Method and device for quickly forming arc for leading wire by using wire clamp to manufacture salient points

A technology of quick leads and bent leads, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as low work efficiency and complex rivet trajectory, and achieve simple rivet trajectory and simple working process , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

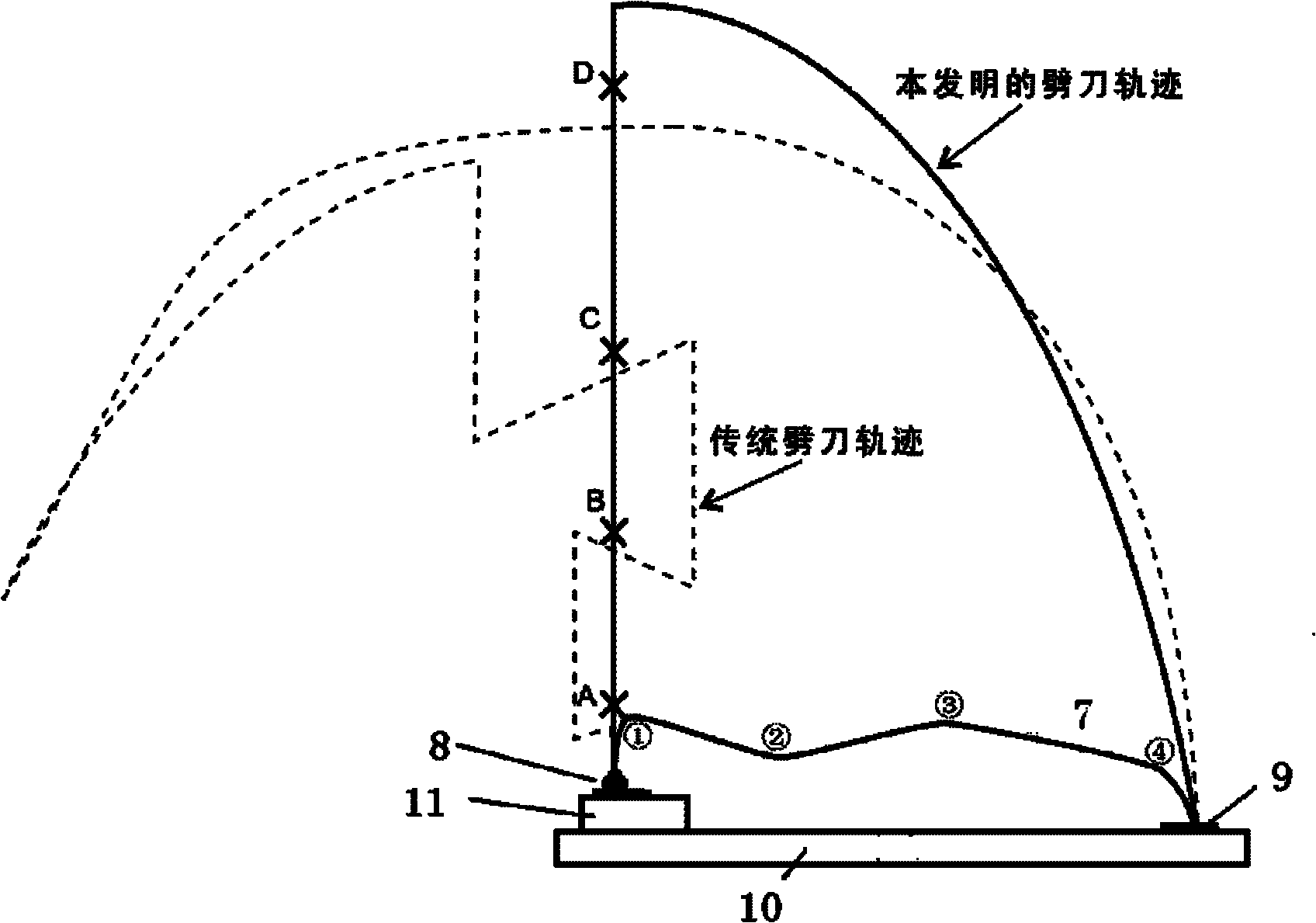

[0043] Example 1: M-line arc process

[0044] The forming method of the M line arc mentioned in the present invention will be based on figure 2 to describe.

[0045] The process of wire bonding consists of three steps:

[0046] 1) The first step is the same as the traditional wire bonding process, the wire passing through the capillary forms a solder ball at the tip of the capillary and is soldered to a solder point.

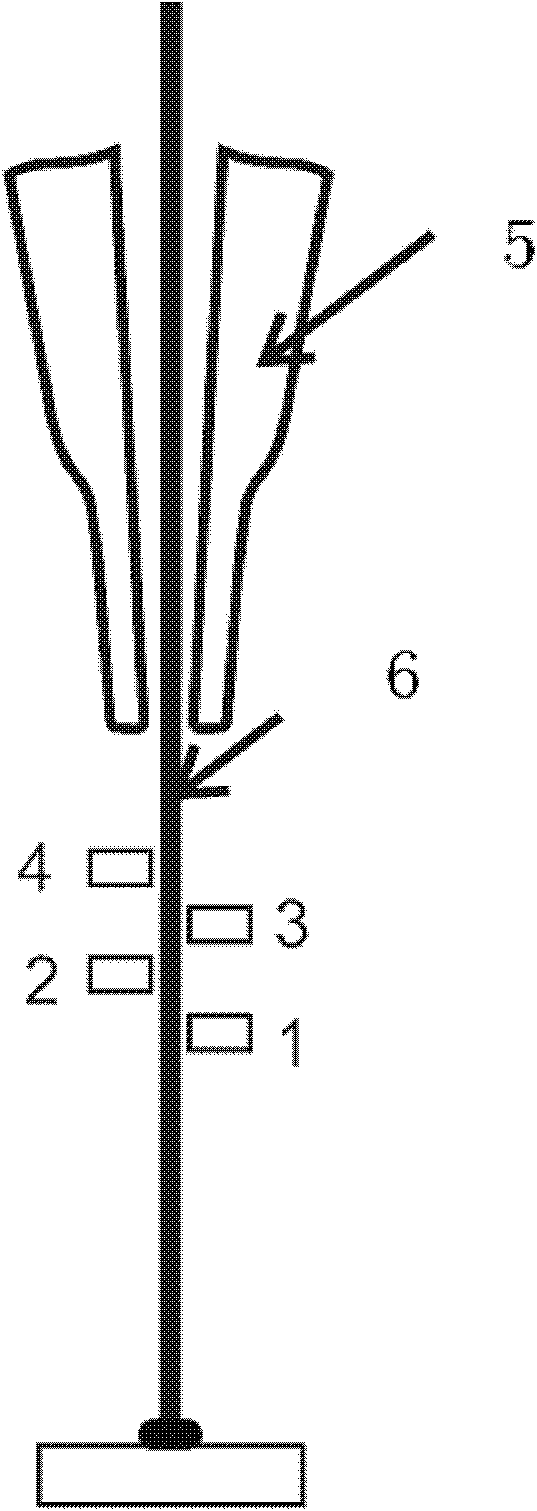

[0047] 2) Then, the capillary rises to the position of point A (130 microns away from the pad) and pauses, and moves into the line clip for manufacturing the folding point to 20 microns below the capillary. At this time, the bonding system sends an instruction to the wire clamp to move the movable arm 2 horizontally to create a left concave inflection point; similarly, move the wire clamp to point B (600 microns away from the pad) to create a right convex inflection point; move the wire Clamp to point C (1200 microns away from the pad) and pause at the crosse...

Embodiment 2

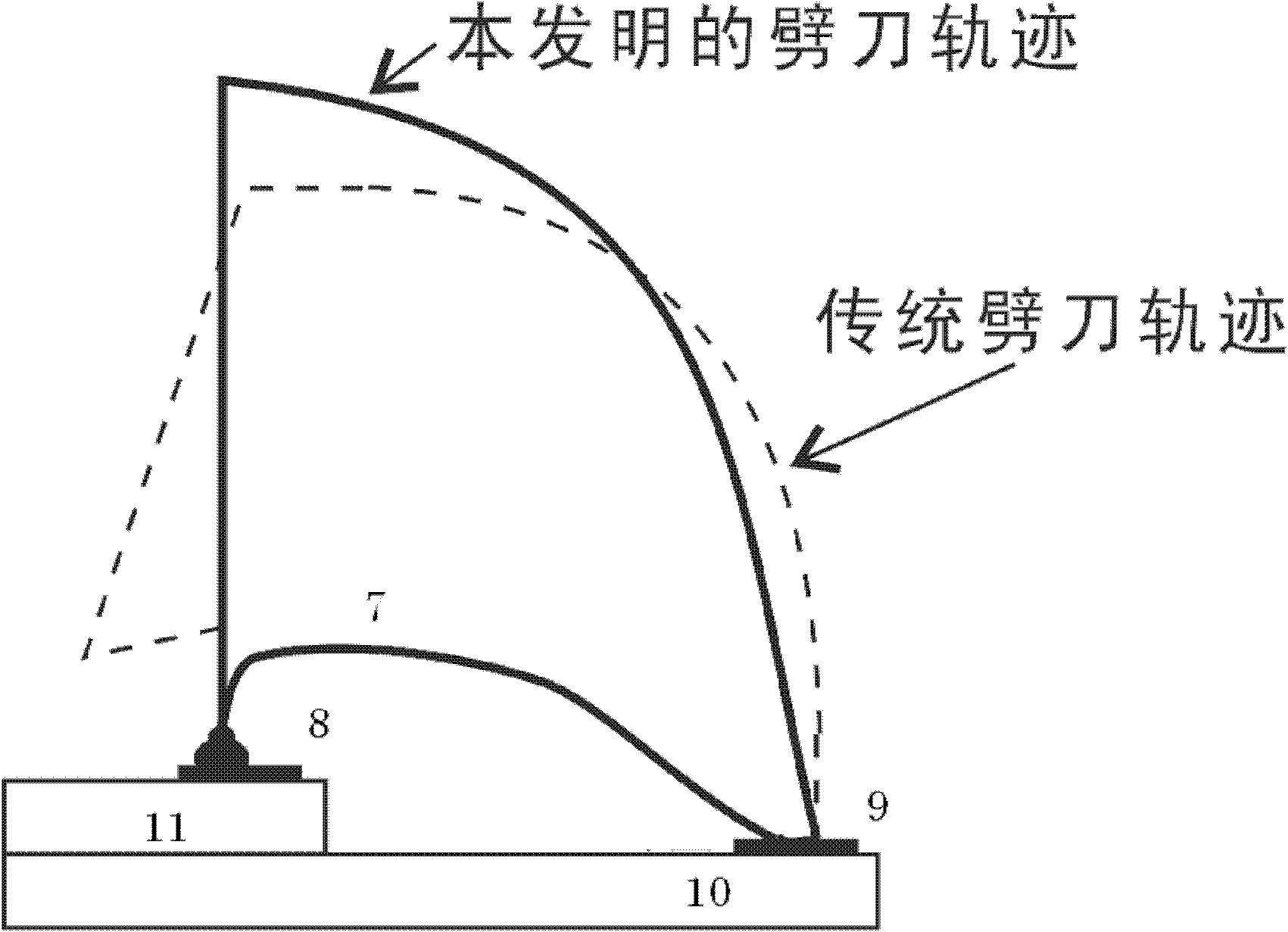

[0050] Embodiment 2: the formation process of STD line type

[0051] The STD line type is the most basic arc in wire bonding and contains only one inflection point. Utilize the method that the present invention forms STD linear pattern as Fig. 4, and its manufacturing process is:

[0052] 1) The first step is the same as the traditional wire bonding process, the wire passing through the capillary forms a solder ball at the tip of the capillary and is soldered to a solder point.

[0053] 2) Then, the capillary rises to the position of point A (130 microns away from the pad) and pauses, and moves into the line clip for manufacturing the folding point to 20 microns below the capillary. At this time, the bonding system sends an instruction to the clamp to move the movable arm 2 horizontally to create a left concave inflection point.

[0054] 3) The riving knife continues to rise to the highest position (1400 microns away from the welding pad), then stop the wire supply, remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com