Dust removal mechanism for highly-folded wall surface

A fold and wall technology, applied in the installation of vacuum cleaners, electrical equipment, suction nozzles, etc., can solve the problems of high difficulty, high height, and large cleaning workload, and achieve the improvement of the scope of application, obvious cleaning efficiency, and improved cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

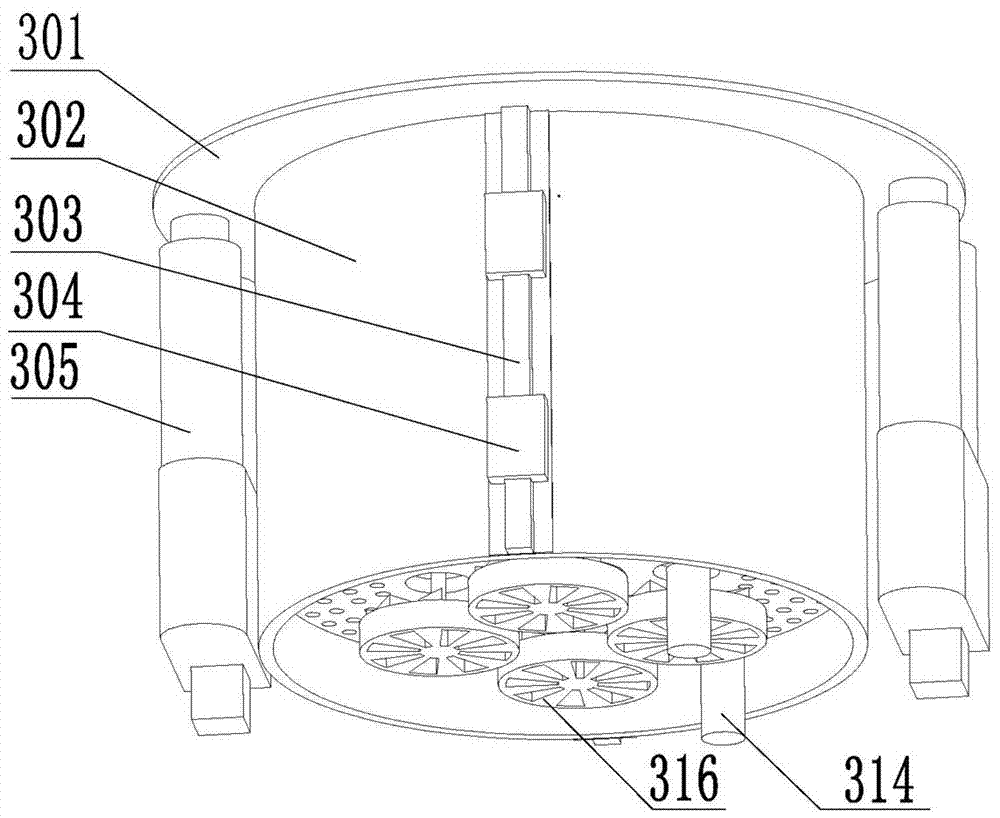

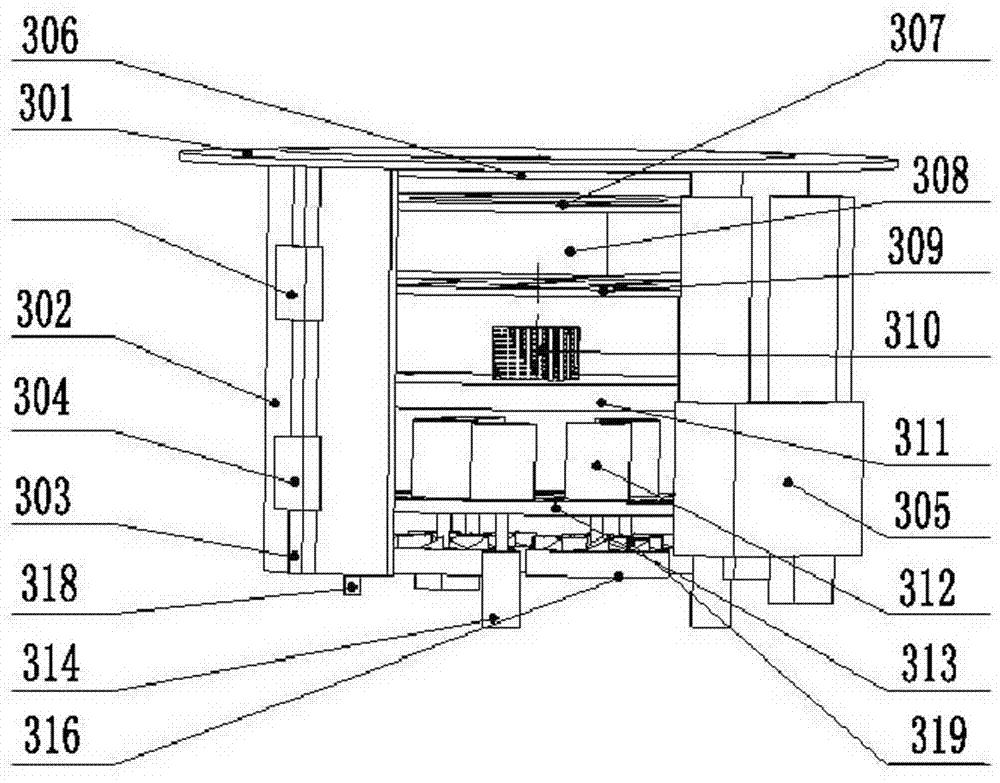

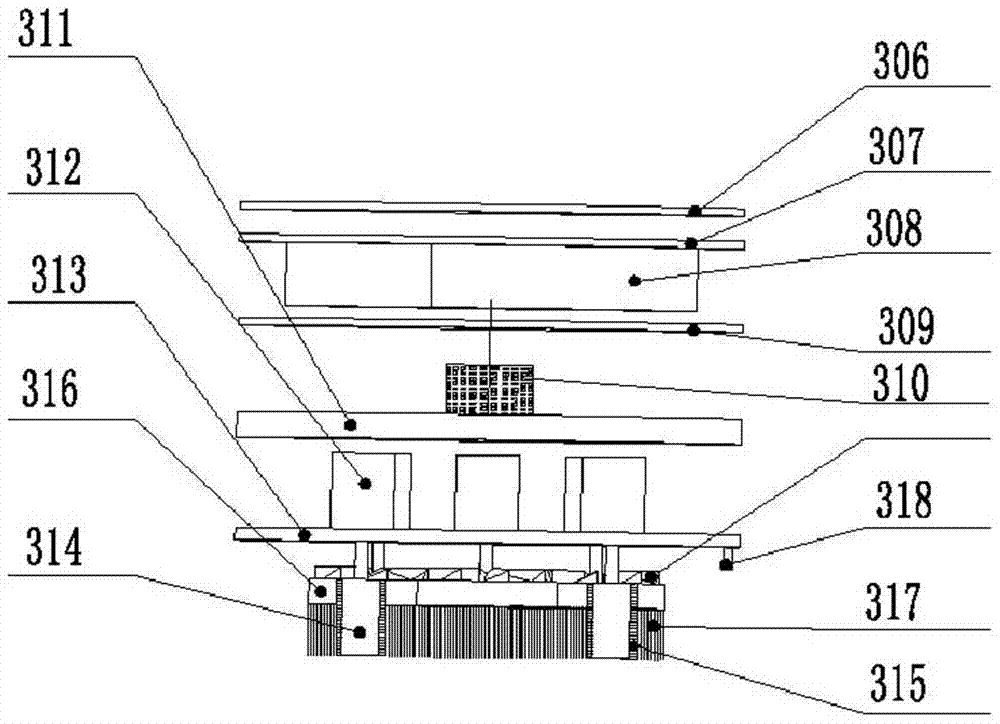

[0024] A dust removal mechanism for highly wrinkled walls, comprising a baffle 301 coaxially arranged, an outer frame 302 and a bottom plate 313 with holes; the outer frame 302 is hollow; the baffle 301 is installed on the top of the outer frame 302; The perforated bottom plate 313 is installed on the bottom of the outer frame 302; the perforated bottom plate 313 is provided with a through hole; the perforated bottom plate 313 is equipped with a cylindrical side brush head 314 and a flat disc brush head 316; Horizontal conical bristles 315 are installed on the side of the side brush head 314 ; vertically spaced flat bristles 317 are installed on the bottom of the planar disc brush head 316 . Both the cylindrical side brush head 314 and the planar disk brush head 316 are connected to the drive motor 312 through the through holes on the bottom plate with holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com