Patents

Literature

46results about How to "Improve drillability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

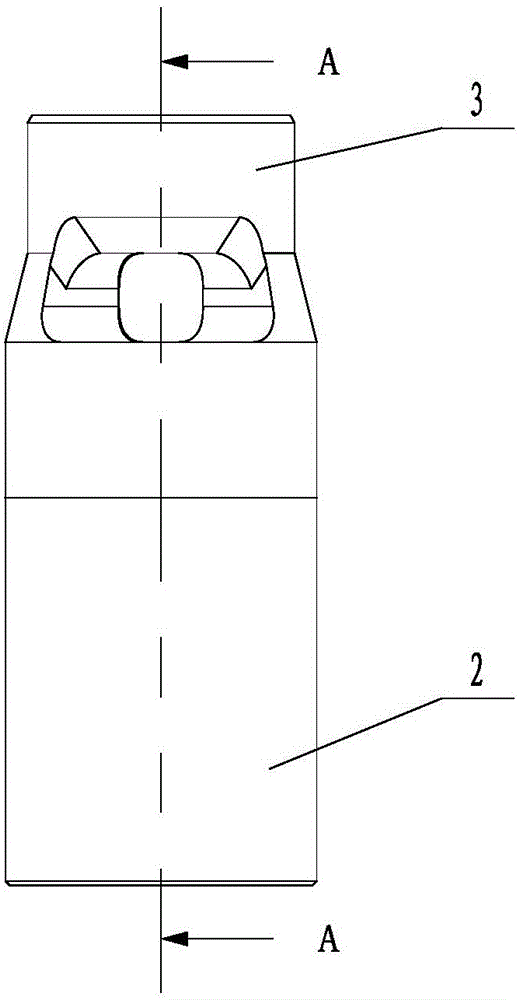

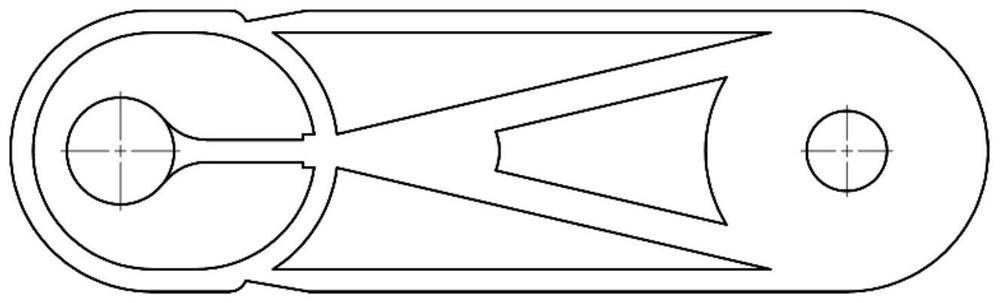

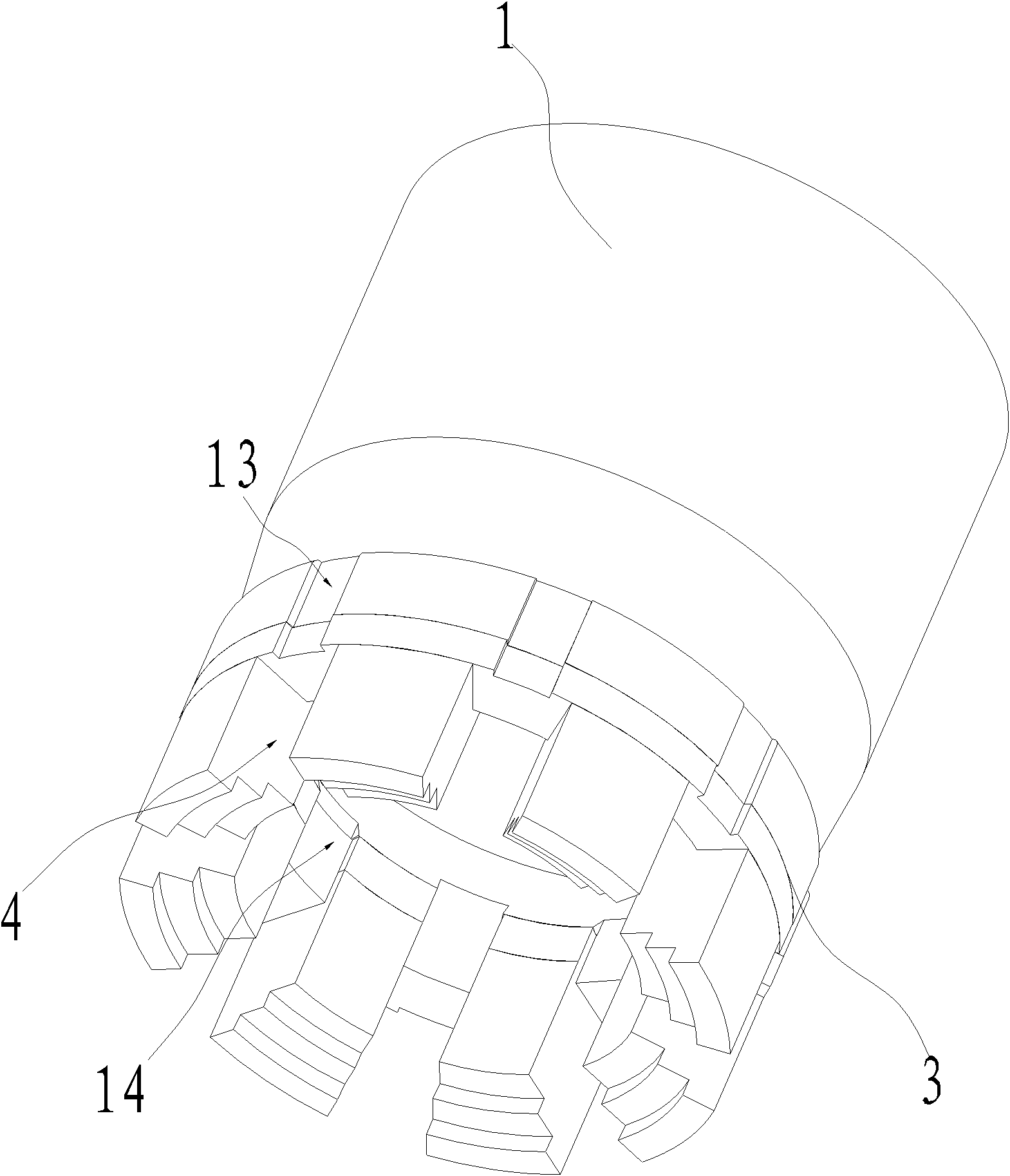

Settable well tool and slips

ActiveUS20130112412A1Improve drillabilityImprove scalabilityFluid removalSealing/packingHardnessCast iron

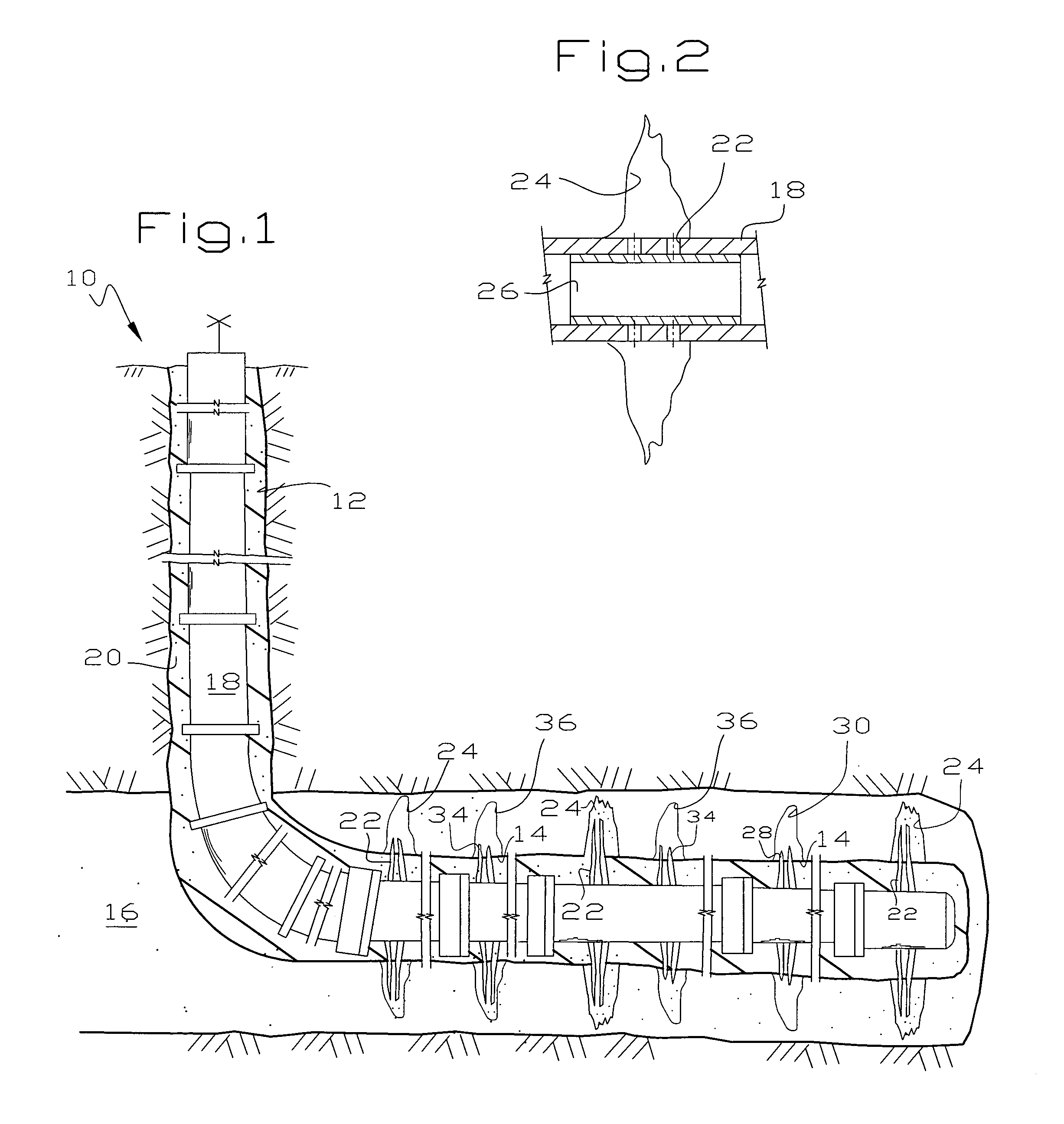

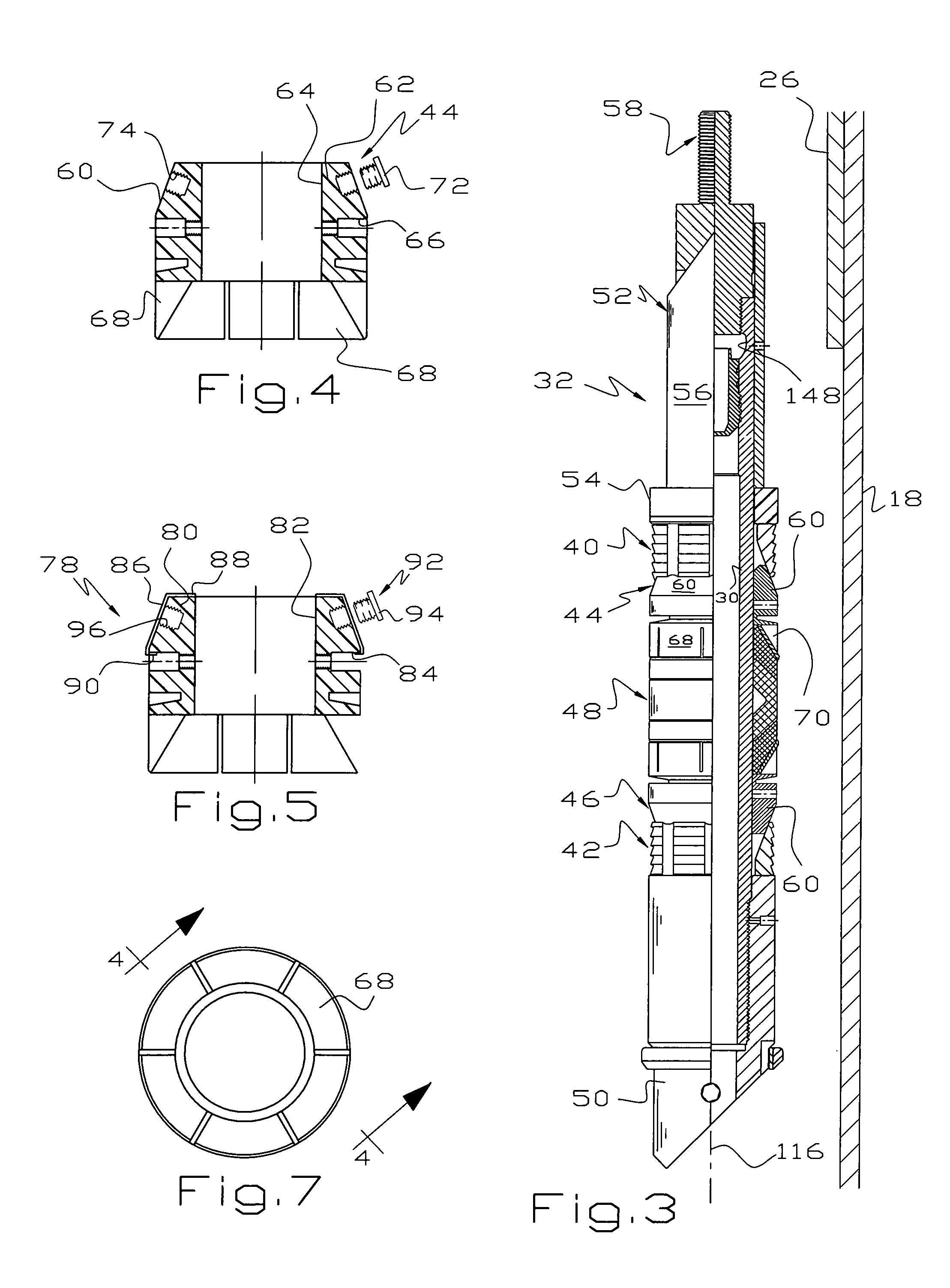

A settable down hole tool is of increased drillability and / or of increased expansibility. The improvement in drillability can be caused by fracturing cast iron slips into a large number of small pieces that can be circulated out of a well without further reduction in size. The improvement in expansibility can be partially caused by providing an expander cone of increased hardness thereby allowing an increased angle on the expander cone and slips. The improvement in expansibility can be partially caused by increasing the thickness of the slips.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

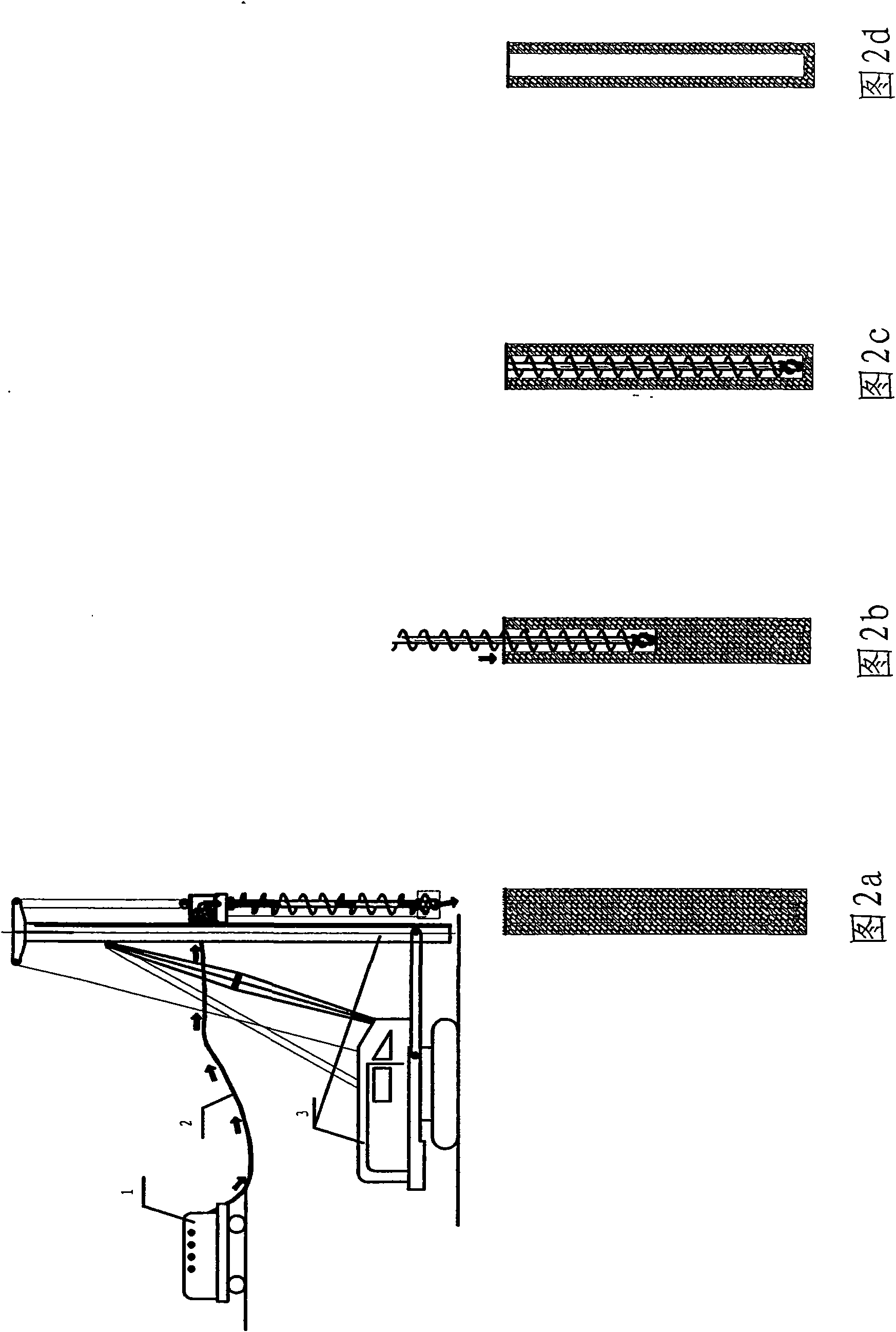

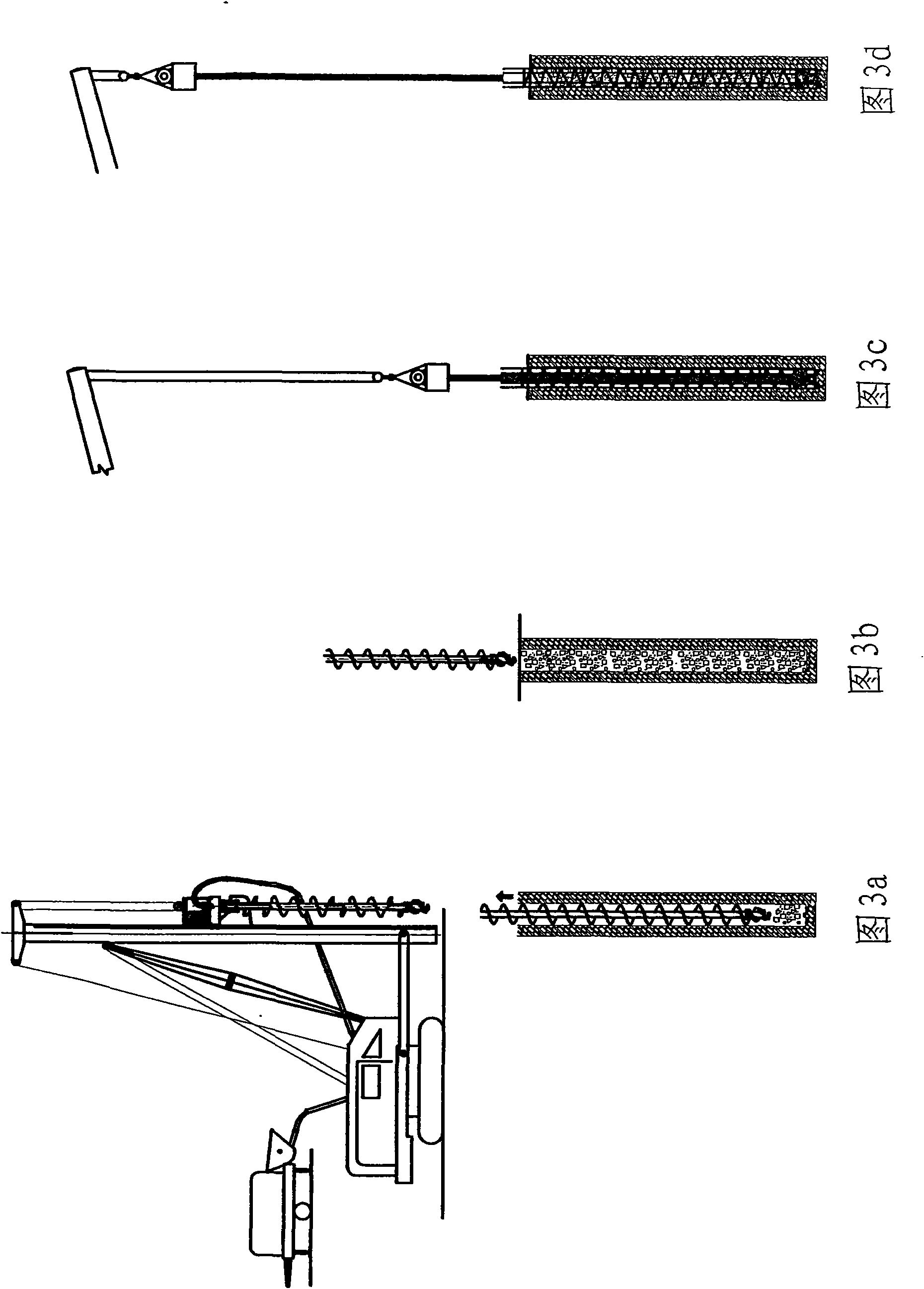

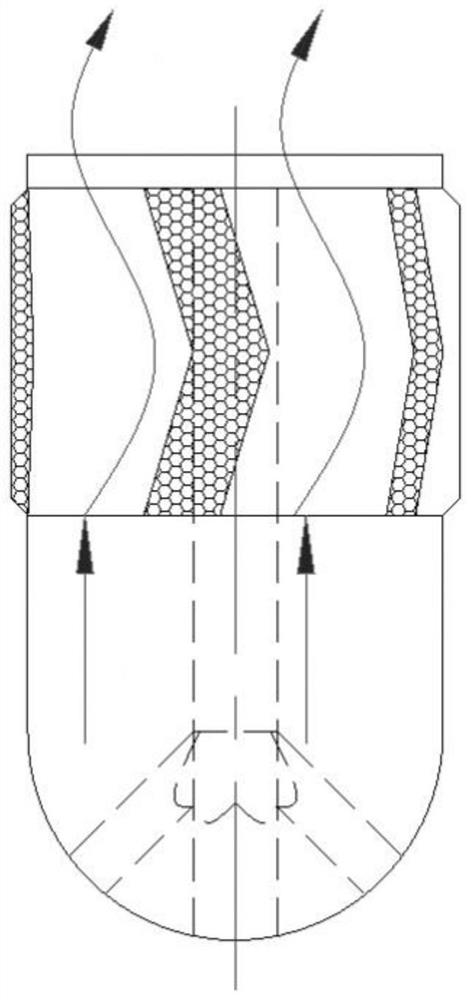

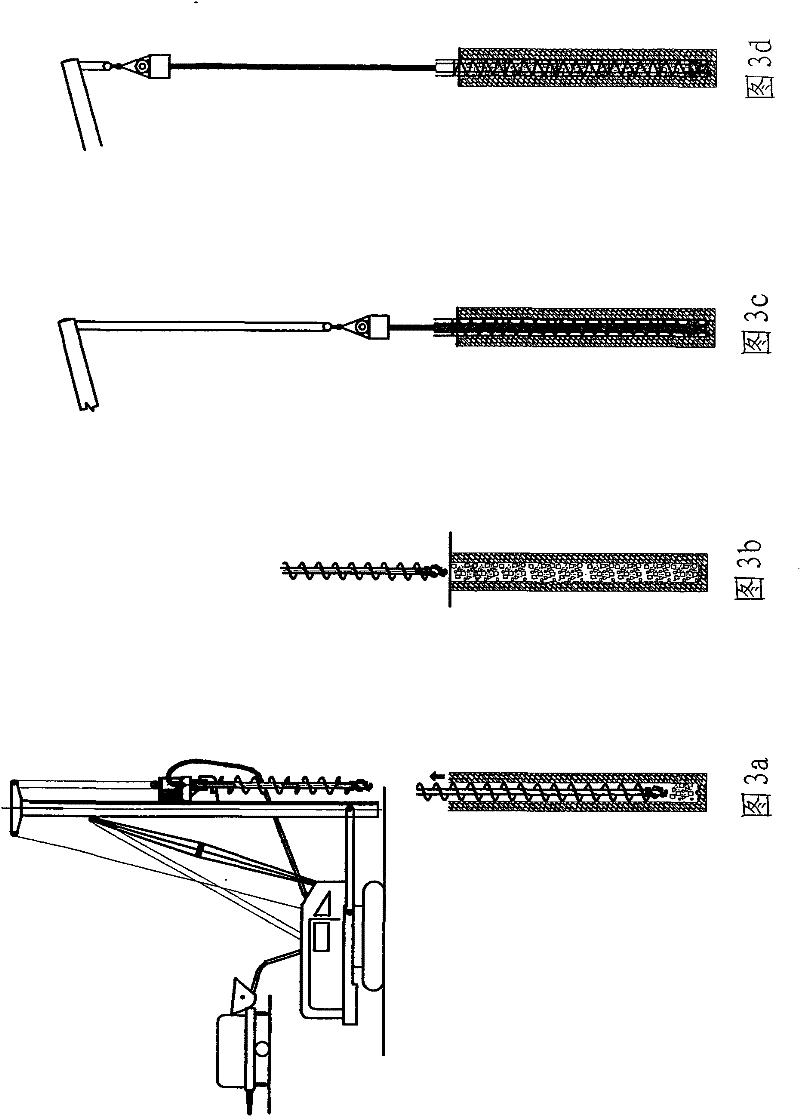

Vibrating bar-inserting long spiral air-cooled drilling rock-socketed pile forming method and equipment

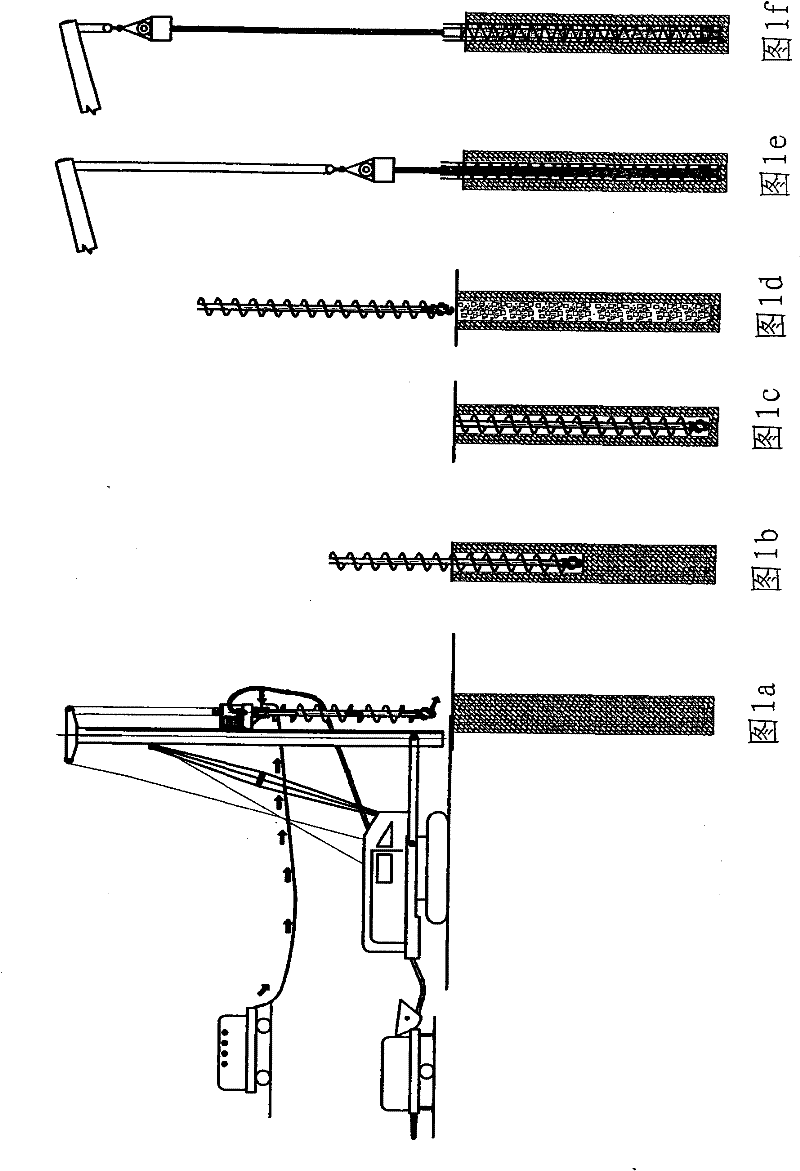

The invention relates to a vibrating bar-inserting long spiral air-cooled drilling rock-socketed pile forming method implemented in sub-hard rocks, soft rocks and weathered rocks, gravel soil layers or hard soil layers. The method comprises the following construction steps of: a, starting an air compressor, and discharging the compressed air from the air outlet of a long spiral rock-socketed drill bit by a blast pipe, a fluid director and an air pipe attached to a spiral drill rod; b, injecting the compressed air to cool the drill bit at the same time of long spiral drilling; c, reaching the designed hole depth; d, pouring concrete into the pile hole by using a concrete conveying pump; and e, vibrating and inserting a steel bar cage to the designed depth in a main rib pulled mode by adopting a vibrating hammer. Because the air can be continuously supplied to the drill bit, the drill bit is effectively cooled and the service life of the drill bit is greatly prolonged, and meanwhile, the drillability of the gas phase in the three-phase ratio of the soil is improved; therefore, the green construction technical process for a vibrating bar-inserting drilling pressure pouring pile can be adopted in the sub-hard rocks, the soft rocks and the weathered rocks, the gravel soil layers or the hard soil layers; and the method increases the quality reliability, reduces the consumption of various materials and improves the construction efficiency, so the method has remarkable economic benefit and social benefit.

Owner:李式仁

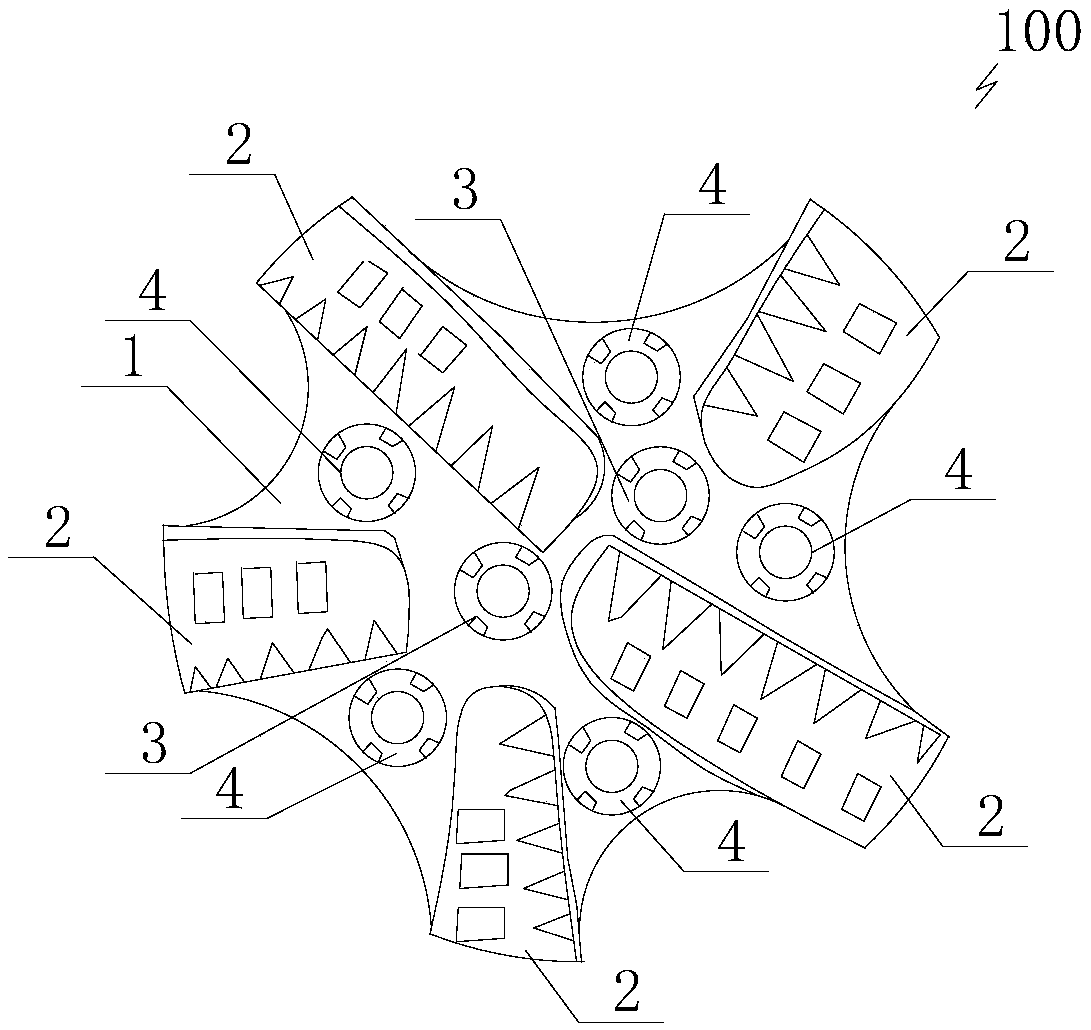

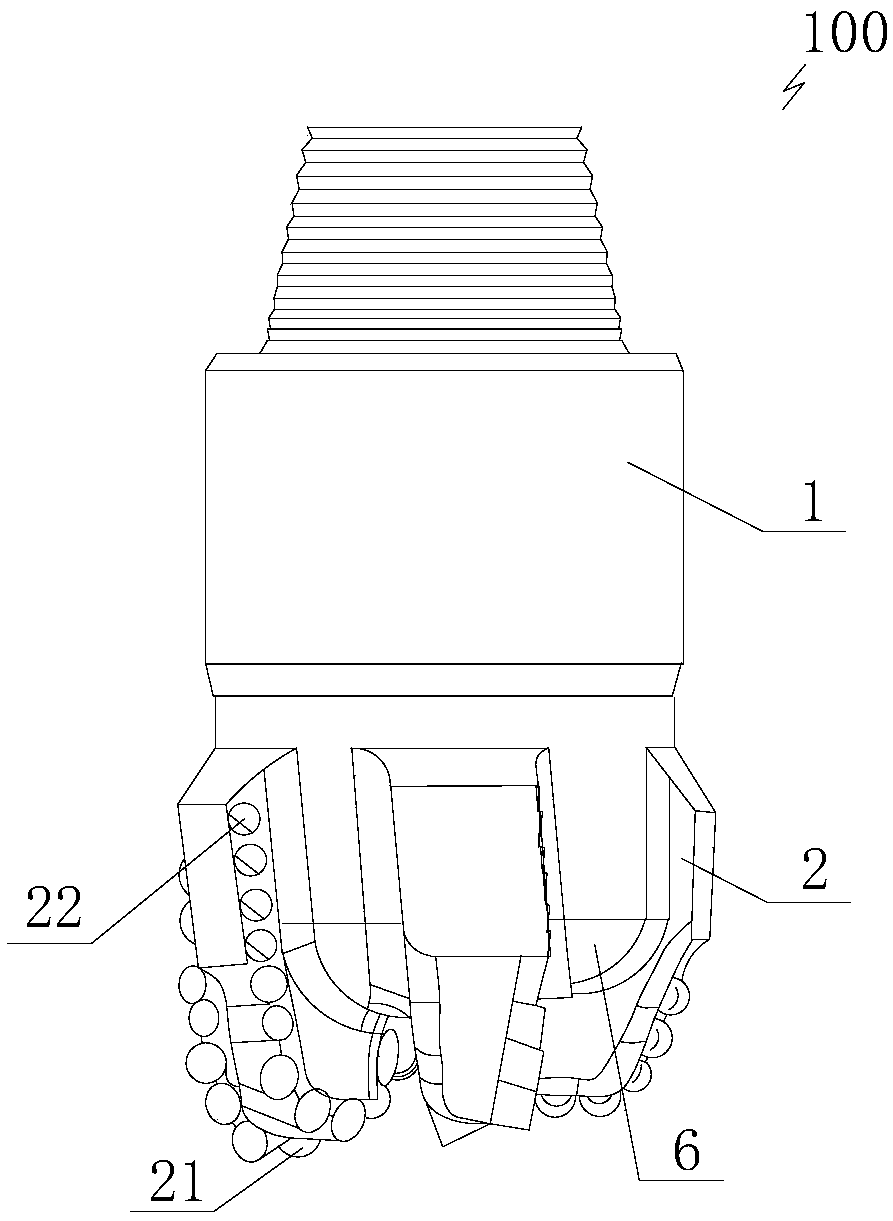

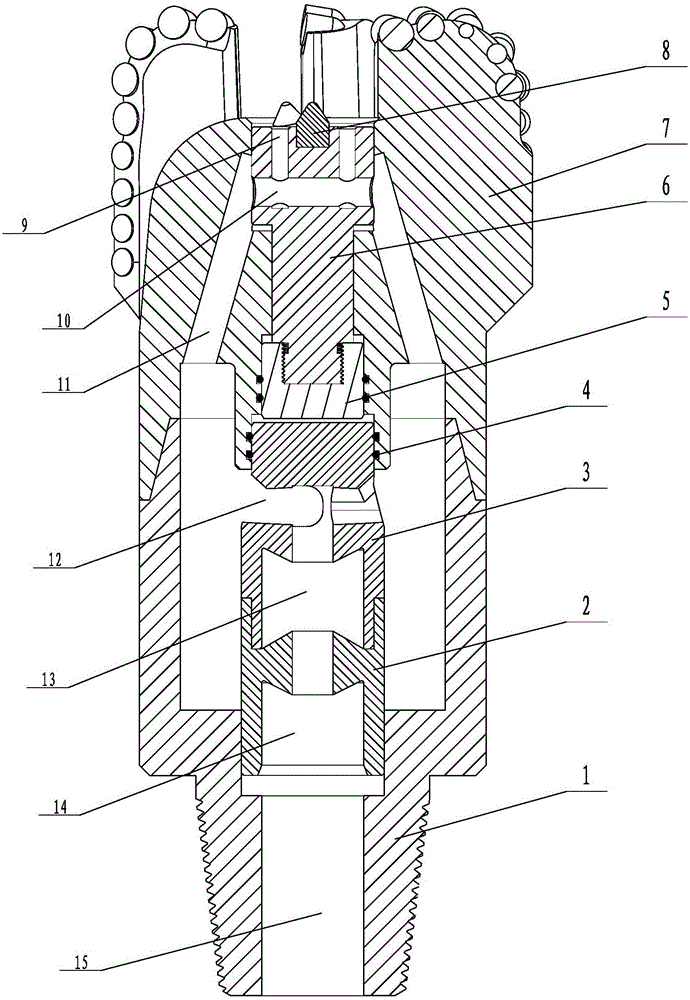

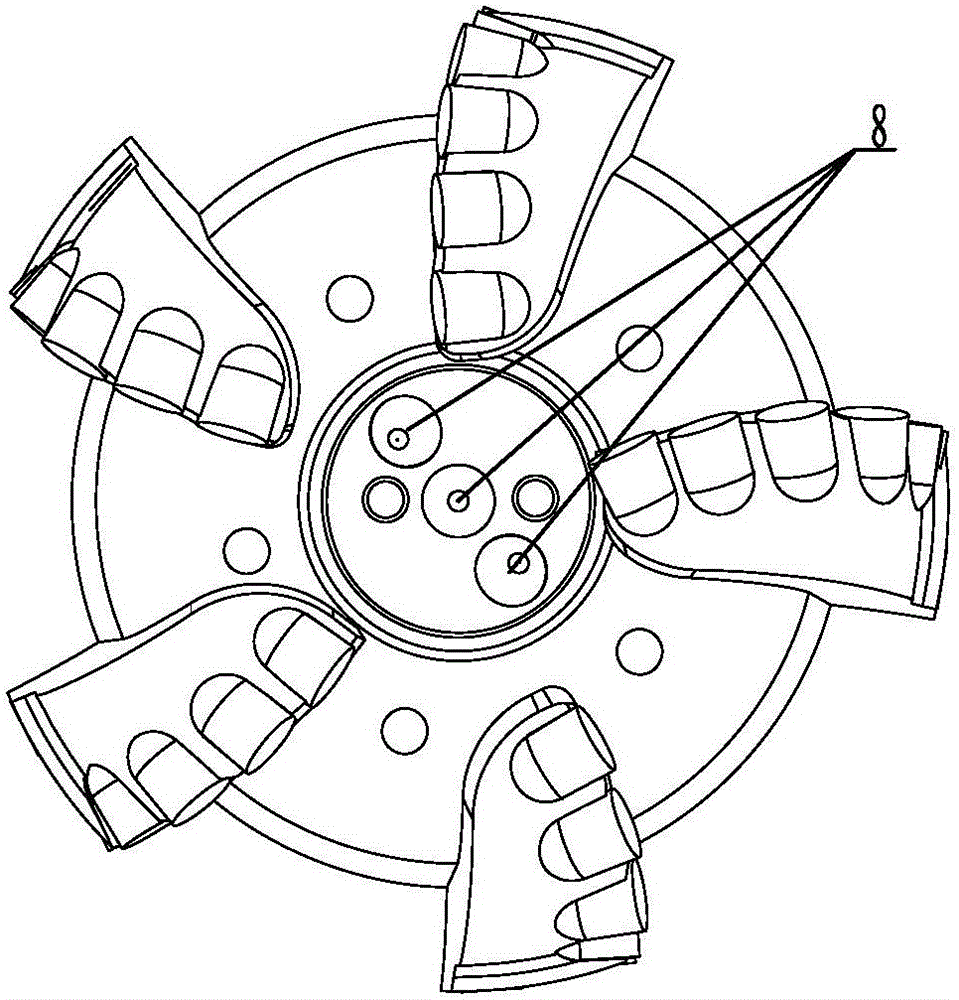

Liquid phase discharge plasma impact wave PDC drill bit

The invention relates to a liquid phase discharge plasma impact wave PDC drill bit, which comprises a drill bit body. Drill bit cutter wings are arranged at one end of the drill bit body at intervalsin the circumferential direction, cutting teeth capable of mechanically cutting rock are arranged on the drill bit cutter wings, and a well drilling liquid flowing channel is formed in the center of the drill bit body; a center water hole communicating with the well drilling liquid flowing channel is formed in the center of one end of the drill bit body in a penetrating mode, a center impact wavegenerator is arranged in the center water hole in a connected mode, and an edge water hole communicating with the well drilling liquid flowing channel is formed in the side wall of one end of the drill bit body in a penetrating mode; and an edge impact wave generator is arranged in the edge water hole in a connected mode, and the center impact wave generator and the edge impact wave generator areused for generating liquid phase discharge plasma impact waves capable of impacting and crushing the rock. According to the liquid phase discharge plasma impact wave PDC drill bit, by taking rock crushing through the liquid phase discharge plasma impact waves as the main and mechanical rock crushing as the auxiliary, rock drillability is improved, the well drilling speed is increased, the rock crushing efficiency of hard strata is improved, the service life of the drill bit is long, and use and promotion are facilitated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

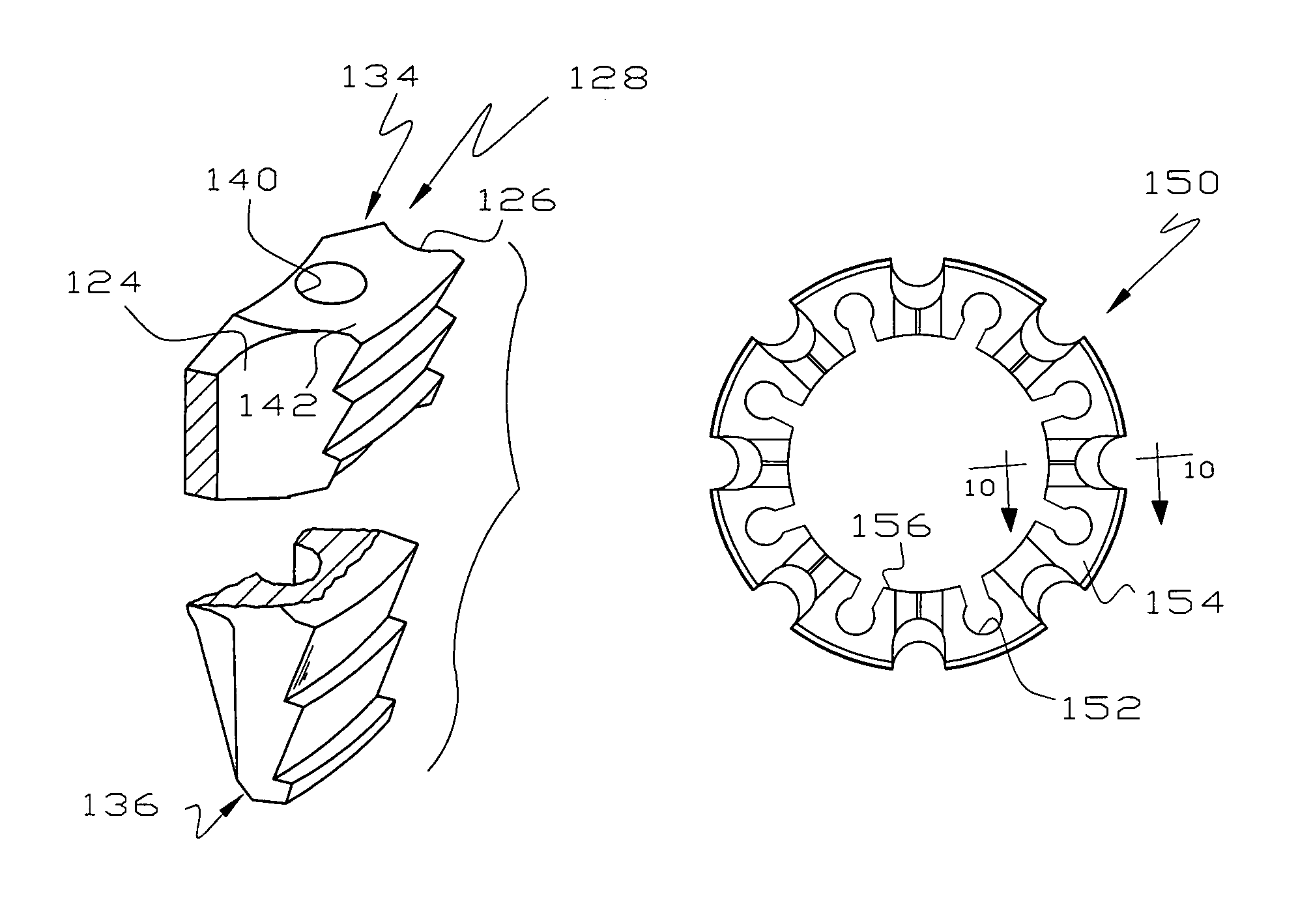

Diamond impregnated wire line coring geological bit and manufacturing method thereof

InactiveCN102128013APreset key functional effectsLarge Broad Spectrum PerformanceDrill bitsConstructionsPigeon toeLatitude

The invention discloses a crown and a steel junction surface of a hierarchical internal cone shaped vortex-type centering pilot diamond impregnated wire line coring geological bit with symmetrical pigeon-toed toes in and a manufacturing method of the bit. The bit comprises a working layer of the diamond bits, a bit steel body, middle isolation scraps and connecting layer materials. The bit has the following beneficial effects: assembly and configuration of the whole set of bit tools of the bit designed in the invention take pairing of each pair of bit tools as the pigeon-toe forming mode; thepairing formula of the bit tools is characterized by female / male layering, symmetry and balance; the bit tools are positioned, arranged and seated to form the internal cone shape; the situation of layered distribution and preset synchronous diminishing of the bit tools forms the preset function of using gentle methods and force; the crown is shaped like vortex-type cone-preserving pigeon-toe (thepreset pigeon-toe is transient equilibrium buffer and synchronous compensation in place of dynamic landing of the bit); the vortex-type pilot centering force is continuously obtained and the continuous vortex-type pilot centering force is the concept of the pigeon-toed toes in; the toes in are effective restraints for controlling advance; the toes in need to control the vertical effective latitude of the bore diameter when being applied in the drilling bit; and the mode of cushioning the toes in with pigeon-toes to control centering pilot is taken as the first key point.

Owner:FOSHAN NANHAI RUILICHEN TOOL

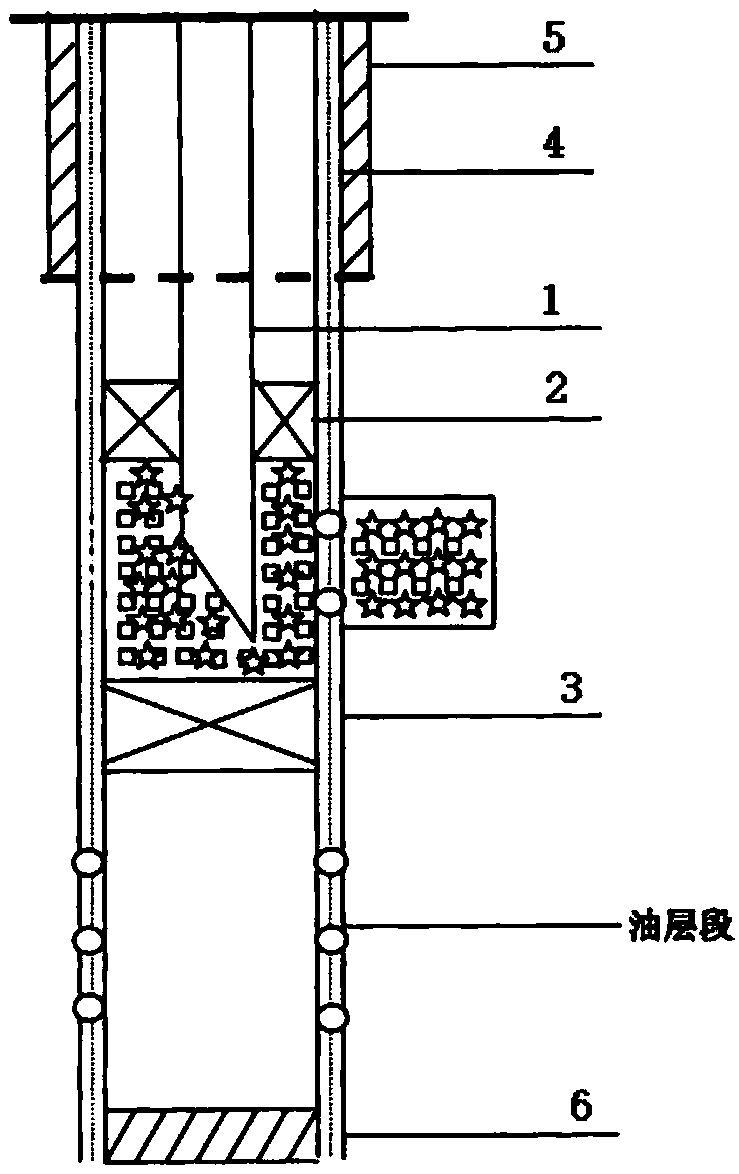

Method for sealing casing breaking point of casing damaged well in oil field

InactiveCN108979585AReduce injection frictionNo Shrink CuringSealing/packingAbsorption capacityOil field

The invention provides a method for sealing a casing breaking point of a casing damaged well in an oil field. The method includes S1, inserting a drillable bridge plug below the casing breaking pointand filling sand to 5m below the casing breaking point, wherein a tubing and plugging type packer are inserted to the upper side of the casing breaking point to be sealed; S2, using the tubing to squeeze clean water to verify the casing breaking point and water absorption capacity thereof; S3, squeezing a low friction blocking agent A and a low viscosity liquid bridging plugging agent B; S4, unplugging the plugging type packer, plugging the wellbore, backwashing the shaft and taking out the tubing; S5, allowing the low friction blocking agent A and the low viscosity liquid bridging plugging agent B to perform non-shrinkage heat curing action at room temperature to form a solidified body after 10-24 hours; S6, inserting a screw drill to remove the plugging-type packer, the solidified body and the drillable bridging plug; S7, testing pressure to be 15MPa with clean water, wherein pressure dropping 0-0.5MPa in 30 minutes is qualified, pumping is completed, or otherwise, plugging is performed once more. With the method, plugging agent injection friction can be reduced, plugging agent injectivity is improved, high strength and non-shrinkage curing of the plugging agent entering cracks are achieved, and permanent plugging is realized.

Owner:PETROCHINA CO LTD

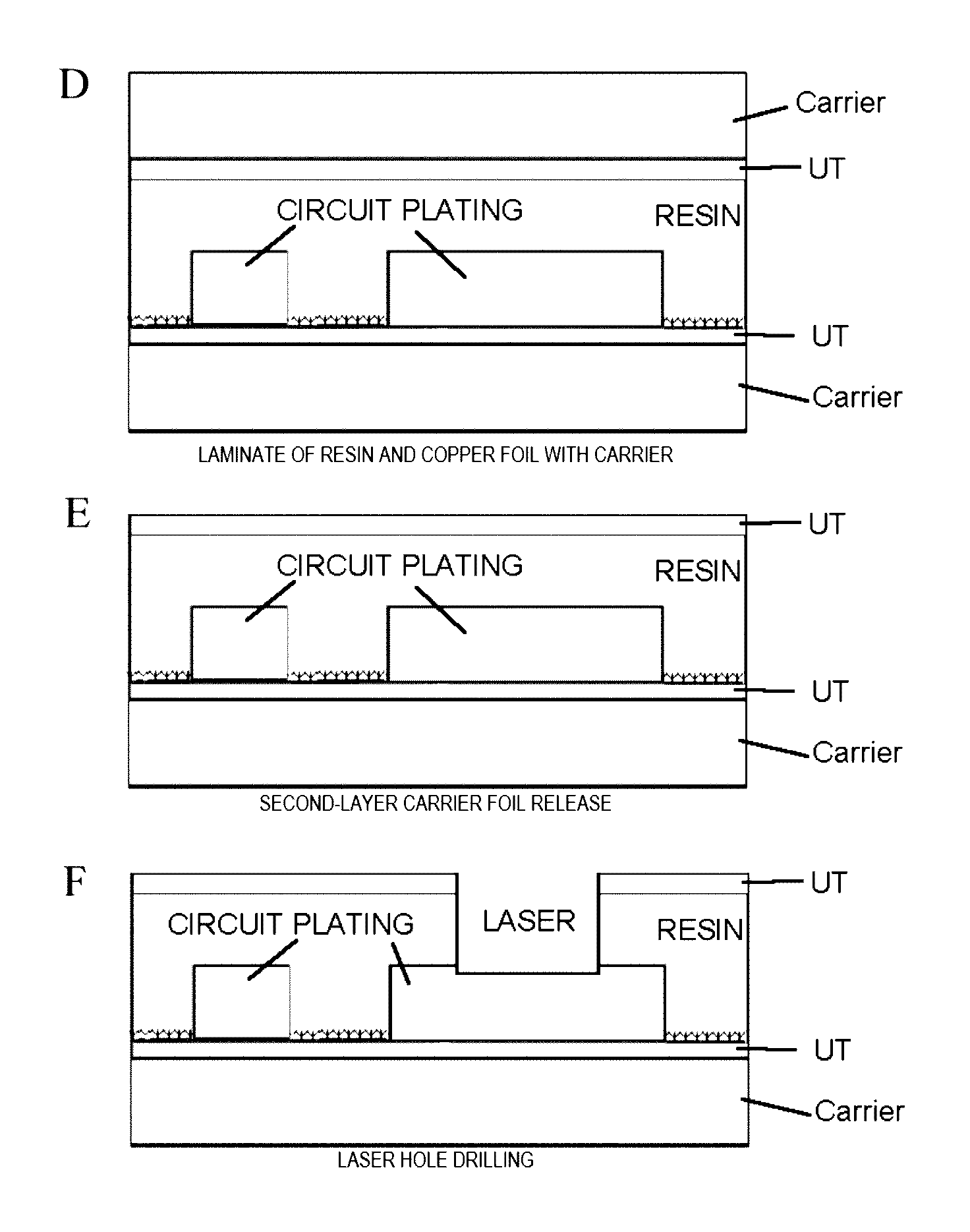

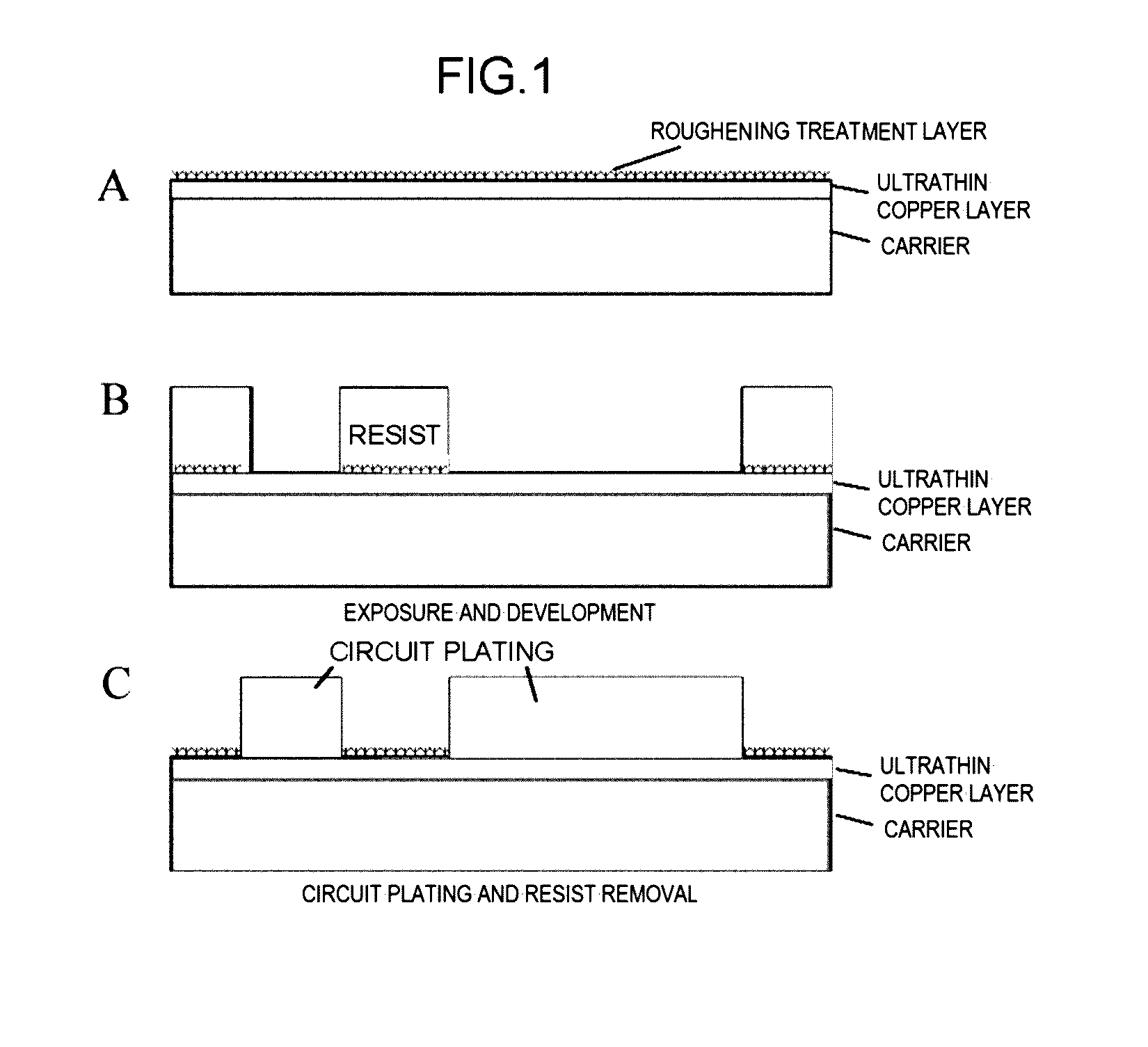

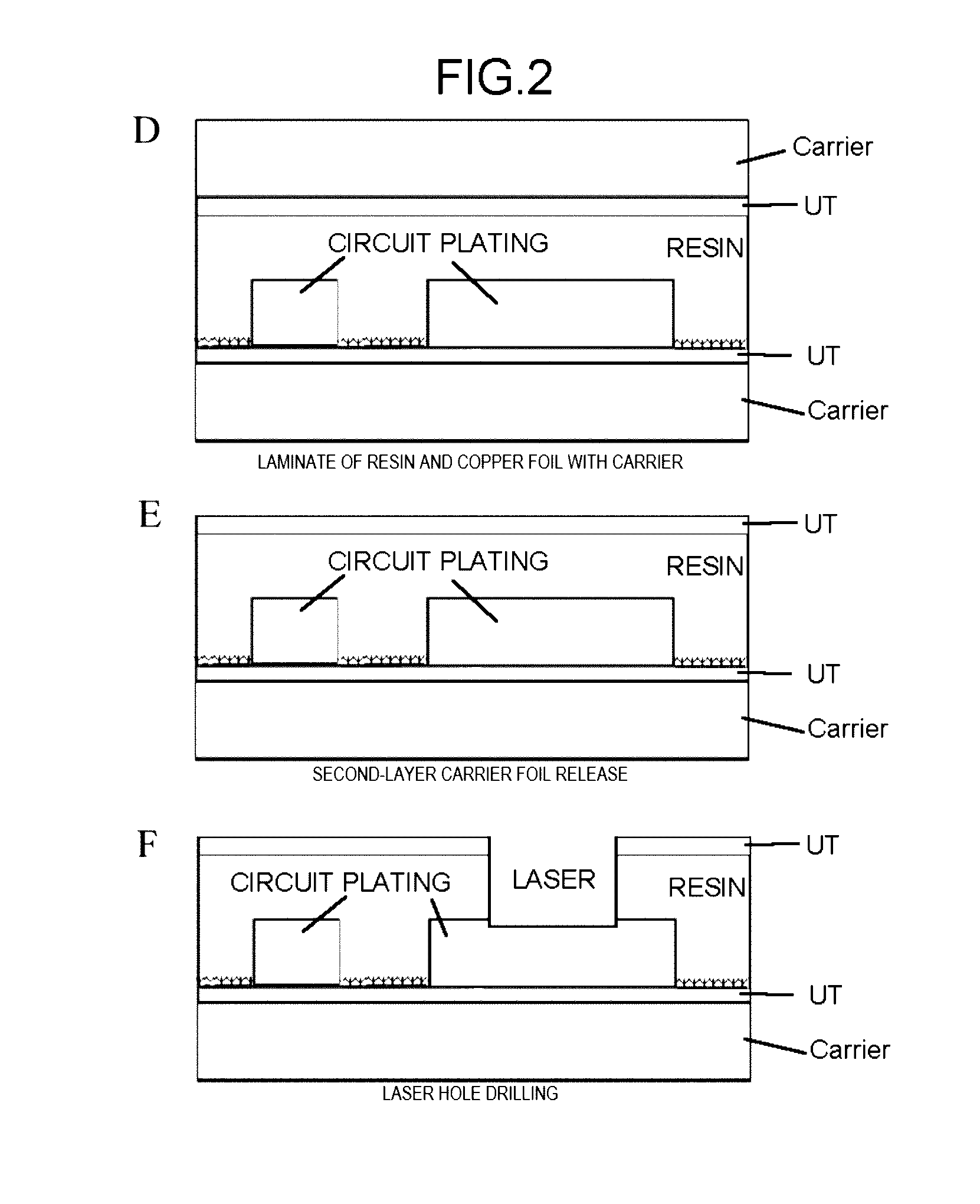

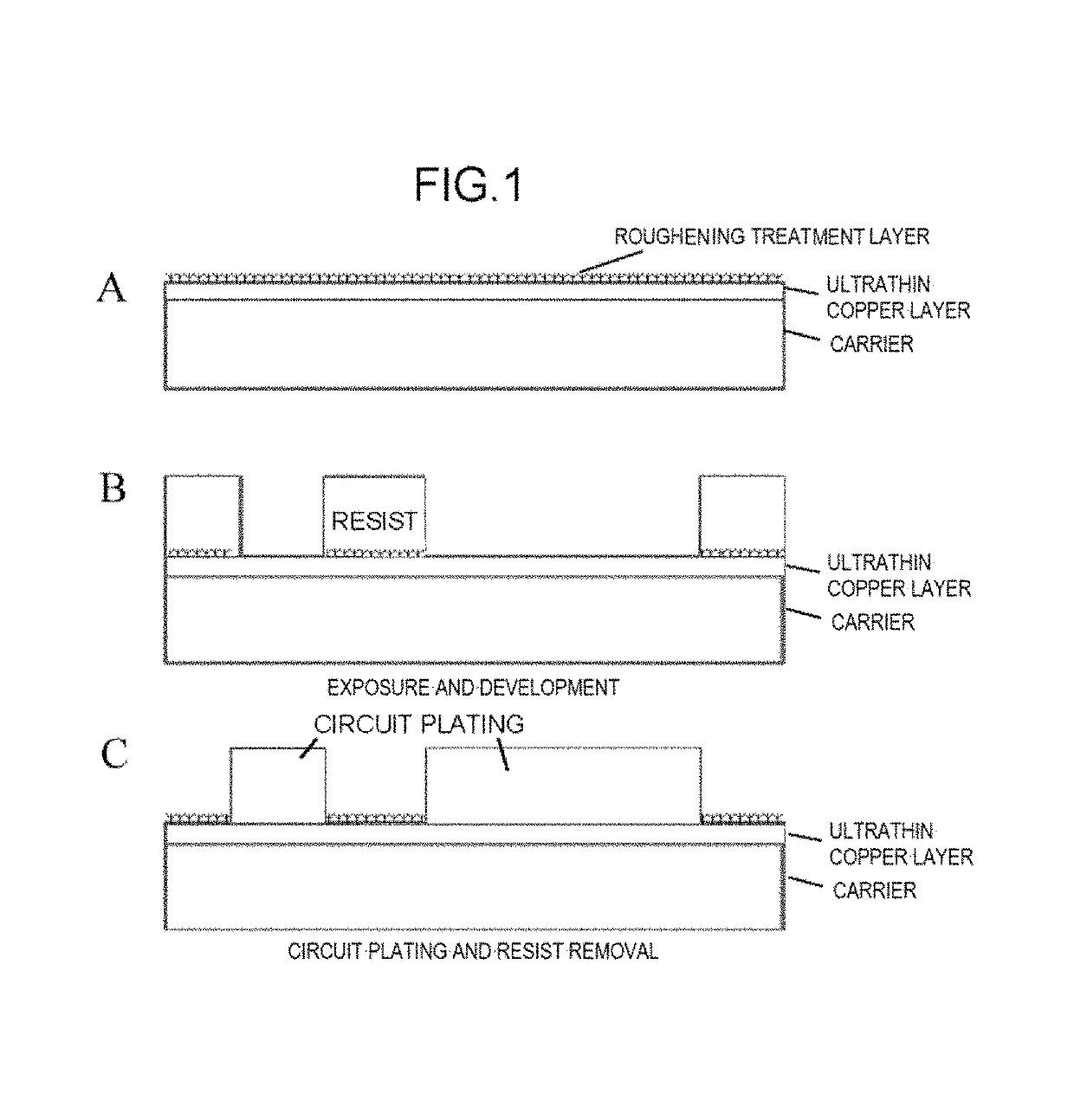

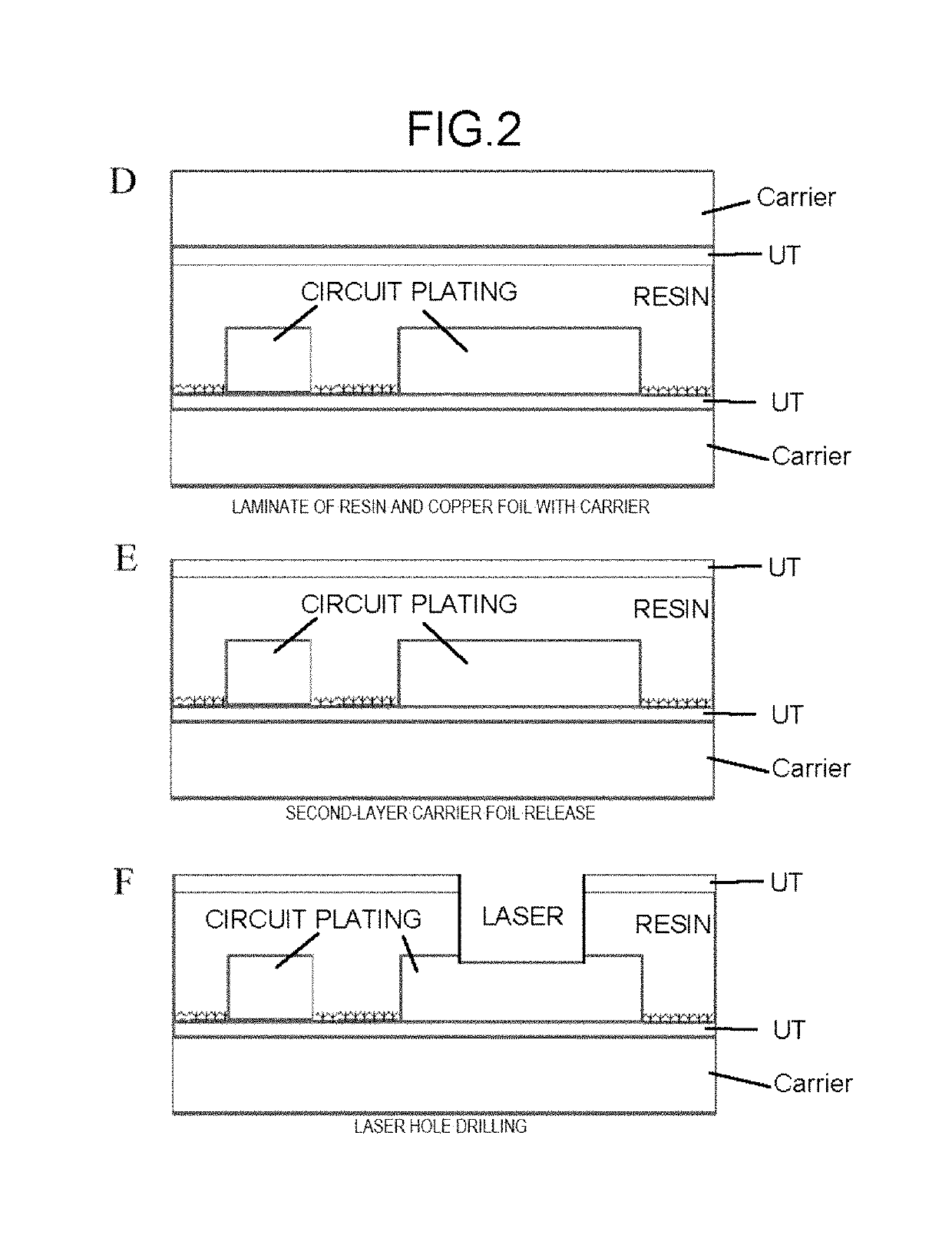

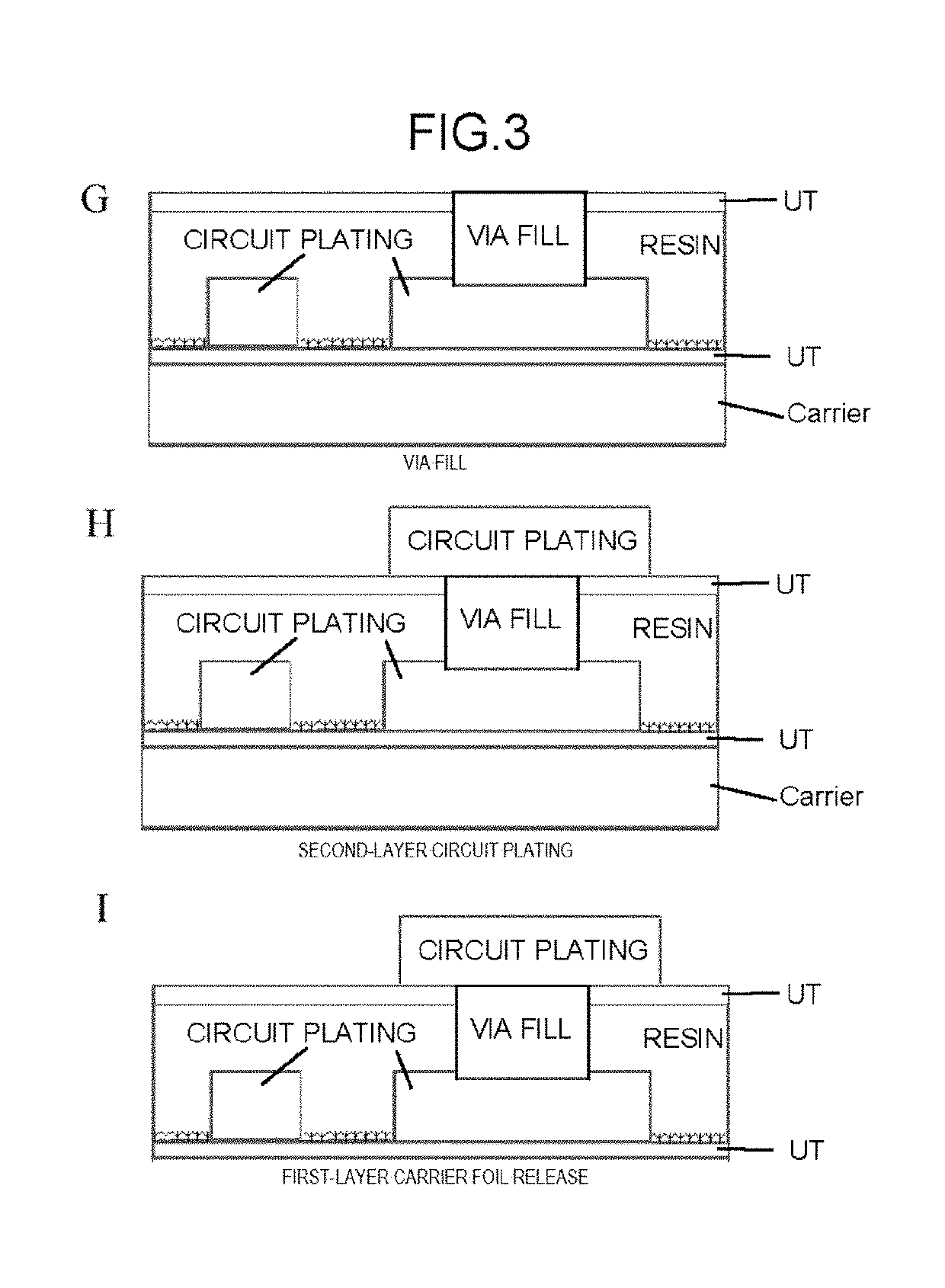

Carrier-Attached Copper Foil, Laminate, Laminate Producing Method, Printed Wiring Board Producing Method, And Electronic Device Producing Method

ActiveUS20170019991A1Improving laser drillabilityImprove drillabilityPrinted circuit aspectsElectrical equipmentInter layerHigh density

Provided herein is a carrier-attached copper foil having desirable laser drillability through an ultrathin copper layer, preferred for fabrication of a high-density integrated circuit substrate. The carrier-attached copper foil includes an interlayer and an ultrathin copper layer that are provided in this order on one or both surfaces of a carrier. The surface roughness Sz and the surface roughness Sa on the interlayer side of the ultrathin copper layer satisfy Sz≦3.6 μm, and Sz / Sa≦14.00 as measured with a laser microscope in case of detaching the carrier from the carrier-attached copper foil according to JIS C 6471 after the carrier-attached copper foil is laminated to an insulating substrate from the ultrathin copper layer side under a pressure of 20 kgf / cm2 and heated at 220° C. for 2 hours. GMD, which is a 60-degree glossiness of the ultrathin copper layer surface on the interlayer side in MD direction, satisfies GMD≦150 in case of detaching the carrier from the carrier-attached copper foil according to JIS C 6471 after the carrier-attached copper foil is laminated using the same procedure.

Owner:JX NIPPON MINING& METALS CORP

High-strength consolidation lost circulation additive

The invention discloses a high-strength consolidation lost circulation additive, which consists of the following components in parts by weight: 20-40 parts of calcium carbonate, 5-10 parts of silicon dioxide, 1-4 parts of calcium chloride, 0.1-0.4 part of polyanionic cellulose, 0.1-0.2 part of an XC biopolymer, 5-10 parts of aluminum oxide, 3-8 parts of magnesium oxide and 10-16 parts of oil well cement. The lost circulation additive is prepared by carrying out the following steps: adding the components into a kneading machine based on the parts by weight at normal temperature and under normal pressure according to the conventional preparation method; mixing and stirring uniformly; drying; smashing into a powdery product being 0.01-0.2 millimeter in particle size. The high-strength consolidation lost circulation additive has the characteristics of wide raw material source, high strength, strong suspending power, high mobility, high pumpability, condensing and plugging capabilities, high minimum inflation performance, high solubility, high leakage plugging success rate, simple process and safety in construction, is widely applied to petroleum and geological drilling processes, and is particularly to be applied to fractured hard formations and karst cave formations.

Owner:DONGYING TAIER GASOLINE TECH

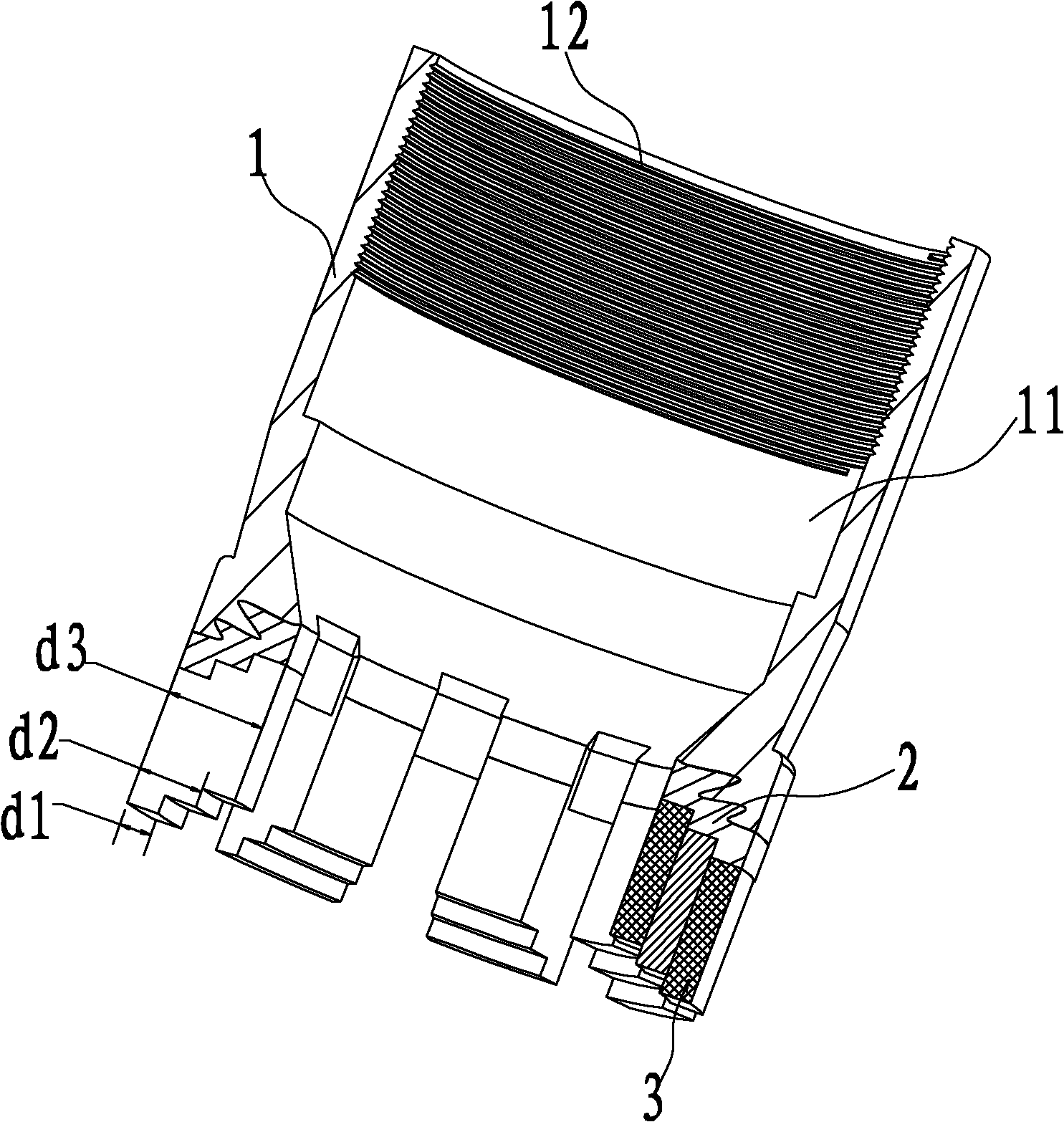

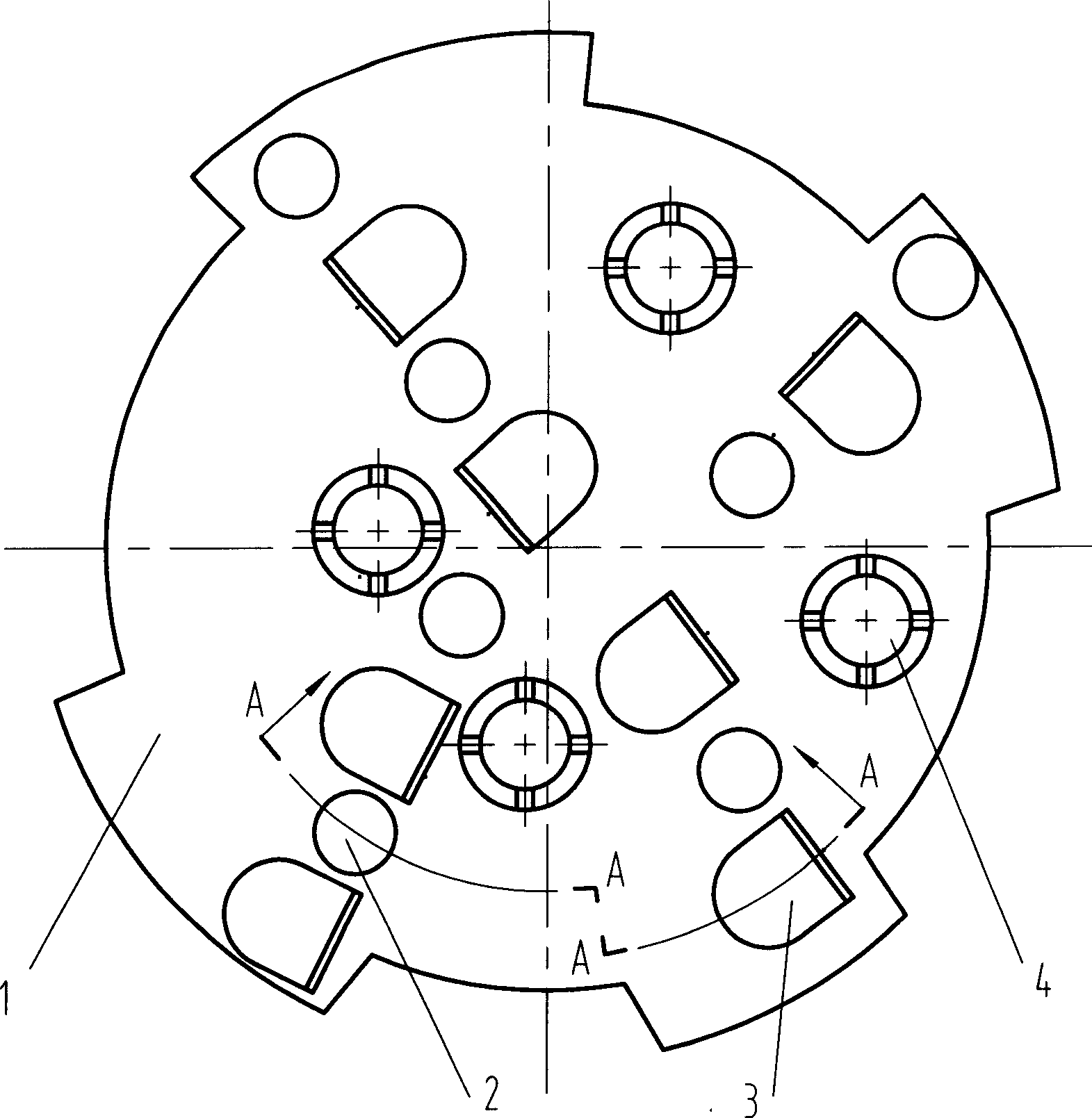

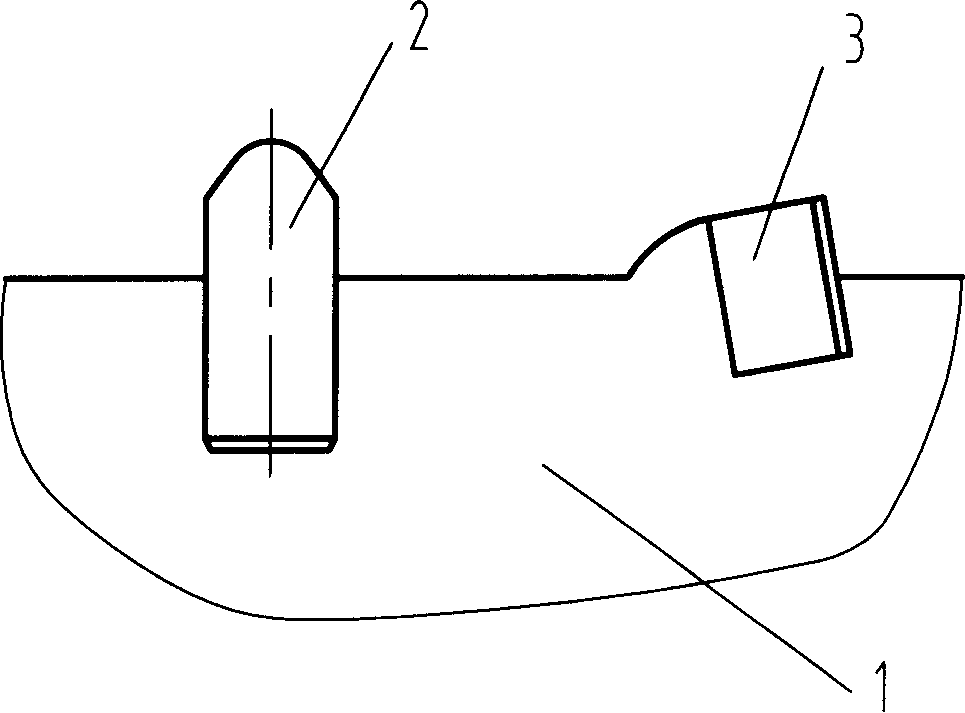

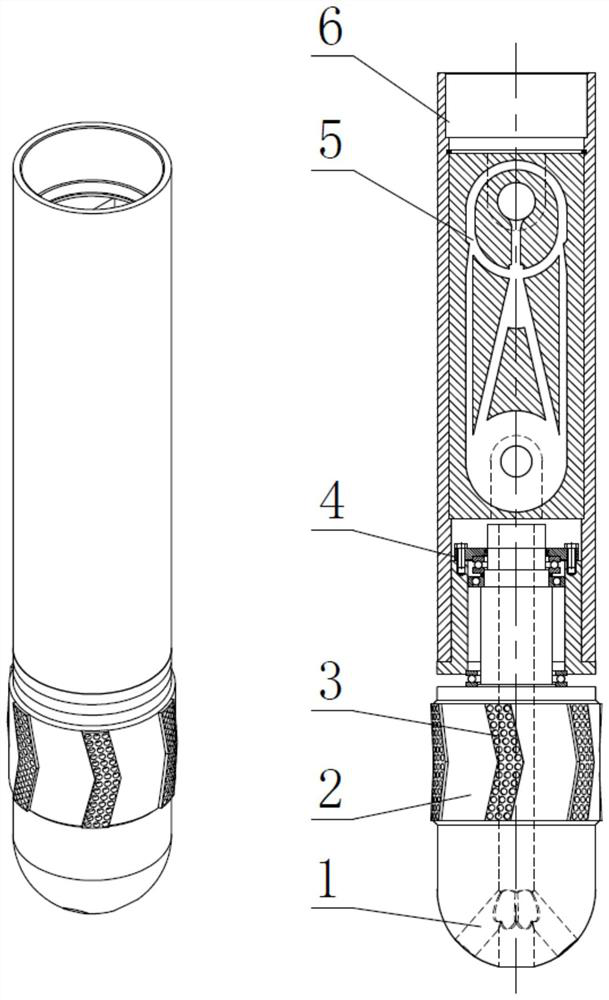

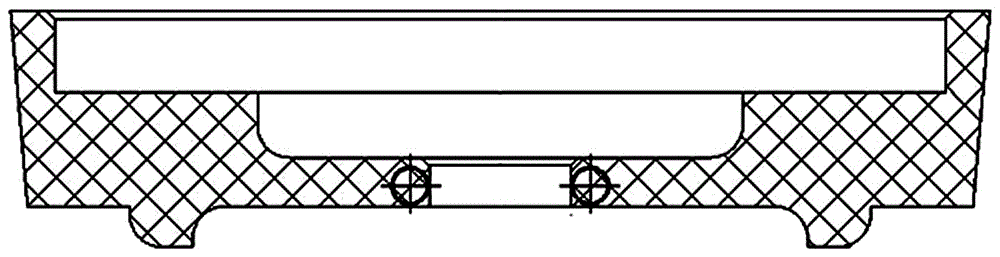

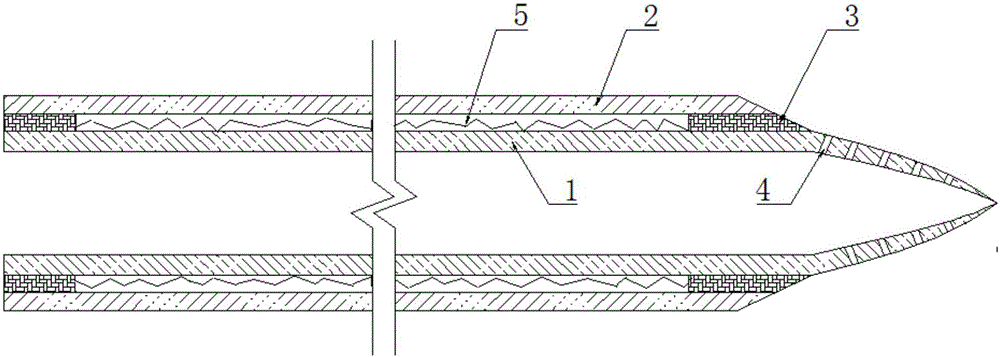

Automatic grouting float collar and float shoe

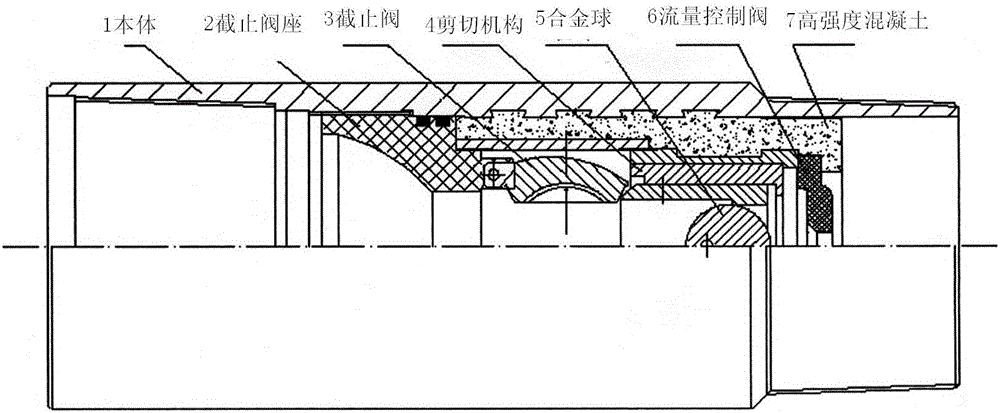

InactiveCN105134128AReduce the amount of returnShorten speedWell/borehole valve arrangementsSealing/packingHigh strength concreteAlloy

The invention discloses an automatic grouting float collar and float shoe. Casing pipe threads are machined at the upper and lower ends of a float collar body (1) or the upper end of a float shoe body (1) and connected with petroleum casing pipes, a guiding cap is installed at the lower end of the float shoe body (1), a stop valve seat (2) is connected to the inner wall of the body (1) through a straight thread, an inclined surface is machined at an inner hole of the stop valve seat (2) as a sealing surface, a stop valve (3) is installed below the stop valve seat (2), the sealing face of a valve body is a spherical surface, a shearing mechanism (4) and a flow control valve (6) are fixedly connected to the portion, on the inner wall of the body (1), below the stop valve seat (2) through high-strength concrete (7) in a sealed mode, the flow control valve (6) is located below the shearing mechanism (4), and an alloy ball (5) is thrown into the shearing mechanism (4). In drilling operation, automatic grouting and automatic flow-limiting designing are performed, in this way, it is effectively avoided that in the process of lowering the casing pipes, surging pressure causes lost circulation, and the product is good in drillability, resistant to corrosion and good in well-cementation quality.

Owner:刘书京

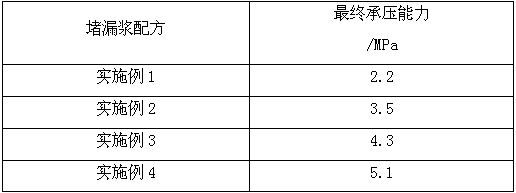

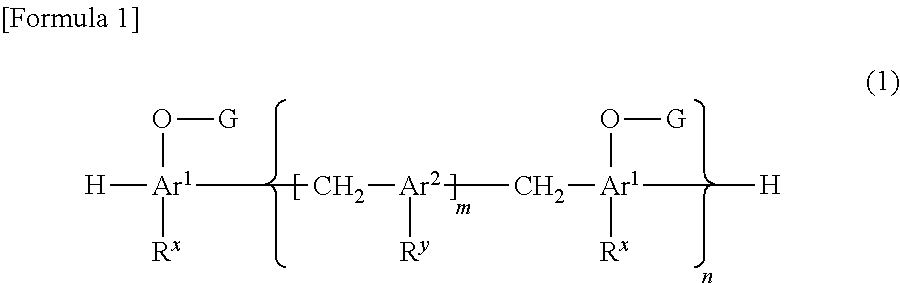

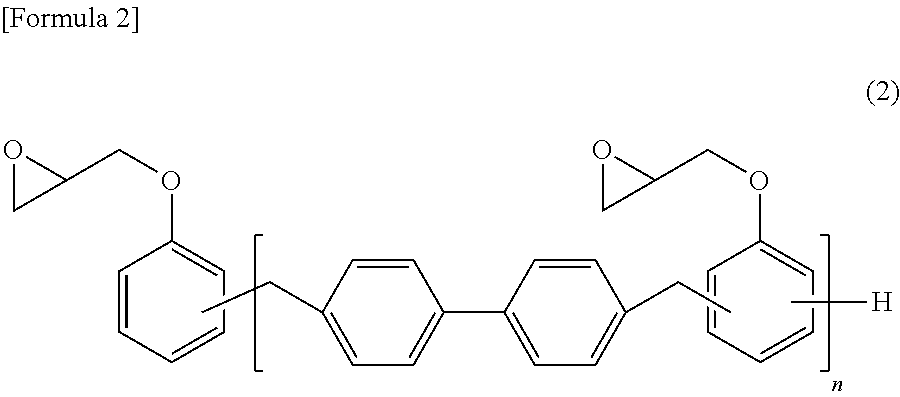

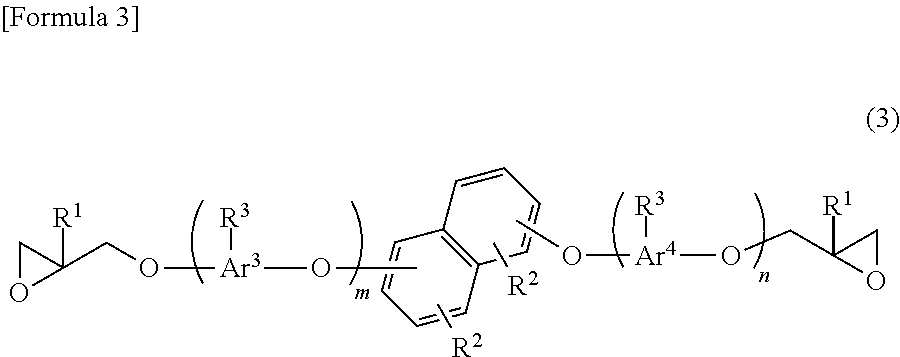

Plugging resin system and application thereof

InactiveCN111793480AImprove liquidityImprove mechanical propertiesDrilling compositionPolymer scienceFirming agent

The invention provides a plugging resin system and application thereof. The plugging resin system is obtained by a reaction of a component A and a component B, the mass ratio of the component A to thecomponent B is 1: 1 to 3: 2, the component A at least comprises epoxy resin, and the component B at least comprises an epoxy resin curing agent. Epoxy resin and a curing agent are mixed and stirred according to different proportions, the mixture is pumped into a casing leakage breaking section, the resin and the curing agent are subjected to addition polymerization reaction within specified timeand under the condition of proper formation temperature to generate a cured product of a net structure, and the purpose of plugging is achieved. And the gelling time can be controlled by the dosages of the components A and B. The compressive strength is greater than 80 MPa, and the chemical plugging construction requirements of the casing damage well are met. According to the plugging resin system, the compressive strength is met, meanwhile, the resin hardness is reduced, the resin toughness is improved, and the resin drillability is improved. And the plug drilling speed can reach 2.5 m / h under the same condition of the plug drilling process, so that the plug drilling time is greatly saved.

Owner:PETROCHINA CO LTD

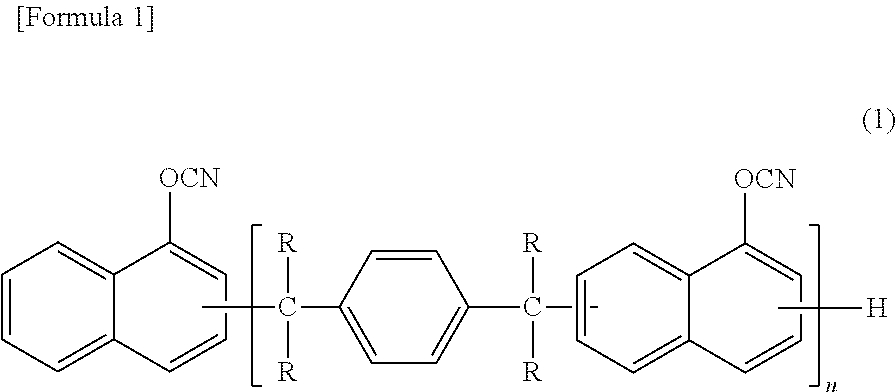

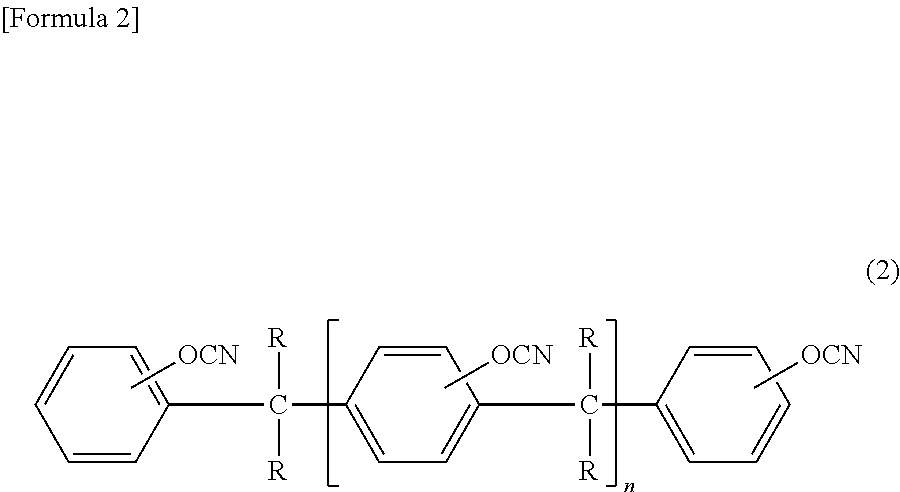

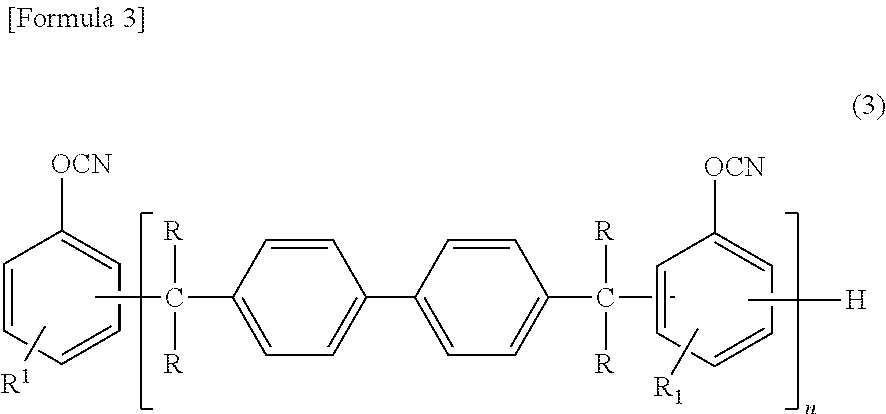

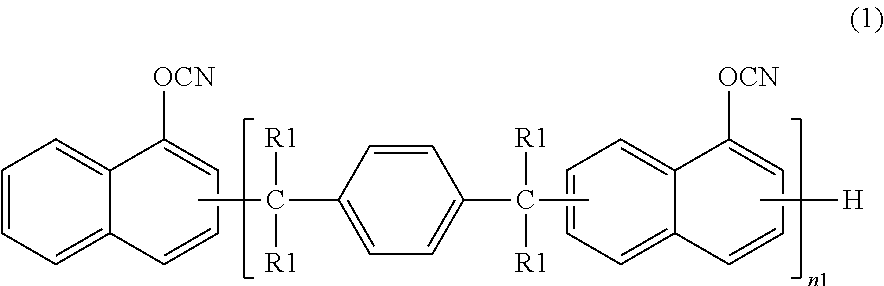

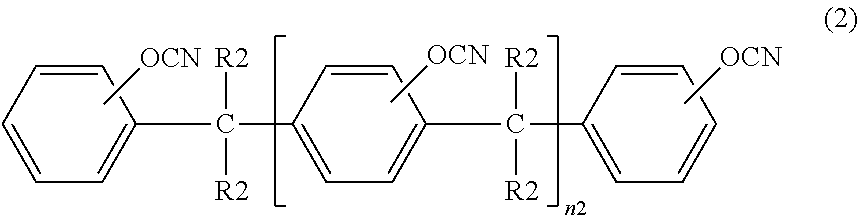

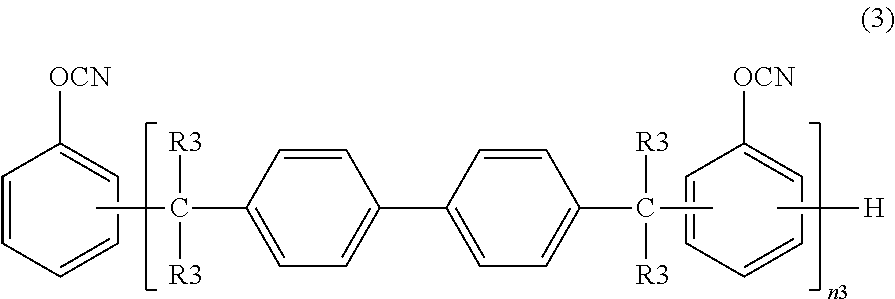

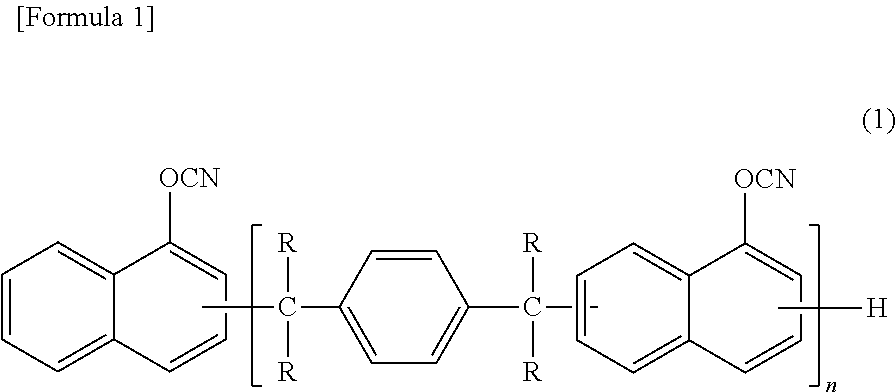

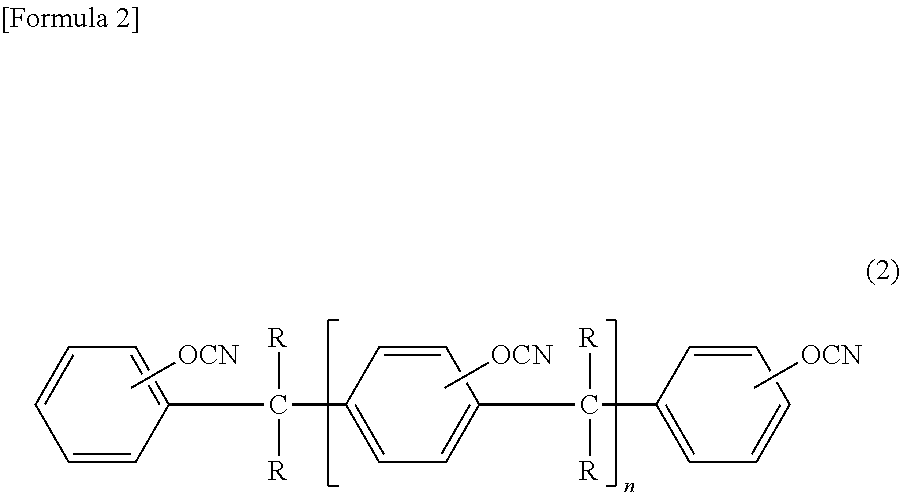

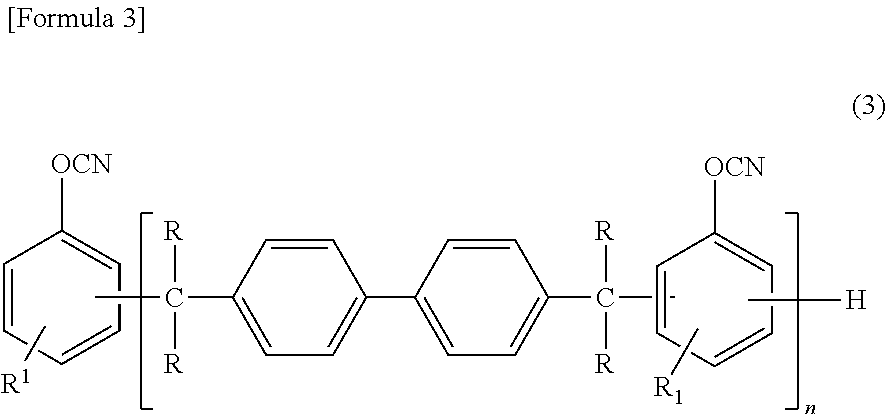

Resin composition, prepreg and laminate

ActiveUS20150050472A1Improve cooling effectImprove the heating effectSynthetic resin layered productsElectrical equipmentMetal foilDiameter ratio

The present invention provides a resin composition which can simply provide, with good reproducibility, a laminate, a printed wiring board, and the like that not only have excellent heat dissipation properties but have good moldability, good mechanical drillability and excellent appearance, and a prepreg, a metal foil-clad laminate, and the like using the same. A resin composition having a cyanate ester compound (A), an epoxy resin (B), a first inorganic filler (C), a second inorganic filler (D), and a molybdenum compound (E), wherein an average particle diameter ratio of the first inorganic filler (C) to the second inorganic filler (D) is in a range of 1:0.02 to 1:0.2.

Owner:MITSUBISHI GAS CHEM CO INC

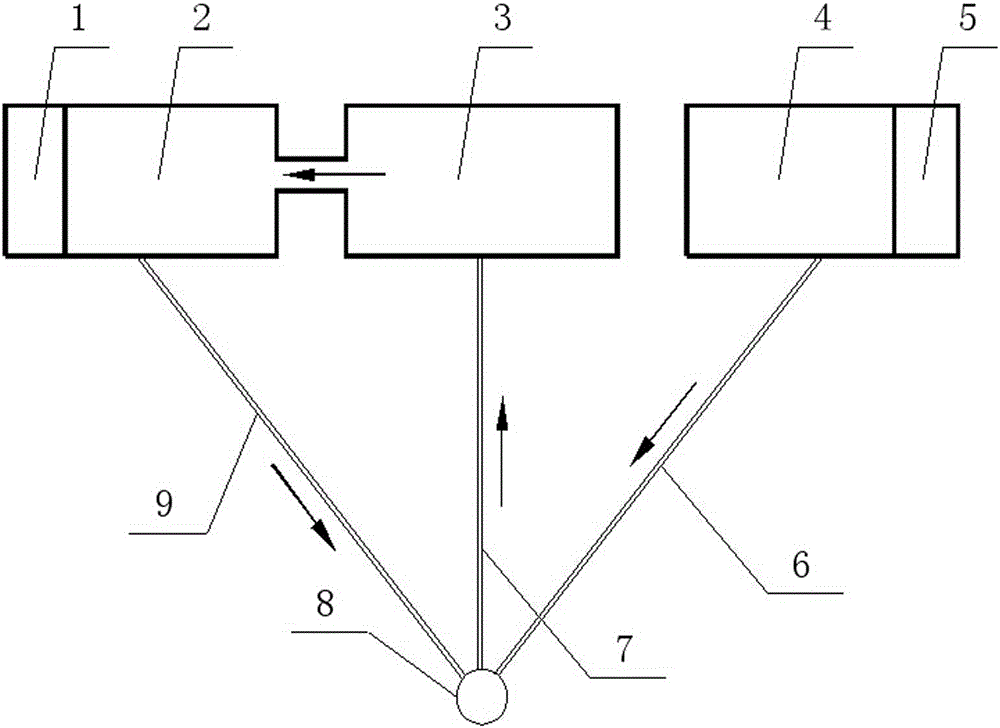

Double-step cutting structure bit

The invention discloses a two-stage cutting bit for petroleum and natural gas drilling, comprising bit body, hard alloy cutting piece, PDC cutting piece and nozzle, where the exposed height of the hard alloy cutting piece is greater than that of the PDC cutting piece, the hard alloy cutting piece composes the first-stage cutting structure and the PDC cutting piece composes the second-stage cutting structure. The distribution density of the hard alloy cutting piece is lower but it can completely cover well bottom, and the distribution density of the PDC cutting piece is equivalent to that of a routine PDC bit. And the two-stage cutting bit can effective drill in a stratum containing gravel layer.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

High-strength consolidation plugging agent

ActiveCN103773340BHas the property of consolidatingHigh strengthDrilling compositionSolubilityCellulose

The invention discloses a high-strength consolidation lost circulation additive, which consists of the following components in parts by weight: 20-40 parts of calcium carbonate, 5-10 parts of silicon dioxide, 1-4 parts of calcium chloride, 0.1-0.4 part of polyanionic cellulose, 0.1-0.2 part of an XC biopolymer, 5-10 parts of aluminum oxide, 3-8 parts of magnesium oxide and 10-16 parts of oil well cement. The lost circulation additive is prepared by carrying out the following steps: adding the components into a kneading machine based on the parts by weight at normal temperature and under normal pressure according to the conventional preparation method; mixing and stirring uniformly; drying; smashing into a powdery product being 0.01-0.2 millimeter in particle size. The high-strength consolidation lost circulation additive has the characteristics of wide raw material source, high strength, strong suspending power, high mobility, high pumpability, condensing and plugging capabilities, high minimum inflation performance, high solubility, high leakage plugging success rate, simple process and safety in construction, is widely applied to petroleum and geological drilling processes, and is particularly to be applied to fractured hard formations and karst cave formations.

Owner:DONGYING TAIER GASOLINE TECH

Resin composition, prepreg, metal foil-clad laminate and printed wiring board

ActiveUS20170145213A1High industrial practicalityImprove electrical characteristicsCircuit thermal detailsSynthetic resin layered productsMetallic foilPolymer science

A resin composition including an inorganic filler (B) having an aluminosilicate (A) having a silicon atom content of from 9 to 23% by mass, an aluminum atom content of from 21 to 43% by mass, and an average particle diameter (D50) of from 0.5 to 10 μm; and any one or more thermosetting compounds selected from the group consisting of an epoxy resin (C), a cyanate compound (D), a maleimide compound (E), a phenolic resin (F), an acrylic resin (G), a polyamide resin (H), a polyamideimide resin (I), and a thermosetting polyimide resin (J), wherein a content of the inorganic filler (B) is from 250 to 800 parts by mass based on 100 parts by mass of resin solid content.

Owner:MITSUBISHI GAS CHEM CO INC

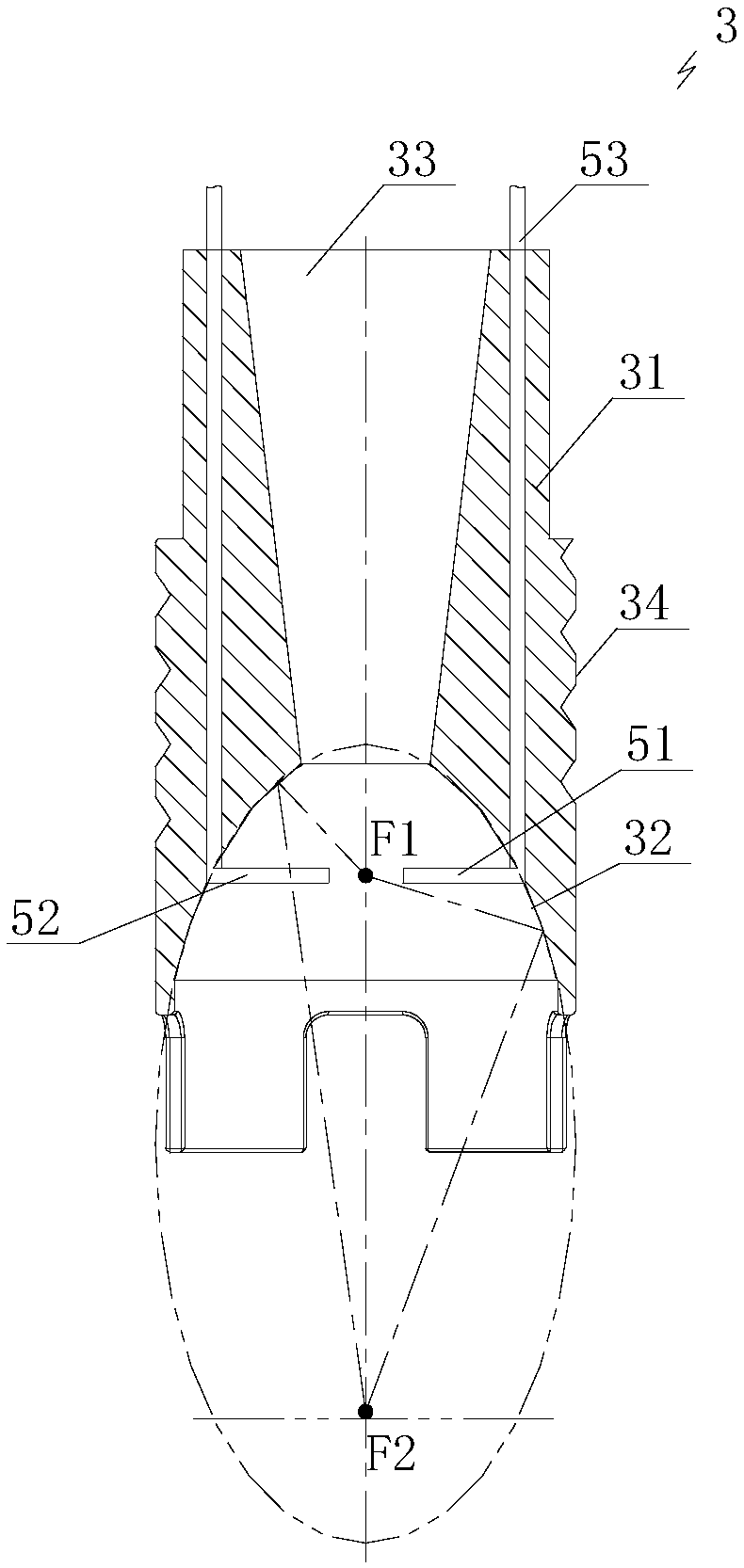

Impact breaking type PDC bit

The invention particularly relates to an impact breaking type PDC bit mainly applied to the field of petroleum drilling. The impact breaking type PDC bit comprises a connector body and a bit body connected with the connector body. A through water-passing cavity is formed in the connector body and the bit body, an upper impact cavity, an impact hammer, an impact cushion block and a rock core breaking hammer which are connected with one another are arranged in the water-passing cavity in sequence from a water inlet to a water outlet, the upper impact cavity is fixed in the connector body, the impact cushion block and the rock core breaking hammer are fixed in the bit body, one end of the impact hammer is fixed in the bit body, the other end of the impact hammer is connected with the upper impact cavity, and conical compacts are arranged at the tail end of the rock core breaking hammer. A traditional shearing rock breaking mode is replaced with the latest conical high-impact-resistance rock breaking mode for the core of the bit, and high-frequency impact is achieved at the core of the bit with pulse energy used by the PDCs, so that the core of the bit works in a rock impact breaking and rock ploughing combined mode, the rock breaking efficiency is improved, the mechanical drilling speed is increased, and the well drilling cost is lowered.

Owner:CHENGDU HUILINGFENG DIAMOND BIT

Resin composition, prepreg and laminate

ActiveUS9944787B2Improve cooling effectImprove the heating effectElectrical equipmentWoven fabricsMetallic foilPolymer science

The present invention provides a resin composition which can simply provide, with good reproducibility, a laminate, a printed wiring board, and the like that not only have excellent heat dissipation properties but have good moldability, good mechanical drillability and excellent appearance, and a prepreg, a metal foil-clad laminate, and the like using the same. A resin composition having a cyanate ester compound (A), an epoxy resin (B), a first inorganic filler (C), a second inorganic filler (D), and a molybdenum compound (E), wherein an average particle diameter ratio of the first inorganic filler (C) to the second inorganic filler (D) is in a range of 1:0.02 to 1:0.2.

Owner:MITSUBISHI GAS CHEM CO INC

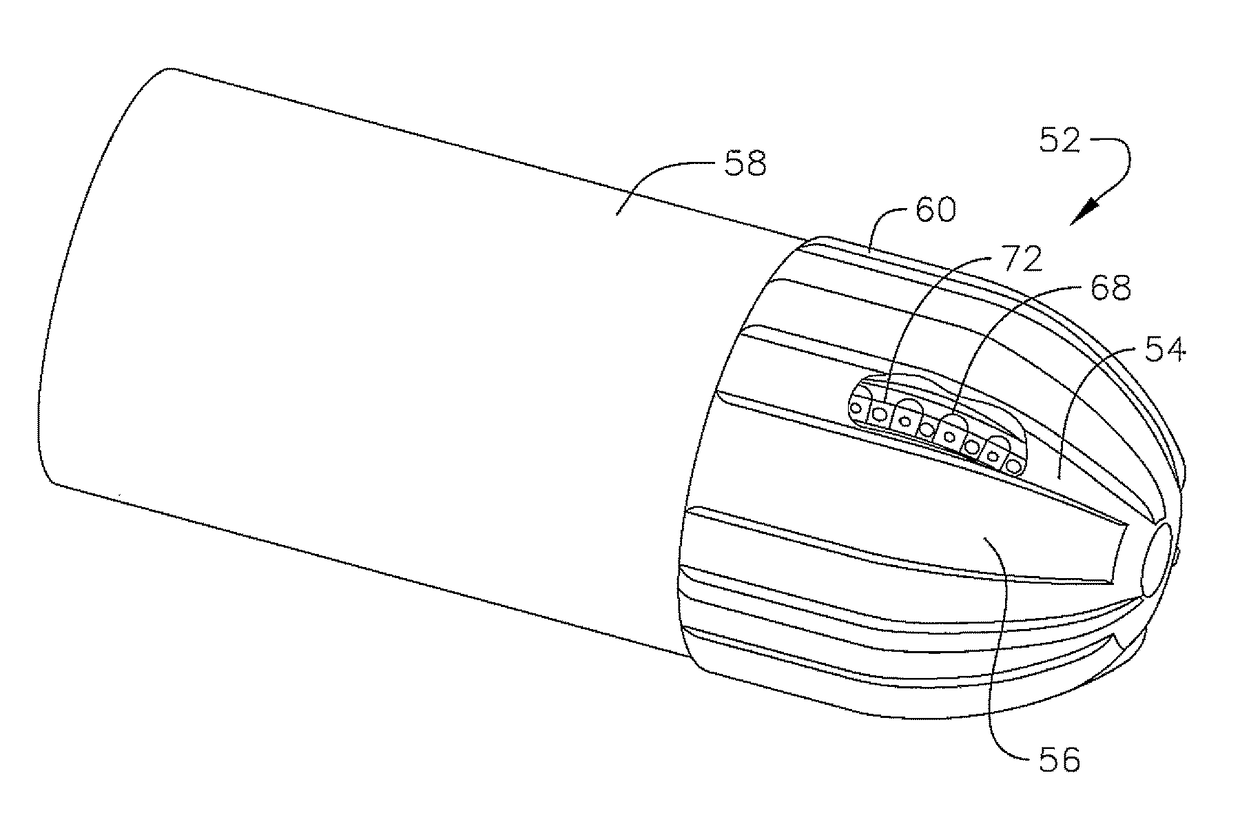

Reamer shoe attachment for flexible casing shoe

A drillable reamer shoe having a reamer body and a nose section having a metallic cage containing a plurality of ceramic inserts made from silicon nitride or aluminum oxide. The drillable reamer shoe is positioned on an end of a flexible wellbore casing guide comprising a tubular body having a stiffness lower than a wellbore casing.

Owner:WWT NORTH AMERICA HLDG

Molybdenum compound powder, prepreg, and laminate

ActiveUS9232648B2Reduce heatImprove drillabilityPigmenting treatmentSynthetic resin layered productsHeat resistanceMetal foil

The present invention provides a novel surface-treated molybdenum compound powder and provides a prepreg, a laminate, a metal foil laminate, a printed wiring board, and the like that have a low thermal expansion coefficient in the planar direction, and excellent drillability, heat resistance, and flame retardancy. The surface-treated molybdenum compound powder of the present invention has at least part of the surface thereof coated with an inorganic oxide, and this is used as a filler.

Owner:MITSUBISHI GAS CHEM CO INC

Downhole hydraulic vibration assisted casing running and well cementation integrated combination tool and using method thereof

PendingCN114183077AGood drillabilityHigh strengthCleaning apparatusLiquid/gas jet drillingWell cementingEngineering

The invention discloses an underground hydraulic vibration assisted casing running and well cementation integrated combination tool and a use method thereof. According to the integrated combination tool, circulation is established to guide fluid to enter the hydraulic self-excitation cavity to generate regular vibration, the sleeve generates axial and radial vibration, and resistance reduction and jam release are achieved; under the action of hydraulic pressure difference, the turbine assembly is pushed to drive the guide head to continuously rotate, and under the cutting action of the alloy teeth, reaming and reaming can be performed, a well wall can be corrected, and a sleeve can be assisted to smoothly enter; in the well cementation process, due to the fact that the outer wall of the tool is designed to be of a rotational flow type structure, cement paste plane flowing can be changed into rotational flow flowing in the cement paste upward returning process, and the cement paste displacement efficiency and flushing efficiency are improved; circulating cement paste flows through the contraction spraying cavity and the nozzle of the self-excitation cavity, so that long-distance high-frequency vibration can be generated, the rheological property of the cement paste is improved, the cement paste is more uniformly hydrated and more compactly solidified, and the well cementation quality is further improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Rotary excavating and drilling method for polymer and bentonite mixed mud

The invention discloses a rotary excavating and drilling method for polymer and bentonite mixed mud. The rotary excavating and drilling method includes the steps that firstly, polymer mud and bentonite mud are prepared in two tanks respectively, the funnel viscosity of the polymer mud is controlled in the range of 30-36 s, the specific gravity of the bentonite mud is controlled to be 1.05, and the pH value of the polymer mud and the pH value of the bentonite mud are controlled in the range of 8-10; secondly, a steel protection cylinder is buried in a conventional method; thirdly, the polymer mud is injected into a hole, and drilling begins to be conducted; fourthly, when leakage happens, the bentonite mud is injected into the hole, and drilling is conducted continuously; fifthly, drilling is stopped for 15-30 min when drilling is conducted to the position above the bottom elevation of the design hole by 50 cm to 100 cm, and then drilling is conducted to the bottom elevation of the design hole; sixthly, mixed mud processing is conducted. The rotary excavating and drilling method has the advantages that the drilling footage speed is high and the mud leakage is small, the comprehensive cost of construction can be obviously reduced, and the technical problems that leakage is large when polymer mud is adopted by a rotary excavating and drilling machine under the conditions of deep and thick sand layers and stratums without underground water and with sparse upper portions and very dense middle and lower portions, and the drilling footage speed is low when bentonite mud is adopted are solved effectively.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

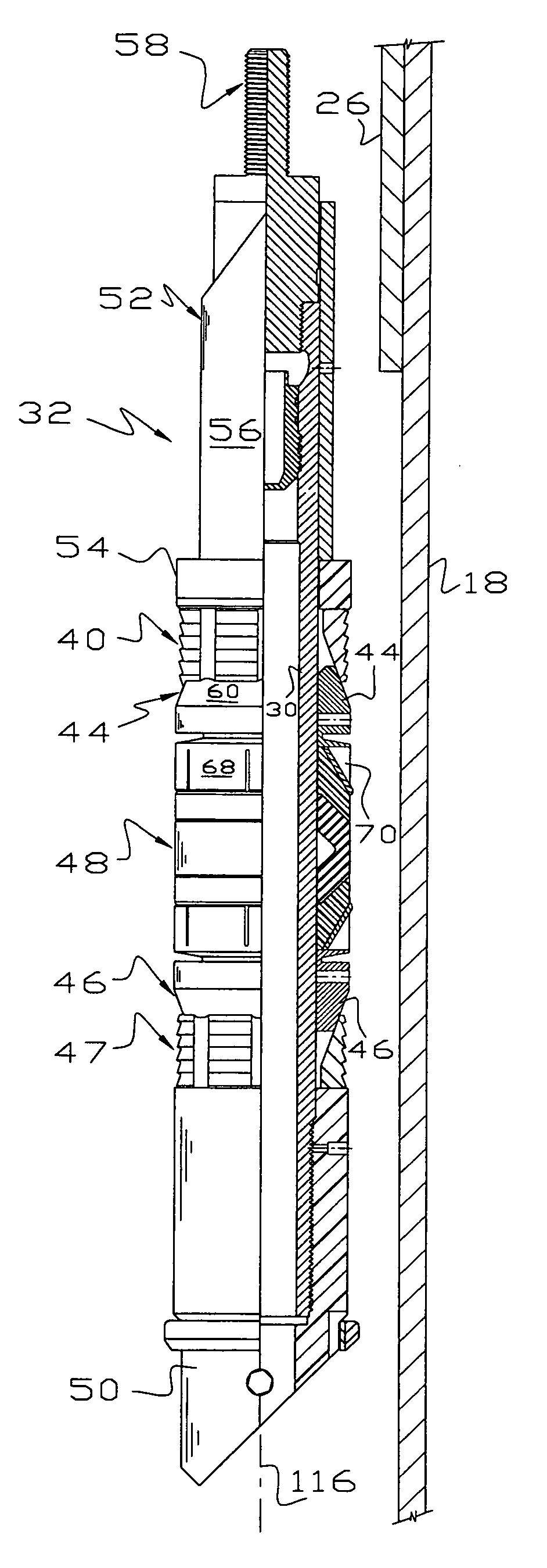

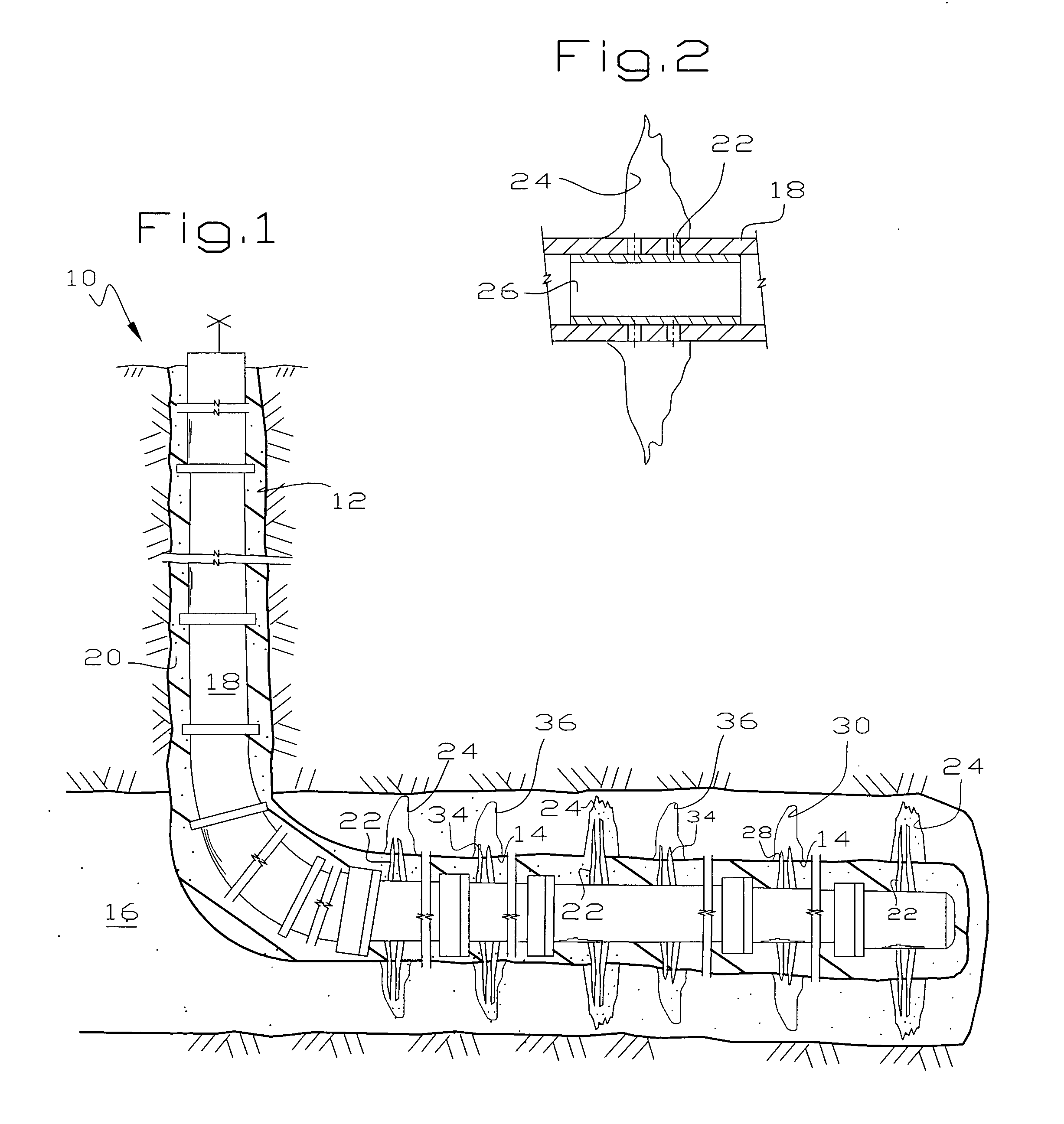

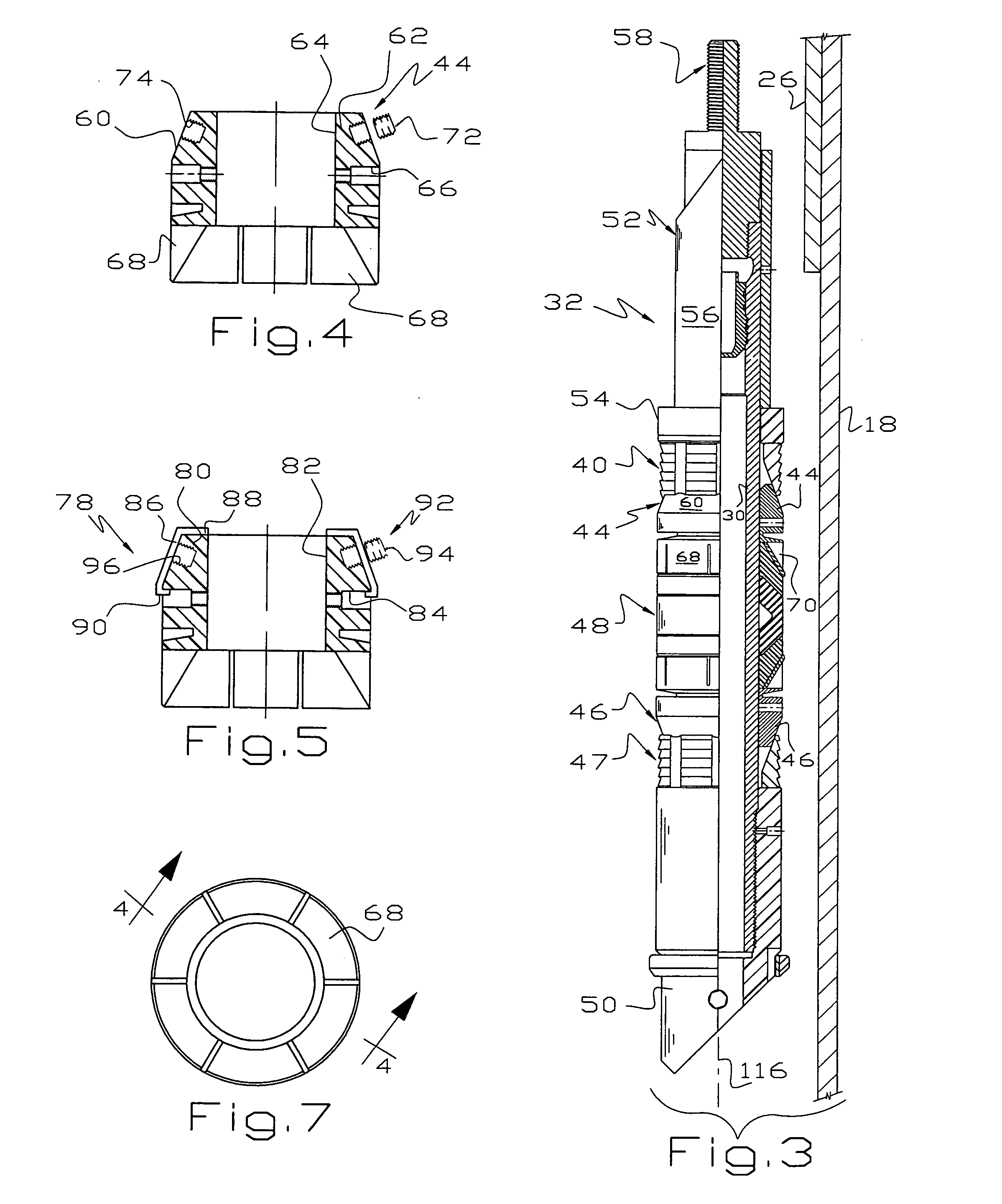

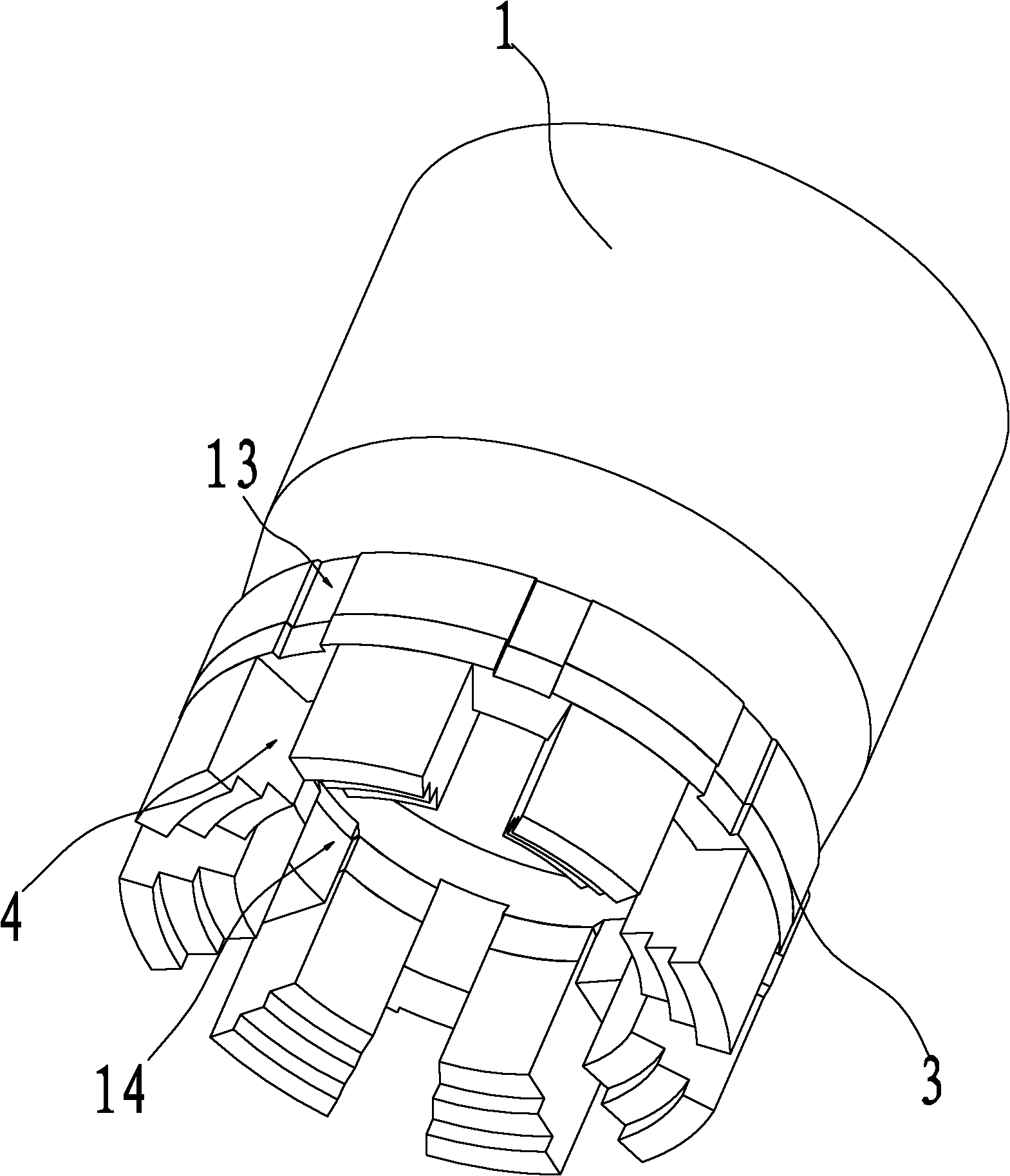

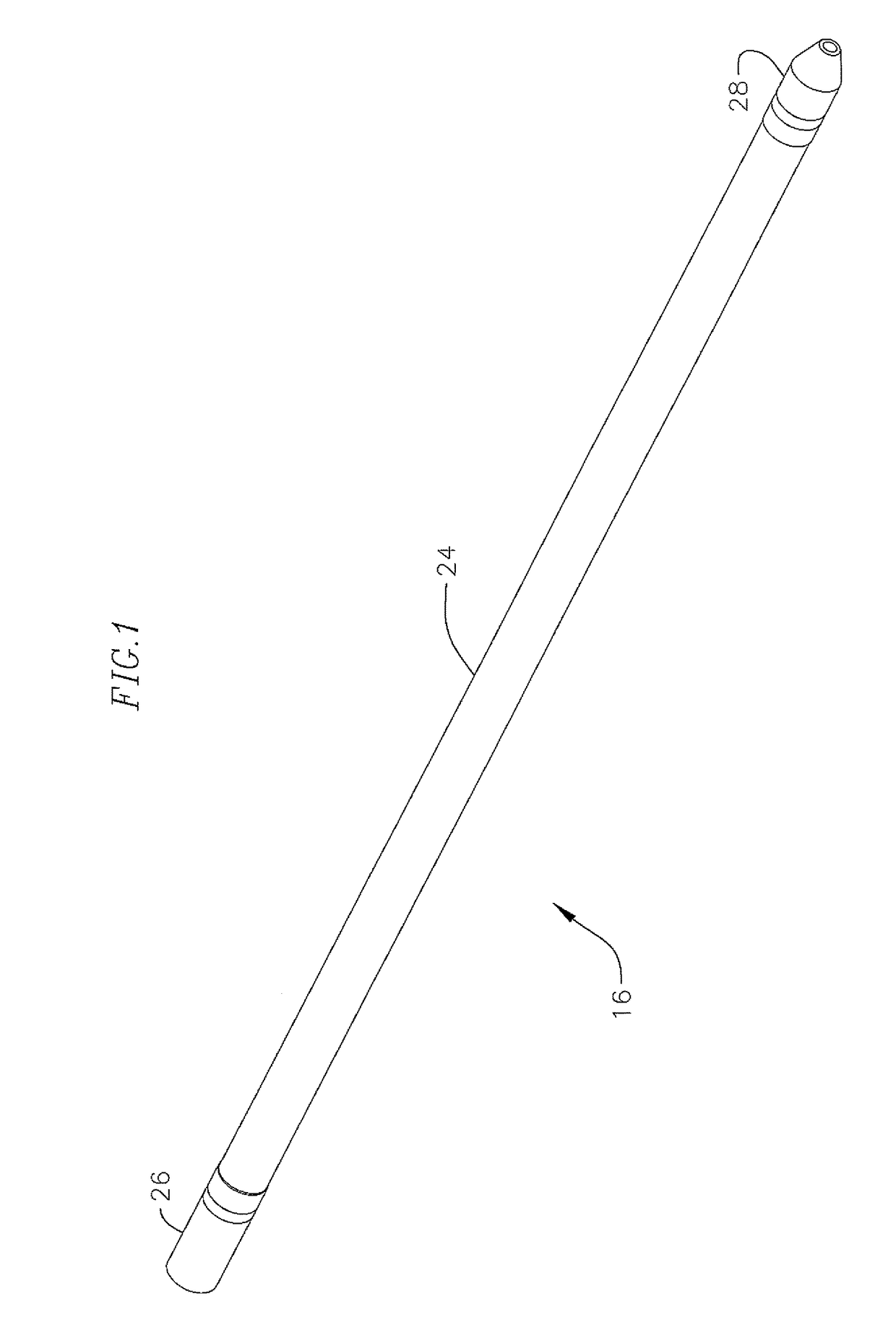

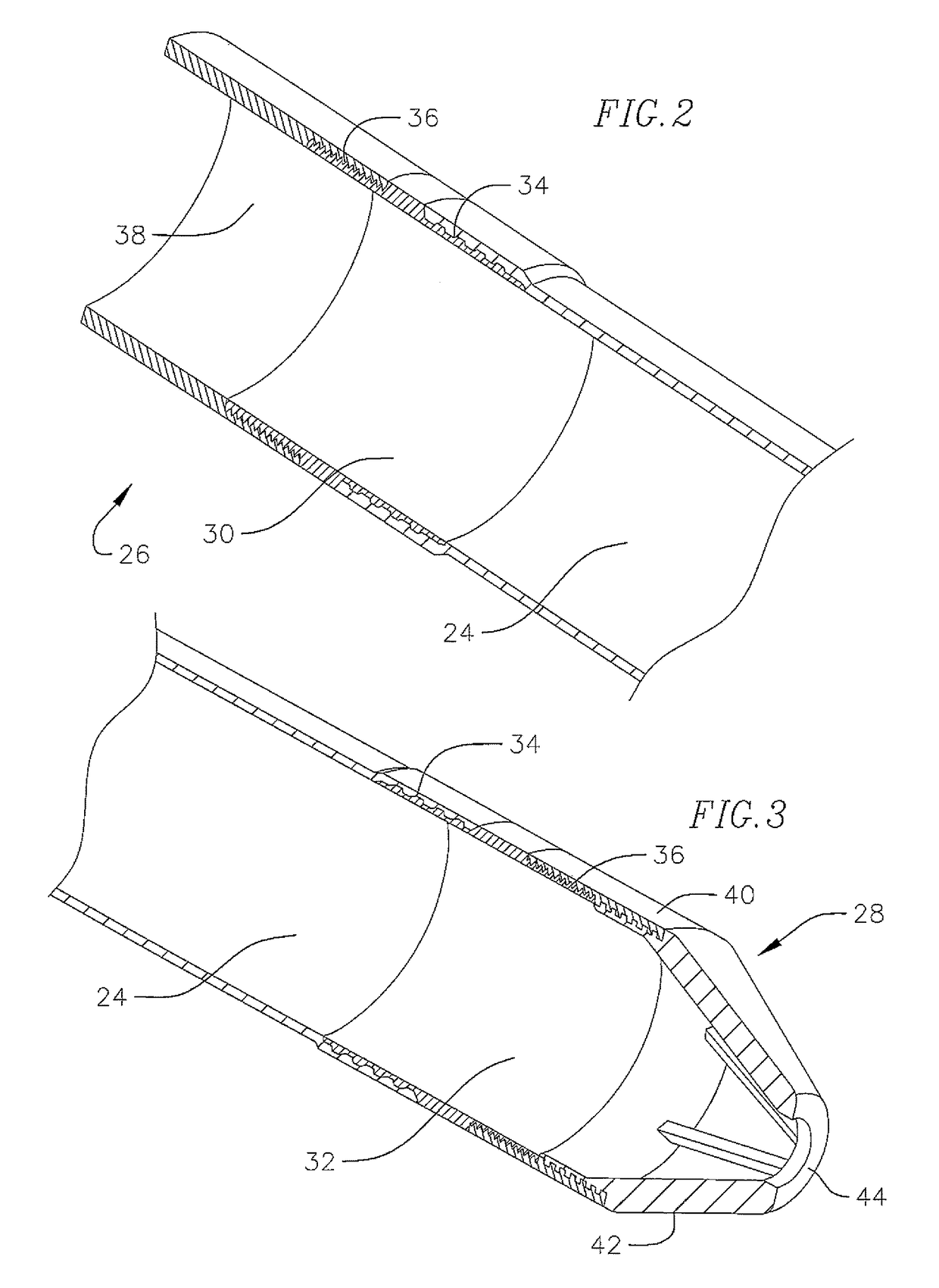

Settable well tool and method

ActiveUS9388662B2Improve drillabilityImprove scalabilityFluid removalSealing/packingEngineeringHardness

A settable down hole includes a set of metal slips which include intersecting zones of weakness in the metal which fracture into a large set of pieces during setting of the tool so the pieces can be circulated out of a well without further reduction in size. One zone of weakness is a closed bore passage extending axially through one or more of the slip segments. An expander cone of increased hardness allows an increased angle on the expander cone and slips.

Owner:NINE DOWNHOLE TECHNOLOLGIES LLC

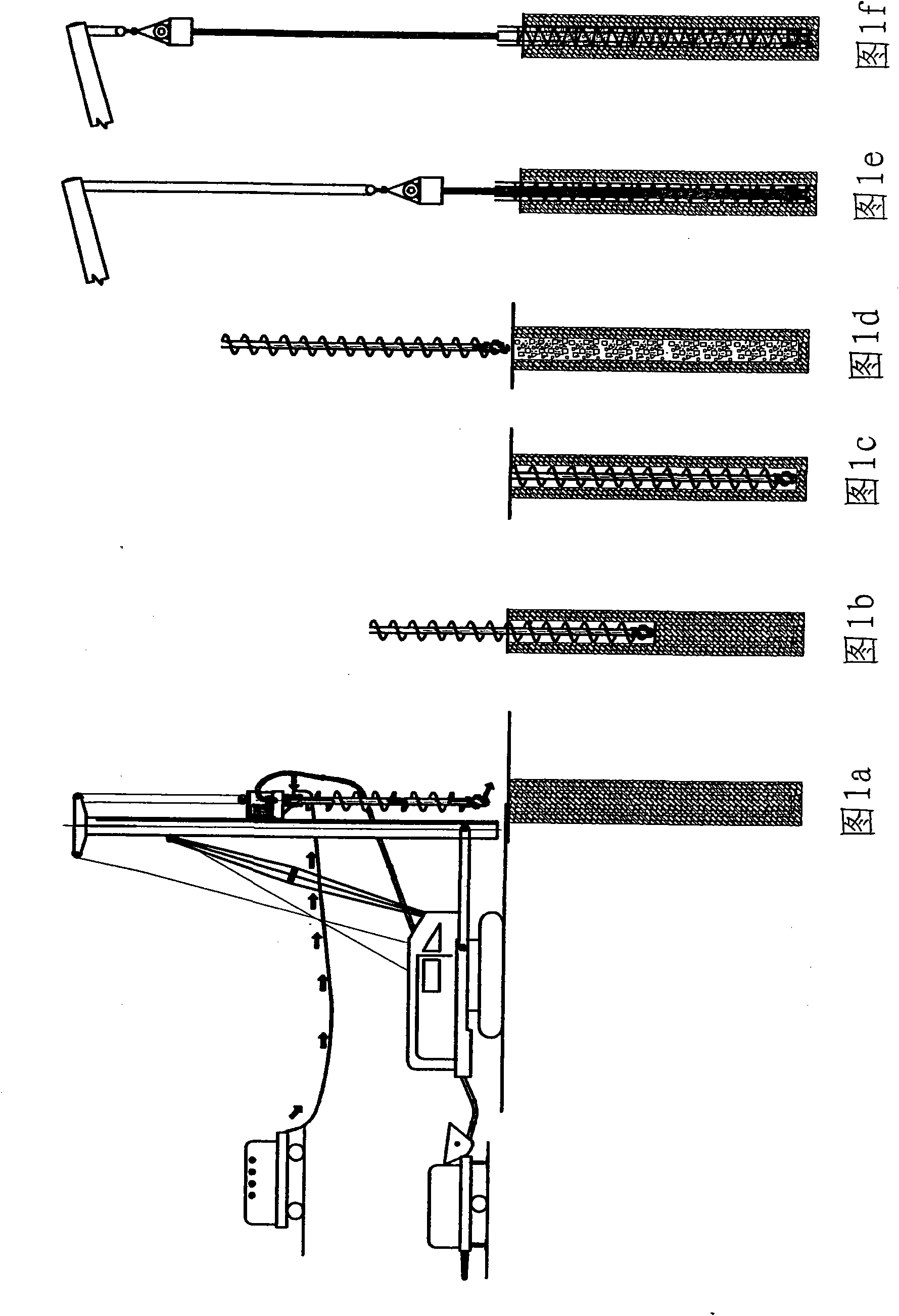

Vibrating bar-inserting long spiral air-cooled drilling rock-socketed pile forming method and equipment

InactiveCN101967826BImprove cooling effectExtend your lifeDrill bitsBulkheads/pilesSocial benefitsGas phase

The invention relates to a vibrating bar-inserting long spiral air-cooled drilling rock-socketed pile forming method implemented in sub-hard rocks, soft rocks and weathered rocks, gravel soil layers or hard soil layers. The method comprises the following construction steps of: a, starting an air compressor, and discharging the compressed air from the air outlet of a long spiral rock-socketed drill bit by a blast pipe, a fluid director and an air pipe attached to a spiral drill rod; b, injecting the compressed air to cool the drill bit at the same time of long spiral drilling; c, reaching the designed hole depth; d, pouring concrete into the pile hole by using a concrete conveying pump; and e, vibrating and inserting a steel bar cage to the designed depth in a main rib pulled mode by adopting a vibrating hammer. Because the air can be continuously supplied to the drill bit, the drill bit is effectively cooled and the service life of the drill bit is greatly prolonged, and meanwhile, the drillability of the gas phase in the three-phase ratio of the soil is improved; therefore, the green construction technical process for a vibrating bar-inserting drilling pressure pouring pile can be adopted in the sub-hard rocks, the soft rocks and the weathered rocks, the gravel soil layers or the hard soil layers; and the method increases the quality reliability, reduces the consumption of various materials and improves the construction efficiency, so the method has remarkable economic benefit and social benefit.

Owner:李式仁

Carrier-attached copper foil, laminate, laminate producing method, printed wiring board producing method, and electronic device producing method

ActiveUS10349531B2Improve drillabilityPrinted circuit aspectsElectrical equipmentInter layerHigh density

Provided herein is a carrier-attached copper foil having desirable laser drillability through an ultrathin copper layer, preferred for fabrication of a high-density integrated circuit substrate. The carrier-attached copper foil includes an interlayer and an ultrathin copper layer that are provided in this order on one or both surfaces of a carrier. The surface roughness Sz and the surface roughness Sa on the interlayer side of the ultrathin copper layer satisfy Sz≤3.6 μm, and Sz / Sa≤14.00 as measured with a laser microscope in case of detaching the carrier from the carrier-attached copper foil according to JIS C 6471 after the carrier-attached copper foil is laminated to an insulating substrate from the ultrathin copper layer side under a pressure of 20 kgf / cm2 and heated at 220° C. for 2 hours. GMD, which is a 60-degree glossiness of the ultrathin copper layer surface on the interlayer side in MD direction, satisfies GMD≤150 in case of detaching the carrier from the carrier-attached copper foil according to JIS C 6471 after the carrier-attached copper foil is laminated using the same procedure.

Owner:JX NIPPON MINING & METALS CORP

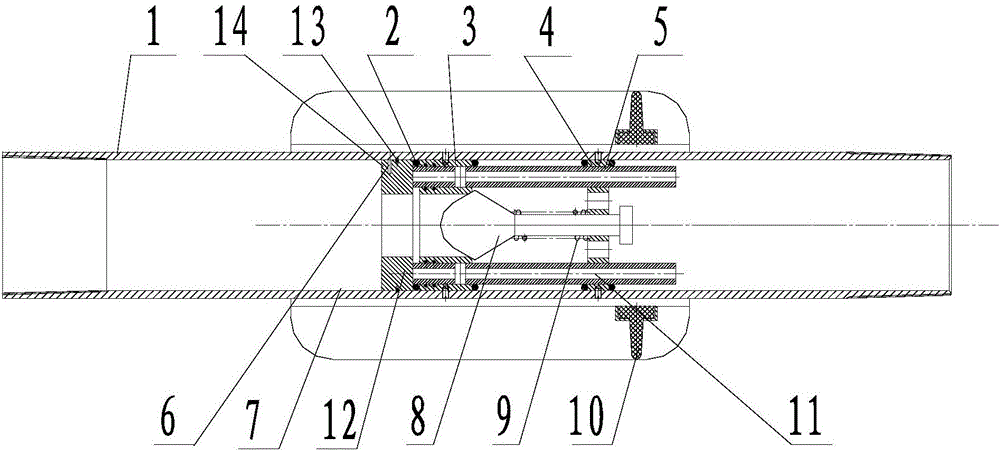

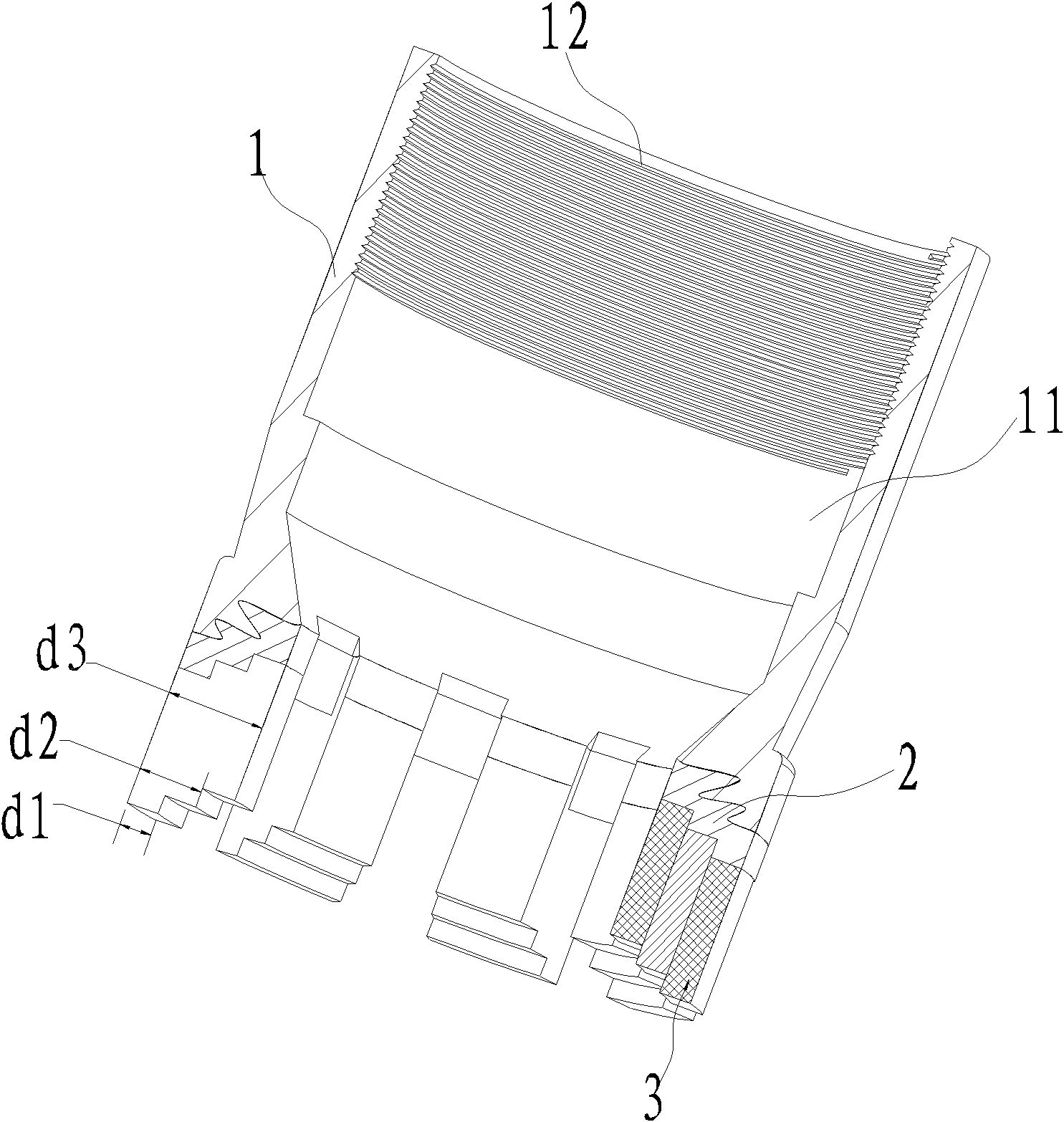

Casing pipe automatic grouting bypass-type bump-pressure device

ActiveCN106499362AImprove centeringImprove replacement efficiencyCleaning apparatusSealing/packingWell cementingEngineering

The invention relates to a casing pipe automatic grouting bypass-type bump-pressure device, and aims to solve the problem that work intensity and products are increased due to the fact that existing devices used in cement job on an oil field need to be installed respectively. The casing pipe automatic grouting bypass-type bump-pressure device is characterized in that an upper guide holder (3) and a lower holder (4) are fixed on the inner wall of an outer cylinder (1) through screws, flow control valves (5) are arranged in guide holes of cross sections of the upper guide holder (3) and the lower holder (4), and a self-filling hole (11) is formed in an axial center of the flow control valves (5); the left end of the flow control valves (5) is connected to a baffle (14), a through hole is formed at the center of the baffle (14), an elastic clamp spring is arranged on the outer wall of the baffle (14), and the baffle (14) is fixed on the outer cylinder (1) through a shear pin (6). According to the casing pipe automatic grouting bypass-type bump-pressure device, a cement job operation procedure is simplified, work intensity of operating personnel is lowered, and thus work time is reduced.

Owner:王震

Leak-proof leak-stopping reinforcing agent

InactiveCN110734749AGood coagulation and reinforcementImprove reinforcement effectDrilling compositionCelluloseCalcium silicate

The invention discloses a leakage-proof leak-stopping reinforcing agent, which is prepared from the following components in parts by weight: 3 to 12 parts of sodium silicate; 1-6 parts of potassium silicate; 10 to 20 parts of calcium silicate; 0.1 to 0.5 part of polyacrylamide PAM; 10 to 25 parts of calcium hydroxide; 0.1 to 1 part of low viscosity polyanionic cellulose PAC-LV; 0.1 to 1 part of water-soluble polyamide resin powder; 2-6 parts of water-soluble urea formaldehyde resin powder. A preparation method comprises the following steps: sequentially adding the above substances into a container according to the components and contents at normal temperature and normal pressure by using a conventional preparation method, uniformly mixing and stirring, and drying, crushing or sieving to obtain a granular product with the particle size of 0.05-0.8 mm. The preparation method has the advantages that the raw materials are widely avaiable; the process is scientific and simple, constructionis safe, and certain coagulation capacity is achieved; single particles are solidified together; on the basis of early-stage filling, the setting and consolidation performance of leakage well walls can be improved, the leakage stratum well walls can be reinforced, the good characteristic of repairing broken easily-leaked stratum well walls is achieved, the compounding performance with different types of plugging slurry is good, the repairing and reinforcing performance of the plugging slurry is achieved, and the leakage-proof leak-stopping reinforcing agent can be widely applied to petroleum and geological drilling engineering.

Owner:DONGYING TAIER GASOLINE TECH

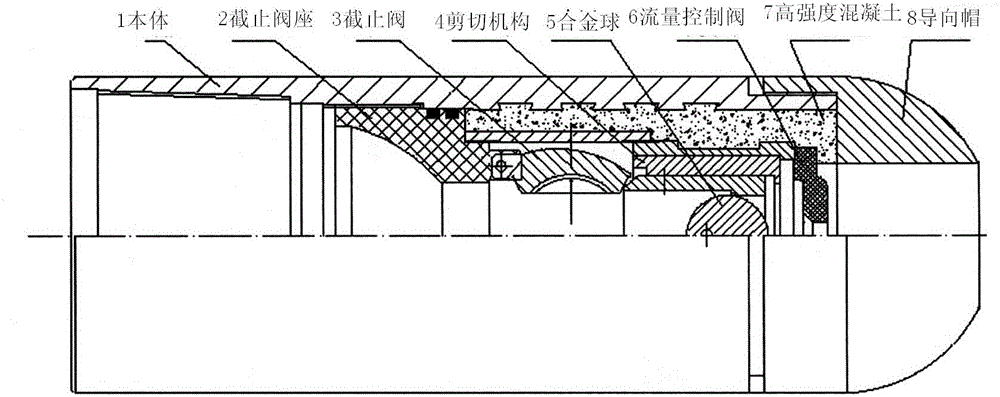

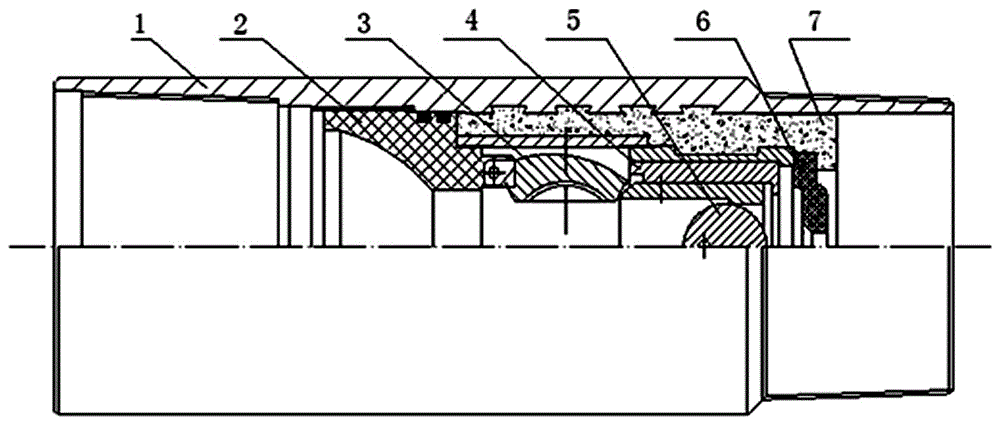

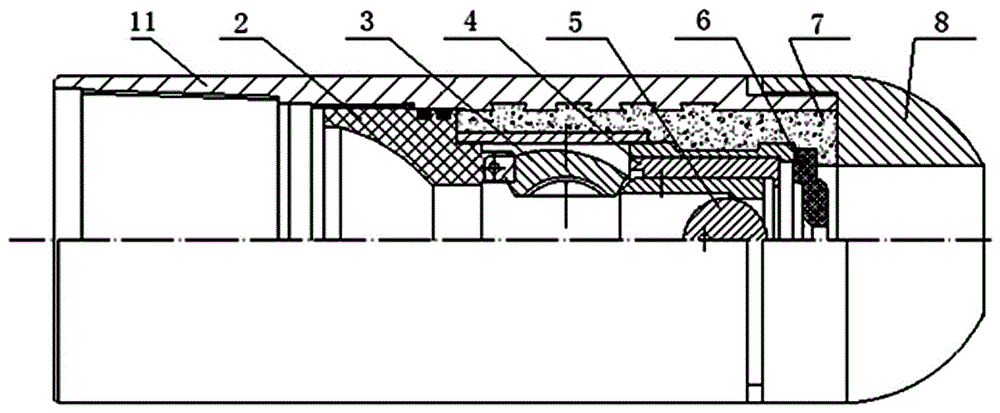

Automatic grouting hoop floating shoes

ActiveCN105696968BShorten speedReduce shock pressureWell/borehole valve arrangementsSealing/packingHigh strength concreteAlloy

The invention discloses an automatic grouting float collar and float shoe. Casing pipe threads are machined at the upper and lower ends of a float collar body (1) or the upper end of a float shoe body (1) and connected with petroleum casing pipes, a guiding cap is installed at the lower end of the float shoe body (1), a stop valve seat (2) is connected to the inner wall of the body (1) through a straight thread, an inclined surface is machined at an inner hole of the stop valve seat (2) as a sealing surface, a stop valve (3) is installed below the stop valve seat (2), the sealing face of a valve body is a spherical surface, a shearing mechanism (4) and a flow control valve (6) are fixedly connected to the portion, on the inner wall of the body (1), below the stop valve seat (2) through high-strength concrete (7) in a sealed mode, the flow control valve (6) is located below the shearing mechanism (4), and an alloy ball (5) is thrown into the shearing mechanism (4). In drilling operation, automatic grouting and automatic flow-limiting designing are performed, in this way, it is effectively avoided that in the process of lowering the casing pipes, surging pressure causes lost circulation, and the product is good in drillability, resistant to corrosion and good in well-cementation quality.

Owner:京鸿石油钻采工程技术有限公司

Diamond impregnated wire line coring geological bit and manufacturing method thereof

InactiveCN102128013BIncreased vortex grinding forceImprove drillabilityDrill bitsConstructionsPigeon toeLatitude

The invention discloses a crown and a steel junction surface of a hierarchical internal cone shaped vortex-type centering pilot diamond impregnated wire line coring geological bit with symmetrical pigeon-toed toes in and a manufacturing method of the bit. The bit comprises a working layer of the diamond bits, a bit steel body, middle isolation scraps and connecting layer materials. The bit has the following beneficial effects: assembly and configuration of the whole set of bit tools of the bit designed in the invention take pairing of each pair of bit tools as the pigeon-toe forming mode; the pairing formula of the bit tools is characterized by female / male layering, symmetry and balance; the bit tools are positioned, arranged and seated to form the internal cone shape; the situation of layered distribution and preset synchronous diminishing of the bit tools forms the preset function of using gentle methods and force; the crown is shaped like vortex-type cone-preserving pigeon-toe (the preset pigeon-toe is transient equilibrium buffer and synchronous compensation in place of dynamic landing of the bit); the vortex-type pilot centering force is continuously obtained and the continuous vortex-type pilot centering force is the concept of the pigeon-toed toes in; the toes in are effective restraints for controlling advance; the toes in need to control the vertical effective latitude of the bore diameter when being applied in the drilling bit; and the mode of cushioning the toes in with pigeon-toes to control centering pilot is taken as the first key point.

Owner:FOSHAN NANHAI RUILICHEN TOOL

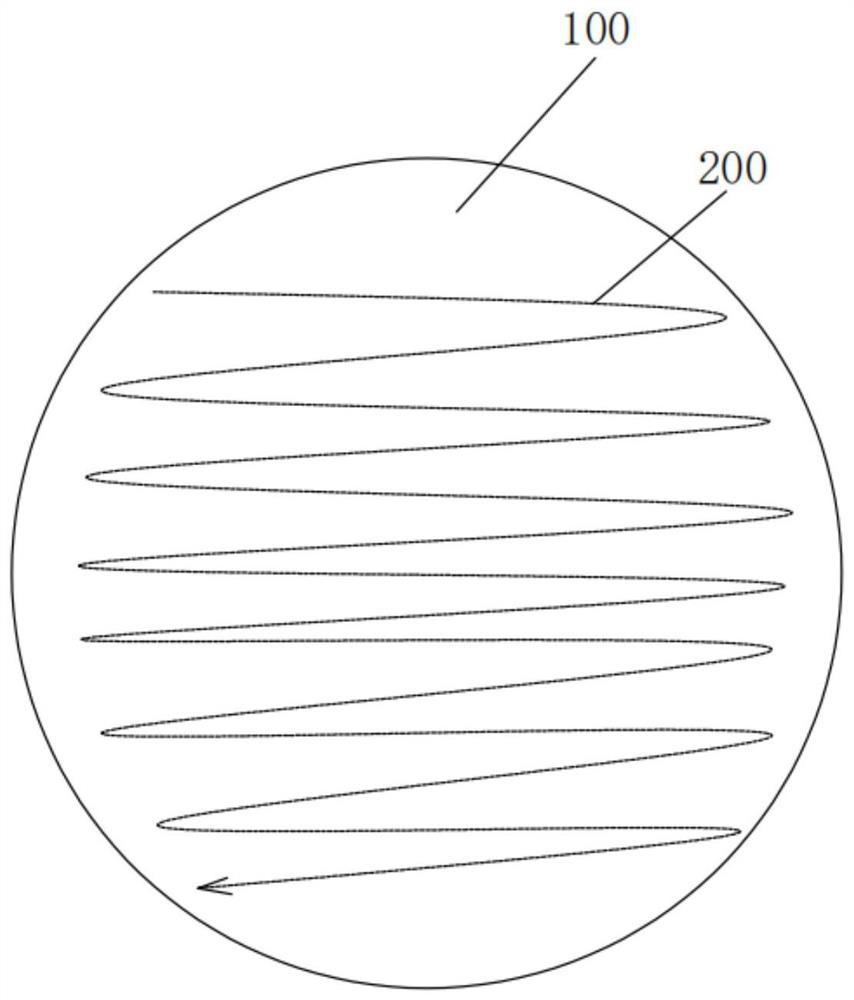

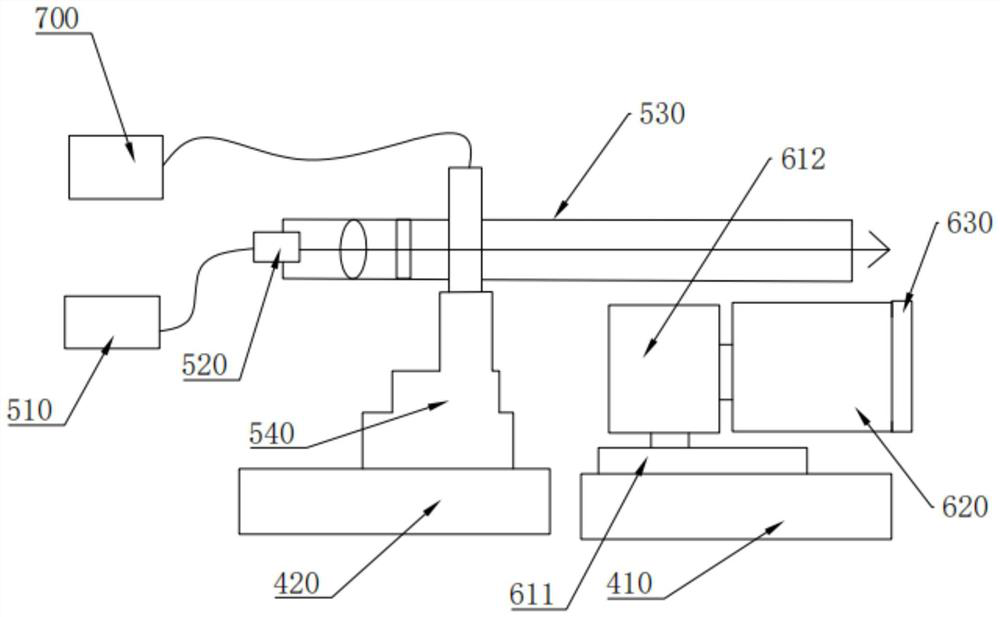

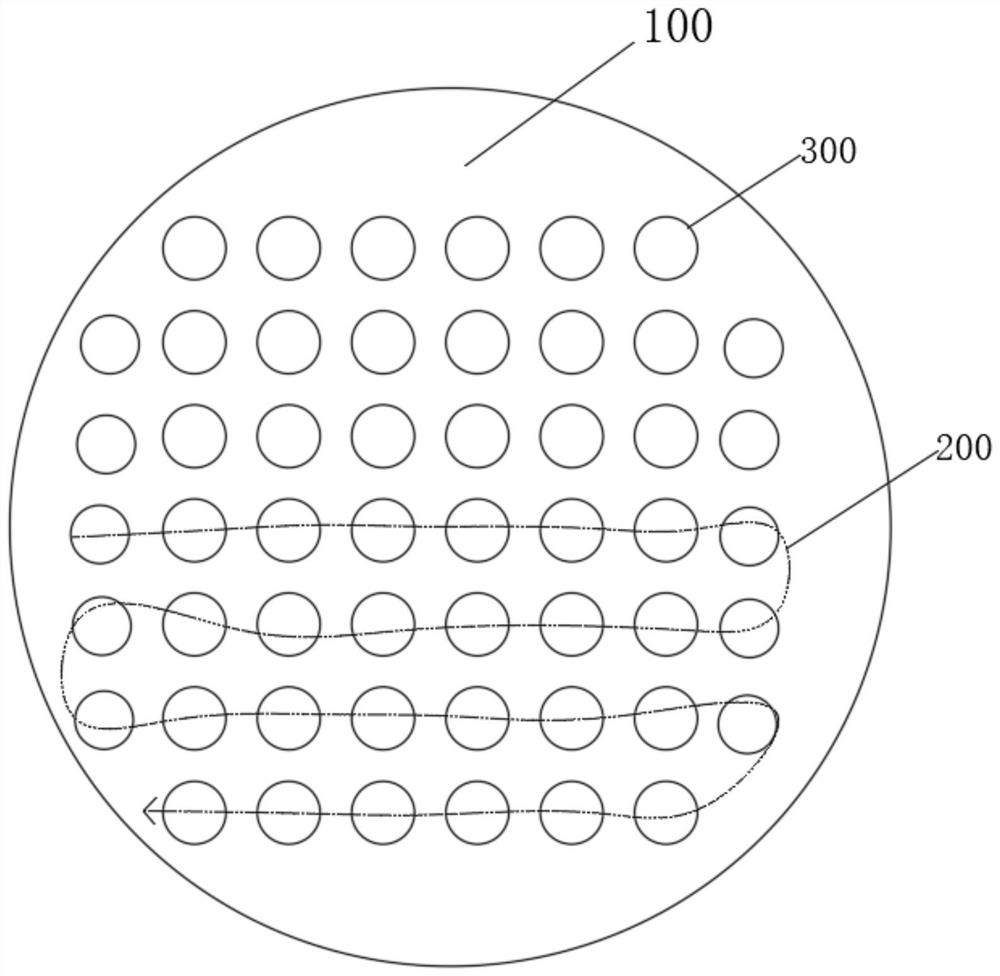

Laser shield tunneling machine and tunneling method

PendingCN112539069AReduce intensityImprove drillabilityTunnelsShield tunnelingMechanical engineering

The invention discloses a laser shield tunneling machine and a tunneling method. The laser shield tunneling machine comprises a laser perforating device and a tunneling device, wherein the laser perforating device is used for perforating a working face, the tunneling device is used for tunneling the working face perforated by the laser perforating device, and the laser perforating device and the tunneling device are of an integrated structure or a split structure. According to the laser shield tunneling machine and the tunneling method, rock array type perforation is conducted through the laser perforating device, working face rock is pre-crushed, the drillability of the working face rock is improved, tunneling is conducted through the tunneling device, the tunneling efficiency is improvedunder the condition that the rock strength is reduced, meanwhile, abrasion of a drill bit is reduced, molten slag in a jetting barrel is blown away through compressed air, a laser output head can bewell protected, the single-light-source multi-machining-head can be adopted for parallel perforation in a light source rapid switching mode, or the multi-light-source multi-machining-head can be adopted for simultaneous perforation, and the tunneling efficiency is further improved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

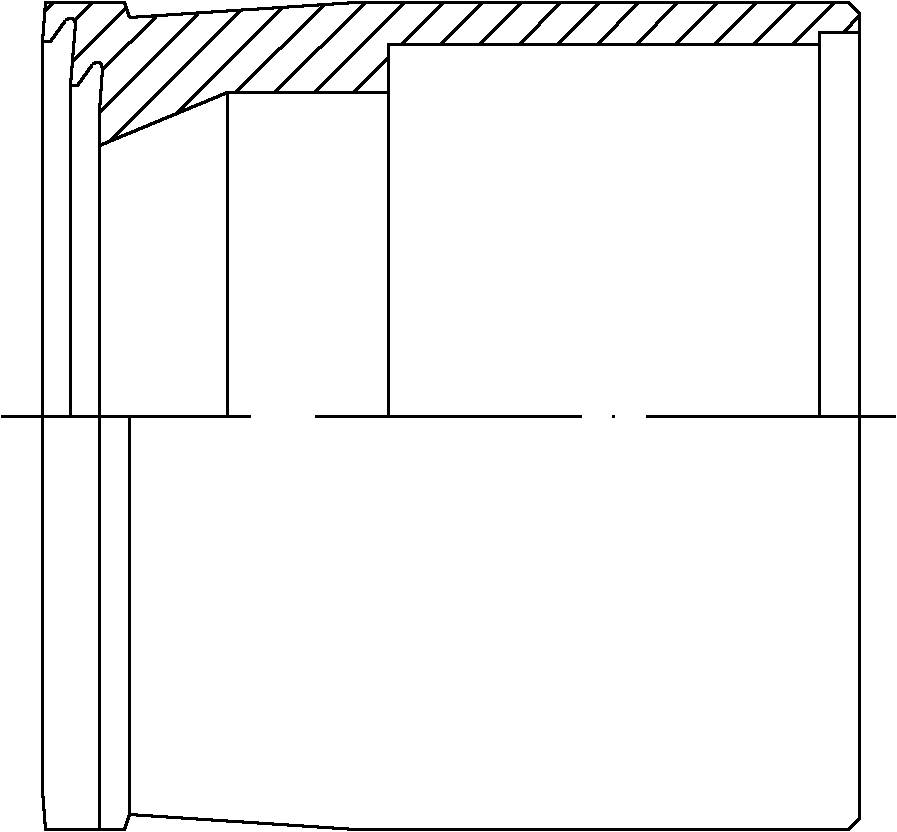

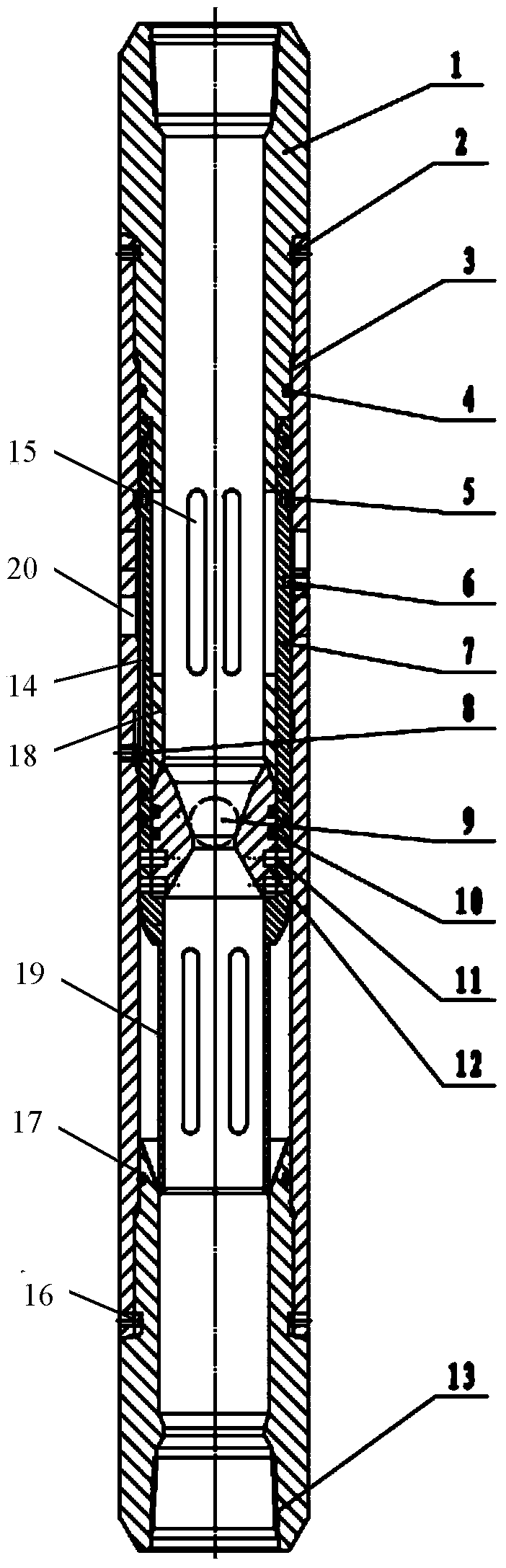

Oil and gas well staged fracturing drillable ball sliding sleeve

ActiveCN102493784BIncrease productionImprove the mining effectFluid removalWell/borehole valve arrangementsEngineeringLow density

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Resin composition, prepreg and laminate

ActiveUS9955573B2Low thermal expansion coefficientImprove drillabilitySynthetic resin layered productsPrinted circuit aspectsSolid componentMohs scale of mineral hardness

It is an object to provide a prepreg for a printed laminate that has a low thermal expansion coefficient in the planar direction, excellent drillability, and further excellent heat resistance and flame retardancy, and a laminate and a metal foil-clad laminate. A resin composition according to the present invention includes a molybdenum compound (A); an epoxy resin (B); a curing agent (C); and an inorganic filler (D), wherein a Mohs hardness of the inorganic filler (D) is 3.5 or more, and a content of the inorganic filler (D) is 40 to 600 parts by mass based on 100 parts by mass of a total of resin solid components.

Owner:MITSUBISHI GAS CHEM CO INC

New type grouting device with fixed point control area

ActiveCN103806920BReduce the amount of re-drillingReduce the frequency of drilling accidentsUnderground chambersTunnel liningEngineeringFrequency of occurrence

The invention discloses a novel fixed point area control grouting device which comprises an auxiliary pipe, a grouting pipe and an injection hole formed in the grouting pipe. The injection hole is circular or oval or square or rectangular. One end of the grouting pipe is conic. The grouting pipe is directly inserted into the auxiliary pipe and located in the auxiliary pipe expect for the conic end. The gradient between the end of the auxiliary pipe and the horizontal plane is 15 degrees to 30 degrees. The novel fixed point area control grouting device has the advantages that a key point weak area can be directly reinforced, the re-drilling amount is reduced, the frequency of occurrence of drill holding accidents is greatly reduced, a construction period is shortened, the grouting cost is saved, and the grouting effect is improved; the novel fixed point area control grouting device is simple in structure and suitable for being manufactured in a site, the grouting pipe can be recycled, a plastic pipe is low in price, and the cost of the novel fixed point area control grouting pipe is remarkably reduced; the auxiliary pipe remaining in a drill hole is good in drillability, the drill hole can be reused, and following drill hole construction is not influenced.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com