Washing apparatus, apparatus for manufacturing plating-filmed web, washing process, and process for manufacturing plating-filmed web

A cleaning method and tablet technology, which are applied to cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as difficulty in cleaning tank sealing, inability to provide cleaning results, and leakage of cleaning liquids. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described based on the drawings. Here, in all the drawings, members having substantially the same function are denoted by the same reference numerals, and repetitive explanations are omitted.

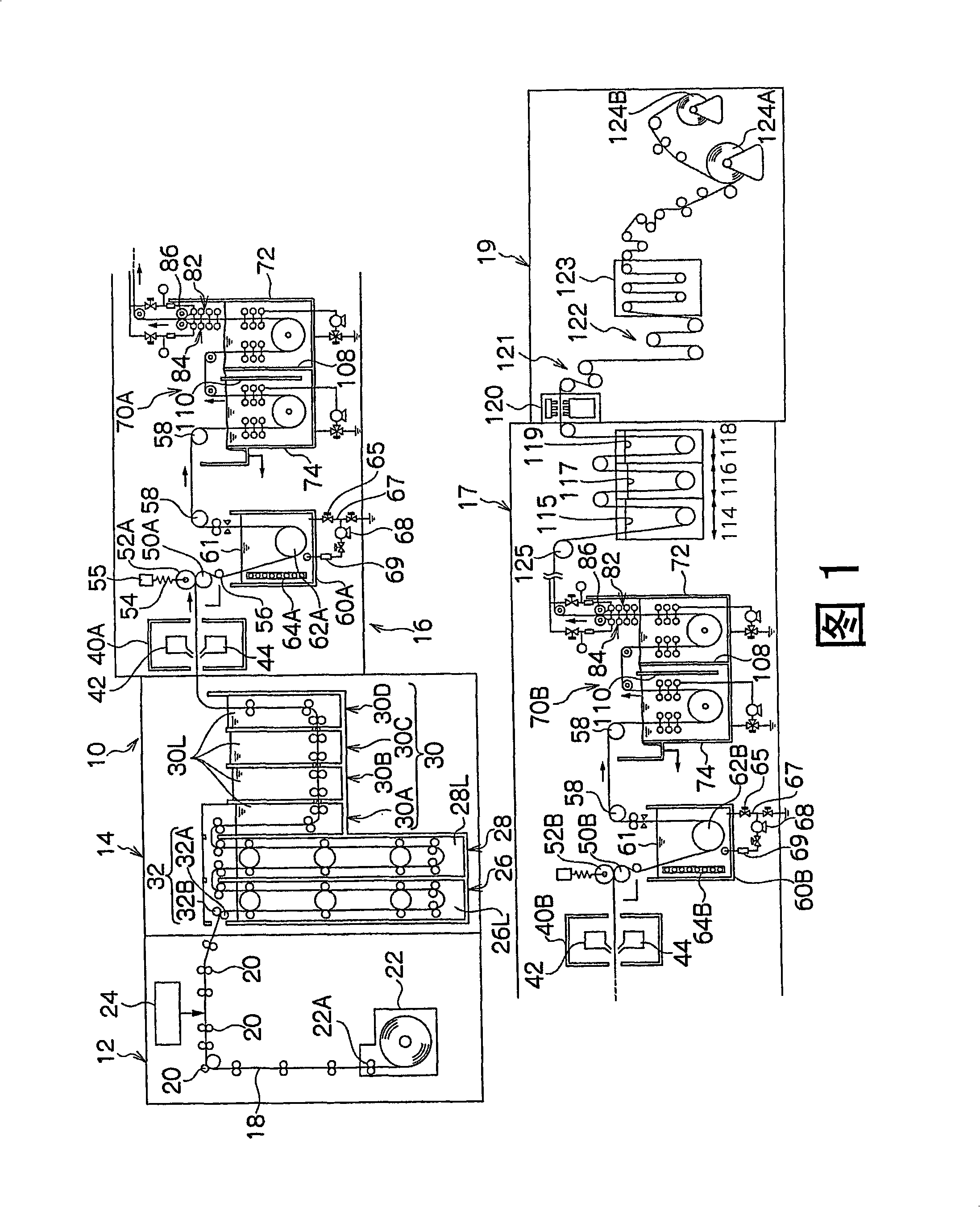

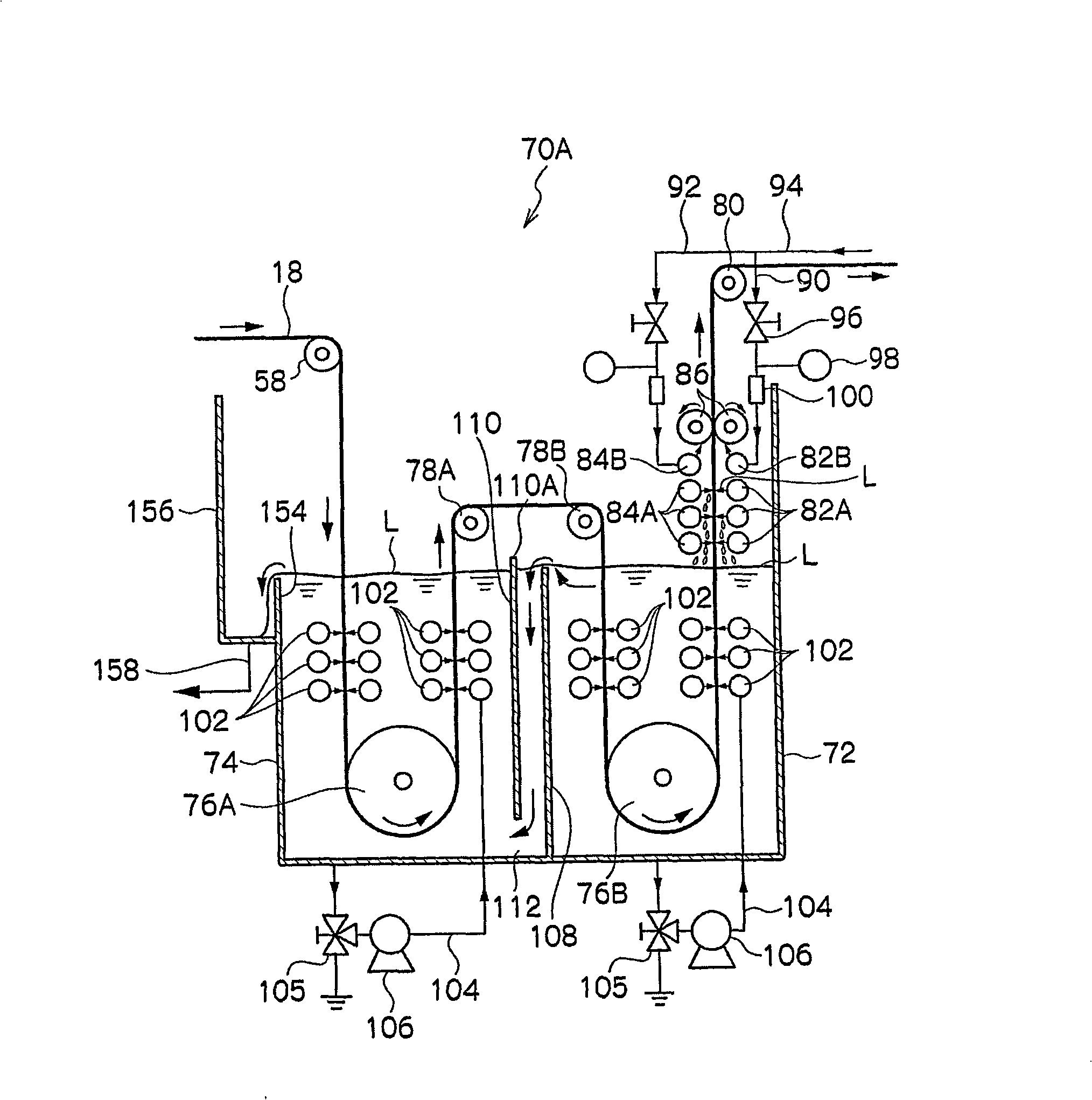

[0027] FIG. 1 is a schematic structural view showing a coating web manufacturing apparatus 10 provided with a cleaning device 70A according to an embodiment of the present invention.

[0028] As shown in FIG. 1 , the coating web manufacturing facility 10 is provided with an exposure device 12 , a developing device 14 , a plating device 16 provided with a cleaning device 70A, a post-processing device 17 , and a winding device 19 .

[0029] First, the exposure device 12 will be explained. The exposure device 12 is a device for achieving desired exposure of a thin line pattern (for example, a lattice pattern, a honeycomb pattern, etc.) while conveying the light-transmitting photosensitive web 18 . The photosensitive web 18 is formed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com