Boosted cleaning mop

A mop and cleaning technology, applied in cleaning equipment, cleaning machinery, vehicle exterior cleaning devices, etc., can solve the problems of mopping effort, loss, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

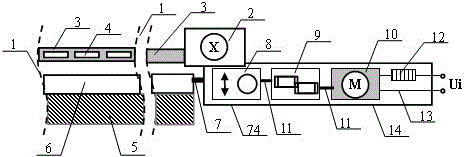

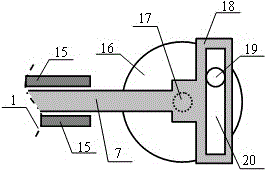

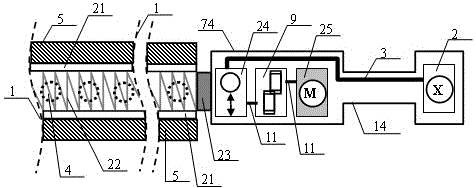

[0055] figure 1 It is a side view partial structural schematic diagram of embodiment 1, figure 2 Yes figure 1 Schematic diagram of the side-view partial detail structure of the "rotational to linear reciprocating motion conversion device" in figure 1 and figure 2 The partial structure schematic diagram of composition embodiment 1. The partial schematic line 1 is intercepted to indicate that it is only a display of local structural features in the figure. The mop whiskers 5 are rooted and supported on the mop whisker planting body 6, and the two are combined to form a brush-like mop head, which is connected to the mop through the telescopic rod 7. The motion conversion device 8 that turns into a straight line and reciprocates is connected to the motor 10 through the gear transmission 9 and the transmission shaft 11, and the input power Ui is connected to the motor 10 through the circuit switch 12 and the wire 13. Vacuum cleaner intake pipe 3 is columnar or flat strip, is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com