Patents

Literature

394results about How to "Increased process reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

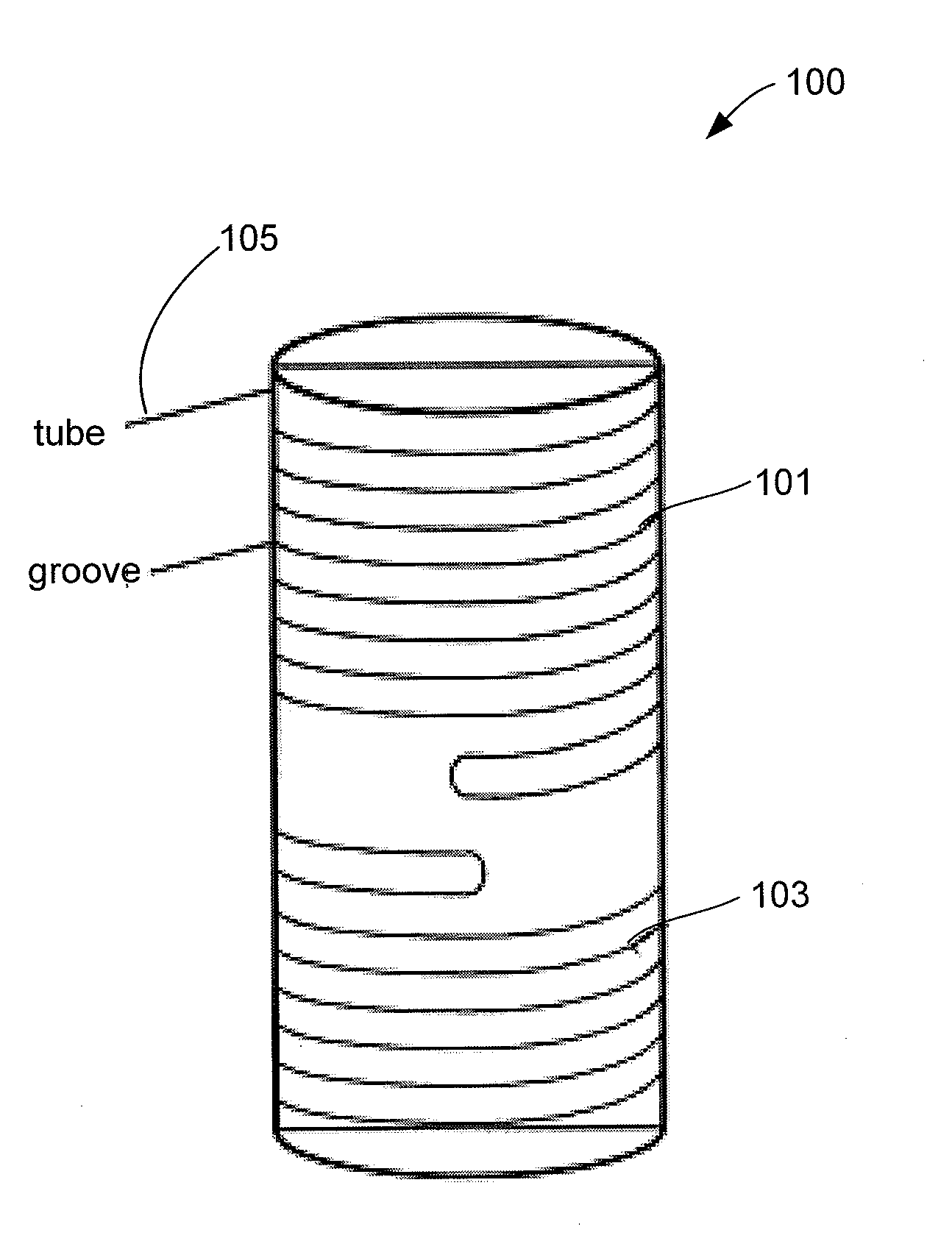

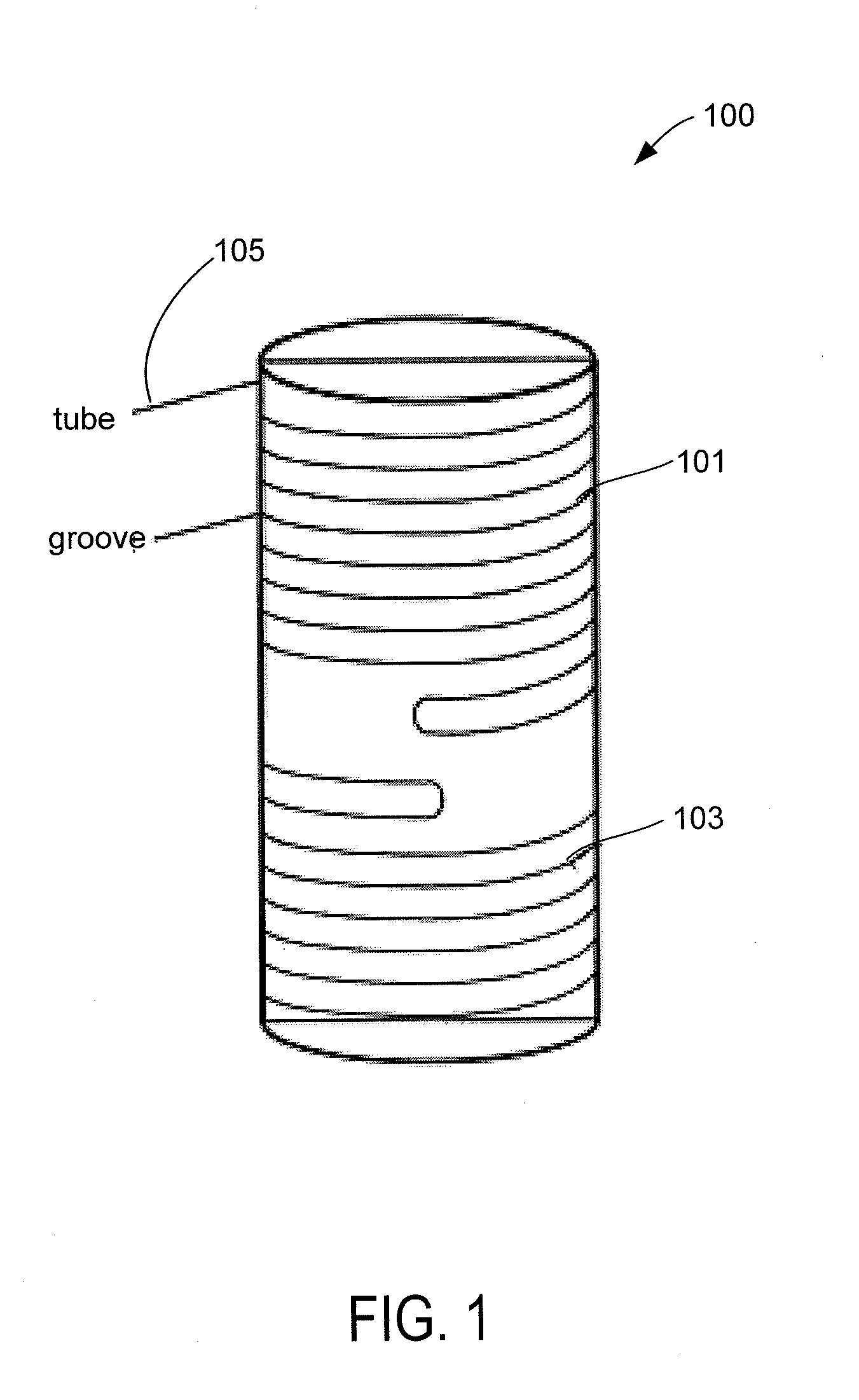

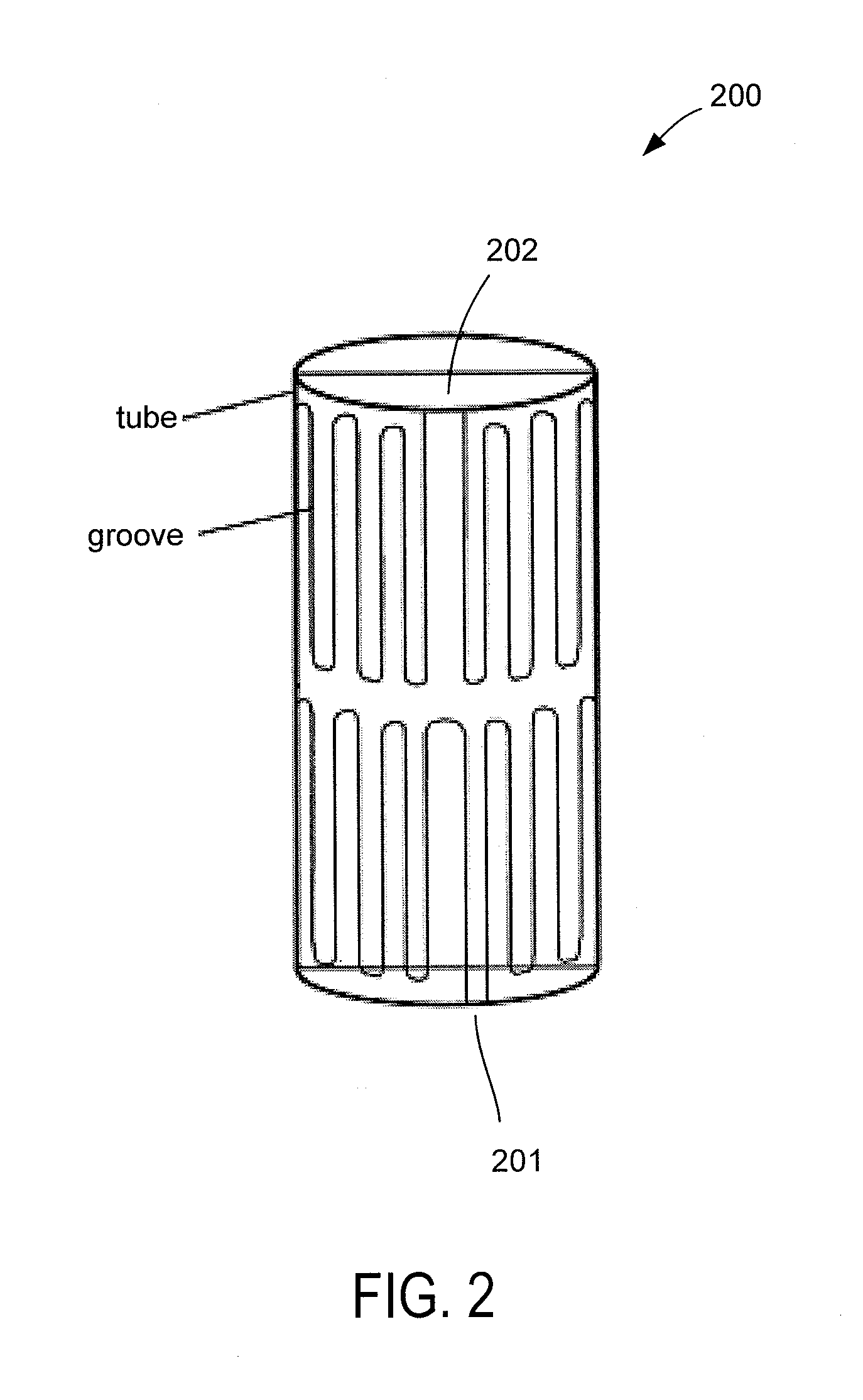

Heater device and method for high pressure processing of crystalline materials

InactiveUS20090320745A1ThinnerEasy to usePolycrystalline material growthFrom melt solutionsCost effectivenessMetallurgy

An improved heater for processing materials or growing crystals in supercritical fluids is provided. In a specific embodiment, the heater is scalable up to very large volumes and is cost effective. In conjunction with suitable high pressure apparatus, the heater is capable of processing materials at pressures and temperatures of 0.2-2 GPa and 400-1200° C., respectively.

Owner:SORAA

Laser-sintering powder with PMMI, PMMA, and/or PMMI-PMMA copolymers, process for its preparation, and moldings produced from this laser-sintering powder

InactiveUS7135525B2High resolutionFlat surfacePretreated surfacesGlass/slag layered productsSelective laser sinteringNylon 12

The present invention relates to a sinter powder composed of polyamide which also comprises PMMI, PMMA, or copolymers with PMMI, in particular PMMI-PMMA copolymers, to the use of this sinter powder for laser-sintering, and also to moldings produced from this sinter powder. The moldings made from the powder of the invention have marked advantages over conventional products in their appearance and in their surface quality, especially as far as roughness and dimensional stability during selective laser sintering (SLS) are concerned. In addition, moldings produced from the sinter powder of the invention also have better mechanical properties than moldings based on conventional nylon-12 powders, in particular in terms of modulus of elasticity and tensile strength. These moldings also have a density close to that of injection moldings.

Owner:EVONIK DEGUSSA GMBH

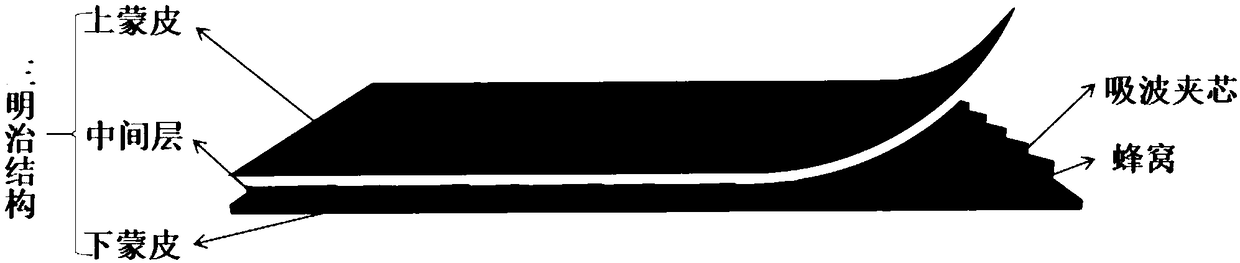

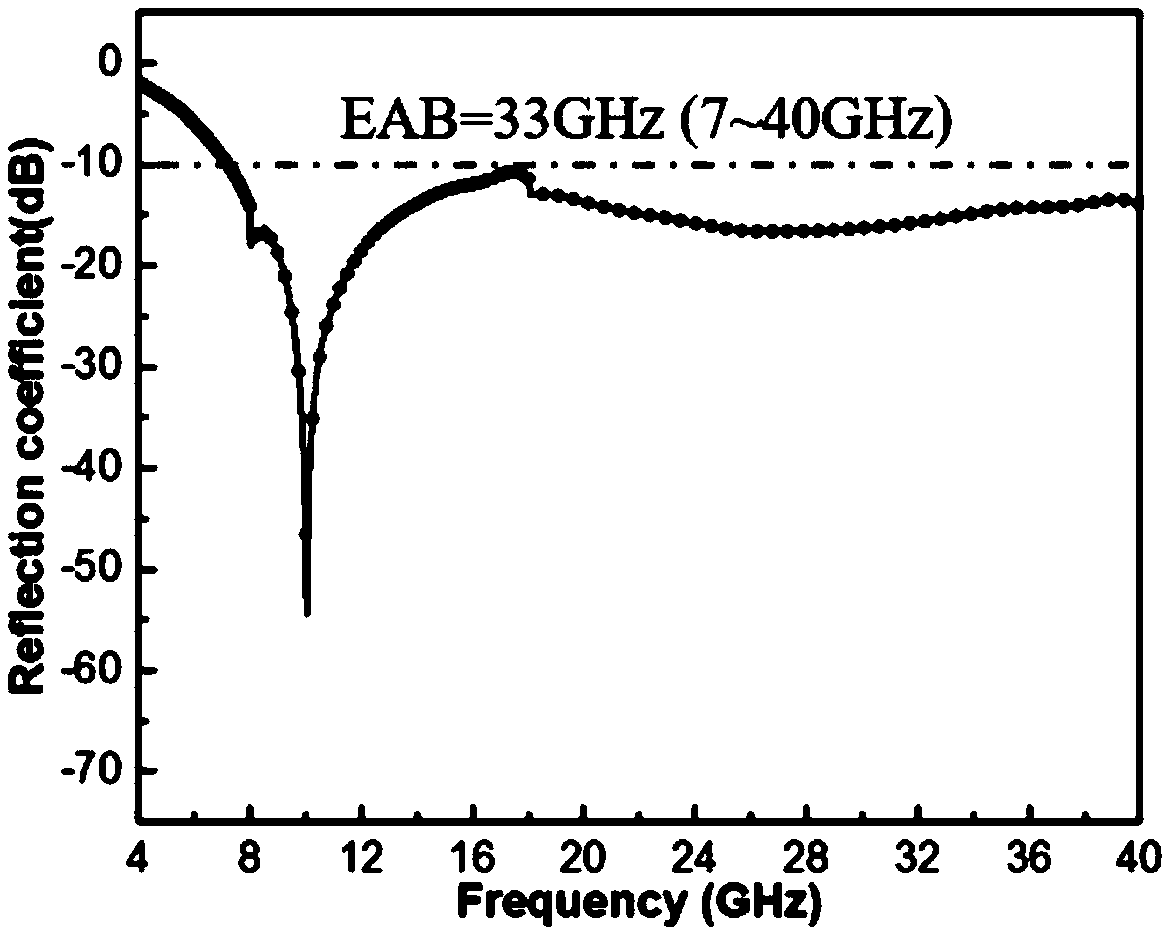

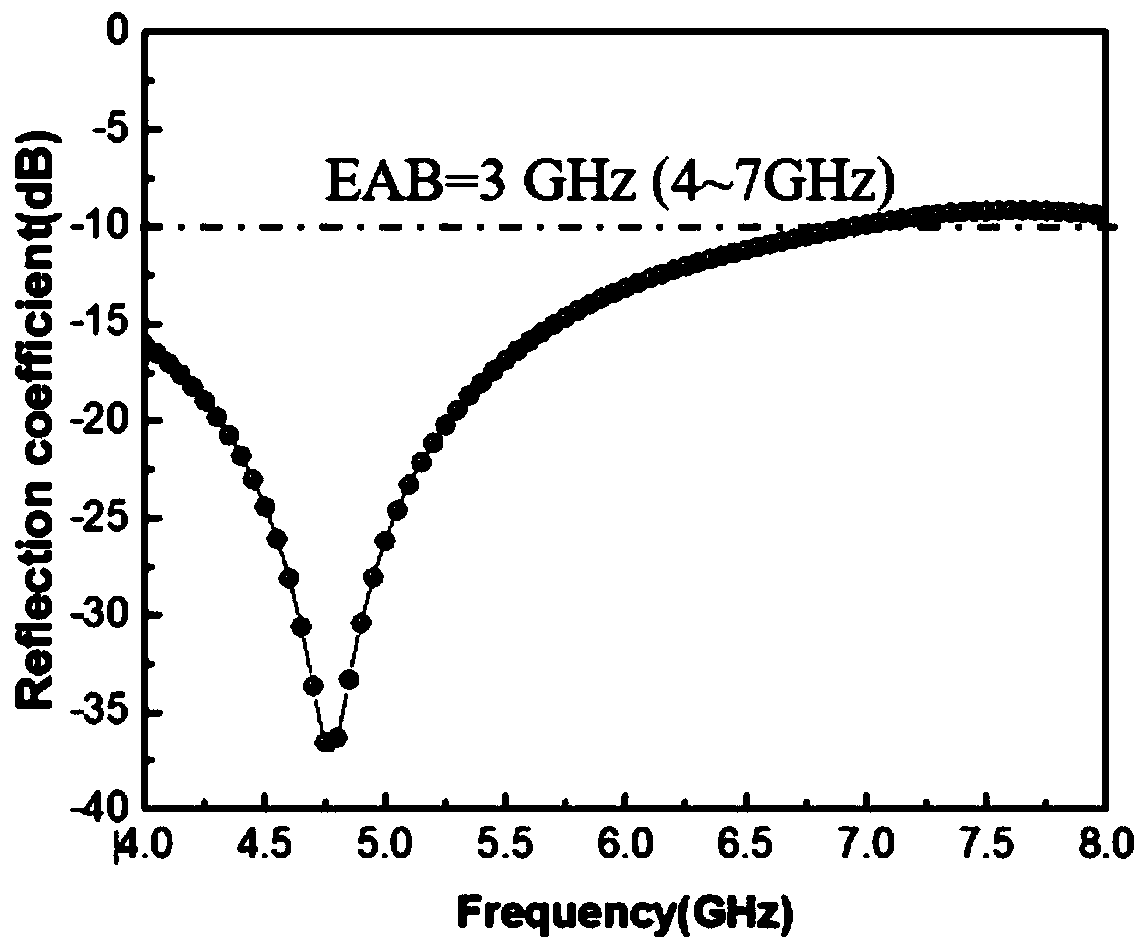

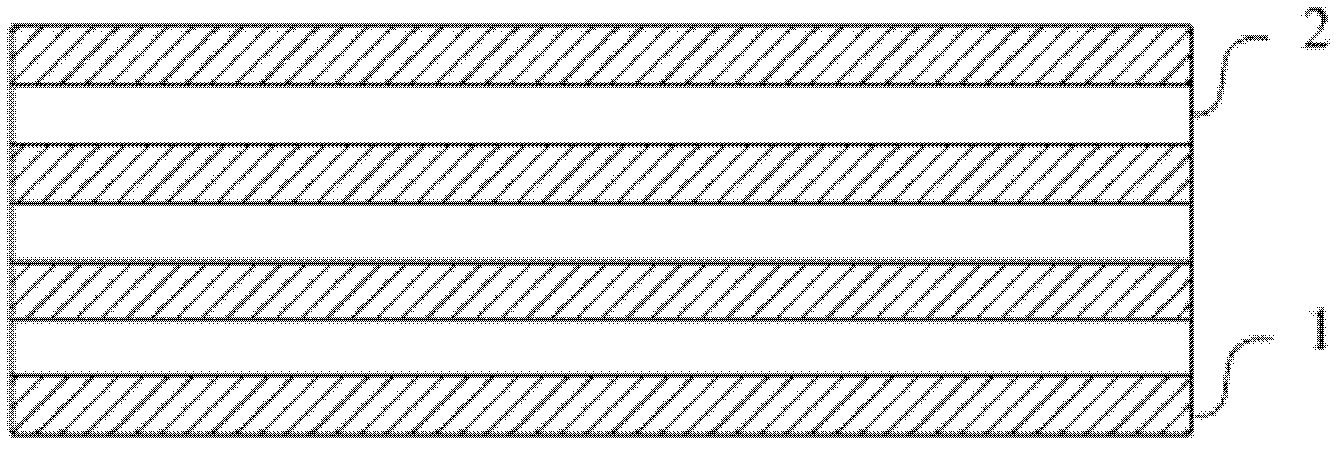

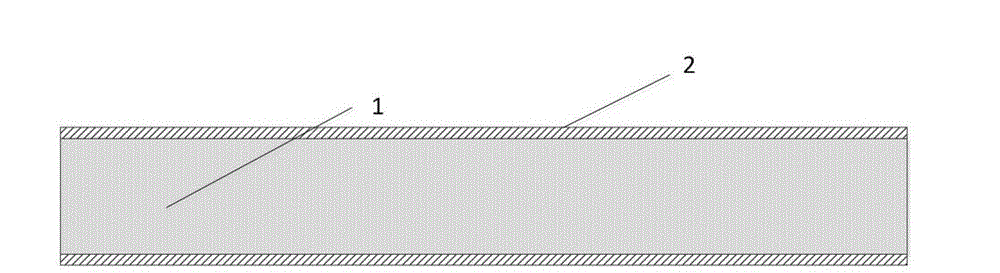

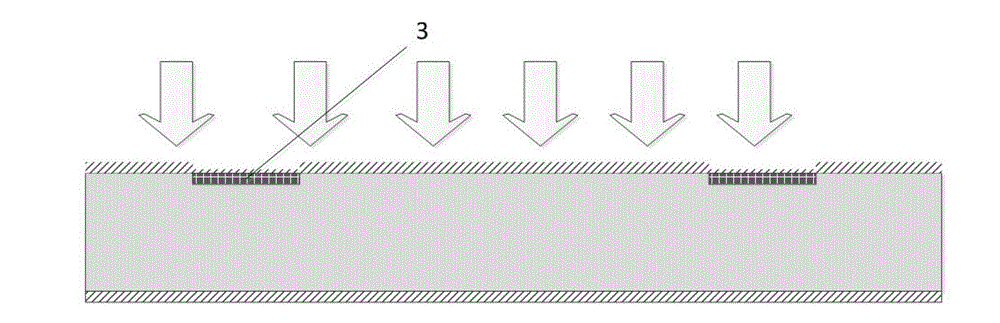

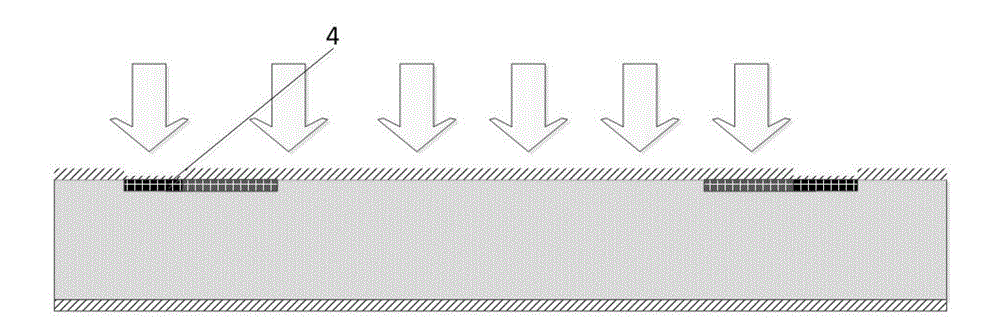

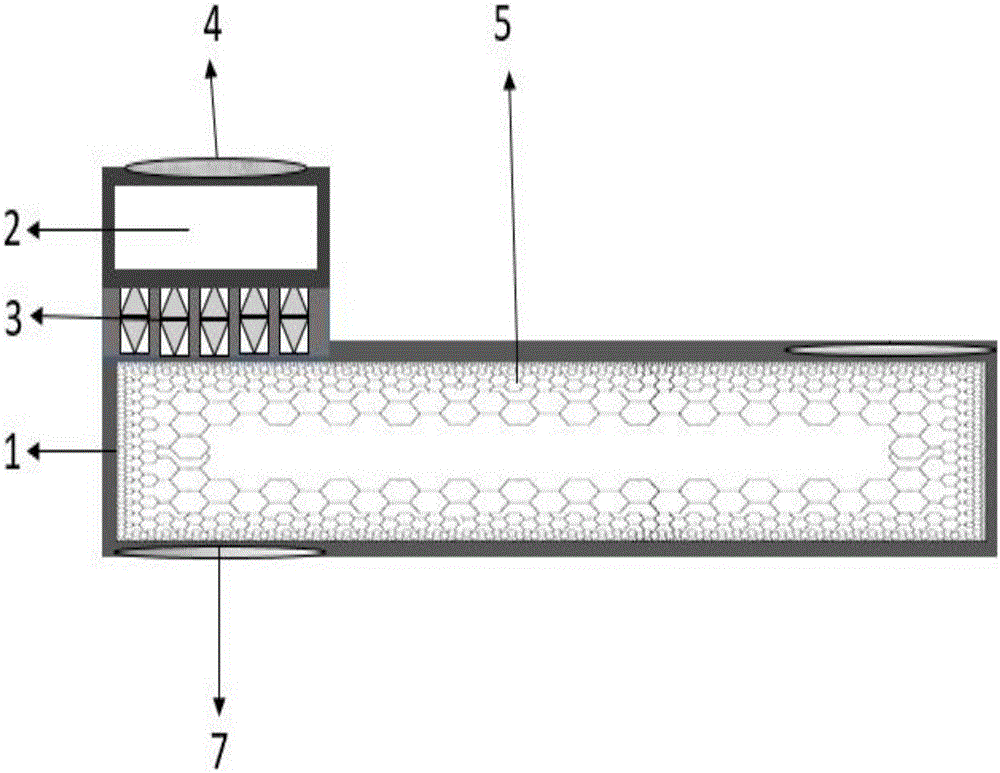

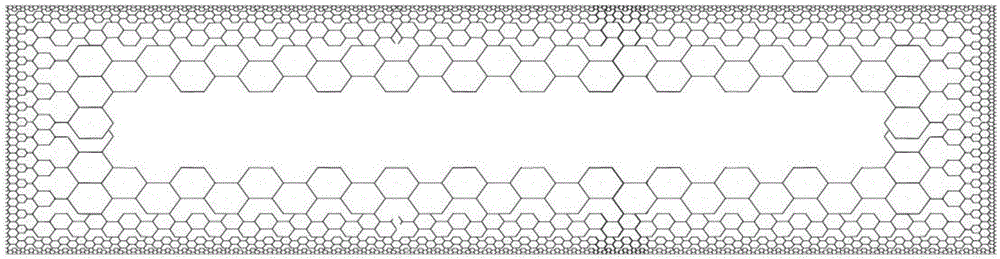

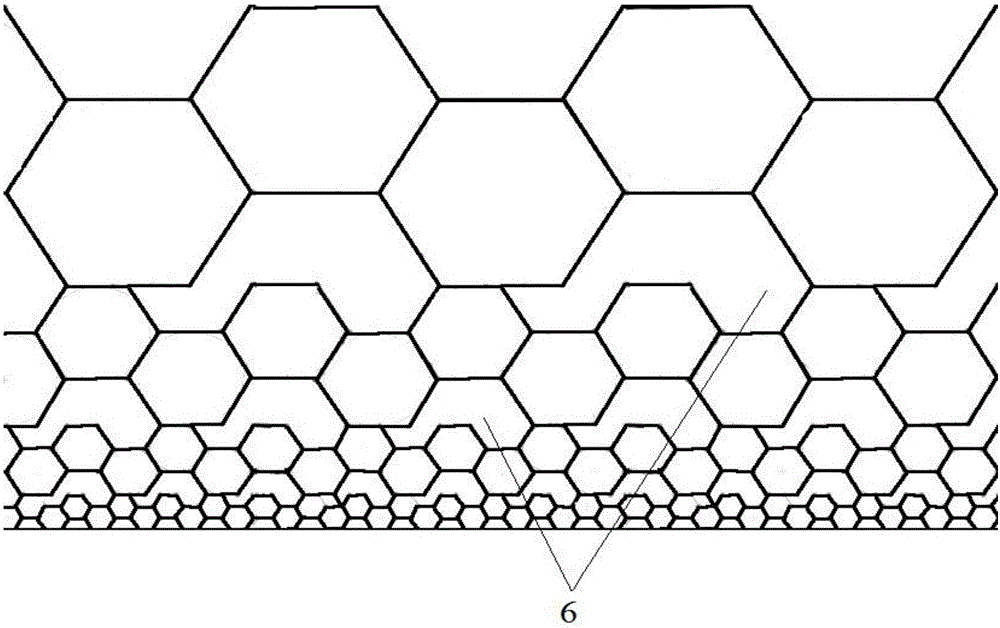

Sandwich structure wave-absorbing composite material and preparation method thereof

ActiveCN108749229AReduce reflectionIncrease secondary absorptionLamination ancillary operationsSynthetic resin layered productsAirplaneCarbon nanotube

The invention relates to a sandwich structure wave-absorbing composite material and a preparation method thereof, an integrated sandwich structure comprises an intermediate layer, an upper skin and alower skin, the intermediate layer is a honeycomb material filled with carbon nanotube / cellulose wave-absorbing foam, the upper skin is a quartz fiber cloth reinforced resin material having electromagnetic wave transmission characteristics, and the lower skin is a carbon fiber cloth-reinforced resin material having electromagnetic wave reflection characteristics. Specifically, the preparation method is carried out according to the following steps: 1. the intermediate layer, namely the honeycomb material filled with the carbon nanotube / cellulose wave-absorbing foam is prepared by a freeze-drying method; 2. the upper kin and the lower skin are prepared by impregnating resin with quartz fiber cloth / carbon fiber cloth; and 3. the intermediate wave-absorbing layer is compounded with the upper kin and the lower skin. The sandwich structure wave-absorbing composite material prepared by the method can replace existing wave-absorbing materials, and is widely used in aircrafts, ground weapon equipment, surface ships and other parts that have stealth requirements for electromagnetic waves.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

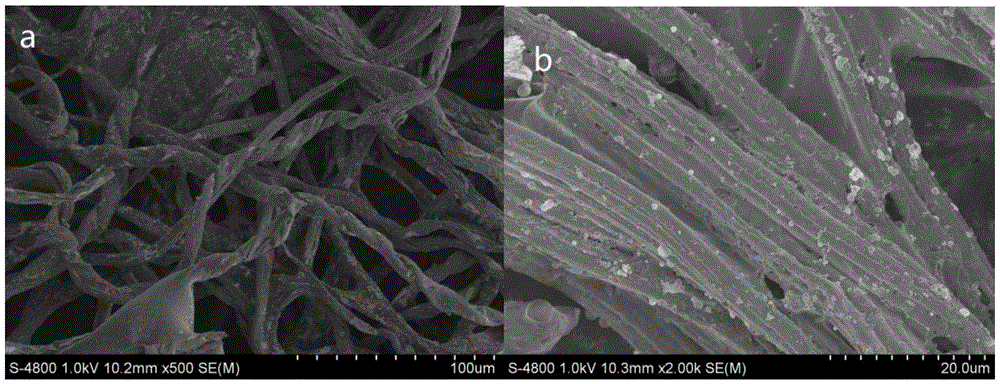

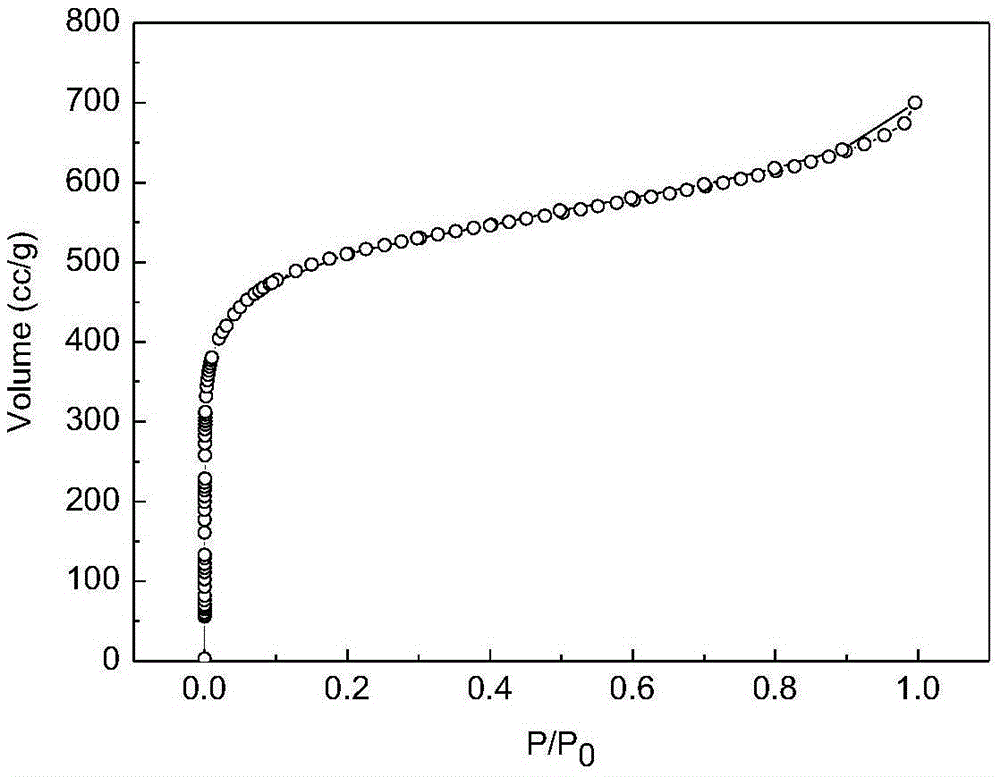

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

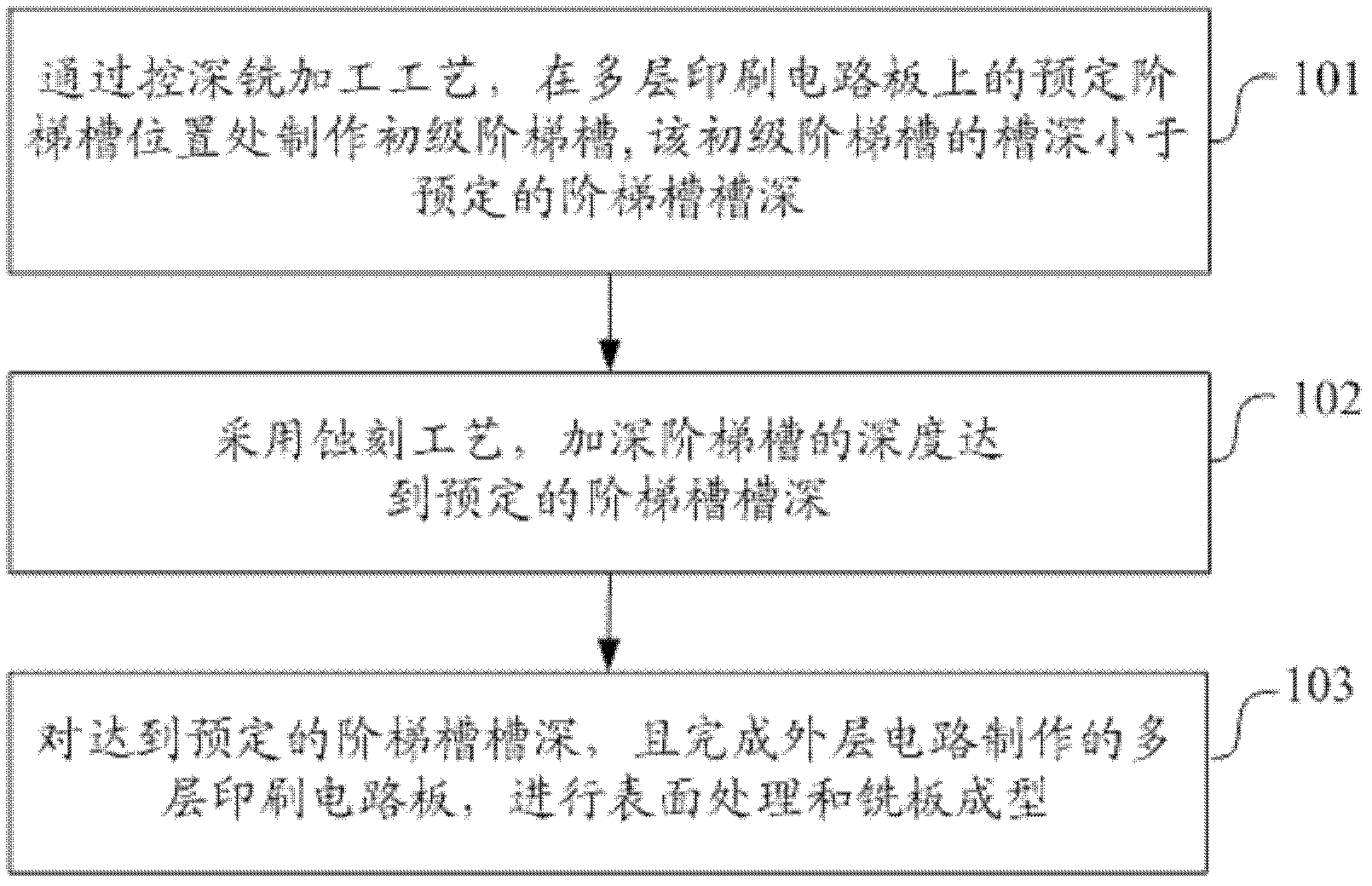

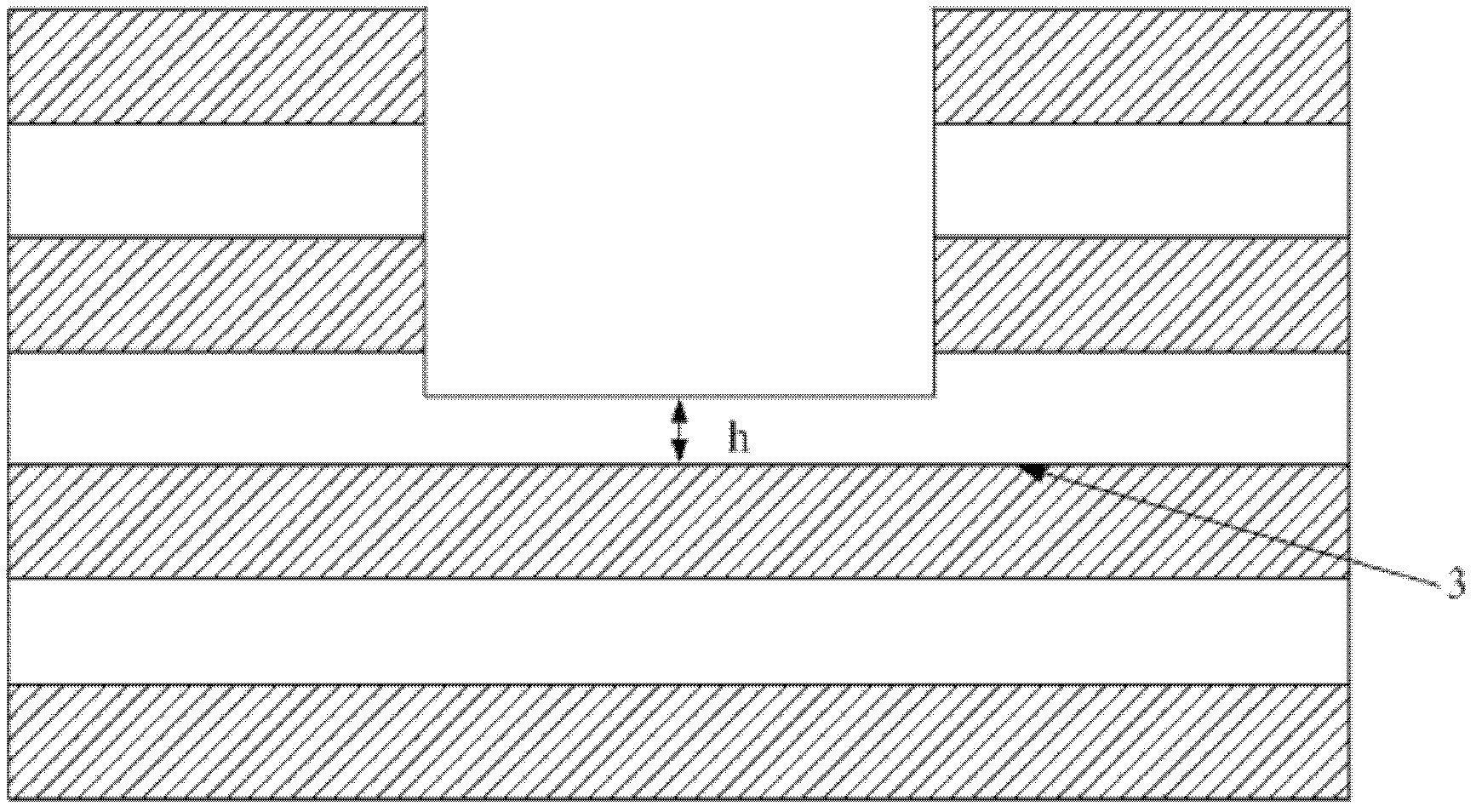

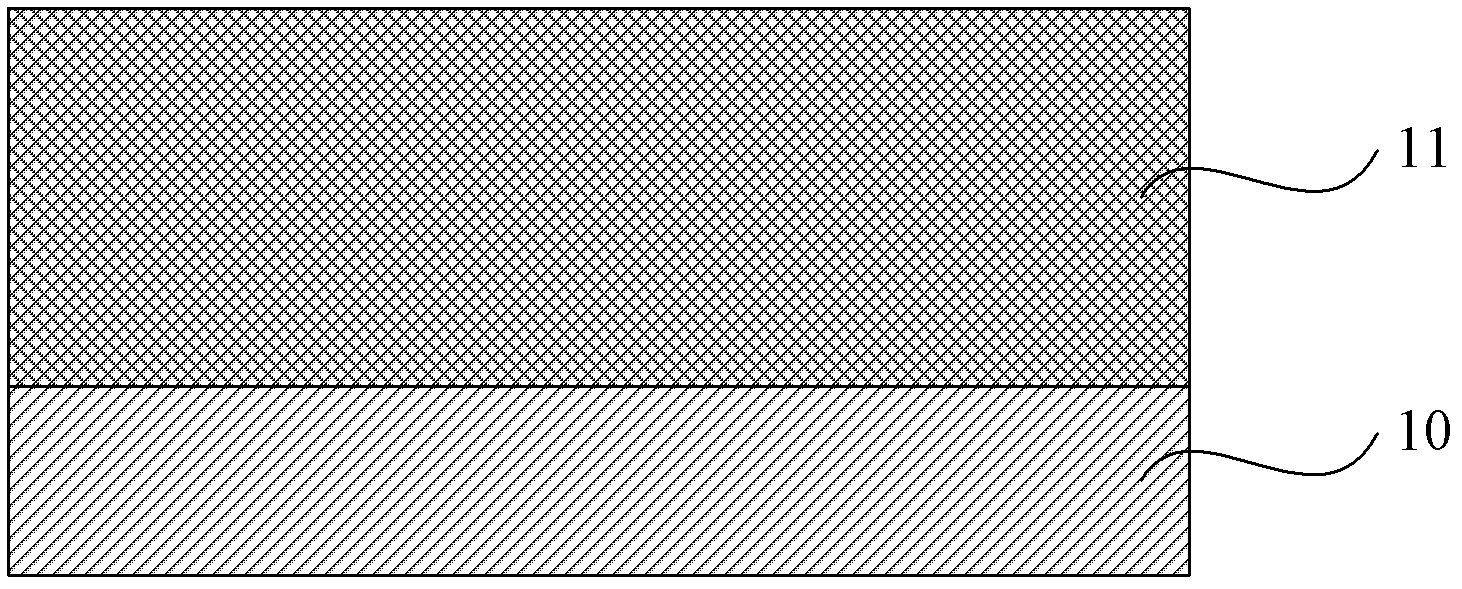

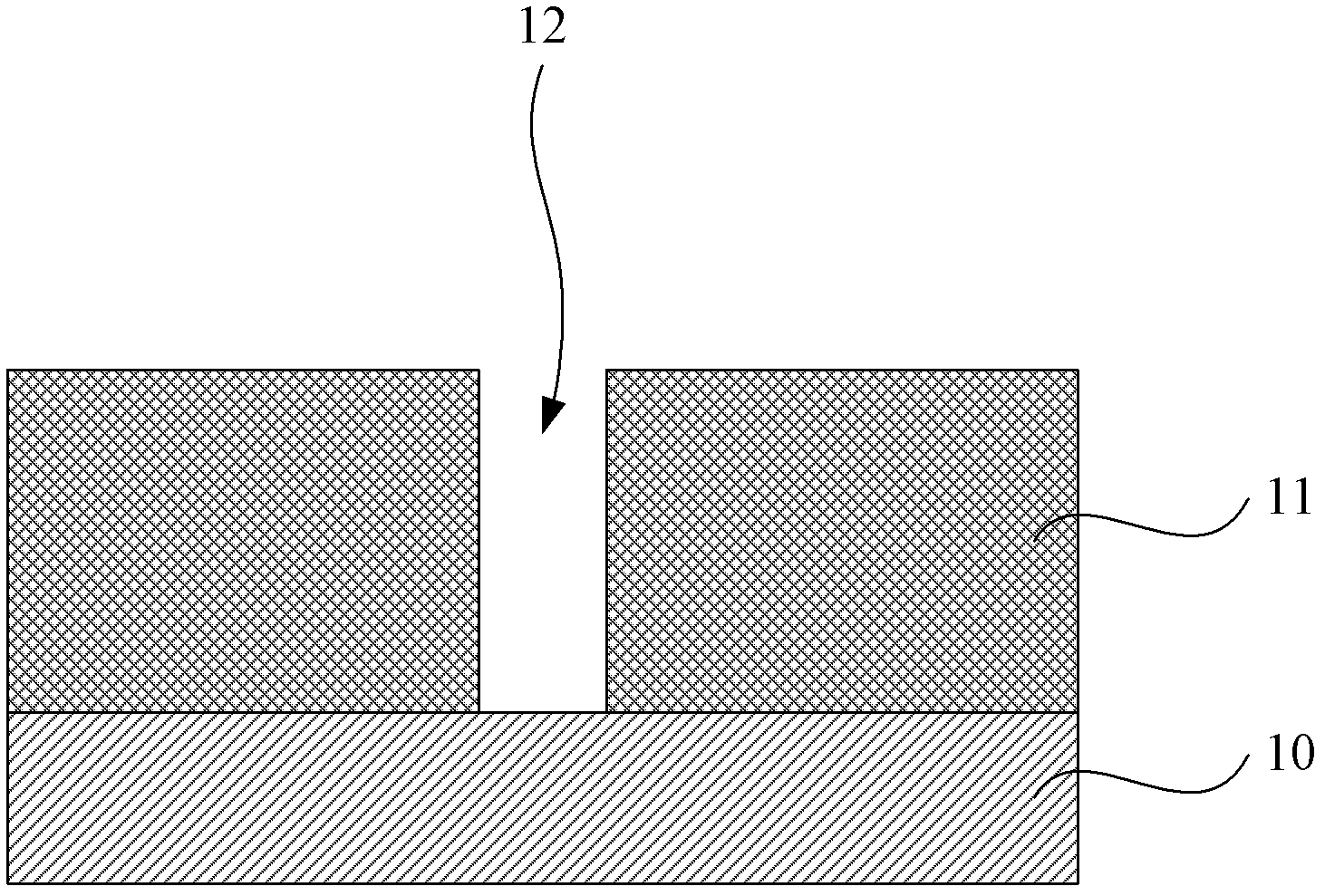

Step printed circuit board and manufacture method of the step printed circuit board

ActiveCN103124469ASimple processEasy to controlMultilayer circuit manufactureEngineeringPrinted circuit board

The invention belongs to the technical field of printed circuit board and in particular to a step printed circuit board and a manufacture method of the step printed circuit board. Deep milling processing technology is controlled, step grooves are roughly manufactured at preset step groove positions on a multilayer printed circuit board manufactured by an outer layer circuit, and then the roughly manufactured step grooves are further exacted to a preset depth through etching technology. The step printed circuit board and the manufacture method of the step printed circuit board have the advantages of being simple in process, easy to control, high in processing reliability and wide in application range, step groove lateral walls manufactured by the method are flat and little in defects, and accordingly high yield can be ensured. Simultaneously, the method does not need to consume auxiliary materials, and manufactured cost is saved.

Owner:NEW FOUNDER HLDG DEV LLC +1

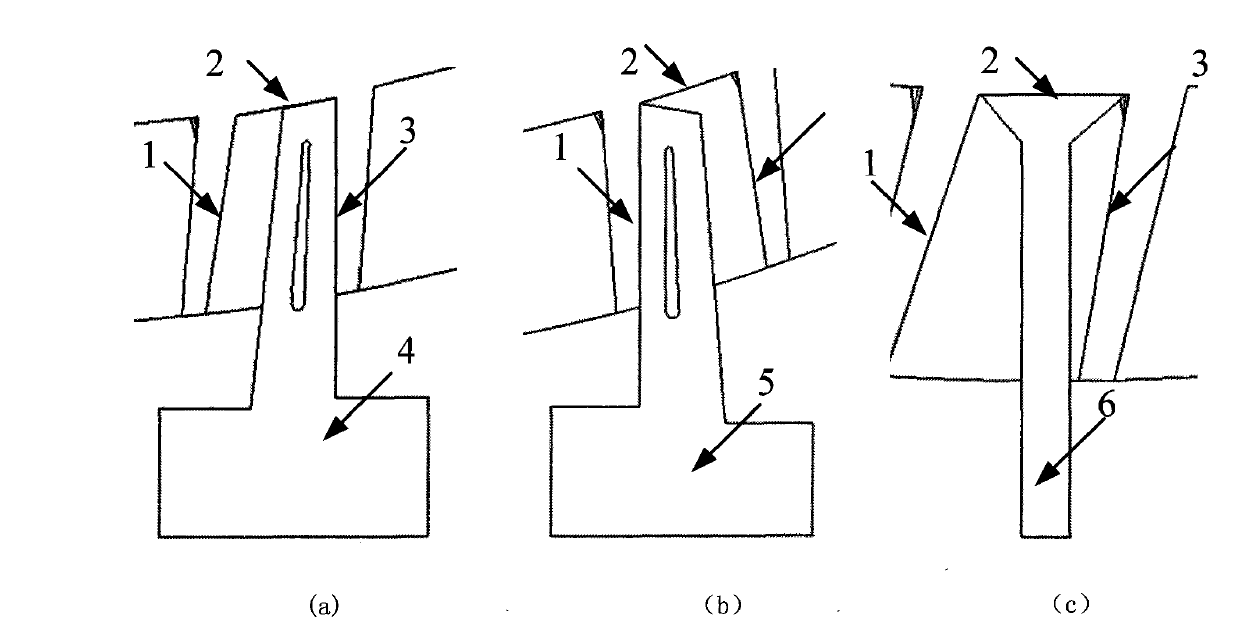

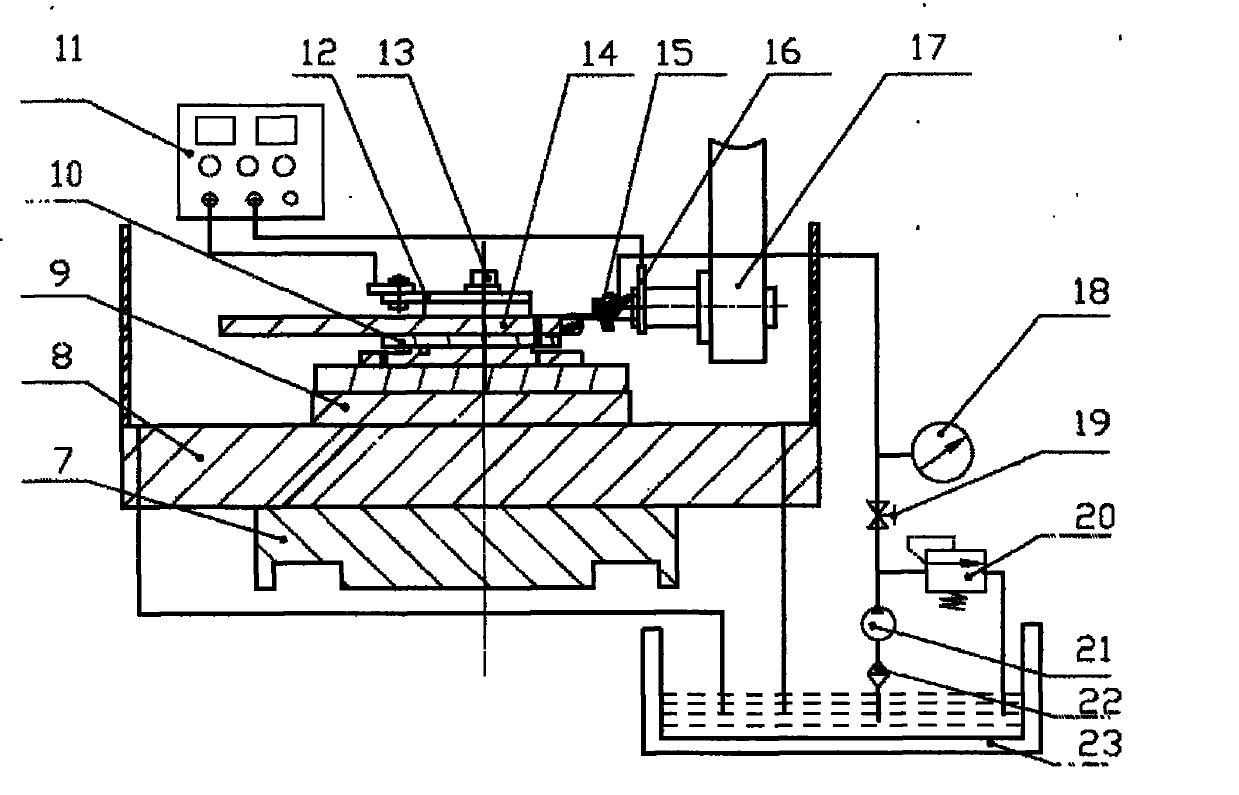

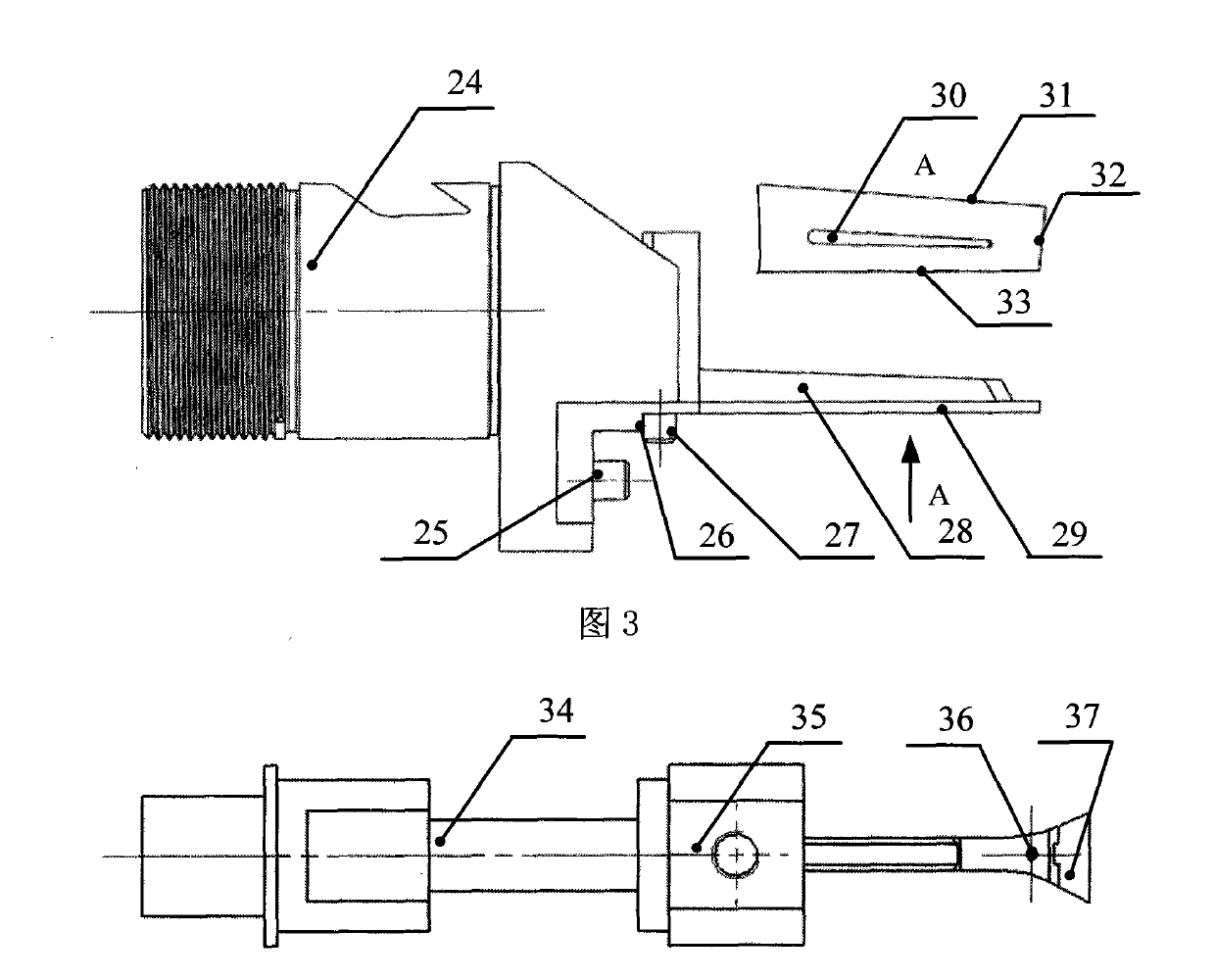

Step and zone type integral impeller electrolytic processing process and device

InactiveCN101767233AGuaranteed machining accuracyImprove machining accuracyElectrochemical machining apparatusImpellerElectrolysis

The invention discloses step and zone type integral impeller electrolytic processing process and device, which belong to the field of impeller electrolytic processing. The integral impeller electrolytic processing has three processing procedures of impeller disc, impeller back and impeller root. The impeller back is firstly processed, then the impeller disc is processed, and the impeller root is processed. The impeller disc, the impeller back and impeller root can be respectively processed along the respective profile by a sweeping forming method. The device comprises an X-axis slide unit, a Y-axis slide unit, a Cw-axis rotary table, an index plate, a processing power supply, an anode conductive plate, a center shaft, a cathode, a cathode conductive plate, a pressure gauge, a ball valve, a water pump, a filter and an electrolytic tank. The invention effectively solves the problem of blade processing of the integral impeller, and is suitable for processing the integral impellers of aerospace engines and advanced power units.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

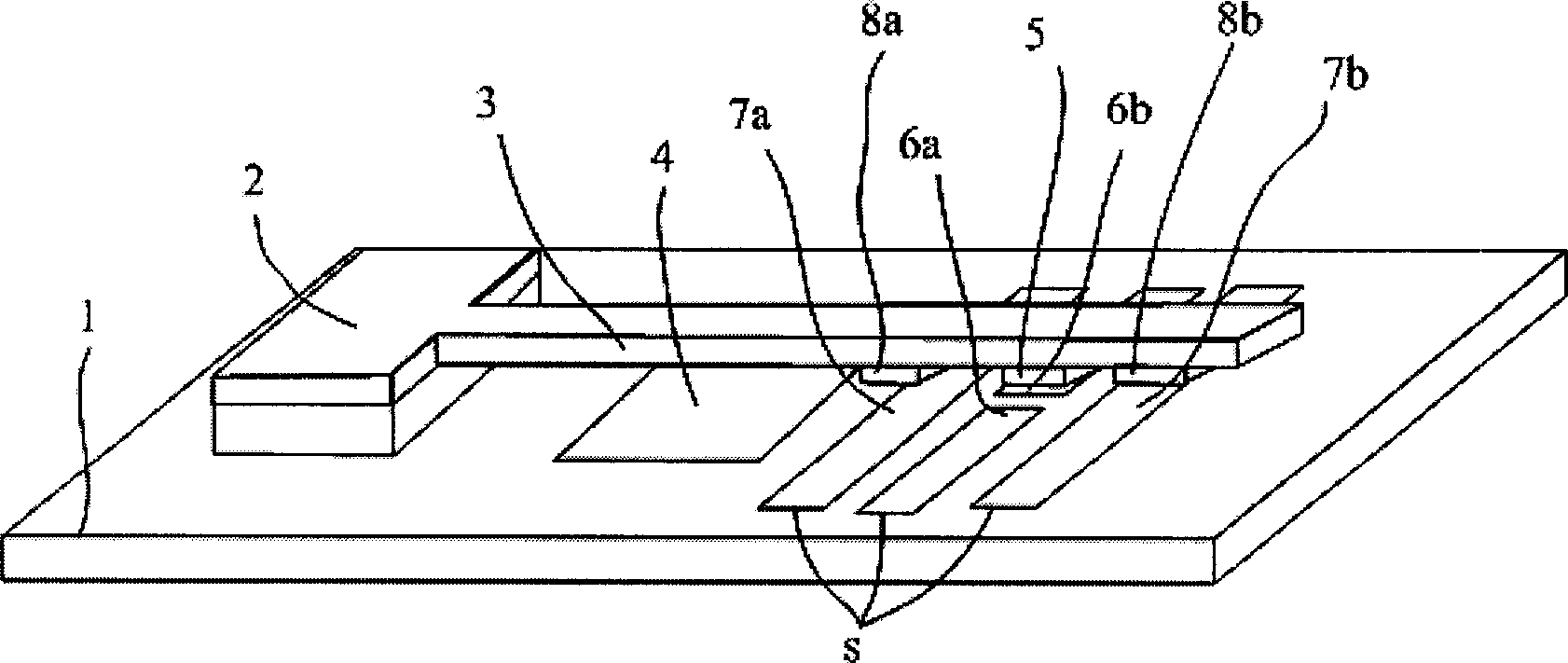

Piezoresistive pressure sensor of MEMS (Micro-Electro-Mechanical Systems) and preparation method thereof

InactiveCN102944339AGood performanceIncreased process reliabilityDecorative surface effectsSolid-state devicesHigh rateAnisotropic etching

The invention relates to a piezoresistive pressure sensor of MEMS (Micro-Electro-Mechanical Systems) and a preparation method thereof; the piezoresistive pressure sensor of the MEMS comprises a strain film and a voltage dependent resistor; an island structure is distributed on the frontal surface edge of the strain film; and the voltage dependent resistor is positioned on the island structure. When the piezoresistive pressure sensor of the MEMS is prepared, the production of the island structure on the frontal surface of the film is carried out before the anisotropic etching of a back cavity, so that the cracking of the strain film is avoided when the island structure is produced on the frontal surface. The pressure sensor of the invention has high sensitivity and high linearity; and the preparation method thereof is compatible with the traditional technique, and has high rate of finished products.

Owner:PEKING UNIV

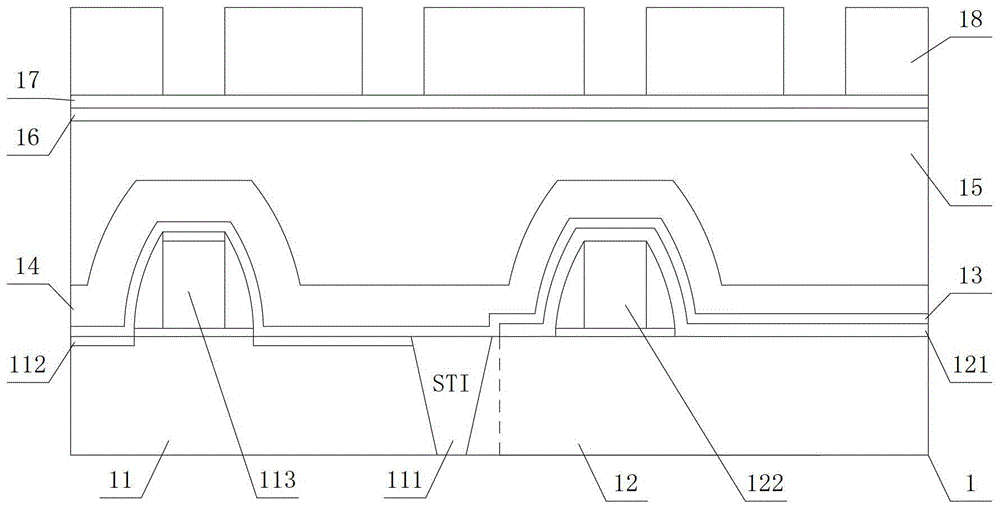

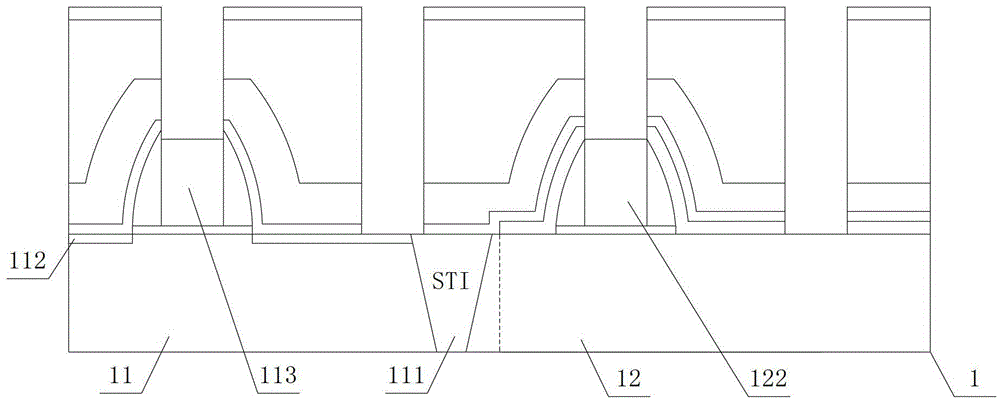

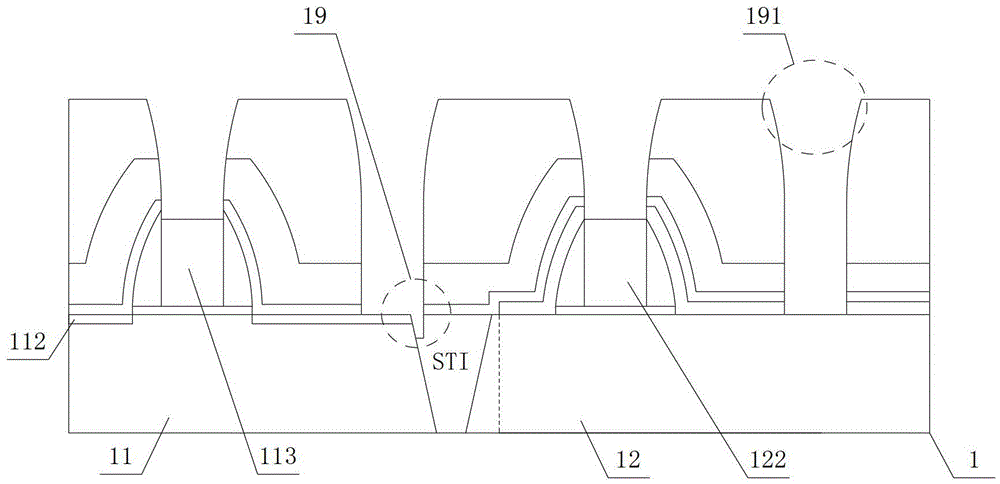

Double-structure contact hole synchronous-etching technology

ActiveCN103337475AReduce the process risk of abnormal connectionReduce lossesSemiconductor/solid-state device manufacturingRadiation controlled devicesDielectric layerMetal

The invention relates to the field of MOS (Metal Oxide Semiconductor) devices, particularly to a double-structure contact hole synchronous-etching technology. The silicon nitride barrier layer in a photosensitive area is removed immediately after a silicon nitride barrier layer is deposited, so that the deposit layer structure of a double-structure contact hole of a CIS (Complementary Metal Oxide Semiconductor Image Sensor) product is changed; the etching selection ratio of an interlayer dielectric layer (insulating dielectric layer) to the barrier layer and a silicone substrate is enlarged in the follow-up etching technology, so that the etching step special for a monox barrier layer at the bottom of the photosensitive area is reduced, the monox loss on STI (Shallow Trench Isolation) of a borderless contact hole in a logic area is reduced while the double-structure contact hole is formed, and the yield of products is improved while the technological reliability and stability are enhanced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

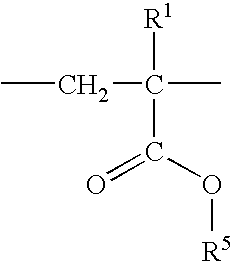

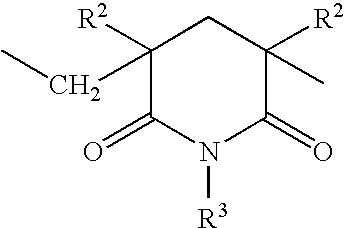

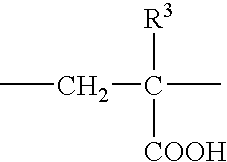

Addition compositions suitable as dispersants and dispersion stabilizers

ActiveCN1692975AIncreased process reliabilitySmall shrinkageTransportation and packagingOrganic dyesOrganic chemistryAmino radical

The invention relates to addition compounds which are obtainable by reacting a) one or more polyisocyanates containing uretdione groups with b) one or more compounds of the formula (I) where XH and Y is are defined in the specification, with the proviso that substantially all free isocyanate groups of component a) are reacted with the compounds of the formula (I) to give an intermediate which contains uretdione groups, and subsequently the uretdione groups are reacted with c) one or more compounds of the general formula (II) in which R and Z are given the meanings in the specification, if desired, after this reaction, reacting any reactive amino groups still present in the reaction - 56 - product with compounds that are reactive towards amino groups; and also salts or quaternization products of the addition compounds. The invention further relates to a process for preparing the addition compounds and to their use, particularly as dispersion stabilizers and dispersants.

Owner:BYK CHEM GMBH

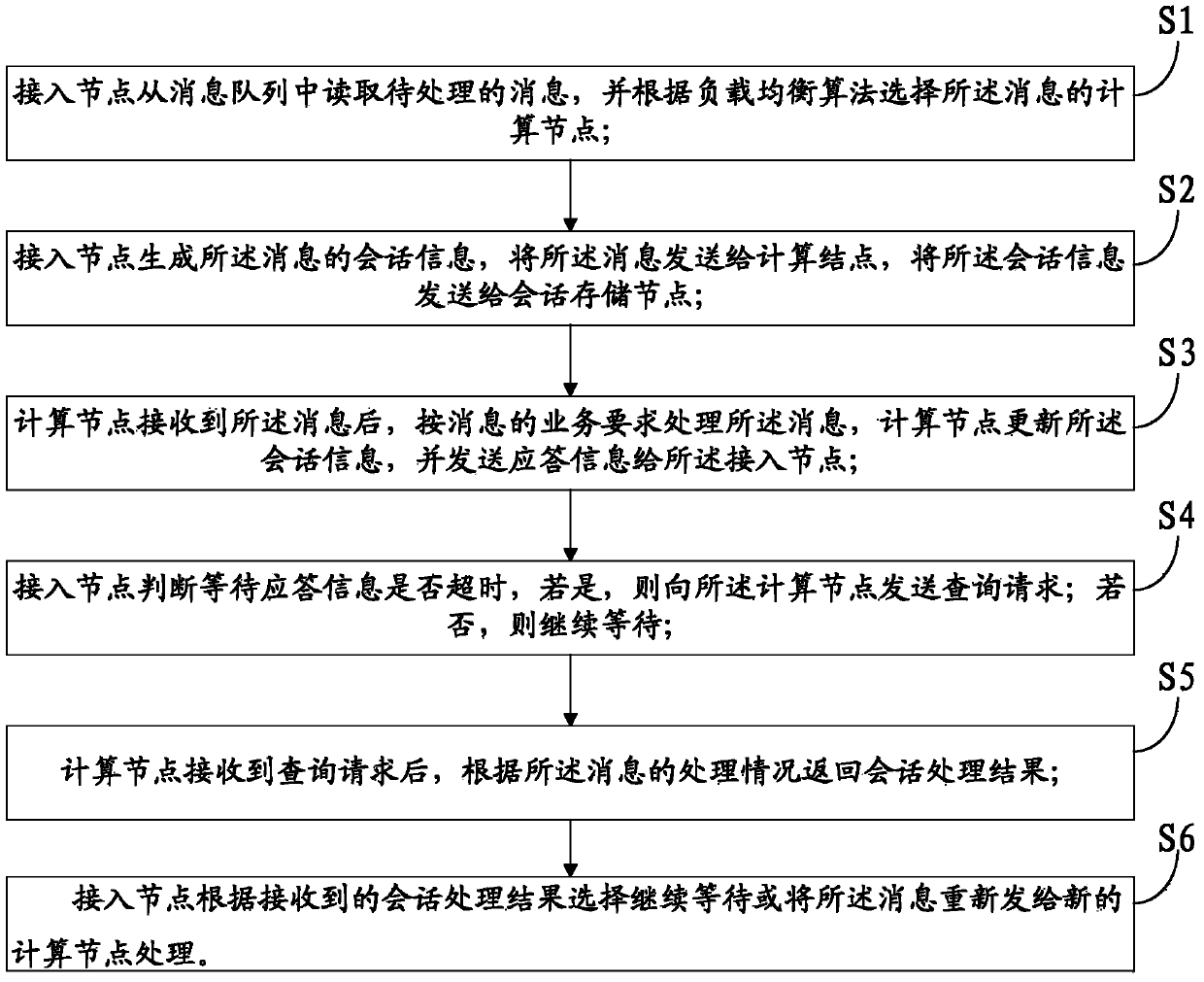

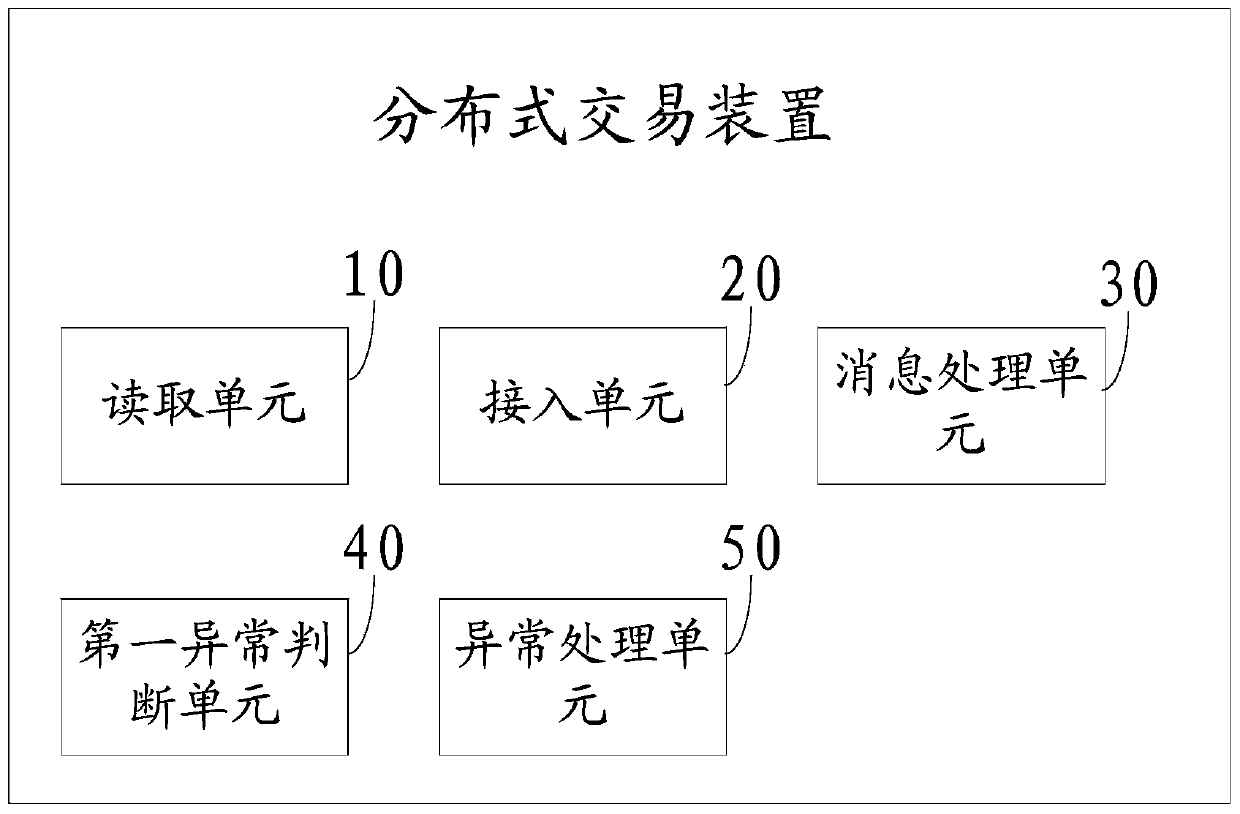

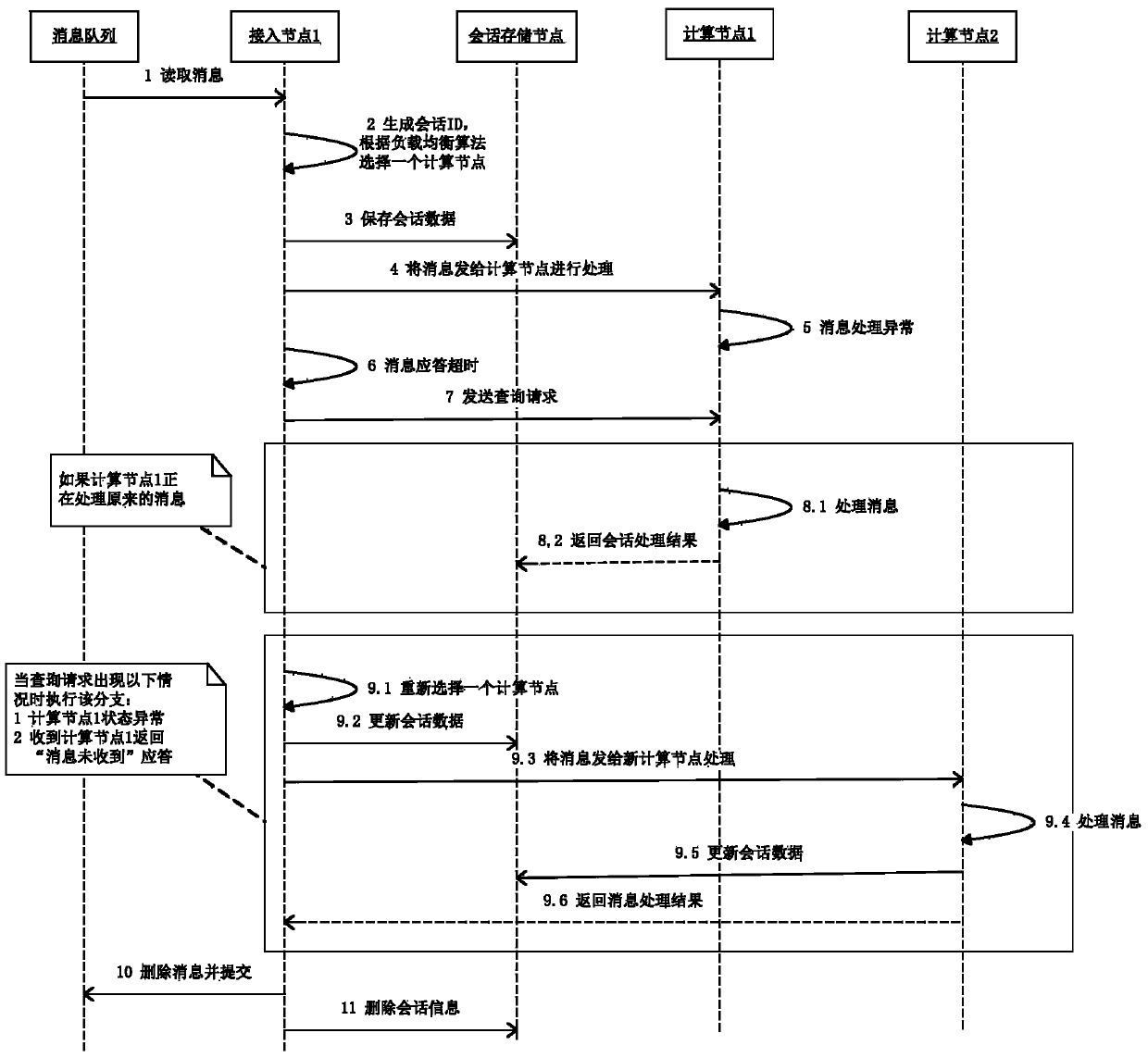

Distributed transaction requesting method and device

ActiveCN104219235AAvoid lossIncreased process reliabilityTransmissionSpecial data processing applicationsMessage queueMessage processing

The invention discloses a distributed transaction requesting method. The distributed transaction requesting method includes reading messages to be processed from a message queue by an access node and selecting a calculation node of the message; generating dialogue information of the messages, transmitting the messages to the calculation node and storing the dialogue information to a dialogue storage node; receiving and processing the messages by the calculation node, updating the dialogue information and transmitting response information to the access node; judging whether waiting for the response information is time out or not by the access node, if yes, transmitting query request to the calculation node; if not, keeping waiting; feeding back dialogue processing results after the calculation node receives the query request; keeping waiting or retransmitting the messages to a new calculation node by the access node according to the received dialogue processing results. The invention further discloses a distributed transaction requesting device. By the distributed transaction requesting method and device, reliability in message processing of a distributed system is effectively improved.

Owner:FUJIAN NEWLAND SOFTWARE ENGINEERING CO LTD

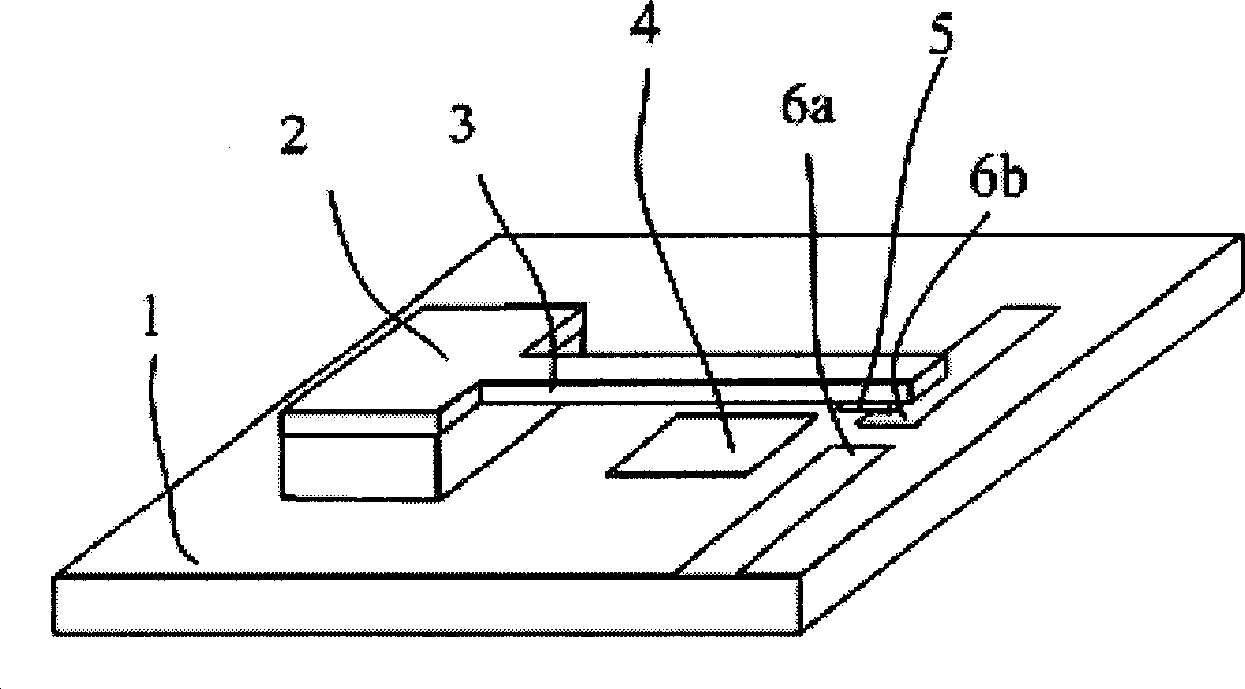

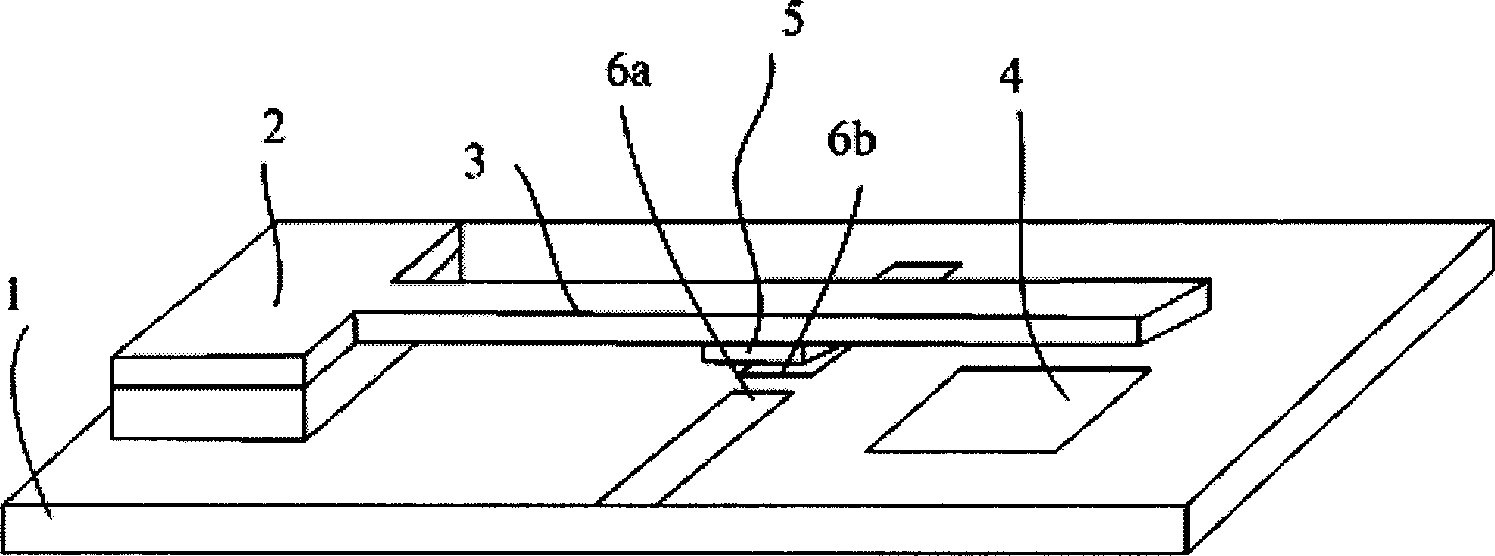

Integrated RF MEMS switch

InactiveCN1716492AIncreased process reliabilityReduce process complexityElectrostatic/electro-adhesion relaysWaveguide type devicesMicroelectromechanical systemsEngineering

The RF switch based on micro electromechanical technology includes micro mechanism (MEMS) part and RF part, and has mobile switch structure for the switching function is set on the MEMS substrate. The MEMS part and RF part are first manufactured separately, and the MEMS substrate and RF substrate are then aligned and bonded together. The switch includes several mobile electrodes and has two kinds of drive states including upward drawing state and downward drawing state. The switch in the technological scheme of the present invention has fast switching speed, low drive voltage, high stability and relatively simple manufacture process with high outer contamination resistance.

Owner:BEIJING UNIV OF POSTS & TELECOMM

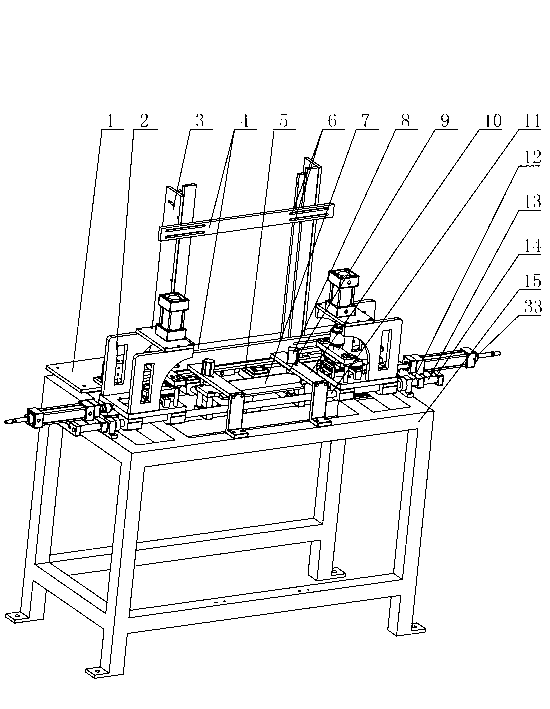

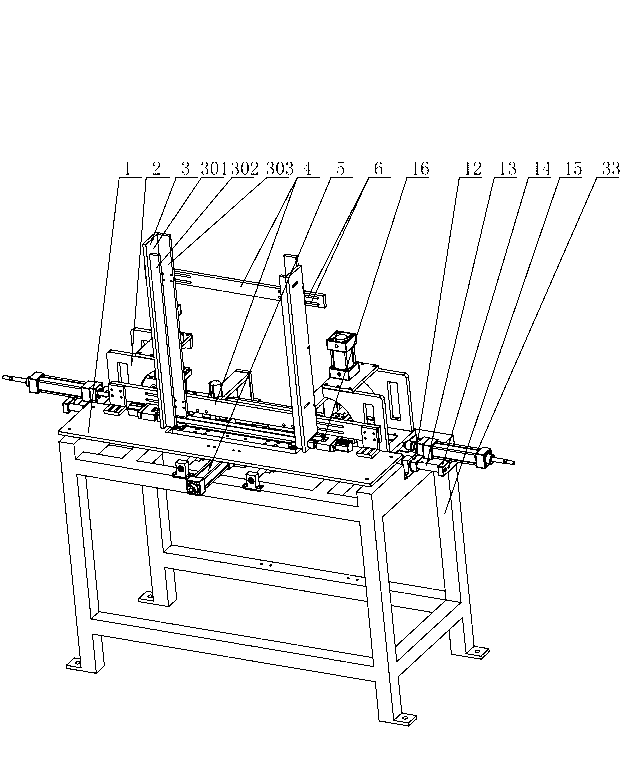

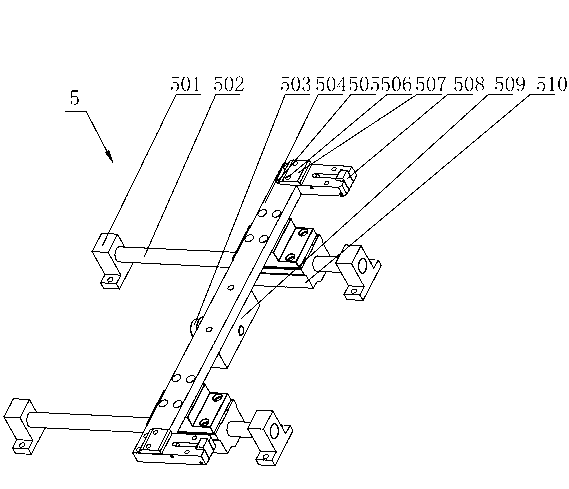

Semi-automatic punching machine for packaging tube

ActiveCN102862183AReasonable structureSimple and fast operationMetal working apparatusPunchingEngineering

The invention relates to a semi-automatic punching machine for a packaging tube, comprising a base, wherein steps are formed on the upper surface of the base, a workbench is arranged at the middle of the first step surface, a main guide rail is arranged on the lower part of the workbench, and punching mechanisms are symmetrically installed on the main guide rail and at the both ends of the workbench respectively; a bottom plate is installed on the second step surface of the base, a groove opening is formed at the middle of the bottom plate, an arranging frame is arranged at the groove opening, packaging tube limit mechanisms are arranged at the outer ends of the bottom of the arranging frame respectively, and a feeding mechanism is arranged on the lower part of the bottom plate; and a pressing mechanism is further arranged above the workbench. The semi-automatic punching machine reduces labour intensity, is high in production efficiency and reliable in working, and guarantees the product quality.

Owner:WUXI JIAXIN ELECTRONICS PRODS

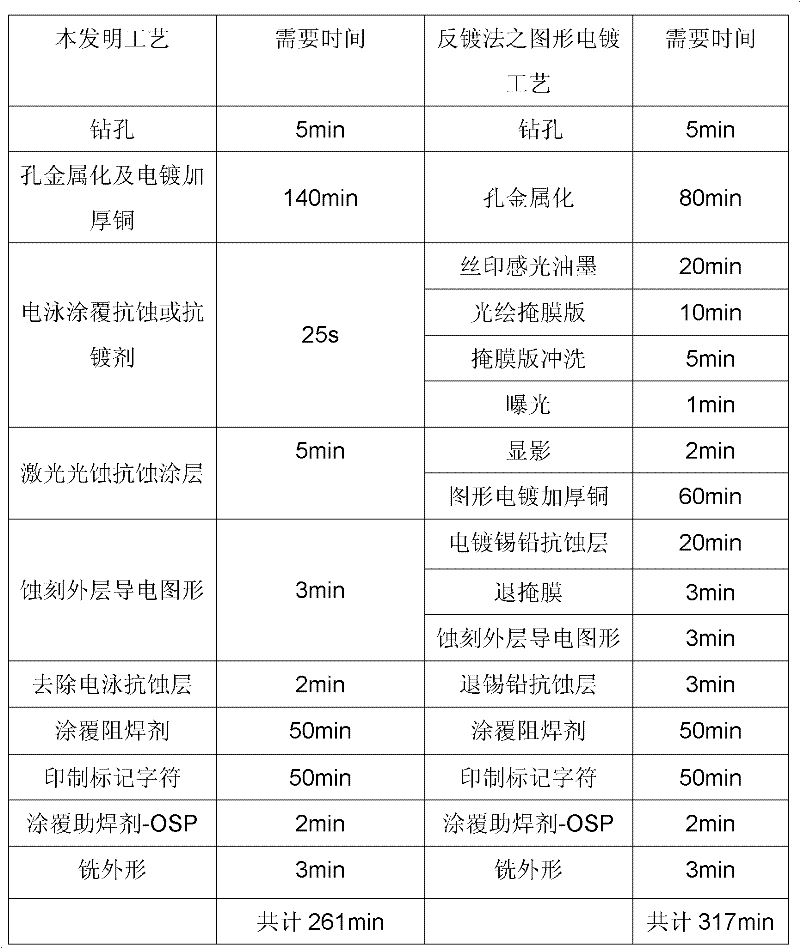

Method for producing anti-corrosion pattern in production of printed circuit board

ActiveCN102510671ASave processSave light paintingConductive material chemical/electrolytical removalResistEtching

The invention relates to a method for producing an anti-corrosion pattern in production of a printed circuit board, and the method comprises the steps of: drilling a hole, metalizing the hole, performing electrophoretic coating of a resist, producing the anti-corrosion pattern by laser, performing chemical etching and the like. The method with the electrophoretic coating of a resist and the production of the anti-corrosion pattern by the laser is adopted for replacing an existing tenting method process with the steps of hot-press lamination of an anti-corrosion photoinduced masking dry film, exposure, developing and the like or replacing the steps of pattern electroplating of an anti-corrosion metal layer and the like. According to the method disclosed by the invention, a process route for producing the anti-corrosion pattern is shortened, the operation steps are simplified, the operability is improved, the anti-corrosion coating is applied by electrophoresis, materials are easy to obtain, the operation is simple and easy, and the formed anti-corrosion coating is thin in thickness, uniform and reliable; and the anti-corrosion pattern formed by direct photoetching through the laser method is high in precision, good in an environment and great in production flexibility. The method disclosed by the invention is suitable for sample, small-batch, multi-variety and higher-precision production of the circuit boards, and is also suitable for production of ordinary circuit boards.

Owner:德中(天津)技术发展股份有限公司

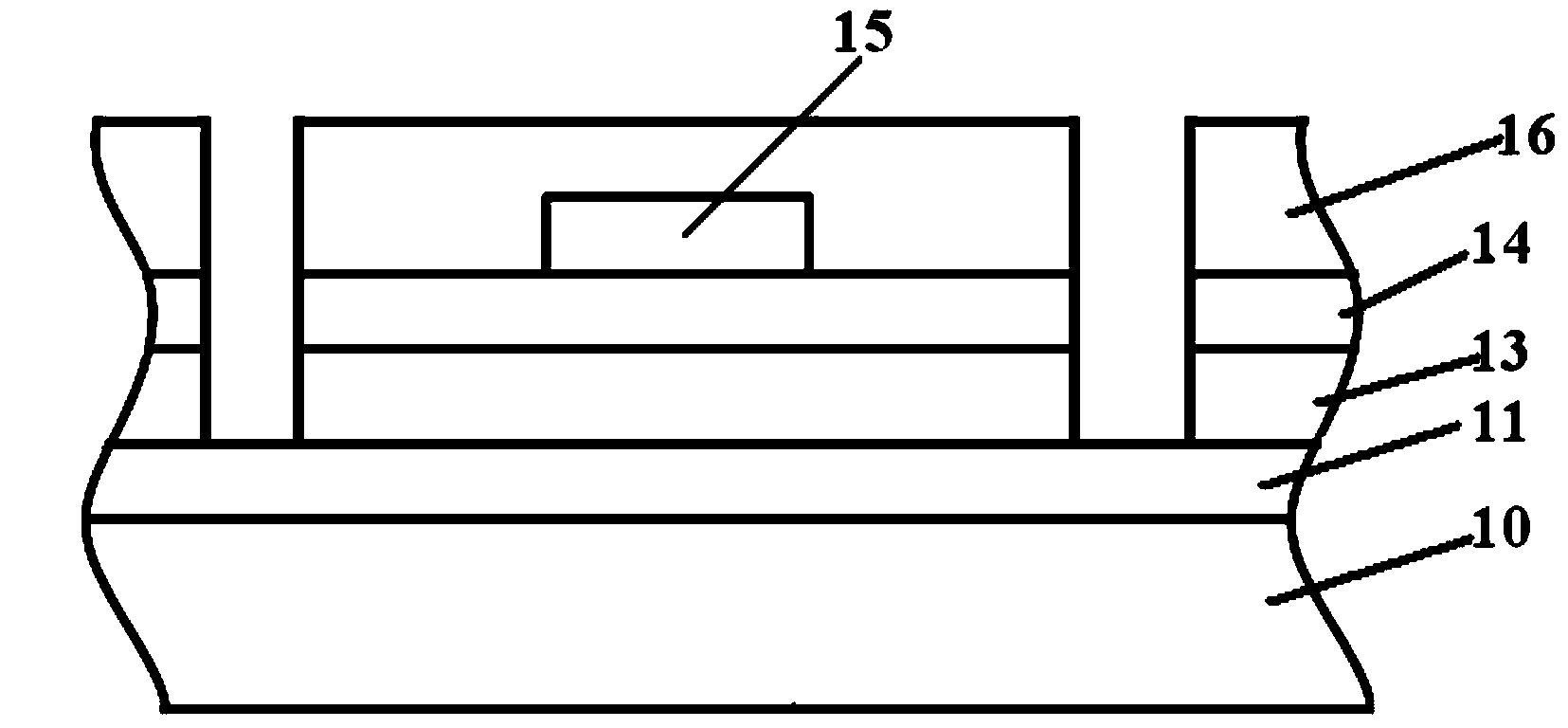

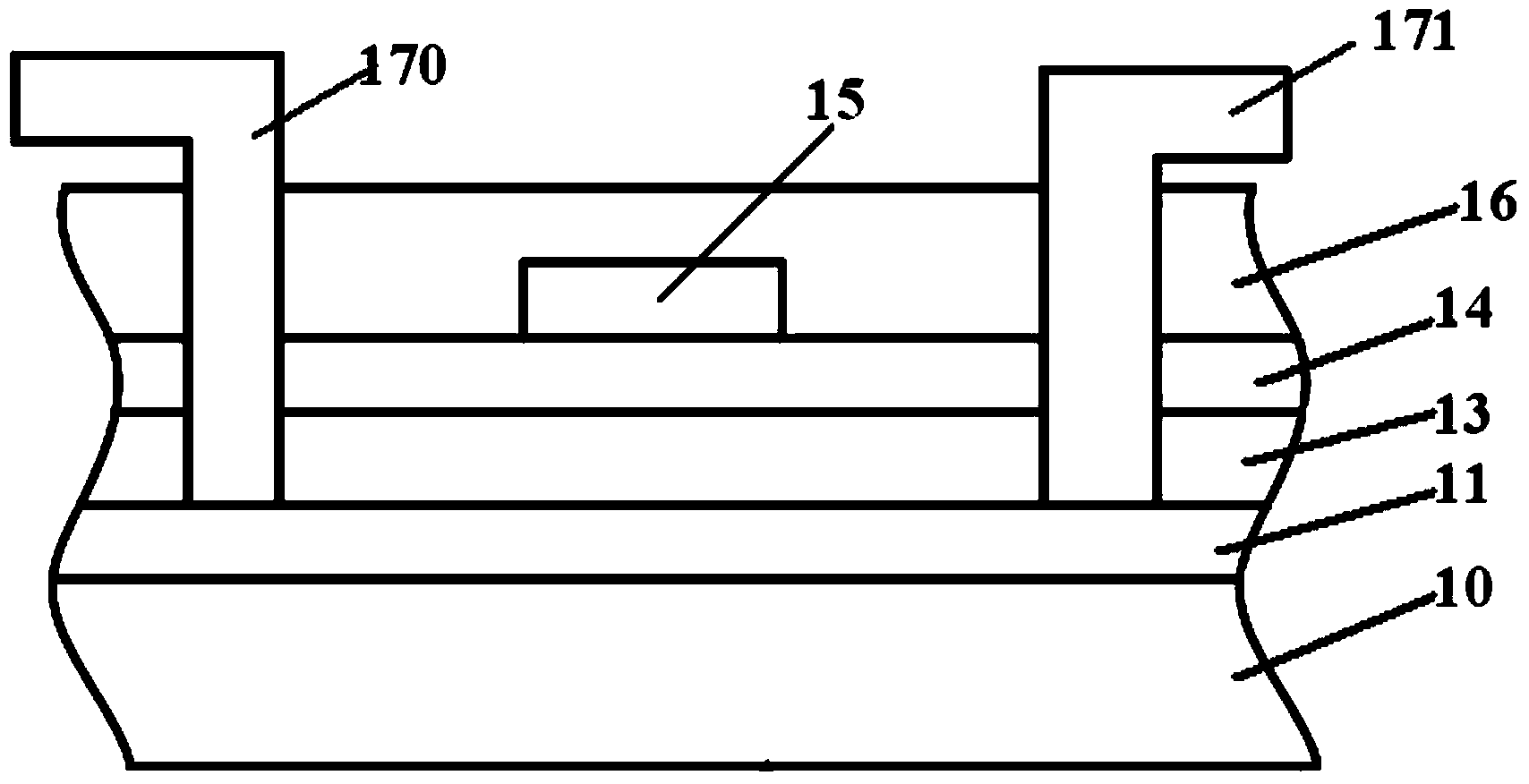

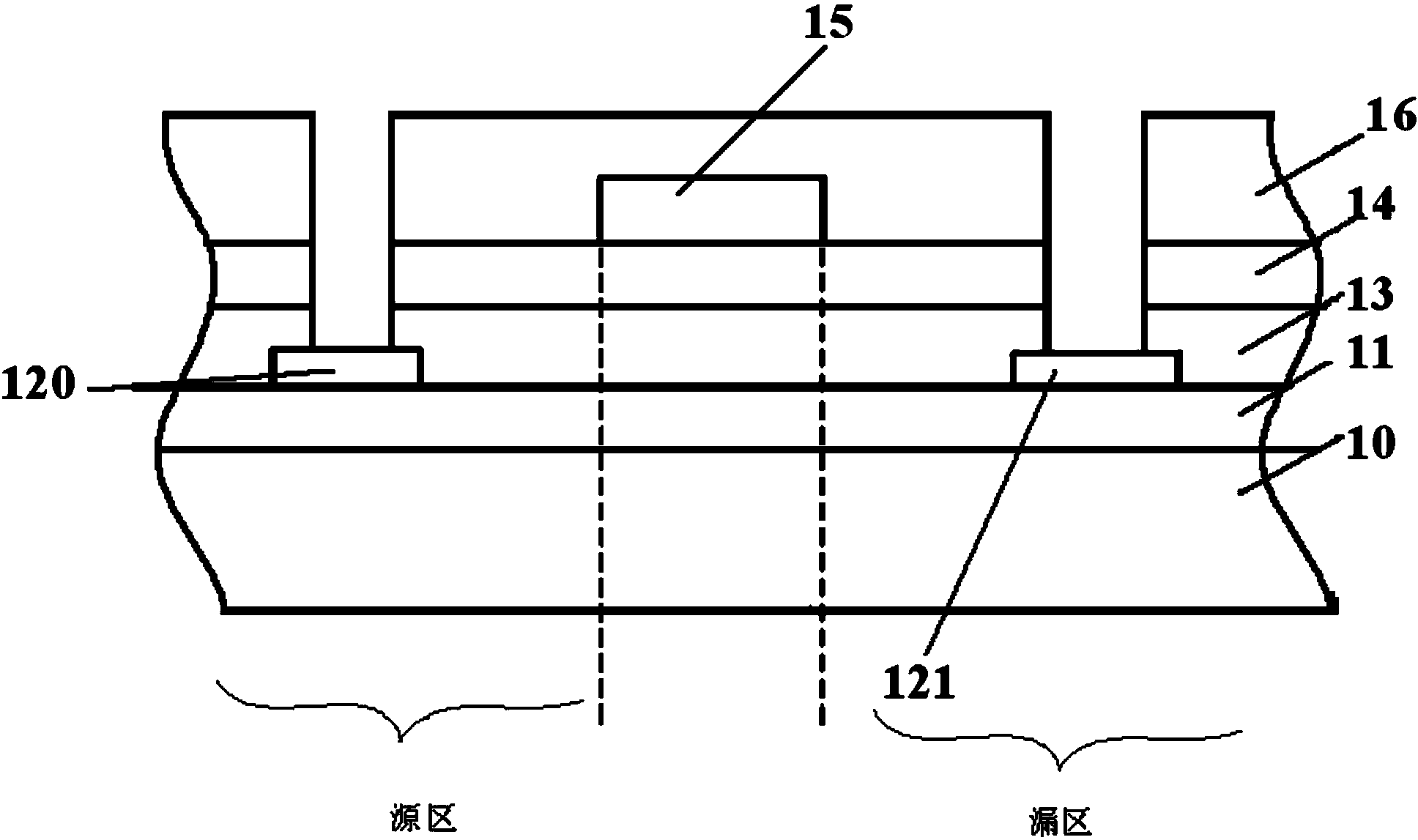

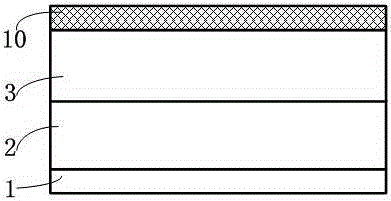

Low-temperature polycrystalline silicon thin film transistor array substrate, manufacturing method thereof and display device

InactiveCN103545319ADoes not affect the doping processGuaranteed display qualityTransistorSolid-state devicesTransistor arrayManufacturing technology

The invention provides a low-temperature polycrystalline silicon thin film transistor array substrate, a manufacturing method of the low-temperature polycrystalline silicon thin film transistor array substrate and a display device, and belongs to the field of the thin film transistor manufacturing technology. The low-temperature polycrystalline silicon thin film transistor array substrate comprises contact holes, wherein a source electrode and a drain electrode of the low-temperature polycrystalline silicon thin film transistor array substrate are connected with an active layer through the contact holes, and conductive patterns which are connected with the active layer are arranged at the bottoms of the contact holes. According to the technical scheme, good Ohmic contact can be formed between the source electrode of the low-temperature polycrystalline silicon thin film transistor array substrate and the active layer, and between the drain electrode of the low-temperature polycrystalline silicon thin film transistor array substrate and the active layer after etching of the contact holes is accomplished, and display quality of the display device is ensured.

Owner:BOE TECH GRP CO LTD

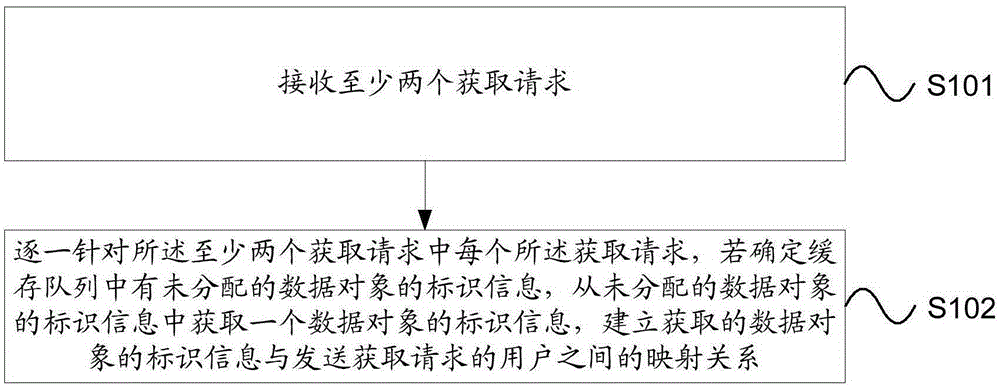

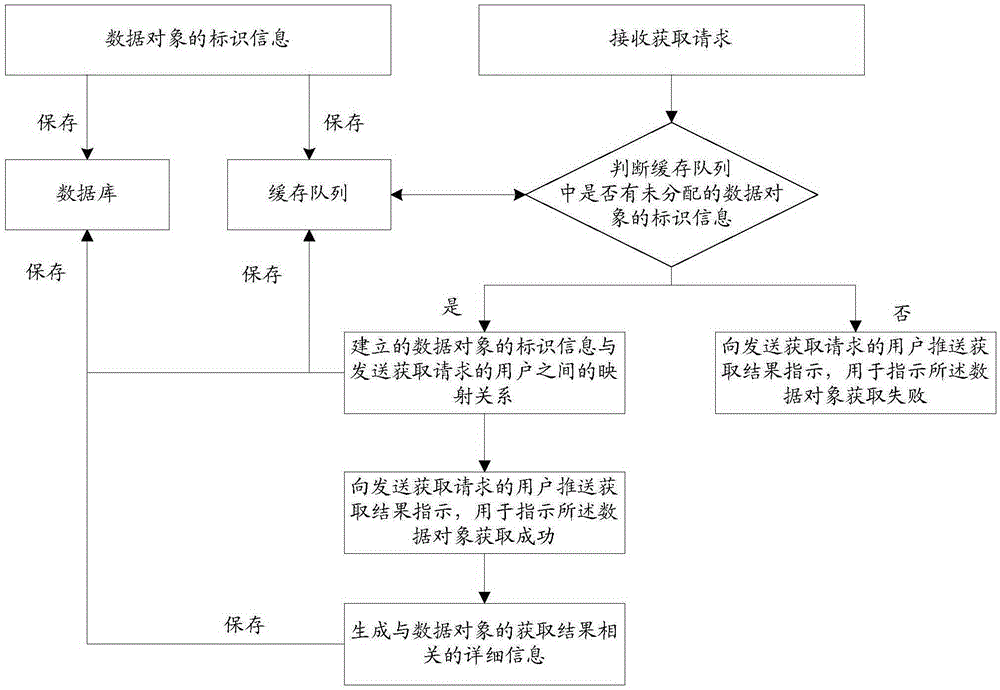

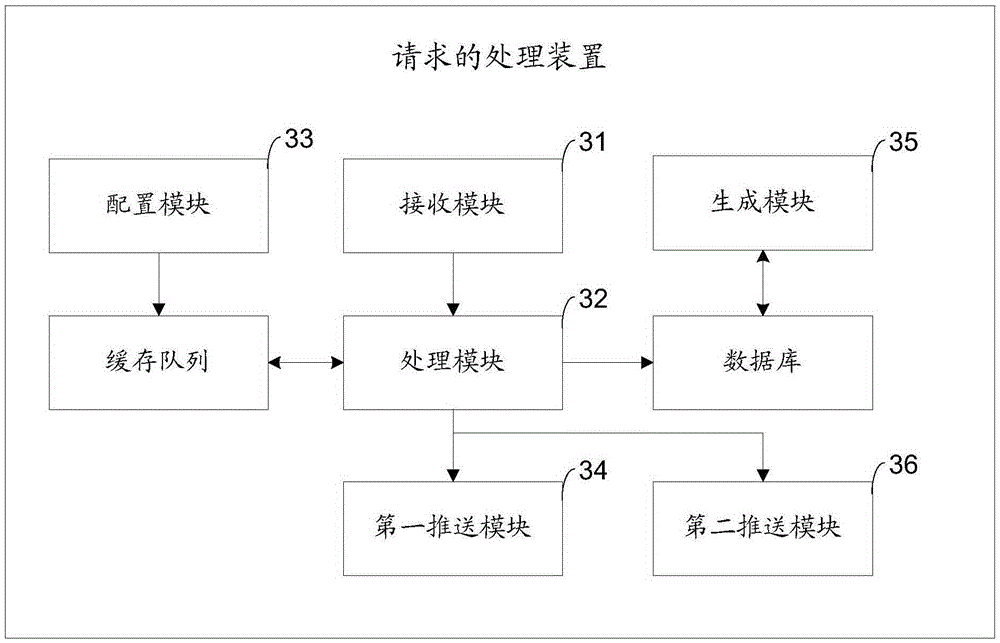

Request processing method and device

InactiveCN105302907AIncreased process reliabilitySolve processing efficiencySpecial data processing applicationsData miningData request

The invention provides a request processing method and device. The method comprises the following steps: receiving at least two acquisition requests; and in allusion to each acquisition request in the at least two acquisition requests, if determining that identification information of undistributed data objects exist in a cache queue, obtaining the identification information of one data object in the identification information of the undistributed data objects and establishing the mapping relationship between the obtained identification information of the data object and the user sending the acquisition requests. Therefore, the request processing method and device provided by the invention can be used for solving the problem that the data request processing manner in the prior art is low in data request processing efficiency and reliability.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

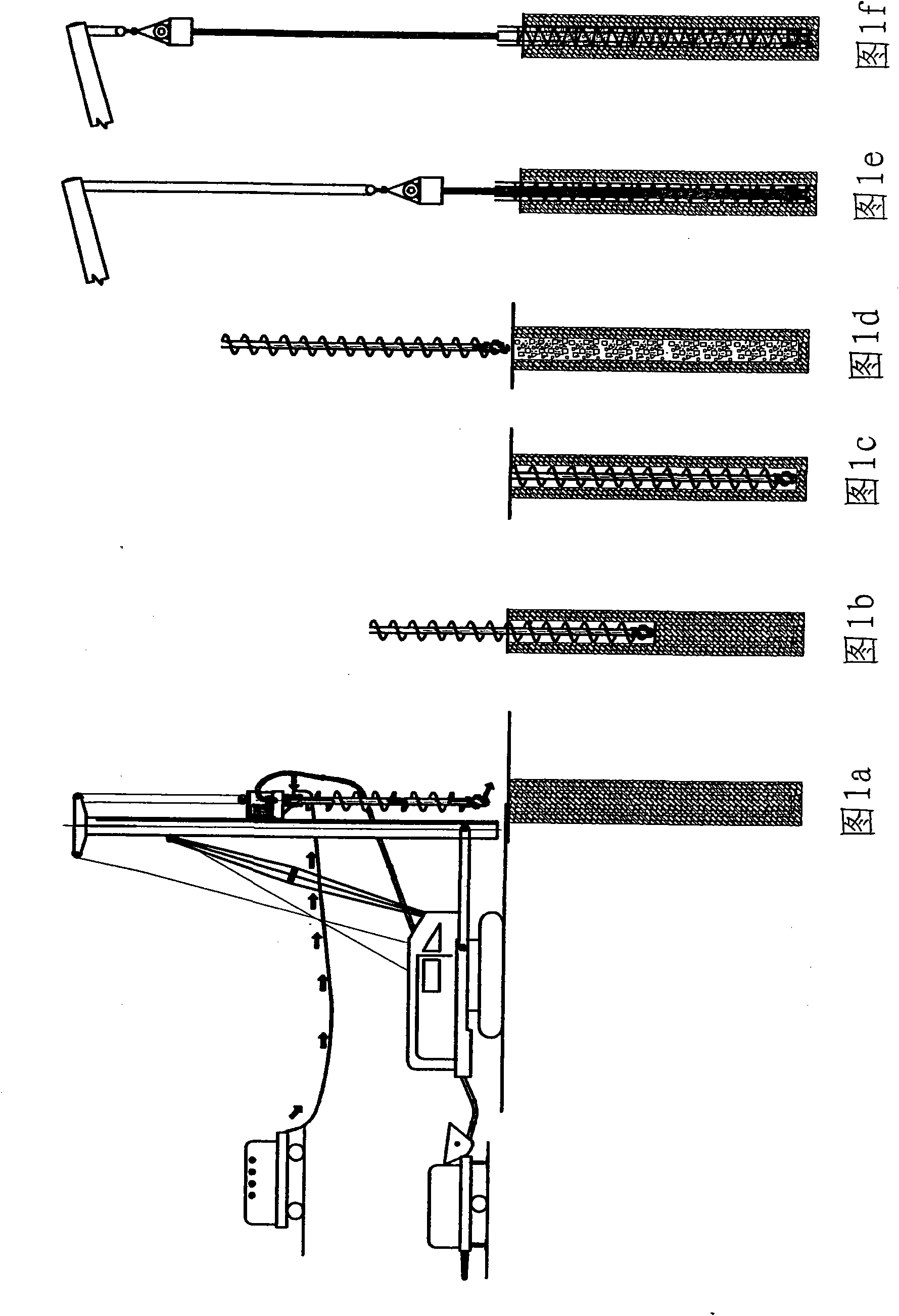

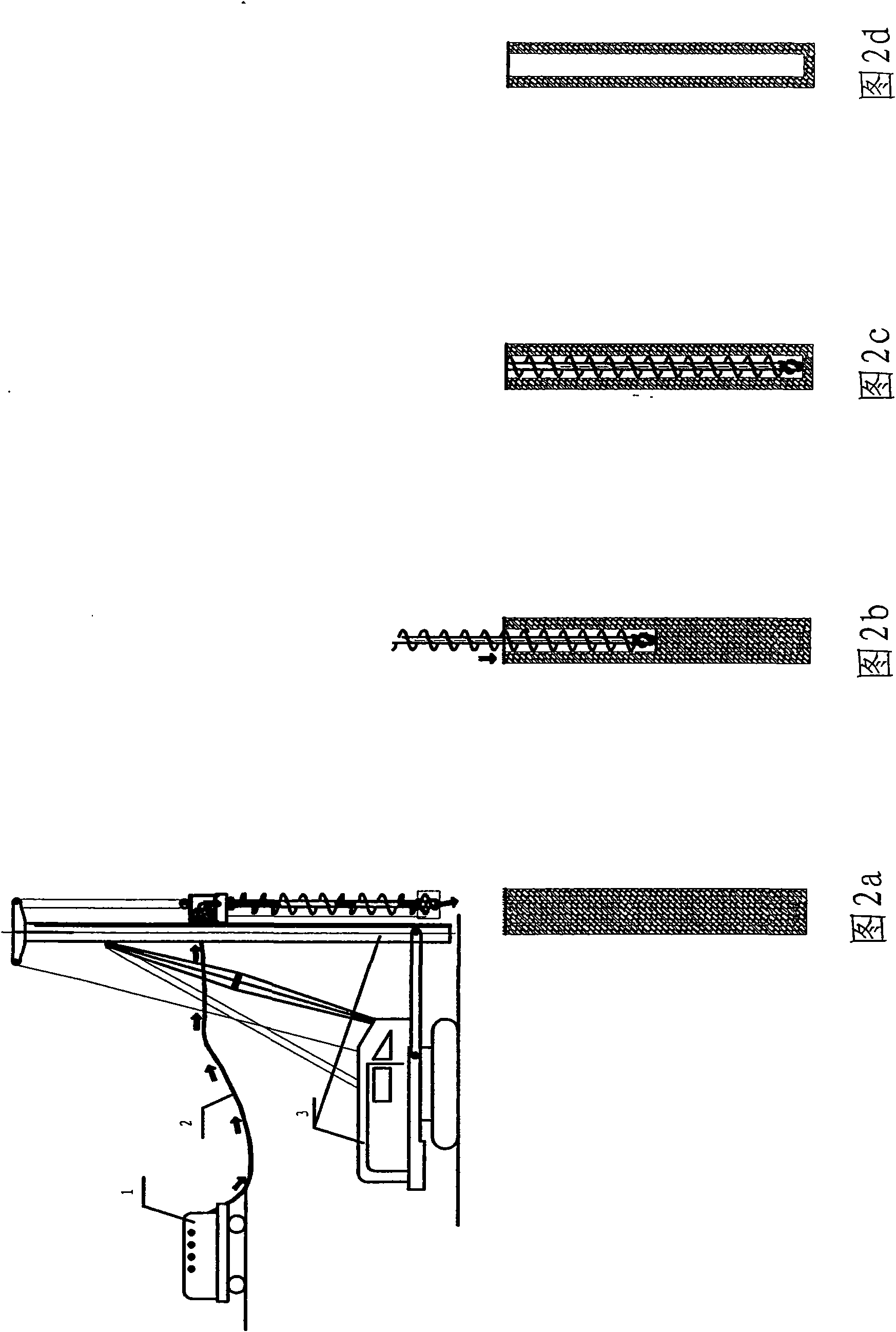

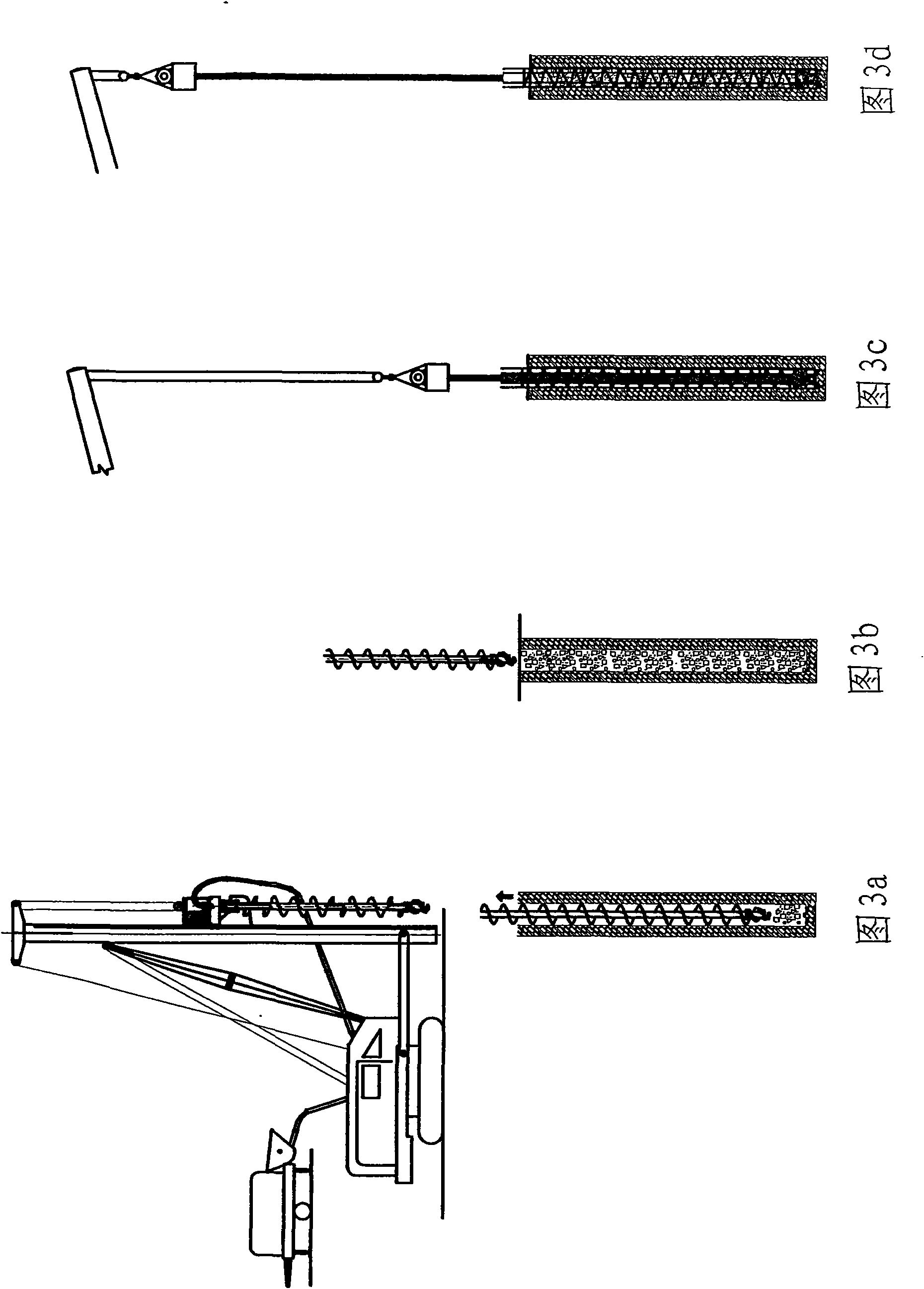

Vibrating bar-inserting long spiral air-cooled drilling rock-socketed pile forming method and equipment

The invention relates to a vibrating bar-inserting long spiral air-cooled drilling rock-socketed pile forming method implemented in sub-hard rocks, soft rocks and weathered rocks, gravel soil layers or hard soil layers. The method comprises the following construction steps of: a, starting an air compressor, and discharging the compressed air from the air outlet of a long spiral rock-socketed drill bit by a blast pipe, a fluid director and an air pipe attached to a spiral drill rod; b, injecting the compressed air to cool the drill bit at the same time of long spiral drilling; c, reaching the designed hole depth; d, pouring concrete into the pile hole by using a concrete conveying pump; and e, vibrating and inserting a steel bar cage to the designed depth in a main rib pulled mode by adopting a vibrating hammer. Because the air can be continuously supplied to the drill bit, the drill bit is effectively cooled and the service life of the drill bit is greatly prolonged, and meanwhile, the drillability of the gas phase in the three-phase ratio of the soil is improved; therefore, the green construction technical process for a vibrating bar-inserting drilling pressure pouring pile can be adopted in the sub-hard rocks, the soft rocks and the weathered rocks, the gravel soil layers or the hard soil layers; and the method increases the quality reliability, reduces the consumption of various materials and improves the construction efficiency, so the method has remarkable economic benefit and social benefit.

Owner:李式仁

GaN-based field effect transistor with high quality MIS structure and preparation method of GaN-based field effect transistor

InactiveCN105336789AImprove performanceThreshold voltage stability is remarkableSemiconductor/solid-state device manufacturingSemiconductor devicesPartial oxidationVoltage stability

The invention belongs to the semiconductor material and device field and discloses a GaN-based field effect transistor with a high quality MIS structure and a preparation method of the GaN-based field effect transistor, in particular, a GaN MISFET device gate dielectric layer and an improvement method of a dielectric layer and GaN interface. The device includes a substrate, an epitaxial layer grown on the substrate as well as a gate electrode, a source electrode, a drain electrode and an insulating layer; the epitaxial layer includes a stress buffer layer which is formed through primary epitaxial growth, a GaN epitaxial layer as well as a second epitaxial layer and a third epitaxial layer which are grown on selective regions on the GaN epitaxial layer; a GaN / AlGaN heterostructure is formed through secondary epitaxial growth, and groove channels are formed; an AlN thin layer is formed through third epitaxial growth; the AlN thin layer is partially oxidized so as to form an AlN / oxide dielectric layer stack structure; gate metal covers the groove channels; a source electrode region and a drain electrode region are formed at two ends; and the source electrode region and the drain electrode region are covered with metal, so that the source electrode and the drain electrode can be formed. The device and preparation process of the invention are simple and reliable. With the preparation method adopted, the high quality MIS structure can be formed, and the performance of the GaN MISFET device can be improved. The preparation method can play a key role in decreasing the electric leakage of the gate electrode, decreasing the resistance of the channels and stabilizing threshold voltage.

Owner:SUN YAT SEN UNIV

Double-chamber heat pipe capable of self-optimizing heat dissipation

InactiveCN106653713AEasy to makeGood process repeatabilitySemiconductor/solid-state device detailsSolid-state devicesHeat fluxSteam pressure

The invention provides a double-chamber heat pipe capable of self-optimizing heat dissipation. The heat pipe comprises a primary chamber, a secondary chamber and a two-way steam switch group, wherein the primary chamber is connected with the secondary chamber through the two-way steam switch group. The filling ratios and the steam pressure of the two chambers are adjusted through opening and closing of the two-way steam switch group between the two chambers. Steam switches have different switching thresholds through adjusting heat power of an electric heating device on the outer wall of the secondary chamber. Compared with a common heat pipe, the double-chamber heat pipe capable of self-optimizing heat dissipation has the advantages that the filling ratio of the heat pipe can be adjusted through the two-way steam switch group between the double chambers to be matched with the heat source power and the heat flux density, thereby achieving the optimal heat dissipation efficiency. The influence of a steam limit in the heat pipe on liquid backflow in a capillary filter element can be effectively inhibited. The heat pipe is simple to manufacture and good in process repeatability and reliability.

Owner:BEIJING UNIV OF TECH

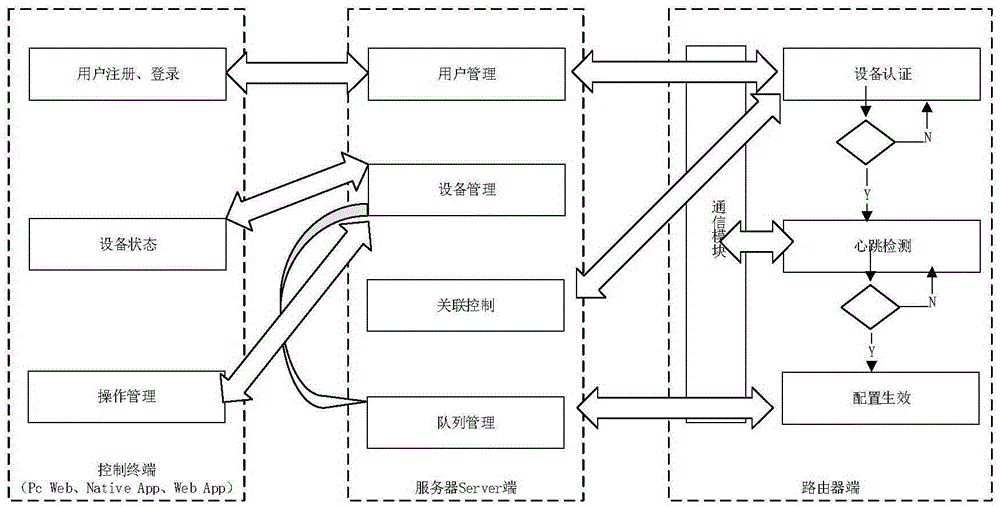

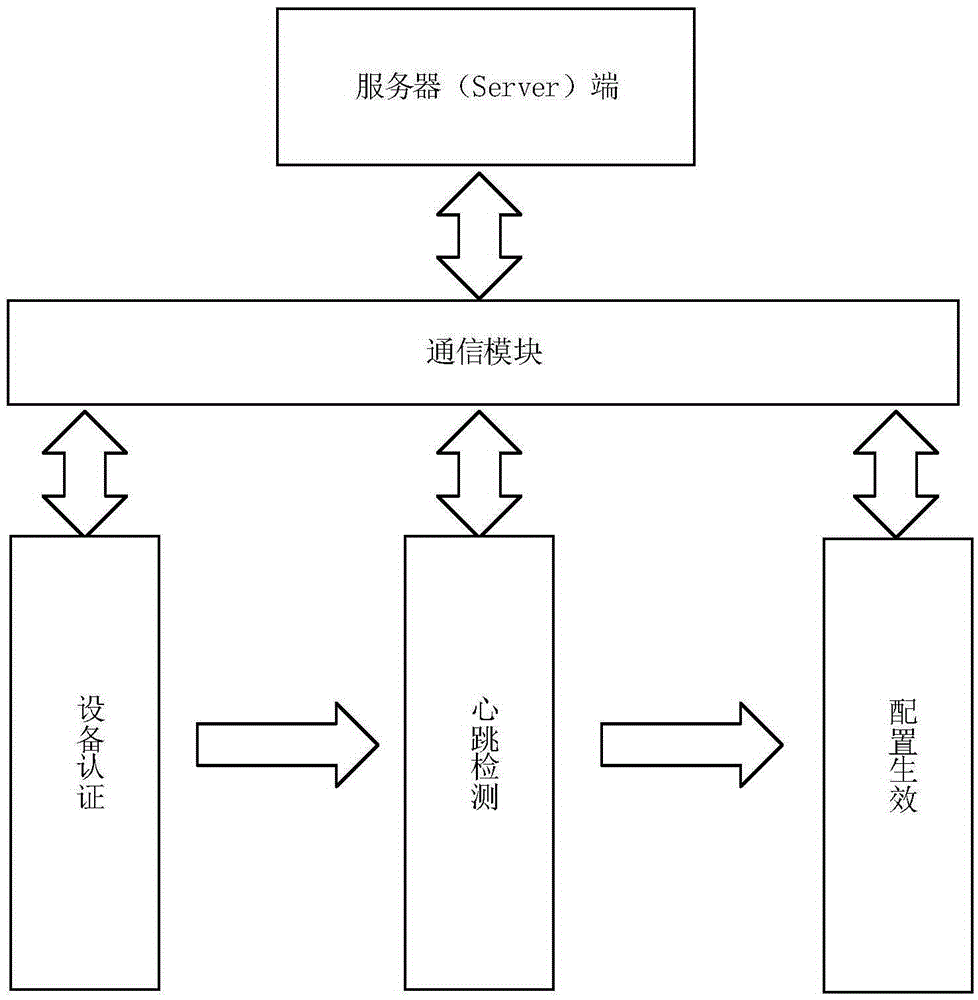

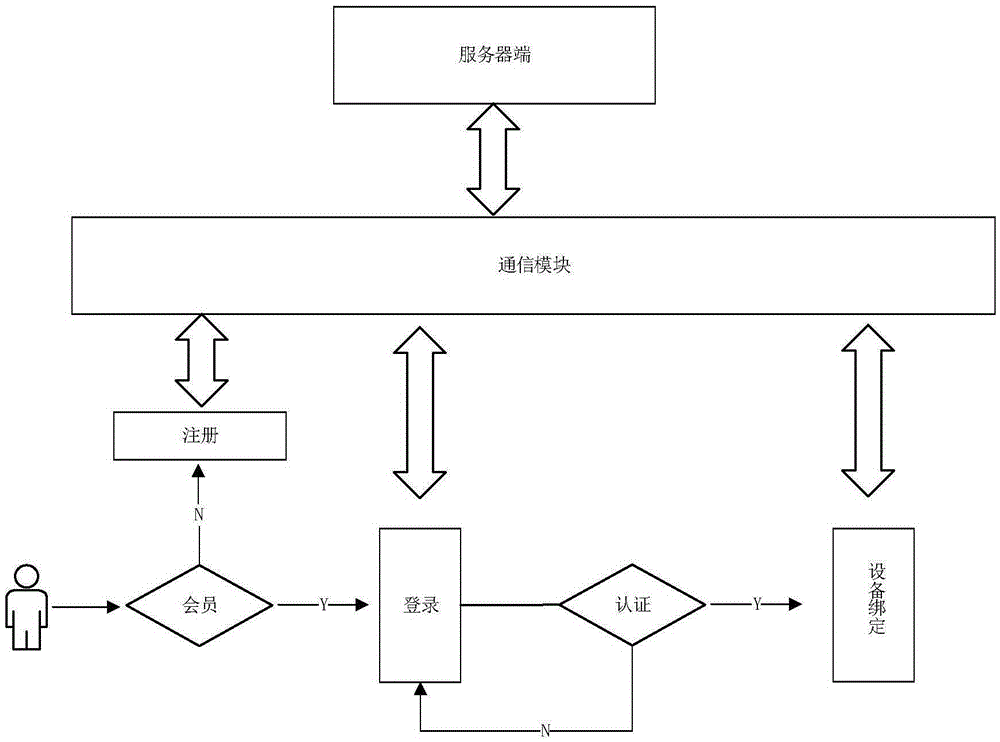

Router remote management system based on hypertext transport protocol (HTTP)

ActiveCN105407172AUse matureEasy to useData switching networksComputer terminalProtocol for Carrying Authentication for Network Access

The invention discloses a router remote management system based on a hypertext transport protocol (HTTP). The remote management system consists of a router end, a server end and a control terminal. An intelligent terminal is used for issuing an operation instruction, and a communication way based on the HTTP is used, thereby realizing router remote management. An adopted HTTP communication is based on a universal port 80, so that communication faults caused by the limitations of a firewall are avoided, and the signal transmission reliability is enhanced. Moreover, the router remote management system further has the advantages of high universality, low development and maintenance costs, and the like.

Owner:NANJING TUNIU TECHNOLOGY CO LTD

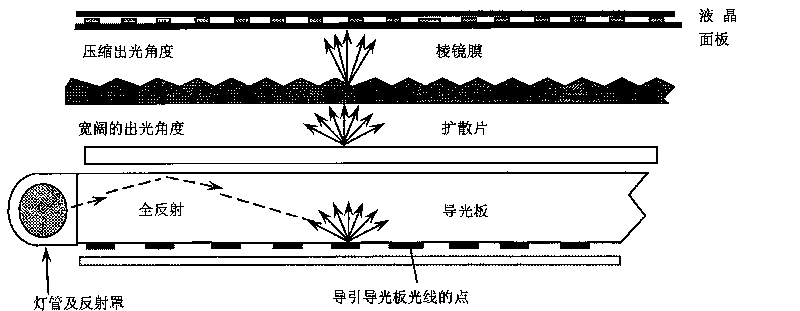

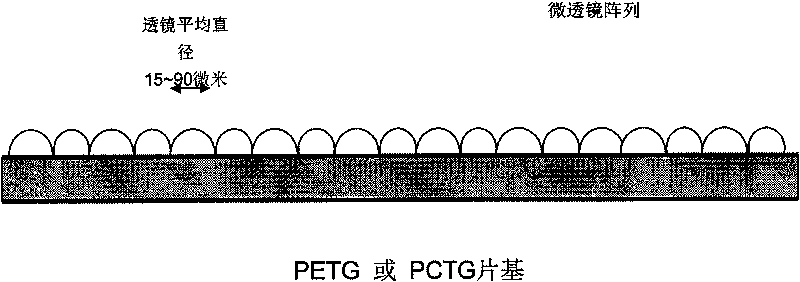

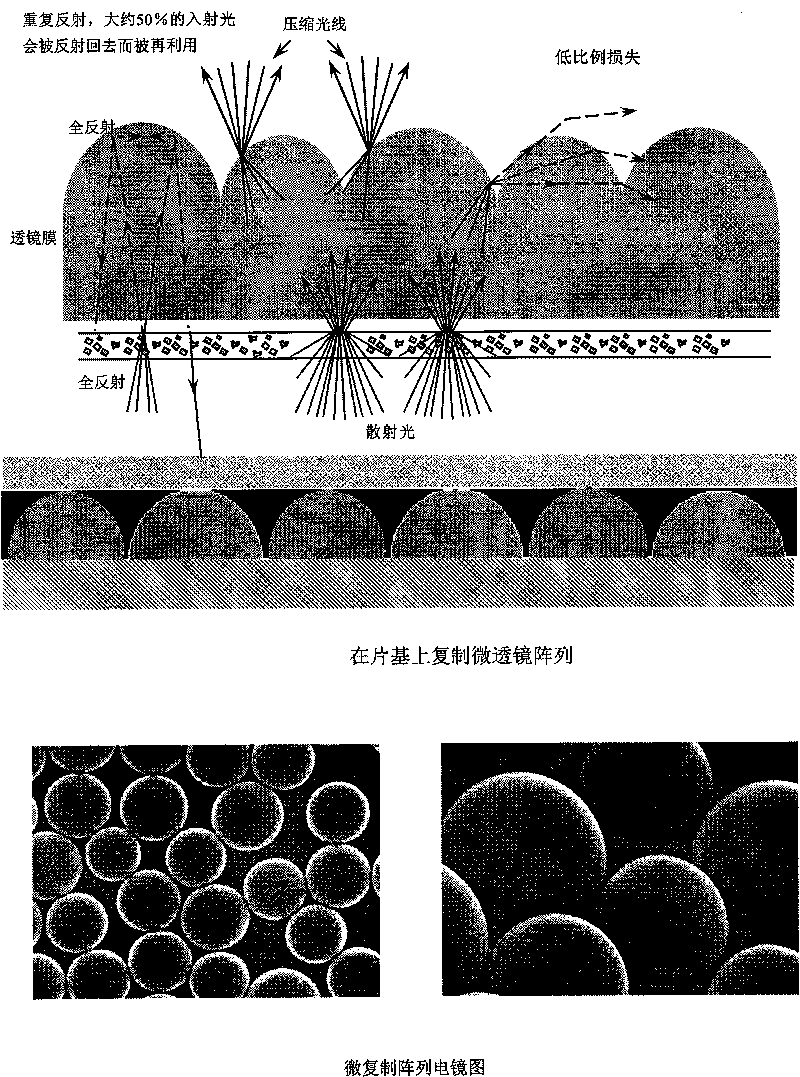

Duplicated array brightness enhancement film of large-viewing angle micro lens

The invention discloses duplication of array brightness enhancement film by a large-viewing angle micro lens and a production method of a duplicating mould. The invention continuously duplicates micro lens array on a film base without birefraction using halogen free and sulphide free resin containing nano particle. On all directions of a horizontal projection, the micro lens array has the function of gathering and condensing view angle to ordinary light or vibration light through utilizing the refraction and reflection of light from high refraction medium to low refraction medium, and the axial brightness can be improved in a larger range of viewing angle. Through using novel hair metal casting technology, the invention provides a mould which can continuously duplicate micro lens array. The invention is used in backlight source module of a liquid crystal display.

Owner:邹竞 +2

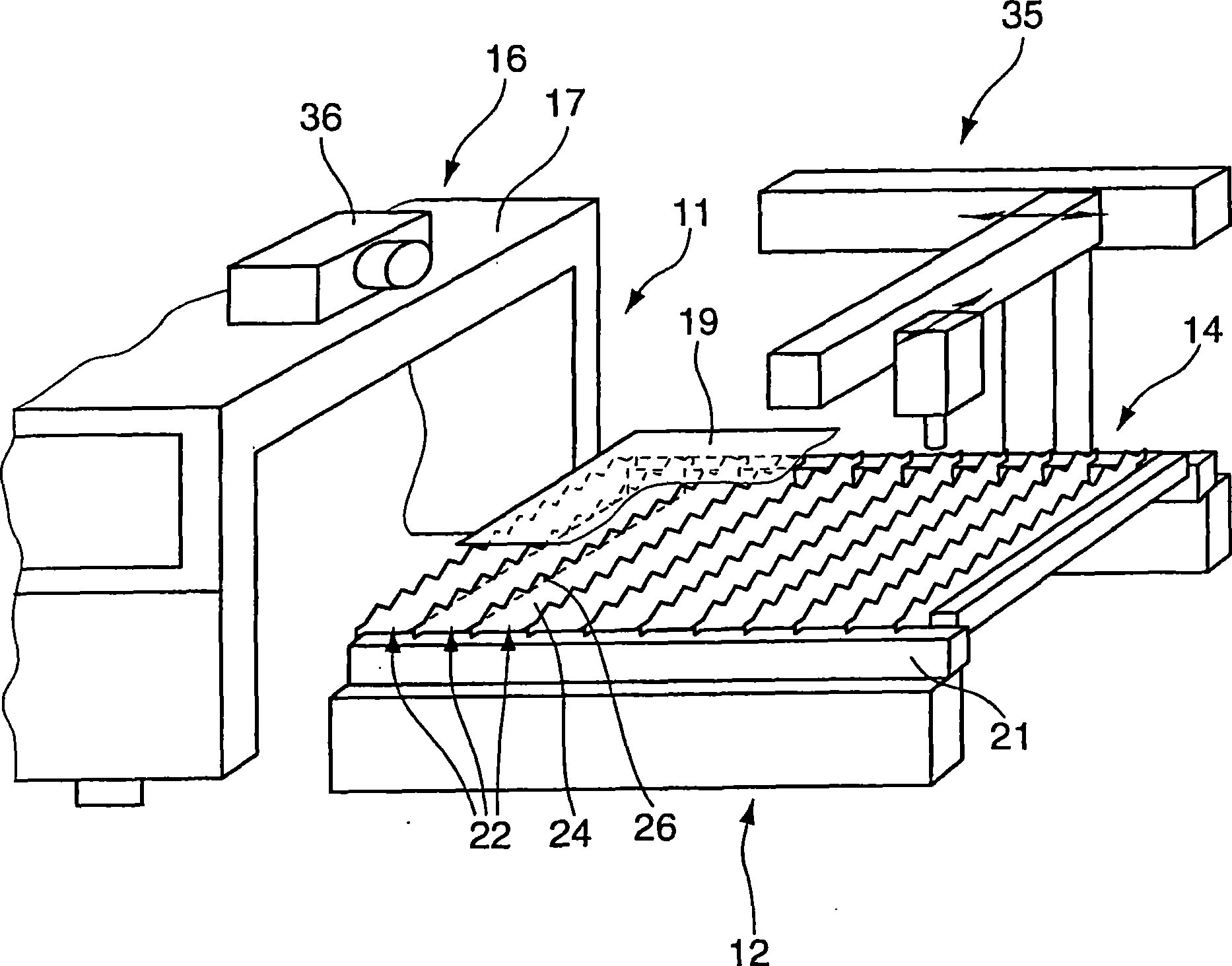

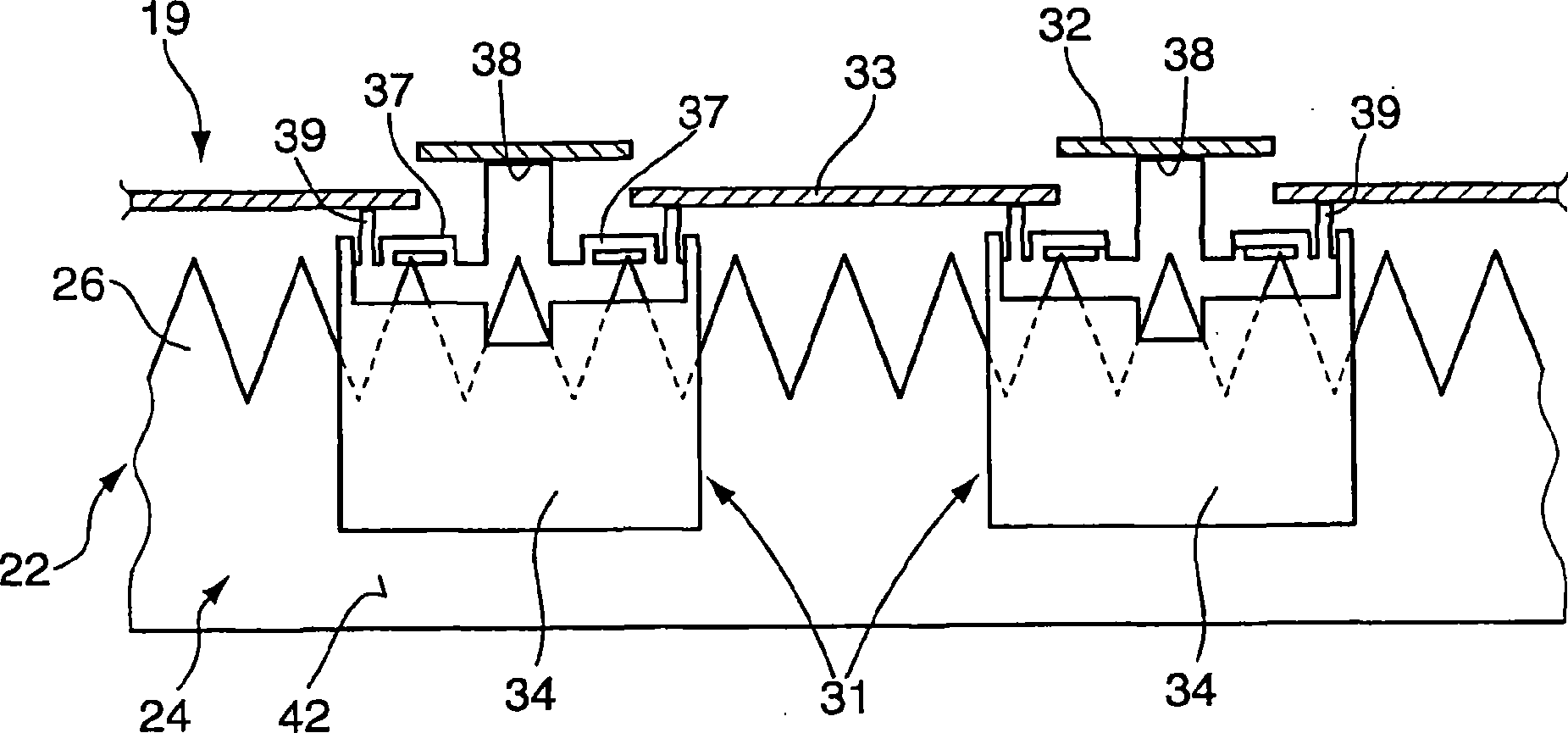

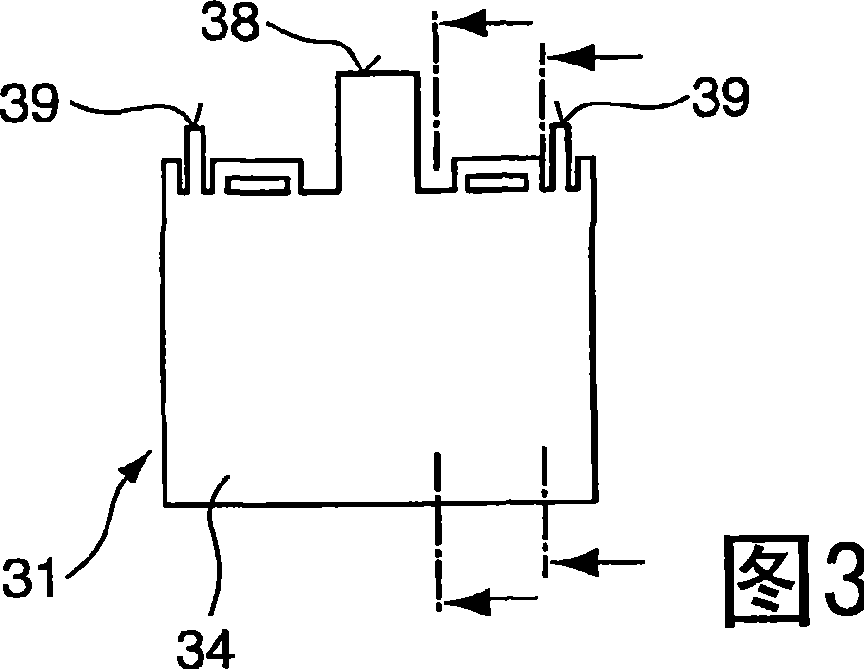

A work support used to contain especially a flat workpiece in a processing unit and having a supporting element capable of being attached to a bearing element

ActiveCN101448605AIncreased process reliabilityWelding/cutting auxillary devicesAuxillary welding devicesLight beamLaser beam machining

The invention relates to a work support used to contain especially a flat workpiece (19) in a processing unit (11) which uses a beam cutting workpiec especially a laser beam processing workpiece (19). Wherein the work support (14) contains multiple bearing elements (22) equipped adjacently in a frame (21). One or multiple supporting elements (31) can be attached to at least a bearing element (22), and the workpiece (19) is placed on the supporting elements.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

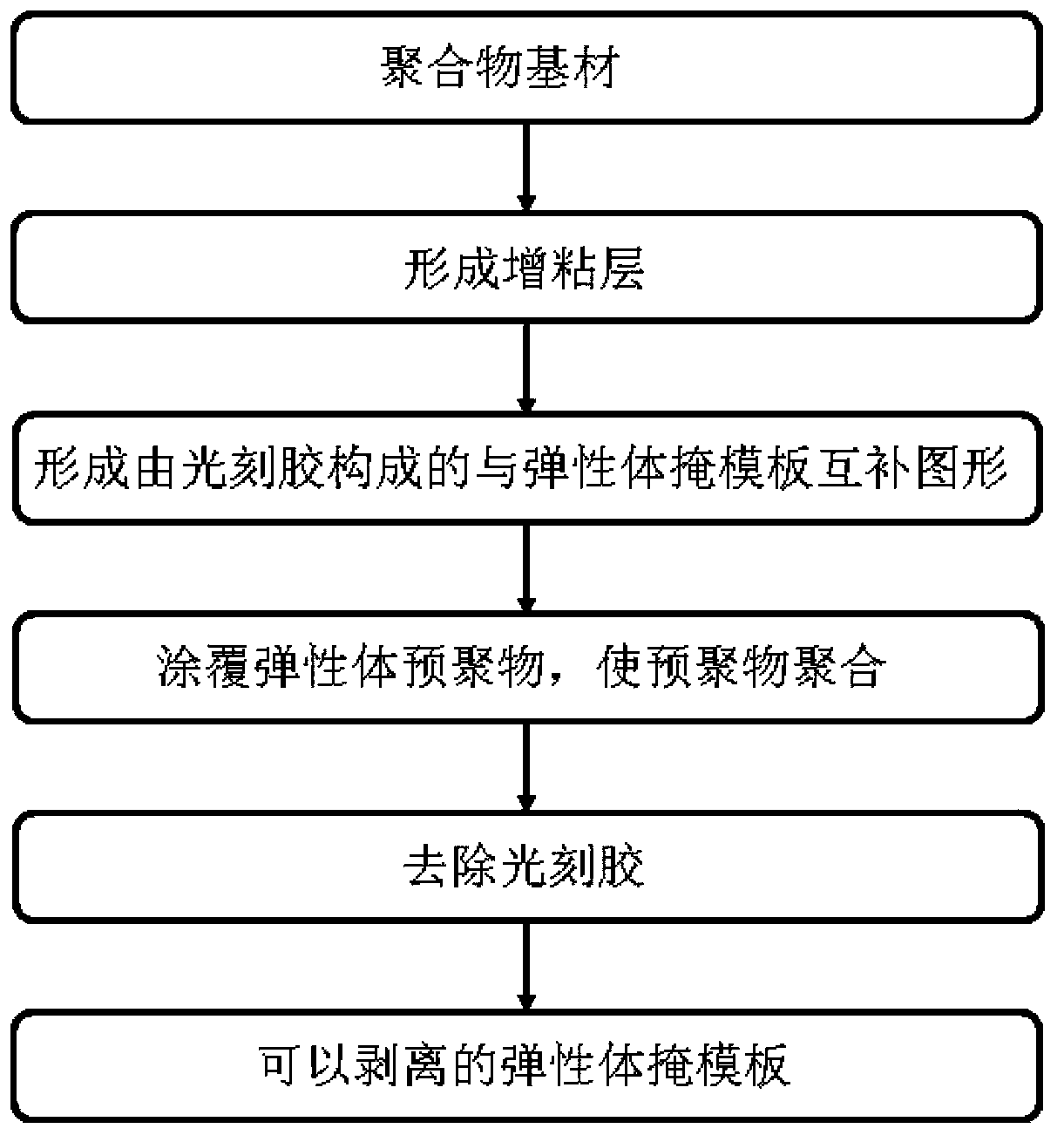

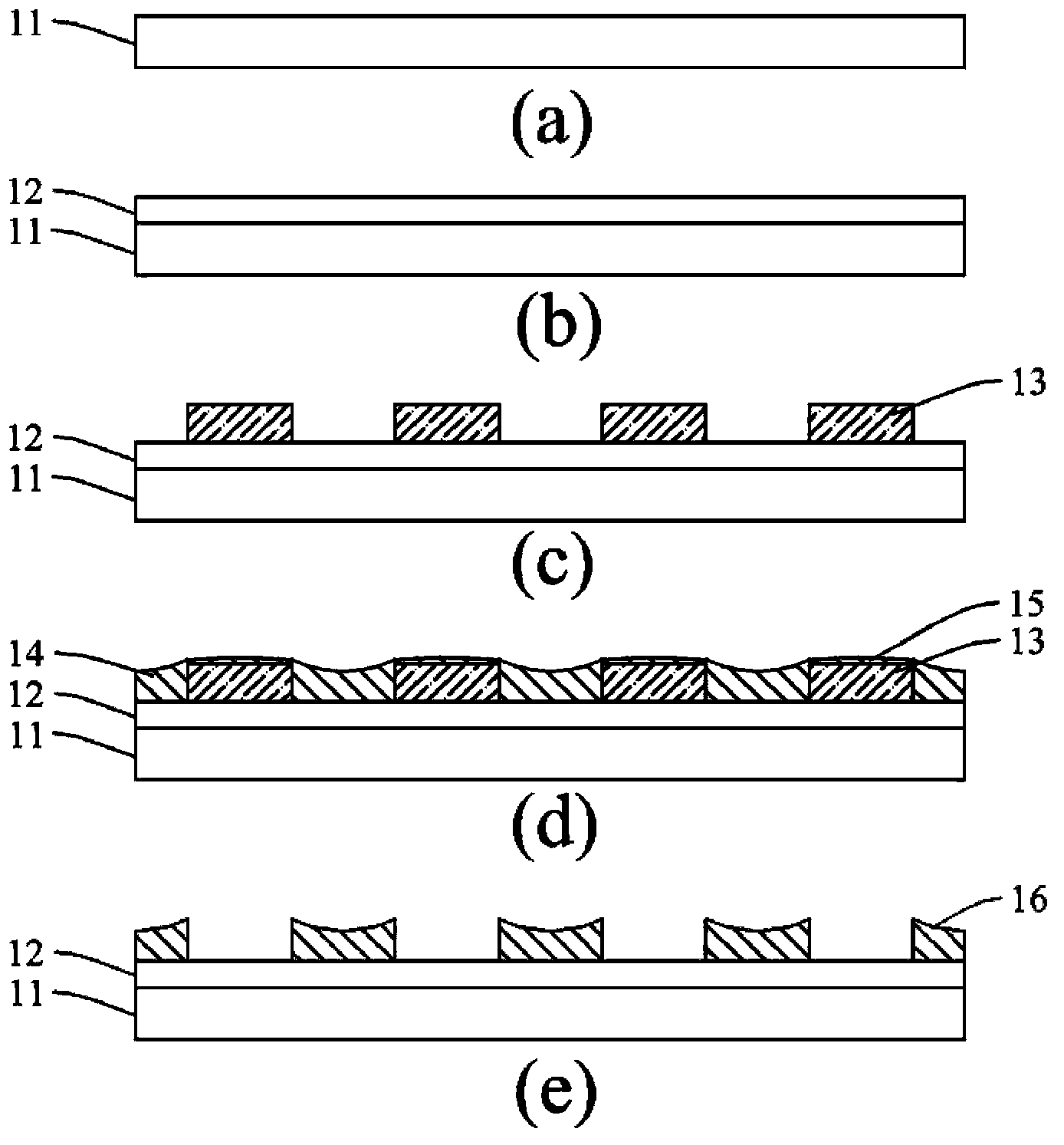

Method for forming peelable elastomer mask plate on surface of polymer base materials

InactiveCN103579531AAvoid difficultiesEasy to processSolid-state devicesSemiconductor/solid-state device manufacturingElastomerPolymer substrate

The invention discloses a method for forming a peelable elastomer mask plate on the surface of polymer base materials. The method comprises the steps that firstly, a coating layer for improving caking property is preformed on the surface of the polymer base materials; secondly, patterns, complementary with the mask plate, formed by photoresist are formed on the surface of the polymer base materials through the photolithography technique; thirdly, an elastomer coating layer with a certain thickness is formed again; fourthly, the photoresist is removed, and the peelable elastomer mask plate is obtained. The elastomer mask plate is used for forming patterned photoelectric functional devices on the polymer base materials.

Owner:西安宙斯光电科技有限公司

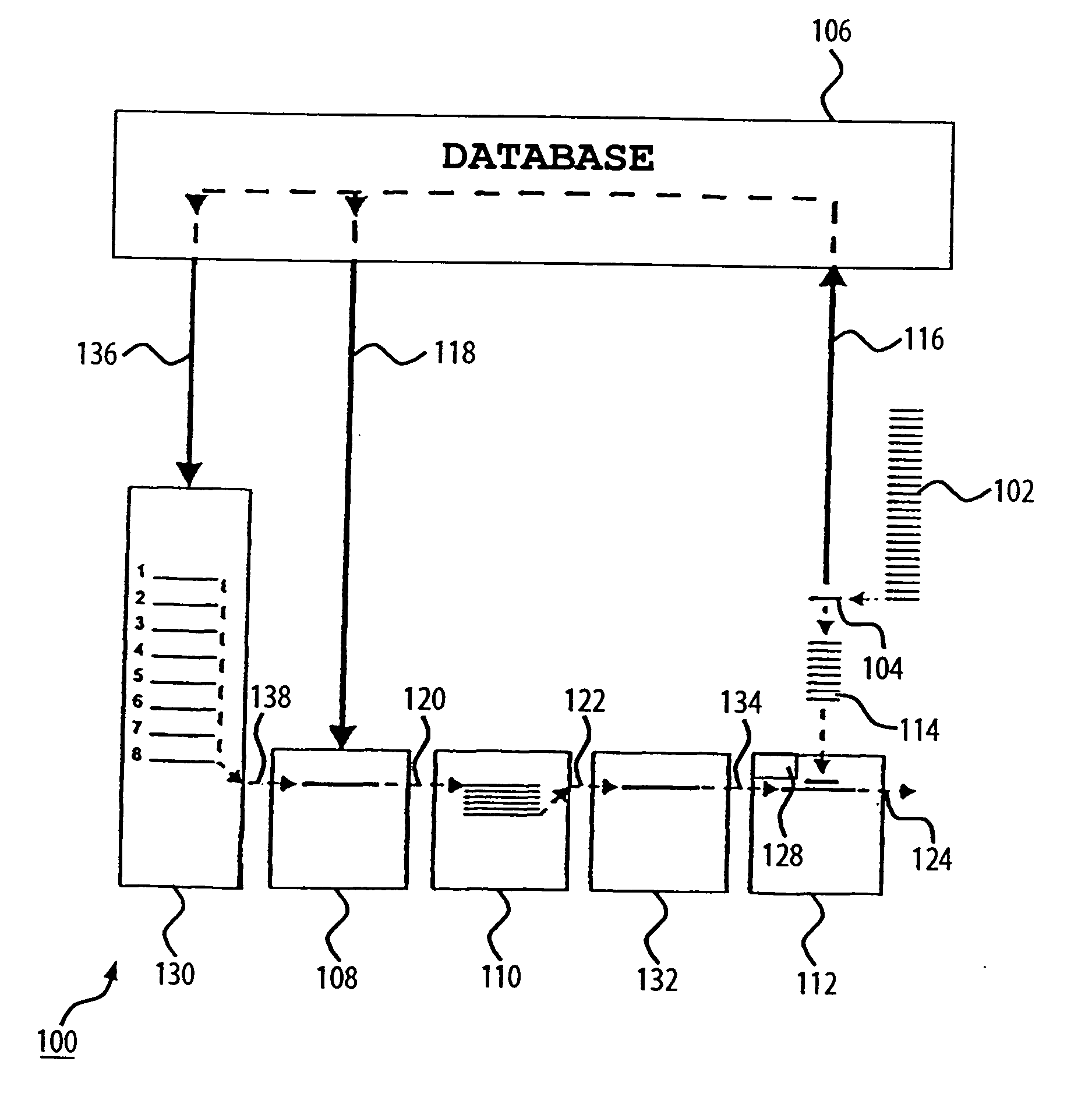

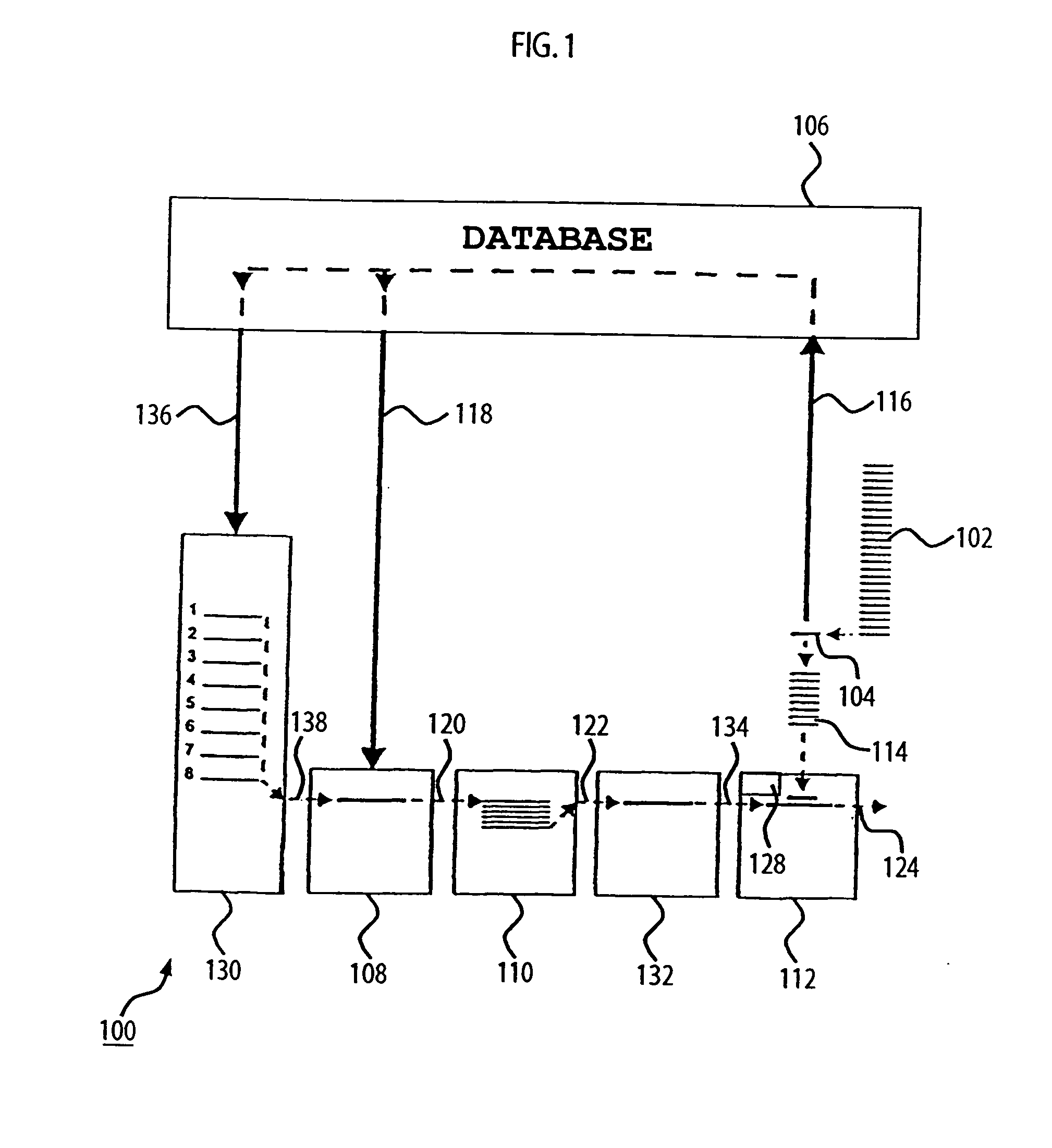

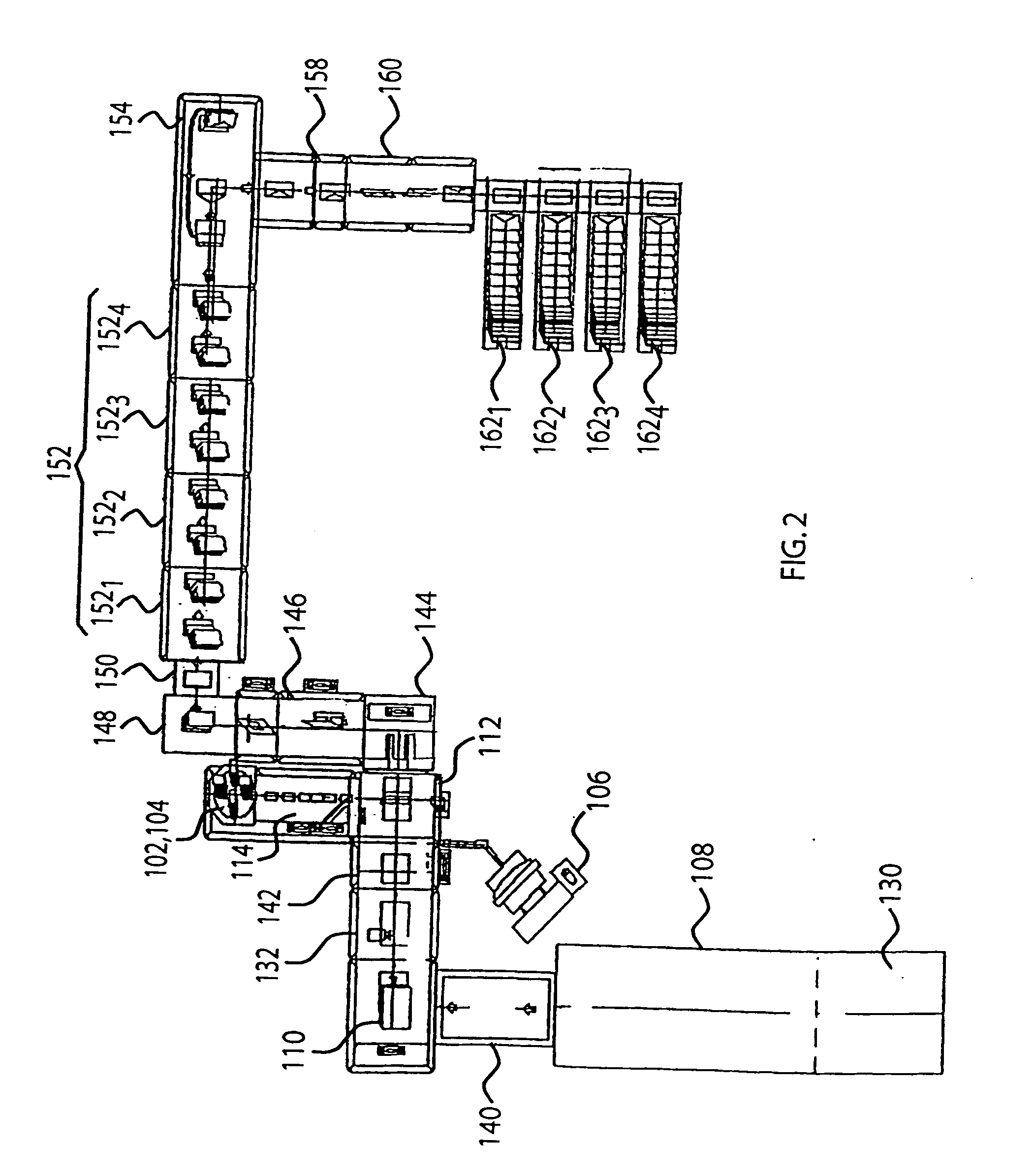

Method and apparatus for providing a card carrier for bringing together with a card

InactiveUS20050139653A1Easy to processIncreased process reliabilityOther printing matterCo-operative working arrangementsComputer hardwareData Applied

In a method and an apparatus for providing a card carrier for bringing it together with a card, the card is initially provided, and card data are acquired from it. On the basis of this card data, a card-carrier blank having a first identification mark is provided. On the basis of the card data, predetermined data and a second identification mark associated with the predetermined data are printed onto the card-carrier blank so as to form the card carrier. Subsequently, the first and the second identification marks are acquired by the card carrier to determine whether the data applied and the blank belong together. If it is determined that the data and the card-carrier blank belong together, the card carrier is provided for bringing it together with the card.

Owner:BOWE SYSTEC AG

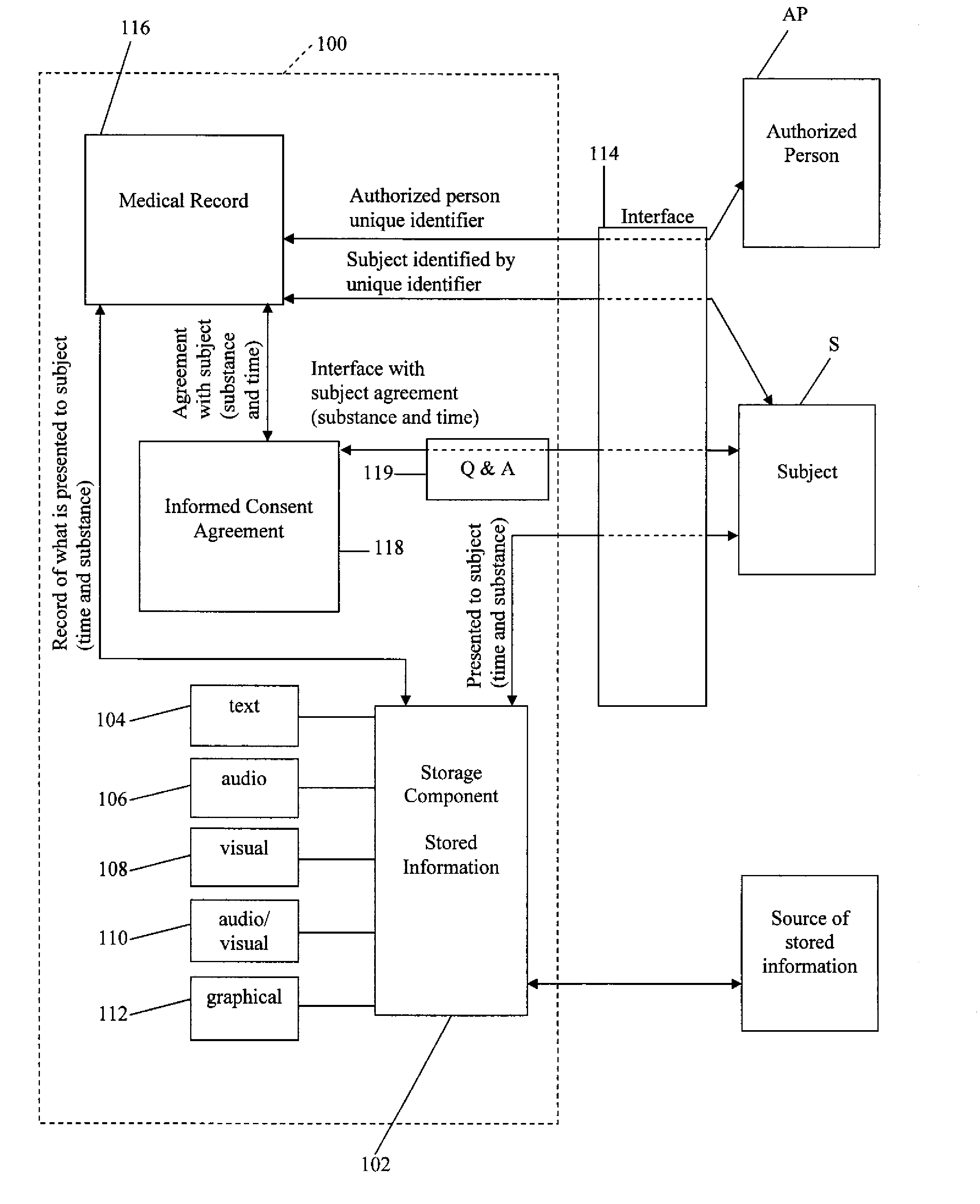

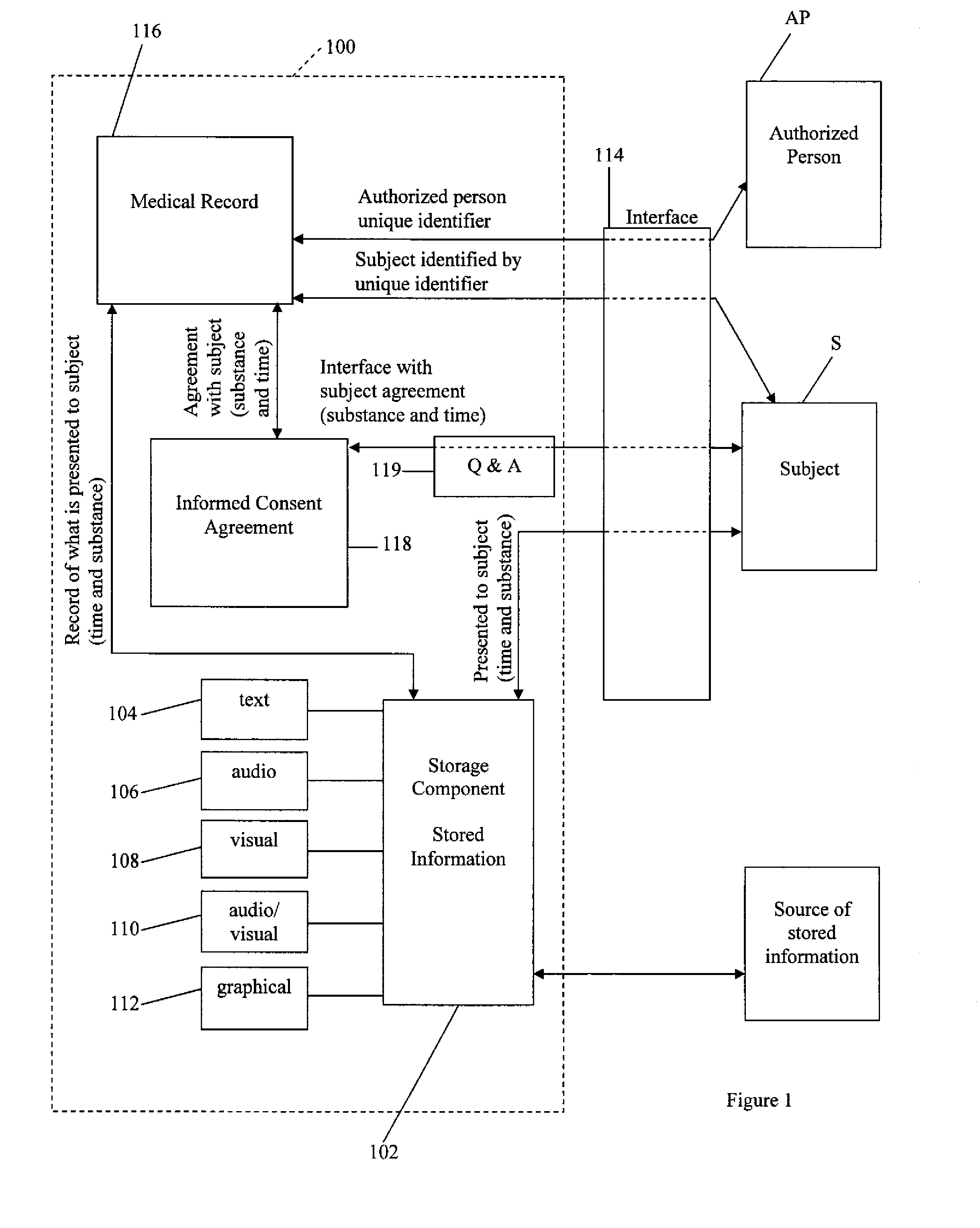

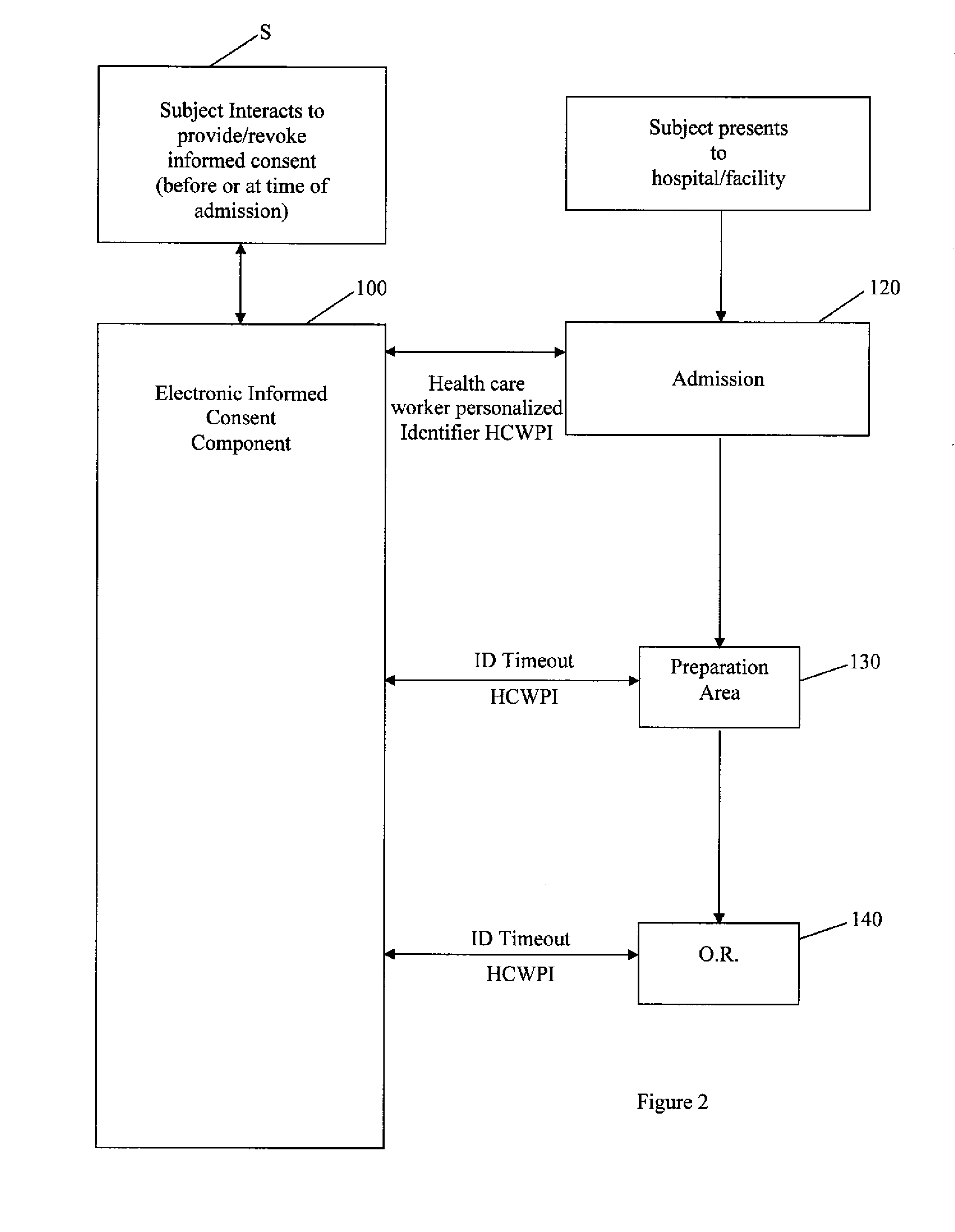

System and Method for Providing Informed Consent

InactiveUS20080300915A1Process reliability be enhanceDiminished waste of timeData processing applicationsMechanical/radiation/invasive therapiesConsent TypeMedical education

A system and method of providing subject informed consent in connection with a medical procedure is provided. According to the invention, a subject interfaces electronically with an electronic consent component that (i) provides the subject with information concerning a medical procedure, (ii) electronically enables the subject to provide an informed consent to the medical procedure, (iii) electronically stores as a medical record for the medical procedure the substance of the informed consent to the medical procedure provided by the subject and the manner in which the informed consent was obtained, such that the subject's medical record can be retrieved during a timeout in the medical procedure, and (iv) enables an authorized person who is seeking to review the subject's medical record to access the electronically stored medical record in a manner that documents the authorized person's access of the stored medical record and produces information as to the stored medical record.

Owner:MOLMENTI ERNESTO P +1

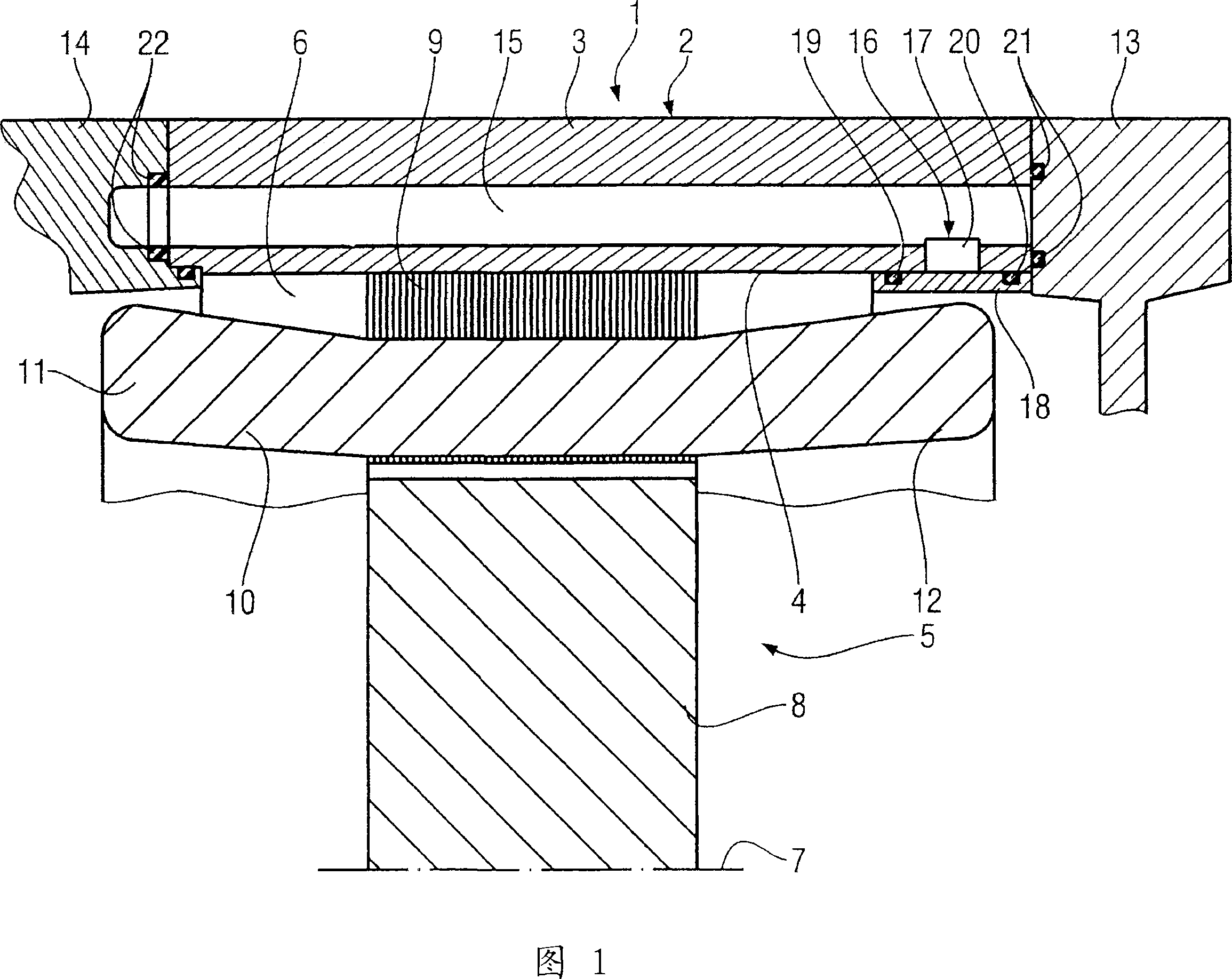

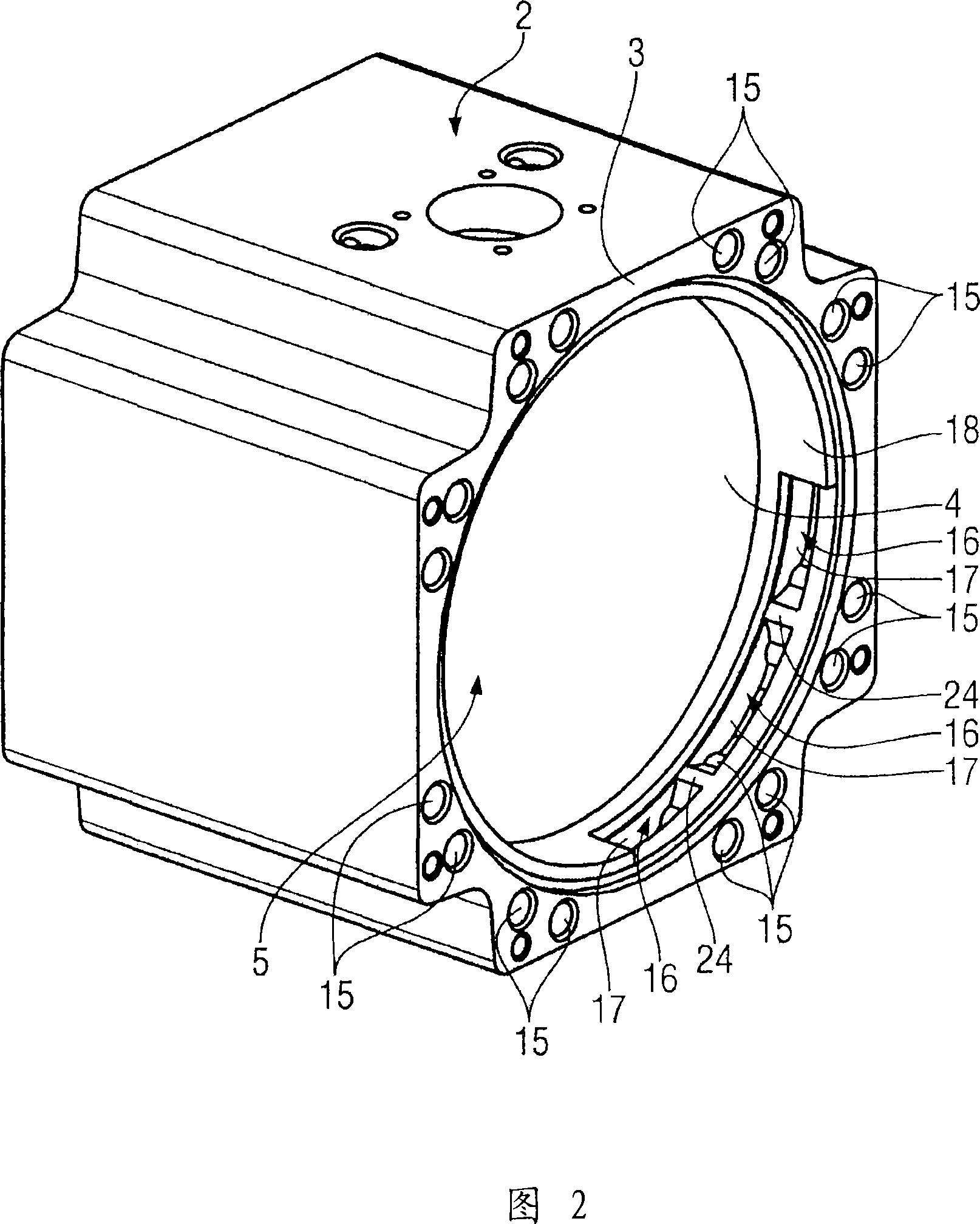

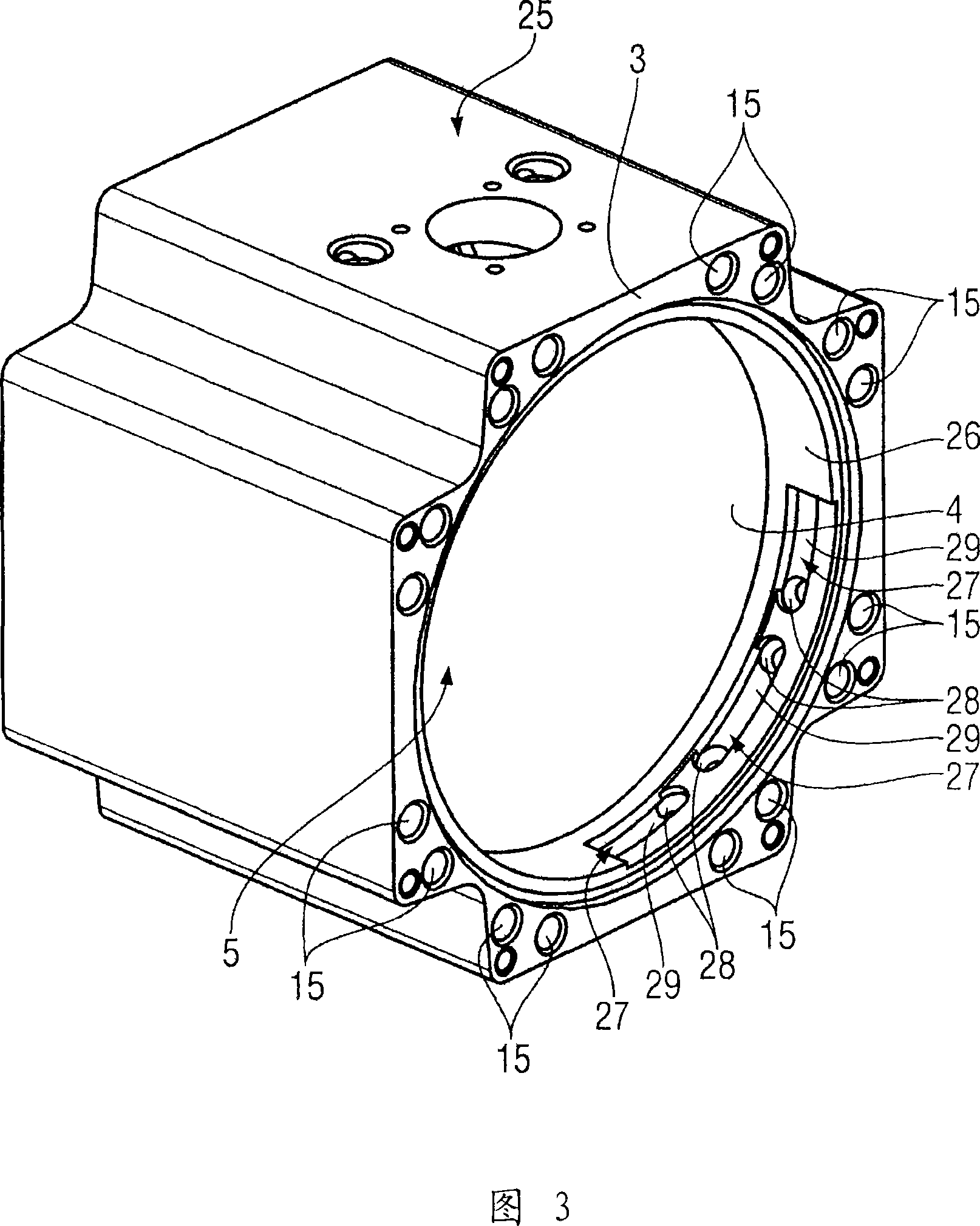

Housing of an electrical machine comprising cooling channels extending in a housing wall

InactiveCN101080863ALow costIncreased process reliabilityCooling/ventillation arrangementSupports/enclosures/casingsMechanical engineeringCooling channel

The invention relates to an electrical machine housing with cooling channels extending towder the inner housing. The housing (2) for an electrical machine (1), said housing comprising a housing wall (3) having an inner surface (4). At least two cooling channels (15) extend inside the housing wall. A connecting deviation channel (16) is provided between two of the cooling channels (15). The inventive housing is also provided with an inner sealing ring (18) applied to the inner surface (4). The housing wall (3) comprises at least one housing recess (17) on the inner surface (4) thereof, in the region of the inner sealing ring (18), such that, together with the inner sealing ring (18), it forms the deviation channel (16).

Owner:SIEMENS AG

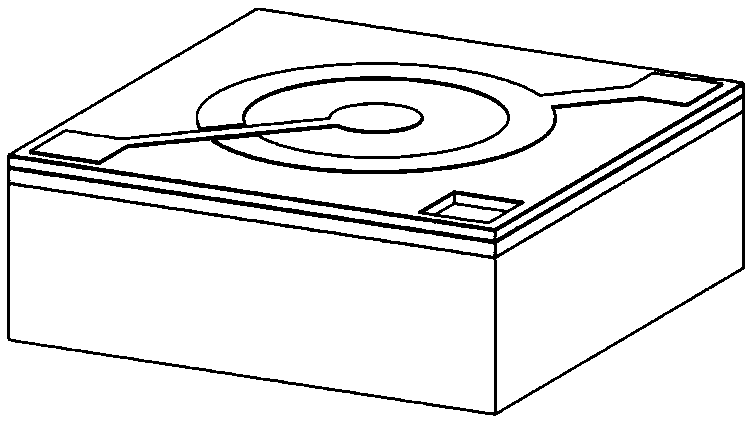

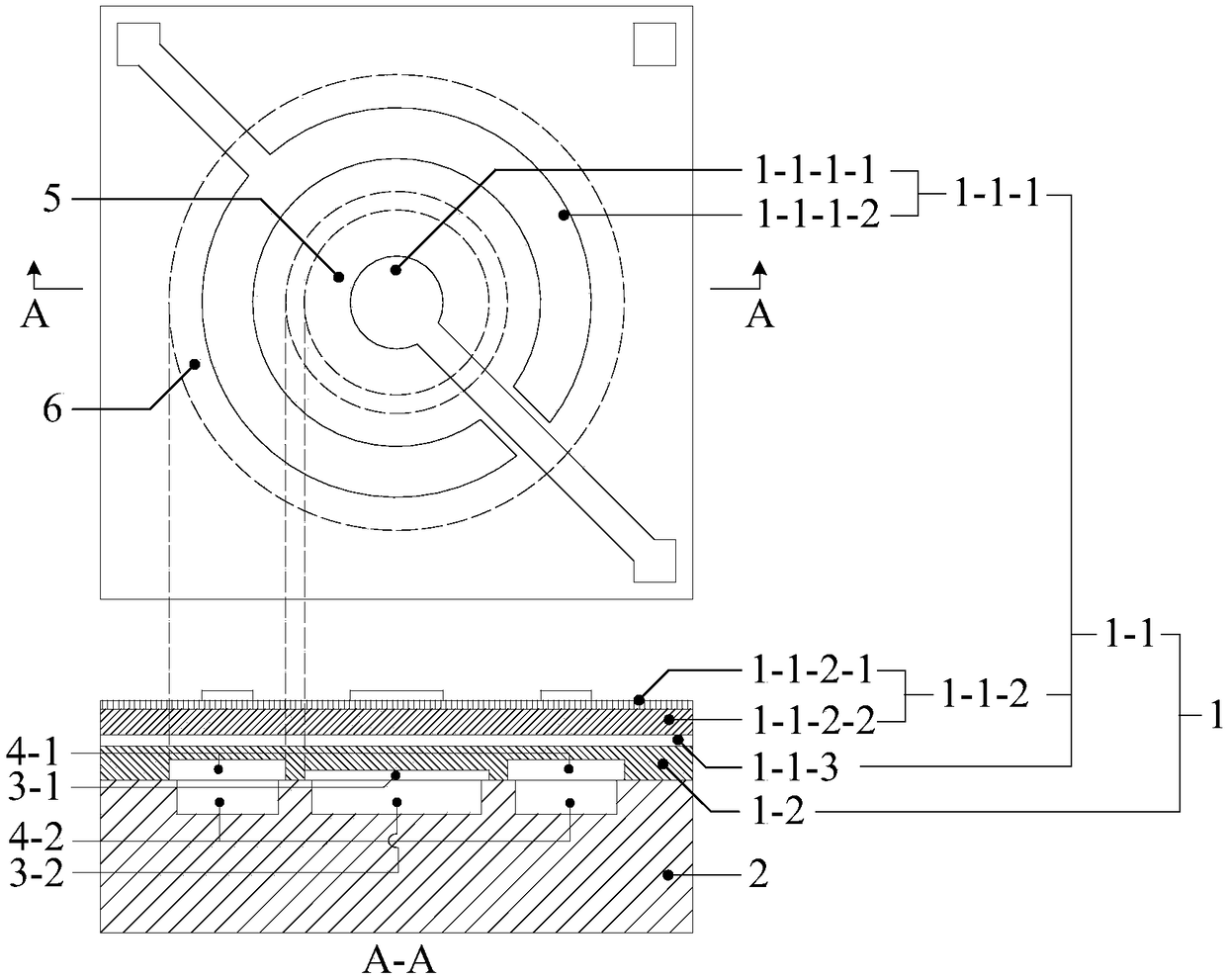

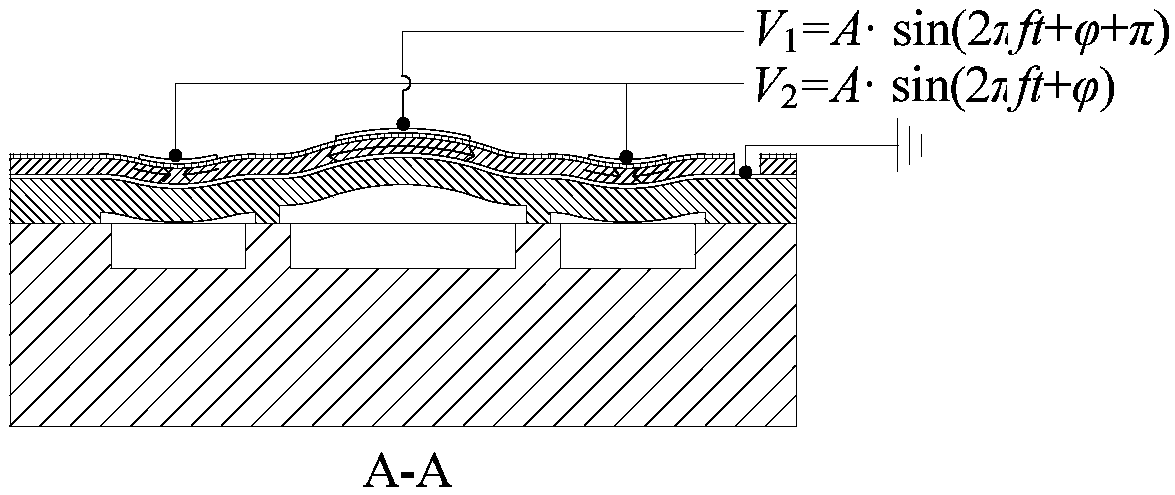

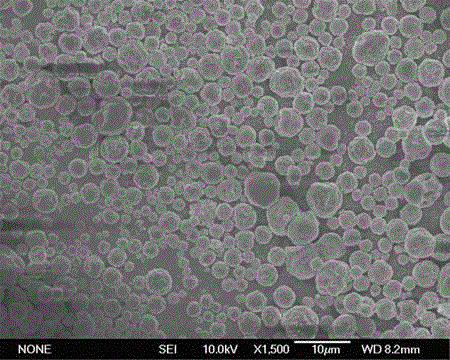

Combined stiffness-variable thin film pMUTs and preparation method thereof

ActiveCN109225789AIncrease the ultrasonic transmission powerImplementation of ultrasonic receptionMechanical vibrations separationResonancePhase difference

The invention provides combined stiffness-variable thin film pMUTs and a preparation method thereof. A combined stiffness-variable thin film structure is composed of circular thin film and annular thin film which surrounds the circular thin film in the circumferential direction and is concentric with the circular thin film; according to different working condition demands, the thickness of the circular thin film and the thickness of the annular thin film are adjusted separately to achieve combined stiffness-variable thin film; the overall structure of the combined stiffness-variable thin filmpMUTs sequentially comprises an upper electrode, a vibration thin film piezoelectric driving layer, a lower electrode, a vibration thin film structural layer, a thin film supporting structure and a base structure from top to bottom; when the combined stiffness-variable thin film pMUTs are used in a mode of emitting ultrasonic waves, the circular thin film and the annular thin film are excited according to a certain phase difference, the coupling effect among the circular thin film, a fluid medium and the annular thin film is achieved, and the unit ultrasonic wave emitting power is greatly increased; when the combined stiffness-variable thin film pMUTs are used for receiving the ultrasonic waves, the ultrasonic wide bandwidth receiving performance is achieved through the resonance frequencydeviation of the circular thin film and the annular thin film in the fluid medium. The combined stiffness-variable thin film pMUTs have the high emitting power and wide bandwidth receiving performance.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

Method for removing tar oil from gasified combustible gas by using waste rubber and plastic crack oil

InactiveCN101186836AImprove purification effectAdaptableLiquid hydrocarbon mixture productionGasoline stabilisationDistillationWaste rubber

The invention relates to a process for removing tar oil with gasification gas. At present, the operating cost and the maintenance cost of the present process for removing tar oil are high, and the second pollution of the waste water of tar oil is brought out. The concrete steps of the invention are that waste rubber and plastic used for schizolysis are conveyed to a schizolysis furnace and oil gas mixture and solid charcoal are generated after the heat schizolysis reaction, the oil gas mixture produced by the schizolysis reaction is separated via a rectifying tower and then oil products and gas are generated, and the distillate with the temperature of 200-350 DEG C is separated out as oil washing distillation cut which is employed to absorb the tar oil in the gasification gas which contains tar oil. Compared with the existing technology, the process for removing tar oil in gasification gas has high process reliability, increases the thermal value of the gas, reduces the operation cost , produces no waste water of tar oil, and promotes the added value of the tar product .

Owner:南京绿展能源有限公司

Preparation method of amorphous iron phosphate

A preparation method of amorphous iron phosphate is disclosed. According to the method, phosphoric acid or a phosphate is adopted as a phosphorus source, an iron salt or a ferrous salt is adopted as an iron source, and ammonia water is adopted as a precipitating agent; the phosphorus source and the iron source are weighed according to a stoichiometric ratio and are added with deionized water to prepare a mixed metal solution; the mixed metal solution and the ammonia water are respectively continuously added to a stirred reactor with the flow being 200-600mL / h, and a chemical reaction for precipitating the iron phosphate is continuously carried out under conditions comprising a reaction temperature being 40-80DEG C and a reaction pH value being 1.8-3.5; and an overflow slurry of the reactor is filtered, washed and dried to obtain the powdery amorphous iron phosphate. The crystal form of the prepared iron phosphate is amorphous, the average particle size D50 of the prepared iron phosphate is 7-15mum, and the tap density of the prepared iron phosphate is equal to or greater than 0.95g / cm<3>.

Owner:徐源庆

Photoresist removing method

ActiveCN103137440AIncreased process reliabilitySemiconductor/solid-state device manufacturingAshingChemistry

The invention provides a photoresist removing method which includes: performing a first ashing process on the photoresist layer through oxygen-containing gas to remove part of the photoresist layer; and performing a second ashing process on the remaining photoresist layer to remove the remaining photoresist layer. Due to the fact that the second ashing process is performed on the remaining photoresist layer through nitrogen-containing gas to remove the remaining photoresist, the problem that during manufacture of a magnetic random access memory (MEAM), when the photoresist is removed through a plasma of the oxygen-containing gas, the oxygen-containing gas can be reacted with a titanium nitride layer to form a titanium oxide layer on the surface of the titanium nitride layer, and a copper metal layer cannot be clearly observed when a process for forming a tunnel junction is performed is solved, and the reliability in forming the tunnel junction is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

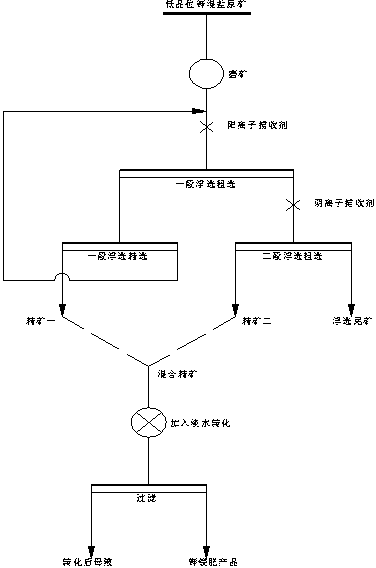

Two-stage flotation process for low-grade mixed potassium salt

The invention discloses a two-stage flotation process for low-grade mixed potassium salt. The process comprises the following steps: (1) grinding low-grade mixed potassium salt until content of the salt with size fraction of -0.15mm is no less than 64.90% by mass; (2) transferring ore pulp obtained from the step (1) to a flotation machine for the first stage of flotation; (3) adding an anionic collector to coarse ore pulp obtained from the step (2) for the second stage of flotation; (4) totally combining potassium chloride concentrate obtained from the step (2) with the second stage of flotation concentrate obtained from the step (3), adding fresh water at a mass ratio of the concentrate to the fresh water of 1: (0.65-0.80), stirring at normal temperature and conducting a conversion reaction fore 1-2h, filtering and drying to obtain a finished potassium sulfate fertilizer product. The process disclosed by the invention has such advantages as simple process, low energy consumption, easy implementation of operation and high K<+> recovery rate, and is suitable for recovering a potassium resource from some low-grade mixed potassium salt complex in potassium mineral composition through flotation.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com