Patents

Literature

36results about How to "Eliminate Control Errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

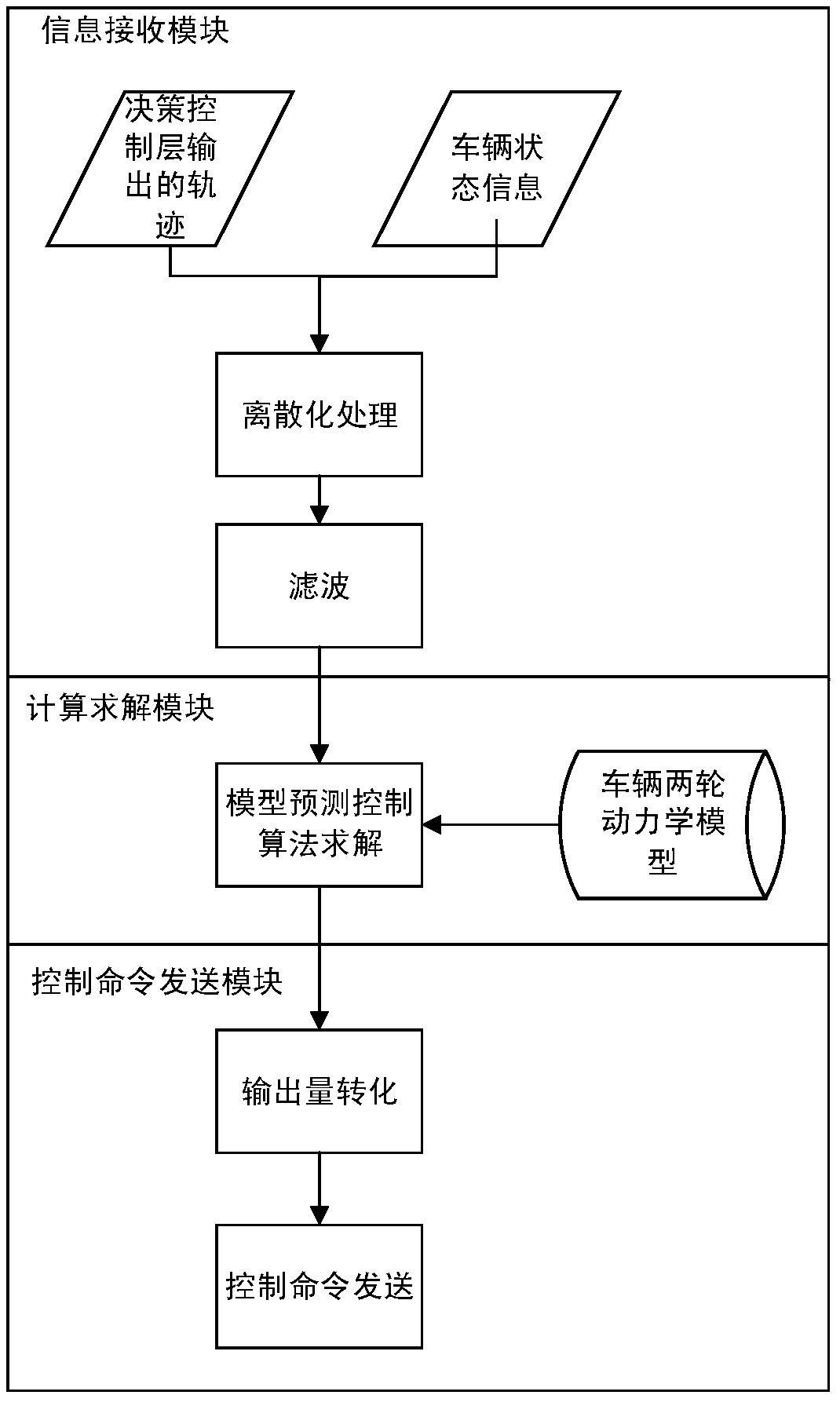

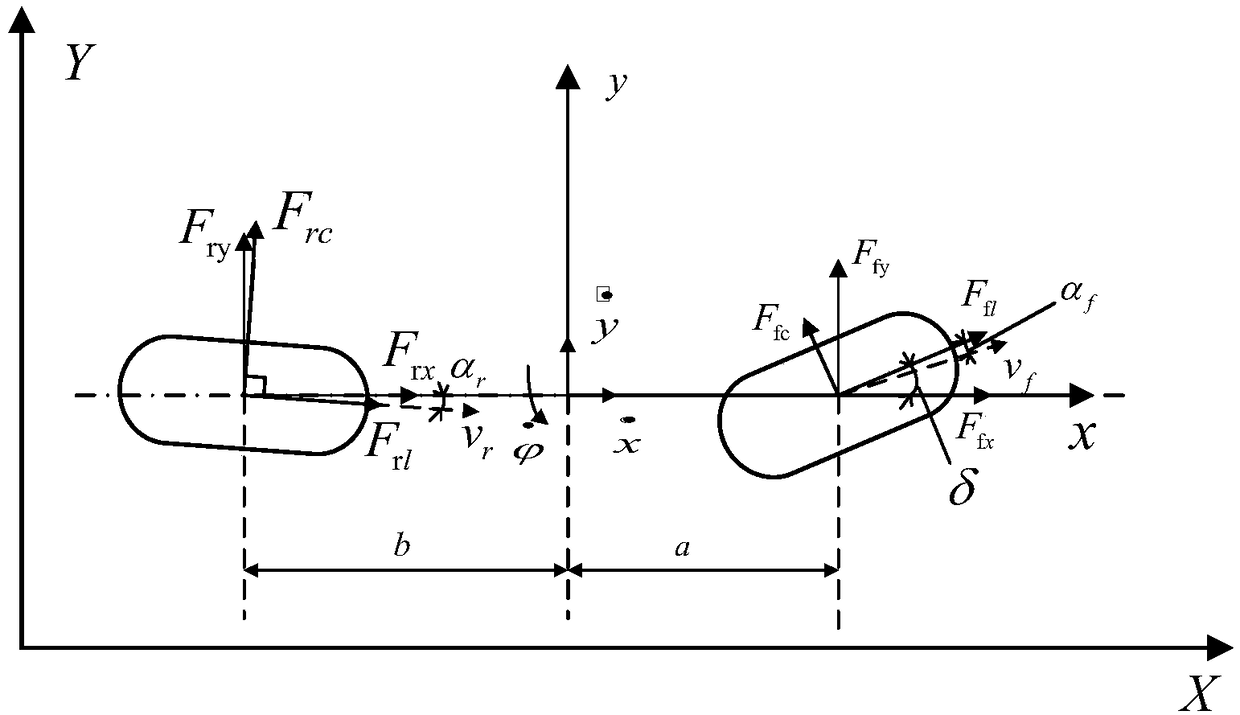

Transverse and longitudinal coordination control trajectory following up control method of unmanned vehicle

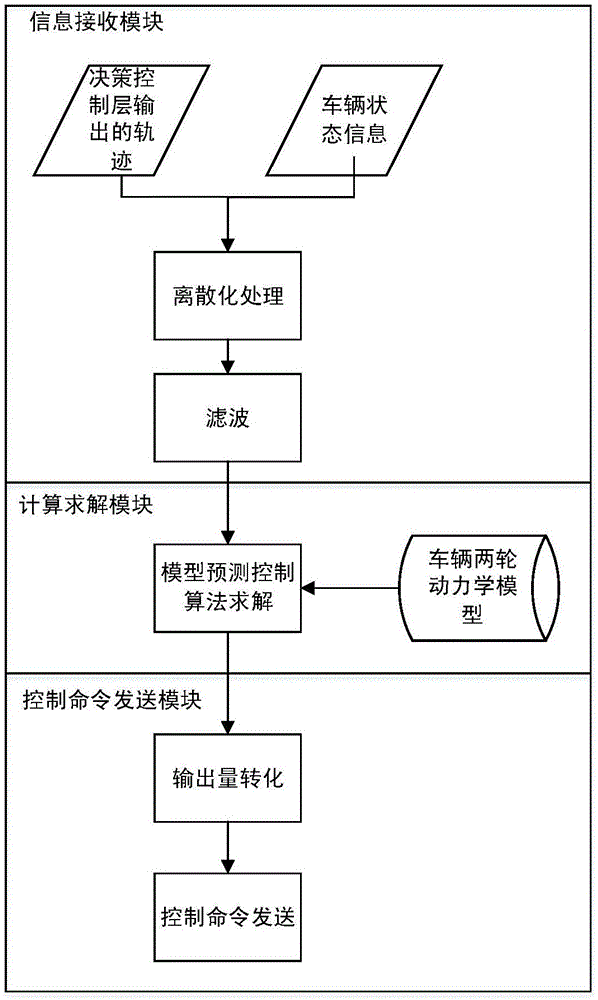

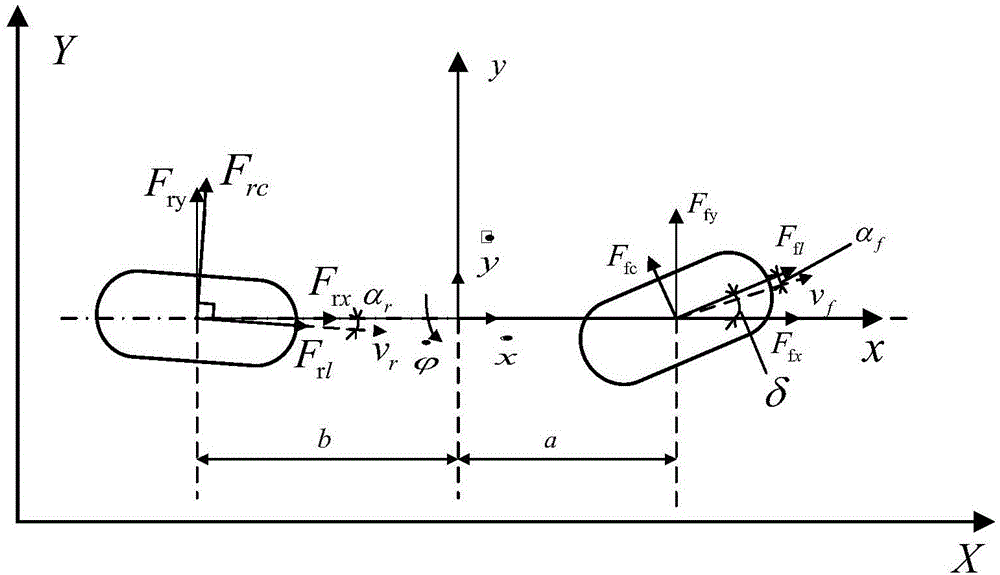

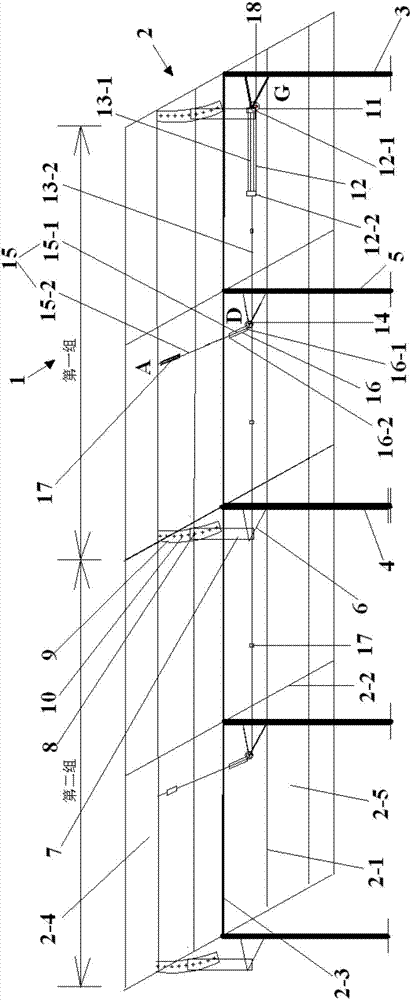

The invention discloses a transverse and longitudinal coordination control trajectory following up control method of an unmanned vehicle. According to the transverse and longitudinal coordination control trajectory following up control method, a control system in the control method comprises an information receiving module, a calculation solving module and a control command sending module. The control method comprises the following steps of step 1, receiving information: receiving information through the information receiving module; step 2, solving calculation: solving calculation through the calculation solving module; and step 3, enabling the control command emitting module to firstly transform front wheel turning angle and wheel driving / braking torque into direct controlling quantity of an executing mechanism. The method has the beneficial effects that the relationship of transverse motion and longitudinal motion of the unmanned vehicle is established by adopting transverse and longitudinal coordination control; and compared with independent control of transverse motion and the longitudinal motion, the transverse and longitudinal coordination control has the advantage that the control error caused by the coupling of transverse and longitudinal motion is eliminated, and the robustness of the control system is increased.

Owner:JILIN UNIV

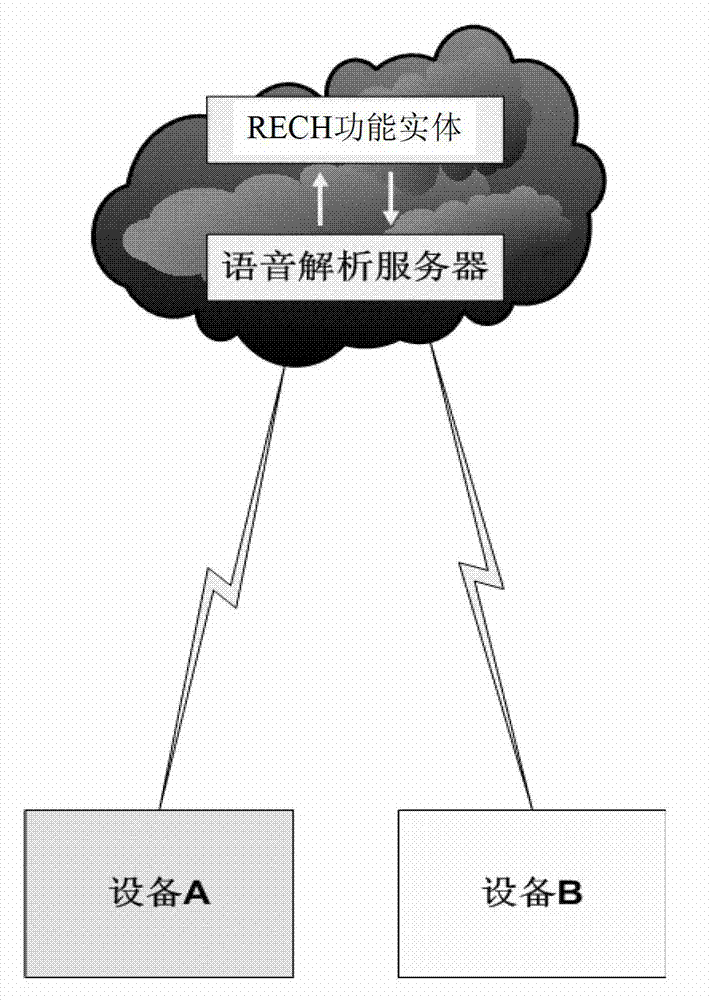

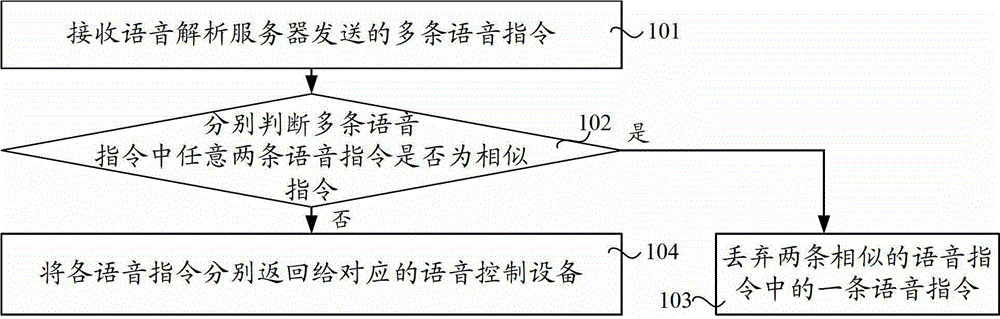

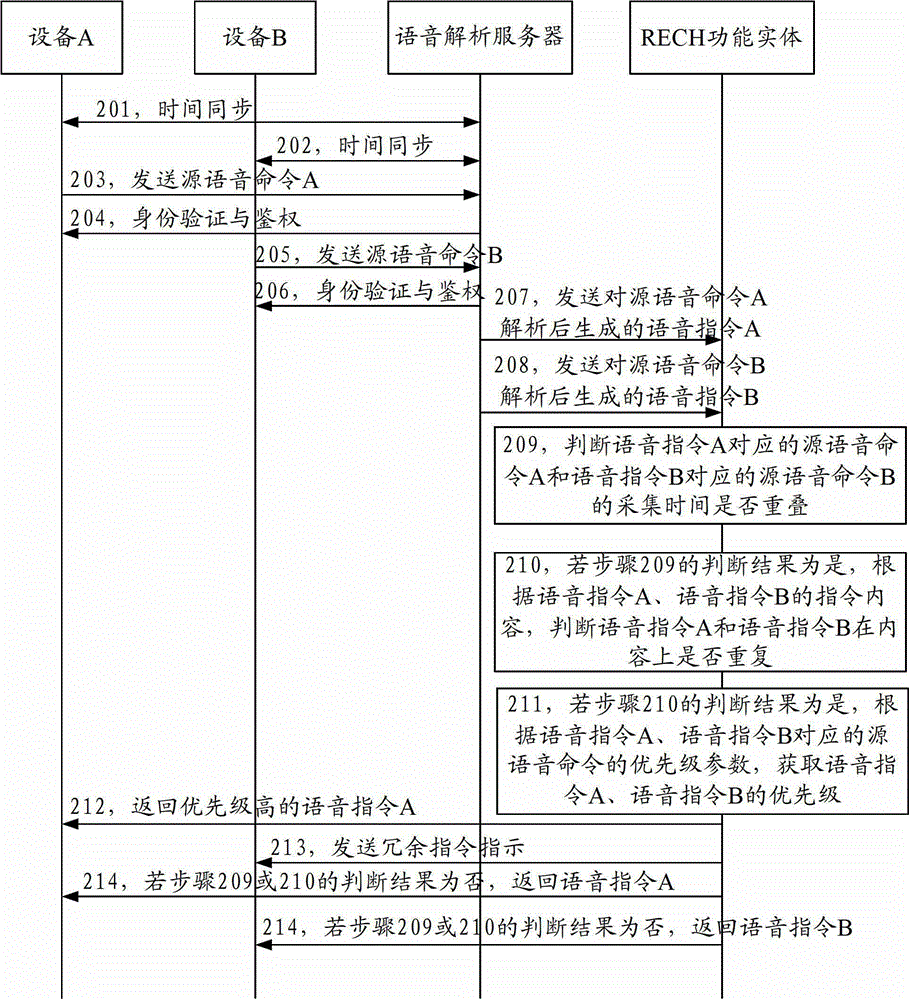

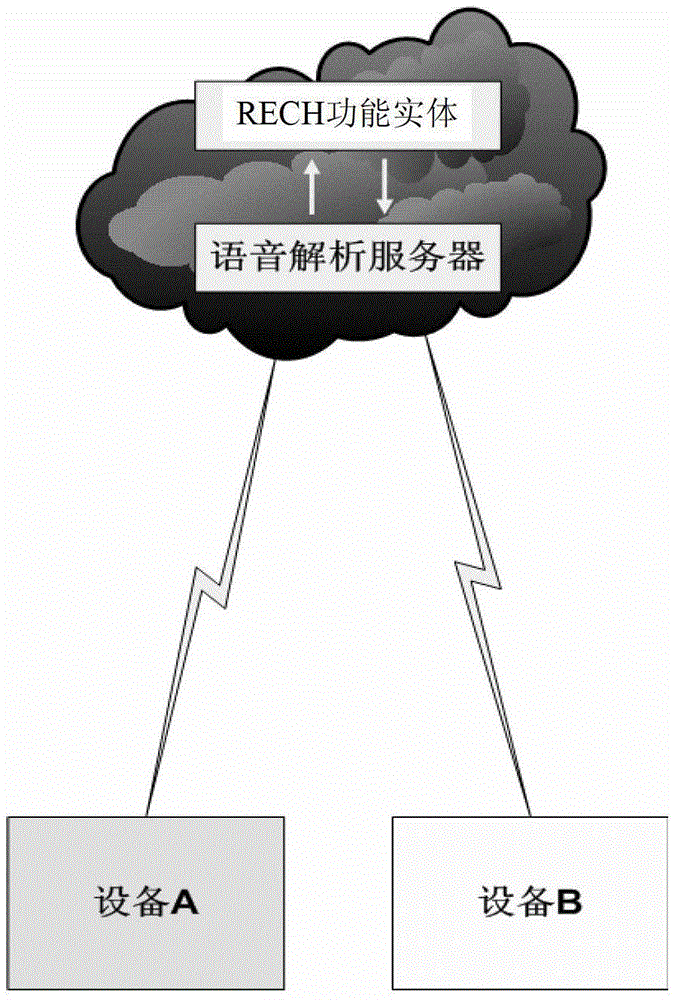

Command processing method, command processing device and command processing system

ActiveCN102831894ATime synchronizationAvoid repeated executionSpeech recognitionVoice analysisSpeech sound

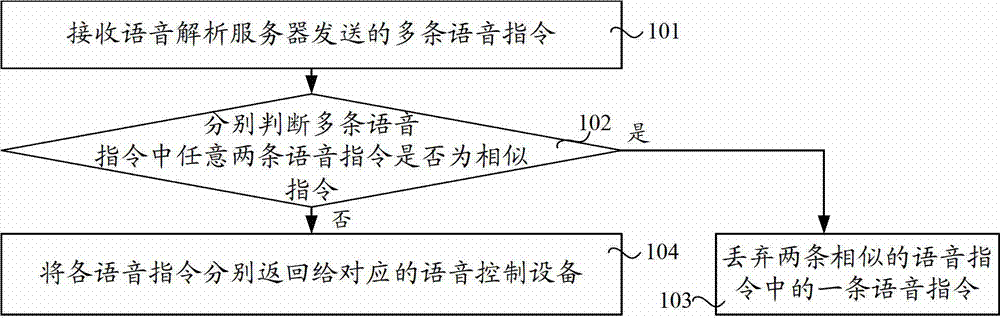

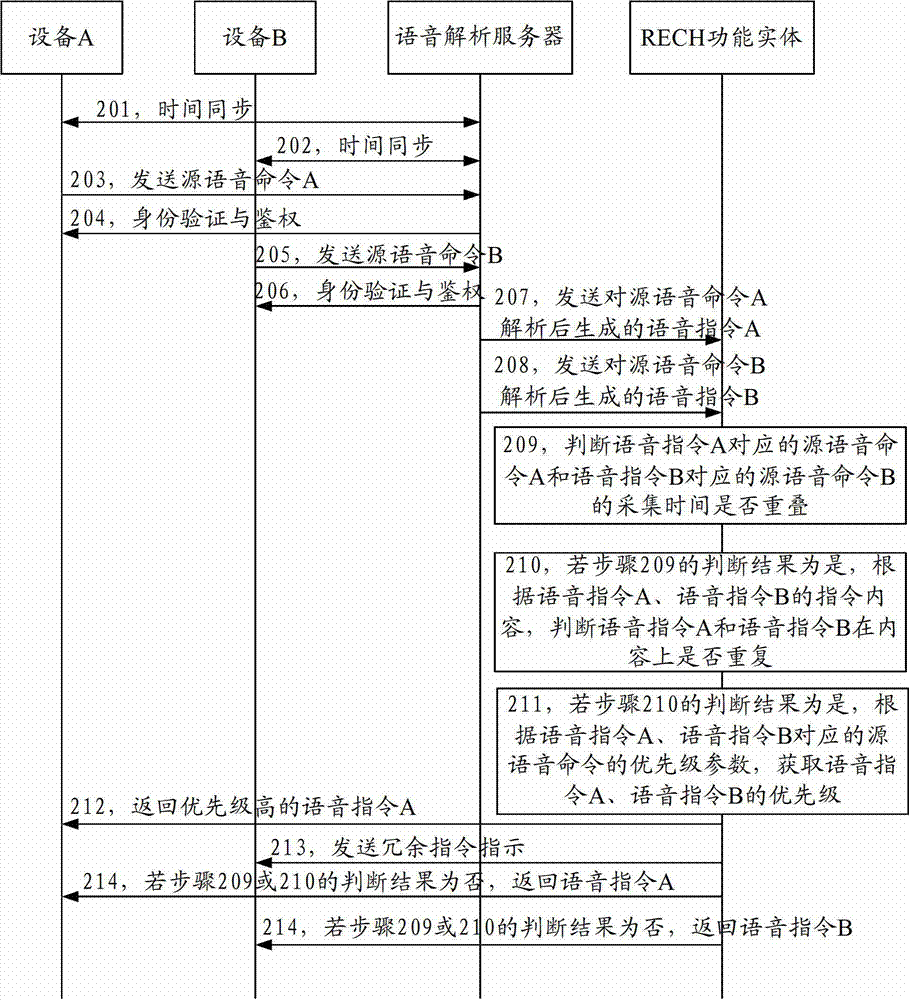

The embodiment of the invention provides a command processing method, a command processing device and a command processing system. The method comprises the steps of: receiving multiple voice commands sent by a voice analysis server, wherein the multiple voice commands are generated after source voice commands coming from different voice control devices are analyzed by the voice analysis server; respectively judging if any two voice commands in the multiple voice commands are similar commands, wherein the similar command is a voice command corresponding to the source voice command obtained by using different voice control devices to capture same voice information; and discarding one voice command in two similar voice commands when two voice commands existing in the multiple voice commands are similar commands. The embodiment of the invention further provides a command processing device and a command processing system. With the adoption of the embodiment, the control mistake brought by the repetitive execution of commands is eliminated.

Owner:HUAWEI DEVICE CO LTD

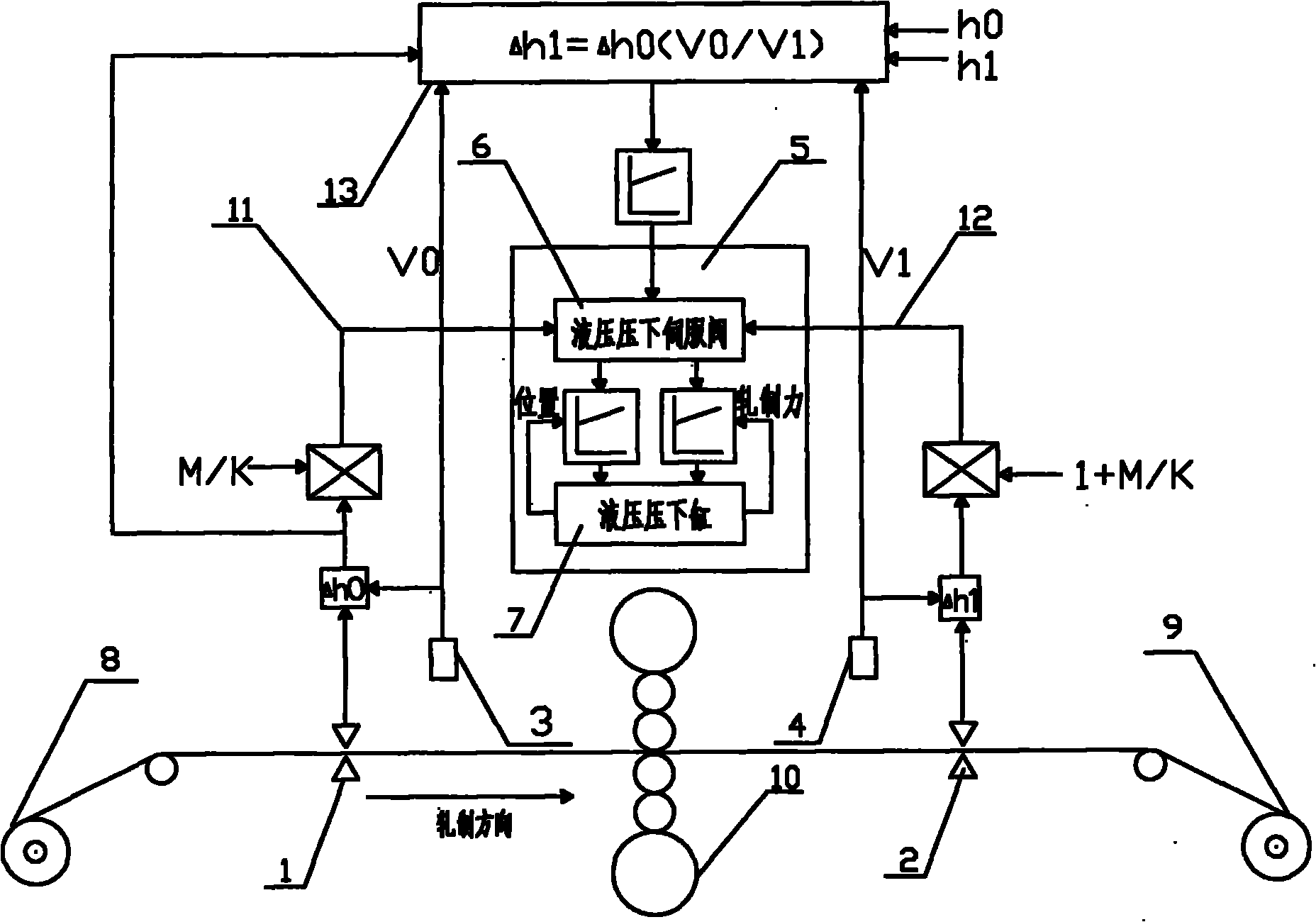

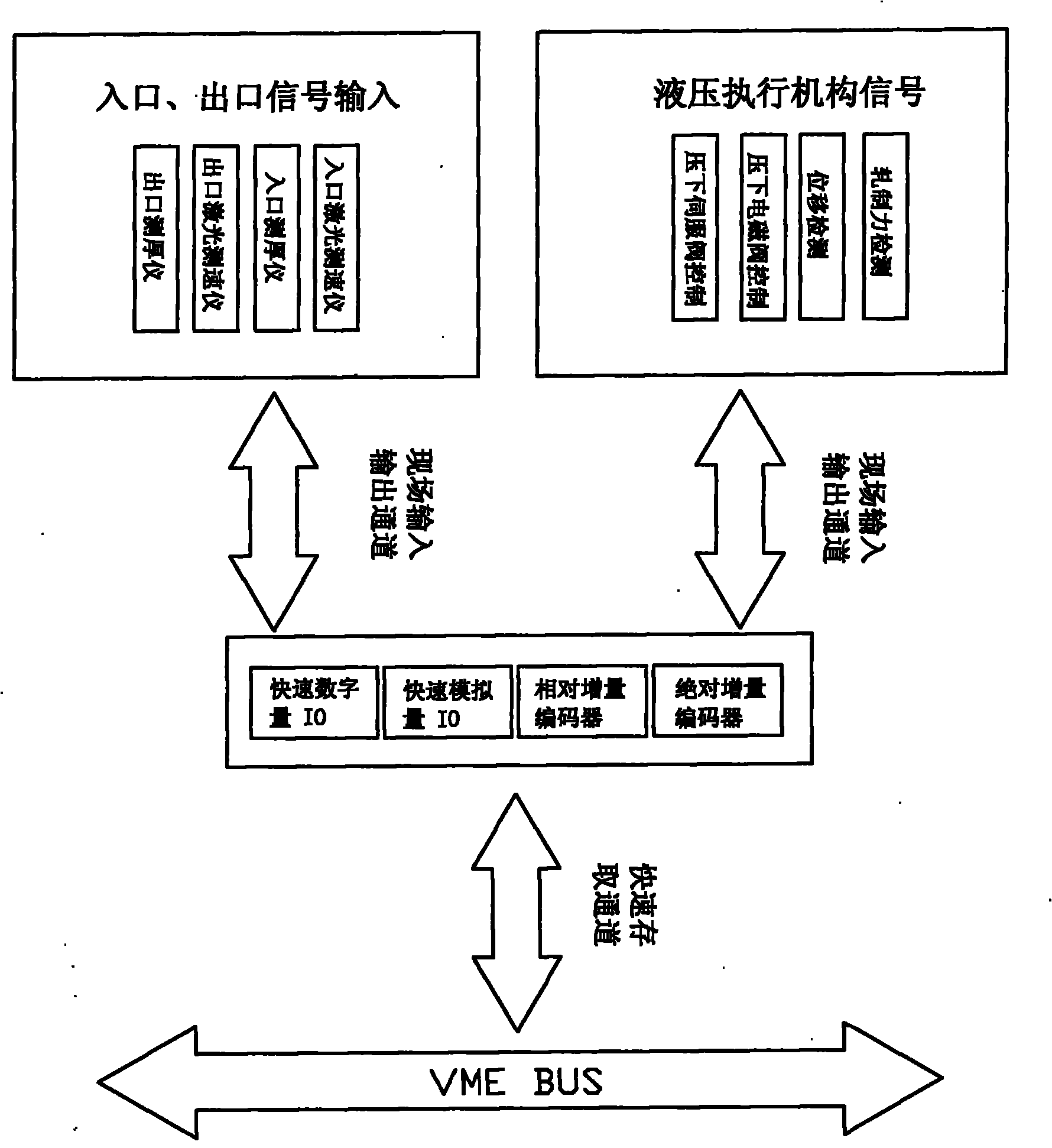

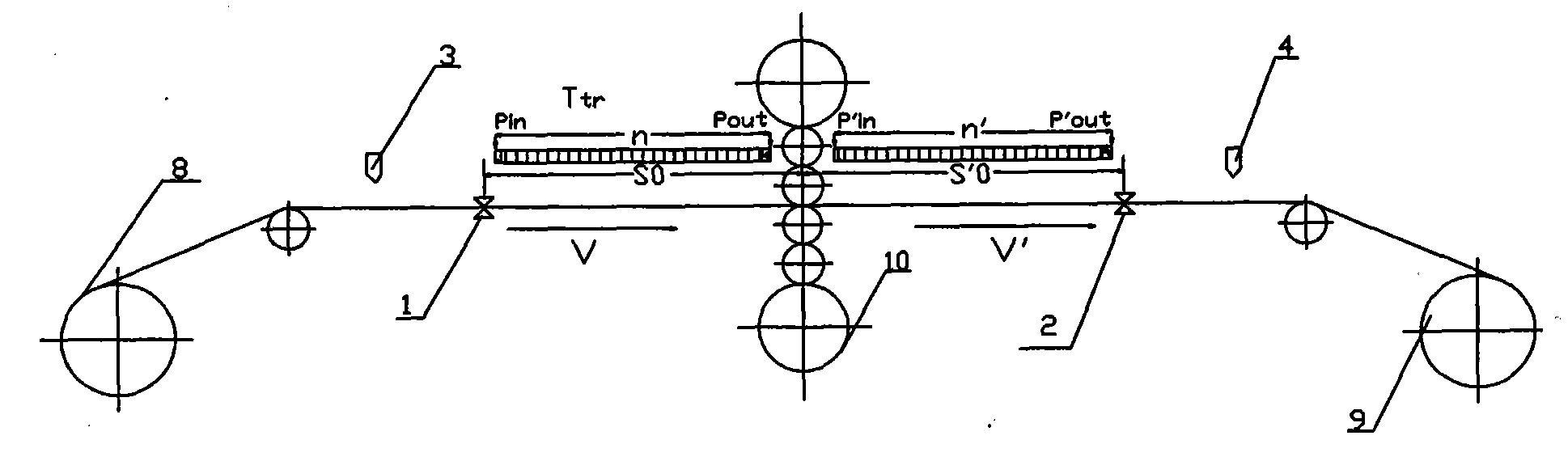

Automatic gauge control (AGC) method for rolling mill

InactiveCN101844155AEliminate time lagHigh precisionRoll force/gap control deviceAutomatic controlControl signal

The invention provides an automatic gauge control (AGC) method for a rolling mill, which comprises AGC. The AGC comprises the following steps of: sampling by using detection devices; transmitting a signal to a rapid analog quantity IO, a rapid digital quantity IO, a relative incremental coder and an absolute incremental coder; converting the signal into a digital signal; transmitting the digital signal through a VME bus and saving the digital signal in a dynamic memory; performing processing and calculation through a high-performance control device to generate a control signal; and outputting the control signal and a control value to a hydraulic performing device by passing through the VME bus, the rapid analog quantity IO and the rapid digital quantity IO in turn to fulfill the aim of hydraulic AGC of the rolling mill. An AGC feedforward control device, a flow rate per second control device and a feedback control device of the rolling mill are combined to provide a set of high-precision data tracking solution for input and output signals, so the aim of precisely controlling the thickness of output strip steel of the rolling mill is fulfilled.

Owner:WISDRI WUHAN AUTOMATION

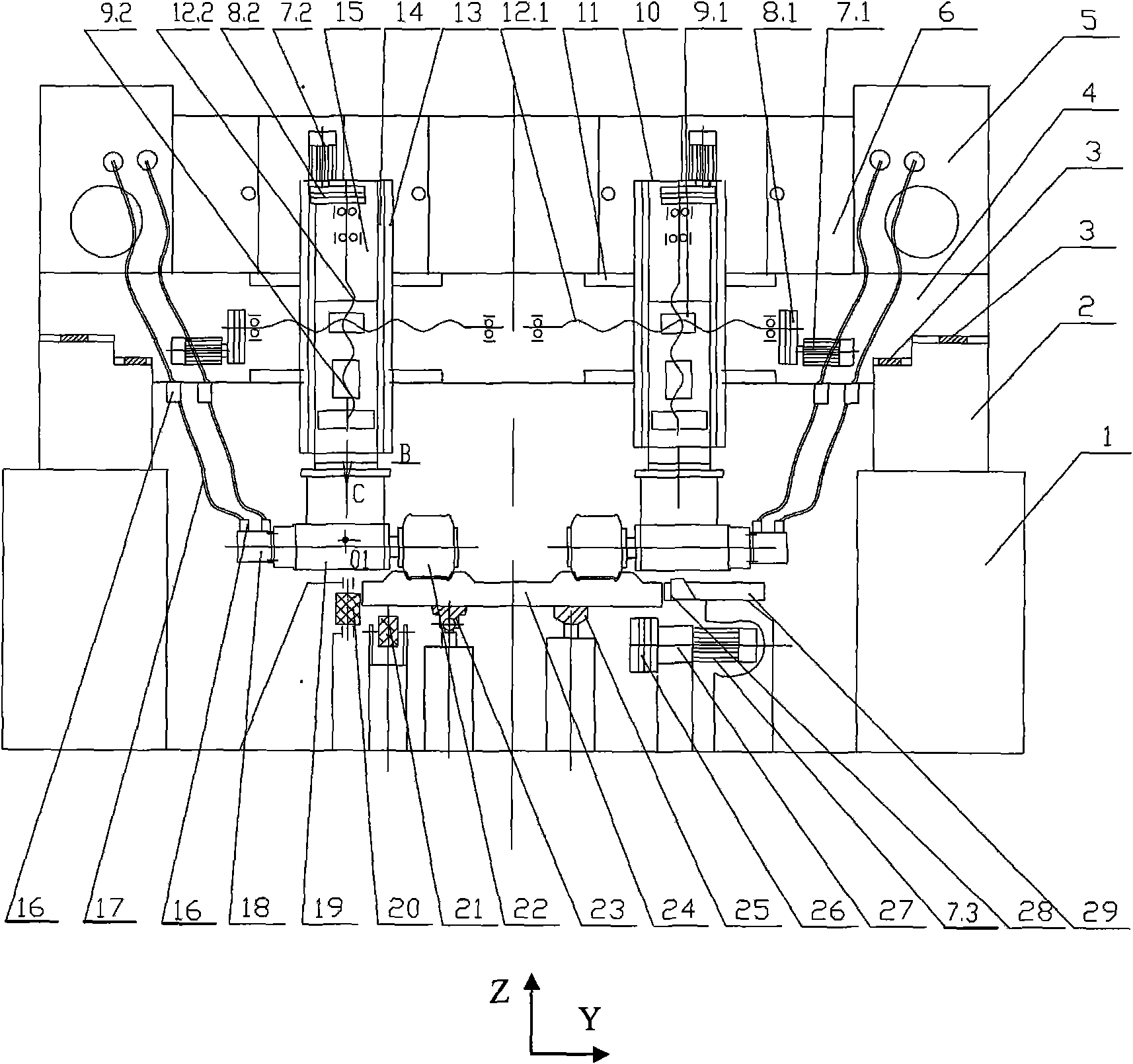

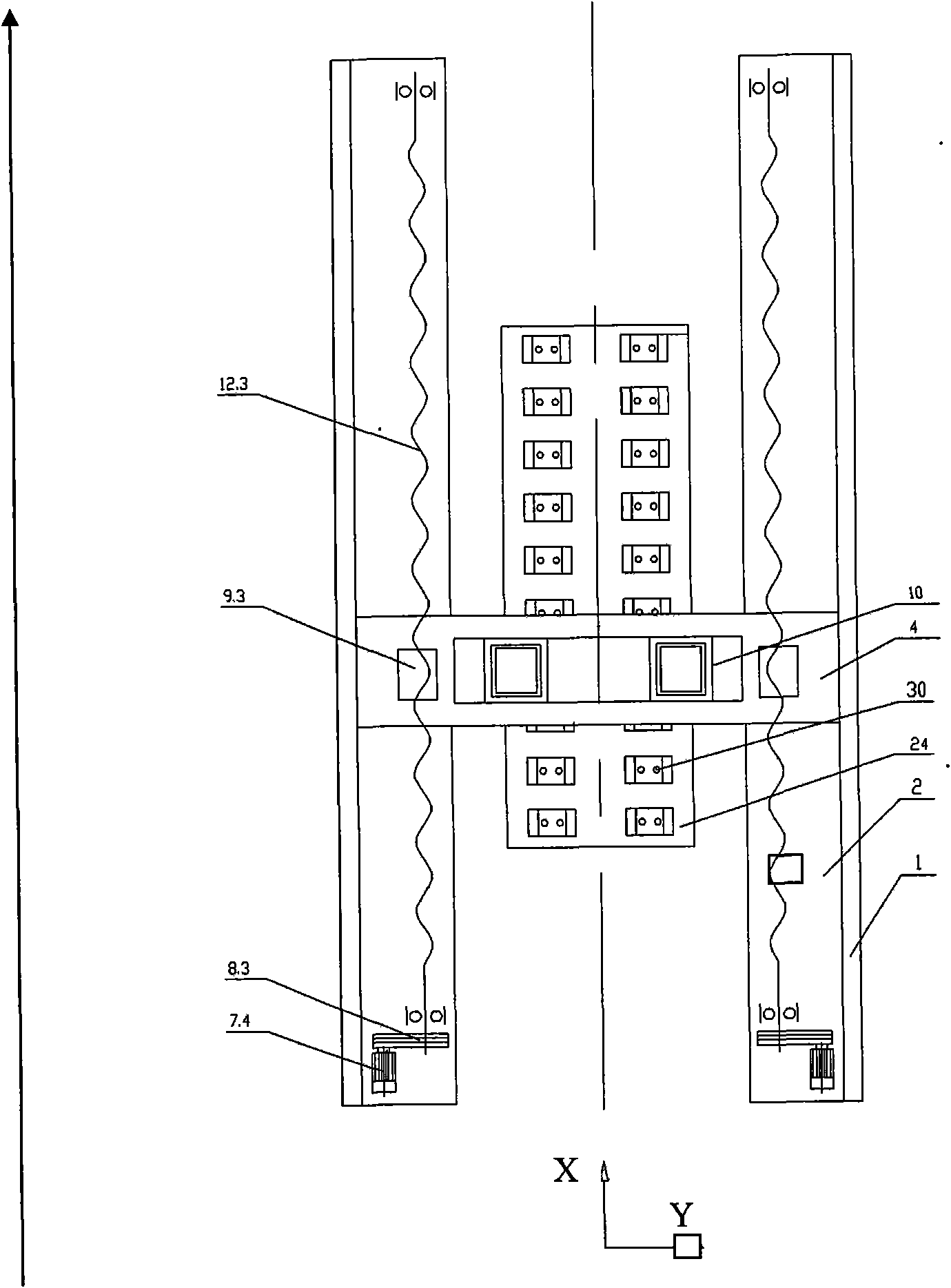

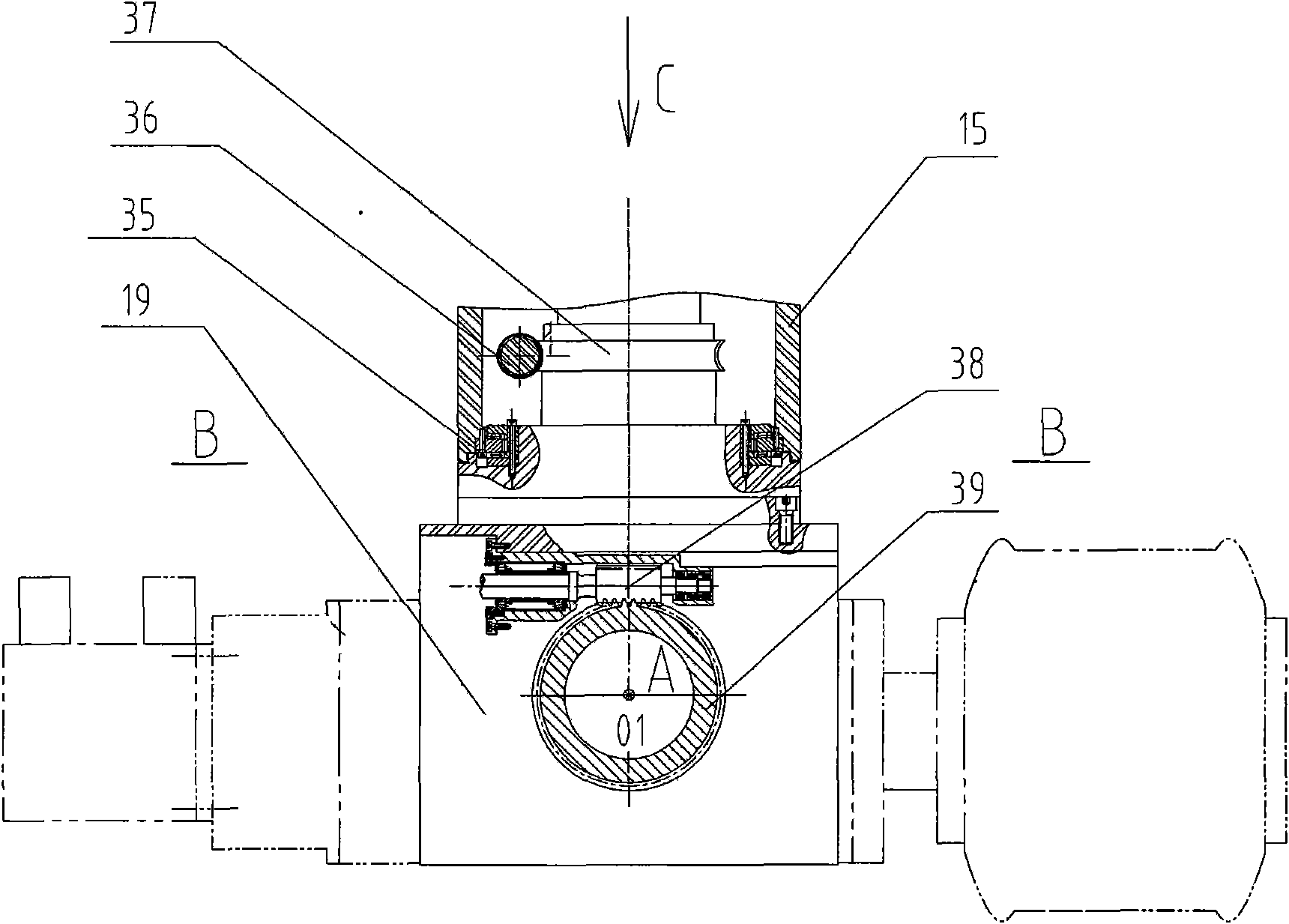

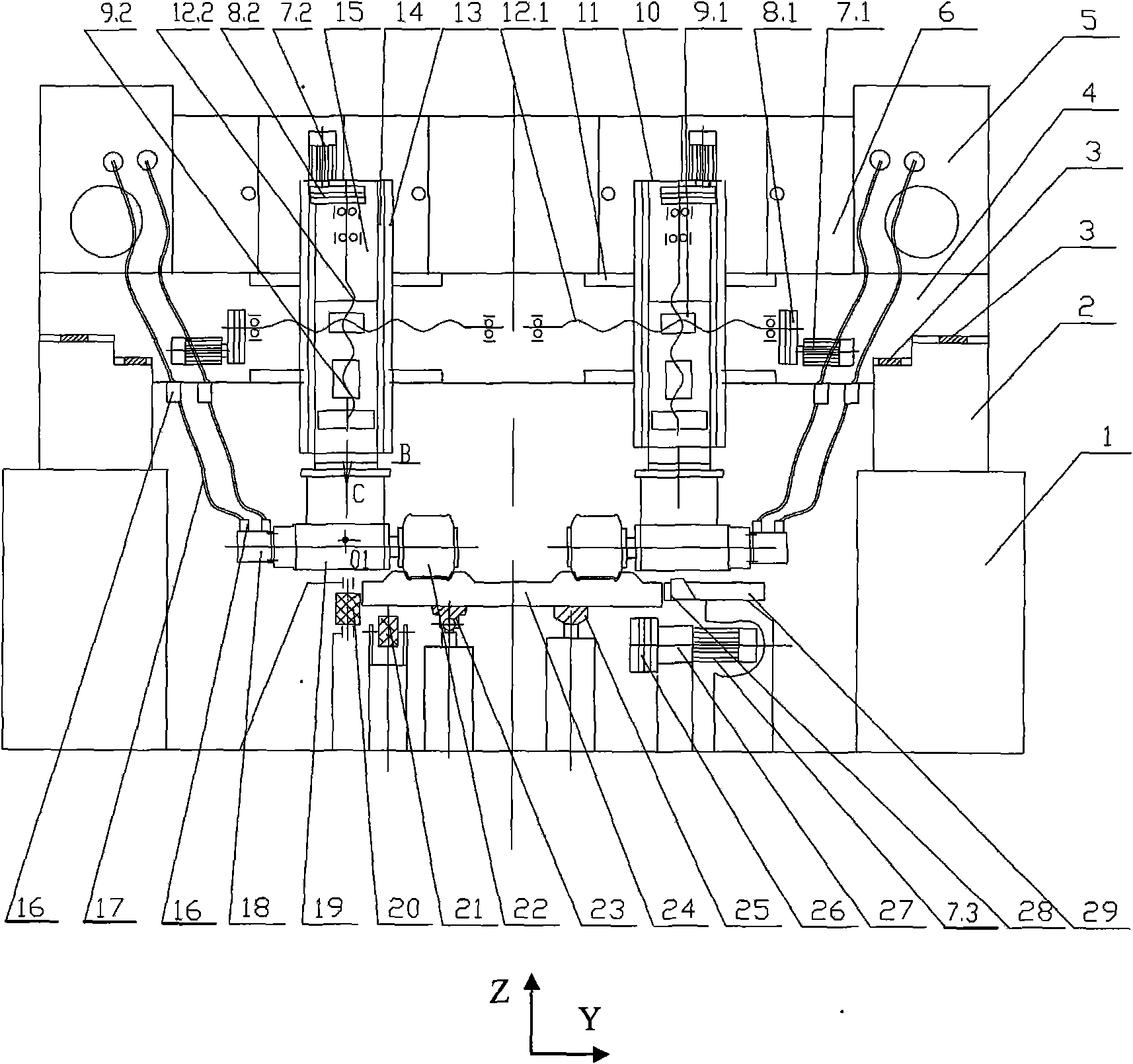

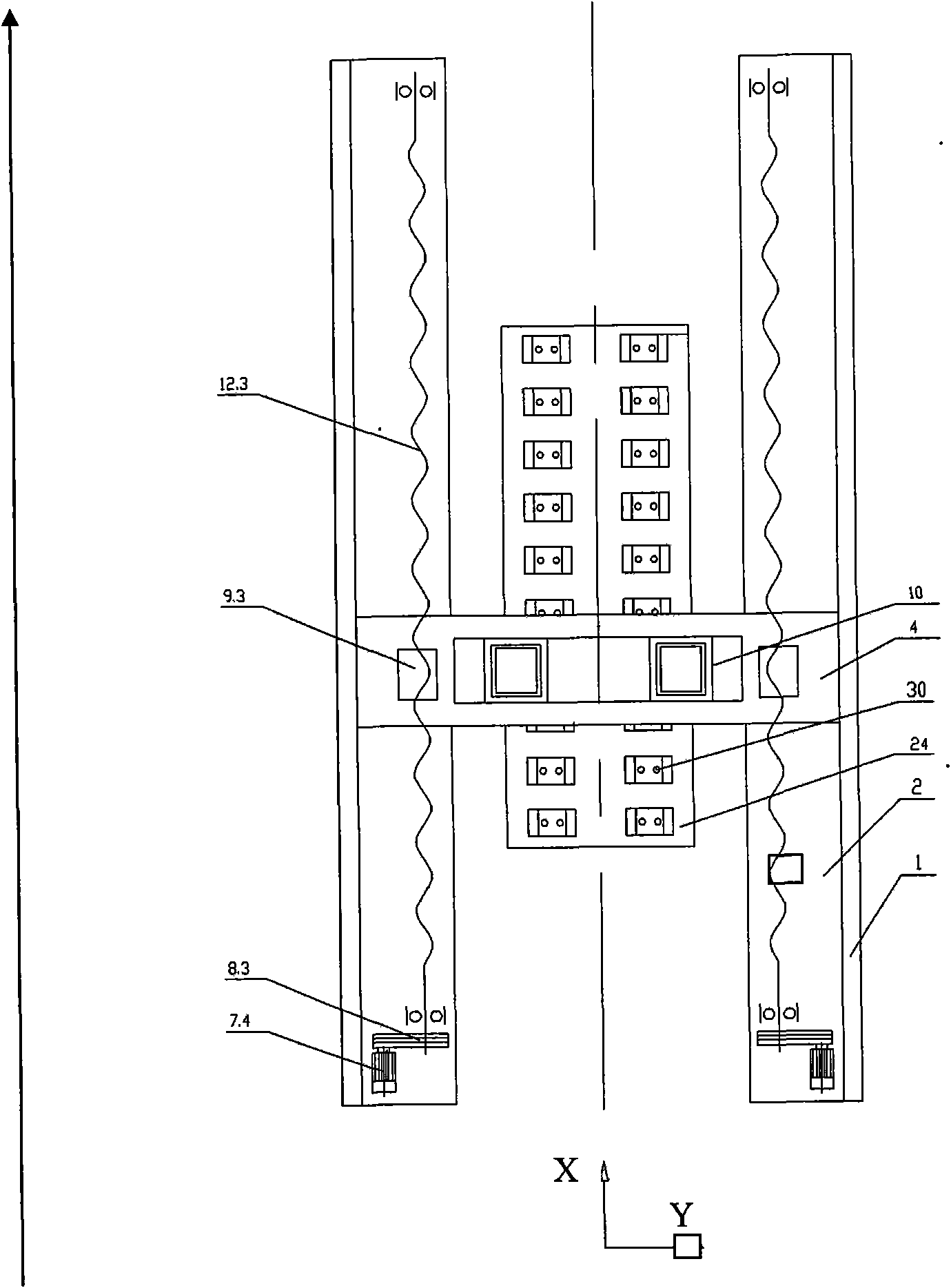

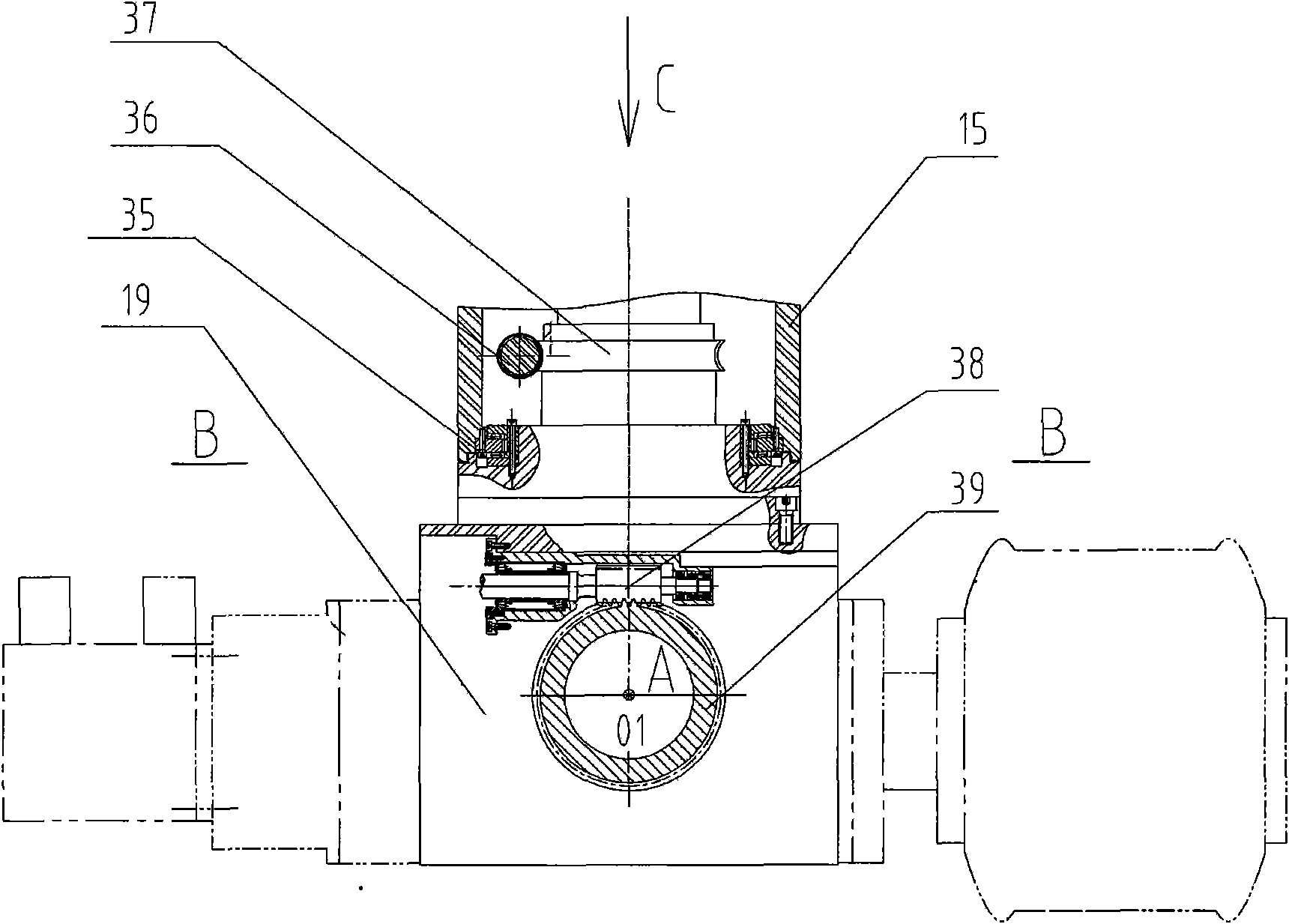

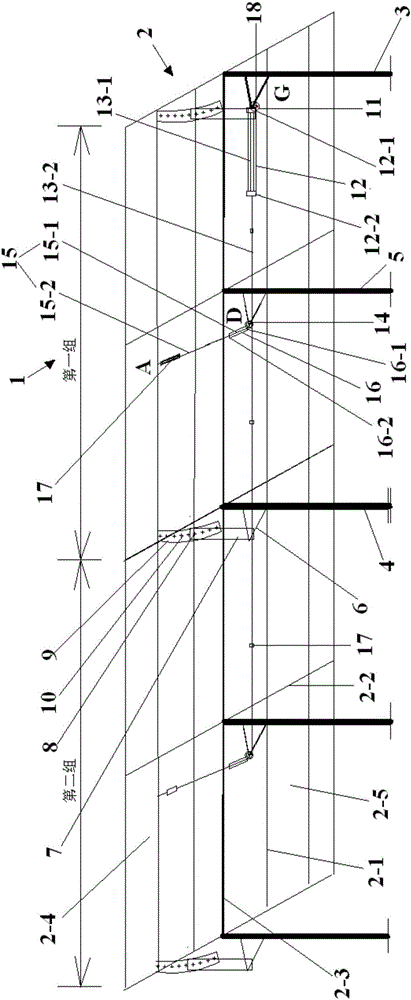

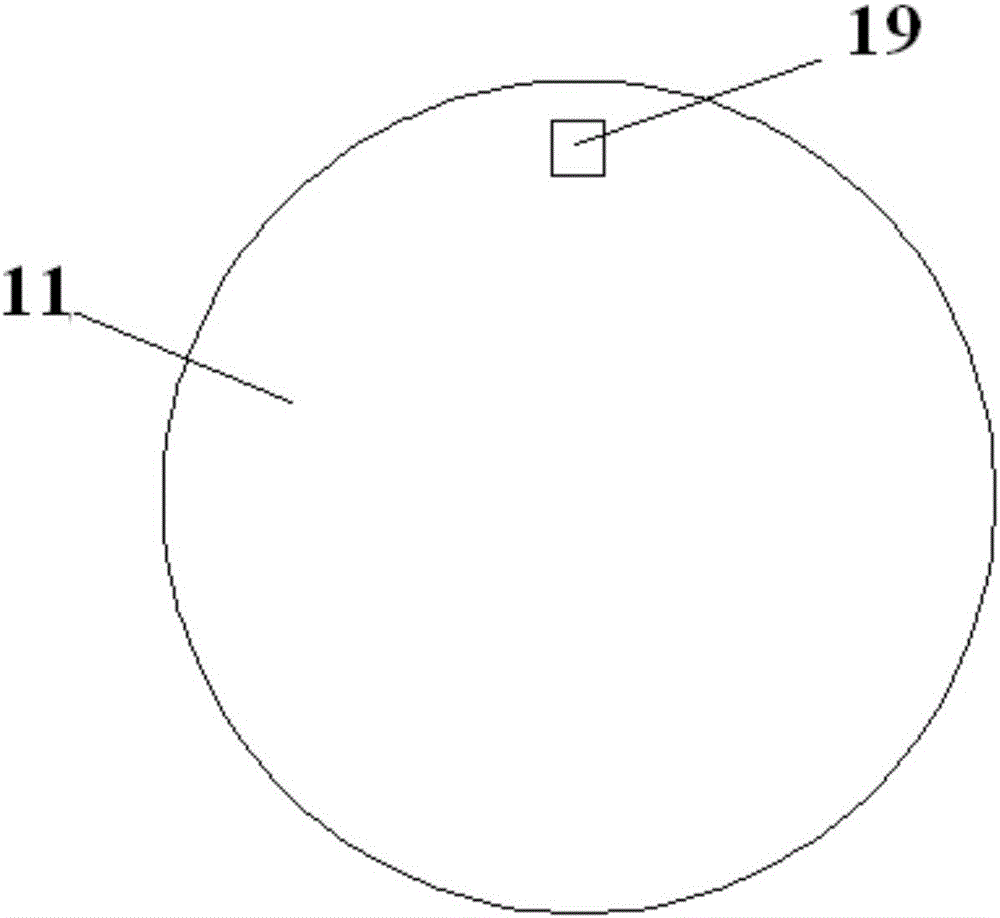

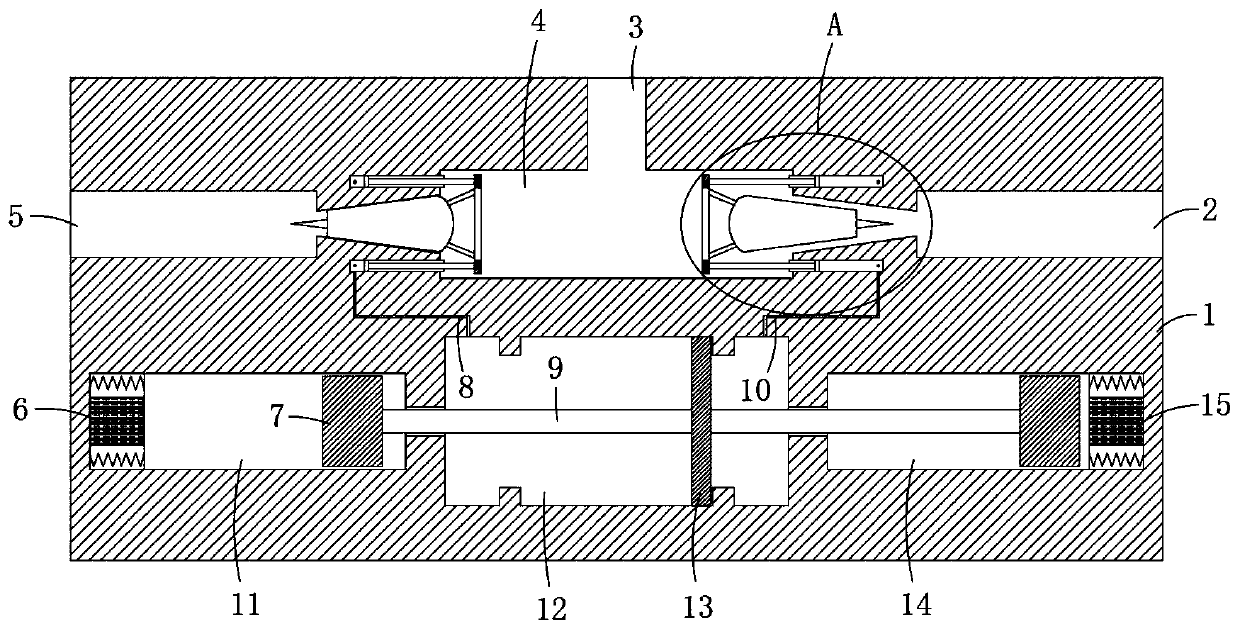

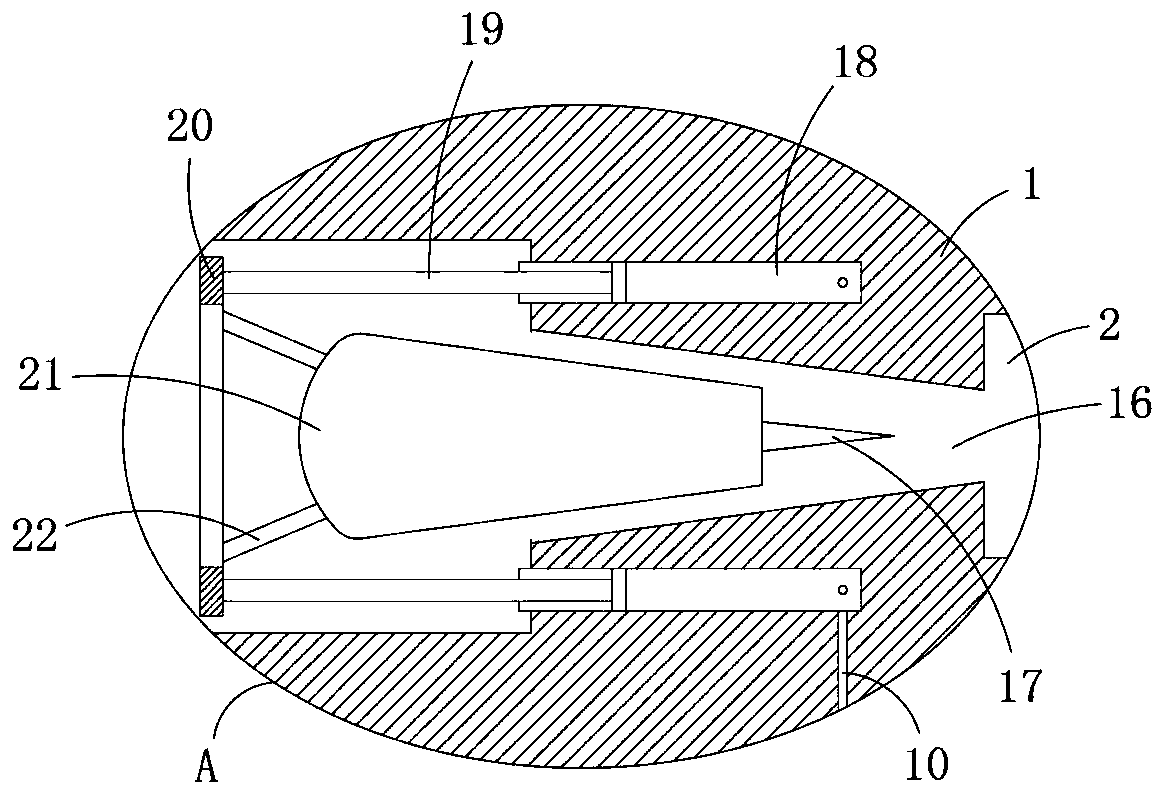

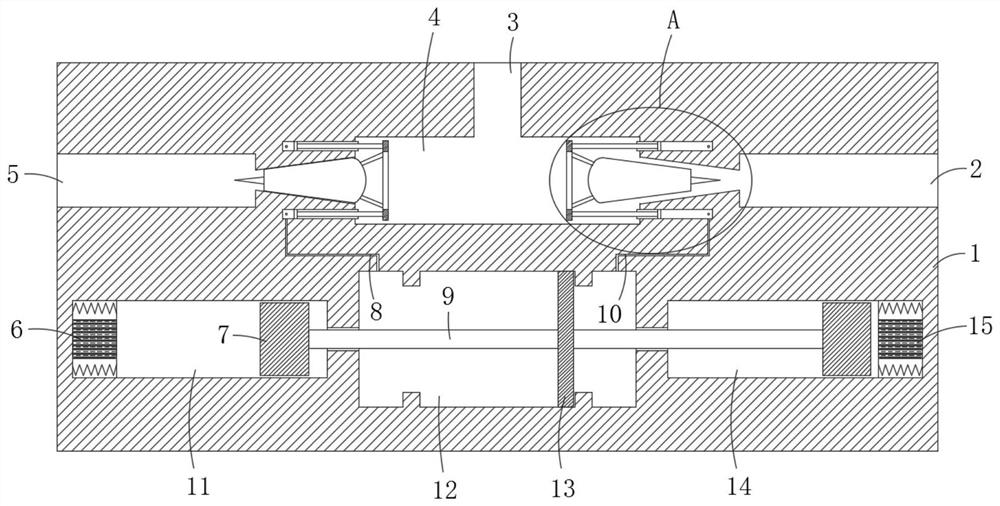

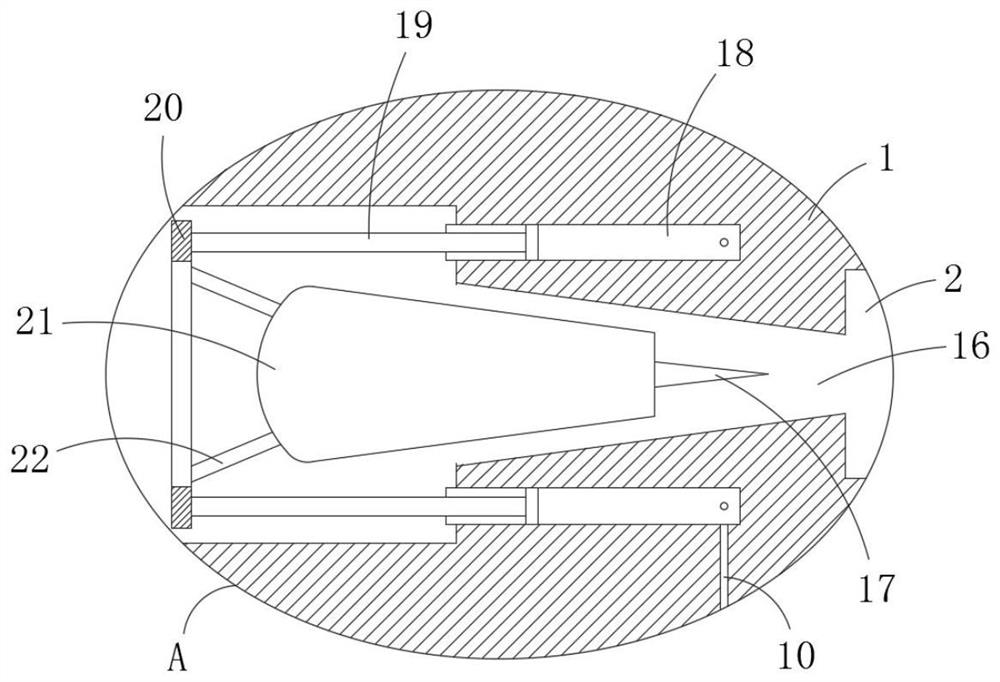

Track slab grinder

ActiveCN101628390ARealize one-time double-sided processingImprove processing efficiencyStone-like material working toolsPlane surface grinding machinesHydraulic motorStructural engineering

The invention is a track slab grinder, and relates to a special grinder for grinding a track slab. The track slab grinder comprises left and right main foundation walls and left and right grinding wheels. The key technology thereof is as follows: the left and right main foundation walls are respectively provided with a main longitudinal girder provided with a main longitudinal guide rail, a main transverse beam is arranged between the main longitudinal guide rails and is provided with left and right transverse guild rails respectively, the transverse guild rail is installed with a transverse sliding box which is internally provided with a vertical guild rail, an inner box is mounted on the vertical guild rail, a main shaft direction adjusting box is arranged at the lower end part of the inner box, a grinding head is arranged at the lower side of the main shaft direction adjusting box, a grinding wheel is mounted on the main shaft of the grinding head, and the main shaft of the grinding head is driven by a hydraulic motor. The track slab grinder in the invention can finish processing both sides of a bearing block at one time, has the advantages of high integral strength, stable movement, good rigidity, high processing efficiency, and can process a standard track slab as well as a track slab grinder of a non-standard track slab.

Owner:四川省宜宾普什集团有限公司

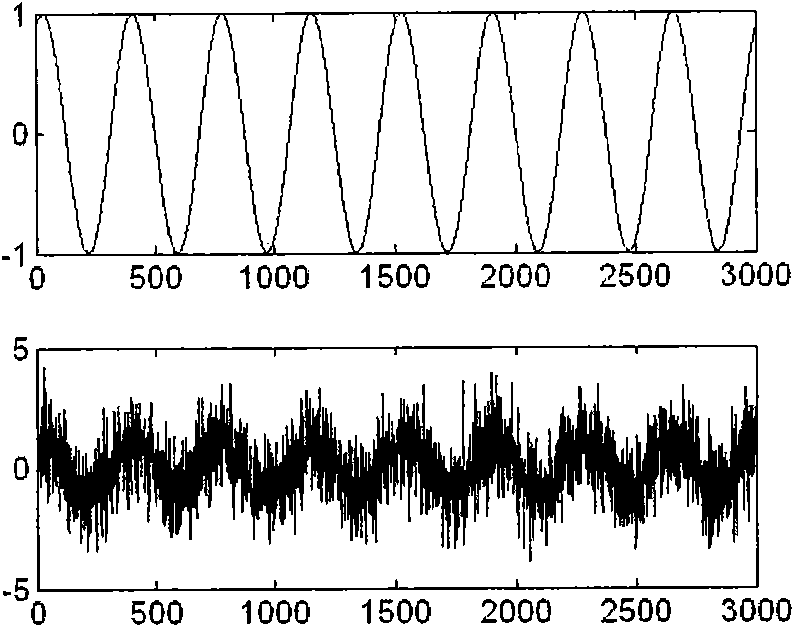

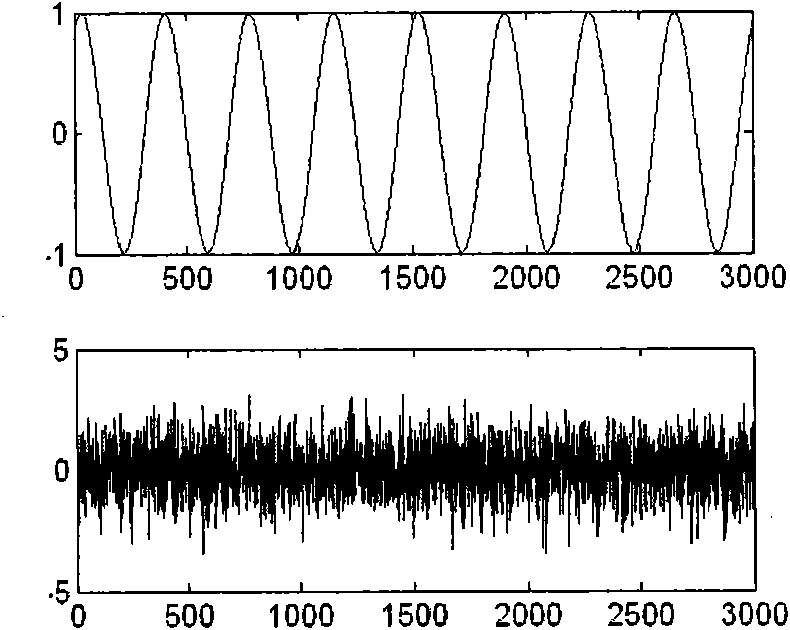

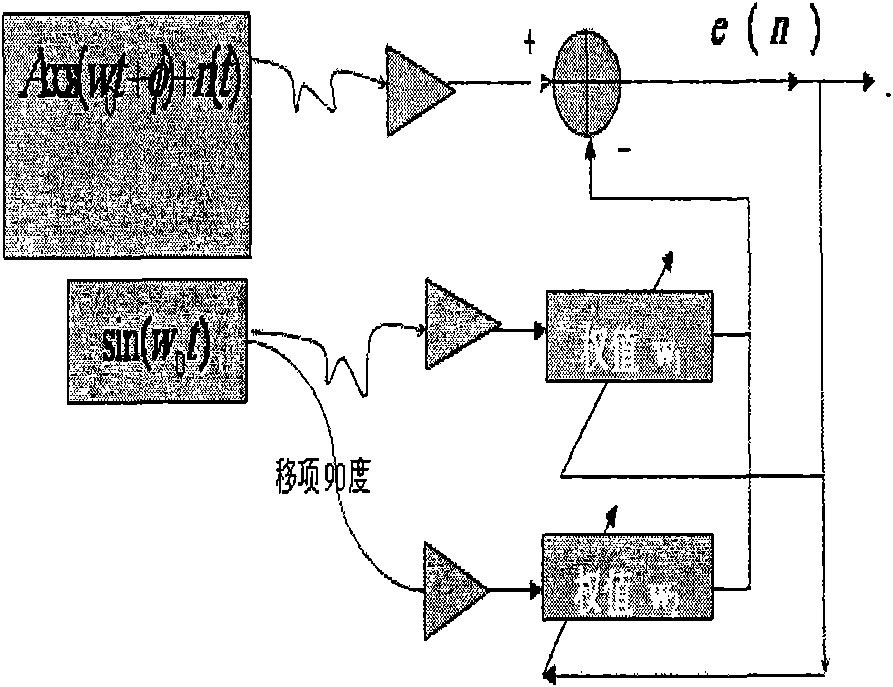

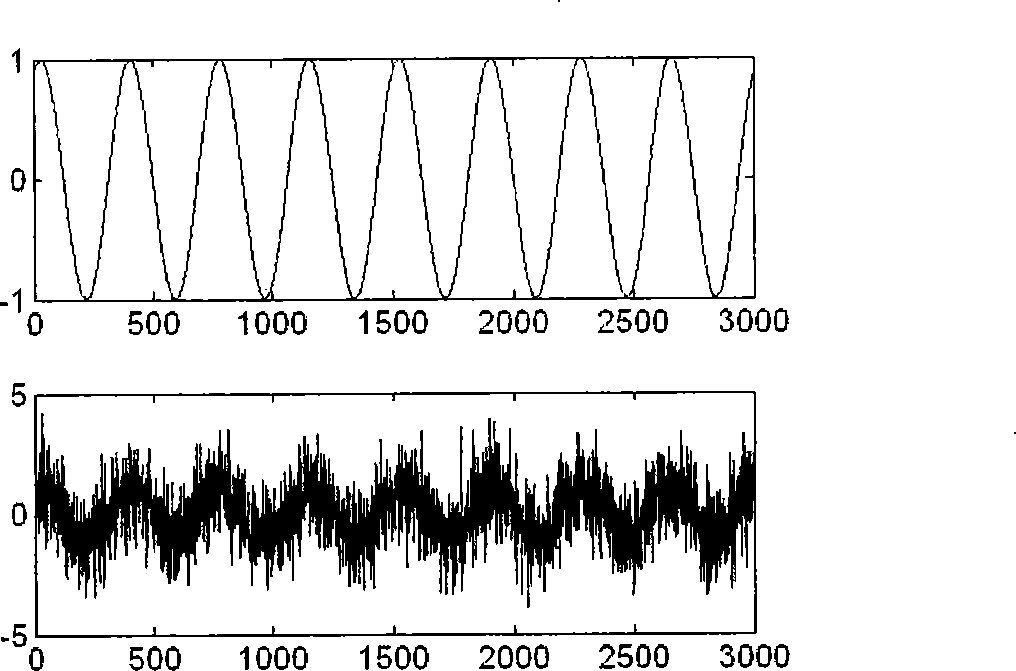

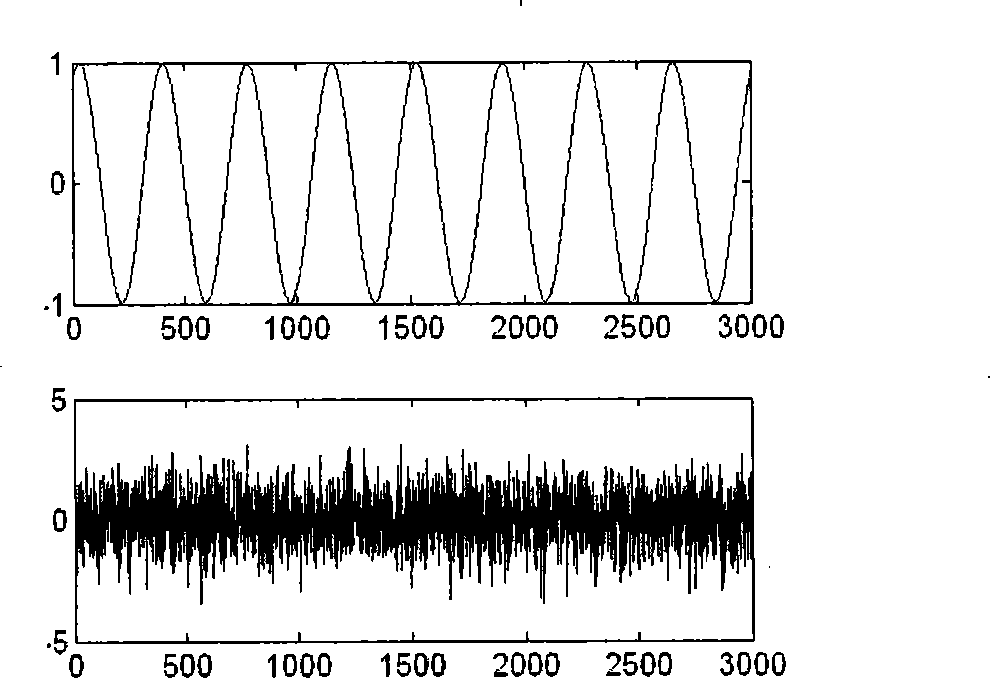

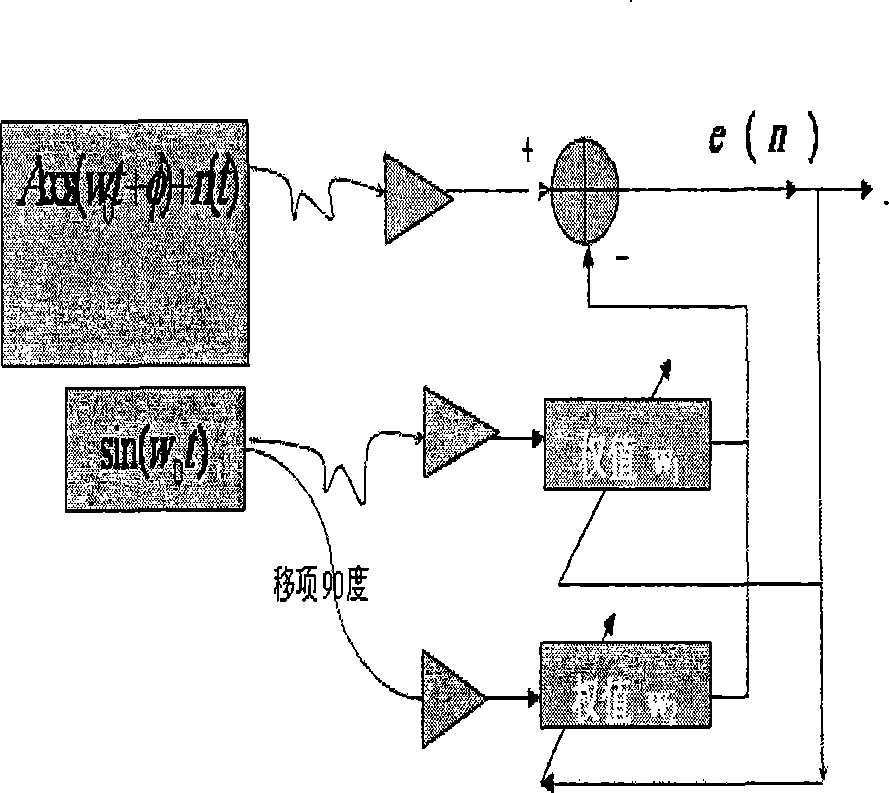

Phase detection method based on adaptive filtering

InactiveCN101576586AFast implementation of phase measurementsImplement phase measurementVoltage-current phase angleSignal-to-noise ratio (imaging)Phase difference

The invention discloses a phase detection method based on adaptive filtering. The method comprises the following steps: performing time-frequency domain transformation on input signals and estimating the approximate frequency value of the input signals in a frequency domain; adjusting the estimated approximate frequency value till the error of the approximate frequency value is not enough to cause burden for signal phase detection; detecting the amplitude and phase of sinusoidal signals with known frequency according to adaptive notch algorithm; and utilizing the negative entropy of Gaussian white noise to check and adjust estimated signals. The method provided by the invention has higher precision than the prior phase detection method, and uses the negative entropy to determine result precision so as to enable algorithm selection to have evidence to be found. The method provided by the invention has certain stability to the phase difference measurement with different signal-to-noise ratio, frequency and initial phases, and is suitable for various applications needing precise signal phase difference measurement.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

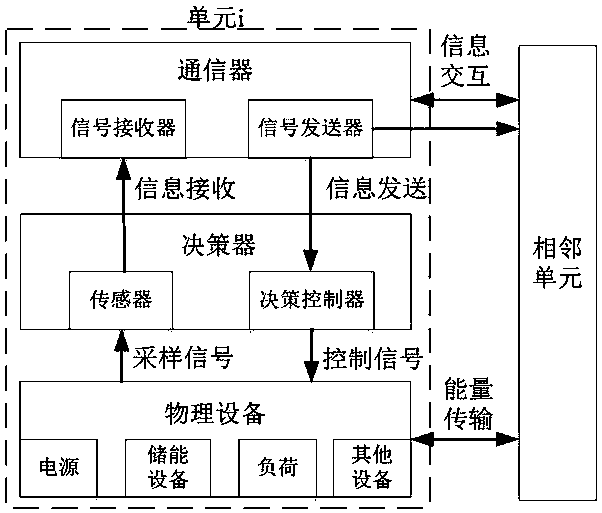

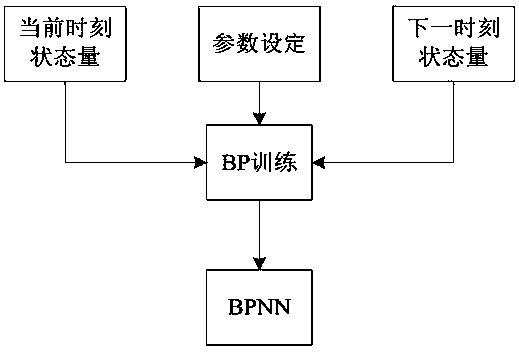

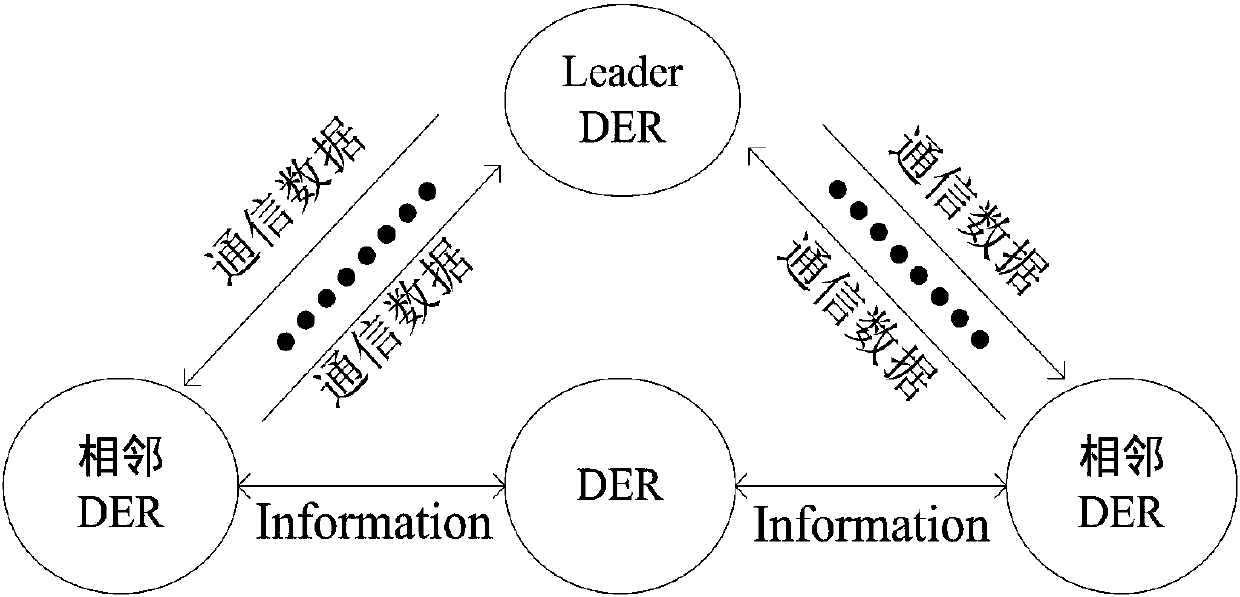

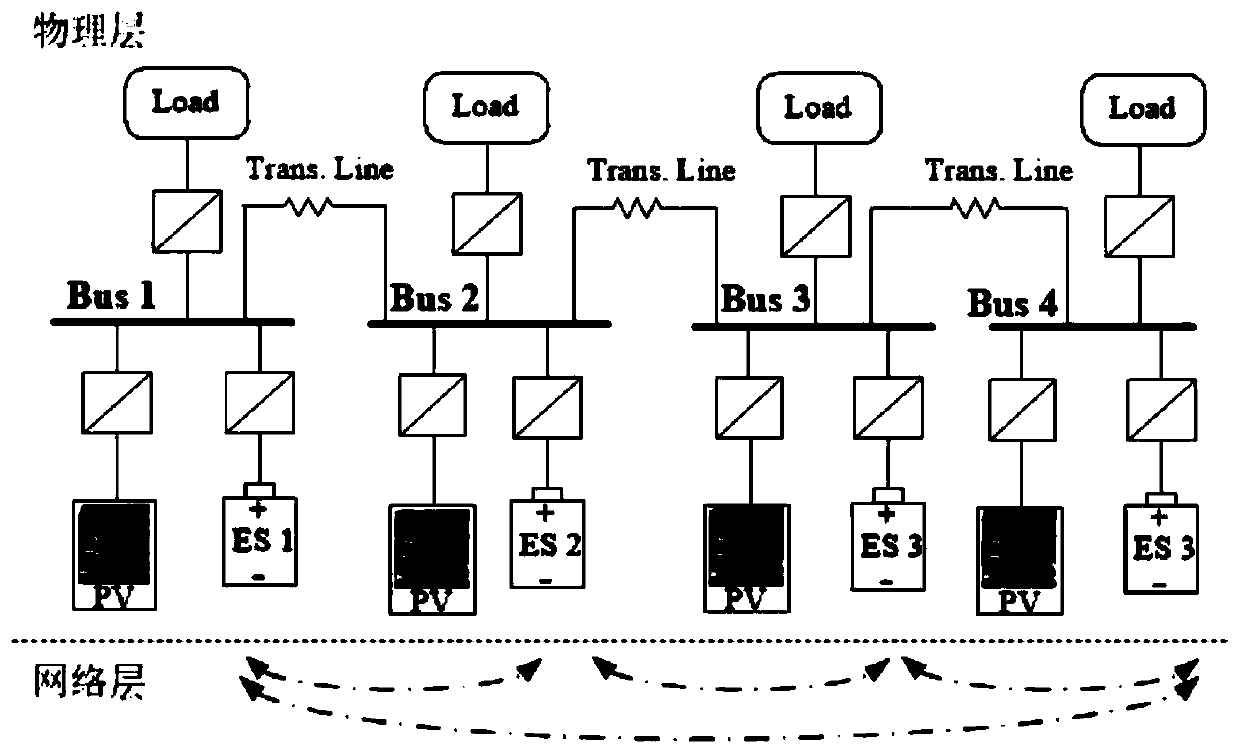

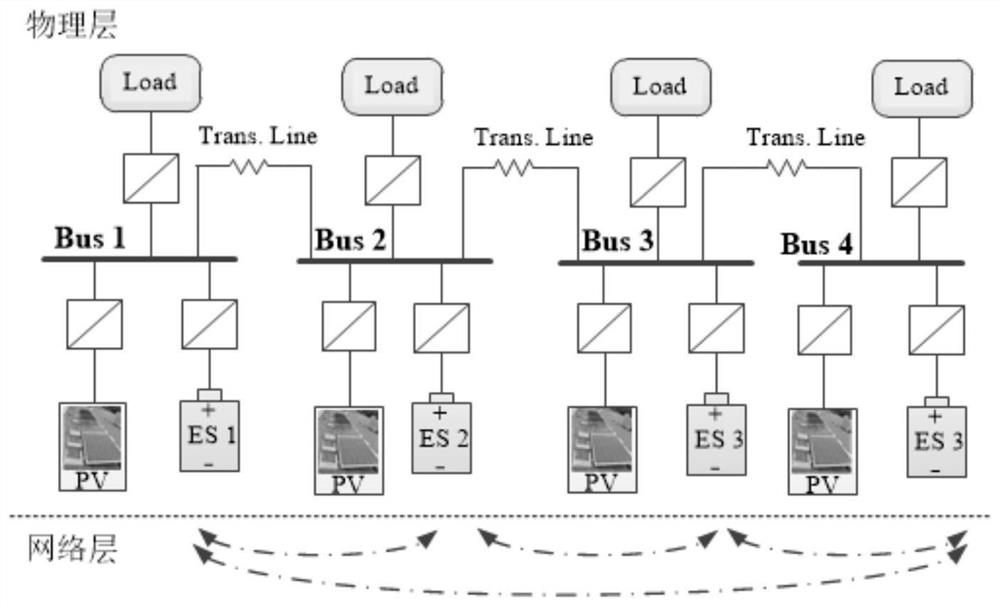

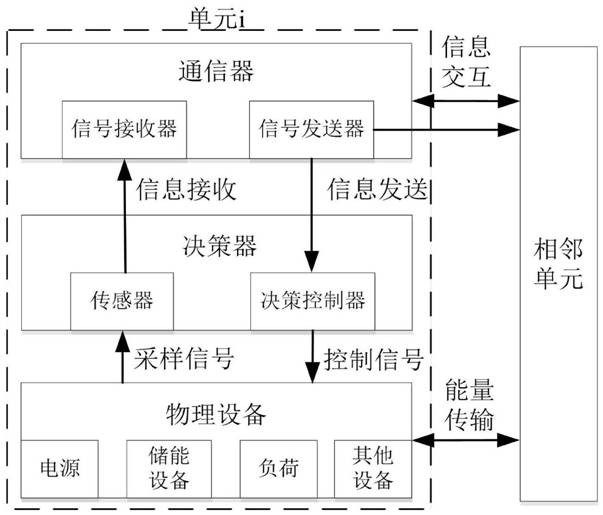

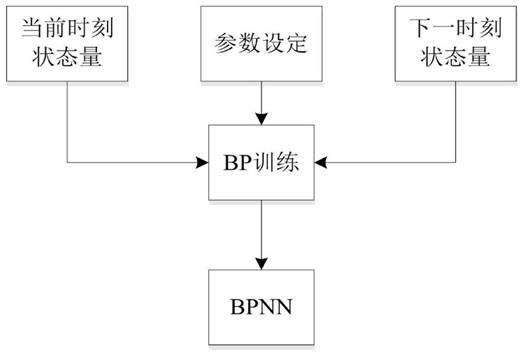

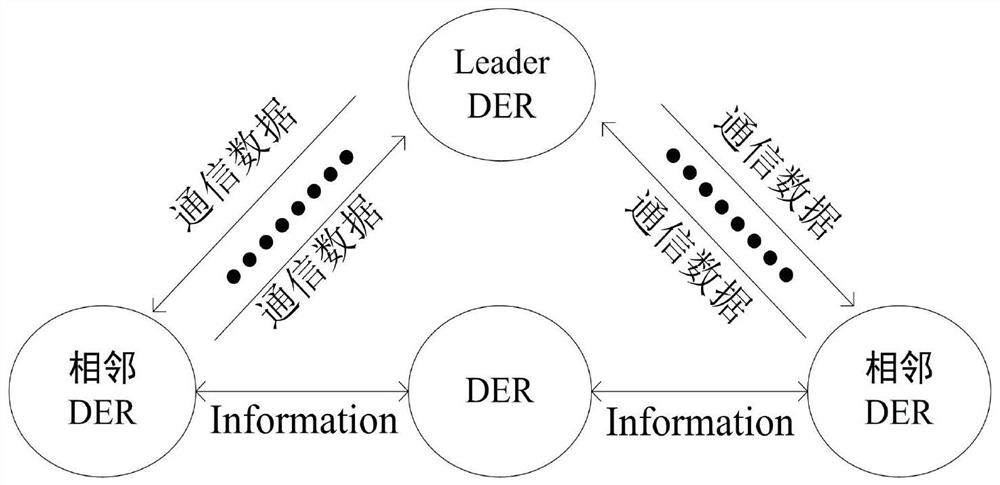

Distributed control method considering time lag and packet loss problems in microgrid under CPS concept

ActiveCN107706939AEliminate Control ErrorsReduce wasteSingle network parallel feeding arrangementsSystems intergating technologiesAngular frequencySystemic model

The invention divides a microgrid control structure into a communication system and a physical system based on the concept of an information physical fusion system, and a novel distributed control strategy is proposed on this structure to improve a control effect of voltage and angular frequency by traditional droop control. Firstly, a microgrid communication system model is proposed based on graph theory knowledge, and communication structures of a plurality of single distributed power supplies form an integral communication system; secondly, in the communication system, a method combining areverse neural network and prediction control is proposed to solve the problem of communication time lag; a novel consistency protocol with a virtual navigator is proposed to solve the problem of packet loss; thirdly, in the physical system, P-omega / Q-U droop control is used as primary control of voltage and angular frequency; and finally, voltage and angular frequency data in the communication system and the proposed novel consistency protocol are utilized to complete secondary control of voltage and angular frequency output by droop control in the physical system, and the control strategy has a distributed cooperative characteristic.

Owner:YANSHAN UNIV

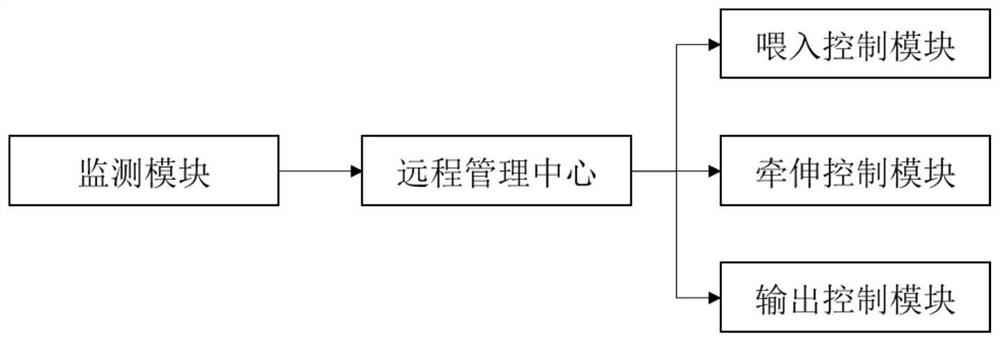

Intelligent drawing management system

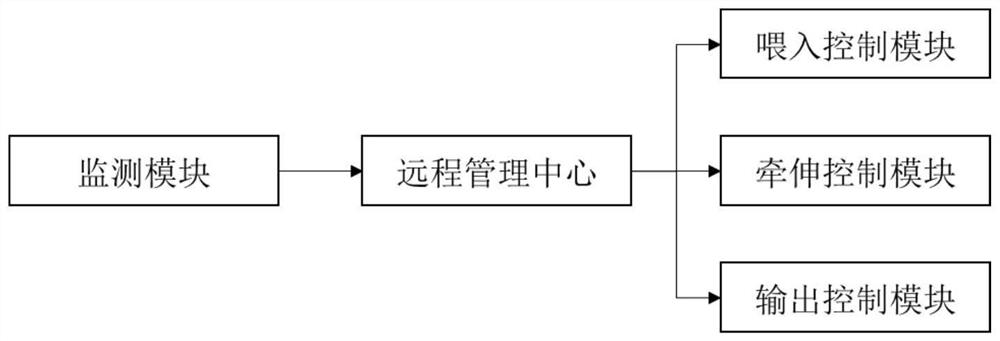

ActiveCN111636124AImprove the leveling rateEliminate monitoring and control errorsTextiles and paperMonitoring dataControl parameters

The invention discloses an intelligent drawing management system. The intelligent drawing management system comprises a monitoring module, a feeding control module, a drafting control module, an output control module and a remote management center, and the monitoring module, the feeding control module, the drafting control module and the output control module are connected with the remote management center. The remote management center calculates cotton feeding, drafting and cotton outputting regulation and control parameters according to monitoring data and sends the cotton feeding, draftingand cotton outputting regulation and control parameters to the cotton feeding control module, the drafting control module and the cotton output control module respectively to control the drawing process, the quality of cotton slivers is monitored in real time, the drafting speed is regulated and controlled in real time, the optimal adaptive regulation and control of the drafting speed and the cotton sliver uniformity are realized, so that the uniformity of the output cotton slivers is obviously improved.

Owner:武汉裕大华纺织有限公司

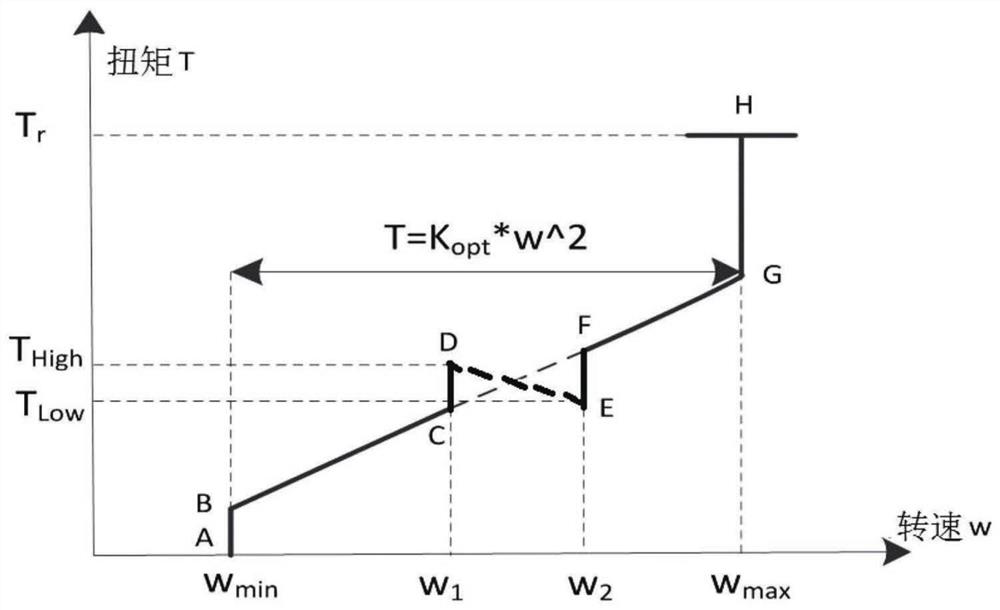

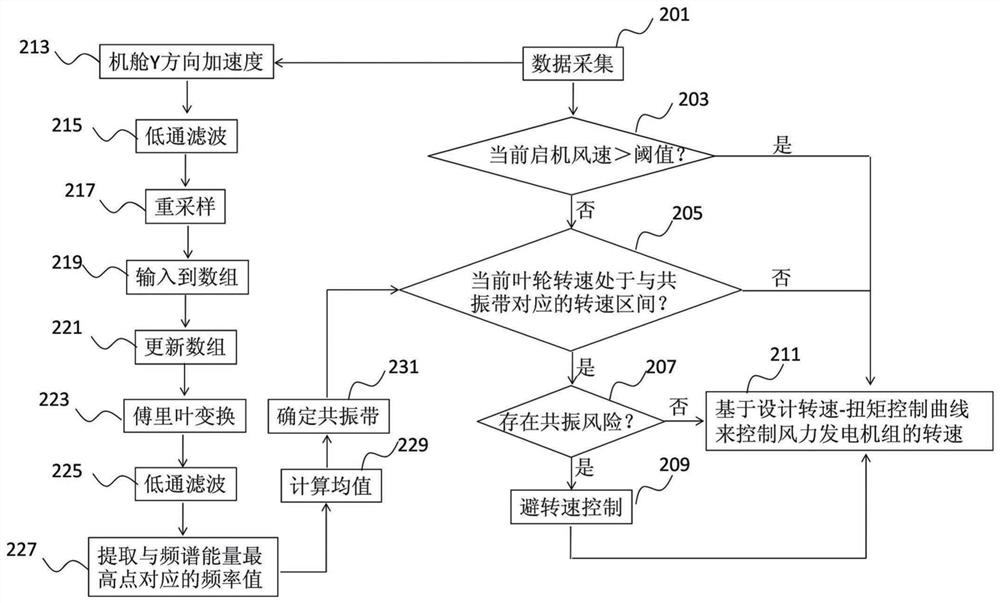

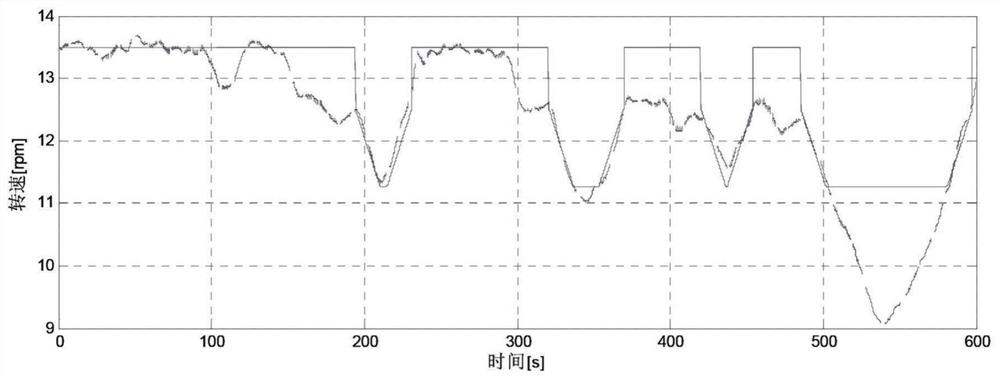

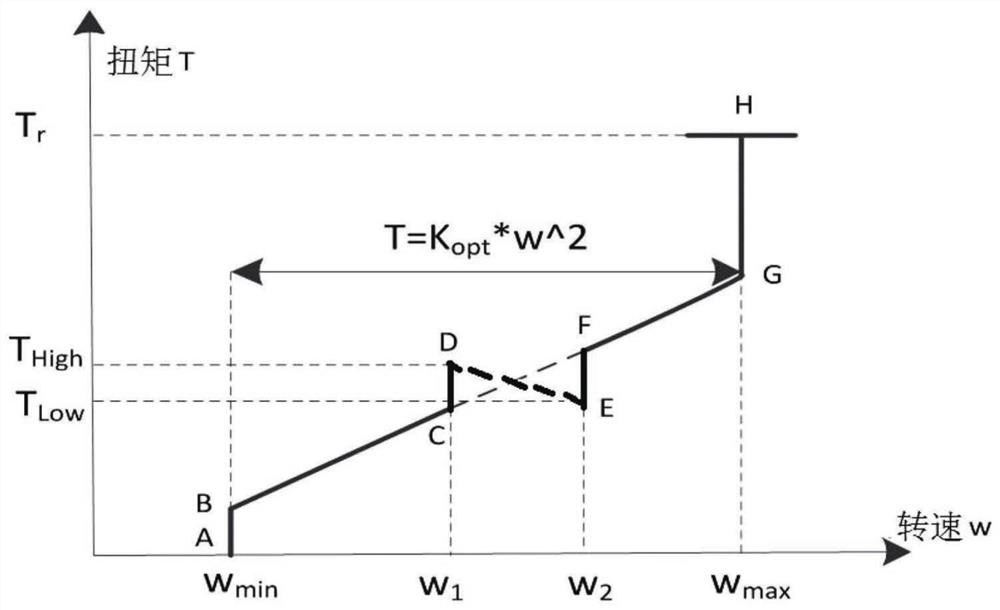

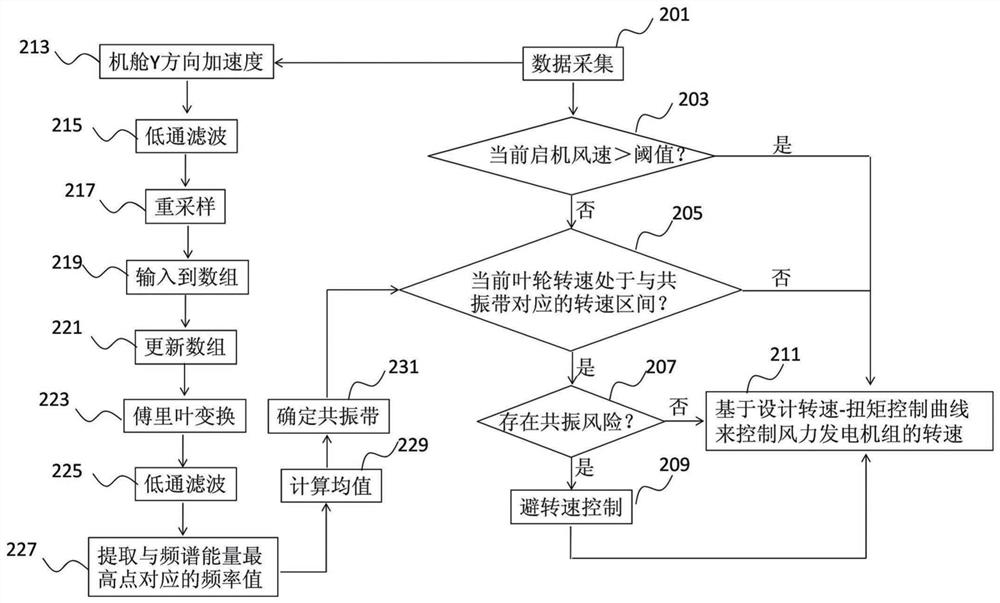

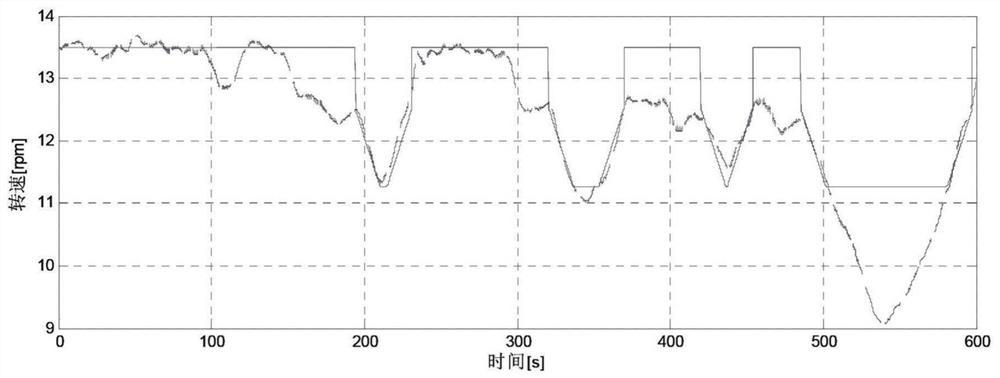

Rotating speed control method and device of wind turbine generator system

ActiveCN111852761AReduce frequent openingReduce shockWind motor controlEngine fuctionsImpellerResonance

The invention provides a rotating speed control method and device of a wind turbine generator system. The rotating speed control method comprises the steps that whether the current impeller rotating speed of the wind turbine generator system is in a rotating speed interval corresponding to a resonance band or not is determined; when the current impeller rotating speed is in the rotating speed interval, resonance recognition is executed to determine whether a resonance risk exists or not; and when it is determined that the resonance risk exists, execution is carried out to enable the current impeller rotation speed to jump to rotation speed avoiding control of the preset impeller rotation speed so as to avoid the resonance risk. According to the rotating speed control method and device of the wind turbine generator system, the reliability and the generating capacity of the wind turbine generator system can be improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

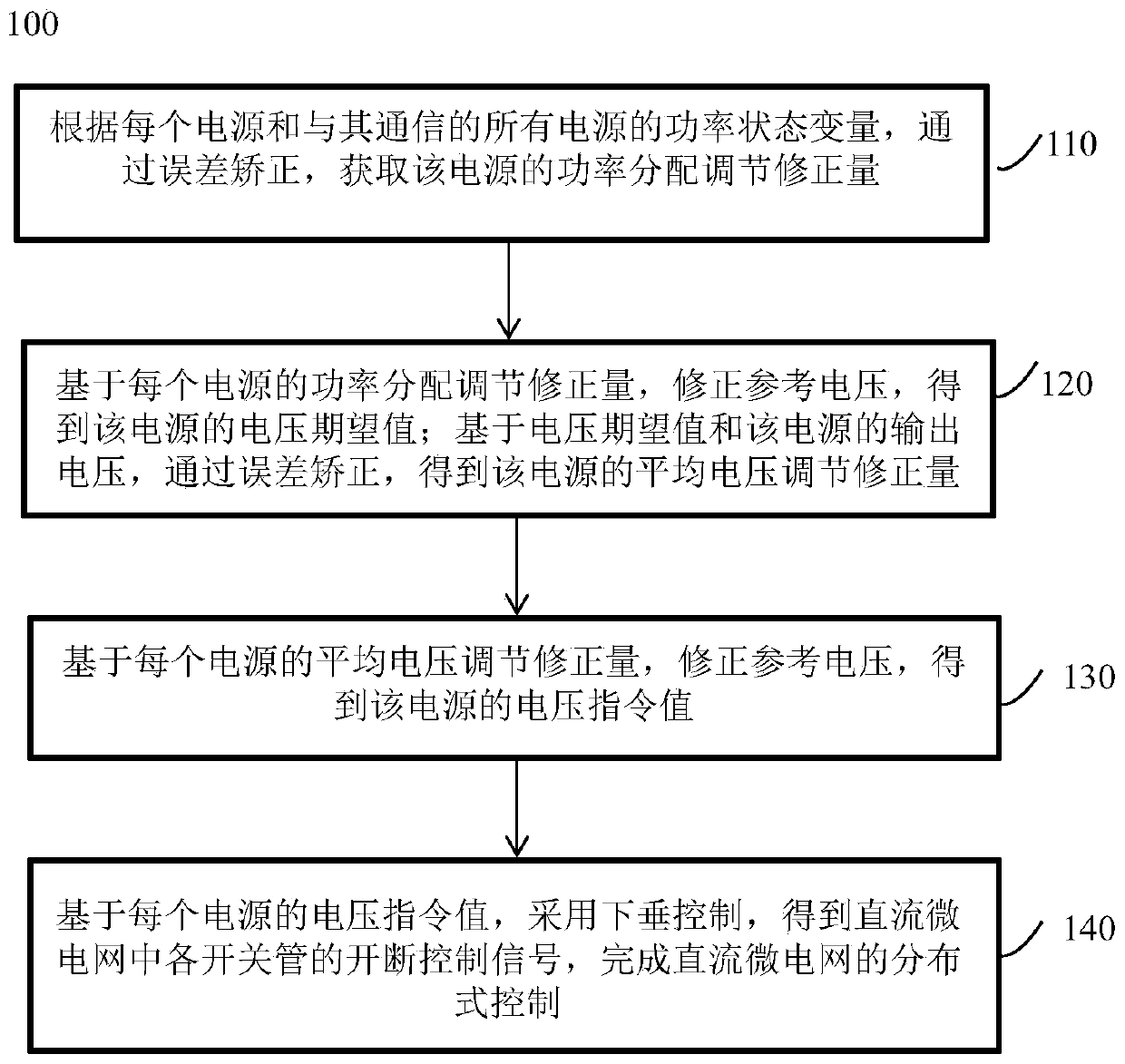

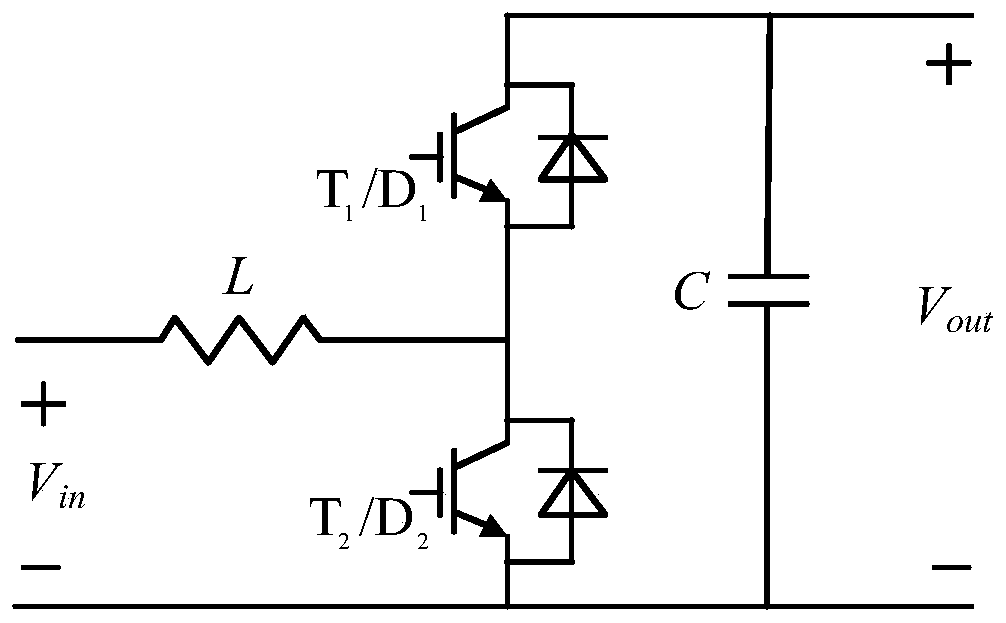

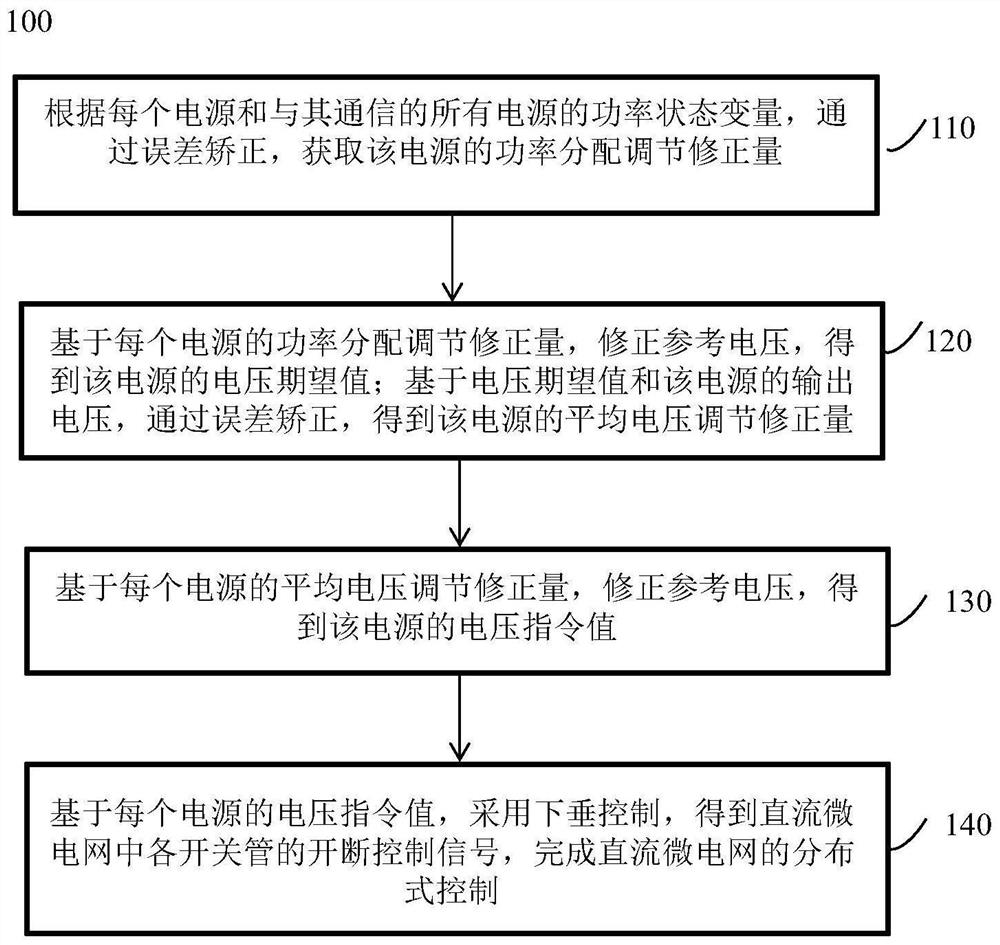

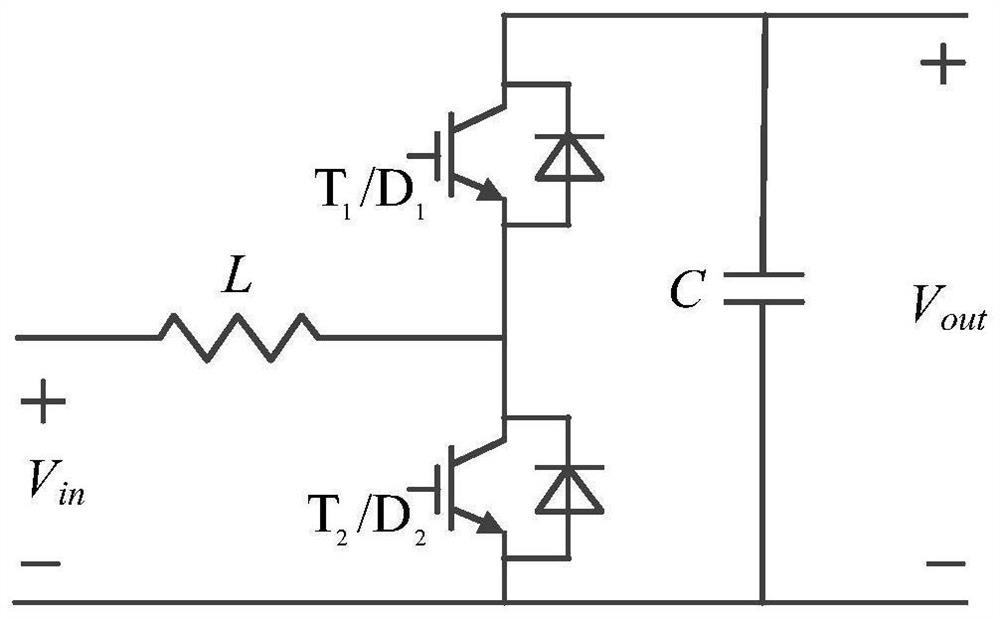

Distributed DC microgrid control method

ActiveCN110429578AReduce trafficReduce communication burdenDc source parallel operationMicrogridState variable

The invention discloses a distributed DC microgrid control method. The distributed DC microgrid control method comprises the steps of: obtaining, according to a power state variable of each power source and all power sources communicating with the power source, the power distribution and regulation and correction amount of the power source through error correction; based on the correction amount,correcting a reference voltage to obtain a voltage expected value; based on a voltage expected value and an output voltage, performing error correction to obtain the average voltage regulation and correction amount of the power source; based on the correction amount, correcting the reference voltage to obtain a voltage instruction value; and based on the voltage instruction value of each power source, adopting the droop control to obtain the cut-off control signal of each switch tube in the DC microgrid. The power distribution regulation and correction amount and the average voltage regulationand correction amount are sneaked into the correction of the reference voltage one by one to eliminate the inherent voltage and power distribution deviation of the primary droop control to achieve the power and voltage control of the DC microgrid so as to reduce the communication amount required by the operation of the distributed controller while maintaining the control performance and reduce the communication burden.

Owner:HUAZHONG UNIV OF SCI & TECH

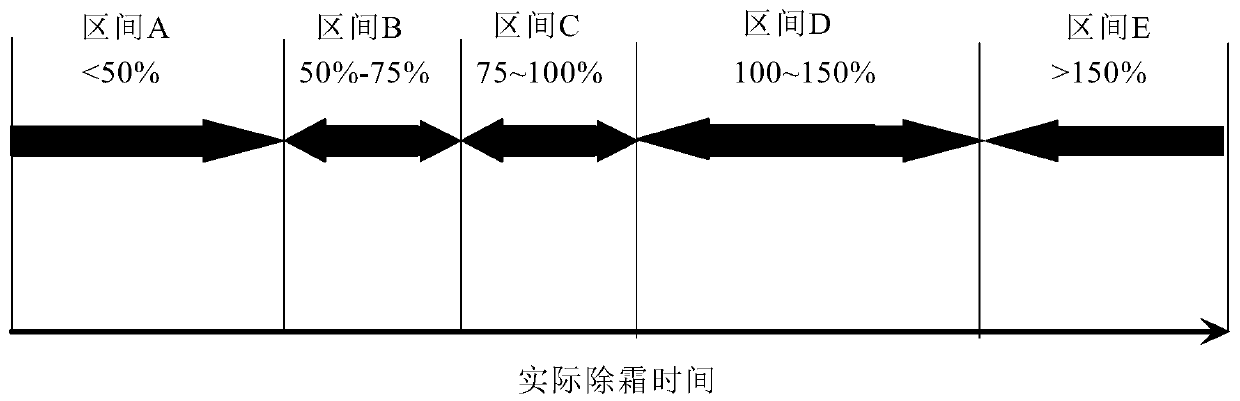

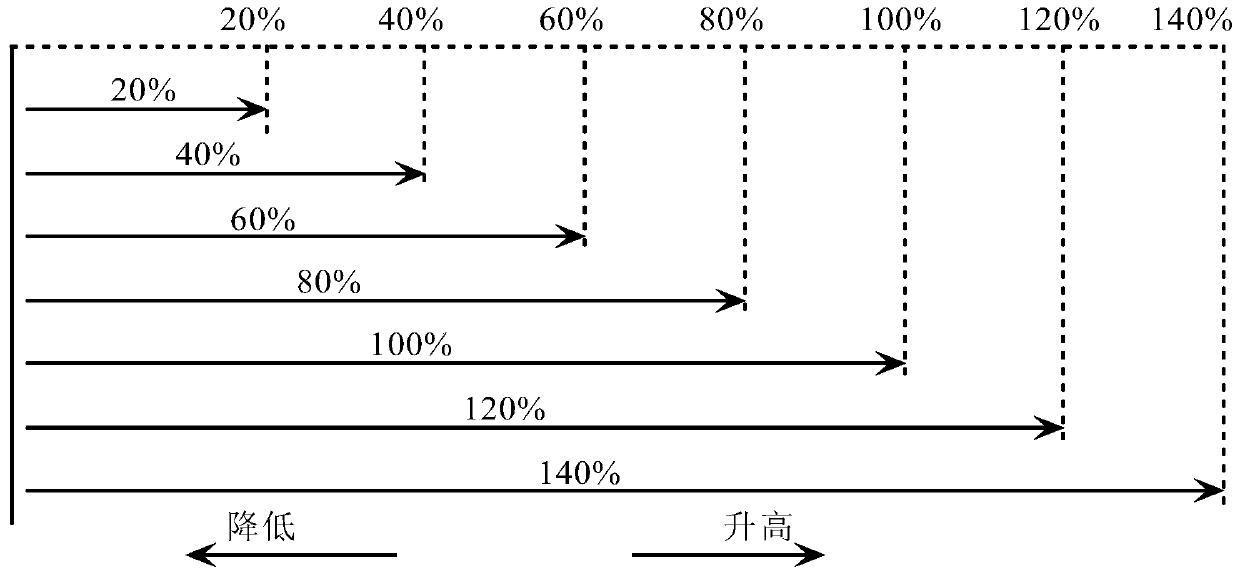

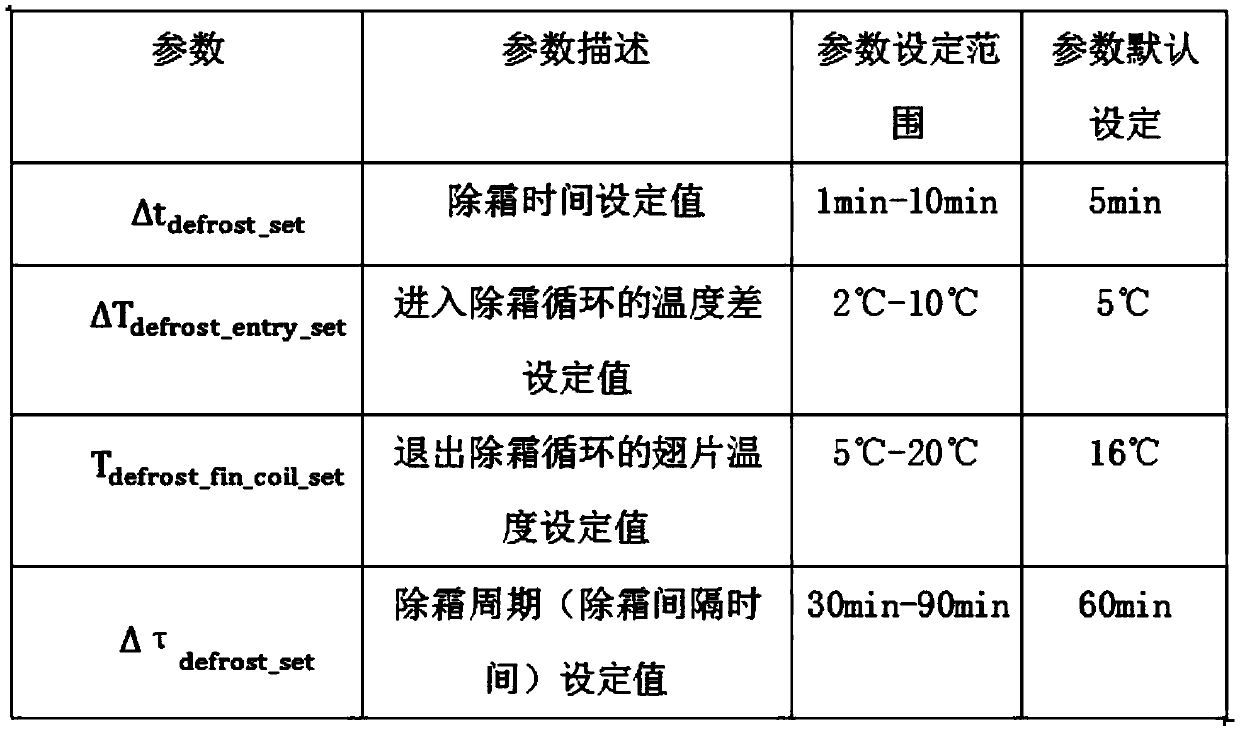

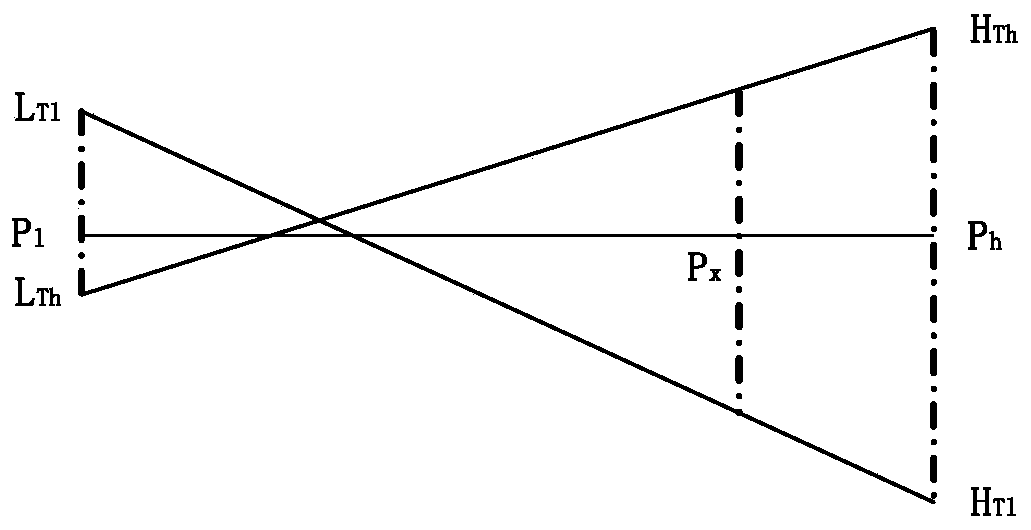

Self-adaptive defrosting control method of air-cooled heat pump system

InactiveCN110736277AGuaranteed reliable operationEliminate Control ErrorsRefrigeration safety arrangementDefrostingSelf adaptiveControl parameters

The invention discloses a self-adaptive defrosting control method of an air-cooled heat pump system. The self-adaptive defrosting control method is characterized by comprising the following steps of:setting four control parameters: (1) setting a defrosting time set value; (2) setting a temperature difference value entering a defrosting cycle; (3) setting a fin temperature exiting the defrosting cycle; and (4) setting an interval time (defrosting cycle) of two defrosting cycles, comparing actual defrosting time with set defrosting time, recording a ratio of the actual defrosting time to the set defrosting time each time, setting an interval according to a ratio range, determining a defrosting interval time according to an interval range to which the defrosting interval time belongs, takingtwo times of defrosting time as a correction interval, adjusting the set value of the defrosting interval time according to two defrosting time intervals recorded by the current times and the previous times, and continuously correcting the defrosting cycle to enable the defrosting cycle to automatically adapt to the change of the temperature and humidity of the environment with a self-correctionvariable step length.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

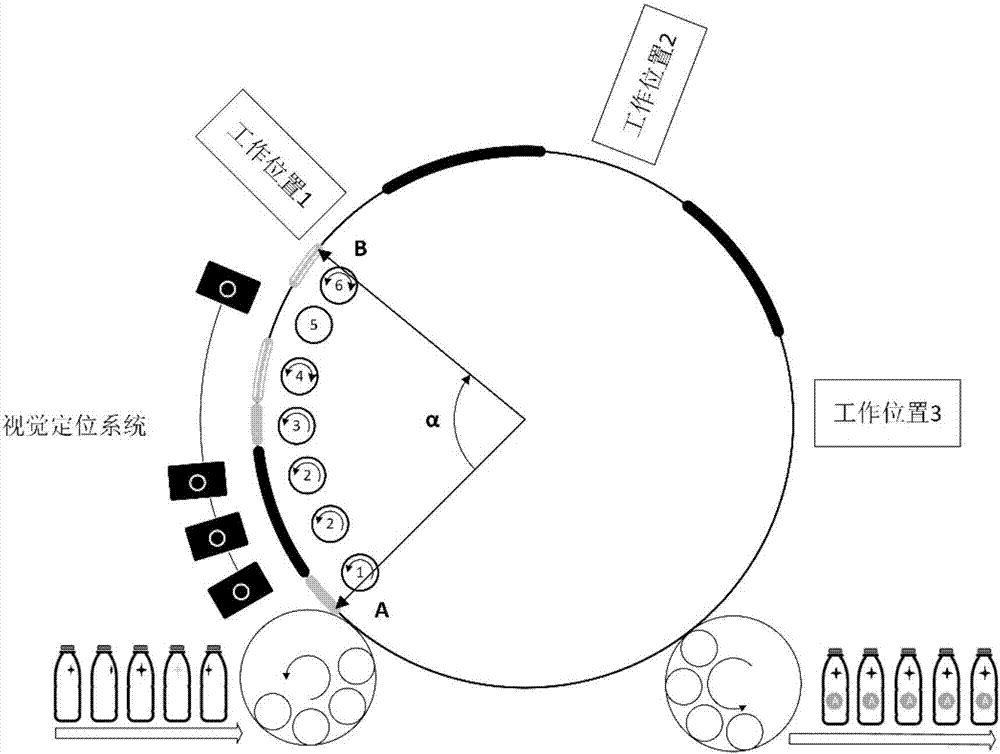

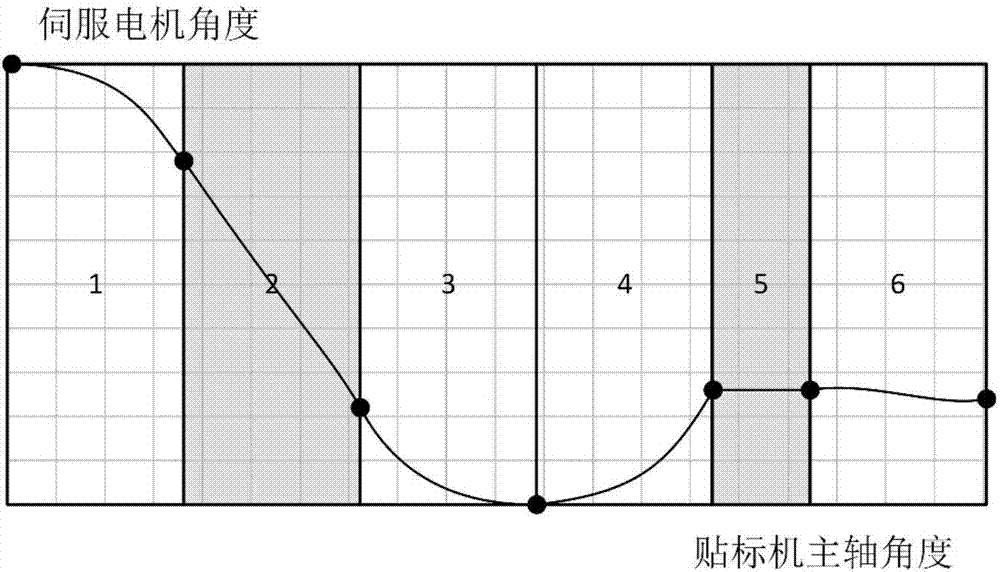

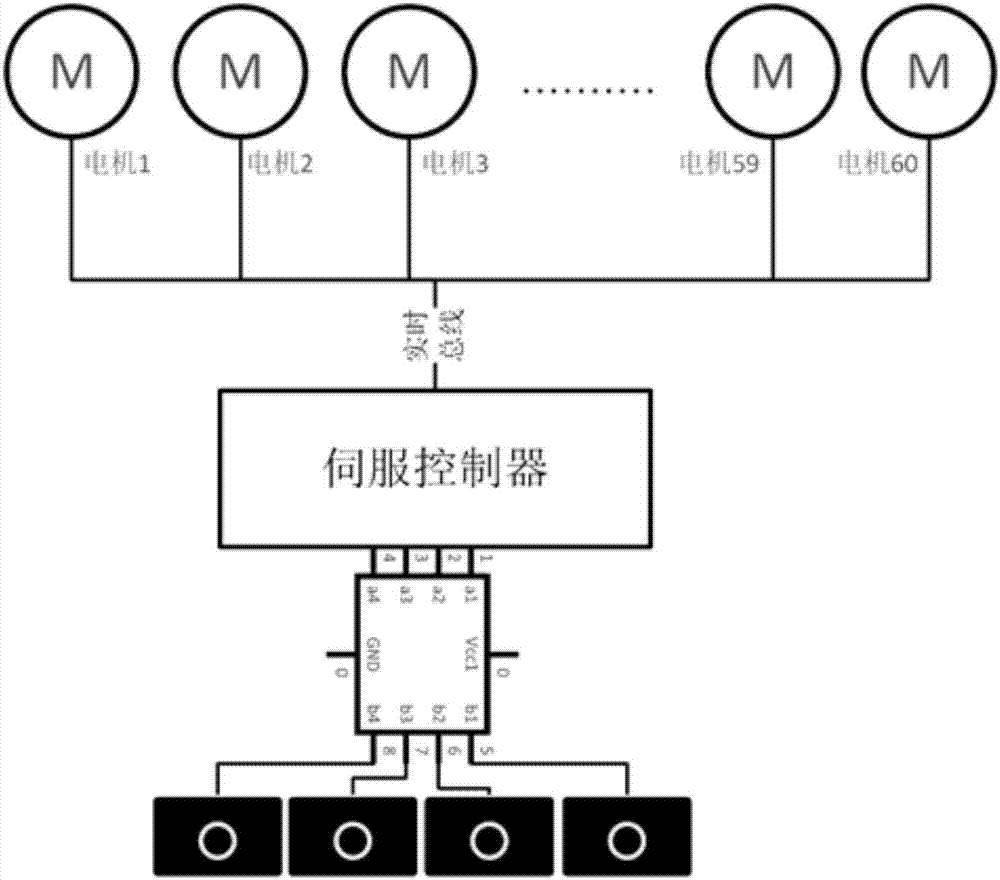

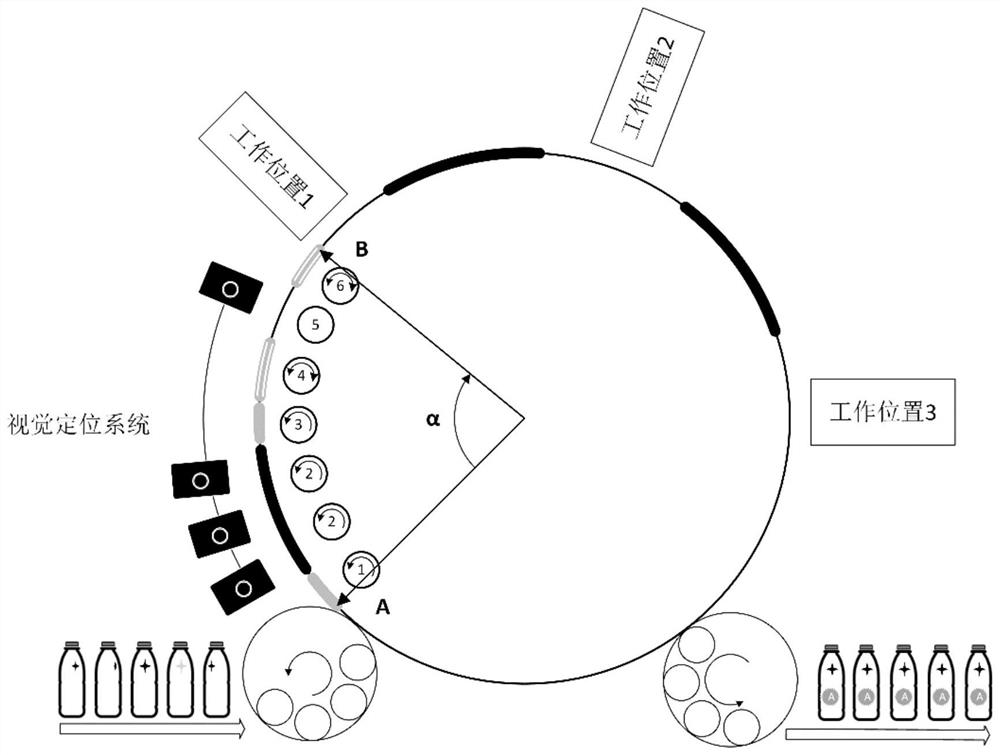

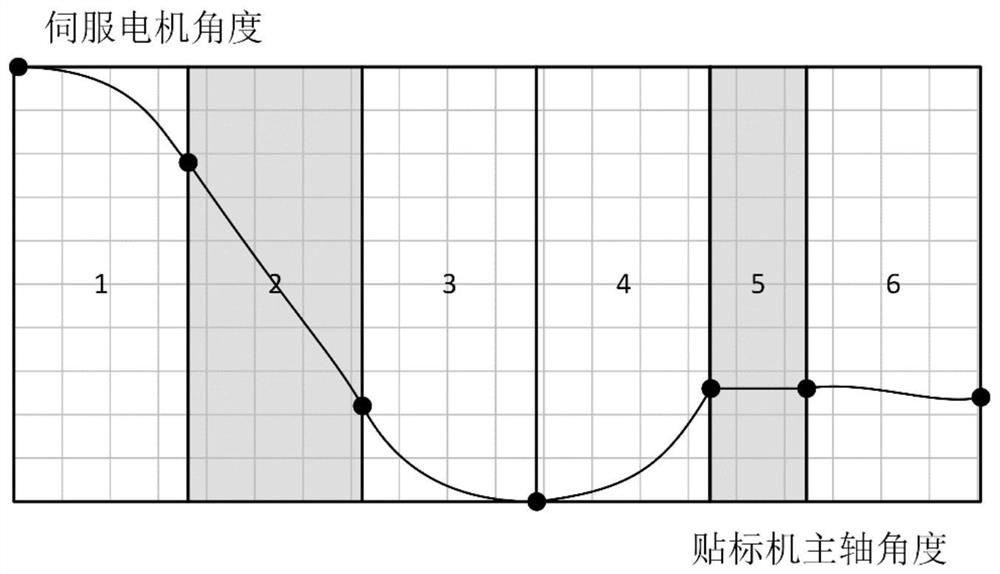

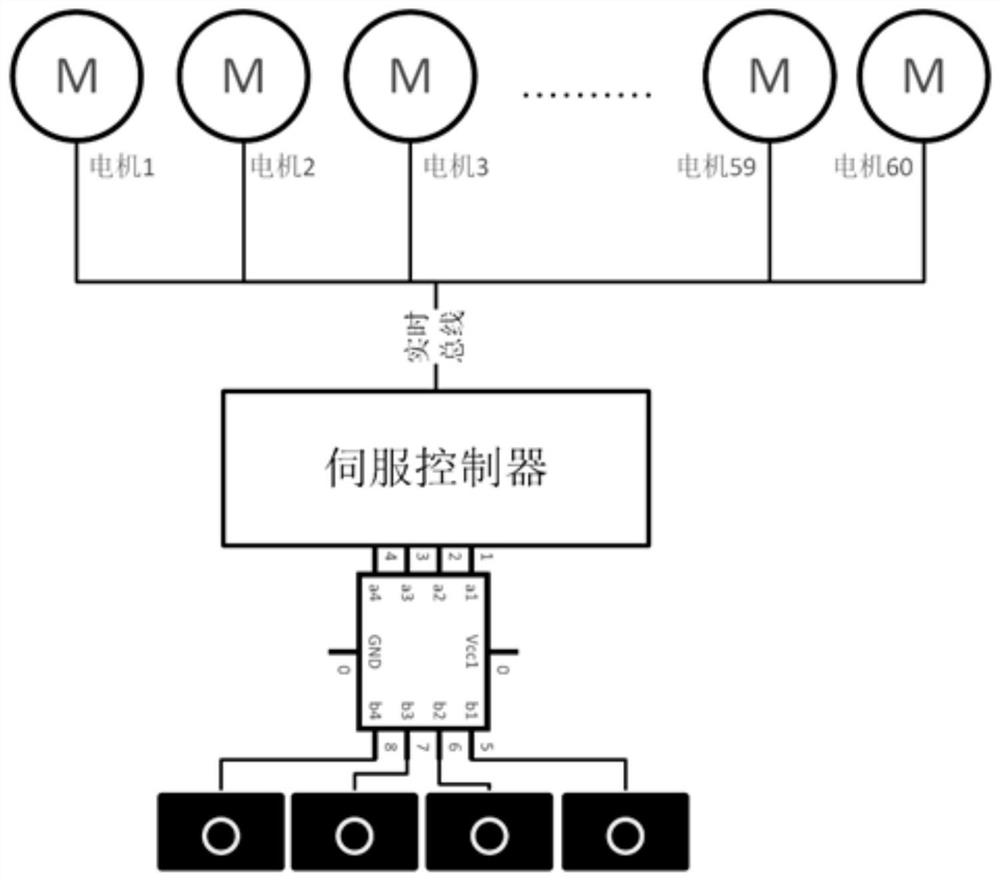

Synchronization method of online vision positioning system

ActiveCN107229291AAchieve synchronizationSmall rotation angleControl using feedbackVisual positioningVisual perception

The invention discloses a synchronization method of an online vision positioning system. The synchronization method comprises the steps of triggering a camera to photograph by a camera trigger signal output from the vision positioning system, transmitting the camera trigger signal to a servo control system so as to initiate interruption of the servo control system, recording a real-time position of a servo motor corresponding to a camera trigger moment through communicating the servo control system with the servo motor by means of a real-time bus, and ensuring that an absolute position of the servo motor is recorded by the servo control system at any moment when the camera photographs a picture, thereby realizing true synchronization between a servo controller and the vision positioning system. By adopting the synchronization method, a labeling machine main shaft rotating angle required for 360-degree imaging is reduced, thus the positioning system requires smaller installation space, the control errors of camera mechanical installation and the servo system are eliminated, the prepositioning precision is improved, the online vision positioning system is more compact, and the market application of the online vision positioning system is wider.

Owner:苏州西斯派克检测科技有限公司

Track slab grinder

ActiveCN101628390BRealize one-time double-sided processingImprove processing efficiencyStone-like material working toolsPlane surface grinding machinesHydraulic motorStructural engineering

The invention is a track slab grinder, and relates to a special grinder for grinding a track slab. The track slab grinder comprises left and right main foundation walls and left and right grinding wheels. The key technology thereof is as follows: the left and right main foundation walls are respectively provided with a main longitudinal girder provided with a main longitudinal guide rail, a main transverse beam is arranged between the main longitudinal guide rails and is provided with left and right transverse guild rails respectively, the transverse guild rail is installed with a transverse sliding box which is internally provided with a vertical guild rail, an inner box is mounted on the vertical guild rail, a main shaft direction adjusting box is arranged at the lower end part of the inner box, a grinding head is arranged at the lower side of the main shaft direction adjusting box, a grinding wheel is mounted on the main shaft of the grinding head, and the main shaft of the grinding head is driven by a hydraulic motor. The track slab grinder in the invention can finish processing both sides of a bearing block at one time, has the advantages of high integral strength, stable movement, good rigidity, high processing efficiency, and can process a standard track slab as well as a track slab grinder of a non-standard track slab.

Owner:四川省宜宾普什集团有限公司

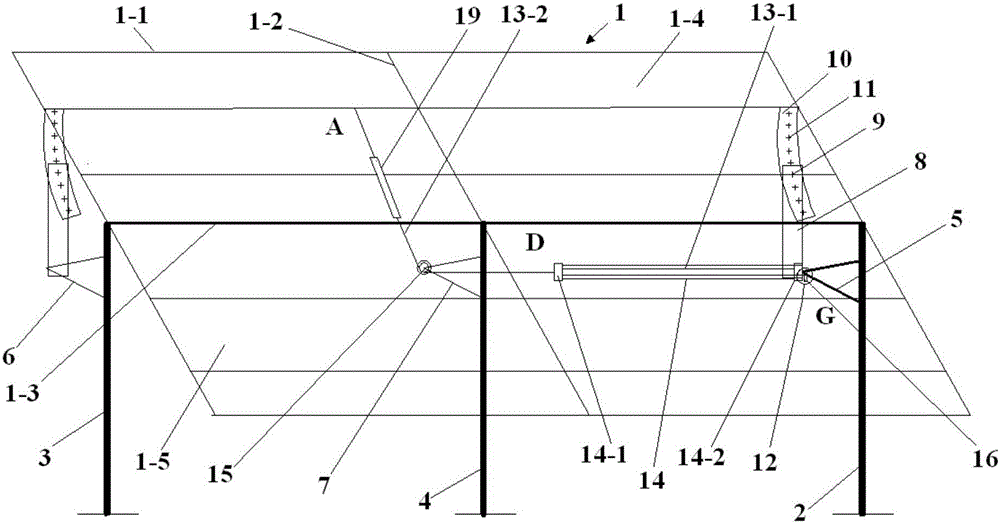

Fixed adjustable solar support controlled by pulley block

ActiveCN105871315AReduce adjustment driveReduce labor intensityPhotovoltaic supportsPhotovoltaic energy generationElevation angleBlock and tackle

The invention provides a fixed adjustable solar support controlled by a pulley block. One end of a lower locating support is fixedly connected with the inside of one end of each supporting frame, and one end of an upper locating support is fixedly connected to a solar assembly bracket above the corresponding lower locating support; a rotary shaft of a rotary wheel is mounted outside the end part of one supporting frame, and a fixed pulley of the pulley block is further mounted on the supporting frame nearby the corresponding lower locating support; one end of a first steel cable is fixedly connected to the rotary wheel, and the other end of the first steel cable penetrates the pulley block, goes out of a movable pulley of the pulley block and is fixedly connected to the fixed pulley; a guiding fixed pulley is mounted at the end part of one supporting frame mounted on a middle supporting column, one end of a second steel cable is fixedly connected to the movable pulley of the pulley block, and the other end of the second steel cable winds around the fixed pulley and is then fixedly connected to one cross beam. The fixed adjustable solar support has the advantages that the pulley block is adopted to reduce the driving force by high power, the labor intensity during adjustment of an elevation angle can be effectively reduced in manners such as flexible adjustment, rigid fixation and the like, and equipment is convenient to maintain and repair.

Owner:GANSU CHINA POWER CONSTRUCTION PORT SHIP ENGINEERING CO LTD

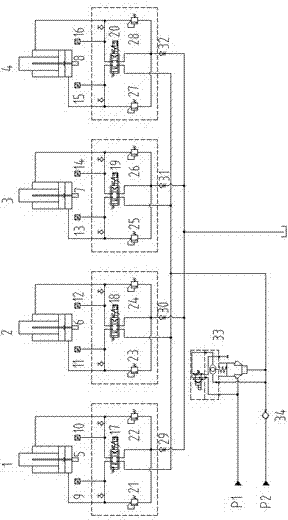

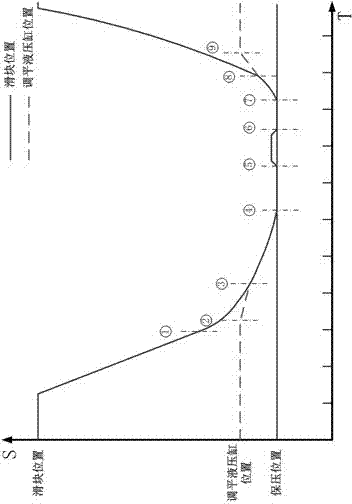

Hydraulic control system and method for passive type four-corner-leveling hydraulic press

The invention discloses a hydraulic control system and method for a passive type four-corner-leveling hydraulic press. The hydraulic control system is provided with two oil sources, namely the high-pressure oil source P1 and the low-pressure oil source P2. The high-pressure oil source P1 can be provided by an energy accumulator control hydraulic system and provides a power source for pre-acceleration motion and mould micro-opening control; the low-pressure oil source P2 can be provided by a circulating cooling pump in a pump station and is manly used for supplementing oil in the upper cavity of a piston hydraulic cylinder in the leveling control process to prevent a rod cavity from being sucked empty. Furthermore, a high-frequency-response proportion servo valve with a closed position loop is adopted as a synchronous control element of a leveling hydraulic cylinder. The hydraulic control system is low in manufacturing cost, strong in anti-pollution capacity and capable of achieving automatic control easily, thereby being applicable to occasions with high power and high synchronous accuracy. Moreover, according to the control method, it is unnecessary that a certain leveling hydraulic cylinder is selected as a driving cylinder, and leveling errors caused by selecting the driving cylinder by experience are eliminated. In addition, the rapid descending / returning speed of the passive type four-corner-leveling hydraulic press can reach 1200mm / s, and the minimum leveling accuracy can reach 0.02mm.

Owner:ZHEJIANG UNIV

Phase detection method based on adaptive filtering

InactiveCN101576586BFast implementation of phase measurementsImplement phase measurementVoltage-current phase angleSignal-to-noise ratio (imaging)Phase difference

The invention discloses a phase detection method based on adaptive filtering. The method comprises the following steps: performing time-frequency domain transformation on input signals and estimating the approximate frequency value of the input signals in a frequency domain; adjusting the estimated approximate frequency value till the error of the approximate frequency value is not enough to causeburden for signal phase detection; detecting the amplitude and phase of sinusoidal signals with known frequency according to adaptive notch algorithm; and utilizing the negative entropy of Gaussian white noise to check and adjust estimated signals. The method provided by the invention has higher precision than the prior phase detection method, and uses the negative entropy to determine result precision so as to enable algorithm selection to have evidence to be found. The method provided by the invention has certain stability to the phase difference measurement with different signal-to-noise ratio, frequency and initial phases, and is suitable for various applications needing precise signal phase difference measurement.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Fixed adjustable solar bracket employing multiple groups of parallel pulley blocks

ActiveCN105897138AReduce adjustment driveReduce labor intensityPhotovoltaic supportsPhotovoltaic energy generationBlock and tacklePhotovoltaic power station

The invention provides a fixed adjustable solar bracket employing multiple groups of parallel pulley blocks. The fixed adjustable solar bracket comprises multiple single-group brackets, wherein solar assembly brackets of the multiple single-group brackets are taken as a whole; each single-group bracket comprises one solar assembly bracket; the solar assembly bracket is aligned through positioning holes in an upper positioning bracket and positioning holes in a lower positioning bracket and then can be inserted into a positioning pin to be fixed; each solar assembly bracket drives a control pulley block through a rotating wheel; and each control pulley block drives branch ropes to adjust the angle. The multiple single-group brackets are connected in parallel, so that the bracket can be suitable for a large photovoltaic power station. Through resistance-reducing pulley blocks, the resistance of the integral solar assembly brackets in the angle adjusting process can be reduced.

Owner:GANSU CHINA POWER CONSTRUCTION PORT SHIP ENGINEERING CO LTD

Bidirectional hydraulic magnetic control valve capable of continuously draining water

ActiveCN110529631AReduce resistancePowerfulOperating means/releasing devices for valvesMultiple way valvesHydraulic cylinderSynchronous control

A bidirectional hydraulic magnetic control valve capable of continuously draining water comprises a valve body, the valve body is divided into a drainage area and a control area, the drainage area comprises a water inlet, a buffer cavity, a first drainage port and a second drainage port, and the conical channels are both formed between the first drainage port and the buffer cavity and between thesecond drainage port and the buffer cavity respectively. According to the present invention, the synchronous control of the two valve mechanisms is achieved through the hydraulic magnetic control mechanism, the control errors are eliminated, and the influence of control on the drainage is reduced. The conical channels of a water impurity blocking device are solved by the conical thorns, the impactforce of the water flow on the valve mechanism is reduced through the buffer cavity, and a first electromagnetic disc and a second electromagnetic disc are buffered through the hydraulic oil in a hydraulic cavity to control a strong magnetic block to move, so that a buffer mechanism does not need to be additionally arranged. The pressure pushing is horizontal and uniform through the communicationof the multiple hydraulic cylinders of the same valve mechanism, and the bidirectional hydraulic magnetic control valve is of an integral structure and is more convenient to assemble and disassemble.

Owner:嘉兴鼎尚信息科技有限公司

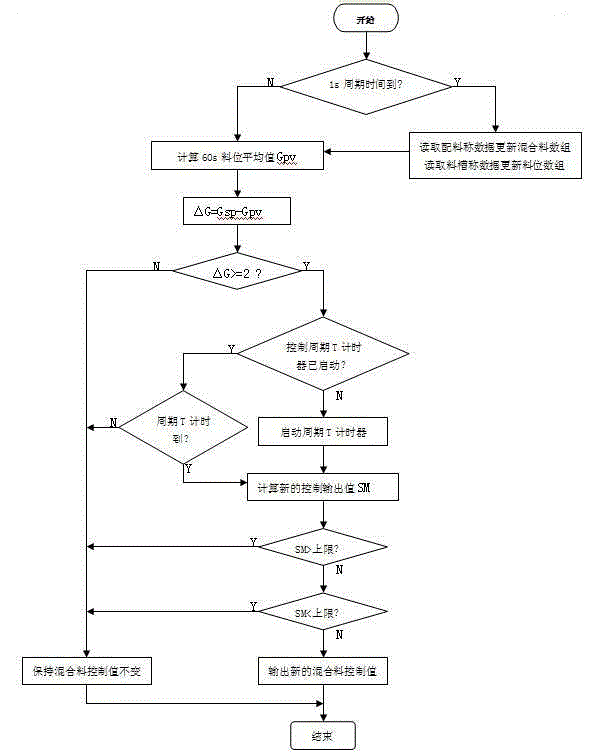

Slot and level control method of sintering mixture

ActiveCN102103370BLengthen the filter periodEliminate Control ErrorsLevel controlProgramme control in sequence/logic controllersArray data structureLag

The invention relates to a slot and level control method of a sintering mixture, which belongs to the field of a metallurgical sintering production control technique. The slot and level control method provided by the invention has the technical scheme: tracking and recording the weight distribution of the mixture in the whole mixing flow by utilizing an array; predicting the weight of the mixturedischarged by a slot; dynamically predicting the variation trend of a level; adjusting the quantity of the mixture in advance; eliminating control errors caused by great lag of a system; prolonging the detecting data filtering period of the weight of the slot; and reducing control fluctuation. The control method provided by the invention tracks and records the weight distribution of the mixture in the whole mixing flow by utilizing the array, predicts the weight of the mixture discharged by the slot, dynamically predicts the variation trend of the level, provides the means for adjusting the quantity of the mixture in advance, eliminates the control errors caused by great lag of the system, prolongs the detecting data filtering period of the weight of the slot and effectively reduces the control fluctuation; the control parameters have actual derivation significances; and the debugging is convenient.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP +2

Wind turbine speed control method and device

ActiveCN111852761BReduce frequent openingReduce shockWind motor controlEngine fuctionsImpellerGenerating capacity

The invention provides a rotational speed control method and device for a wind power generating set. The speed control method includes: determining whether the current speed of the impeller of the wind turbine is in a speed range corresponding to the resonance zone; when the current speed of the impeller is in the speed range, performing resonance identification to determine whether there is a risk of resonance; When there is a risk of resonance, a rotational speed avoidance control that causes the current rotational speed of the impeller to jump to a predetermined rotational speed of the impeller is executed to avoid the risk of resonance. The rotational speed control method and device of the wind power generator set of the present invention can improve the reliability and power generation of the wind power generator set.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

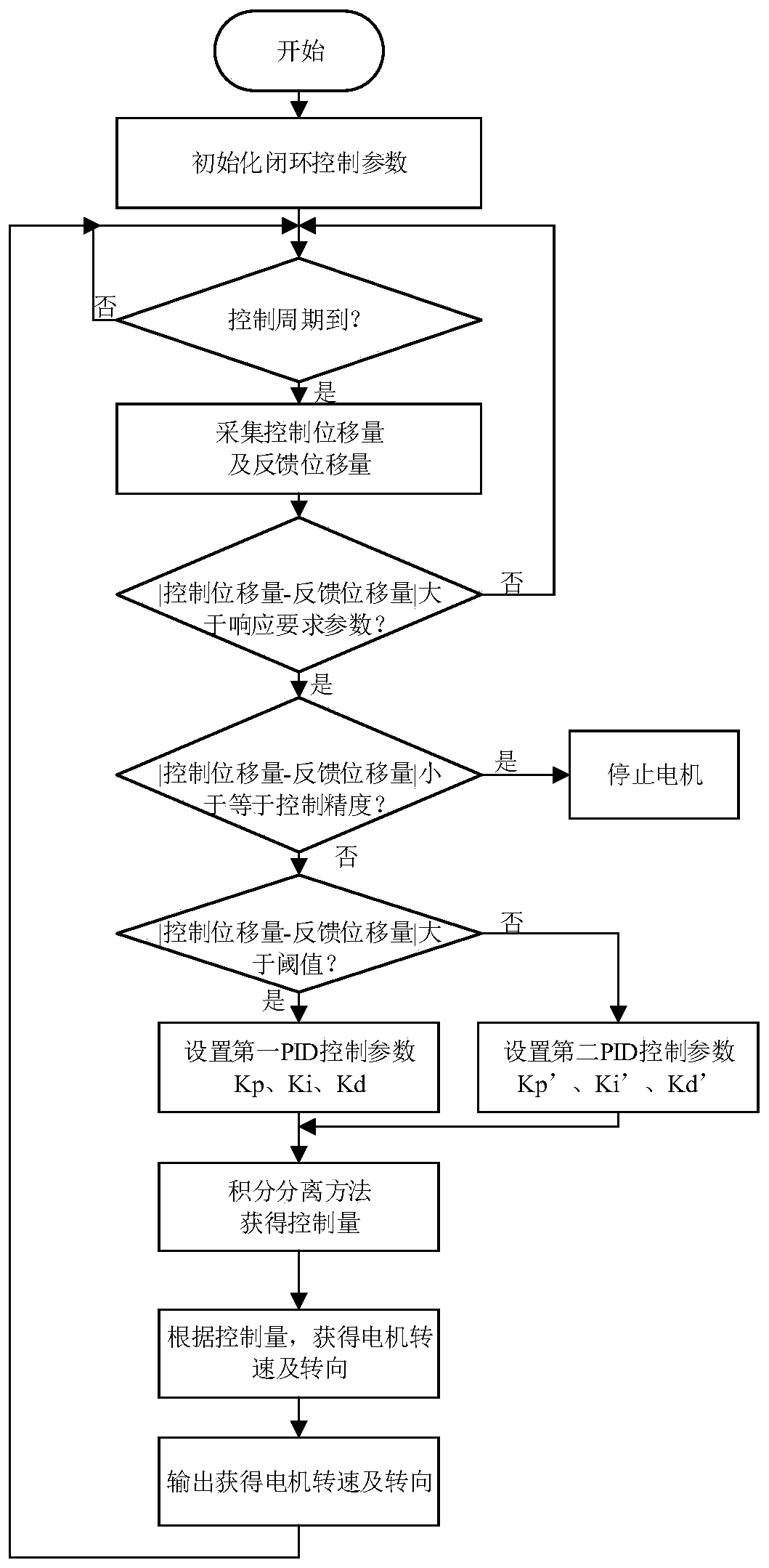

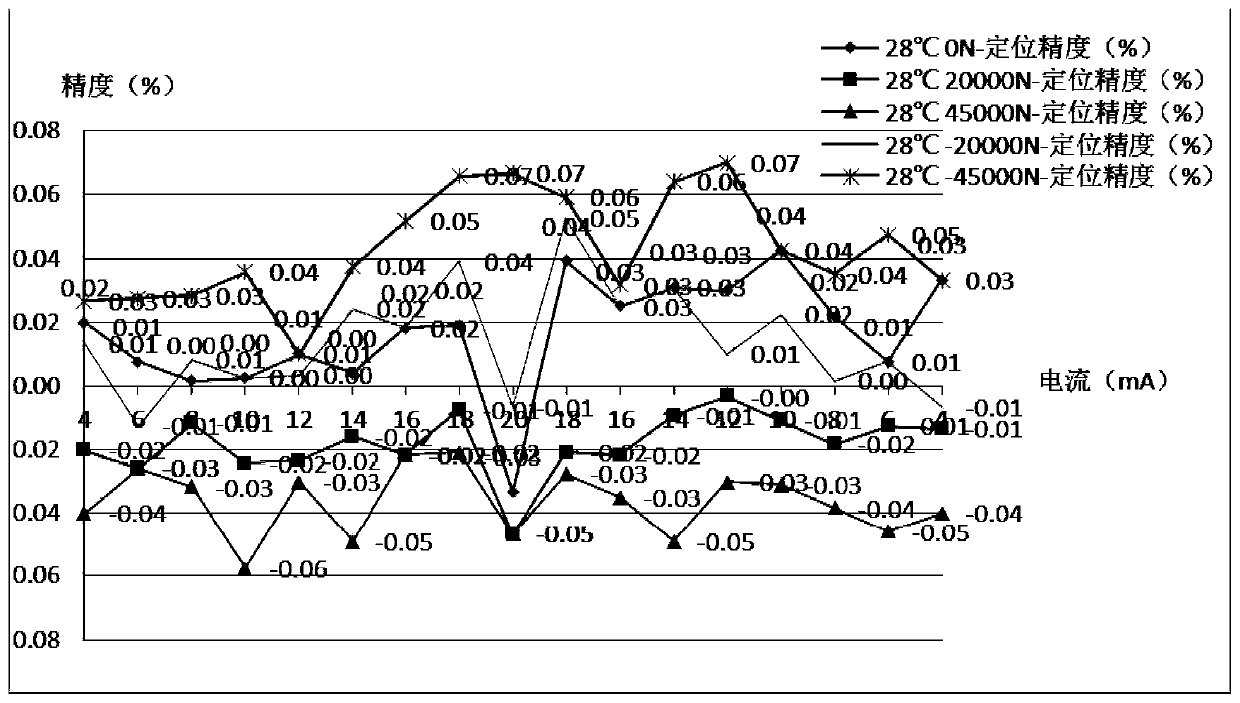

A Displacement Control Method of Electro-hydraulic Actuator

ActiveCN109488654BImprove control efficiencyHigh control precisionServomotor componentsServometer circuitsHydraulic cylinderLoop control

The invention discloses a displacement control method of an electro-hydraulic executer. A segmented PID closed-loop control method is used for indirectly controlling the displacement of an output shaft of a hydraulic cylinder in the electro-hydraulic executer, the displacement, collected by a displacement sensor, of the output shaft in the hydraulic cylinder serves as the feedback quantity to participate in closed-loop control, the output execution amount is controlled to be the rotating speed and the steering direction of a servo motor, and a temperature compensation method is used for compensating for the overall temperature drift of the electro-hydraulic executer. The control efficiency of the control method is improved, the control precision of the control method is improved, errors caused by the temperature drift are eliminated, and the control precision of the electro-hydraulic executer under the multi-load work condition is met.

Owner:CHINA PETROLEUM & CHEM CORP +2

An Intelligent Drawing Frame Management System

ActiveCN111636124BGood fit regulationLeveling rate improvedTextiles and paperControl engineeringTampon

Owner:武汉裕大华纺织有限公司

Command processing method, command processing device and command processing system

ActiveCN102831894BTime synchronizationAvoid repeated executionSpeech recognitionEngineeringSpeech sound

Owner:HUAWEI DEVICE CO LTD

A Synchronization Method for Online Vision Positioning System

ActiveCN107229291BAchieve synchronizationSmall rotation angleControl using feedbackControl systemControl engineering

The invention discloses a synchronization method of an online vision positioning system. The synchronization method comprises the steps of triggering a camera to photograph by a camera trigger signal output from the vision positioning system, transmitting the camera trigger signal to a servo control system so as to initiate interruption of the servo control system, recording a real-time position of a servo motor corresponding to a camera trigger moment through communicating the servo control system with the servo motor by means of a real-time bus, and ensuring that an absolute position of the servo motor is recorded by the servo control system at any moment when the camera photographs a picture, thereby realizing true synchronization between a servo controller and the vision positioning system. By adopting the synchronization method, a labeling machine main shaft rotating angle required for 360-degree imaging is reduced, thus the positioning system requires smaller installation space, the control errors of camera mechanical installation and the servo system are eliminated, the prepositioning precision is improved, the online vision positioning system is more compact, and the market application of the online vision positioning system is wider.

Owner:苏州西斯派克检测科技有限公司

A multi-group parallel pulley block fixed and adjustable solar support

ActiveCN105897138BReduce adjustment driveReduce labor intensityPhotovoltaic supportsPhotovoltaic energy generationBlock and tacklePhotovoltaic power station

The invention provides a fixed adjustable solar bracket employing multiple groups of parallel pulley blocks. The fixed adjustable solar bracket comprises multiple single-group brackets, wherein solar assembly brackets of the multiple single-group brackets are taken as a whole; each single-group bracket comprises one solar assembly bracket; the solar assembly bracket is aligned through positioning holes in an upper positioning bracket and positioning holes in a lower positioning bracket and then can be inserted into a positioning pin to be fixed; each solar assembly bracket drives a control pulley block through a rotating wheel; and each control pulley block drives branch ropes to adjust the angle. The multiple single-group brackets are connected in parallel, so that the bracket can be suitable for a large photovoltaic power station. Through resistance-reducing pulley blocks, the resistance of the integral solar assembly brackets in the angle adjusting process can be reduced.

Owner:GANSU CHINA POWER CONSTRUCTION PORT SHIP ENGINEERING CO LTD

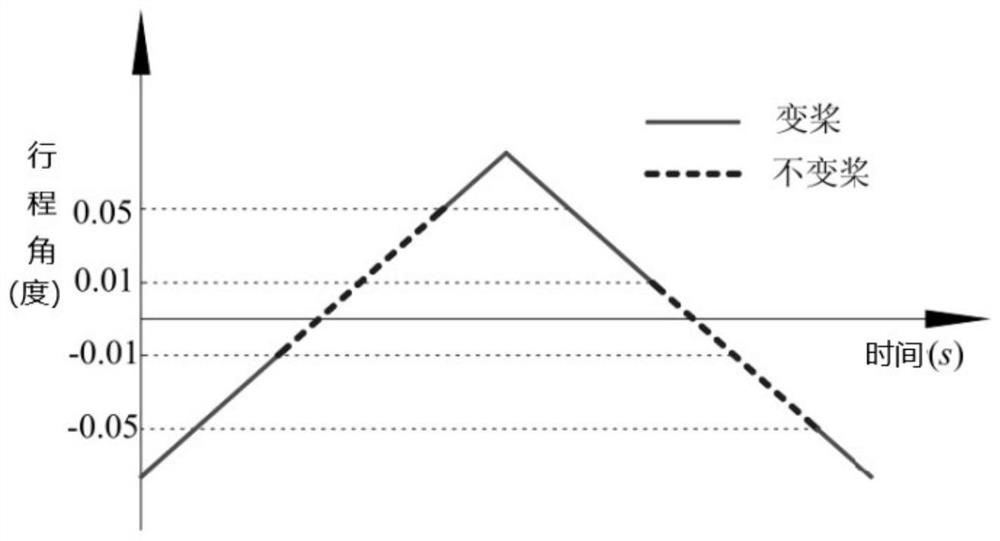

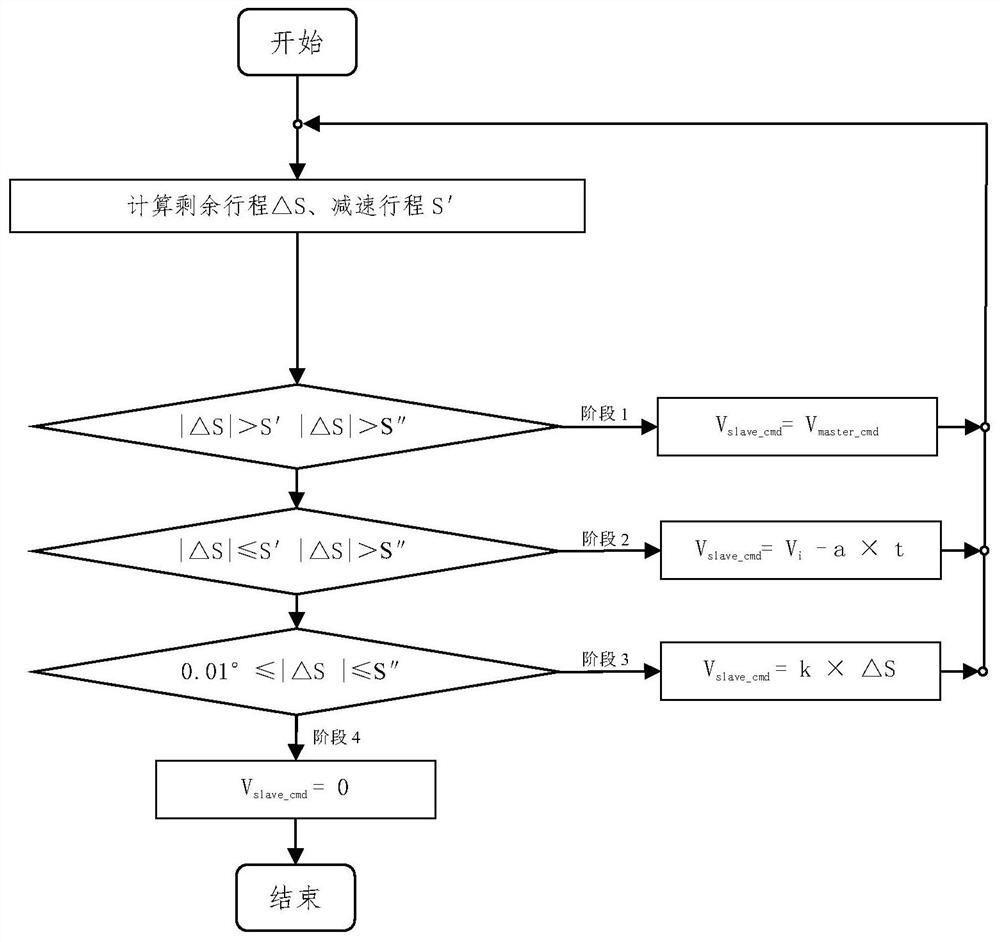

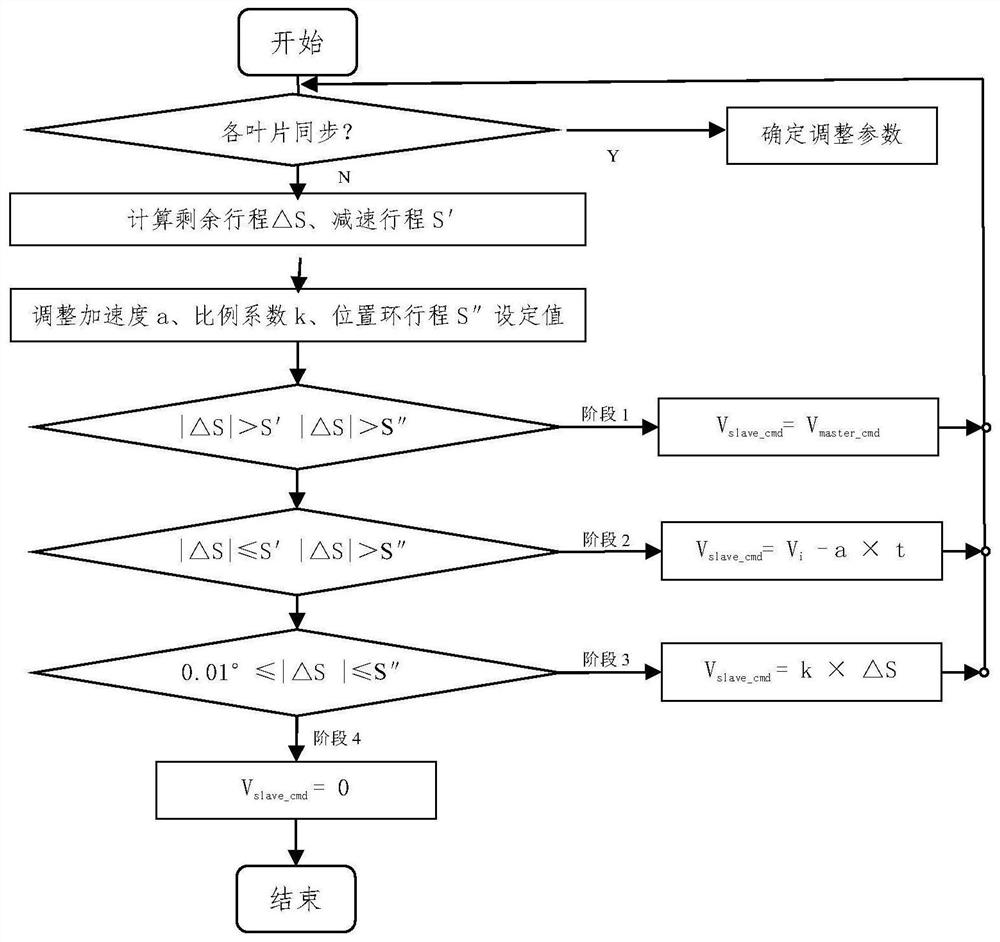

A method and application of wind turbine position control and synchronous debugging

ActiveCN111425349BImprove controlGuaranteed real-time synchronizationWind motor controlMachines/enginesProportional controlSimulation

The invention relates to a method and application of position control and synchronous debugging of wind turbines. The position control process of fan blades is divided into four stages: pitch change stroke, deceleration stroke, difference elimination stroke and stop stroke. Each speed command has its own planning method, and the proportional control used in the prior art solution is mainly applied in the differential stroke proposed by the present invention. In terms of synchronous debugging of the position of the fan blades, the existing technical solutions only have the proportional coefficient k available for adjustment, and it is often impossible to make a good trade-off between the control performance and the synchronization performance during the blade pitching process. And the technical scheme that the present invention proposes, these 3 parameters of the deceleration acceleration a of each blade, the position loop stroke S " of the third stage and the position proportional coefficient k of the third stage are available for debugging. Can significantly improve the blade position control performance At the same time, the real-time synchronization between the blade positions is effectively guaranteed.

Owner:XUCHANG XUJI WIND POWER TECH +1

A Distributed DC Microgrid Control Method

ActiveCN110429578BReduce trafficPower distribution is precisely achievedDc source parallel operationMicrogridControl signal

The invention discloses a distributed DC microgrid control method. The distributed DC microgrid control method comprises the steps of: obtaining, according to a power state variable of each power source and all power sources communicating with the power source, the power distribution and regulation and correction amount of the power source through error correction; based on the correction amount,correcting a reference voltage to obtain a voltage expected value; based on a voltage expected value and an output voltage, performing error correction to obtain the average voltage regulation and correction amount of the power source; based on the correction amount, correcting the reference voltage to obtain a voltage instruction value; and based on the voltage instruction value of each power source, adopting the droop control to obtain the cut-off control signal of each switch tube in the DC microgrid. The power distribution regulation and correction amount and the average voltage regulationand correction amount are sneaked into the correction of the reference voltage one by one to eliminate the inherent voltage and power distribution deviation of the primary droop control to achieve the power and voltage control of the DC microgrid so as to reduce the communication amount required by the operation of the distributed controller while maintaining the control performance and reduce the communication burden.

Owner:HUAZHONG UNIV OF SCI & TECH

A two-way hydraulic magnetic control valve capable of continuous drainage

ActiveCN110529631BNormal drainageDrainage impactOperating means/releasing devices for valvesMultiple way valvesHydraulic cylinderSynchronous control

Owner:嘉兴鼎尚信息科技有限公司

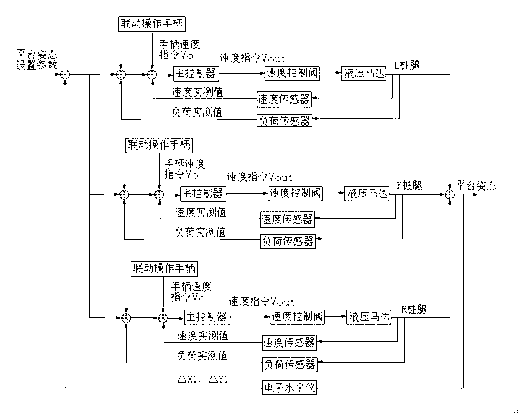

Automatic control method and device for lifting ocean platform

ActiveCN102400454BSmooth liftEnsure safetyArtificial islandsUnderwater structuresHydraulic motorAutomatic control

An automatic control method for lifting an ocean platform is disclosed, and comprises the steps that an electronic level meter detects the inclined angle of the platform and inputting the inclined angle to a main controller; the main controller corrects the inclination data of the platform according to predetermined coefficients Kx and Ky; a linkage operating handle inputs the handle speed command Vo to the main controller and the main controller applies PID (Proportion Integration Differentiation) algorithm to acquire the leg running speed Vout and inputting the Vout to a speed control valve; the speed control valve controls a hydraulic motor to control the leg to run according to the speed command till the platform is lifted. The invention further discloses an automatic control device for lifting an ocean platform. The electric level meter is connected on the platform. The output end of the electric level meter is connected with the input end of the main controller and the output end of the main controller is connected with the speed control valve of each leg. The automatic control method and device for lifting an ocean platform control the leg to life synchronously and maintain the platform by adopting closed-loop control of platform gesture, and are simple to operate and have high safety.

Owner:WUHAN MARINE MACHINERY PLANT

A trajectory following control method for horizontal and vertical coordinated control of unmanned vehicles

The invention discloses a transverse and longitudinal coordination control trajectory following up control method of an unmanned vehicle. According to the transverse and longitudinal coordination control trajectory following up control method, a control system in the control method comprises an information receiving module, a calculation solving module and a control command sending module. The control method comprises the following steps of step 1, receiving information: receiving information through the information receiving module; step 2, solving calculation: solving calculation through the calculation solving module; and step 3, enabling the control command emitting module to firstly transform front wheel turning angle and wheel driving / braking torque into direct controlling quantity of an executing mechanism. The method has the beneficial effects that the relationship of transverse motion and longitudinal motion of the unmanned vehicle is established by adopting transverse and longitudinal coordination control; and compared with independent control of transverse motion and the longitudinal motion, the transverse and longitudinal coordination control has the advantage that the control error caused by the coupling of transverse and longitudinal motion is eliminated, and the robustness of the control system is increased.

Owner:JILIN UNIV

Distributed control method considering delay and packet loss in microgrid under cps concept

ActiveCN107706939BEliminate Control ErrorsReduce wasteSingle network parallel feeding arrangementsSystems intergating technologiesPacket lossMicrogrid

The invention divides a microgrid control structure into a communication system and a physical system based on the concept of an information physical fusion system, and a novel distributed control strategy is proposed on this structure to improve a control effect of voltage and angular frequency by traditional droop control. Firstly, a microgrid communication system model is proposed based on graph theory knowledge, and communication structures of a plurality of single distributed power supplies form an integral communication system; secondly, in the communication system, a method combining areverse neural network and prediction control is proposed to solve the problem of communication time lag; a novel consistency protocol with a virtual navigator is proposed to solve the problem of packet loss; thirdly, in the physical system, P-omega / Q-U droop control is used as primary control of voltage and angular frequency; and finally, voltage and angular frequency data in the communication system and the proposed novel consistency protocol are utilized to complete secondary control of voltage and angular frequency output by droop control in the physical system, and the control strategy has a distributed cooperative characteristic.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com