Casing pipe automatic grouting bypass-type bump-pressure device

An automatic grouting and general-type technology, which is applied to cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems that the products cannot be guaranteed to be produced by the same manufacturer, the quality and function coordination cannot be guaranteed, and the work intensity of operators is increased. , to achieve the effect of improving replacement efficiency, saving operating time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

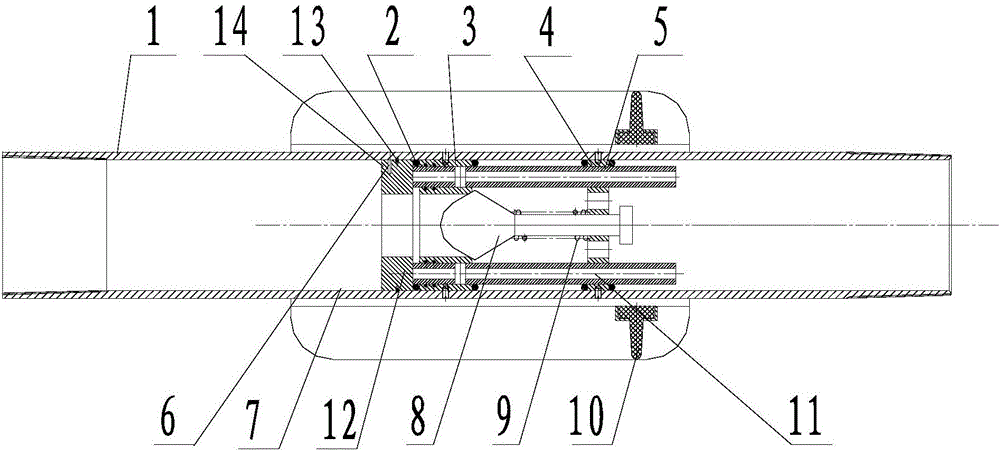

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Depend on figure 1 As shown, a casing automatic grouting bypass type bumper device includes an outer cylinder 1, an upper guide seat 3 and a lower guide seat 4 are fixed on the inner wall of the outer cylinder 1 by screws, and the upper guide seat 3 and the lower guide seat The two ends of 4 are provided with fixing sleeve 2 respectively, and fixing sleeve 2 can play the role of sealing. There are several guide holes on the section of the upper guide seat 3 and the lower guide seat 4, each guide hole is equipped with a flow control valve 5, and the axial center of the flow control valve 5 is provided with a self-filling hole 11, And the flow control valve 5 is provided with a diversion hole 12 perpendicular to the self-irrigation hole 11 on the outer wall on the left side. The size of the aperture of the self-irrigation hole 11 can control the self-irrigation flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com