Aluminium profile circulating band saw full-automatic traction apparatus

A kind of traction device and circulating technology, applied in the field of automatic traction device of circulating band saw, can solve the problems of uneven traction force transmission, traction speed limit, reduce production efficiency, etc., to achieve rapid and direct speed change control, rapid speed synchronization, The effect of saving exercise time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

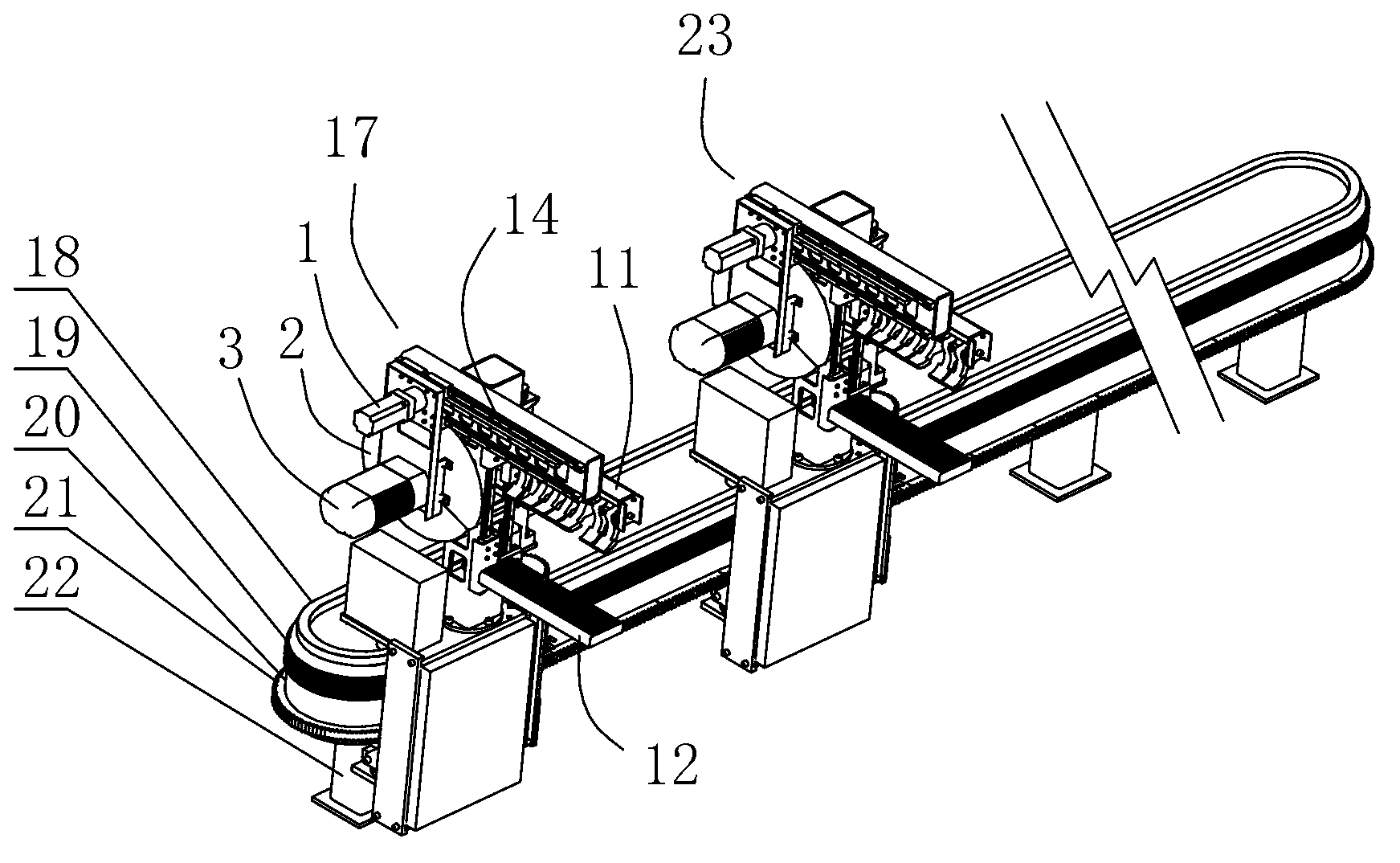

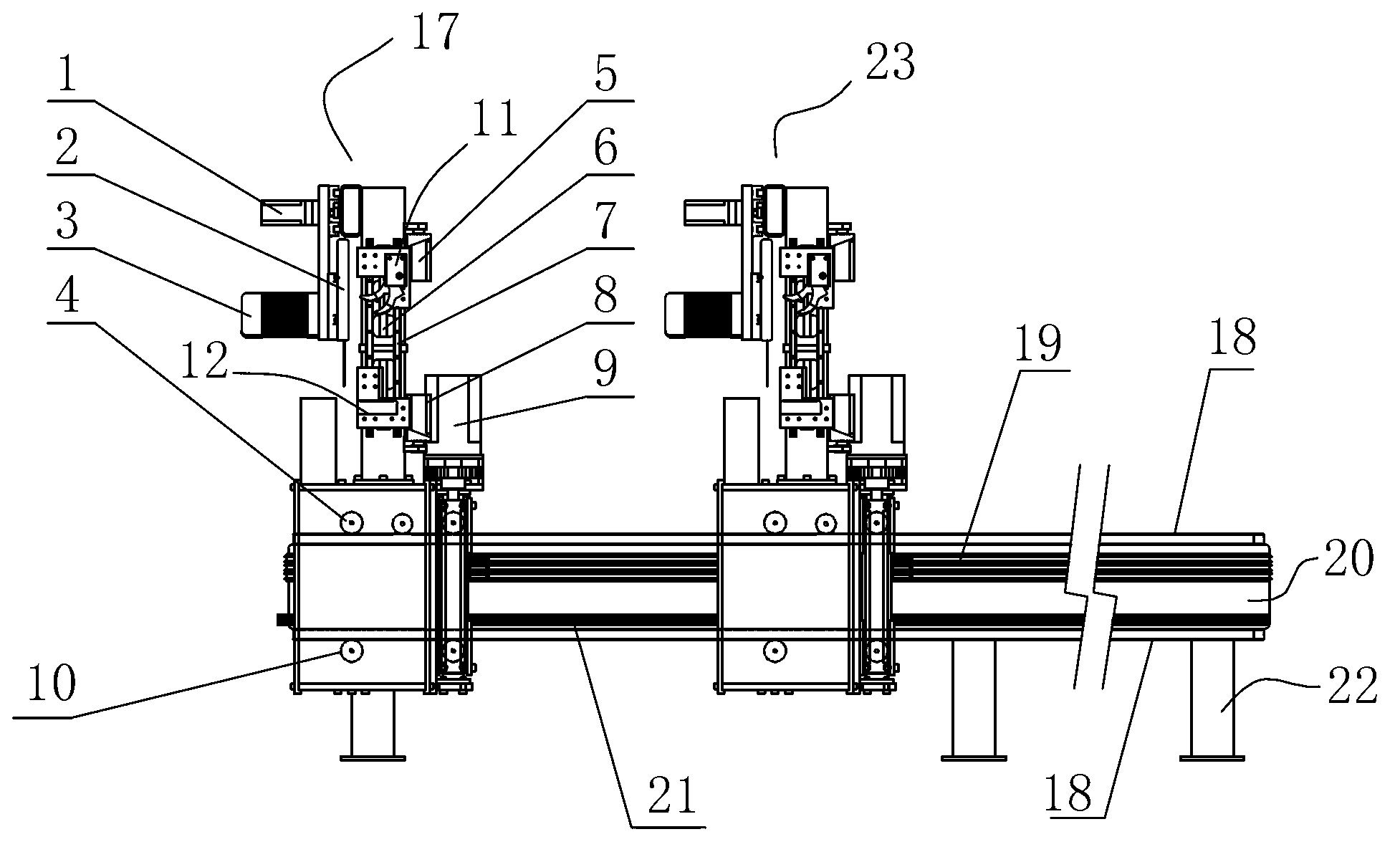

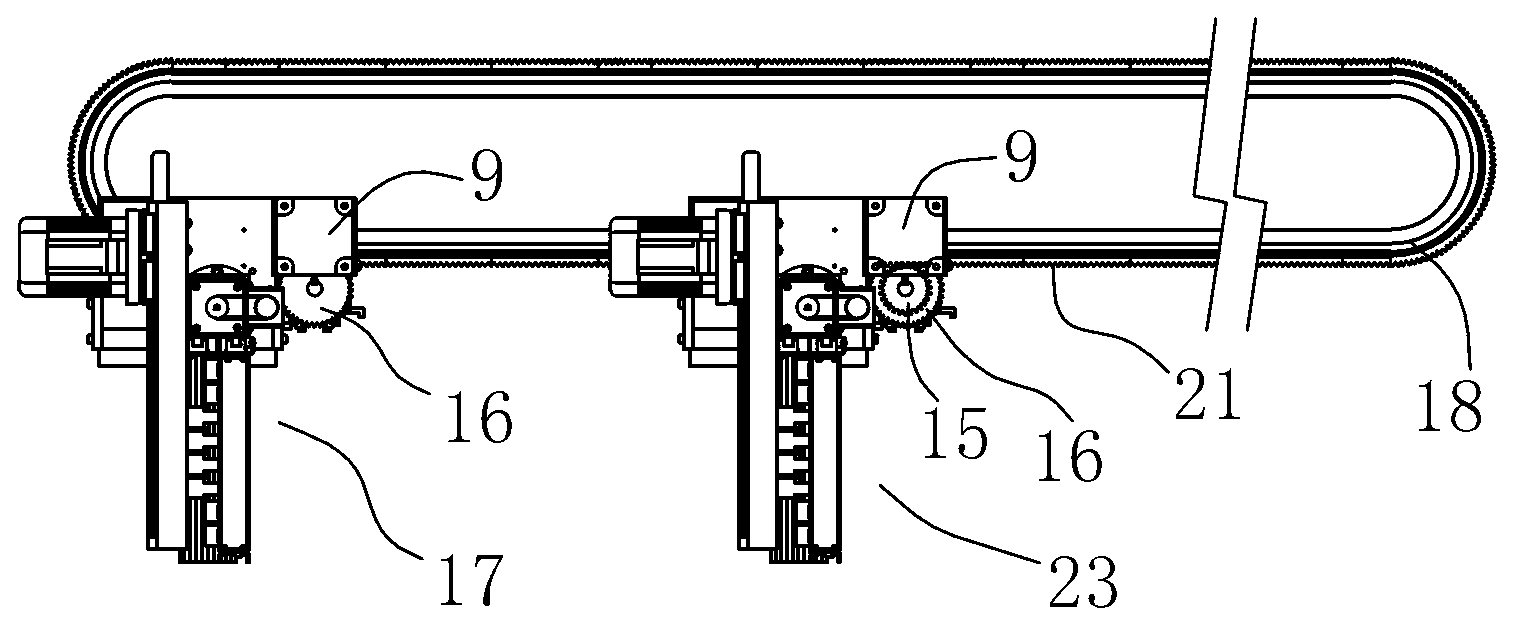

[0022] Taking the circular band saw automatic traction device of the present invention with two tractors as an example, a detailed description will be made of the specific implementation of the present invention in conjunction with the accompanying drawings:

[0023] Such as figure 1 , figure 2 with image 3 As shown, the aluminum profile circular band saw automatic traction device related to the present invention includes a guide rail platform 20 and two tractors 17, 23 that can move on the guide rail platform 20 and a control system. The guide rail platform 20 is controlled by the guide rail machine feet 22 Support, the structures of the tractors 17 and 23 are the same, and a flying saw 2 for sawing aluminum profiles is arranged on it. On the guide rail platform 20, there is an annular guide rail 18 for the tractor vehicle to slide, and the guide rail platform 20 is also provided with an annular rack 21 consistent with the direction of the annular guide rail 18; on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com