Supporting component for spatial large-aperture reflector

A mirror support and large space technology, which is applied in the aerospace field, can solve the problems of increased difficulty in the assembly process of the mirror support hole processing technology and support structure, and achieve the effects of improving the accuracy of the assembly after the assembly, making full use of the space, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

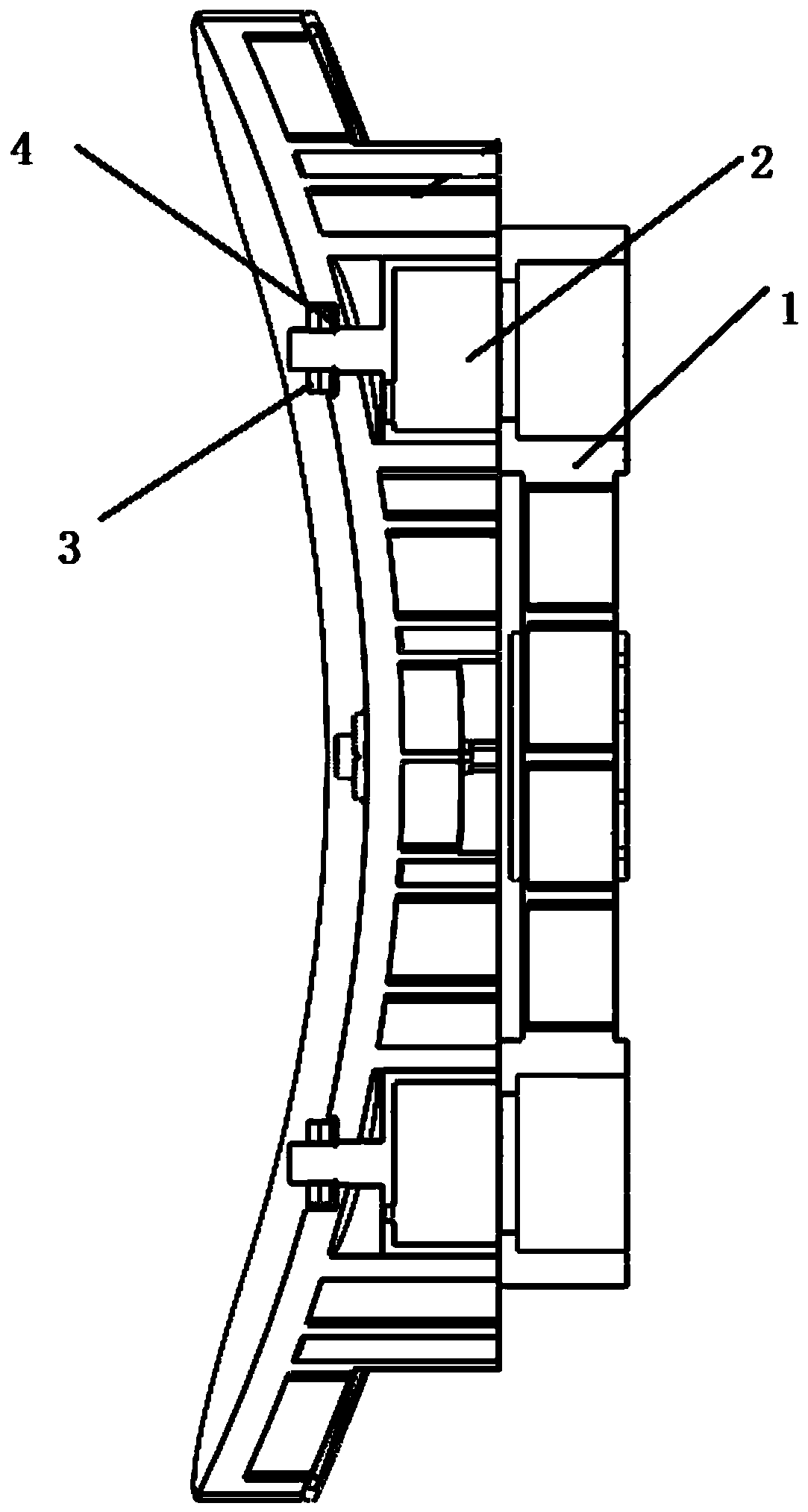

[0032] Attached below figure 1 It is described in detail in order to better illustrate the structural features and functional features of the present invention, but not to limit the protection scope of the present invention.

[0033] The large-diameter reflector support assembly of the present invention adopts a matching taper sleeve (reflector support 2), and the locking nut 3 is axially locked. The large-aperture reflector is made of silicon carbide, and the back adopts a three-point support method. The 3 installation holes of the reflector and the support 2 of the reflector are oppositely ground, the installation holes of the reflector and the support 2 of the reflector are pre-installed, and the support 2 of the reflector is repaired, so that the three support surfaces are coplanar, and the coplanarity is required to be within 2 μm. The flatness of the processed mounting surface of the reflector back plate 1 and the reflector support is required to be within 2 μm. During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com