Speckle manufacturing method based on transfer print technology

A production method and speckle technology, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of frequent rework of the object to be measured, difficult control of speckle particles, and complicated speckle production methods, and achieve long production cycle , low cost, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

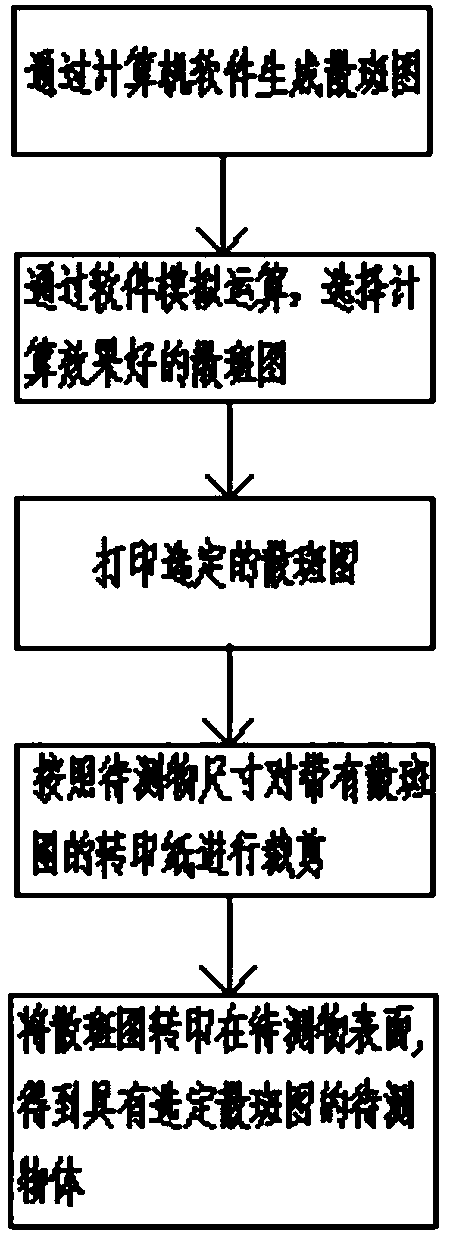

[0036] Figure 4 It is a flow chart of the production method of speckle production by water transfer sticker technology. The specific implementation steps are as follows:

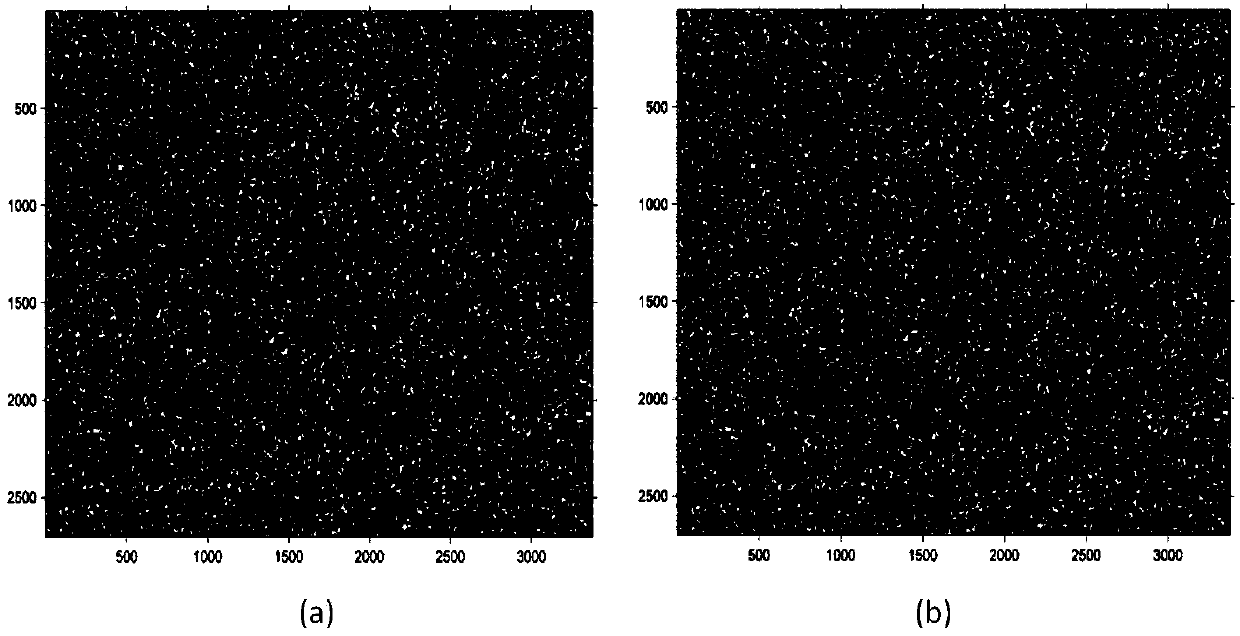

[0037] a. Three pairs of speckle patterns are generated by computer software. In this embodiment, the software adopts Gaussian algorithm. The calculation formula is as follows, and the calculation formula of the undistorted speckle pattern is: The formula for calculating the deformed speckle pattern is: I ( x , y ) = Σ k = 1 s [ i 0 * exp ( - ( x - x k ...

Embodiment 2

[0047] Figure 5 It is a flow chart of the production method of speckle production by thermal transfer sticker technology. The specific implementation steps are as follows:

[0048] a. Generate three pairs of speckle patterns by computer software, and perform simulation operations to select the speckle pattern with the best calculation effect. In this embodiment, the software adopts the Gaussian algorithm. The calculation formula is as follows, and the calculation formula of the undistorted speckle pattern is: I ( x , y ) = Σ k = 1 s [ i 0 * exp ( - ( x - x ...

Embodiment 3

[0055] Figure 6 It is a flow chart of the production method of speckle production by cold transfer sticker technology. The specific implementation steps are as follows:

[0056] a. Generate three pairs of speckle patterns by computer software, and perform simulation operations to select the speckle pattern with the best calculation effect. In this embodiment, the software adopts the Gaussian algorithm. The calculation formula is as follows, and the calculation formula of the undistorted speckle pattern is: I ( x , y ) = Σ k = 1 s [ i 0 * exp ( - ( x - x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com