Patents

Literature

98results about How to "Moderate clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

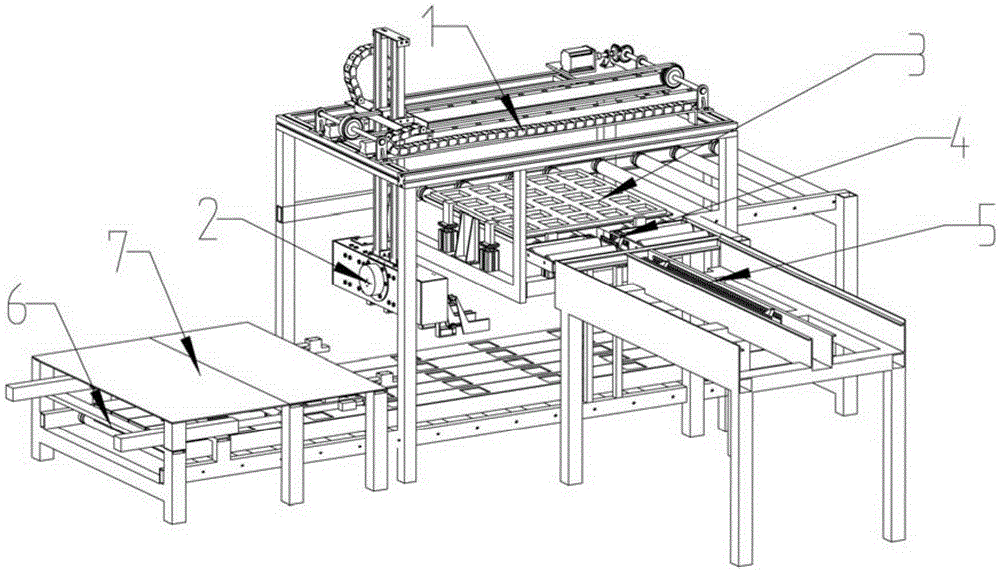

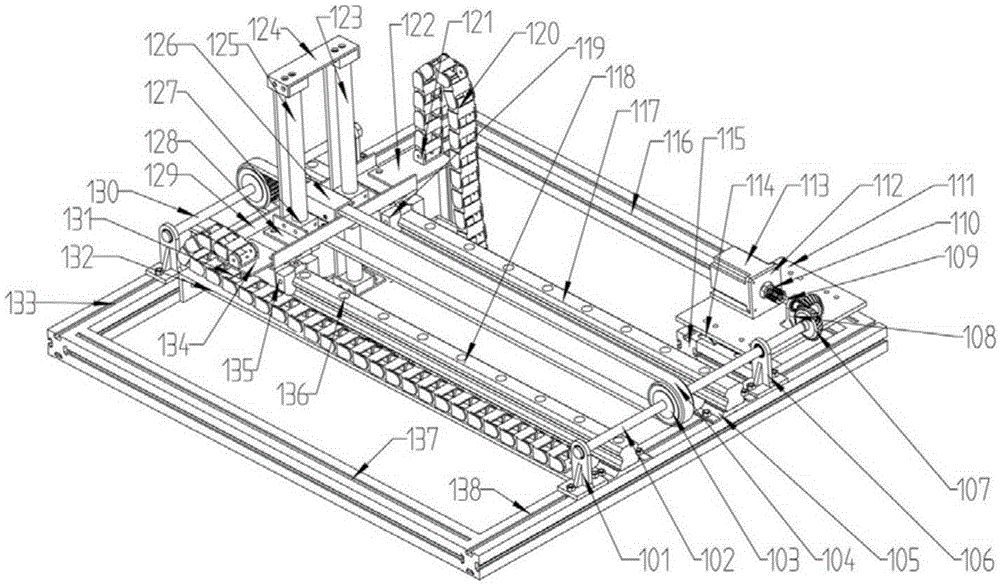

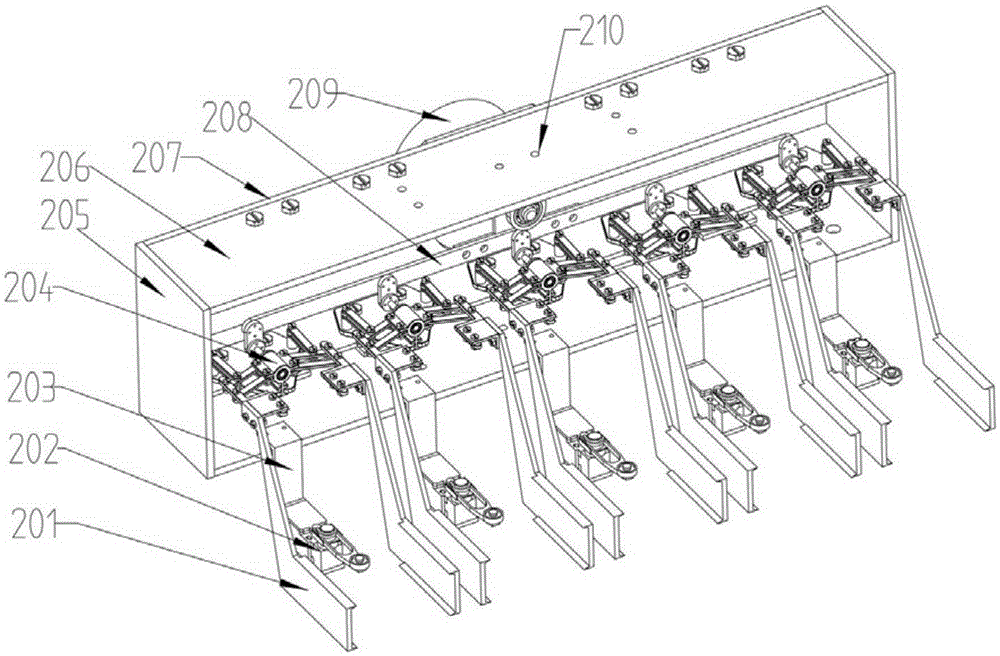

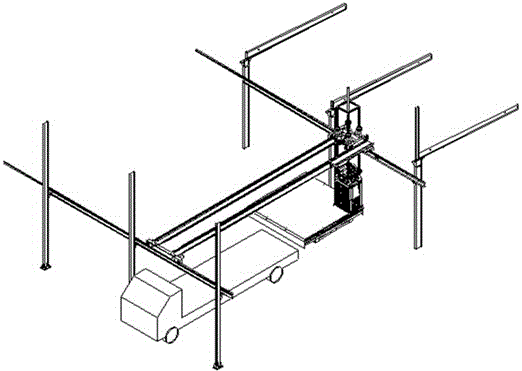

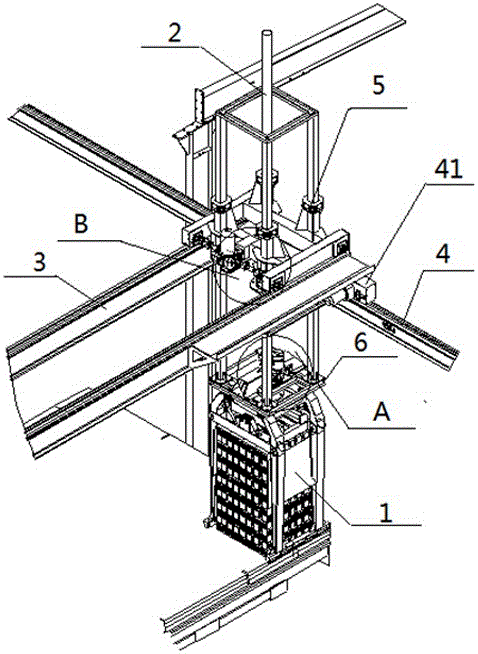

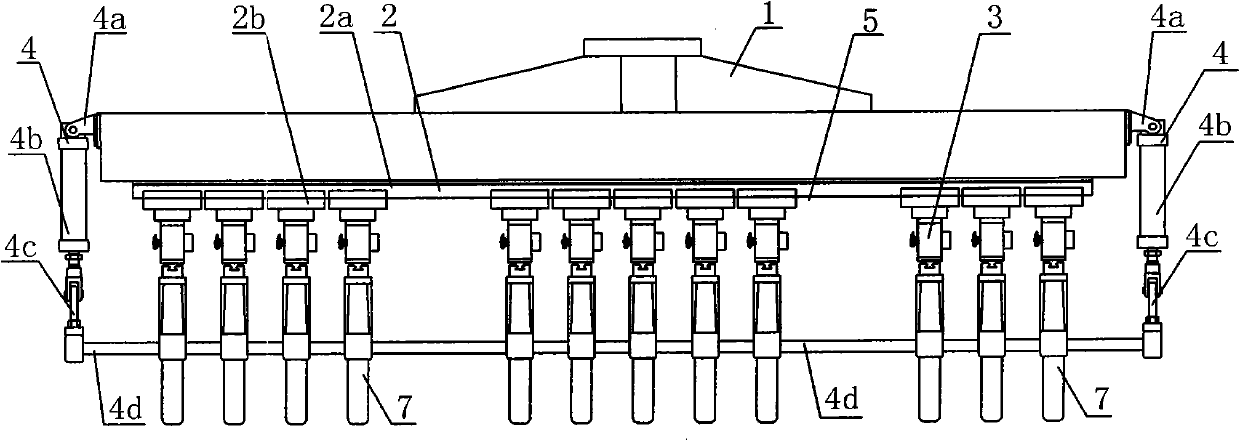

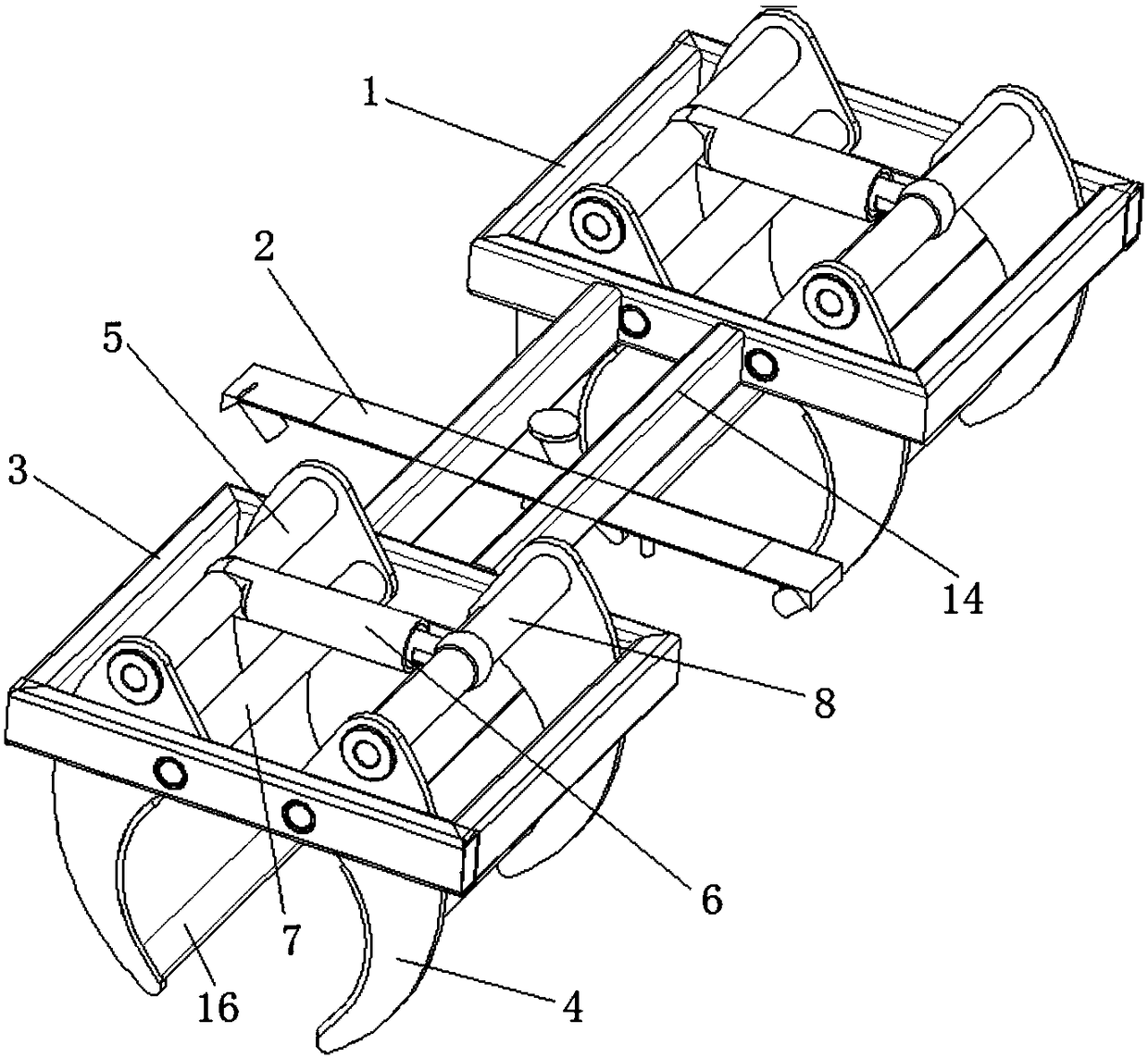

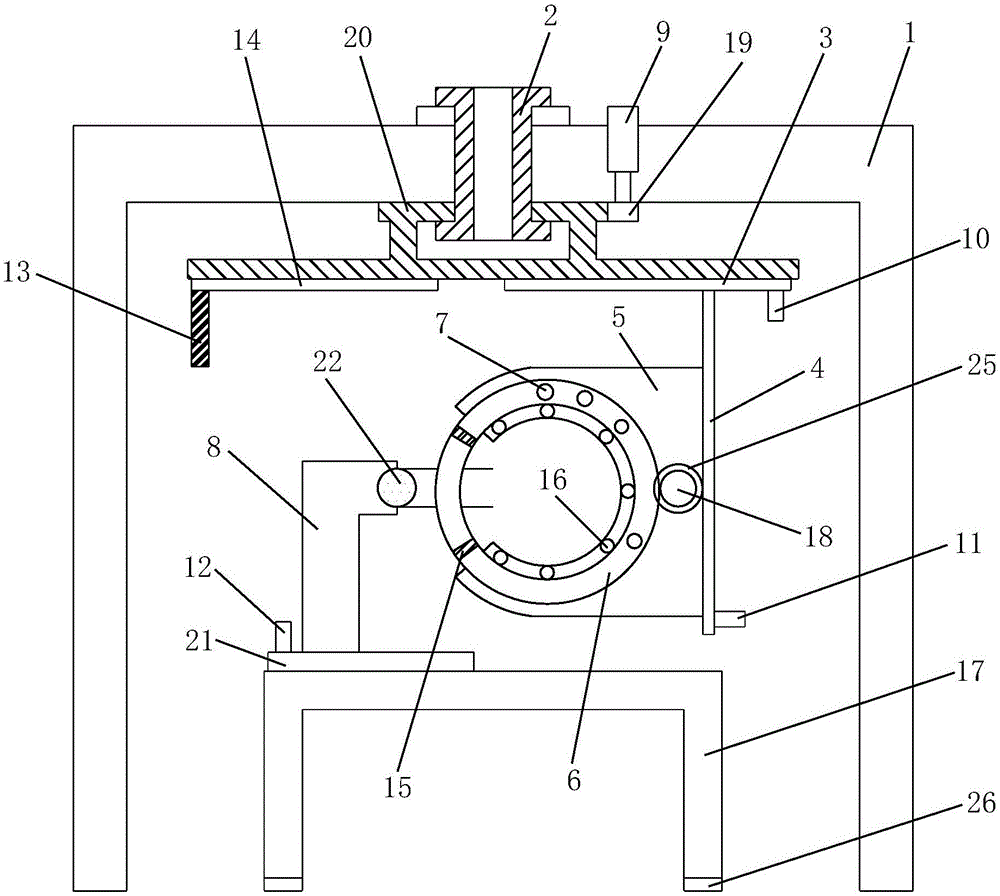

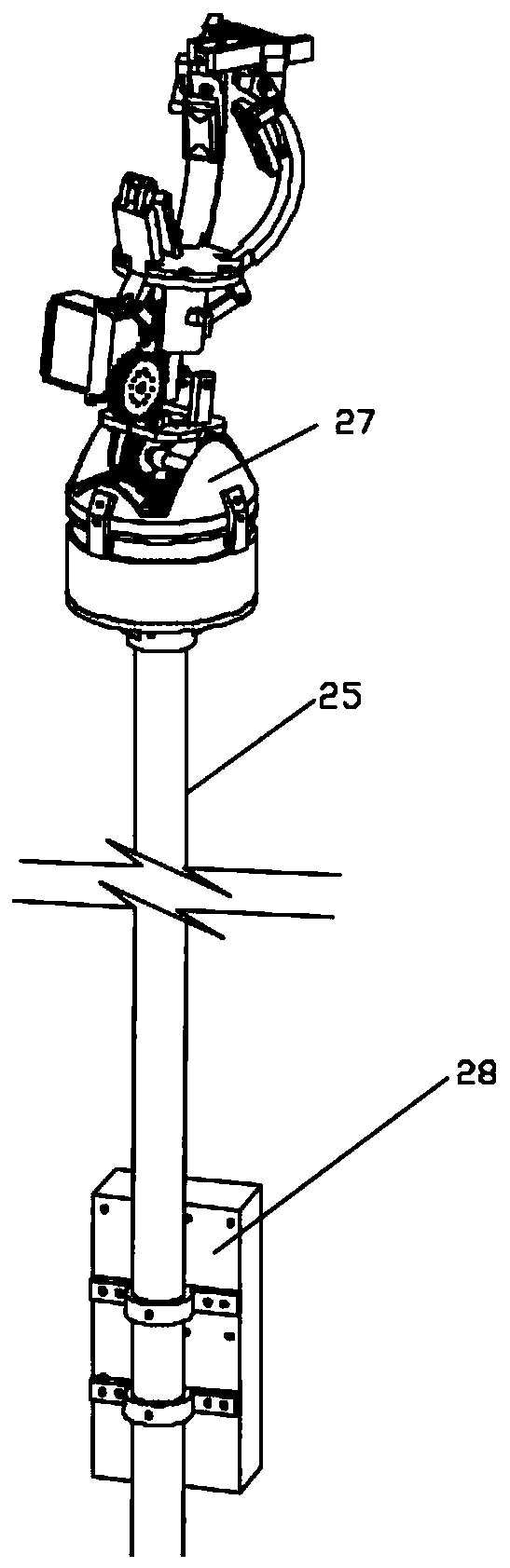

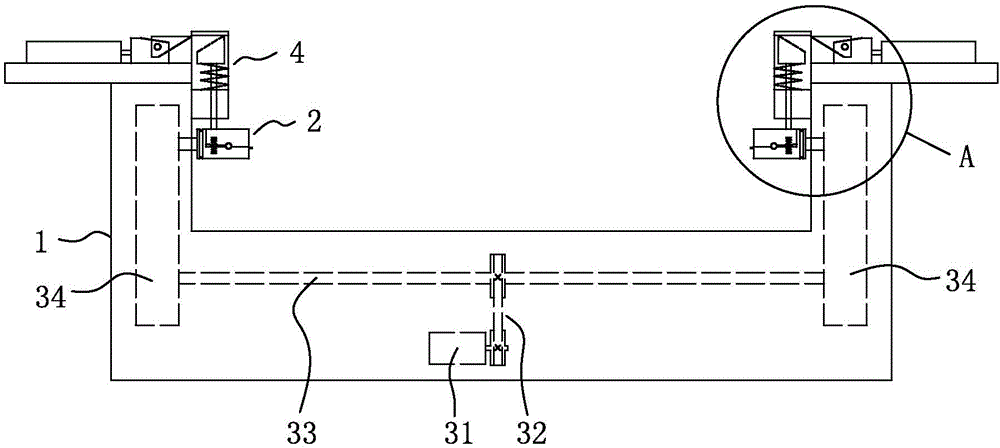

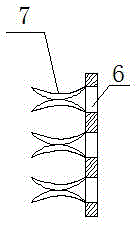

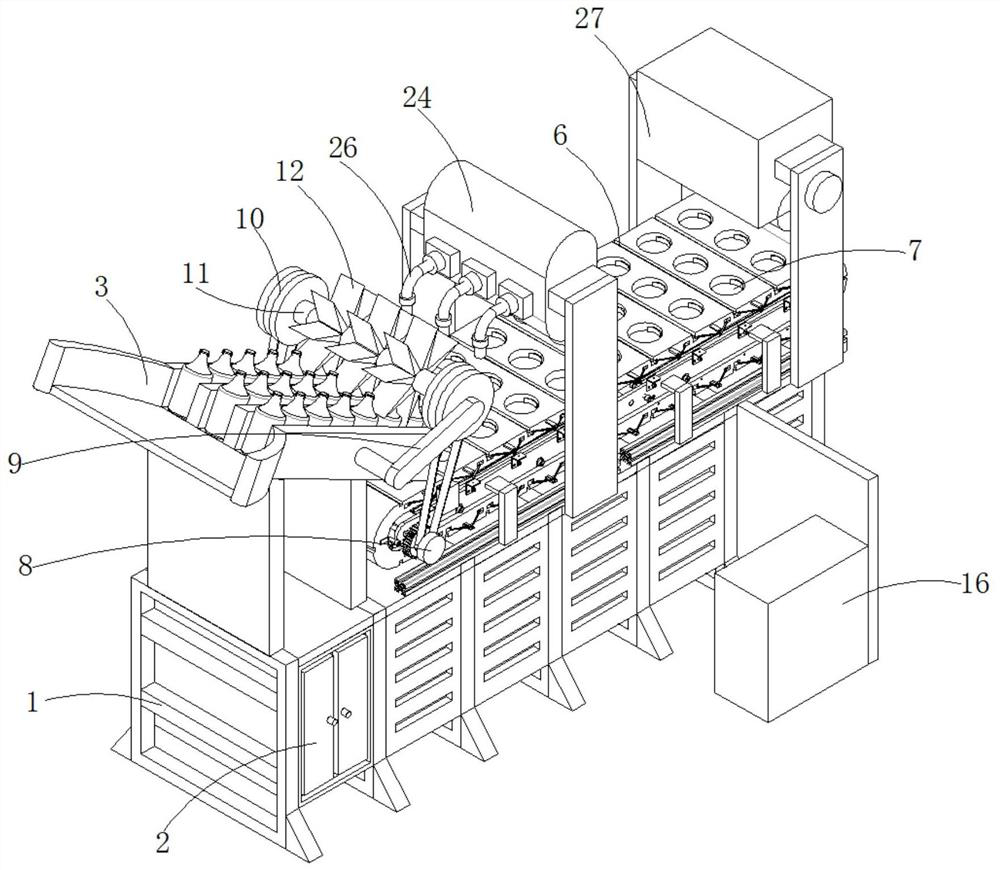

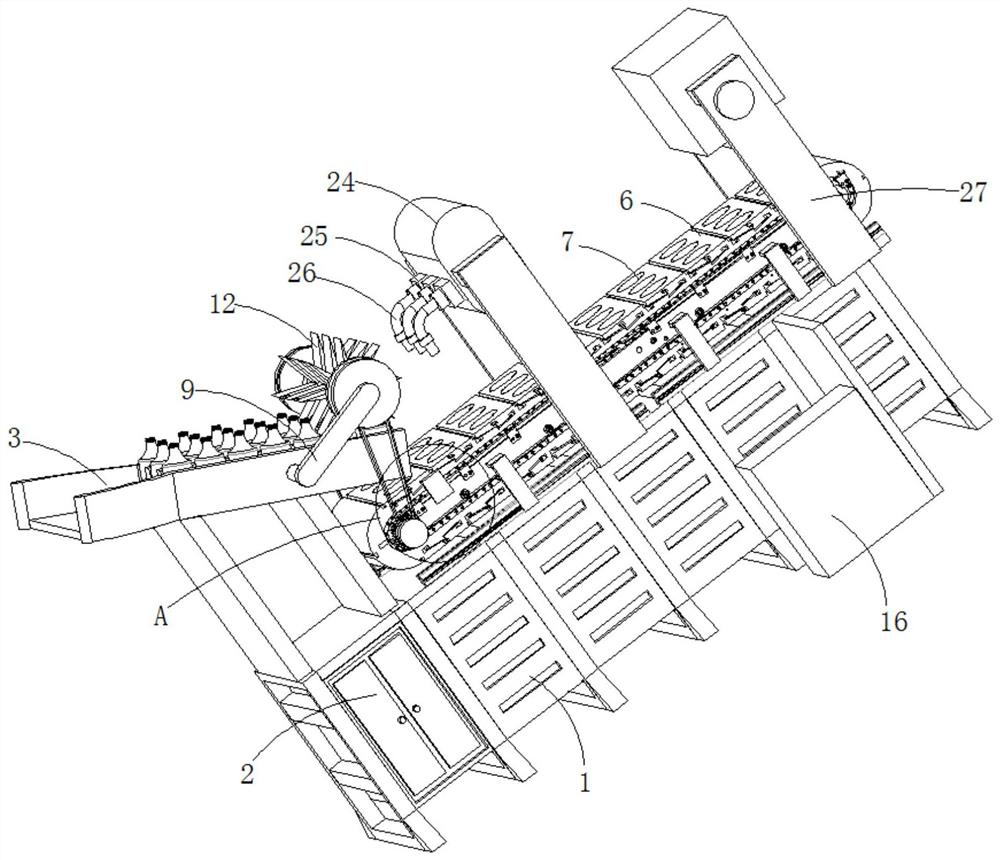

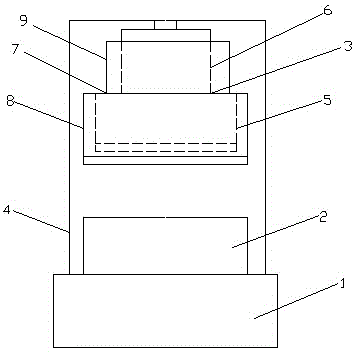

Transplanter for greenhouse vegetable seedlings

ActiveCN105409407ASuitable for transplantingIncrease productivityTransplantingAgricultural scienceAgricultural engineering

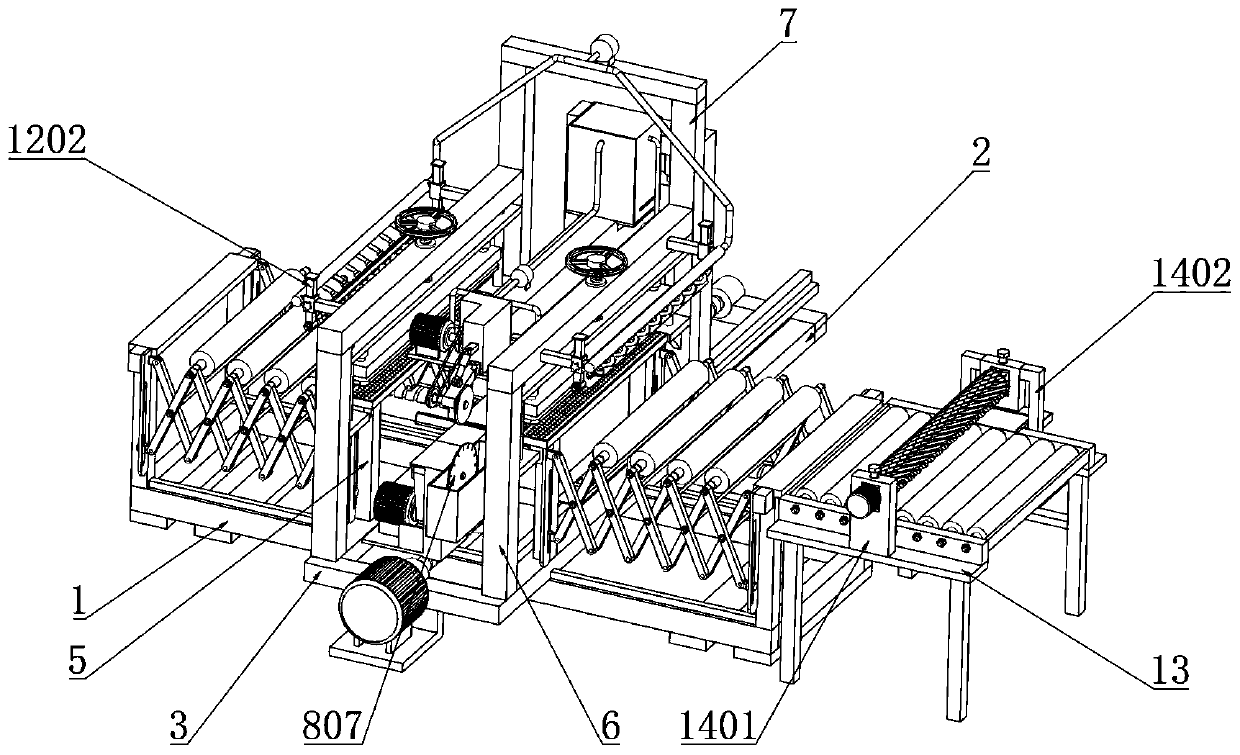

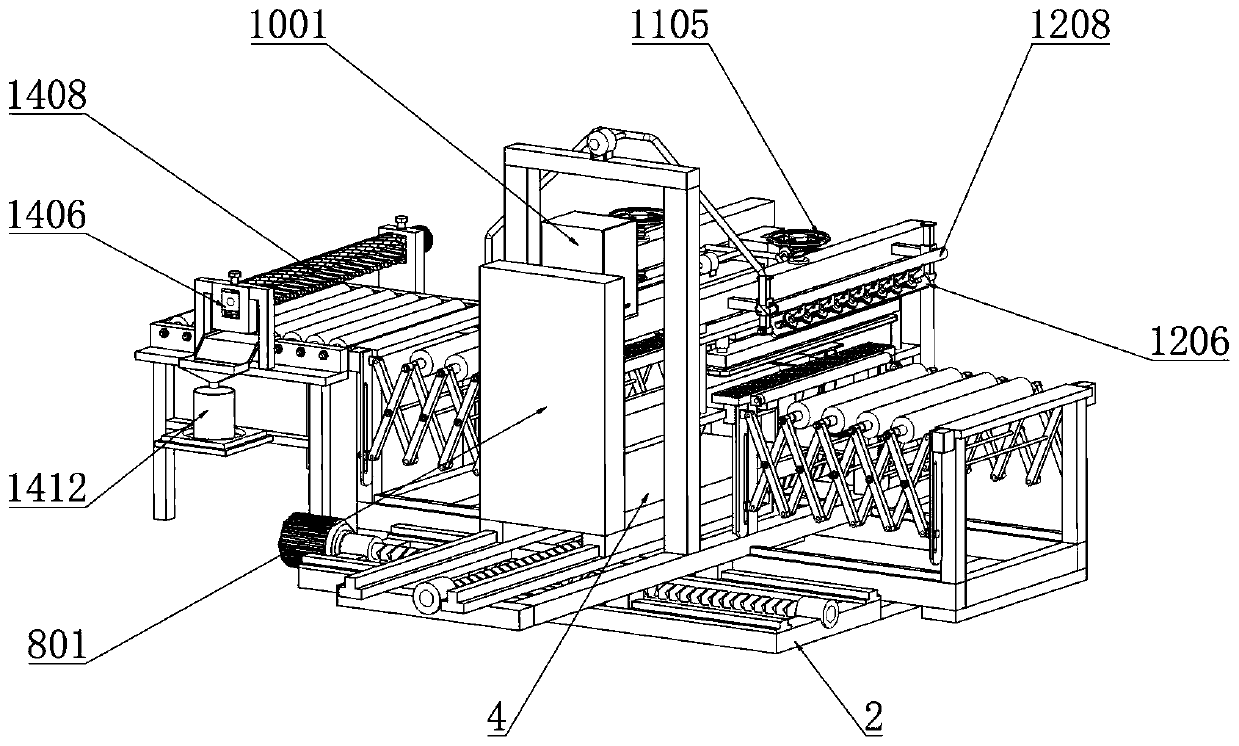

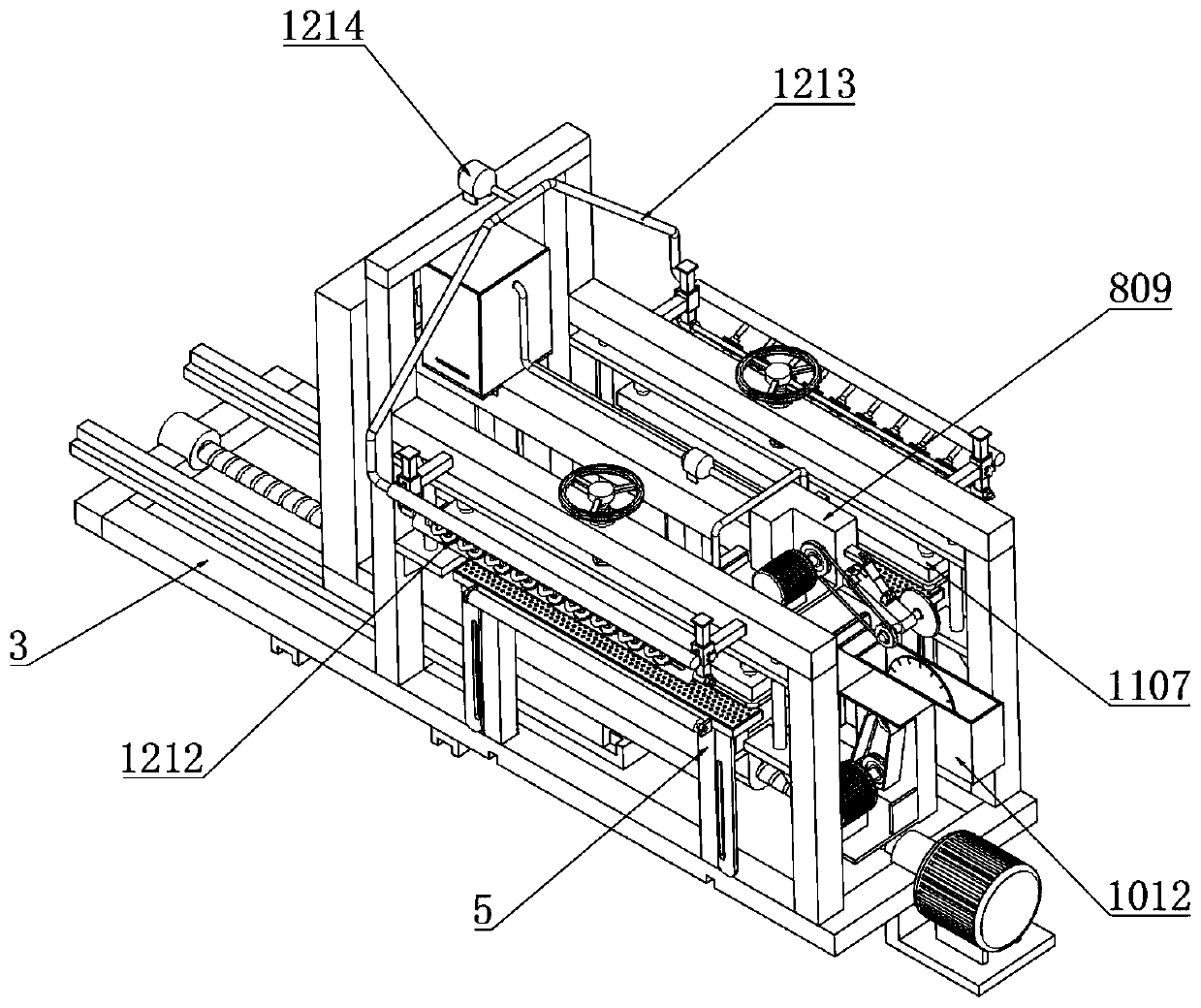

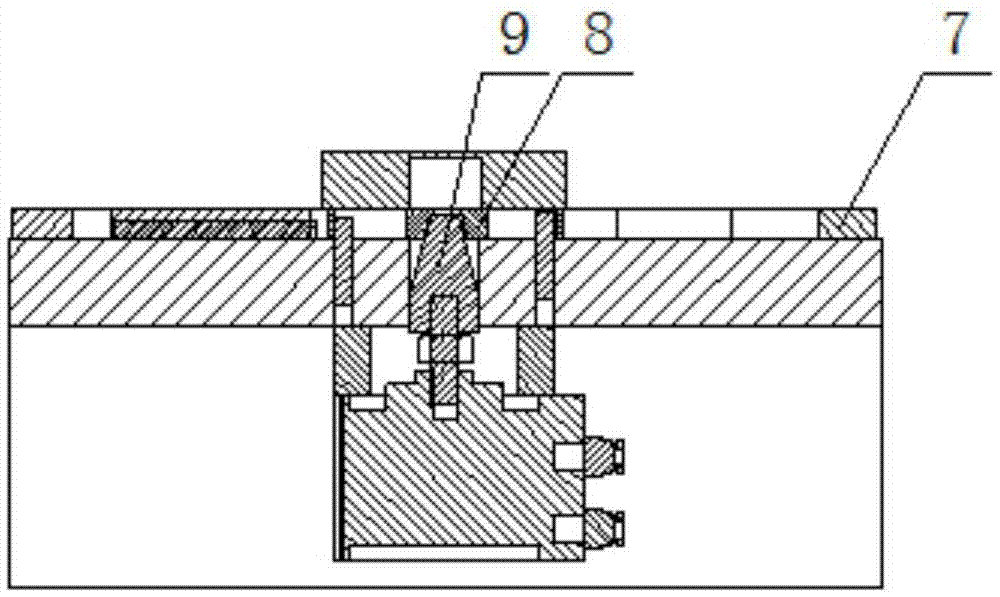

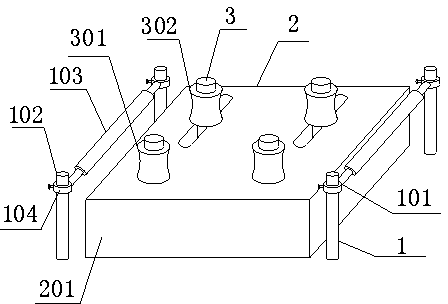

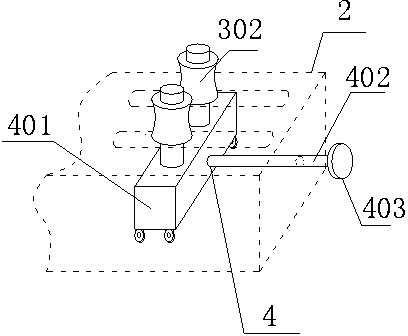

The invention discloses a transplanter for greenhouse vegetable seedlings. The transplanter comprises a mechanical arm (1), a mechanical hand (2) and an automatic feeding system; the automatic feeding system comprises a seedling conveying device (3), a steering device (4), an empty tray recovering device (5), a seedling receiving device (6) and a protective pedal (7), wherein the seedling conveying device (3) is connected with the empty tray recovering device (5) through the steering device (4), the mechanical arm (1) is arranged above the seedling conveying device (3), the mechanical hand (2) is installed on the mechanical arm (1), the seedling receiving device (6) is arranged below the seedling conveying device (3), and the protective pedal (7) is arranged above the seedling receiving device (6). The greenhouse vegetable seedlings can be automatically transplanted through the transplanter, the transplanter is used for automatically conveying and receiving the seedlings, collecting seedling trays and conveying planting floating plates in the transplanting process of the greenhouse vegetable seedlings, the transplanting operation is not limited by manual seedling feeding speed and intensity any more, and the production efficiency of greenhouse vegetables is substantially improved.

Owner:WENZHOU UNIVERSITY +1

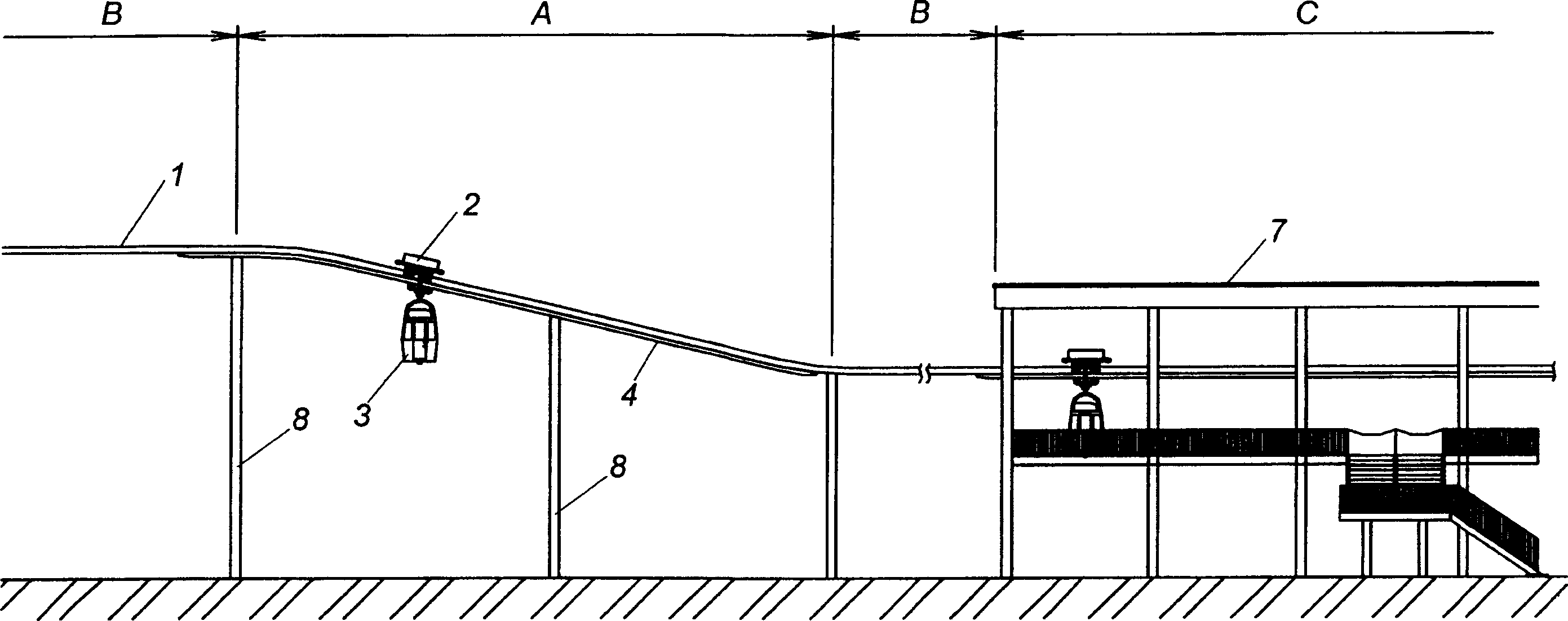

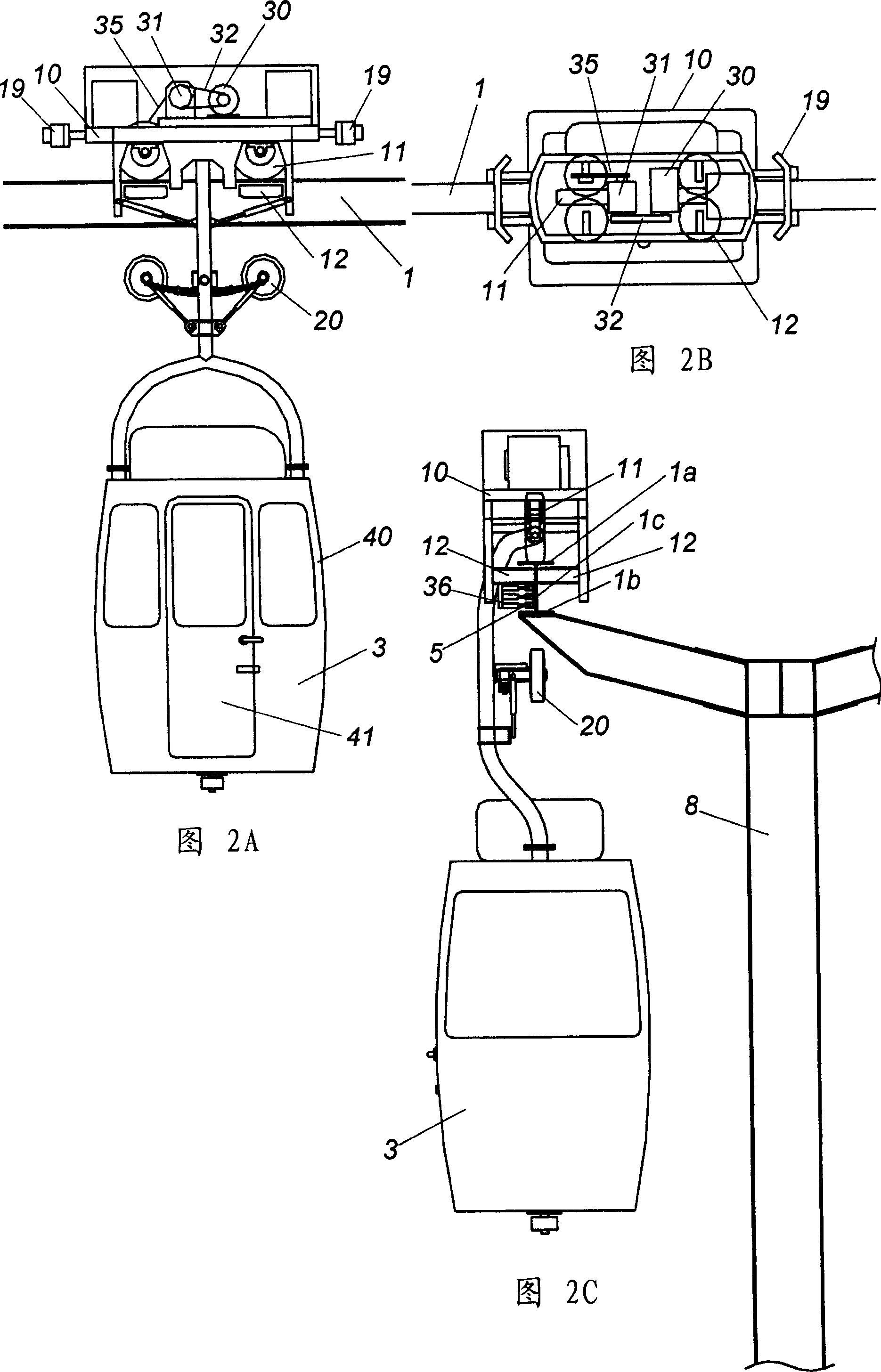

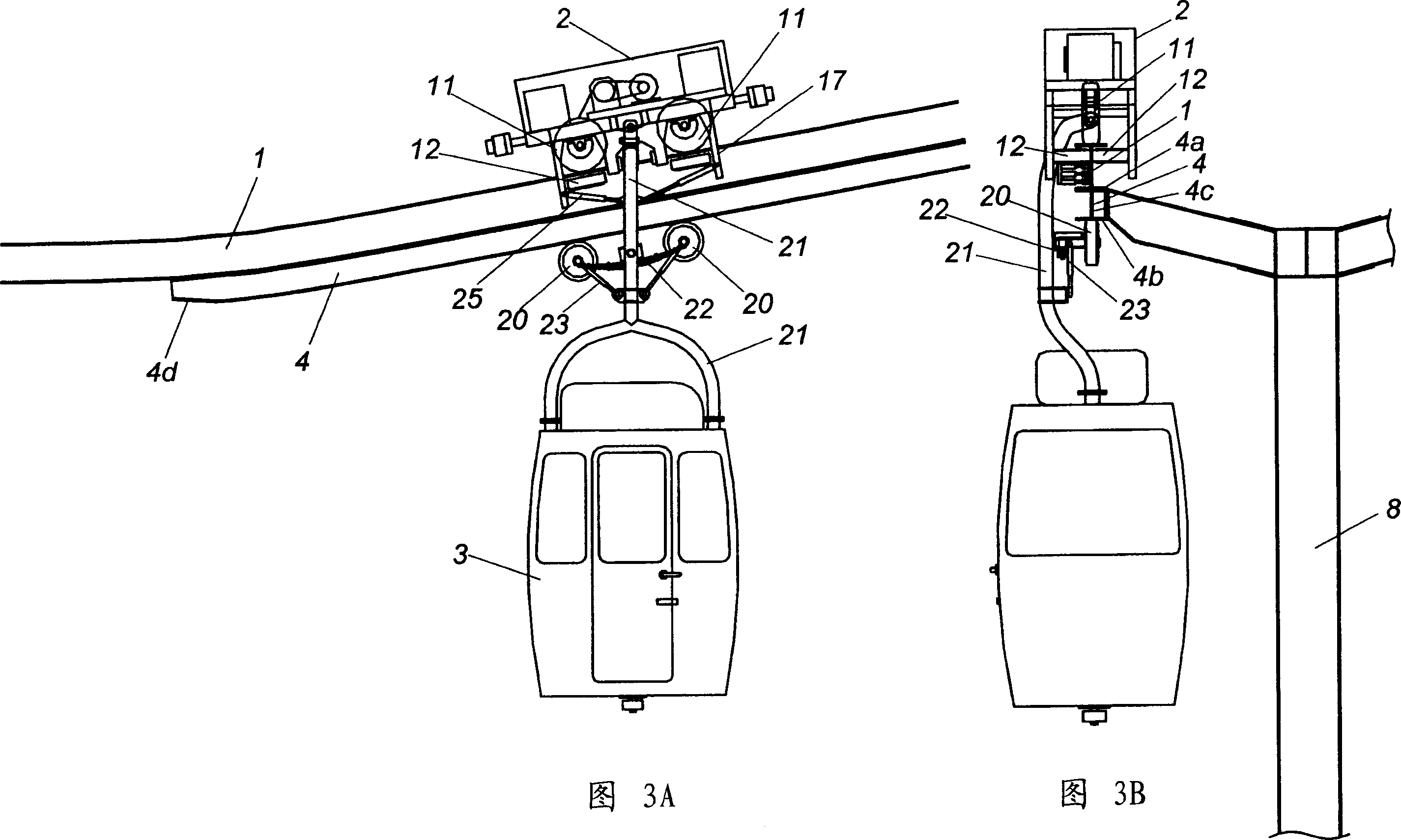

Carrying system

A carrying system for safely and efficiently transporting a carried object by increasing a grip force (contact pressure) against the rail of drive wheels in a rail inclined area, comprising a main rail, a vehicle having the drive wheels rolling on the main rail and a drive wheel drive means, a connection means having one end connected to the vehicle and the other end connected to the carried object, an auxiliary rail installed on the lower surface of the main rail in the main rail inclined area, auxiliary wheels held by the connection means so as to roll on the auxiliary rail without coming into contact with the main rail, and an elastic force loading means for providing an elastic force to the auxiliary rings in a direction for pressing the auxiliary wheels against the auxiliary rail.

Owner:SENYO KIKO

Circuit board clamp

InactiveCN103702517AWide range of sizesModerate clamping forcePrinted circuit manufactureSpring forceThin walled

The invention relates to a circuit board clamp and belongs to the technical field of structural parts of a circuit board. The maximum amount of compression of a spring is adjusted by screwing down and out a spring force regulating part, so that the aim of regulating the magnitude of the clamping force of the spring force regulating part is achieved, the clamping force applied to the circuit board is moderate, and the problems that the circuit board is moved or shaken during maintenance is solved; when being clamped by the clamp, a thin-wall board part does not easily deform, the clamping force of the clamp is conveniently adjusted, the operation of positioning, clamping and loosening a workpiece is convenient and reliable; through the structural design of a clamping device, the board surface of the circuit board can be positioned at any angle, and rapid operation can be performed on a double-face panel. Further, multiple specifications of circuit boards can be clamped through regulating fastening screws and moving a left support plate and a right support plate; after one specification of workpiece is clamped, a mark is made on a guide bar, the positions of the support plates when different specifications of workpieces are clamped can be rapidly determined, and the clamping efficiency is improved.

Owner:CHINA NORTH VEHICLE RES INST

Crane brick holding machine

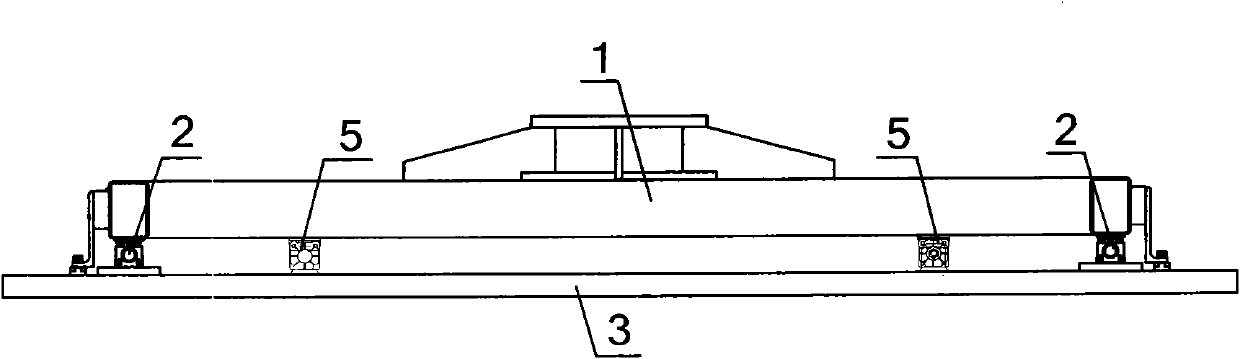

InactiveCN105858463AEasy to operateNo need for manual handlingLoading/unloadingRunwaysMotor driveBrick

The invention discloses a crane brick holding machine. The crane brick holding machine comprises a brick holding machine clamp, a lifting oil cylinder and a horizontal movement device; the lifting oil cylinder drives the brick holding machine clamp to move up and down and is fixed to the horizontal movement device; the horizontal movement device comprises a cross beam, a longitudinal beam and a movement motor; a transverse walking device is arranged on the cross beam and provided with an installing frame; the lifting oil cylinder is fixed to the installing frame; the longitudinal beam is provided with a longitudinal walking device; the cross beam is fixed to the longitudinal walking device; and the movement motor drives the transverse walking device and the longitudinal walking device to move. Operation is easy, manual carrying is not need, mechanical operation is achieved, hundreds or thousands of bricks can be carried at a time, and the work efficiency is improved; and the problem that manpower resources are wasted is solved, and serious slowdown caused by personnel shortage in special seasons such as busy farming seasons or hot summer is avoided.

Owner:SICHUAN PINXING YAOLU TECH DEV CO LTD

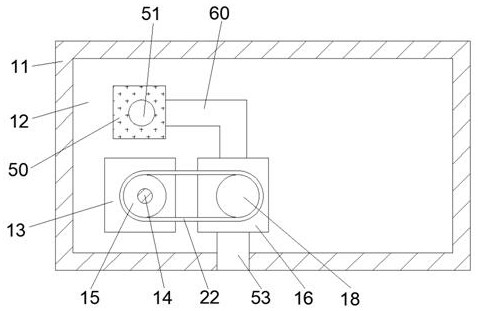

Shoe polishing device

The invention discloses a shoe polishing device. The shoe polishing device comprises a clamping mechanism, a walking mechanism and a shoe polishing mechanism, wherein the clamping mechanism is used for clamping a shoe; the walking mechanism comprises a pair of sliding rails which are arranged in parallel; the shoe polishing mechanism is slidably arranged on the sliding rails of the walking mechanism and moves back and forth on the sliding rails; the shoe polishing mechanism comprises a front surface roller and a side surface roller, wherein the front surface roller and the side surface roller are respectively used for polishing a front surface and a side surface of the shoe. The shoe polishing device disclosed by the invention solves the defect that the shoe polishing device in the prior art can only polish the front shoe surface and the shoe edge, and realizes the full-coverage polishing of the front surface and side surface of the shoe; in addition, the shoe polishing device can adapt to shoes with different sizes, the shoe clamping force and friction force are moderate, the shoe is flexibly polished and no damage is caused to the shoe.

Owner:SHAOGUAN COLLEGE

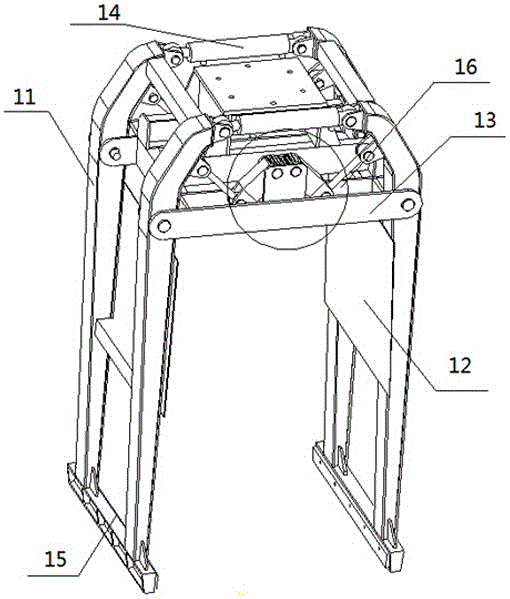

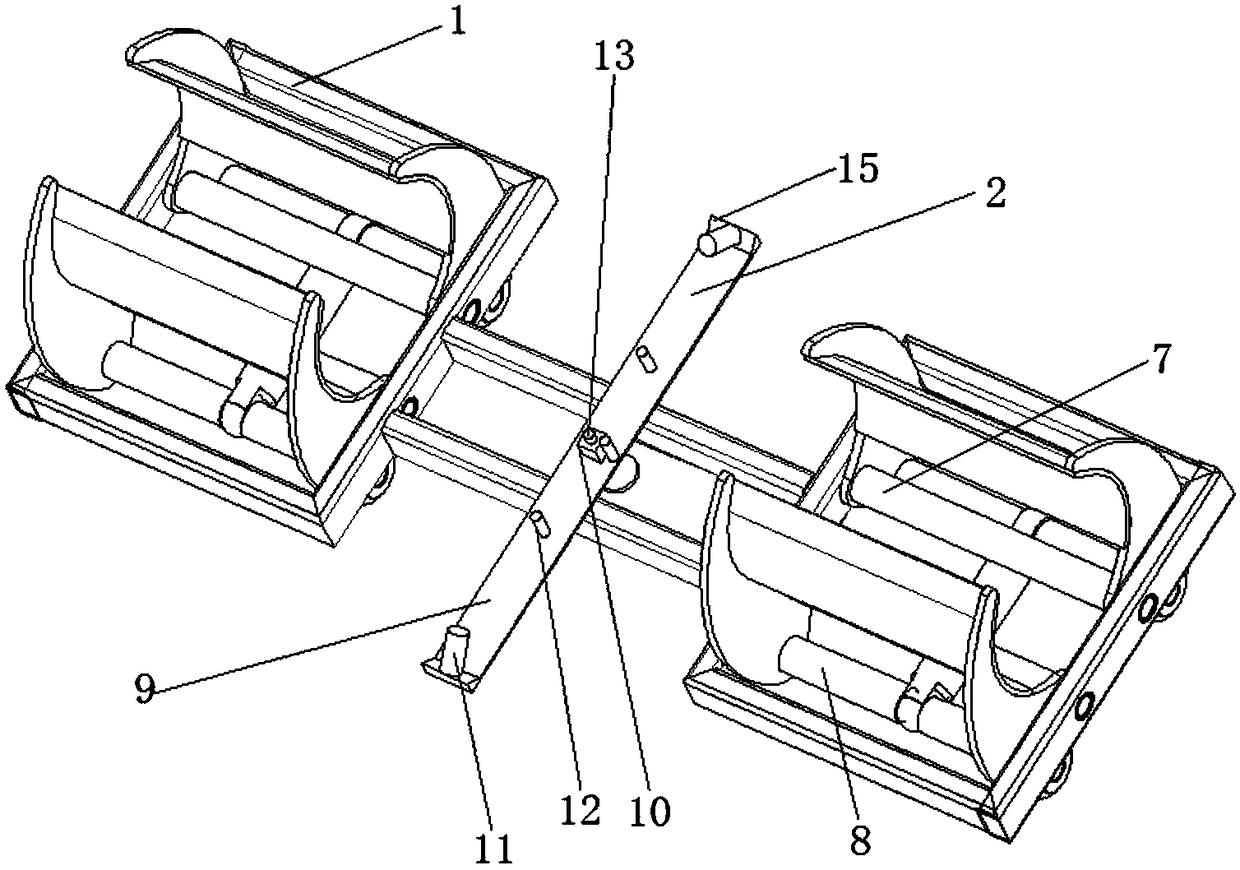

Grasping mechanism for automatic green brick stacking device

ActiveCN102167231AGuaranteed to be fixedWon't scratchStacking articlesDe-stacking articlesBrick clampEngineering

The invention provides a grasping mechanism for an automatic green brick stacking device. The grasping mechanism for the automatic green brick stacking device comprises a hanging bracket, a support rod and a brick clamping mechanism; the support rod is horizontally arranged at the bottom of the hanging bracket, and the support rod is provided with the brick clamping mechanism; the brick clamping mechanism comprises a fixed bracket, movable brackets, a clamping cylinder, sliding pairs, limit connecting plates, limit pins and clips; the upper end of the fixed bracket is fixed on the support rod; the upper end of each movable bracket is connected with the support rod via a sliding pair; the movable brackets are arranged on one side of the fixed bracket; the clamping cylinder is fixed on the fixed bracket; a piston rod of the clamping cylinder is connected with the movable bracket on the outermost side; the fixed bracket and the movable bracket adjacent to the fixed bracket, and the movable brackets are connected via the limit connecting plates; and the movable brackets are provided with strip guiding limit holes, the limit pins are arranged in the strip guiding limit holes, and the lower ends of the fixed bracket and the movable bracket are provided with clips respectively. The grasping mechanism has the advantages that: the structure is simple, the clamping force is precisely controlled, and the stacking position of the green brick is precisely located.

Owner:信阳雄狮装备科技股份有限公司

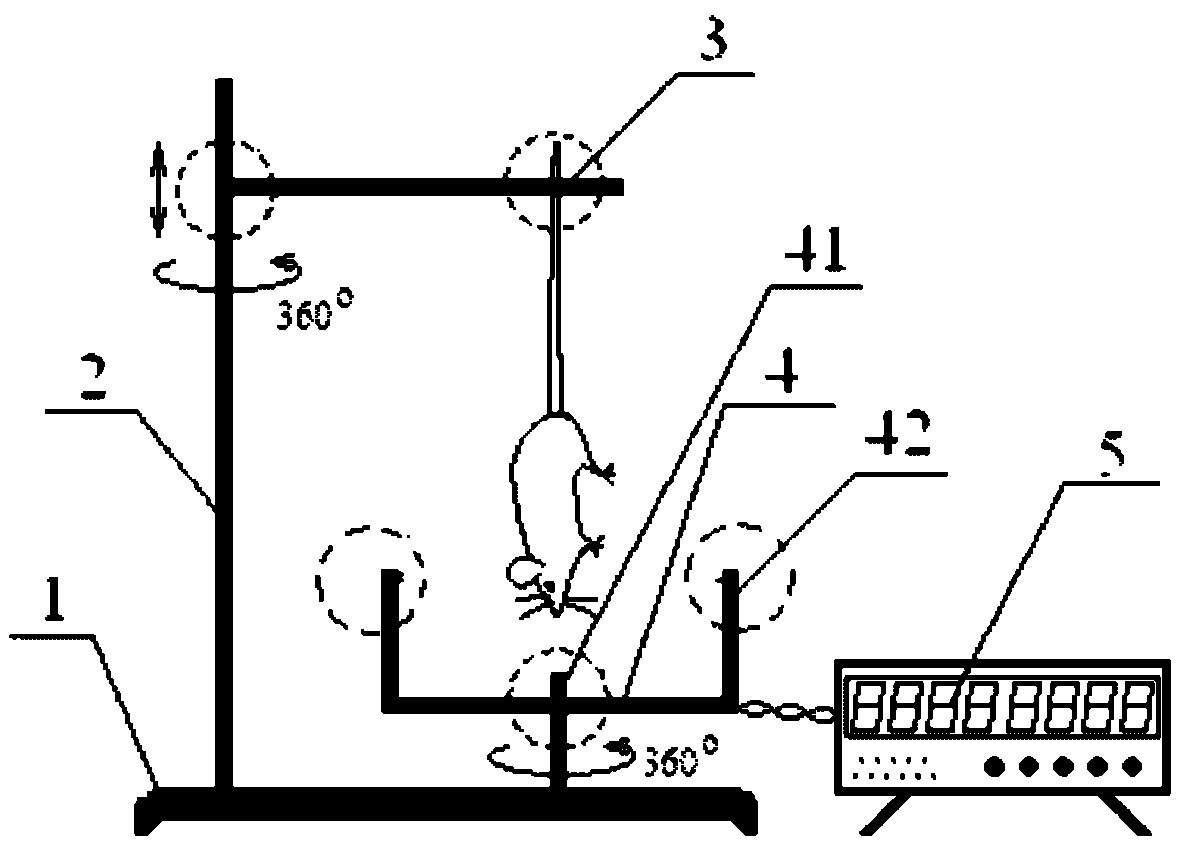

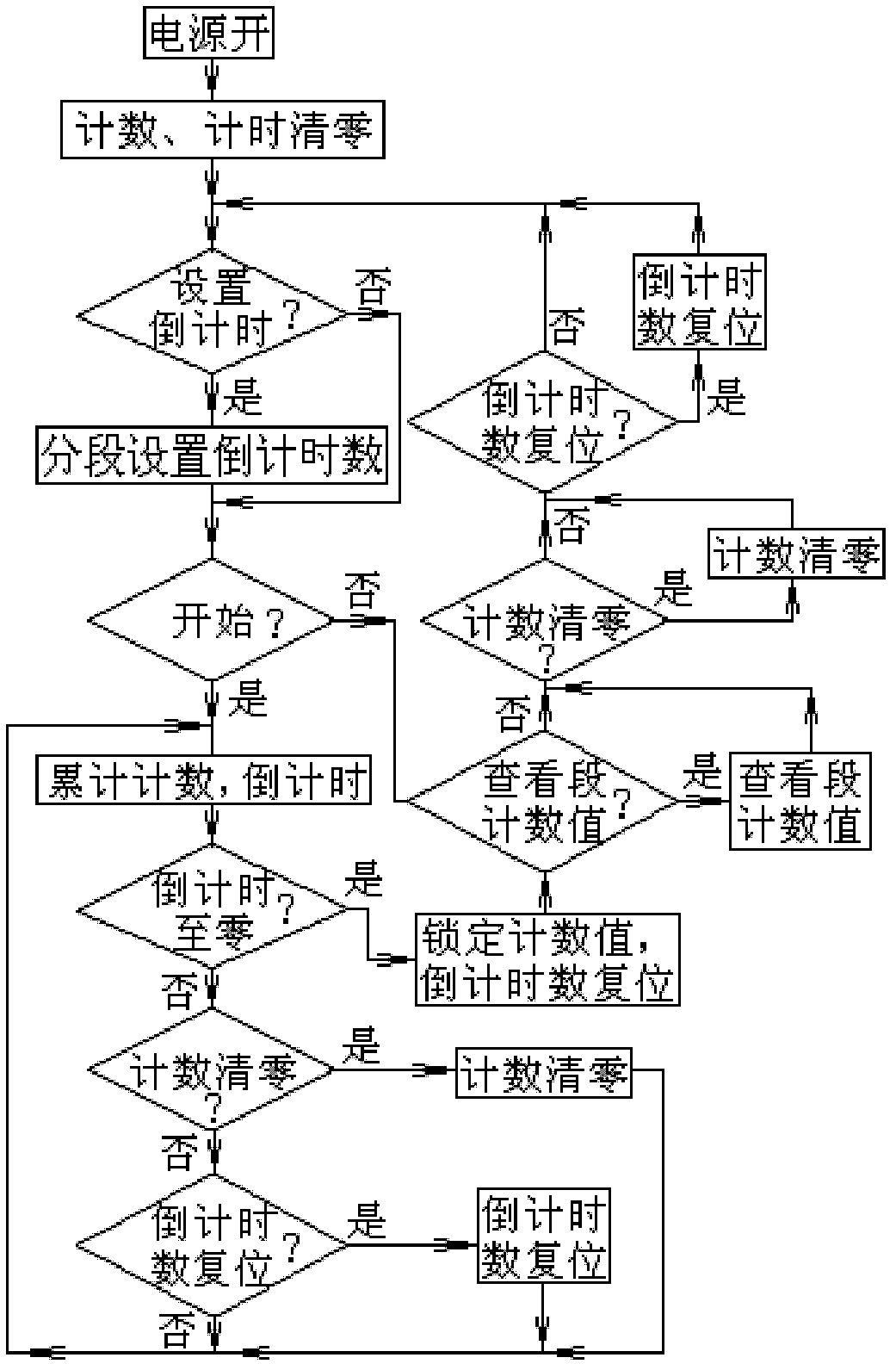

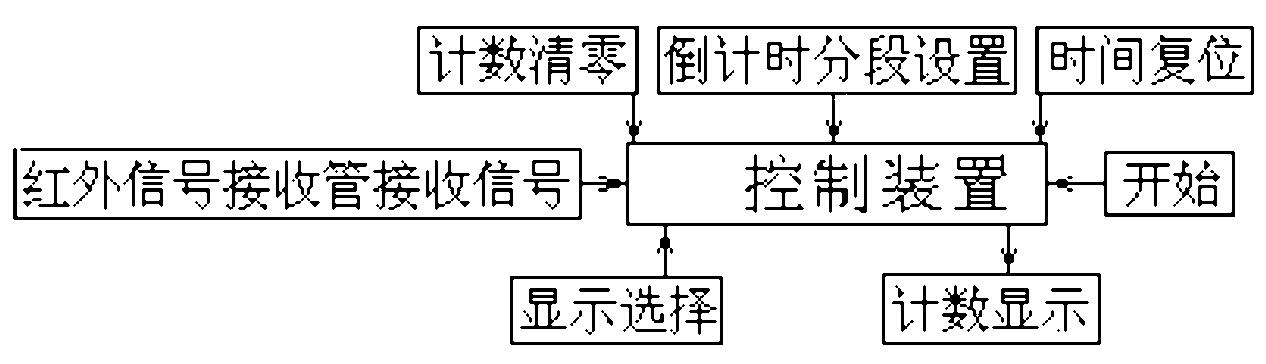

Animal tail suspension experiment device

ActiveCN102641119AModerate clamping forceEliminate the interference of human factorsDiagnostic recording/measuringSensorsElectricityAnti jamming

The invention relates to an animal tail suspension experiment device, comprising a base, a bracket, a tail clamper, a sensing locator and a control device; a bottom end of the bracket is fixed on the base, an upper end is connected with the tail clamper; the sensing locator is electrically connected with the control device; the sensing locator comprises a mounting shaft and an U-shaped rotating handle; a lower end of the mounting shaft is fixed on the base; the U-shaped rotating handle is mounted on the upper end of the mounting shaft; two ends of the U-shaped rotating handle raise up to be U-shaped; an end of the U-shaped rotating handle is equipped with an infrared signal transmitting tube and a located signal source, the other one end is equipped with an infrared signal receiving tube matched with the infrared signal transmitting tube; the infrared signal transmitting tube, the located signal source and the infrared signal receiving tube are controlled by the control device. The animal tail suspension experiment device provided by the invention has the advantages that proper clamping force is provided, man-made interference is removed, anti-jamming capability is strong, operations are simple, and use is convenient.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Lever-type mobile phone clamping seat structure

PendingCN107979678AClamp firmlyNot easy to fallTelephone set constructionsEngineeringMechanical engineering

The invention discloses a lever-type mobile phone clamping seat structure, and aims to provide a lever-type mobile phone clamping seat structure which adopts a lever transmission principle and can clamp mobile phones with different thicknesses. The lever-type mobile phone clamping seat structure comprises a back plate and a supporting seat, a first clamping lever and a second clamping lever are arranged on the left side and the right side of the back plate, clamping columns are arranged on the first clamping lever and the second clamping lever, the supporting seat is arranged on the lower portion of the back plate, a supporting column is arranged on the supporting seat, a supporting point of the first clamping lever is arranged on a first rotating shaft of the back plate, a supporting point of the second clamping lever is arranged on a second rotating shaft of the back plate, a first moving shaft hole is formed in one end of the first clamping lever, a second moving shaft hole is formed in one end of the second clamping lever, a third moving shaft hole is formed in the supporting seat, and the first moving shaft hole, the second moving shaft hole and the third moving shaft hole sleeve a moving shaft. The lever-type mobile phone clamping seat structure is simple and convenient to adjust, firm, free from excessive clamping, adaptable to the thicknesses of different mobile phonesand applicable to mobile phone use environments.

Owner:遂宁欧菲斯电子科技有限公司

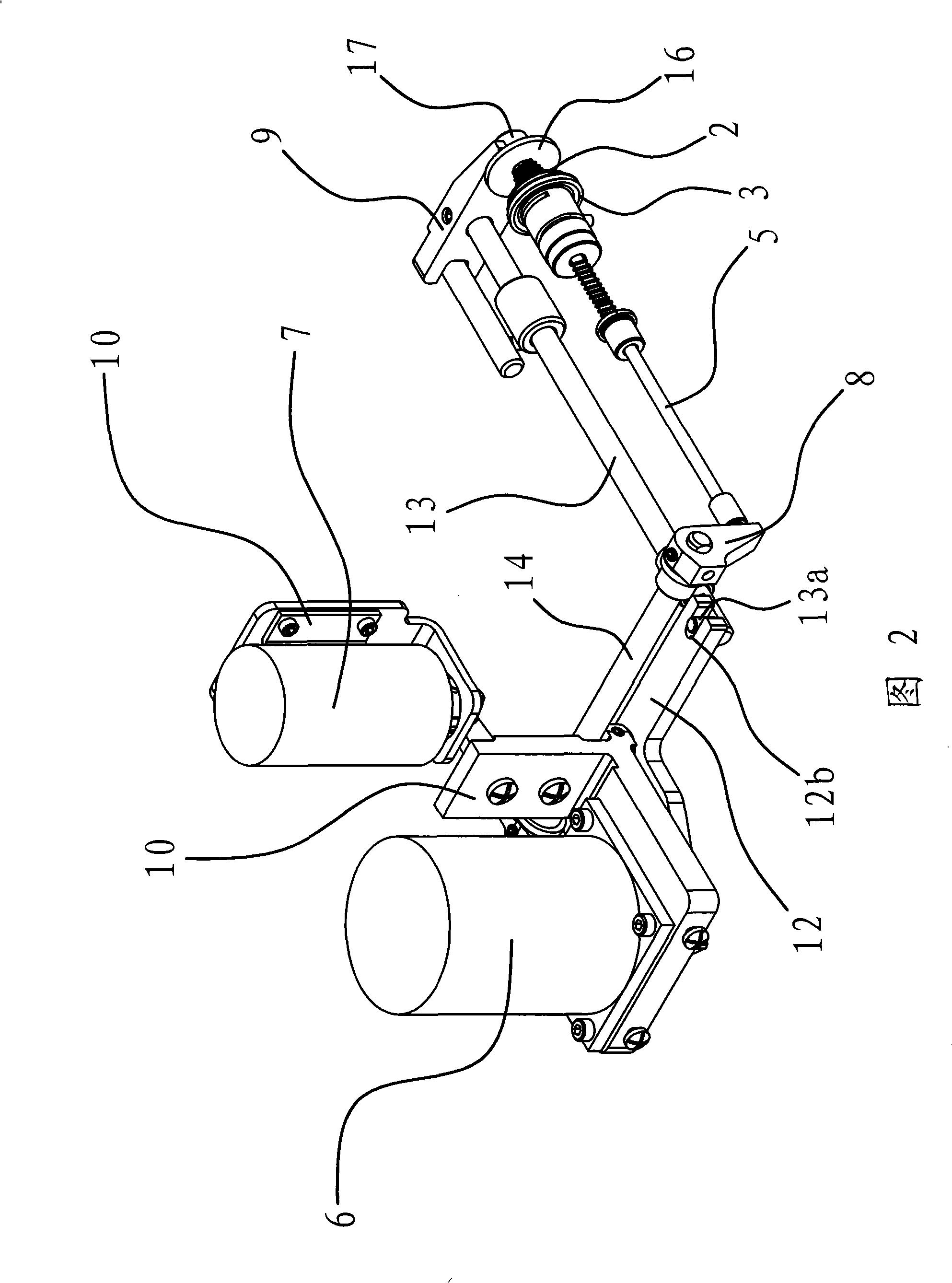

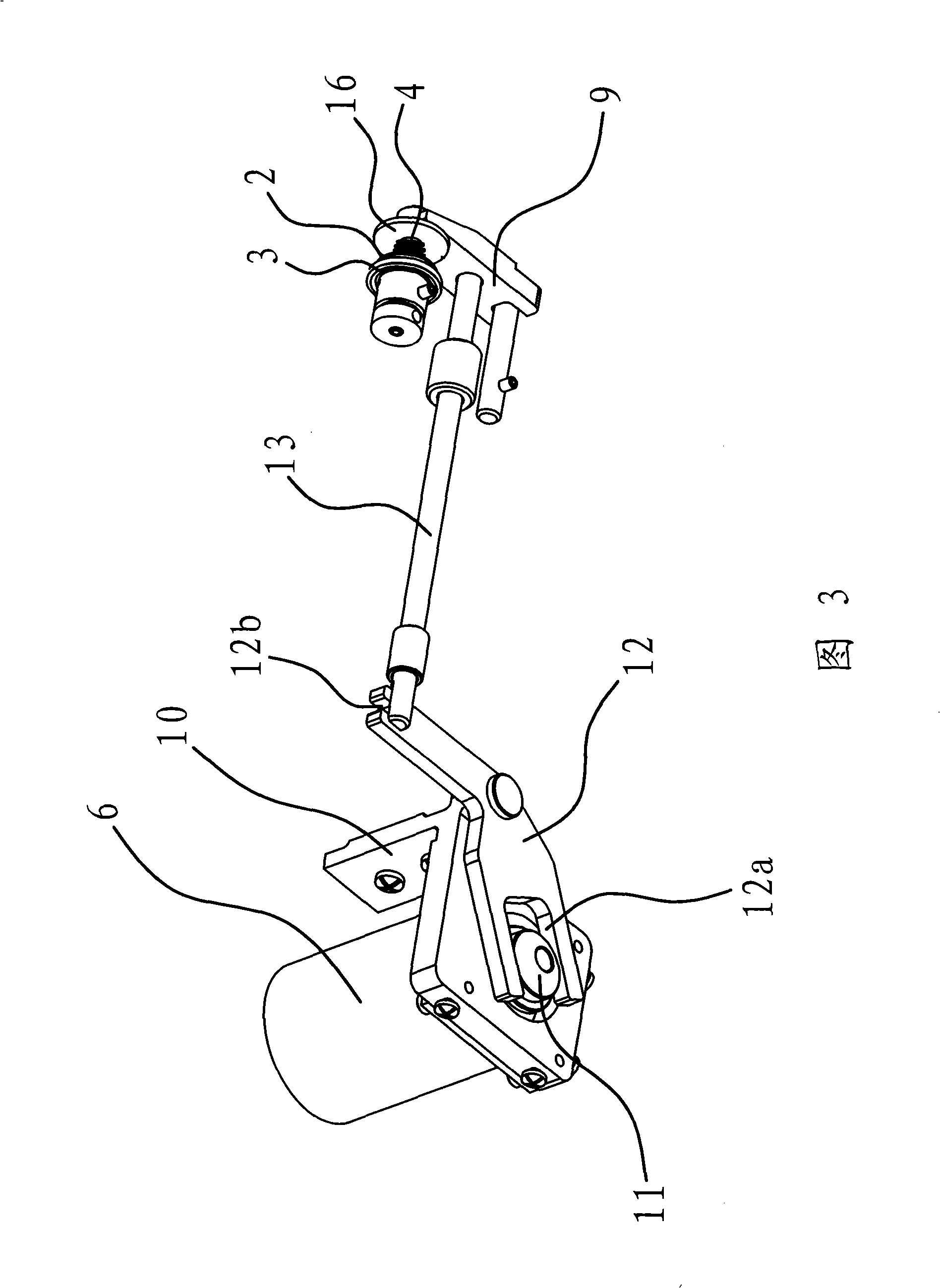

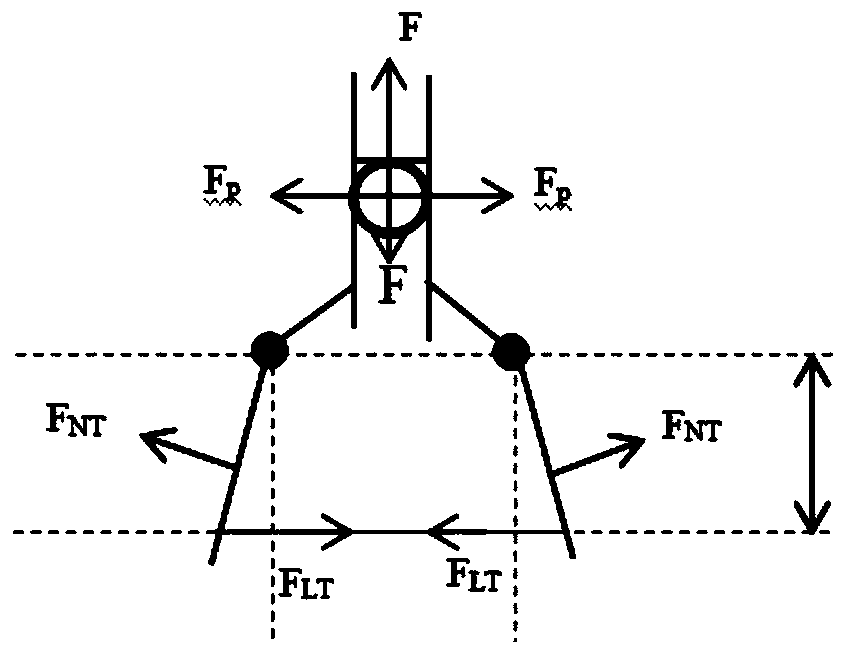

Hydraulic mechanical gripper having identification positioning function and capable of grabbing rods of various sizes

PendingCN108058182AHigh degree of automationAccurate captureGripping headsHydraulic cylinderMotor drive

The invention belongs to the technical field of industrial automation equipment and particularly relates to a hydraulic mechanical gripper having an identification positioning function and capable ofgrabbing rods of various sizes. The hydraulic mechanical gripper comprises two clamping mechanisms and a positioning mechanism, and the two clamping mechanisms are symmetrically arranged on the two sides of the positioning mechanism correspondingly. Each clamping mechanism comprises a supporting frame, two clamping jaws, rotating shafts and a hydraulic cylinder, wherein the rotating shafts comprise the first rotating shaft and the second rotating shaft which are arranged on the two clamping jaws correspondingly; the left and right ends of the first rotating shafts are fixed to the supporting frames; the two second rotating shafts are connected through the hydraulic cylinders; the positioning mechanism comprises a fixing frame, and the fixing frame is provided with an industrial camera, twoline lasers and three point lasers; and the industrial camera is provided with a lighting light source. The hydraulic mechanical gripper is simple in structure, the time and labor are saved, the hydraulic mechanical gripper can replace a traditional motor-driven manipulator, replaces workers to complete the task efficiently and adapts to the harsh working environment, the safety of the workers can be guaranteed, and the production cost is reduced.

Owner:INST OF INTELLIGENT MFG TECH JITRI

Control device for yarn trapper in sewing machine

InactiveCN101314897AImprove job stabilityModerate clamping forceSewing-machine control devicesTensioning devicesYarnElectric machinery

The invention provides a control device of a conductor holder in a sewing machine, belongs to the mechanical technology field, and solves the problems of the prior conductor holder, such as low accuracy, etc. caused by manually regulating a line tension pulley of the conductor holder for controlling the line tension. The control device of the conductor holder in the sewing machine is characterized in that the conductor holder is arranged on the frame side part of the sewing machine; the control device comprises an electric motor, an electromagnet, a wire loosing rod and a wire clamping block; the electric motor is permanently connected with the frame; a wire clamping transmission mechanism which enables the wire clamping block to compress a spring is arranged between the electric motor and the wire clamping block; the electromagnet is permanently connected with the frame; and a wire loosing transmission mechanism which enables the wire loosing rod to prop against the outer end of a thimble is arranged between the electromagnet and the wire loosing rod. The control device realizes line tightening by the electric motor and the line clamping transmission mechanism, and the clamping force between an upper chuck and a lower chuck is always maintained to be proper during the process of line tightening. The control device of the conductor holder in the sewing machine has higher working stability and simple structure.

Owner:ZHEJIANG ZOJE SEWING MACHINE

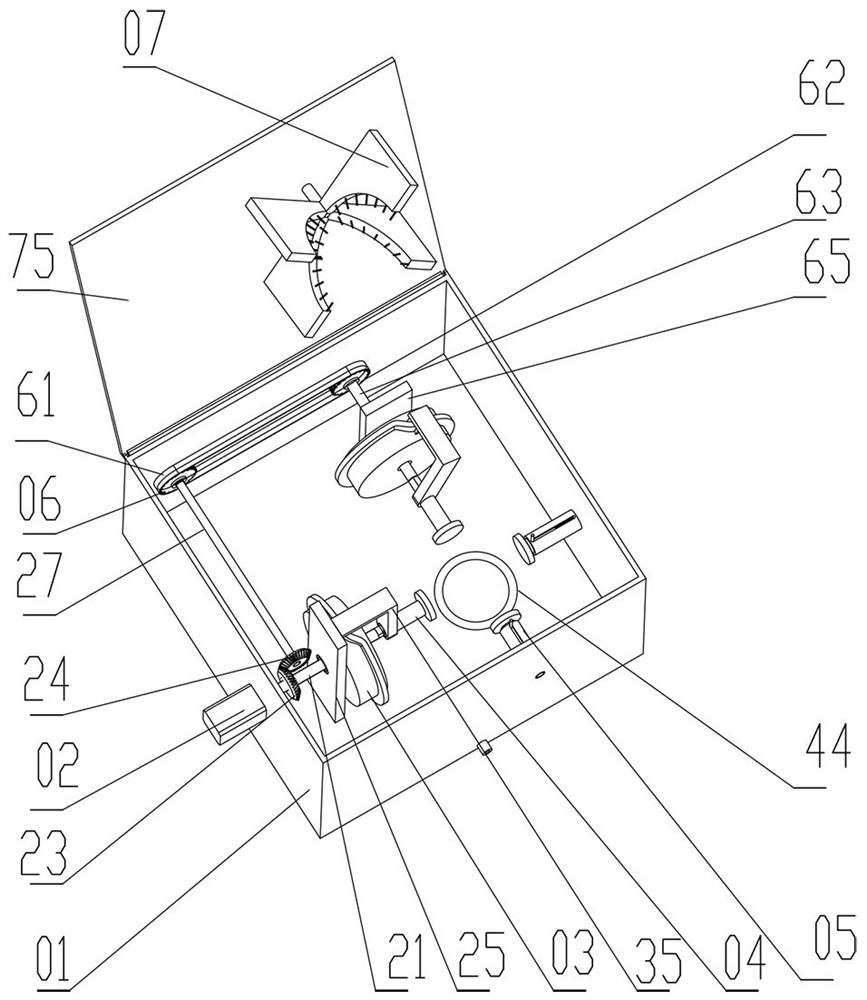

Manufacturing equipment of light-weight, waterproof and environment-friendly composite board

ActiveCN111496543AScientific and reasonable structureEasy to useGrinding machine componentsOther manufacturing equipments/toolsComposite plateIndustrial engineering

The invention discloses manufacturing equipment of a light-weight, waterproof and environment-friendly composite board. The equipment comprises a lower supporting frame. One side of the lower supporting frame is fixedly connected with a side supporting frame. The middle of the top end of the lower supporting frame is movably connected with a middle slide support. The middle of the top end of the middle slide support is movably connected with an upper slide support. Internal supporting frames are fixedly connected to the positions, corresponding to the two sides of the upper slide support, of the top end of the middle slide support correspondingly. One end of the top of the upper slide support is fixedly connected with a cutting and grinding mechanism. According to the manufacturing equipment provided by the invention, a grinding disc is lifted down while the upper slide support moves backwards so that one end surface of the composite board can be ground and chamfered, sharp burrs formed on the side portions of a metal plate on the upper layers of the end surfaces of the composite board are effectively removed, hidden safety hazards in the transporting and using process of the composite board are eliminated, the using safety of the composite board is improved, the two steps of cutting and grinding are completed in the two-way process of the upper slide support, and the production process of the composition board is optimized.

Owner:SHENZHEN LANDUN WATERPROOF ENG

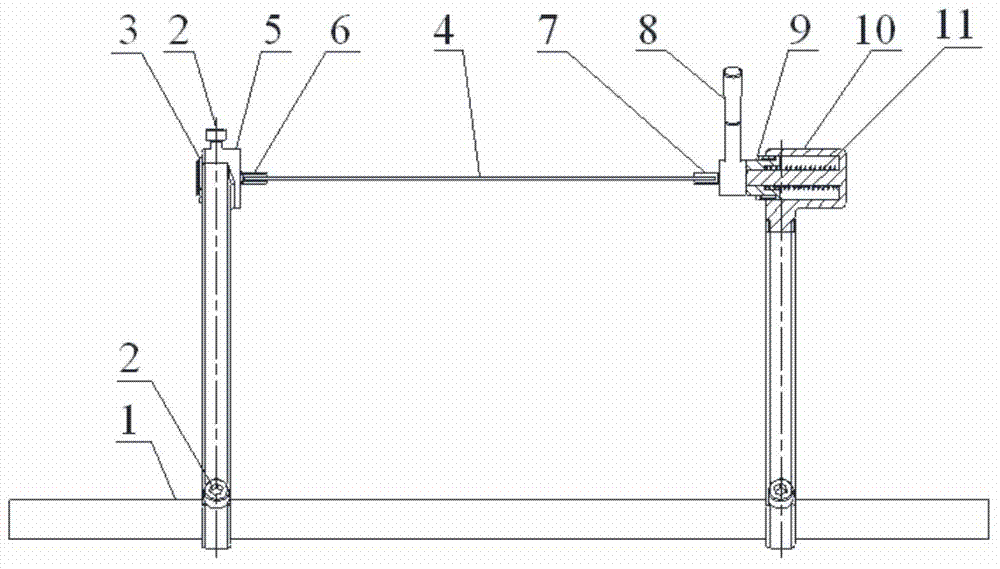

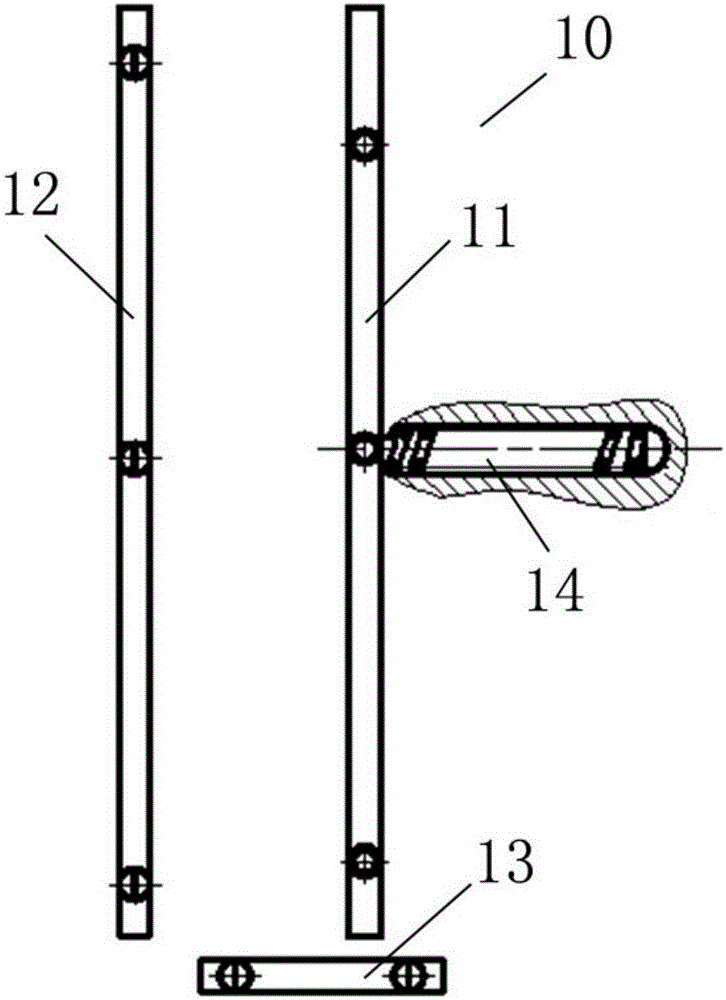

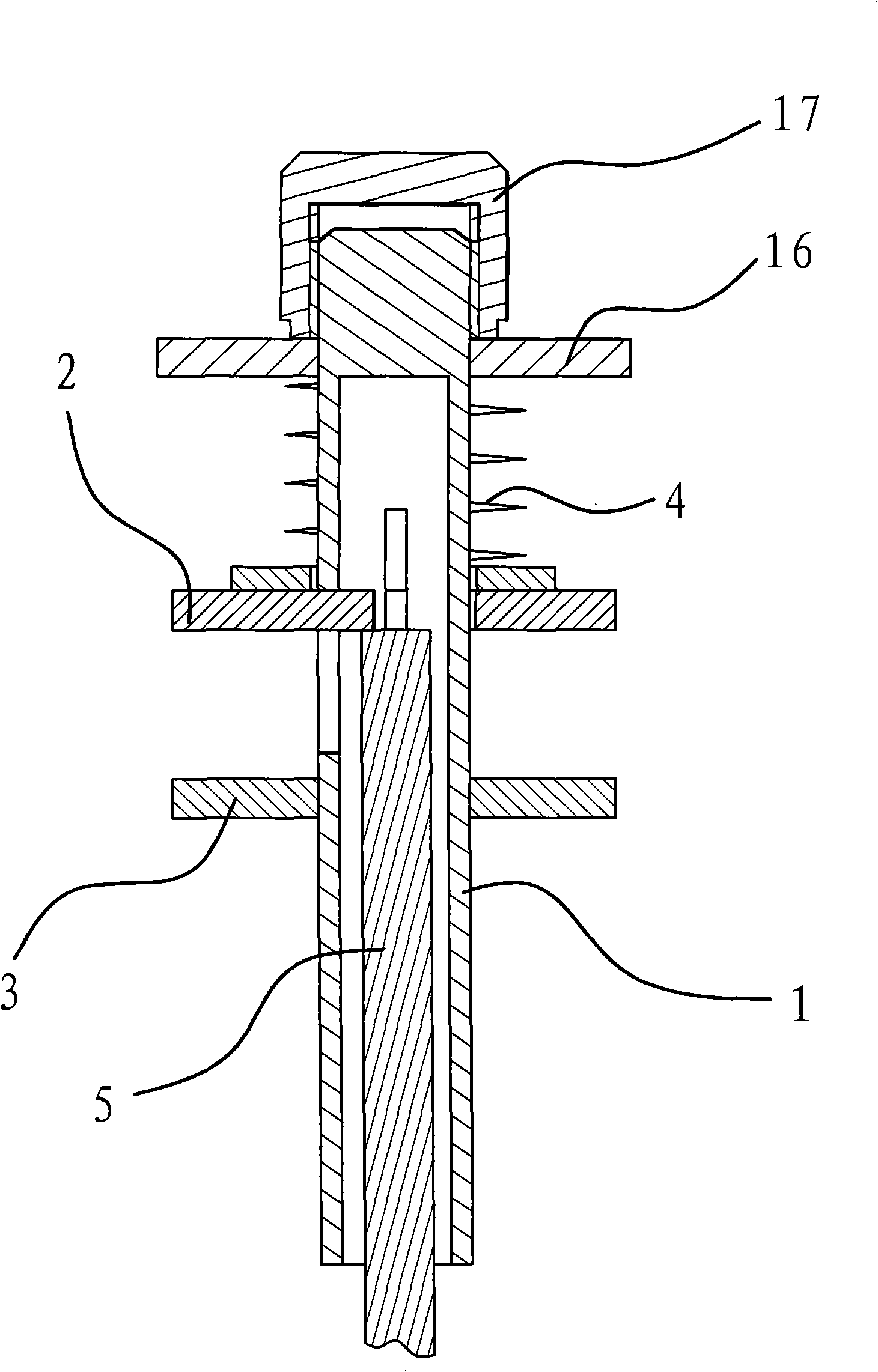

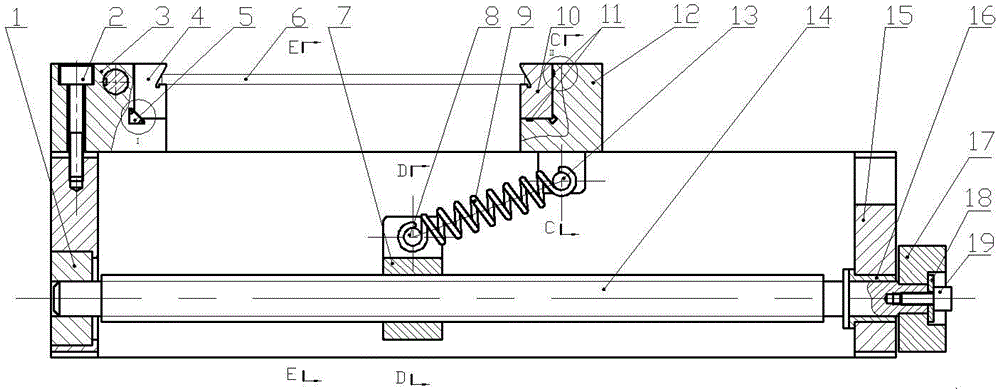

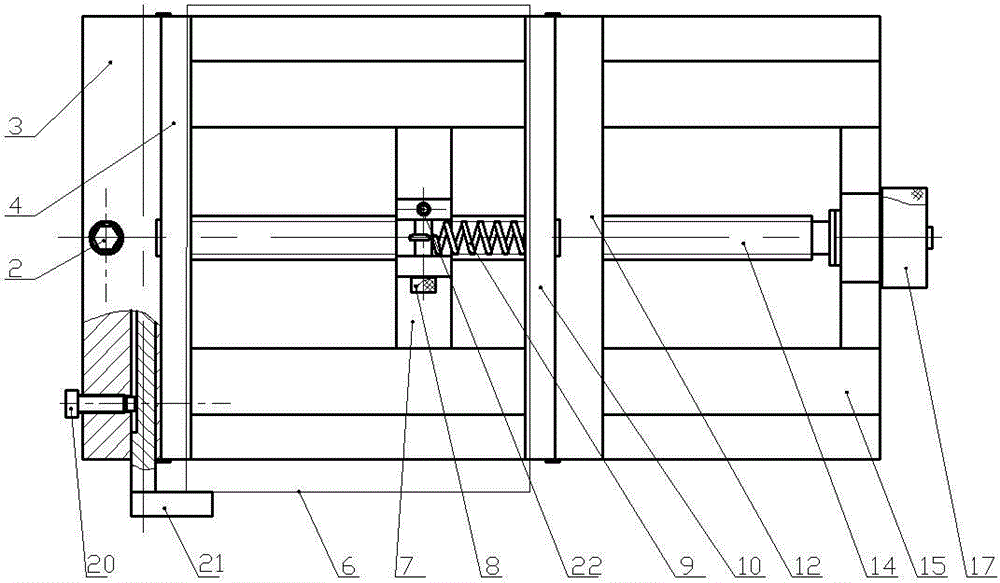

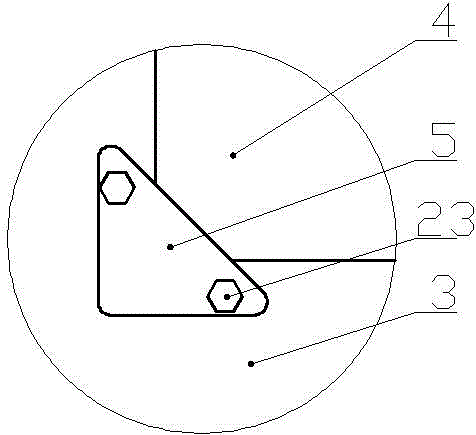

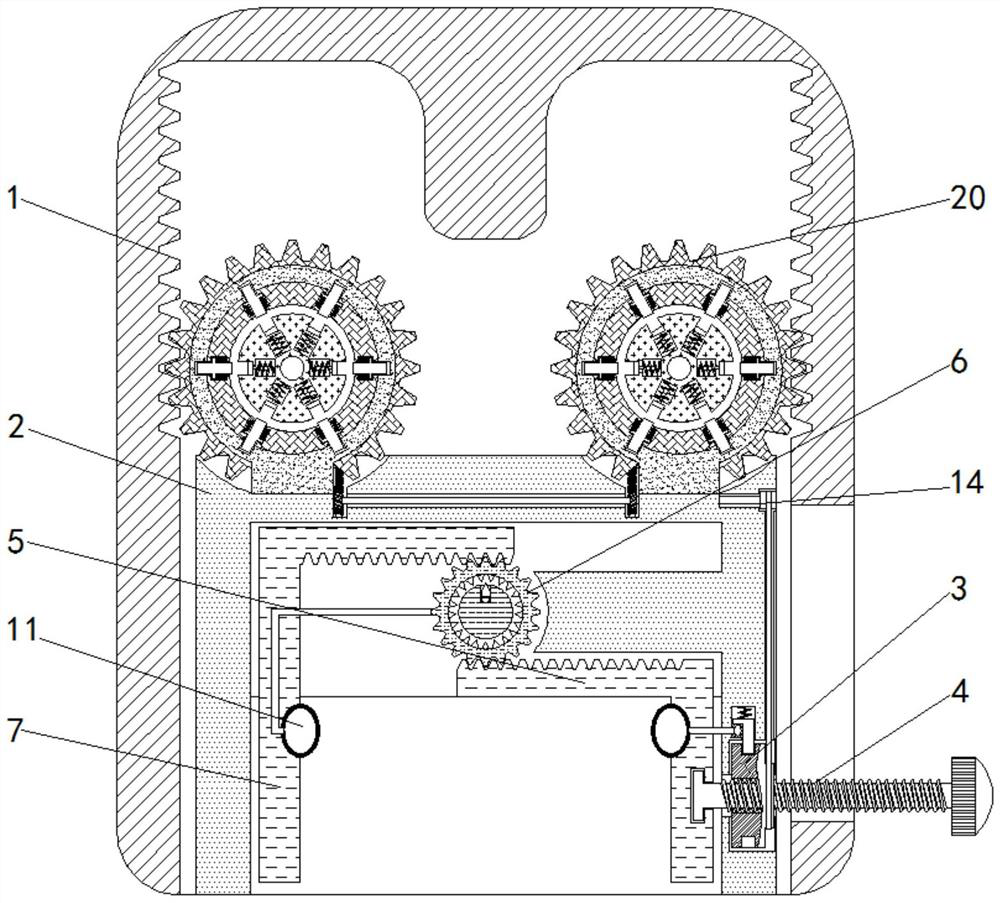

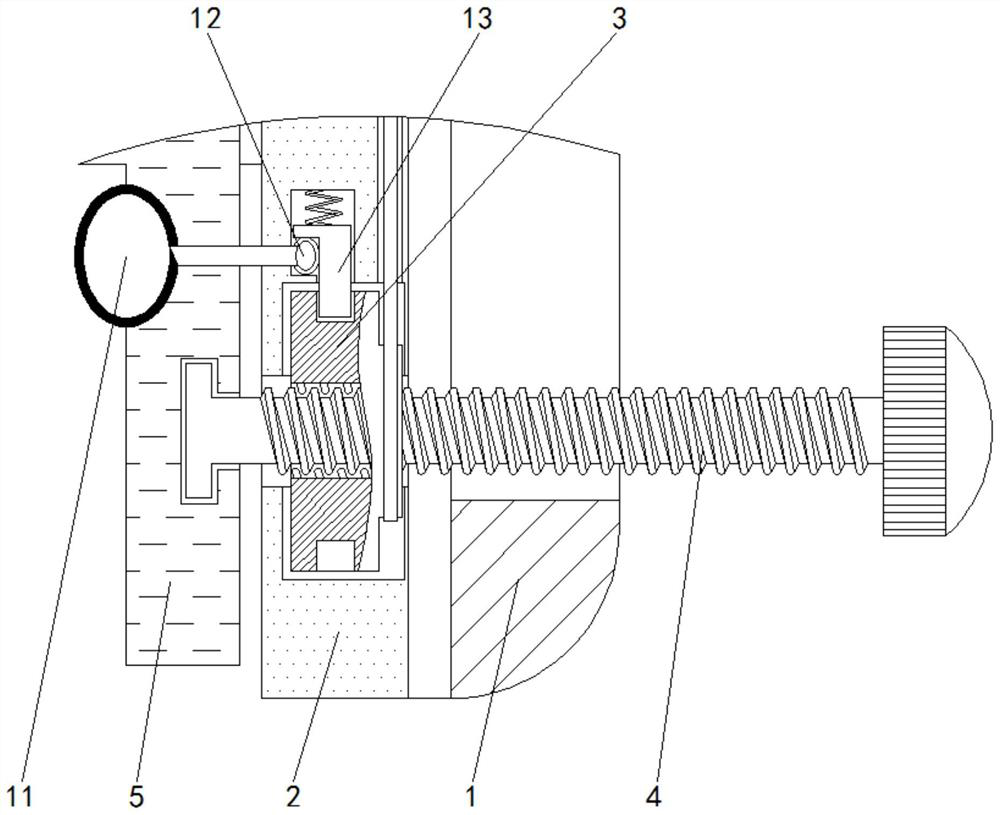

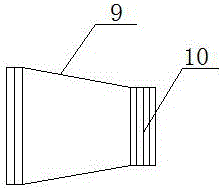

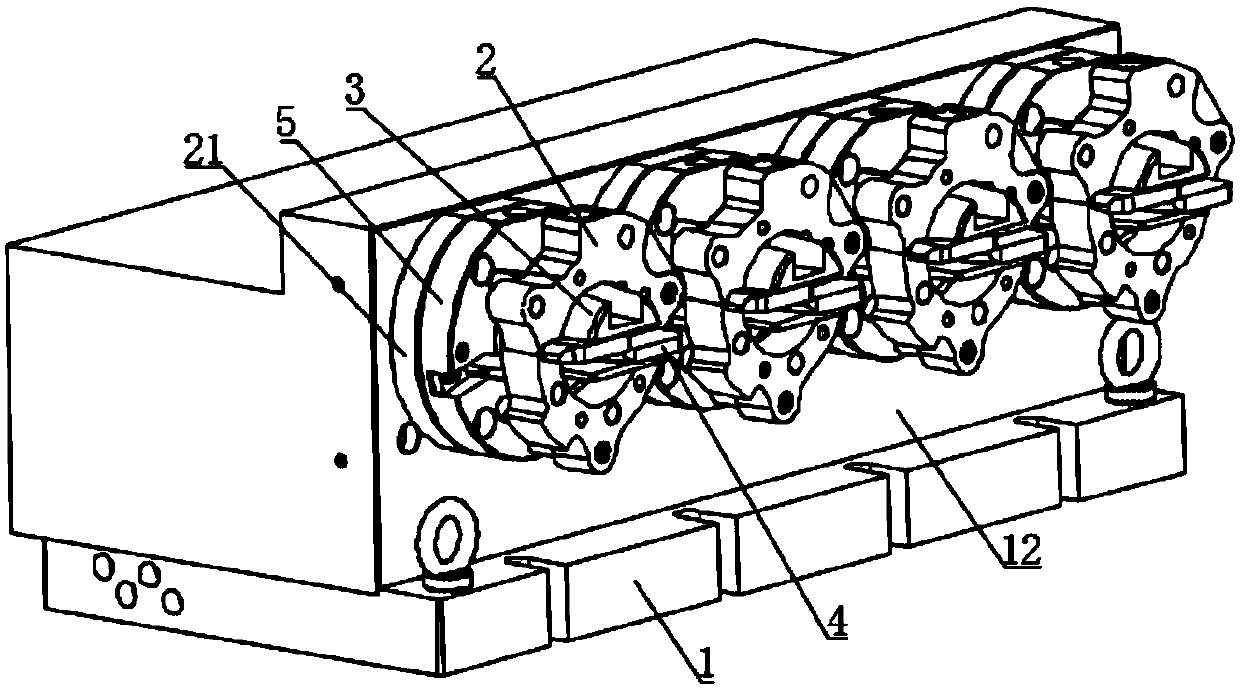

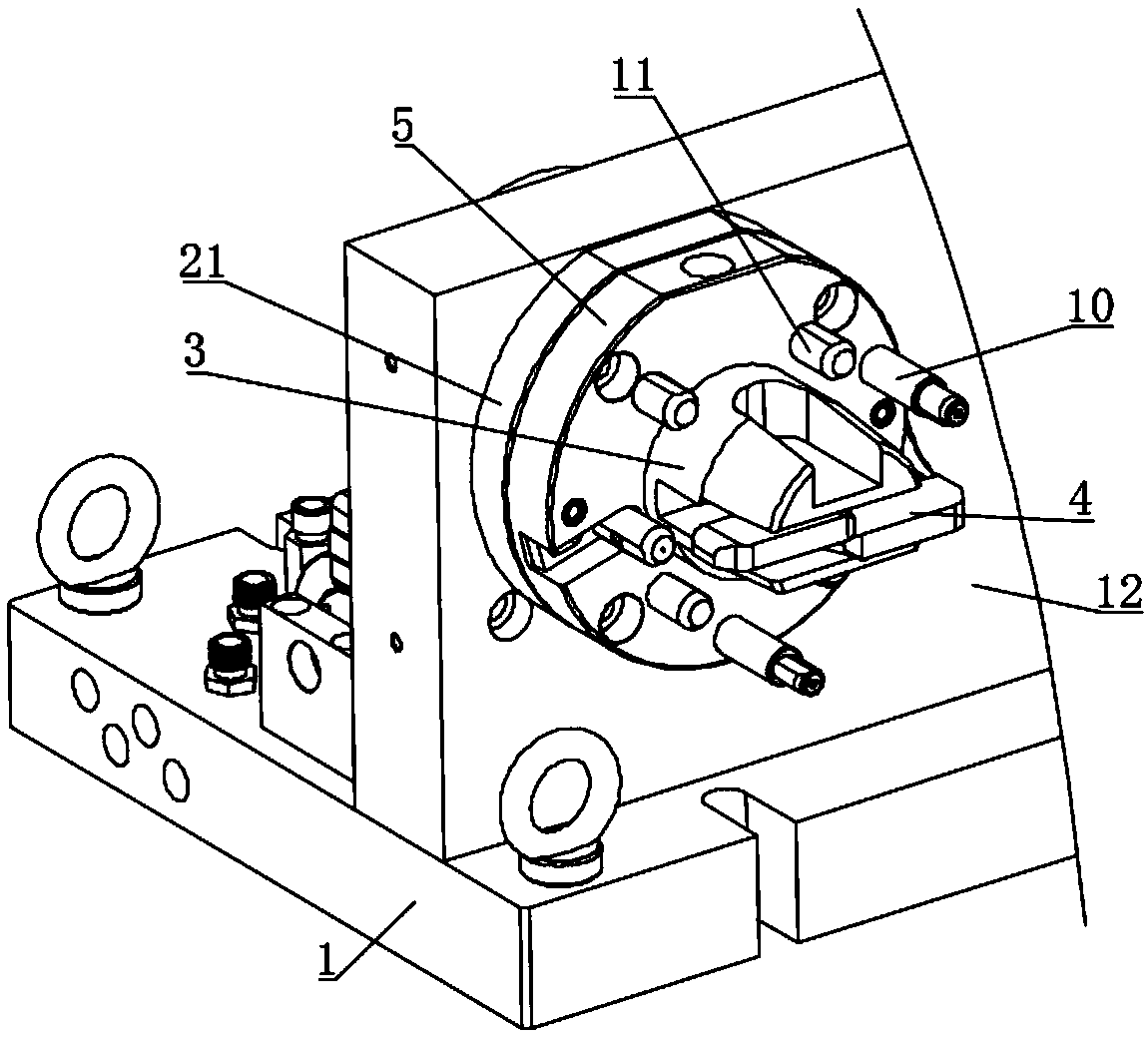

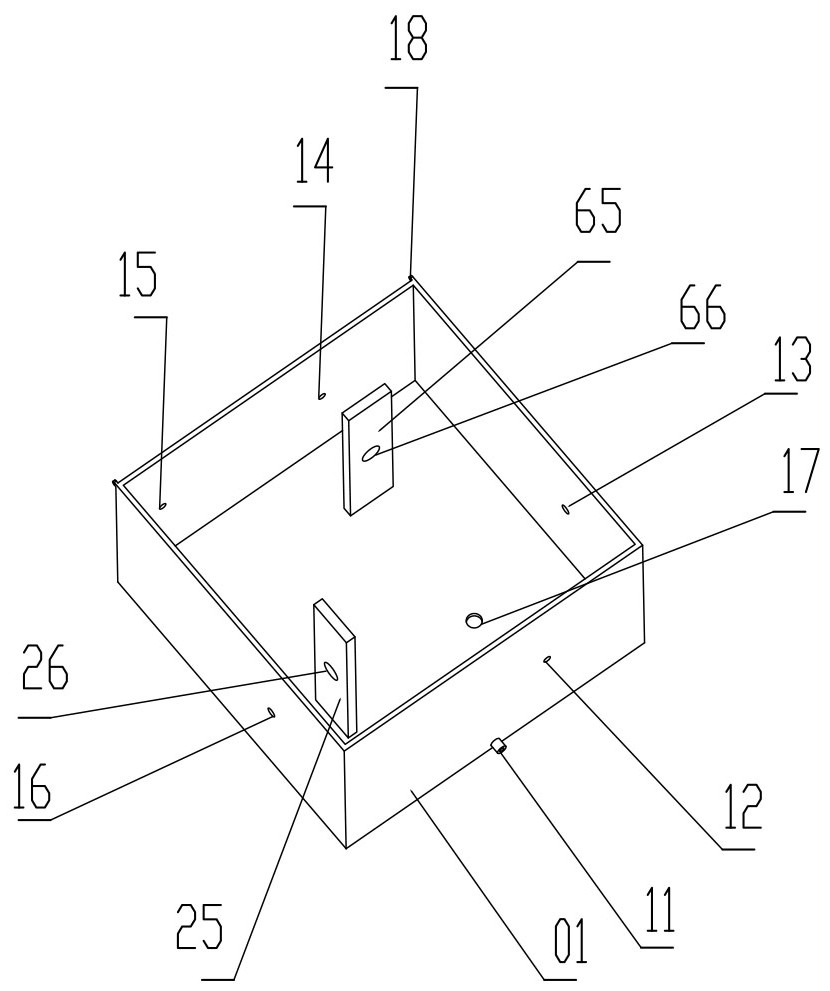

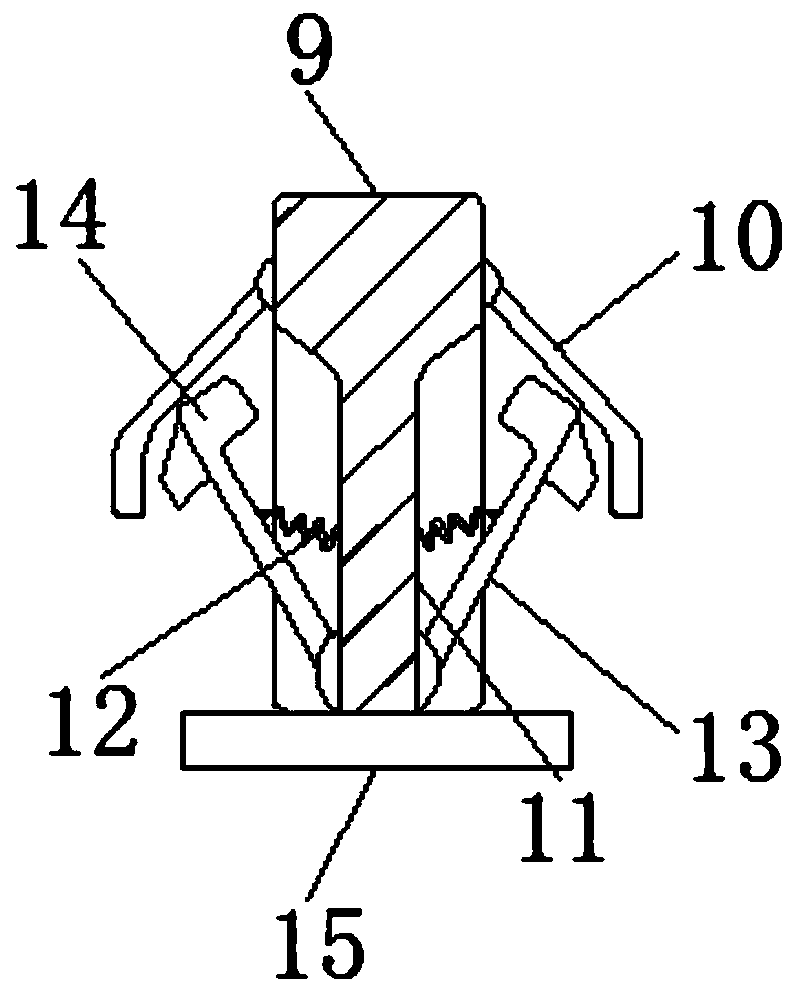

Elastic clamp applied to thin sheet parts of laser micromachining machine tool

InactiveCN105312784AMeet the clamping requirementsEffective adjustment of clamping forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine tool

The invention discloses an elastic clamp applied to thin sheet parts of a laser micromachining machine tool. The clamp comprises a clamp body (15), a fixed clamp base (3), a movable clamp base (12) and a screw rod (14), wherein a nut (7) is connected to the middle of the screw rod (14); the screw rod (14) penetrates through a through groove of the clamp body (15); the left end of the screw rod (14) is inserted into a left end hole of the clamp body (15); the right end of the screw rod (14) is inserted into a right end hole of the clamp body (15); a rotary knob (17) is fixed to the right end of the screw rod (14); the nut (7) is clamped in the through groove in the middle of the clamp body (15); the fixed clamp base (3) is fixed to the clamp body (15); a dovetail groove under the movable clamp base (12) is connected to a dovetail at the upper part of the clamp body (15); the movable clamp base (12) is connected to the nut (7) through a spring I (9). The elastic clamp is simple in structure, convenient to adjust, low in cost and wide in adjusting range, and has good generality.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

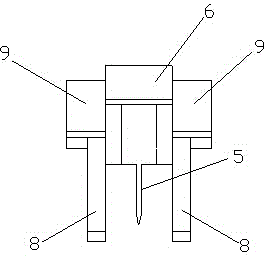

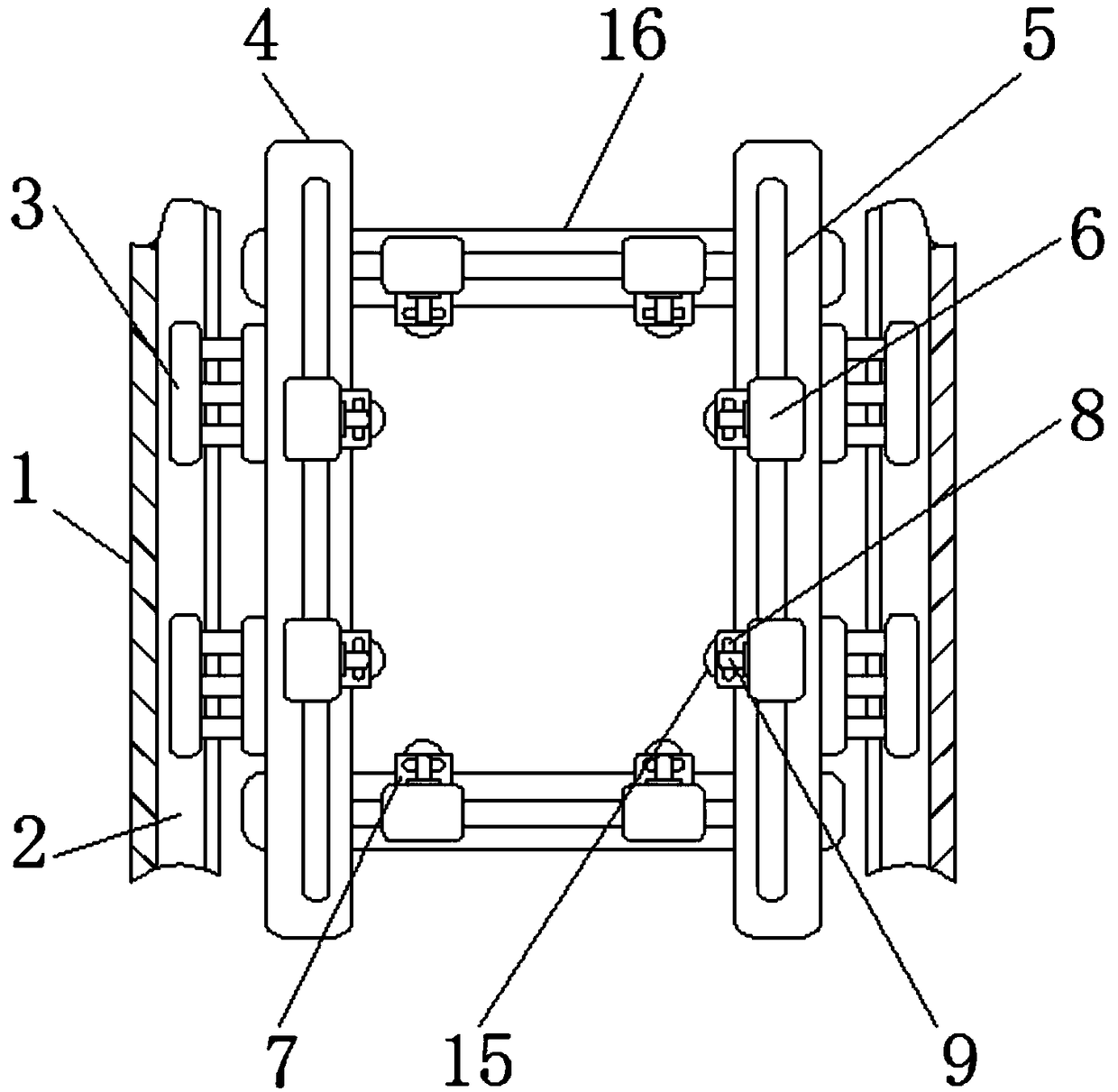

Clamping equipment special for machining double holes in gasket

InactiveCN106914782AImprove processing efficiencyImprove consistencyWork clamping meansPositioning apparatusPiston rodMotherboard

The invention relates to clamping equipment special for machining double holes in a gasket. The clamping equipment comprises a pedestal, fixed positioning blocks, slide compressing blocks and compressing cylinders. The pedestal is composed of a main plate and supporting plates. A row of the compressing cylinders which are vertically arranged upwards are evenly installed on the lower bottom face of the main plate. A piston rod of each compressing cylinder is connected with a wedge-shaped block. The slide compressing blocks abut against the front side wall and the rear side wall of each wedge-shaped block, and the contact surfaces of the slide compressing blocks and the wedge-shaped blocks are inclined planes. Each slide compressing block is arranged on the upper surface of the main plate. The outer side of each slide compressing block is provided with one corresponding fixed positioning block. The inner wall surfaces of the slide compressing blocks and the inner wall surfaces of the fixed positioning blocks are both provided with grooves used for positioning workpieces. Two through holes are formed in the main plate and located between the slide compressing blocks and the fixed positioning blocks. The clamping equipment special for machining the double holes in the gasket is ingenious in design, reasonable in structure, and easy and convenient to operate. By the adoption of the clamping equipment, working efficiency can be improved, product quality is improved, the amount of labor is decreased and enterprise cost is reduced.

Owner:TIANJIN JINLAI PRECISION MACHINERY

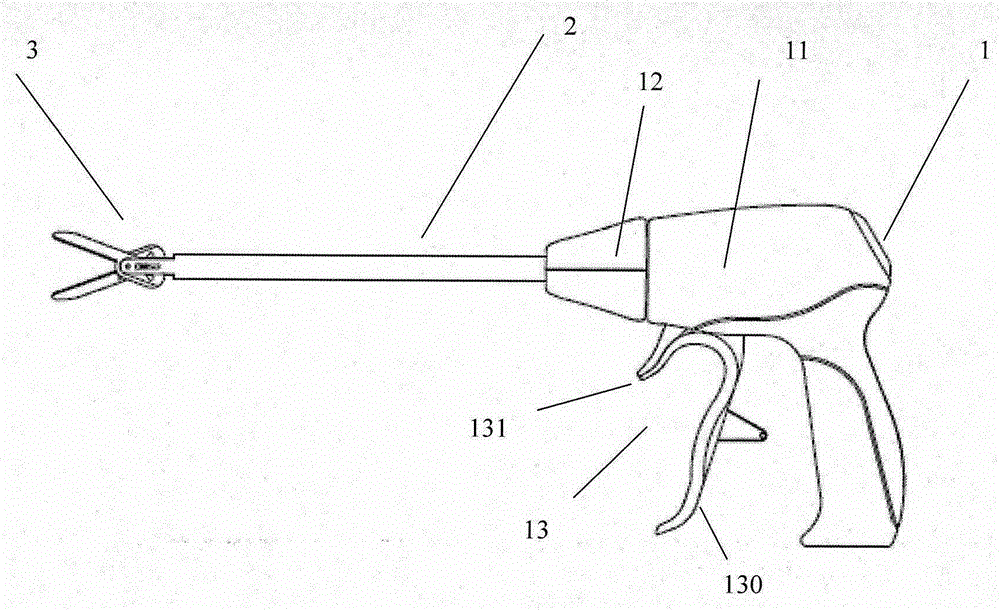

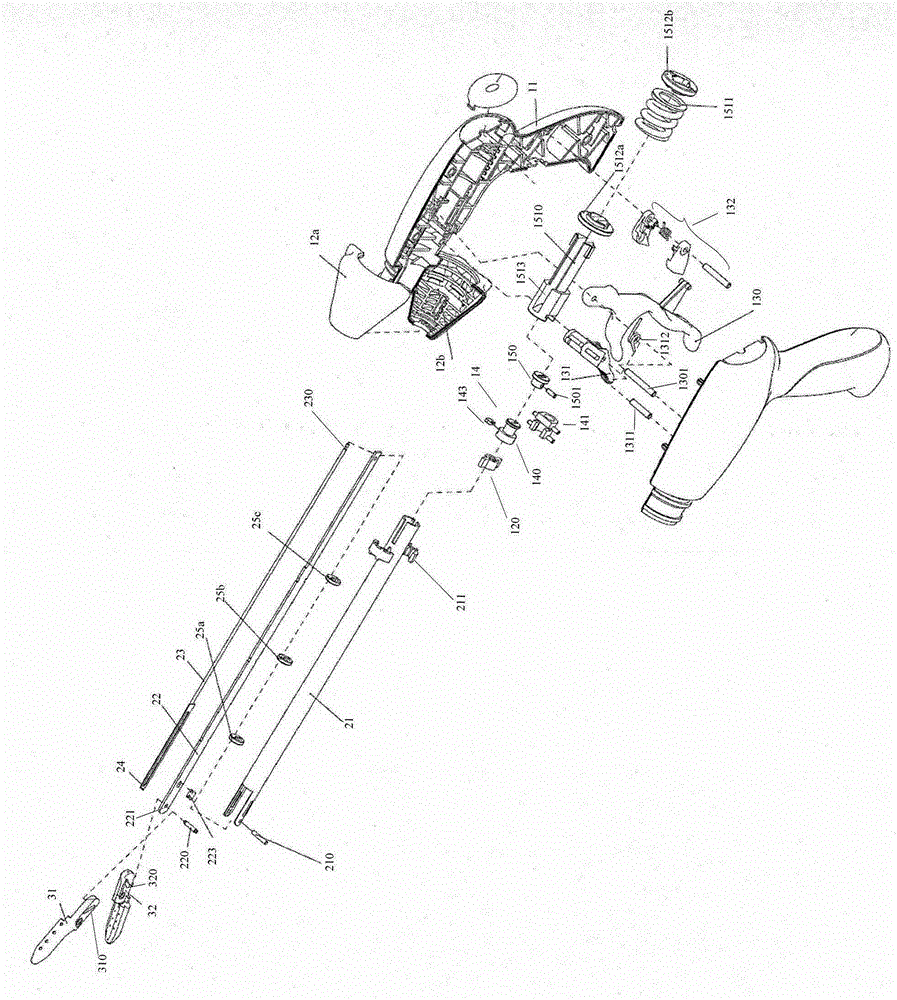

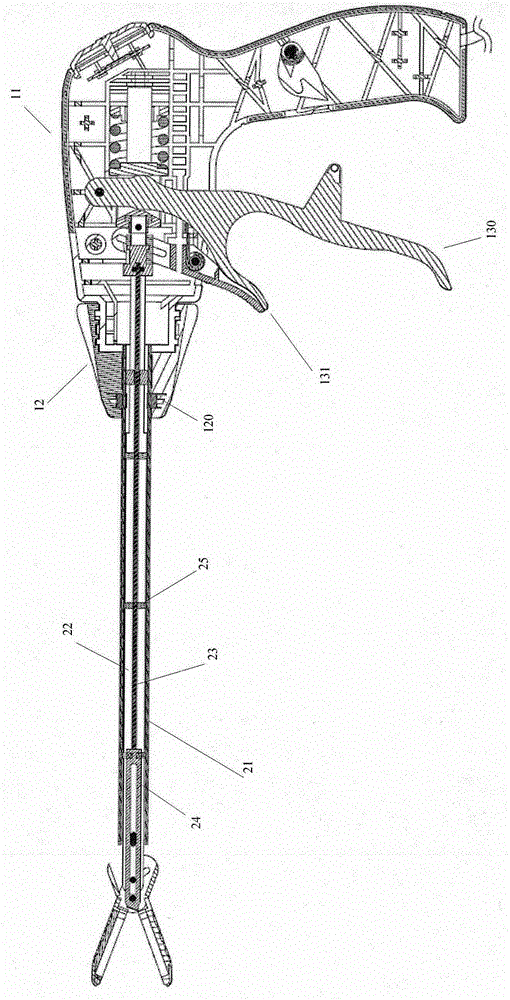

High-frequency electric surgical operating instrument and driving device thereof

ActiveCN106264714AReduce frictionReduce the burden onSurgical instruments for heatingElectrosurgeryEngineering

The invention discloses a high-frequency electric surgical operating instrument. The high-frequency electric surgical operating instrument comprises a handheld component which comprises a trigger unit and is used for generating driving, a connection rod which extends from the handheld component to the far end, and a clamping device which is arranged at the far end of the connection rod and is used for clamping a tissue, wherein the connection rod comprises an outer sleeve, a pull rod and a tool push rod; the near end of the outer sleeve is connected with the far end of the handheld component; the far end of the outer sleeve is connected with the clamping device; the pull rod is arranged in the outer sleeve and is of a platy structure; the trigger unit drives the pull rod to move so as to further control the clamping device to be opened and closed; the tool push rod and the pull rod are arranged side by side; a cutter is arranged at the far end of the tool push rod. As the pull rod is of the platy structure which replaces the sleeve structure in the prior art, and the tool push rod and the pull rod are arranged in the outer sleeve side by side, the space in a gun tube is saved; the pull rod is of the platy structure which enhances the part intensity, so that the service lives of the parts such as the pull rod are prolonged, and the fault rate of the electric surgical operating instrument is reduced.

Owner:REACH SURGICAL

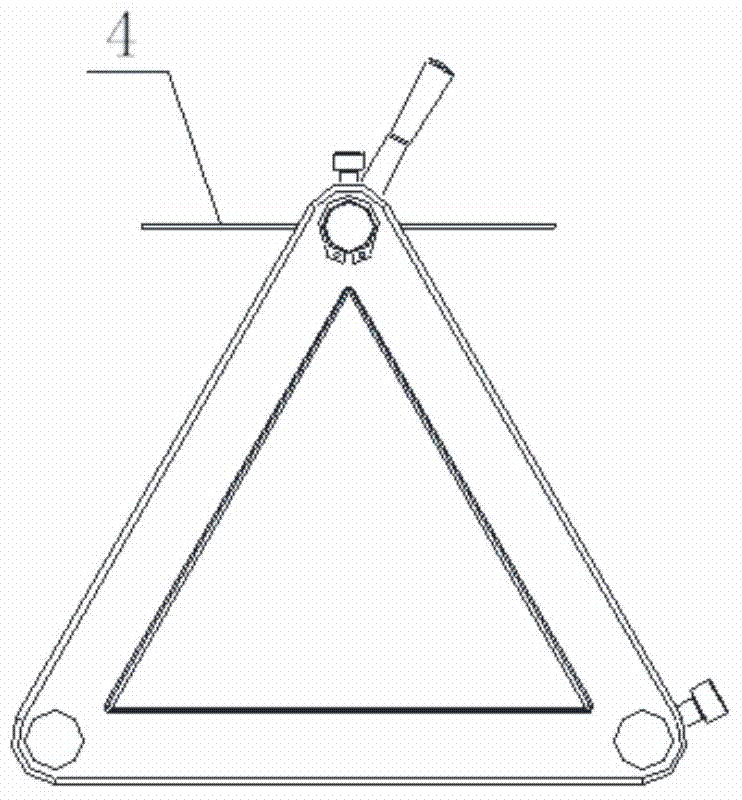

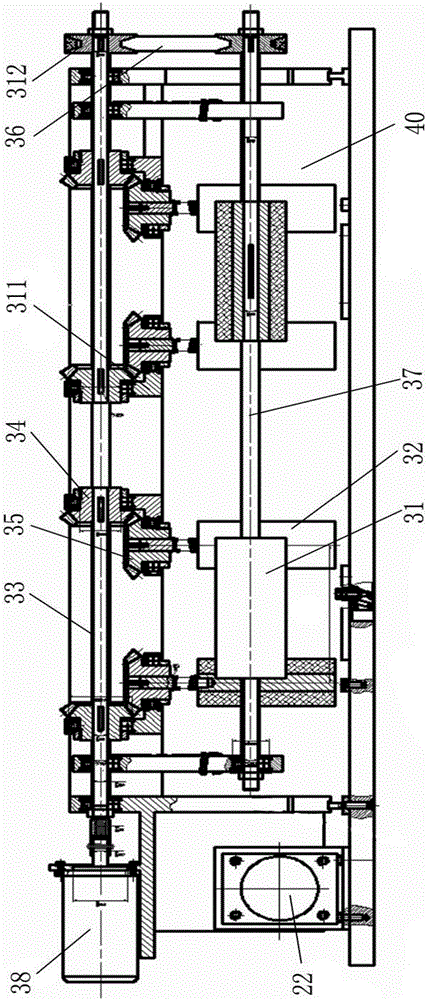

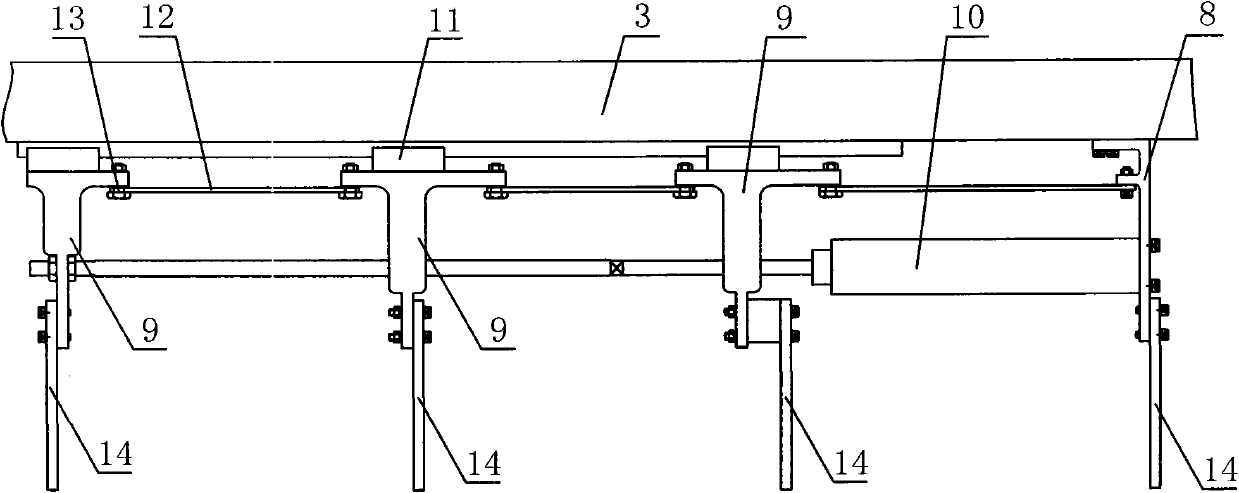

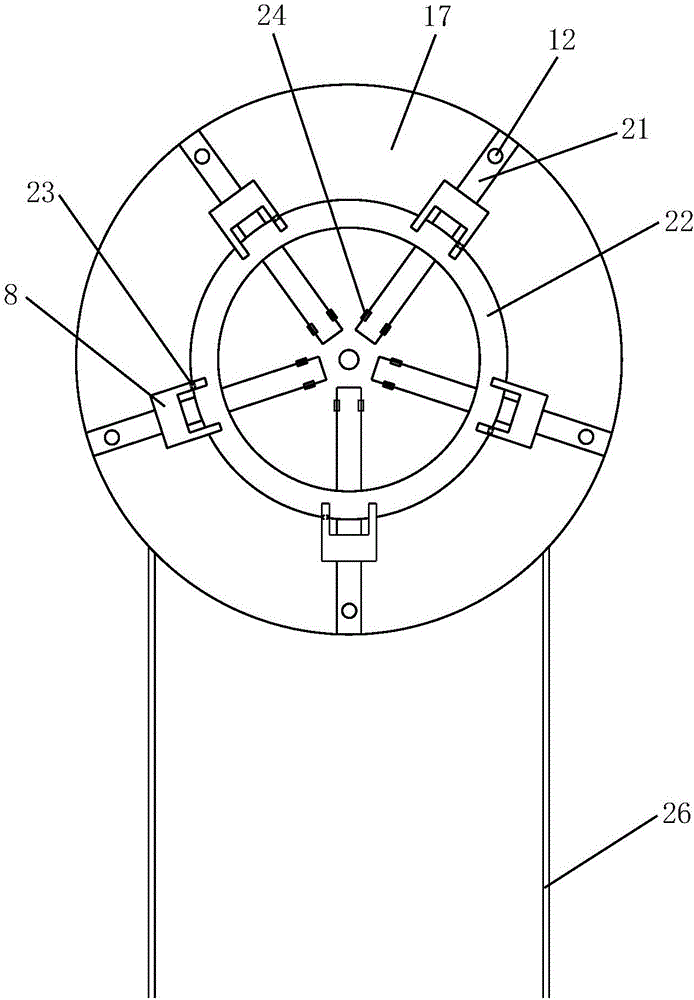

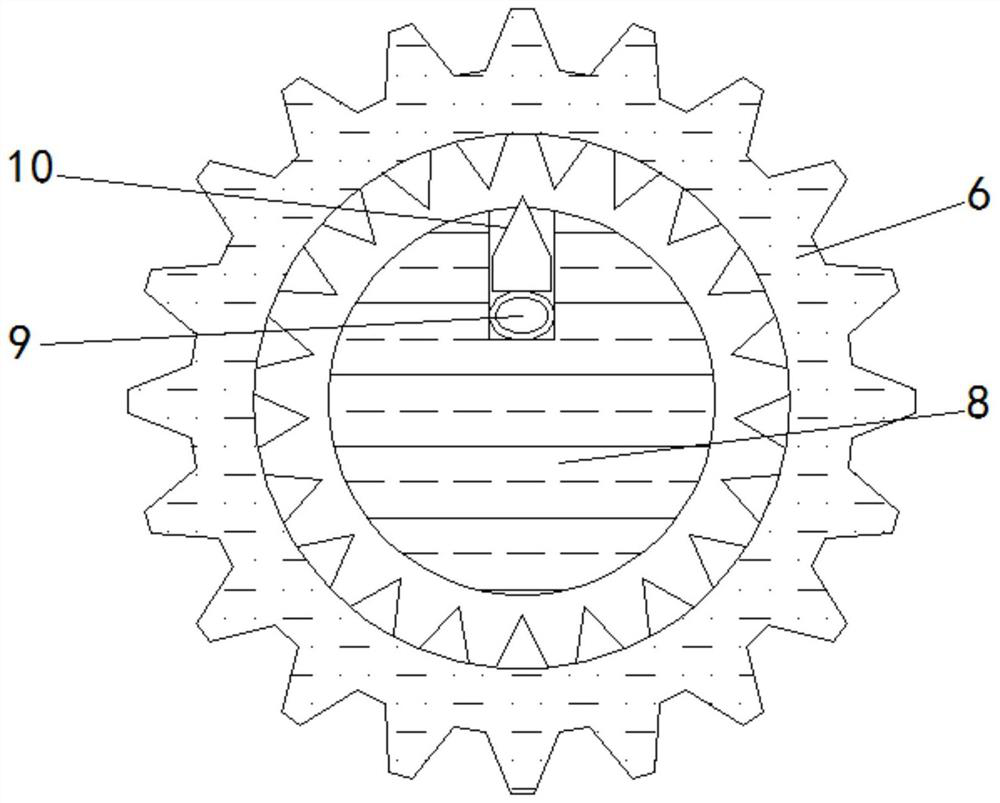

Gantry type annular container winding machine

The invention discloses a gantry type annular container winding machine. The gantry type annular container winding machine comprises a gantry bracket, a base and a wire nozzle bracket, wherein the base is arranged in the gantry bracket, the wire nozzle bracket is arranged above the base, a plurality of core mold clamping devices for fixing an annular core mold are mounted on the base, a wire nozzle bracket rotating device for driving the wire nozzle bracket to rotate around the periphery of the outer side of the annular core mold is mounted on the top of the gantry bracket, the wire nozzle bracket is mounted in the bottom of the wire nozzle bracket rotating device, an annular wire nozzle is mounted on the wire nozzle bracket, a driving mechanism for driving the annular wire nozzle to rotate around the periphery of the cross section of the annular core mold, and yarn guiding wheels are mounted on the annular wire nozzle. According to the gantry type annular container winding machine disclosed by the invention, the annular core mold is immobilized by virtue of the core mold clamping devices, the annular wire nozzle rotates around the periphery of the outer side of the annular core mold and around the periphery of the cross section of the annular core mold, and a fiber is wound on the surface of the core mold by rotational synthesis, so that the problem of inaccurate locating and yarn grinding caused by a friction drive mode of the annular core mold is solved.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

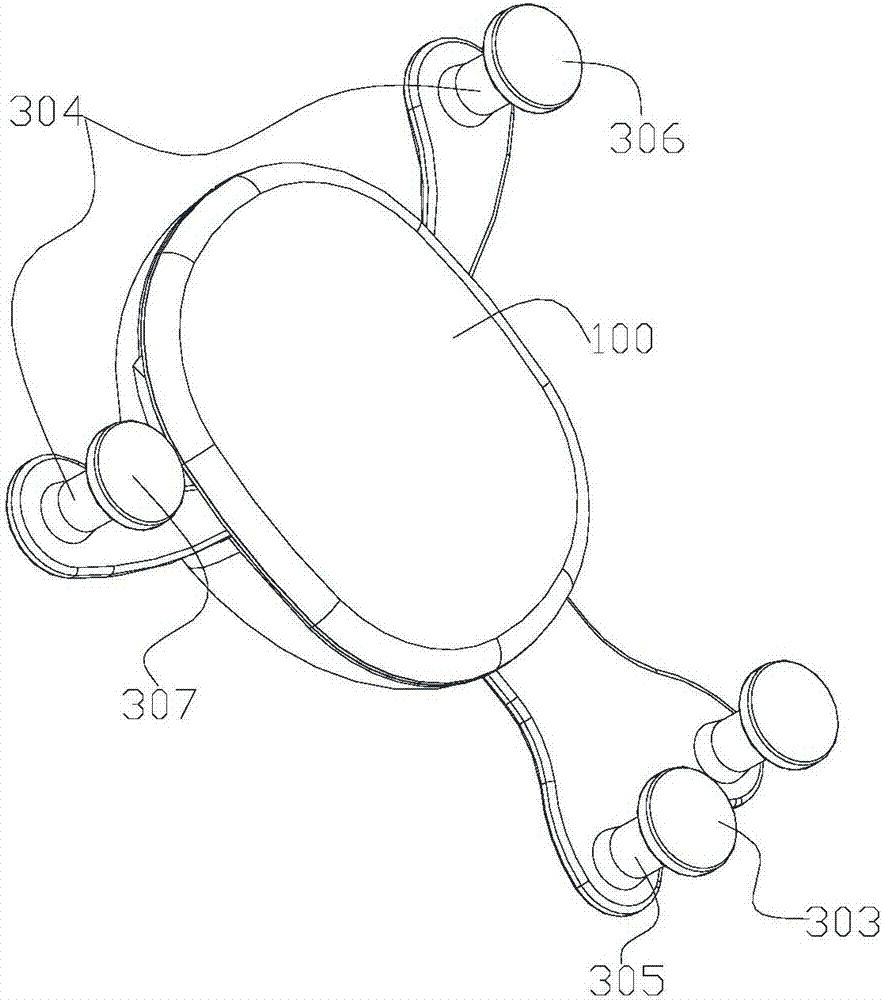

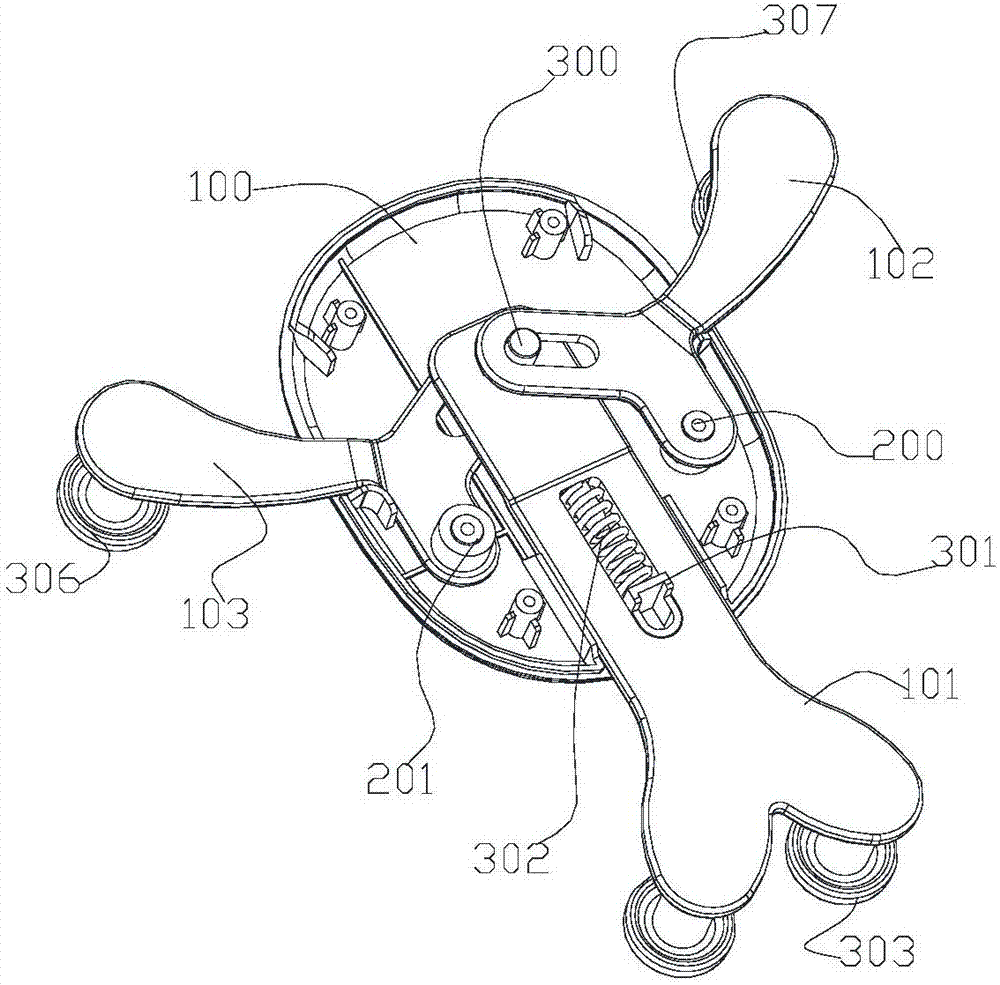

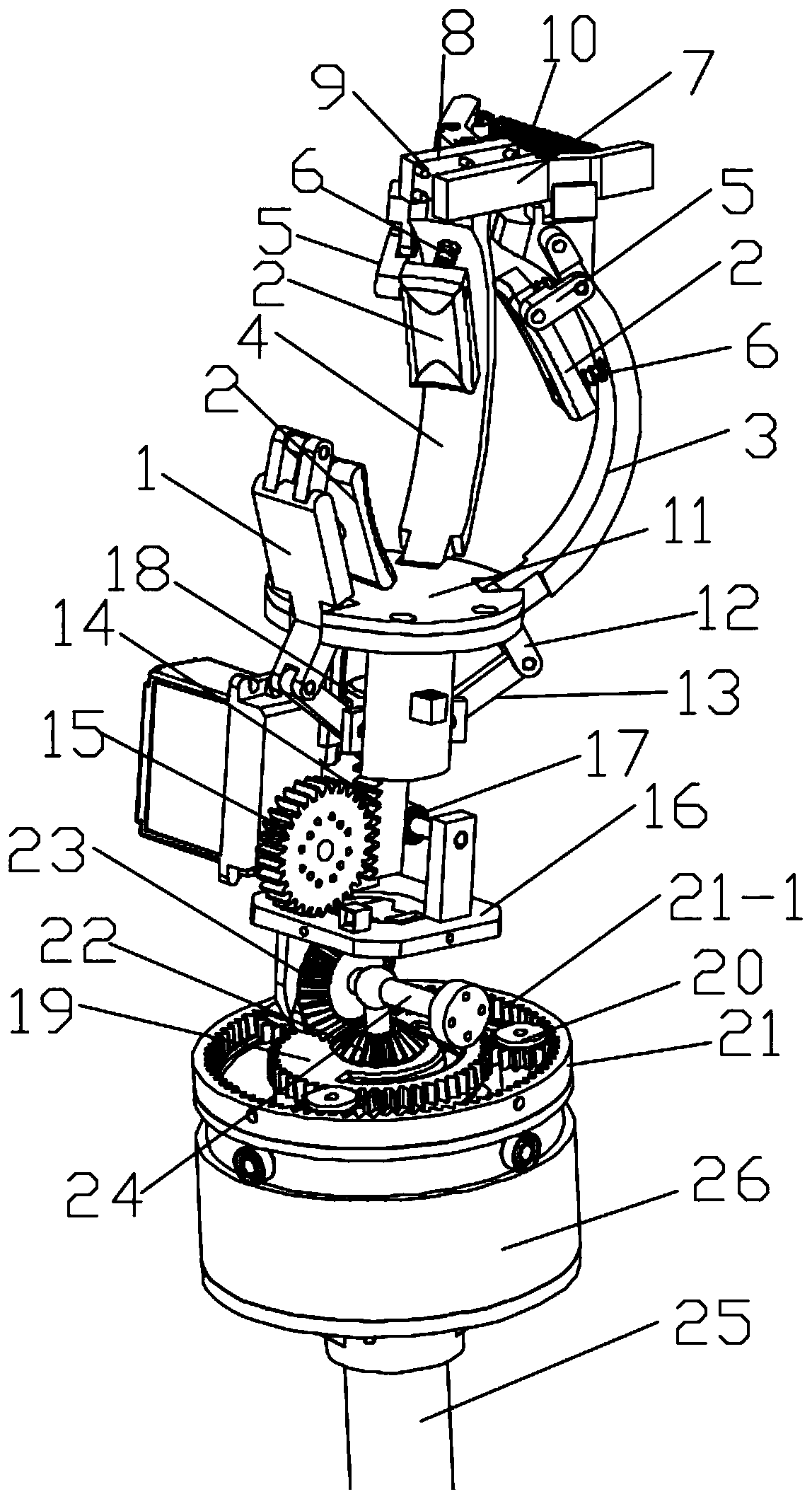

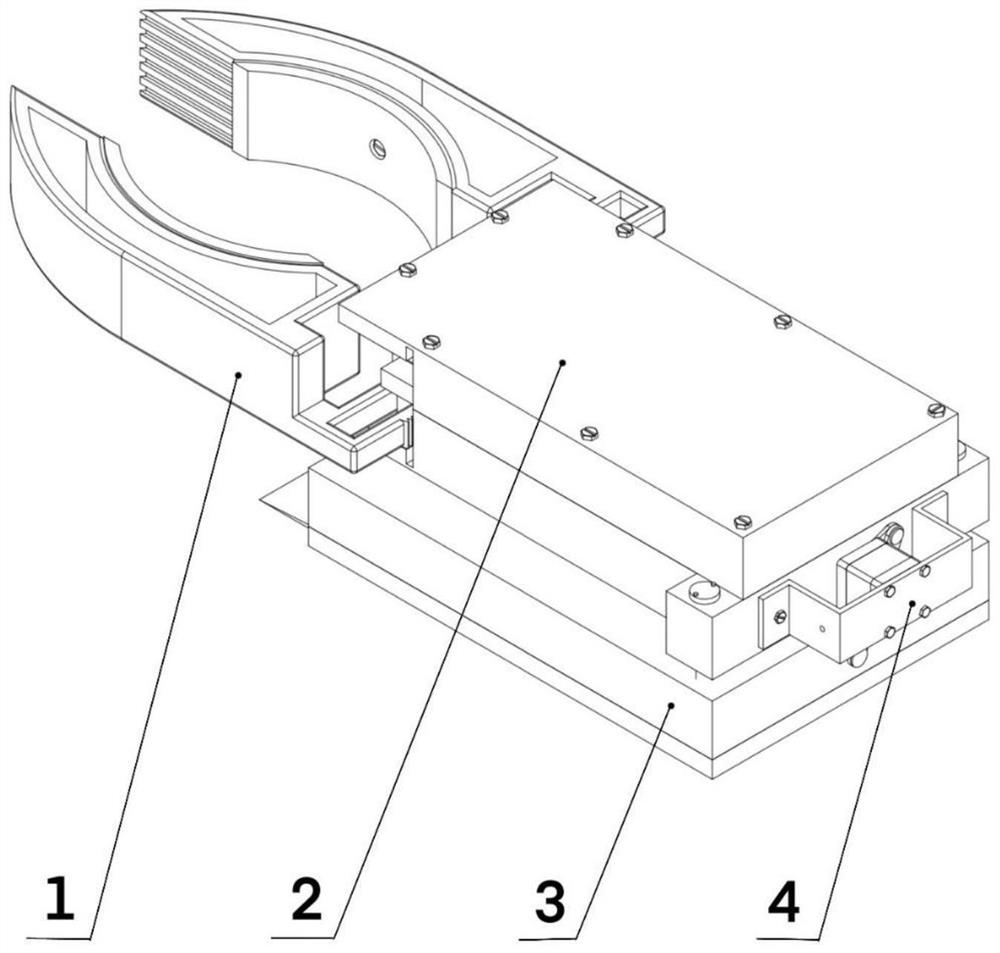

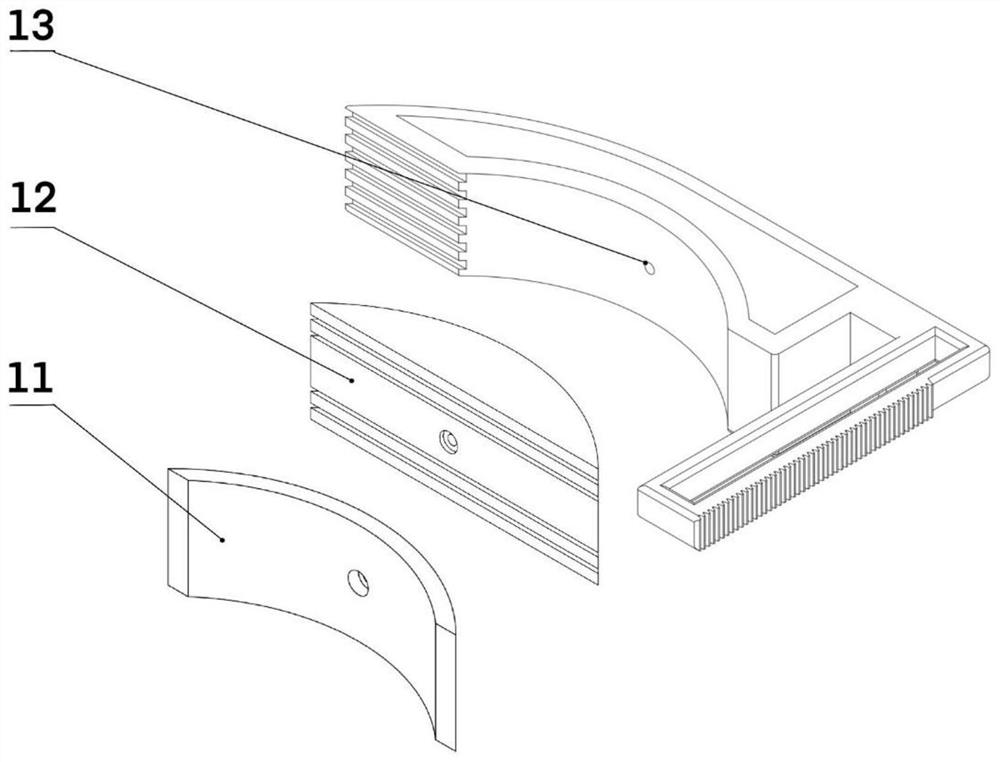

Mechanical arm for picking up bergamot pears

The invention relates to the field of bergamot pear picking, and provides a mechanical arm for picking up bergamot pears. The mechanical arm for picking up bergamot pears comprises a clamping mechanism, wherein the clamping mechanism comprises a fruit clamping component, a fruit stem clamping component and a clamping driving mechanism; the fruit clamping component comprises a supporting disk and aplurality of clamping jaws hinged to the circumferential direction of the supporting disk; a cambered surface space matched with the outer surface of a bergamot pear is formed among the plurality ofclamping jaws; the fruit stem clamping component comprises a first fruit stem clamping plate and a second fruit clamping plate, wherein the first fruit stem clamping plate and the second fruit clamping plate are rotatably connected to the upper ends of the two clamping jaws, and one end of the first fruit stem clamping plate and one end of the second fruit clamping plate are connected through an elastic element; the clamping driving mechanism is arranged below the supporting disk and is independently hinged to the lower end of a thumb clamping jaw, the lower end of an index finger clamping jawand the lower end of a middle finger clamping jaw through a hinging rod; a rotation mechanism comprises a horizontal rotation mechanism and a vertical rotation mechanism and is used for driving the clamping mechanism to simultaneously carry out horizontal rotation and vertical rotation; and a control mechanism is independently connected with the clamping driving mechanism and the rotation mechanism. The mechanical arm of the invention has proper clamping force for the bergamot pear, and can conveniently pick up the bergamot pear.

Owner:TARIM UNIV

Convenient-to-disassemble tool fixture for automobile part machining tool

InactiveCN112453973AEasy to disassembleModerate clamping forcePositioning apparatusMetal-working holdersMotor vehicle partEngineering

The invention relates to the technical field of automobile part machining, and discloses a convenient-to-disassemble tool fixture for an automobile part machining tool. The tool fixture comprises a fixed frame; a support is connected with the fixed frame in a sliding manner; the interior of the support is fixedly connected with an adjusting wheel; limiting rods are connected with the interior of agear in a sliding manner; the outer side of each limiting rod is fixedly connected with reset springs; and the front face of the gear is fixedly connected with a limiting wheel. According to the convenient-to-disassemble tool fixture for the automobile part machining tool, an adjusting rod is rotated, and moves leftwards under the action of the adjusting whee; the adjusting rod drives a right clamping plate to move leftwards; the right clamping plate drives a driving wheel to rotate; the driving wheel drives a left clamping plate to move rightwards; the right clamping plate and the left clamping plate drive pressure balls to get close to a tool; the tool makes the pressure ball compressed; the pressure balls are compressed to make a push ball to expand; the push ball drives a snap rod toascend; and then the snap rod and the adjusting wheel are used in cooperation, so that the effect of guaranteeing proper clamping force is achieved.

Owner:李永刚

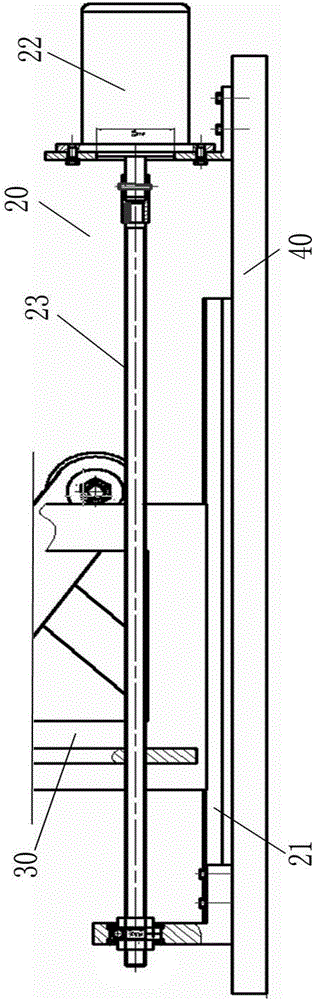

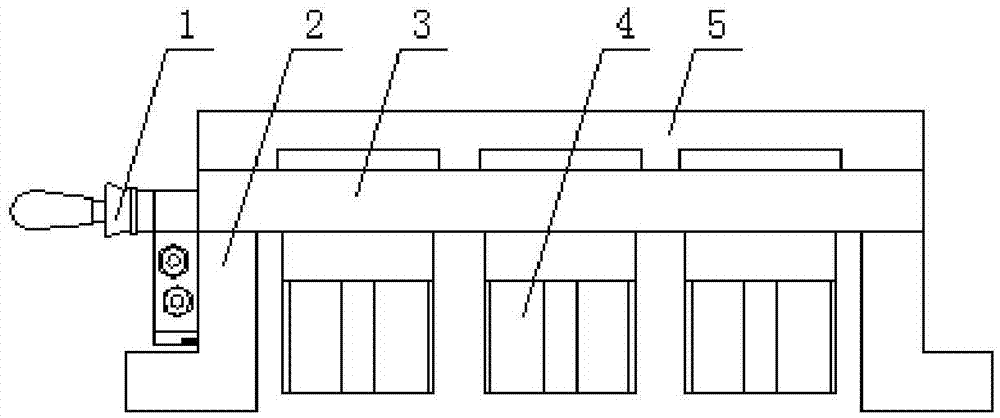

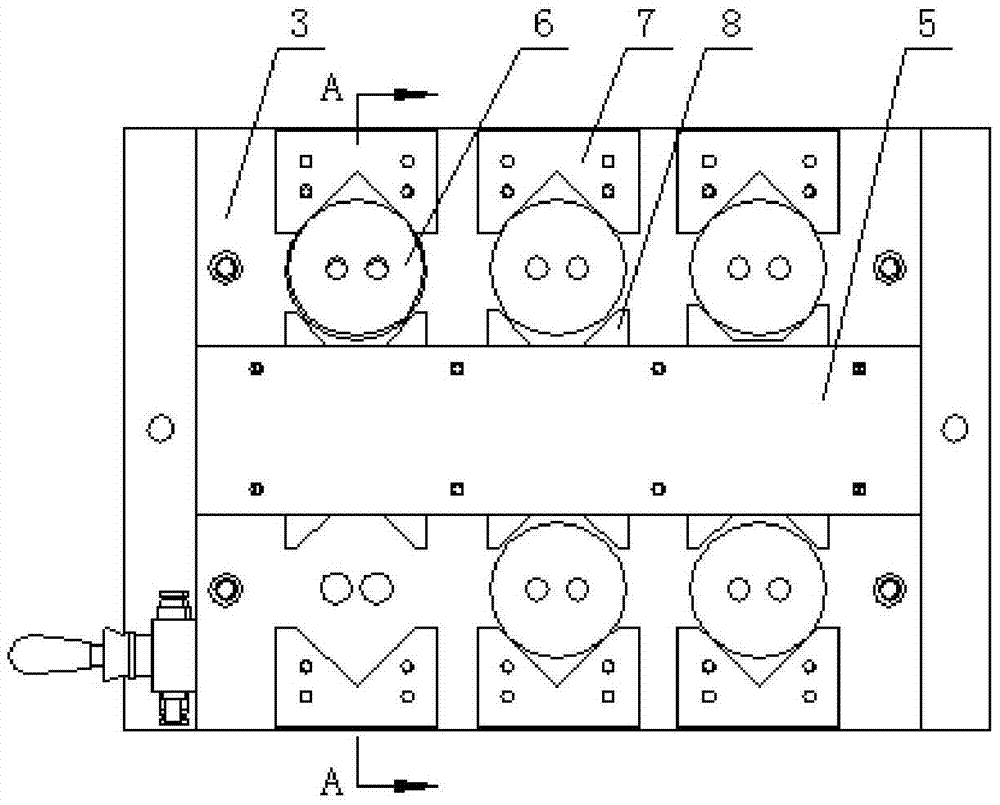

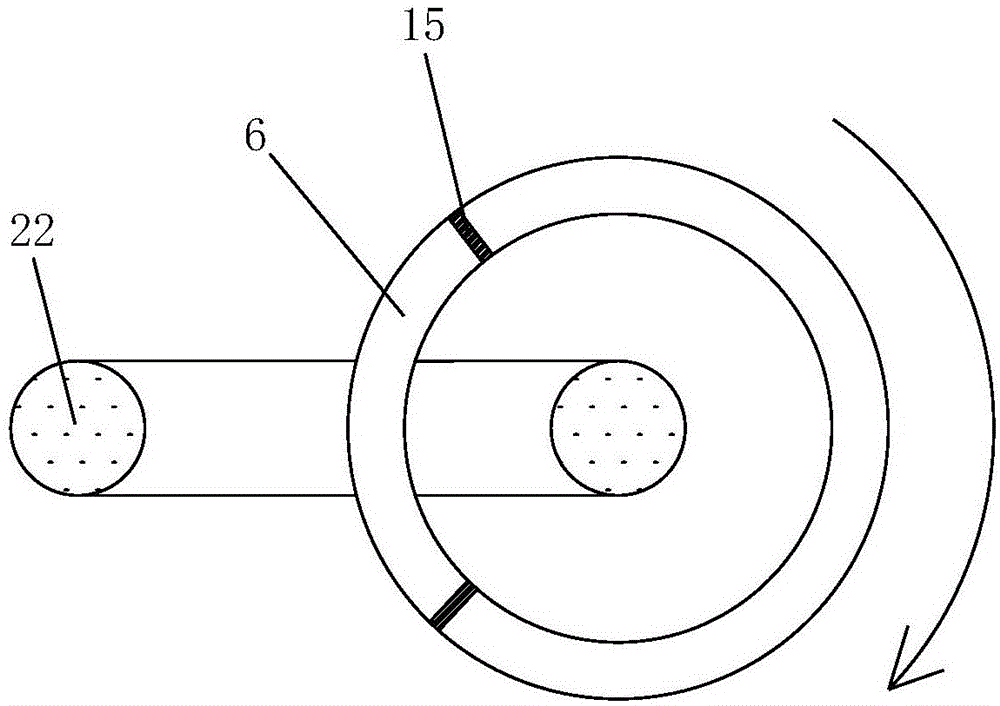

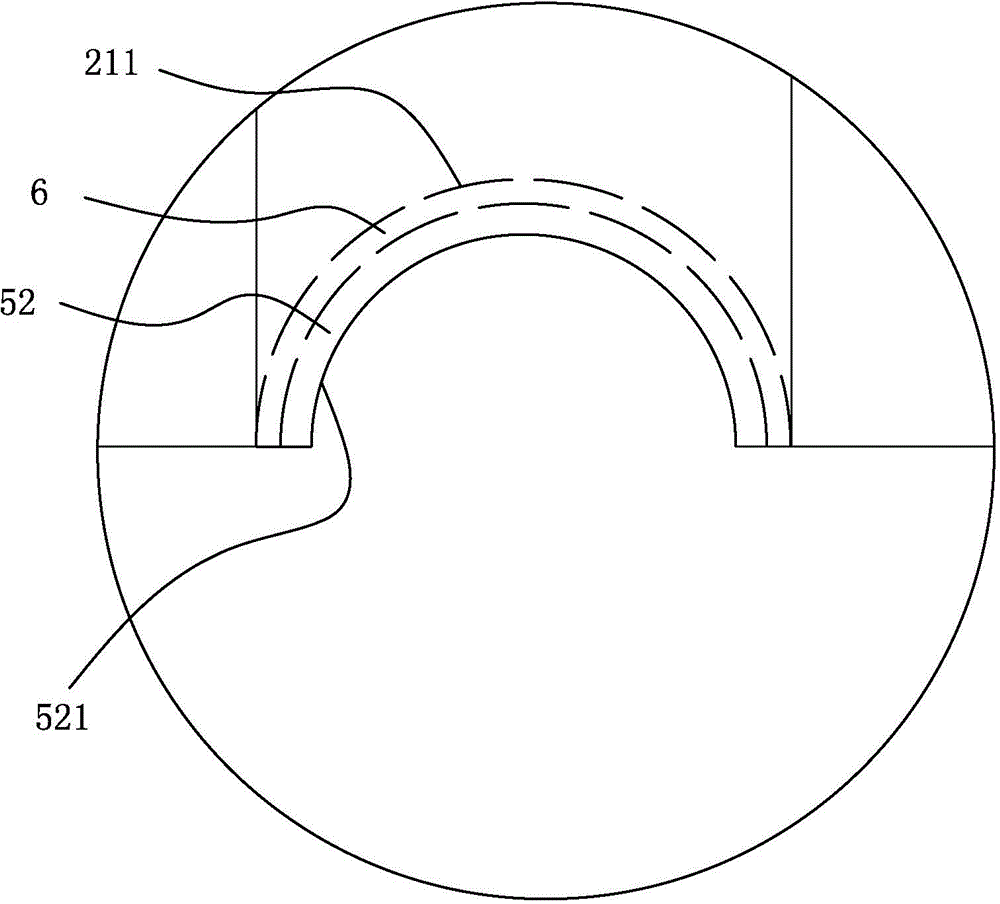

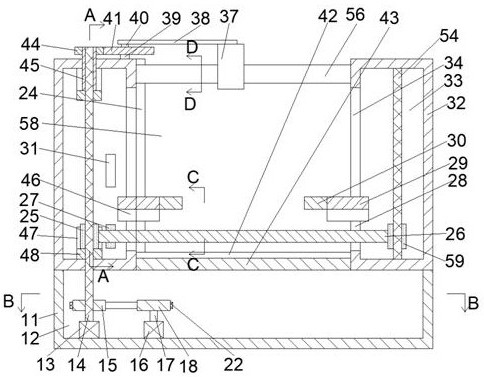

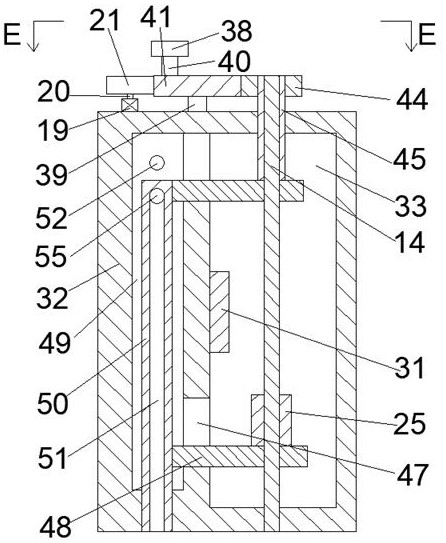

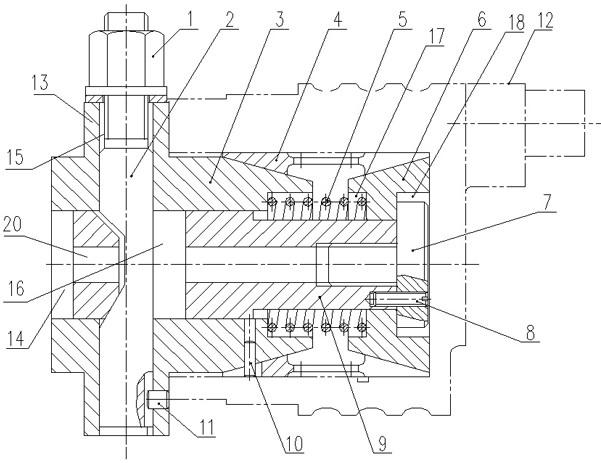

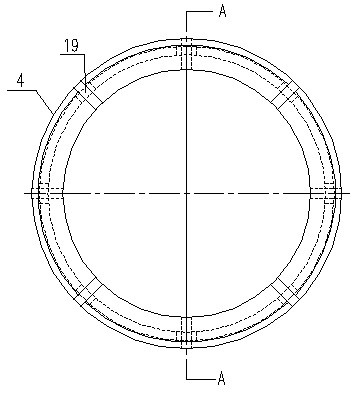

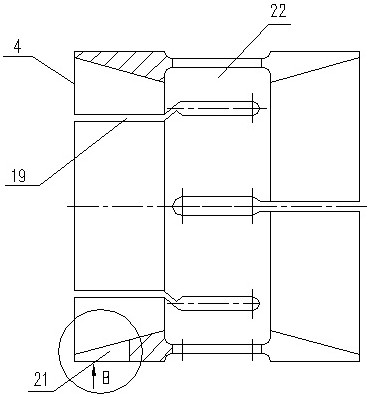

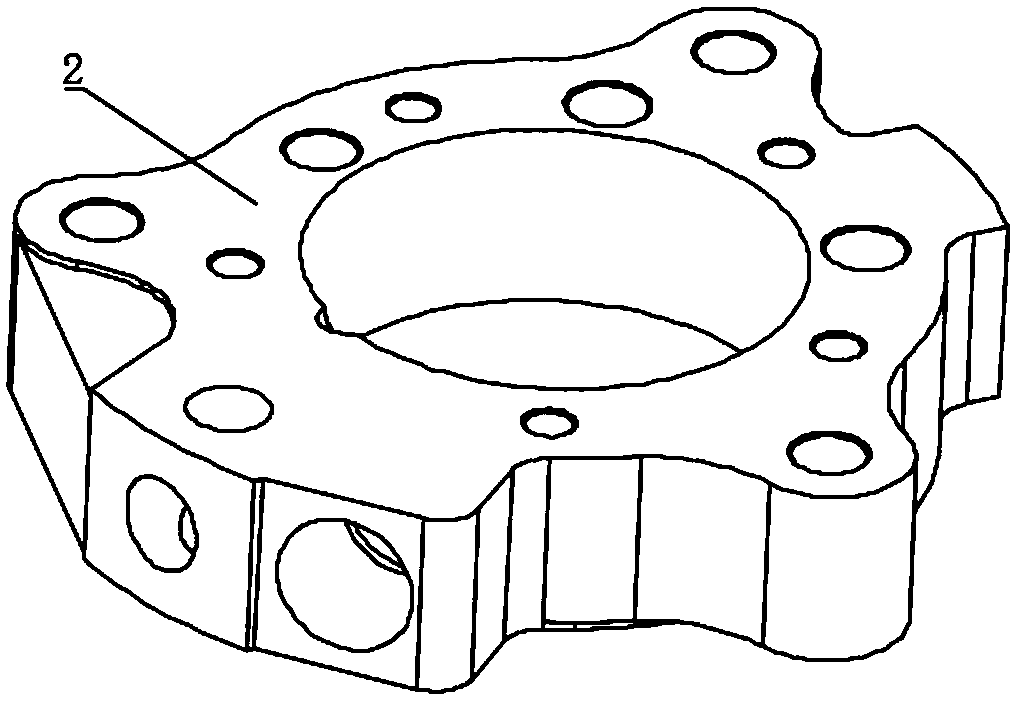

Workpiece clamping device of filament winder

The invention discloses a workpiece clamping device of a filament winder. The workpiece clamping device comprises a rack and an automatic loosening and tightening clamping mechanism. The automatic loosening and tightening clamping mechanism comprises rotating clamping heads located at the two ends of the rack and used for clamping a filament winding plate, and clamping head rotating driving devices driving the rotating clamping heads to rotate. Each rotating clamping head comprises a first clamping block fixed to the rack, wherein the first clamping block and a second clamping block are hinged, a clamping head closing elastic piece for driving the first clamping block and the second clamping block to be closed at the other side of the hinged position is arranged between the side, located at the hinged position, of the first clamping block and the second clamping block, and a clamping head loosening driving device used for exerting pressure on the second clamping block to enable the clamping head closing elastic piece to be compressed and releasing the pressure to enable the clamping head closing elastic piece to be expanded is arranged above the rotating clamping head. According to the structure, automatic loosening and tightening of the rotating clamping heads can be achieved, the loosening and tightening operation can be achieved without manual operation, time and labor are saved, and the production efficiency is high.

Owner:何雲彬

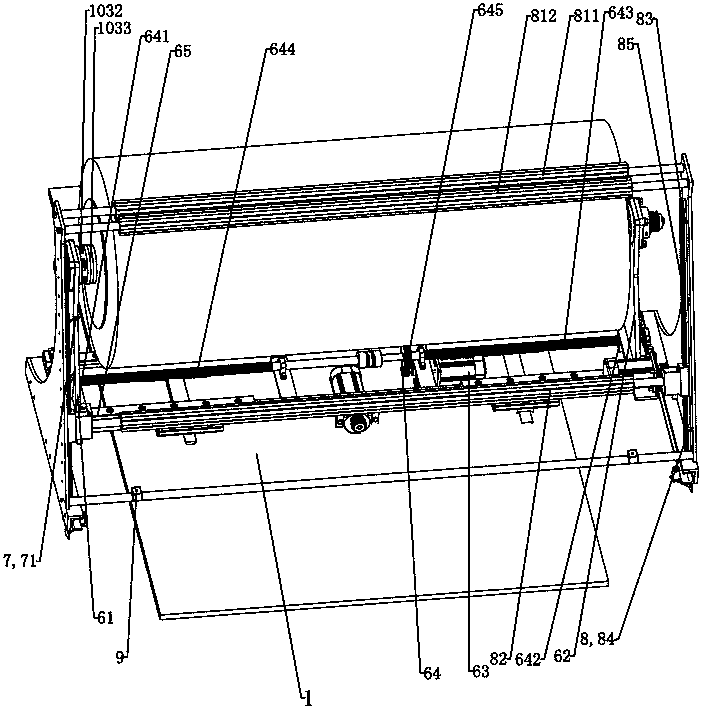

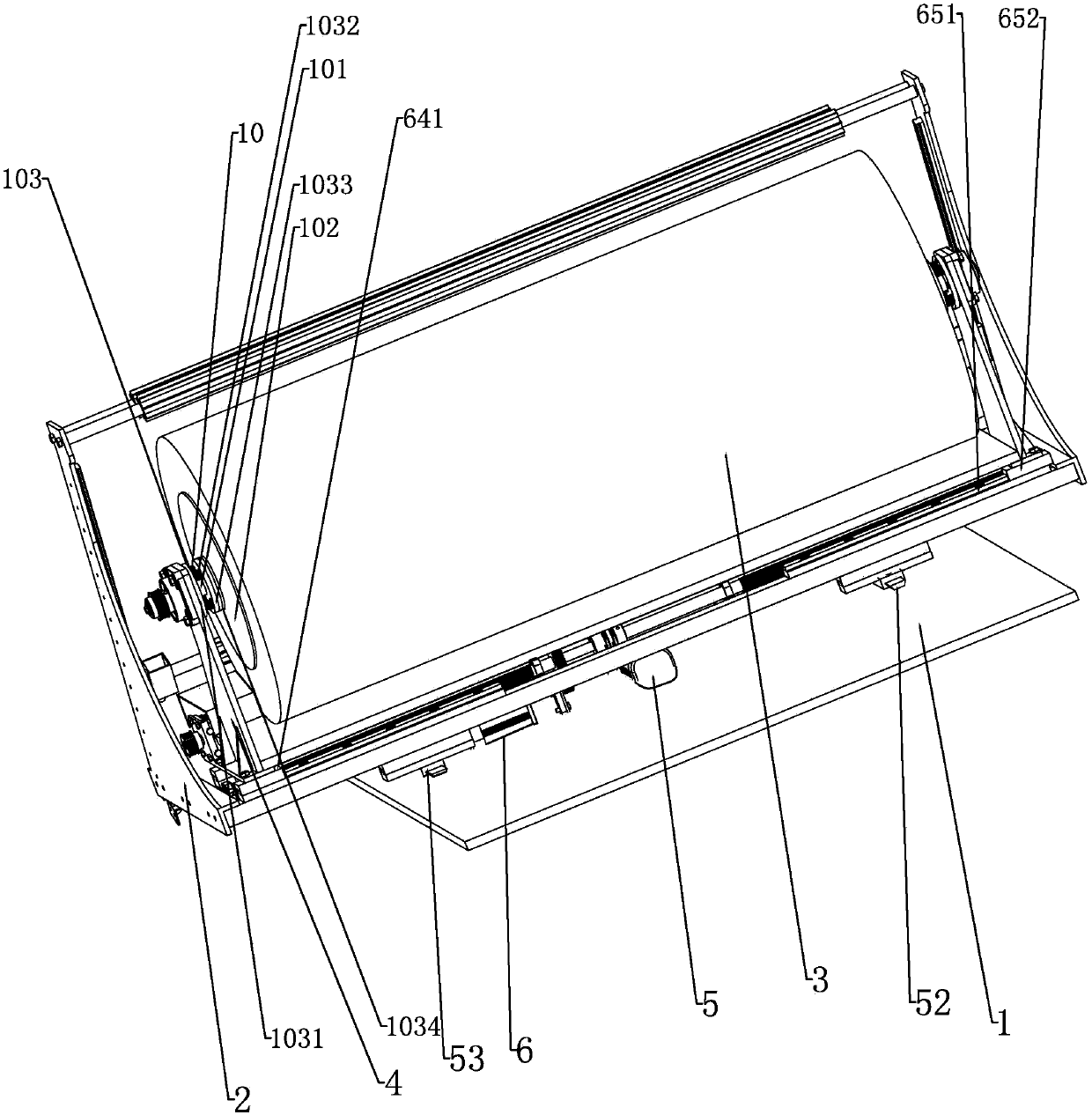

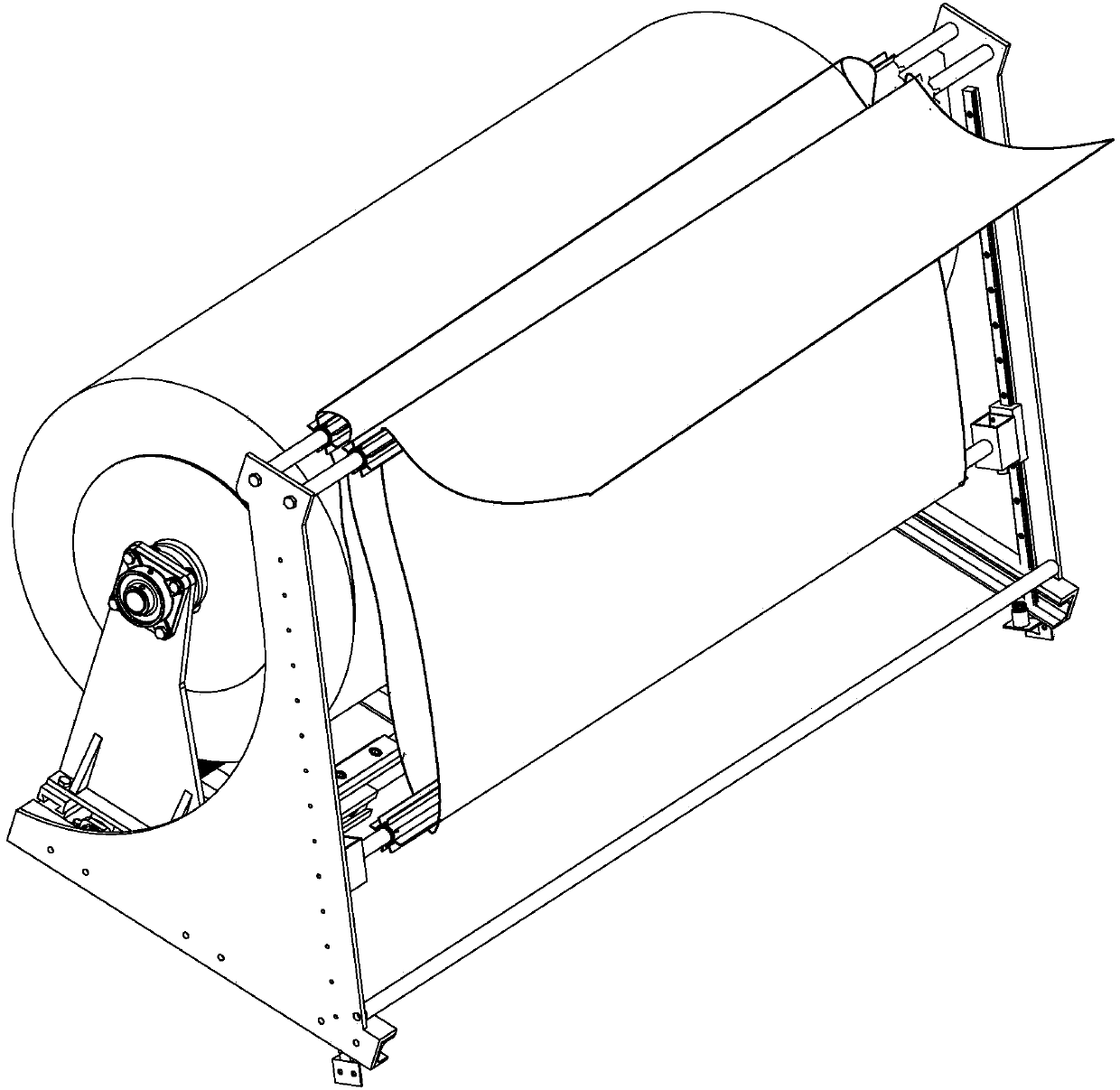

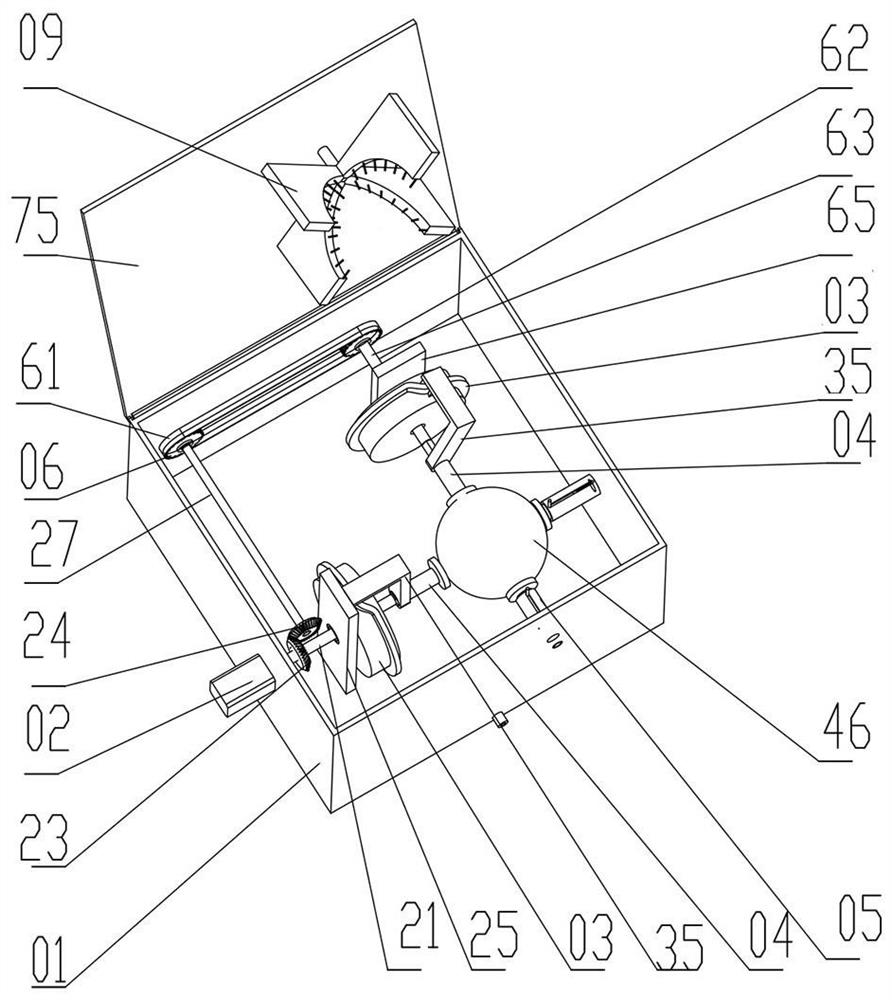

Multifunctional integrated device for coiled material processing

The invention provides a multifunctional integrated device for coiled material processing. The multifunctional integrated device comprises a base frame, wherein a material frame is arranged on the base frame, a support frame for supporting coiled materials is arranged on the material frame, the bottom of the material frame is provided with an inlet and an outlet device capable of being conveniently used for replacing materials and discharging materials, an automatic material clamping centering device realizing the centering function after the coiled materials are well loaded is arranged on the material frame, and a material quantity sensing device and a material storage sensing device are arranged on the base frame. In addition, the multifunctional integrated device also comprises an aligning device realizing the automatic deviation correcting function during the coiled material traction, a pressure sensing device used for clamping the coiled materials is also arranged on the support frame, and in addition, the multifunctional integrated device also comprises a material conveying device for conveying the coiled materials. The multifunctional integrated device has the advantages that the integration degree is high, the use effect is good, durability and reliability are realized, and the like.

Owner:久力科技(广东)有限公司

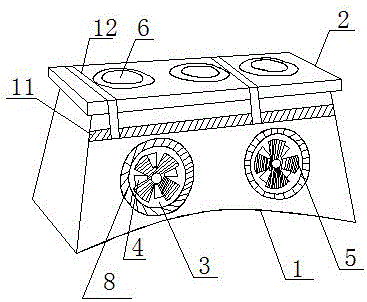

Temperature-adjustable moxibustion box

InactiveCN106137736ASimple structureReasonable designDevices for heating/cooling reflex pointsEngineeringExhaust pipe

The invention relates to the technical field of moxibustion equipment, in particular to a moxibustion box with adjustable temperature; it includes a box body, a box cover and a metal mesh at the bottom of the box body. There are a number of ventilation holes, and holes with several triangular holes are installed on the ventilation holes. The triangular holes are opened symmetrically in the center of the holes. The holes are movably connected with a baffle through bolts. The baffle includes several Blocking sheet; there are some moxa stick holes on the box cover, and elastic clips are installed in the moxa stick holes, and the elastic clips are evenly distributed on the circumference where the moxa stick holes are located, and the box cover is also connected with a handle; the moxibustion box of the present invention , simple structure, reasonable design, easy to use, safe, and will not affect the indoor environment. There is a circle of external threads on the top of the exhaust hood. The external threads are used to connect the exhaust pipe. The external thread connection can improve the sealing of the connection and avoid The smoke leaks out, and the threaded connection makes installation and disassembly more convenient.

Owner:刘海燕

Circuit board double-sided cleaning device

InactiveCN111842301AAchieve clampingClean evenlyDrying gas arrangementsCleaning using liquidsStructural engineeringMechanical engineering

The invention discloses a circuit board double-sided cleaning device. The device comprises a main body. The main body is provided with a power chamber with an opening upward, the left side and the right side of the upper end face of the main body are respectively fixedly connected with fixed blocks, the fixed blocks are provided with a processing cavity penetrating back and forth and with an opening upward, the lower side wall of the processing cavity is fixedly connected with a water tank, the water tank is provided with a water tank with an opening upward, and the inner of the fixed blocks is provided with a working chamber. When a clamping circuit board moves, the device can automatically turn over to realize the cleaning and drying of both sides of the circuit board gradually. Througha connection block to drive a nozzle to reciprocate, the circuit board is evenly cleaned. When the circuit board moves to the limit position, automatically switch cleaning and drying functions can beachieved. The clamping of the circuit board is realized by a magnet, and the clamping force is appropriate. The device can not cause damage to components on the circuit board and internal micro circuits.

Owner:宁波立项电子有限公司

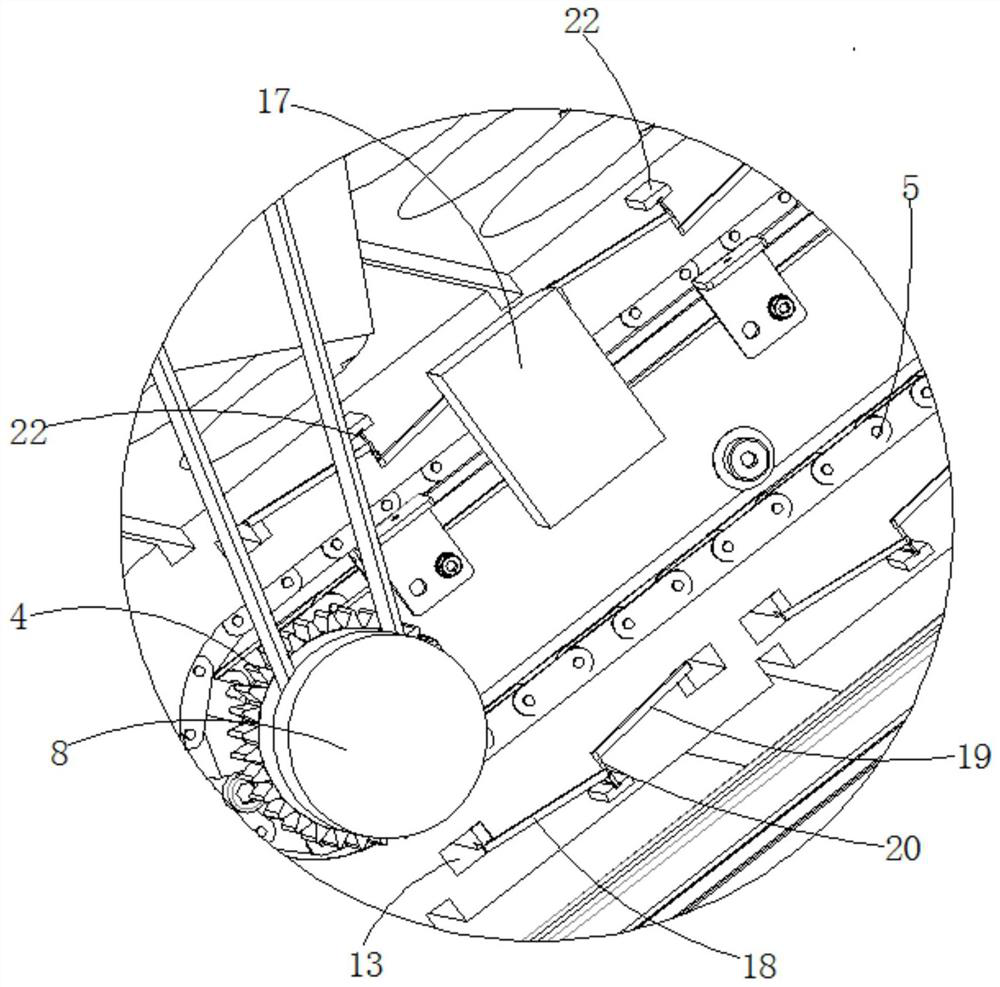

Liquid filling device and using method thereof

ActiveCN111704095ARealize the distribution functionAvoid disorderFouling preventionConveyorsTransmission beltControl engineering

The invention discloses a liquid filling device and a using method thereof, and belongs to the technical field of packaging equipment. The liquid filling device comprises a machine frame and a PLC electric cabinet, wherein the PLC electric cabinet is mounted on the machine frame, the top of the machine frame is fixedly connected with a bottle feeding hopper and a driving roller which are obliquelyarranged through a mounting frame, the bottom of the bottle feeding hopper is provided with a vibration exciter, the driving roller is driven by a servo motor and is controlled by PLC programming, the end of the driving roller is linked with a transmission chain, the driving roller is connected with a conveyor belt through the transmission chain, the outer surface of the conveyor belt is providedwith uniformly distributed positioning grooves, the outer wall of the conveyor belt is fixedly connected with a driving belt wheel, the outer wall of the bottle conveying hopper is connected with a driven belt wheel through a rotating rod, and the driven belt wheel is connected with the driving belt wheel through a transmission belt. According to the liquid filling device, the allocating functionof bottle bodies at the position of the bottle feeding hopper and the fixing function of the bottle bodies are achieved while the conveyor belt is used for conveying the bottle bodies, the center ofgravity of the bottle bodies is kept stable, and the conveying stability and the cover rotating stability are improved.

Owner:山东宏旭化学股份有限公司 +1

Clamping and positioning tool for inner hole of thin-wall shell part

The invention discloses a clamping and positioning tool for an inner hole of a thin-wall shell part. The clamping and positioning tool comprises a main body, a clamping shaft, a nut, a pull rod, a spring, a clamping spring, a conical block and a push-pull block with a connecting rod, wherein a propeller root outer sleeve is sleeved on the main body and an outer circle of the clamping spring , the nut is screwed down, the clamping shaft moves upwards, the left end of the clamping shaft is provided with a conical surface used in cooperation with the conical surface of the left end wall of a clamping shaft mounting hole in the pull rod, the lower end face of the conical surface presses the pull rod to move leftwards, the pull rod drives the conical block to move leftwards, the conical block compresses the spring and jacks the clamping spring at the same time, the clamping spring clamps an inner hole of the propeller root outer sleeve for positioning; and after the propeller root outer sleeve is machined, the nut is unscrewed, the clamping shaft moves downwards and is separated from the pull rod, the conical block moves rightwards under the action of the spring, the clamping spring retracts inwards and resets, and the propeller root outer sleeve is taken down. The clamping and positioning tool is accurate in positioning, proper in clamping force, free of damage to the surface of an inner hole of a part and convenient in use.

Owner:AVIC HUIYANG AVIATION PROPELLER

Cutting device for vacuum molding machine

InactiveCN104943143AHigh degree of automationReasonable structural designMetal working apparatusMolding machineEngineering

The invention discloses a cutting device for a vacuum molding machine. The cutting device comprises a working table, a knife holder, a cutting assembly and a connecting frame; the cutting assembly is arranged on the upper portion of the connecting frame and is mainly composed of a cutting knife, a driving device and a control device, and the knife holder is arranged on a table board of the working table; a knife groove corresponding to the cutting knife is formed in the middle of the knife holder, and a workpiece clamping device is arranged on the cutting assembly; and the workpiece clamping device is composed of clamping plates, a power device and a control device. The cutting device for the vacuum molding machine is reasonable in structural design, easy and convenient to operate and unique in function; the workpiece clamping device additionally arranged on the cutting assembly can automatically complete locating and clamping of a workpiece, and the workpiece can be accurately positioned; clamping force magnitude is moderate and adjustable; and the precision and efficiency of the cutting knife in the process of implementing the blanking operation are effectively improved, and the automation degree of the vacuum molding machine is improved.

Owner:SUZHOU HUACHONG PRECISION MACHINERY

Angle-changeable air cylinder side hole machining fixing tool

PendingCN109571095ANot easy to damageModerate clamping forcePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses an angle-changeable air cylinder side hole machining fixing tool. The angle-changeable air cylinder side hole machining fixing tool comprises a base and a station installed onthe base. The station comprises a mounting seat which is transversely connected to the interior of a main body supporting block in an inserting mode. A cavity with an opening in the front side is formed in the mounting base. An oil cylinder piston capable of sliding is arranged in the cavity. Two overlapped vertical frames are rotationally mounted on the oil cylinder piston and comprise two long edges and two short edges perpendicular to the long edges. The long edges are connected with a piston oil cylinder. The two short edges extend to the outside of the mounting base, extend in opposite directions, are used for pressing a workpiece, and penetrate through an opening groove. The angle-changeable air cylinder side hole machining fixing tool is moderate in clamping force and firm in fixingand does not damage the workpiece easily. Positioning plates can be replaced on the same tool to be compatible with a plurality of products with different models. Feeding and discharging can be conveniently carried out. The labor is saved. The productivity of an enterprise is improved.

Owner:马鞍山市德善金属成型科技有限公司

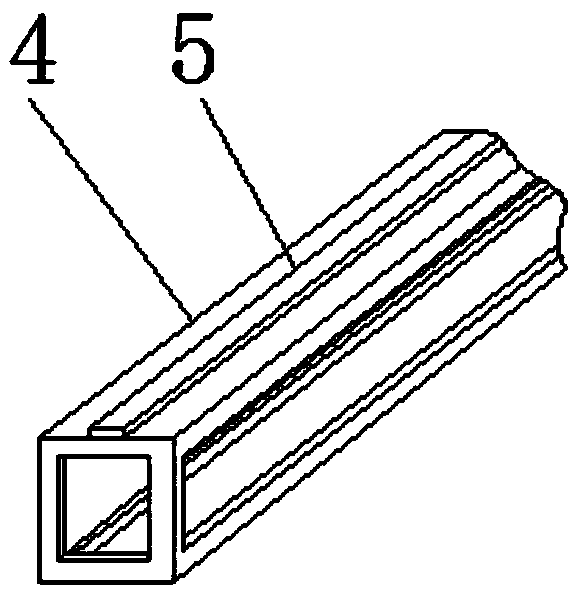

High-power cable output machine

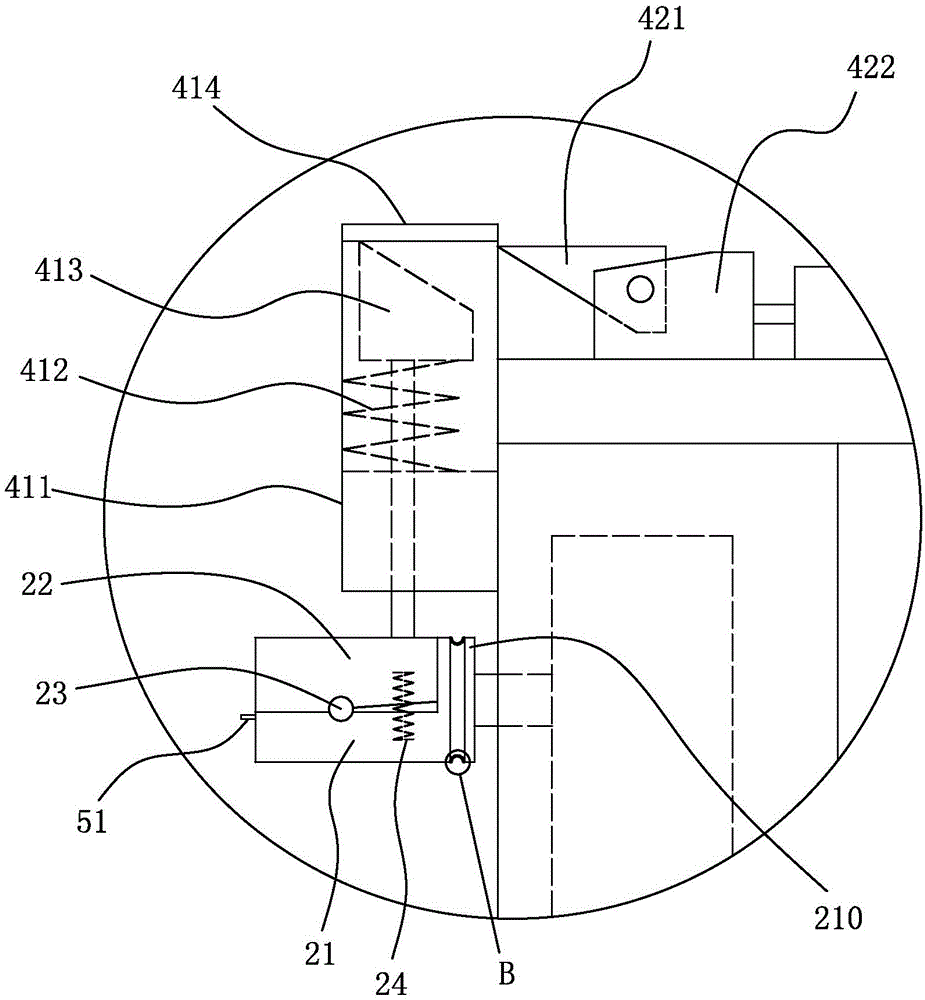

ActiveCN104030082AEnsure safe deliveryModerate clamping forceFilament handlingElectric machineryEngineering

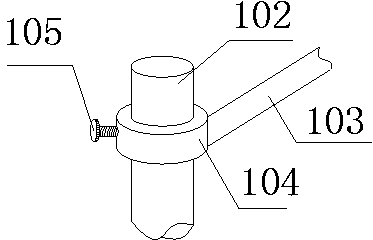

The invention discloses a high-power cable output machine which comprises a supporting device (1) and a conveying device (2). The supporting device (1) comprises two supporting drums (101), the conveying device (2) is positioned between the supporting drums (101) and comprises a cabinet body (201) and at least two roller drivers (3), each roller driver (3) comprises a movable roller (301) and a static roller (302), each of the movable rollers (301) and the static rollers (302) is driven by a motor to rotate, and an annular pressure sensor (5) is arranged between a body (304) of each static roller (302) and a wheel shaft of the corresponding static roller (302). The high-power cable output machine has the advantages that multiple groups of rollers are arranged, and each roller is driven by the corresponding motor solely, so that power output is guaranteed; by arranging the sensors to test clamping force, applied on a cable, of the static rollers and the movable rollers, safety in conveying of the cable is guaranteed due to the clamping force which is moderate.

Owner:STATE GRID SICHUAN ELECTRIC POWER

Basketball cleaning device and operation method

The invention discloses a basketball cleaning device and an operation method. The basketball cleaning device comprises a box body, a drainage hole, a motor, a first bevel gear, a second bevel gear, a cam, a cam surface, a cam clamping groove, a driven frame, a chuck, a shaft head, a first synchronous wheel, a second synchronous wheel, a brush handle, a water injection hole, a brush frame, an arc surface, a brush and a box cover; a motor shaft hole is formed in the left side surface of the box body; a right elastic shaft hole is formed in the right side surface of the box body; a hinge hole is formed in the rear side of the box body; a left shaft hole is formed in the rear side face of the box body; a right shaft hole is formed in the right side of the left shaft hole; the drainage hole and a front elastic shaft hole are formed in the front side face of the box body; a first cam frame is arranged on the bottom face of the box body; a first cam frame hole is formed in the upper part of the first cam frame; a tray hole is formed in the right side of the first cam frame; a second cam frame is formed in the rear side of the tray; and a second cam frame hole is formed in the upper portion of the second cam frame.

Owner:HARBIN INST OF PHYSICAL EDUCATION

Padlock fixing device for laser cutting of metal plate

InactiveCN108705217AEasy to moveAvoid secondary moving clampingLaser beam welding apparatusArchitectural engineeringTroffer

The invention discloses a padlock fixing device for laser cutting of a metal plate. The padlock fixing device comprises sliding rails, vertical support plates and buckle plates, and each sliding railis internally provided with a rail slot of which the inner side is provided with a movable block; the surface of each vertical support plate is welded with a bar rail, and the vertical support platesare located on the inner sides of the movable blocks; the middle of each bar rail is provided with clamping blocks of which the inner sides are fixedly provided with clamping plates, and the middle ofeach clamping plate is provided with a straight slot; the right and left sides of each buckle plate are each provided with a lift plate, and each buckle plate is located in the middle of the straightslot; grooves are fixedly formed in the positions below the buckle plates, and the outer sides of each groove are provided with springs of which the outer sides are provided with connecting plates; and the upper sides of the connecting plates are welded with buckle blocks, and holding plates are fixed below the connecting plates. The padlock fixing device for the metal plate is easy to install, and the clamping force is moderate; and the length and width can be adjusted according to the metal plate, and the adaption degree of the metal plate is higher.

Owner:WUXI YICHEN MOLD TECH

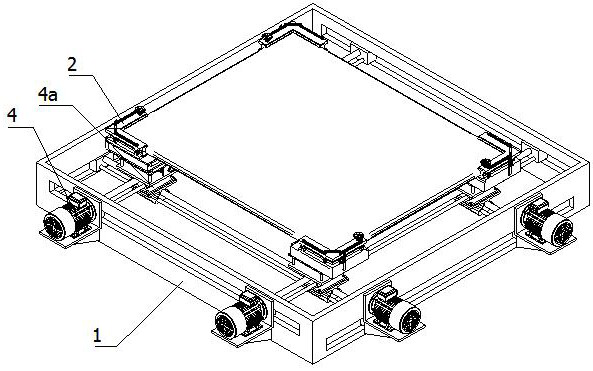

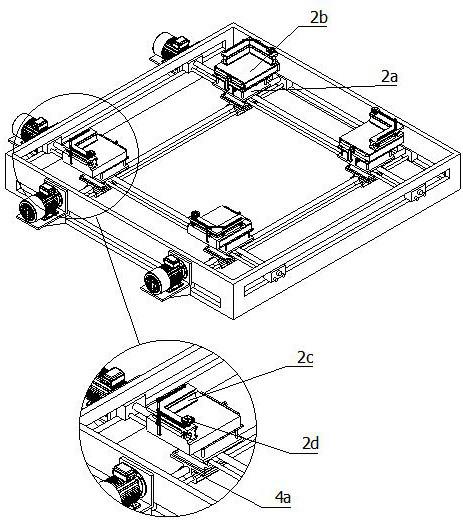

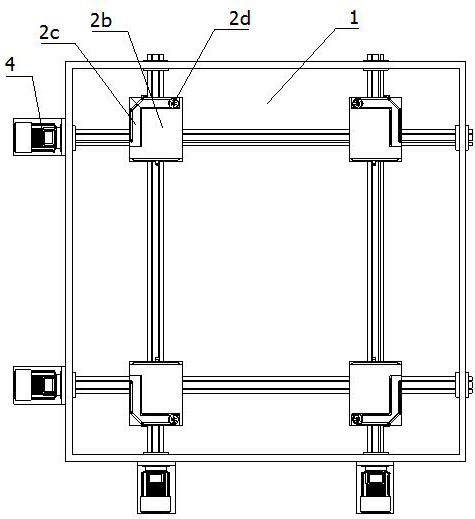

Display safety test tool with high compatibility

ActiveCN114871972AImprove compatibilityFacilitate the follow-up inspection processWork holdersDisplay deviceStructural engineering

The invention relates to the technical field of display equipment, in particular to a display safety test tool with high compatibility. Comprising a base, an angle deflection mechanism and a mounting frame, and further comprises four clamping mechanisms and a displacement driving mechanism, the displacement driving mechanism comprises four sliding mounting seats capable of horizontally displacing, and the four clamping mechanisms are fixedly mounted on the four sliding mounting seats correspondingly; the clamping mechanism comprises a mounting base, a bearing frame, a right-angle clamping assembly and a height adjusting assembly, the right-angle clamping assembly is arranged on the bearing frame and comprises an adjustable clamping plate and an elastic clamping device, the adjustable clamping plate is horizontally and fixedly mounted on the bearing frame, and the output end of the height adjusting assembly is in transmission connection with the right-angle clamping assembly. The tool can stably clamp different types of displays, is high in compatibility, can accurately adjust the clamping thickness and range, can clamp a plurality of small displays at the same time, and improves the detection efficiency.

Owner:如东恒远智能设备有限公司

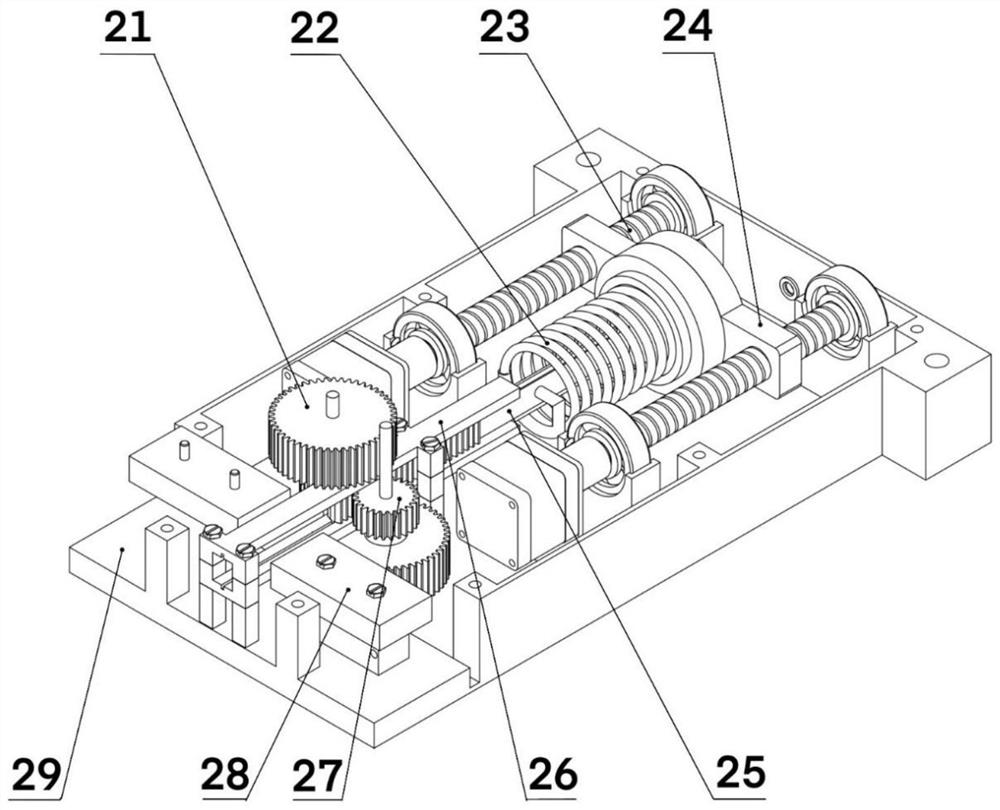

Clamp replaceable type two-jaw manipulator

The invention discloses a clamp replaceable type two-jaw manipulator including a clamping jaw, a clamping jaw driving device, a cushioning plate expansion device, and a cushioning plate attaching adjustment device. The clamping jaw includes a flexible backing ring, a rigid backing block, and a clamp replacement hole; the clamping jaw driving device includes a big gear wheel, a spring, a lead screw, a sliding block, a rack, a rack sliding rail, a small gear wheel, a clamping jaw fixing block and a driving device shell body; the cushioning plate expansion device includes a cushioning plate, a cushioning plate driven rod, and a cushioning plate driving rod; and the cushioning plate attaching adjustment device includes a cushioning platform shell body, a cushioning platform driving rod, a cushioning platform driven rod, and a cushioning platform guide column. The manipulator is used to clamp goods, and according to the difference of shapes of the clamped goods, a replaceable clamp matchedwith the clamping jaw is arranged to achieve intelligent clamping under the cooperation of a cushioning device. According to the difference of fragility of the clamped goods, the manipulator has corresponding clamping actions and methods so that the clamped goods can be protected to an extreme.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com