Double-chamber heat pipe capable of self-optimizing heat dissipation

A dual-chamber, self-optimizing technology, applied in the field of heat exchange, can solve problems such as the narrow optimal working efficiency range of heat pipes, the influence of liquid filling rate and saturated vapor pressure limit of heat pipes, and the inability to meet the requirements of heat dissipation, so as to achieve process repeatability. And good reliability, best heat dissipation efficiency, simple production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

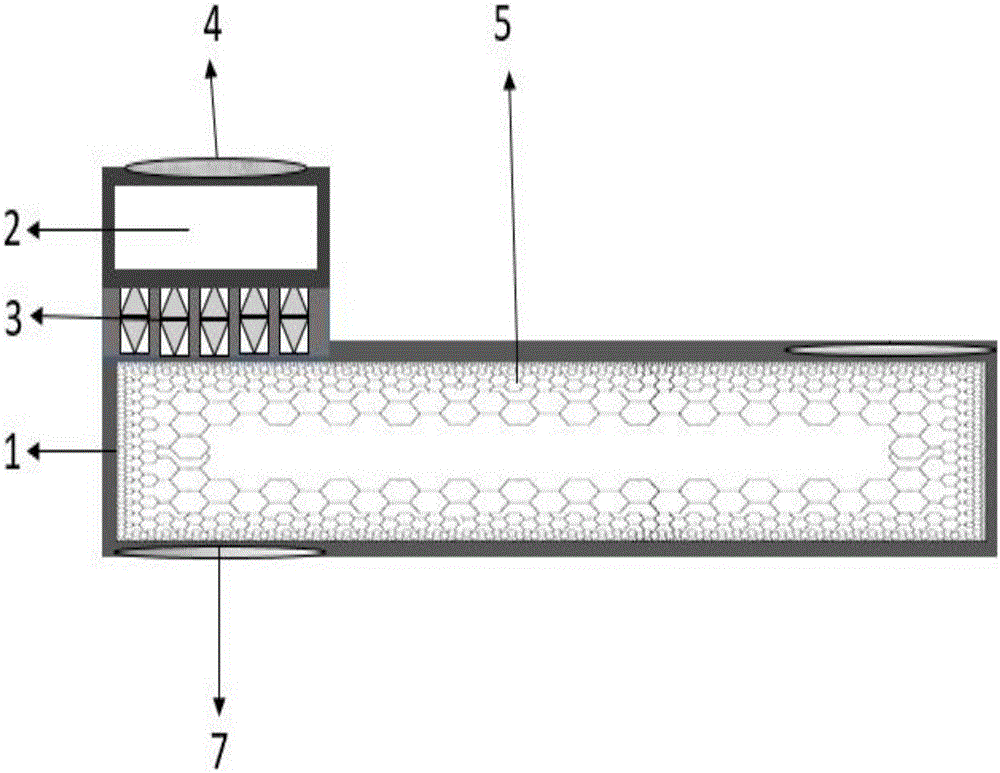

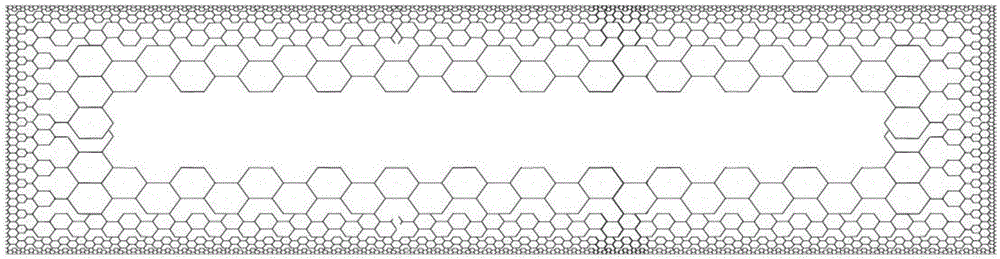

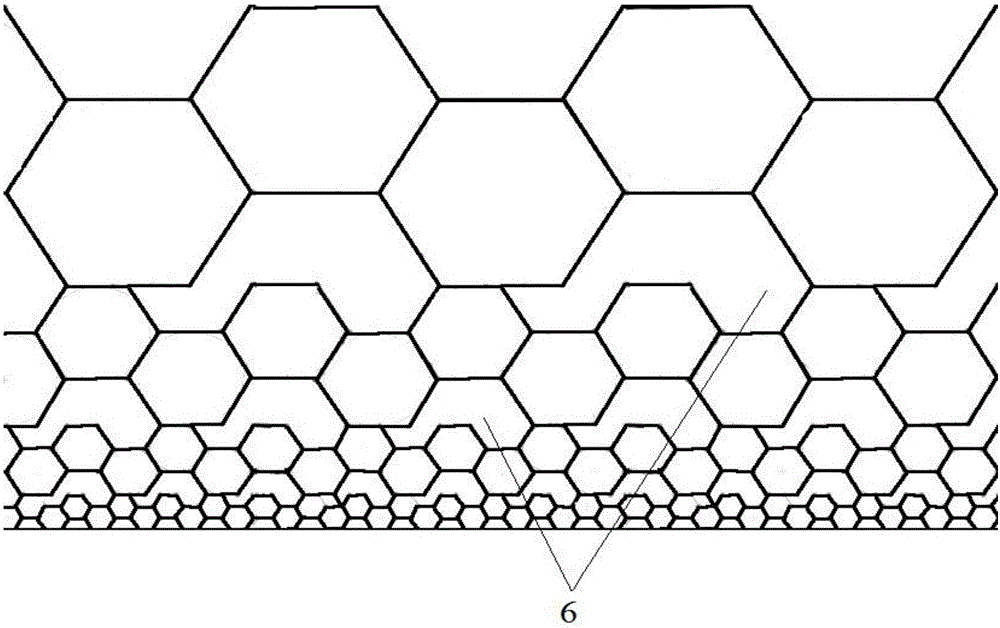

[0029] In one embodiment according to the present application, refer to figure 1 , providing a dual-chamber heat pipe with self-optimized heat dissipation, the heat pipe includes a main chamber 1, a secondary chamber 2 and a two-way steam switch group 3, and the main chamber 1 communicates with the secondary chamber through the two-way steam switch group 3 Chamber 2 is connected. The heat pipe adds a secondary chamber 2 on the basis of the single chamber of the traditional heat pipe, and adjusts the liquid filling rate and vapor pressure of the two chambers through the opening and closing of the two-way steam switch group 3 between the two chambers.

[0030] The main cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com