Slot and level control method of sintering mixture

A technology for sintering mixture and material level control, applied in liquid level control, electrical program control, non-electric variable control and other directions, can solve problems such as set value change, material break or stacking, harsh environment, etc., and achieve elimination control. error, reducing control fluctuation, and lengthening the effect of filter period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

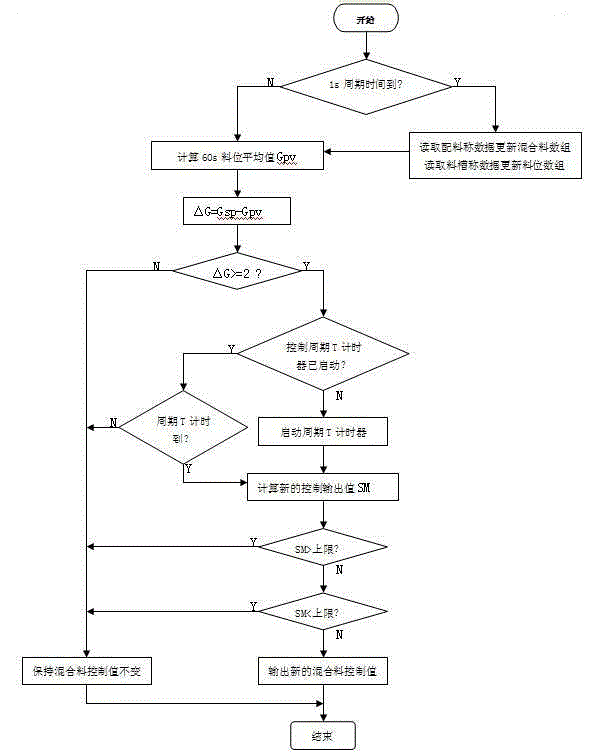

[0021] A method for controlling the material level of a sintering mixture trough, comprising the following process steps: 1. Establishing a trough weight array, and continuously recording the weight of the trough within a period of time in seconds; 2. Establishing a mixture weight array, recording The weight of the mixture from the batching room to the mixing tank, the weight of the mixture is recorded and updated every second, and as the mixture advances in the batching process, the data moves forward in the array; 3. Calculate the incoming material of the mixture The weight of the trough in the previous period, calculate the data of the last multiple elements of the array and the weight of the mixture that will enter the trough during this time period; 4. Calculate the weight of the discharge of the mixture trough in the same period It cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com