Beside-roadway escribing pressure relief method of roadway driving along gob of small coal pillar influenced by dynamic pressure

A technology for side-cutting, top-cutting and pressure relief of gob-side roadway is applied in the field of roadway surrounding rock deformation and support difficulty, which can solve the problems of reducing the cost and difficulty of gob-side roadway support, and reduce the amount of slewing and subsidence. Movement time, elimination of intrinsic adverse effects, elimination of stress concentration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

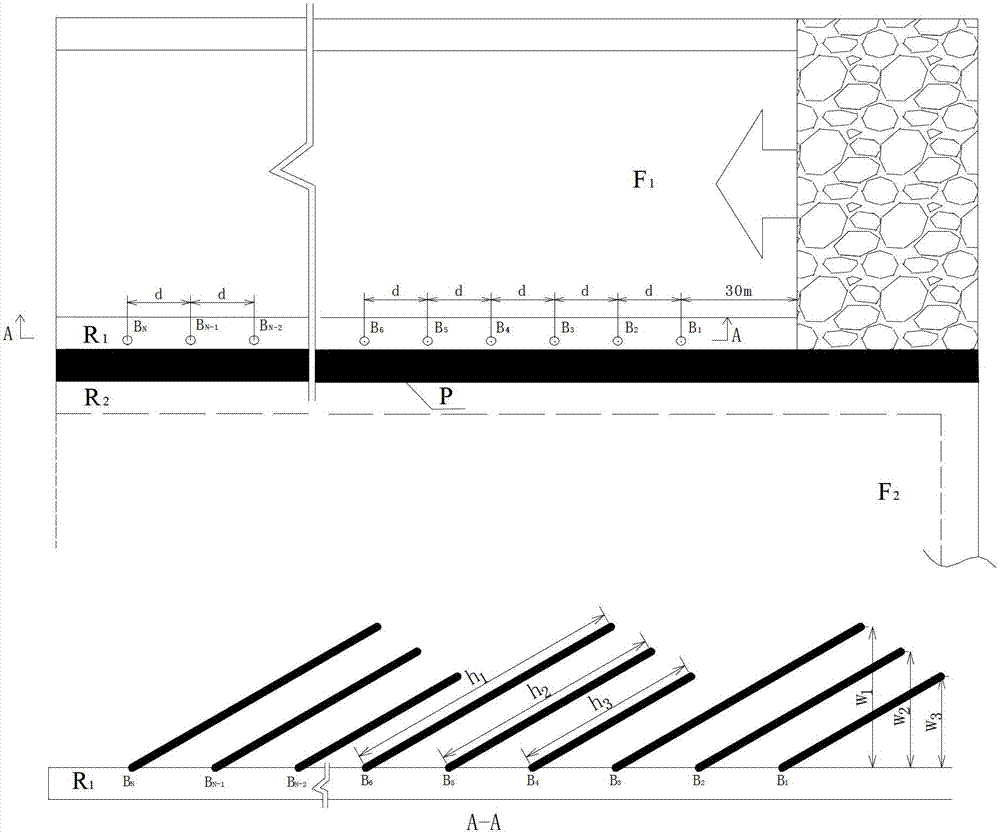

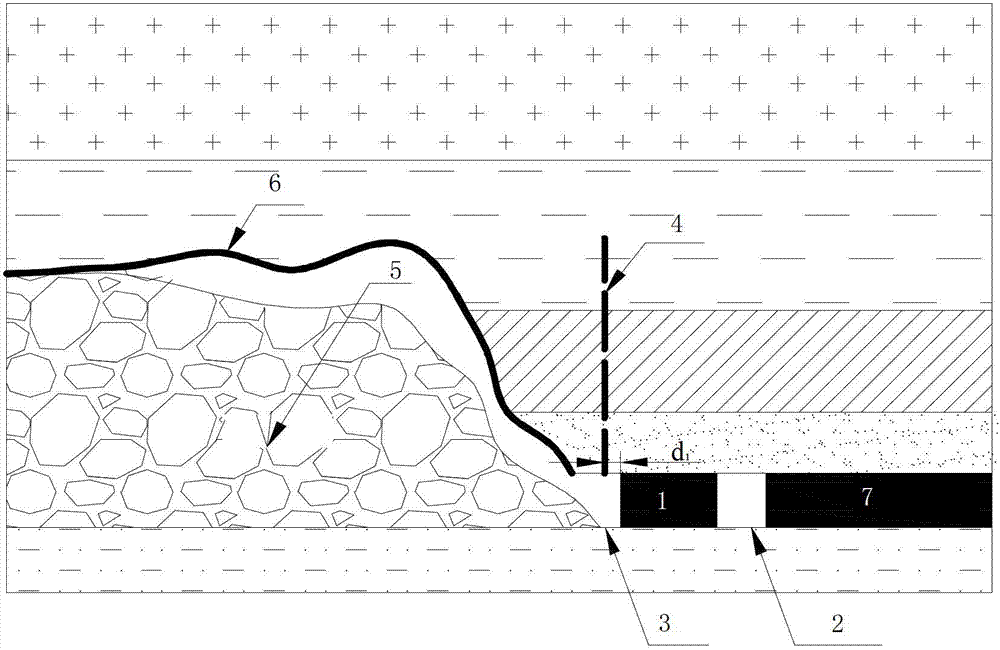

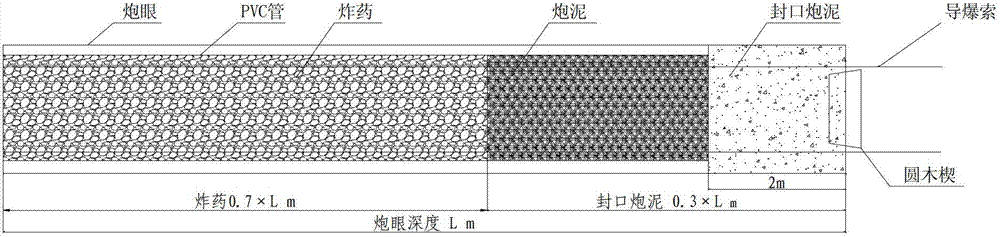

[0032] combine Figure 1 to Figure 5 , the method of roof cutting and pressure relief for small coal pillars along the gob-side entry roadway affected by dynamic pressure, including the following steps:

[0033] 1. Select the roofing method, construction time and location of the roadside roofing

[0034] Such as figure 1 As shown in Fig. 1, the roof is forced to be cut by blasting deep holes in the roof along the groove of the full-length side working face. The construction site is chosen to be along the groove R of the adjacent side working face 1 Inside, segmental blasting and roof cutting operations are implemented during the mining process of the working face.

[0035] 2. Determine the position and depth of the blast hole beside the roadway for roof cutting and pressure relief

[0036] The position of the blasthole for roof cutting and pressure relief beside the roadway should be selected on the side working face along the trough roof and close to the side of the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com