Producing method of master batch for agricultural film

A production method and masterbatch technology, which are applied in chemical instruments and methods, raw material extrusion and granulation, and devices that can reverse the axial direction of the swirl flow, etc. , difficult to control the process and other problems, to achieve the effect of improving production efficiency and product performance indicators, simplifying the production process, and saving cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Determination of the process conditions of agricultural film masterbatch

[0040] (1) Raw materials

[0041] Linear low density polyethylene (LLDPE), 7042, Daqing Petrochemical;

[0042] Antistatic agent, ASP-2, Beijing Research Institute of Chemical Industry;

[0043] Calcium carbonate, Beijing Chemical Building Materials Factory;

[0044] (2) Formulation design

[0045] LLDPE:ASP-2:CaCO 3 =3:3:2

[0046] (3) Dosage

[0047] LLDPE 7042: 455kg ASP-2: 455kg CaCO 3 : 303.5kg

[0048] (4) Setting of process parameters

[0049] Table 1

[0050] Conveyor screw for regranulation (Hz)

10

Feeding screw (Hz)

10

Hopper lift (Hz)

45

Compaction pressure (MPa)

4

Compaction speed (Hz)

30

Whole grain speed (Hz)

35

Forced feeding (Hz)

3

Mixing speed (Hz)

10

Mixing time (min)

15

other

-

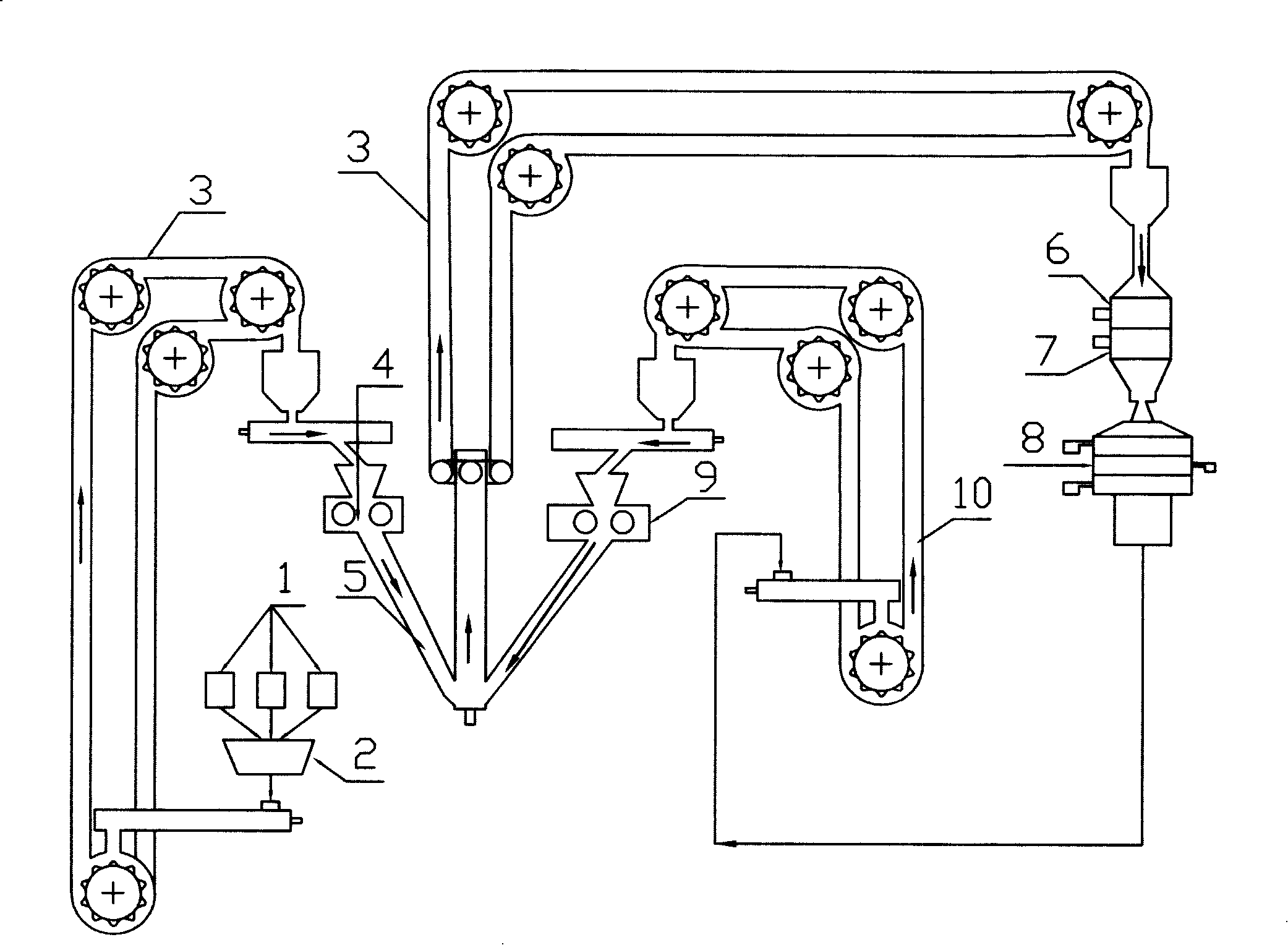

[0051] (5) Process

[0052] Such as figure 1 , 2 as shown, f...

Embodiment 2

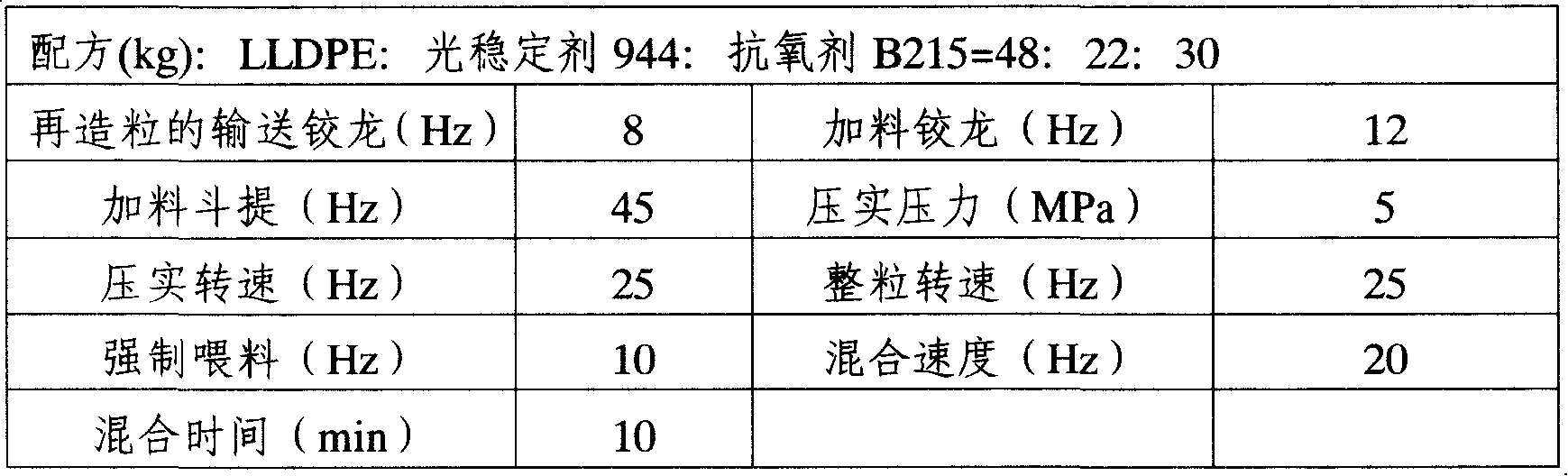

[0067] Process is the same as embodiment 1, and difference is prescription and processing condition:

[0068]

[0069] Since the granulation method is dry granulation, no loss of additives is caused during the production process.

Embodiment 3

[0071] Process is the same as embodiment 1, and difference is prescription and processing condition:

[0072]

[0073] Since the granulation method is dry granulation, no loss of additives is caused during the production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com