Low-cost coal-fired flue gas various pollutant ultralow emission system and low-cost coal-fired flue gas various pollutant ultralow emission method

A technology for coal-fired flue gas and emission systems, which is applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve the problems of inapplicability, high investment, high cost, and high renovation costs in areas where water resources are scarce, so as to reduce liquid Drop carrying, prevent equipment corrosion, and ensure the effect of uniform water film distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

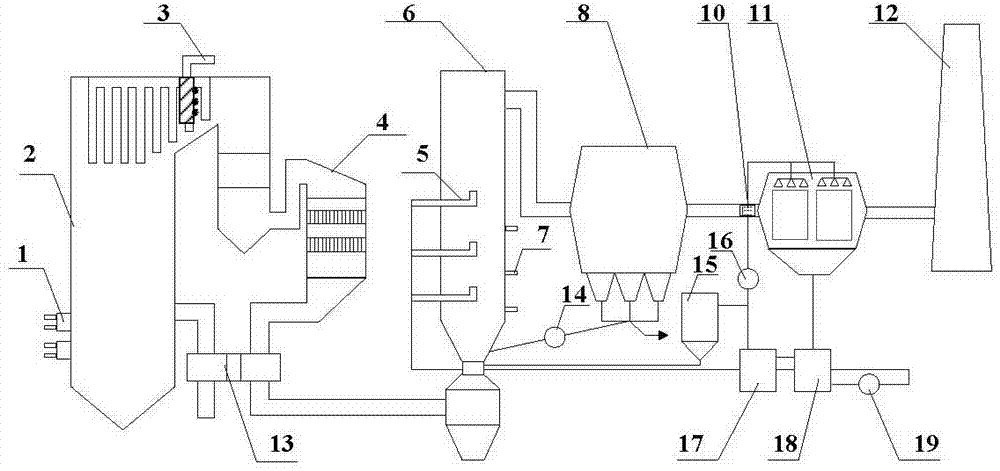

[0047] refer to figure 1 , a low-cost coal-fired flue gas multi-pollutant ultra-low emission system, the emission system includes a nitrogen oxide cascade control system, a semi-dry flue gas purification system and a wet electrostatic deep purification system in series,

[0048] The nitrogen oxide cascade control system includes a sequentially connected low-nitrogen burner 1, a selective non-catalytic reduction denitrification device 3 and a selective catalytic reduction denitrification device 4, and the low-nitrogen burner 1 is arranged in the boiler 2. The non-catalytic reduction denitrification device 3 is arranged on the top of the boiler 2;

[0049] The semi-dry flue gas purification system includes an absorption tower 6, a bag filter 8, a feeding device 14 and a lime digestion device 15, the bag filter 8 is connected to the absorption tower 6 through the feeding device 14, and the lime digestion device 15 communicates with the absorption tower 6; the absorption tower 6 ...

Embodiment 2

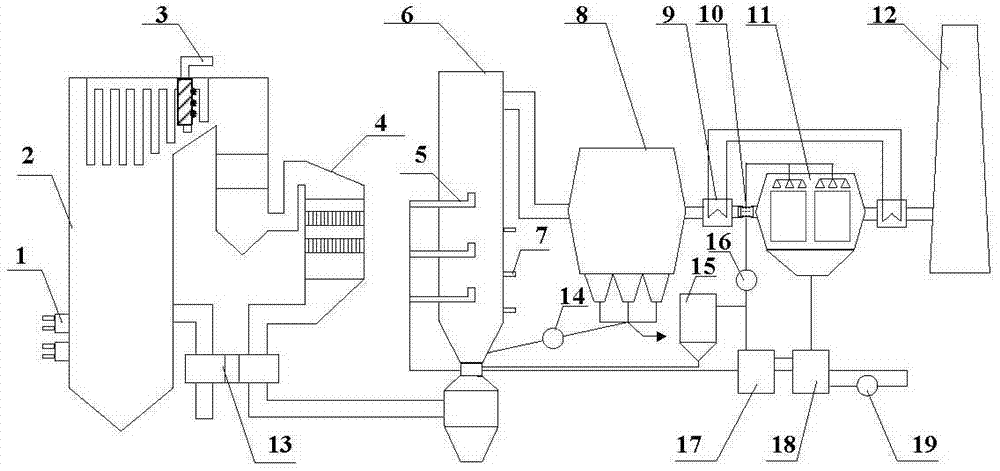

[0054] refer to figure 2 , a low-cost coal-fired flue gas multi-pollutant ultra-low emission system, the emission system includes a nitrogen oxide cascade control system, a semi-dry flue gas purification system and a wet electrostatic deep purification system in series,

[0055] The nitrogen oxide cascade control system includes a sequentially connected low-nitrogen burner 1, a selective non-catalytic reduction denitrification device 3 and a selective catalytic reduction denitrification device 4, and the low-nitrogen burner 1 is arranged in the boiler 2. The non-catalytic reduction denitrification device 3 is arranged on the top of the boiler 2;

[0056] The semi-dry flue gas purification system includes an absorption tower 6, a bag filter 8, a feeding device 14 and a lime digestion device 15, the bag filter 8 is connected to the absorption tower 6 through the feeding device 14, and the lime digestion device 15 communicates with the absorption tower 6; the absorption tower 6...

Embodiment 3

[0061] refer to figure 1 , a method for ultra-low emission of various pollutants in low-cost coal-fired flue gas, comprising the following steps:

[0062] (1) Air and pulverized coal enter the low-nitrogen burner 1 for preliminary control of the concentration of nitrogen oxides. After the treatment by the low-nitrogen burner 1, the concentration of nitrogen oxides in the flue gas at the furnace outlet is lower than 200mg / m 3 Then enter the selective non-catalytic reduction denitrification device 3 to reduce the concentration of nitrogen oxides successively. The selective non-catalytic reduction denitrification device 3 injects a reducing agent into the area where the furnace temperature is 850-1100 ° C, and the nitrogen oxides in the flue gas N 2 and water, and the excess ammonia participates in the denitrification reaction of the selective catalytic reduction denitrification device 4; Reduced to 50mg / m 3 the following;

[0063] (2) The flue gas after passing through the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com