Track slab grinder

A track plate and grinding machine technology, which is applied to grinding machines, machine tools suitable for grinding workpiece planes, grinding/polishing equipment, etc., can solve the problems of complicated mechanism, difficulty in ensuring accuracy, and rotating mechanism that affects grinding efficiency. Improve rigidity and bending resistance, eliminate tool mark error, and save movement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

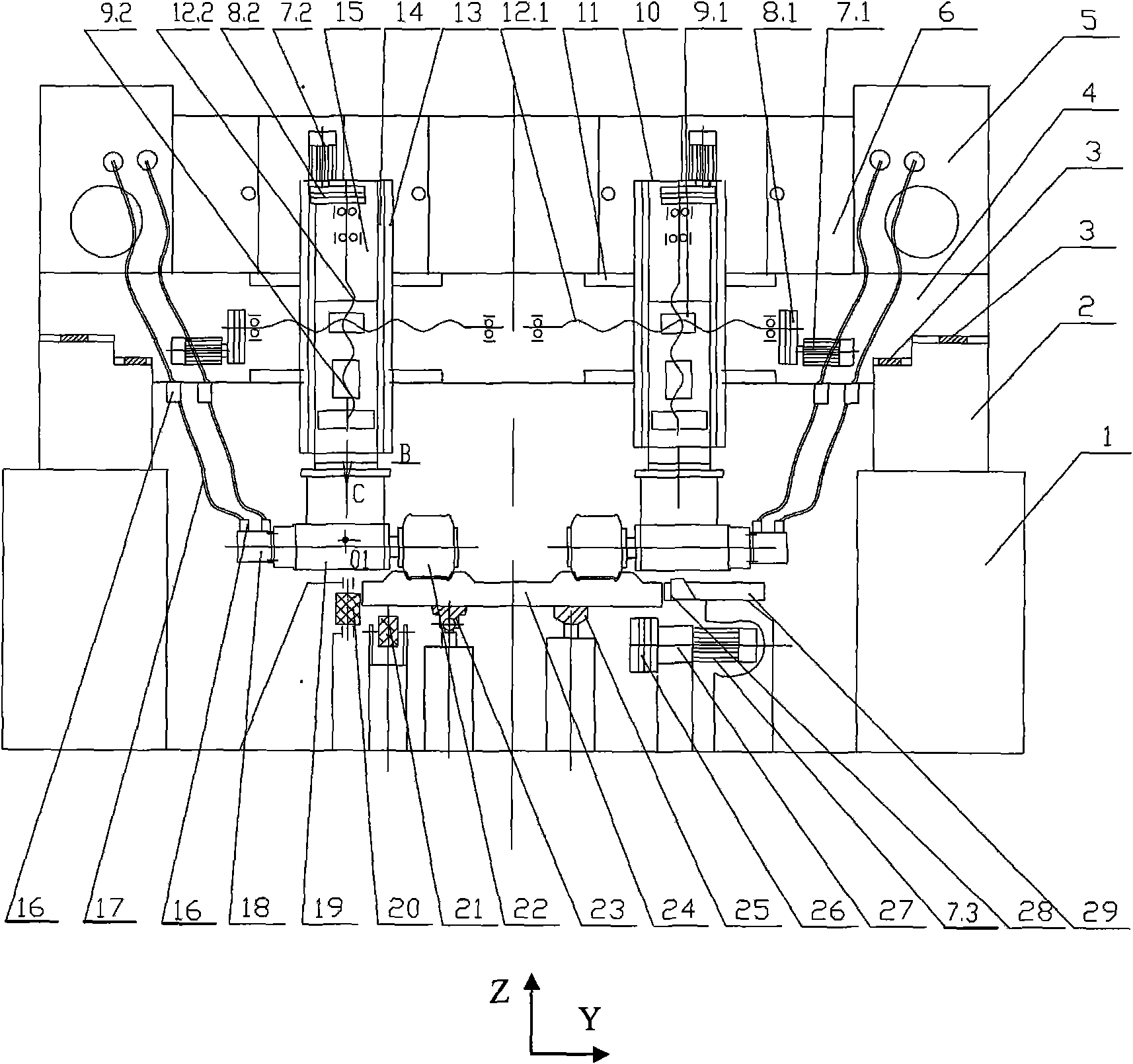

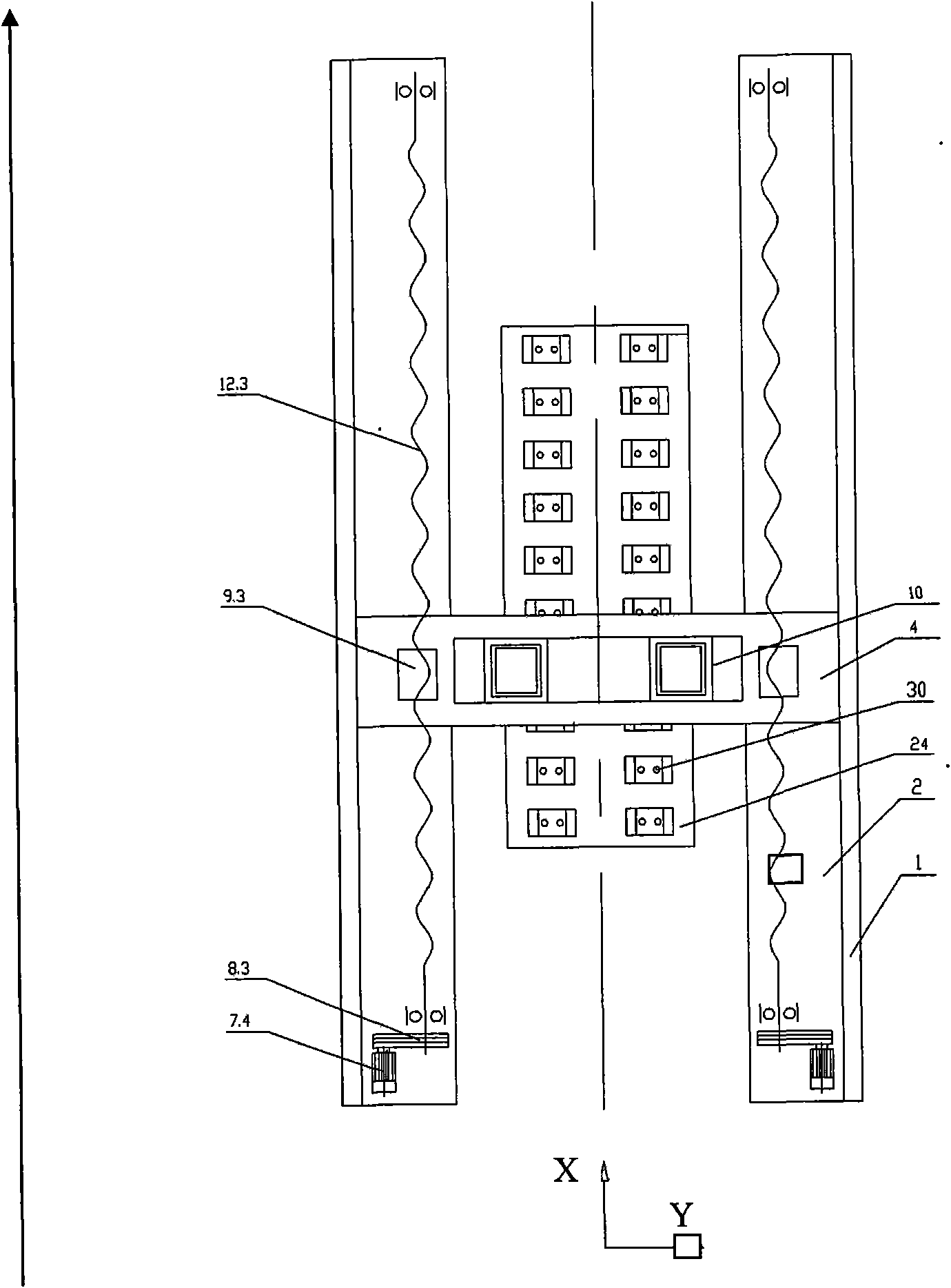

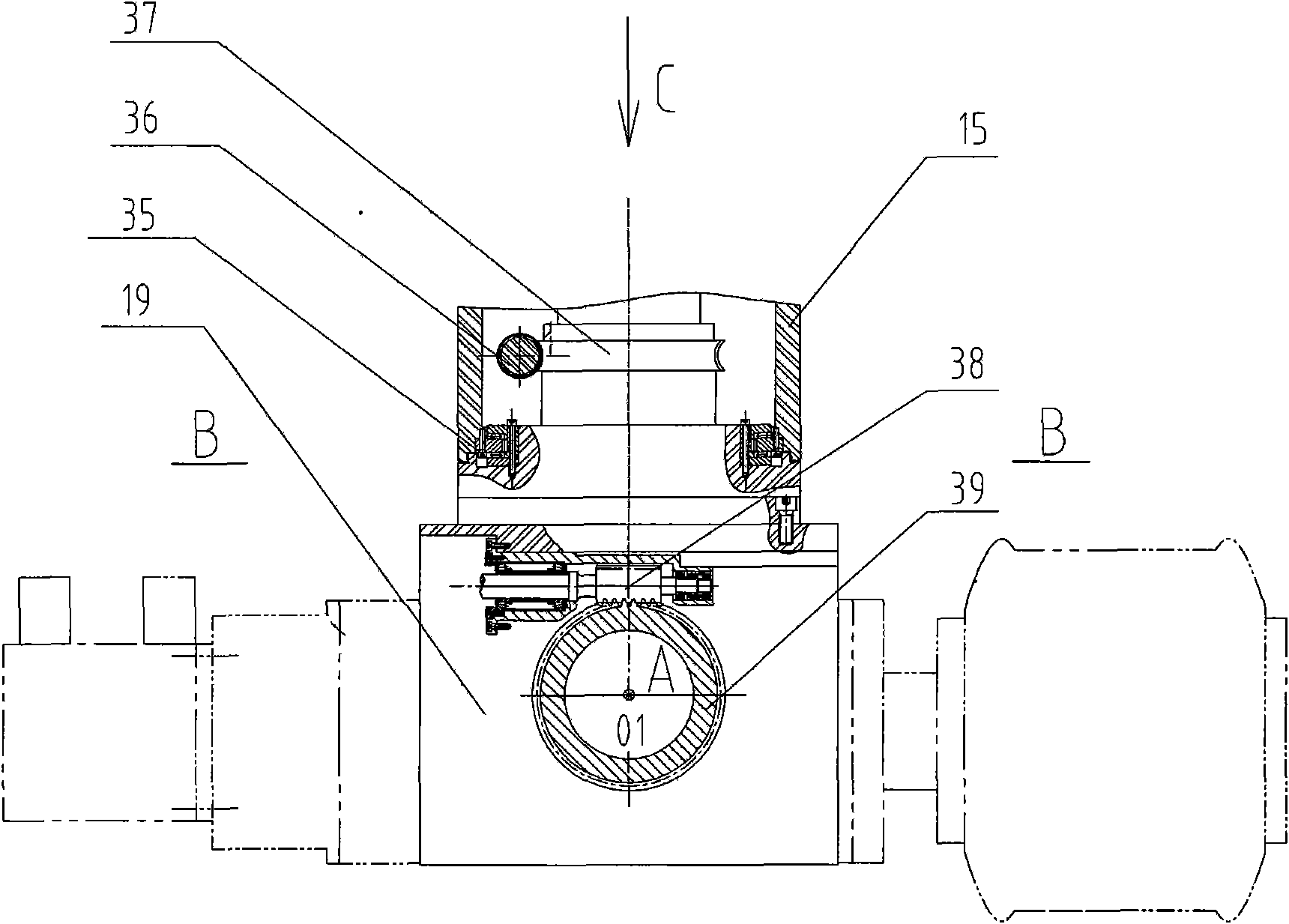

[0018] see figure 1 with figure 2 , the present invention comprises the wall plate type elevated gantry structure and left and right grinding wheel 22 that left and right main base walls 1 constitute. The key technology is to install the left and right main longitudinal beams 2 on the left and right main foundation walls 1 respectively, install two main longitudinal guide rails 3 on the main longitudinal beams 2 to form a ladder shape, and install boxes between the main longitudinal guide rails 3 The main beam 4 of the shaped beam structure is such that the main beam 4 is supported on the main longitudinal beam 2 through the main longitudinal guide rail 3, and the main beam 4 constitutes a full-frame symmetrical four-rail structure. The driving device of main beam 4 comprises servo motor 7.4 and leading screw 12.3, and servo motor 7.4 connects belt pulley 8.3, and belt pulley 8.3 connects leading screw 12.3, and leading screw 12.3 is connected with main beam 4 by nut 9.3. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com