Crane brick holding machine

A brick-holding machine and brick machine technology, which is applied in the direction of loading/unloading, load hanging components, track systems, etc., can solve the problems of low work efficiency, high labor intensity of workers, and consumption of human resources, so as to improve work efficiency and solve problems. The waste of human resources and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

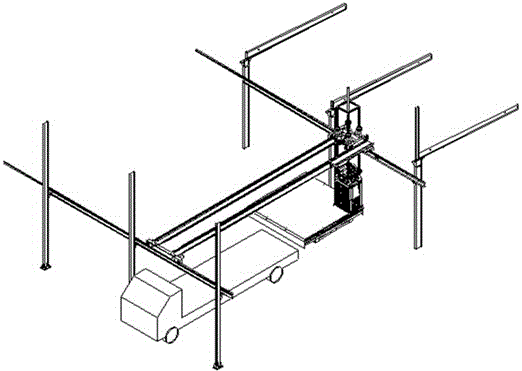

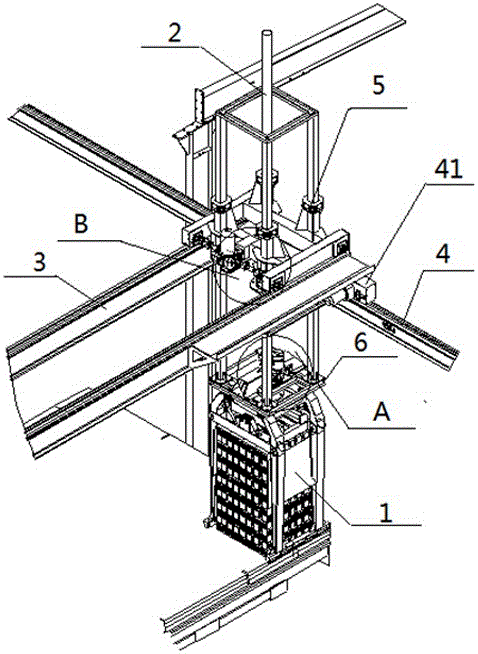

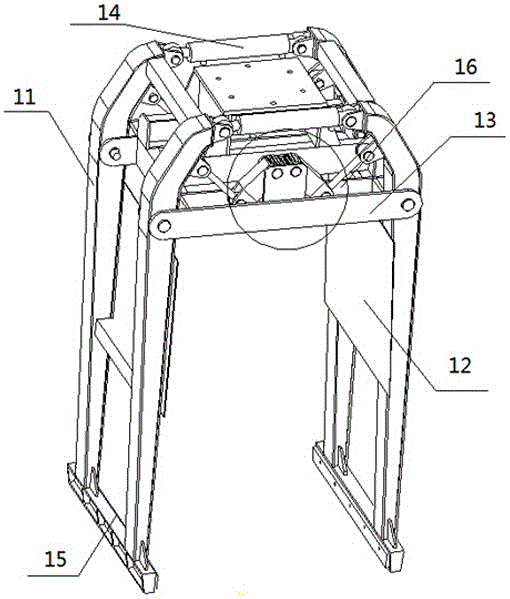

[0033] Such as Figure 1-Figure 3 as well as Image 6 As shown, a driving brick holding machine includes a brick holding machine fixture 1, a lifting cylinder 2, and a horizontal moving device. The lifting cylinder 2 drives the brick holding machine fixture 1 to move up and down, and the lifting cylinder 2 is fixed on the horizontal moving device. , the horizontal moving device includes a crossbeam 3, a longitudinal beam 4, and a moving motor 31, the crossbeam 3 is provided with a transverse traveling device 34, the transverse traveling device 34 is provided with a mounting bracket, and the lifting cylinder 2 is fixed on the installation On the frame, the longitudinal beam 4 is provided with a longitudinal traveling device 41, the crossbeam 3 is fixed on the longitudinal traveling device 41, and the moving motor 31 drives the transverse traveling device 34 and the longitudinal traveling device 41 to move; the brick holding machine Clamp 1 comprises movable arm 11, fixing devi...

Embodiment 2

[0038] Such as Figure 4 As shown, further optimized on the basis of the driving brick holding machine described in Embodiment 1, a synchronization device 16 is also provided between the two groups of movable arms 11, and the synchronization device 16 includes a connecting arm 161, a transmission arm 162, Synchronizing gear set 163 and synchronizing device fixing seat 164, described synchronizing device fixing seat 164 is fixed on the fixing device 13, described synchronizing gear set 163 is installed in the synchronizing device fixing seat 164, and described transmission arm 162 is provided with two, The transmission arm 162 is respectively fixed on two ends of the synchronous gear set 163 , and the other end of the transmission arm 162 is connected with the connecting arm 161 , and the connecting arm 161 is connected with the movable arm 11 .

[0039] The working principle of the synchronization device 16 provided in this embodiment is: when the movable arm 11 on one side ro...

Embodiment 3

[0042] Such as figure 2 , Figure 7 As shown, further optimized on the basis of the driving brick holding machine described in Embodiment 1, a connecting frame 6 is also provided between the lifting cylinder 2 and the brick holding machine clamp 1, and a guide device is provided at the upper end of the connecting frame 6 5. The guide device 5 includes a guide column 51, a guide wheel 52, and a guide sleeve 53, the guide sleeve 53 is fixed on the mounting frame, the guide column 51 is set inside the guide sleeve 53, and the guide wheel 52 is installed On the guide sleeve 53.

[0043] In this embodiment, when the brick-holding machine moves up and down, the guide column 51 moves up and down inside the guide sleeve 53, which avoids deviation from the direction when the brick-holding machine moves up and down. At the same time, the setting of the guide wheel 52 can effectively adjust the tightness of the guide column 51. And the friction is changed to rolling friction, which re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com