Portable residual stress measurement device and method

A technology of residual stress and measuring equipment, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of unsuitable residual stress measurement requirements on engineering sites, complicated equipment, etc., and achieve the effect of easy operation and portable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] specific implementation plan

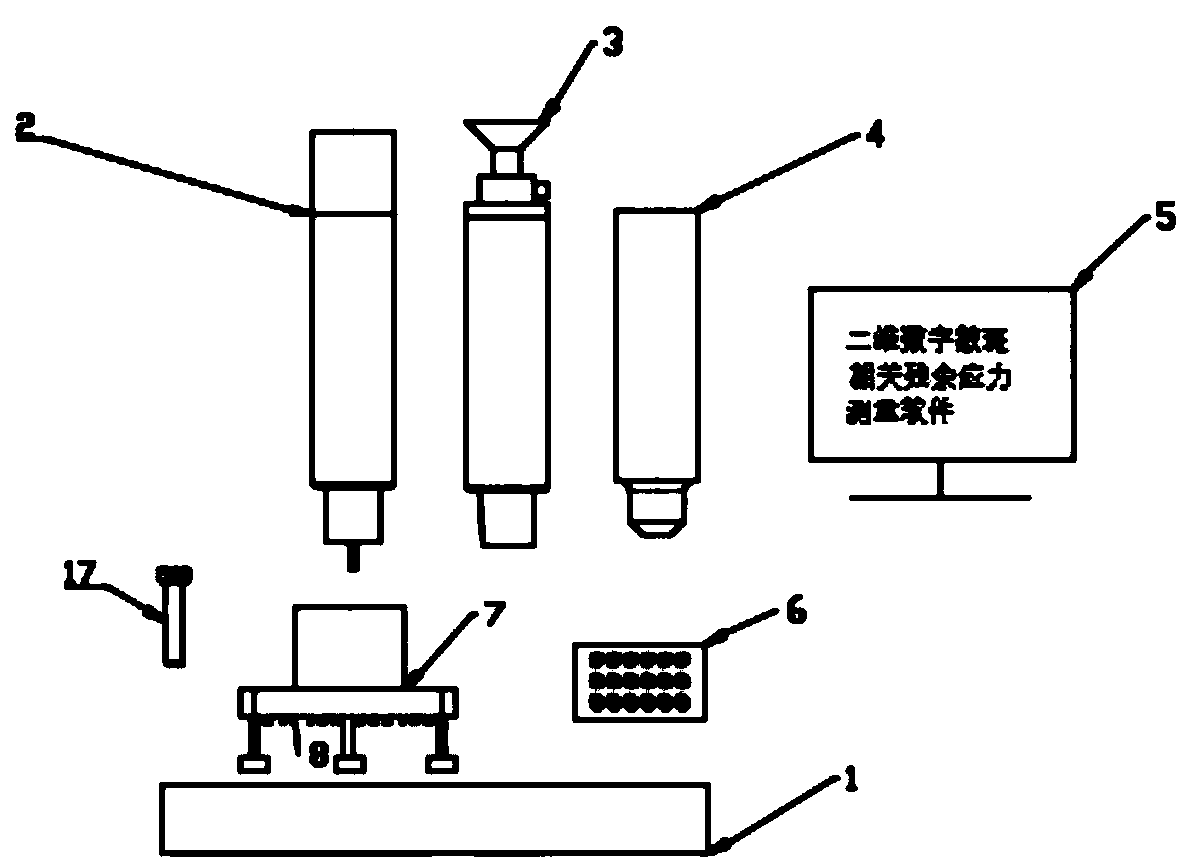

[0027] The residual stress measurement equipment and method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 2-Figure 5 As shown, the convenient and flexible residual stress measurement method provided by the present invention comprises the following steps in order:

[0029] 1) Prepare the test piece Partially polish the test piece 1, and spray the white primer and black speckle on the test piece in turn.

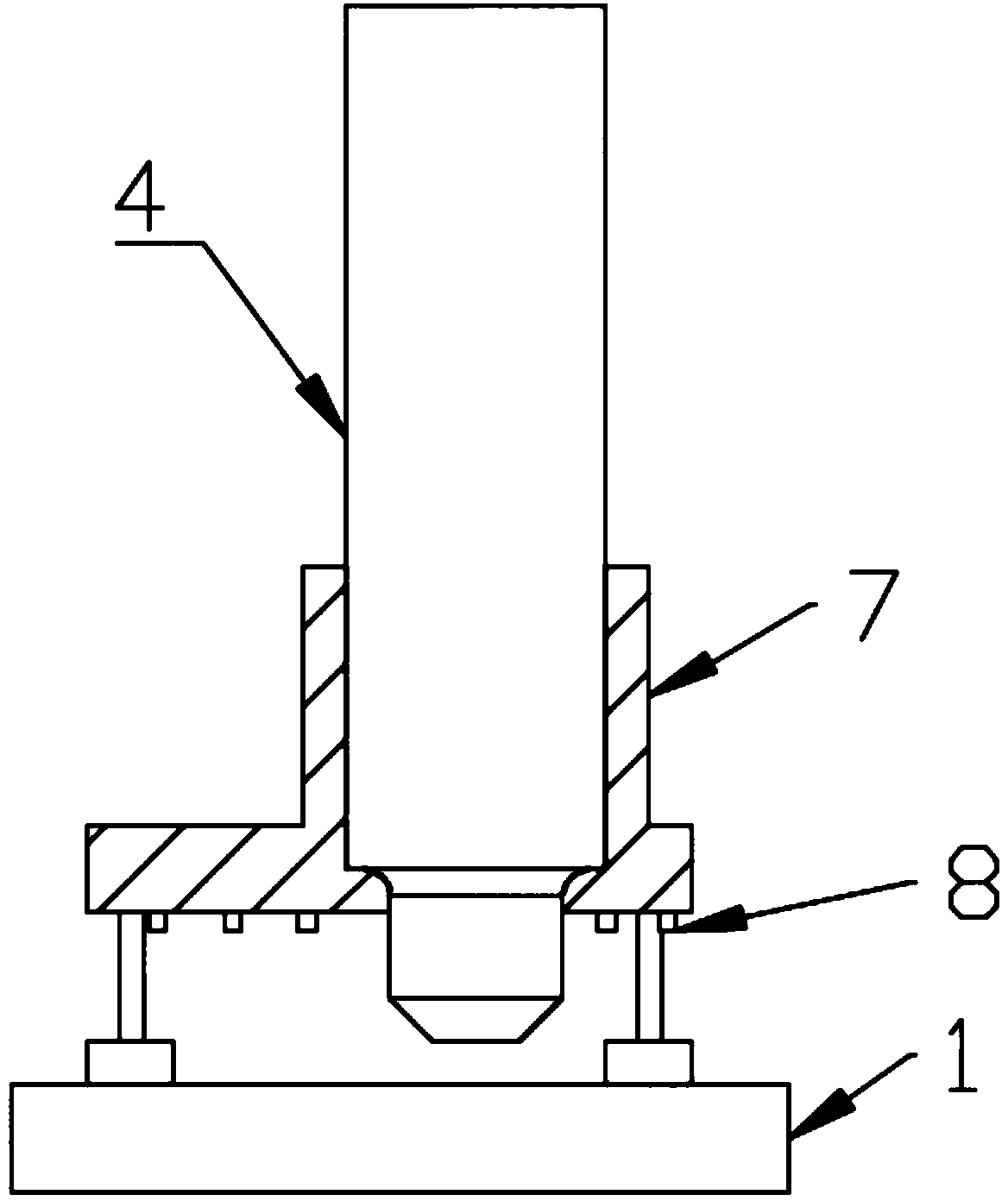

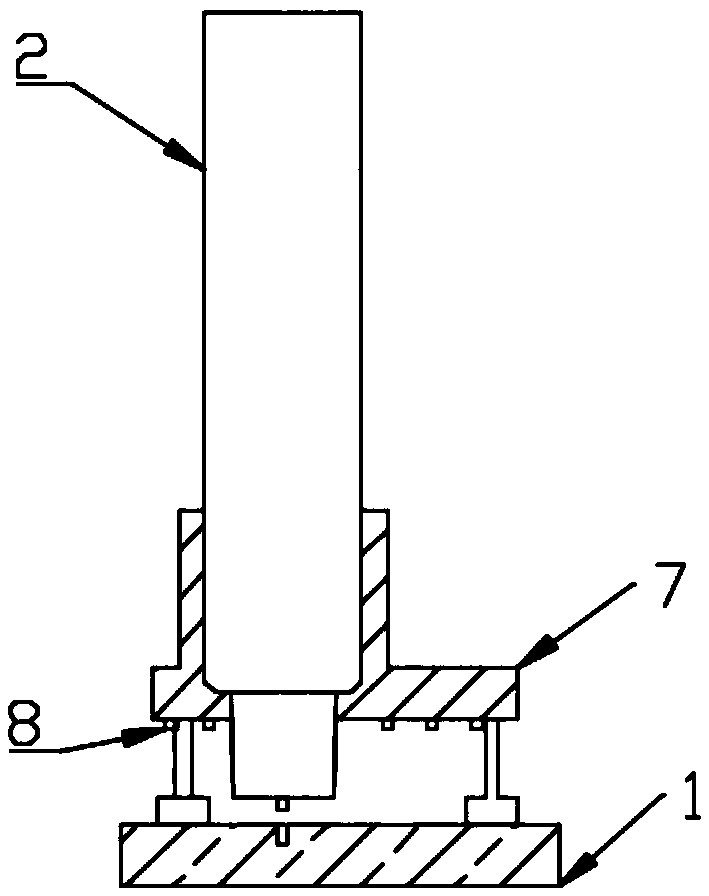

[0030] 2) Install the component 3, fix the three magnetic brackets of the component 3 on the specimen, adjust the height of the bracket 8 and the electron microscope 4, and turn on the LED lighting 8, so that the microscope 4 can obtain a clear image.

[0031] 3) The calibration plate 6 is placed between the microscope 4 and the test piece 1, the electron microscope 4 takes images of the calibration plate 6, and the internal parameters of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com