Device and method for coil induction auxiliary electromagnetic pulse pipe fitting welding

A technology of electromagnetic pulse and excitation device, which is applied in welding equipment, non-electric welding equipment, applications, etc., can solve the problem that electromagnetic pulse welding equipment does not have enough power, and achieve the effect of ensuring welding effect, reducing strength and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

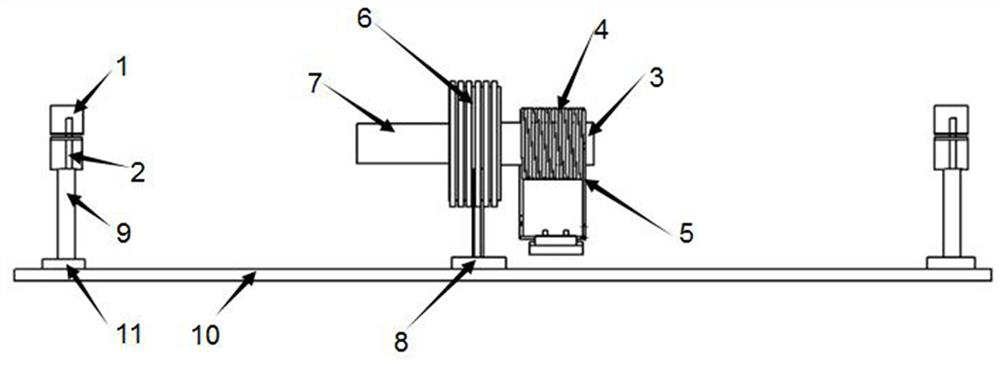

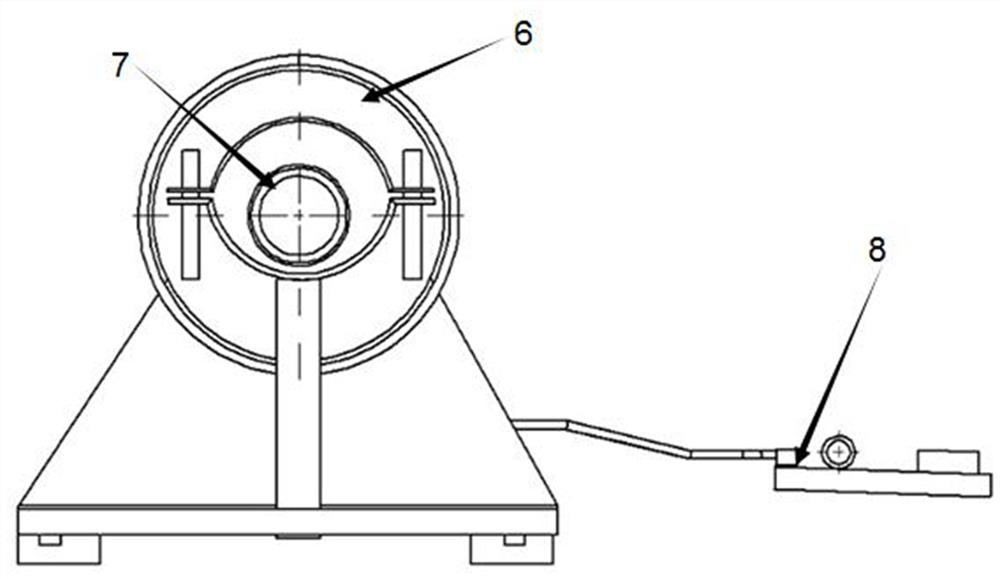

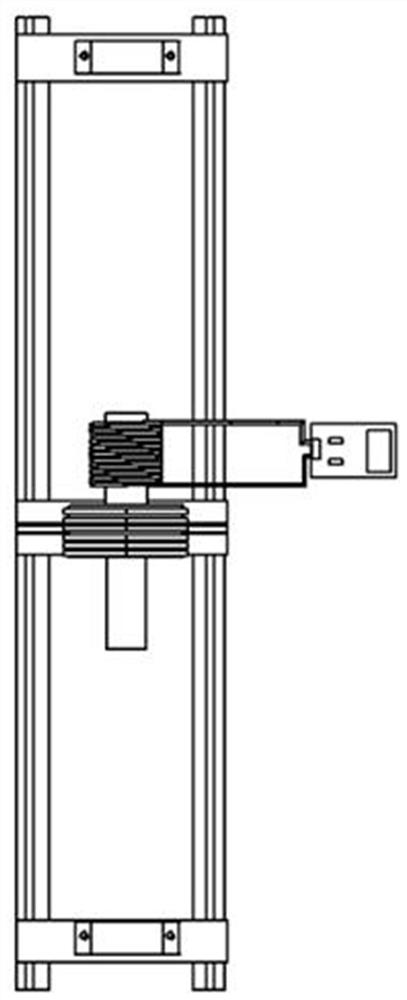

[0035] As shown in the figure, the coil induction heating assisted electromagnetic pulse welding high-strength pipe fittings device is used to reduce the strength of the outer pipe fittings before electromagnetic pulse welding, so as to realize the metallurgical connection between high-strength pipe fittings through electromagnetic pulse welding. The device includes a set Magnet 5 and the heater 6 that is close to the magnetic collector; The magnetic collector includes an excitation device that can accommodate the welded end of the first pipe 3 and the welded end of the second pipe 7; Heated induction heating coil; the inner diameter of the induction heating coil is greater than the outer diameter of the first pipe; when welding, the first pipe is placed at the induction heating coil, the welding end of the first pipe 3 and the second pipe 7 The welding ends are all placed in the excitation device of the magnet collector. When the induction heating coil heats the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com