Patents

Literature

109results about How to "Meet the clamping requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

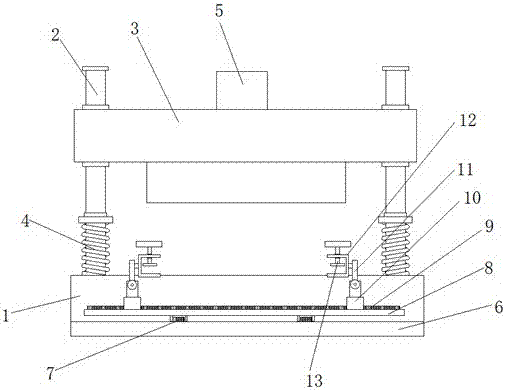

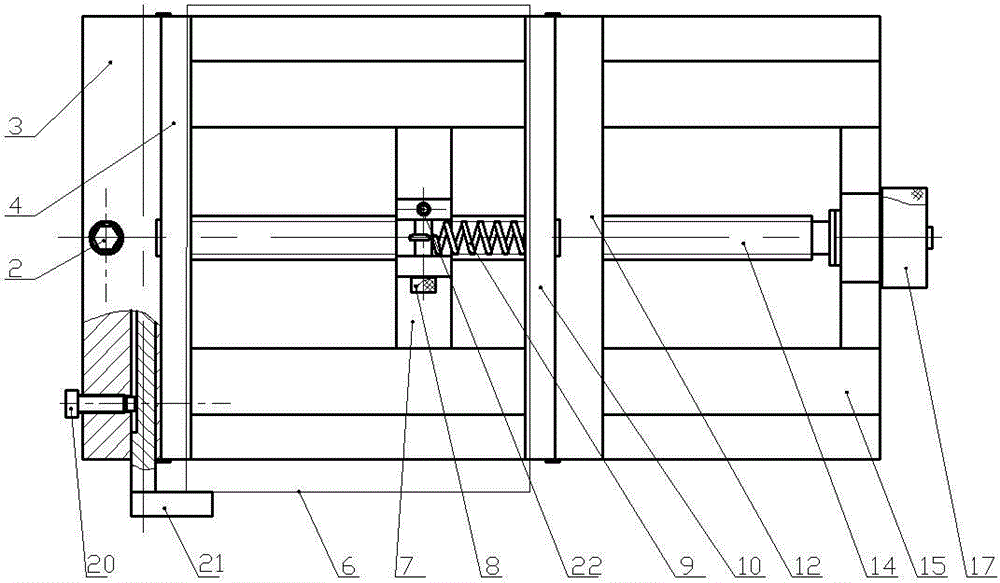

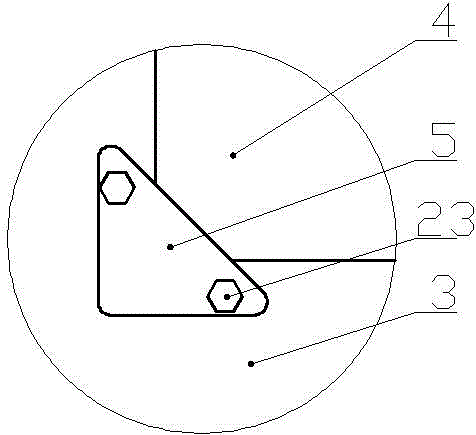

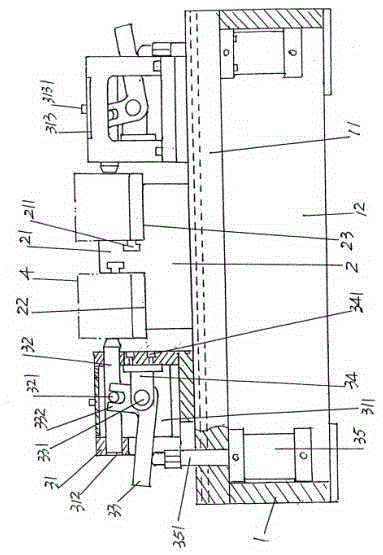

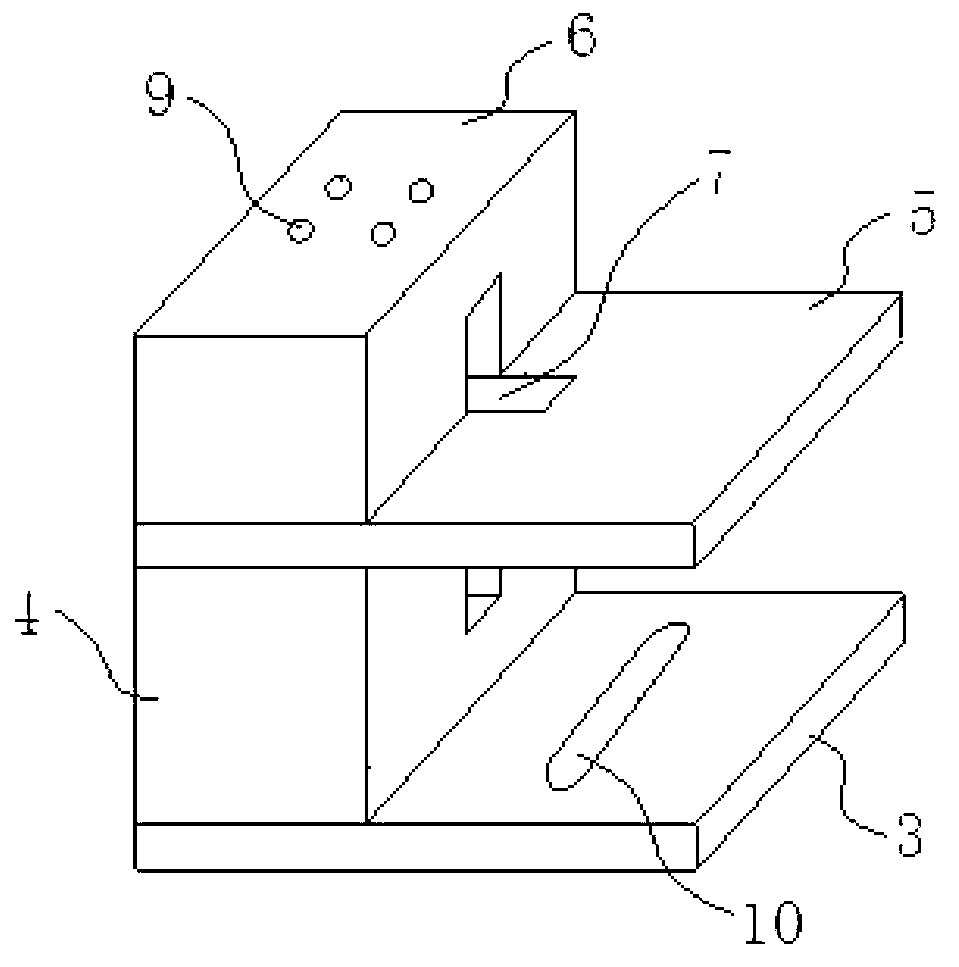

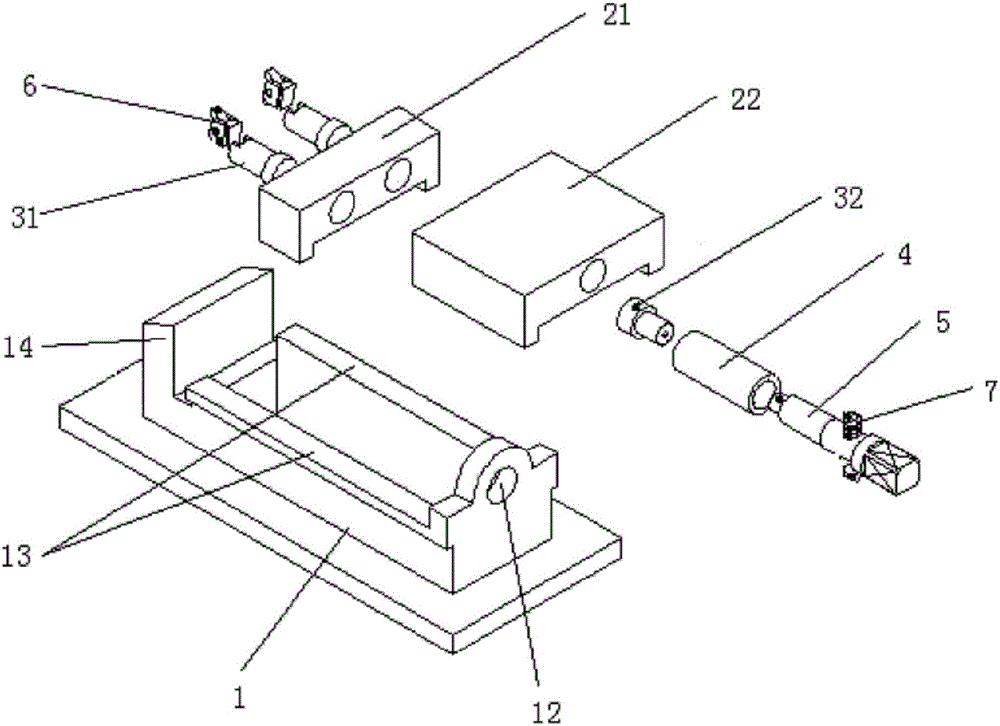

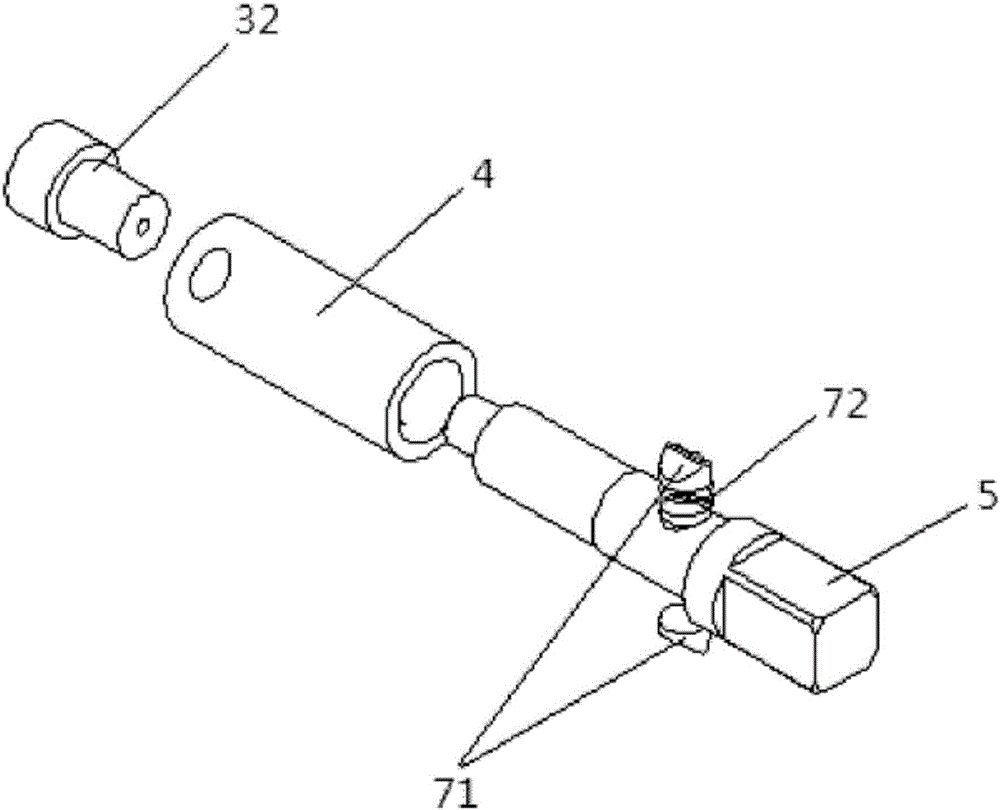

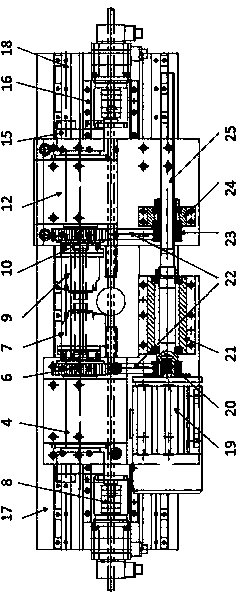

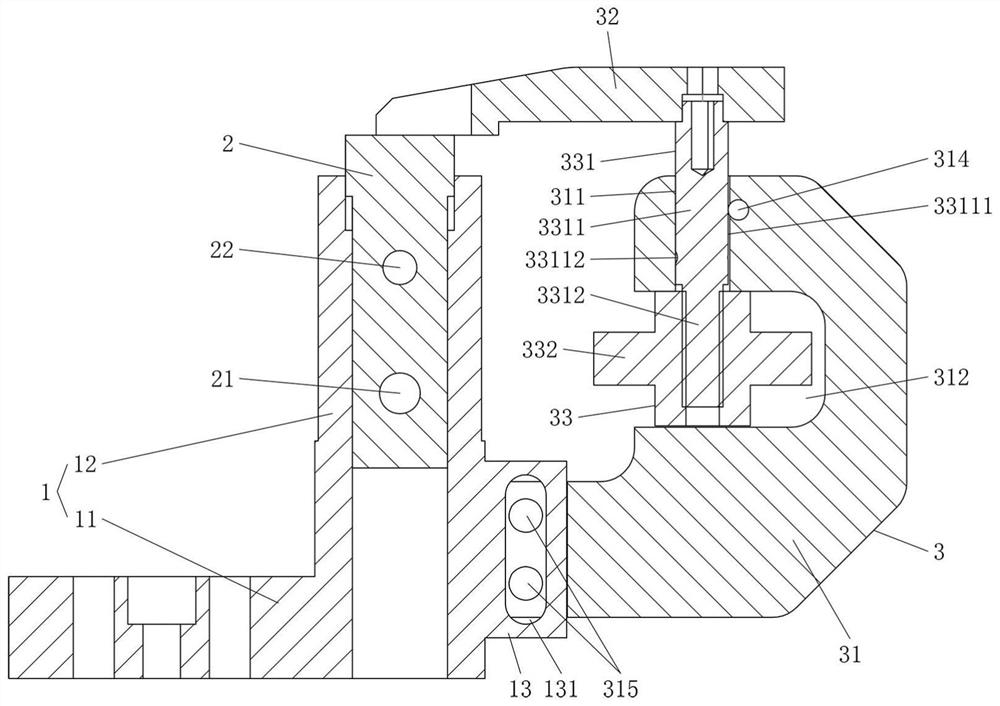

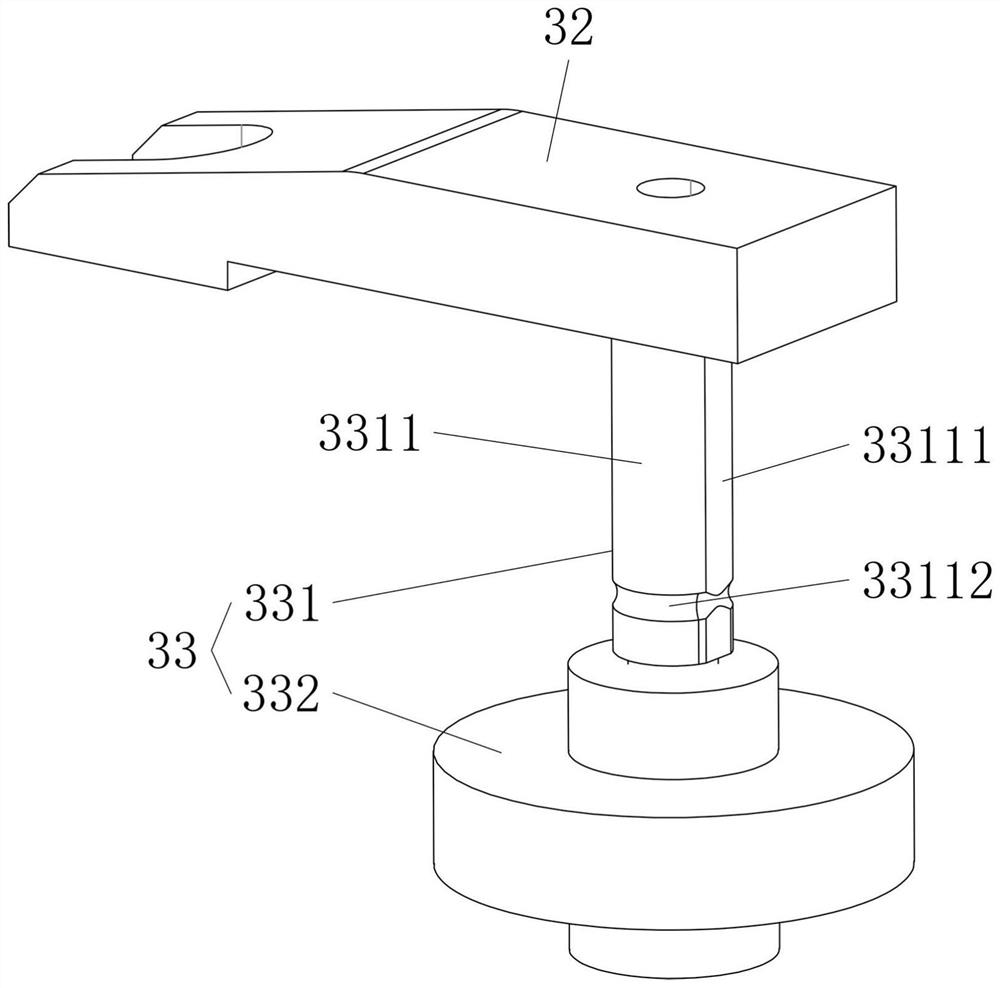

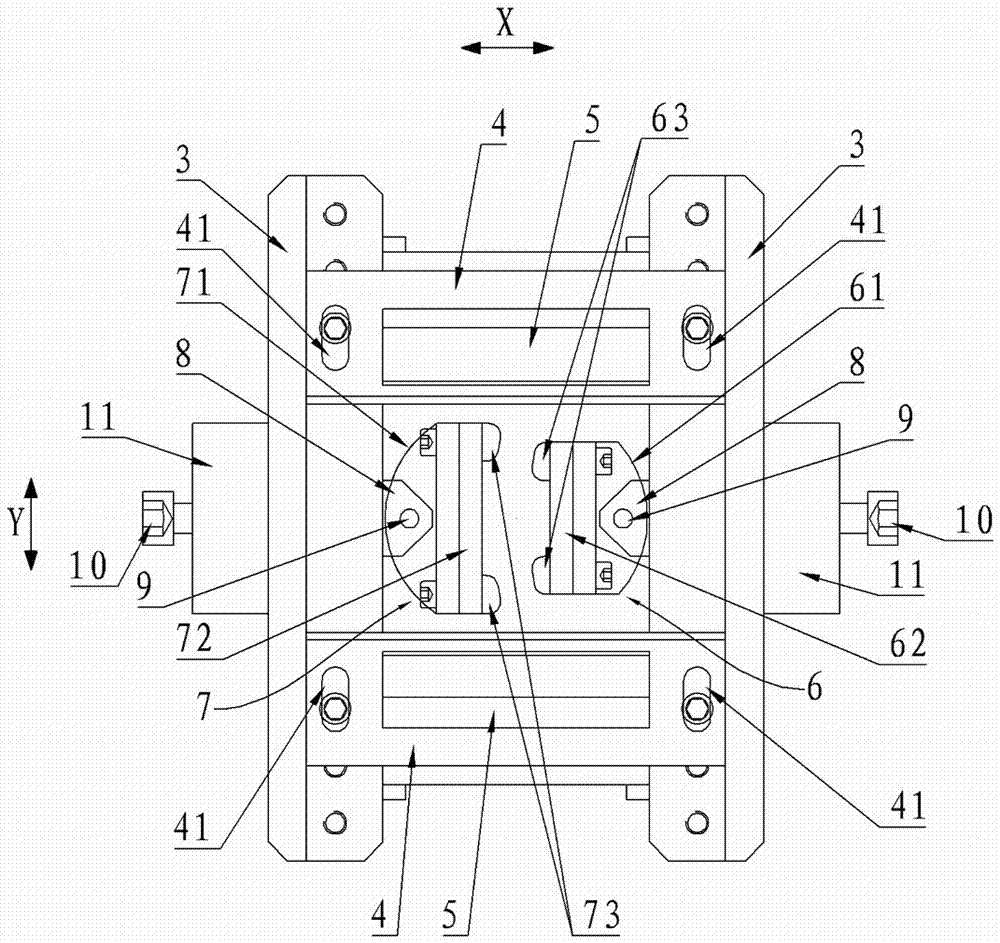

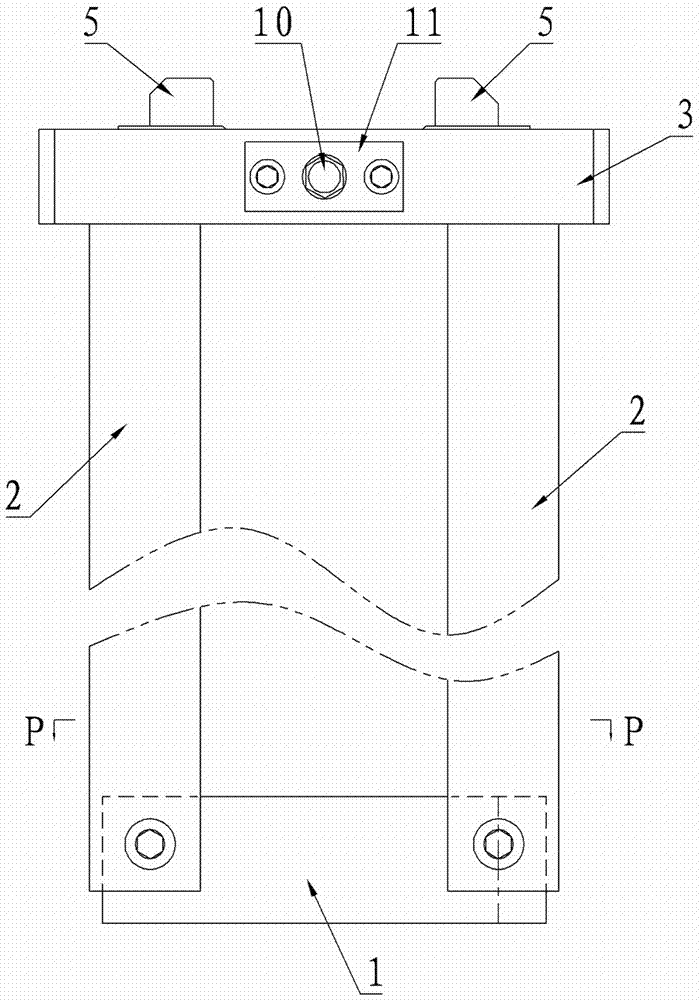

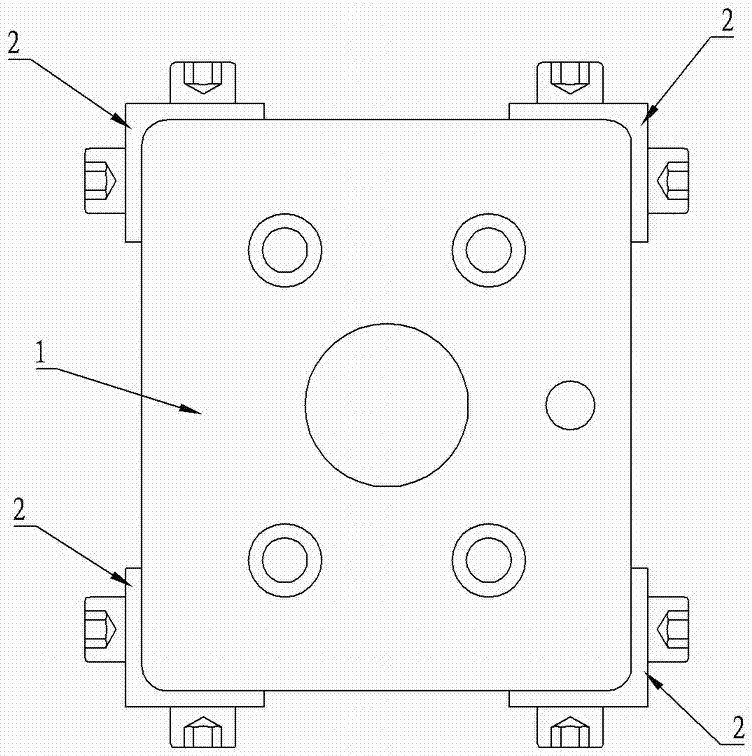

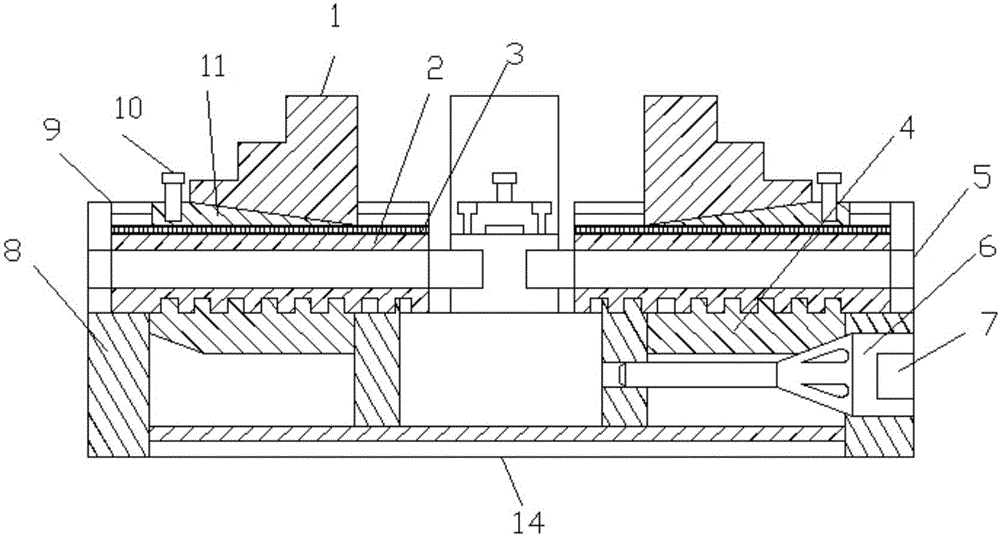

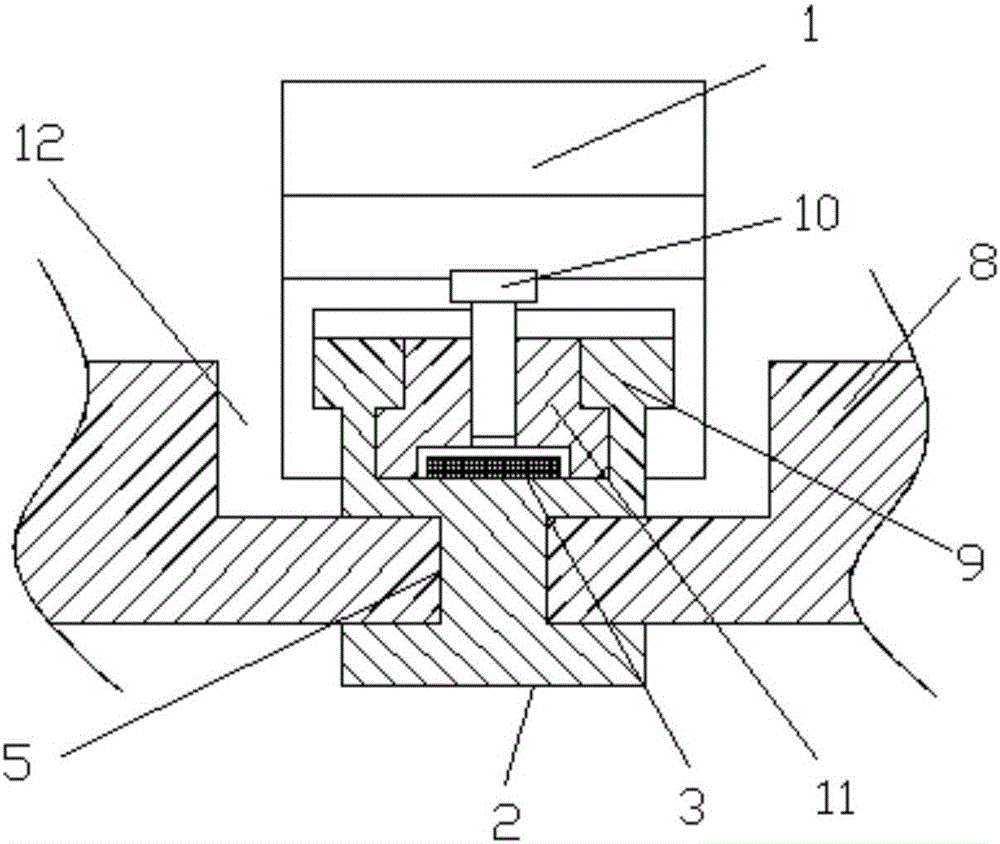

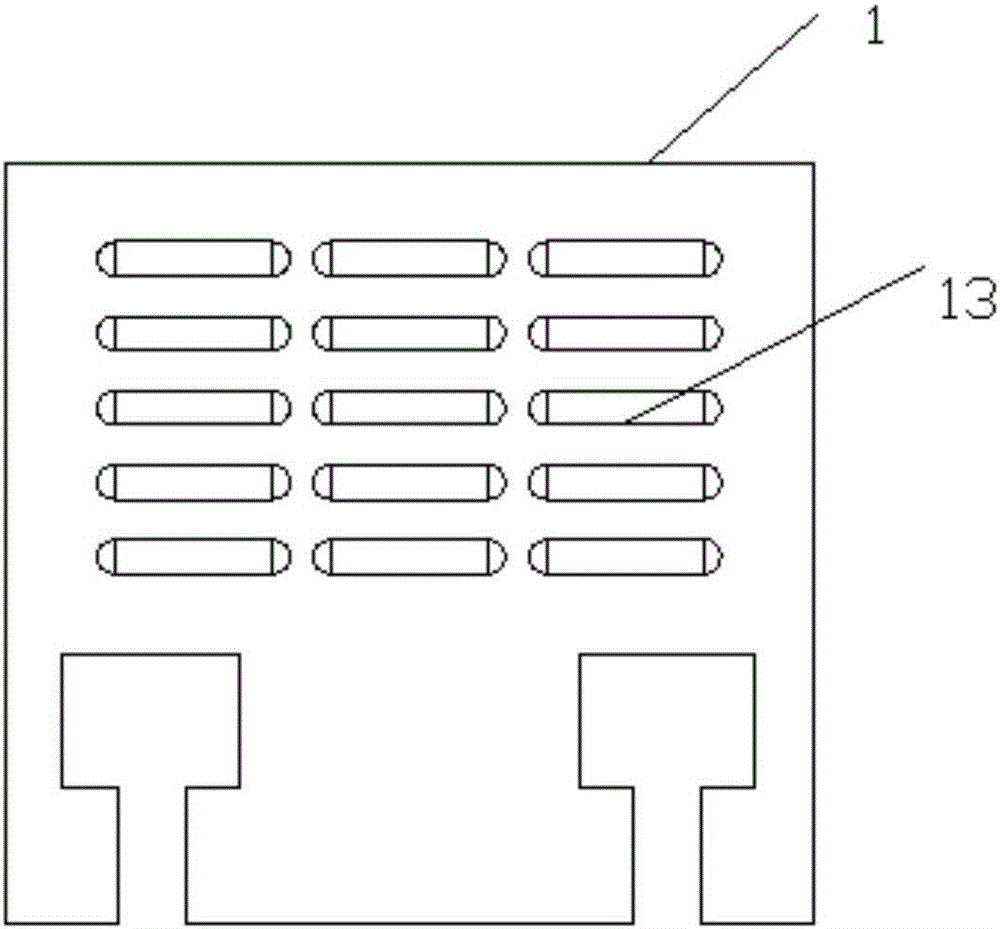

Clamping device for air conditioner shell stamping

InactiveCN107377794AMeet the clamping requirementsImprove stabilityShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a clamping device for air conditioner shell stamping. The clamping device comprises a lower die base. The four corners of the upper surface of the lower die base are all provided with sliding guide rods, and the sliding guide rods are movably arranged on the four corners of an upper die base in a sleeving manner. The sliding guide rods between the lower die base and the upper die base are provided with buffer springs. A connection base is arranged at the center of the side, far away from the lower die base, of the upper die base. Symmetrical bottom plates are arranged on the two sides of the lower die base. The bottom plate is provided with two sets of parallel first guide rails, the two sets of first guide rails are perpendicular to the side edge of the lower die base, and the two sets of first guide rails are movably provided with a movable bottom plate. A C-shaped fixture can be adjusted in the X direction and the Y direction on the bottom plate so as to meet clamping requirements of stamping raw materials in various specifications, the stamping raw materials are pressed tightly through locking bolts, clamping firmness of the fixture is guaranteed, the success rate of air conditioner shell stamping is increased, and the waste of raw materials is reduced.

Owner:滁州华宇机件有限公司

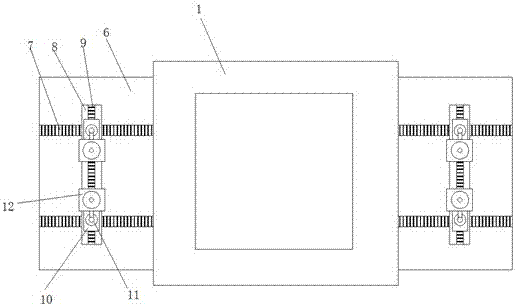

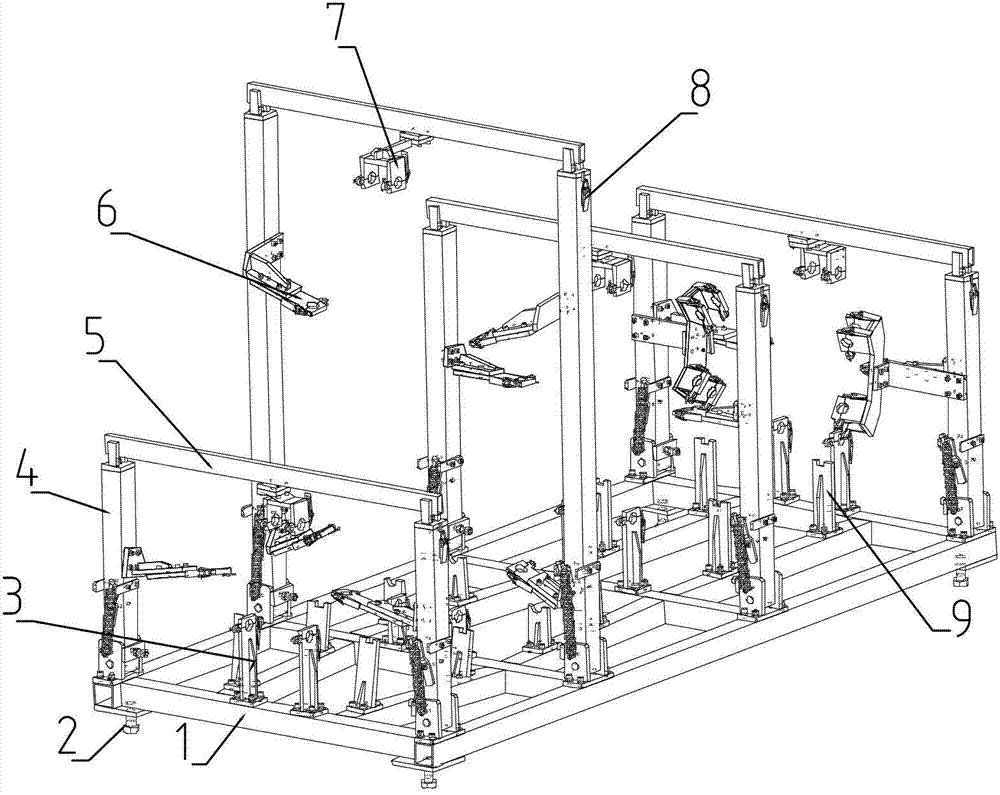

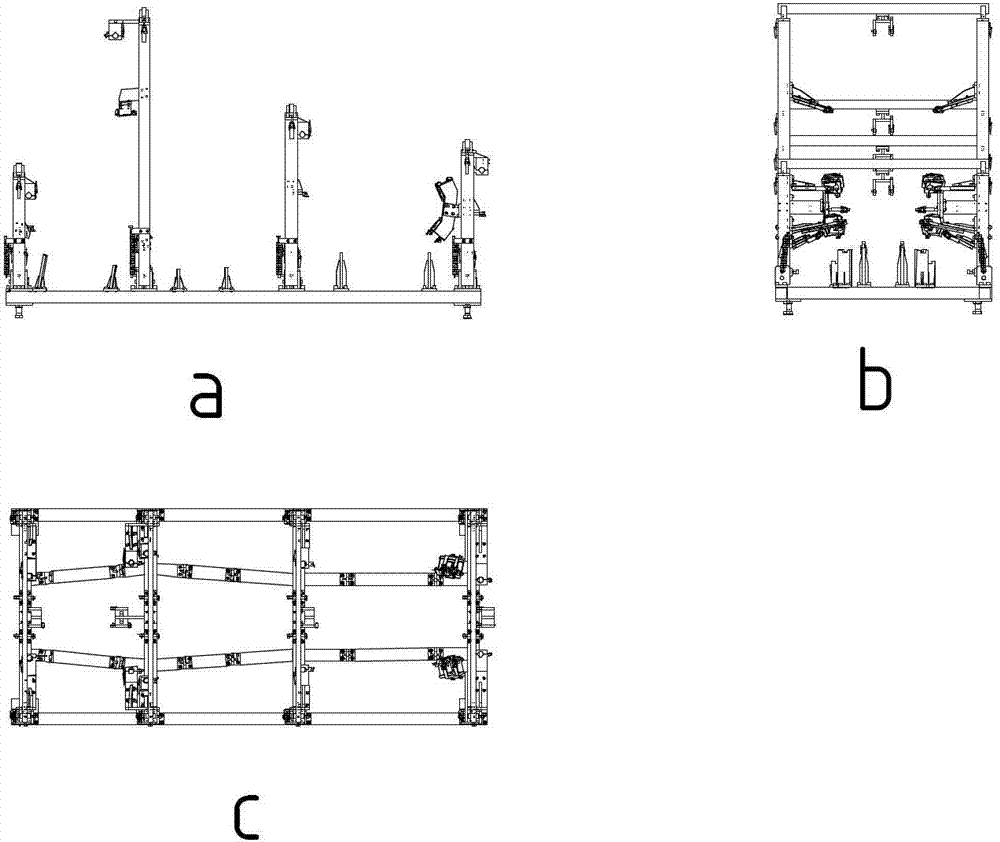

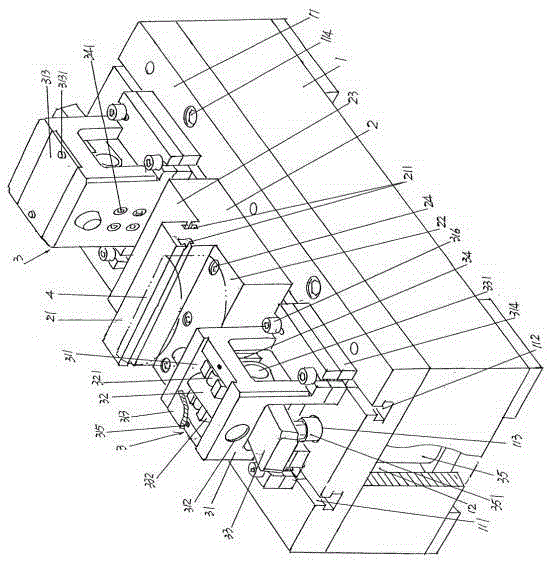

Welding fixture for formula racing

InactiveCN103240556AMeet clamping requirementsEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding deformation

A welding fixture for formula racing comprises a flexible base, a horizontal adjustment bolt, a main positioning clamping unit, an auxiliary positioning unit, a stand column mechanism, a top positioning beam, a lateral positioning clamping unit and an upper positioning clamping unit. The horizontal adjustment bolt, the main positioning clamping unit and the auxiliary positioning unit are fixedly arranged on the flexible base; the stand column mechanism has limiting and safety functions; the top positioning beam is connected with the stand column mechanism; the lateral positioning clamping unit is fixedly arranged on the stand column mechanism; the upper positioning clamping unit is fixedly arranged on the top positioning beam; the main positioning clamping unit, the auxiliary positioning unit, the lateral positioning clamping unit and the upper positioning clamping unit can move on the flexible base, the stand column mechanism and the top positioning beam; and the stand column mechanism comprises a stand column, a stand column fixing seat, a limiting block, a limiting switch and a limiting spring. According to the welding fixture for the formula racing, correct relative positions of parts can be guaranteed when assembling positioned welding and welding deformation of workpieces can be prevented or reduced.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

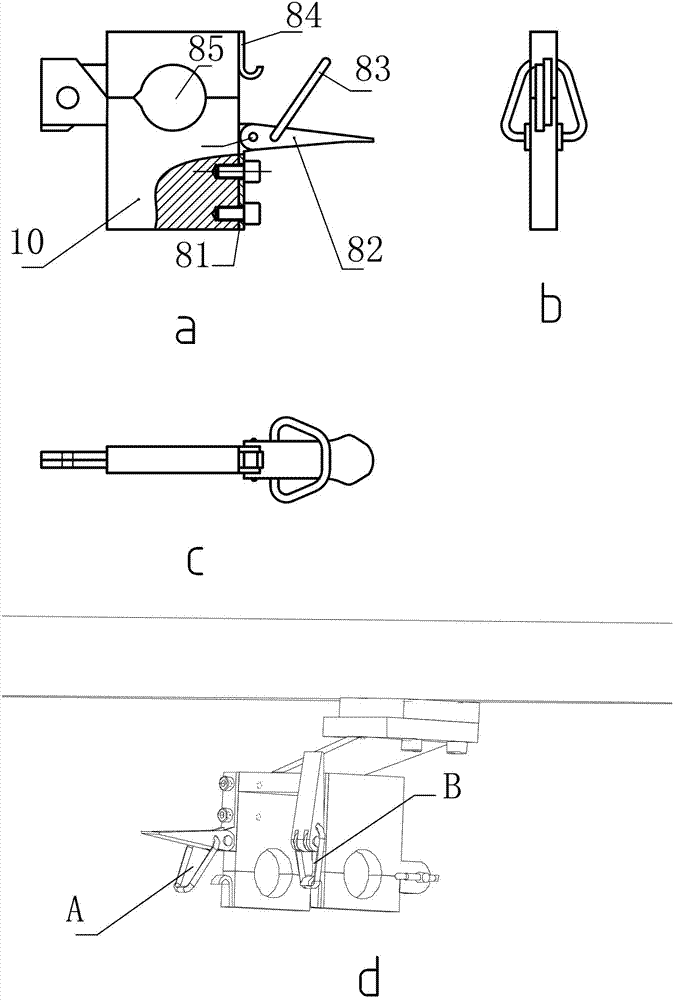

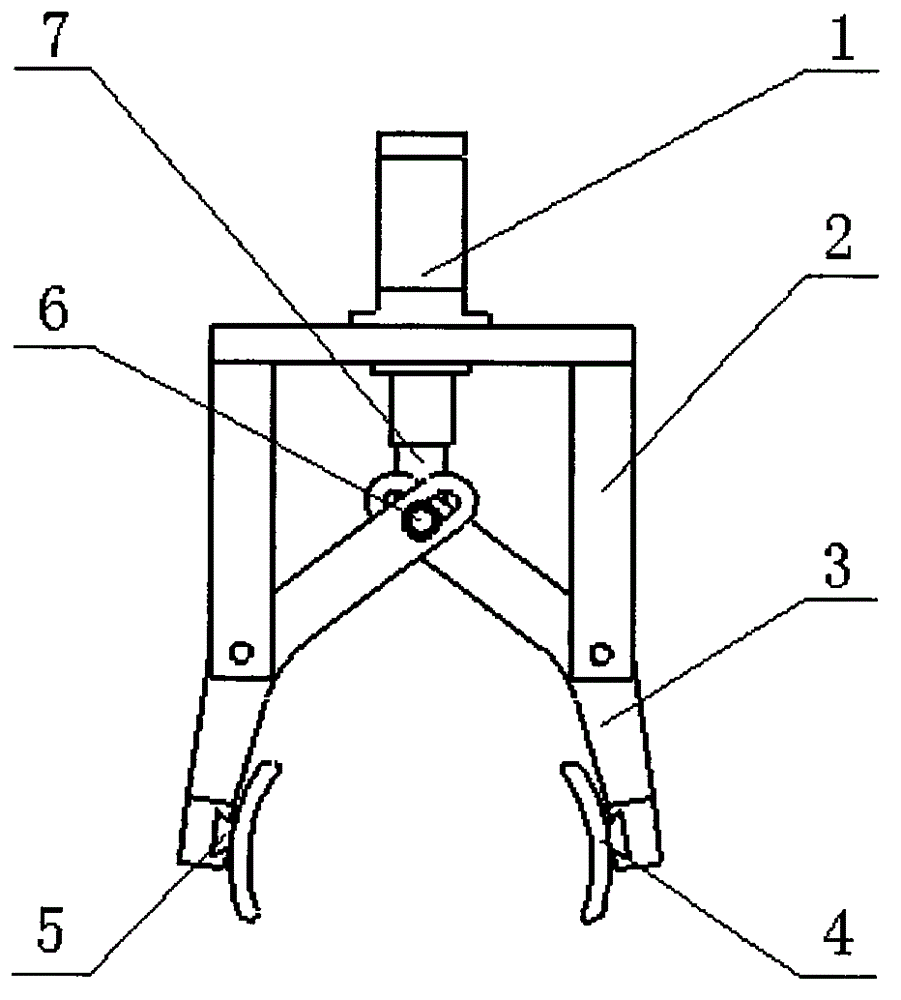

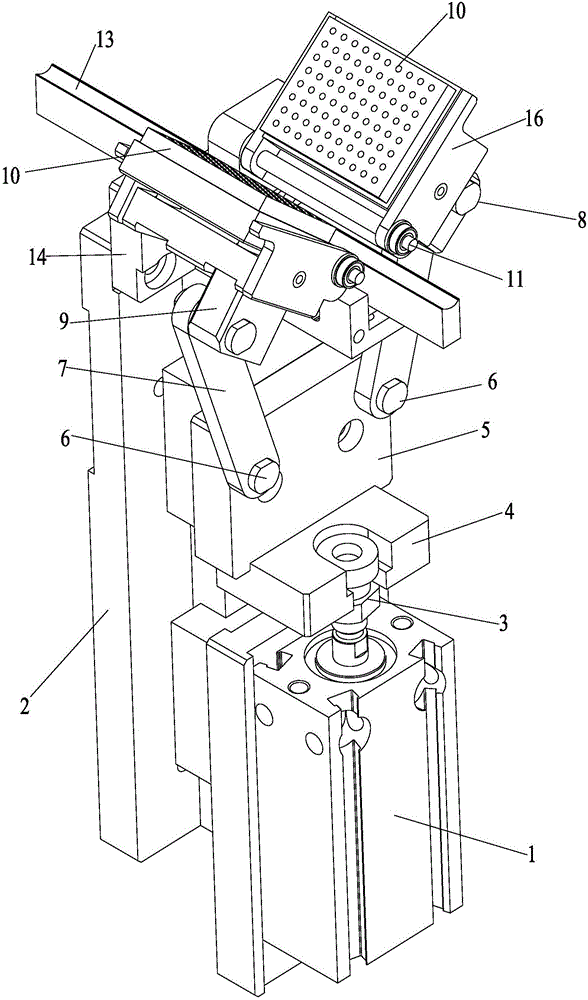

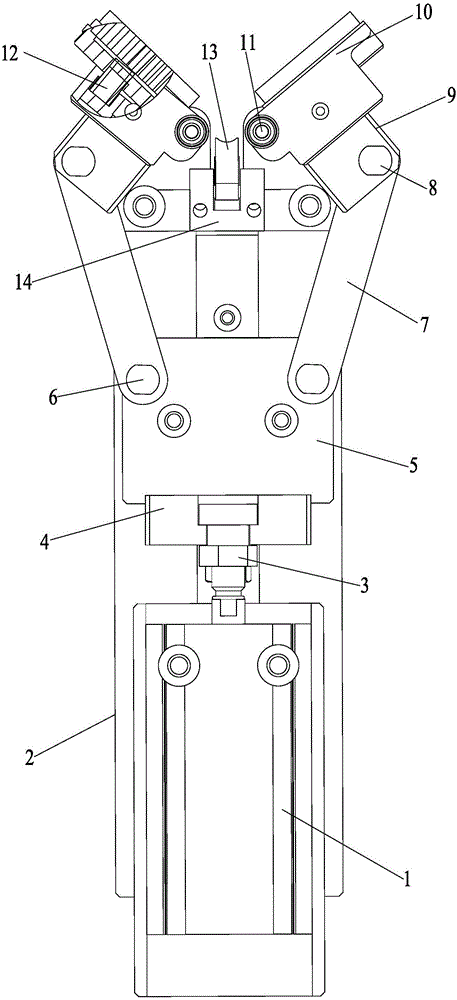

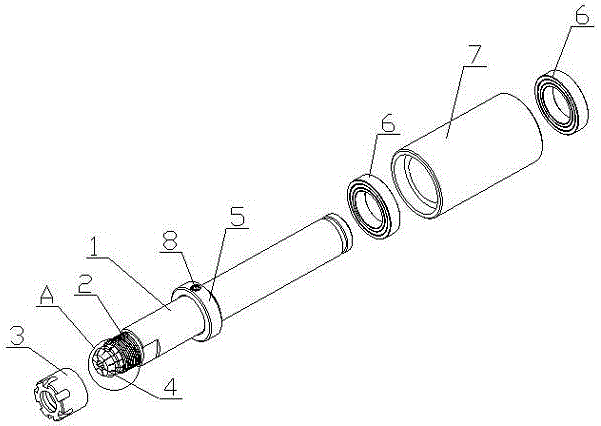

Design of replaceable simple-joint robot flexible hand

InactiveCN102717389AMeet the clamping requirementsEasy to installGripping headsHydraulic cylinderRobot hand

The invention belongs to the field of mechanical manufacturing and provides a design of adopting replaceable simple-joint finger to clamp a series of workpieces of different shapes aiming at the defects that the hands of a common robot palletizer and a transfer robot are single in finger structure and have less possibility of reliably clamping the workpieces of different shapes and different sizes at present. The mechanism adopts a hydraulic system for driving; by virtue of controlling the stroke of the piston rod of a hydraulic cylinder and controlling the folding and unfolding states of the finger according to the clamping force requirements of workpieces of different shapes, corresponding clamping forces can be provided for satisfying the workpiece clamping requirements; the strokes of the designed piston rod are consistent; the fingers of the robot hand are connected with a connecting rod through dovetail grooves; the size of each dovetail groove on the connecting rod is fixed, the fingers of different shapes and sizes can be conveniently replaced only if matched dovetail groove interfaces are arranged, so as to meet the clamping requirements of different workpieces. The mechanism can be used for saving materials, saving the replacement time, increasing the working efficiency, rapidly designing and manufacturing corresponding replaceable fingers according to the shape and size requirements of different workpieces and meeting the high-efficiency production requirement.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

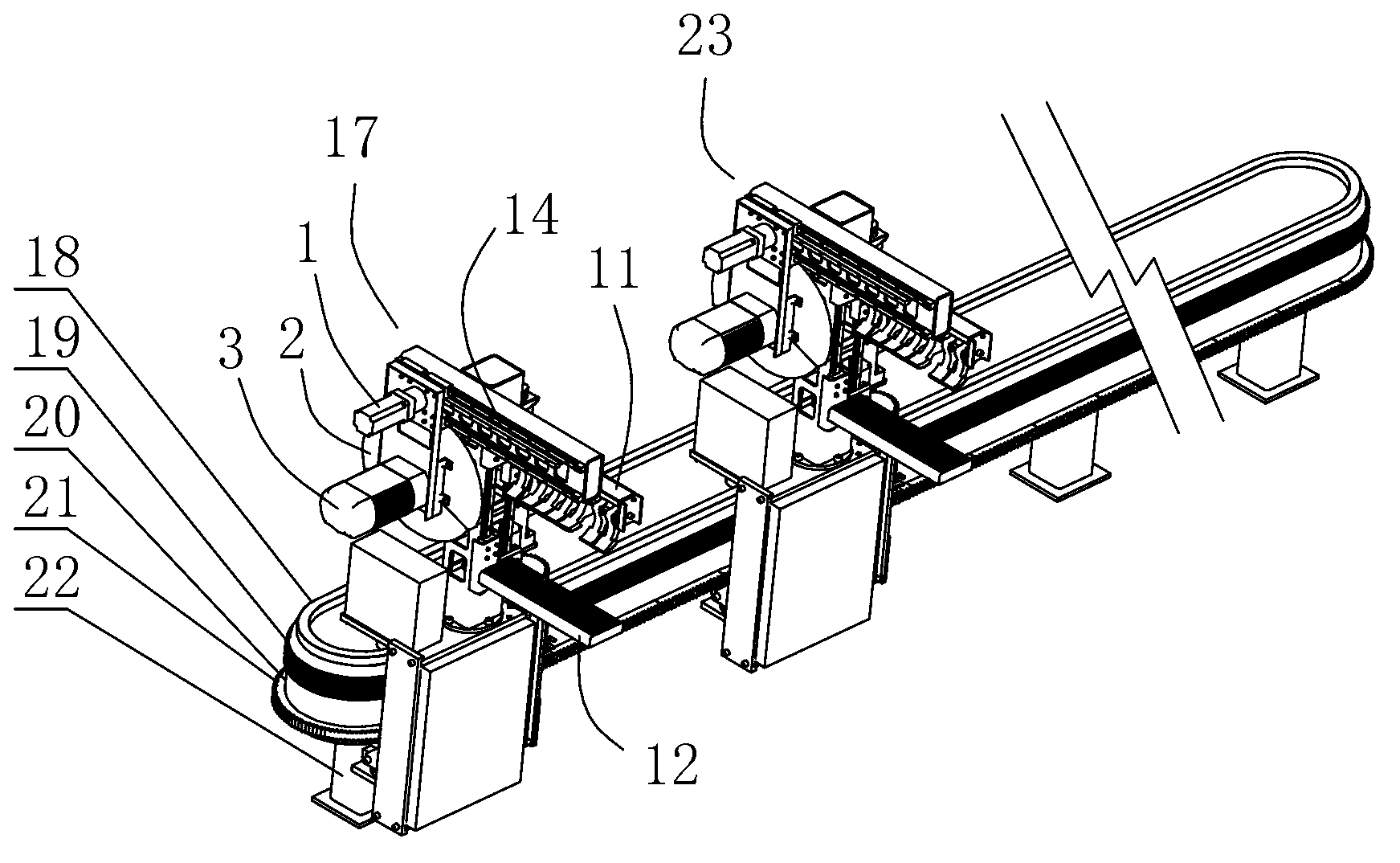

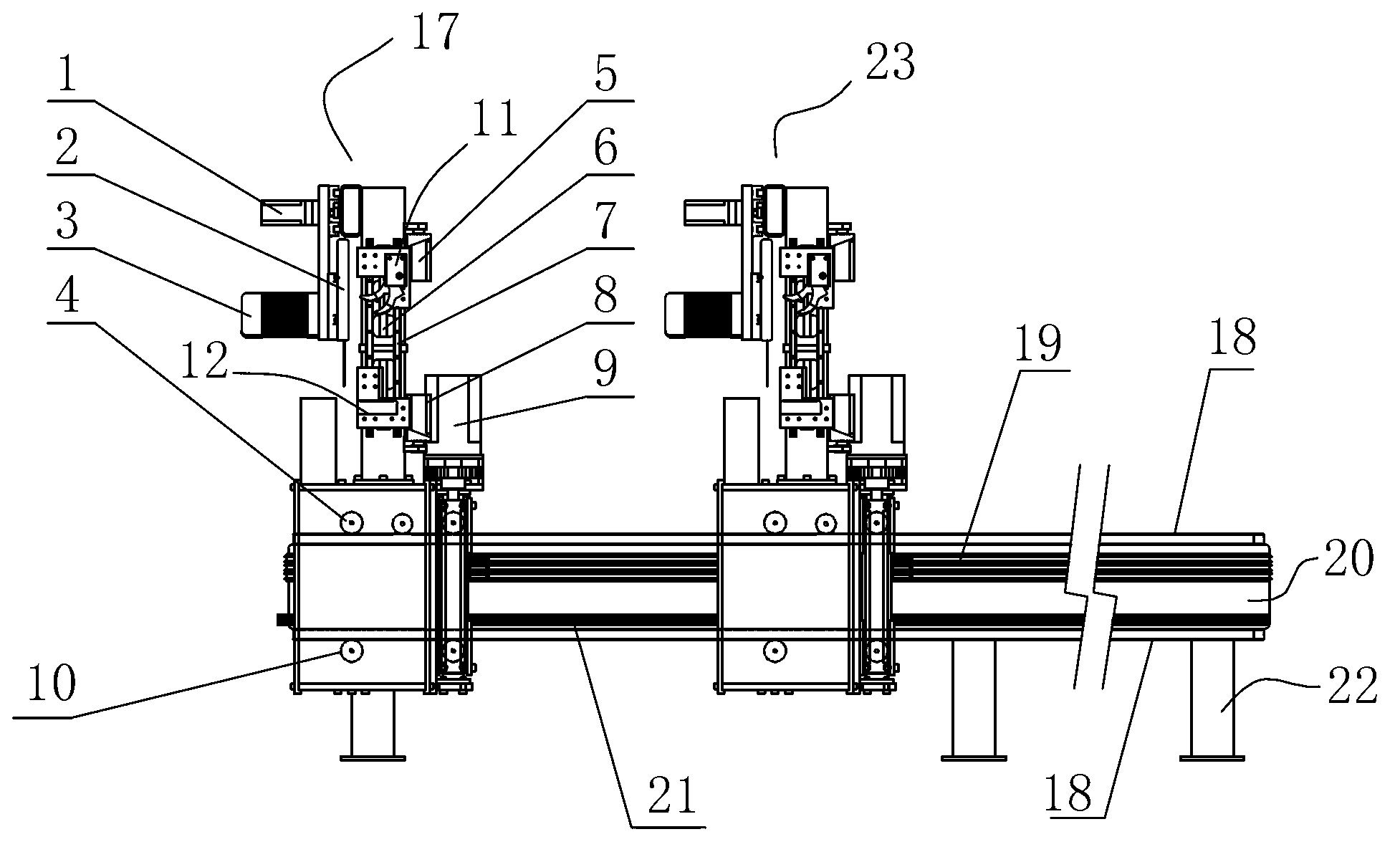

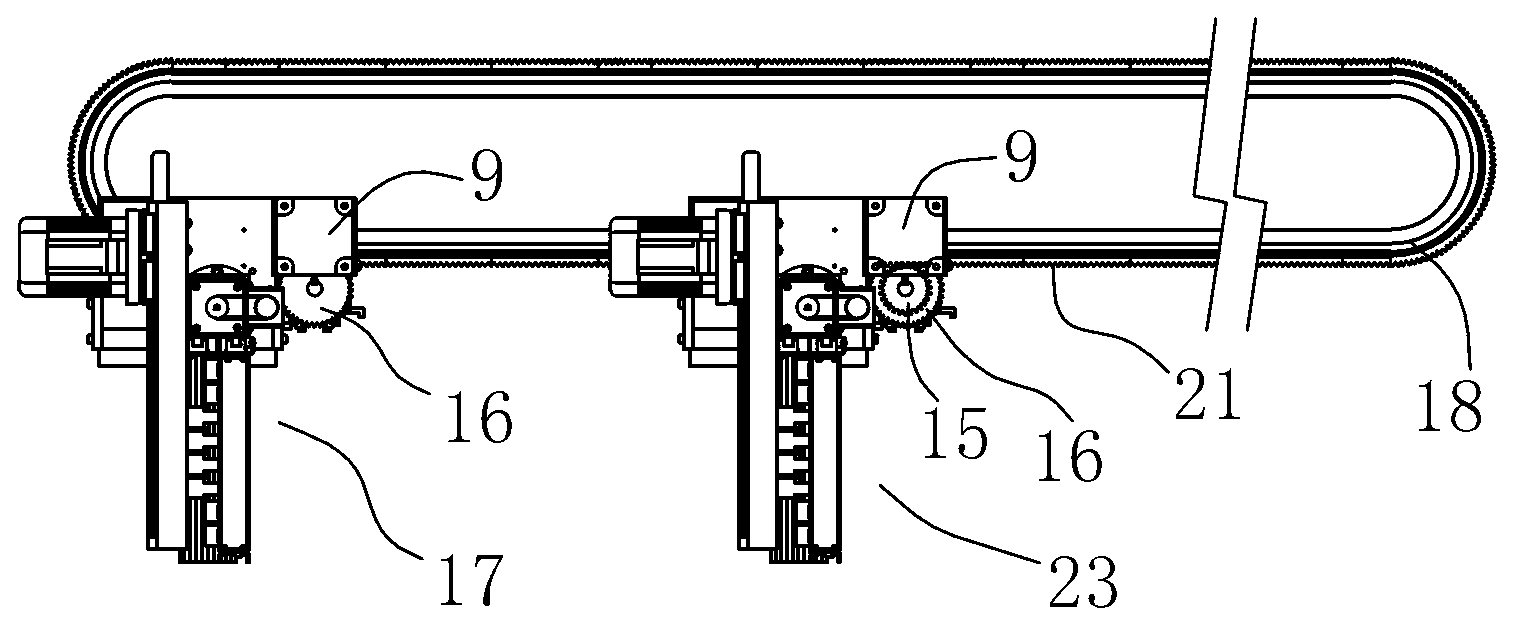

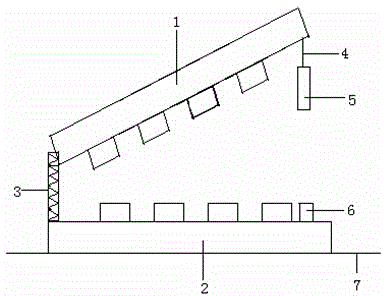

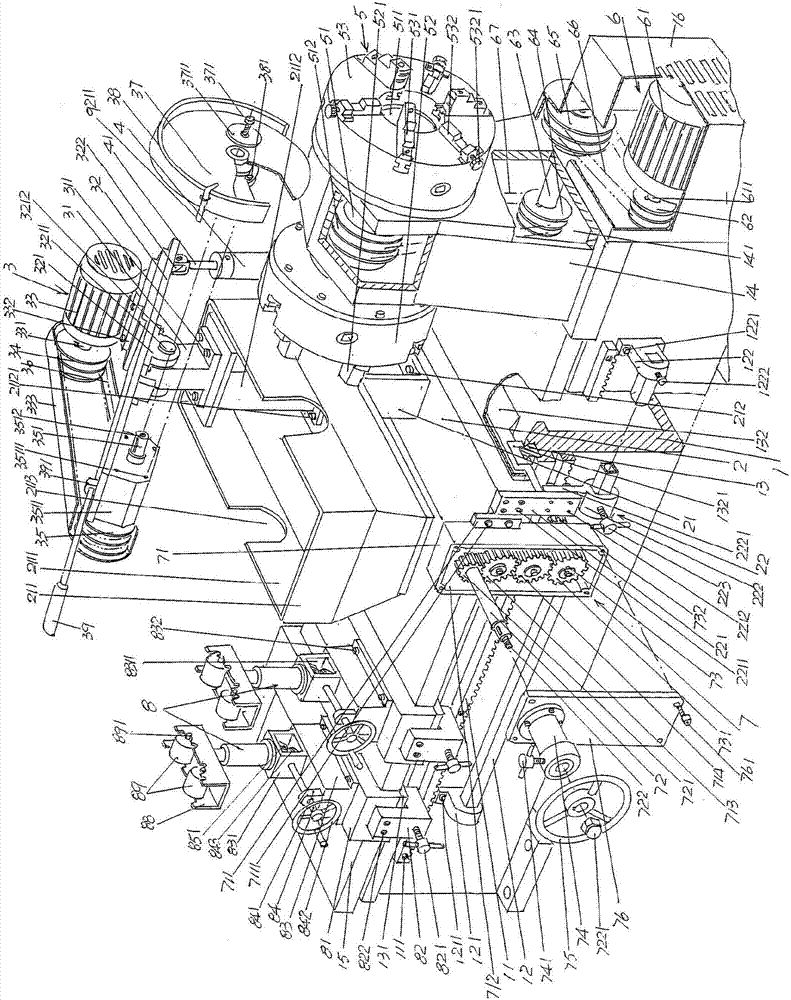

Aluminium profile circulating band saw full-automatic traction apparatus

The invention discloses an aluminium profile circulating band saw full-automatic traction apparatus which has high efficiency and can continuously work. The aluminium profile circulating band saw full-automatic traction apparatus can totally meet the production requirement on high-speed discharge of an extrusion discharge port and simultaneously further improves production quality of an aluminium profile. The traction apparatus comprises a guide rail station, at least two tractors and a control system, wherein the tractors and the control system can move on the guide rail station; the tractors are provided with flying saws for carrying out saw cutting on the aluminium profile; the guide rail station is provided with ring-shaped guide rails for enabling the tractors to slide; moreover, the guide rail station is also provided with ring-shaped racks of which the directions are consistent with those of the ring-shaped guide rails; the tractors are provided with traction power servo motors; and the traction power servo motors are matched with the ring-shaped racks through gear mechanisms. The aluminium profile circulating band saw full-automatic traction apparatus is mainly applied to extrusion production of the small-scale aluminium profile.

Owner:林志萍

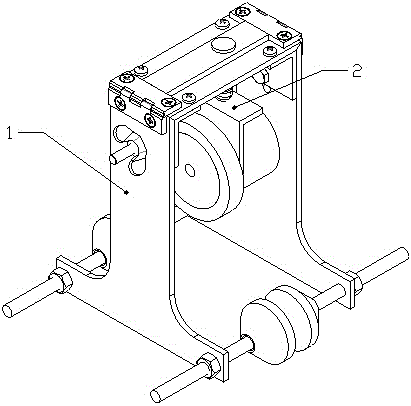

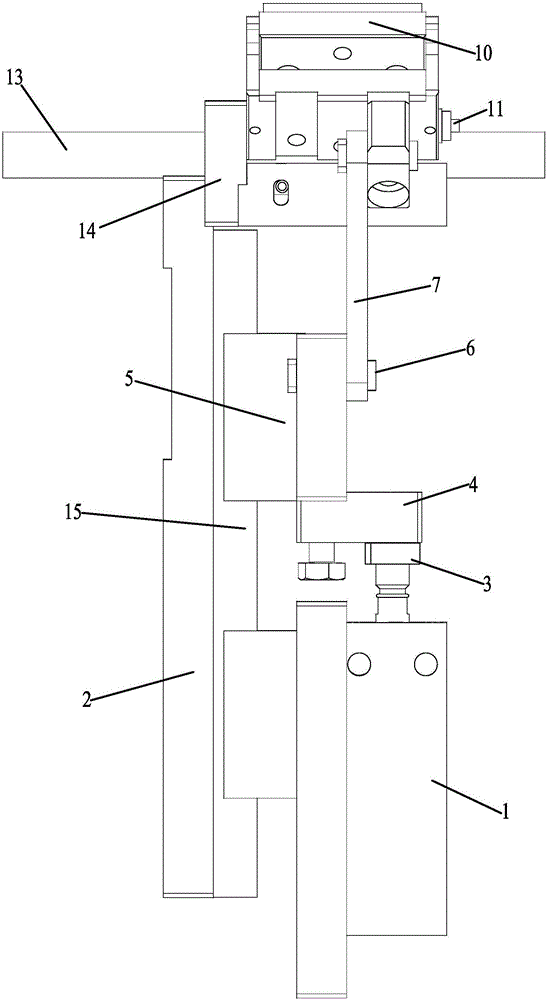

Escalator hand strap speed measuring clamp

InactiveCN103910276AMeet the clamping requirementsAbsorb uncertain shocksLinear/angular speed measurementEscalatorsEngineeringLever pressing

The invention provides an escalator hand strap speed measuring clamp. The escalator hand strap speed measuring clamp comprises a clamp part and an elastic pressing part; the clamp part is connected with the elastic pressing part through a pressing rod which penetrates a transverse board; the clamp part comprises the transverse board, two side boards and four universal hooves, the side boards are fixed on two sides of the transverse board through hinges, and each universal hoof penetrates the two side boards during usage and is fastened through fastener butterfly nuts; the elastic pressing part comprises an encoder, a mounting plate, a compressed spring and the pressing rod. According to the escalator hand strap speed measuring clamp, the two side boards can be mutually closed and the encoder can completely contact with a hand strap so that the clamping firmness of the speed measuring clamp can be greatly improved.

Owner:SHANGHAI UNIV

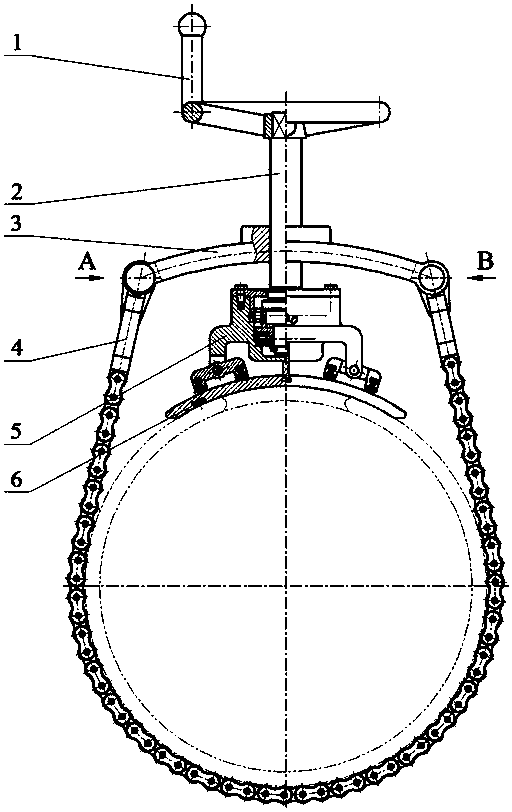

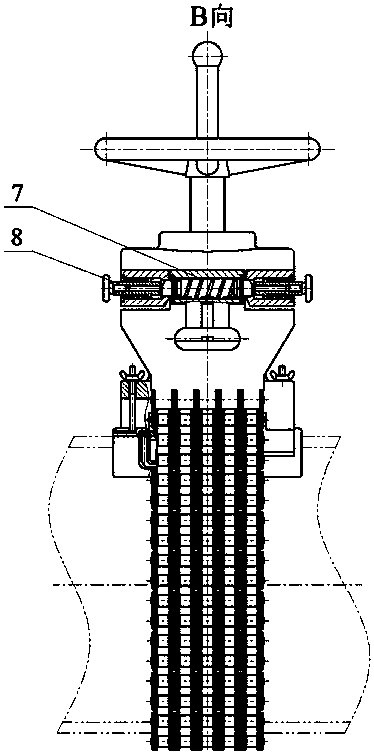

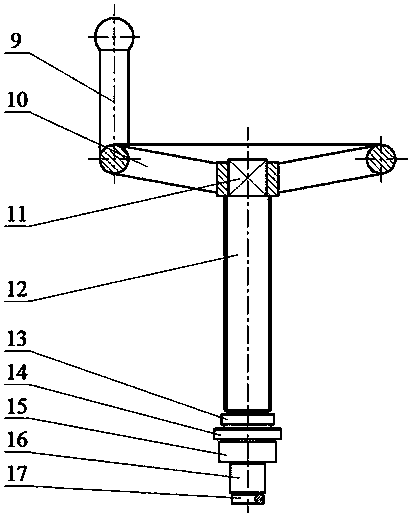

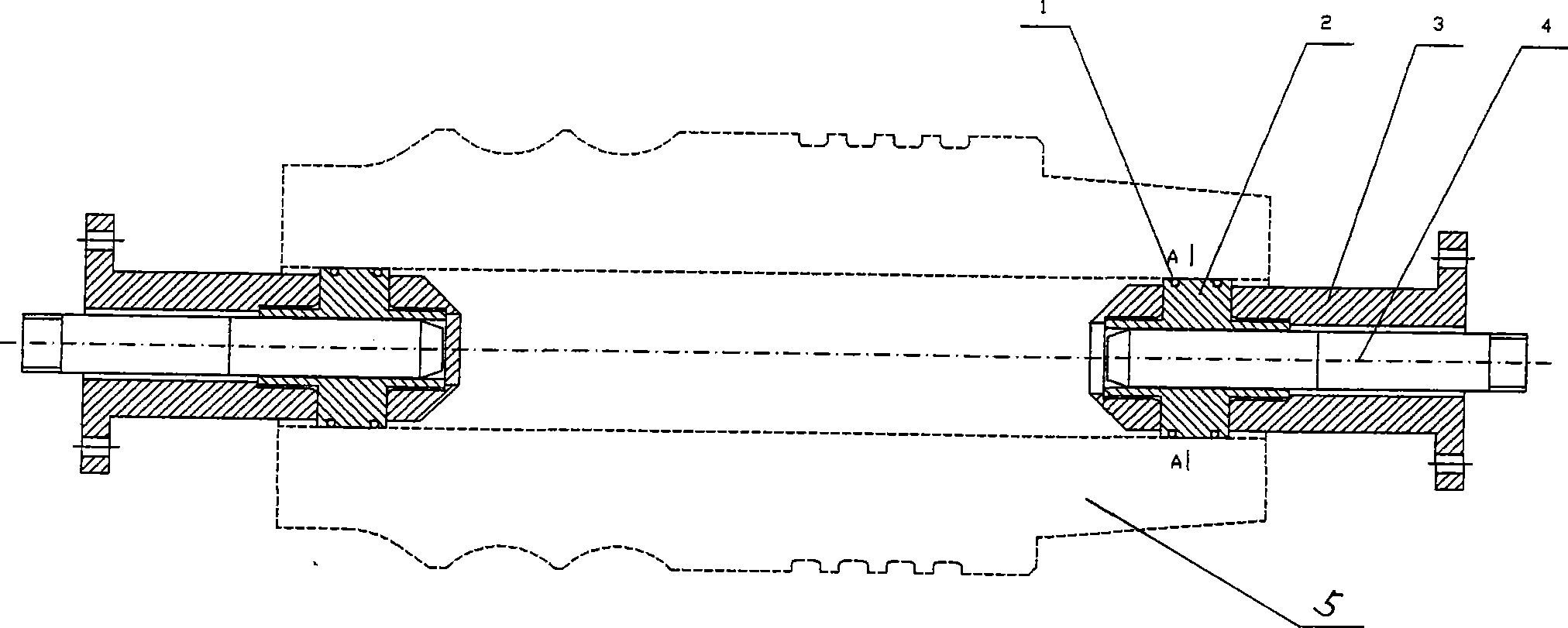

Under-pressure leaking stoppage device for oil and gas conveying pipeline

The invention provides an under-pressure leaking stoppage device for an oil and gas conveying pipeline, which has the characteristics of short operation time, small construction intensity and high leaking stoppage efficiency. The quick leaking stoppage of pipelines of different diameters under pressure or temperature or under the condition of no shutdown can be realized. The under-pressure leaking stoppage device for the oil and gas conveying pipeline comprises a rotary hand wheel, a transmission shaft, an upper slips, a lower slips, a locking block, an unlocking block, a pressing body and a leaking stoppage paster, wherein the transmission shaft is used for realizing the quick compression of the leaking stoppage paster and the self locking of the device by trapezoidal threads; the lower slips can be used for clamping pipelines of different diameters by multiple rows of roller chains; a locking pin is cooperated with the lower slips and a locking block eyehole by a spring to realize the quick locking of the device; an unlocking pin is cooperated with the upper slips and an unlocking block eyehole by a spring to realize the quick unlocking and the automatic resetting of the unlocking pin; the pressing body is provided with a cylindrical roller and a thrust roller bearing to ensure the coaxiality and the perpendicularity of the pressing body and the transmission shaft and realize the transferring of the action force; the O-shaped sealing ring of the leaking stoppage paster is pressed by the pressing body; the leaking stoppage operation can be finished by soldering the leaking stoppage paster.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Large-piece processing clamping method

ActiveCN101362295AHigh strengthLarge tensionPositioning apparatusMetal-working holdersRubber ringCircular cone

The invention discloses a clamping method for the processing of a supper-long large work piece vehicle. Both ends of a work piece are supported by utilizing a double way automatic hydraulic pressure chuck and a pair of expansion core fixtures, the movement of the push rod inside of the expansion core fixtures is driven by a hydraulic piston inside the chuck, a group of radial slide blocks inside the expansion fixture are pushed and inner bores on both ends of the work piece are expanded, a rubber ring for resetting is installed on the slide block, and the contact part between the push rod and the axial slide block is a cone surface. As the coaxiality of the double way automatic hydraulic pressure chuck is good, the strength of the expansion fixture is high, the distensible force is large, the clamping requirement on the processing of the supper-long large work piece vehicle can be met, the turnaround of the vehicle is not required during the processing, the problem of free swinging knife does not exist, the coaxiality precision and the relevant processing precision of the work piece can be ensured, the operation is convenient, the production efficiency is high, and the clamping method can be suitable for clamping work pieces with different bore diameters by replacing the slide block.

Owner:JIANGSU SHUGUANG OIL DRILLING EQUIP CO LTD

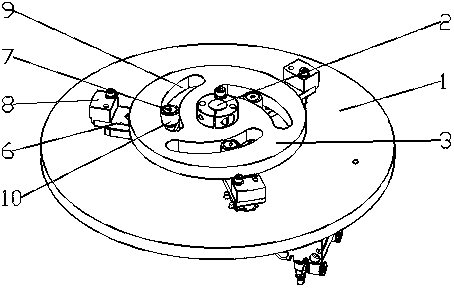

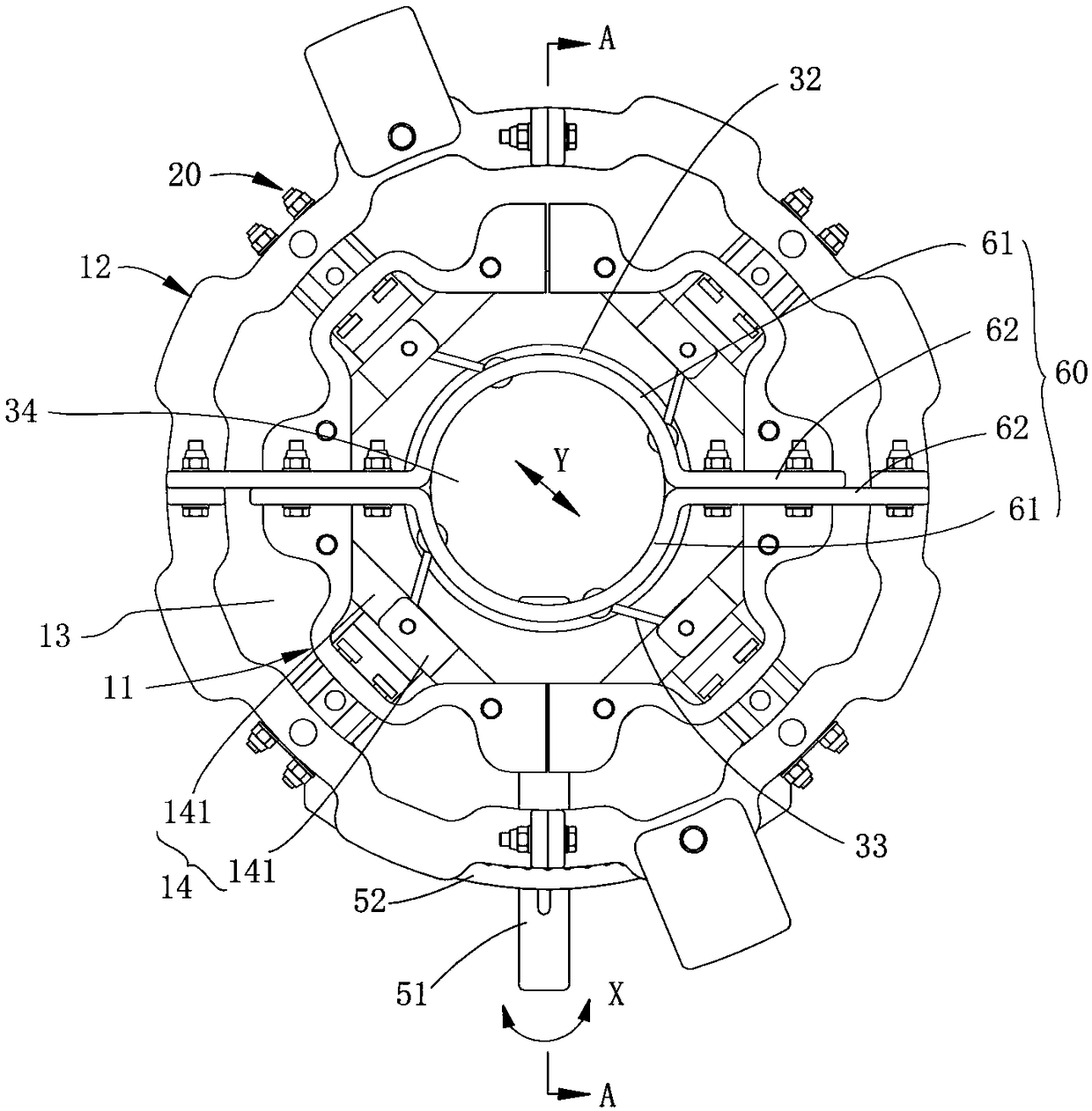

Self-adaption inner cylinder clamping manipulator

The invention discloses a self-adaptive inner cylinder clamping manipulator, which includes a chassis, a rotating shaft cooperating with the rotating shaft is arranged in the center of the bottom plate, a control disk is set on the rotating shaft, and at least three clamps are evenly arranged in a ring between the control disk and the chassis. holding unit; the clamping unit includes a radial slide seat fixedly installed on the chassis, a slide rail is provided on the radial slide seat for sliding cooperation with it, a connecting block is fixedly installed on the slide rail, and one end of the connecting block radially inward There is a sliding shaft, and the radially outward end of the connecting block is provided with a clamping head. The axis of the sliding shaft is parallel to the axis of the rotating shaft. The control panel is provided with a stroke groove corresponding to the sliding shaft, and the sliding shaft extends into the stroke groove. and cooperate with the stroke groove; the distance y between the centerline of the stroke groove and the axis of the rotating shaft satisfies: y=aθ+b, θ is the radial direction of any point on the centerline of the stroke groove relative to the axis of the rotating shaft and the distance between the stroke groove The angle between the point where the centerline is closest to the shaft axis and the radial direction of the shaft axis.

Owner:WENZHOU POLYTECHNIC

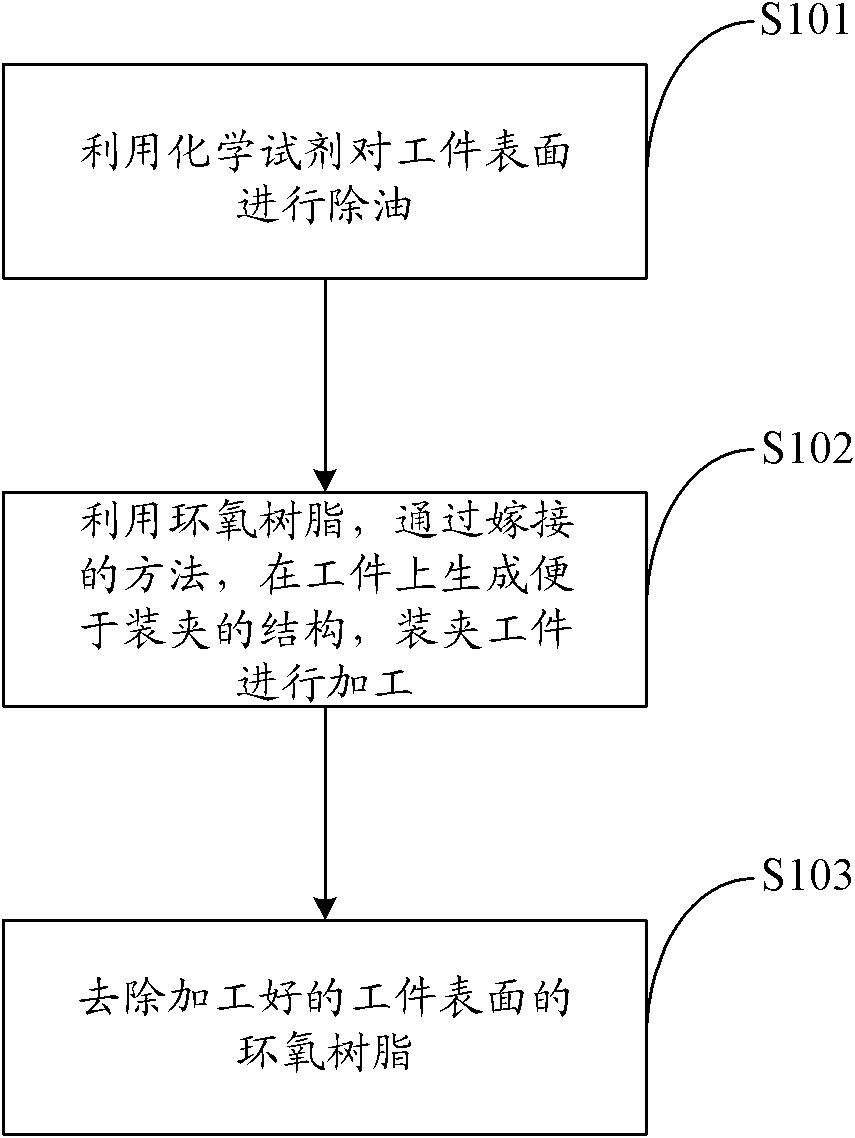

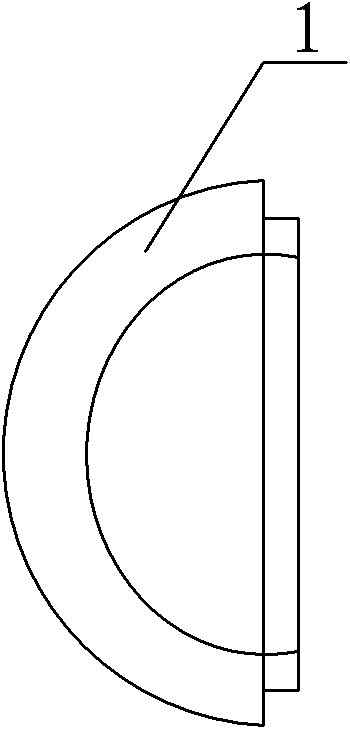

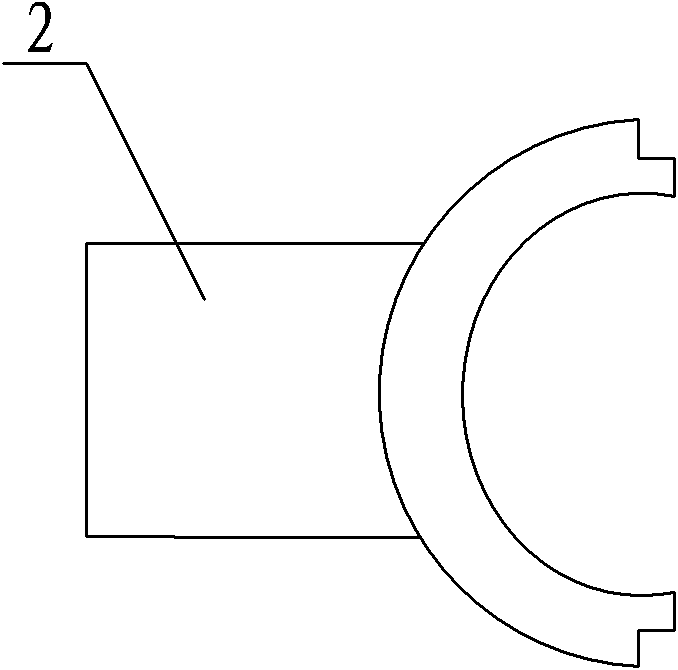

Method for machining mechanical parts

InactiveCN102303249AHigh bonding strengthCause damageGrinding machinesPositioning apparatusEngineeringChemical agents

The invention is suitable for the field of parts machining and provides a method for machining mechanical parts. The method comprises the following steps of: deoiling the surface of a workpiece by using a chemical agent; generating a structure which is convenient for being clamped on the workpiece by using epoxy resin, and clamping the workpiece and machining; and removing the epoxy resin on the surface of the machined workpiece. According to the invention, an engrafting method is adopted, the structure which is convenient for being clamped is generated on the workpiece by using the epoxy resin, the epoxy resin can excellently combine with the workpiece, and the combining strength between the shaped structure and the workpiece is high, so that the basic clamping requirements are satisfied; and after the workpiece is finished machining, the epoxy resin adhesive part is completely removed from the workpiece through heating to soften, and no damage to the workpiece can be caused.

Owner:BRITISH JOINT VENTURE PERKINS ENGINES TIANJIN

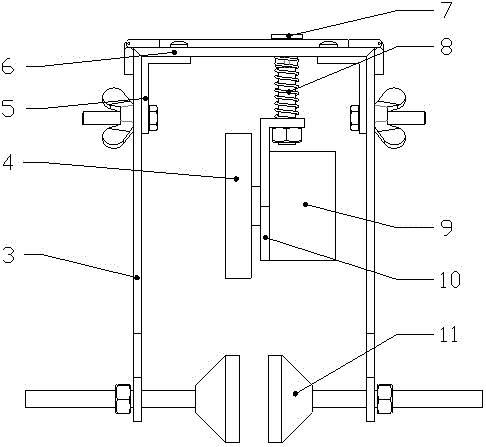

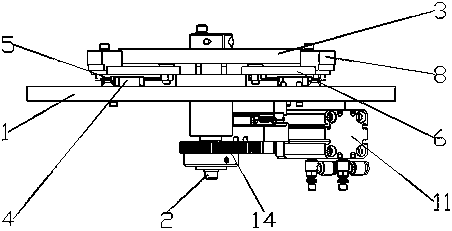

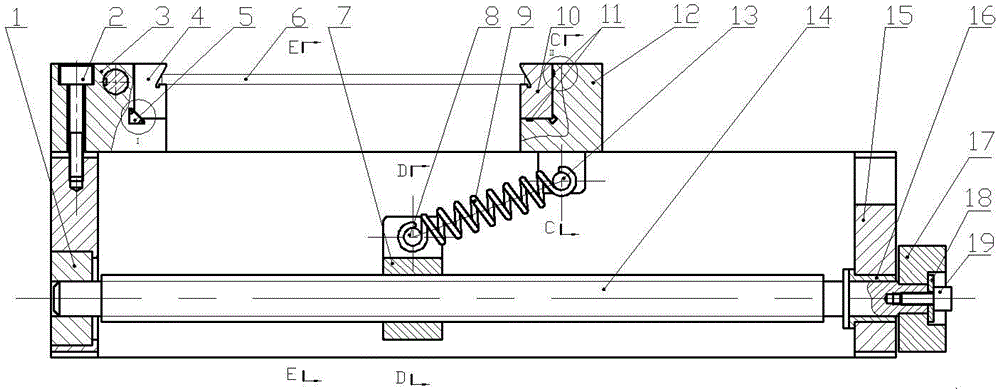

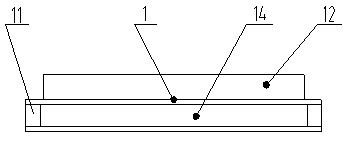

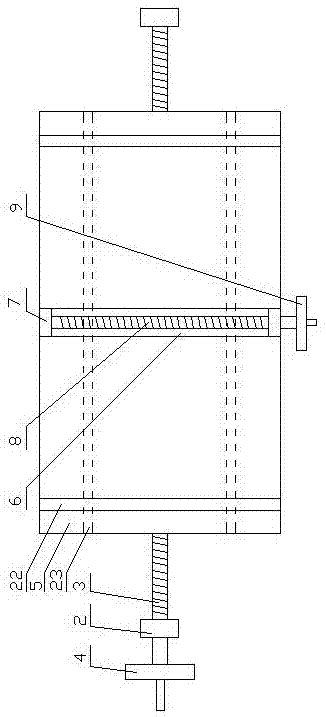

Elastic clamp applied to thin sheet parts of laser micromachining machine tool

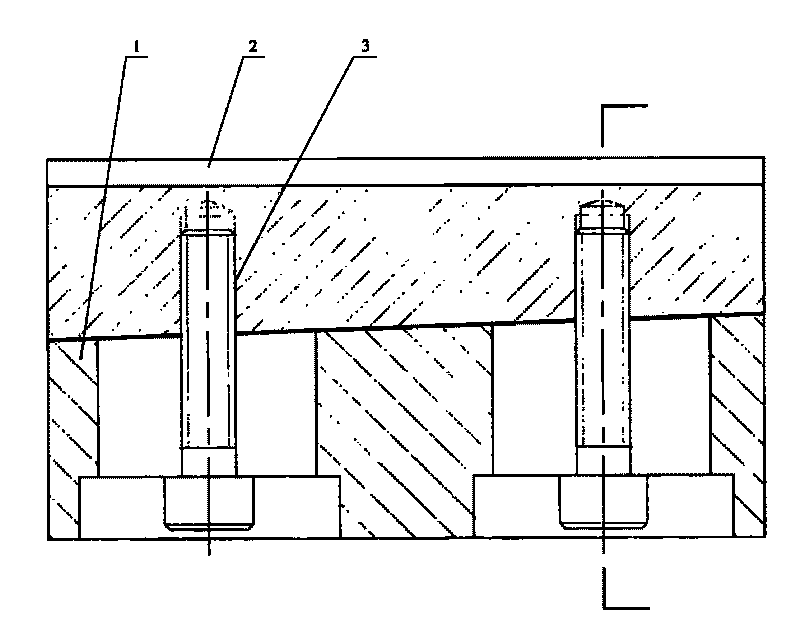

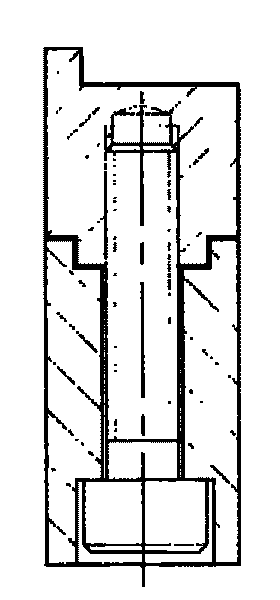

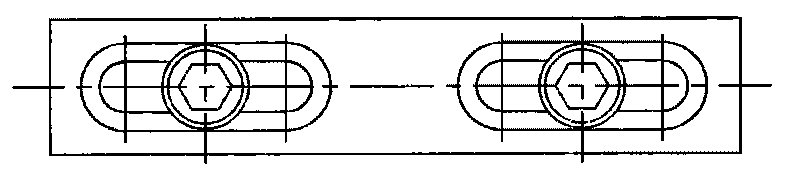

InactiveCN105312784AMeet the clamping requirementsEffective adjustment of clamping forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine tool

The invention discloses an elastic clamp applied to thin sheet parts of a laser micromachining machine tool. The clamp comprises a clamp body (15), a fixed clamp base (3), a movable clamp base (12) and a screw rod (14), wherein a nut (7) is connected to the middle of the screw rod (14); the screw rod (14) penetrates through a through groove of the clamp body (15); the left end of the screw rod (14) is inserted into a left end hole of the clamp body (15); the right end of the screw rod (14) is inserted into a right end hole of the clamp body (15); a rotary knob (17) is fixed to the right end of the screw rod (14); the nut (7) is clamped in the through groove in the middle of the clamp body (15); the fixed clamp base (3) is fixed to the clamp body (15); a dovetail groove under the movable clamp base (12) is connected to a dovetail at the upper part of the clamp body (15); the movable clamp base (12) is connected to the nut (7) through a spring I (9). The elastic clamp is simple in structure, convenient to adjust, low in cost and wide in adjusting range, and has good generality.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

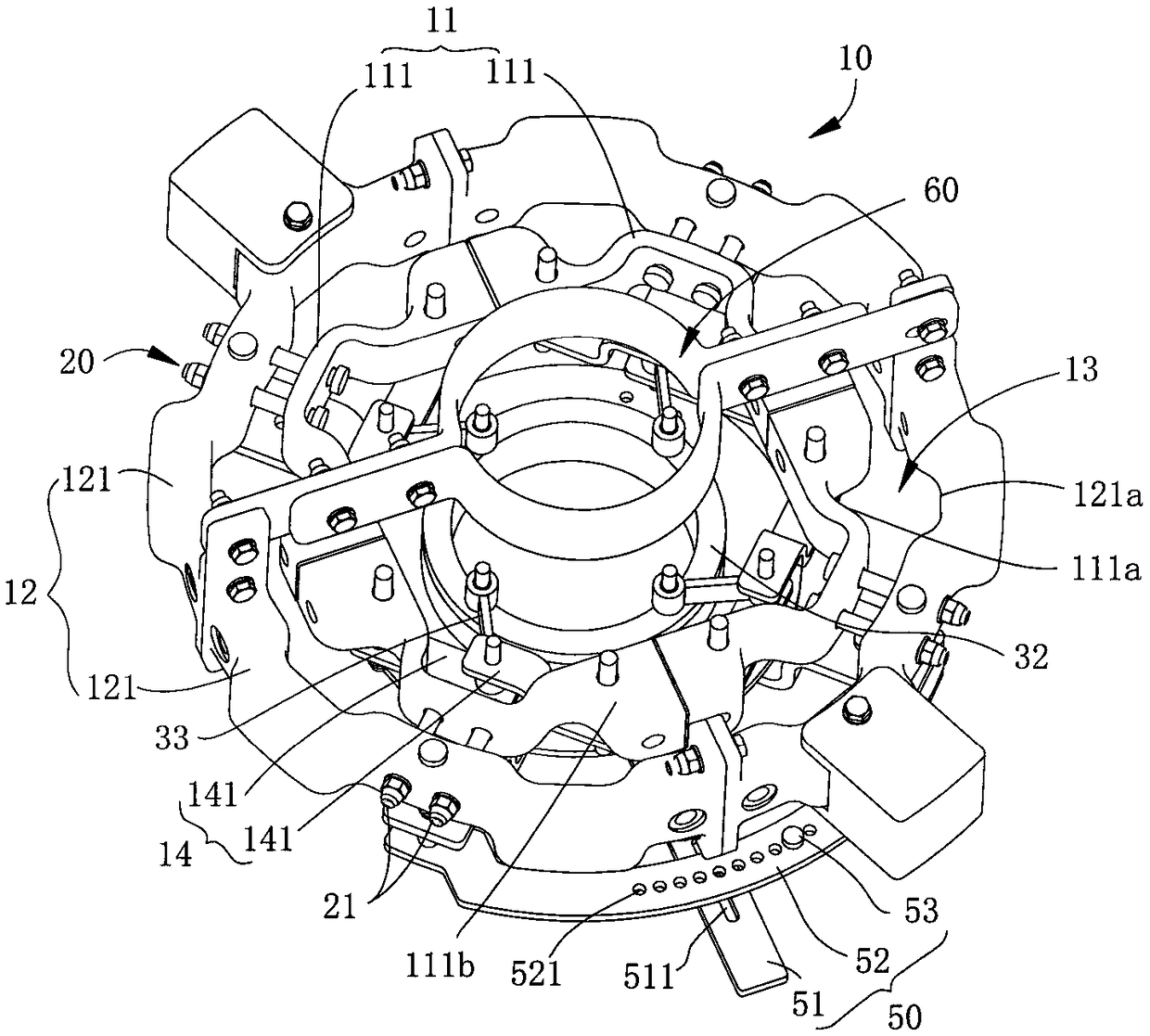

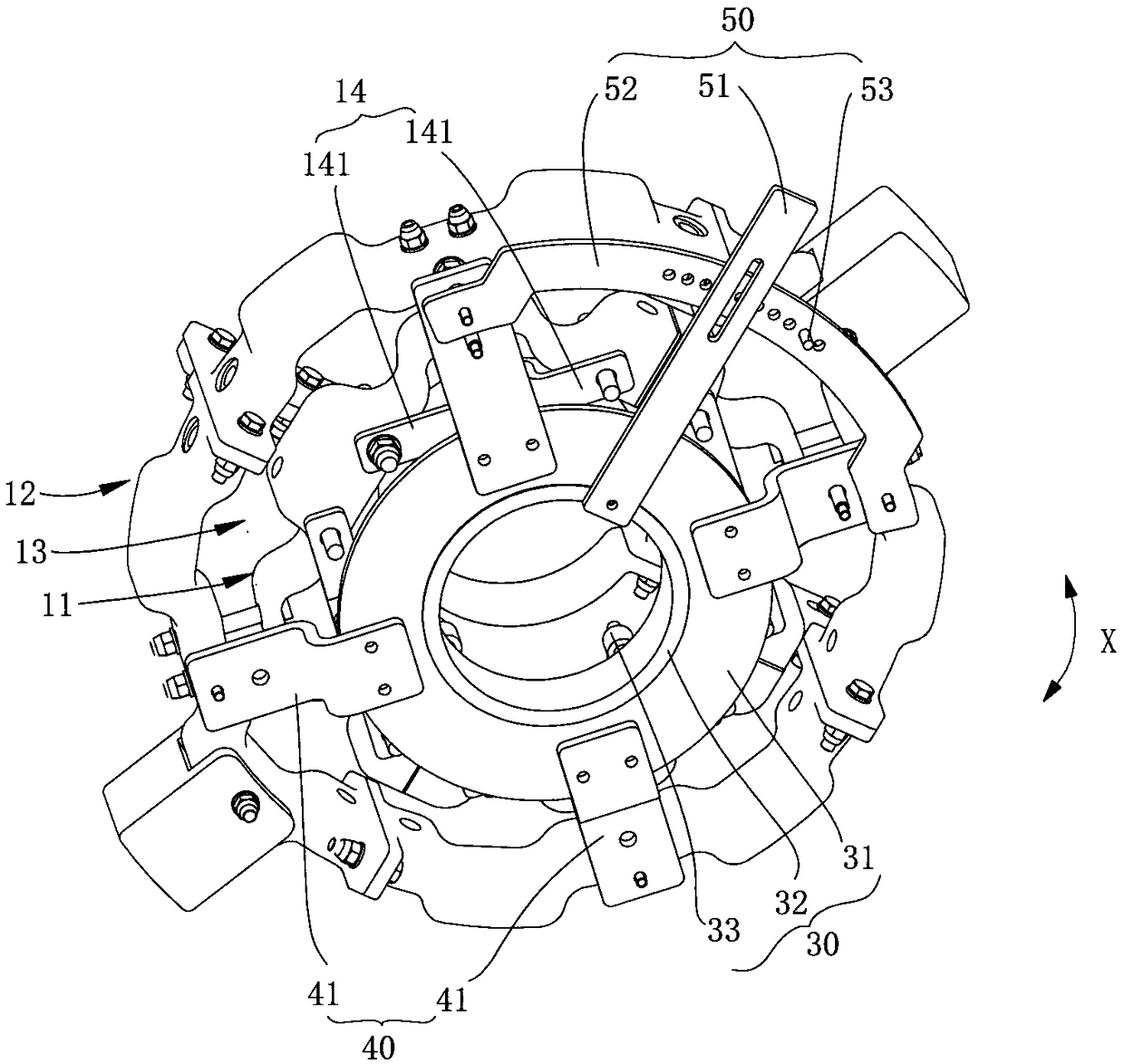

Freely station-switchable welding fixture for multiple vehicle types

InactiveCN108568628AEasy to switch and adjustImprove practicalityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBolt connection

The invention discloses a freely station-switchable welding fixture for multiple vehicle types. The welding fixture comprises a bottom box; support pillars are respectively connected with the four corners of the outer wall of the bottom of the bottom box by means of bolts; the outer wall of one side of the bottom box is connected with a mounting rod by means of a bolt; the outer wall of the top ofthe mounting rod is connected with a rotating bearing by means of a bolt; the mounting rod is connected with a cross beam by means of the rotating bearing; the inner wall of the bottom of the bottombox is connected with a first sliding rail by means of a bolt, a sliding groove of the first sliding rail is internally connected with a sliding block in a sliding way, and the first sliding rail is connected with a storage box by means of the sliding block; a mounting groove is formed in the outer wall of one side of the storage box, and the inner wall of the top of the mounting groove is weldedwith a sleeve. The freely station-switchable welding fixture for the multiple vehicle types can conveniently adjust and switch welding stations, thus meeting the clamping requirements of parts which are of different models and belong to the different vehicle types, and effectively improving the efficiency of a welding work; the storage box is conveniently drawn out by means of a handle, and scrapsfalling into the storage box can be cleaned, so that the practicality of the device is effectively improved.

Owner:湖北深成机械设备股份有限公司

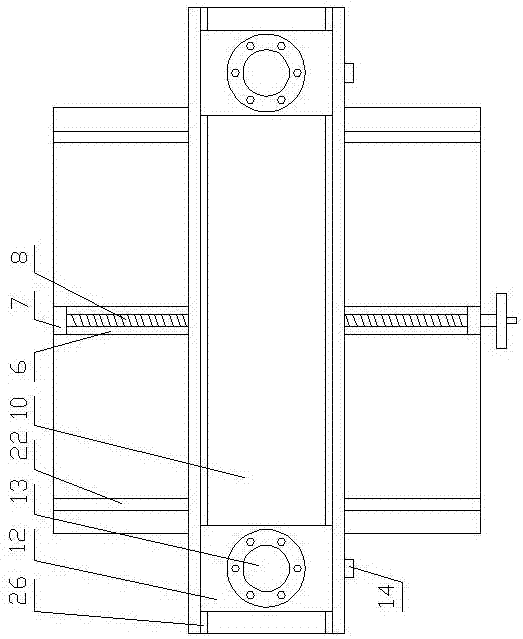

Fixtures for processing glass mold dies

ActiveCN104162800BMeet the clamping requirementsReduce the intensity of clamping operationsPositioning apparatusMetal-working holdersNumerical controlMechanical engineering

The invention provides a clamp used for machining a glass die and belongs to the technical field of tool clamps. The clamp comprises a base, a die joint face limiting base and a pair of die outer circular face clamping mechanisms, wherein the upper portion of the base is fixedly provided with a base platform, and the position, corresponding to the lower side of the base platform, of the base is provided with a base cavity; the die joint face limiting base is arranged on the upward side of the base platform and is located in the middle of the length direction of the base platform; the die outer circular face clamping mechanisms are arranged on the upward side of the base platform, one of the die outer circular face clamping mechanisms corresponds to the left side of the die joint face limiting base and the other die outer circular face clamping mechanism corresponds to the right side of the die joint face limiting base. The clamping requirement of a numerical control machining center machining a reference position on the end face of a semi-die blank of the die can be met; due to the fact that the overall structure is simple, the clamp is very convenient to manufacture and assemble, a good automatic clamping effect can be reflected, and the clamping operation difficulty of workers can be reduced.

Owner:CHANGSHU JIANHUA MOLD TECH

Air cylinder clamping jaw

InactiveCN106629022AMeet the clamping requirementsImprove work efficiencyConveyorsGripping headsEngineeringMechanical engineering

Owner:WUXI TEHENG TECH CO LTD

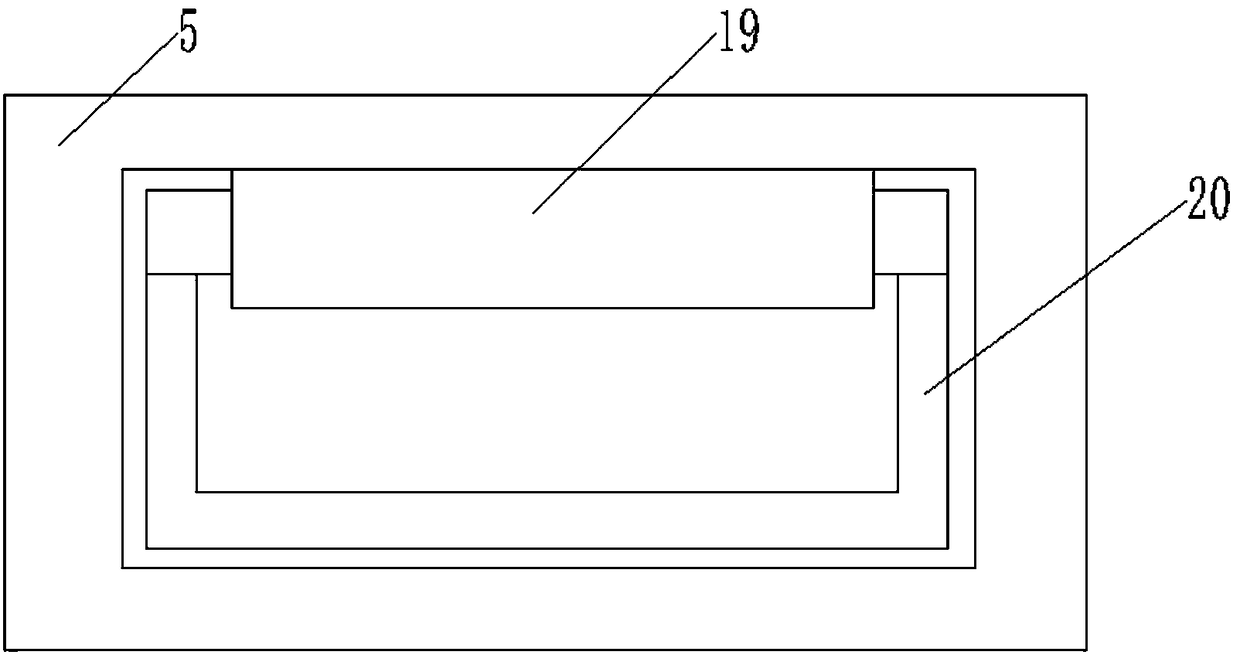

Indexable containing device for panel type electronic equipment

InactiveCN104633417AAvoid damageIncrease the effective range of useStands/trestlesRotation functionArchitectural engineering

The invention relates to an indexable containing device for panel type electronic equipment. The indexable containing device for the panel type electronic equipment comprises a base, base support plates, an upper cover, a connecting plate, an indexable plate and a telescopic clamping device, wherein the base support plates are located between the base and the upper cover, the base is connected with the upper cover through a thread, the base is connected with the base support plates in a riveting mode, the upper cover is connected with the connecting plate through a rotating shaft, and the connecting plate is connected with the indexable plate through a spring; the telescopic clamping device comprises an adjustable baffle, clamping groove plates and a support, the support is connected with the upper cover, the rotating shaft is installed on the support, the clamping groove plates are installed on the indexbale plate, the adjustable baffle is installed on the connecting plate, and the adjustable baffle matches with the clamping groove plates. The indexable containing device for the panel type electronic equipment facilitates a user to place panel type electronic equipment with different sizes; the panel type electronic equipment can be observed from different angles by taking advantage of the rotating function provided by the device, and the user is facilitated to find a suitable observing angle.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

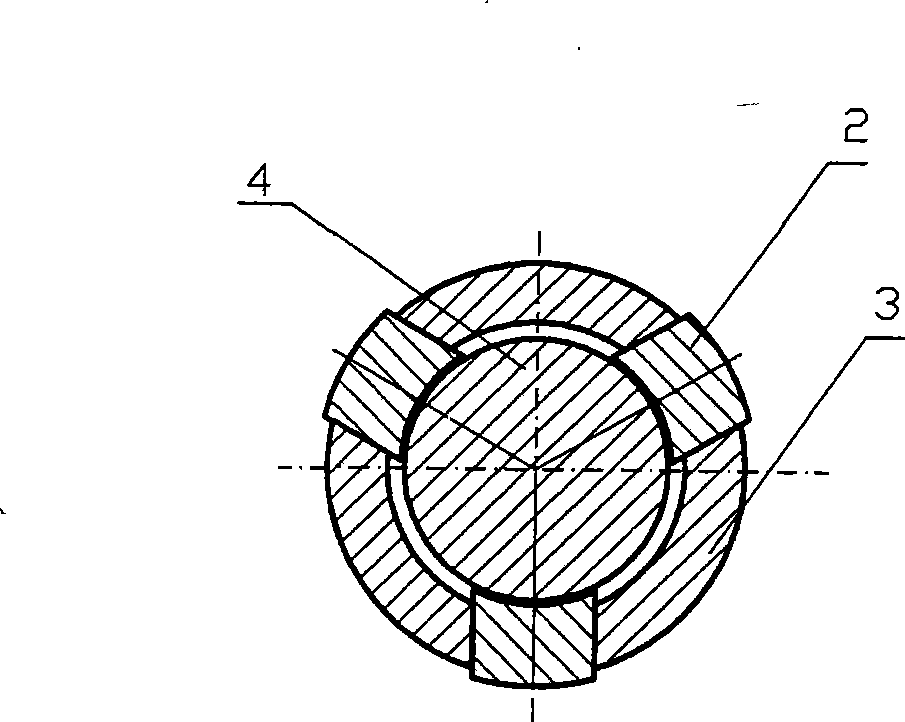

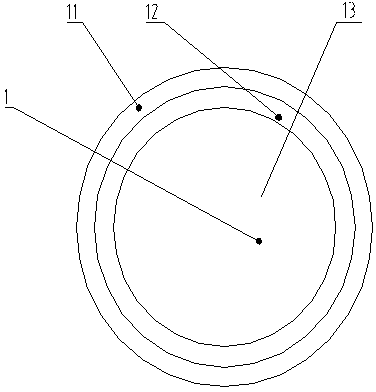

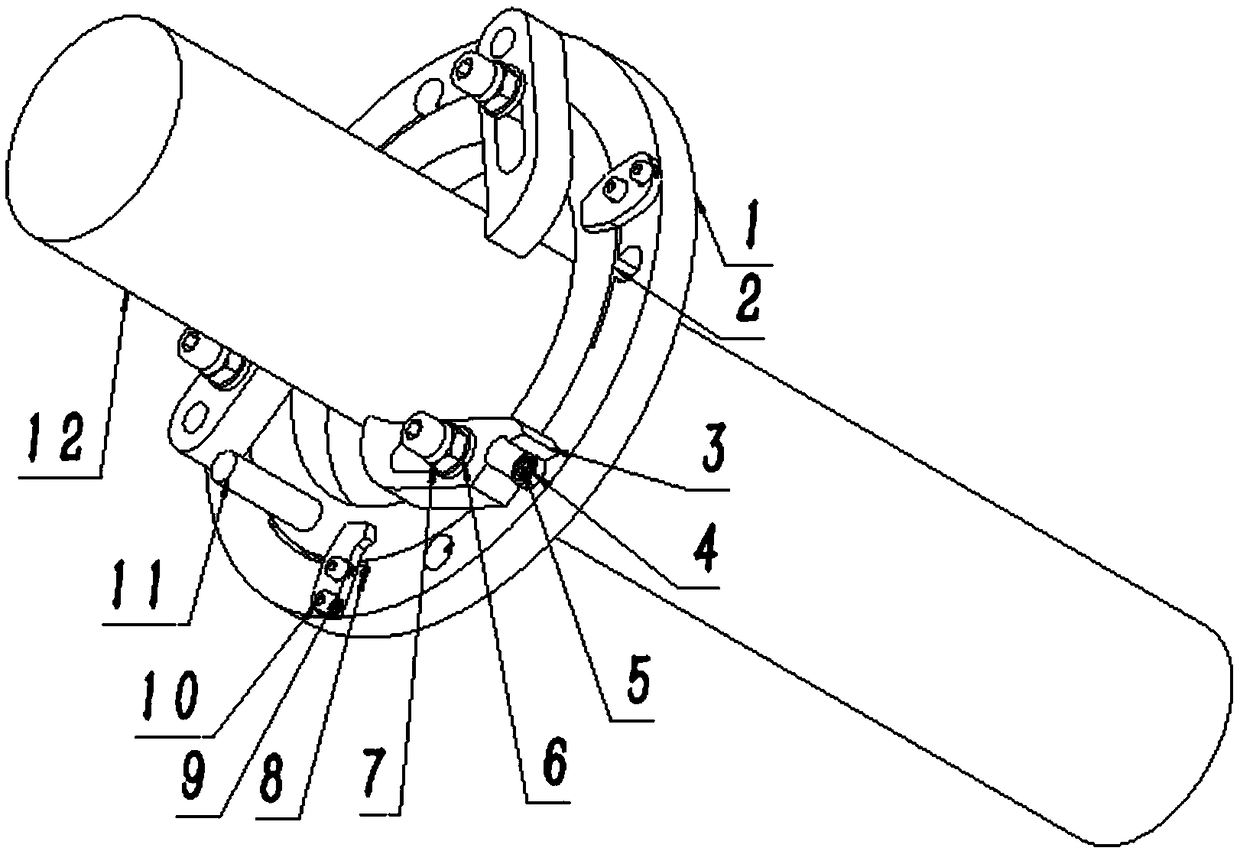

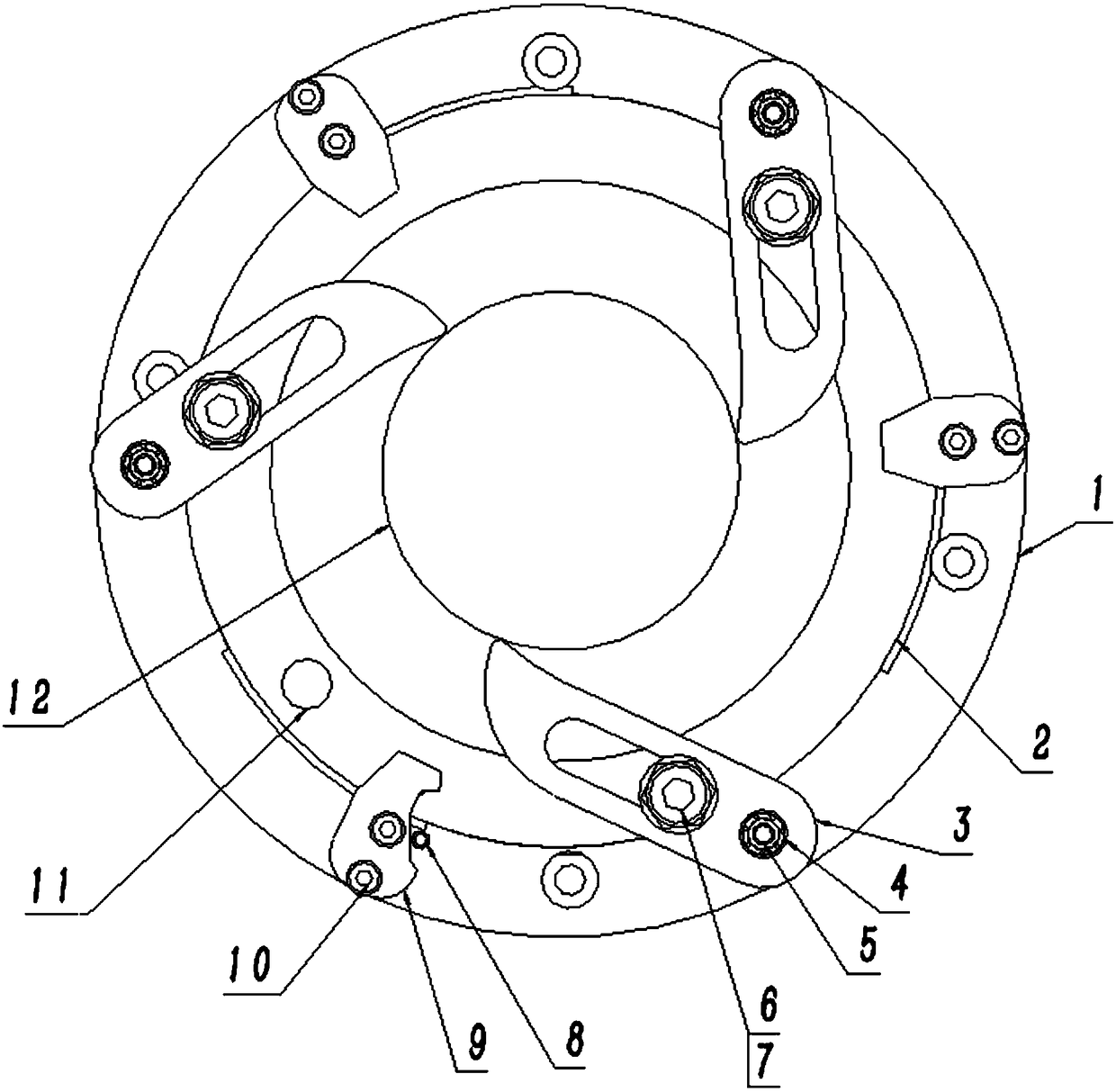

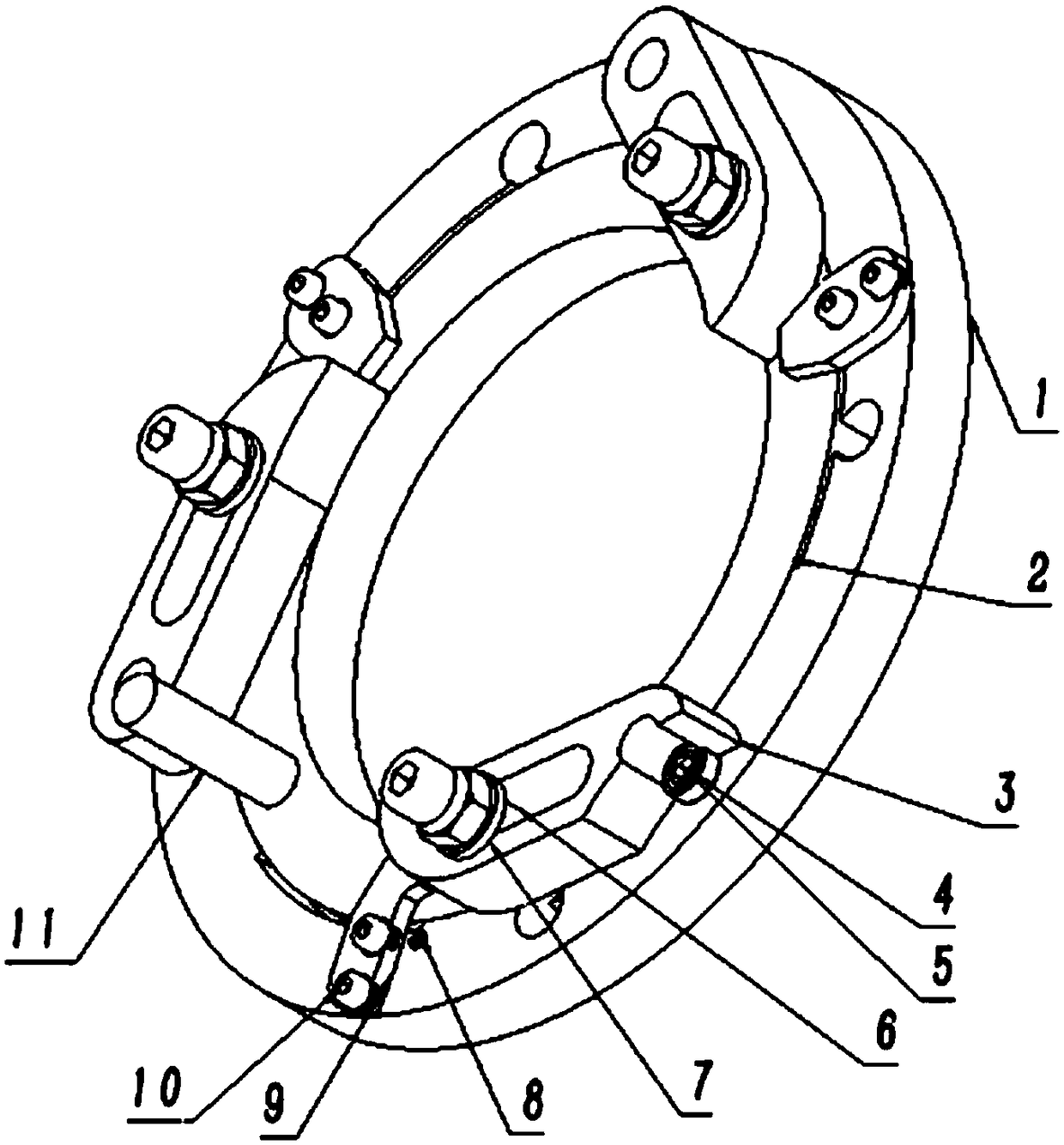

Locating clamping mechanism applied to columnar load

PendingCN109373831ASimple structureReduce weightAmmunition testingWork holdersEngineeringMechanical engineering

The invention provides a locating clamping mechanism applied to a columnar load. A three-jaw centering structure is adopted for the locating clamping mechanism. An inner ring and an outer ring rotateto drive three-jaw centering, two-stage locking is arranged, and then clamping requirements of multiple models of products are met. The clamping structure has the characteristics of being simple in structure, small in weight, small in occupied space, high in clamping precision and high in stability.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

High-accuracy tool clamp easy to operate

InactiveCN104858680AMeet the clamping requirementsPrecision locking and fixingPositioning apparatusMetal-working holdersElastic componentEngineering

The invention provides a high-accuracy tool clamp easy to operate. The high-accuracy tool clamp easy to operate comprises a clamping device, a fixing device and a support, wherein the fixing device is arranged on the clamping device and used for fixing a tool; the clamping device is fixed on the support and comprises a first clamping plate and a second clamping plate, and one end of the first clamping plate is movably connected with one end of the second clamping plate through a first elastic component; the fixing device comprises a first convex column and a second convex column, the first convex column is arranged on the inner side of the first clamping plate, one end of the first convex column is movably connected with the first clamping plate through a second elastic component, and threads are formed in the other end of the first convex column; the second convex column is hollow and provided with threads inside, and the threads of the first convex column are matched with the threads in the second convex column. The high-accuracy tool clamp is simple and precise in structure and simple to operate and can guarantee accuracy and improve the production efficiency.

Owner:JIANGSU KANG BAISI MECHANICAL TECH

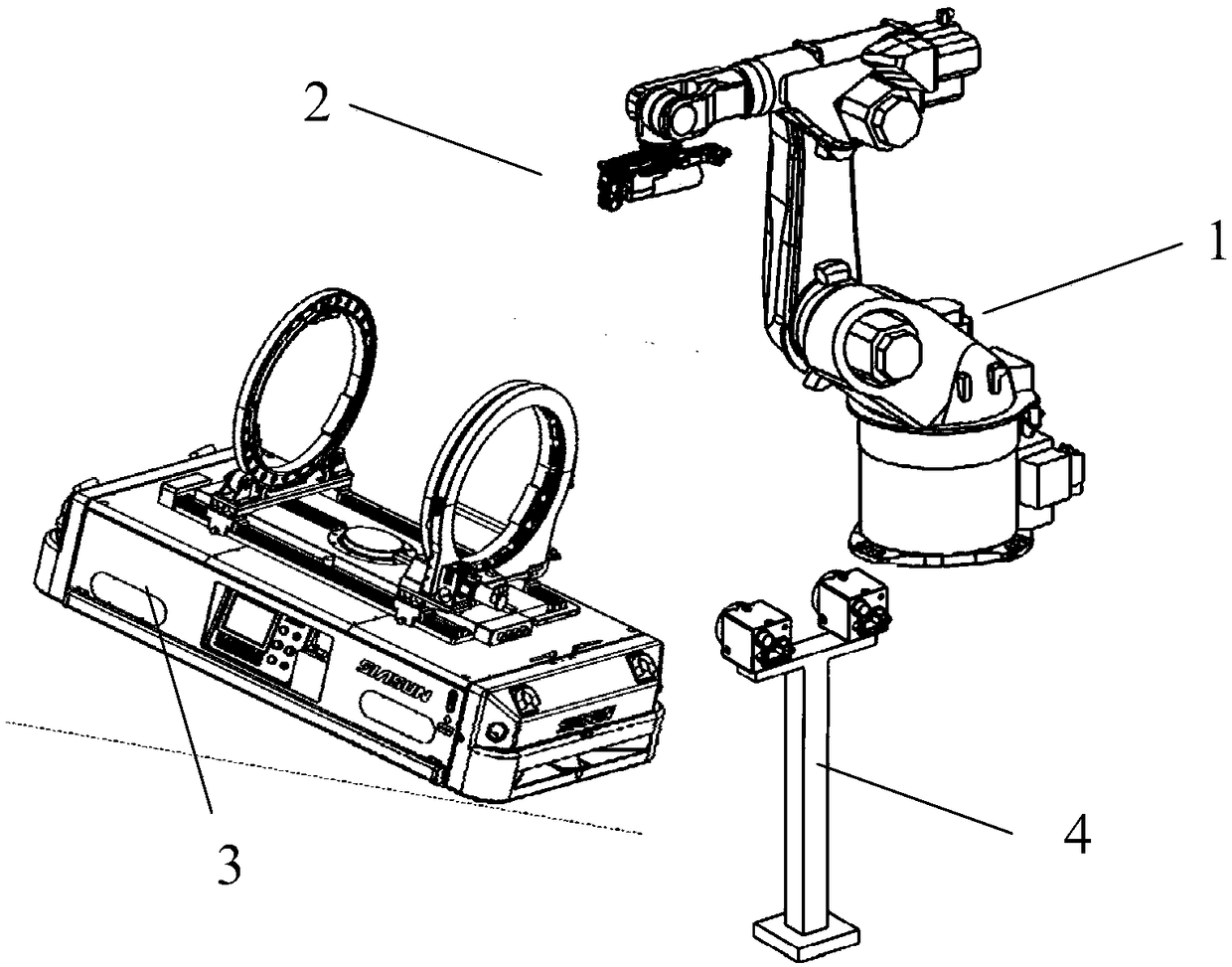

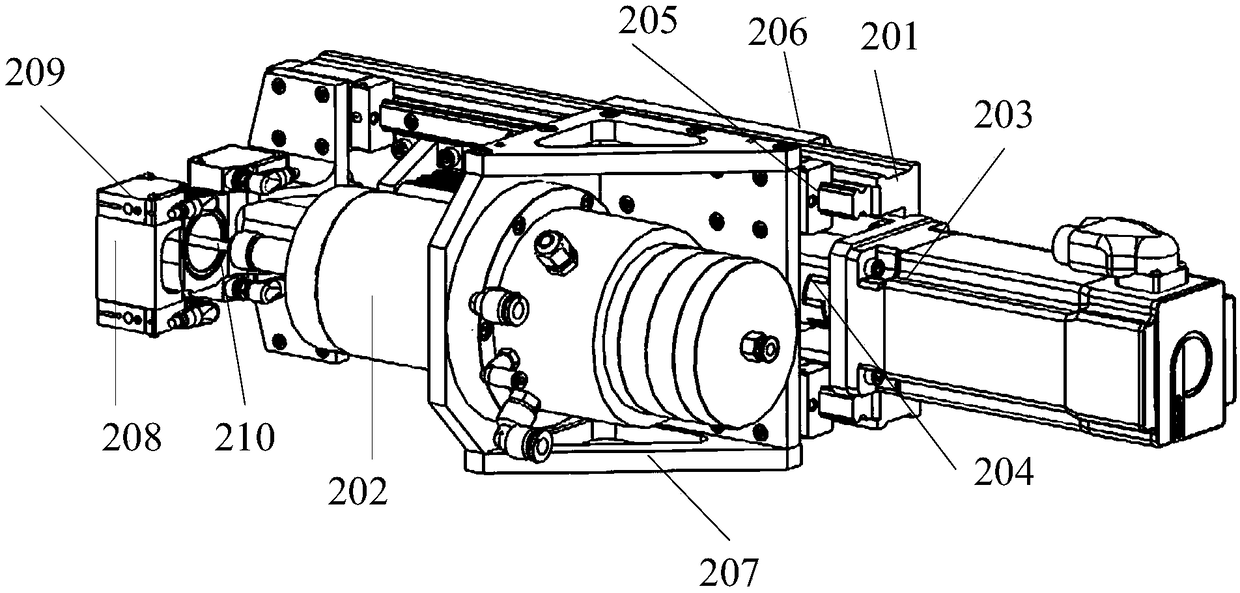

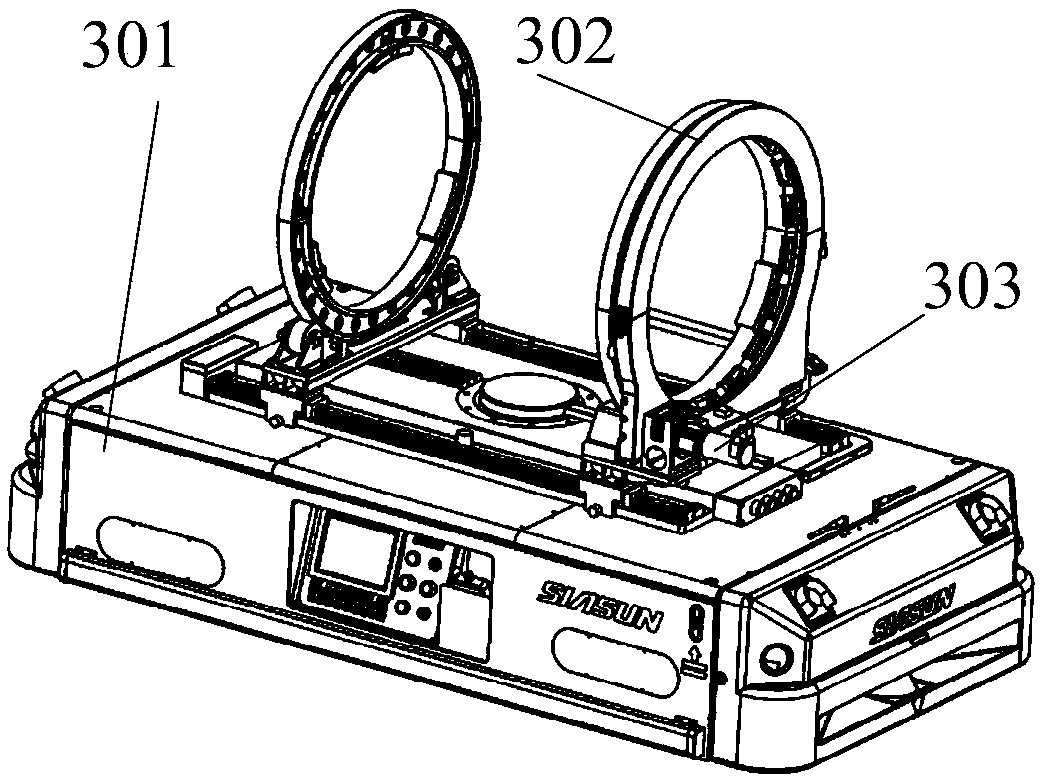

Mechanical arm drilling device and drilling method adapting to automatic logistics

ActiveCN108858218ARealize automatic circulationImprove positioning accuracy and measurement efficiencyProgramme-controlled manipulatorDrilling systemTransfer function

The invention discloses a mechanical arm drilling device and drilling method adapting to automatic logistics, and used for carrying out product drilling working with high accuracy and high automationdegree. The mechanical arm drilling device comprises a series mechanical arm (1), a drilling end executer (2), an automatic logistics vehicle (3) and a vision measurement assembly (4). By realizing anautomatic transfer function of the drilling end executer (2) and the automatic logistics vehicle (3) in a drilling process, the problems that timely adjustment for the positions and the distances ofcomponents during a drilling process for a drilling product cannot be realized, and the drilling accuracy is low, in an existing drilling system, are solved; and the mechanical arm drilling device isstable in drilling structure and high in drilling efficiency.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

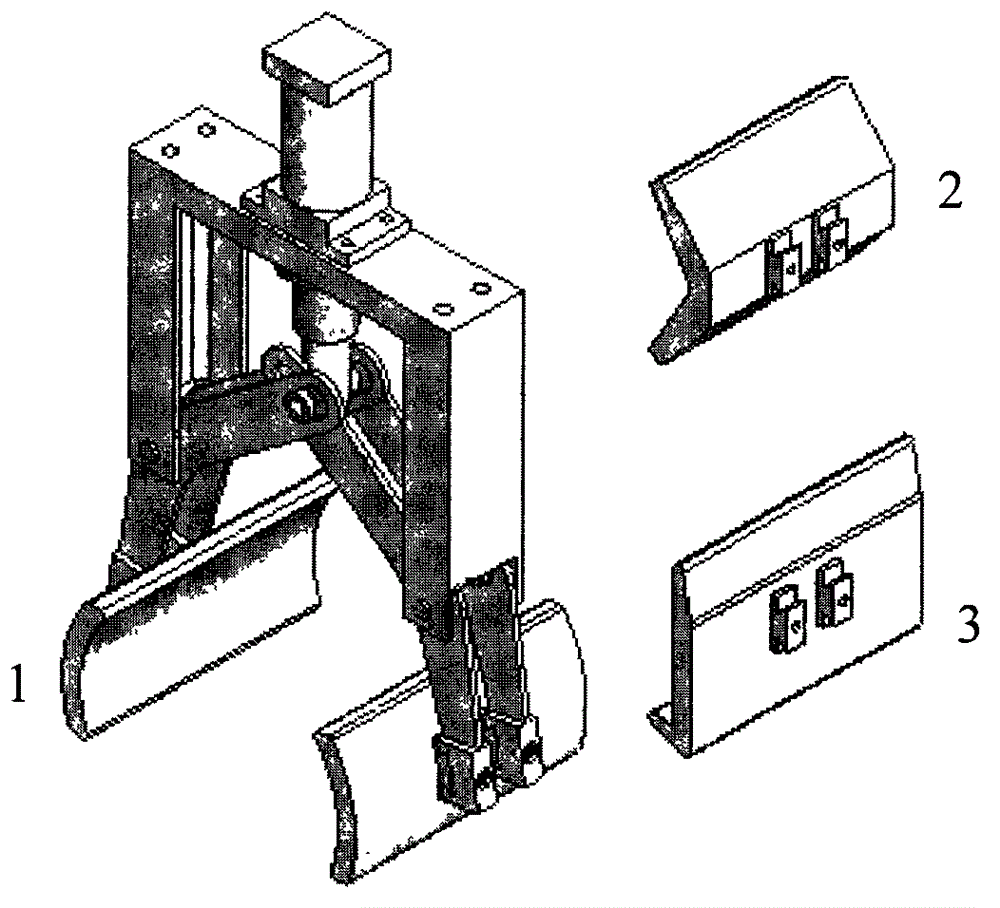

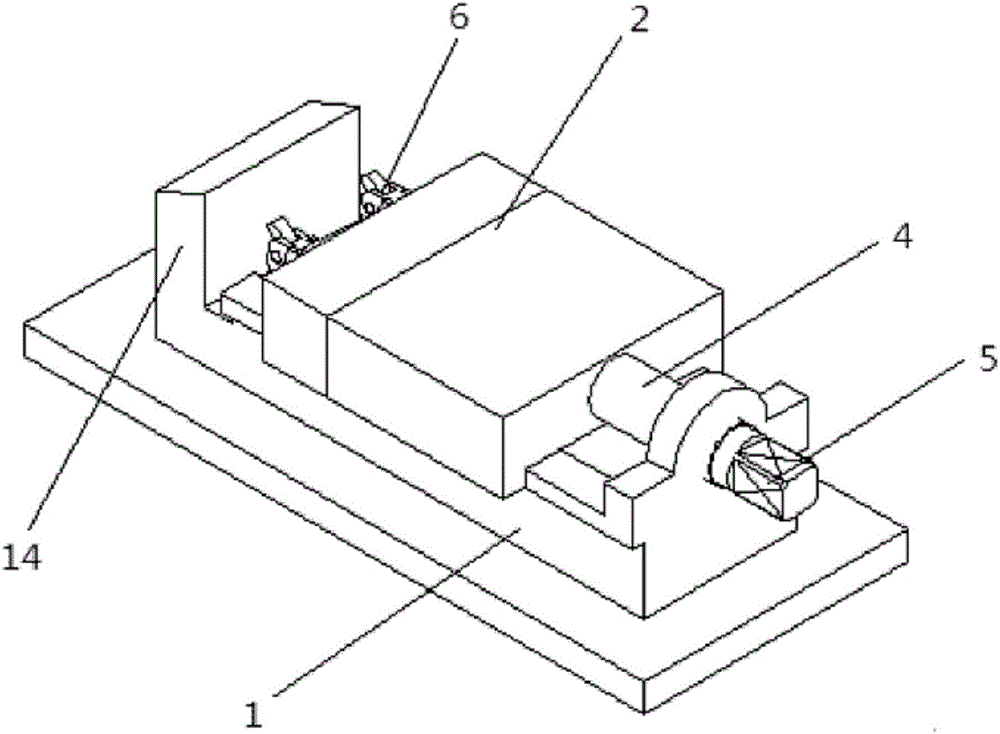

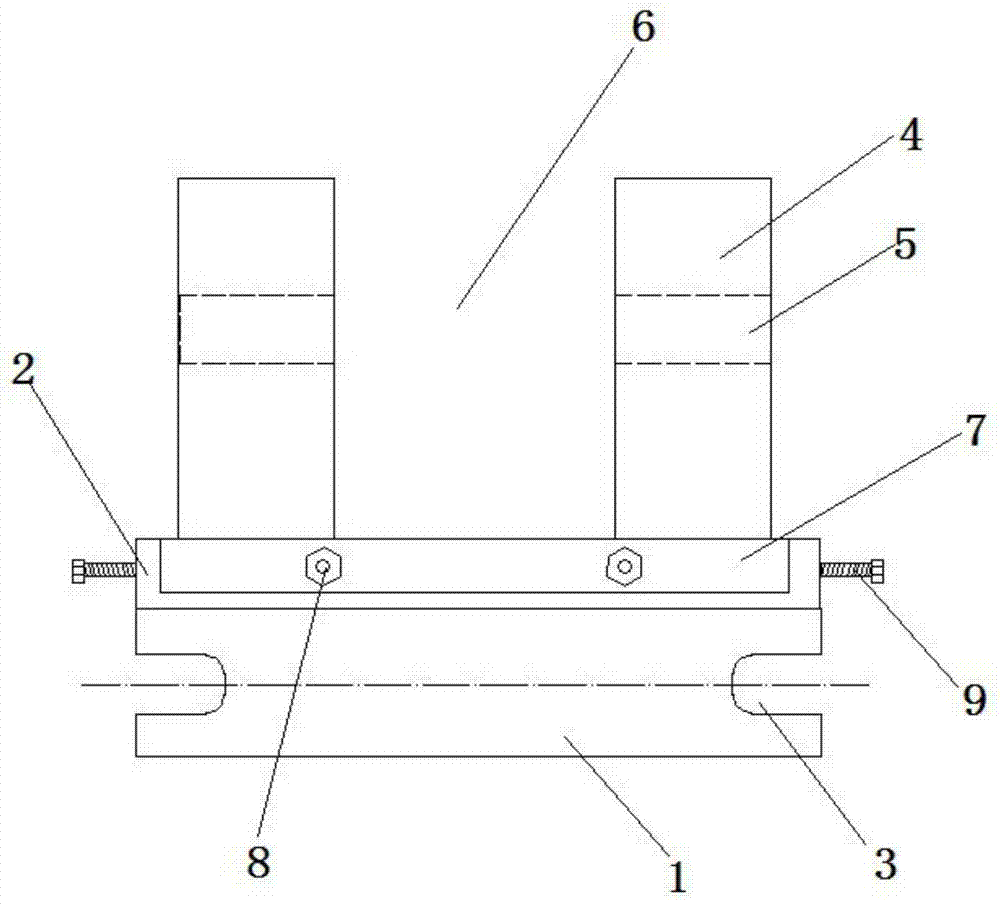

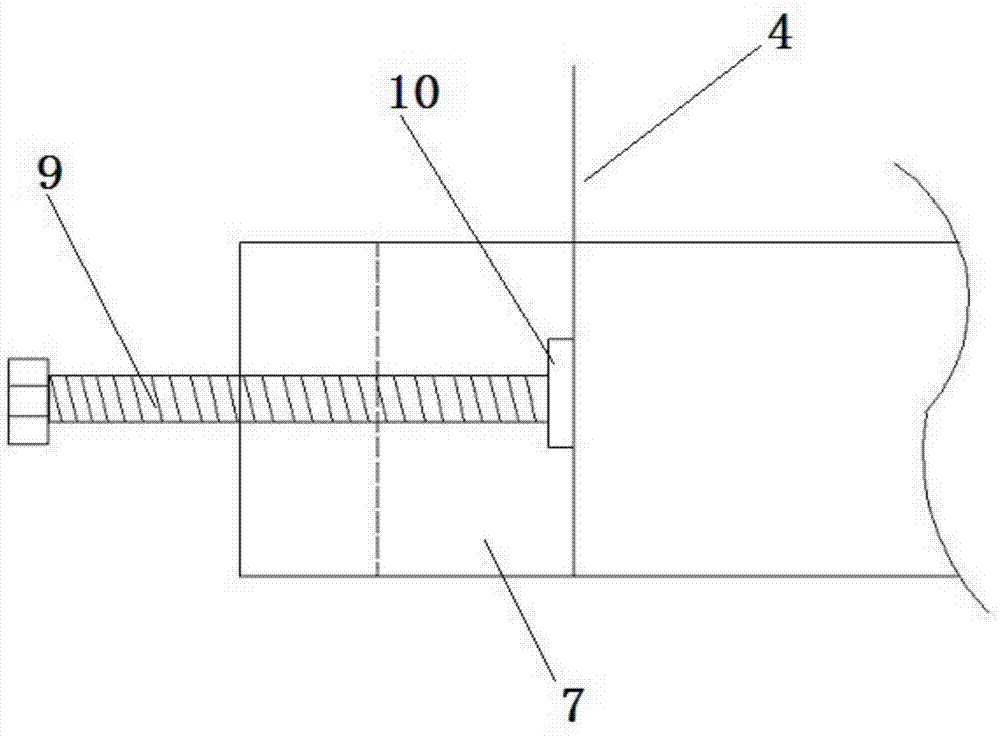

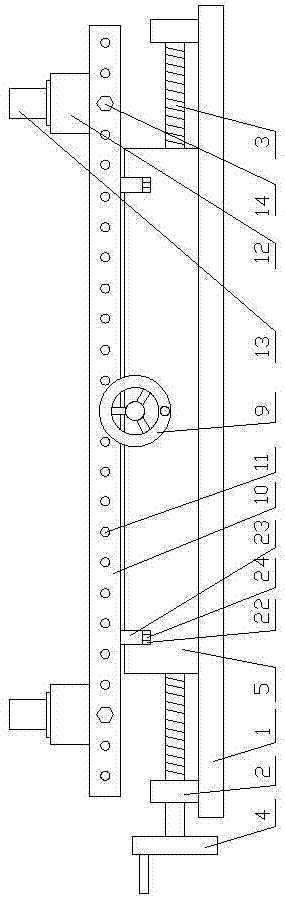

Combined double-shaft-shoulder friction stir welding fixture

InactiveCN103212932AMeet the clamping requirementsPrevent twisting up and downWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHeat sink

The invention discloses a combined double-shaft-shoulder friction stir welding fixture which comprises a clamping die block and a heat sink die block. The clamping die block comprises a fixed plate, a lower platform, a supporting plate and an upper platform which are fixedly connected from bottom to top in sequence. The supporting plate is provided with an exposed bearing end corresponding to the upper platform and the lower platform. The heat sink die block is a cooling panel and is placed on the bearing end of the supporting plate. The combined double-shaft-shoulder friction stir welding fixture is capable of meeting clamping requirements of trial panels with different thicknesses and different sizes, prevents the trial panels from distorting and moving up and down in the welding process due to axial acting force of a stir-welding head, is capable of achieving a test of extrusion force of the stir-welding head to a workpiece, and is simple in structure and strong in practicality.

Owner:JIANGSU UNIV OF SCI & TECH

Multipurpose hydraulic vice and using method thereof

InactiveCN105666211AIncrease adjustment elasticityReasonable designPositioning apparatusMetal-working holdersEngineeringHigh pressure

The invention discloses a multipurpose hydraulic vise, which comprises a metal fixed clamp body, a movable clamp body assembly, a central plunger pump assembly, a pre-clamping screw and a clamping screw; the pre-clamping screw and the clamping screw pass through their own The rotation pushes the movable vise body assembly to move on the metal fixed vise body, and the workpiece is clamped by the central plunger pump assembly. The use method of the multi-purpose hydraulic vise described in the present invention, by rotating the pre-clamping screw rod, the movable clamp body moves forward; after the force becomes larger, the ratchet pin presses down the spring, the clamping screw rod continues to rotate, and pushes the center plunger pump column The plug generates high-pressure oil, thereby pushing the piston rods of the two clamps to move to realize the clamping of the workpiece; at the same time, the invention also has the advantages of reasonable design, simple and compact structure, long service life, wide application range, and low production, operation and maintenance costs. , easy to popularize and use.

Owner:徐明

Clamp used for milling machine

InactiveCN106891179AEasy to push and moveMeet the clamping requirementsPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a clamp used for a milling machine. The clamp comprises a fixed frame, a stabilizing base, long holes, clamping plates, screw holes, a variable concave groove, a sliding groove and fastening screws. The stabilizing base is arranged at the upper end of the fixed frame. The sliding groove is formed in the stabilizing base and internally provided with the symmetrically-arranged clamping plates. The screw holes are formed in the clamping plates. The two clamping plates can slide in the sliding groove. The two clamping plates and the sliding groove form the variable concave groove. The fastening screws are arranged on the side portion of the sliding groove and used for fixing the positions of the clamping plates in the sliding groove. The long holes are formed in the two sides of the fixed frame. The clamp used for the milling machine is simple in structure, convenient to use, wide in clamping range and good in fastening effect.

Owner:天津顺鑫福泰机械加工有限公司

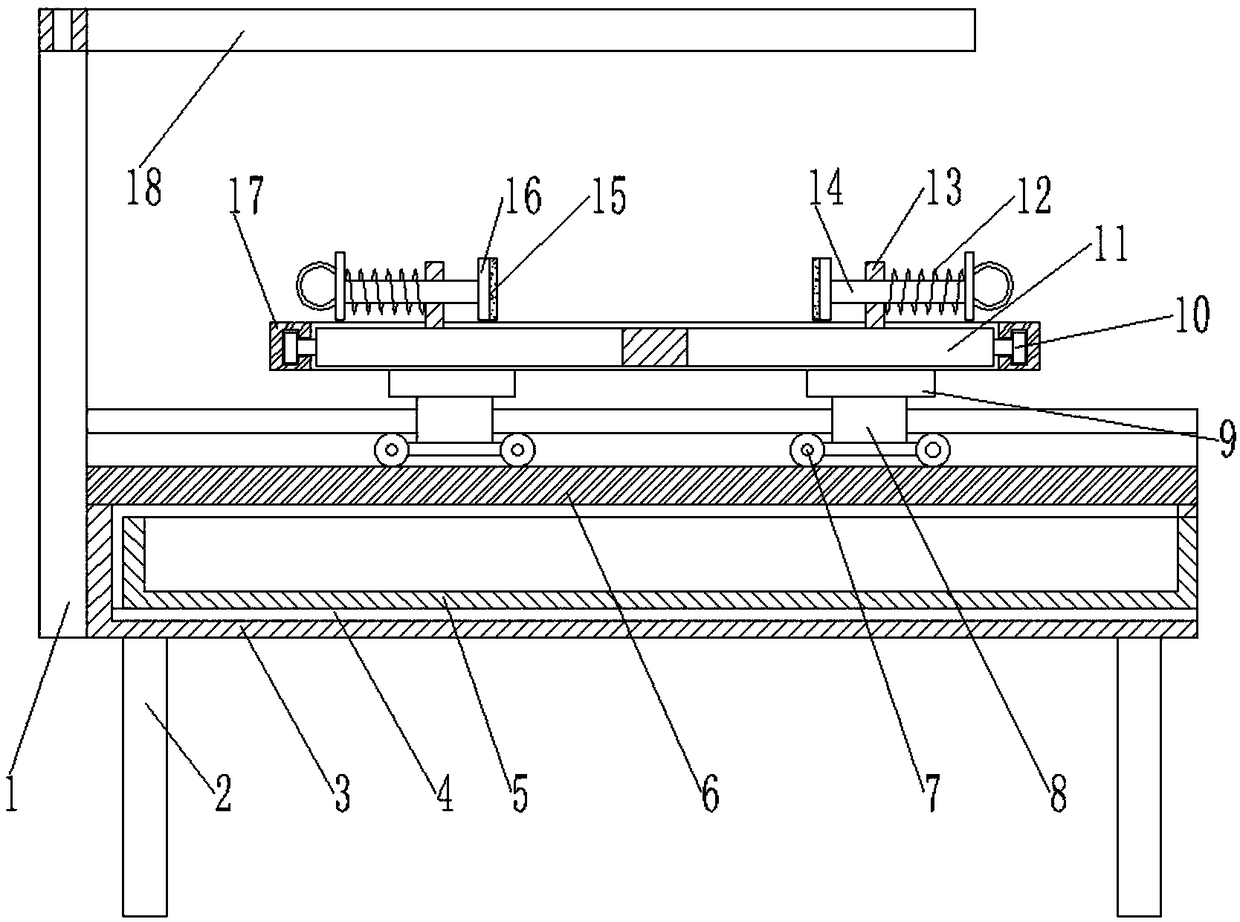

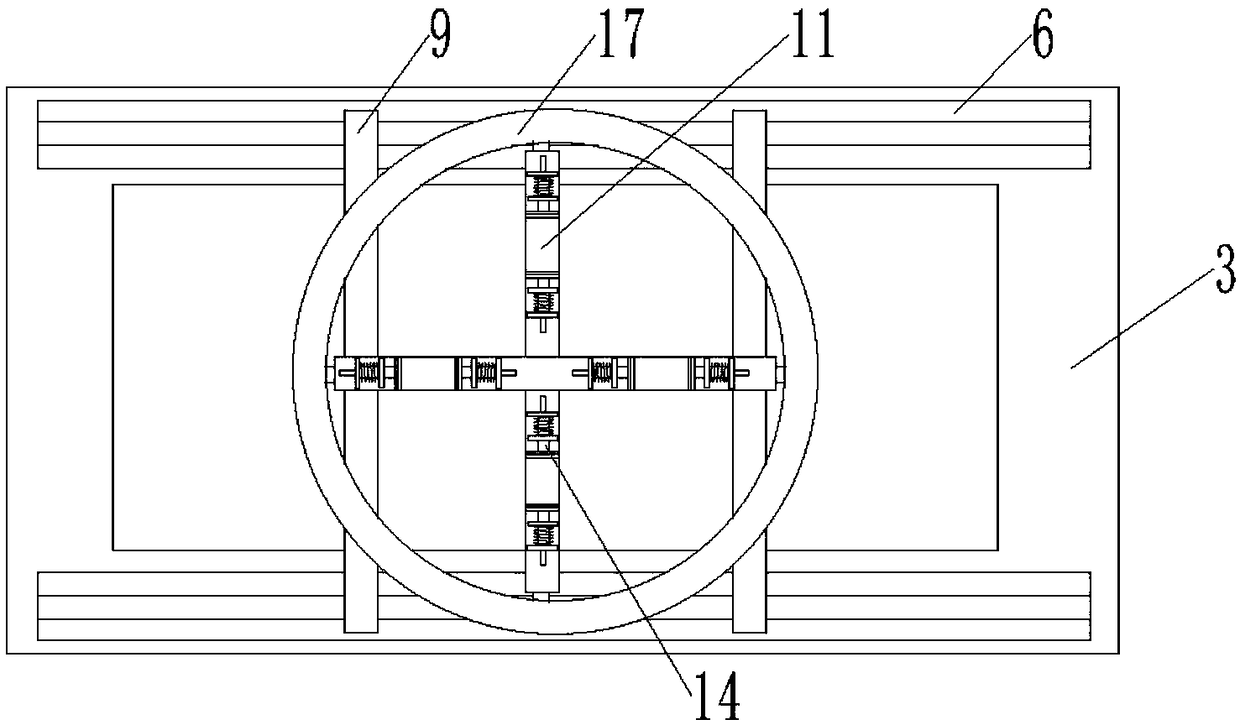

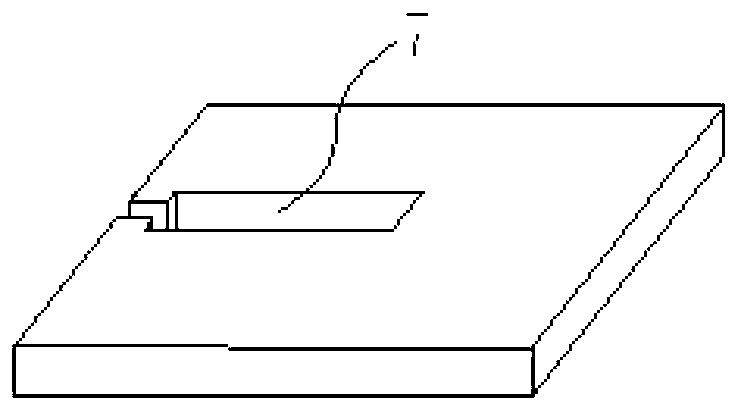

Mechanical clamp table for board part machining

InactiveCN107414548AAdjustable distanceMeet the clamping requirementsPositioning apparatusMetal-working holdersOn boardEngineering

The invention discloses a mechanical fixture platform for processing plate parts, which comprises a base on which a traverse screw seat is arranged, the traverse screw seat cooperates with the traverse screw, and the traverse screw is connected with the traverse screw The middle frame cooperates, and the upper part of the middle frame is provided with a screw groove, and the screw groove is matched with the vertically moving screw, and the vertically moving screw is matched with the main table, and a group of oil cylinder frames are slidably installed on the main table , an oil cylinder is installed on the oil cylinder frame, and the oil cylinder frame is positioned and matched with the main table surface through positioning bolts, and the oil cylinder is matched with the pressure plate seat, and the pressure plate seat is connected with the pressure plate through a set of thrust springs, and the pressure plate Contacts are connected to the top, and a storage battery is installed on the press plate seat, and the storage battery is electrically connected with the lamp bead and the switch. The mechanical fixture table for processing plate parts can quickly clamp plate-shaped or bar-shaped parts, facilitate processing work, and has a wide range of applications, and can be applied to the fixing work of plate parts of various specifications.

Owner:芜湖挺优机电技术有限公司

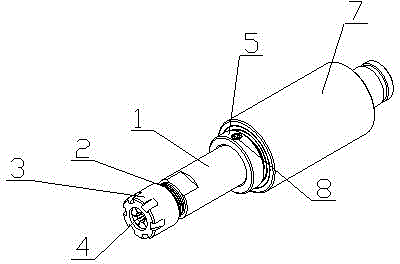

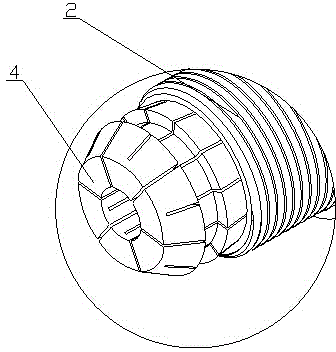

Tool clamping mechanism used in machining center

InactiveCN104625782AReduce manufacturing costImprove adaptabilityPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to the technical field of tool clamping mechanisms, in particular to a tool clamping mechanism used in a machining center. The tool clamping mechanism used in the machining center comprises a handle, wherein an outer thread is arranged at the head of the handle and connected with a fastening nut, and a sleeve used for clamping a tool is sleeved with the handle. According to the tool clamping mechanism used in the machining center, fixing sleeves of different diameter sizes are sleeved with the handle so that the tool clamping mechanism can clamp tools of different diameter sizes.

Owner:李明科

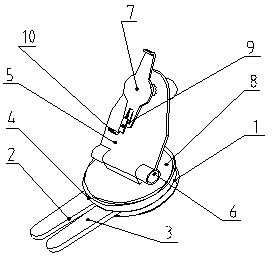

Cable-clamping device and method method for using the same

ActiveCN109244974AEasy to operateImprove work efficiencyElectrical apparatusEngineeringMechanical engineering

The invention relates to a cable clamping device and a method for using the same. The cable clamping device comprises a clamping assembly including an inner ring, an outer ring and a cable clamping groove formed between the inner ring and the outer ring, which are spaced apart from each other. a connecting assembly connecting inner ring and outer ring; The adjusting assembly comprises a fixed partand a rotating part sleeved with each other and two or more adjusting levers movably connected to the rotating part; The fixing part is fixedly connected with the outer ring, two or more adjusting levers are arranged at intervals around the axis of the inner ring and are both rotatably connected with the inner ring, and the rotating part is rotatably connected with the fixing part and can drive the adjusting lever to swing so as to drive the inner ring to expand in the direction close to the outer ring or contract in the direction far from the outer ring along the connecting assembly. The cable clamping device and the use method thereof provided by the embodiment of the invention can meet the clamping requirements of the cable, can simultaneously complete the adjustment of the clamping force of each cable clamped by the clamping device at one time, and can effectively improve the work efficiency of the operator.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

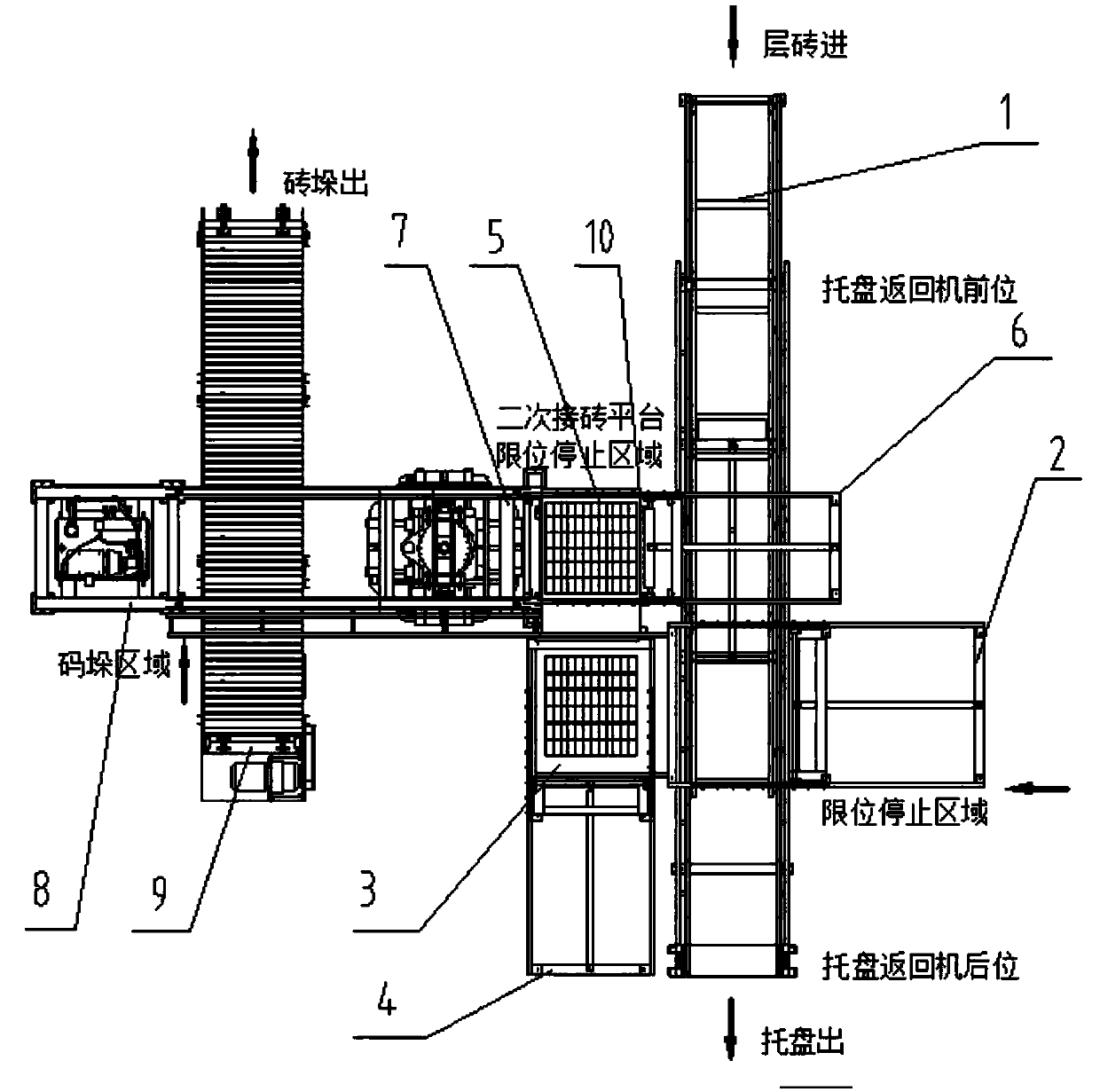

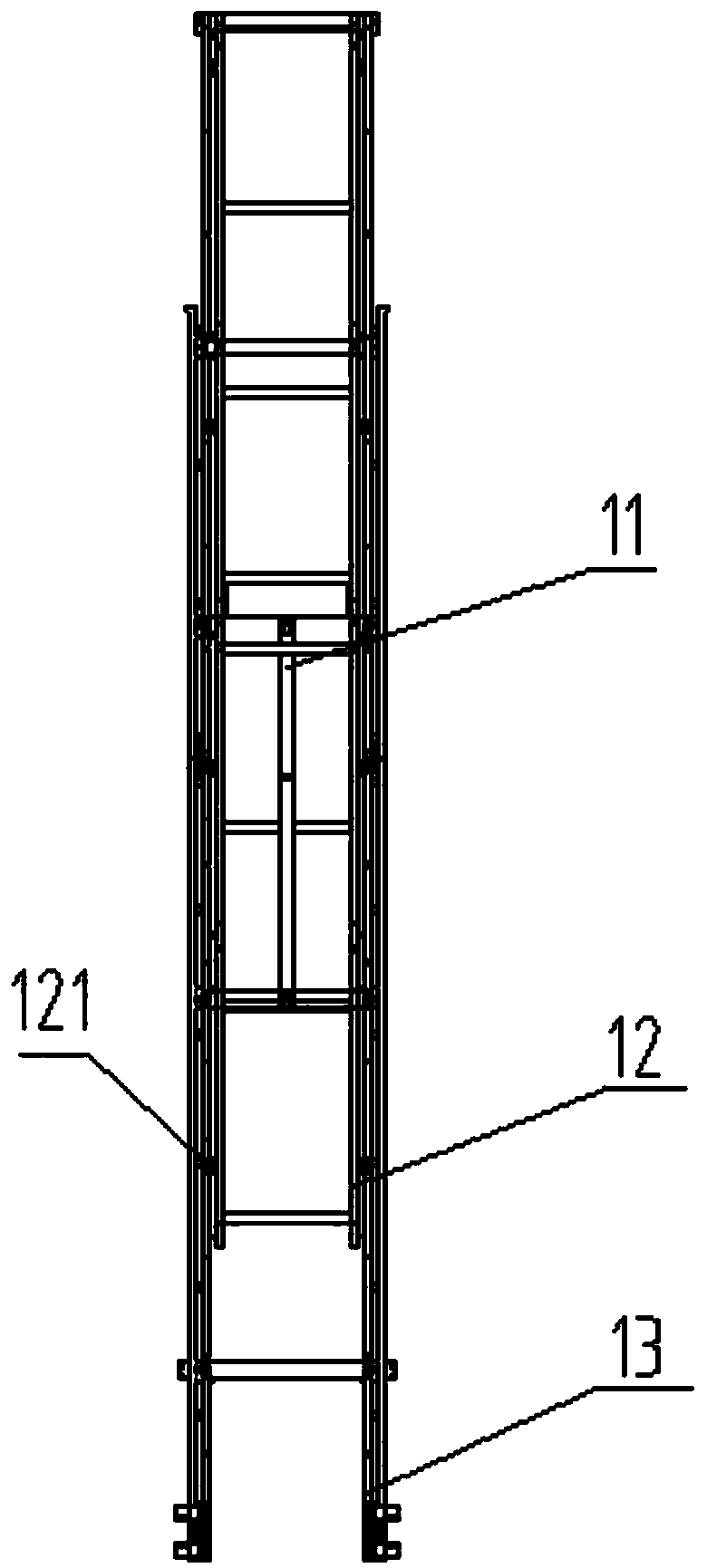

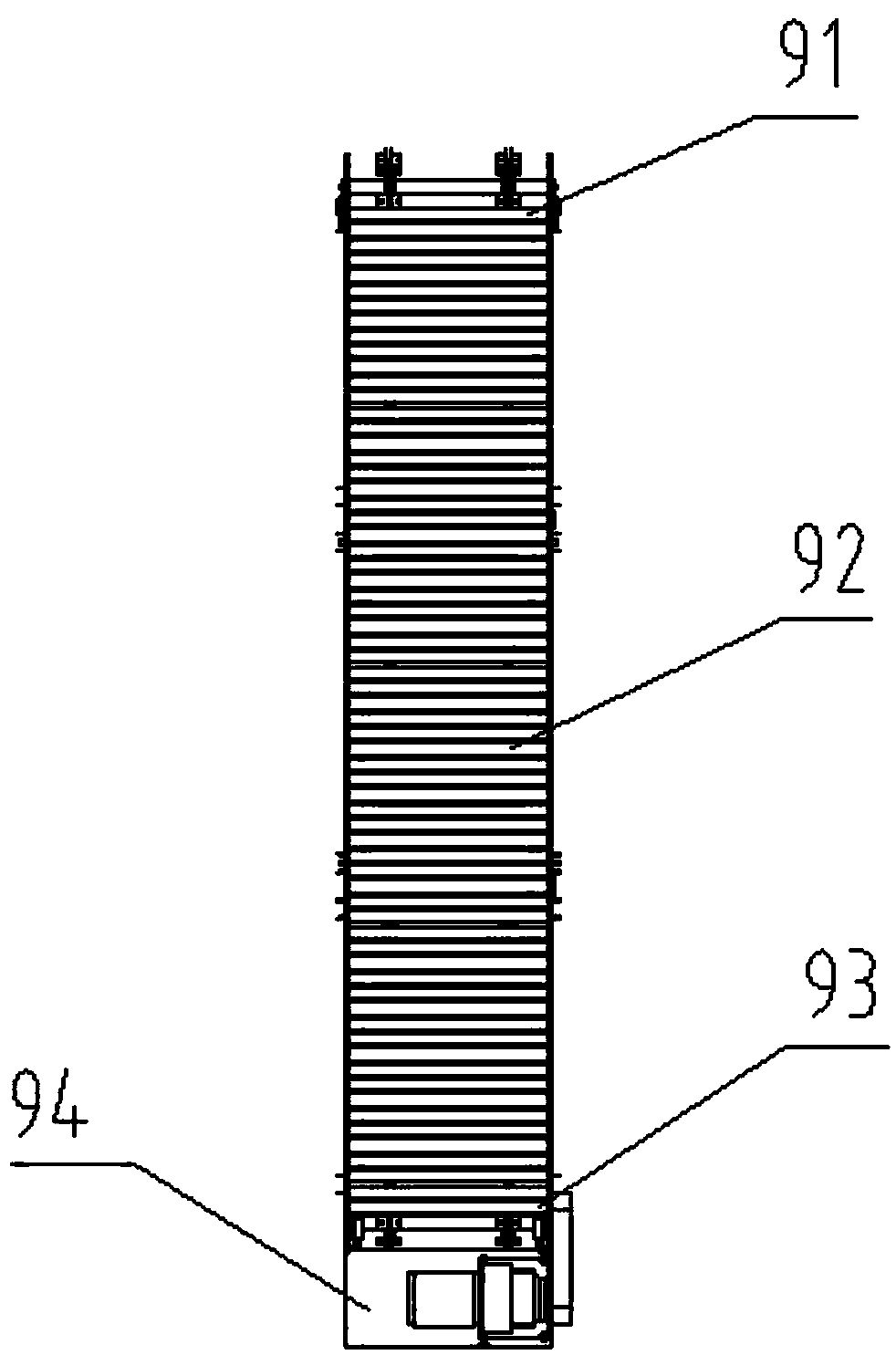

Pallet-free off-line stacking device

ActiveCN109665329AReliable transportationEfficient transportStacking articlesDe-stacking articlesBrickStack machine

The invention discloses a pallet-free off-line stacking device. The pallet-free off-line stacking device comprises a pallet returning machine, a primary brick push mechanism, a primary brick receivingplatform, a secondary brick push mechanism, a secondary brick receiving platform, a third brick push mechanism, a third brick receiving platform, a fully-automatic green brick stacking machine and apiled brick conveyor. By means of the primary brick push mechanism, bricks on each single layer can be pushed from the pallet returning machine to the primary brick receiving platform. By means of thesecondary brick push mechanism, the bricks on each single layer can be pushed from the primary brick receiving platform to the secondary brick receiving platform. By means of the third brick push mechanism, the bricks on each single layer can be pushed from the secondary brick receiving platform to the third brick receiving platform. By means of the fully-automatic green brick stacking machine, the bricks on each single layer can be clamped and delivered from the third brick receiving platform to the piled brick conveyor. The third brick push mechanism comprises two movable push block platesand multiple third fixing push plates, wherein the movable push block plates are used for pushing the bricks, and the third fixing push plates are used for achieving hole reservation operation of thebricks on each single layer. The pallet-free off-line stacking device is good in operation stability, reliable in stacking process, high in locating precision and capable of automatically stacking thebricks into piled bricks with lifting holes.

Owner:浙江诺丰环保科技有限公司

Sizing block with adjustable height for flat tongs

InactiveCN101716755AMeet the needs of random height adjustmentRealize precise displacement adjustmentVicesEngineeringMachining

The invention belongs to a sizing block (cushion block) in mechanical clamps, and in particular relates to a sizing block with adjustable height for flat tongs; in the invention, an integral sizing block is changed into two sections of slanting sizing blocks which can slide relatively in a guide groove, so as to realize possibility that the height of the sizing block can be fine-tuned accurately. The sizing block can be applied to machinery processing of flat tongs, and clamps, check tools and other mechanical devices; by adopting the special function that the height of the sizing block can be fine-tuned accurately, the processing and manufacturing cost can be remarkably saved.

Owner:寿震森

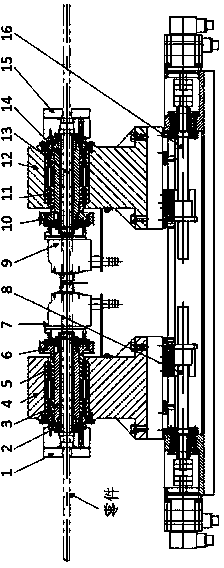

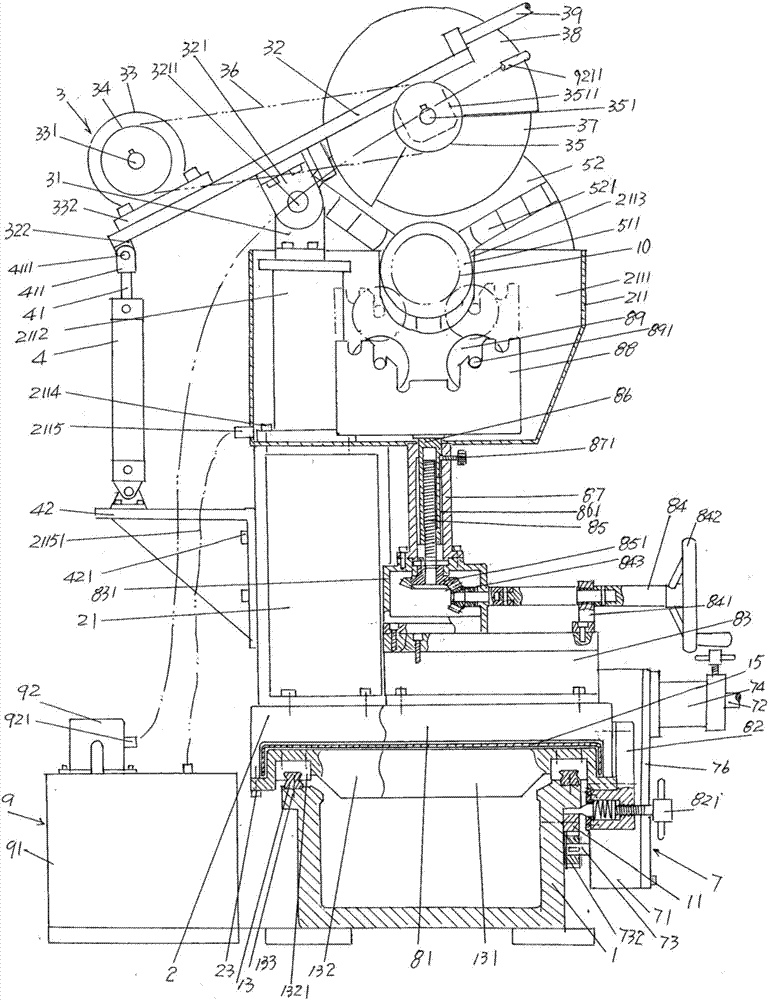

Long shaft double-head turning and clamping drive device and method

The invention discloses a long shaft double-head turning and clamping drive device and method. The long shaft double-head turning and clamping drive device comprises a left clamping unit, a right clamping unit and a power drive unit. A left clamping drive unit and a right clamping drive unit are installed on sliding blocks of a guide rail of a rack through a left main shaft box and a right main shaft box. A left Z-axis drive unit is arranged under the left clamping drive unit, a right Z-axis drive unit is arranged under the right clamping drive unit, and the power drive unit is installed on the side face of the left main shaft box. The long shaft double-head turning and clamping drive device has the advantages that the traditional mode of two-time clamping and two-time machining is replaced, and the production efficiency and capacity are improved; the clamping point of a long shaft component is clamped commonly through a left hydraulic power chuck and a right hydraulic power chuck, and flexibility can be achieved conveniently according to machined components of different sizes; the same power drive unit is adopted in left clamping unit and the right clamping unit, the long shaft component is commonly clamped, the clamping rigidity of the long shaft component is improved, and synchronism is good.

Owner:上海奇灏特自动化工程有限公司

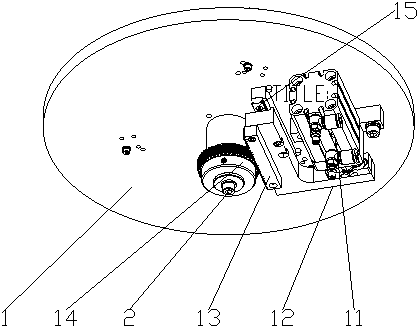

Optical fiber preform cutting device

ActiveCN107056038AMeet clamping requirementsReduce work intensityGlass severing apparatusGlass productionElectric machineryMachine tool

An optical fiber preform cutting device comprises a machine tool bed body, an upper drag plate, a preform cutting mechanism, a cutting motor fixed plate connection acting cylinder, a preform clamping mechanism, a power transmission mechanism, an upper drag plate left and right displacement driving mechanism and a preform auxiliary holding and lifting mechanism, wherein the front side of the machine tool bed body is provided with a rack; the top of the front and the rear sides of the machine tool bed body is provided with a bed body guide rail; the upper part of the right end of the machine tool bed body is provided with a bed head box; a left lower tray plate and a right lower drag plate are arranged on the bed body guide rail; the upper drag plate is fixed to the right lower tray plate, and a bracket is arranged above the upper drag plate; the top of the bracket is provided with a cooling water collecting tank; a cutting mechanism bearing seat is arranged in a cavity of the water collecting tank; the end surface of the front end of the upper drag plate is provided with an upper tray plate locking mechanism; the preform cutting mechanism is supported on the cutting mechanism bearing seat; the cutting motor fixed plate connection acting cylinder is supported on the bracket; the preform clamping mechanism is supported on the bed head box; the power transmission mechanism is fixed to the end surface of the right end of the machine tool bed body; the upper drag plate left and right displacement driving mechanism is fixed to the upper tray plate locking mechanism; the preform auxiliary holding and lifting mechanism is arranged on a left lower tray plate, and locked or unlocked with the front side of the machine tool bed body. The device has the advantages that the operation strength is reduced; the cutting efficiency is improved; the case of being picky on the optical fiber preform type is avoided; the environment is protected.

Owner:QINGHAI ZHONGLI OPTICAL FIBER TECH CO LTD

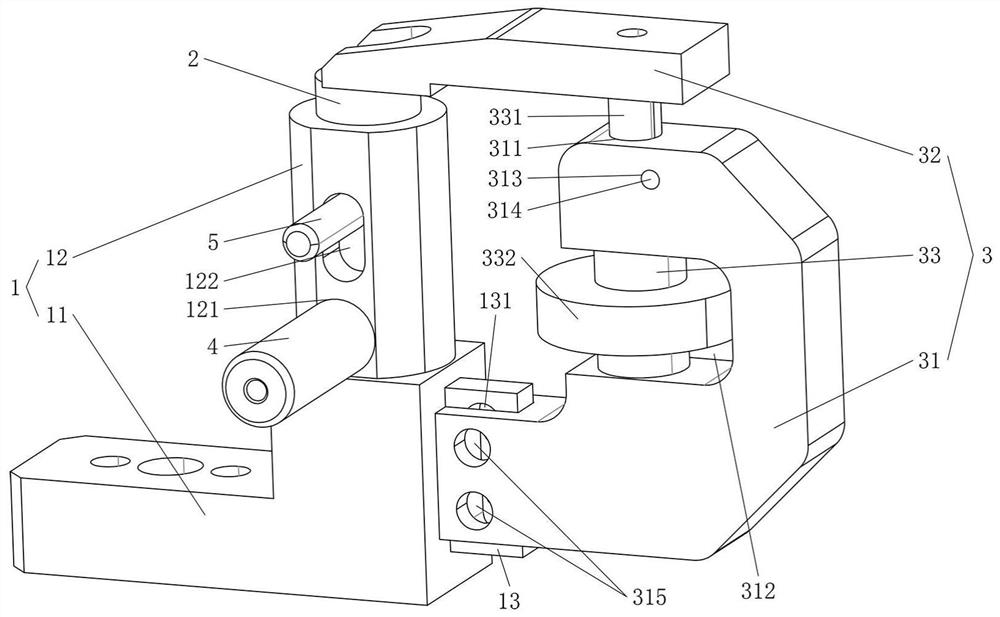

Automobile testing fixture quantitatively-adjustable movable reference mechanism and adjusting method

ActiveCN112013737AAvoid interferenceMeet the clamping requirementsMechanical measuring arrangementsStructural engineeringMechanical engineering

The invention discloses an automobile testing fixture quantitatively-adjustable movable reference mechanism and an adjusting method. The mechanism comprises a reference pin installation base which comprises a fixed pedestal and an installation column which is located on the fixed pedestal and is integrally connected with the fixed pedestal, wherein the side surface of the fixed pedestal is provided with a chuck assembly connecting piece; a reference pin which is mounted at the mounting column; and a chuck assembly which comprises a chuck mounting base, a chuck and a chuck driving mechanism, wherein the chuck mounting base is connected with the chuck assembly connecting piece, the chuck is located above the chuck mounting base and connected with the chuck mounting base through the chuck driving mechanism, and the chuck driving mechanism is mounted at the vertical extending part of the chuck mounting base. The chuck driving mechanism comprises a driving rod and a driving disc; a vertically extending driving rod mounting hole and a driving disc mounting notch communicated with the driving rod mounting hole are formed in the vertically extending part of the chuck mounting base; scalesfor recording circumferential angle values are marked on the circumference of the driving disc; and an indicator pointing to the scales is arranged on the chuck installation base.

Owner:台州屹丰汽车模具有限公司

Universal shot blasting fixture used for shot blasting of root of compressor blade

ActiveCN105437087AMeet clampingMeet clamping requirementsAbrasive machine appurtenancesSlide plateCompressor blade

The invention provides a universal shot blasting fixture used for shot blasting of the root of a compressor blade. The universal shot blasting fixture aims at solving the problem of high jig manufacture and maintenance cost due to poor universality of an existing shot blasting fixture of the compressor blade and comprises a base, a positioning and adjusting component and an adjustable blade profile enclasping component, wherein height supports with equal heights are respectively vertically arranged at four corner ends of the base, the positioning and adjusting component is supported on the height supports, the adjustable blade profile enclasping component is arranged on the positioning and adjusting component; the positioning and adjusting component comprises positioning guide blocks and sliding plates, the two positioning guide blocks are arranged on the height supports in parallel along the longitudinal direction and are connected through the two horizontally parallel sliding plates, and the sliding plates can move along the positioning guide blocks to achieve adjustment; and a blade inner arc pressing device and a blade back arc pressing device of the adjustable blade profile enclasping component are respectively oppositely arranged at the horizontal inner sides of the two positioning guide blocks with adjustable angles.

Owner:WUXI TURBINE BLADE

Cutting machine tool universal chuck

The invention relates to the technical field of chucks, in particular to a cutting machine tool universal chuck. The cutting machine tool universal chuck comprises a shell; four movable blocks are movably mounted on one surface of the shell; plane threads are arranged at the bottoms of the movable blocks; a tooth disc and a small bevel gear are rotationally mounted in the shell; a thread on the upper surface of the tooth disc is engaged with the threads at the bottoms of the movable blocks; a thread on the lower surface of the tooth disc is engaged with the small bevel gear; an adjusting hole is formed in the small bevel gear; the disc tooth and the small bevel gear are matched to synchronously adjust four clamping jaws to synchronously advance and retreat; for workpieces with circular sections, the quick clamping can be realized; the clamping jaws and the movable blocks are relatively displaced; the position adjustment of the clamping jaws can be finished only by loosening a stop body; the speed is fast; the adjustment is flexible; and the clamping requirements of various irregular workpieces can be satisfied.

Owner:张斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com