Construction method of T-shaped pile and T-shaped drilling tool for construction of T-shaped cast pile

A construction method and drilling tool technology, applied in the direction of earthwork drilling, drill bit, sheet pile wall, etc., can solve the problems of high energy consumption, high horsepower, unfavorable use, etc., to improve the bearing capacity of the foundation, use less time, and increase the bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

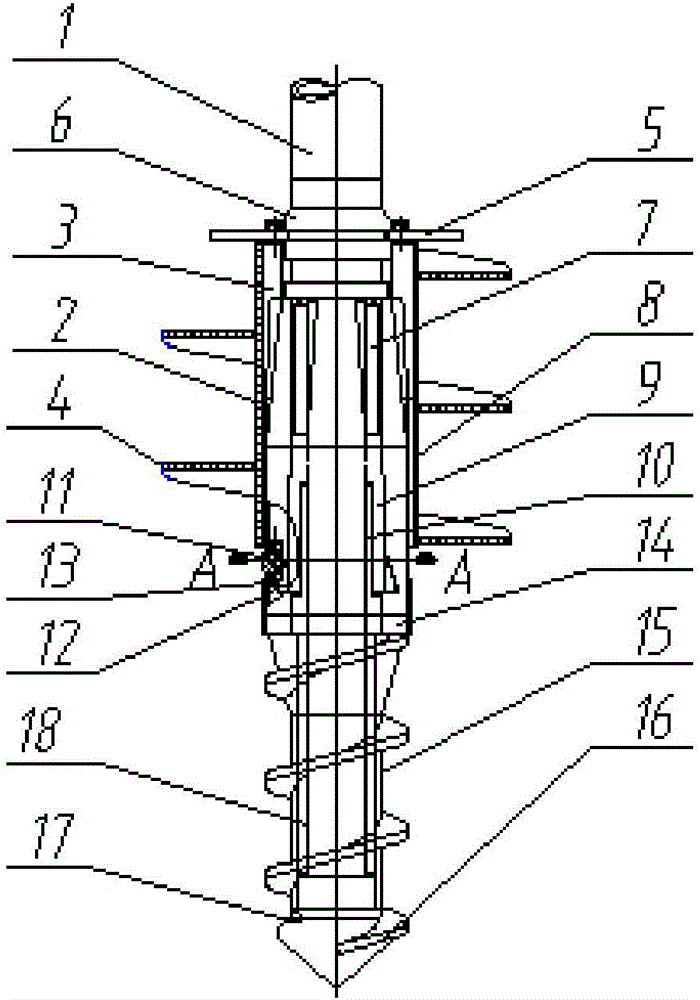

[0042] The present invention will be further described below in conjunction with accompanying drawing.

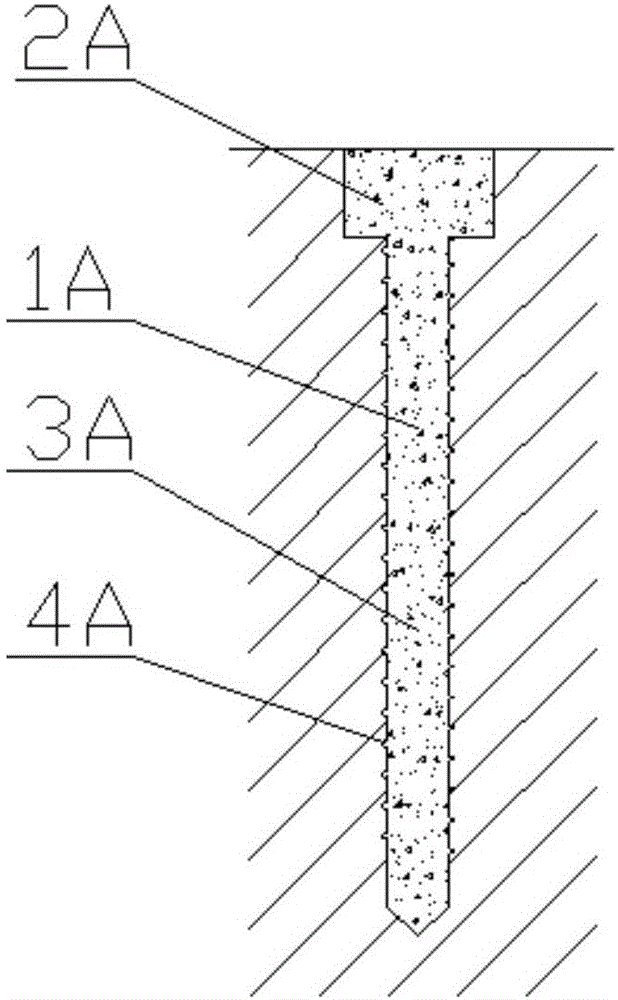

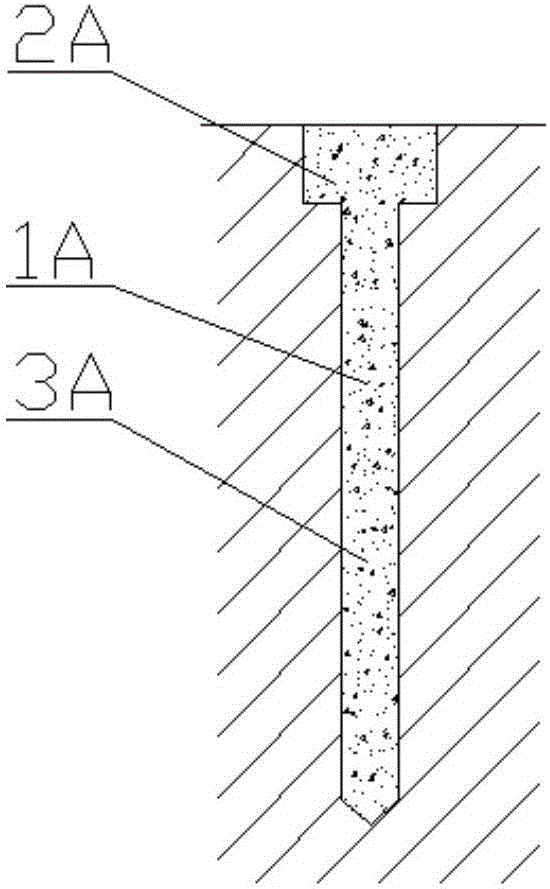

[0043] Such as figure 1 As shown, a compact threaded T-shaped pile of the present invention includes a T-shaped pile 1A, a pile cap 2A, a pile shaft 3A, and a pile thread 4A, and the T-shaped pile 1A includes a pile cap 2A and a pile shaft 3A. Wherein the pile cap 2A is arranged on the top of the pile rod 3A, the diameter of the pile cap 2A is large, and the diameter of the pile rod 3A is small, so that the T-shaped pile 1A is a cylindrical solid pile with a large diameter at the top and a small diameter at the bottom, and the structure of the pile body The symmetrical center section shape is "T" shape. Such as figure 1 As shown, the outside of the pile cap 2A of the present invention has no thread, and the outside of the pile shaft 3A is provided with a pile thread 4A. Both the pile cap 2A and the pile rod 3A of the present invention can complete one-time pile formation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com