Patents

Literature

71results about How to "Realize the vibration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for implementing vibration output commands in mobile terminal devices

InactiveCN1914583ARealize the vibration effectImitate completeInput/output for user-computer interactionCurrent supply arrangementsTerminal equipmentEngineering

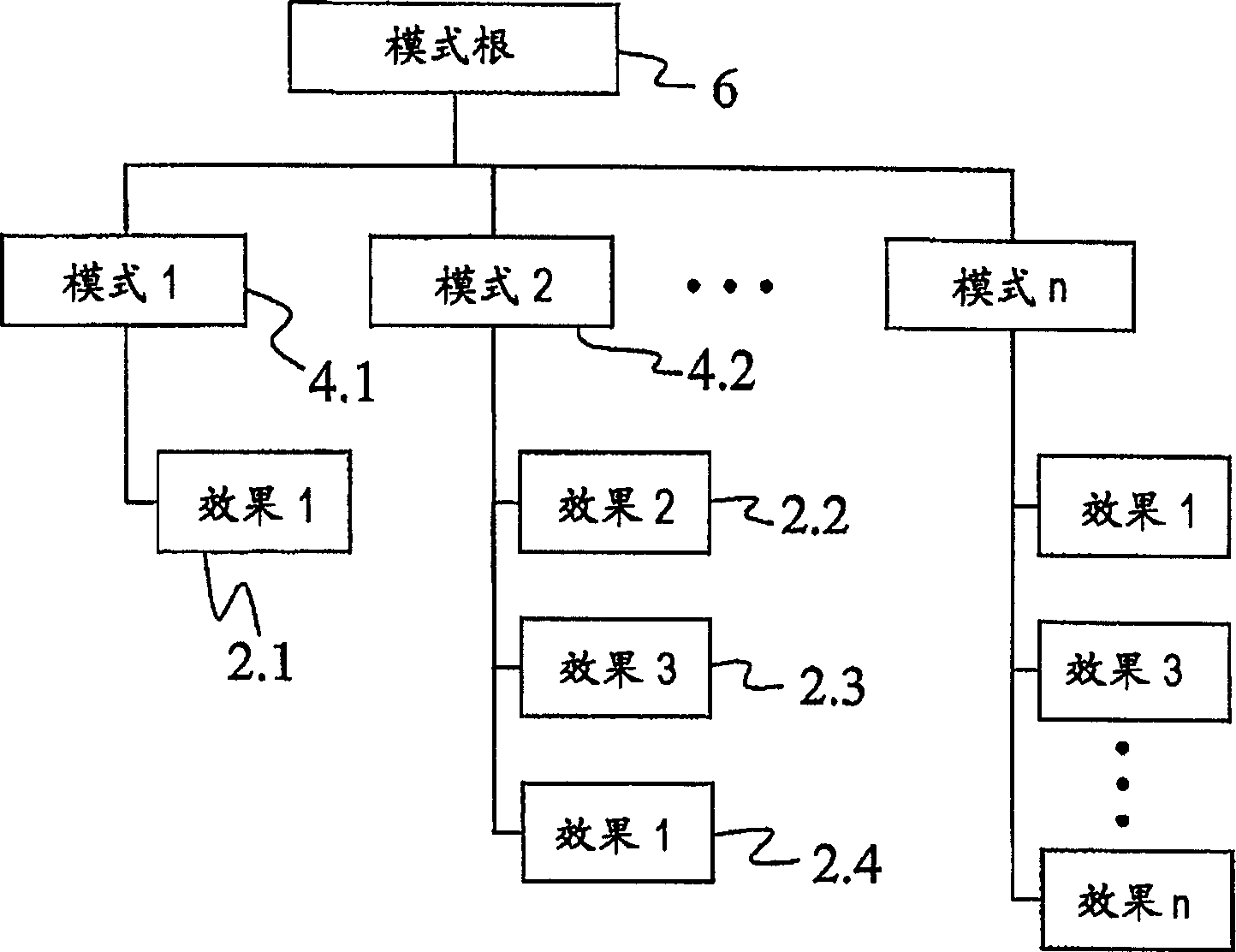

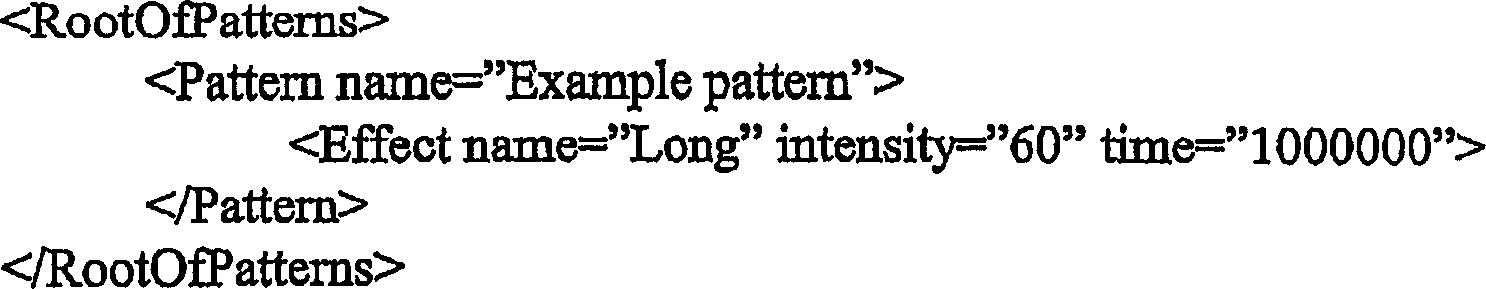

The present invention relates to method implementing vibration output commands for controlling a vibration actuator of a mobile terminal device and mobile terminal devices to execute this method. The method is based on defining at least one vibration effect, defined by at least one vibration signal parameter, defining at least one vibration pattern by at least one of said vibration effects, and storing said at least one vibration pattern into a storage.

Owner:NOKIA CORP

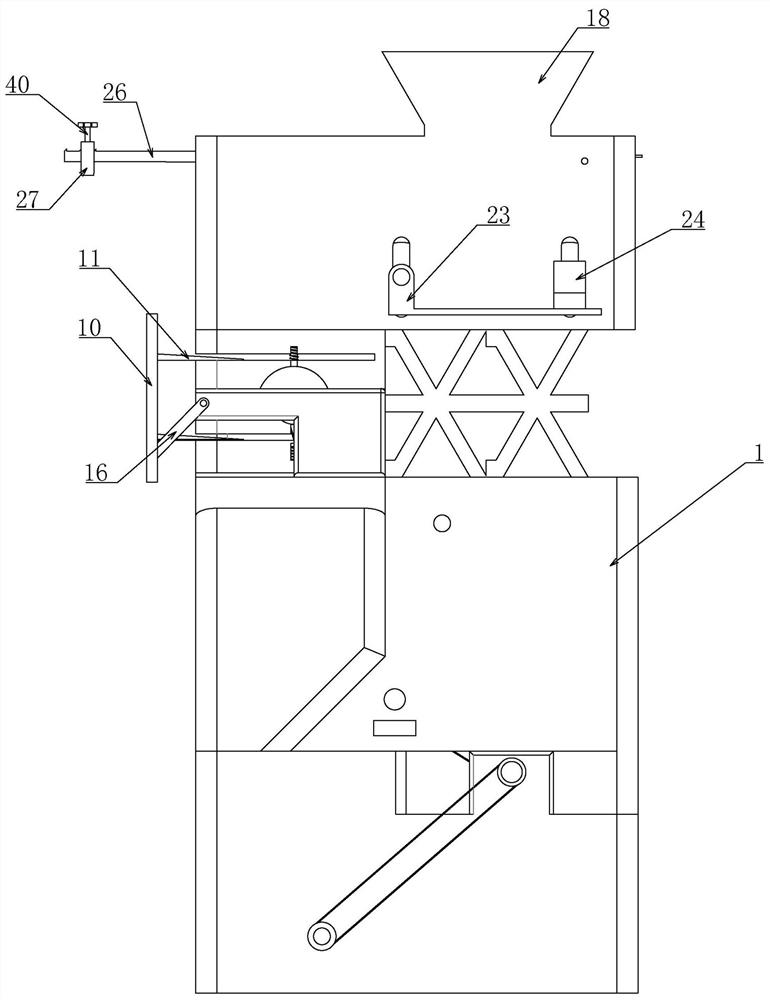

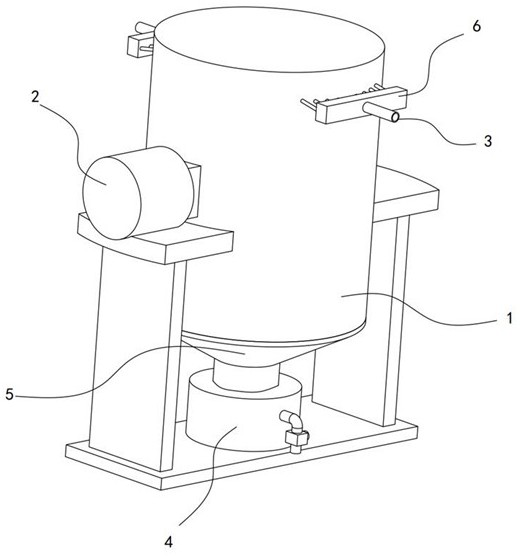

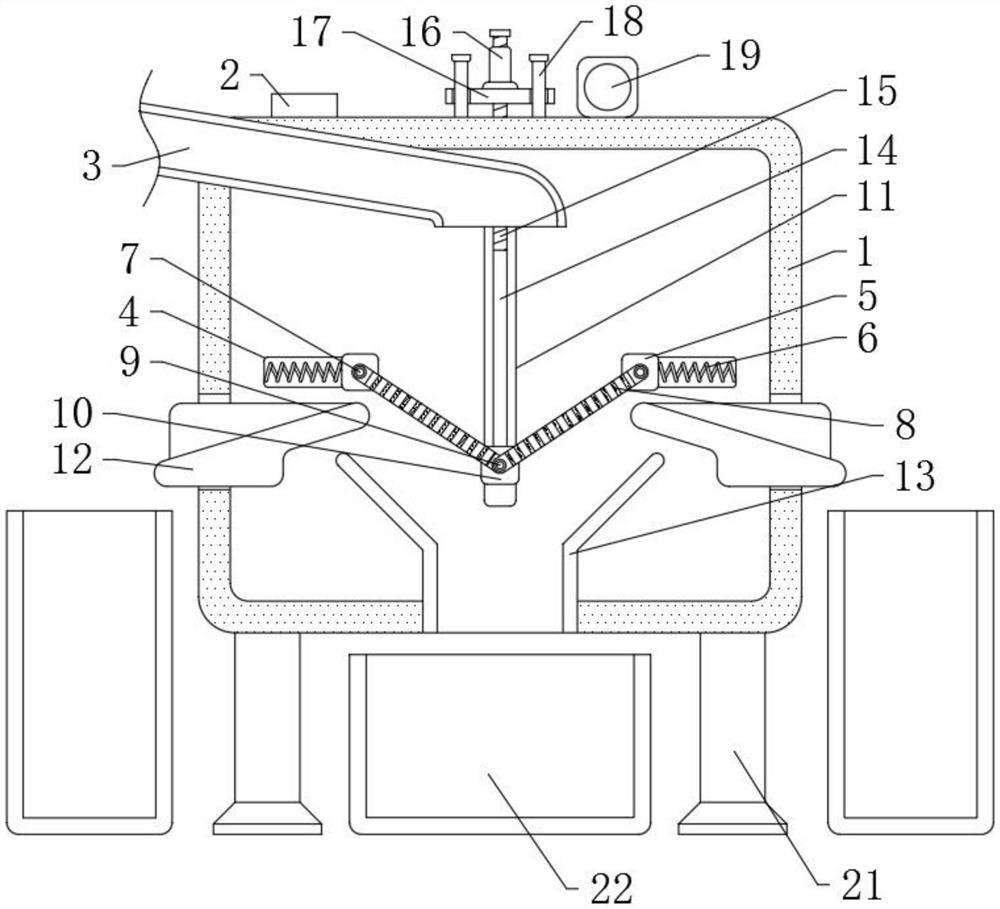

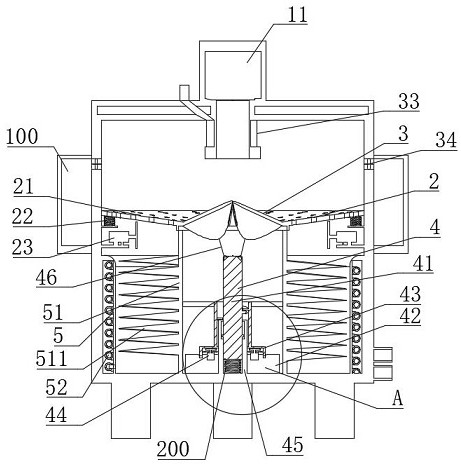

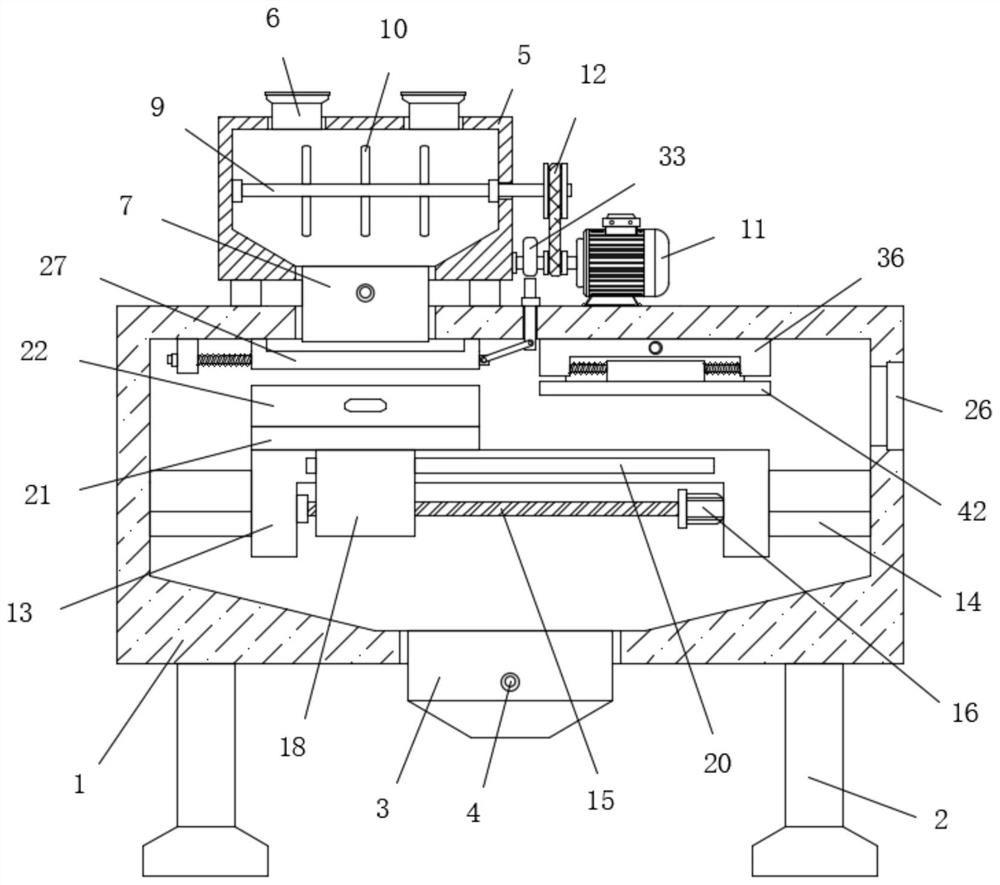

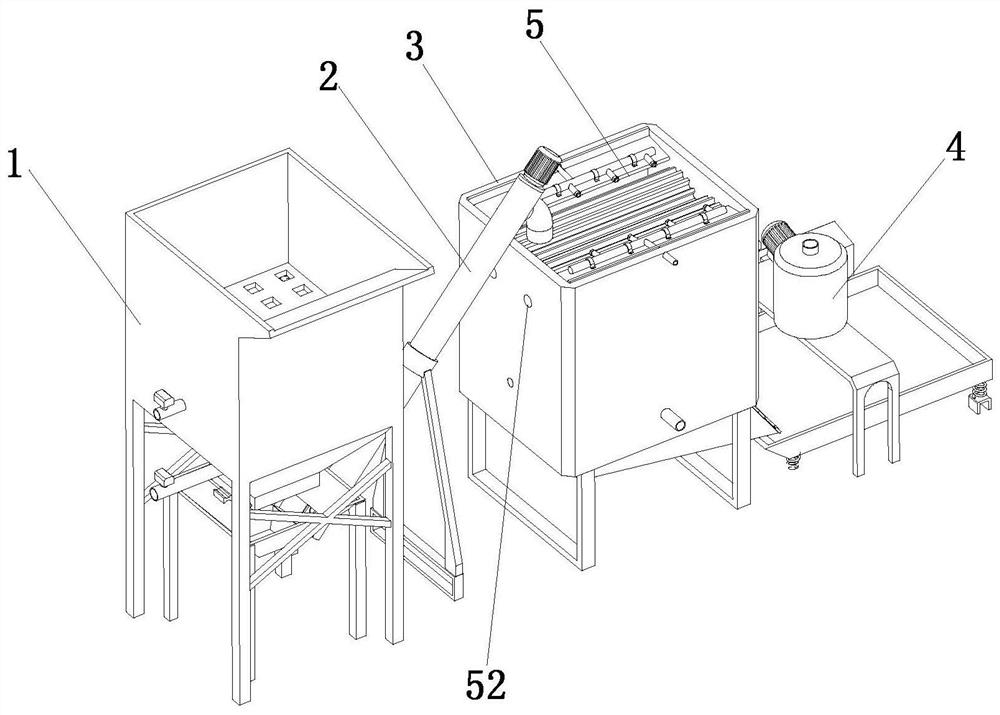

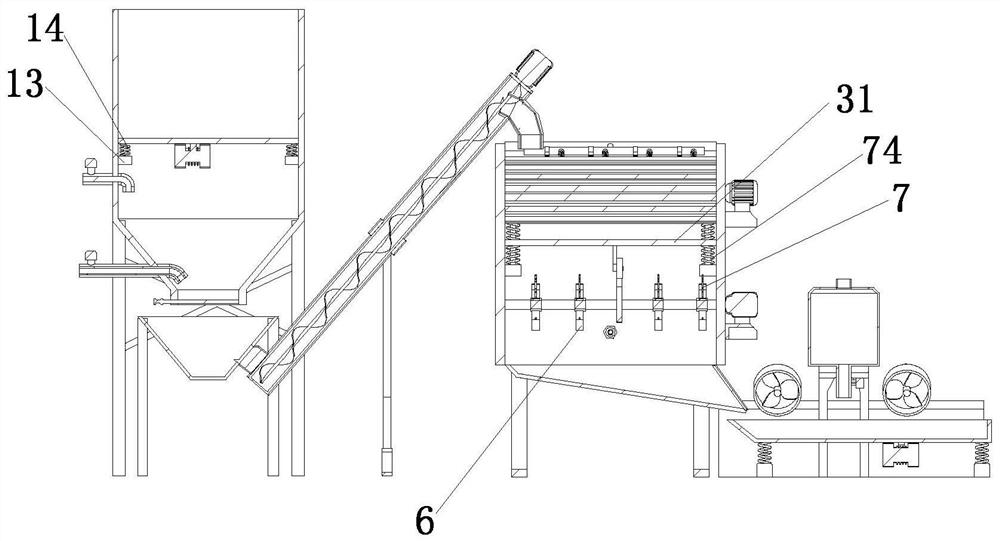

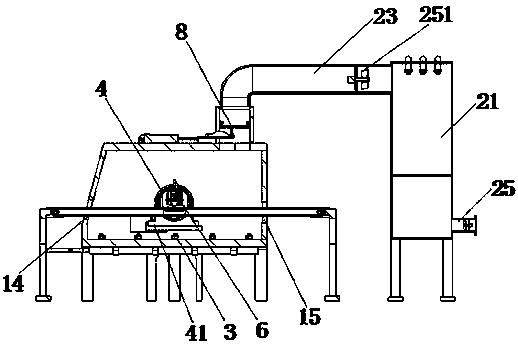

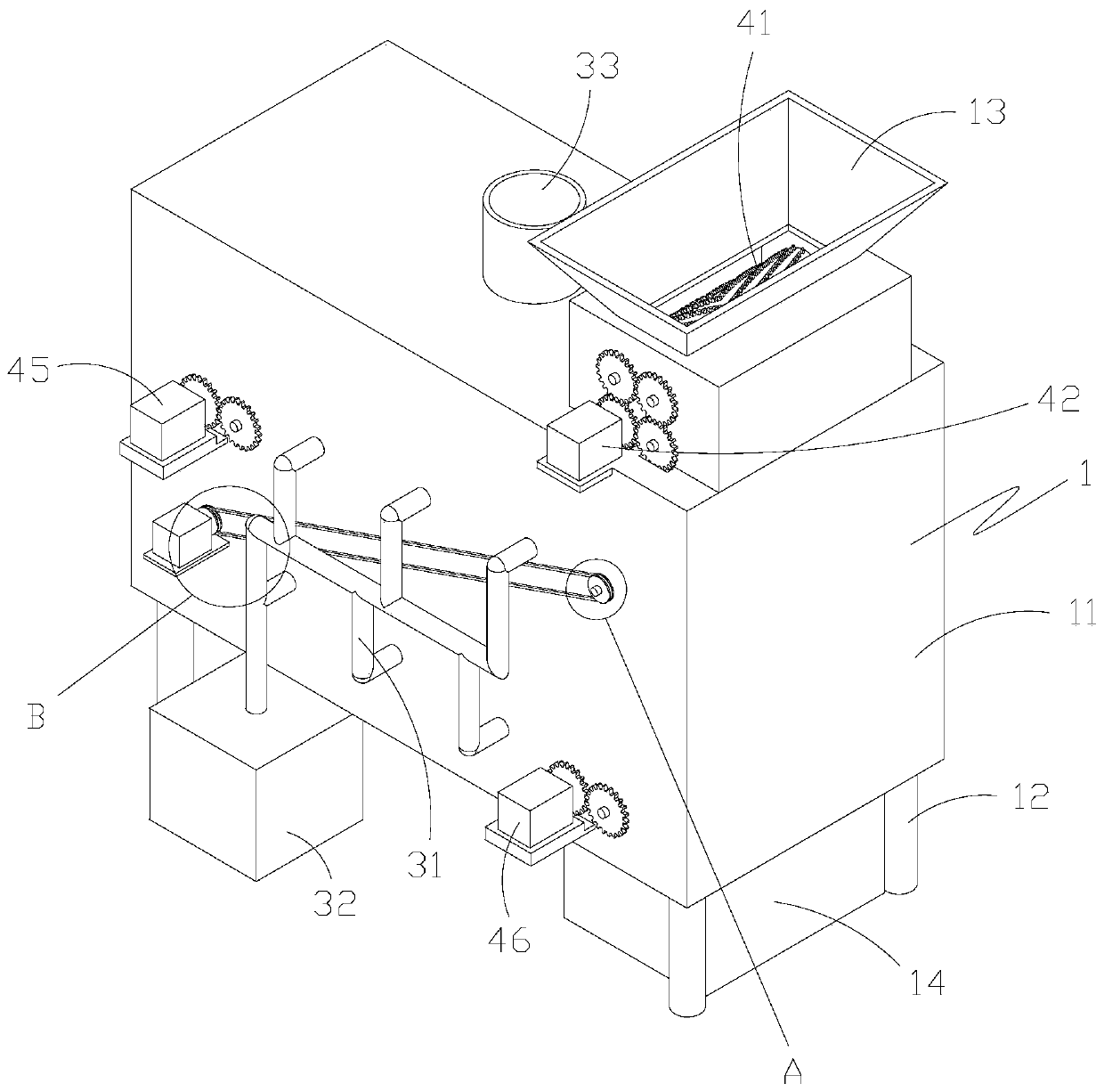

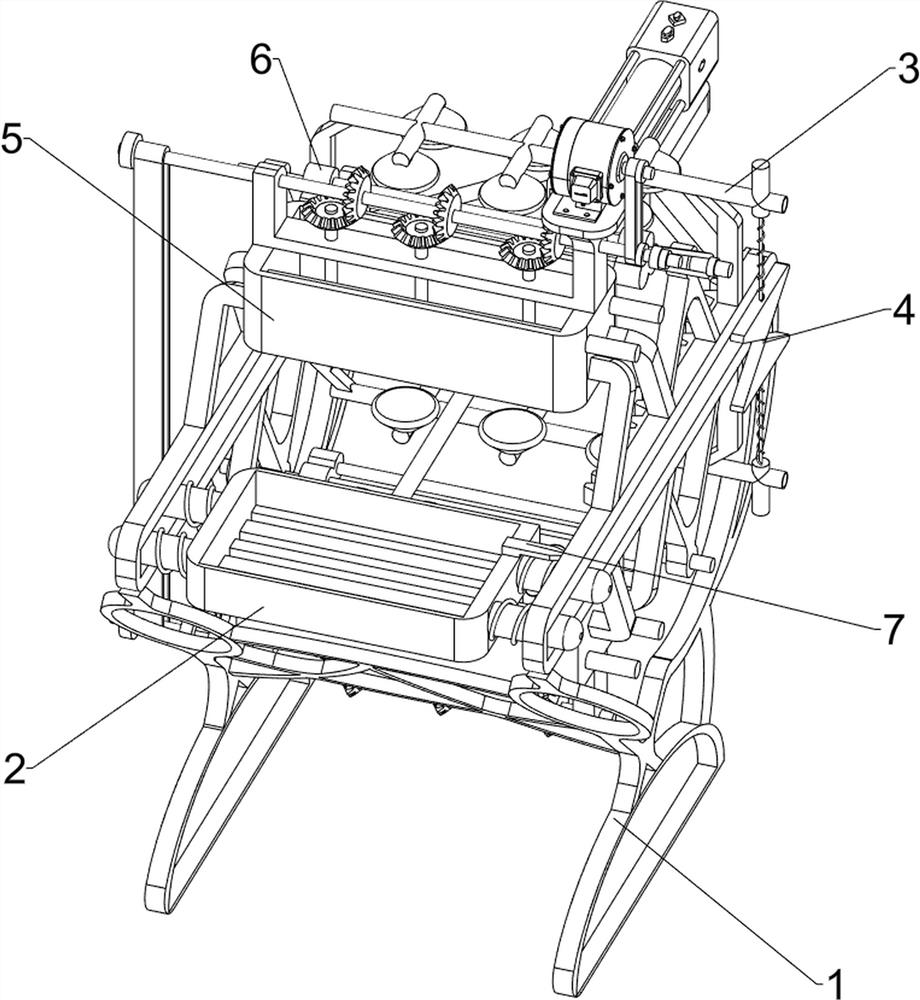

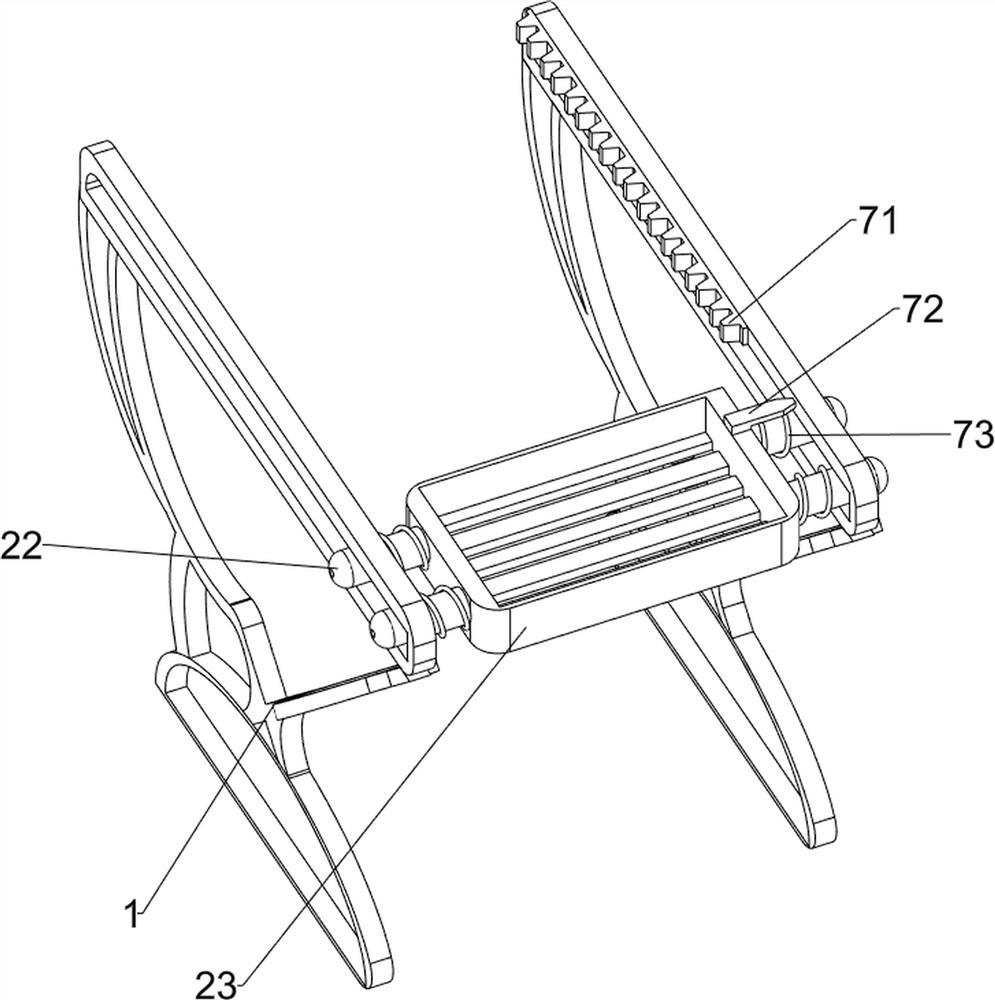

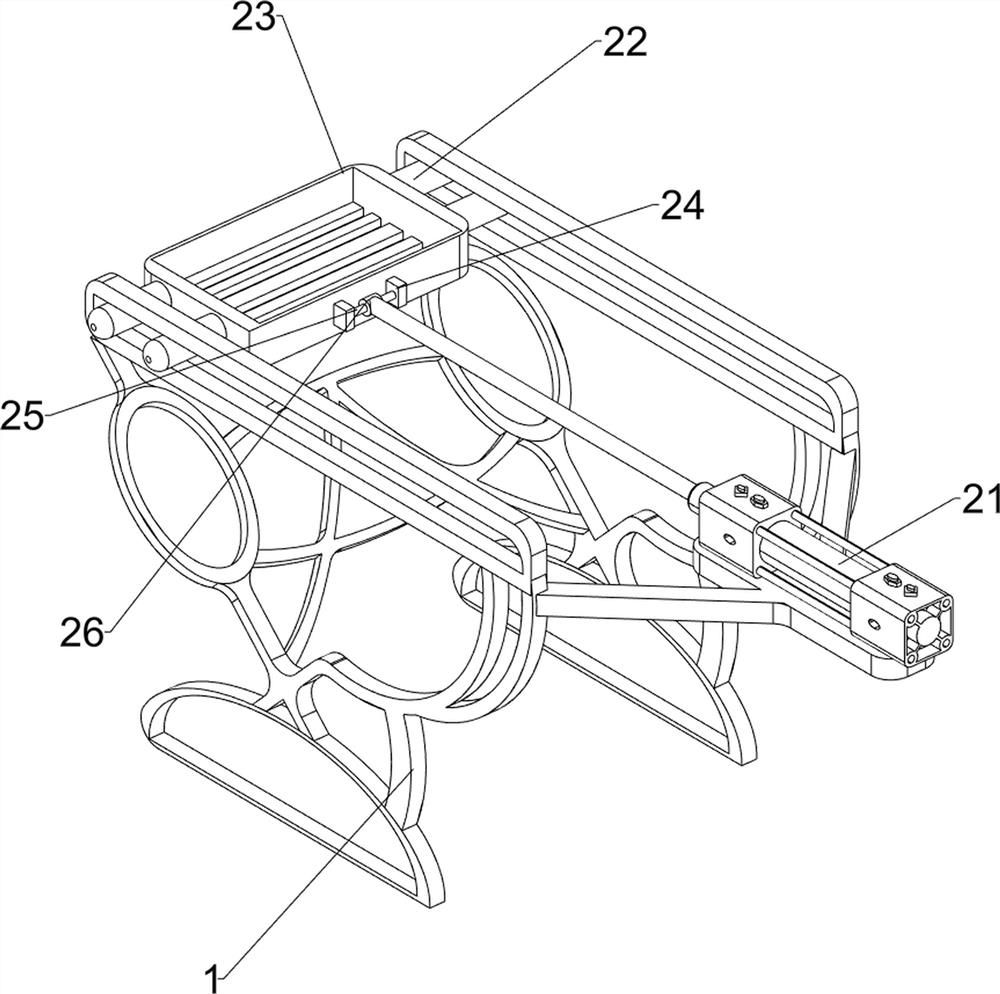

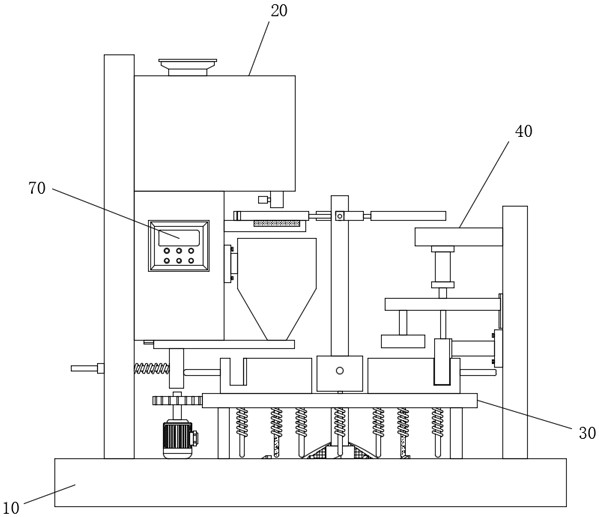

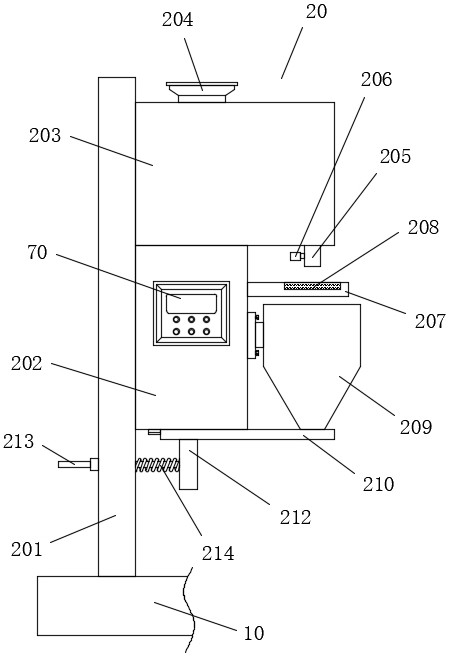

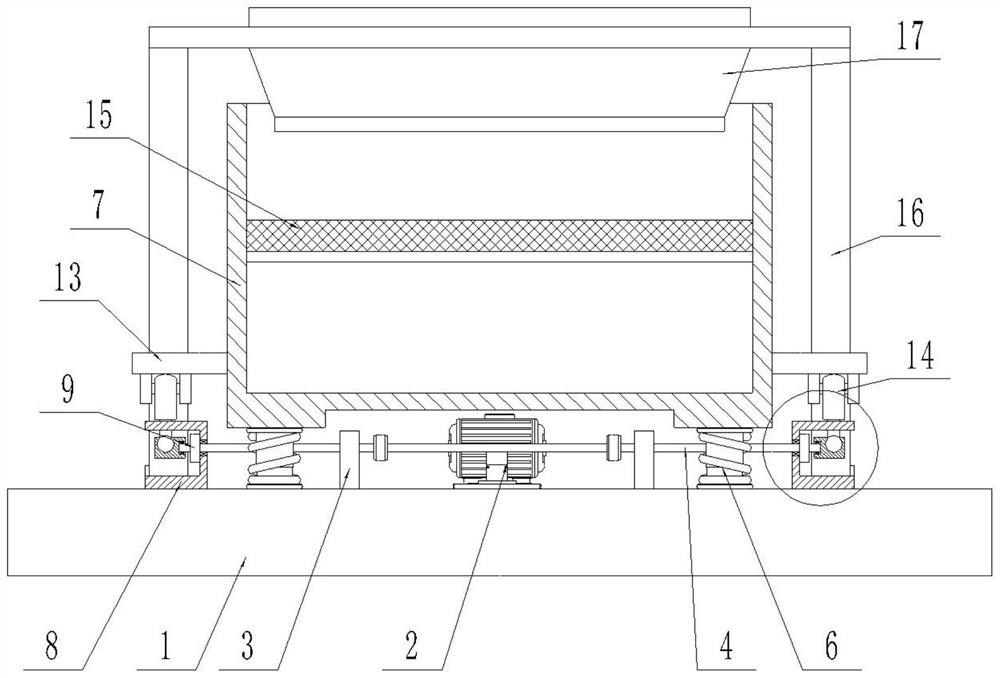

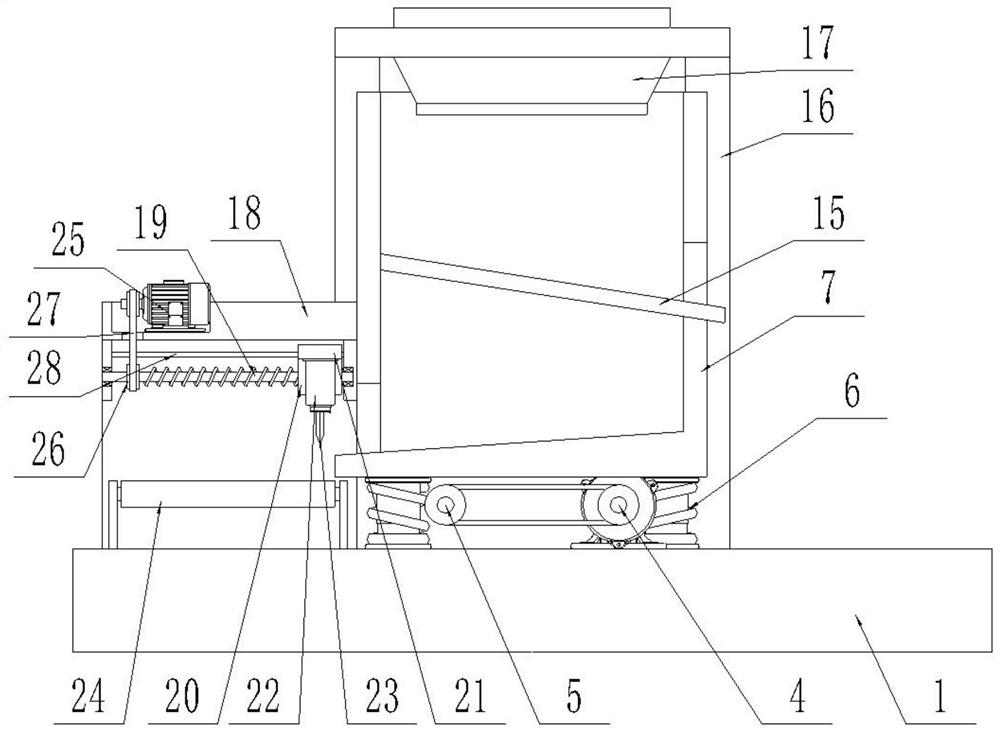

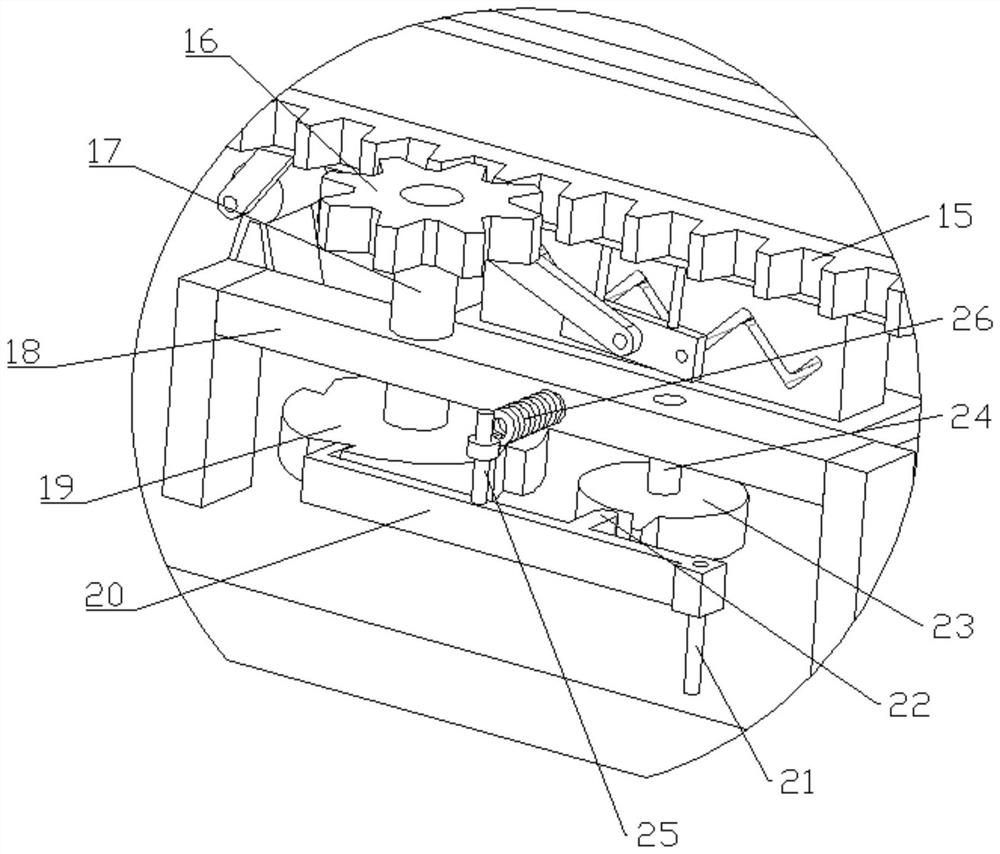

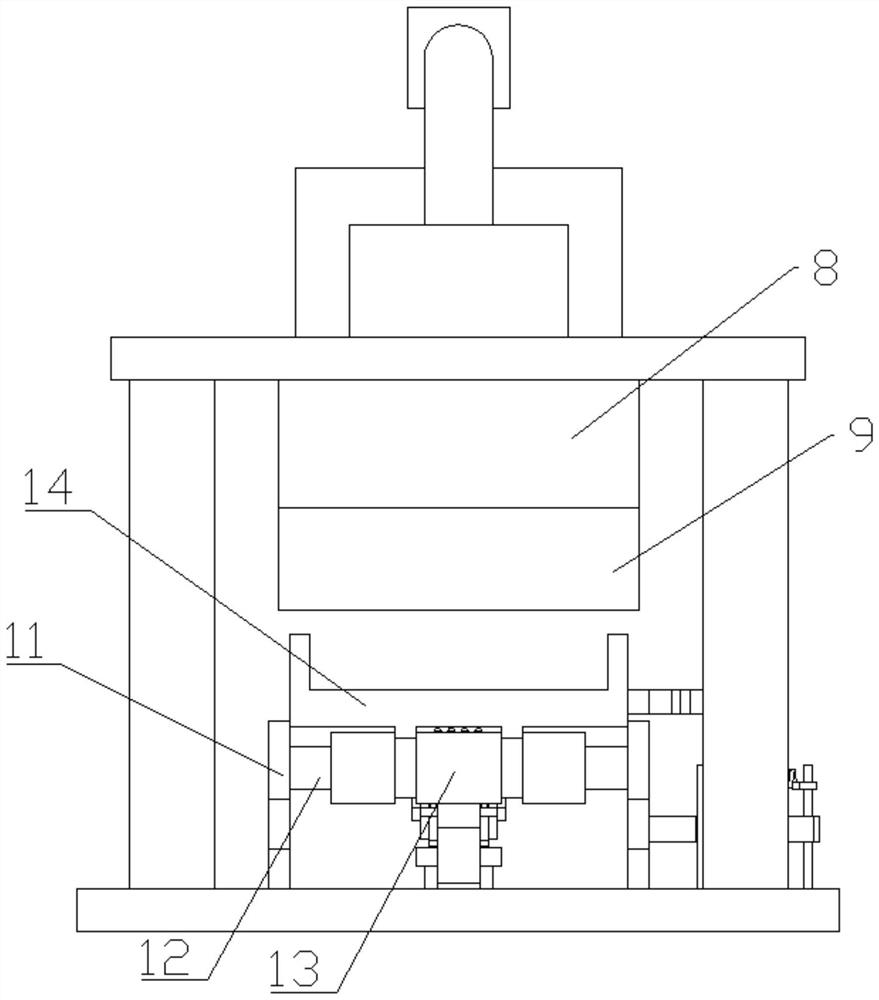

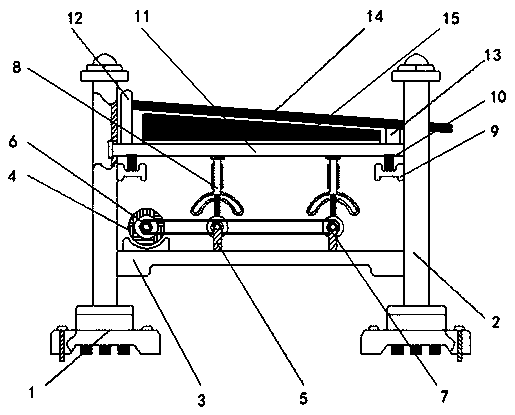

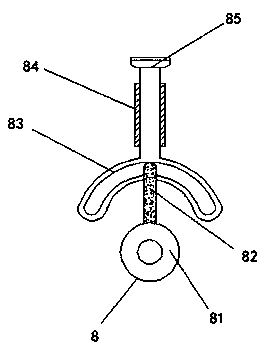

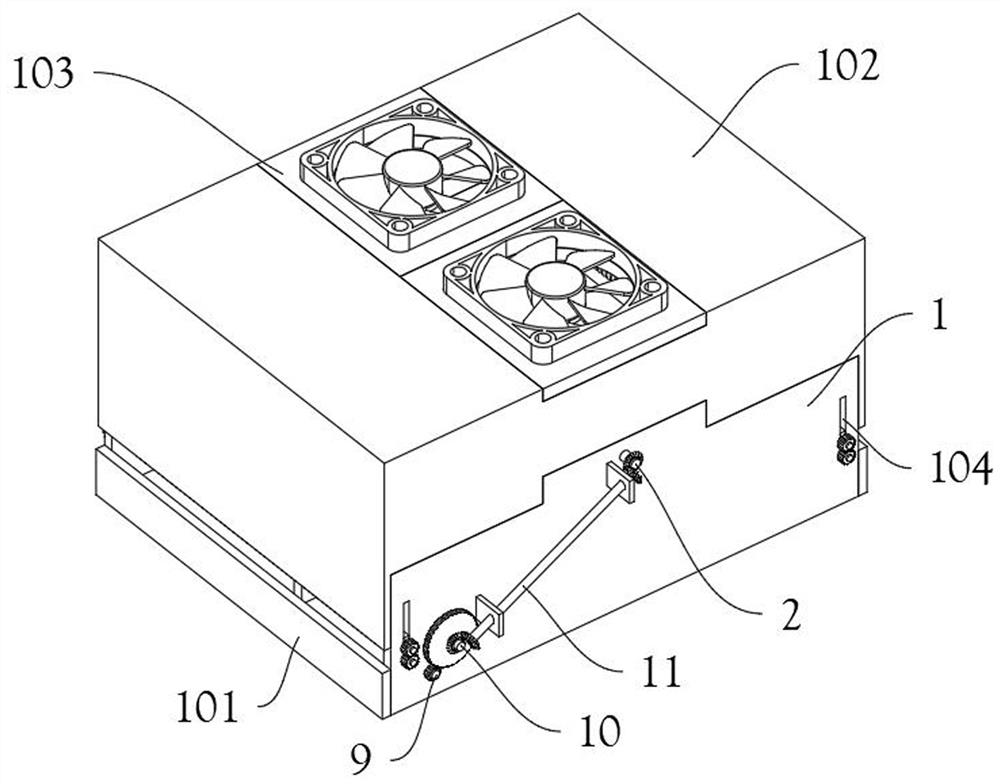

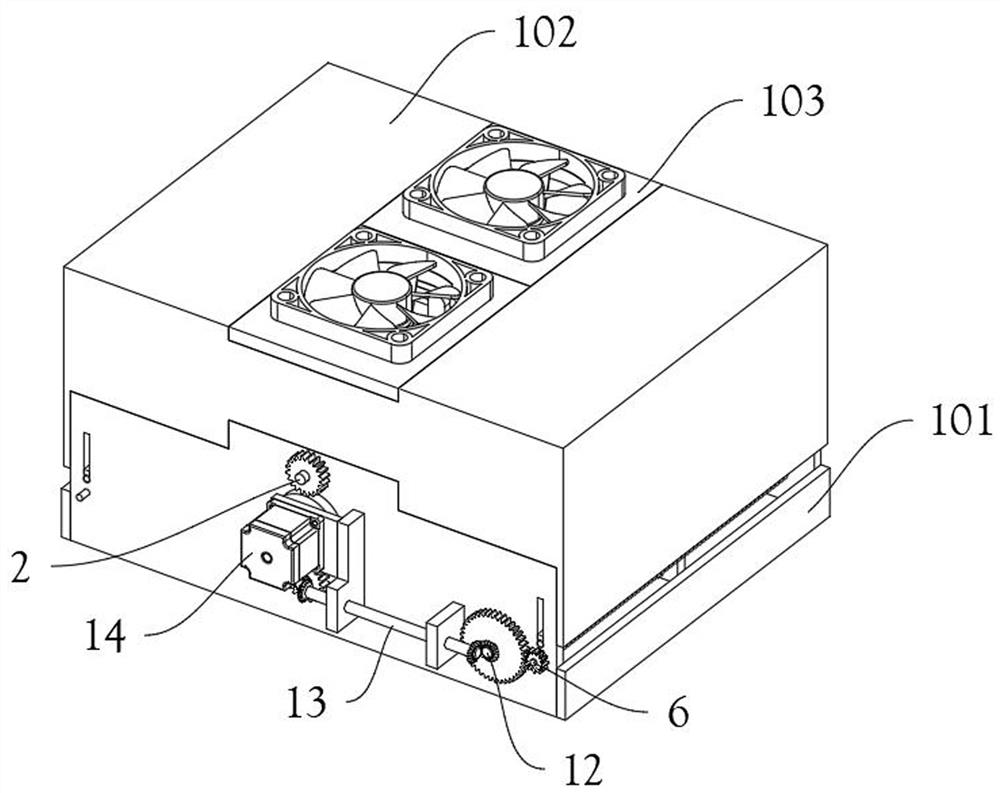

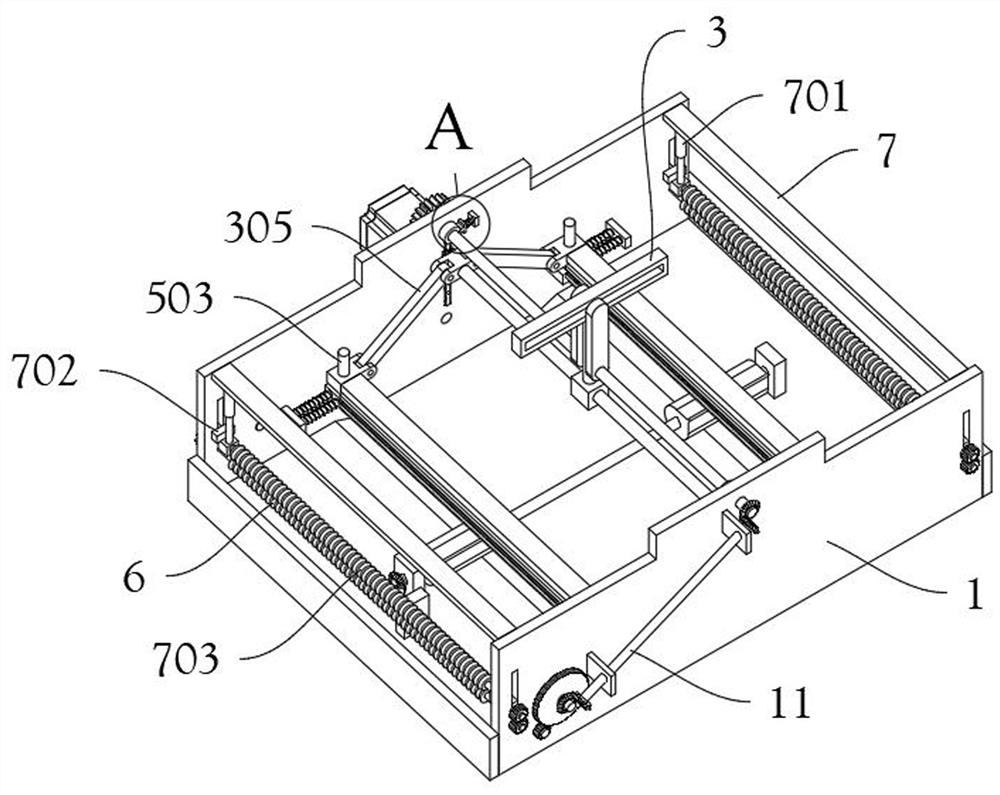

Environment-friendly building construction waste recycling device

InactiveCN112893423ARealize the vibration effectUniform control quantitySievingConstruction waste recoveryArchitectural engineeringWaste treatment

The invention relates to an environment-friendly building construction waste recycling device. Two sets of screens which are used in a matched manner are adopted in the device, long-strip-shaped holes used for leaking materials are formed in the two sets of screens, and the long-strip-shaped holes in the two sets of screens are perpendicular to each other, so that bar-shaped bamboos, wood, iron bars and the like cannot pass through the second layer of screen even if passing through the first layer of screen; the vibrating effect on the screens is achieved through cooperation of a cam and a reset spring, materials are prevented from being clamped at the positions of the long-strip-shaped holes, the cam drives a reciprocating driving device to sweep and concentrate the bar-shaped materials on the screens, and meanwhile, the number of the materials entering the screens is evenly controlled through the self-adaptive adjusting function of the weight in the even feeding process; and a crushing device and an iron material adsorption device are arranged at the lower end of a rack, so that crushing and classification treatment work of the materials is achieved. The environment-friendly building construction waste recycling device is high in building construction waste treatment efficiency, capable of recycling various different types of waste, high in practicability and suitable for application and popularization.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

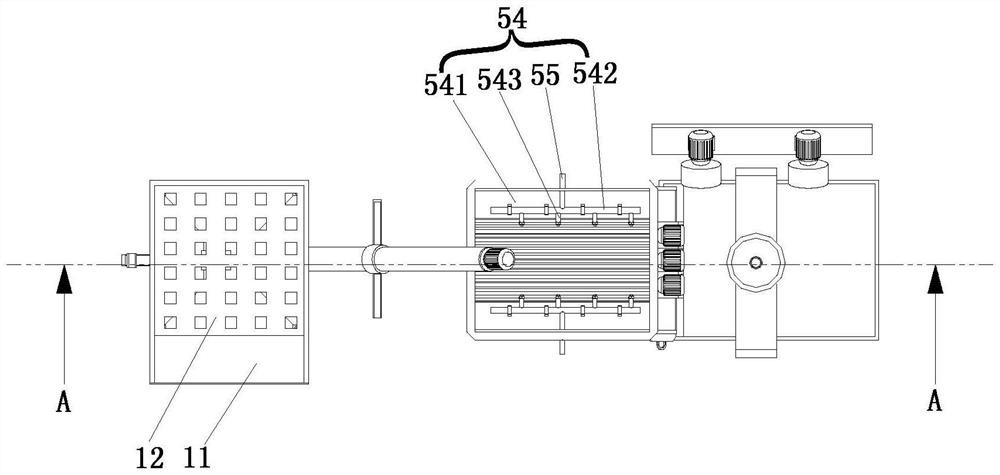

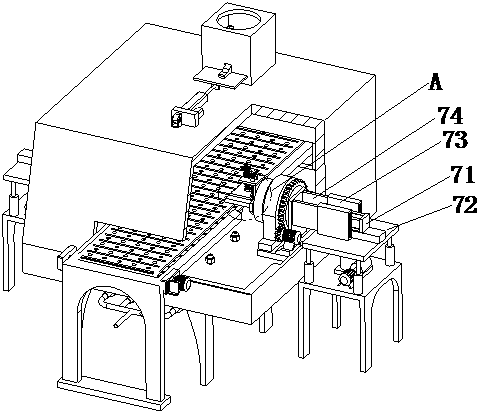

System for producing and processing wheat flour

InactiveCN110064619AQuality is not affectedFit tightlyCleaning using liquidsWet separationBiologyWheat flour

The invention belongs to the technical field of agricultural equipment, and particularly relates to a system for producing and processing wheat flour. The system aims to solve the problems that in theprior art, a large amount of wheat is generally placed in water for soaking and cleaning, obviously, it is difficult for the cleaning effect of the wheat to meet the edible requirement, meanwhile, some shrunken grains generally doped in the wheat are required to be removed, however, it is impossible to remove the shrunken grains by the general cleaning process. According to the scheme, the systemcomprises a base; one side of the top of the base is fixedly provided with a cleaning tank; a filter barrel is slidably clamped in the cleaning tank; a through hole is formed in the bottom of the filter barrel; a filter plate is arranged in the through hole, and the filter plate is clamped to the filter barrel; a connecting column is rotatably connected to the filter plate; and stirring blades are arranged on the connecting column. The system is economical and practical; the wheat can be cleaned and selected through the filter barrel in the cleaning tank, and thus the cleanliness of the wheatcan meet the processing requirement; and meanwhile, the shrunken grains can be removed so as not to affect the quality of flour while the wheat is processed.

Owner:罗峰

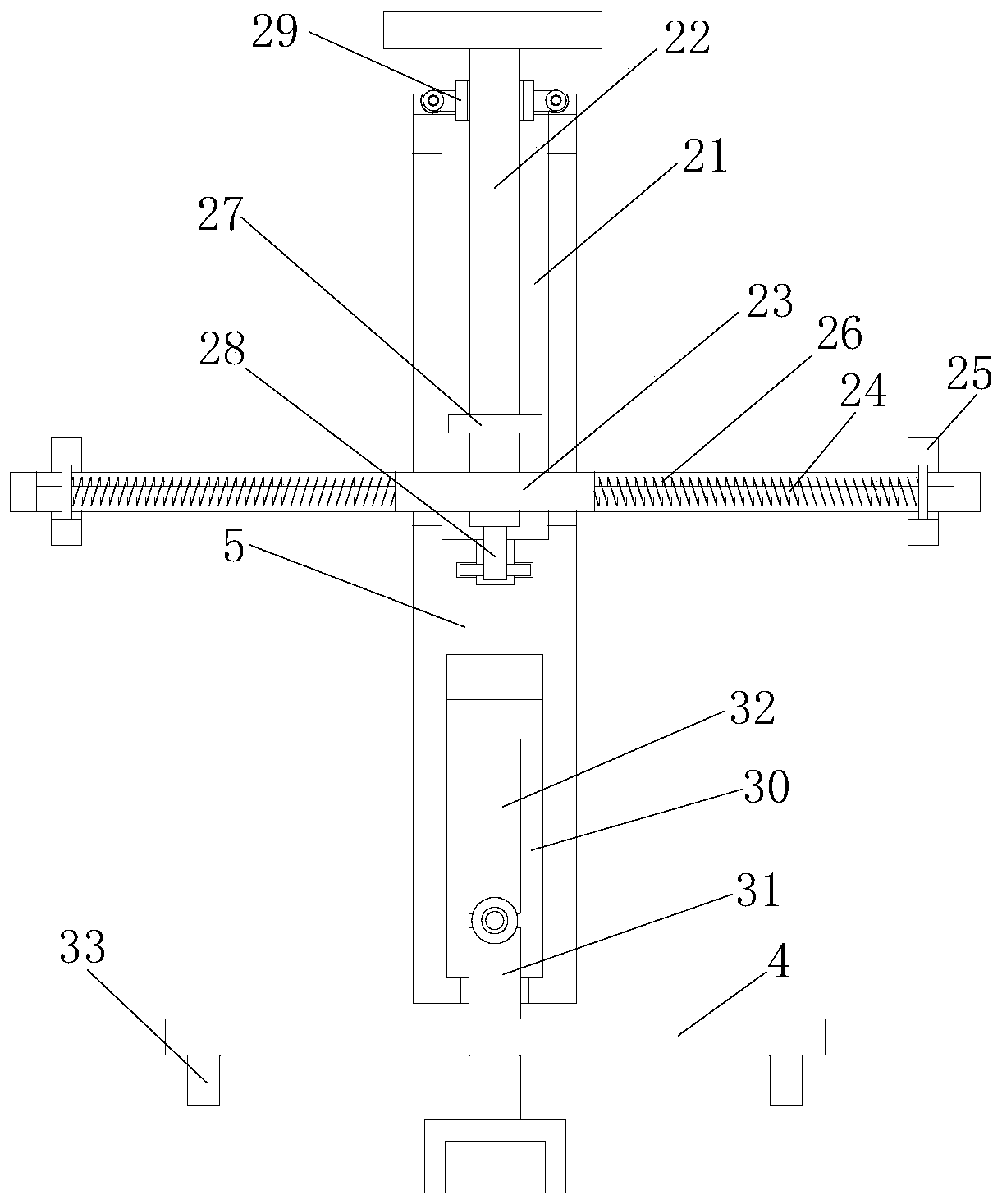

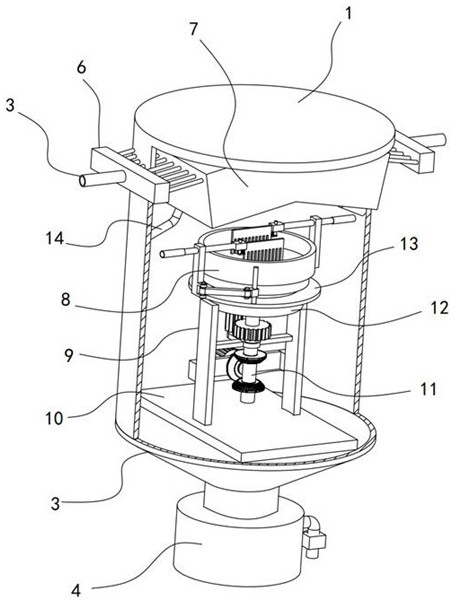

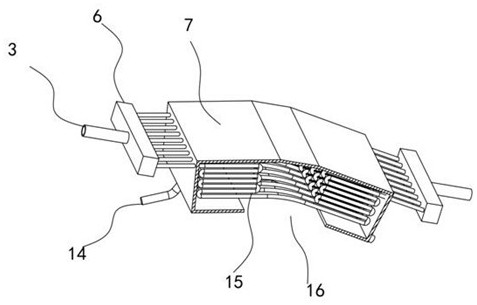

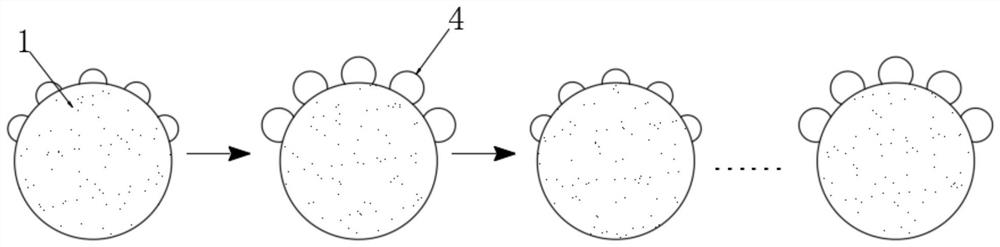

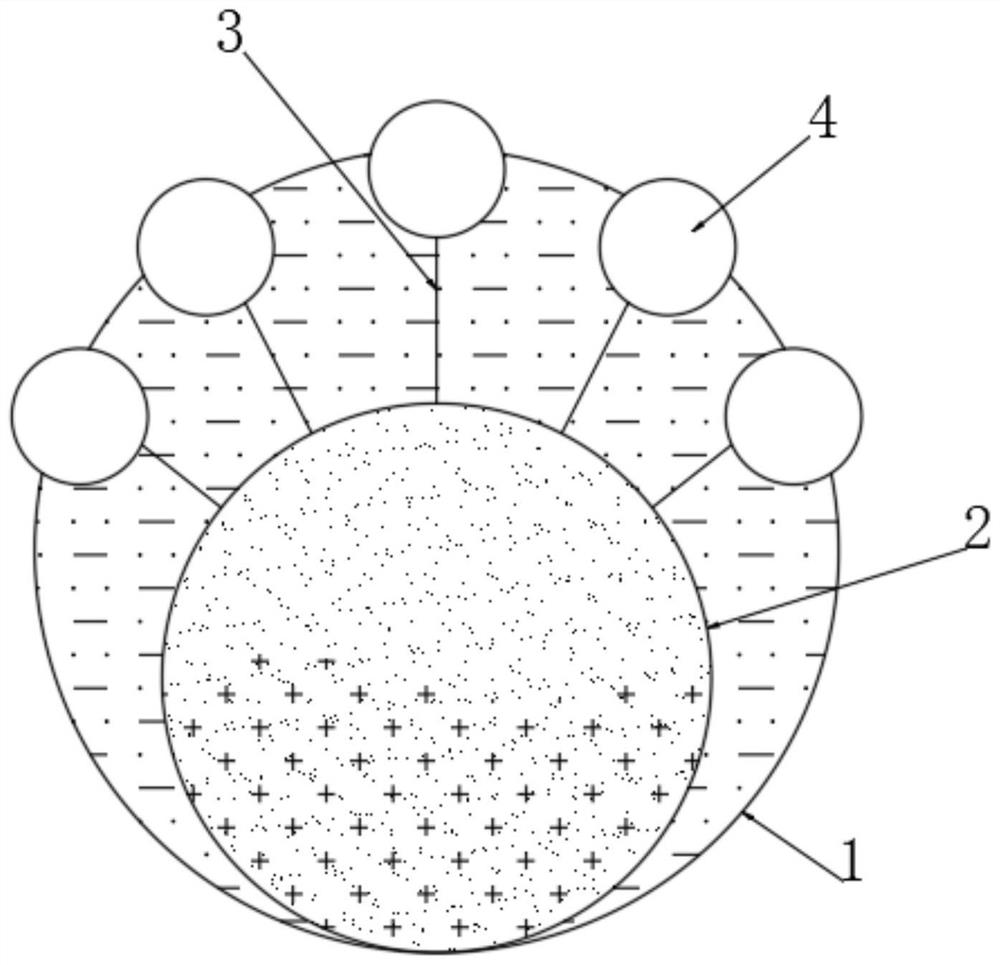

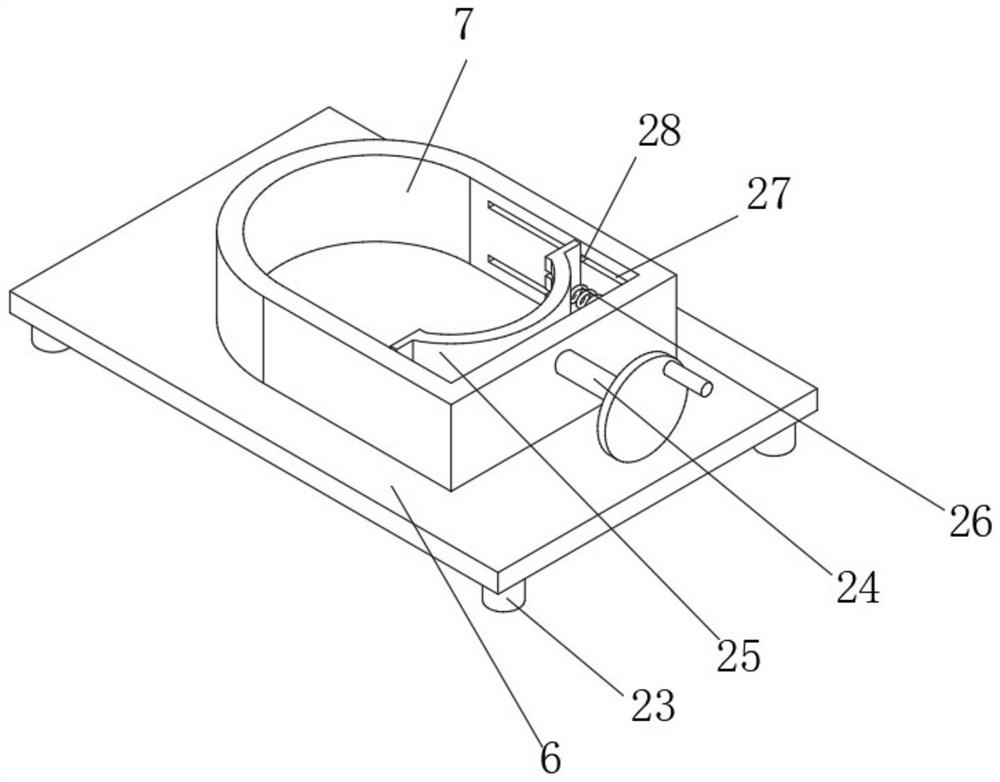

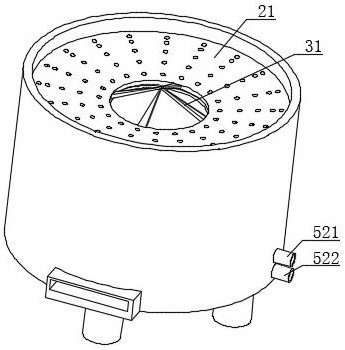

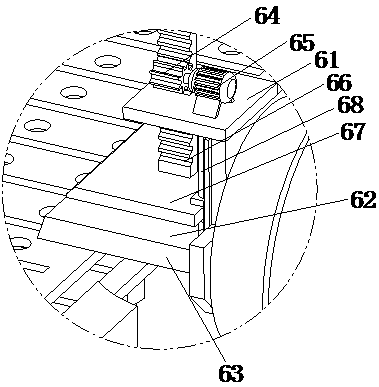

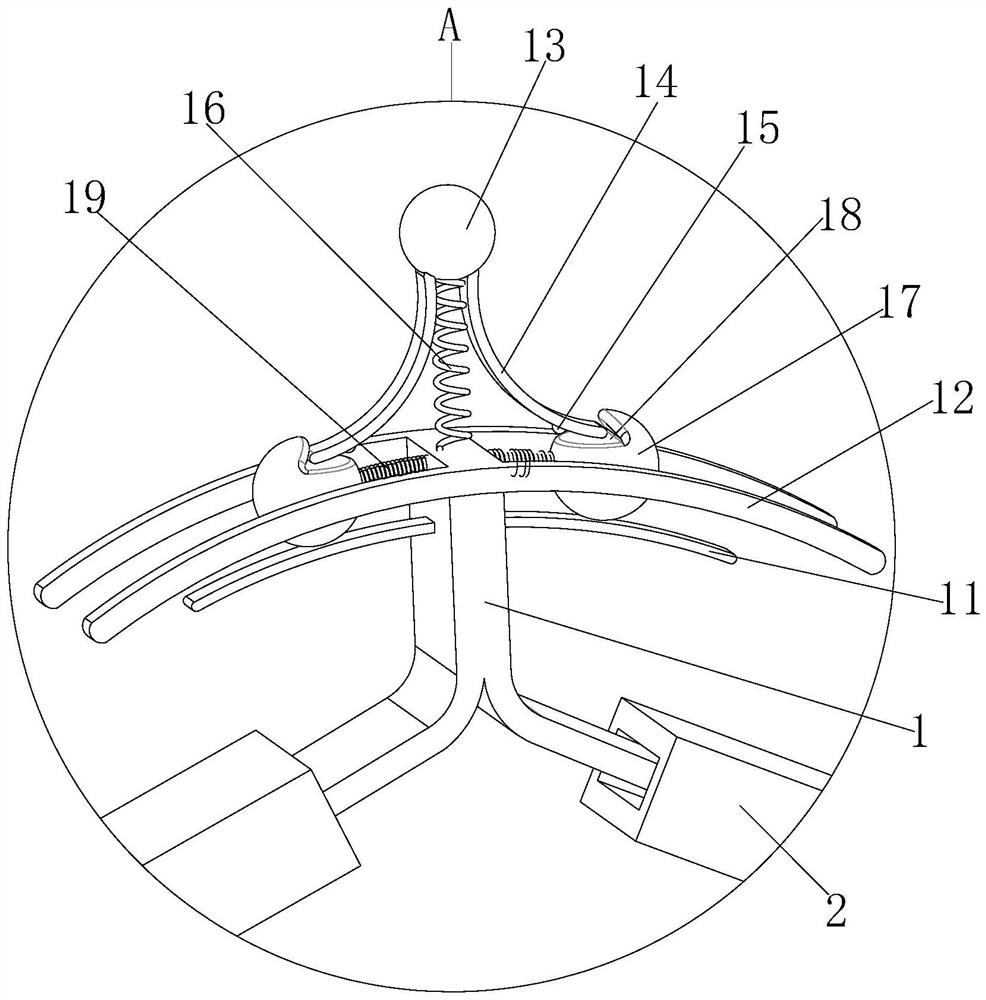

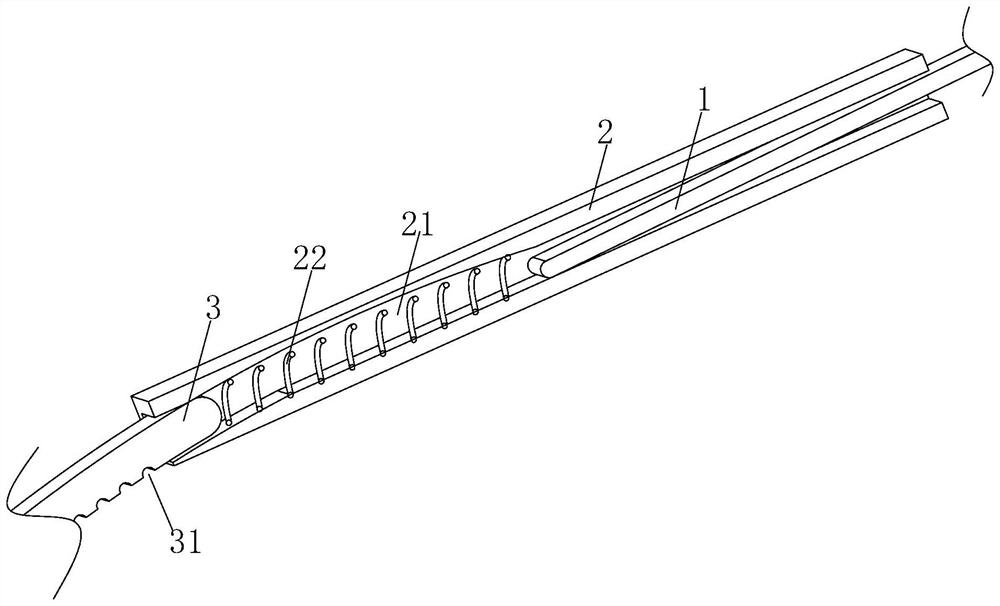

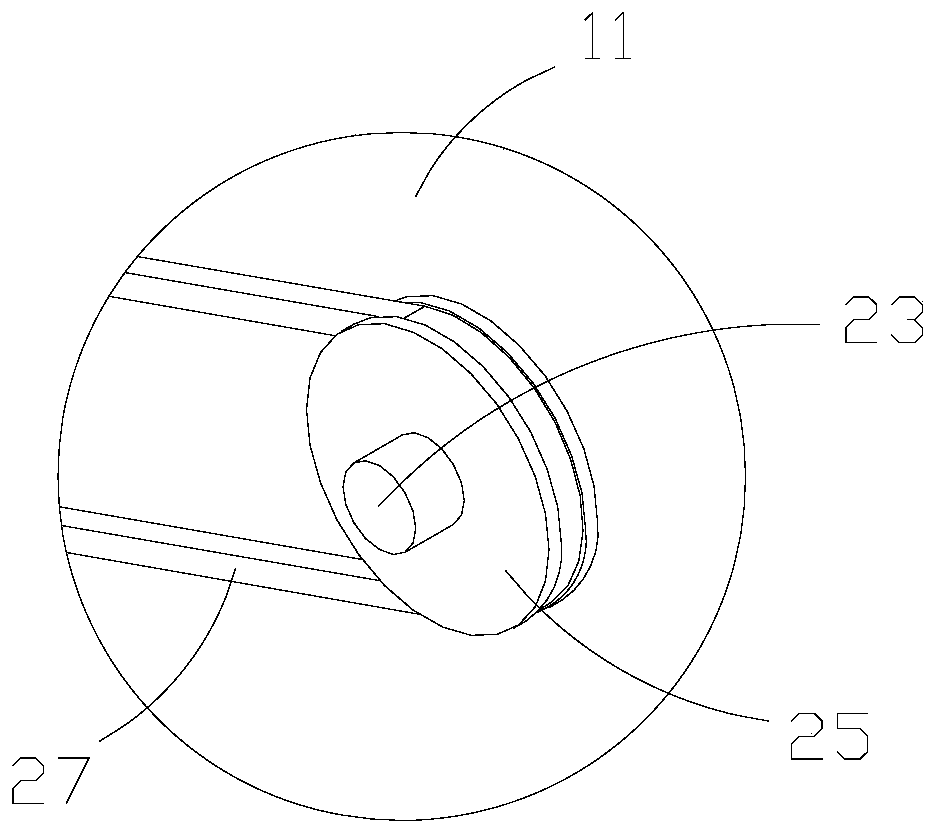

Rotational vibration disc

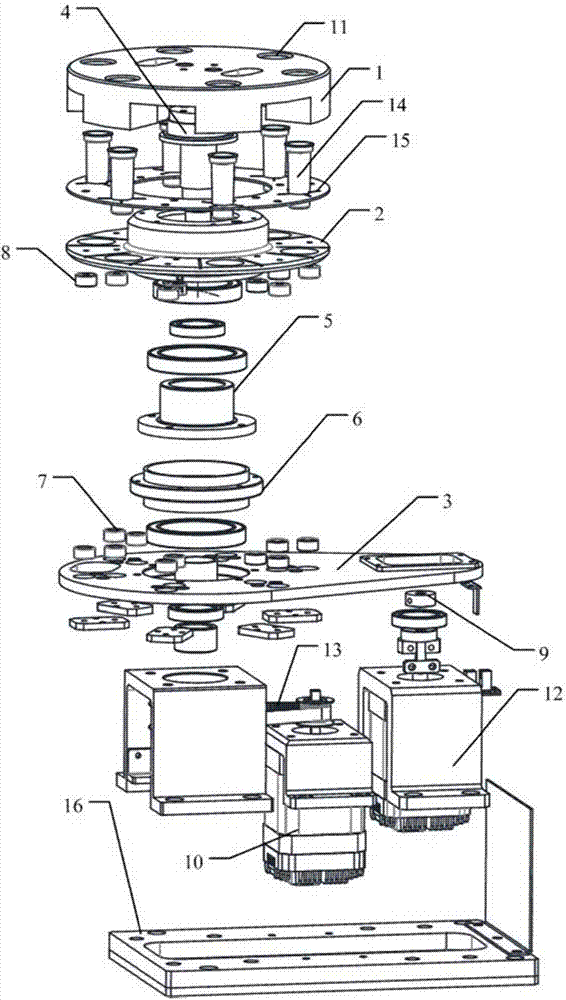

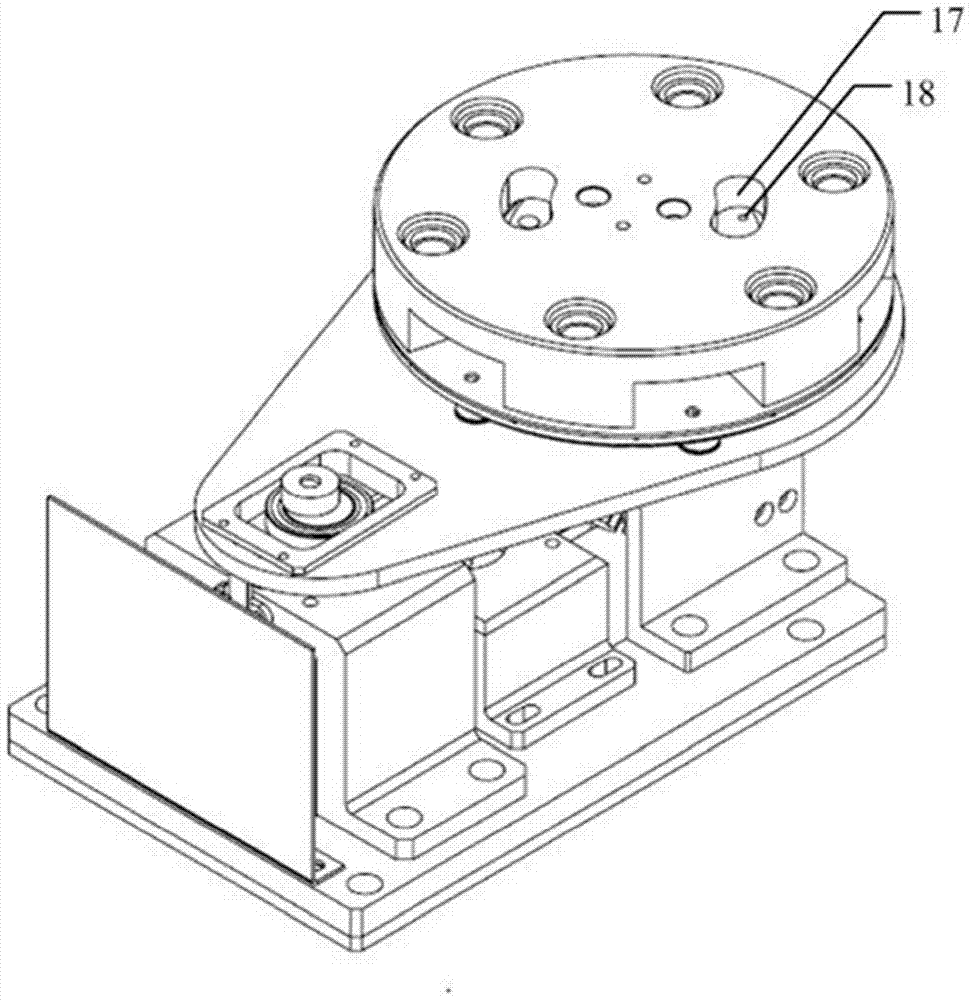

ActiveCN104722232ARealize the vibration effectImplement batch operationsShaking/oscillating/vibrating mixersMaterial analysisRotational vibrationBatch operation

The invention discloses a rotational vibration disc capable of automatically operating and carrying out vibration uniformly-mixing on a liquid in a buffer solution cup during a rotation process, thus increasing the detection efficiency. The rotational vibration disc disclosed by the embodiment of the invention comprises a rotational disc connected to a main shaft and rotating with the main shaft, wherein a follow-up tray is arranged below the rotational disc, the follow-up tray is assembled with the main shaft through a first bearing group, a vibration tray is arranged below the follow-up tray, the vibration tray is assembled with the main shaft through a second bearing group, and rotational power is provided for the main shaft by a power component; buffer solution cup mouths are formed in the rotational disc and the follow-up tray; the vibration tray is provided with a first magnet group, and the follow-up tray is provided with a second magnet group on a position corresponding to the first magnet group. The rotational vibration disc is capable of realizing vibration uniformly-mixing on the liquid in the buffer solution cup during the rotation process, and capable of carrying out batched operation on a plurality of pieces of sampling buffer solutions, thus operation time is saved, and the working efficiency is improved.

Owner:GUANGZHOU WONDFO BIOTECH

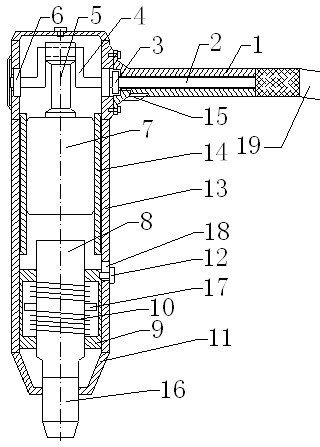

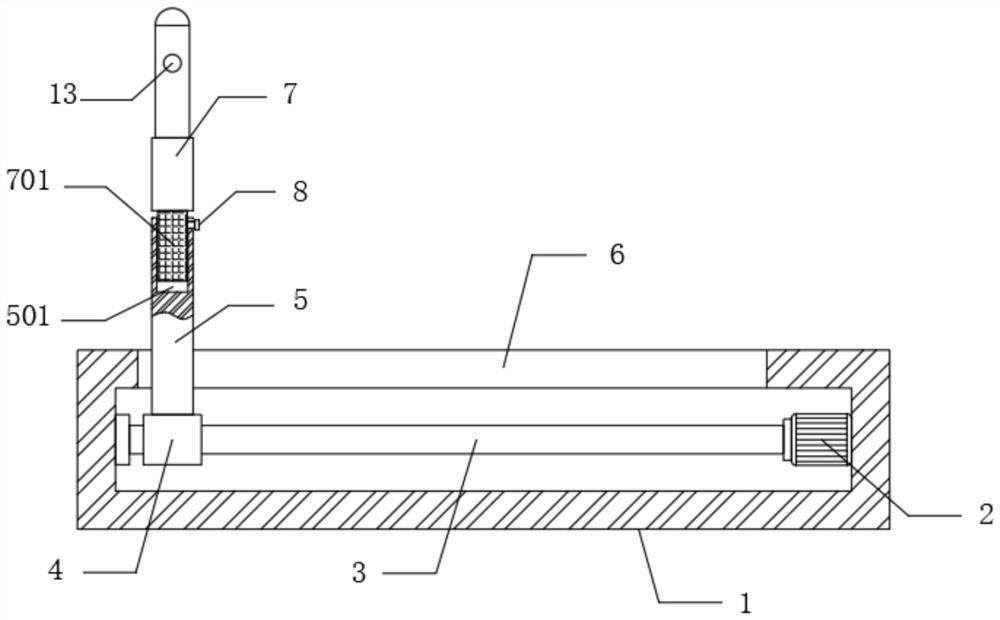

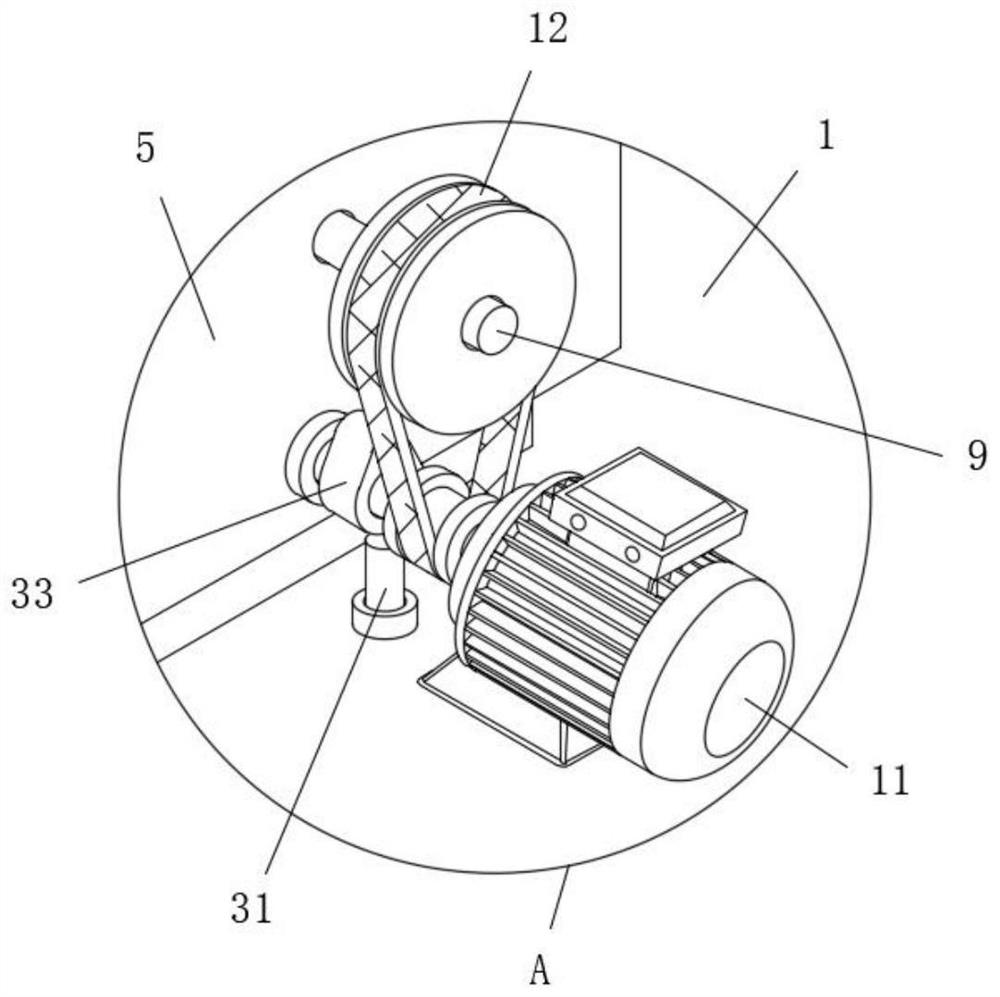

Frequency-variable impact multifunctional electric tool

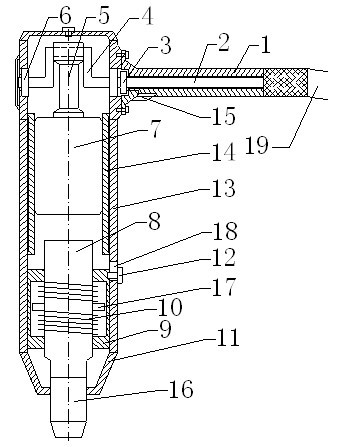

InactiveCN102601775ARaise the natural frequencyAchieve vibrationPortable percussive toolsDrive shaftPower tool

The invention discloses a frequency-variable impact multifunctional electric tool, which comprises a shell (13) and a handle (1), wherein the handle (1) is arranged at one side of the upper end of the shell (13). The frequency-variable impact multifunctional electric tool is characterized in that an inner-handle transmission shaft (2) is arranged in the handle (1), one end of the inner-handle transmission shaft (2) is connected with a crankshaft (4), the crankshaft (4) is arranged at the upper end of the shell (13) by a bearing (6), a plug hammer (7) is arranged in the middle segment of the shell (13), the top of the shell (13) is connected with the crankshaft (4) through a connecting rod (5), dual spring oscillators are arranged at the lower segment of the shell (13), and the lower ends of oscillators (8) of the dual spring oscillators are connected with a tool piece (16). The frequency-variable impact multifunctional electric tool solves the problem that a handheld outer power tool can not realize the high-frequency vibration beating function, is light and durable, and can realize the actions of hammering, shoveling, riveting, matting, cutting, carving, chiseling and the like.

Owner:GUIZHOU ACAD OF SCI

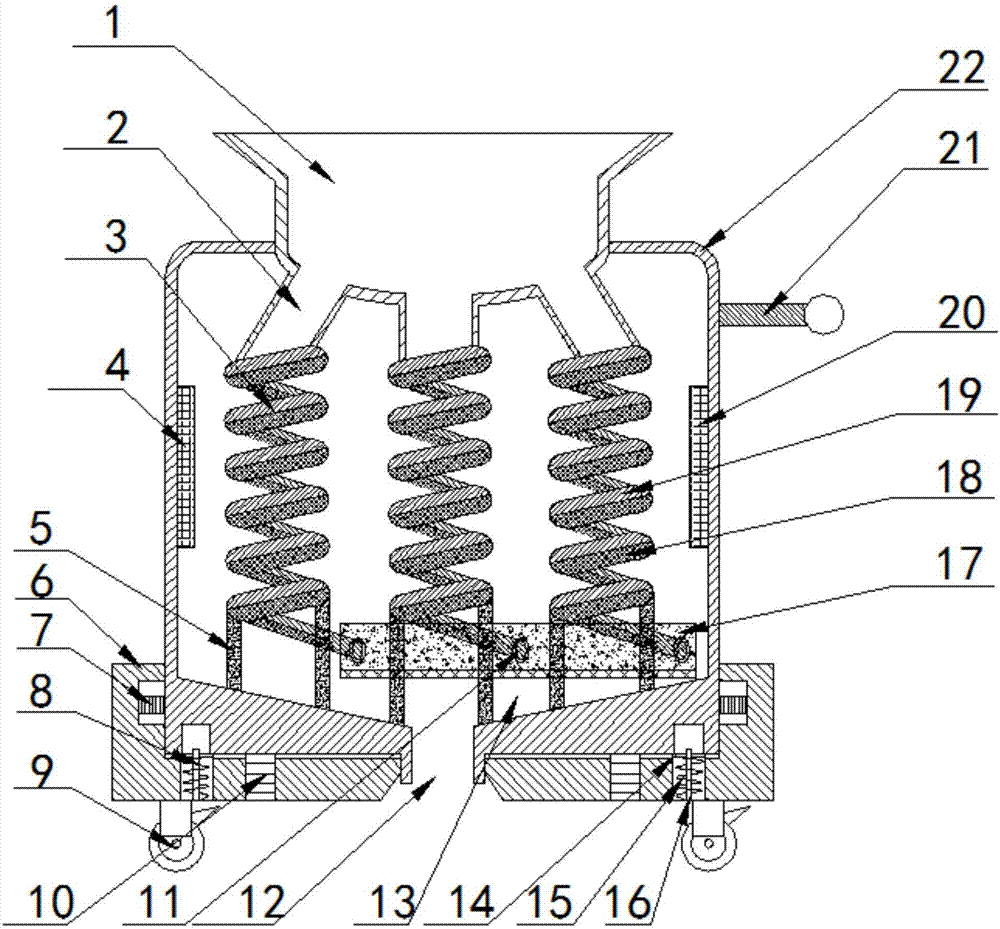

Vacuum low-temperature continuous drying equipment

ActiveCN113983792AAchieve vibrationRealize the vibration effectDrying solid materials without heatDrying chambers/containersEngineeringVacuum pump

The invention discloses vacuum low-temperature continuous drying equipment, and relates to the technical field of drying equipment, the vacuum low-temperature continuous drying equipment comprises a straight barrel and a vacuum pump connected with the straight barrel, a conical barrel is mounted at the bottom of the straight barrel, a horizontal frame is fixed in the straight barrel, a vertical frame is mounted on the horizontal frame, and a plurality of upper convex blocks are uniformly mounted at the bottom of a heating disc in the circumferential direction; a rotating disc is provided with a plurality of lower convex blocks which abut against the upper convex blocks in a sliding mode, the rotating shaft is connected with a rotating mechanism, the rotating mechanism is used for driving the heating disc to rotate, the rotating mechanism is provided with an outer ring plate, the outer ring plate is connected with an evacuation mechanism through a traction mechanism, and the traction mechanism is used for driving the evacuation mechanism to linearly slide relative to the heating disc; the transmission mechanism can drive the rotating disc to rotate, the lower convex blocks and the upper convex blocks on the rotating disc slidably abut against each other so that the heating disc can achieve the vibration effect, materials on the heating disc can be promoted to vibrate, the materials can be turned over and evenly heated, and precipitation of water is effectively promoted.

Owner:ZHUCHENG XINZHENGDA MACHINERY CO LTD

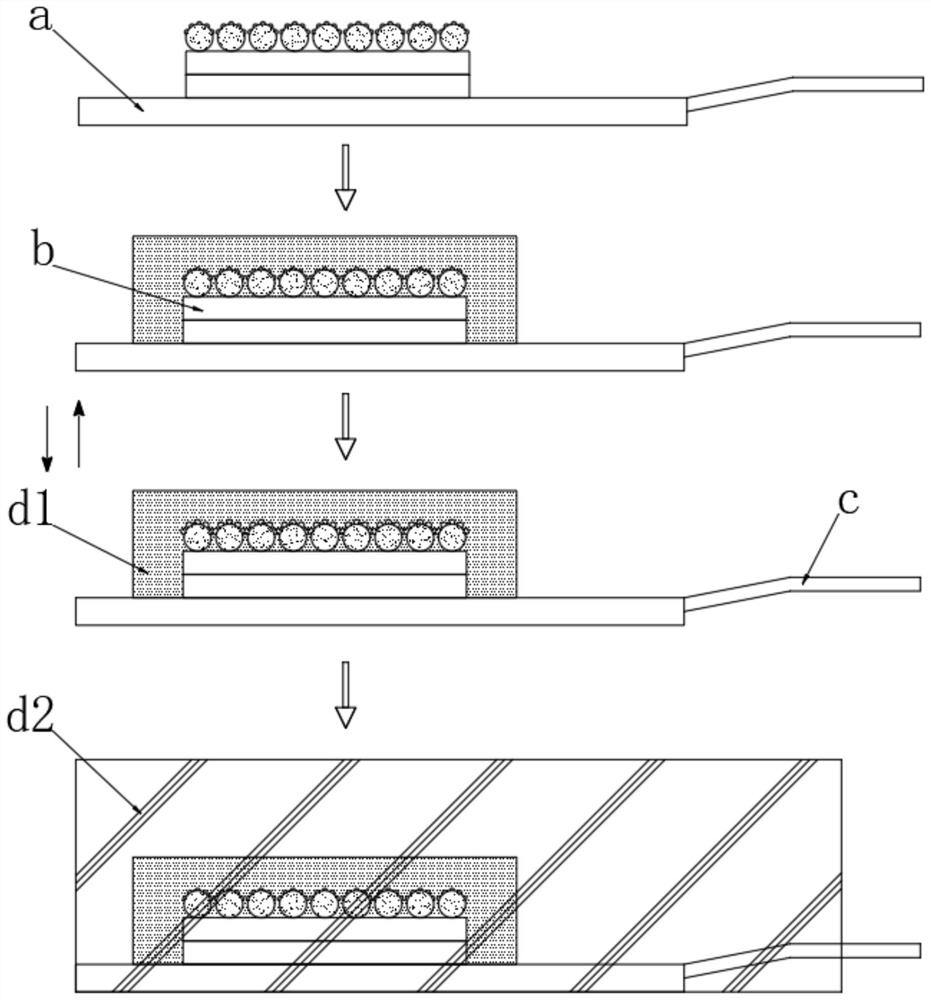

Defoaming packaging process of electronic component

ActiveCN113270330AEliminate voidsAvoid crackingSemiconductor/solid-state device manufacturingEpoxyEngineering

The invention discloses a defoaming packaging process of an electronic component, and belongs to the field of electronic component packaging. The defoaming packaging process of the electronic component comprises the following steps: pouring an epoxy resin layer for several times, and laying a layer of internal breathing balls on the electronic component during the first pouring; through heating treatment, expanding the internal breathing movable ball; performing rapid cooling treatment, so the internal breathing movable ball is restored to the original shape; sequentially and repeatedly performing heating and rapid cooling, so the internal breathing movable ball continuously repeats the expansion-recovery process, and the breathing state is presented. Therefore, the epoxy resin is vibrated from the inside, and the situation that air is introduced due to external stirring or external force application is effectively avoided; meanwhile, internal gaps during epoxy resin pouring can be effectively eliminated, it is effectively guaranteed that the first epoxy resin layer on the electronic element is not prone to cracking in the using process; compared with the prior art, the electronic element is better protected, and packaging is completed by pouring the second epoxy resin layer later.

Owner:深圳市智楠科技有限公司

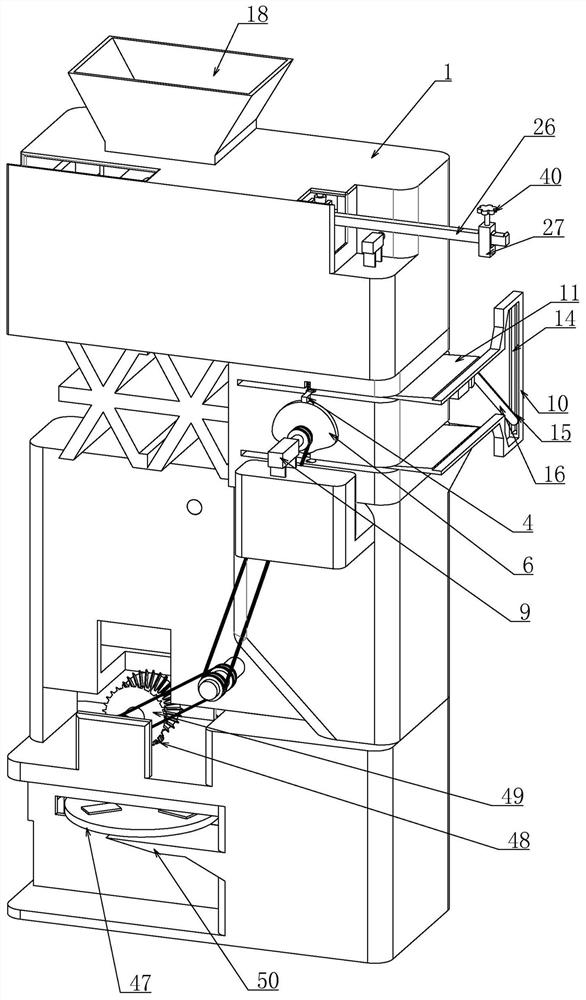

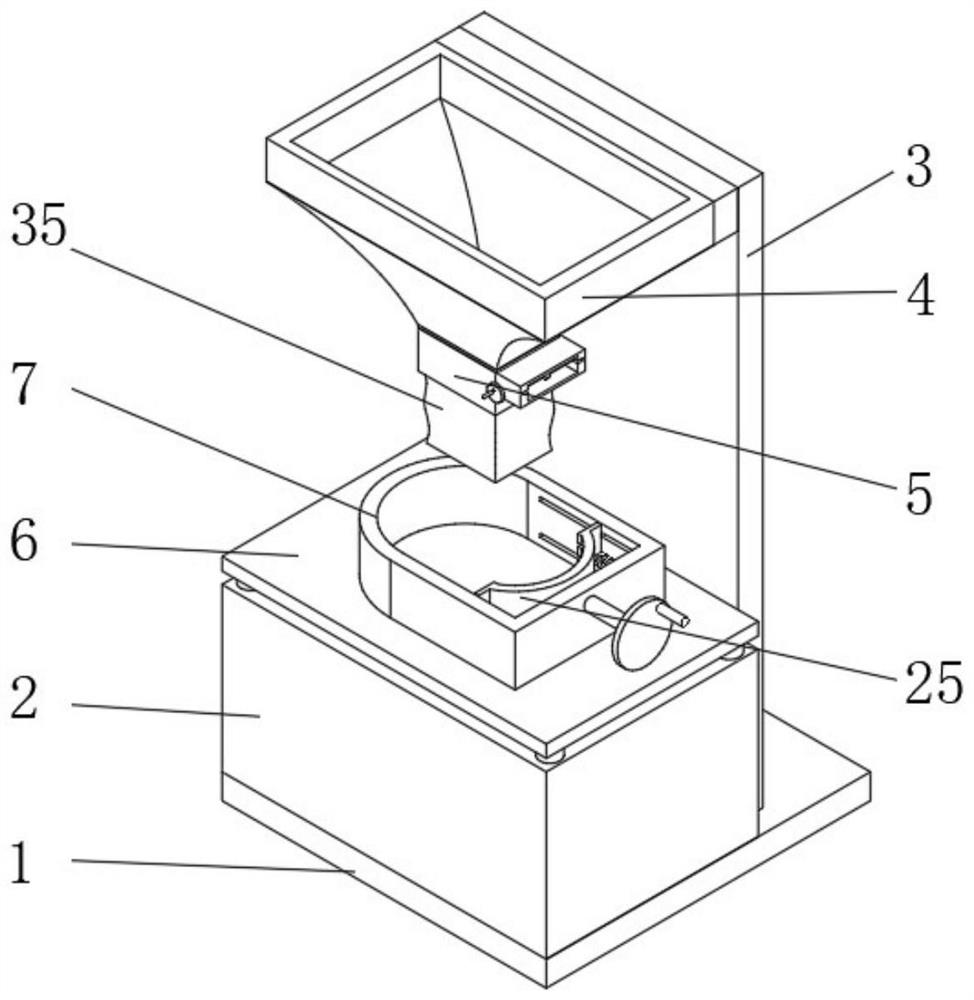

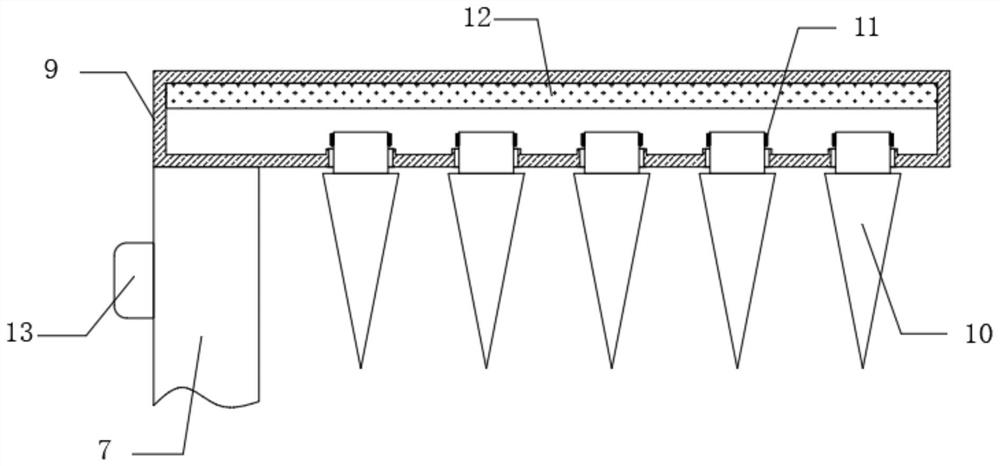

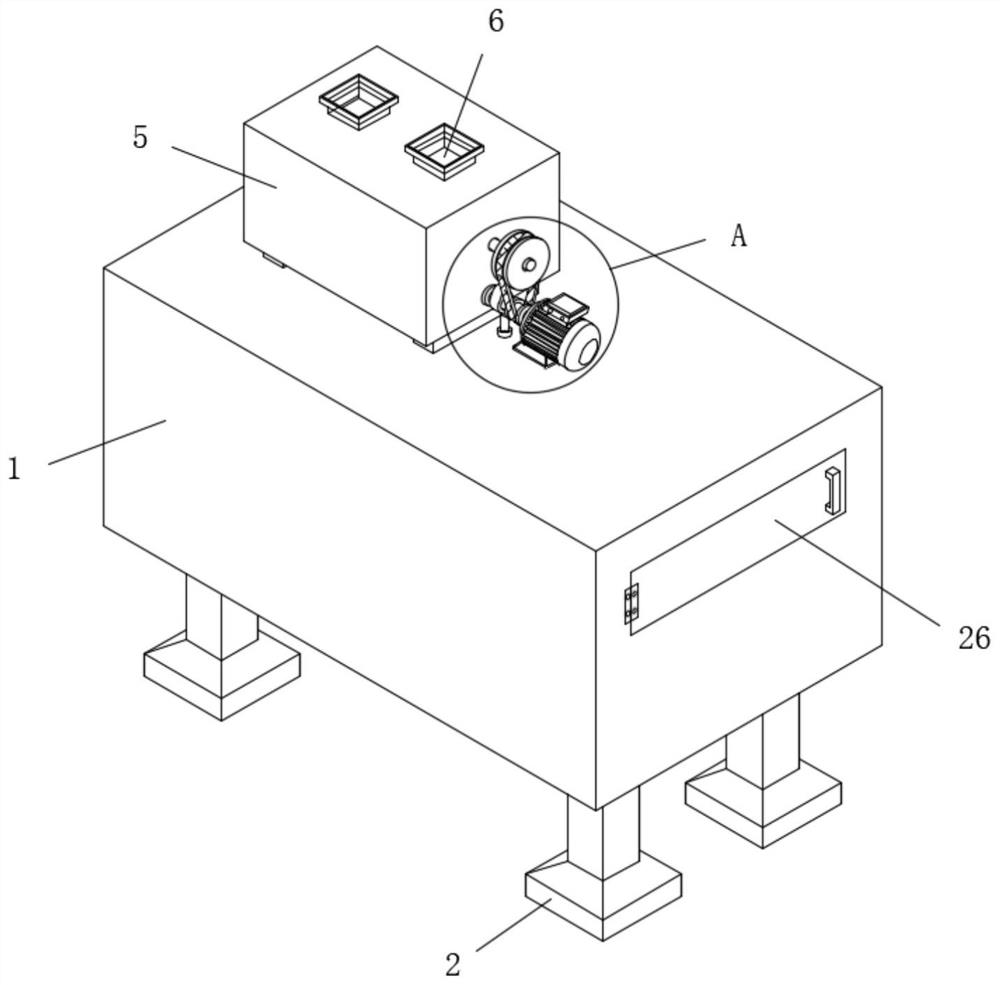

Filling device for fireproof plugging material

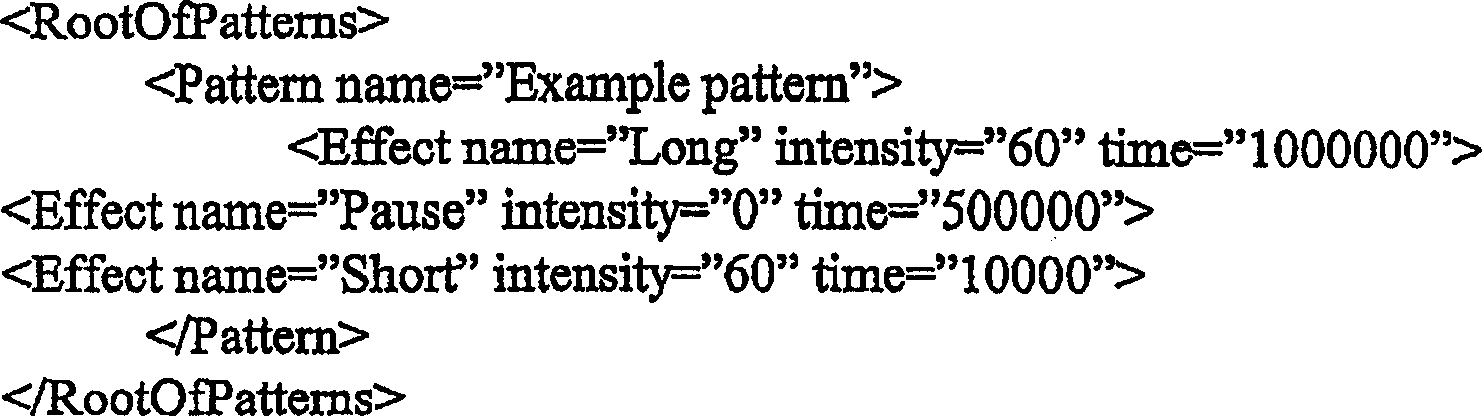

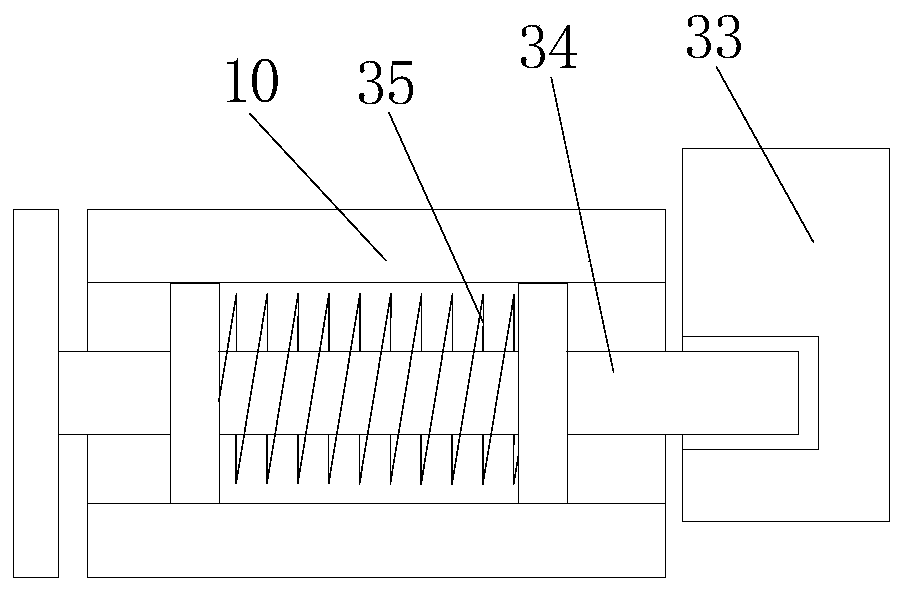

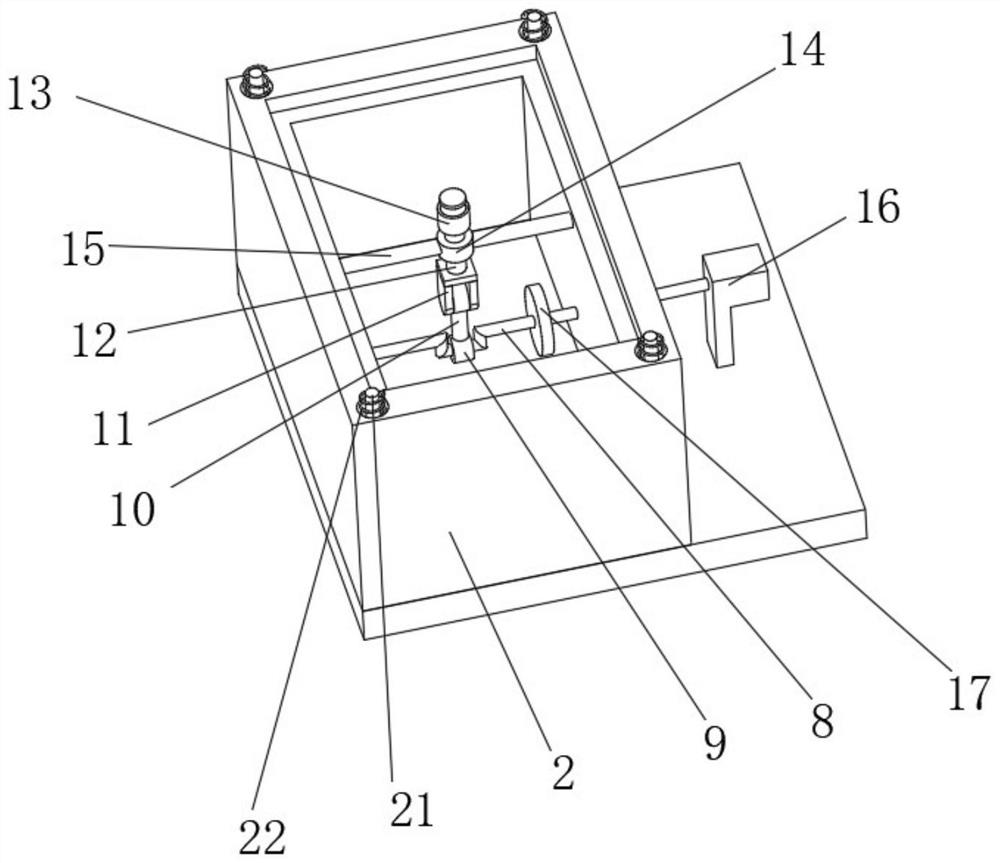

InactiveCN112572852APromote enrichmentRealize the vibration effectLarge containersSolid materialEngineeringCrankshaft

The invention provides a filling device for a fireproof plugging material, and relates to the field of fireproof plugging materials. The filling device comprises a base, wherein the top end of the base is fixedly connected with a power box body, one side of the power box body is fixedly connected with a side plate, the bottom end of the side plate is fixedly connected with the top end of the base,the top of the front surface of the side plate is fixedly connected with a discharging hopper, a connecting pipe is fixedly connected to the bottom end of the discharging hopper, a vibration plate isarranged at the top end of the power box body, a clamp base is fixedly connected to the top end of the vibration plate, a crankshaft is rotatably connected to the inner wall of the power box body, asleeve rotatably sleeves the middle of the crankshaft, a first connecting rod is fixedly connected to the outer side of the sleeve, and a movable base is hinged to the top end of the first connectingrod. Through the design of the vibration plate, a top cap collides with the vibration plate repeatedly to enable the vibration plate to move up and down repeatedly, so that the vibration effect is achieved, the filling fullness of fireproof plugging material in a tank body is improved, the situation of a cavity is avoided, and more fireproof blocking materials can be contained in the tank body.

Owner:宋广生

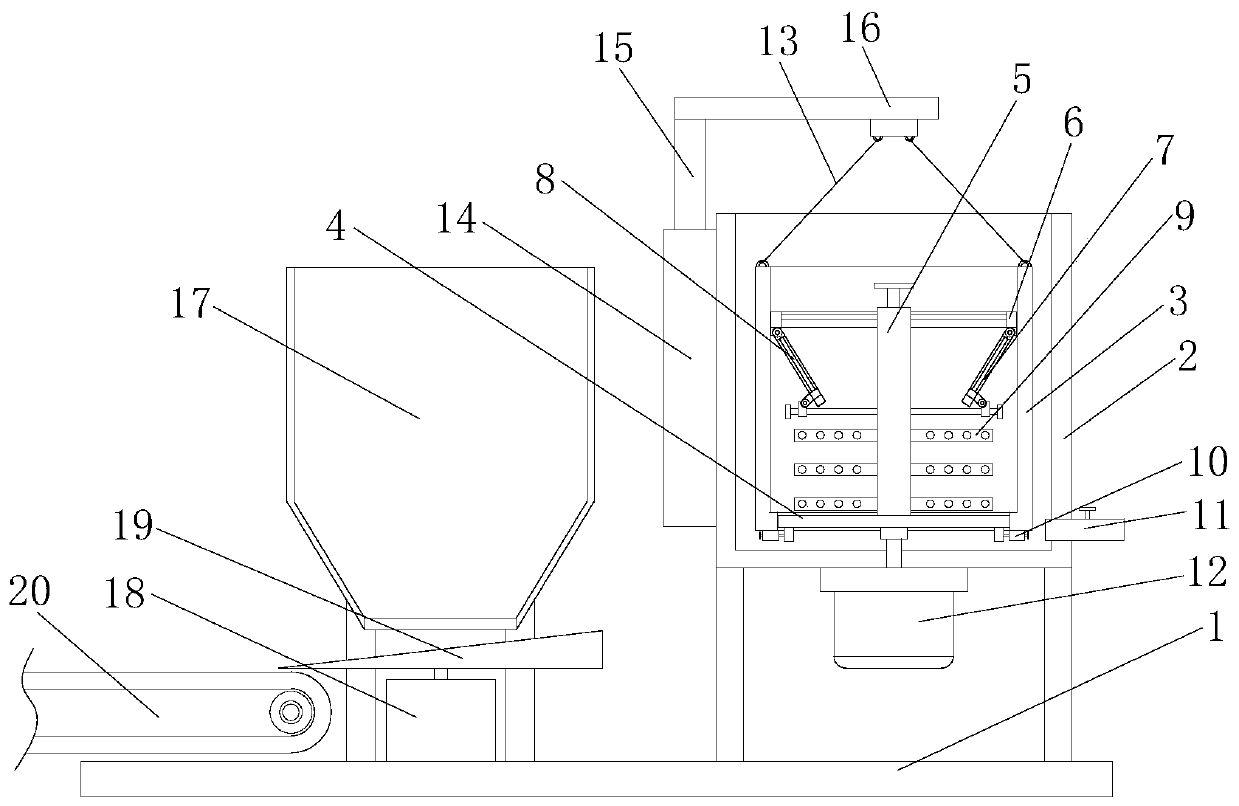

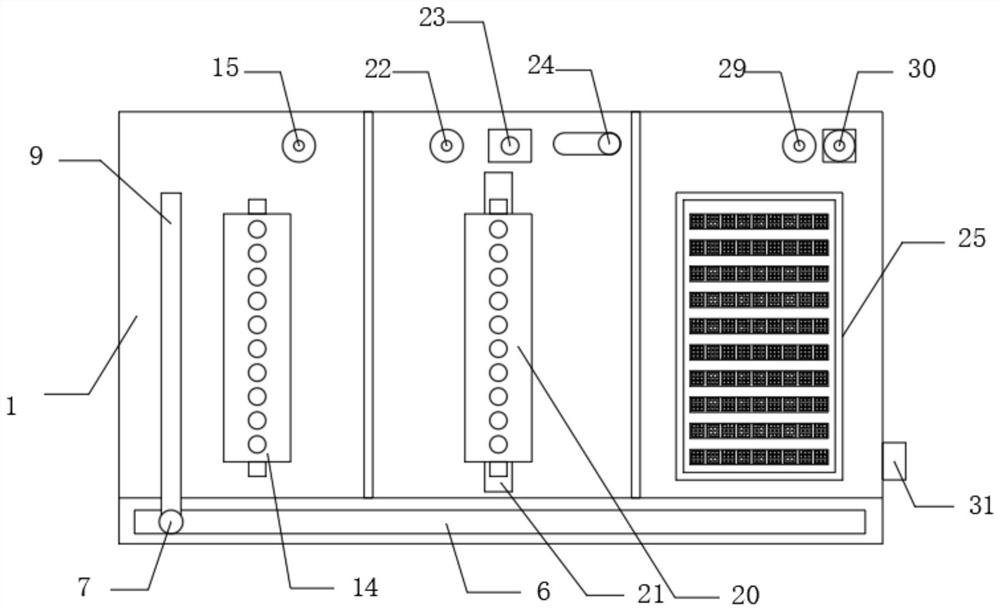

Cell counting apparatus and use method thereof

PendingCN111979112ARealize semi-automatic operationImprove work efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsPipetteElectric machinery

The invention discloses cell counting apparatus and a use method thereof, and belongs to the field of medical testing. The cell counting apparatus comprises a bottom plate, wherein the side wall of one side of the bottom plate is equipped with a power switch, the bottom plate is of a hollow structure, the inner wall of one side of the bottom plate is equipped with a first motor, an output end of the first motor is connected with a screw, the screw is in threaded connection with a nut, the side wall of the upper end of the nut is fixedly connected with an automatic sample-loading device arranged vertically, the side wall of the upper end of the bottom plate is provided with a slide way, the automatic sample-loading device penetrates the slide way, the upper end of the automatic sample-loading device is connected with a telescopic rod, the upper end of the telescopic rod is fixedly connected with a support rod arranged horizontally, the lower end of the support rod communicates with a plurality of sample-loading pipette heads, and the sample-loading pipette heads are connected with the automatic sample-loading device. The cell counting apparatus can realize semi-automatic operation,can manipulate specimens in batches to improve work efficiency, and at the same time can reduce a manual error caused by human factors in the aspects of sample-loading and cell-filling counting.

Owner:郑州金域临床检验中心有限公司

Solid-liquid sewage separation treatment device

InactiveCN112138455ARealize the vibration effectEasy to separateMoving filtering element filtersSewageSewage treatment

The invention discloses a solid-liquid sewage separation treatment device, and relates to the technical field of sewage treatment; the solid-liquid sewage separation treatment device comprises a separation box, a control switch is fixedly installed on the left side of the upper surface of the separation box, a water inlet pipe is fixedly connected to the upper end of the left side wall of the separation box, and first T-shaped sliding grooves are formed in the left and right sides of the front and rear side walls of the separation box. Through mutual cooperation of an I-shaped sliding block I,a spring, a movable plate, an I-shaped sliding block II, a threaded rod, a threaded sleeve, a supporting plate, a sliding rod and an arc-shaped plate, the arc-shaped plate can be driven by a motor torotate clockwise, and the arc-shaped plate drives the supporting plate to slide on the sliding rods on the two sides during rotation, so that the threaded rod in threaded connection with the threadedsleeve is driven to move up and down, and thus, the threaded rod drives sleeving positions of opposite ends of the movable plates on two sides to move upwards through connecting rod; and when the arc-shaped plate is not in lap joint with the supporting plate, the second I-shaped sliding block returns to the lower end again through the elastic force of the spring, the vibration effect during solid-liquid separation is achieved, and the separation effect is improved.

Owner:张家财

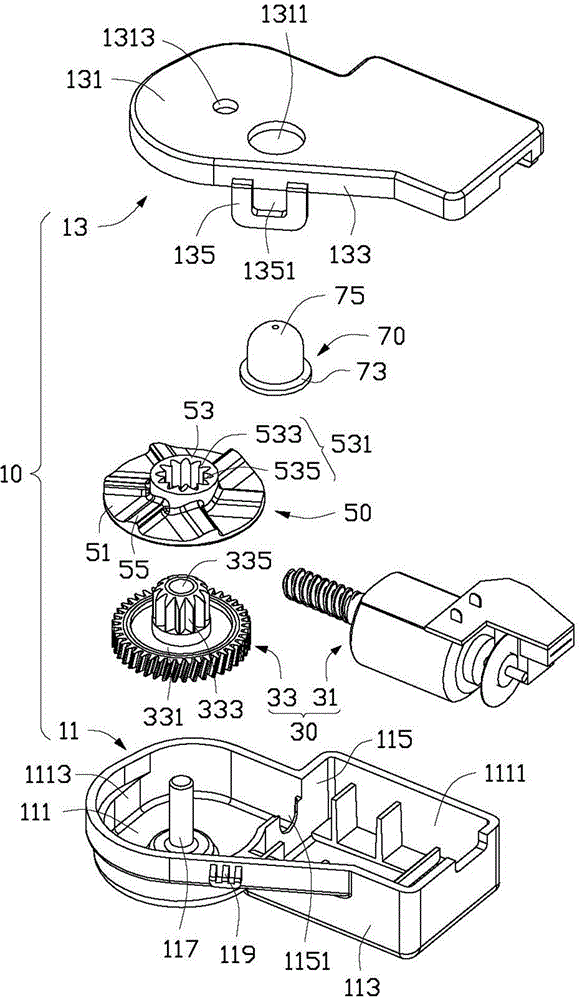

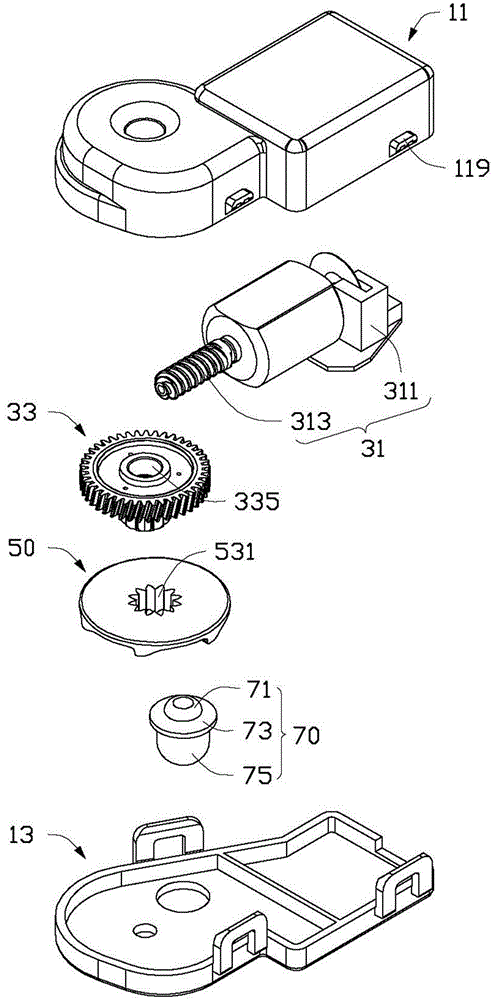

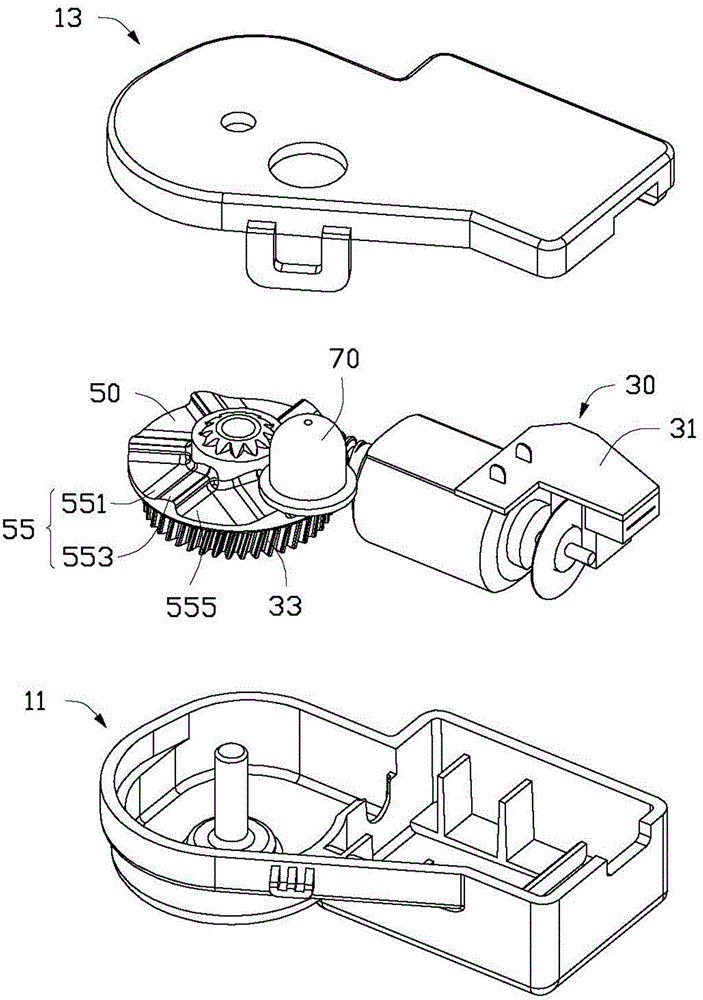

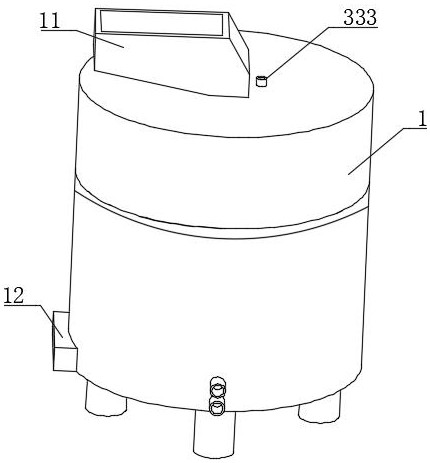

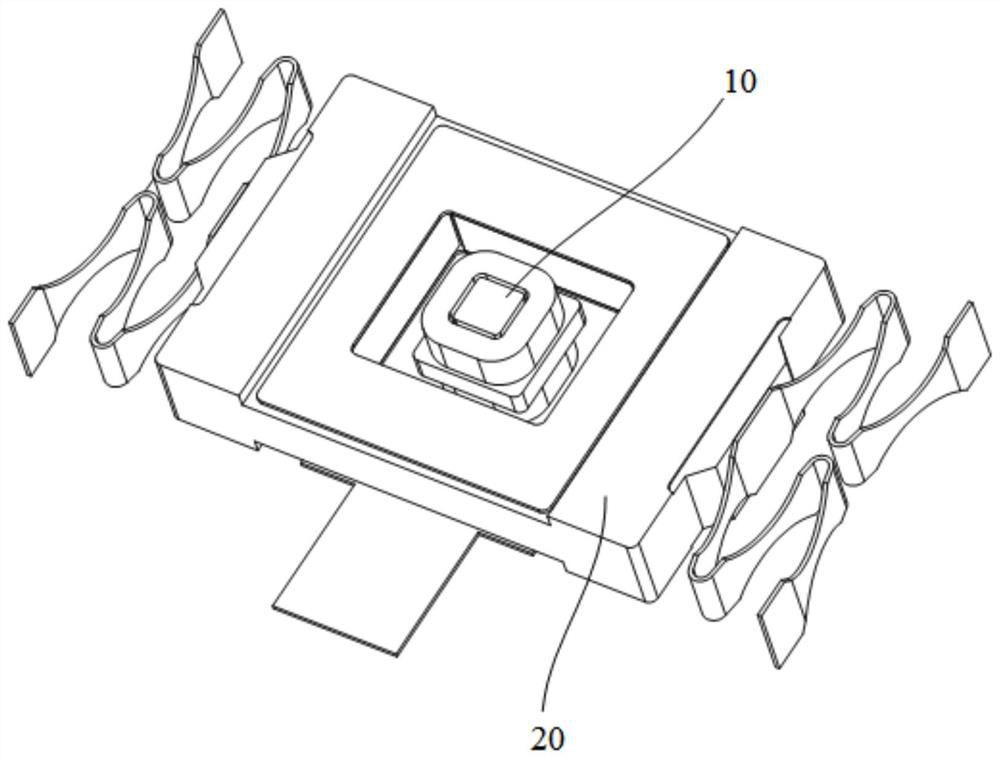

Vibration device

InactiveCN104415903ARealize moving up and downStrong vibrationMechanical vibrations separationEngineeringMechanical engineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Agricultural corn seed screening device

ActiveCN114210568ARealize the vibration effectAffect qualitySievingGas current separationAgricultural scienceHusk

The invention is suitable for the field of screening devices, and provides an agricultural corn seed screening device which comprises a shell, a vibration screening mechanism, an air screening mechanism and a drying mechanism, a feeding port is formed in the upper end of the shell, and a discharging port is formed in one side of the lower end of the shell. The vibrating screen mechanism comprises a vibrating screen movably installed on the inner wall of the shell and a vibrating motor fixedly installed on the inner wall of the shell. The output end of the vibration motor is in contact with the vibration screen; the air screening mechanism comprises a support arranged at the position of a through hole in the middle of the vibrating screen, a plurality of elastic films installed on the support, an elastic driving mechanism located below the support and an air nozzle located above the support. The output end of the elastic driving mechanism is connected with the elastic film; therefore, the vibrating screen and the air screen can be combined, the occupied space of the device is small, and the screening effect is good; meanwhile, the drying mechanism is arranged in the device and can intermittently dry the materials, and the situation that the seed quality is affected due to serious one-time water loss of the seeds is avoided.

Owner:WEIFANG UNIV OF SCI & TECH

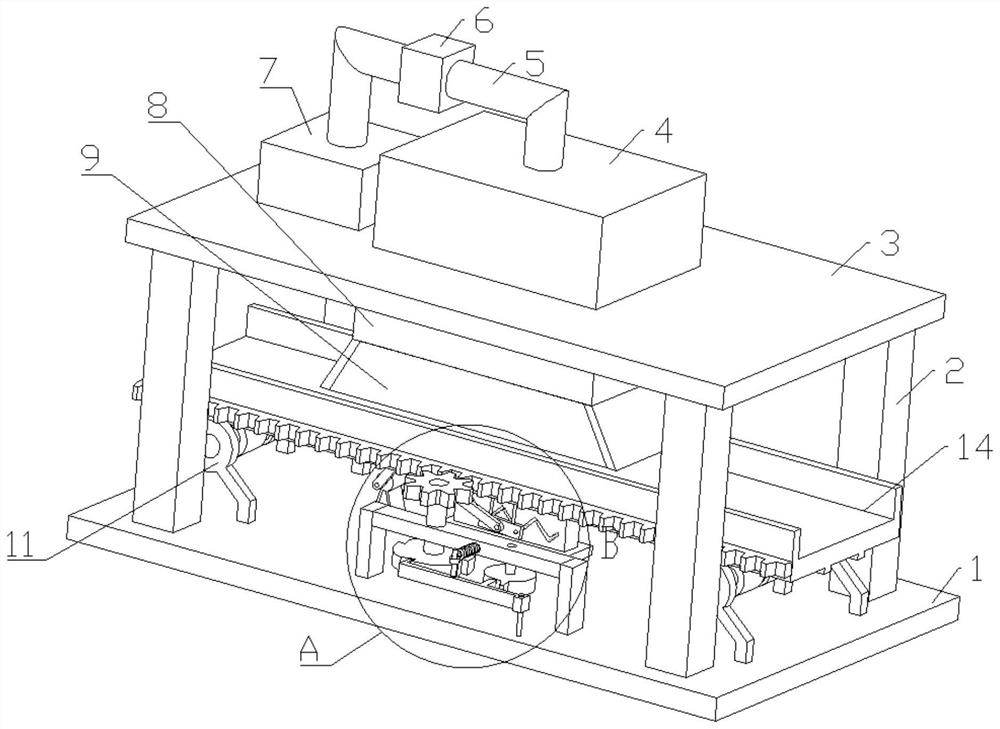

Novel sand mold casting equipment and casting method thereof

PendingCN113305271AAchieving Stirring and MixingEasy to fill sandMoulding toolsMould handling/dressing devicesElectric machineryProcess engineering

The invention belongs to the technical field of sand mold casting devices, especially relates to novel sand mold casting equipment and a casting method thereof, and aims at solving the problems that in the prior art, a large amount of manual labor and production time cost are consumed, the working efficiency is low, the casting mold precision is poor, moroever, a corresponding proportioning function is lacked, so that sand filling is troublesome, and meanwhile, excessive molding sand overflowing during sand filling is troublesome to recycle, so that the utilization rate of waste sand is reduced. The following scheme is disclosed: the novel sand mold casting equipment comprises a casting sand box, wherein supporting legs are arranged at the four corners of the outer wall of the bottom of the casting sand box, a sand discharging pipe is arranged at the bottom of the casting sand box, and a sand discharging valve is installed on the sand discharging pipe. According to the invention, by starting a stirring motor, the function of stirring a proportioning box can be realized, so that proportioning is facilitated, and during sand filling, a sieve screen can be driven to move back and forth at the same time, and a vibration effect is realized, so that refining for molding sand is facilitated, a high automation degree is achieved, the manual operation intensity is reduced, and the casting precision is improved.

Owner:毛飞飞

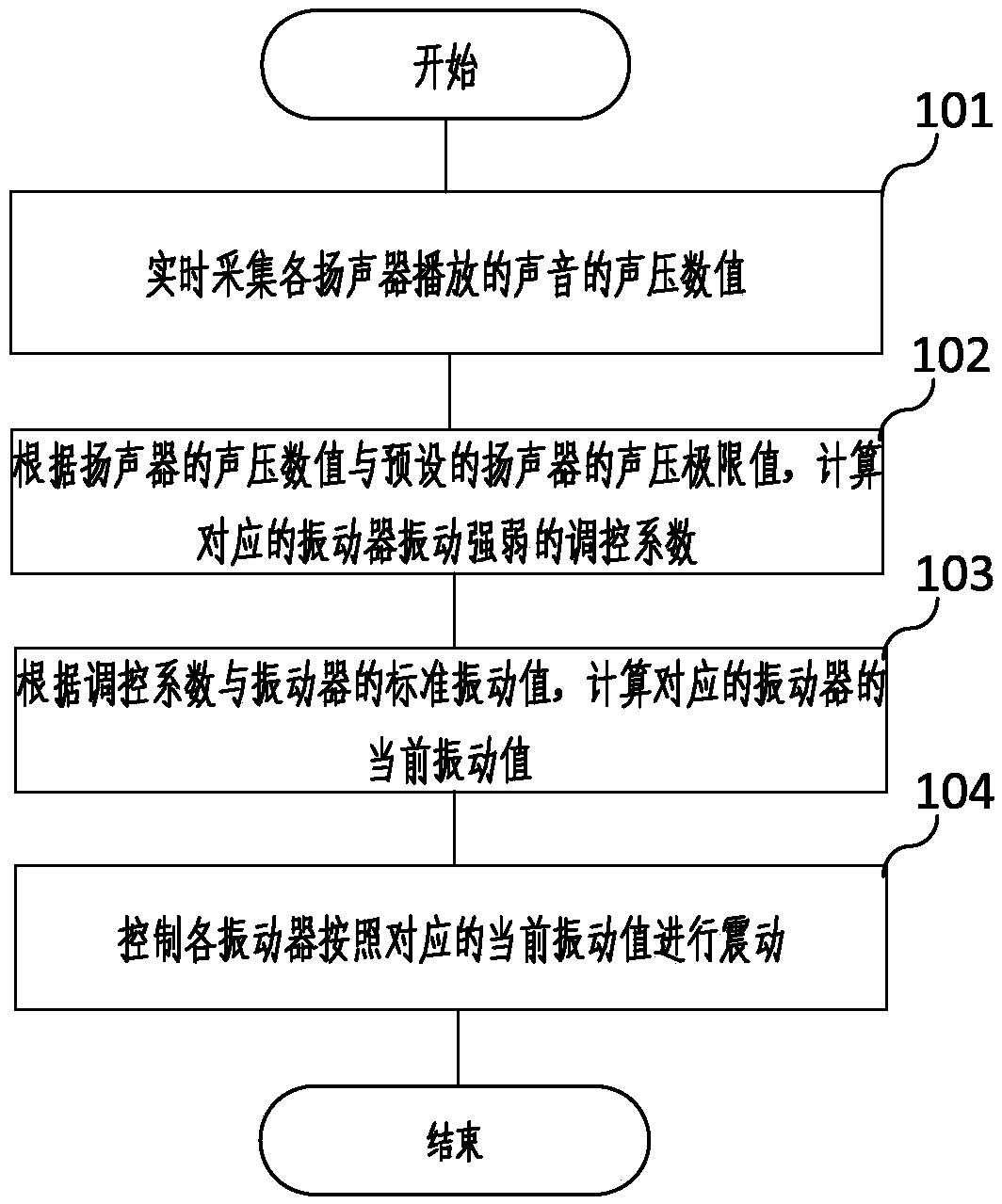

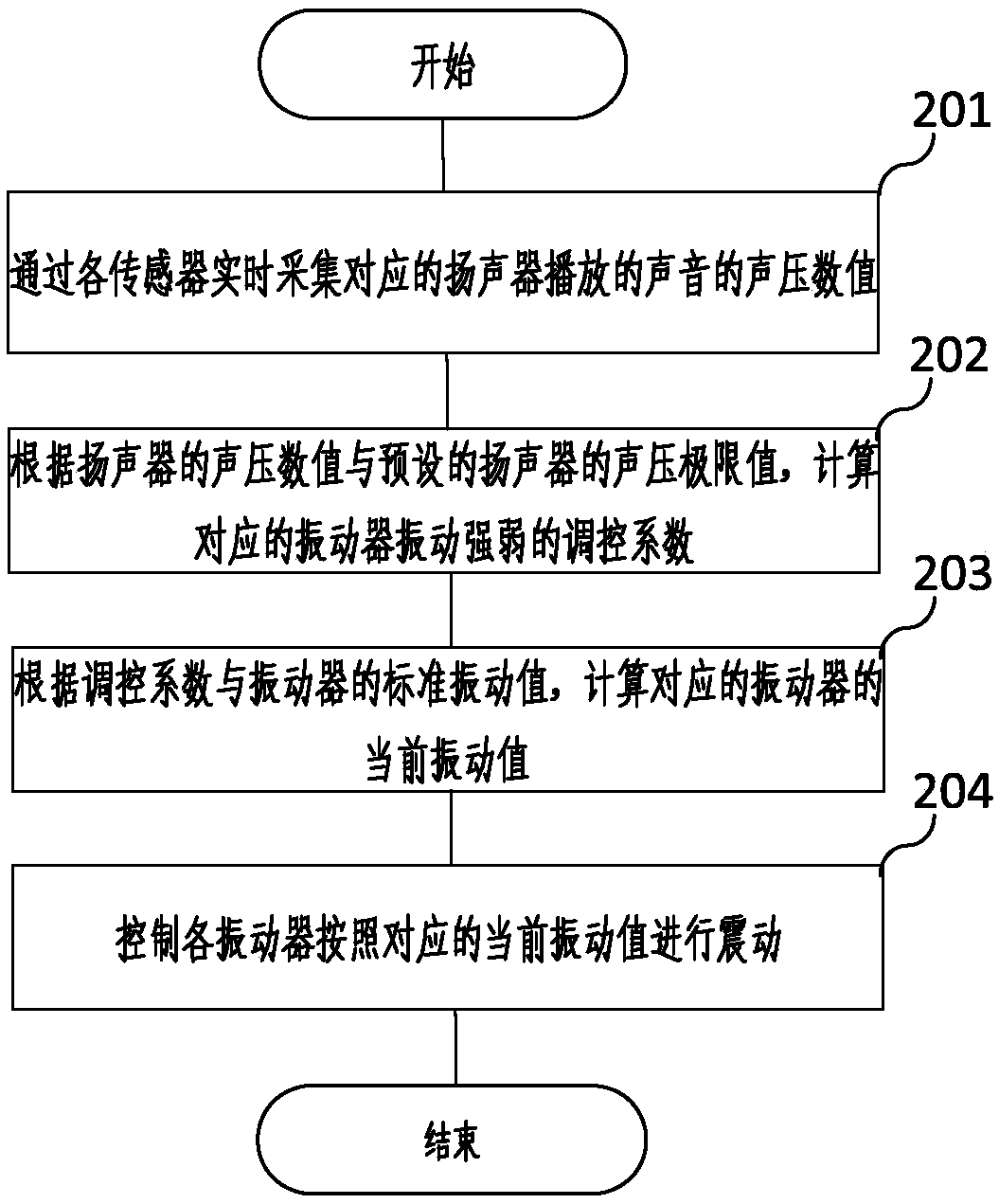

Terminal and regulation and control method for vibrators thereof

ActiveCN109246554ARealize the vibration effectLoudspeakersBone conduction transducer hearing devicesVibration amplitudeComputer terminal

The embodiment of the invention relates to the field of the electronic technology, and discloses a terminal and a regulation and control method for vibrators thereof. In the embodiment of the invention, the terminal comprises N loudspeakers and N vibrators, wherein N is a natural number greater than one, and the loudspeakers are corresponding to the vibrators in a one-to-one corresponding manner.The method comprises the steps: collecting a sound pressure value of sound played by each of the speakers in real time; calculating a regulation and control coefficient of the vibration amplitude of the corresponding vibrator according to the sound pressure value of the corresponding loudspeaker and a preset sound pressure limit value of the loudspeaker; calculating a current vibration value of the corresponding vibrator according to the control coefficient and a standard vibration value of the vibrator; and controlling each of the vibrators to vibrate according to the corresponding current vibration value. The embodiment of the invention further provides the terminal. The embodiment of the invention implements a 3D vibration effect and provides a 3D tactile experience for a user.

Owner:AAC TECH PTE LTD

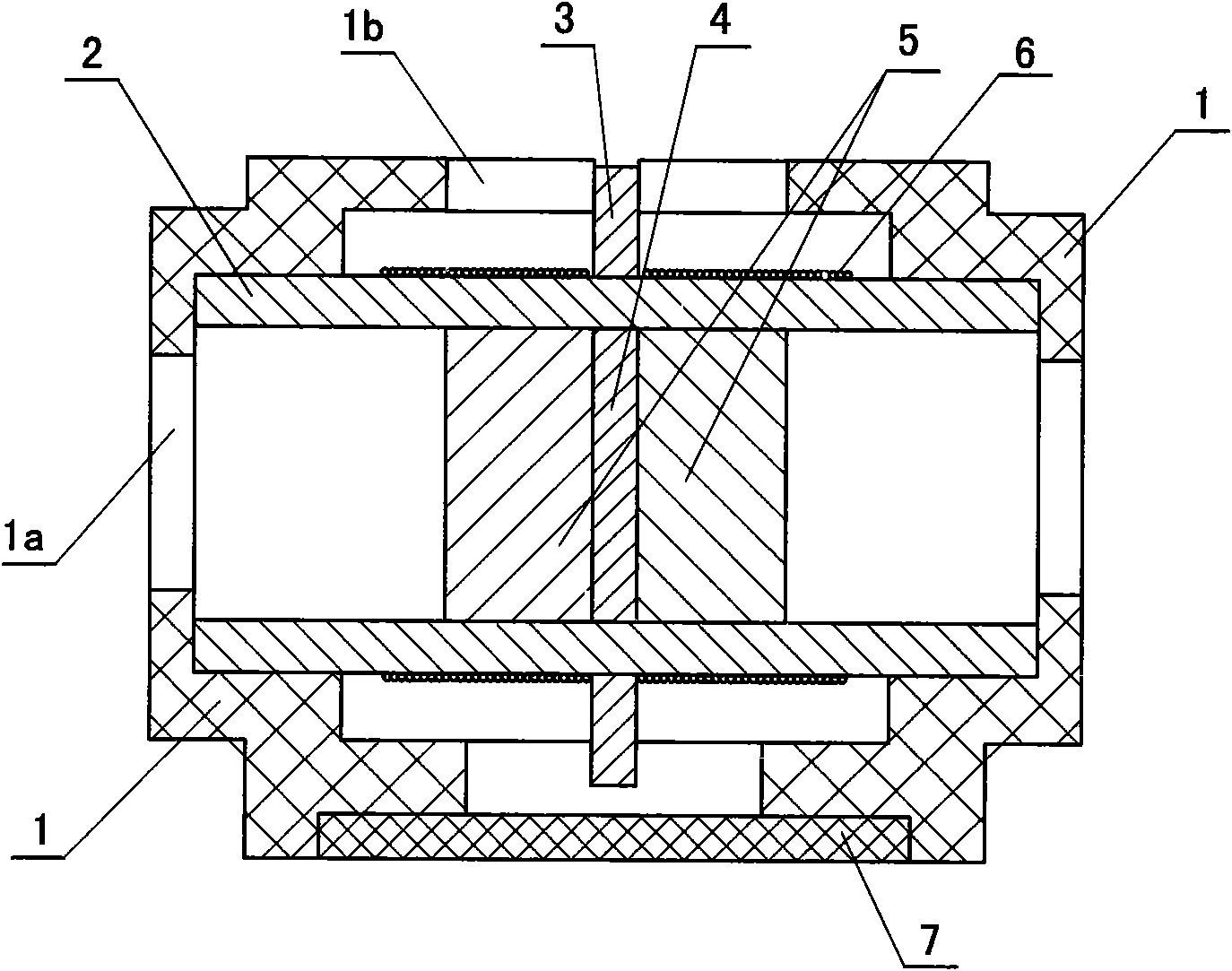

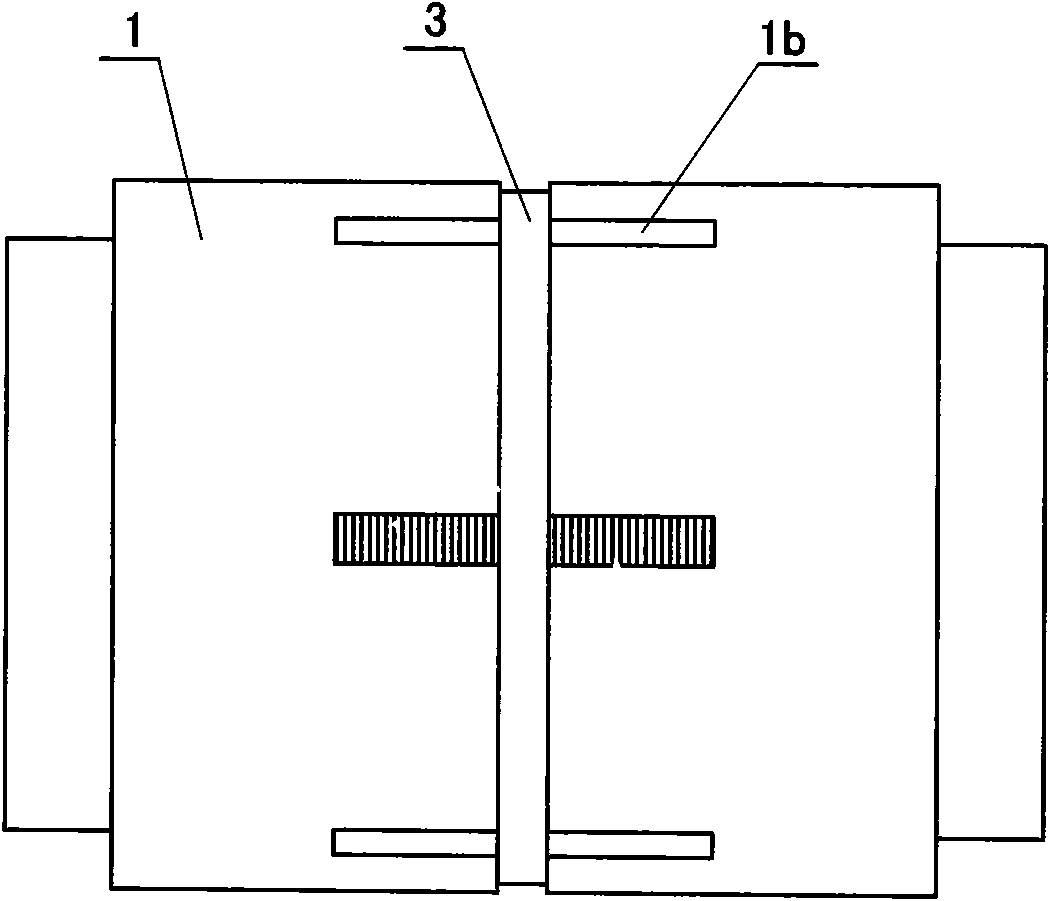

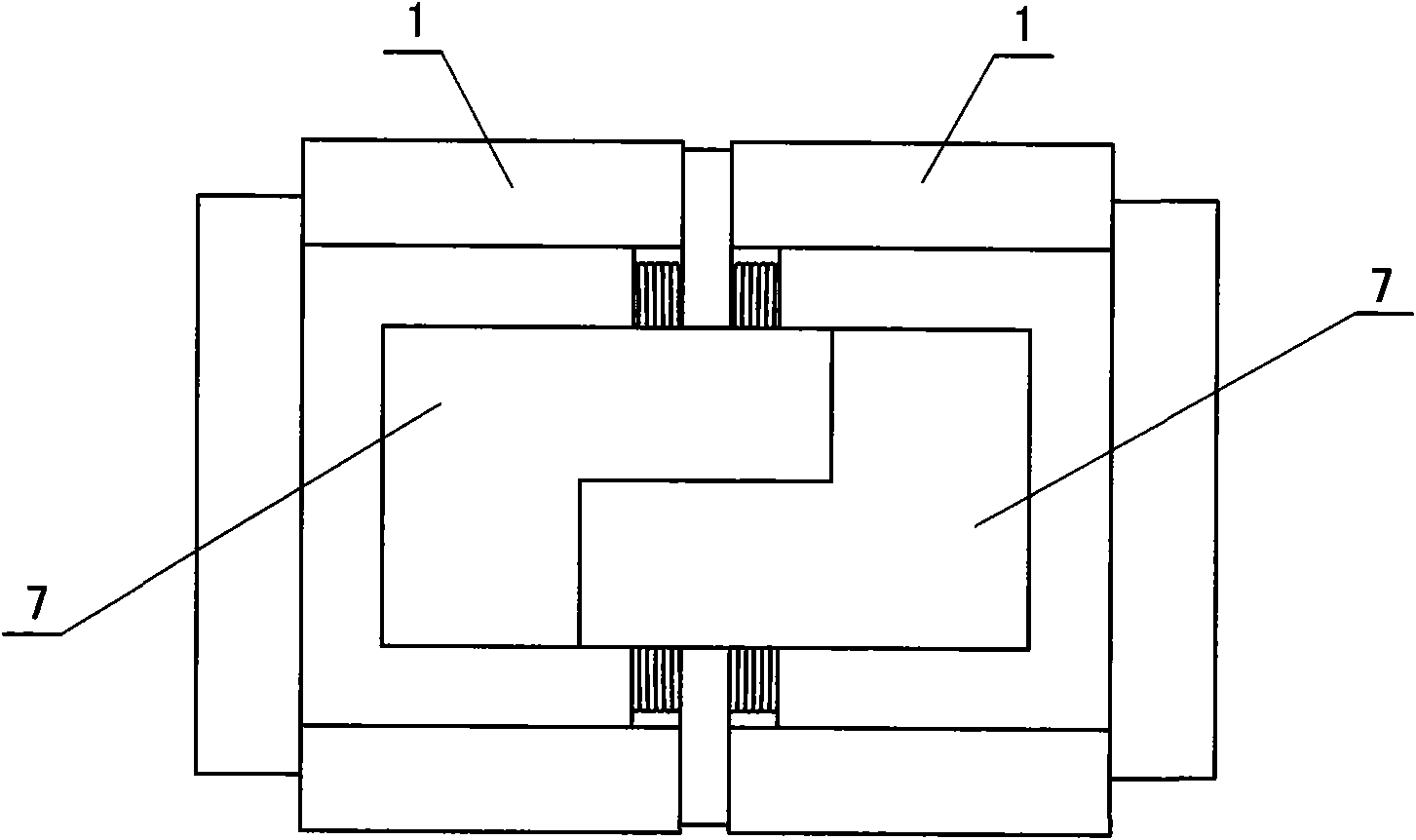

Vibrator

The invention relates to a vibrator which comprises permanent magnets, a coil and a hollow cylinder body, wherein, the permanent magnets are one pair, the two permanent magnets are respectively fixedon two sides of a magnetic conductive sheet, the ends with the same polarity of the two permanent magnets are opposite, the two permanent magnets and the magnetic conductive sheet are positioned in acavity of the cylinder body, a magnetic conductive ring is sheathed at the middle part of the surface of the cylinder body, the coil is divided into two parts and wound on the surface of the cylinderbody which is positioned on two sides of the magnetic conductive ring, a housing is sheathed outside the cylinder body, and two ends of the coil are introduced out of the housing. The vibrator has theadvantages of reasonable structure, sensitive vibration, good vibration effect and long service life, and can be widely applied on products like massage devices, sex toys, mobile phones and the like.

Owner:夏怀远

Heavy metal contaminated soil remediation device

ActiveCN111069257BRinse evenlyRealize rinse operationContaminated soil reclamationSoil scienceAtomizer nozzle

The invention discloses a heavy metal contaminated soil restoration device, which belongs to the technical field of soil restoration and includes a soil filtering mechanism, a screw feeder, a restoration box, a soil air-drying mechanism, a crushing mechanism, and a soil-turning and washing mechanism. There is a filter plate installed horizontally inside, and there are screening holes on the filter plate. The soil turning and washing mechanism includes a driving motor, a soil turning component, a reciprocating vibration component, a rotating shaft and two spray pipes. Atomizing nozzles are provided at the liquid outlets, a guide slideway is provided at the bottom of the repair box, and a closing plate is provided on the right side of the guide slideway. The invention can realize the washing operation of the soil through the soil turning and washing mechanism, and the soil can be turned over so that the soil can be evenly washed, and the crushing operation of the soil can be realized under the action of the crushing mechanism, so that the soil can be crushed Broken into smaller particles, so that the soil and reactants fully react.

Owner:江苏环保产业技术研究院股份公司

Dividing and spiral-screening cart

InactiveCN107297330AAvoid cloggingImprove filtering effectSievingGas current separationCause blockageScreening effect

The invention discloses a flow-splitting screw sand trolley, which comprises a feeding device, a flow pipe, a spiral sand screening device, a drying device, a coarse sand collection and screening device, a vibration device, a heterosexual fixed support platform, a casing and universal wheels; The device of the present invention processes the sand in the feeding device in batches through the setting of three shunt pipes at the bottom of the feeding device, which has the effect of accelerating the screening rate; The movement route of the sand increases the screening effect of the sand; through the setting of the second screen at the bottom of the coarse sand collection and screening device, it has the function of re-screening; through the setting of the drying device, it has the function of drying the moisture in the sand. The function of preventing sand from sticking to the screen and causing blockage; the setting of the internal vibration device of the fixed support platform realizes the function of vibration of the upper device and prevents the blockage of the feeding device, shunt pipe and spiral sand screening device .

Owner:RUIAN JIRUI INFORMATION TECH CO LTD

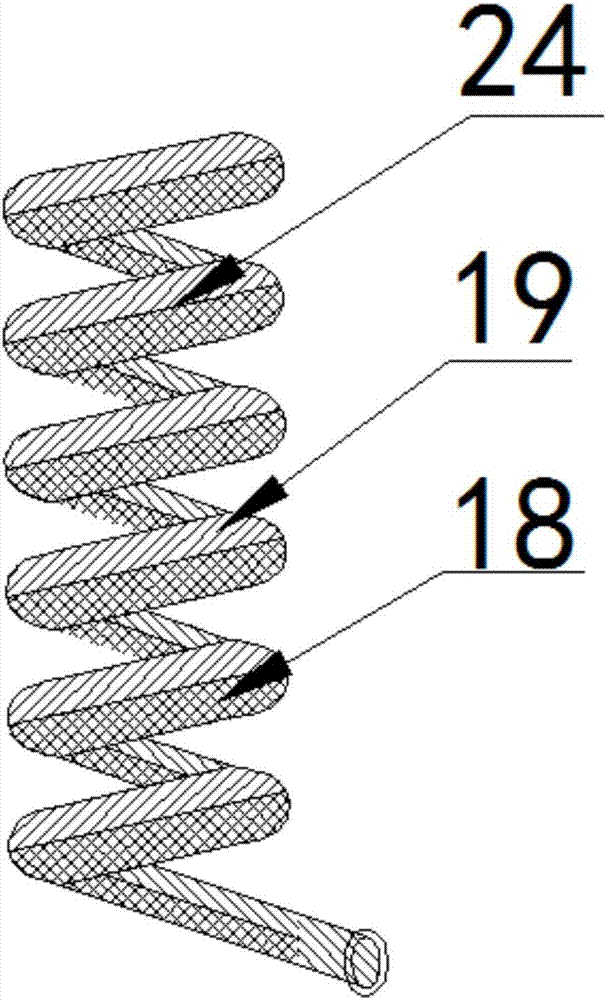

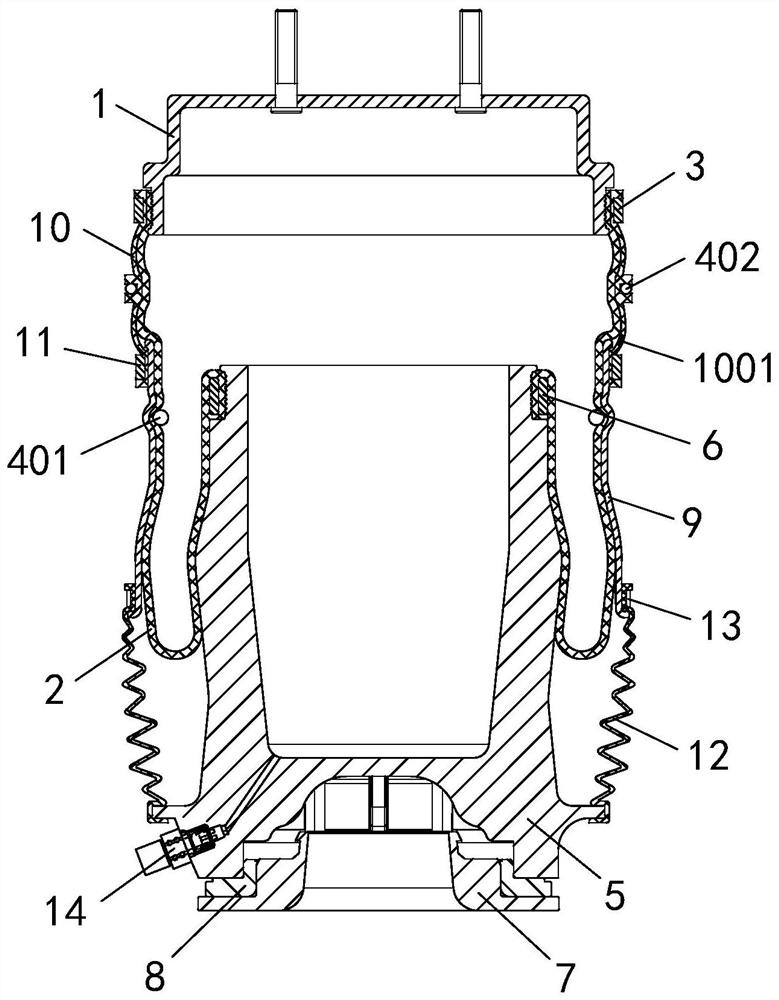

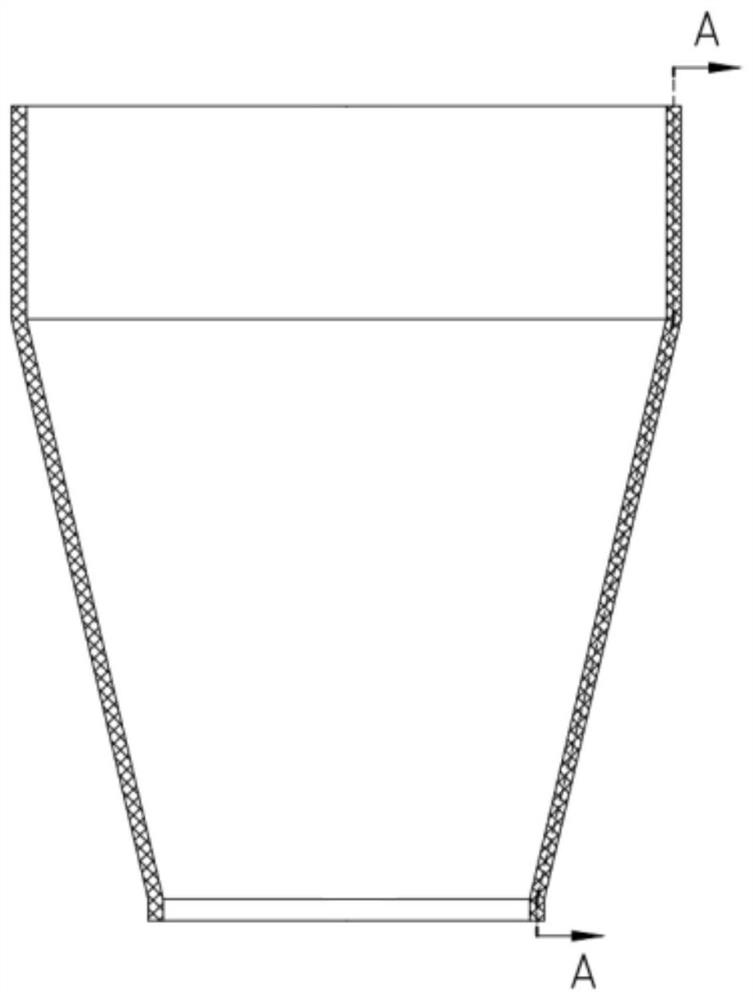

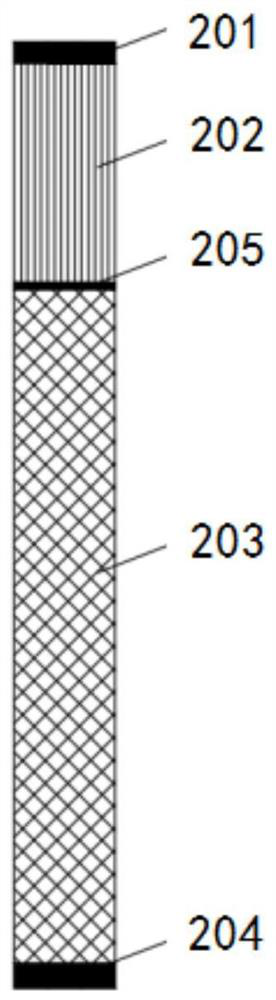

Air spring and multi-connecting-rod independent suspension

The invention relates to an air spring and a multi-connecting-rod independent suspension. The air spring comprises an upper cover; an airbag, arranged below the upper cover, and the top end of the airbag being connected with the upper cover through a first snap ring; a first restraint ring, arranged on the inner wall of the airbag and dividing the airbag into two sections, at least two layers of smooth cord threads being adopted for the exposed part of the upper-section airbag, and crossed cord threads being adopted for the other parts of the airbag; a piston, arranged below the airbag and forms a sealed container with the upper cover and the airbag, and the outer edge of the top end of the piston being connected with the airbag through a second snap ring; a base, arranged below the piston, and the upper end being connected with the piston; a bearing, arranged between the base and the piston and connected with the upper end of the base; and a restraining cover, arranged on the outer wall of the lower-section air bag and connected with the first restraining ring and the lower-section air bag into a whole. The air spring solves the problem that a traditional air spring cannot achieve torsion and deflection, and is small in installation space, low in cost and long in service life.

Owner:QINGDAO BORUI ZHIYUAN ANTI-VIBRATION TECH CO LTD

Porous metal heat treatment device

ActiveCN110699534AHeating evenlyHeating evenly and comprehensivelyCombination devicesFurnace typesExhaust fumesChain conveyor

The invention discloses a porous metal heat treatment device, and belongs to the technical field of heat treatment devices. The porous metal heat treatment device comprises a furnace body, a waste gaspurification mechanism, a reduction hydrogen convening mechanism and a uniform heating mechanism, wherein exhaust chimney communicating with the interior of the furnace body is arranged at the top ofthe furnace body, electric heating wires are arranged on the inner walls of the top end and the bottom end of the furnace body, a plate chain conveyor belt is arranged in the furnace body, the uniform heating mechanism comprises two turnover components which are identical in structure and symmetrically arranged, each turnover component comprises a lifting component, a pressing component and an overturning component, and the pressing component is arranged on the side wall of the overturning component. The device has the beneficial effects that overturning operation of a porous metal product can be achieved through the uniform heating mechanism, so that the porous metal product can be comprehensively and uniformly heated, impurity particles in the waste gas can be filtered through the wastegas purification mechanism, and screen holes of the impurity filter screen can be prevented from being blocked by impurity particles.

Owner:XIAN UNIV OF SCI & TECH

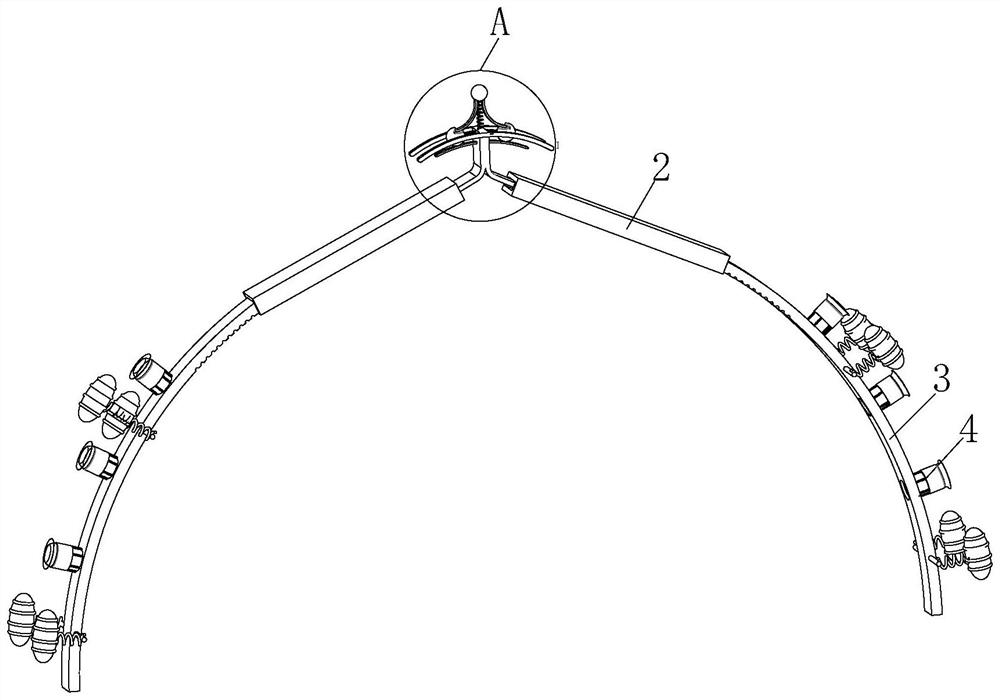

Agricultural greenhouse support

InactiveCN114271132AQuick fixImprove the greenhouse effectRoof coveringClimate change adaptationGreenhouseAgricultural engineering

The invention relates to the technical field of agriculture, and discloses an agricultural greenhouse support which comprises an elastic supporting rod and a rectangular sleeve, the lower end of the elastic supporting rod is divided into two parts, a special-shaped sliding groove penetrating through the two ends of the rectangular sleeve is formed in the rectangular sleeve, a branch at the lower end of the elastic supporting rod is slidably clamped in the special-shaped sliding groove, and an arc-shaped frame is arranged at the lower end of the rectangular sleeve. The upper end of the arc-shaped frame is arranged in the special-shaped sliding groove in a sleeved mode, and an adsorption assembly is arranged on the outer wall of the arc-shaped frame. According to the device, the interior of the fixing sleeve can be in a negative pressure state, a plastic film is adsorbed, the plastic film can be rapidly fixed, the plastic film does not need to be perforated and bound, the greenhouse effect in a greenhouse is better, snow can smoothly slide down along an inclined plane, icing and shielding are prevented, and the device is convenient to use. And the plastic film can be prevented from being scraped.

Owner:浙江极智农业开发有限公司

Waste plastic recycling equipment

InactiveCN109910202AModerate vibrationLess prone to noisePlastic recyclingMechanical material recoveryEngineeringMechanical engineering

The invention discloses waste plastic recycling equipment which comprises a machine shell, a drying device and a crushing device, wherein the drying device is arranged in the machine shell, and the crushing device is matched with the drying device. The drying device comprises an air outlet structure capable of providing hot air, a vibration structure for enabling plastic to be in full contact withhot air and a vibration driving structure matched with the vibration structure, wherein the vibration structure comprises an upper vibrating plate capable of moving back and forth, a lower vibratingplate capable of moving back and forth, and material blocking plates matched with the upper vibrating plate and the lower vibrating plate. The water content of the plastic is reduced through the arrangement of the drying device, so that bubbles or cracking of plastic products is avoided, the rate of finished products is improved, and the rejection cost is reduced; through the arrangement of the upper vibrating plate and the lower vibrating plate, the drying effect is better, and drying is more efficient.

Owner:浙江安尚电气有限公司

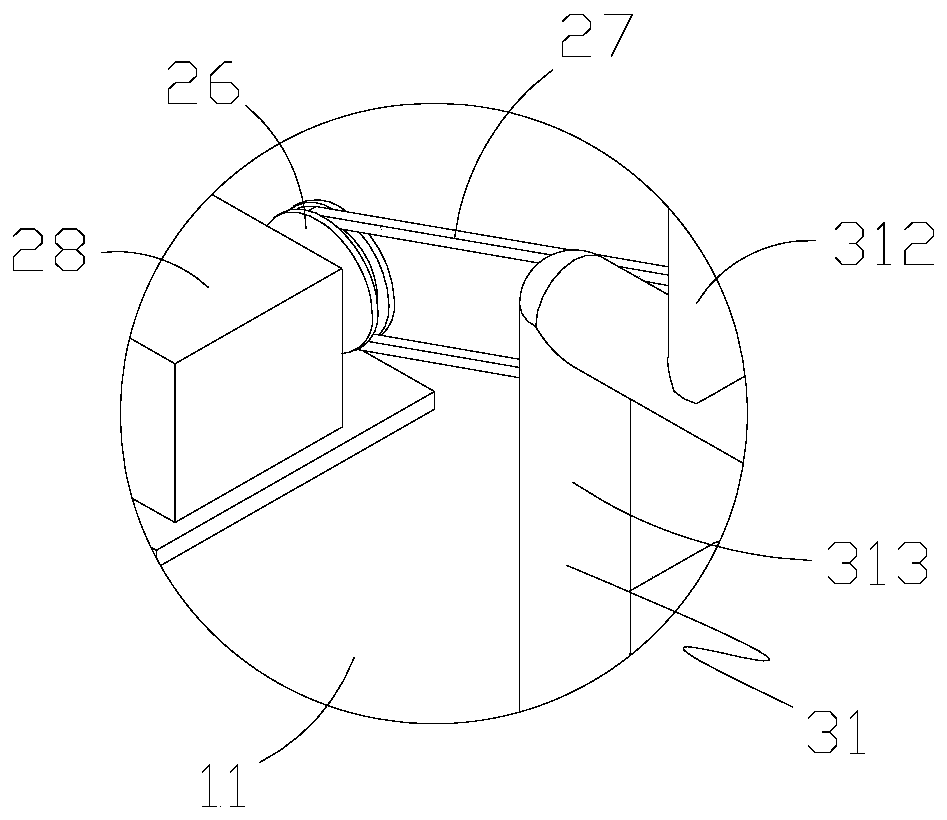

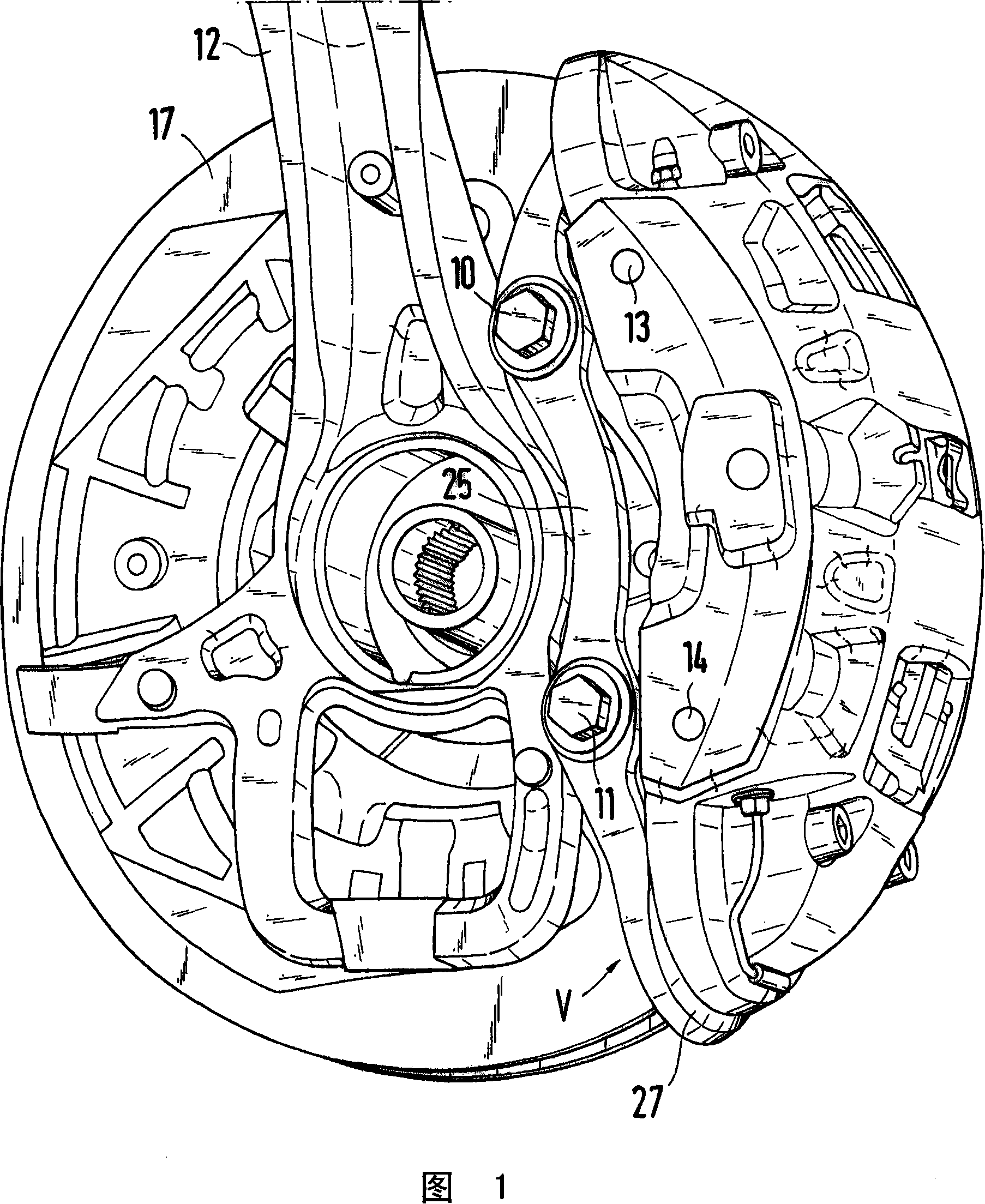

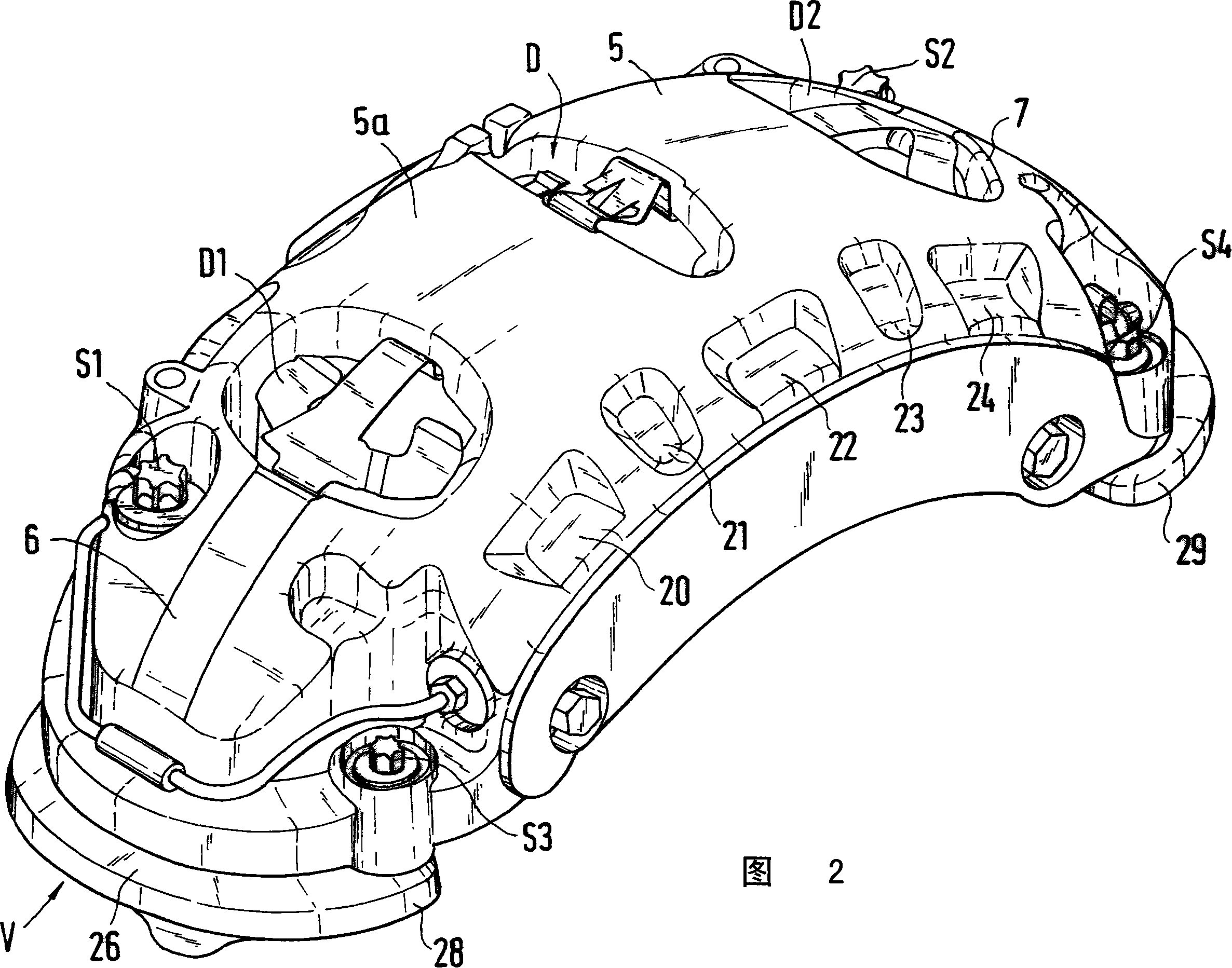

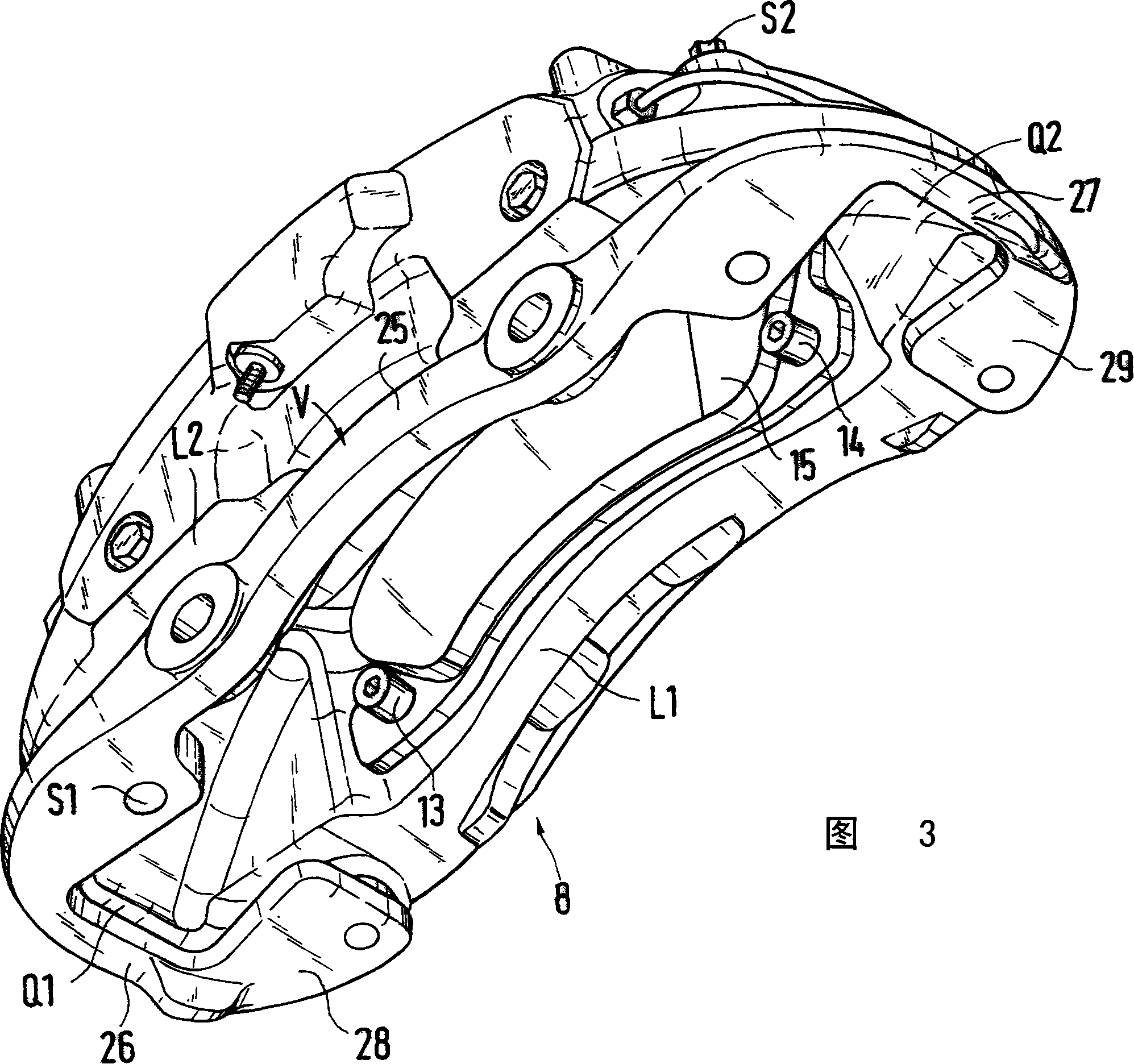

Disc brake calliper for a motor vehicle

InactiveCN101109419ASuppression of natural vibration formsSuppression of distortionBraking element arrangementsNoise/vibration controlCalipersBrake pad

In order to avoid oscillations and brake screeching associated with such oscillations, a brake caliper is provided with a reinforcing element. The reinforcing element is formed with a C-shaped profile element that is connected to the brake caliper on the underside of the housing of said brake caliper. The reinforcing element can also be configured in order to hold the brake pads and linings and therefore relieve the housing of the braking torque.

Owner:DR ING H C F PORSCHE AG

Operation assisting device for surgical operation

PendingCN112791215ARealize the operationAchieve disinfectionDrying gas arrangementsLavatory sanitorySurgical operationReciprocating motion

The invention relates to an assisting device, in particular to an operation assisting device for a surgical operation. The operation assisting device for the surgical operation integrates pushing, disinfection and sterilization. The operation assisting device for the surgical operation comprises: a base frame and a pushing mechanism, wherein the pushing mechanism is arranged on the upper side of the base frame; and a disinfection mechanism, which is arranged on the base frame. According to the invention, a second sliding rod and a first fixing block are driven to move back and forth in a reciprocating mode, then a containing tray and a first sliding rod are driven to move back and forth in a reciprocating mode, so the operation of pushing instruments is achieved; a disinfectant is injected into a liquid guide pipe and then sprayed onto the instruments from an atomizing spray head, so a disinfection effect is achieved; and a bevel gear set and a second rotating shaft rotate, then a fan rotates, under the action of a heating rod, hot air is blown out by the fan, the blow-drying speed of the instruments is increased, and the air-drying effect of the instruments is achieved.

Owner:章金源

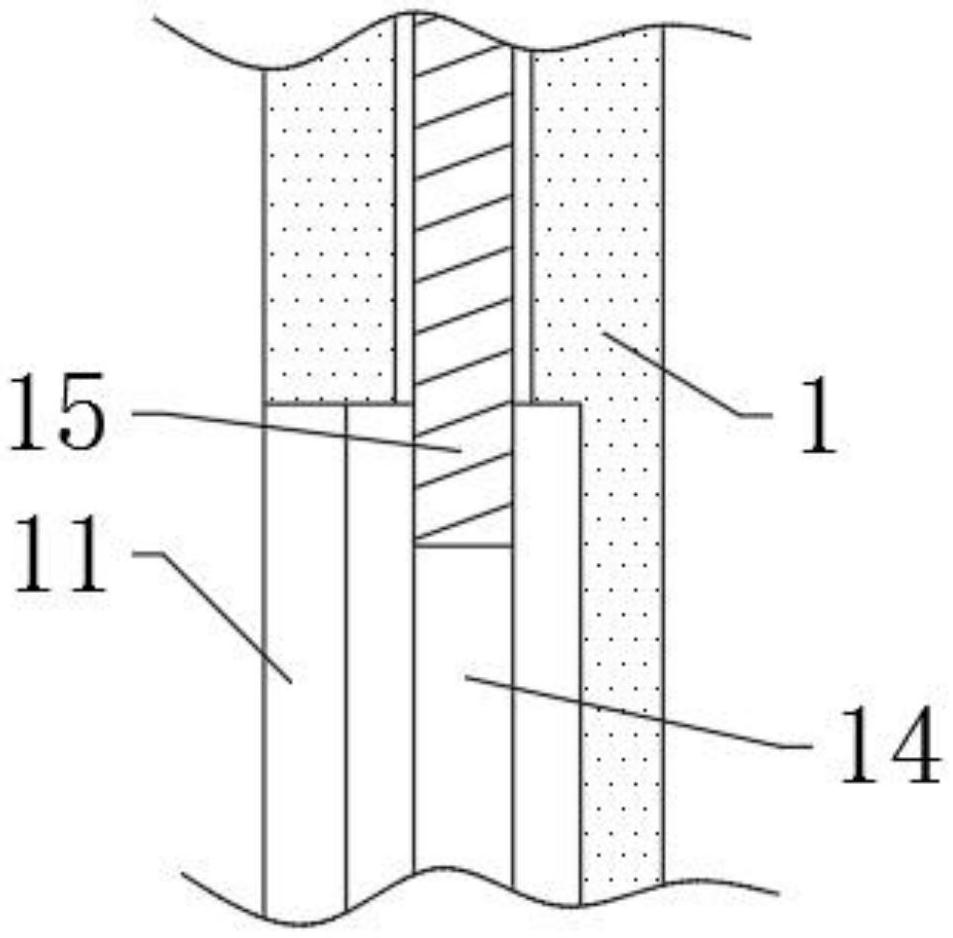

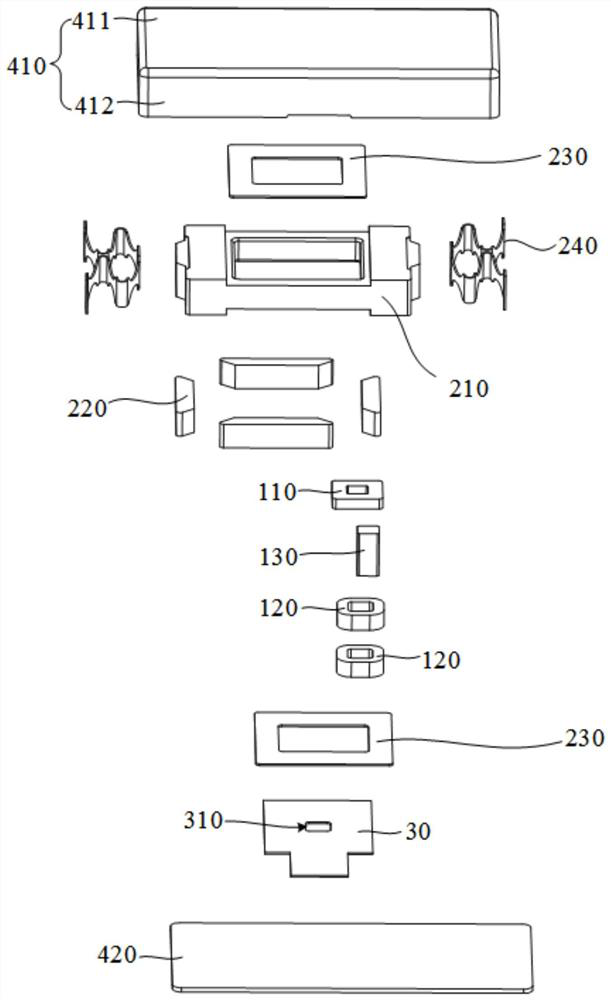

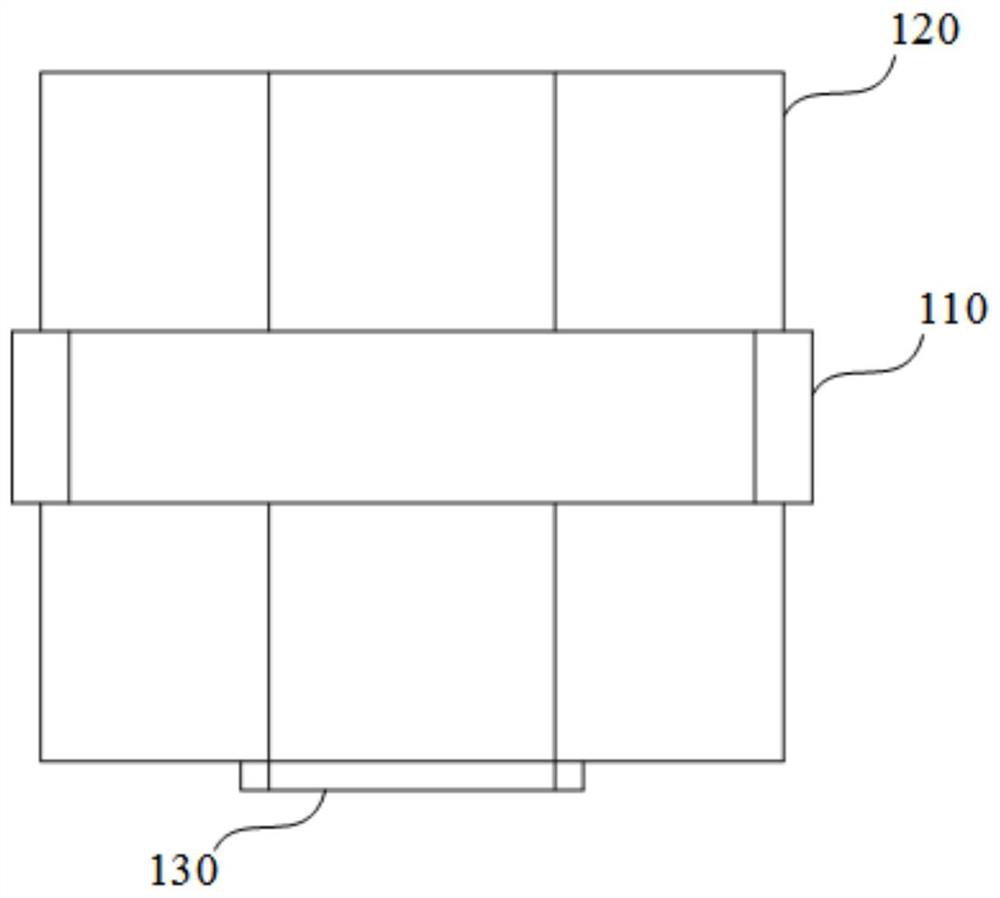

Vibrator and electronic equipment

ActiveCN112865470ARealize the vibration effectAchieve two-way vibrationDynamo-electric machinesMagnetElectronic equipment

The invention discloses a vibrator and electronic equipment. The vibrator comprises a shell, a stator assembly and a vibrator assembly, wherein the shell is enclosed to form a mounting space; the stator assembly is arranged in the mounting space, the stator assembly comprises a coil and a magnetic conductive piece, and the magnetic conductive piece is arranged on one side of the axial direction of the coil; the vibrator assembly has at least two inherent frequencies, the vibrator assembly comprises a balancing weight located in the mounting space, permanent magnets connected to the balancing weight and an elastic piece, the balancing weight is suspended in the mounting space through the elastic piece, the number of the permanent magnets is multiple, the multiple permanent magnets are arranged around the magnetic conduction piece and are magnetically coupled with themagnetic conduction piece, and the plurality of permanent magnets form two magnetic field directions of which the extension directions are crossed. According to the technical scheme, vibration can be achieved in two directions, and therefore the vibration feedback effect is improved.

Owner:GOERTEK INC

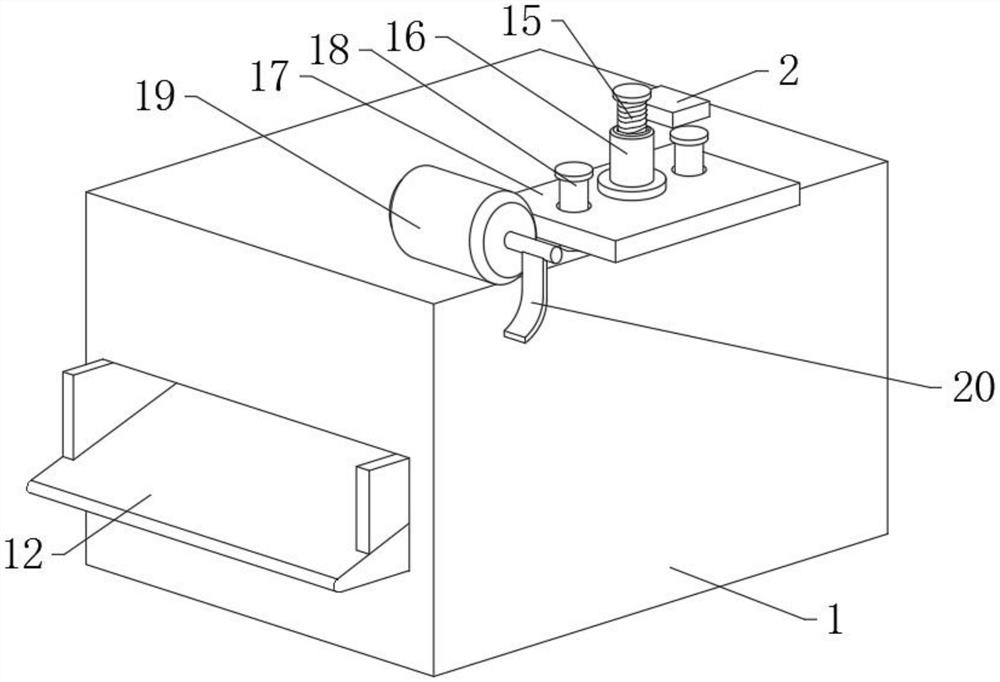

An intelligent packaging and weighing device for tea production and its use method

ActiveCN112895562BRealize the effect of automatic quantitative dischargeImprove stabilityWeighing apparatus for materials with special property/formWeighing auxillary devicesProcess engineeringTea leaf

The invention belongs to the technical field of tea production devices, in particular to an intelligent sub-packaging and weighing device for tea production, which includes a base, a discharge mechanism and a pressing mechanism are respectively provided on both sides of the top of the base, and a discharge mechanism and a pressing mechanism are located on the two sides of the top of the base. The feeding mechanism between the mechanisms, the discharge mechanism includes a first vertical plate fixedly connected to the top side of the base, the side of the first vertical plate close to the feeding mechanism is fixedly connected with a fixed seat, and the top of the fixed seat is fixedly connected with a storage The top of the material storage box is provided with a feeding port; it also discloses a method of use. In the present invention, the whole device has reasonable structure, few power sources, low energy consumption, simple and practical operation, convenient control, and strong overall linkage, from discharging, weighing, conveying, feeding, feeding to pressing and finally finished product discharging All the automatic operation is realized, and at the same time, the vibration effect can be realized during the feeding process, which improves the flatness of the tea leaves, and greatly improves the work efficiency and processing accuracy.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

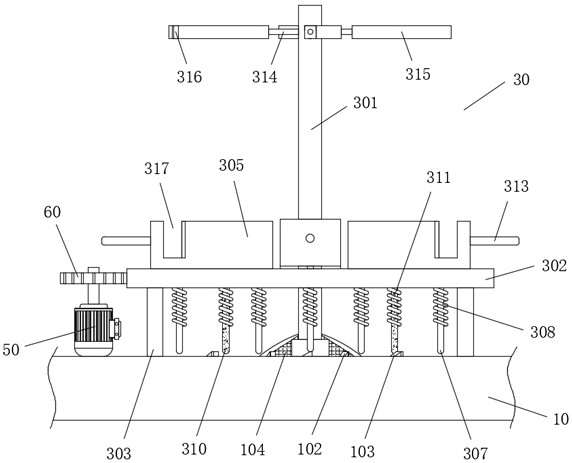

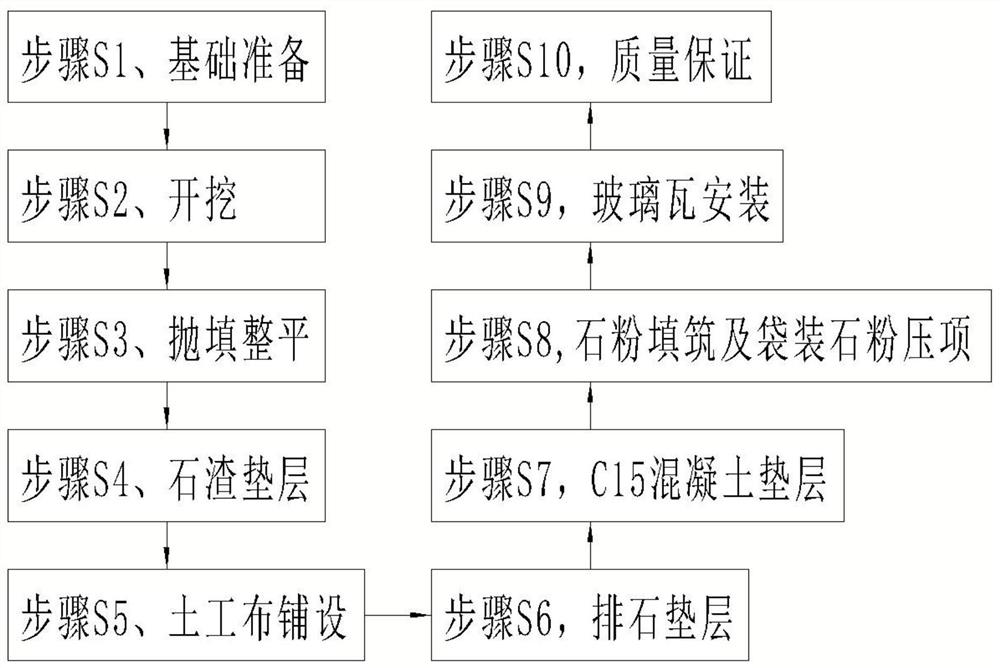

Alkali residue soil hydraulic cofferdam construction process and construction equipment

PendingCN114045791ARealize the vibration effectNo need for manual handlingEmbankmentsLand reclamationMaterials preparationCrushed stone

The invention discloses an alkali residue soil hydraulic cofferdam construction process and construction equipment, and the construction process comprises the following operation steps: step S1, foundation preparation, step S2, excavation, step S3, throw filling and leveling, step S4, rock ballast cushion, step S5, geotextile laying, step S6, stone cushion removal, step S7, C15 concrete cushion, step S8, stone powder filling and bagged stone powder pressing, step S9, glass tile installation and step S10, the quality is ensured; S1, technology preparation, material preparation and machine tool preparation are conducted; S2, after the step S1 is completed, a total station is used for controlling a plane in a point position mode, retesting and drawing are conducted, the actually-needed excavation amount is calculated, and excavation machinery conducts timed monitoring. The process has the beneficial effects that the vibration effect on the box body is achieved, the situation that due to the fact that stone is easily clamped on screen meshes, the screen meshes are blocked is prevented, broken stone can be moved to a conveying belt to be conveyed, manual carrying is not needed, and meanwhile, the construction site is not occupied, and construction is facilitated.

Owner:天津津港建设有限公司

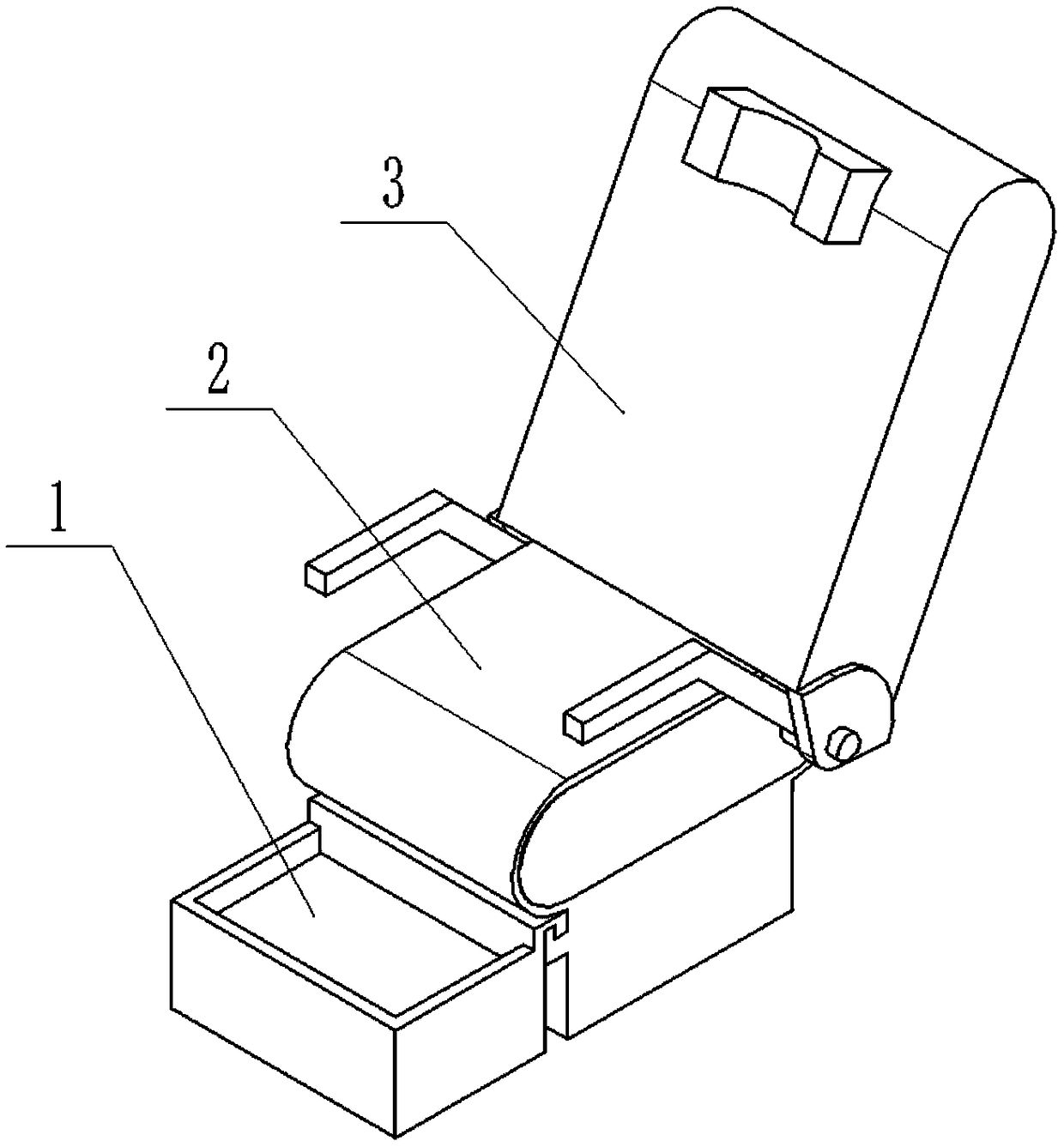

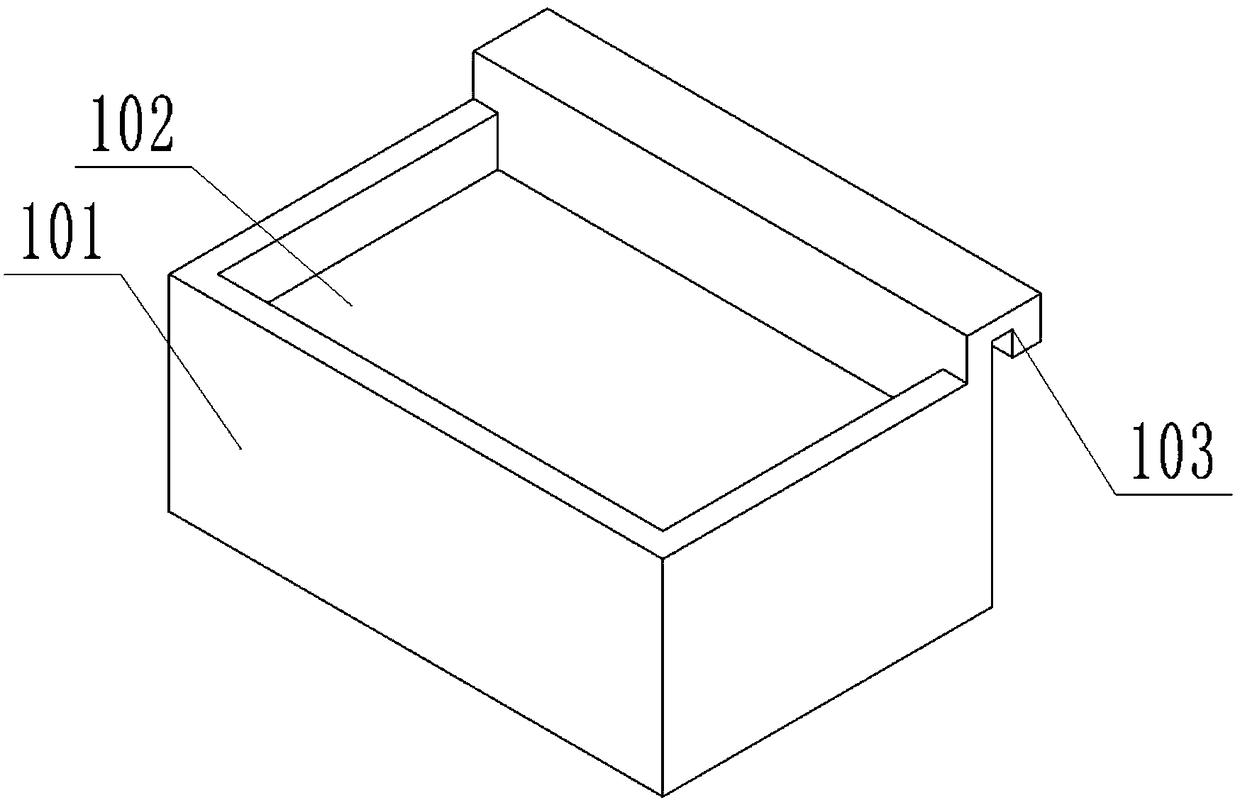

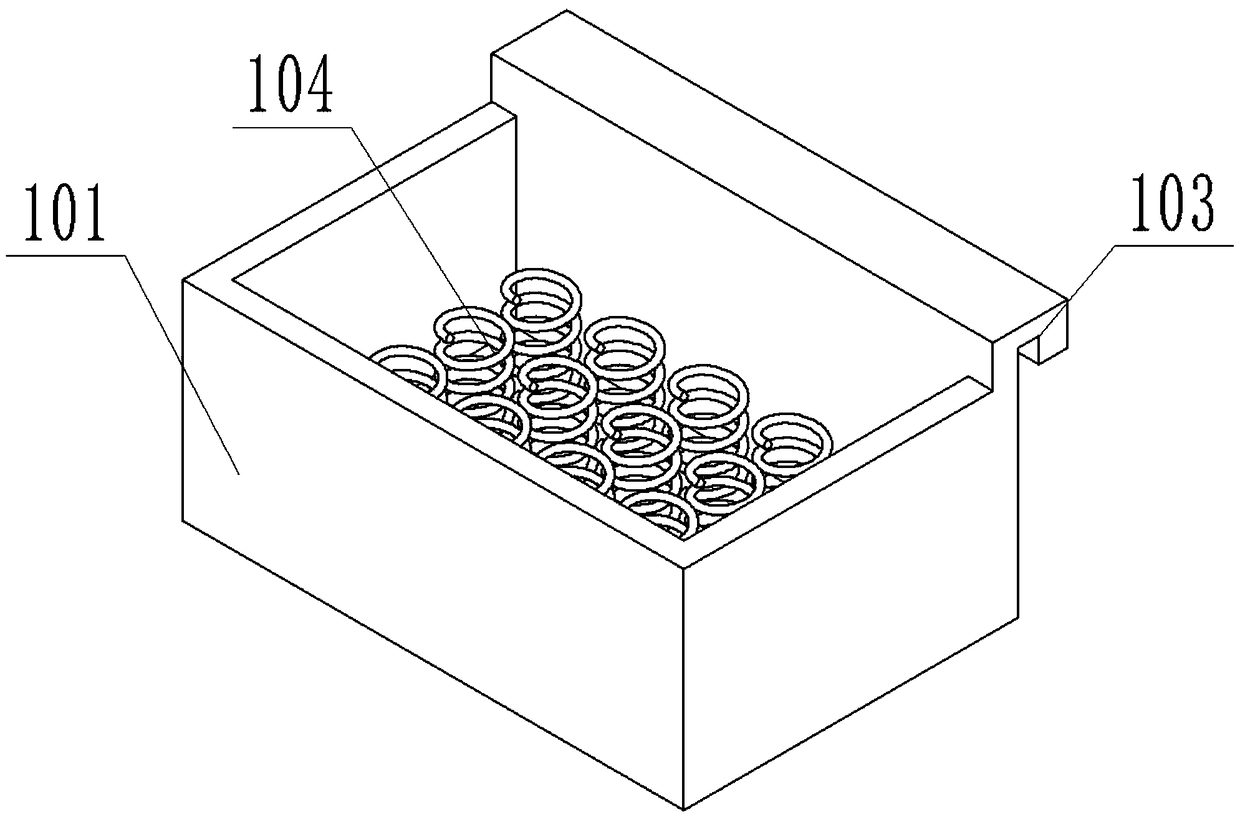

Airborne aviation massaging and relaxing seat

InactiveCN108820225AAct as a shock absorberRealize the vibration effectSeating arrangementsVibration massageAviationEngineering

The invention provides an airborne aviation massaging and relaxing seat and belongs to the field of aviation service products. The airborne aviation massaging and relaxing seat comprises a foot massager, a massaging seat and a backrest; the foot massager is mounted at the front part of the massaging seat; the backrest is mounted at the rear part of the massaging seat; the foot massager comprises amassager shell, a vibration mechanism, a mounting claw and a spring; the vibration mechanism comprises a mechanism shell, a small cover plate, a rotating shaft, an eccentric wheel, a long belt, a main motor, a main shaft and a short belt; and the massaging seat comprises a seat cushion, a base, a mounting groove, a handrail, a big cover plate, an external shaft, an internal shaft, a big belt, a massaging wheel, a small motor, a small shaft and a small belt. The airborne aviation massaging and relaxing seat has the advantages that the massaging effect on each part of the body of a passenger taking an airplane is realized by designing the foot massager, the massaging seat and the backrest.

Owner:晨龙飞机(荆门)有限公司

Energy-saving and environment-friendly drying box for chemical raw material production

InactiveCN113108577AGuaranteed drying effectImprove drying effectDrying gas arrangementsDrying machines with non-progressive movementsProcess engineeringRaw material

The invention relates to the technical field of chemical production, and discloses an energy-saving and environment-friendly drying box for chemical raw material production. The drying box comprises a base and a box body structure, the box body structure comprises a top plate arranged at one side of the base and a bracket fixedly arranged between the base and the top plate, and further comprises a drying mechanism fixedly mounted on the top plate, and used for drying crushed chemical raw materials, a conveying mechanism and a uniform drying mechanism. The conveying mechanism is fixedly arranged at the side, close to the drying mechanism, of the base, comprises a transmission assembly and an alternating assembly and is used for periodically conveying the crushed chemical raw materials to the bottom of the drying mechanism; the uniform drying mechanism is fixedly arranged in the middle of the base, comprises a vibration assembly and an elastic assembly, and is used for vibrating the crushed chemical raw materials on the conveying mechanism, so that the crushed chemical raw materials can be continuously bounced to change positions, and the raw materials are dried while being vibrated and can be uniformly dried; and through the drying mechanism, the conveying mechanism and the uniform drying mechanism, uniform and environment-friendly drying of the crushed chemical raw materials is achieved.

Owner:何红

Laba bean screening and detecting device

The invention discloses a Laba bean screening and detecting device and relates to the technical field of food processing. The device comprises two mounting bases. Supporting plates are fixedly mountedon the tops of the mounting bases, a fixed plate is fixedly mounted between the two supporting plates, a transmission motor is fixedly mounted on the top of the fixed plate, two supporting rods located on the right side of the transmission motor are fixedly mounted on the top of the fixed plate, a transmission wheel is fixedly mounted on an output shaft of the transmission motor through a coupling, driven wheels are movably mounted on the two supporting rods, and vibrating parts located on the back faces of the driven wheels are movably mounted on the two supporting rods. According to the Laba bean screening and detecting device, soybeans which are relatively small in dimension fall into a filter box, and residual high quality soybeans are screened, so that the soybeans for manufacturingLaba beans are excellent in quality. The manufactured Laba beans are excellent in flavor and the screening effect of a bad main material soybeans in manufacturing the Laba beans is achieved.

Owner:湖南省美衡食品有限公司

Textile Cloth Conveying Device Based on Intermittent Tensioning and Vibrating Drainage Drying Structure

ActiveCN113249908BImprove dehydration effectPrevent deviationLiquid/gas/vapor removal by vibrationTextile treatment carriersStructural engineeringMechanical engineering

The invention discloses a textile cloth conveying device based on an intermittent tensioning and vibration drainage drying structure, relates to the technical field of textile processing, and solves the problem that the currently used conveying device does not have an automatic intermittent tensioning mechanism and does not have a corresponding tensioning and dehydrating component , the problem that the fabric cannot be dehydrated quickly. The textile cloth conveying device based on the structure of intermittent tension and vibration drainage and drying includes a main shell plate. The number of the main shell plates is set as two groups. The adjacent part of the bottom of the lower group plate is set as a slope structure; the top of the main shell plate is fixedly equipped with an upper cover, and the top of the upper cover is equipped with two sets of dryers; both sides of the lower group plate are provided with strip holes , by providing a dryer, a crankshaft, a bar frame and a fixed plate, an automatic intermittent tensioning mechanism is provided for the conveying device, as well as a corresponding tensioning dehydration component, which can realize the automatic rapid dehydration function.

Owner:江苏盈彩纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com