Bistable permanent-magnet operating mechanism dispersedly exciting on two sides of brake opening and closing working air gaps

A working air gap, permanent magnet operation technology, applied in the direction of the power device inside the switch, can solve the problems of unsatisfactory mechanical characteristics, large peak current of the opening coil and closing coil, etc., to increase the excitation effect and reduce the peak current. Small, touch time and motion time reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

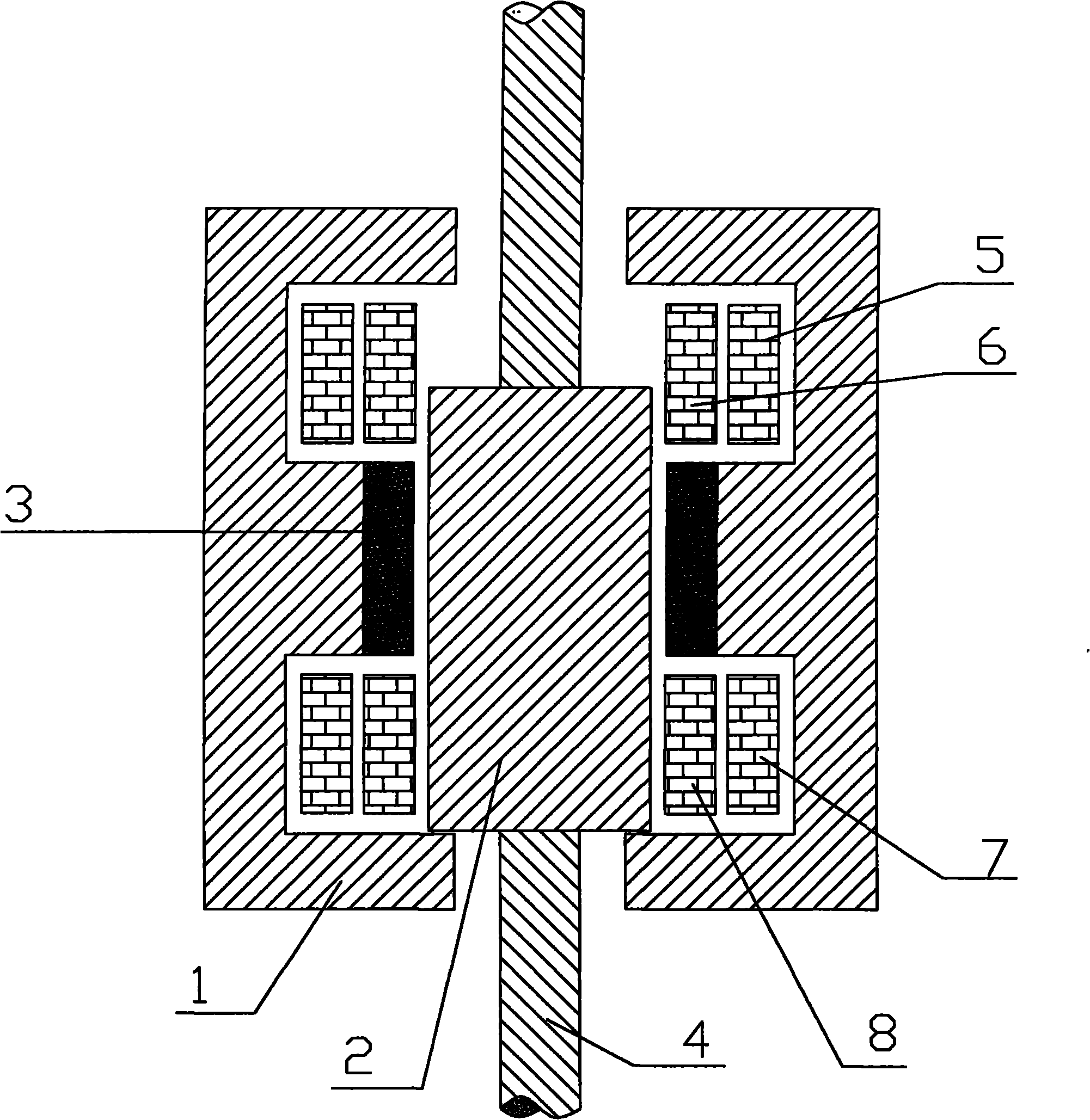

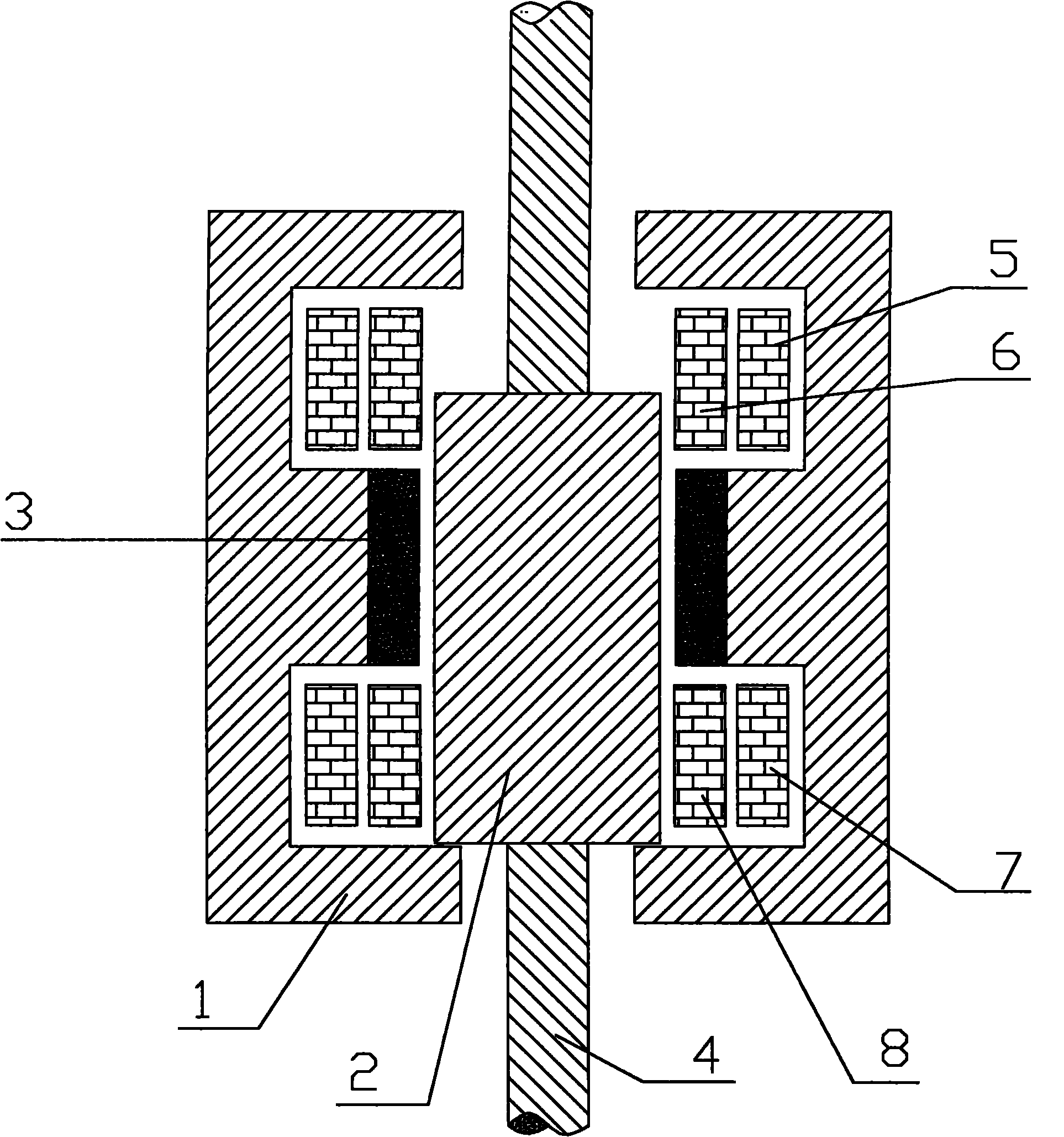

[0017] figure 1 It is the operation diagram of the bistable permanent magnet with dispersed excitation on both sides of the opening and closing working air gap. In the figure, 1 is the static iron core, 2 is the moving iron core, 3 is the permanent magnet, and 4 is the driving rod (non-magnetic material) ), 5 is the main closing coil, 6 is the auxiliary opening coil, 7 is the main opening coil, and 8 is the auxiliary closing coil. The moving iron core 2 is located at the opening position. Such as figure 1 As shown, this kind of bistable permanent magnet operating mechanism with distributed excitation on both sides of the opening and closing working air gap places the main closing coil 5 and auxiliary opening coil 6 on the side of the closing working air gap, The main opening coil 7 and the auxiliary closing coil 8 are placed on one side of the working air gap.

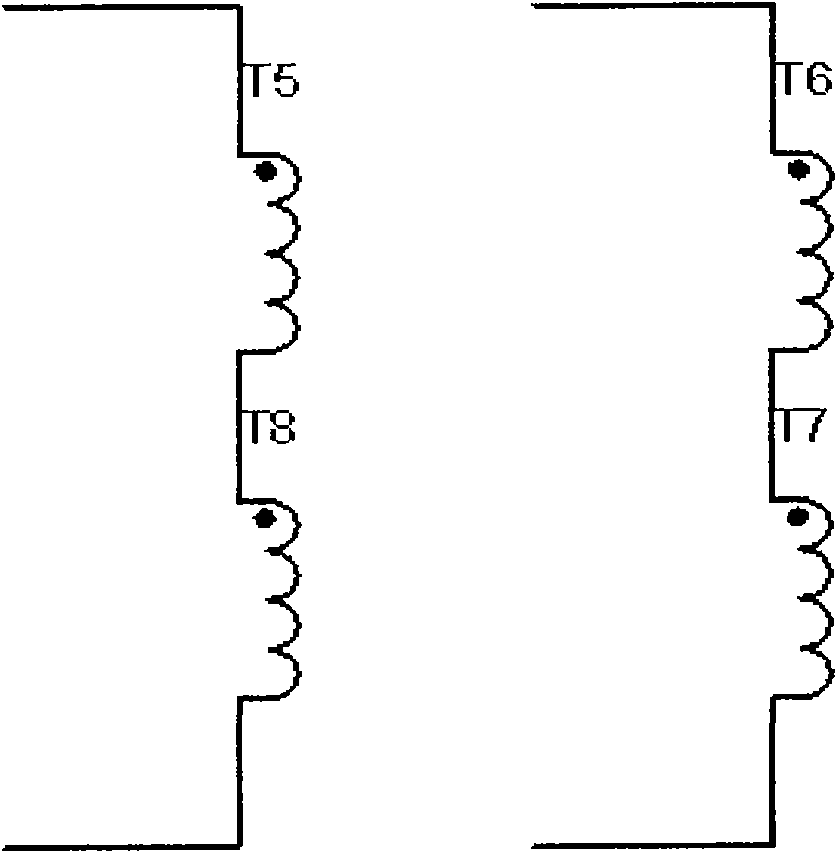

[0018] figure 2 Wiring diagram for main closing coil, auxiliary closing coil, main opening coil and auxiliary o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com