One-way vibration system, device and method based on linear motors

A linear motor and vibration system technology, applied in the direction of linear DC motor control, control system, AC motor control, etc., can solve the problems of limiting the application field of the motor and the single vibration effect of the motor, and achieve the effect of increasing the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

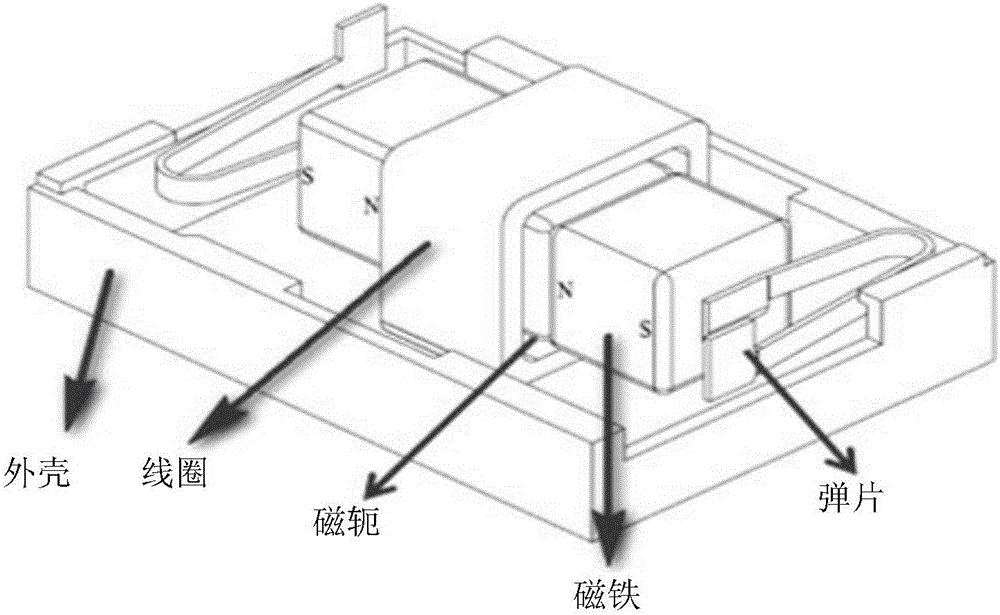

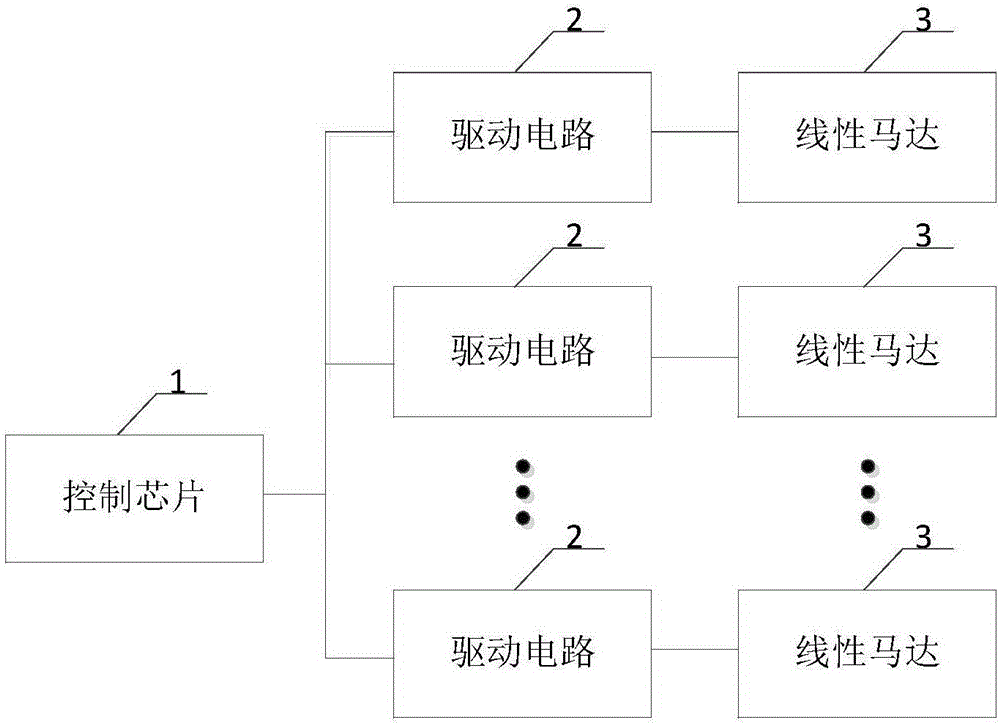

[0038] Please refer to figure 2 , figure 2 A structural schematic diagram of a unidirectional vibration system based on a linear motor provided by the present invention, the system includes:

[0039] A plurality of linear motors 3, wherein the resonance frequencies of any two linear motors 3 differ by an integer multiple;

[0040] Specifically, in order to realize that the vibrations of the multiple linear motors 3 can achieve the effect of unidirectional vibration after synthesis, it is required that the resonance frequencies of any two linear motors 3 in the multiple linear motors 3 differ by an integer multiple, for example, can be 2 times . Of course, the integer multiples and the specific resonance frequency values of the multiple linear motors 3 are not particularly limited here, and they are determined according to actual conditions.

[0041] The control chip 1 is configured to output drive signals corresponding to each linear motor 3 one-to-one according to a first user ...

Embodiment 2

[0053] Please refer to Figure 4 , Figure 4 This is a schematic structural diagram of another one-way vibration system based on a linear motor provided by the present invention.

[0054] The system is based on the above embodiments:

[0055] Preferably, the number of linear motors is two, namely the first linear motor 31 and the second linear motor 32, and the two drive signals respectively correspond to the first drive signal and the second drive signal, and the two drive circuits respectively Corresponding to the first driving circuit 21 and the second driving circuit 22.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com