Semi-automatic laminating machine and laminating method thereof

A laminating machine, semi-automatic technology, applied in chemical instruments and methods, lamination devices, optics, etc., can solve the problems of inaccurate positioning, low yield, wrinkles, etc., to ensure lamination accuracy, improve production efficiency, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

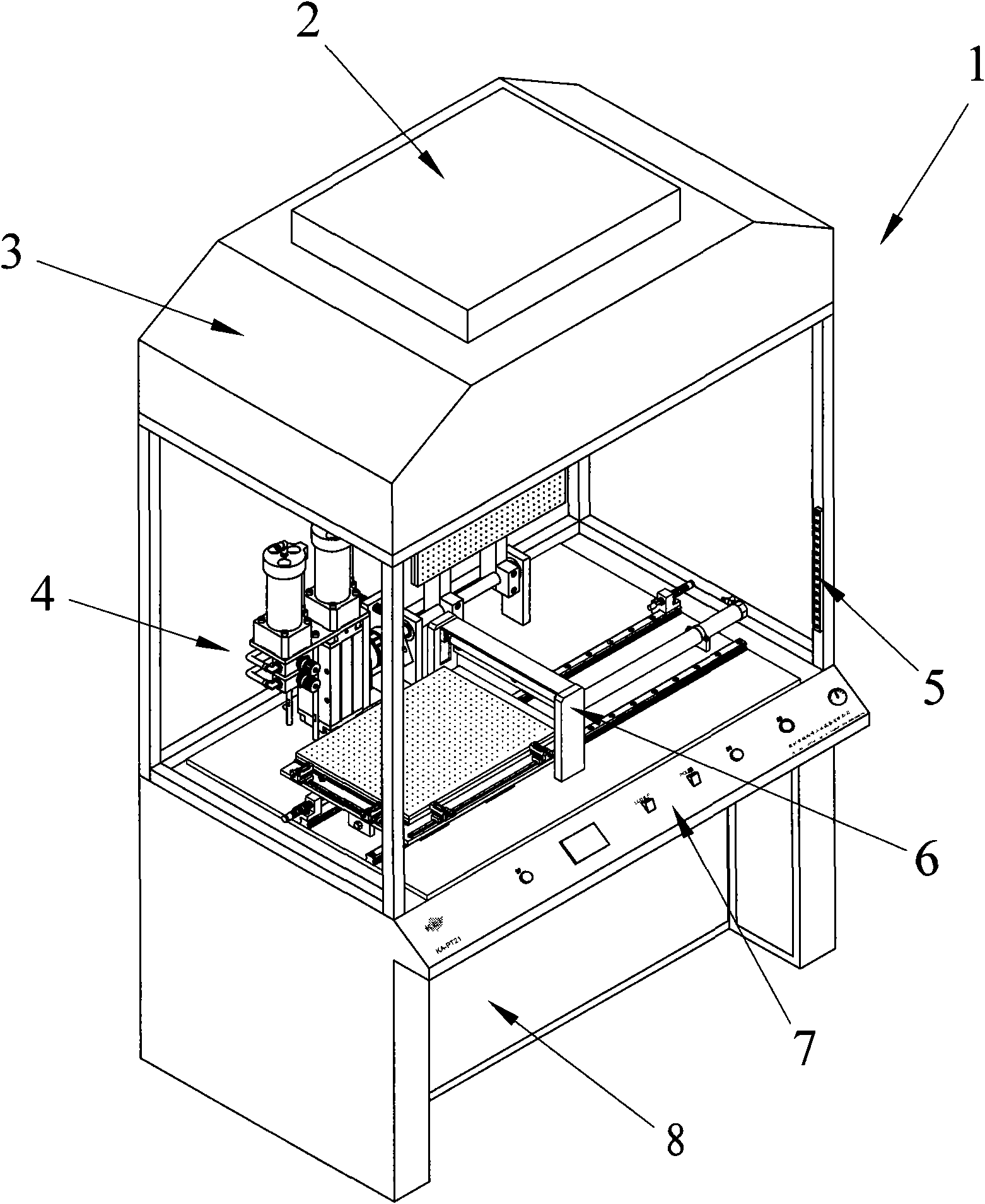

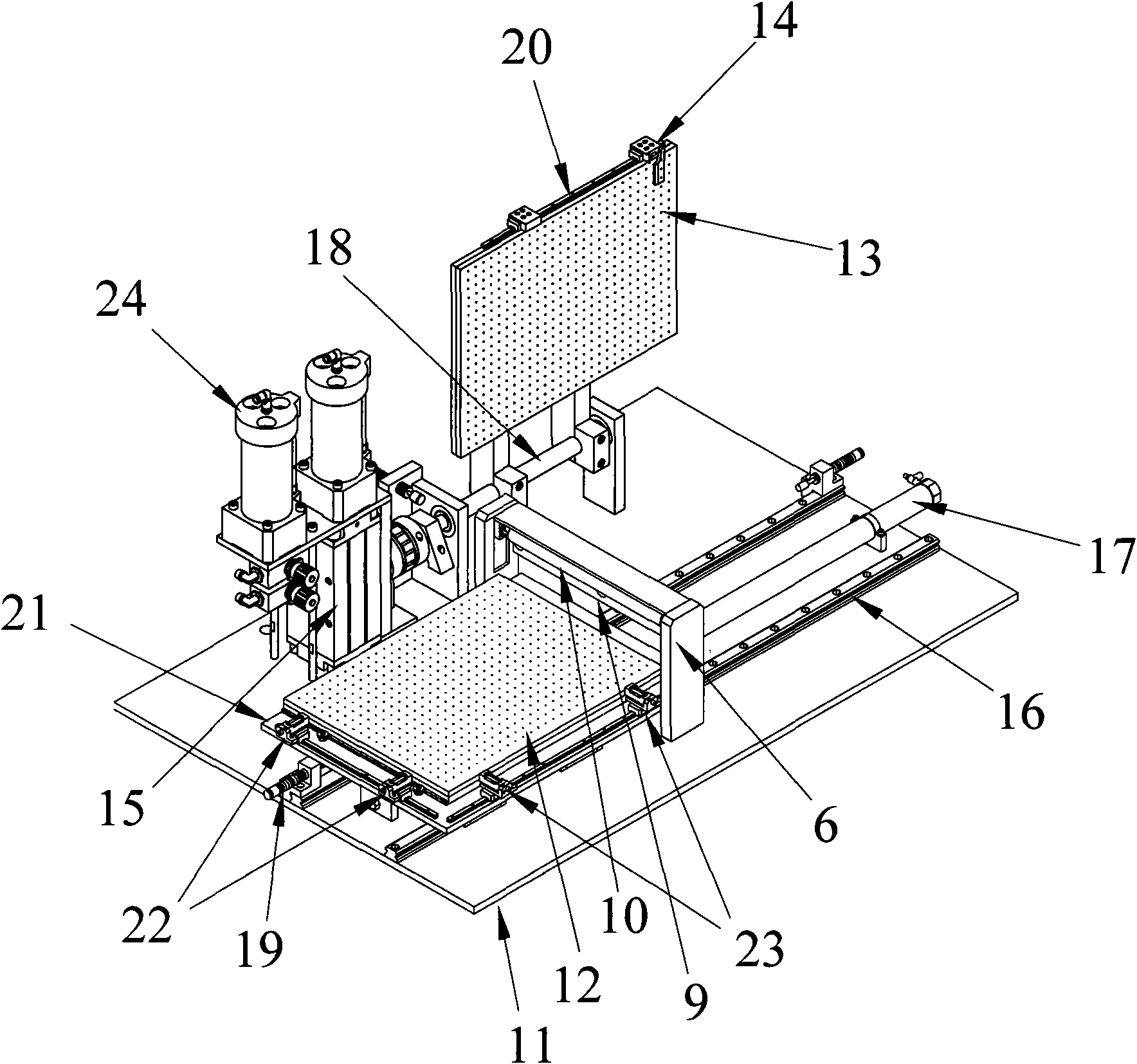

[0027] Please also refer to figure 1 and figure 2 , figure 1 It is the overall structure diagram of the semi-automatic laminating machine, figure 2 It is the structural diagram of the bonding device. As shown in the figure, the semi-automatic laminating machine has a frame 1; a working space for accommodating the laminating device 4 in the middle of the frame 1; an electrical component box 8 installed in the frame 1 and located below the laminating device 4; The air inlet 2 at the top of the frame 1 and the air cleaner 3 placed on the top of the frame 1; the operation panel 7 installed on the frame 1 for controlling the laminating machine; the laminating device further includes an organic table 11, which is installed The power unit on the machine platform 11 and two linear slide rails 16; the power unit further includes an oil-gas converter 24 and a rotary hydraulic cylinder 15; Oil pressure limiter is selected; the linear cylinder 17 installed on the machine platform 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com