Patents

Literature

164results about How to "Shorten exercise time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

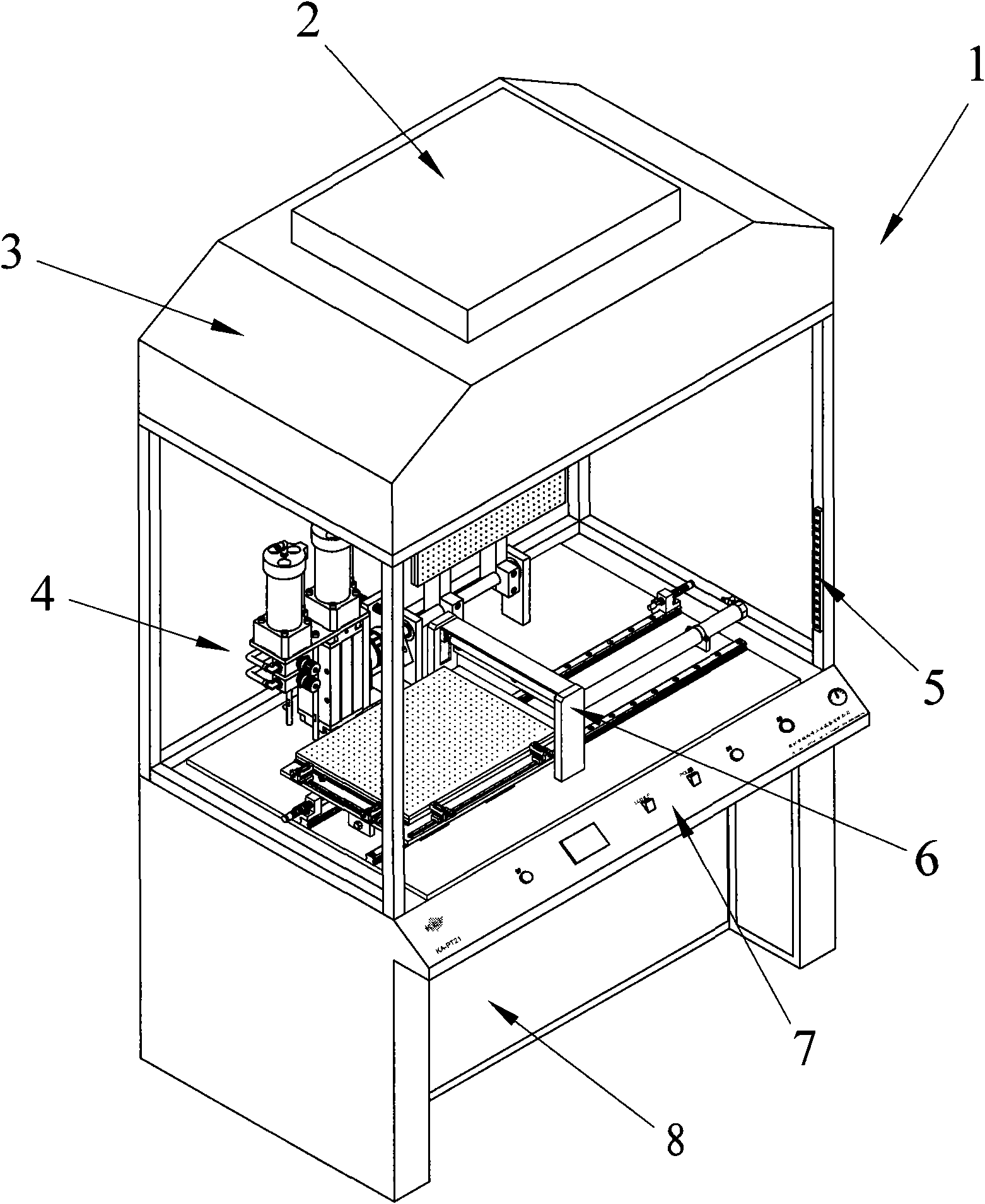

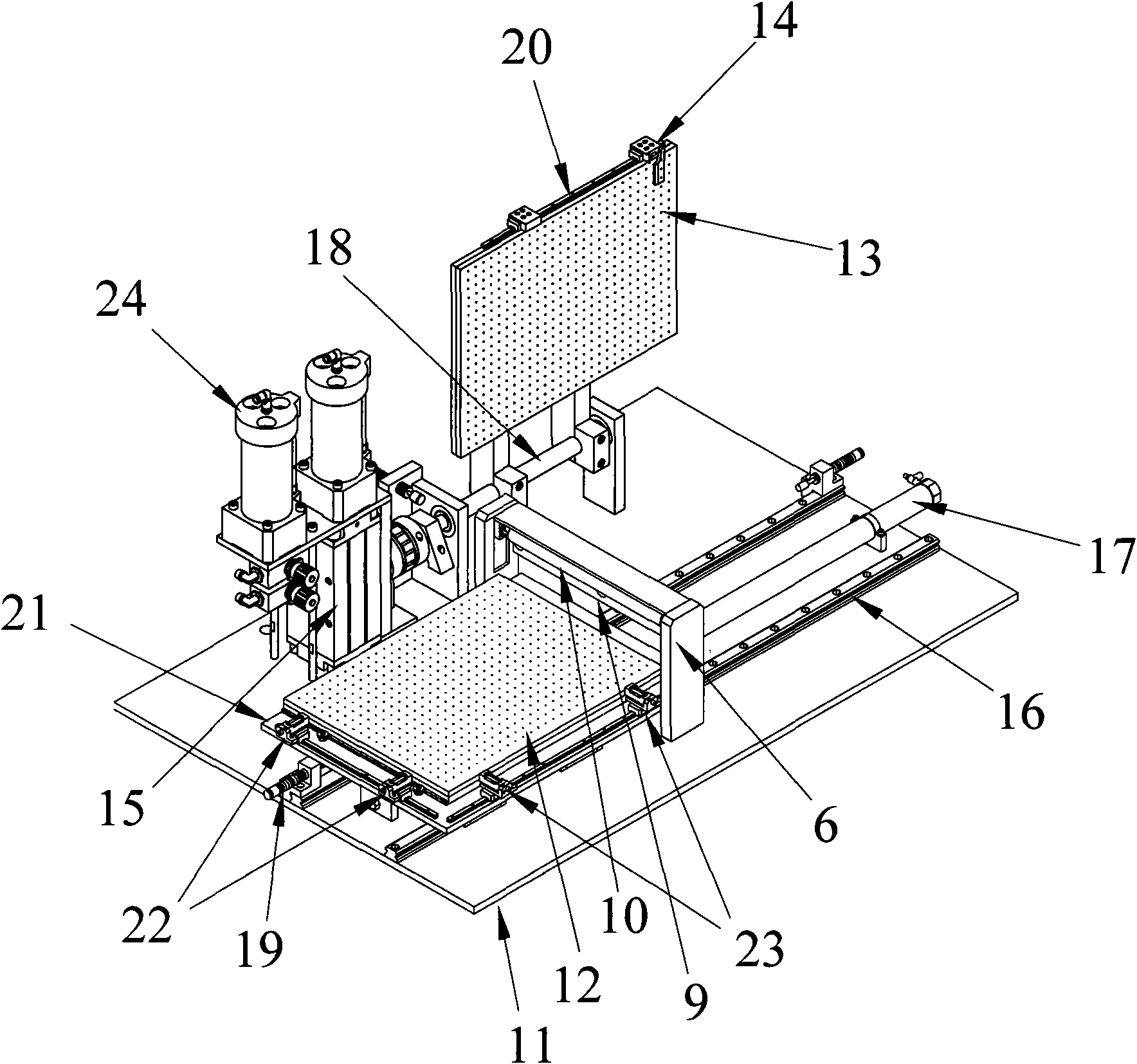

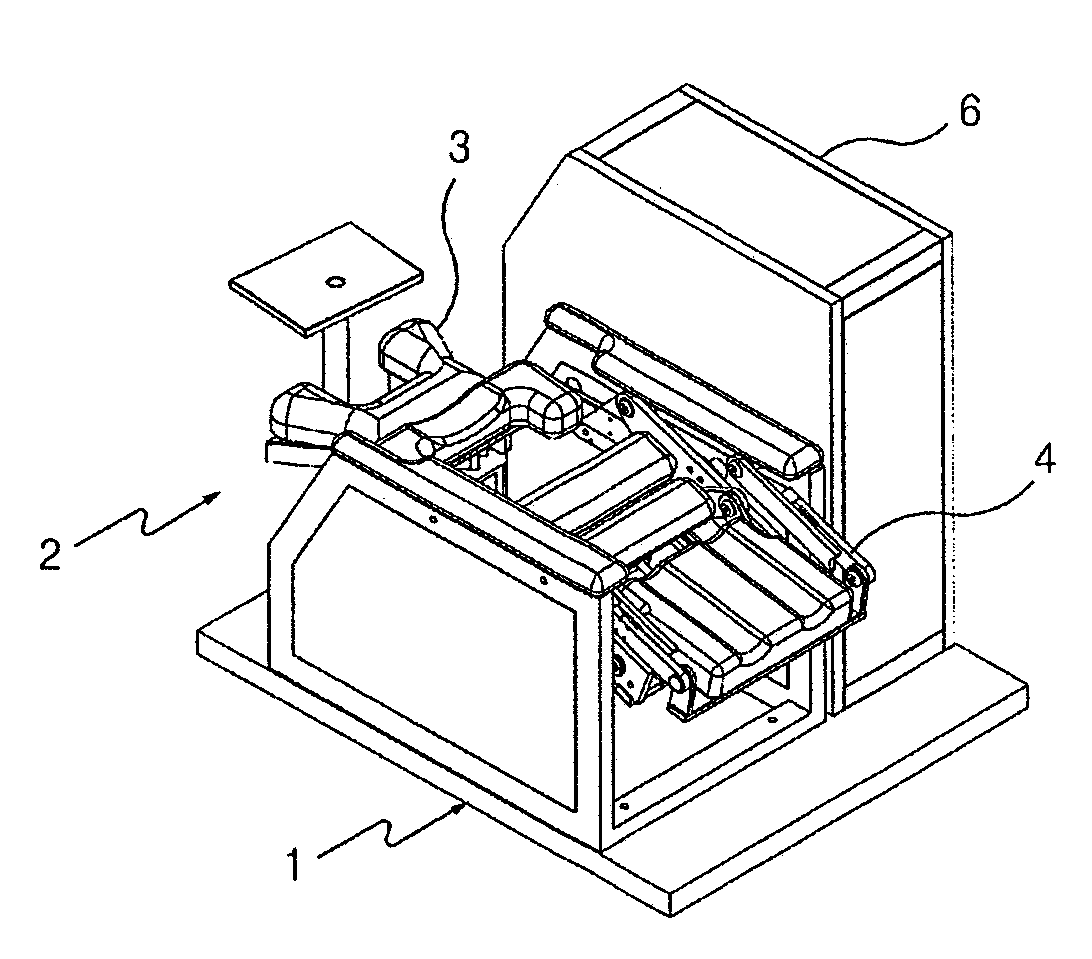

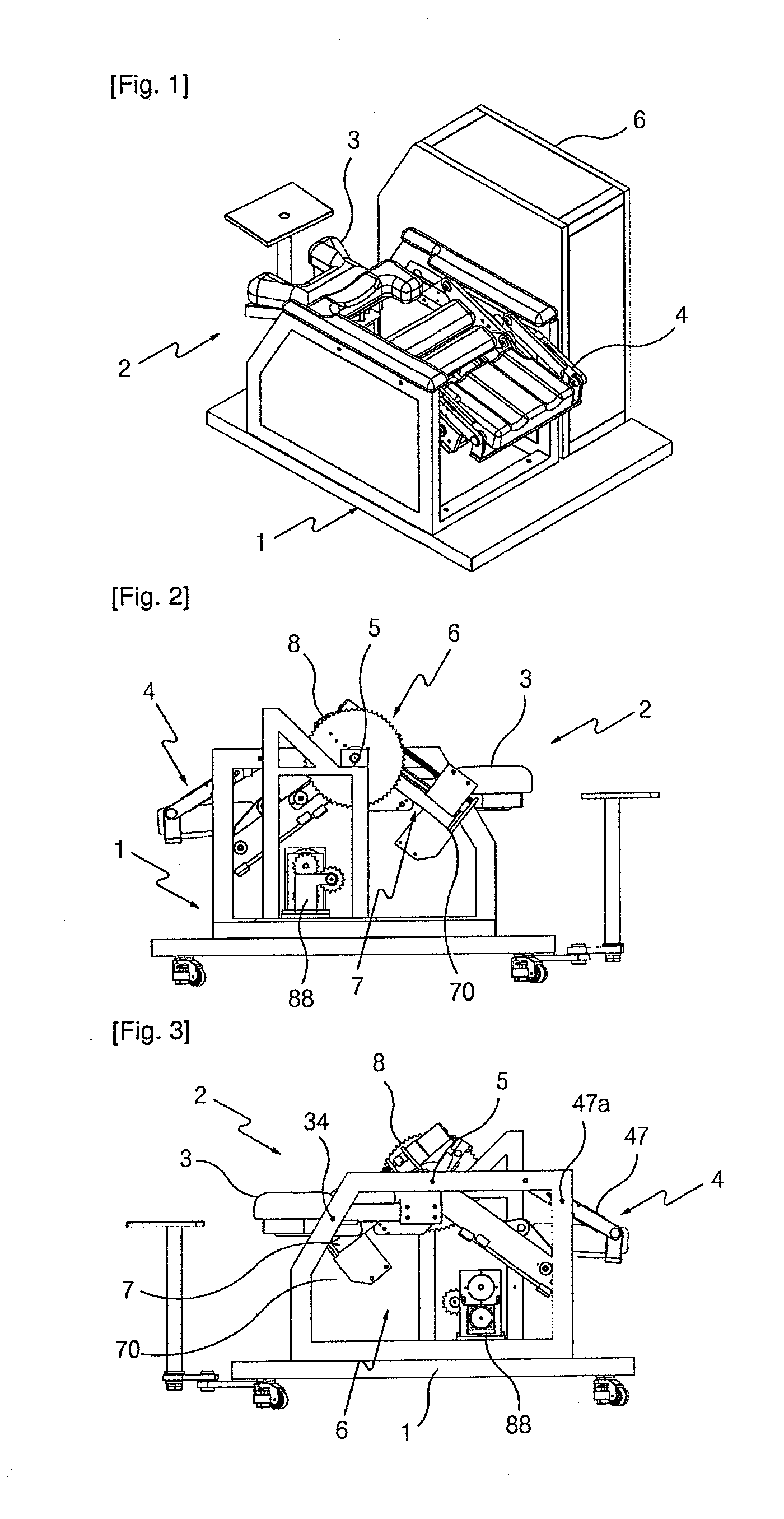

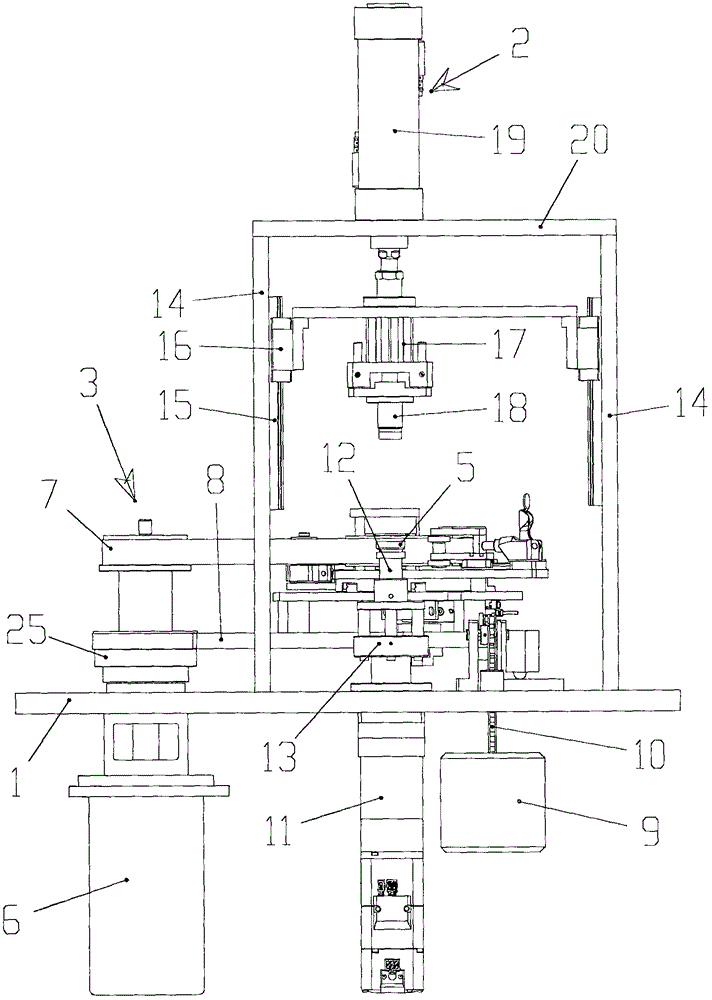

Semi-automatic laminating machine and laminating method thereof

InactiveCN101581850AGuaranteed cleanlinessEasy to operateLaminationLamination apparatusSemi automaticAtmospheric pressure

The invention discloses a semi-automatic laminating machine and a laminating method thereof. The semi-automatic laminating machine is provided with a stand, wherein an operating space for accommodating a laminating device is arranged in the middle part of the stand, an electric component box is placed in the stand and positioned below the laminating device, an air inlet opening is arranged at the top of the stand, an air purifier is placed at the top of the stand and an operating panel is installed on the stand and used for controlling the laminating machine. The material laminating is carried out by material placing, aligning, laminating by pressure roller, laminating completion and returning for standby. The semi-automatic laminating machine adopts various ways of vacuum adsorption, mechanical positioning and pneumatic motion to be provided with a precision fine adjustment device, a limitator, an oil-gas convertor, a linear slide rail and other precision components, thereby ensuring the laminating accuracy, reducing the dependence on the operators, overcoming the phenomenon of inaccurate positioning, low yield, air bubble, gauffer and defects existing in the laminating process of the diaphragm and the base material, reducing the running time due to the overlapped type motion and improving the production efficiency.

Owner:郑春晓

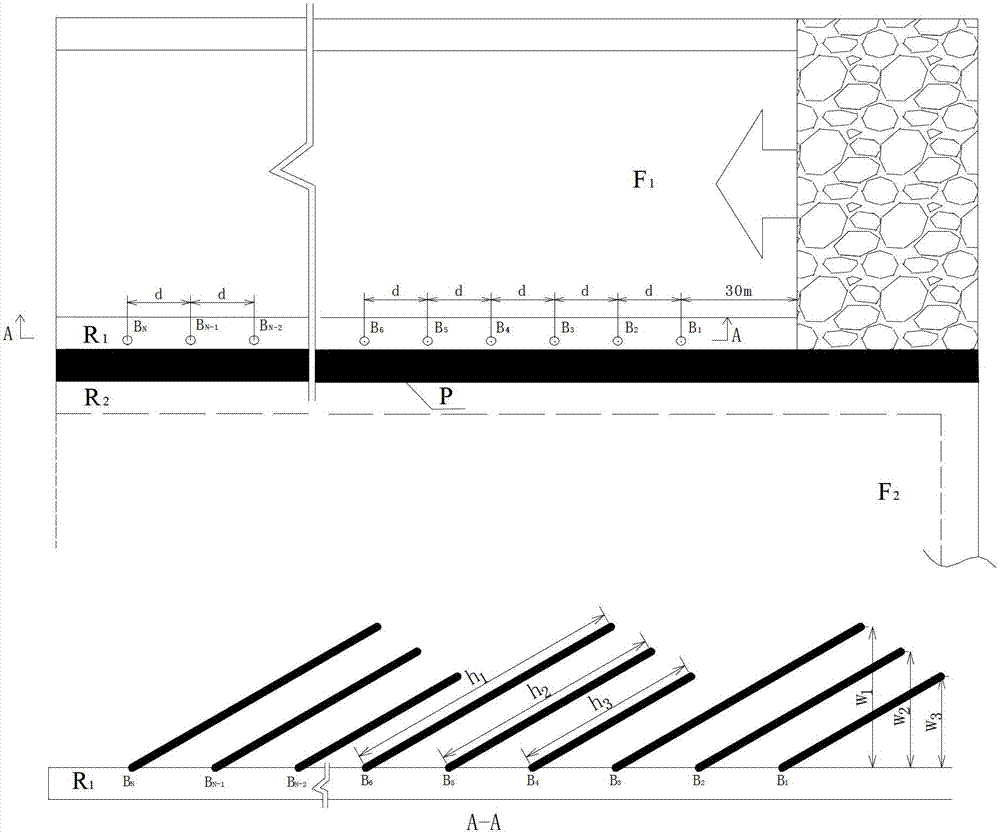

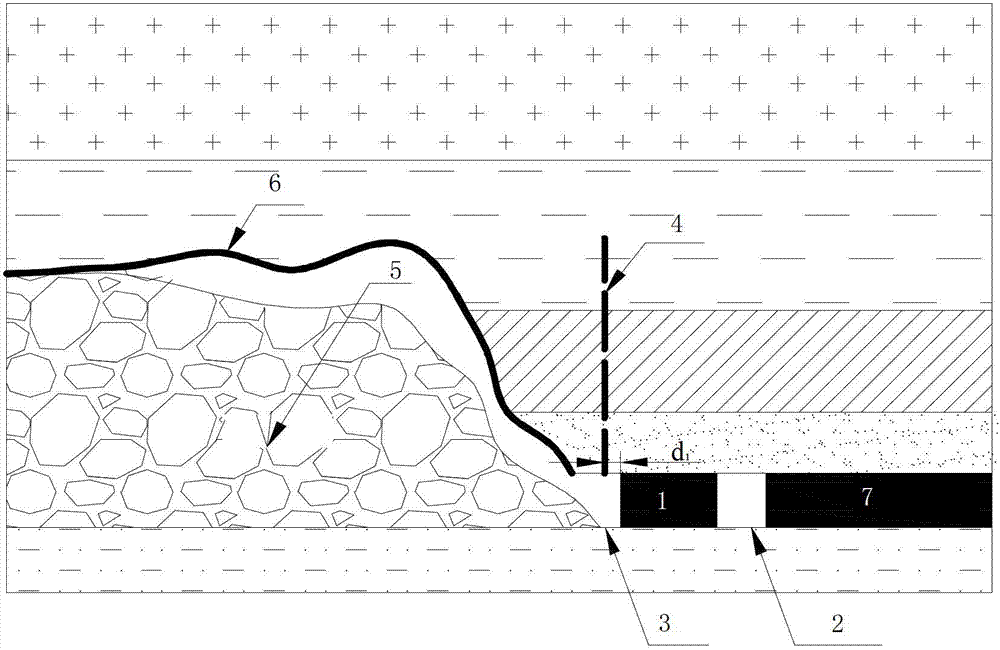

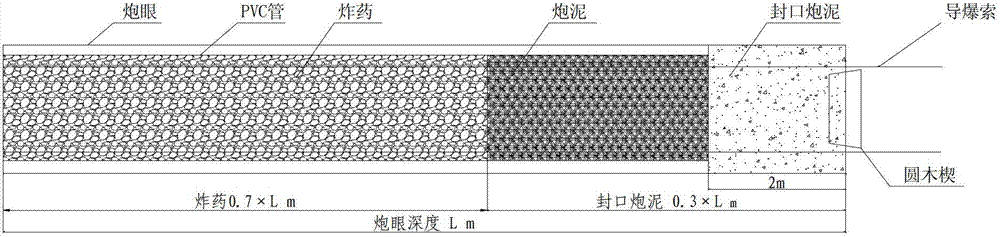

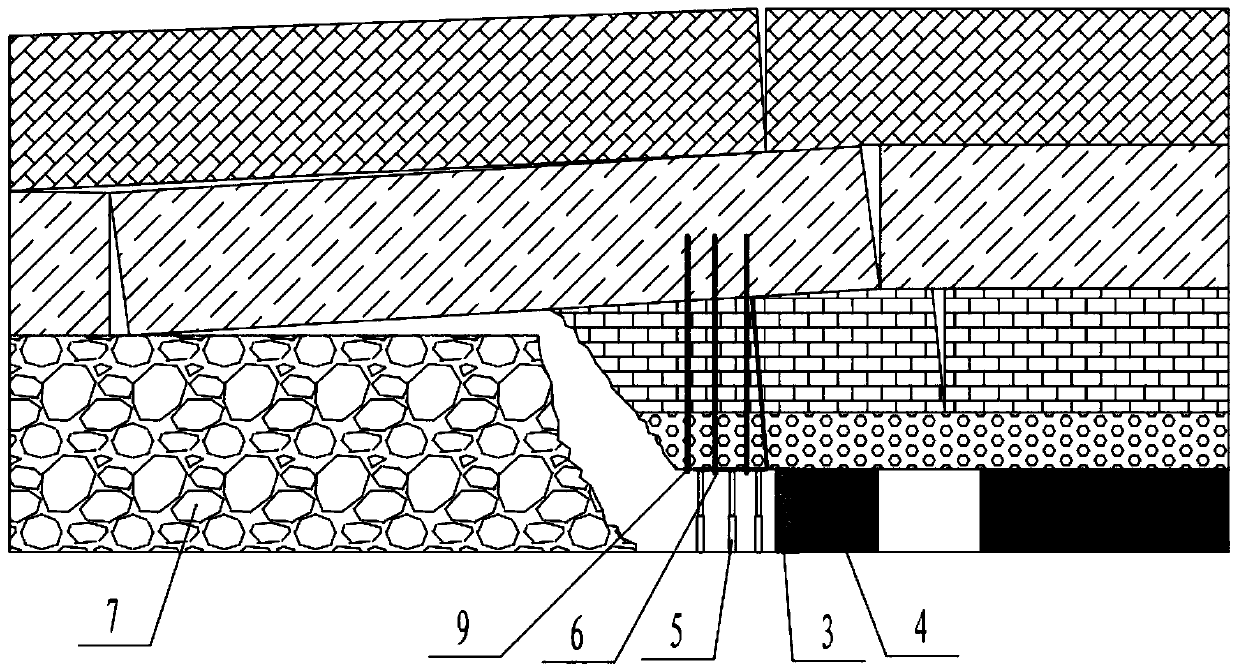

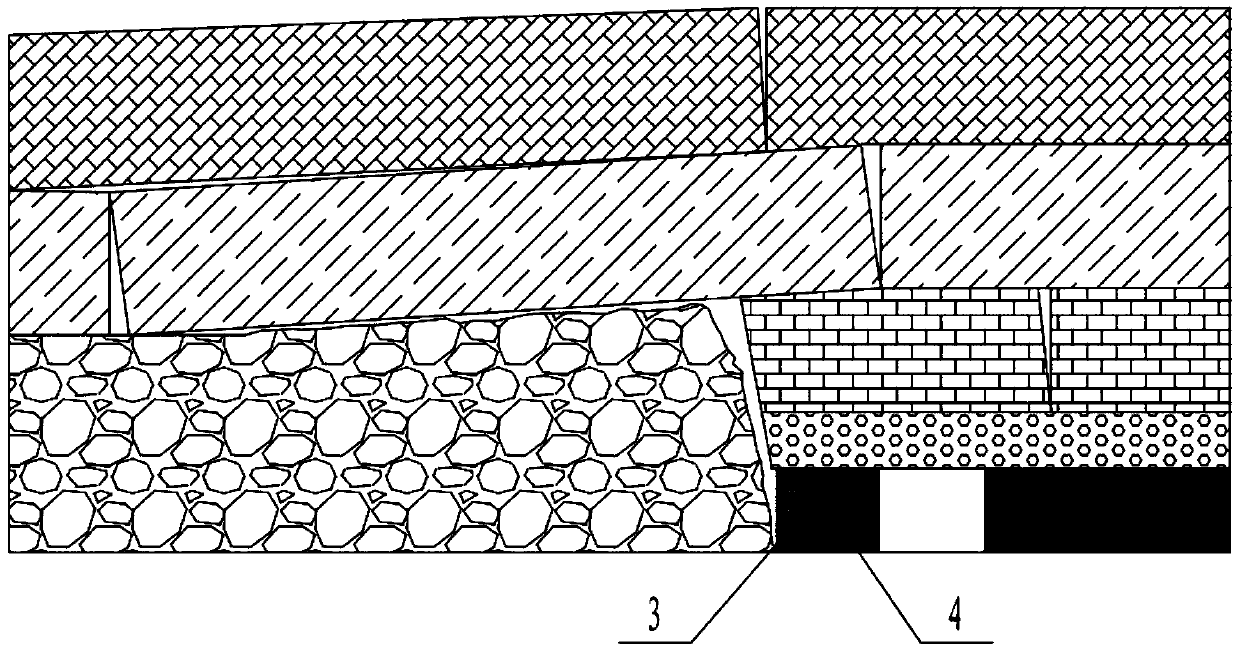

Beside-roadway escribing pressure relief method of roadway driving along gob of small coal pillar influenced by dynamic pressure

InactiveCN102778182AShorten exercise timeEliminate mining dynamic pressureBlastingEngineeringCoal pillar

The invention discloses a beside-roadway escribing pressure relief method of roadway driving along a gob of a small coal pillar influenced by dynamic pressure. The method includes the following steps: adopting roadway roof deep hole blasting as the escribing method, arranging escribing shot holes within the overall length range of an adjacent working surface crossheading of the roadway driving along the gob, and implementing stage blasting operation during back production of the working surface, wherein the escribing shot holes need to be close to the small coal pillar as far as possible, the depth of the escribing shot holes is determined according to the mining height of the back production working surface and the free caving height of the roof of the working surface, the shot holes need to be arranged with a distance away from the working surface, and the distance among the shot holes need to be determined reasonably; then performing explosive filling and hole blocking; performing ahead blasting operation in front of the working surface or lag blasting operation after the shot holes enter a gob area; and instantly performing roadway driving along the gob when the bad influence on the essence of the roadway driving along the gob of the small coal pillar caused by dynamic pressure of the working surface can be basically eliminated when back production of the adjacent working surface is finished. By means of the beside-roadway escribing pressure relief method, normal production of a back production working surface is ensured, and the cost and difficulty in roadway support along the gob are greatly reduced.

Owner:SHANDONG UNIV OF SCI & TECH

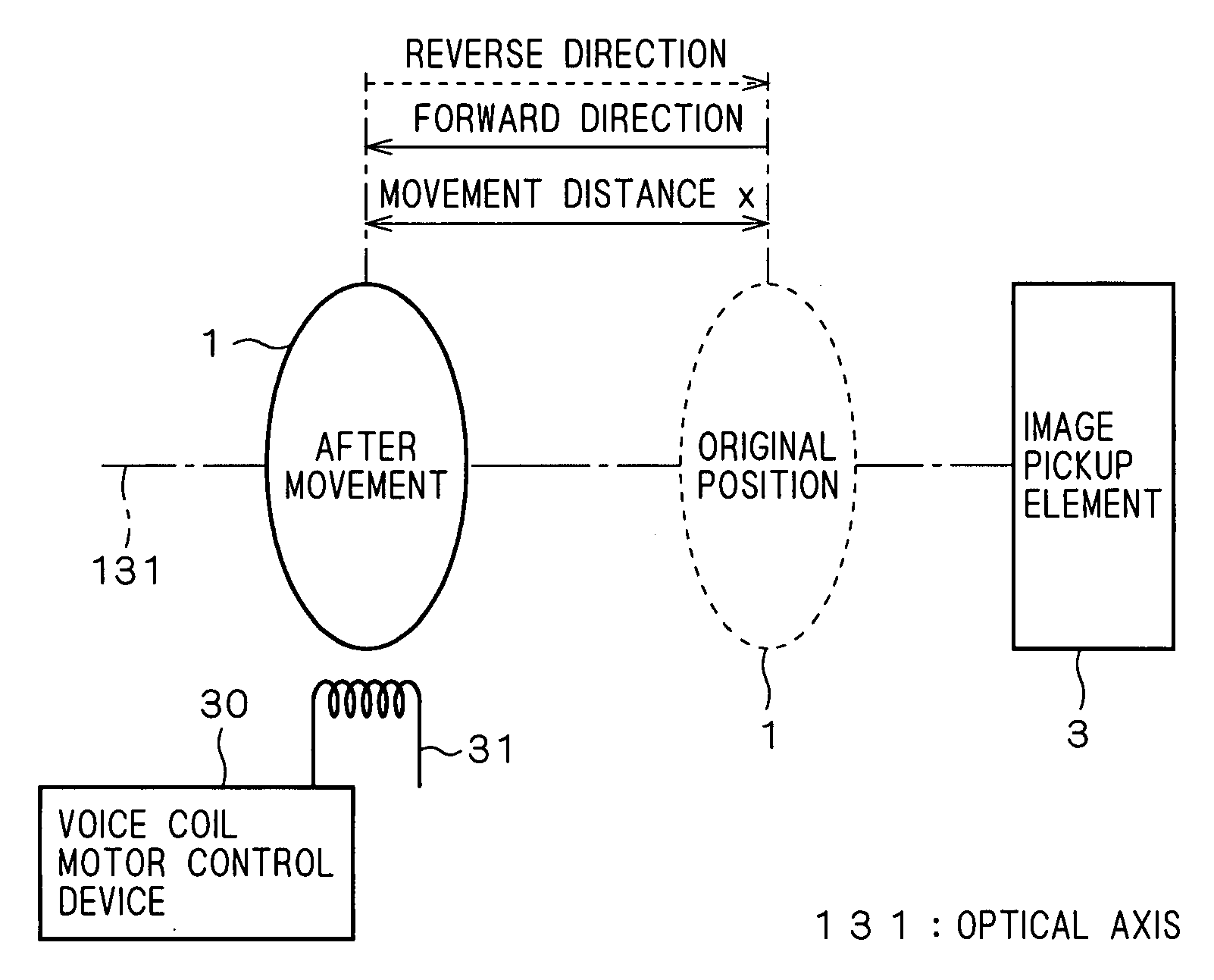

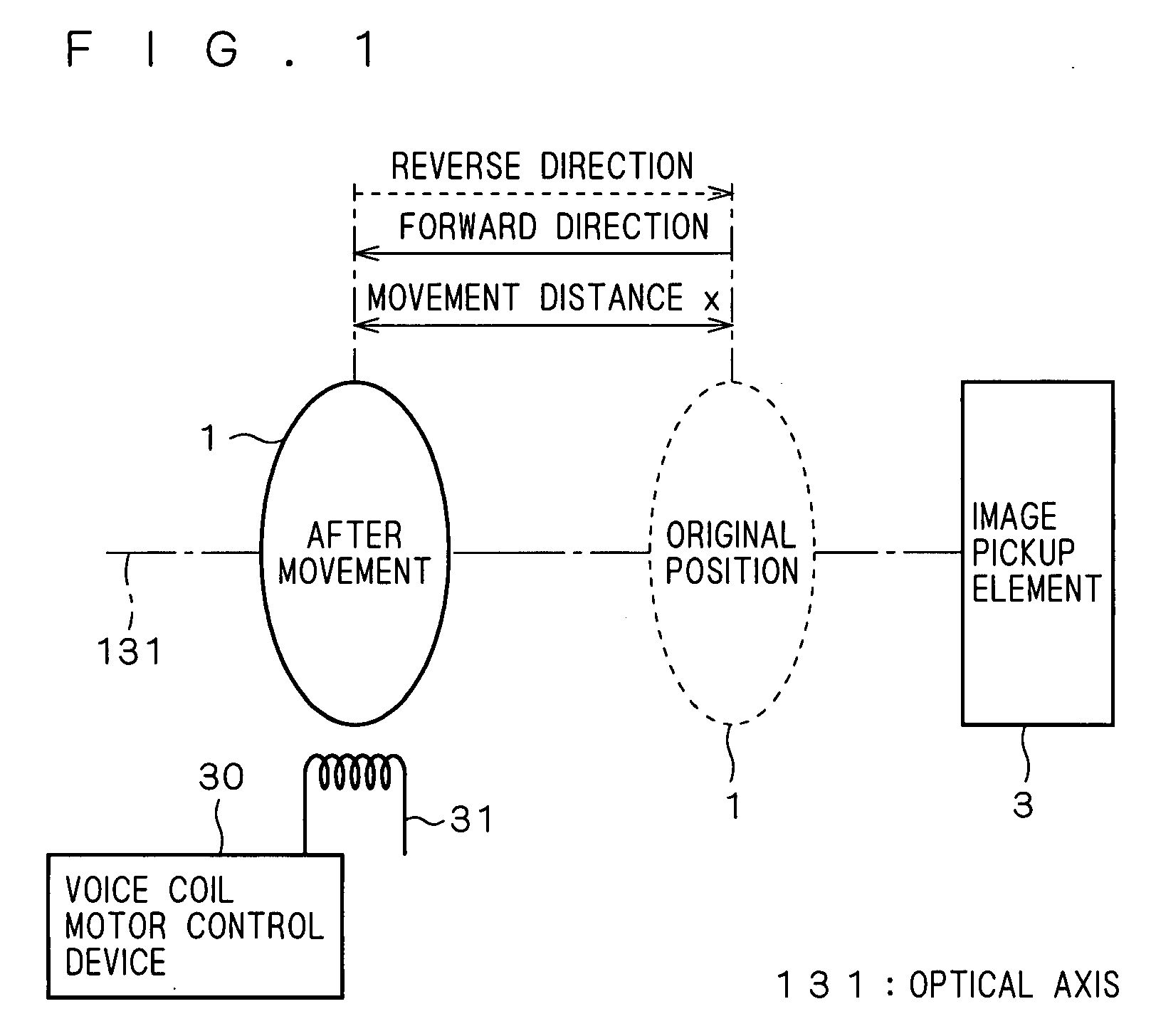

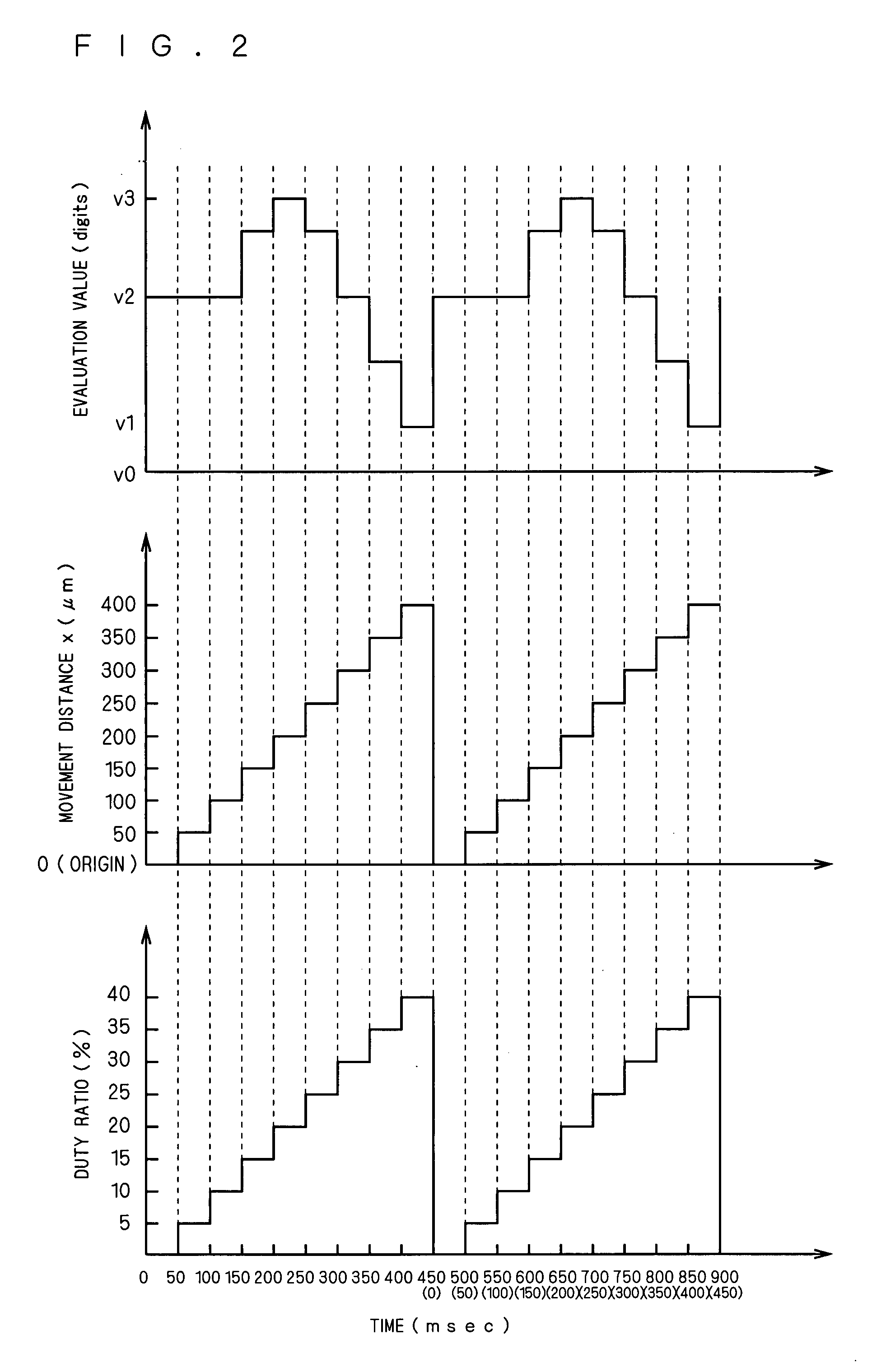

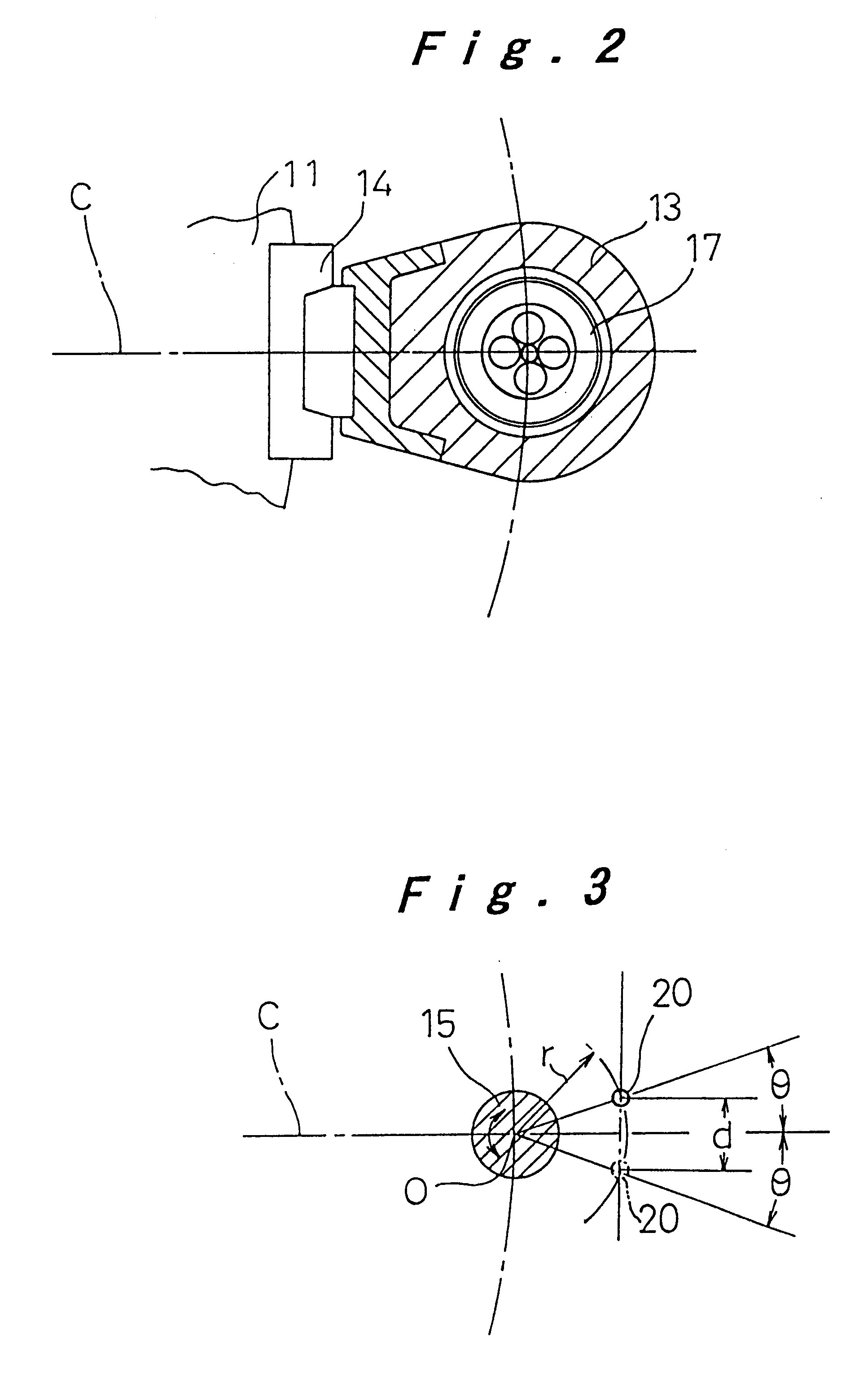

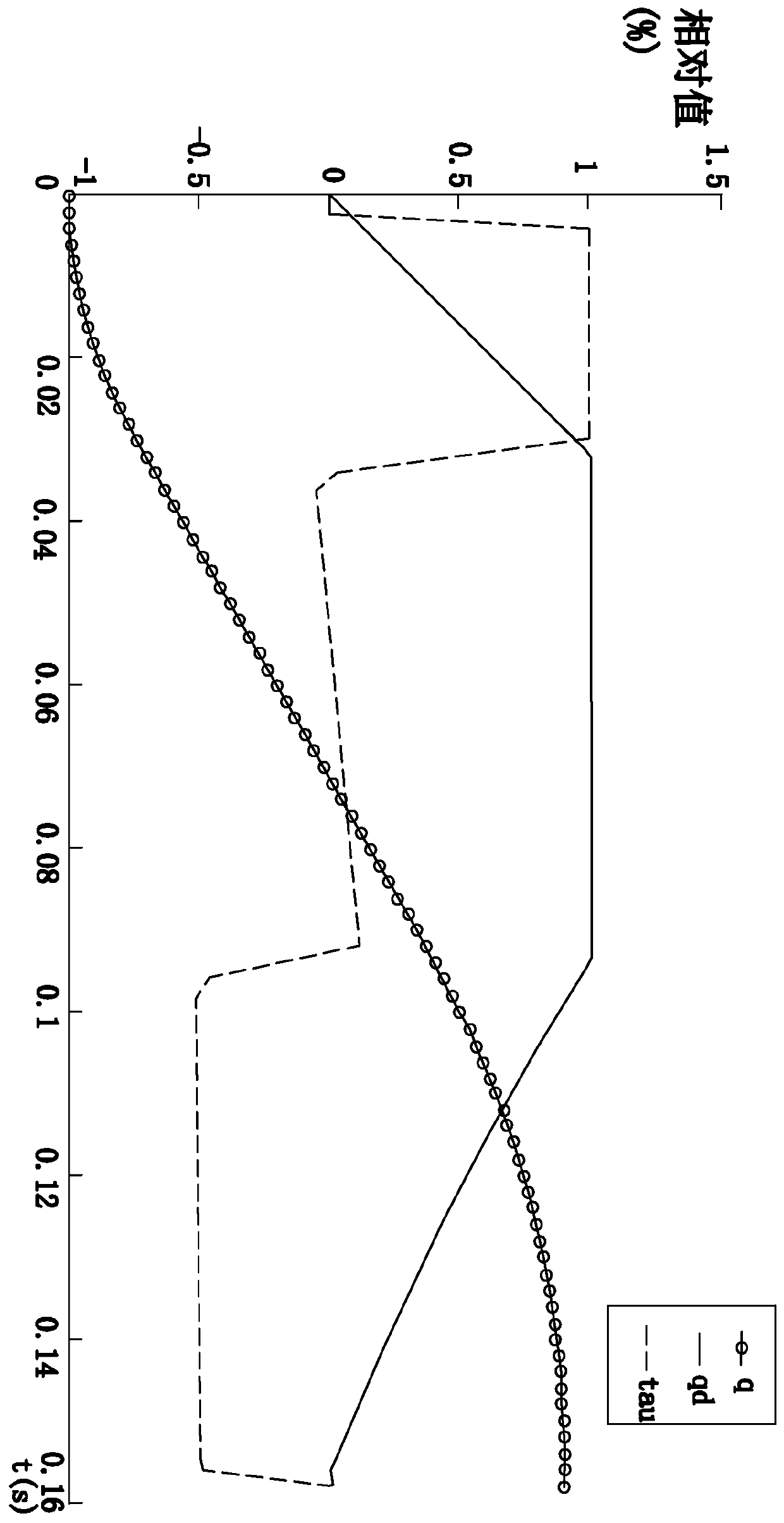

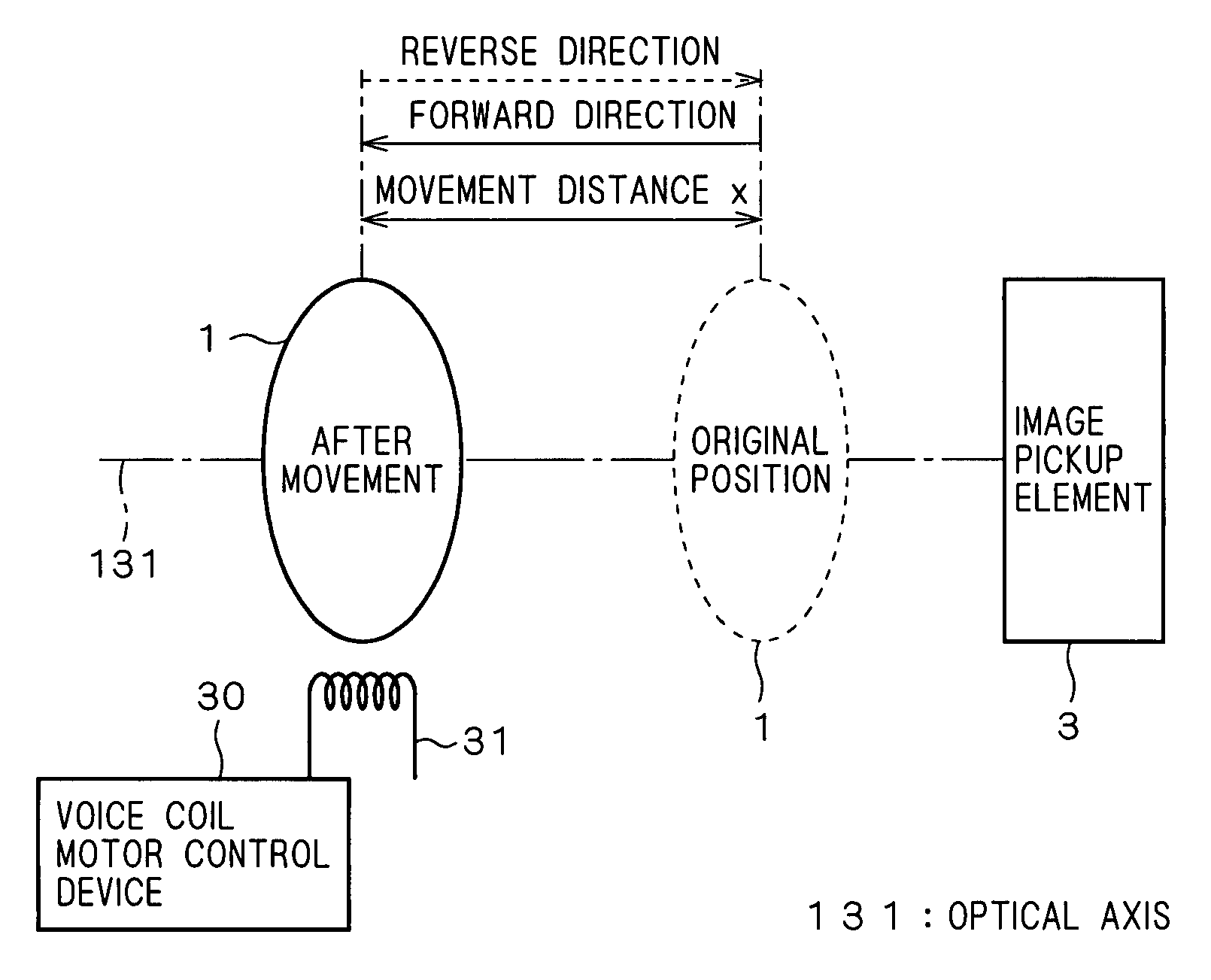

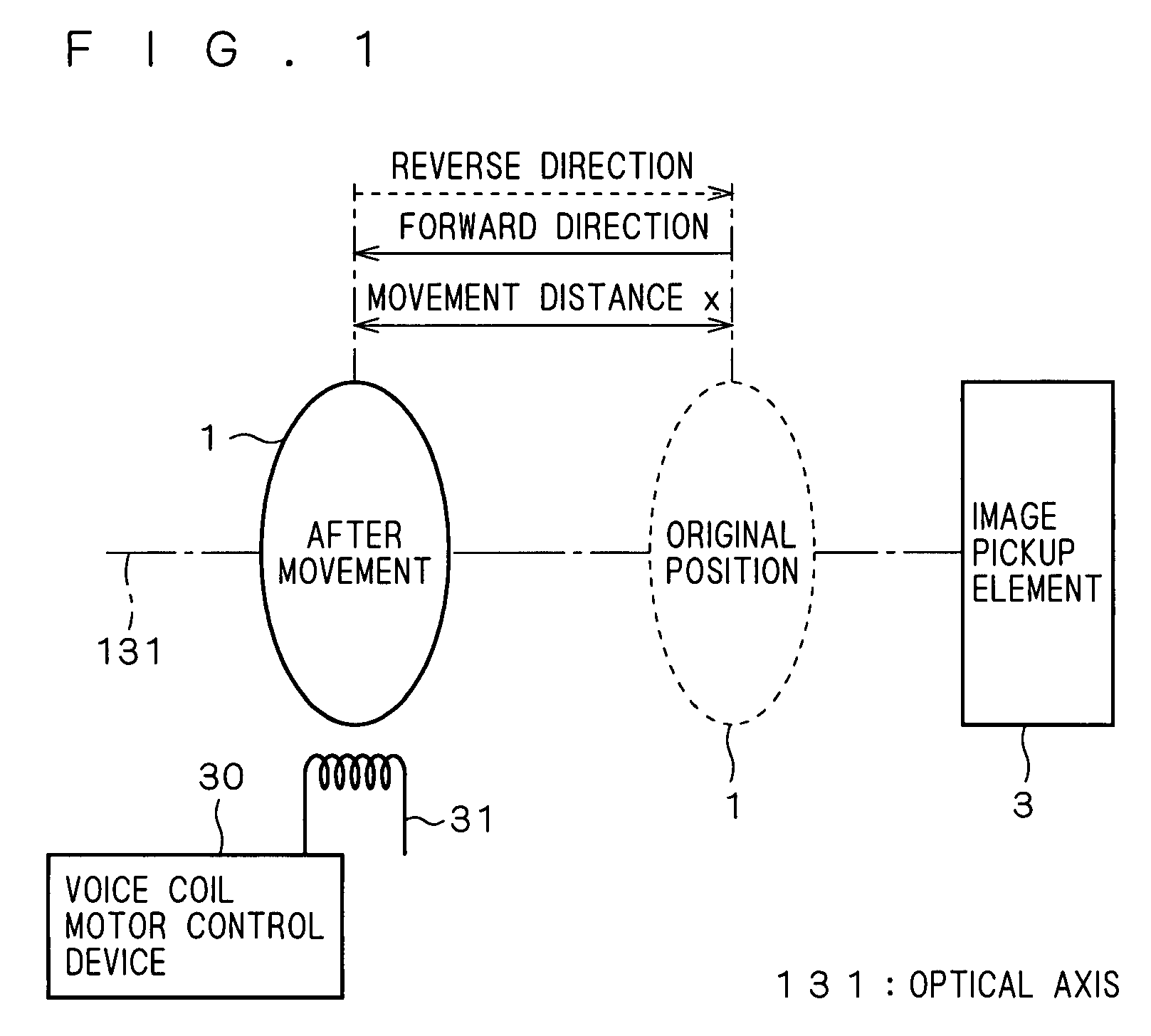

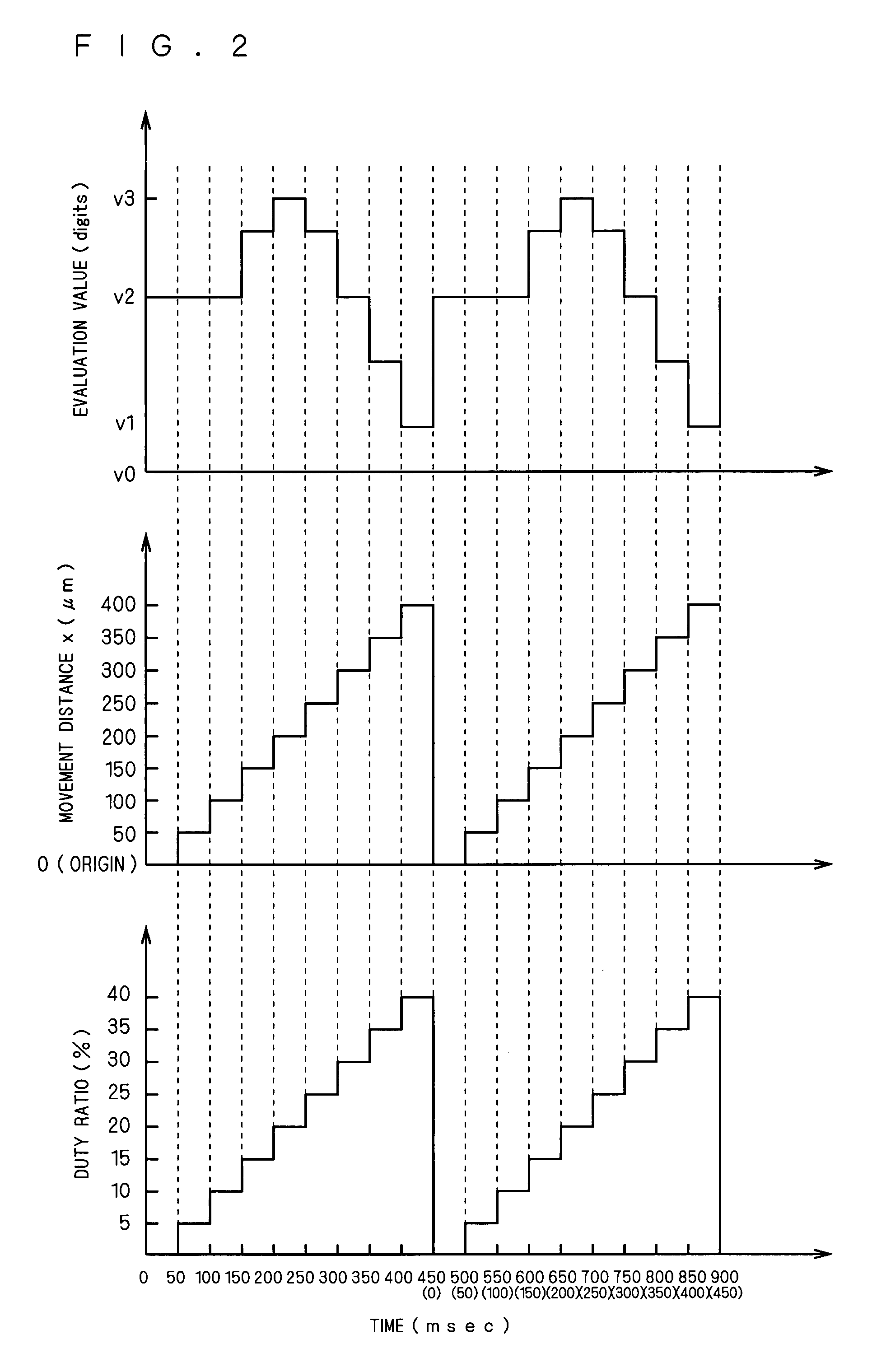

Voice Coil Motor Control Device and Method of Driving the Same, Image Pickup Device

InactiveUS20080130134A1Hysteresis characteristicSuitable lensTelevision system detailsAC motor controlDriving currentHysteresis

The present invention provides a control device capable of improving hysteresis characteristics of a voice coil motor (31) and attaining a suitable lens position without complicating the structure of the control device. As solving means of the invention, a voice coil motor control device (30) includes a driving current control part (34) that controls a driving current supplied to the voice coil motor (31) in accordance with a driving pulse subjected to pulse width modulation, and a driving pulse control part (32) that divides a drive period of the voice coil motor (31) into a movement period and a holding period, and controls the driving pulse by changing the duty ratio of the driving pulse during the movement period in accordance with a duty setting value and fixing the duty ratio of the driving pulse during the holding period to the duty setting value.

Owner:MITSUBISHI ELECTRIC CORP

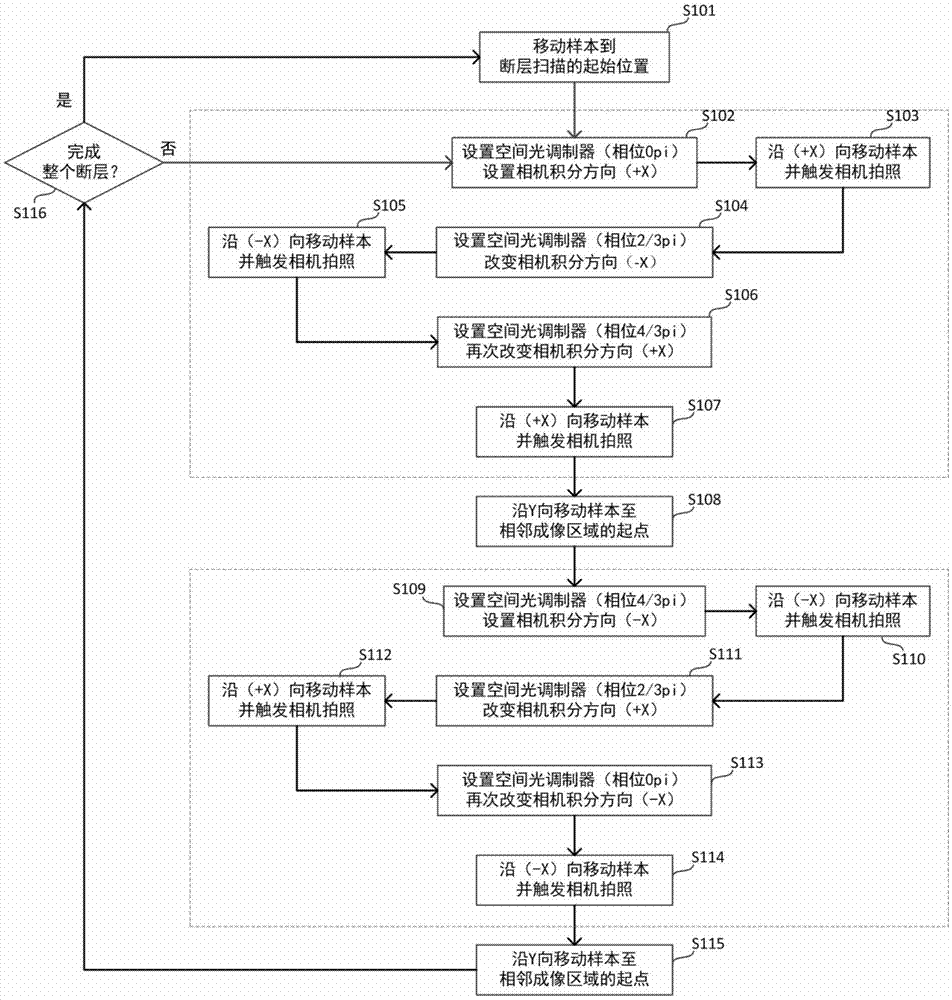

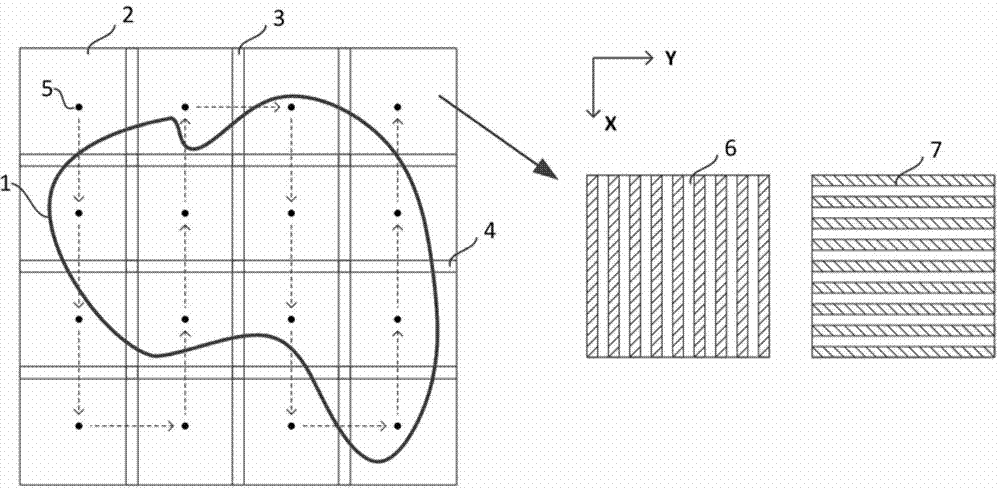

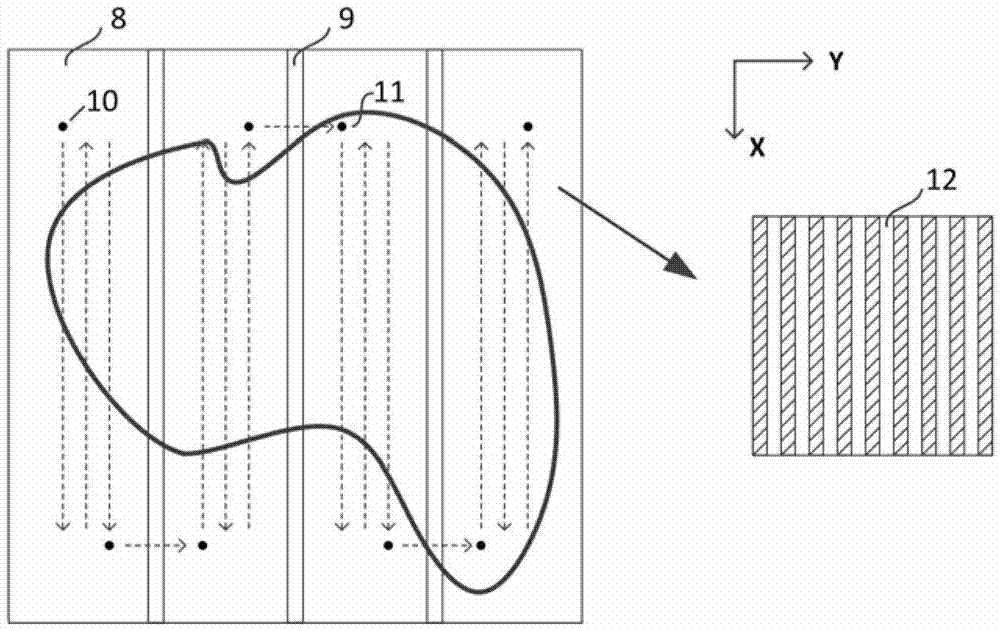

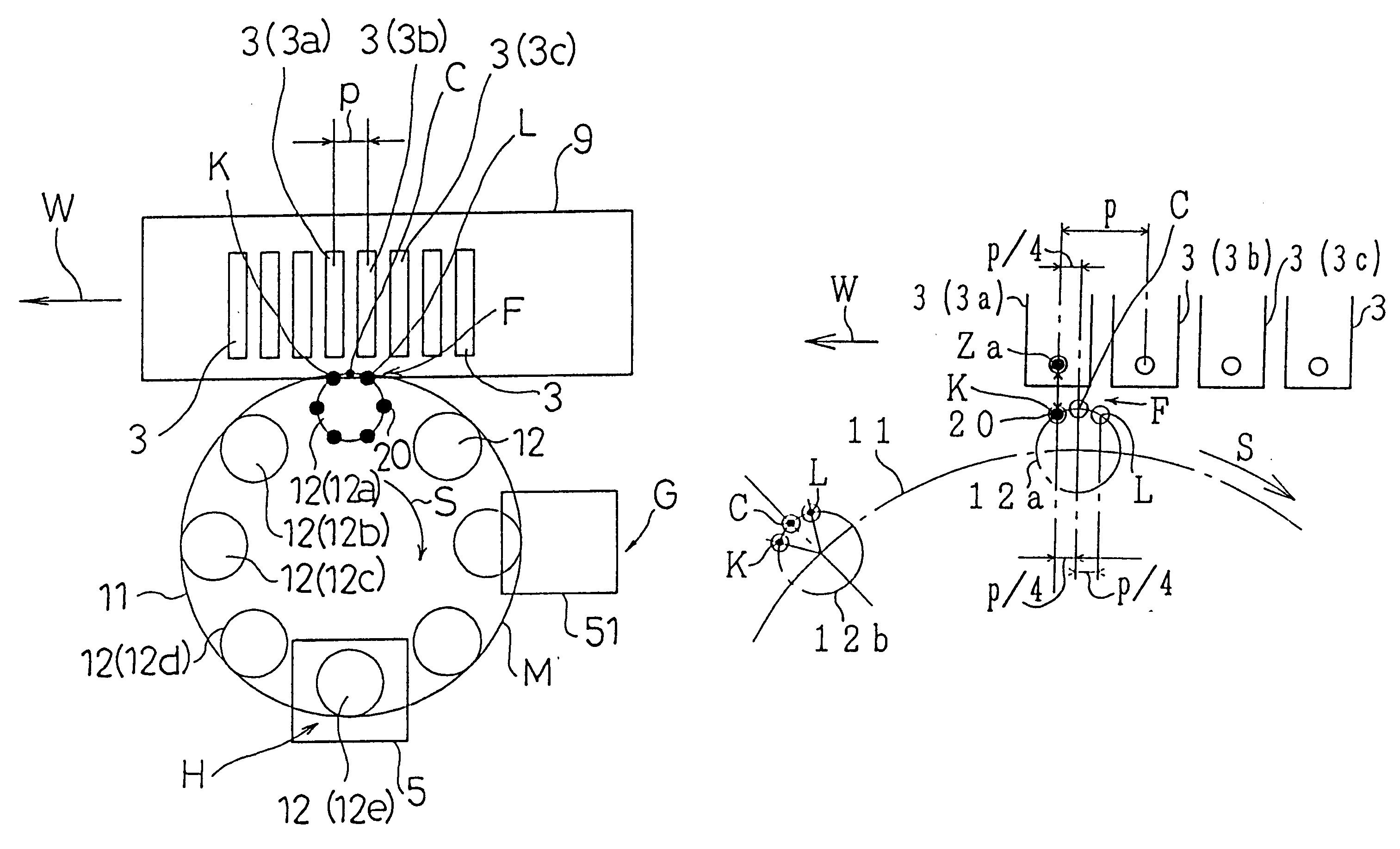

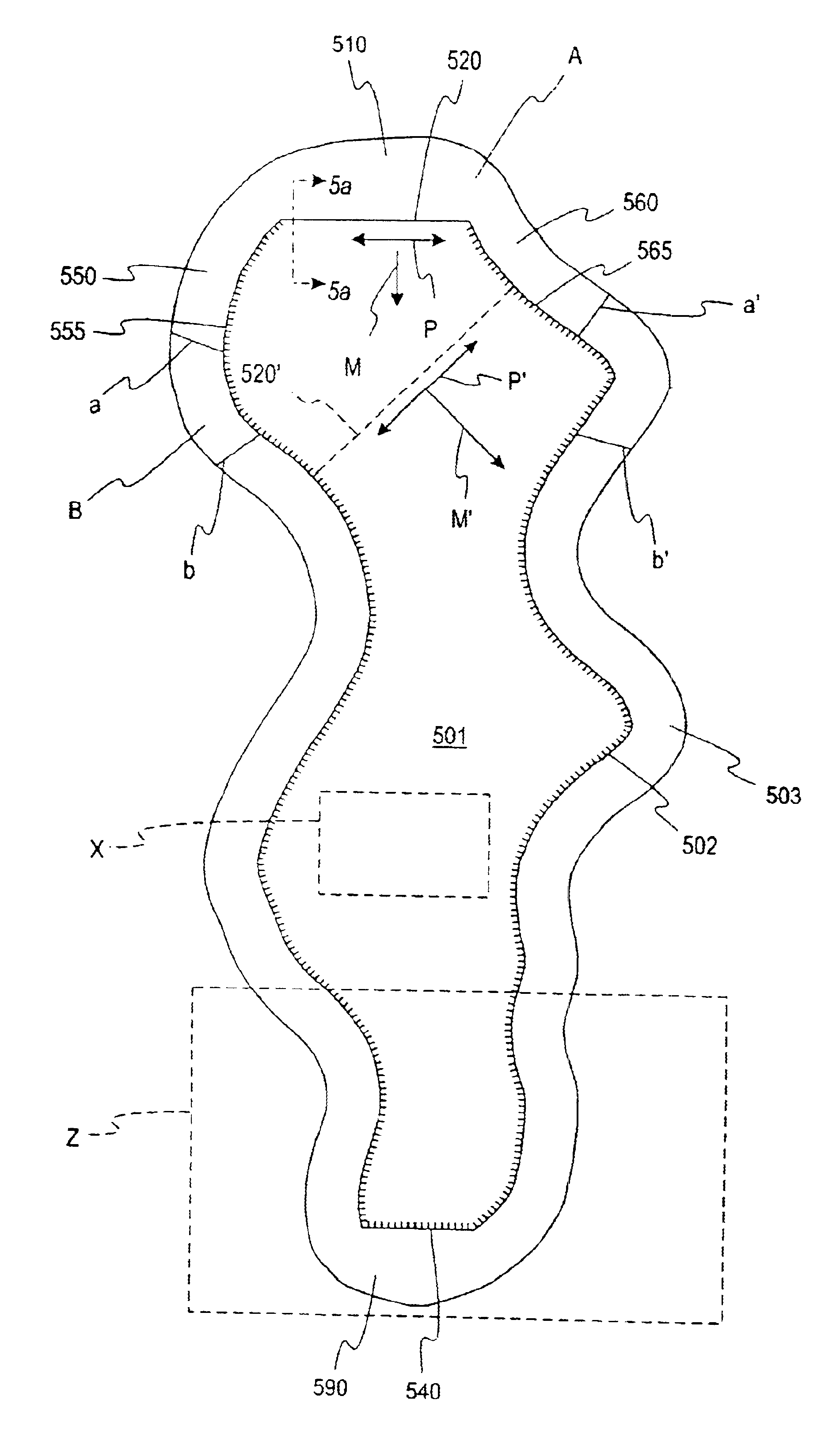

Structured light quick scanning microscopic imaging method

ActiveCN103207449AReduced modulation speed dependenceReduced robustness requirementsMicroscopesModulation patternPhysics

The invention relates to a structured light quick scanning microscopic imaging method. The method comprises the following steps of: (1) controlling a spatial light modulator to generate a modulation pattern with single spatial frequency by a computer, and projecting the modulation pattern on a sample fracture; (2) under the condition that the phase of the modulation pattern is unchanged, driving a sample to move by an electric control movement platform, and synchronously triggering a line-scan digital camera to take a picture; (3) changing the phase of the modulation pattern, and scanning the same imaging region until different lighting phase images required by structured light imaging is acquired; and (4) moving a sample, and executing the steps (2) to (4) for the subsequent adjacent imaging region until the whole sample fracture is scanned. By performing phase change for one time before scanning motion is performed at each time, requirements of imaging on the speed and robustness of the modulator are reduced; and in single-time scanning motion, a complete image is acquired, and adjacent images are partially overlapped. Sample motion and camera exposure are synchronously performed, so that time is saved, and imaging speed is increased.

Owner:WUHAN OE BIO CO LTD

Strengthening and rehabilitation exercise apparatus

ActiveUS20110275500A1Easy to implementLoad minimizationChiropractic devicesStiltsProne positionLumbar

A strengthening and rehabilitation exercise apparatus includes a hip joint strengthening and rehabilitation exercise apparatus for strengthening a pelvis, an abdominal region, and a waist through exercise of a lower body symmetrically interlocking with a weight while fixing an upper body in a prone position, a hip joint strengthening and rehabilitation exercise apparatus for strengthening the pelvis, the abdominal region, and the waist through exercise of the upper body interlocking with the weight while fixing the lower body in a sitting position, a waist joint strengthening and rehabilitation exercise apparatus for strengthening the waist and the abdominal region through exercise of the upper body interlocking with the weight while fixing legs and the pelvis in a straight line in a supine position, and a stretching apparatus for performing muscle exercise of a back and shoulders using hands and arms in the sitting position.

Owner:HUR YOUNG BAEK

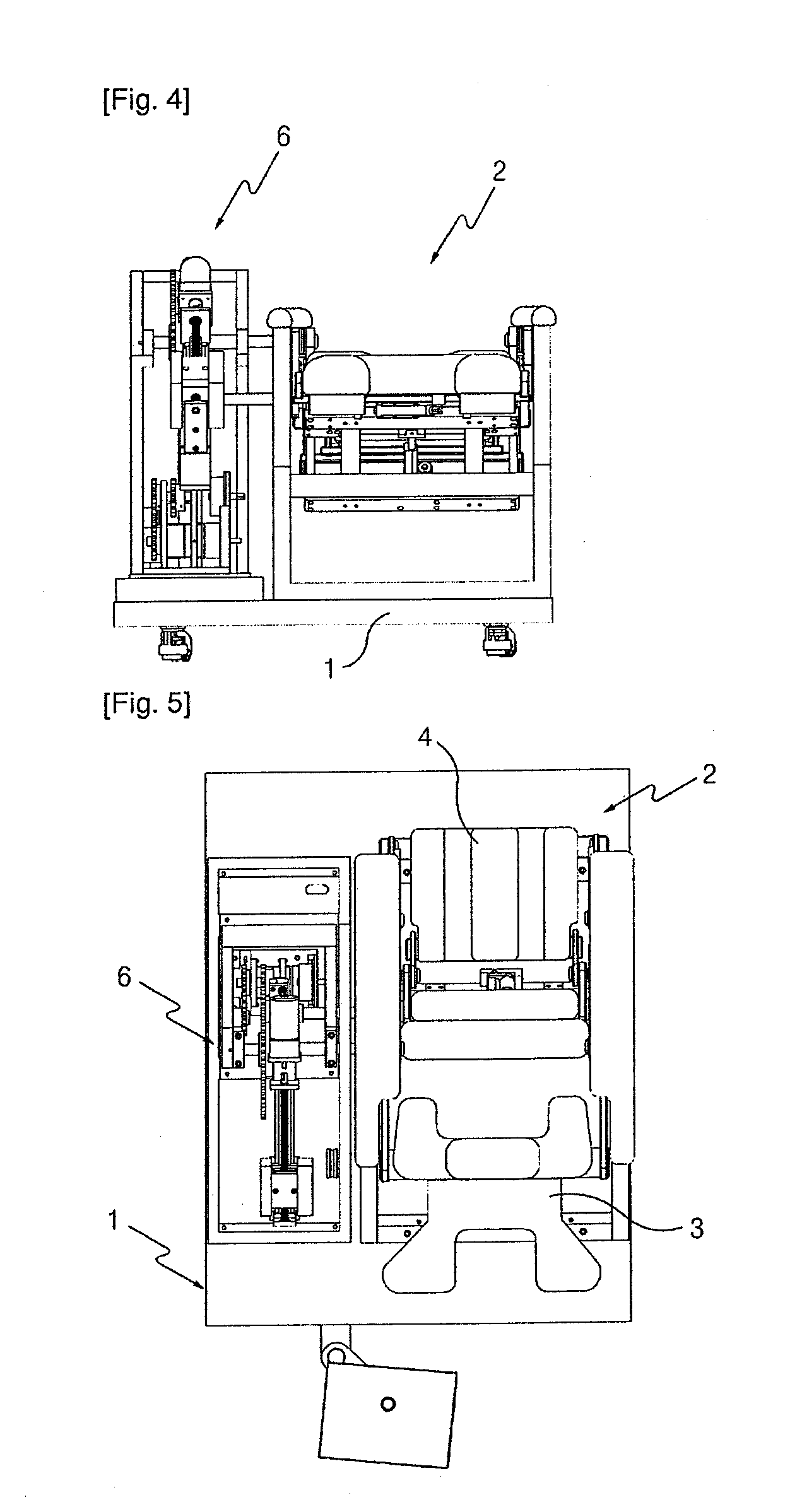

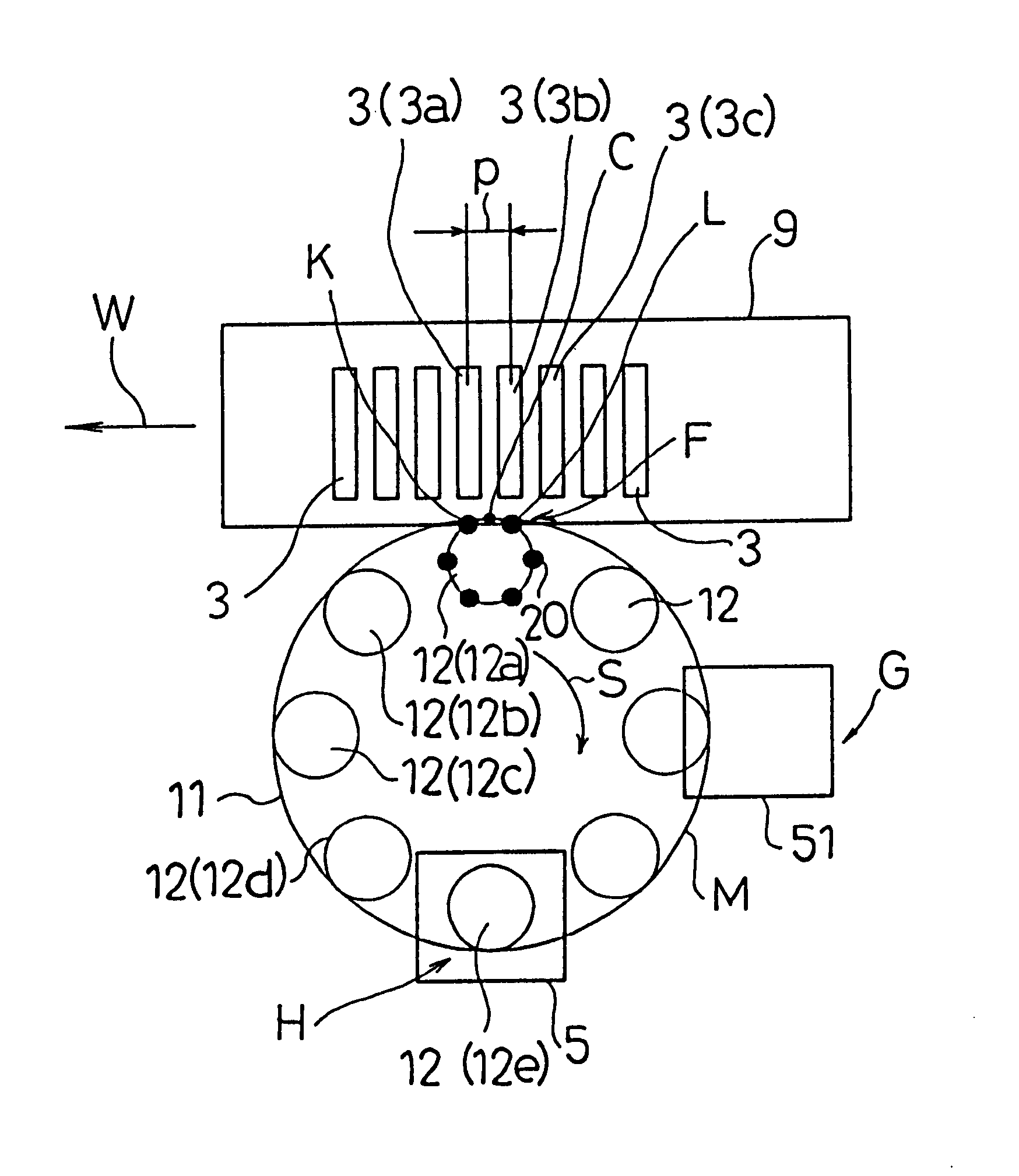

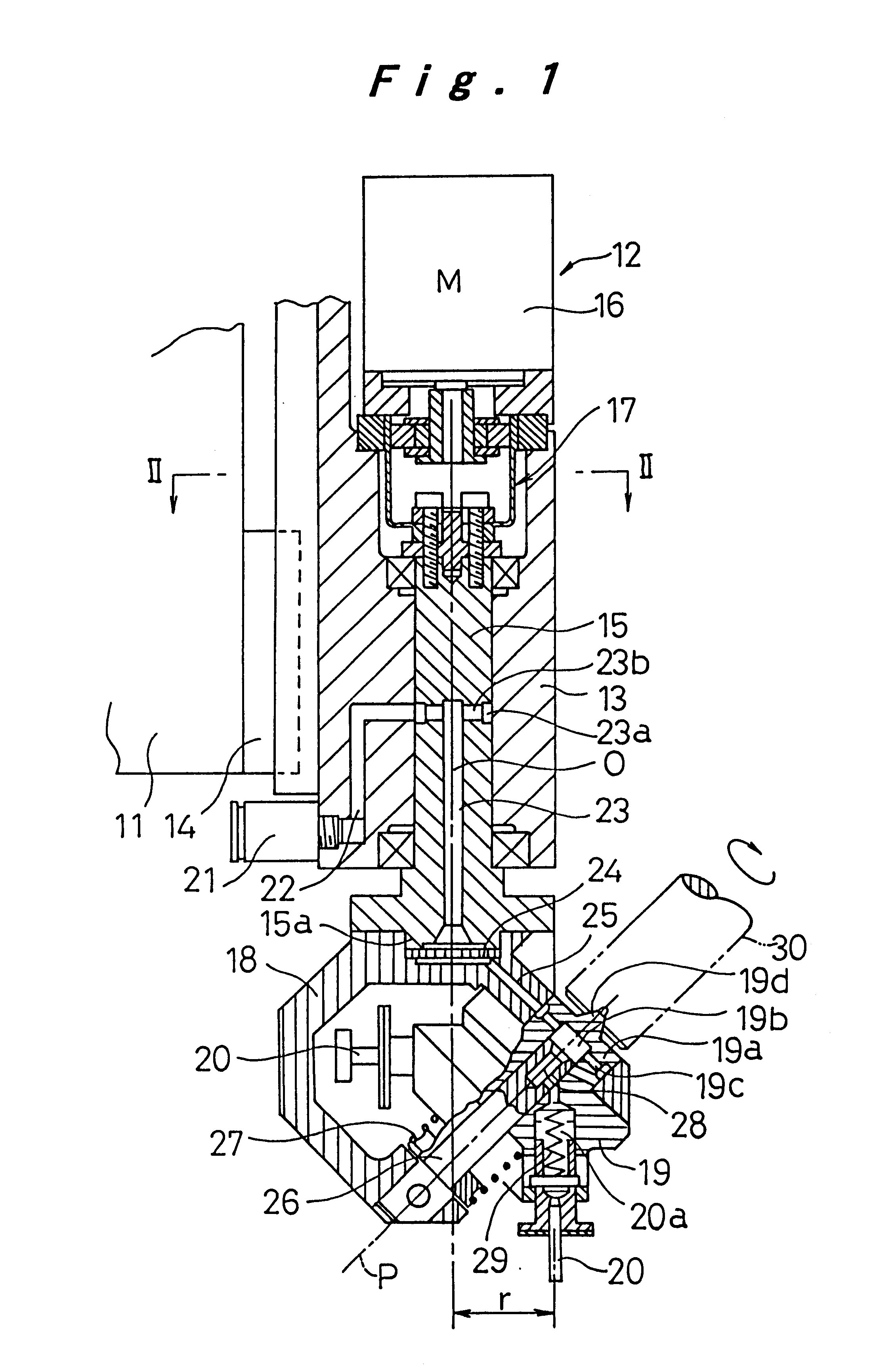

Method for mounting component

InactiveUS6195878B1Reduce exerciseShorten exercise timePrinted circuit assemblingGripping headsNozzle

A method for mounting components using mounting heads for which a plurality of suction or mounting operating positions are set for suction nozzles in a state where the mounting head is at rest in a component supply position or component mounting position, it being possible to select any of these operating positions, comprising a first step of selecting a component supply position or component mounting position such that the amount of movement of component feeder holding components to be mounted, or the amount of movement of the substrate to the mounting position for the next component to be mounted becomes a minimum, and moving the component feeder or substrate accordingly; and a second step of selecting a suction nozzle position corresponding to the component suction position or component mounting position in the first step, whilst the mounting head is moving towards the component suction position.

Owner:PANASONIC CORP

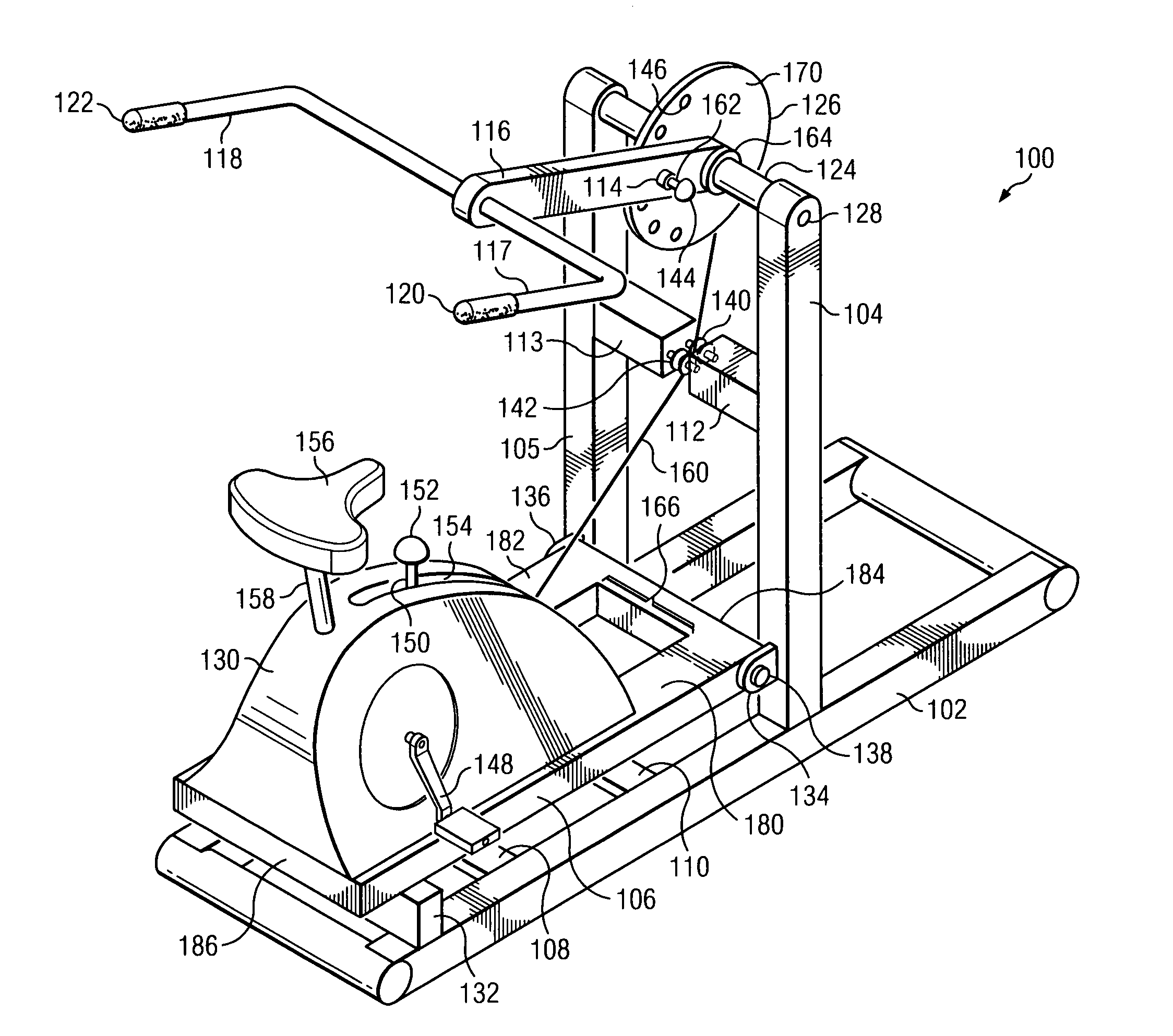

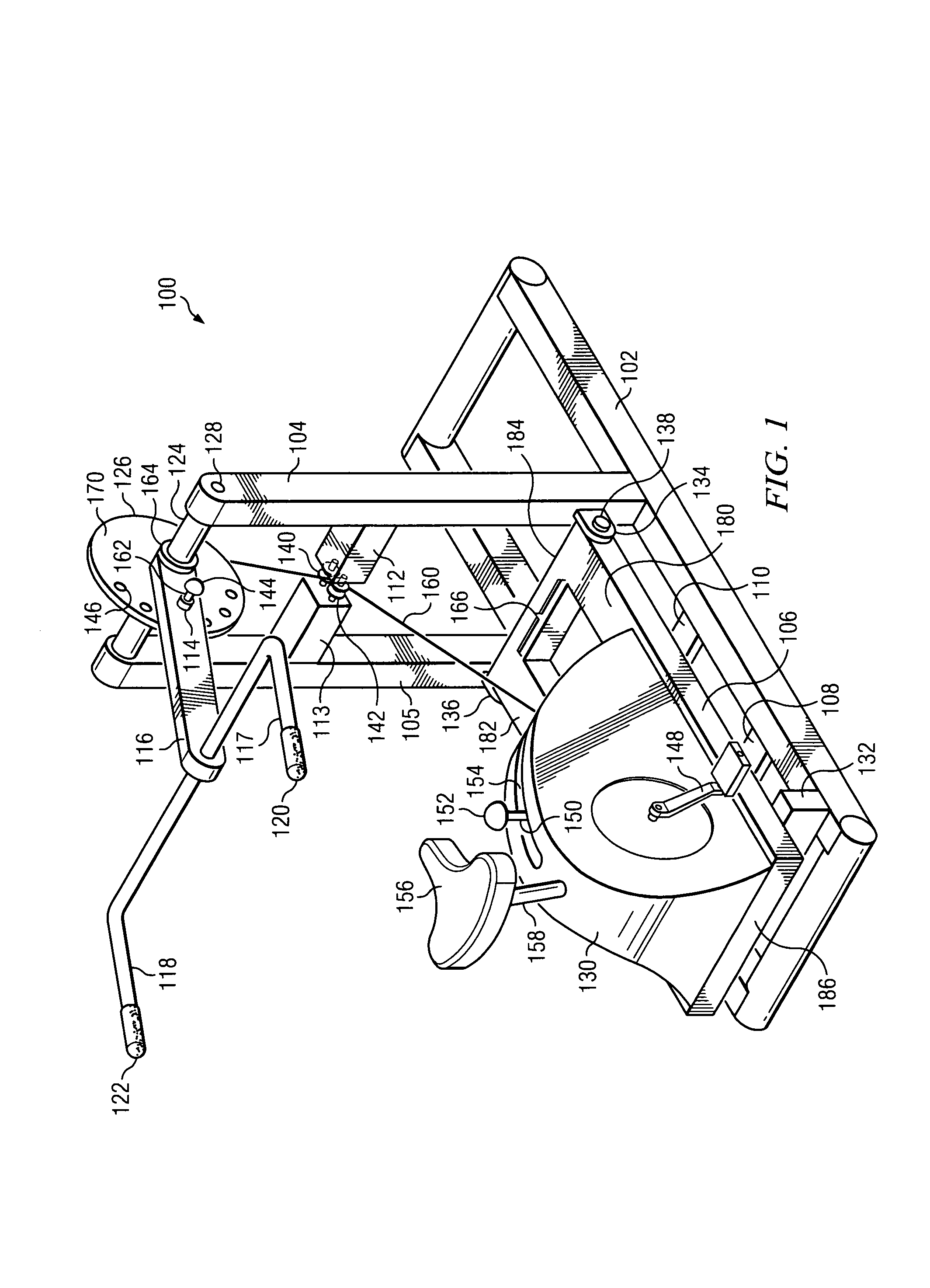

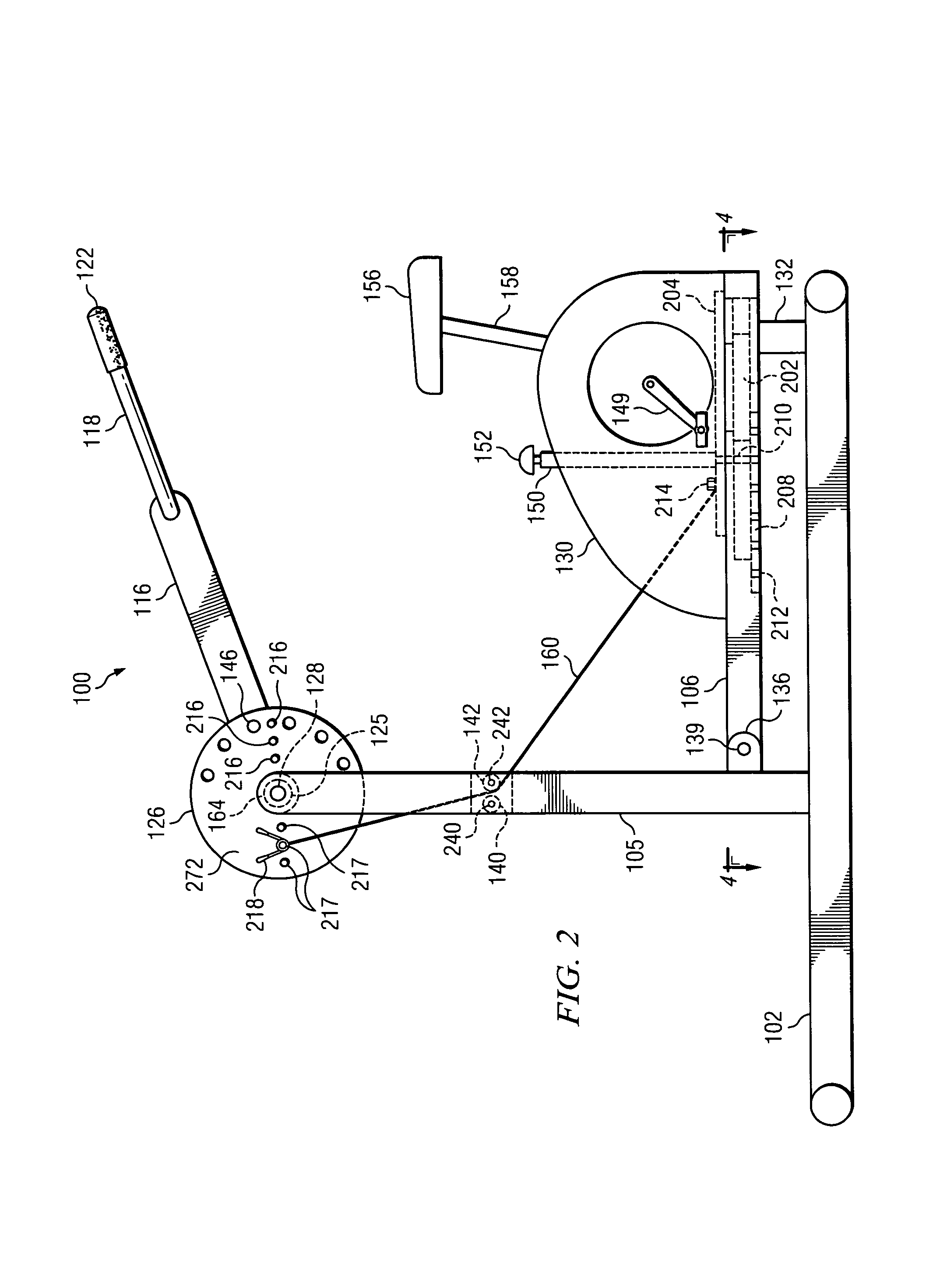

Multimotion exercise apparatus and method

InactiveUS7695411B2Shorten exercise timeLess total time exercisingStiltsMovement coordination devicesEngineeringBody weight

A multimotion exercise bicycle capable of providing a cardiovascular exercise simultaneously with an upper body weight training exercise. The cardiovascular exercise is accomplished by a pedaling movement connected to a resistance means. The upper body exercise is accomplished by a pushing or a pulling movement of a handlebar and arm setup connected to a disk which is further connected to a cable attached to a weight bearing platform. The weight of the user provides the resistance for the upper body movement. The difficulty level of the upper body movement is adjustable by changing the location of the handlebars relative to the disk and by changing where the cable attaches to the disk. As the user performs these exercises simultaneously, the invention allows the user to burn more calories and reduce work-out time in half.

Owner:CORE FITNESS SYST +2

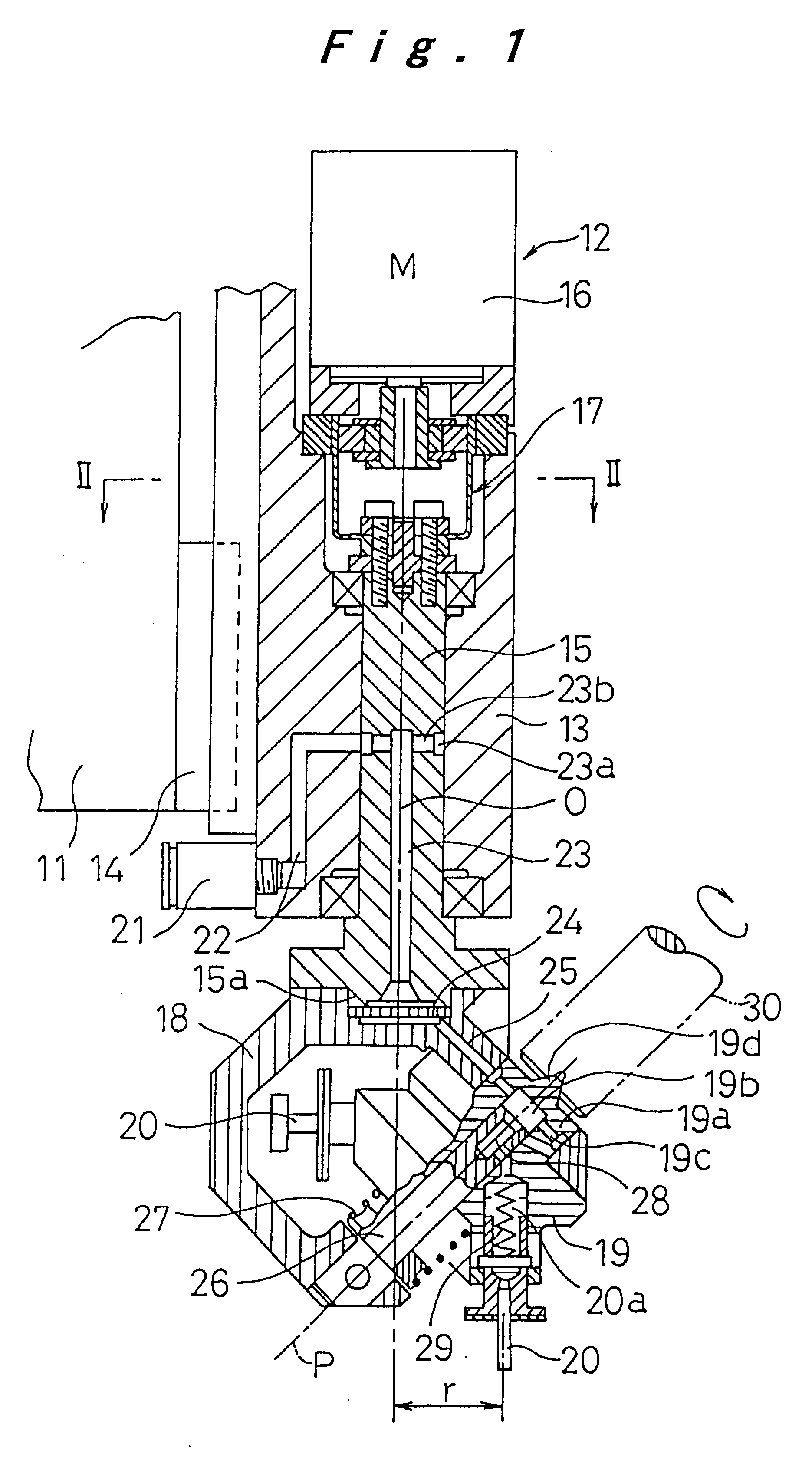

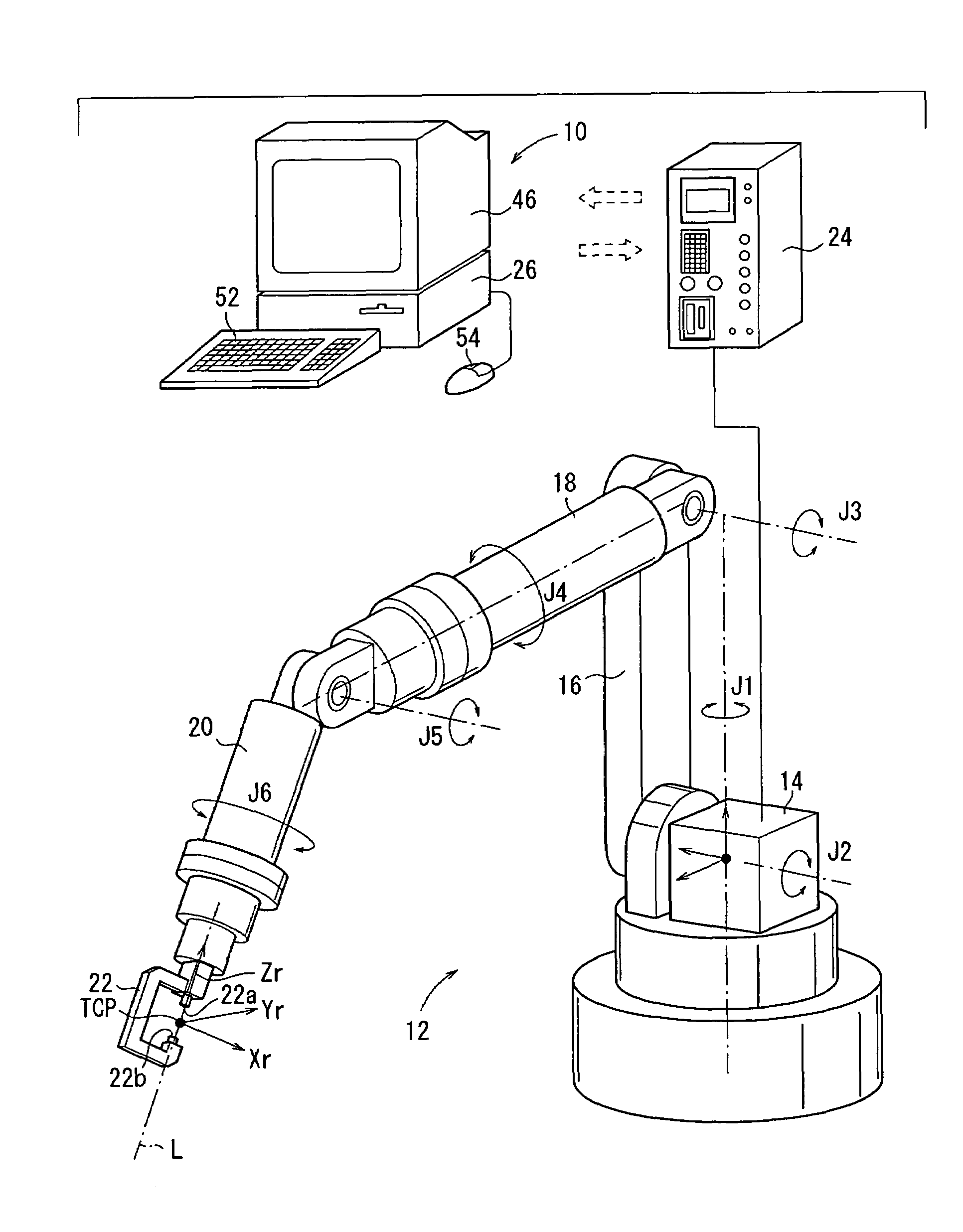

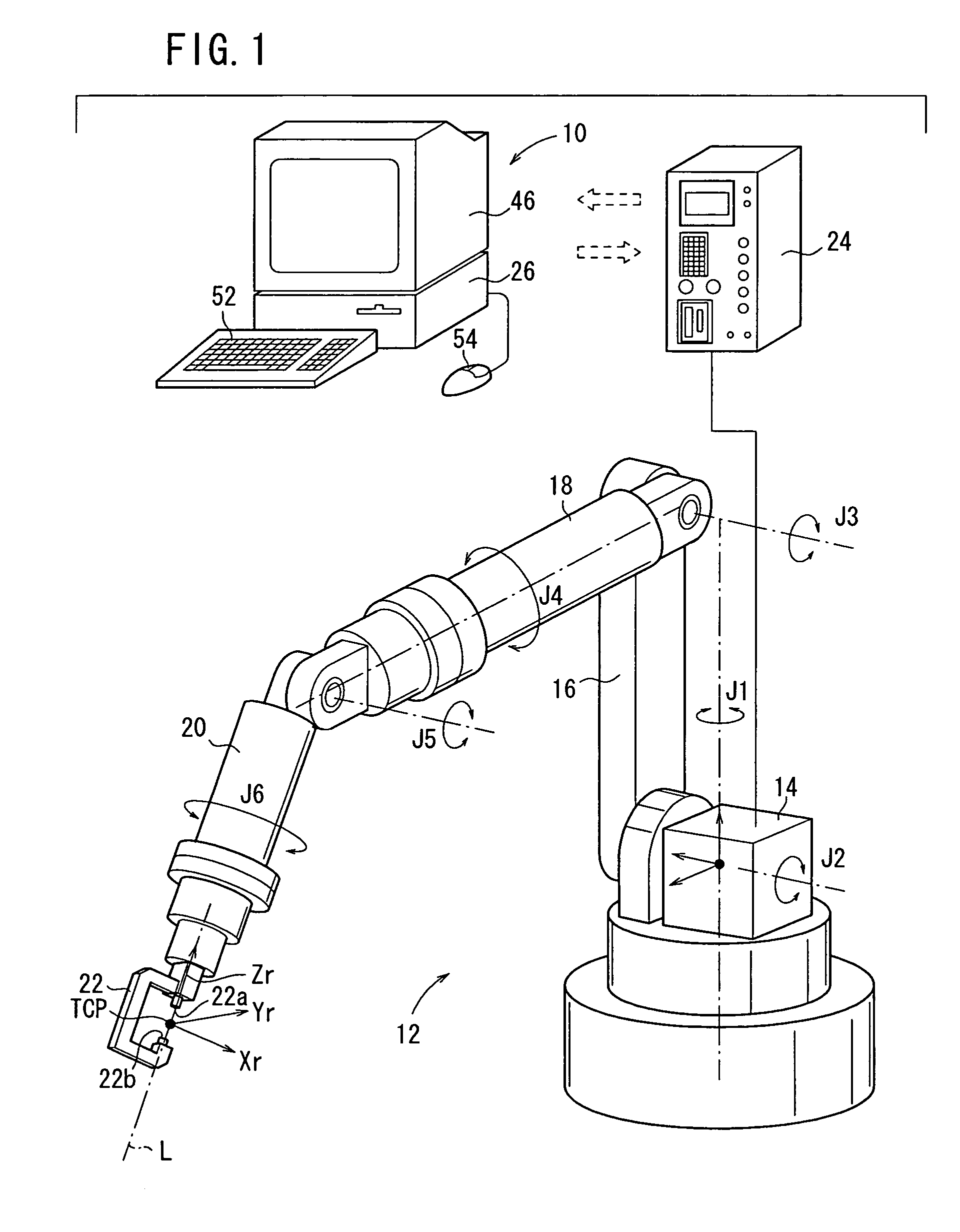

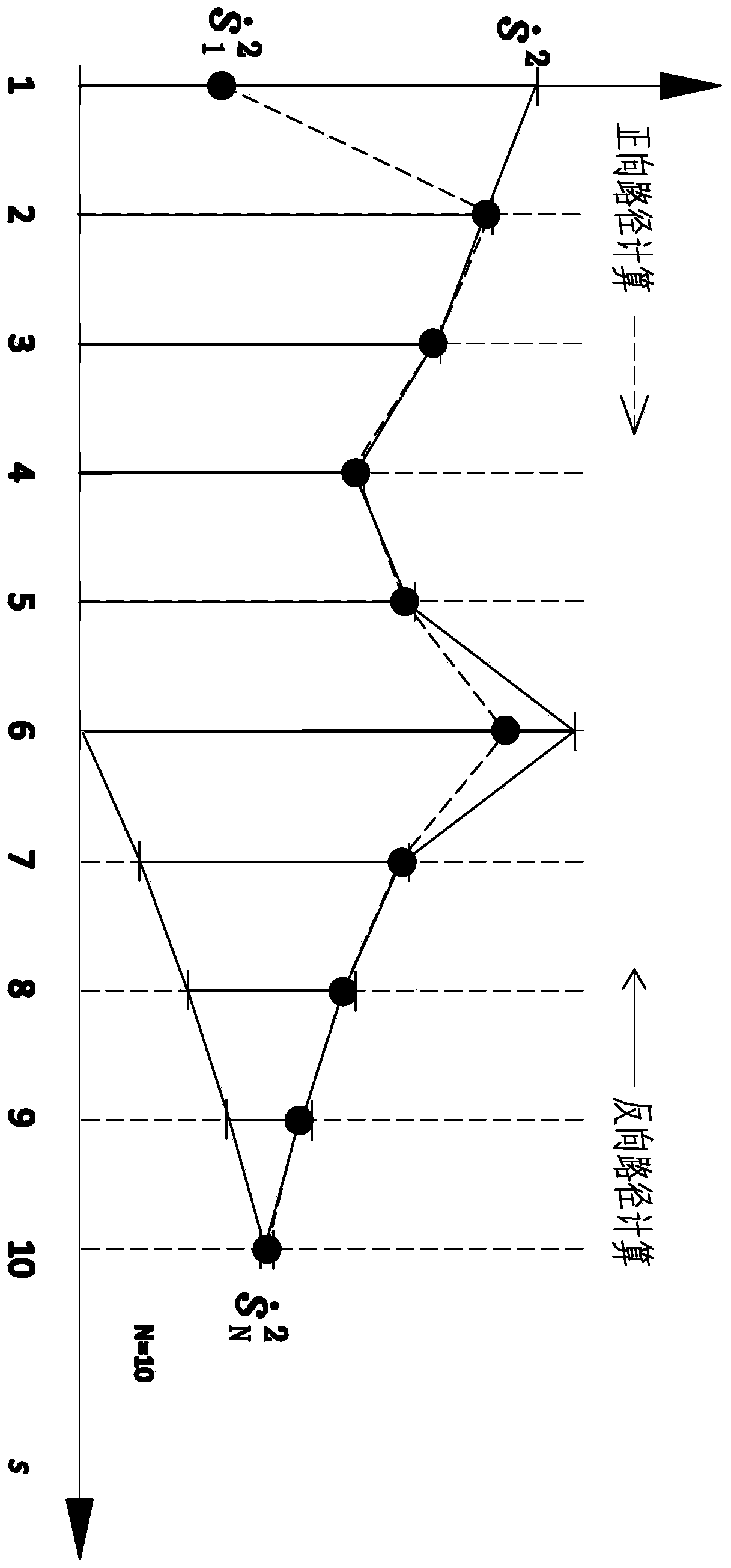

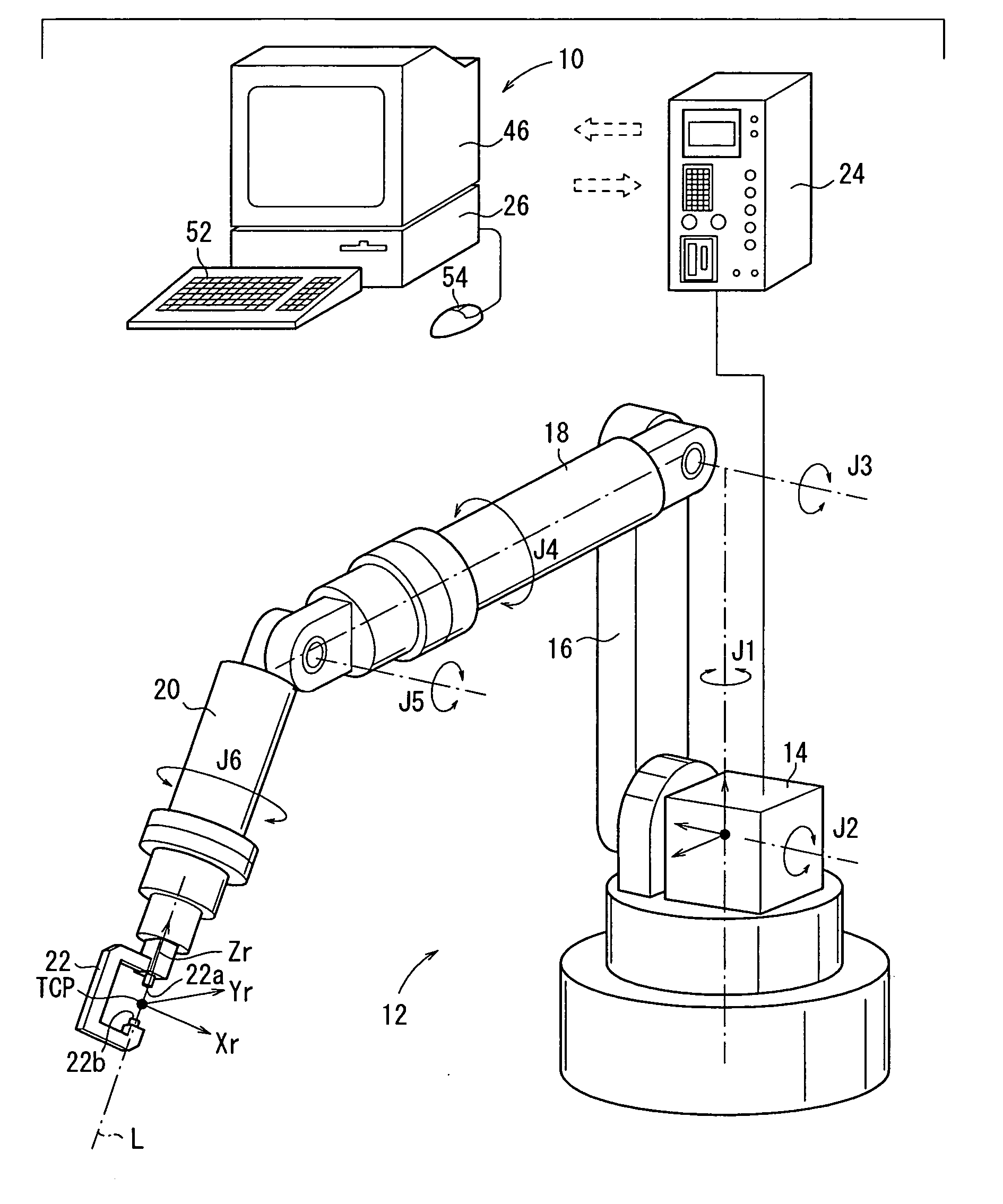

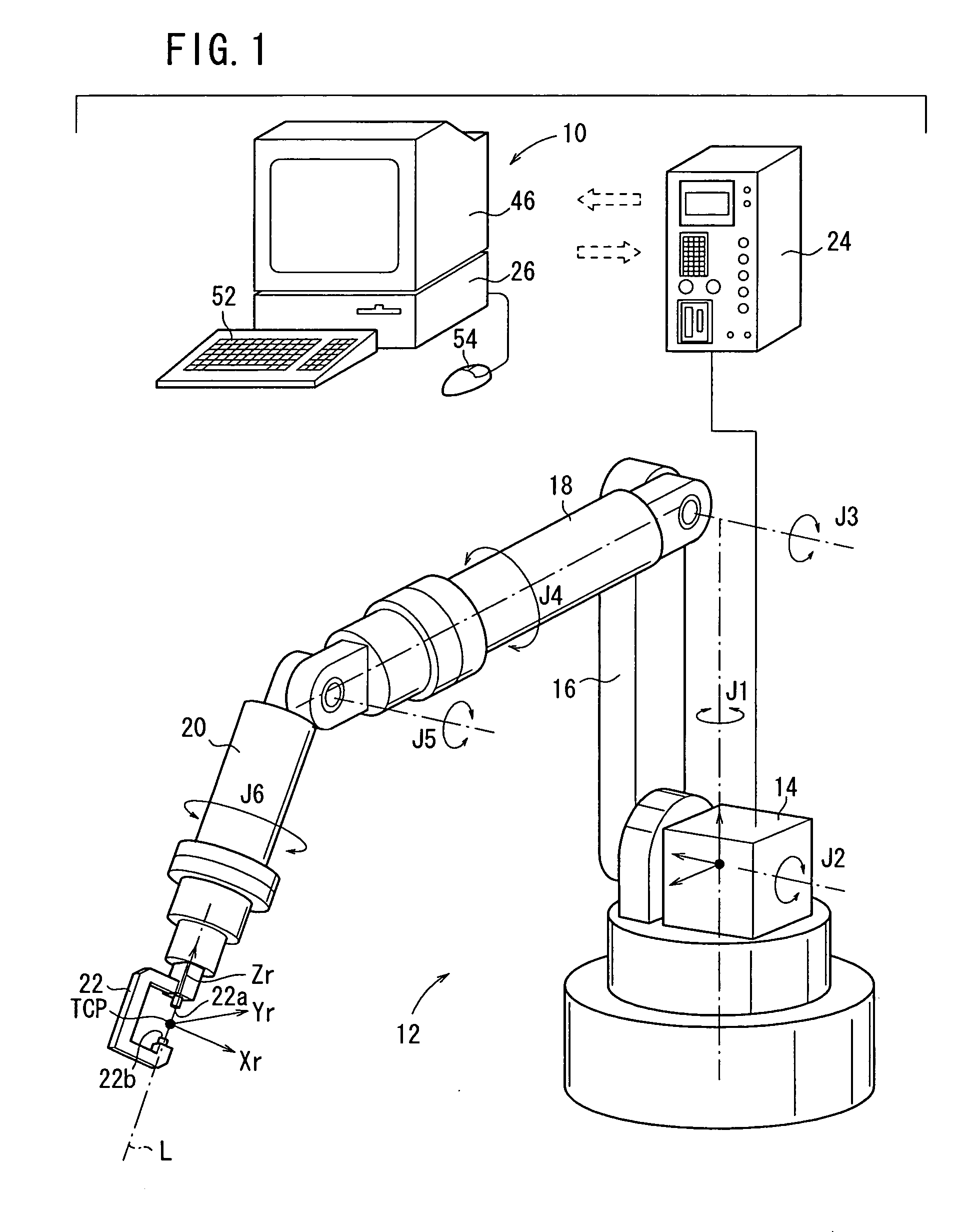

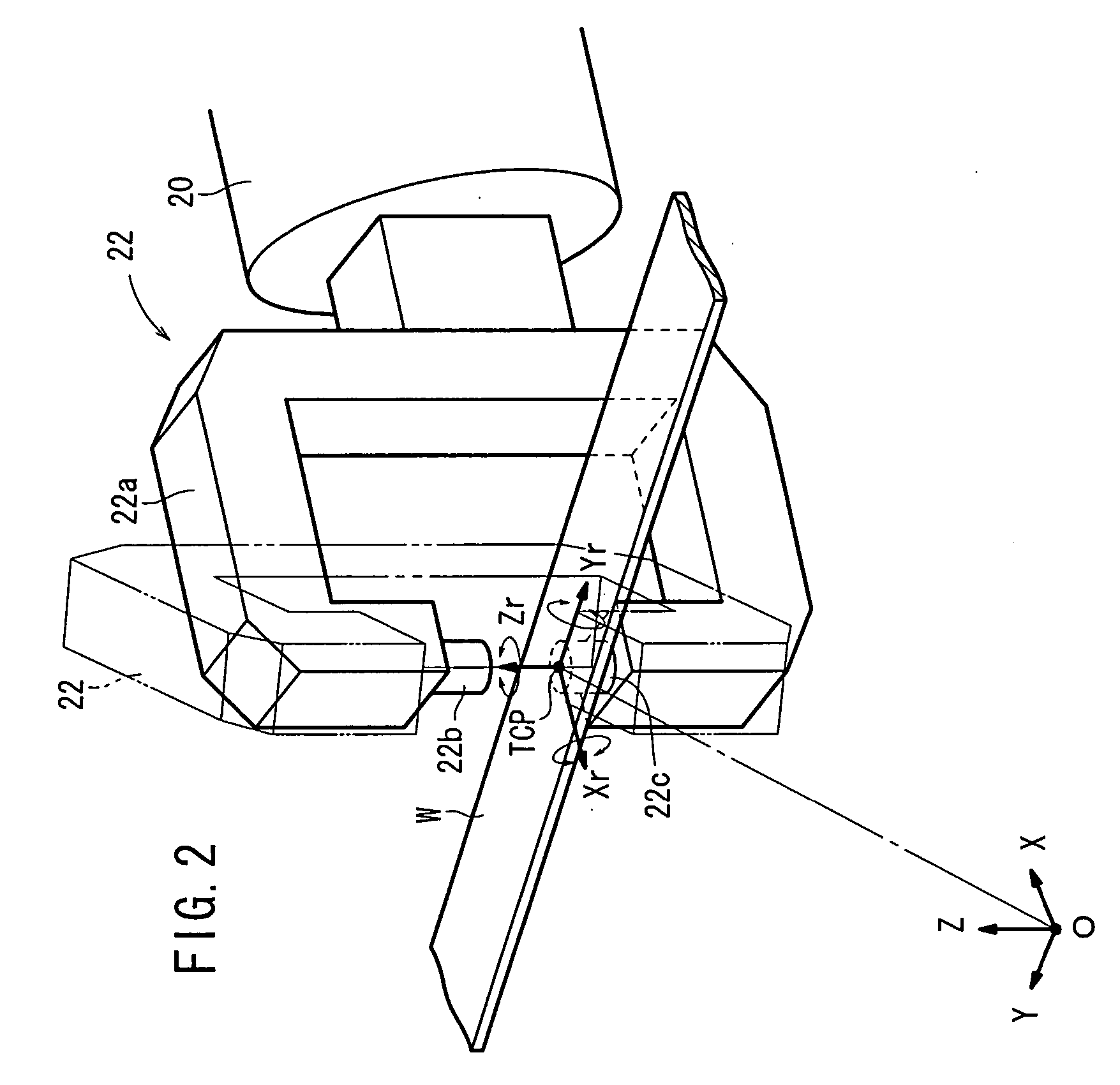

Teaching data preparing method for articulated robot

ActiveUS7248012B2Smoothly moving the articulated robotShorten exercise timeProgramme-controlled manipulatorComputer controlData preparationEngineering

Set the first temporary attitude of an end effector for a plurality of work points (step S3). Determine the attitude of an articulated robot at one-end first work point out of a plurality of work points (step S4). Determine the attitude of an articulated robot at the other-end final work point out of a plurality of work points (step S5). Set the second temporary attitudes of an end effector respectively for the other work points so that the attitude of an end effector gradually changes from the first work point toward the final work point (step S6). Correct the first temporary attitude with the second temporary attitude (step S7).

Owner:HONDA MOTOR CO LTD

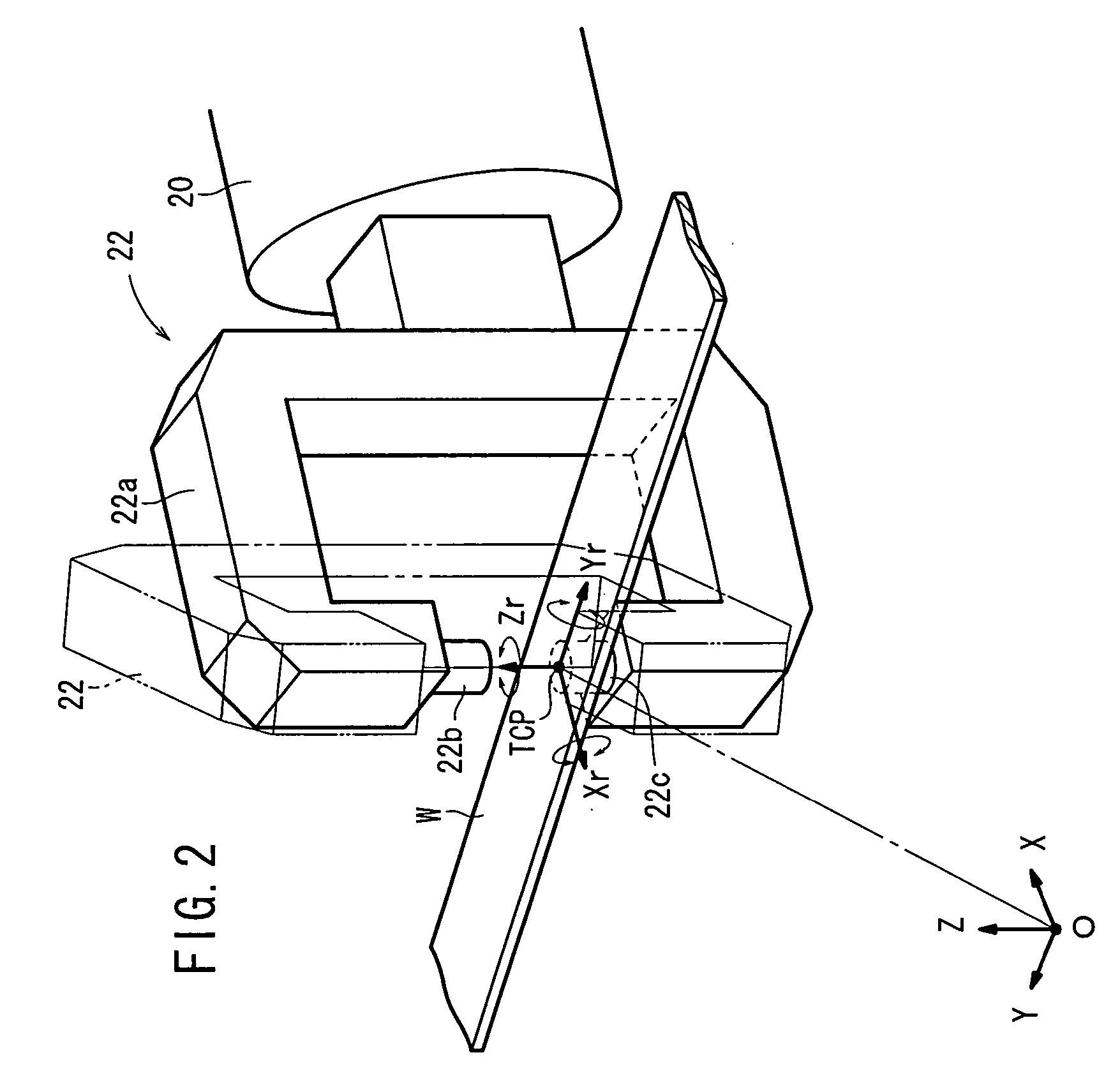

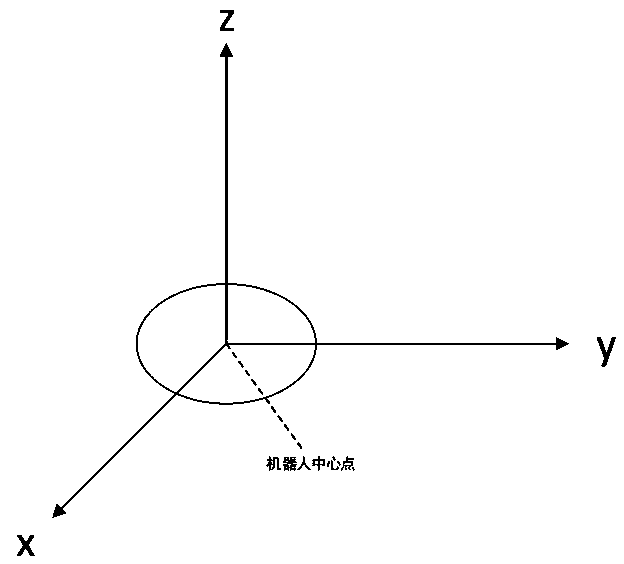

Robot time optimal trajectory planning method

ActiveCN111399514AGuaranteed accuracyGuaranteed smoothnessPosition/course control in two dimensionsRobot controlTrajectory planning

The invention provides a robot time optimal trajectory planning method, and belongs to the technical field of robot control. The trajectory planning method solves the problem that in the prior art, atrack planning method is poor in practical applicability. The robot time optimal trajectory planning method comprises the steps of obtaining and discretizing a task path and obtaining coordinates of discrete points, and further comprises the steps of A, obtaining kinematics parameters; B, determining variables and constraint conditions, and establishing a constraint inequality; C, calculating to obtain an optimal variable constraint maximum value and an actually allowable optimal solution; D, acquiring information of each discrete point, and generating a discrete point interpolation array; andE, regenerating a discrete point sequence about time, and calculating and outputting joint information about time, so that the adaptability of method application is improved, the calculation difficulty is reduced, and the working efficiency is improved.

Owner:ZHEJIANG QIANJIANG ROBOT CO LTD

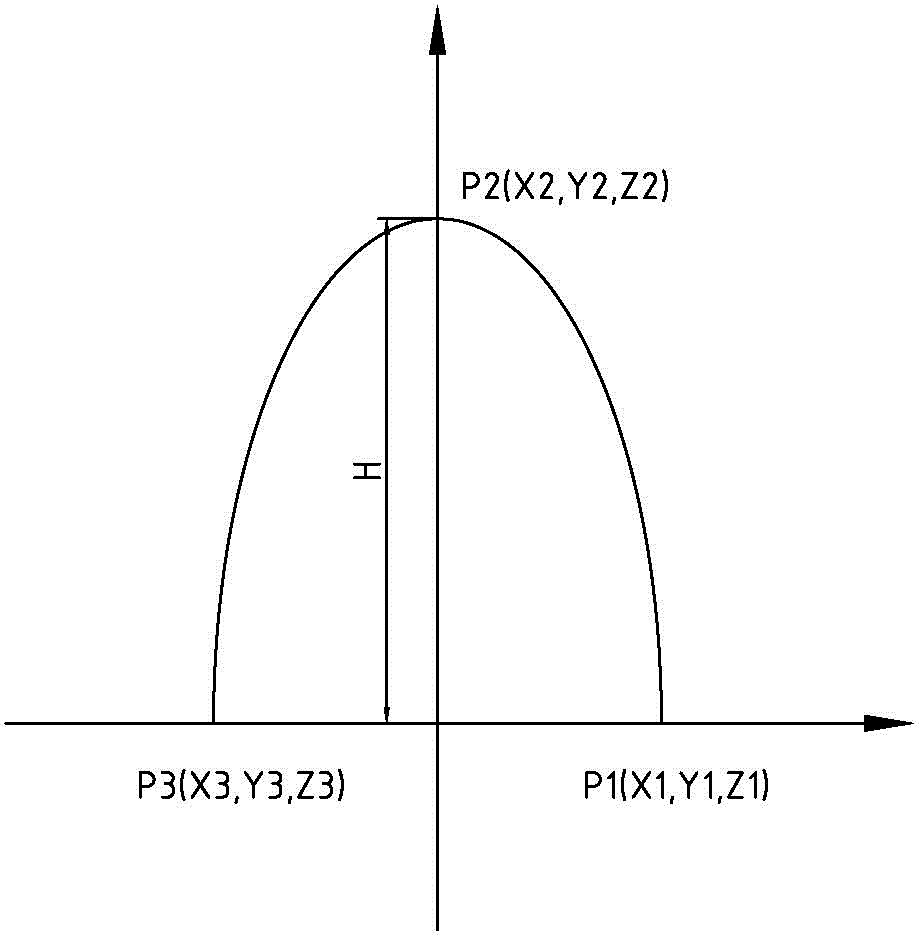

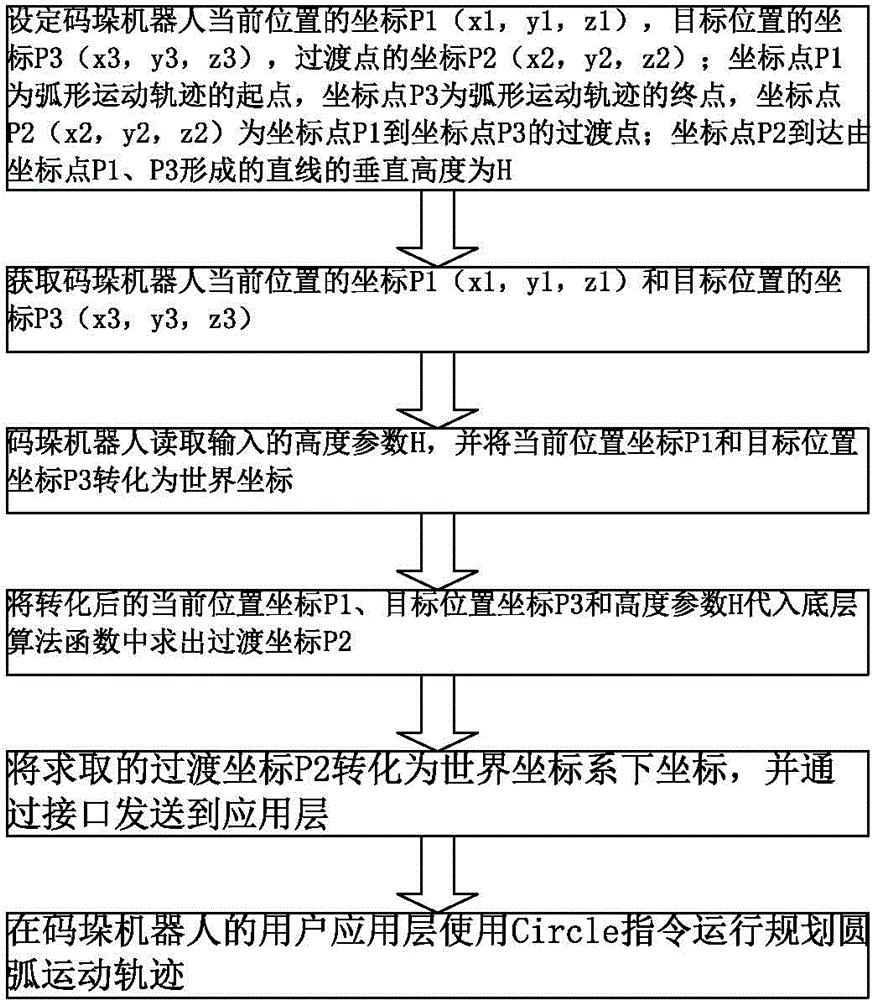

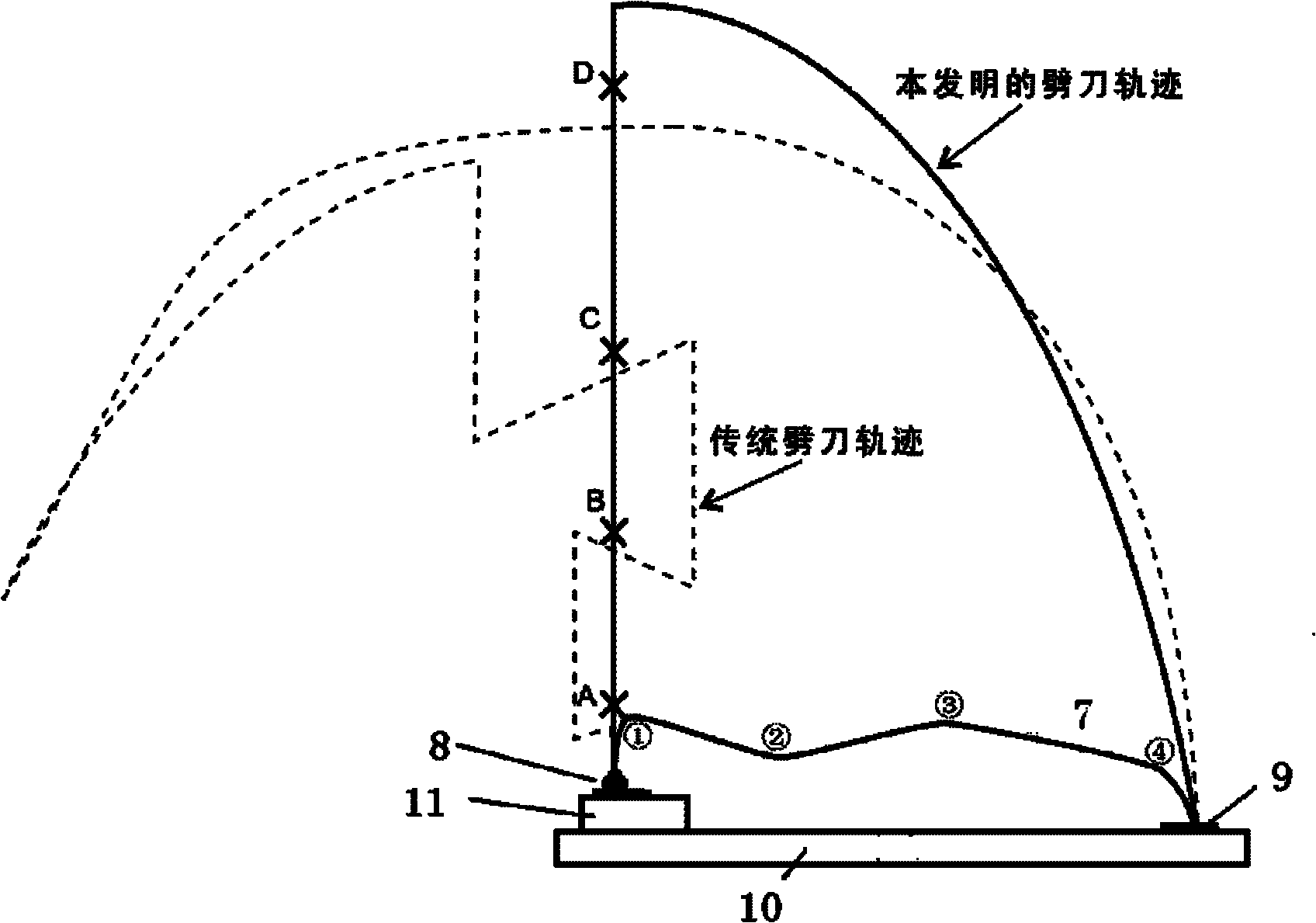

Arc-shaped movement-track algorithm for palletizing robot

InactiveCN104570735AReduce exercise distanceShorten exercise timeAdaptive controlMechanical engineeringProtocol Application

The invention provides an arc-shaped movement-track algorithm for a palletizing robot. The arc-shaped movement-track algorithm comprises the following steps: (2) acquiring the coordinate P1( x1, y1, z1) of the current position of the palletizing robot, and the coordinate P3 (x3, y3, z3) of the target position of the palletizing robot; (3) enabling the palletizing robot to read an input height parameter H, and converting the current-position coordinate P1 and the target-position coordinate P3 into a world coordinate; (4) bringing the current-position coordinate P1, the target-position coordinate P3 and the height parameter H into a basic arithmetic function so as to obtain an interim coordinate P2; (5) converting the obtained interim coordinate P2 into a coordinate under the world coordinate, sending the obtained coordinate to an application layer through a port; (6) using a Circle command to plan an arc-shaped movement track at a user application layer of the palletizing robot. Because the movement track of the palletizing robot is planned into a parabola, the movement distance of the robot is shortened, so that the movement time of the robot in each period is shortened, and besides, the movement of the robot is more flexible.

Owner:佛山市湘德智能科技有限公司

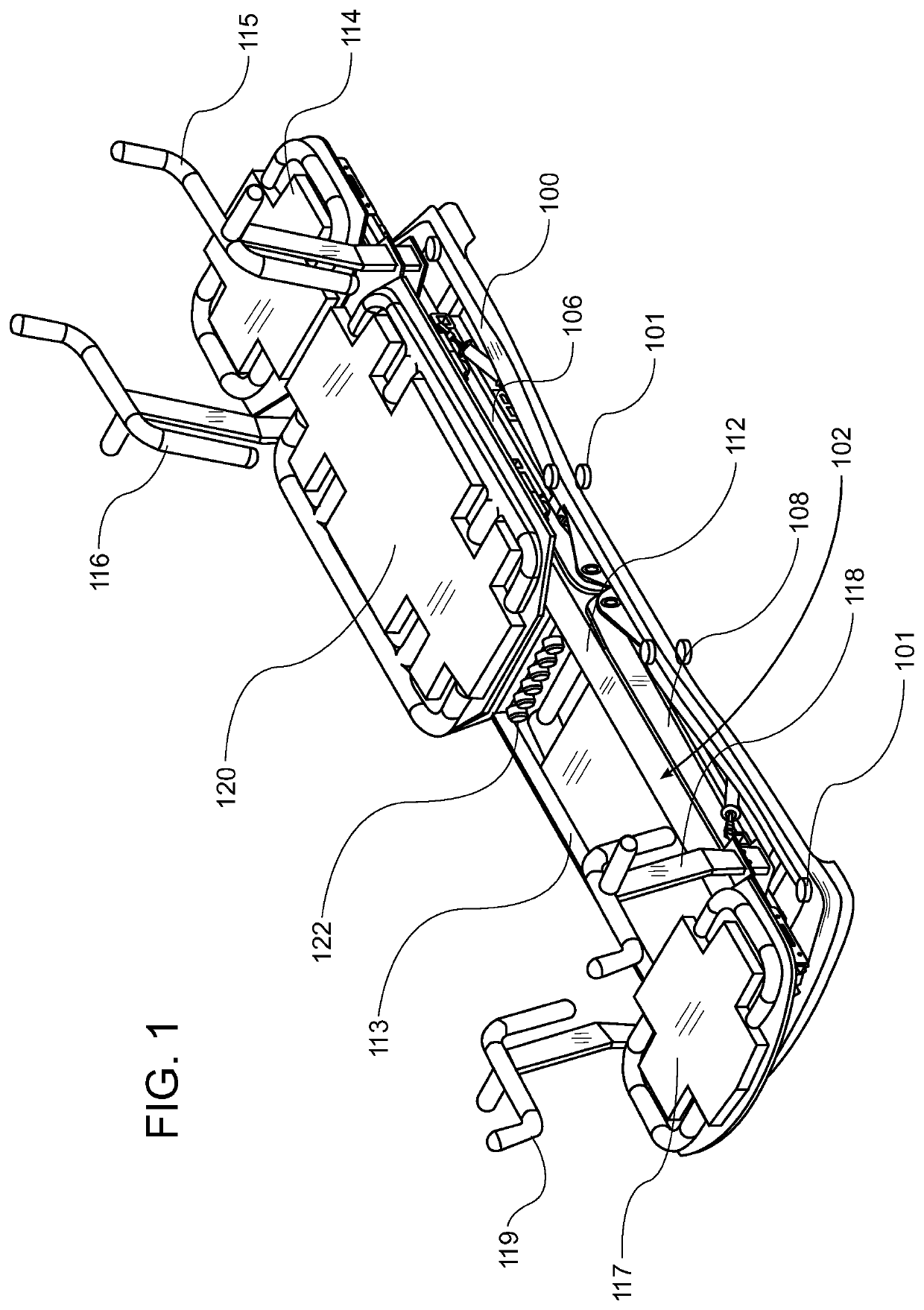

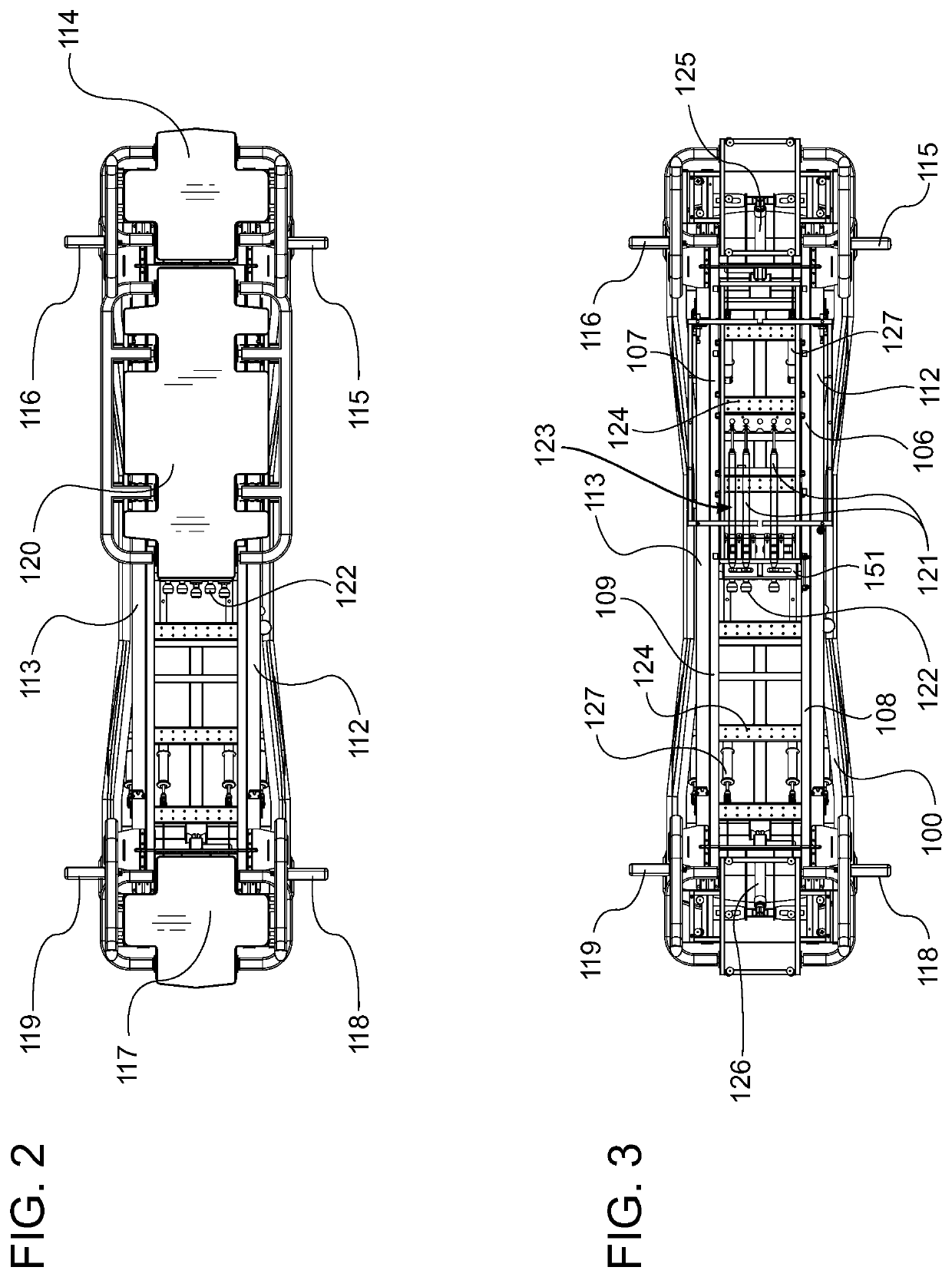

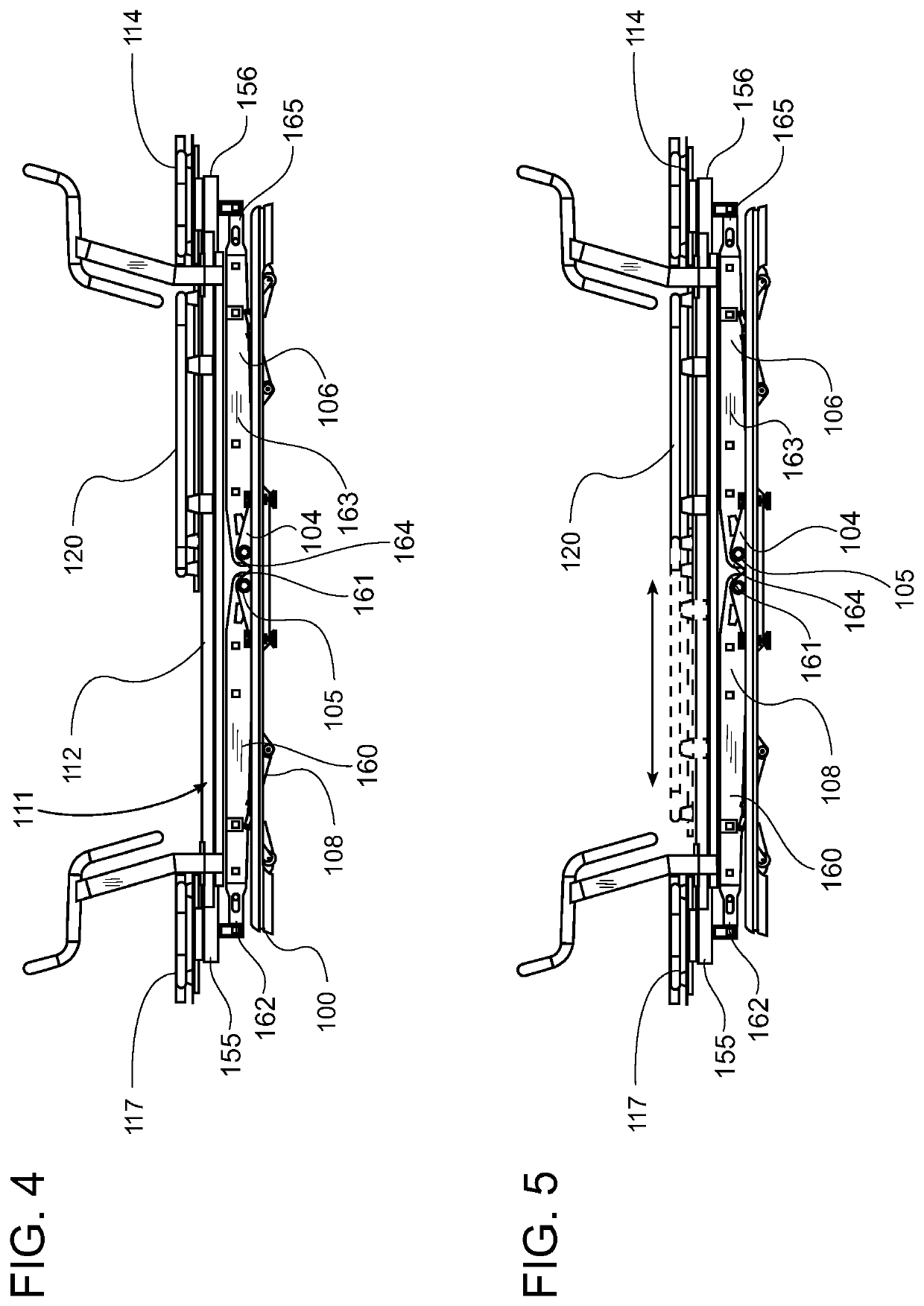

Adjustable Exercise Machine

ActiveUS20200030657A1High strengthShorten exercise timeMuscle exercising devicesMovement coordination devicesReciprocating motionClassical mechanics

An adjustable exercise machine for performing resistance exercises comprises a base and an upper frame including front and back end stationary exercise platforms, and a movable exercise platform that reciprocates between the stationary platforms. A plurality of biasing members is selectable by an exerciser via selector knobs to generate a bias force against the movable platform. A plurality of pivotable lift supports are connected between the base and the upper frame. Front and back actuators are connected between the base and the lift supports by lifting yokes to selectively raise and lower the front and back ends of the machine. The movable platform may be connected to move along the exercise machine by trolley wheel assemblies. A plurality of travel limit decelerators mounted on the rails engage and rapidly decelerates the movable platform as it reaches its limits of travel on the rails.

Owner:LAGREE TECH INC

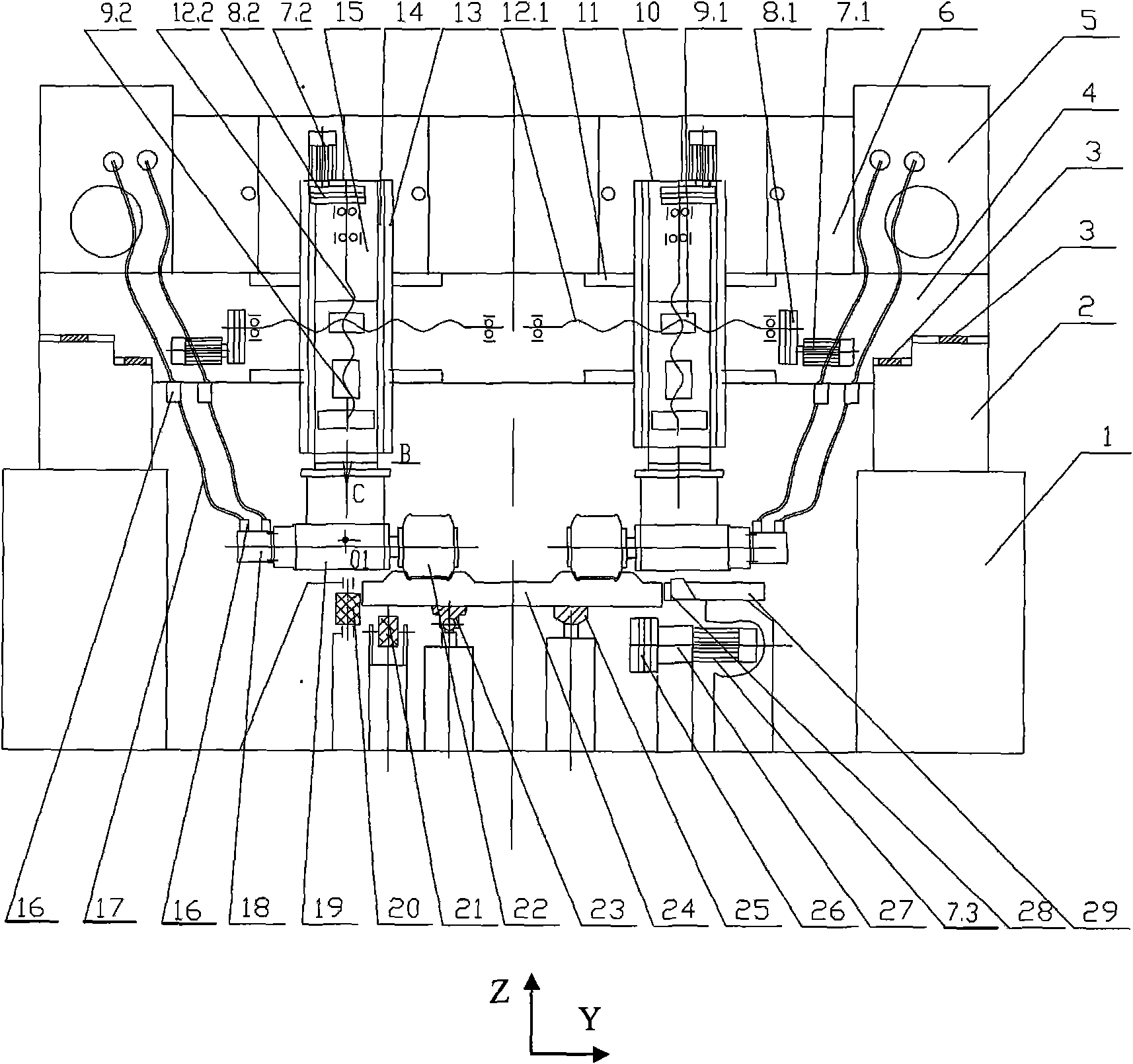

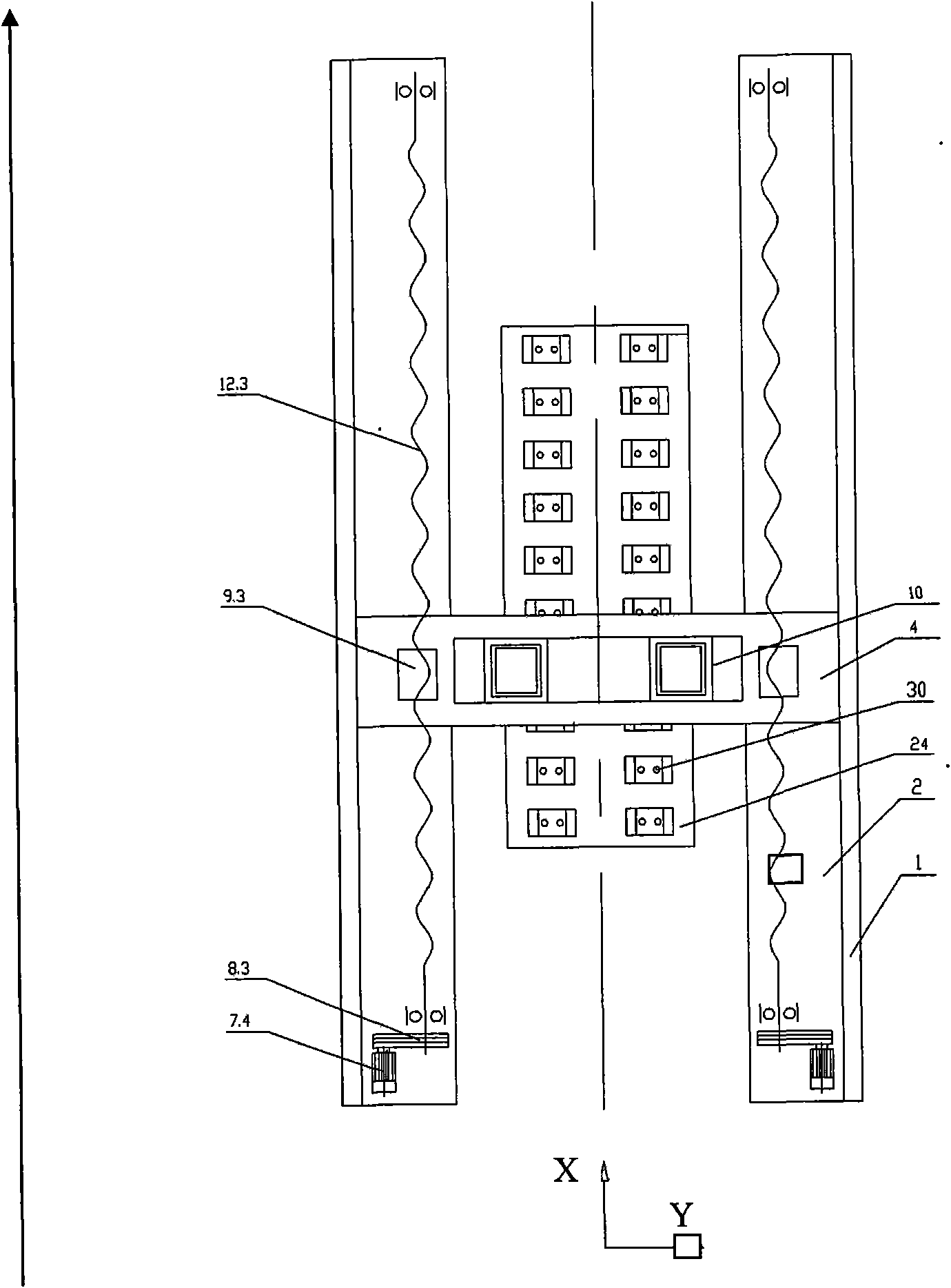

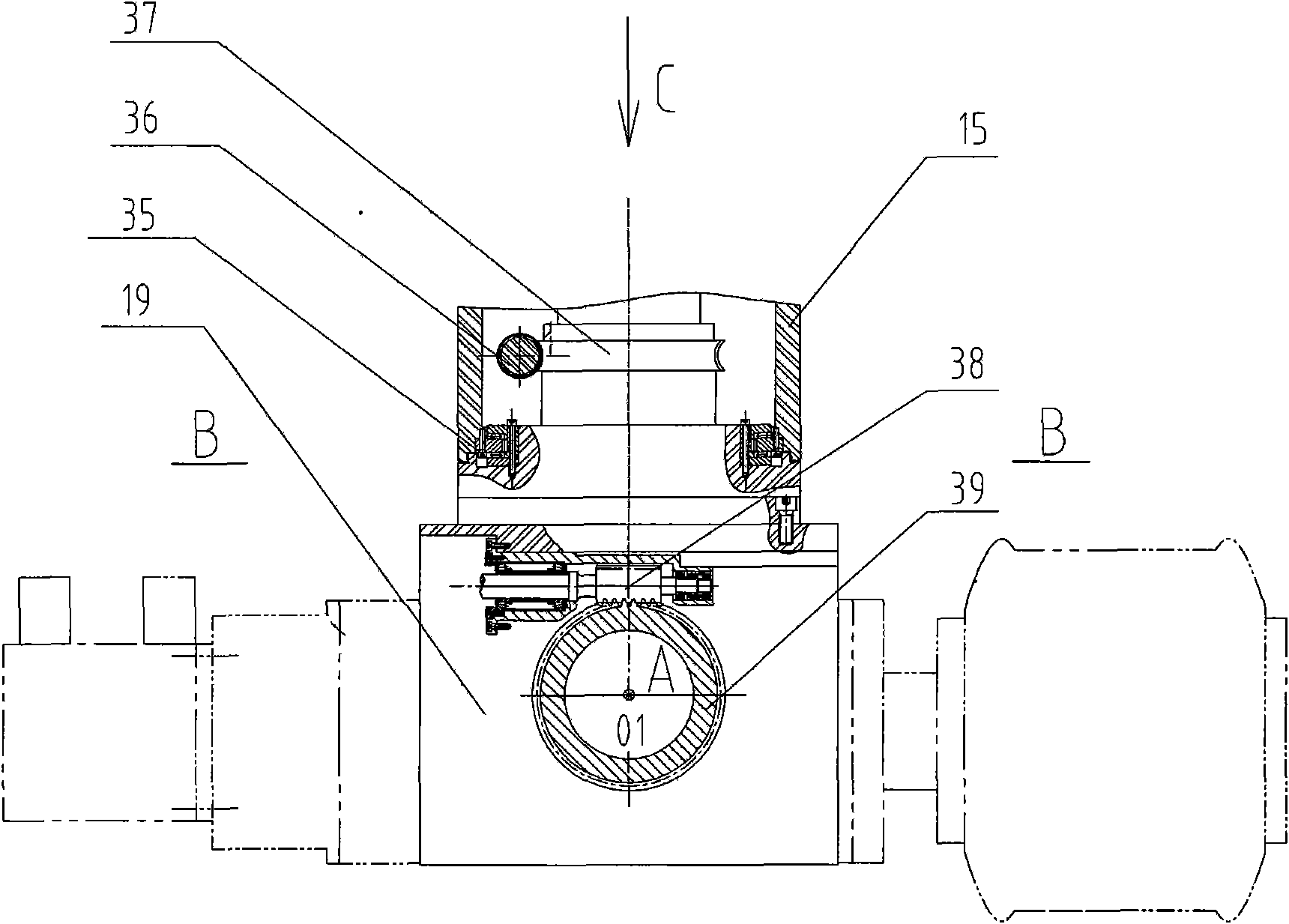

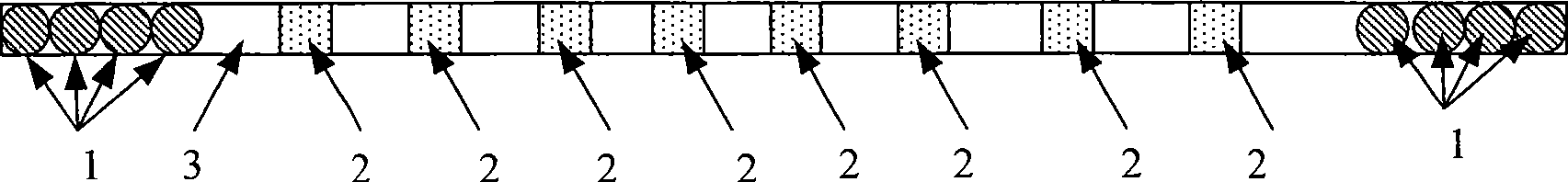

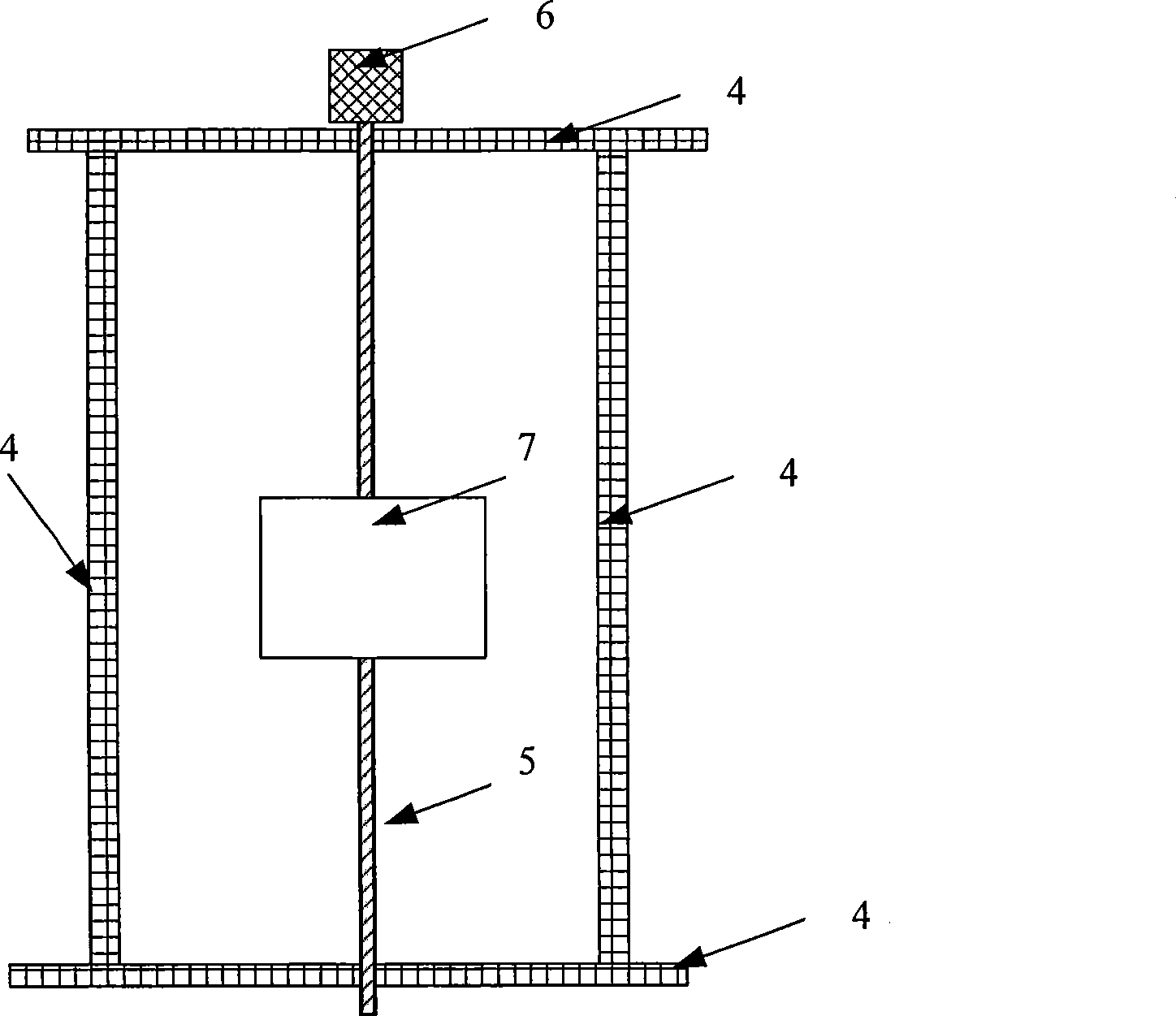

Track slab grinder

ActiveCN101628390ARealize one-time double-sided processingImprove processing efficiencyStone-like material working toolsPlane surface grinding machinesHydraulic motorStructural engineering

The invention is a track slab grinder, and relates to a special grinder for grinding a track slab. The track slab grinder comprises left and right main foundation walls and left and right grinding wheels. The key technology thereof is as follows: the left and right main foundation walls are respectively provided with a main longitudinal girder provided with a main longitudinal guide rail, a main transverse beam is arranged between the main longitudinal guide rails and is provided with left and right transverse guild rails respectively, the transverse guild rail is installed with a transverse sliding box which is internally provided with a vertical guild rail, an inner box is mounted on the vertical guild rail, a main shaft direction adjusting box is arranged at the lower end part of the inner box, a grinding head is arranged at the lower side of the main shaft direction adjusting box, a grinding wheel is mounted on the main shaft of the grinding head, and the main shaft of the grinding head is driven by a hydraulic motor. The track slab grinder in the invention can finish processing both sides of a bearing block at one time, has the advantages of high integral strength, stable movement, good rigidity, high processing efficiency, and can process a standard track slab as well as a track slab grinder of a non-standard track slab.

Owner:四川省宜宾普什集团有限公司

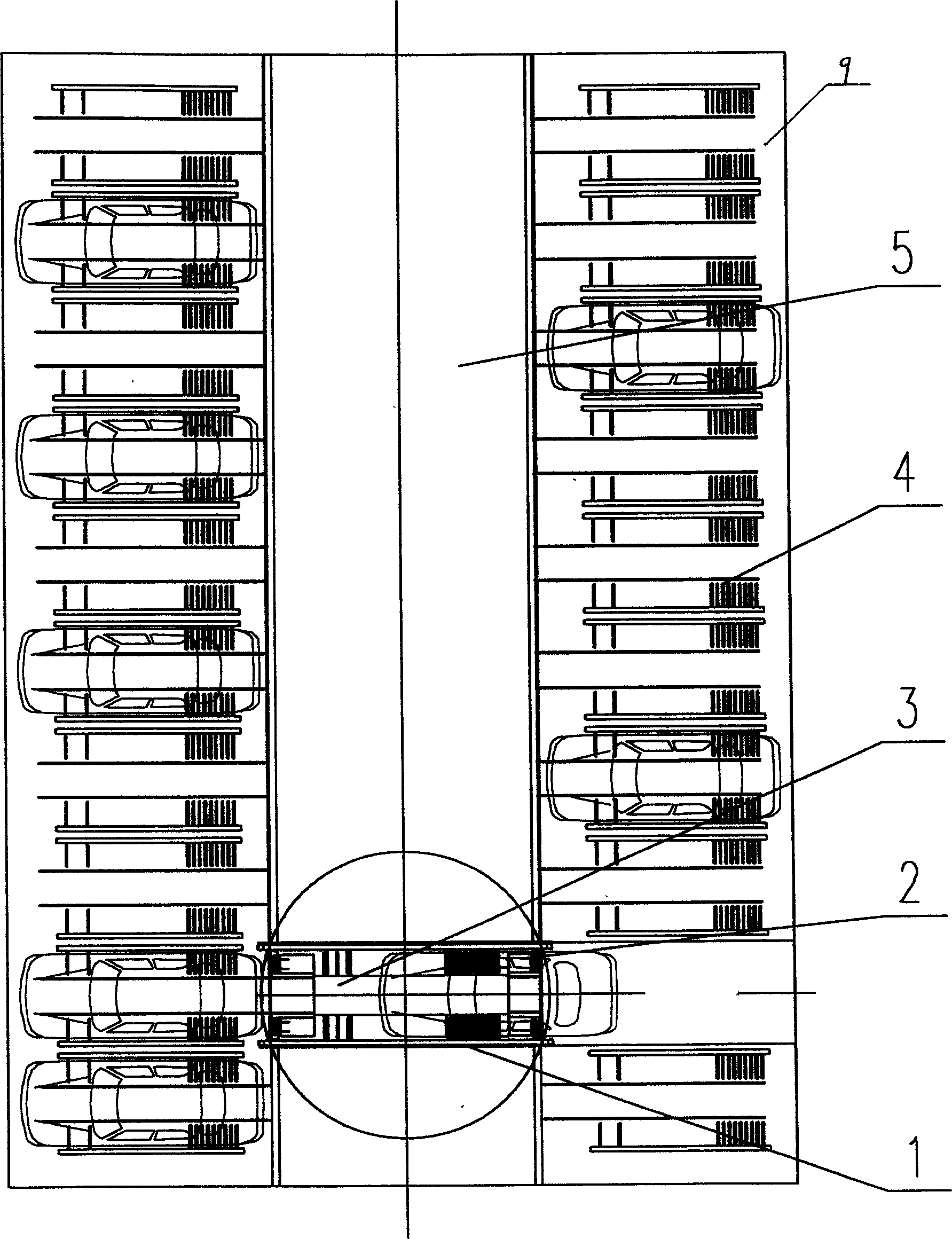

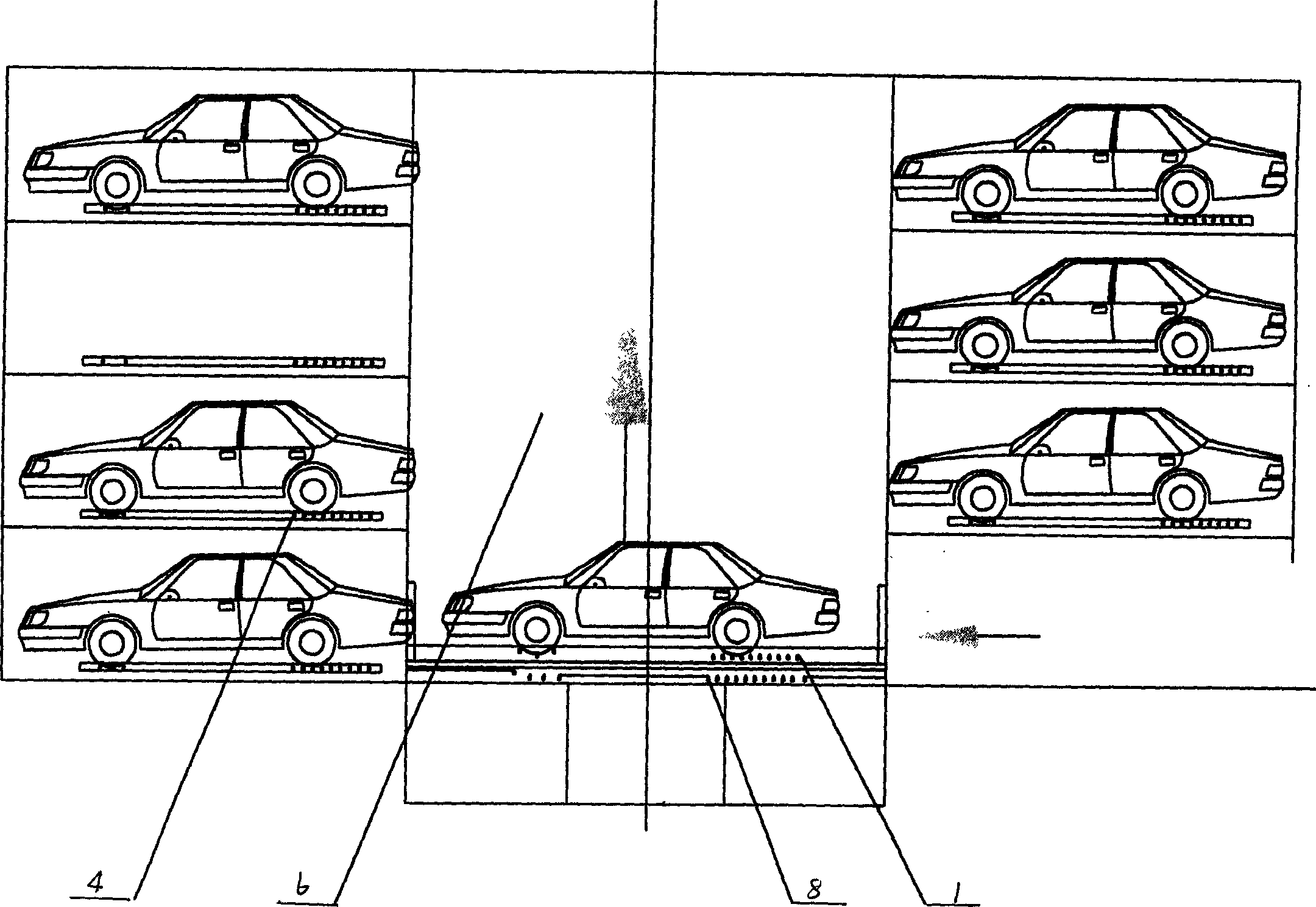

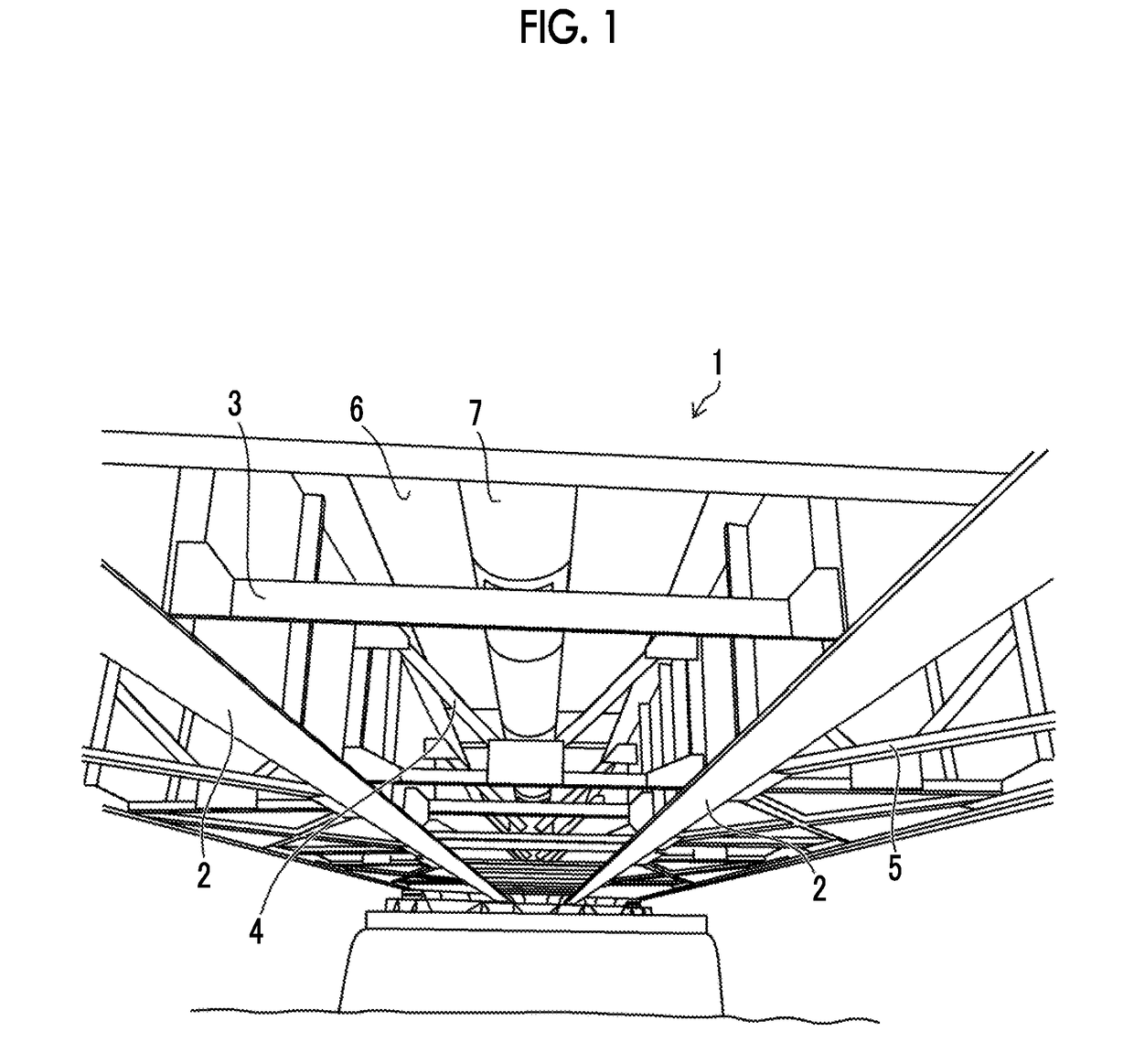

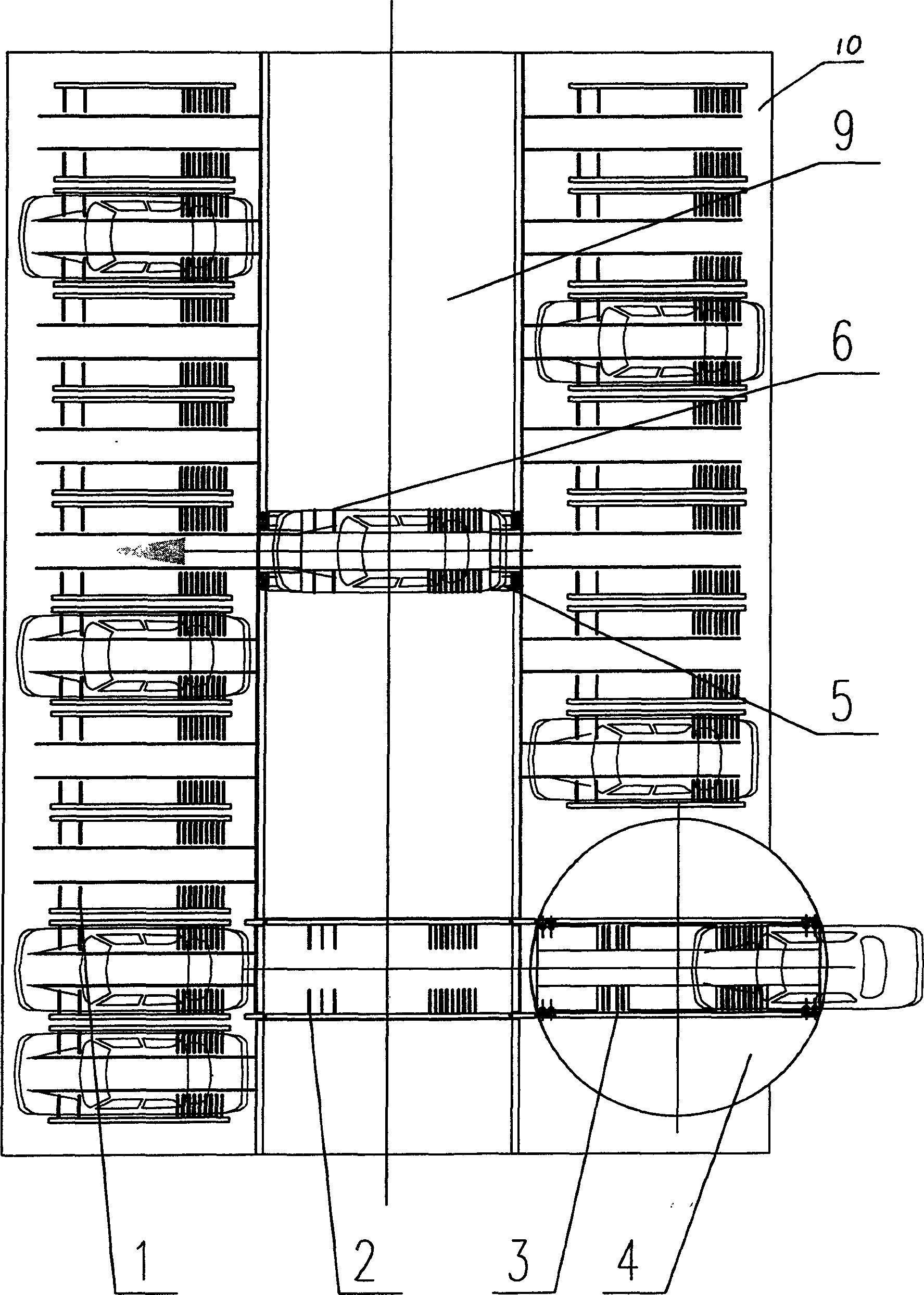

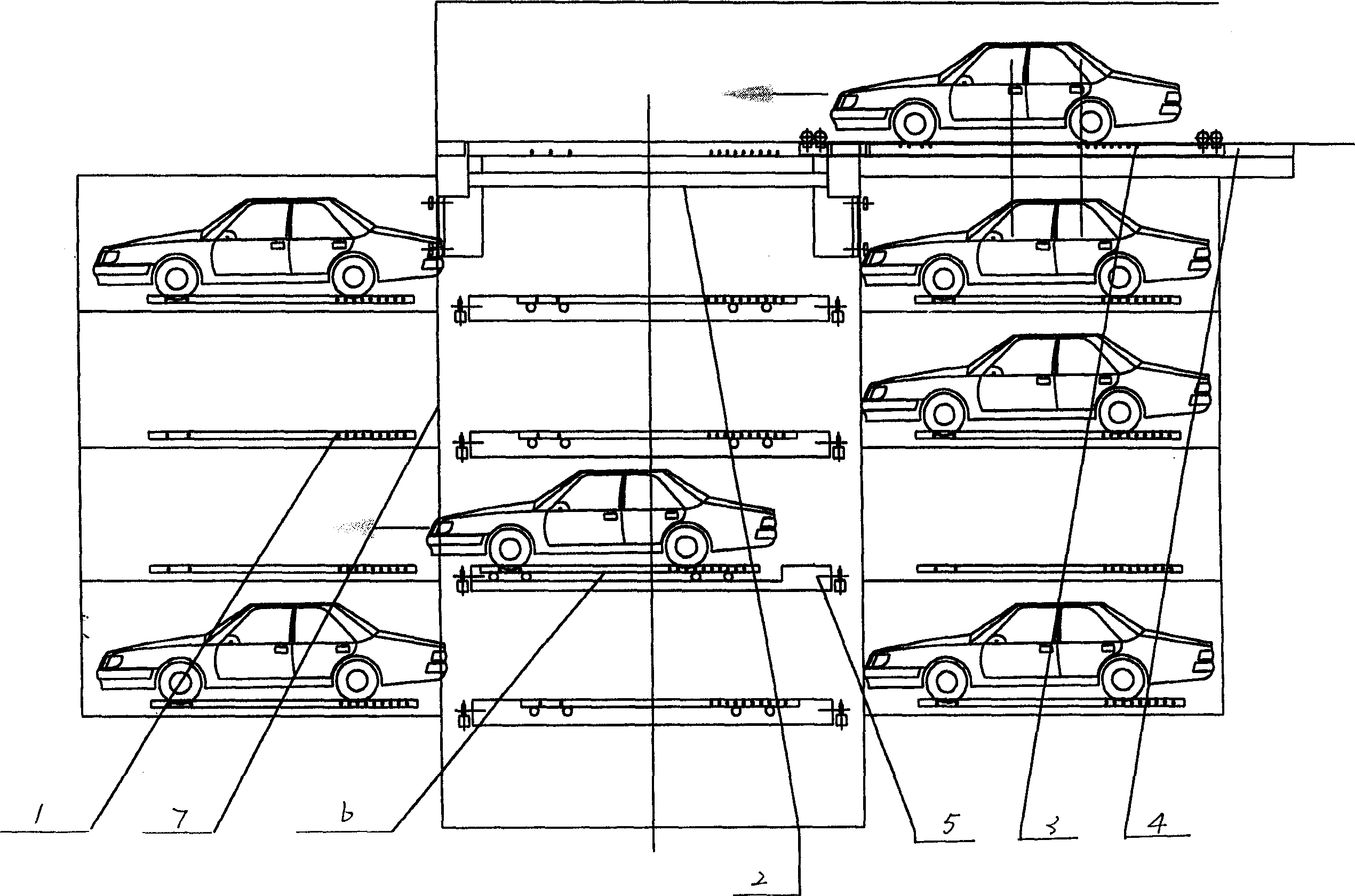

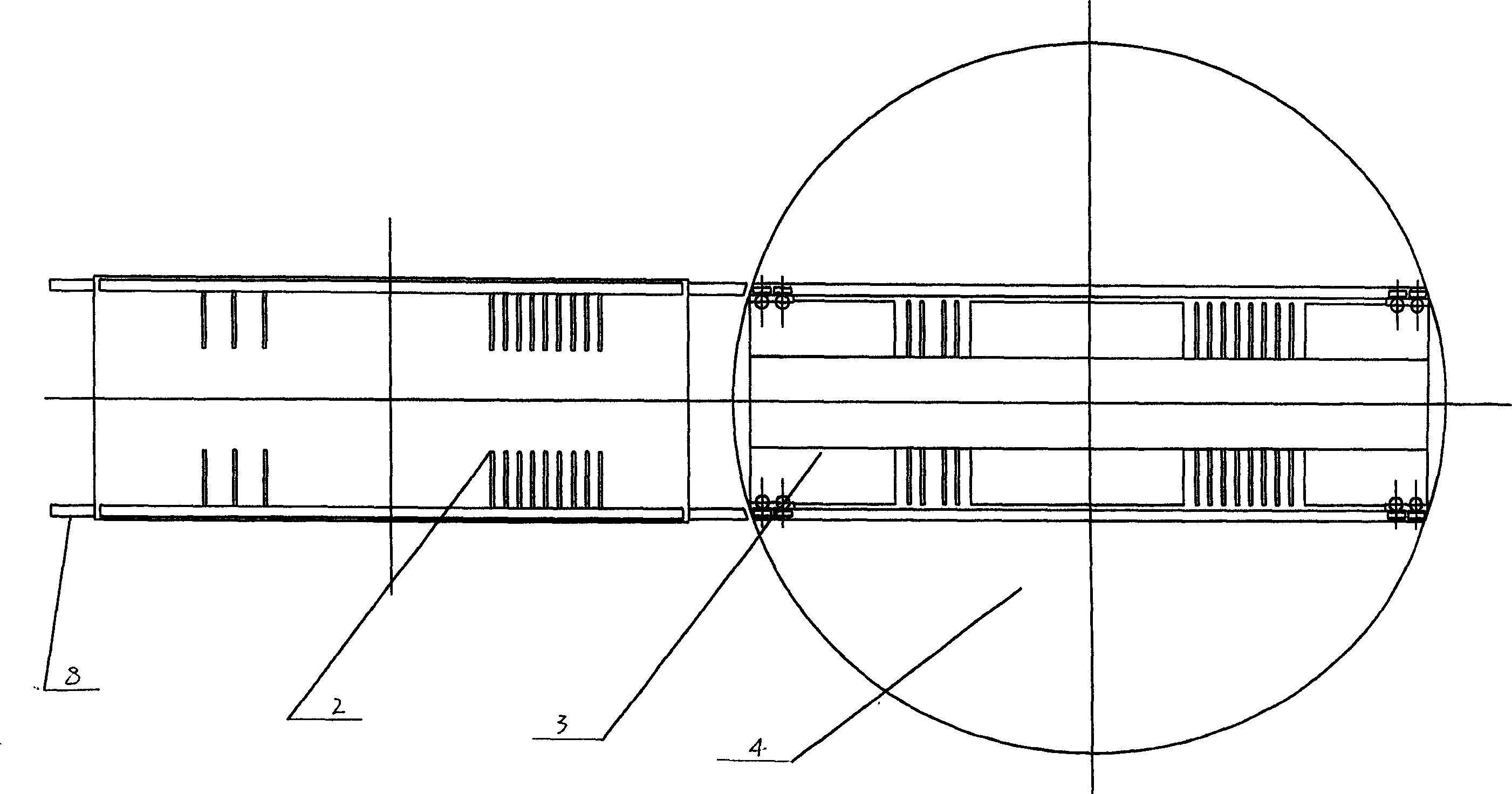

Horizontal mobile parking equipment

A car parking device of area mobile type is prepared as arranging gallery at middle of said device and parking positions at right and left sides of gallery, setting well path on position of gallery, using comb frame to carry car and setting lift porter in well path, forming lift porter by two halves of comb frame, setting walk porter on gallery, setting broach wheel barrow on walk porter, setting rotation plate in well path, setting broach on rotation plate outwards and symmetrically.

Owner:江苏利创新能源有限公司

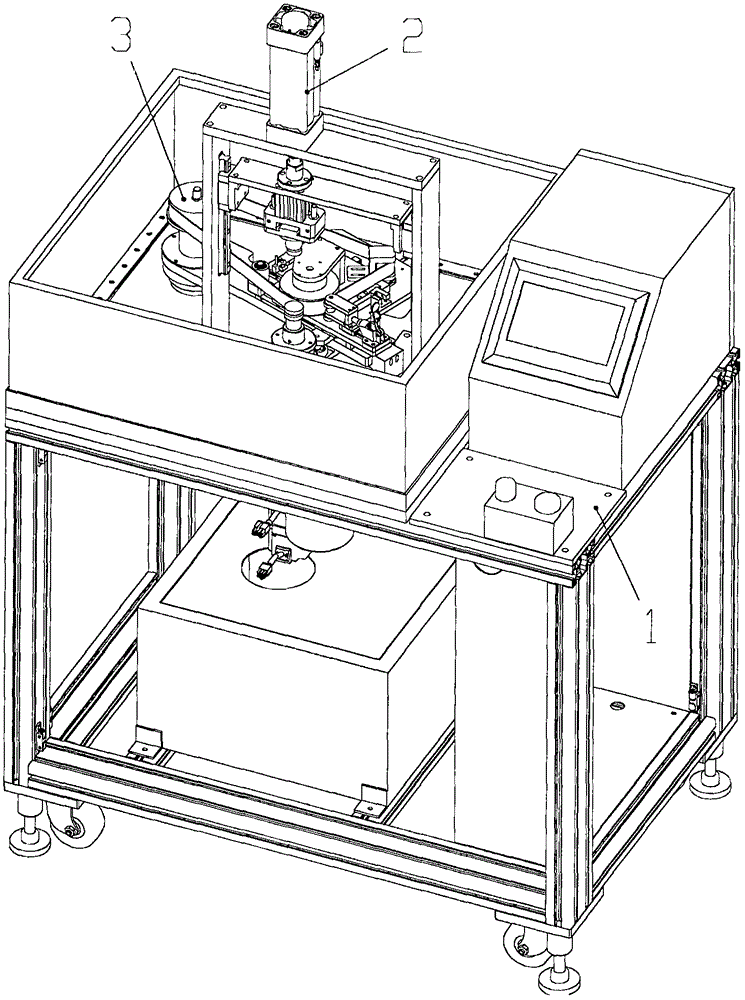

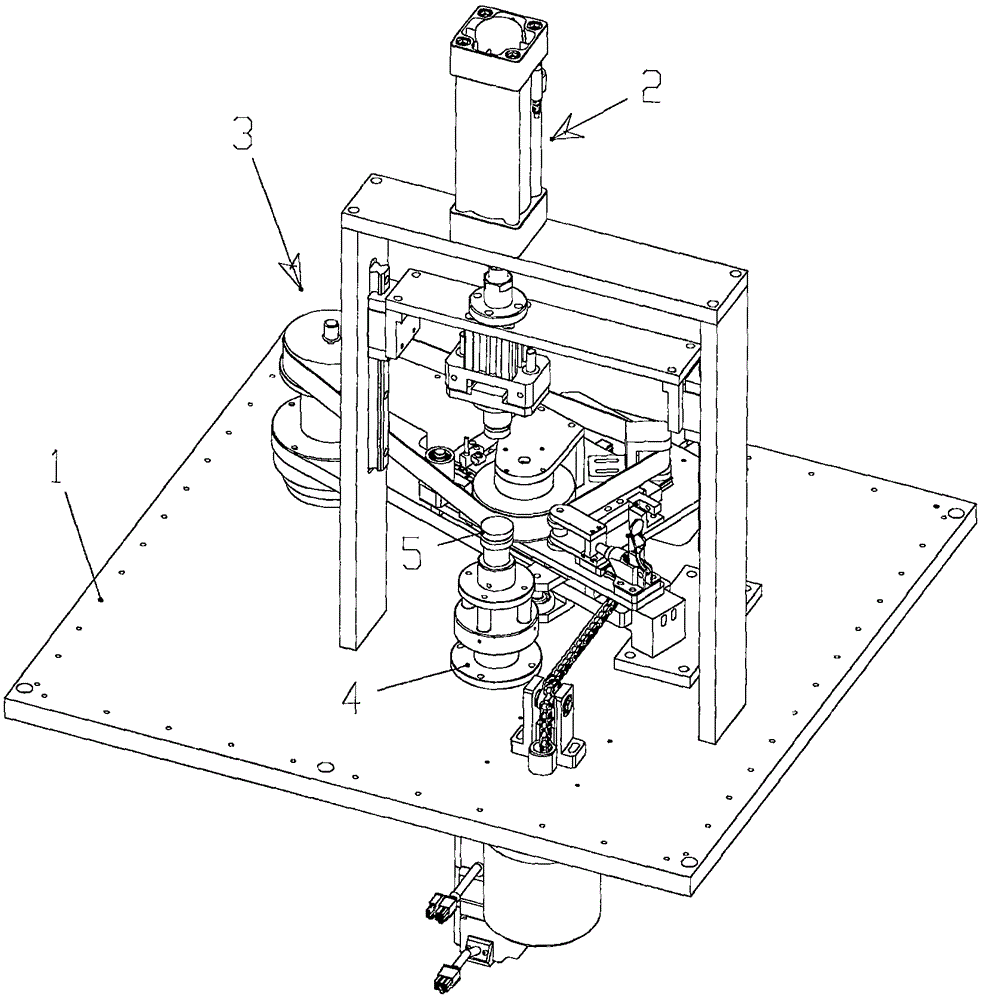

Outer surface force control type flexible polishing equipment of bearing outer ring

ActiveCN105773359AHigh strengthImprove stabilityBelt grinding machinesGrinding work supportsSurface finishConstant force

The invention relates to automatic polishing equipment, in particular to automatic polishing equipment of bearing fittings. The equipment comprises a worktable, a clamping mechanism for realizing clamping and positioning of the bearing outer ring, a polishing mechanism for realizing polishing of the outer surface of the bearing outer ring, and a fixture for mounting the bearing outer ring; the clamping mechanism, the polishing mechanism and the fixture are fixedly connected to the worktable; the fixture is positioned at the lower part of the clamping mechanism; and an abrasive belt of the polishing mechanism is contacted with the outer surface of the bearing outer ring. The outer surface force control type flexible polishing equipment of the bearing outer ring is used for polishing the outer surface of the bearing outer ring to improve the surface smoothness in a mode of not removing materials, realizes flexible contact between the abrasive belt and the outer surface of the bearing outer ring, realizes polishing by dint of constant force, monitors tangential force suffered by the bearing outer ring in real time, keeps constant tangential force and pressure of the bearing outer ring, and guarantees the polishing quality consistency; and after the bearing outer ring coats the fixture, the automatic mounting and polishing operation can be realized, and the automation degree is high.

Owner:滁州辉煌无纺科技有限公司

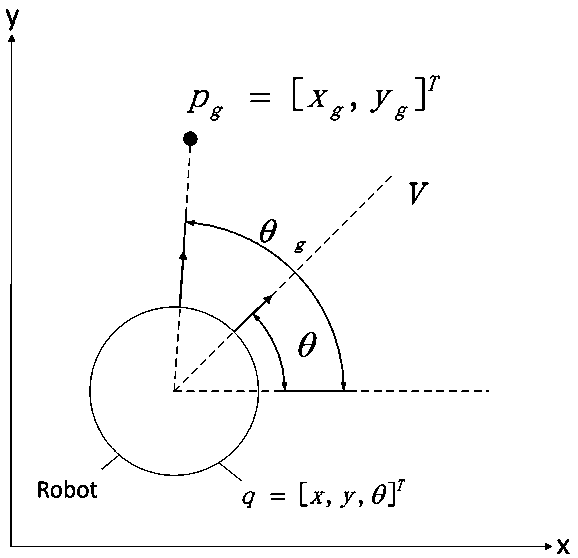

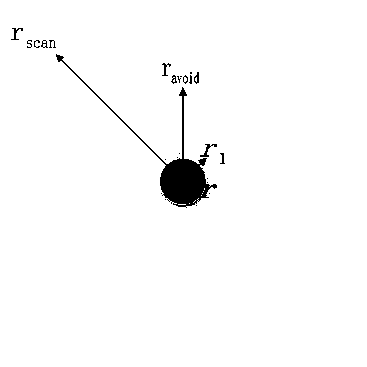

Robot distributed cooperative obstacle avoidance method based on independent virtual center point

ActiveCN109597418AAccurately obtainedAccurate real-time current poseAutonomous decision making processPosition/course control in two dimensionsAngular velocityOdometer

The present invention relates to a robot distributed cooperative obstacle avoidance method based on an independent virtual central point. The method comprises the following steps: step 1: using an extended Kalman filter to fuse an inertial measurement unit with odometer data to obtain current pose information of the robot; step 2: through network communication, sharing the speed and position information between the robots, and calculating the virtual center point of each robot, wherein the virtual center point moves with the movement of the robot; step 3: according to the current position, thetarget point position and the virtual center point position of each robot, obtaining the target vector and the repulsion vector of the robot; step 4: defining a switching signal to determine whetherthe movement mode of the robot is an obstacle avoidance mode or an obstacle-free mode; and step 5: using the vector differential method to obtain the desired speed and the desired angle of the robot,and according to the control law, obtaining the real-time speed and the angular velocity of the robot to guide the movement of the robot. According to the obstacle avoidance method provided by the present invention, the robot rotates around the virtual center point and perpendicular to the direction of the repulsion vector; and the obstacle-free mode means that the robot always moves toward the target vector, so that the robot is guided to orderly avoid obstacles.

Owner:FUZHOU UNIV

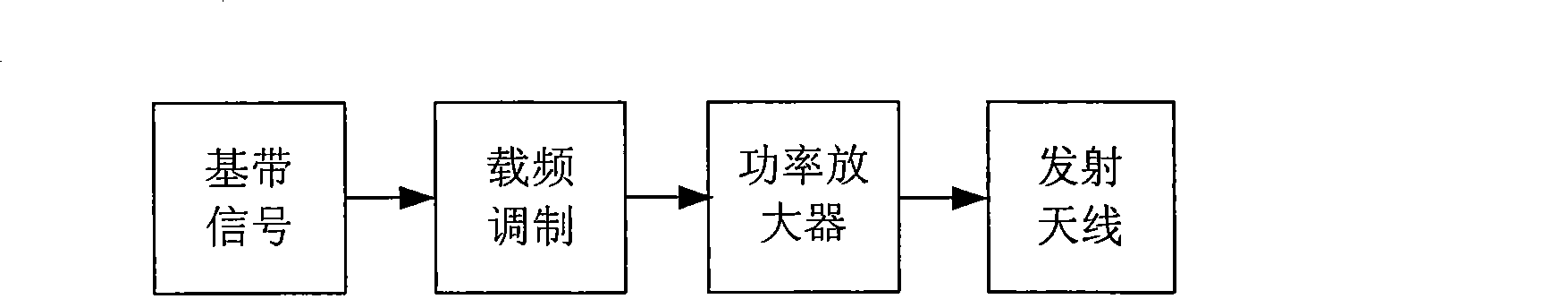

Three-dimensional target scattering coefficient measurement method based on MIMO array technology

ActiveCN101509974ARealize three-dimensional high-resolution measurementImprove measurement efficiencyRadio wave reradiation/reflectionMultiple inputElectromagnetism

The invention provides a method for measuring the scattering coefficient of a three-dimensional target, which is based on the multiple-input and multiple-output array technology, and the method synthesizes a large two-dimensional antenna array by controlling the antenna of the multiple-input and multiple-output array to accurately move on a one-dimensional platform, and then obtaining three-dimensional high resolution distribution of the scattering coefficient of the target by being combined with the pulse compressing technology in signal processing, thus realizing three-dimensional high resolution measurement to the scattering coefficient of the target. The method overcomes the defects of large calculation amount, approximate error, difficult application and complicated target and broadband signal of the method for calculating the scattering coefficient of the target on the basis of computational electromagnetics and the defects of low resolution and being incapable of measuring large targets in the method for measuring the scattering coefficient of the target in a microwave dark room. The method is applicable to the fields of target scattering property research, stealth material / aircraft design, and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

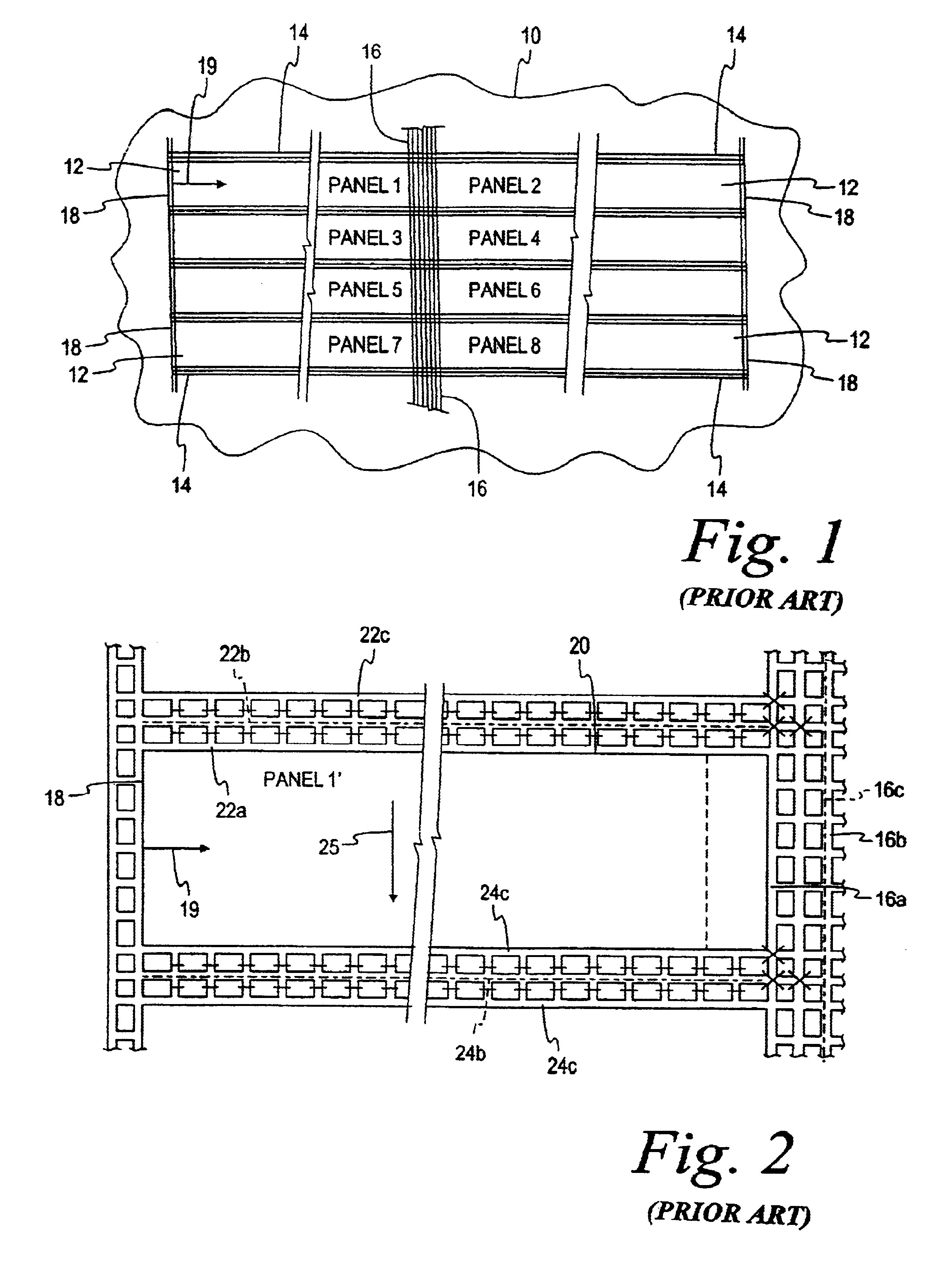

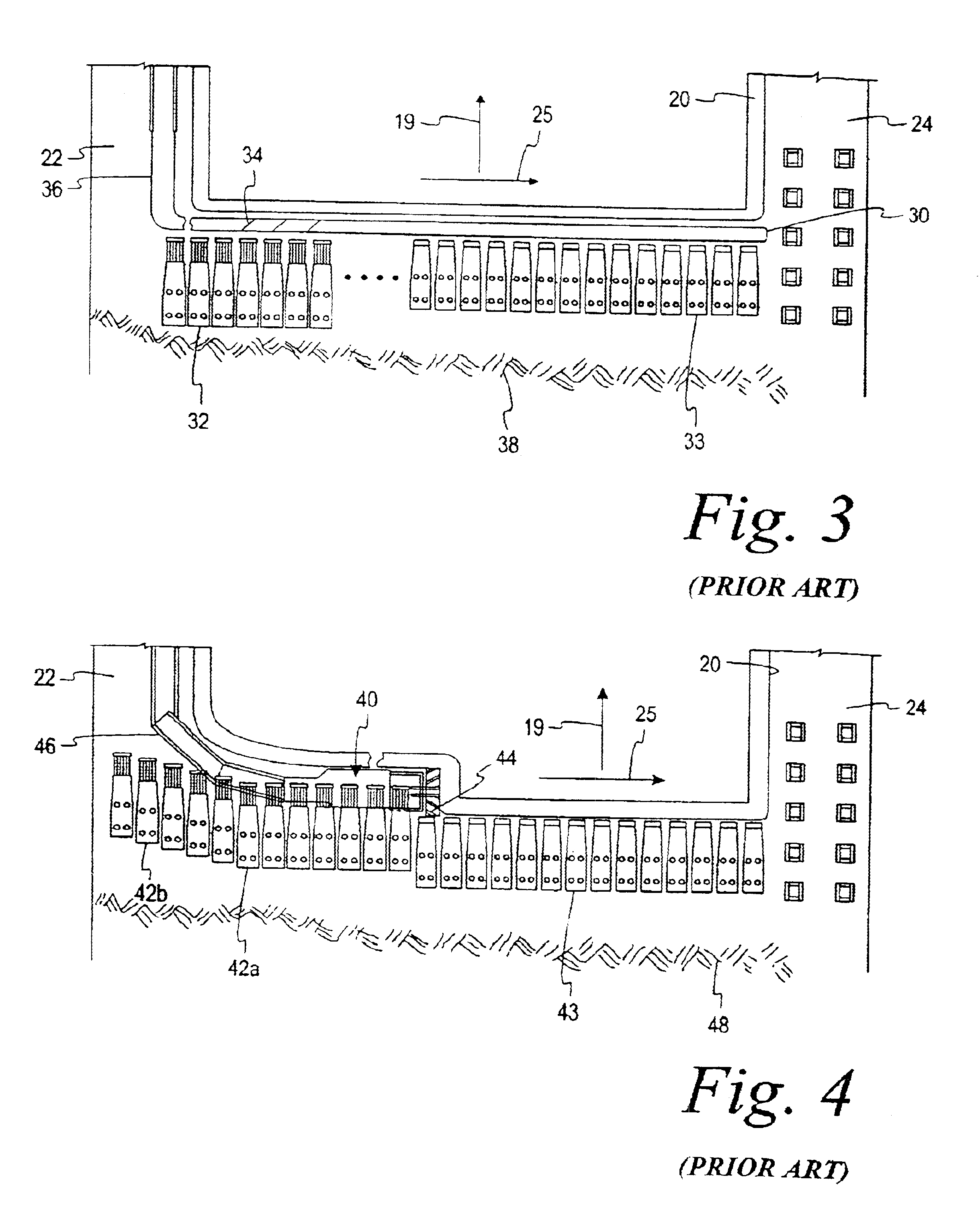

Mining system

InactiveUS6913321B2Easy accessEasy to insertDisloding machinesUnderground miningLongwall miningEngineering

A method for extracting mineral deposits in a mineral reserve, a portion being accessible from a sloping surface and the remaining portion being inaccessible, is disclosed. The sloping surface is mined to create a bench and highwall for providing access to the mineral reserve around the accessible portion. Then, a surface is formed in the highwall to create an insertion highwall between an endwall extending from the insertion highwall and the inaccessible portion of the mineral reserve. A starter entry is created for cutting into the mineral reserve across the entire length of the insertion highwall from the endwall to the inaccessible portion of the mineral reserve. Roof supports are advanced into the starter entry with spoil added to form a starter passage from the endwall to the inaccessible portion of the mineral reserve. Shortwall or longwall mining techniques are then used to mine the mineral reserve along the starter passage. Canopies are positioned at both ends of the starter passage to seal the passage and provide ventilation of the active mining area by the introduction of air along the face of the mineral seam. A single-gate passage is formed extending from the insertion highwall adjacent the inaccessible portion of the mineral reserve to allow the continuous miner to form another opposing endwall. Mining then continues in the starter passage along the insertion highwall from the single-gate passage to the opposing endwall, thereby forming a production passage into which the roof supports are farther advanced with gob forming behind.

Owner:CLECO CORP

Teaching data preparing method for articulated robot

ActiveUS20060255758A1Smooth movementShorten exercise timeProgramme-controlled manipulatorComputer controlEngineeringData preparation

Set the first temporary attitude of an end effector for a plurality of work points (step S3). Determine the attitude of an articulated robot at one-end first work point out of a plurality of work points (step S4). Determine the attitude of an articulated robot at the-other-end final work point out of a plurality of work points (step S5). Set the second temporary attitudes of an end effector respectively for the other work points so that the attitude of an end effector gradually changes from the first work point toward the final work point (step S6). Correct the first temporary attitude with the second temporary attitude (step S7).

Owner:HONDA MOTOR CO LTD

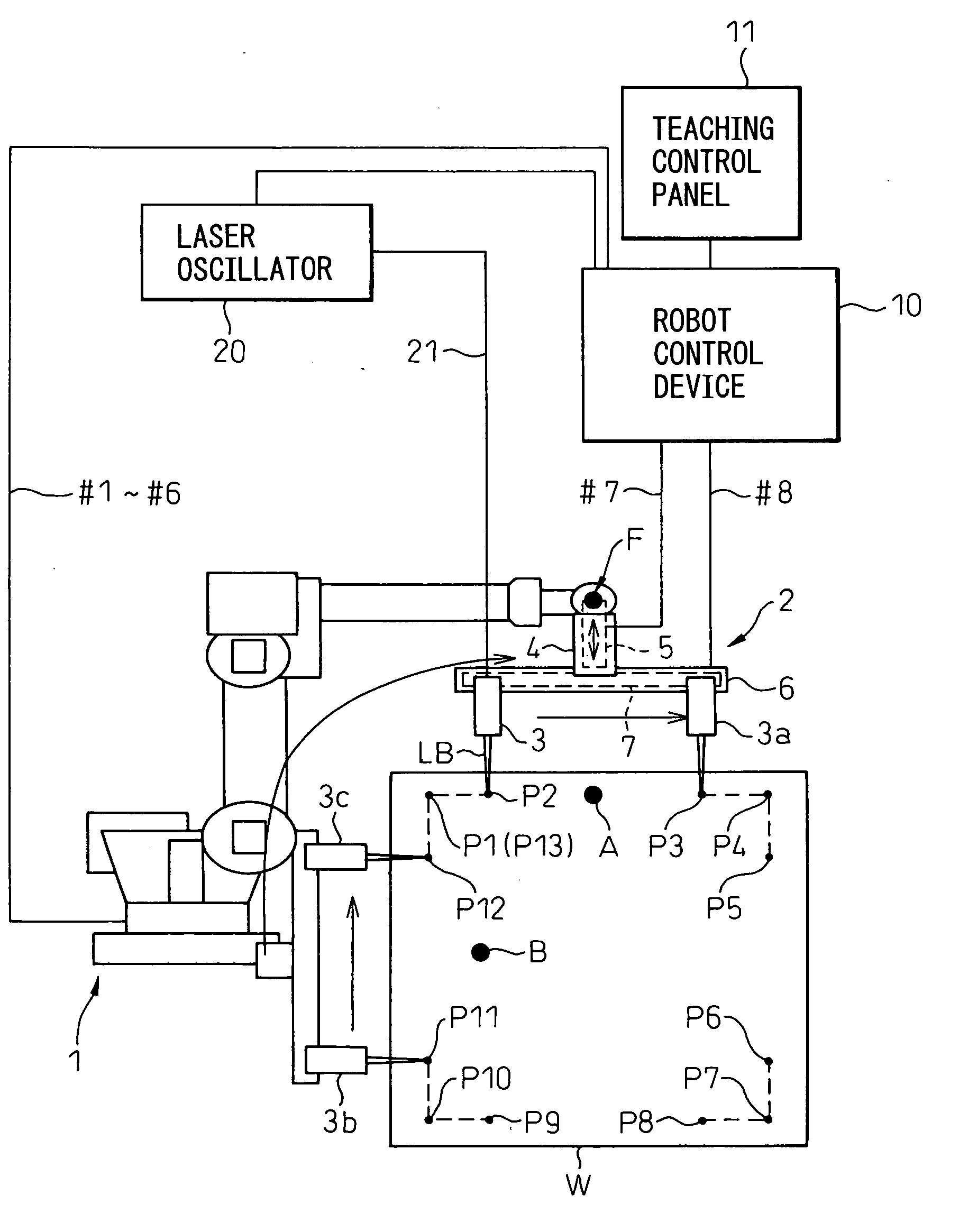

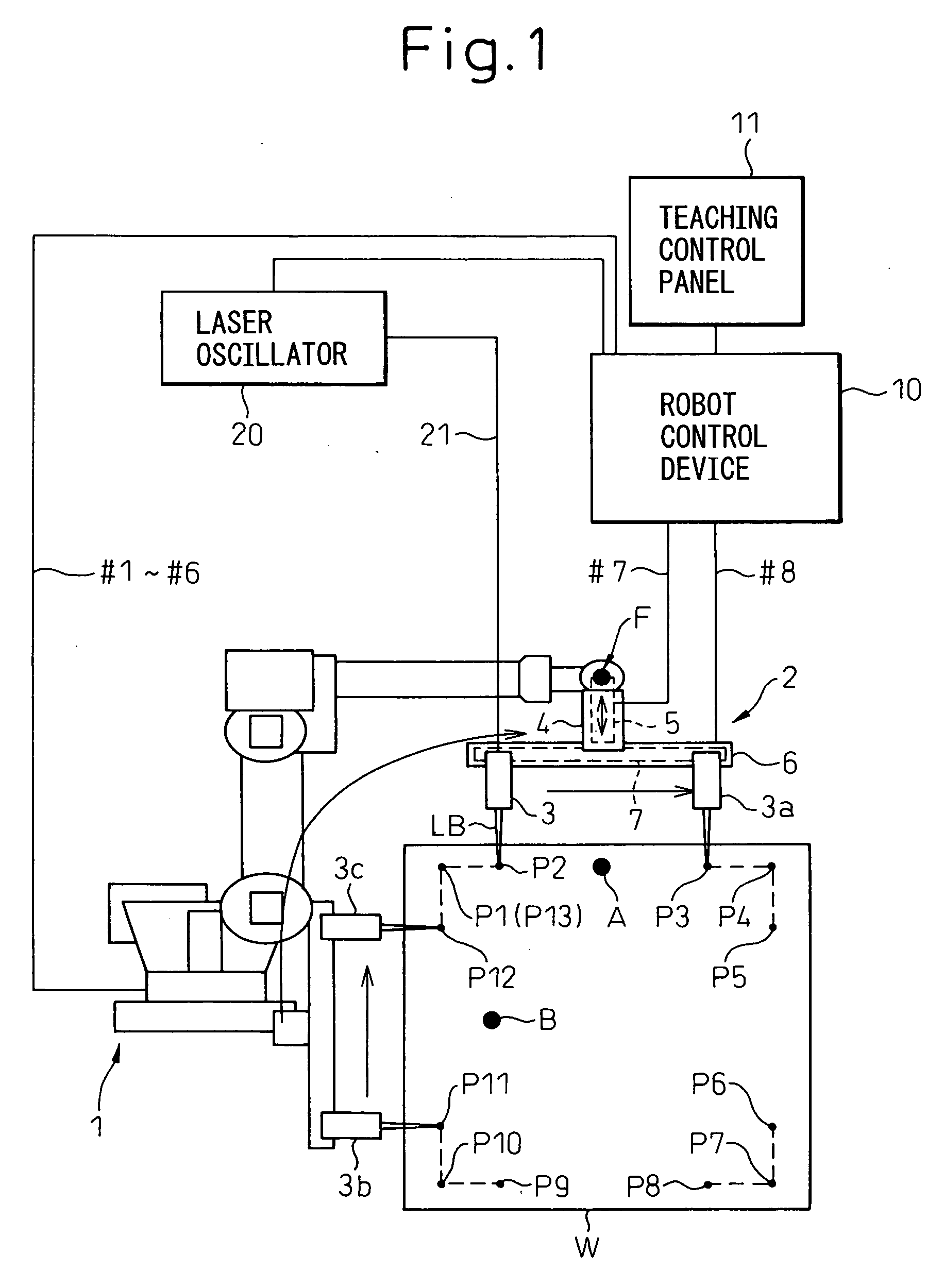

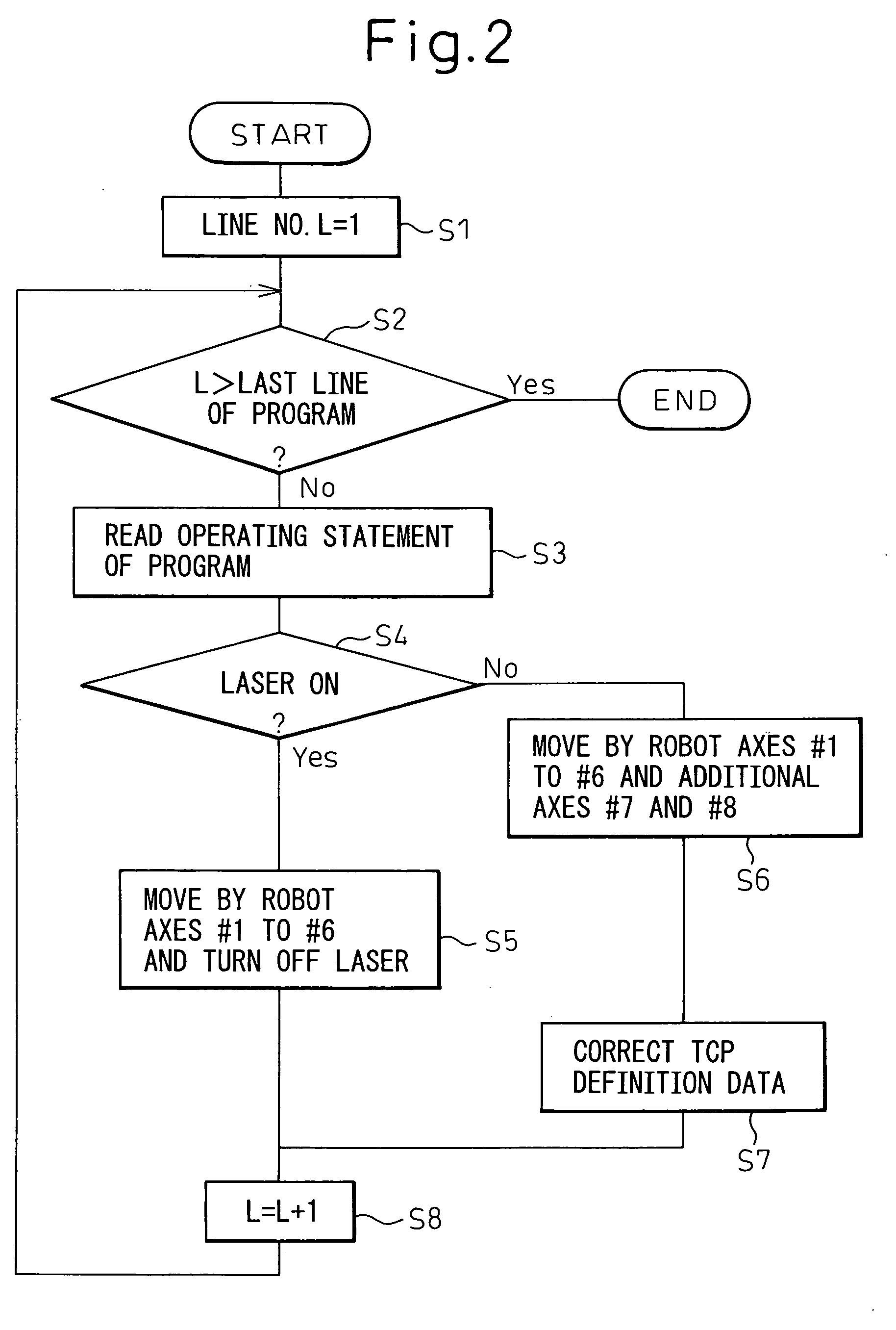

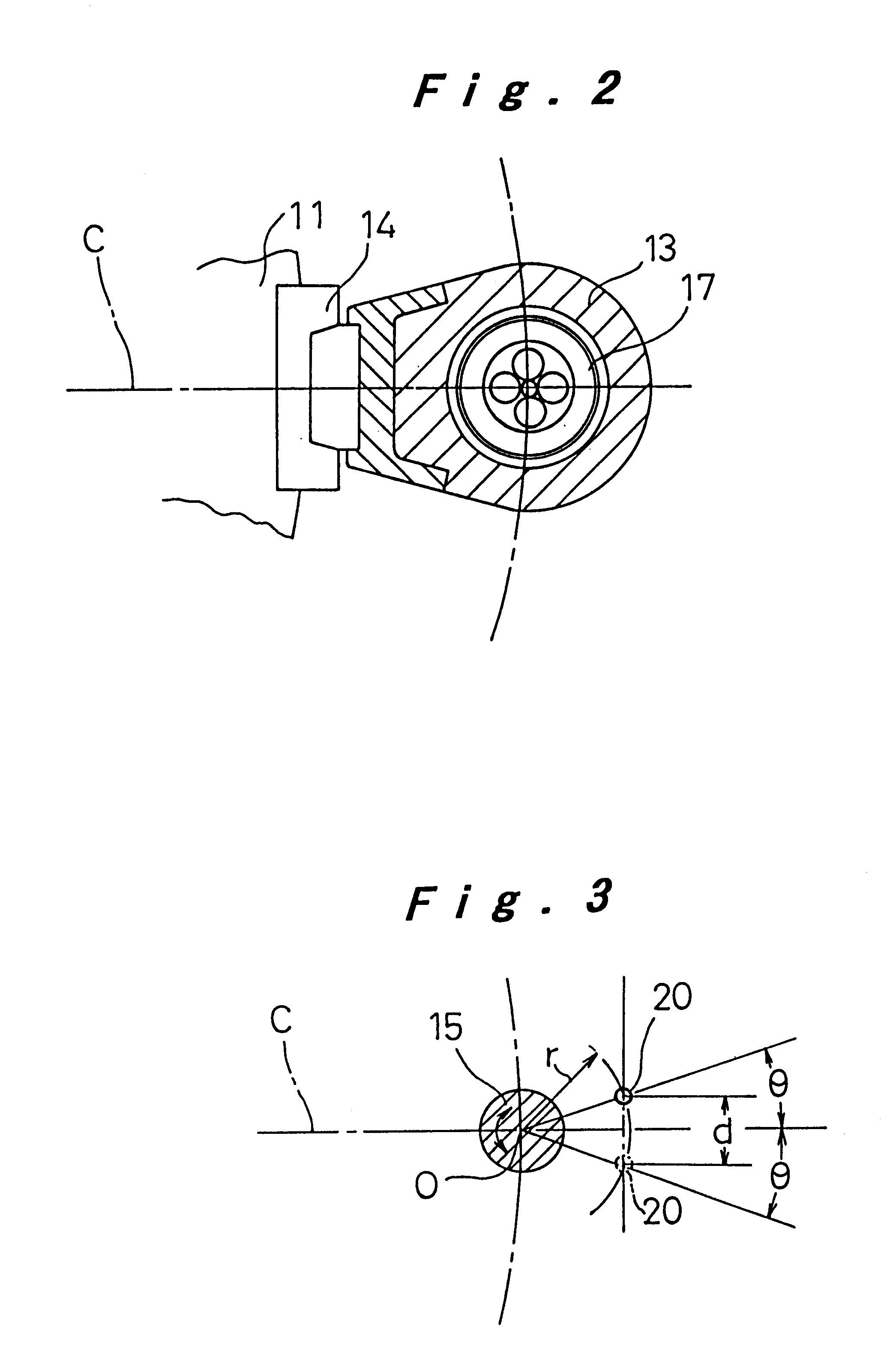

Laser processing apparatus

InactiveUS20060037951A1Shorten cycle timeImprove processing efficiencyLaser beam welding apparatusLaser processingEngineering

A laser processing apparatus includes a six-axis robot operating by robot axes controlled by a robot control device and a processing tool mounted on the end of the arm of the robot. A processing head is provided on a horizontal movement mechanism provided on a horizontal movement mechanism support base, which is in turn supported by a carrier able to move on a vertical movement mechanism. The vertical movement mechanism and the horizontal movement mechanism are driven by additional axes controlled by the robot control device. In a non-processing section of the workpiece etc., only the additional axes are operated to move the processing head at a high speed and shorten the cycle time. When operating the additional axes to move, the data of the relative position of the control point (tool end point) with respect to a fixed point on the arm forward end is corrected each time.

Owner:FANUC LTD

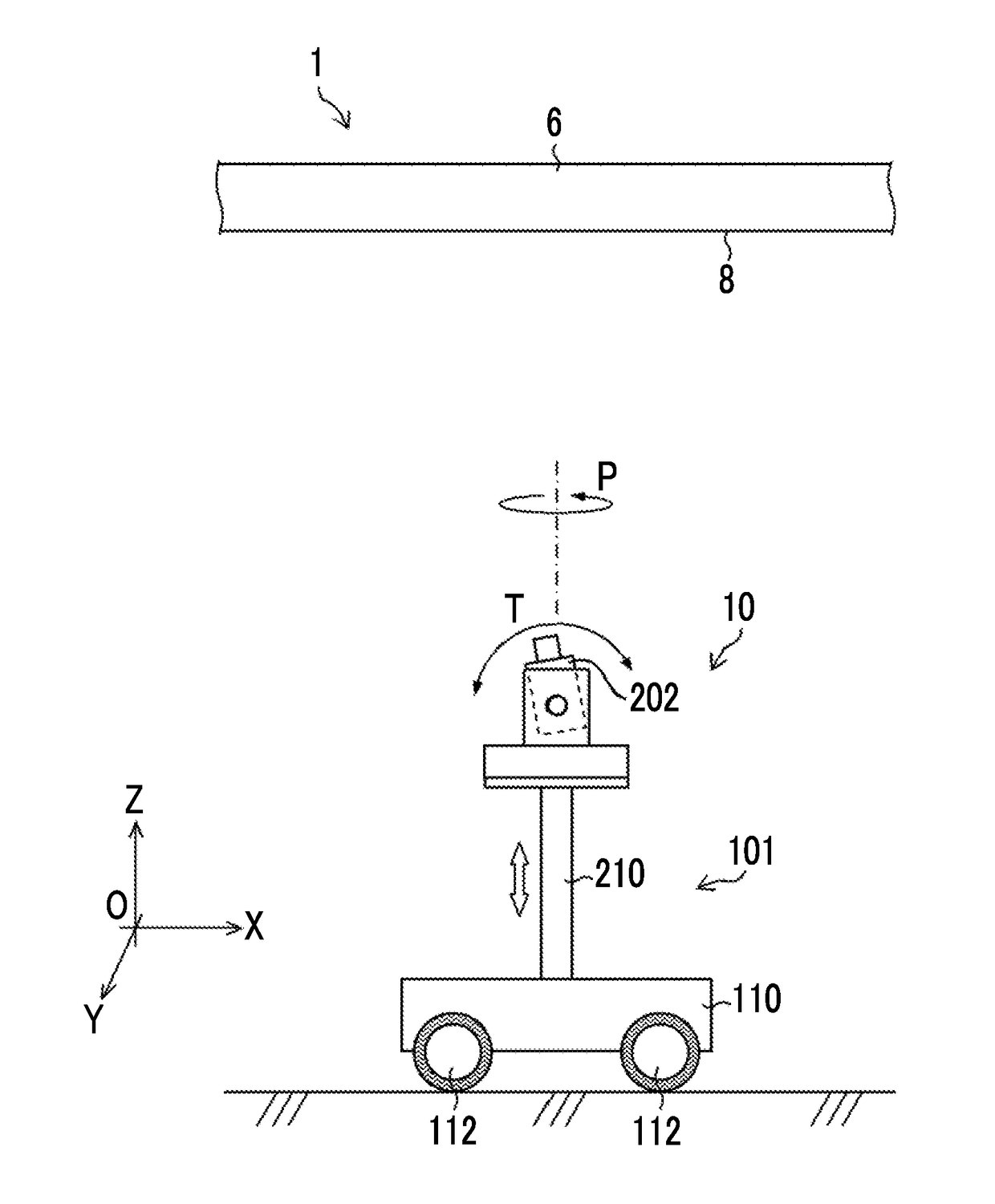

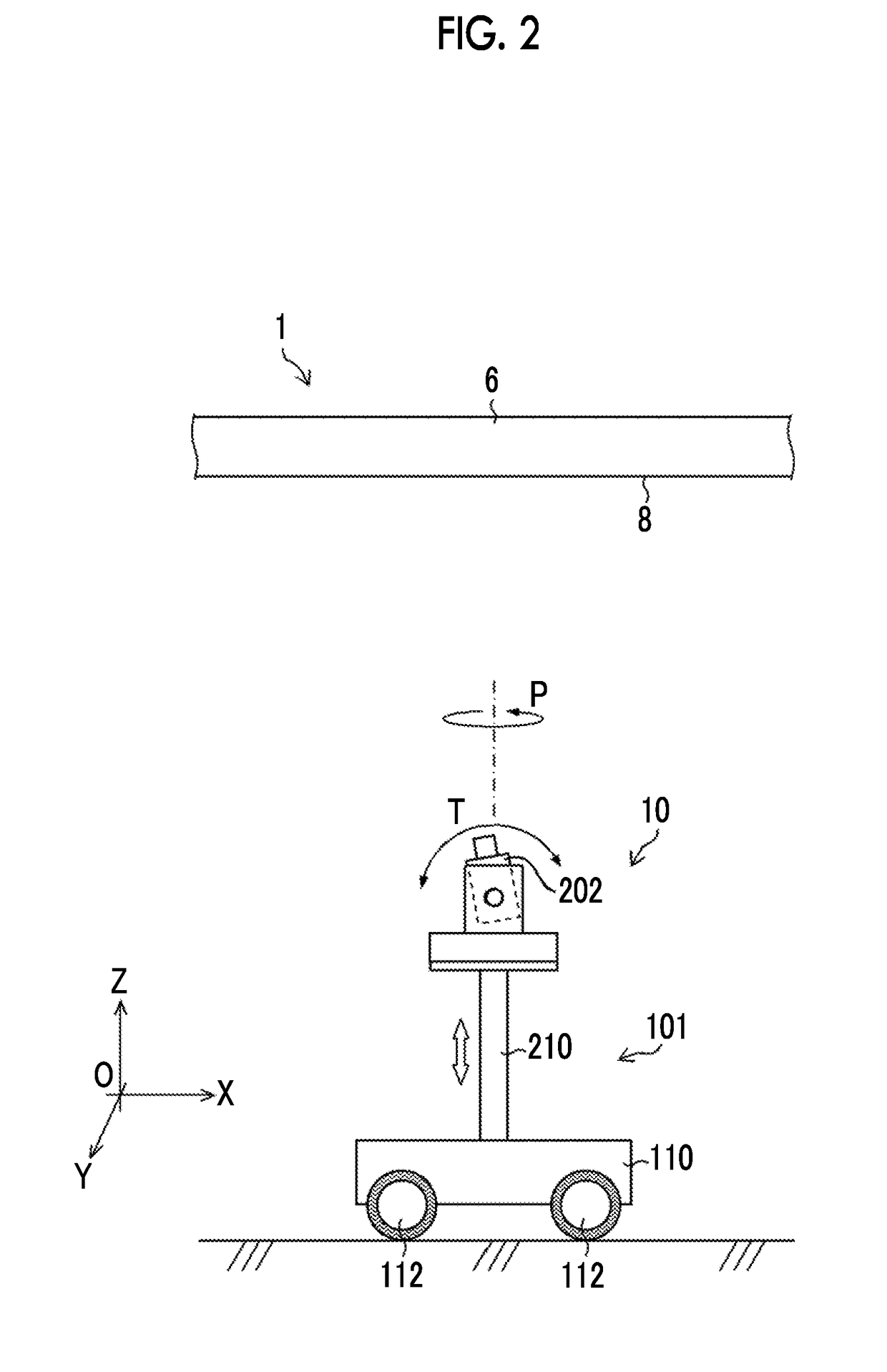

Movable imaging device and movable imaging method

ActiveUS20180124326A1Shorten the timeShorten exercise timeImage enhancementTelevision system detailsComputer visionControl unit

A movable imaging device includes a camera, a moving body, a definition calculation unit that calculates definition of an image for inspection, a determination unit that determines whether the definition is equal to or higher than required definition required for inspection accuracy of an object to be inspected, a pan / tilt control unit that operates a pan / tilt mechanism in a case in which the determination unit determines that the calculated definition is equal to or higher than the required definition, a moving body control unit that moves a moving body in a case in which the pan / tilt mechanism is operated and it is determined that the definition is lower than the required definition, and an imaging control unit that images the object to be inspected by the camera in a case in which it is determined that the definition is equal to or higher than the required definition.

Owner:FUJIFILM CORP

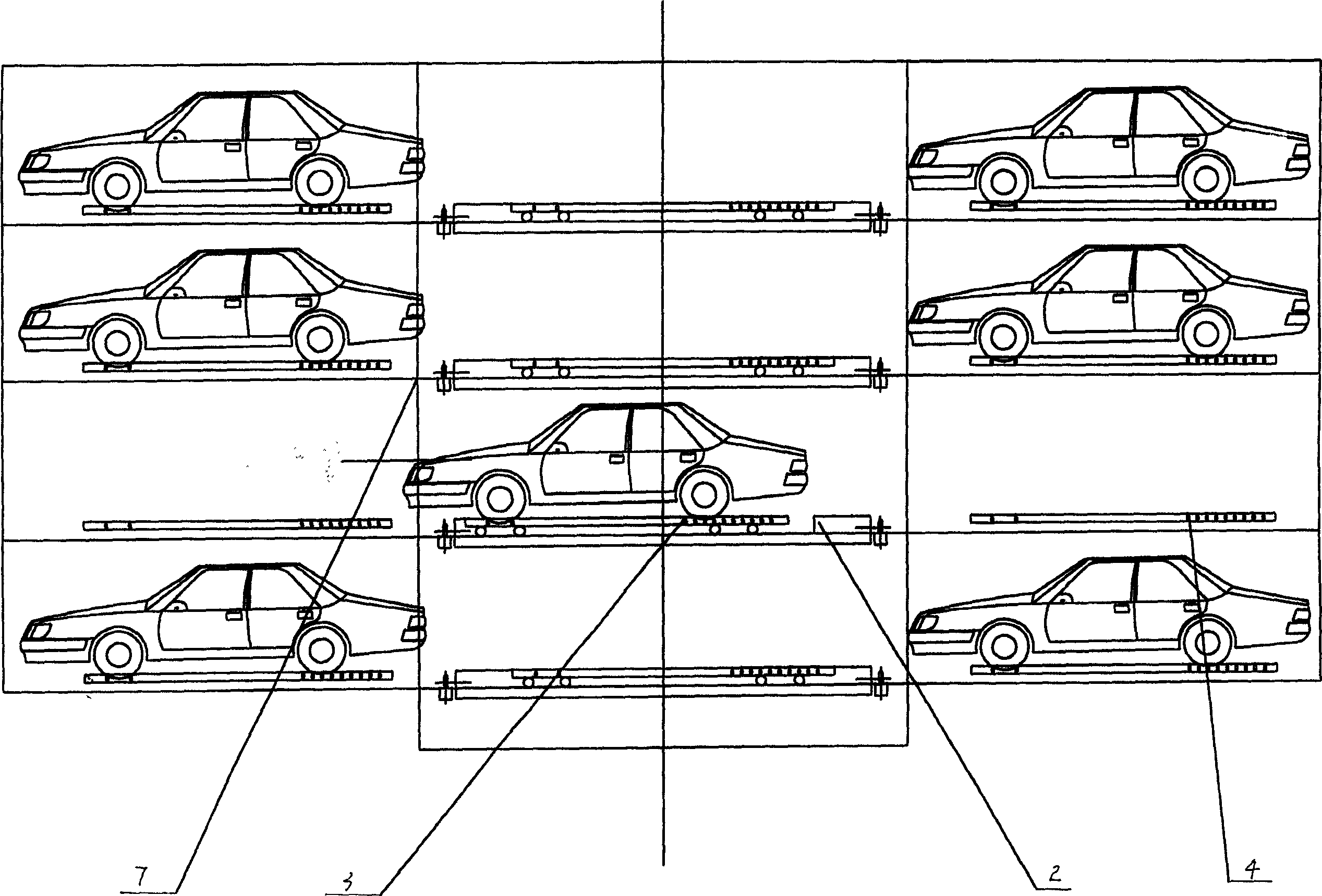

Novel plane-shifting type parking equipment

Owner:江苏利创新能源有限公司

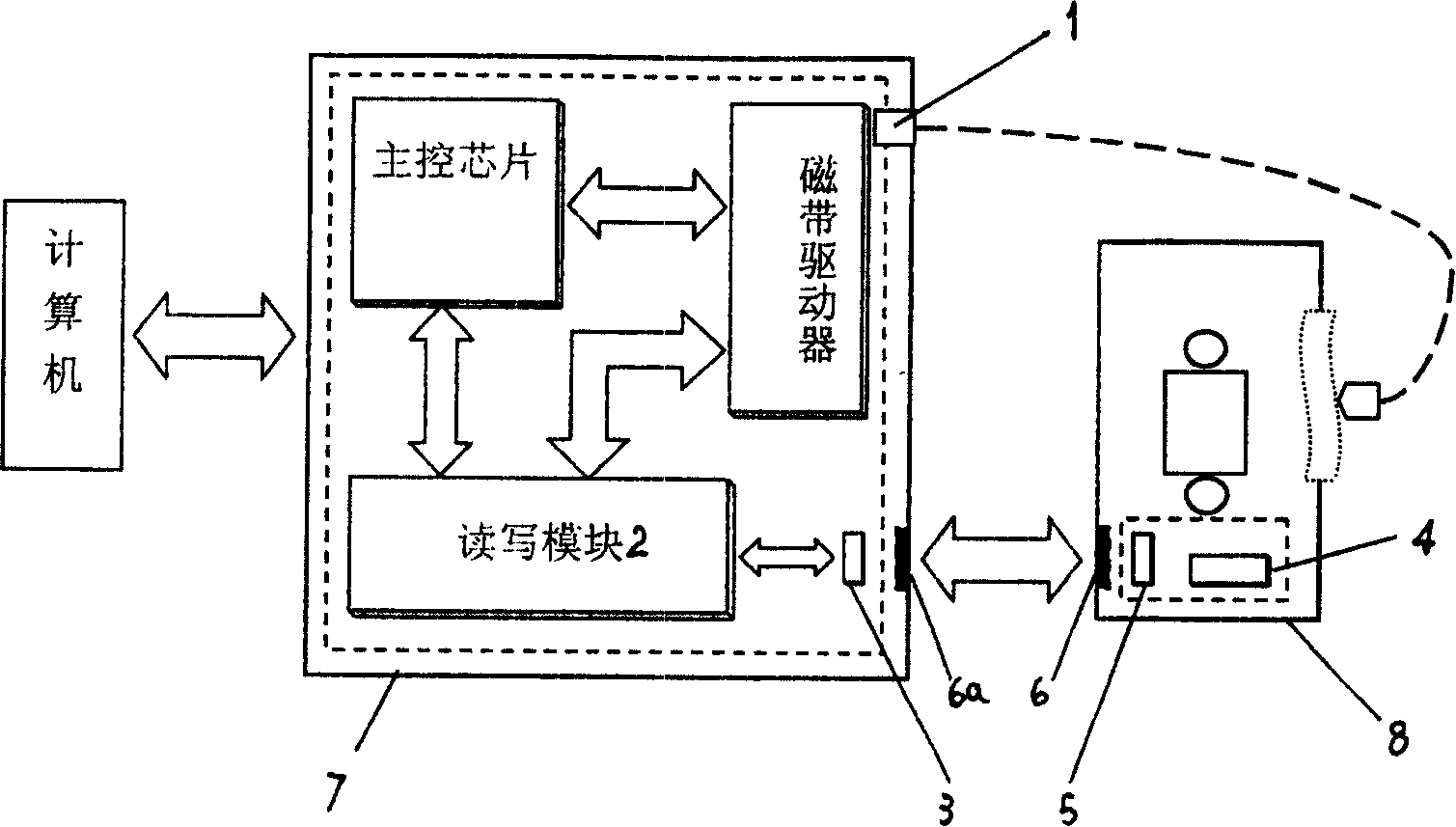

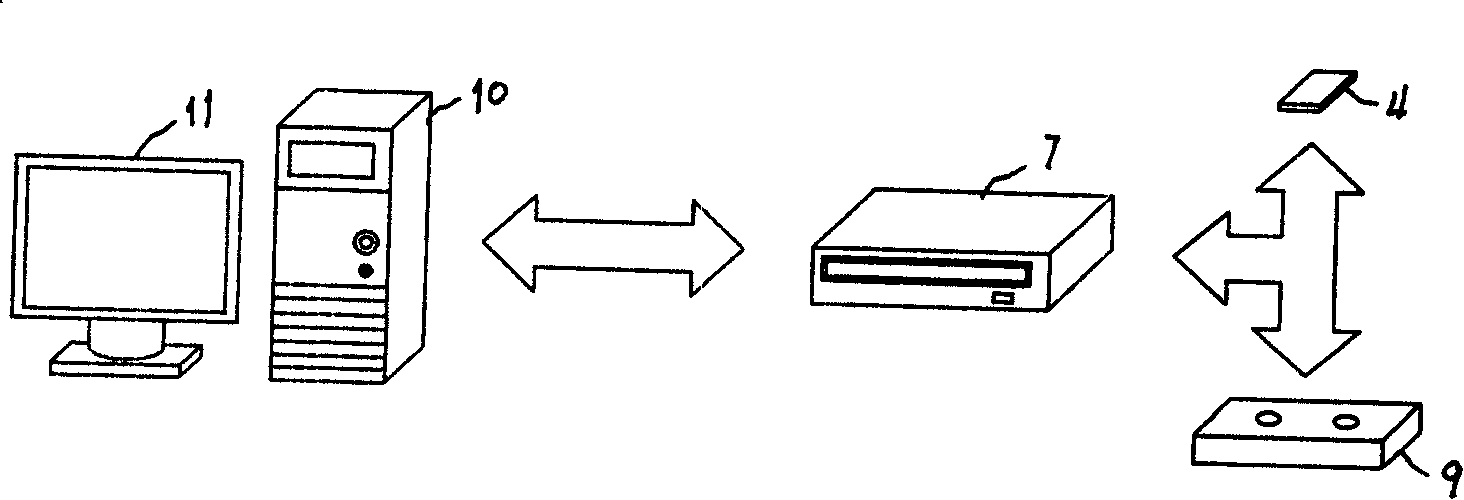

Novel intelligent tape unit and data processing method

InactiveCN101197177AReduce seek timeIncreased durabilityRecord information storageDigital storageMemory chipElectricity

The invention discloses a novel intelligent tape driver and a data processing method thereof, belonging to a chip-tape storage device and a data processing method thereof, which comprises a memory chip arranged inside a tape cassette and an interface circuit thereof, and a memory chip read-write module arranged on the tape driver and an interface circuit thereof, wherein, the two interface circuits are electrically connected by a pair of metal contacts. The tape driver processor is connected with the memory chip through an interface circuit after being connected with the memory chip read-write module. Only a data area is arranged on the tape. The memory chip is divided into an index mark section, a writing cache, a read cache and other data section, wherein, both reading and writing requests of data are performed in the reading and writing caches, other than in the tape driver. The combination of the sequential memory of the tape and the random memory of the chip reduces the frequent mechanical motion of the tape driver, thereby improving the retrieval speed and the memory efficiency and prolonging the service life of the tape driver.

Owner:WISESOFT CO LTD +1

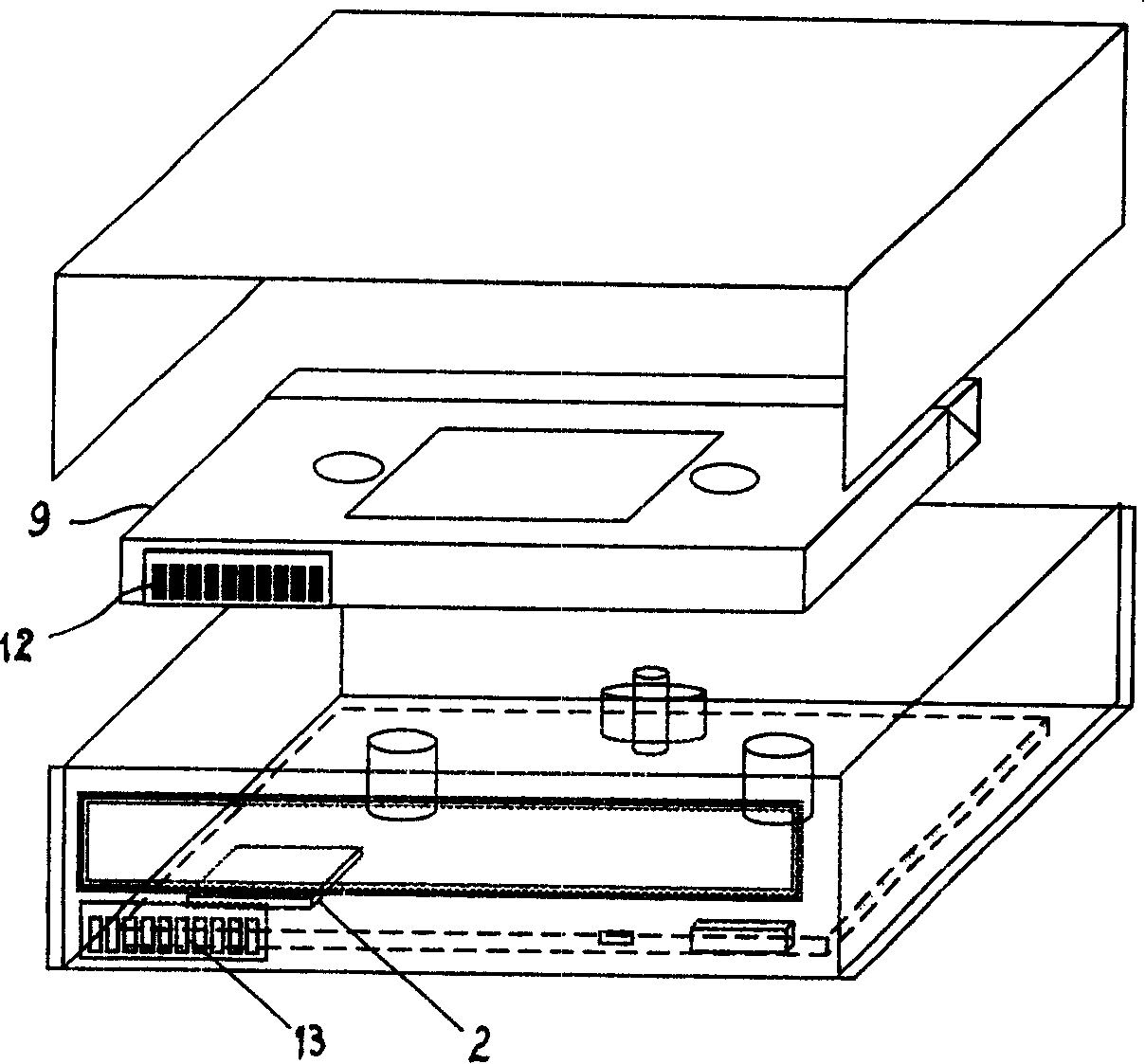

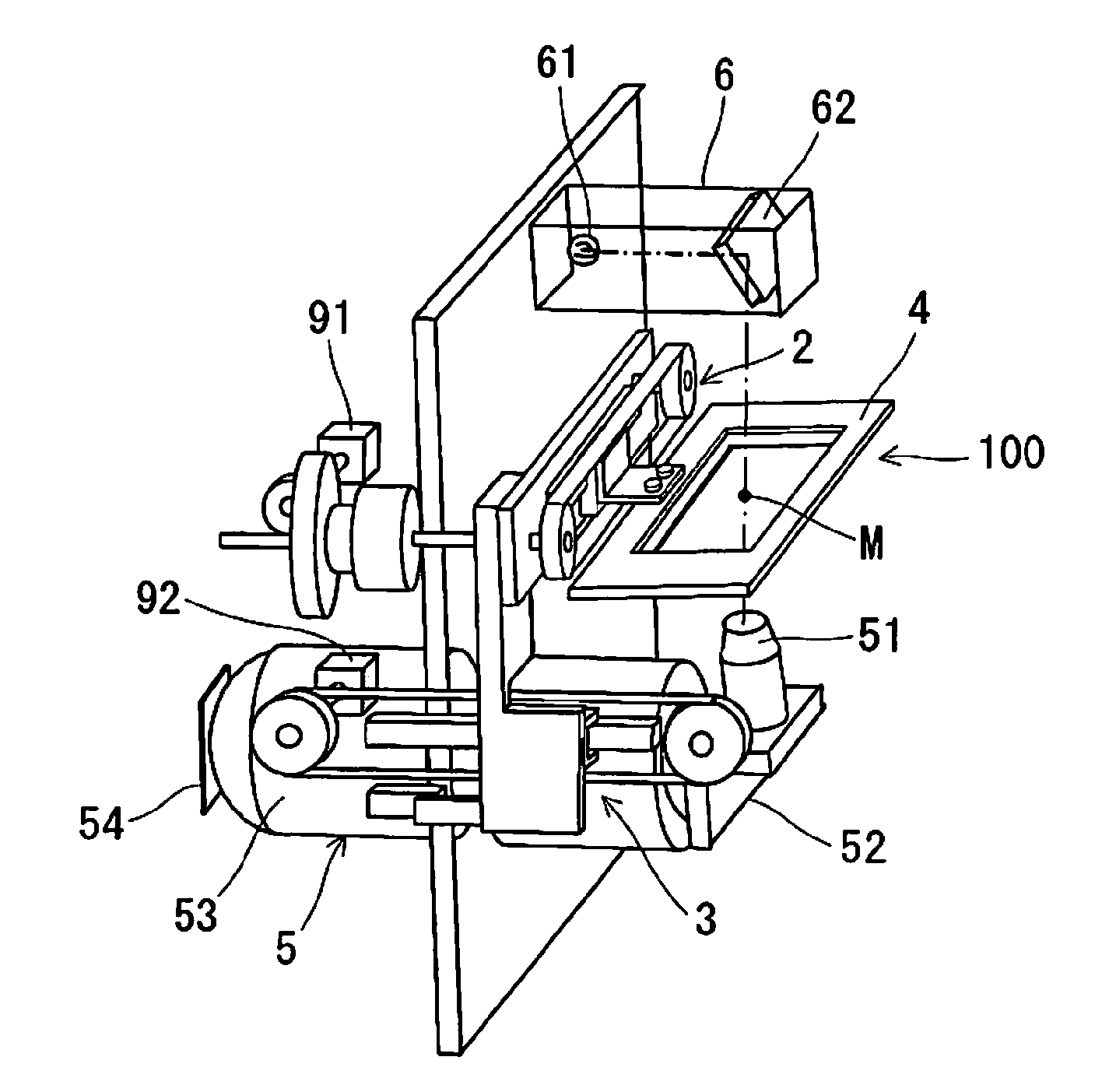

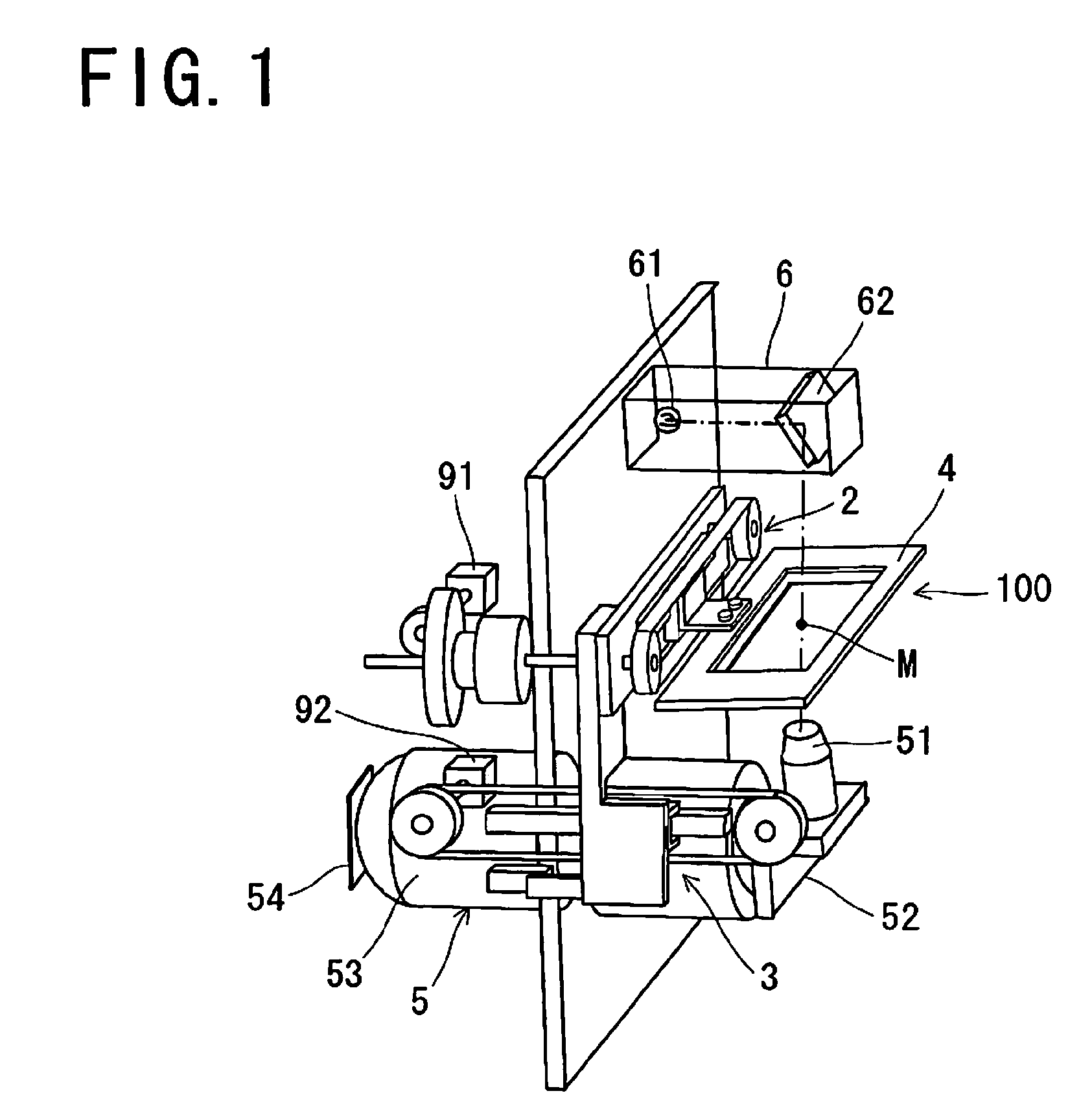

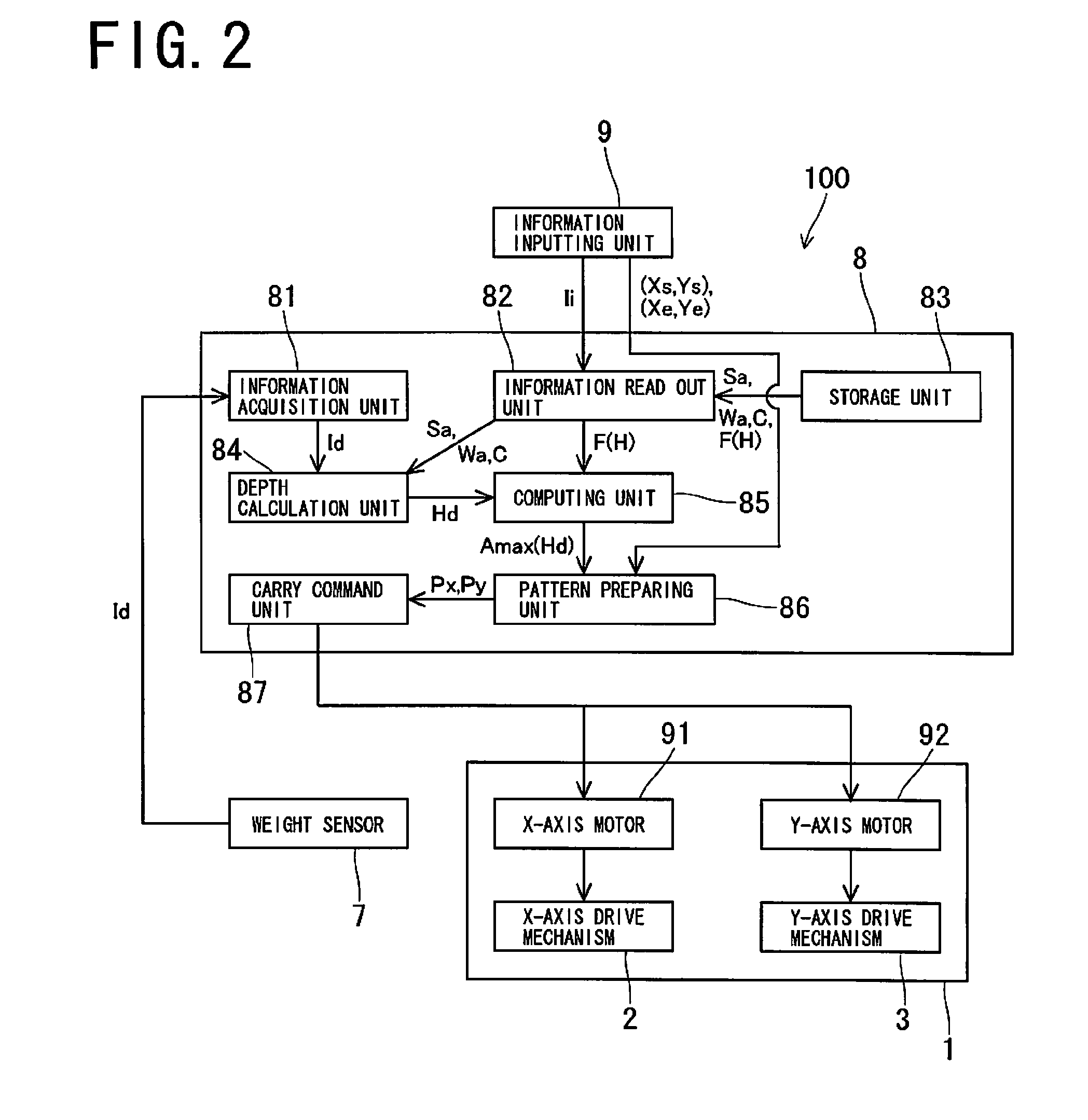

Carrying device, control device and program

InactiveUS20100179698A1Quick carryAvoid vibrationBioreactor/fermenter combinationsBiological substance pretreatmentsEngineering

The carrying device comprises a carrying mechanism carrying a fluid vessel containing liquid, a detection device detecting depth information changing with depth of the liquid in the fluid vessel, and a control device controlling the carrying mechanism. The control device comprises: an information acquisition unit acquiring the depth information detected by the detection device; a computing unit calculating a maximum value of an acceleration which can be given to the fluid vessel when carried based on the depth information acquired by the information acquisition unit; and a carry command unit giving the carrying mechanism a command for carrying the fluid vessel at acceleration of the maximum value or smaller. The computing unit calculates a greater value as the maximum value of the acceleration as the depth of the liquid in the fluid vessel increases, and a smaller value as the maximum value of the acceleration as the depth of the liquid in the fluid vessel decreases.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

Device for mounting components

InactiveUS6691401B2Reduce exerciseShorten exercise timePrinted circuit assemblingPliersRotary stageRelative motion

A device for mounting components using mounting heads having a plurality of suction nozzles that provide a plurality of component pickups, positions or mounting operating positions. The mounting heads are positioned on a rotating table that is cooperatively positioned adjacent a component supply table having a plurality of component feeder members. The control unit can rotate the rotating table to position a mounting head at a component supply position and further position one of the plurality of suction nozzles to a first, second and third section operating position for picking up a component from a component feeder. The relative movement of the component supply table and the positioning of first and second suction operating positions relative to our reference point where the edge of the rotating table contacts the line of movement of the component supply table can increase the pickup speed of components.

Owner:PANASONIC CORP

Medicinal composition for treating nervous system disease and its preparation method

InactiveCN1579465AIncrease the frequency of drinking waterIncrease the number of shocksNervous disorderUnknown materialsAdditive ingredientChinese traditional

Owner:BEIJING BEILU PHARM CO LTD

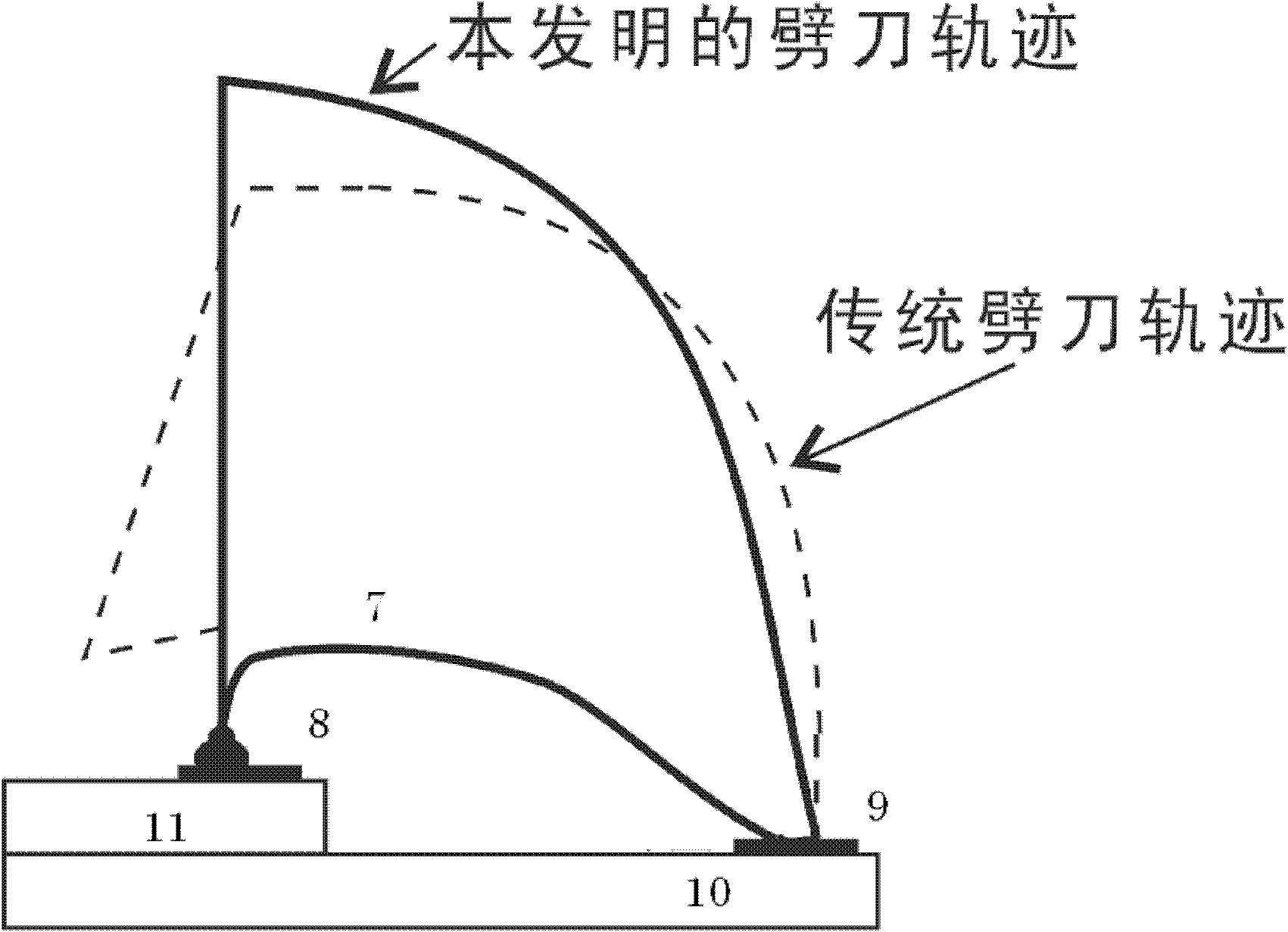

Method and device for quickly forming arc for leading wire by using wire clamp to manufacture salient points

InactiveCN102437111AThe riving knife trajectory is simpleAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingWeldingSalient point

The invention discloses a method and a device for quickly forming an arc for a leading wire by using a wire clamp to manufacture salient points. The method comprises the following steps of: 1, forming a first welding spot on a chip bonding pad, then fixing a free end of the leading wire by a cleaver, and clamping and bending the leading wire between the cleaver and the first welding spot by using the wire clamp so as to form a series of salient points; 2, in the operational process of bending the leading wire, staggering two fixed arms at an upper position and a lower position, arranging the two fixed arms on two sides of the wire clamp respectively to clamp the leading wire, staggering two movable arms at an upper position and a lower position, and arranging the two movable arms on two sides of the wire clamp; and 3, loosening the wire clamp, driving the leading wire to move by the cleaver to weld the free end of the leading wire on a second bonding pad so as to finish the process of forming the arc for the leading wire. When the method and the device for quickly forming the arc for the leading wire by using the wire clamp are used to manufacture the salient points, the problems of complex cleaver tracks and low working efficiency in the conventional leading wire forming method can be solved.

Owner:CENT SOUTH UNIV

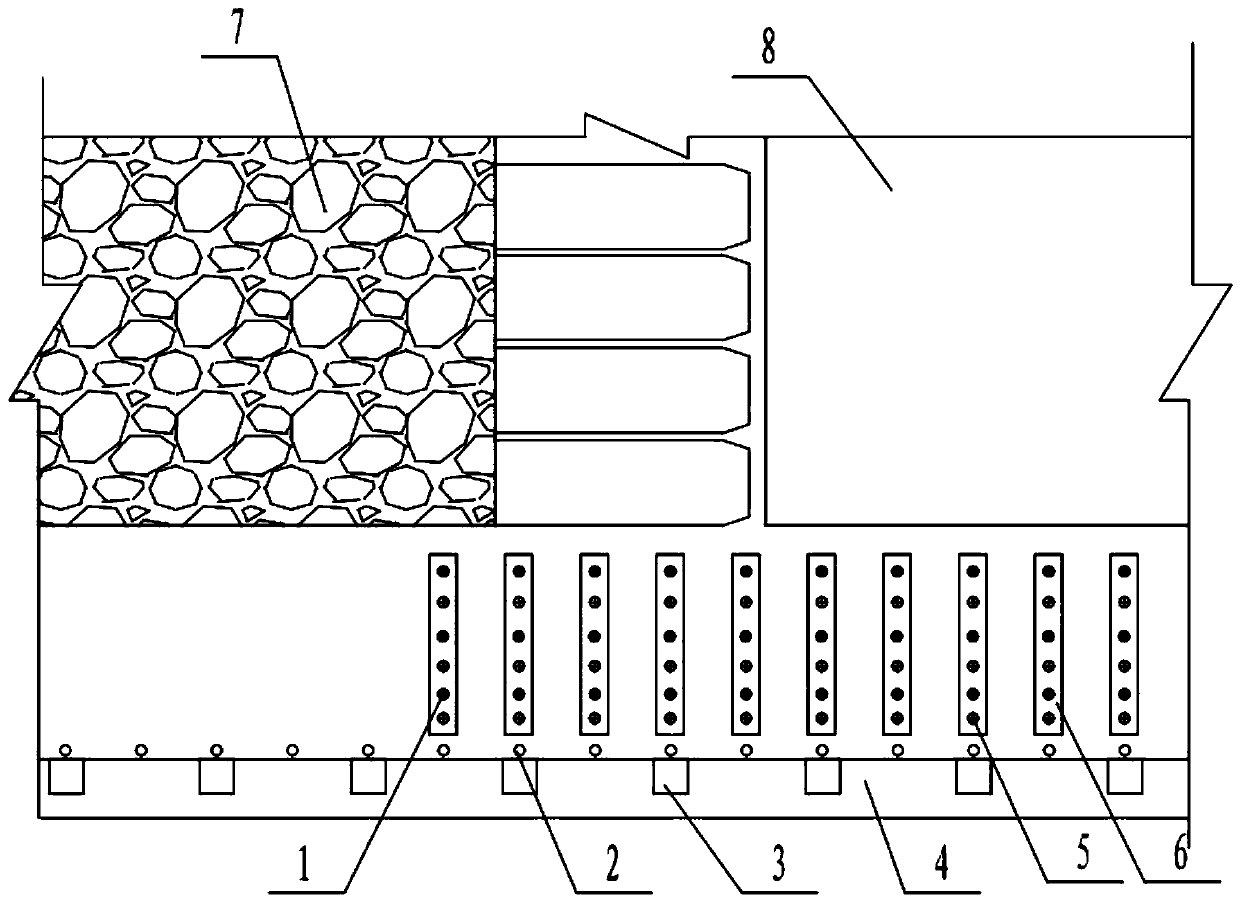

Non-blasting roof-cutting gob-side entry driving method for pier stud

ActiveCN110939466AReduce surrounding rock deformationShorten exercise timeUnderground chambersTunnel liningArchitectural engineeringCoal pillar

The invention discloses a non-blasting roof-cutting gob-side entry driving method for a pier stud. The method comprises the following steps of forming a plurality of joint-cutting holes which jointlyform a pre-cracking kerf, and drilling 60-100 m of a first advance of the joint-cutting holes; excavating an upper of a coal pillar on one side, close to the coal pillar, in a gateway close a next working face at every 5-10 m and arranging concrete pier stud dies; using a single hydraulic support pillar and n-type steel in the gateway as temporary support; carrying out anchor-retreating construction in the gateway next to the next working surface; recovering the single hydraulic support pillar following 2-5 m behind the working surface closely; and forming a pre-cracking joint-cutting caving on a top plate next to a gob-side entrydriving lane along the joint-cutting holes, eliminating a hanging arch, filling a gob, and carrying out gob-side entrydriving construction at 3-5 m coal pillar after recovery of adjacent gob. By adopting non-blasting roof-cutting pressure relieving for the pier stud, a gob-side entrydriving operation for a small coal pillar can be carried out on adjacent working surface, so that a mine excavation succeeding tension situation is alleviated greatly, the repair cost of the gob-side entry driving is reduced, and the coal recovery rate is improved.

Owner:GUIZHOU UNIV

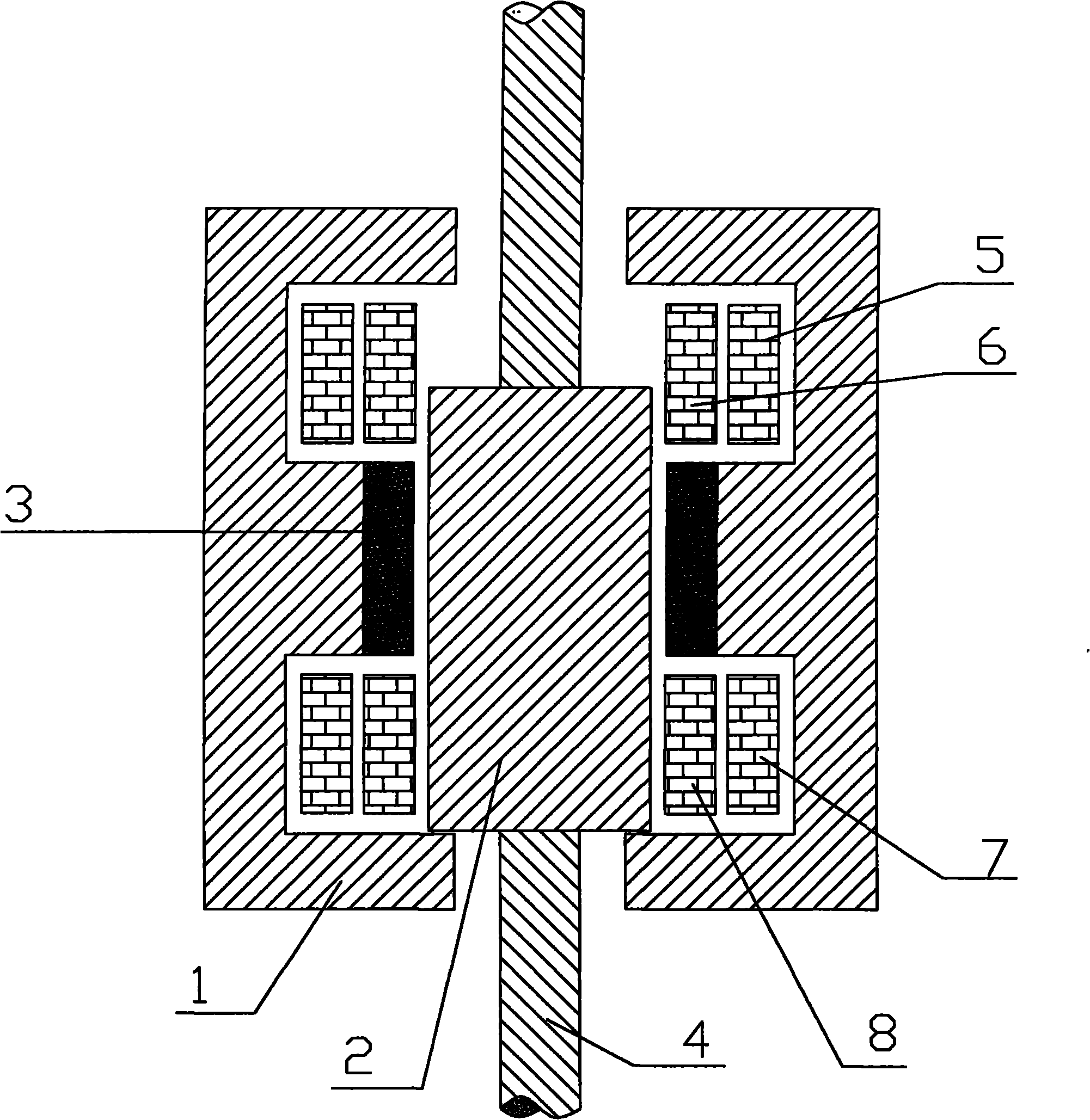

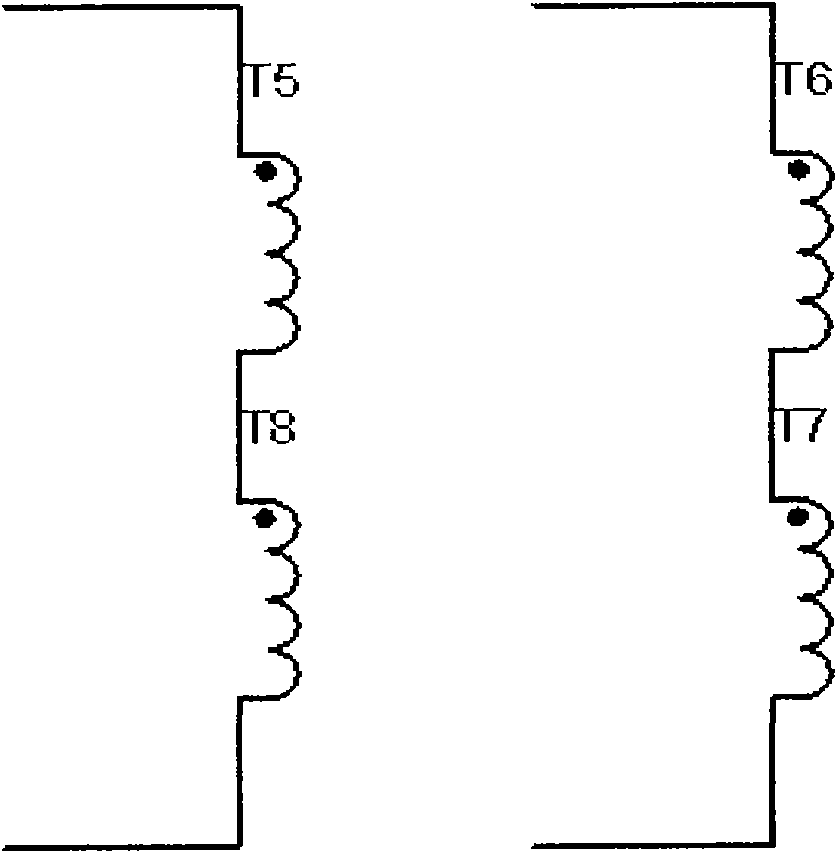

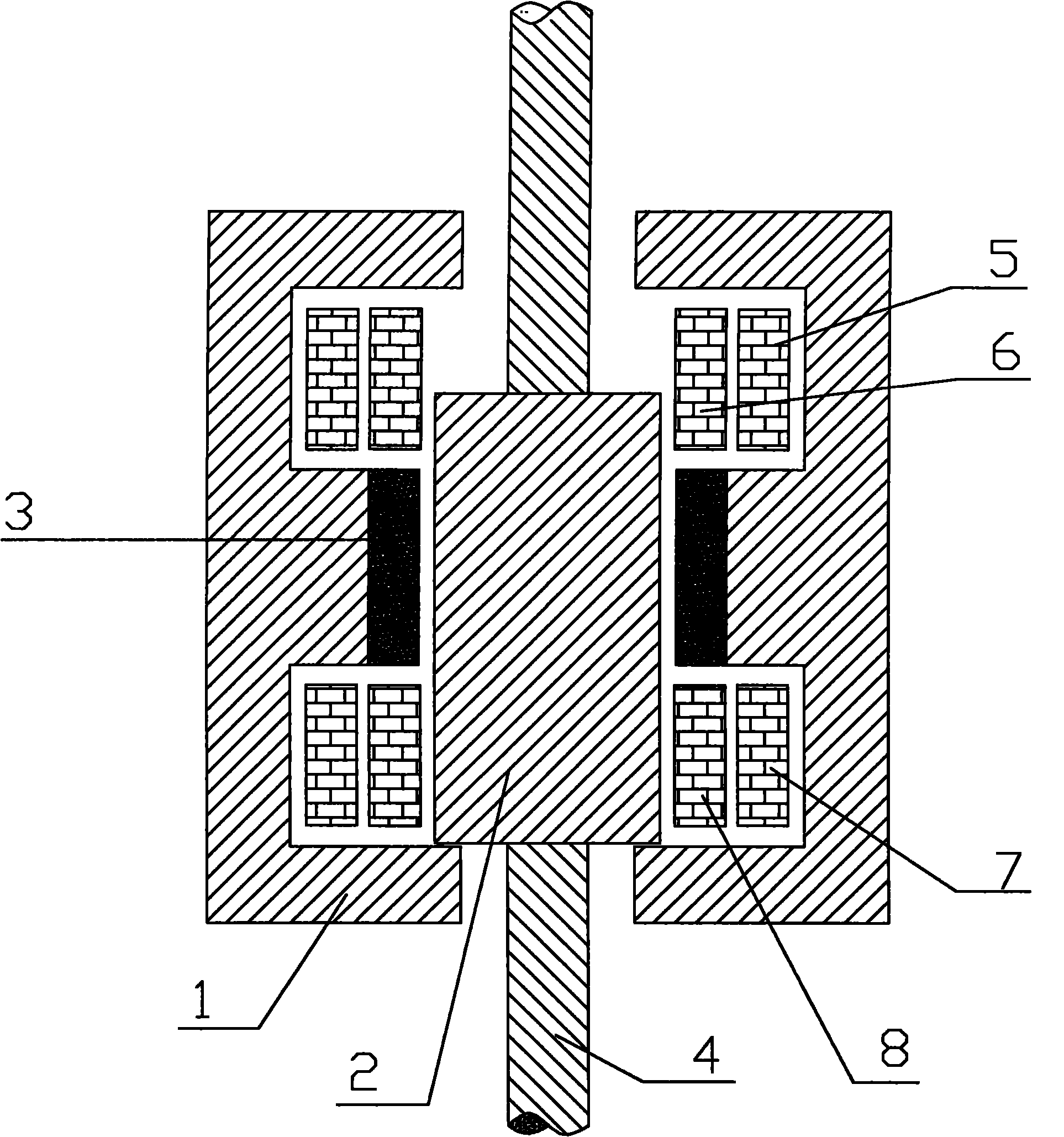

Bistable permanent-magnet operating mechanism dispersedly exciting on two sides of brake opening and closing working air gaps

InactiveCN101826402AImprove excitation performanceShorten the timeSwitch power arrangementsLow voltagePeak current

The invention discloses a bistable permanent-magnet operating mechanism dispersedly exciting on two sides of brake opening and closing working air gaps, which is suitable to be used for driving a contact terminal to move in single-phase, multi-phase high-voltage, intermediate-voltage and low-voltage switches and is characterized in that a main brake closing coil and an auxiliary brake opening coil are arranged on one side of a brake closing working air gap, and a main brake opening coil and an auxiliary brake closing coil are arranged on one side of a brake opening working air gap, wherein the main brake closing coil and the auxiliary brake closing coil are connected in series; and the main brake opening coil and the auxiliary brake opening coil are connected in series. The invention has favorable excitation effect; a moving iron core can obtain enough operation power in a whole movement process; the contact time and the movement time are reduced, the peak current of an exciting coil is reduced, the energy consumption of an energy storage capacitor is decreased, and the mechanical properties are well matched with brake opening properties and brake closing properties of the contactterminal.

Owner:沈阳明鑫智能电器有限公司

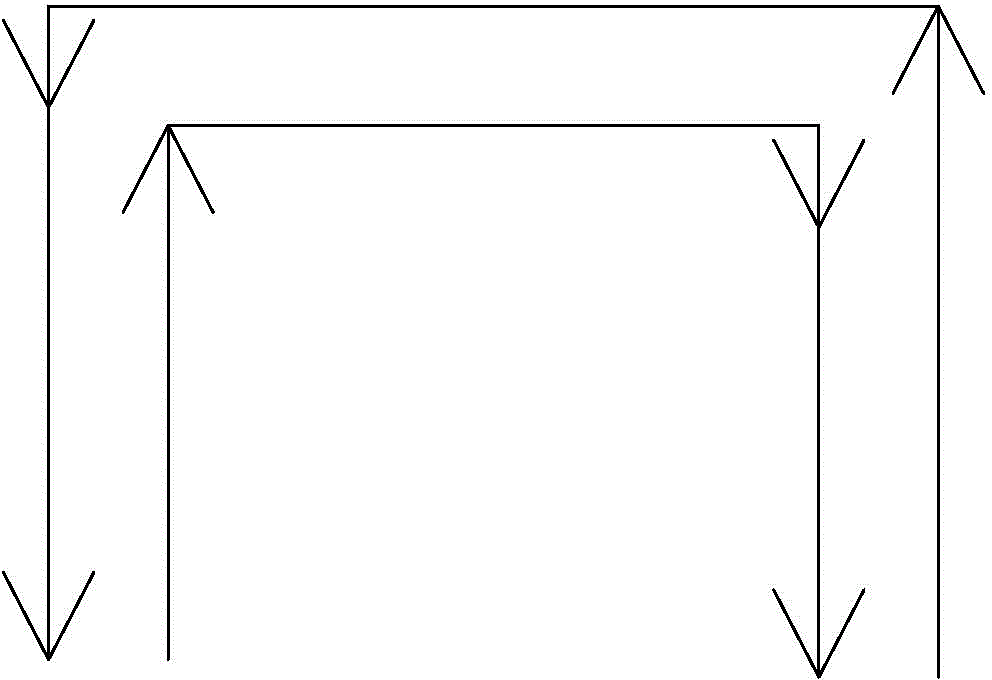

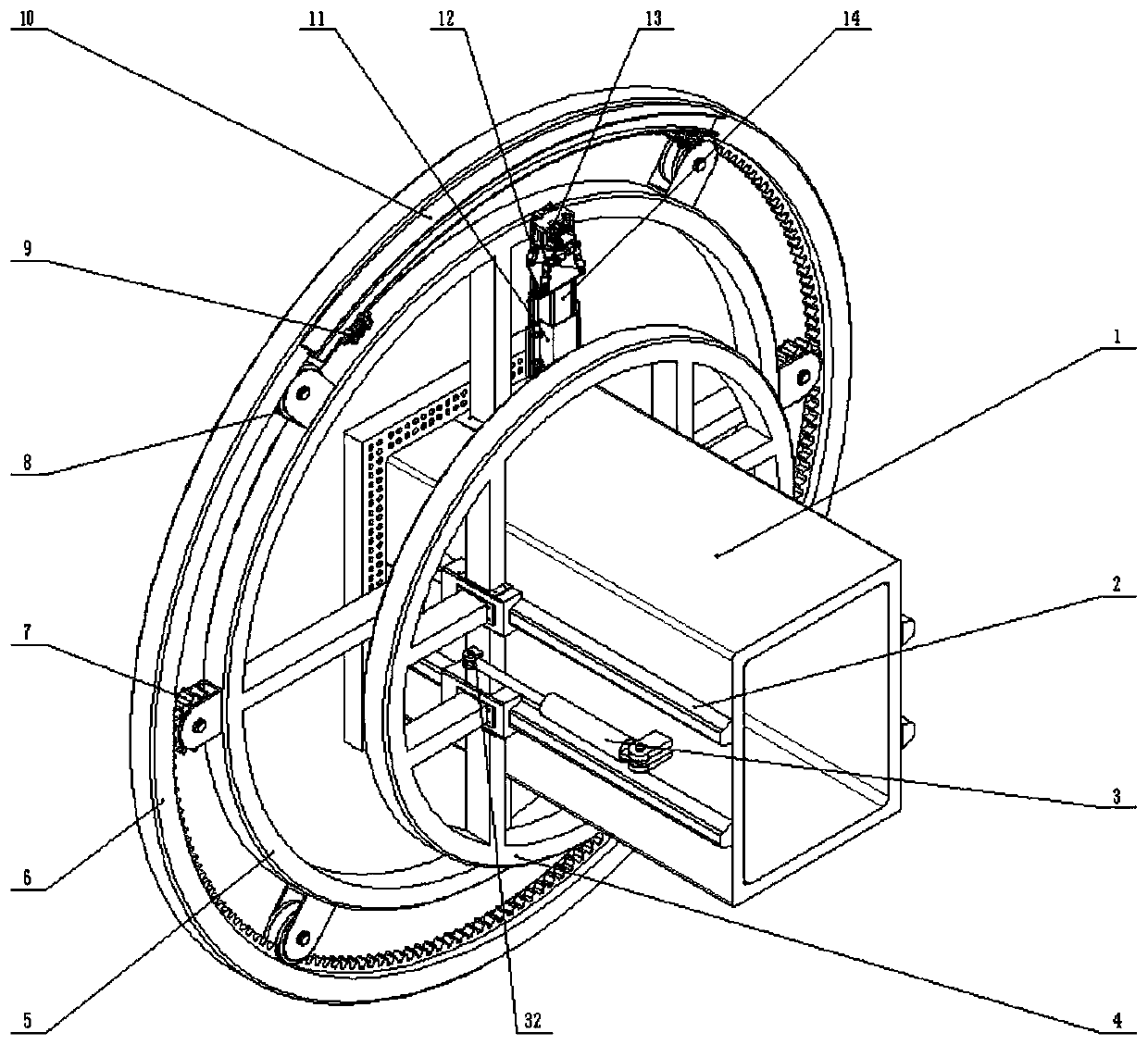

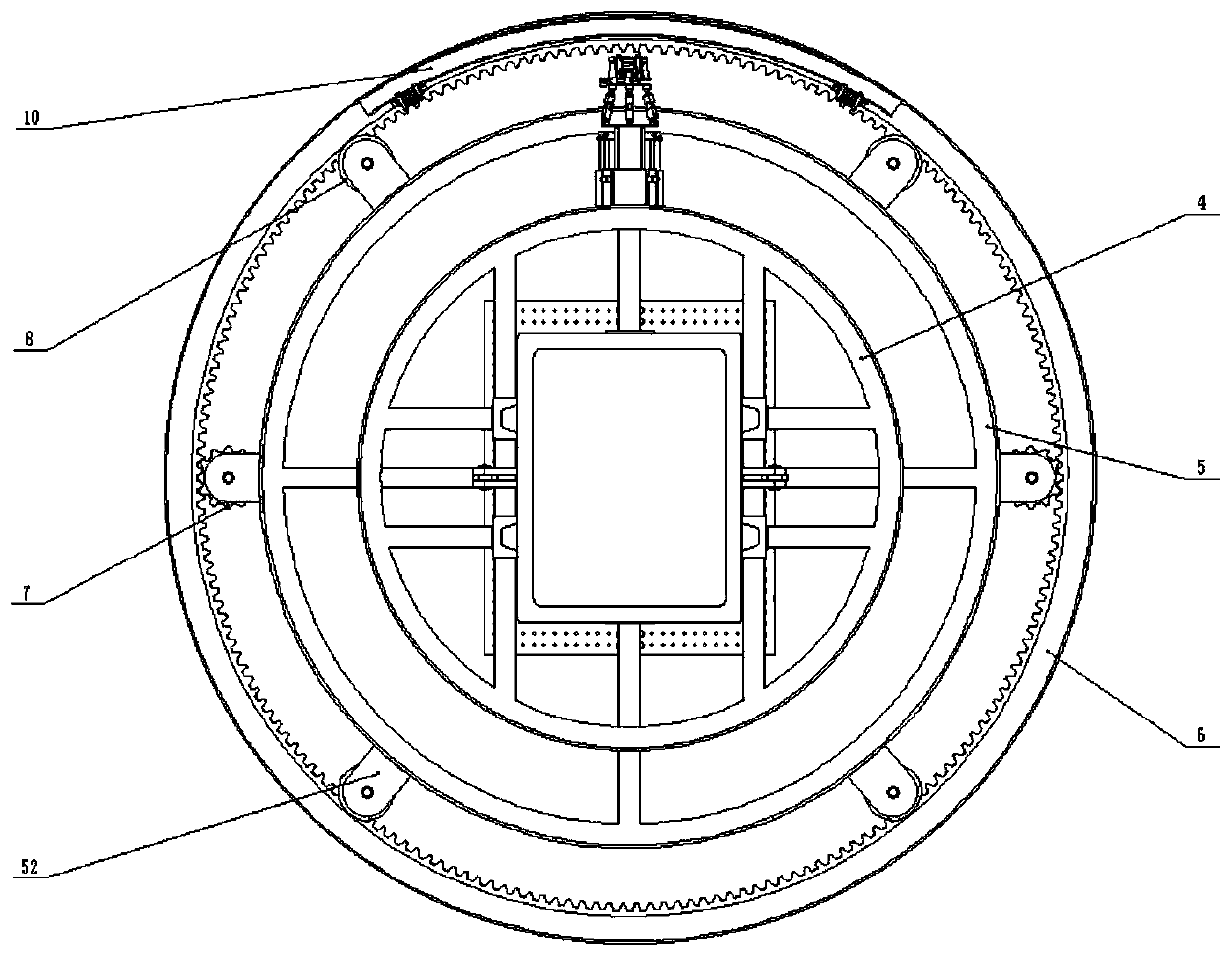

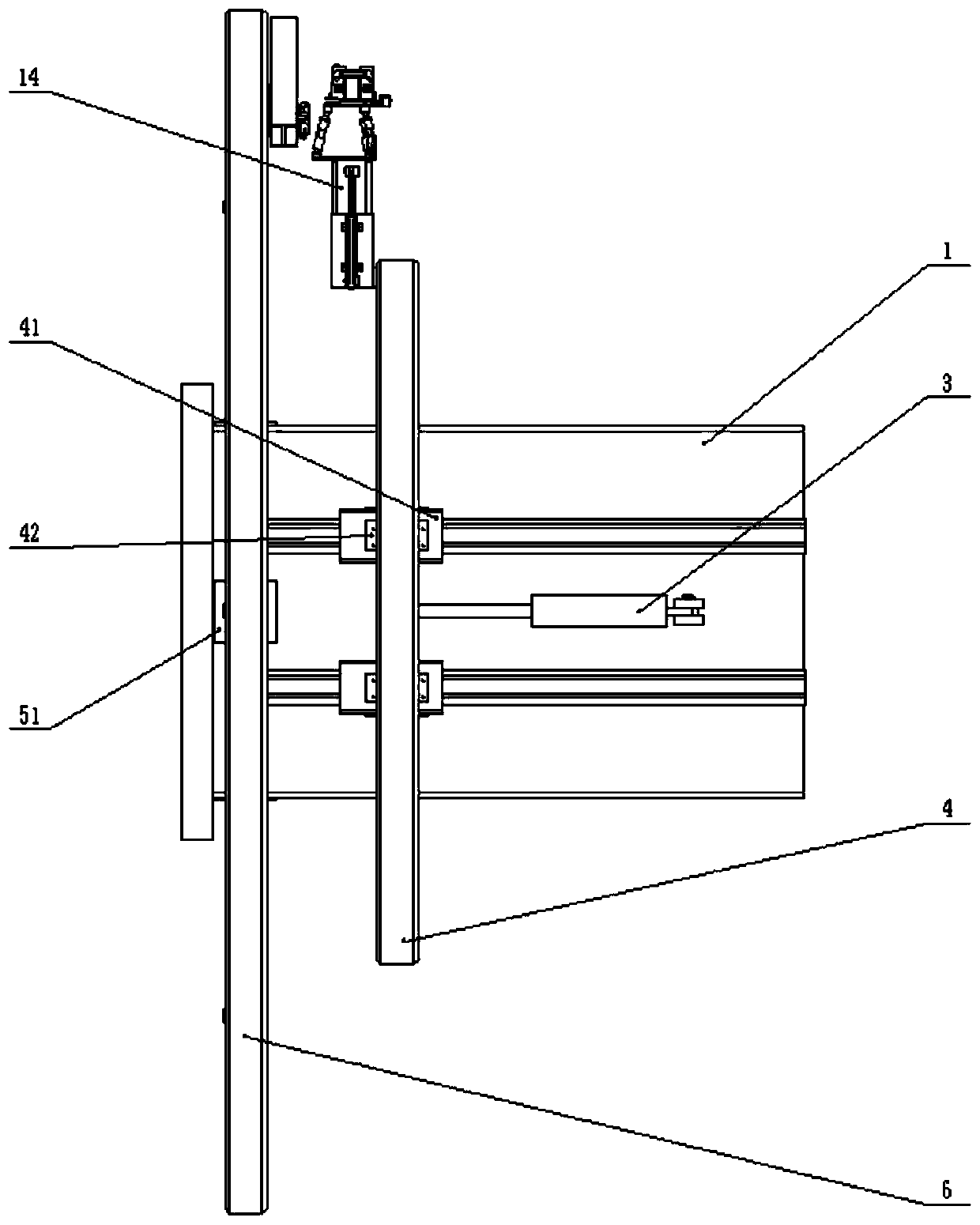

Automatic assembling operation device and method for open-type TBM steel arch frame

PendingCN109848956AShorten exercise timeImprove assembly efficiencyGripping headsArmsDrive wheelArchitectural engineering

The invention discloses an automatic assembling operation device and method for an open-type TBM steel arch frame. The automatic assembling operation device for the open-type TBM steel arch frame comprises a main beam, a traveling ring, a traveling oil cylinder, a rotating ring, driving wheels, a steel arch frame clamp and a steel arch frame assembling manipulator, wherein the traveling ring is connected with the main beam through sliding guide rails; two ends of the traveling oil cylinder are respectively hinged on the main beam and the traveling ring, and the traveling ring can be driven tomove along the horizontal direction; the rotating ring is fixed on the main beam through a flange plate and driven by the two symmetrically arranged driving wheels; the steel arch frame clamp is circumferentially arranged and welded on the side surface of the rotating ring; the steel arch frame assembling manipulator comprises a telescopic arm, a posture adjusting mechanism and the steel arch frame clamp; and the steel arch frame assembling manipulator is fixedly connected to the side surface of the traveling ring through a flange plate. By means of the automatic assembling operation device, the postures of the steel arch frame can be adjusted, so that the high-efficiency automatic assembly of the steel arch frame is achieved.

Owner:ZHEJIANG UNIV

Voice coil motor control device and method of driving the same, image pickup device

InactiveUS7760442B2Hysteresis characteristicSuitable lens position without complicating the structure of the control deviceTelevision system detailsAC motor controlHysteresisDriving current

The present invention provides a control device capable of improving hysteresis characteristics of a voice coil motor (31) and attaining a suitable lens position without complicating the structure of the control device. As solving means of the invention, a voice coil motor control device (30) includes a driving current control part (34) that controls a driving current supplied to the voice coil motor (31) in accordance with a driving pulse subjected to pulse width modulation, and a driving pulse control part (32) that divides a drive period of the voice coil motor (31) into a movement period and a holding period, and controls the driving pulse by changing the duty ratio of the driving pulse during the movement period in accordance with a duty setting value and fixing the duty ratio of the driving pulse during the holding period to the duty setting value.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com