Method for analyzing force transmission of anchor rod

An analysis method and bolt technology, applied in the direction of analyzing materials, using stable tension/compression to test the strength of materials, measuring devices, etc., can solve the unclear force transmission mechanism of the anchoring system, the influence of model simplification, the anchor bolt experimental model and Analytical methods are not comprehensive enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] A kind of bolt force transmission analysis method, concrete implementation method is as follows:

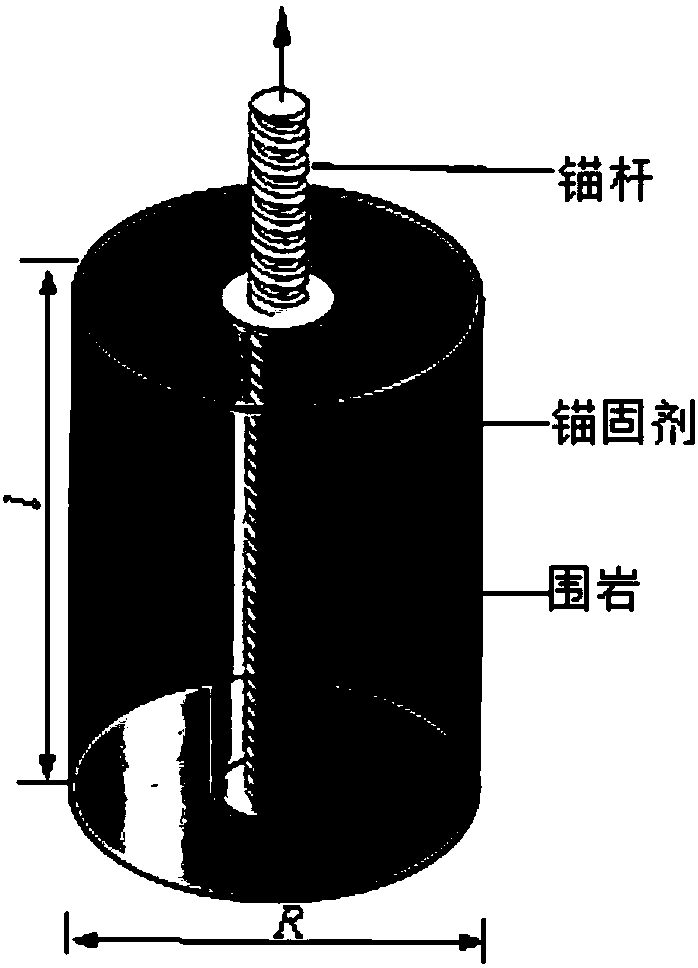

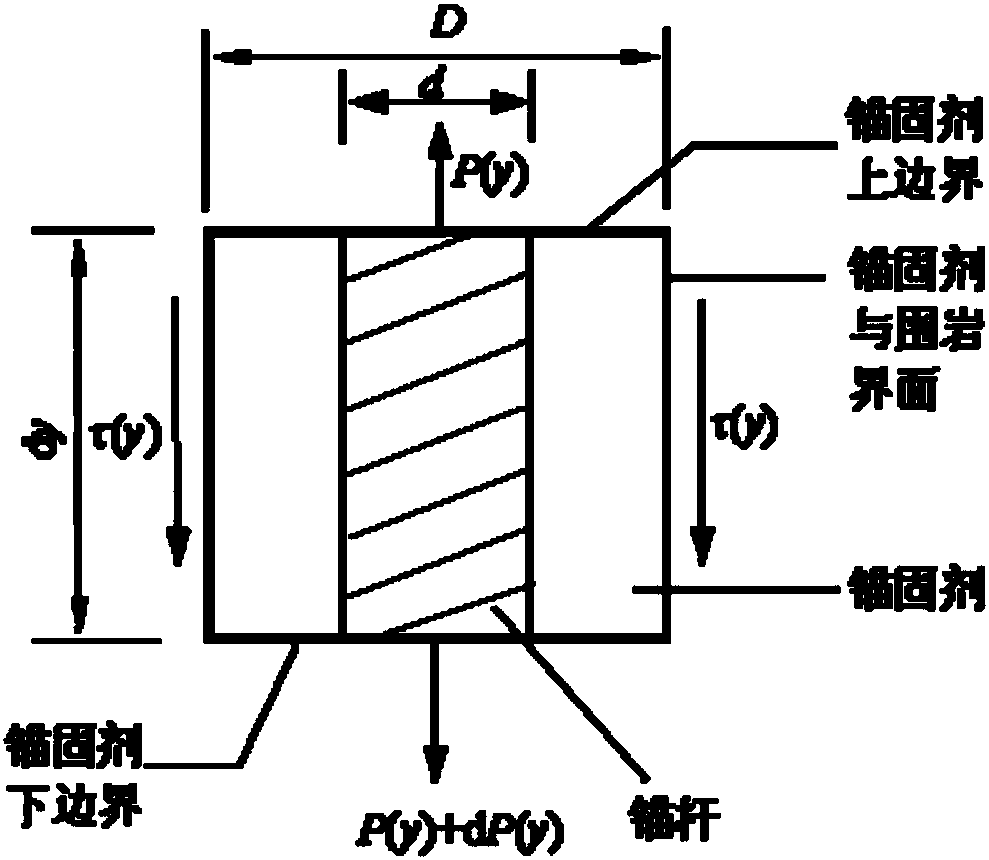

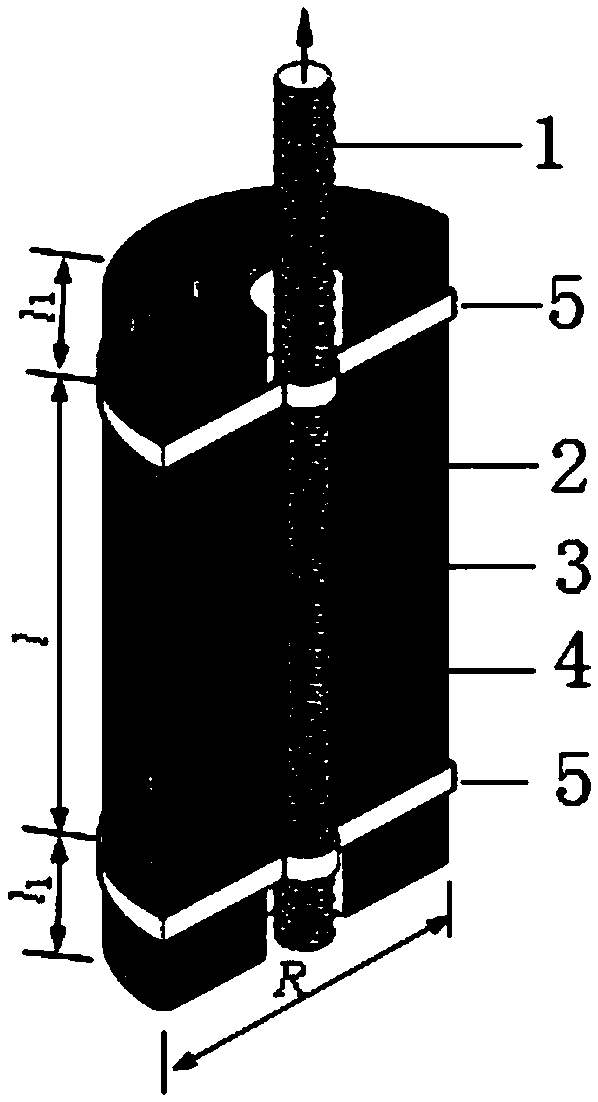

[0035] (1) Material parameters: Anchor rod 1 is made of HRB400 rebar with a length of 1.2m and a diameter of 25mm. The modulus of elasticity is 2.05×105MPa, Poisson’s ratio is 0.3, and the anchorage length is 500mm. Surrounding rock model 2 is simulated by concrete with a mass ratio of cement: sand: crushed stone of 1:1.65:3.25. The compressive strength is 48.5MPa, the elastic modulus is 3.25×104MPa, and the Poisson’s ratio is 0.23; Anchoring agent 3 has a compressive strength of 68.5MPa, an elastic modulus of 1.8×104MPa, and a Poisson’s ratio of 0.27.

[0036] (2) Model making of anchorage system:

[0037] ① Production of surrounding rock model 2: pour concrete into a semicircular steel cylinder mold with an inner diameter of 350mm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com