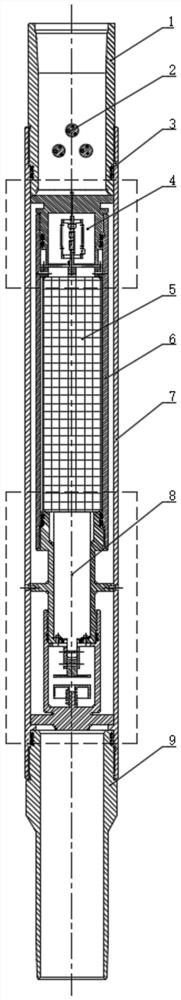

Linear motor vibration well cementation device based on RFID control and well cementation method

A linear motor and cementing technology, which is applied to vibration generating devices, electromechanical devices, and cooperating devices, etc., can solve problems such as uncontrollable amplitude, achieve low processing costs, simple operation methods, and ensure interface bonding strength and cementing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

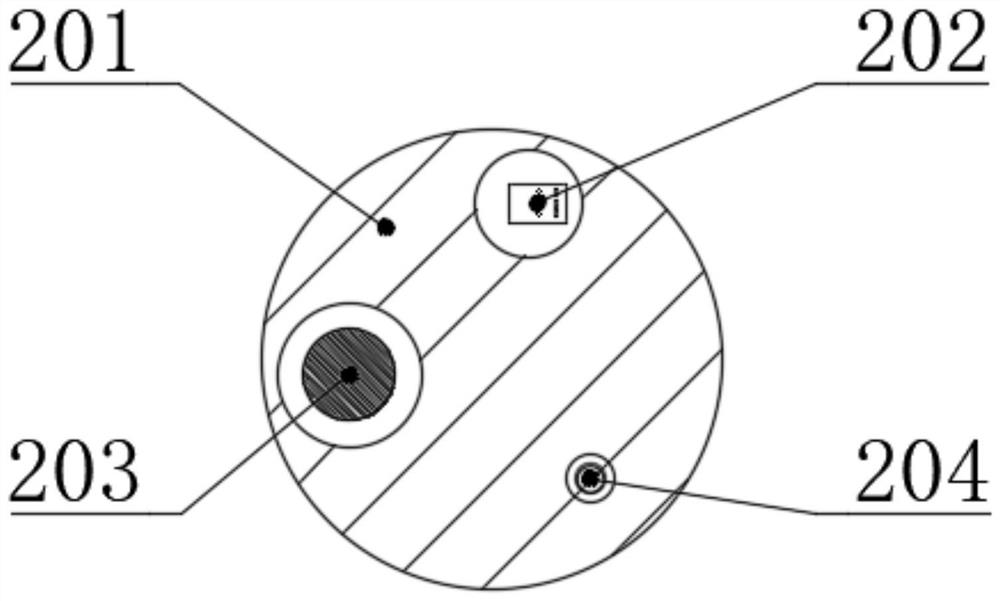

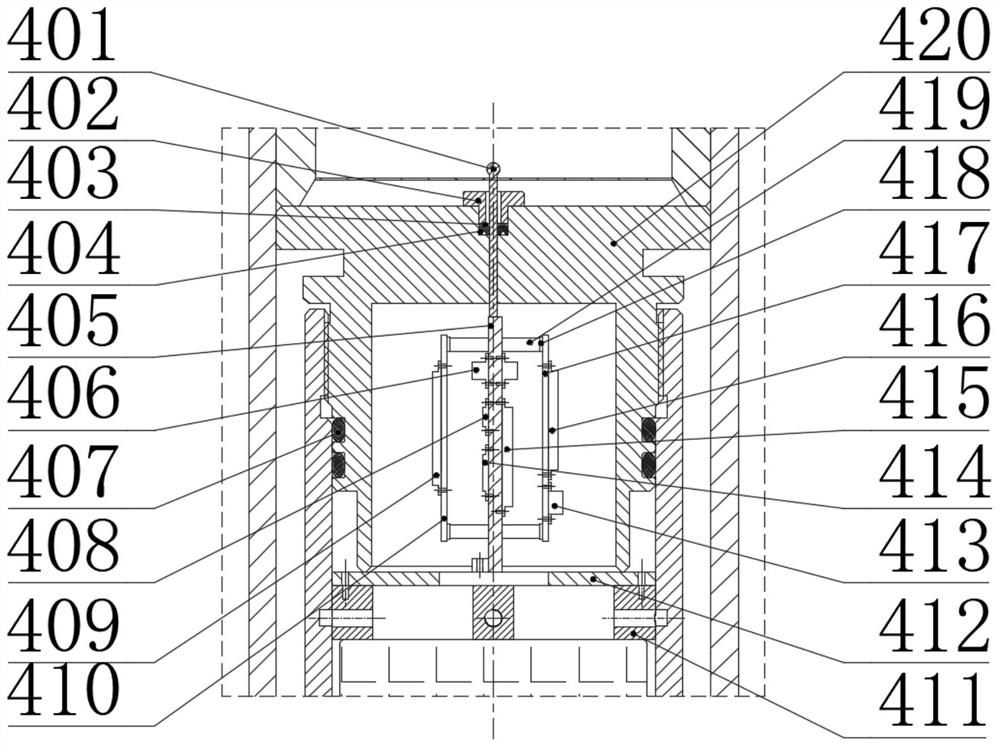

[0036] The cementing method based on the RFID-controlled linear motor vibration cementing device is applied to the vibration cementing stage in the oil drilling process. First, the RFID-controlled linear motor vibration cementing A certain number of signal generating balls 2, the signal generating balls 2 continuously emit microwave signals to the surroundings during the falling process, when the signal generating balls 2 are lowered into the interior of the upper joint 1, the signal receiving antenna 401 receives the microwave signals and transmits them to the The reader 406, the reader 406 is in a dormant state, is activated after receiving the microwave signal, and the reader 406 enters the working state; the motor control circuit board 415 starts to work, and the pair of control components 4 and the vibration generation component 8 in the high temperature resistant battery 5 The linear motor 801 in starts to supply power. The linear motor 801 starts to reciprocate after be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com