Vibrating bar-inserting long spiral air-cooled drilling rock-socketed pile forming method and equipment

A long spiral and pile-forming technology, which is applied in the direction of drilling equipment, drill bits, sheet pile walls, etc., can solve the problems of difficult construction, low construction efficiency, and pollution of the environment by waste mud, achieving significant economic and social benefits, and improving construction efficiency , Drillability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

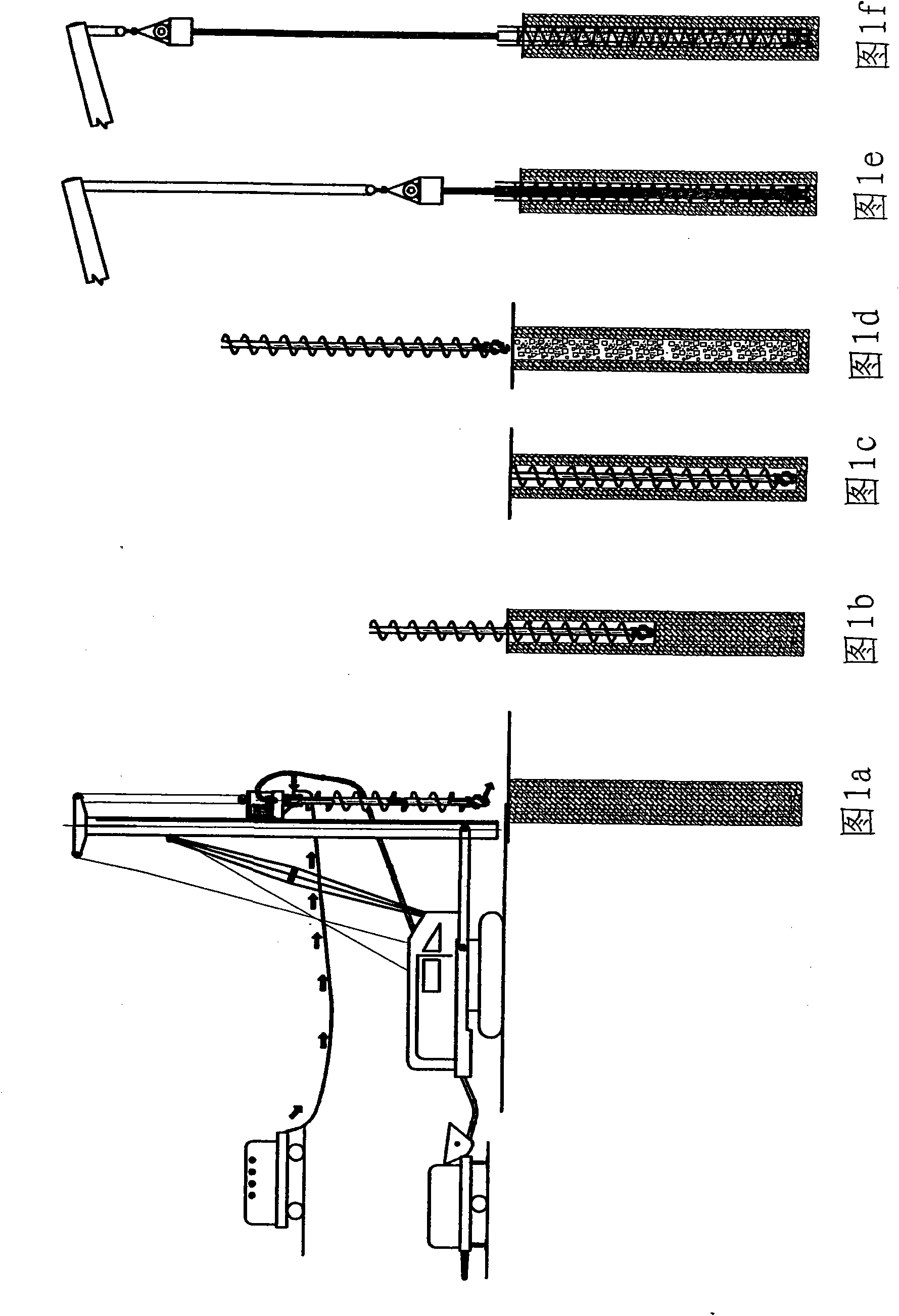

[0087] A technology of vibrating and inserting ribs, drilling and pouring combined with a long helical air-cooled drilling and rock-socketed pile. The drilling rig is equipped with an air supply system independent of the concrete pouring system, and communicates with the air outlet of the drill bit check valve. The construction steps as follows:

[0088] a. Drilling and irrigation combined with a long helical air-cooled drilling rock-socketed pile drilling rig for positioning, start the air compressor 1, and the compressed air passes through the air supply pipe 2, the side air guide 6 and the attached wall attached to the auger drill pipe The air pipe 6-6 is finally discharged from the air outlet 8a-1 of the valve-type conical helical pick rock socket bit 8a, the one-way valve has the function of opening when the air is supplied, and automatically closing when the air is stopped;

[0089] b. Inject compressed air to cool the drill bit while performing long helical drilling;

...

Embodiment 2

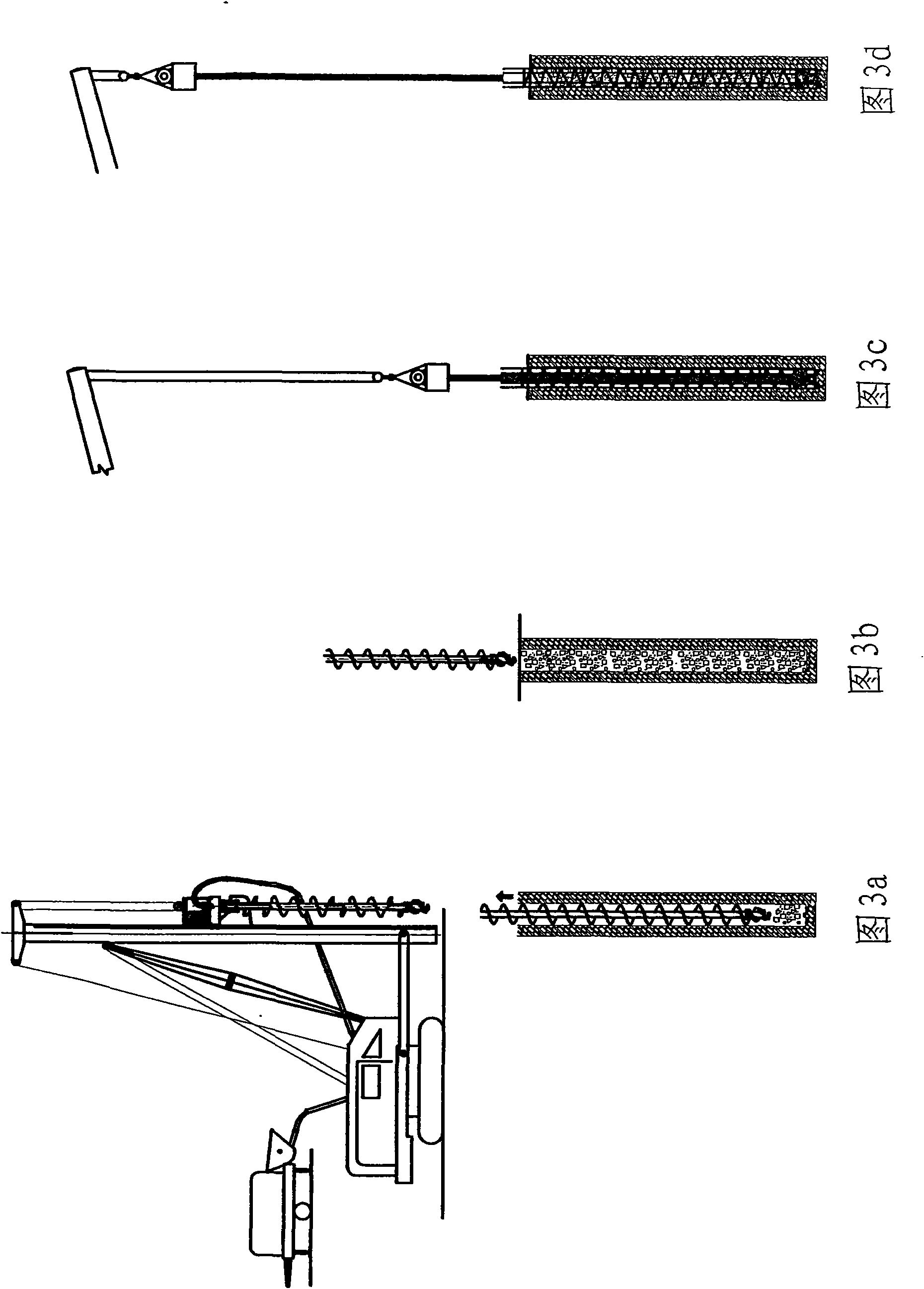

[0096] A technology of vibrating, inserting, drilling, pouring and separating long spiral air-cooled drilling into rock-socketed piles. The drilling is completed by vibrating, inserting, inserting, drilling, and separating long spiral air-cooled lead-hole rock-socketed drilling rigs, and the perfusion is performed by long spiral perfusion drilling rigs of known technology. After completion, the construction process is divided into two types: pilot hole and pouring:

[0097] Drilling and irrigation separation long spiral air-cooled lead hole rock-socket construction steps:

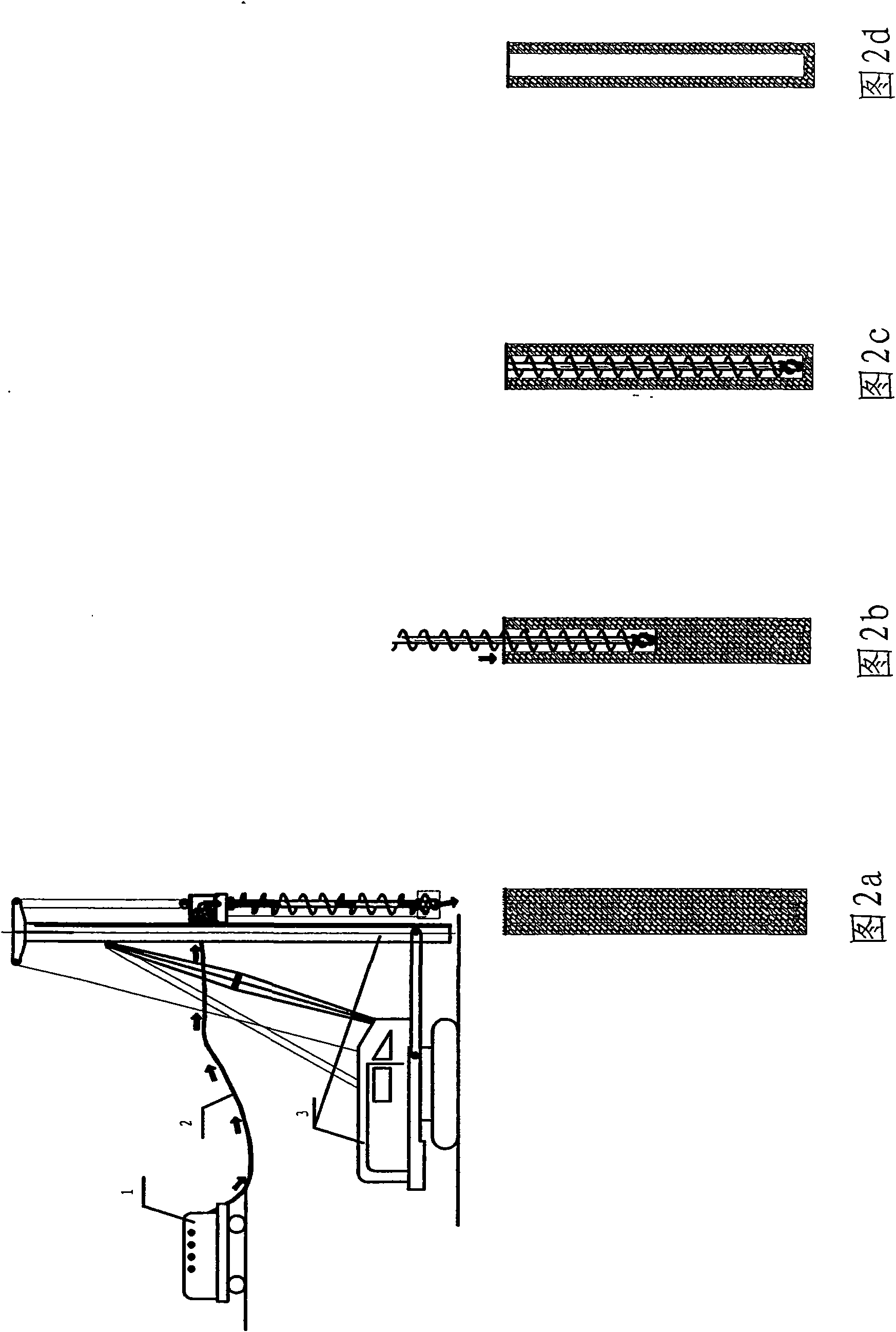

[0098] a.( Figure 2a) Align the long helical air-cooled lead hole rock-socketed drilling rig, start the air compressor 1, and the compressed air will be discharged from the air outlet of the long helical rock-socketed drill bit through the air supply pipe 2, the deflector and the air pipe attached to the drill pipe;

[0099] b. Long helical drilling while injecting compressed air ( Figure 2b );

[0100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com