Performance prediction method applicable to dynamic scheduling for semiconductor production line

A technology of dynamic scheduling and performance prediction, applied in prediction, data processing application, calculation, etc., can solve the problem that the learning speed cannot meet high real-time performance, and achieve the effect of convenient implementation, good real-time performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

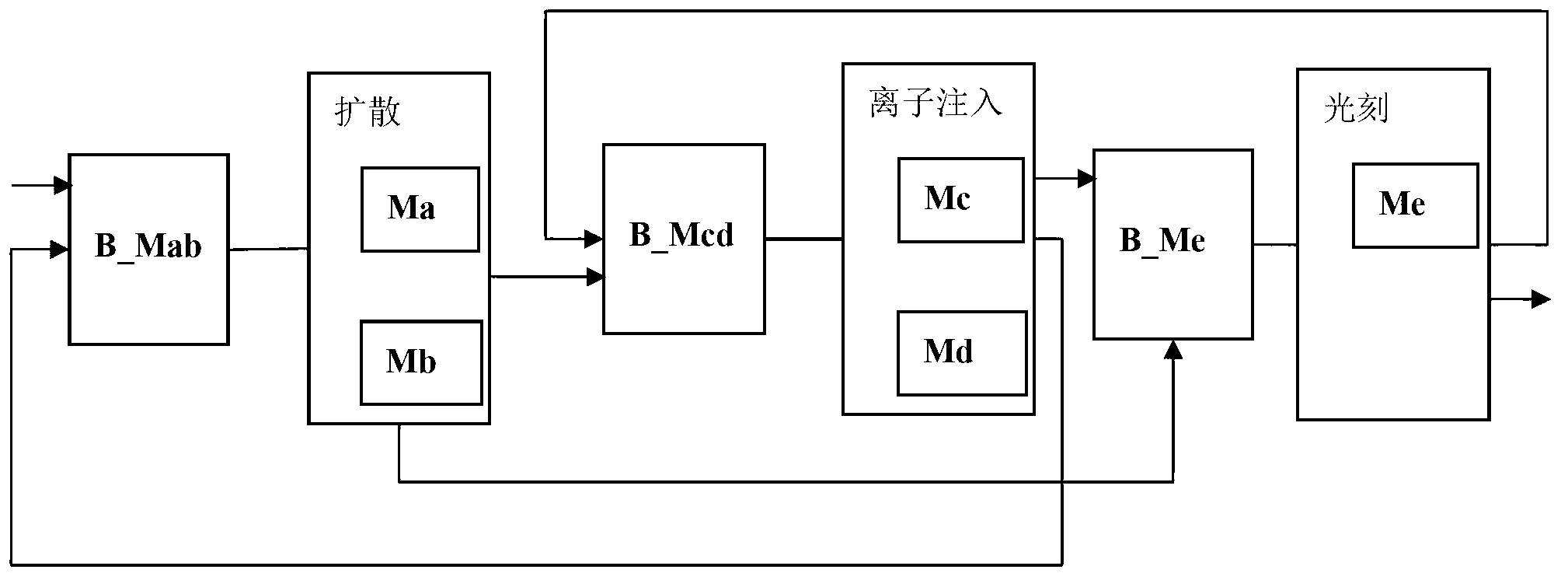

[0025] To better explain the control method of the scheduling system of the present invention, please refer to figure 1 .

[0026] figure 1 Simplified model diagram for the semiconductor production line, classified by production process, there are three equipment groups, a total of five equipment, namely diffusion equipment group, ion implantation equipment group and lithography equipment group. The diffusion equipment group includes a first diffusion equipment Ma and a second diffusion equipment Mb; the ion implantation equipment group includes a first ion implantation equipment Mc and a second ion implantation equipment Md; and the lithography equipment group includes a lithography equipment Me. In front of each equipment group, a first buffer area B_Mab, a second buffer area B_Mcd, and a third buffer area B_Me are respectively set up to store information about workpieces that need to be processed. Through the above-mentioned equipment group, six processes can be realized, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com