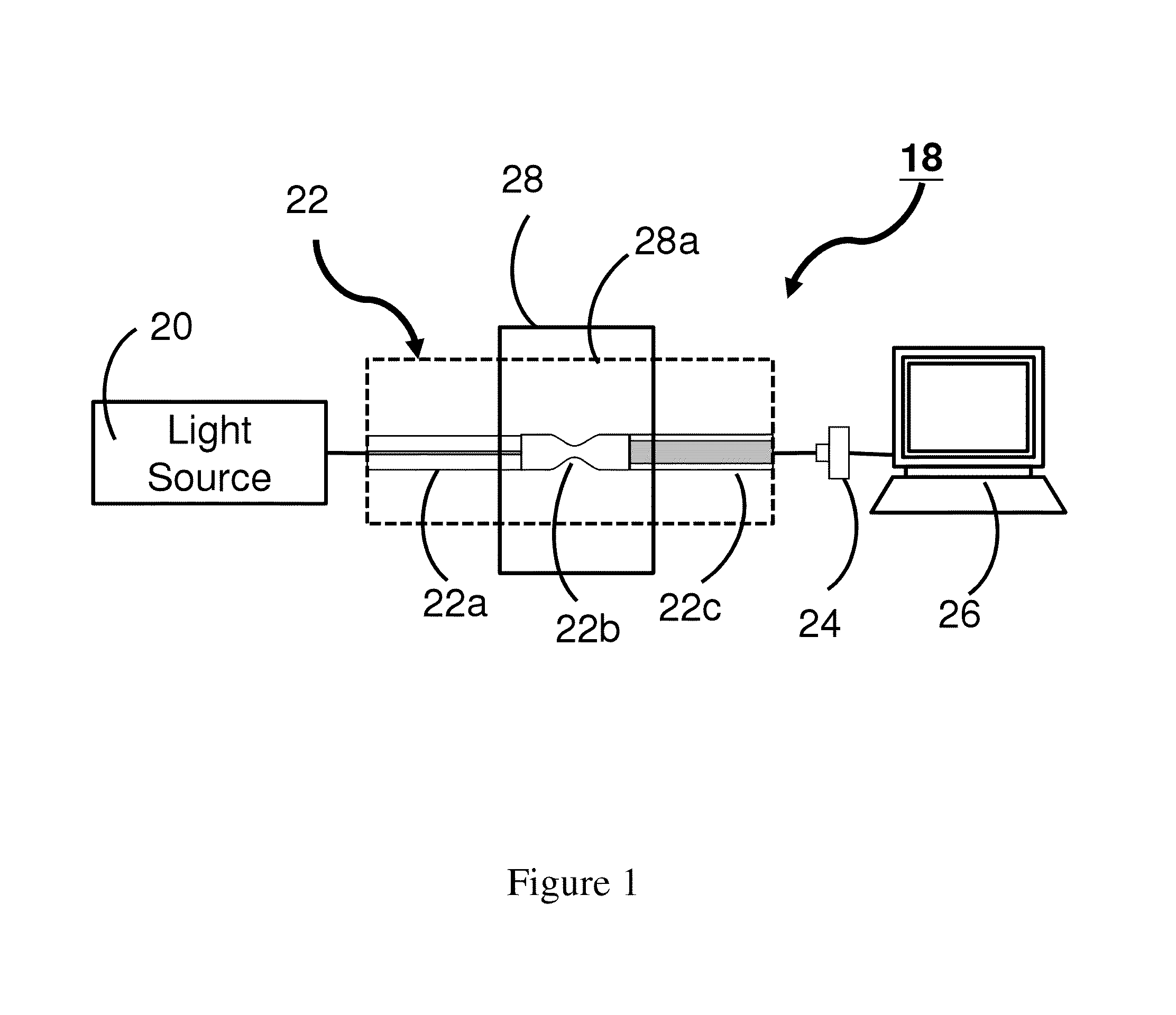

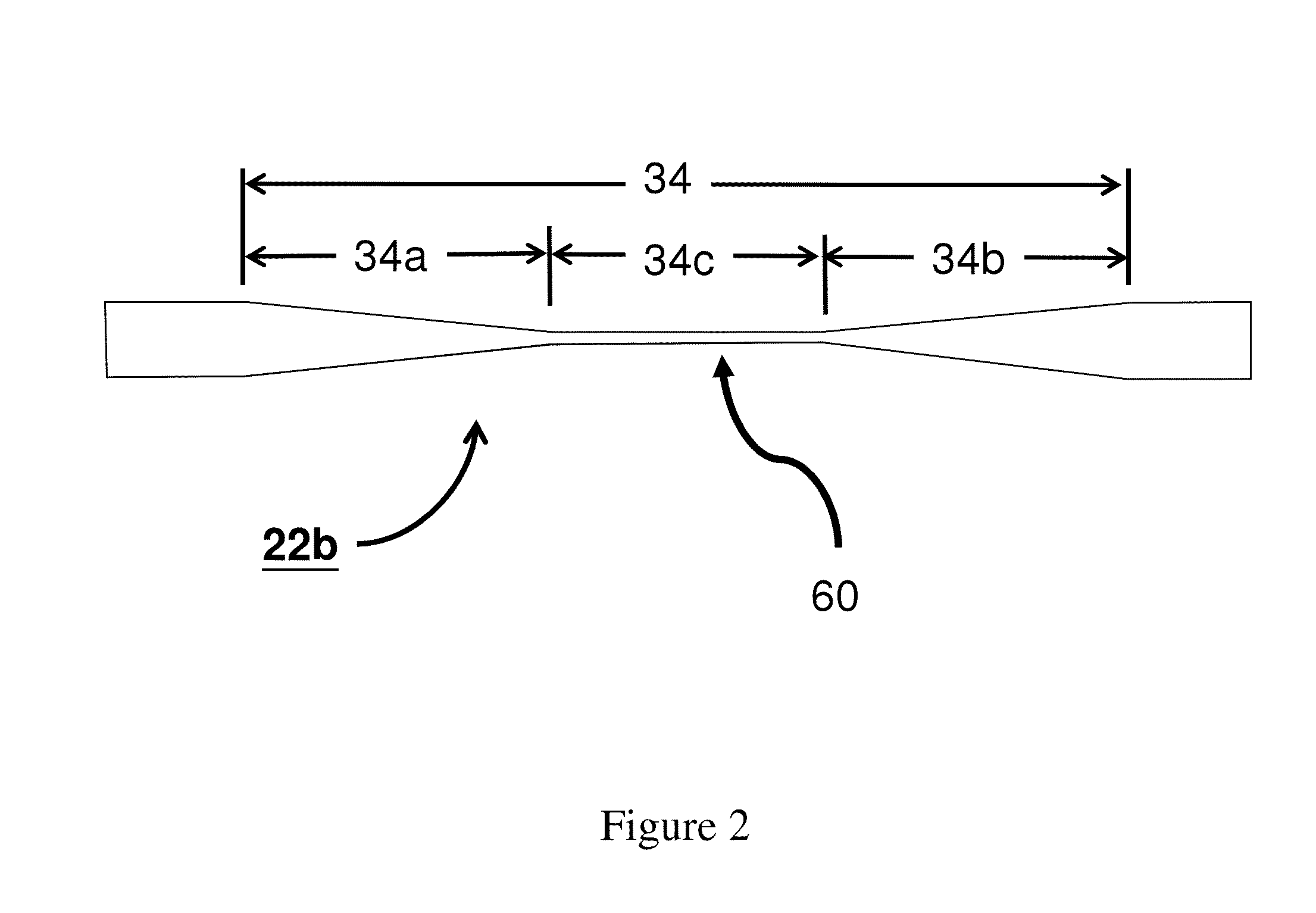

Optical Refractive Index Measuring System Based on Speckle Correlation

ActiveUS20140354979A1High sensitivityLow manufacturing difficultyPhase-affecting property measurementsAnalyteRefractive index

An optical detection system for measuring a refractive index of a liquid analyte comprising a light transmitting assembly fiber, which includes a single-mode fiber, an optical fiber sensing module and a multi-mode fiber. The optical detection system is configured to emit a coherent light beam to one end of the assembly fiber; and a detector is configured to capture a specklegram from an exit end of the assembly fiber. When the optical detection system is in operation, the optical fiber sensing module is configured to be submerged into the liquid analyte. By analyzing the correlation between the specklegram corresponding to the liquid analyte and the reference specklegram, the refractive index of the liquid analyte can be obtained.

Owner:MACAU UNIV OF SCI & TECH

Anchor rod pallet load visualization digital imaging method

ActiveCN107328502AEasy to useFast realization of 3D deformationForce measurement by measuring optical property variationUsing optical meansBack calculationEngineering

The invention relates to an anchor rod pallet load visualization digital imaging method suitable for a non-contact measurement method of a stressed underground anchor rod. The anchor rod pallet load visualization digital imaging method specifically comprises the following steps: a plurality of images of a pallet before and after a deformation is shot using a CCD camera, space identification is performed on the multiple images of the pallet before and after the surface deformation through adoption of a digital speckle correlation technology, a three-dimensional coordinate is obtained through calculation, a three-dimensional model before and after the surface deformation of the pallet is established through fitting, and data before and after the surface deformation of the pallet are obtained; and a strain field is obtained through a rapid three-dimensional deformation analysis and comparison of the three-dimensional space data before and after the deformation of the pallet, a stress field is obtained through a combination with pallet bending rigidity, and a real-time load of an anchor rod can be obtained through integral back calculation of the stress field. Compared with a traditional strain foil, a traditional displacement sensor, a traditional anchor rod puller and a traditional hydraulic pillow, the anchor rod pallet load visualization digital imaging method is advantageous in that usage of a pallet load visualization digital imaging technology is simple and convenient, and three-dimensional deformation and strain measurement are achieved rapidly.

Owner:CHINA UNIV OF MINING & TECH

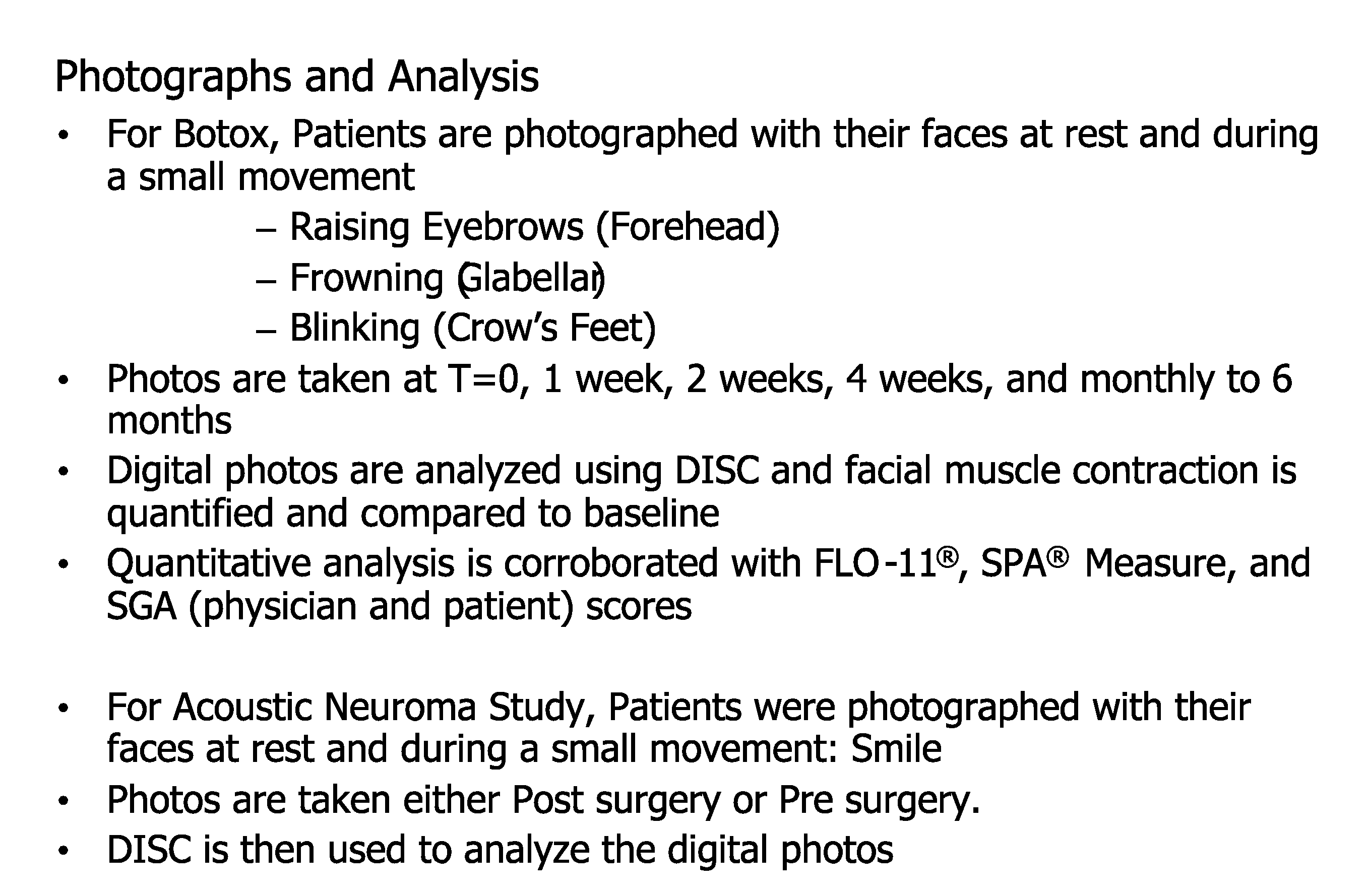

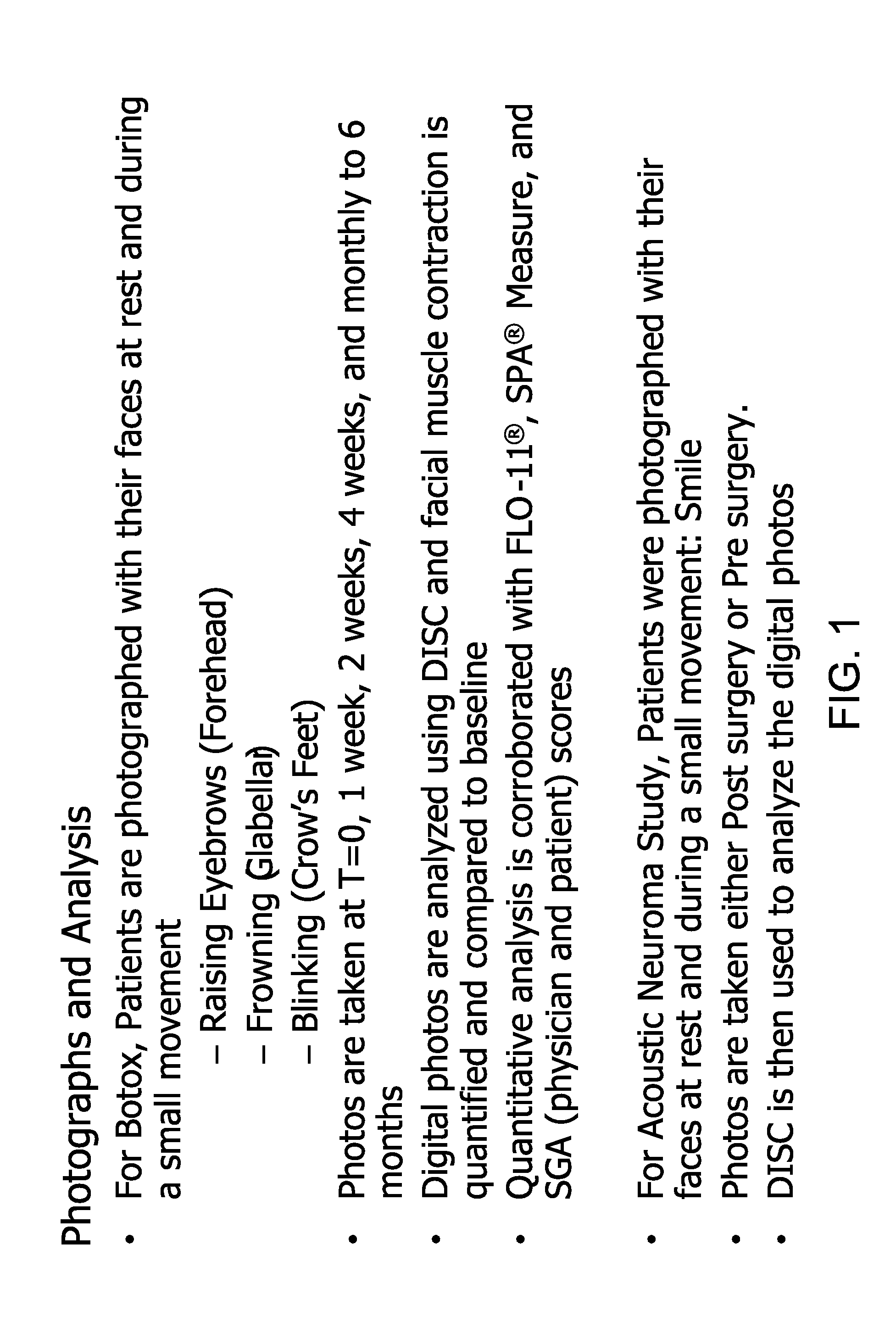

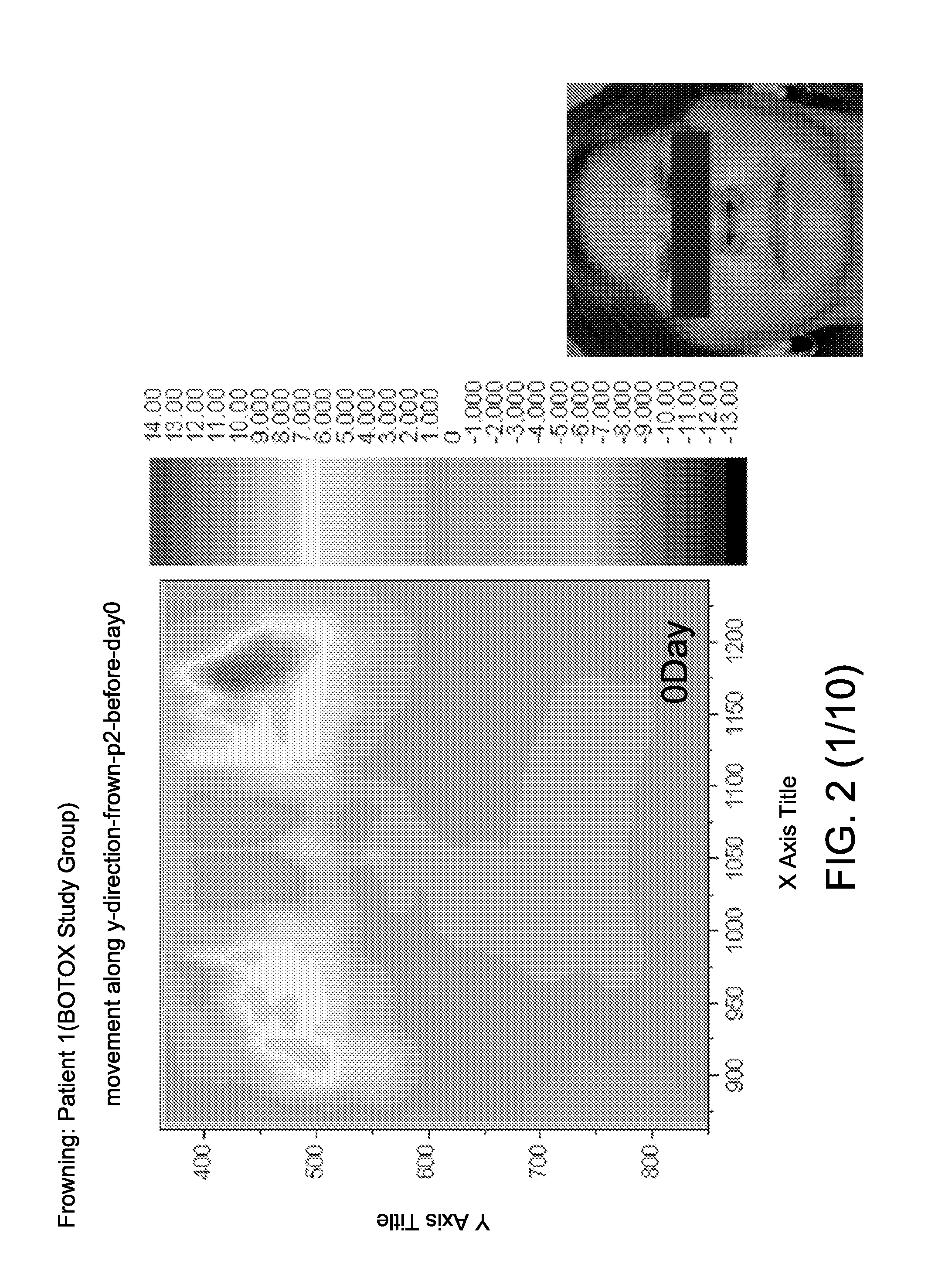

Methods Useful in Optimizing the Treatment of Neuropathies and Targeting Tissues with Cosmetic Botulinum Injections

InactiveUS20130123647A1Enhances clinical judgmentConvenient treatmentDiagnostic recording/measuringSensorsMedicineSpeckle correlation

The present invention pertains to methods of determining where, on the skin, a diagnostic, therapeutic, or cosmetic agent is likely to be most effectively applied (e.g., injected), and to methods for monitoring a patient after such an agent has been administered. The monitoring can produce information useful in determining whether a diagnostic, therapeutic (e.g., surgical), or cosmetic regime should be initiated, continued, continued in a modified fashion, or terminated (e.g., for a brief or prolonged period of time). The methods can be repeated periodically and use a non-invasive, in vivo form of digital image speckle correlation (DISC) to track deformation of the skin.

Owner:THE RESAERCH FOUND FOR THE STATE UNIV O

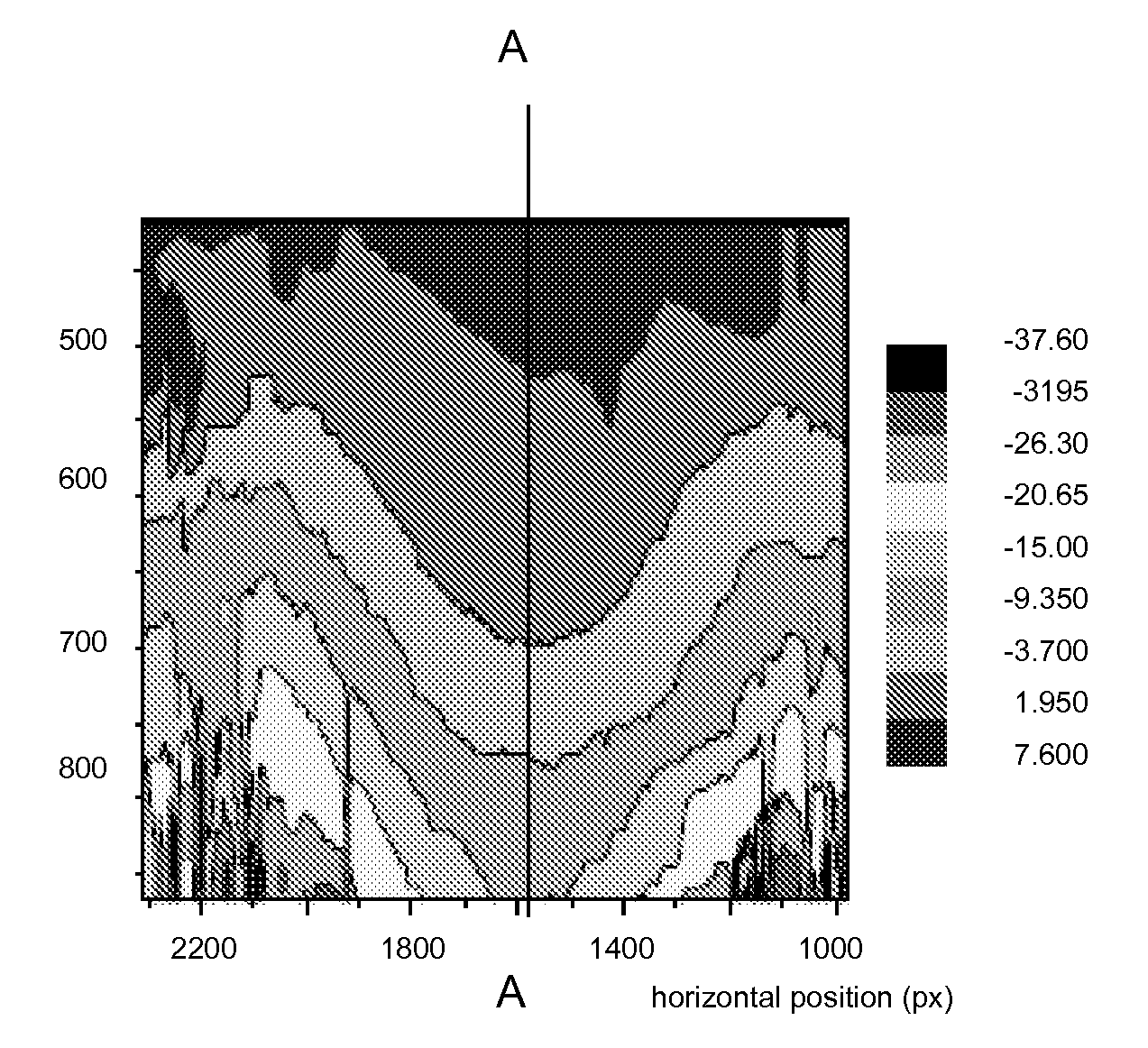

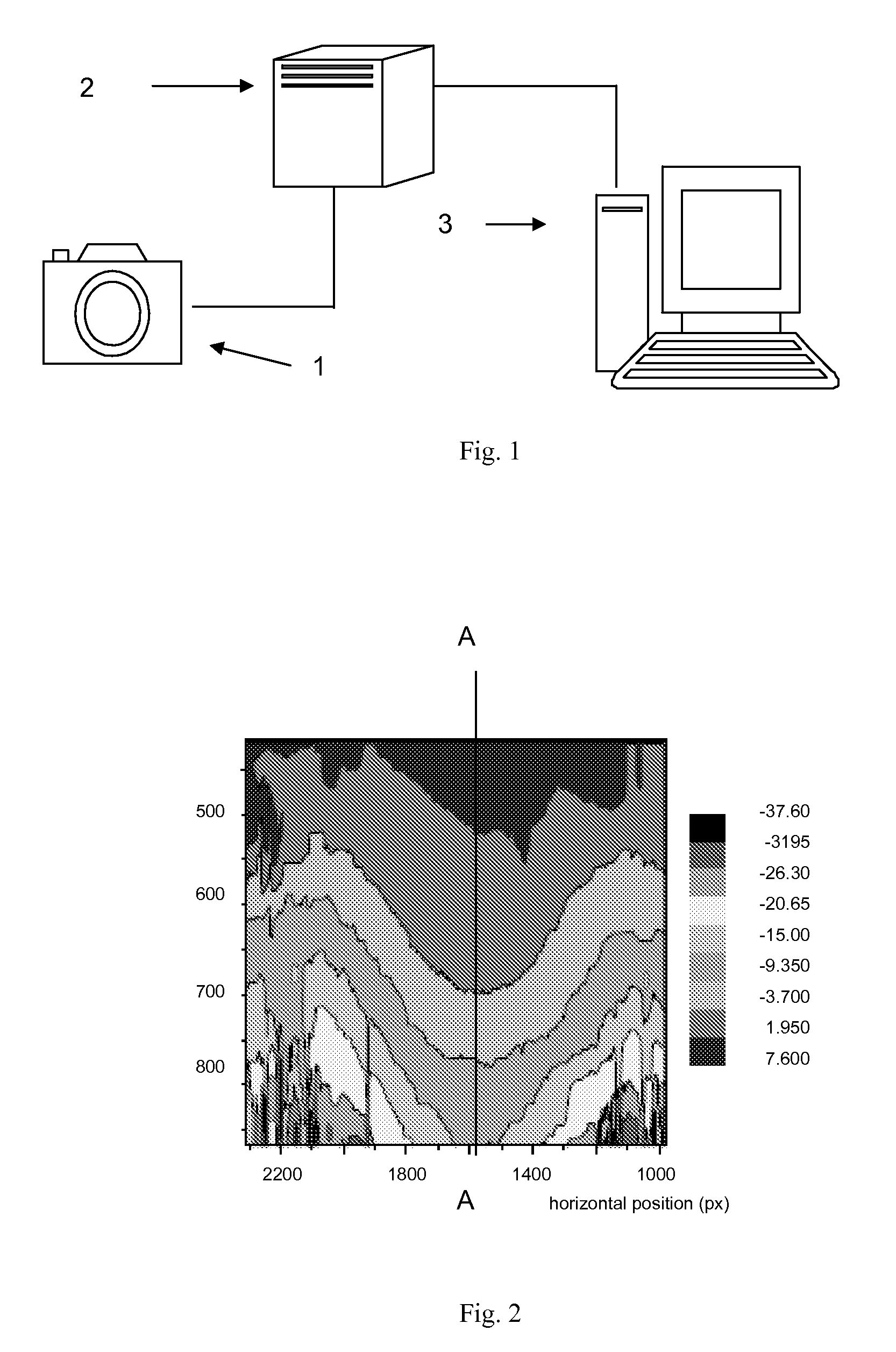

Evaluation Of Immediate-Effect Skin Molding Agents Using DISC

InactiveUS20090022665A1Good curative effectImprove comfortCompounds screening/testingCharacter and pattern recognitionNon invasiveSpeckle correlation

The present invention pertains to methods of characterizing the effects on the skin of skin-molding agents and to methods of characterizing the physical behavior of the skin-molding agents themselves. A preferred embodiment of the present invention uses a non-invasive, in vivo form of digital image speckle correlation to track deformation of human skin caused by the application of a skin-molding agent, in particular, an immediate-effect skin molding agent. The skin-molding agent may or may not be part of a composition. The application to the skin of a skin-molding agent may or may not be part of a treatment regimen. The present invention may be applied to any surface of the human body, to non-humans and to inert matter. Unlike in vitro methods and unlike invasive, in vivo methods that tension the skin with an apparatus, the present invention relies on the applied skin-molding agent to create before and after deformation images. From those images, it is possible to develop quantitative and qualitative characterizations of skin's movement and of the skin-molding agent itself. These characterizations will aid in the development of improved and / or customized skin molding agents and improved compositions comprising skin-molding agents. Generally, the data collected by the methods described herein, may also suggest improved and / or customized treatment regimens for molding the skin.

Owner:ELC MANAGEMENT LLC

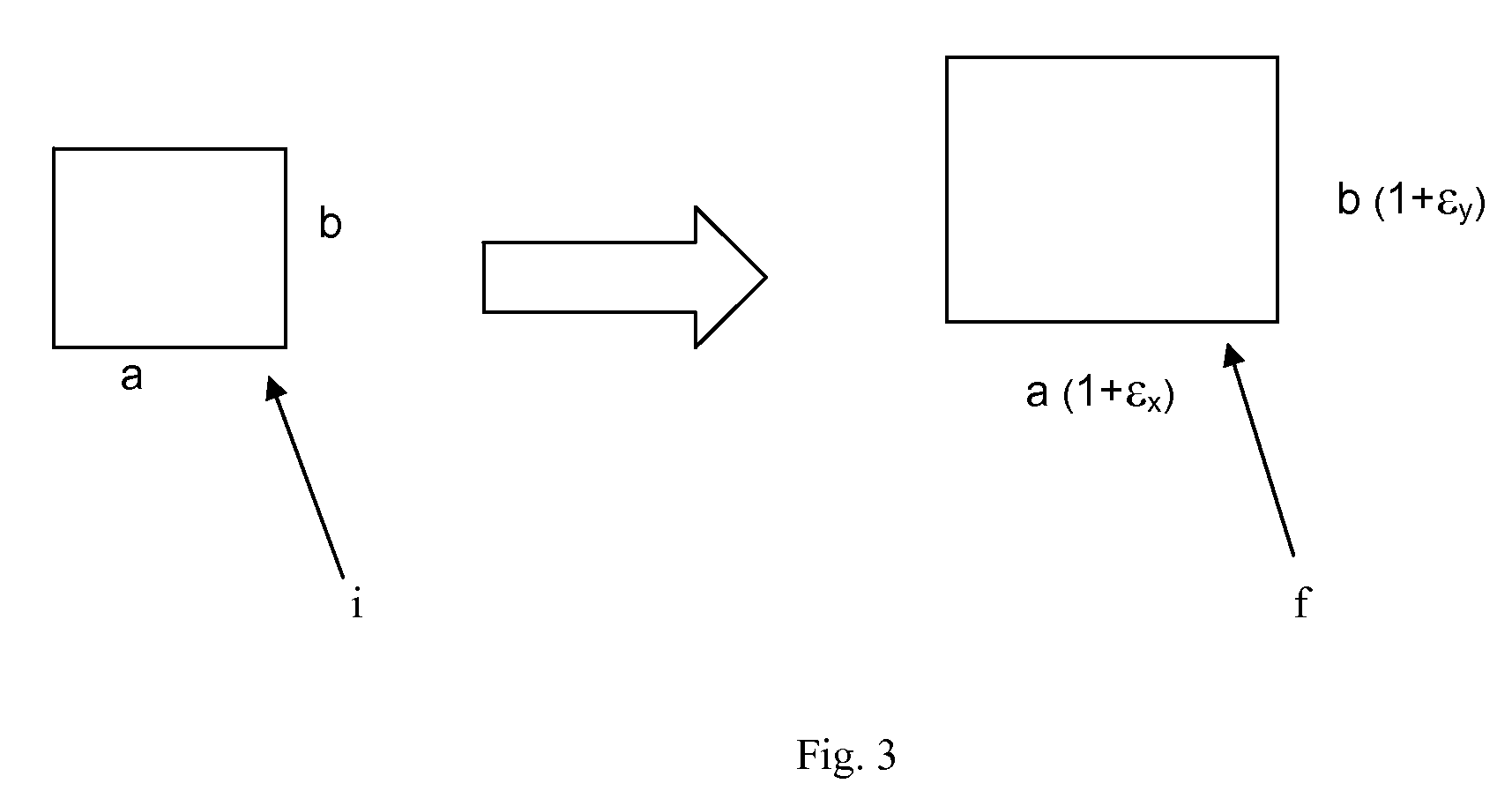

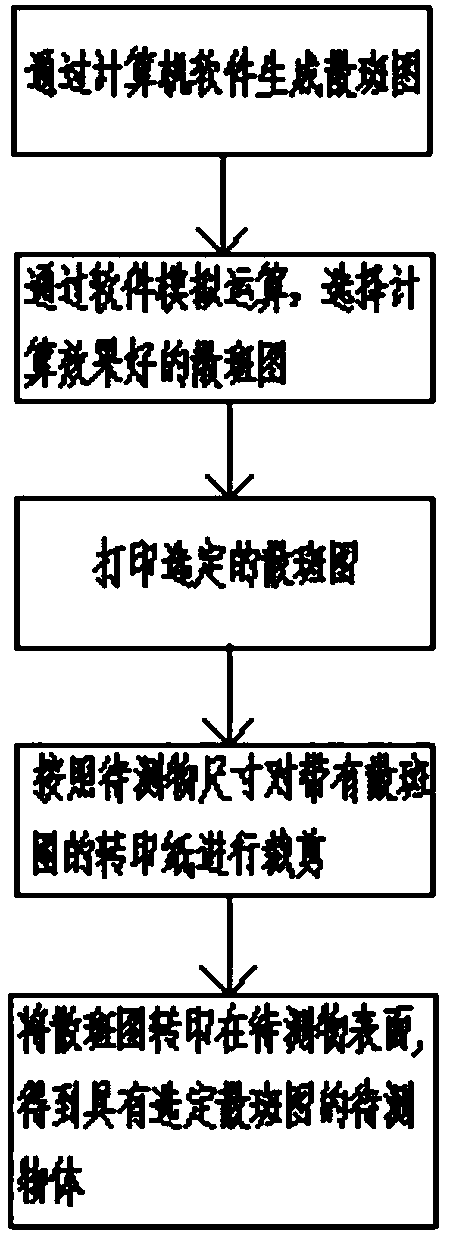

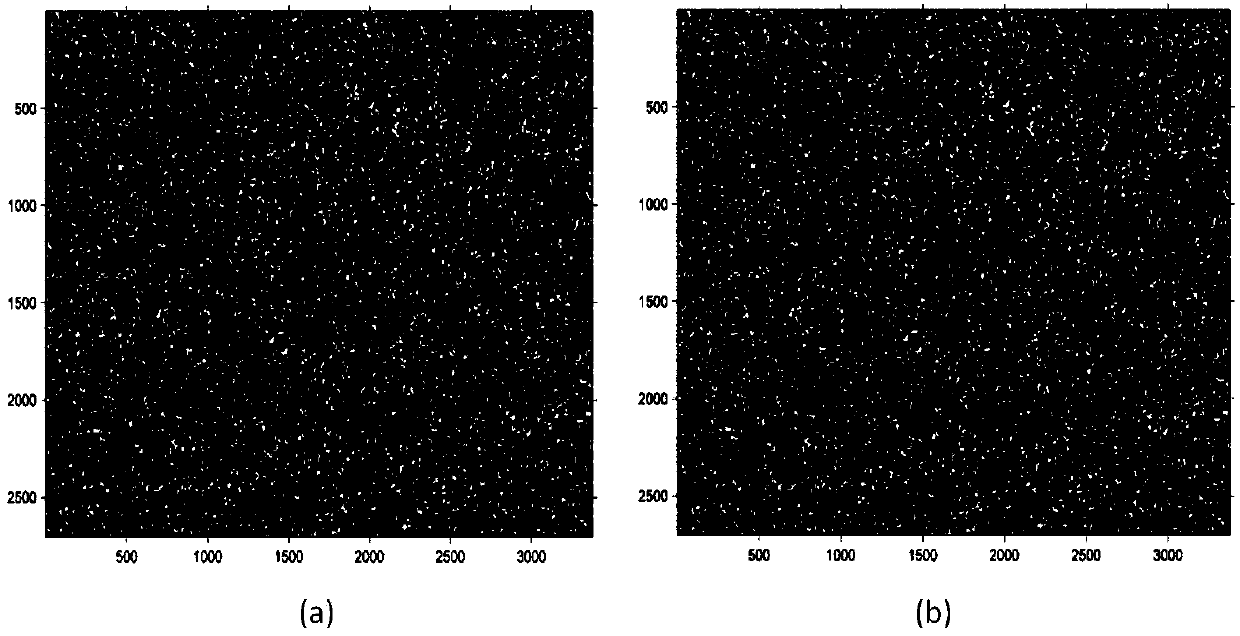

Speckle manufacturing method based on transfer print technology

InactiveCN103994727AImprove matchEasy to makeUsing optical meansSpeckle correlationComputer software

The invention provides a speckle manufacturing method based on a transfer print technology. The method includes the steps that the size, the number, the deformation and other parameters of speckles are input through computer software, so that two or more pairs of speckle images are generated; digital speckle correlation operation is performed on all the speckle images through the software, and the speckle image highest in speckle matching degree is selected according to the calculation result; the selected speckle image is printed; the speckle image is cropped according to the size of an object to be detected; the speckle image is arranged on the surface of the object to be detected in a transfer print mode through the transfer print technology, so that the object, to be detected, including the selected speckle image is obtained. The speckle manufacturing method has the advantages of being easy and rapid to manufacture, convenient to operate, high in precision, low in price and wide in application range.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Image correcting system for deformation measurement of speckle correlation methods

InactiveCN103673912AImprove reliabilityHigh sensitivityUsing optical meansCamera lensSpeckle correlation

An image correcting system for deformation measurement of speckle correlation methods is provided. The image correcting system comprises an outer direction mark, a light source, a CCD, a camera support and an image data acquiring and processing device. The outer direction mark is attached to the middle of the plane of a speckle to be measured, the light source is arranged at the front end of a lens of the CCD and is coaxial with the lens, and the CCD is fixed to the camera support and connected with the image data acquiring and processing device. The camera support is used for fixing the CCD and the light source and ensuring the relative fixed position relation. The image data collecting and processing device is connected with the light source and the CCD through wires at the same time. The image correcting system for deformation measurement of speckle correlation methods can conduct initial posture evaluation on the acquired speckle image in the deformation measurement process of the speckle correlation methods, fast identification and locating are conducted on the outer direction marker on the speckle image to be corrected, and the three-dimensional coordinate is resolved, so that the flexibility and speed of strain measurement of the speckle are improved, and reliability of the deformation measurement is improved to a certain degree.

Owner:CIVIL AVIATION UNIV OF CHINA

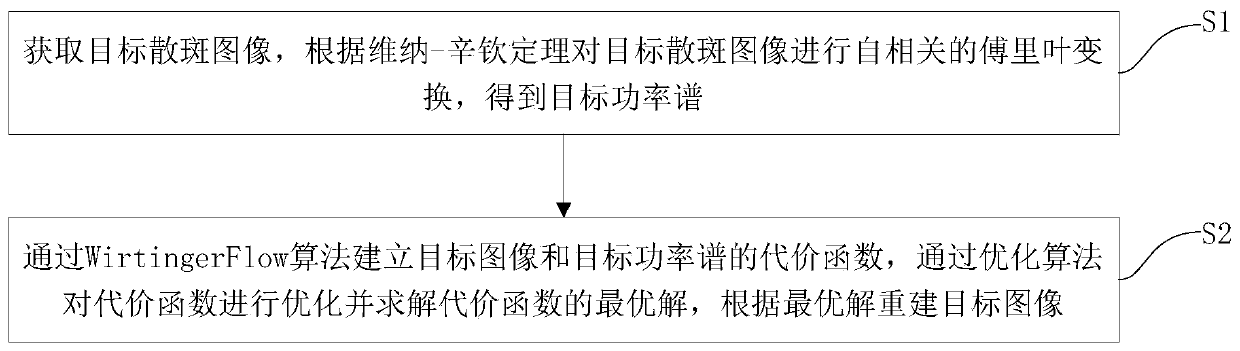

Speckle correlation imaging method and speckle correlation imaging device based on Wirtinger Flow algorithm

ActiveCN110807822AImprove robustnessQuality improvementImage enhancementReconstruction from projectionAlgorithmSpeckle correlation

The invention discloses a speckle correlation imaging method and device based on a Wirtinger Flow algorithm, and the method comprises the steps: S1, obtaining a target speckle image, and carrying outthe autocorrelation Fourier transform of the target speckle image according to the Wiener-Khinchin theorem, and obtaining a target power spectrum; and S2, establishing a cost function of the target image and the target power spectrum through a Wirtinger Flow algorithm, optimizing the cost function through an optimization algorithm, solving an optimal solution of the cost function, and reconstructing the target image according to the optimal solution. According to the method, the robustness of the target reconstruction process to measurement noise and system distortion can be improved, any prior information of the target is not needed, and the quality of the reconstructed target is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

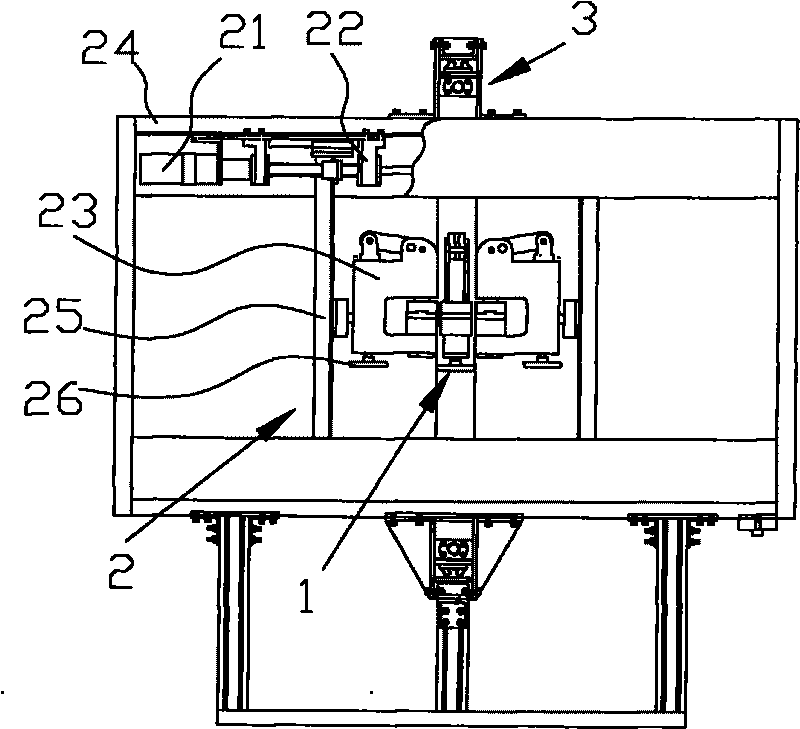

Mechanical property test method for fabric and textile structural composite materials

InactiveCN101694444AThree-dimensional multi-directional force failure performance is accurateAccurate analysisMaterial strength using tensile/compressive forcesMethod testFiber

The invention provides a mechanical property test method for fabric and textile structural composite materials. The test method includes steps of tensioning or compressing to-be-tested materials in an X-axis direction and / or a Y-axis direction by aids of an X-axis tension and compression unit and / or a Y-axis tension and compression unit, exerting abutting force along a direction which forms an included angle of 90 degrees with a plane of the X-axis and the Y-axis by a vertical bursting unit when performing X-axis tensioning and / or Y-axis tensioning on fabric and textile structural composite materials, and measuring deformation of the to-be-tested materials when damaged by force via a digital speckle correlation method test unit (DSCM). By performing one-way tension and compression and two-way tension and compression tests on the to-be-tested materials and exerting the vertical abutting force to observe vertical bursting property of the to-be-tested materials when performing tension test on the to-be-tested materials, accurate analysis and predication to three-dimensional multidirectional stressed damage property of the to-be-tested materials is realized.

Owner:湖北楚风竹韵科技有限公司

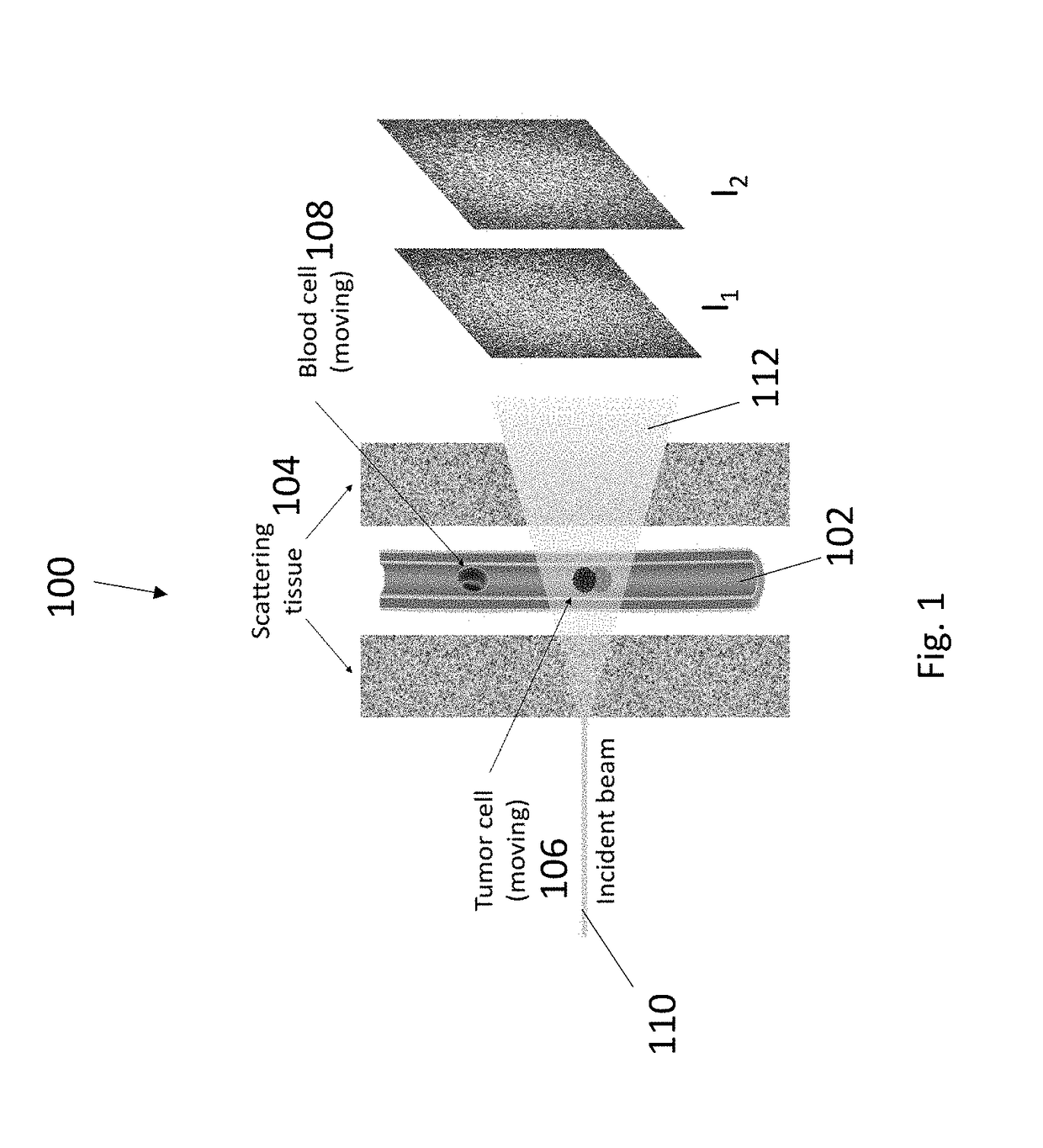

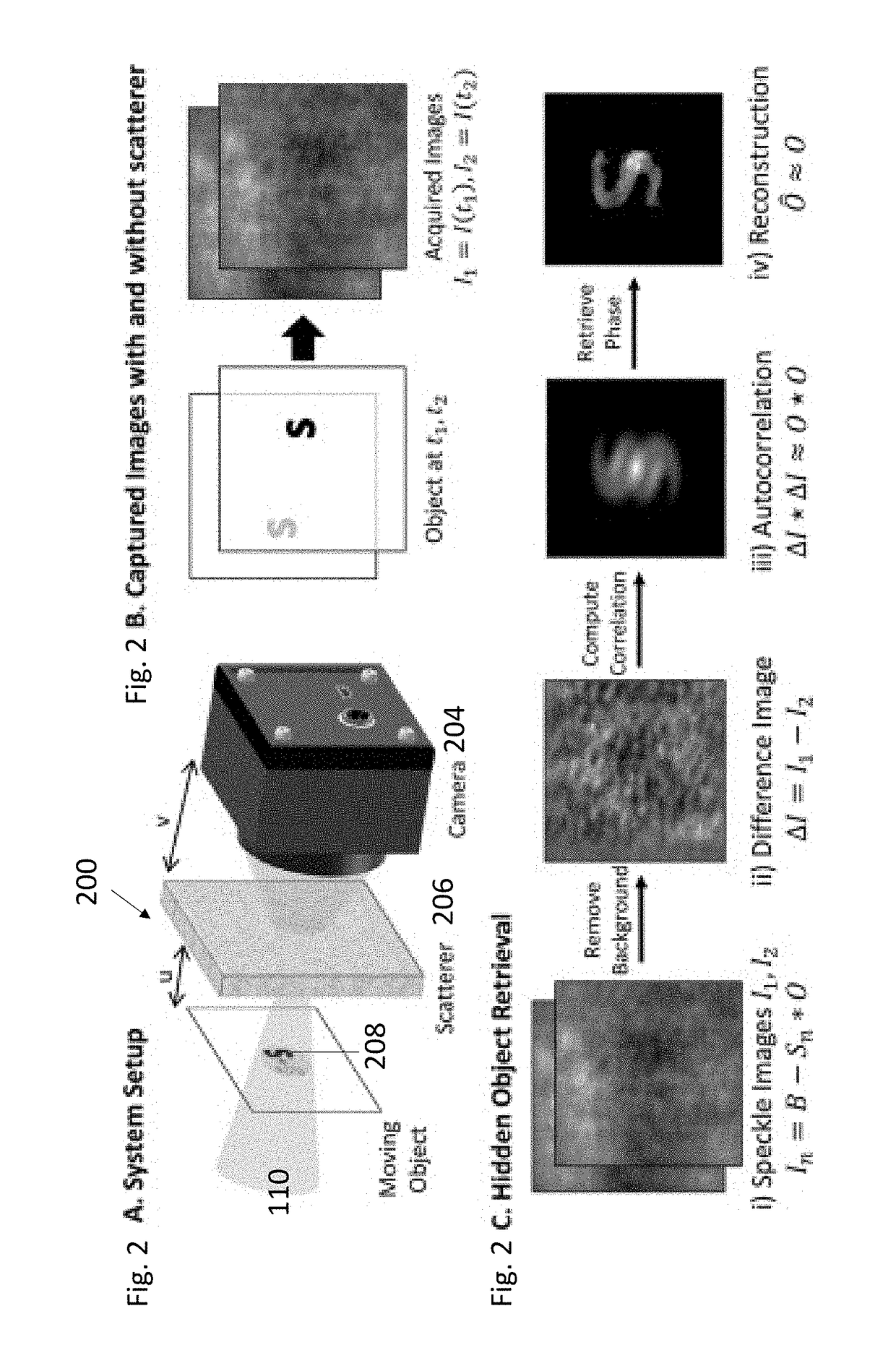

Noninvasive, label-free, in vivo flow cytometry using speckle correlation technique

A system and method for performing speckle correlation flow cytometry (SCFC). By subtracting out the stationary background when shining light through a sample (e.g., a vessel within a biological tissue), light only scattered by the desired targets (e.g., cells) can be captured and different types of targets (e.g., cells) can be distinguished by the autocorrelation of the speckle pattern. In this way, the targets (e.g., cells) can be classified and counted based on the features of their speckle correlations. The technique can be applied not only for noninvasive, label-free, in vivo CTC counting but also for counting other types of blood cells such as white blood cells or red blood cells.

Owner:CALIFORNIA INST OF TECH

A dual-optical-path three-dimensional speckle interference system based on spectroscopes

InactiveCN106052565ASimple structureEasy to measureUsing optical meansLaser processingThermal deformation

The invention discloses a dual-optical-path three-dimensional speckle interference system based on spectroscopes. The system comprises a laser, a first spectroscope, a second spectroscope, a third spectroscope, a fourth spectroscope, a fifth spectroscope, a first totally-reflecting mirror, a second totally-reflecting mirror, a third totally-reflecting mirror, a fourth totally-reflecting mirror, a first beam expanding mirror, a second beam expanding mirror, an amplification system and a CCD camera. The advantages are that transient three-dimensional displacement in the laser processing process can be given, and time and space resolution capability can be improved with further development of a high-speed photography system and a long-distance microscope; and electronic speckle interferometry and digital speckle correlation are combined organically and respective advantages thereof are utilized, thereby facilitating measurement and providing effective and practical experimental means for micro-scale transient three-dimensional thermal deformation needed in the study of laser processing.

Owner:TIANJIN UNIV

Using DISC to Evaluate The Emotional Response Of An Individual

InactiveUS20080043025A1Improve FACS-basedImproved odorous compositionAnimationAcquiring/recognising facial featuresPattern recognitionSpeckle correlation

The present invention comprises the use of Digital Image Speckle Correlation (DISC) to map facial deformations due to voluntary and / or involuntary, often subtle, facial expressions. The facial expressions may be the result of a response to internal or external stimuli. It is possible to develop quantitative and qualitative characterizations of the individual's response. The techniques of the present invention can be used to extend and improve the FACS, which includes assigning human emotions to facial expressions. It is also possible to use test subject feedback to correlate facial expressions to human emotion.

Owner:ELC MANAGEMENT LLC

Crane static stiffness measuring method and device

InactiveCN108489692AEliminate points that are not in the middle of the girderEliminate disadvantages such as the need to paste markersElasticity measurementSpeckle correlationMagnification

The invention discloses a crane static stiffness measuring method, which belongs to the technical field of digital close range measurement. Digital images of a crane girder before and after loading ofthe crane are acquired respectively, based on a digital speckle correlation measurement technology, the number of moving pixels of steel beam digital images before and after deformation on the targetsurface of an image plane image sensor is calculated, an image distance and an included angle between an image acquisition system and a horizontal plane are measured, the system magnification is calculated, the actual displacement before and after loading of the crane girder is thus calculated, and a girder stiffness numerical value is obtained. The method and the device have the advantages of long distance, non contact and no need of pasting of a marker, and can be applied to displacement measurement under effects of displacement load along any point under the crane girder, the test result is high in precision, the use is convenient, and the test speed is quick.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

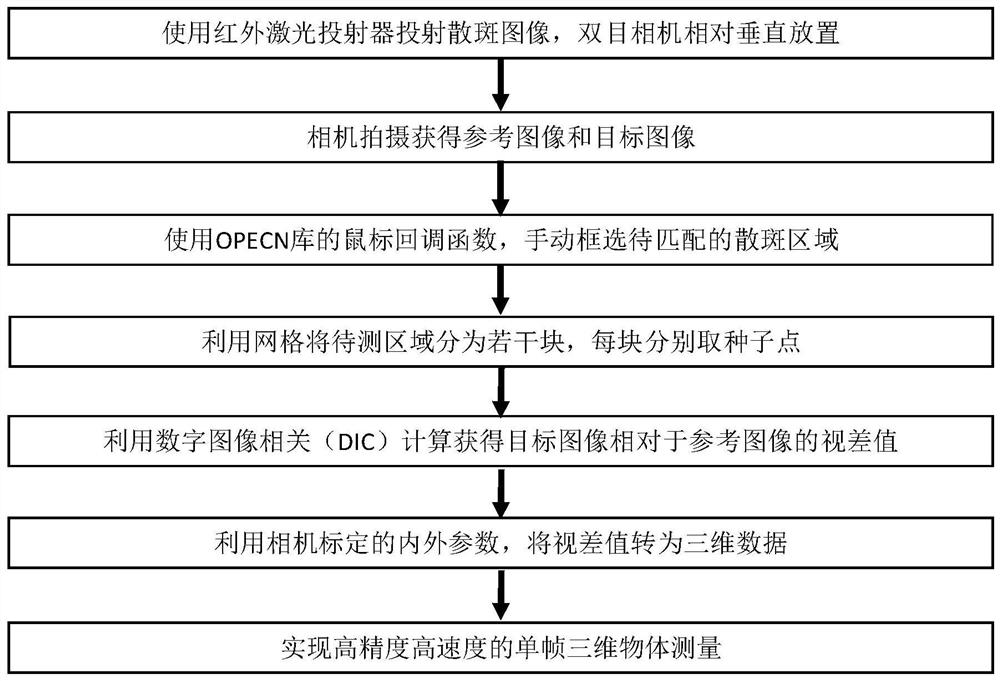

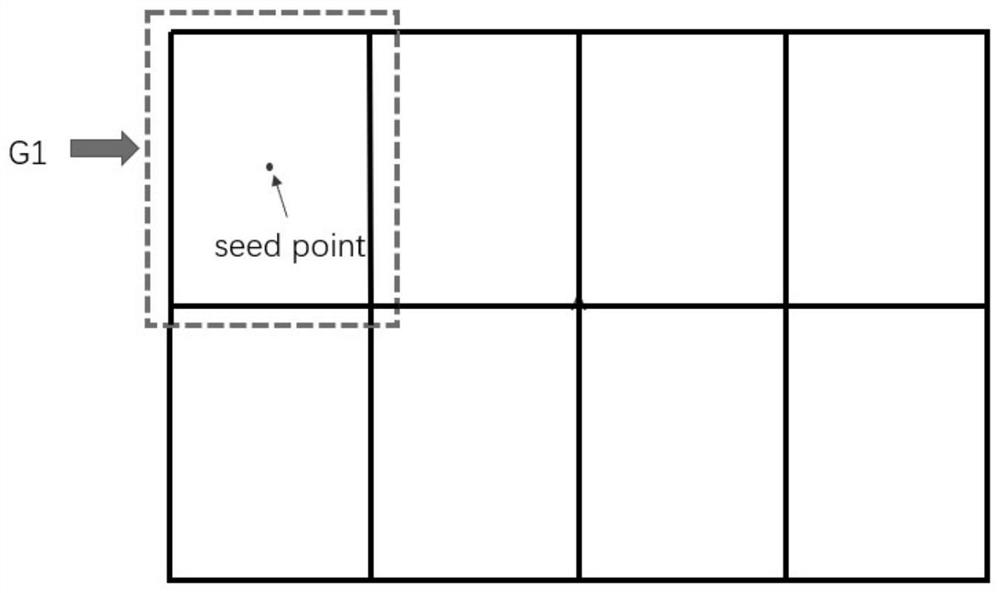

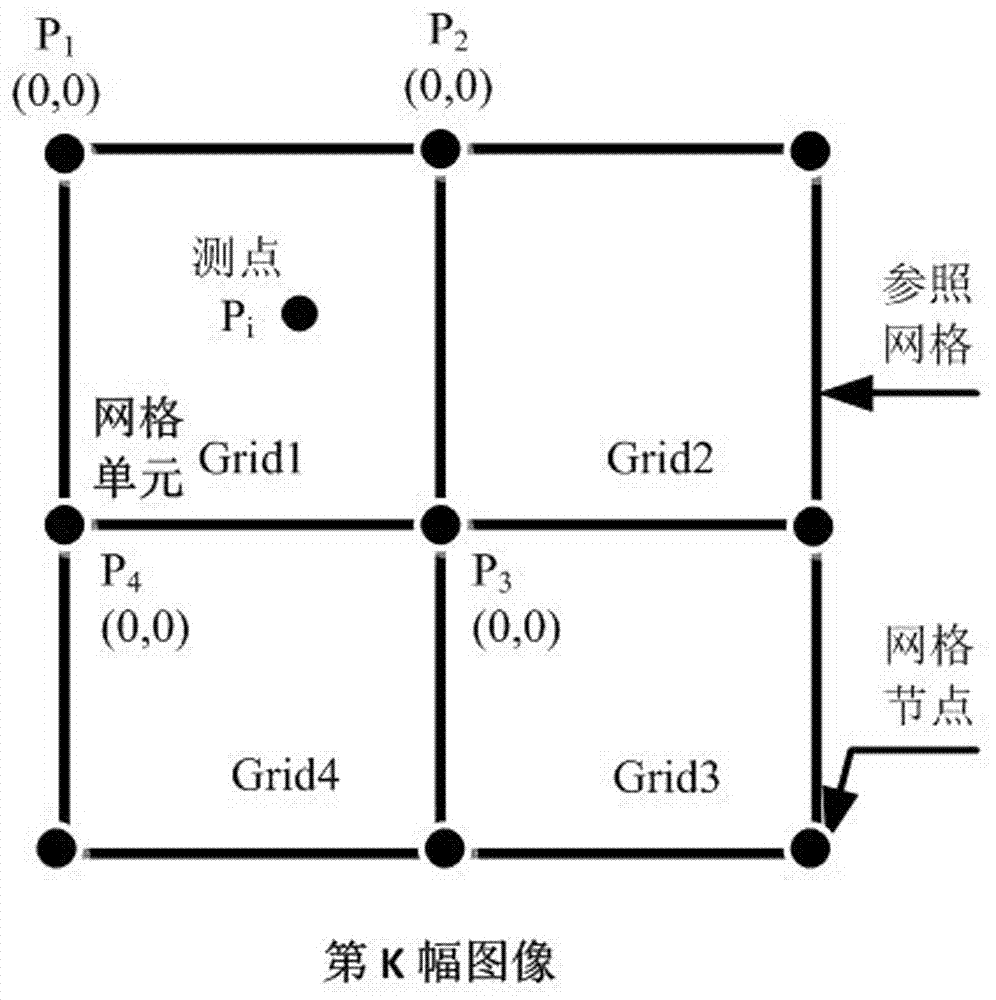

Digital speckle correlation rapid implementation method for extracting seed points based on grids

ActiveCN113091608AEase of parallel processingImprove computing efficiencyImage enhancementImage analysisImage calibrationSpeckle correlation

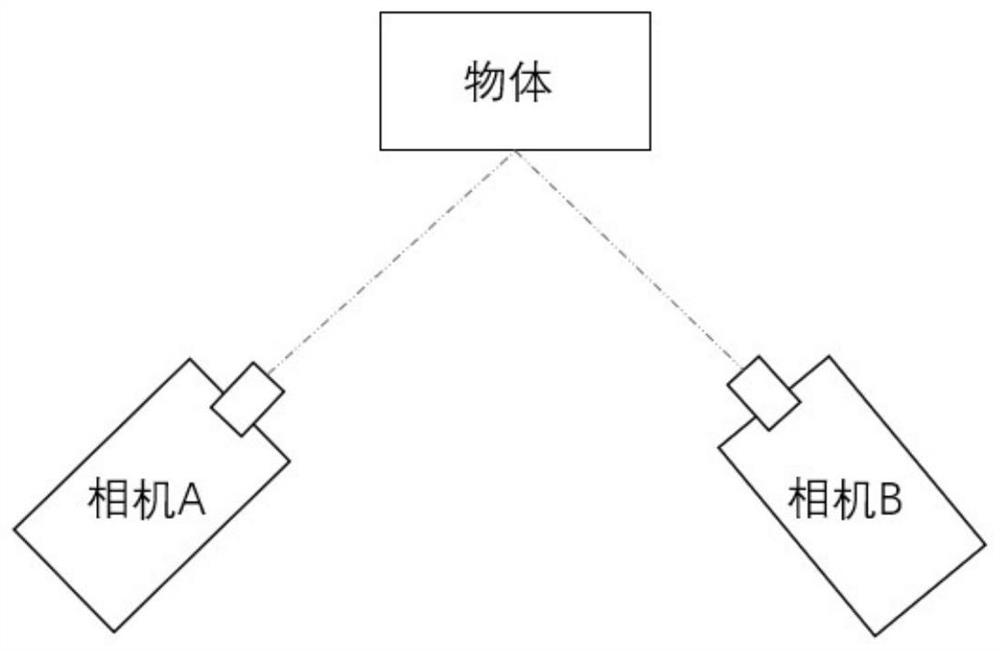

The invention discloses a digital speckle correlation rapid implementation method for extracting seed points based on grids, which comprises the following steps of projecting a speckle image to an object to be measured by using an infrared laser projector, and shooting the image by using a binocular camera, calibrating the cameras, acquiring internal and external parameters of the cameras, enabling the two cameras to shoot two-dimensional speckle images of an object respectively, enabling one image to serve as a reference image, and the other image to serve as a target image, using a mouse callback function of the OpenCV library to frame out a speckle region to be measured in the reference image, dividing the speckle area to be measured into eight blocks with the same size by using grids, and setting the central point of each block as a seed point, solving the parallax value of each point in the speckle areas to be measured of the reference image and the target image by using a digital image correlation algorithm, and converting the parallax value into three-dimensional data by using internal and external parameters calibrated by a camera, and performing 3D reconstruction. According to the method, the calculation efficiency is remarkably improved while the high measurement precision is ensured.

Owner:NANJING UNIV OF SCI & TECH

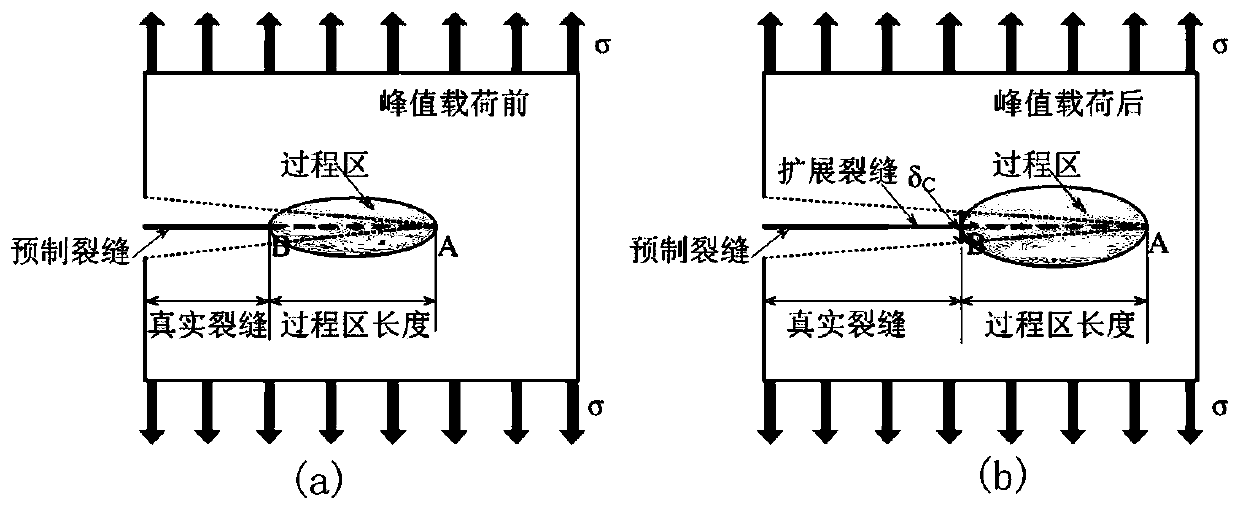

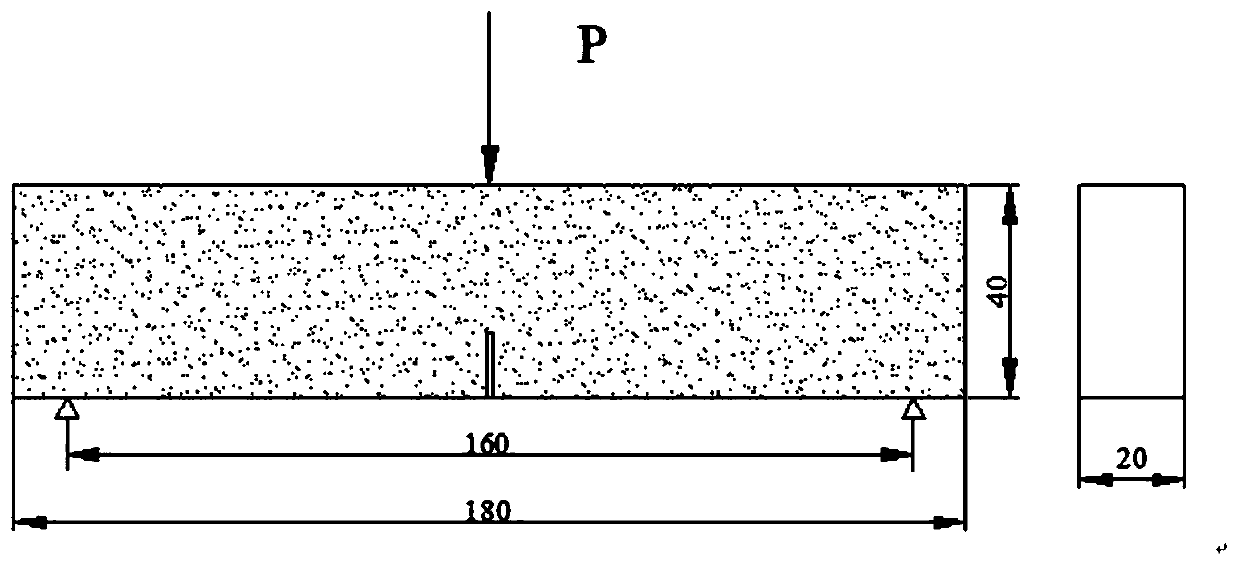

Method for determining length of fracture process region of rock-like material

InactiveCN110726625AAvoid dependenceSure method is accurateMaterial strength using steady bending forcesUsing optical meansComputational scienceSpeckle correlation

The invention relates to a method for determining the length of a fracture process region of a rock-like material, and belongs to the technical field of rock mechanics and engineering. On the theoretical basis of a virtual crack model, displacement field data within the vicinity of the fracture process region are obtained by a digital speckle correlation method DIC, and the position of a tip of the process region is judged by using the Laida criterion to calculate the length of the fracture process region. The method for determining the fracture process region is more accurate, and the dependence on the data processing experience when determining the position of the tip of the process region is avoided.

Owner:ZHONGBEI UNIV

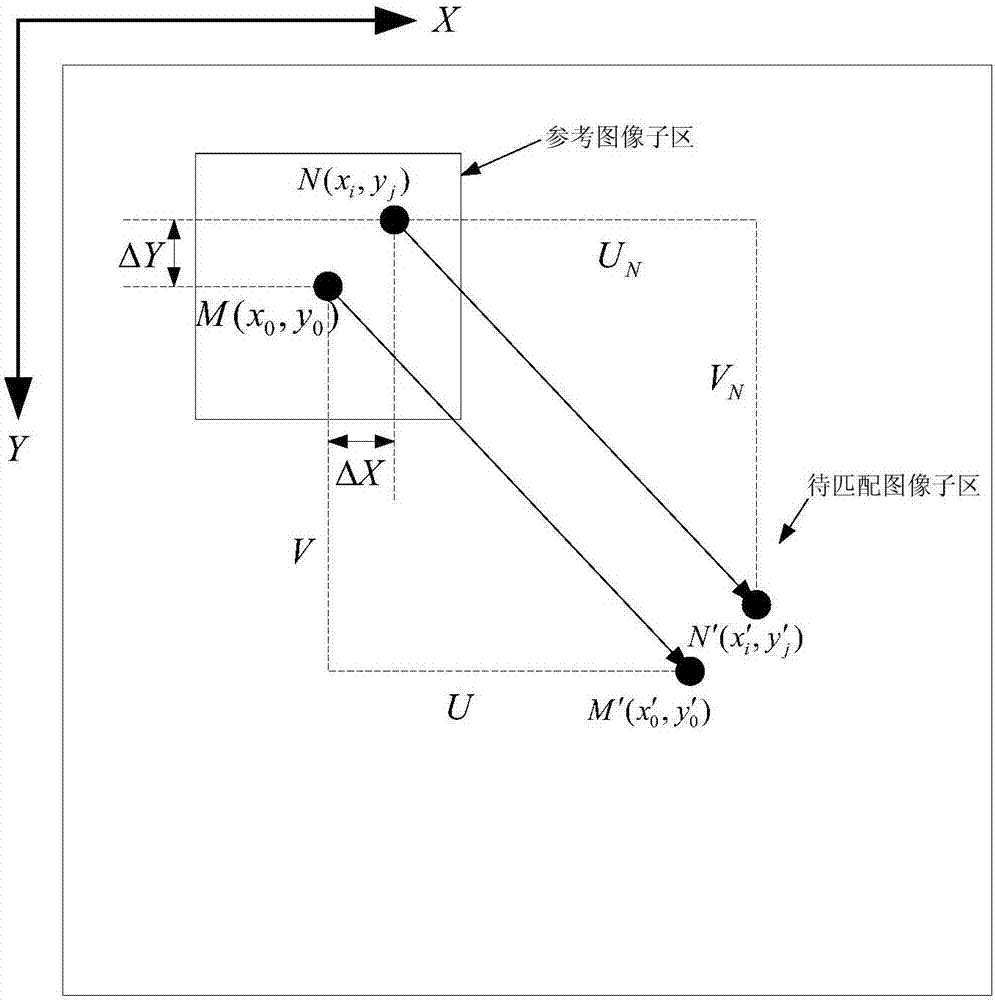

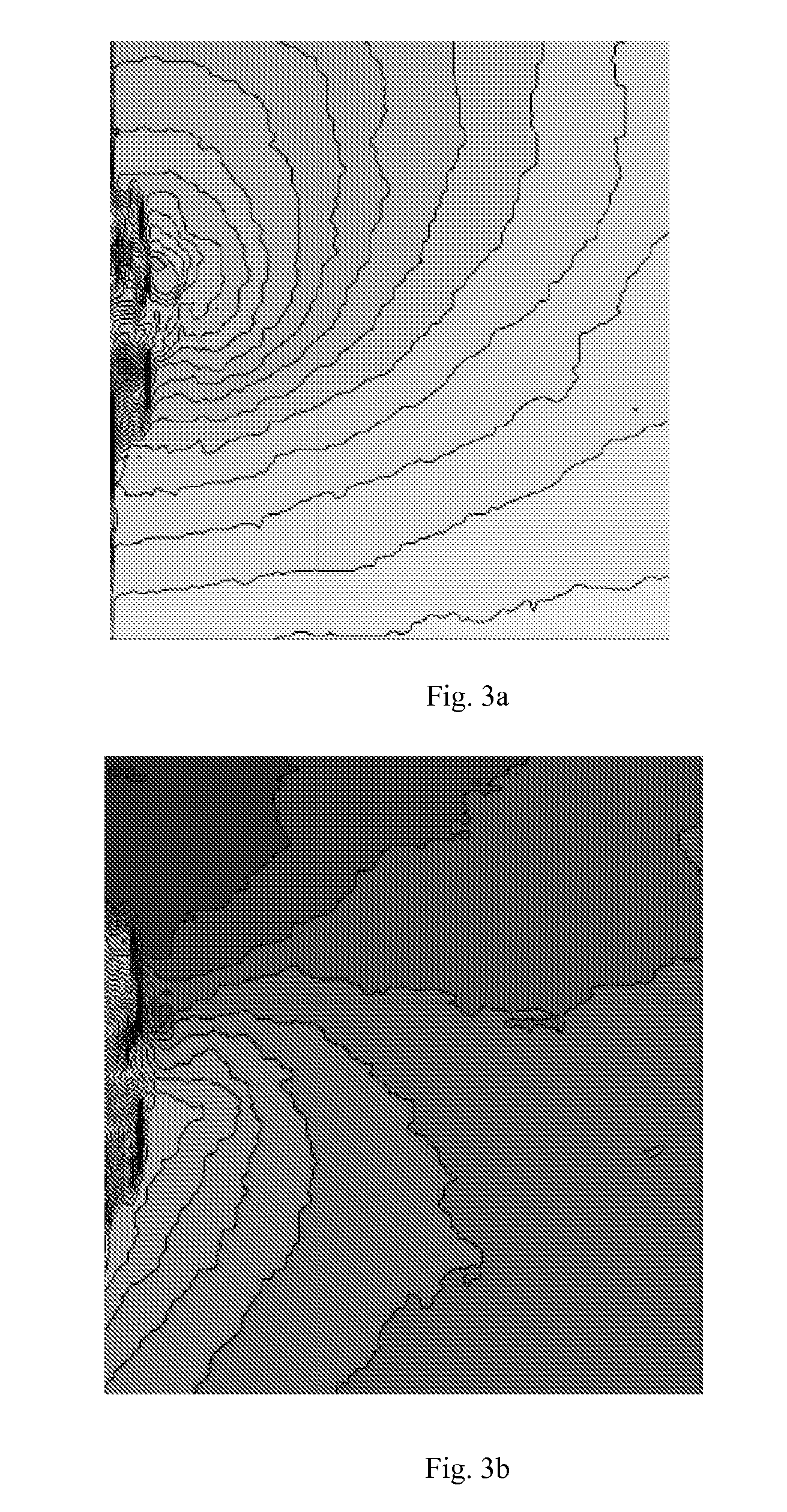

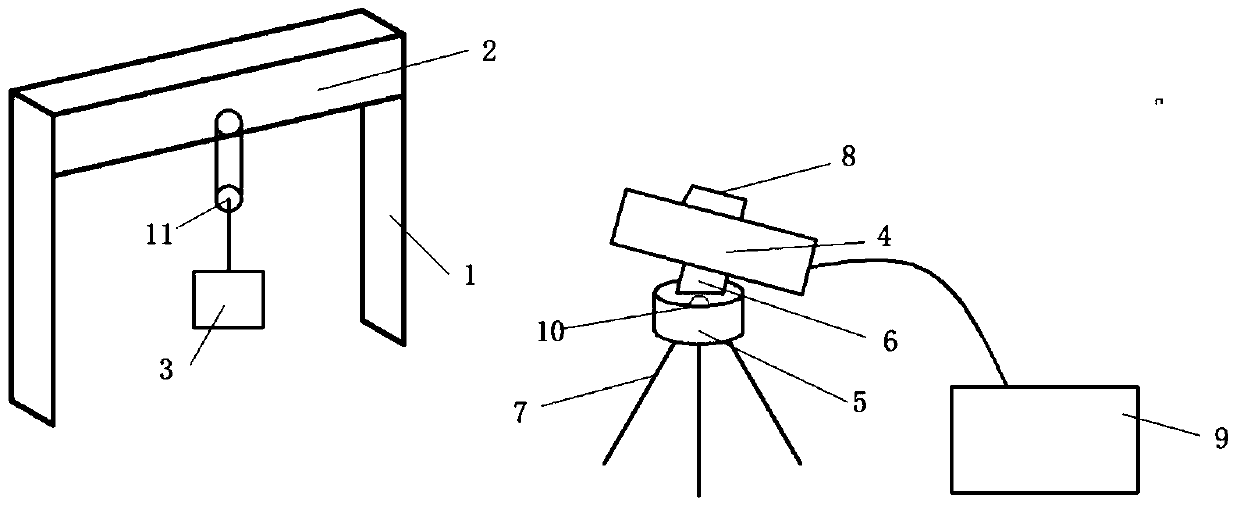

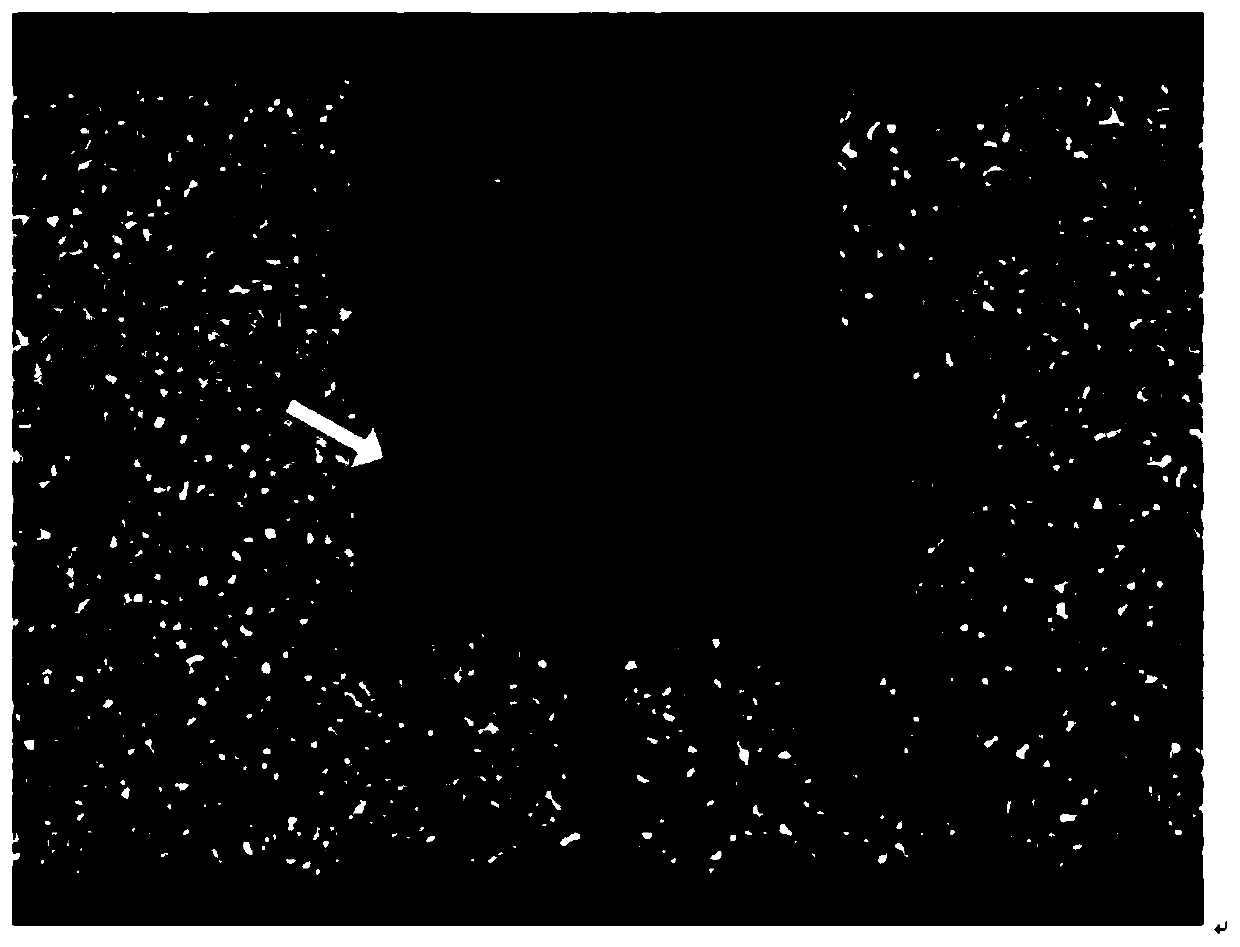

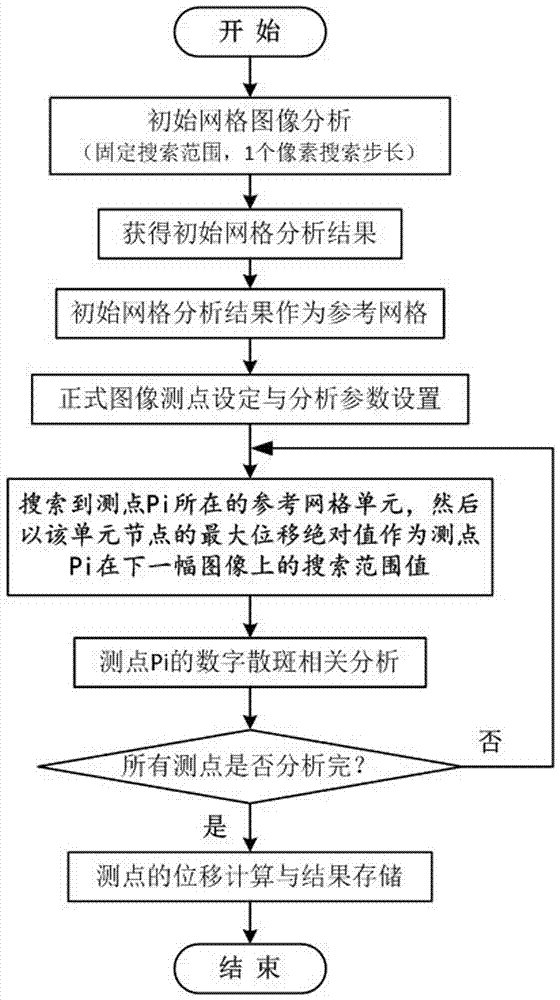

DSCM analyzing method based on geotechnical material deformation space-time non-uniform characteristics

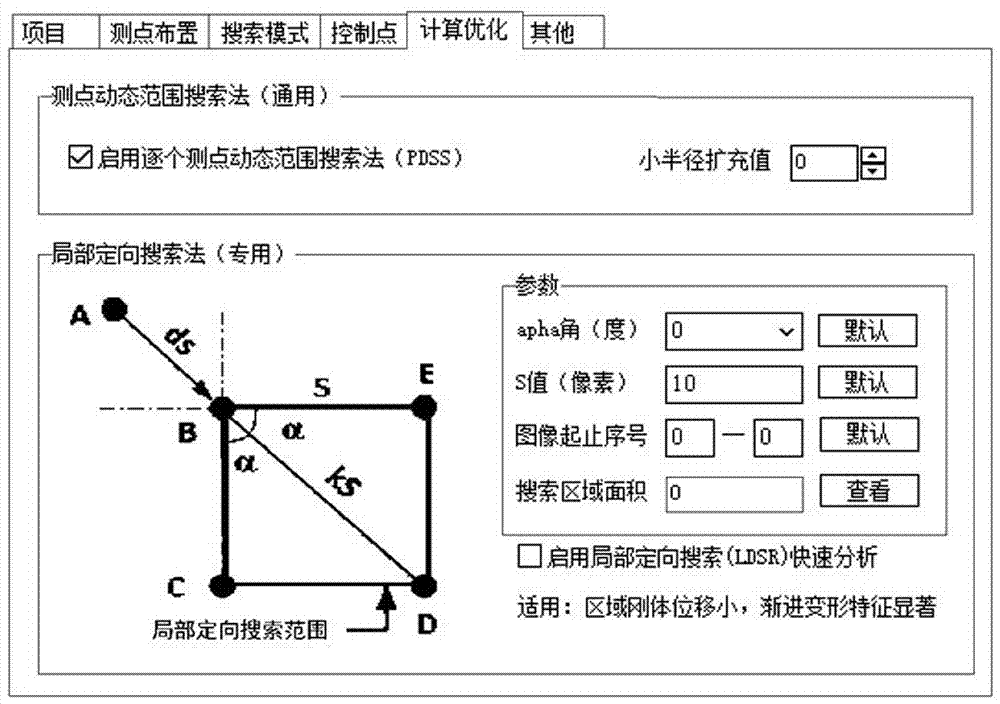

ActiveCN107292876AFast analysisHigh measurement accuracyImage enhancementImage analysisImaging analysisCorrelation analysis

The invention discloses a DSCM analyzing method based on geotechnical material deformation space-time non-uniform characteristics. Image analyzing efficiency is improved by dynamically adjusting a searching range of pixel measuring points. Based on the geotechnical material deformation space-time non-uniform characteristics, the searching range of all of the pixel measuring points in the image is determined according to analyzing results of reference grids. The DSCM analyzing method is realized in software by adopting a programming technology, and is suitable for the digital speckle correlation analysis of the geotechnical materials of various types, and a number of pixel points of image correlation analysis is greatly reduced, and therefore the image analysis speed of the digital speckle correlation method is effectively accelerated. By combining with the precision optimization method of the digital speckle correlation analysis considering rock fracture influences, the image analyzing speed is accelerated at the same time of improving calculation precision. Measuring point displacement analysis errors or mistakes caused by image noises are effectively inhibited, and therefore the digital speckle correlation measurement precision of the geotechnical material deformation is improved.

Owner:CHINA UNIV OF MINING & TECH

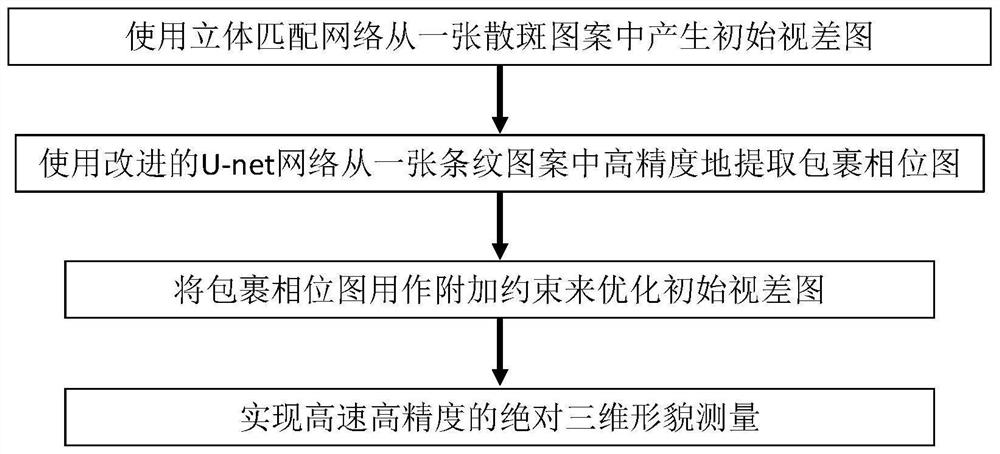

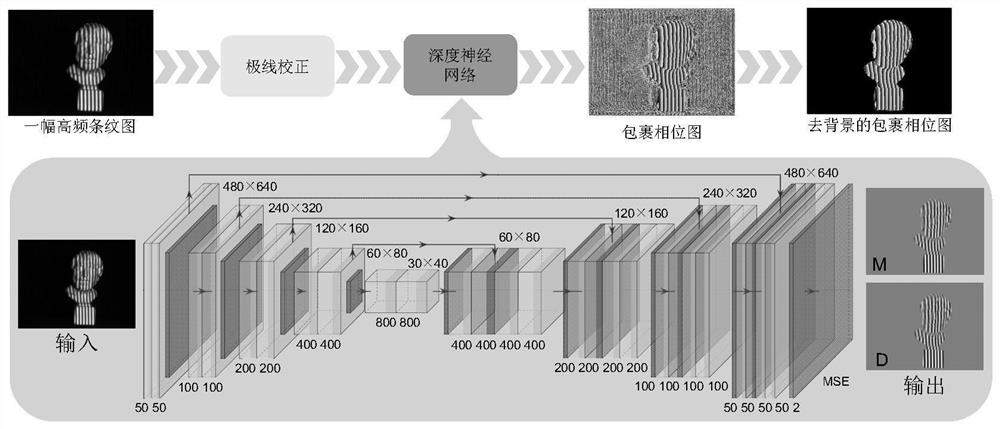

Stripe phase recovery and speckle correlation three-dimensional measurement method based on learning

ActiveCN111947599AHigh-speed and high-precision absolute 3D shape measurementUsing optical meansStereo matchingAlgorithm

The invention discloses a stripe phase recovery and speckle correlation three-dimensional measurement method based on learning. Firstly, an initial disparity map is generated from a speckle pattern using a stereo matching network. Secondly, a wrapped phase diagram is extracted from an additional stripe pattern with high precision by using a Unet network. Finally, initial disparity map is optimizedby taking a wrapped phase diagram as an additional constraint, so that high-speed and high-precision absolute three-dimensional topography measurement is finally realized. According to the invention,high-speed and high-precision absolute three-dimensional topography measurement can be realized only by two projection patterns.

Owner:NANJING UNIV OF SCI & TECH

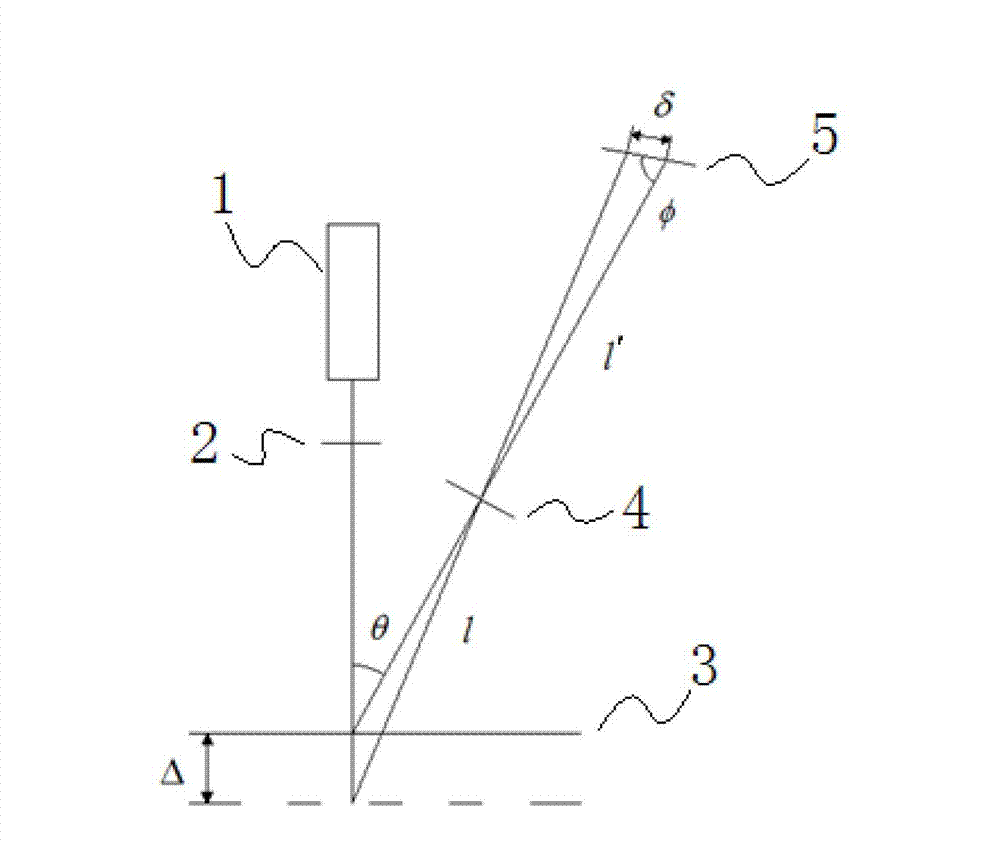

Measurement method of crack tip stress intensity factor of cylindrical shell with axial crack

InactiveCN105548199AReduce cumbersome proceduresData processing is simpleOptically investigating flaws/contaminationElectricityCrazing

A measurement method of a crack tip stress intensity factor of a cylindrical shell with axial crack belongs to the technical fields of fracture mechanics, and optical testing. The method uses caustics optical testing technique; a CCD camera is employed to shoot a shadow spot photography of the cylindrical shell with axial crack after loading; characteristic size of the shadow spot is measured; and through the relationship between the stress intensity factor and the characteristic size of the shadow spot, the crack tip stress intensity factor of cylindrical shell with axial crack under certain load is obtained. The present invention uses non-contact measurement; and compared to optical technologies such as photoelastic method and digital speckle correlation method, the method has simple data processing and reliable test results; compared with a traditional electric measurement method, the method eliminates complex process of plastering strain gauges each time, and is more simple and convenient. For the measurement of the crack tip stress intensity factor of the cylindrical shell with axial crack, the invention provides a caustics measurement method, introduces the radius of curvature and thickness of the cylindrical shell into the relationship of stress intensity factor and characteristic size of the shadow spot, so as to reach more accurate results.

Owner:TSINGHUA UNIV

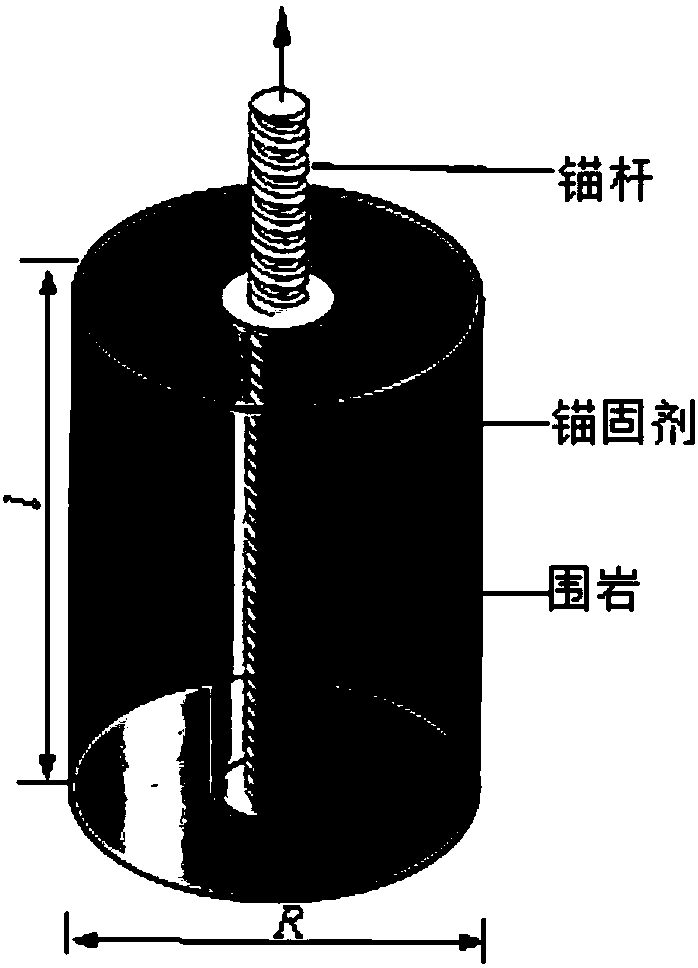

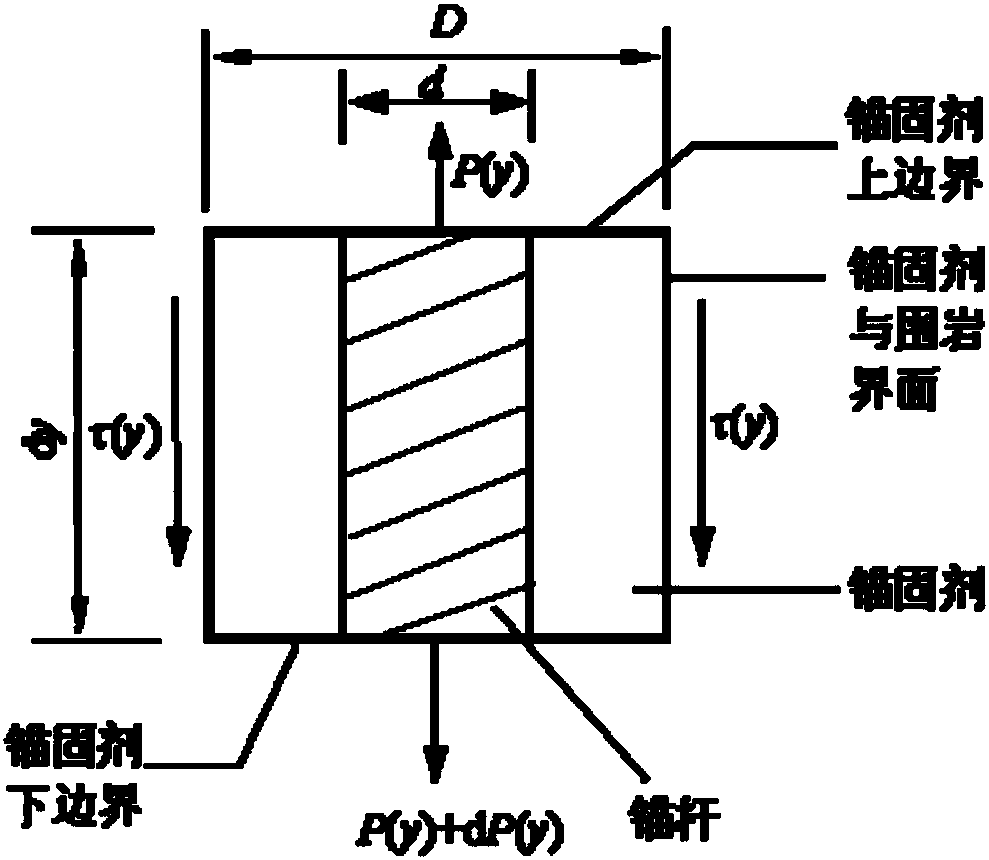

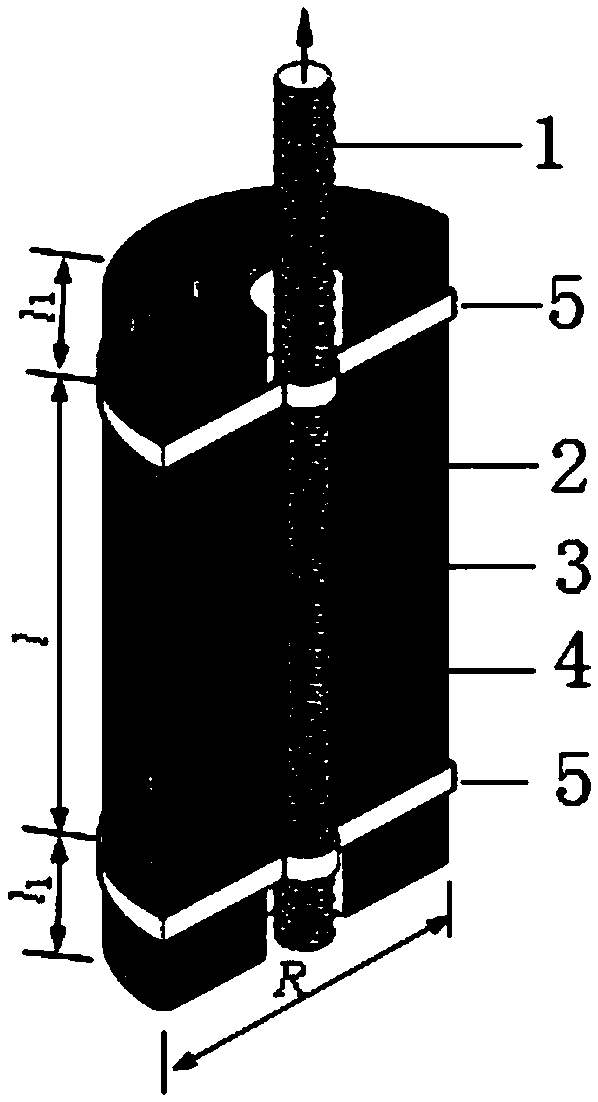

Method for analyzing force transmission of anchor rod

InactiveCN107860651AMonitoring deformation evolution featuresFacilitate the law of force transmissionMaterial strength using tensile/compressive forcesPull forceSpeckle correlation

The invention provides a method for analyzing the force transmission of an anchor rod. The method comprises the following steps: taking the anchor rod, simulating the material of surrounding rocks tomake a surrounding rock model with the axial through hole diameter being more than the diameter of the anchor rod, wherein the surrounding rock model is a semi-cylinder; bonding and fixing the anchorrod to the axial through hole of the surrounding rock model through an anchoring agent to make an anchoring system model; carrying out a pulling experiment on the anchoring system model, and acquiringthe anchor rod deformation data in the anchor rod pulling process by a strain gauge; carrying out grading loading on the anchoring system model through adopting a pulling instrument, recording the pulling force and the strain value of the anchor rod after the load value of every grade loading is stable, and repeating the above process until anchoring is invalid; and analyzing obtained experimentdata by using a digital speckle correlation technology to obtain the force transmission rule of the interface of the anchoring system and the gradient change rule of the vertical stress of the upper interface and the lower interface of the anchoring agent. The method completes traditional anchor rod pulling experiment models and analysis methods, and finely researches the mutual relation among theanchor rod, the anchoring agent and the interface force and the force transmission rule of the anchoring system.

Owner:MCC COMM CONSTR GRP CO LTD +1

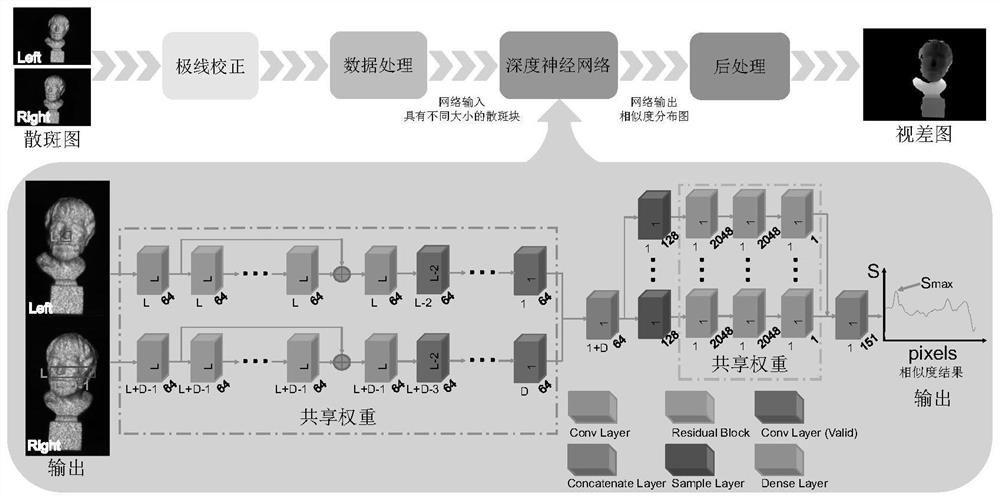

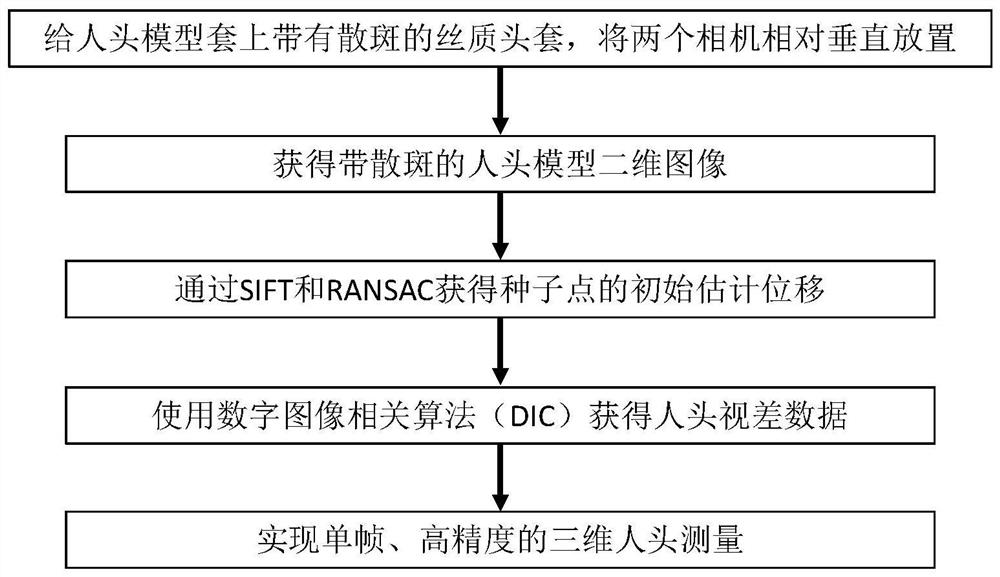

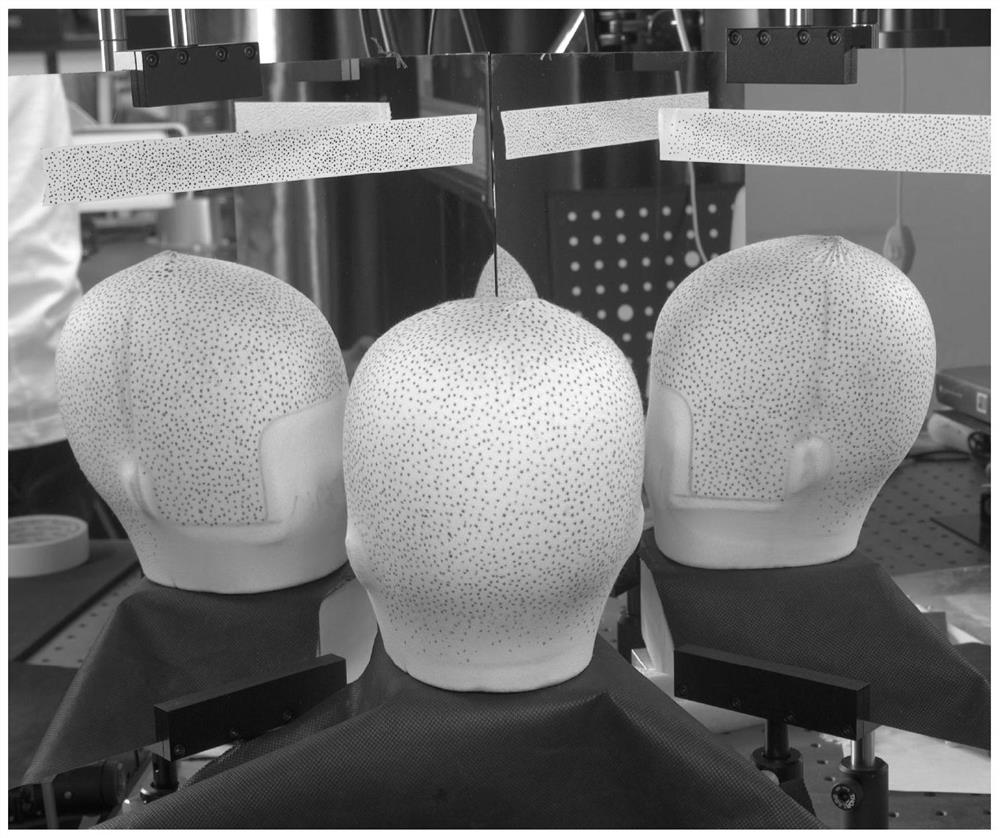

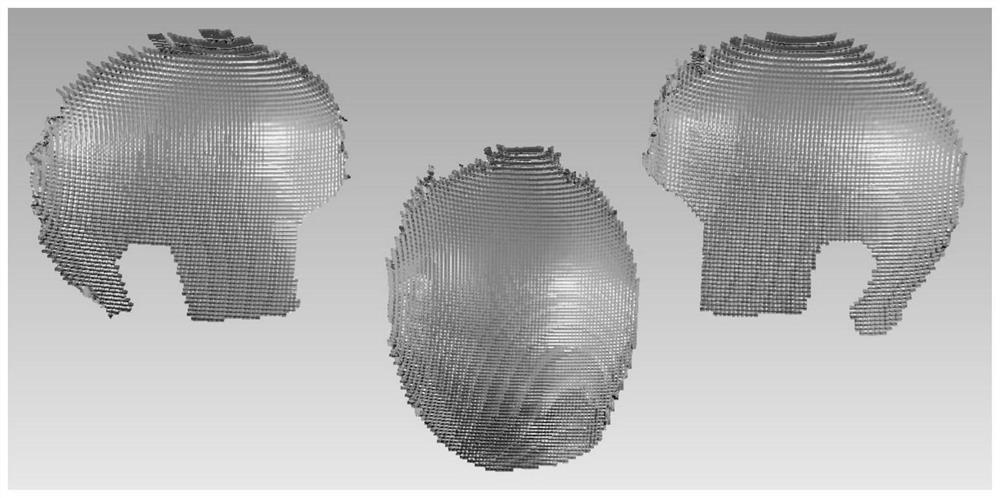

Quick three-dimensional human head measurement method based on digital speckle correlation

ActiveCN112001973AHigh precisionImage analysisGeometric image transformationParallaxComputer graphics (images)

The invention discloses a quick three-dimensional human head measurement method based on digital speckle correlation. The method comprises the steps: enabling a human head model to be sleeved with a silk head sleeve with speckles, and enabling two cameras to be placed oppositely and vertically, so as to obtain a human head model two-dimensional image with speckles; marking a speckle area to be measured in the image, setting the central point of the speckle area as a seed point, and obtaining the initial estimated displacement of the seed point through SIFT and RANSAC; head parallax data between two camera visual angles can be obtained by using a digital image correlation algorithm (DIC), and the parallax data is converted into three-dimensional information by using calibration parameters of the cameras. According to the invention, single-frame and high-precision three-dimensional human head measurement can be realized.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com