Rotary excavating and drilling method for polymer and bentonite mixed mud

A technology of bentonite mud and drilling method, which is used in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of large consumption of single-hole mud, increased construction comprehensive cost, long time for single-hole drilling, etc. The effect of reducing mud leakage, improving drillability and reducing overall construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples serve to illustrate the invention.

[0025] The site of a certain project is located in Yulin City, Shaanxi Province, China, on the edge of the Mu Us Desert. It is designed as rotary drilling bored piles, with a project volume of about 2,800 piles, a pile diameter of 800mm, and a pile length between 17m and 43m. The fine sand layer of the site is well sorted and the soil quality is uniform. The upper fine sand layer is medium-dense to dense, the middle and lower fine sand layer is dense, and the pile ends enter the ③ layer and ④ layer of dense fine sand layer respectively. greater than 70 meters. Adopt rotary drilling method of the present invention to specifically comprise the following steps:

[0026] ⑴Mud preparation

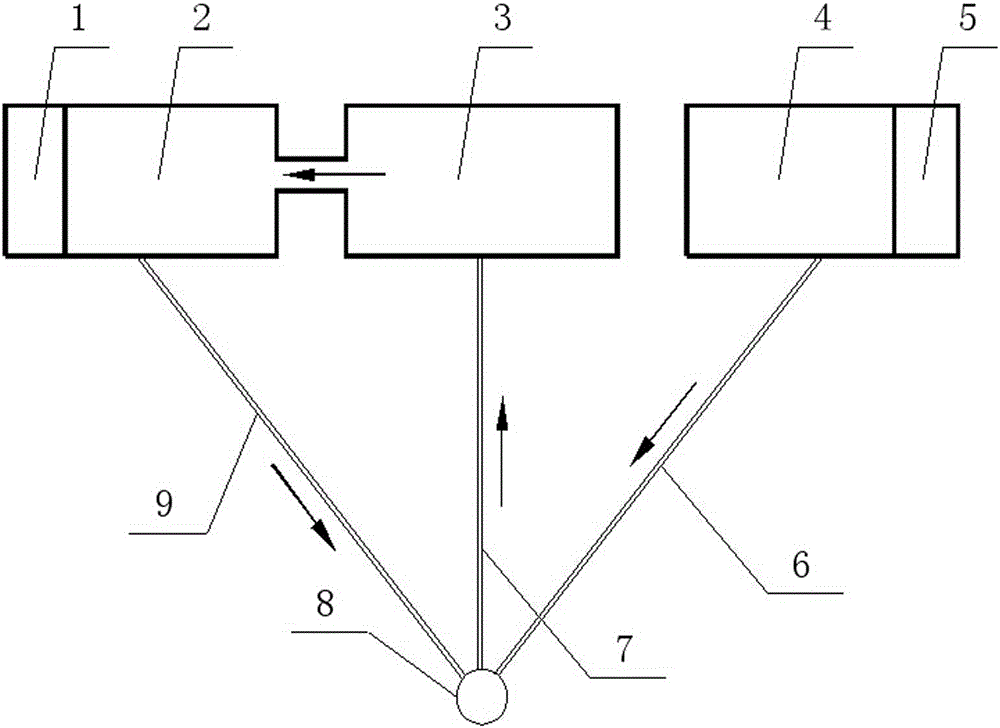

[0027] see figure 1 , polymer mud and bentonite mud are prepared in two mud tanks 1 and 5 respectively, and the pH value of the stirring water is adjusted to 8~10 when preparing, and the polymer mud is prepared by commercially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| sand content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com