Test device and test method for measuring residual stress of bent pipe

A technology of residual stress and experimental equipment, which is applied in the direction of measuring the change force of optical properties of materials when they are stressed, and can solve problems such as cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

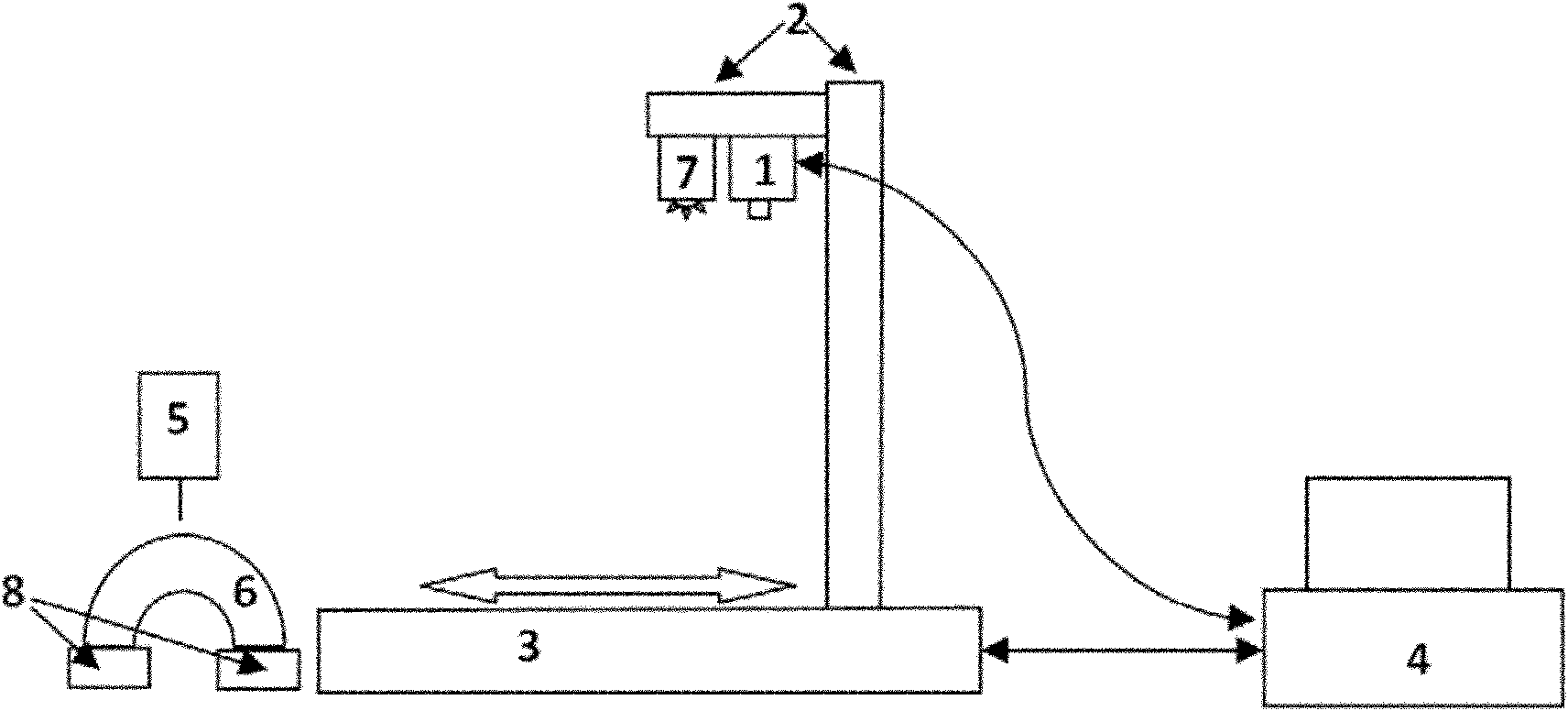

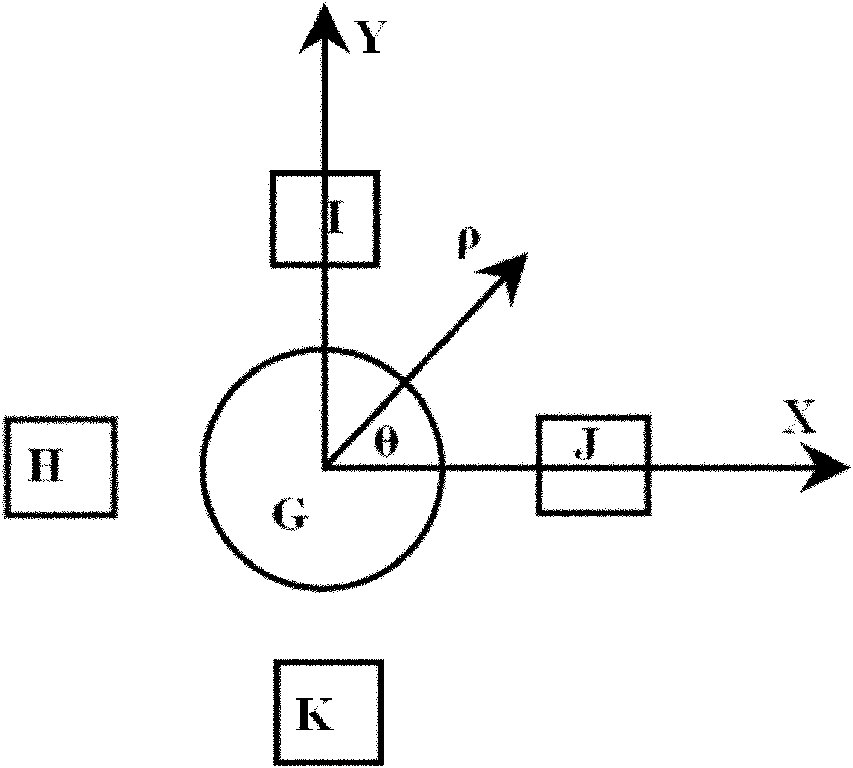

Method used

Image

Examples

Embodiment

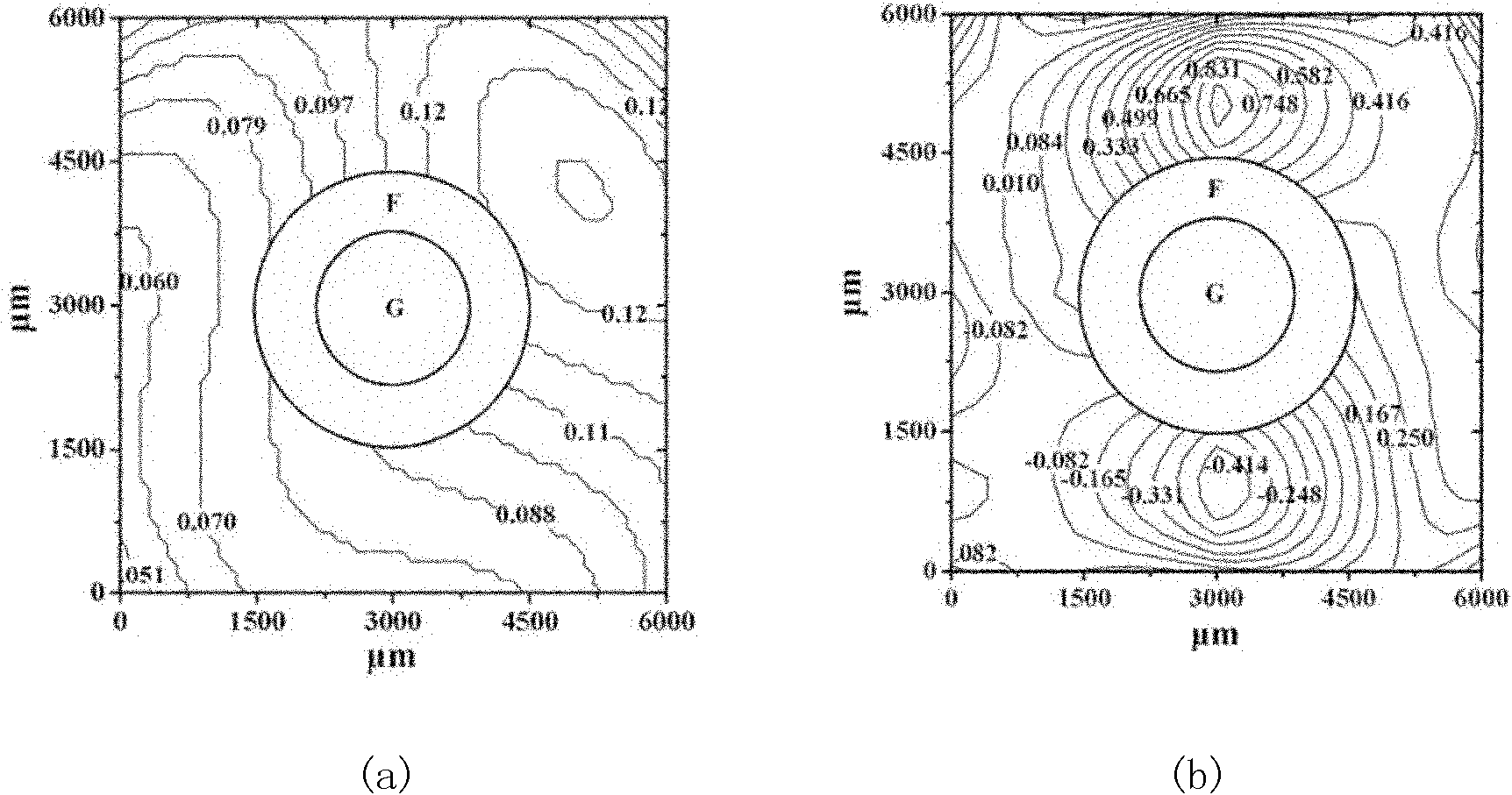

[0065] Consider a concrete situation: image 3 is the displacement field calculated by digital speckle correlation before and after drilling, where image 3 (a) is the displacement field in the X direction, image 3 (b) is the displacement field in the Y direction, and the distance from the center of the small hole is r=1.7mm. The opening displacement at both ends is 0.10 μm in the X direction and 1.39 μm in the Y direction. The drilling radius a is 0.85mm, the elbow radius R=12.5mm, the wall thickness h=5mm, the material elastic modulus E=210GPa, and the material Poisson’s ratio v=0.3 into the formula ⑥, the residual stress in the X direction is 101.0MPa , the residual stress in the Y direction is 187.9MPa. The residual stress of the same specimen measured by the traditional electric drilling method is 105.4MPa in the Y direction and 200.5MPa in the X direction, and the two results are in good agreement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com