Deep well small coal pillar gob-side entry retaining method based on roof lower key layer roof-breaking pressure relief

A key layer and small coal pillar technology, applied in earthwork drilling, underground mining, directional drilling, etc., can solve the problems of difficult support, difficult to block the infiltration of harmful gas, and high cost, so as to ensure the recovery rate and control The amount of roadway deformation to ensure the effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

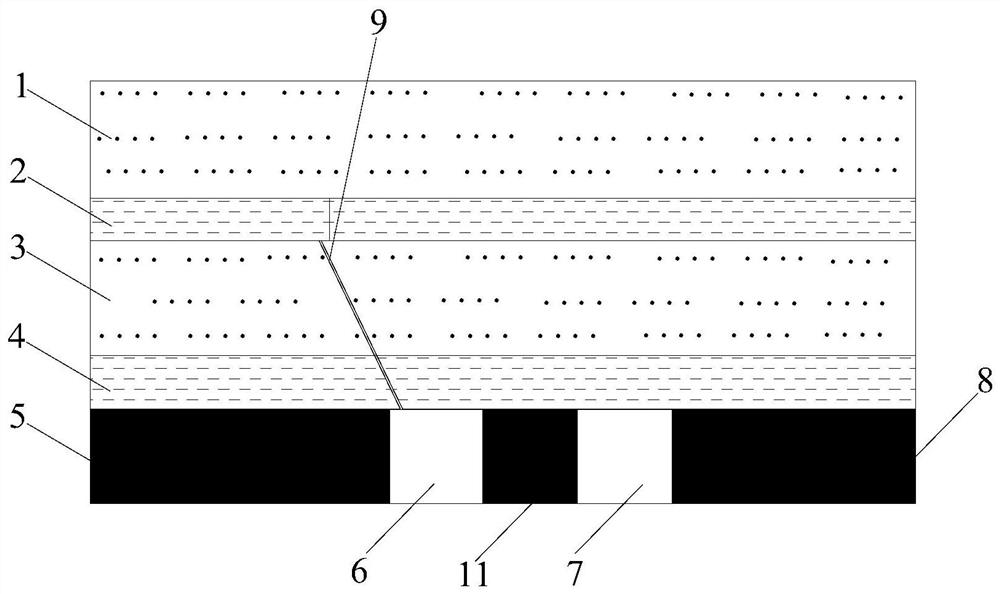

[0044] Due to deep mines with thick coal seams, especially high-gas mines, there are difficulties in the ventilation of the mining roadway and the tension of mining continuity, so it is necessary to adopt the layout of the mining roadway along the gob-side entry. As a result, small coal pillars need to withstand high bearing pressure and mining pressure, and it is difficult for small coal pillars to maintain stability. In addition, during the mining process of small coal pillar gob-side entry retaining, it is difficult to determine the parameters of construction broken roof pressure relief and support parameters. Therefore, a deep mine small coal pillar gob-side entry retaining method based on the pressure relief of the key layer below the roof is provided. method, the specific steps include:

[0045] Step A. Determine the geological conditions of the coal seam roof; wherein the geological conditions of the roof include the roof lithology and roof thickness, and also include t...

Embodiment 2

[0060] On the basis of Example 1, taking the working face of a mine that adopts the method of retaining entry along the gob of a small coal pillar in a deep shaft based on the pressure relief of the key layer below the roof as an example, the support effect of this method is further explained through the monitoring situation .

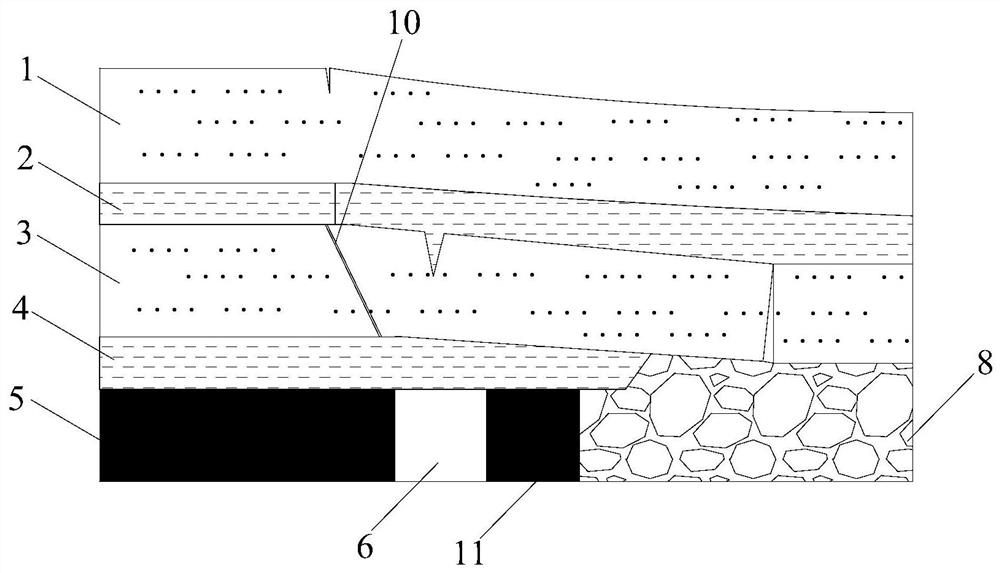

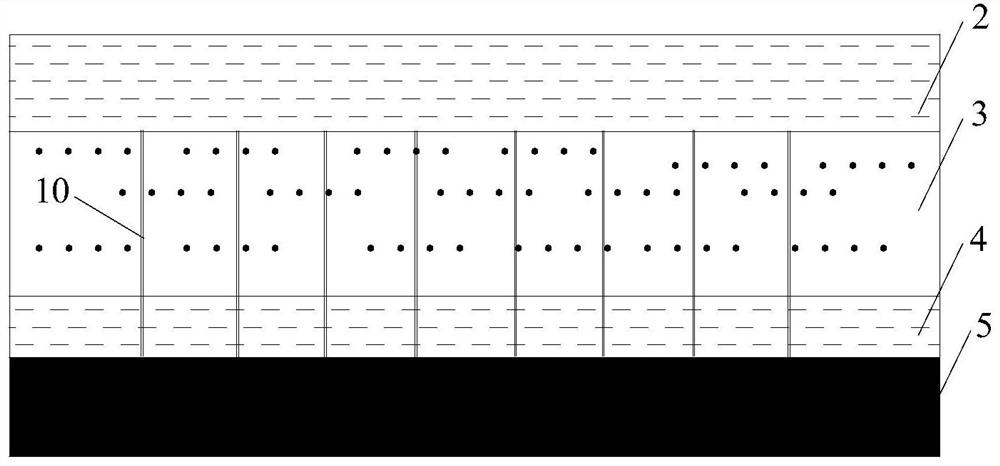

[0061] to combine Figure 7 to Figure 10 As shown, comparing the roof subsidence before and after the pressure relief of the broken roof, the approaching amount of the solid coal side roadway, the approaching amount of the roadside and the change of the working resistance of the bolt, it can be seen that the lower position of the coal seam roof by cutting off the "transfer rock beam" in advance The key layer can effectively transfer the high stress acting on the small coal pillar and gob entry to the farther coal rock layer, so that the small coal pillar and gob entry will be subjected to lower stress and mining dynamic pressure impact, which is benef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com