Patents

Literature

106 results about "Dynamic priority scheduling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

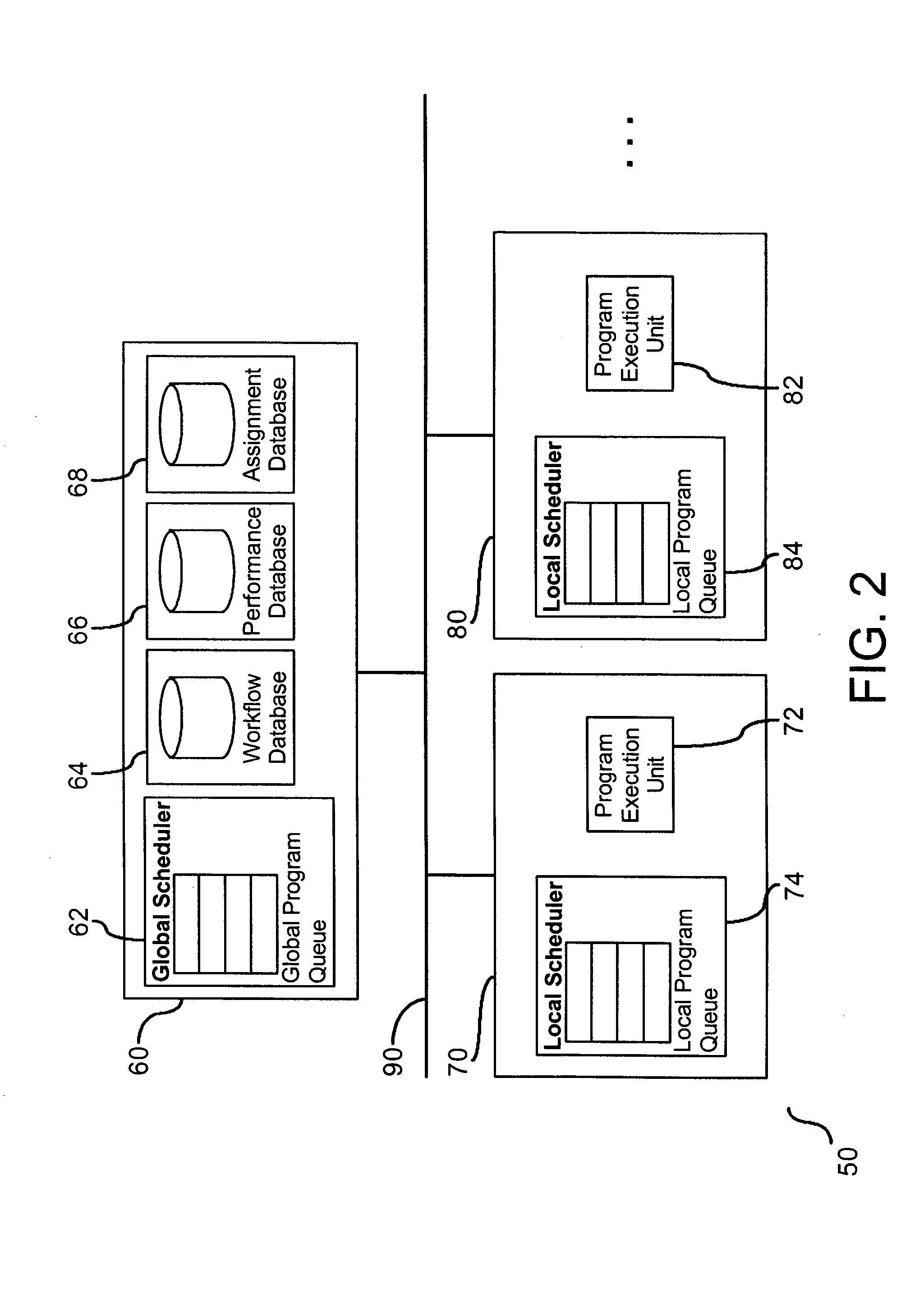

Dynamic priority scheduling is a type of scheduling algorithm in which the priorities are calculated during the execution of the system. The goal of dynamic priority scheduling is to adapt to dynamically changing progress and form an optimal configuration in self-sustained manner. It can be very hard to produce well-defined policies to achieve the goal depending on the difficulty of a given problem.

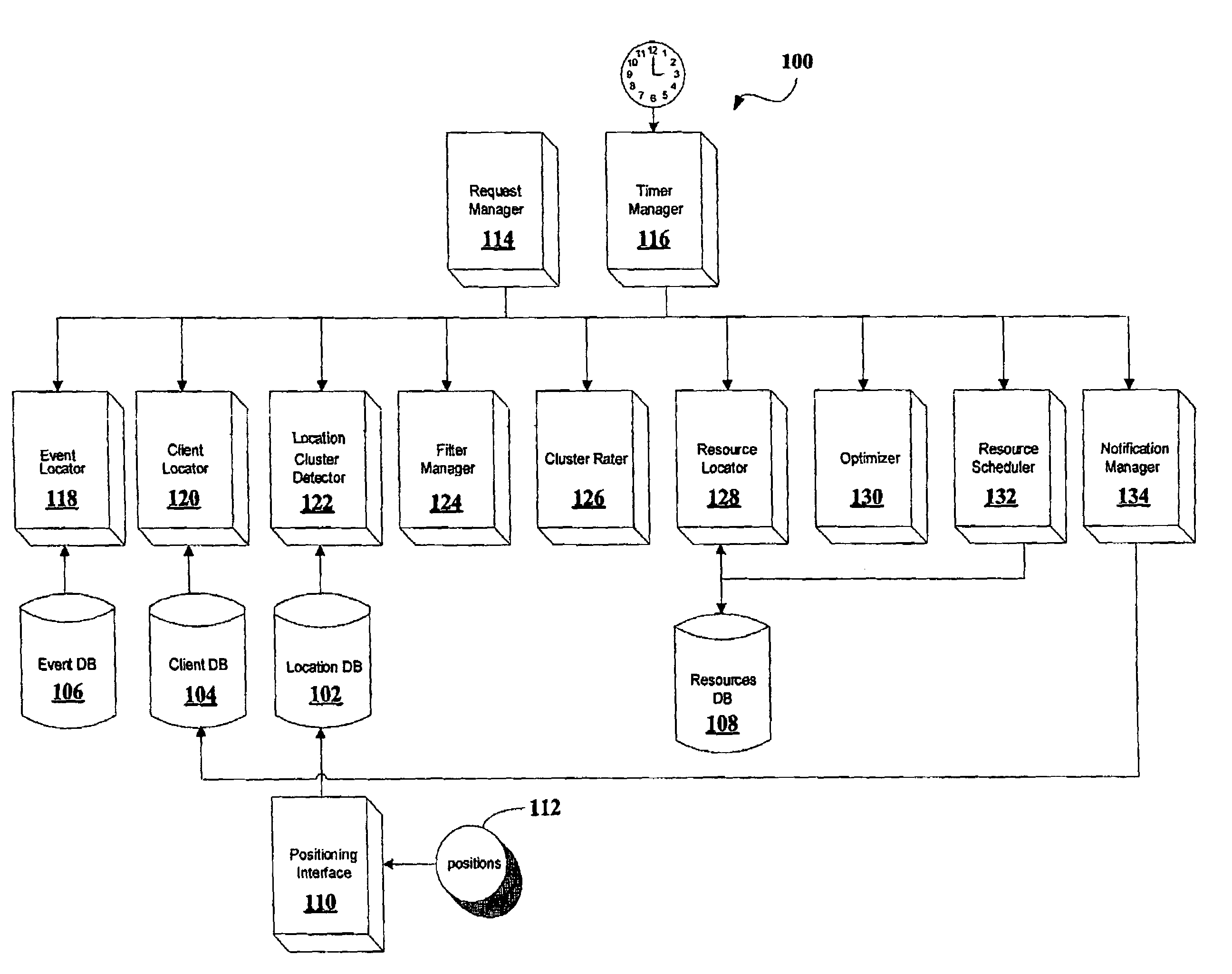

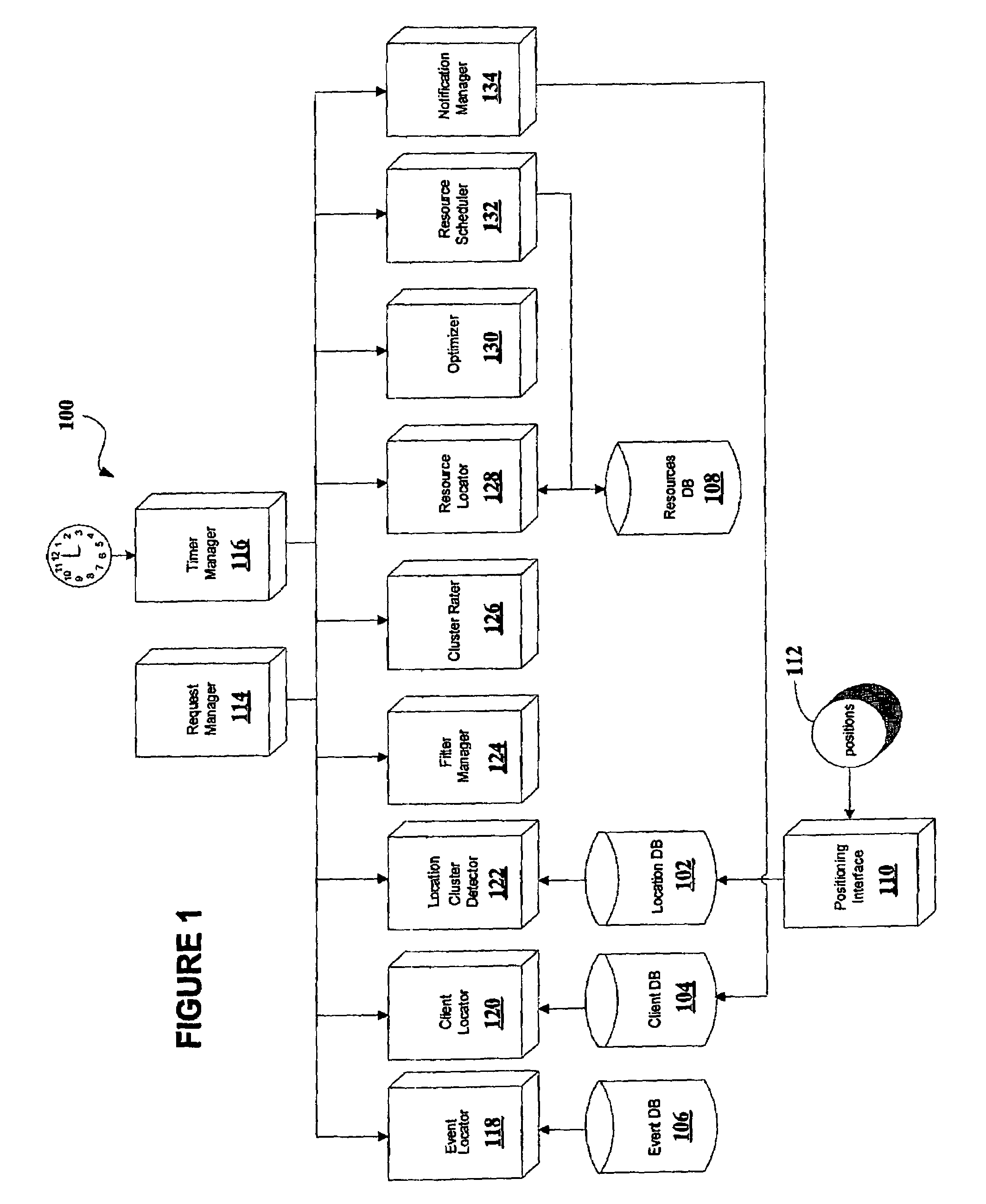

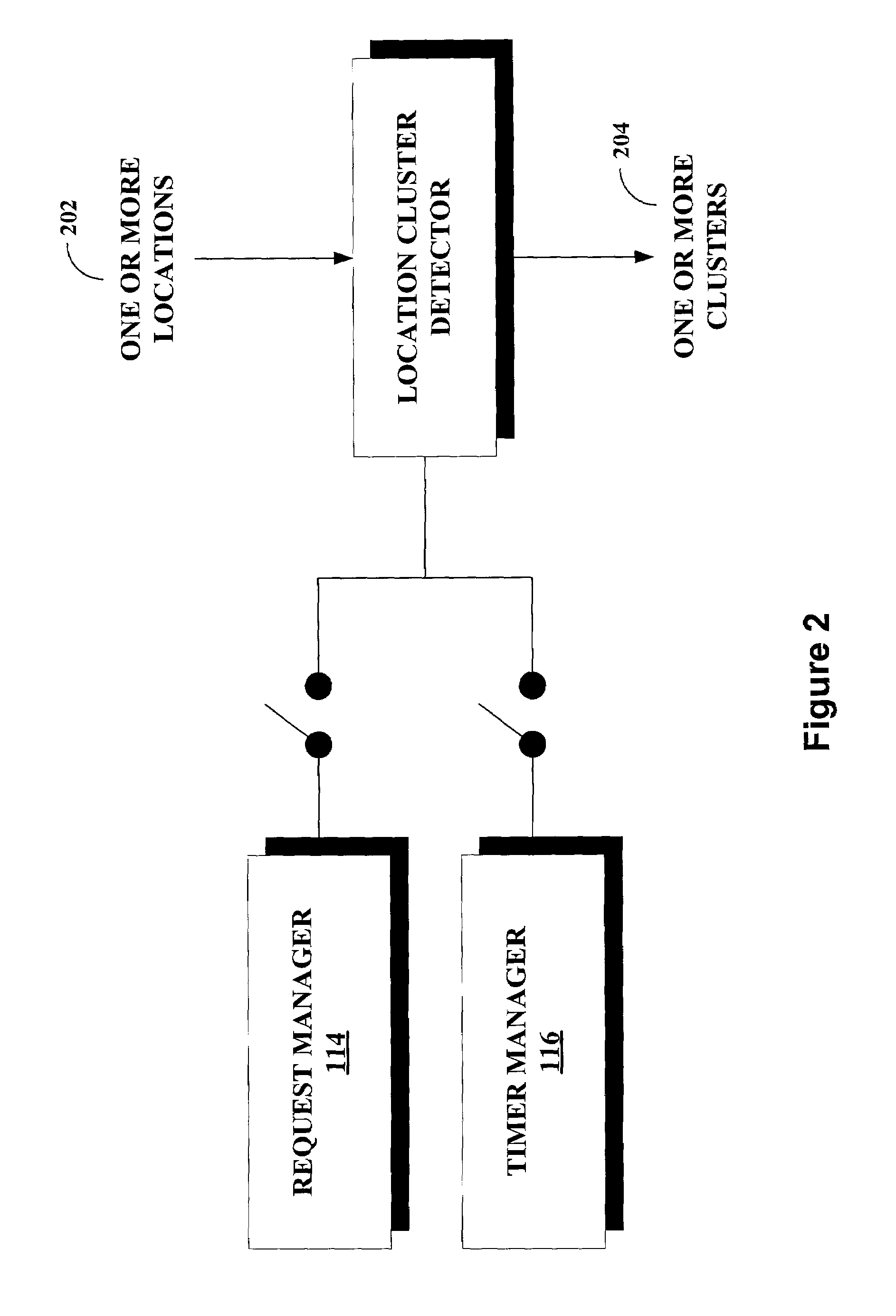

Dynamic resource scheduling to optimize location of meeting participants

A global positioning system (GPS) is used to detect locations (dynamic locations) associated with meeting participants and the proximity between participants is used to create one or more location clusters. Next, the availability of suitable meeting locations (static locations) are identified and an optimum meeting location, given the participant clusters and their proximity to the available meeting locations, is determined. Additionally, the center of mass associated with each of the clusters is also used to determine optimal meeting locations. Lastly, participants are notified regarding the optimized location for the meeting.

Owner:IBM CORP

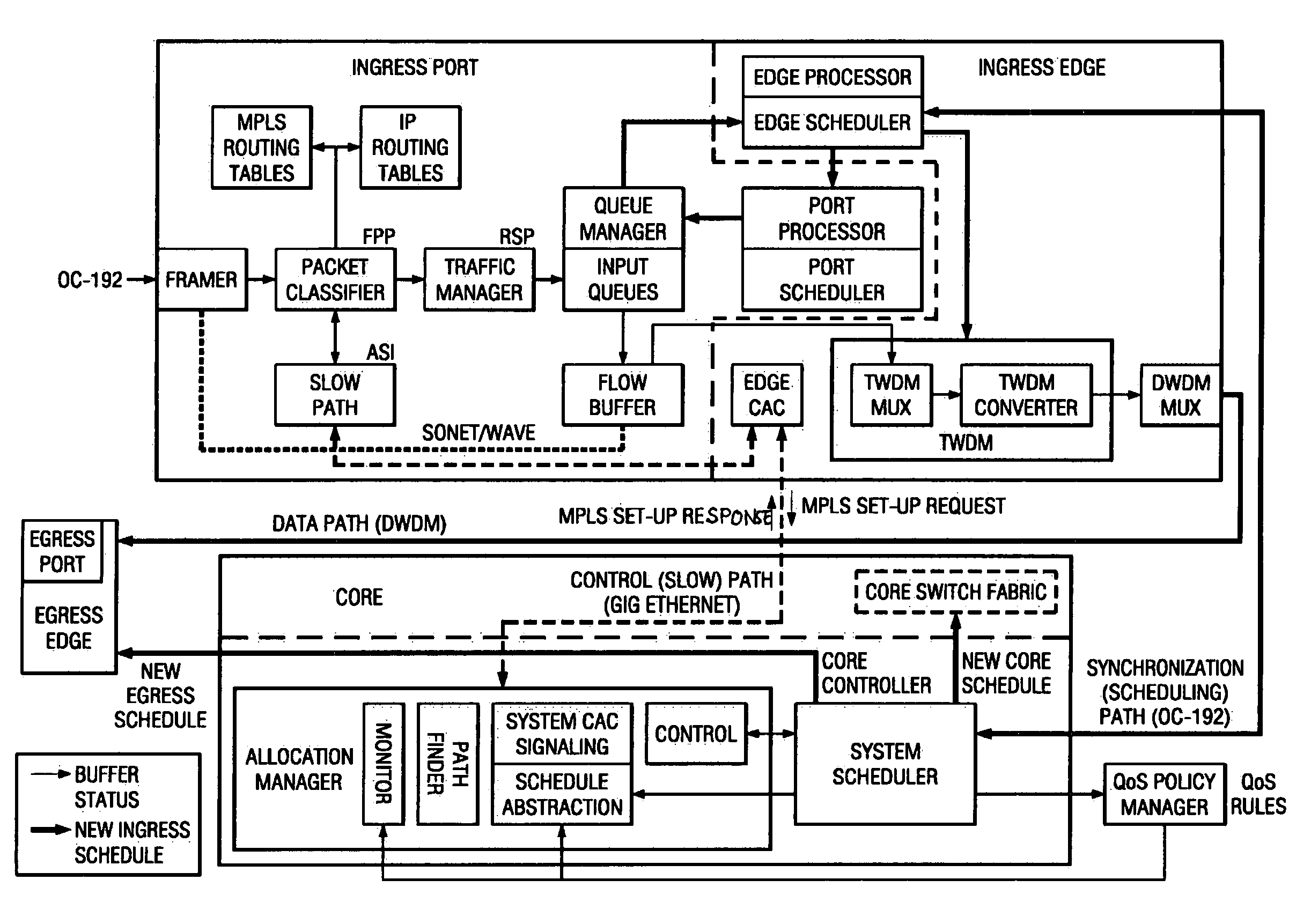

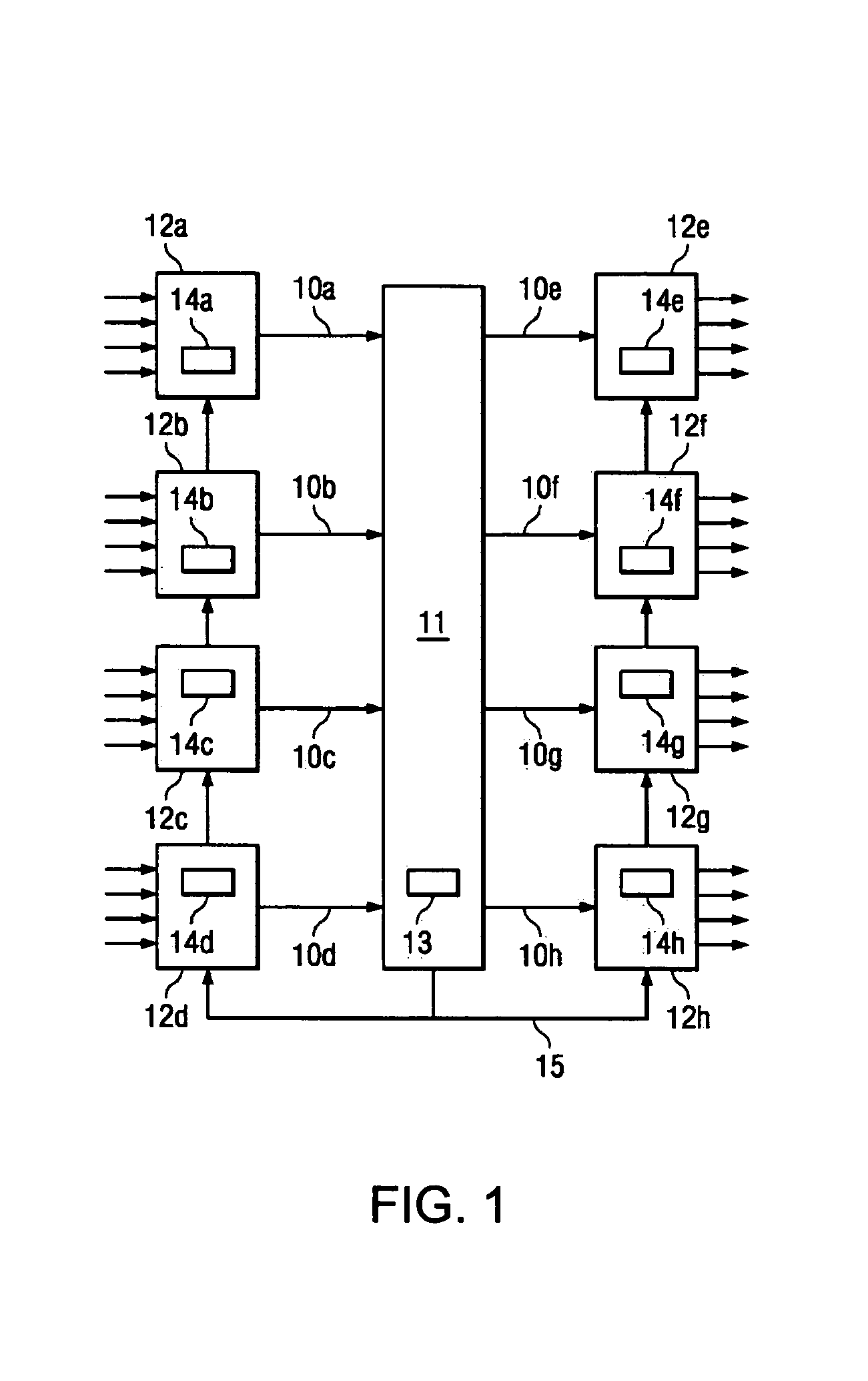

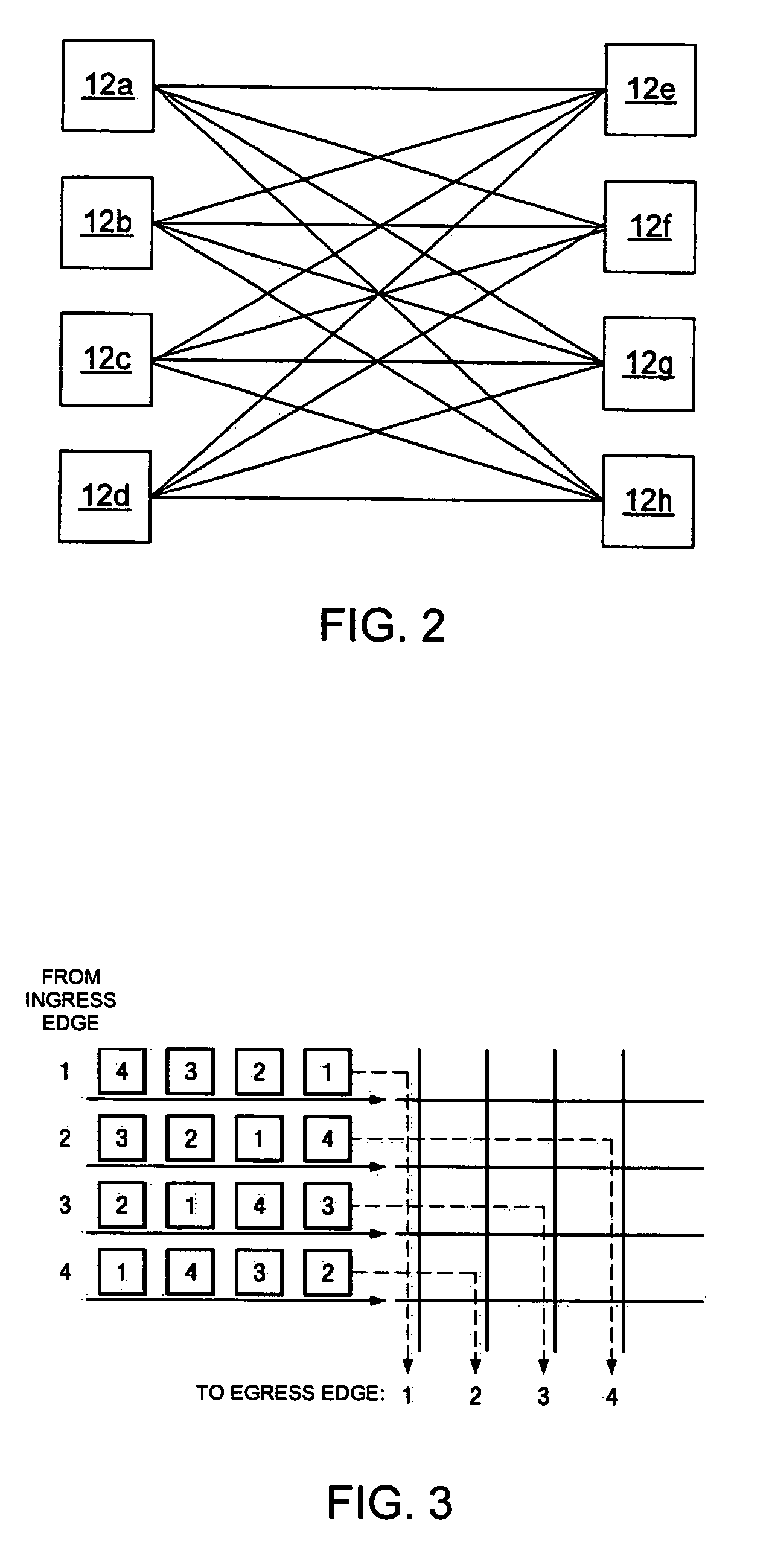

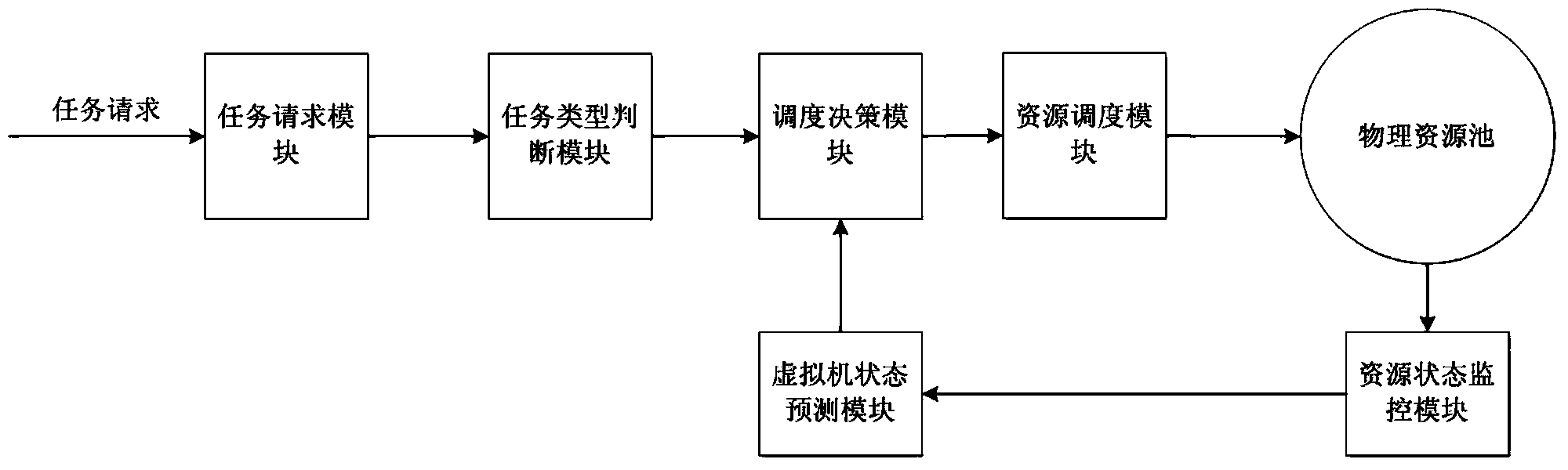

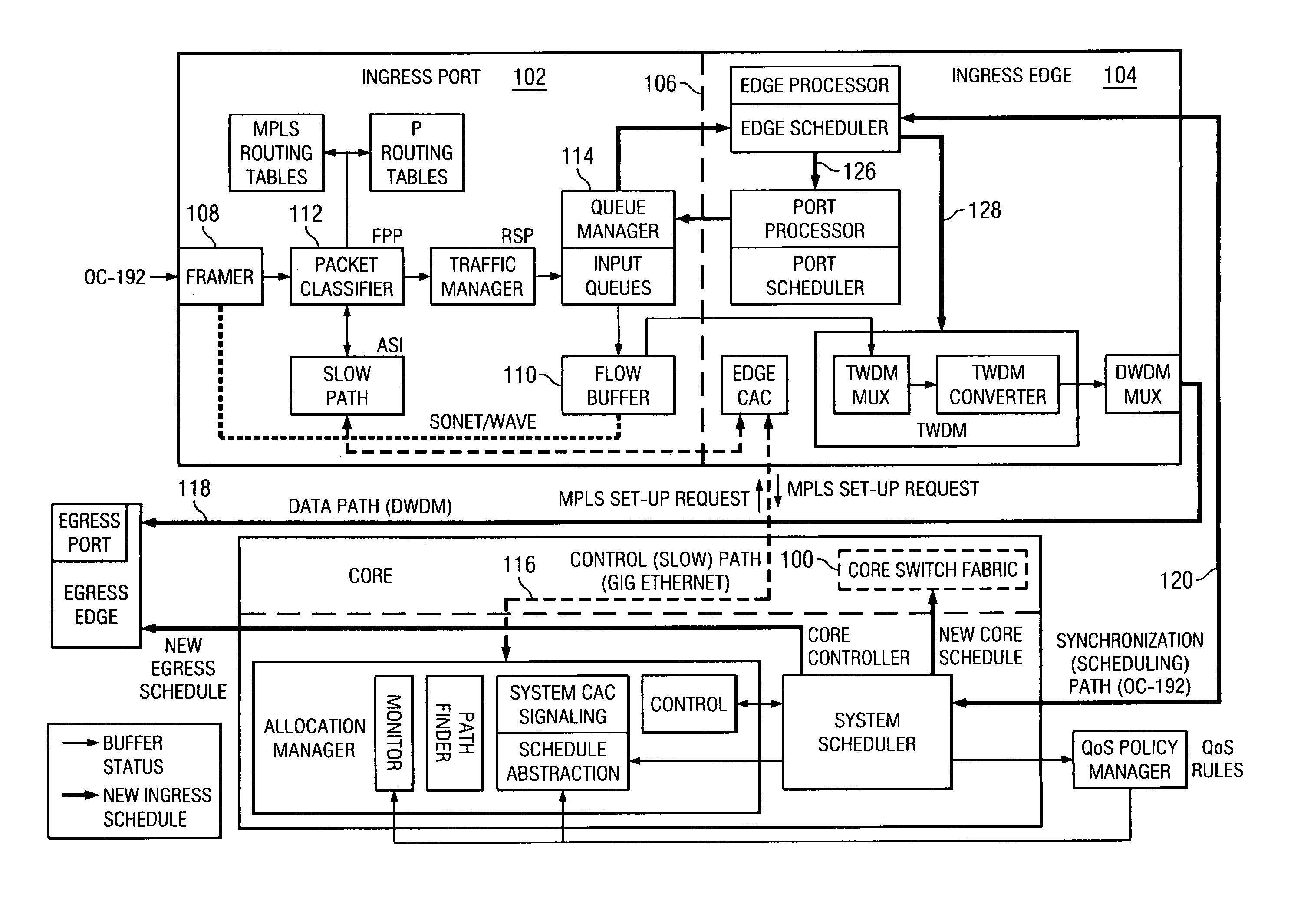

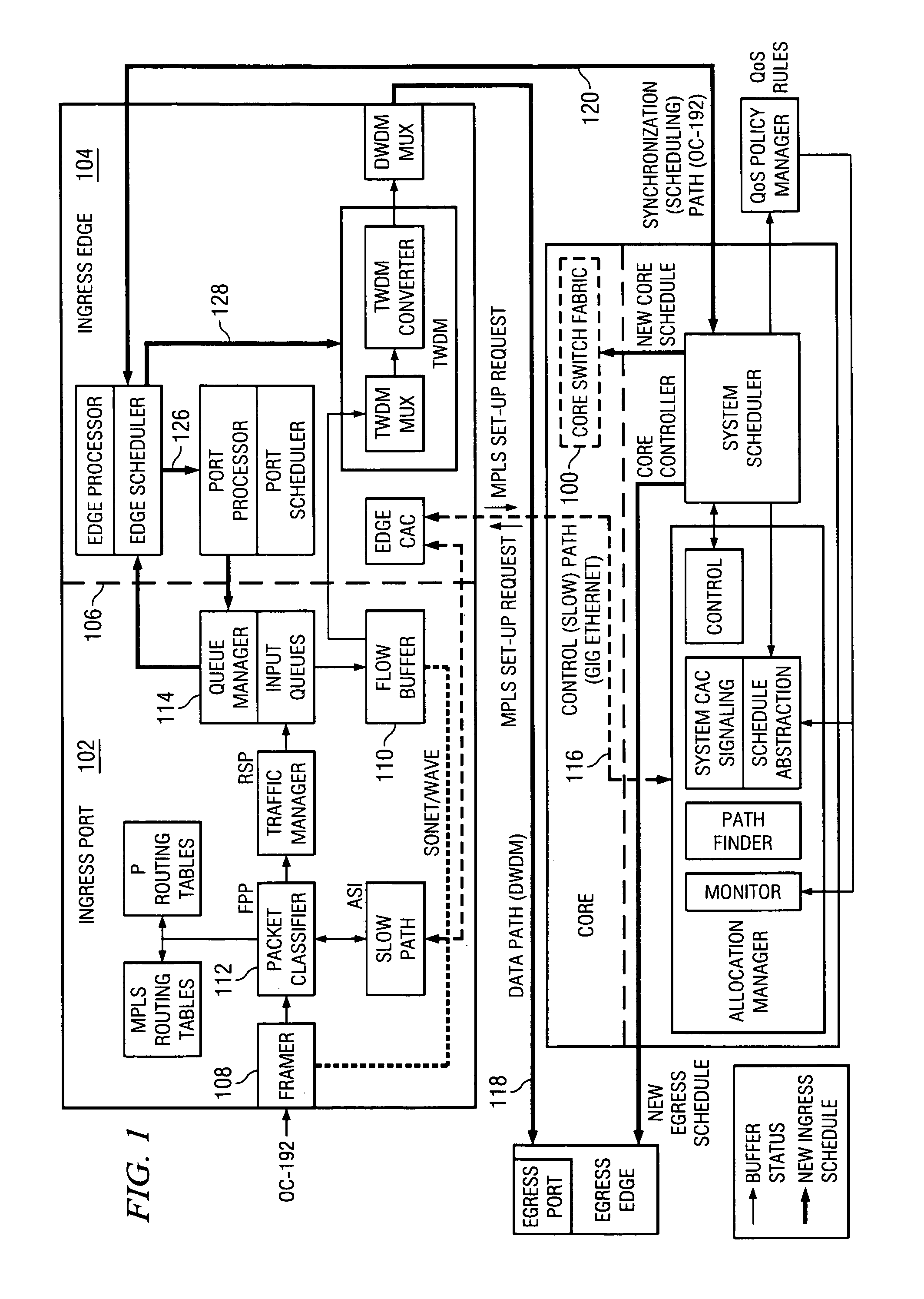

System for switching data using dynamic scheduling

ActiveUS7218637B1Lower latencyImprove performanceData switching by path configurationTime scheduleData interchange

An architecture and related systems for improving the performance of non-blocking data switching systems. In one embodiment, a switching system includes an optical switching core coupled to a plurality of edge units, each of which has a set of ingress ports and a set of egress ports. The switching system also contains a scheduler that maintains two non-blocking data transfer schedules, only one of which is active at a time. Data is transferred through the switching system according to the active schedule. The scheduler monitors the sufficiency of data transferred according to the active schedule and, if the currently active schedule is insufficient, the scheduler recomputes the alternate schedule based on demand data received from the edges / ports and activates the alternate schedule. A timing mechanism is employed to ensure that the changeover to the alternate schedule is essentially simultaneous among the components of the system.

Owner:UNWIRED BROADBAND INC

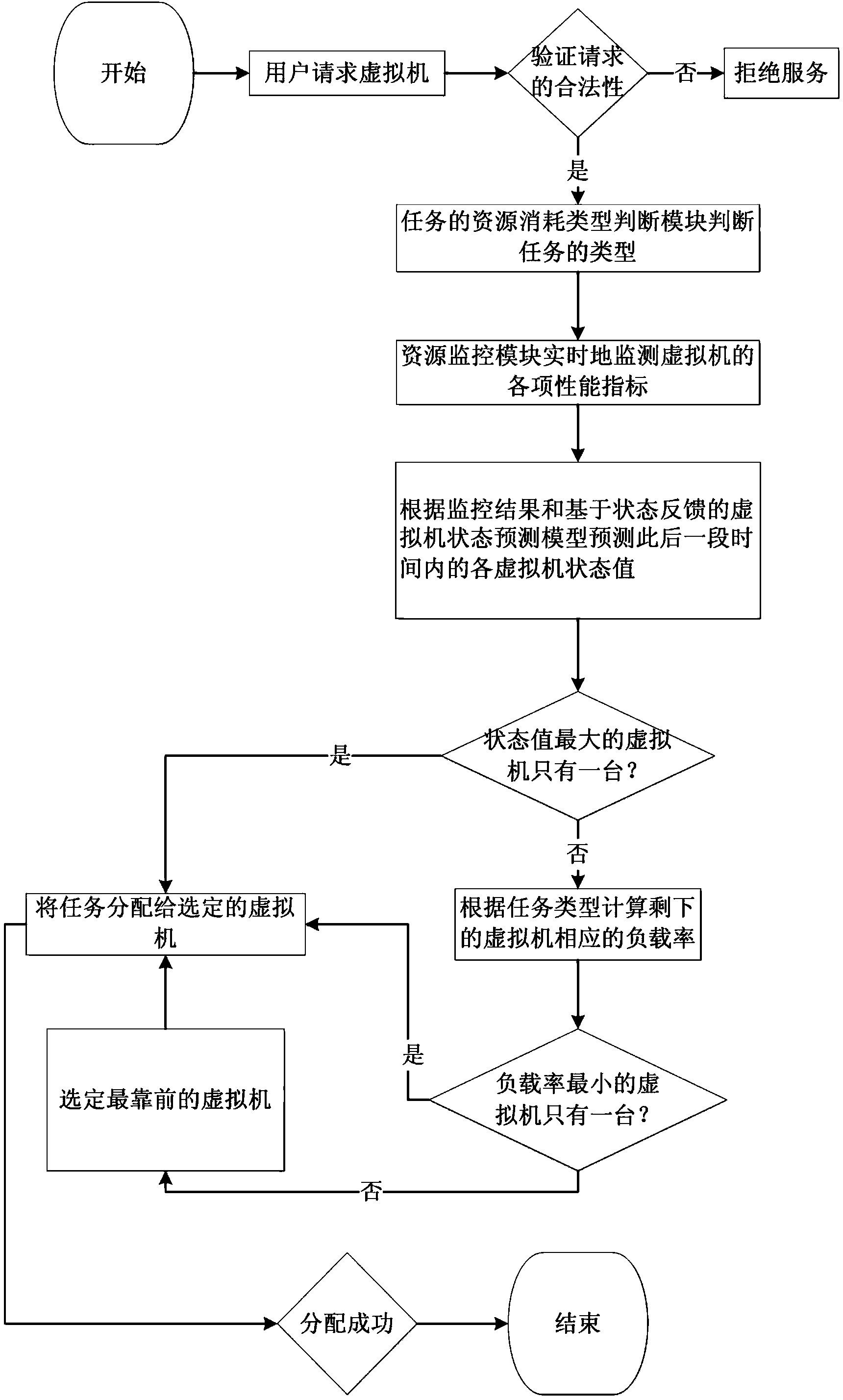

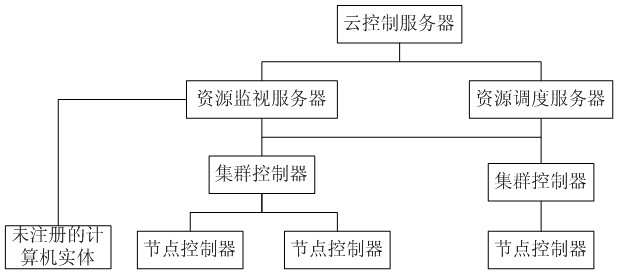

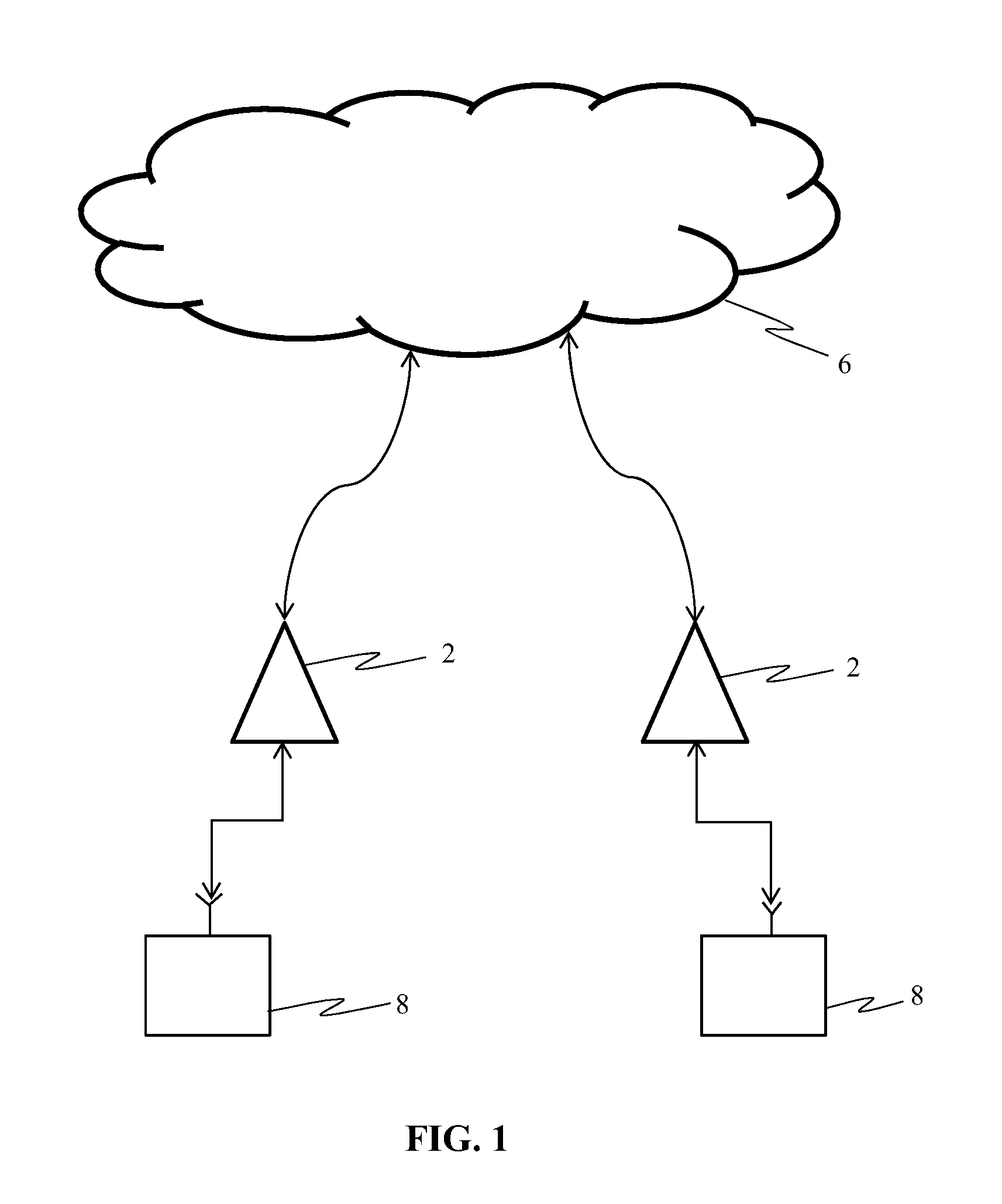

Cloud computing dynamic resource scheduling system and method

InactiveCN104065745AReasonable distributionOptimizing Dynamic SchedulingResource allocationTransmissionComputer resourcesState prediction

The invention relates to the dynamic resource scheduling technique in the cloud computing field, and provides a cloud computing dynamic resource scheduling method based on the feedback and a prediction mechanism. The method aims to overcome the defects of the cloud computing resource distribution and scheduling technique in the prior art, and can achieve balance use of various computer resources in a cloud computing environment, obtain satisfactory load balance under small pay expenses and improve comprehensive efficiency of system scheduling. According to the scheme, various performance indexes of virtual machines are monitored in real time in operation processes of the virtual machines, operation circumstances of all the current virtual machines within a next short period of time are predicted according to the monitored various current performance indexes of the virtual machines and a virtual machine state prediction model based on state feedback when a task request comes, and the most adaptive virtual machine is selected by combining a prediction result and a required task type and the required task is distributed. In addition, the invention further discloses a corresponding cloud computing dynamic resource scheduling system applicable to dynamic resource scheduling.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

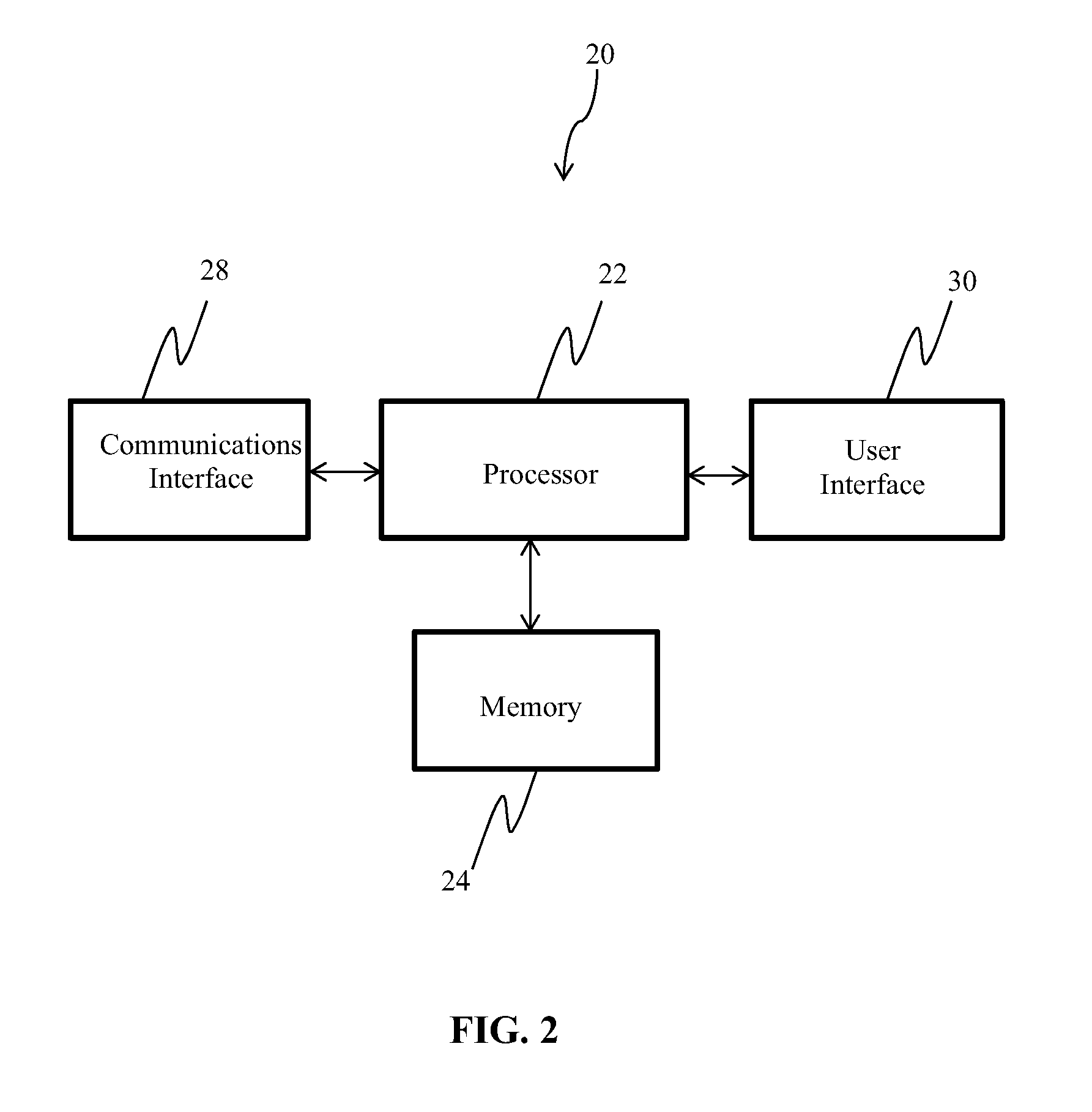

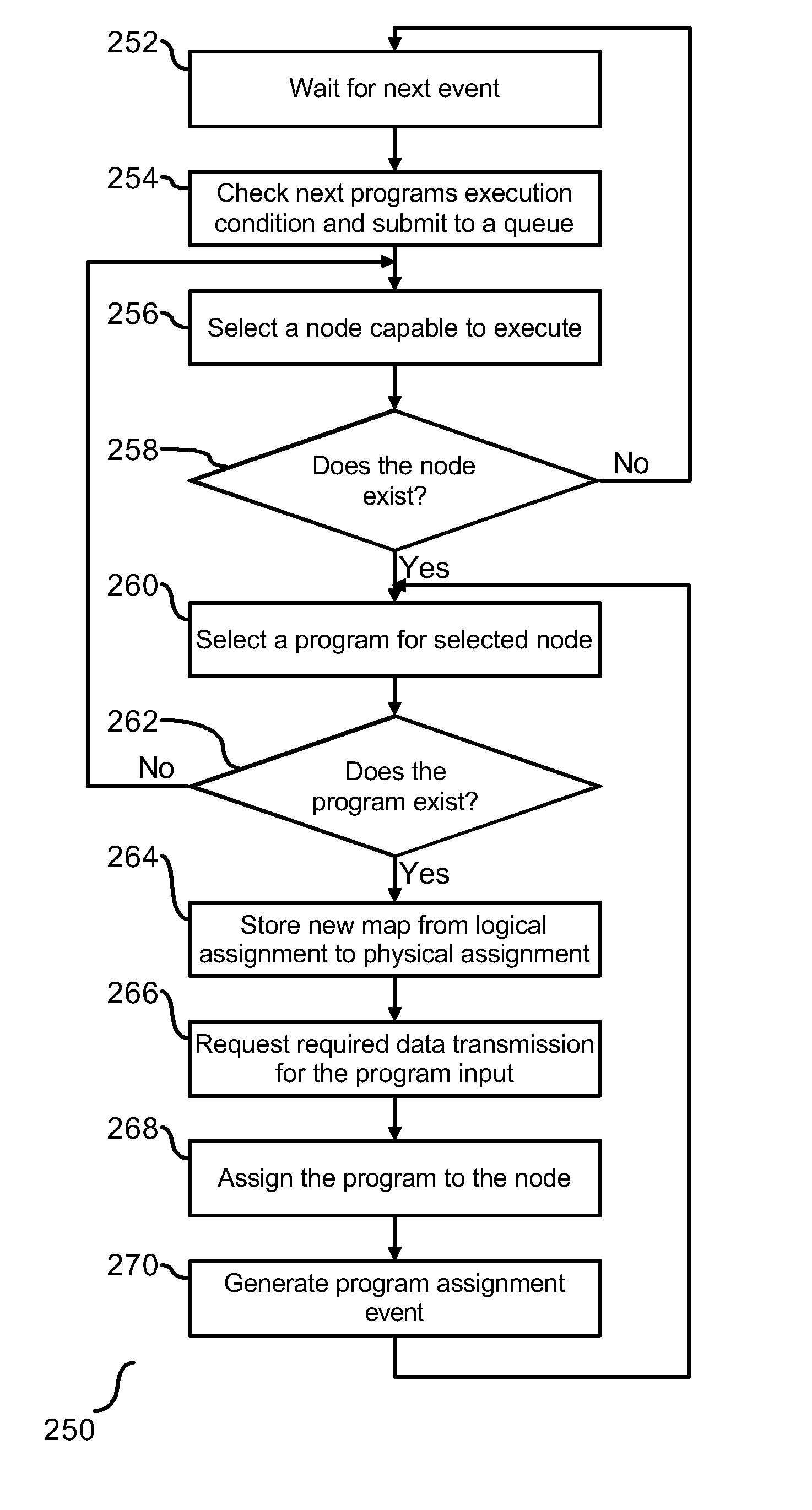

Method for dynamic scheduling in a distributed environment

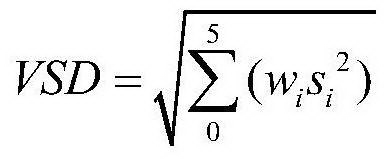

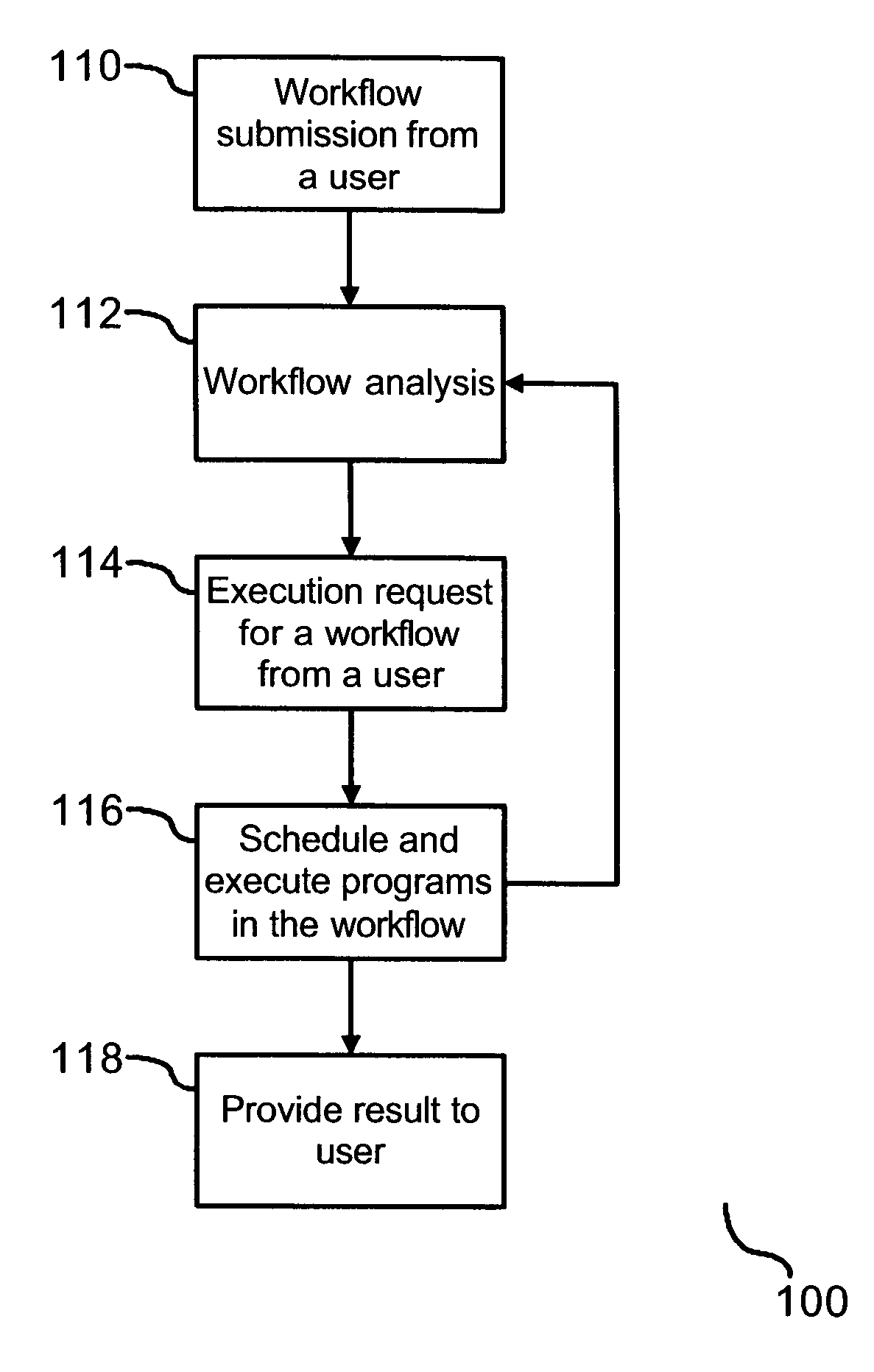

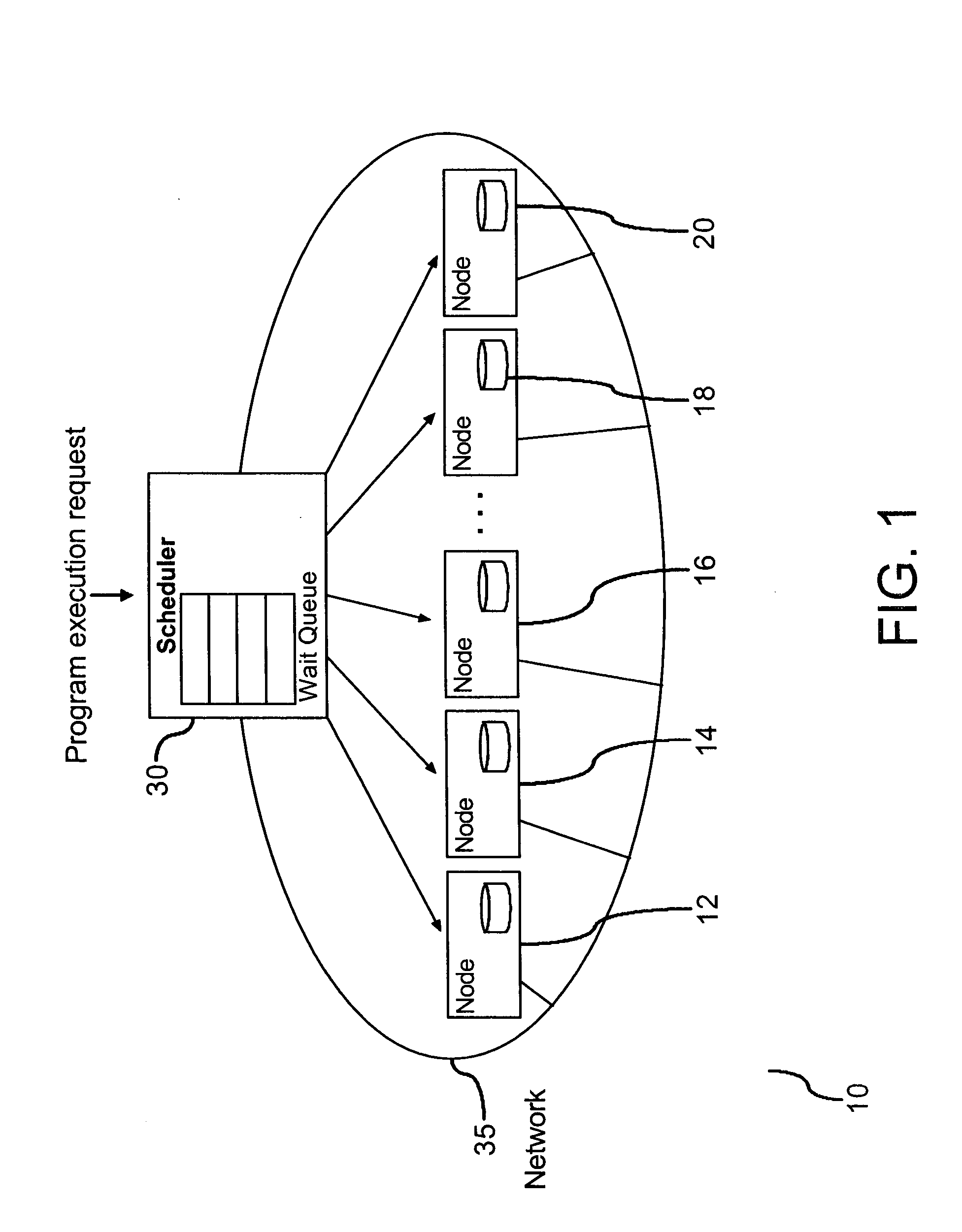

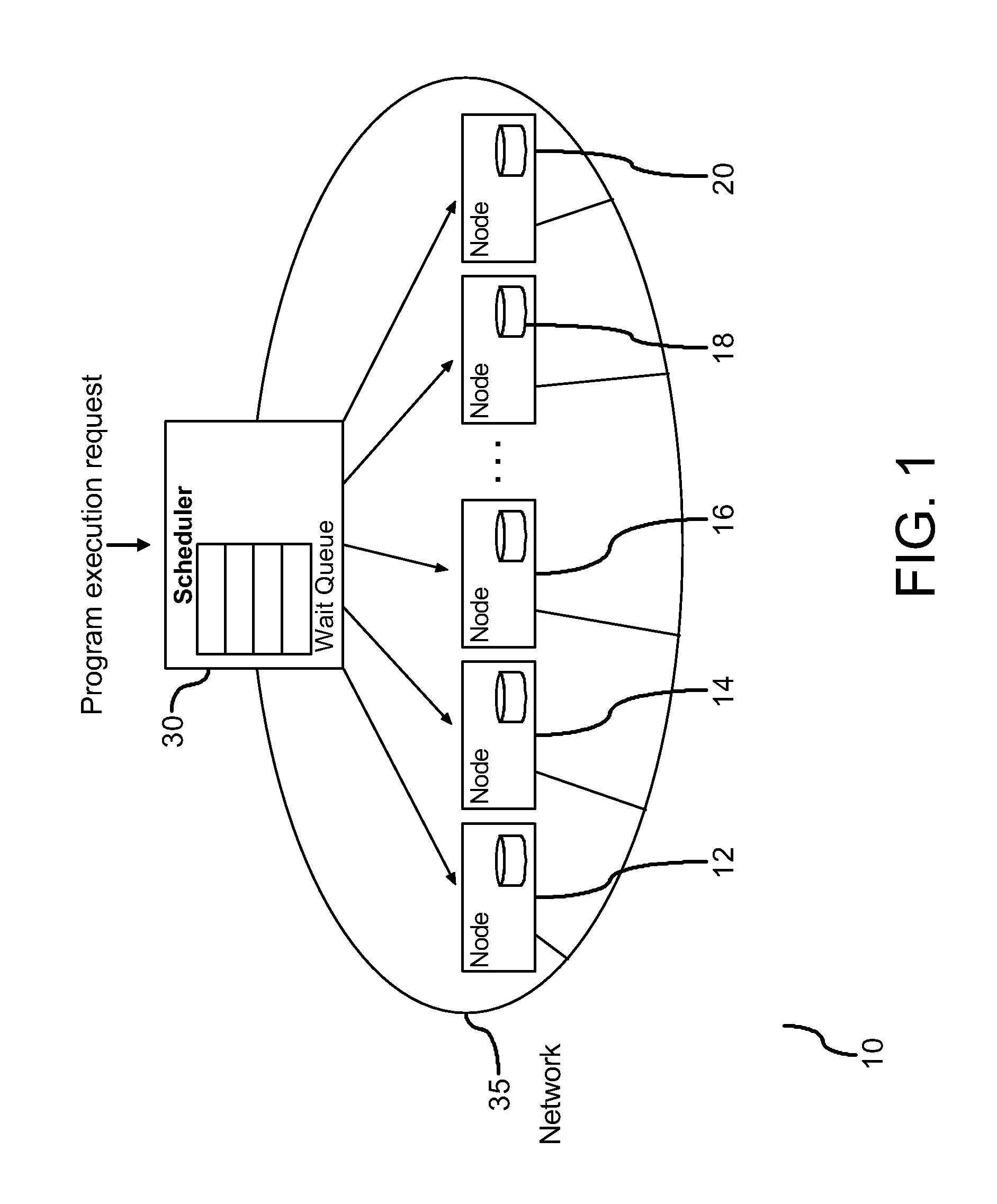

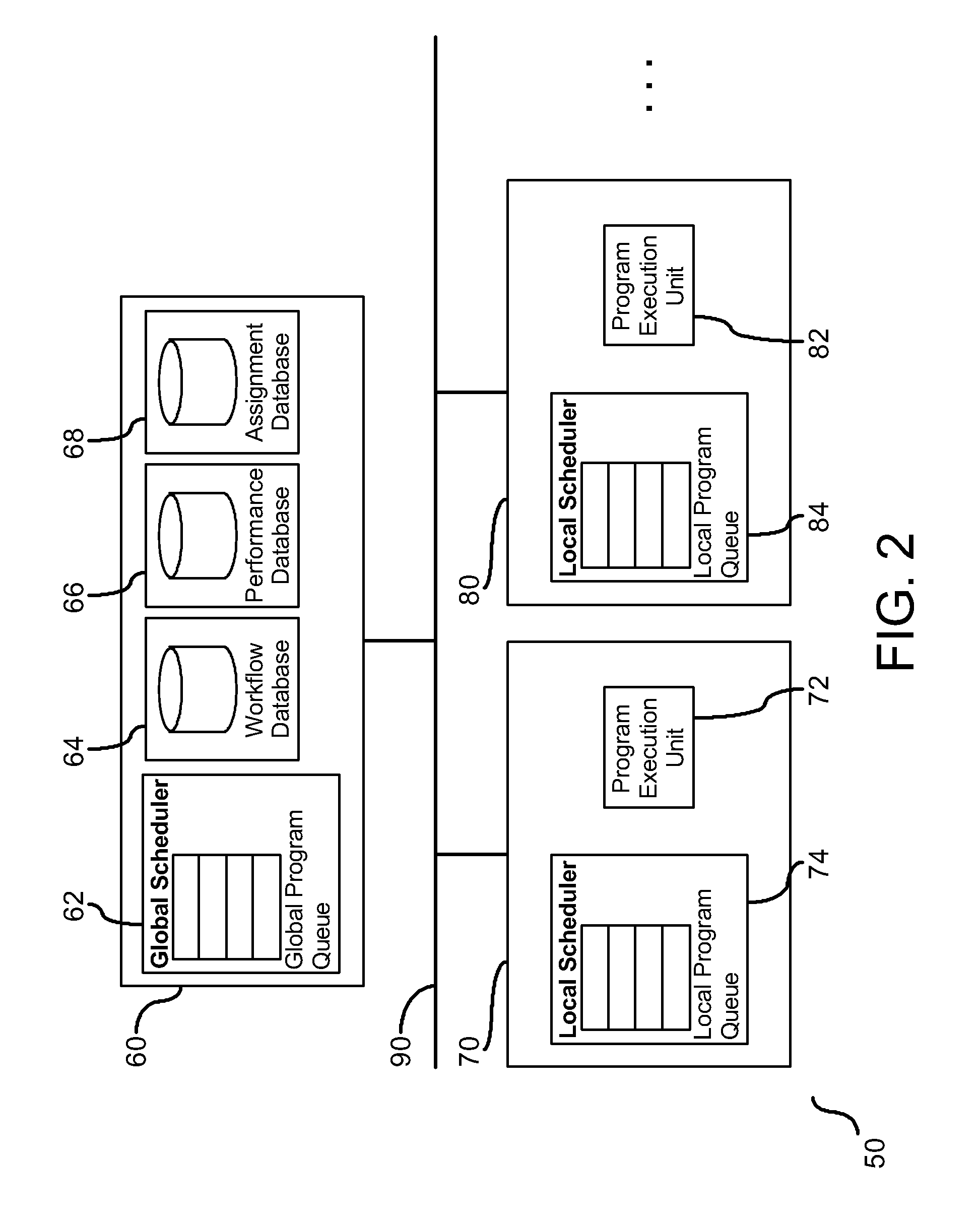

InactiveUS20060112388A1Multiprogramming arrangementsMemory systemsWorkflowDynamic priority scheduling

A method and system is provided for assigning programs in a workflow to one or more nodes for execution. Prior to the assignment, a priority of execution of each program is calculated in relation to its dependency upon data received and transmitted data. Based upon the calculated priority and the state of each of the nodes, the programs in the workflow are dynamically assigned to one or more nodes for execution. In addition to the node assignment based upon priority, preemptive execution of the programs in the workflow is determined so that the programs in the workflow may not preemptively be executed at a selected node in response to the determination.

Owner:SERVICENOW INC

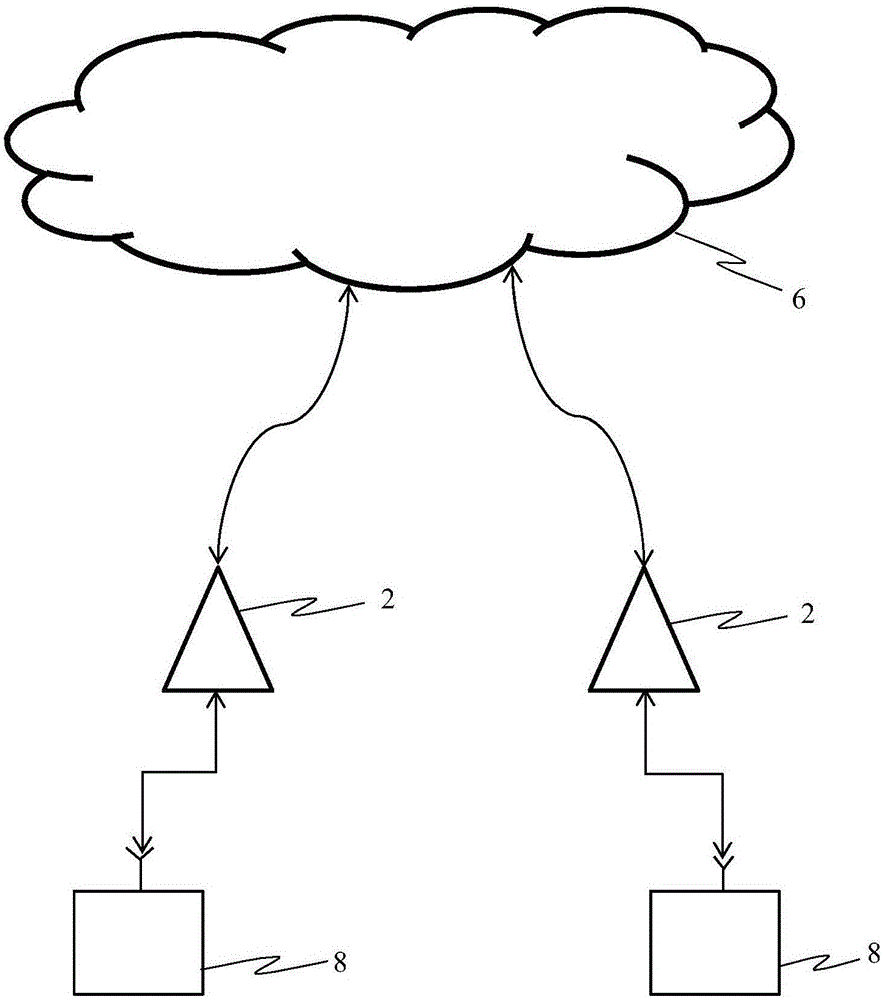

Method and system for dynamic scheduling of virtual resources in cloud computing network

InactiveCN102170474AEfficient use ofLoad balancingData switching networksDistributed computingDynamic priority scheduling

The invention provides a method and system for dynamic scheduling of virtual resources in a cloud computing network, the system comprises a cloud control server, a resource monitoring server, a resource scheduling server, at least one cluster controller and at least one node controller, and the method comprises: the resource monitoring server collects running information and sends the running information to the cloud control server; the node controller in which a virtual machine is positioned sends a real-time migration request to the cloud control server when achieving virtual resource bottleneck; the cloud control server sends the running information to the resource scheduling server; and the resource scheduling server searches the node controller with sufficient scheduling resources in the running information for performing real-time migration. The dynamic scheduling of the virtual resources is realized by adopting the real-time migration method, load balancing is dynamically realized, and the virtual resources in a cloud are utilized with high efficiency through the high-efficient load balancing.

Owner:GCI SCI & TECH

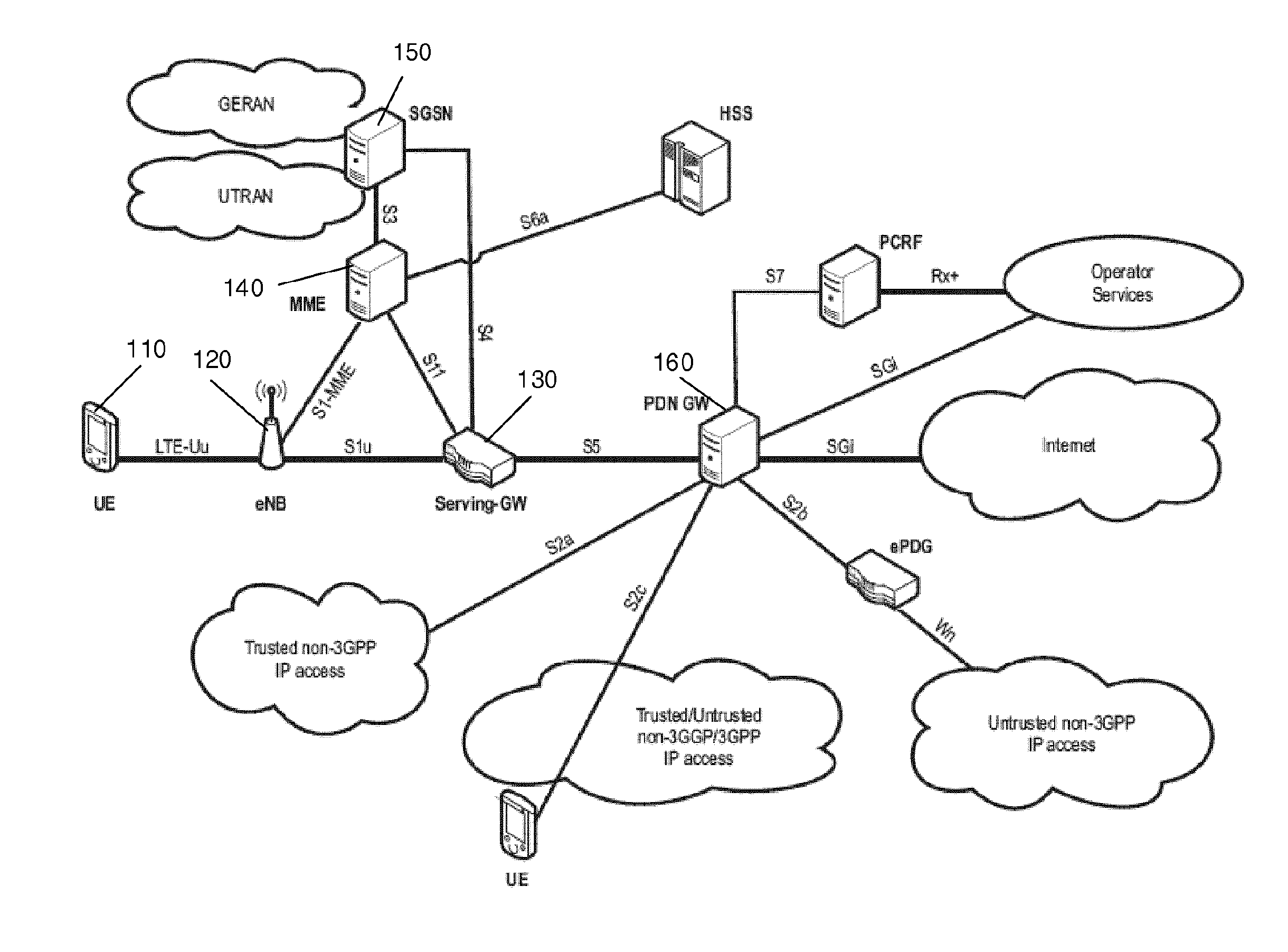

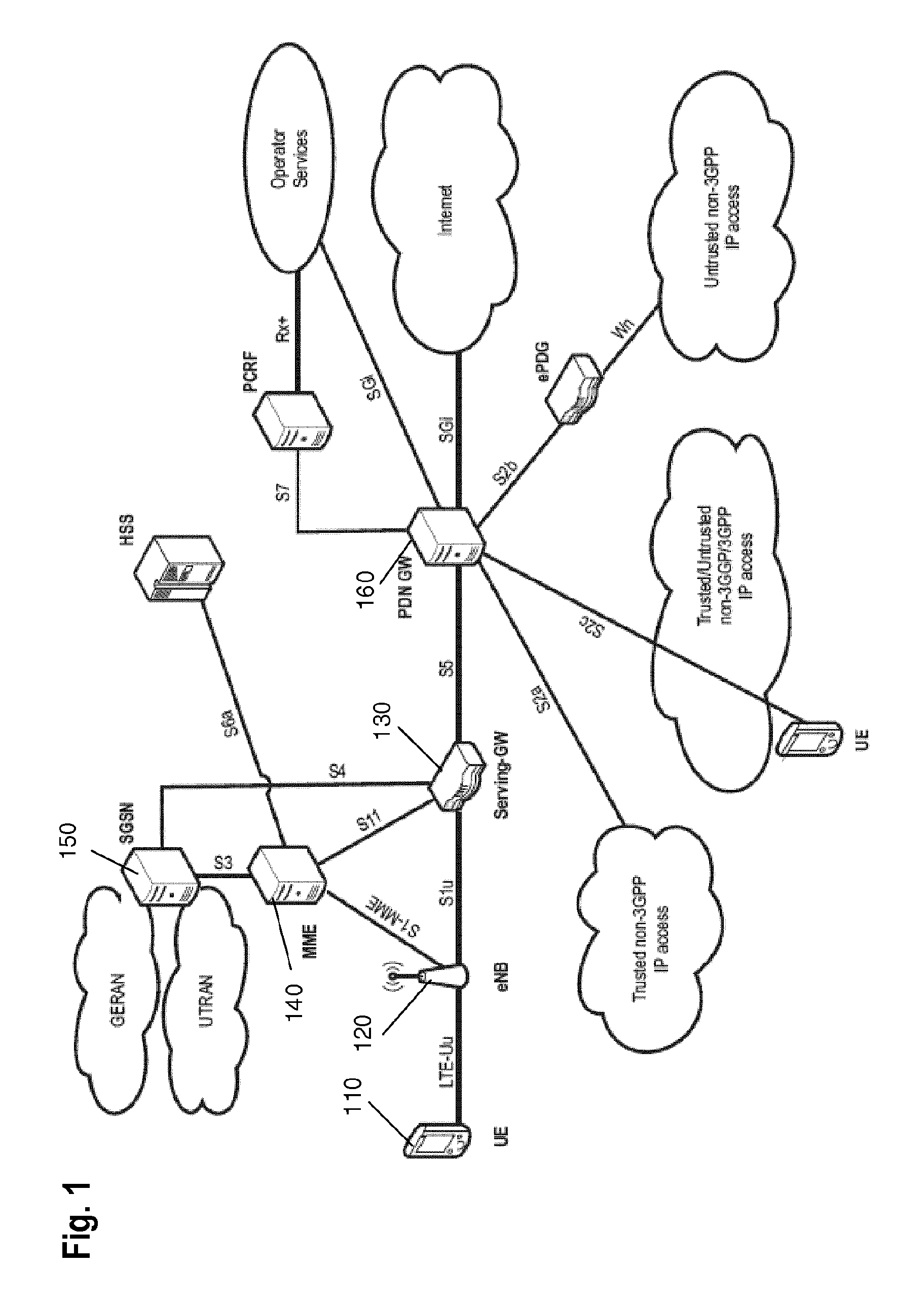

Dynamic scheduling for subframe bundling

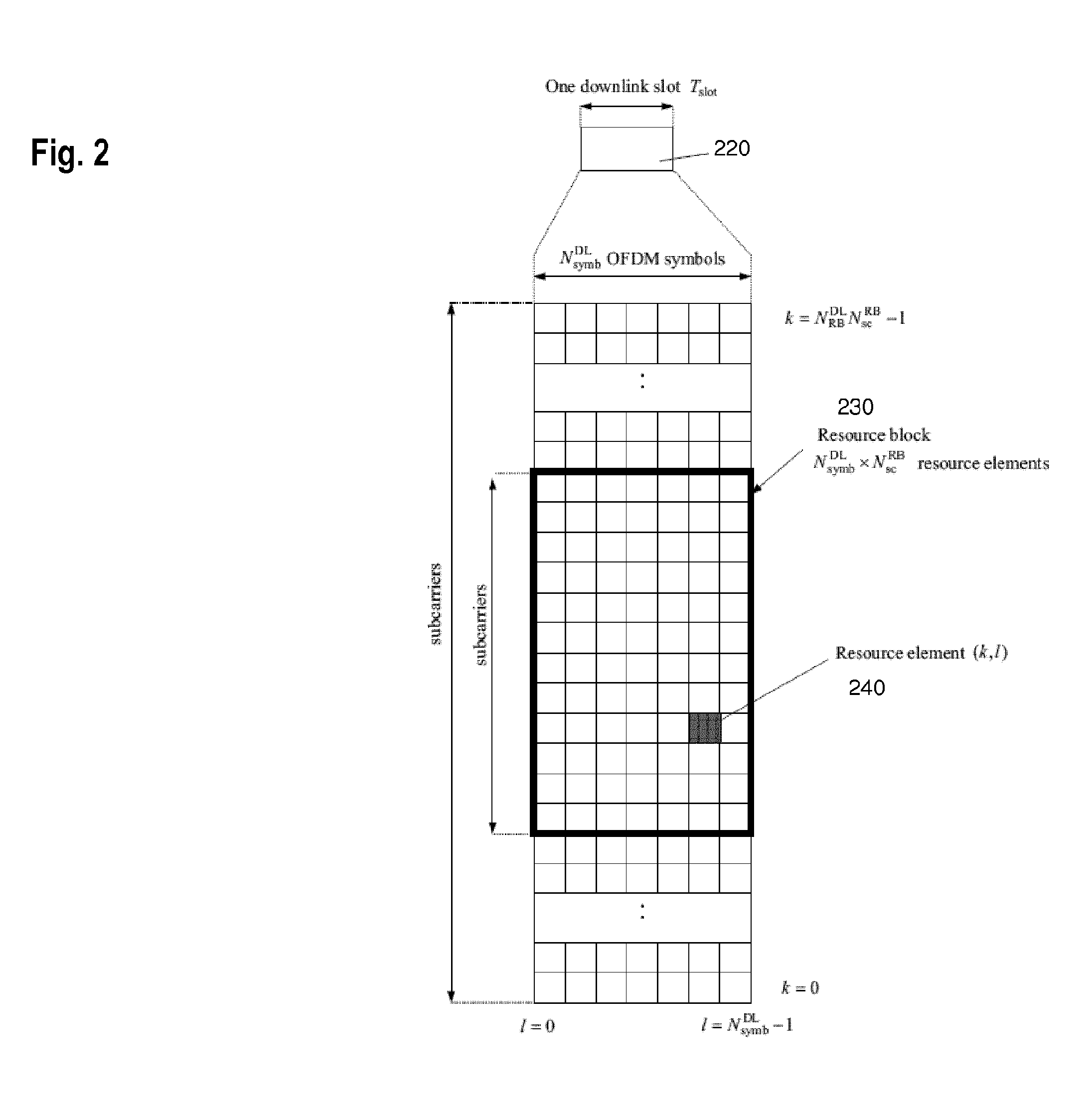

ActiveUS20160164643A1Reduce in quantityError prevention/detection by using return channelSignal allocationCommunications systemData transmission

The present invention relates to transmitting data on a shared communication channel in a communication system supporting multiple hybrid automatic repeat request processes and configurable to apply a bundling of transmission time intervals. The data transmitting including mapping of TTIs of the HARQ processes cyclically onto subframes. In order to efficiently support dynamic bundle scheduling, when a grant is received during a bundle transmission, this grant becomes a shifting grant, according to which the bundle is transmitted and according to the location of which the timing of the grant reception and the data transmission is adapted. The transmission of the shifted bundle is performed in accordance with the state of its retransmission process, i.e. the bundle is either initially transmitted or retransmitted.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

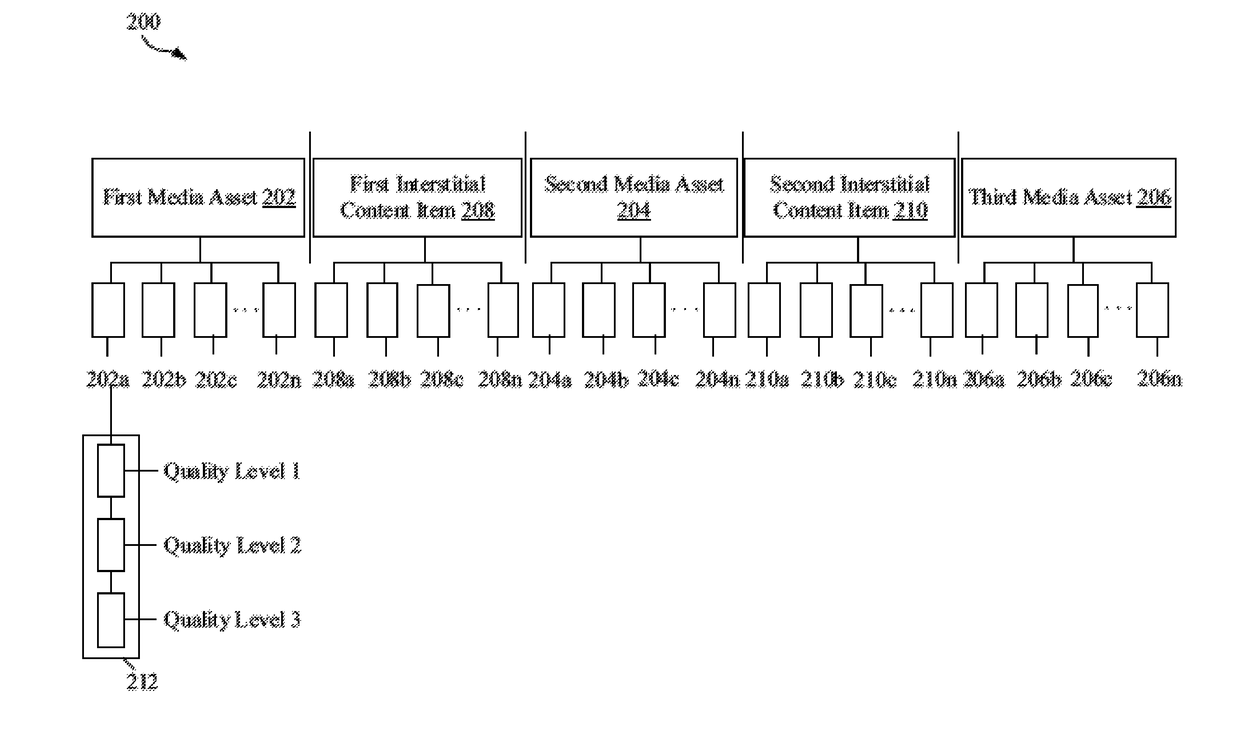

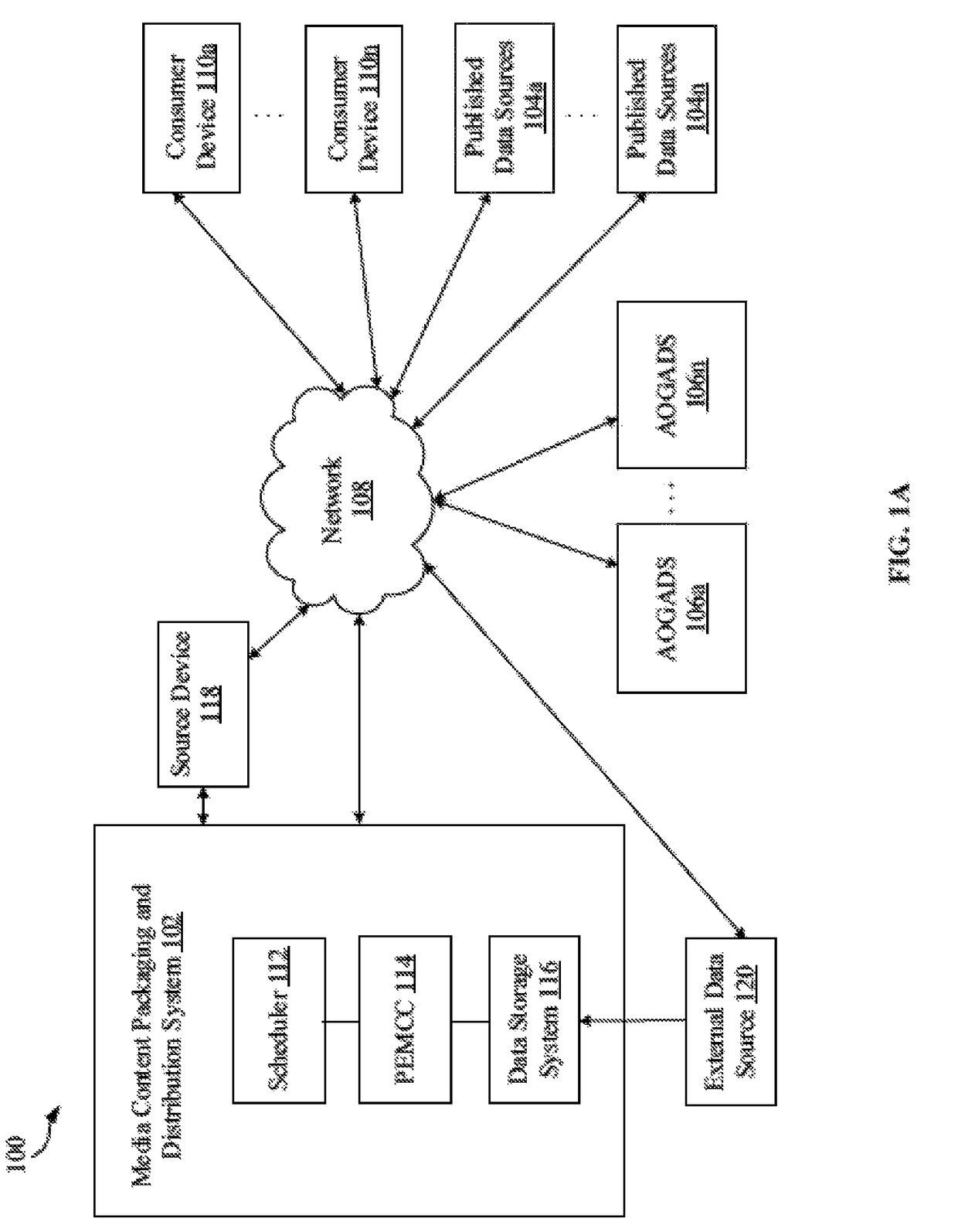

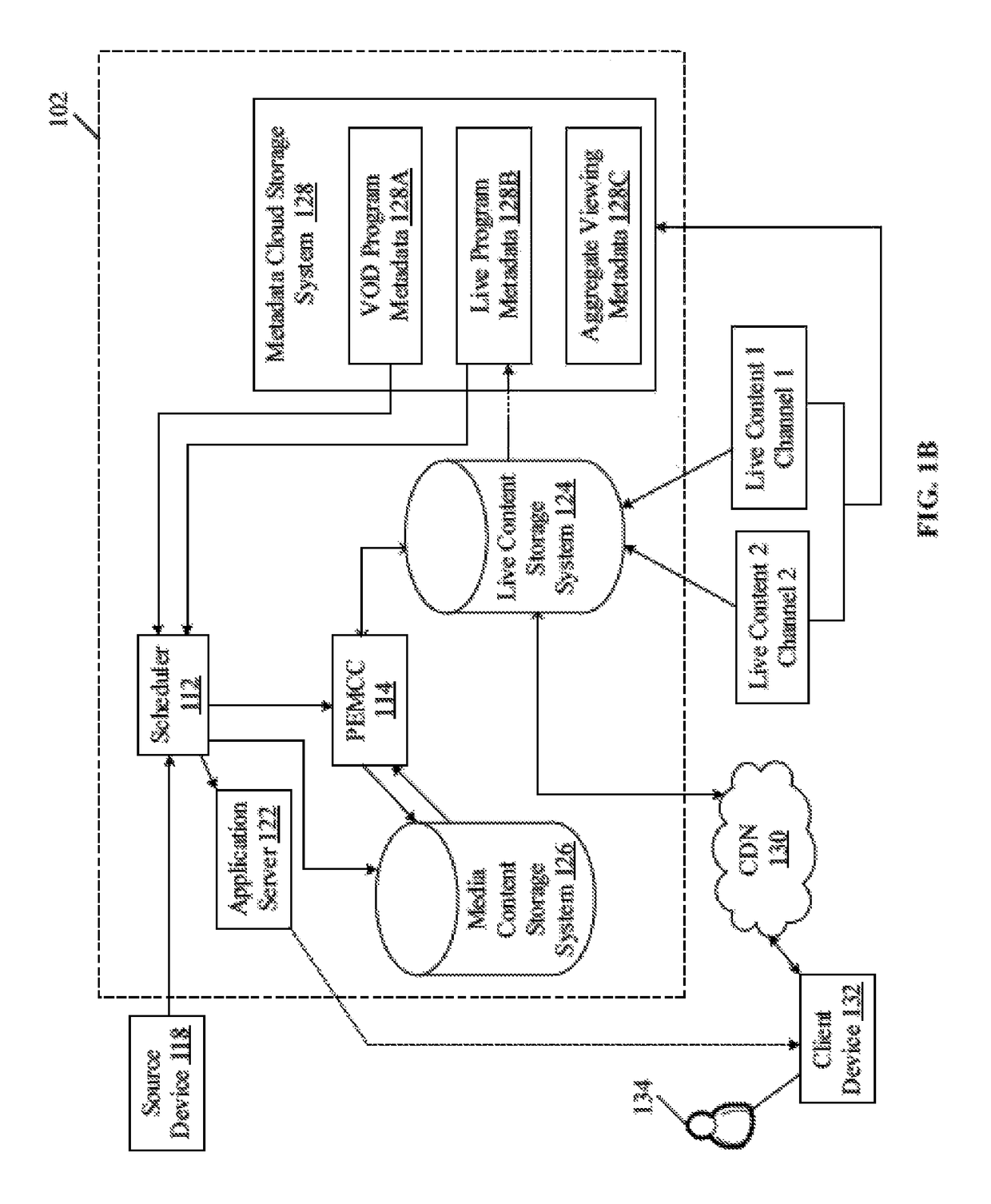

Dynamic scheduling and channel creation based on user selection

ActiveUS10075753B2Selective content distributionElectrical cable transmission adaptationUser inputDistribution system

A content packaging and distribution system that handles distribution of channels to be viewed on a plurality of consumer devices, receives a media feed and a first programming schedule of a first channel from a source device. An input that corresponds to a user-selection is received on a first consumer device of the plurality of consumer devices over a distribution system, and a media item to be inserted in the media feed of the first channel is determined based on criteria related to the user-selection. The determined media item may be dynamically scheduled in the media feed of the first channel to be delivered over the distribution system to be viewed on the first consumer device, based on the user-selection related criteria. The user-selection includes a first criterion that corresponds to a real time or a near-real time user input corresponding to the user-selection on the first consumer device.

Owner:TURNER BROADCASTING SYST INC

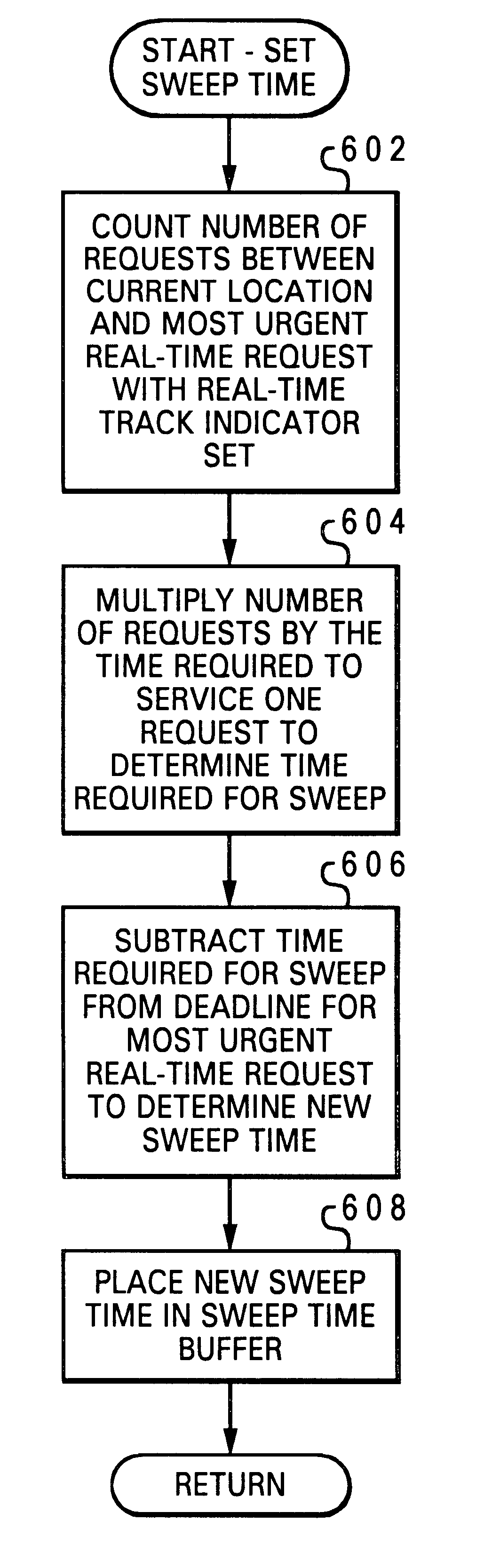

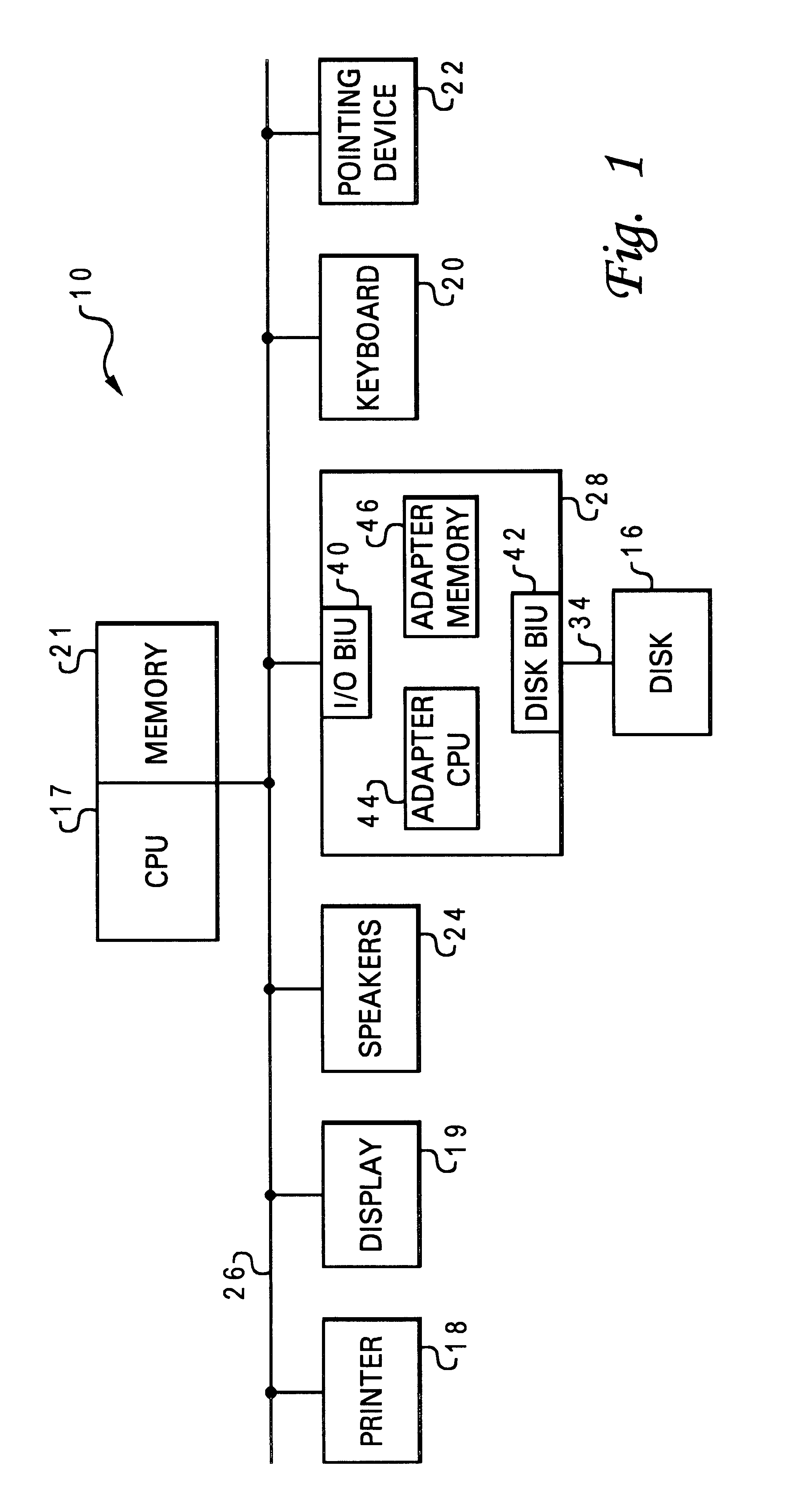

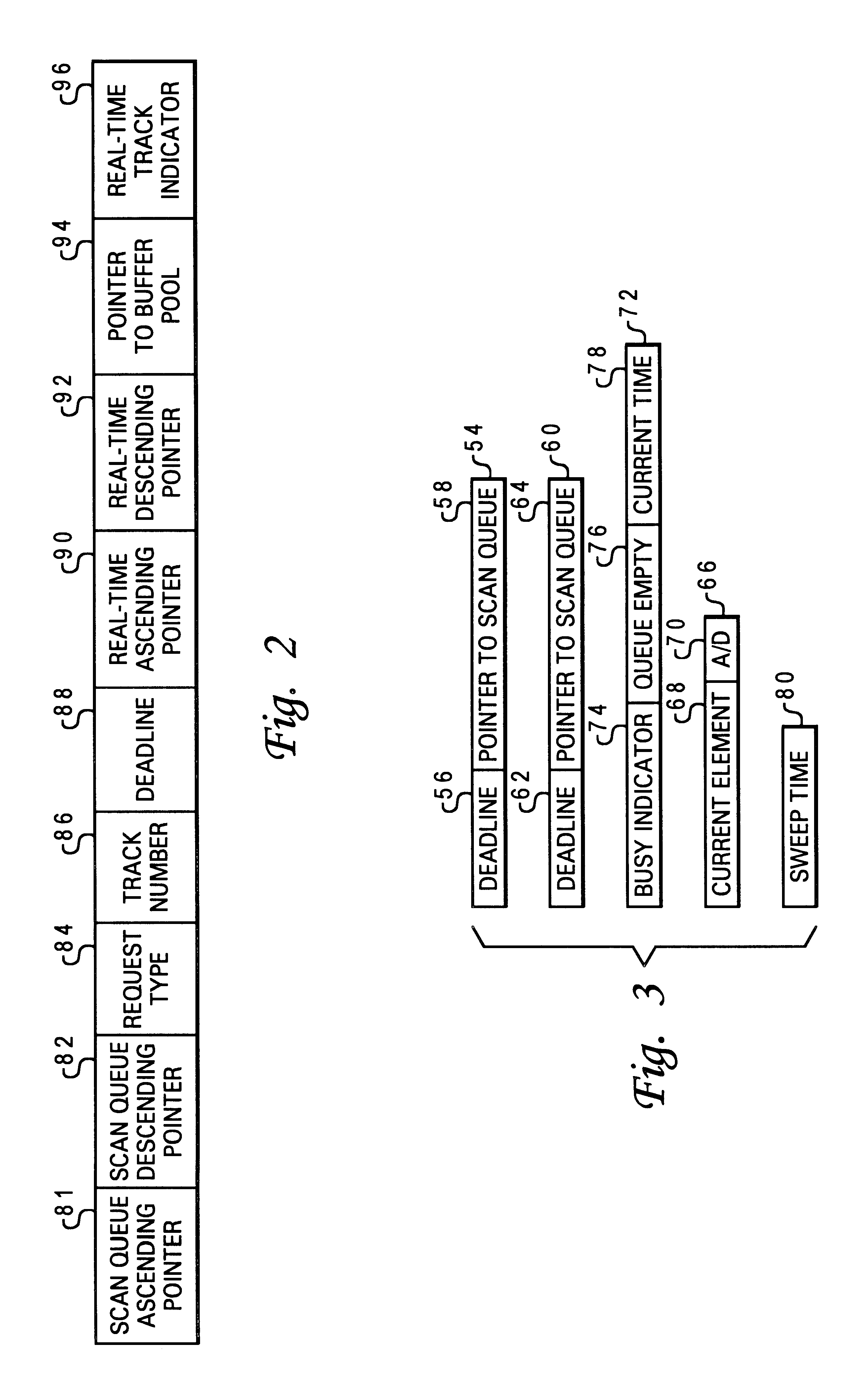

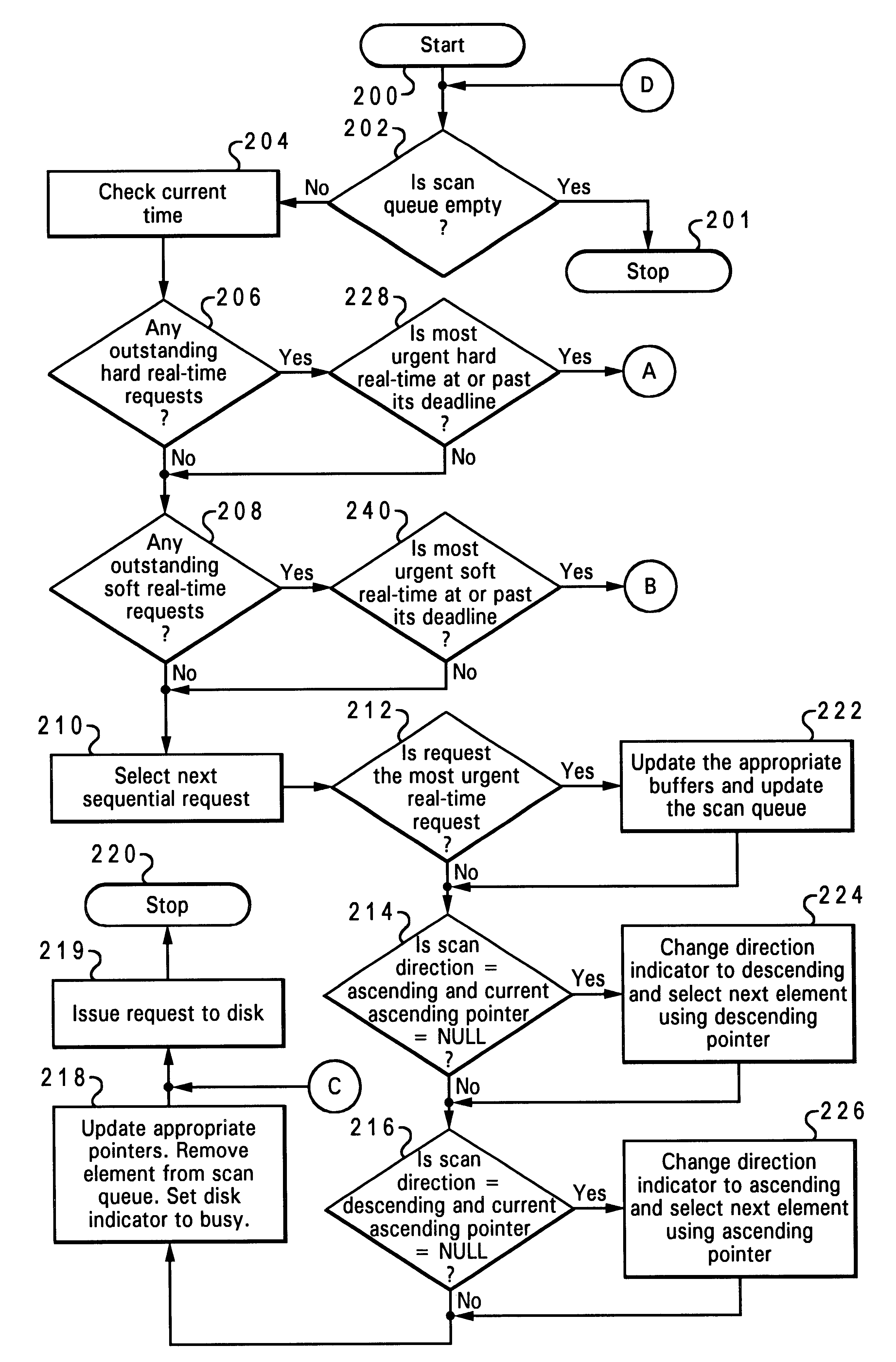

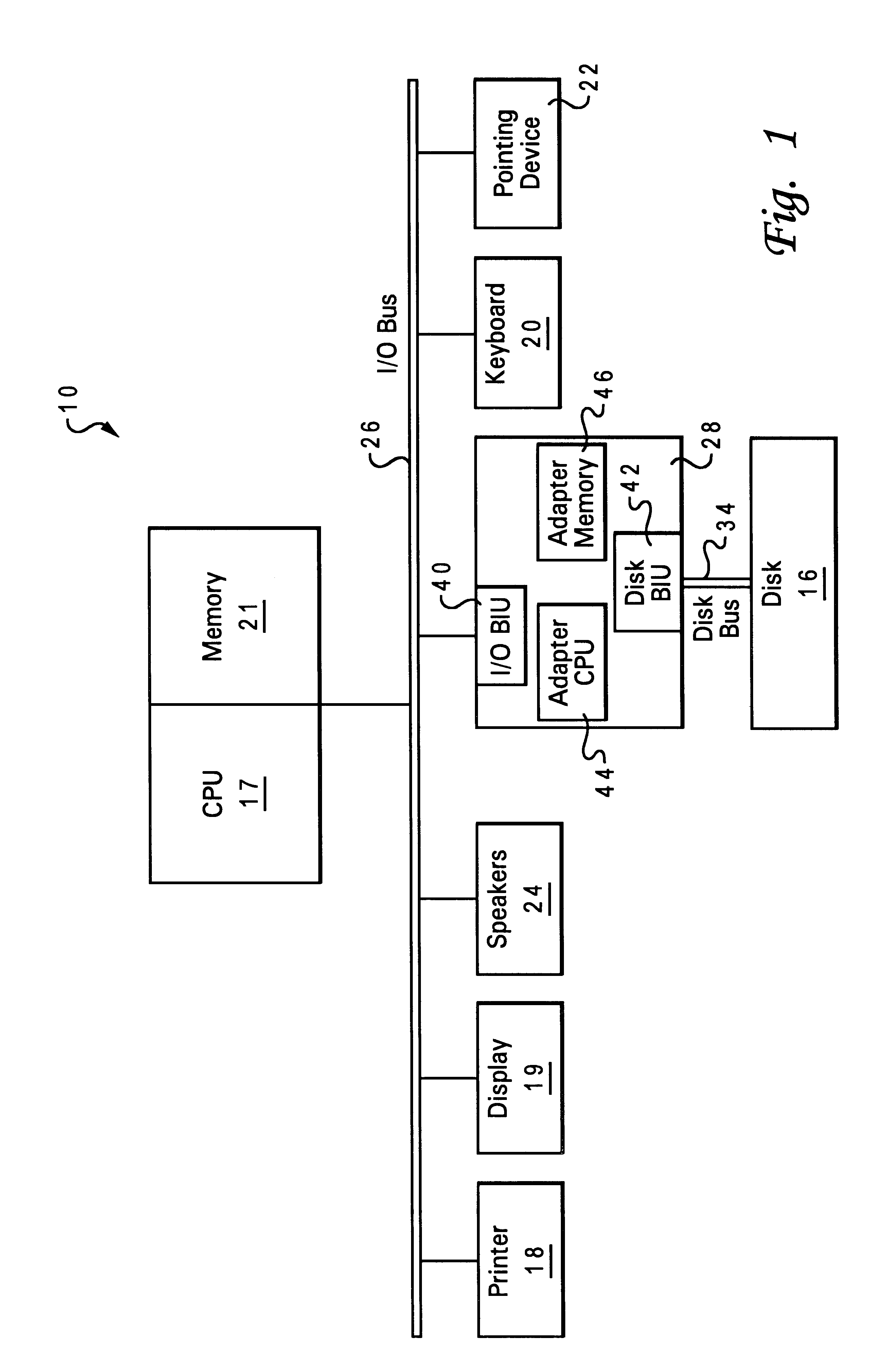

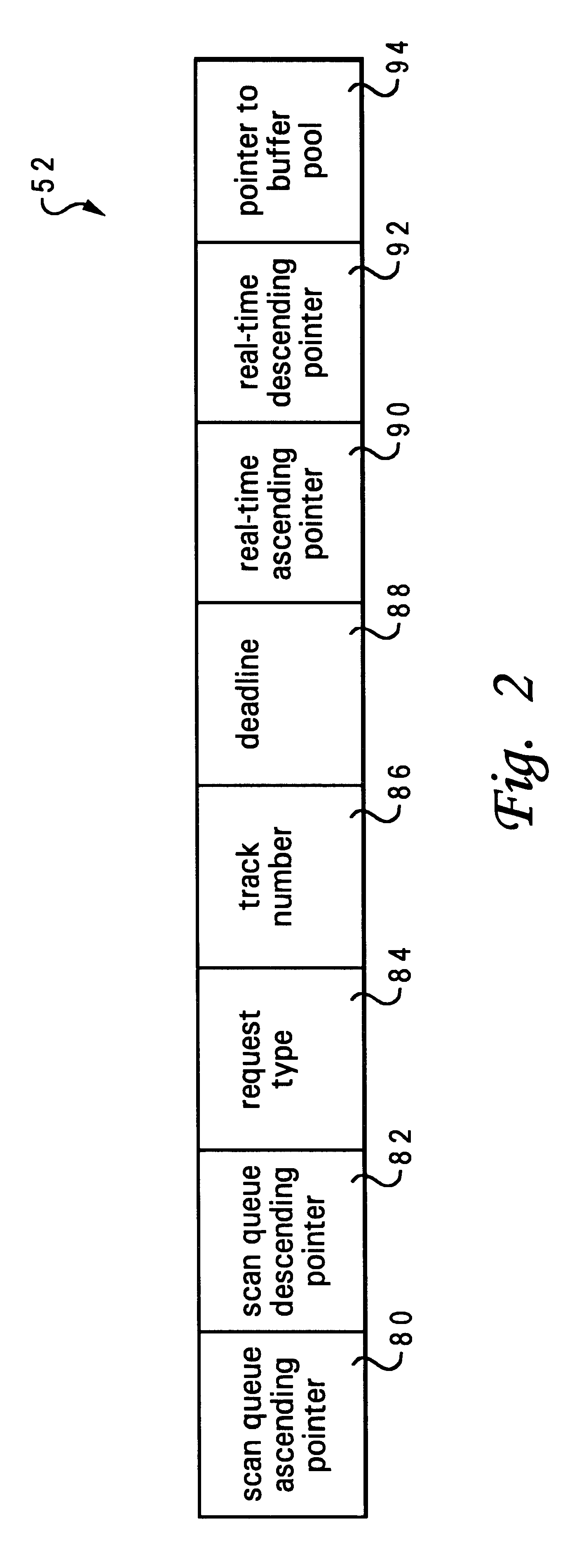

Method of and system for the dynamic scheduling of requests to access a storage system

InactiveUS6442648B1Minimizing back-and-forth movementInput/output to record carriersMemory systemsData processing systemPosition dependent

A method and system in a data processing system for dynamically scheduling the processing of a plurality of requests to access a disk, in which each of the plurality of requests is associated with a location on the disk, processes the requests in a first sequential order and determines the amount of time necessary to process a selected number of requests associated with locations between the current location on the disk and the most urgent request. At a time that is earlier than the deadline for processing the most urgent request by the amount of time necessary to process the selected number of requests, the method commences processing of the selected number of requests in a second sequential order.

Owner:LENOVO GLOBAL TECH INT LTD

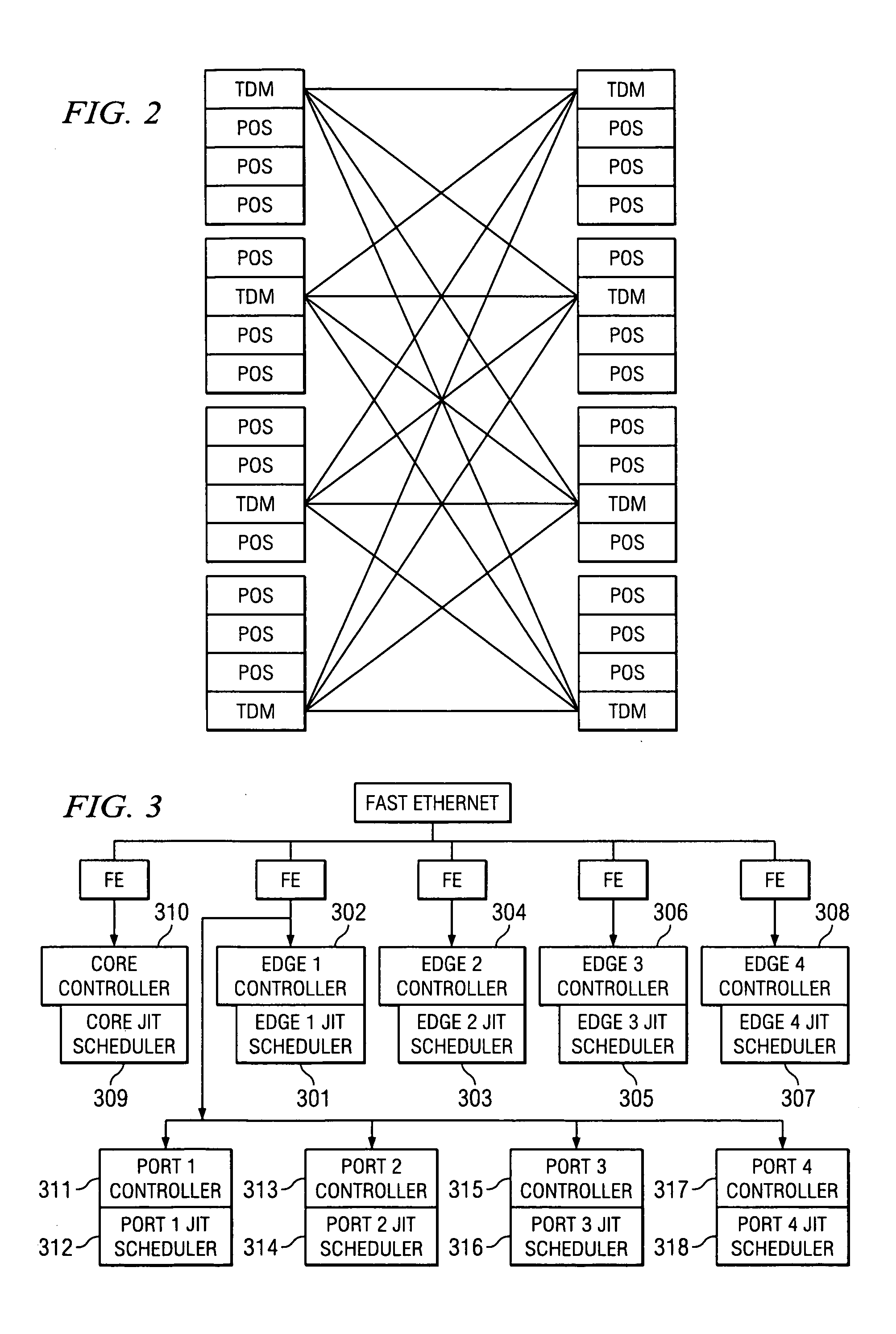

System and method for implementing dynamic scheduling of data in a non-blocking all-optical switching network

InactiveUS7190900B1Multiplex system selection arrangementsOptical multiplexTraffic capacityTime schedule

Owner:UNWIRED BROADBAND INC

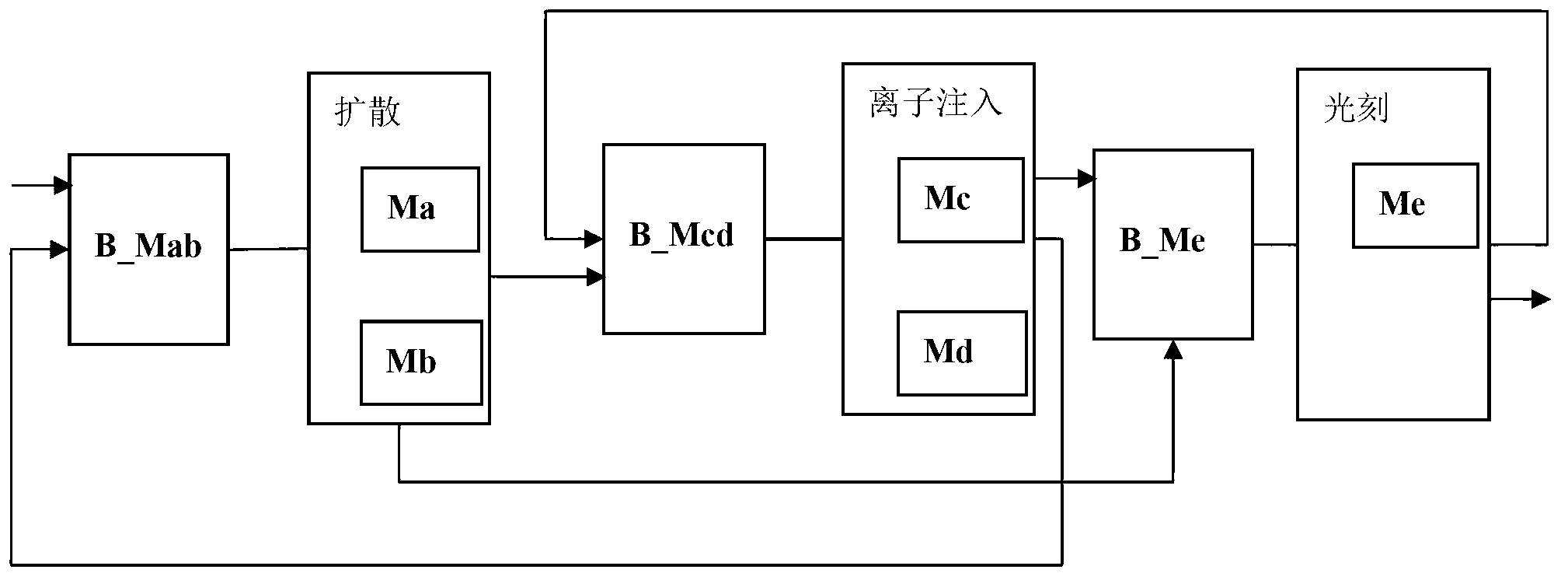

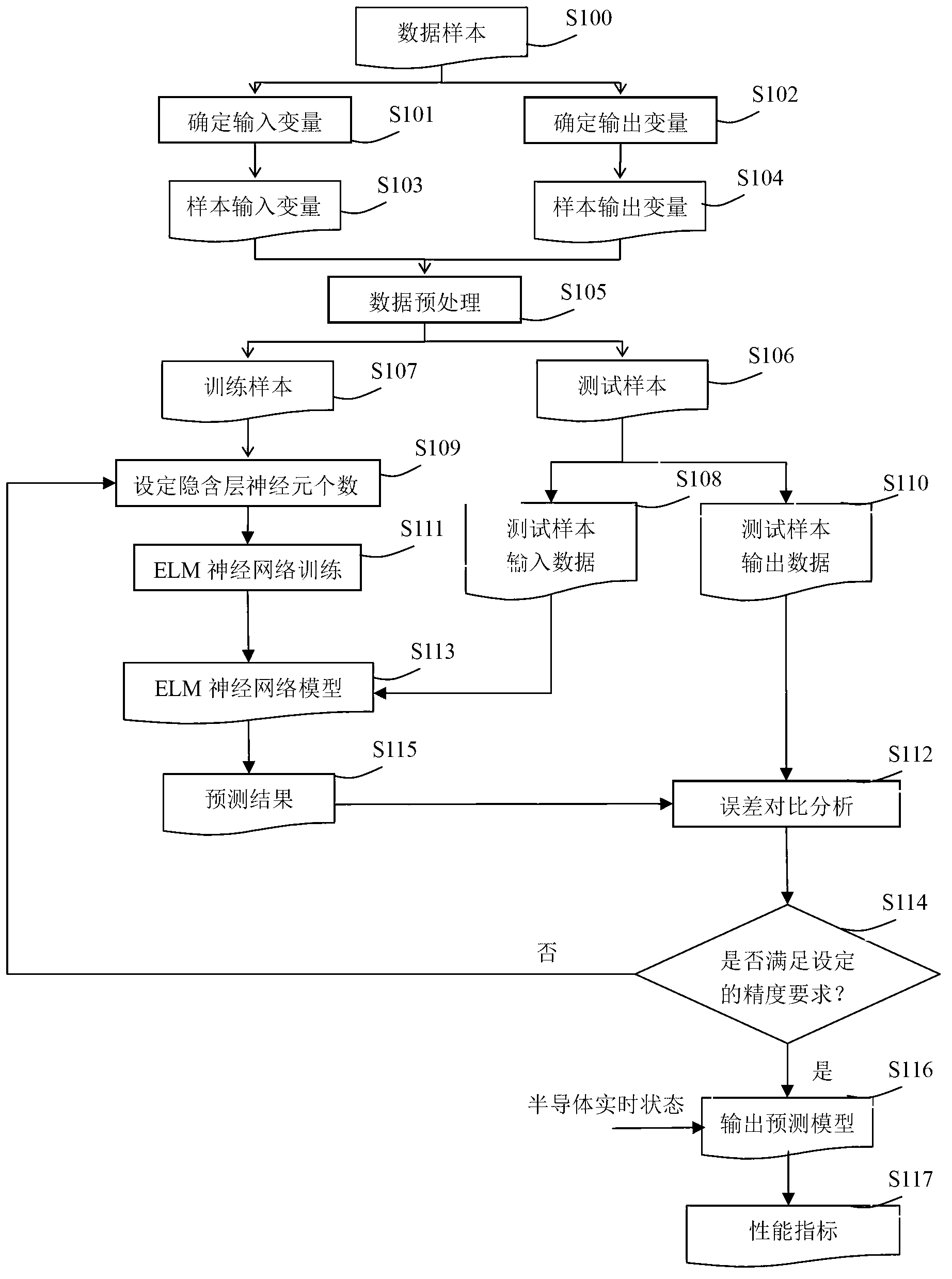

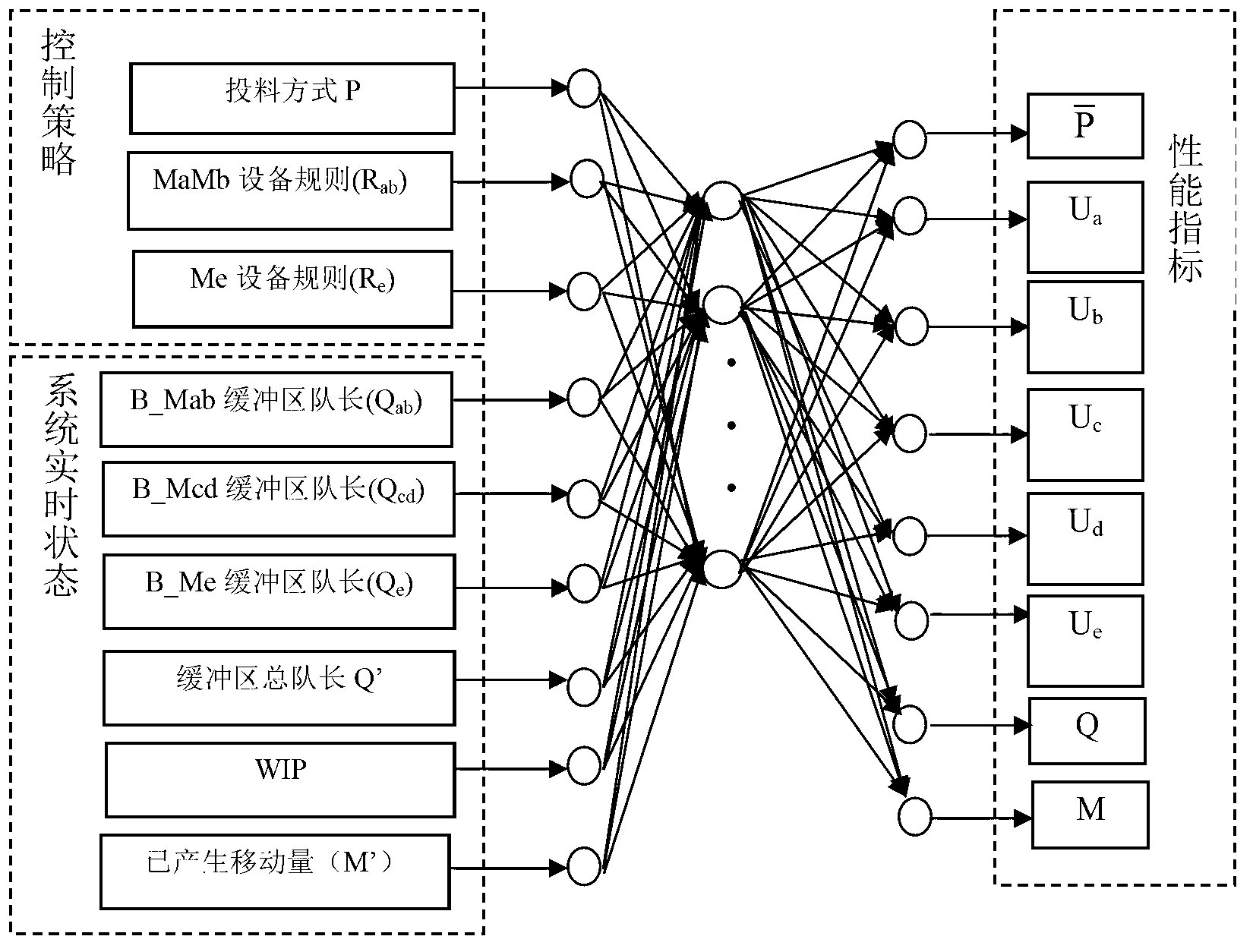

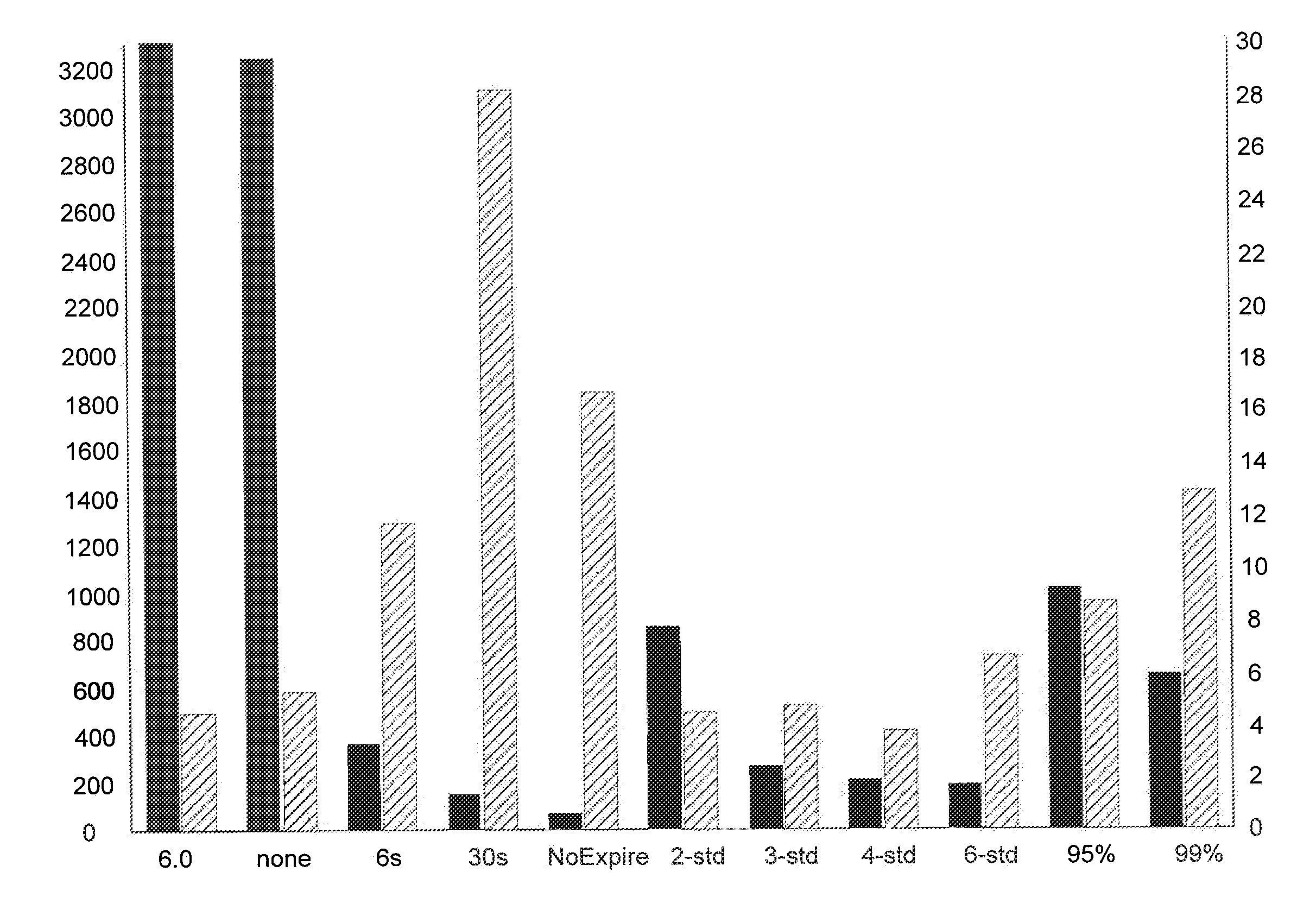

Performance prediction method applicable to dynamic scheduling for semiconductor production line

InactiveCN103310285AReduce the need for reschedulingRealize real-time online optimization controlForecastingLearning machineOptimal control

The invention discloses a performance prediction method applicable to dynamic scheduling for a semiconductor production line. An extreme learning machine (ELM) is applied to prediction and modeling in the performance prediction method. Feeding control and scheduling rules are considered in a unified manner in the method, short-term scheduling key performance indexes such as an equipment utilization rate and a movement step number are predicted on the basis of a real-time state of a system, and a foundation is provided for dynamic real-time scheduling. A novel feed-forward neural network of the ELM is introduced into the semiconductor manufacturing system, and a prediction model is built by the aid of available data of the production line. As shown by test results, ideal prediction results can be quickly acquired by the method implemented by the aid of the ELM, the method has obvious advantages and an obvious application prospect in the aspects of parameter selection and learning speed as compared with the traditional neural network modeling method, and a new idea is provided for online optimal control.

Owner:TONGJI UNIV

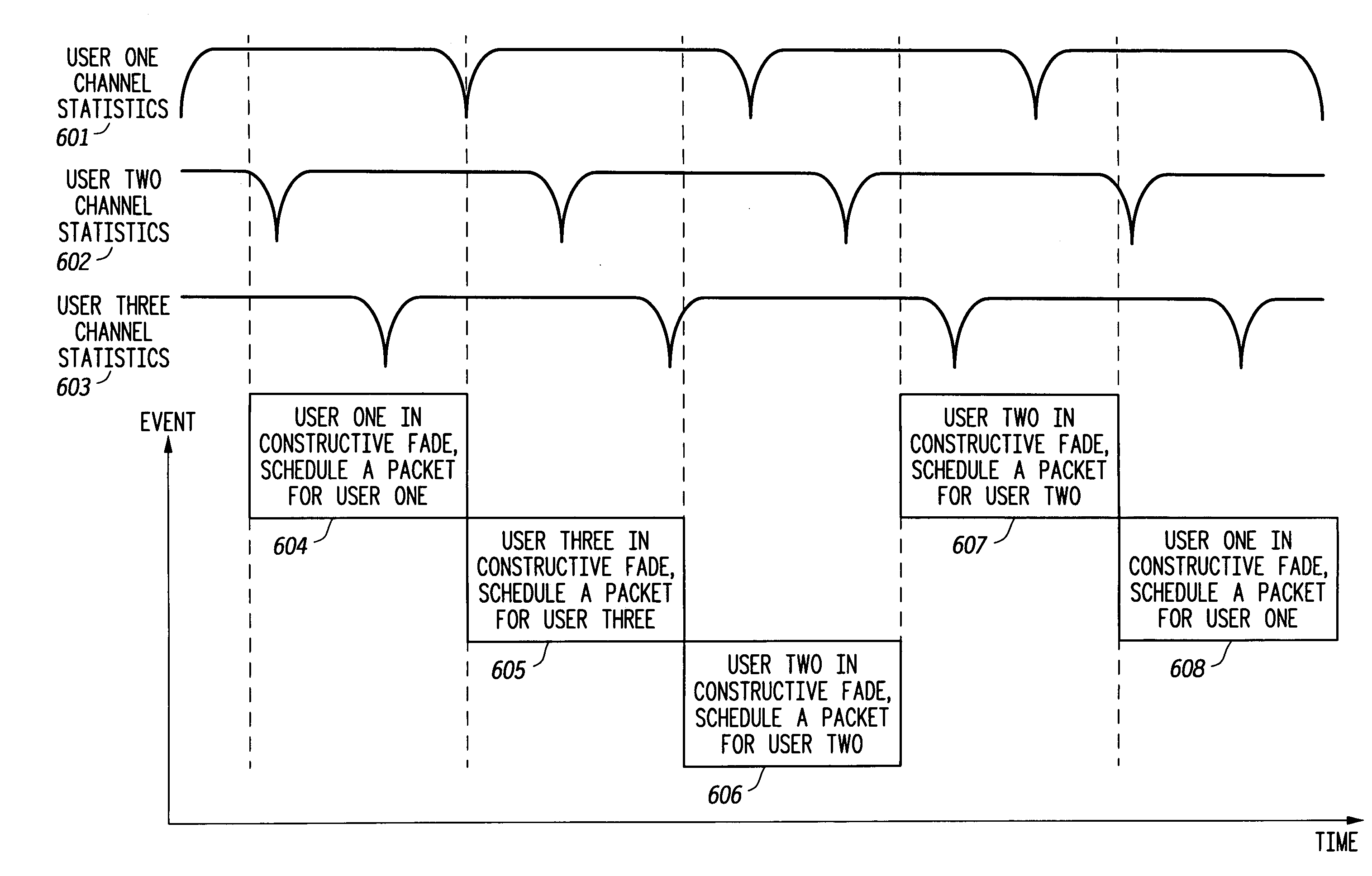

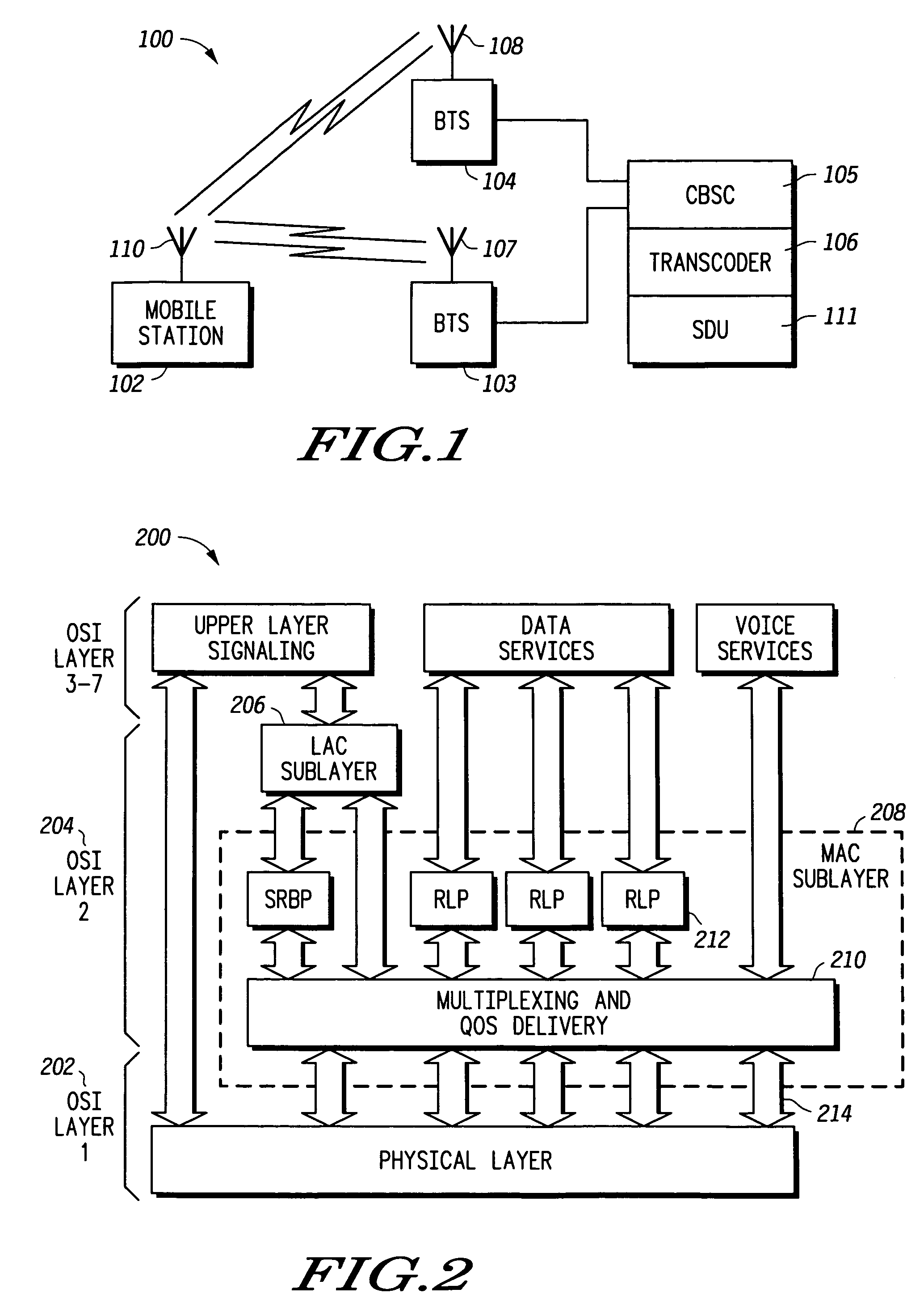

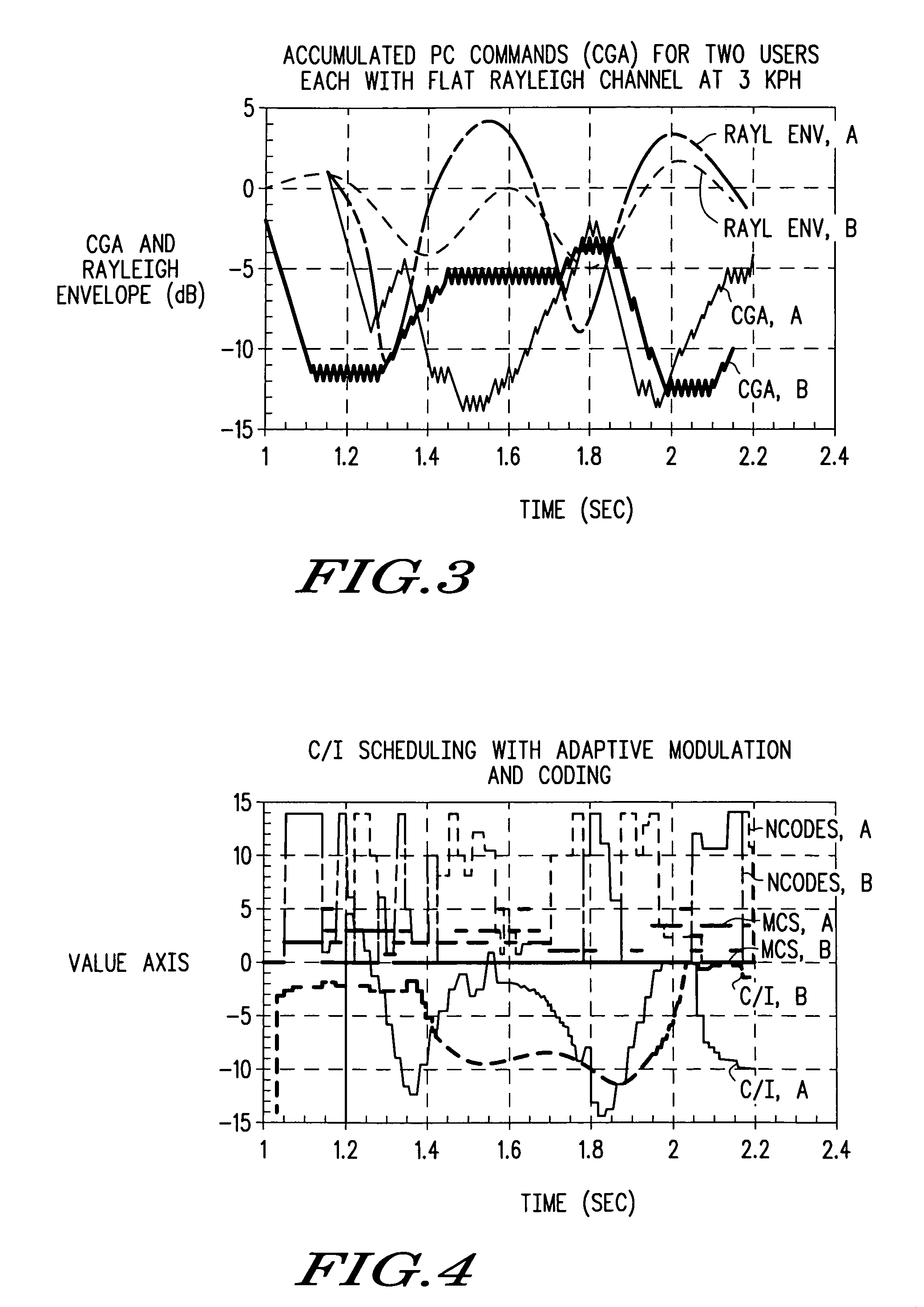

Method of dynamic transmit scheduling using channel quality feedback

A method and system for dynamic rate switching via medium access channel layer signaling is disclosed, wherein data rates for high data rate channels are automatically shifted up or down based on a predetermined metric. In a preferred embodiment, data rates are automatically shifted up or down based on transmit channel gain required to maintain a required signal to noise ratio.

Owner:GOOGLE TECHNOLOGY HOLDINGS LLC

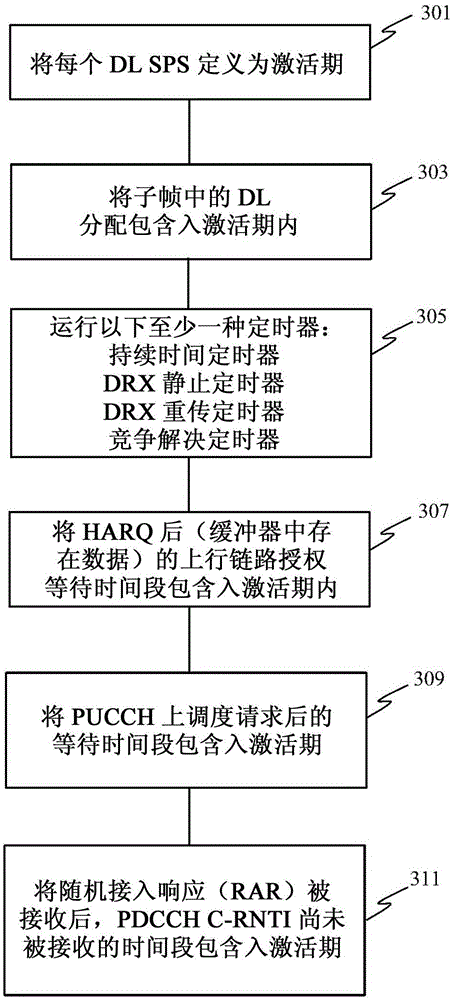

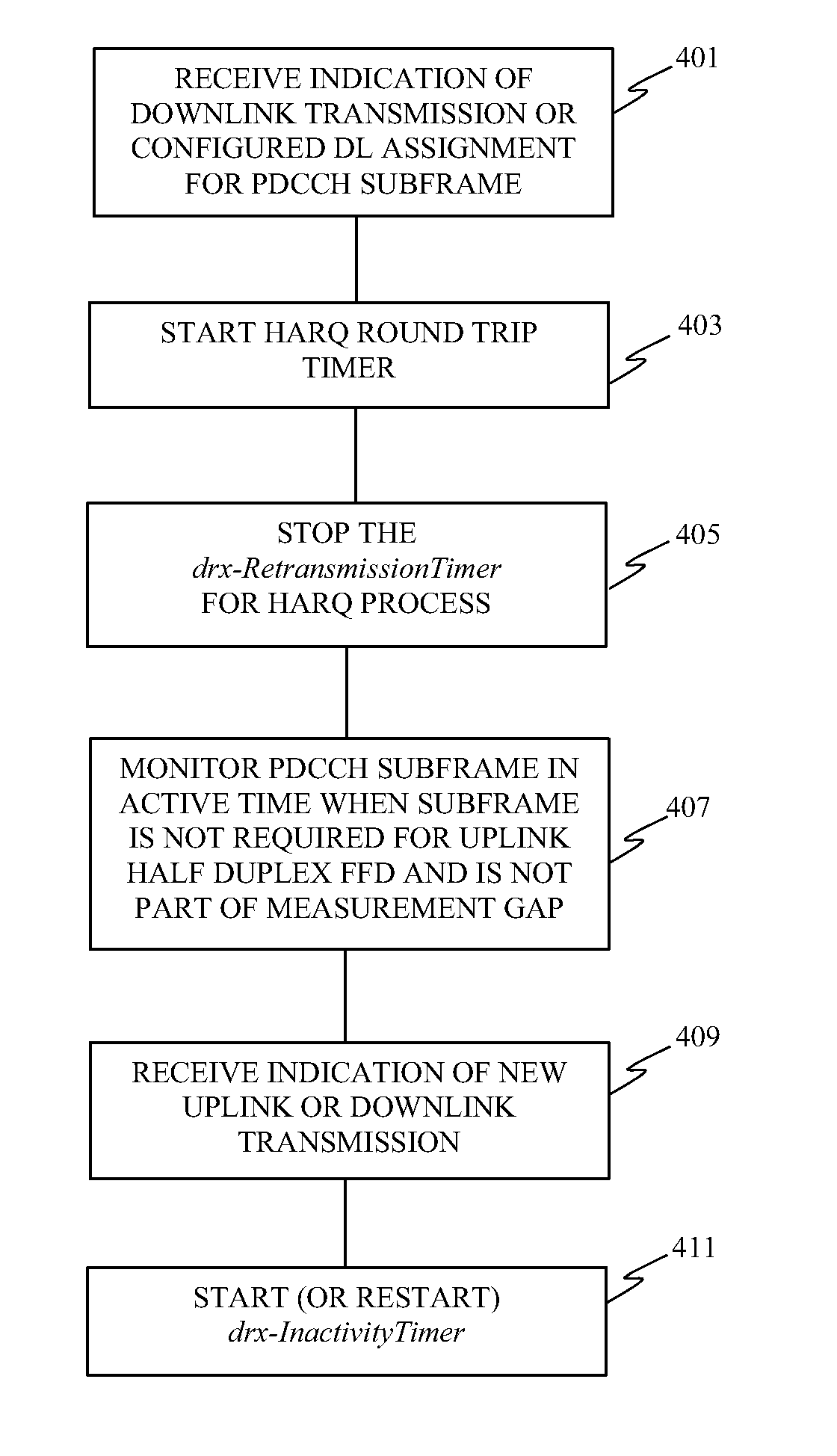

Handling downlink semi-persistent scheduling retransmission in wireless networks

Owner:AVAGO TECH INT SALES PTE LTD

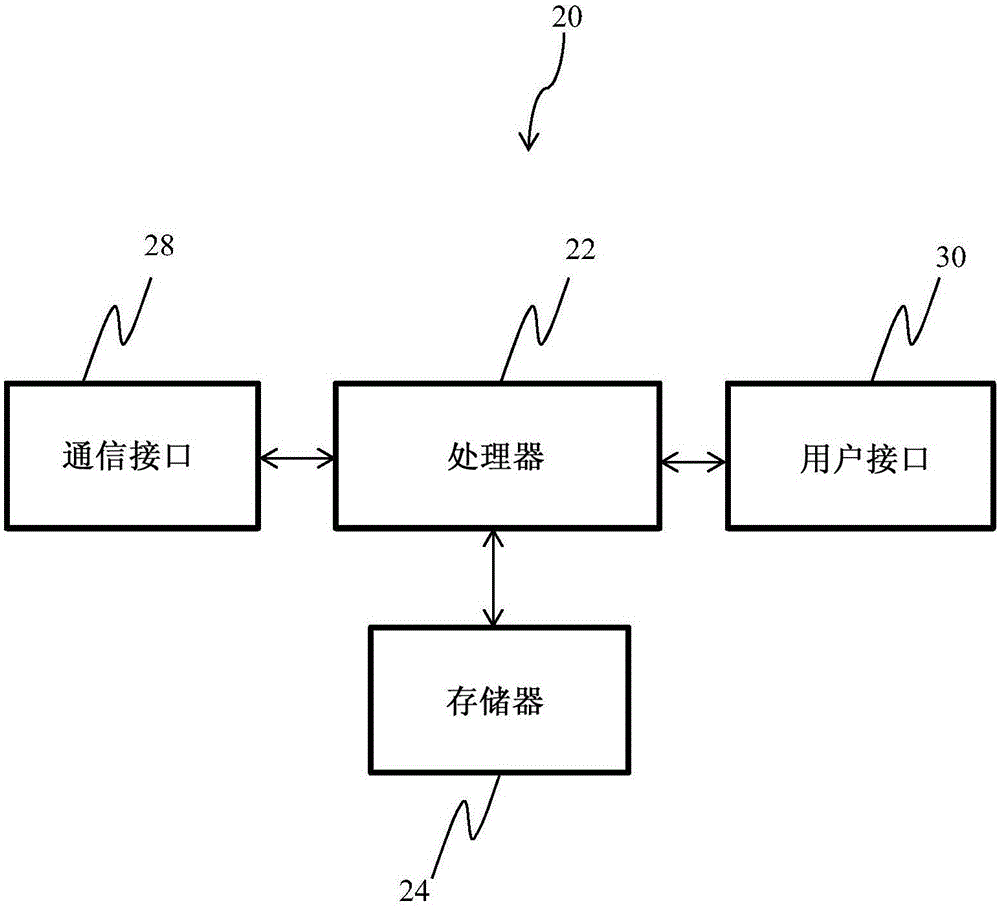

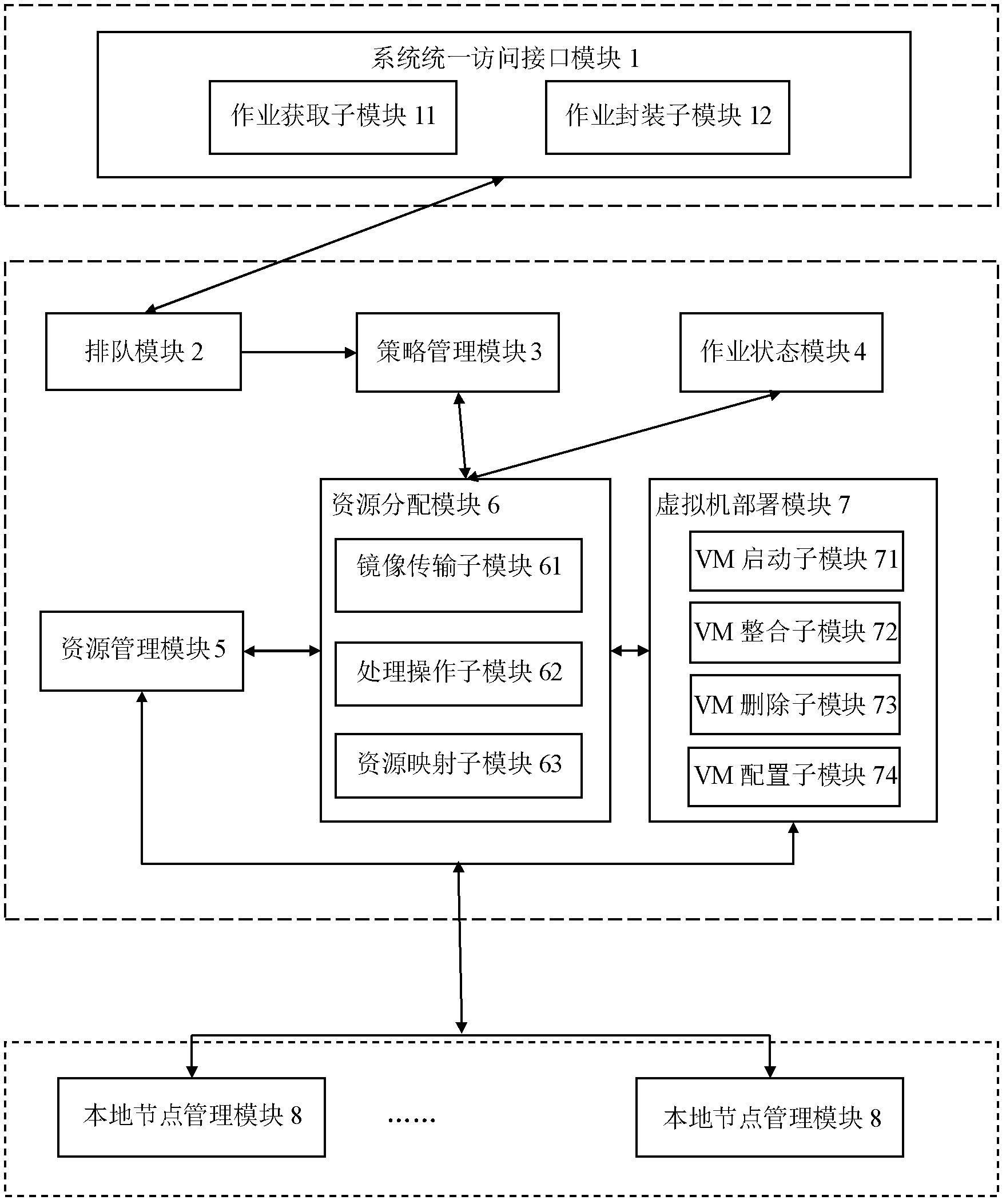

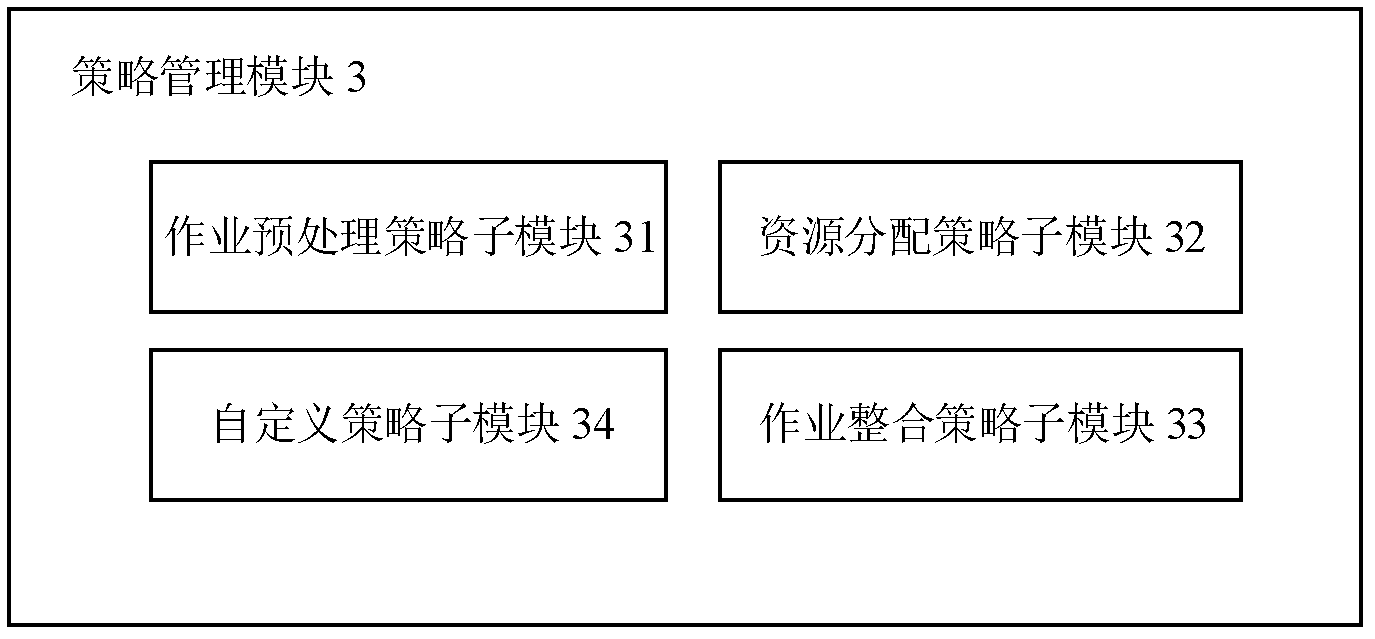

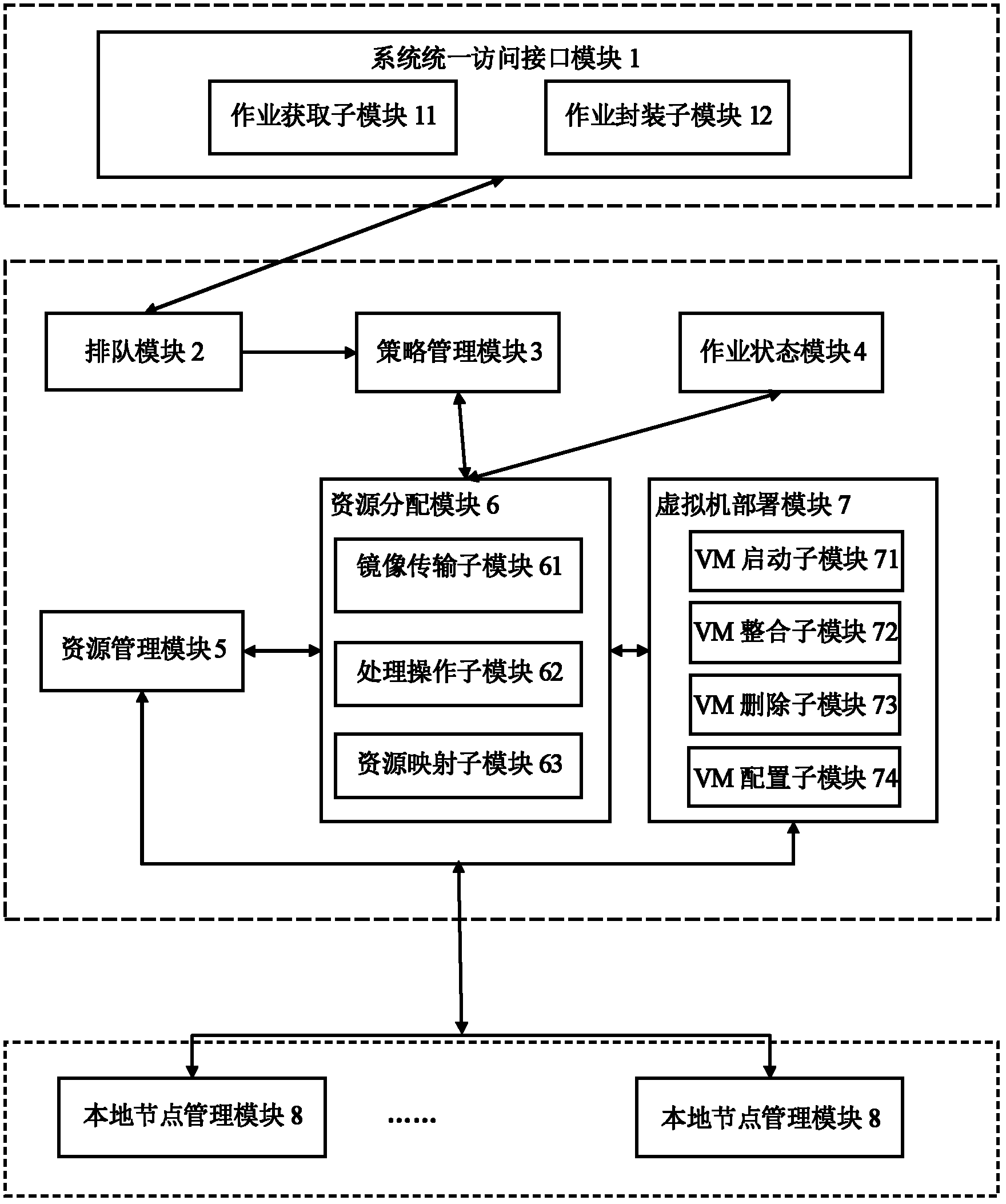

Dynamic operation scheduling system of virtual machine

InactiveCN102609295AReduce time overheadFlexible deploymentProgram initiation/switchingSoftware simulation/interpretation/emulationExtensibilityOperation scheduling

The invention discloses a dynamic operation scheduling system of a virtual machine. The system can be conveniently connected to various cloud platforms to supply unified resource management for the various popular cloud platforms. The system can dynamically allocate the operation pretreatment strategy, placement strategy and integration strategy of the virtual machine, can be realized in a plug-in mode and has high dynamic characteristics and good extensibility. In comparison with the prior art, the system provided by the invention not only has the advantages of dynamic allocation and suitability to various cloud platforms, but also can schedule and execute the preparation operation before turning on the virtual machine as well as the cleanup operation after turning off the virtual machine in a task form, thereby improving the deployment efficiency of the virtual machine and improving the resource utilization rate. In addition, the system has good extensibility, and supports heterogeneous virtual machine platform, thereby improving the transparence of resource utilization.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and system for the dynamic scheduling of requests to access a storage system

InactiveUS6343351B1Input/output to record carriersMemory systemsData processing systemPosition dependent

A method and system in data processing system are disclosed for the dynamic scheduling of a plurality of requests to access a disk. Each of the requests is associated with a location on the said disk which each of the requests is attempting to access. A scan queue is established for storing the plurality of requests. The plurality of requests are processed in a sequential order. The sequential order is determined utilizing the location on the disk being accessed by each of the requests. Upon one of the stored requests being urgent, the urgent request is processed. The urgent request is associated with a first location on said disk. Processing of the requests then continues in a second sequential order. The second sequential order is determined utilizing the first location. The next request to be processed is one of the requests which is associated with a physically closest location on the disk.

Owner:LENOVO PC INT

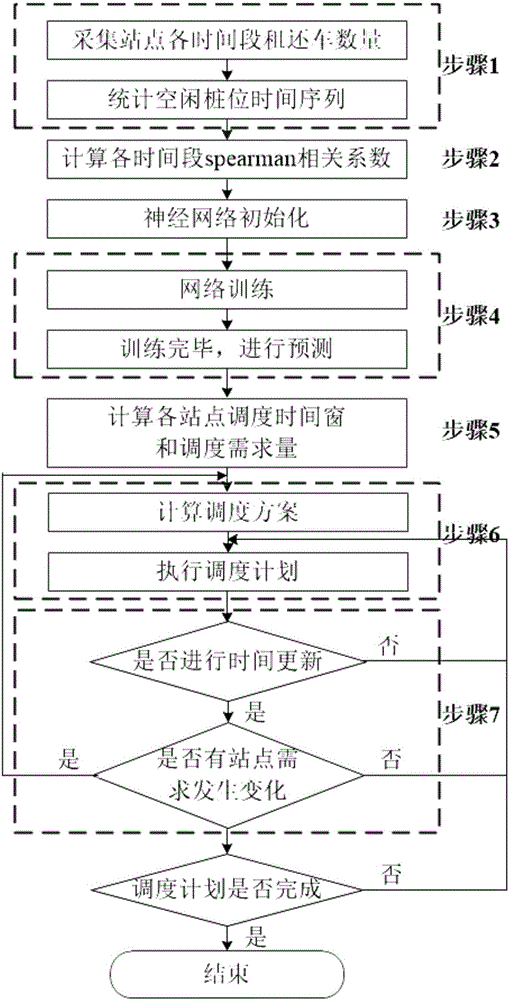

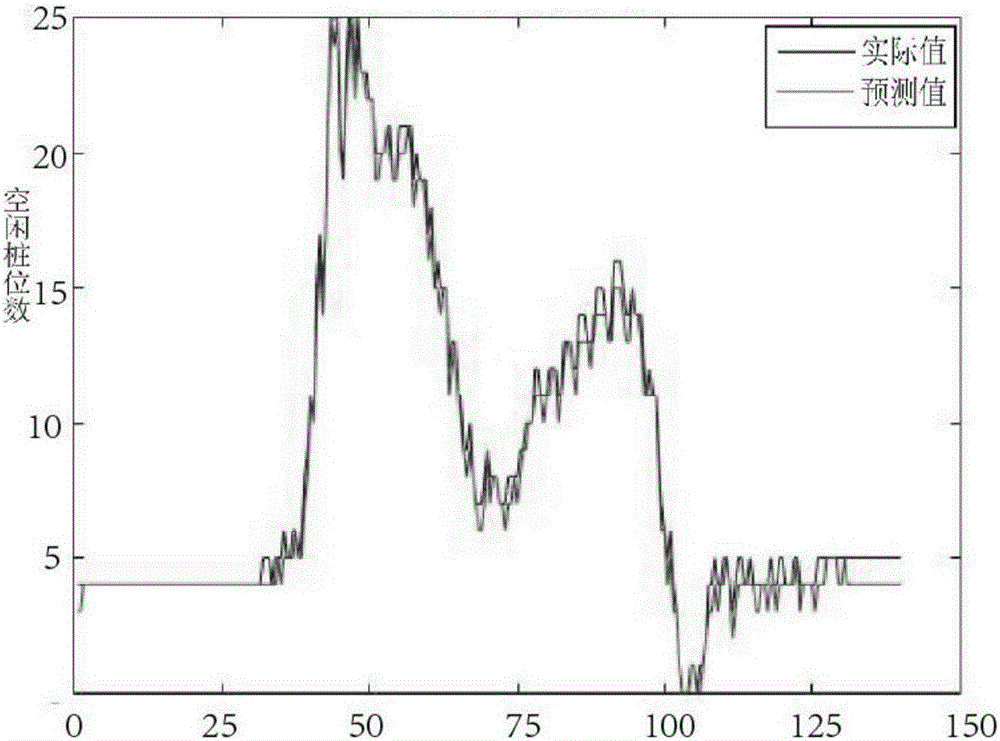

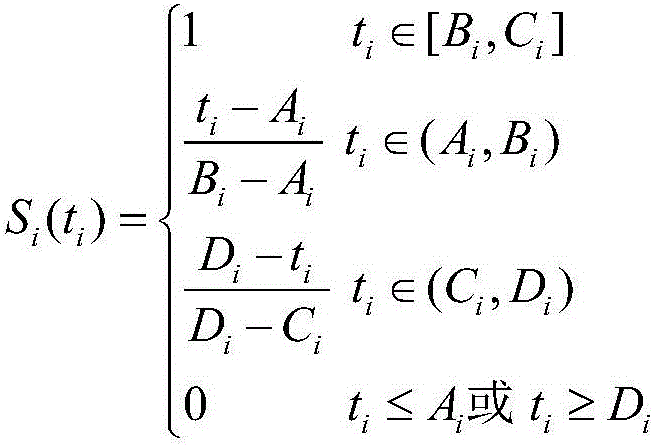

Public bicycle dynamic scheduling method based on site short-term demand prediction

InactiveCN106503869AGuarantee high efficiencyGuaranteed accuracyForecastingBuying/selling/leasing transactionsNumber timesNetwork model

The invention discloses a public bicycle dynamic scheduling method based on site short-term demand prediction. The method comprises the steps of collecting a site free pile number time sequence, constructing a neural network model to predict the short-term demand of each site, calculating the scheduling time window and demand on the basis, constructing a dynamic scheduling model minimizing the cost of scheduling and maximizing satisfaction, solving a scheduling scheme, and adjusting the scheduling plan through information updating. By combining site short-term demand prediction and dynamic scheduling, the efficiency and accuracy of public bicycle scheduling are ensured, the service level of public bicycles is improved, and public bicycles are made more attractive.

Owner:SOUTHEAST UNIV

Handling downlink semi-persistent scheduling retransmission in wireless networks

During discontinue reception (DRX) operation of a mobile terminal of a wireless communications network, methods to ensure that user equipment is in an awake mode when a network node sends a scheduling grant on the physical downlink control channel (PDCCH). Dynamic scheduling (DS) and semi-persistent scheduling (SPS) grants may appear on PDCCH only once. One method defines every received downlink (DL) semi-persistent scheduling (SPS) signal in a subframe as active time in a configured DRX cycle and includes in said defining active time any occurrence of a DL assignment being configured for the subframe. A second method receives an indication of a downlink transmission or a configured downlink assignment configured for the current PDCCH subframe, starts a Hybrid Automatic Repeat request (HARQ) Round Trip Timer (RTT) whether UE is in active time or not, and stops a drx-RetransmissionTimer for the corresponding HARQ process whether UE is in active time or not.

Owner:AVAGO TECH INT SALES PTE LTD

Dynamic scheduling in a distributed environment

ActiveUS8185908B2Multiprogramming arrangementsMultiple digital computer combinationsDynamic priority schedulingReal-time computing

A method and system is provided for assigning programs in a workflow to one or more nodes for execution. Prior to the assignment, a priority of execution of each program is calculated in relation to its dependency upon data received and transmitted data. Based upon the calculated priority and the state of each of the nodes, the programs in the workflow are dynamically assigned to one or more nodes for execution. In addition to the node assignment based upon priority, preemptive execution of the programs in the workflow is determined so that the programs in the workflow may not preemptively be executed at a selected node in response to the determination.

Owner:SERVICENOW INC

Methods and systems for providing, by a referral management system, dynamic scheduling of profiled professionals

A method for matching a professional with a referral opportunity includes automatically generating, by a profile generator executing on a first computing device, a profile of a professional. The method includes receiving, by an analysis engine executing on the first computing device, from a second computing device, an identification of a referral opportunity having at least one requirement. The method includes determining, by the analysis engine, that the generated profile satisfies the at least one requirement. The method includes transmitting, by the analysis engine, to the second computing device, the identification of the professional. The method includes receiving, by the first computing device, an indication that a user of the second computing device made a referral to the professional. The method includes scheduling, by a workflow engine executing on the first computing device, an appointment with the professional for a subject of the referral opportunity.

Owner:KYRUUS

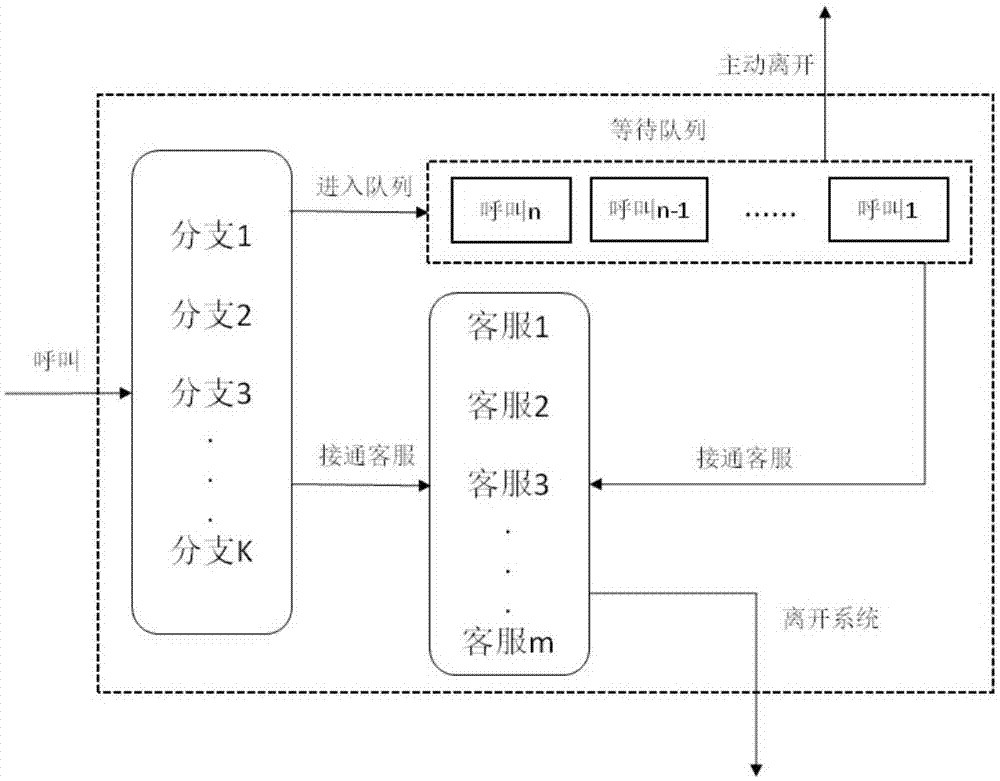

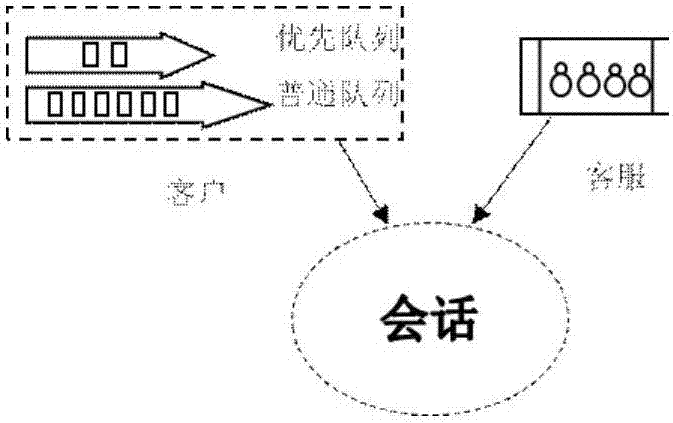

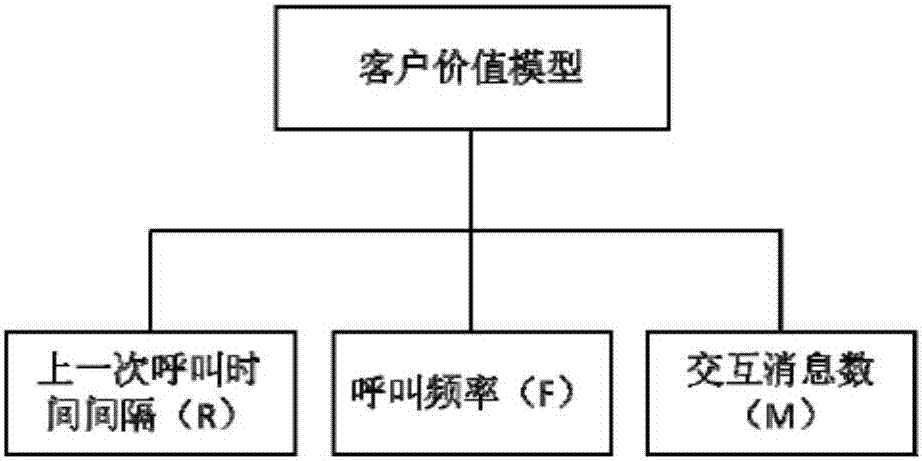

Automatic call distribution method based on dynamic priority queuing

InactiveCN107426448ATimely serviceAutomatic exchangesData switching networksPriority queuingDynamic priority scheduling

The invention discloses an automatic call distribution method based on dynamic priority queuing, which is characterized in that customers with high values are preferentially served, the resource benefit of a customer service system is improved, the customers are also avoided from waiting for a long time, and the customer satisfaction is improved. The technical scheme is that category division is performed according to the contribution degree of the customers, then the customers are placed in an ordinary queue or a priority queue based on the customer category, different priorities are divided in the priority queue, customers with the highest priority are extracted from the priority queue and preferentially served, and the customers in the ordinary queue are served according to a sequence of the waiting time. In addition, the priority queue is implemented in the form of a stack data structure, and the stack data structure of the priority queue is organized again under the condition that a customer gets into the priority queue, is extracted from the priority queue and voluntarily leaves the priority queue so as to keep a big root stack structure. The invention further provides a time-out polling mechanism so as to ensure customers waiting in a timeout manner to receive timely services.

Owner:上海神计信息系统工程有限公司

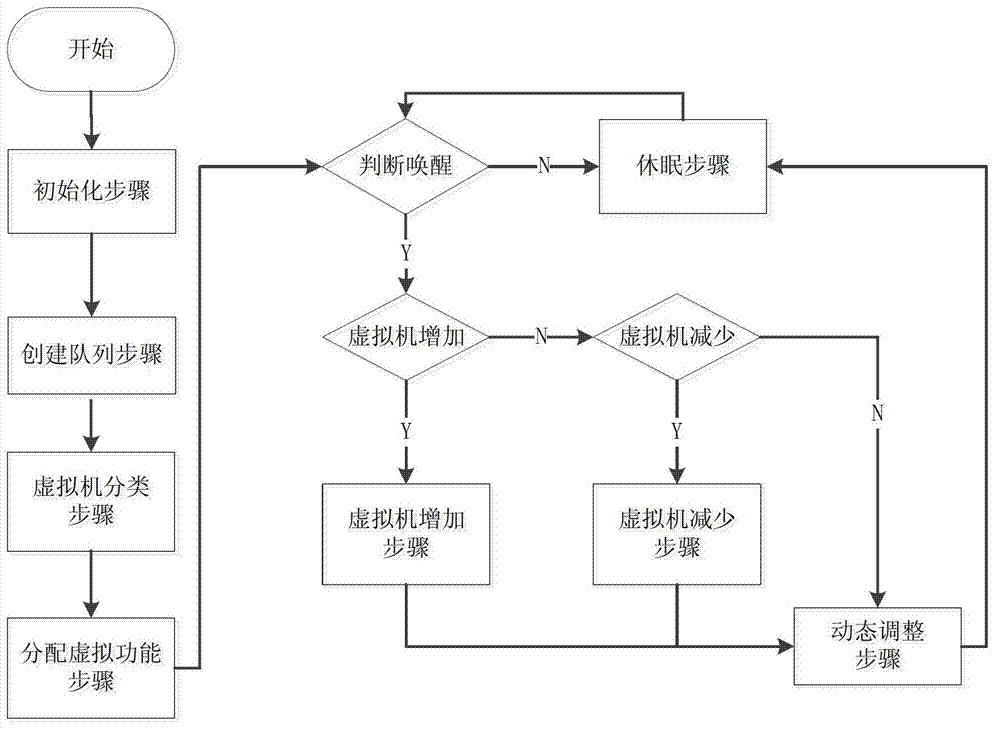

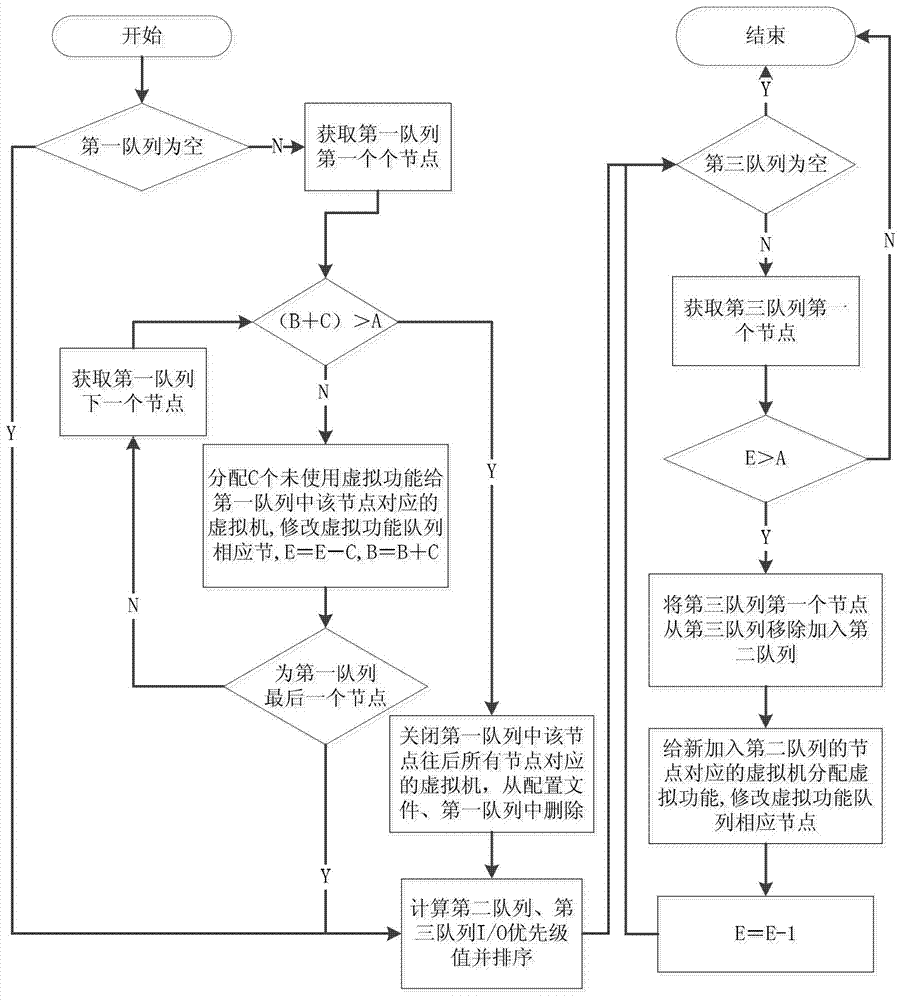

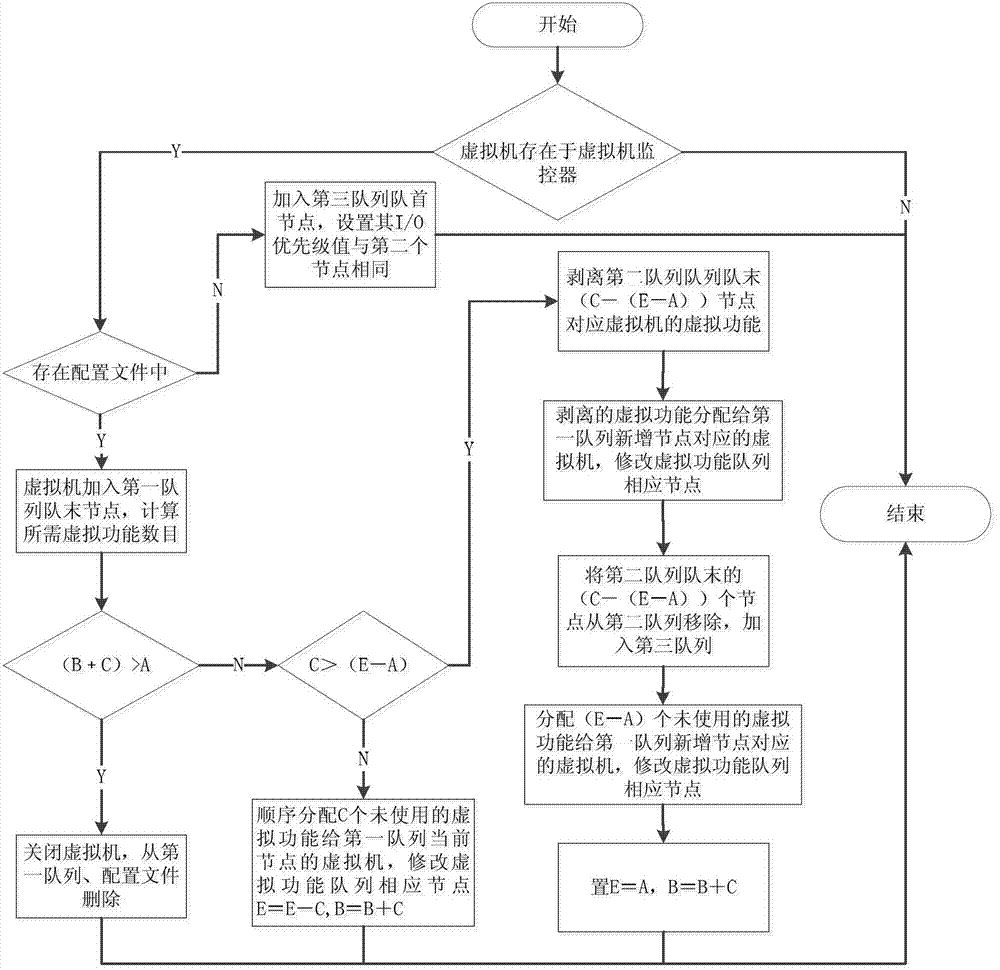

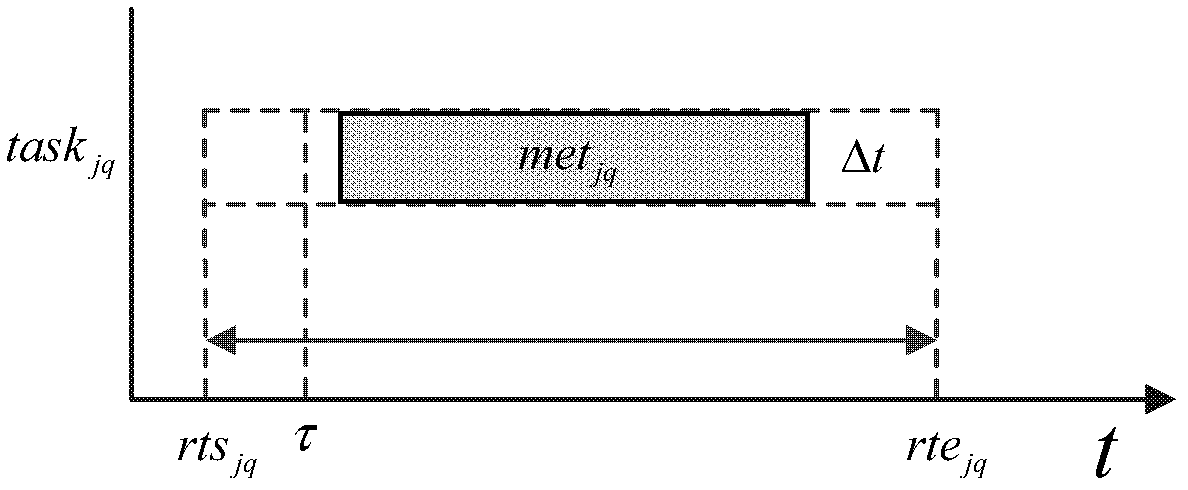

Dynamic scheduling method with virtual function

ActiveCN103049331AEasy to useImprove performanceResource allocationSoftware simulation/interpretation/emulationSleep timeDistribution method

The invention relates to a dynamic scheduling method with a virtual function, belongs to the field of computer virtualization, and solves the problems of insufficient expandability and poor flexibility in using of virtual functions provided by a single root input and output virtualization standard network card so as to improve use ratio of the network card. The dynamic scheduling method with the virtual function comprises the steps of initializing, establishing queues, classifying virtual machines, distributing virtual functions, judging and wakening, adding virtual machines, dynamically adjusting and sleeping. During a period, the dynamic scheduling method with the virtual function performs dynamic scheduling on the virtual functions provided by the single root (input / output) I / O virtualization standard network card through statistics of I / O interruption times and sleeping time of the virtual machines, guarantees that the virtual function is utilized by a virtual machine with the largest I / O priority value, improves, network performance, fully utilizes hardware, and is used for supporting virtual machine platforms with a device direct distribution method.

Owner:HUAZHONG UNIV OF SCI & TECH

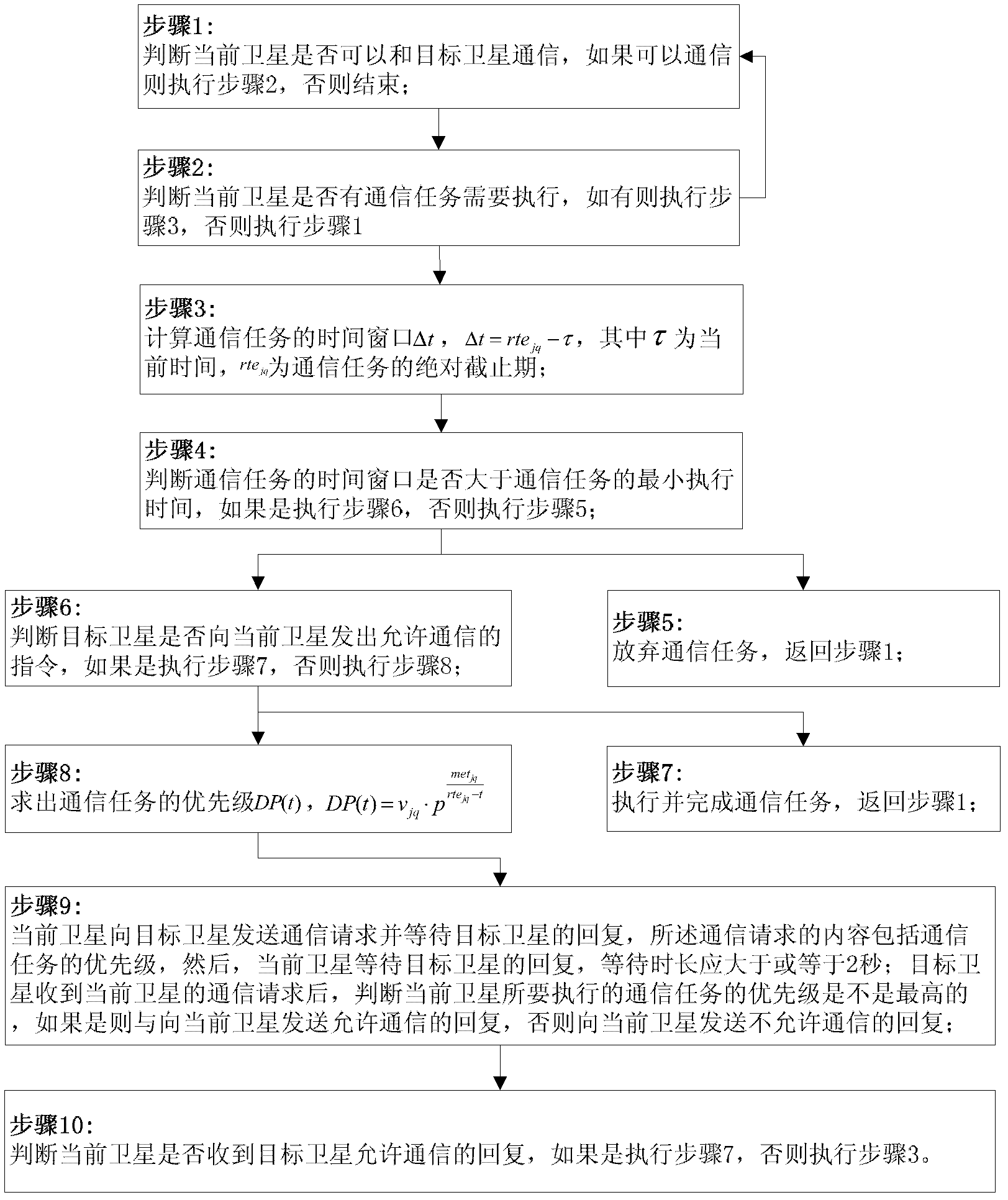

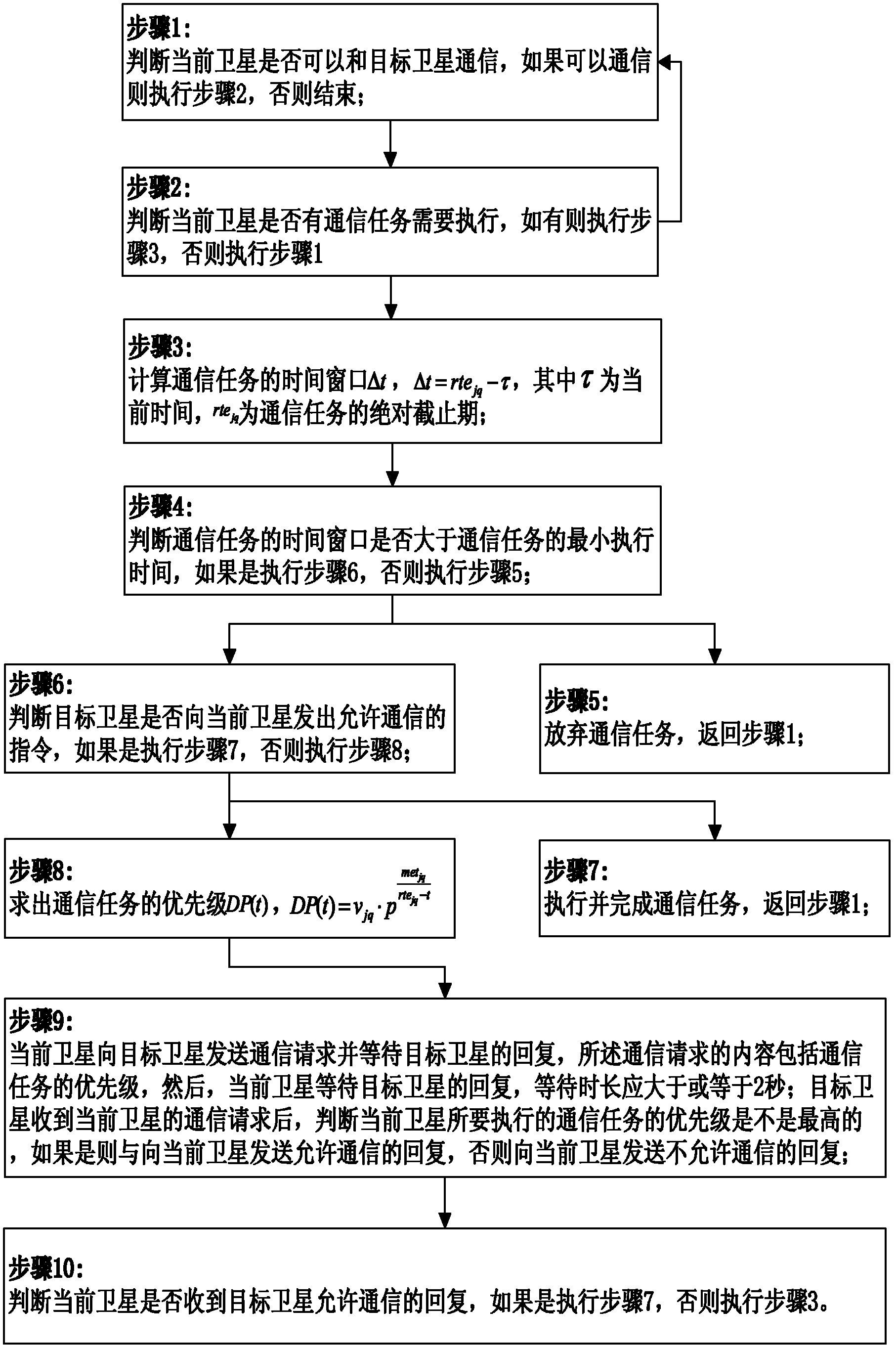

Dynamic priority dispatching method of satellite network many-to-one communication conflicts

ActiveCN102594433AExtend communication timeHigh utility valueTransmission control/equalisingSpare timeComputer science

A dynamic priority dispatching method of satellite network many-to-one communication conflicts belongs to the satellite communication network field. The method includes calculating the time window of a current satellite communication task, judging whether the time window of the communication task is larger than the minimum execution time of the communication task, calculating the priority of the communication task if the communication task is larger than the minimum execution time of the communication task, judging whether the priority of the current satellite communication task is the highest by a target satellite, and communicating with the current satellite if the priority of the current satellite communication task is the highest. The method has the advantages that randomness of the communication task is considered, the method is suitable for relay satellite communication system with fixed or random communication tasks; the change of the task priority dynamic can fully utilize the task spare time, so that the communication time of the satellite is improved; the algorithm is simple, the needed resources are less, and the method is suitable for satellite communications with limited communication resources.

Owner:DALIAN UNIV

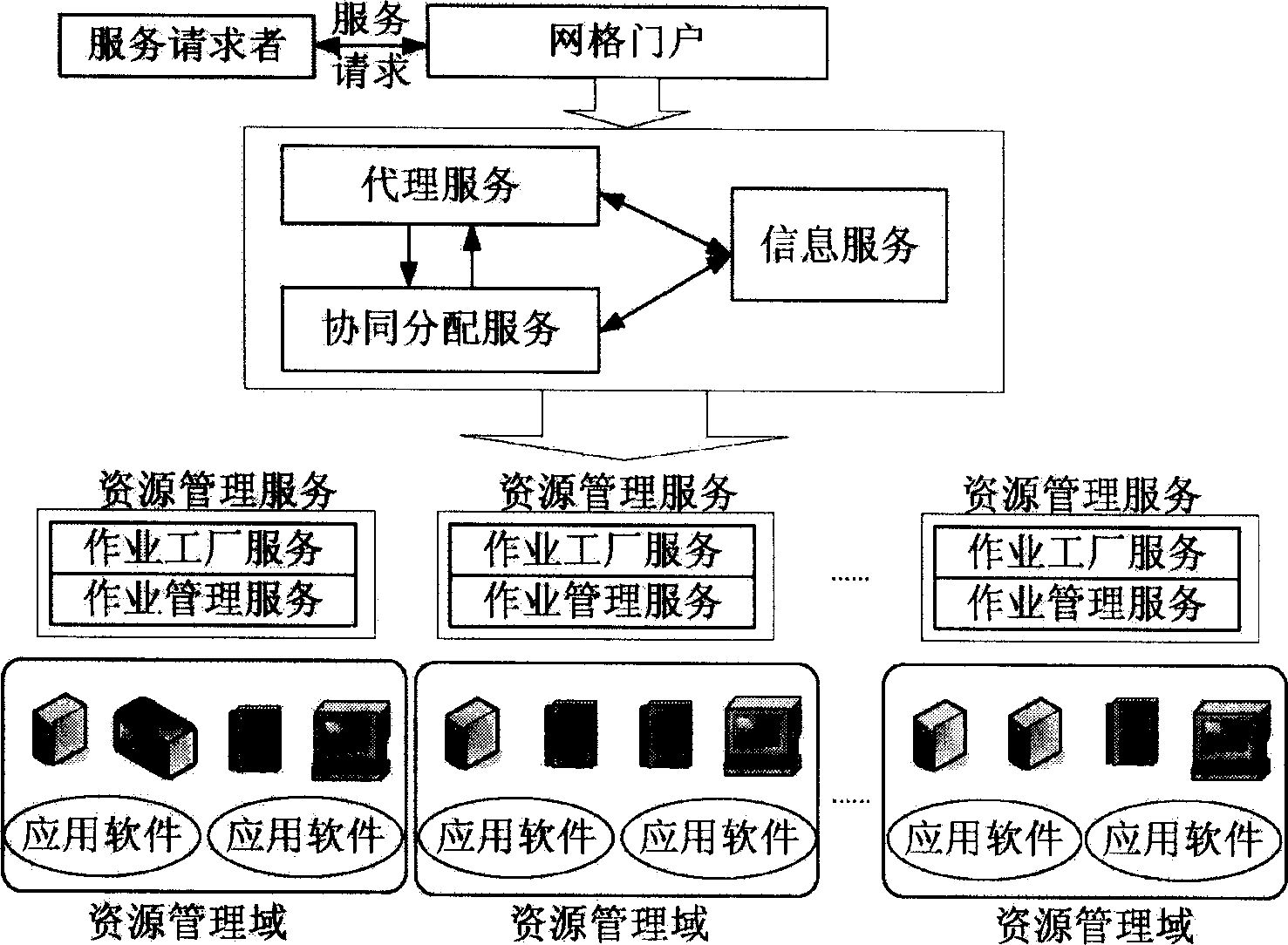

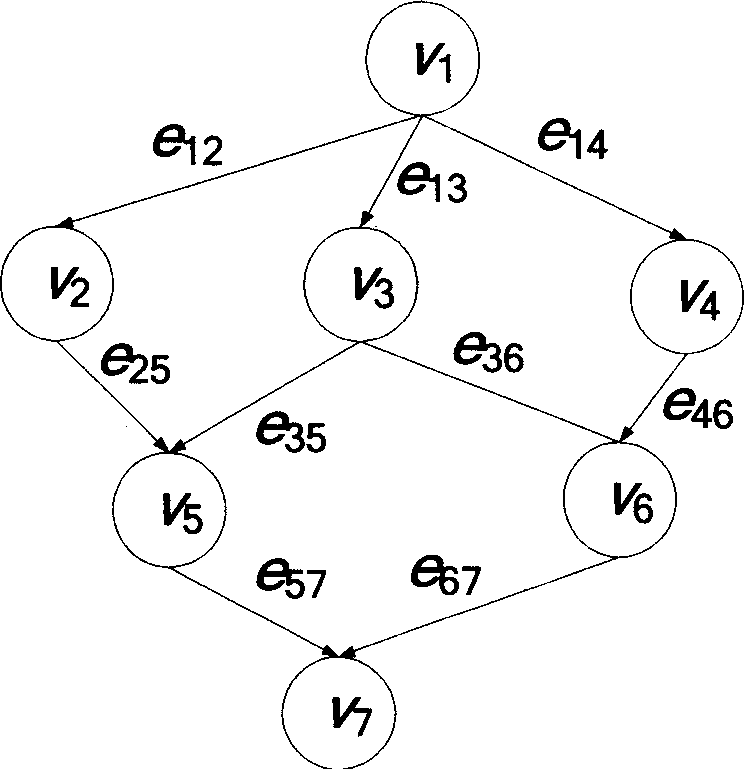

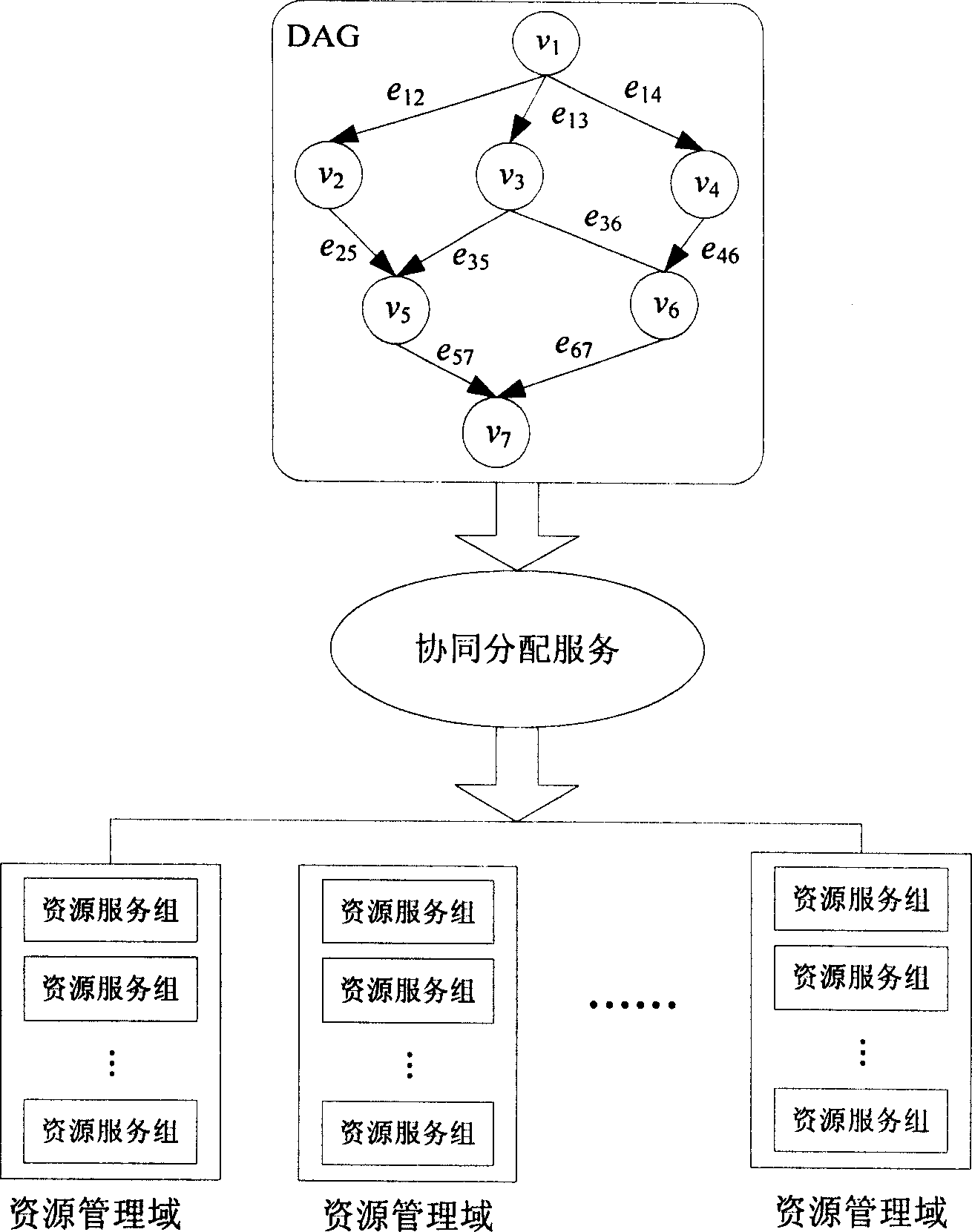

Service oriented high-performance grid computing job scheduling method

InactiveCN1845075AImprove performanceMultiprogramming arrangementsService-orientationDynamic priority scheduling

The invention relates to a network high-performance calculation transfer method faced to service. It uses face-service method; the grid system is formed by distributed resource server group; according to the character of high-performance calculation application, and the character of cooperation treatment between different calculating stations in the grid calculation, decomposing one high-performance calculation application into one calculation subtasks with data input and output relationships; using direction non-cycle graph to express the data relativity between the subtasks; using improved dynamic priority transfer algorism to synchronously match the ready subtask and usable resource server group; then transferring selected subtask to selected resource server group; the invention has considered the condition that one subtask can be executed only in some special resource server group, while it can realize the high-efficiency transfer of high-performance calculation in the grid range.

Owner:SHANGHAI JIAO TONG UNIV

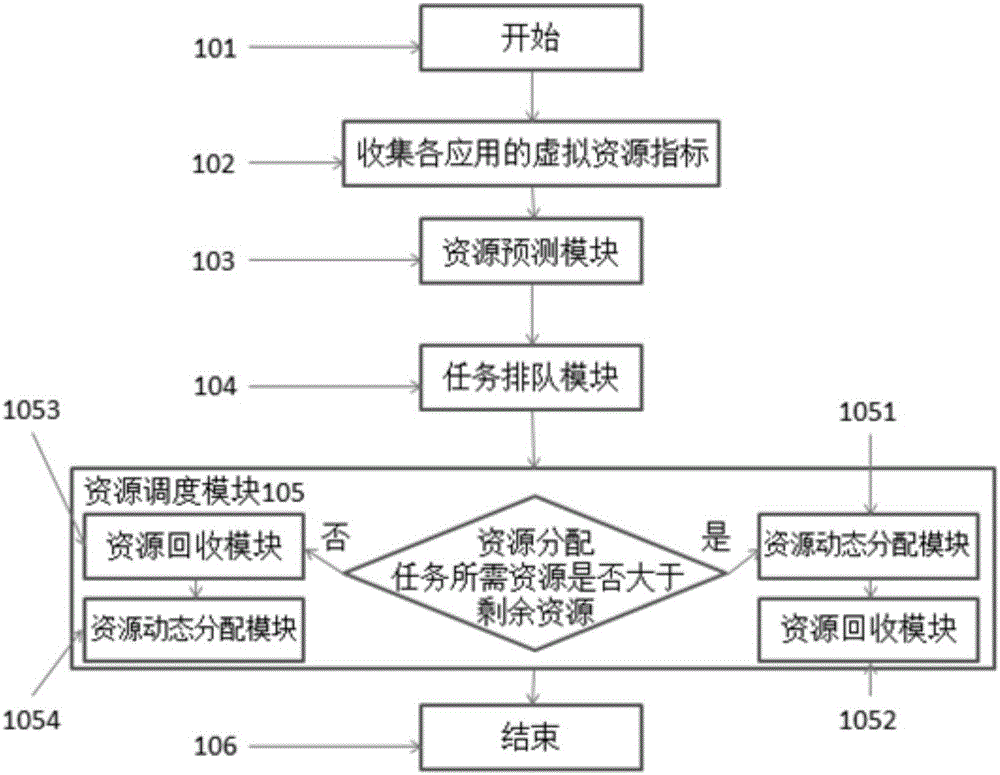

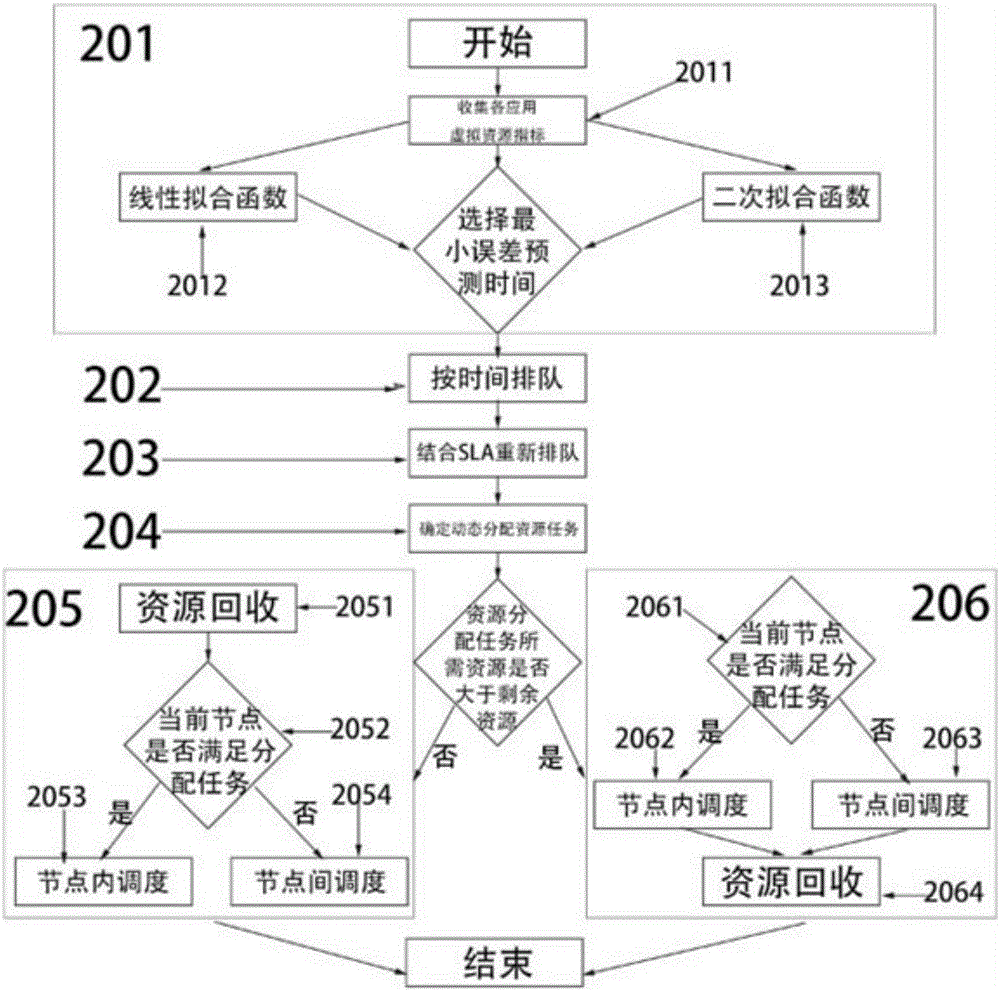

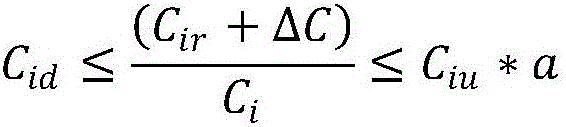

Ultra-lightweight virtual machine-based cloud computing dynamic resource scheduling system and method

ActiveCN106020933AEasy to useImprove efficiencyResource allocationSoftware simulation/interpretation/emulationLower limitDynamic resource

The invention discloses an ultra-lightweight virtual machine-based cloud computing dynamic resource scheduling system and method. The method comprises the steps of collecting a virtual resource index of each application instance from a cloud computing environment, and predicting the time when a virtual resource of one application instance reaches a usage rate upper limit by using a prediction function with a minimum error as a prediction function of the application instance through a fitting function; performing task ranking on each application instance subjected to resource dynamic allocation according to the predicted upper limit time and a signed SLA protocol; and scheduling the application instance selected in a task queuing module to a demander according to a ranking sequence, and recovering the virtual resource, of which the usage rate already exceeds a lower limit, of an application, thereby realizing resource dynamic allocation. According to the system and the method, the resource balanced use is realized more efficiently, satisfactory load balancing is achieved under low consumption, and the comprehensive efficiency of resource scheduling is improved.

Owner:SHANDONG UNIV

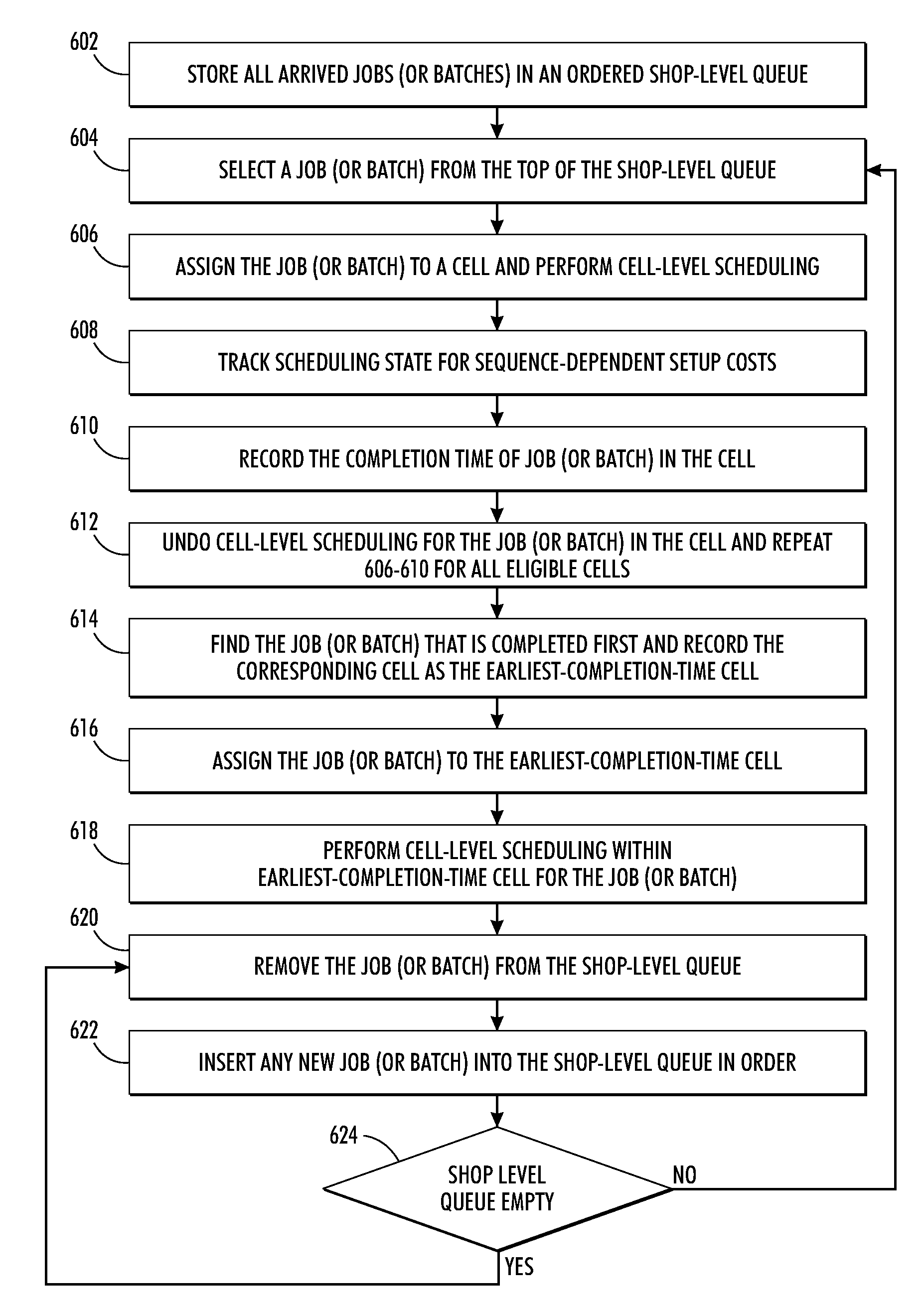

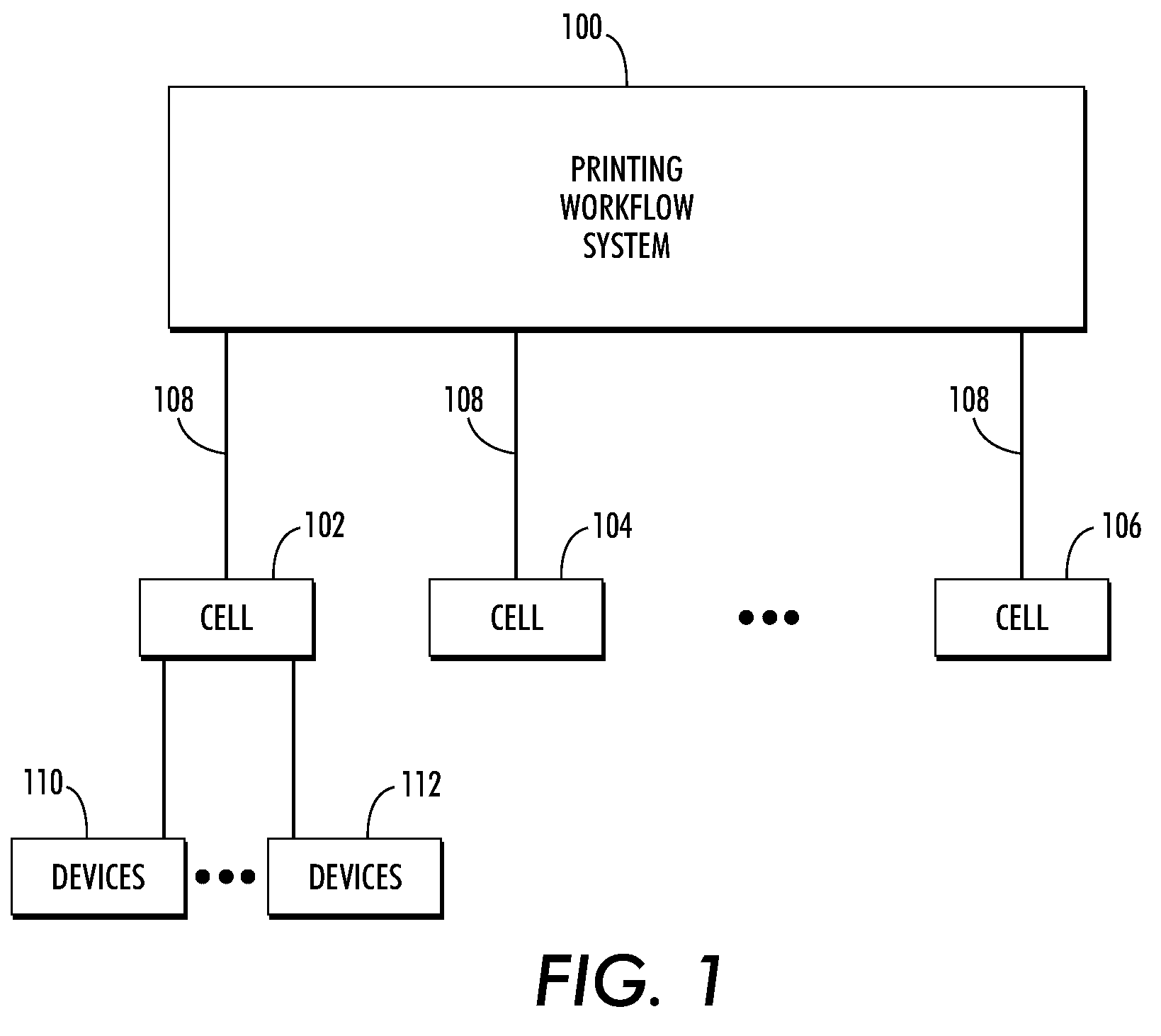

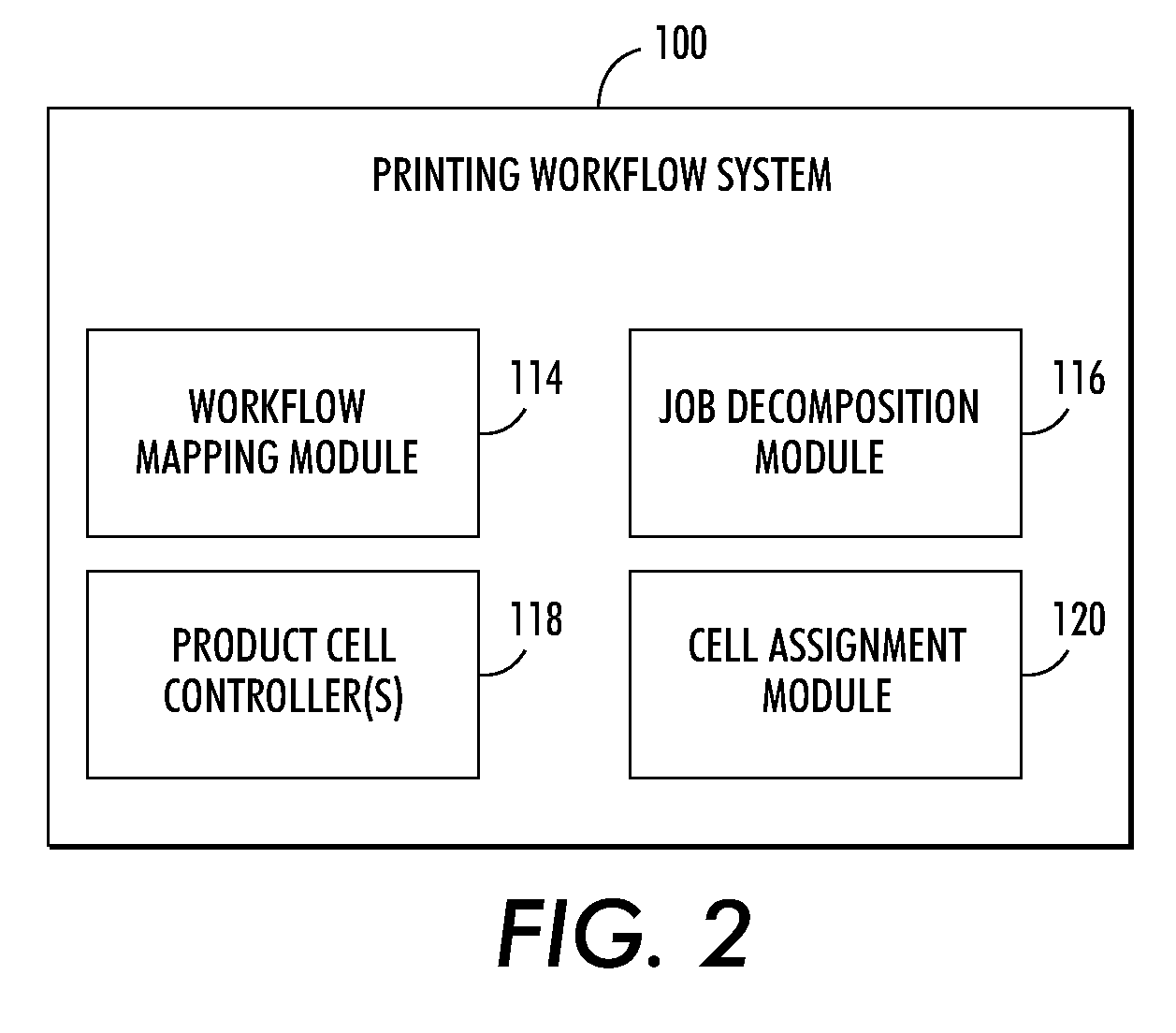

System and methods for dynamic scheduling in cellular manufacturing with batch-splitting

ActiveUS20110066269A1Increase productionImprove efficiencyProgramme controlMultiprogramming arrangementsCompletion timeBatch processing

The present application a new and improved system and method of enhanced Lean Document Production (LDP), which applies cellular manufacturing to document printing operations. The LDP process incorporates process friendly cells and, a push model to order to improve efficiency, reduce work in progress and smooth out the “frictions” in production environments. The current application presents an earliest-completion-time strategy for assigning jobs to cells and a dynamic-priority-based-batch-scheduling algorithm.

Owner:PALO ALTO RES CENT INC +1

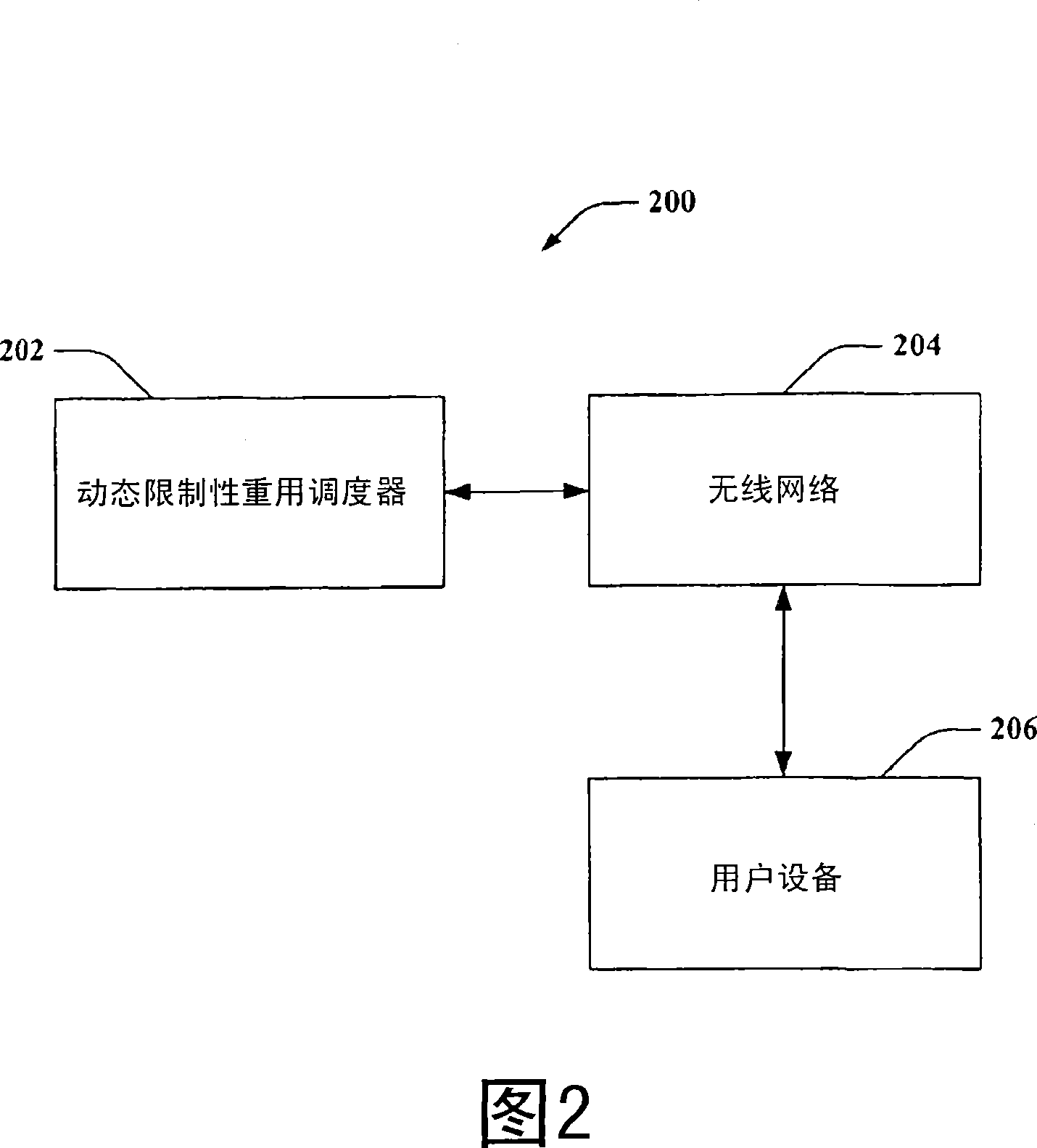

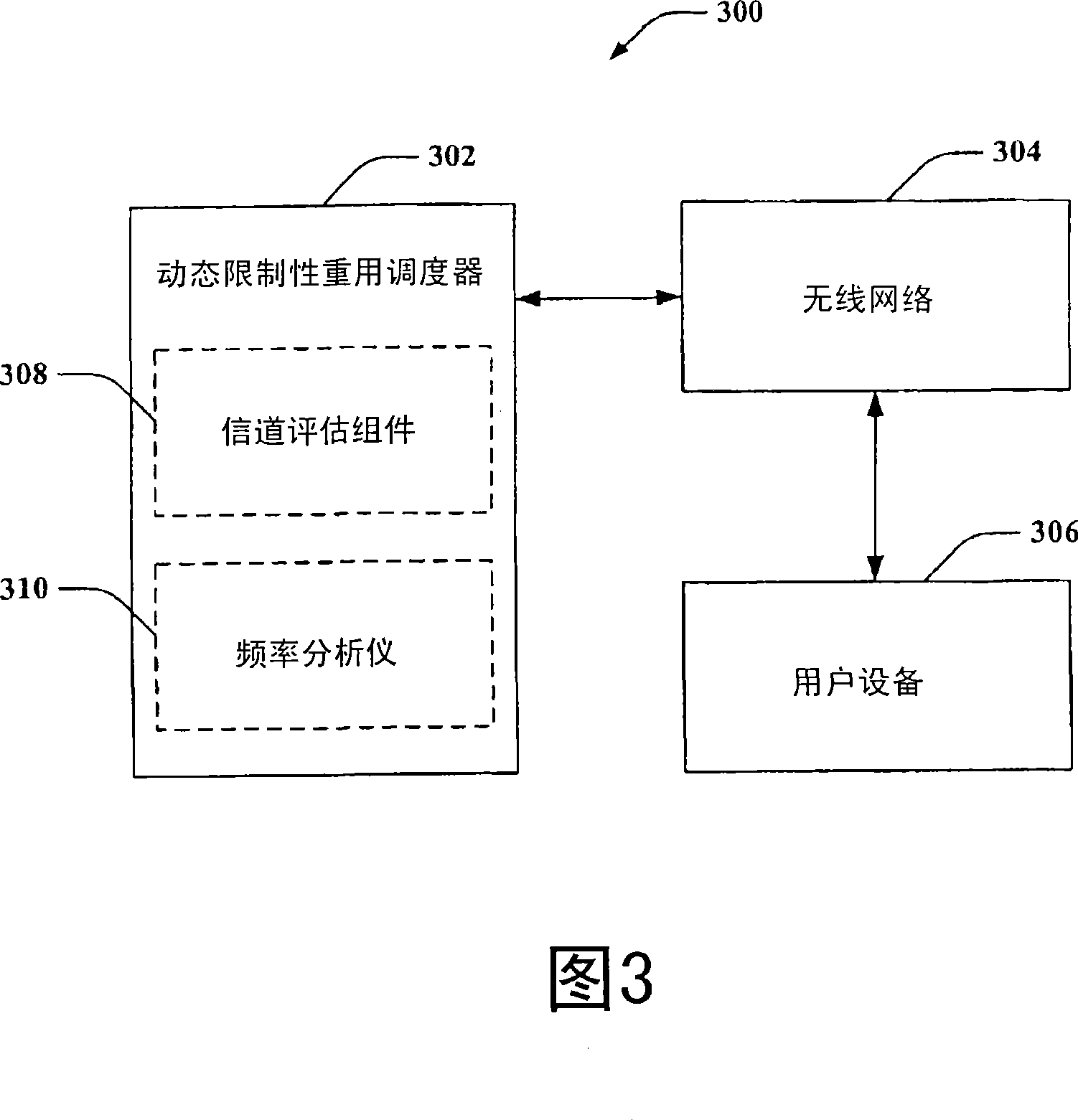

Dynamic asbr scheduler

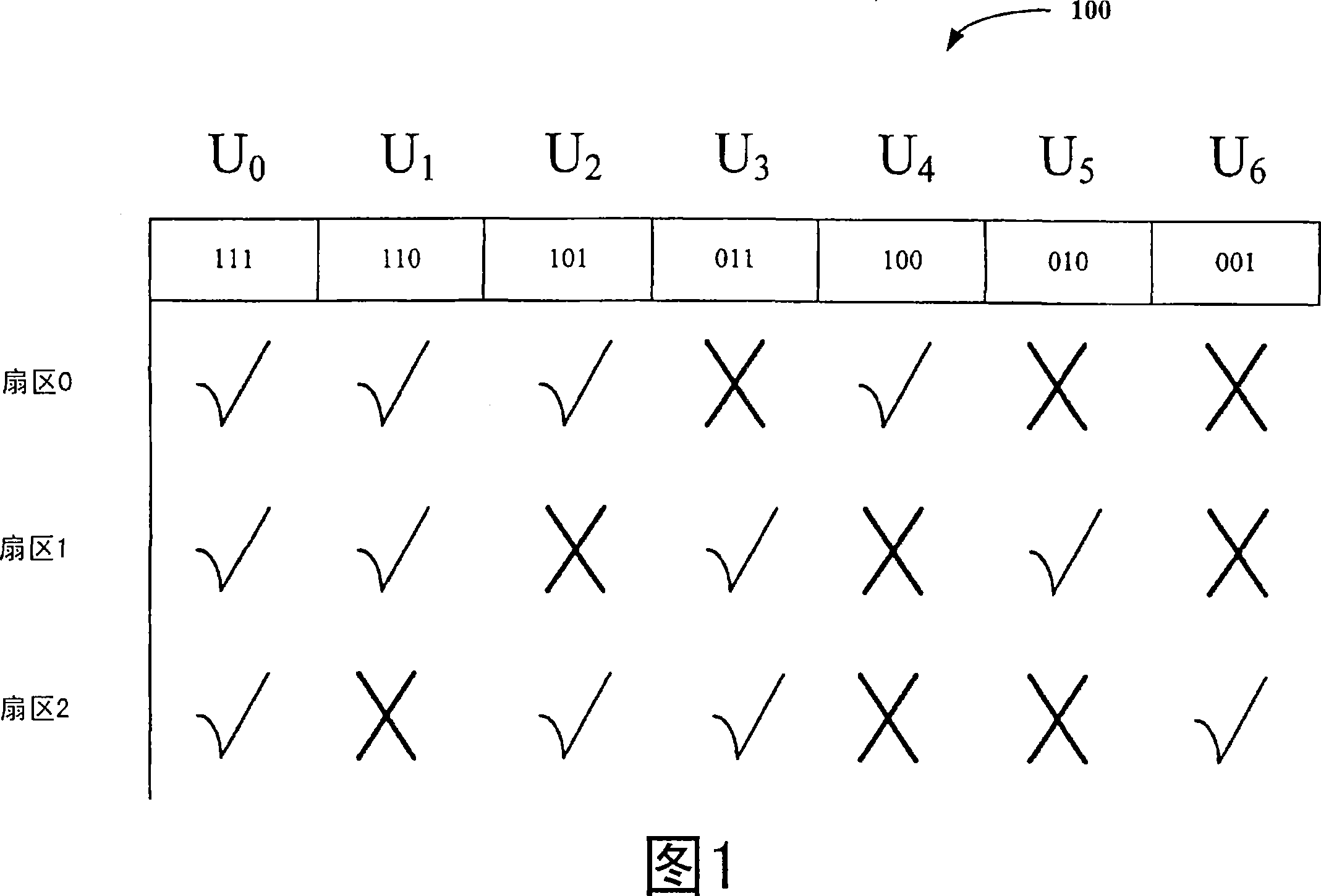

ActiveCN1994018ARadio/inductive link selection arrangementsData switching networksUser equipmentDynamic priority scheduling

Systems and methodologies are described that facilitate dynamically scheduling frequency sets for reuse by user devices to reduce inter-cell interference by evaluating an overall scheduling metric for each user device in a wireless communication region. The overall scheduling metric can be evaluated by determining a fairness metric for each user device in a wireless communication region, an overall channel peak desirabality metric for each user device, and a channel delay desirability metric for each user device. The overall scheduling metric can be the function of the fairness metric and one or more of the overall channel peak desirability metric and the channel delay desirability metric. A user device with a highest overall scheduling metric score for a given round of dynamic scheduling can be awarded a frequency set.

Owner:QUALCOMM INC

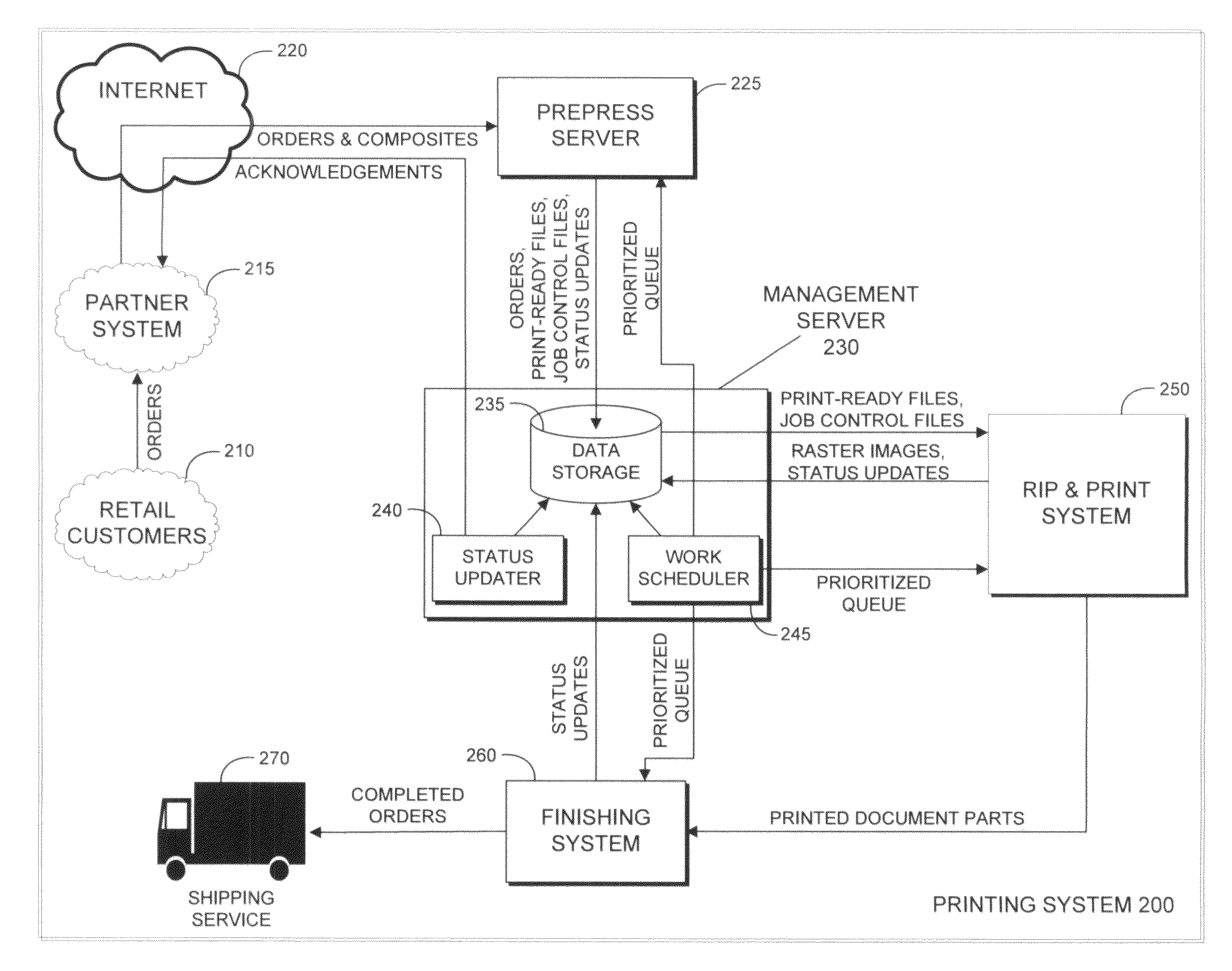

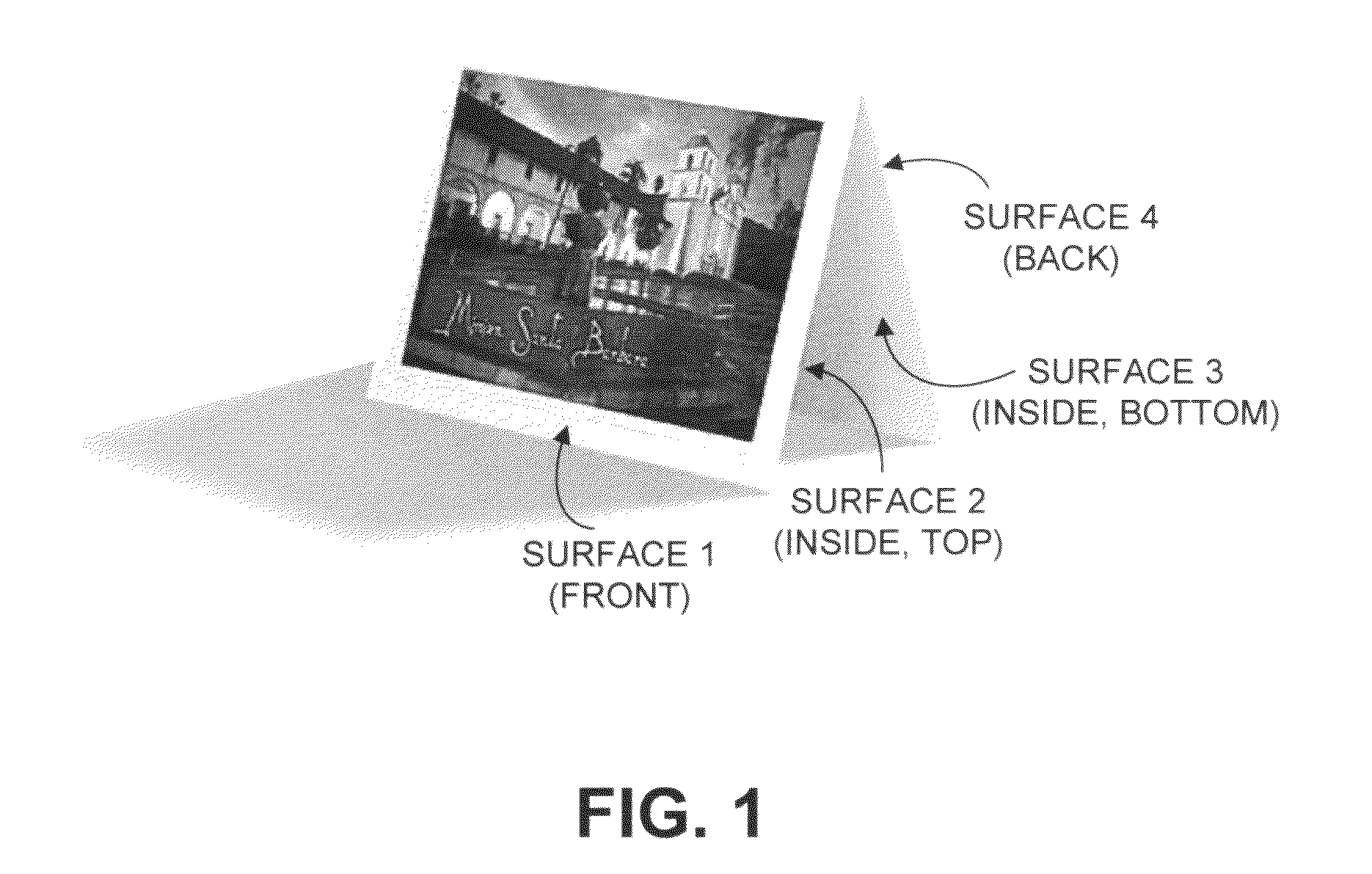

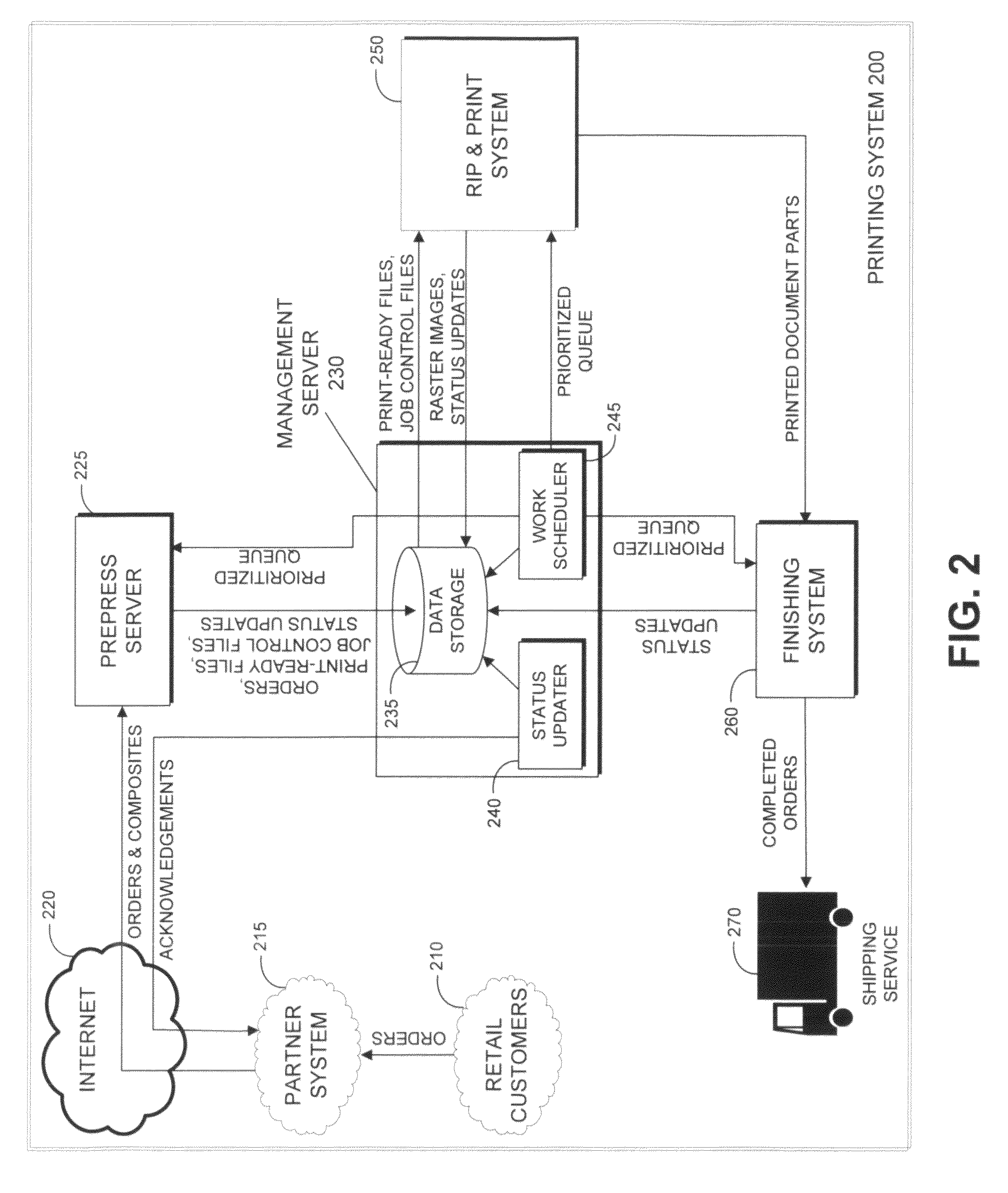

Multiproduct printing workflow system with dynamic scheduling

ActiveUS8310696B2Maximize efficiencyMaximize profitabilityVisual presentationResourcesPersonalizationService-level agreement

A method for end-to-end printing, including entering into service level agreements with each of a plurality of partner systems that enable customers to order personalized print products, wherein a service level agreement designates maximum delays for finishing customer print orders, receiving customer print orders forwarded from the plurality of partner systems, each print order specifying at least one personalized print product, serializing the print orders into a plurality of work items, each work item corresponding to a part of a personalized print product that is to be printed on printable material, dynamically assigning priorities to the work items, dynamically advancing the work items through a plurality of print processing states, wherein each processing state processes work items in order of their priorities.

Owner:REISCHLING PRESS

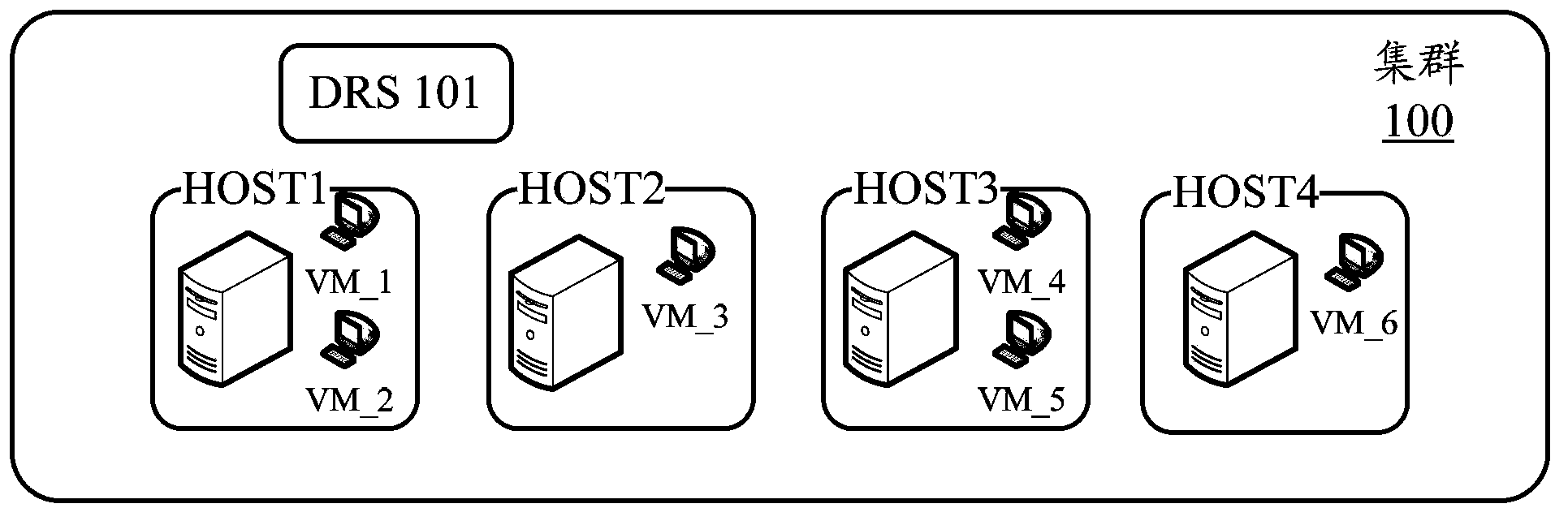

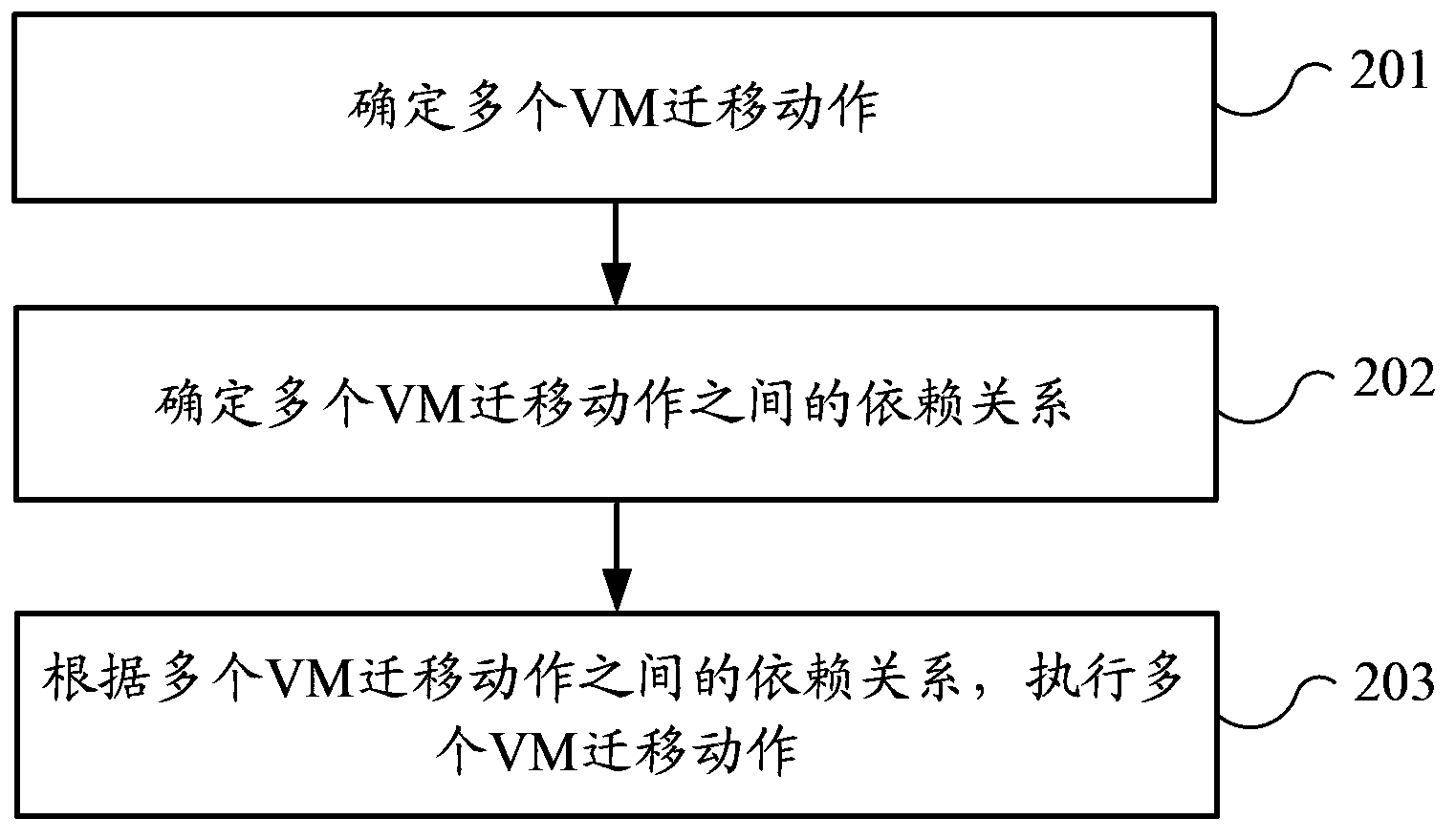

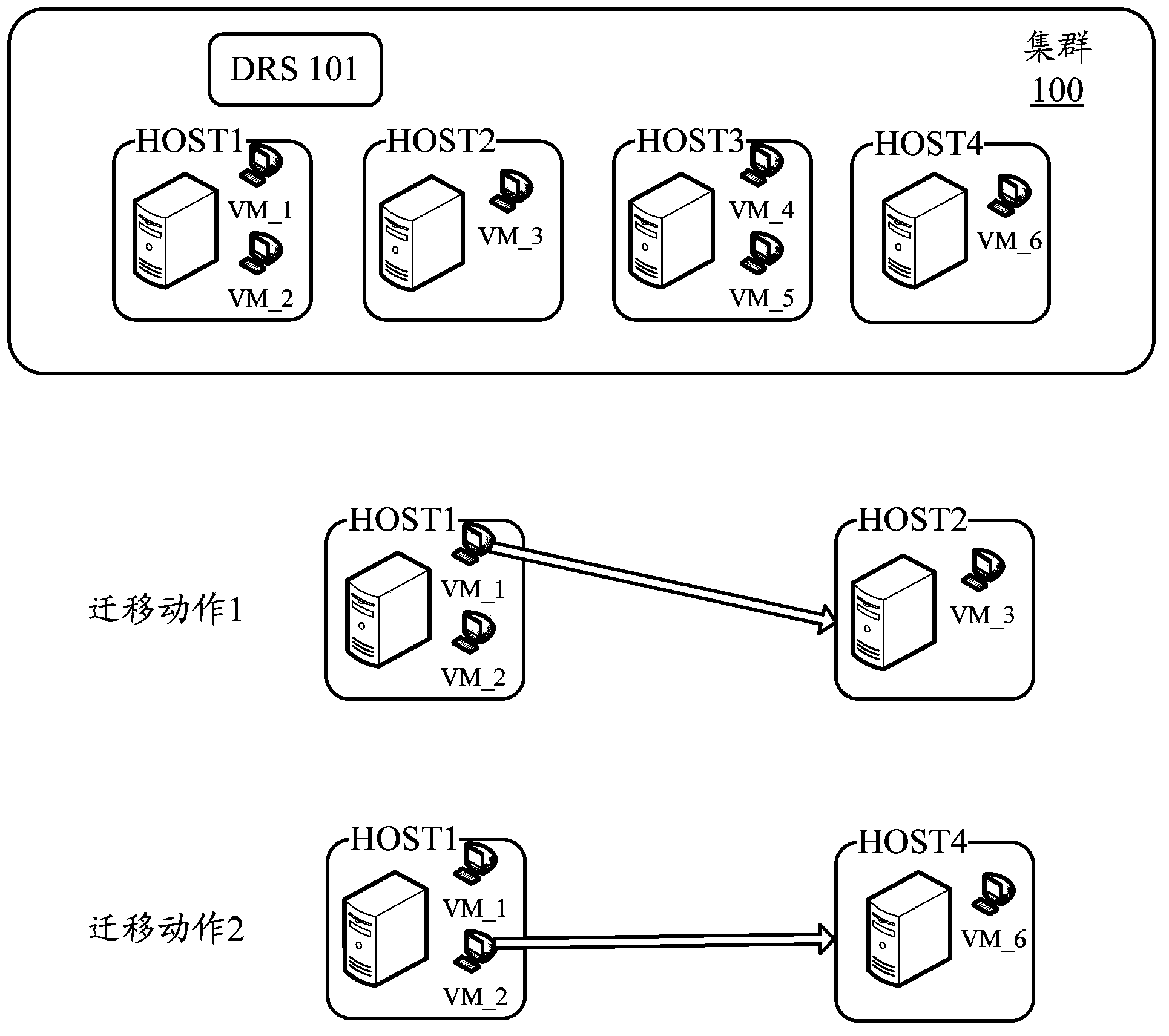

Dynamic resource scheduling method and dynamic resource scheduler

ActiveCN103856548AImprove scheduling efficiencyProgram initiation/switchingTransmissionDynamic resourceComputer science

The embodiment of the invention provides a dynamic resource scheduling method and a dynamic resource scheduler. The dynamic scheduling method and the dynamic resource scheduler can improve the efficiency of dynamic resource scheduling. The dynamic resource scheduling method comprises the steps that a plurality of virtual machine migration movements are determined, the dependency relation among the virtual machine migration movements is determined, and the virtual machine migration movements are executed according to the dependency relation among the virtual machine migration movements. Due to the fact that the dependency relation among the virtual machine movements is taken into consideration when the virtual machine migration movements are executed instead of the manner of executing the virtual machine migration movements according to the sequence, the efficiency of dynamic resource scheduling can be improved.

Owner:HUAWEI TECH CO LTD

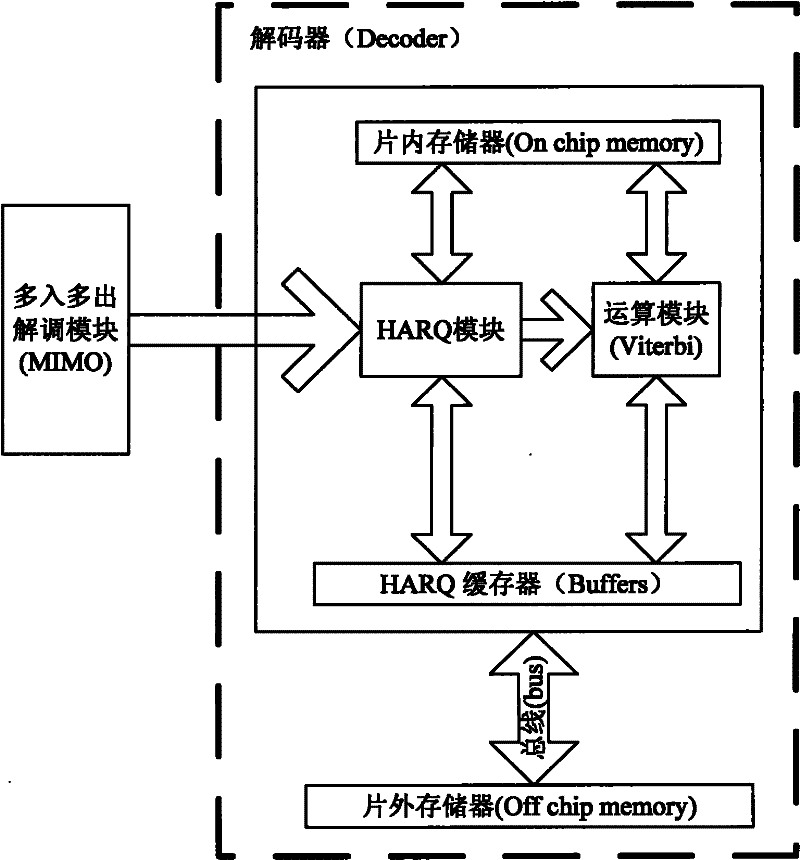

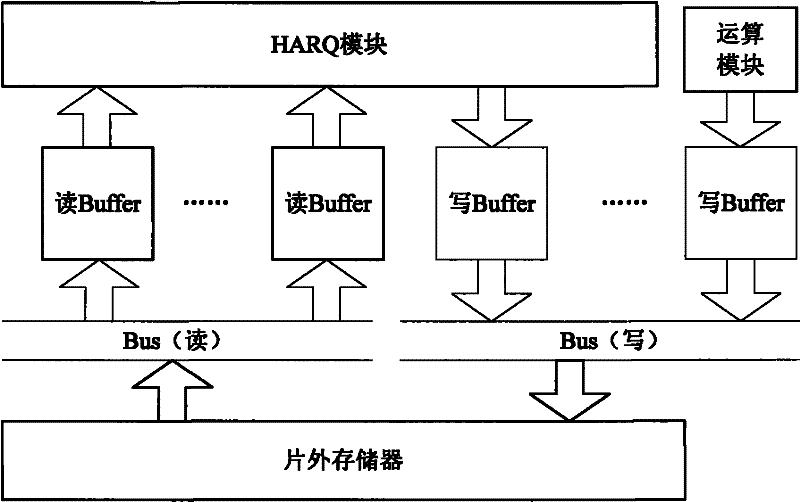

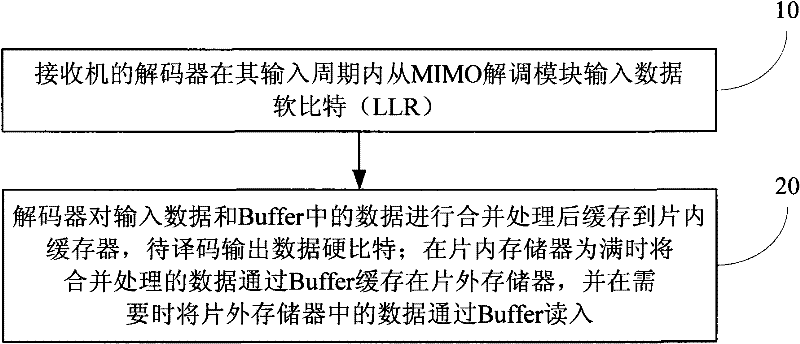

Method and device for implementing hybrid automatic repeat request memory dynamic scheduling

InactiveCN102271033AImprove transmission efficiencyDynamic Scheduling SimplifiedError prevention/detection by using return channelWireless communicationAutomatic repeat requestOperating system

A method and device for implementing dynamical scheduling of a hybrid automatic repeat request (HARQ) memory are disclosed in the present invention, wherein, the method relates to a decoder which includes an on-chip memory, an off-chip memory and a buffer. The method includes: after combining input data and data in the buffer in the input period, the decoder buffers the combined data in the on-chip memory for decoding and output; when the on-chip memory is full, the combined data is written and buffered in the off-chip memory through the buffer. The invention greatly promotes transmission efficiency of the bus, and effectively enables the dynamical scheduling of HARQ data between the on-chip memory and the off-chip memory. Furthermore, a dynamical scheduling method for priorly scheduling the first depleted buffer is provided, which greatly simplifies the implementation of the system, and satisfies the requirement of the system for combining the HARQ data.

Owner:SANECHIPS TECH CO LTD

A dynamic production scheduling system and a production scheduling method for a composite material workshop

ActiveCN109598416AImprove adaptabilityImprove real-time performanceResourcesManufacturing computing systemsProduction scheduleReal-time data

The invention relates to a dynamic production scheduling system and a production scheduling method for a composite material workshop. the methodcomprises the steps: reading perception data of a workshop Internet of Things perception system in real time, including workshop workpiece processing real-time data and production disturbance event information, and obtaining disturbance events, such as a workshop workpiece processing state, an equipment fault, a production schedule delay, an alignment problem, and the like; And based on the perception information, analyzing the current resource use condition and the influence generated by the disturbance event, and feeding back the current resource use condition and the influence to the production scheduling calculation module in real time. Throughcoagulation, analysis and mining of actual machining process data, a production scheduling knowledge base is formed, and all process procedure knowledge, procedure machining resource configuration knowledge and the like of the workpiece machining process are stored; And after the production scheduling calculation module receives the rearrangement instruction, the corresponding technological process, stations corresponding to the processes, and resource configuration data and process processing man-hour data of equipment / personnel can be automatically generated according to the characteristicsof the workpieces, so that the production scheduling scheme is calculated and output, and the production scheduling efficiency is improved.

Owner:中国航天系统科学与工程研究院

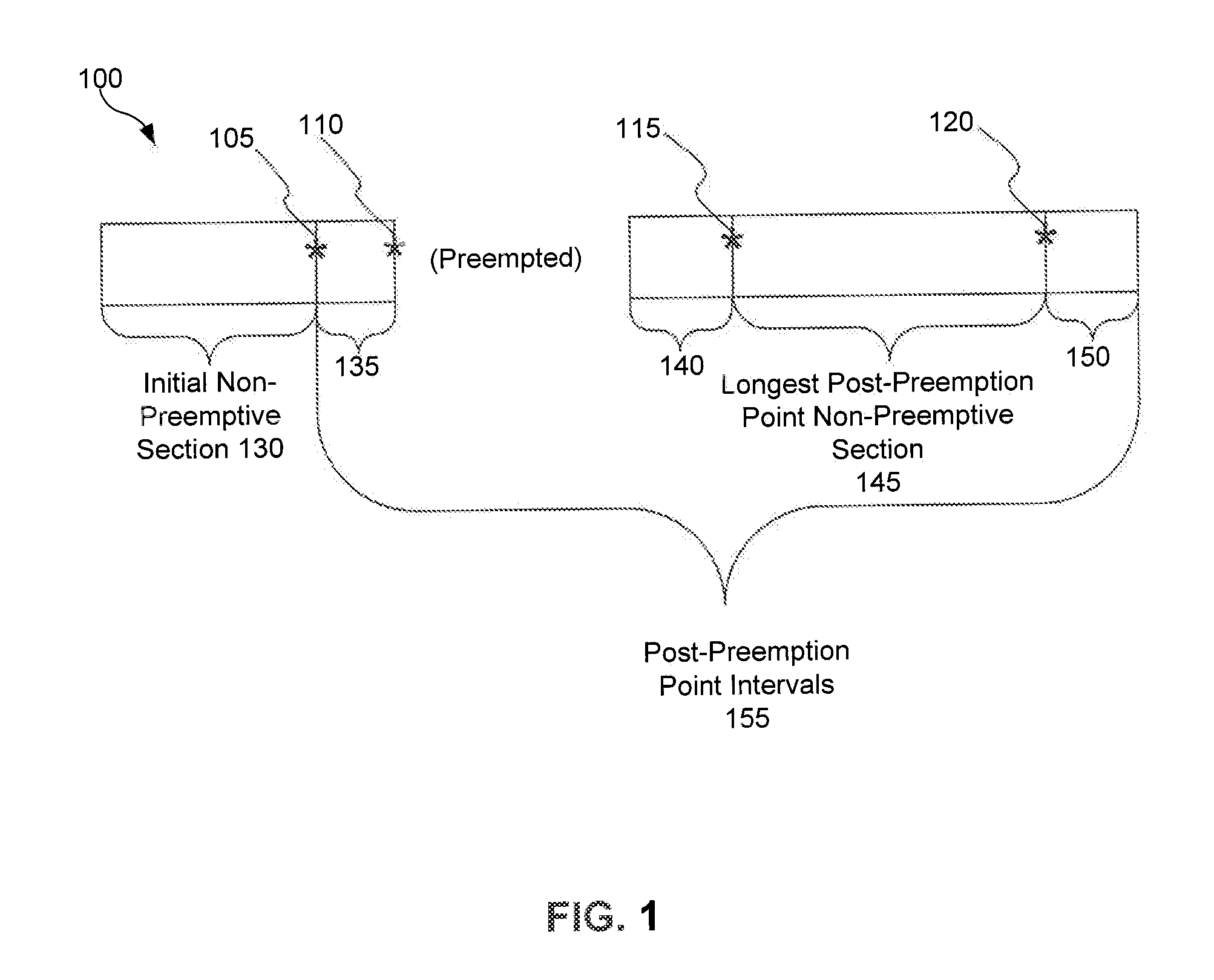

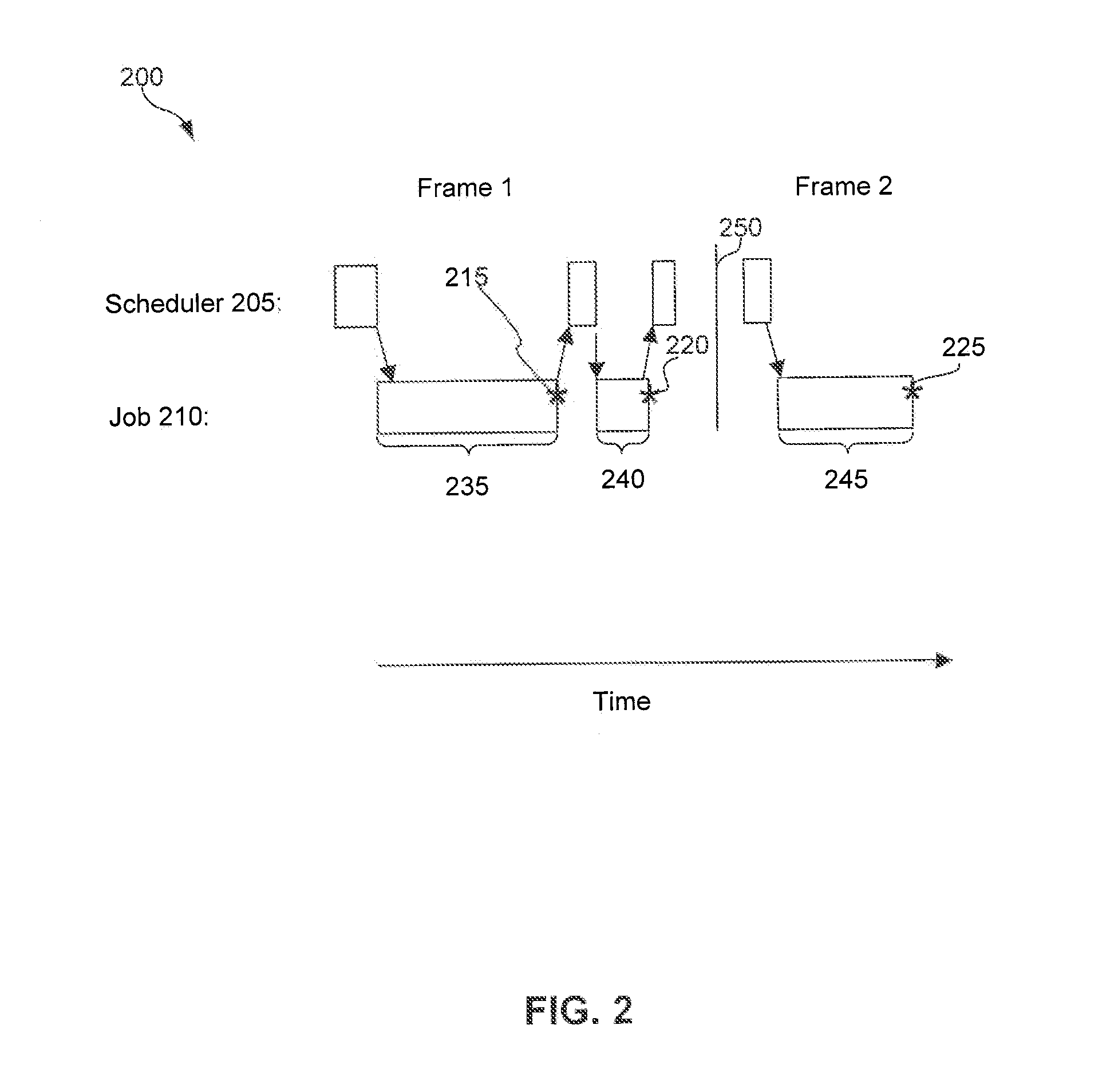

Dynamic Scheduling for Frames Representing Views of a Geographic Information Environment

InactiveUS20130097606A1Multiprogramming arrangementsMemory systemsInformation environmentDynamic priority scheduling

An exemplary method for scheduling jobs in frames representing views of a geographic information environment is disclosed. An exemplary method includes determining a remaining frame period in a frame representing a view of a geographic information environment. The exemplary method also includes identifying a dynamic job in a scheduling queue. The dynamic job has a non-preemptive section that is between a start of the job and a preemption point of the job. The exemplary method further includes determining an estimated execution time for executing the job. When the estimated execution time is not greater than the remaining frame period, the exemplary method includes executing the non-preemptive section of the job in the frame. When the estimated execution time is greater than the remaining frame period, the exemplary method includes postponing the execution of the job in the frame.

Owner:GOOGLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com