Patents

Literature

544results about How to "No need for manual handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

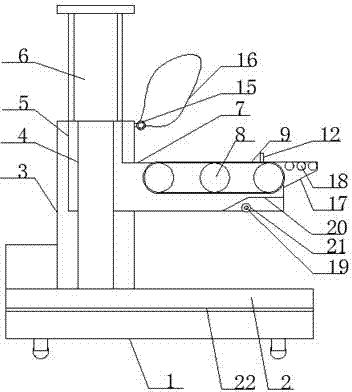

Instrument cleaning and disinfection device for supply room nursing

InactiveCN104826148ASimple structureSimple and fast operationCleaning using liquidsHeatEngineeringHuman power

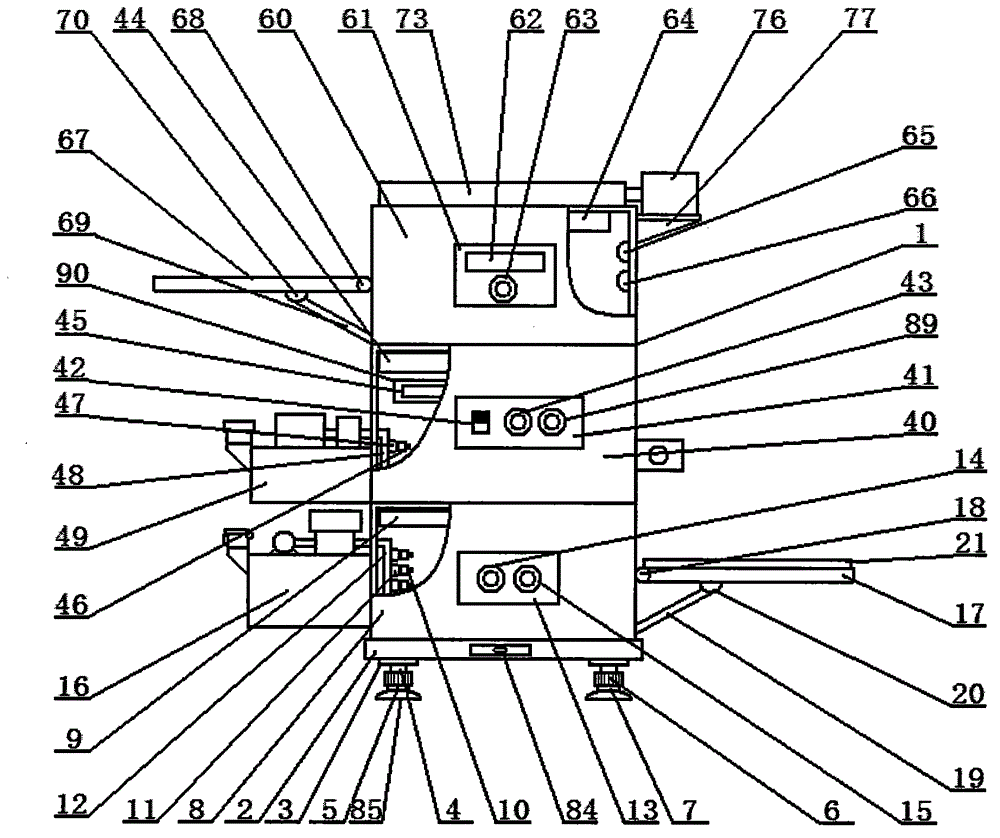

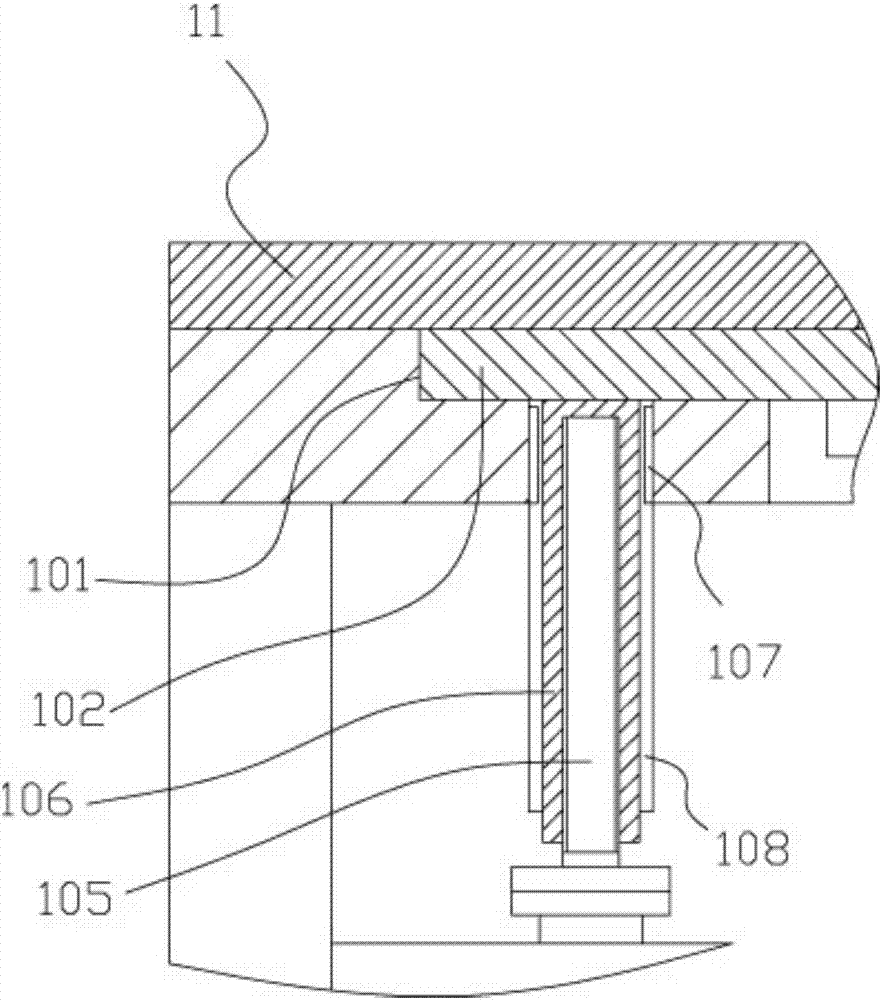

The invention relates to an instrument cleaning and disinfection device for supply room nursing, and belongs to the technical field of supply room nursing instruments. The instrument cleaning and disinfection device for supply room nursing comprises a stander, wherein the lower side of the stander is provided with a fixed base, the lower side of the fixed base is provided with a supporting fixed connector, the lower side of the supporting fixed connector is provided with a fixed support leg, the lower side of the fixed support leg is provided with a height adjuster, the outer side of the height adjuster is provided with a height adjusting anti-skid grain, the lower side of the height adjuster is provided with a fixed support foot, the upper side of the fixed base is provided with a washing room, the washing room is internally provided with an ultrasonic generator, the lower side of the ultrasonic generator is provided with a washing spray head, and the left side of the washing spray head is provided with a spray head rotating adjuster. The instrument cleaning and disinfection device disclosed by the invention is simple in structure and easy and convenient to operate, and has no need of manual carrying in a whole process, thus saving the manpower and time and improving the working efficiency.

Owner:孙严

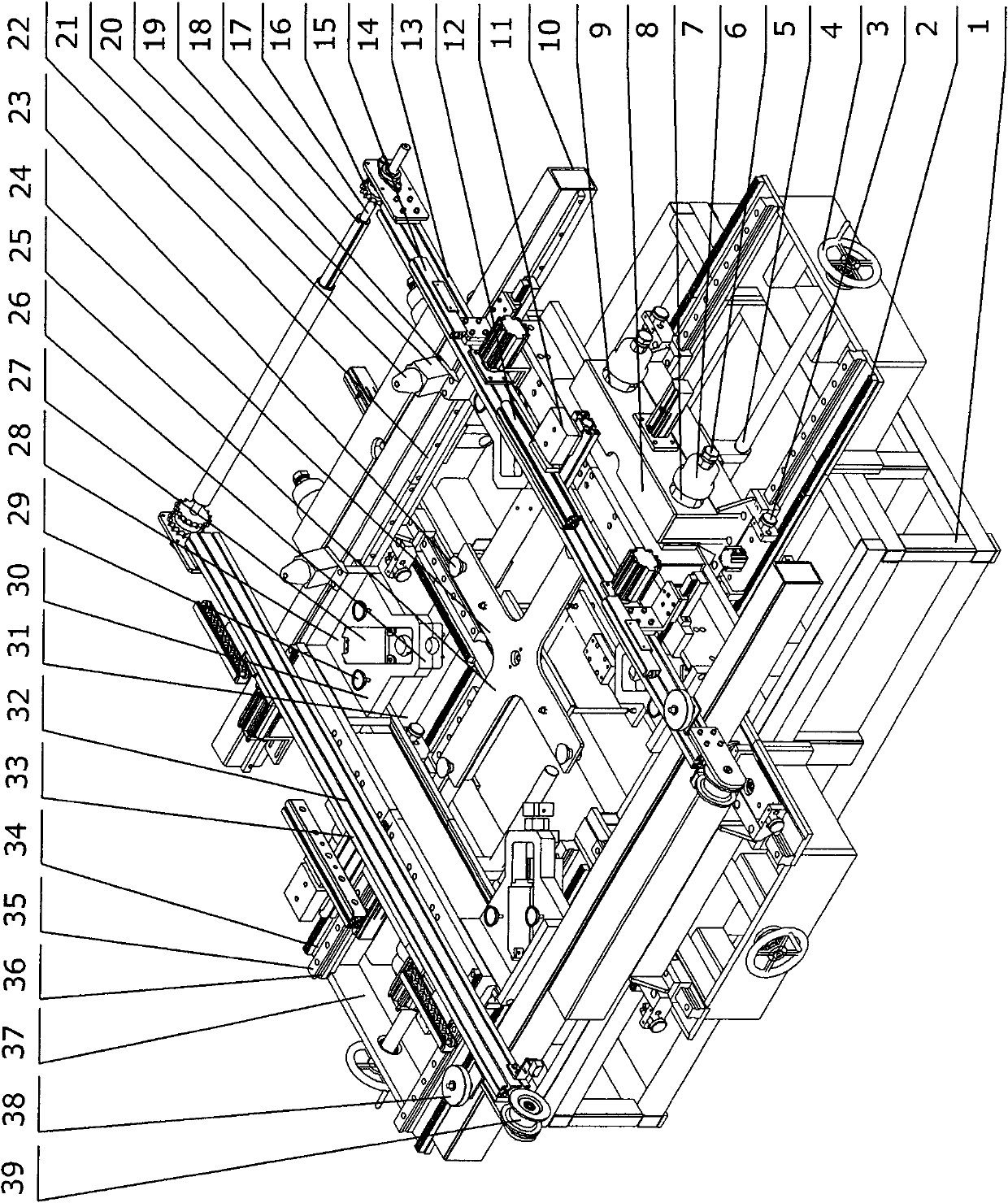

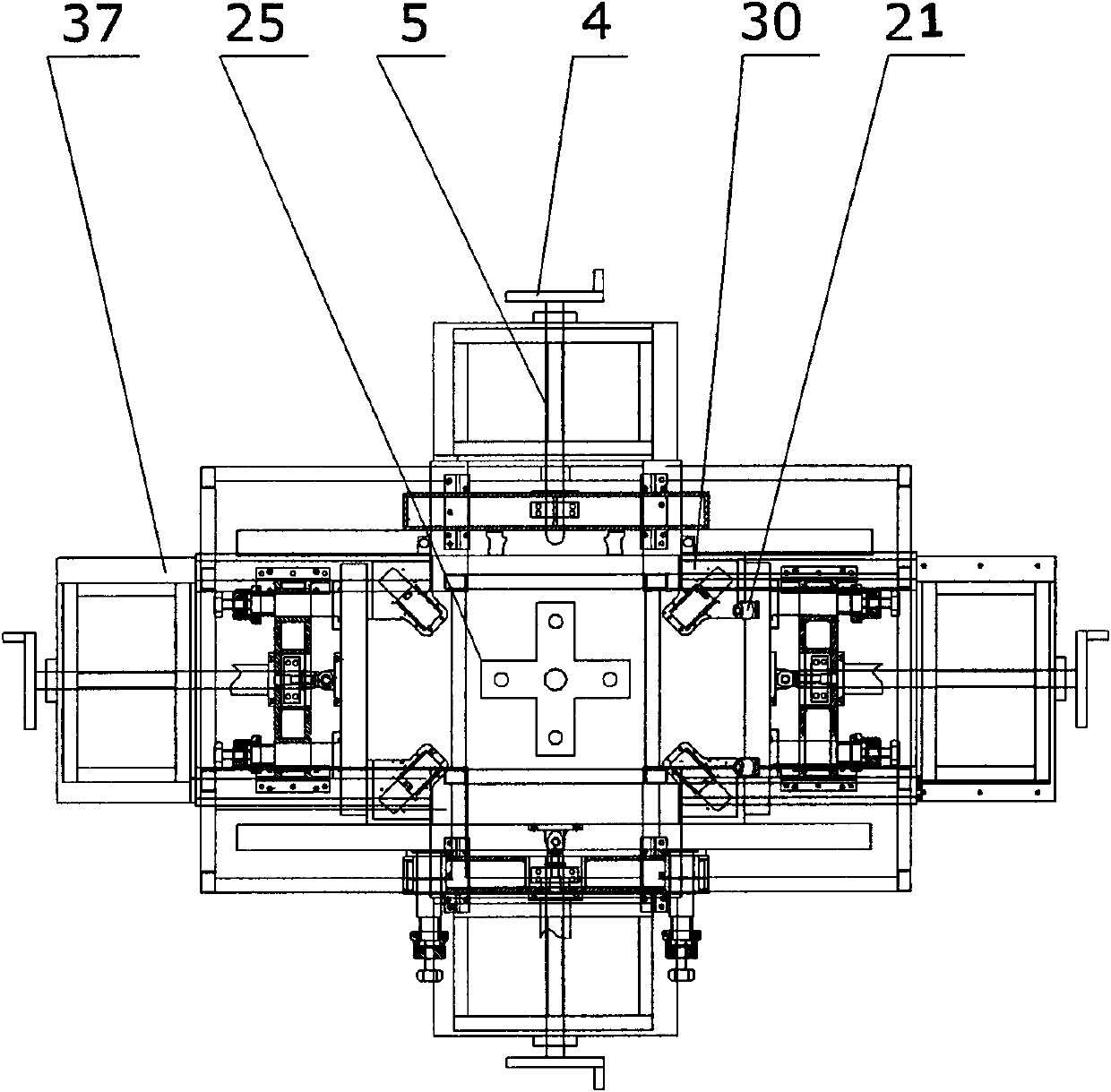

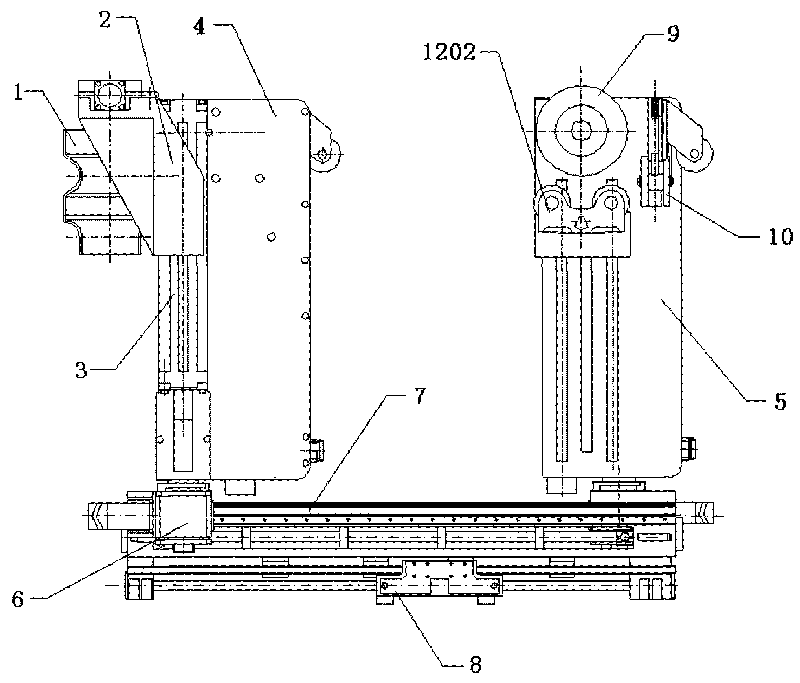

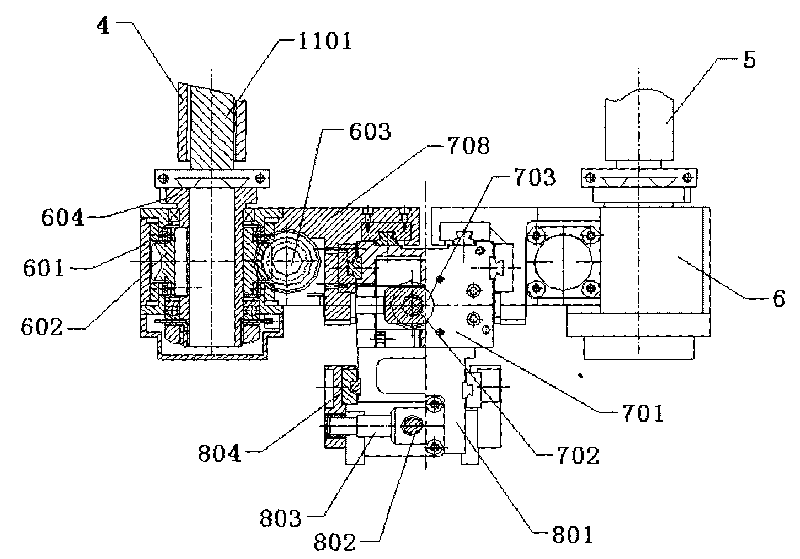

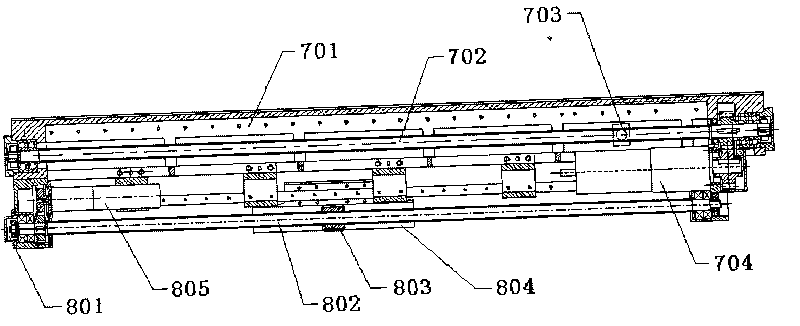

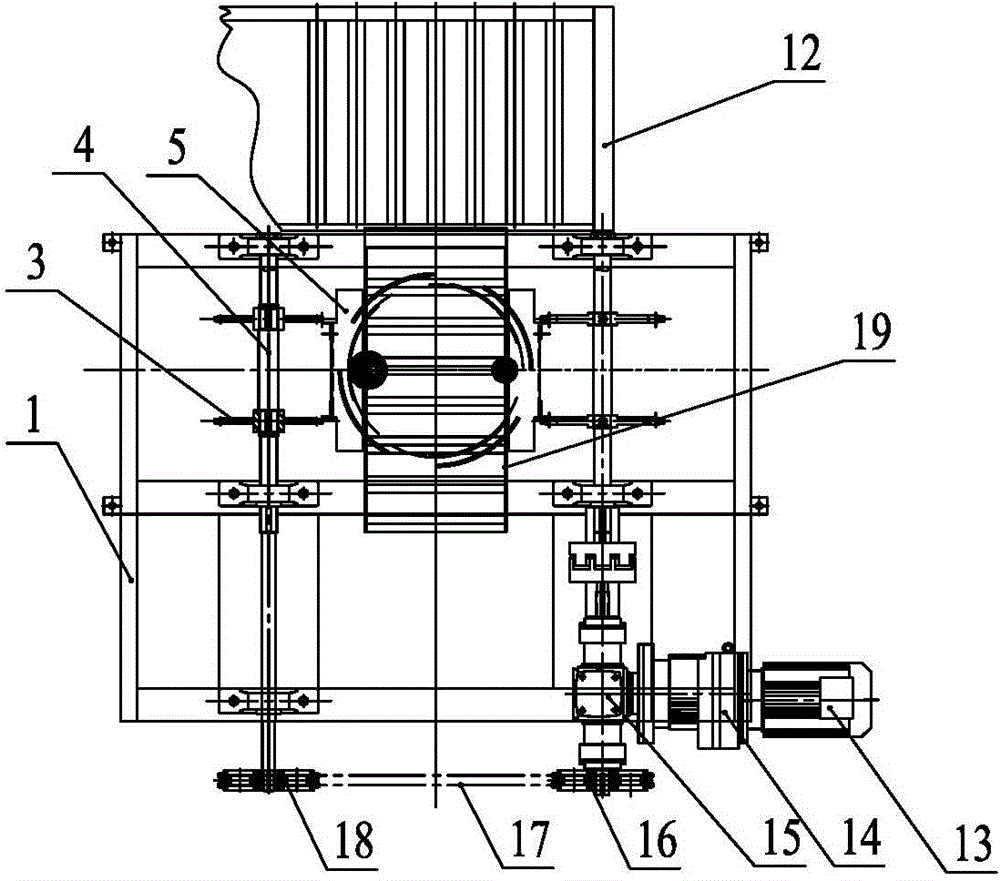

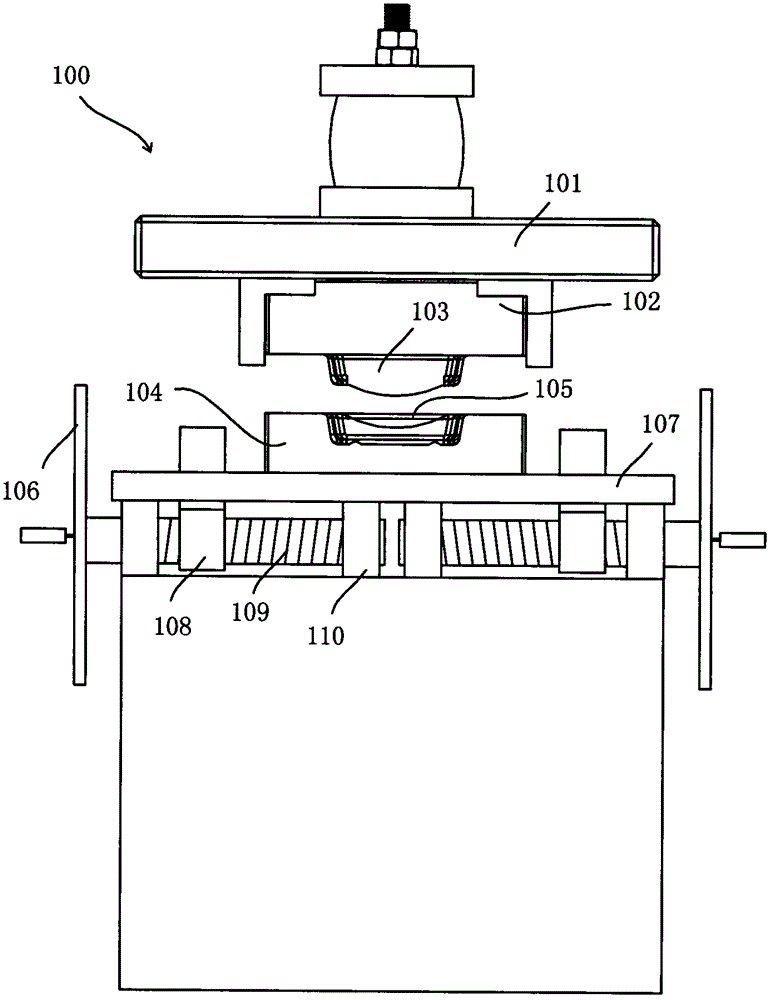

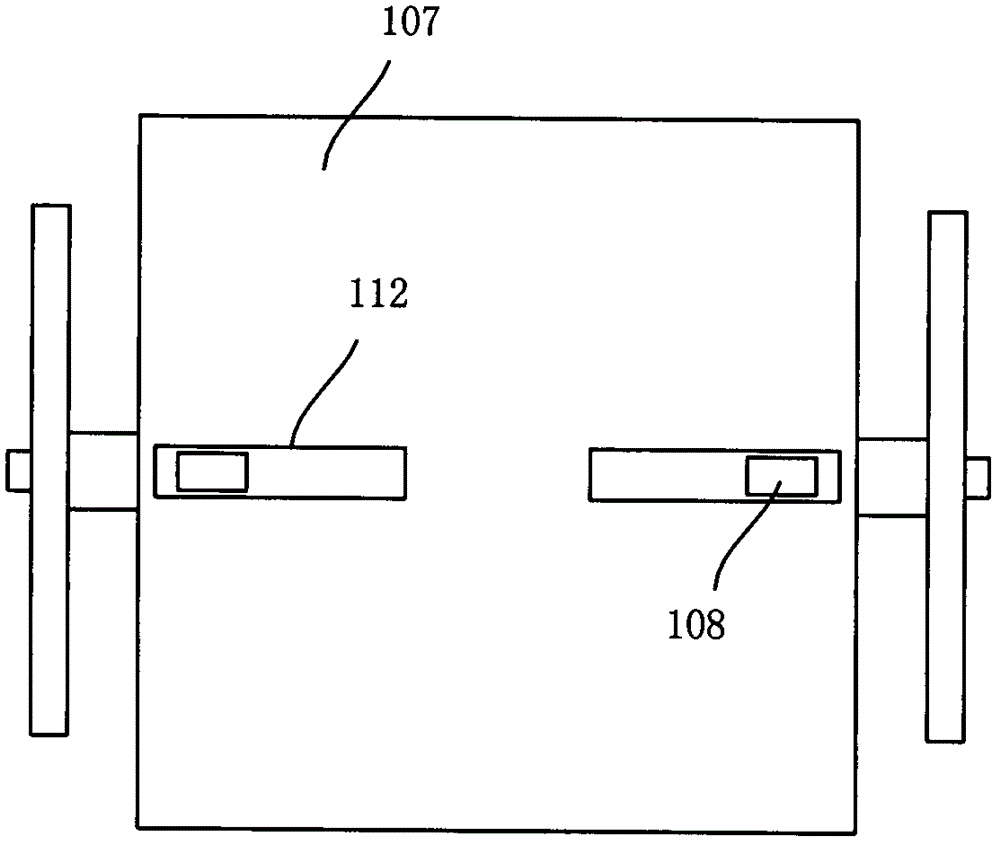

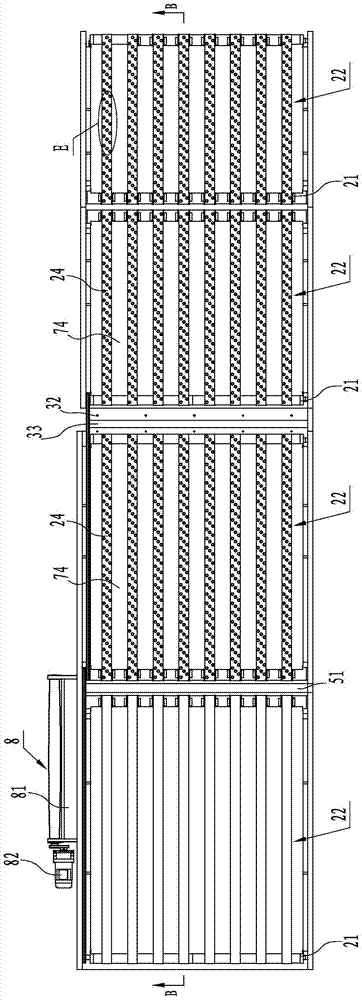

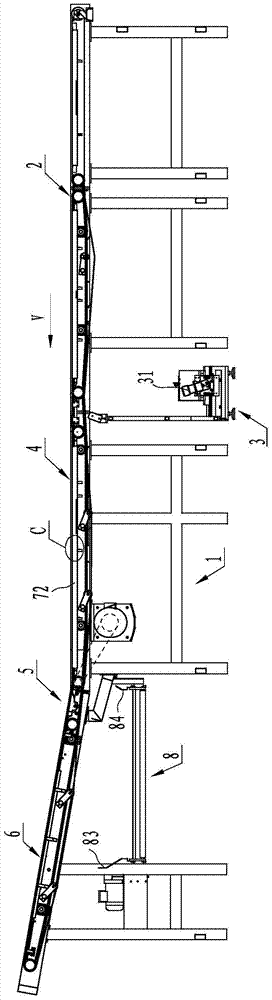

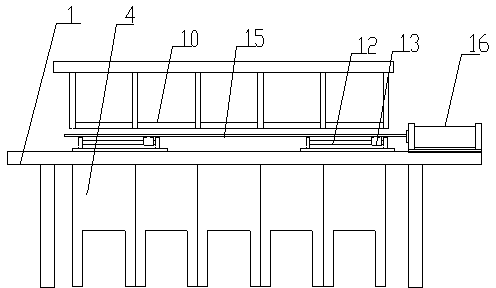

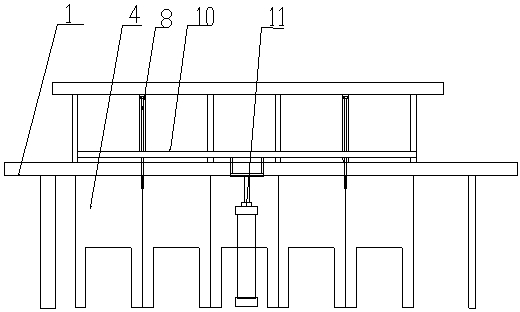

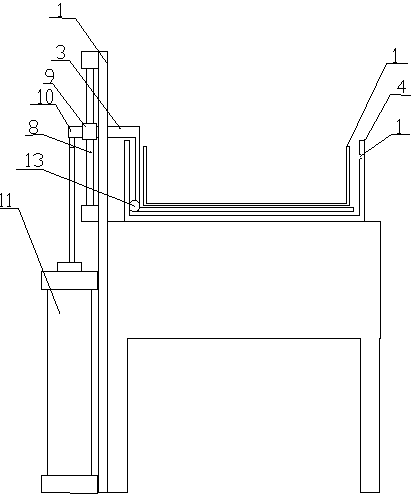

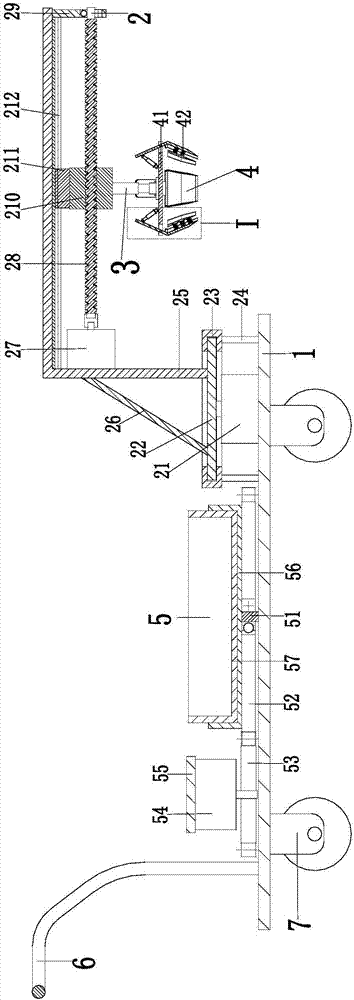

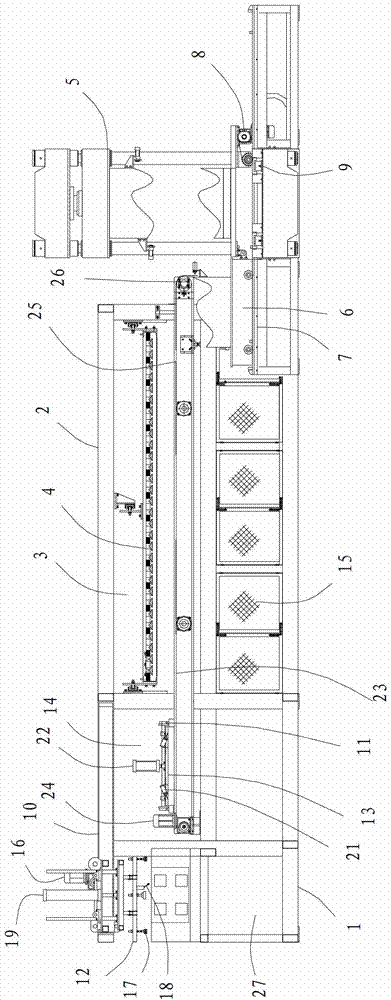

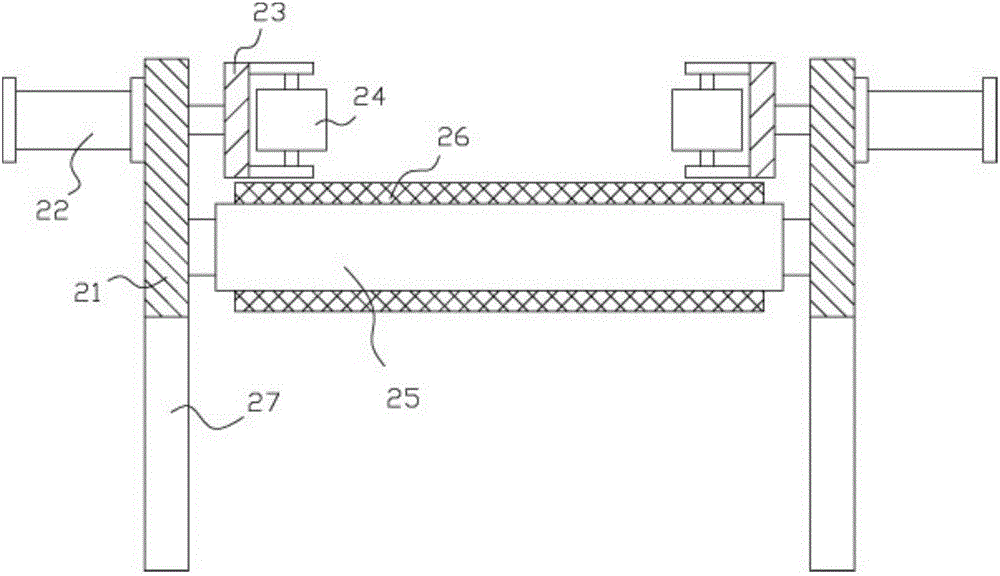

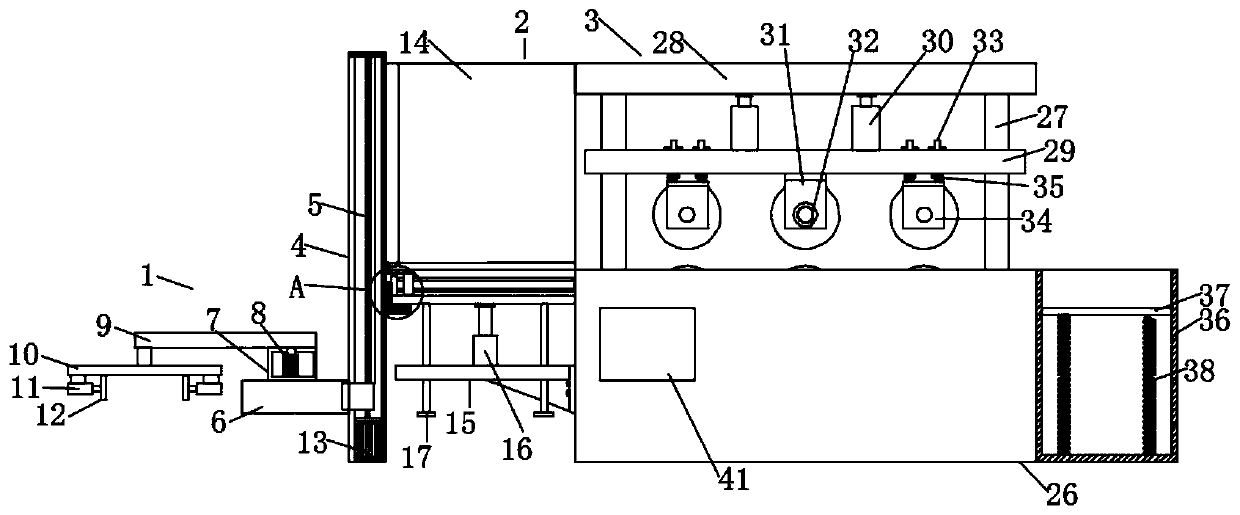

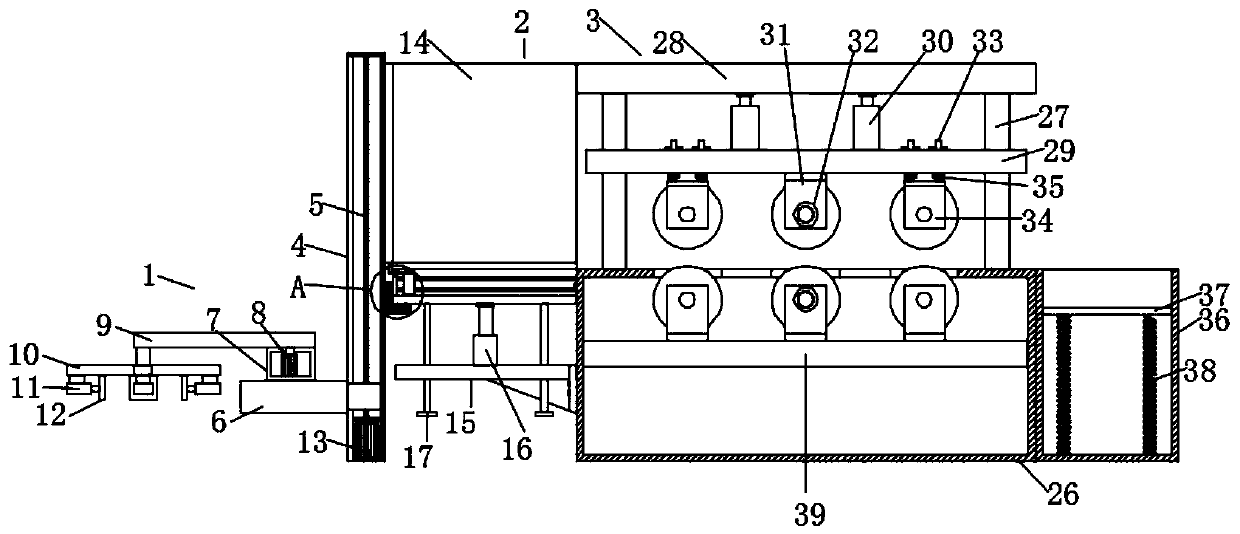

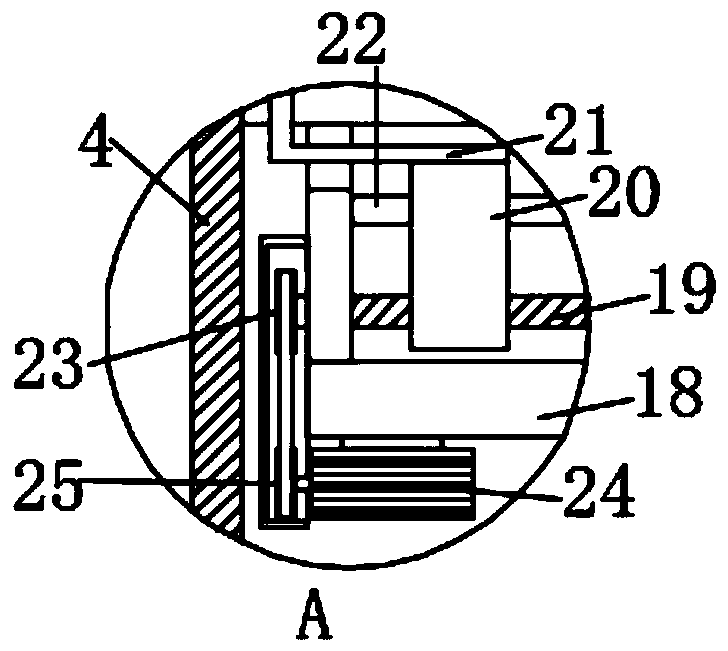

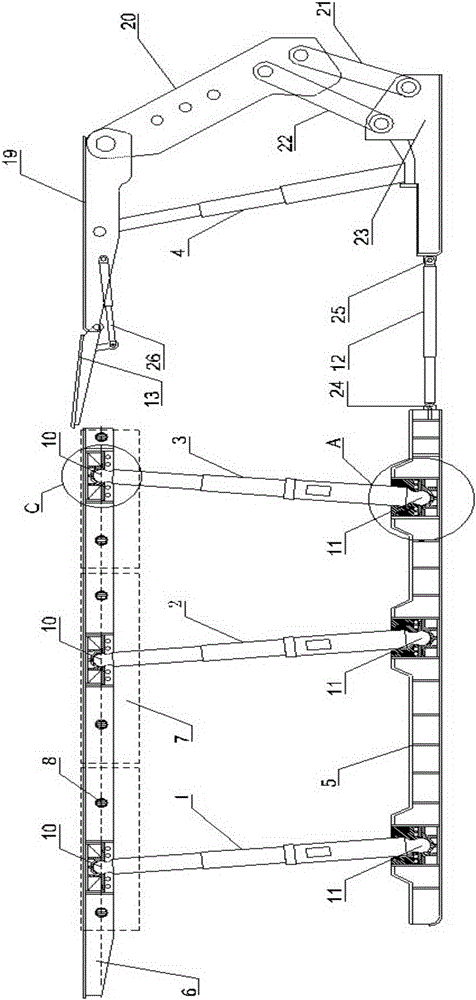

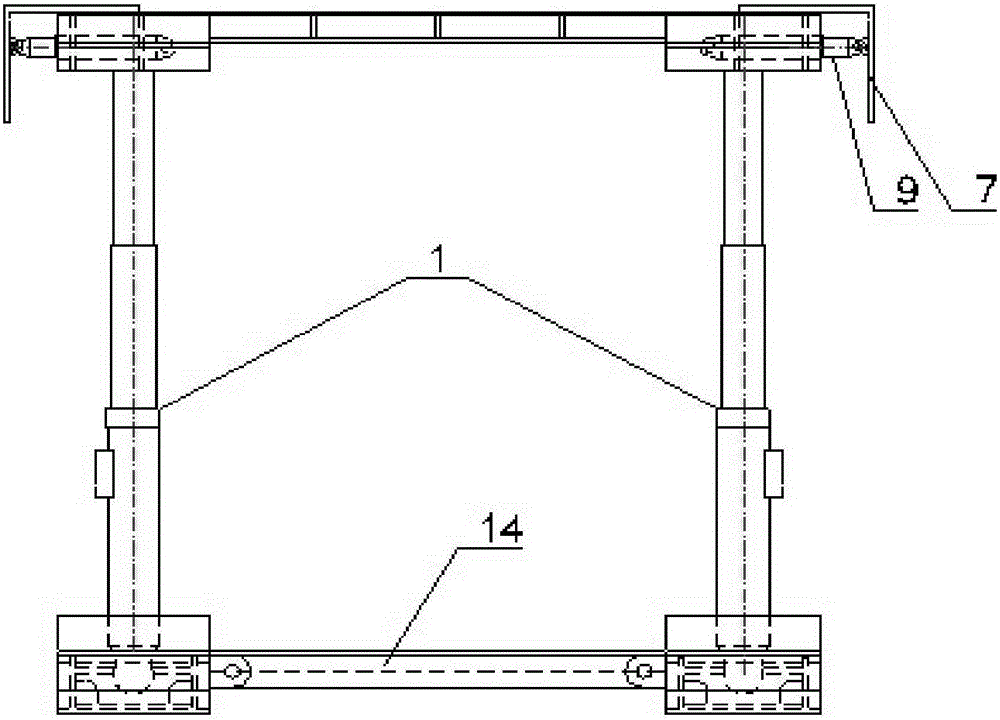

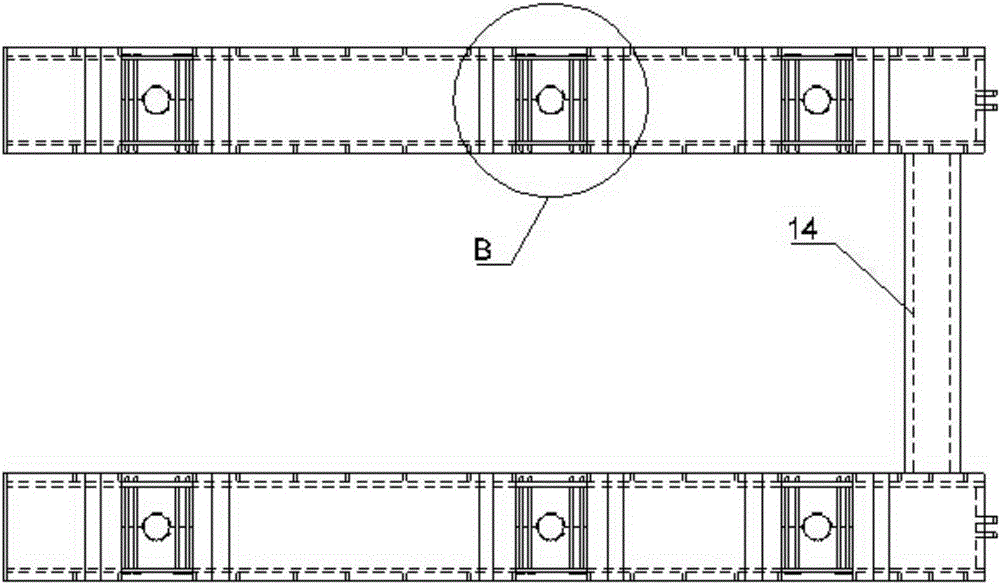

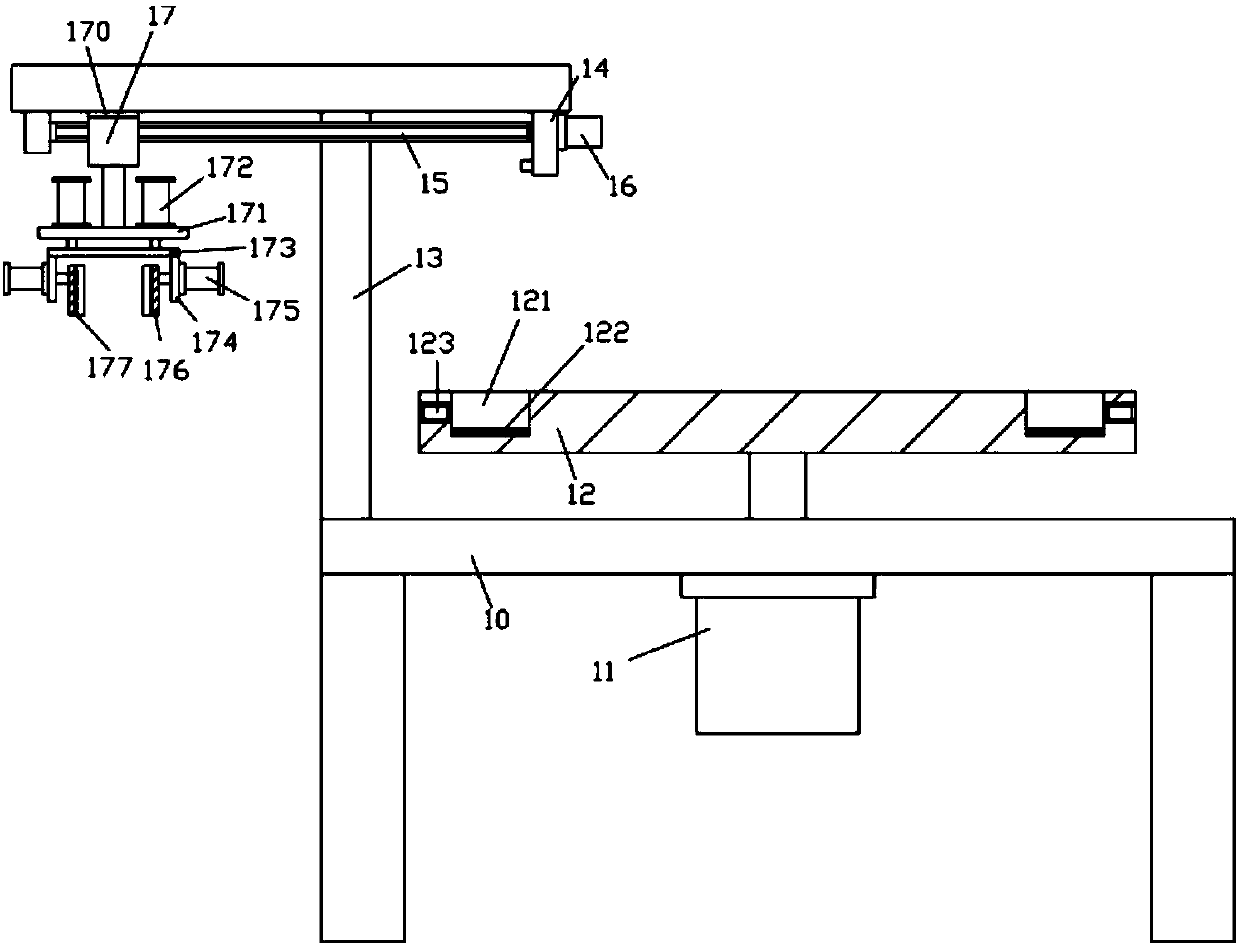

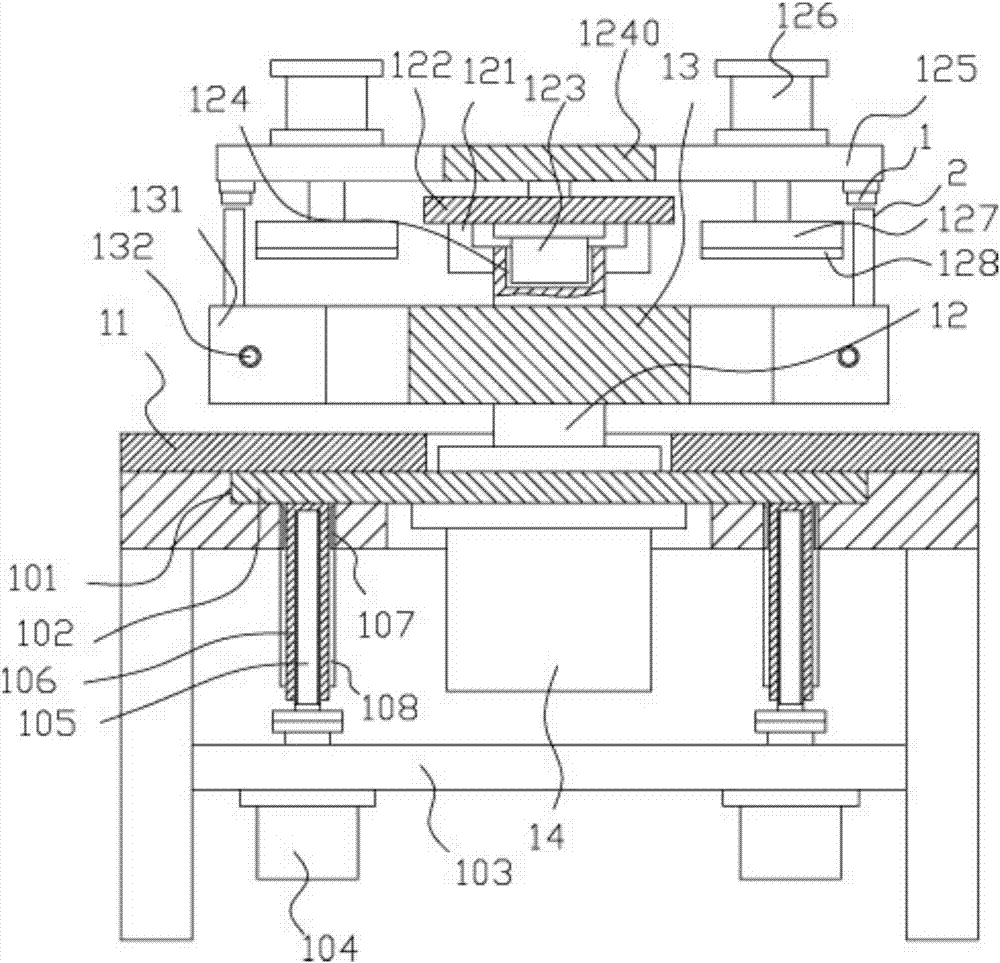

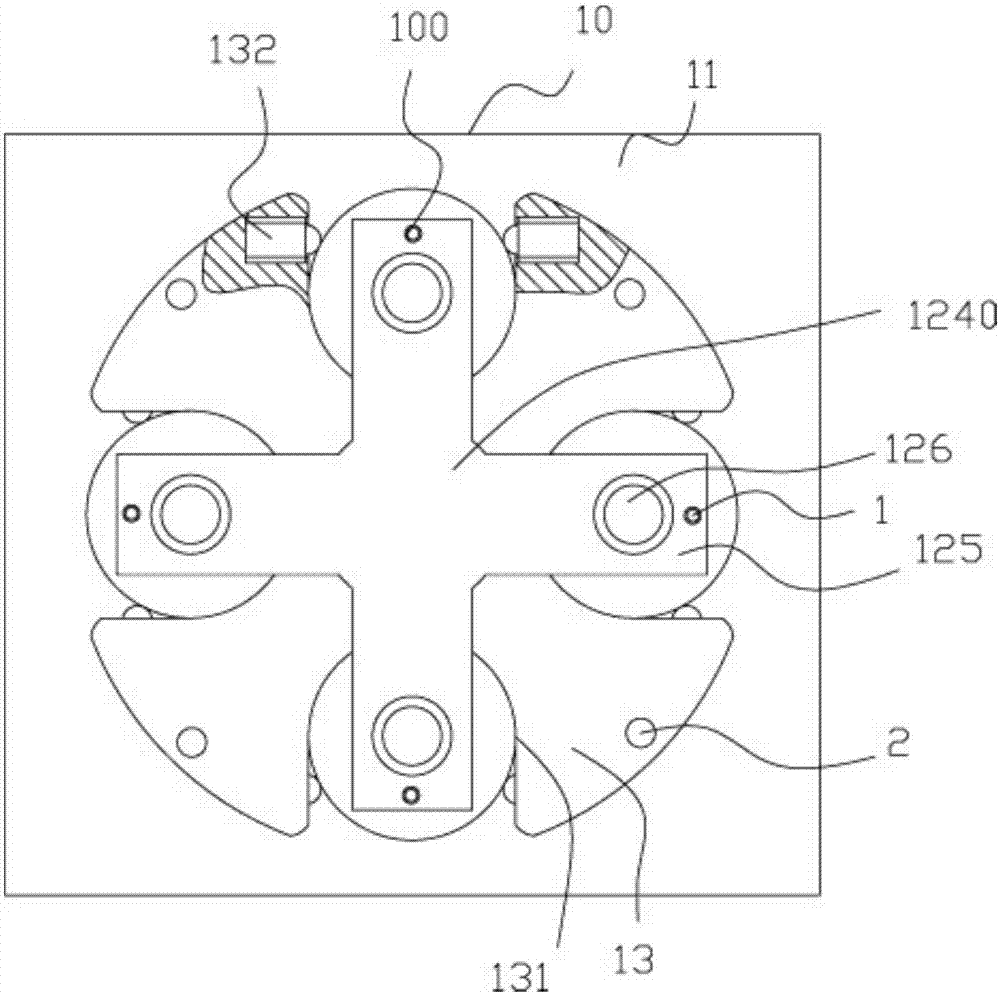

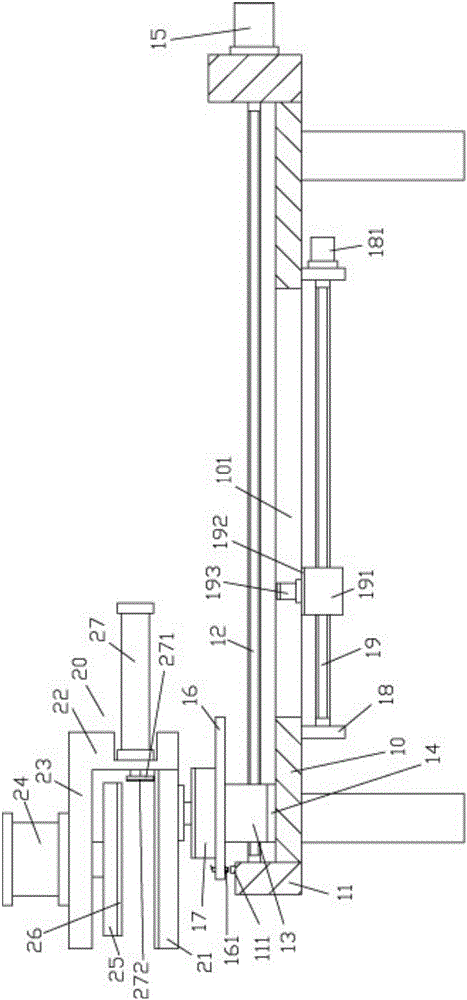

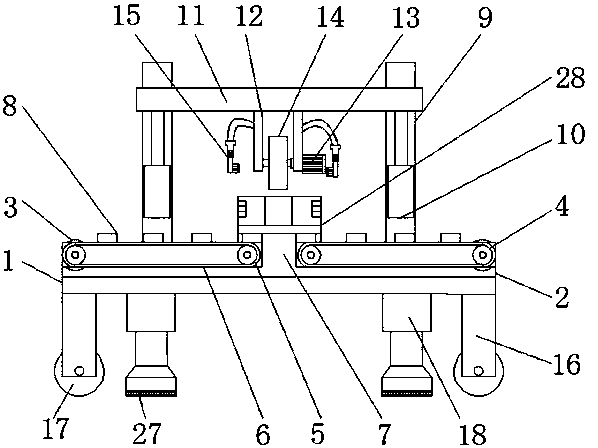

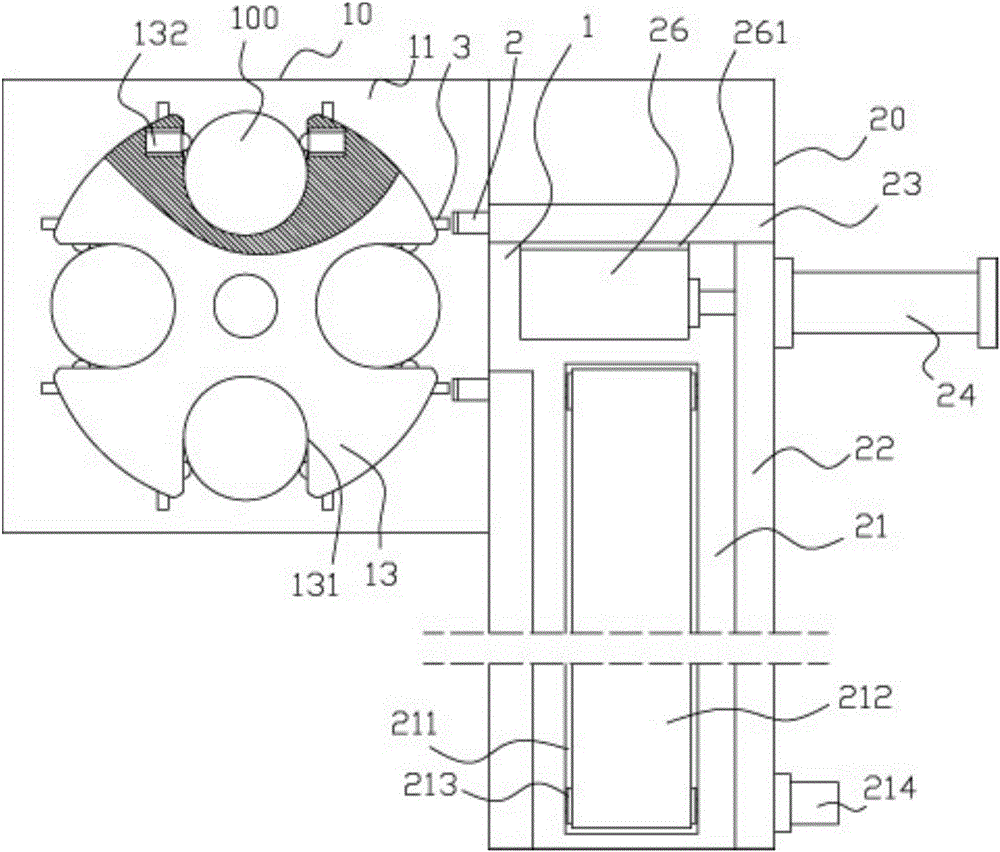

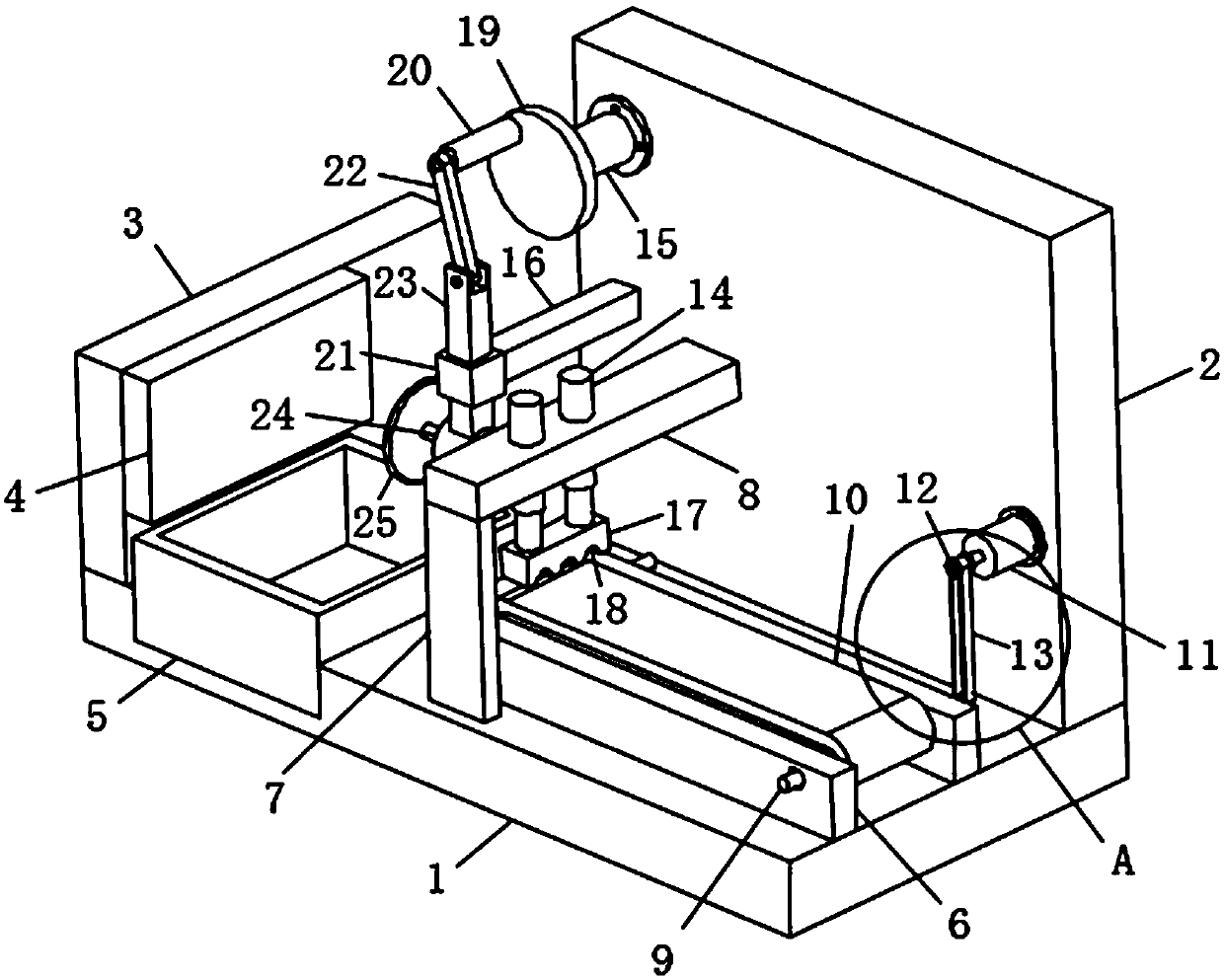

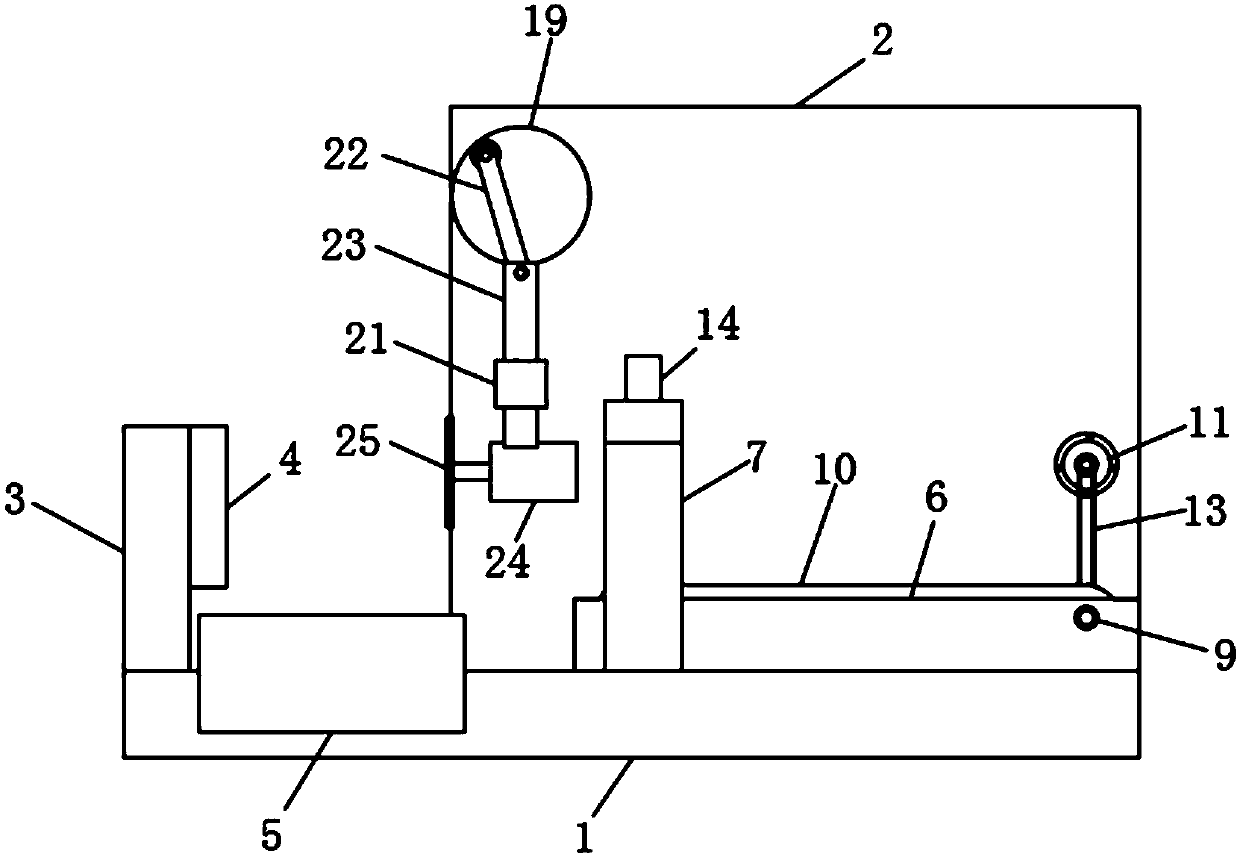

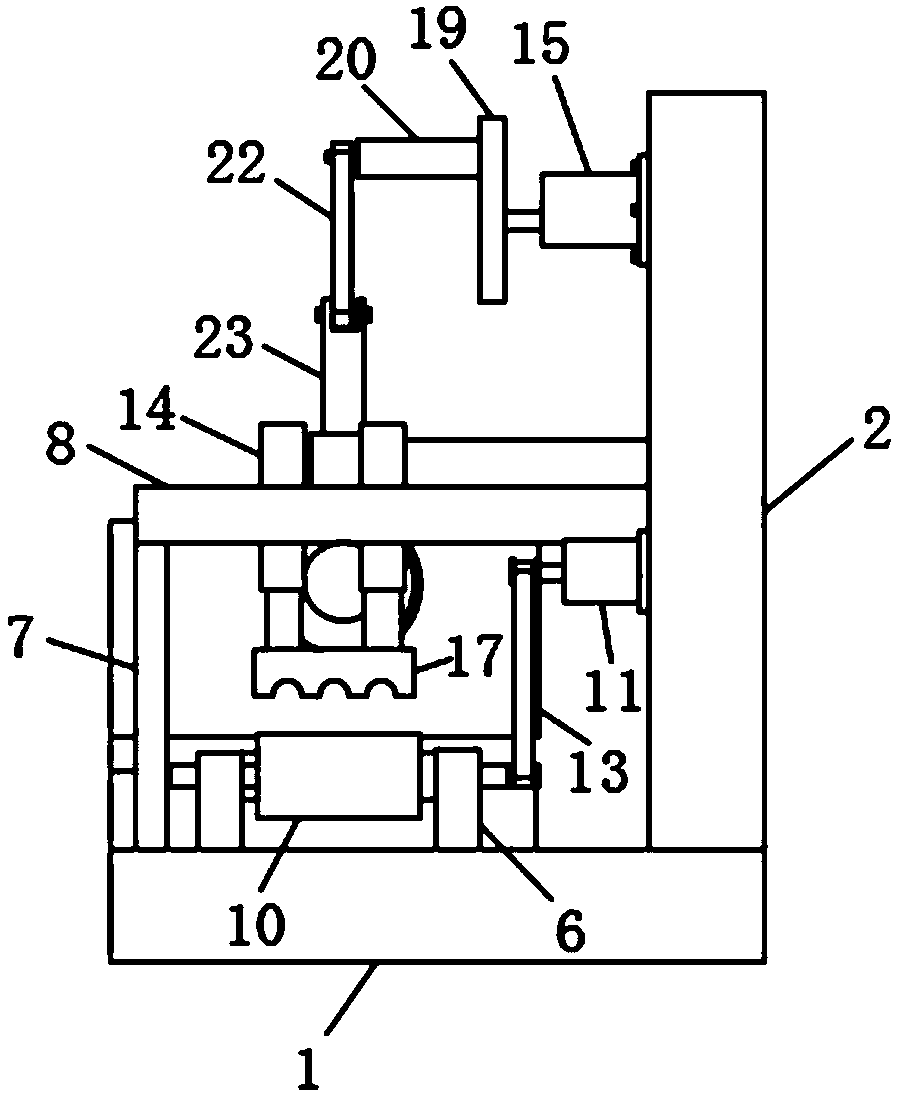

Solar cell assembly frame and angle assembling device and process thereof

InactiveCN102024868ARealize semi-automationNo need for manual handlingFinal product manufactureSemiconductor devicesDrive wheelEngineering

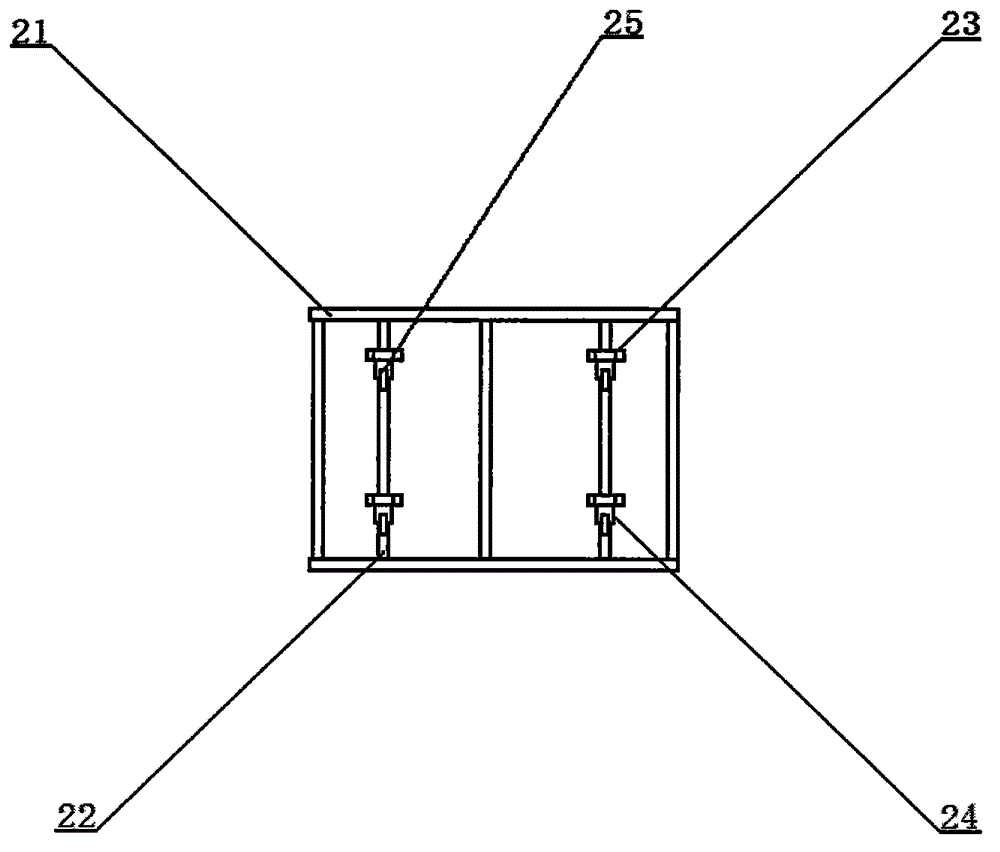

The invention discloses a solar cell assembly frame and angle assembling device and a process thereof, and relates to a solar cell assembly device. The invention provides the solar cell assembly frame and angle assembling device with good comprehensive use performance, scientific and reasonable structure, simple process and high automation degree. The device comprises a rack; the center of the rack is provided with a lifting mechanism; the sides of the lifting mechanism are provided with locking and adjusting mechanisms respectively, fixed on the rack and connected with movable supports; the movable supports are provided with frame assembling cross beams for connecting an upper guide plate and a lower guide plate respectively, the lower guide plate fixes an angle assembling bottom plate of an angle assembling cylinder and is connected with the frame assembling cross beam, and the angle assembling bottom plate fixed on the inner round angle of the rack is provided with an angle assembling mechanism; the upper guide plate of the frame assembling cross beam is provided with a transmission mechanism consisting of a motor, a telescopic pipe and a driving wheel set, and the two corresponding sides of the transmission mechanism are provided with positioning guardrails; and the transmission mechanism is connected with a frame closing mechanism.

Owner:YINGKOU JINCHEN MACHINERY

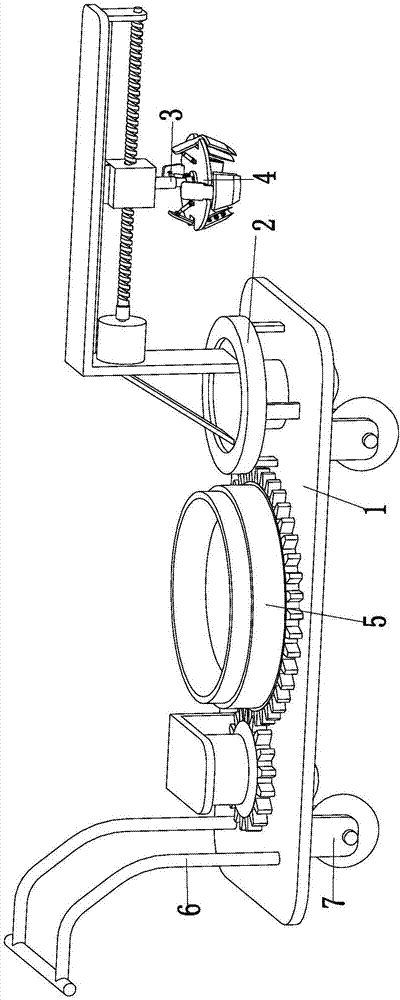

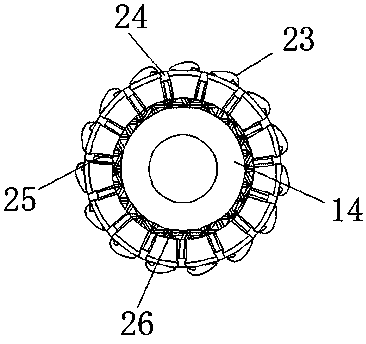

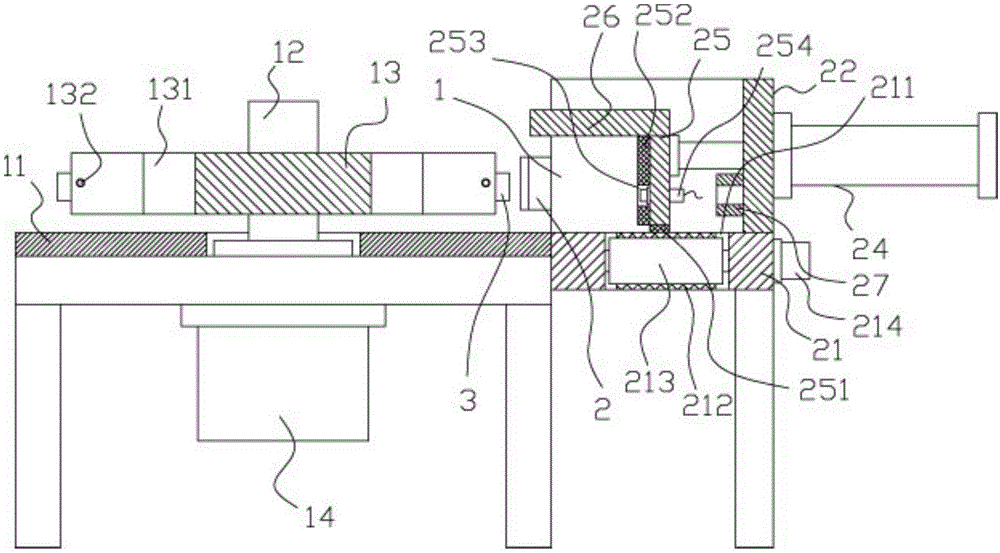

Robot for de-icing of power transmission lines

ActiveCN101728803ASo as not to damageGood deicing effectOverhead installationManipulatorEngineeringHigh pressure

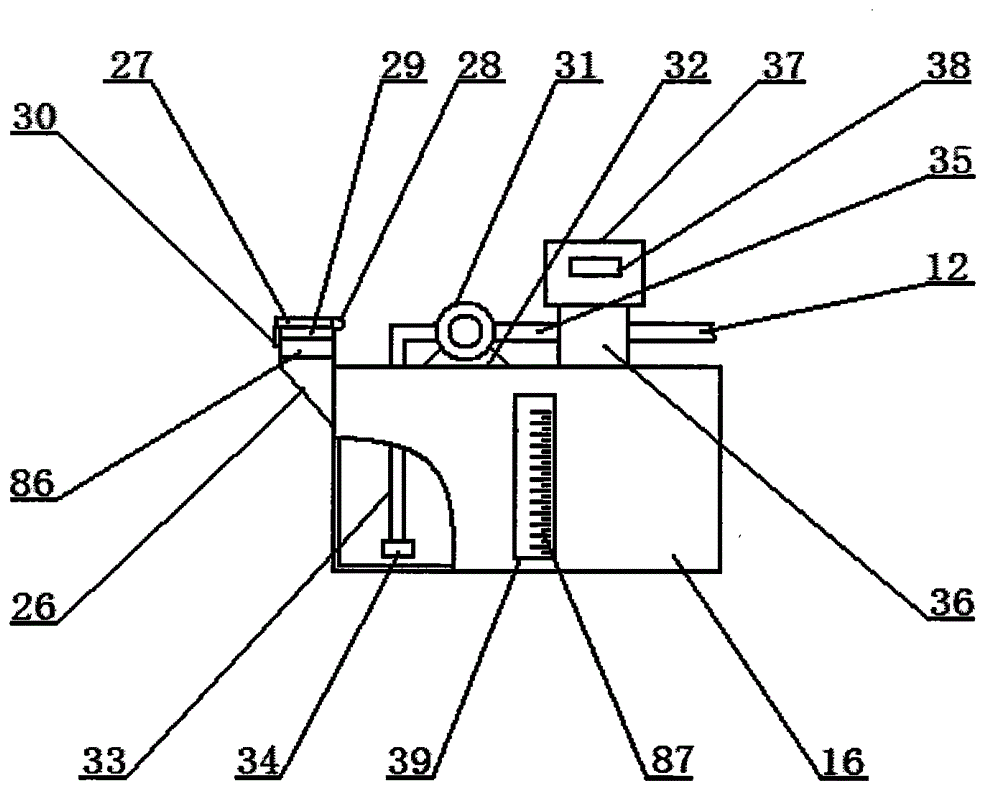

The invention relates to a troubleshooting device for high-voltage power transmission lines, in particular to a robot for de-icing of the power transmission lines. The robot is creatively provided with a de-icing mechanism on a front arm, the de-icing mechanism is connected on the front arm through a lifting mechanism, the action of the de-icing mechanism is to carry out the de-icing through the rotation of a de-icing knife and the extrusion of a plurality of the power transmission lines by a walking mechanism and a pressing mechanism during the process that the robot walks along the power transmission lines, and the robot can automatically cross barriers without the need of manual handling, thereby having the advantages of good de-icing effect, high efficiency, wide range of applications and high safety factor.

Owner:GUANGDONG KEYSTAR INTELLIGENCE ROBOT CO LTD

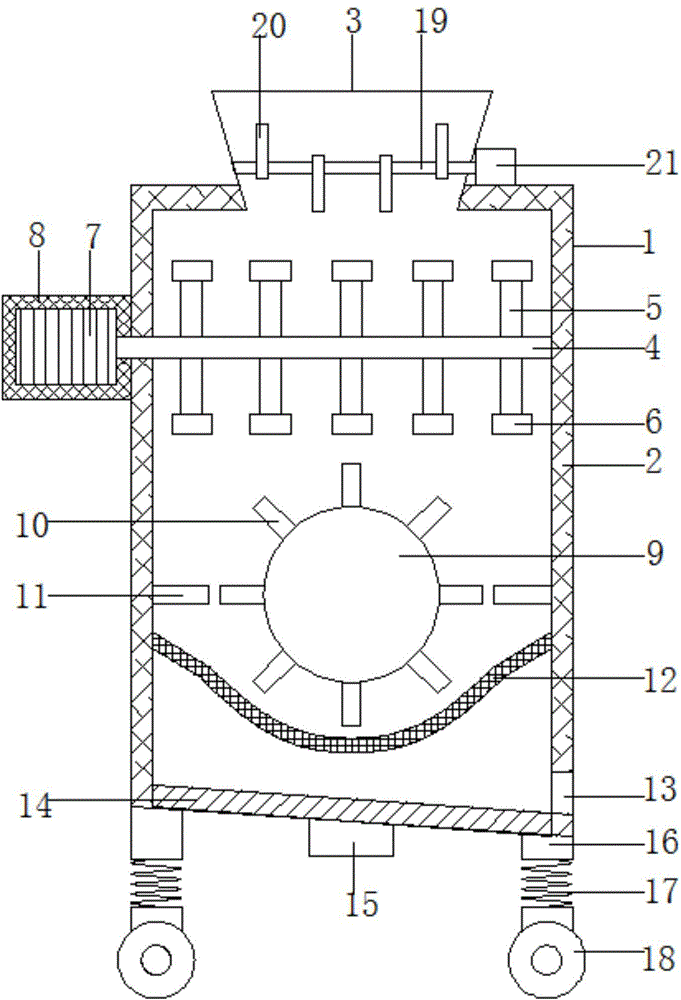

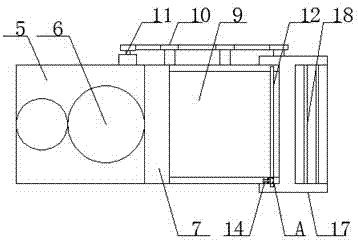

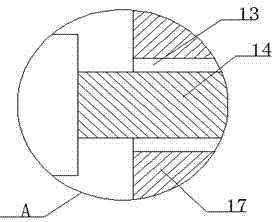

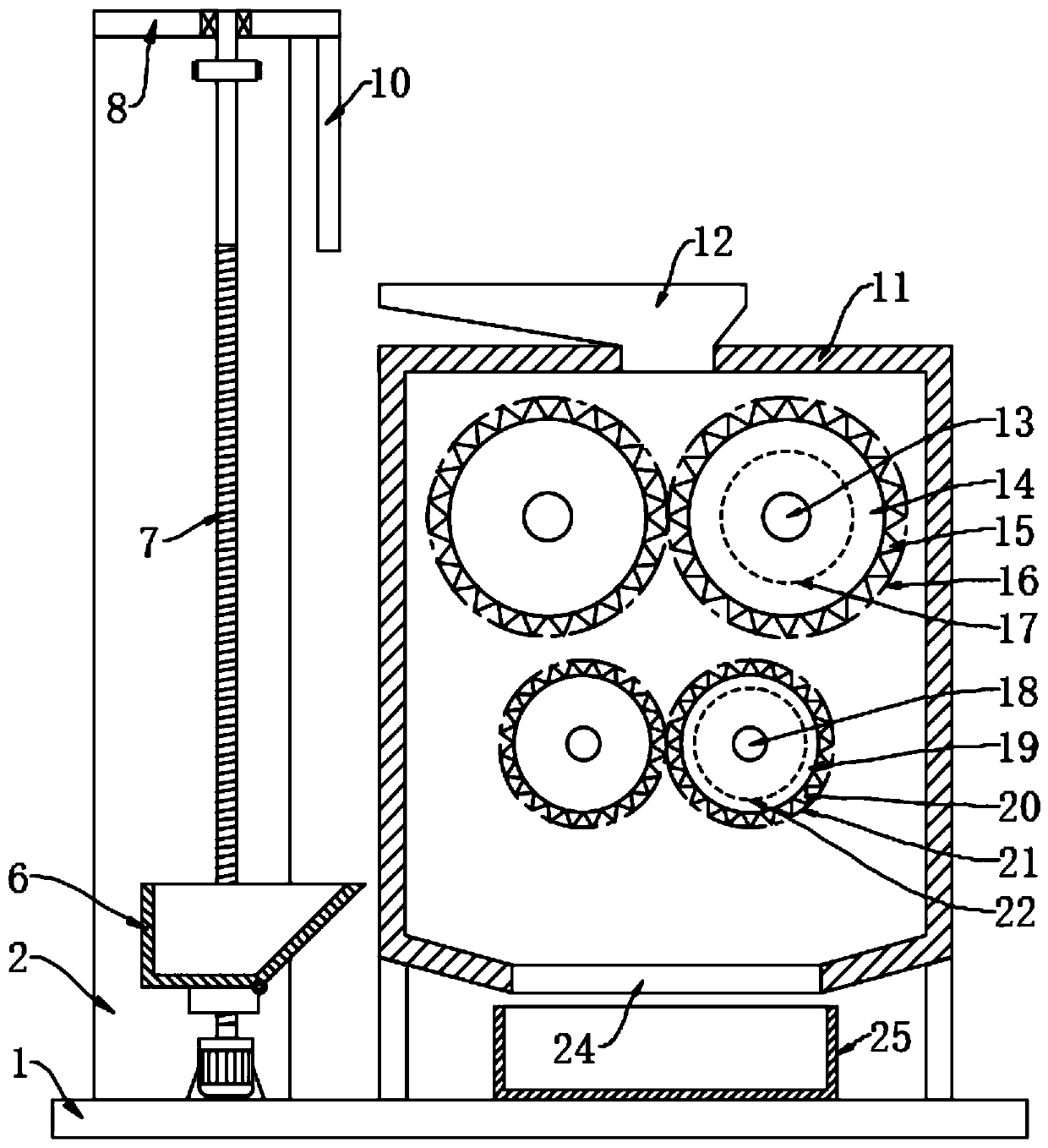

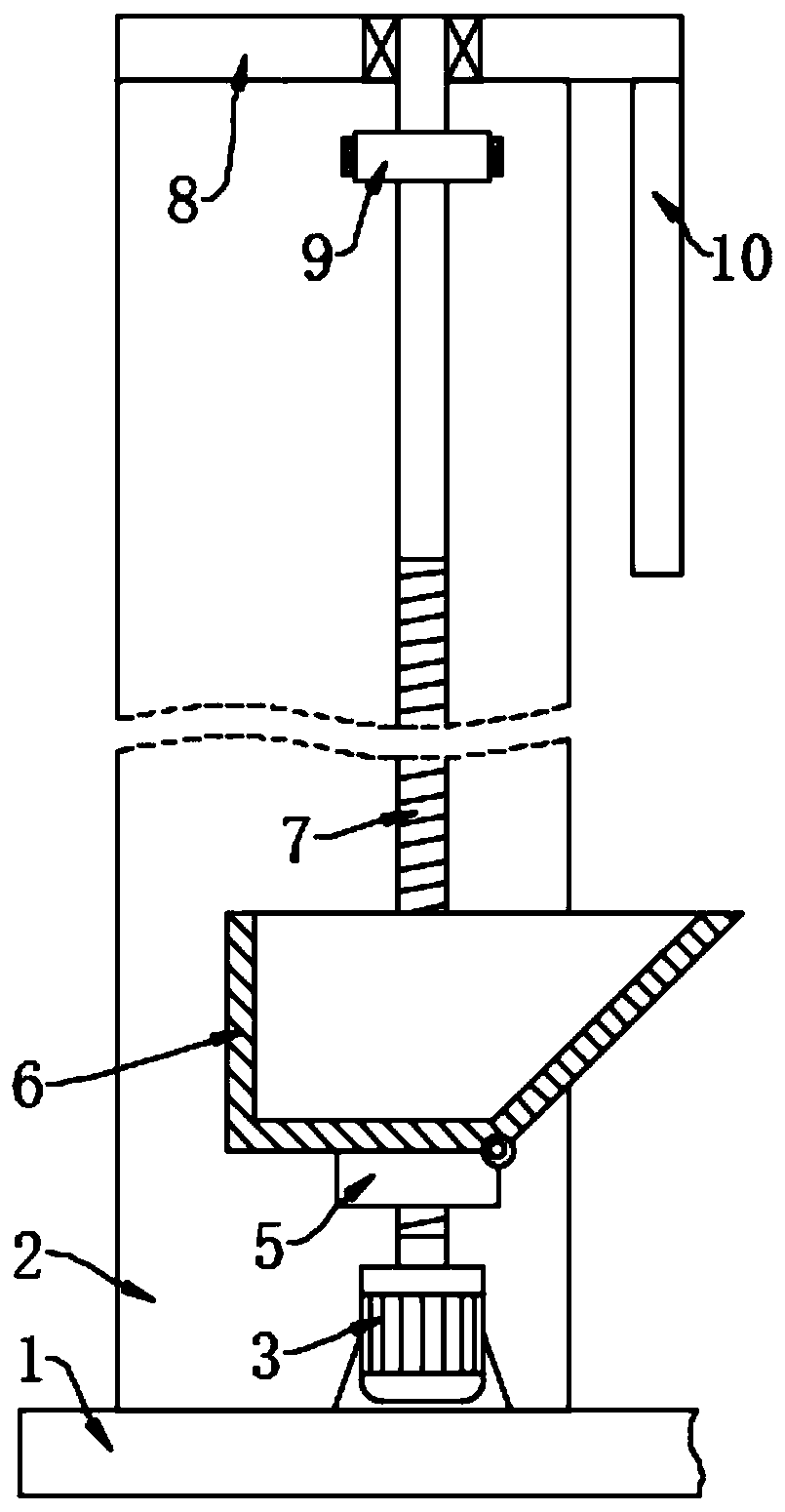

Movable anti-blocking pulverizer for ceramic production

InactiveCN104923344AAvoid cloggingImprove crushing effectGrain treatmentsElectric machineryDrive motor

The invention discloses a movable anti-blocking pulverizer for ceramic production. The movable anti-blocking pulverizer for ceramic production comprises a pulverizer body, a rotary shaft and eccentric wheels, wherein an electric heating layer evenly covers the outer wall of the pulverizer body, a feeding funnel is connected to the upper side of the pulverizer body, the rotary shaft is horizontally arranged in the feeding funnel, the eccentric wheels are evenly arranged on the rotary shaft, the centers of the eccentric wheels are evenly distributed around the rotary shaft, and the right end of the rotary shaft extends out of the feeding funnel to be connected with a driving motor. The movable anti-blocking pulverizer for ceramic production adopts two pulverizing mechanisms to pulverize a material, can fully pulverize the material, the working efficiency of the pulverizer is improved, the pulverizing effect is ensured, the material is heated and dried in the pulverizing process, material production efficiency is improved, vibration can be effectively reduced through the arranged eccentric wheels, material blockage in the feeding funnel can be prevented, and continuous feeding is ensured. In addition, noise of the pulverizer during working is small, the pulverizer can be freely and conveniently moved, and practicability and convenience are high.

Owner:顾广才

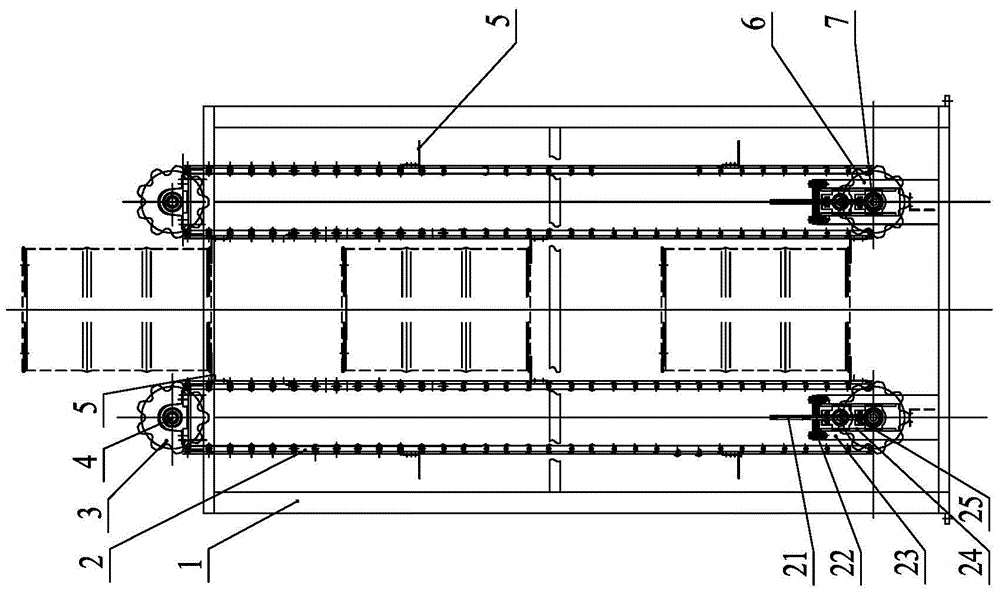

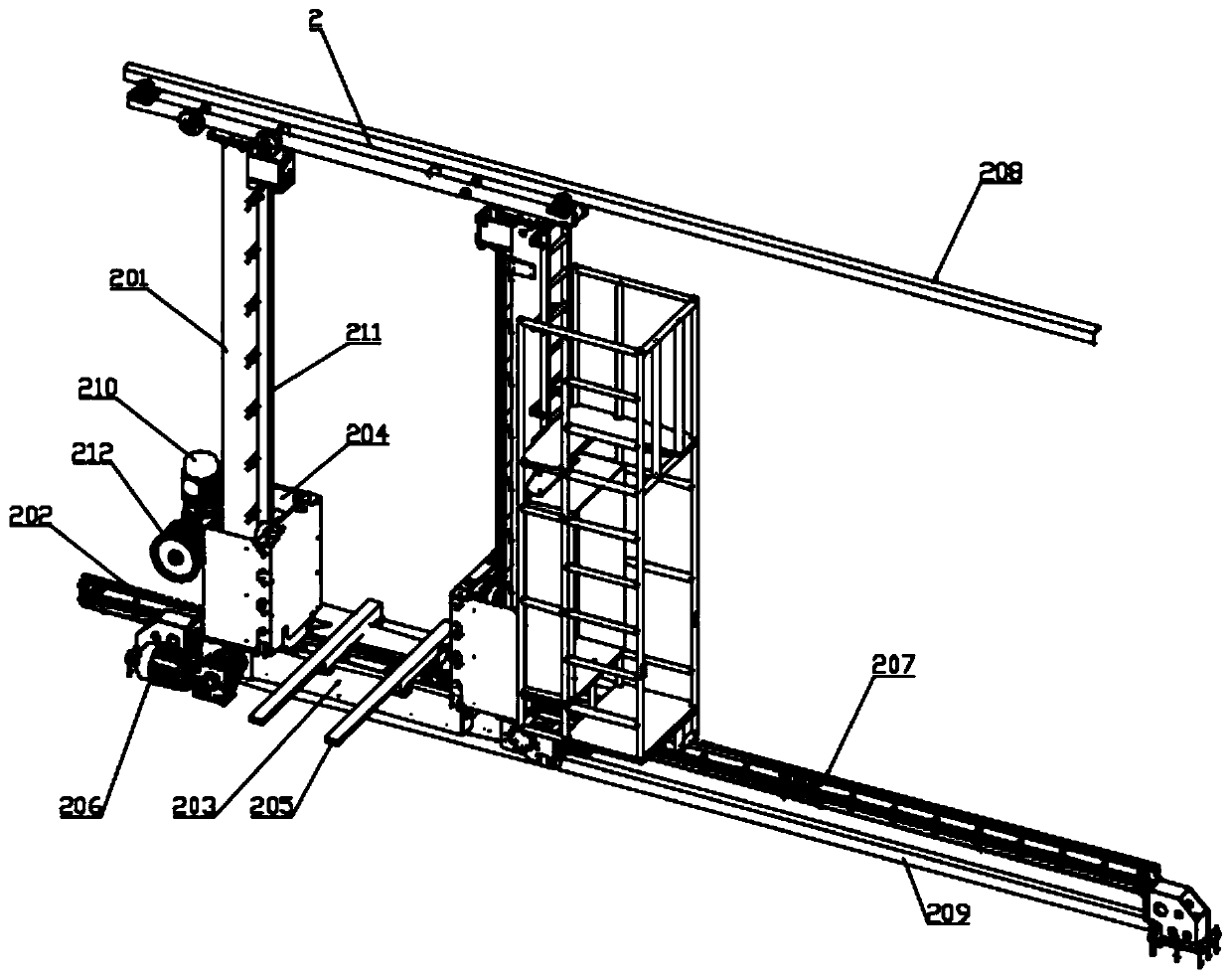

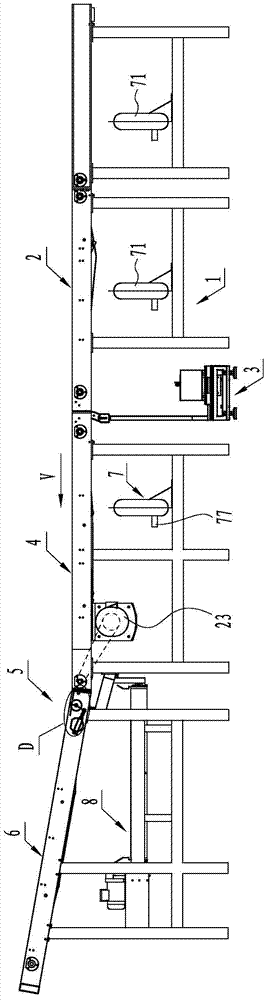

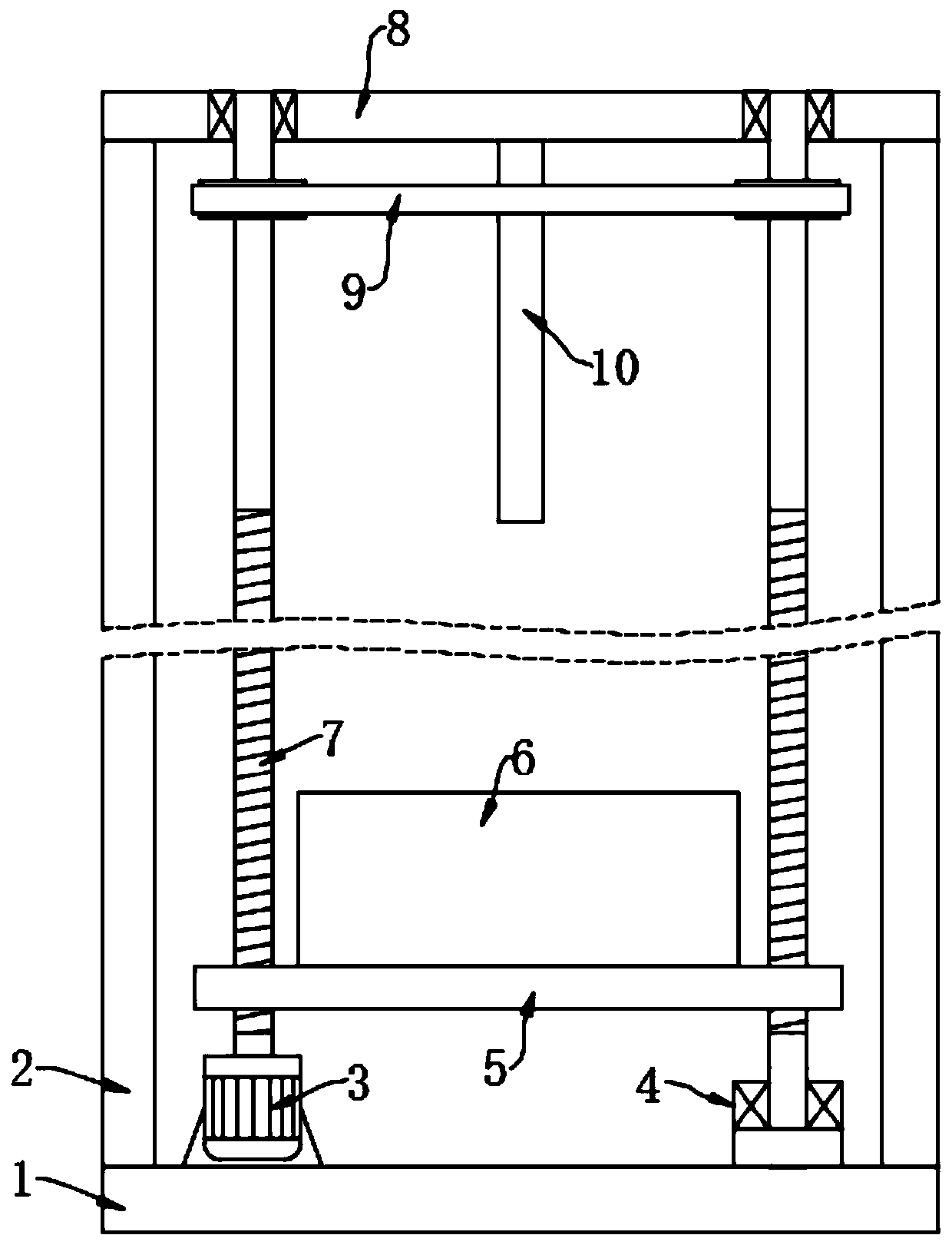

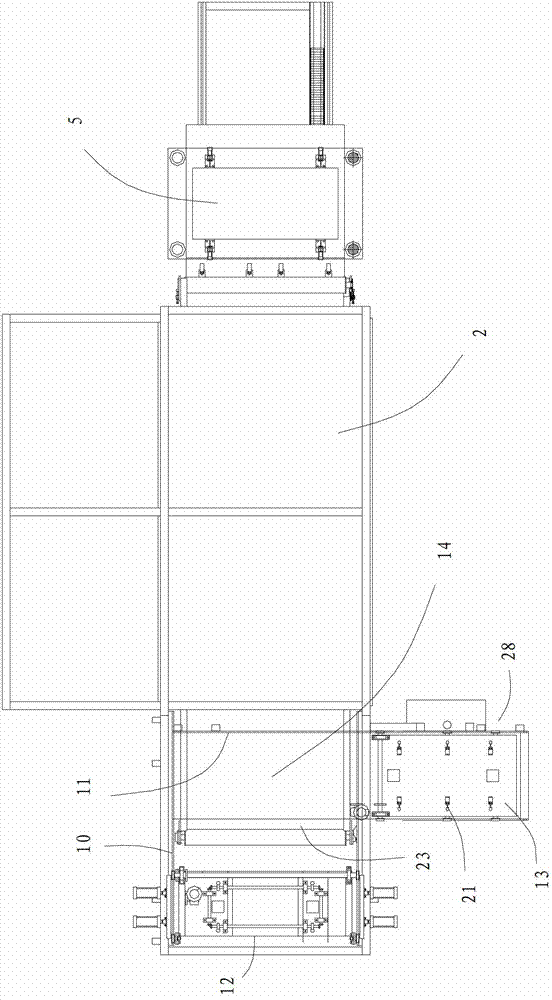

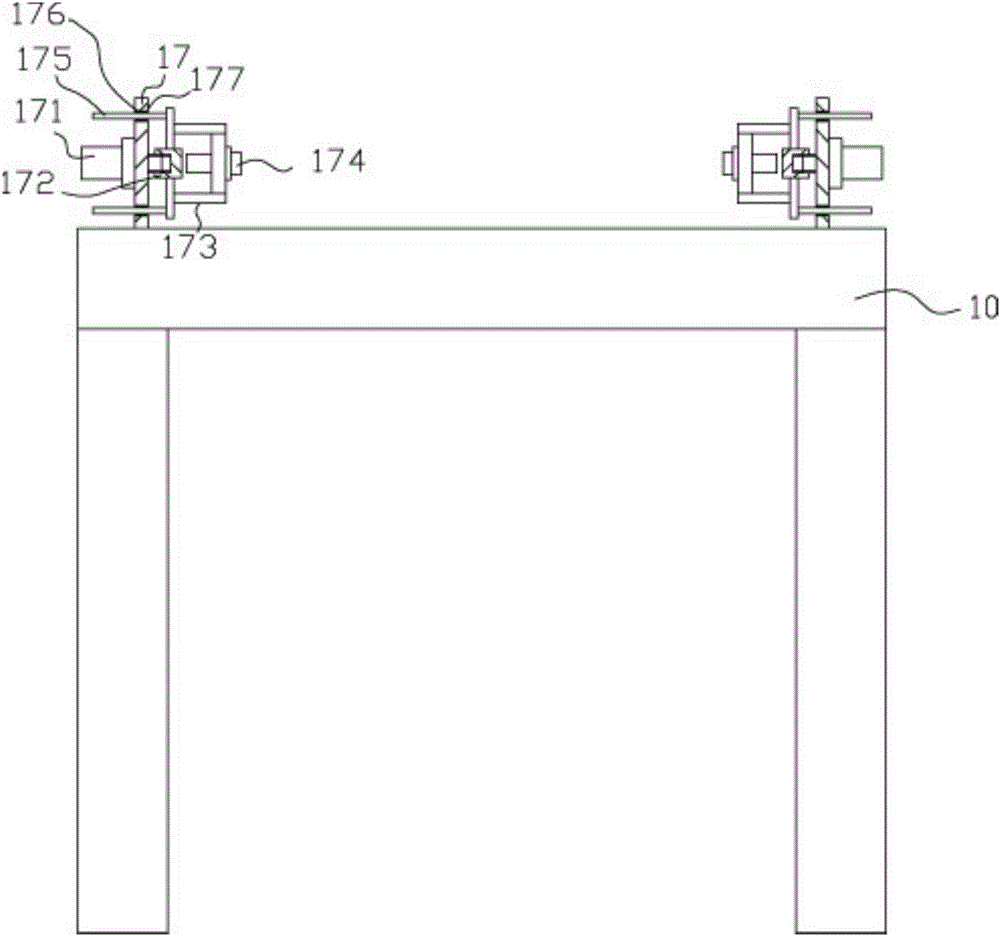

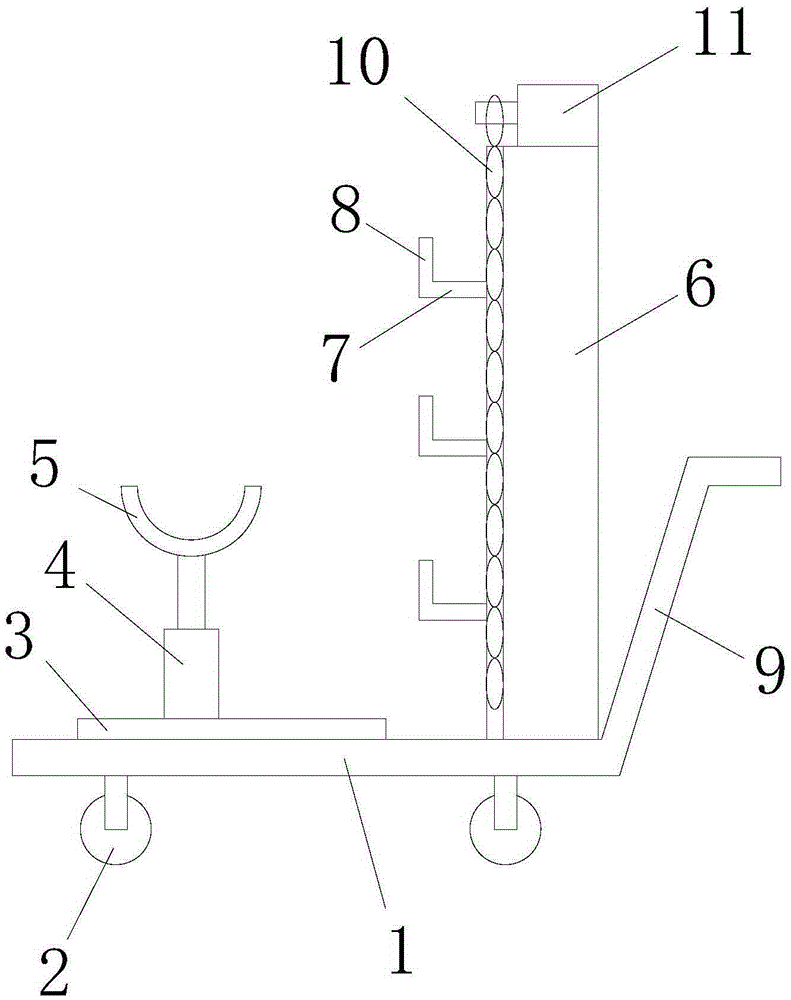

Vertical conveyer for steel drum stereoscopic warehouse

ActiveCN104444000ACompact and reasonable layoutOptimize layoutStorage devicesConveyor partsSprocketChain link

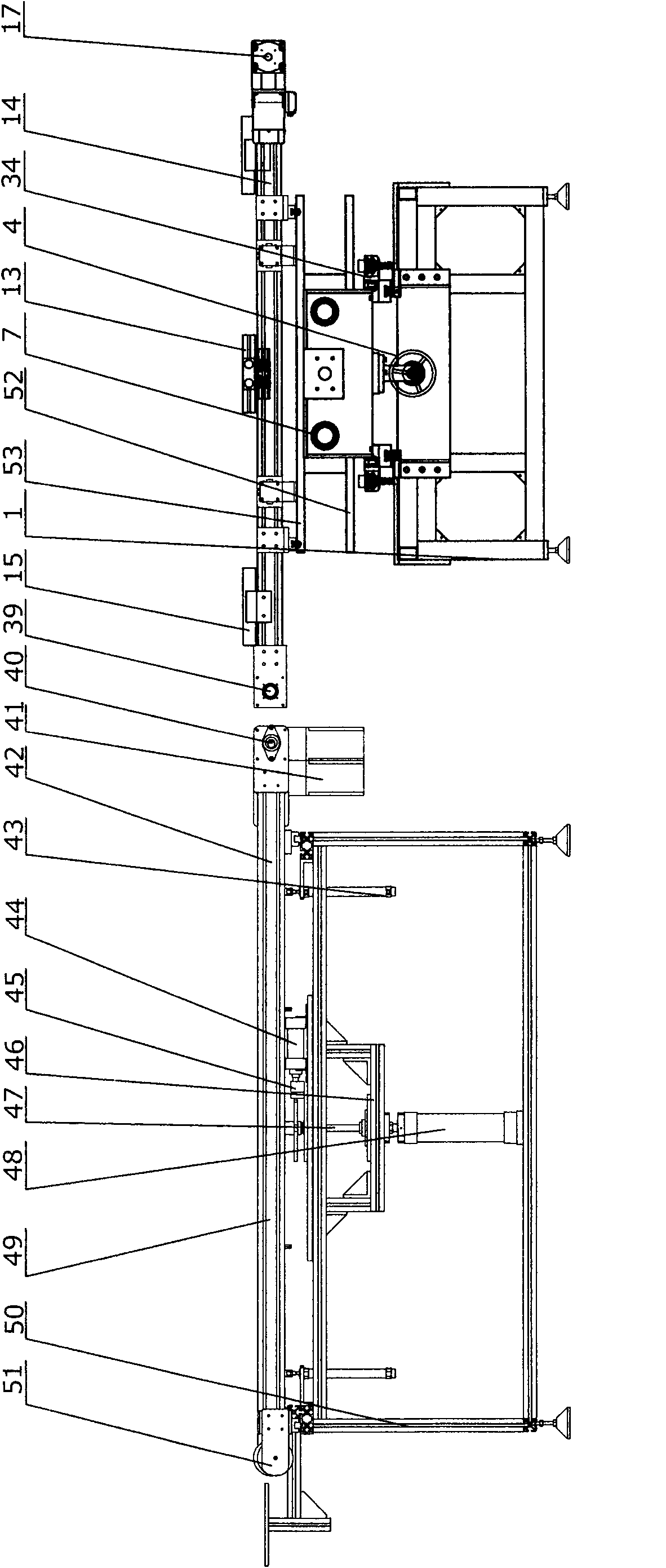

The invention relates to a vertical conveyer for a steel drum stereoscopic warehouse. According to the vertical conveyer for the steel drum stereoscopic warehouse, a steel drum lifting and conveying channel is arranged in the middle of a machine frame, a layer of conveyance rolling way is arranged below the steel drum lifting and conveying channel, the two sides of the steel drum lifting and conveying channel are each provided with a steel drum lifting device, and the two steel drum lifting device are symmetrically arranged; in each steel drum lifting device, an upper chain wheel is installed on an upper shaft on the upper portion of the machine frame, a lower chain wheel is installed on a lower shaft on the lower portion of the machine frame, the upper chain wheel and the lower chain wheel are sleeved with a lifting chain, the upper chain wheel and the lower chain wheel are driven by a driving mechanism to drive the lifting chain to rotate in a circulating mode, multiple L-shaped supporting plates which are distributed at equal intervals are installed on the lifting chain, a steel drum conveyed in place is supported by the L-shaped supporting plates and are lifted, a drum pushing device is installed on the machine frame and is arranged on the side opposite to a storage and conveyance rolling way, and the drum pushing device is used for pushing the steel drum lifted in place to the storage and conveyance roller way. The vertical conveyer for the steel drum stereoscopic warehouse is simple in structure, convenient to operate and capable of achieving automatic lifting and conveyance of the steel drum in the height direction.

Owner:TAICANG SIFANG YOUXIN DRUM-MFG CO LTD

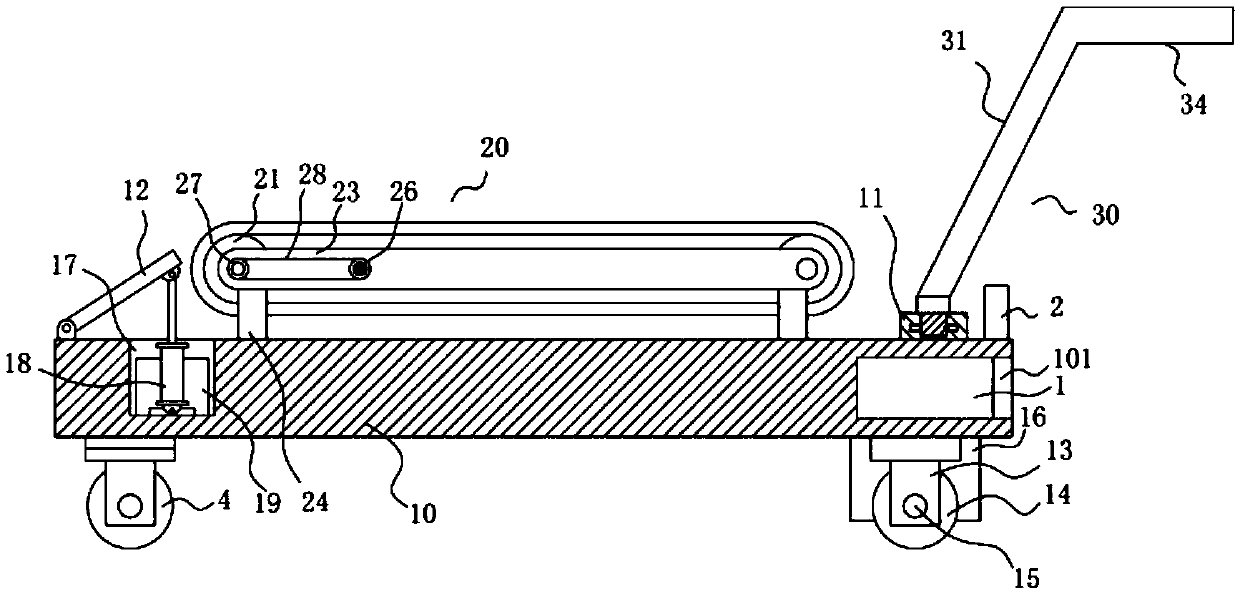

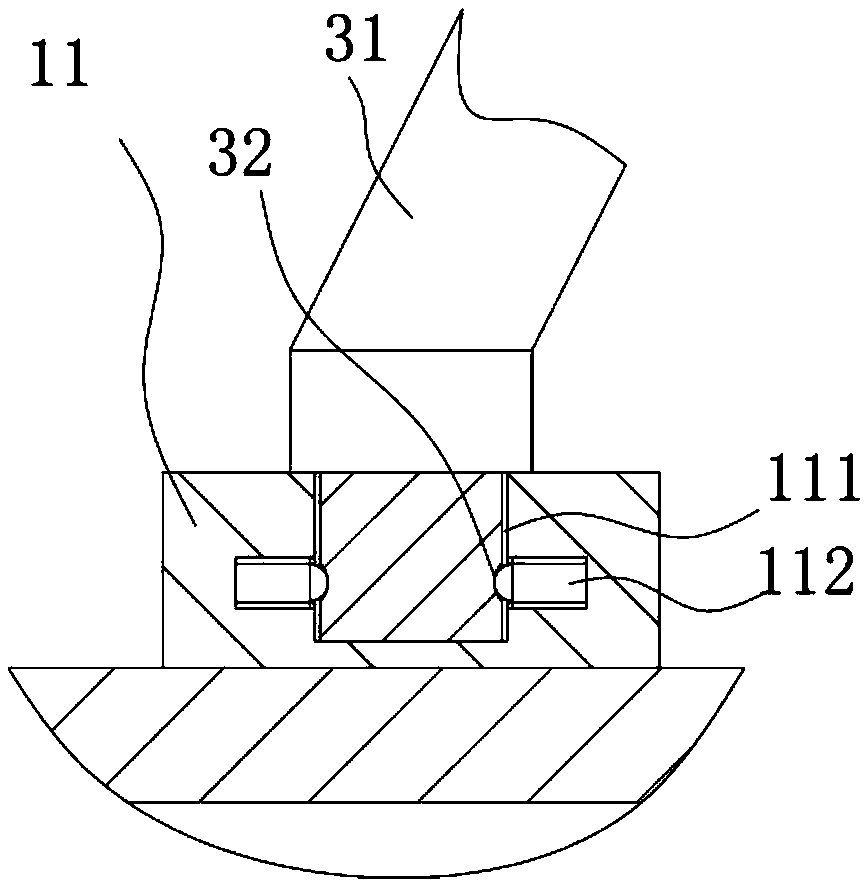

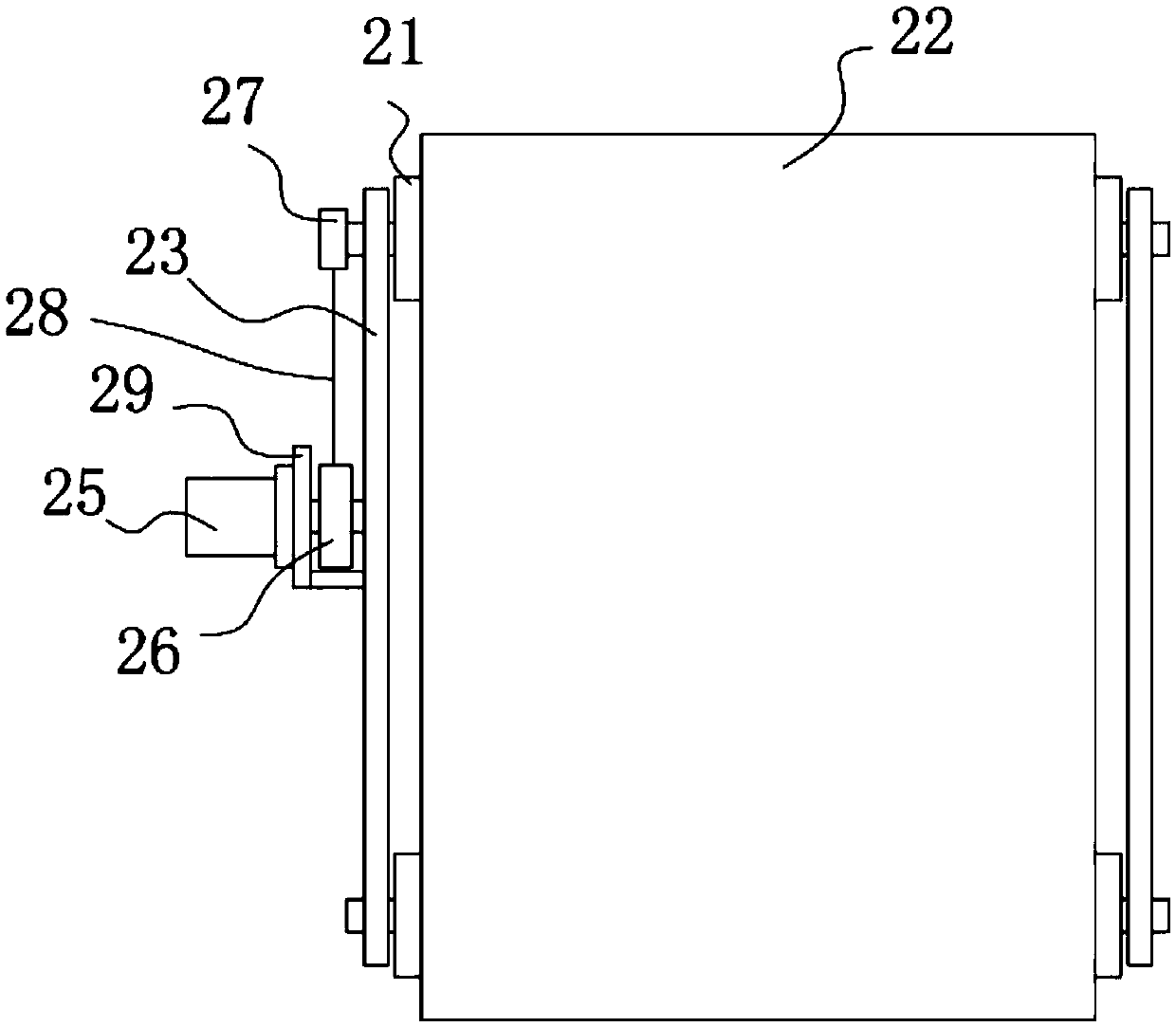

Power distribution cabinet lifting device

The invention discloses a power distribution cabinet lifting device and relates to the technical field of power distribution cabinet equipment. The power distribution cabinet lifting device comprises a transport trolley, wherein a load bearing installation plate is arranged on the transport trolley, a cylinder is arranged at the left end of the load bearing installation plate, cylinder fixing guide rails are arranged in the cylinder, an L-shaped lifting platform is arranged on the cylinder, a piston rod is arranged at the upper part of the cylinder, an object carrying platform is arranged on the L-shaped lifting platform, 3-5 belt rollers are arranged on the object carrying platform, a conveying belt is arranged on the belt rollers, certain ends of the belt rollers are connected with a sprocket, the sprocket is connected with a driving motor, a limiting plate is arranged on the right side of the object carrying platform, one end of the limiting plate is hinged onto the object carrying platform, and the other end of the limiting plate is provided with a hole and is fixed on the object carrying platform through a bolt. The lifting device has the advantages that the power distribution cabinet is convenient to transport, the time and labor are saved and the safety is high.

Owner:SUZHOU SHIJIJINGYUAN OPTIC

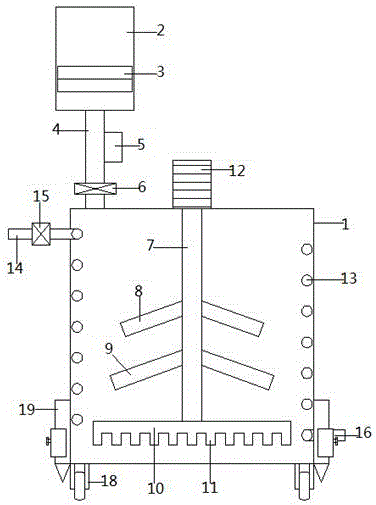

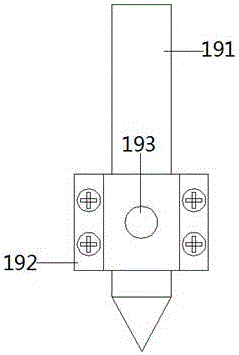

Effective-stirring high-performance reactor

InactiveCN106040157AEfficient crushingEasy to moveRotary stirring mixersTransportation and packagingReaction rateEngineering

The invention discloses an effective-stirring high-performance reactor, comprising a body. The upper left of the body is provided with a feed port, the upper side of the body is provided with a stock bin, a crushing mechanism is disposed in the stock bin, the crushing mechanism comprises a horizontally arranged crushing spindle and crushing blades disposed on the outer wall of the crushing spindle, a discharge port in the bottom of the stock bin is connected with the feed port of the body through a discharge pipe, the sidewall of the discharge pipe is provided with a vibrating motor, the discharge pipe is provided with a discharge valve, the discharge valve is an electromagnetic valve, and a stirring spindle is vertically disposed in the center of the body. The effective-stirring high-performance reactor may quickly crush materials and feed them in for reaction, reacting speed is increased, the stirring effect is good, stirring is sufficient, the materials are more sufficiently reacted, the materials can be heated or cooled quickly, reacting efficiency is further improved, and in addition, the reactor is convenient to fix and move and is high in portability.

Owner:李明波

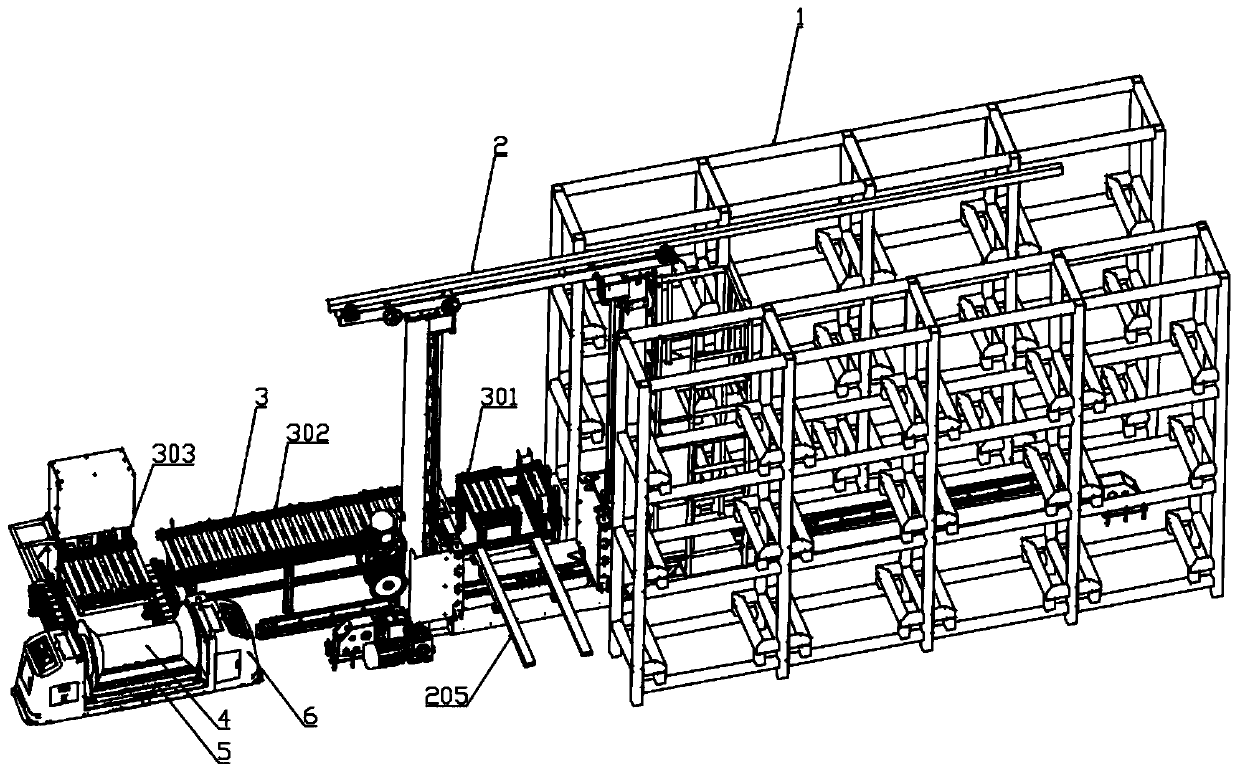

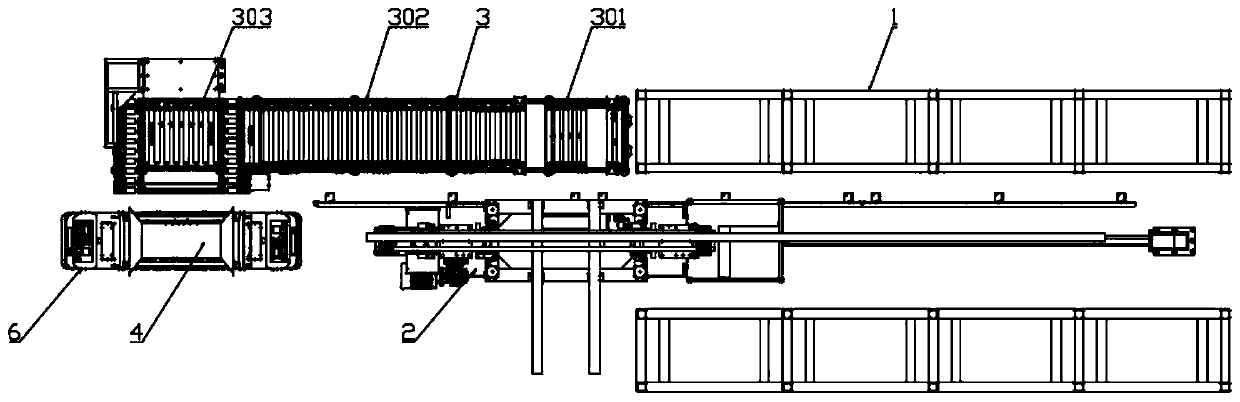

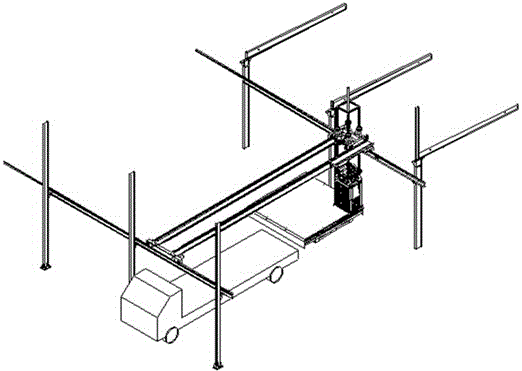

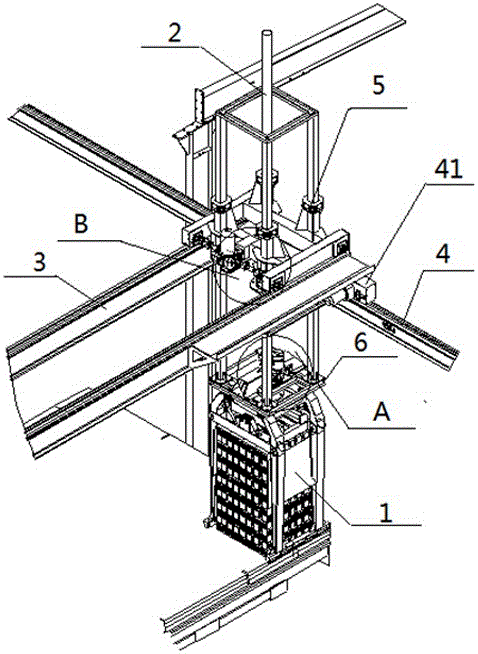

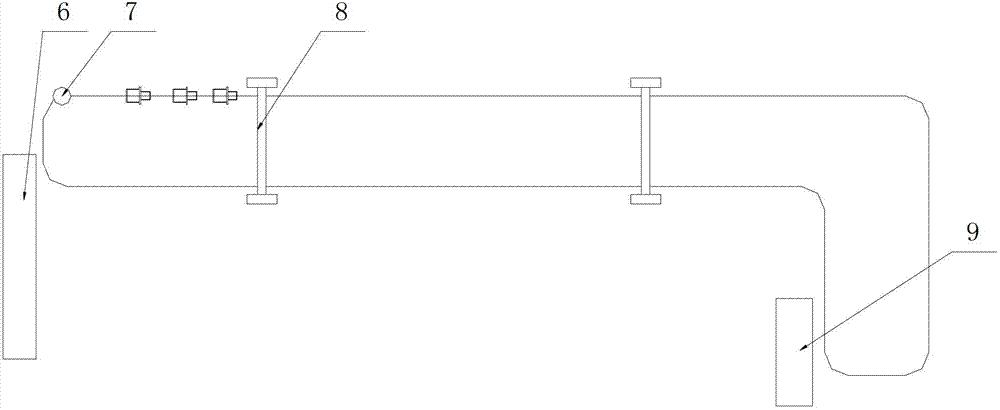

Spool storage system

PendingCN110844439AImprove work efficiencySave labor cost and production areaConveyorsStorage devicesCartManufacturing engineering

The invention discloses a spool storage system. The spool storage system comprises a spool goods shelf, a stocker and a warehouse out-put and in-put conveying line. The spool goods shelf is used for storing spools and trays, the stocker comprises a stacking rack, a walking system, a cargo carrying table, a cargo carrying table lifting mechanism and a fork, and the warehouse out-put and in-put conveying line comprises a horizontal-movement conveying line, a lifting conveying line and a storage butt joint conveying line. According to the spool storage system, the spools and trays are stored on the spool goods shelf, the stocker can automatically take the spools and trays on the spool goods shelf to the warehouse out-put and in-put conveying line, the warehouse out-put and in-put conveying line performs horizontal-movement conveying and lifting conveying on the spools and trays, finally the spools and trays are in butt joint conveying to a spool transport cart, warehouse out-put of the spools is achieved accordingly, and the warehouse in-put process is opposite. Therefore, the spool storage system automatically stores the spools in a three-dimensional mode, manual carrying is not needed, the work efficiency is improved, and the labor cost and production area are reduced.

Owner:成都瑞克西工业自动化技术有限公司

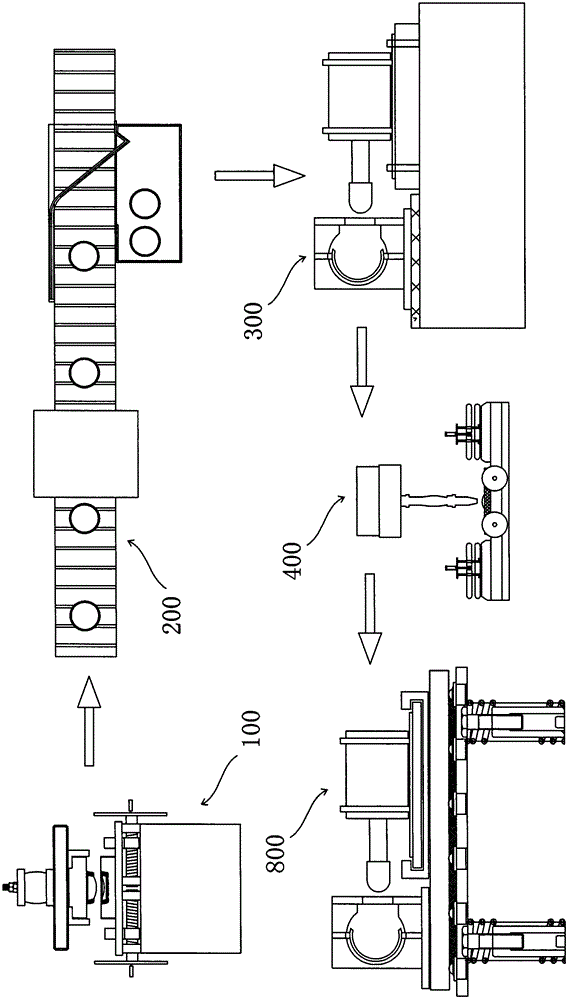

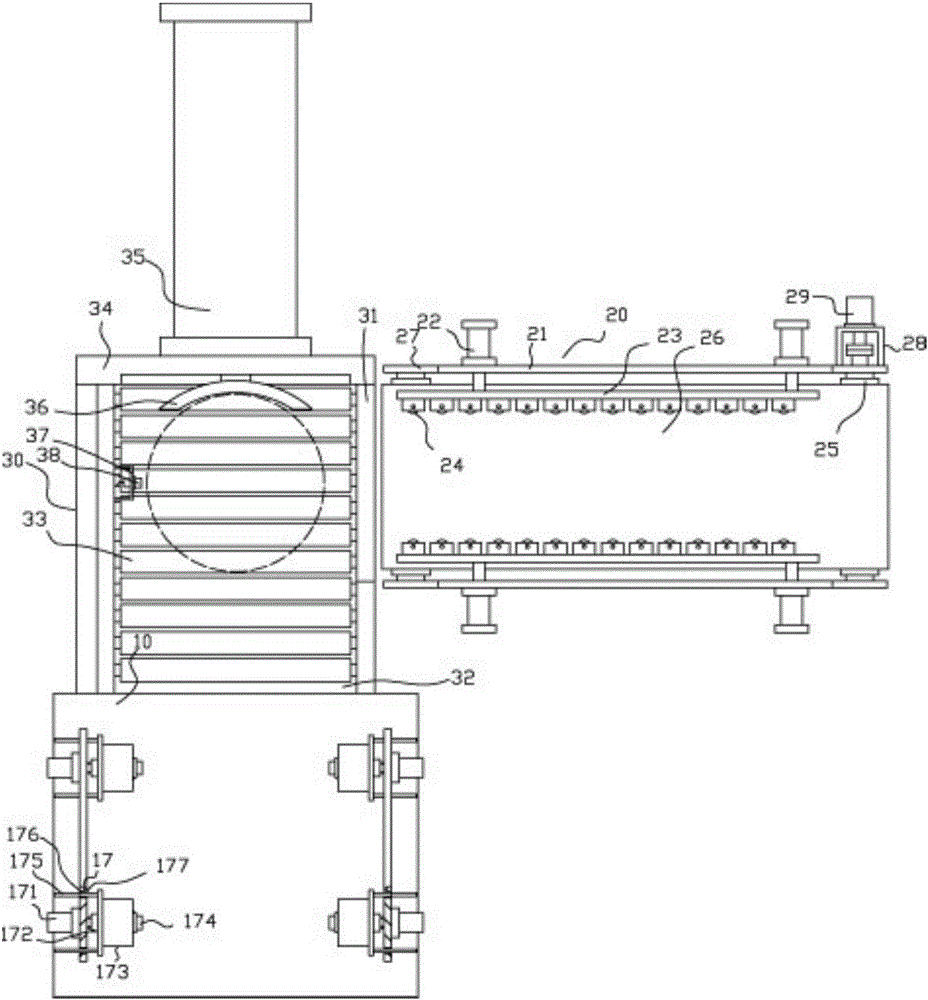

Automotive brake pad production line

ActiveCN104476200AHigh precisionImprove processing efficiencyOther manufacturing equipments/toolsProduction lineHeat transfer efficiency

The invention relates to an automotive brake pad production line which comprises a tabletting device, a thermal treatment device, a grinding device, a drilling device, a code spraying device and a conveying device connected among the former. Through the tabletting device, a concave die can be closely clamped, so that position of the concave die can be adjusted accurately; through the thermal treatment device, an automotive brake pad storage shelf after being subjected to thermal treatment can be automatically conveyed to a goods storage area, and heat transfer efficiency of a drum brake pad is improved; through the grinding device, an automotive brake pad is closely clamped, and position of an automotive brake pad clamp can be adjusted accurately, so that grinding accuracy is improved remarkably; through the drilling device, the automotive brake pad is closely clamped, the position of the automotive brake pad can be adjusted accurately, and a clamping clamp can be accurately positioned, so that drilling accuracy is improved remarkably; through the code spraying device, the brake pad is clamped closely, code spraying accuracy is improved, and one-step code spraying forming of multiple batches of brake pads is realized.

Owner:HUANGSHAN FEIYING AUTO PARTS

Single corrugated paperboard quality detecting machine

The invention discloses a single corrugated paperboard quality detecting machine, and relates to the technical field of corrugated paperboard detection. The single corrugated paperboard quality detecting machine comprises a rack, wherein the rack is sequentially provided with a first conveying unit, a detecting unit, a second conveying unit, a waste removing unit and a third conveying unit along the forward direction of the corrugated paperboard; the waste removing unit comprises a waste removing turnover plate arranged between the second conveying unit and the third conveying unit; the single corrugated paperboard quality detecting machine also comprises a control system and adsorbing units, wherein the control system is used for controlling the waste removing turnover plate to move or not according to the detection result of the detecting unit; the adsorbing units are respectively arranged on the inner sides of the conveying belts of the first conveying unit and the second conveying unit and are used for adsorbing corrugated paperboards on the conveying belts. The single corrugated paperboard quality detecting machine can automatically detect the printing quality and die cutting quality of the corrugated paperboard, is high in accuracy and high in detection speed, and also can separate qualified products from unqualified products, so that the production efficiency is improved greatly.

Owner:SHANDONG CENTURY MACHINERY

Frame type ultrasonic cleaning device

ActiveCN104241171AEasy accessSimple structureSemiconductor/solid-state device manufacturingCleaning using liquidsMechanical engineeringMechanics

Owner:YANGTAI PHARMA SHANDONG

Electronic garbage recovery treatment equipment

The invention discloses electronic garbage recovery treatment equipment, and relates to the technical field of electronic garbage treatment. The electronic garbage recovery treatment equipment comprises a base; a crushing box is fixedly arranged at the top of the base through a bracket; left and right first rotating shafts are arranged in the crushing box in the front-back direction, and are rotationally connected with the front and back walls of the crushing box; first crushing rollers are fixedly mounted on the parts, positioned in the crushing box, of the left and right first rotating shafts; multiple first crushing teeth are uniformly arranged on the side walls of the first crushing rollers; left and right second rotating shafts are arranged in the crushing box in the front-back direction, and are rotationally connected with the front and back walls of the crushing box; second crushing rollers are fixedly mounted on the parts, positioned in the crushing box, of the left and right second rotating shafts; and multiple second crushing teeth are uniformly arranged on the side walls of the second crushing rollers. Through opposite rotation of the first crushing rollers, waste electronic garbage is primarily crushed; and through opposite rotation of the second crushing rollers, the waste electronic garbage is crushed again, so that the electronic garbage is fully crushed.

Owner:湖南聚义岩科技有限公司

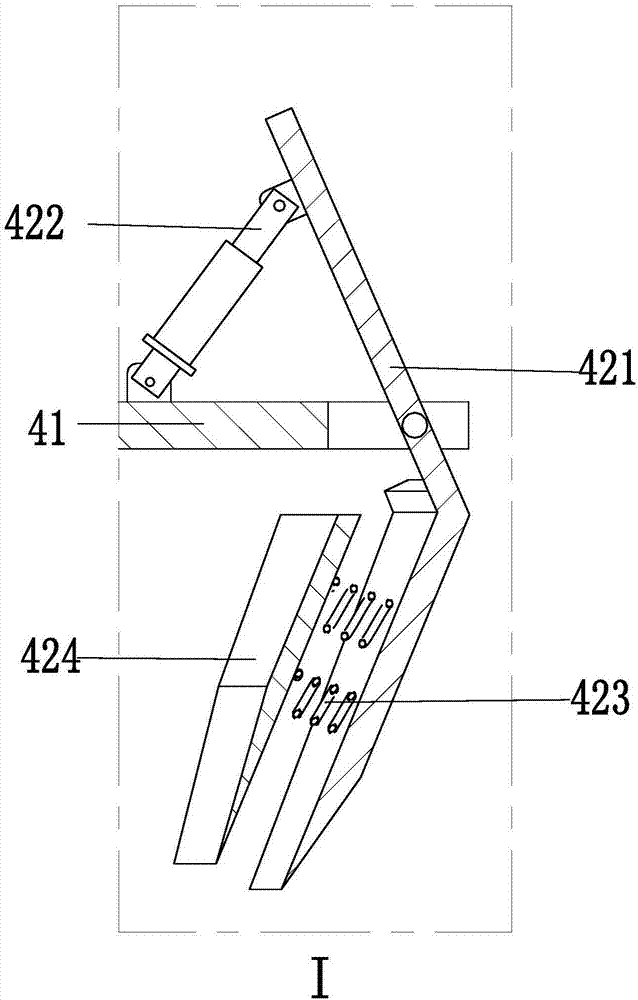

Efficient automatic fruit sorting robot

ActiveCN106976102AGrasp firmlyReduce labor intensityGripping headsConveyor partsHydraulic cylinderEngineering

The invention relates to an efficient automatic fruit sorting robot comprising a base plate. An adjusting mechanism is mounted at the front end of the base plate. A lifting hydraulic cylinder is mounted at the lower end of the adjusting mechanism. The bottom end of the lifting hydraulic cylinder is mounted on a hard-shell fruit grabbing mechanism through a flange. A collecting mechanism is mounted in the middle of the base plate, and a pushing handle is mounted at the rear end of the base plate. Four universal wheels are mounted symmetrically at the lower end of the base plate. The adjusting mechanism can drive the hard-shell fruit grabbing mechanism to conduct position adjusting. The adjusting mechanism, the hard-shell fruit grabbing mechanism and the collecting mechanism are mutually matched to complete the process of fruit sorting. The problems that in the existing fruit sorting process, soft-shell fruit and hard-shell fruit need to be carried through labor, the surface of the soft-shell fruit is prone to damaging, fruit selling is affected, and carrying of the hard-shell fruit through the labor is large in labor intensity and low in working efficiency can be solved, and the function of efficient fruit sorting can be achieved.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

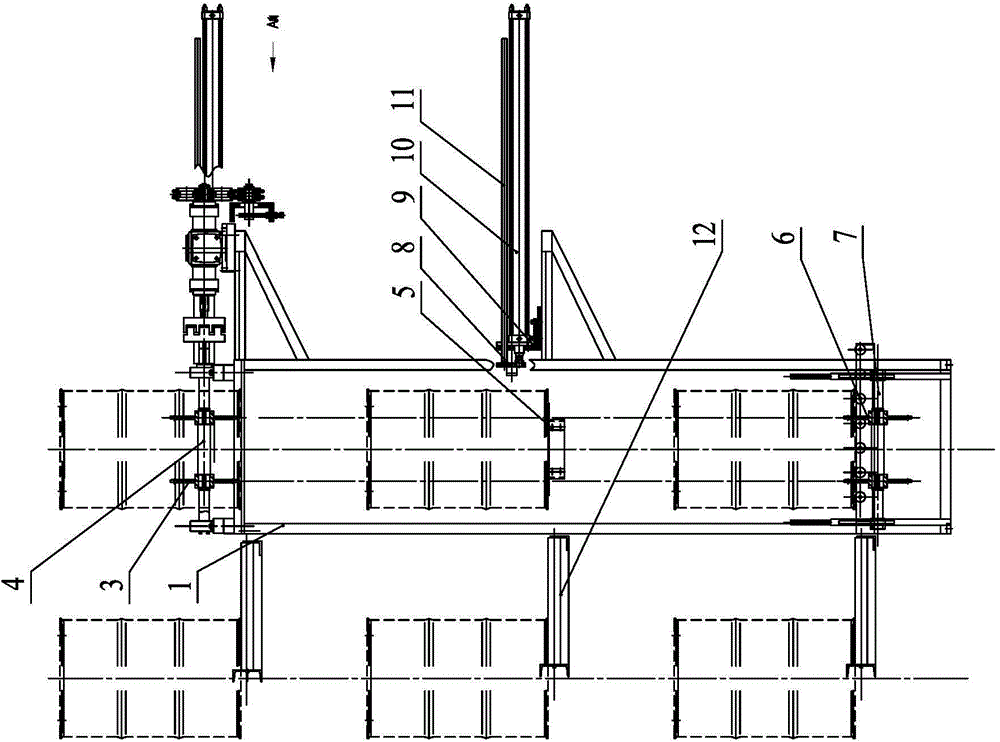

Bilateral adsorption composite feeding system and production method thereof

The invention discloses a bilateral adsorption composite feeding system and a production method thereof. The bilateral adsorption composite feeding system is used for feeding materials for a moving mold table of a press and comprises a frame and a dryer provided with a tunnel type heating area. A second loading frame selects a second raw material sheet in a second loading area through a needling material taking cylinder, moves to an overlapping area, puts down the second raw material sheet on a main conveying belt in the overlapping area and then returns to the second loading area. A first loading frame selects a first raw material sheet in a first loading area through a vacuum sucker, moves to the overlapping area, overlays the first raw material sheet on the second raw material sheet and then returns to the first loading area. The main conveying belt is started up, the sheets in the overlapping area are sent to the tunnel type heating area of the dryer; the sent-in sheets are heated and roasted in the tunnel type heating area in the dryer; and an auxiliary conveying belt is started up, and the roasted sheets are conveyed to the moving mold table from the main conveying belt to finish the feeding operation. According to the bilateral adsorption composite feeding system and the production method thereof, production efficiency can be greatly improved, labor intensity can be reduced, positioning is accurate, and product quality can also be ensured.

Owner:海南华福汽车零部件制造有限公司

Cylinder packaging barrel conveying device

ActiveCN106347979ANo need for manual handlingImprove efficiencyConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a cylinder packaging barrel conveying device which comprises a conveying frame and a rear supporting frame. The conveying frame is fixed to the position of the right side of the rear supporting frame, position adjusting cylinders are fixed to the left ends and the right ends of the upper portions of beams on the front side and the rear side of the conveying frame, push rods of the two position adjusting cylinders of the beams penetrate the beams, and side adjusting plates are fixed to the push rods. A plurality of side transmission roller bodies are hinged to the side adjusting plates, the side transmission roller bodies of the side adjusting plates on the two beams are opposite in a left-right mode, the left end of the conveying frame is opposite to a feeding port on the right side of the rear supporting frame, the front end of the rear supporting frame is provided with a discharging port, and the discharging port is opposite to the rear of a placing frame. Transverse connecting plates are fixed to the top surfaces of the left side and the right side of the placing frame, adjusting motors are fixed to the front ends and the rear ends of the transverse connecting plates, output shafts of the adjusting motors extend out of the transverse connecting plates and are spirally connected into connecting thread sleeves. According to the cylinder packaging barrel conveying device, a cylinder packaging barrel can be conveyed through an automatic conveying belt to the follow-up processing placing frame from the previous processing position, manual carrying is not needed, and the cylinder packaging barrel conveying device is high in efficiency and good in effect.

Owner:QINGDAO SANXIN PACKAGING TECH CO LTD

Modified plastic-wood profile embossing device and embossing process thereof

PendingCN110328729AIncrease the scope of applicationAutomateConveyorsWood compressionEngineeringHook plate

The invention discloses a modified plastic-wood profile embossing device and an embossing process thereof. The embossing device comprises a feeding mechanism, a conveying mechanism and an embossing mechanism, wherein the embossing mechanism is composed of a working table, distance adjusting slide rods, a top plate, an adjusting sliding plate, a distance adjusting air cylinder, pressing rollers, adriving motor, a buffering sliding rod, an auxiliary roller, a buffer spring, a collecting box, a material receiving plate and a return spring, wherein the four corners of the top of the working tableare fixedly connected with the distance adjusting slide rods. According to the modified plastic-wood profile embossing device and the embossing process thereof, through arranging the feeding mechanism and under the action of a lifting motor and a clamping air cylinder, profiles can be automatically fed without manual carrying, which leads to the saving of time and labor; in addition, under the action of the distance adjusting air cylinder, distances between the pressing rollers can be flexibly adjusted, so that the device can be applied to the profiles of different thickness, which improves the application range of the device; finally, through setting a storage box and a push hook plate, the automatic conveying and adding of the profiles is facilitated, so that both automation and intelligentization can be realized, thus reducing labor intensity of workers as well as improving embossing processing efficiency of modified plastic-wood profiles.

Owner:南京聚锋新材料有限公司 +1

Self-moving type termination point hydraulic support based on parallel mechanism and application of termination point hydraulic support

InactiveCN105221175AMaintain integrityReduce usageMine roof supportsUltimate tensile strengthMechanical engineering

Owner:SHANDONG UNIV OF SCI & TECH

Medicine bottle grabbing and conveying mechanism

InactiveCN107934535ANo need for manual handlingImprove efficiencyConveyor partsRotary conveyorsEngineeringMechanical engineering

The invention discloses a medicine bottle grabbing and conveying mechanism. The mechanism comprises a frame; a driving servo motor is fixed on the bottom surface of the middle part of a top plate of the frame; an output shaft of the driving servo motor penetrates through the top plate of the frame, and is fixed with a rotating plate; multiple mounting grooves are formed in the edge part of the topsurface of the rotating plate; an upper support frame is fixed on the top surface of the left side of the top plate of the frame; connecting plates are fixed on the left and right sides of the bottomsurface of a transverse beam of the upper support frame; the two ends of a transverse screw rod are hinged to the two connecting plates; a movable motor is fixed on the outer side wall of one connecting plate; an output shaft of the movable motor is a spline shaft; the spline shaft is inserted in a spline hole formed in one end of the transverse screw rod; a movable block is screwed into the transverse screw rod; and a horizontal support plate is fixed on the bottom surface of the movable block. The mechanism can be mounted at the tail end of a conveying belt for grabbing and carrying medicines bottles on the conveying belt onto the rotating plate, performs subsequent machining through rotation of the rotating plate, needs no manual carrying, and is high in efficiency and excellent in effect.

Owner:DONGGUAN SHENGRONG AUTOMATION TECH CO LTD

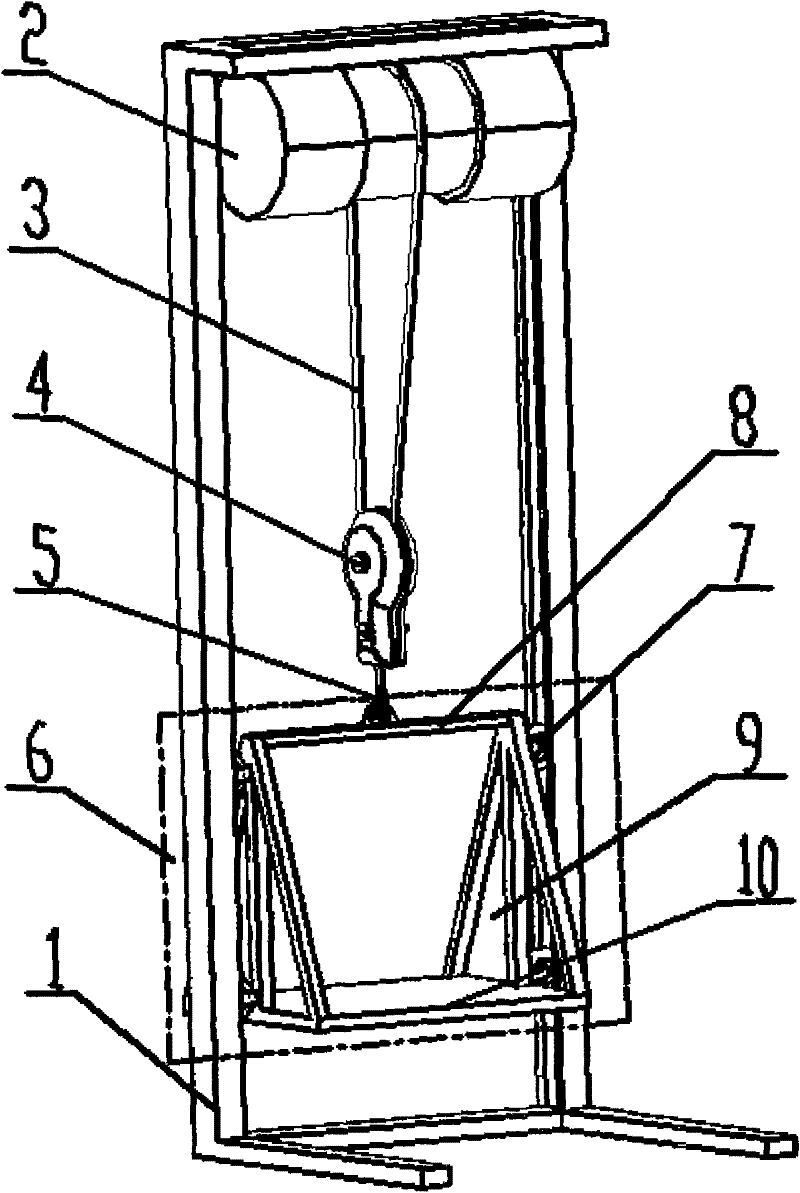

A hoisting crane

InactiveCN102295247AHandling automaticNo need for manual handlingLifting framesElectric machineryScroll wheel

Owner:LIWANG CHEM NANTONG

Transferring and lifting rotating mechanism for processing and conveying of cosmetics

The invention discloses a transfer lifting and rotating mechanism for cosmetics processing and conveying, which comprises a rotating frame. The middle part of the top surface of the top plate of the rotating frame has a mounting groove, and the lifting plate is inserted into the mounting groove and pressed against the mounting groove. On the bottom surface of the groove, the bottom surface of the lifting plate is fixed with a driving servo motor, and the driving servo motor is inserted into the through hole in the middle of the bottom surface of the installation groove. The top surface of the lifting plate is fixed with a self-lubricating sliding plate, and the self-lubricating sliding plate On the top surface of the top plate of the rotating frame, the lower part of the rotating frame is provided with a lower horizontal support plate, and a lifting motor is fixed on both sides of the bottom surface of the lower horizontal supporting plate. The output shaft of the lifting motor is connected with a transmission screw, and the screw on the transmission screw Connected with a lifting screw sleeve, the top of the lifting screw sleeve is fixed on the bottom surface of the lifting plate; it can be installed between two conveying mechanisms, and the cosmetic box of one conveying mechanism is transported to the rotating disk, which does not require manual handling Conveying, the effect is good and the efficiency is high.

Owner:徐文

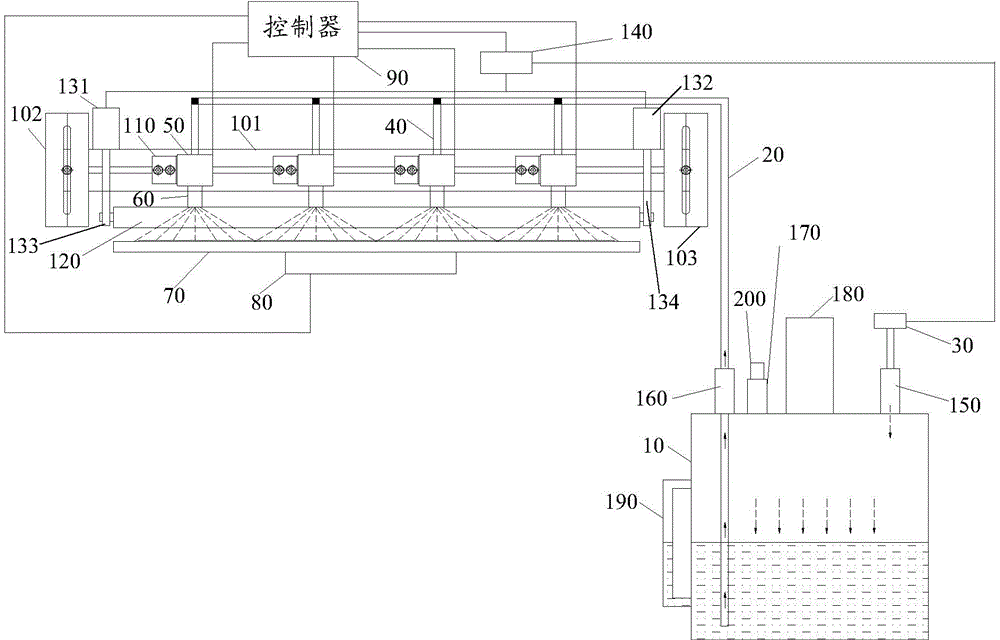

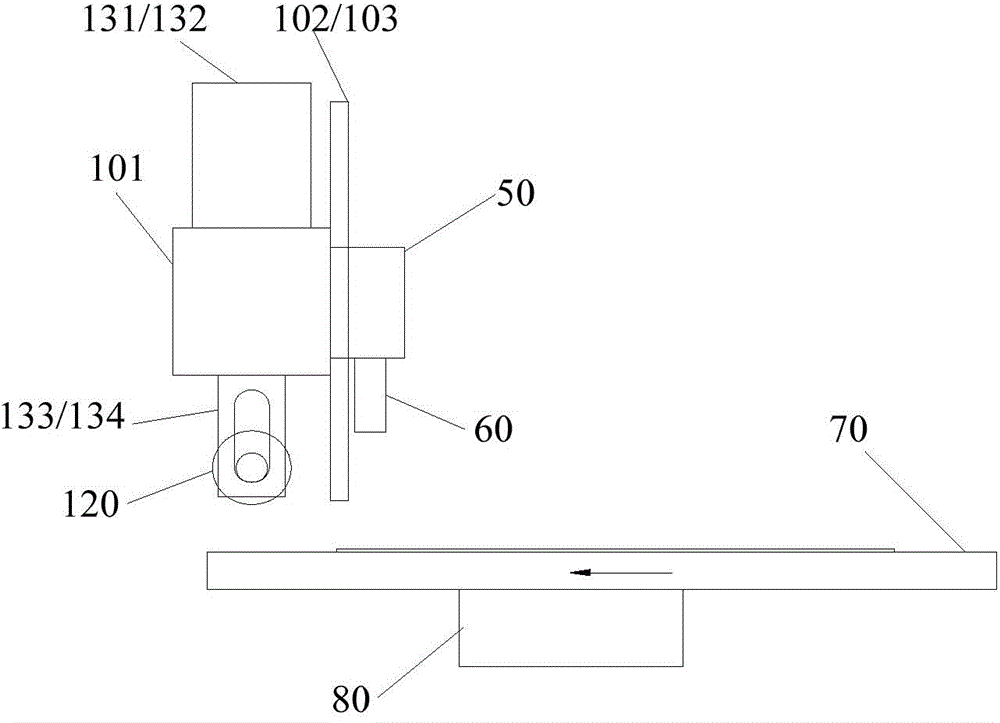

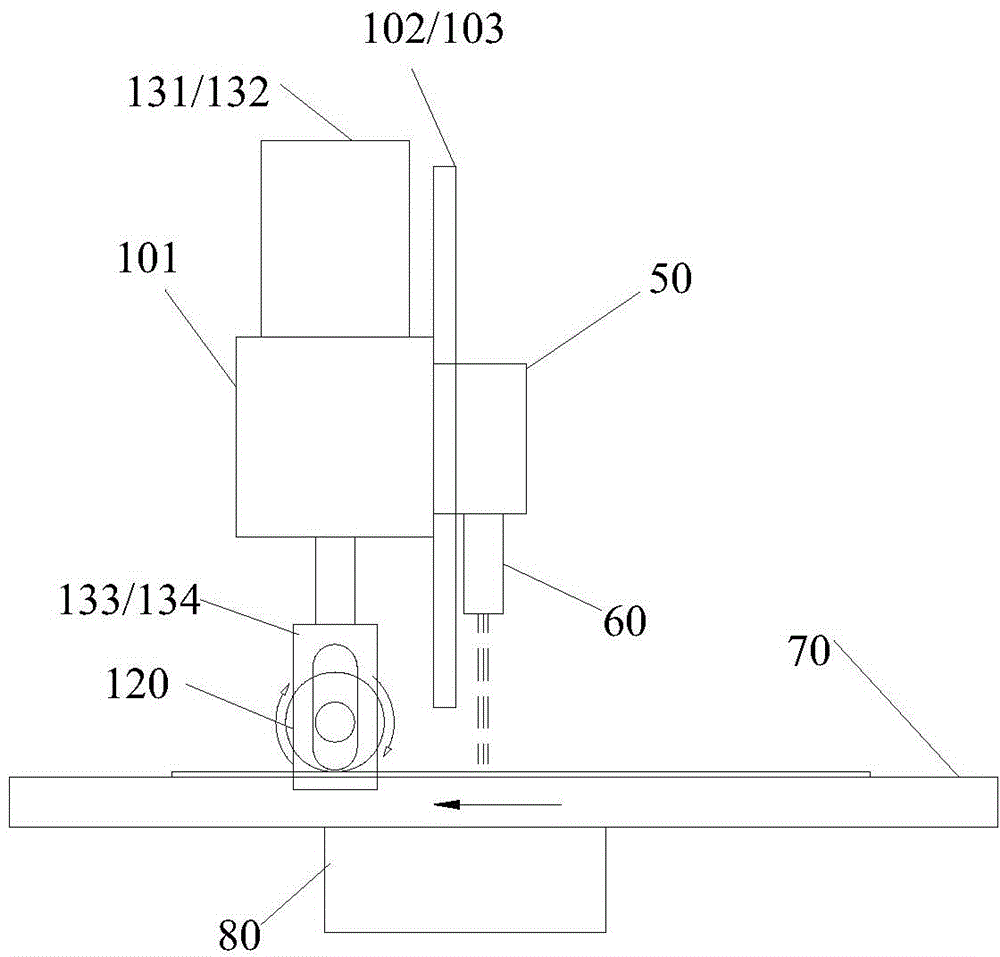

Liquid spraying device of digital printing machine and control method thereof

ActiveCN104476928AImprove injection efficiencyRealize automatic injectionTypewritersPower drive mechanismsSolenoid valveLiquid storage tank

The invention provides a liquid spraying device of a digital printing machine and a control method of the liquid spraying device. According to the liquid spraying device of the digital printing machine and the control method of the liquid spraying device, a power mechanism is controlled to deliver compressed air into a liquid storage tank to press treating fluid in the liquid storage tank into a main pipeline, and then the treating fluid enters all branch pipelines, so that when first solenoid valves mounted at the outlet ends of all the branch pipelines are opened, the treating fluid is sprayed from nozzles mounted at the outlet ends of the first solenoid valves to the surface of a printing medium on a platform located below the nozzles. In this way, the treating fluid is automatically sprayed to the surface of the printing medium, it is guaranteed that the treating fluid sprayed onto the printing medium is uniform, time and labor are saved, and the treating fluid spraying efficiency is greatly improved.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

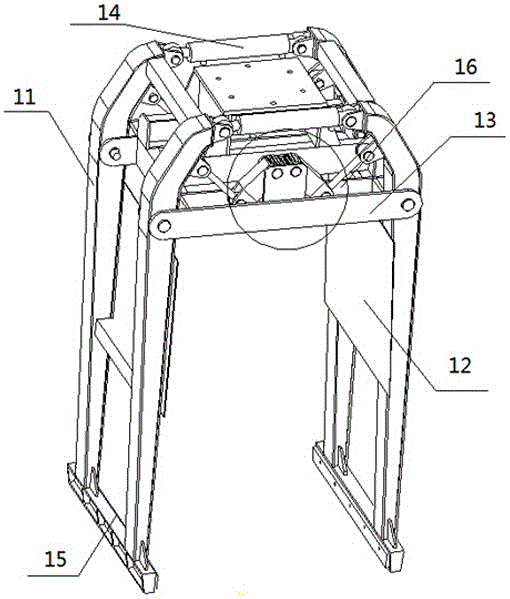

Crane brick holding machine

InactiveCN105858463AEasy to operateNo need for manual handlingLoading/unloadingRunwaysMotor driveBrick

The invention discloses a crane brick holding machine. The crane brick holding machine comprises a brick holding machine clamp, a lifting oil cylinder and a horizontal movement device; the lifting oil cylinder drives the brick holding machine clamp to move up and down and is fixed to the horizontal movement device; the horizontal movement device comprises a cross beam, a longitudinal beam and a movement motor; a transverse walking device is arranged on the cross beam and provided with an installing frame; the lifting oil cylinder is fixed to the installing frame; the longitudinal beam is provided with a longitudinal walking device; the cross beam is fixed to the longitudinal walking device; and the movement motor drives the transverse walking device and the longitudinal walking device to move. Operation is easy, manual carrying is not need, mechanical operation is achieved, hundreds or thousands of bricks can be carried at a time, and the work efficiency is improved; and the problem that manpower resources are wasted is solved, and serious slowdown caused by personnel shortage in special seasons such as busy farming seasons or hot summer is avoided.

Owner:SICHUAN PINXING YAOLU TECH DEV CO LTD

Circuit board substrate grabbing and rotary conveying mechanism

ActiveCN106586541AEasy to adjust controlNo need for manual handlingConveyor partsEngineeringMechanical engineering

Owner:ANHUI LINCHI ELECTRONICS CO LTD

Chemical raw material bag carrier

ActiveCN105501883ANo need for manual handlingReduce the amount of manual laborSupporting framesCouplingCompound (substance)

The invention discloses a chemical raw material bag carrier which comprises a frame body. An upper conveying frame is fixed on the top surface of the frame body, a connecting seat is fixed at the right end of the frame body, a handheld portion is fixed on the connecting seat, a lifting plate is arranged at the left end of the frame body, two vertical plates are fixed on each of two sides of the right end of the undersurface of the frame body, wheels are hinged on the two corresponding vertical plates through a connecting shaft, universal wheels are fixed on two sides of the left end of the undersurface of the frame body, a two-output-shaft driving motor is fixed in the middle of the undersurface of the right side of the frame body, and two output ends of the two-output-shaft driving motor are connected with the connecting shaft fixed on the corresponding wheels through a coupler. The chemical raw material bag carrier can convey chemical raw material plates to specific places and then automatically unload the same, and manual carrying is not needed, so that labor load of manpower is reduced greatly and efficiency is improved.

Owner:浙江重拓科技有限公司

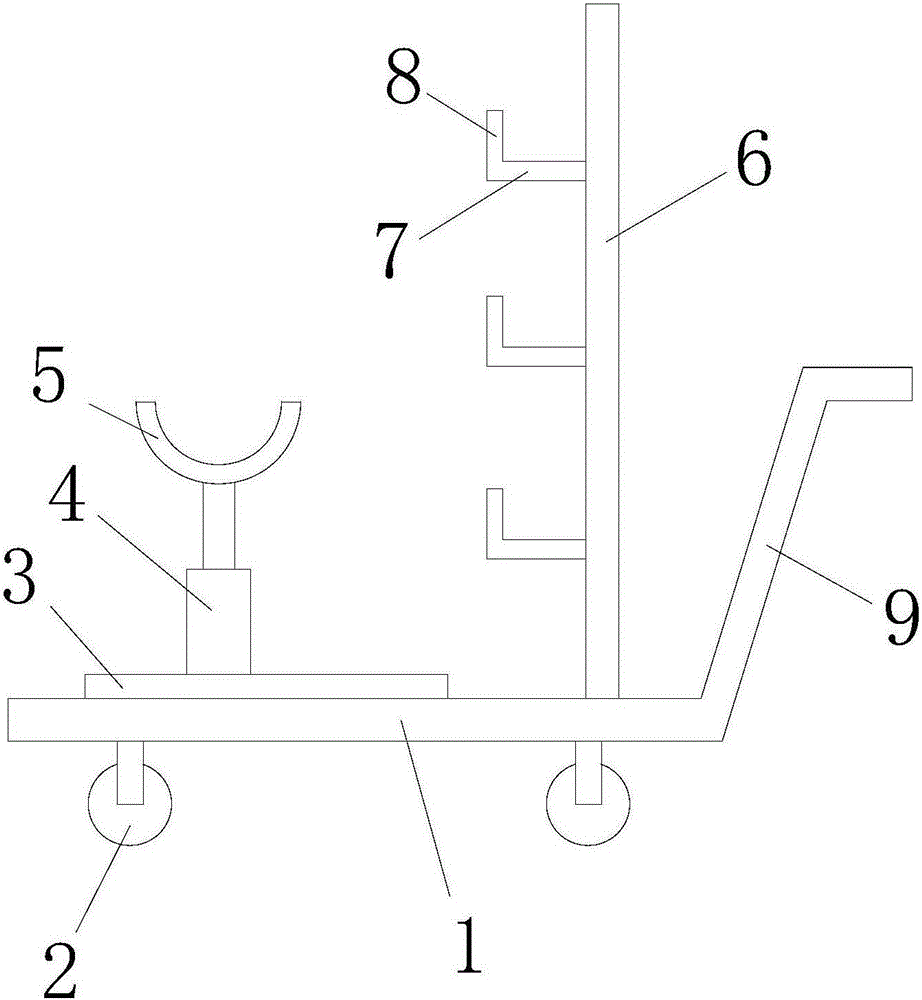

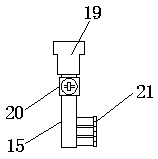

Spinning transport vehicle

InactiveCN105216843AThe process is convenient and fastNo need for manual handlingHand carts with multiple axesEngineeringMechanical engineering

The invention discloses a spinning transport vehicle which comprises a base (1), an extensible bracket, a bearing frame and a plurality of rolling wheels (2). The extensible bracket is installed on the top end of the base (1), the bearing frame is vertically arranged at the top end of the base, and the rolling wheels (2) are installed at the bottom end of the base (1). The extensible bracket can support winding rollers for spinning and is close to or away from the bearing frame so as to place the winding rollers to the bearing frame or take down the winding rollers from the bearing frame. The spinning transport vehicle can achieve convenient and rapid replacement and bulk transportation of the winding rollers which finish winding in the spinning operation, and production efficiency is improved.

Owner:WUHU KANGDAOER TEXTILE SCI

Tubular aluminum profile cutting device

InactiveCN108380961AAvoid damageWell formedTube shearing machinesMaintainance and safety accessoriesCouplingEngineering

The invention provides a tubular aluminum profile cutting device, and relates to the technical field of aluminum profile machining equipment. The tubular aluminum profile cutting device comprises an operating table, wherein moving frames are arranged on the left side and the right side of the top of the operating table, and first motors are arranged on the back faces of the moving frames; and theoutput ends of the first motors are fixedly provided with first rolling wheels through couplings, the front faces and the back faces of the inner walls of the movable frames are movably connected withsecond rolling wheels through rotating shafts, and the first rolling wheels and the second rolling wheels are in transmission connection through conveyor belts. According to the tubular aluminum profile cutting device, water mist spray can be sprayed on an aluminum profile in real time through spray pipes and spray heads, wherein the mist spray is at low temperature and flows, and a cutting bladecan be cooled more quickly, and therefore, the aluminum profile can be well formed; heat dissipation holes are formed in one side of the cutting blade, and therefore, heat can be dissipated in time;and expansion grooves are expanded after heated, so that the heat dissipation holes are expanded, and the influence of thermal stress on saw blades during cutting of the saw blades can be effectivelyrelieved or counteracted.

Owner:陈洁

Textile transporting vehicle

InactiveCN105398478ANo need for manual handlingIncrease productivitySupporting partsHand carts with multiple axesEngineeringMechanical engineering

The invention discloses a textile transporting vehicle. The textile transporting vehicle comprises a base (1), a telescopic bracket, a bearing frame and a plurality of rollers (2), wherein the telescopic bracket is mounted at the top end of the base (1); the bearing frame is vertically arranged at the top end of the base; the plurality of rollers (2) are mounted at the bottom end of the base (1). The telescopic bracket can support a winding roller used for spinning and moves towards or away from the bearing frame to place the winding roller on the bearing frame or to take off the winding roller from the bearing frame. The bearing frame comprises a vertically arranged bearing plate (6), a plurality of bearing supporting arms (7), a traction rope (10) and a motor (11); one end of the traction rope is connected with a rotating shaft of the motor; the other end of the traction rope extends in a height direction of the bearing plate; the bearing supporting arms are detachably mounted on the traction rope and extend towards the telescopic bracket; and the tail ends of the bearing supporting arms are also provided with stopping pieces (8). Through the adoption of the textile transporting vehicle, winding rollers in rolls in the spinning operation can be conveniently and rapidly replaced and transported in batch so that the production efficiency is increased.

Owner:WUHU KANGDAOER TEXTILE SCI

Automatic rotation mechanism for cosmetic box conveyance

InactiveCN106829444AEasy to grab and transportNo need for manual handlingConveyor partsEngineeringSlide plate

The invention discloses a rotary mechanism for automatic conveying of a cosmetic box, which comprises a rotating frame and a conveying frame, a conveying frame is fixed on the right side of the rotating frame, a self-lubricating sliding plate is fixed on the top surface of the top plate of the rotating frame, The left side wall of the front end of the conveying top plate of the conveyor frame is close to the right side wall of the self-lubricating sliding plate. The middle part of the conveying top plate has a conveying channel, and the conveyor belt is in the conveying channel. The two ends of the roller are hinged on the two inner side walls of the conveying channel, and the conveying drive motor is fixed on the side wall of the conveying top plate, and the top surface of the conveyor belt is level with the top surface of the conveying top plate; it can convey cosmetics in a straight line through the conveyor belt The box body is placed on the rotating disk, and rotated by the rotating disk, the cosmetic box body is changed to the conveying direction and adjusted to the conveying rack that needs to be conveyed, so as to facilitate the grabbing mechanism of the corresponding conveying rack to grab and convey, and it does not need to be transported manually. It has good effect and high efficiency.

Owner:徐文

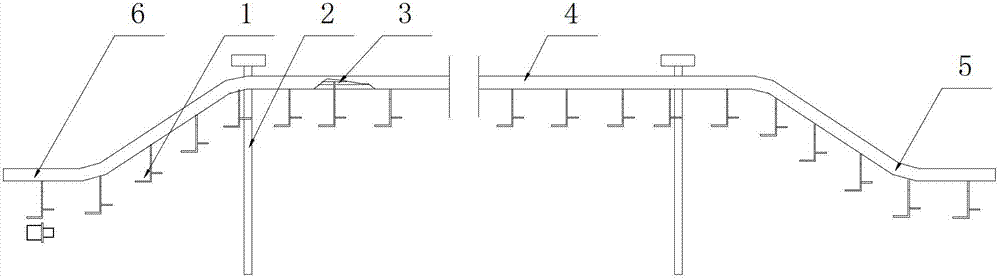

Workpiece transfer device for compressor cylinder body production line

InactiveCN102897479AHighly innovativeScientific and reasonable structure designConveyorsProduction lineDrive motor

The invention relates to a workipece transfer device for a compressor cylinder body production line. The workipece transfer device is characterized by comprising a plurality of supports, a transfer rail, a conveying chain, a plurality of workpiece brackets and a driving motor, the transfer rail is mounted in a suspension manner by the aid of the supports and is a circulating rail, the conveying chain is mounted in the transfer rail, the workpiece brackets are mounted on the conveying chain in a suspension manner through hooks, and the chain is driven by the driving motor through drive sprockets. The workipece transfer device for the compressor cylinder body production line is scientific and reasonable in structural design, capable of achieving transfer of cylinder bodies on the production line without manual carrying, low in labor intensity and high in efficiency, does not occupy floor space and is highly innovative.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

Intelligent cutting equipment for rapid distance measurement of air conditioner copper pipe

InactiveCN109676187AReasonable structureFunctionalTube shearing machinesShearing machine accessoriesEngineeringCopper

The invention discloses intelligent cutting equipment for rapid distance measurement of an air conditioner copper pipe. The intelligent cutting equipment comprises a device base, wherein the rear sideof the upper end face of the device base is fixedly connected with a supporting platform, the supporting platform is perpendicular to the device base, the left side of the upper end face of the device base is connected with a vertical plate, the right side face of the vertical plate is fixedly connected with a distance measurement baffle, and the vertical plate and the distance measurement baffleare perpendicular to the device base; a groove is formed in the upper end face, located on the right side of the distance measurement baffle, of the device base; a copper pipe collecting base is arranged in the groove; the upper end face, located in front of the supporting platform, of the device base is provided with two conveying frames; and the upper end face, located in front of the conveyingframes, of the device base is fixedly connected with a fixed support. The intelligent cutting equipment is high in practicability, the air conditioner copper pipe is conveyed to the position below acutting wheel pipe through a conveying belt during work, transferring is convenient, and no manual carrying is required. Quantitative and fixed distance cutting of pipes can be realized, there is no need to press or cut time and time again, and the work efficiency is greatly promoted.

Owner:盐城唯宏特通用机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com