Patents

Literature

55results about How to "Guarantee cementing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whole-process leakage-plugging and well-cementing design method for high-temperature and high-pressure ultra-deep well

ActiveCN106437609AGuaranteed successReduce risk of leakageDesign optimisation/simulationSealing/packingWell cementingCement slurry

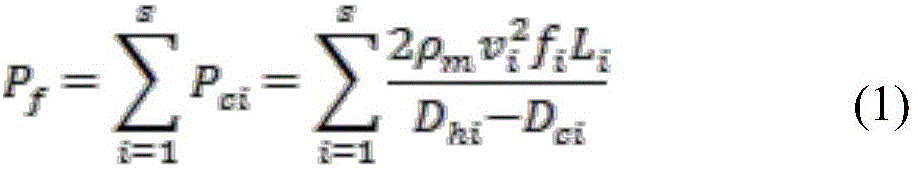

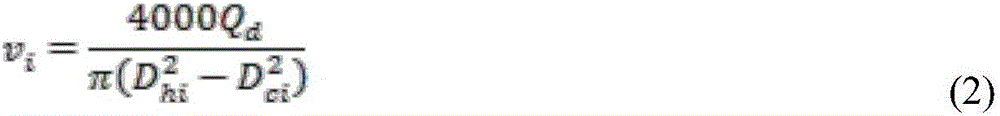

The invention discloses a whole-process leakage-plugging and well-cementing design method for a high-temperature and high-pressure ultra-deep well. The whole-process leakage-plugging and well-cementing design method sequentially comprises the following steps: A, pigging, calculating the annular total circulating pressure loss during pigging circulation, and using the annular total circulating pressure loss as stratum pressure bearing capacity; B, according to the stratum pressure bearing capacity, calculating the running speed of a casing pipe or a tail pipe, and then running a casing pipe string or a tail pipe string; C, according to the stratum pressure bearing capacity, calculating the drilling fluid circulating displacement after running the casing pipe or the tail pipe, and then circulating a drilling fluid; D, calculating the flow-plugging critical displacement during cement-injecting operation; E, calculating the safe critical displacement during the cement-injecting operation; F, according to the flow-plugging critical displacement and the safe critical displacement during the cement-injecting operation, determining the actual operation displacement, performing the flow-plugging and cement-injecting operations, and sequentially injecting a spacer fluid, a cement slurry and a slurry replacing fluid. By the whole-process leakage-plugging and well-cementing design method, guidance can be provided for plugging and well cementation of deep and ultra-deep wells so as to ensure that the ultra-deep well cementing operation is successful and improve the well-cementing quality.

Owner:SOUTHWEST PETROLEUM UNIV

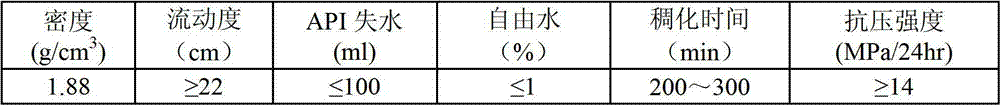

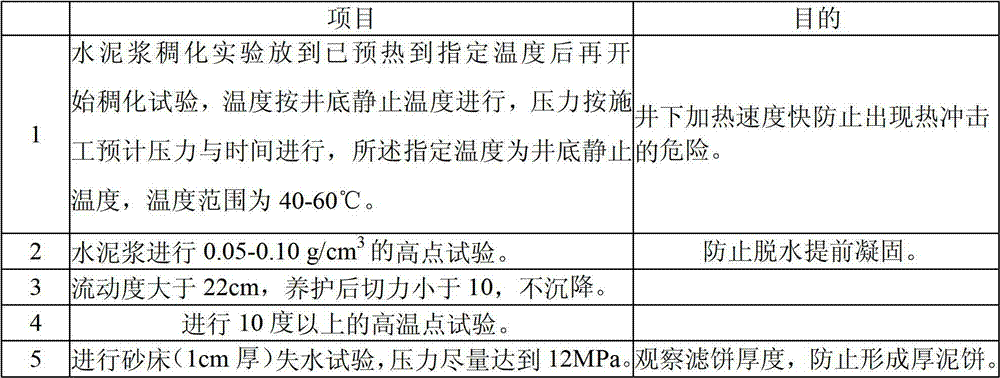

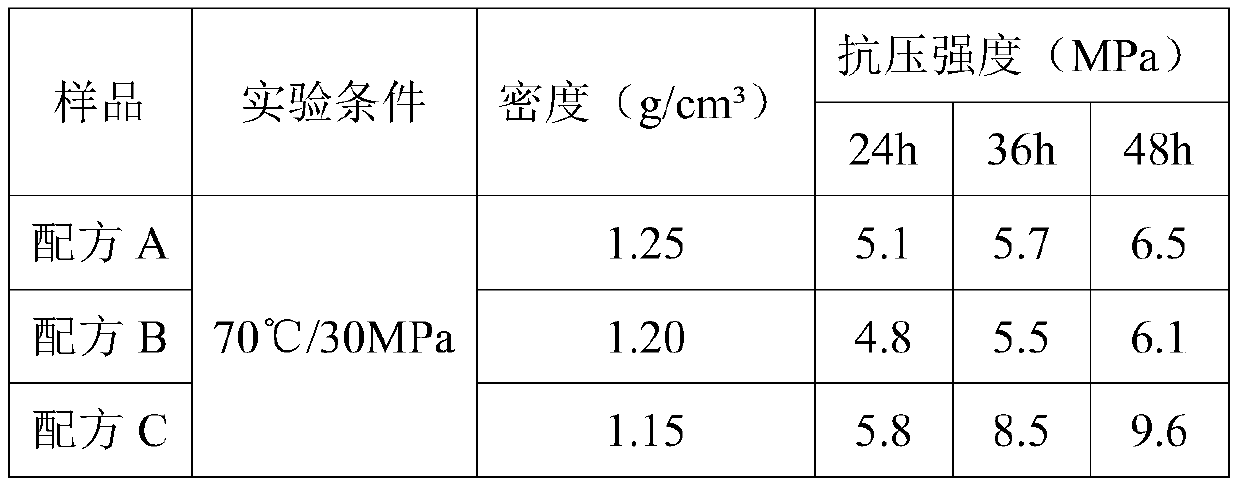

High-strength and low-density cement paste using fluid loss agent

The invention discloses a high-strength and low-density cement paste using a fluid loss agent, relating to the technical field of oil field well sealing cement paste. The high-strength and low-density cement paste using the fluid loss agent comprises the following components in part by weight: 100 parts of G-level oil well cement, 23-50 parts of lightening admixture 6.5-8 parts of microsilica, 2 parts of fluid loss agent and 0.05-0.15 parts of setting retarder, wherein the using amounts of the fluid loss agent and the setting retarder are the percentage of the total mass of the G-level oil well cement, the lightening admixture and the microsilica; the ratio of water to solid in the cement paste is 0.7-0.75 and is the ratio of water to the total mass of the G-level oil well cement, the lightening admixture and the microsilica. The cement paste has a density of 1.20-1.35g / cm<3>, has high strength, good fluidity, no free water and good systematic stability, and can meet well sealing requirements on long-term sealing or full sealing of a deep well in an easily-leaking stratum.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

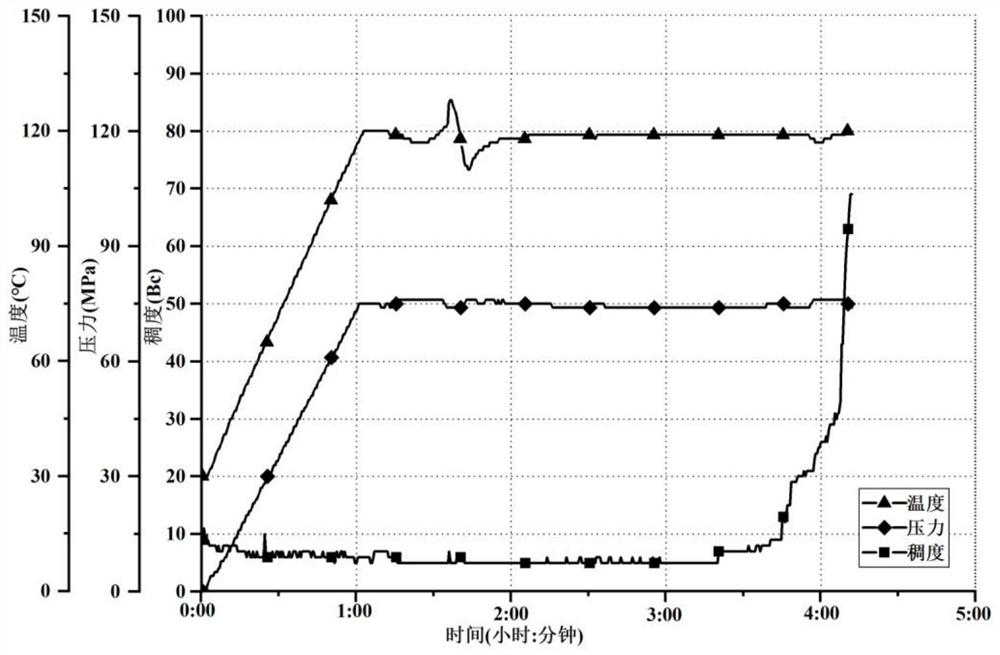

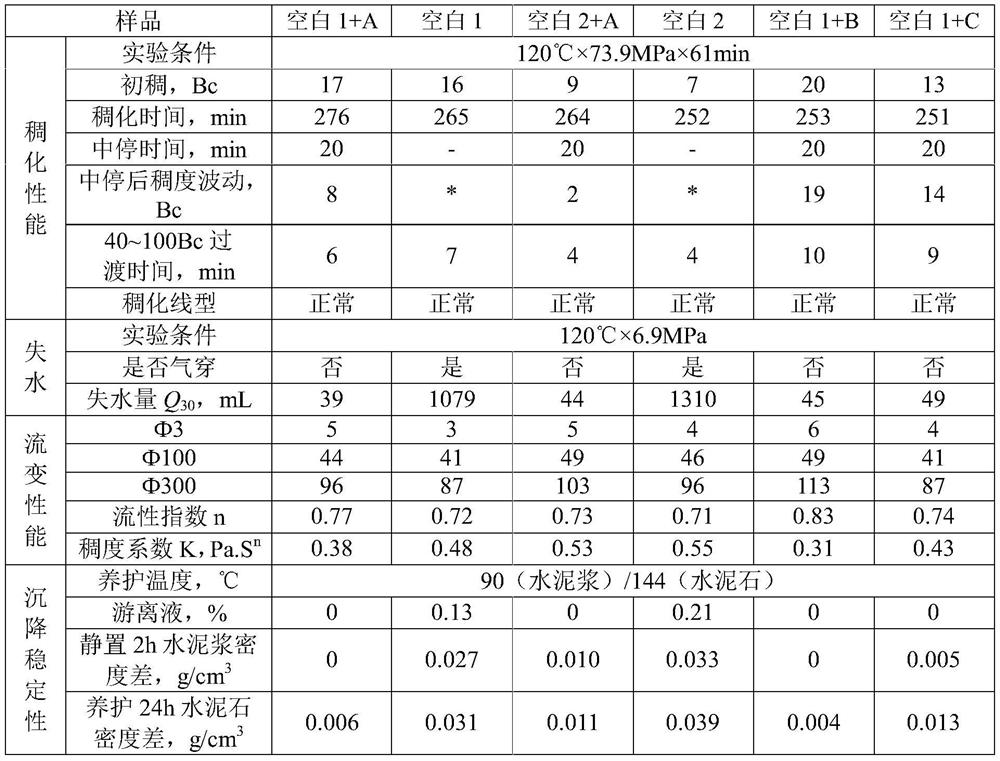

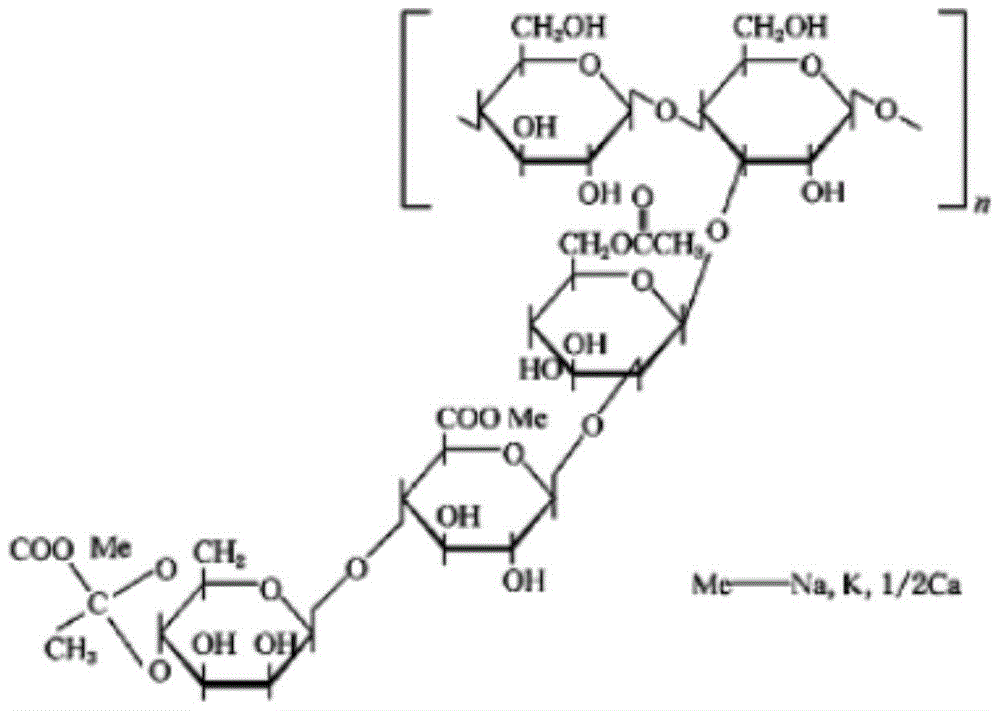

Well cementing cement slurry stabilizer, preparation method and applications thereof

ActiveCN105176505AImprove stabilityDoes not affect graying timeDrilling compositionPolyvinyl alcoholWell cementing

The present invention provides a well cementing cement slurry stabilizer, a preparation method and applications thereof, wherein the well cementing cement slurry stabilizer comprises, by weight, 54-89 parts of quartz sand, 2-20 parts of Welan gum, 0-8 parts of xanthan gum, 3-10 parts of polyvinyl alcohol, and 3-8 parts of a grafted macromolecule polymer. According to the present invention, the stability of the cement slurry can be improved through the stabilizer, the stabilizer does not provide adverse effects on other properties of the cement slurry during the use process, and the stabilizer further provides the benefit on the compressive strength of the cement stone.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

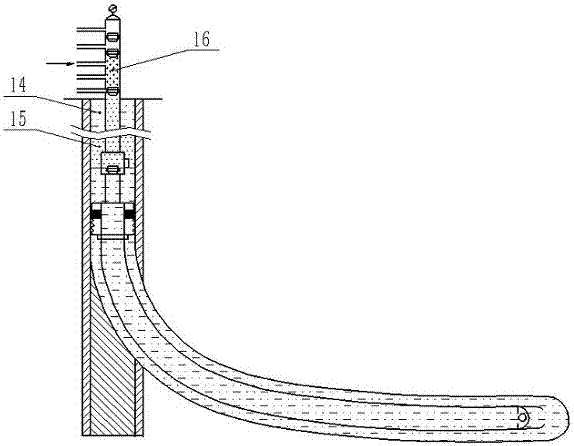

Cement-free well cementation method for horizontal section of horizontal well

ActiveCN104514513ASimple construction processReduce well completion costsSealing/packingWork cycleWell cementing

The invention relates to a cement-free well cementation method for a horizontal section of a horizontal well. The cement-free well cementation method the step of constructing a well completion system structural pipe string of a horizontal section sleeve fixing tool; delivering the constructed pipe string to the bottom of an oil-gas well, performing mud circulation, starting the sleeve fixing tool, effectively fixing a sleeve and the well wall, and establishing internal circulation of the well; throwing balls into the well, building and testing the pressure, increasing and stabilizing the pressure until a packer inflatable channel in a non-drilling plug tool is open, and inflating and sealing the packer; increasing and stabilizing the pressure until the packer inflatable channel is closed; increasing the pressure until a cement injection channel is opened; delivering a well cementation rubber plug to a close seat of the non-drilling plug tool, and closing the cement injection channel; and salvaging the inner cylinder of the non-drilling plug tool, matching accessories and the well cementation rubber plug to complete the whole construction process. By using the method, the construction process can be simplified, the working cycle can be shortened, and the well completion cost is reduced.

Owner:CHINA PETROCHEMICAL CORP +1

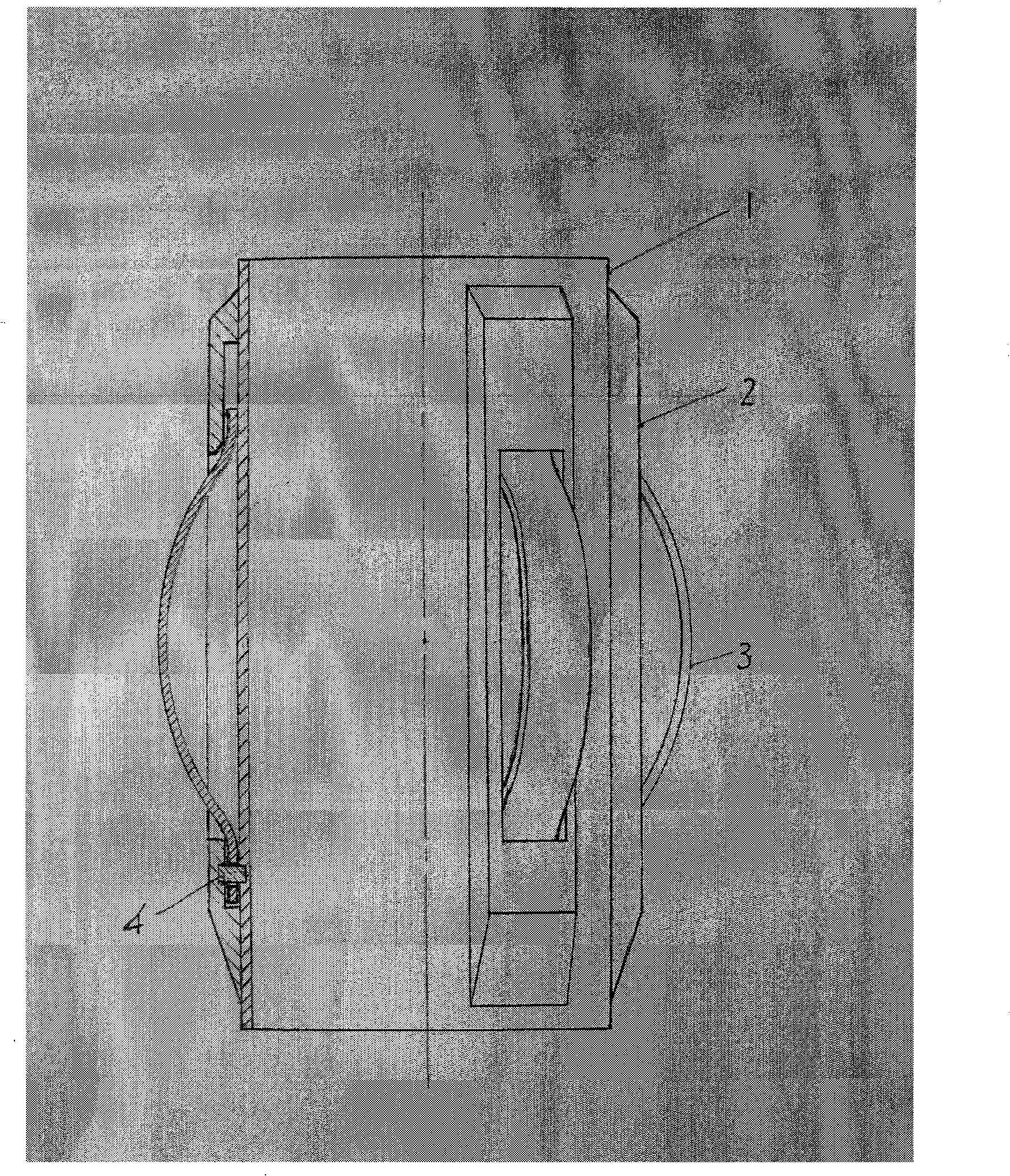

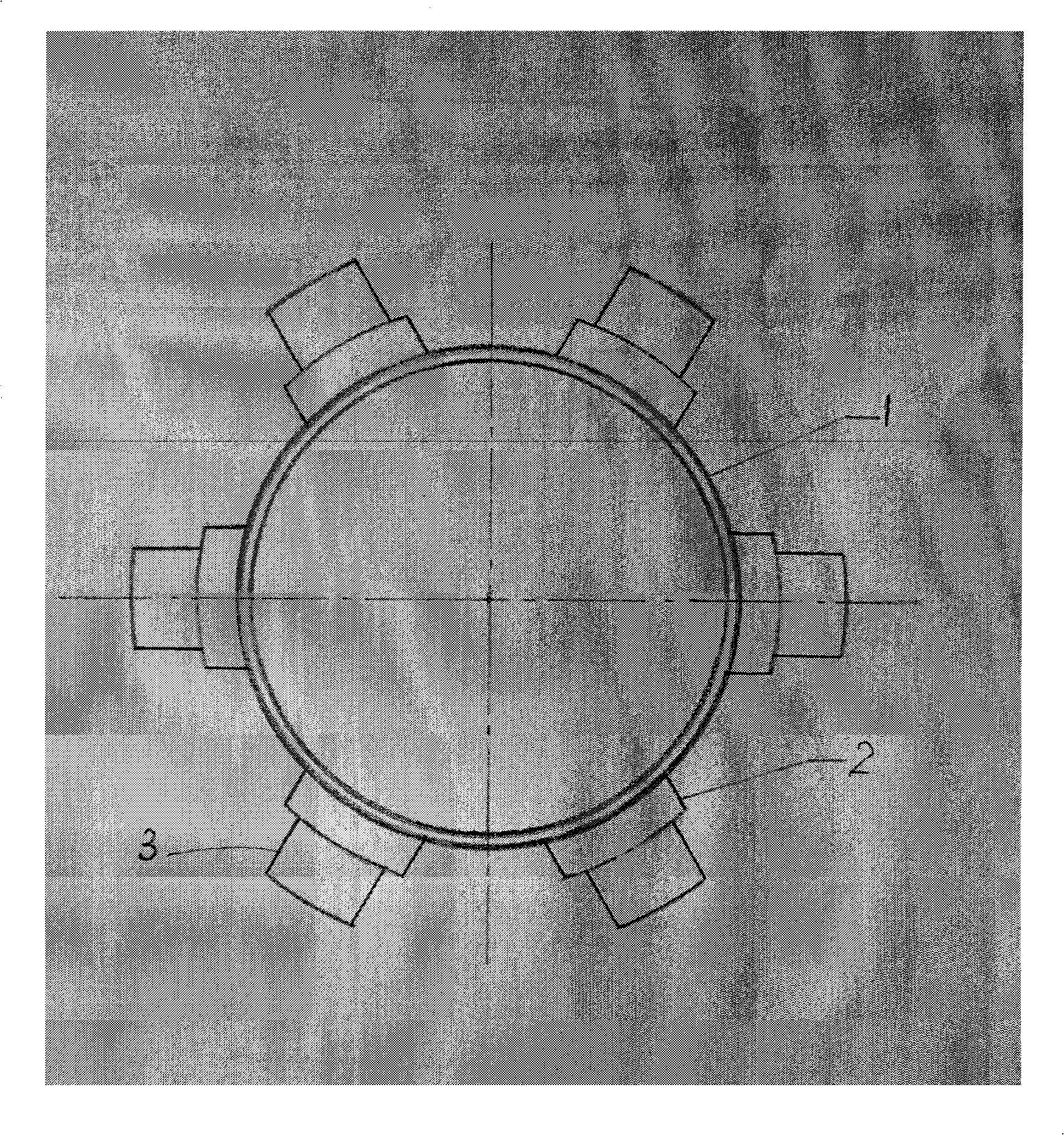

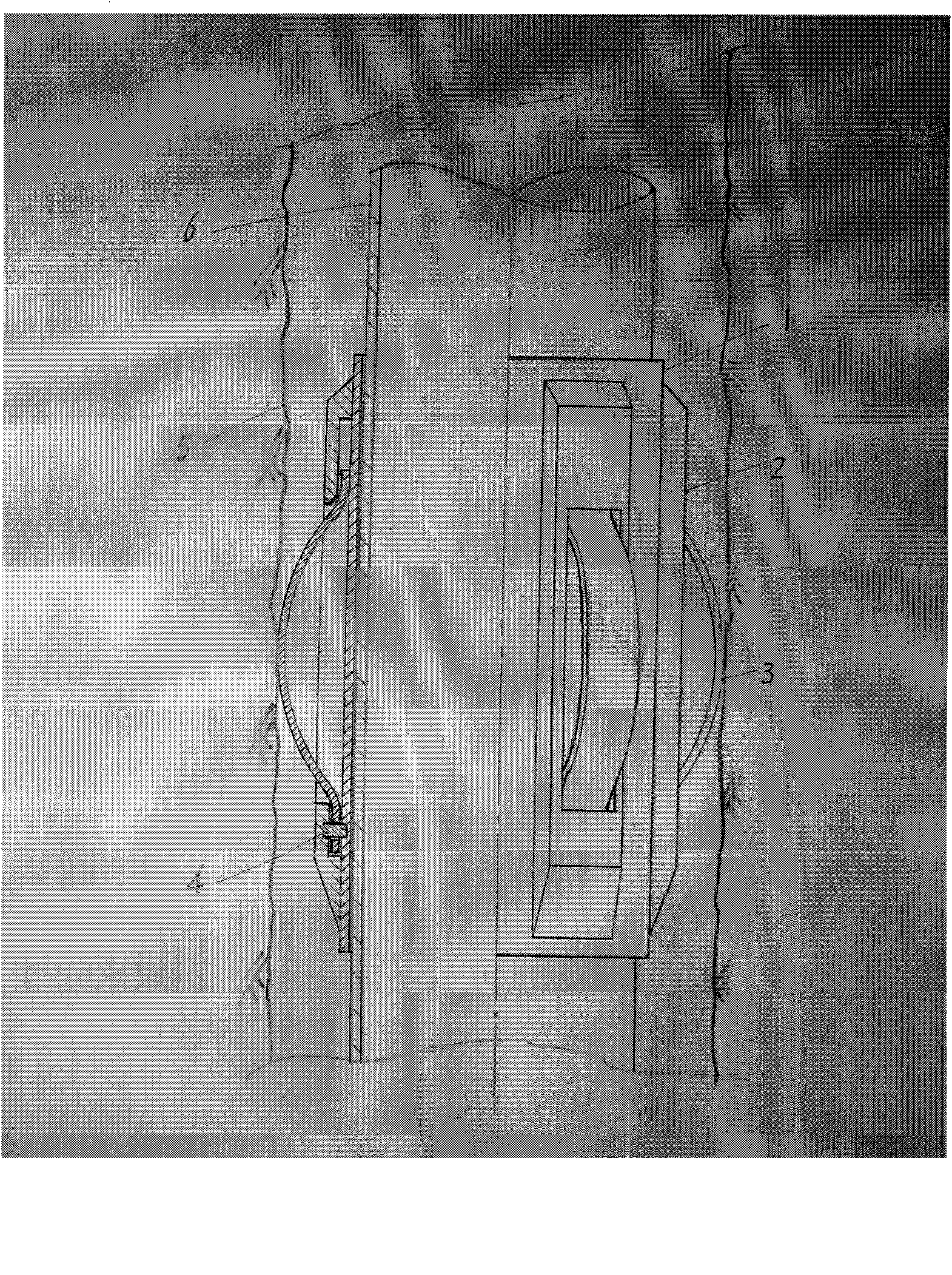

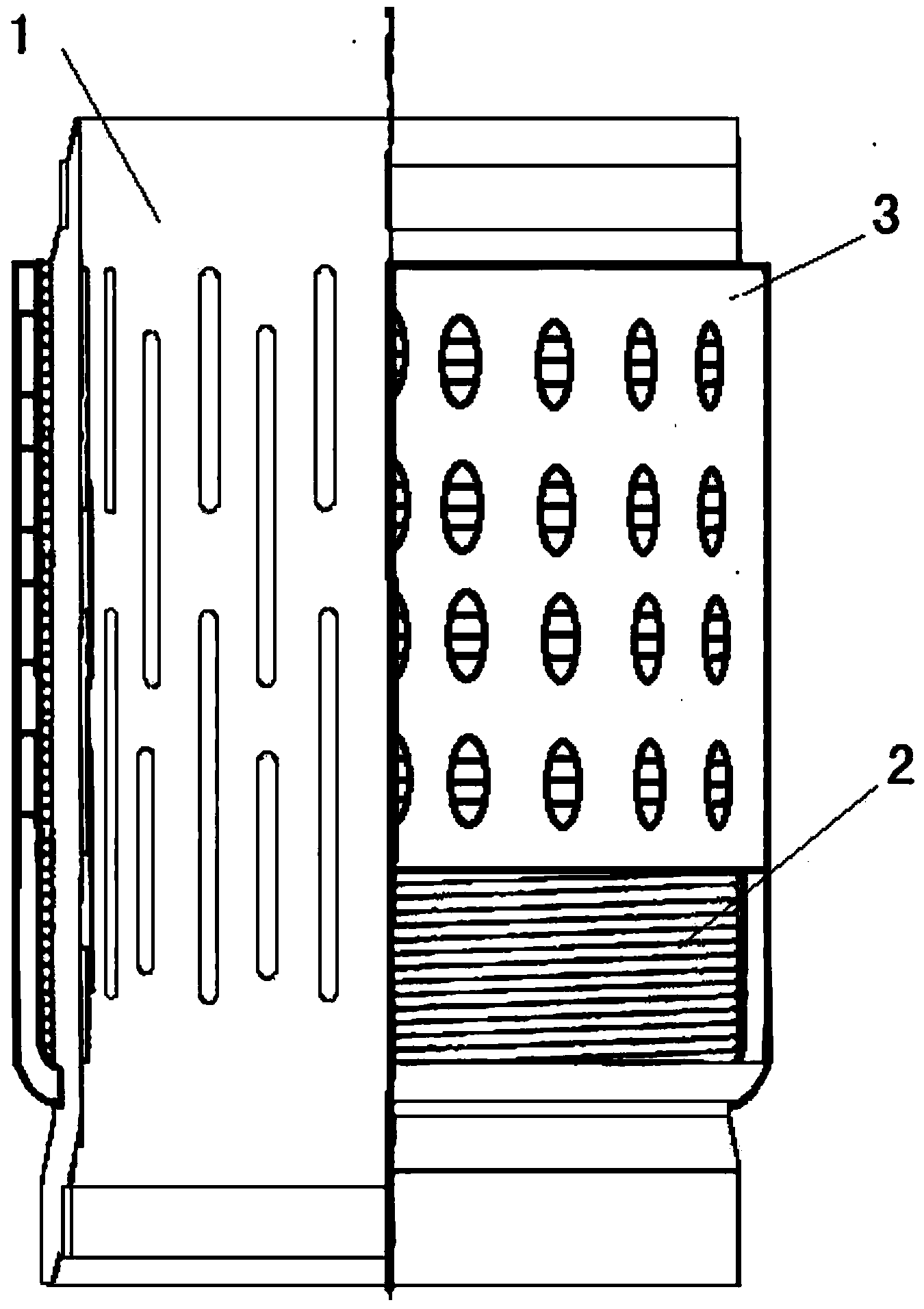

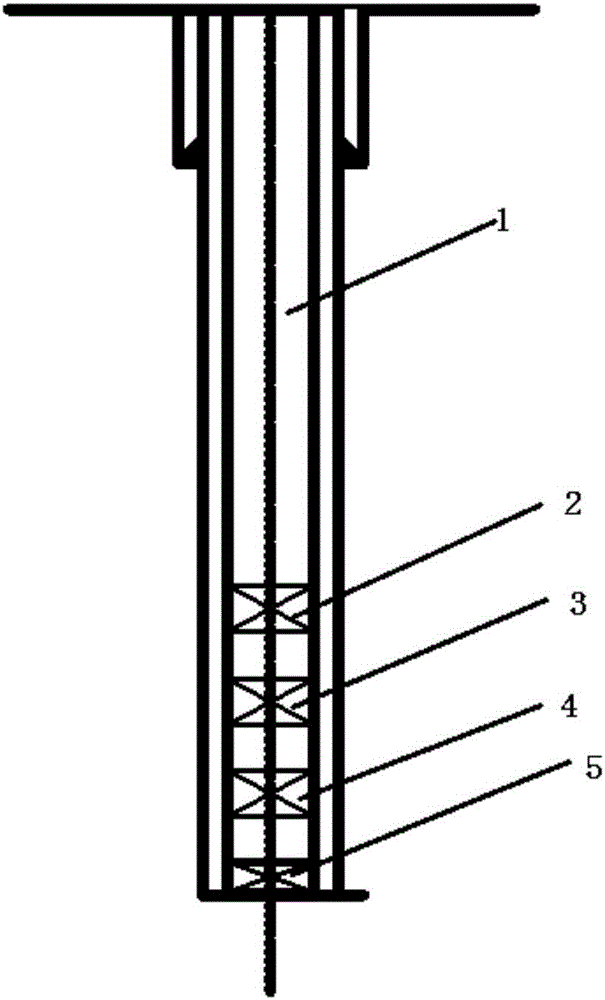

Elastic rigid centralizer

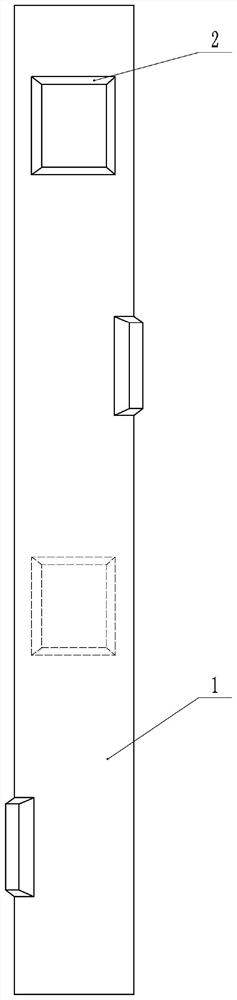

InactiveCN101824970ASmooth entryImprove the righting effectDrilling rodsDrilling casingsHorizontal wellsWell cementing

The invention relates to an elastic rigid centralizer which mainly comprises a main body (1) , a plurality of rigid centralizing slats (2) and a plurality of plate spring centralizing sheets (3), wherein the rigid centralizing slats (2) and the plate spring centralizing sheets (3) are evenly distributed on the circumference on the main body (1).Each plate spring centralizing sheet (3) is installed in the chute of each rigid centralizing slat (2), thereby forming the novel casing centralizer which has the characteristic of large supporting force of the rigid centralizer and high elasticity of the plate springs. Thus, the invention can restrict the maximum eccentricity and maximally centralize the casing string by using the large centralizing force of the plate springs, thereby ensuring centering. Meanwhile, the integral internal fixation structure prevents the centralizing sheets from shedding, and the peculiar ski function of the cambered plate spring steel sheets can prevent the phenomena of poor casing centering degree and unqualified well cementation caused by decreased centralizer consumption since more casings can result in difficulty in descending the well in the prior well cementation engineering circle. The invention has the advantages of simple structure, reliable performance, high firmness, wear resistance and convenient operation. The invention is suitable for straight wells, and especially suitable for inclined shafts, horizontal wells and slim wells.

Owner:李越

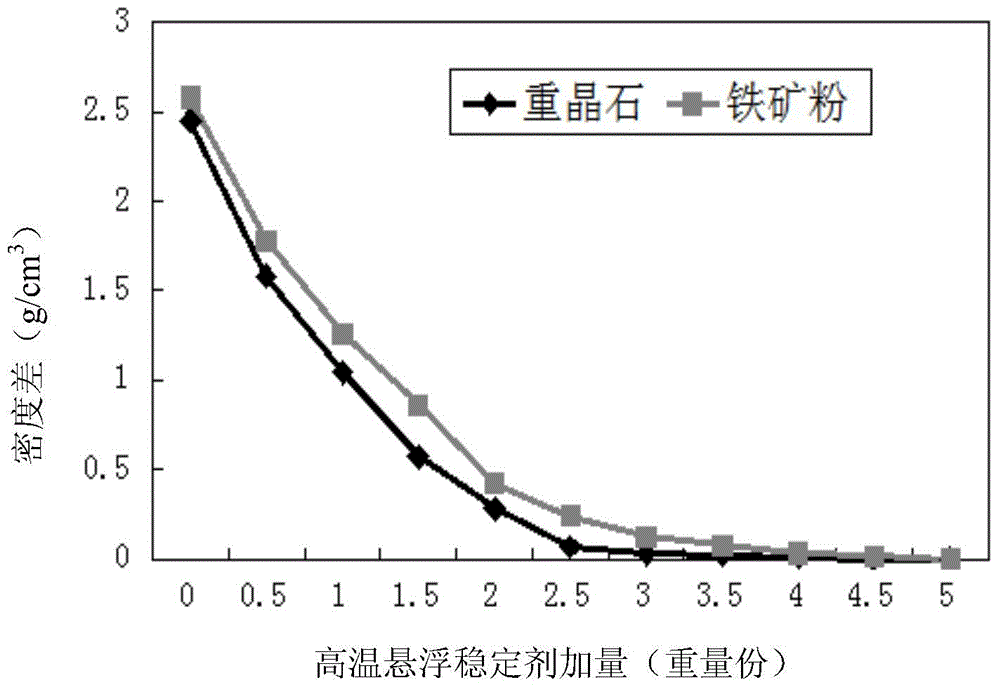

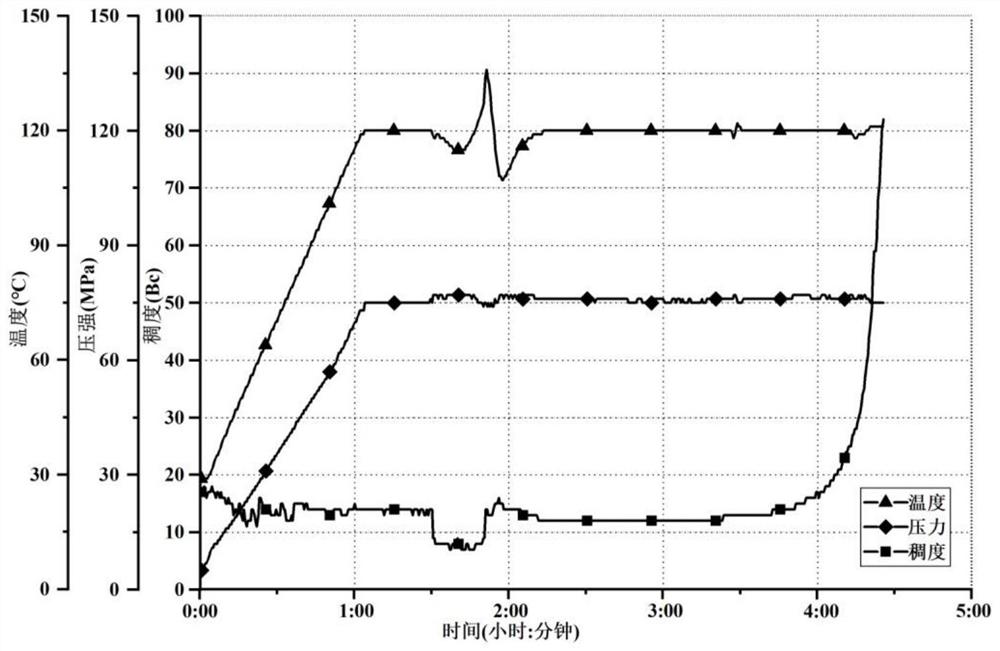

High-temperature spacer fluid suspension stabilizer for well cementation, preparation method of high-temperature spacer fluid suspension stabilizer and application of high-temperature spacer fluid suspension stabilizer

InactiveCN104962260ANo effect on rheological propertiesImprove stabilityDrilling compositionSealing/packingHigh resistanceInorganic salts

The invention provides a high-temperature spacer fluid suspension stabilizer for well cementation, a preparation method of the high-temperature spacer fluid suspension stabilizer and application of the high-temperature spacer fluid suspension stabilizer. The high-temperature spacer fluid suspension stabilizer for well cementation comprises the following ingredients in part by weight: 58-85 parts of clay substances, 8-20 parts of welan gum, 0-5 parts of xanthan gum, 5-10 parts of inorganic salt and 2-8 parts of high-molecular polymer. The high-molecular polymer comprises one or more than one of polyvinyl alcohol, hydroxymethyl cellulose, hydroxyethyl cellulose and hydroxypropyl starch ether. The suspension stabilizer serves as an additive and is added into spacer fluid; and after being added with the suspension stabilizer, the spacer fluid has high suspension stability, high consistency, high rheological property and high resistance to elevated temperature.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

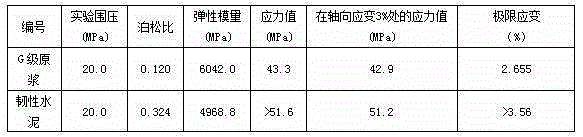

Tough oil well cement

InactiveCN106278003AStrong ability to change laterallyLow elastic modulusSolid waste managementFiberPlastic yielding

The invention discloses tough oil well cement. The cement is characterized by being prepared from components in parts by weight as follows: 100 parts of cement, 1-15 parts of active filler, 1-5 parts of a toughening material, 0.01-0.05 parts of staple fibers, 1-5 parts of an additive, 0.1-0.2 parts of a water educing agent, 1-5 parts of a fluid loss agent, 1-2 parts of an antifoaming agent and 1-5 parts of a retarder. An oil well cement sheath is high in lateral deformation capacity, low in elasticity modulus, high in plastic yielding point and good in elasticity; the oil well cement ring has very high ultimate strain value, can absorb larger impact energy and greatly improves the deformation performance of set cement compared with raw slurry, so that the requirement for cement performance in the oil and gas well development process is met, and cementing quality and follow-up development are guaranteed.

Owner:JIAHUA SPECIAL CEMENT

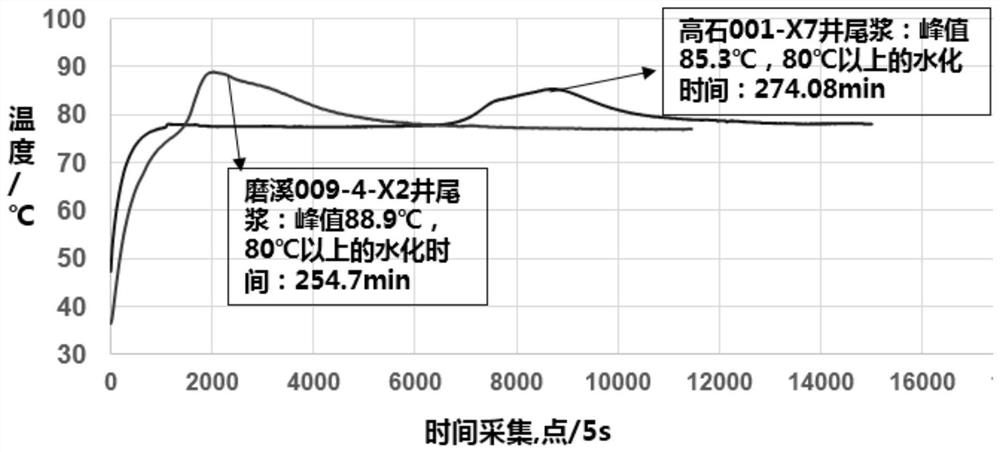

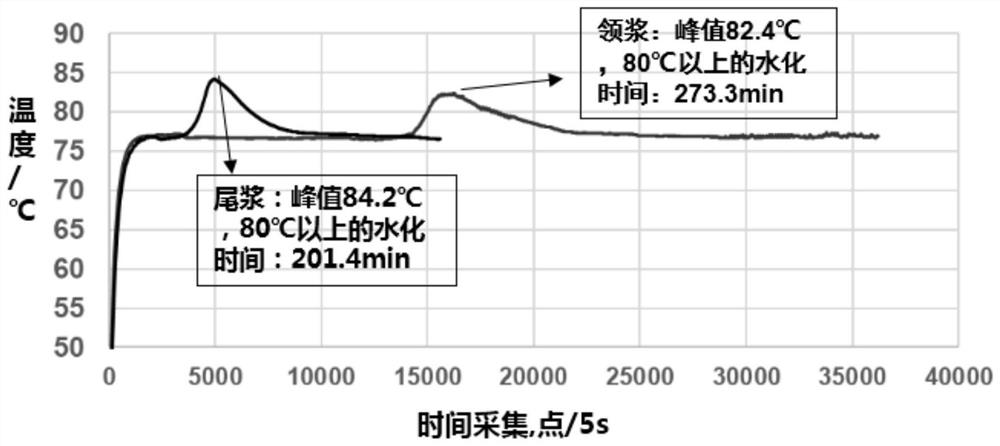

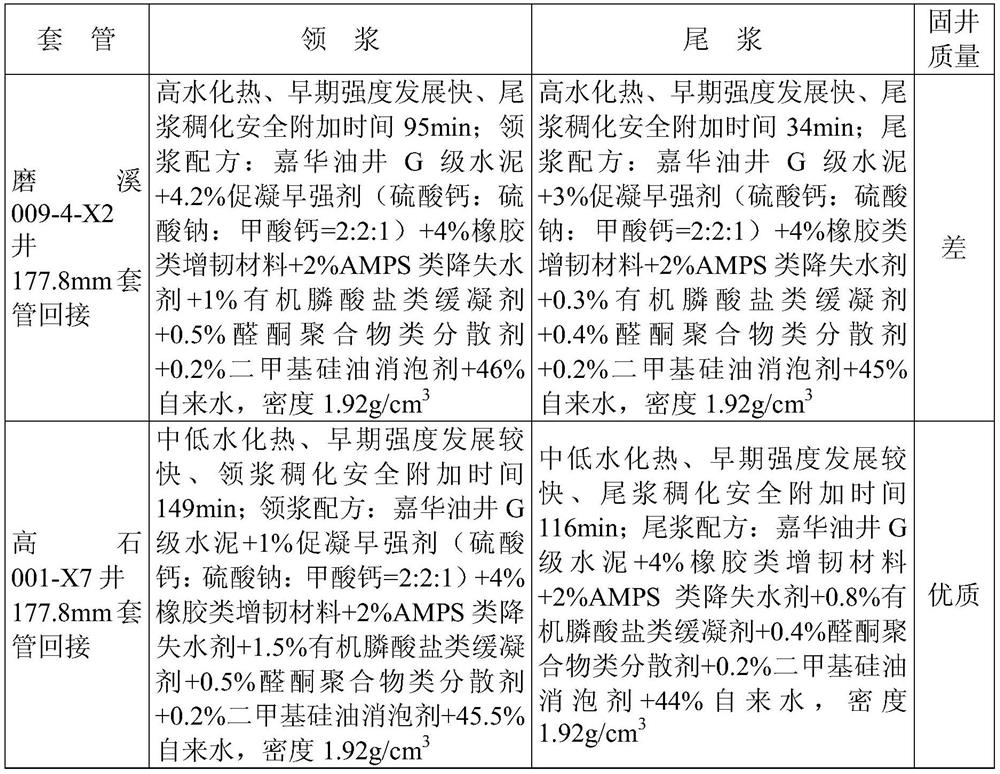

Well cementation method for controlling hydration heat of cement paste and improving well cementation quality

ActiveCN112127830AImprove bonding qualityImprove the bonding quality effectSolid waste managementDrilling compositionThermodynamicsWell cementing

The invention provides a well cementation method for controlling hydration heat of cement paste and improving the well cementation quality. According to the method, by controlling the hydration heat release degree and / or hydration heat release rate of the cement paste, the hydration heat release condition in the process of forming set cement by curing the cement paste is improved, the cementing quality of the set cement and an interface is improved, and the well cementation quality of an open hole section and / or an overlapping section is further improved. The invention provides the well cementation method for controlling the hydration heat of the cement paste and improving the well cementation quality for the first time, belongs to the staged and milestone type breakthrough of the well cementation technology, can greatly promote the technical progress of the well cementation industry, provides powerful technical support for improvement of the well cementation quality of an oil-gas welland reduction of the annulus pressure risk, and has great significance to guarantee the sustainable development of exploration and development of oil and gas resources.

Owner:PETROCHINA CO LTD +2

Delayed coagulation well cementation method of high-pressure gas underground gas storage wells

The invention relates to a delayed coagulation well cementation method of high-pressure gas underground gas storage wells, comprising the following steps of: A. drilling well; B. grouting: grouting retarding cement slurry to the bottom of a well cylinder and an annular space between the outer wall of a drill stem and the wall of the well cylinder through an inner cavity of the drill stem from down to top until the retarding cement slurry overflows the ground; C. installing a storage well device: lifting the drill stem, sinking the gas storage well device to the well cylinder filled with retarding cement slurry to a set position of the well cylinder, and completing filling of the cement slurry; D. and testing pressure: carrying out pressure test on the gas storage well device for 4 hours; lifting the gas storage well device and repeating the operations from step A to step D when pressure test is not qualified; and completing well cementation when the pressure test is qualified. The well cementation method has good well cementation quality, the combination of the gas storage well device and the wall of the well cylinder is firm, and the gas storage well has good sealing performance, high security and strong reliability, thereby the possibility of accidents of air leak, and the like is greatly reduced.

Owner:徐英 +3

Small-diameter sleeve window sidetrack drilling traction type well fixing method

The invention relates to a small-diameter sleeve window sidetrack drilling traction type well fixing method, and belongs to the technical field of petroleum and gas well fixing. According to the technical scheme of the small-diameter sleeve window sidetrack drilling traction type well fixing method, a smart short-circuit circulating short joint along with a well fixing pipe column enters a well together; an original well drilling liquid is injected, an annulus is washed, then a special-amount conventional extra-low density well drilling fluid (or branch water), a separating liquid, cement paste and the original well drilling liquid are injected in sequence; a short-circuit circulating channel is opened, and the conventional extra-low density well drilling fluid (orbranch water) enters the annulus; and after the conventional extra-low density well drilling fluid (or branch water) fully passes, the short-circuit circulating channel is closed; the cement paste is pressed into the annulus by using the pressure difference, and the traction type well fixing is formed. The small-diameter sleeve window sidetrack drilling traction type well fixing method has the advantages that by reducing the annulus liquid density, the total pressure borne by the well bottom is reduced, pressing crack of the well bottom is prevented, the one-time success rate of small-diameter sleeve window sidetrack drilling well fixing is greatly improved, the well fixing quality is ensured, the cost is reduced, and pollution of an oil-gas layer is avoided.

Owner:SOUTHWEST PETROLEUM UNIV

Expansion screen pipe

InactiveCN103967456APrecise control of particle sizeReduce resistanceFluid removalEngineeringCrude oil

The invention provides an expansion screen pipe which comprises an inner layer pipe, a middle layer pipe and an outer layer pipe, wherein the inner layer pipe, the middle layer pipe and the outer layer pipe are fixed and mounted in a sleeved mode in sequence from inside to outside. Multiple kerfs are distributed in the pipe wall of the inner layer pipe, the middle layer pipe is formed by coiling filaments spirally, and multiple holes are also distributed in the pipe wall of the outer layer pipe. The expansion screen pipe has the advantages that the granulometric class of filtered gravel can be controlled accurately, an oil drainage area is enlarged through expansion hole enlargement, oil flow resistance is reduced at the same time, and crude oil produced by a single well daily can be improved by 30-50 percent.

Owner:TIANJIN TOP CLOUD EAST ENERGY TECH

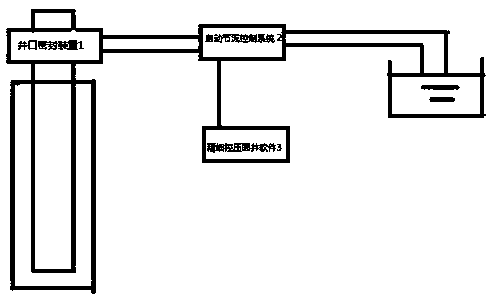

Fine pressure control well cementing operation method

InactiveCN109630062AImprove cementing qualityFine control of wellhead pressureSealing/packingConstruction designWellhead

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Dry wellbore well cementation cement slurry

ActiveCN102732237AAvoid substitution complicationsGuaranteed safe entryDrilling compositionFiberSocial benefits

The present invention discloses a dry wellbore well cementation cement slurry, which comprises the following components, by weight, 100 parts of class G cement, 1-2 parts of a fluid loss additive, 2-3 parts of an anti-channeling agent, 0.5-1.5 parts of an anti-salt retarder, 0.1-0.5 parts of an antifoaming agent, and 0.1-0.5 parts of fiber, wherein the fluid loss additive is one or a plurality of materials selected from an AMPS polymer, a ketoaldehyde condensation material and a PVA system, the anti-channeling agent is fibrous powder and silicon oxide, the anti-salt retarder is an AMPS polymer, and the antifoaming agent is a polyether. The beneficial effects of the cement slurry of the present invention are that: the cement slurry has characteristics of strong anti-dehydration performance, wall making performance, strong blocking performance and good flow property, and is insensitive to changes of density and temperature; the occurrence of the complex condition of gas-liquid replacement is avoided, and safe downward entering of casing, operation safety and well cementation quality are ensured so as to provide important practical significances, good social benefits, technical benefits and economic benefits.

Owner:成都欧美克石油科技股份有限公司

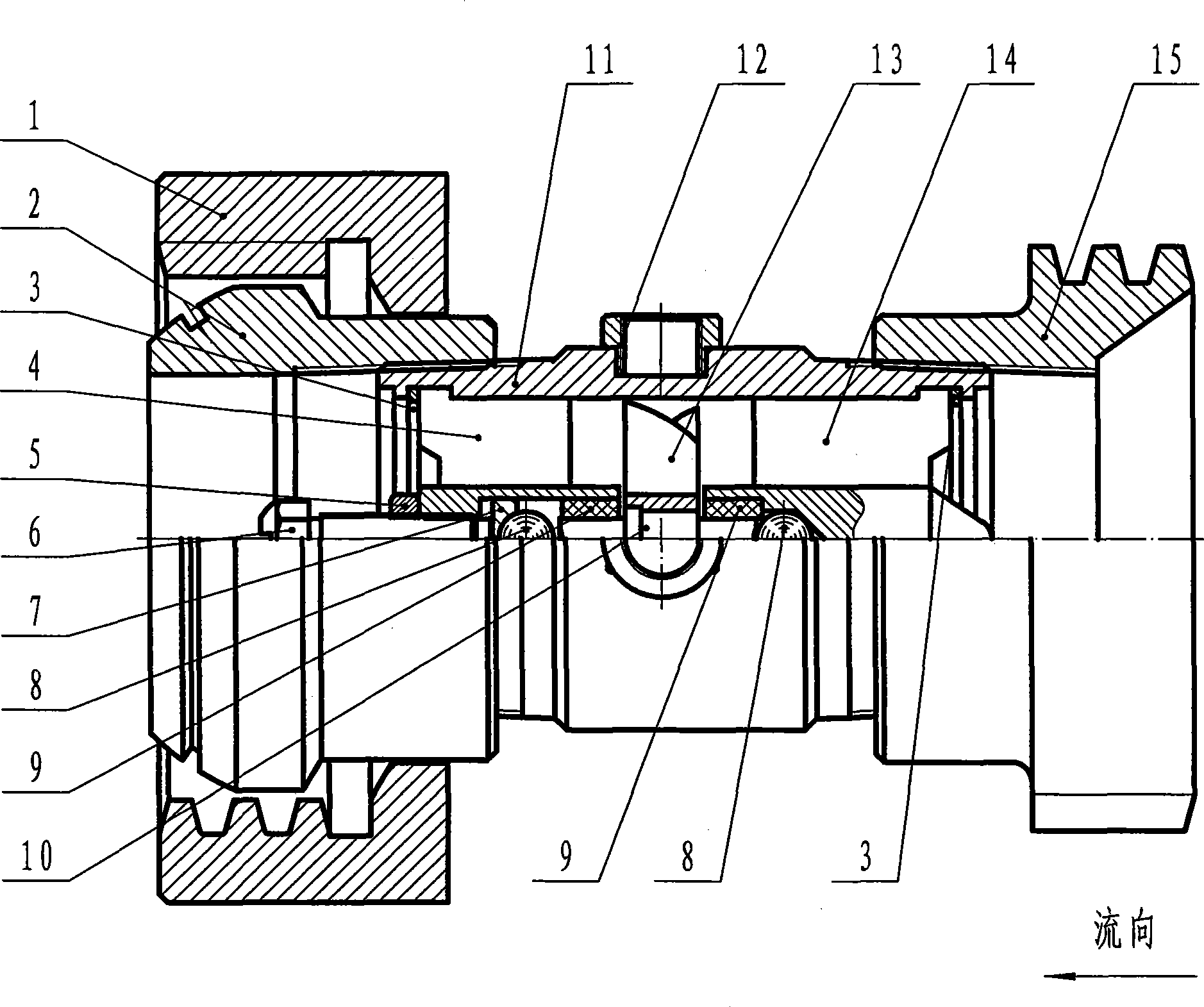

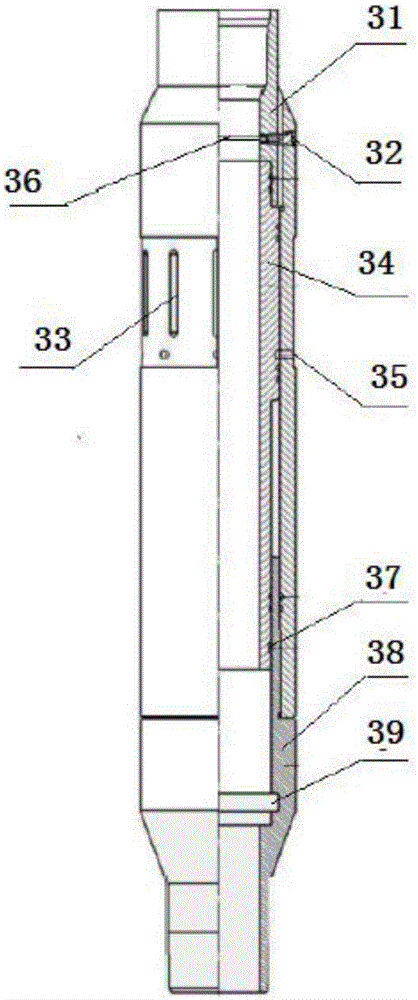

Claw-sleeve type multi-stage cementing device

ActiveCN108005611ASimplify the assembly processReduce processing costsSealing/packingHydraulic actionEngineering

The invention discloses a claw-sleeve type multi-stage cementing device comprising a cylindrical body, a slide sleeve covered by the cylindrical body, a close sleeve and an open sleeve. The close sleeve and the open sleeve are orderly coated by the inner side of the slide sleeve from top to bottom; circulating holes communicating with each other are formed in the cylindrical body and the slide sleeve; the opening sleeve seals the circulating hole parts at first; elastic jaws on the top end of the slide sleeve are fixed on the cylindrical body via the close sleeve; guide spacing grooves are formed in the outer wall of the middle of the slide sleeve to space a downward movement distance between the slide sleeve and the cylindrical body, so the circulating holes formed in the cylindrical bodyand the slide sleeve can be staggered; the close sleeve and the open sleeve are separately arranged and fixed by shearing pins and the slide sleeve; and therefore, during the use, the circulating holes can be opened and closed when the close sleeve and the open sleeve downwardly move with a hydraulic action. Improvements are made on the basis of a traditional cementing device, so device structureand assembling technology are simplified and processing cost can be reduced; production efficiency can be improved; and stable performance is provided during the use, and well cementation quality canbe guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Well cementation flushing fluid for oil-based drilling fluid and preparation method and use method of well cementation flushing fluid

InactiveCN110846013AImprove securitySimple recipeFlushingDrilling compositionActive agentDioxyethylene Ether

The invention discloses a well cementation flushing fluid for oil-based drilling fluid as well as a preparation method and a use method of the well cementation flushing fluid. The well cementation flushing fluid comprises fresh water, a nonionic surfactant I, a nonionic surfactant II, a normal salt cosolvent and an acidic salt cosolvent, wherein the nonionic surfactant I is a fatty alcohol-polyoxyethylene ether nonionic surfactant, and the nonionic surfactant II is a nonylphenol polyoxyethylene ether nonionic surfactant; the nonionic surfactant II has good emulsifying property, and an hydrophilic base end is easily adsorbed on the surfaces of an oil-water interface, a sleeve and a well wall; the non-ionic surfactant I is used as a main agent of the flushing fluid, has good wettability, foamability, detergency and emulsifying power, has relatively high degreasing capacity, hard water resistance, is easy to biodegrade and has good compatibility; the normal salt cosolvent and the acidic salt cosolvent are used for assisting dissolution of the two nonionic surfactants, and meanwhile, the elution capacity of the well cementation flushing fluid on drilling fluid and oil-based mud cake isenhanced; safety is high, the formula is simple, cost is low, and environment friendliness is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Low-density cement paste for well cementation operation, and cement composition for well cementation operation

InactiveCN111019616AImprove stabilityImprove liquidityDrilling compositionMicrofine cementPhysical chemistry

The invention relates to low-density cement paste for well cementation operation, and a cement composition for well cementation operation, and belongs to the technical field of oil well drilling engineering. The low-density cement paste for well cementation operation comprises water and the following components in parts by weight: 70-100 parts of oil well cement, 0-30 parts of superfine cement, 35-80 parts of a lightening material and 15-20 parts of micro-silicon, wherein the lightening material comprises at least one of floating beads and glass micro-beads. According to the invention, the cement paste is good in performance of each component material and moderate in addition proportion, the density of the cement paste prepared from various components can reach 1.15-1.25 g / cm<3>, and the cement paste is high in stability, good in fluidity and high in strength, so that the risk of well cementation leakage can be reduced, and the well cementation quality and the displacement efficiency are improved.

Owner:CHINA PETROCHEMICAL CORP +2

Well cementation method suitable for shale gas well refracturing

ActiveCN112983363AIncrease pressureGuarantee plugging effectDrilling rodsConstructionsThermodynamicsWell cementing

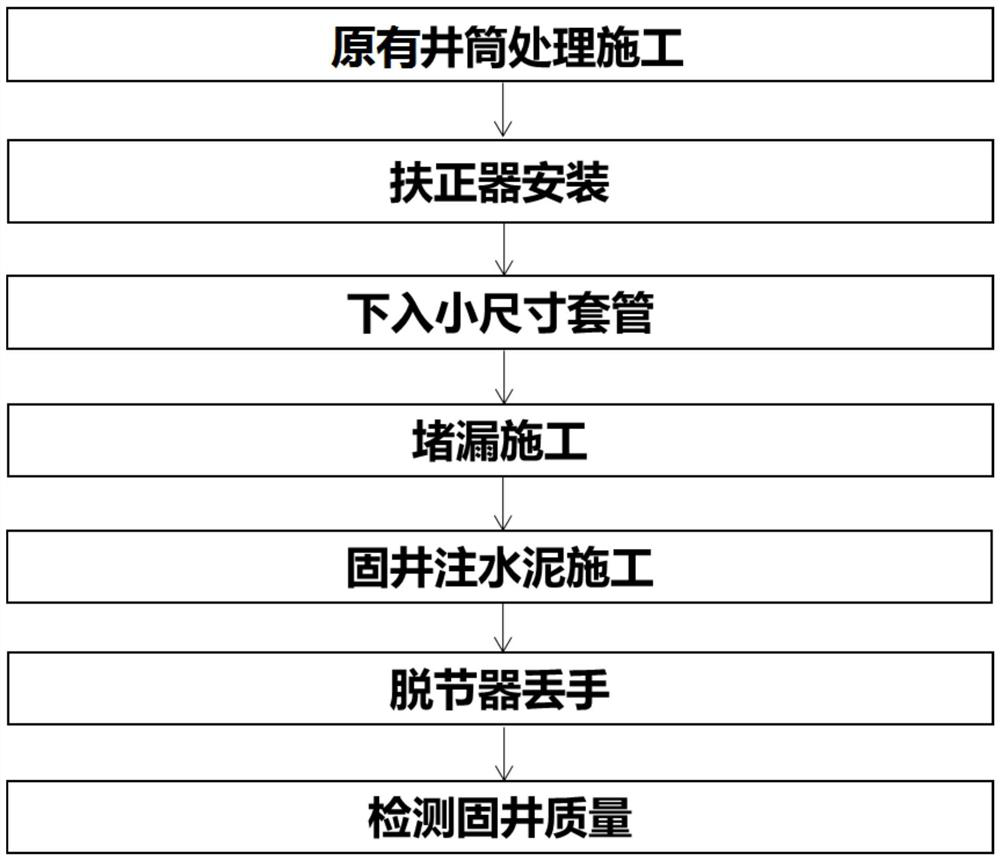

The invention belongs to the technical field of shale gas exploitation, and particularly discloses a well cementation method suitable for shale gas well refracturing. The well cementation method comprises the following steps that (1) original shaft treatment construction is conducted; (2) a centralizer is mounted; (3) a small-size casing pipe is put in; (4) leaking stoppage construction is conducted; (5) well cementation cement injection construction is conducted; (6) a disjointer is released; and (7) the well cementation quality is detected. Compared with the prior art, the method has the advantage that the problems that in the casing-in-casing-fixation refracturing technology, the small-size casing pipe is difficult to put in, the leakage risk is large, and the small-size casing pipe is not prone to centering during well cementation can be solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

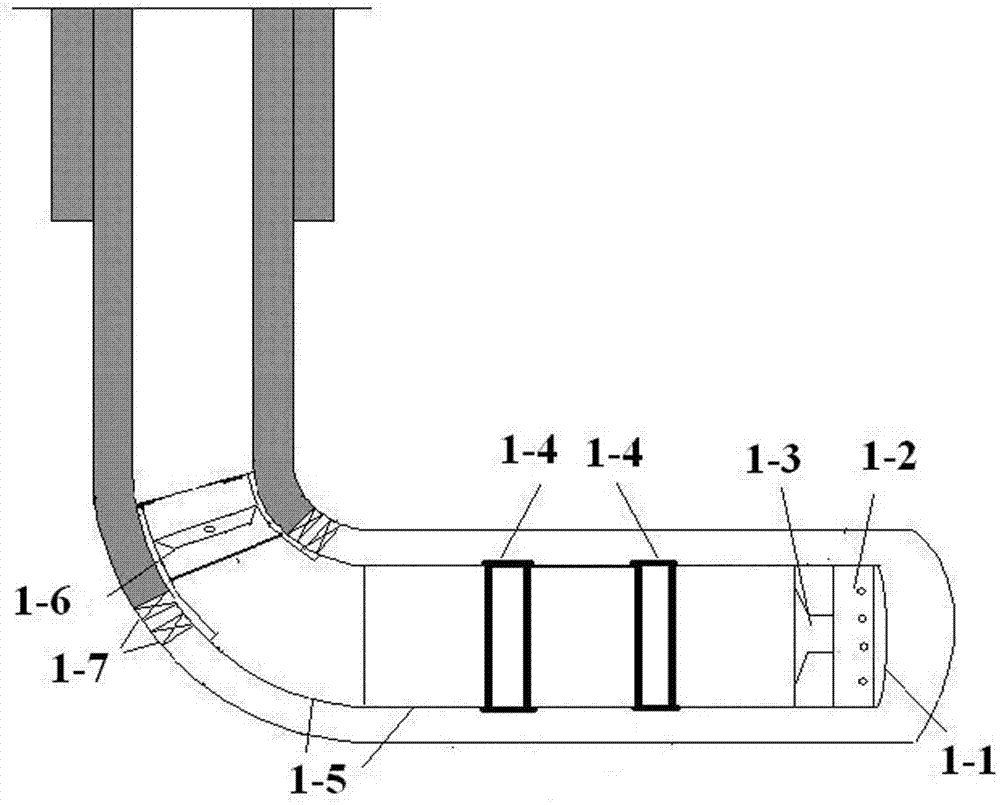

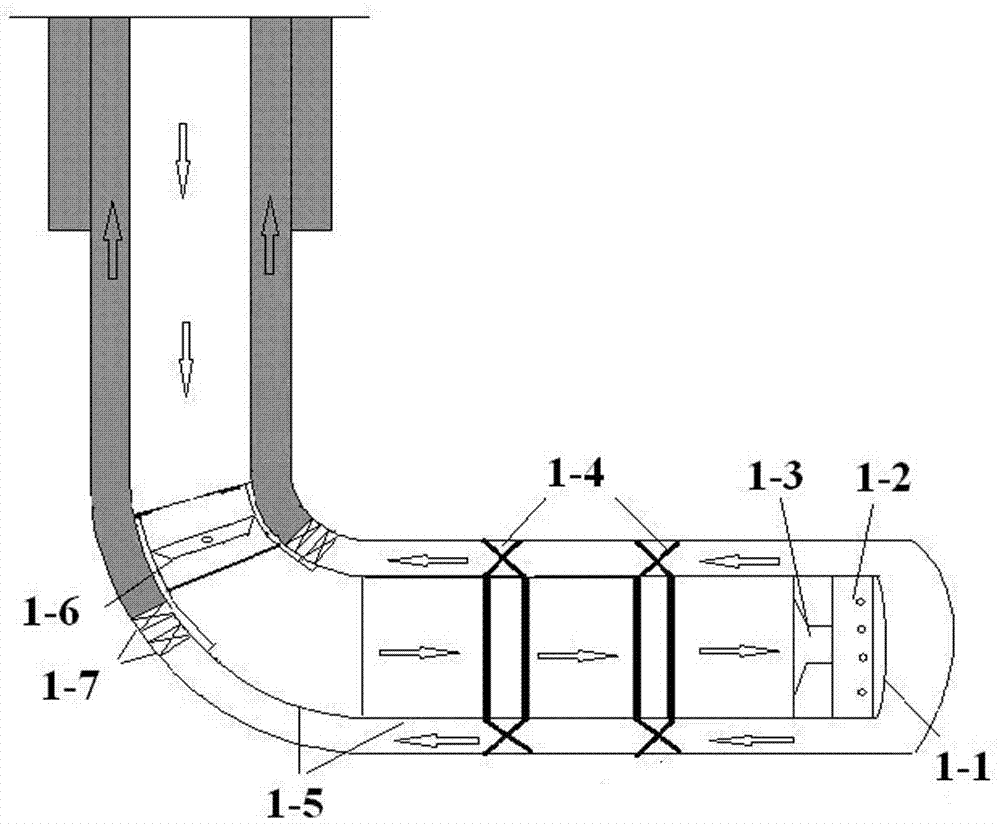

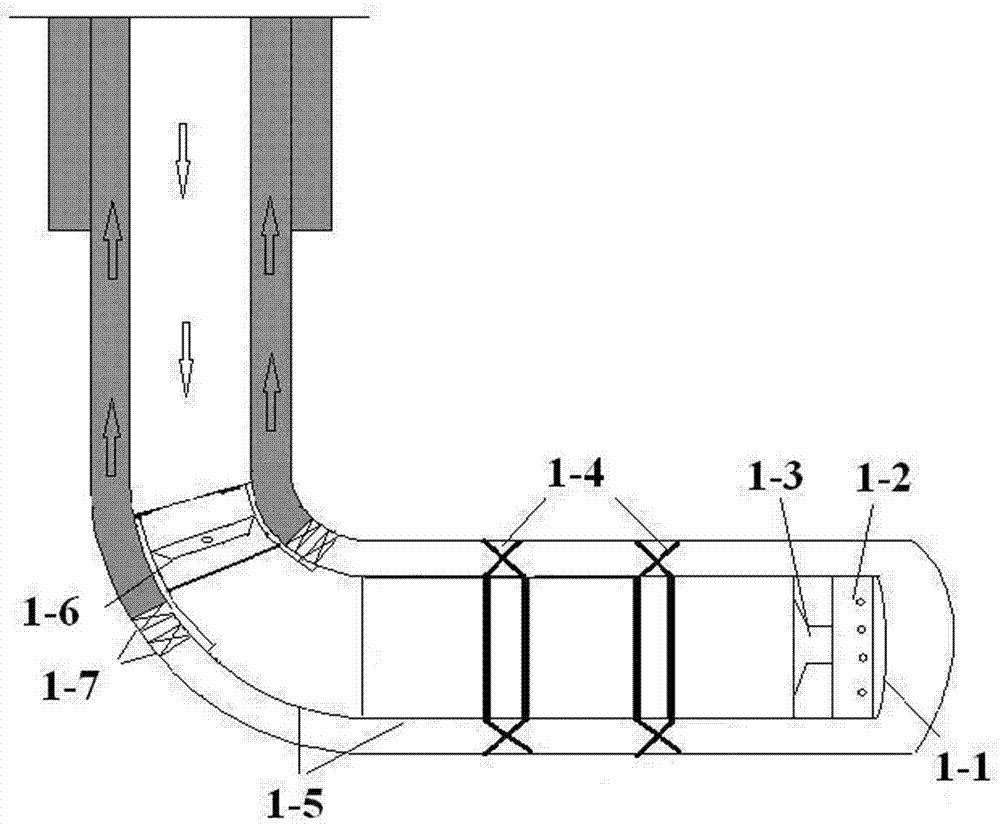

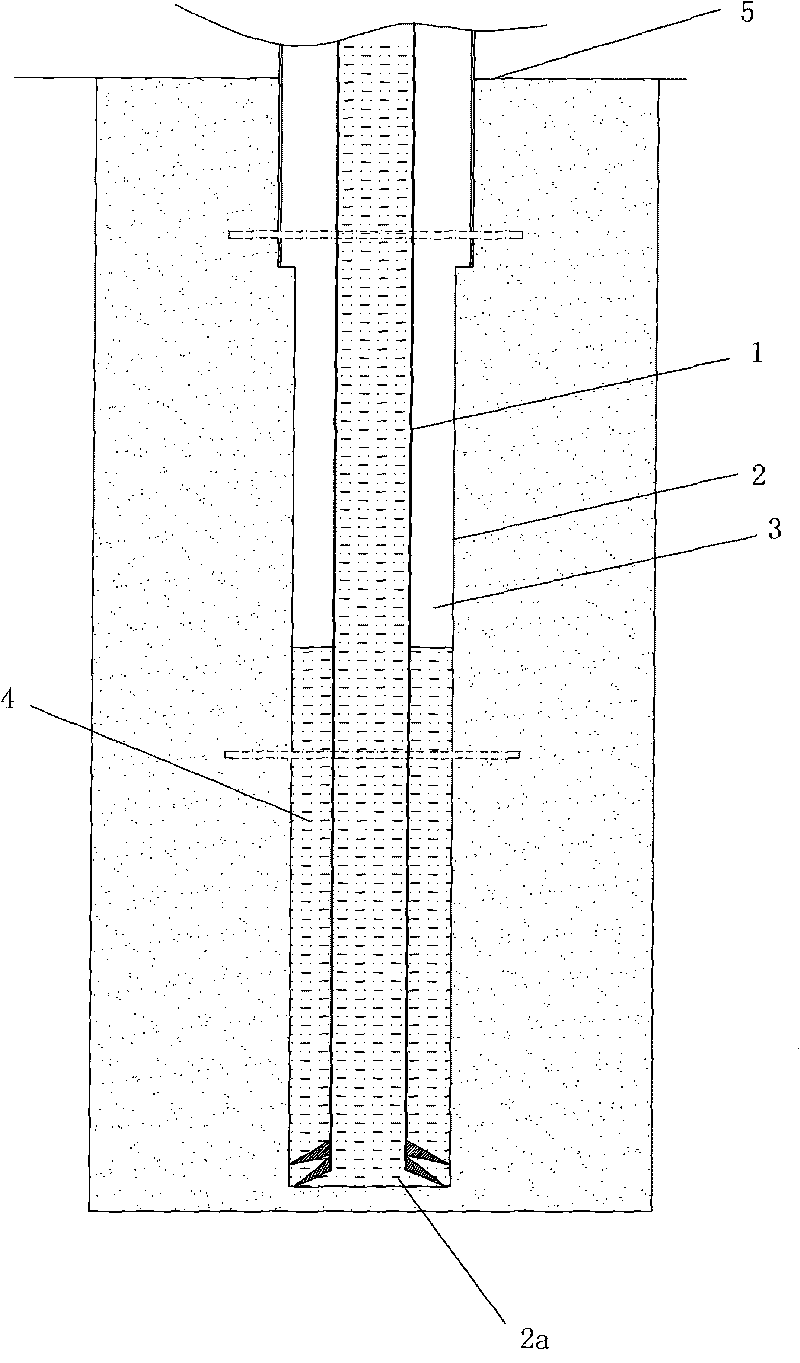

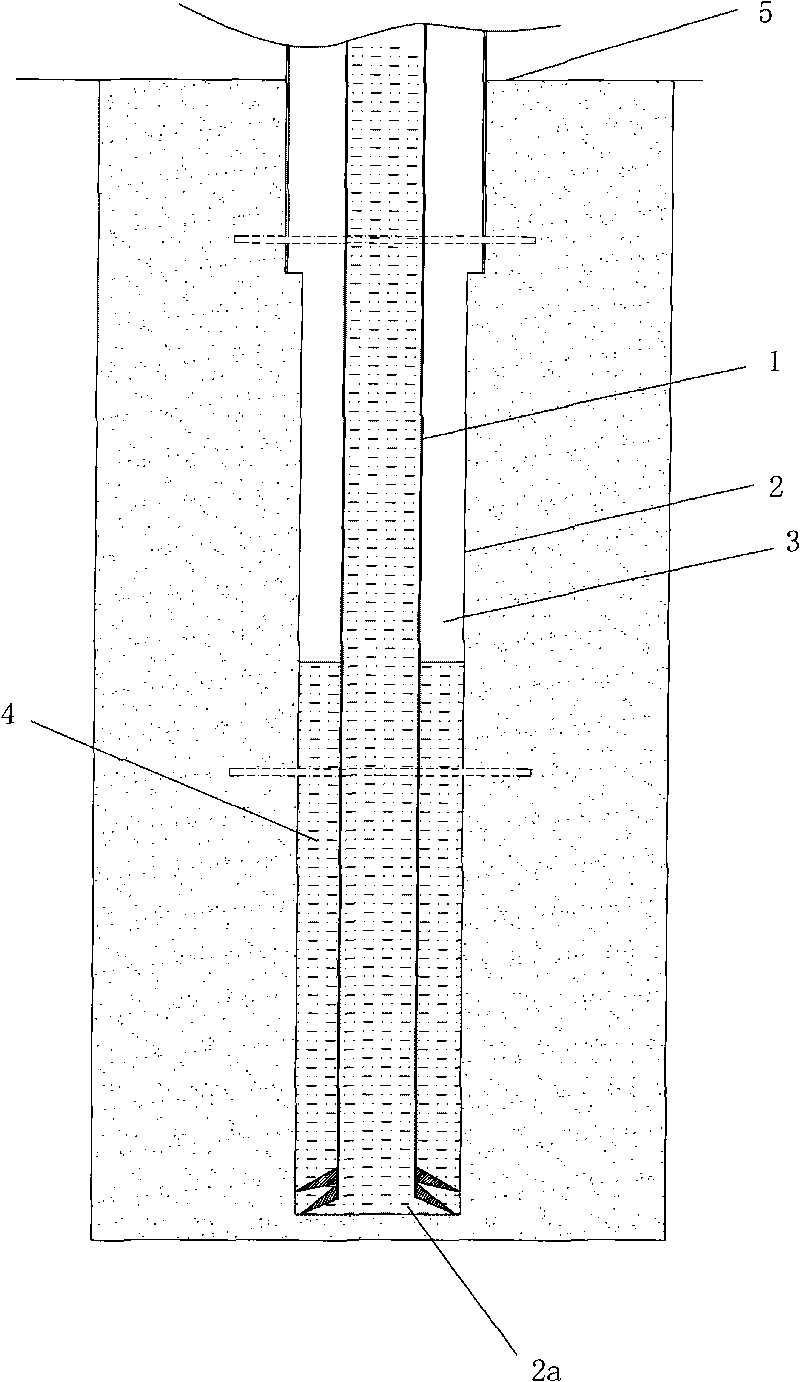

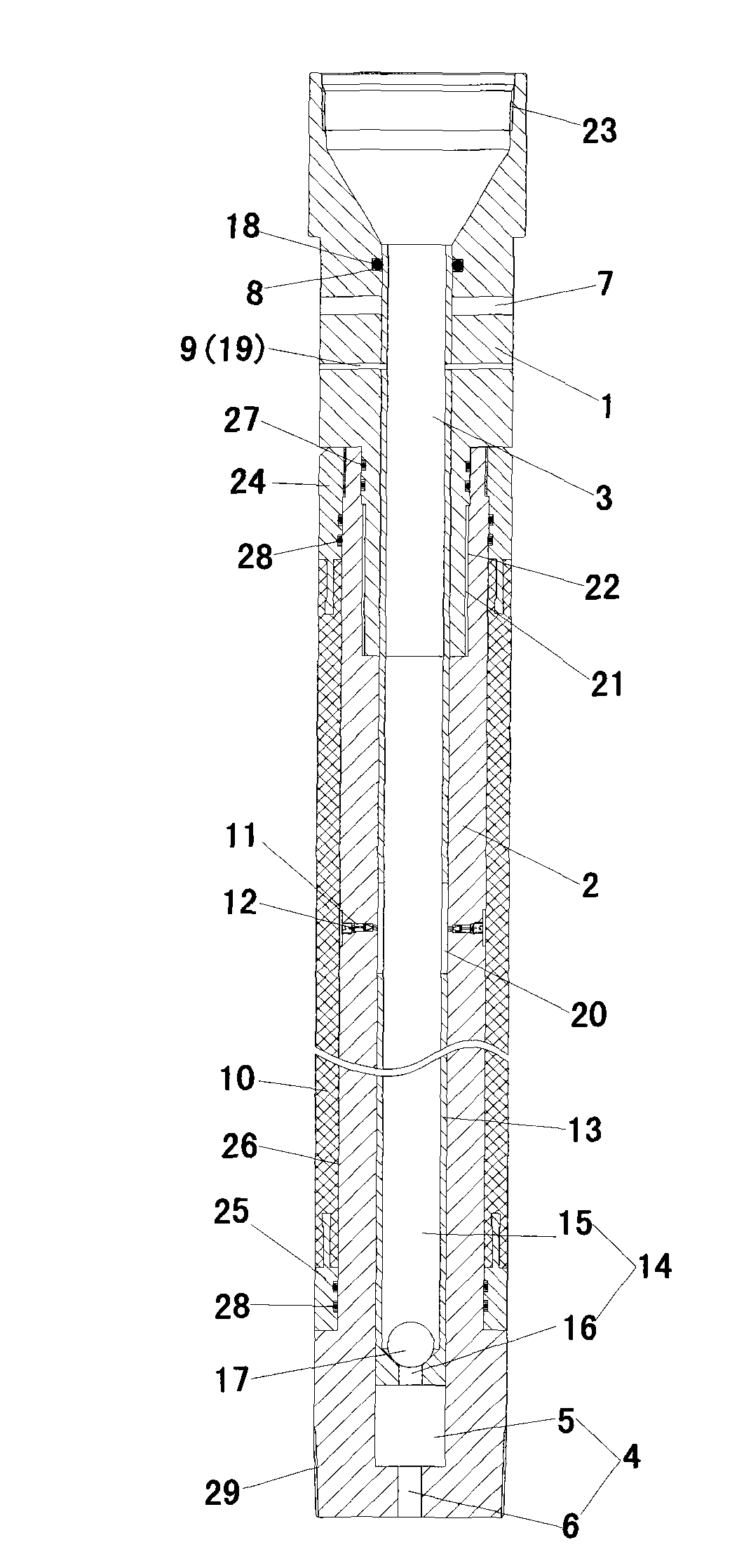

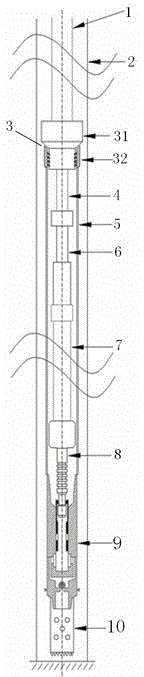

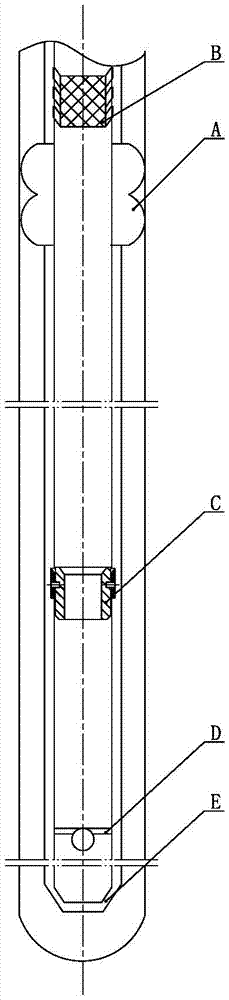

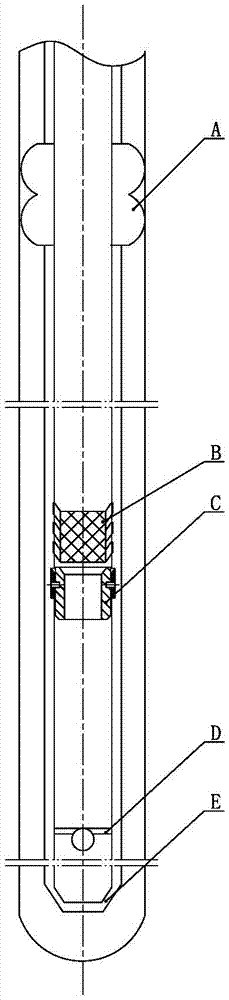

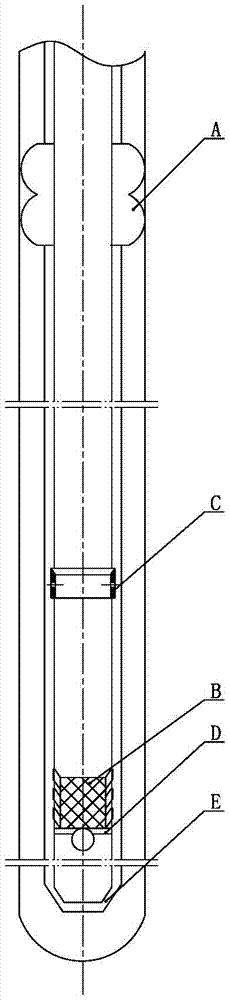

Shaft bottom leakage-proof plugging system and method for cementing well with same

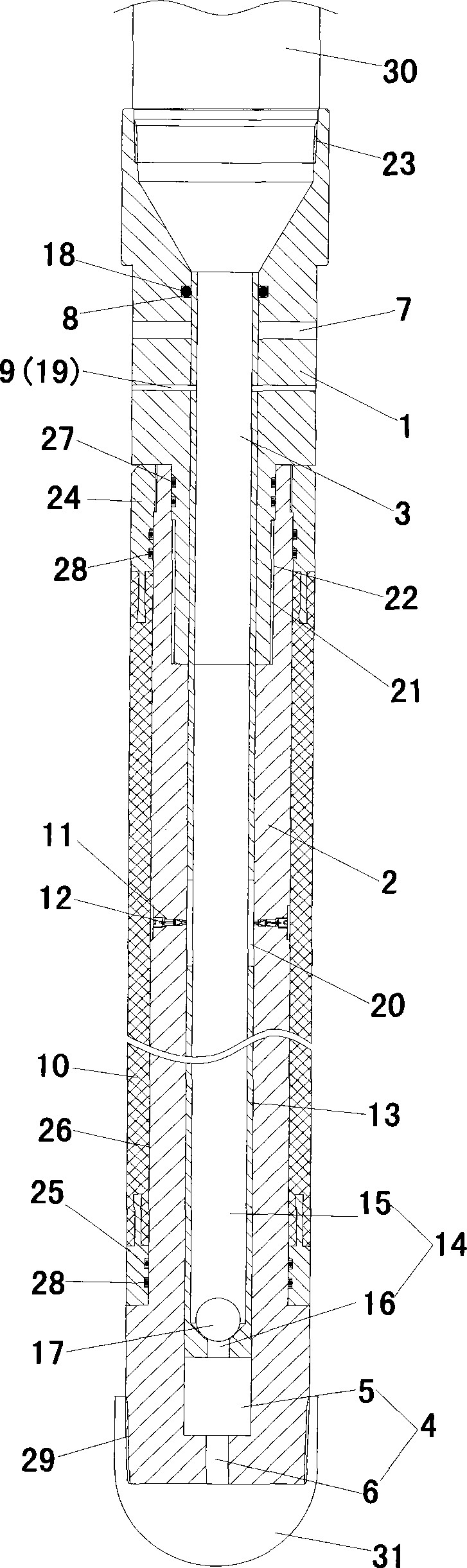

ActiveCN103510911ASimple structureSimple methodWell/borehole valve arrangementsSealing/packingWell drillingWell cementing

The invention discloses a shaft bottom leakage-proof plugging system and a method for cementing a well with the system, and belongs to petroleum drilling and well cementation construction operations. The system is composed of an upper connector, a lower connector, a casing pipe and a casing shoe, the upper connector is connected with the lower connector, and the casing pipe and the casting shoe are arranged on the upper connector and the lower connector respectively. In the well cementation process, when the system is arranged down to the well, after the casing pipe is down to a preset depth, a ball is put in, the ball reaches the second step face of a valve seat barrel, pressurization is carried out in the valve seat barrel, a rubber sleeve expands due to pressure and extrudes a well wall, fixed sealing and isolation is achieved, then pressurization is carried out further, a shear pin is shorn, the pressure pushes the valve seat barrel to move to the first step face, a bypass hole of the upper connector is exposed out, cement paste is poured in through the upper end of the casing pipe, flows out of the bypass hole, and is filled into the space between the well wall and the casing pipe, the normal well cementation operation is carried out, the poured-incement paste in the well cementation process can be prevented from being leaked through a well bottom leakage layer, the smooth well cementation operation is guaranteed, well cementation quality is guaranteed, and the system is simple in structure and convenient to mount.

Owner:XINJIANG GRAND OILFIELD TECH

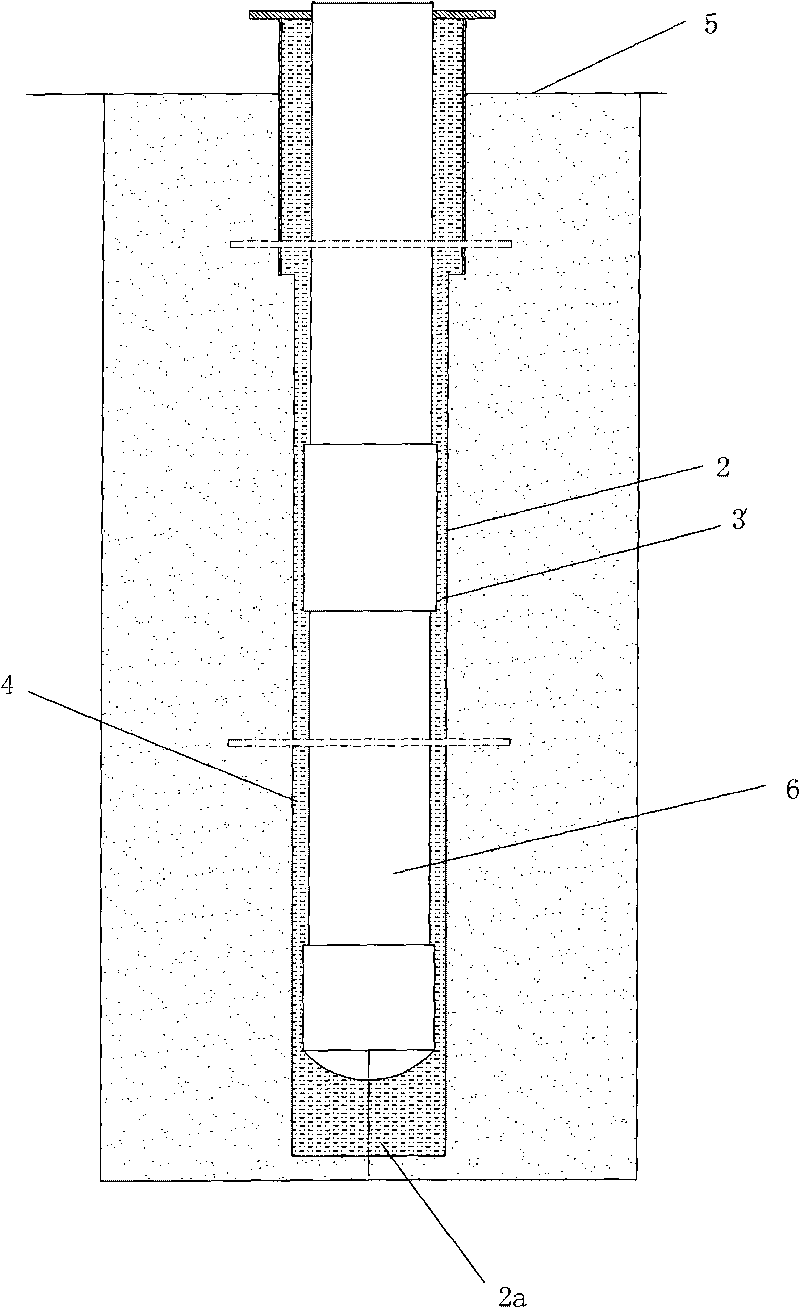

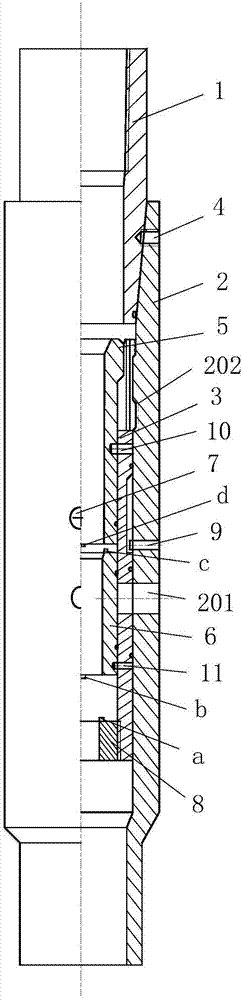

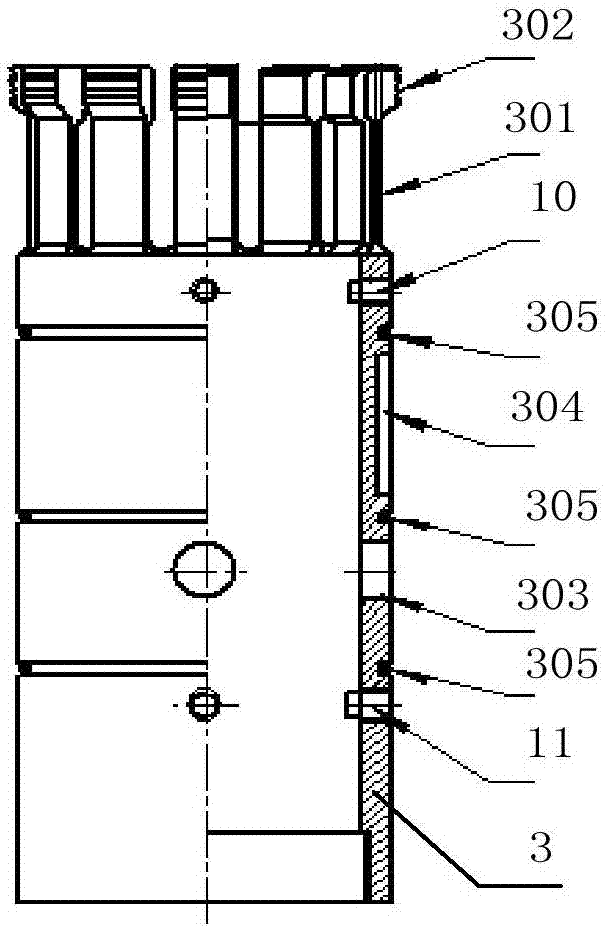

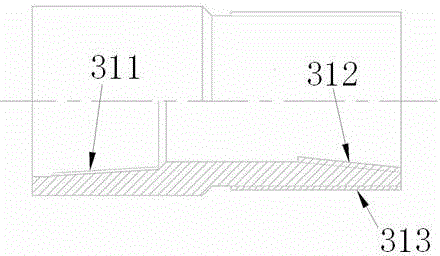

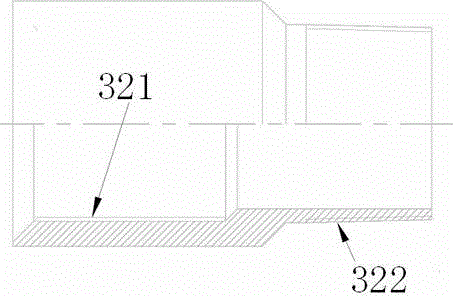

Shaft bottom leakage-proof plugging device for well cementation

ActiveCN103510904ASimple structureRealize the purpose of sealing the leakage layer at the bottom of the wellSealing/packingWell cementingEngineering

The invention discloses a shaft bottom leakage-proof plugging device for well cementation, and belongs to petroleum drilling well cementation construction operation. The shaft bottom leakage-proof plugging device comprises an upper connector and a lower connector which are connected with each other. The center of the upper connector is provided with a first through hole, and the center of the lower connector is provided with a second through hole. The second through hole is a big-end-up stepped hole which is composed of a first cylindrical hole and a second cylindrical hole. The outer surface of the upper connector is provided with a plurality of by-pass holes and shear pin holes in the circumferential direction, wherein the shear pin holes are located below the by-pass holes. An inner cavity of the upper connector is provided with an annular packing groove which is located above the by-pass holes. The outer surface of the lower connector is connected with a rubber sleeve in a sleeved mode. The middle portion of the lower connector is provided with a plurality of check valves in the circumferential direction. A valve seat barrel is mounted in the first through hole and the second through hole. A third through hole in the center of the valve seat barrel is a big-end-up stepped hole which is composed of a third cylindrical hole and a fourth cylindrical hole. Balls are placed on step surfaces. Packing is mounted between the upper portion of the valve seat barrel and the packing groove. The valve seat barrel is connected with the upper connector through a plurality of shear pins. The valve seat barrel is provided with a plurality of fourth through holes communicated with the check valves. The shaft bottom leakage-proof plugging device can guarantee smooth proceeding of a cement job and cementing quality, and is simple in structure and convenient to install.

Owner:XINJIANG GRAND OILFIELD TECH

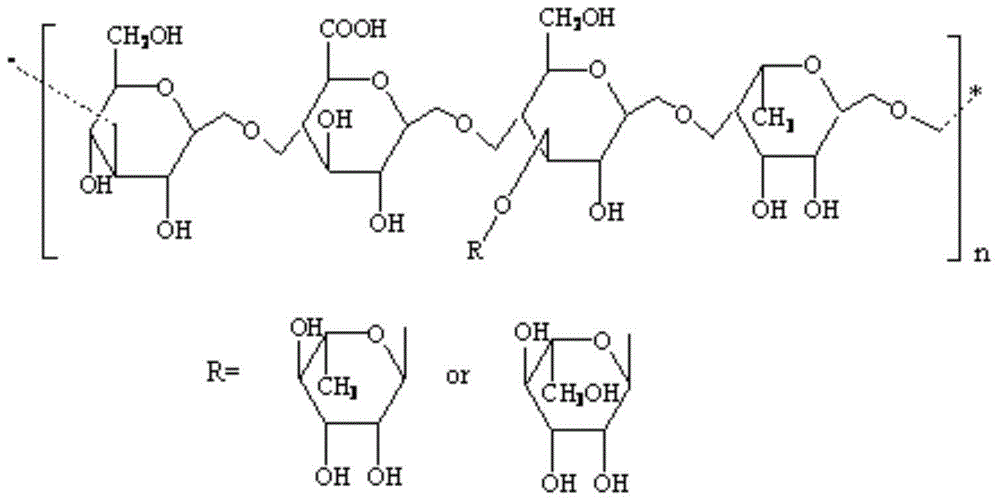

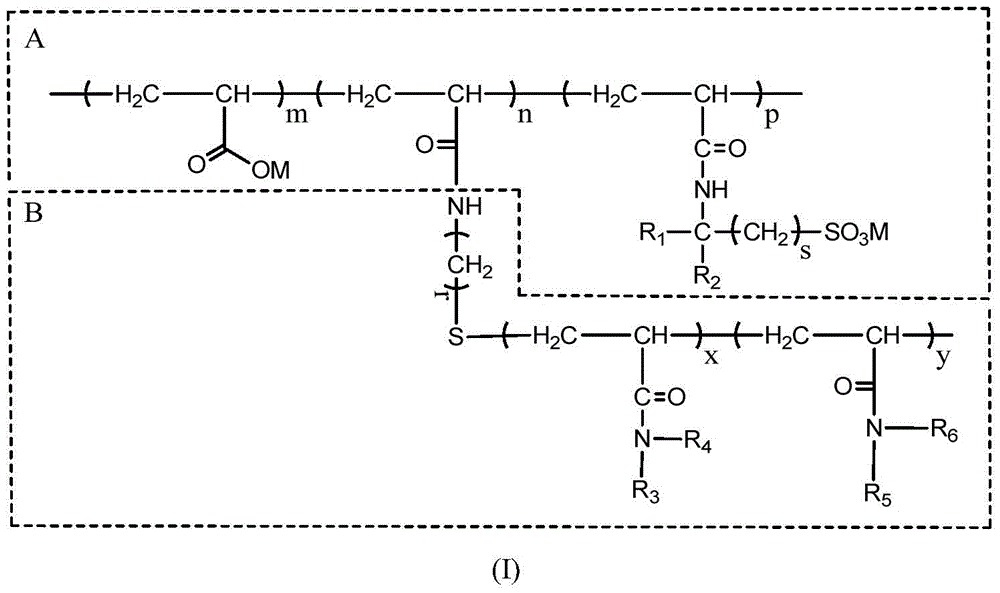

Suspended stable fluid loss agent, preparation method thereof and application of fluid loss agent in horizontal well cementation

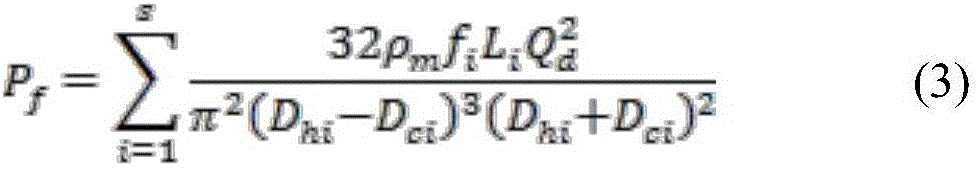

ActiveCN113336896ADegree of reductionReduce apparent viscosityDrilling compositionSealing/packingAcryditePolymer science

The invention provides a suspended stable fluid loss agent, a preparation method thereof and application of the fluid loss agent in horizontal well cementation. The preparation method comprises the following steps: S1, carrying out polymerization reaction on 4-7 parts by weight of sodium p-styrenesulfonate, 4-6 parts by weight of acrylic acid, 3-5 parts by weight of N, N-dimethylacrylamide and 0.5-2 parts by weight of N-vinyl pyrrolidone to obtain a linear main chain polymer; and S2, carrying out graft copolymerization modification on the linear main chain polymer by adopting 0.5 to 2 parts by weight of 2-acrylamido-2-methylpropanesulfonic acid, 0.2 to 1.0 part by weight of acrylic acid, 0.2 to 1.2 parts by weight of N, N-dimethylacrylamide and 0.05 to 0.3 part by weight of methyl acrylate, so as to obtain the suspended stable fluid loss agent. The suspended stable fluid loss agent has the characteristics of fluid loss reduction property, suspension stability, low viscosity, good compatibility and low cost, and can improve the well cementation quality of a horizontal well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

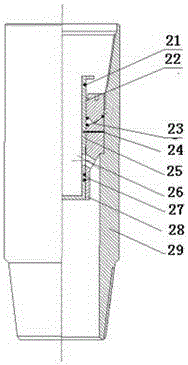

Turbine type flow sensor for oil field well cementing

InactiveCN101413813AHigh concentricityReduce measurement errorVolume/mass flow by dynamic fluid flow effectSealing/packingEngineeringSteel ball

The invention discloses a turbine flow sensor used in well cementing of an oil field. The turbine flow sensor consists of a sensor body, a through-shaft turbine assembly, an inlet flow guide frame, an outlet flow guide frame, an inlet joint and an outlet joint. The sensor body is a cylindrical metal tube; the through-shaft turbine assembly comprises a turbine, a turbine shaft, a shaft sleeve, steel balls, a steel ball cushion, an adjusting bolt, a spring retaining ring and a lock nut; the through-shaft turbine assembly is fixed in the sensor body by the inlet flow guide frame and the outlet flow guide frame; the inlet joint and the outlet joint are respectively a detachable structure and are hermetically connected with two ends of the sensor body by screw threads; and the sensor body is provided with a signal amplifier interface. The turbine flow sensor has the advantages of having high concentricity, tiny measurement error, simple structure and low fabrication cost by using the through-shaft turbine assembly, achieving fast and convenient disassembly by using the detachable interface, greatly prolonging the service life by the shaft sleeve made of polyurethane, accurately monitoring the flow rate of the injected slurry and assuring the quality of the well cementation by accessing a signal detection amplifier and a secondary instrument which are set according to a magnetic force line cutting principle.

Owner:天津市大港仪表有限公司

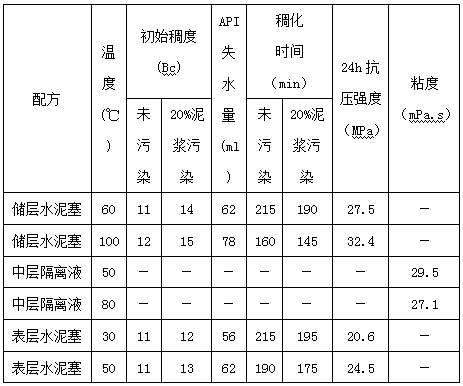

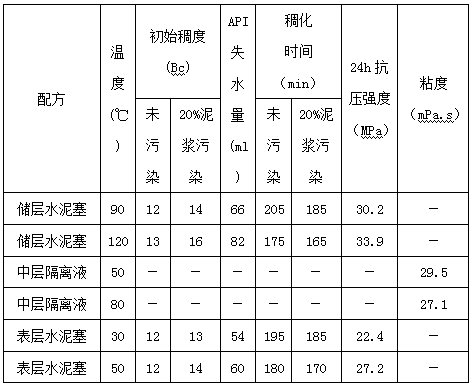

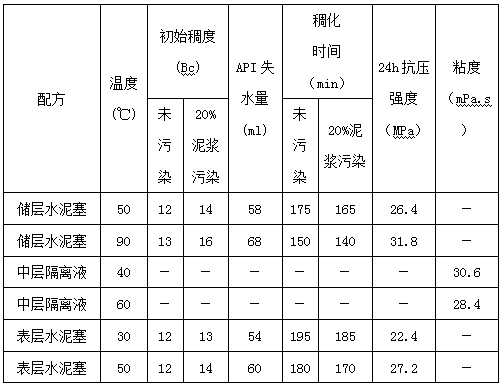

A suspended cement plug suitable for coiled tubing operations and its application method

The invention relates to a suspended cement plug applicable to continuous oil pipe injection and an application method of the suspended cement plug. The suspended cement plug comprises the following three formulae: a reservoir cement formula, an intermediate layer isolating liquid formula and a surface layer cement plug formula, wherein the reservoir cement formula is prepared by adding 1%-2% of a dispersant, 1%-2% of a fluid loss agent, 5%-10% of micro-silicon and 0.1%-0.5% of a retarder into G-level high sulfate resistant oil well cement, and the water cement ratio is 0.45; the intermediate layer isolating liquid formula is prepared by starting to apply 0.5% polyacrylamide water solution to a position which is 500m lower than the contact surface between clean water and a surface layer cement plug, and the 0.5% polyacrylamide water solution needs to be prepared before 4h; the surface layer cement plug formula is prepared by adding 1% of a dispersant, 1% of a fluid loss agent and 0-0.2% of a retarder into the G-level high sulfate resistant oil well cement, and the water cement ratio is 0.45. According to the suspended cement plug, expensive cement slurry is replaced with intermediate layer isolating liquid, so that the production cost is greatly lowered when the sealing quality is guaranteed, and furthermore, the cement slurry at the reservoir and the surface layer is good in performance and rheological property and strong in anti-pollution capacity and can still maintain good overall performance when 20% of cement slurry is polluted. The suspended cement plug is applicable to the sealing of abandoned wells.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

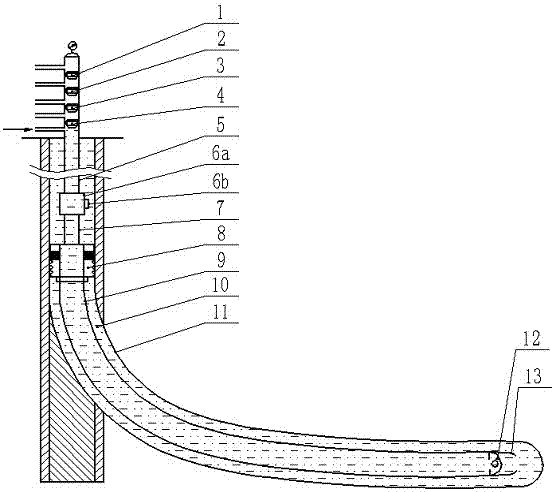

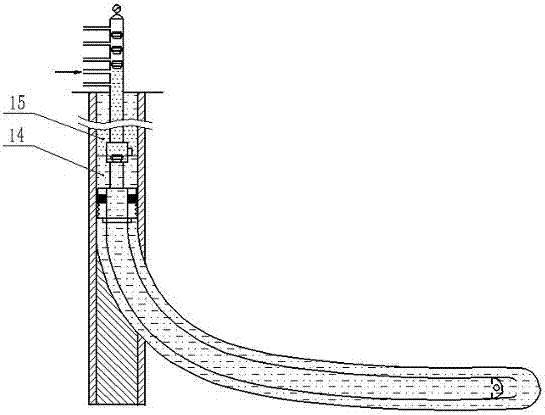

Secondary well cementing technique and secondary well cementing device by liner pipe

ActiveCN104879089AReasonable structural designImprove reliabilityDrilling rodsWell/borehole valve arrangementsWell cementingPipe

The invention discloses a secondary well cementing technique and a secondary well cementing device by a liner pipe. The secondary well cementing device mainly comprises a conveying pipe string, an inner string and an outer string, wherein the conveying string mainly comprises an upper release sub body and a lower release sub body which are in screwed connection with a tubing I, the inner string mainly comprises a tubing nipple, a tubing length compensator, a tubing II and an inserting pipe which are in screwed connection with the upper release sub body sequentially, and the outer string mainly comprises the liner pipe, an inserting pipe well cementing valve and a zigzag screen pipe which are in screwed connection with the lower release sub body sequentially. The secondary well cementing technique adopting the secondary well cementing device includes the steps of determining a well cementing segment, placing the outer string and the inner string in the well cementing segment, performing pumping injection, boosting, using workover fluid for washing a well bore, injecting cement for well cementation, backwashing a well and the like. The secondary well cementing device has the advantages of reasonable structural design, wide application range, high reliability, high sealability, simple technology and capabilities of guaranteeing well cementing quality, substantially improving operation efficiency and substantially reducing construction cost.

Owner:中国石油化工股份有限公司华东油气分公司泰州采油厂

Oil and gas well cementation tubular column and well cementation method

PendingCN106761545AImprove construction efficiencyReduce operational riskWell/borehole valve arrangementsSealing/packingWell cementingSelf locking

The invention discloses an oil and gas well cementation tubular column and a well cementation method. The oil and gas well cementation tubular column comprises a casing pipe. A float shoe, a float collar, a blasting sliding sleeve and a well shut-in sliding sleeve are sequentially arranged on the sleeve from bottom to top. A blasting piece and a piston are arranged in the blasting sliding sleeve. The blasting piece is used for pushing the piston to move to form a fluid channel in the blasting sliding sleeve for well cementation construction, a self-locking device is arranged in the well shut-in sliding sleeve and used for closing the fluid channel, a cement plug is formed, and well cementation construction is completed. The novel well cementation method that the float collar and the float shoe fail to be opened, and after the well cementation tubular column descends to a preset position, pumping cannot establish circulation is provided, construction efficiency is improved, and working risks are reduced.

Owner:PETROCHINA CO LTD

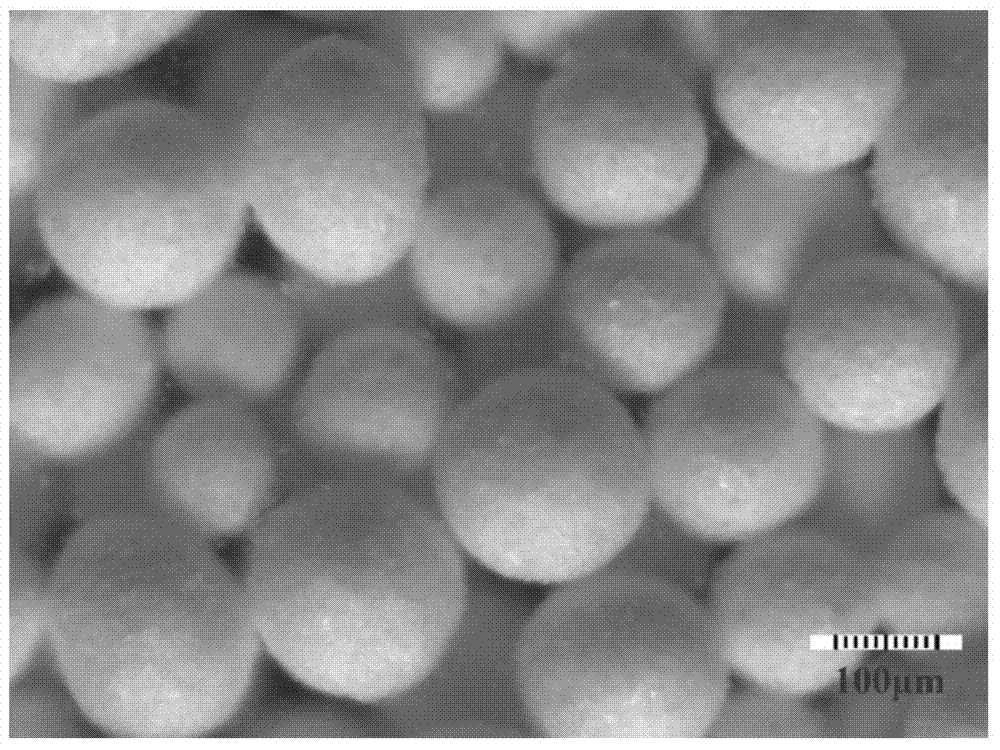

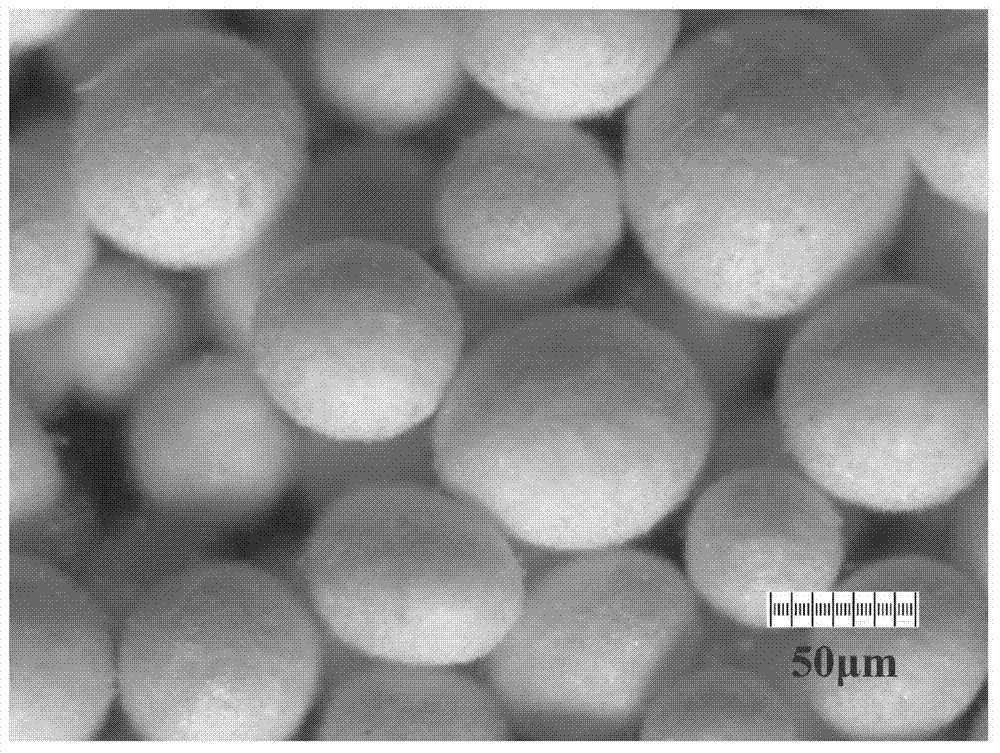

Gypsum microspheres and low elasticity modulus expansion well cementation cement system

ActiveCN104774601ALow elastic modulusWith micro-expansion propertiesDrilling compositionMicrosphereSilicon

The invention discloses gypsum microspheres and a low elasticity modulus expansion cement system suitable for medium and low temperature well cementation. The gypsum microspheres are obtained through inverse setting and hardening of a certain proportion of anhydrite, alpha-type hemihydrate gypsum and water. The low elasticity modulus expansion cement system comprises 100 parts of oil well cement, 10-40 parts of gypsum microspheres, 5-10 parts of micro-silicon and 65-75 parts of water, and the volume expansion of set cement and the reduction of elasticity modulus of the set cement are simultaneously realized due to the addition of the gypsum microspheres. The low elasticity modulus expansion cement system meets the long-term requirements of cement sheath isolation completeness and has important engineering significance for ensuring well cementation quality and long-term safety production of oil-gas wells.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

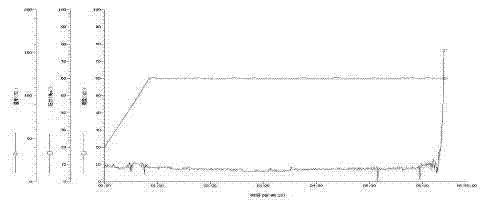

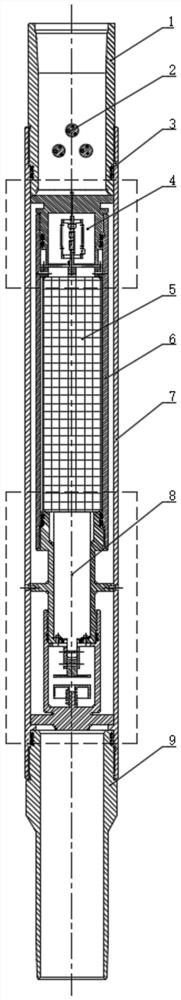

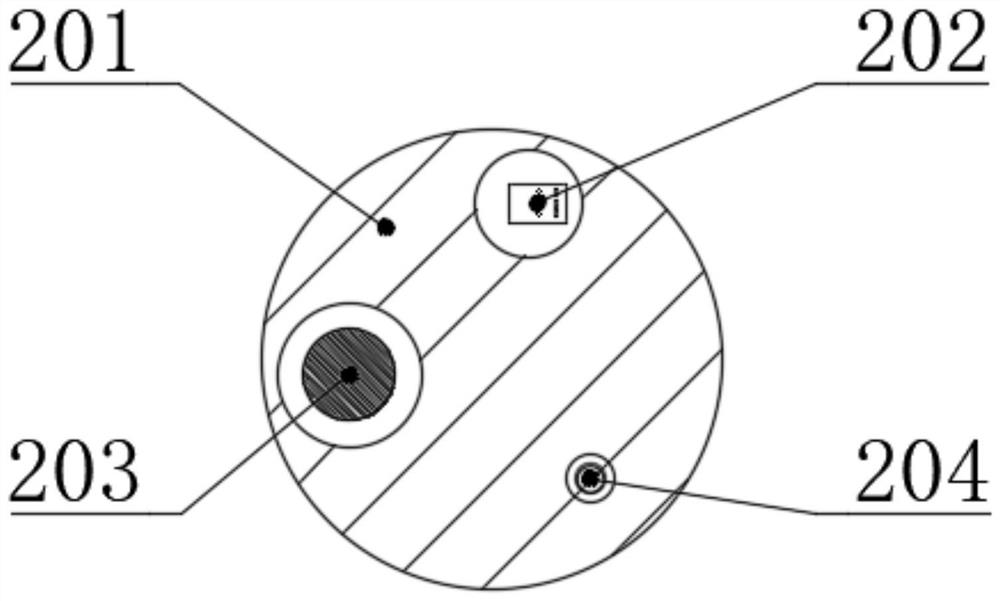

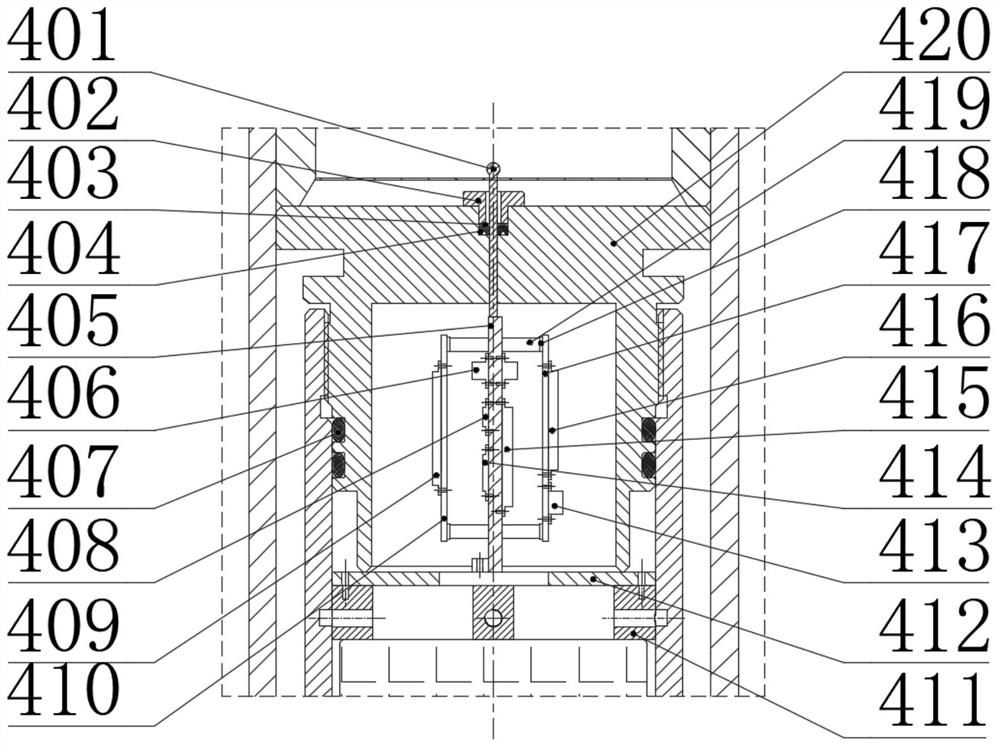

Linear motor vibration well cementation device based on RFID control and well cementation method

ActiveCN112901109ARealize sweeping vibrationImprove liquidityAC motor controlCo-operative working arrangementsVibration amplitudeVibration acceleration

The invention discloses a linear motor vibration well cementation device based on RFID control and a well cementation method, and belongs to the technical field of oil and gas well engineering. The device comprises an upper joint, a signal generating ball, a sealing ring, a control assembly, a high-temperature-resistant battery, a battery mounting sleeve, an outer sleeve, a vibration generating assembly and a lower joint. The RFID-controlled linear motor vibration well cementation device is put into a preset position in a horizontal well, a signal generation ball is put into a casing string at a ground wellhead, a control assembly is activated, the control assembly controls a high-temperature linear motor to work, a vibration generation assembly works to generate vibration, an acceleration sensor detects the acceleration generated by vibration, and the acceleration sensor detects the acceleration generated by vibration. The acceleration circuit board tests the vibration amplitude of the vibration well cementation device, through algorithm analysis, the frequency sweep circuit board finds the optimal vibration frequency in the frequency sweep range, and the motor control circuit board controls the high-temperature-resistant linear motor to continuously work at the optimal vibration frequency point.

Owner:CHINA AGRI UNIV

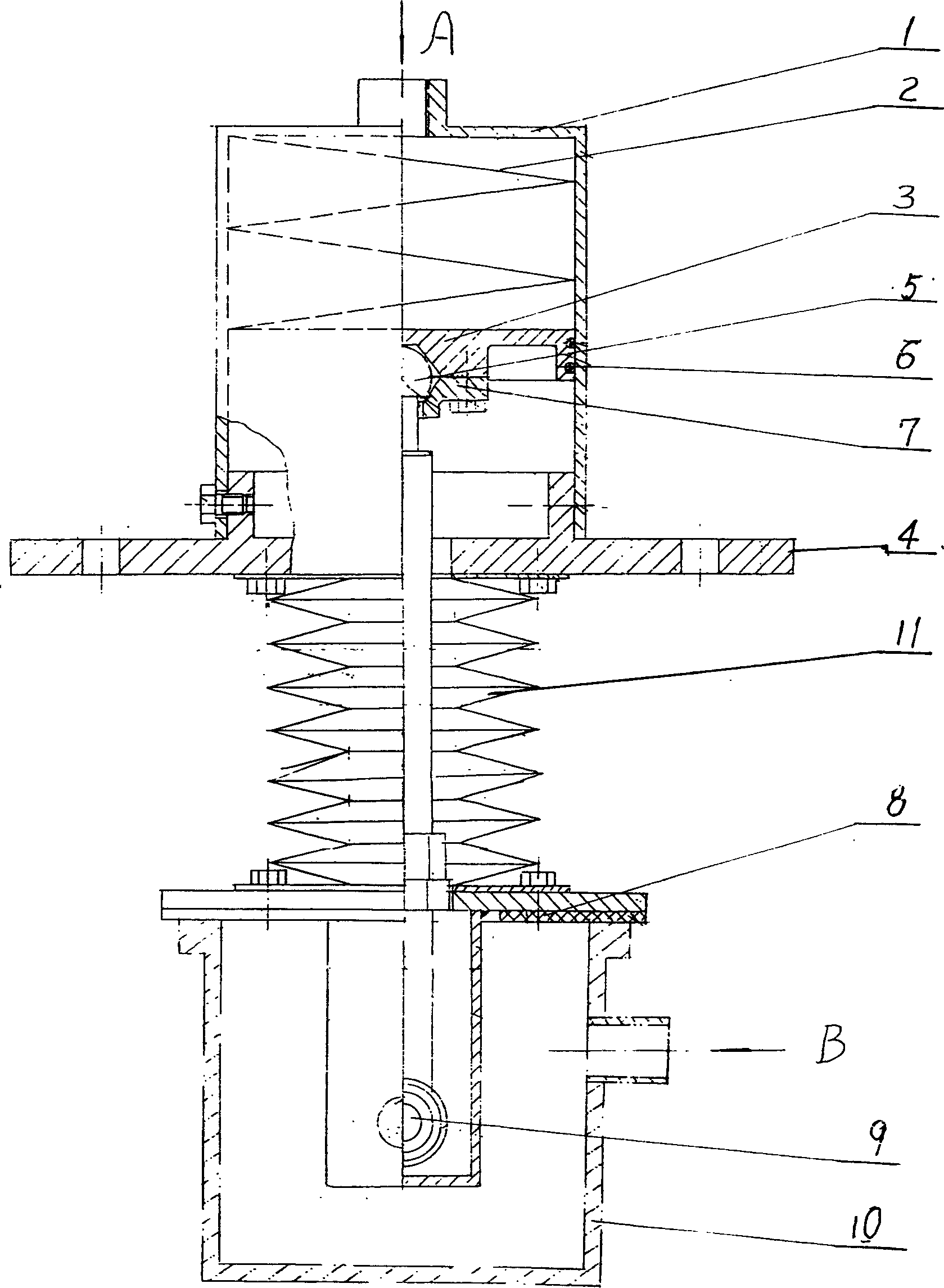

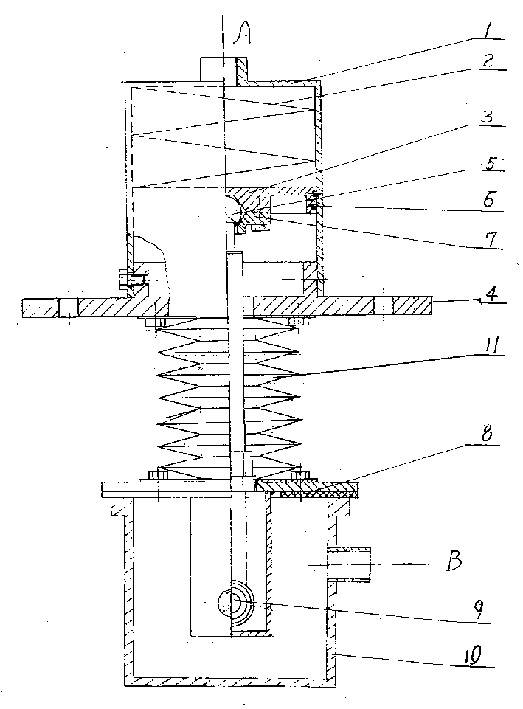

Cylinder unit for constant-pressure tank

InactiveCN1506558AEliminates the problem of air leaksGuarantee cementing qualitySealing/packingCylinder headWell cementing

The present invention is cylinder unit for constant-pressure tank for well cementing operation in exploiting petroleum and natural gas. The present invention consists of constant-pressure container, sealing unit to ensure the constant-pressure sealing of the constant-pressure container, seal ensuring unit and sealing cap. The sealing unit includes cylinder, piston and elastic part inside the cylinder, and cylinder head; the seal ensuring unit pinshaft and other parts. The present invention can ensure the constant pressure of the constant pressure tank reliably without leakage, and its use can raise the exploitation quality of oil and gas well.

Owner:华丽缘

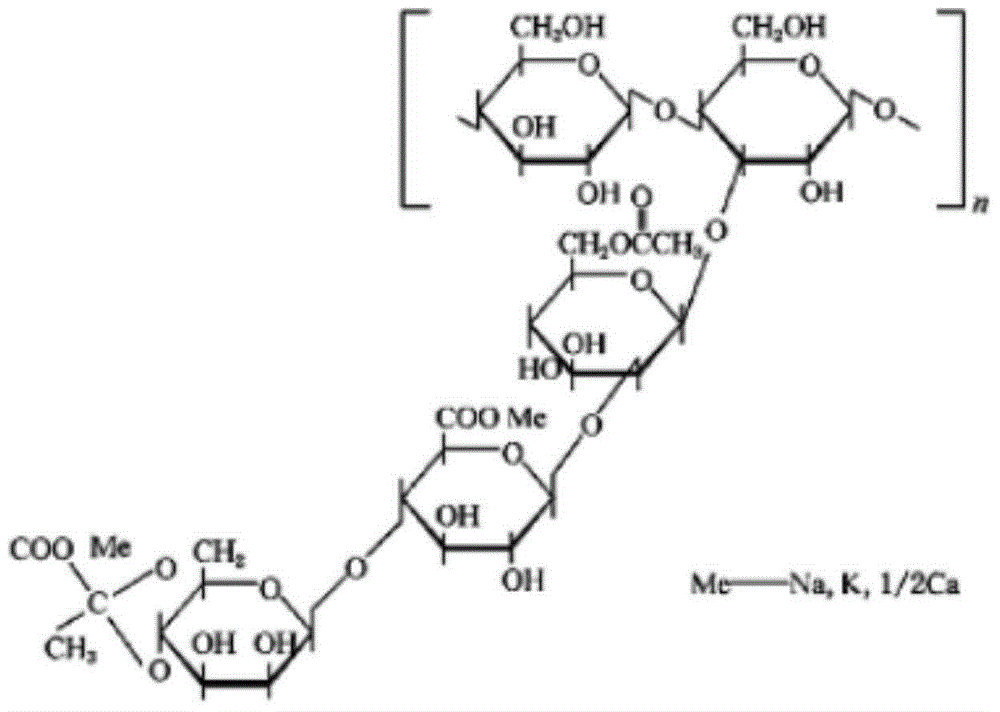

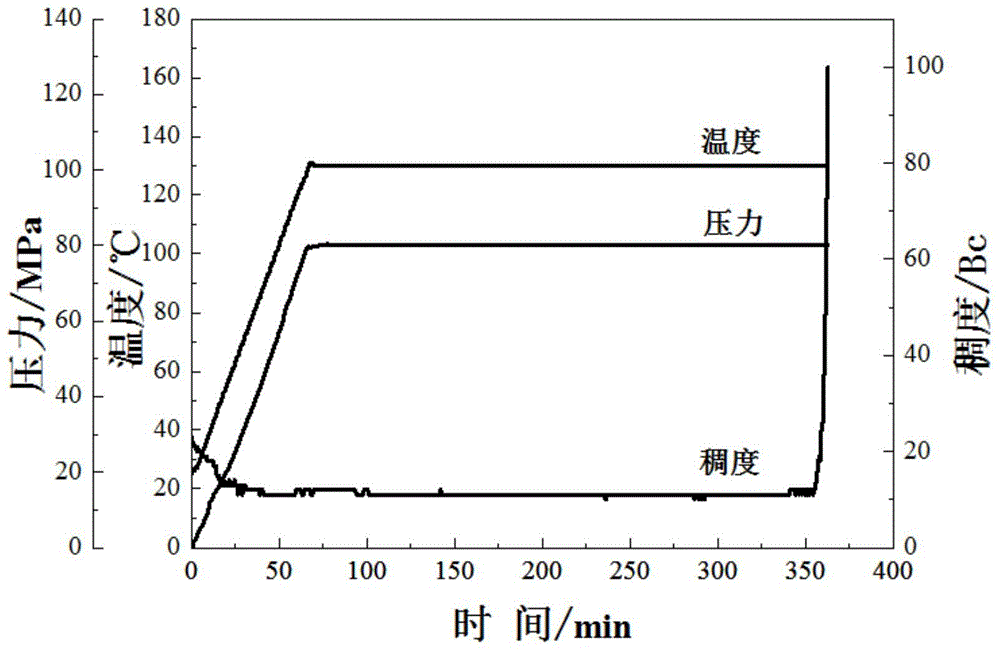

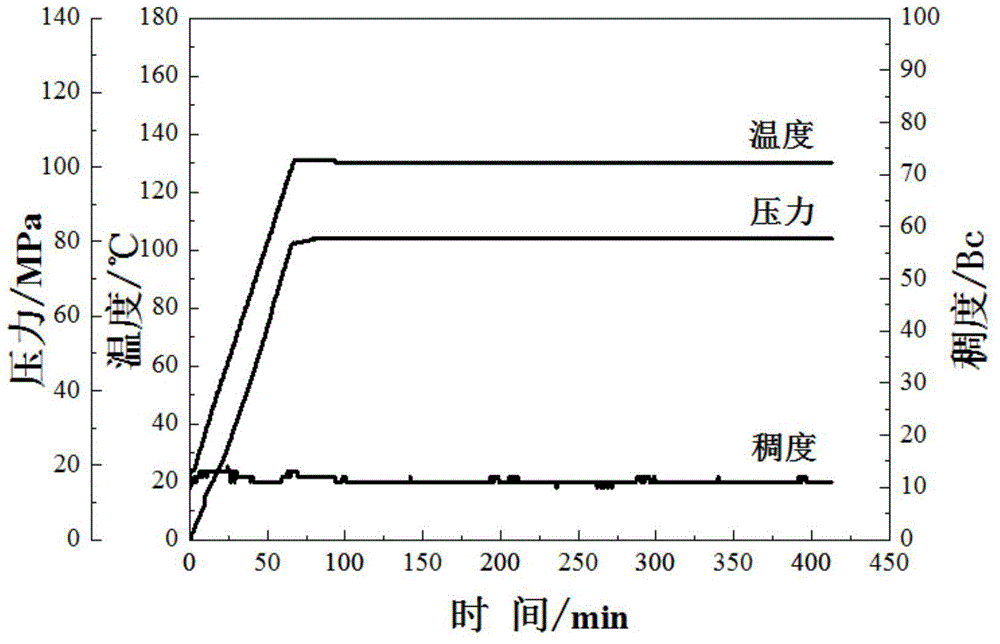

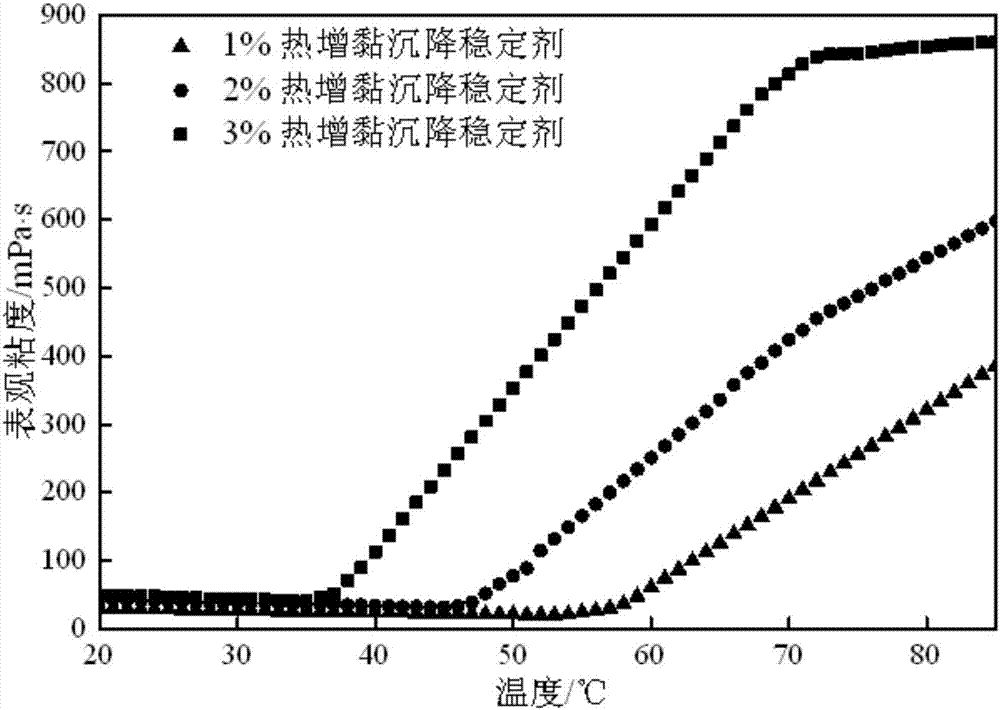

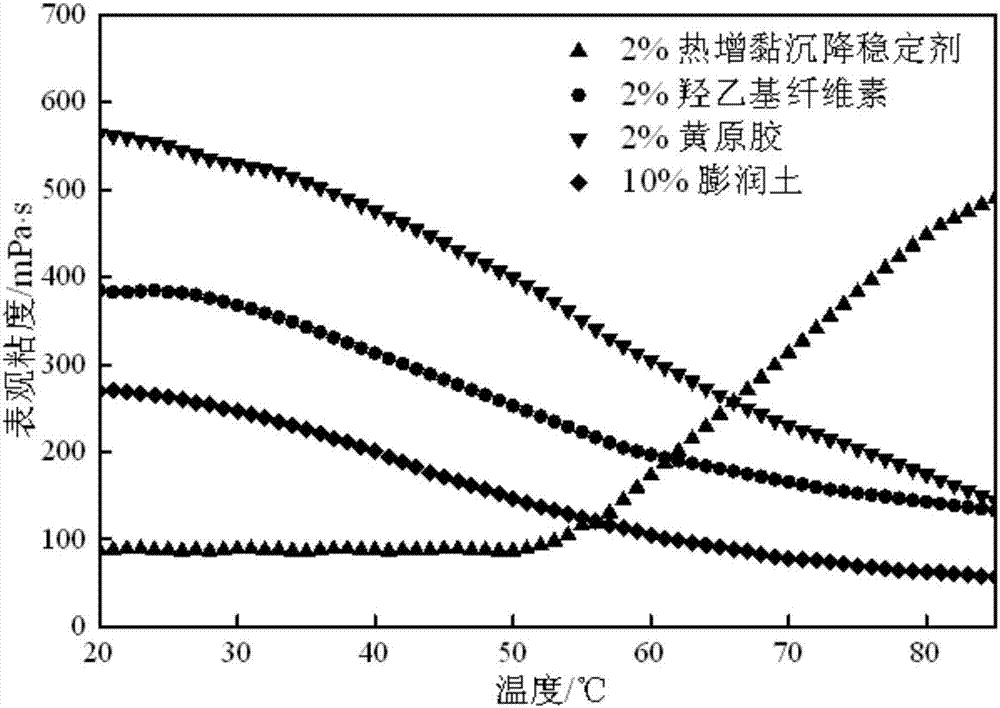

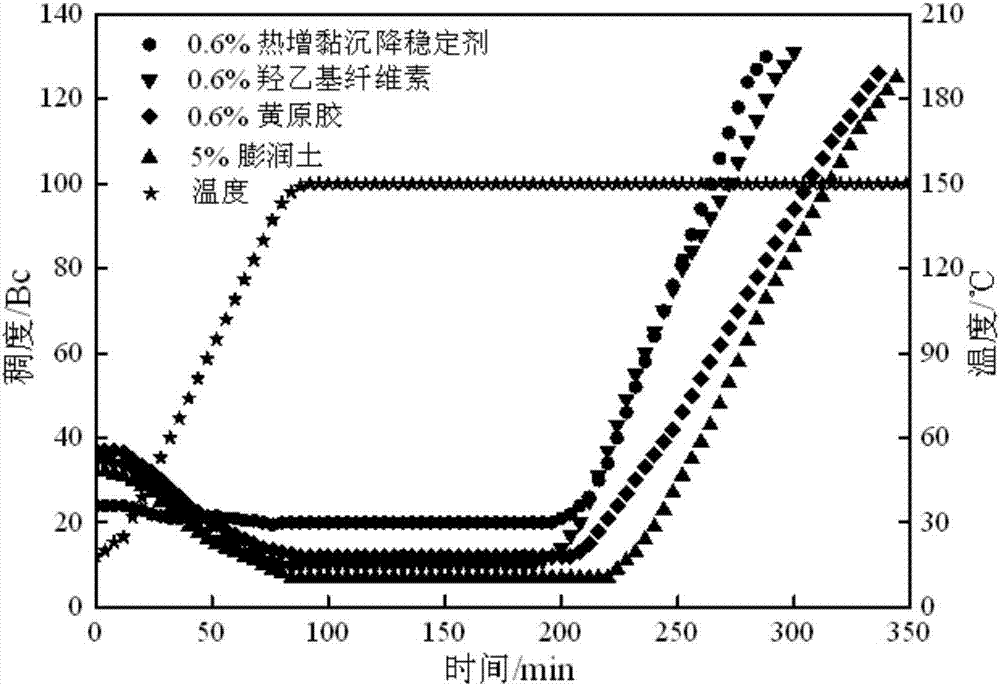

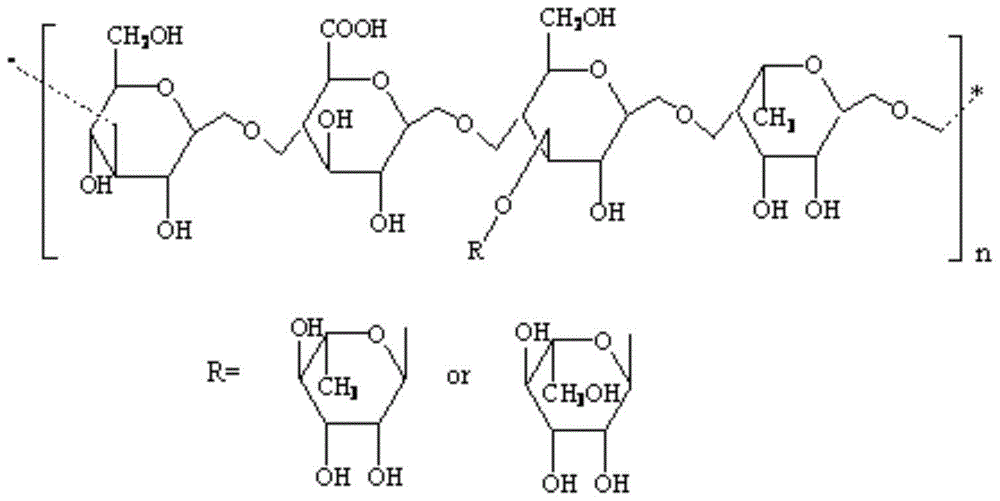

Heat viscosity increasing settling stabilizer for oil well cement paste, preparation method thereof and application

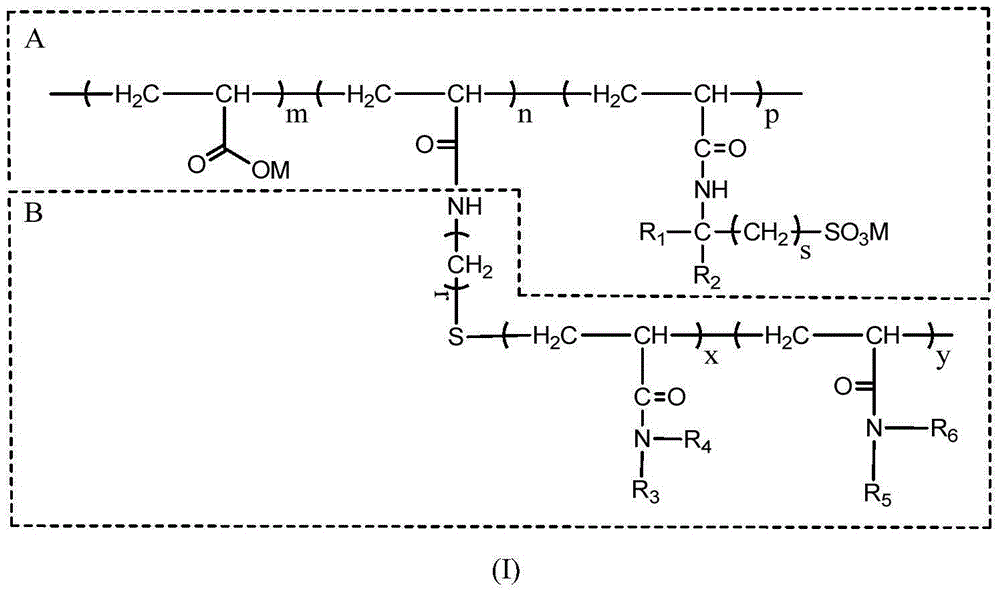

ActiveCN106967397ASolve the problem of subsidence instabilityHas thermal viscosity-increasing propertiesDrilling compositionAlkaneCellulose

The invention relates to a heat viscosity increasing settling stabilizer for oil well cement paste, a preparation method thereof and an application. The effective component has the structure shown as below: [C6H7O2(OH)2O-R1-OH]m-[C6H7O2(OH)2O-R1-O-R2]n, R1 is -CH2CH2 or CH(CH3)CH2-; R2 is long-chain alkyl, wherein m: n=1: (0.1-0.01), m+n=integer of 100-500. The cellulose is dissolved in alkali solution, and stirred evenly; then soluble salt is added to settle, separate out and filter the molecular weight cellulose; the cellulose is added in alkylene oxide to perform etherification reaction; the product performs hydrophobic modification reaction with long-chain halogenated alkane, the reaction solution is neutralized and filtered; the solid is washed and dried, thus the stabilizer is acquired. The settling stabilizer has the heat viscosity increasing property, and can realize the goal of 'not increasing viscosity under low temperature, and increasing thickness under high temperature' of the oil well cement paste.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A cement slurry stabilizer for well cementing and its preparation method and application

The present invention provides a well cementing cement slurry stabilizer, a preparation method and applications thereof, wherein the well cementing cement slurry stabilizer comprises, by weight, 54-89 parts of quartz sand, 2-20 parts of Welan gum, 0-8 parts of xanthan gum, 3-10 parts of polyvinyl alcohol, and 3-8 parts of a grafted macromolecule polymer. According to the present invention, the stability of the cement slurry can be improved through the stabilizer, the stabilizer does not provide adverse effects on other properties of the cement slurry during the use process, and the stabilizer further provides the benefit on the compressive strength of the cement stone.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cementing device for thin interlayer adjustment wells

ActiveCN107503709AGuarantee cementing qualityShorten the lengthSealing/packingGeothermal energy generationCasing stringWell cementing

The invention relates to a cementing device for thin interlayer adjustment wells. The cementing device comprises a casing string positioned in a borehole; a lower part of the casing string is provided with a thin interlayer linear seal packer; the thin interlayer linear seal packer is corresponding to the borehole thin interlayer in position; a lower end of the thin interlayer linear seal packer is connected with an annulus pressure compensator through a sleeve; a lower end of the annulus pressure compensator is connected with a float collar through a sleeve; a lower end of the float collar is connected with a float shoe through a sleeve. the thin interlayer linear seal packer comprises an upper joint and a center pipe; and upper end of the upper joint is screwed with an upper sleeve; an upper end of the center pipe is screwed on a lower end of the upper joint; the center pipe is sleeved by a rubber sleeve in the middle part; an upper end of the rubber sleeve is embedded in a rubber sleeve support which is installed on the center pipe in a sleeved mode; an elastic support mechanism is installed between an upper part of the rubber sleeve and the upper joint; two rubber sleeve clamp grooves are installed on a periphery of the middle part of the rubber sleeve and setting collars are embedded in the clamp grooves; a lower end surface of the rubber sleeve is provided with a hydraulic compression mechanism. By means of the device, thin interlayer can be reliably sealed and gas and water channeling is avoided.

Owner:SINOPEC SSC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com