Device for detecting mechanical property of multifunctional film

A detection device and multi-functional technology, which is applied in the field of multi-functional thin film mechanical property detection devices, can solve problems such as the influence of measurement results, the limitation of loading range, and the error of experimental results, so as to avoid uneven loading speed, adjust the measurement field of view, The effect of high deformation measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The principle, specific structure and characterization method of the multifunctional film mechanical property detection device provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

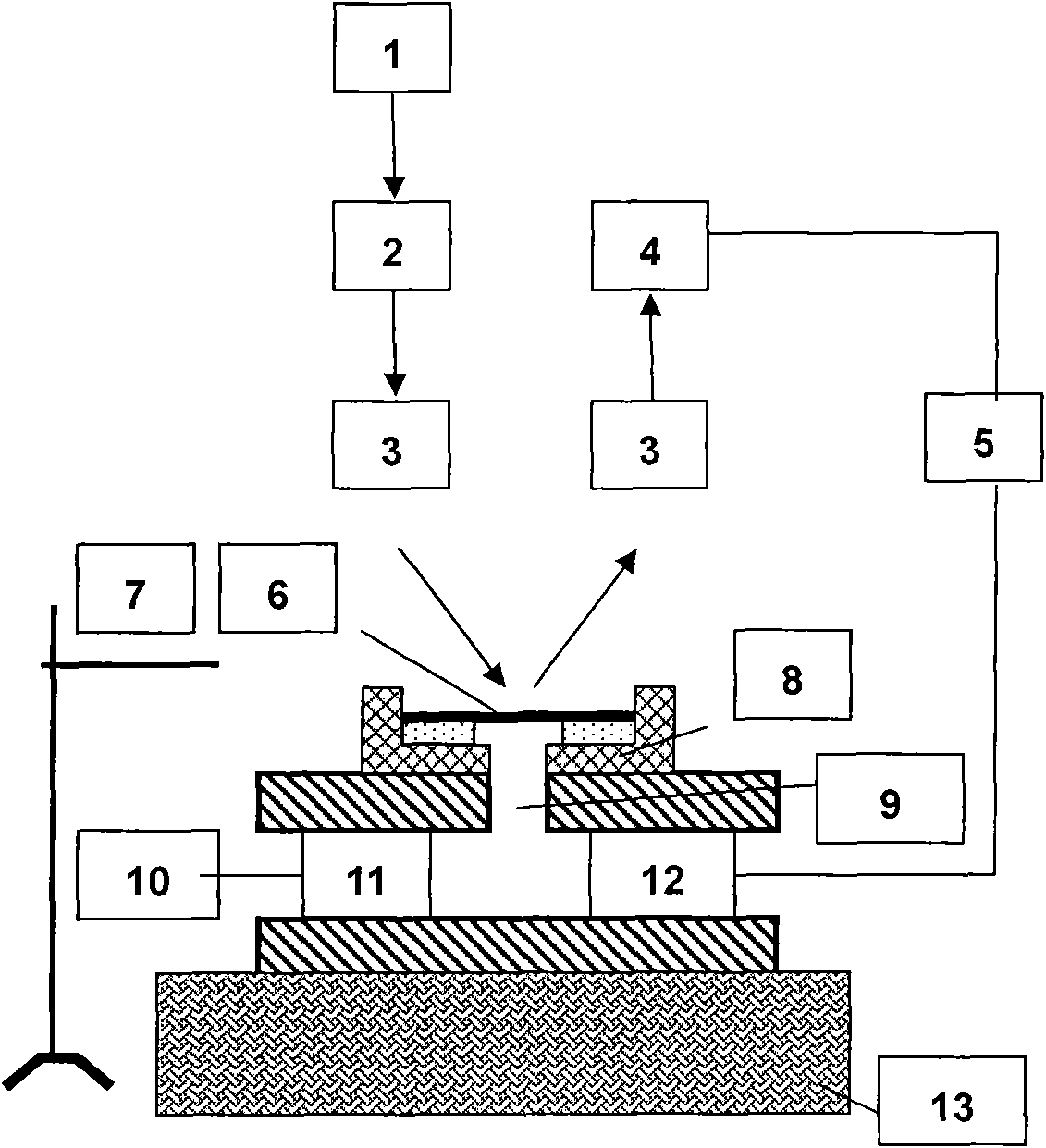

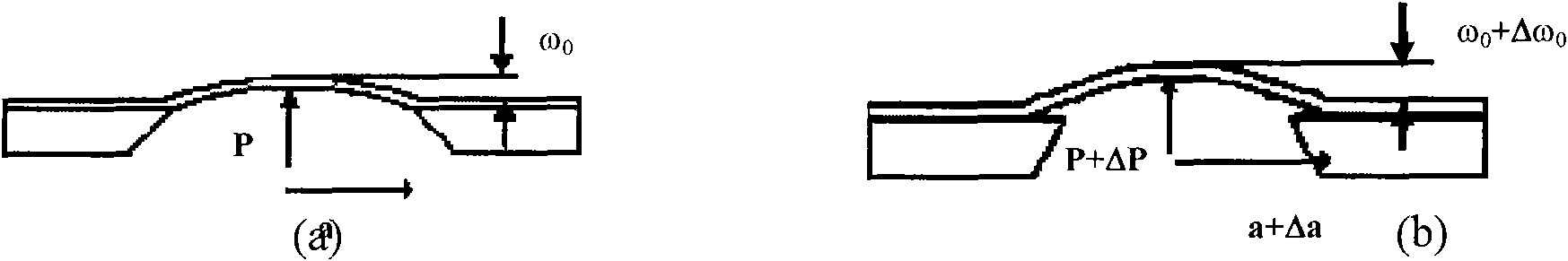

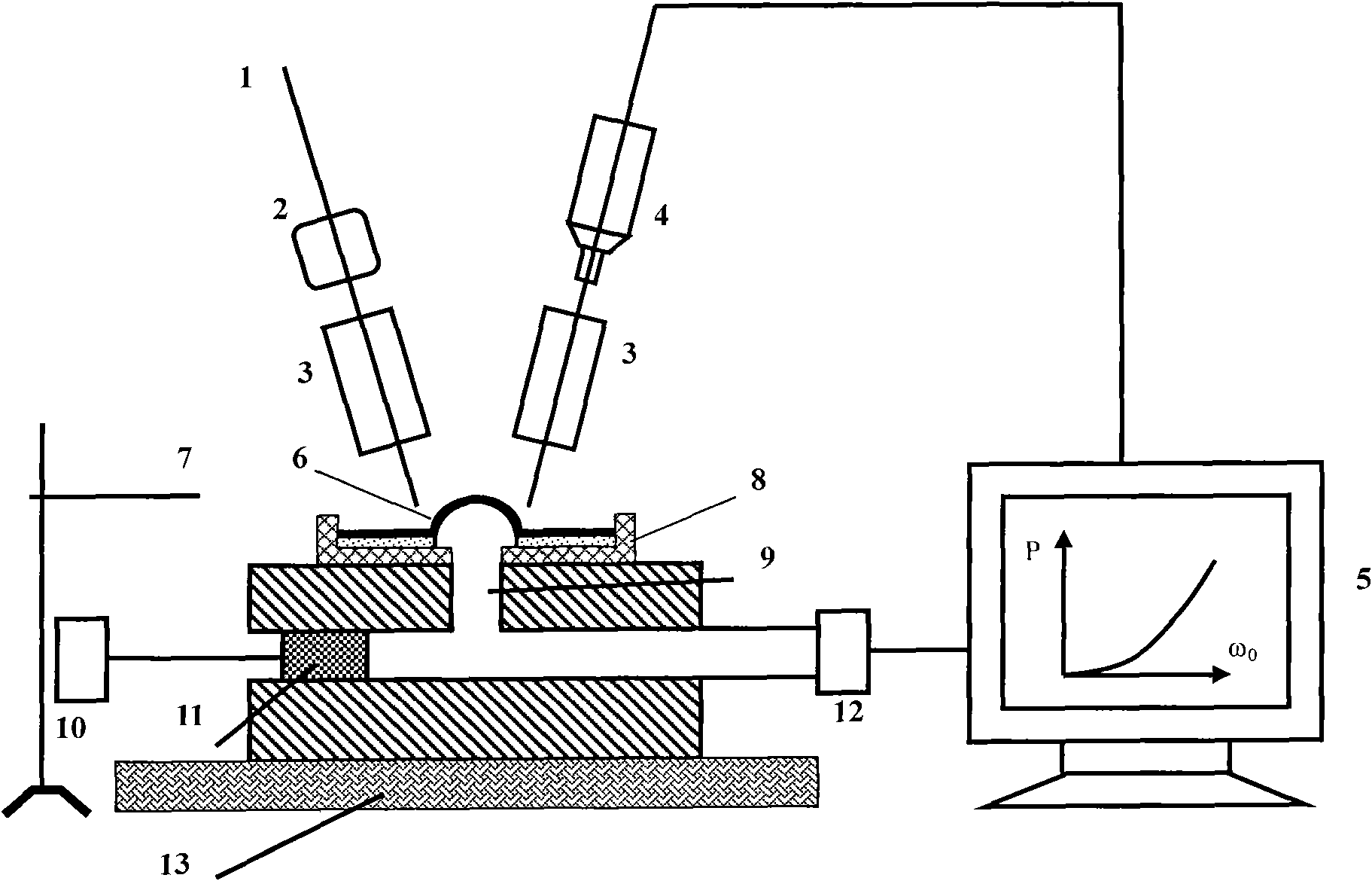

[0055] When using the bubbling method to measure the mechanical properties of thin films, the figure 1 In the process, the film sample 6 is fixed on the sample stage 8, and the sample 6 is a film window formed by removing a circular or square area from the substrate coated with the film by etching or etching. The sample stage 8 , the piston 11 and the pressure sensor 12 are connected with the oil chamber 9 . The oil chamber is filled with hydraulic oil, and the stepping motor 10 drives the piston 11 to apply uniform pressure to the film sample. The film sample bulges under the action of the pressure, and when the pressure reaches a certain value, the film and the substrate are peeled off. The pressure during the pressurization pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com