Patents

Literature

57results about How to "Reduce the difficulty of support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

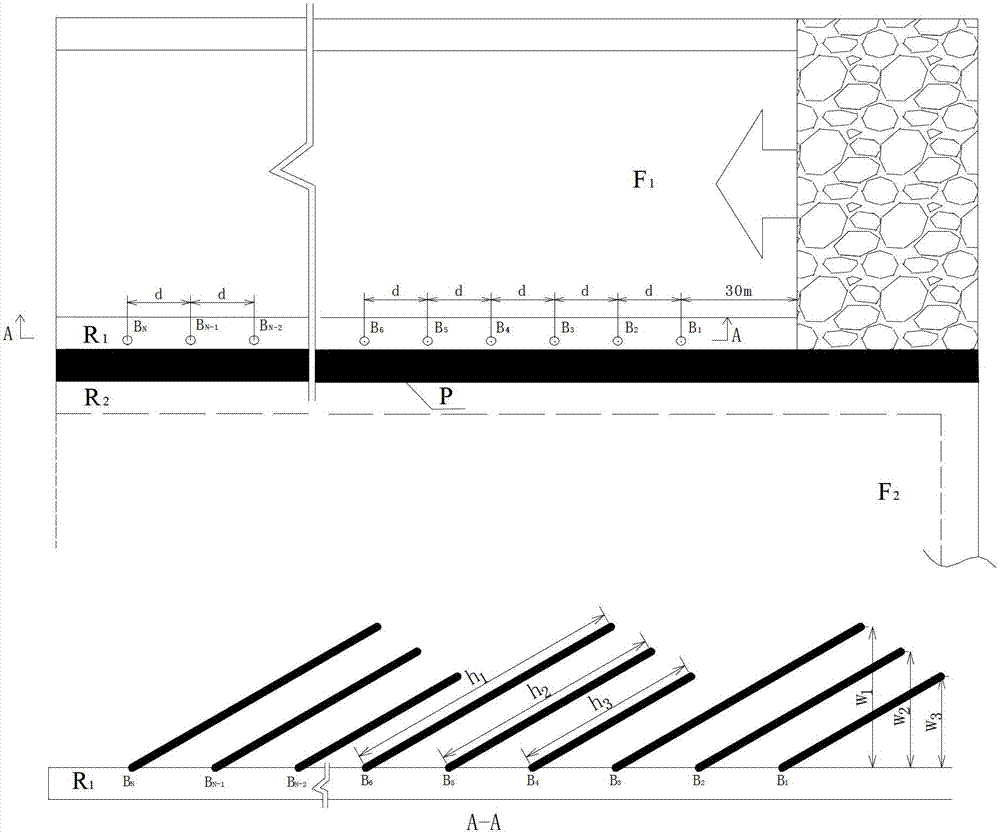

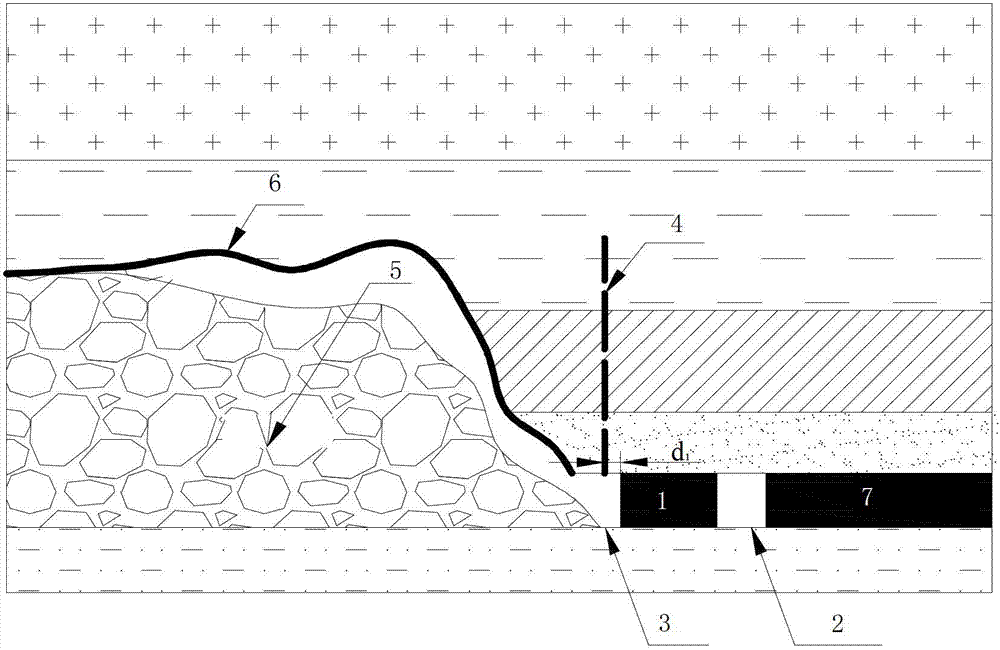

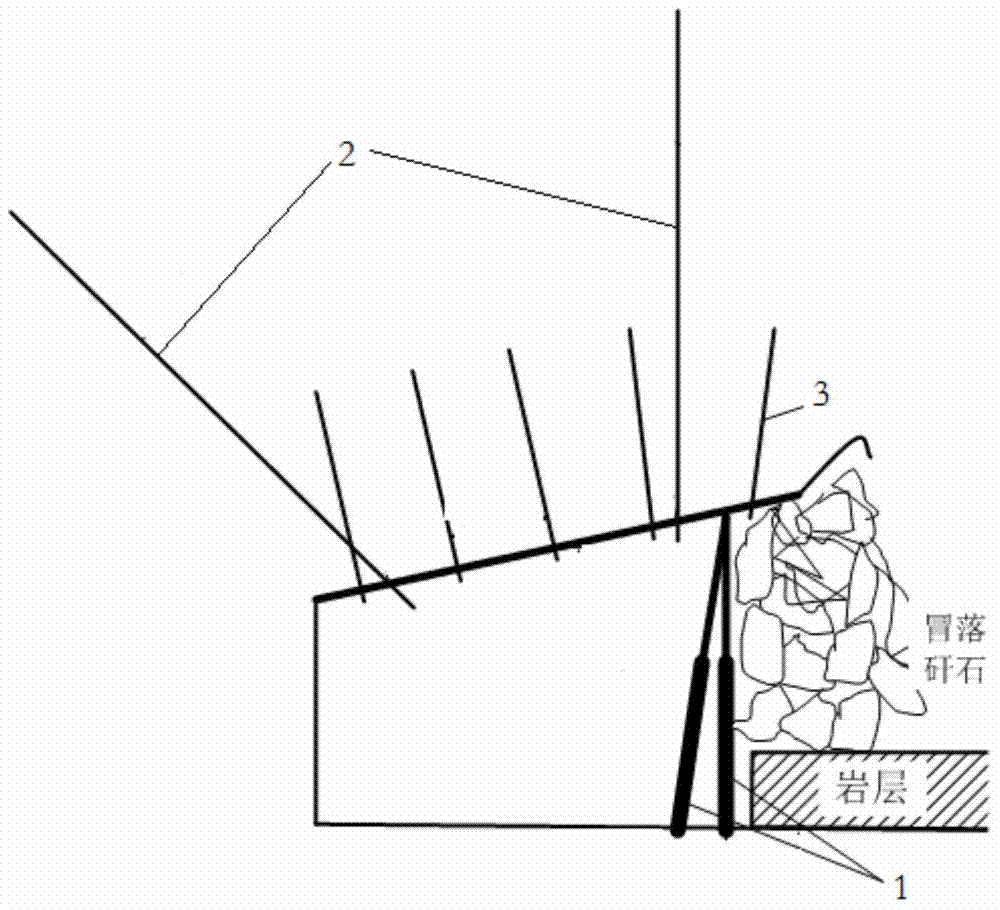

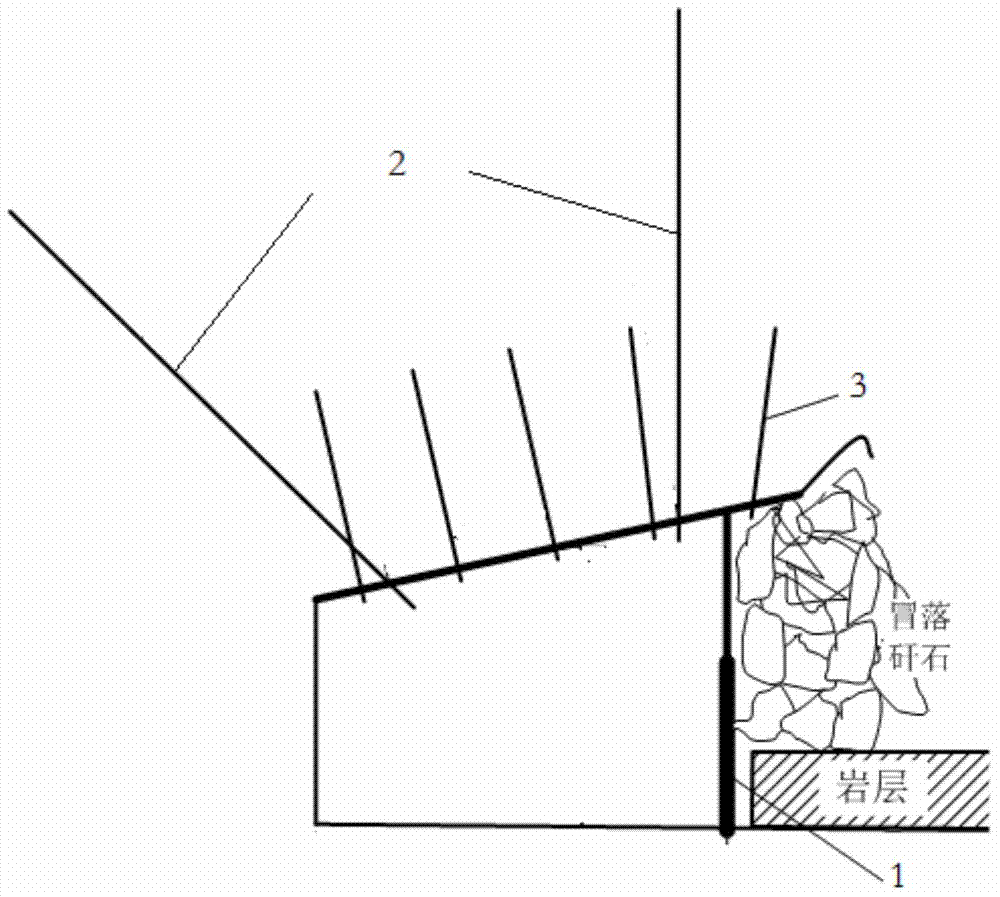

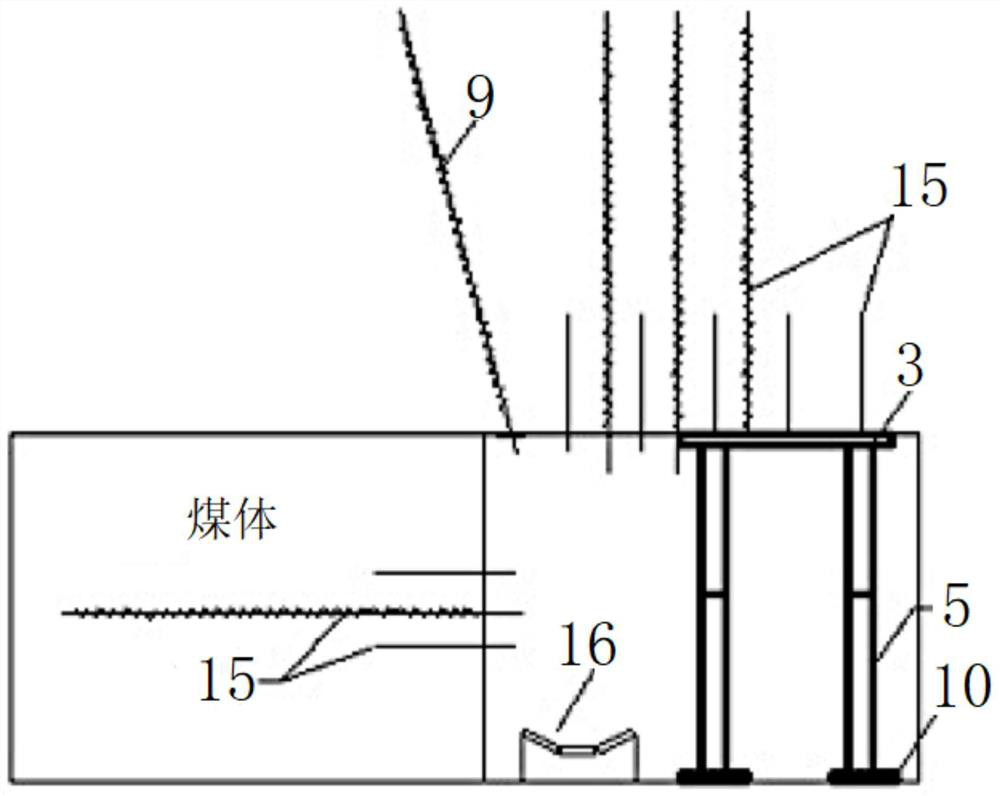

Beside-roadway escribing pressure relief method of roadway driving along gob of small coal pillar influenced by dynamic pressure

InactiveCN102778182AShorten exercise timeEliminate mining dynamic pressureBlastingEngineeringCoal pillar

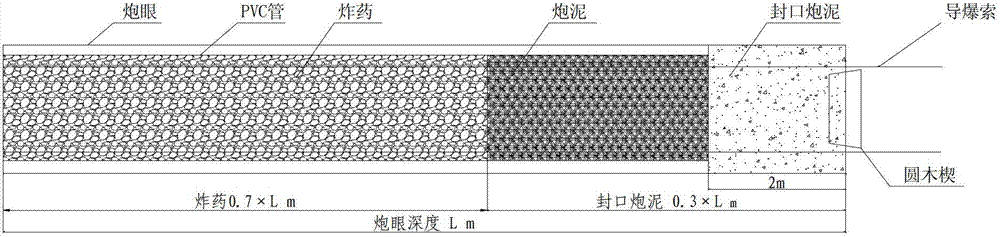

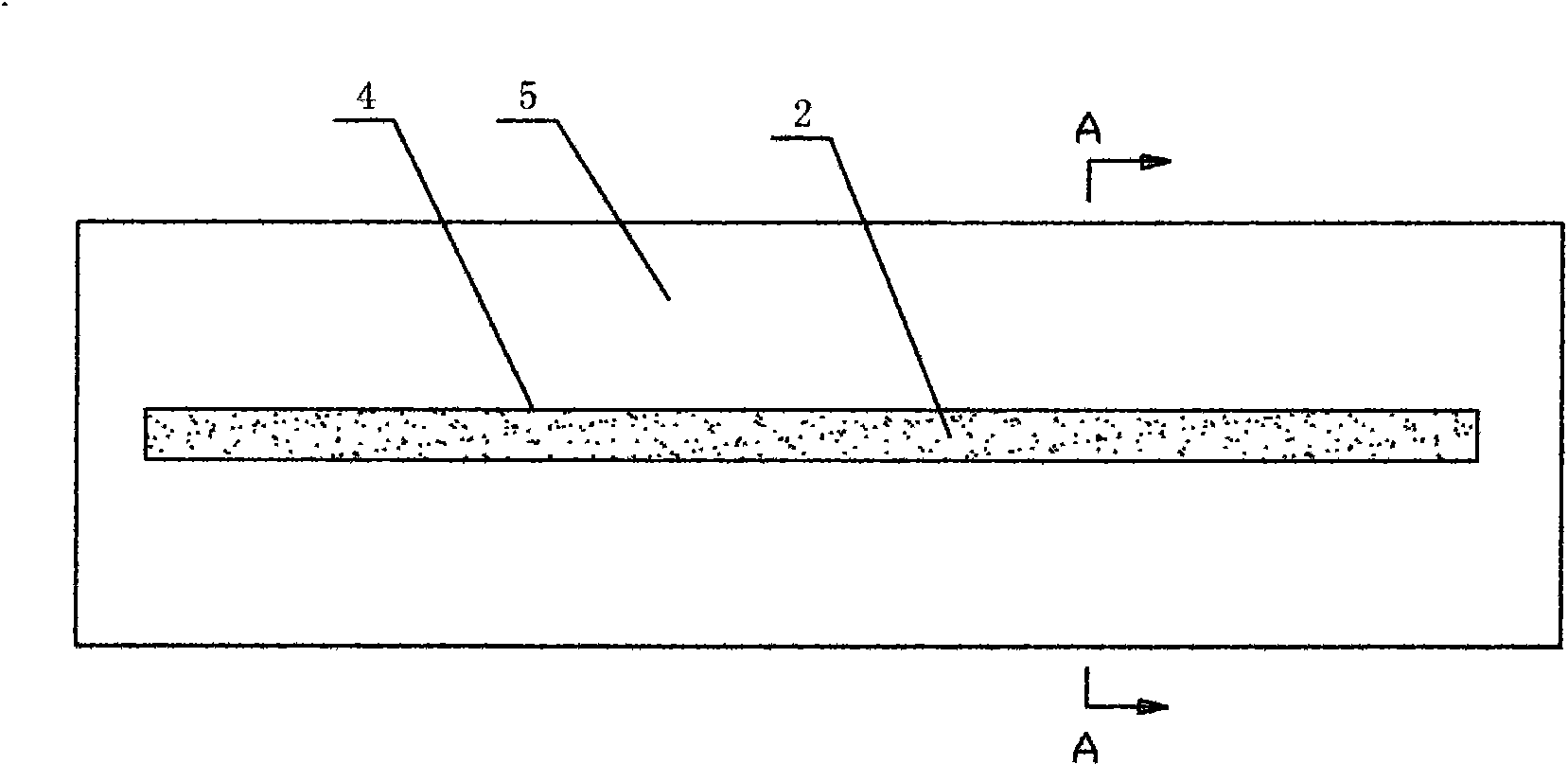

The invention discloses a beside-roadway escribing pressure relief method of roadway driving along a gob of a small coal pillar influenced by dynamic pressure. The method includes the following steps: adopting roadway roof deep hole blasting as the escribing method, arranging escribing shot holes within the overall length range of an adjacent working surface crossheading of the roadway driving along the gob, and implementing stage blasting operation during back production of the working surface, wherein the escribing shot holes need to be close to the small coal pillar as far as possible, the depth of the escribing shot holes is determined according to the mining height of the back production working surface and the free caving height of the roof of the working surface, the shot holes need to be arranged with a distance away from the working surface, and the distance among the shot holes need to be determined reasonably; then performing explosive filling and hole blocking; performing ahead blasting operation in front of the working surface or lag blasting operation after the shot holes enter a gob area; and instantly performing roadway driving along the gob when the bad influence on the essence of the roadway driving along the gob of the small coal pillar caused by dynamic pressure of the working surface can be basically eliminated when back production of the adjacent working surface is finished. By means of the beside-roadway escribing pressure relief method, normal production of a back production working surface is ensured, and the cost and difficulty in roadway support along the gob are greatly reduced.

Owner:SHANDONG UNIV OF SCI & TECH

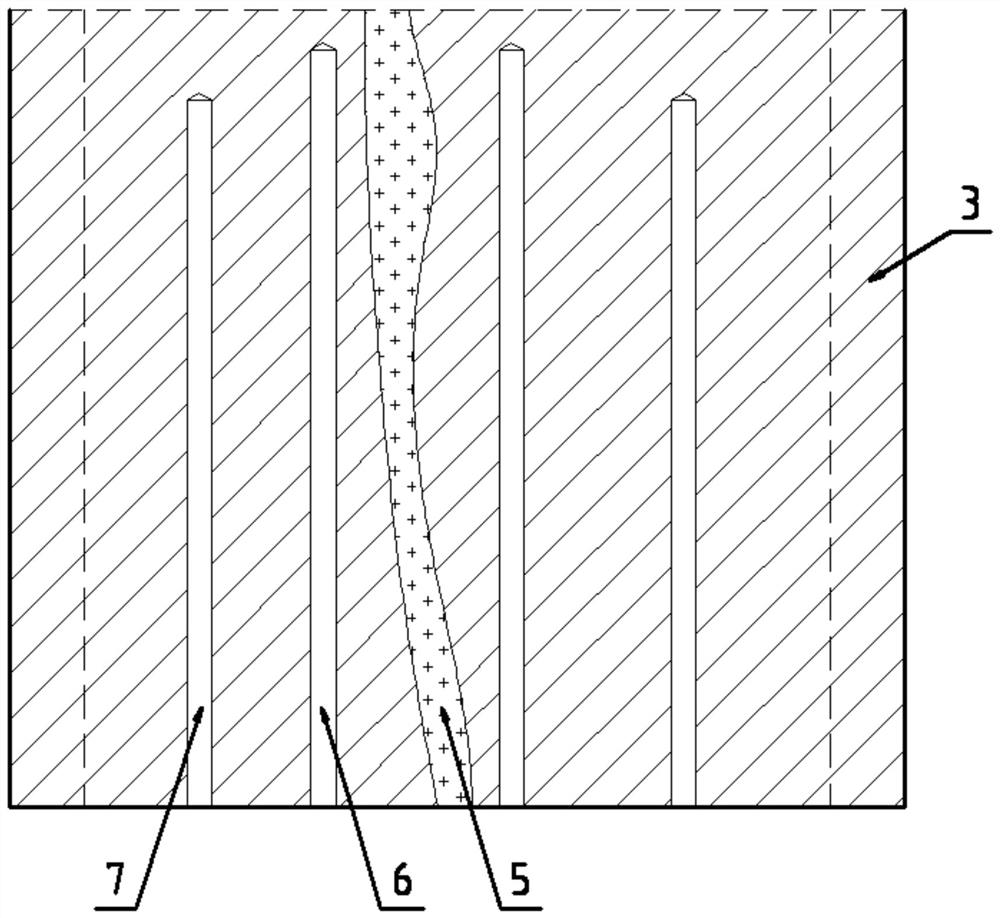

Directional rock blasting crack propagation method and device

The invention discloses a directional rock blasting crack propagation method and a directional rock blasting crack propagation device. The directional rock blasting crack propagation device consists of kerf pipes and explosive, wherein each kerf pipe is symmetrically provided with double kerfs along the longitudinal wall. During directional blasting of peripheral blast holes of a roadway or presplit blasting of an open pit slope, the kerf pipes and the explosive are filled in the blast holes to finish directional crack blasting, wherein an included angle of the kerf direction and the presplit blasting outline direction is less than 150 degrees. The energy of the explosive is preferably released along the kerf direction in a centralized way, so that a blasting fracture surface is accurately controlled, the number of blasting cracks in other directions such as a surrounding rock, a slope and the like is greatly reduced, the length for the blasting crack propagation in the direction to be protected is limited, the production efficiency is high, and the construction cost is low; the device has a simple overall structure and is convenient to use, and is particularly suitable for directional controlled blasting of a rock gangway, a tunnel and the slope.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

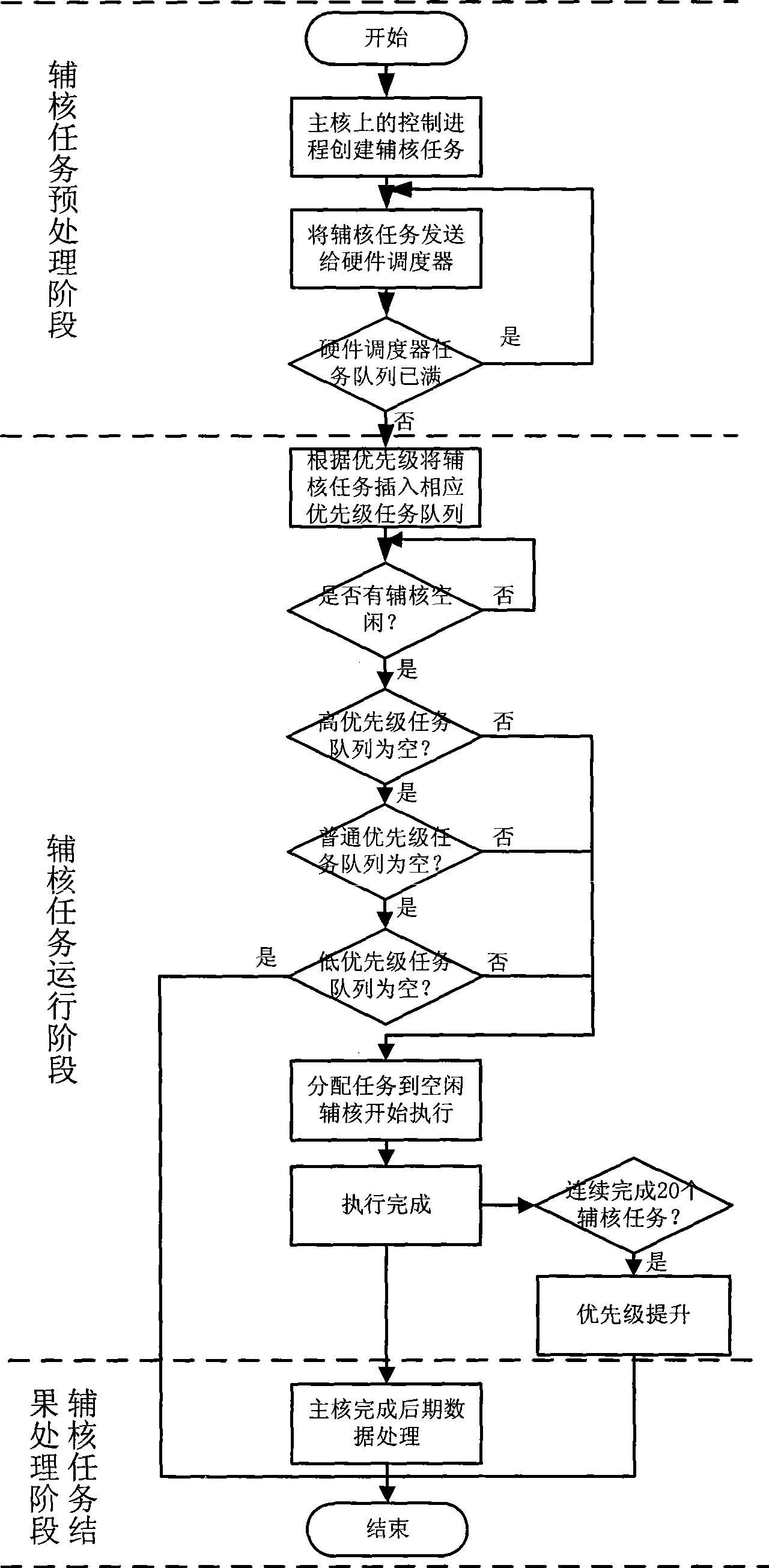

Method for implementing assist nuclear task dynamic PRI scheduling with hardware assistant

InactiveCN101414270AReduce the burden onEliminate performance bottlenecksResource allocationDynamic priority schedulingCore system

The invention discloses an implementation method for hardware-assisted dynamic priority scheduling of slave core tasks. The method comprises the following steps: architectural support is provided for scheduling by an operating system based on a main core plus slave core system so as to assist the operating system scheduler to schedule the slave core tasks, a hardware scheduler maintains hardware queues of three ready tasks, arrived tasks are inserted into the corresponding ready task queues according to a task priority, and the circumstance that the slave core task is starved is avoided by periodic priority promotion. The method effectively reduces the difficult in supporting an embedded heterogeneous multi-core system by a software system through the architectural support, lightens the burden of the main core scheduling and the slave core tasks management, and obviously increases the throughput of the slave core tasks. The method has more obvious effects under the conditions of numerous types and a great number of slave cores and complex scheduling algorithms.

Owner:ZHEJIANG UNIV

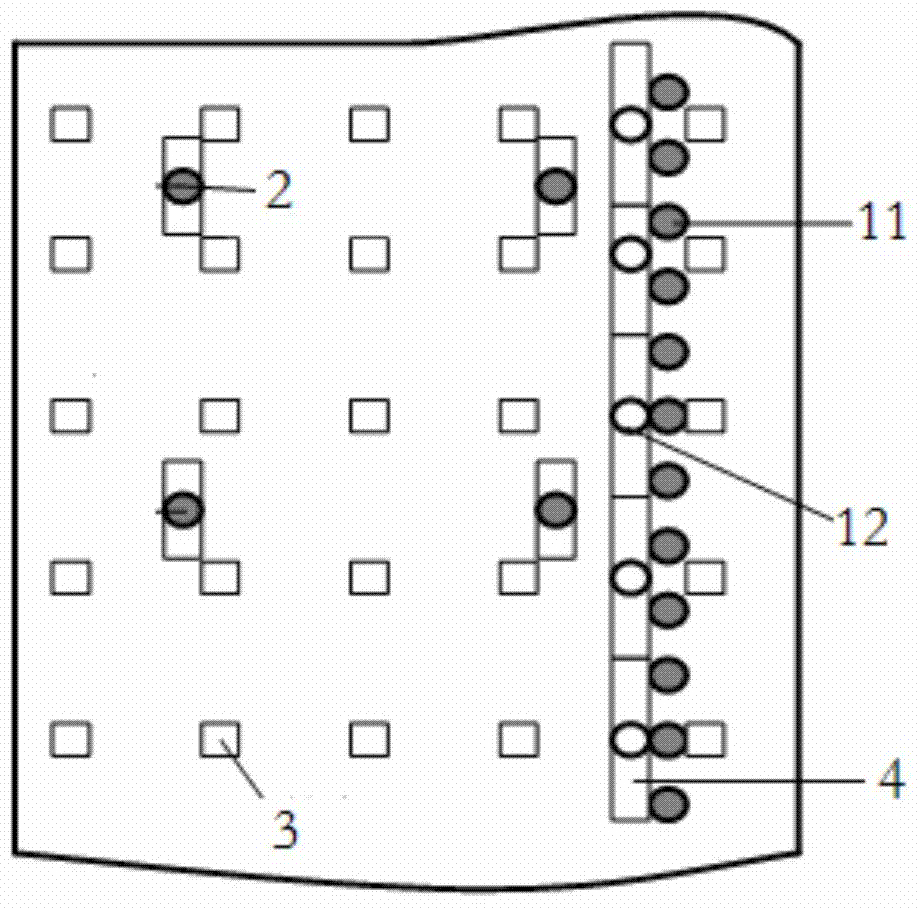

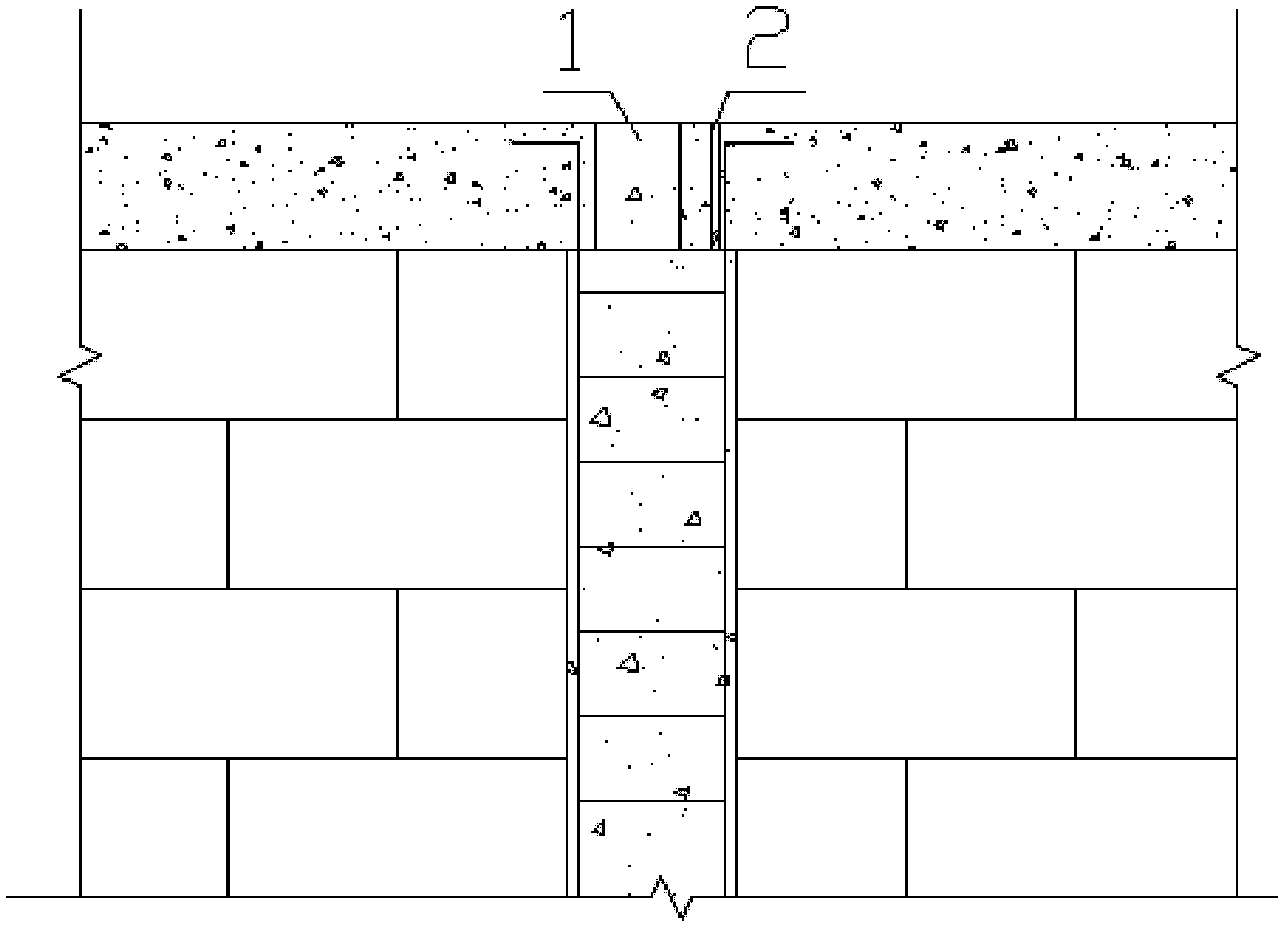

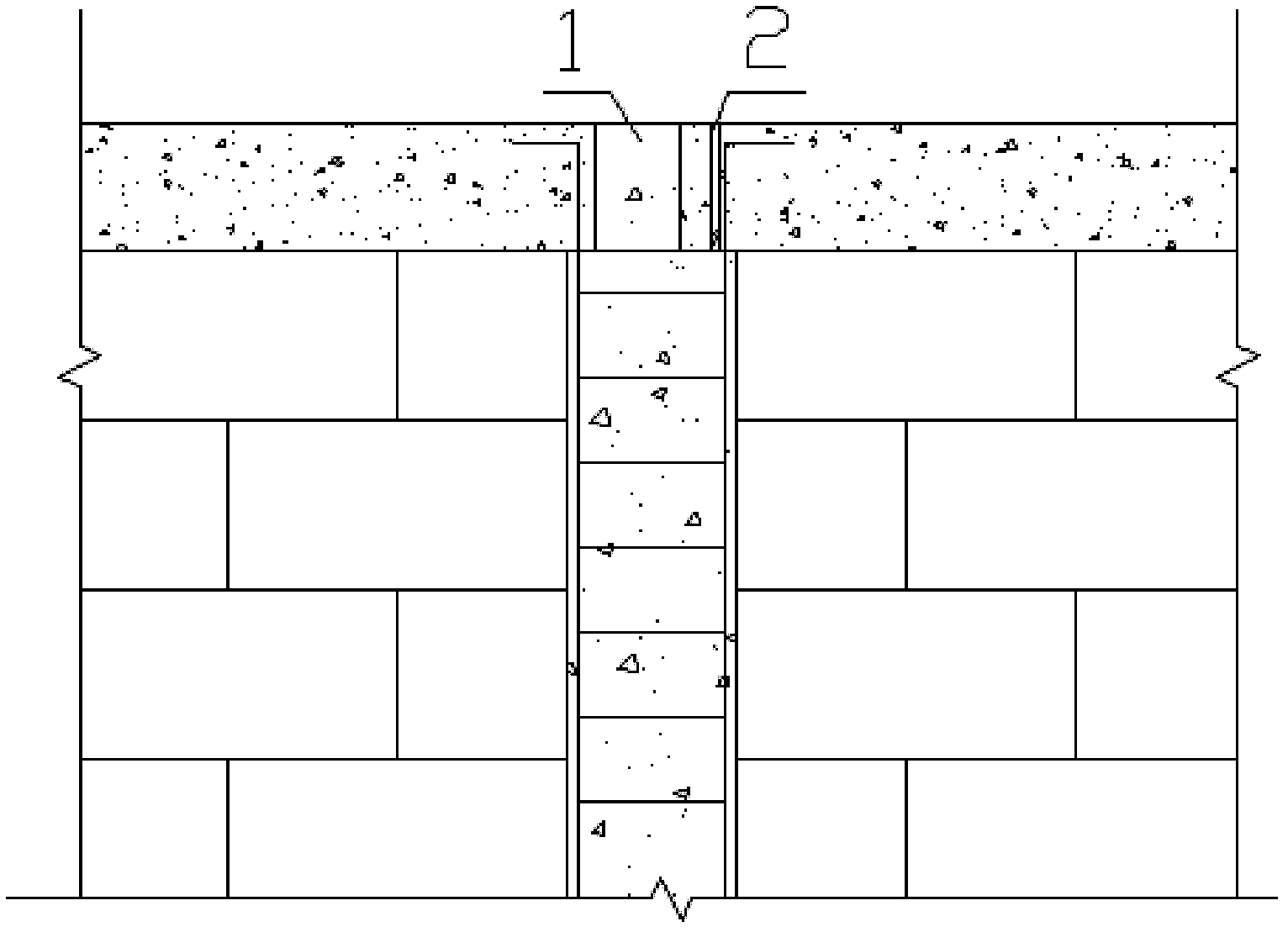

Coal mine gob-side entry retaining side supporting method

InactiveCN103758529AImprove resource recoveryImprove damageUnderground chambersTunnel liningSupporting systemCoal

The invention discloses a coal mine gob-side entry retaining side supporting method. The coal mine gob-side entry retaining side supporting method comprises the following steps of supporting the coal mine gob-side entry retaining side through intensive individual hydraulic supporting columns; constructing anchor cable supports for the gob-side entry retaining top plates based on the original rocker bolt supports, enabling the gob-side entry retaining to adopt double-line rocker bolt supports, enabling the distance between the rocker bolts to be 2 m and the row distance to be 2.2 m and enabling the anchor bolts which are close to one side of the coal wall to be installed along a certain inclination angle and the anchor bolts which are close to one side of a gob to be installed perpendicular to the top plates; constructing a row of single hydraulic supporting columns on the inner side of the intensive single hydraulic supporting columns after the designed pretress of the anchor bolts is achieved and enabling the column distance to be 1.2 to 1.5 m; enabling the insensitive single hydraulic supporting columns to be out successively from back to front and enabling supplement single hydraulic supporting columns and the installed anchor bolts to be formed into a gob-side entry retaining side auxiliary supporting system. The coal mine gob-side entry retaining side supporting method solves the problem that the gob-side entry retaining side supporting is difficult.

Owner:BEIJING HAOHUA ENERGY RESOURCE

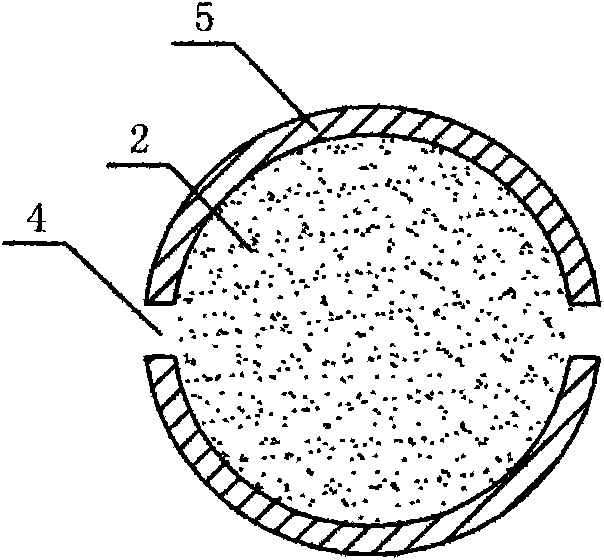

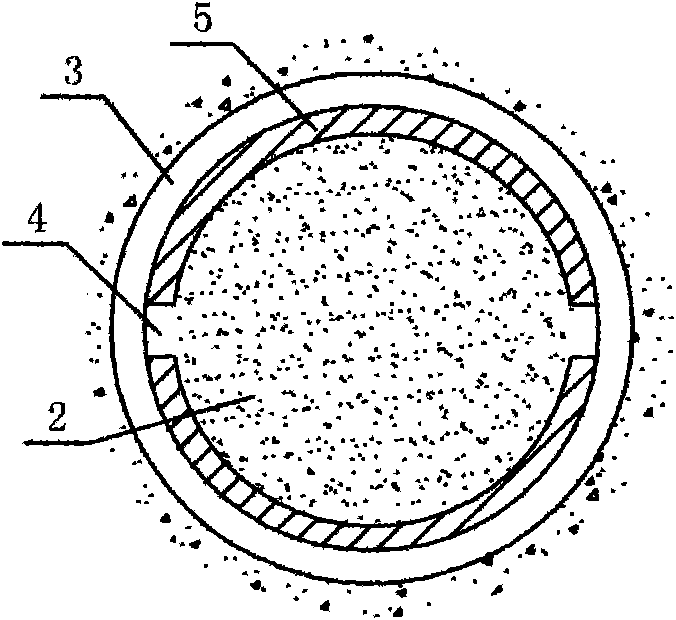

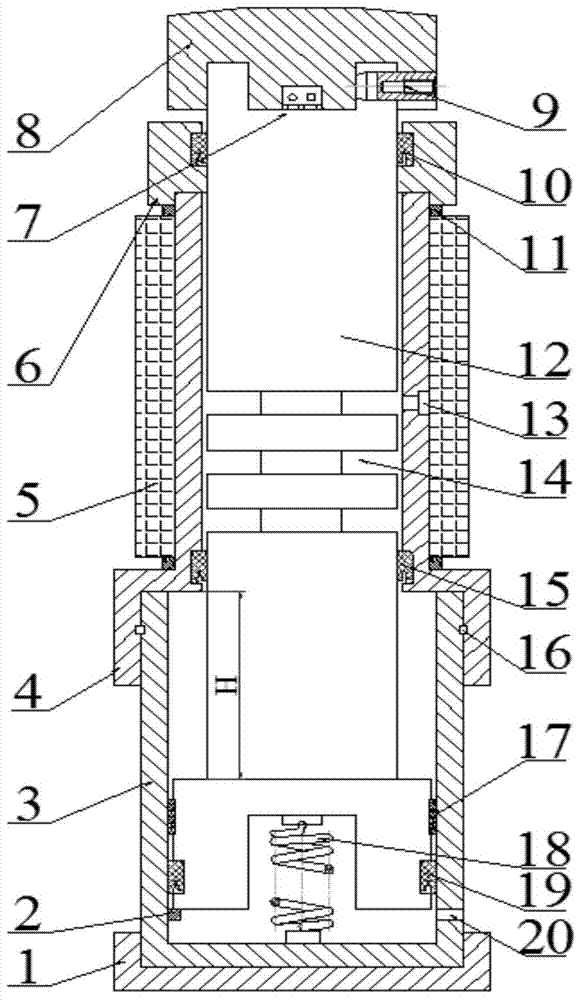

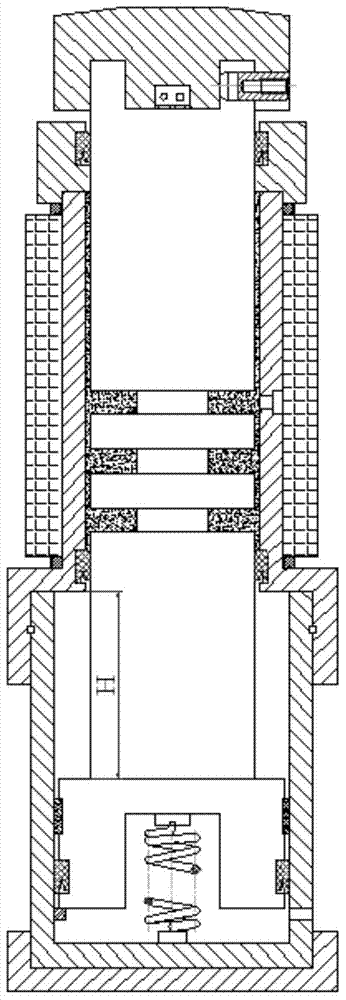

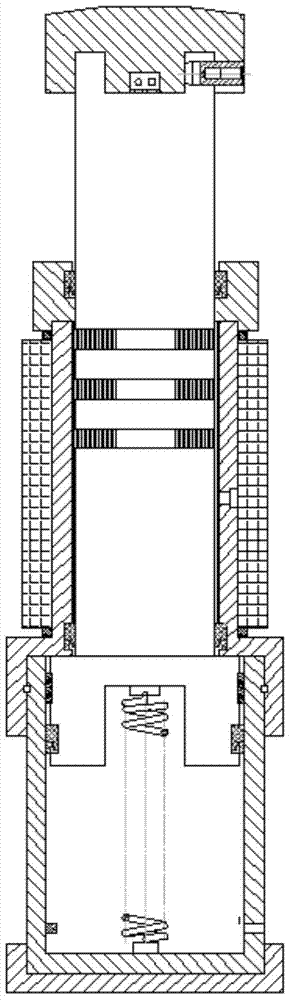

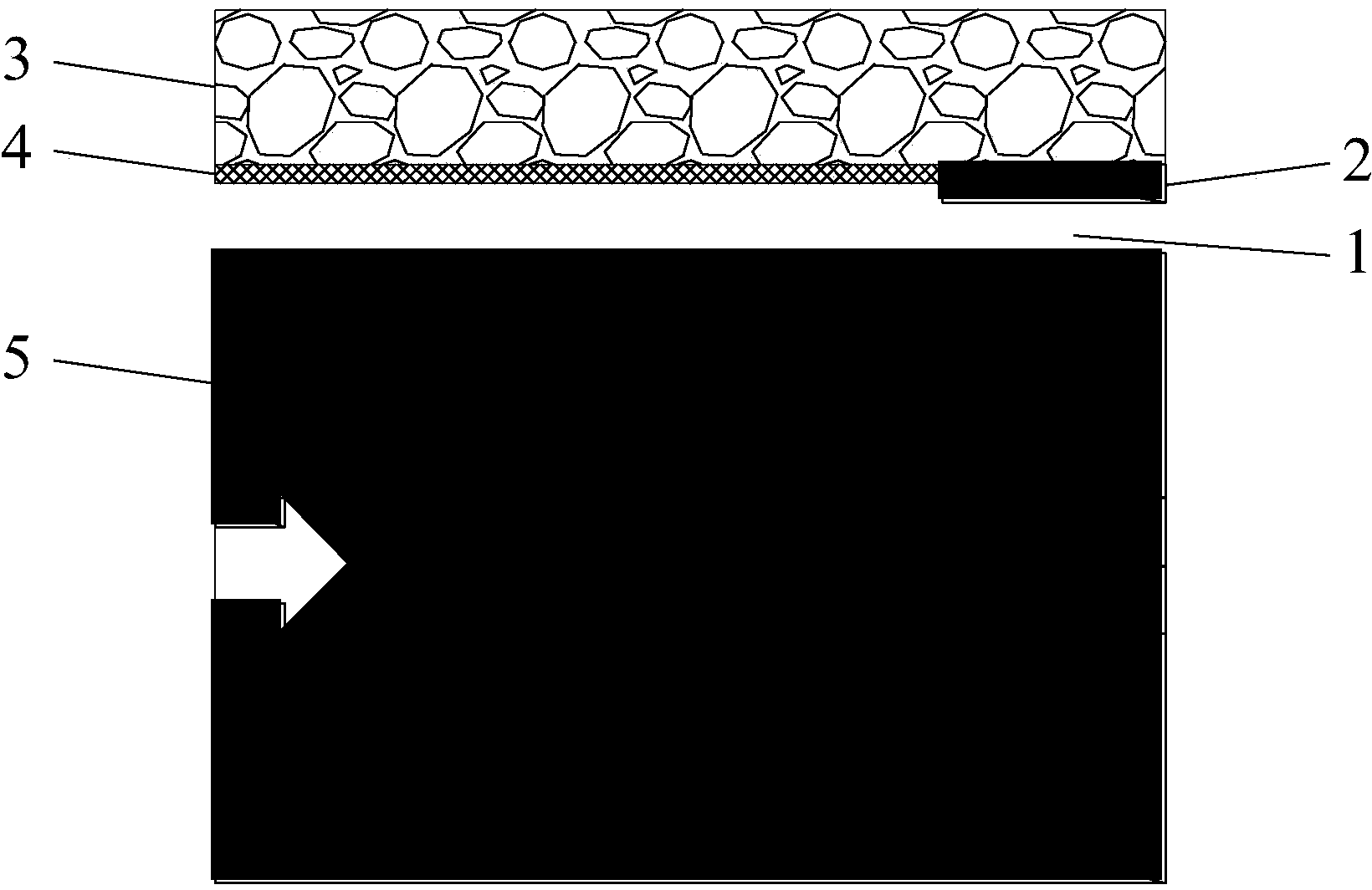

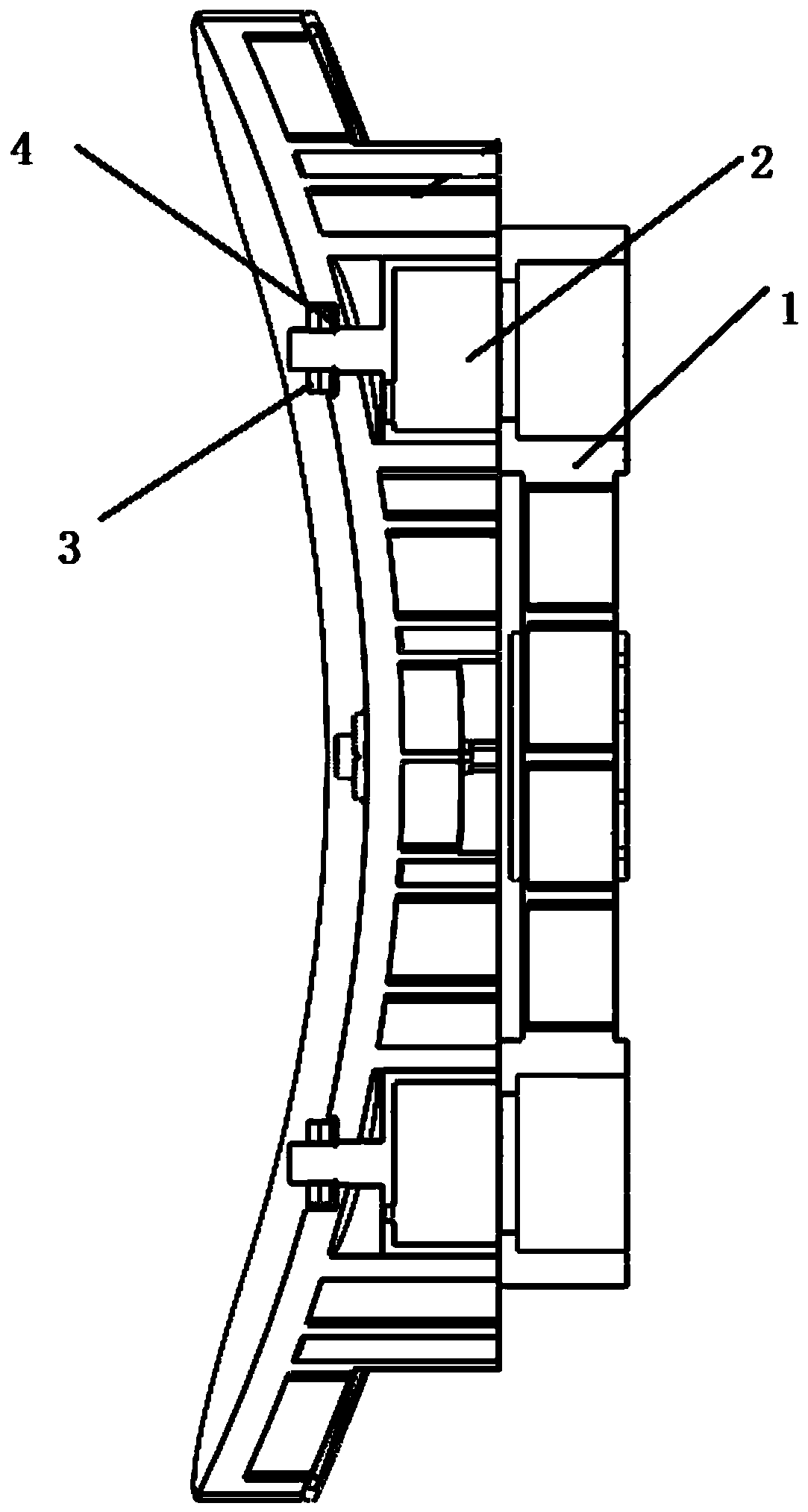

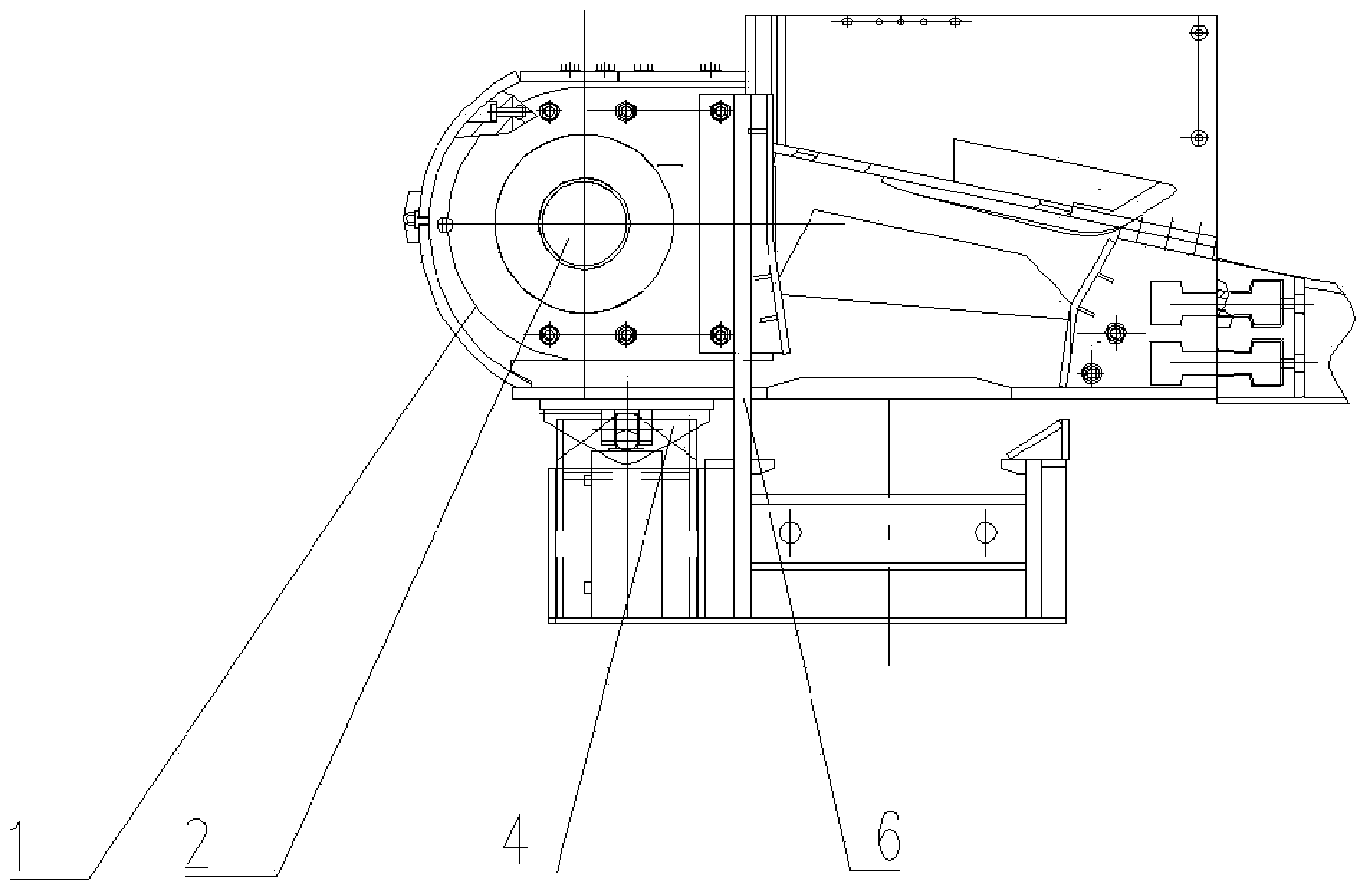

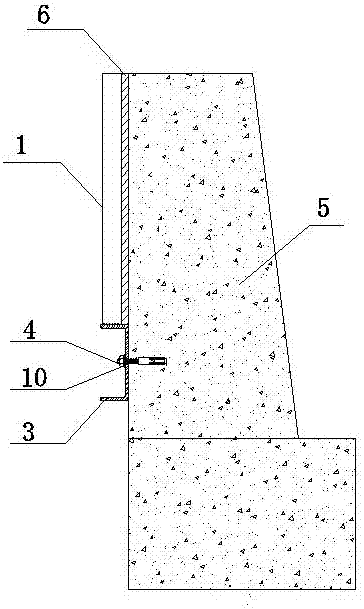

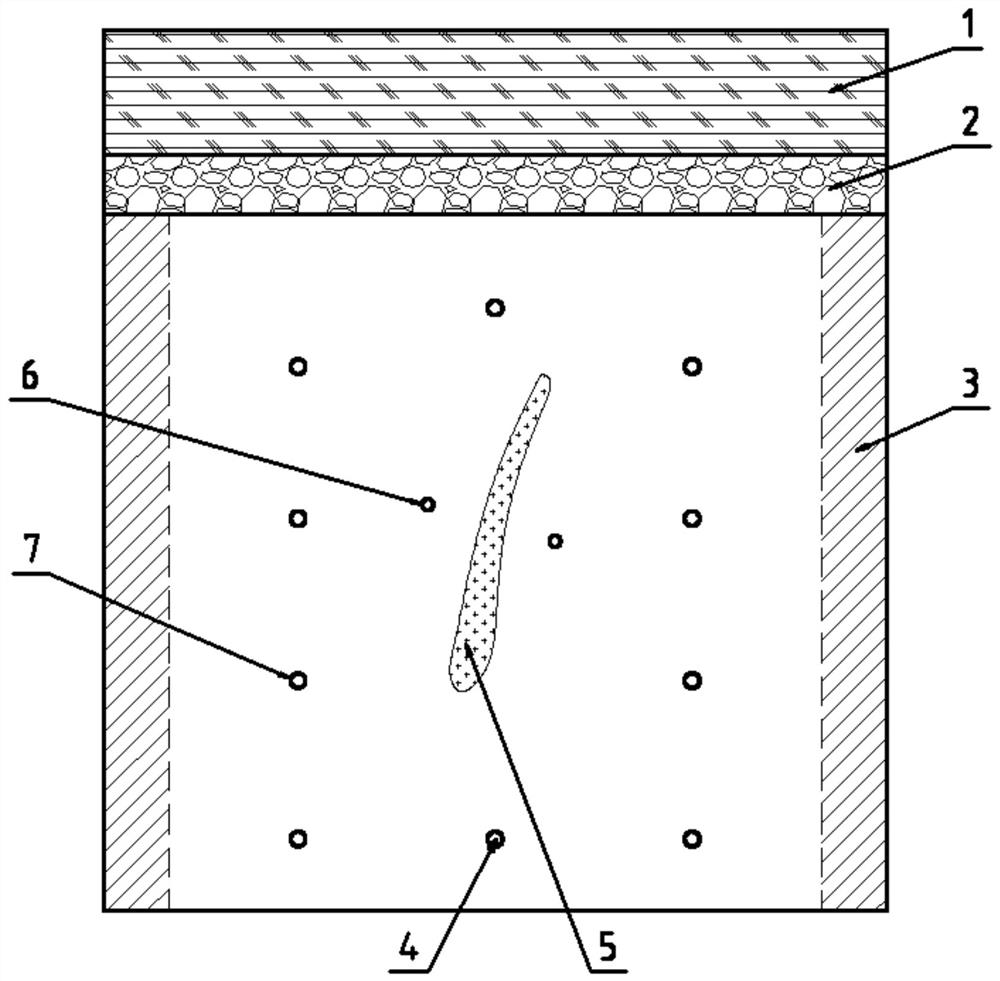

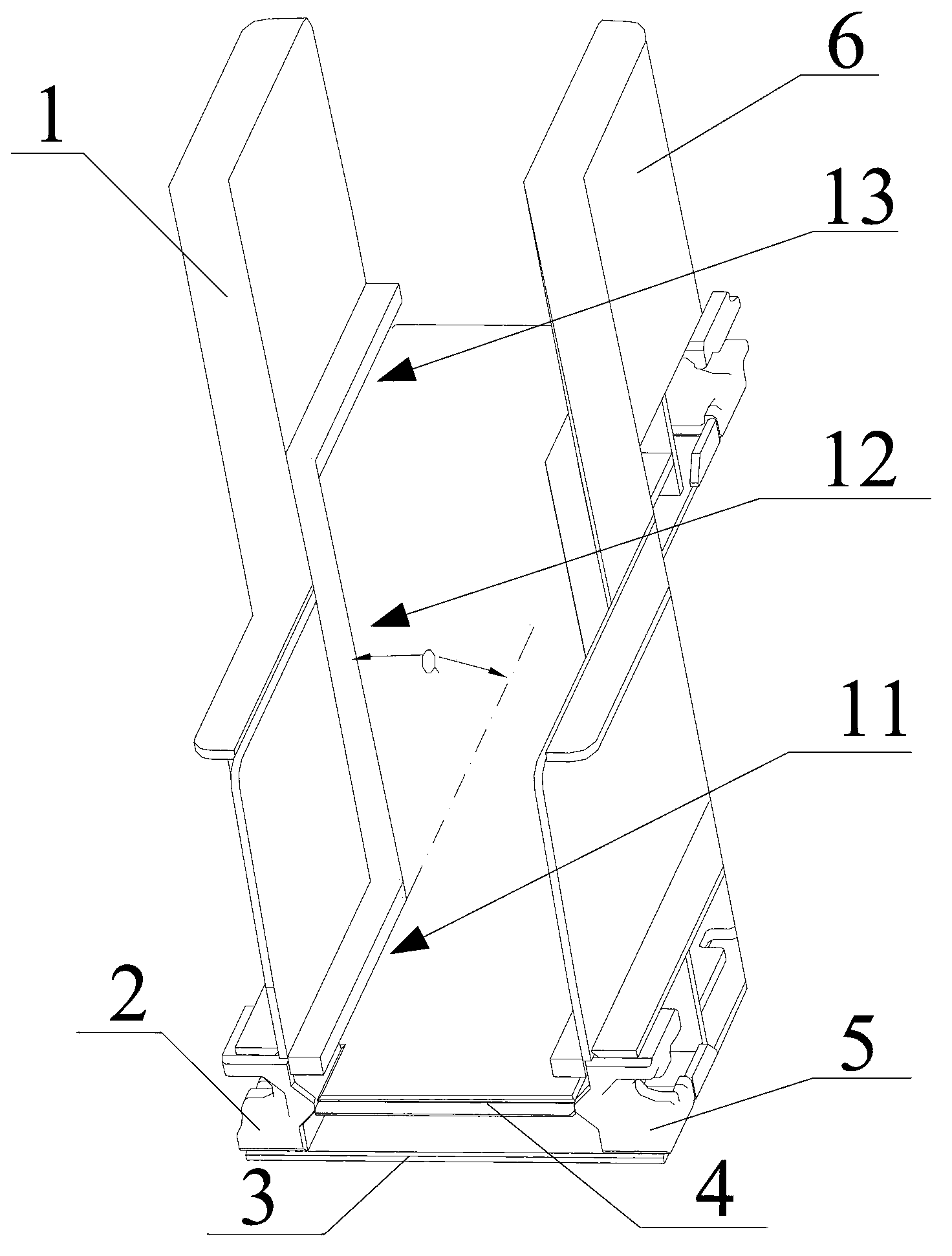

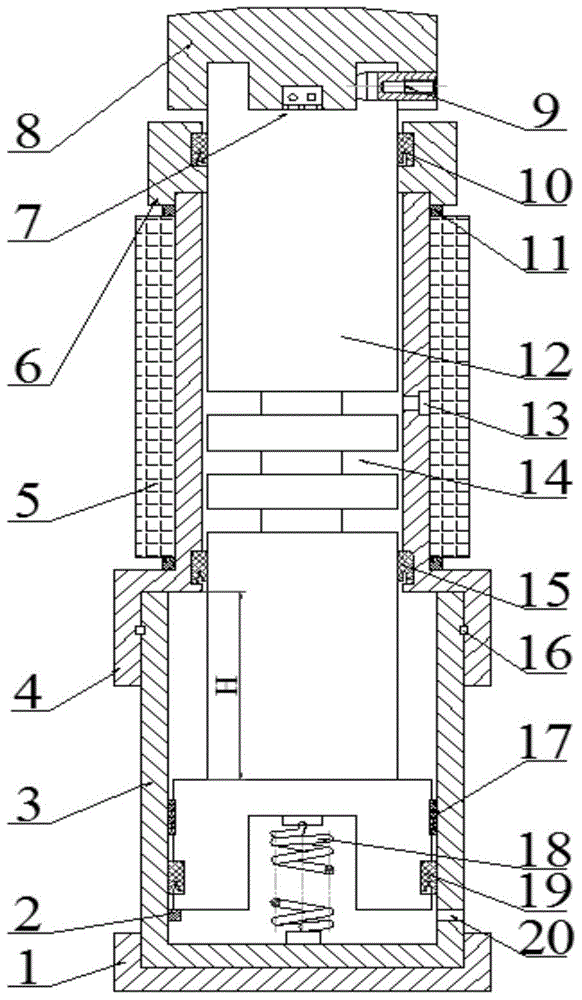

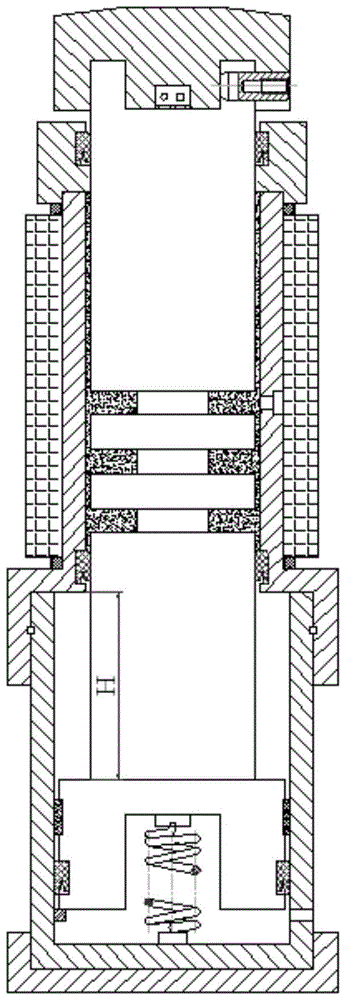

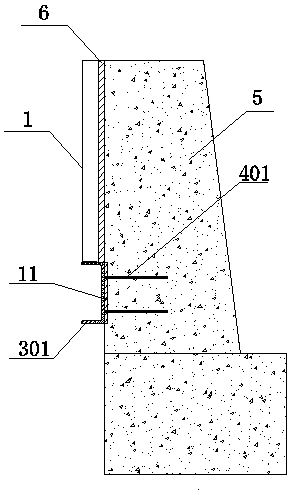

Self-adjustment magnetorheological fluid single prop

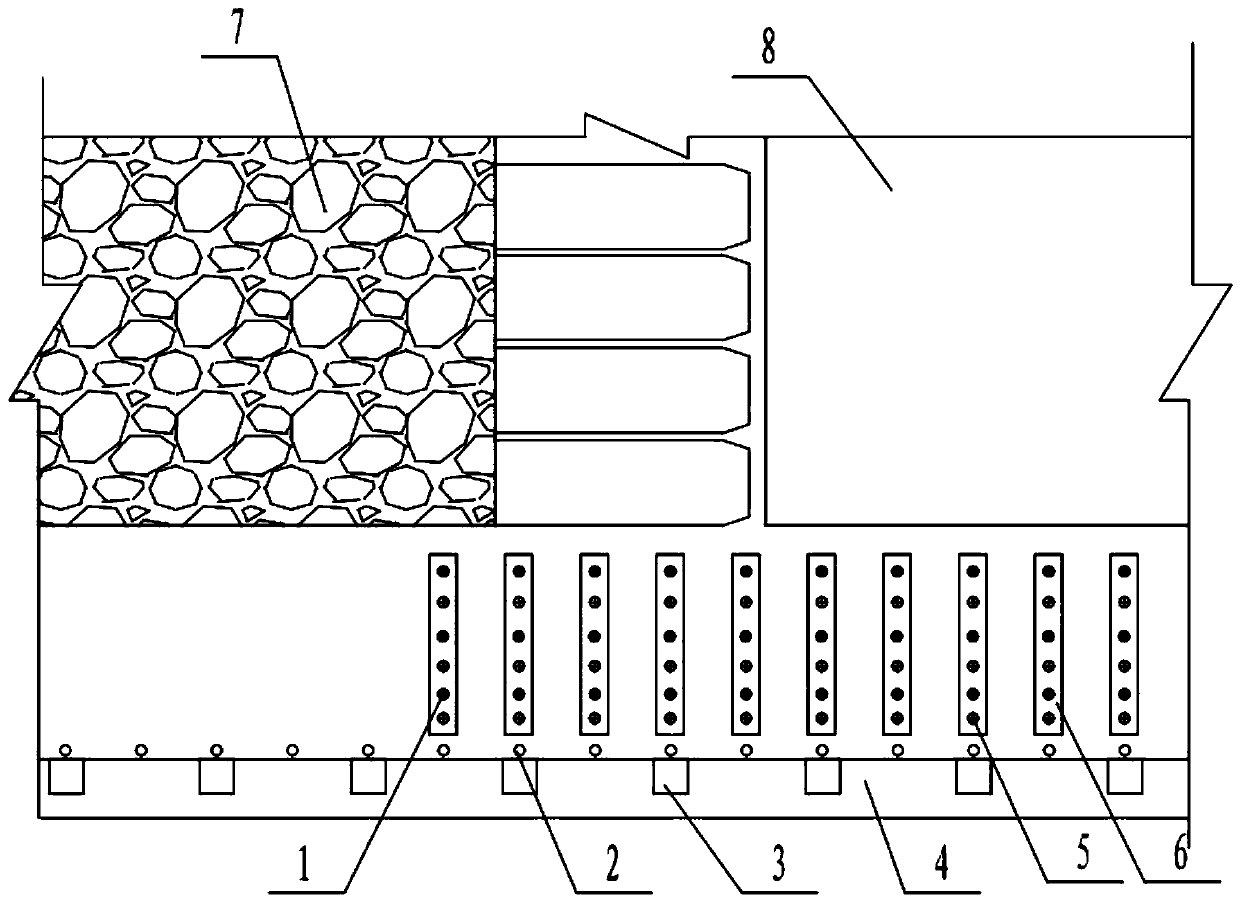

InactiveCN104775835AImprove reliabilityReduce the difficulty of supportProps/chocksSupporting systemHydraulic cylinder

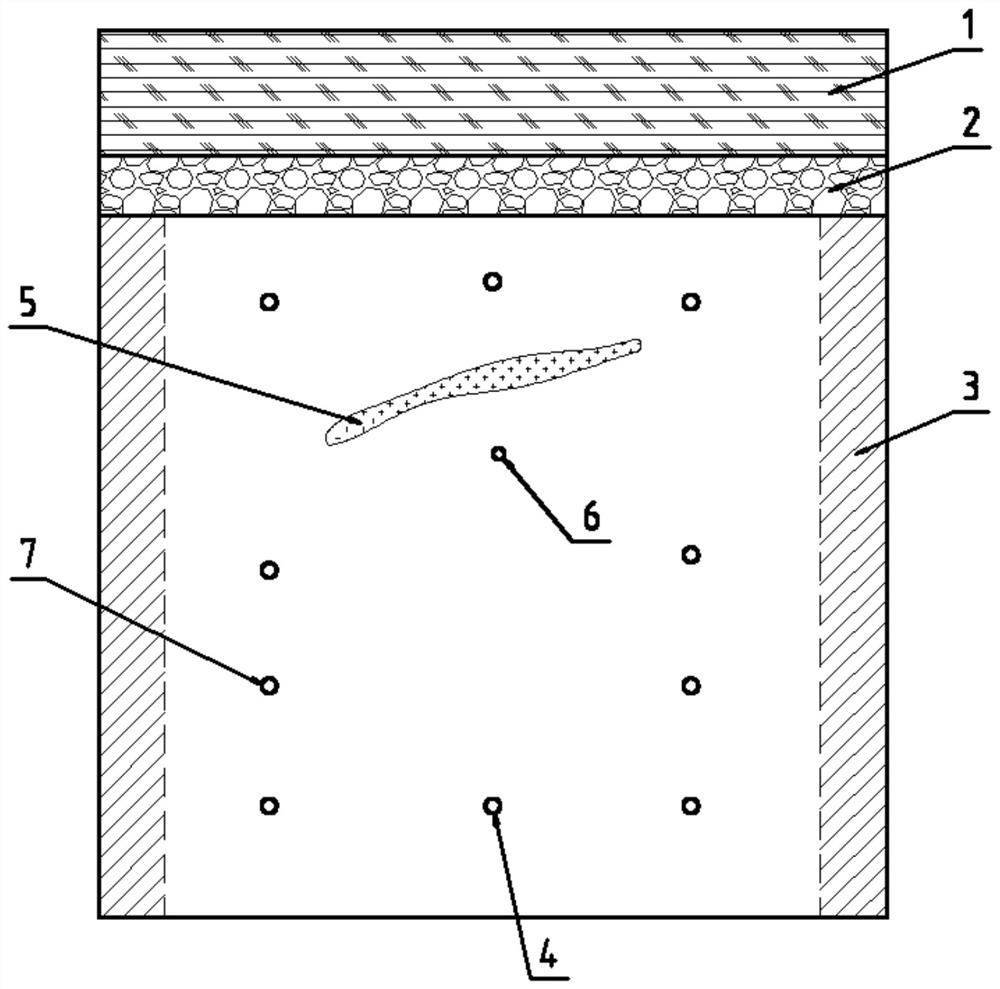

The invention discloses a self-adjustment magnetorheological fluid single prop. The self-adjustment magnetorheological fluid single prop comprises a hydraulic positioning system and a magnetorheological fluid support system, wherein the hydraulic positioning system comprises a base (1), a positioning block (2), a hydraulic cylinder body (3), a piston column (12), a guide ring (17), a return spring (18), a sealing ring III (19) and a bottom hydraulic oil inlet (20); and the magnetorheological fluid support system comprises a magnetorheological cylinder body (4), a coil (5), an end cover (6), a pressure sensor (7), a support block (8), a cylinder pin (9), a sealing ring I (10), a separation magnetic ring (11), a piston column (12), an upper magnetorheological fluid injecting port (13), a magnetorheological fluid (14), a sealing ring II (15) and a connecting steel wire (16). The self-adjustment magnetorheological fluid single prop needs no pump station to provide great support, has no need to mount a valve base of a three-purpose valve, is lower in processing requirements on sealing pieces and inner surfaces of mobile columns, and can preferably and automatically adjust the support strength when support loads are suddenly changed.

Owner:CHINA UNIV OF MINING & TECH

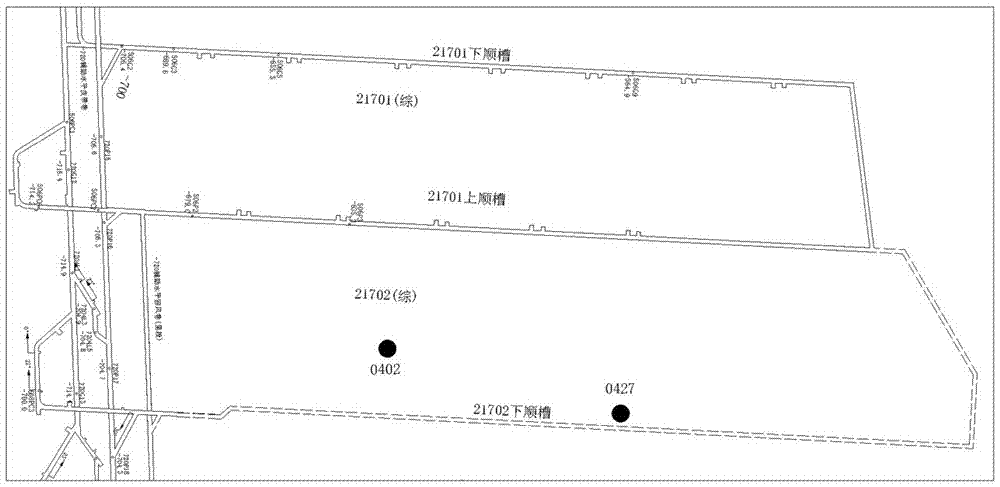

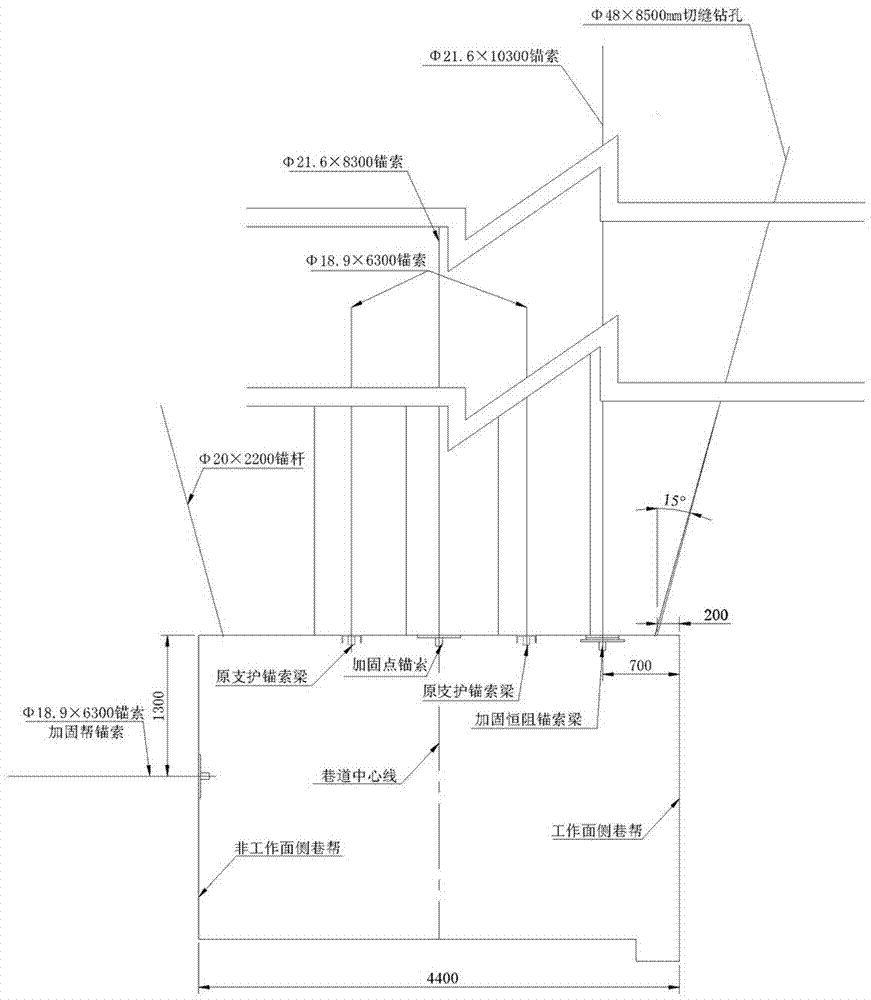

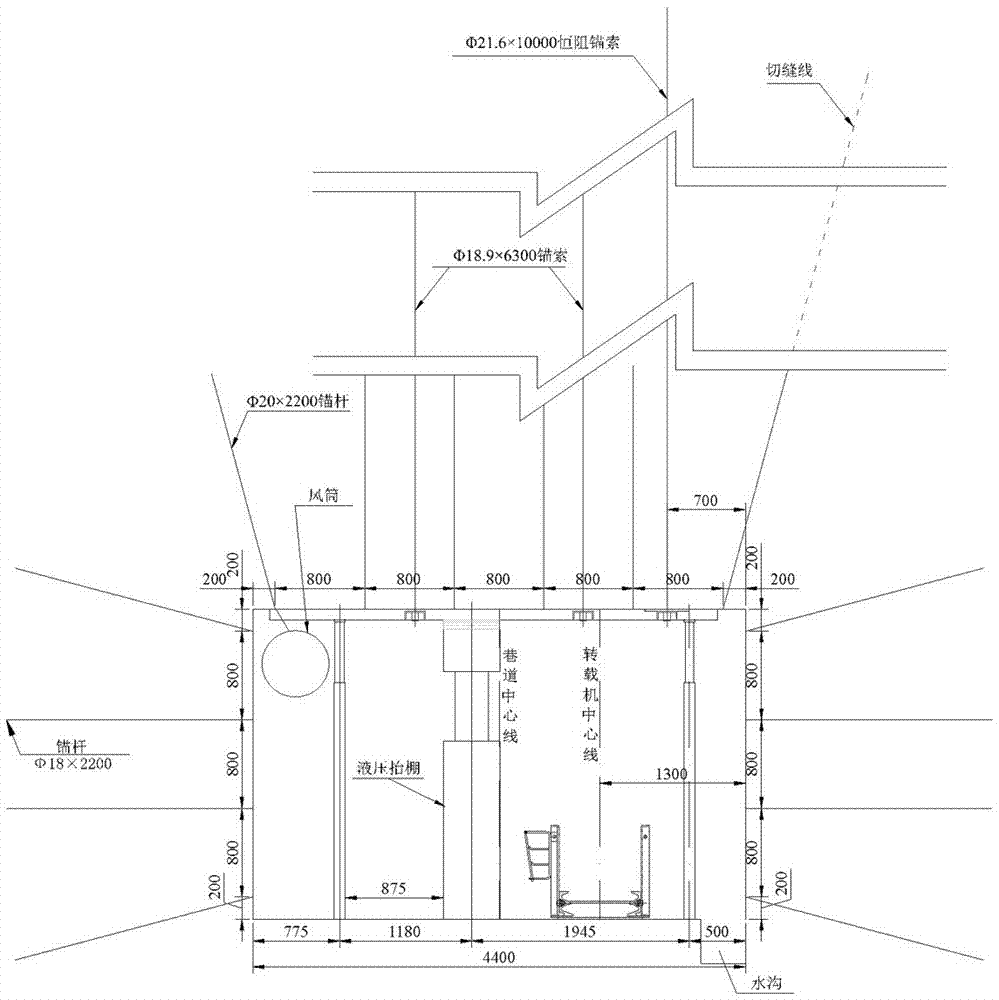

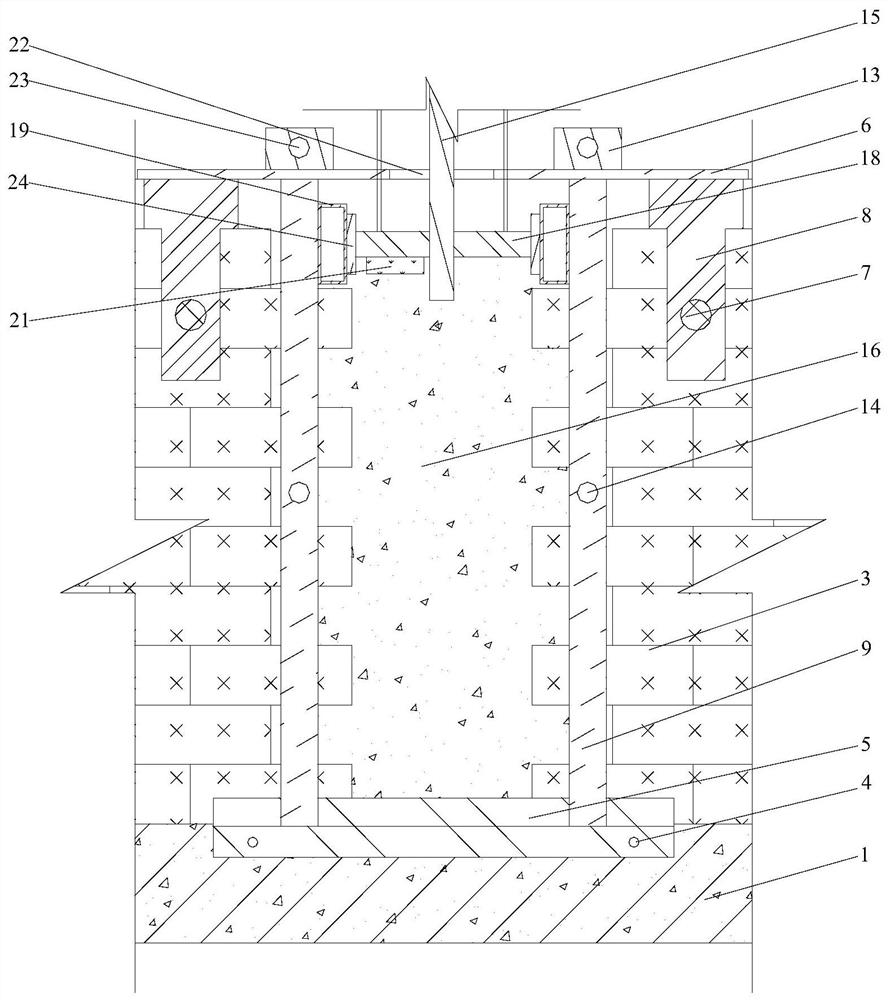

Gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method

ActiveCN107191208AImprove resource recoveryHigh recovery rateMine roof supportsMine roof capsResource recoveryStructural engineering

The invention relates to a gob-side-entry-retaining supporting method, in particular to a gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method. The method comprises the steps that a row of point-anchor rope reinforced roadway top plates are arranged in a roadway in the tunneling period, a row of point-anchor rope reinforced roadway ribs are arranged in the side roadway rib of the non-working surface, and a row of constant-resistance anchor rope beam reinforced roadway top plates are arranged on the position a certain distance away from the side roadway rib of the working surface; and according to the data changing situation of the mine pressure in a retained roadway in the period of backstopping of the working surface and the showing situation of the roadway mine pressure, an entry-in supporting area in the retained roadway is divided into an advance supporting area, a lagging supporting area, a roadway-forming to-be-stable area and a roadway-forming stable area. According to the gob-side-entry-retaining flexible roadside support and rigid entry-in support combined supporting method, through the successful practice of cross heading under the 21702 working surface, an excessive coal safety pillar with the width of 5 m is recycled compared with tunneling of an original gob-side entry driving, the coal resource recovery rate is improved, a solid foundation is laid for popularization of the gob-side entry retaining technology in other mining-area working surfaces of the whole mine, and a brand-new thinking is provided for the excavation-replacement layout of the whole mine.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

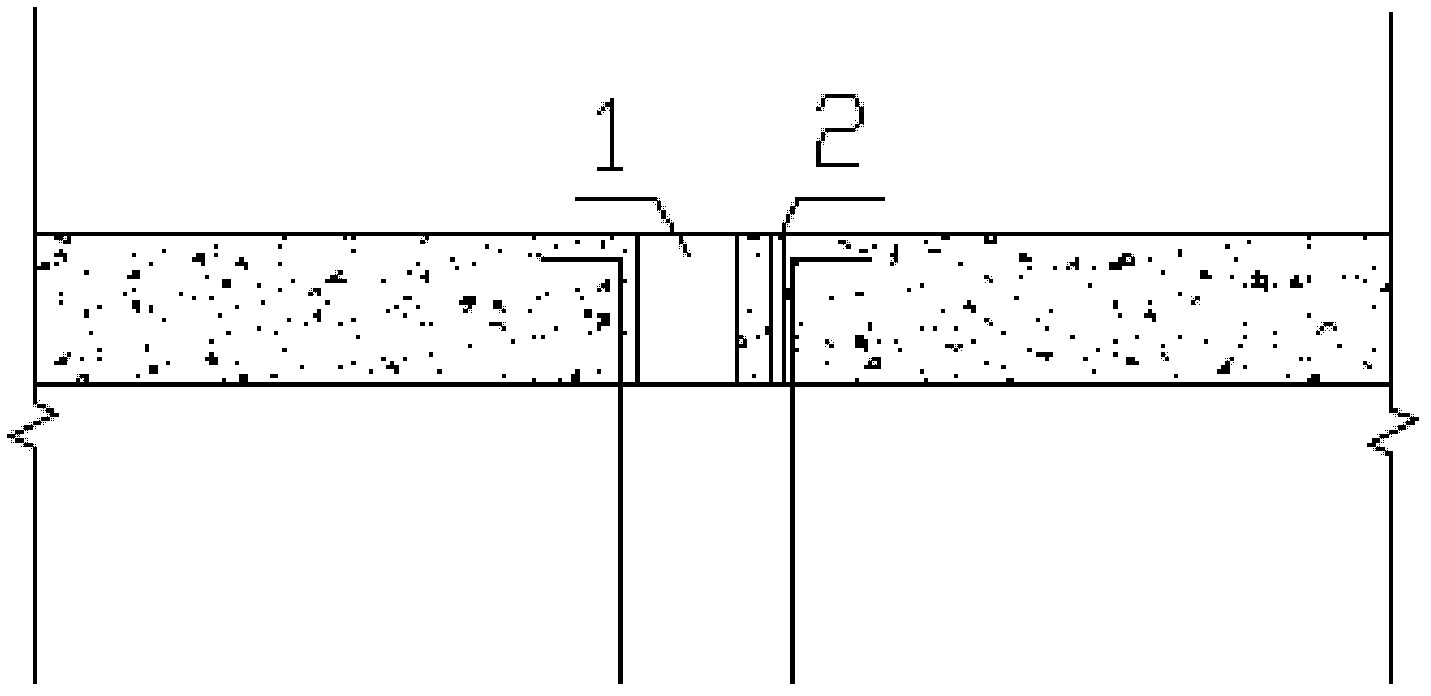

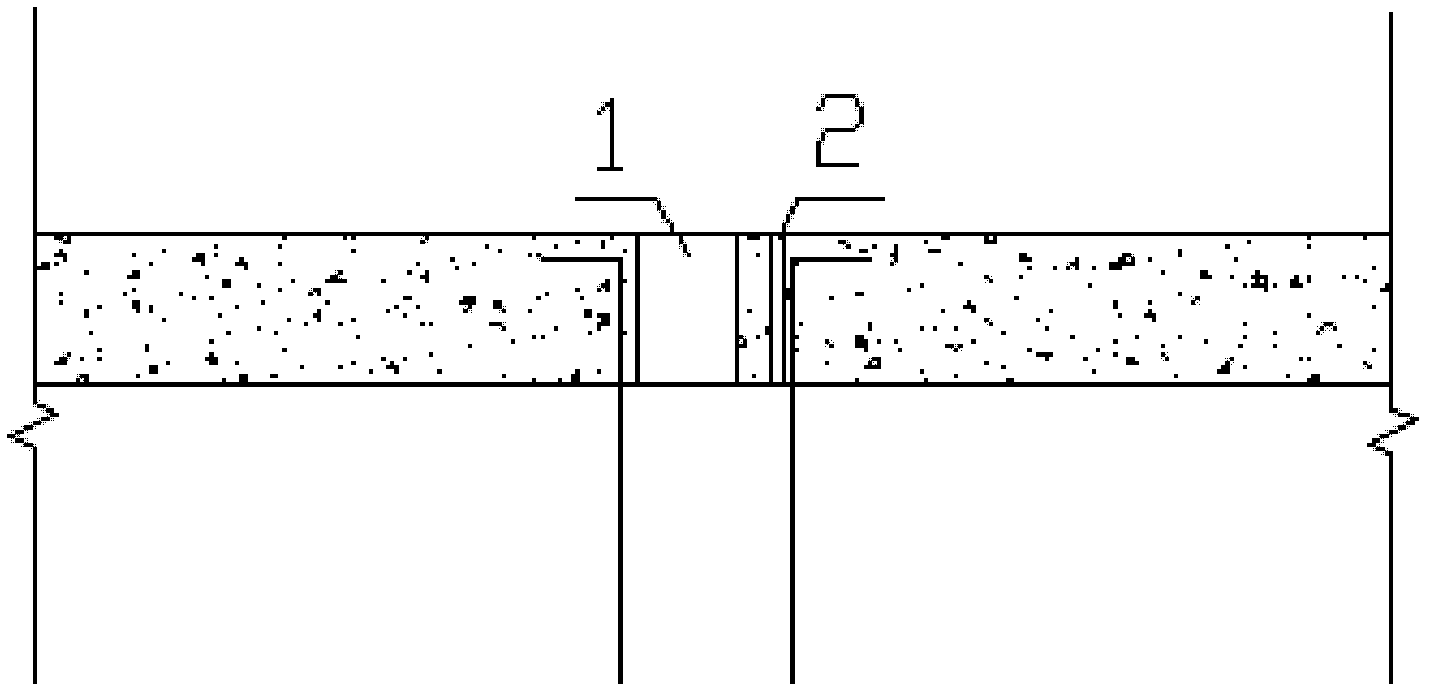

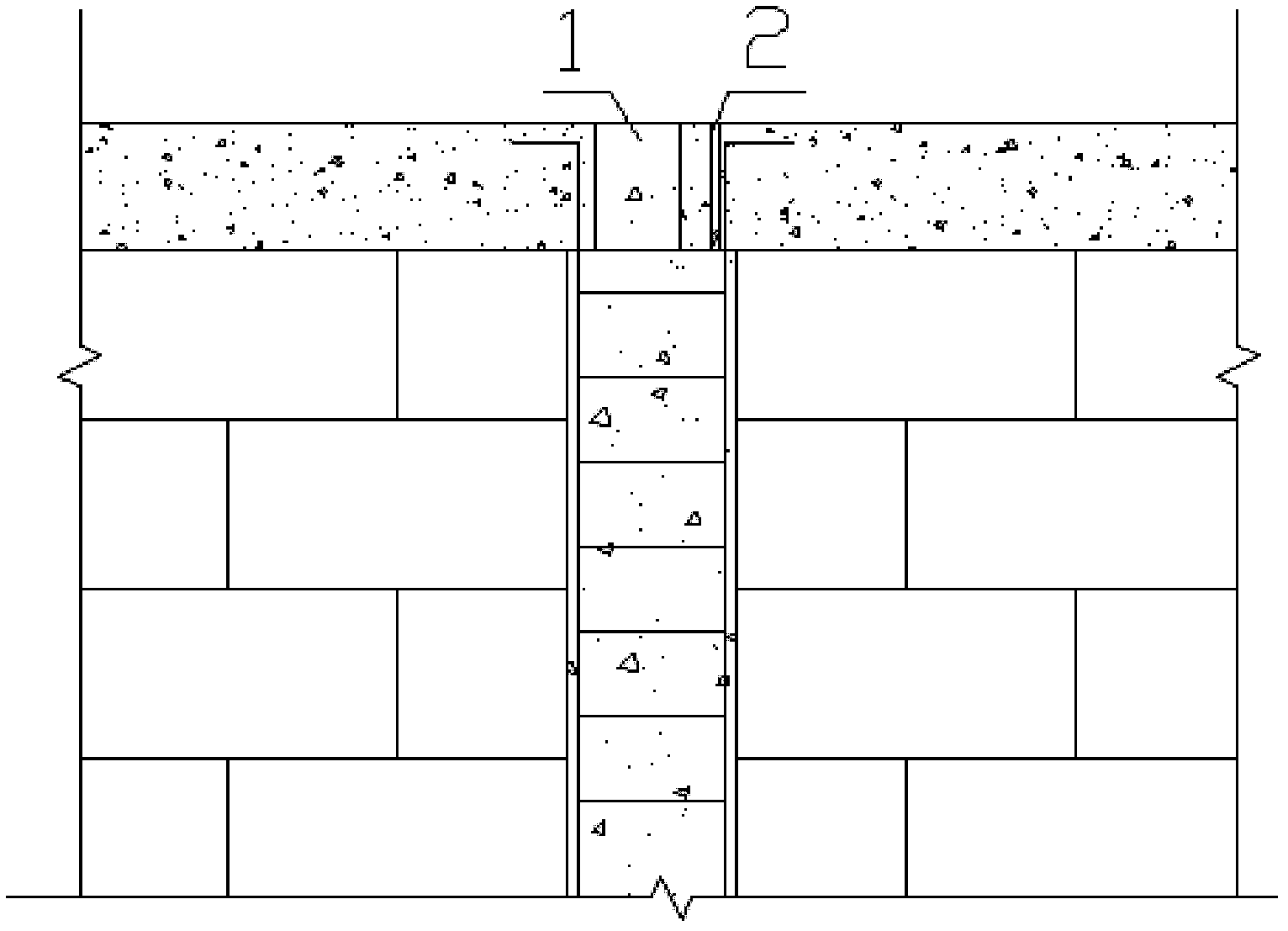

Constructional column top concreting method

ActiveCN102535849AGuarantee the construction qualityReduce the difficulty of supportBuilding material handlingFloor slabEngineering

The invention relates to a constructional column top concreting method, which is characterized in that steps include embedding sleeves on an upper-layer floor slab at the position of a constructional column during structural construction, embedding exhaust tubes beside the sleeves, and concreting the top of the constructional column via the embedded sleeves during construction of the constructional columns. The heights of the sleeves and the exhaust tubes are equal to the height of a structural beam or the thickness of a structural plate. The constructional column top concreting method has the advantages that installation and concreting are convenient, and the concreting quality of the constructional column is improved. The problem of incompact concreting of the top of the constructional column is resolved.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +3

Non-chain-pillar exploitation method

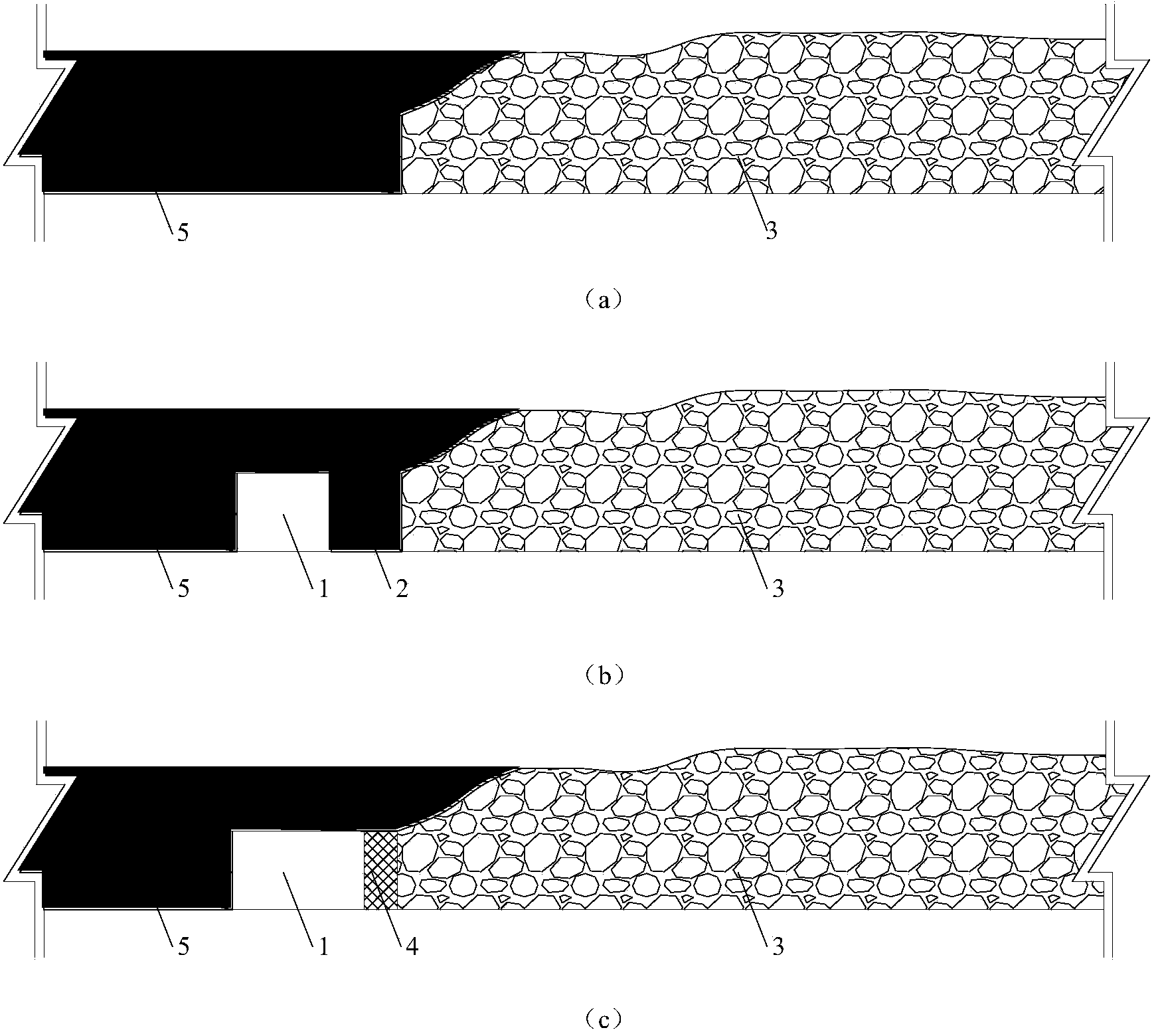

InactiveCN103953346AReduce the difficulty of supportAchieve miningUnderground miningSurface miningLower zoneEnvironmental geology

The invention discloses a non-chain-pillar exploitation method. The method comprises the following steps: tunneling a lower zone track lane along a reserved narrow chain pillar in a goaf after recovery of an upper zone working surface is ended; replacing the reserved narrow chain pillar with a filling body constructed along the edge of the goaf ahead a lower zone working surface after tunneling of a lower zone mining roadway is ended; gradually constructing the filling body in sections along with extending of the working surface until recovery of the lower zone working surface is finished; and sequentially circulating until coal mining of an overall area is finished. The support difficulty of gob-side entry driving is lowered, deformation of gob-side entry driving is effectively controlled, the goaf is isolated, and the recovery rate of coal resources is improved. The method is simple, safe, reliable and environmentally friendly, and has a useful effect.

Owner:CHINA UNIV OF MINING & TECH

Non-blasting roof-cutting gob-side entry driving method for pier stud

ActiveCN110939466AReduce surrounding rock deformationShorten exercise timeUnderground chambersTunnel liningArchitectural engineeringCoal pillar

The invention discloses a non-blasting roof-cutting gob-side entry driving method for a pier stud. The method comprises the following steps of forming a plurality of joint-cutting holes which jointlyform a pre-cracking kerf, and drilling 60-100 m of a first advance of the joint-cutting holes; excavating an upper of a coal pillar on one side, close to the coal pillar, in a gateway close a next working face at every 5-10 m and arranging concrete pier stud dies; using a single hydraulic support pillar and n-type steel in the gateway as temporary support; carrying out anchor-retreating construction in the gateway next to the next working surface; recovering the single hydraulic support pillar following 2-5 m behind the working surface closely; and forming a pre-cracking joint-cutting caving on a top plate next to a gob-side entrydriving lane along the joint-cutting holes, eliminating a hanging arch, filling a gob, and carrying out gob-side entrydriving construction at 3-5 m coal pillar after recovery of adjacent gob. By adopting non-blasting roof-cutting pressure relieving for the pier stud, a gob-side entrydriving operation for a small coal pillar can be carried out on adjacent working surface, so that a mine excavation succeeding tension situation is alleviated greatly, the repair cost of the gob-side entry driving is reduced, and the coal recovery rate is improved.

Owner:GUIZHOU UNIV

Supporting component for spatial large-aperture reflector

InactiveCN110780416AHigh precisionReduce the difficulty of supportMountingsOptical surfaceOptic system

The invention discloses a supporting component for a spatial large-aperture reflector. The supporting component is composed of a reflector supporting back plate, a supporting cylinder, a locking nut and a flexible gasket. The supporting cylinder is used for limiting the other five-dimensional freedom degree of the reflector except an axial direction, and the locking nut is used for fixing the axial freedom degree of the reflector. The supporting component has the advantages that the supporting component solves the problems that a reflector supporting structure in an original large-caliber off-axis three-mirror optical system is complex in design, high in assembly process requirement and the like. The supporting component is simple in structure, and does not need complicated assembly process and part repair. The problem that additional stress is brought to a reflector body due to cantilever support, temperature field change and an installation detection mode of a traditional large-caliber supporting structure is solved. The influence of supporting on the optical surface type can be effectively reduced. The structure is simple, so that the supporting component has practical engineering significance for the light weight of the spatial large-aperture optical load.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

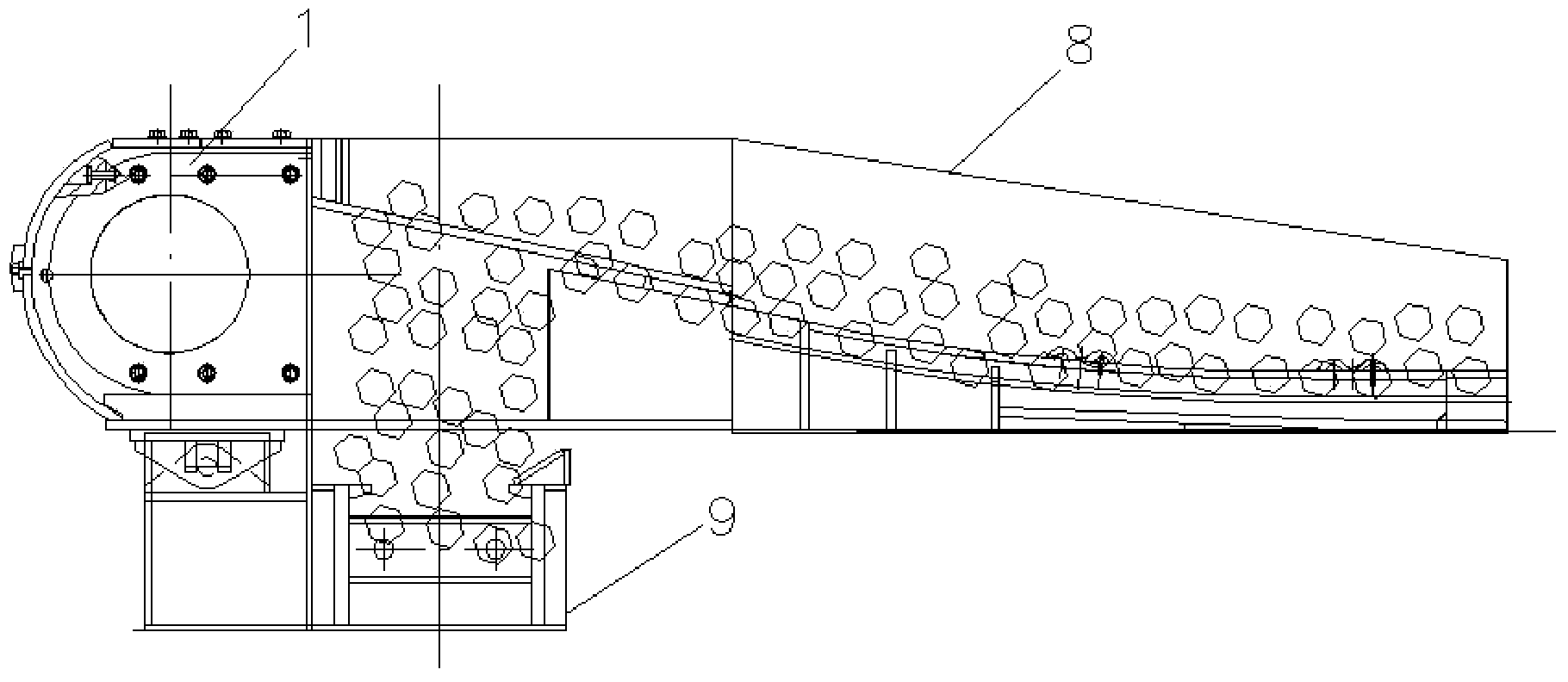

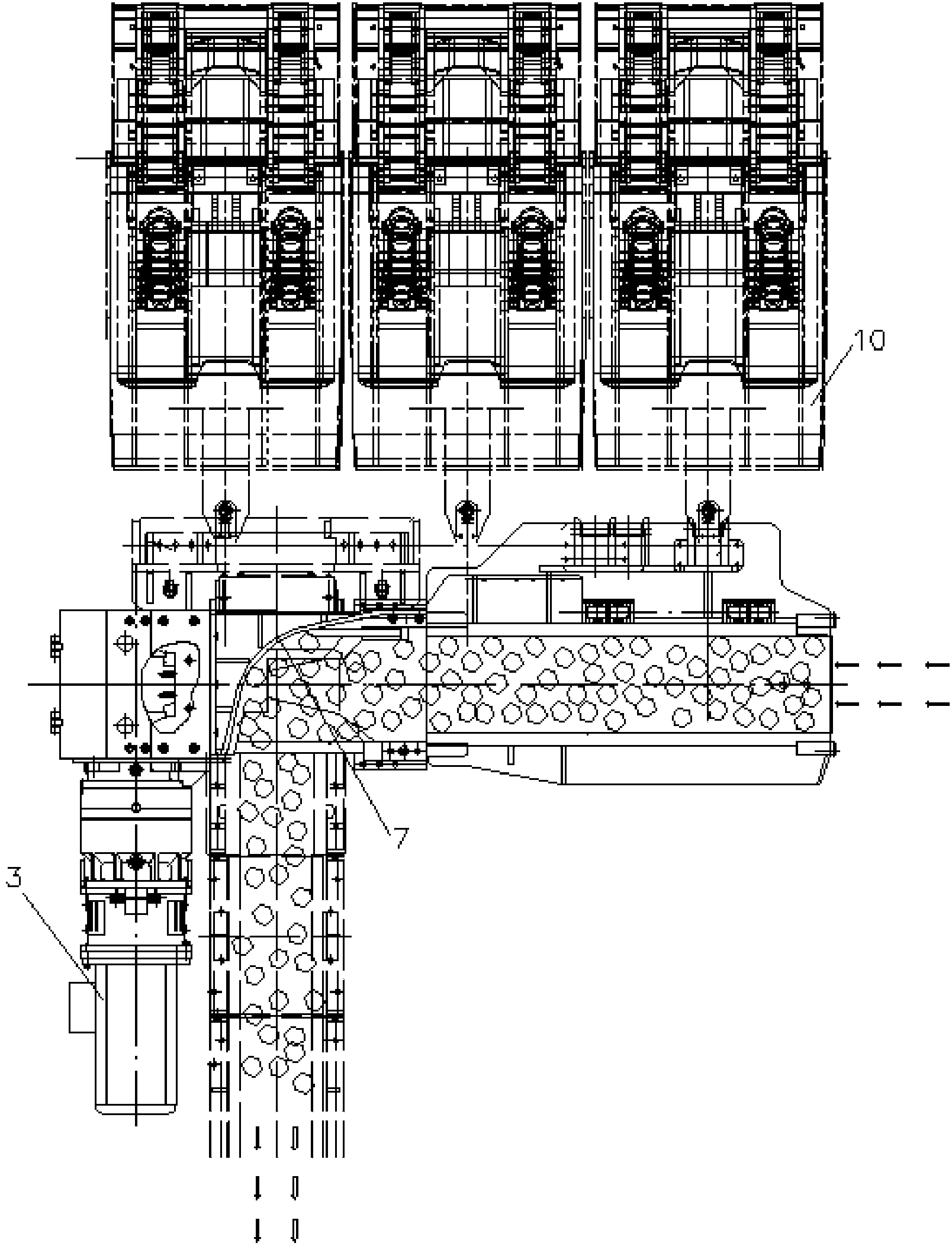

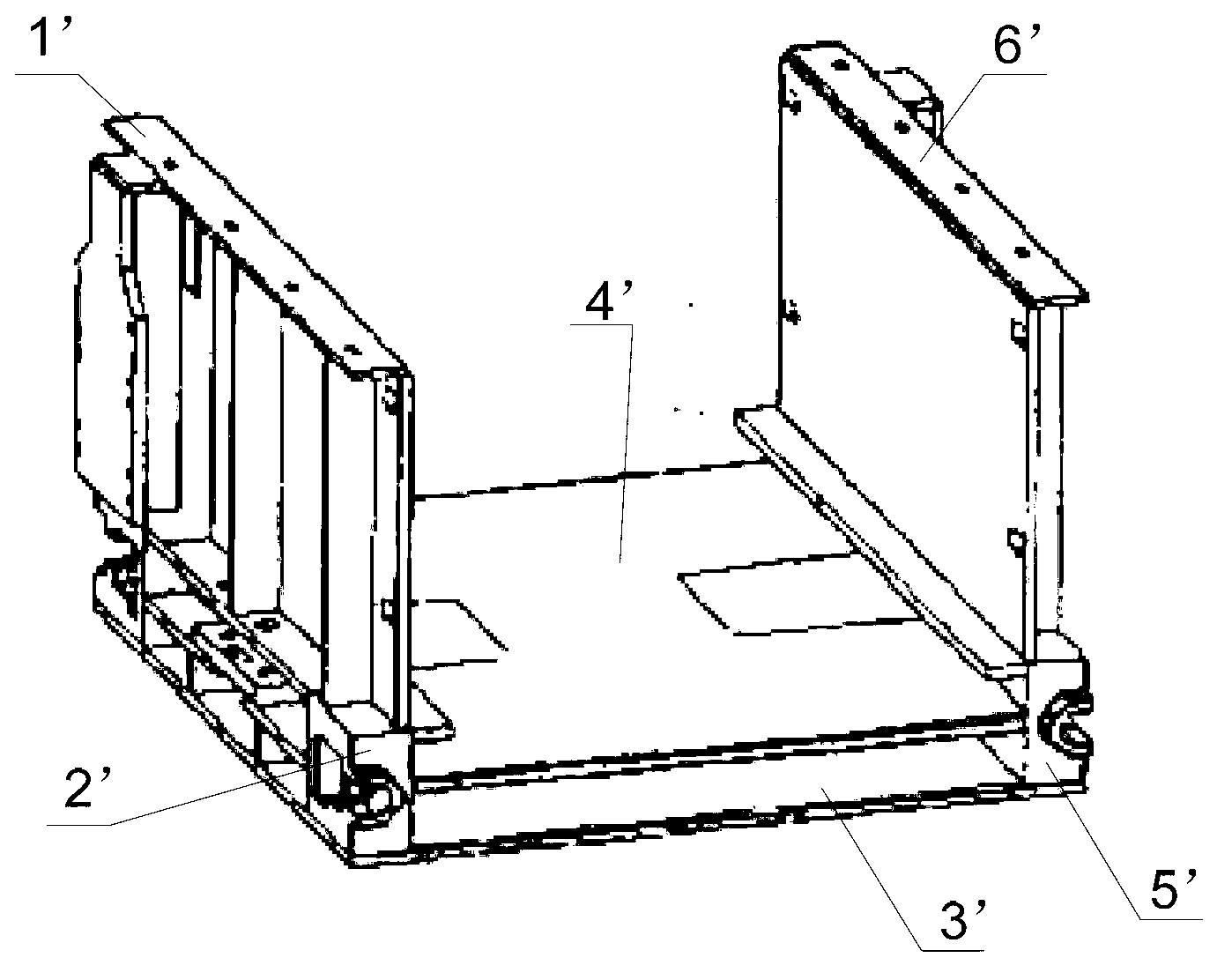

Novel thin coal seam overlapped side-unloading structure

ActiveCN103775082AUnreasonable solutionAvoid excessive lag problemsSlitting machinesHysteresisEngineering

The invention relates to a working surface scraper conveyer and a reversed transportation roadway loader, and in particular relates to a novel thin coal seam overlapped side-unloading structure. The novel thin coal seam overlapped side-unloading structure comprises a conveyor (8) and a reversed loader (9), and is characterized in that an unloading connection groove (5) is formed in the tail of the reversed loader (9); the head of the conveyor (8) is fixedly lapped to the unloading connection groove (5) in the tail of the reversed loader (9). According to the technical scheme, the problem of unreasonable installation position of a power part caused by an existing end-unloading mode is solved, and the problems of over-hysteresis and non-smooth ventilation of an end hydraulic support and a hydraulic support on a working surface are avoided. According to the technical scheme, by changing the loading mode of the head, the structure of the head and the installation position of the power part, the arrangement spaces of the head of the conveyor, the tail of the reversed loader and the hydraulic supports are improved, the roadway support difficulty of the head is reduced, and the safety and coal mining efficiency of the working surface are improved.

Owner:NINGXIA TIANDI BENNIU IND GRP

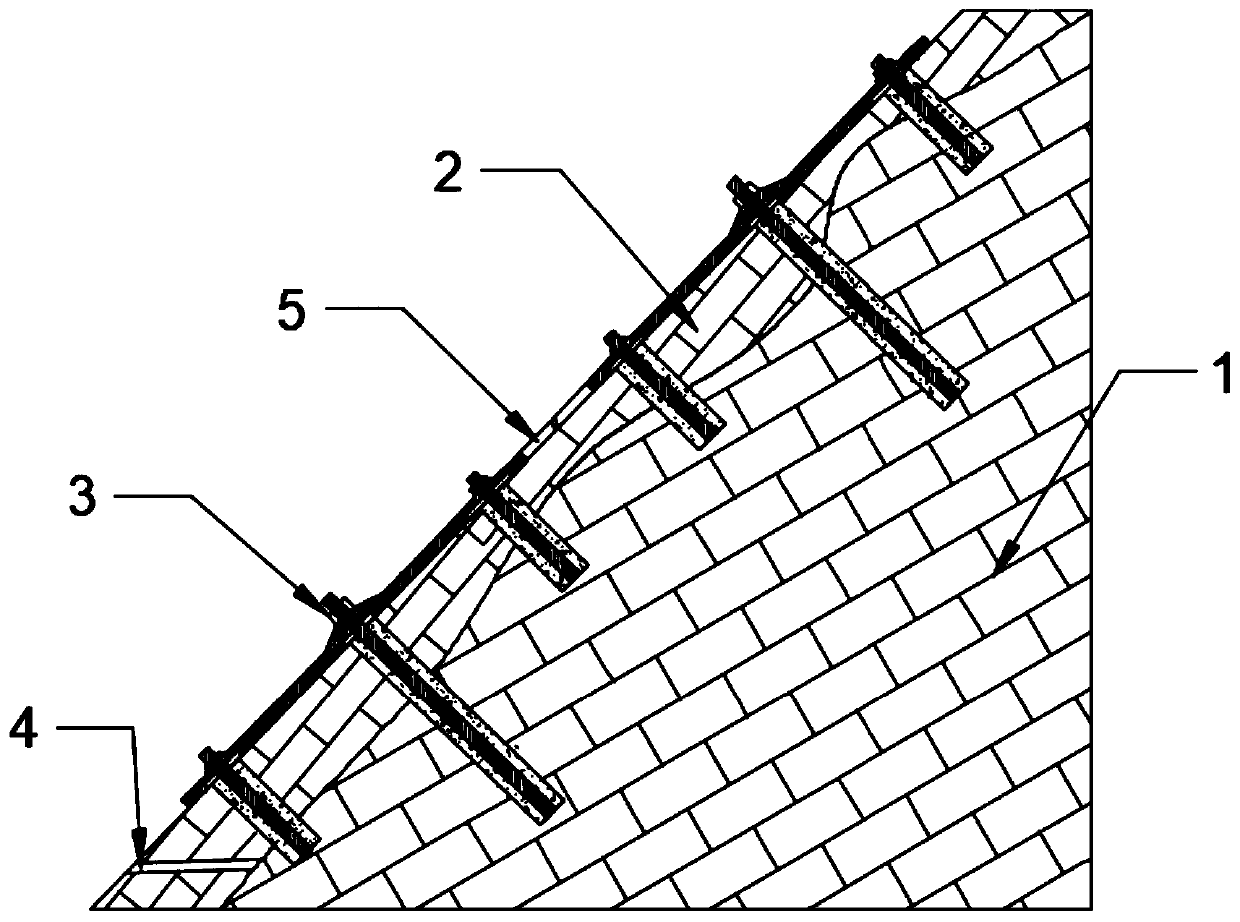

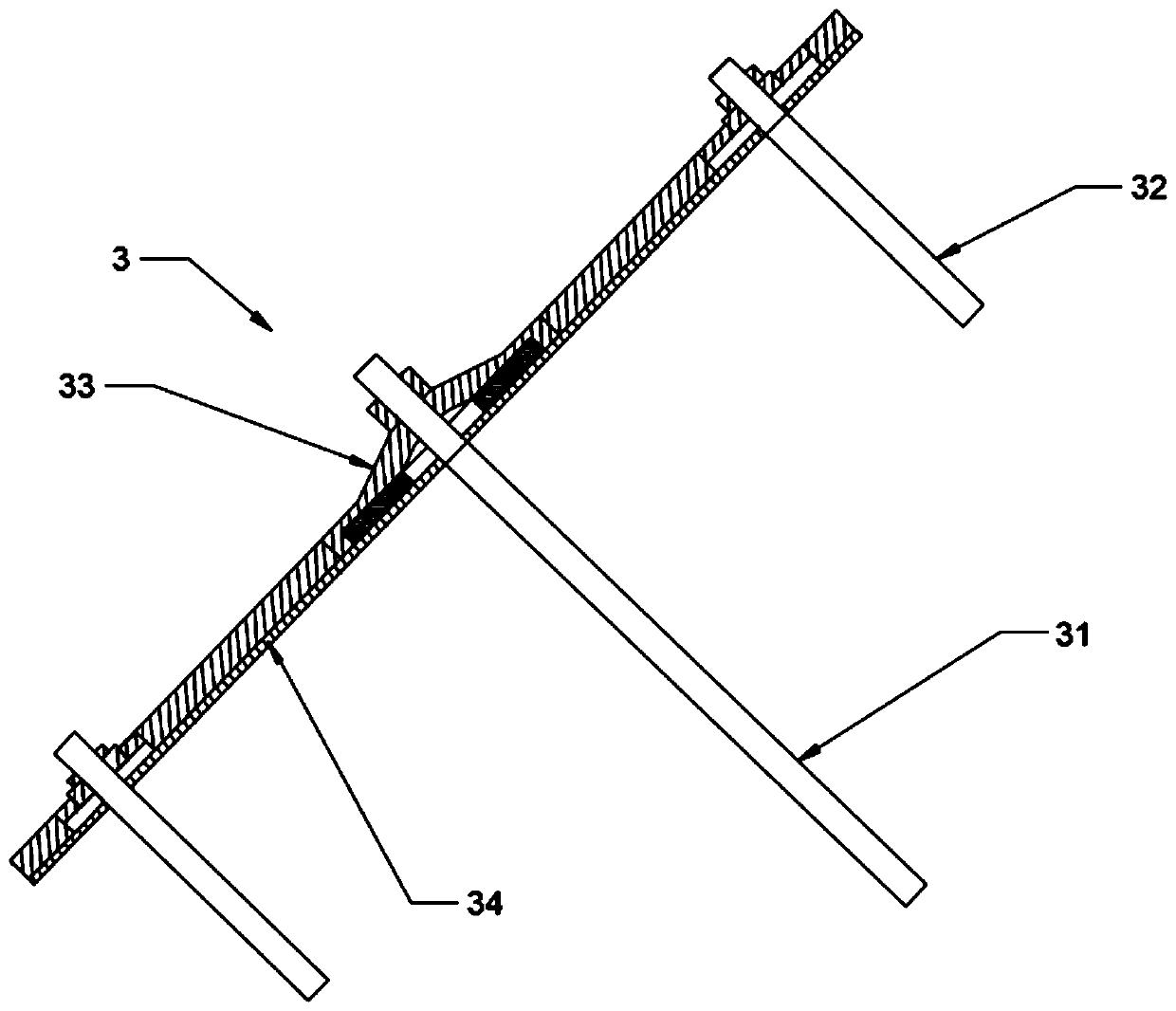

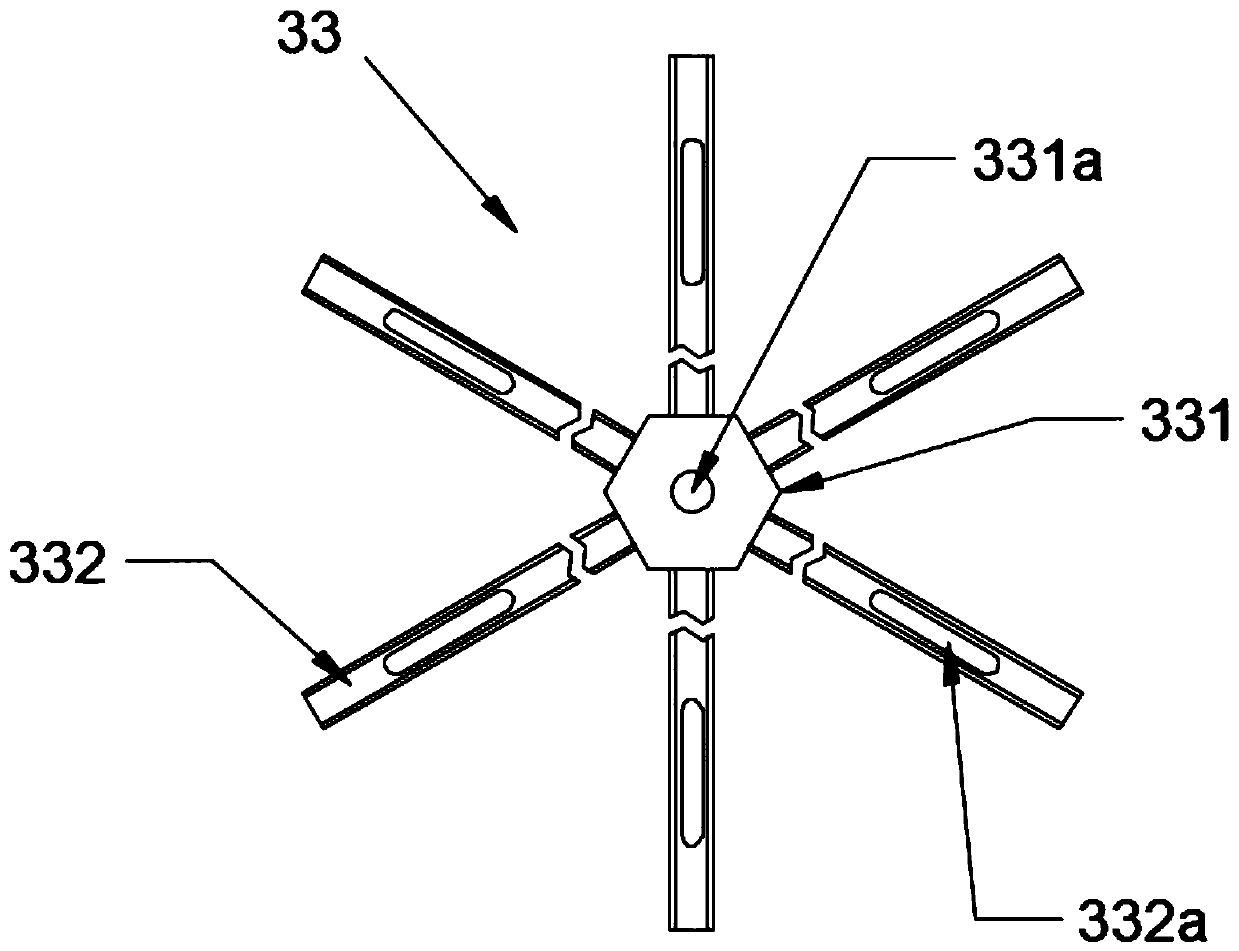

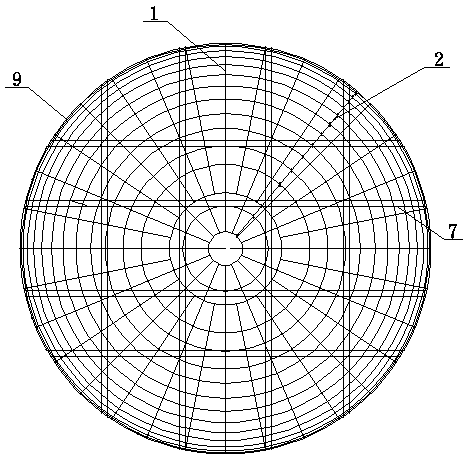

Method for enhancing stability of landslide slope of abandoned mine

The invention provides a method for enhancing the stability of a landslide slope of an abandoned mine. The method includes the following steps that S10, basic data are acquired; S20, drainage holes are constructed; S30, reinforcing units are constructed, and each reinforcing unit comprises a pre-stressed anchor cable, a wall-attached tray and multiple anchor rods; S40, connecting beams are constructed, and a branch support plate of one reinforcing unit is connected with a branch support plate of another adjacent reinforcing unit through the corresponding connecting beam. According to the method for enhancing the stability of the landslide slope, the stable stratum and the unstable stratum are connected through the pre-stressed anchor cables, so that the unstable stratum can be effectivelyprevented from side-slipping; the pre-stressed anchor cables and the anchor rods are connected into a whole through the wall-attached trays, so that a complete stressed body is formed in the slope protection zone, the slope protection area can be increased, and the support stability can be improved; and when the unstable stratum has the downwards slipping tendency, the anchor rods, the pre-stressed anchor cables and the wall-attached trays can be stressed simultaneously, and the threat caused by strain can be weakened.

Owner:厦门海石生态环境股份有限公司

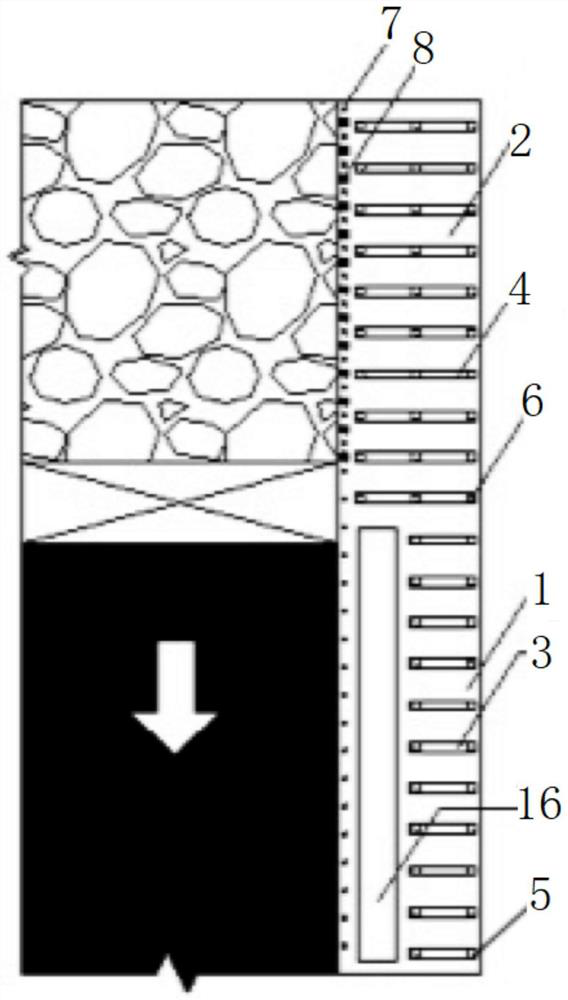

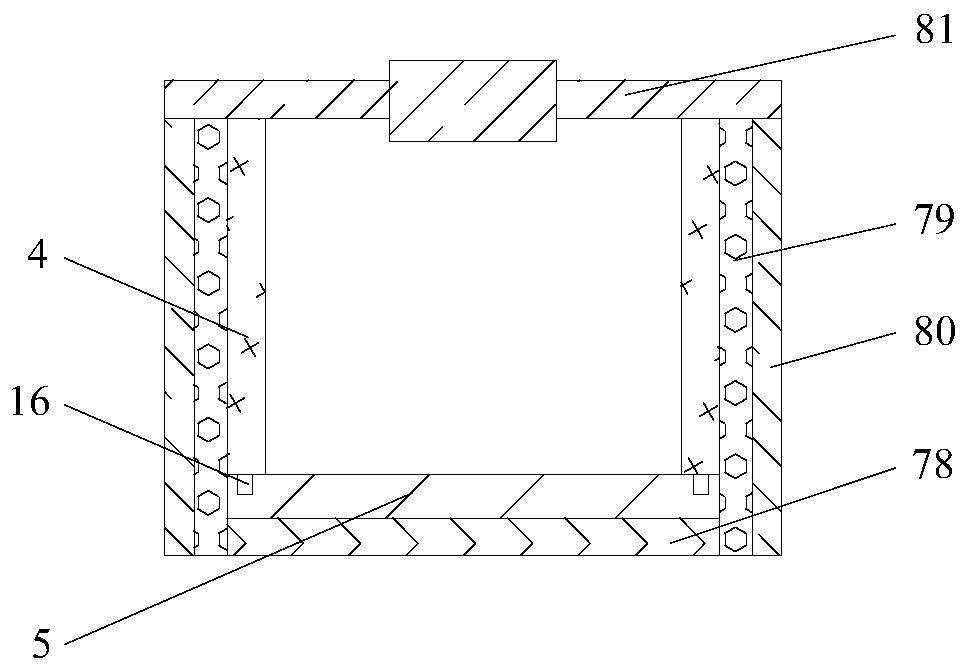

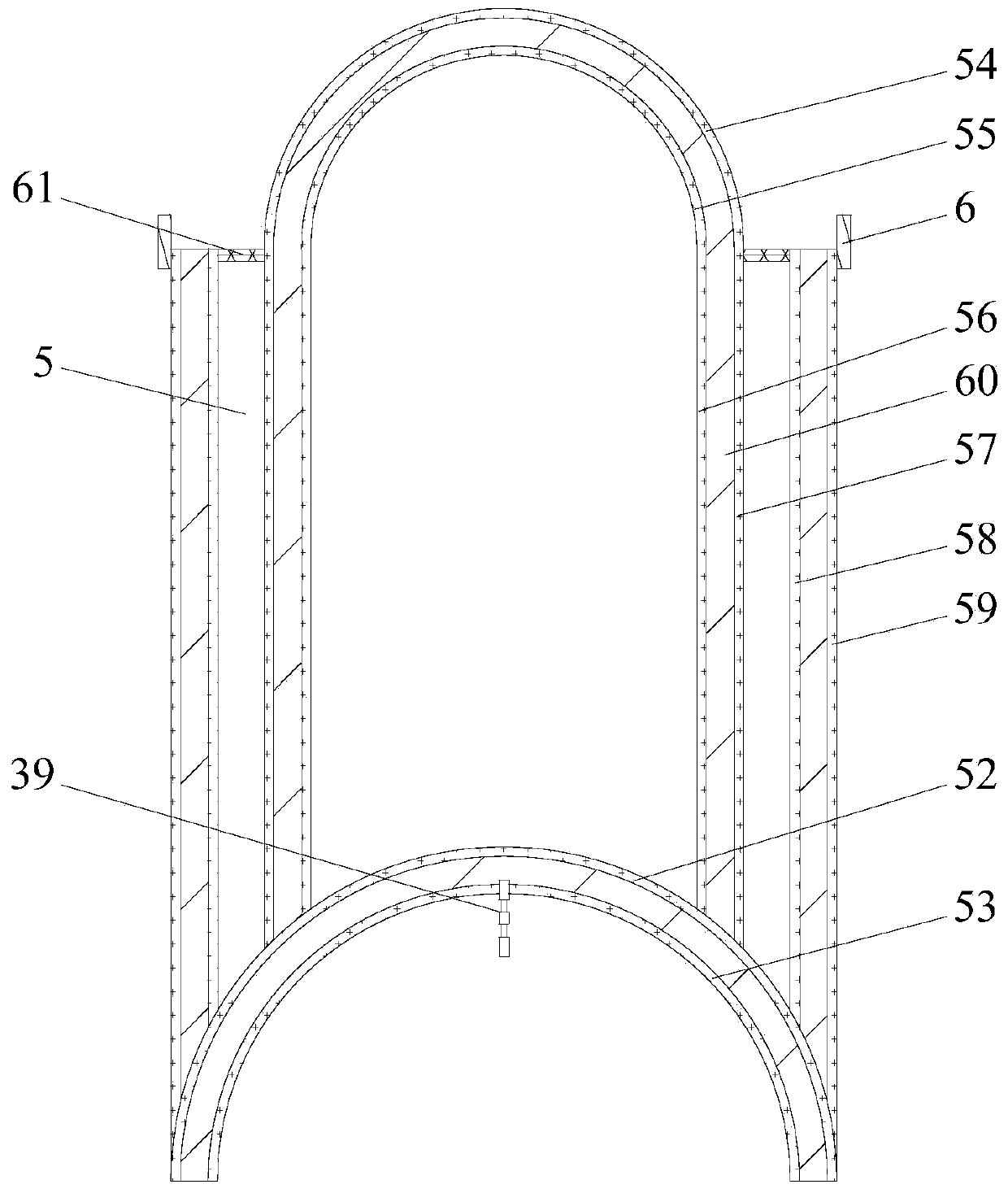

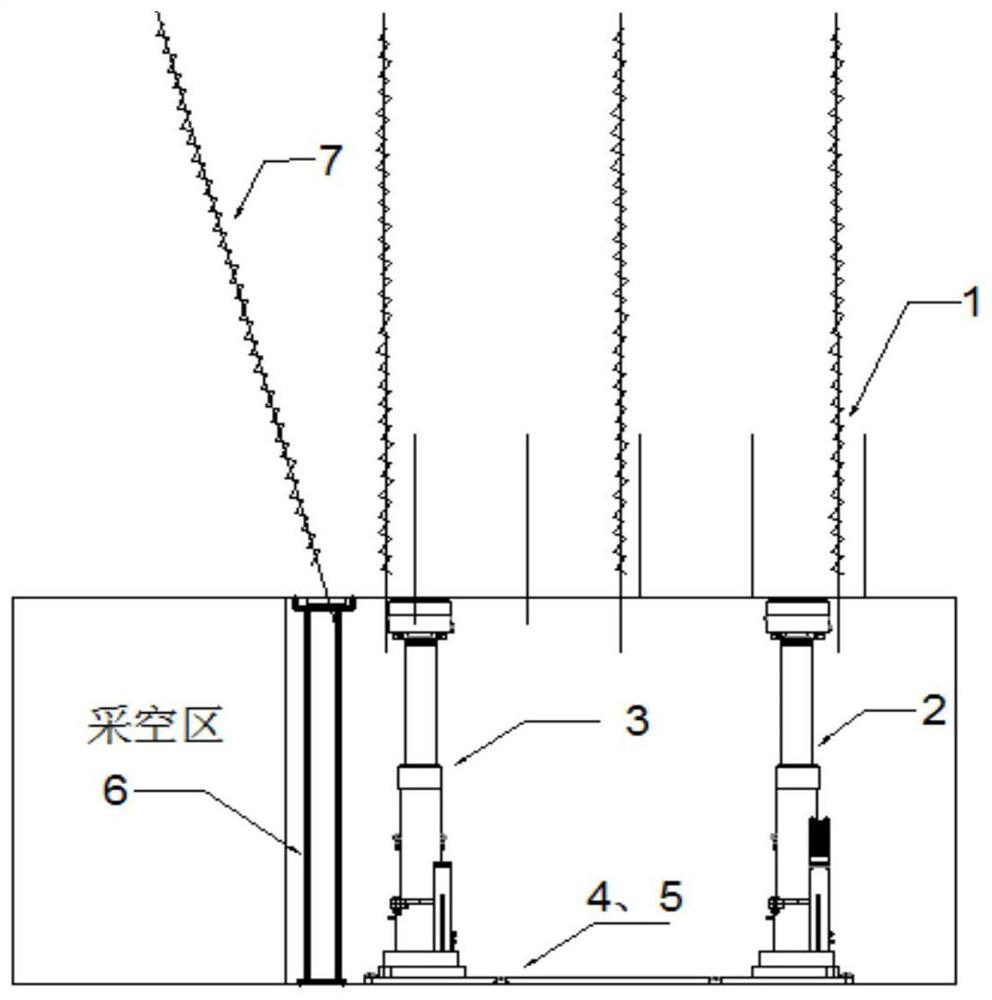

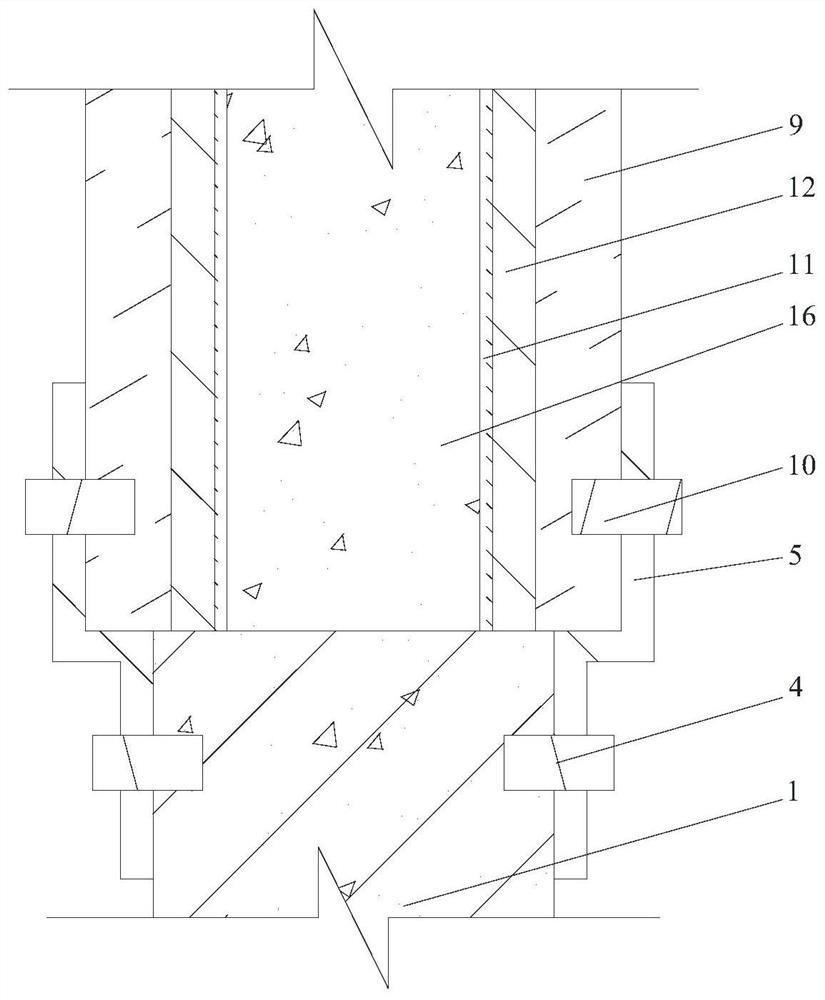

Coal pillar-free mining gob-side entry retaining roadway supporting system and method for three-soft-stratum coal seam

ActiveCN111734466AControl swing sinkingControl deformationMine roof supportsSupporting systemCoal pillar

The invention discloses a coal pillar-free mining gob-side entry retaining roadway supporting system and method for a three-soft-stratum coal seam. The system comprises a plurality of first pi-shapedbeams, wherein the plurality of first pi-shaped beams are uniformly arranged in an advancing roadway; a plurality of second pi-shaped beams are uniformly arranged in a lagging roadway; single props are arranged below the first and second pi-shaped beams; a plurality of gangue blocking pillars are uniformly arranged in the lagging roadway at intervals and are arranged close to a gob side; the sides, approaching the gob side, of the gangue blocking pillars are provided with a gangue blocking net; a top plate on the side wall of the advancing roadway is provided with a row of edge locking anchorropes; and the edge locking anchor ropes are located on a coal wall side of a working face. According to the system and the method, the support is strengthened by the edge locking anchor ropes; the reinforced support to the top plate approaching the gob side is realized; the sinking of the top plate is controlled in advance; by adopting the combination of the pi-shaped beams and the single props,the support to the top plate for a gob-side entry retaining roadway is realized; the support resistance is high; the lateral pressure and side bulging of a gangue side are effectively controlled by arranging the gangue blocking pillars and the gangue blocking net; and by using the system and the method, the rotatory sinking of the top plate for the gob-side entry retaining roadway and the deformation of the gob-side entry retaining roadway are effectively controlled.

Owner:SHAANXI COAL & CHEM TECH INST

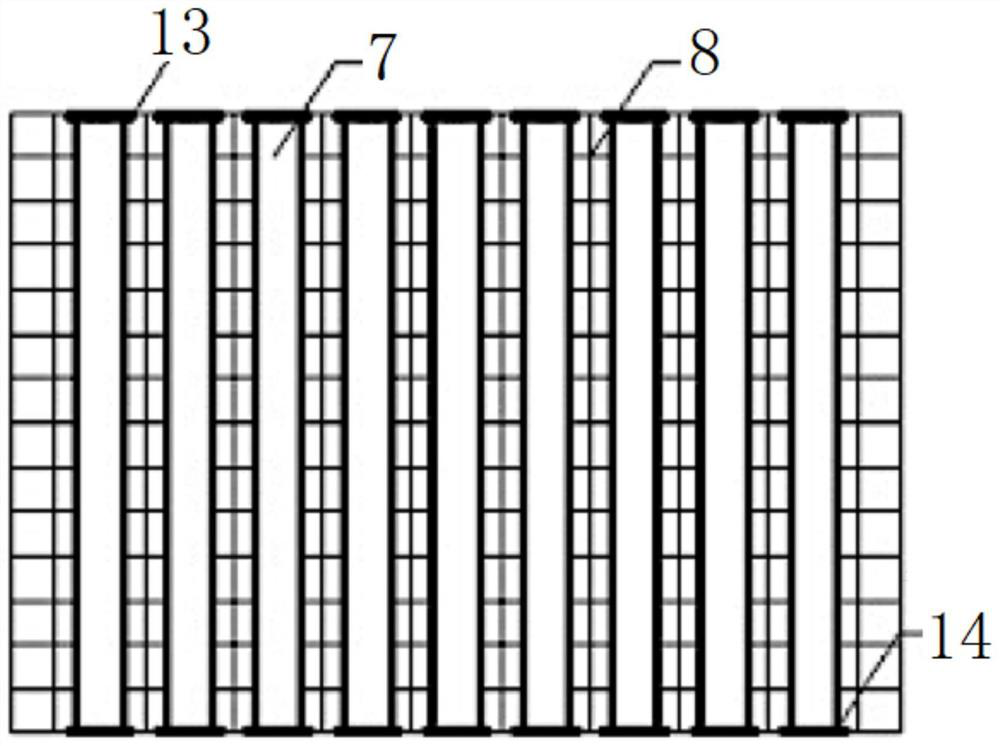

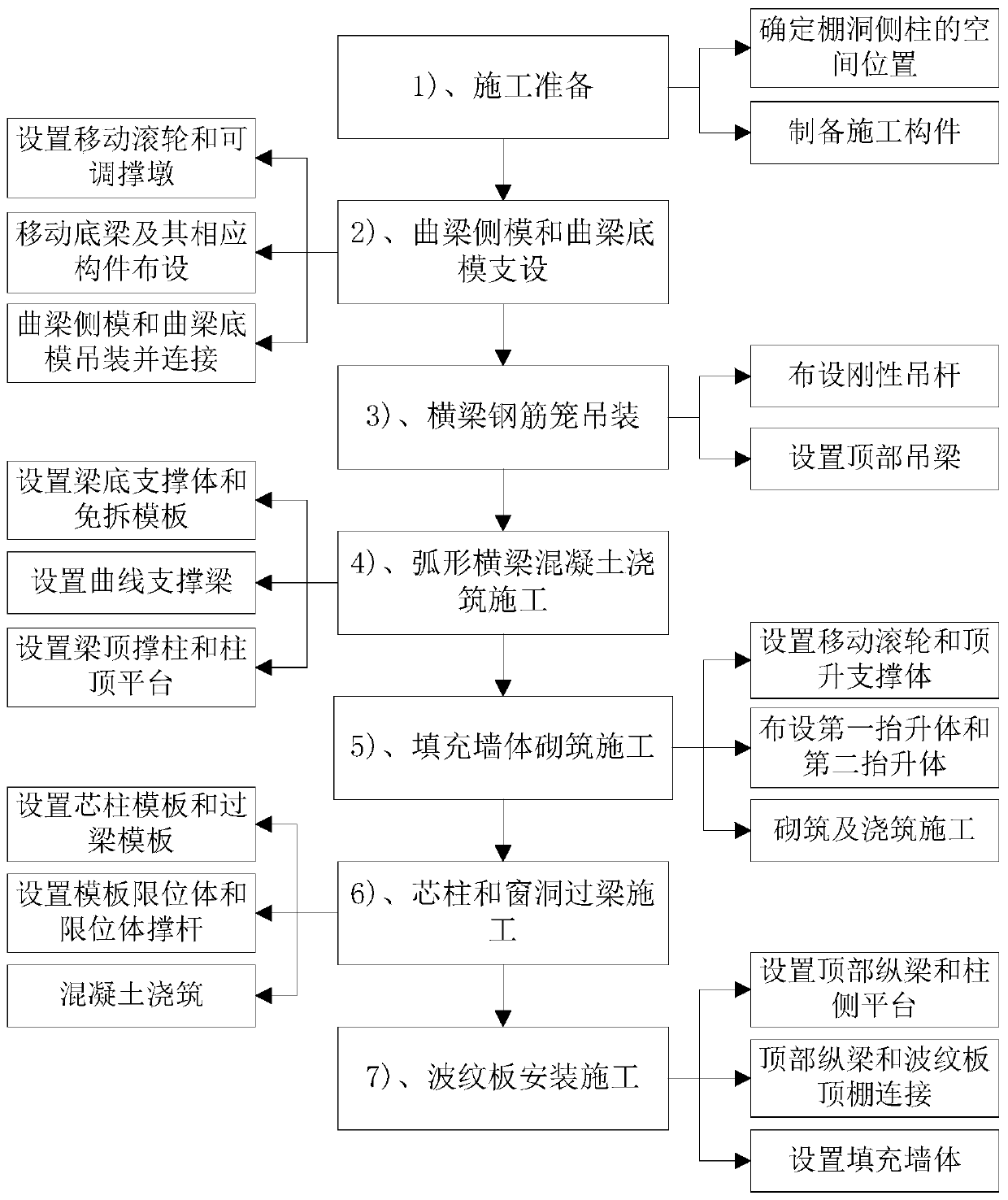

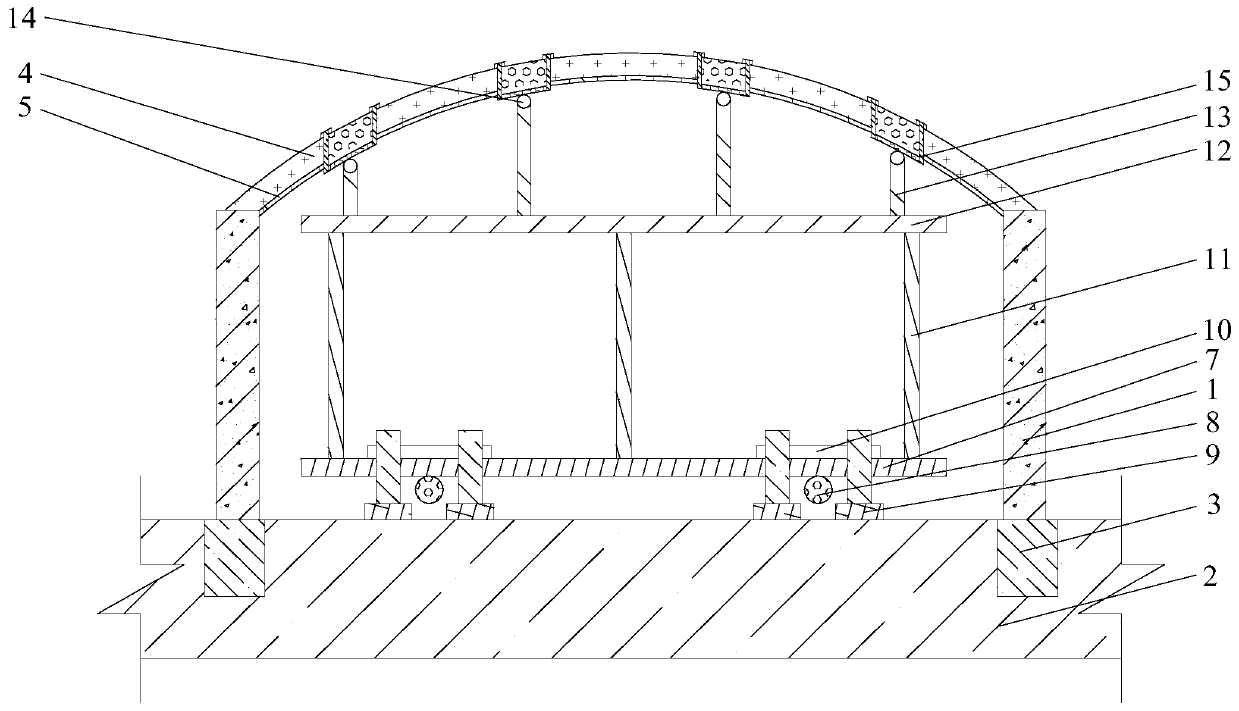

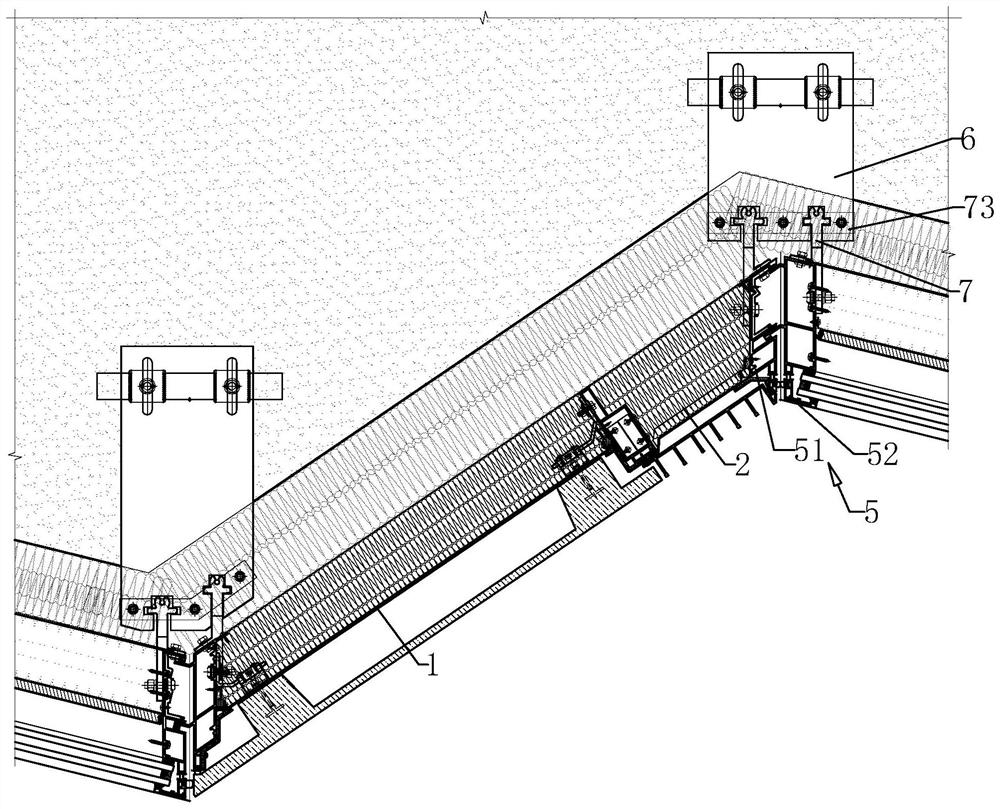

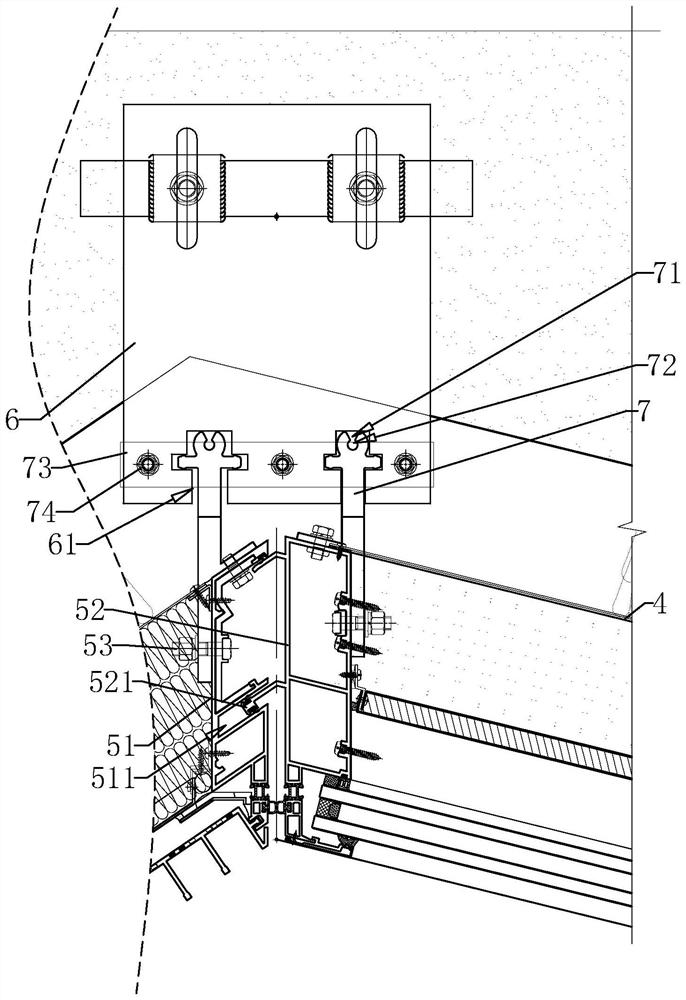

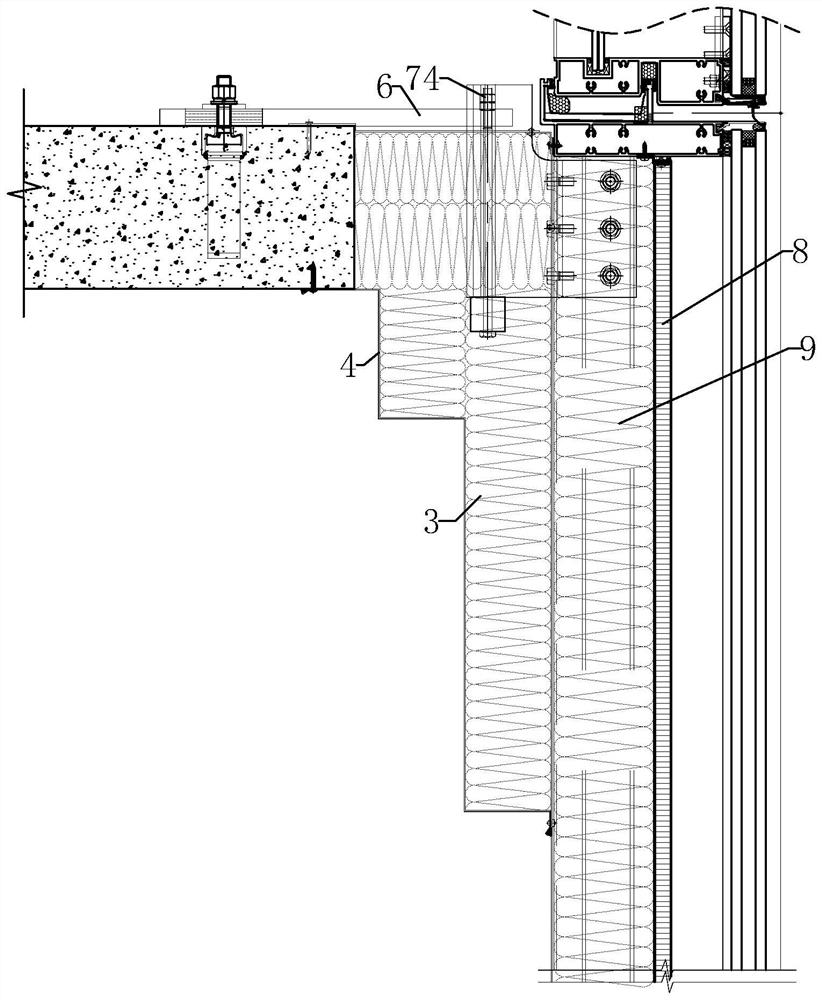

Construction method of shed tunnel and steel corrugated plate combined type wind-snow prevention system

ActiveCN110184957AEasy to locate and installImprove the limit strengthProtective constructionSupporting systemUltimate tensile strength

The invention relates to a construction method of a shed tunnel and steel corrugated plate combined type wind-snow prevention system. The construction method comprises the following steps that 1), carrying out construction preparation; 2), supporting and erecting a curved beam side mold and a curved beam bottom mold; 3), hoisting a beam reinforcement cage; 4), carrying out concrete pouring construction on an arc-shaped cross beam; 5), carrying out laying construction on filling wall body; 6), carrying out lintel construction on core columns and window holes; and 7), carrying out installation construction on corrugated plates. The construction method has the beneficial effects that the curved beam side mold and the curved beam bottom mold are convenient in supporting and erecting, mountingand positioning treatment, the template structure integrity is good, the template limiting strength is high, meanwhile, a template supporting system is prone to move on site and high in bearing capacity, and the construction difficulty of template supporting and erecting can be effectively improved; the reinforcement cage is convenient to hoist and connect, the reinforcement cage is prone to locate on site, and the damage of reinforcement cage on site hoisting to the reinforcement cage can be reduced; and arc-shaped cross beam concrete pouring is prone to control, and the concrete compactnessis convenient to control.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

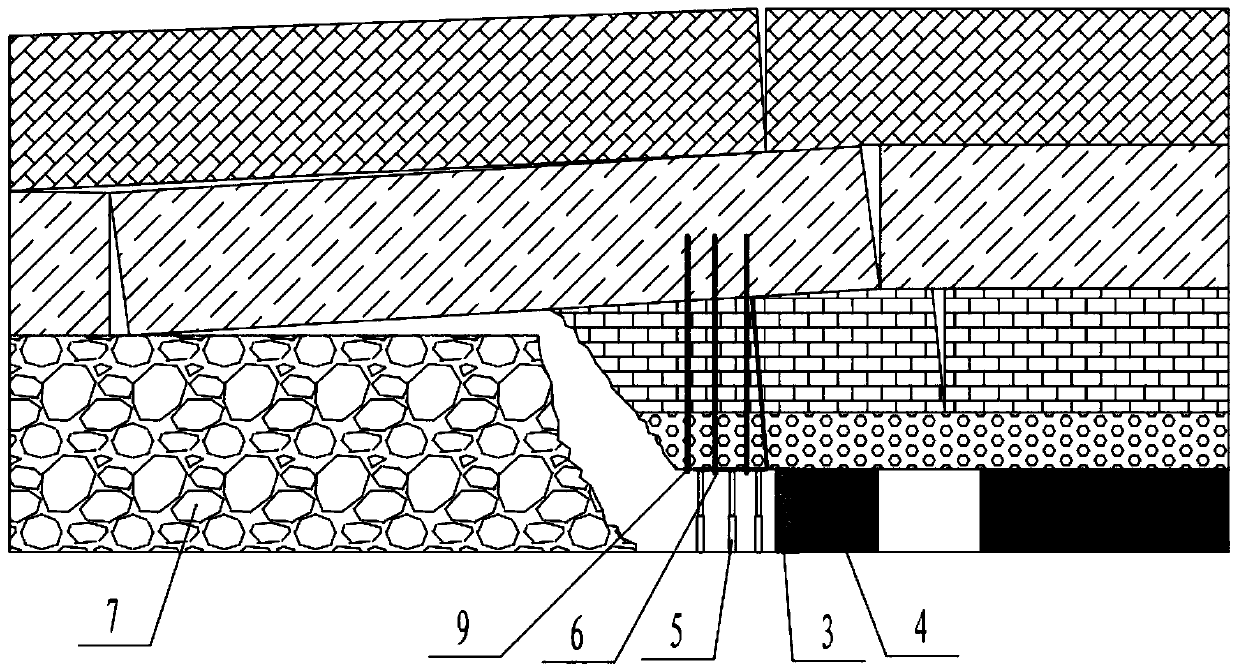

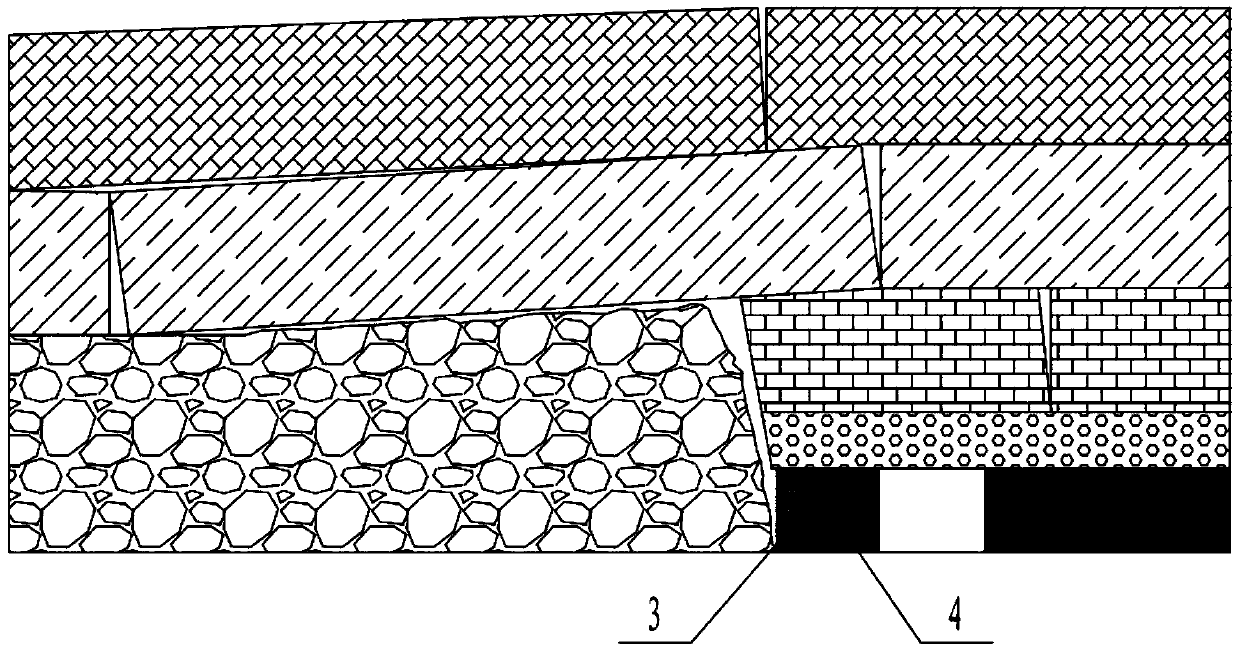

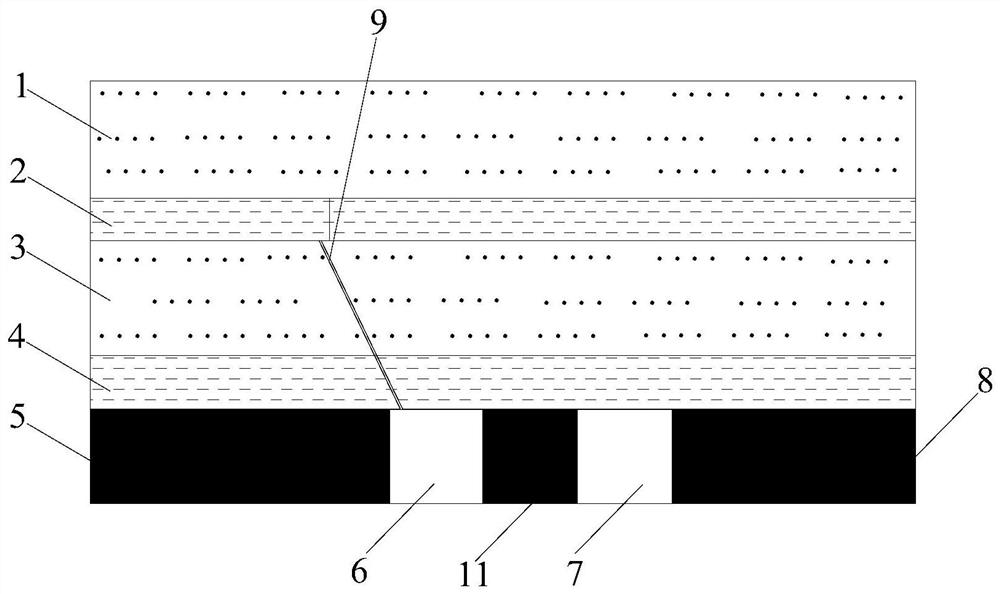

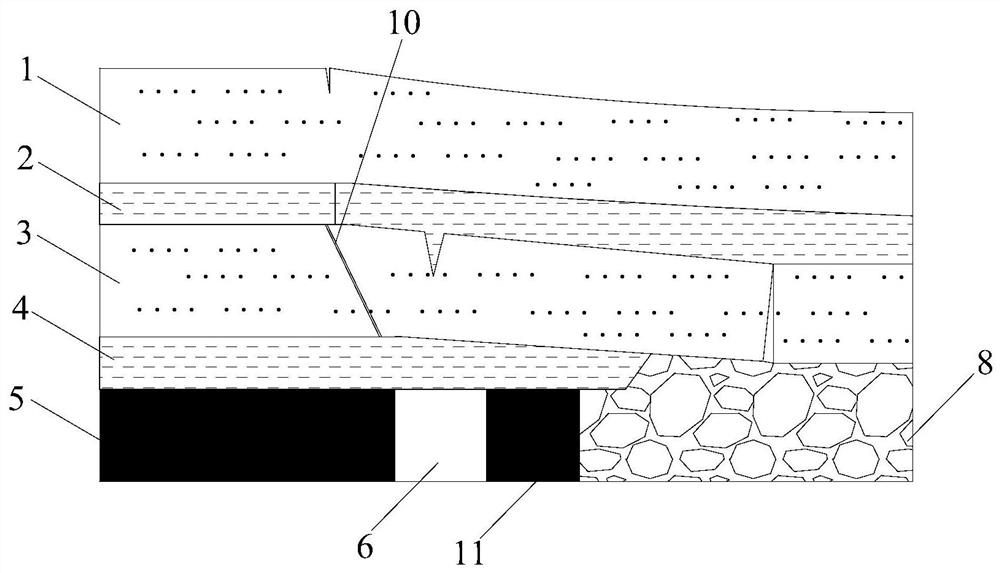

Deep well small coal pillar gob-side entry retaining method based on roof lower key layer roof-breaking pressure relief

ActiveCN112377193AEfficient productionSolve the problem of continuous tension in miningMining devicesUnderground miningMining engineeringCoal pillar

The invention provides a deep well small coal pillar gob-side entry retaining method based on roof lower key layer roof-breaking pressure relief, and relates to the technical field of coal mining. Ventilation and support in deep well gob-side entry retaining are improved. The deep well small coal pillar gob-side entry retaining method comprises the steps that roof geological conditions are determined, blasting parameters are determined according to the roof geological conditions, the roof-breaking pressure relief effects of lower key layers with different thicknesses are numerically simulated,and roof-breaking parameters of a roadway are determined; then excavating blast is conducted in the test roadway, and a displacement monitoring station, an anchor rod and an anchor cable stress monitoring station are arranged on surrounding rock in the roadway; and the supporting parameters are corrected, excavating blast is conducted in the gob-side entry retaining roadway, and supporting is conducted according to the corrected supporting parameters. According to the method, blasting is conducted on the side, deviating from solid coal, of a coal seam roof, stress transmission of the key layer is cut off at the lower key layer of the pre-split coal seam roof, thus high stress acting on small coal pillars and gob-side entry retaining is transferred, therefore the roadway environment is improved, and roadway maintenance is facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

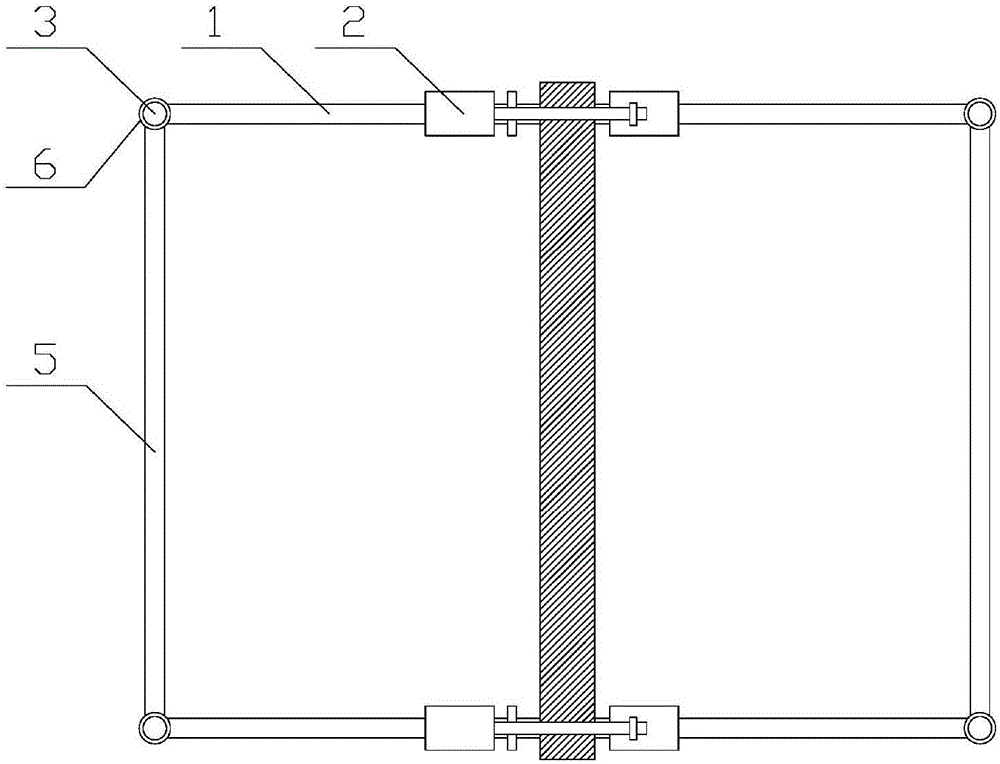

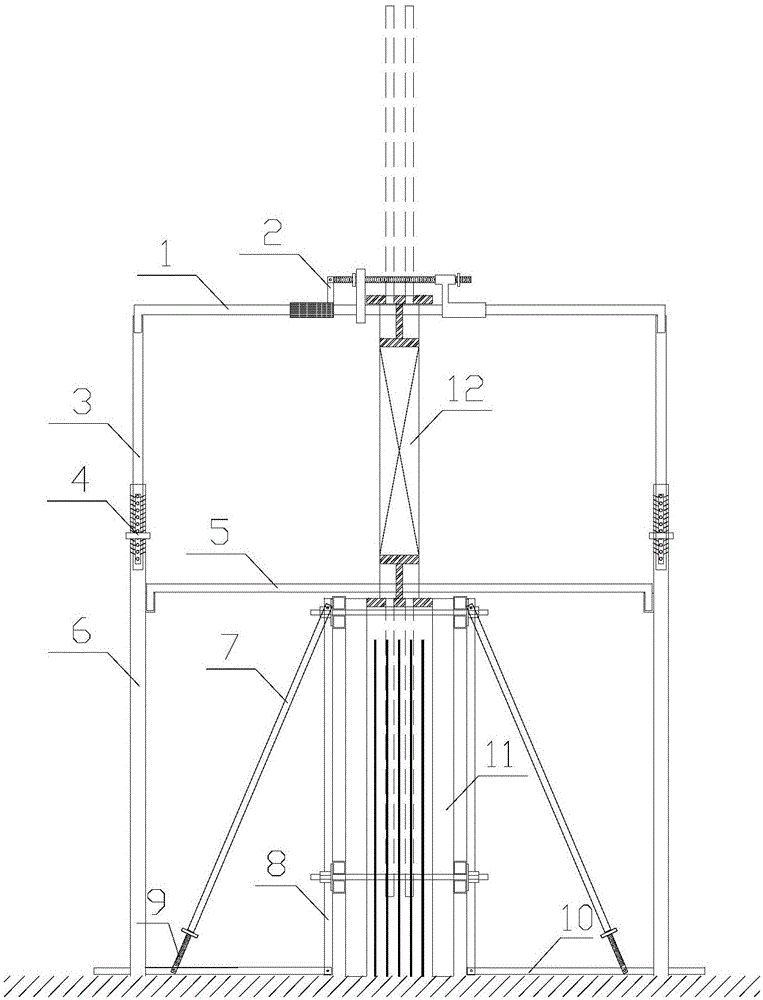

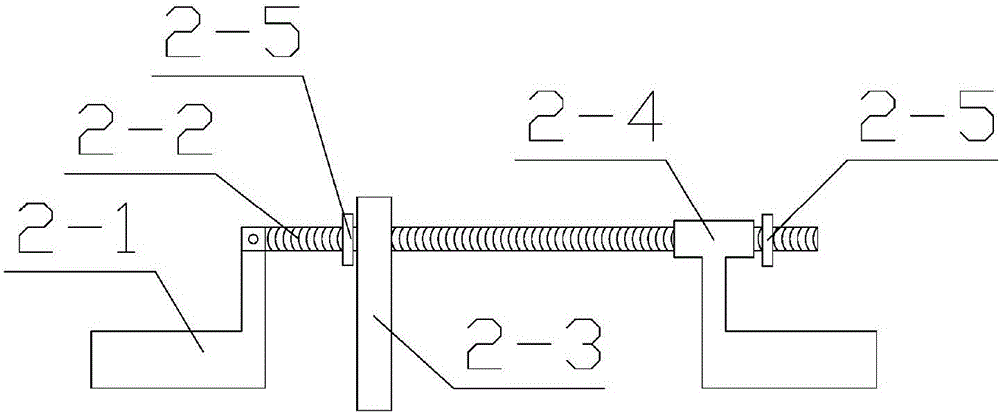

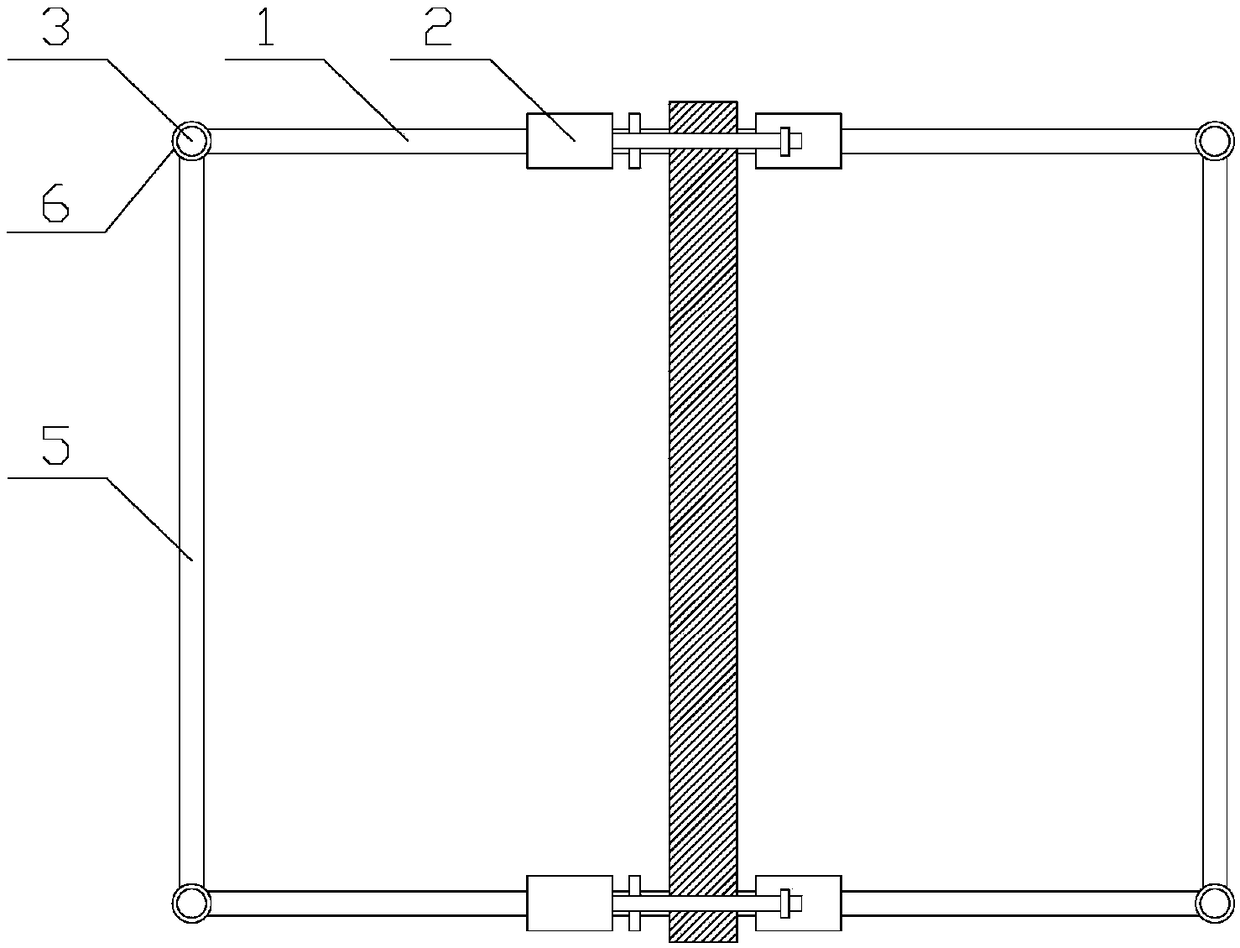

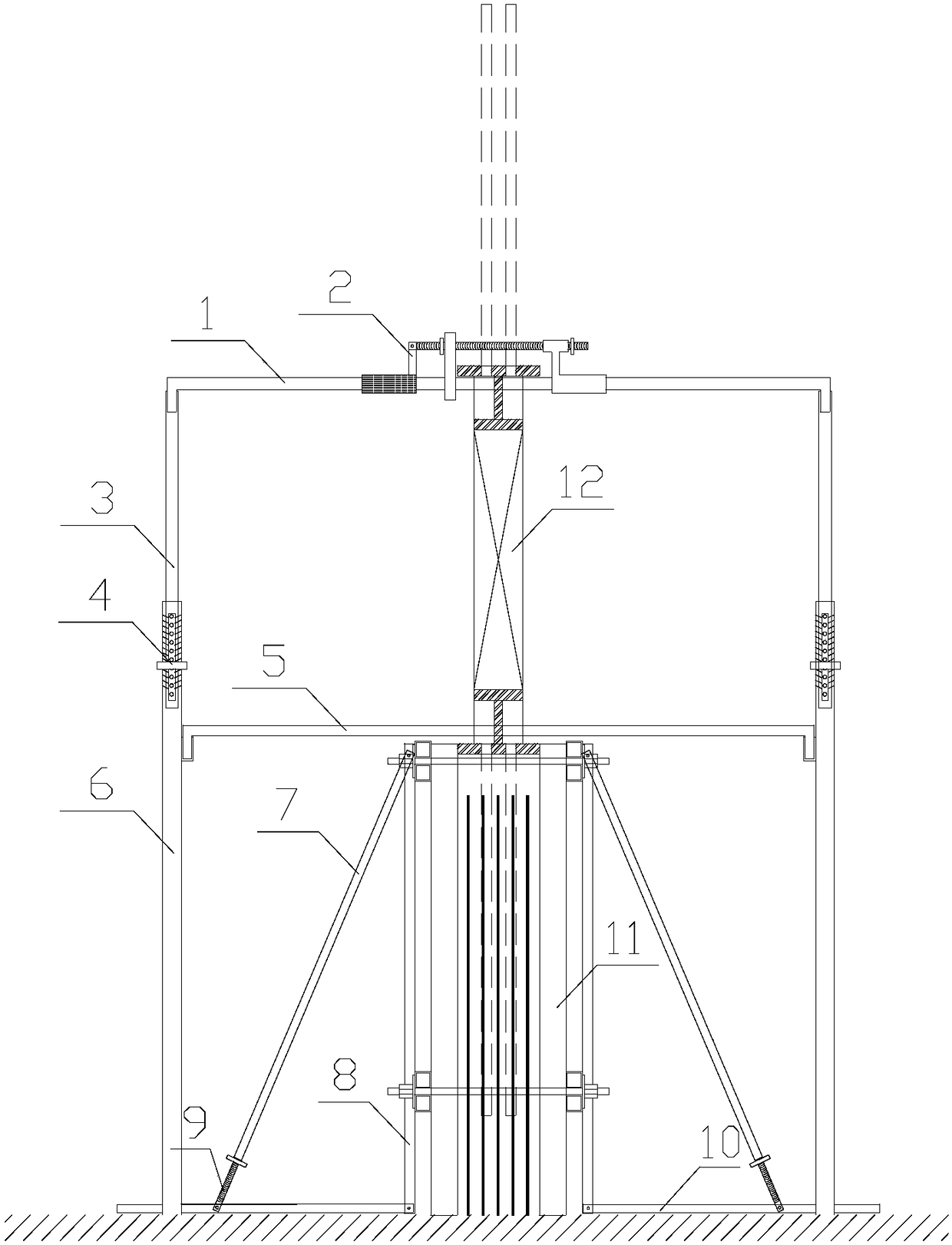

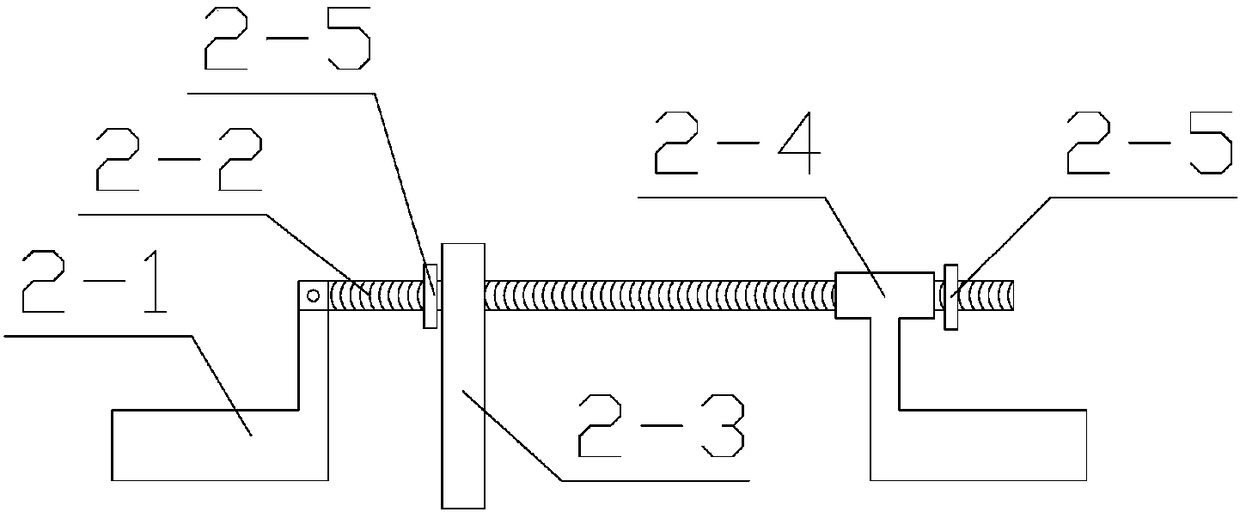

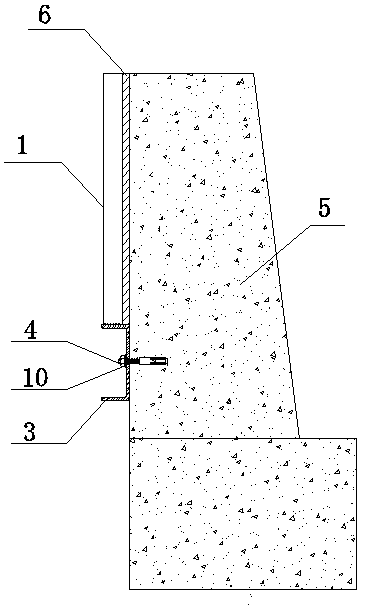

Viscous damping wall integrated supporting system and construction method

ActiveCN106150123AReduce the difficulty of supportGuarantee the construction qualityWallsBuilding material handlingViscous dampingSupporting system

The invention relates to a viscous damping wall integrated supporting system and a construction method. A supporting system device comprises four load bearing upright rods, two load bearing horizontal rods, six horizontal pull rods, four inclined strutting rods, two bottom steel channels, four steel channels and adjusting devices. A damper is supported by the load bearing upright rods and the load bearing horizontal rods, and by means of jackscrews of the inclined strutting rods and the adjusting devices on the load bearing horizontal rods, fine adjustment of the flatness and the perpendicularity of a damping wall is achieved. According to the construction method, viscous damping wall construction and main structure construction are synchronous, the damping wall and a vertical structure are constructed synchronously and are constructed before a horizontal structure, the damper is supported by the load bearing upright rods and the load bearing horizontal rods of the viscous damping wall integrated supporting system, and by means of the jackscrews of the inclined strutting rods and the adjusting devices on the load bearing horizontal rods, the fine adjustment of the flatness and the perpendicularity of the damping wall is achieved. The supporting system has the advantages that manufacturing is easy, the supporting system is made of an ordinary template supporting material, all rod pieces are mounted and dismounted conveniently on site, and the high-precision requirement purpose of damping wall construction is achieved.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

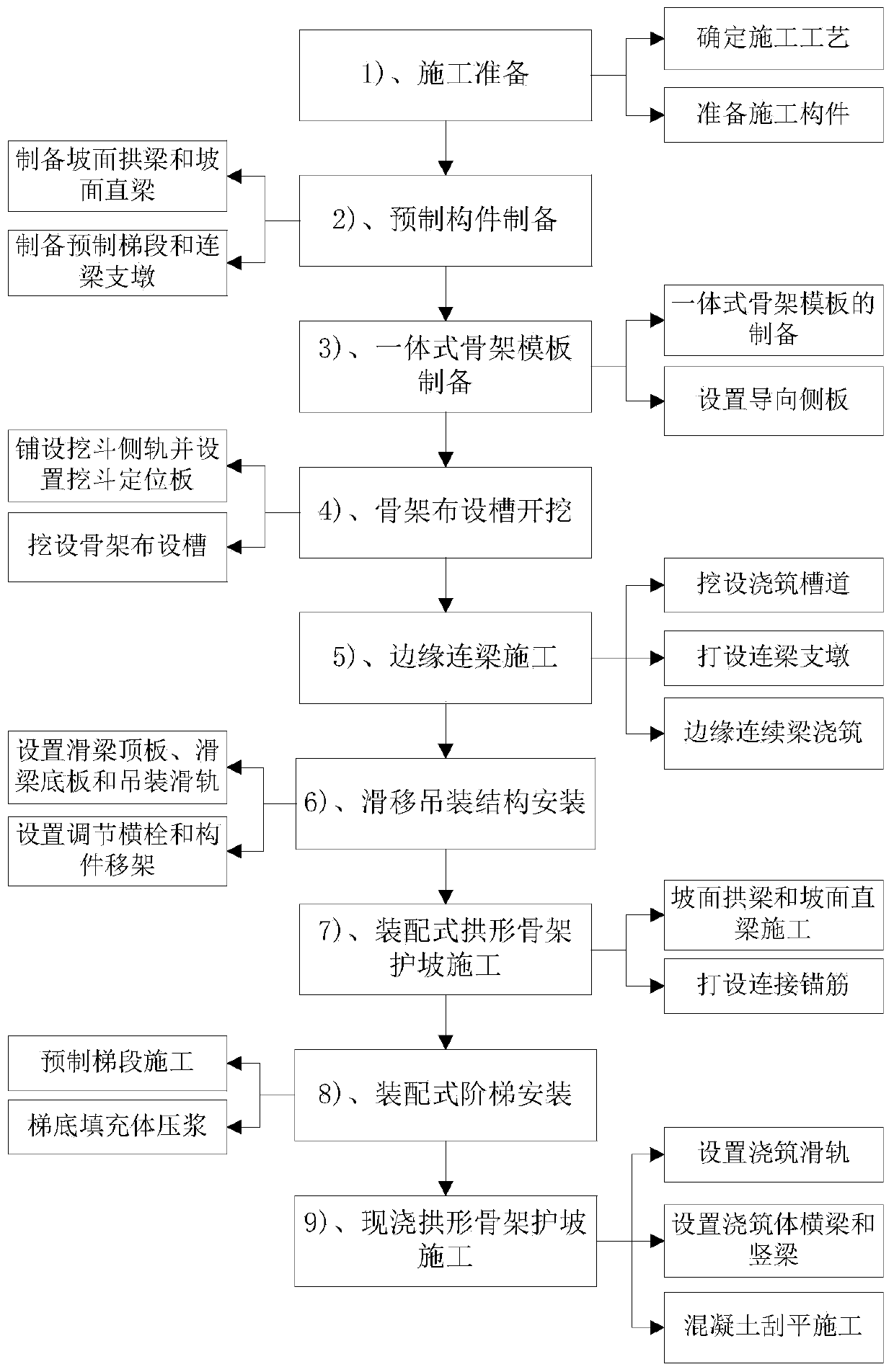

Construction method of concrete arch-shaped framework revetment

ActiveCN111119204AReduce difficultyImprove carrying capacityExcavationsArchitectural engineeringStructural engineering

The invention relates to a construction method of a concrete arch-shaped framework revetment. The construction method comprises the following steps of 1) construction preparation; 2) preparation of aprefabricated member; 3) preparation of an integrated framework template; 4) excavation of a framework arranging slot; 5) construction of an edge coupling beam; 6) mounting of a slip hoisting structure; 7) construction of an assembled arch-shaped framework revetment; 8) mounting of an assembled step; and 9) construction of a cast-in-situ arch-shaped framework revetment. The construction method hasthe beneficial effects that mold top cover plates are separately arranged between a first straight mold and a second straight mold, a third straight mold and a fourth straight mold, a first arc-shaped mold and a second arc-shaped mold and a third arc-shaped mold and a fourth arc-shaped mold of the integrated framework template, so that effects of concrete spouting and integrated framework template enhancing can be met synchronously; and guiding side plates are separately arranged on two sides of the fourth straight mold of the integrated framework template, so that the mounting and positioning difficulty of the integrated framework template can be reduced.

Owner:中国路桥集团西安实业发展有限公司

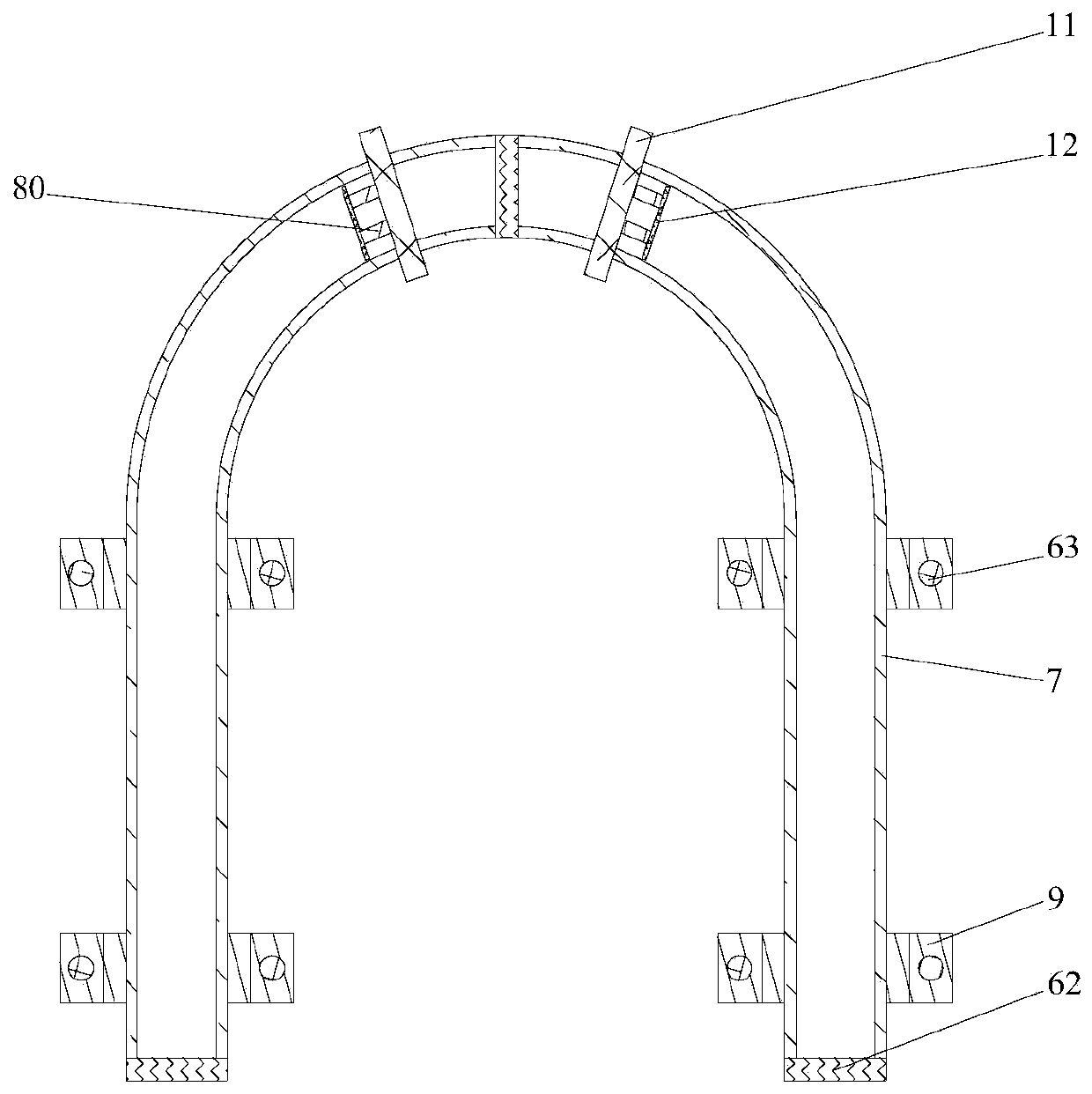

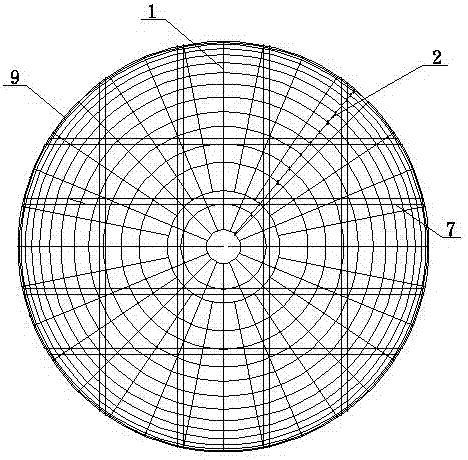

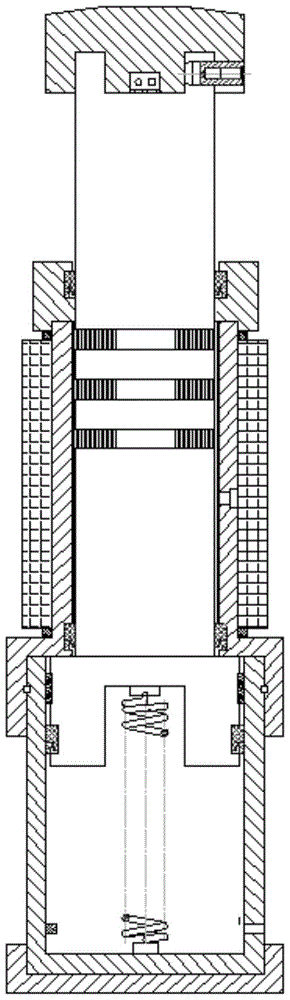

Support lattice shell of concrete spherical shell structure and construction method

ActiveCN107060094ASolve construction problemsReduce the difficulty of supportArched structuresVaulted structuresSupporting systemConcrete beams

The invention discloses a support lattice shell of a concrete spherical shell structure and a construction method. The support lattice shell of the concrete spherical shell structure comprises radial steel tubes, annular steel tubes, annular components of expansion bolts, annular components of built-in fittings, the expansion bolts, the built-in fittings, a concrete wall body, frameworks, spherical shell concrete beams, concrete shells, a support lattice shell, fragment lattice shells, through holes and fixing plates of the built-in fittings. In the construction process of the construction method, firstly the radical steel tubes and the annular steel tubes are mounted one segment by another, and are fixed to a concrete wall body structure through the annular components, and finally the frameworks are laid to form a support lattice shell of the spherical shell structure. By adoption of the construction method, the structure accuracy can be guaranteed, supporting and arranging difficulties of the frameworks can be reduced, and the construction efficiency and the construction quality can be improved. In addition, the support lattice shell of the spherical shell structure is a steel structure, can be recycled, not only can decrease wood consumption, but also is environmentally friendly; and the problems that the molding accuracy of the concrete wall body structure is low and the support system of the concrete wall body structure is difficult are solved, and the problem of framework construction of the concrete wall body structure is solved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

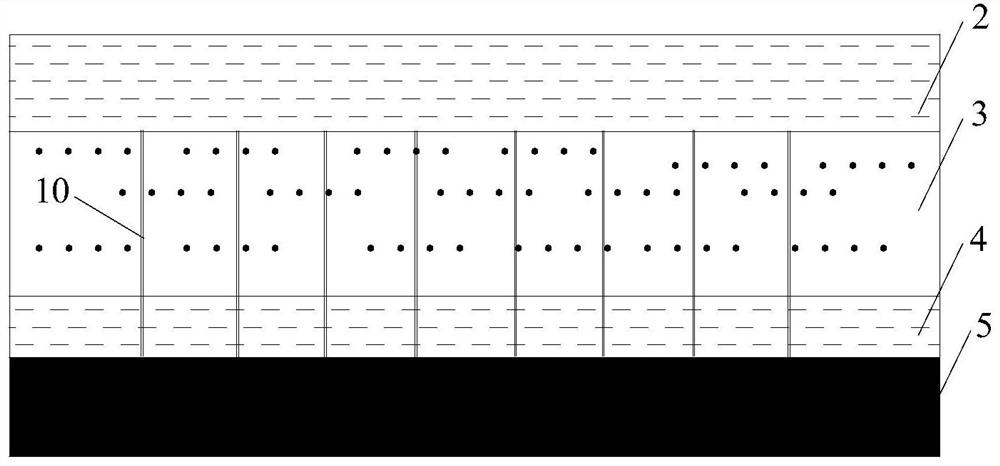

Gob-side entry retaining roadway supporting method for three-soft coal seam coal-pillar-free mining

ActiveCN111963197AAvoid breakingImprove integrityMining devicesUnderground chambersMining engineeringCoal pillar

The invention discloses a gob-side entry retaining roadway supporting method for three-soft coal seam coal-pillar-free mining. The method comprises the steps that a row of lockrand anchor cables are constructed on the part, close to a coal side, of an advance roadway; an iron gauze is laid on the part, close to the goaf side, of a lagging roadway, and a silicomanganese steel pipe gangue blocking column is arranged outside the iron gauze in a blocking mode; a movable base is laid on a bottom plate of a following working face of a reserved roadway, two combined hydraulic supports are installed on the movable base, one combined hydraulic support is installed through a solid coal side, the other combined hydraulic support is installed through a goaf, and the combined hydraulic supports are lifted to initial supporting force after installation is completed; and after the length of the reserved roadway exceeds the preset length, the combined hydraulic supports are dismantled, and when the combined hydraulic supports are dismantled, the far-end combined hydraulic support is dismantled step by step along with advancing of the working face from the preset length lagging behind the working face. The three-soft coal seam roadway surrounding rock deformation control effect is better, and the effects of high supporting strength and high safety are achieved for goaf side gangue blocking supporting and rear roadway surrounding rock top and bottom plates.

Owner:SHAANXI COAL & CHEM TECH INST

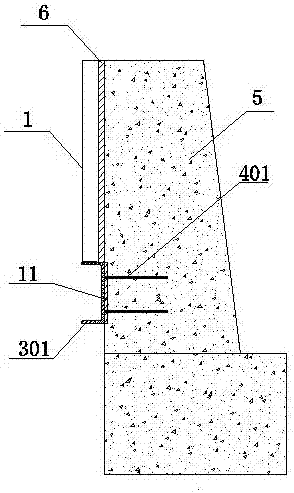

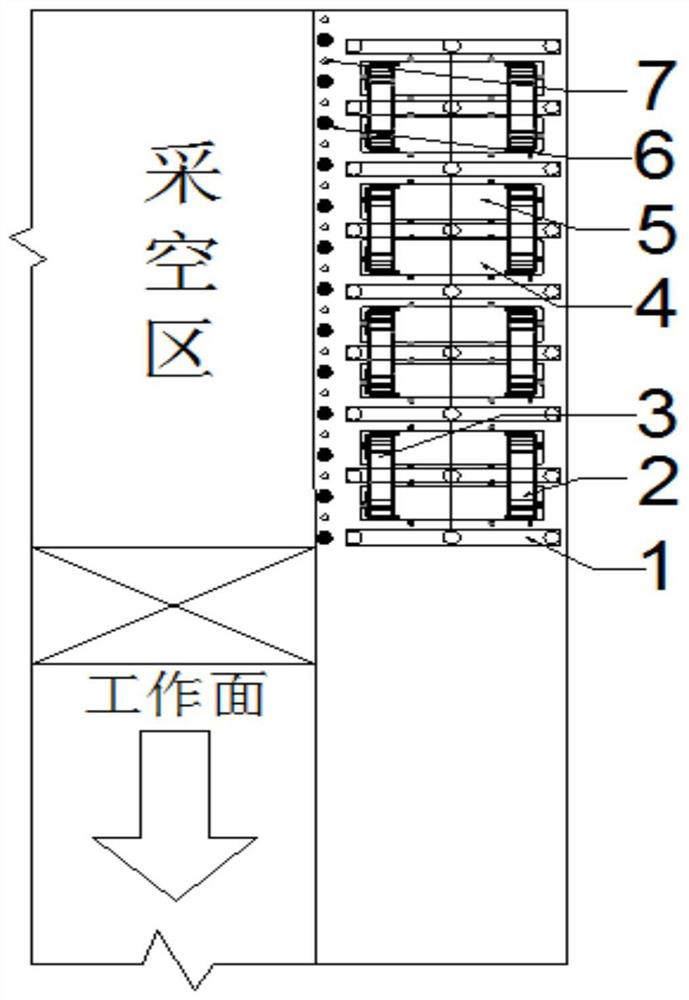

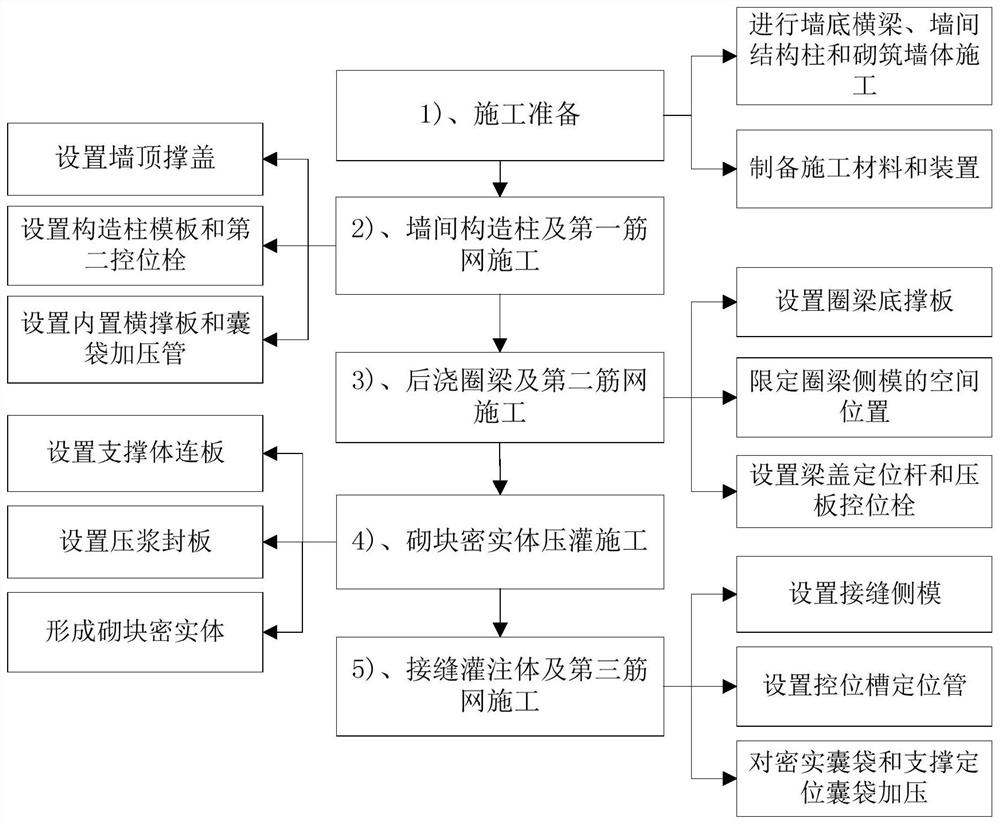

Frame shear wall column and masonry filler wall connecting structure and construction method

ActiveCN112609841AReduce difficultyReduce the impactWallsBuilding material handlingJoint (building)Quoin

The invention relates to a frame shear wall column and masonry filler wall connecting structure and a construction method. A wall top supporting cover is arranged at the top end of a masonry wall; a guide side plate, a first position control bolt and a second position control bolt are used for controlling the position of a constructional column formwork; a side supporting bag and a pressure test body are used for controlling the pouring quality of a constructional column; a beam formwork position correcting bolt and an opposite-pull anchor bar are used for limiting a ring beam side formwork; a wall top connecting bar and a wall top connecting groove are arranged at the top of the masonry wall; the quality of a post-poured ring beam is improved through a beam top pressing plate; grouting sealing plates are arranged on the two sides of the post-poured ring beam in a supported mode respectively; an external grouting pipe is used for grouting a gap of the masonry wall to form a building block dense body; a joint side formwork at the joint of the inter-wall structural column and the masonry wall is in a broken line shape; the joint pouring quality is controlled through a dense bag; a first rib net and the constructional column formwork are synchronously arranged; a second rib net and the ring beam side formwork are synchronously arranged; and a third rib net and the joint side formwork are synchronously arranged. According to the invention, the formwork supporting difficulty can be reduced, the concrete pouring quality can be improved, and the performance of the connecting structure can be improved.

Owner:四川尧顺建设集团有限公司

Micro-disturbance cutting-free blasting method

ActiveCN111854551AReduce consumptionThe amount of opening construction is smallUnderground miningBlastingLodeExplosive Agents

The invention relates to a micro-disturbance cutting-free blasting method which is applied to approach mining of a weak broken narrow lode. The micro-disturbance cutting-free blasting method comprisesthe following steps of (1) through measurement and data analysis, determining a position of a main weak structure face of a tunnel face; (2) digging slotting holes in two sides or one side of the weak structure face, and digging peripheral holes in the periphery of the tunnel face; (3) after carrying out drift stoping on a higher slice, laying a buffer layer with the thickness ranging from 10 to20cm on a bottom plate; (4) reserving wall protection ores with the thickness ranging from 10 to 20cm on two sides of an extracting drift; (5) adopting full-hole charging; and (6) adopting inverse differential initiation. Through the implementation of the steps, the damage degree of blasting vibration to a higher slice cemented filling layer and upper and lower wall rocks is solved fundamentally,and the difficulty and the cost of late supporting are effectively reduced. According to the micro-disturbance cutting-free blasting method provided by the invention, a weak structure of a rock mass body is used as a free face, and the wall protection ores are reserved on two sides of the extraction drift, so that the arrangement number of blast holes is greatly reduced, the construction amount oftrepanning and the consumption of explosives are further greatly reduced, and the comprehensive mining efficiency is improved.

Owner:嵩县前河矿业有限责任公司 +1

Fireproof vertical plate and fireproof plugging integrated construction process

ActiveCN114718229AReduce the difficulty of operationReduce the difficulty of supportWallsClimate change adaptationMechanical engineeringIndustrial engineering

The invention relates to a fireproof vertical plate and fireproof plugging integrated construction technology, belongs to the field of building technology, and adopts a galvanized steel sheet and fireproof rock wool form node construction means, so that the support difficulty can be reduced, the installation precision is ensured, the operation difficulty of workers can be reduced, the construction period is effectively shortened, and the construction cost is reduced. And the production cost is saved.

Owner:THE THIRD CONSTR OF CHINA CONSTR FIRST GROUP +1

Auxiliary supporting device for 500kV electroscope

PendingCN113719715AGuaranteed accuracyStable supportStands/trestlesElectroscopeMechanical engineering

The invention relates to the technical field of electric power, and discloses an auxiliary supporting device for a 500kV electroscope, which comprises an insulating rod used for supporting the electroscope at a preset height and a plurality of auxiliary supporting rod used for supporting the insulating rod, wherein the length of each auxiliary supporting rod is larger than the length from the middle position of the insulating rod to the bottom end of the insulating rod, the top end of each auxiliary supporting rod is fixedly connected to the middle position of the insulating rod, and the auxiliary supporting rods are arranged around the insulating rod at uniform included angles so as to support the insulating rod on the ground. The auxiliary supporting device can replace a manual lifting mode, can be used for stably and reliably supporting the electroscope, lowers the supporting difficulty, improves the efficiency, improves the supporting stability, can accurately control the distance between the electroscope and an electrified part of 500kV equipment, and guarantees the accuracy of a measurement result.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU

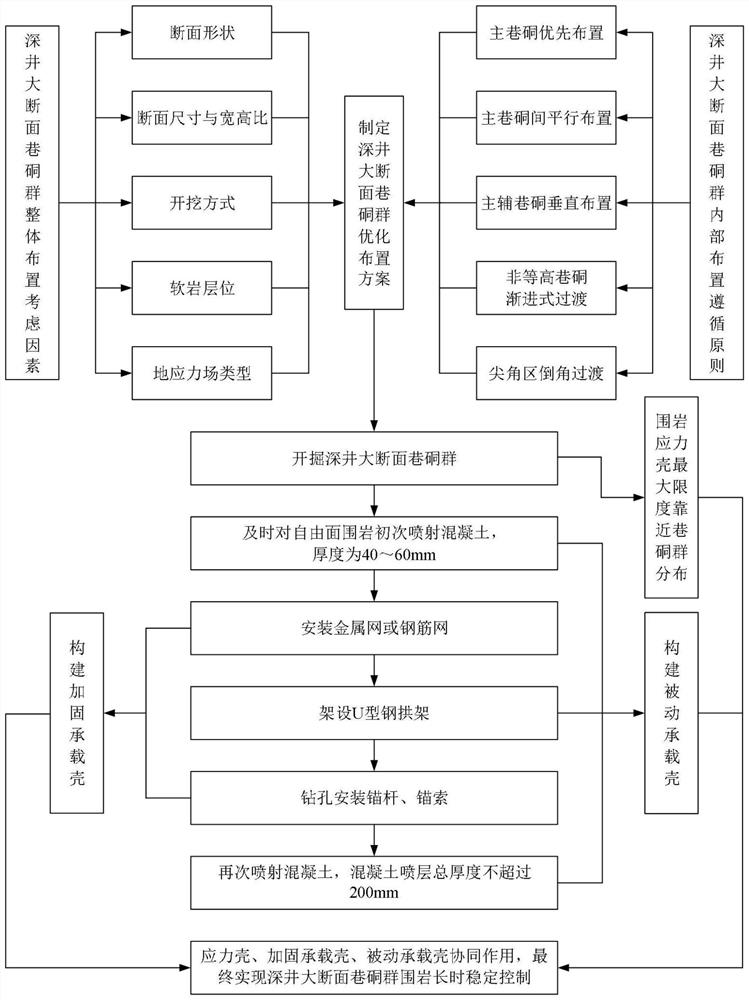

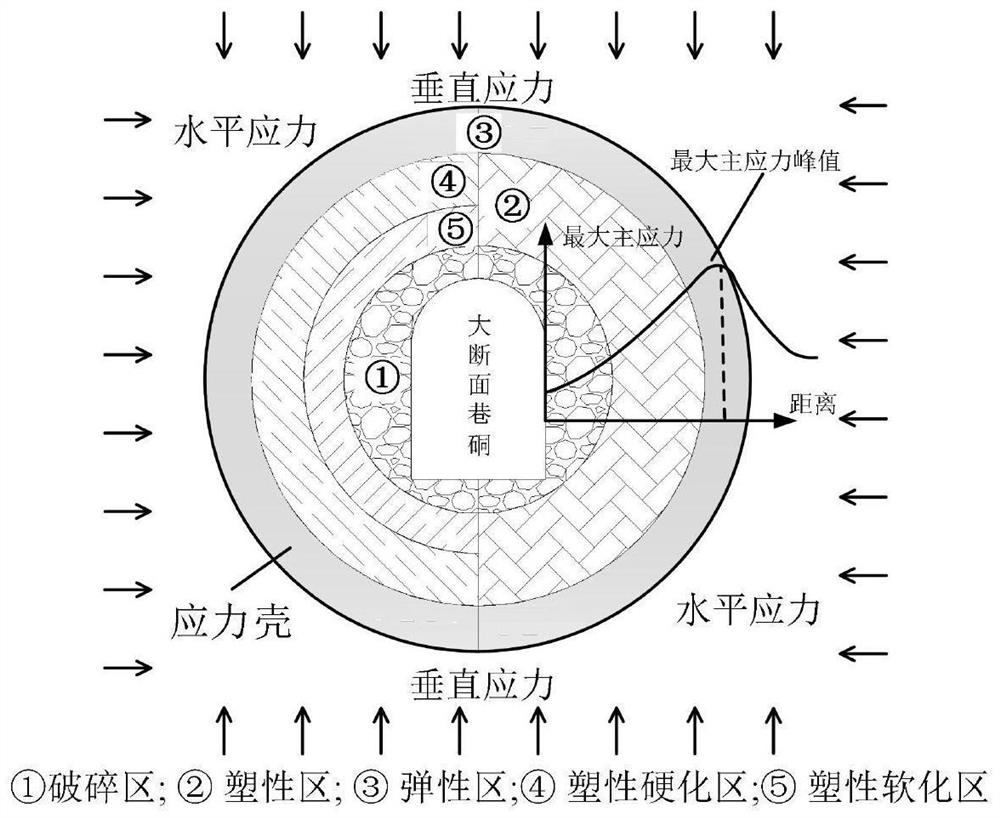

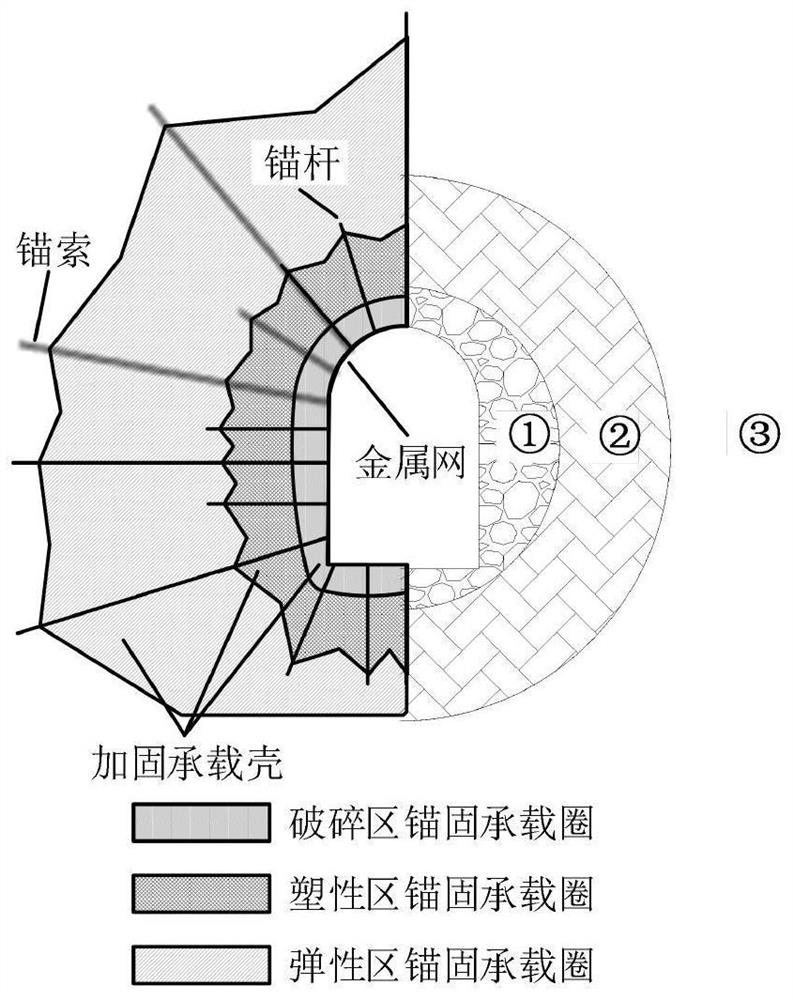

Three-shell collaborative supporting method for surrounding rock of deep well large-section roadway and chamber group

ActiveCN113356895AReduce the difficulty of supportUnderground chambersTunnel liningClassical mechanicsGradual transition

The invention relates to a three-shell collaborative supporting method for surrounding rock of a deep well large-section roadway and chamber group. Based on the factors of the section shape, the optimal arrangement axial direction, the section size and aspect ratio, the excavation mode and the soft rock stratum position, the overall arrangement scheme of the deep well large-section roadway and chamber group is preliminarily planned; meanwhile, based on the five principles of preferential arrangement of the main roadway and chamber, parallel arrangement of the main roadway and chamber, mutual perpendicular arrangement of the main roadway and chamber and the auxiliary roadway and chamber, gradual transition of the non-equal-height roadway and chamber, and chamfer transition of sharp corner areas, a deep well large-section roadway and chamber group optimization arrangement scheme is finally formulated; then based on the formulated deep well large-section roadway and chamber group optimization arrangement scheme, the three-shell collaborative supporting method is further formulated, coordinated deformation and unified bearing of a supporting structure and surrounding rock can be achieved through the combined action of a reinforcing bearing shell and a passive bearing shell, and it is ensured that a stress shell is in a steady state; and the problems that the deformation amount of the surrounding rock of the deep well large-section roadway and chamber group is large, and the supporting structure is prone to instability are solved, and long-time stable control over the surrounding rock of the deep well large-section roadway and chamber group is achieved.

Owner:CHINA UNIV OF MINING & TECH

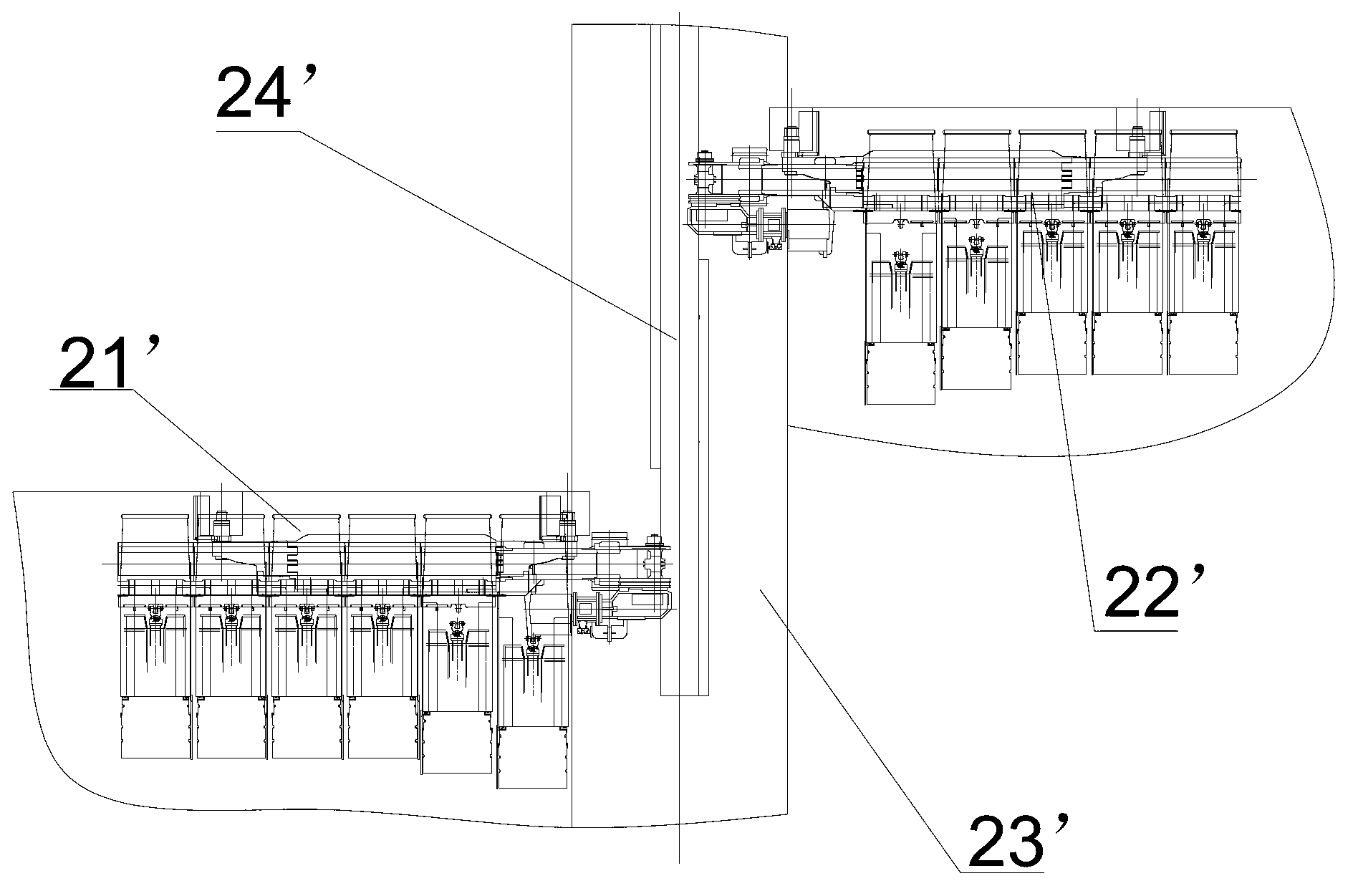

Transfer machine middle groove and transfer machine

ActiveCN102795449ADoes not affect unloading distanceReduce widthConveyorsSlitting machinesShortest distanceArchitectural engineering

The invention provides a transfer machine middle groove which comprises a first baffle, a first groove ledge, a middle plate, a bottom plate, a second groove ledge and a second baffle, wherein the bottom plate and the middle plate are fixedly connected with the first groove ledge and the second groove ledge respectively; the middle plate is positioned above the bottom plate; and the first baffle and the second baffle are fixedly connected with the first groove ledge and the second groove ledge respectively. The transfer machine middle groove further comprises a first section, a second section and a third section, wherein the second section is positioned between the first section and the third section; both ends of the second section are fixedly connected with one end of the first section and one end of the third section; and the first section and the third section are mutually parallel straight sections, but are not positioned in the same straight line. The invention further provides a transfer machine. As the bent middle groove is adopted, the transfer machine middle groove can meet short distance bending requirements and bent section fixity requirements; and in addition, the width of a transport gate road is reduced when the unloading distance between a scraper conveyer head and the transfer machine is ensured, therefore, the support difficulty and tunneling cost of the transport gate road are reduced.

Owner:SANY HEAVY EQUIP

Constructional column top concreting method

ActiveCN102535849BGuarantee the construction qualityReduce the difficulty of supportBuilding material handlingFloor slabEngineering

The invention relates to a constructional column top concreting method, which is characterized in that steps include embedding sleeves on an upper-layer floor slab at the position of a constructional column during structural construction, embedding exhaust tubes beside the sleeves, and concreting the top of the constructional column via the embedded sleeves during construction of the constructional columns. The heights of the sleeves and the exhaust tubes are equal to the height of a structural beam or the thickness of a structural plate. The constructional column top concreting method has the advantages that installation and concreting are convenient, and the concreting quality of the constructional column is improved. The problem of incompact concreting of the top of the constructional column is resolved.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU +3

Viscous damping wall integrated support system and construction method

ActiveCN106150123BReduce the difficulty of supportGuarantee the construction qualityWallsBuilding material handlingSupporting systemViscous damping

The invention relates to a viscous damping wall integrated supporting system and a construction method. A supporting system device comprises four load bearing upright rods, two load bearing horizontal rods, six horizontal pull rods, four inclined strutting rods, two bottom steel channels, four steel channels and adjusting devices. A damper is supported by the load bearing upright rods and the load bearing horizontal rods, and by means of jackscrews of the inclined strutting rods and the adjusting devices on the load bearing horizontal rods, fine adjustment of the flatness and the perpendicularity of a damping wall is achieved. According to the construction method, viscous damping wall construction and main structure construction are synchronous, the damping wall and a vertical structure are constructed synchronously and are constructed before a horizontal structure, the damper is supported by the load bearing upright rods and the load bearing horizontal rods of the viscous damping wall integrated supporting system, and by means of the jackscrews of the inclined strutting rods and the adjusting devices on the load bearing horizontal rods, the fine adjustment of the flatness and the perpendicularity of the damping wall is achieved. The supporting system has the advantages that manufacturing is easy, the supporting system is made of an ordinary template supporting material, all rod pieces are mounted and dismounted conveniently on site, and the high-precision requirement purpose of damping wall construction is achieved.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

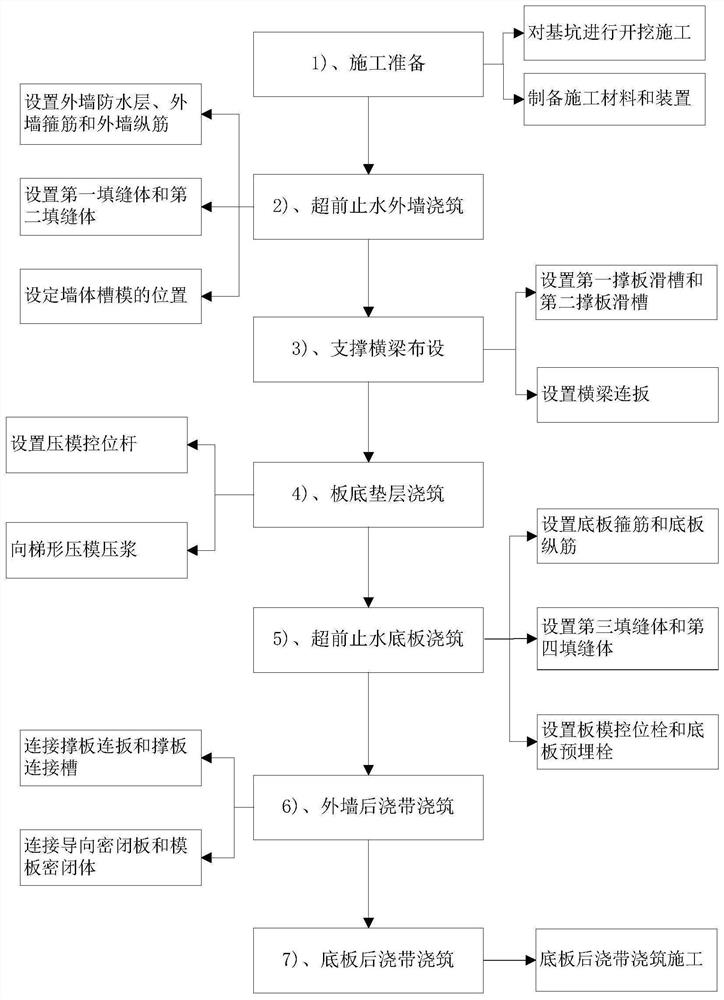

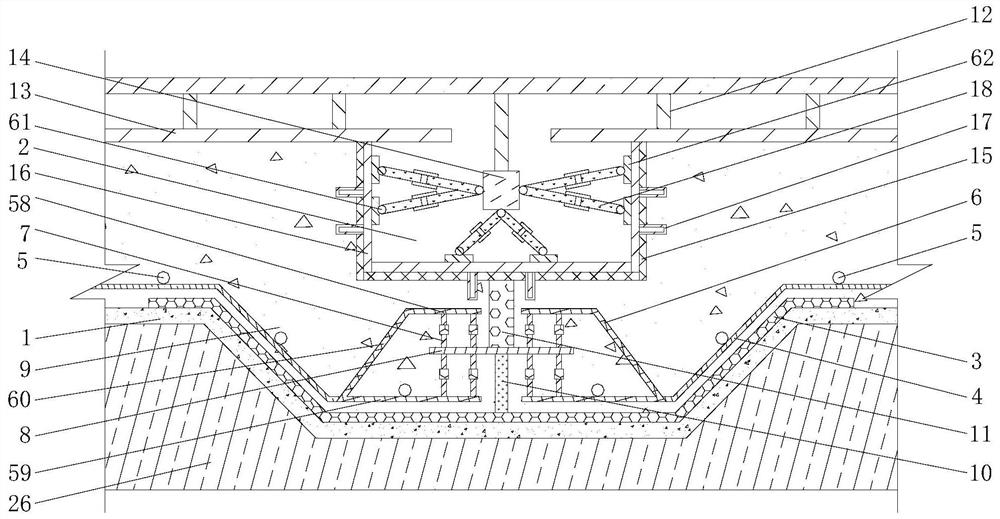

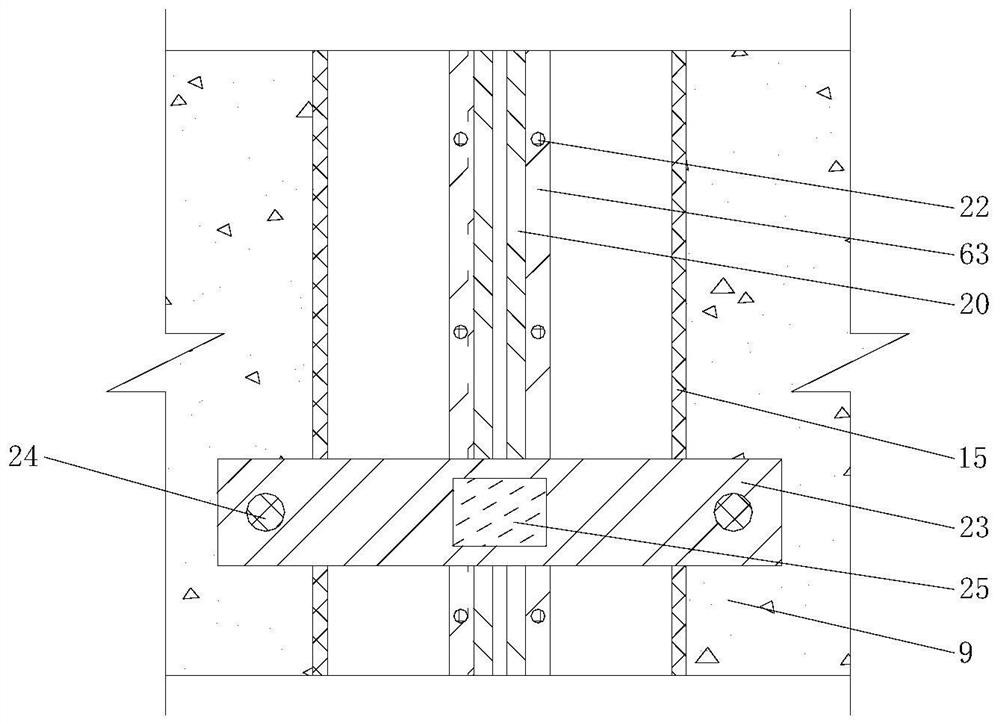

Construction method of advanced water stop and post pouring belt

ActiveCN112695806BImprove positioning accuracyPrecise control of spatial positionArtificial islandsProtective foundationWater stopArchitectural engineering

The invention relates to a construction method of a water-stopping post-pouring belt. The scheme includes firstly preparing for construction; pouring an exterior water-stopping wall in advance; laying out a support structure; pouring a slab bottom cushion; Post-pouring belt: After pouring the base plate post-casting belt, the difficulty of wall post-casting belt construction is effectively reduced through the above steps, and the laying quality of the advanced water stop board can be significantly improved at the same time.

Owner:亚都建设集团有限公司

A self-regulating magnetorheological fluid single pillar

InactiveCN104775835BImprove reliabilityReduce the difficulty of supportProps/chocksSupporting systemHydraulic cylinder

Owner:CHINA UNIV OF MINING & TECH

Supporting reticulated shell of a concrete spherical shell structure and its construction method

ActiveCN107060094BSolve construction problemsReduce the difficulty of supportArched structuresVaulted structuresSupporting systemConcrete beams

The invention discloses a support lattice shell of a concrete spherical shell structure and a construction method. The support lattice shell of the concrete spherical shell structure comprises radial steel tubes, annular steel tubes, annular components of expansion bolts, annular components of built-in fittings, the expansion bolts, the built-in fittings, a concrete wall body, frameworks, spherical shell concrete beams, concrete shells, a support lattice shell, fragment lattice shells, through holes and fixing plates of the built-in fittings. In the construction process of the construction method, firstly the radical steel tubes and the annular steel tubes are mounted one segment by another, and are fixed to a concrete wall body structure through the annular components, and finally the frameworks are laid to form a support lattice shell of the spherical shell structure. By adoption of the construction method, the structure accuracy can be guaranteed, supporting and arranging difficulties of the frameworks can be reduced, and the construction efficiency and the construction quality can be improved. In addition, the support lattice shell of the spherical shell structure is a steel structure, can be recycled, not only can decrease wood consumption, but also is environmentally friendly; and the problems that the molding accuracy of the concrete wall body structure is low and the support system of the concrete wall body structure is difficult are solved, and the problem of framework construction of the concrete wall body structure is solved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com