Patents

Literature

88results about "Linear DC motor control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linear motor controller

ActiveUS20050168179A1Decline in power responseAvoid Compressor DamageWorking fluid for enginesElectric motor speed/torque regulationLinear compressorGas compressor

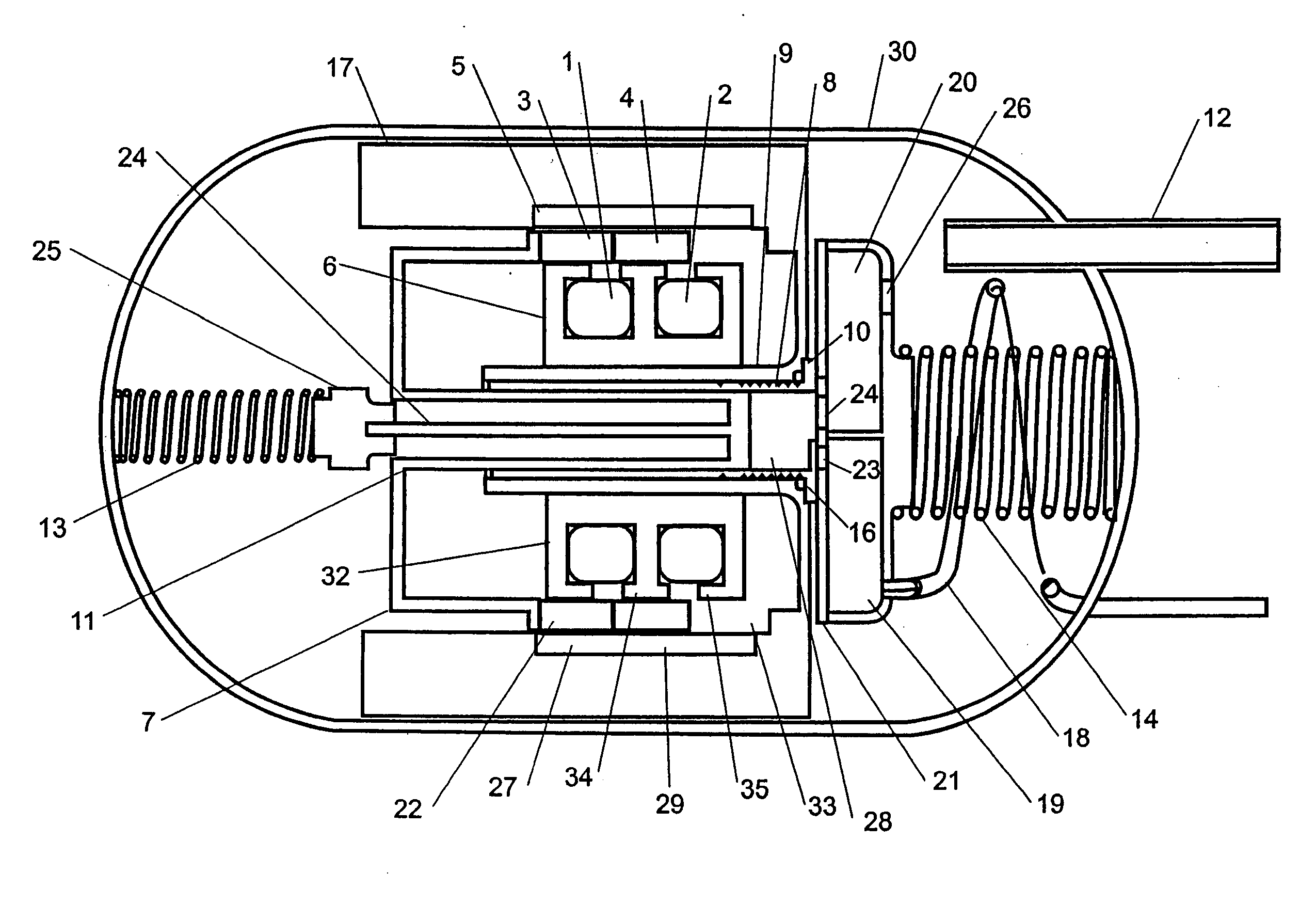

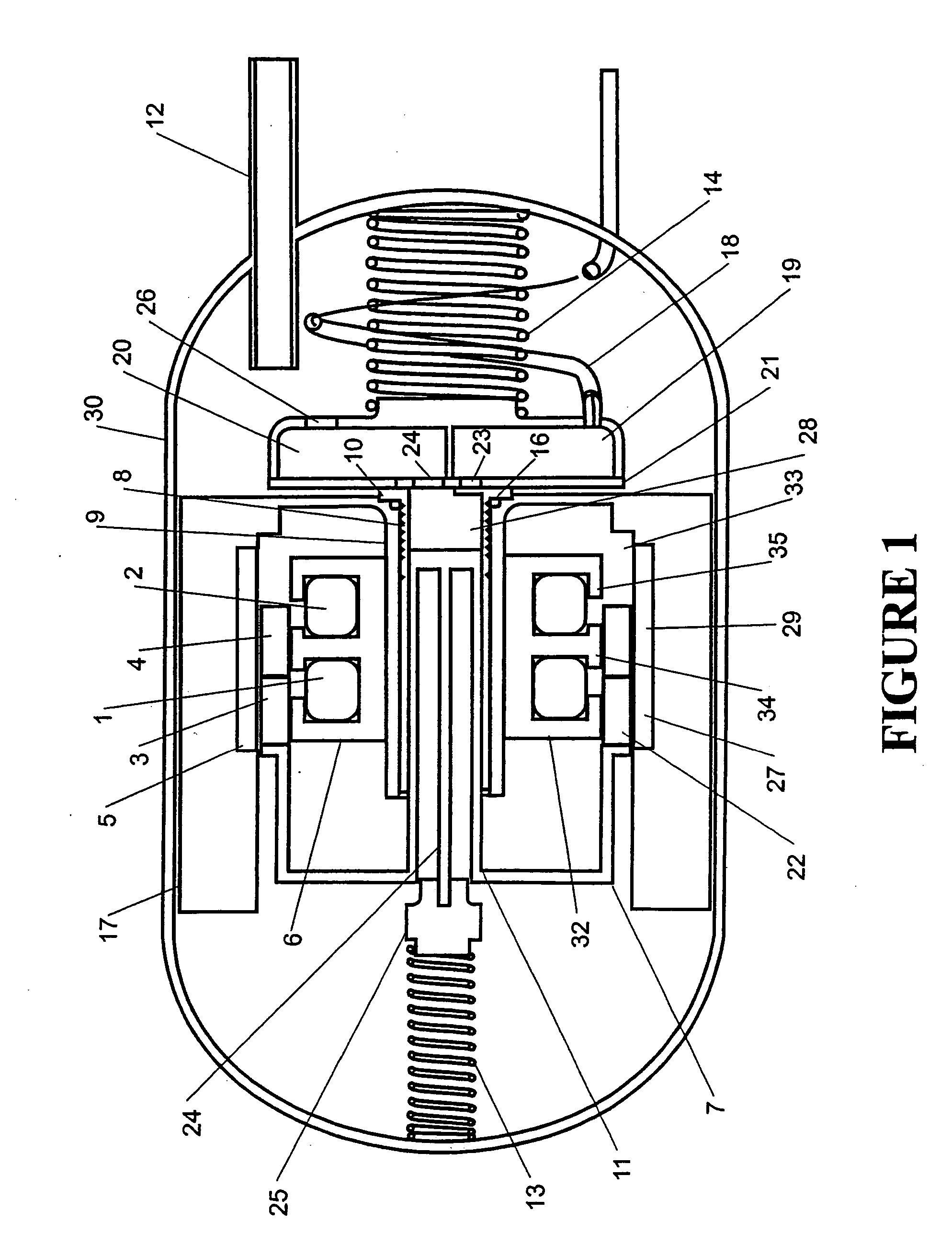

A sensorless method of detecting piston collisions in a reciprocating free piston linear compressor driven by an electronically commutated linear motor having at least one excitation winding is provided. A free piston gas compressor is also provided.

Owner:FISHER & PAYKEL APPLIANCES LTD

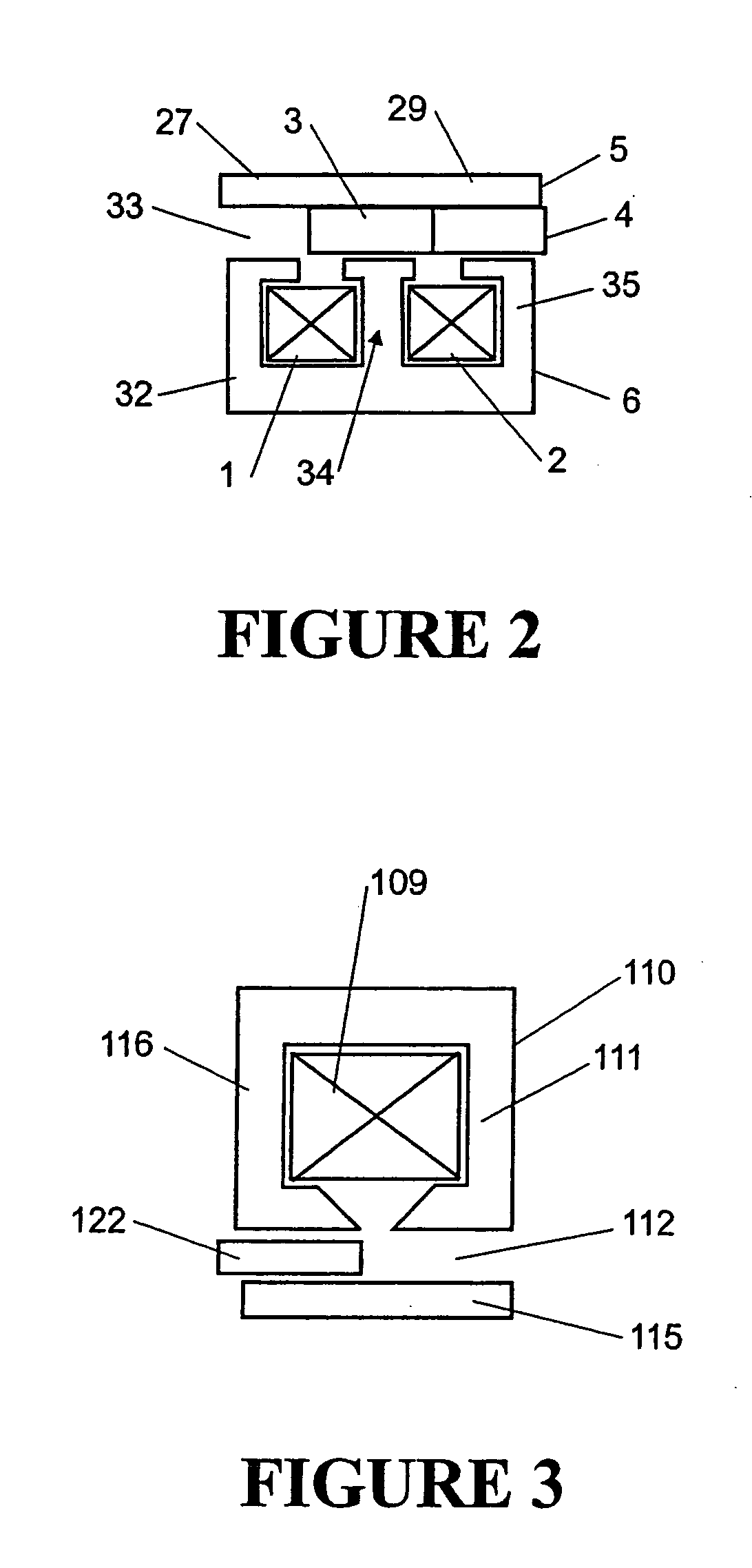

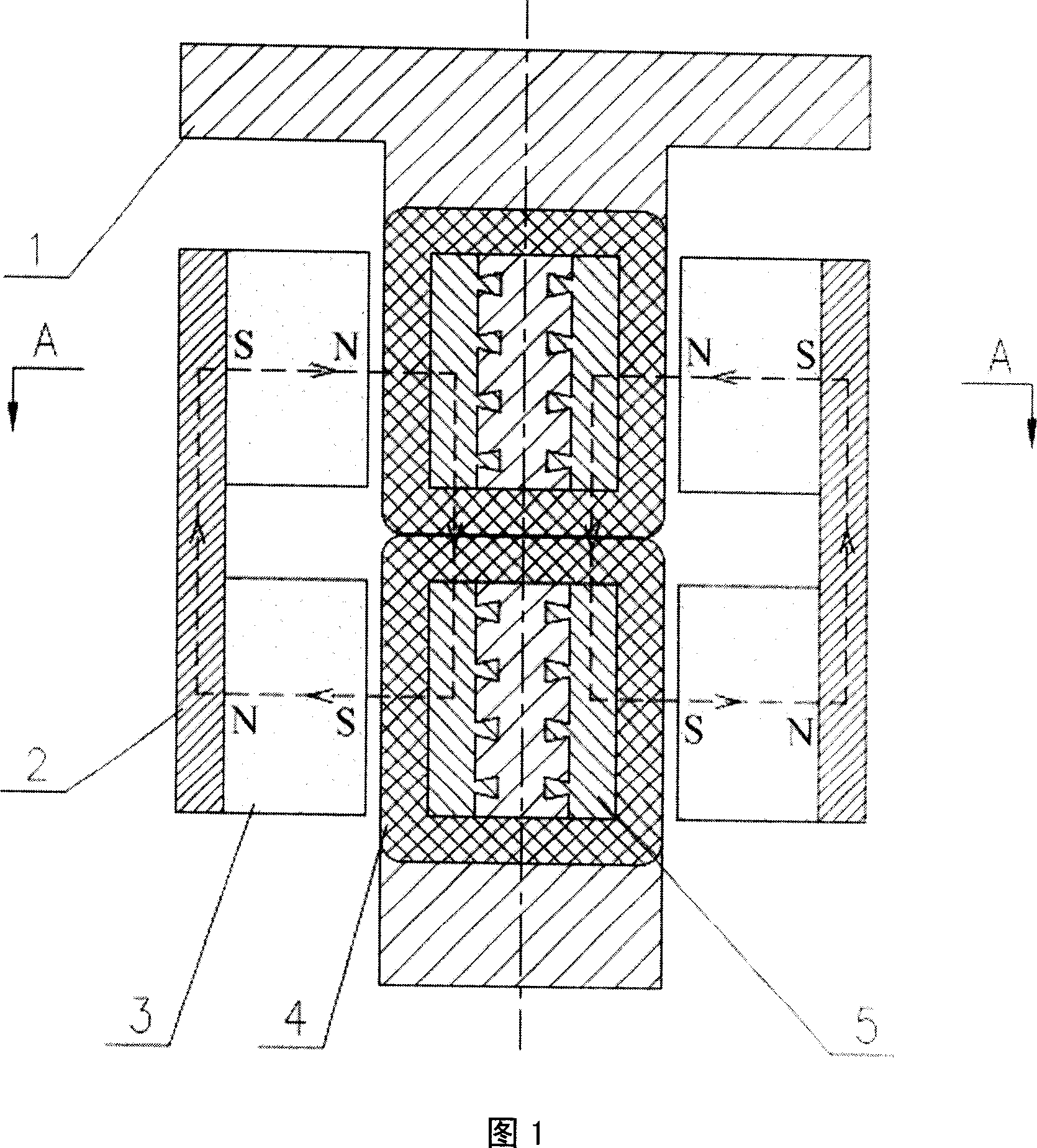

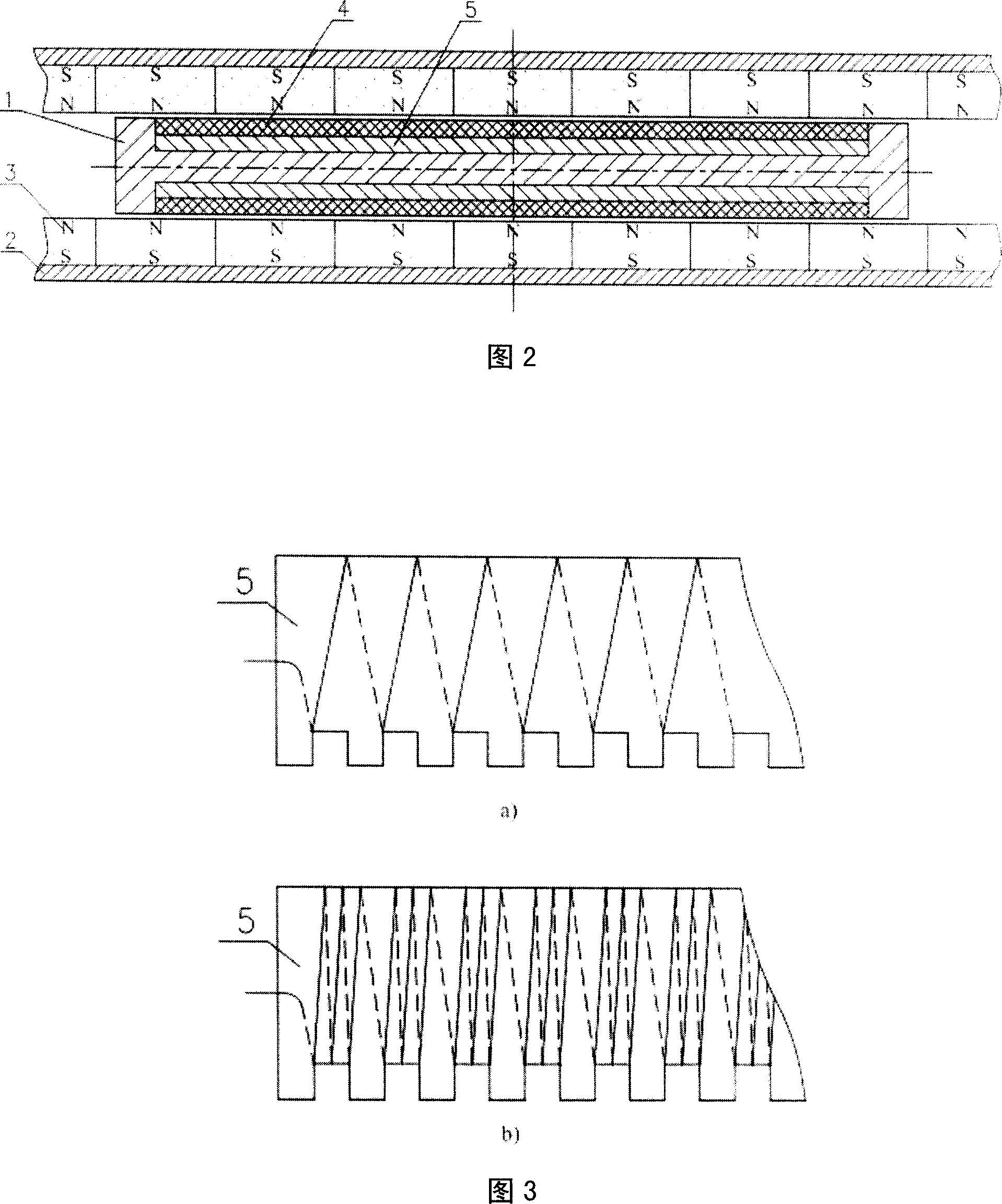

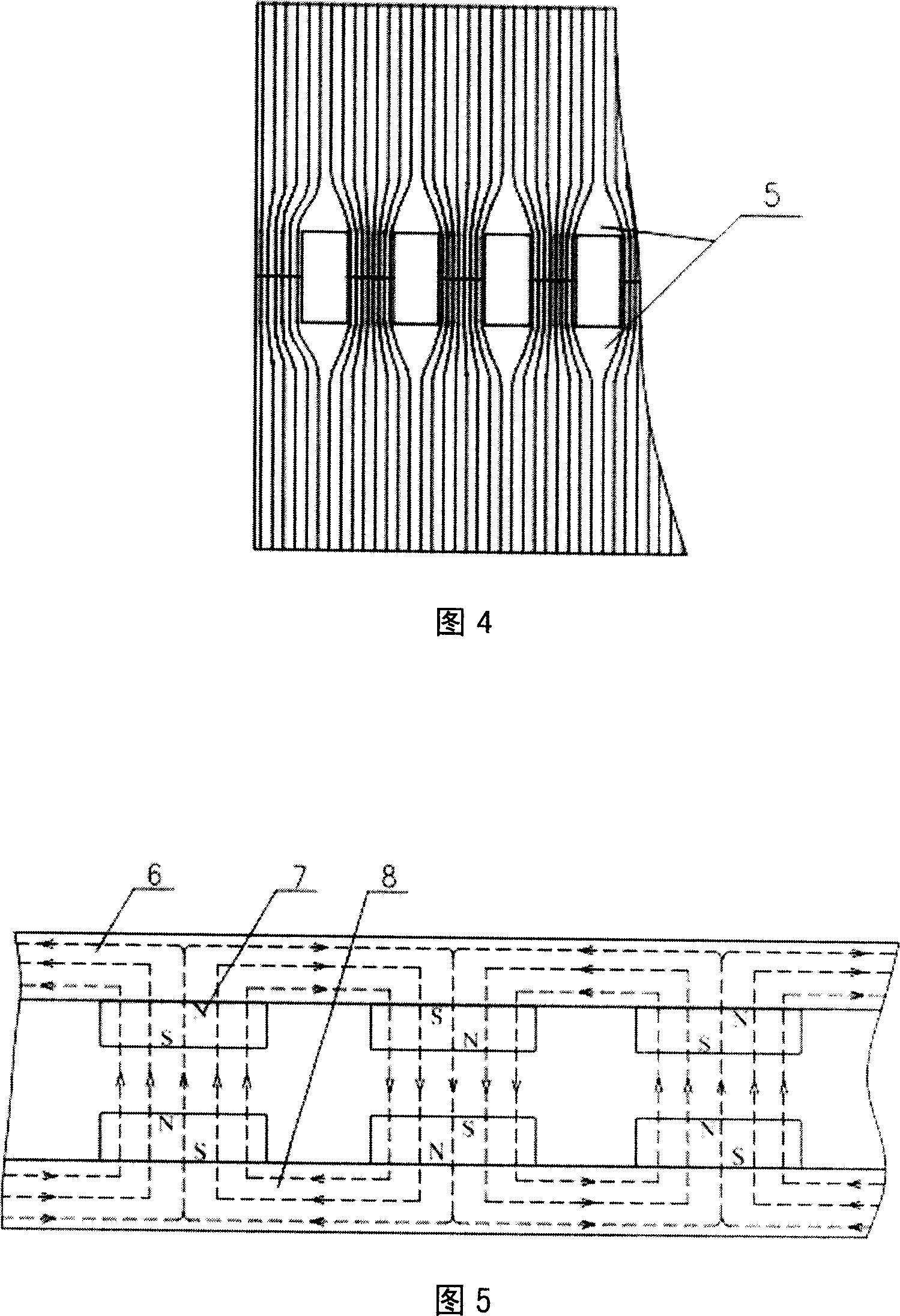

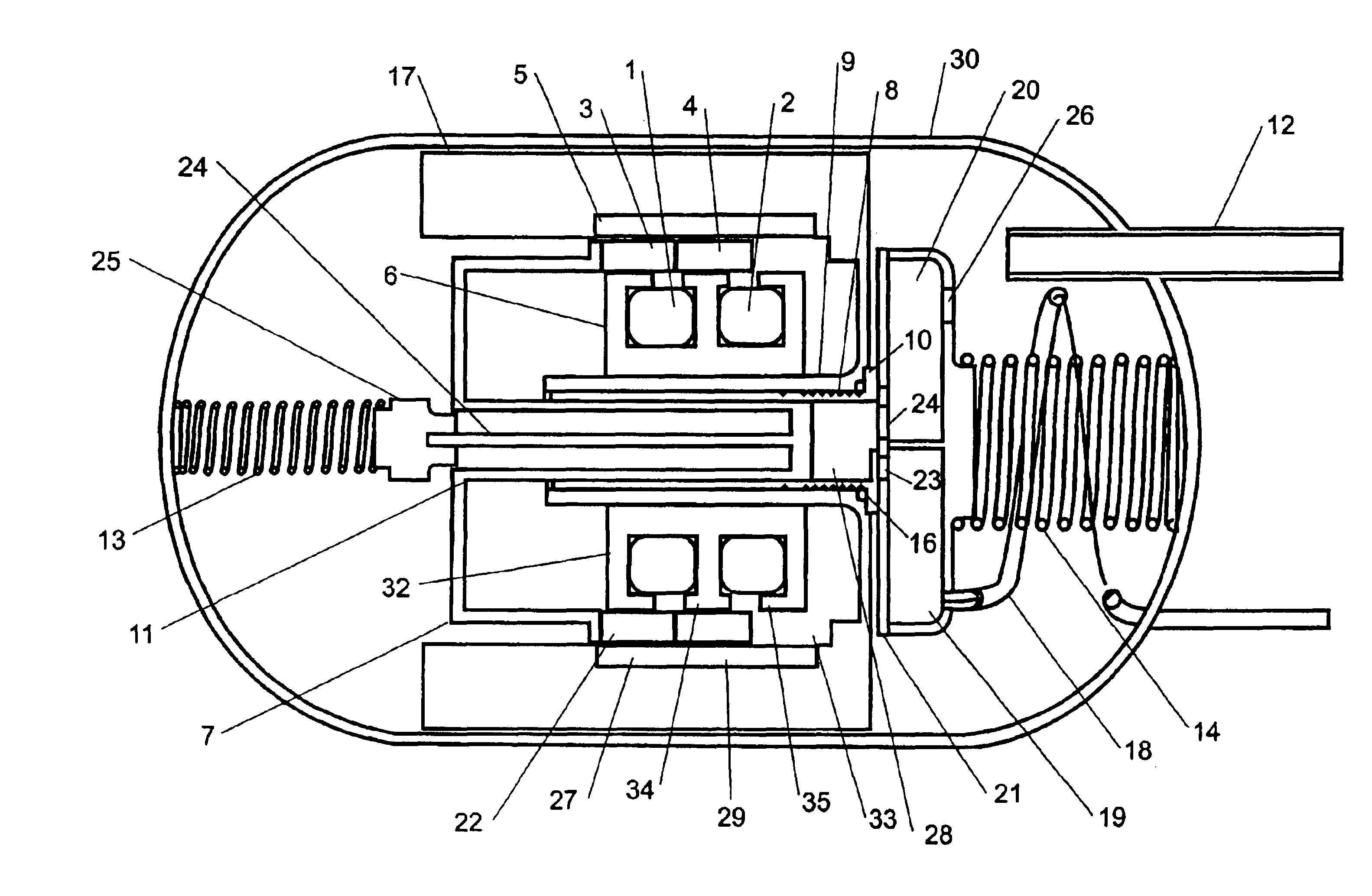

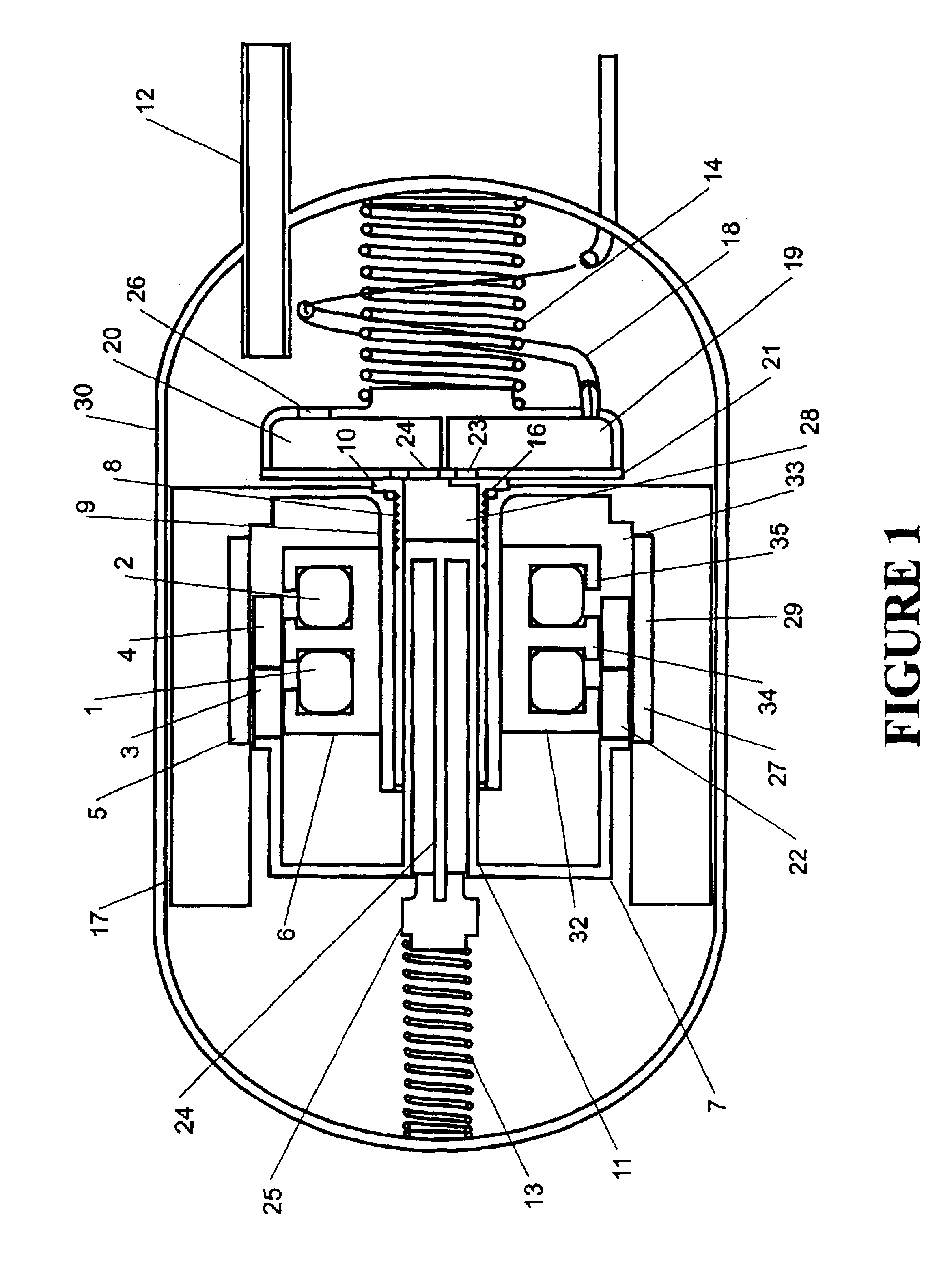

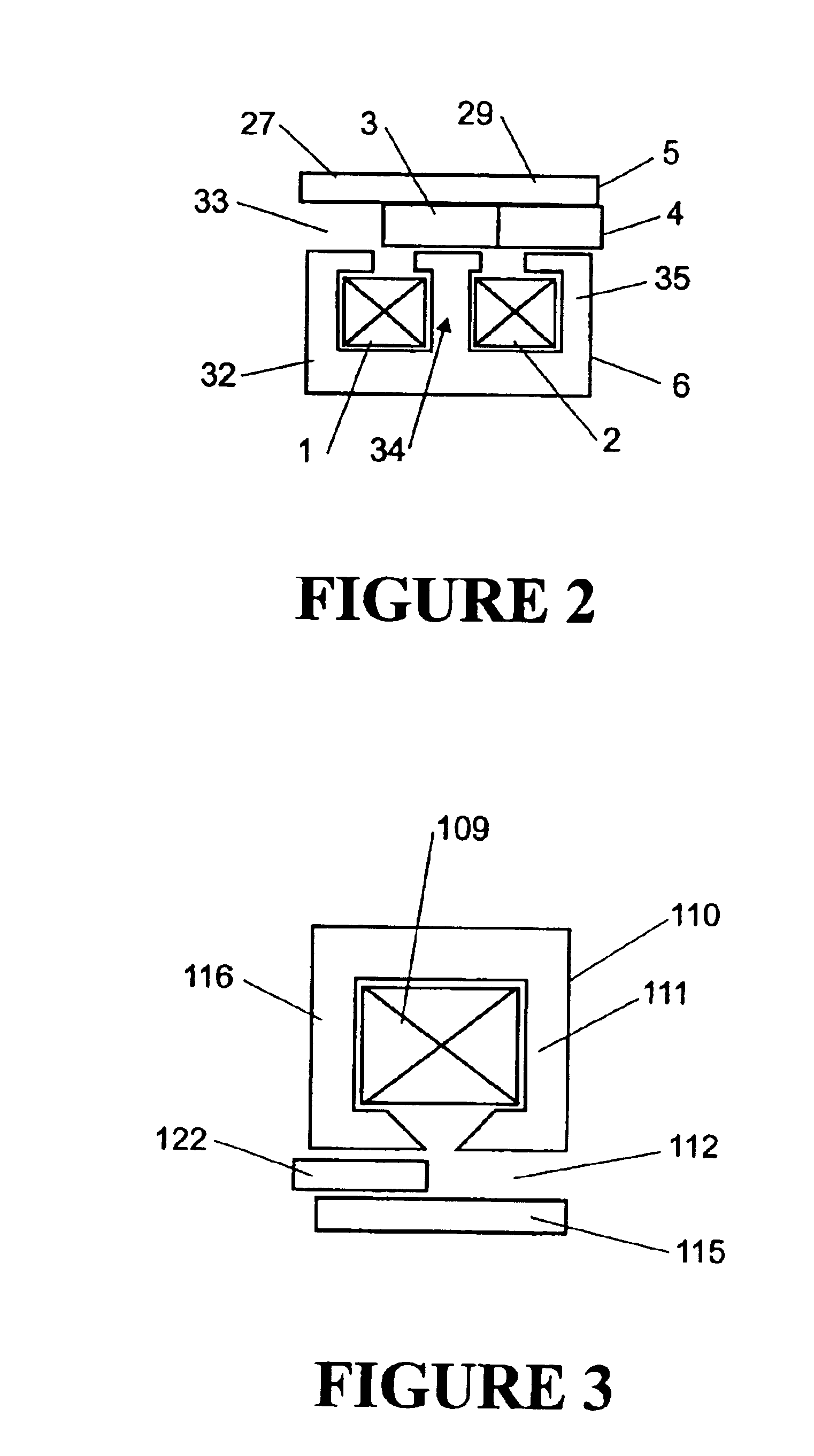

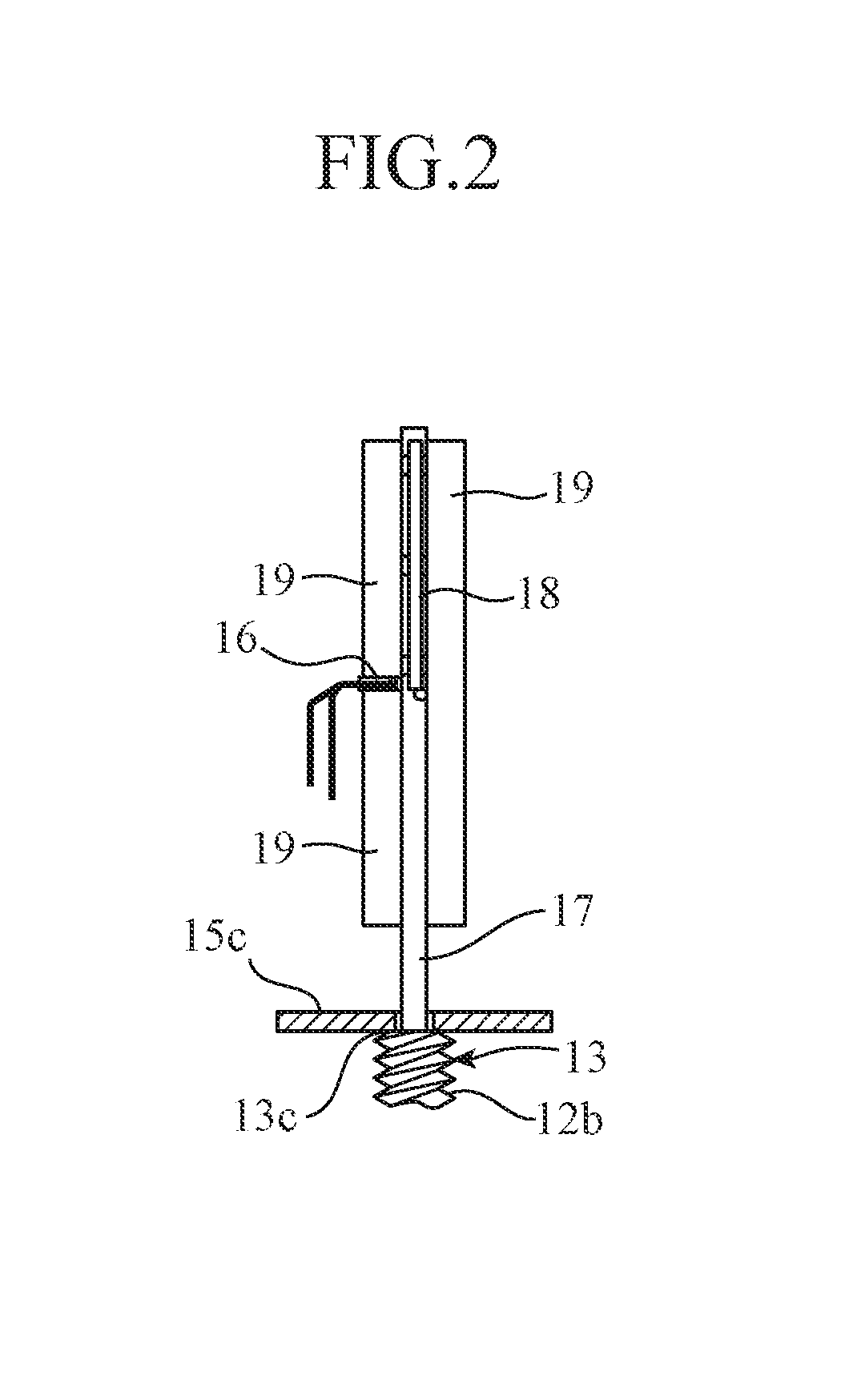

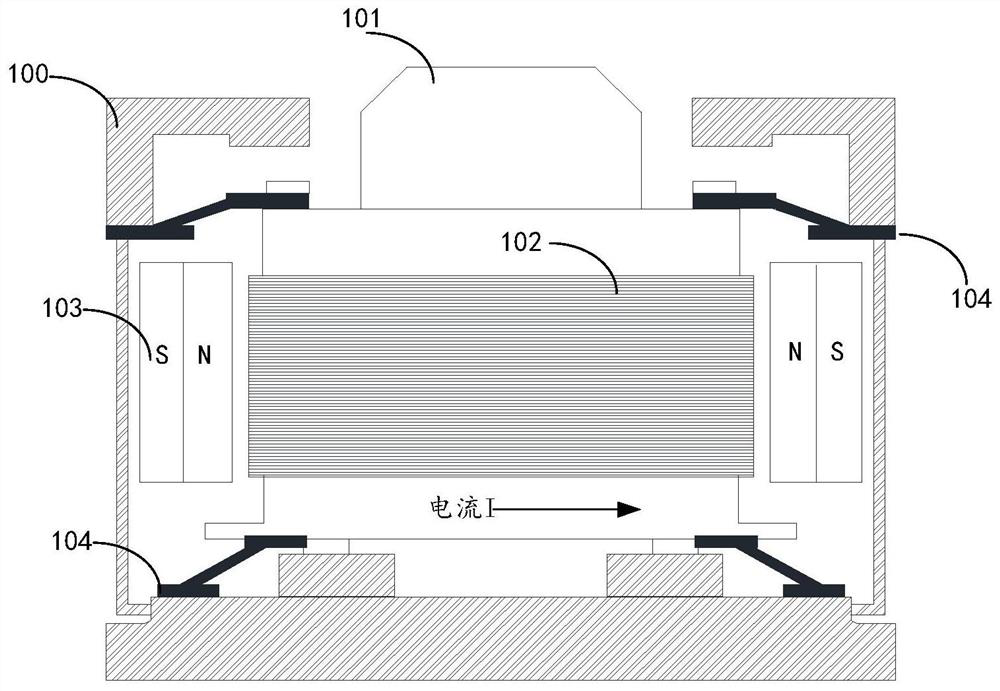

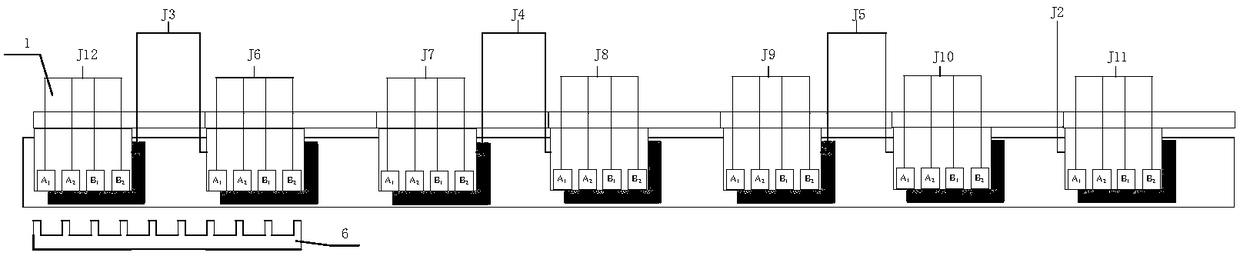

Long range big-push force permanent-magnet brushless linear DC motor

InactiveCN101009455AGood magnetic conductivityHigh resistivityAC motor controlMagnetic circuit rotating partsNumerical controlSpeed control system

A long journey big thrust permasyn brushless beeline direct electromotor that includes stator part, rotor part and position and speed controlling system of the electromotor. The stator part composes permanent-magnet (3) and magnetic yoke (2), magnetizer (5) is connected with rack (1) via coattail groove structure, and two windings (4) with different direction current circle the magnetizer to form rotor part. The invention adopts the two-sized stator structure to eliminate the single sized magnetic pull, and the thrust is big, journey is long, the weight of rotor is light, without contact running and cost is low, it is fit for common numerical control machine tool feeding system, special numerical control machine tool feeding system which adopts gas floating or magnet floating guiding track and other high speed and high acceleration direct feeding systems.

Owner:DALIAN JIAOTONG UNIVERSITY

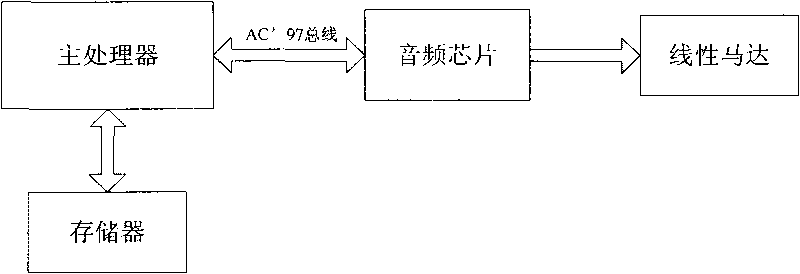

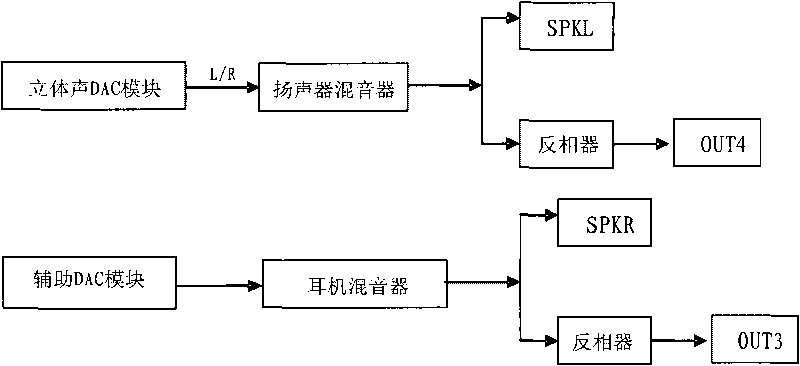

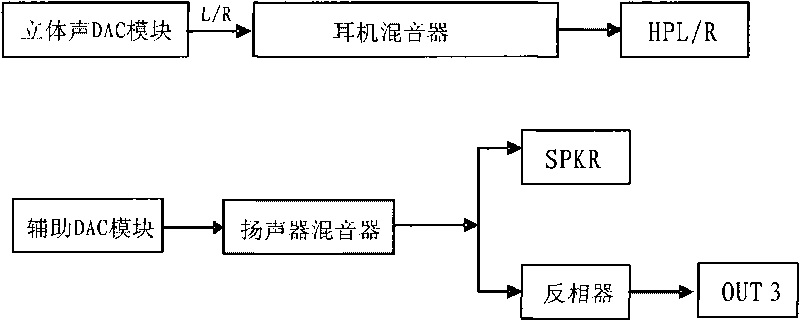

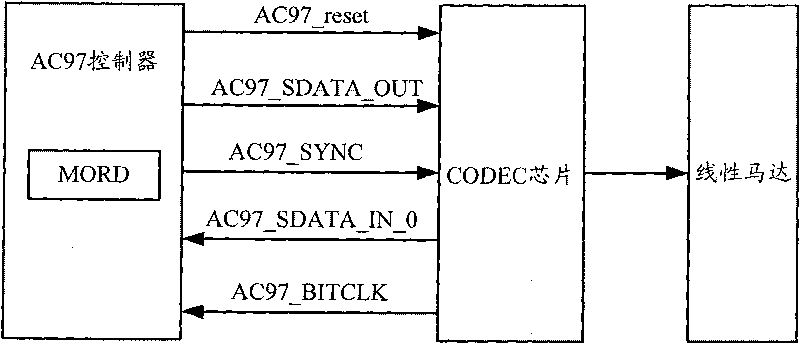

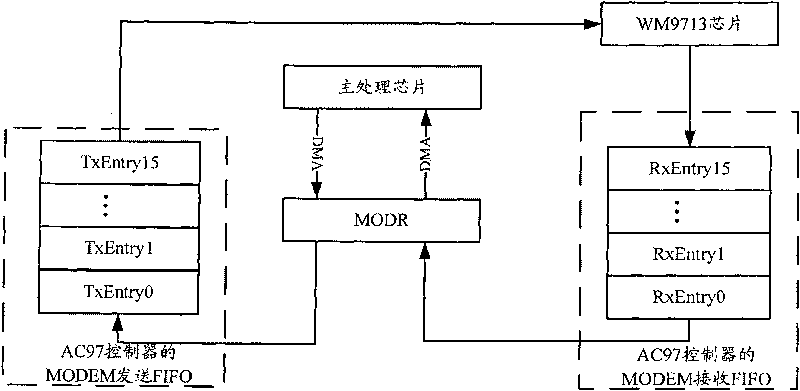

Method for driving motor of mobile phone and mobile equipment

ActiveCN101729625ARealize drive controlImprove control effectLinear DC motor controlTelephone set constructionsData fileAnalog signal

The invention discloses a method for driving a motor of a mobile phone and mobile equipment. The method comprises the following steps of: firstly, generating a specific audio data file according to a set frequency; secondly, supplying the specific audio data file to an audio chip for digital-to-analogue conversion when a linear motor in the mobile phone needs to be driven to vibrate; and finally,sending an analog signal generated by conversion to the linear motor via the audio chip so as to drive the linear motor to vibrate. The method drives the linear motor to vibrate via the analog signalproduced by the audio chip in the mobile phone, so driving control on the linear motor can be realized without adding a special driving chip or a peripheral circuit. The method not only realizes low-cost design of a hardware circuit, but also achieves an excellent control effect on the linear motor on the basis of not affecting normal audio play, so the overall performance of a mobile phone product is improved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Method of controlling a reciprocating linear motor

InactiveUS6954040B2Working fluid for enginesElectric motor speed/torque regulationReciprocating motionGas compressor

A free piston gas compressor comprising a cylinder, a piston reciprocable within the cylinder and a reciprocating linear electric motor derivably coupled to the piston having at least one excitation winding. A measure of the reciprocation time of the piston is obtained, any change in the reciprocation time is detected and the power input to said excitation winding is adjusted in response to any detected change in reciprocation time.

Owner:FISHER & PAYKEL APPLIANCES LTD

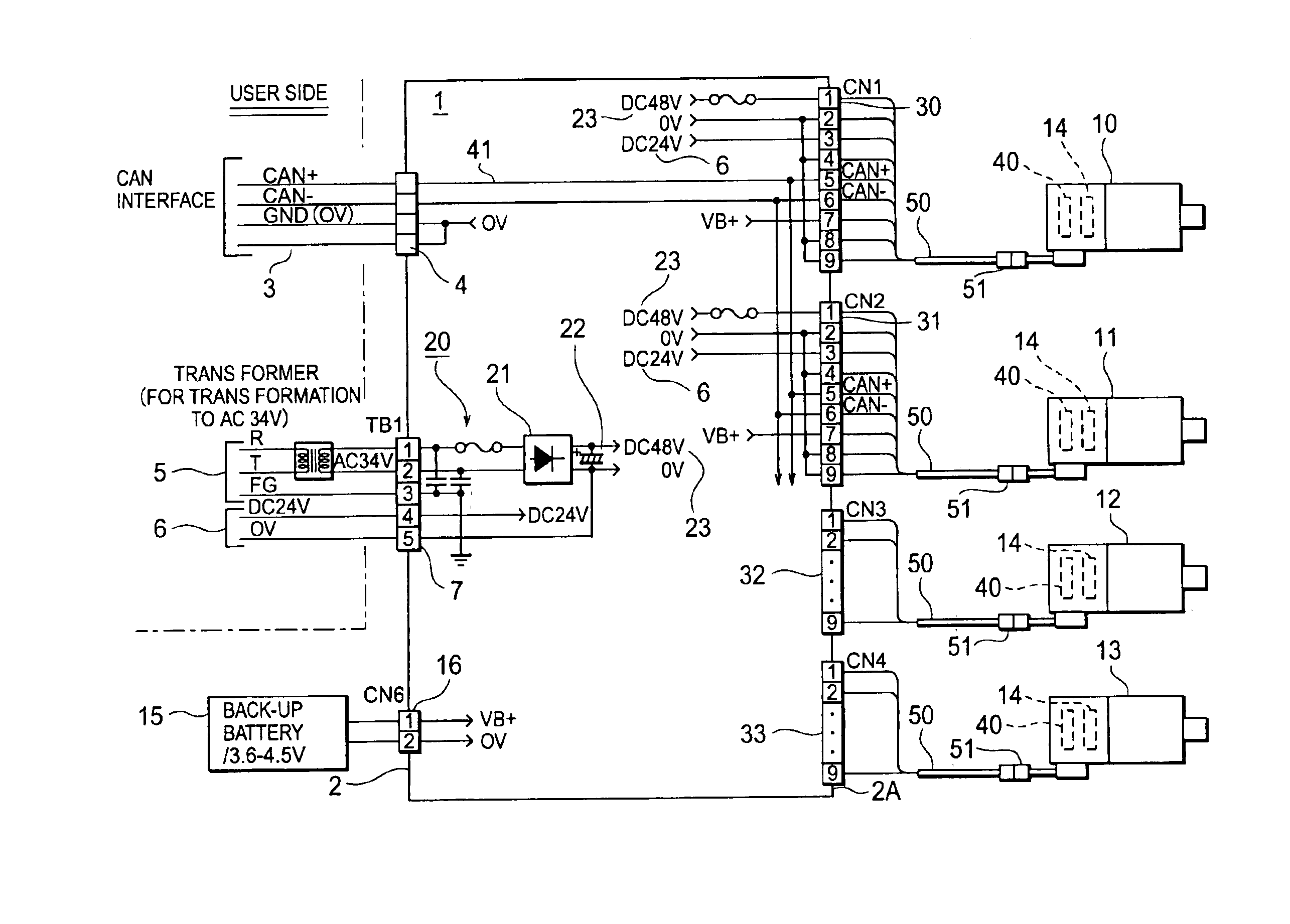

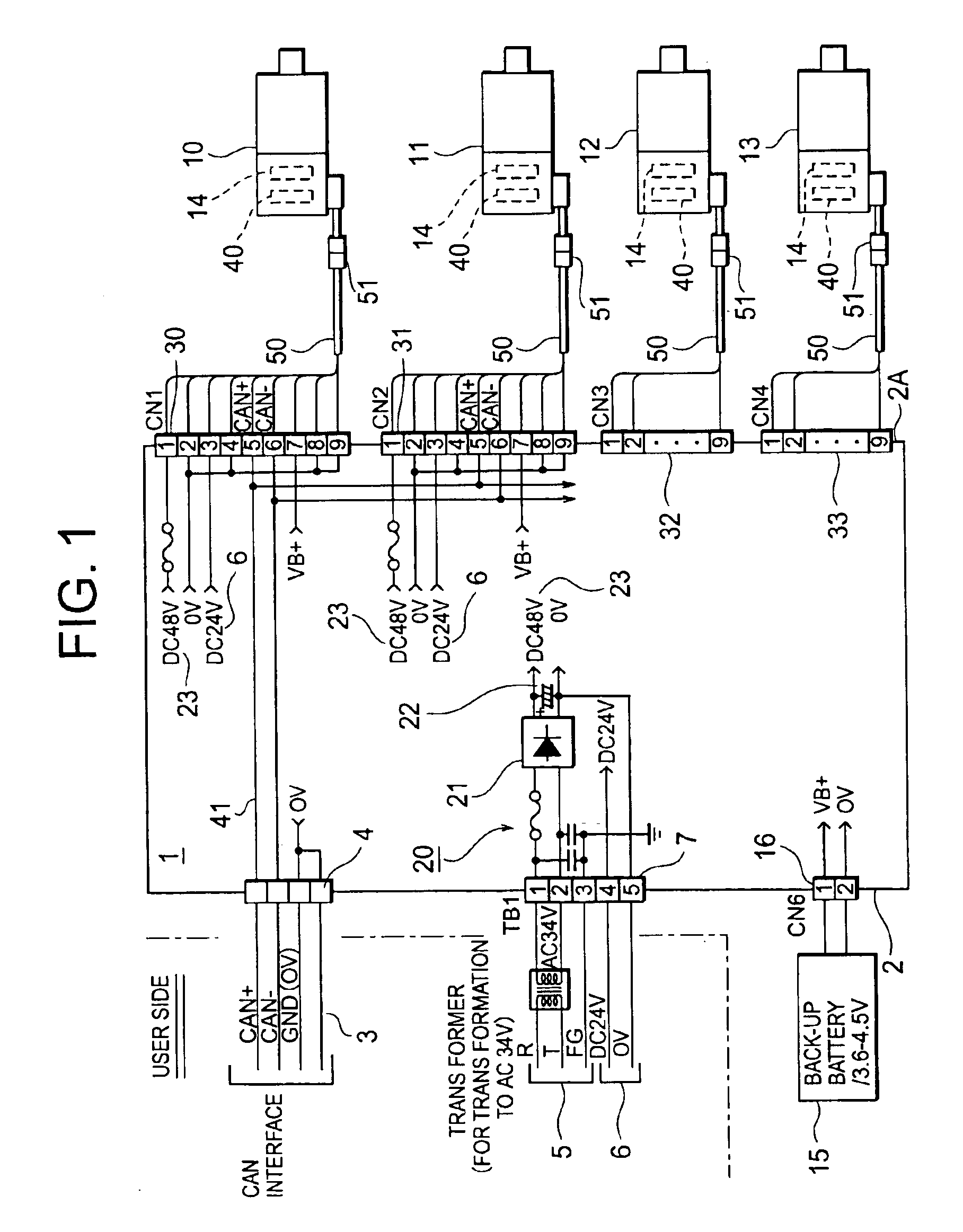

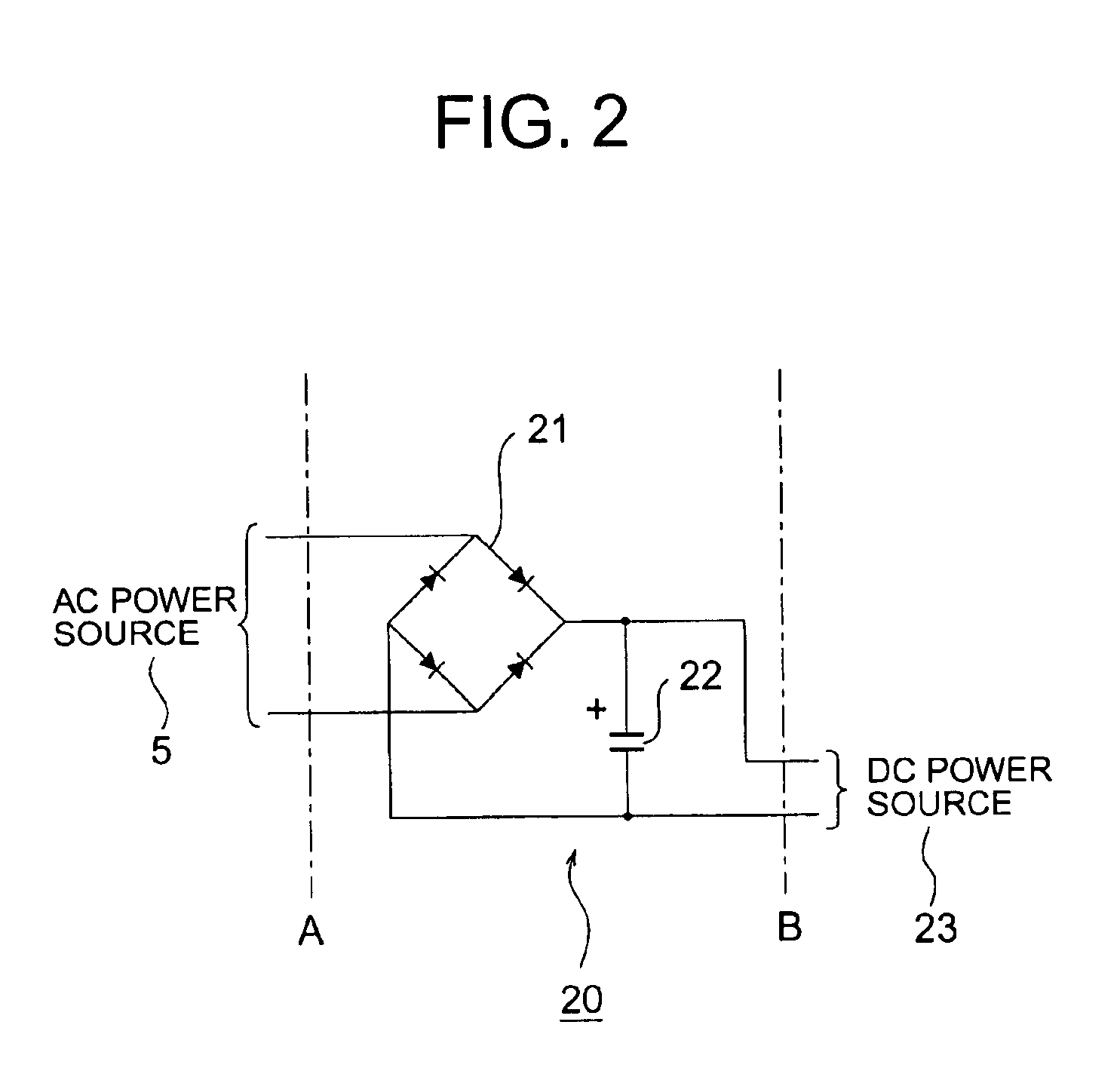

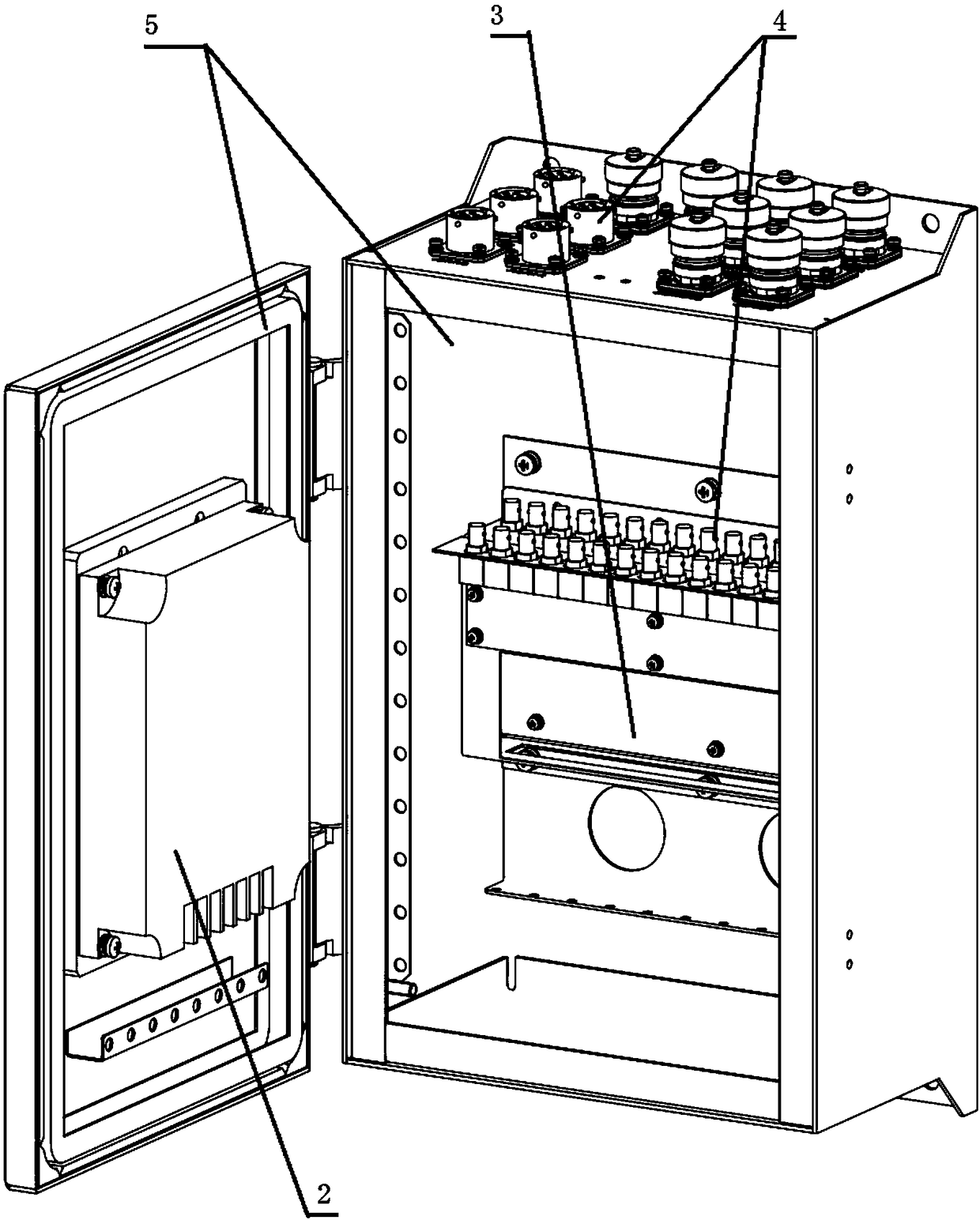

Method of driving a servo motor with a built-in drive circuit

InactiveUS6933698B2Reduction in servo motor sizeEasy to installDc network circuit arrangementsMultiple dynamo-motor startersEngineeringDistributed power

Disclosed is a method of driving a servo motor with a built-in drive circuit in which a common rectifying circuit is provided on a distribution board to which a plurality of the servo motors with built-in drive circuits are connected, to thereby achieve a reduction in size of each servo motor. In this method, there is used a common distribution board for distributing power to be supplied to a plurality of servo motors with built-in drive circuits and for distributing a communication line, an external communication signal and external input power are supplied through the distribution board.

Owner:TAMAGAWA SEIKI CO LTD

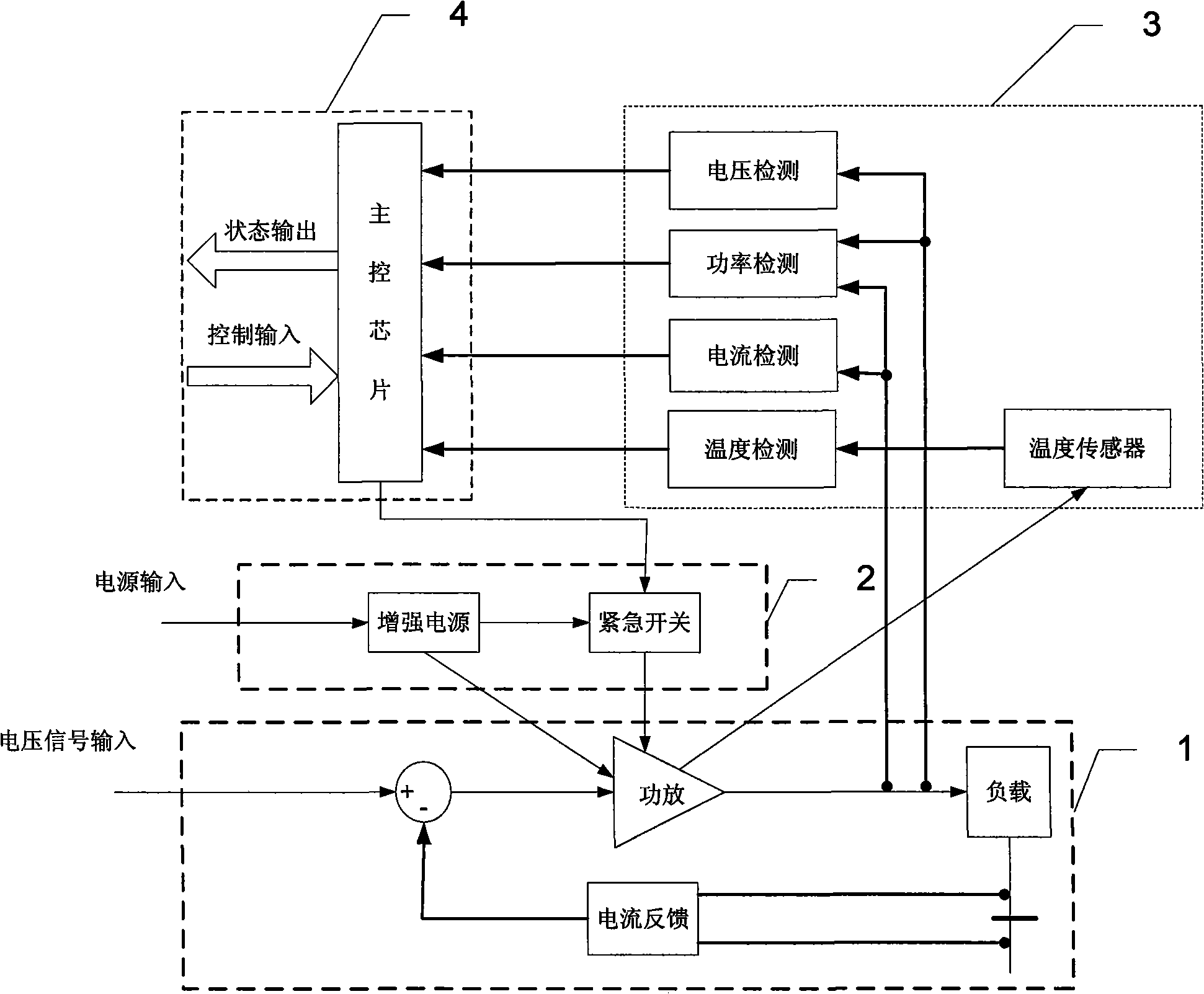

Linear motor driver

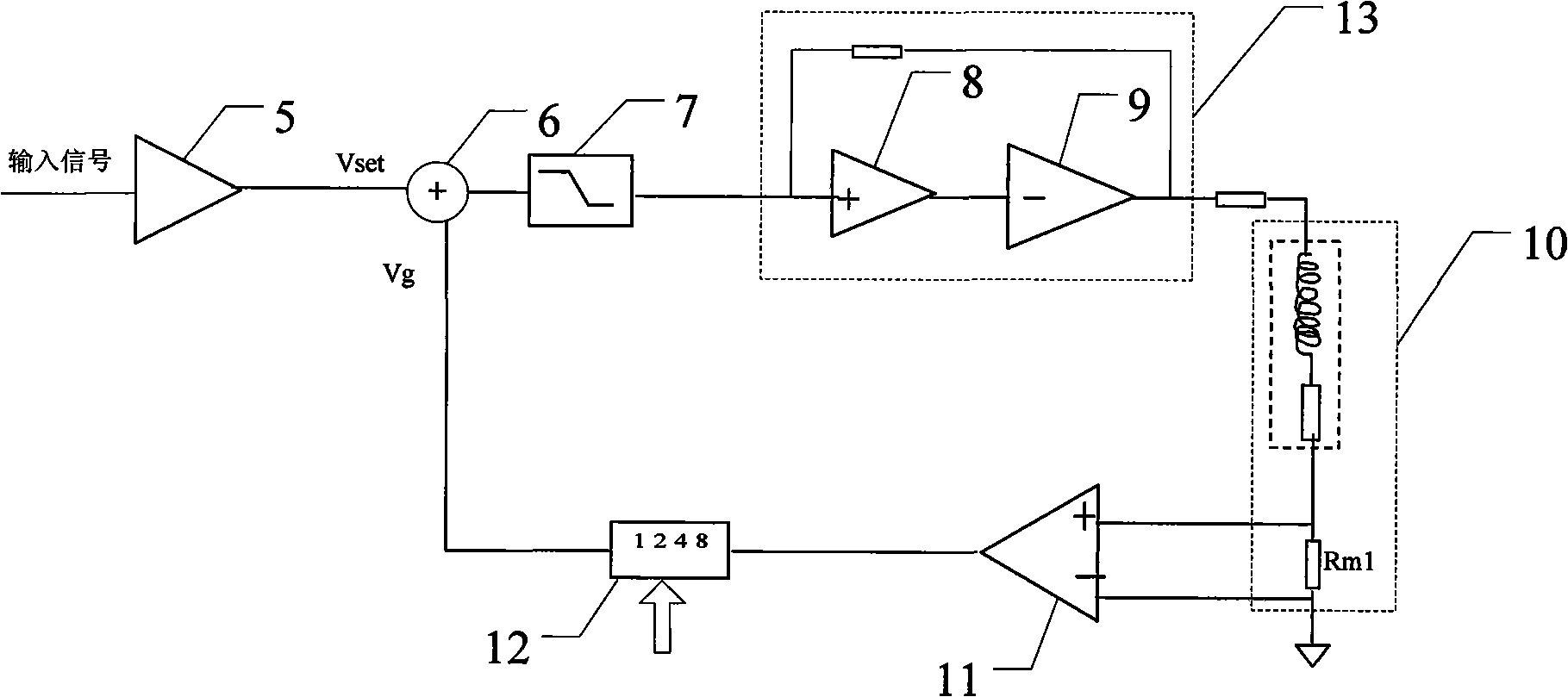

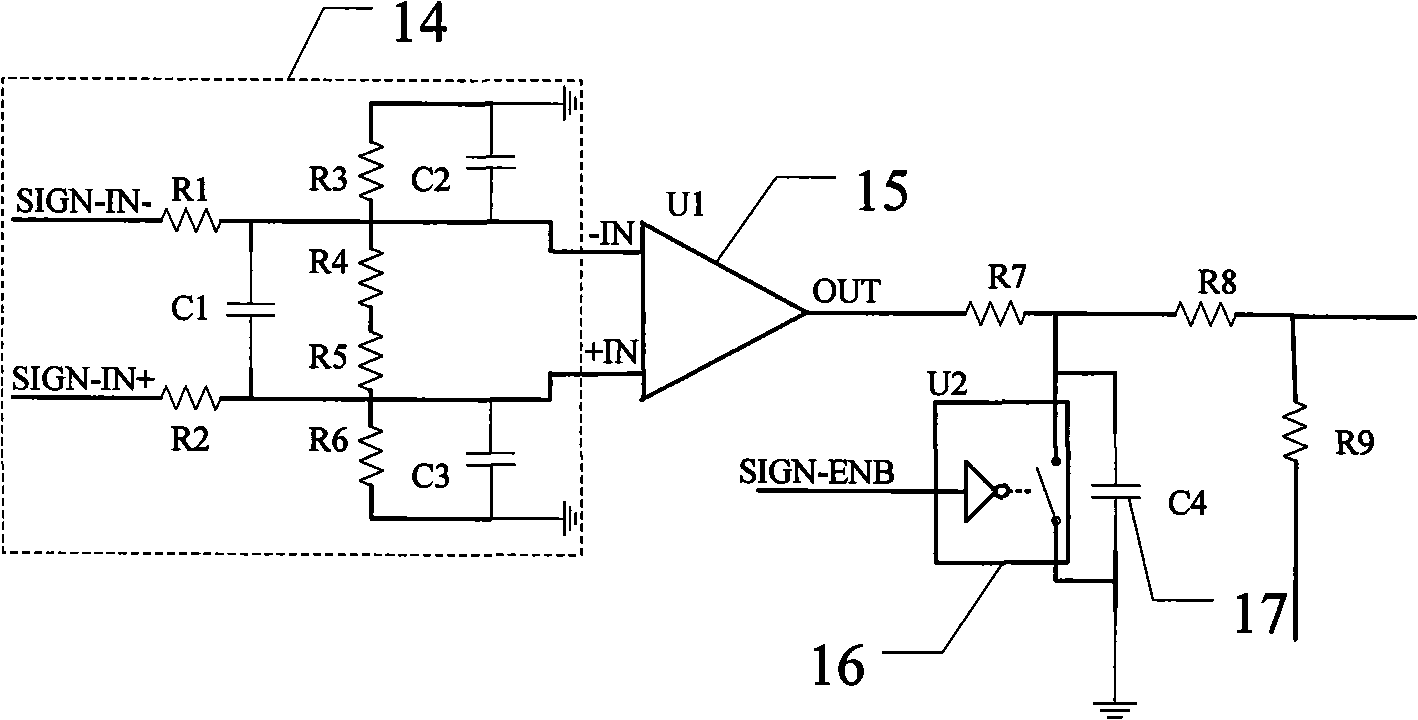

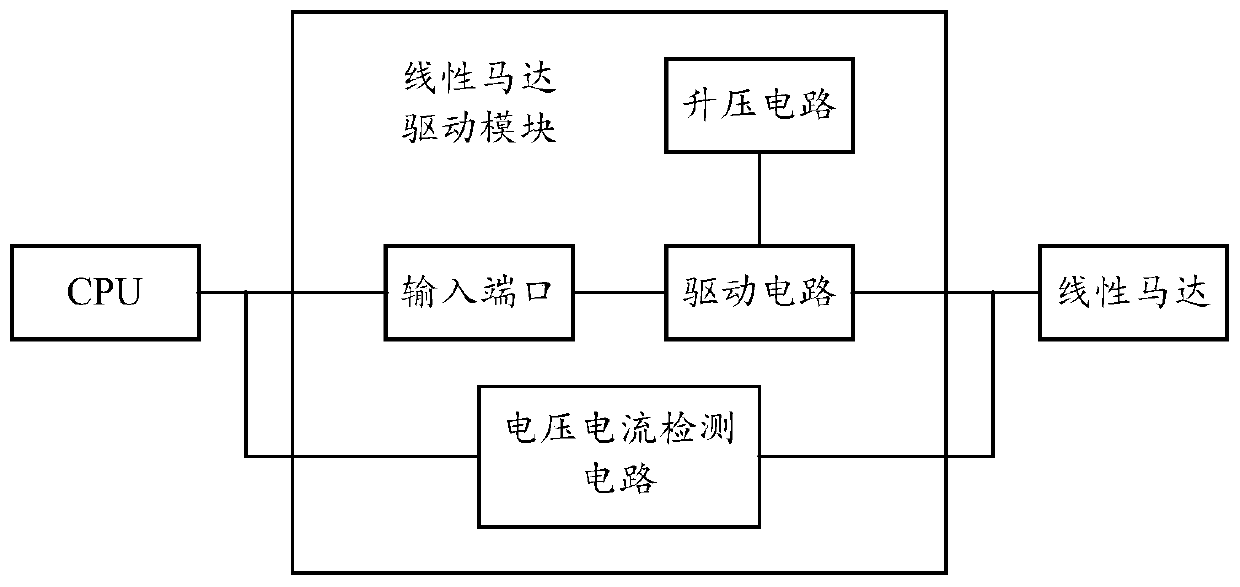

InactiveCN101577519ALarge output currentIncrease conversion rateAC motor controlLinear DC motor controlCurrent sampleAudio power amplifier

The invention provides a linear motor driver which comprises a current feedback loop module, a power module, a detecting module, and a state analysis and control module. The motor driver is characterized in that the current feedback loop module comprises a preposing input stage module, an adder module, a low pass filter module, a power amplification feedback module, a loading module, a current sampling amplification module and a gain adjustment module which are connected in sequence; and the output signal of the gain adjustment module is connected on the input end of the adder module finally, thus forming a loop. The linear motor driver has the characteristics of high linearity, wide bandwidth, good stability, small interference to outside, and strong capacity of resisting disturbance, and is small in volume and low in cost. As the temperature coefficient of the drain-source resistance of the power amplifier is positive, when the temperature of the power amplifier rises, the current is limited, therefore, no thermal breakdown occurs, and consequently, no secondary breakdown occurs.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

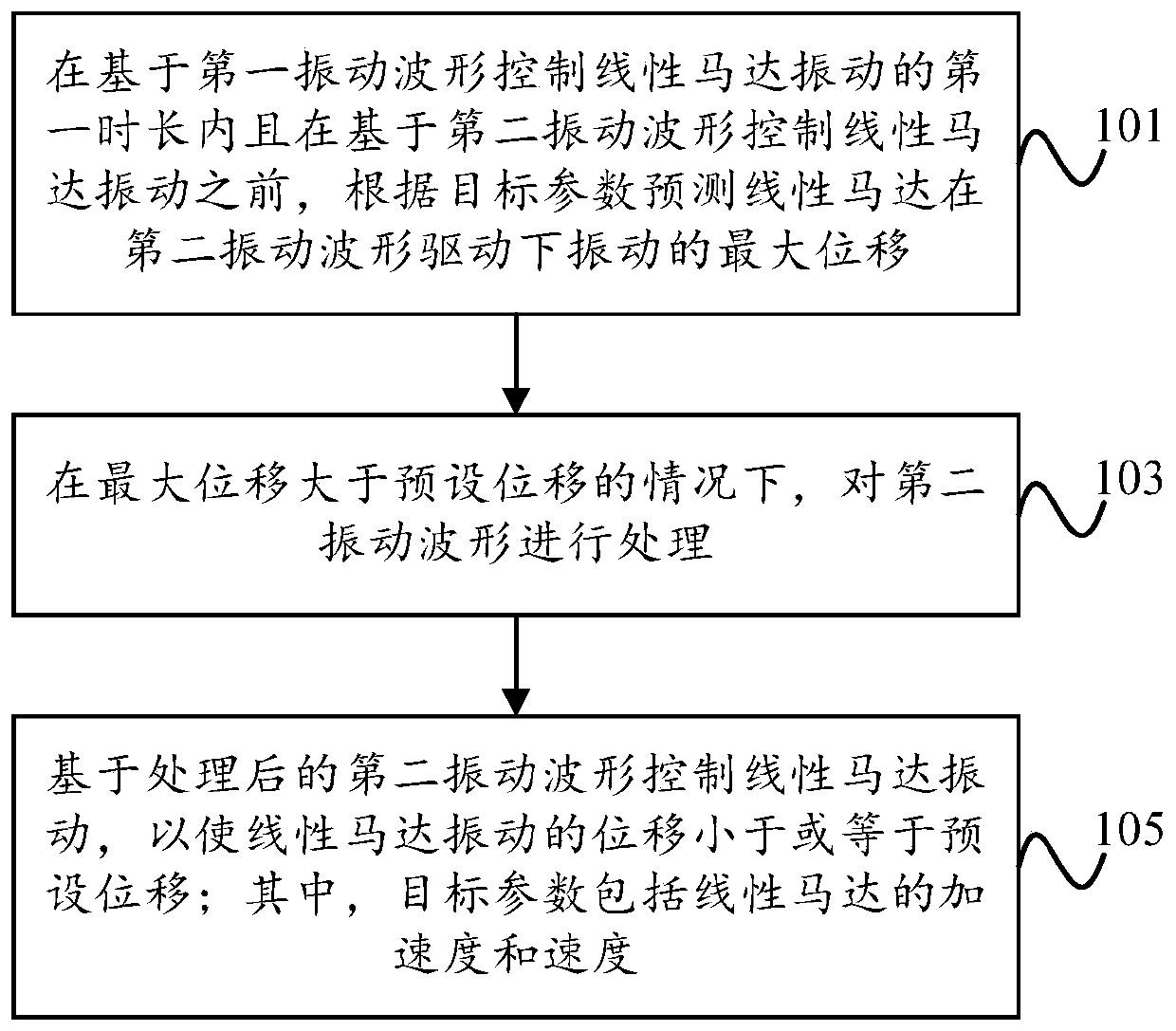

Vibration control method of linear motor and mobile terminal

ActiveCN110112984AAvoid noiseImprove experienceAC motor controlLinear DC motor controlVibration controlWave shape

The embodiment of the invention discloses a vibration control method of a linear motor. The method comprises the steps of: predicting the maximum displacement of vibration of a linear motor under thedrive of a second vibration waveform according to target parameters within the first duration when the vibration of the linear motor is controlled based on a first vibration waveform and prior to thecontrol of the vibration of the linear motor based on the second vibration waveform; in a condition that the maximum displacement is larger than a preset displacement, processing the second vibrationwaveform; and controlling the vibration of the linear motor based on the processed second vibration waveform to allow the displacement of the vibration of the linear motor to be smaller than or equalto the preset displacement, wherein the target parameters comprise the accelerated speed and the speed of the linear motor. According to the embodiment of the invention, the noise generated by the collision of the mass block of the linear motor and the shell of the linear motor due to overlarge displacement can be avoided, and the user experience is improved.

Owner:VIVO MOBILE COMM CO LTD

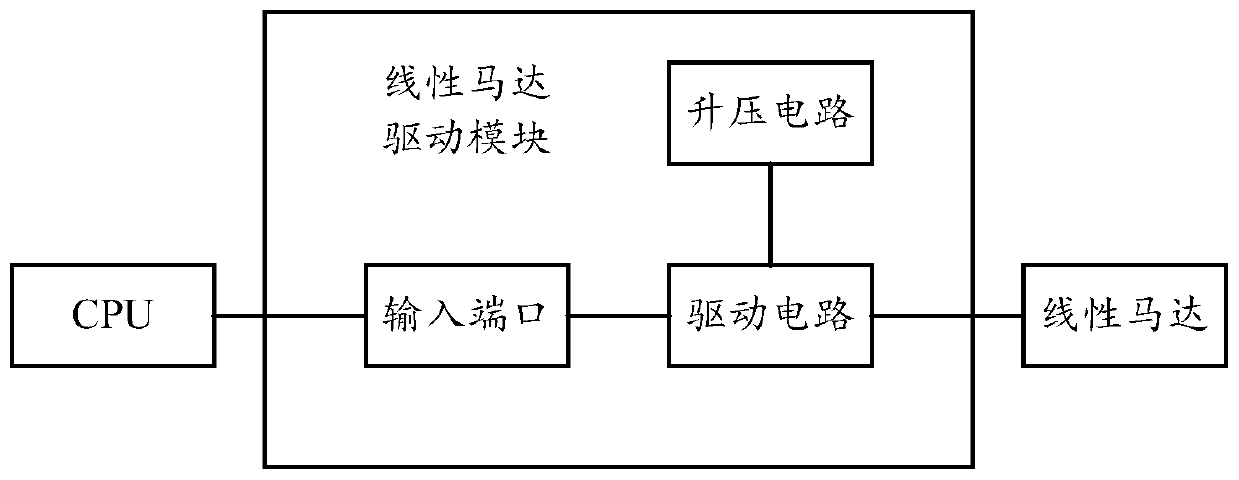

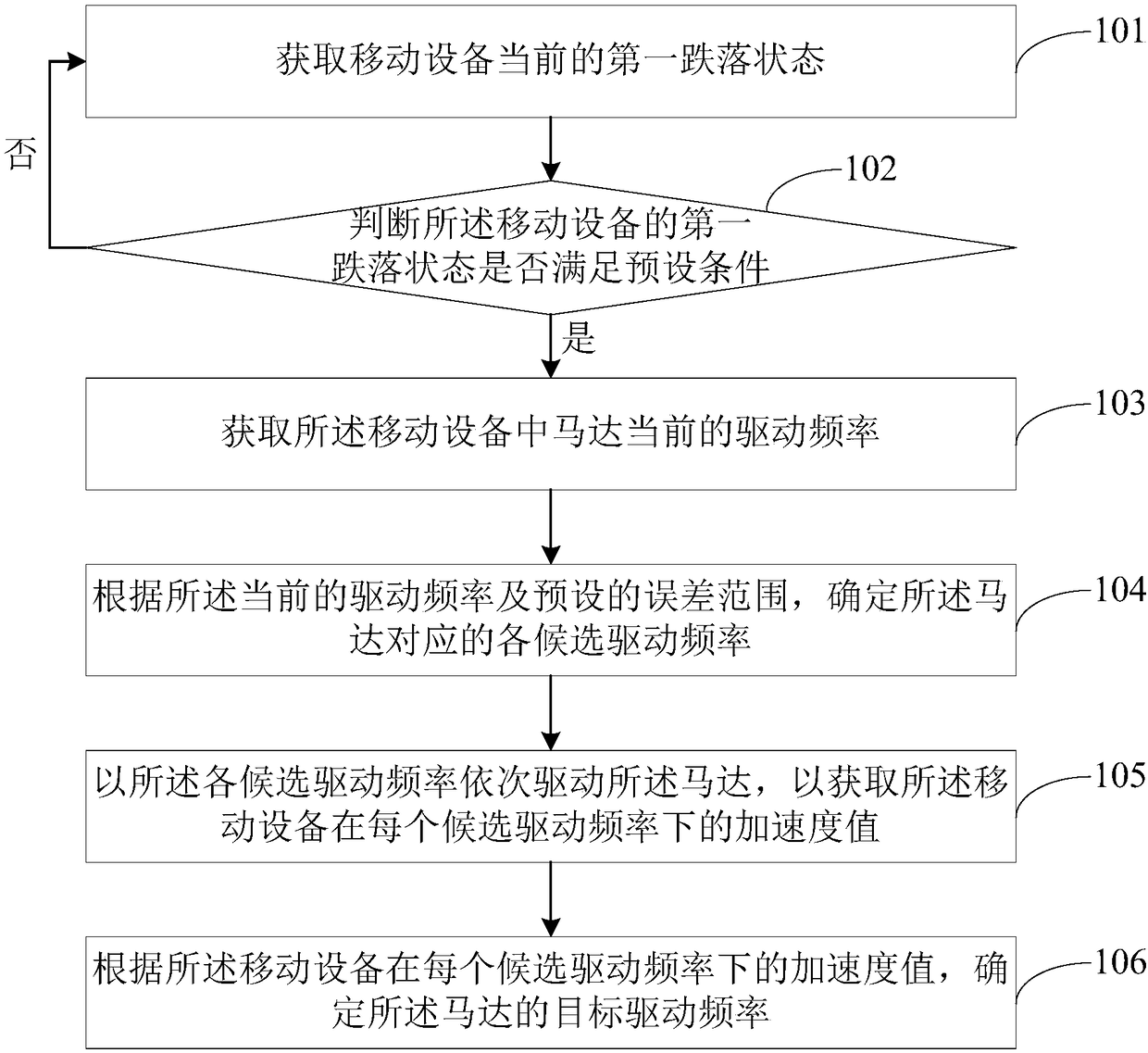

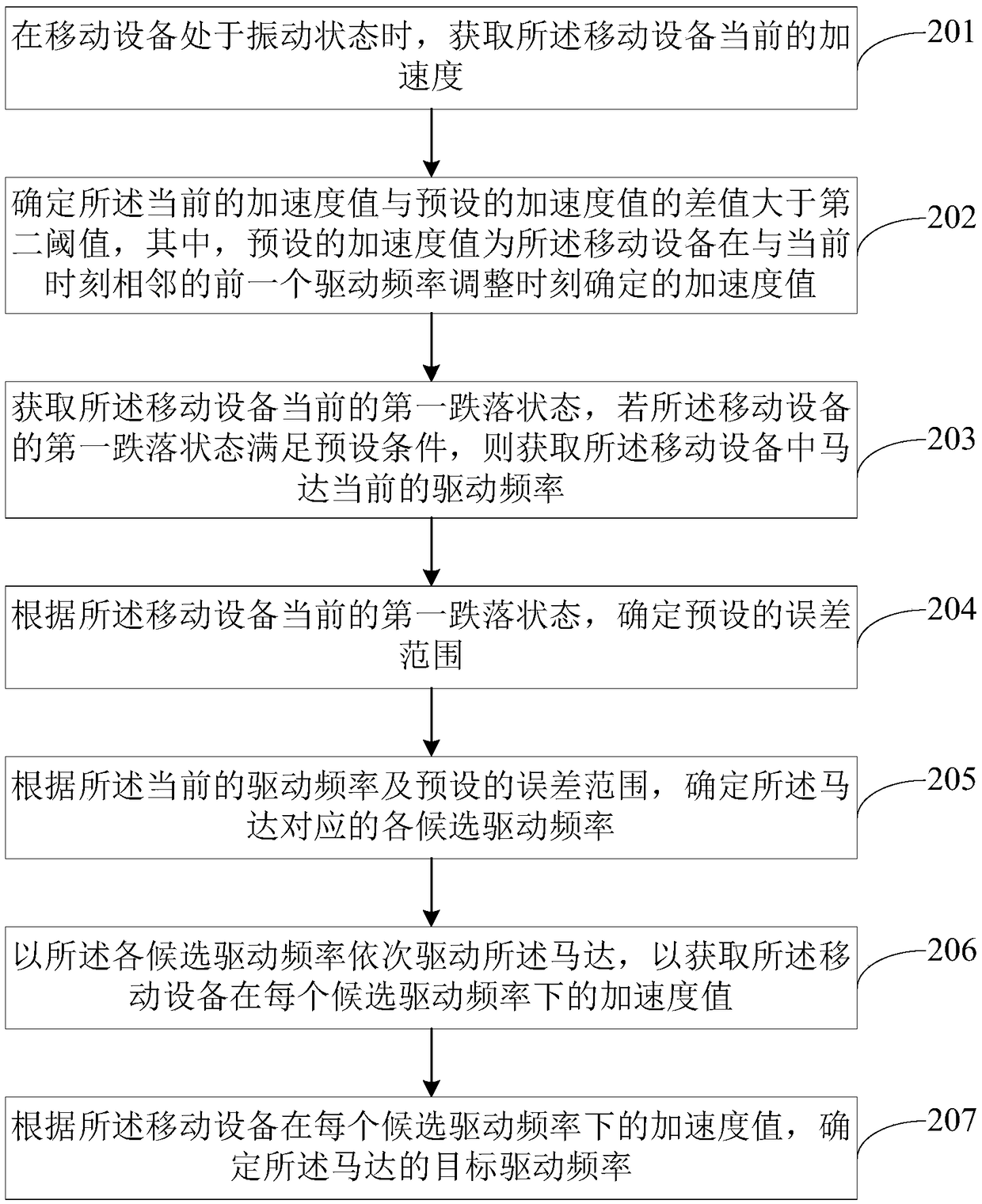

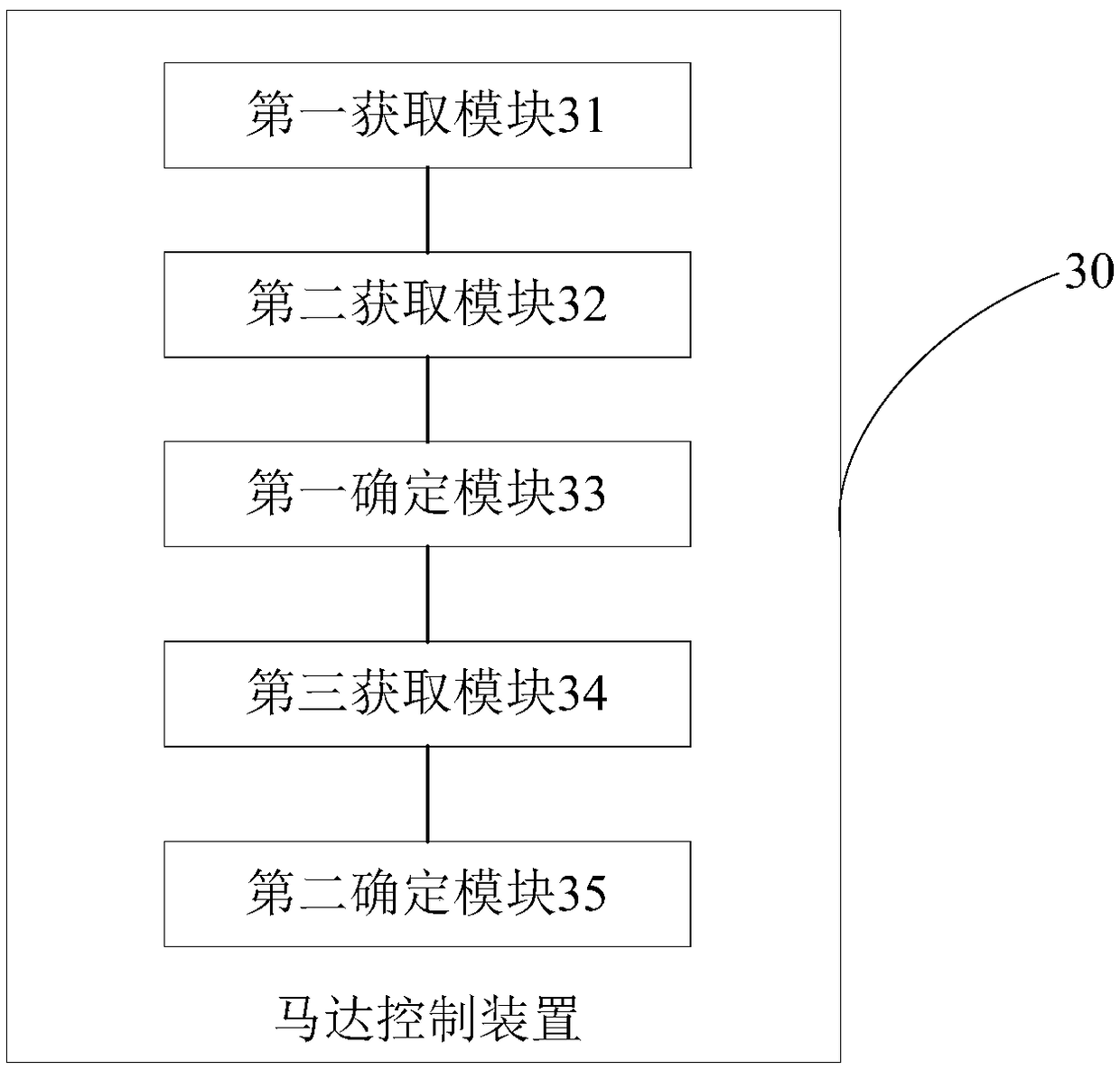

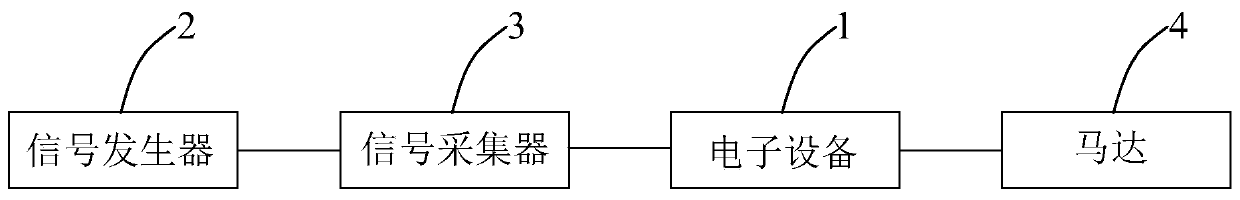

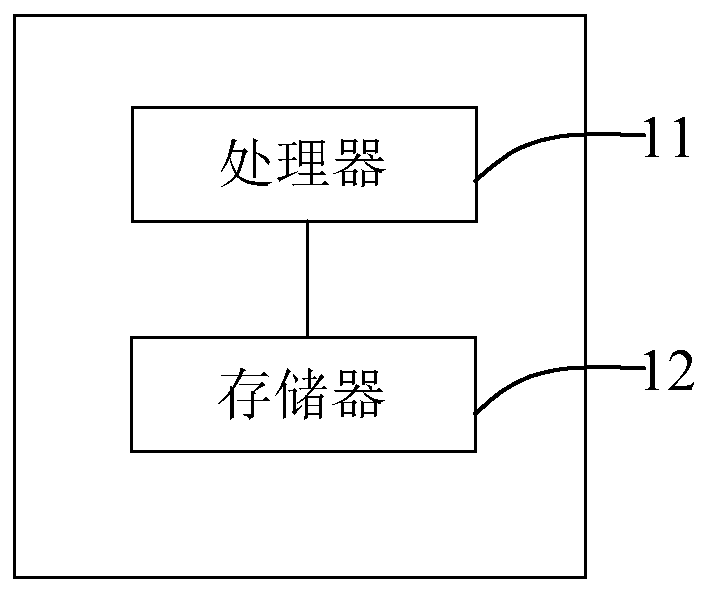

Motor control method, apparatus, electronic device, and storage medium

ActiveCN109274309AImprove vibration feedback effectEnsure consistencyInput/output for user-computer interactionAC motor controlFeedback effectMotor vibration

The present application provides a motor control method, device, electronic device and storage medium, belonging to the field of electronic technology. The method comprises the following steps: acquiring a current first falling state of the mobile device; Acquiring a current driving frequency of a motor in the mobile device if the first falling state of the mobile device satisfies a preset condition; Determining each candidate driving frequency corresponding to the motor according to the current driving frequency and the preset error range; Sequentially driving the motors at each candidate driving frequency to obtain acceleration values of the mobile device at each candidate driving frequency; A target drive frequency of that motor is determine based on the acceleration value of the mobiledevice at each candidate drive frequency. Thus, the motor control method realizes the automatic calibration of the driving frequency of the motor when the driving frequency of the motor and the resonant frequency do not match, ensures the consistency of the motor vibration quantity, improves the vibration feedback effect of the mobile device, and improves the user experience.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

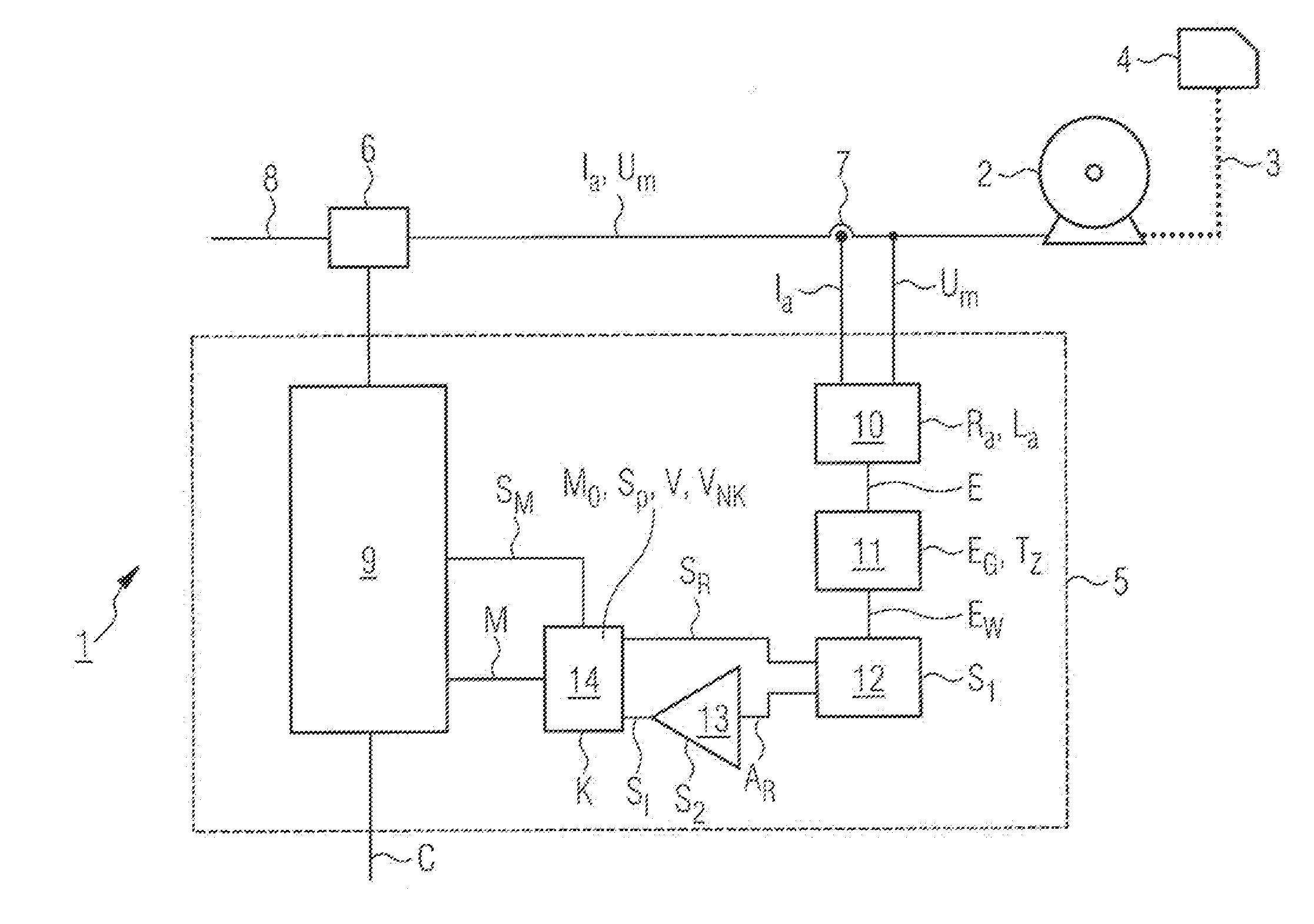

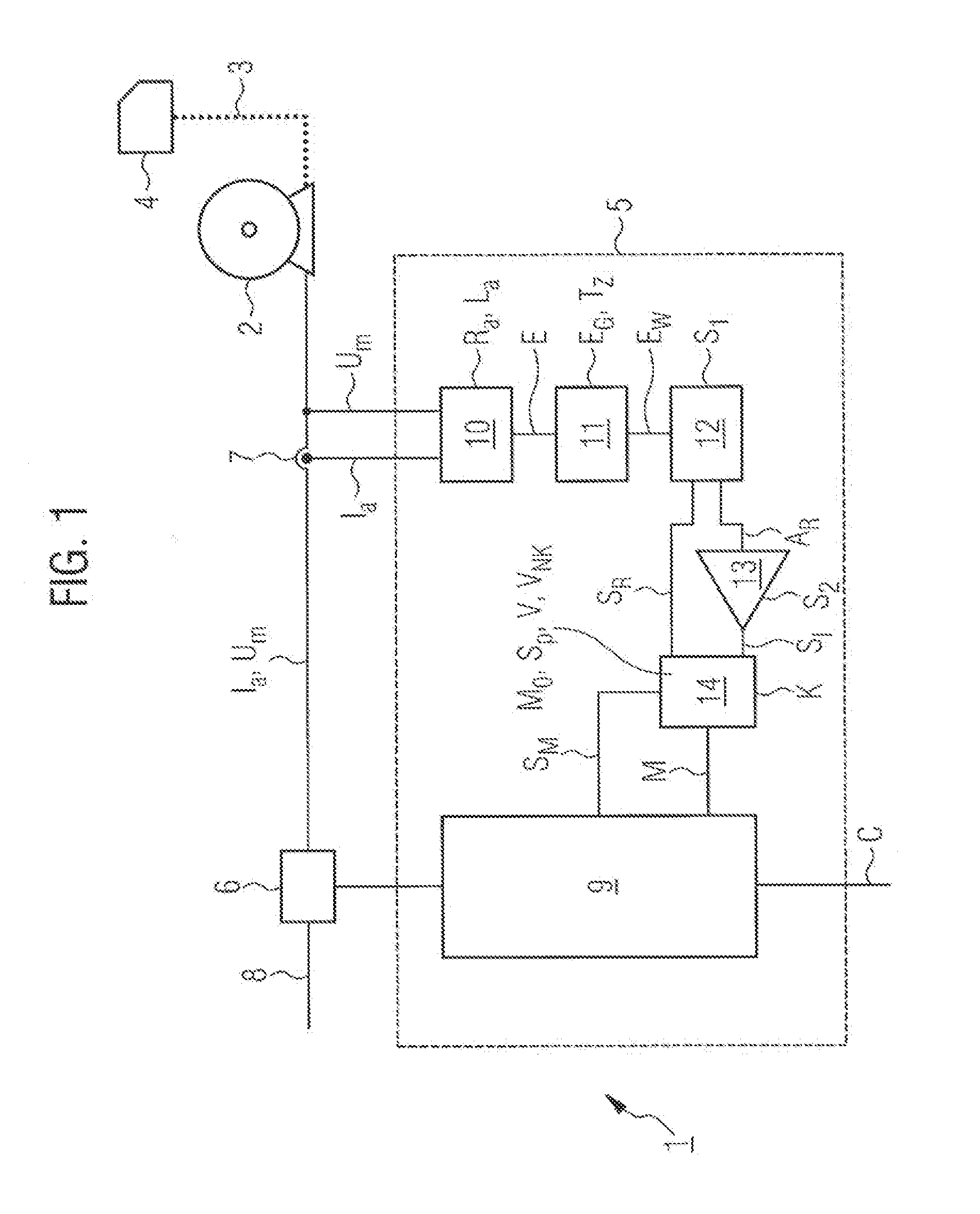

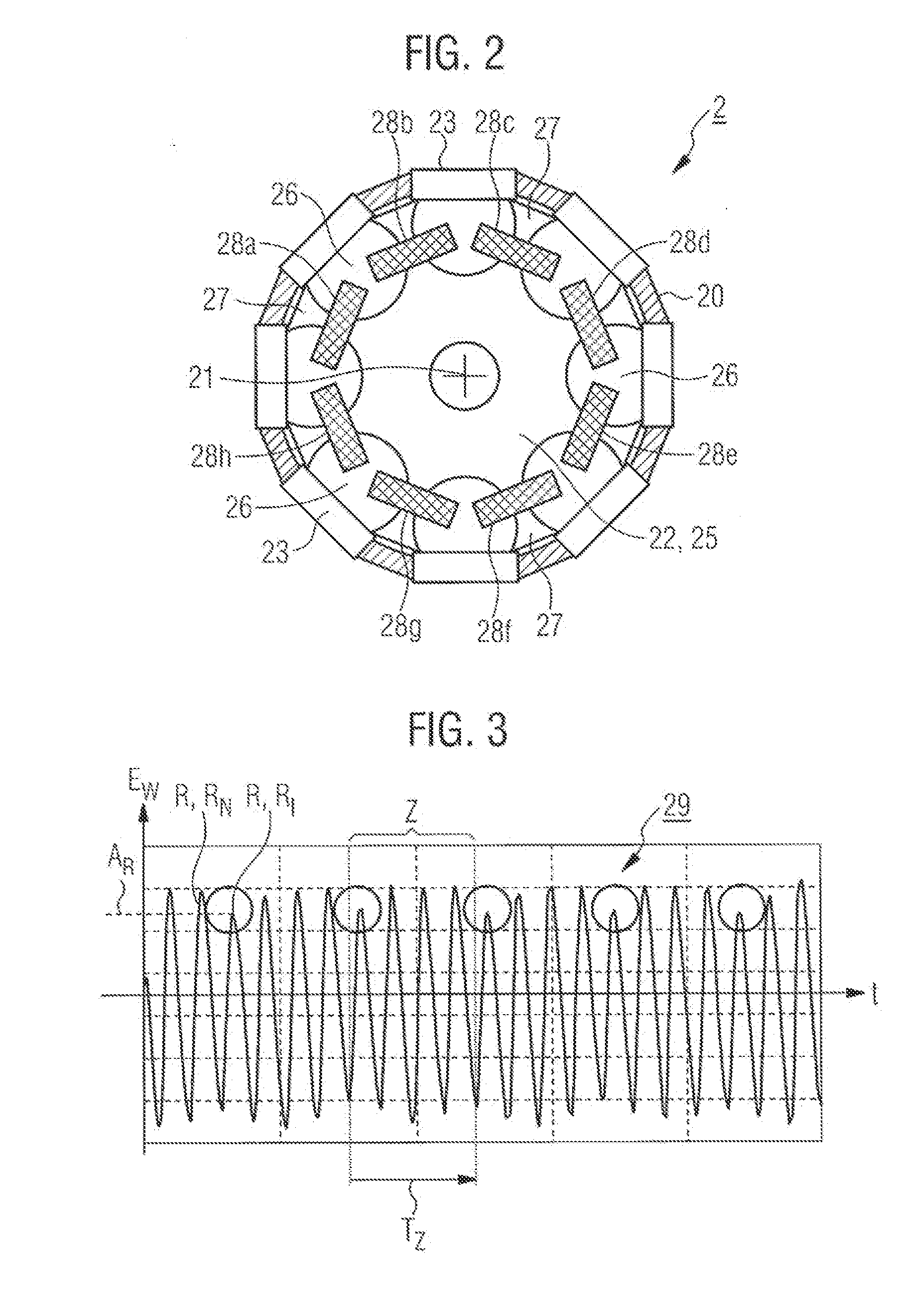

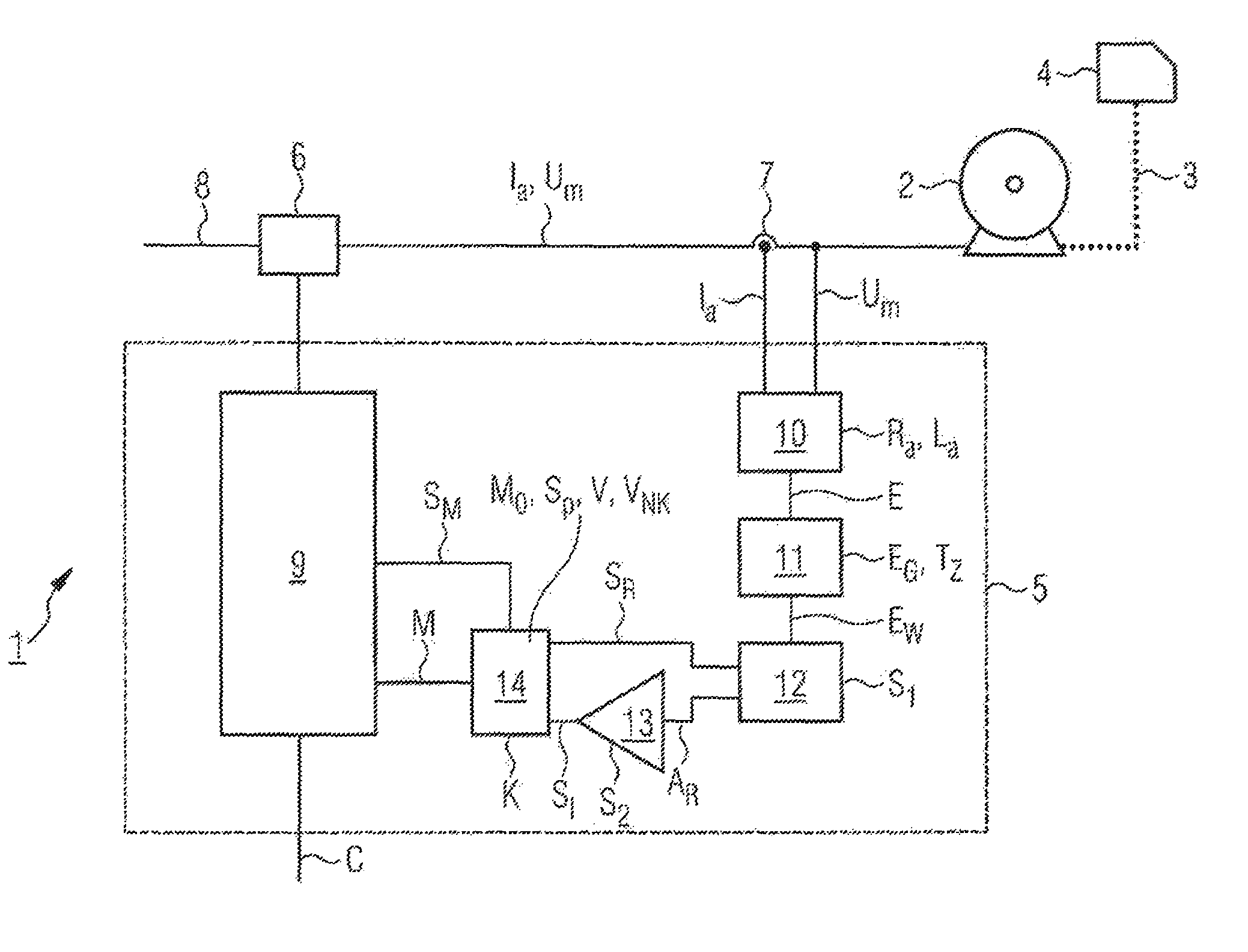

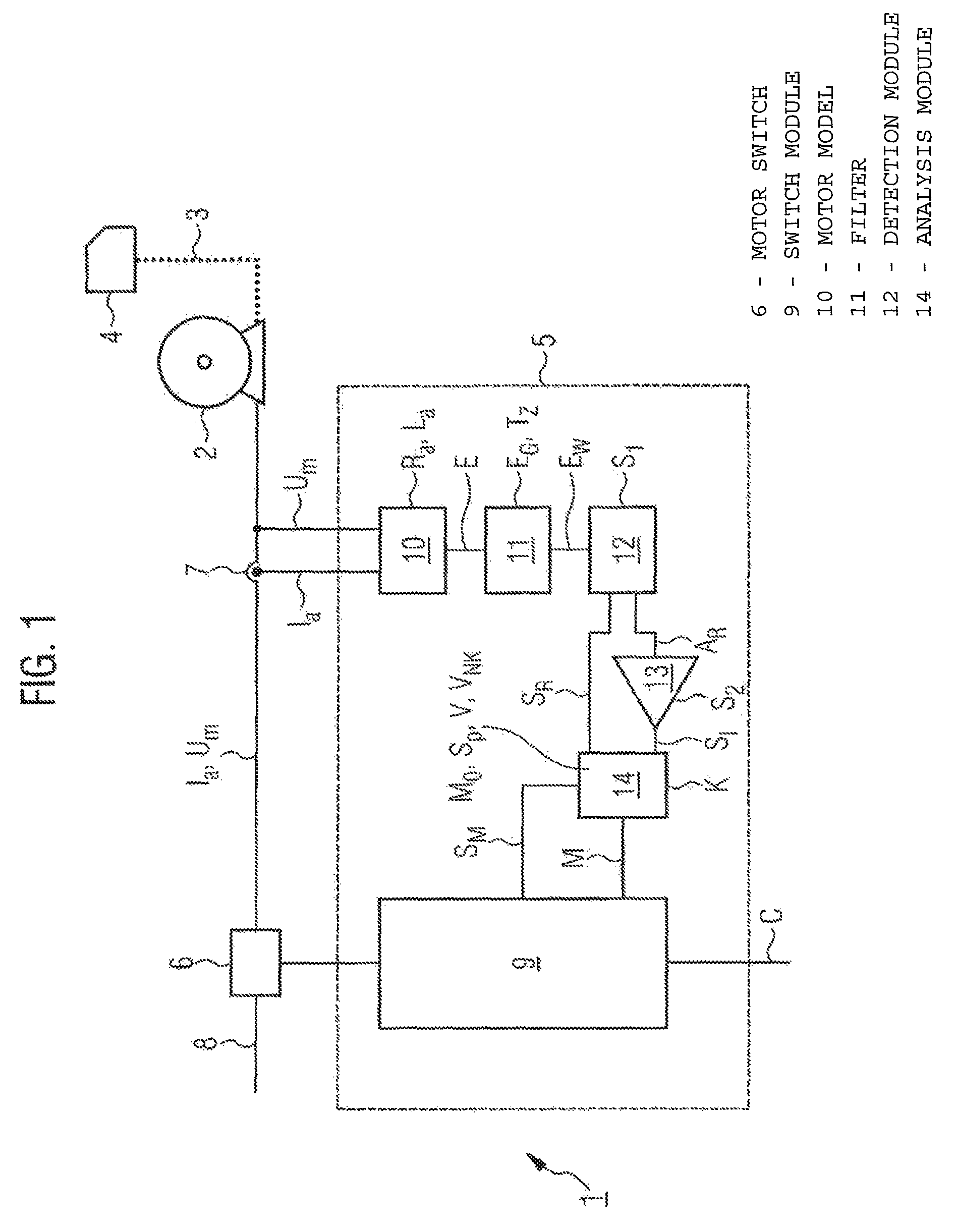

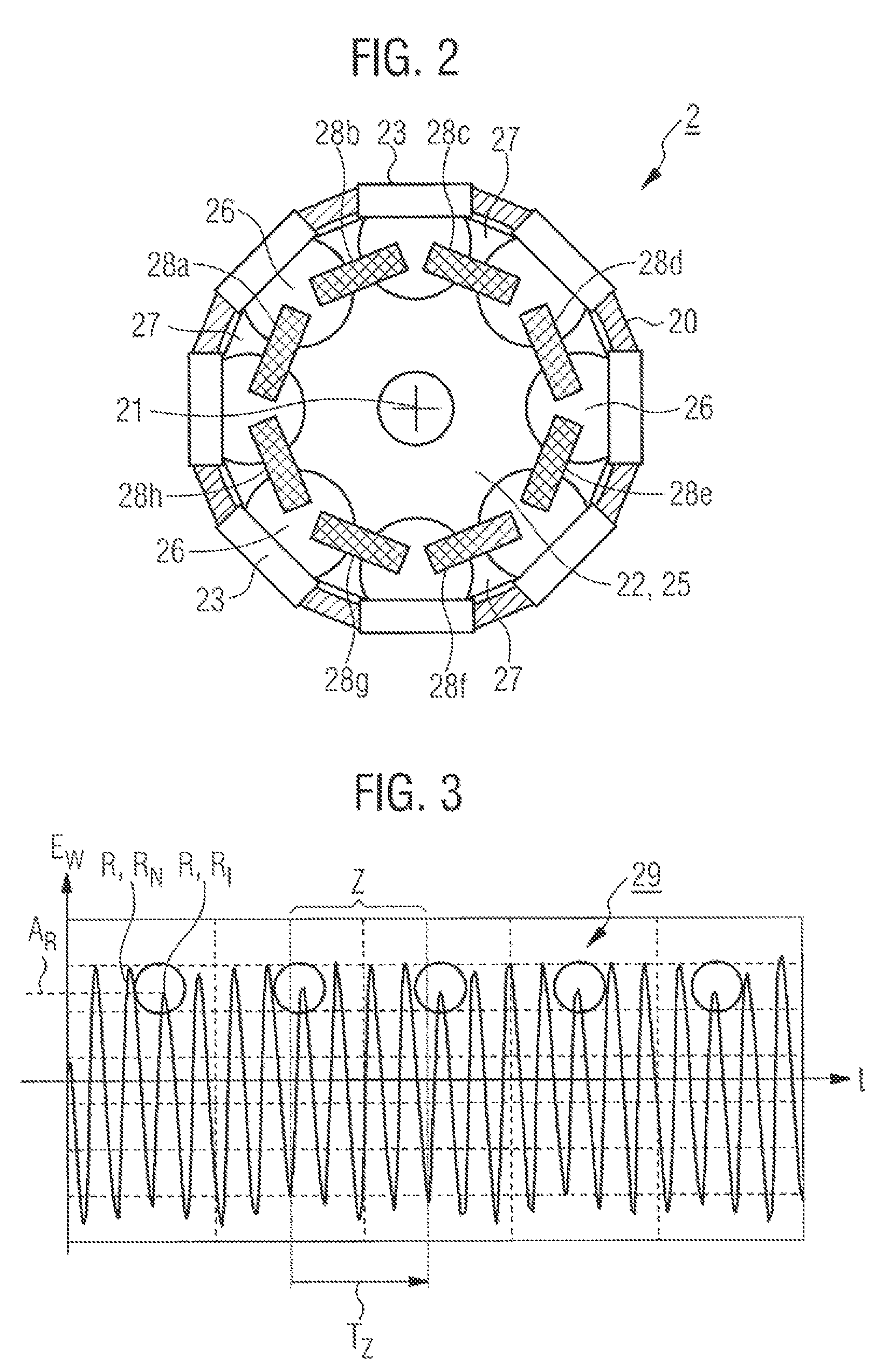

Correction of counting errors in the evaluation of current ripples in a DC motor

InactiveUS20120091938A1Correction errorTorque ripple controlSynchronous motors startersMotor modelCounter-electromotive force

A method for detecting a regulating variable of a mechanically commutated DC motor in a positioning device for a motor vehicle is provided. The DC motor has a standard ripple pattern, which contains per engine cycle or semi-cycle at least one index ripple, which is classified with regard to amplitude, duration and / or time position. The counter-electromotoric power is calculated from a measured motor current and the measured motor voltage by a motor model. An alternating element corresponding to the current ripples is extracted from the counter-electromotoric power, which in turn is used to determine the current ripples. Further, in at least one engine cycle or engine semi-cycle the index ripple is identified and the total identified current ripples are counted. The result of the count is hereby corrected when the index ripple is not counted at the expected position.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

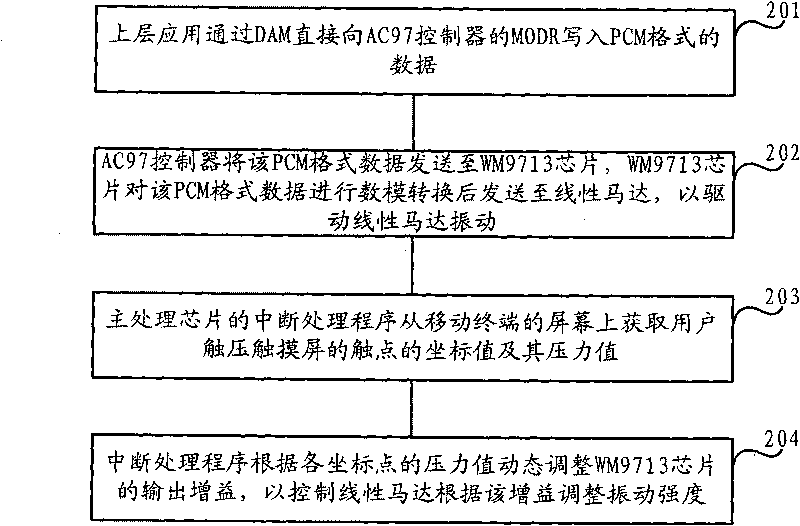

Method for controlling vibration of linear motor

InactiveCN101697470AReduce difficultyRich vibration effectsLinear DC motor controlProgramme control in sequence/logic controllersVocal tractComputer terminal

The invention discloses a method for controlling the vibration of a linear motor for solving the problem of difficult control of the vibration of the linear motor in the prior art. The method comprises: monophonic audio data are generated; a main processing chip transmits the monophonic audio data to an audio coding and decoding chip; the audio coding and decoding chip converts the monophonic audio data into an analog signal and sends the analog signal to the linear motor to control the linear motor to vibrate according to the analog signal; a processing interruption program in the main processing chip acquires the value of a pressure at a screen touch point and adjusts the output gain of the audio coding and decoding chip according to the obtained value of the pressure; and the linear motor adjusts the vibration intensity according to the gain. According to the technical scheme of the invention, the vibration of the linear motor can be realized without improving the traditional mobile terminal and the control difficulties of the vibration of the linear motor are reduced.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

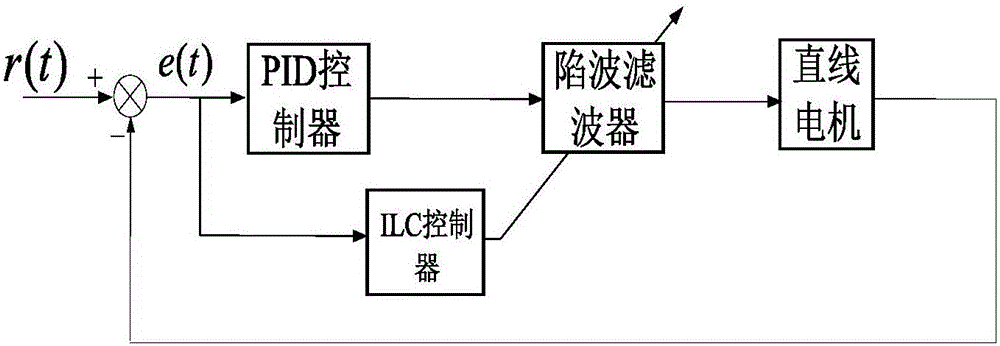

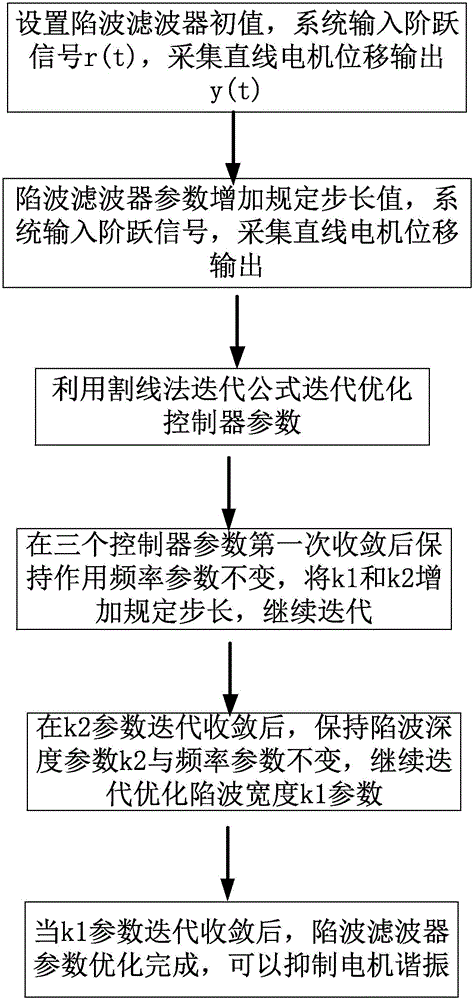

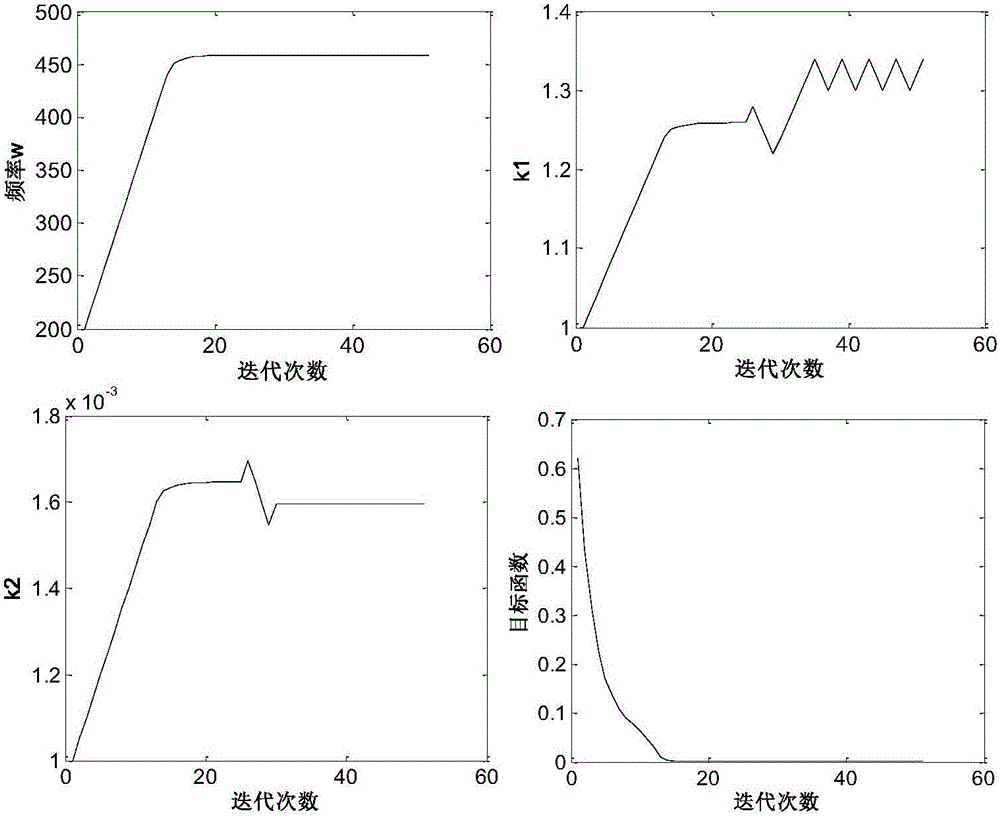

Linear servo system mechanical resonance control method

InactiveCN105929865ASolve the problem of resonance suppressionSimple control methodAC motor controlMechanical oscillations controlIterative learning algorithmSystem requirements

The invention discloses a linear servo system mechanical resonance control method which belongs to the field of mechanical equipment control. According to a control method in the prior art, on-line automatic adjustment of control parameters of a notch filter cannot be realized; a mechanical resonance suppression effect is poor; and the system requirements of high speed and high precision linear servo cannot be met. The invention provides a secant-based iterative learning algorithm to optimize the control parameters of the notch filter to solve the problem of resonance suppression of a linear servo system. The control method provided by the invention is simple, practical and highly precise.

Owner:ZHEJIANG SCI-TECH UNIV

Correction of counting errors in the evaluation of current ripples in a DC motor

InactiveUS8310185B2Correction errorTorque ripple controlAC motor controlMotor modelElectromotive force

A method for detecting a regulating variable of a mechanically commutated DC motor in a positioning device for a motor vehicle is provided. The DC motor has a standard ripple pattern, which contains per engine cycle or semi-cycle at least one index ripple, which is classified with regard to amplitude, duration and / or time position. The counter-electromotoric power is calculated from a measured motor current and the measured motor voltage by a motor model. An alternating element corresponding to the current ripples is extracted from the counter-electromotoric power, which in turn is used to determine the current ripples. Further, in at least one engine cycle or engine semi-cycle the index ripple is identified and the total identified current ripples are counted. The result of the count is hereby corrected when the index ripple is not counted at the expected position.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

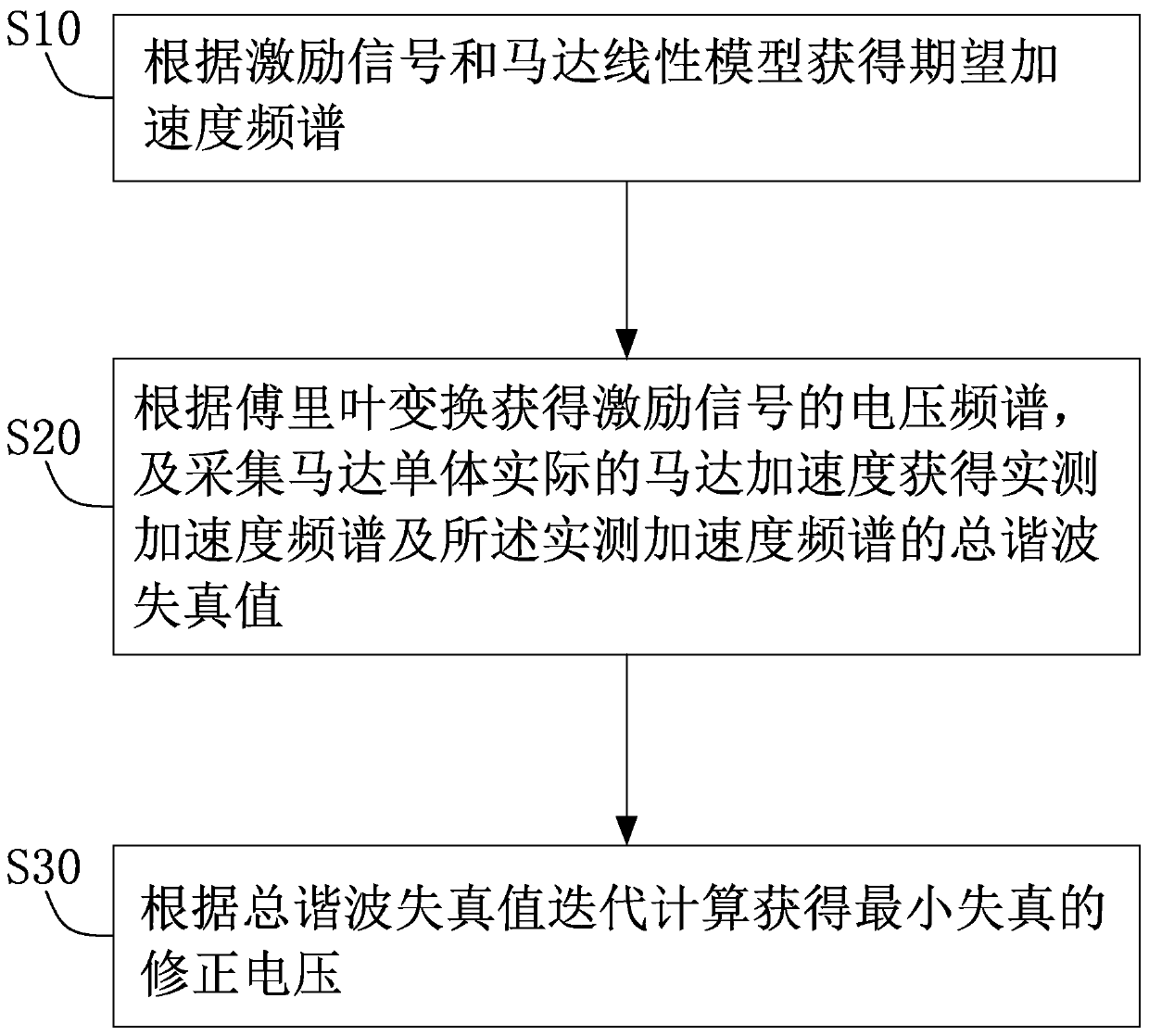

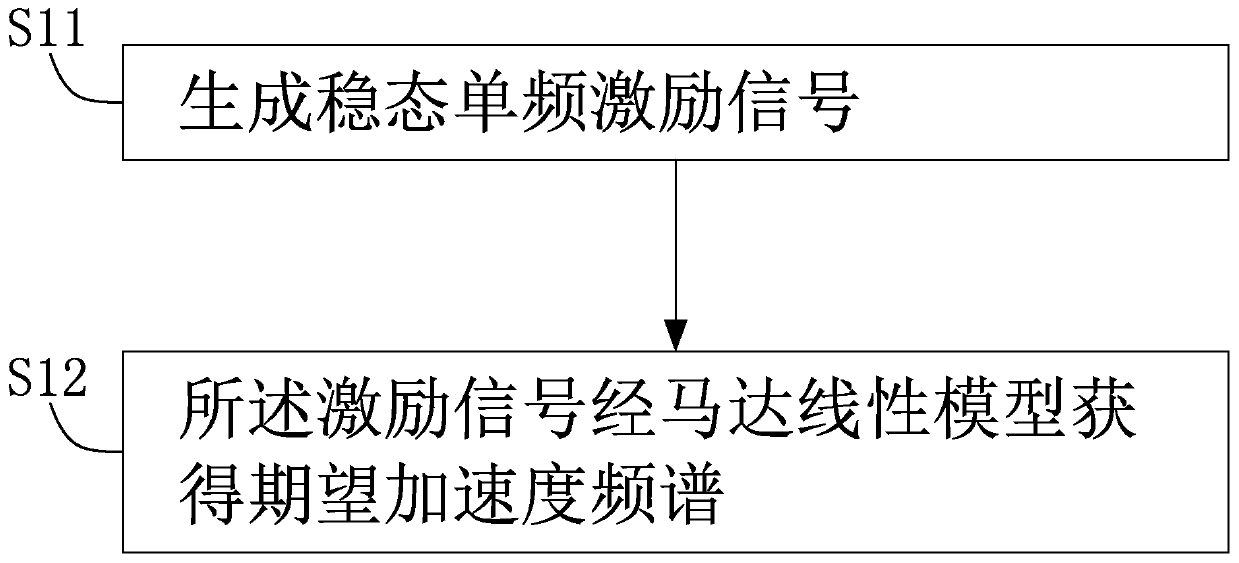

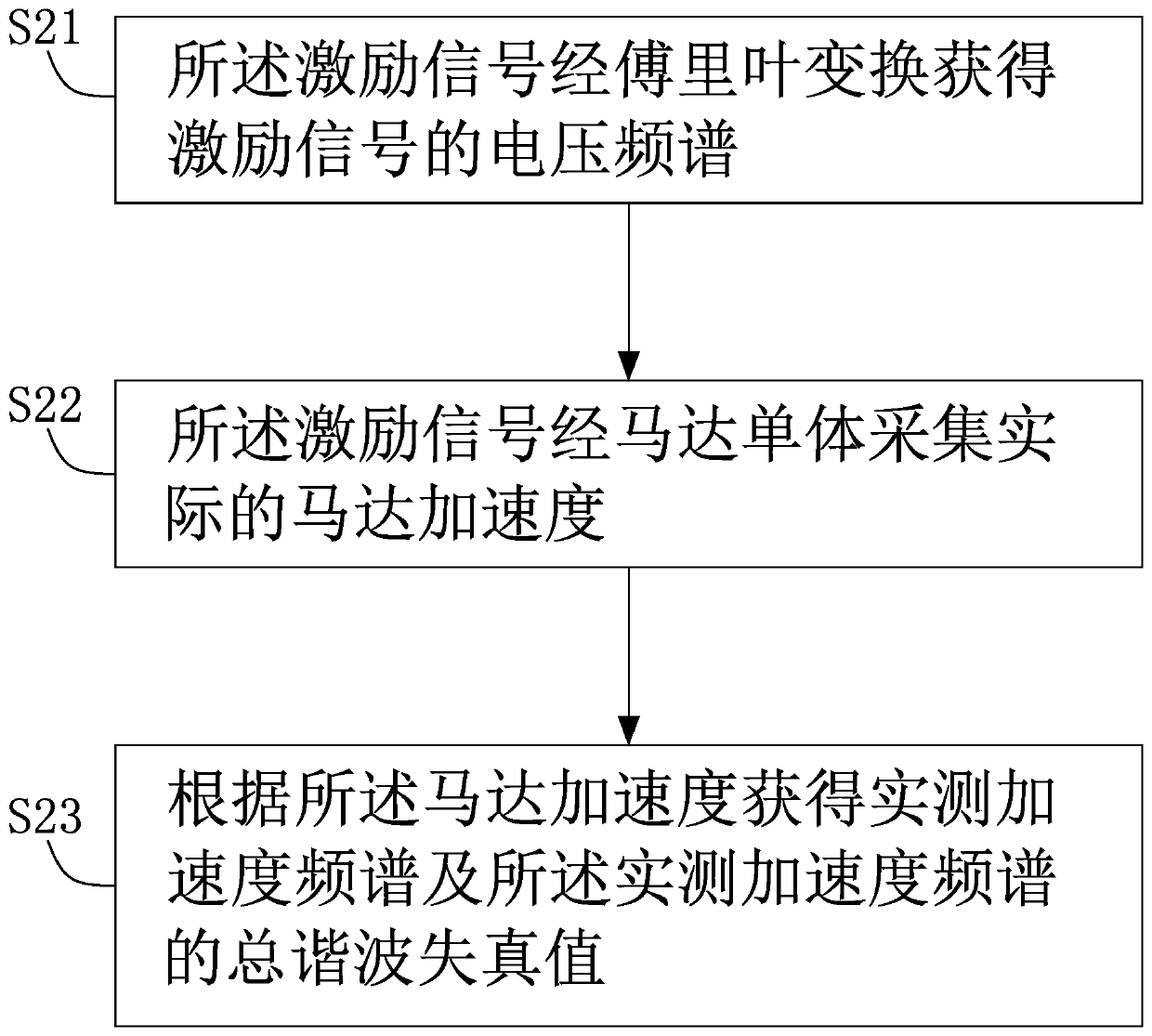

Motor steady-state single-frequency distortion compensation method and motor steady-state single-frequency distortion compensation device

PendingCN111478630AReduce adverse effectsLinear DC motor controlFrequency spectrumTotal harmonic distortion

The invention provides a motor steady-state single-frequency distortion compensation method, which comprises: a construction step: obtaining an expected acceleration frequency spectrum according to anexcitation signal and a motor linear model; an obtaining step: obtaining the voltage frequency spectrum of the excitation signal according to Fourier transform, and collecting the actual motor acceleration of a motor monomer to obtain an actual measurement acceleration frequency spectrum and a total harmonic distortion value of the actual measurement acceleration frequency spectrum; and a compensation step: carrying out iterative calculation according to the total harmonic distortion value to obtain a correction voltage with minimum distortion. With the method and the device, the adverse effect of nonlinearity of the motor on the tactile experience is reduced.

Owner:AAC TECH PTE LTD

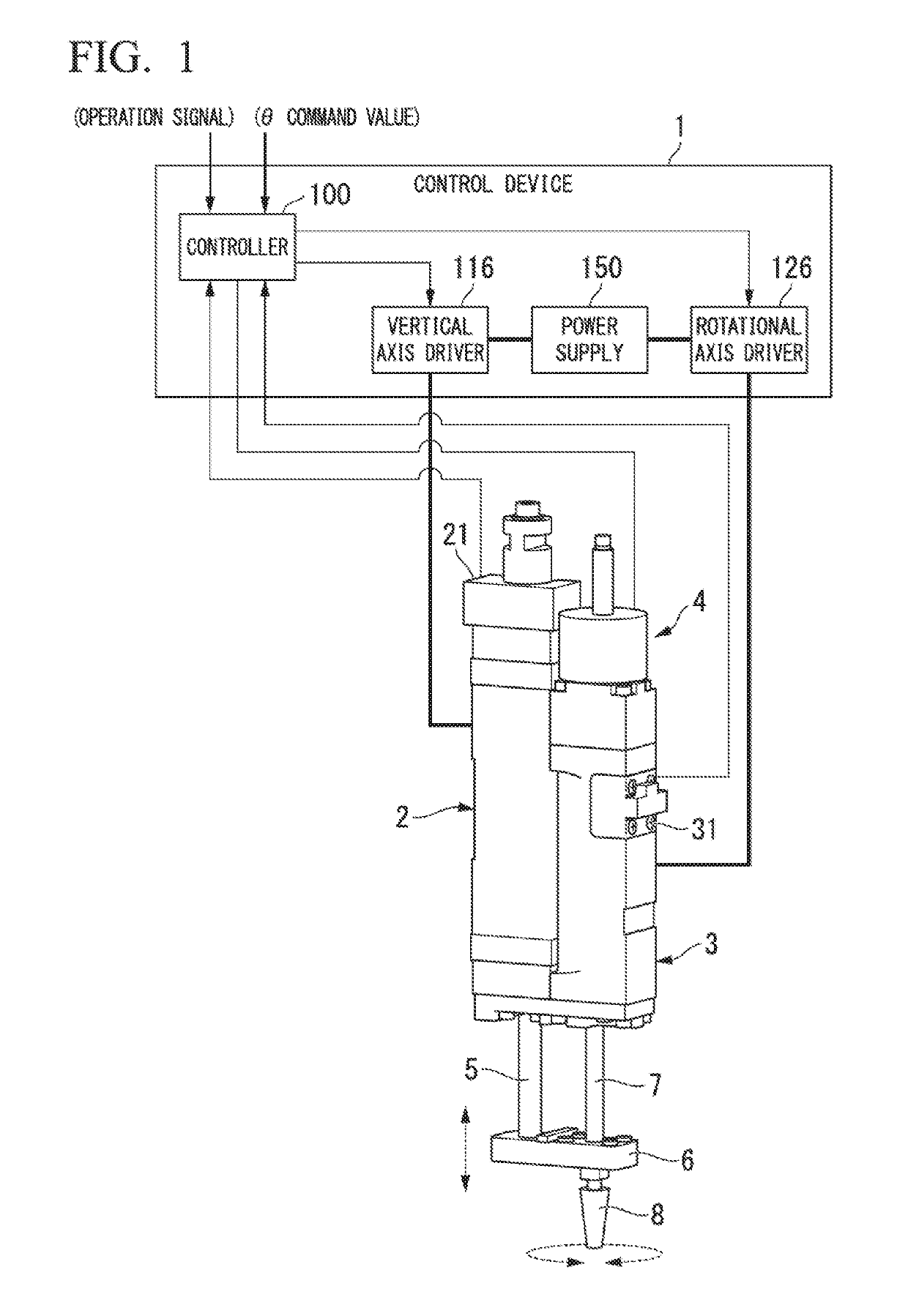

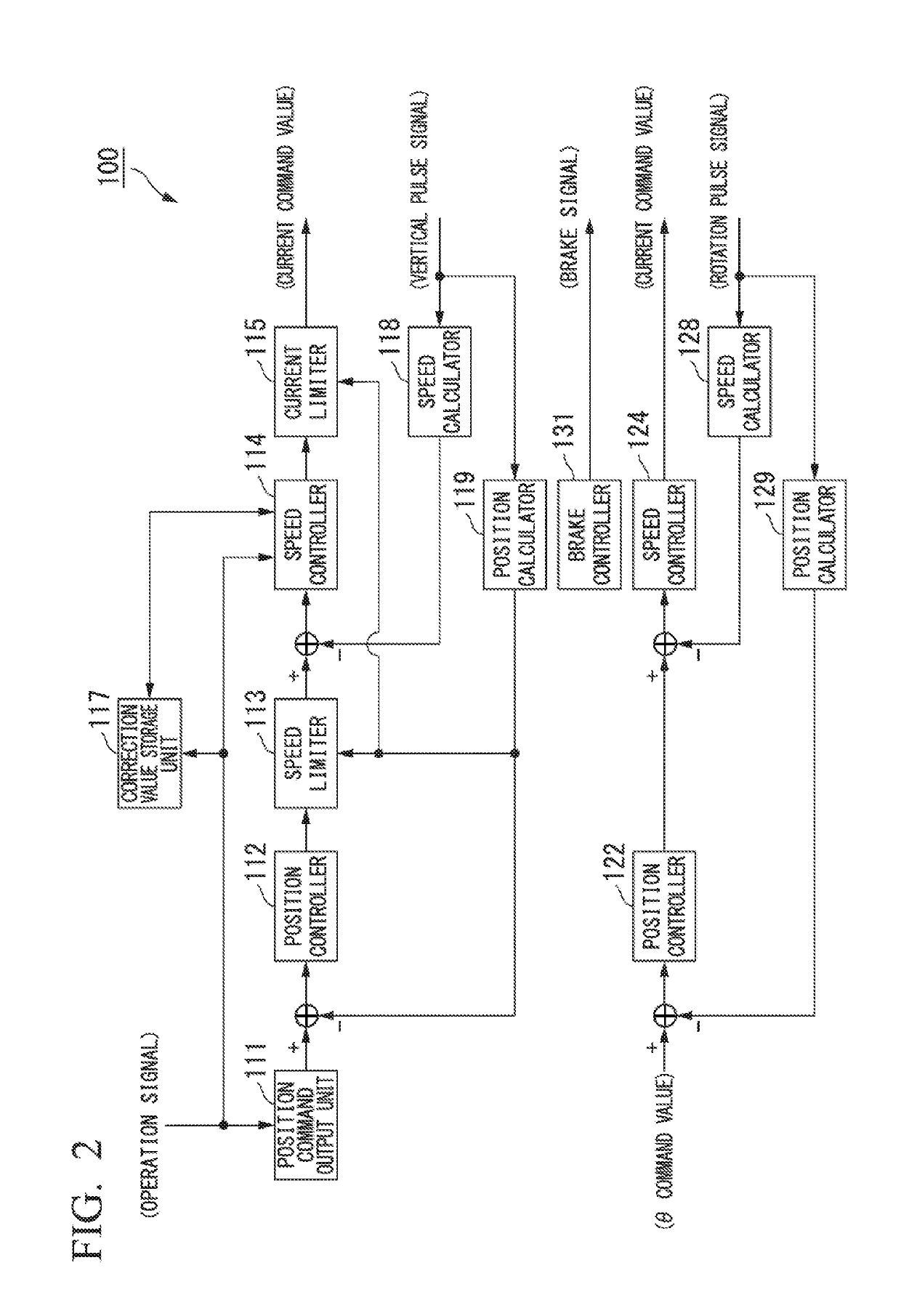

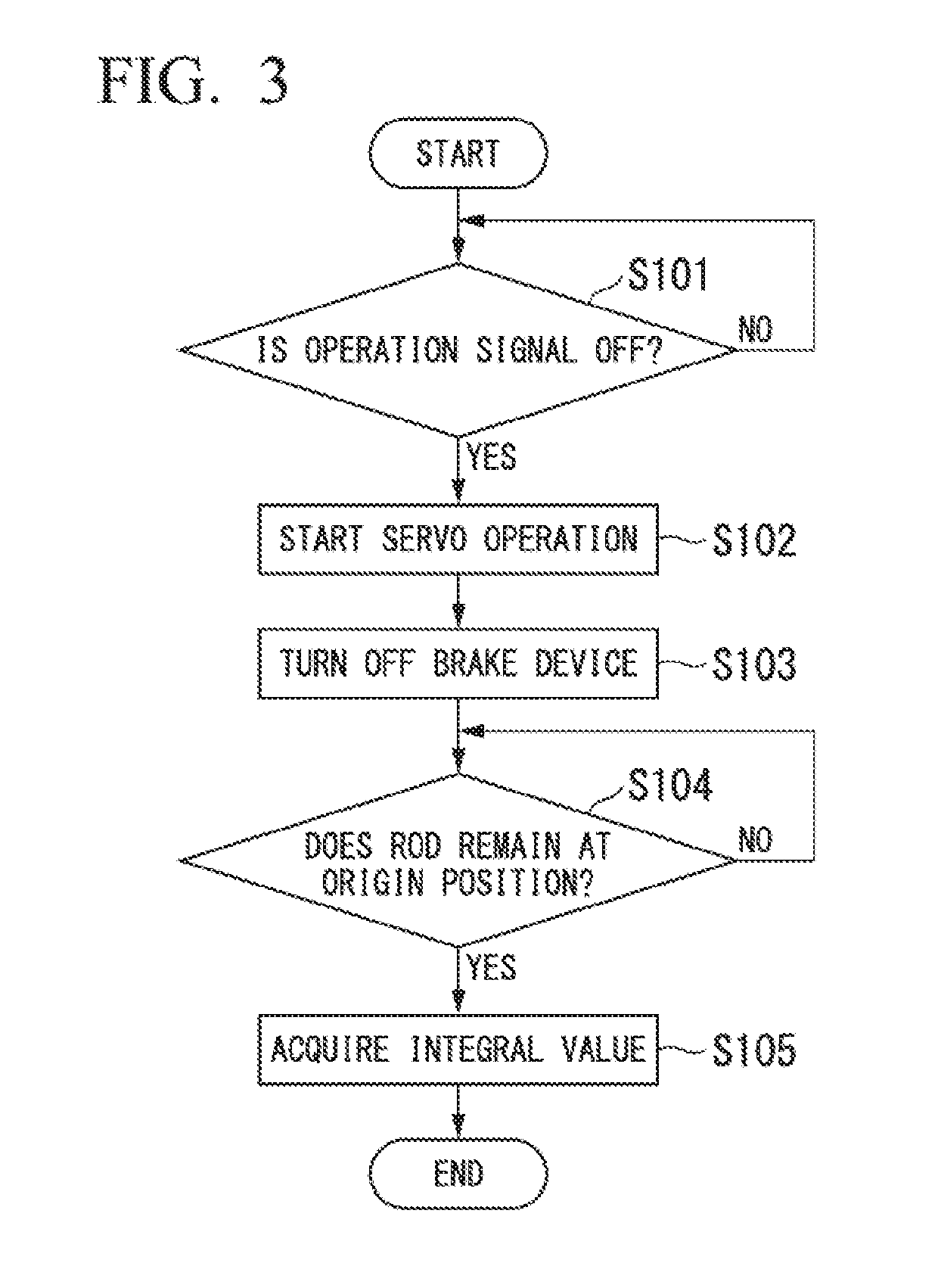

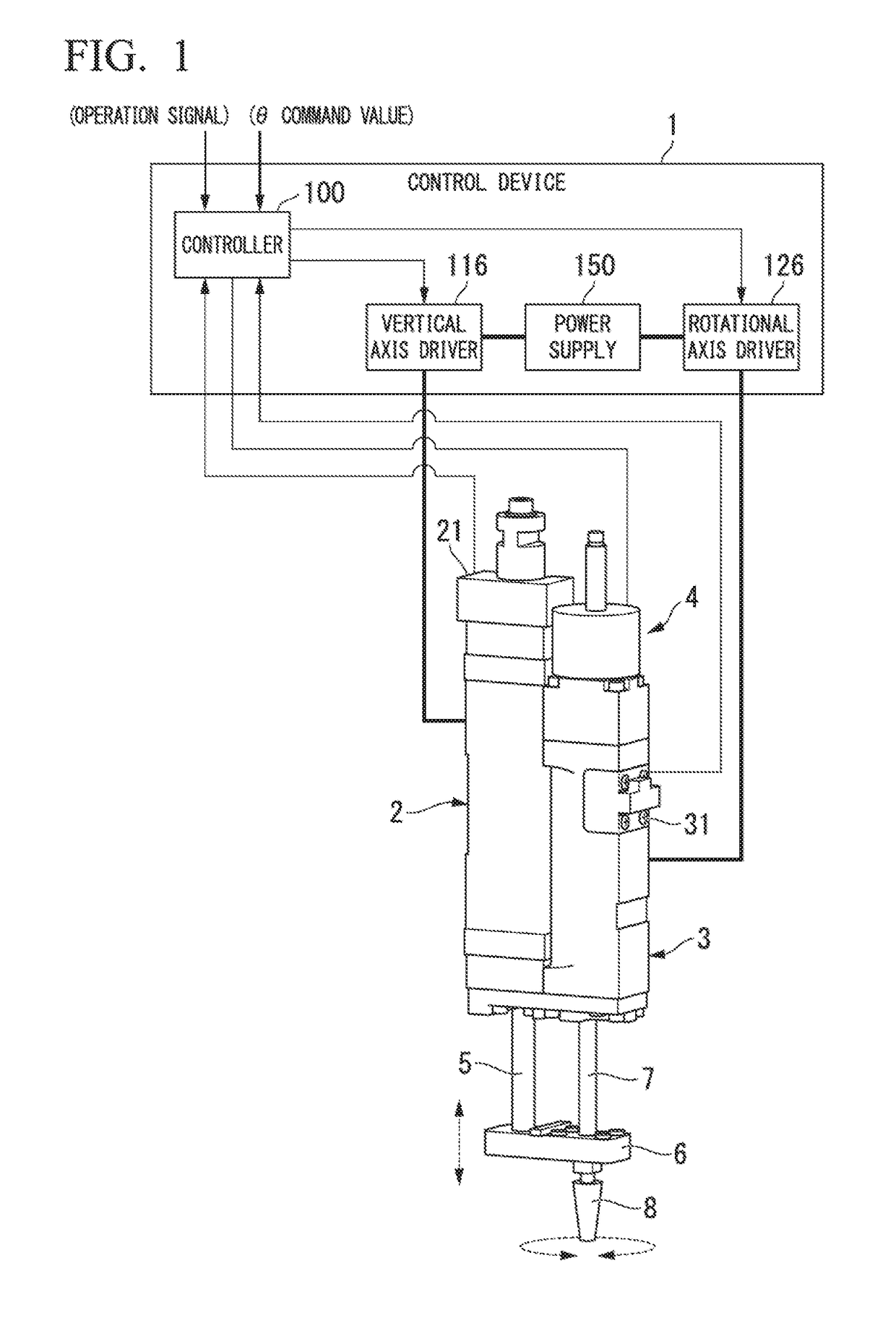

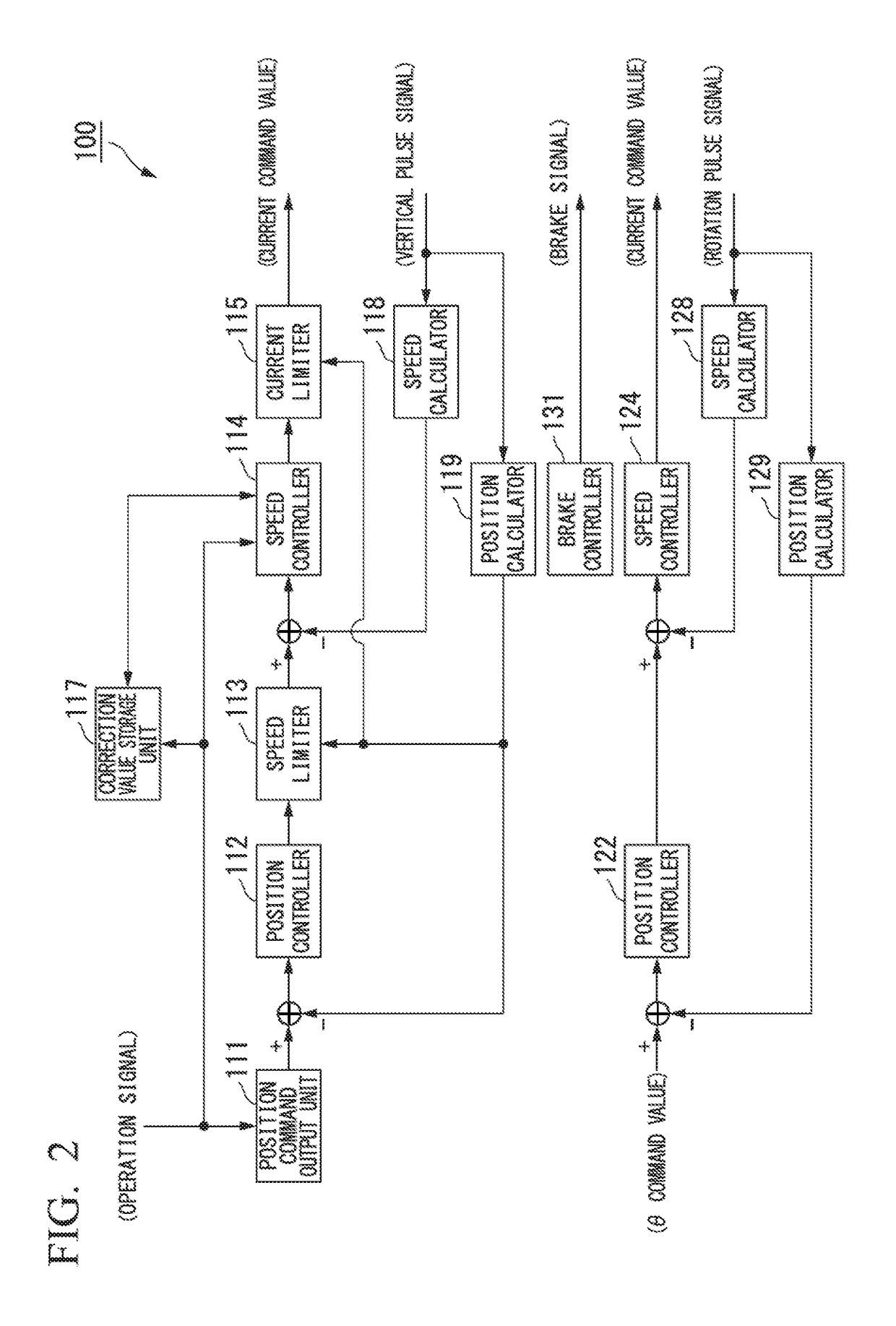

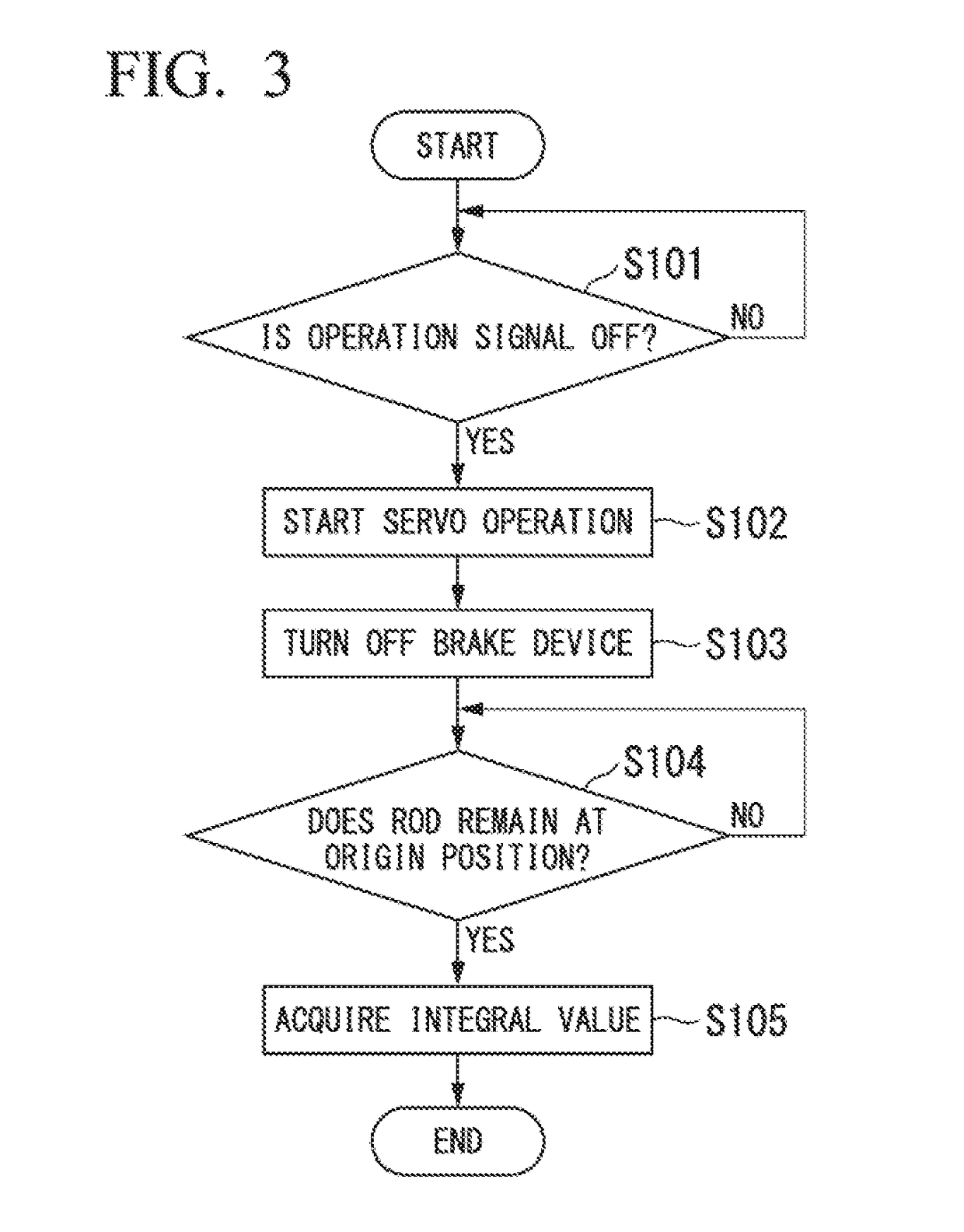

Device and method for controlling linear motor

ActiveUS10498263B2Improve responsivenessMotor/generator/converter stoppersSingle motor speed/torque controlLinear motorVelocity controller

A control device for a linear motor includes a speed controller that calculates a current command value by an integration operation using a first integral value of a difference between a moving speed of a movable element provided in the linear motor and a speed command value calculated on the basis of a position command value, a current controller that applies a voltage to the linear motor on the basis of the current command value, and a correction value storage unit that stores the first integral value of the speed controller when the movable element remains at a position indicated by the position command value. When resuming control of the linear motor, the speed controller sets the first integral value stored in the correction value storage unit as an initial value for the integration operation before the brake controller turns off the brake device.

Owner:THK CO LTD

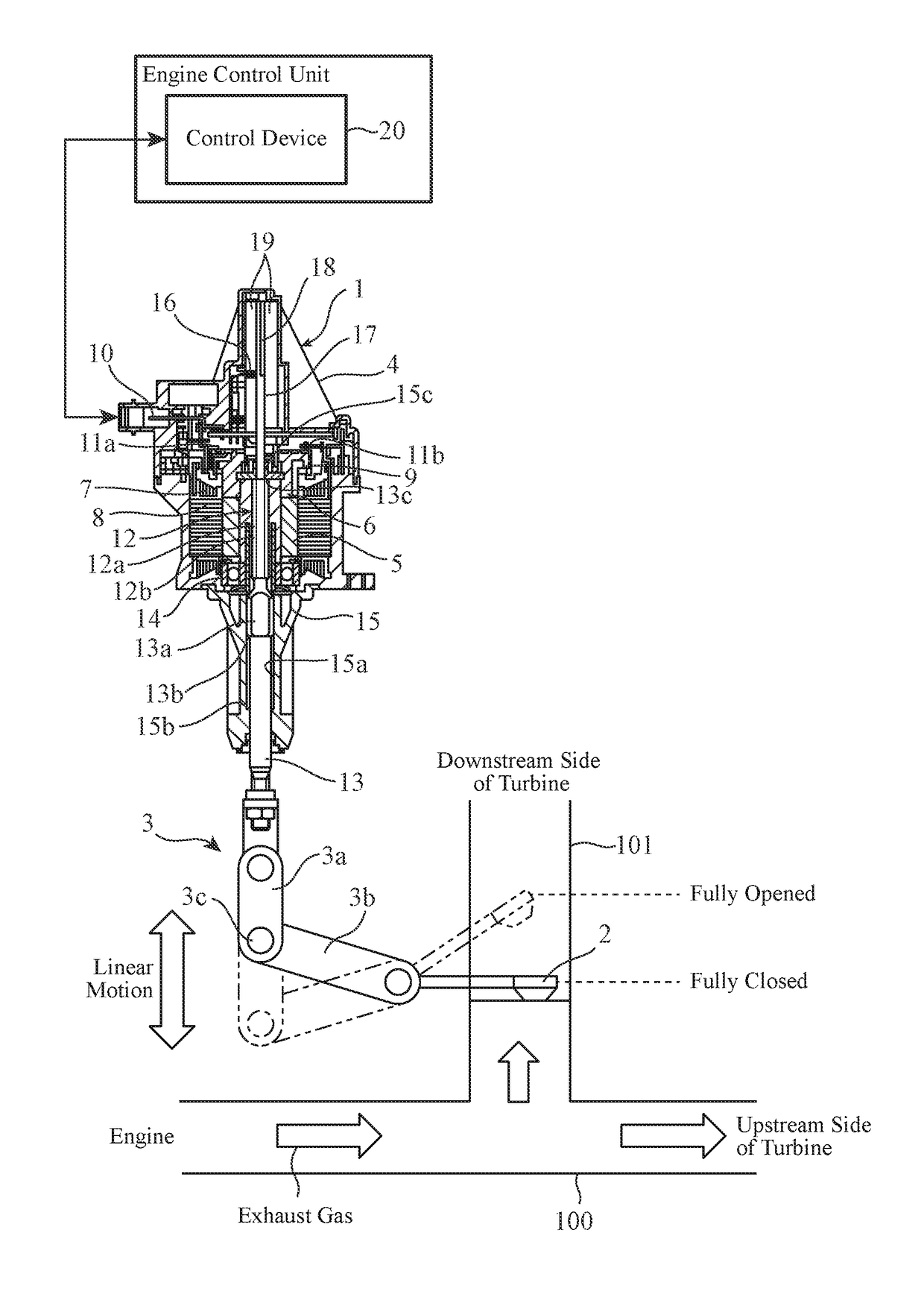

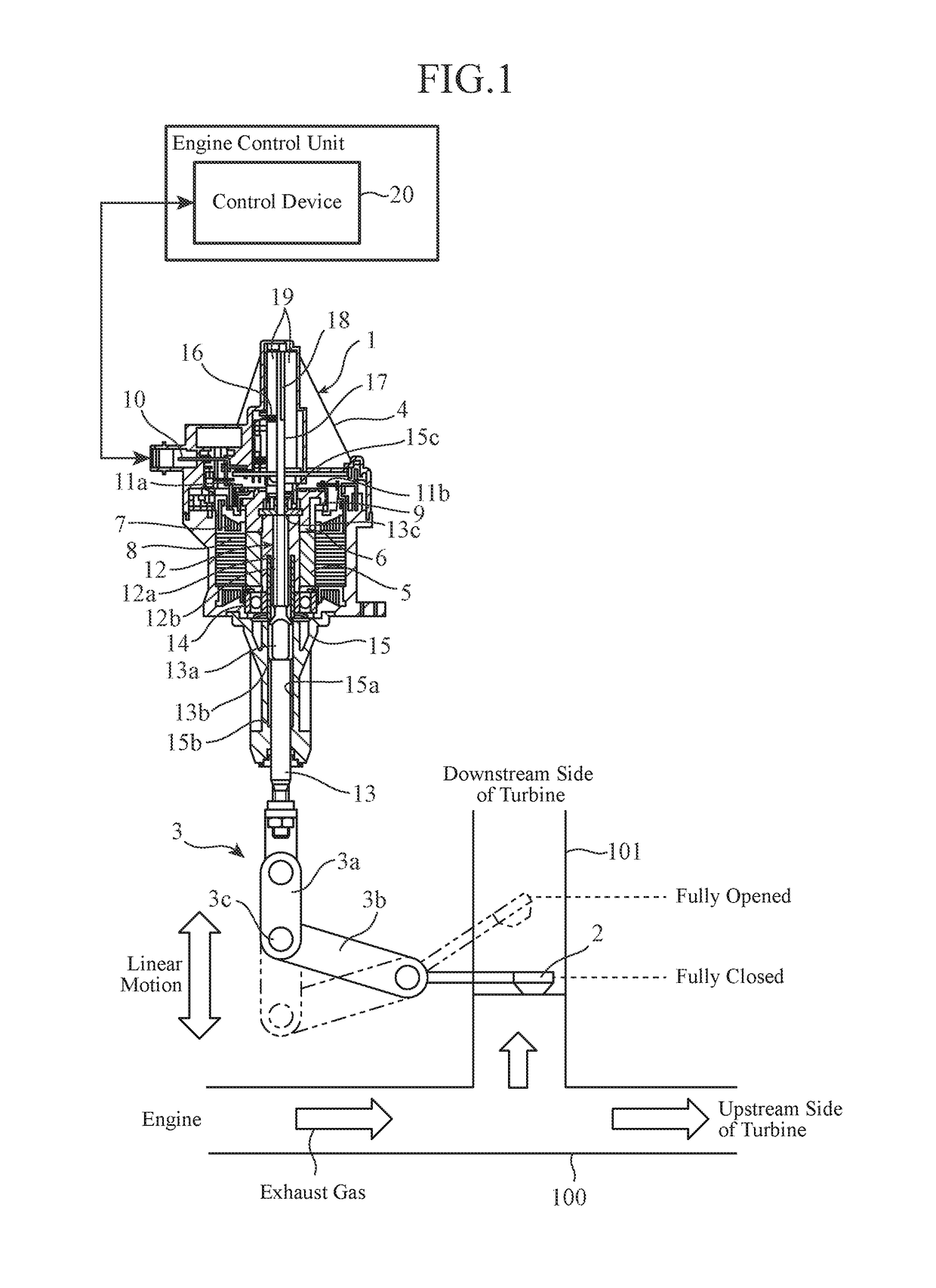

Control device for actuator, actuator, valve driving device and control method for actuator

ActiveUS20180041156A1Accurate internal temperatureSpeed controllerElectric motor controlActuatorControl theory

A position sensor mounted in an actuator includes a magnetic detecting element for detecting the position of a shaft, and a temperature detecting element for detecting intra-sensor temperature which is used for correction of the temperature characteristics of the magnetic detecting element, the magnetic detecting element and the temperature detecting element being built therein. A control device for the actuator acquires both the temperature-corrected position of the shaft and the intra-sensor temperature from the position sensor, and uses them for control of the actuator.

Owner:MITSUBISHI ELECTRIC CORP

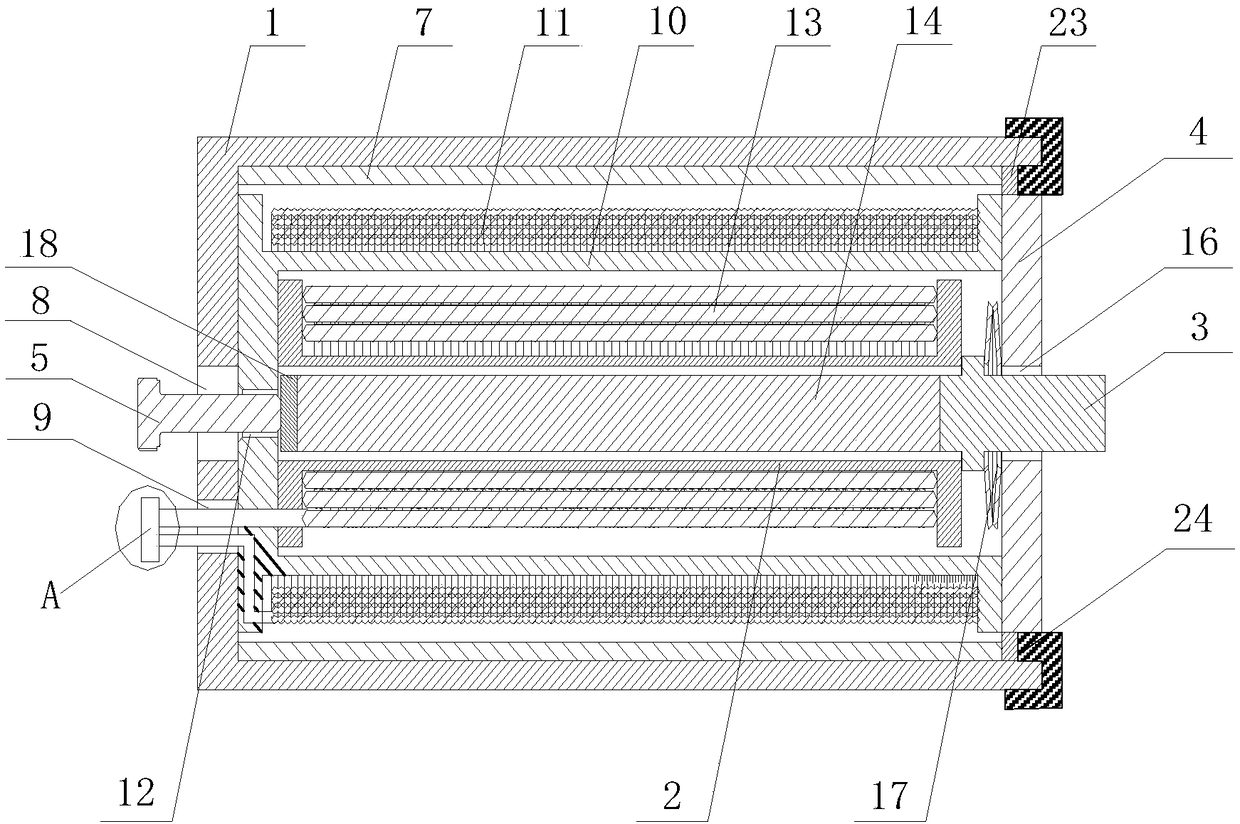

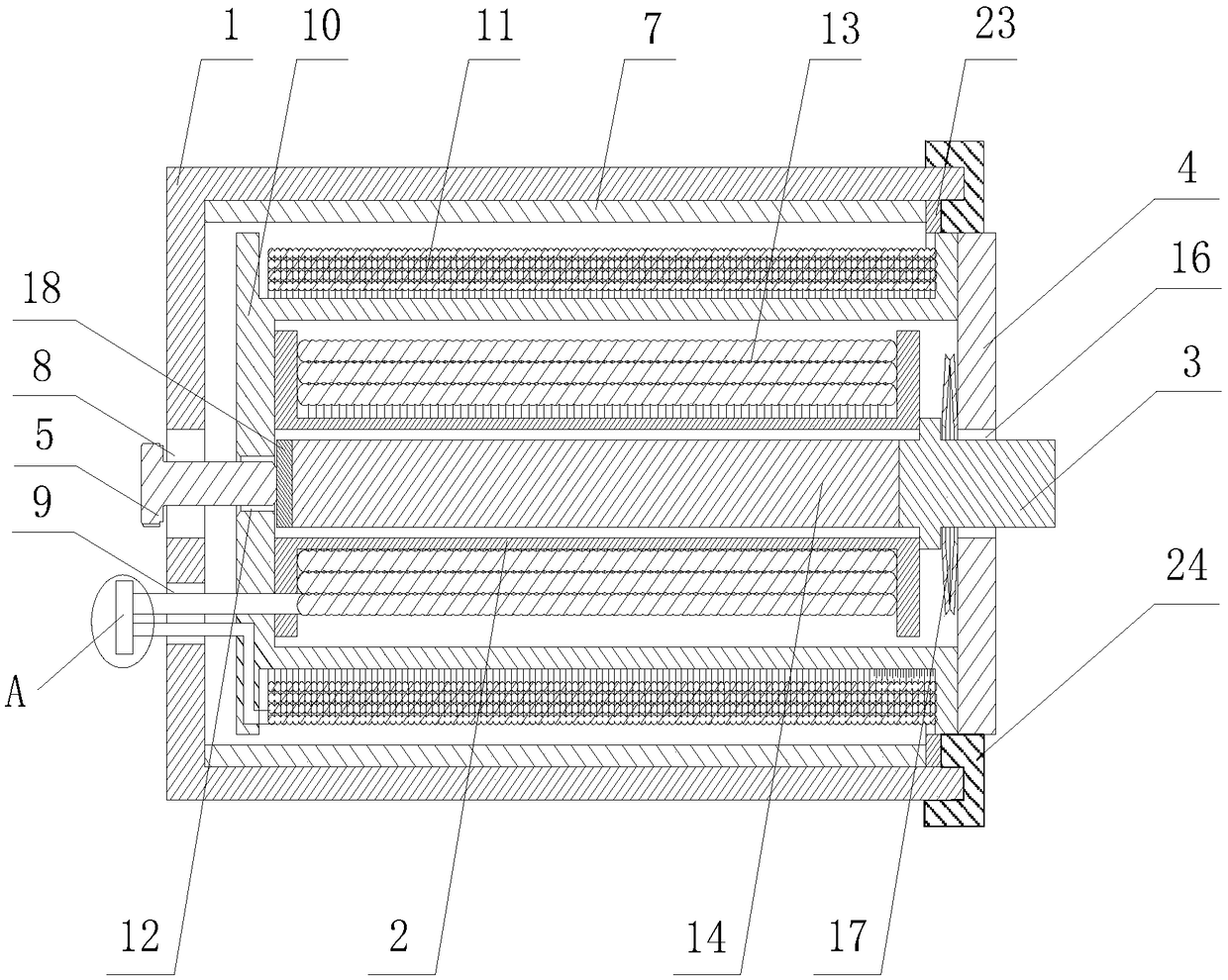

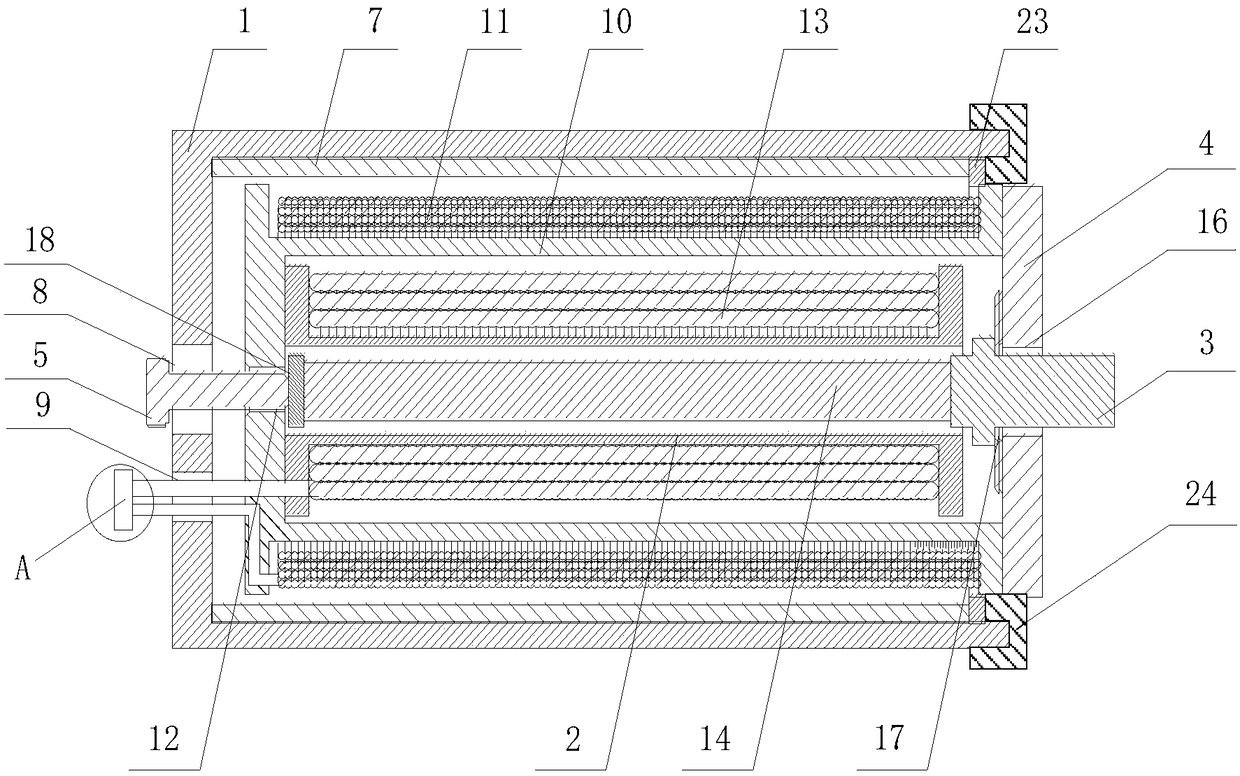

Micro-macro two-stage driver and control method thereof

PendingCN108206621ALarge outputHigh precisionElectric motor controlPiezoelectric/electrostriction/magnetostriction machinesPositional TechniqueMagnet

The invention discloses a micro-macro two-stage driver and a control method thereof, and belongs to the technical field of precision positioning. The micro-macro two-stage driver comprises an outer casing, a second coil skeleton, an output rod, an end cover, a pre-tightening screw and a wiring terminal, wherein a permanent magnet cylinder is arranged in the outer casing to provide a radial magnetic field; a first coil skeleton is arranged in the permanent magnet cylinder, and is used for winding a first coil; a second coil skeleton is arranged in the first coil skeleton, and is used for winding a second coil; a giant magnetostictive telescopic rod is arranged in the second coil skeleton; the end cover is fixedly connected with the first coil skeleton through a bolt; an output hole is formed in the center of the end cover; the output rod penetrates through the output hole; the pre-tightening screw penetrates through the circular hole and is connected with a threaded hole by threads; both ends of the first coil are respectively connected with a first conducting wire and a second conducting wire. The micro-macro two-stage driver has the advantages that by adjusting the size of currentwhich is led into the first coil to control the macro-moving of the driver, and adjusting the size of current which is led into the second coil to control the micro-moving of the driver, the large-travel and high-accuracy drive effect can be realized.

Owner:ANHUI UNIV OF SCI & TECH

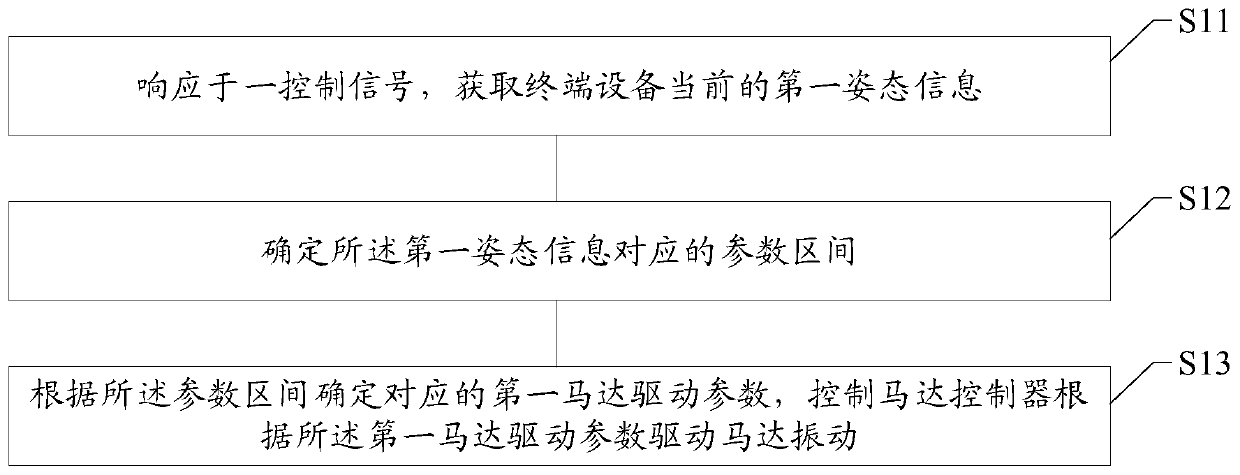

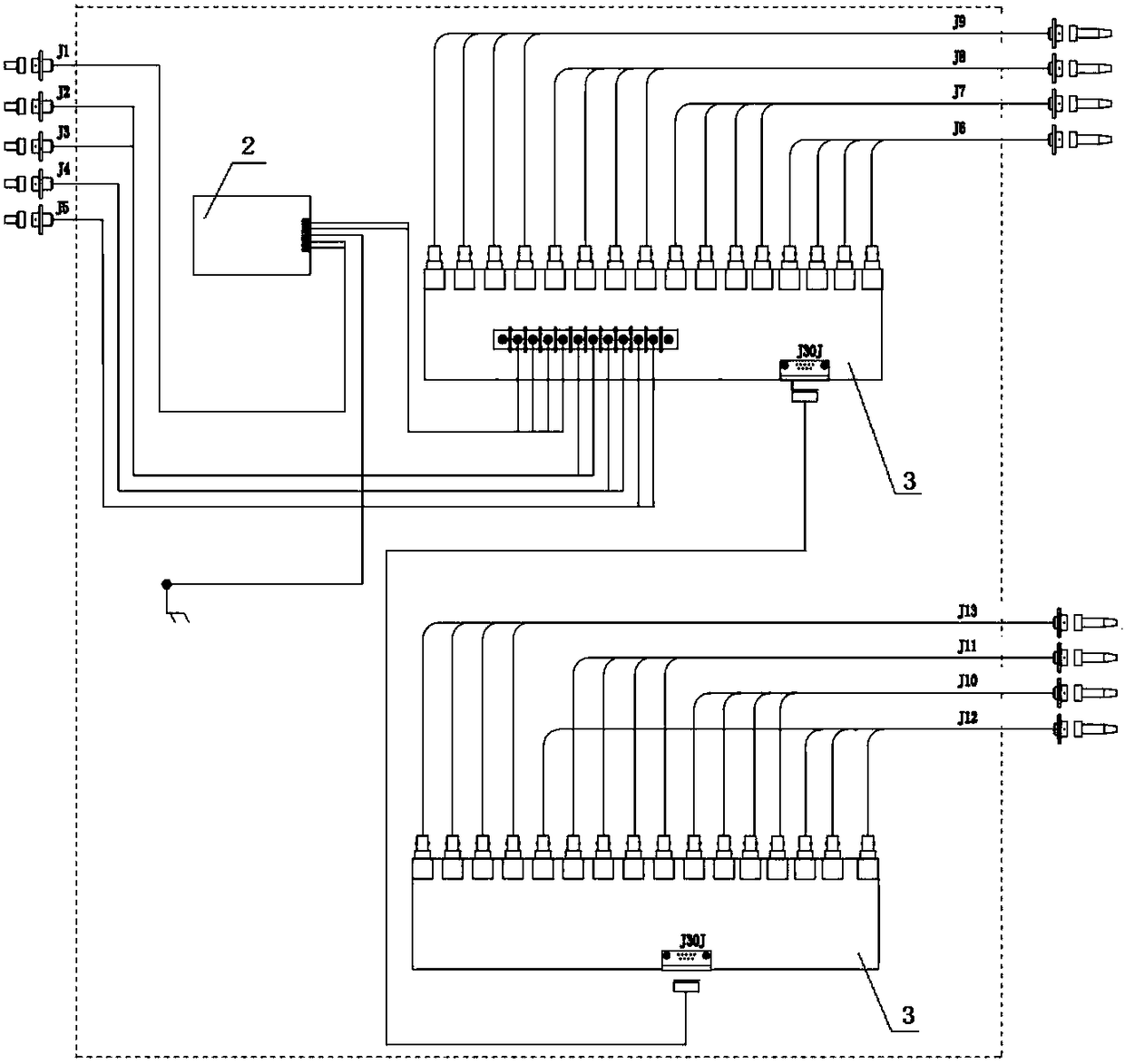

Motor control method and device, computer readable medium and terminal equipment

ActiveCN111182140AAchieving Adaptive ControlLinear DC motor controlSubstation equipmentControl signalControl engineering

The invention relates to the technical field of electronic equipment, in particular to a motor control method, a motor control device, a computer readable medium and a wireless communication terminal.The method comprises the following steps: in response to a control signal, acquiring current first attitude information of terminal equipment; determining a parameter interval corresponding to the first attitude information; and determining a corresponding first motor driving parameter according to the parameter interval, and controlling a motor controller to drive a motor to vibrate according tothe first motor driving parameter. According to the method, different motor driving parameters can be executed according to different attitudes of the terminal equipment, and self-adaptive control over the motor is achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

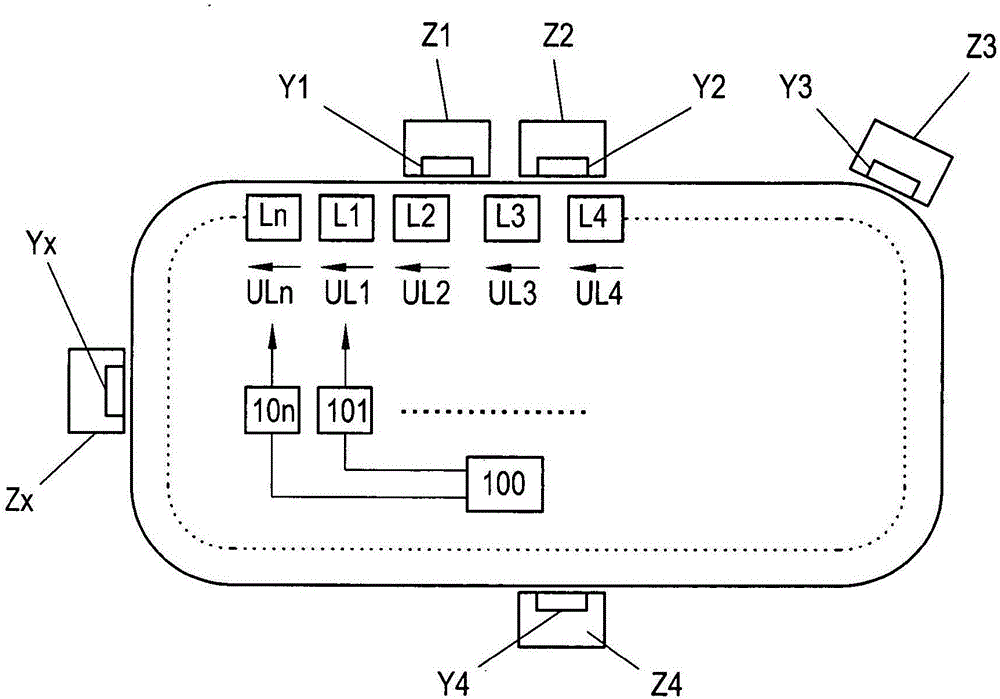

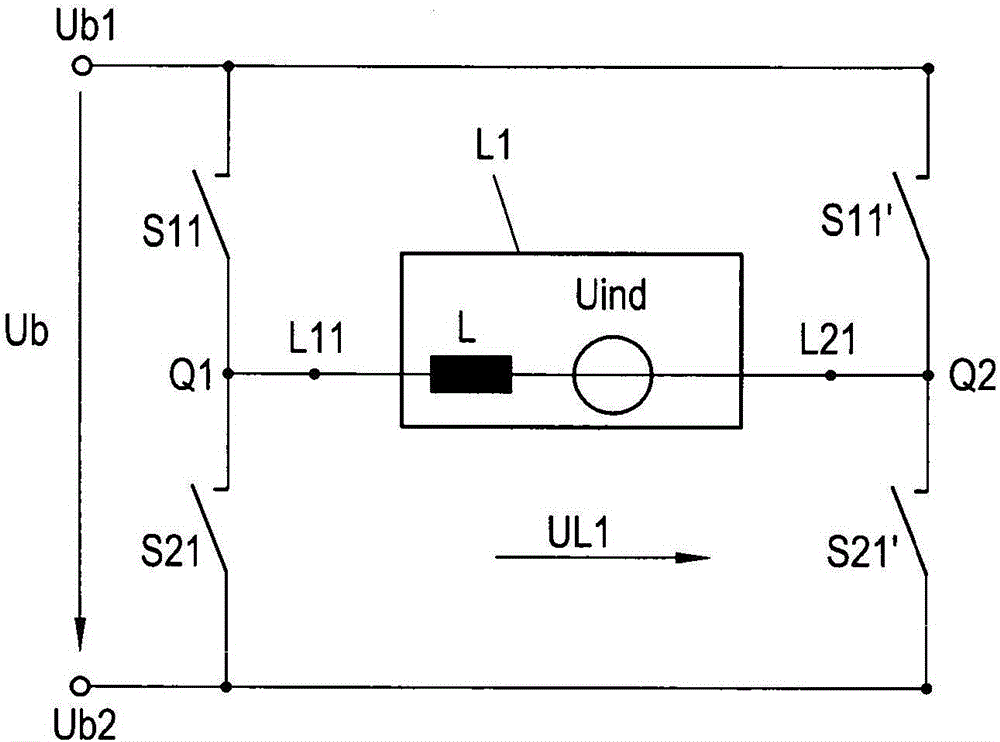

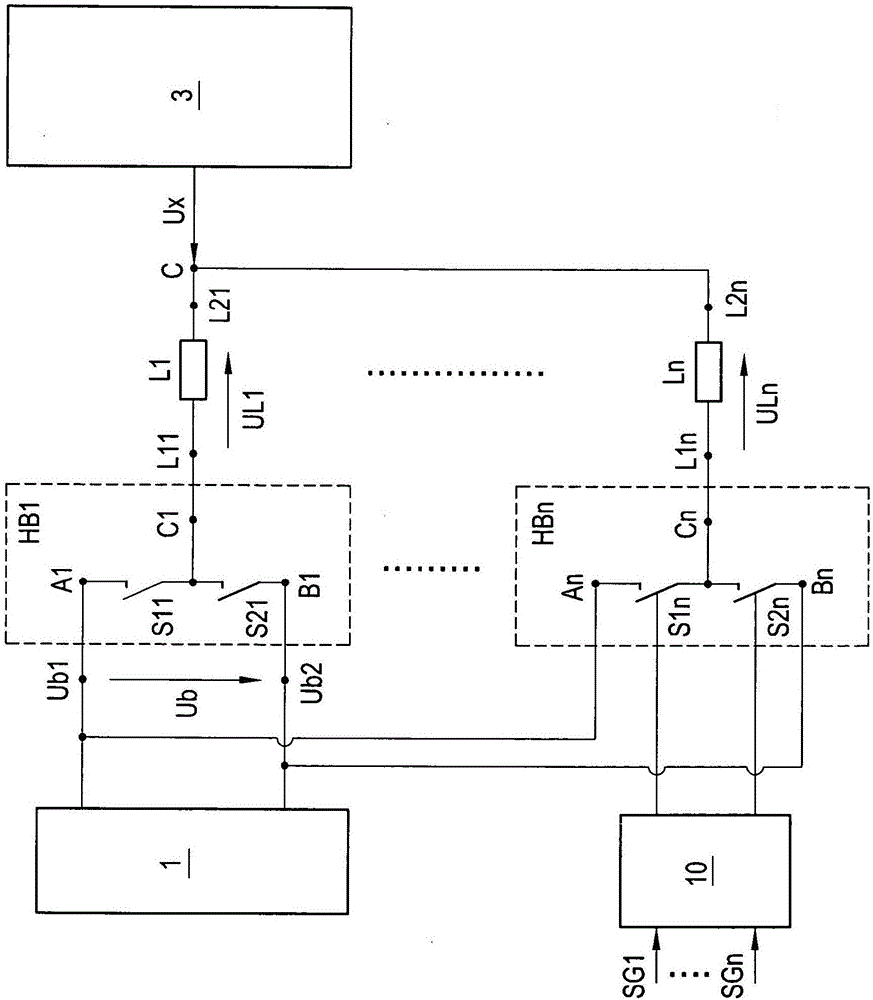

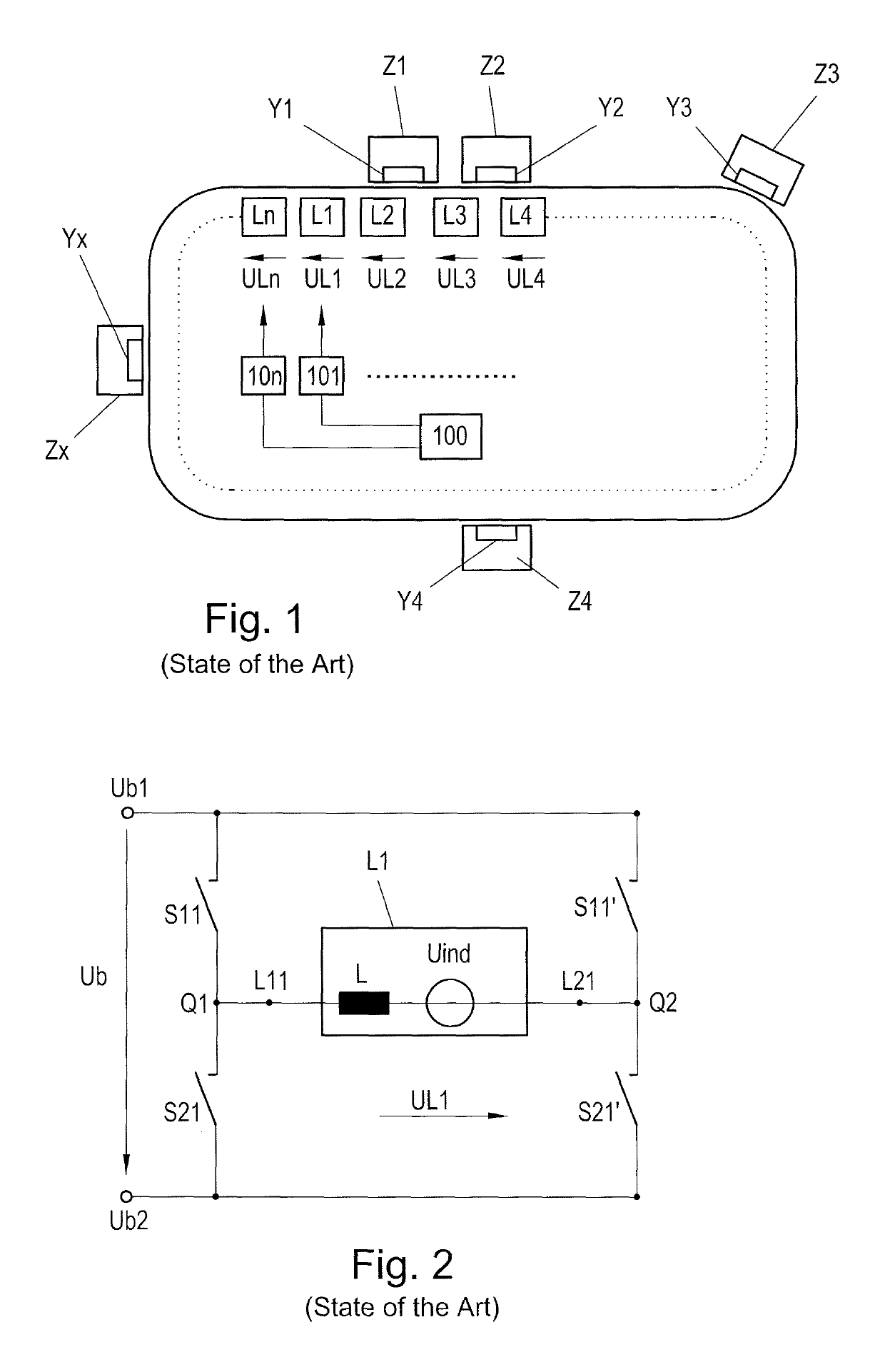

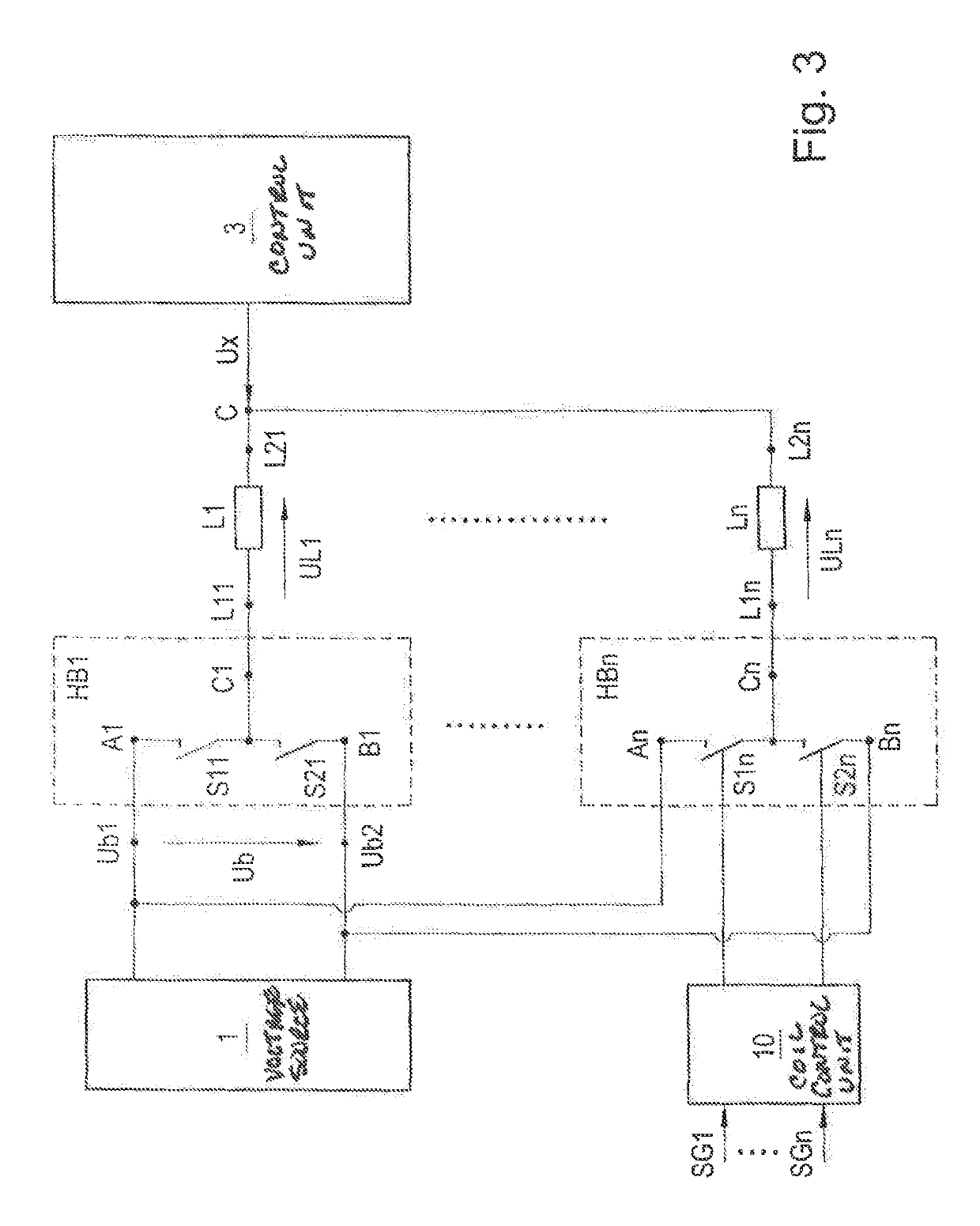

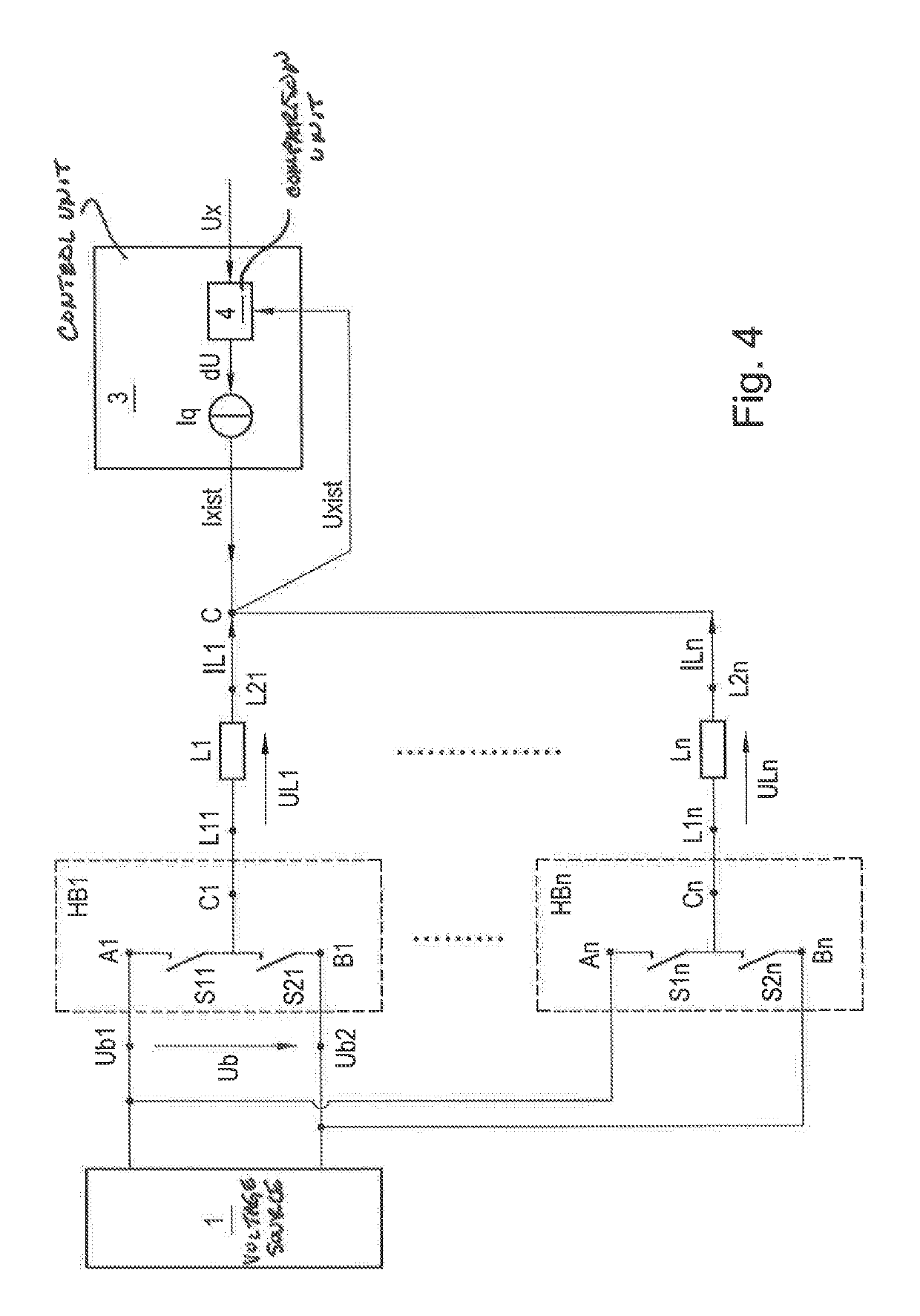

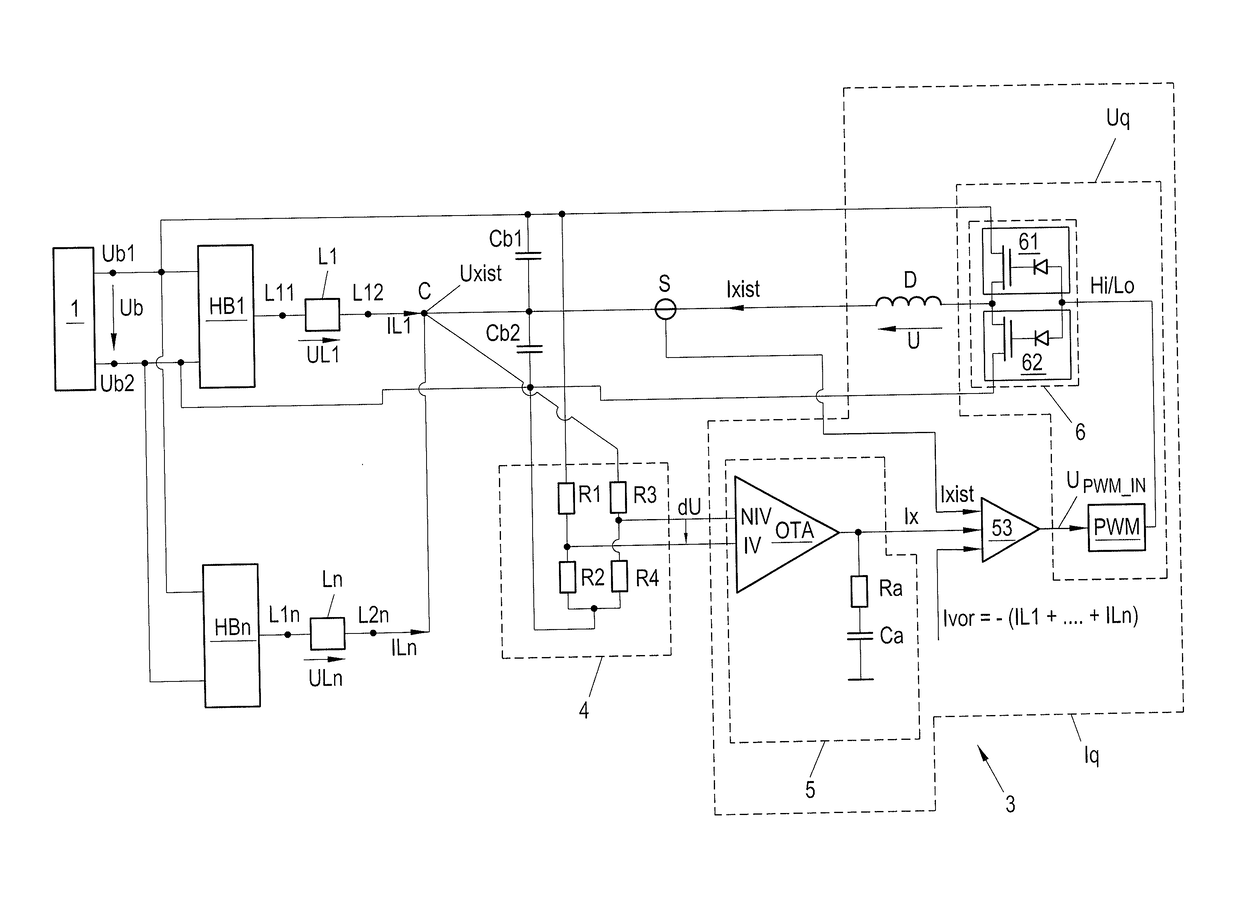

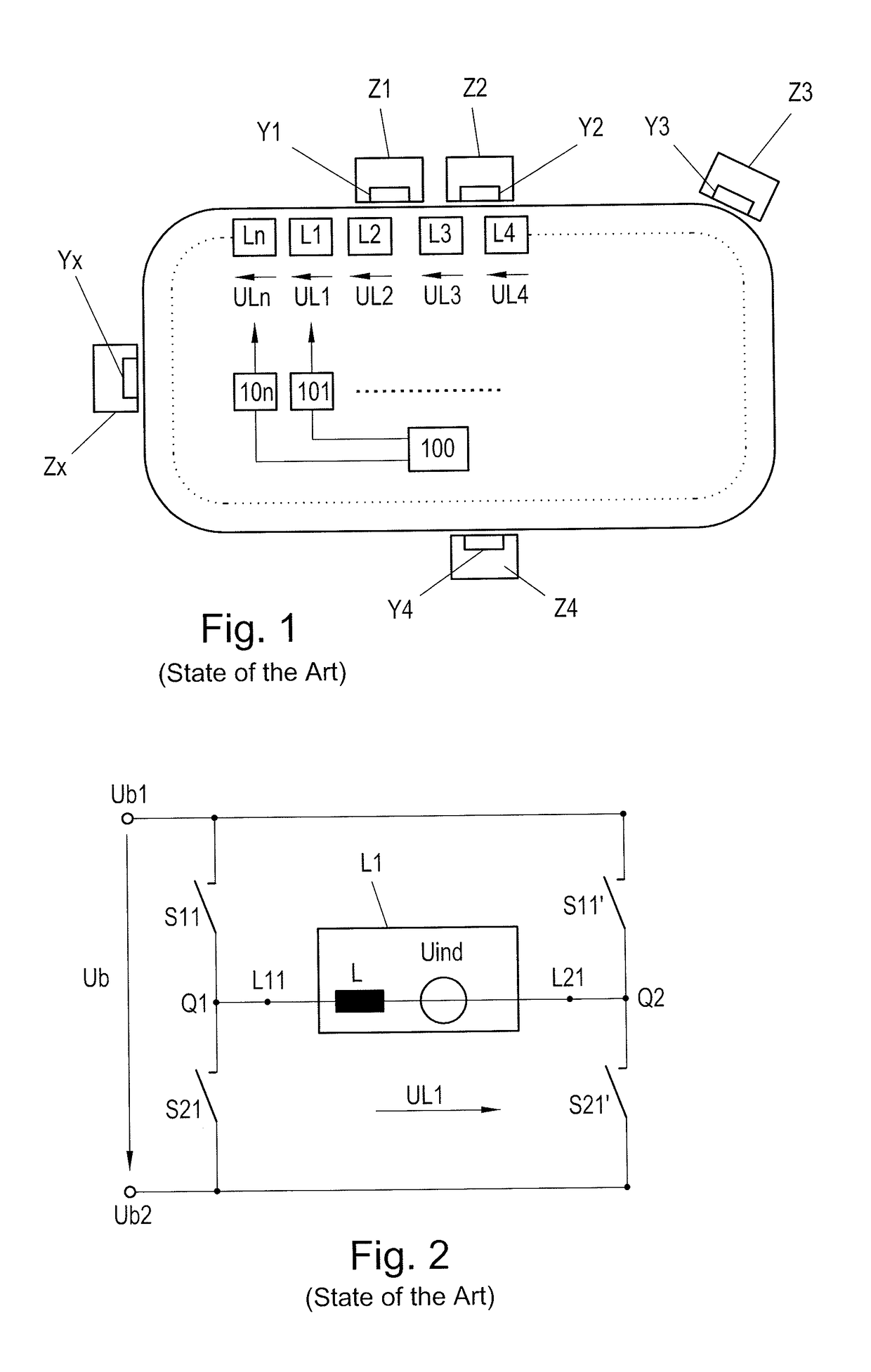

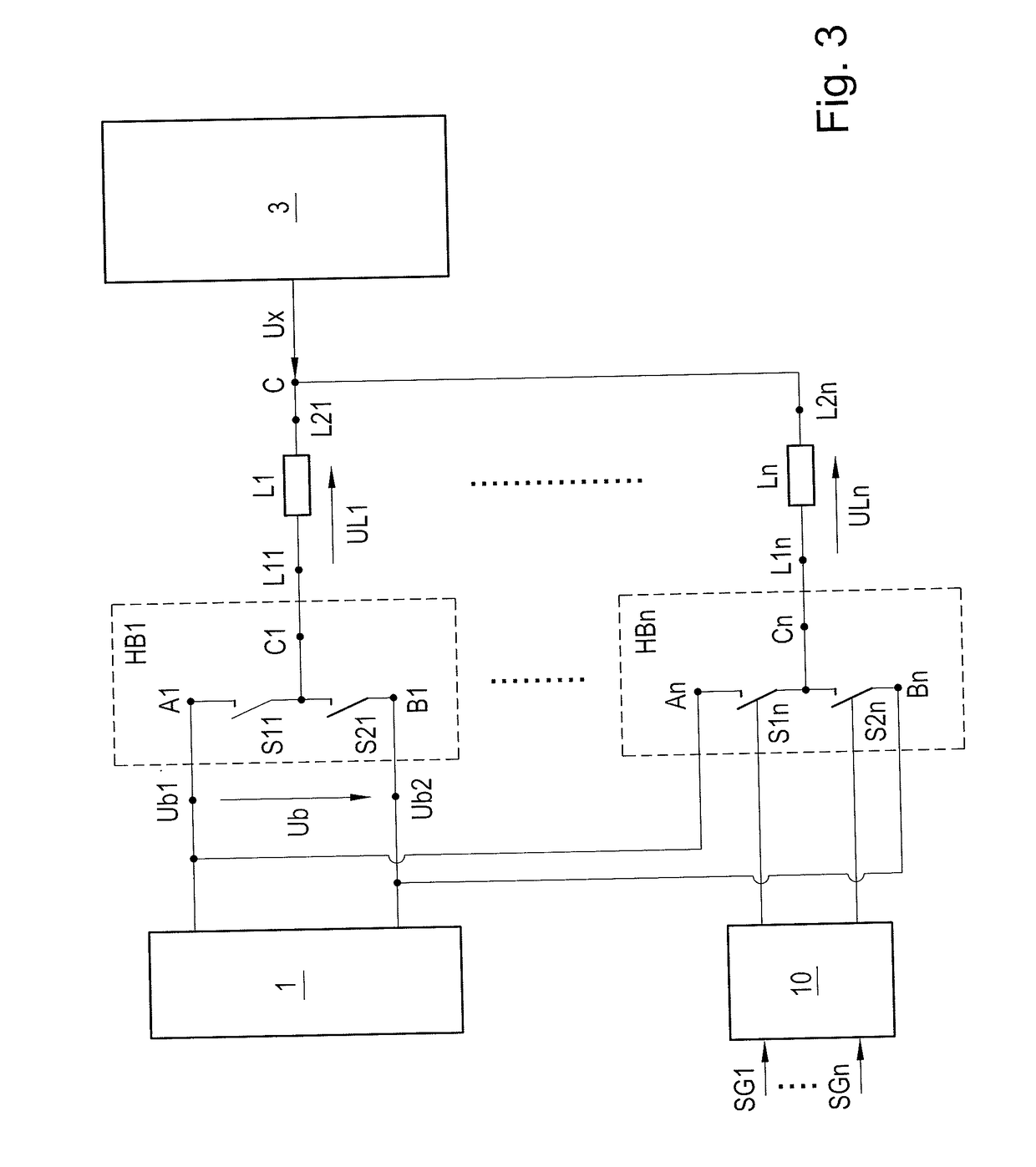

Control of long-stator linear motor coils of long-stator linear motor stator

ActiveCN107437916AAvoid switching lossesRealize intermittent operationAC motor controlMultiple ac dynamo-electric motors controlCircuit complexityElectrical polarity

The present invention provides a method and device for controlling the n LLM coils (L1, . . . Ln) of an LLM stator making it possible to change the polarity of the coil voltage (UL1, . . . , ULn) of the n LLM coils (L1, . . . Ln) more easily and with little circuit complexity. It is proposed to apply a first operating potential (Ub1) to n first input terminals (A1, . . . , An) of n half bridges (HB1, . . . , HBn), and apply a second operating potential (Ub2) to n second input terminals (B1, . . . , Bn) of the n half bridges. For each half bridge (HB1, . . . HBn), a first switch (S11, . . . , S1n) is connected between a center point (C1, . . . , Cn) of the respective half bridge (HB1, . . . , HBn) and the first input terminal (A1, . . . , An), and a second switch (S21, . . . , S2n) is connected between the center point (C1, . . . , Cn) of the relevant half bridge (HB1, . . . , HBn) and the second input terminal (B1, . . . , Bn). The center point (C1, . . . , Cn) of the n half bridges is connected in each case to n first terminals (L11, . . . , L1n) of the n LLM coils (L1, . . . , Ln), and the second terminals (L11, . . . , L1n) of the n LLM coils (L1, . . . , Ln) are connected in a control point (C) that is regulated to a predetermined potential (Ux).

Owner:B&R IND AUTOMATION GMBH

Control of long-stator linear motor coils of long-stator linear motor stator

ActiveUS10250176B2Easy to implementLess circuit complexityAC motor controlMultiple ac dynamo-electric motors controlCircuit complexityEngineering

A method and device for controlling the n LLM coils of an LLM stator making it possible to change the polarity of the coil voltage of the n LLM coils more easily and with little circuit complexity. It is proposed to apply a first operating potential to n first input terminals of n half bridges, and apply a second operating potential to n second input terminals of the n half bridges. For each half bridge, a first switch is connected between a center point of the respective half bridge and the first input terminal, and a second switch is connected between the center point of the relevant half bridge and the second input terminal. The center point of the n half bridges is connected in each case to n first terminals of then LLM coils, and the second terminals of then LLM coils are connected in a control point that is regulated to a predetermined potential.

Owner:B&R IND AUTOMATION GMBH

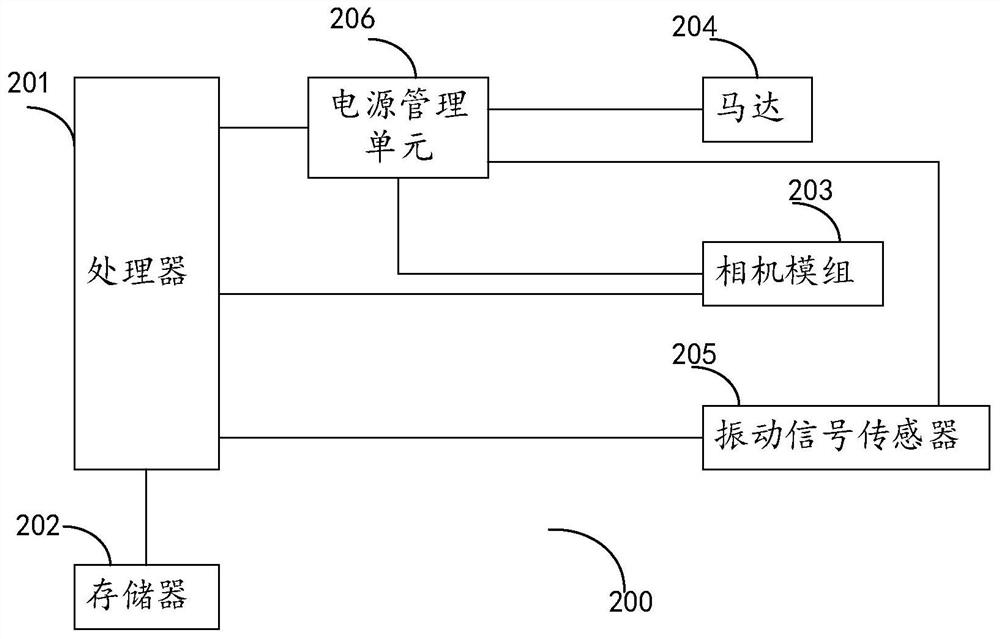

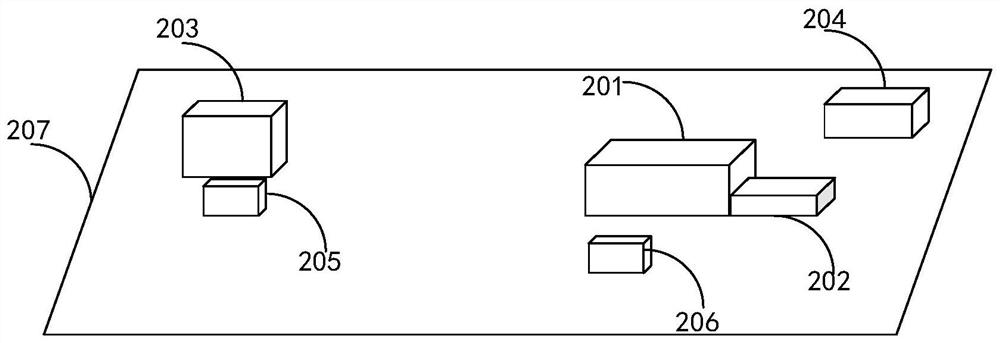

Control method and device, electronic equipment and readable storage medium

ActiveCN113286091AAvoid resonanceImprove shooting stabilityTelevision system detailsAC motor controlFrequency spectrumResonance

The invention discloses a control method and device, electronic equipment and a readable storage medium, and belongs to the technical field of electronic equipment. In the embodiment of the invention, when a camera module and a motor in the electronic equipment are both in a working state, a first vibration signal is acquired through a vibration signal sensor; and when the first frequency spectrum information obtained by the first vibration signal contains a frequency component equal to the self-resonant frequency of the camera module, changing the vibration frequency of the motor, so that the changed vibration frequency of the motor is different from the self-resonant frequency of the camera module. In this way, the phenomenon that the motor resonates with the shooting module when the motor vibrates in the working state can be avoided, then the problems that due to the resonance phenomenon, focusing is unstable when a user shoots, and a shot picture shakes are solved, the shooting stability is improved, and the user experience is improved.

Owner:VIVO MOBILE COMM CO LTD

Control of long-stator linear motor coils of long-stator linear motor stator

ActiveUS20170346434A1Avoid switching lossesEasy to implementAC motor controlMultiple ac dynamo-electric motors controlCircuit complexityEngineering

The present invention provides a method and device for controlling the n LLM coils (L1, . . . Ln) of an LLM stator making it possible to change the polarity of the coil voltage (UL1, . . . , ULn) of the n LLM coils (L1, . . . Ln) more easily and with little circuit complexity. It is proposed to apply a first operating potential (Ub1) to n first input terminals (A1, . . . , An) of n half bridges (HB1, . . . , HBn), and apply a second operating potential (Ub2) to n second input terminals (B1, . . . , Bn) of the n half bridges. For each half bridge (HB1, . . . HBn), a first switch (S11, . . . , S1n) is connected between a center point (C1, . . . , Cn) of the respective half bridge (HB1, . . . , HBn) and the first input terminal (A1, . . . , An), and a second switch (S21, . . . , S2n) is connected between the center point (C1, . . . , Cn) of the relevant half bridge (HB1, . . . , HBn) and the second input terminal (B1, . . . , Bn). The center point (C1, . . . , Cn) of the n half bridges is connected in each case to n first terminals (L11, . . . , L1n) of the n LLM coils (L1, . . . , Ln), and the second terminals (L11, . . . , L1n) of the n LLM coils (L1, . . . , Ln) are connected in a control point (C) that is regulated to a predetermined potential (Ux).

Owner:B&R IND AUTOMATION GMBH

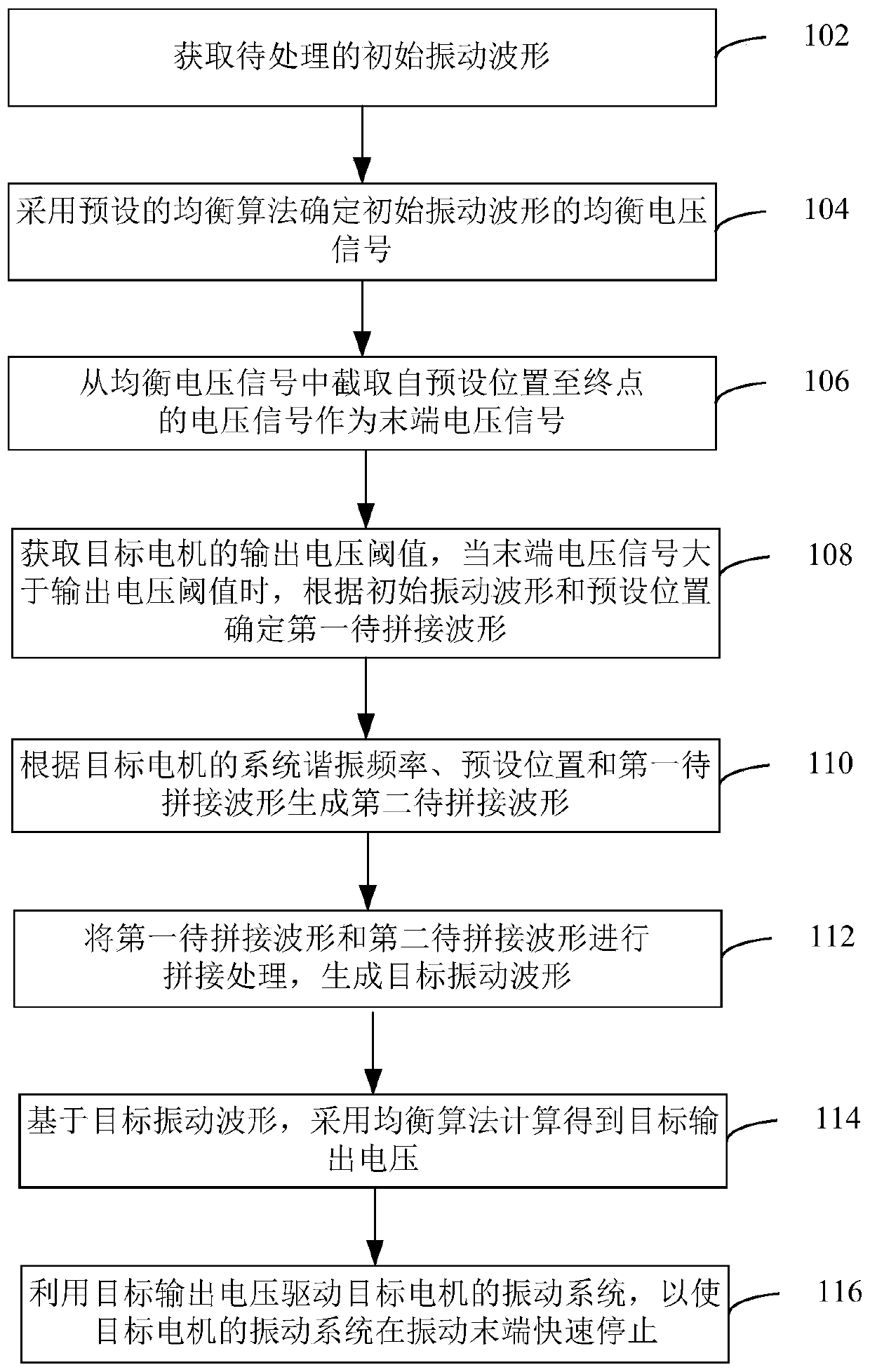

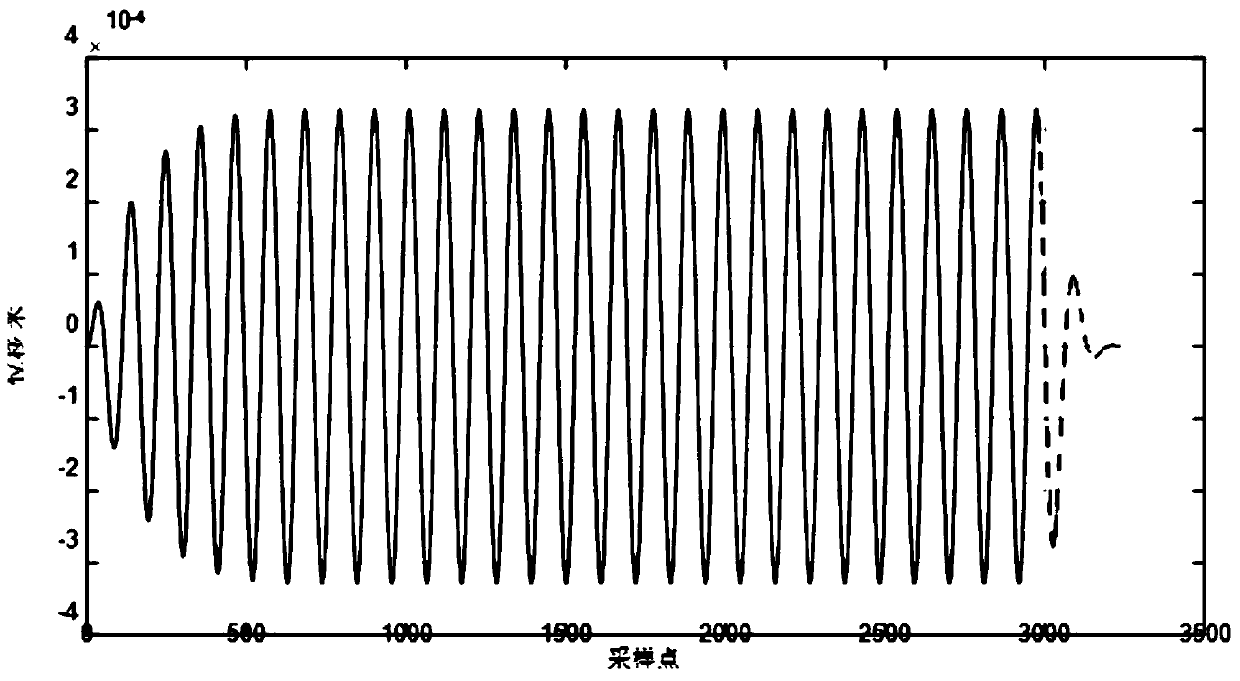

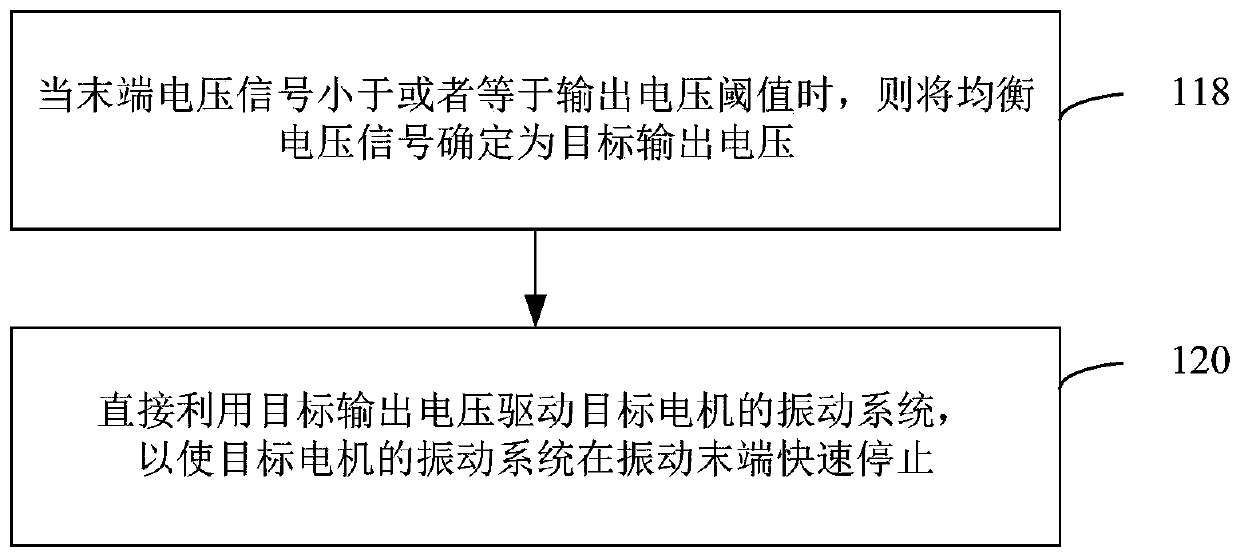

Method and device for rapidly stopping vibration system, computer equipment and storage medium

ActiveCN111552379AImprove the vibration effectRealize quick stop functionInput/output for user-computer interactionAC motor controlElectric machineryEqualization

The embodiment of the invention discloses a method for rapidly stopping a vibration system. The method comprises the following steps: acquiring a to-be-processed initial vibration waveform; determining an equalization voltage signal of the initial vibration waveform by adopting a preset equalization algorithm; intercepting a voltage signal from a preset position to an end point from the equalization voltage signal as a tail end voltage signal; obtaining an output voltage threshold of a target motor, and determining a first waveform to be spliced according to the initial vibration waveform anda preset position; generating a second waveform to be spliced according to the system resonant frequency of the target motor, the preset position and the first waveform to be spliced; and splicing thefirst to-be-spliced waveform and the second to-be-spliced waveform, and driving a vibration system of the target motor by utilizing the target output voltage, so that the vibration system of the target motor is quickly stopped at the vibration tail end. By optimizing the initial vibration waveform, the design efficiency and the generation efficiency of the target vibration waveform are improved,and the vibration effect of a vibration system of the motor is improved so as to realize a quick stop function of the motor.

Owner:AAC TECH PTE LTD

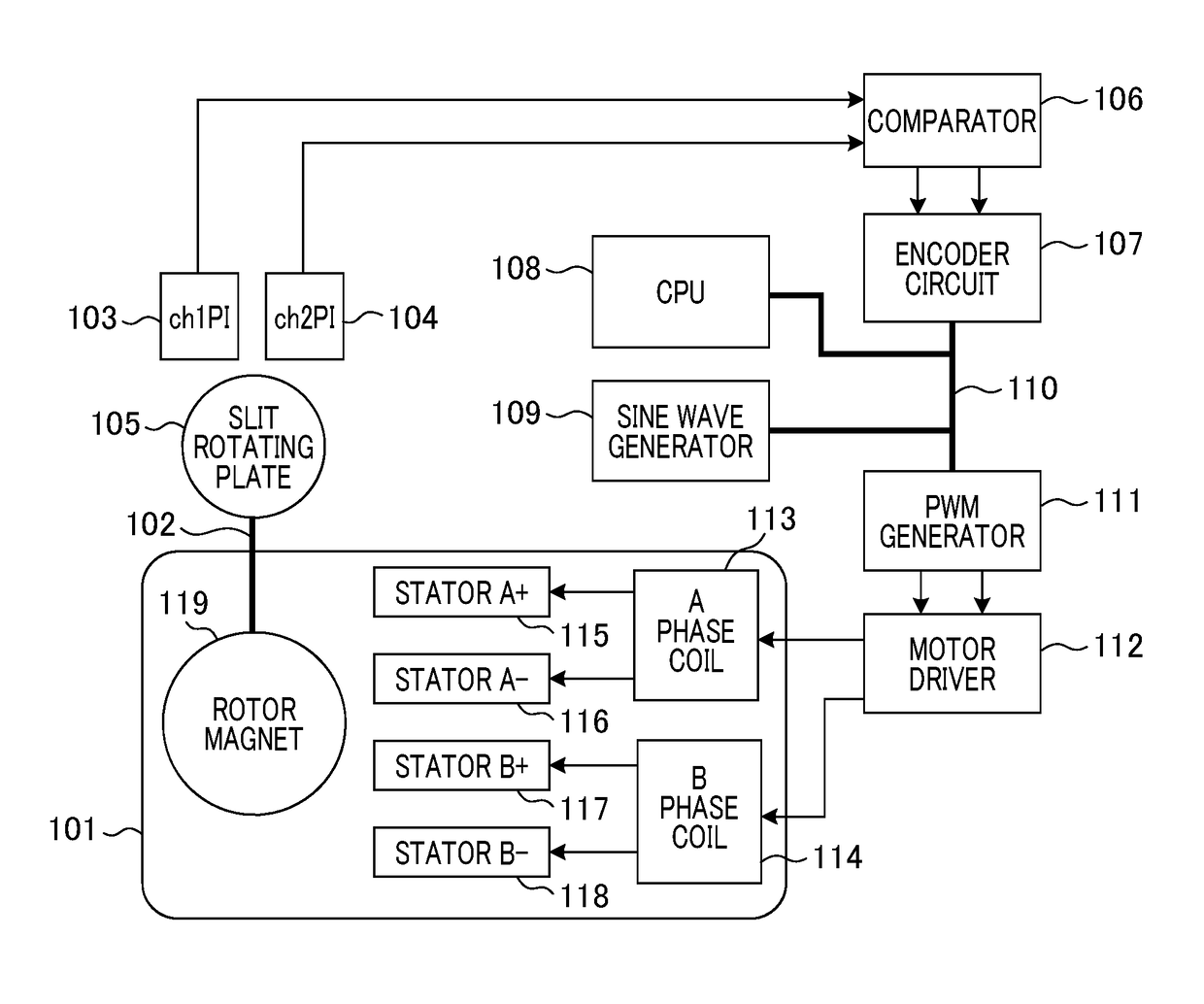

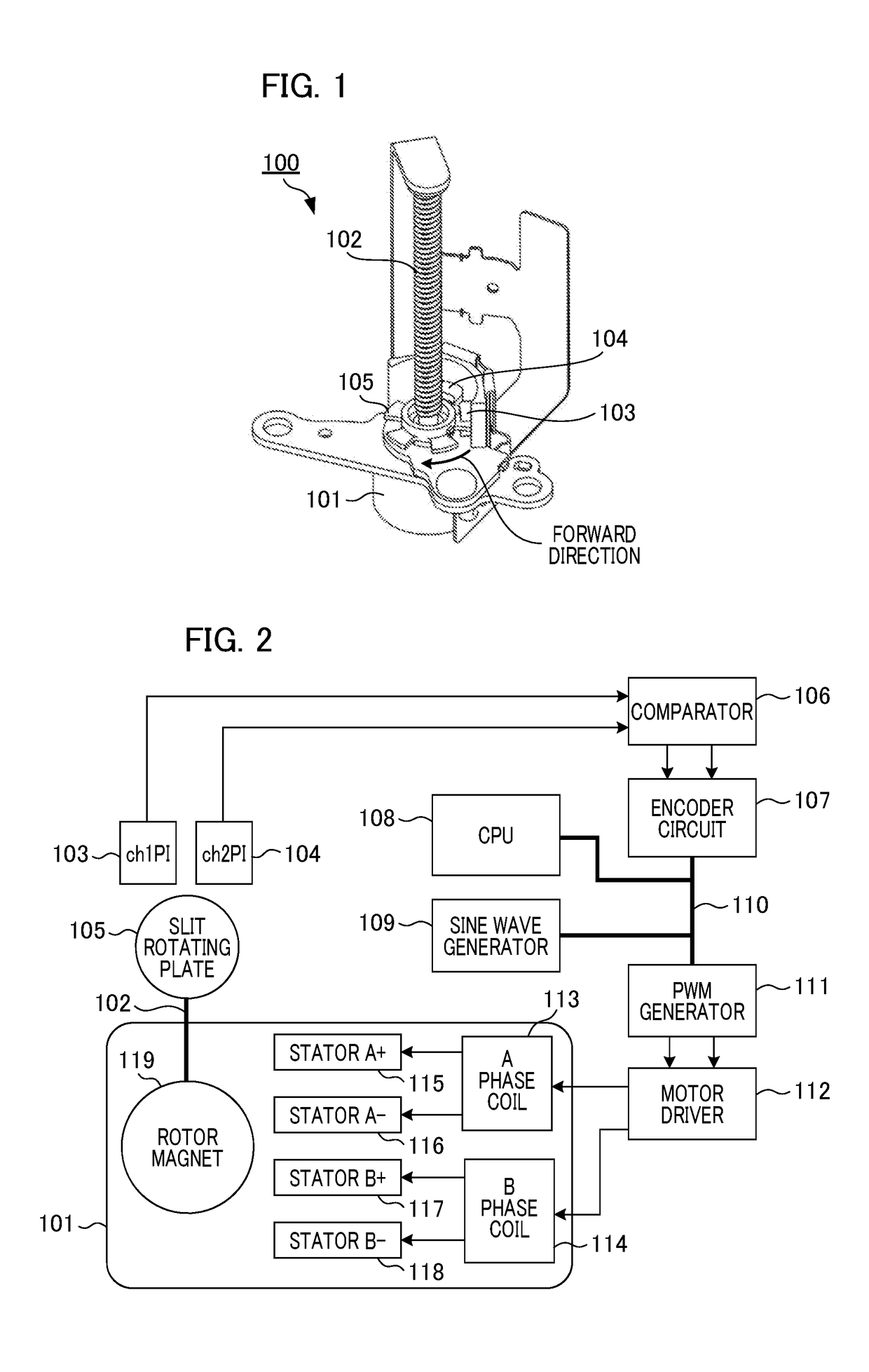

Electric motor control device, electric motor system and electric motor control method

ActiveUS20180069496A1Electric motor controlSingle motor speed/torque controlEngineeringExecution control

An electric motor control device includes a drive waveform generating unit configured to generate a drive waveform (a sine wave or a pseudo-trapezoidal wave) to an electric motor. A plurality of photo interrupters detect a rotational phase of an electric motor, and a information of rotational speed is detected by an encoder circuit based on a detected signal of the rotational phase of the electric motor. The control unit controls the drive waveform generating unit on the basis of detection information of the rotational phase of the electric motor and performs control so that a phase relationship between the rotational phase of the electric motor and the phase of the drive waveform is kept constant. Furthermore, the control unit sets an amplitude value of the drive waveform generated by the drive waveform generating unit in accordance with a difference between a target speed and the detected information of rotational speed and performs speed control so that a speed of the electric motor is kept constant. The control unit calculates an amplitude setting value with which correction for suppressing non-linearity is performed in a region in which an amplitude setting value of the drive waveform and actual work given to the electric motor is non-linear and controls the speed.

Owner:CANON KK

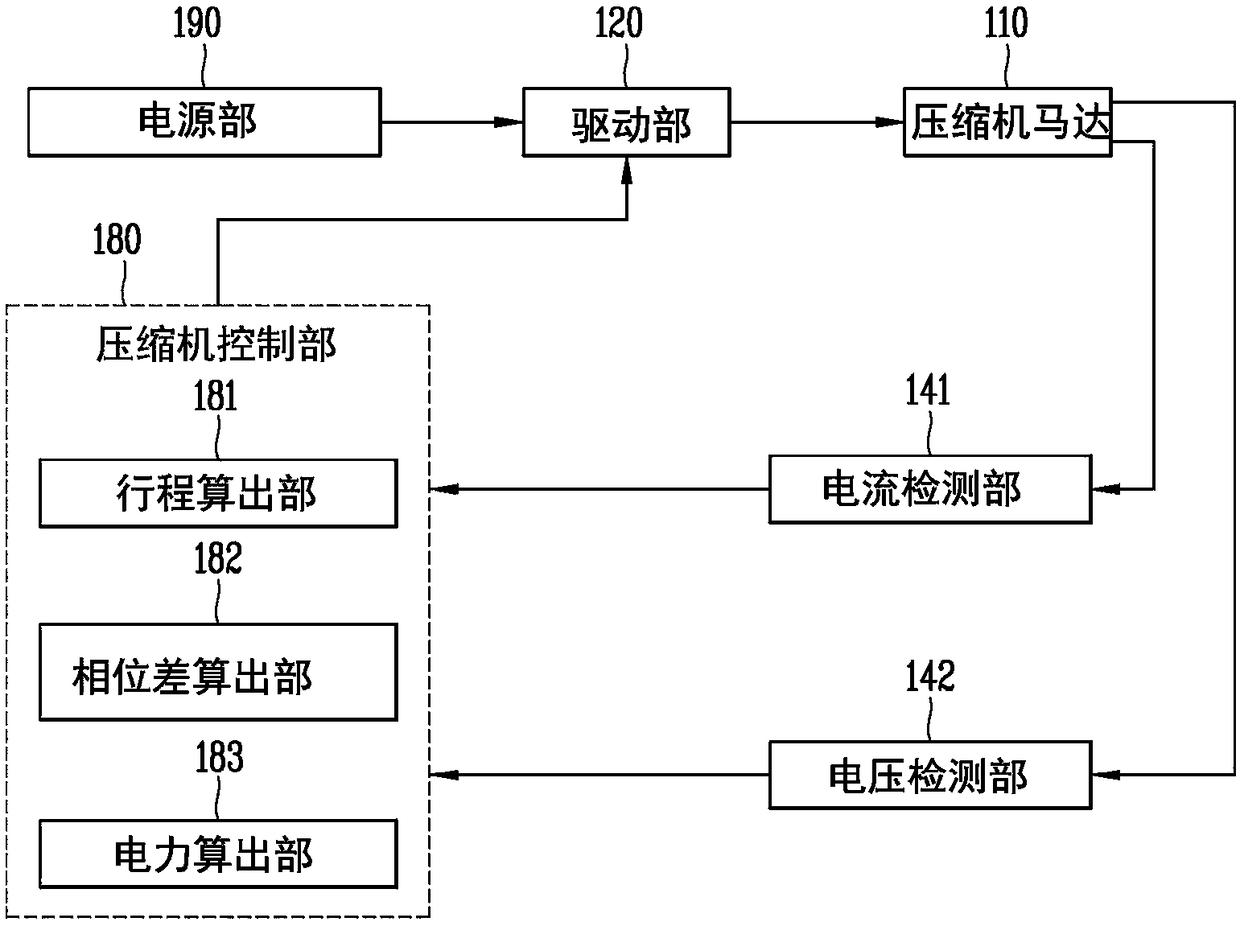

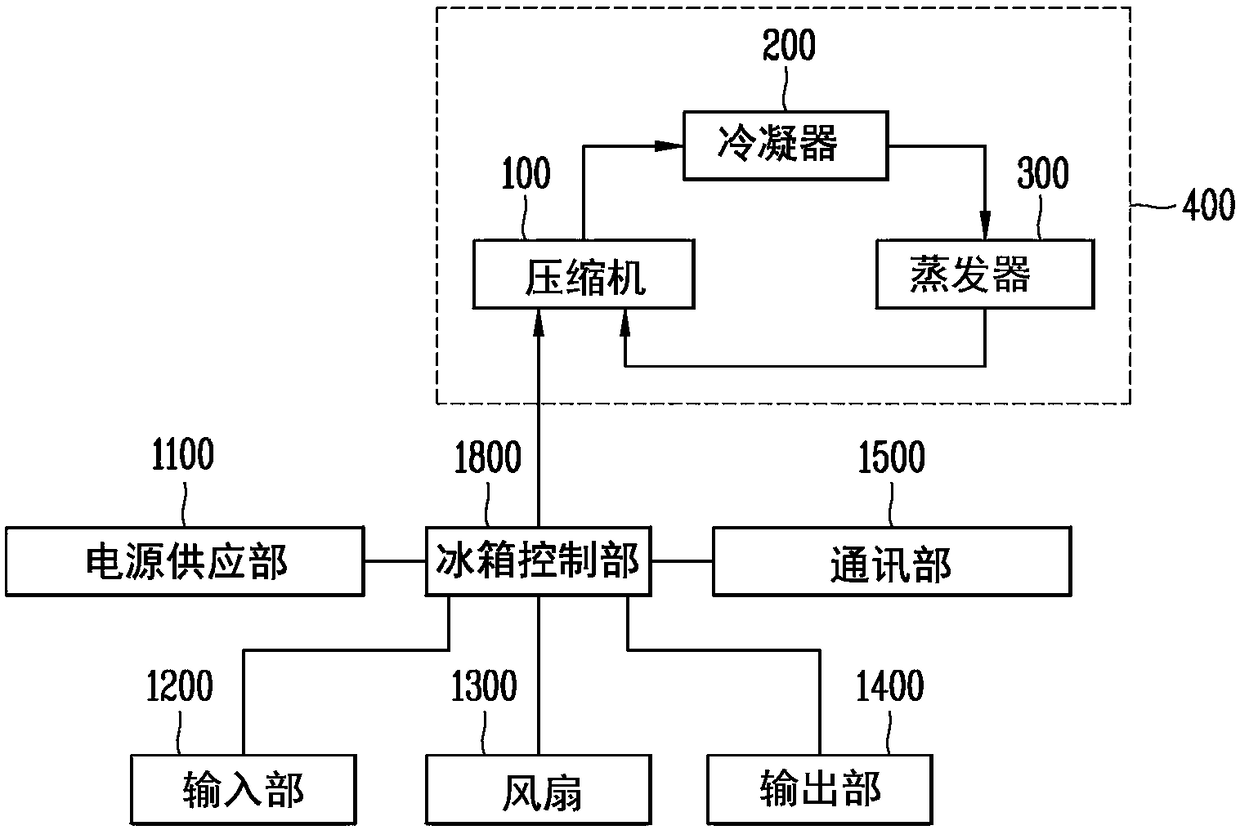

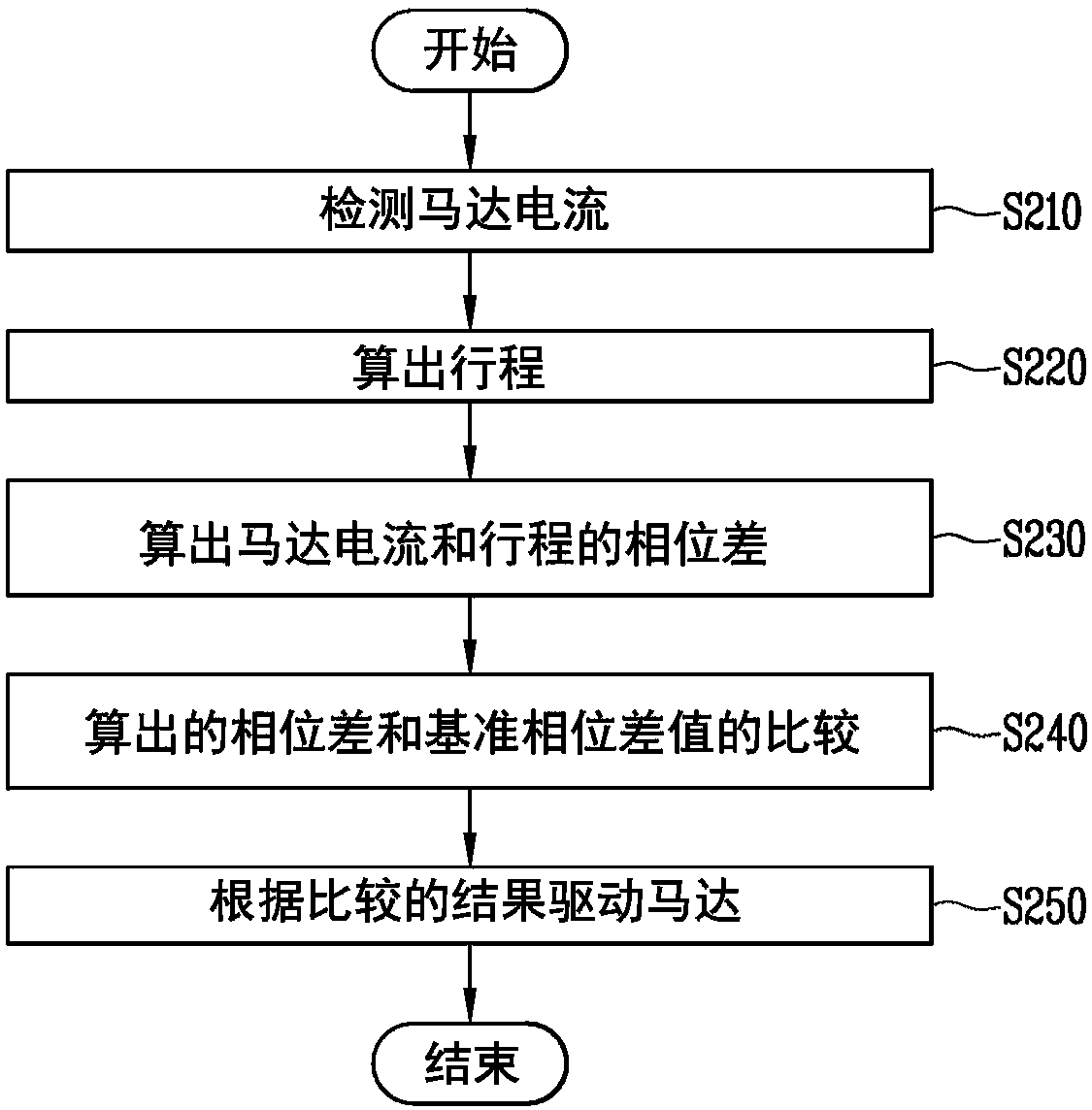

Compressor and control method for compressor

ActiveCN108463634AOptimized operating efficiencyGuaranteed control stabilityAC motor controlLinear DC motor controlPower flowReciprocating motion

The objective of the present invention is to provide a compressor that is applied to a refrigerator without a cycle matching capability or a refrigerator without a control unit and can control the driving of a linear motor by itself, in order to solve the problems of conventional compressors; and a control method therefor. To this end, a compressor installed in an apparatus including a refrigerantcycle disclosed in the present specification comprises: a piston reciprocating in a cylinder; a linear motor for providing a driving force for the movement of the piston; a sensing unit for sensing amotor current of the linear motor; and a compressor control unit for detecting information related to a load of the apparatus, separately from a control unit for controlling a main body of the apparatus, wherein the compressor control unit calculates a phase difference between a stroke of the piston and the sensed motor current, compares the calculated phase difference with a reference phase difference value, and controls the driving of the linear motor in accordance with the detected load on the basis of the comparison result.

Owner:LG ELECTRONICS INC

Device and method for controlling linear motor

ActiveUS20180375447A1Improve responsivenessMotor/generator/converter stoppersMagnetic circuitLinear motorStorage cell

A control device for a linear motor includes a speed controller that calculates a current command value by an integration operation using a first integral value of a difference between a moving speed of a movable element provided in the linear motor and a speed command value calculated on the basis of a position command value, a current controller that applies a voltage to the linear motor on the basis of the current command value, and a correction value storage unit that stores the first integral value of the speed controller when the movable element remains at a position indicated by the position command value. When resuming control of the linear motor, the speed controller sets the first integral value stored in the correction value storage unit as an initial value for the integration operation before the brake controller turns off the brake device.

Owner:THK CO LTD

Method and device for integrated processing of active cell position signal

InactiveCN108233816AGuaranteed redundancyReduce in quantityAC motor controlLinear DC motor controlEngineeringActive cell

The invention discloses a method for integrated processing of an active cell position signal. The method comprises the following steps: acquiring a reference position signal and a real-time position signal of an active cell by a position sensor, and successively carrying out filtering, noise eliminating, frequency discrimination and frequency multiplication processing on the real-time position signal; carrying out missing judgment on a processed signal; if missing exists, compensating the missing; if no missing is found, carrying out delay judgment; if delay occurs, carrying out delay compensation; and if the delay does not occur, acquiring the moving direction and the real-time displacement of the active cell by combining with the reference position signal. The invention also discloses adevice for integrated processing of the active cell position signal. The method and the device disclosed by the invention have the advantages that multipath active cell position signals from the sensor can be accepted, the processed position signal is transmitted to a superior controller and precise control of a linear motor is realized.

Owner:湖南省军民融合装备技术创新中心 +1

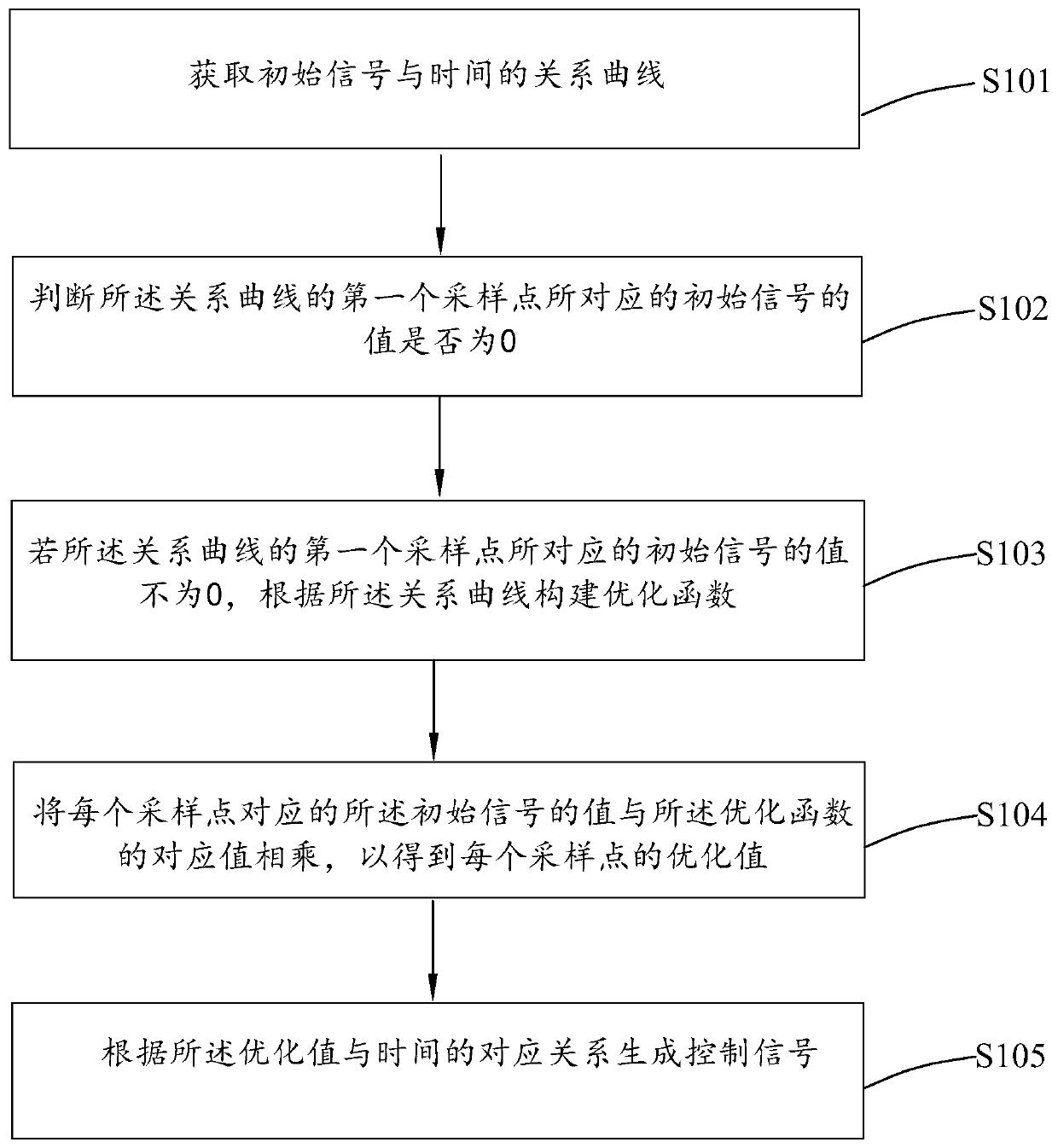

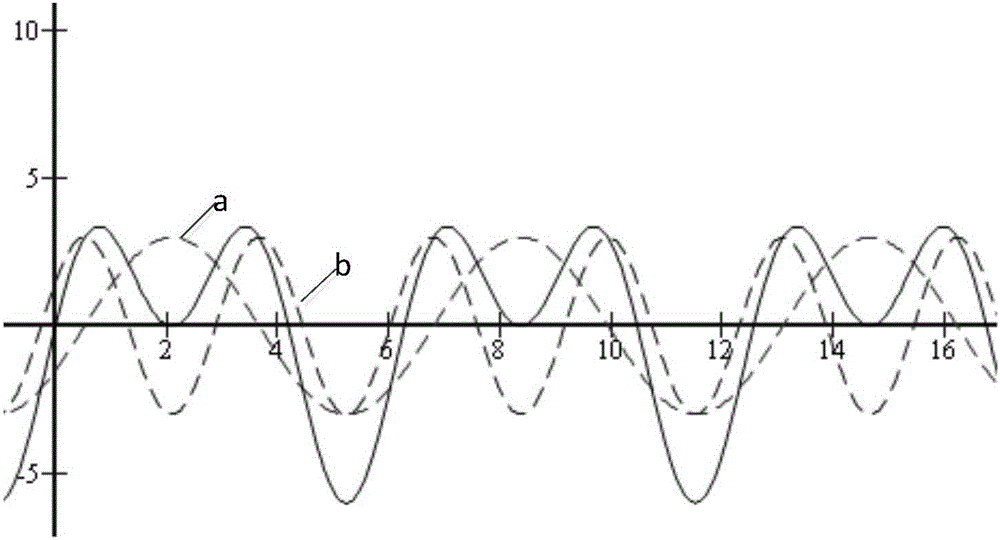

Generation method of control signal, electronic equipment and storage medium

ActiveCN110380665AImprove experienceReduce oscillatory responseAC motor controlLinear motor controlControl signalComputer science

The invention provides a generation method of a control signal, a piece of electronic equipment and a storage medium. The method includes the following steps: acquiring a relation curve between initial signals and time, wherein the relation curve includes a number of sampling points and the time and the value of the initial signal corresponding to each sampling point; judging whether the value ofthe initial signal corresponding to a first sampling point of the relation curve is 0 or not; if the value of the initial signal corresponding to the first sampling point of the relation curve is not0, constructing an optimization function according to the relation curve; multiplying the value of the initial signal corresponding to each sampling point by a corresponding value of the optimizationfunction to get an optimization value of each sampling point; and generating a control signal according to the correspondence between optimization values and time, wherein the control signal is used to drive a motor to vibrate. The generation method of a control signal in the invention can reduce the oscillation response and improve the user experience.

Owner:AAC TECH PTE LTD

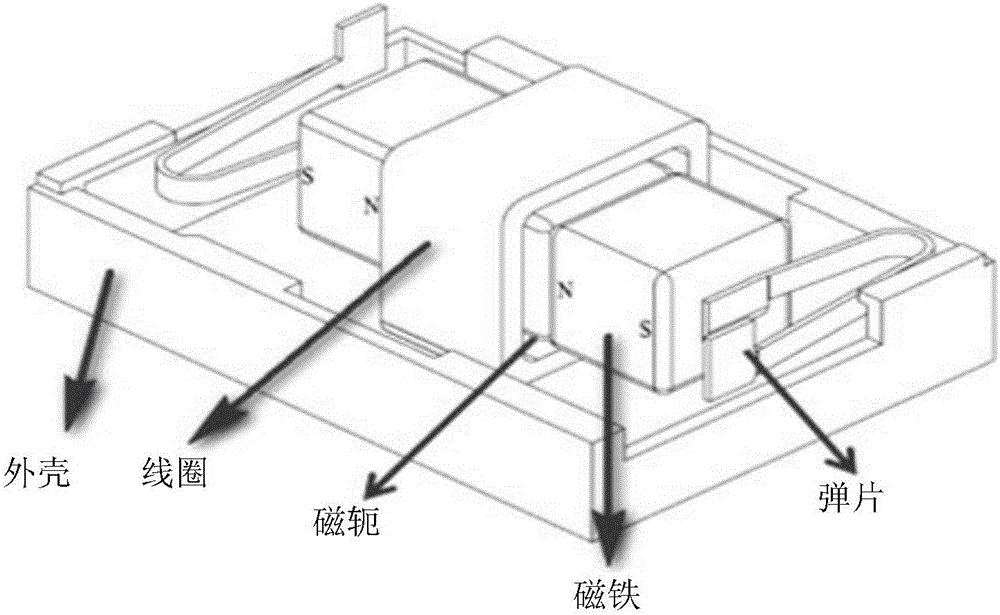

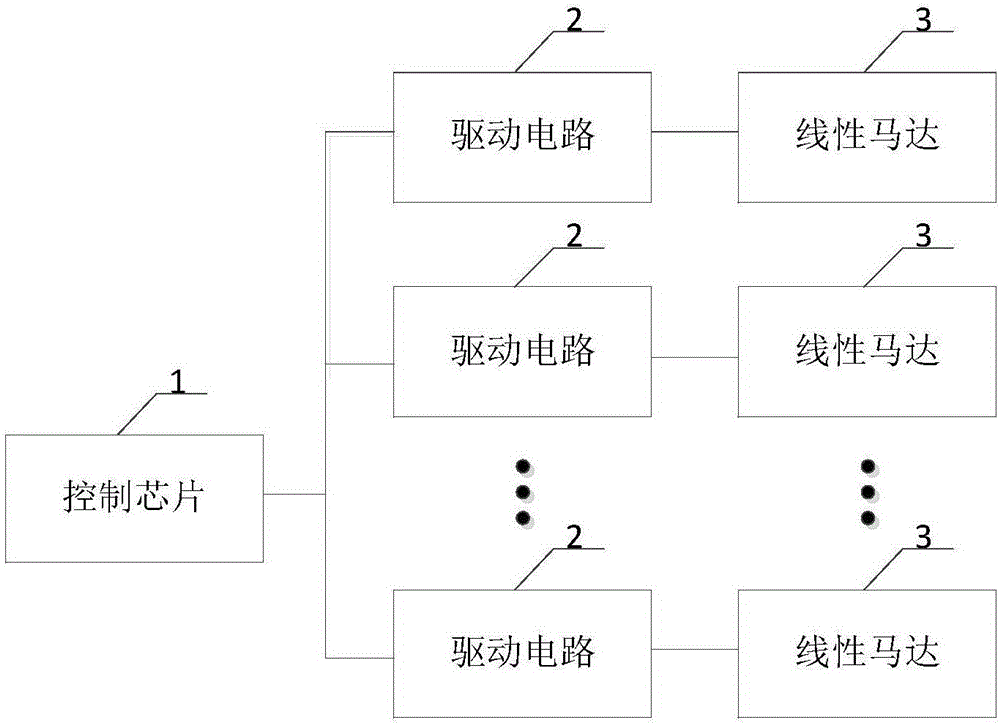

One-way vibration system, device and method based on linear motors

ActiveCN106849761ARealize the vibration effectGet a one-way vibration effectAC motor controlLinear DC motor controlDriver circuitLinear motor

The invention discloses a one-way vibration system, device and method based on linear motors. The system comprises the multiple linear motors, a control chip and driving circuits, wherein the resonant frequencies between any two linear motors differ in integral multiple, the control chip is used for outputting driving signals corresponding to the linear motors one to one according to a first user instruction, the frequency of each driving signal is within the preset range by adopting the resonant frequency of the corresponding linear motor as the reference, and any two driving signals have phase angles with adjustable phases; the driving circuits correspond to the linear motors one to one and are used for driving and amplifying the driving signals, and sending the driven and amplified driving signals to the corresponding linear motors so as to control the corresponding linear motors, and then the one-way vibration effect is obtained. It is thus clear that the vibration effects of the multiple linear motors can be equivalent to one-way vibration after being synthesized, and the application range is enlarged.

Owner:TRULY OPTO ELECTRONICS

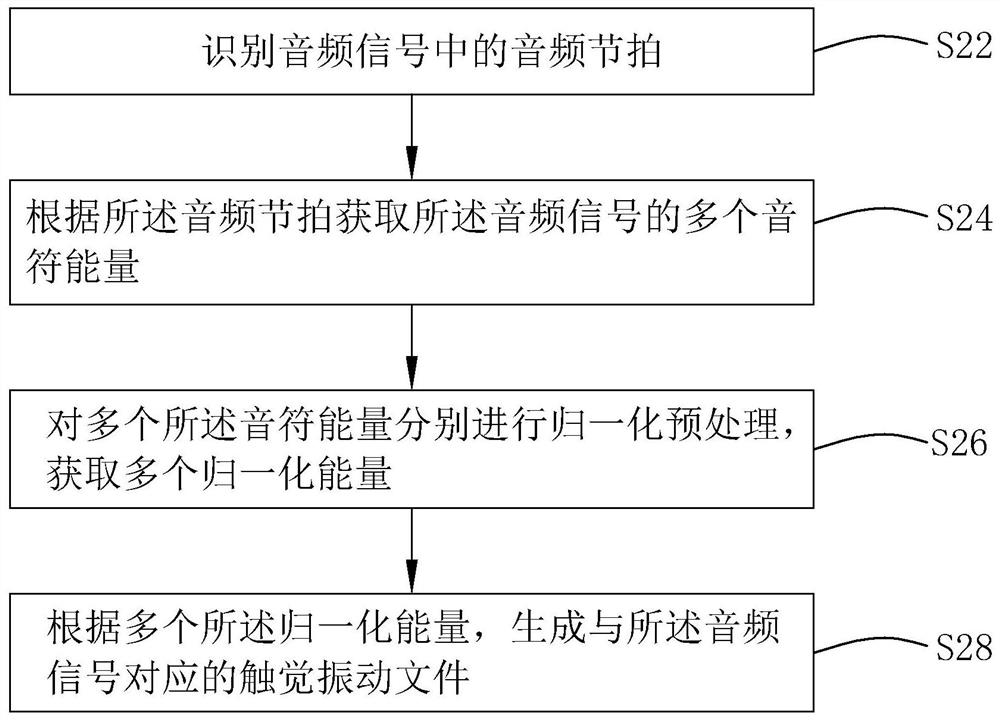

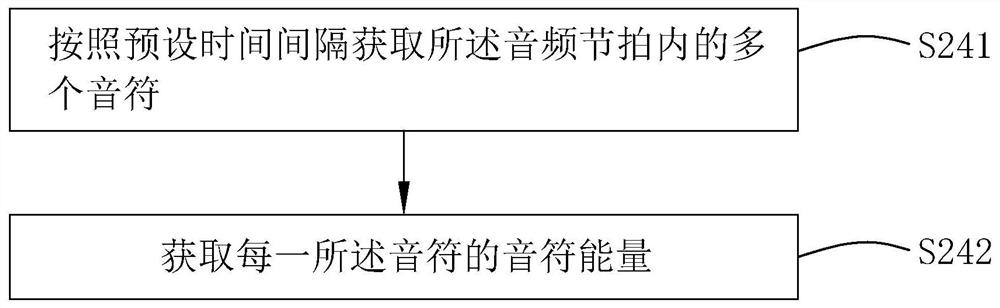

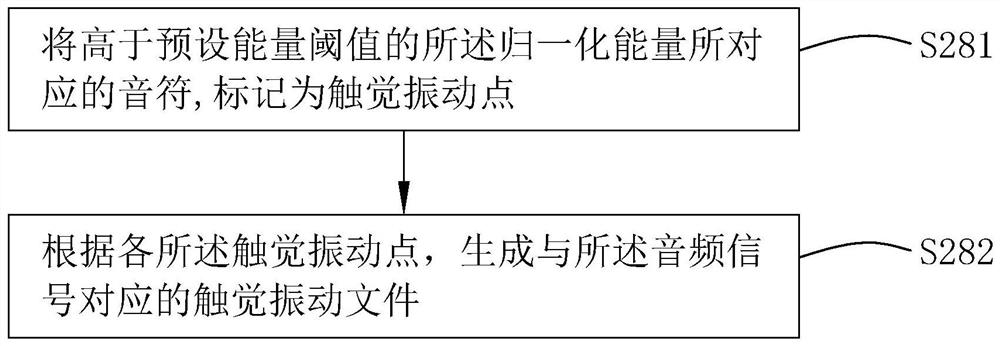

Vibration generation method, vibration control method and related equipment

PendingCN112466267AImprove coordinationEnhance listening experienceElectrophonic musical instrumentsAC motor controlVibration controlTactile sensation

The invention relates to a vibration generation method and device, a vibration control method and system, electronic equipment and a storage medium. The vibration generation method comprises the following steps: identifying an audio beat in an audio signal, acquiring a plurality of note energies of the audio signal according to the audio beat, respectively carrying out normalization preprocessingon the plurality of note energies to obtain a plurality of normalization energies, and according to the plurality of normalized energies, generating a tactile vibration file corresponding to the audiosignal. By adopting the method, the tactile vibration effect can be flexibly matched with the beat of the audio signal, and the matching accuracy is high.

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU +1

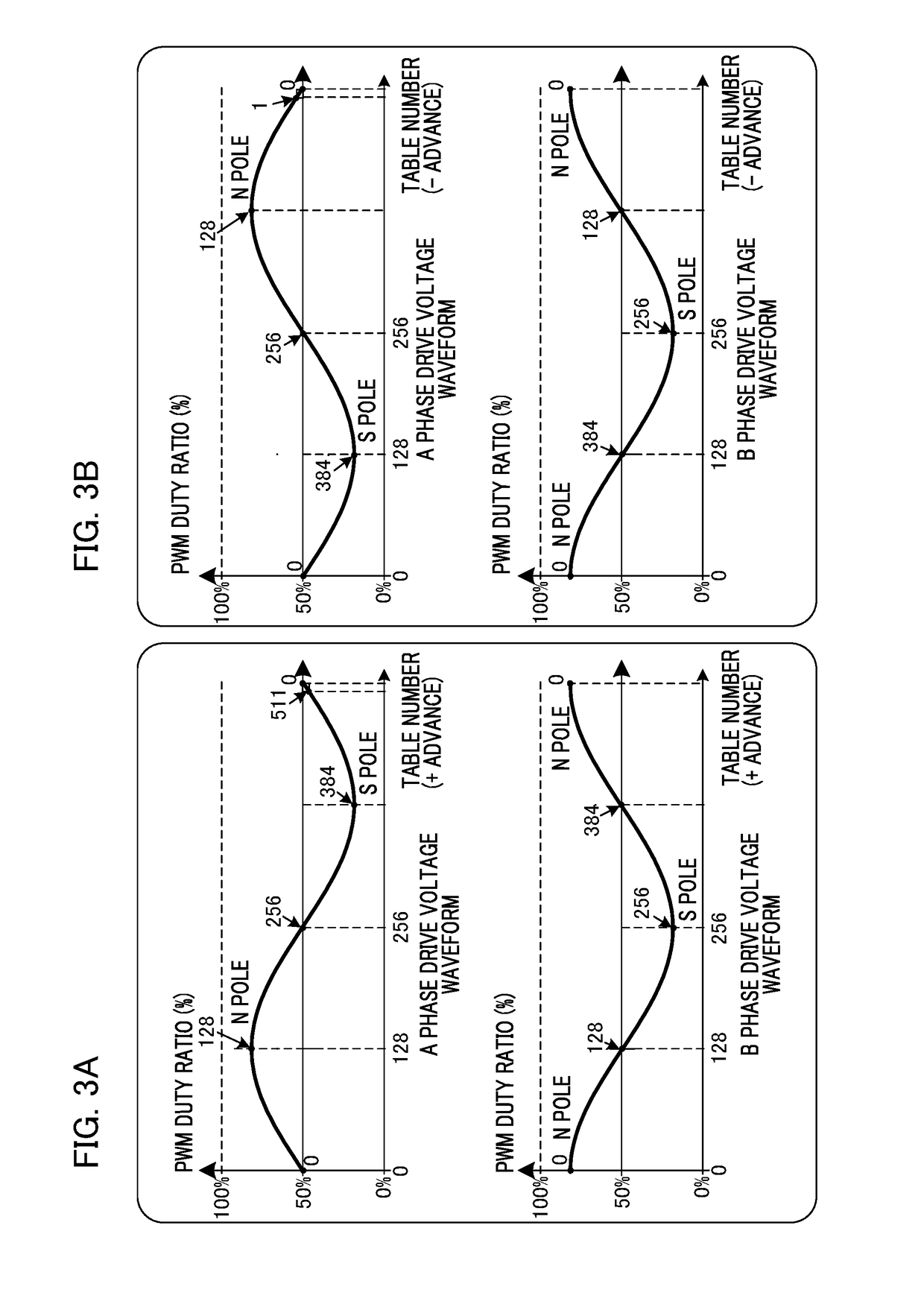

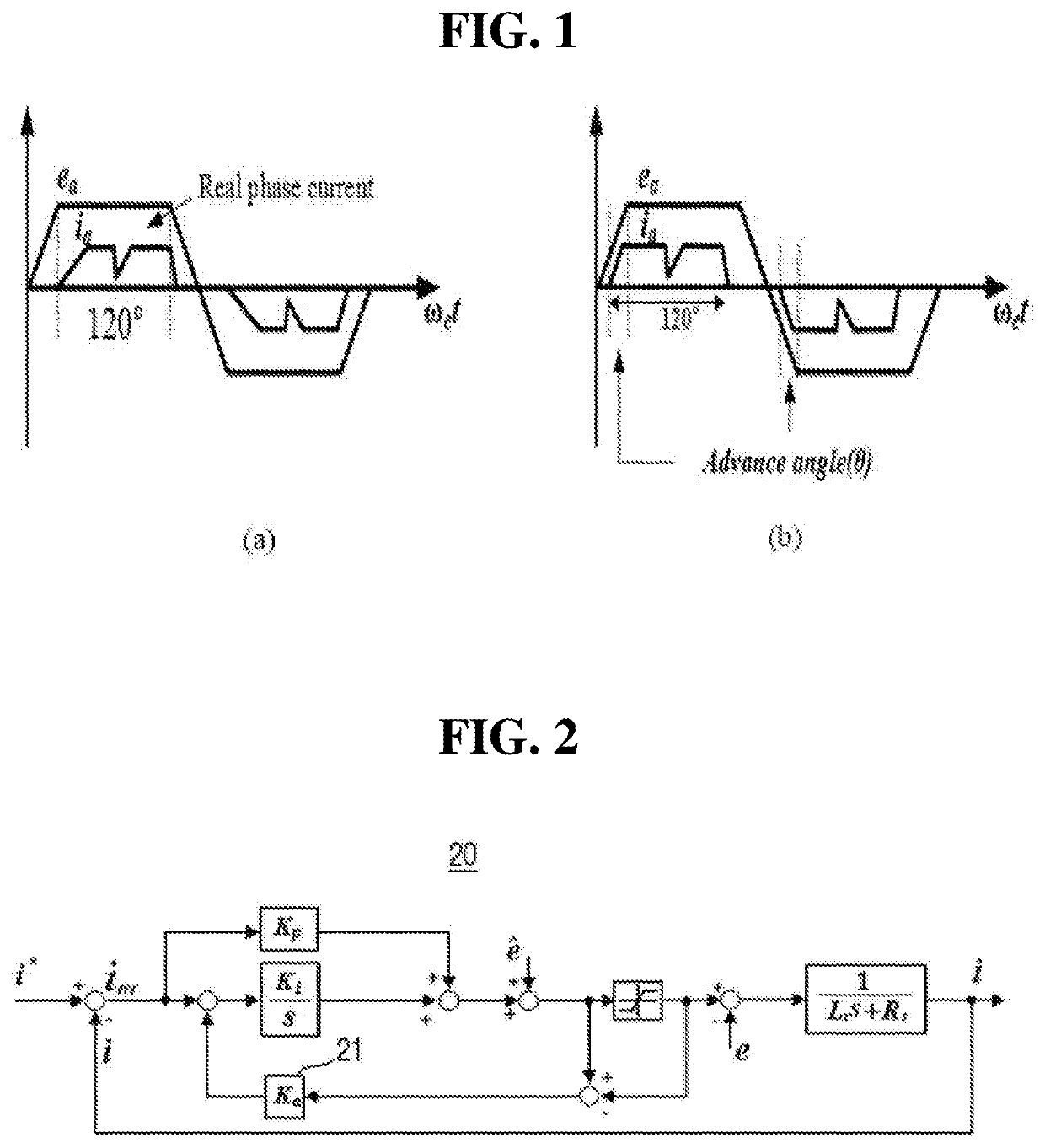

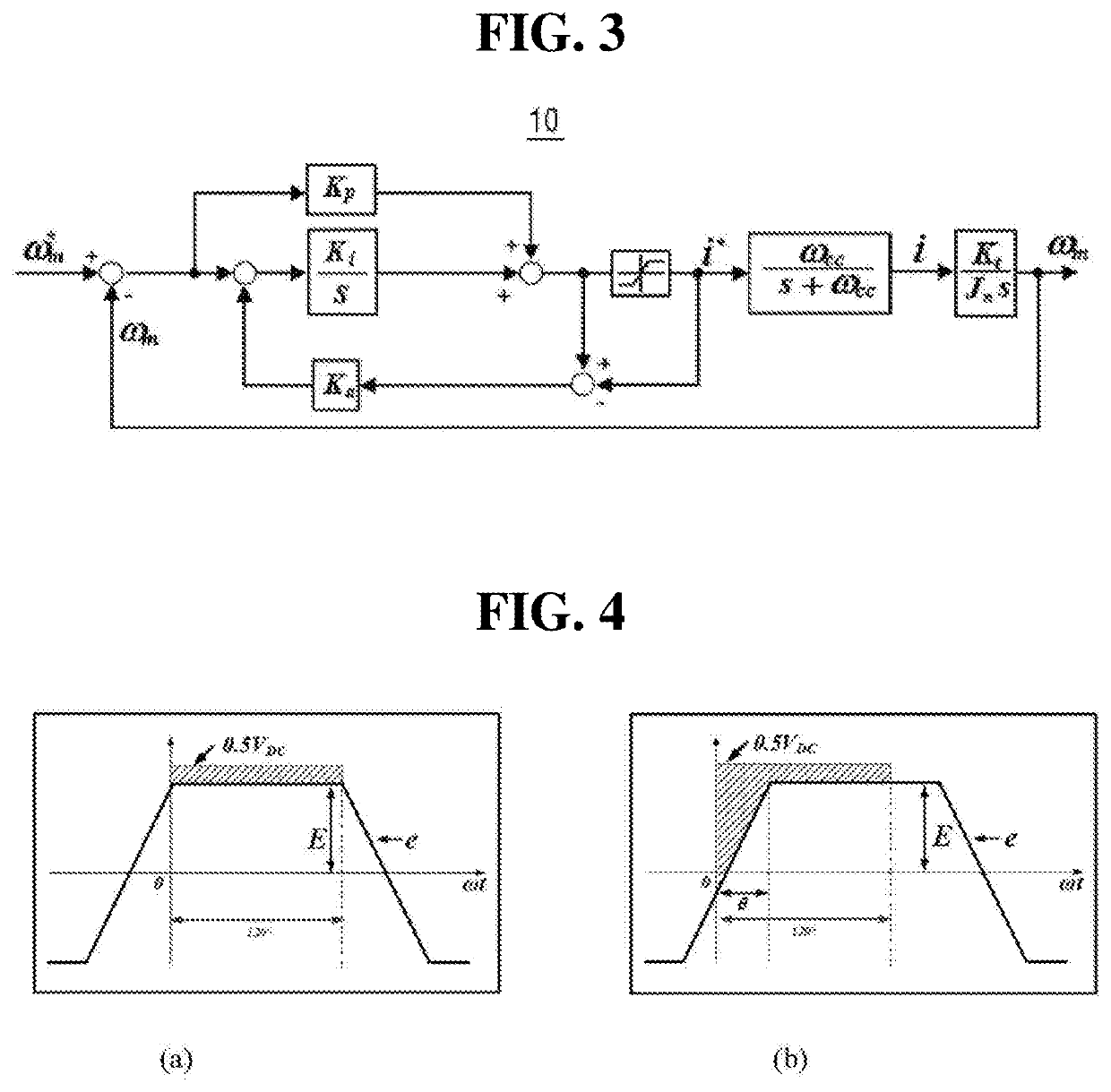

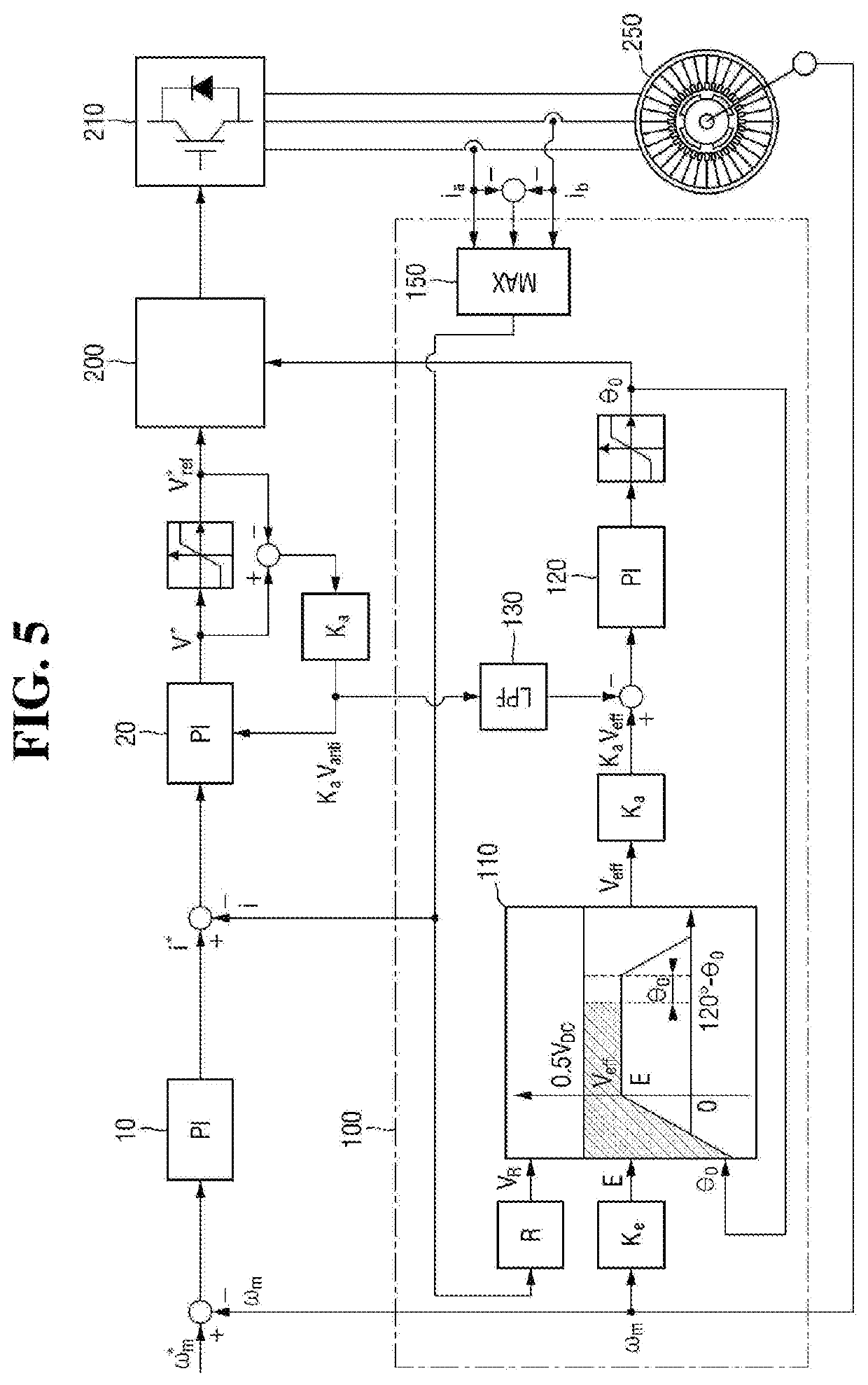

Automatic Advance Angle Control System And Method For Brushless Linear Direct Current Motor

ActiveUS20190363653A1Easy to operateGuaranteed uptimeSingle motor speed/torque controlField or armature current controlPhase currentsControl system

Provided are an automatic advance angle control system and method for a brushless linear direct current (BLDC) motor. The automatic advance angle control system for the BLDC motor includes a current controller configured to generate an anti-windup output for compensating for accumulated errors of an output voltage provided to the BLDC motor; a voltage headroom calculator configured to generate a voltage headroom from a counter-electromotive force and the output voltage provided to the BLDC motor; and an advance angle controller configured to generate an advance angle for controlling a phase of a phase current of the BLDC motor by performing proportional integration on a difference between the anti-windup output and the voltage headroom when the anti-windup output is generated and configured to ignore the generation of the advance angle when the anti-windup output is not generated.

Owner:PUSAN NAT UNIV IND UNIV COOPERATION FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com