Measurement method of crack tip stress intensity factor of cylindrical shell with axial crack

A technology of stress intensity factor and cylindrical shell, which is applied in the field of fracture mechanics and optical testing, can solve problems that hinder the expansion of fracture mechanics engineering applications, and achieve reliable test results, simple data processing, and accurate experimental results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific structure, working principle and working process of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited by this.

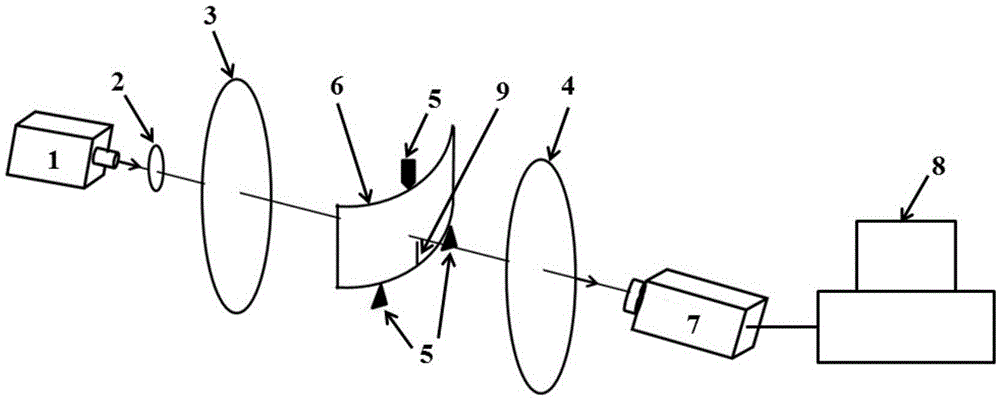

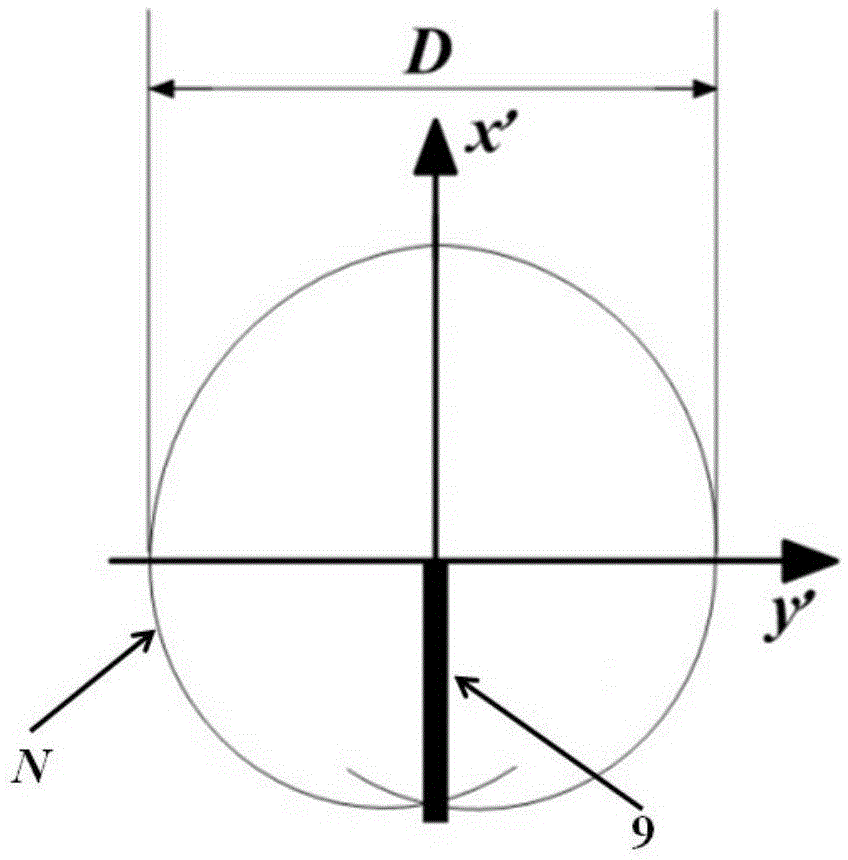

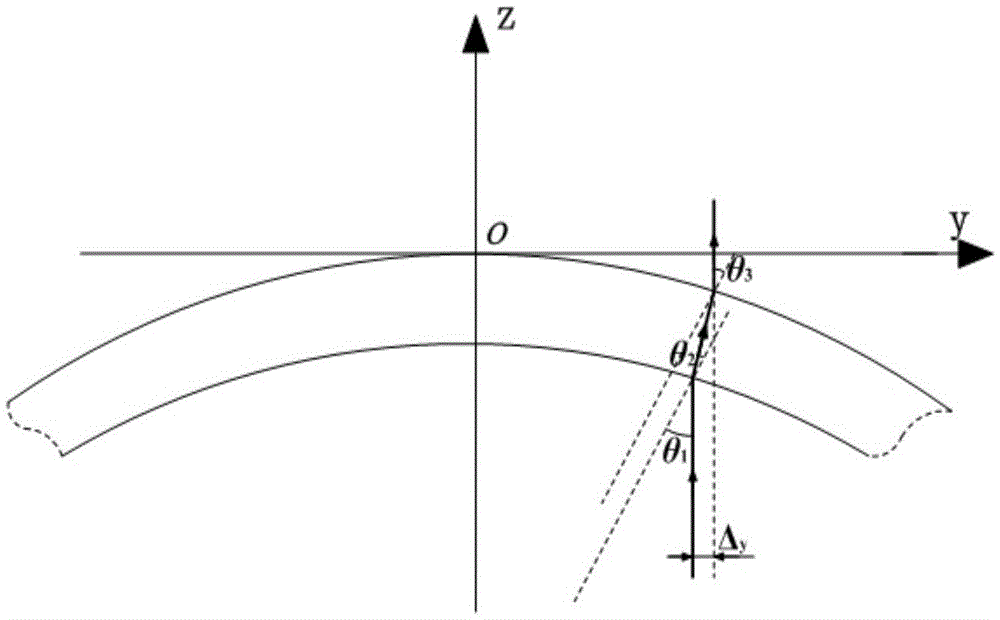

[0022] figure 1 It is a schematic diagram of the structure principle of the projected caustics optical testing system provided by the present invention, the system includes a laser light source 1, a beam expander 2, a first imaging lens 3, a second imaging lens 4, a three-point bending loading device 5, and a CCD camera 7 and a computer 8; the laser light emitted by the laser light source 1 is acted on by the beam expander 2, refracted by the first imaging lens 3 and becomes parallel light, and passes through the cylinder containing the axial crack 9 bearing the three-point bending load The shell specimen 6 is converged by the second imaging lens 4, and the image is received by the CCD camera 7. The CCD camera 7 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com