Wing vibration detection device and method based on three-dimensional digital speckle correlation method

A vibration detection and three-dimensional digital technology, which is applied in the direction of measuring devices, elastic testing, optical devices, etc., to achieve accurate and reliable signals, high flexibility, and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

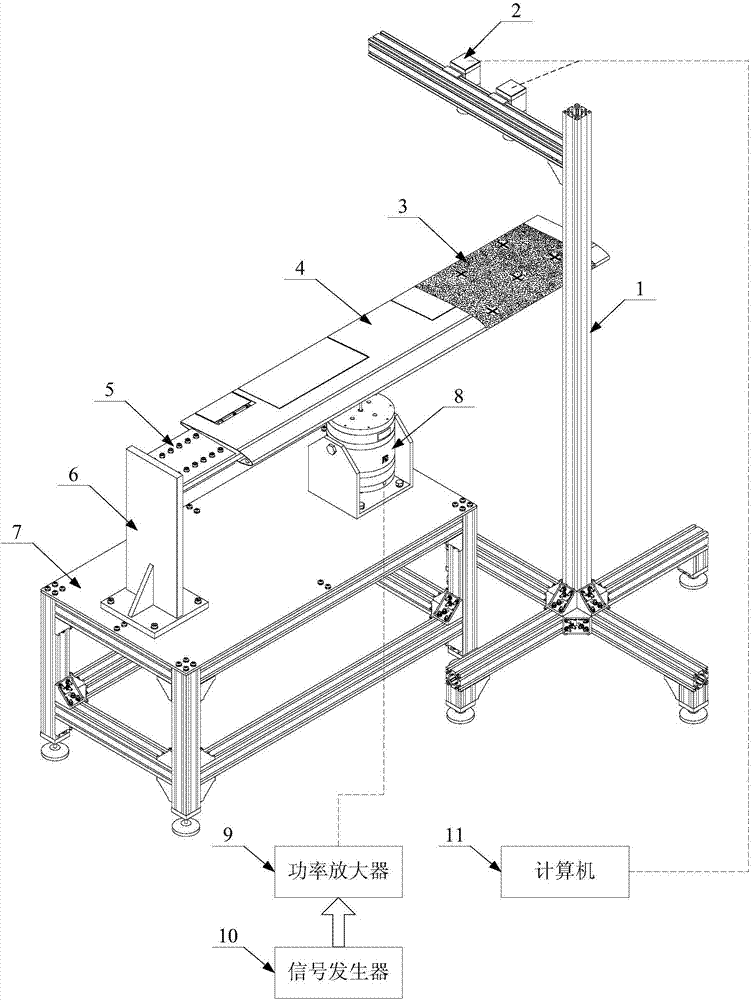

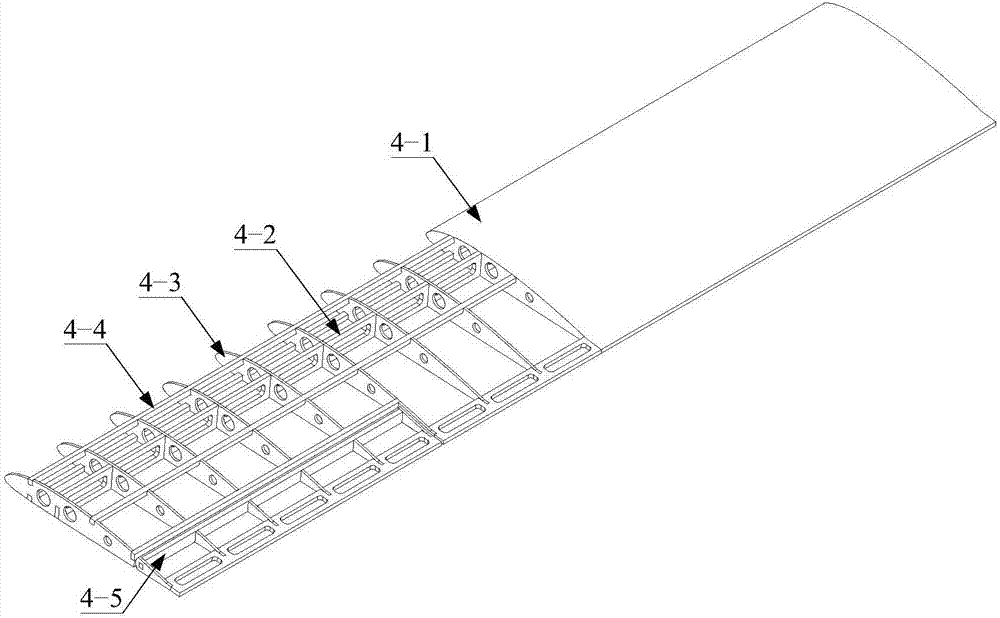

[0031] Such as figure 1As shown, the present embodiment provides a wing vibration detection device based on a three-dimensional digital speckle correlation method, including a wing body part, a vibration detection part, a vibration excitation part and a computer (11), and the wing body part includes The wing (4) and the film (3) painted with dense spots, the film (3) is closely attached to the surface of the wing (4), so that the upper surface of the wing (4) shows continuous and evenly distributed spots, the wing (4) One end is mechanically connected to the metal support (6) through a splint (5), the metal support (6) is vertically installed on the horizontally placed test platform (7), and the other end of the wing (4) is a free end, After the installation is completed, the surface of the wing (4) is in a horizontal state, and is parallel to the surface of the test stand (7), and the end pasted with dense spot film (3) is a free end; the vibration detection part includes two...

Embodiment 2

[0036] This embodiment provides a wing vibration detection method based on a three-dimensional digital speckle correlation method, the method comprising the following steps:

[0037] Step 1, the vibration excitation signal that signal generator (10) produces passes to exciter (8) after power amplifier (9) amplifies, and exciter (8) carries out vibration excitation to wing body part, in wing ( 4) Loads of different forms and degrees are applied near the free end to cause corresponding deformation on the surface of the wing (4);

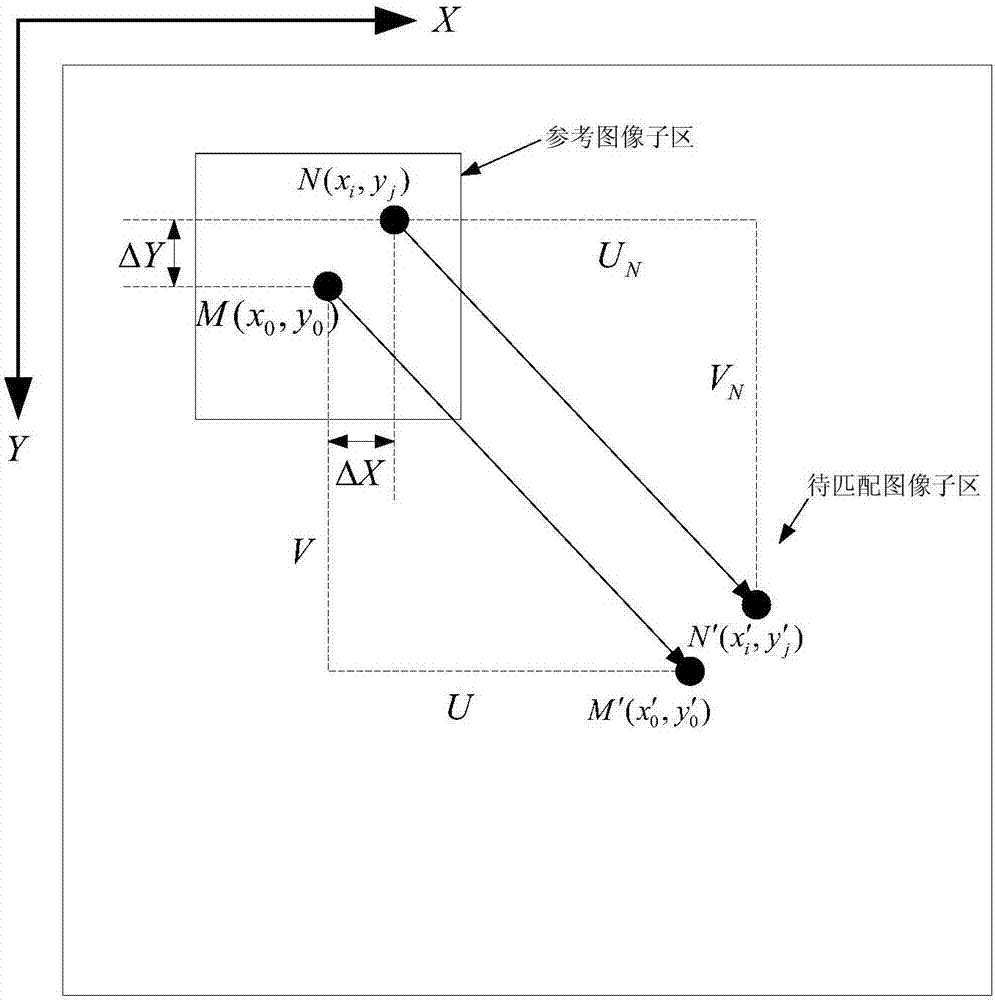

[0038] Step 2. After the corresponding deformation occurs on the surface of the wing (4), the two high-speed cameras (2) in the vibration detection part perform synchronous and continuous image acquisition on the surface area of the wing (4) showing dense spots. The image is transmitted to the computer (11), and sub-regions with independent speckle features are divided and selected on the image. After corresponding image matching and three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com