Anchor rod pallet load visualization digital imaging method

A technology of digital imaging and pallet, applied in the field of digital imaging of bolt pallet load visualization, can solve the problems of large theoretical calculation error, single function, limited data, etc., and achieve the effect of simple and convenient use, simple optical path, and wide range of objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

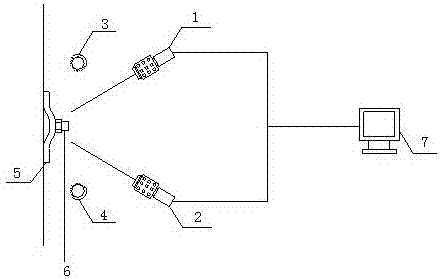

[0036] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0037] Such as figure 1 As shown, the present invention includes the following technical features: a first camera 1 , a second camera 2 , a first light source 3 , a second light source 4 , an anchor rod 5 , a pallet 6 , and a control computer 7 .

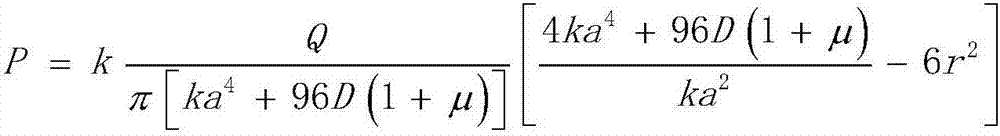

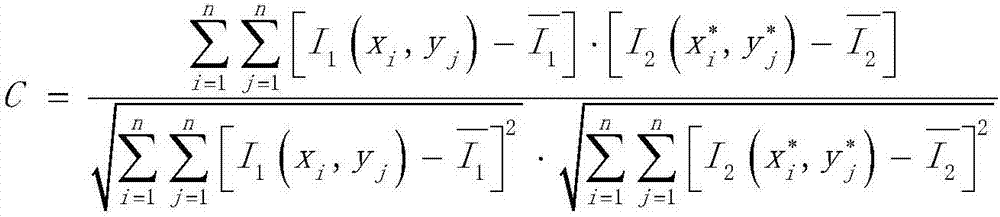

[0038] A kind of bolt pallet load visualization digital imaging method of the present invention, comprises the following steps:

[0039] Step 1: Install the pallet on the wall of the roadway, and then fix the anchor rod at the center of the pallet. When no pre-tightening force is applied, it is defined as the pallet before deformation, and after pre-tightening force is applied, it is defined as the deformed pallet;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com