Patents

Literature

63results about How to "Guaranteed recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solvent process for synthesizing cartap

The present invention discloses a solvent process for synthesizing cartap, comprising that a monosultap alkaline aqueous solution and sodium cyanide undergo a cyanation reaction in a halohydrocarbon solvent and at a temperature of between 20 DEG C below zero and 80 DEG C to give an intermediate thiocyanide solution; and then, the intermediate thiocyanide solution together with methanol and hydrochloric acid gas undergoes a hydrolysis reaction at a temperature of between 50 DEG C below zero and 100 DEG C, for 2 to 30 hours, to give a crude product of the cartap. The method solves the problems in the production of complex process, serious three wastes, instable product yield and instable quality, etc. The method can be suitable for large-scale industrialized and commercialized production.

Owner:JIANGSU TIANRONG GROUP

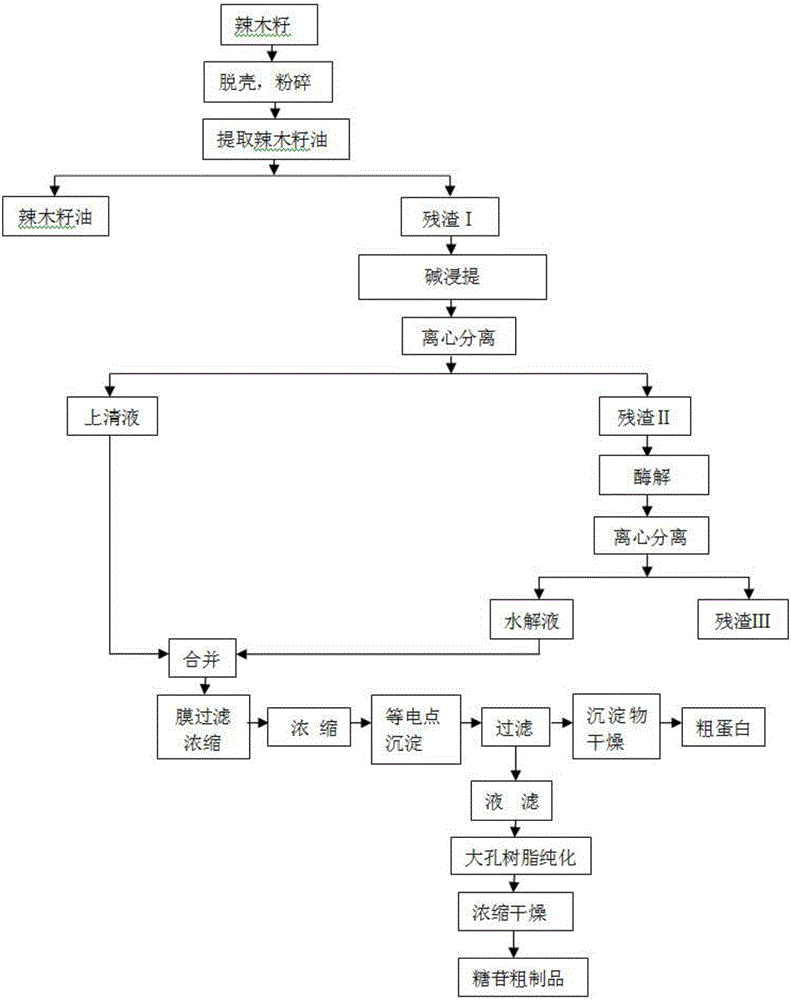

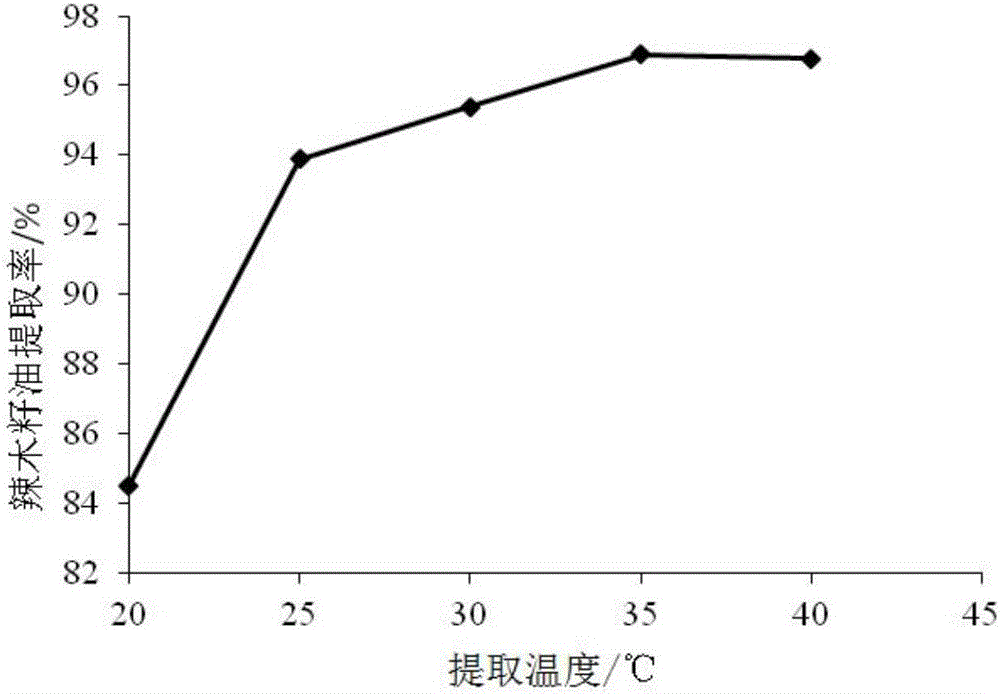

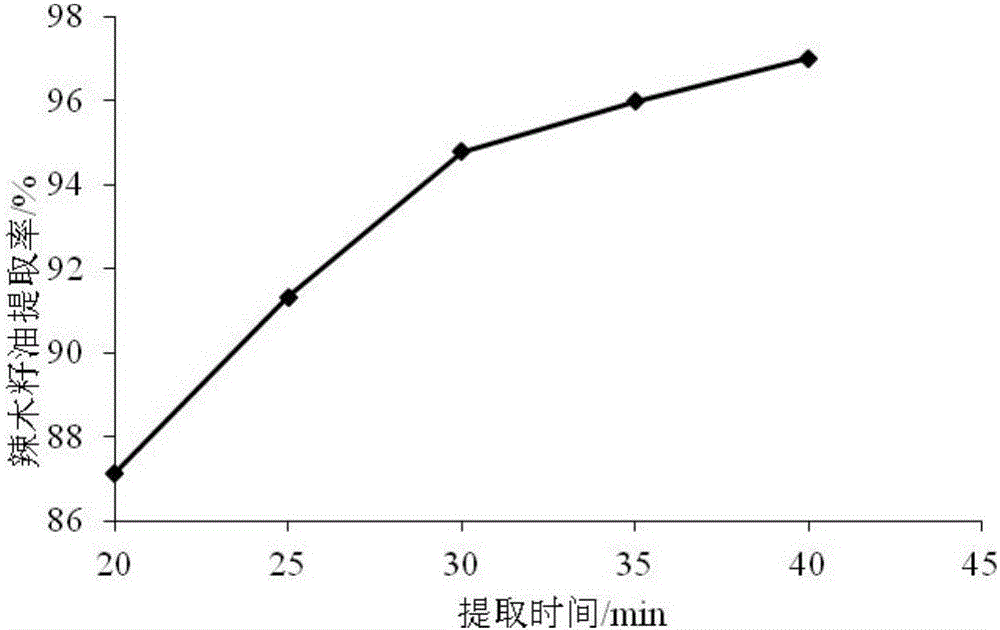

Method for simultaneously extracting oil and protein and/or glucoside in moringa seeds

InactiveCN106282282AIncrease added valueIncrease profitFatty-oils/fats productionFermentationGlycosideMoringa

The invention discloses a method for simultaneously extracting oil and protein and / or glucoside in moringa seeds. Alkali liquor is added into residues obtained after moringa seed oil is extracted, after ultrasonic treatment and pertinent enzyme treatment are completed, treatment means such as membrane separation and isoelectric precipitation are taken, and crude protein and glucoside crude products are obtained after recovery is completed. According to the method, through organic combination of multiple optimizing treatment means, effective ingredients in the moringa seeds are efficiently extracted, and the oil extraction rate is larger than 90%, the protein and glucoside recovery rate can reach up to 85% or above. The moringa seed oil obtained through the method is high in quality, good in protein functional character and high in glucoside purity, and simultaneous extraction of oil, protein and glucoside in the moringa seeds is creatively achieved.

Owner:SOUTH CHINA AGRI UNIV

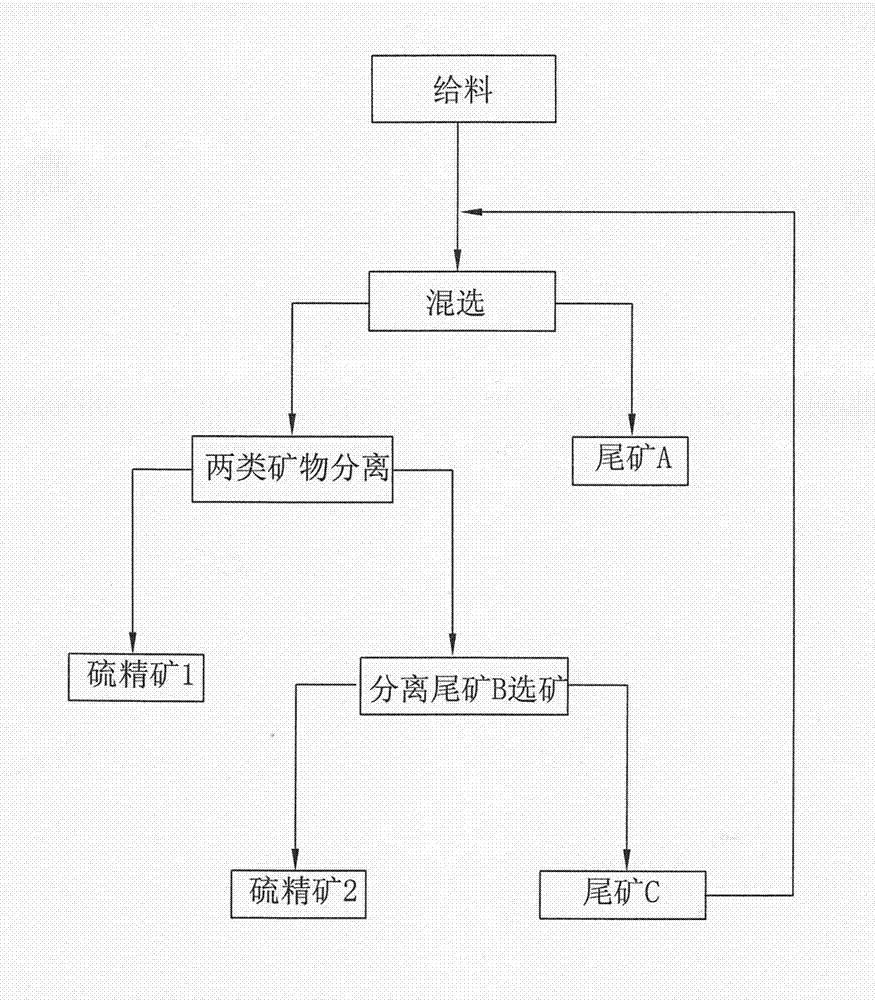

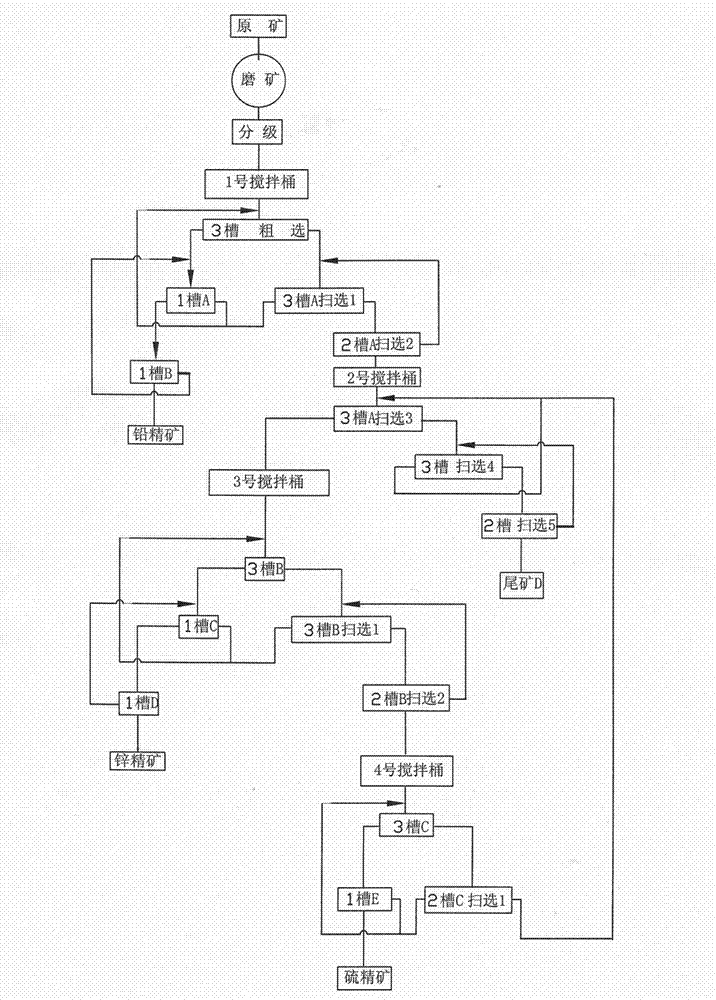

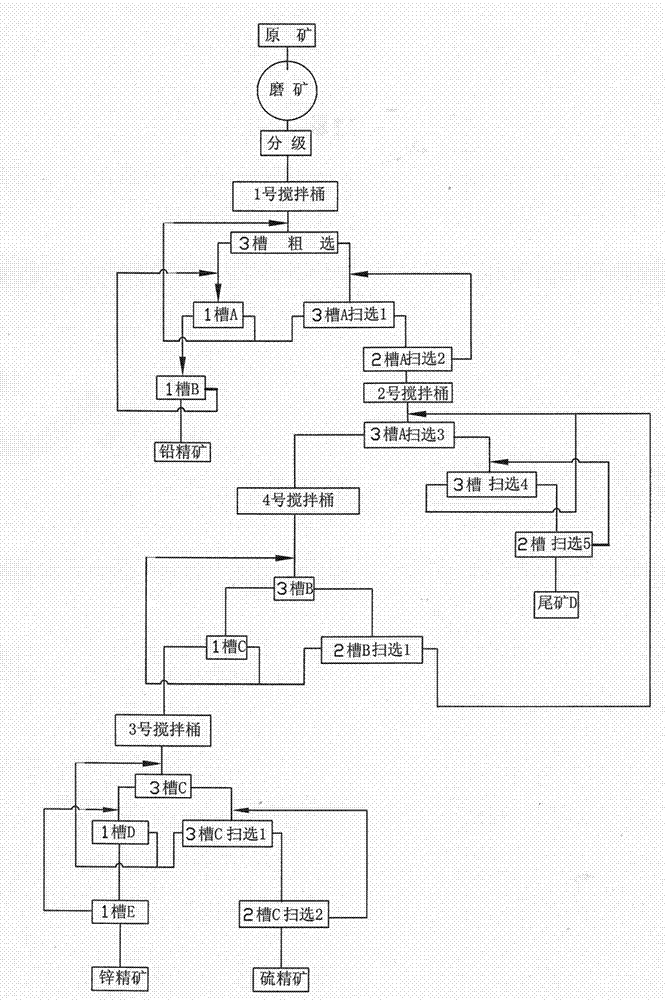

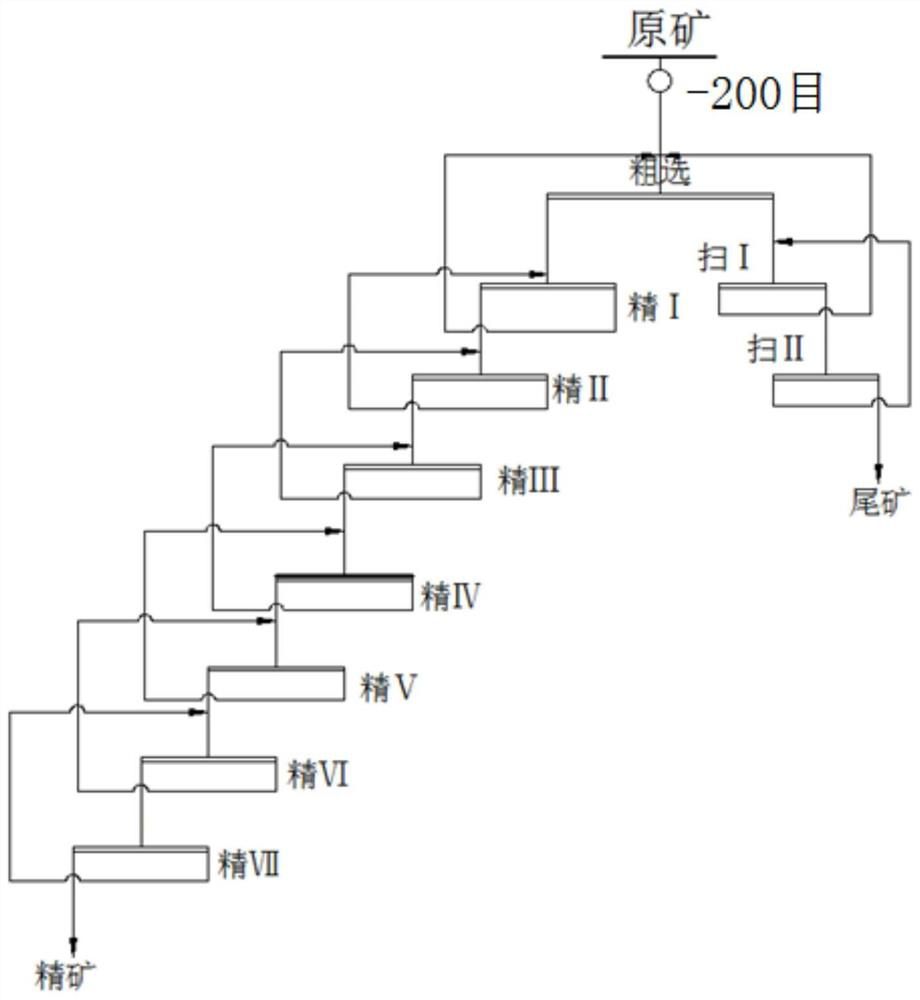

Flotation method for re-cleaning lead zinc ore and sulfur concentrate after preferable mixing separating

ActiveCN102896038AQuality assuranceGuaranteed recovery rateFlotationWet separationMining engineeringWastewater

The invention relates to a flotation method for re-cleaning lead zinc ore and sulfur concentrate after preferable mixing separating. The flotation method comprises a conventional preferable mixing separating process for the lead zinc ore and the sulfur concentrate and further comprises the following steps: 1) feeding: pouring sulfur concentrate pulp into a mixing separating tank; 2) performing mixing separating: separating a mixed concentrate from a first tailing through mixing separating, wherein the first tailing is formed by the other ores and gangue; 3) separating two ores: performing the two-ore separation on the mixed concentrate, thereby obtaining a first concentrate and a separated tailing; 4) beneficiating the separated tailing: performing beneficiation on the separated tailing, thereby obtaining a second sulfur concentrate and a second tailing; and 5) sending the second tailing into the second step of mixing separating. According to the process, the zinc entering into the sulfur concentrate caused by an operate error can be recycled; the recovery rate of the zinc is increased by about 0.5%; the quality-improving technical processes for the two sulfur concentrates both do not generate new waste water, waste residue and waste gas; and a new factor for damaging environment is not added.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

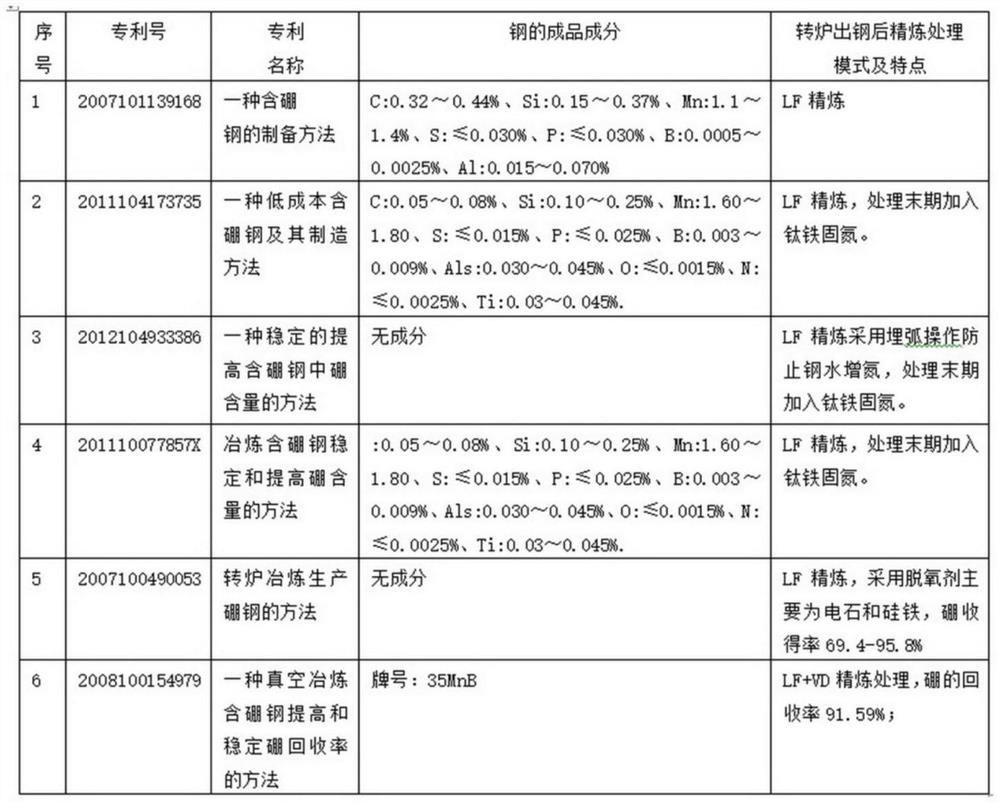

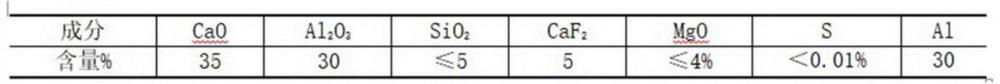

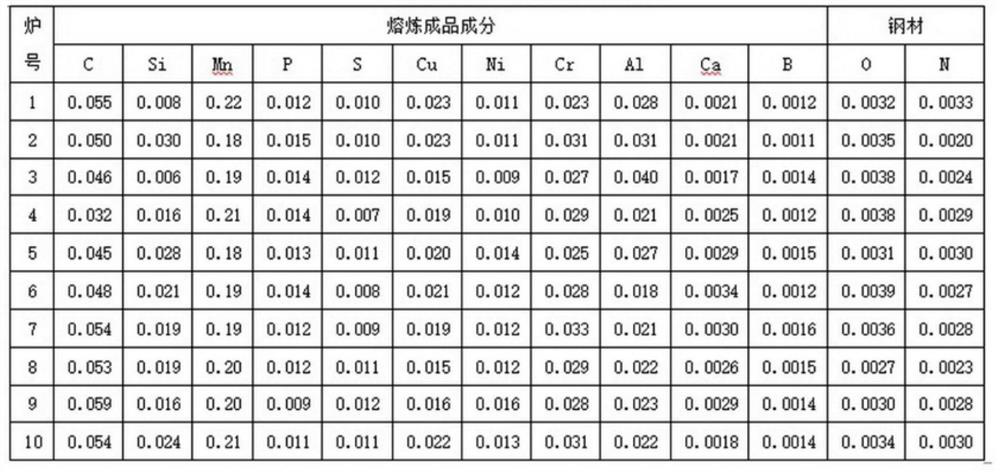

Preparation method of low-carbon-emission cold-rolled base material steel strip

ActiveCN113215477AGuaranteed recovery rateImprove performance and stabilityManufacturing convertersProcess efficiency improvementRefining (metallurgy)Slag

The invention discloses a preparation method of a low-carbon-emission cold-rolled base material steel strip, and belongs to the field of ferrous metallurgy. The preparation method is a method for producing a low-carbon and low-silicon boron-containing cold-rolled deep-drawing base strip steel coil by adopting process routes of top-bottom combined blown converter smelting, converter tapping slag washing and inclusion removal, slab continuous casting and hot continuous rolling. According to the material prepared through the method, the low-carbon and low-silicon component design is adopted, the LF refining procedure is omitted, and through deoxidation, inclusion removal and continuous casting in the converter tapping process, the recovery rate of boron is guaranteed, and the performance stability of steel is improved. As the LF refining procedure is omitted, the nitrogen content in the steel is reduced, the quality of the strip steel is improved, electrode consumption does not exist in the production process, power consumption and carbon dioxide emission are reduced, and a novel method is provided for converter smelting and slab continuous casting of boron-containing low-carbon and low-silicon cold-rolled base material steel strips.

Owner:XINJIANG BAYI IRON & STEEL

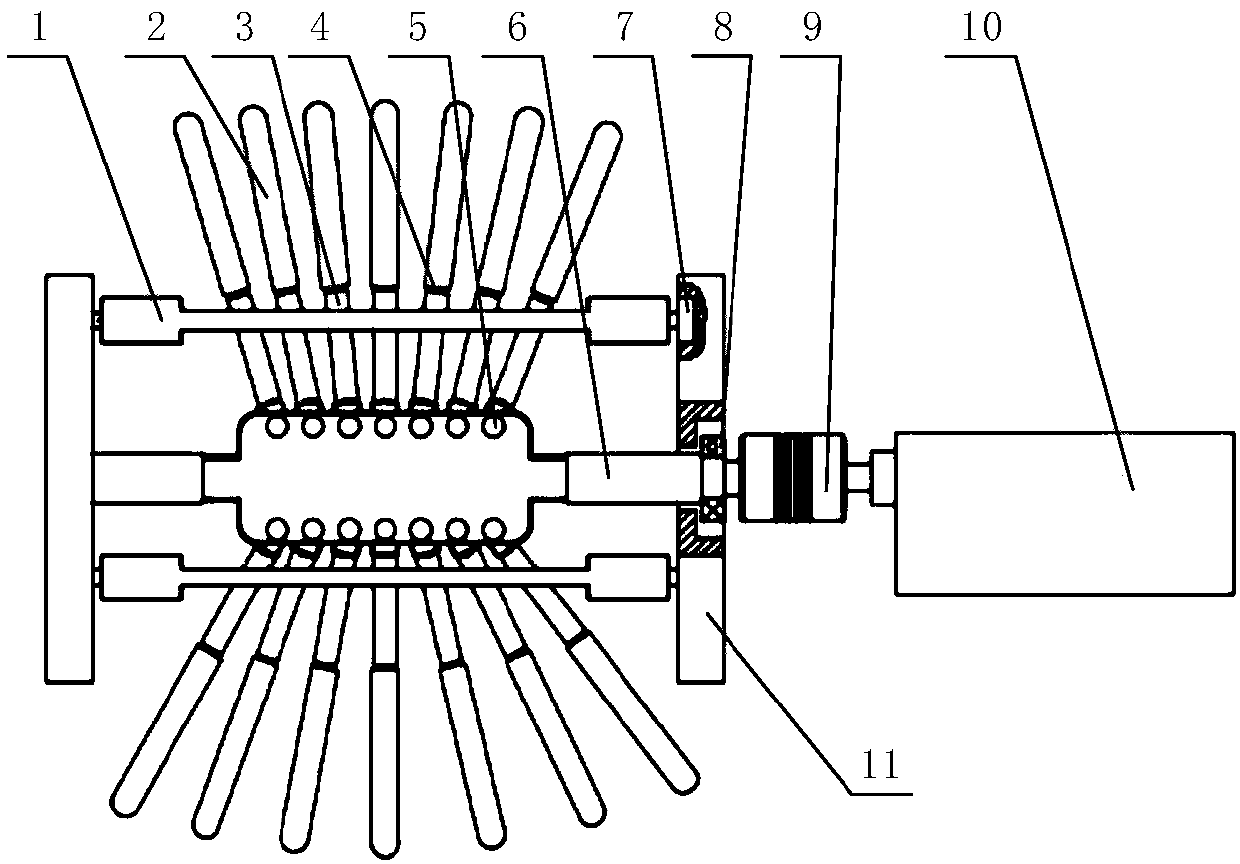

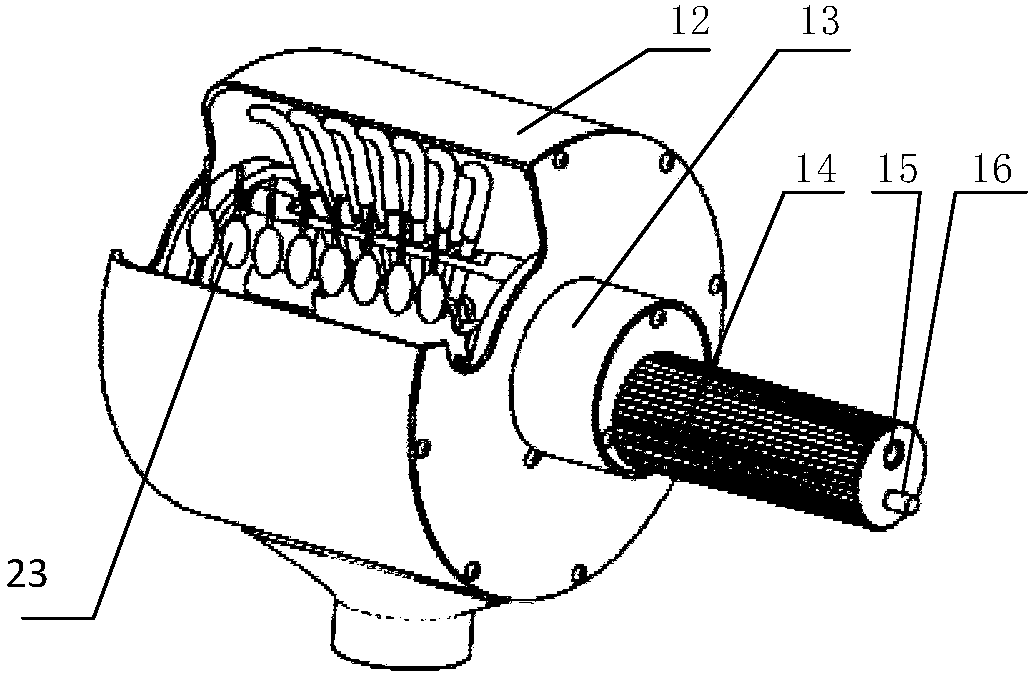

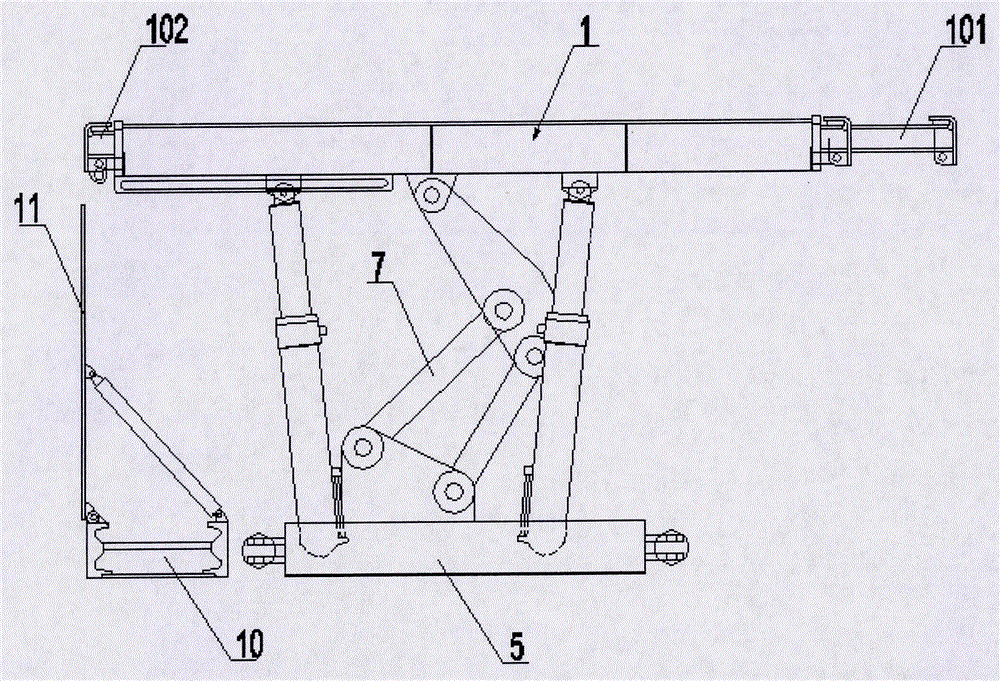

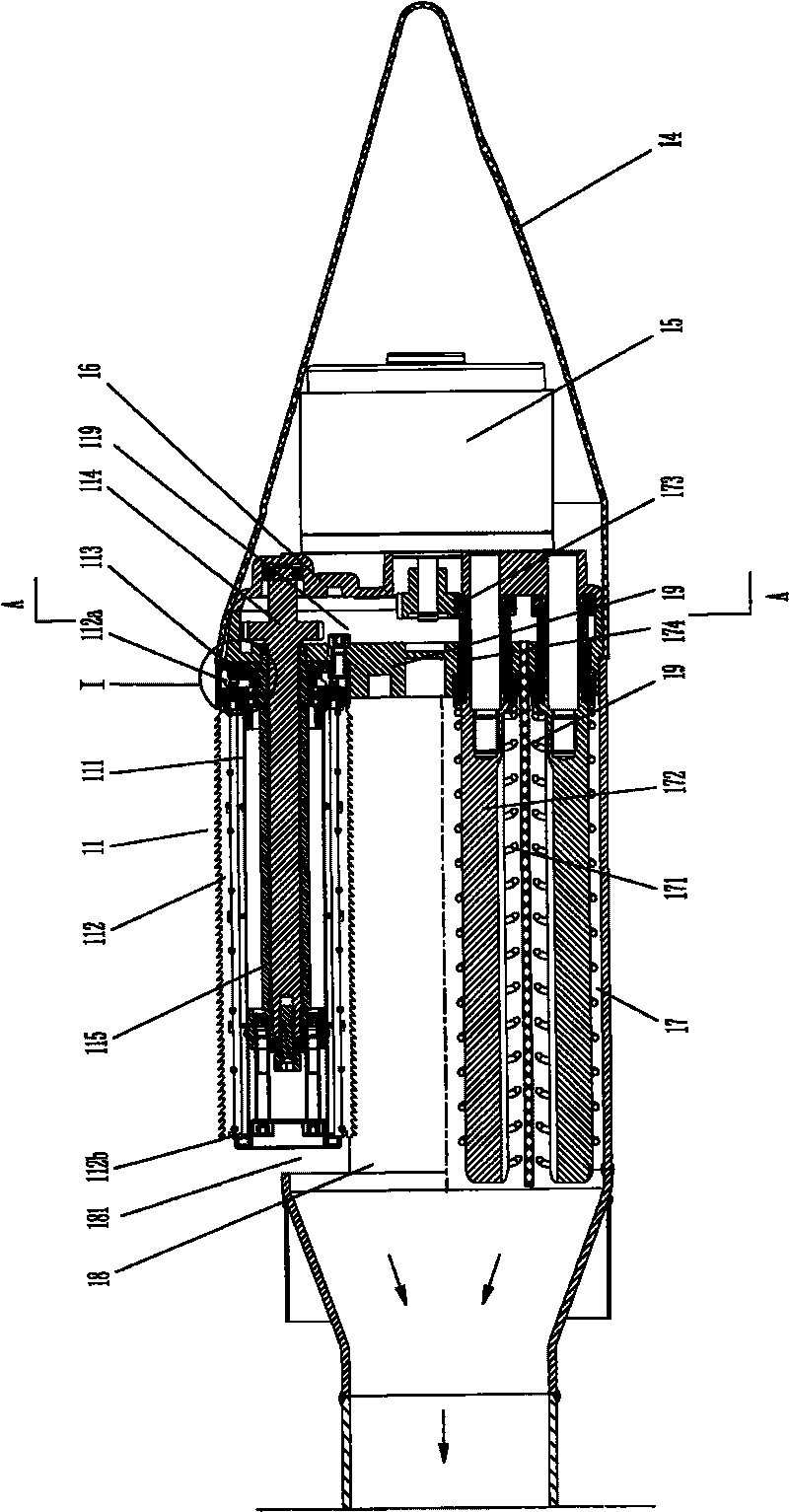

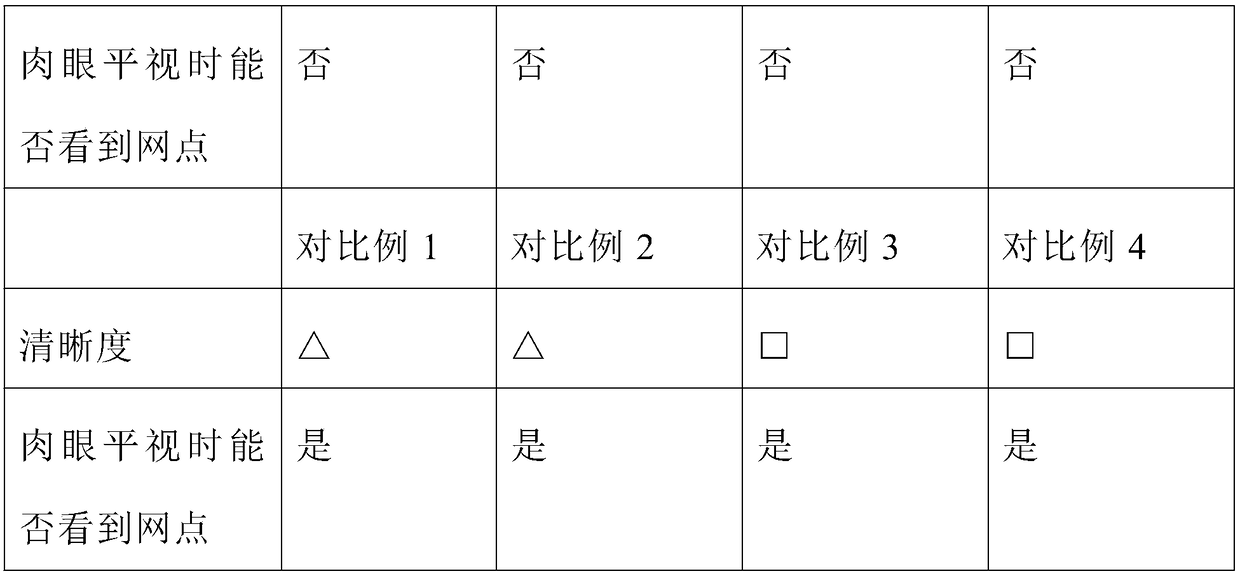

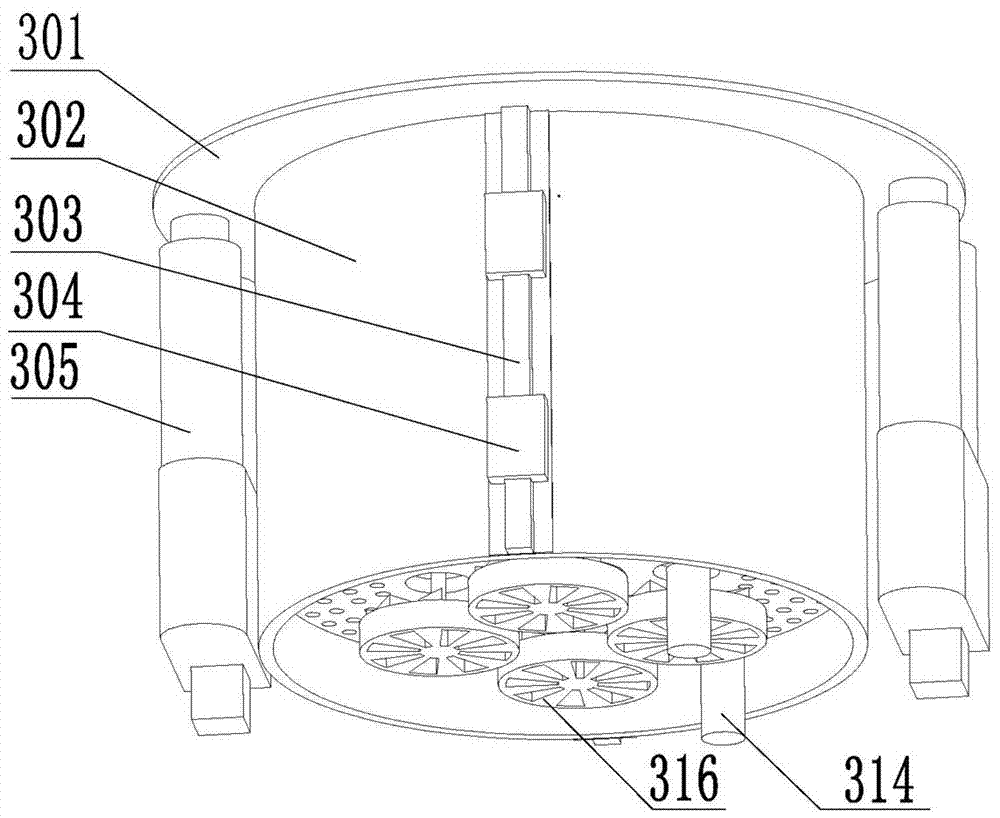

Combing-brush profile-modeling fructus-lycii picking tail-end executor

The invention belongs to the technical field of agricultural machines, and particularly relates to a combing-brush profile-modeling fructus-lycii picking tail-end executor. The combing-brush profile-modeling fructus-lycii picking tail-end executor comprises a main shaft and groove cams connected to the two ends of the main shaft. A plurality of picking fingers are hinged to the middle of the mainshaft, and are combined together to be in emission shapes from inside to outside, a ring of cam groove is formed in the inner side of the each groove cam in a milled mode, and cam driven bearings arearranged in the cam grooves and can freely roll along the cam groove; pressing plates are installed between the corresponding cam driven bearings on the two groove cams, a plurality of holes are formed in the pressing plates, each picking finger penetrates through the middle of each hole, the picking fingers are driven to rotate when the main shaft rotates, and drive the pressing plates to rotate,the holes in the pressing plates slide up and down at the lower ends of the picking fingers, and therefore gap changes between the picking fingers are oppressed. The structure is simple, the cost islow, and mature fruits can be effectively screened and picked; the breakage rate of fructus lycii is greatly reduced; meanwhile, friction force between the picking fingers and the fructus lycii is enlarged, and the net picking rate is guaranteed.

Owner:CHINA AGRI UNIV

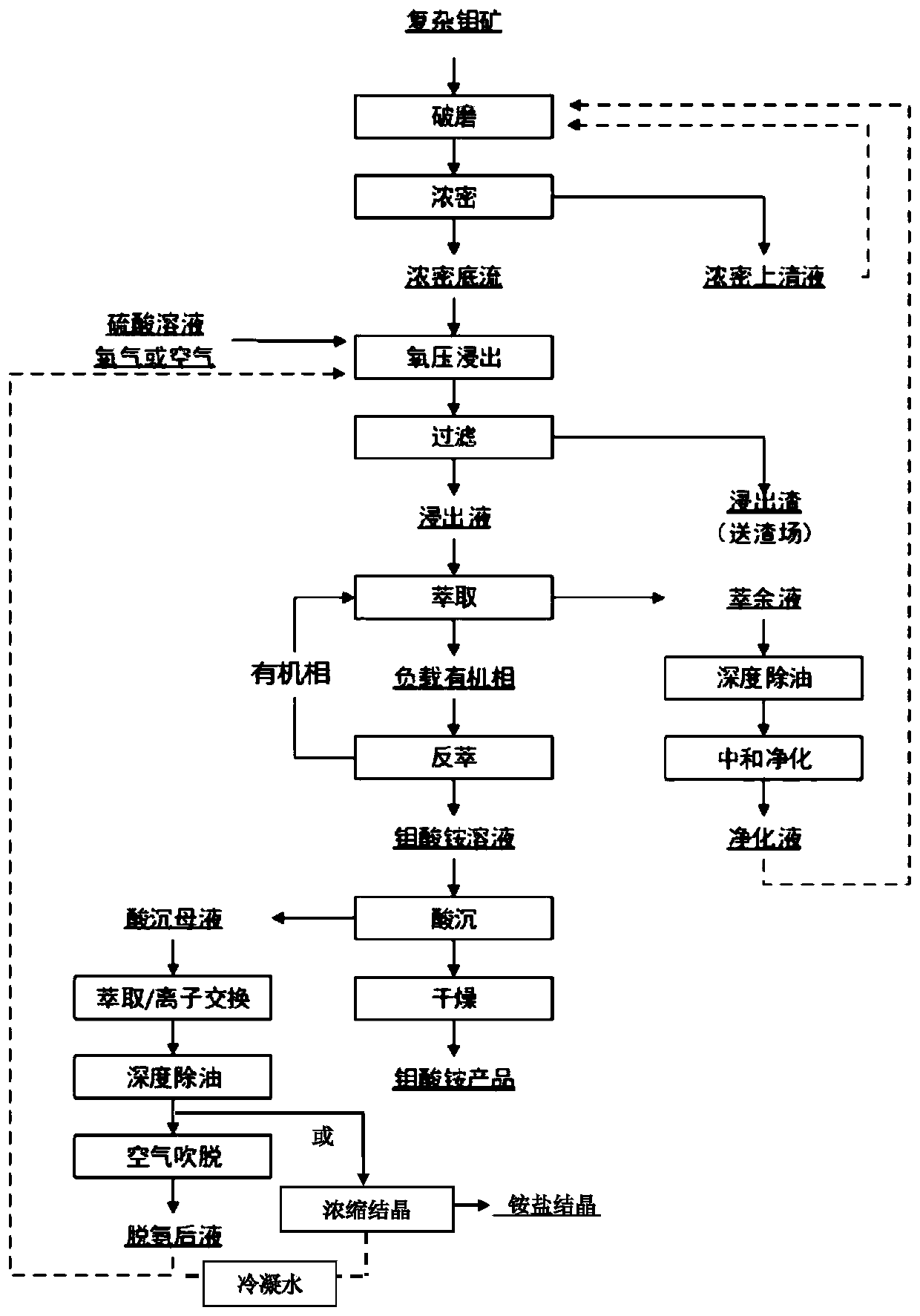

Method for efficiently utilizing complex molybdenum ore with wastewater self-circulation

ActiveCN111455172AGuaranteed recovery rateRealize economic development and utilizationProcess efficiency improvementWastewaterProcess engineering

The invention discloses a method for efficiently utilizing complex molybdenum ore with wastewater self-circulation, and belongs to the technical field of molybdenum comprehensive recovery. The methodaims at the problems such as large wastewater discharging amount and difficulty in economic and efficient treatment caused by the fact that existing complex molybdenum ore is used for metallurgy directly without being subjected to beneficiation enrichment; combined with the characteristics of wastewater process and through the processes of ball milling pulping, oxygen pressure leaching, ammonium molybdate preparation, raffinate purification and recycling and acid precipitation mother liquor purification and recycling from the angles of classification treatment and quality separation recycling,the molybdenum recovery rate in the complex molybdenum ore is 90% or above, and waste water is fully recycled in a system; and the economic development and utilization of the complex molybdenum ore under the current industrial technical background is further realized, and the method has important significance for promoting the green development of the low-grade complex molybdenum ore in China.

Owner:中核沽源铀业有限责任公司

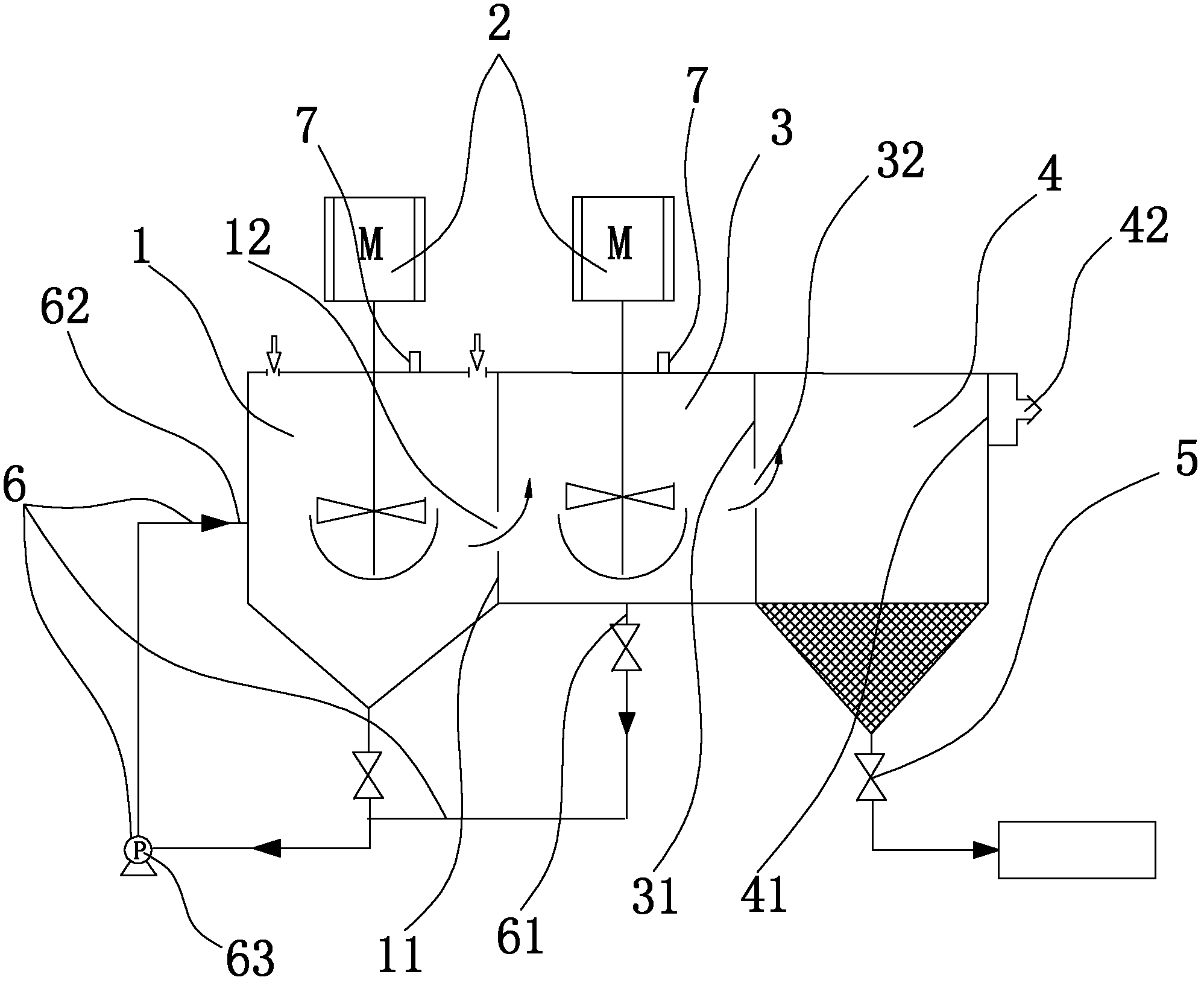

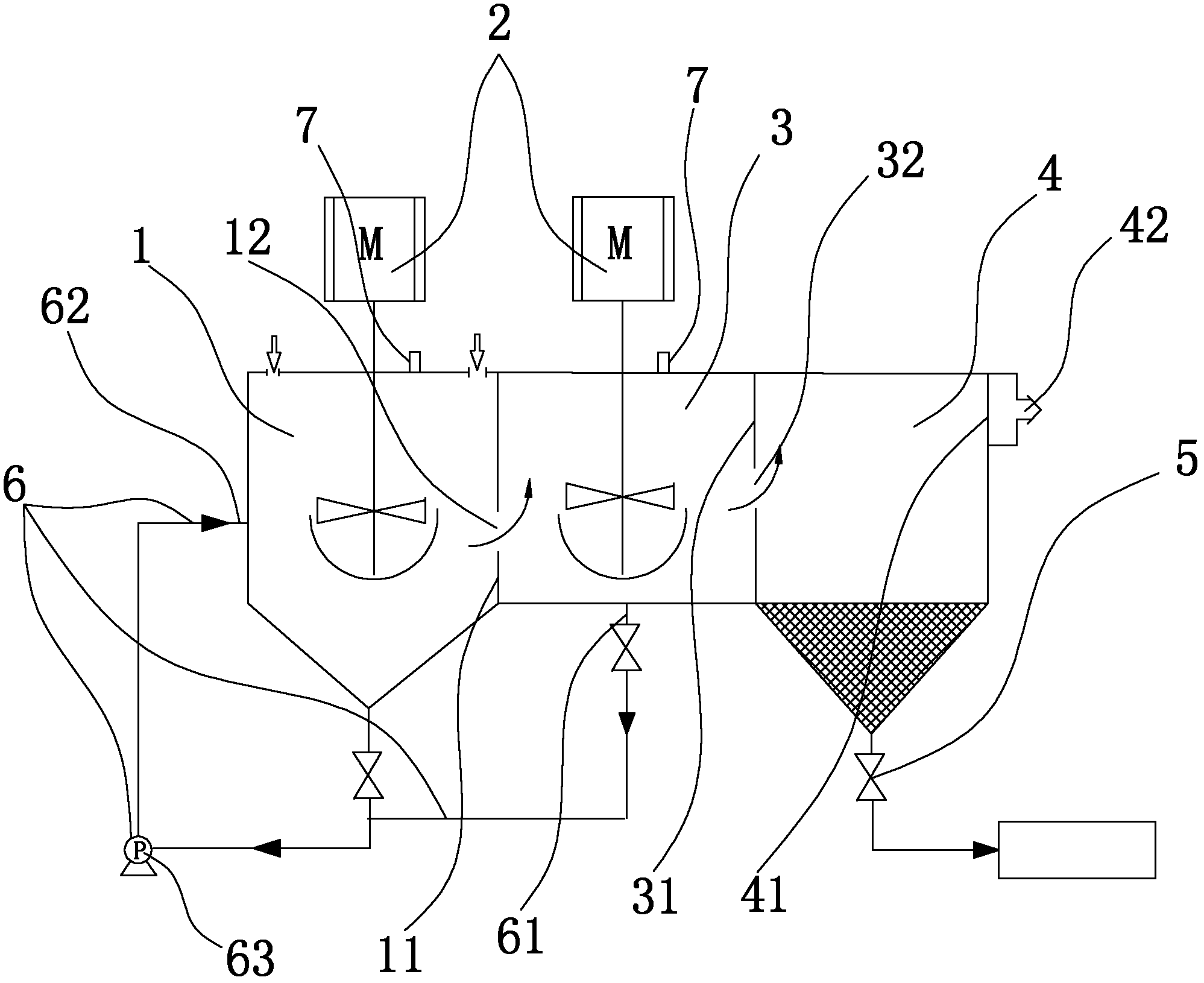

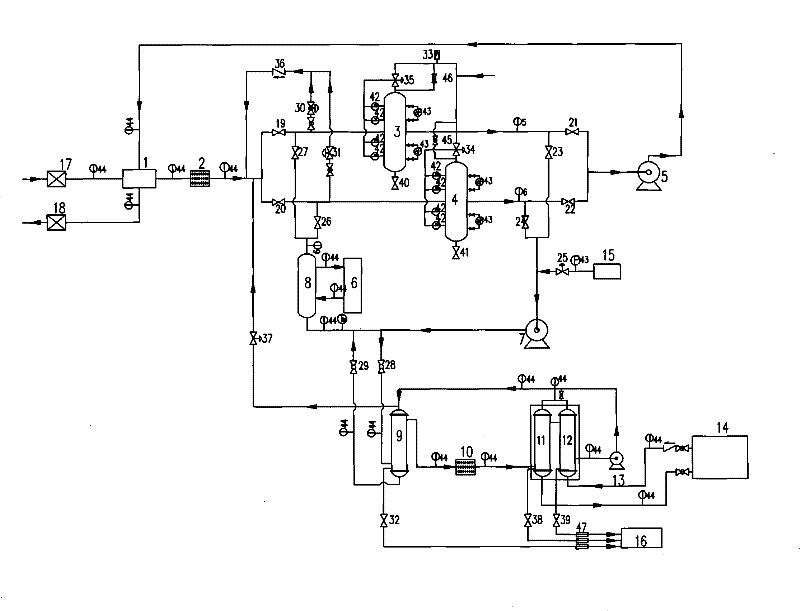

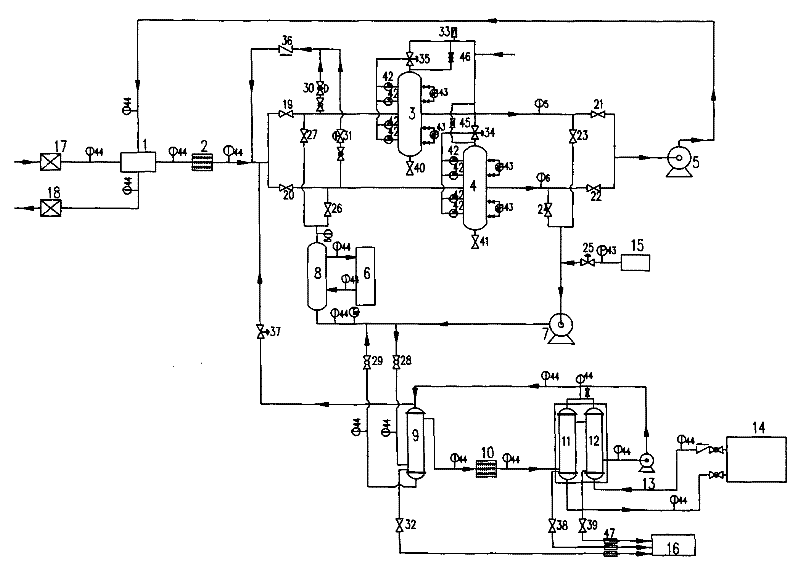

Copper sponge preparation process by reducing copper contained acidic leachate with iron powder

InactiveCN102312099AQuick responseGuaranteed recovery rateProcess efficiency improvementIron powderManufacturing technology

The invention discloses a copper sponge preparation process, especially a copper sponge preparation process by reducing a copper contained acidic leachate with iron powder, and belongs to the technical field of chemical production and manufacture. Provided is copper sponge preparation process by reducing a copper contained acidic leachate with iron powder, with a low labor intensity and high automation degree. The intermediate comprises steps of: the iron powder and the copper contained acidic leachate, which participate in a reaction, are added into a main reaction tank of a reactor at a certain speed and treated with a certain displacement reaction under effect of a stirrer; then the mixture is sent into an intermediate reaction tank and treated with a slaking displacement reaction to generate copper sponge and ferrous sulphate; then the mixture is sent into a settler to separate the copper sponge at a settler bottom and a tail washing in an upper and middle part of the settler; at last, the copper sponge is collected through a dump valve at the settler bottom, and the tail washing is discharged from an overflow mouth at settler top.

Owner:PANZHIHUA QINGHONGYUAN ENVIRONMENTAL PROTECTION TECH

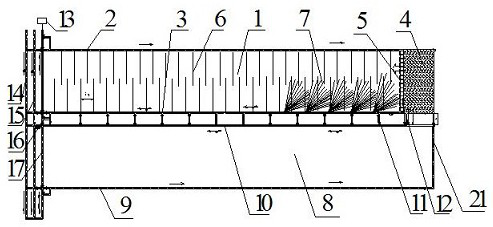

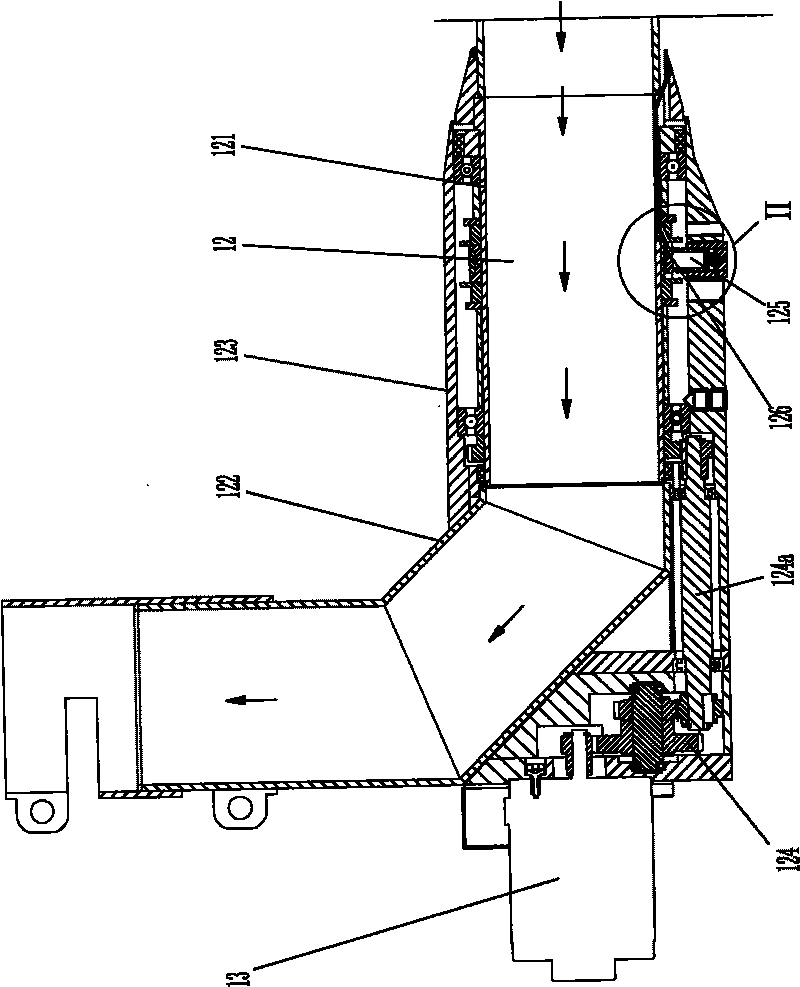

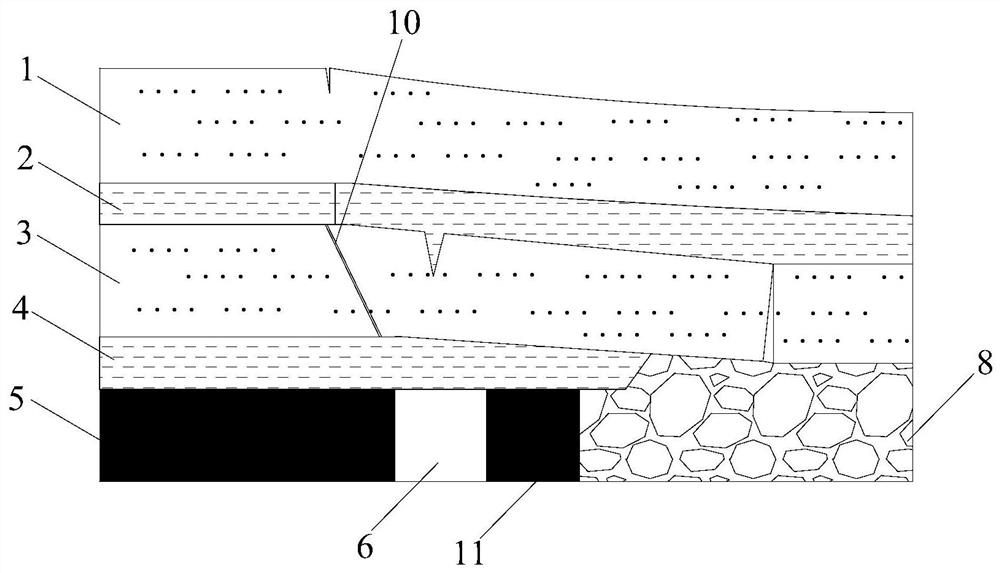

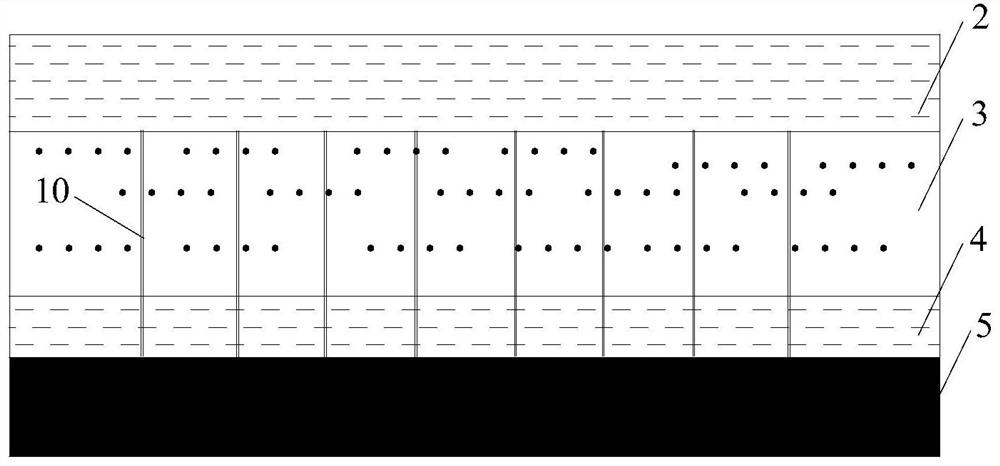

Method for ensuring fully-mechanized top coal caving recovery rate of three-soft thick coal seam roadway tunneling along top

InactiveCN105134212AGuaranteed recovery rateIncrease productionUnderground miningSurface miningActive supportMineralogy

The invention relates to a method for ensuring the fully-mechanized top coal caving recovery rate of three-soft thick coal seam roadway tunneling along top, and effectively solves the problem of ensuring the fully-mechanized top coal caving recovery rate of three-soft thick coal seam roadway tunneling along top. The method includes: employing a rectangular tunnel cross-section, conducting tunneling along coal seam roof, and performing bolt-mesh-anchor active support; performing tunneling along the tunnel roof to a mining area boundary, and carrying out bottom digging downward to make the tunnels along the coal seam floor; conducting tunneling along the seam floor to hole through two roadways so as to form open-off cut; laying a caving coal hydraulic support, a conveyor and a coal mining machine on a working surface, arranging two large mining height end hydraulic supports respectively at the ends connecting the working surface and the two side roadways, making the two roadways always in an advanced bottom digging tunneling state, conveying the tunnelled coal to a working surface conveyor by a loading machine, ensuring the tunnels and the bottom plate of the working surface always at one plane triangle coal and leaving no triangle coal. The method provided by the invention has the advantages of simplicity, easy operation and use, low cost and good effect, can effectively guarantee the fully-mechanized top coal caving recovery rate of three-soft thick coal seam roadway tunneling along top, and improves coal production output.

Owner:HENAN POLYTECHNIC UNIV

Micro-sperm cryopreservation method

The invention discloses a micro-sperm cryopreservation method and aims to provide a micro-sperm (including single sperm like testis puncture sperm, epididymis puncture sperm and sperms of patients suffering serious oligozoospermia and asthenozoospermia) cryopreservation carrier, which has the advantages of relatively small volume, closed space, easiness in operation and high sperm activity, and acryopreservation method. The cryopreservation method comprises the following steps: when the sperm thaws, taking out a cryovial from a liquid nitrogen tank; taking out the cryopreservation carrier, byusing a pipet, from the cryovial, and quickly adding the cryopreservation carrier into a sperm culture dish (37 DEG C); carefully searching for the sperm in the cryopreservation carrier under an inverted microscope (100-200-time magnification); grabbing the sperm with a single sperm injection needle in ovarian follicle, and transferring into a sperm culture medium of the sperm culture dish, for follow-up sperm immobilization and ICSI of ripe ovum.

Owner:大连敏慧精益科技有限公司

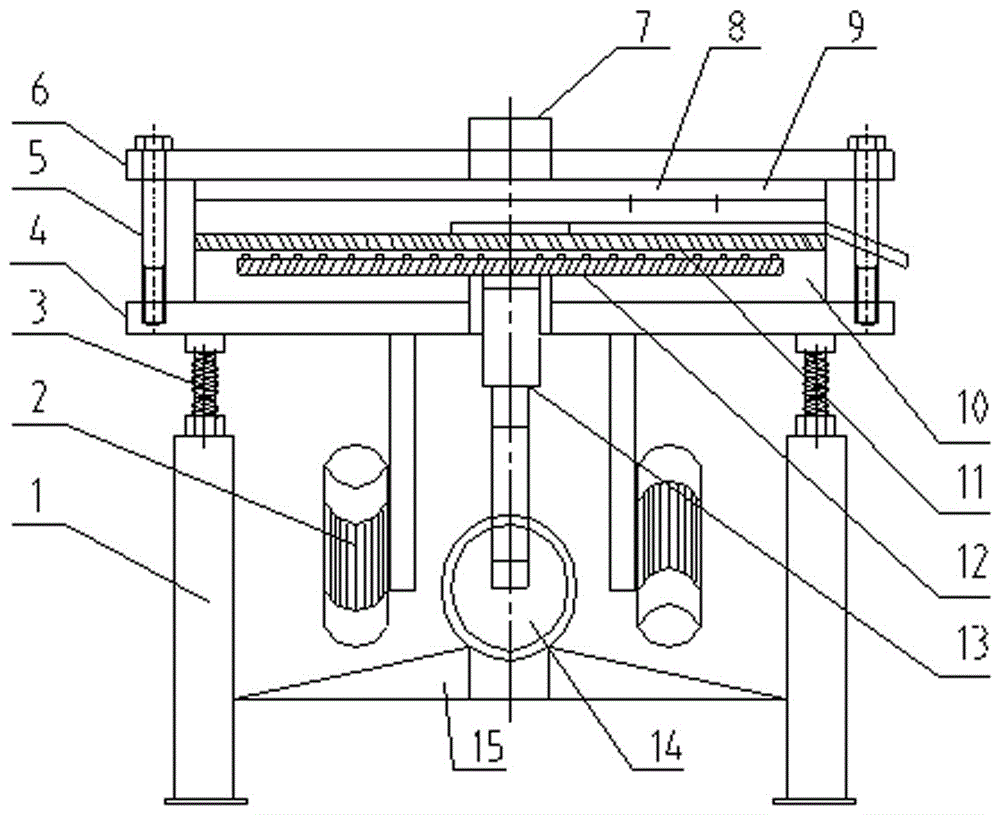

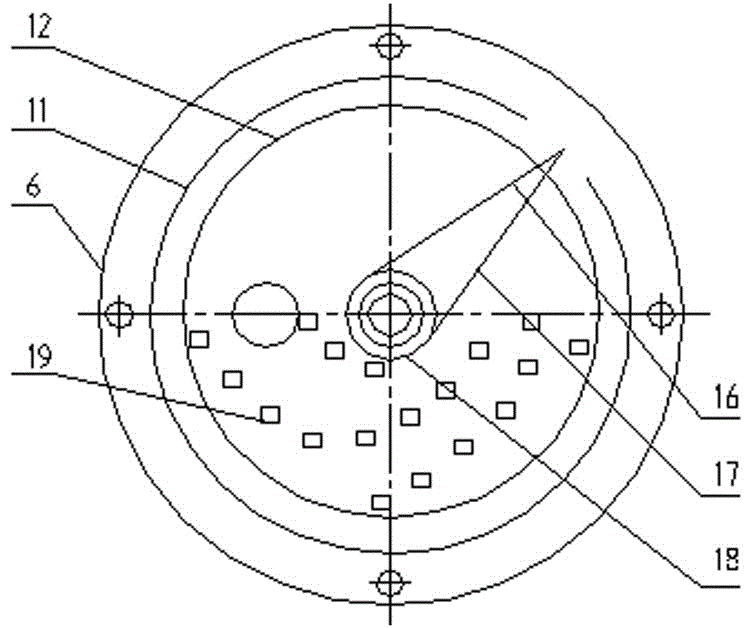

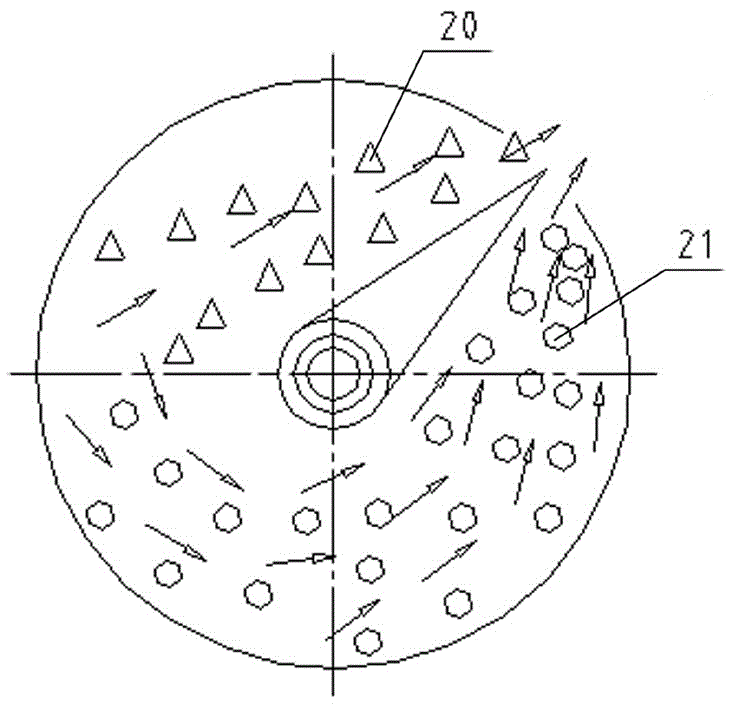

Weak-magnetic-field dry-type magnetic separating device with involute-arranged permanent magnet system

InactiveCN105665127AGuaranteed Scattered EntryGuaranteed gradeMagnetic separationElastic vibrationNon magnetic

The invention discloses a weak-magnetic-field dry-type magnetic separating device with an involute-arranged permanent magnet system. The weak-magnetic-field dry-type magnetic separating device comprises a body base installed at the upper ends of supports through elastic vibration pieces and vibration motors installed at the bottom of the body base. A top cover is installed above the body base, and a closed cavity is jointly formed by the body base and the top cover; a first feeding hole is formed in the center of the top cover; the closed cavity is divided by a disc support arranged in the cavity into an upper cavity body and a lower cavity body, a partition plate is arranged in the upper cavity body on the disc support, a second feeding hole is formed in the portion, bias arranged on one side of the center, of the partition plate, and a magnetic disc is arranged in the lower cavity body below the disc support, and is composed of a magnetic disc body and a plurality of pieces of permanent magnet steel arranged in an involute mode in the circumferential direction of the magnetic disc body; a discharging opening is formed in the side wall of the upper cavity body on the disc support, and a non-magnetic material baffle and a magnetic material baffle are arranged in the center of the upper plane of the disc support, wherein the tail end of the non-magnetic material baffle and the tail end of the magnetic material baffle extend to the discharging opening. By means of the weak-magnetic-field dry-type magnetic separating device, high-grade recycling of magnetic-mineral ore concentrate is achieved.

Owner:HENAN POLYTECHNIC UNIV

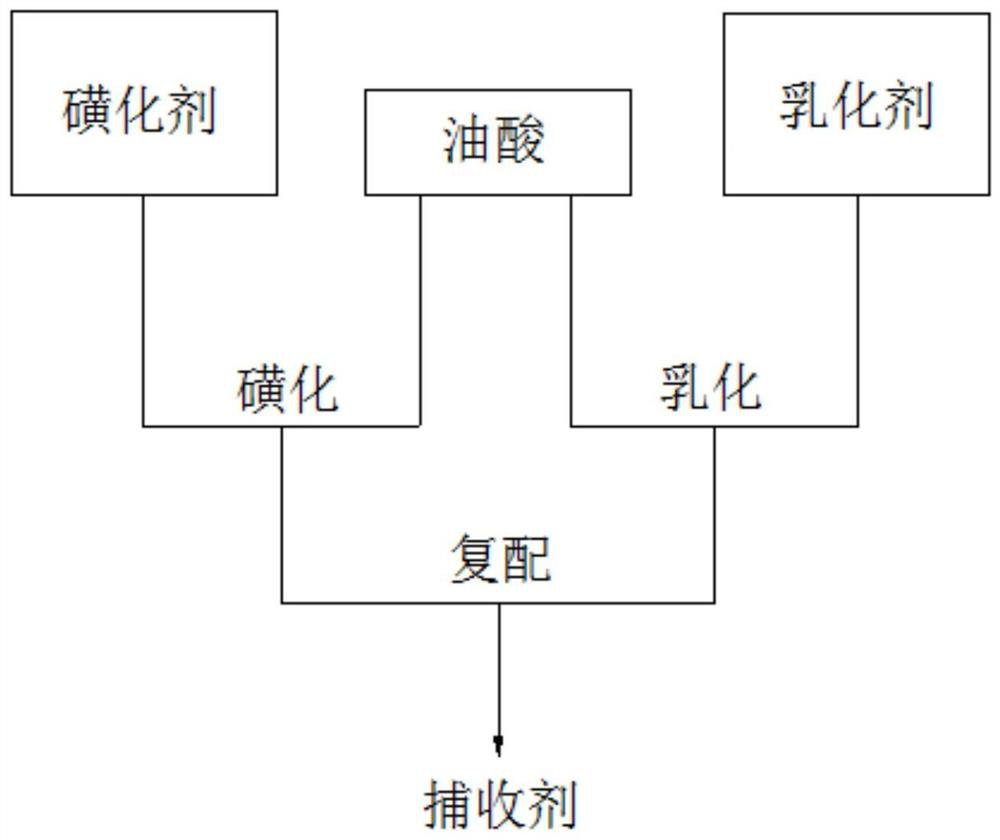

Fluorite flotation collecting agent as well as preparation method and application thereof

ActiveCN113441285AGuaranteed recovery rateAdjustable recovery rateFlotationOleic Acid TriglycerideSULFONATED OLEIC ACID

The invention relates to the technical field of fluorite beneficiation, in particular to a fluorite flotation collecting agent and a preparation method and application thereof. The fluorite flotation collecting agent provided by the invention comprises the following raw materials: sulfonated oleic acid and emulsified oleic acid. According to the fluorite flotation collecting agent provided by the invention, sulfonated oleic acid and emulsified oleic acid have a complementary synergistic effect and are matched with each other, so that the solubility and dispersity are greatly enhanced, the fluorite surface action is more stable, the efficiency is higher, the fluorite collecting capacity and rate can be greatly improved, and the fluorite flotation collecting agent has relatively strong low-temperature resistance; and the fluorite recovery rate in the low-temperature environment can be guaranteed, the flotation effect is improved, the beneficiation cost is reduced, and meanwhile the purposes of saving energy, reducing consumption and protecting the environment are achieved.

Owner:ZHEJIANG UNIV OF TECH +1

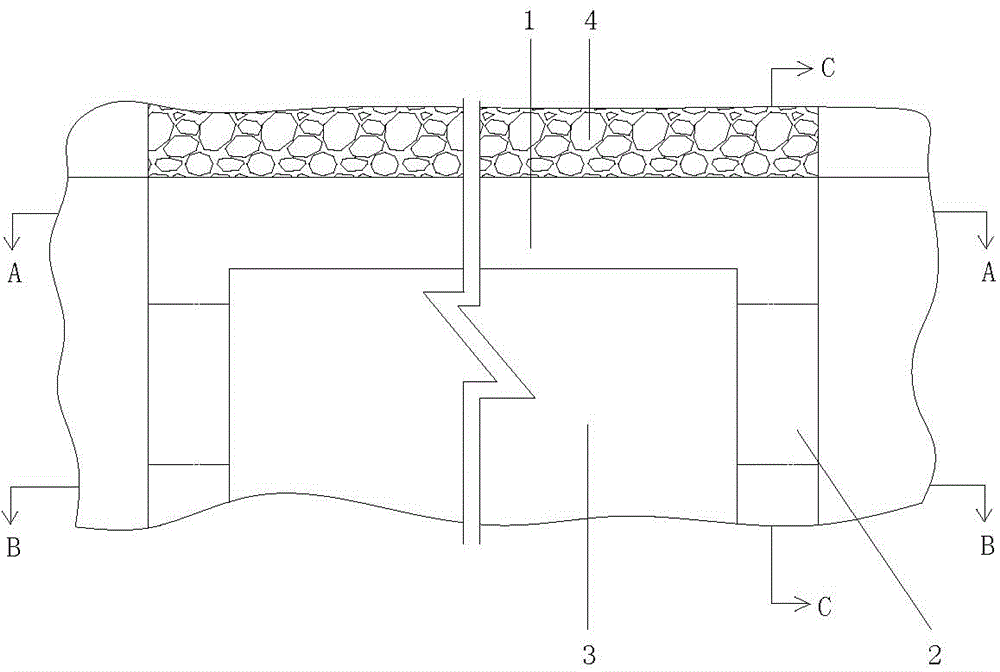

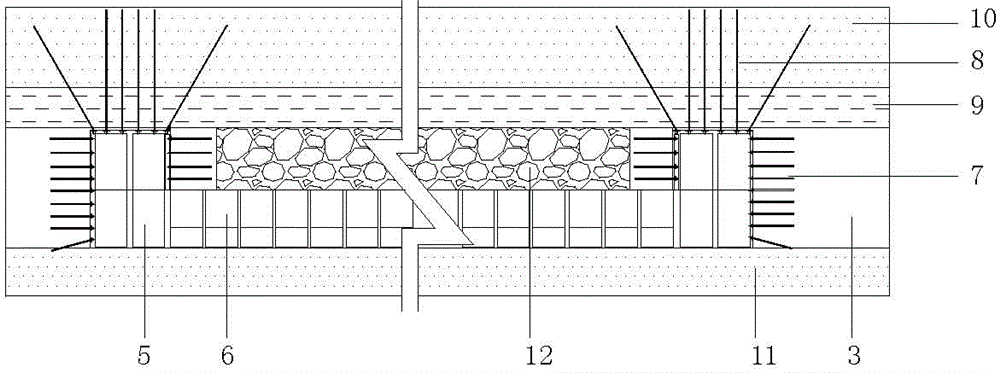

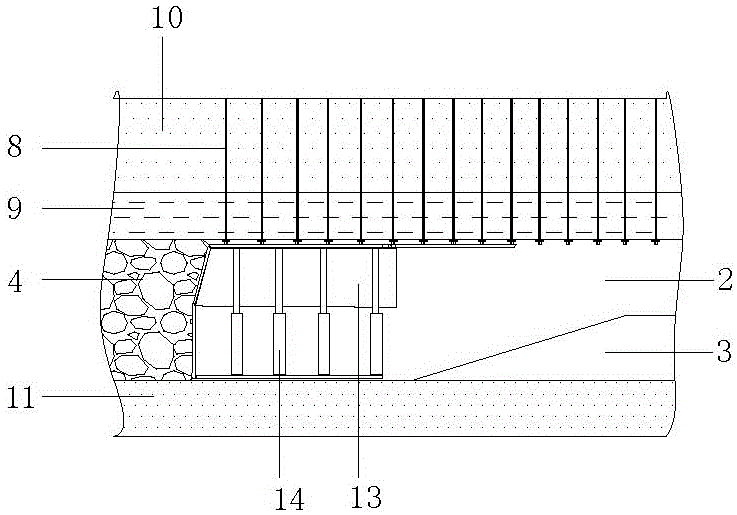

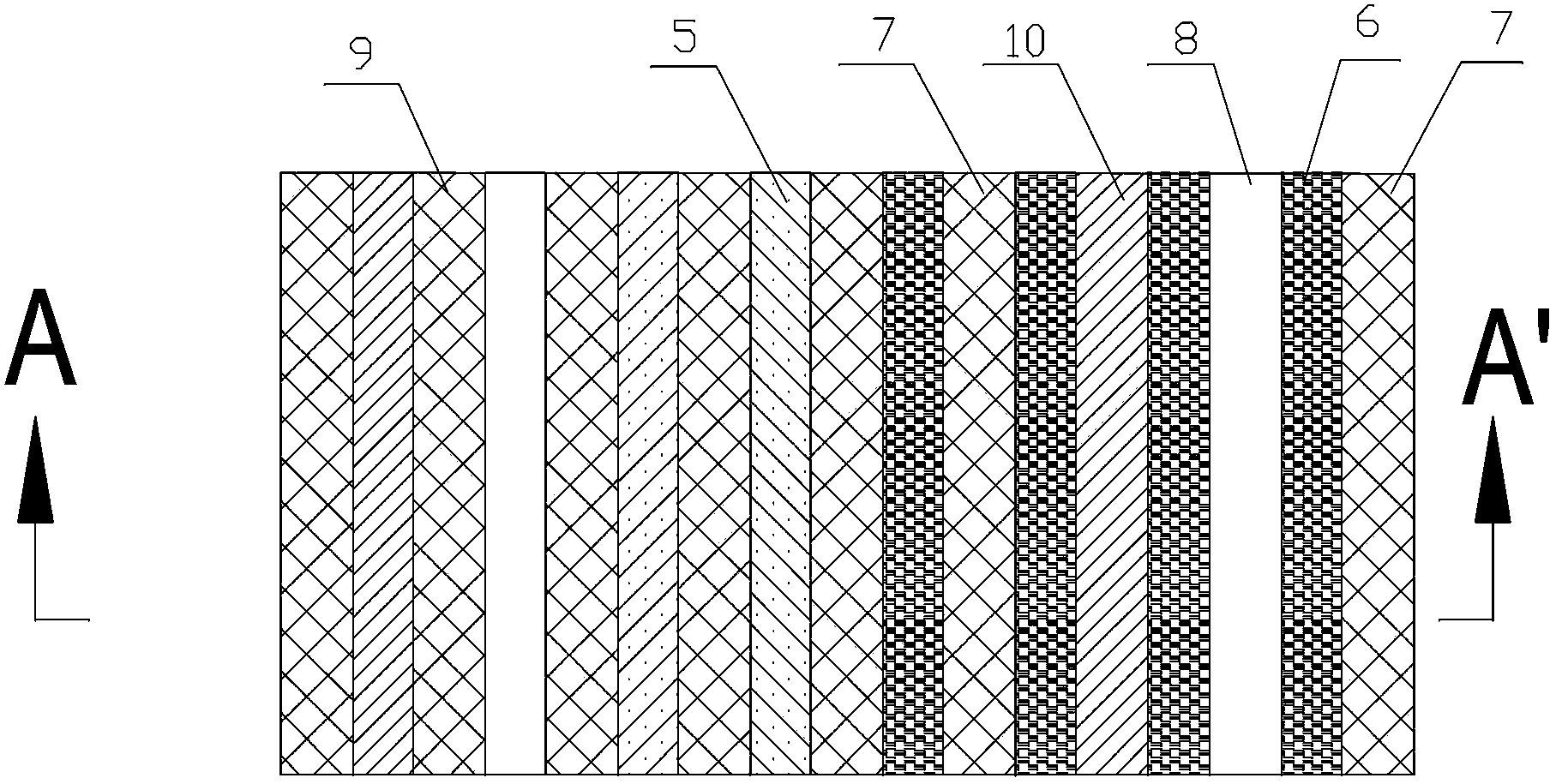

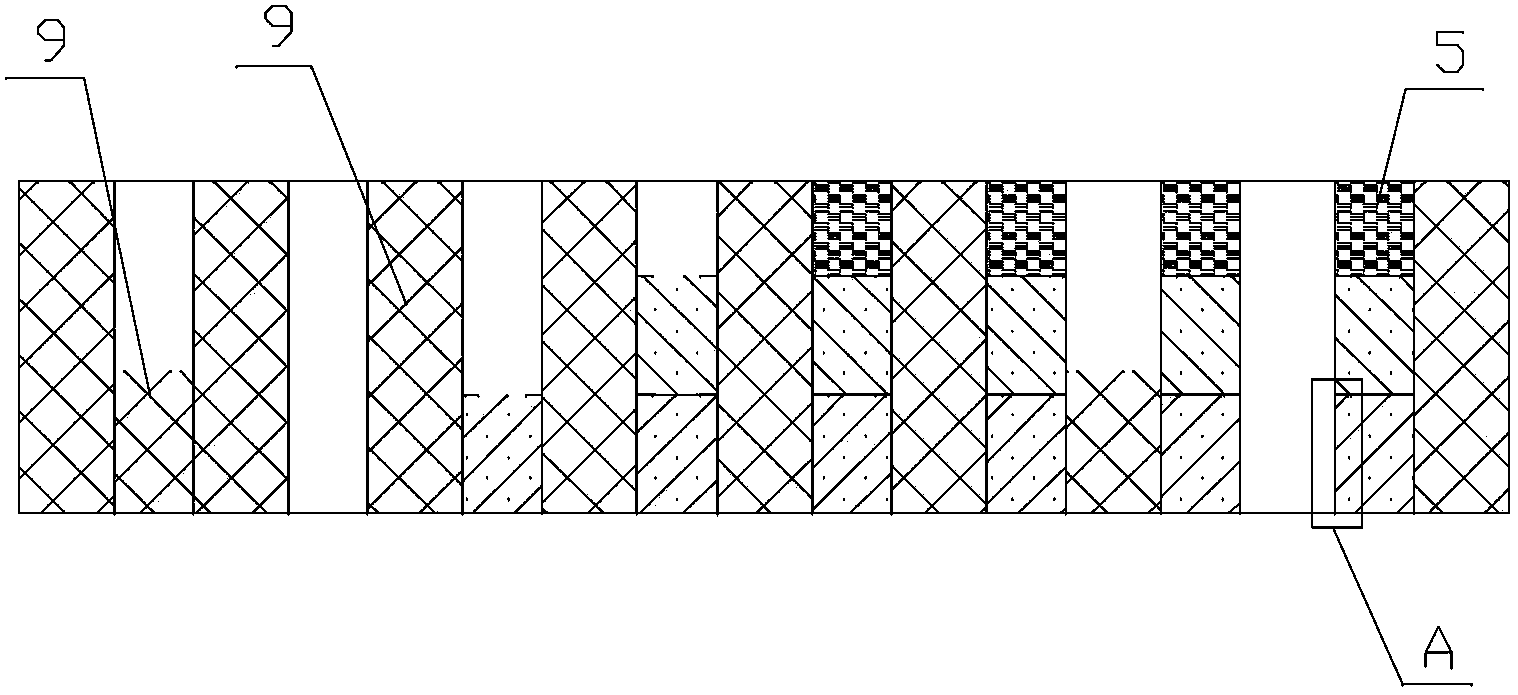

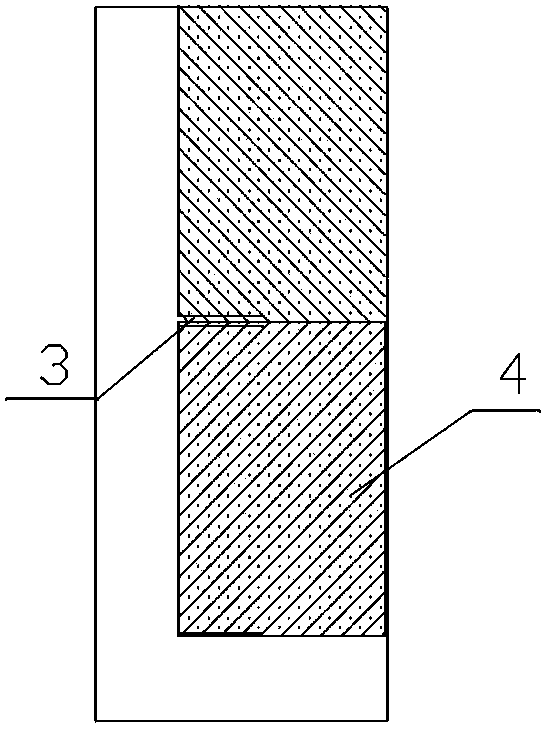

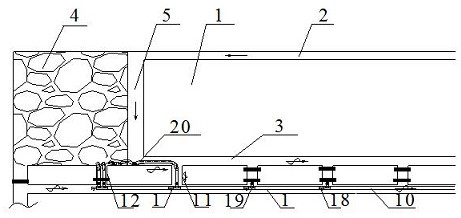

Horizontal moderately thick mine body compartment type filling mining method

ActiveCN103161467BSolving Stacking Handling IssuesMining Safety and the EnvironmentUnderground miningSurface miningBody compartmentEngineering

The invention discloses a horizontal moderately thick mine body compartment type filling mining method. Manual supporting columns are laid in at least a part of a stoping channel formed between mine layer top plates and mine layer bottom plates. A laying method comprises that at least one layer of steel wire meshes are laid along two sides of a channel bottom plate, barren rocks are filled in the steel wire meshes, and concrete is conveyed to the inner sides of the steel wire meshes to form the manual supporting columns. The horizontal moderately thick mine body compartment type filling mining method can mine all ores under the condition of ensuring security of a mining area, ensures that a recovery ratio reaches more than 90%, and meanwhile adopts byproducts, namely the barren rocks, produced by tunneling when filling is carried out, solves the stacking processing problem of the barren rocks, and enables mining of a thick mine body to be safe and environment-friendly.

Owner:HUBEI SHANSHUYA MINING SCI & TECH DEV

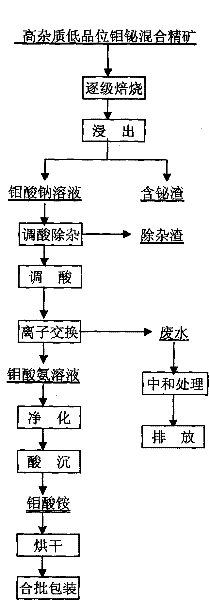

Method for producing ammonium molybdate from molybdenum-bismuth bulk concentrates of high impurity content and low grade

InactiveCN102220500AImprove leaching rateHigh recovery rateProcess efficiency improvementDesorptionFiltration

The invention discloses a method for producing ammonium molybdate from molybdenum-bismuth bulk concentrates of high impurity content and low grade. The method is characterized by: roasting molybdenum-bismuth bulk concentrates of high impurity content and low grade in a reverberatory furnace or a rotary kiln for 8-16 hours continuously from a low temperature of 200 DEG C to a high temperature of 700 DEG C step by step; mixing calcine, mixed base and tap water for leaching molybdenum; subjecting the lixivium from last step to acid adjustment and impurity removal; adding an acid adjusted and impurity removed filtrate into industrial inorganic acid and adjusting the pH value to a range between 2-5; exchanging weak base anion resin for molybdenum; adding magnesium chloride into an ammonium molybdate solution obtained from desorption for purifying so as to remove P and Si; Adding industrial hydrochloric acid or industrial nitric acid into the purified ammonium molybdate solution bring the pH value ranging from 1.5 to 2.5, and conducting a vacuum filtration, thus obtaining ammonium molybdate crystals; drying and interlotting the crystals so as to obtain an ammonium molybdate product.

Owner:HUNAN RONGHONG MOLYBDENUM MATERIAL

''U-and-U plus upper corner pump drainage'' stoping surface gas control method

ActiveCN111810221ASolve the overrun problemAvoid exception spewing problemsGas removalDrill holeCoal

The invention relates to a ''U-and-U plus upper corner pump drainage'' stoping surface gas control method. The method comprises the steps of U-and-U roadway arrangement, underground fixed extraction pump station system building and stoping surface normal bedding drilling, roof high-position drilling, and upper corner pump drainage arrangement. The manner of U-and-U roadway arrangement comprises two U-shaped ventilation system roadways; extraction is conducted through normal bedding drilling in a stoping surface air inlet roadway and a stoping surface air return roadway as well as roof high-position drilling in the stoping surface air return roadway; a backup surface air return roadway is used for stoping surface assisting air return; an embedded tube is arranged in a goaf and an extractionpipeline is arranged at an upper corner; and goaf embedded tube extraction and stoping surface upper corner extraction are realized. Compared with the prior art, the problem that large air amount isinduced into the stoping surface in case of multi-roadway ventilation so air leakage in mined-out areas is intensified and causes abnormal emission of gas is avoided, and the problems that in thick coal layer mined-out areas, excessive residual coal causes low stoping efficiency and stoping surface safety production is restricted by large emission of the gas in the mined-out areas are solved.

Owner:HENAN POLYTECHNIC UNIV

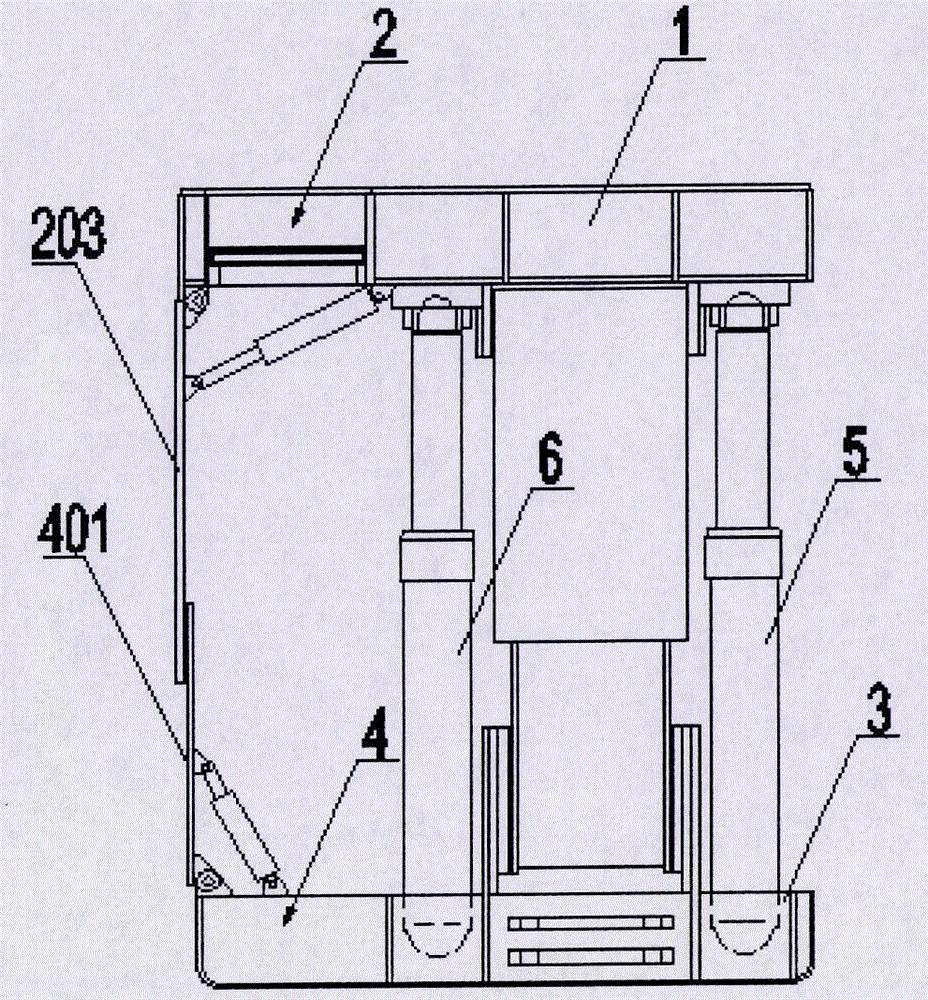

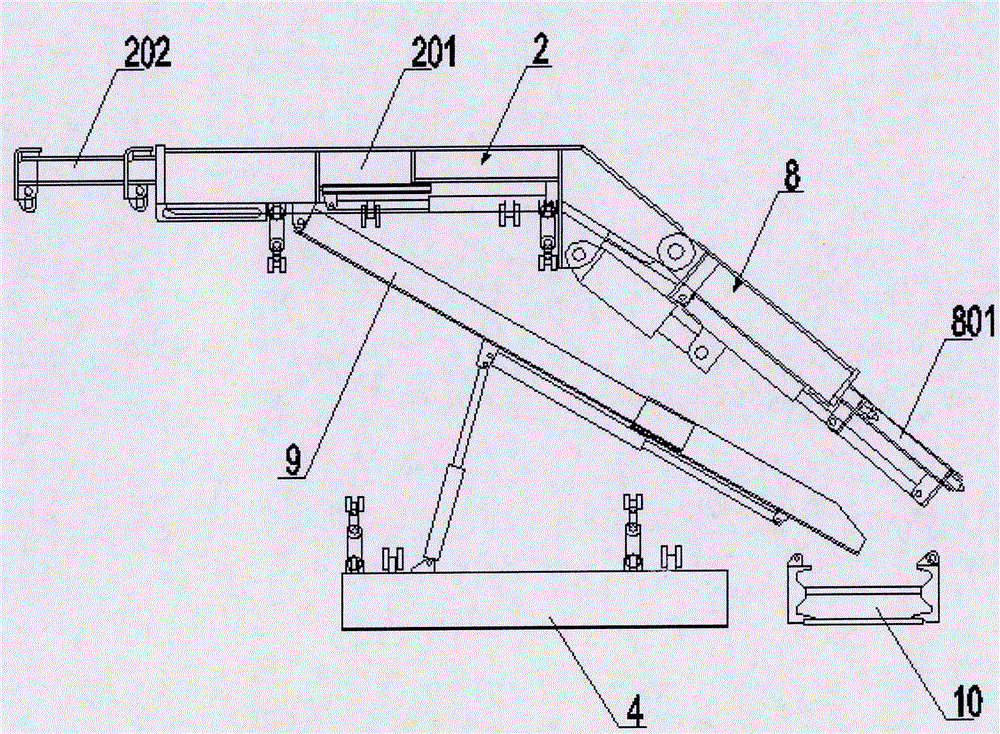

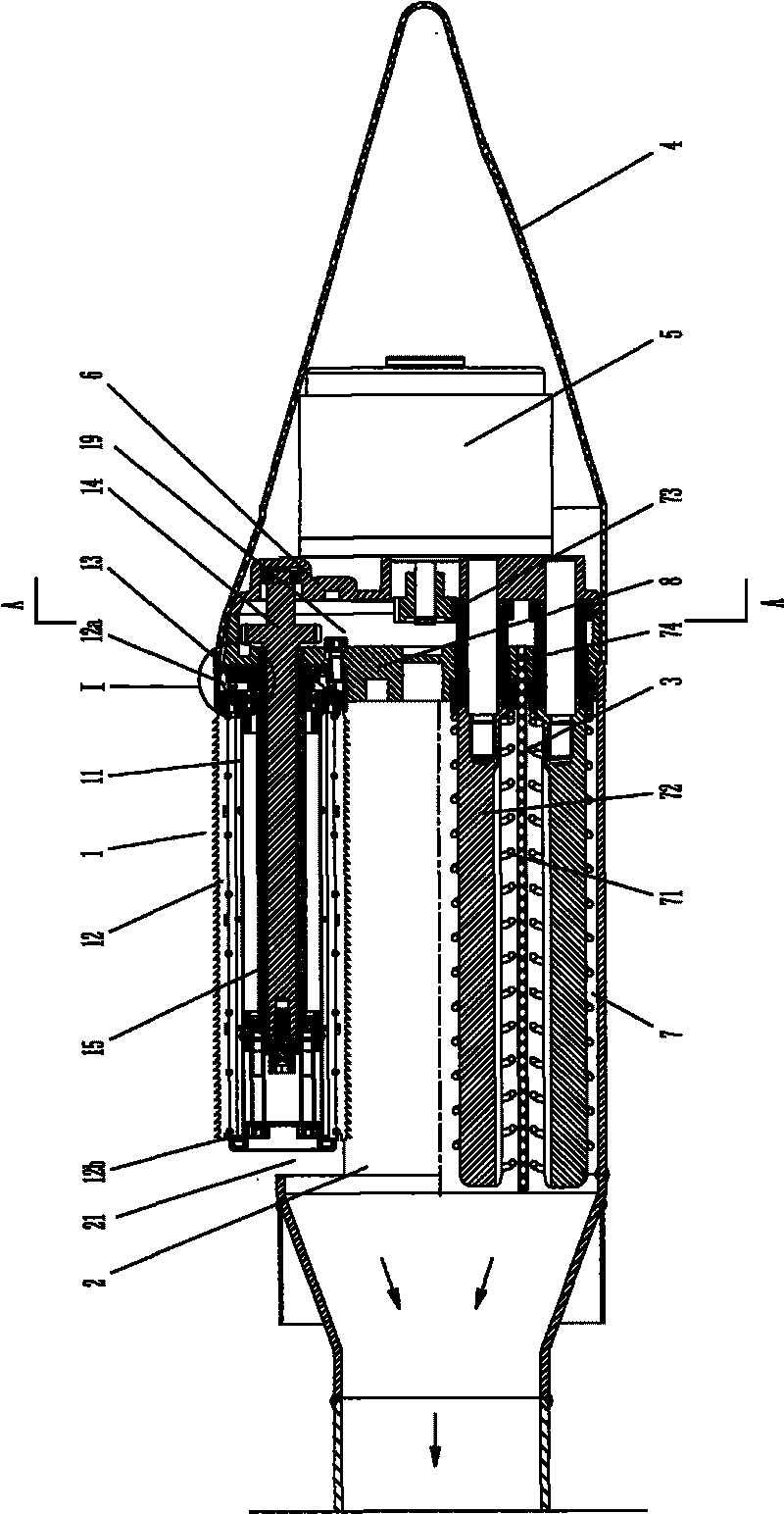

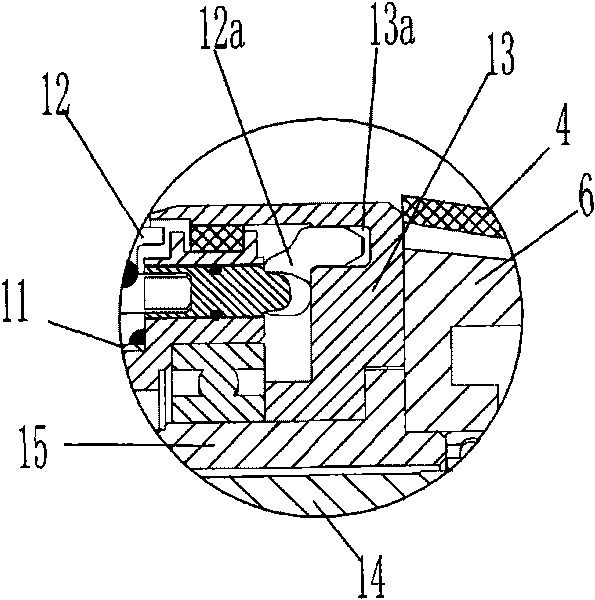

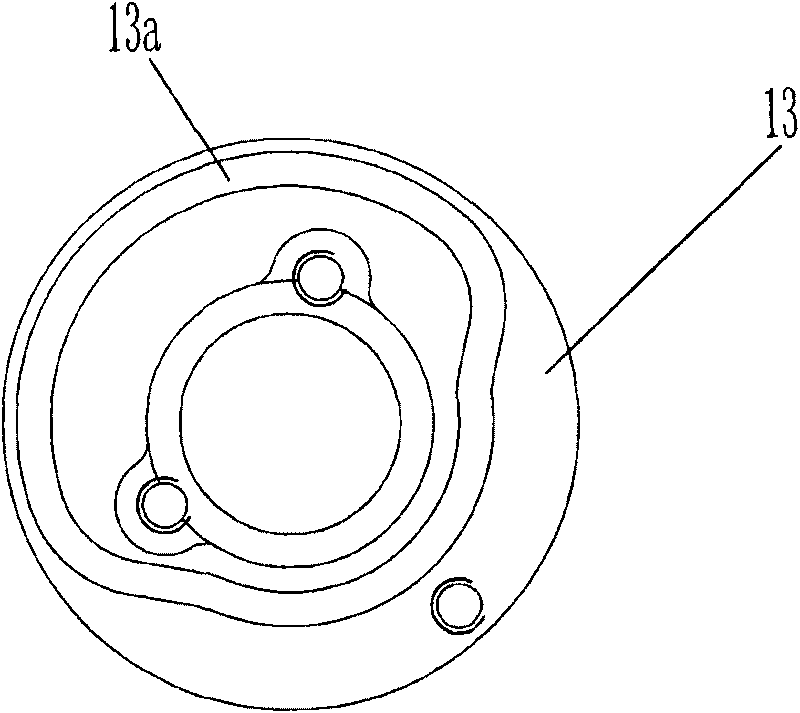

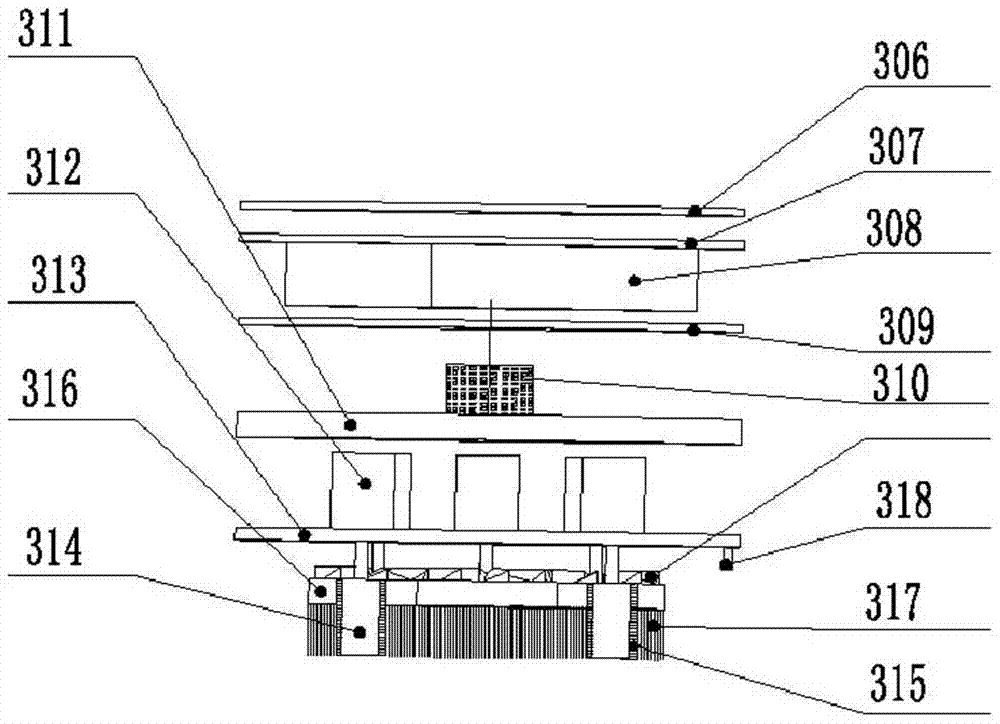

Top coal caving hydraulic bracket combined body for exploiting 4-10 m steeply-inclined coal seam

ActiveCN106437805ARealize mechanized productionReduce labor intensityMine roof supportsEngineeringSupport point

A top coal caving hydraulic bracket combined body for exploiting a 4-10 m steeply-inclined coal seam comprises a main frame and a secondary frame, wherein the main frame is used for supporting a top plate and discharging top coal; the secondary frame and the main frame are supporting points for each other to realize left and right movement of the combined body; the main frame consists of a right part and a left part; the right part comprises a right part top beam (1), a right part pedestal (3), a right upright column (5) and a left upright column (6); the left part comprises a left part top beam (2), a left part pedestal (4) and a back end beam (8); the right upright column (5) and the left upright column (6) are used for realizing ascending and descending of the right part top beam (1) and the left part top beam (2); the back end beam (8) is connected with the back end of the left part top beam (2) and is provided with a low-position coal discharging port (801) for discharging top coal falling on the back end beam (8) from the back end of the left part of the main frame. The top coal caving hydraulic bracket combined body for exploiting a 4-10 m steeply-inclined coal seam can realize top coal caving mechanical mining of the 4-10 m steeply-inclined coal seam, effectively improves the coal mining efficiency and the production safety and greatly reduces the labor intensity of workers to a great degree.

Owner:中煤科工集团国际工程有限公司

Method for extracting purified Tth DNA polymerases

InactiveCN103966182ASimple production processAvoid heat treatmentTransferasesMicroorganism based processesProtein targetGlycerol

The invention provides a method for extracting purified Tth DNA polymerases. The method comprises the following steps: taking engineering bacteria of Tth DNA polymerases for activation, and adding IPTG for inducible expression; adding DTT and tween-20 after the engineering bacteria are treated with lysozyme at room temperature, treating for a period of time on ice and then centrifuging to obtain crude protein; slowing adding silicon dioxide particles in the crude protein, stirring in a magnetic stirring apparatus, centrifuging to remove precipitates; allowing supernatant to flow through an Ni<2+>-chelated Ni-NTA column after the supernatant is supplemented with NaCl, then washing sequentially with washing buffer solutions which have 5 times of bed volume, and at last, eluting the target protein with an eluent, and receiving the eluent containing the target protein; desalting to obtain the purified Tth DNA polymerases; adding glycerol in the obtained purified Tth DNA polymerases, so that the volume fraction is 50%, and saving at -20 DEG C. The method is simple, small in enzyme activity loss, and high in purity and recovery capacity of the recovered protein.

Owner:厦门安普利生物工程有限公司

Intelligent monitoring device for ore pulp and foam fullness of flotation cell, and monitoring method thereof

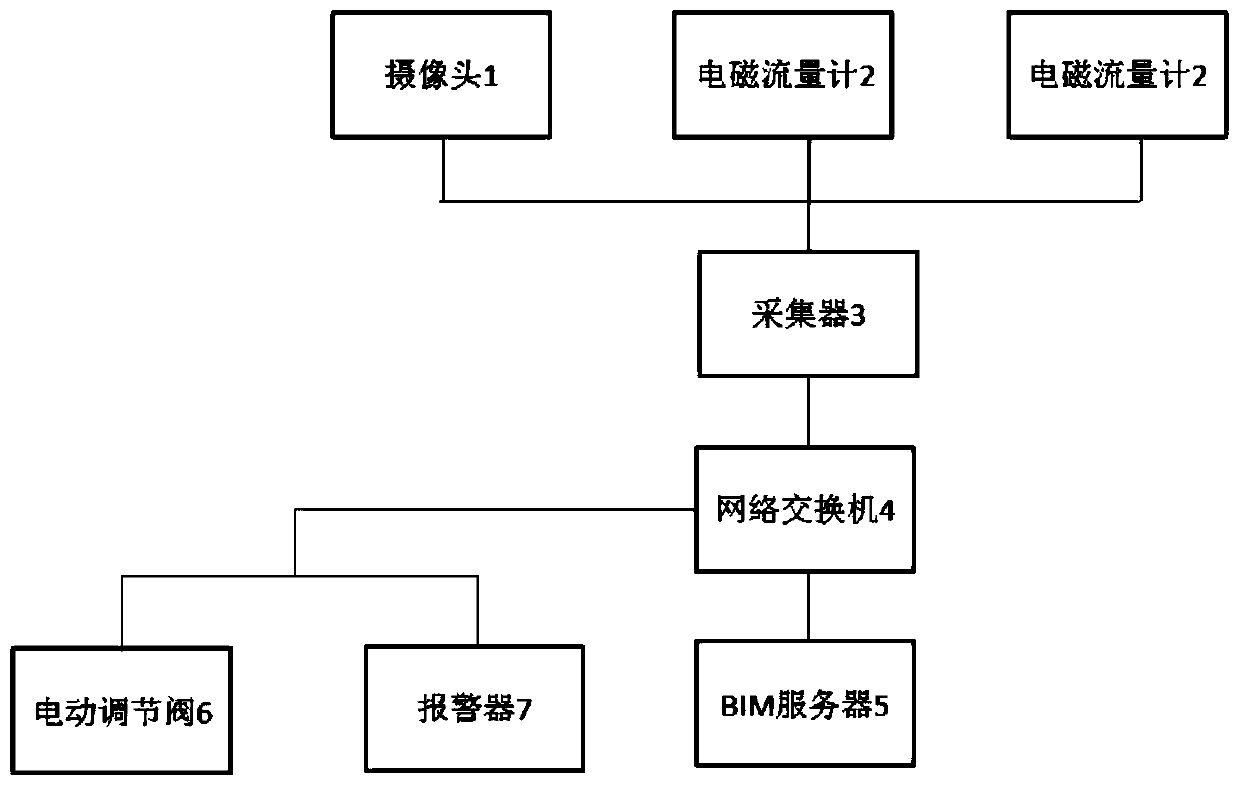

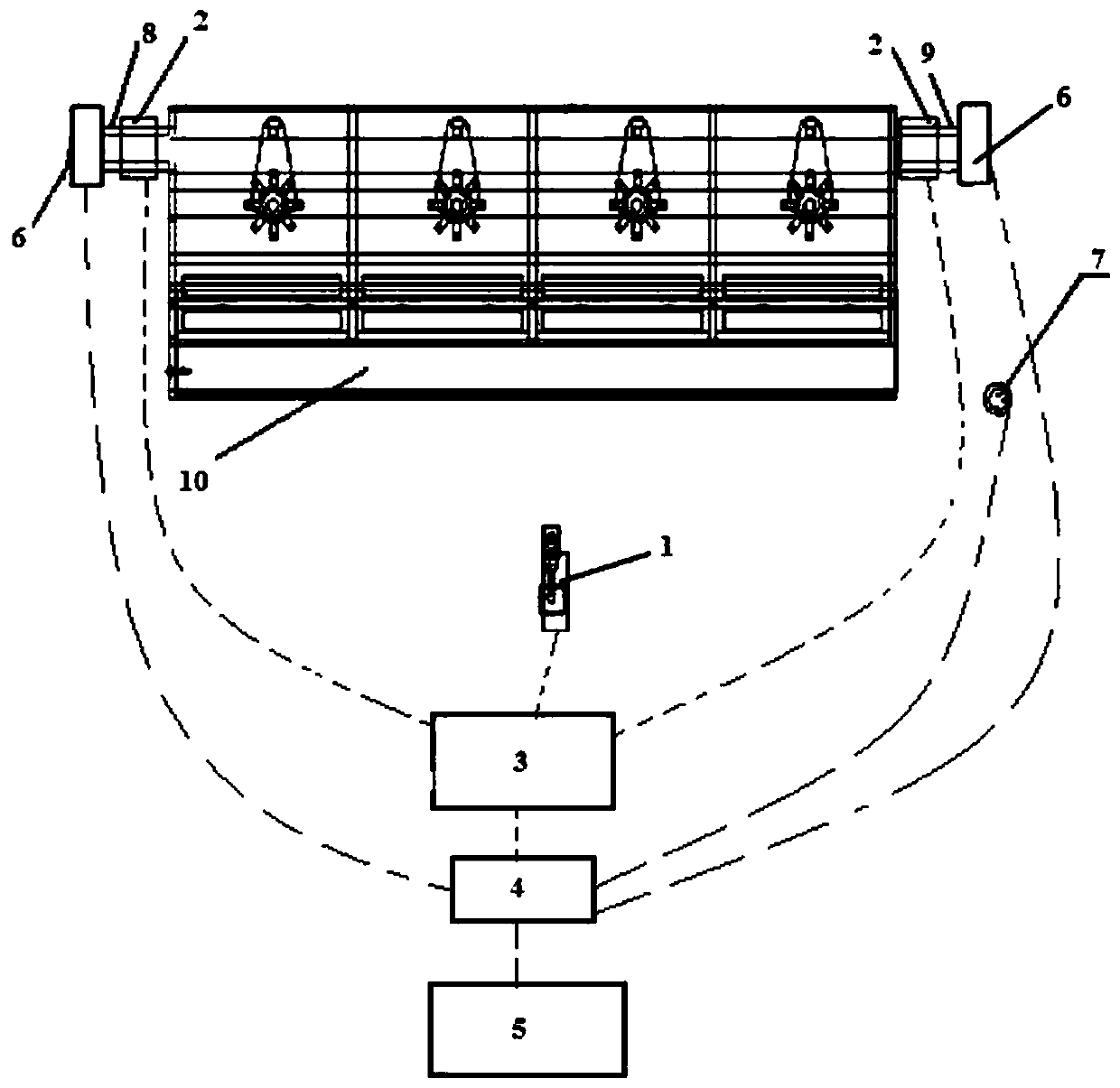

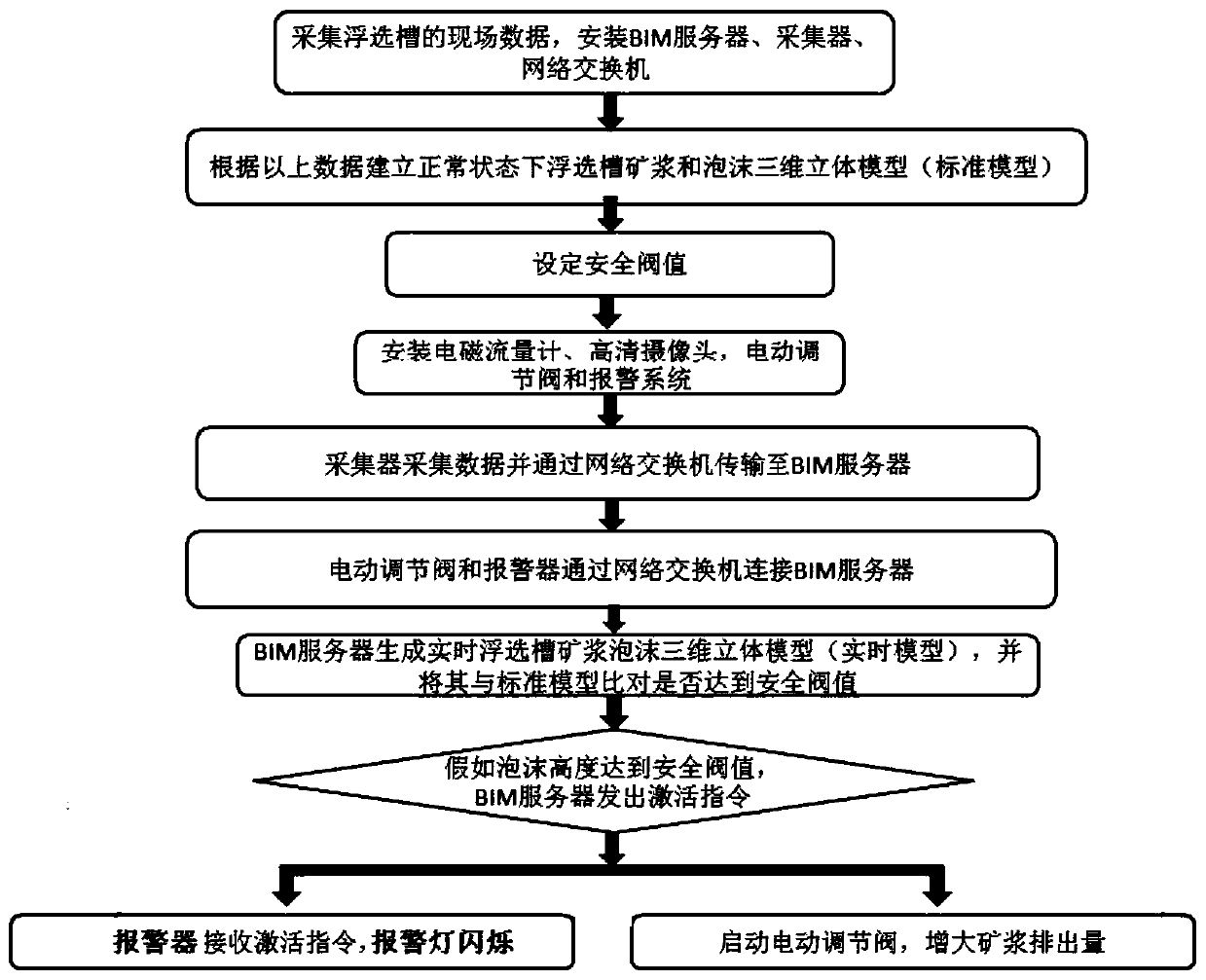

PendingCN110899005AAvoid lostGuaranteed gradeLevel controlPhotogrammetry/videogrammetryControl systemControl engineering

The invention discloses an intelligent monitoring device for ore pulp and foam fullness of a flotation cell, and a monitoring method thereof. The flotation cell is provided with a camera, an electromagnetic flowmeter, a collector, a network switch, a BIM server, an electric control valve and an alarm; the BIM server receives the data, transmitted by the network switch, of the collector, the electric control valve and the alarm, model building software in the BIM server generates a real-time three-dimensional model, and the control system automatically compares the real-time three-dimensional model with a standard model; and if the foam height reaches a safety valve value, the control system of the BIM server sends an activation program instruction to the alarm and the electric actuator ofthe electric control valve through the network switch, an alarm program is activated, and the electric control valve is synchronously started to regulate the ore pulp output caliber. The device and the method have the advantages of high automation degree, ensuring of smooth flotation production, reduction of the safety risk caused when a flotation device runs at a high speed and the tank is full,avoiding of mineral losses, and ensuring of the grade and the recovery rate of flotation concentrate products.

Owner:JIANGXI UNIV OF SCI & TECH

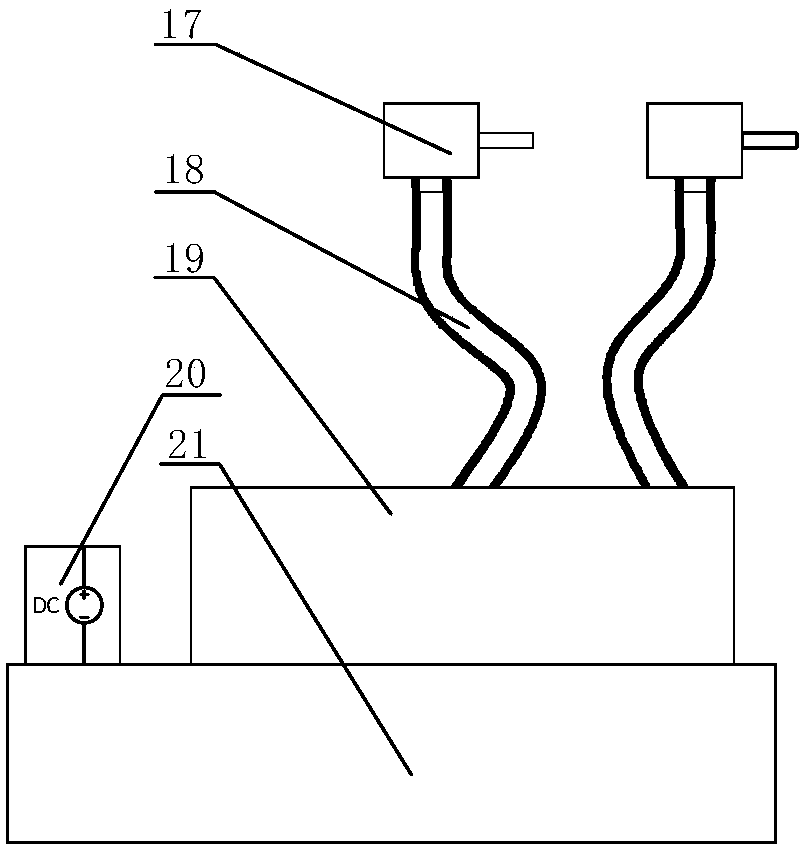

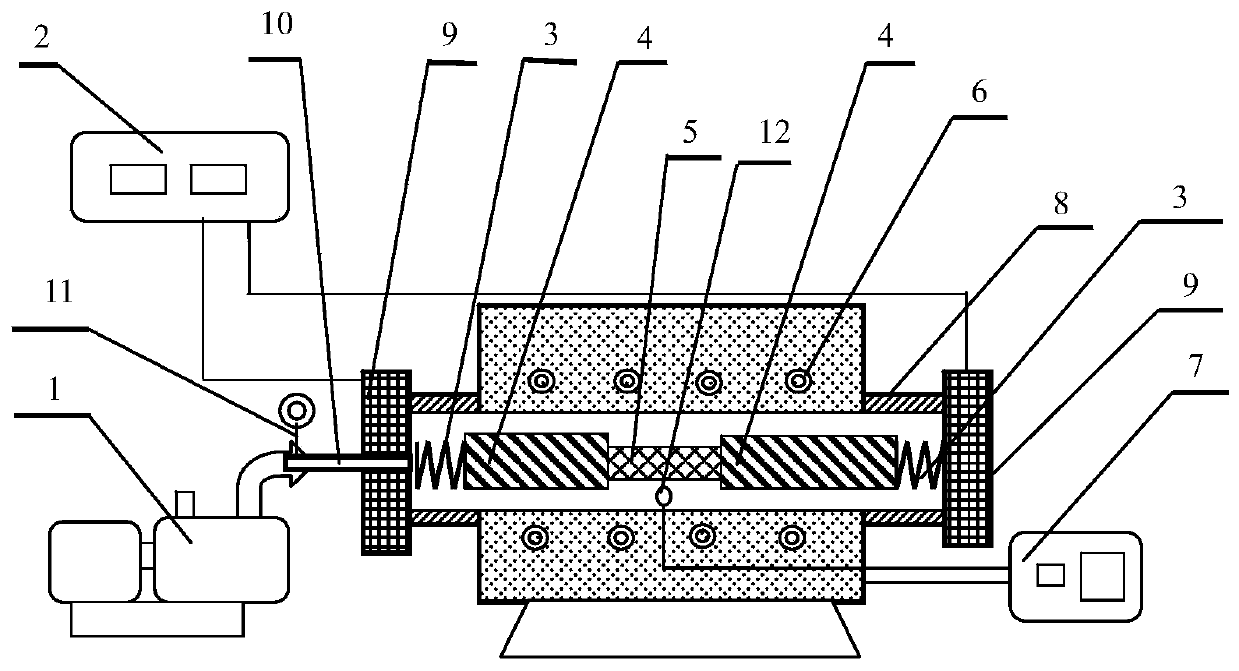

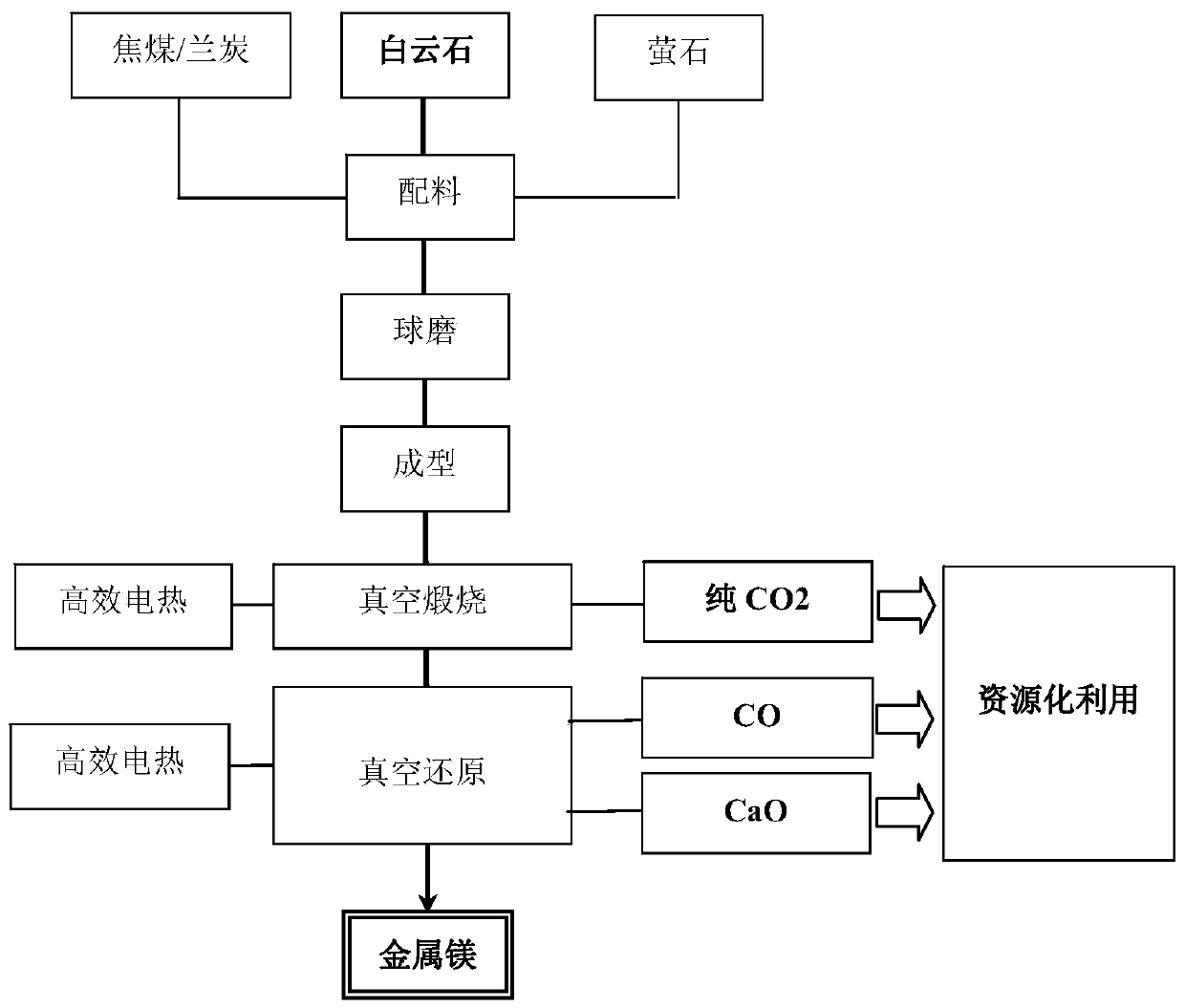

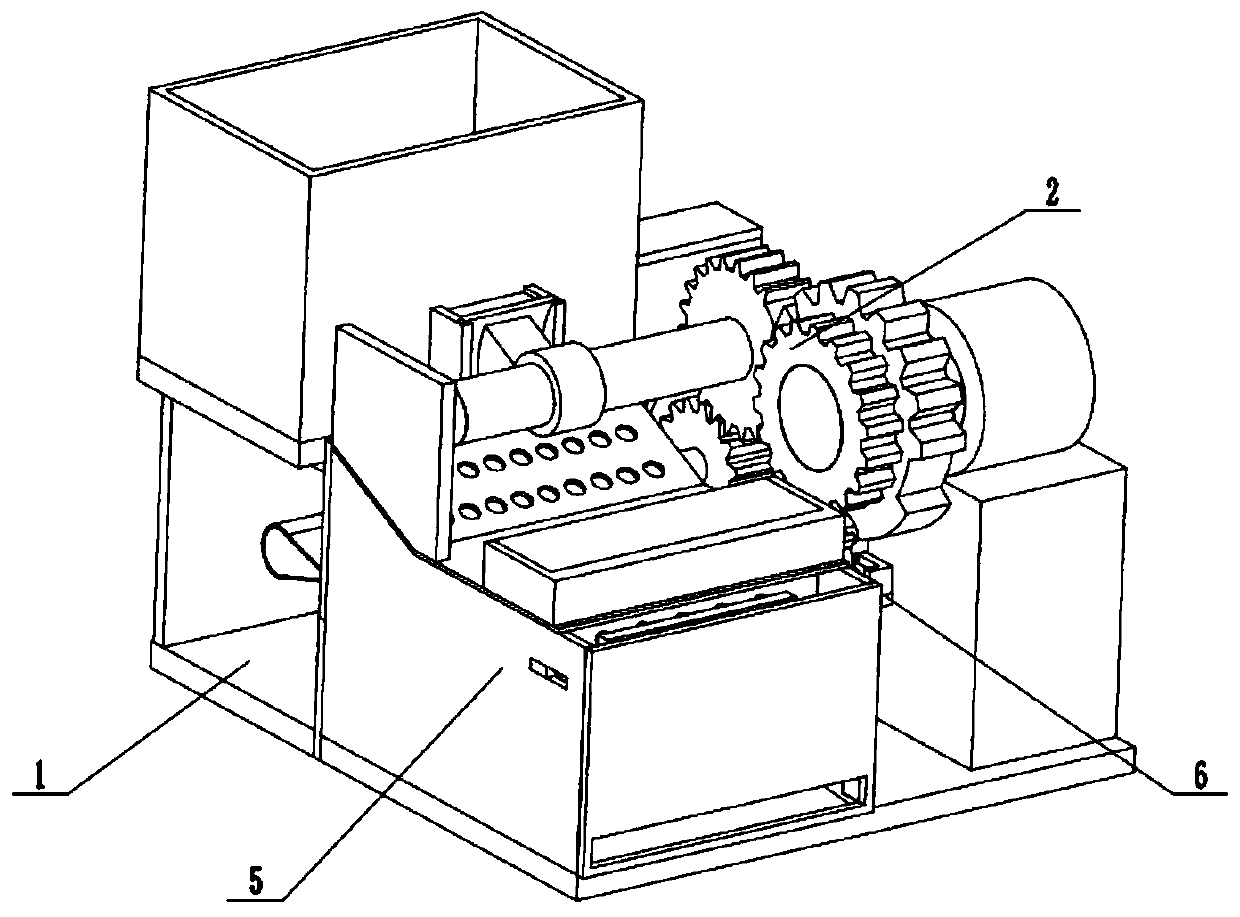

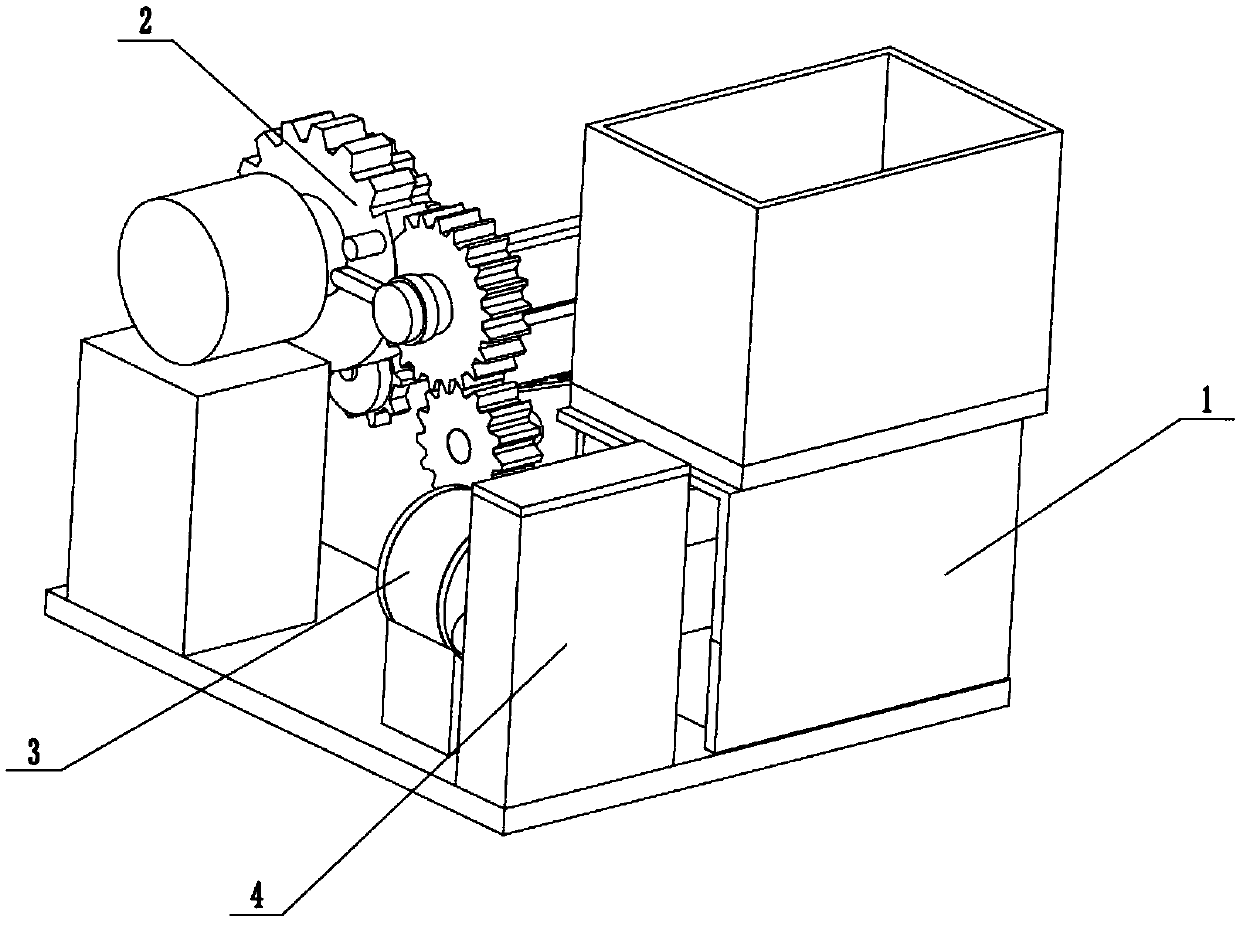

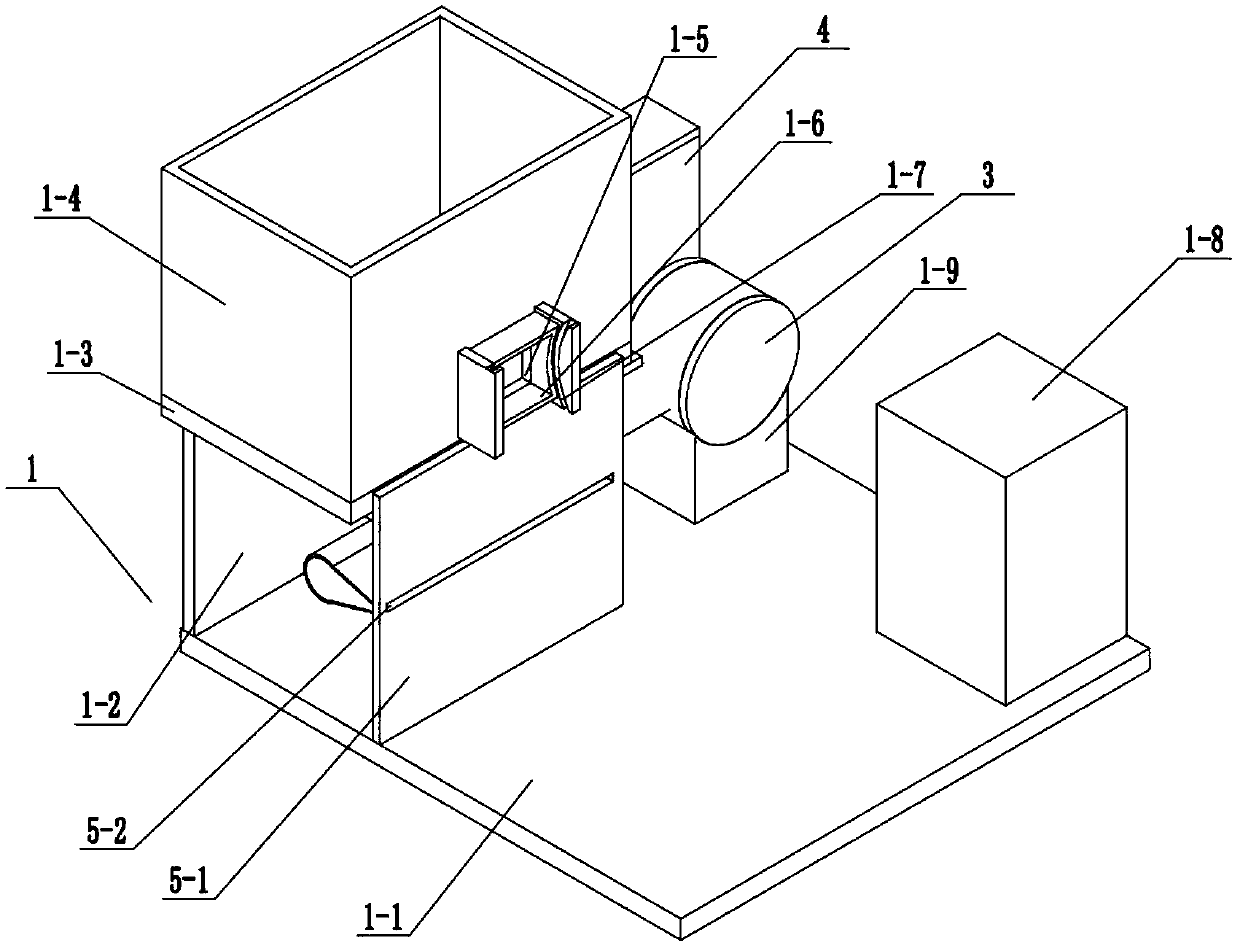

Metal magnesium carbon thermal reduction process and device

The invention discloses a metal magnesium carbon thermal reduction process and device. The process comprises the following steps that a magnesium-containing raw material, a carbon-containing reducingagent and a catalyst are used as raw materials, the raw materials are subjected to uniform mixing and forming, under certain temperature and vacuum degree conditions, current is directly conducted atthe two ends of a formed sample, and the current is controlled to carry out power-on reduction reaction, and the cooling is carried out to obtain the metal magnesium after the reaction is finished. The device comprises a reactor, a positive electrode, a negative electrode, a position buffer and a sealing cover, wherein the reactor is used for performing a metal magnesium reduction reaction, the positive electrode and the negative electrode are used for directly applying current to the reaction raw material formed parts, the position buffer is used for regulating the positive and negative electrodes, and the sealing cover is used for sealing the reactor. The process and device overcome the series of problems such as high reduction temperature, long reduction time, reversible reaction and the like of an existing carbon thermal method metal magnesium, the temperature of the reduction device can be greatly reduced, the metal magnesium can be initially reduced at room temperature, the reduction speed of the metal magnesium is greatly improved, and the process is green and environmentally friendly.

Owner:CHANGAN UNIV

Power ultrasound promoted light material separating device for soil remediation device

InactiveCN109675806ALarge contact recovery areaGuaranteed recovery rateSievingGas current separationSoil remediationLarge particle

The invention relates to the field of soil remediation, in particular to a power ultrasound promoted light material separating device for a soil remediation device. The power ultrasound promoted lightmaterial separating device comprises a storage box base, a discharge driver, a light material exhaust fan, a light material recycling box, a material separating box and a heavy material discharge switch, wherein the light material exhaust fan, the discharge driver, the light material recycling box and the material separating box are fixedly connected onto the storage box base; and the left end ofthe discharge driver is in clearance fit onto the storage box base. The power ultrasound promoted light material separating device for the soil remediation device has the beneficial effects that: to-be-recycled soil can be automatically added quantitatively in batch, the biggest light material contact and recycling area is guaranteed, waste is avoided, small-particle soil is dispersed and stirred, a recovery rate is guaranteed, large-particle soil blocks are stirred in a classified mode on the premise of guaranteeing dispersing and stirring, and waste in a recycling process is avoided.

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

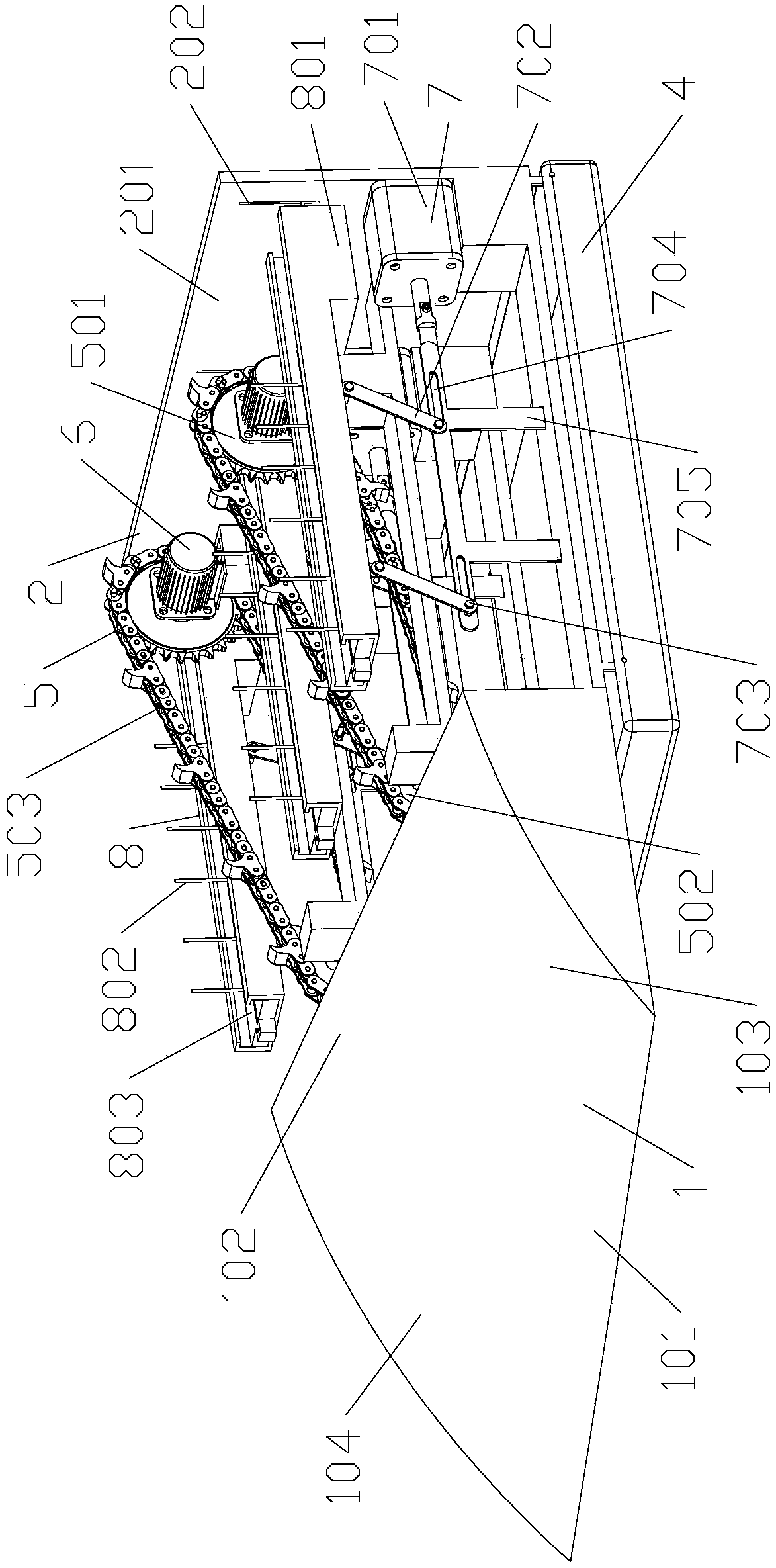

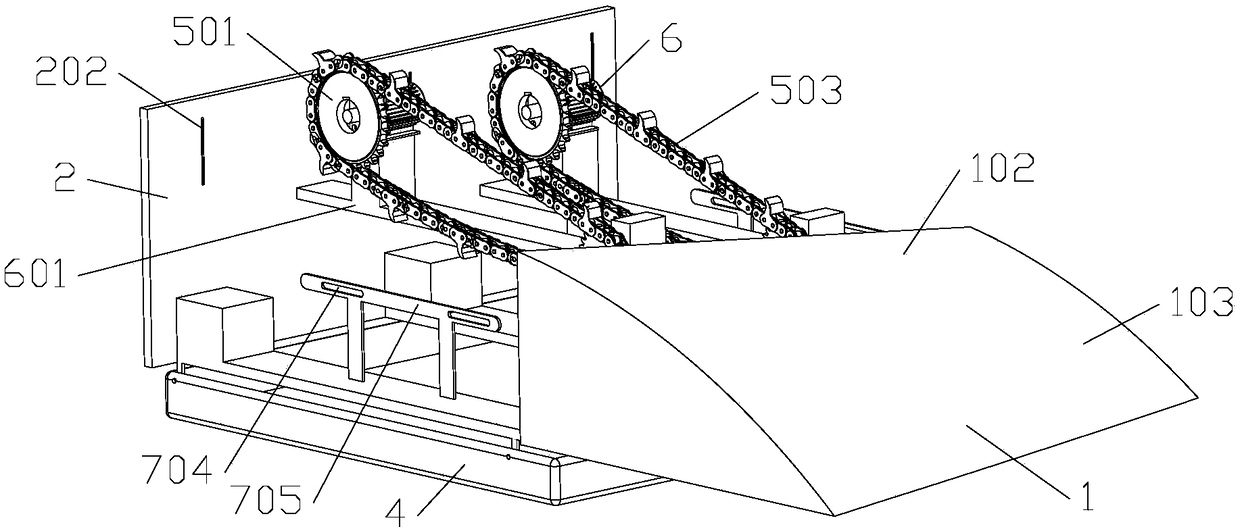

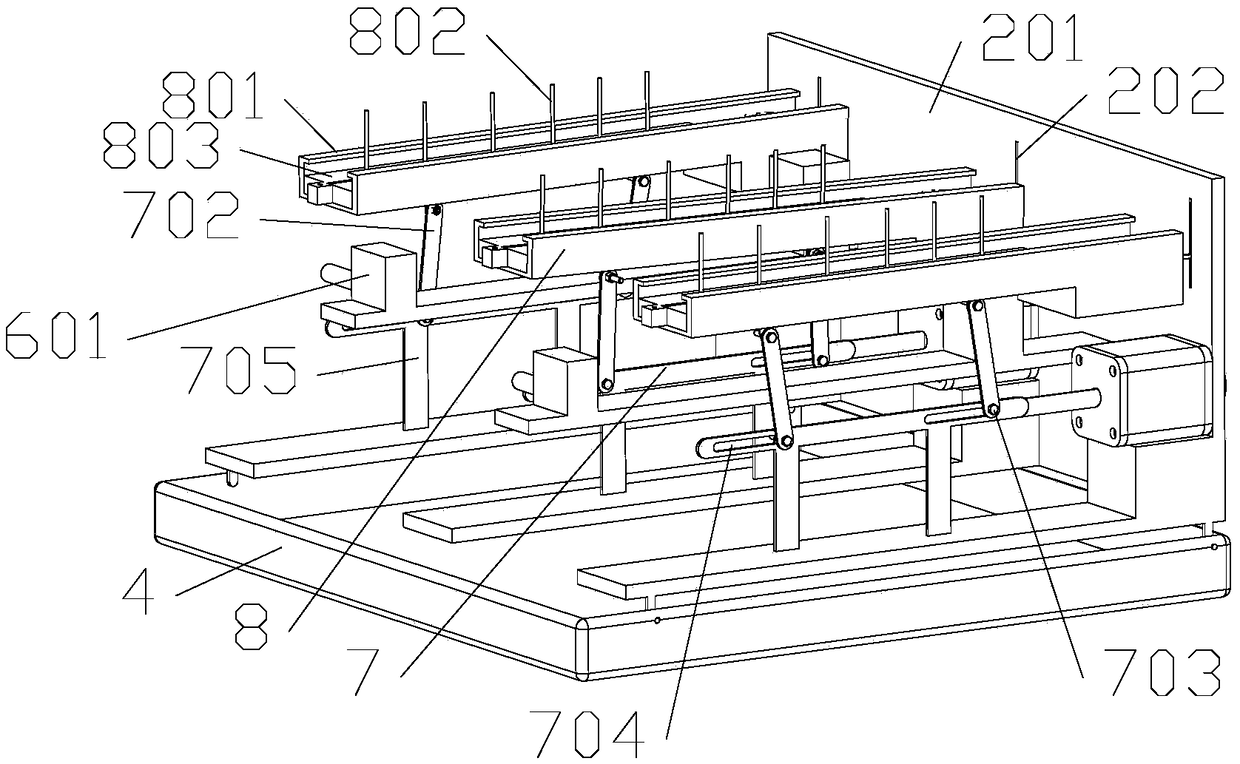

Compact vibration harvesting device for fruit harvesting

The invention provides a compact vibration harvesting device for fruit harvesting. The device lowers the fruit and branch damage rate and is suitable for harvesting of berries of fruit trees planted in a dwarfing close planting mode; a collecting box is arranged in the front of the bottom of a vertical plate, and a branch supporting device and an insertion tooth vibrating device are arranged abovethe collecting box; the branch supporting device comprises at least two front-back extending chains, and each chain surrounds a front chain wheel and a rear chain wheel; the insertion tooth vibratingdevice comprises a tooth insertion guide rail extending in the front-back direction, an insertion tooth fixing plate in sliding connection with the tooth insertion guide rail and a plurality of upward extending insertion teeth arranged on the insertion tooth fixing plate, and a vibrating mechanism for driving the insertion tooth fixing plate to reciprocate along the insertion tooth guide rail isarranged on the insertion tooth guide rail; the insertion tooth guide rail is in sliding connection with the vertical plate in the vertical direction, and the insertion tooth guide rail is connected with a vertical driving mechanism; the insertion tooth guide rail and the chains are arranged in a spaced mode.

Owner:NANJING FORESTRY UNIV

Fully automatic cotton picker

The invention discloses a fully automatic cotton picker, comprising a machine body as well as a cotton picking apparatus, an impurity separating apparatus and a clean cotton storage apparatus which are arranged on the machine body. A picking head in a needle wheel barrel structure is adopted and passes through a gap in a free state of cotton plants horizontally. The cotton plants during the cotton picking process are not over squeezed so that the cotton plants are not destroyed. During leafiness period, cotton leaves and flowers are not destroyed when cotton is picked. Therefore, the cotton can be picked for many times step by step and divided into classes; the cotton picked during picking is prevented from being polluted, and the impurity ratio of the cotton is reduced; the cotton picking head automatically rotates within 360 degrees, thereby ensuring the cotton picking ratio; cotton fiber during transportation is not destroyed to ensure quality of the cotton; the impurity separating apparatus separates the cotton due to density contrast of the cotton and impurities thoroughly and conveys the clean cotton by using a spiral rod, thereby improving quality of the clean cotton; the cost of cotton picking and the subsequent machining cost are reduced. The cotton picker is small in volume, light in weight and low in manufacturing cost.

Owner:黄晖 +1

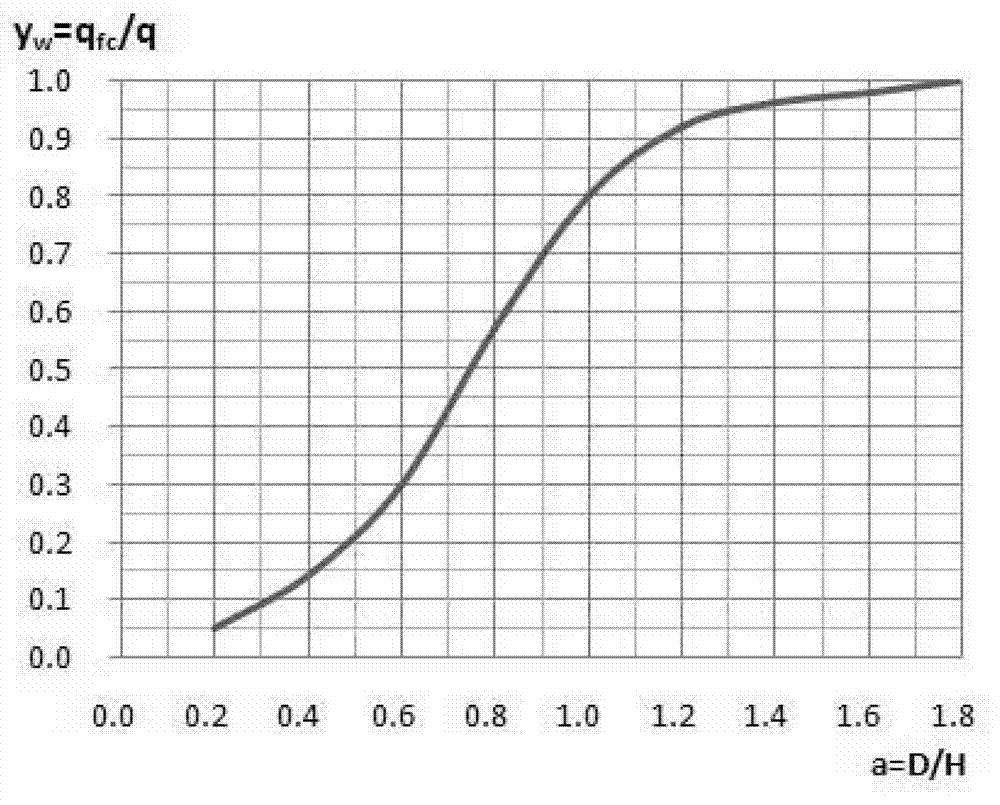

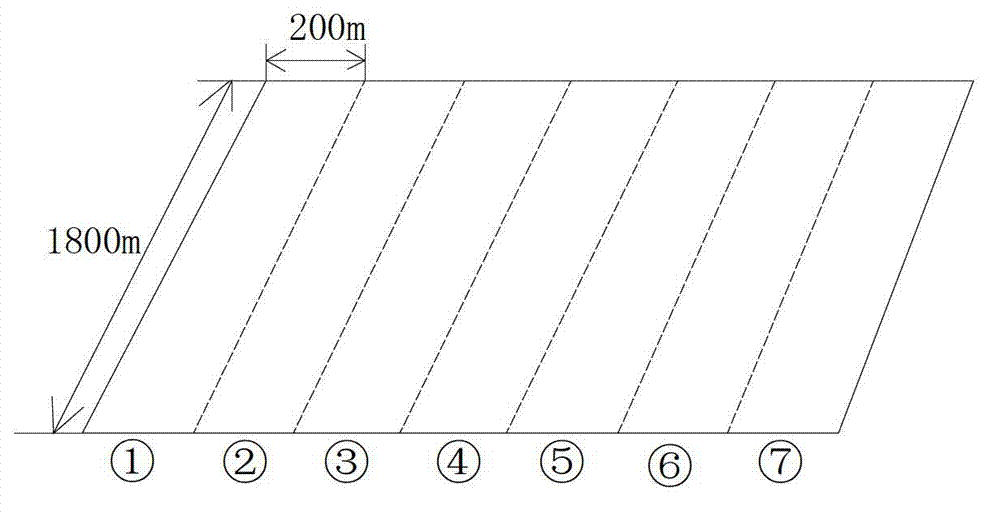

Underground working face mining sequence optimization method for prolonging service time of surface land

ActiveCN103206216AGuaranteed recovery rateDownhole production is convenientUnderground miningSurface miningLand utilizationCoal

The invention discloses an underground working face mining sequence optimization method for prolonging service time of surface land and belongs to the field of mining technology, land utilization and land reclamation. The method comprises the steps of obtaining an insufficiently mined surface subsidence coefficient fitted curve of a location, determining a subsidence coefficient corrected parameter under a ground critical water accumulation condition, determining underground mining width Dc under the ground critical water accumulation condition, and optimizing an underground working face mining sequence according to the underground mining width Dc. The method optimizes the underground working face mining sequence by analyzing a surface subsidence movement rule of the location under the insufficient mining condition, so that the emergence time of the maximum surface subsidence value is changed, and the service time of the surface land is prolonged relatively. Finally, all underground coal can be mined, so that the coal recovery ratio is ensured, and the service time of the ground land, particularly cultivated land, is considered to a certain extent. The method is a green mining mode taking the land surface into account.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

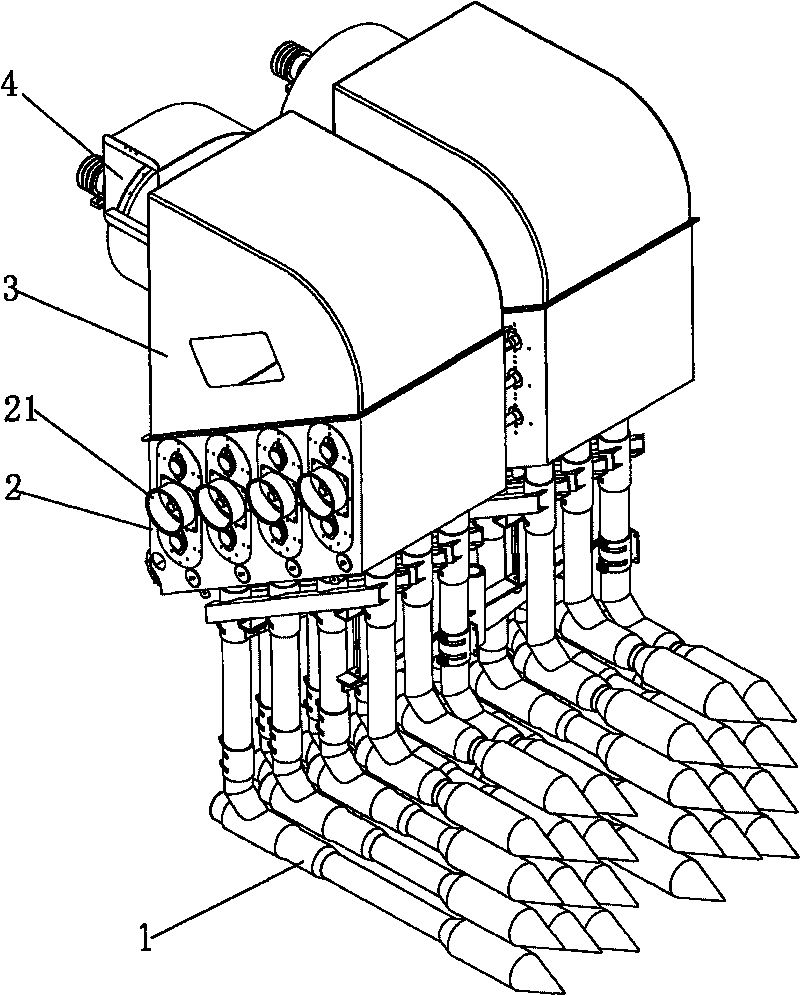

Picking head assembly of fully automatic cotton picker

The invention discloses a picking head assembly of a fully automatic cotton picker, comprising a driving motor, a cylindrical picking head housing, a needle wheel barrel and a spring convey mechanism. A picking head in needle wheel barrel structure is adopted and passes through a gap in a free state of cotton plants horizontally to distribute the cotton flowers evenly within 360 degrees peripherally. During leafiness period, cotton leaves and flowers are not destroyed when cotton is picked. Therefore, the cotton can be picked for many times step by step and divided into classes; the picked cotton is separated directly from impurities, for instance, cotton leaves, cotton stems and the like, thereby the cotton picked during picking is prevented from being polluted, and the impurity ratio of the cotton is reduced; the cotton picking head automatically rotates within 360 degrees, thereby ensuring high-level cotton picking ratio and the final picking ratio of 98% above; and the spring convey mechanism separates and conveys the cotton from the needle wheel barrel by utilizing the spiral convey theory. Cotton fiber is not destroyed to ensure the quality of the cotton; the invention has no special requirements for subsequent processing device and reduces the subsequent machining cost.

Owner:黄晖 +1

Method for extracting and purifying M-MLV reverse transcriptase

InactiveCN104250642AHigh purityReduce the chance of non-specific adsorptionTransferasesMicroorganism based processesWater bathsReverse transcriptase

The invention provides a method for extracting and purifying an M-MLV reverse transcriptase. The method comprises the steps of: activation and expression of engineering bacterium: activating M-MLV reverse transcriptase engineering bacteria, and adding IPTG for induced expression to obtain expressed engineering bacteria; treating the bacteria with lysozyme at room temperature, adding DTT and Twain-20, treating on ice for a period of time, and centrifuging to obtain a crude protein; slowly adding silica particles into the crude protein, stirring by a magnetic mixer, and centrifuging to remove sediment and obtain a supernatant; transferring the supernatant water to a water bath preheated to 60 DEG C, incubating, centrifuging, and removing precipitate to obtain the supernatant; passing the supernatant through a Ni-NTA column with Ni<2+> chelated, then desalinating to obtain purified M-MLV reverse transcriptase; and preserving the obtained M-MLV reverse transcriptase by adding glycerol to reach the volume fraction of 50% at -20 DEG. The invention has the advanategs of small enzyme activity loss, and high purity, high activity and high recovery amount of recovered protein.

Owner:厦门安普利生物工程有限公司

Process for recovering ethanol in gruffs

ActiveCN101306983AGuaranteed recovery rateAchieve reuseOrganic compound preparationHydroxy compound preparationSteam condensationSteam distillation

The invention relates to a method for reclaiming ethanol in medicine residue. The method comprises the steps of reclaiming through dry process and reclaiming through wet process; firstly, the reclaiming through the dry process is carried out: a steam valve which leads to an extraction tank is opened; steam is led to the bottom of the medicine residue for water steam distillation and ethanol reclaiming; the distilled ethanol passes through a cooling system and enters a storage tank; after a concentration of the distilled ethanol is equal to or slightly lower than a concentration of the used and extracted ethanol by ten percent, heating is stopped; then, the reclaiming through the wet process is carried out: drinking water or steam condensation water at a temperature of between 50 and 80 DEG C is added from the bottom of the extraction tank till immerging the surface of the medicine residue; the steam valve which leads to a jacket is opened; the residual ethanol is reclaimed by adopting peripheral heating and boiling maintenance under the condition of normal atmosphere or micro-vacuum; and the distilled ethanol passes through the cooling system and enters the storage tank; when the concentration of the distilled ethanol is between 2 and 10 percent, the heating is stopped and the ethanol reclaiming is finished. The method has high reclaiming rate, realizes the repeated use and the maximum reclaiming of the ethanol, changes waste into valuable and quite meets the need of national energy conversation and emission reduction. Compared with the prior reclaiming method, the method reduces the reclaiming time by 3 to 6 hours, thereby reducing the reclaiming cost.

Owner:ZHEJIANG CONBA PHARMA

Deep well small coal pillar gob-side entry retaining method based on roof lower key layer roof-breaking pressure relief

ActiveCN112377193AEfficient productionSolve the problem of continuous tension in miningMining devicesUnderground miningMining engineeringCoal pillar

The invention provides a deep well small coal pillar gob-side entry retaining method based on roof lower key layer roof-breaking pressure relief, and relates to the technical field of coal mining. Ventilation and support in deep well gob-side entry retaining are improved. The deep well small coal pillar gob-side entry retaining method comprises the steps that roof geological conditions are determined, blasting parameters are determined according to the roof geological conditions, the roof-breaking pressure relief effects of lower key layers with different thicknesses are numerically simulated,and roof-breaking parameters of a roadway are determined; then excavating blast is conducted in the test roadway, and a displacement monitoring station, an anchor rod and an anchor cable stress monitoring station are arranged on surrounding rock in the roadway; and the supporting parameters are corrected, excavating blast is conducted in the gob-side entry retaining roadway, and supporting is conducted according to the corrected supporting parameters. According to the method, blasting is conducted on the side, deviating from solid coal, of a coal seam roof, stress transmission of the key layer is cut off at the lower key layer of the pre-split coal seam roof, thus high stress acting on small coal pillars and gob-side entry retaining is transferred, therefore the roadway environment is improved, and roadway maintenance is facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

Recovering and purifying device of organic solvent and method

ActiveCN101530713BReduce energy consumptionLow costDispersed particle separationVapor condensationSorbentDesorption

Owner:SHANGHAI TONGJI CONSTR TECH

Method for enriching europium in samarium-europium-gadolinium chloride solution

ActiveCN107326200AGuaranteed recovery rateGood restoration effectProcess efficiency improvementDecompositionChemistry

A method for enriching europium in a samarium-europium-gadolinium chloride solution sequentially comprises the steps as follows: a solution with the REO being 70-150 g / L is prepared from the samarium-europium-gadolinium chloride solution, glacial acetic acid is added, the solution is stirred for 10-30 min, and the pH value is adjusted to range from 1.5 to 3; magnesium sulfate is added to the solution in step (1), and the solution is stirred for 30-60 min; then zinc powder is added, and the solution is stirred for 30-120 min; europium-containing filter residues and a samarium-gadolinium-chloride-containing filtrate are obtained through filtration, the europium-containing filter residues are washed with diluted hydrochloric acid with the concentration being 0.5-2 mol / L, and the washing water is used for preparing the samarium-europium-gadolinium chloride solution; a hydrochloric acid solution is added to the europium-containing filter residues in step (2), and the solution is stirred for 30-60 min; hydrogen peroxide is added, and the solution is stirred for 1-5 h; water being 0.5-4 times the addition amount of the hydrochloric acid solution is added for dilution; a tri-valent europium solution is obtained through stirring and filtration, and the filter residues are returned for decomposition treatment. With the method, the energy consumption is reduced, the method is easy to operate, and the cost is low.

Owner:GUANGDONG INST OF RARE METALS

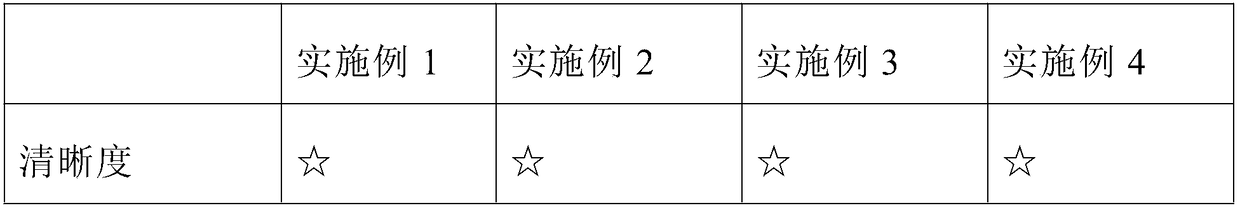

Preparation method of water transfer printing stained paper

InactiveCN108656771ASimple methodEasy to operateDuplicating/marking methodsOther printing apparatusHardnessPulp and paper industry

The invention provides a preparation method of water transfer printing stained paper. The preparation method comprises the following steps that (1) an electronic manuscript is subjected to color separation; (2) a film is manufactured, and the film net hanging precision ranges from 176 lines to 210 lines; (3) a screen is manufactured, and the number of meshes of the screen ranges from 380 to 450; (4) photoresist with the resolution rate being larger than 800 LP / mm is sprayed, and the film is pasted to the screen for exposure; (5) the screen obtained after exposure is immersed into water for 1-2min by being away from light and then is taken out, and the un-exposed part on the screen is washed with water; and (6) a scraping knife with the Vickers hardness ranging from 75 to 80 is adopted forprinting, an angle ranging from 60 degrees to 85 degrees is formed between the scraping knife and the screen, and after printing is completed, drying is carried out, and the paper can be obtained. The preparation method of the water transfer printing stained paper is simple and easy to operate, the effect that net points cannot be seen under the eye level condition of naked eyes can be achieved,and textures and / or patterns of products are clear and attractive.

Owner:胡华斌

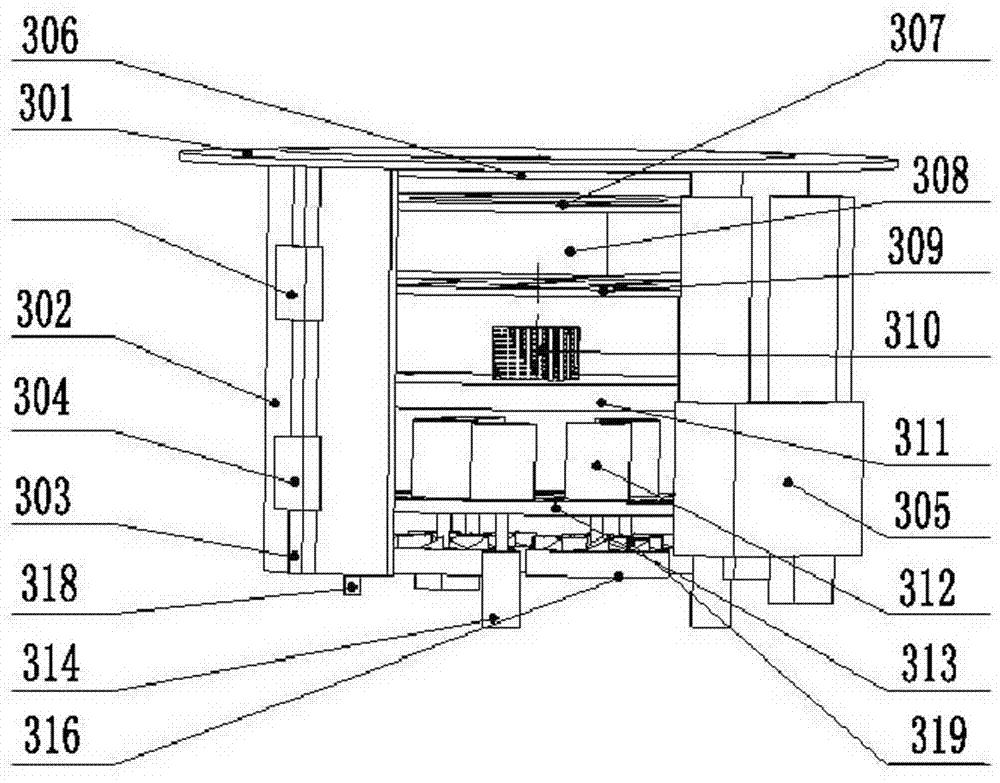

Dust removal mechanism for highly-folded wall surface

ActiveCN106859483AEfficient cleaningFully automaticSuction filtersSuction nozzlesCircular discElectric machinery

The invention relates to a dust removal mechanism for the highly-folded wall surface, and belongs to the technical field of control devices. The dust removal mechanism comprises a baffle, an outer frame and a drilled base plate which are coaxially arranged; the outer frame is arranged in a hollowed mode, the baffle is installed on the top of the outer frame, the drilled base plate is installed at the bottom of the outer frame, the drilled base plat is provided with through holes, a cylindrical side face brush head and a planar disc brush head are installed on the drilled base plate, and the cylindrical side face brush head and the planar disc brush head both penetrate through the through holes formed in the drilled base plate to be connected with a driving motor. The dust removal mechanism can achieve efficient cleaning of complex wall surfaces such as the highly-folded wall surface, when cleaning is conducted, the device is installed on a wall surface carrying device, that is to say, a full-automatic cleaning on the wall can be achieved. Due to the fact that the design adopts the design idea of directly combining the brush heads with a suction device, the recovery rate to the wall surface dust is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com