Frame type ultrasonic cleaning device

An ultrasonic cleaning, frame-type technology, applied in cleaning methods and utensils, cleaning methods using liquids, conveyor objects, etc., can solve problems such as inconvenient movement, and achieve the effects of low production cost, simple structure, and convenient sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

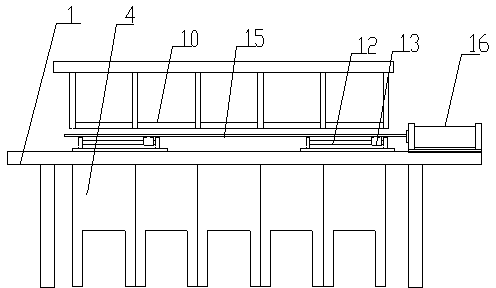

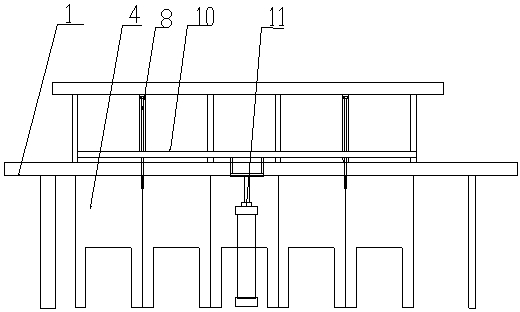

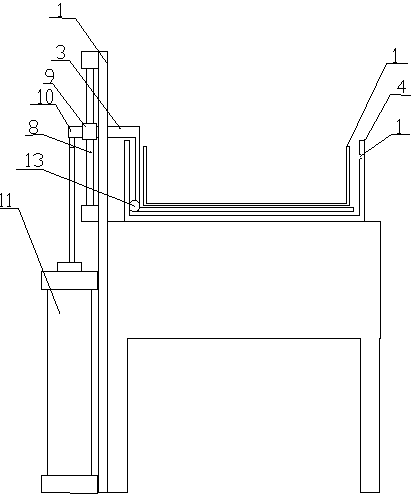

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a frame-type ultrasonic cleaning device of the present invention includes a cleaning tank 4, a cleaning tank support 1, a tooling basket 2, a tooling basket bracket 3, a basket mechanism and a basket pushing mechanism. There are five cleaning tanks 4, which are arranged in parallel On the cleaning tank support 1, and each cleaning tank 4 is provided with a tooling basket bracket 3, the tooling basket 2 is placed in the cleaning tank through the limit position of the tooling basket bracket 3, and the tooling basket is placed in the cleaning tank through the basket lifting mechanism and the pushing basket mechanism. 2 Push to the next cleaning tank for cleaning in the next process;

[0022] Above-mentioned cleaning tank 4 has five, is divided into two kinds, is respectively common cleaning tank and ultrasonic cleaning tank, and common cleaning tank is washing tank, and ultrasonic cleaning tank is alcohol c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com