Hydraulic control system and method for passive type four-corner-leveling hydraulic press

A hydraulic control system and four-corner leveling technology, used in presses, manufacturing tools, etc., can solve problems such as affecting production, affecting the parallel accuracy and error of the pressing process, reducing cleanliness requirements, wide application range, and improving reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

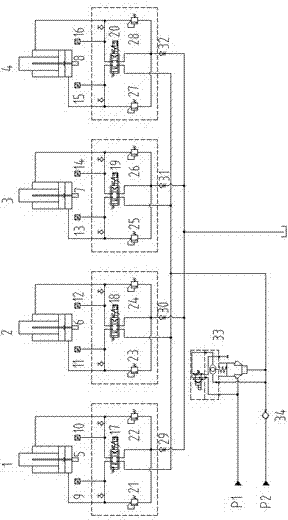

[0030] Specific embodiments are given below in conjunction with the accompanying drawings to further illustrate how the hydraulic control system and control method of the passive four-corner leveling hydraulic machine of the present invention are realized.

[0031] Such as figure 1 As shown, the hydraulic control system of the passive four-corner leveling hydraulic machine includes the first piston hydraulic cylinder 1, the second piston hydraulic cylinder 2, the third piston hydraulic cylinder 3, the fourth piston hydraulic cylinder 4, the first displacement sensor 5, the second displacement Sensor 6, third displacement sensor 7, fourth displacement sensor 8, first pressure sensor 9, second pressure sensor 10, third pressure sensor 11, fourth pressure sensor 12, fifth pressure sensor 13, sixth pressure sensor 14 , the seventh pressure sensor 15, the eighth pressure sensor 16, the first high-response proportional servo valve 17, the second high-response proportional servo valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com