Patents

Literature

73results about How to "Ensure even distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

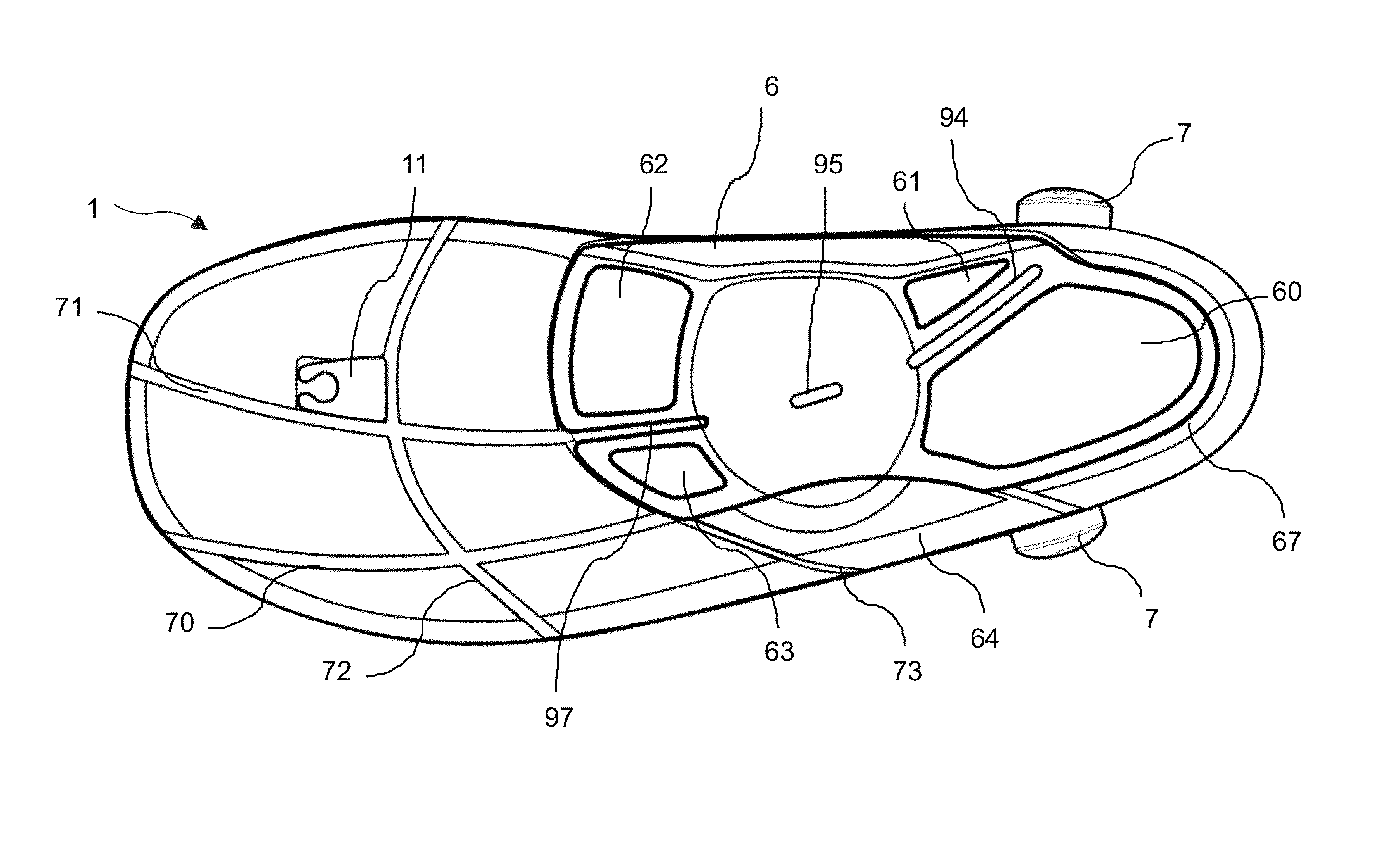

Footwear sole construction

InactiveUS20070295451A1Less waiting timeEnsure even distributionSolesUpperAdhesiveThermoplastic polyurethane

A footwear adhesion system including a thermoplastic film, a sole component, and a footwear component. In one embodiment, the thermoplastic film is a thermoplastic polyurethane (“TPU”) film. The film is sandwiched between the sole component and the footwear component. The film may be activated, for example, by high frequency welding, to form a bond between the sole component and the footwear component without releasing the amount of volatile organic compound emissions typical with conventional adhesives. Use of the film reduces or eliminates the need for conventional environmentally unfriendly cement in footwear construction.

Owner:WOLVERINE WORLD WIDE

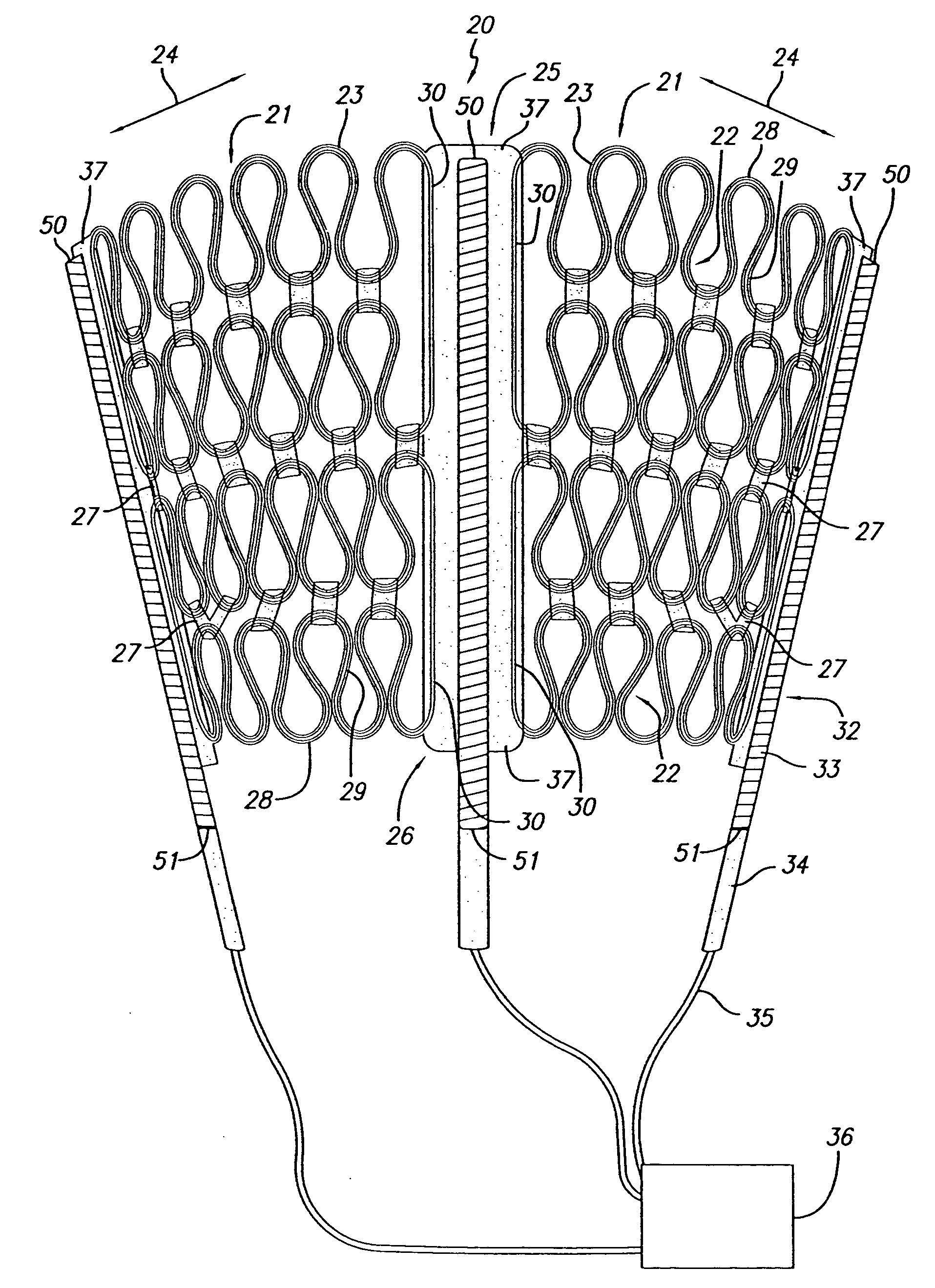

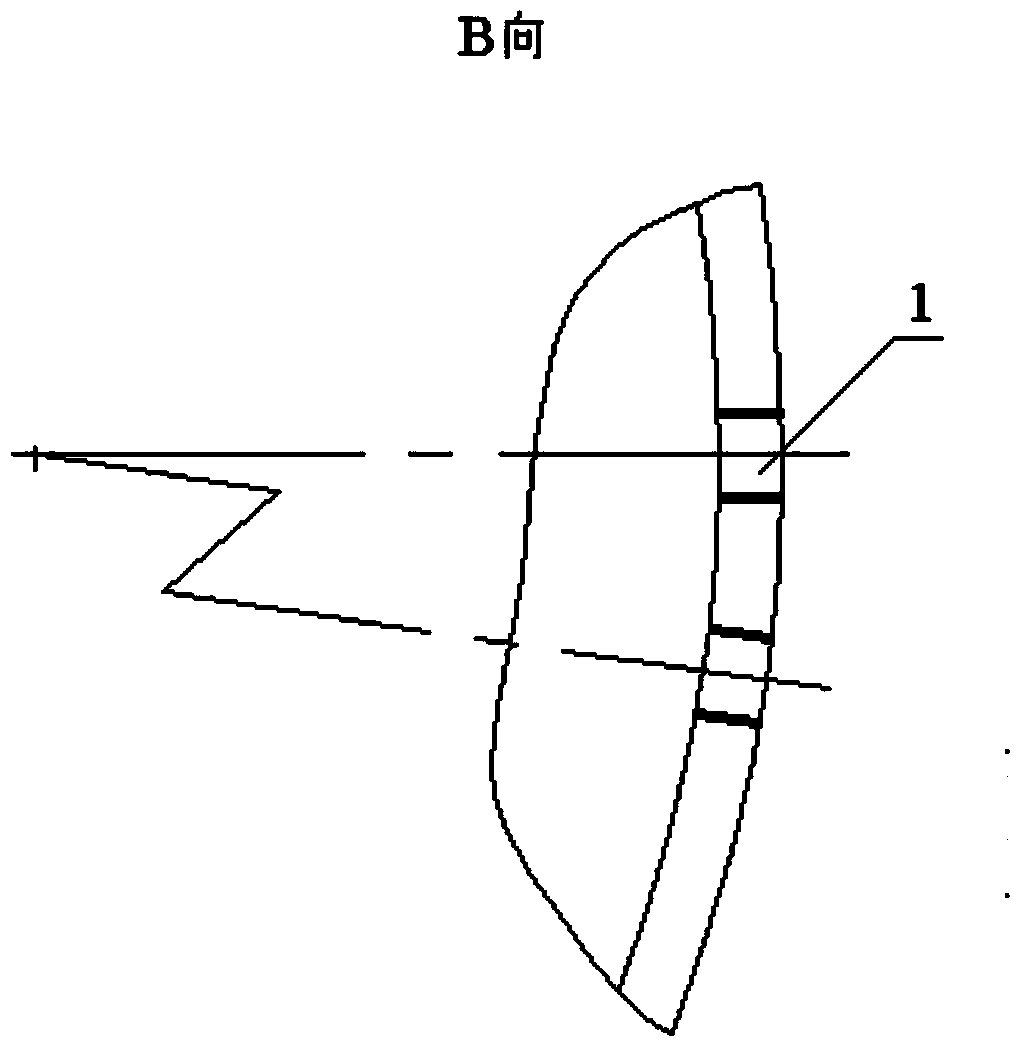

Device for heating an aerofoil

InactiveUS6031214AImprove the immunityLimit heating deficitHeater elementsDe-icing equipmentsFiberLeading edge

The heating device comprises electrically conducting longitudinal fibers extending substantially parallel to a leading edge of the aerofoil close to said leading edge, and means for electrically connecting the ends of the longitudinal conducting fibers to an electric power supply. The conducting fibers are grouped together in conducting rovings forming part of a hybrid fabric which furthermore includes a weft of electrically insulating fibers woven together and woven with the conducting rovings.

Owner:EUROCOPTER

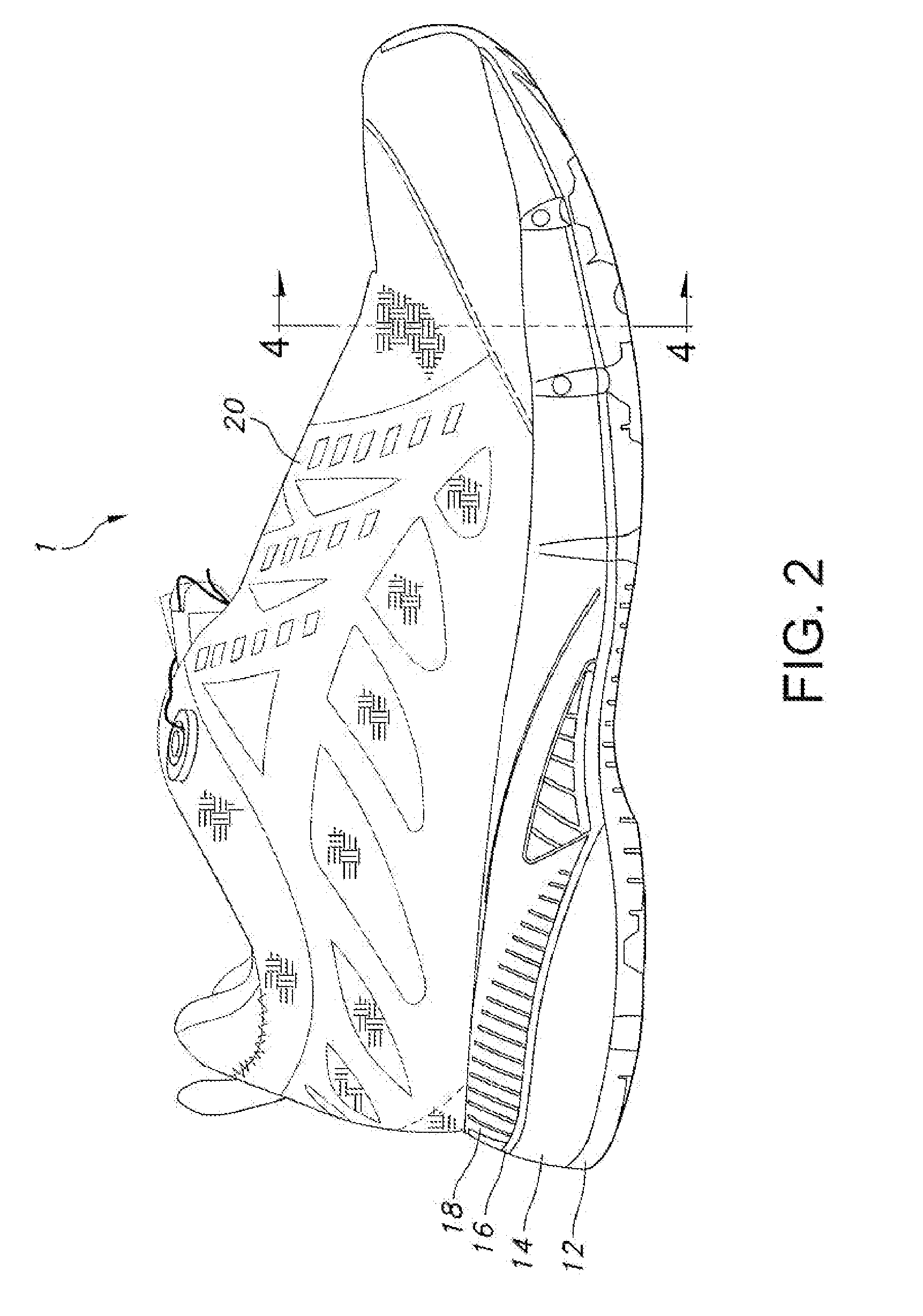

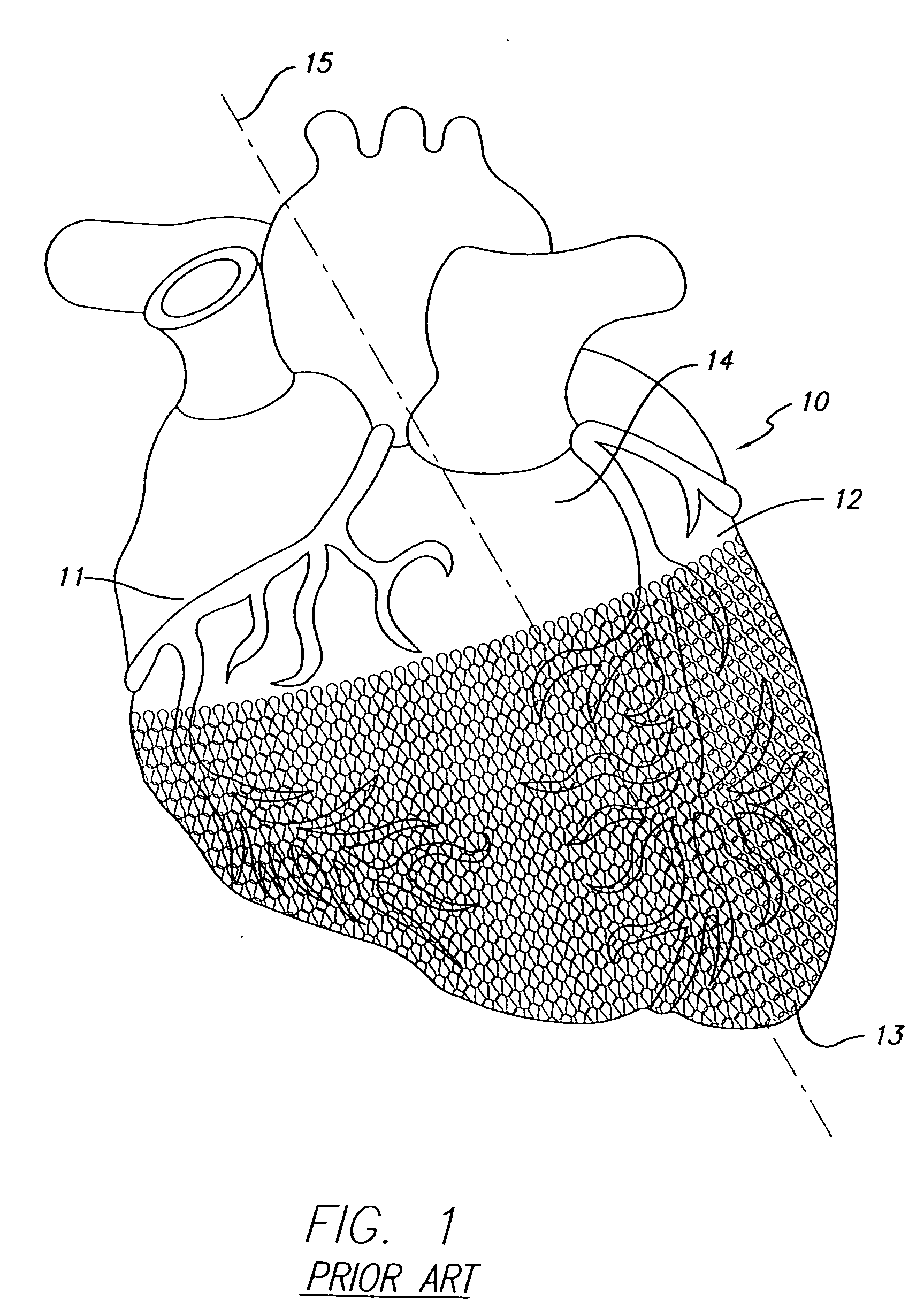

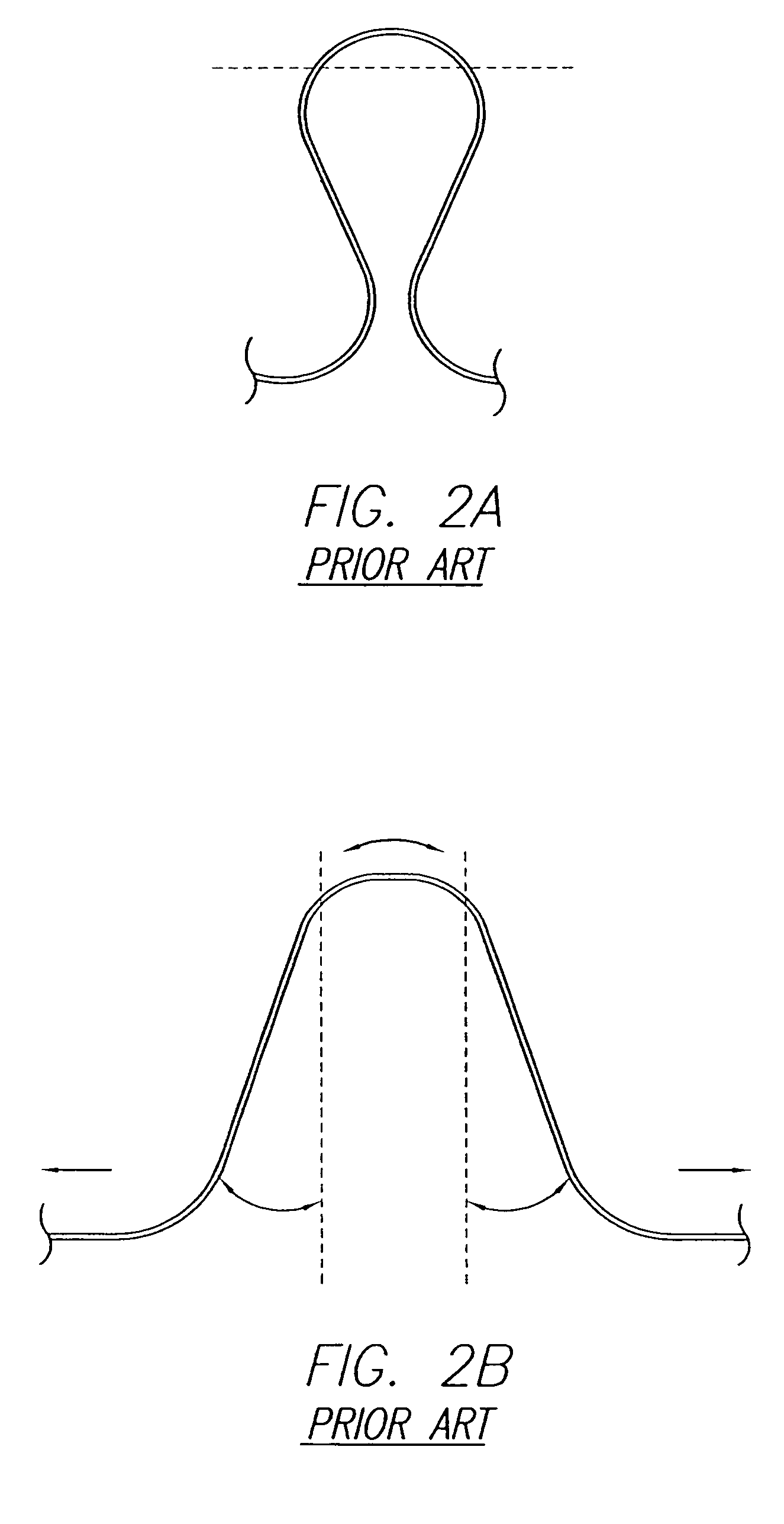

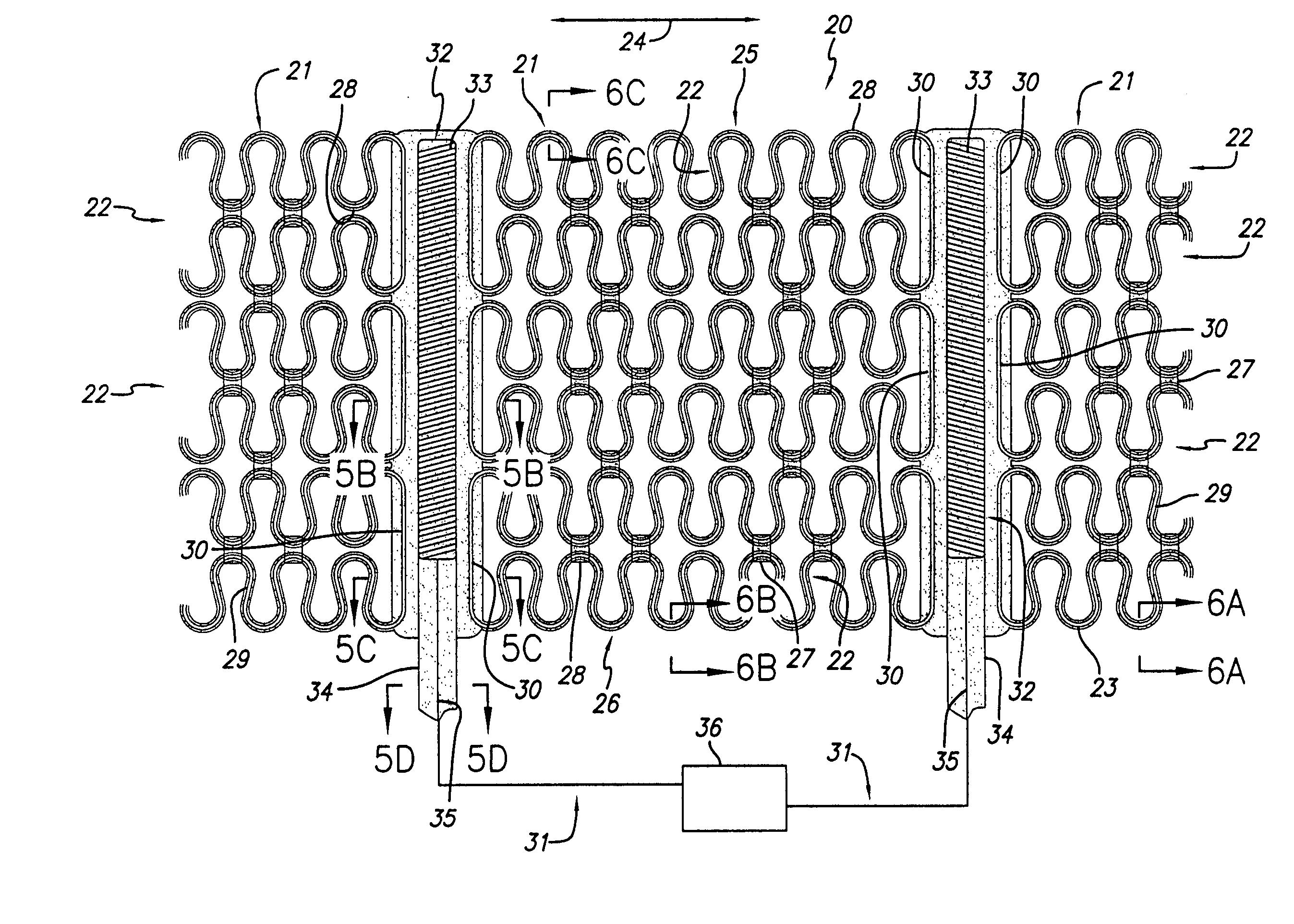

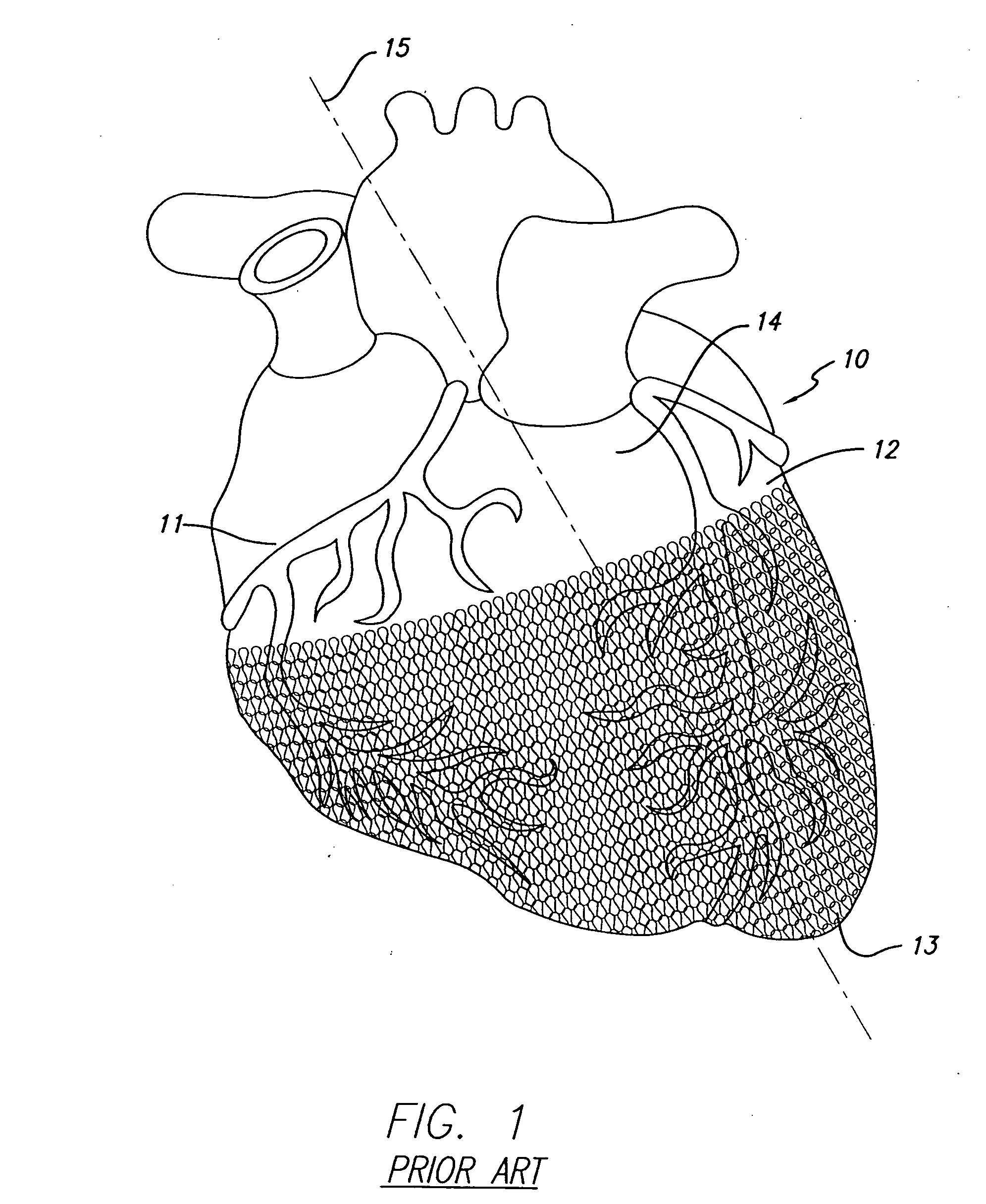

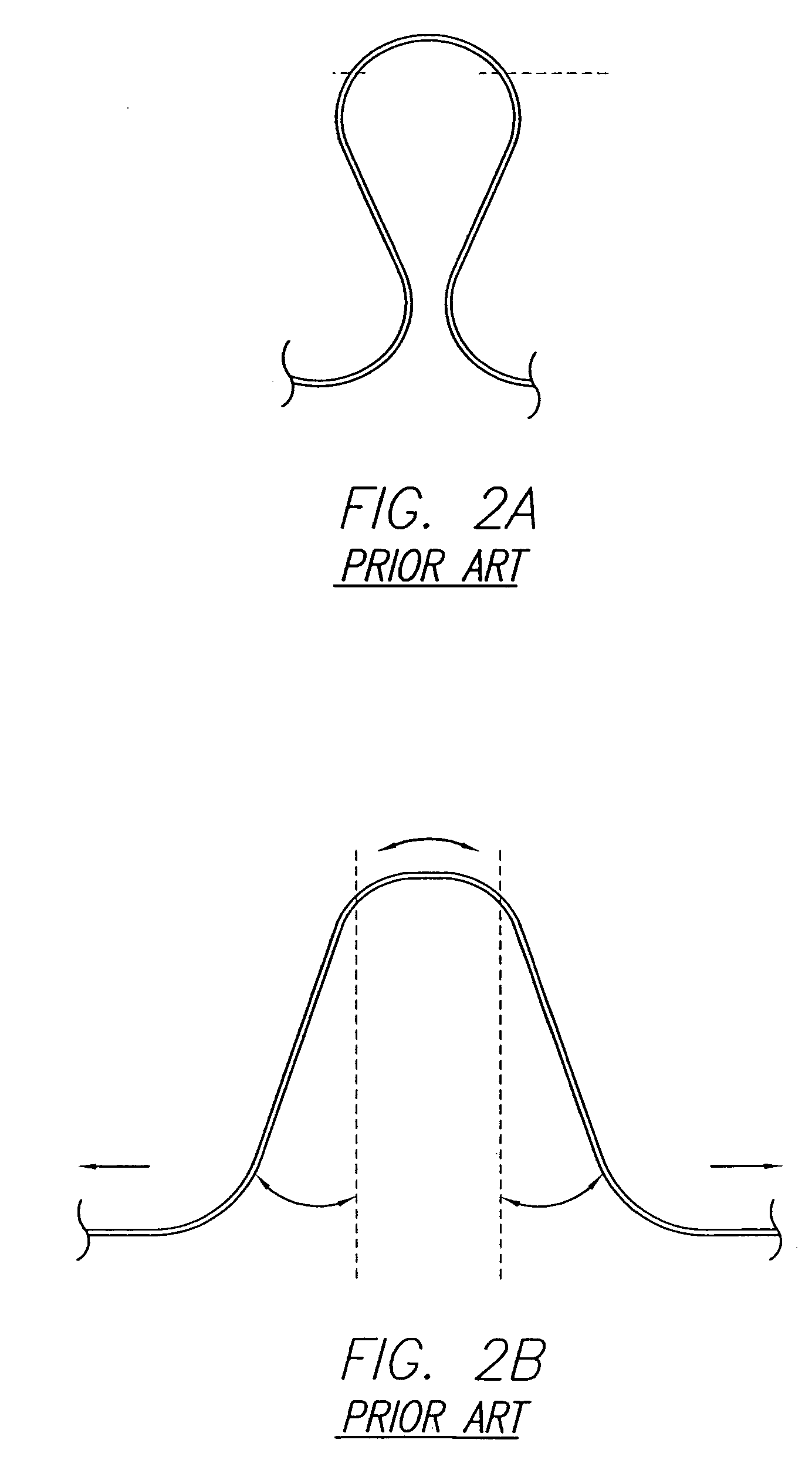

Cardiac harness assembly for treating congestive heart failure and for pacing/sensing

InactiveUS20070106359A1Low profileResists side-to-side movementElectrocardiographyEpicardial electrodesMinimally invasive proceduresCongestive heart failure chf

A pace / sense electrode is associated with a cardiac harness for treating the heart. The pace / sense electrode is positioned on the epicardial surface of the heart, preferably under the cardiac harness, to provide pacing and sensing therapy to the heart. Compressive forces from the cardiac harness serve to hold the pace / sense electrode in place and to push the electrode into direct contact with the epicardial surface of the heart. Various means are provided for placing the pace / sense electrode under the cardiac harness in a minimally invasive procedure.

Owner:PARACOR MEDICAL

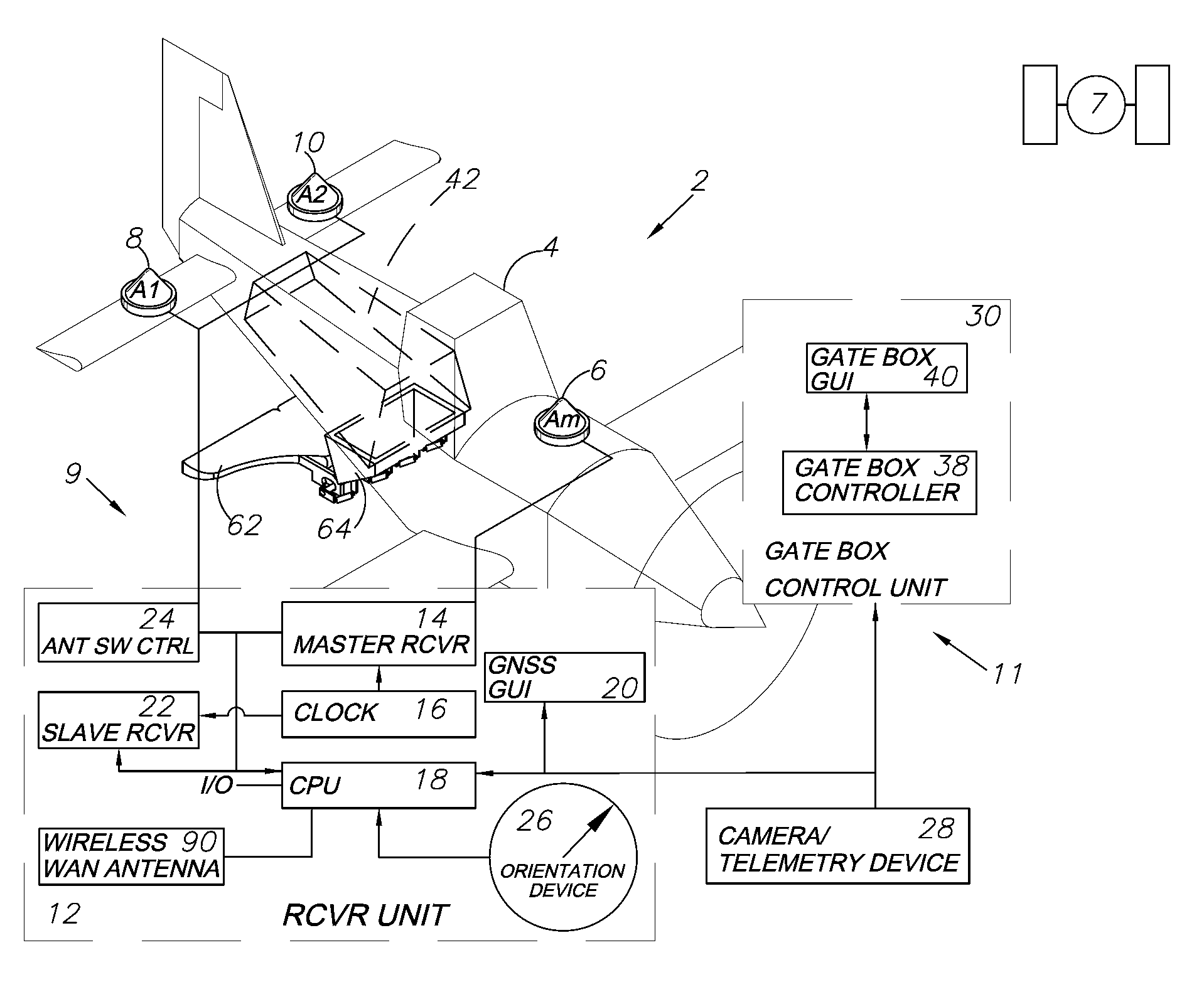

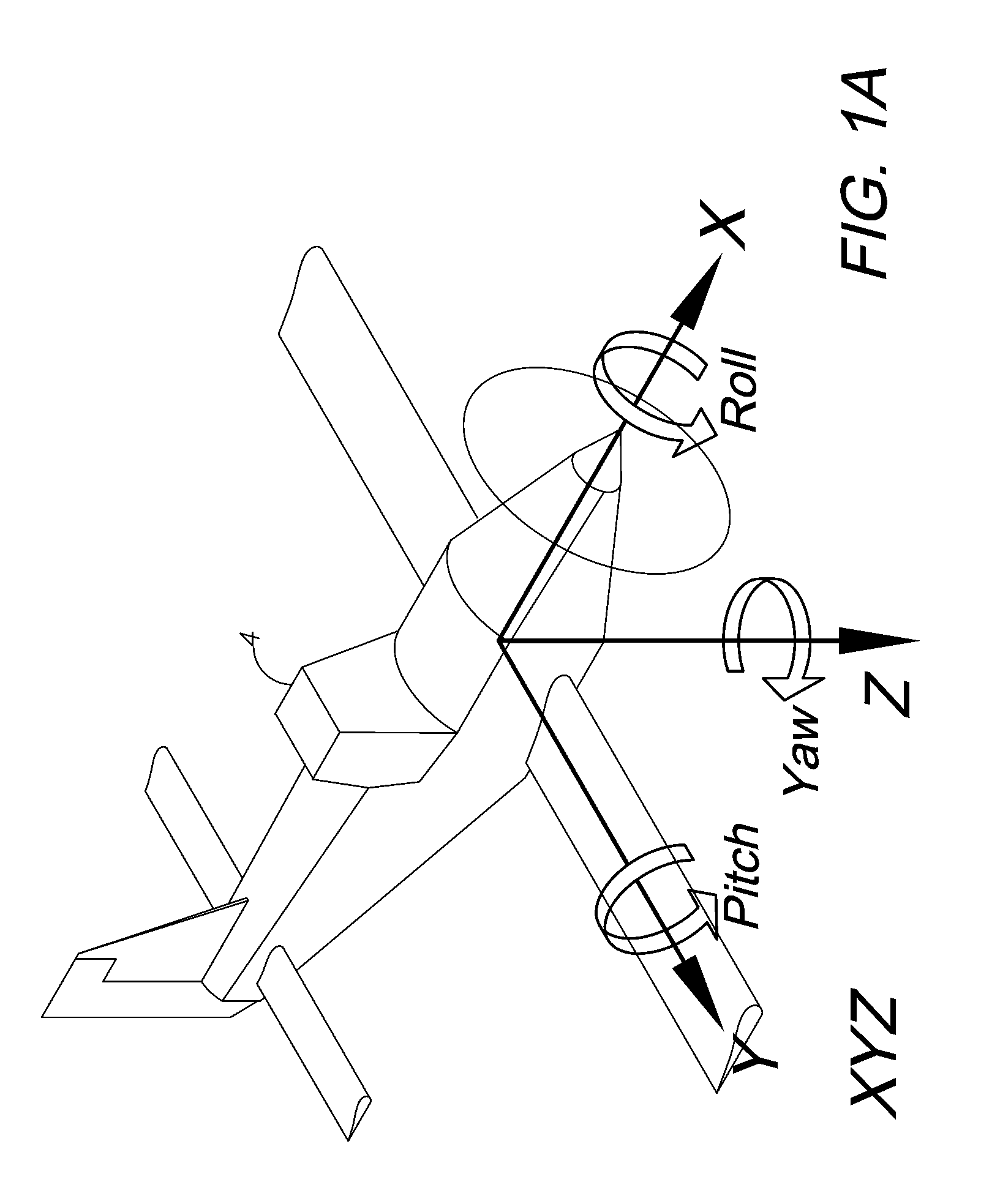

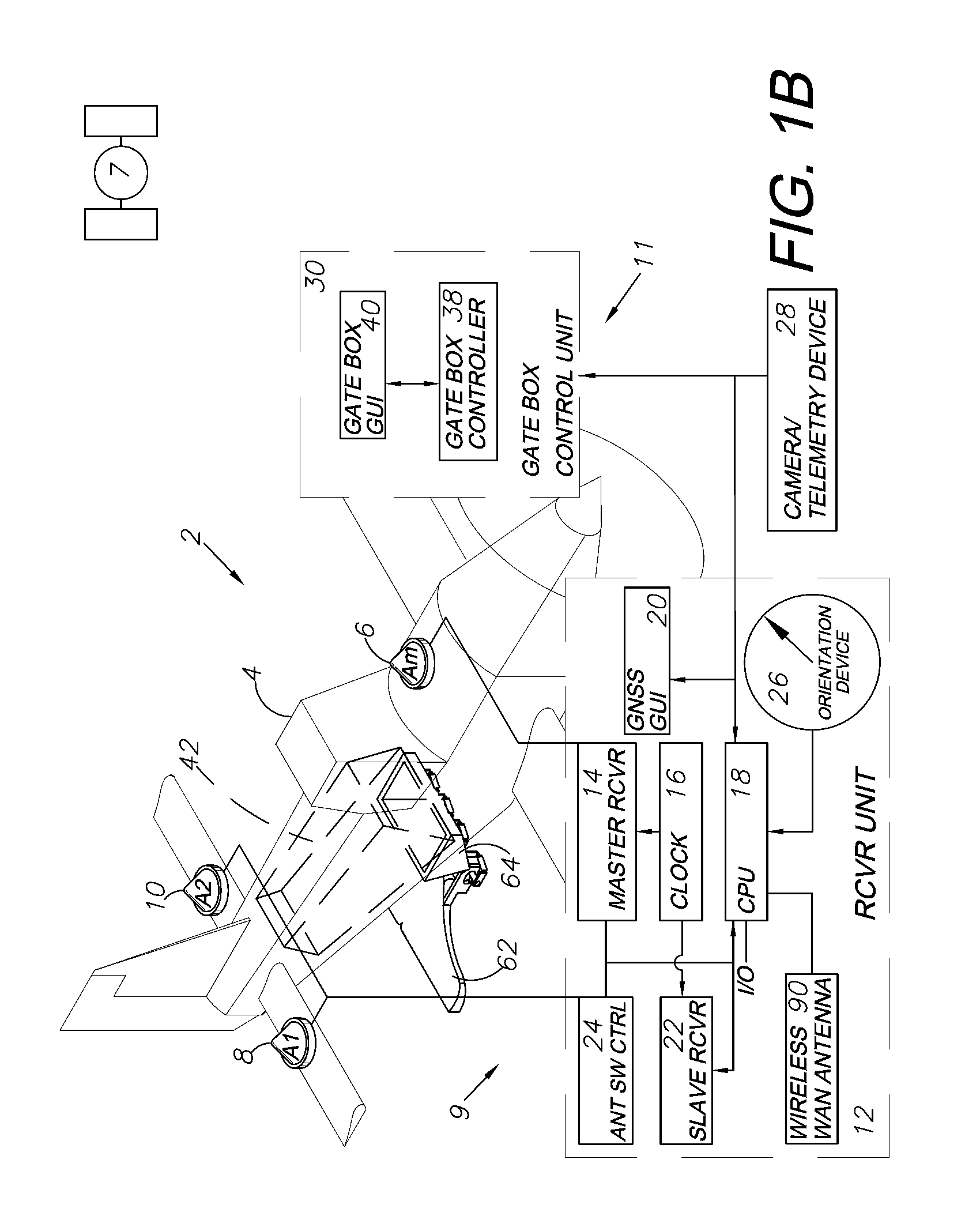

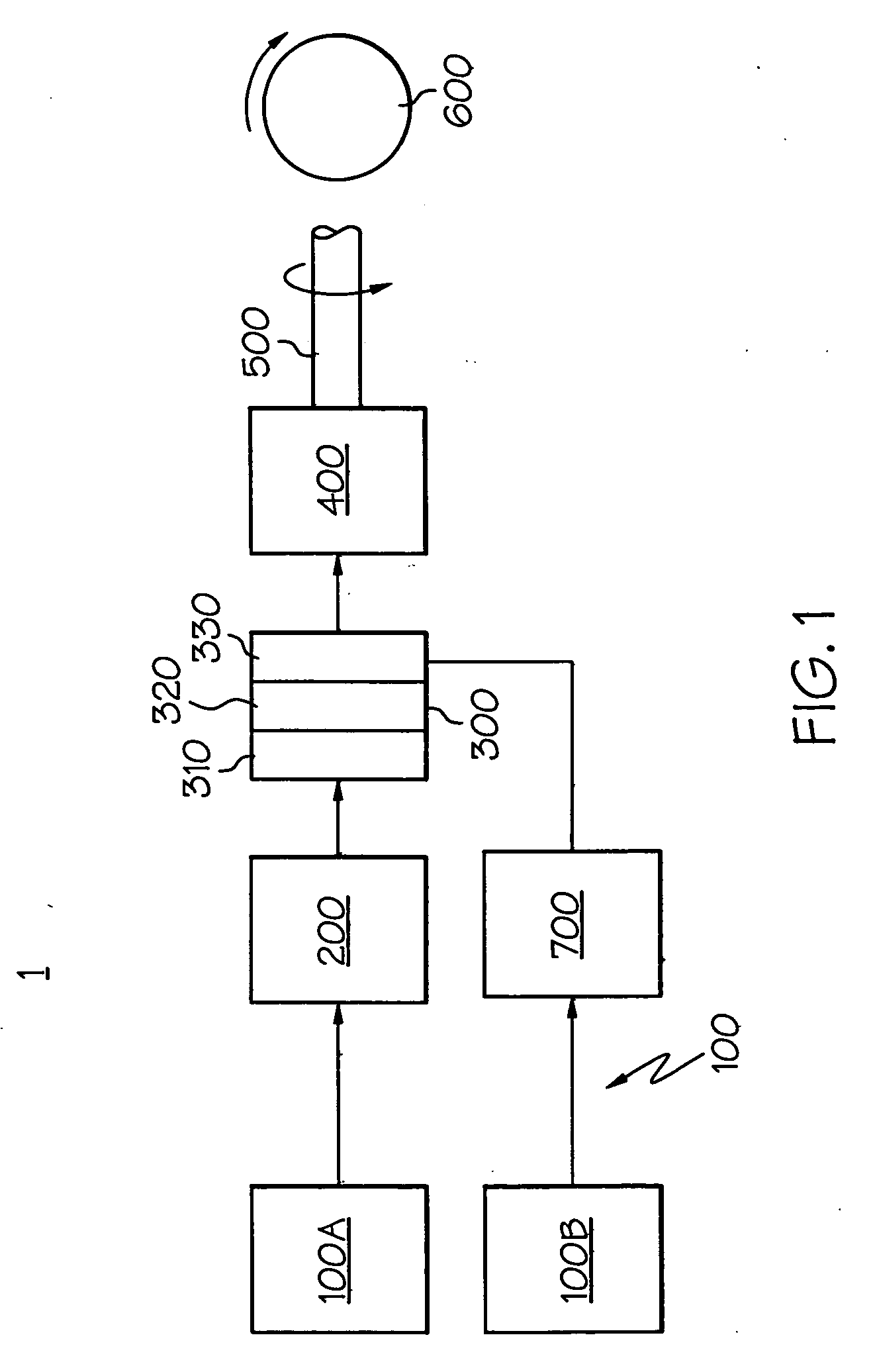

GNSS optimized aircraft control system and method

ActiveUS20110264307A1Ensure even distributionAircraft componentsDigital data processing detailsGraphicsDriver/operator

A GNSS system in combination with a hydraulically-actuated, airborne dispenser for a dry material crop dusting system to optimize the distribution of dry materials over a particular tract of land. A GNSS subsystem is included using at least one GNSS antenna and one GNSS receiver located on the aircraft. The aircraft is equipped with an electronic / hydraulic crop dusting subsystem connected to a GNSS CPU. The GNSS ranging signals received by the antennas are processed by a receiver and processor system for determining the vehicle's position and dynamic attitude in three dimensions (3D). A graphical user interface (GUI) placed in the vehicle will give the driver a real-time view of his or her current bearing as well as a calculated “optimal path” based on calculations and variable data, such as wind speed and direction, material moisture content, altitude, air speed and other conditions. The system is adapted for operation in a differential GNSS (DGNSS) mode utilizing a base station at a fixed location.

Owner:EFC SYST

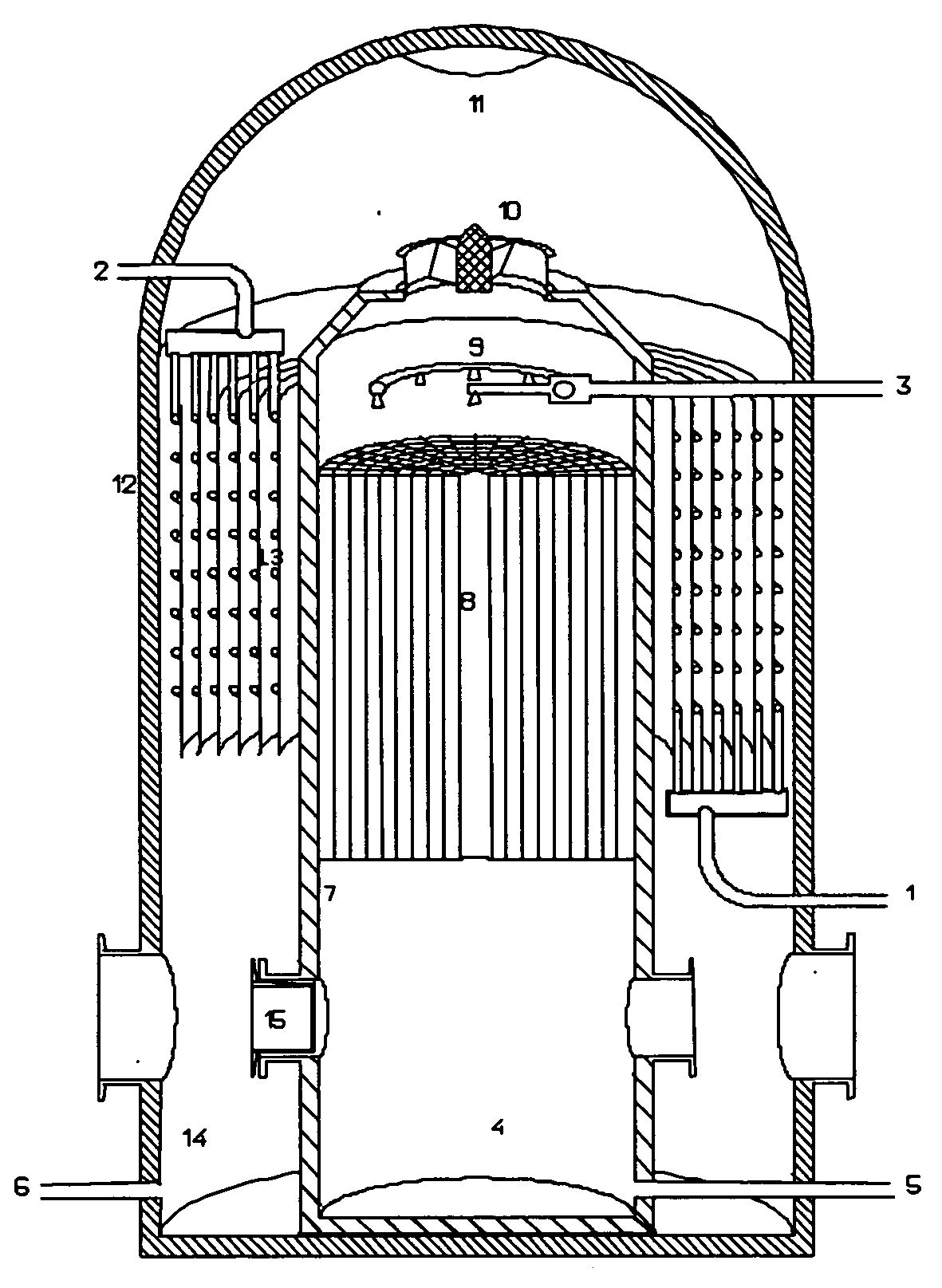

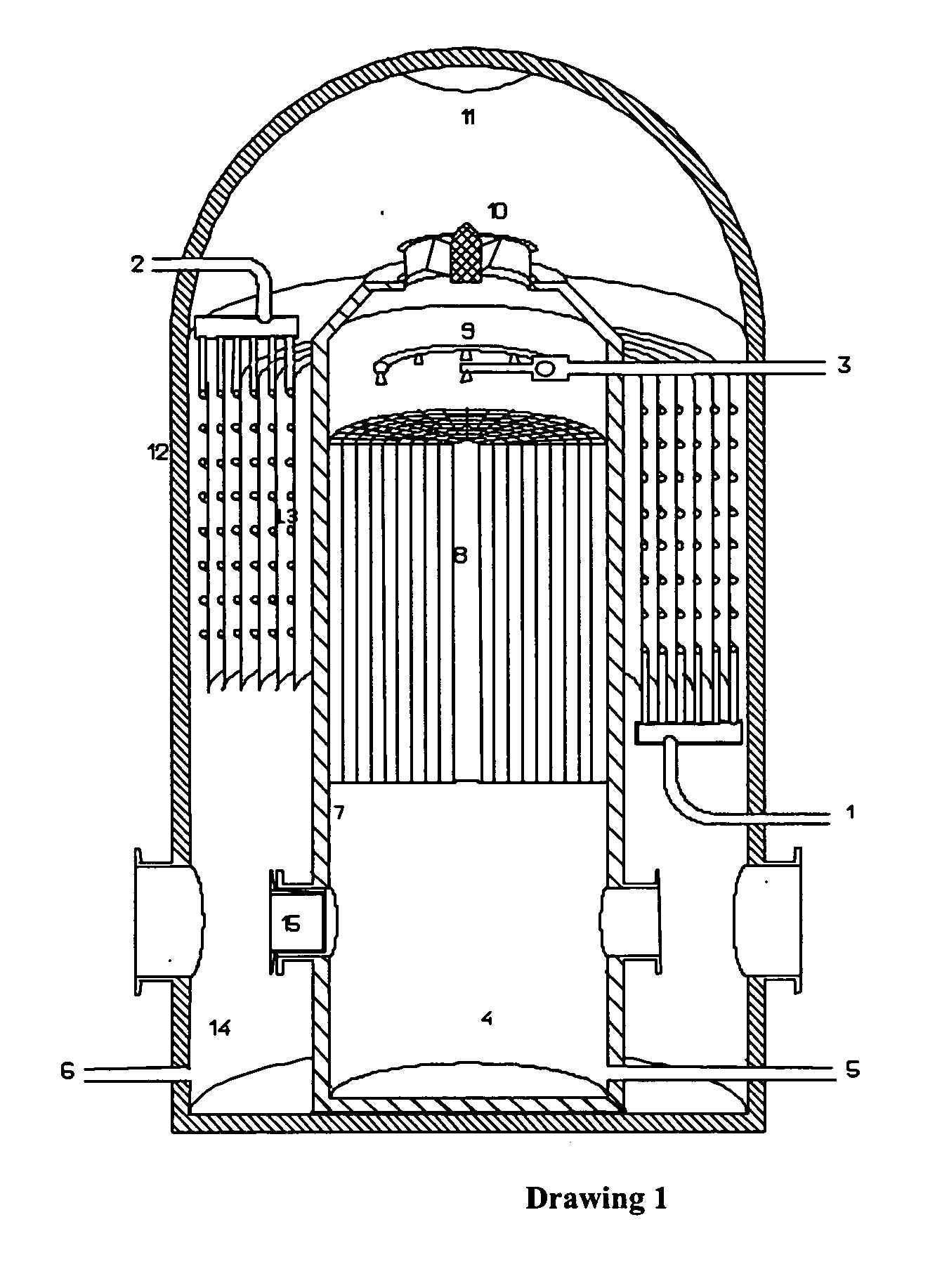

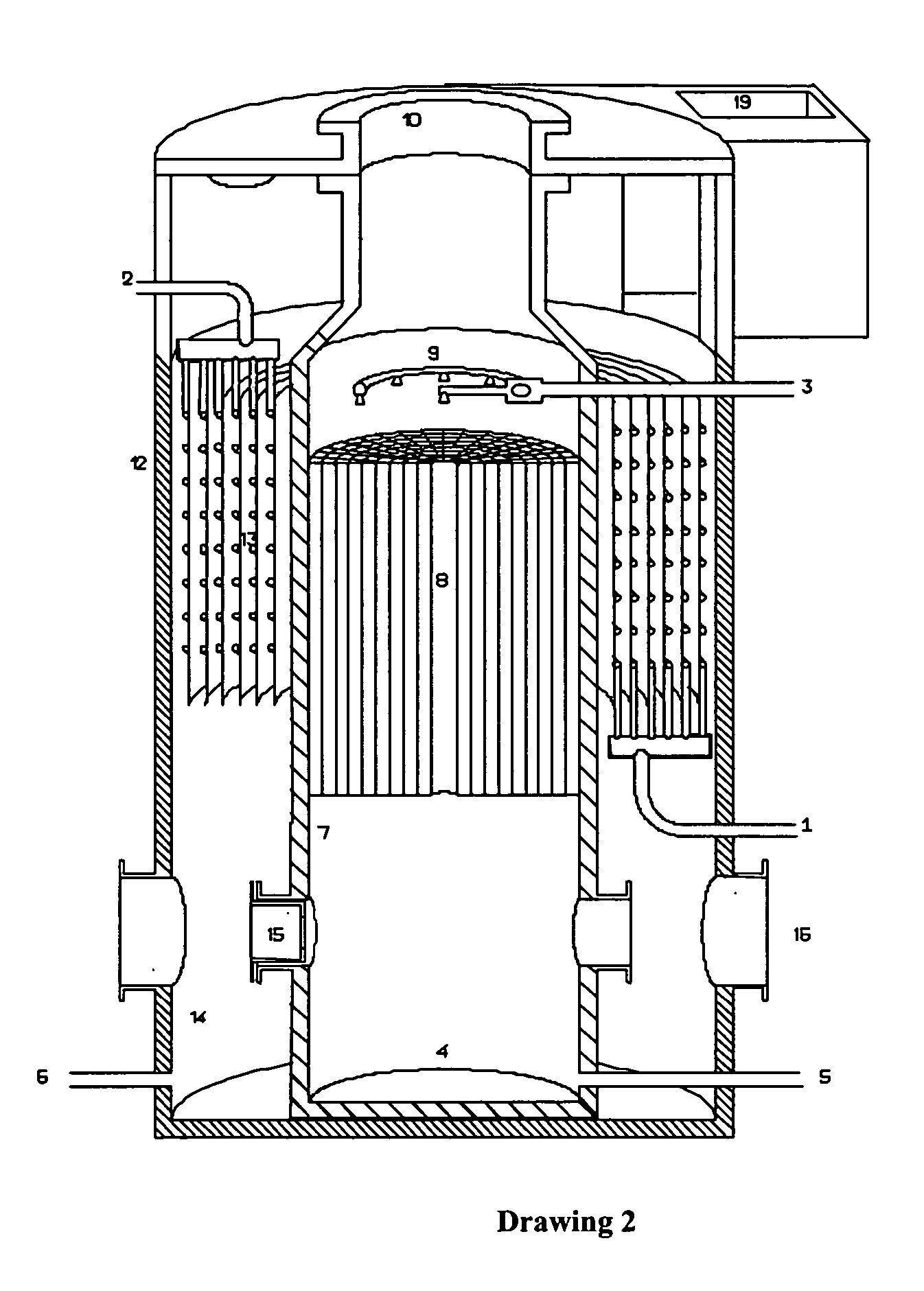

Installation used to obtain salt-free sea water at a low temperature with continuous operation and enthalpy recovery

InactiveUS20050011743A1Low costReduce energy consumptionGeneral water supply conservationAuxillariesWater desalinationThermal insulation

The invention relates to a sea water desalination installation that employs an evaporation-condensation system which operates continuously at a low temperature and which enables the recovery of energy released. The inventive installation comprises a cylindrical evaporator having a large evaporation surface and a concentric condenser with a large surface area. Sea water is used to cool the condenser and said water is subsequently sent to the evaporator. A static high-pressure ventilator is used to: (i) drive the vapour / air in a closed circuit between the evaporator and the condenser and (ii), using a calibrated nozzle, create a pressure gradient that is equivalent to the pressure of the saturated vapour at working temperature between said two zones. The aforementioned evaporator and condenser are thermally insulated in relation to one another and to the external environment.

Owner:HERNANDEZ HERNANDEZ MARIA FERNANDO +1

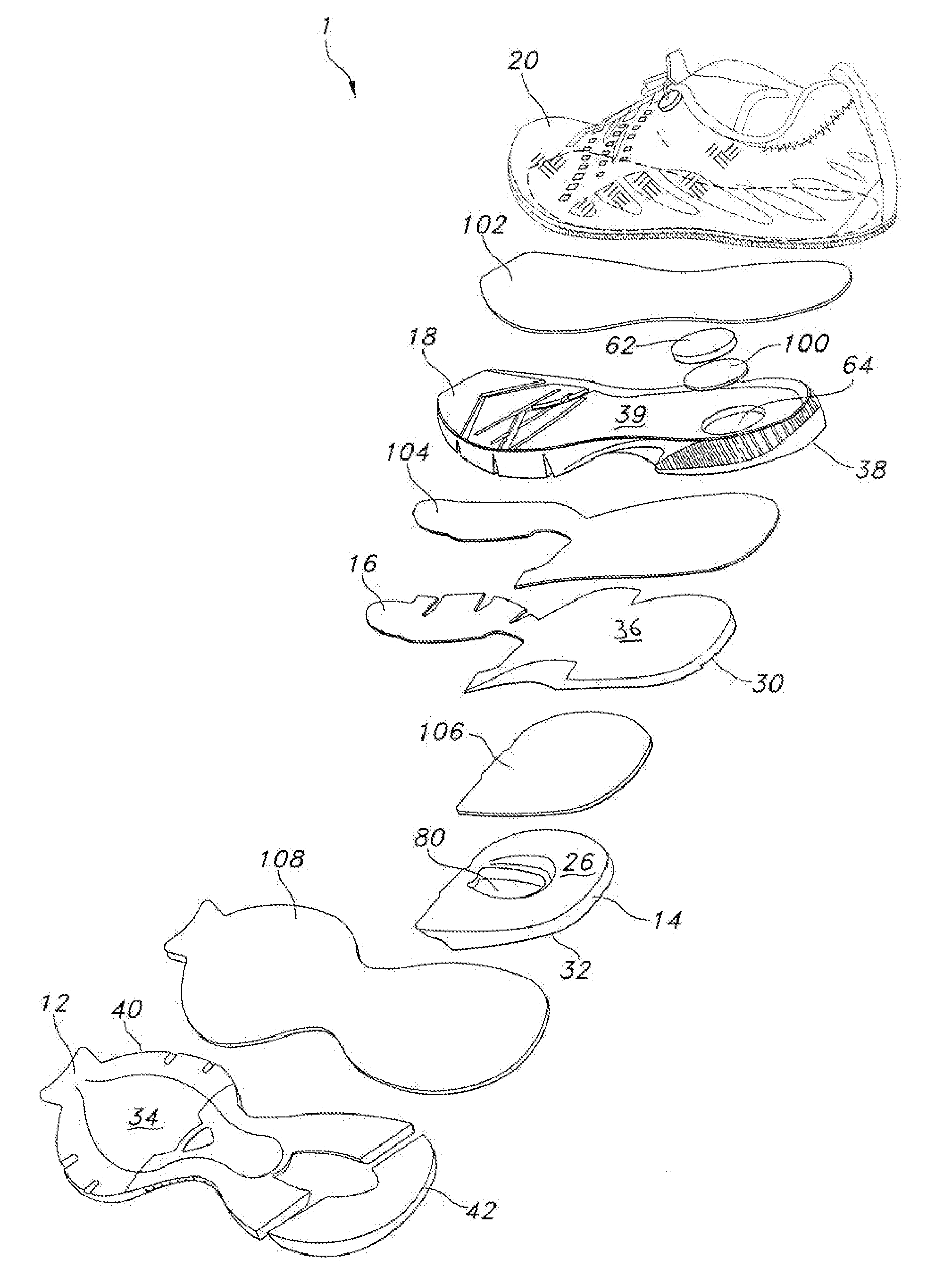

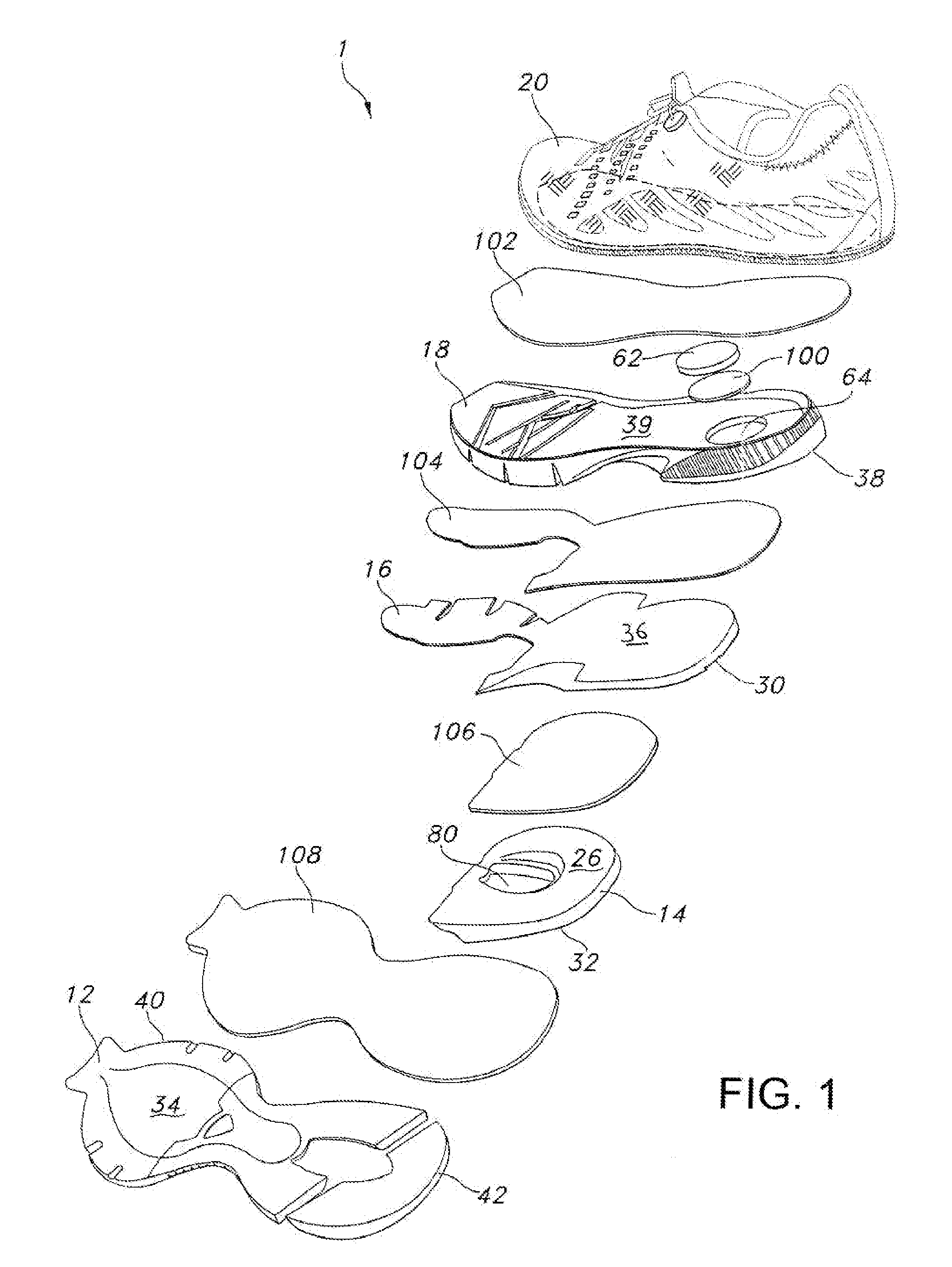

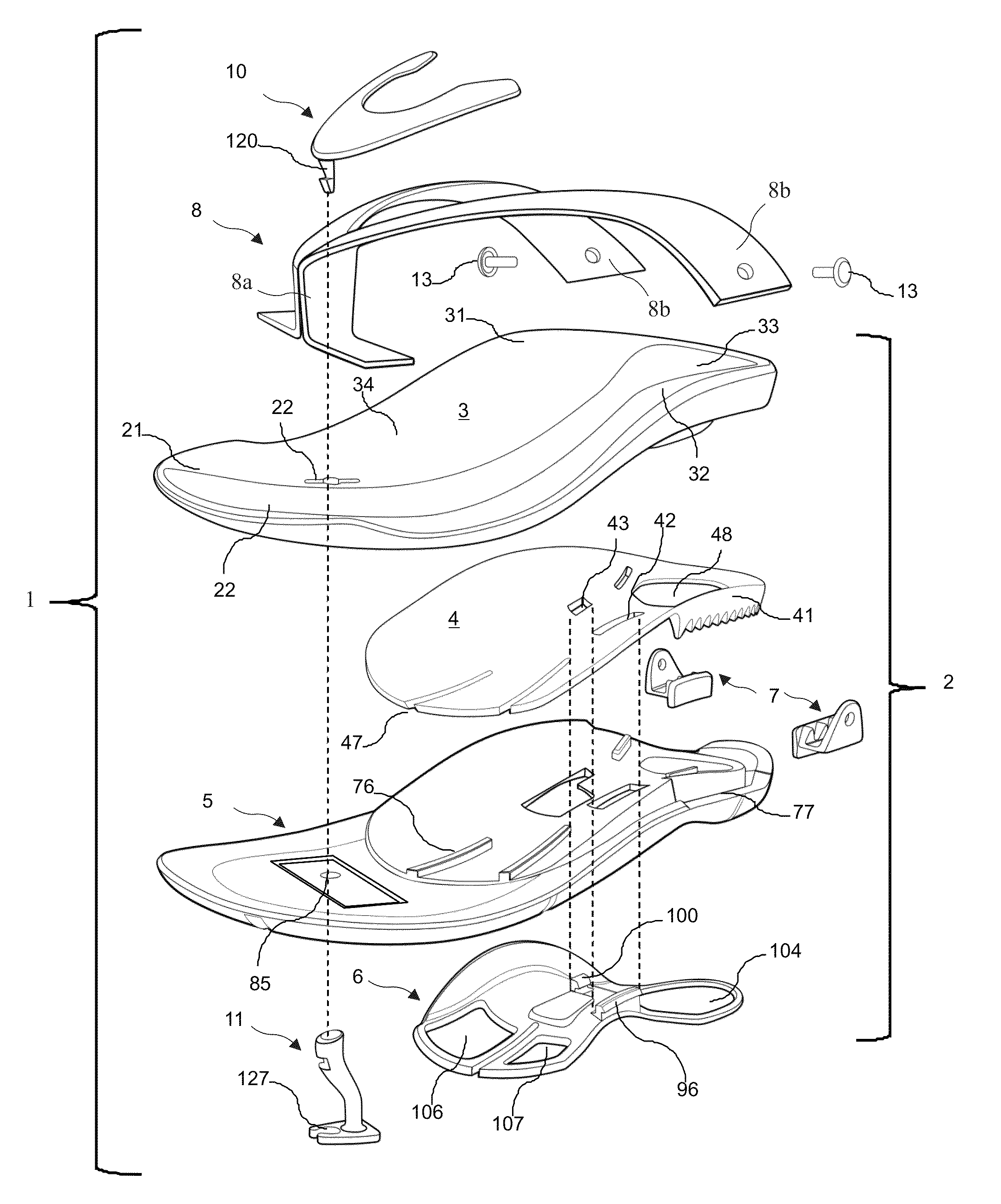

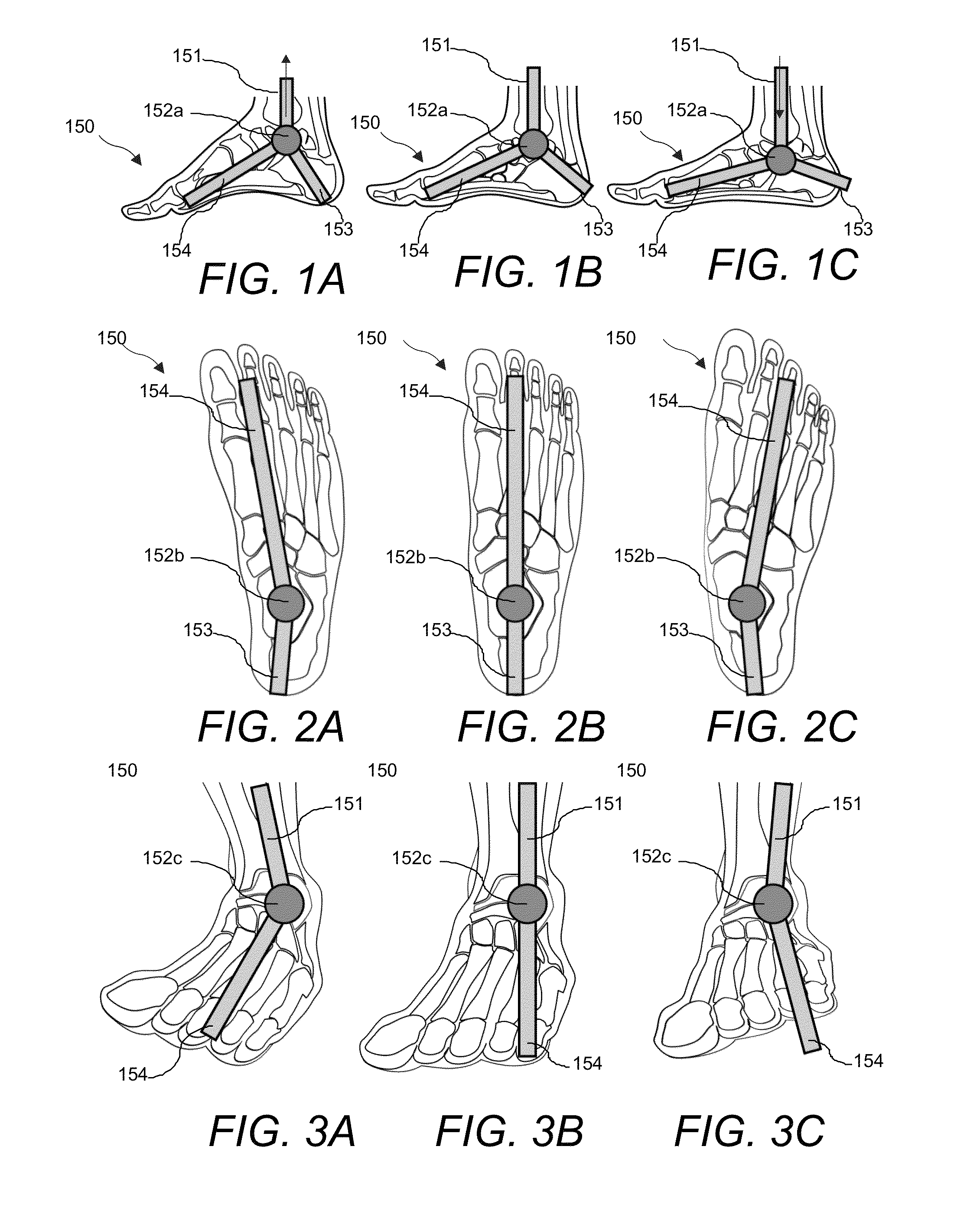

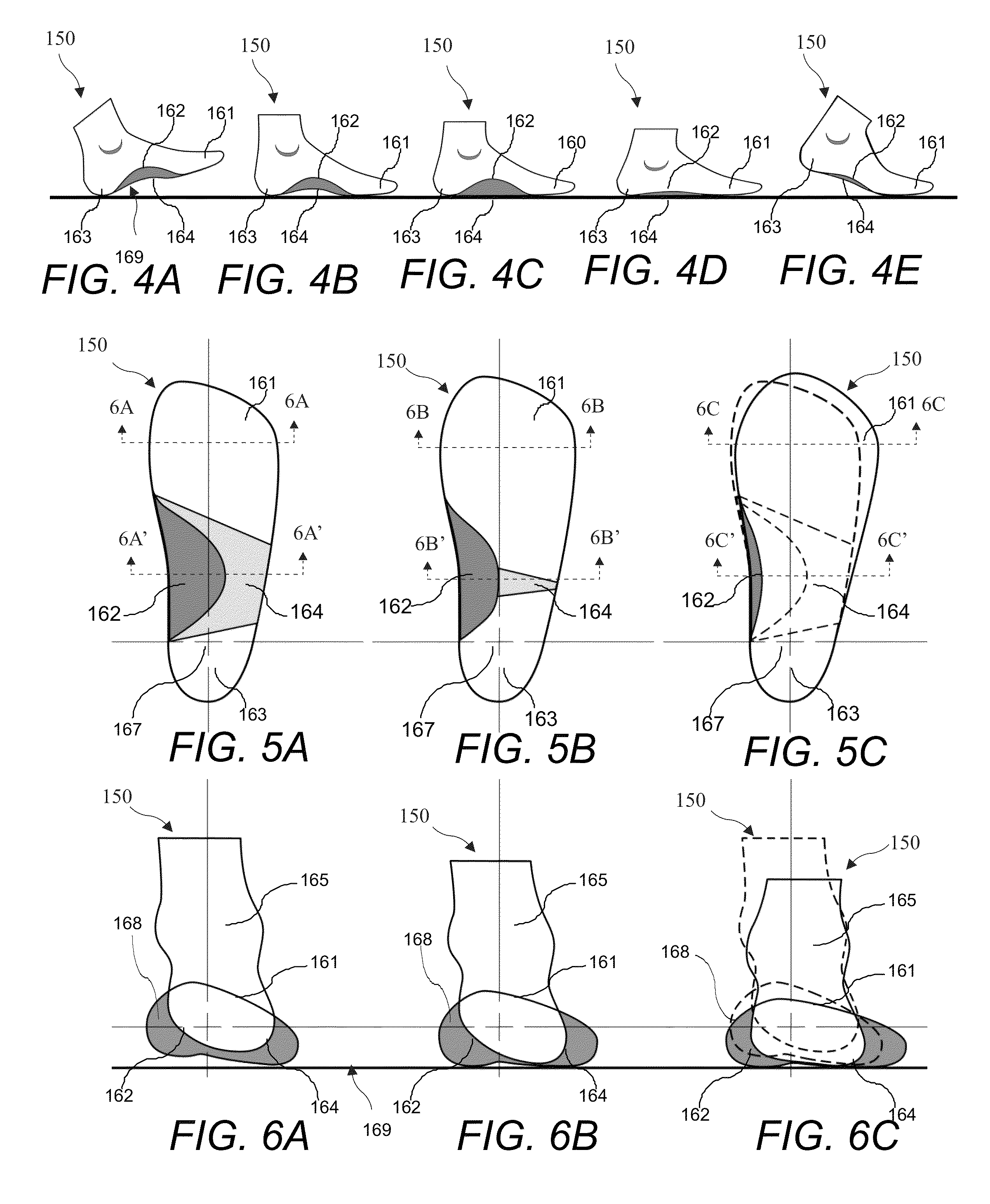

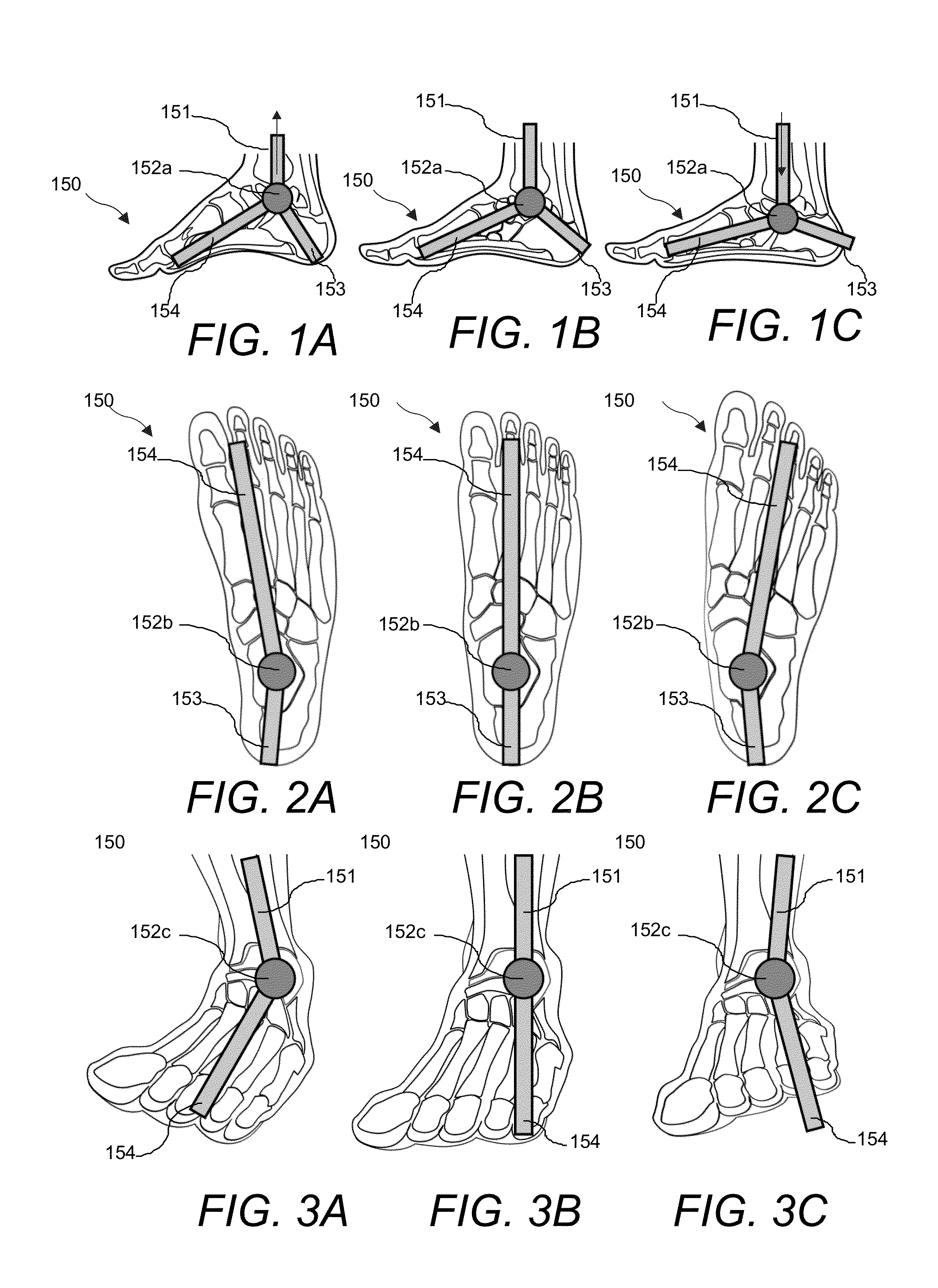

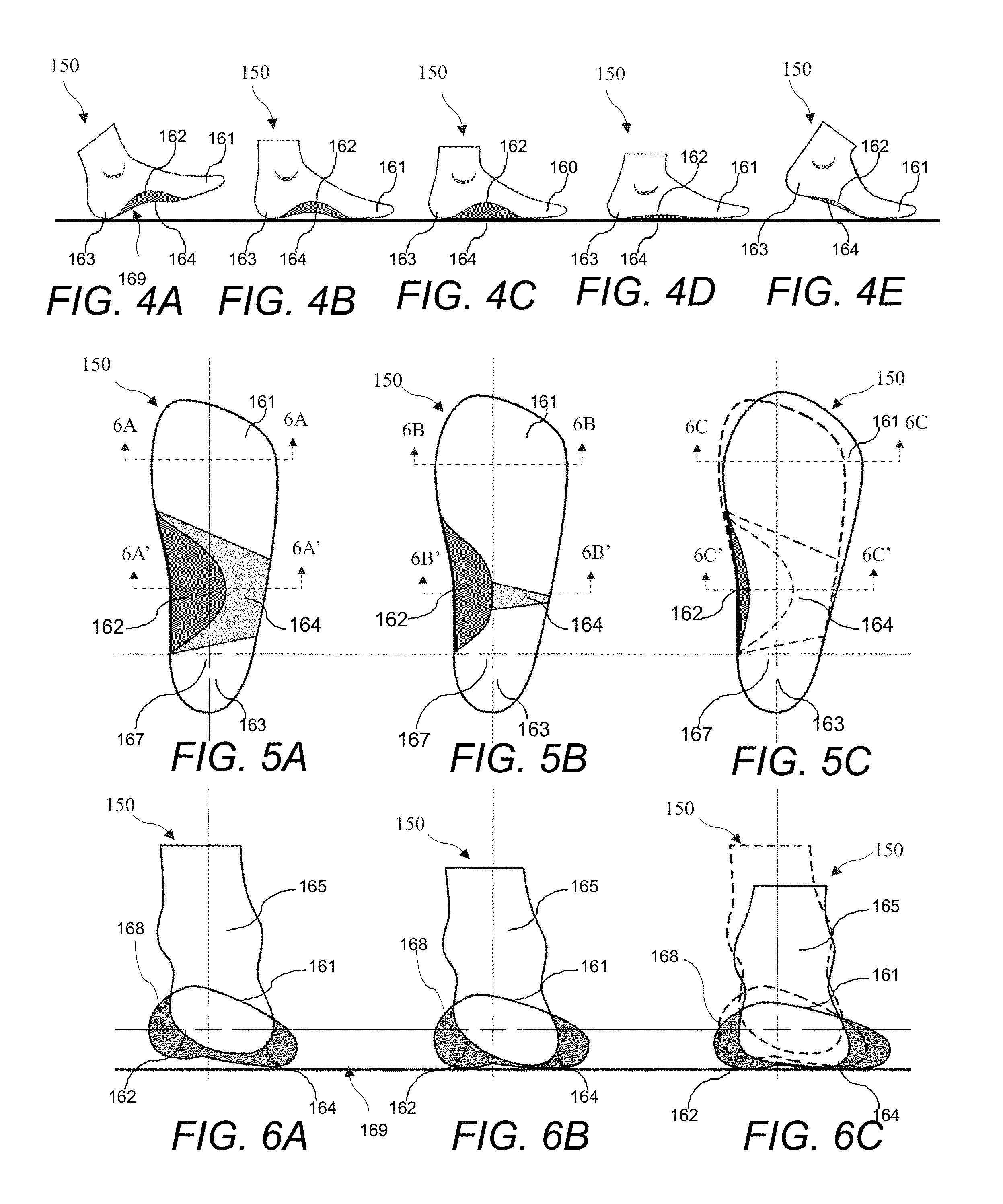

Article of footwear with embedded orthotic devices

InactiveUS8640363B2Enhance comfort and fit and utilityMovement of footSolesNon-surgical orthopedic devicesCalcaneusFoot region

Footwear including an integrated orthotics system provides support with progressive resistance in pronation and supenation motions of the foot during a gait cycle. The orthotics system includes an orthotic device between the mid-sole and the outsole and extend from the rear foot's calcaneus region to the forefoot region where the phalanges and metatarsal joints meets. The orthotic device includes contours mimicking a foot sole shape in an unloaded state. The orthotic system may also include a secondary external orthotic device embedded underneath the outsole to provide control in the mid foot region to achieve progressive compression resistance in the mid foot arch zones. The secondary device may be customizable to achieve a wide range of resistance level needed in mid foot compression by the wearer. The orthotics combined with the midsole and outsole provide progressive mid foot compression resistance and directional flex associated with pronatory motions of the foot.

Owner:HSU HENRY

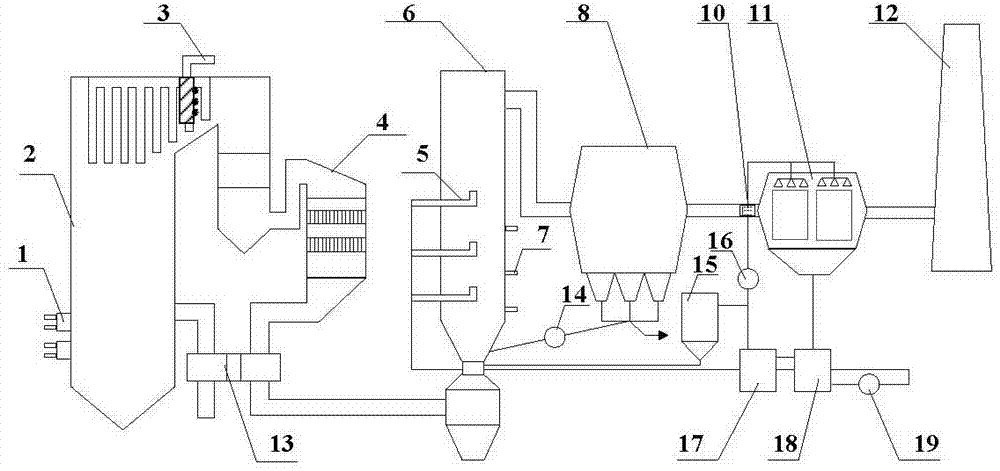

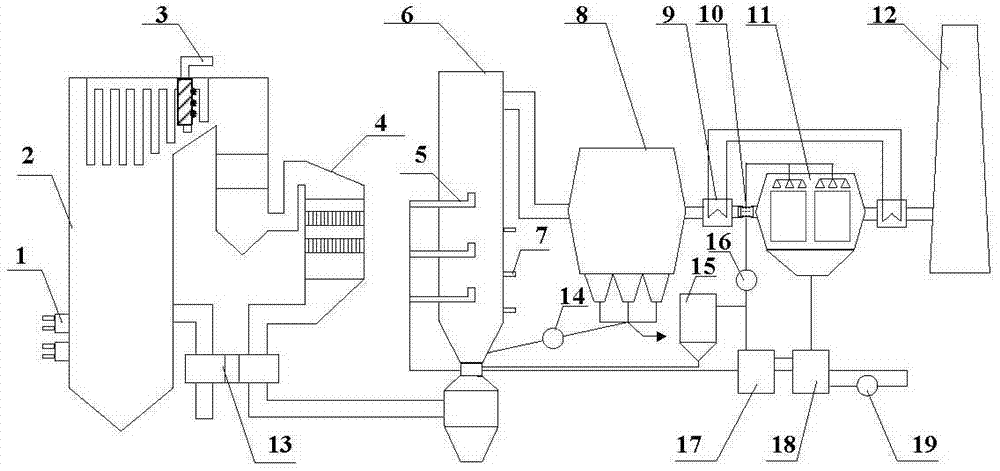

Low-cost coal-fired flue gas various pollutant ultralow emission system and low-cost coal-fired flue gas various pollutant ultralow emission method

InactiveCN104759192AReduce consumptionSmall and portableCombustion using gaseous and pulverulent fuelCombination devicesControl systemMulti pollutant

The invention relates to a low-cost coal-fired flue gas various pollutant ultralow emission system and a low-cost coal-fired flue gas various pollutant ultralow emission method. The system mainly includes a nitrogen oxide gradient control system, a semidry flue gas purifying system and a wet-type static deep purification system. In the invention, by means of the nitrogen oxide gradient control system, the emitted NOx is less than 50 mg / Nm3 in concentration; by means of the semidry flue gas purifying system, the removal efficiency of SO2 can be reach not less than 90%, the removal efficiency of SO3 can be reach not less than 90%, the removal efficiency of acidic gas can be reach not less than 95% and the dust is less than 30 mg / Nm3; and by means of the wet-type static deep purification system, the PM is less than 5 mg / Nm3 and the removal efficiency of SO2 can be reach not less than 50%. The dust-containing waste water in the wet-type static deep purification system is used for slaking limestone and moistening and activating an absorbent in the semidry flue gas purifying system, so that near-zero emission of the waste water in the system is achieved and finally it is achieved that the pollutant emission concentrations of PM is less than 5 mg / Nm3, the emission concentration of SO2 is less than 35 mg / Nm3 and the emission concentration of SO2 is less than 50 mg / Nm3 in a coal-fired power plant, thereby achieving an ultralow emission requirement of the main pollutant under a condition of the near-zero emission of the waste water.

Owner:ZHEJIANG UNIV

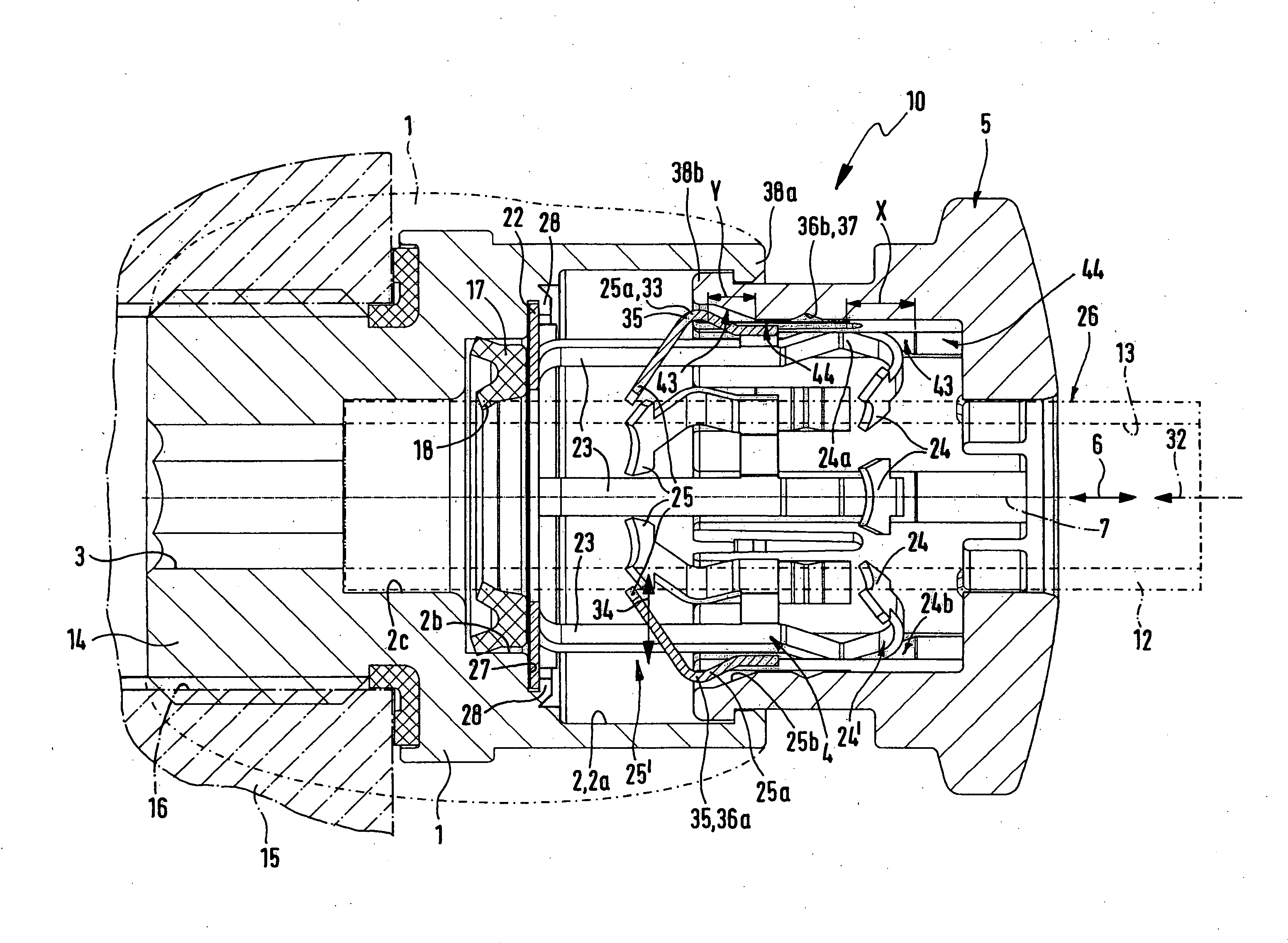

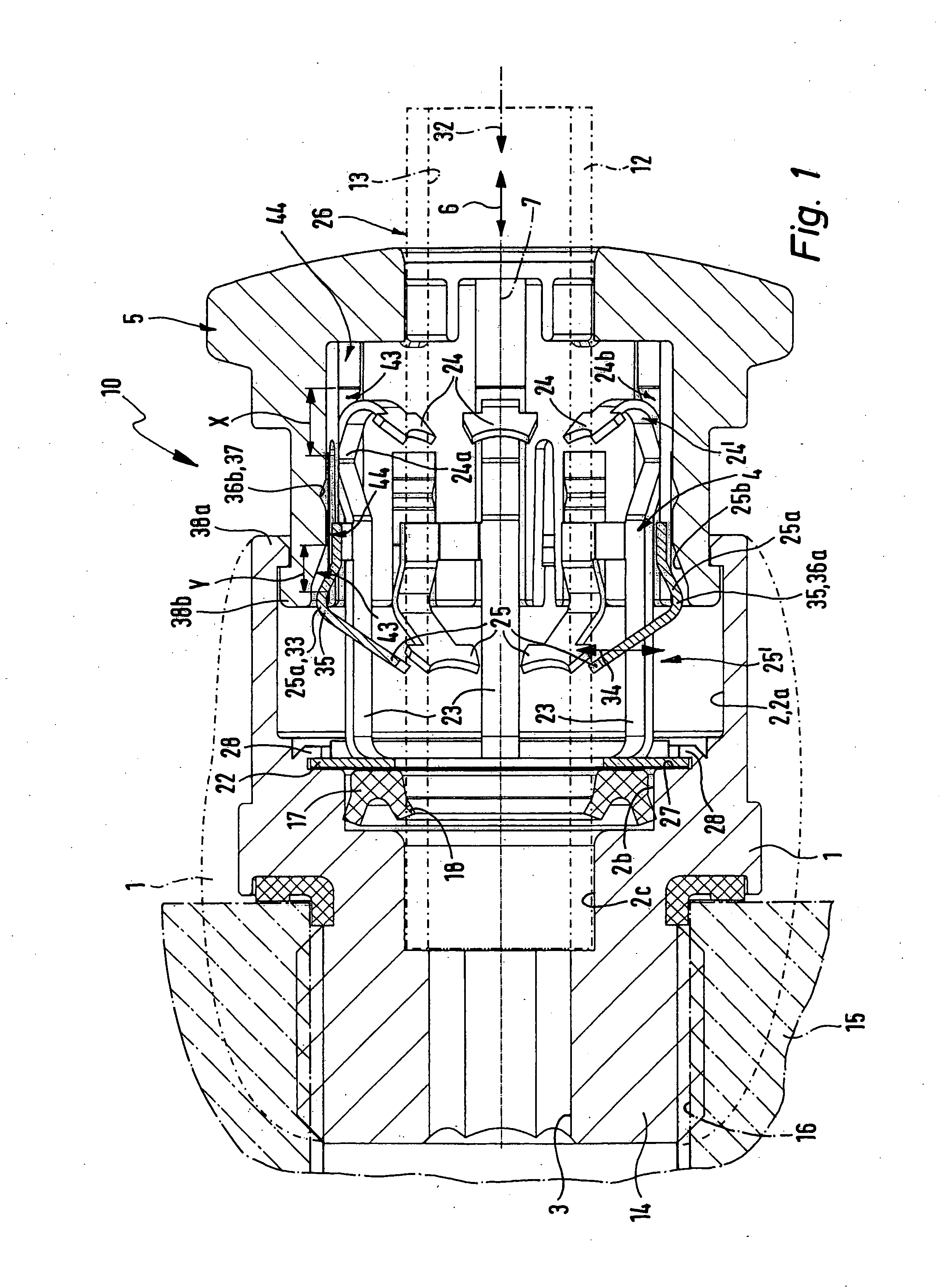

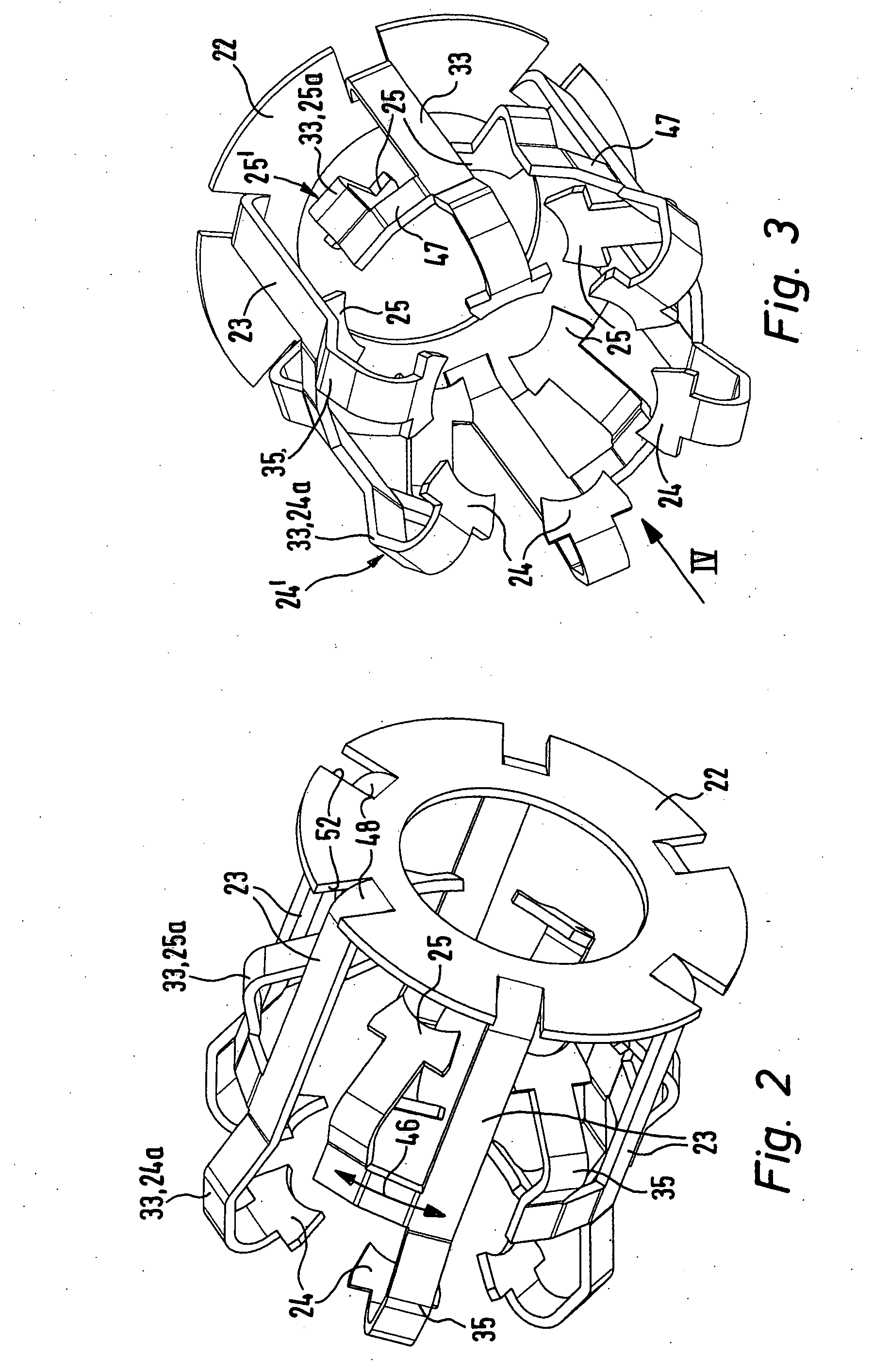

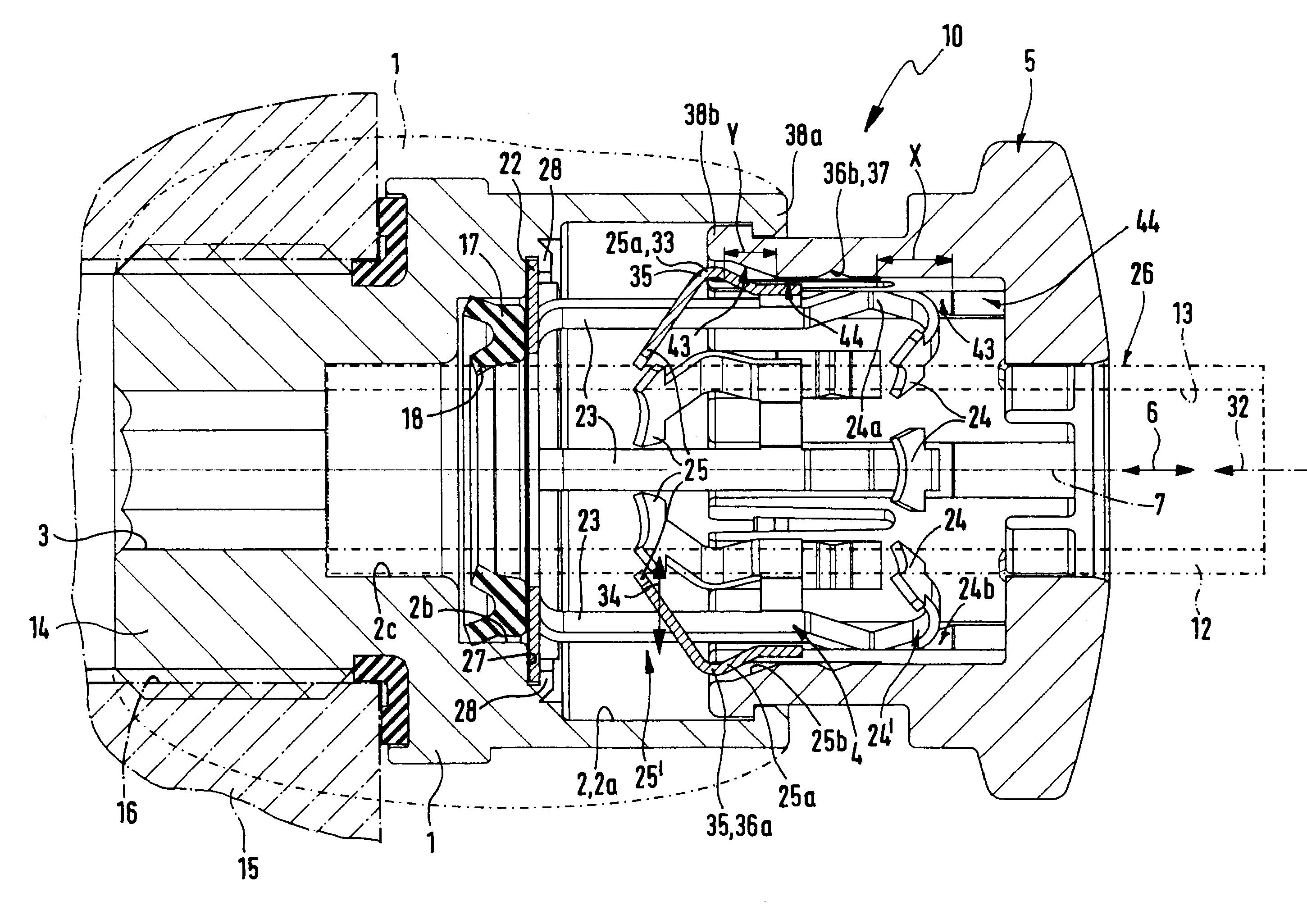

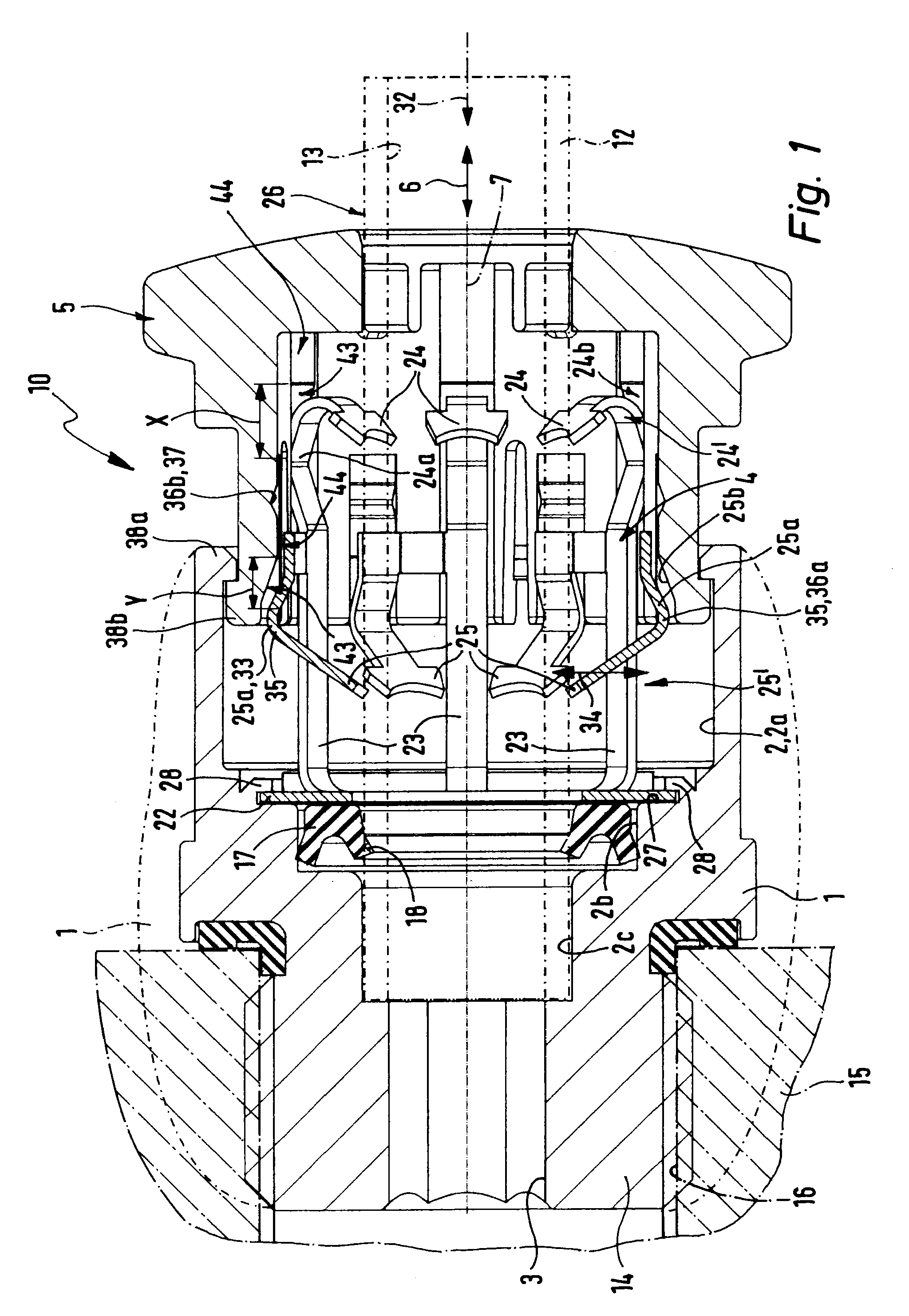

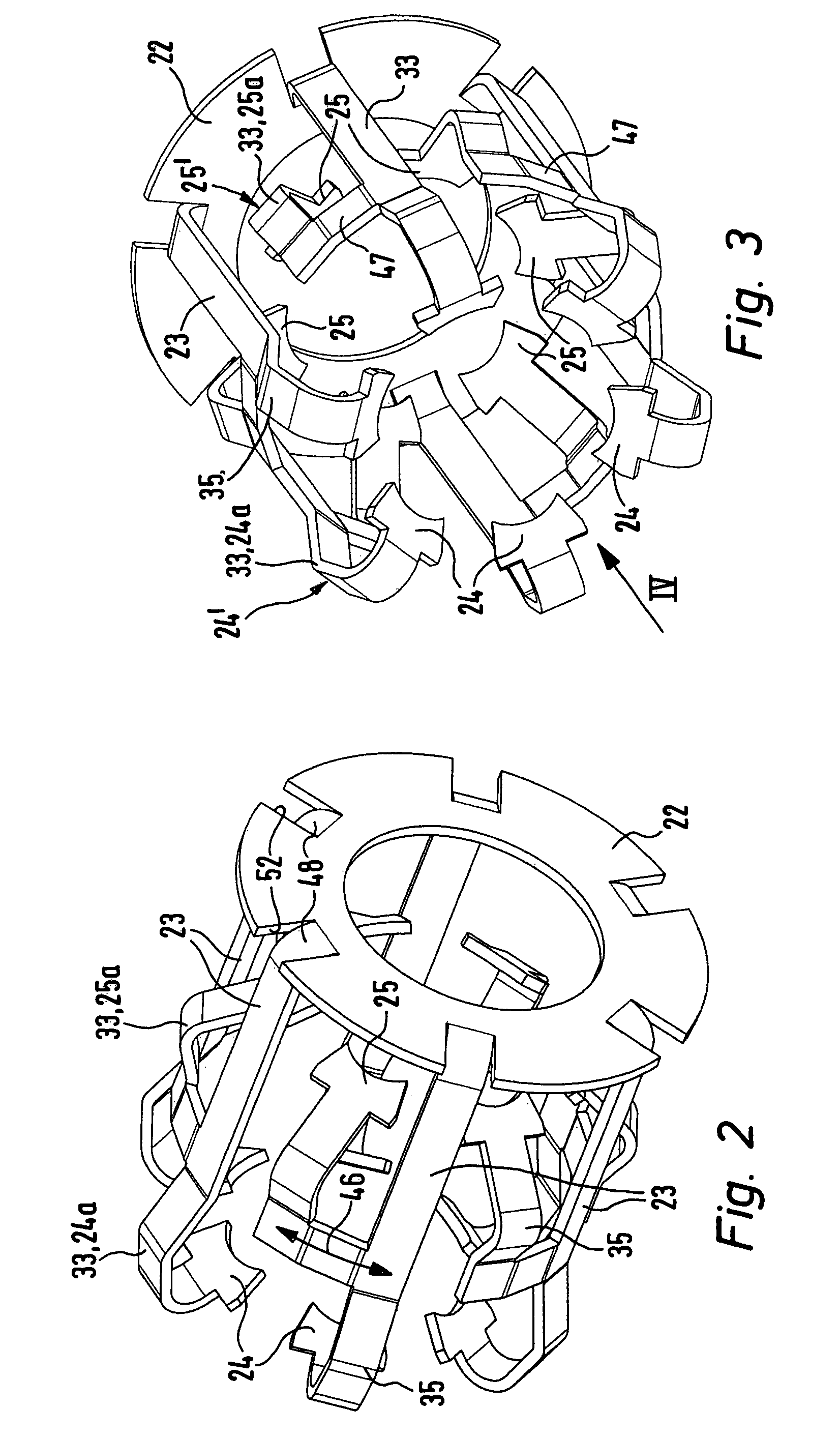

Coupling device for a fluid line

InactiveUS20080238096A1Easy to operateAvoid interferenceSleeve/socket jointsFluid pressure sealed jointsEngineeringCollet

A coupling device for a fluid line has a collet and an axially movable actuating sleeve serving for operation of the collet. The collet bears several gripping teeth with associated actuating portions able to be acted on by actuating faces on the actuating sleeve in order to hold the inserted fluid line. In the non-operated state of the actuating sleeve there are at least partly different distances between the mutually associated actuating portions and actuating faces so that on actuation of the actuating sleeve several actuating portions of the collet are acted on one after the other. This means that the necessary actuating force is reduced.

Owner:FESTO AG & CO KG

Article of Footwear with Embedded Orthotic Devices

Footwear including an integrated orthotics system provides support with progressive resistance in pronation and supenation motions of the foot during a gait cycle. The orthotics system includes an orthotic device between the mid-sole and the outsole and extend from the rear foot's calcaneus region to the forefoot region where the phalanges and metatarsal joints meets. The orthotic device includes contours mimicking a foot sole shape in an unloaded state. The orthotic system may also include a secondary external orthotic device embedded underneath the outsole to provide control in the mid foot region to achieve progressive compression resistance in the mid foot arch zones. The secondary device may be customizable to achieve a wide range of resistance level needed in mid foot compression by the wearer. The orthotics combined with the midsole and outsole provide progressive mid foot compression resistance and directional flex associated with pronatory motions of the foot.

Owner:HSU HENRY

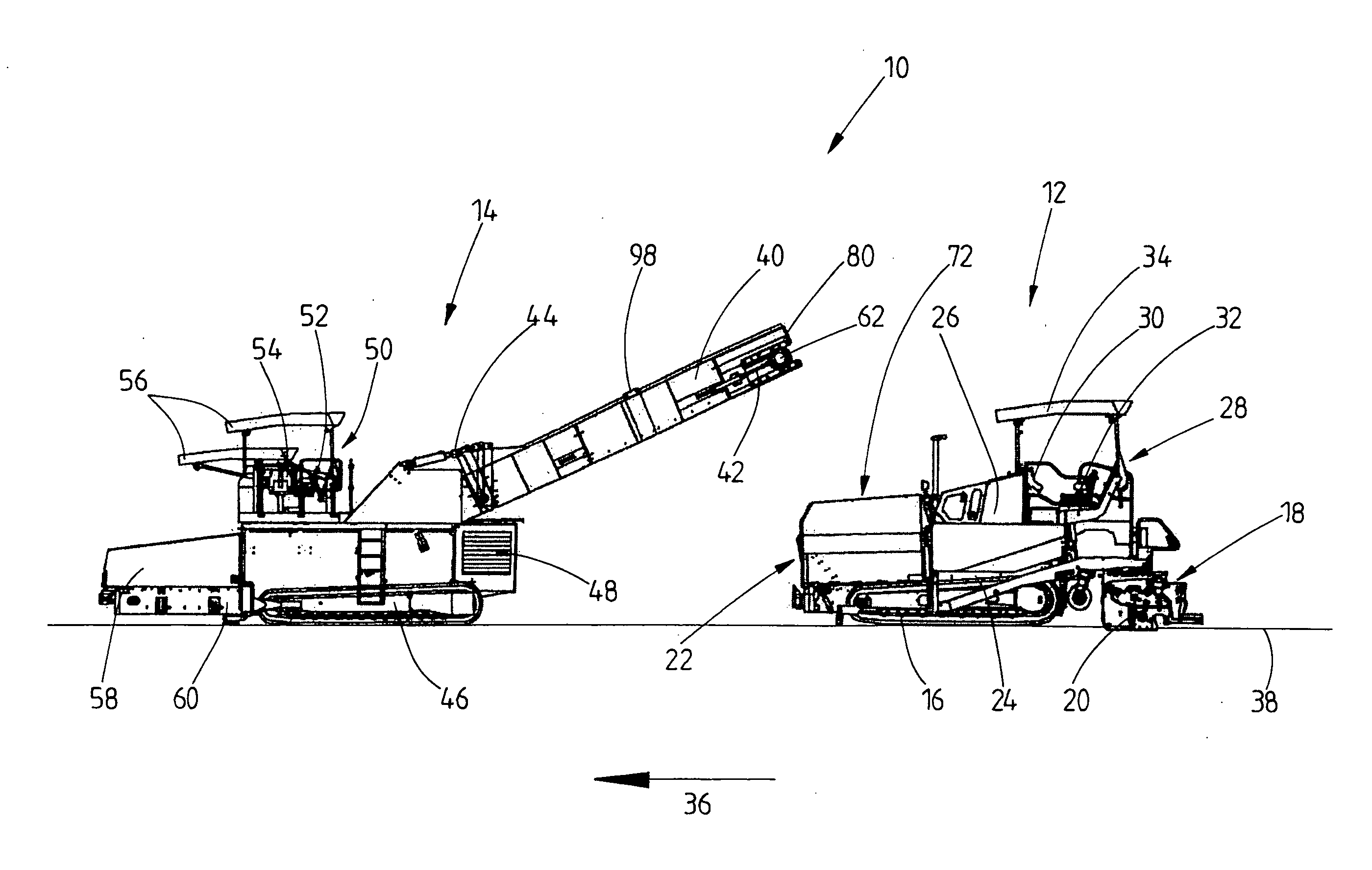

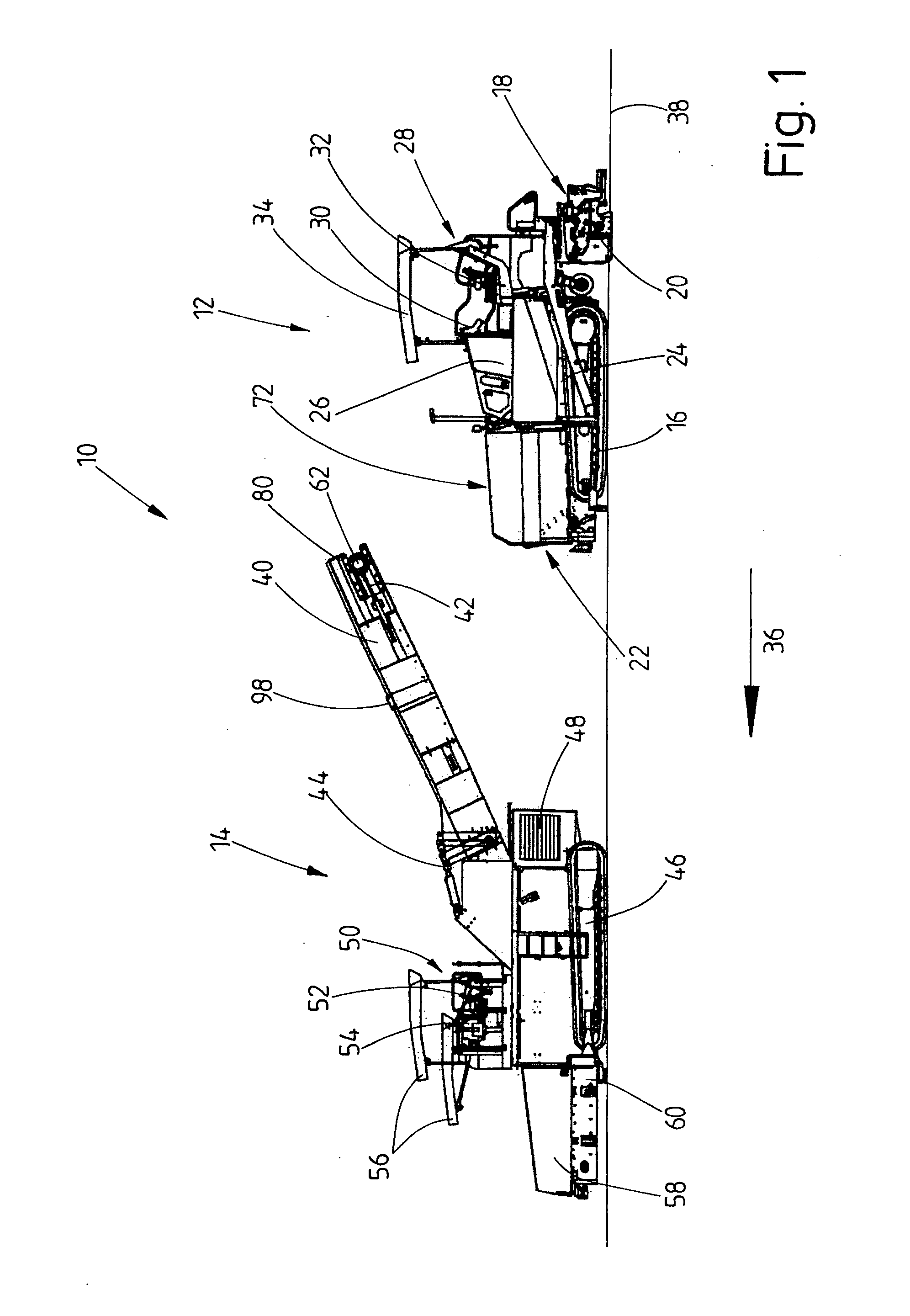

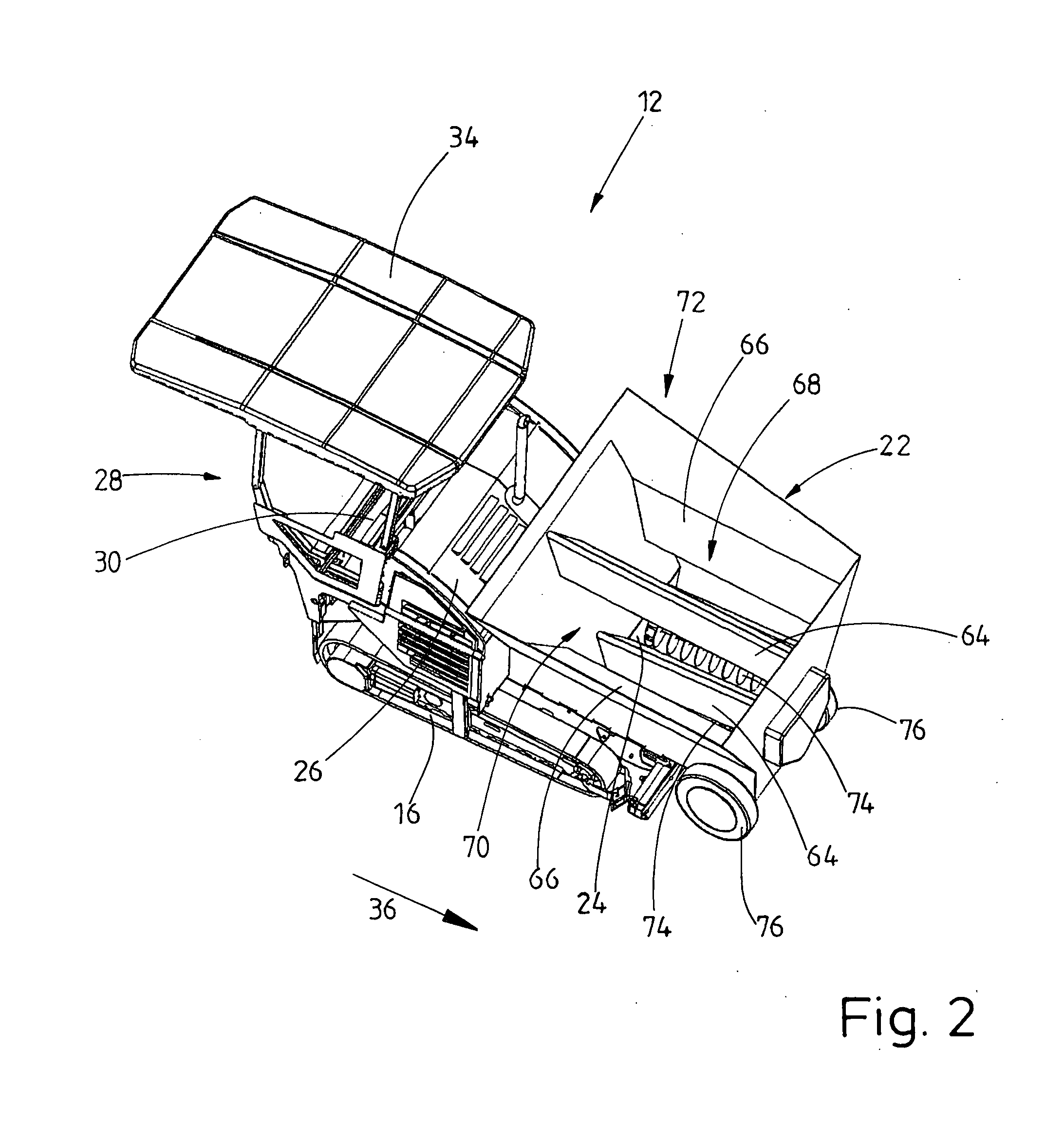

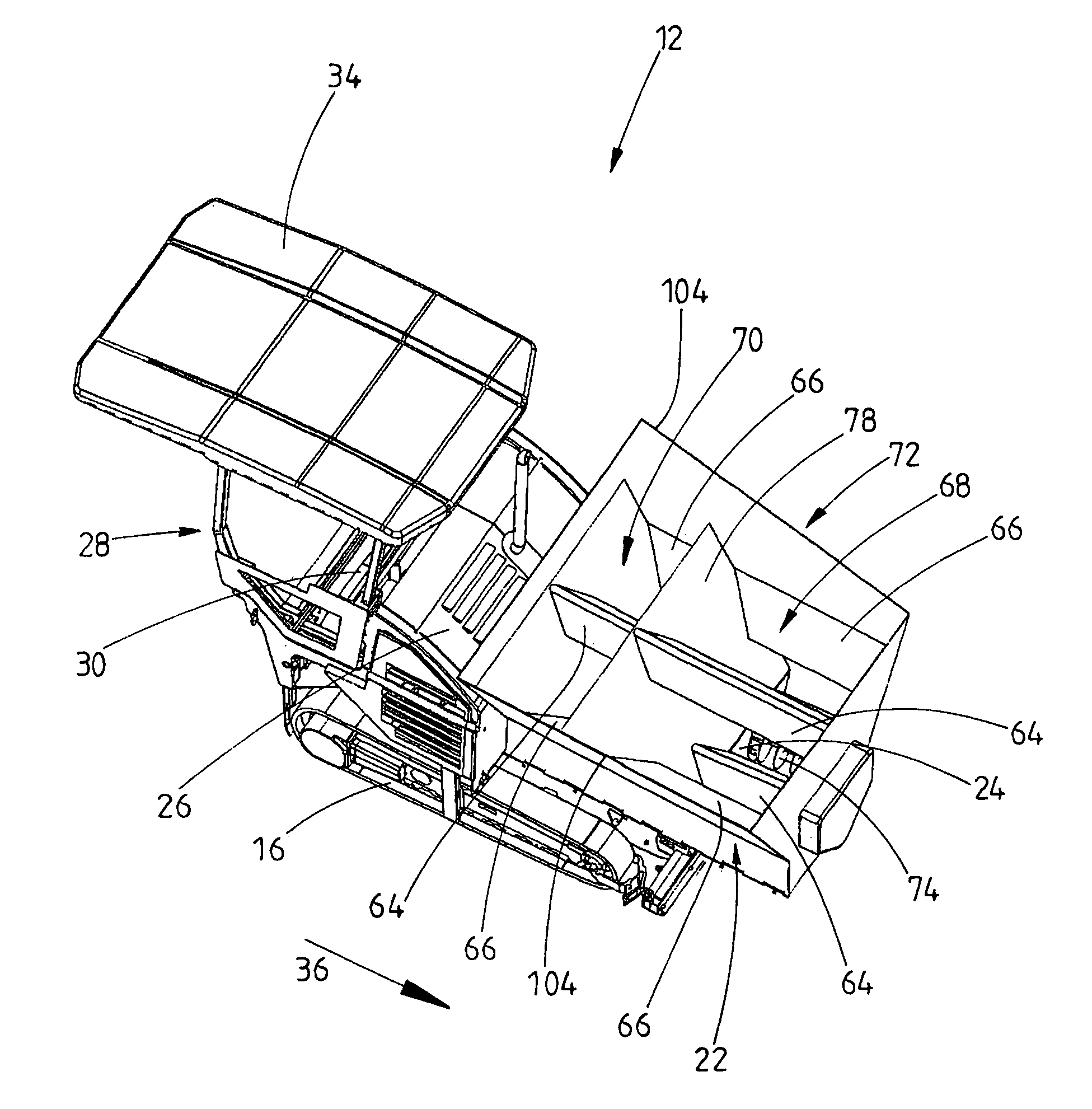

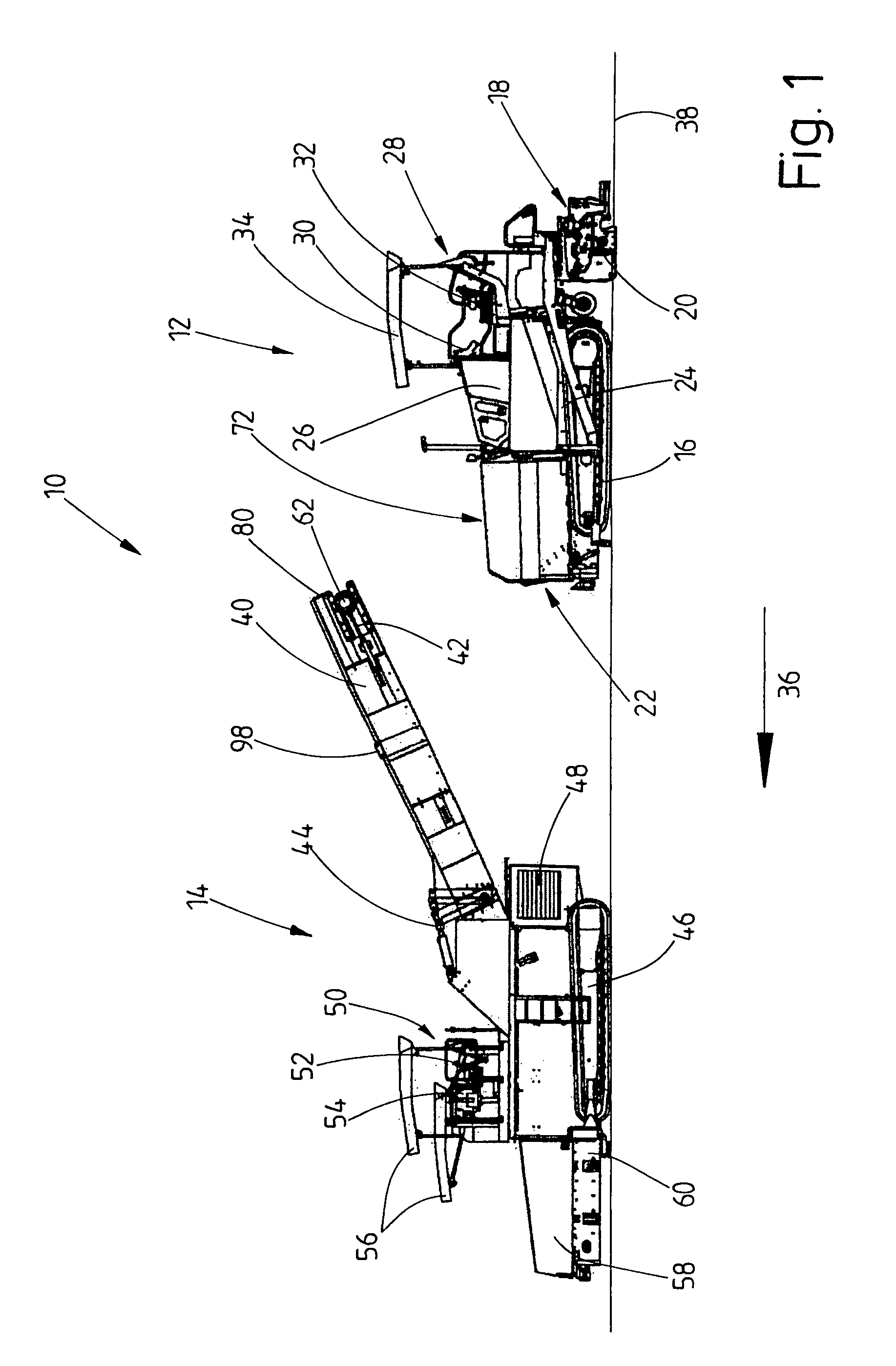

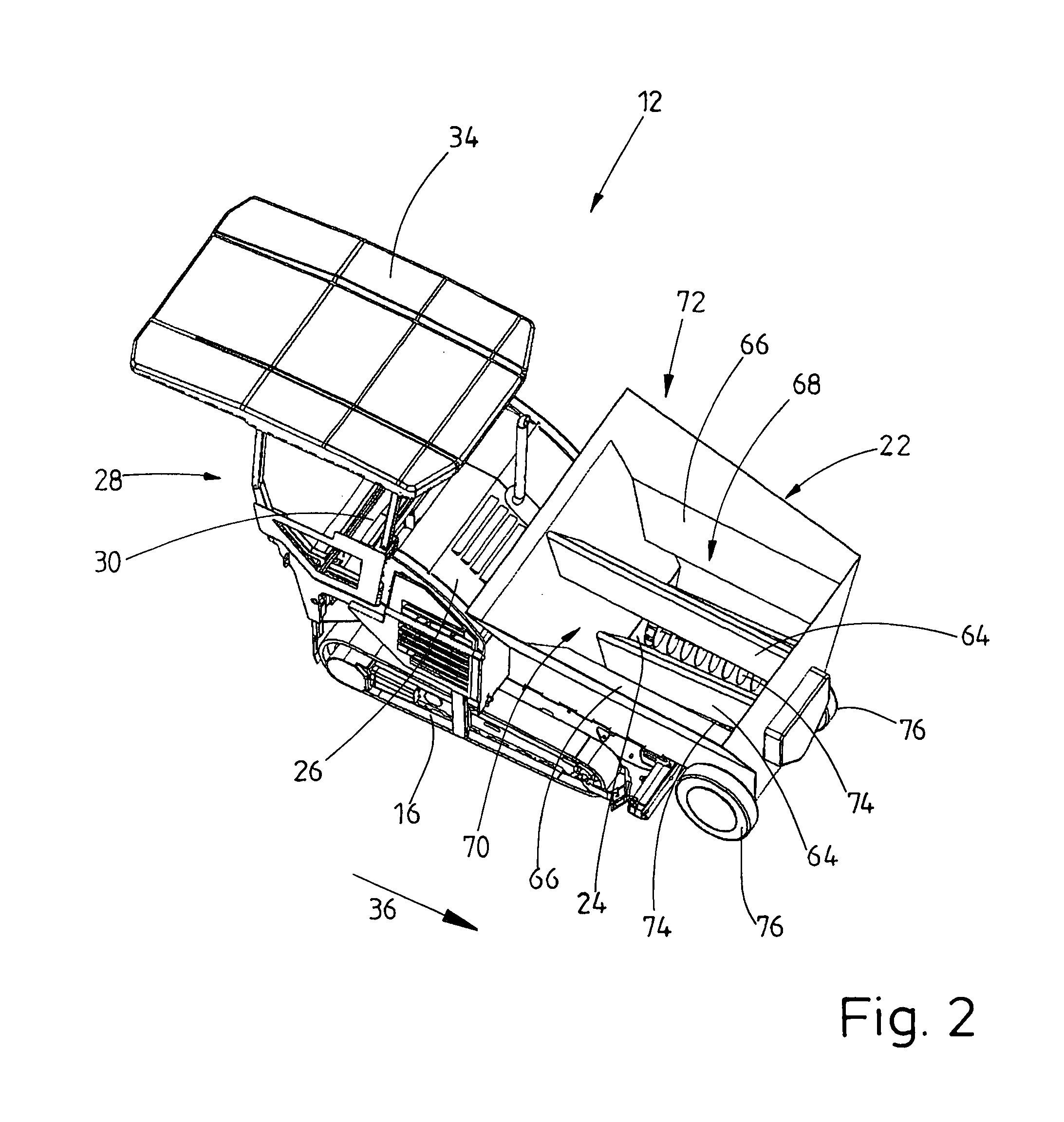

Process for producing a road covering, feeder, road paver and paving train

ActiveUS20110318102A1Quality improvementHigh consumptionPaving detailsRoads maintainenceAsphaltCivil engineering

Owner:DYNAPAC

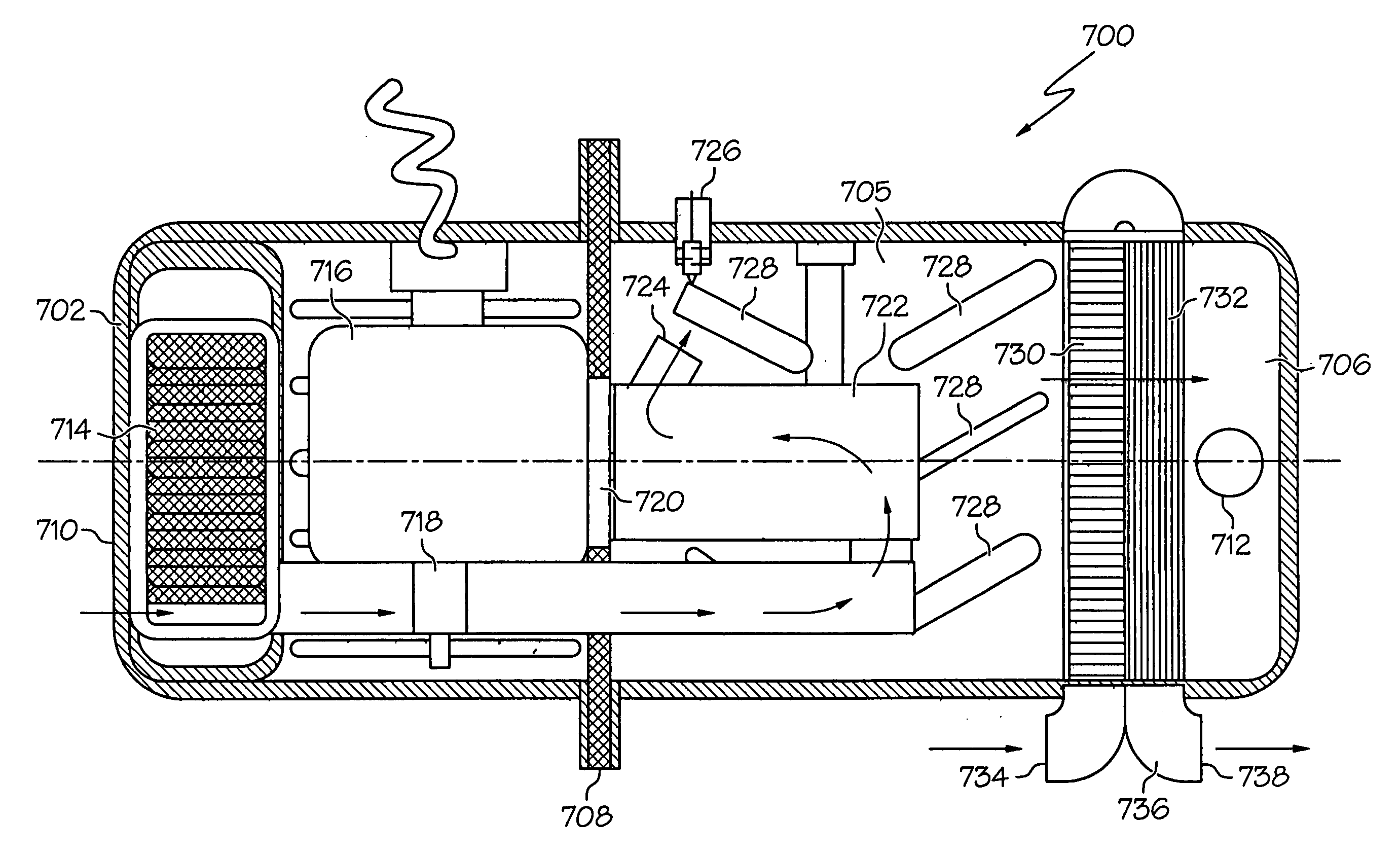

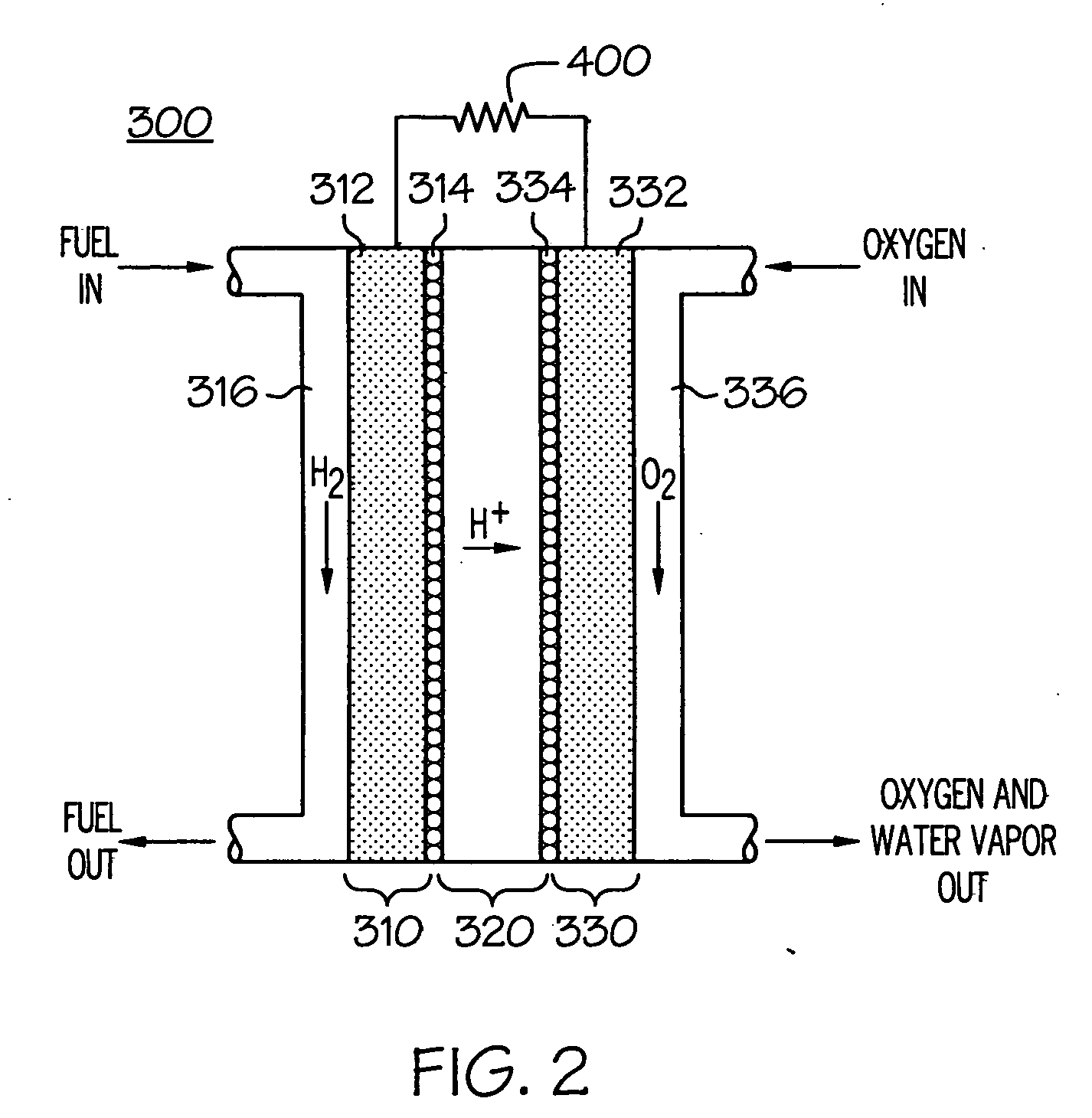

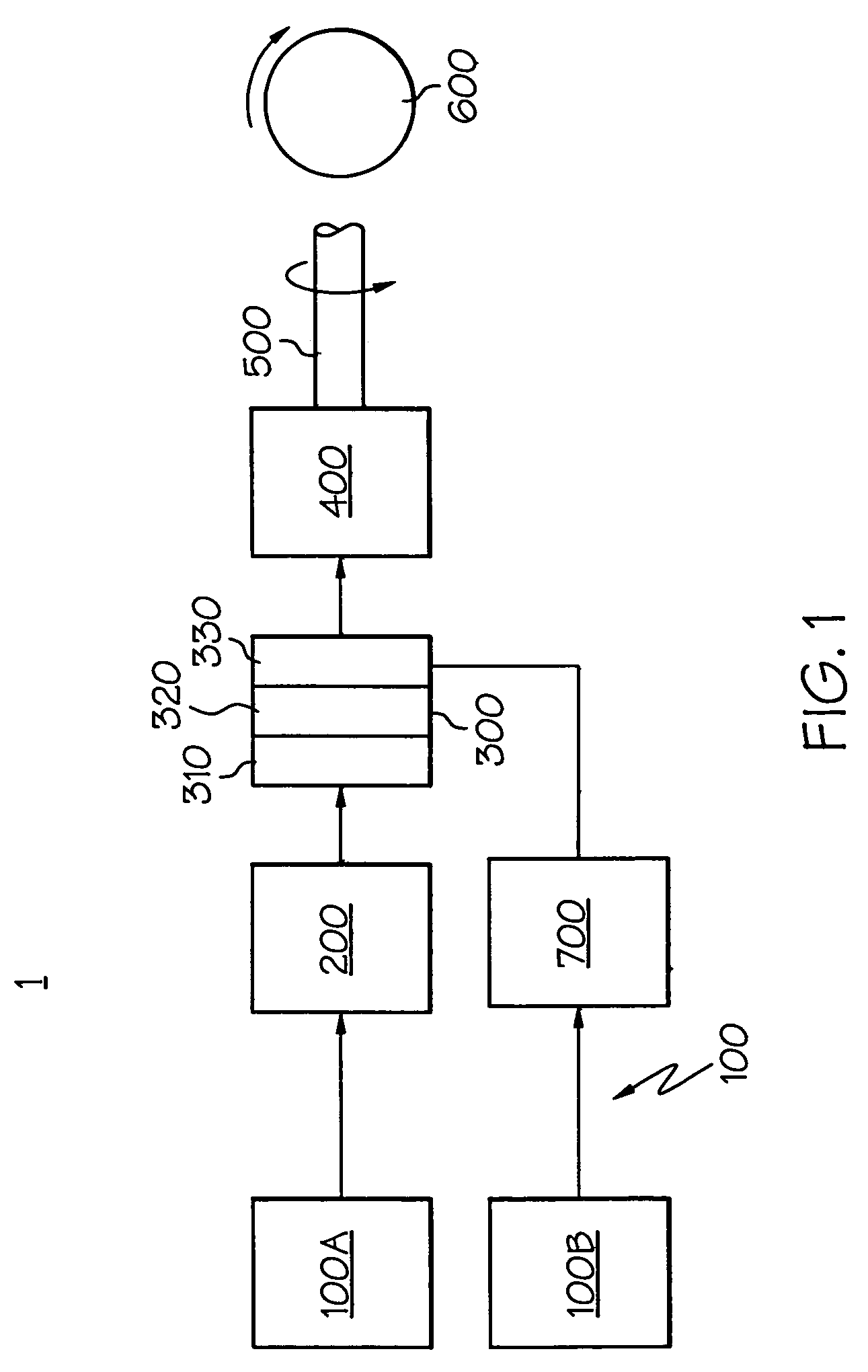

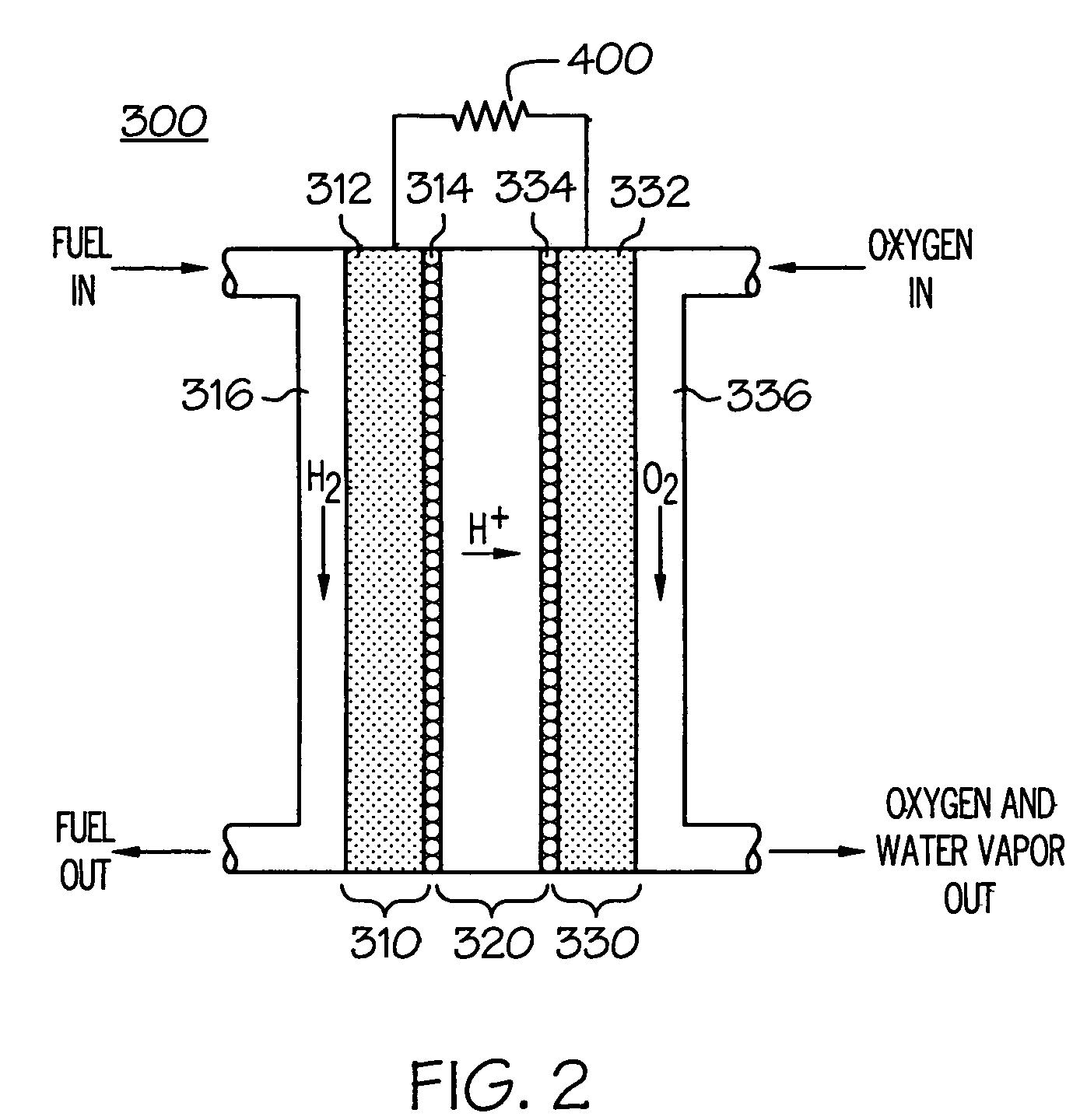

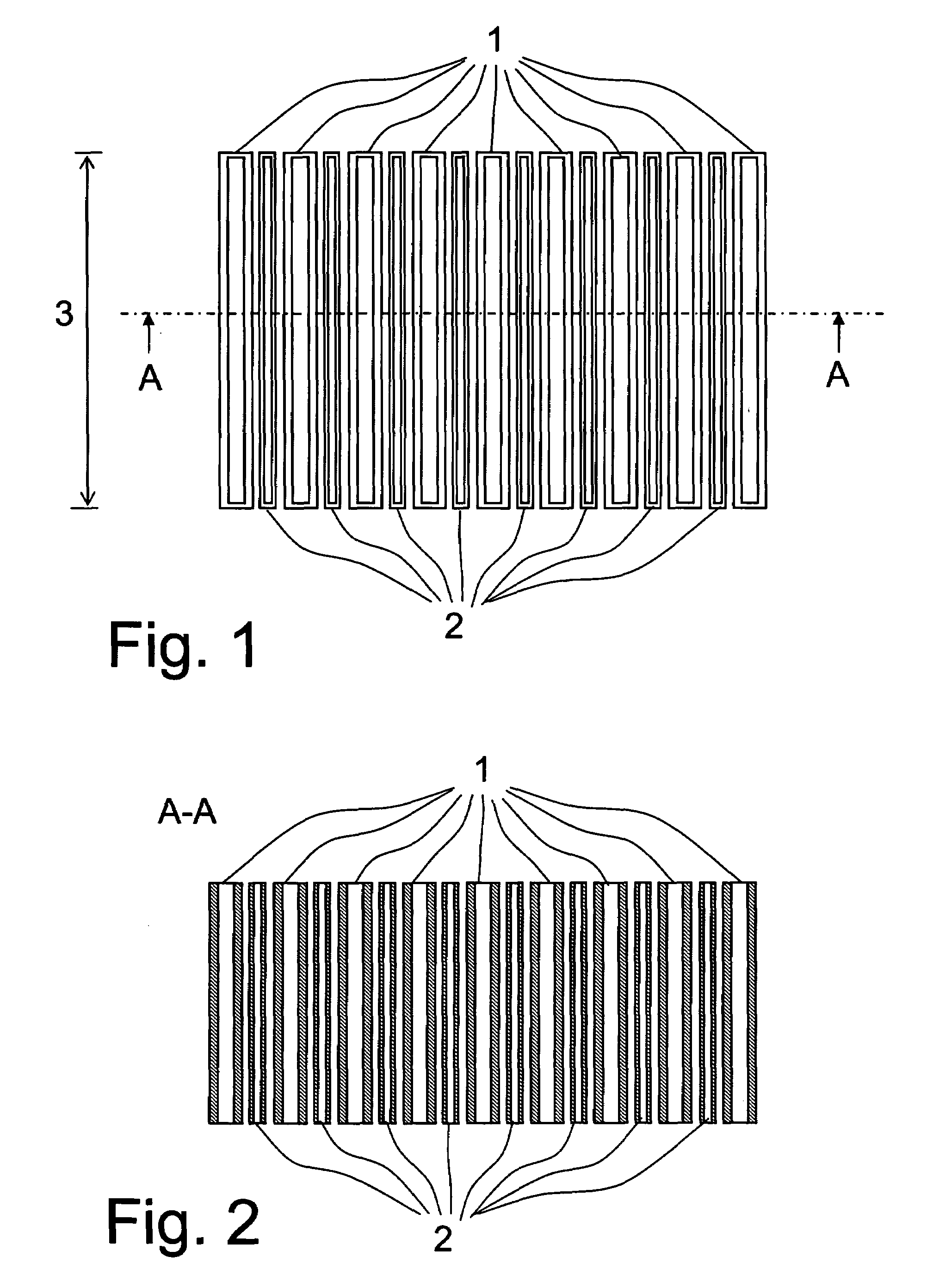

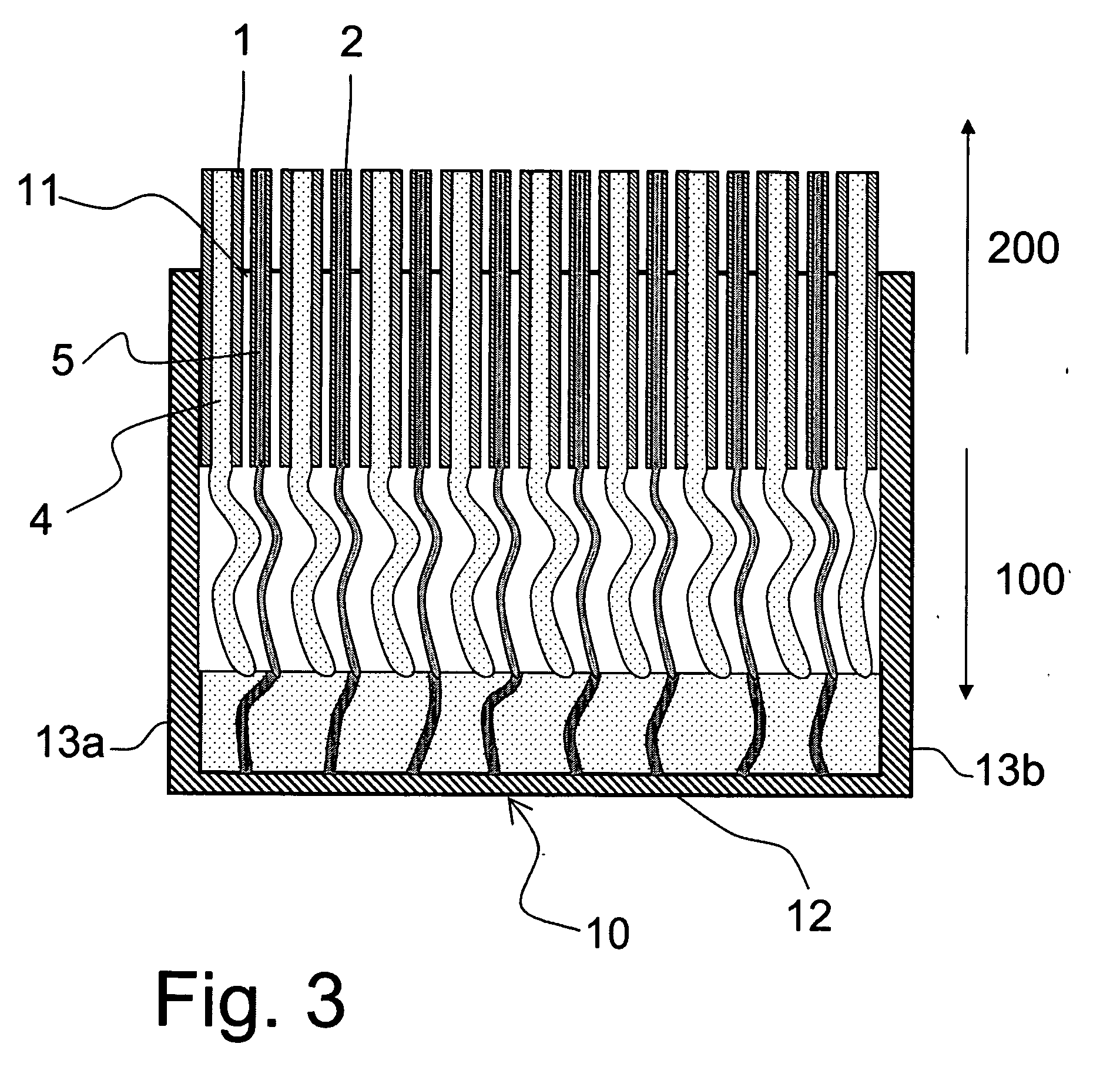

Integrated air supply with humidification control for fuel cell power systems

InactiveUS20070082242A1Minimize complexityMinimize componentFuel cell auxillariesMotive system fuel cellsElectricityFuel cells

A fluid delivery device for an electrochemical conversion assembly. In one embodiment, the electrochemical conversion assembly is a fuel cell system. The device includes one or more fluid-manipulating components combined into a housing to minimize weight, size and complexity. In one form, the device may include a compressor, heat exchanger and a water vapor transfer unit, at least the latter two of which are located within a chamber defined by the housing. A controller can be used to monitor and selectively vary the extent to which at least one of these components modifies properties a fluid (such as air) that can be used as a reactant in the electrochemical conversion assembly. In a particular form, the heat exchanger and water vapor transfer unit can cooperate to promote the hydration of the reactant.

Owner:GM GLOBAL TECH OPERATIONS LLC

Cardiac harness assembly for treating congestive heart failure and for pacing/sensing

InactiveUS20070106336A1Low profileResists side-to-side movementEpicardial electrodesHeart valvesMinimally invasive proceduresCongestive heart failure chf

A pace / sense electrode is associated with a cardiac harness for treating the heart. The pace / sense electrode is positioned on the epicardial surface of the heart, preferably under the cardiac harness, to provide pacing and sensing therapy to the heart. Compressive forces from the cardiac harness serve to hold the pace / sense electrode in place and to push the electrode into direct contact with the epicardial surface of the heart. Various means are provided for placing the pace / sense electrode under the cardiac harness in a minimally invasive procedure.

Owner:PARACOR MEDICAL

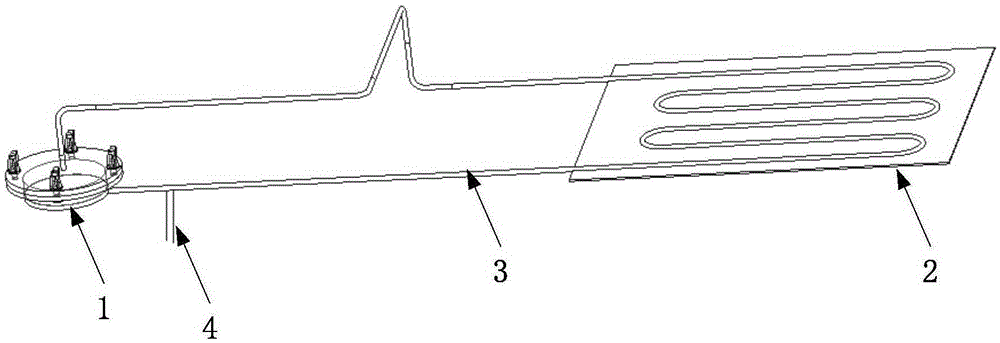

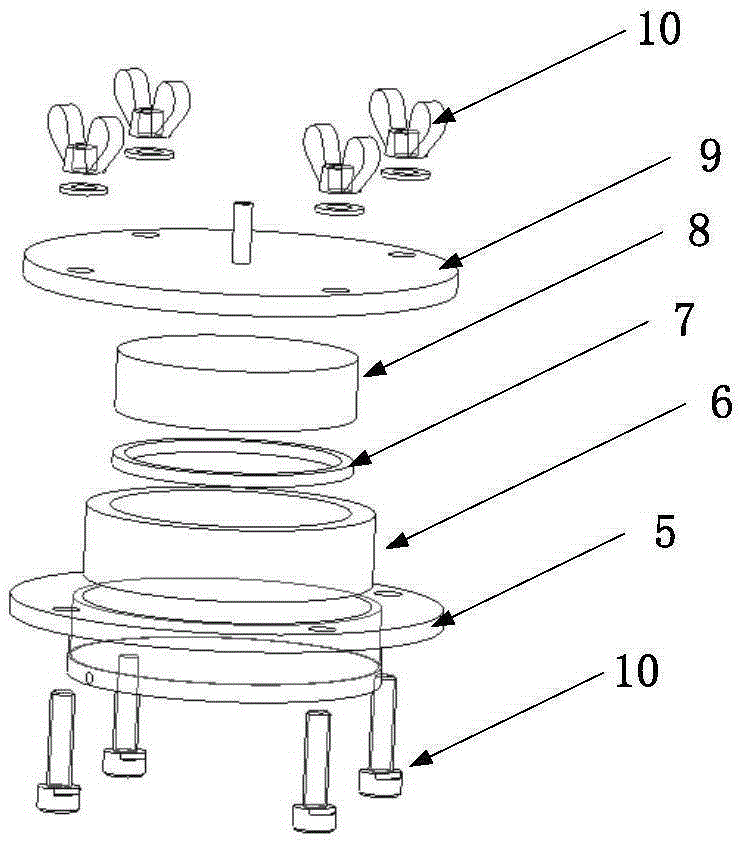

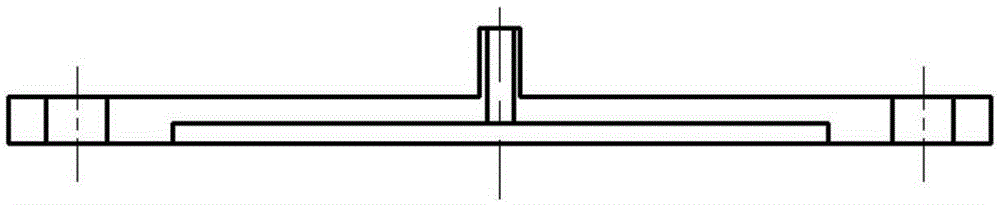

Performance testing apparatus and method for flat-plate LHP capillary core

InactiveCN105352993ALower requirementReduce testing costsMaterial heat developmentEngineeringTest fixture

The invention provides a performance testing apparatus and method for a flat-plate LHP capillary core. An evaporator of the apparatus comprises an evaporator main shell, an evaporator cover plate, a main sealing ring, a secondary sealing ring, a to-be-tested capillary core and a fastener. The method comprises the following steps: bonding of a heater with a measuring point; testing of heat transfer capability; and testing of inverse gravity capability. The performance testing apparatus provided by the invention can simulate an ideal combination state and maximally reduce influence of other non-relevant factors on result, is repeatedly usable, and adaptive to to-be-tested capillary cores of different sizes by changing the sizes of the main and secondary sealing rings, so test cost is decreased.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Coupling device for a fluid line

InactiveUS7793993B2Easy to operateAvoid interferenceSleeve/socket jointsFluid pressure sealed jointsColletEngineering

A coupling device for a fluid line has a collet and an axially movable actuating sleeve serving for operation of the collet. The collet bears several gripping teeth with associated actuating portions able to be acted on by actuating faces on the actuating sleeve in order to hold the inserted fluid line. In the non-operated state of the actuating sleeve there are at least partly different distances between the mutually associated actuating portions and actuating faces so that on actuation of the actuating sleeve several actuating portions of the collet are acted on one after the other. This means that the necessary actuating force is reduced.

Owner:FESTO AG & CO KG

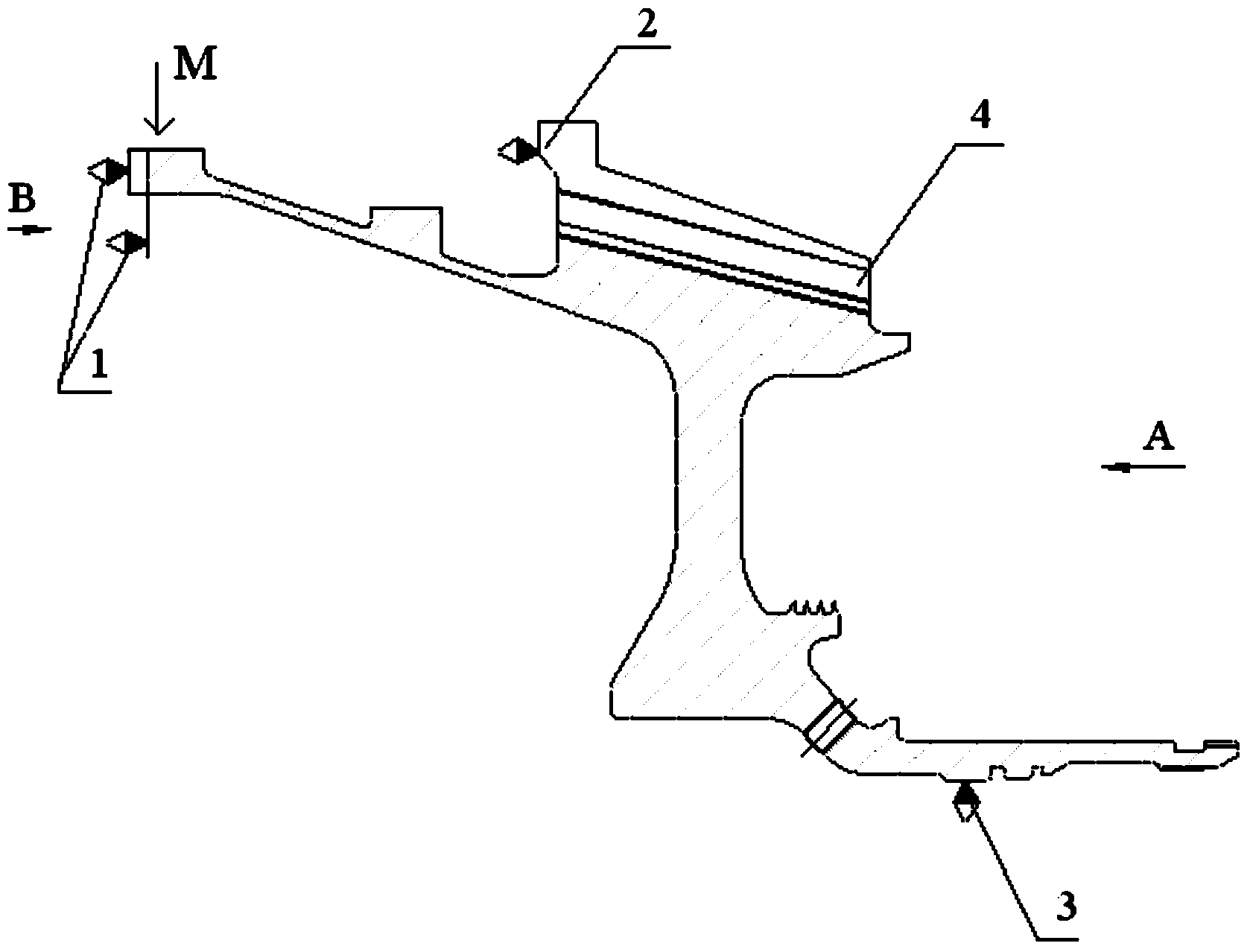

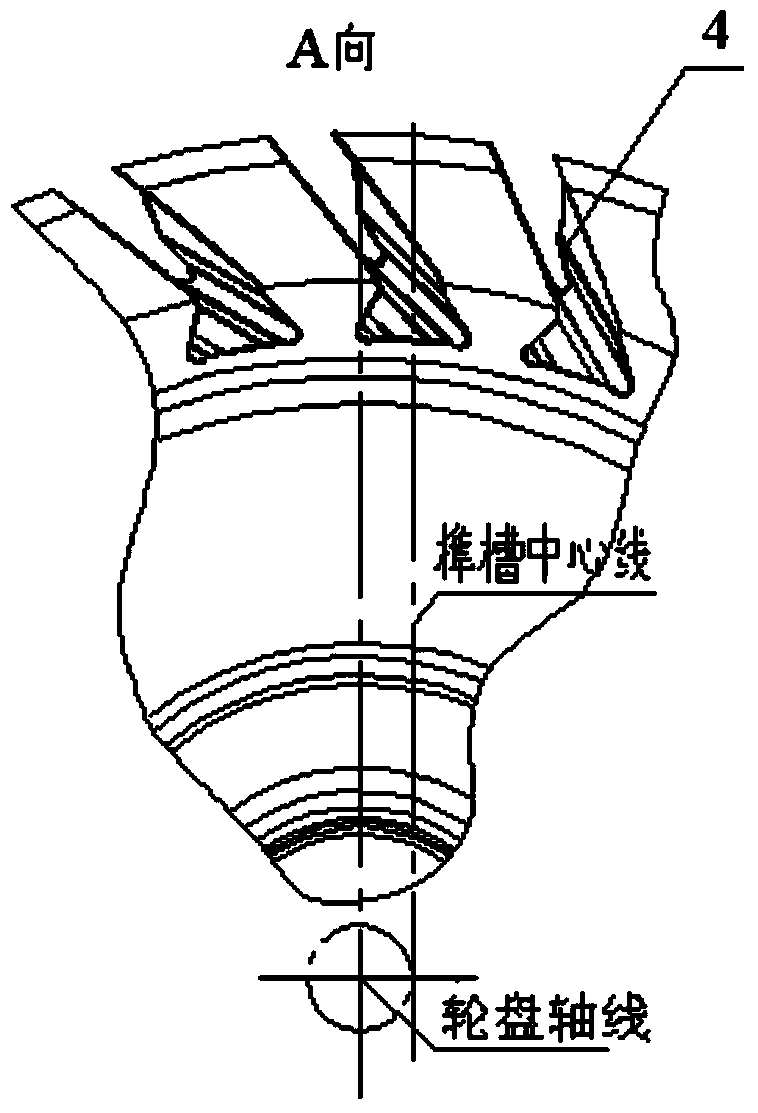

Method for improving broaching precision of mortises in excircle of wheel disc part

ActiveCN103769679AImprove stabilityEasy to operateBroaching machinesDimensional precisionEngineering

The invention discloses a method for improving the broaching precision of mortises in the excircle of a wheel disc part and belongs to the technical field of aero-engine part manufacturing. The adopted technical scheme is that the method comprises the following steps: installing an excircle process platform with a plurality of angular locating slots on the excircle of the to-be-processed wheel disc part; installing two angular locating slots in the excircle process platform if the number of the mortises in the excircle of the to-be-processed wheel disc part is an even number, and broaching the mortises of the wheel disc part in twice; installing three angular locating slots in the excircle process platform if the number of the mortises in the excircle of the to-be-processed wheel disc part is an add number, and broaching the mortises of the wheel disc part in three times. According to the method disclosed by the invention, the contact area between locating surfaces of the mortises of the part and an included angle is effectively increased, so that the stability of fixture positioning is enhanced. Meanwhile, the part angular displacement caused by an angular component generated by broaching is decomposed. The method is simple in operation and skillful in design. Through the method, the fixture rigidity can be greatly enhanced, the deformation of the broached part is reduced, and the dimensional precision of the part is improved.

Owner:AECC AVIATION POWER CO LTD

Process for producing a road covering, feeder, road paver and paving train

ActiveUS8562246B2Quality improvementHigh consumptionPaving detailsRoads maintainenceRoad surfaceAsphalt

Owner:DYNAPAC

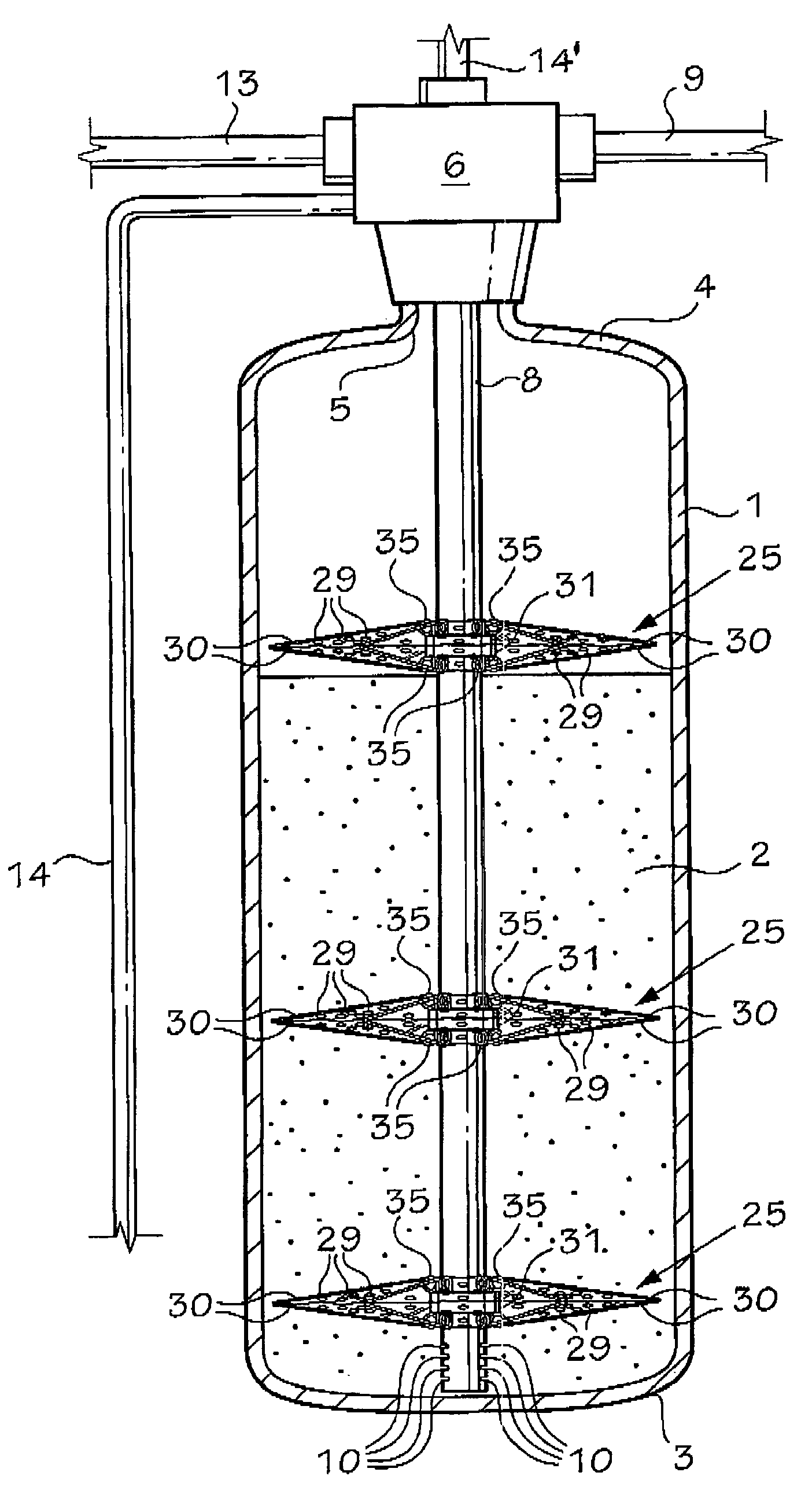

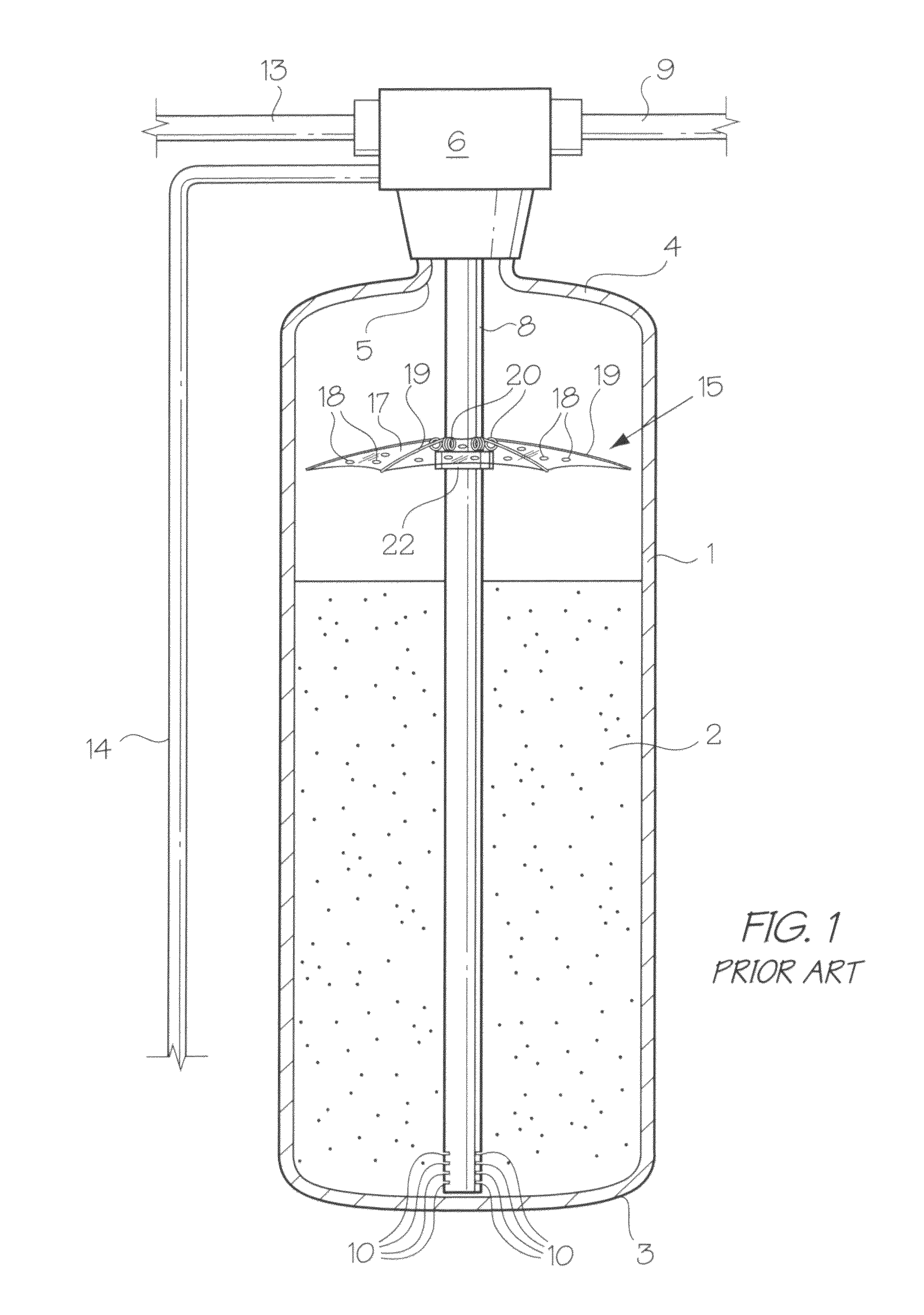

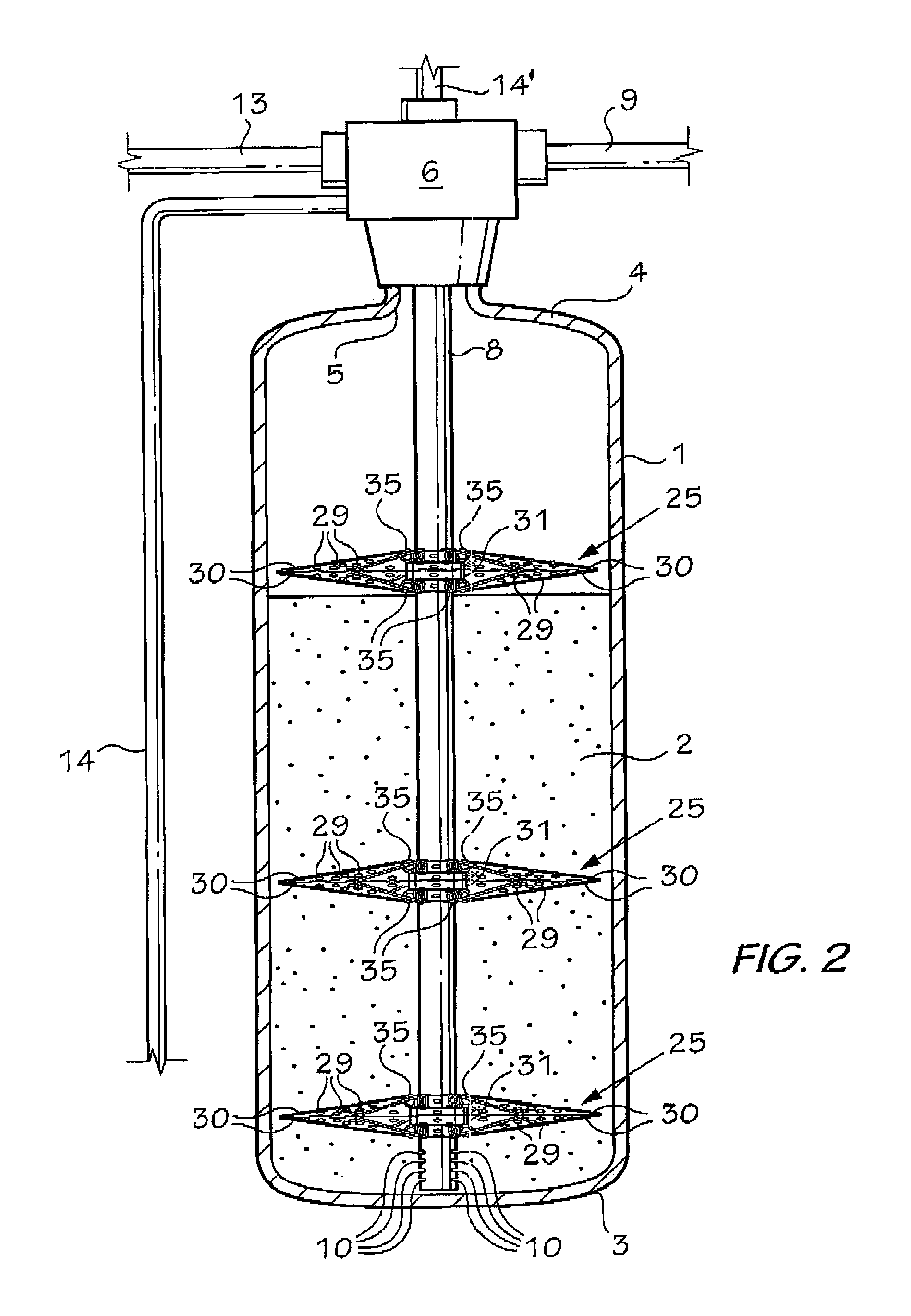

Water conditioner assembly

InactiveUS8349183B2Improve distributionEnsure even distributionIon exchange regulation/controlIon-exchanger regenerationParticulatesWater flow

A distributor for use on a dip tube in the particulate bed of a water conditioner includes a sleeve mounted on the dip tube, a plurality of resilient vanes extending radially outwardly from the sleeve, thin membranes on the vanes, and holes in the membranes, whereby water flowing through the bed is evenly distributed throughout the bed and the bed is agitated by up and down flexing of the distributor in the bed.

Owner:FIELD GEORGE RAYMOND

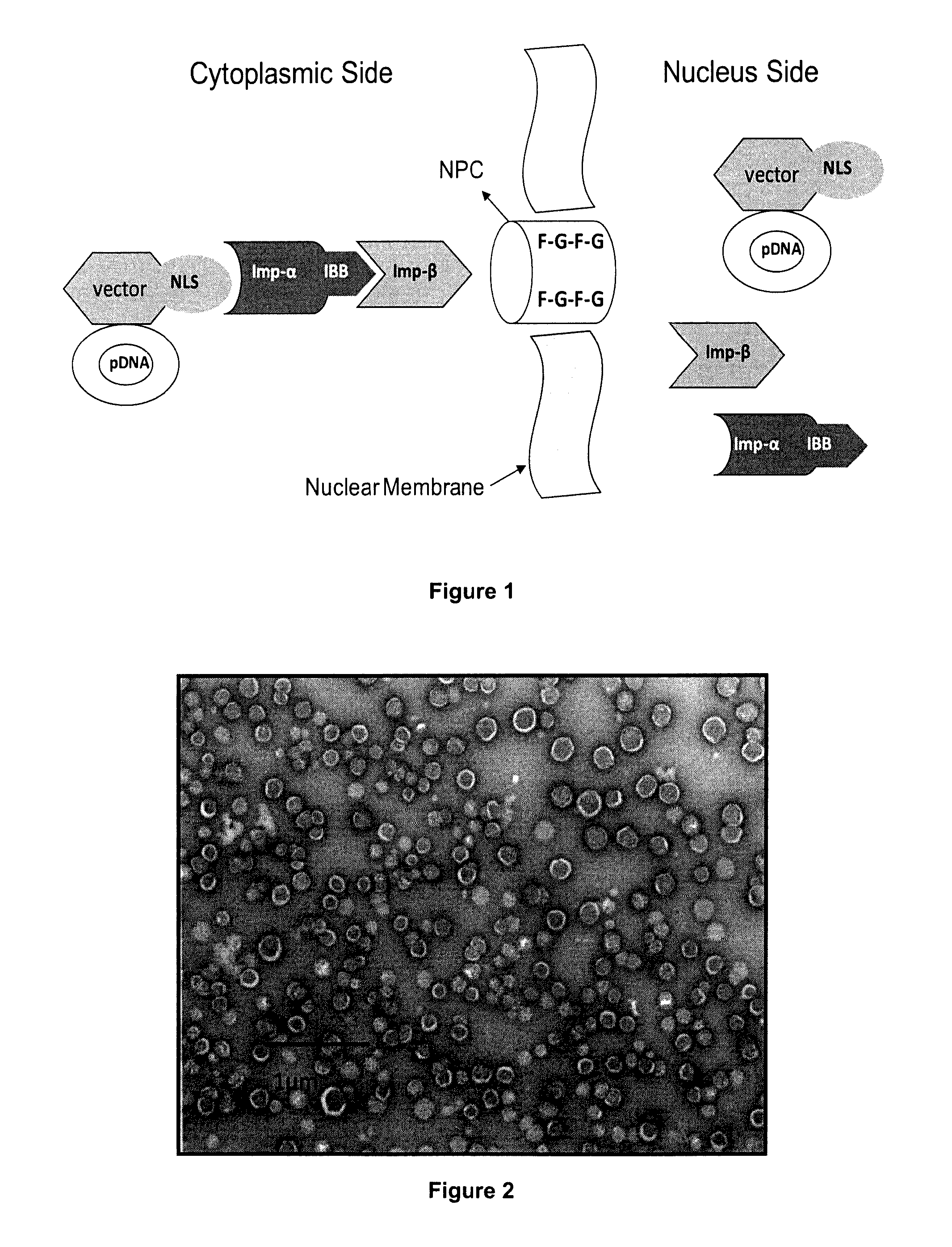

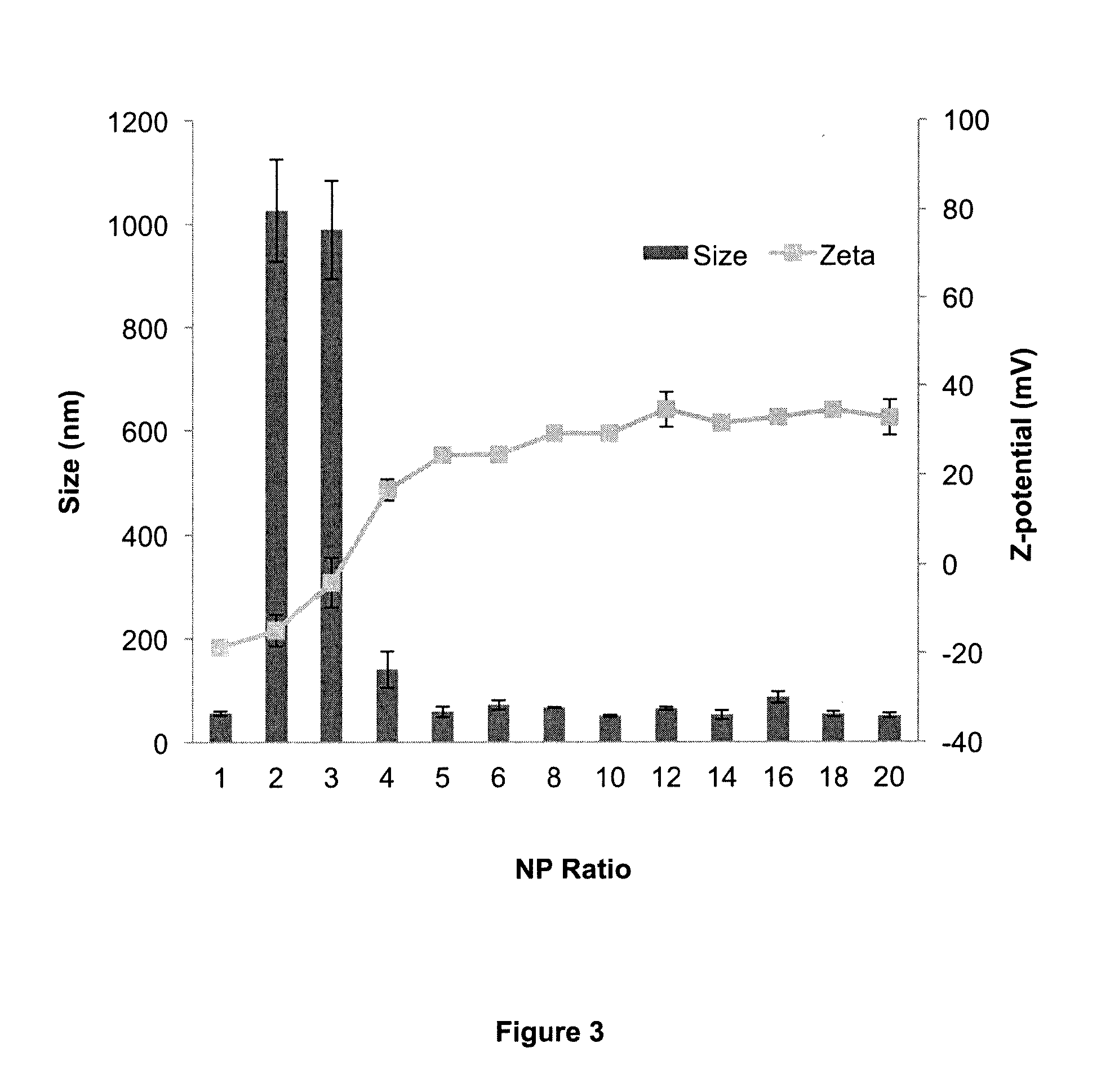

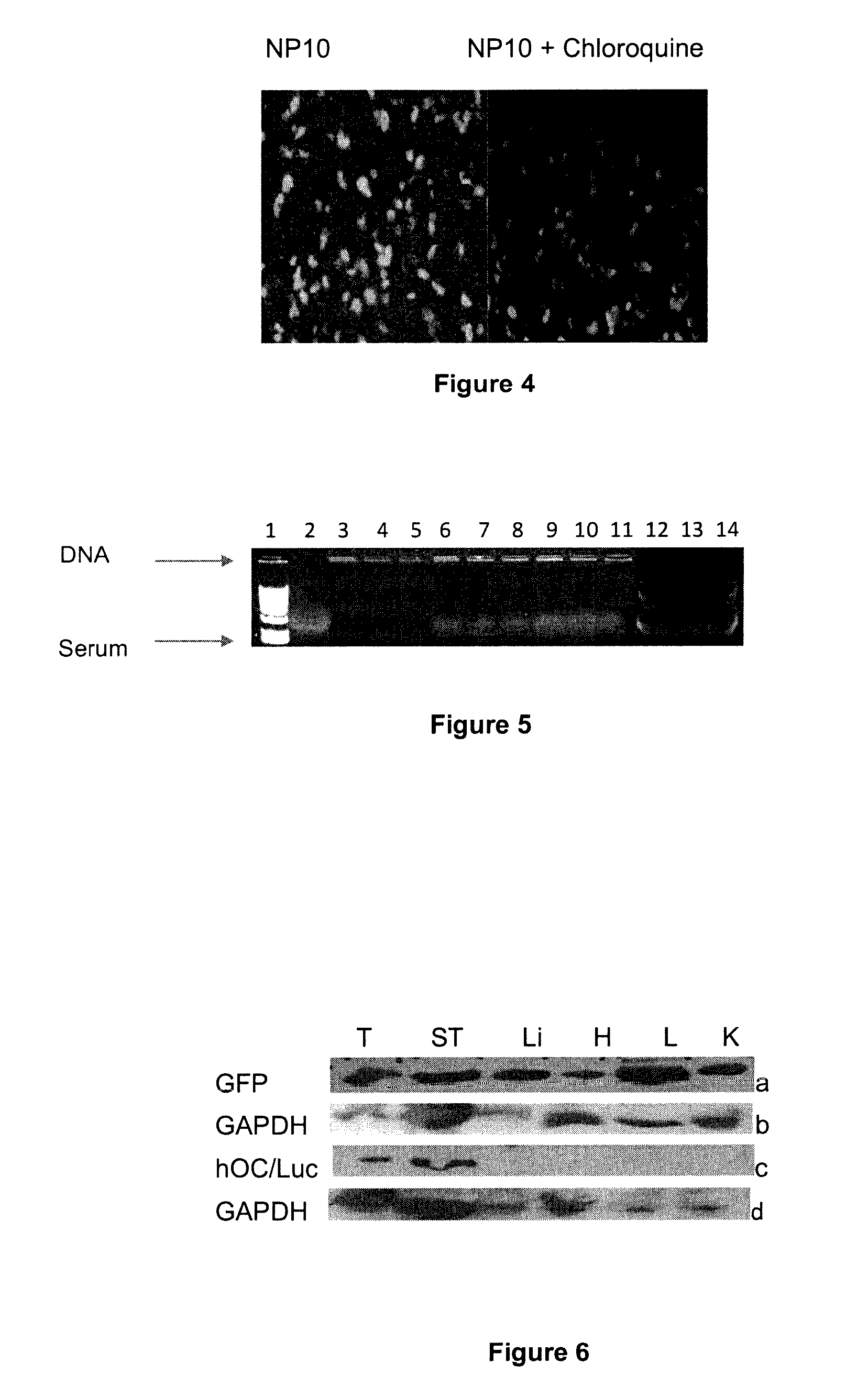

Amphipathic peptide

ActiveUS20150314011A1Improve bioavailabilityImprove cellular uptakeOrganic active ingredientsHeavy metal active ingredientsCysteine thiolateArginine

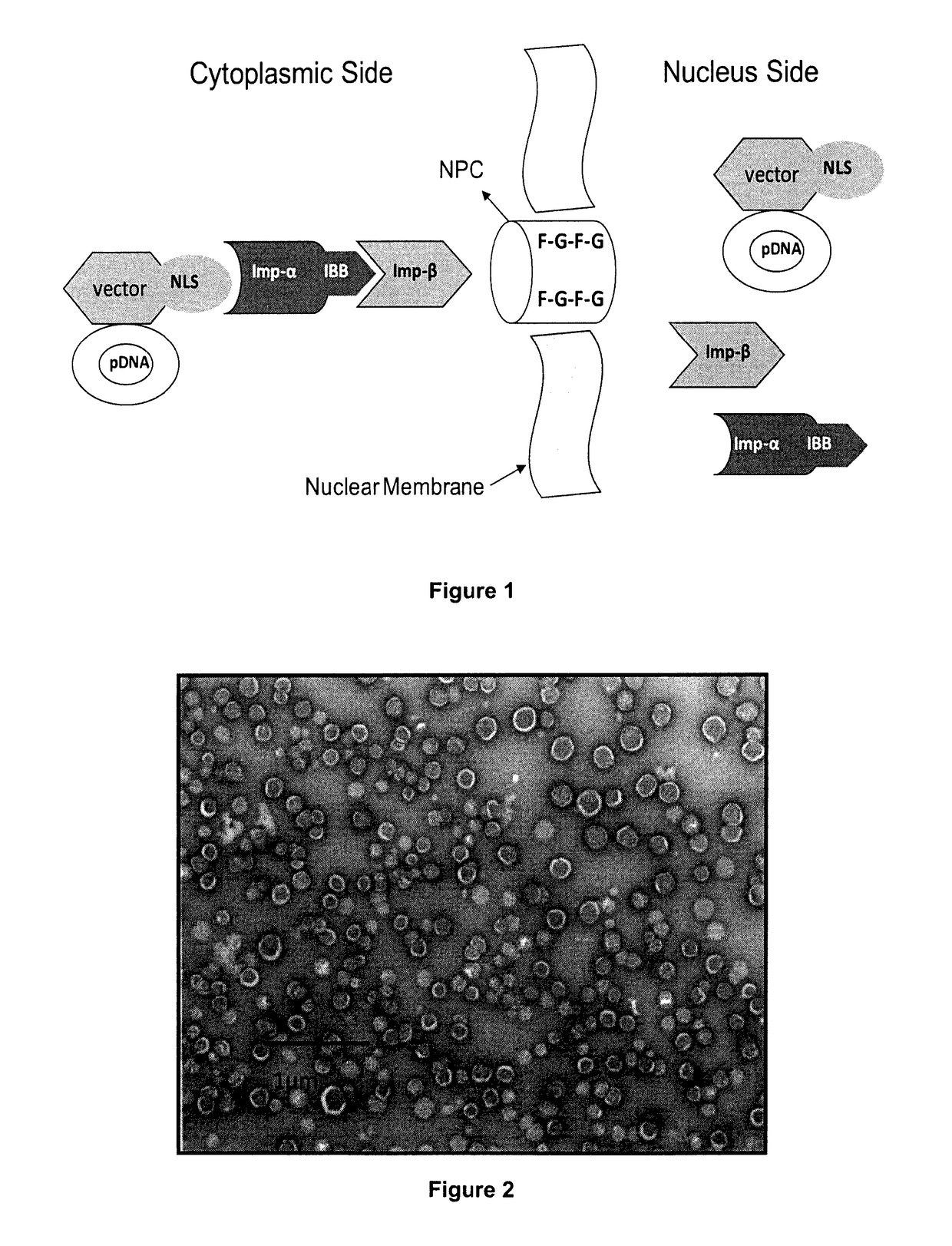

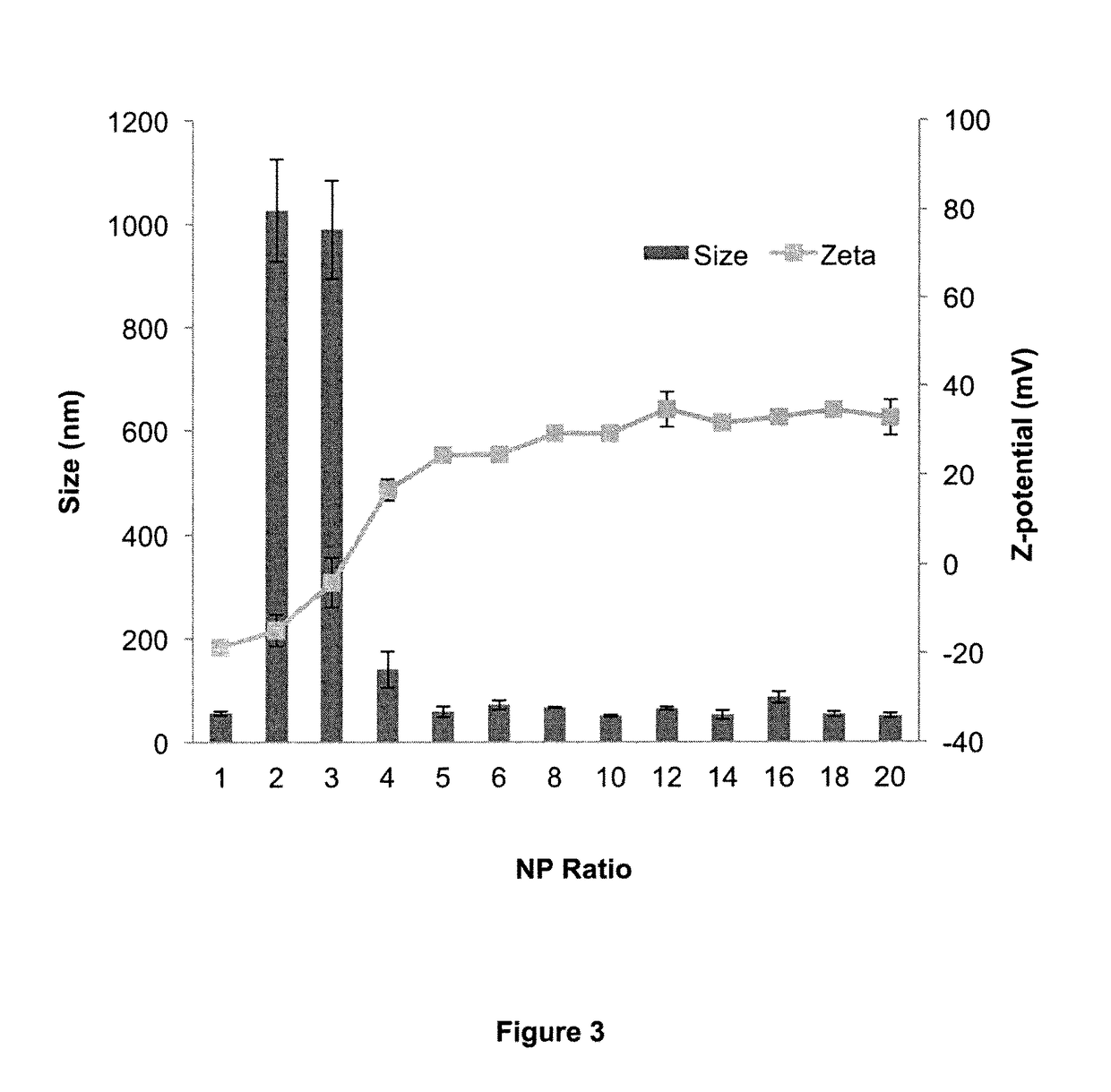

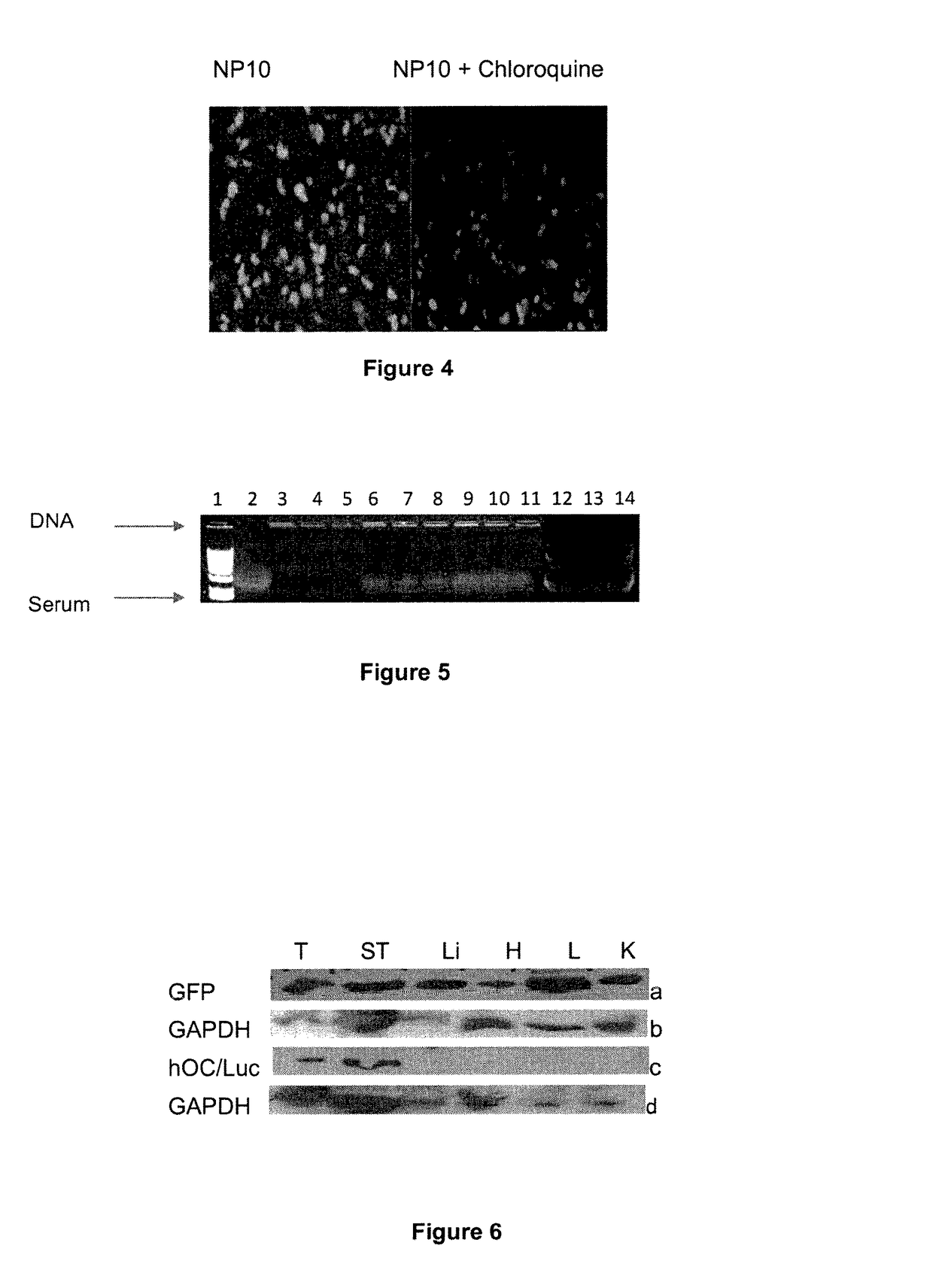

The present invention is directed to an amphipathic peptide and methods of using the amphipathic peptide for delivering small molecule agents to a cell. Ideally, the amphipathic cell penetrating peptide comprises less than approximately 50 amino acid residues with at least 6 arginine residues, at least 12 Alanine Residues, at least 6 leucine resiues, optionally at least one cysteine residue, and at least two but no greater than three glutamic acids wherein the arginine residues are evenly distributed along the length of the peptide; and the peptide has a defined ratio of arginine to negatively charged amino acid residues and a defined ratio of hydrophilic amino acid residues to hydrophobic amino acid residues. The present invention is also directed to a nanoparticle and cell delivery system comprising the amph ipathic cell penetrating peptide of the invention. The peptide, nanoparticle or cell delivery sys tem of the invention may be used in therapy. For example, the peptide may be used as a therapeutic agent delivery system, in which the therapeutic agent may include nucleic acids or other small molecules.

Owner:PHION THERAPEUTICS LTD

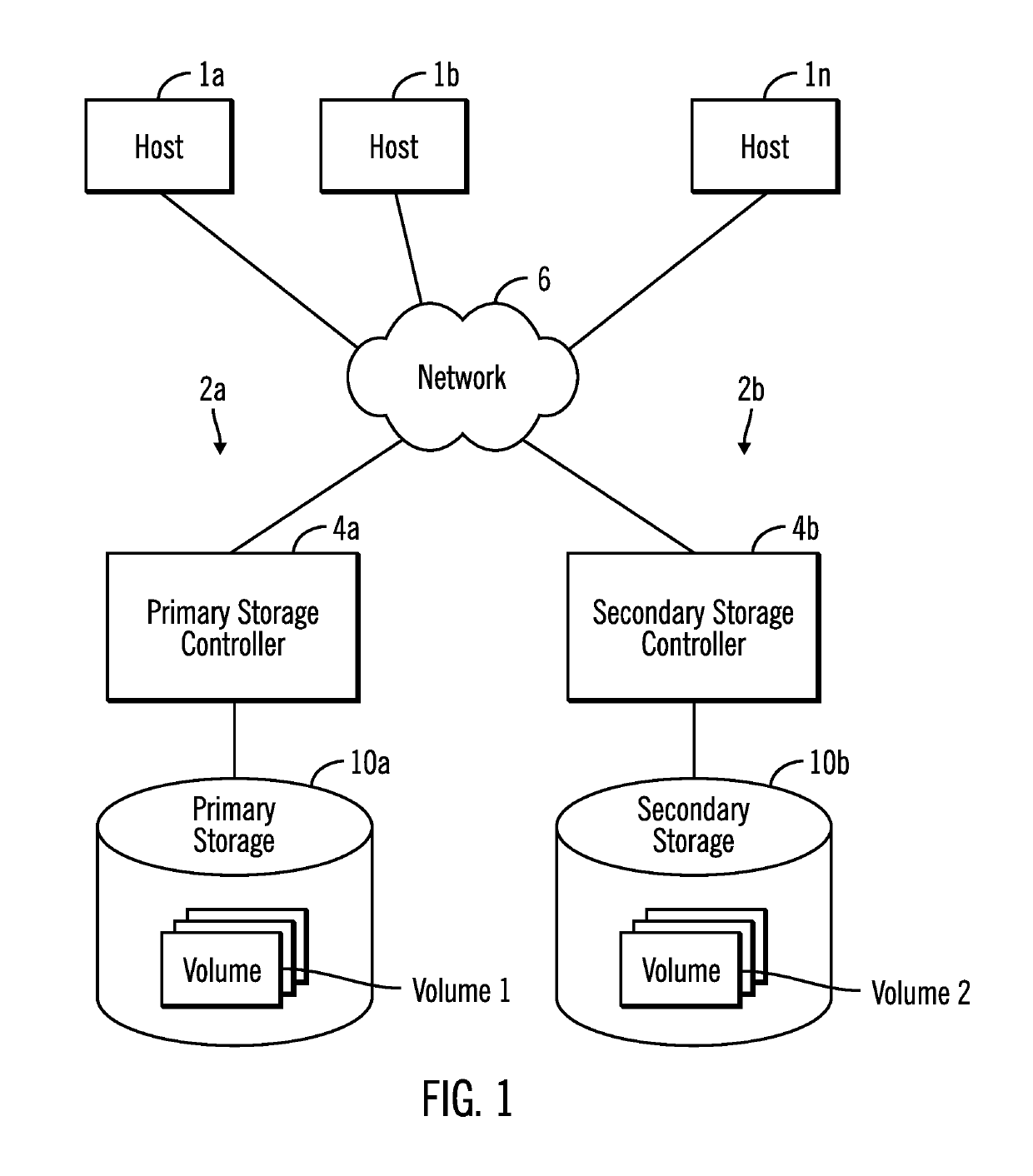

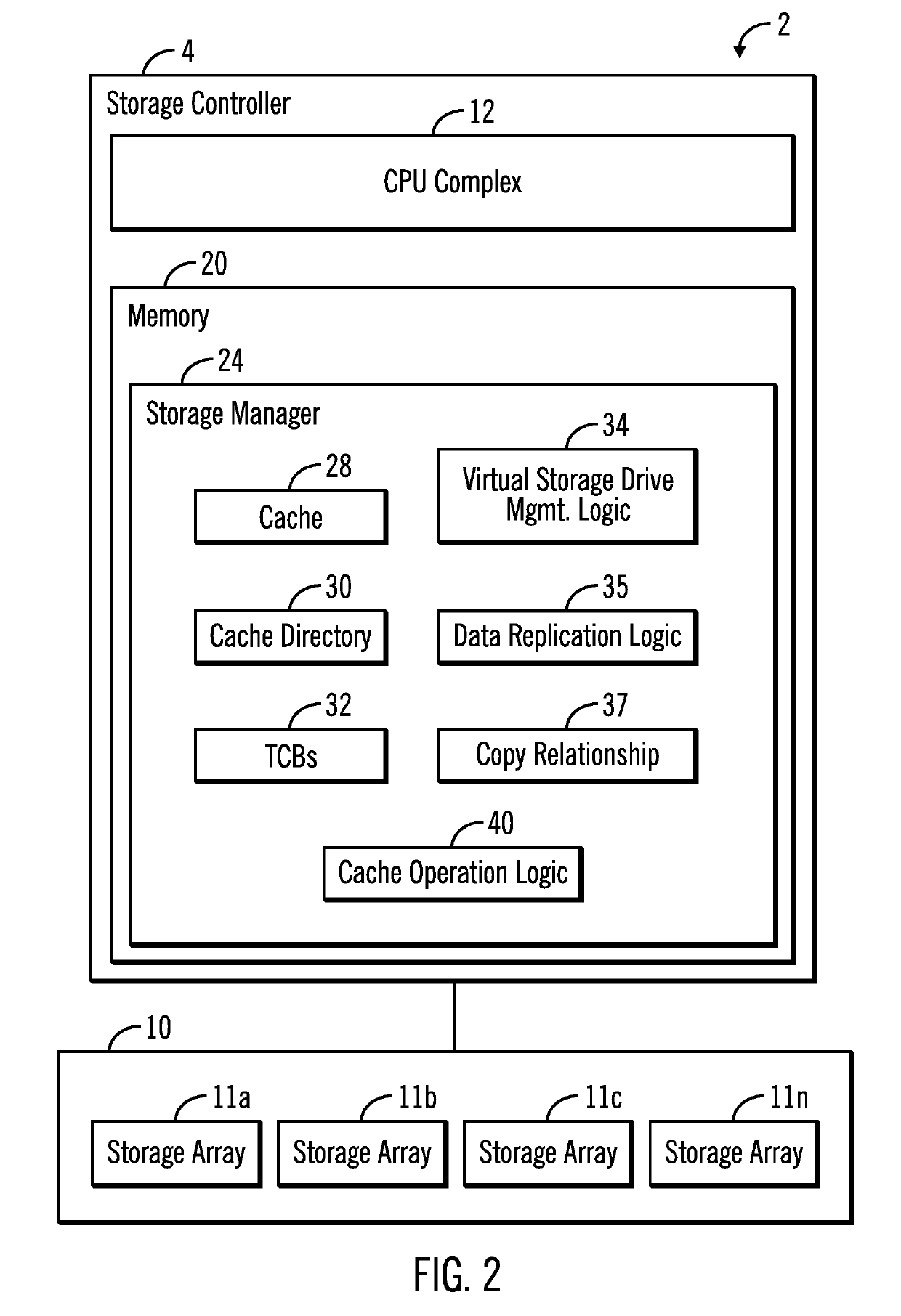

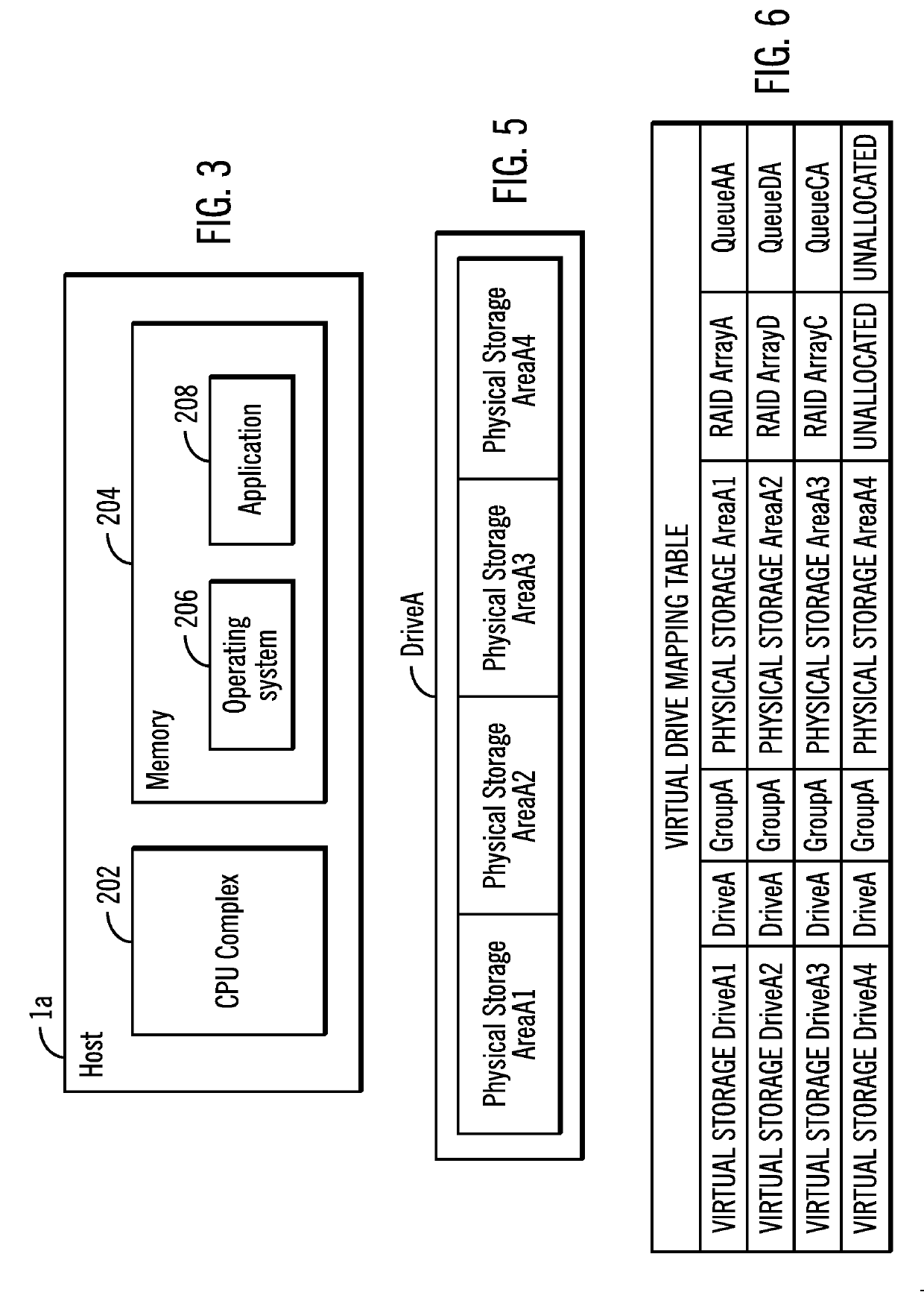

Virtual storage drive management in a data storage system

ActiveUS20190266062A1Easy to rebuildReducing and minimizing numberInput/output to record carriersRedundant hardware error correctionRAIDError processing

In one embodiment, virtual storage drives are allocated to RAID arrays so that no two virtual storage drives of a RAID array are mapped to the same physical storage drive. In another aspect, error handling routines are limited to virtual storage drives impacted by an error in a physical storage drive so that virtual storage drives of the physical storage drive not impacted by the error are bypassed. In yet another aspect, cache operations to a target virtual storage drive may be throttled as a function of both a limit imposed on cache operations directed to the RAID array to which the virtual storage drive is allocated, and a separate limit on cache operations directed to a group of virtual storage drives which are mapped to the same physical storage drive as the target virtual storage drive. Other features and aspects may be realized, depending upon the particular application.

Owner:IBM CORP

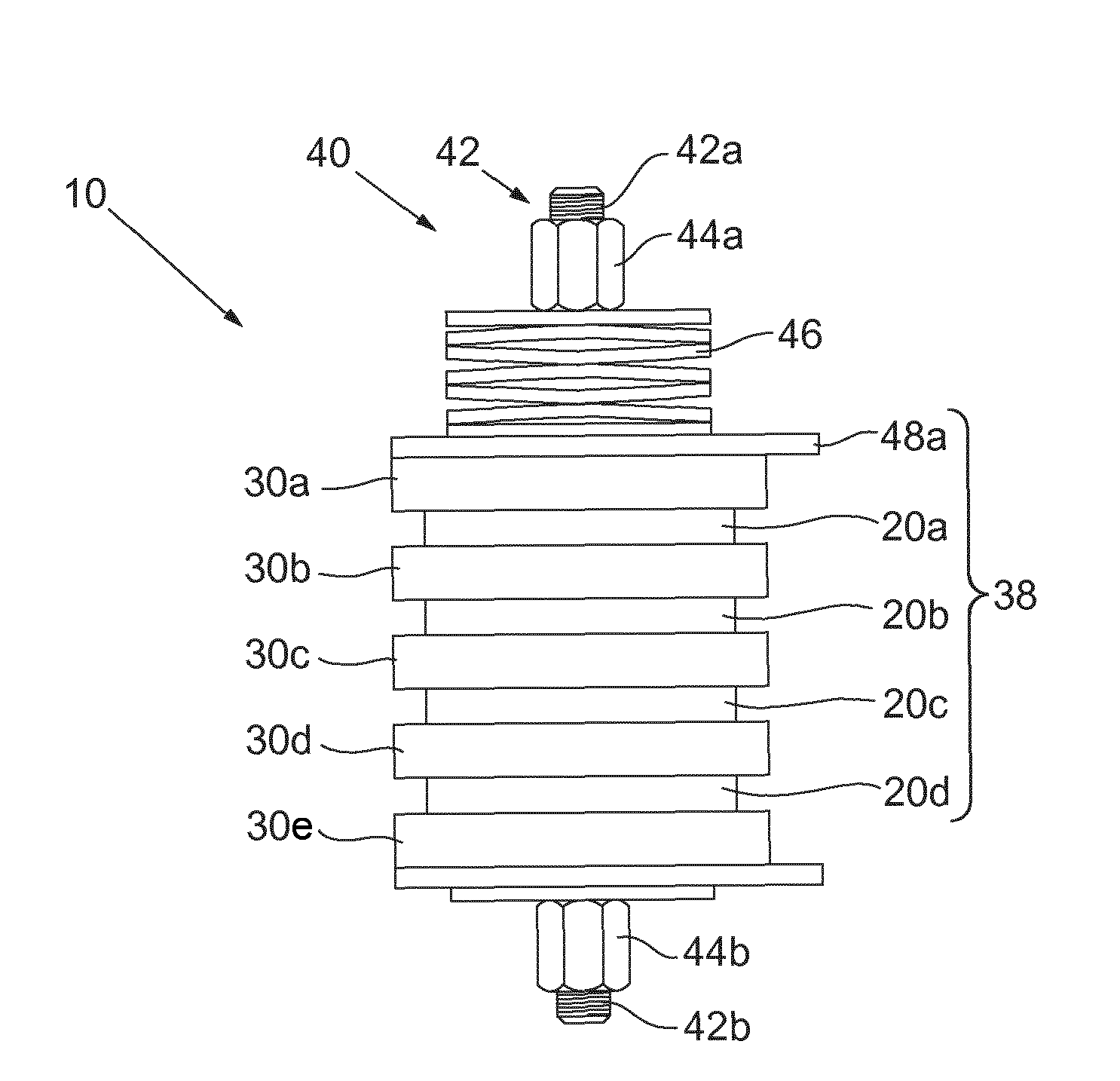

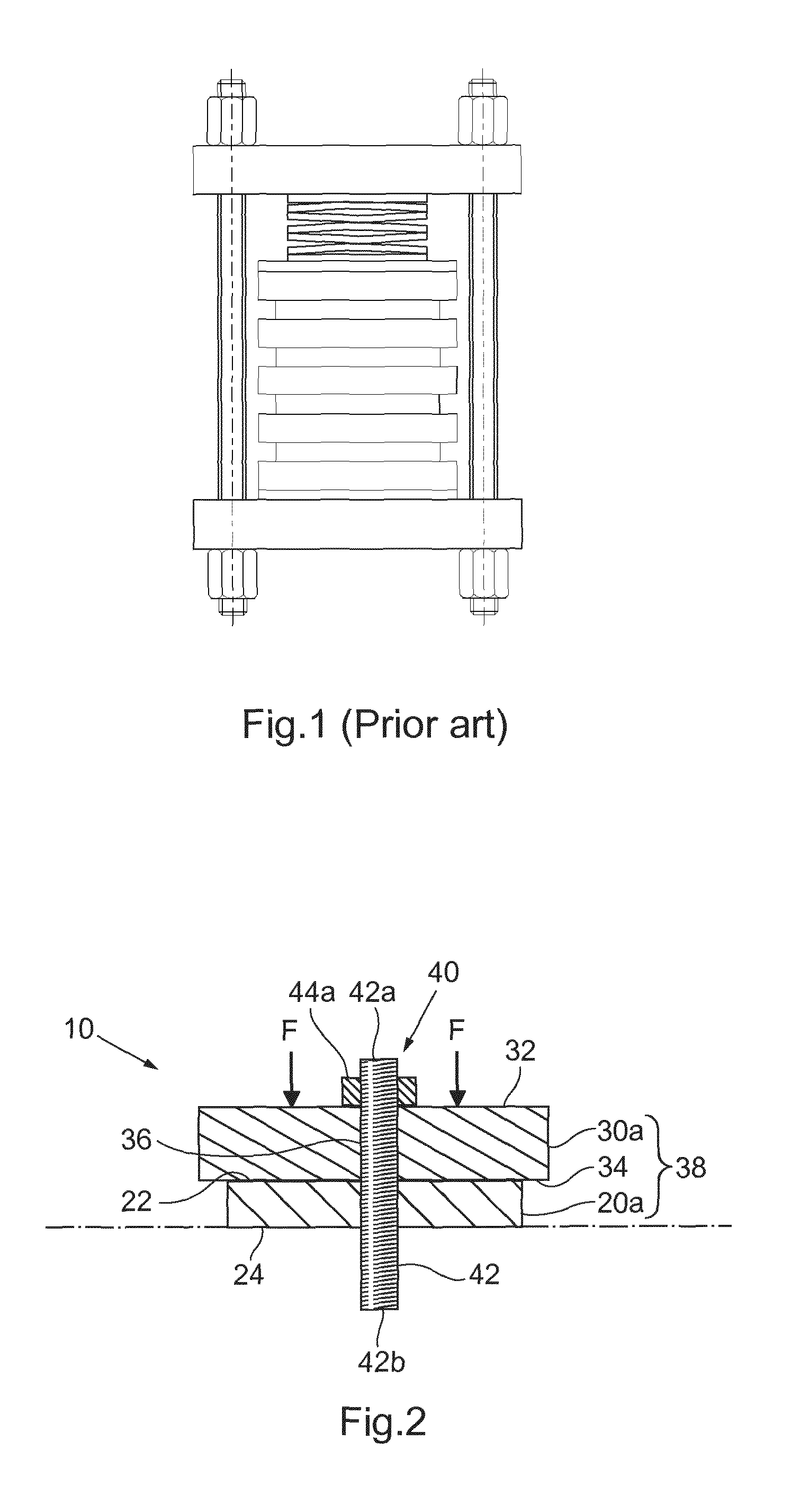

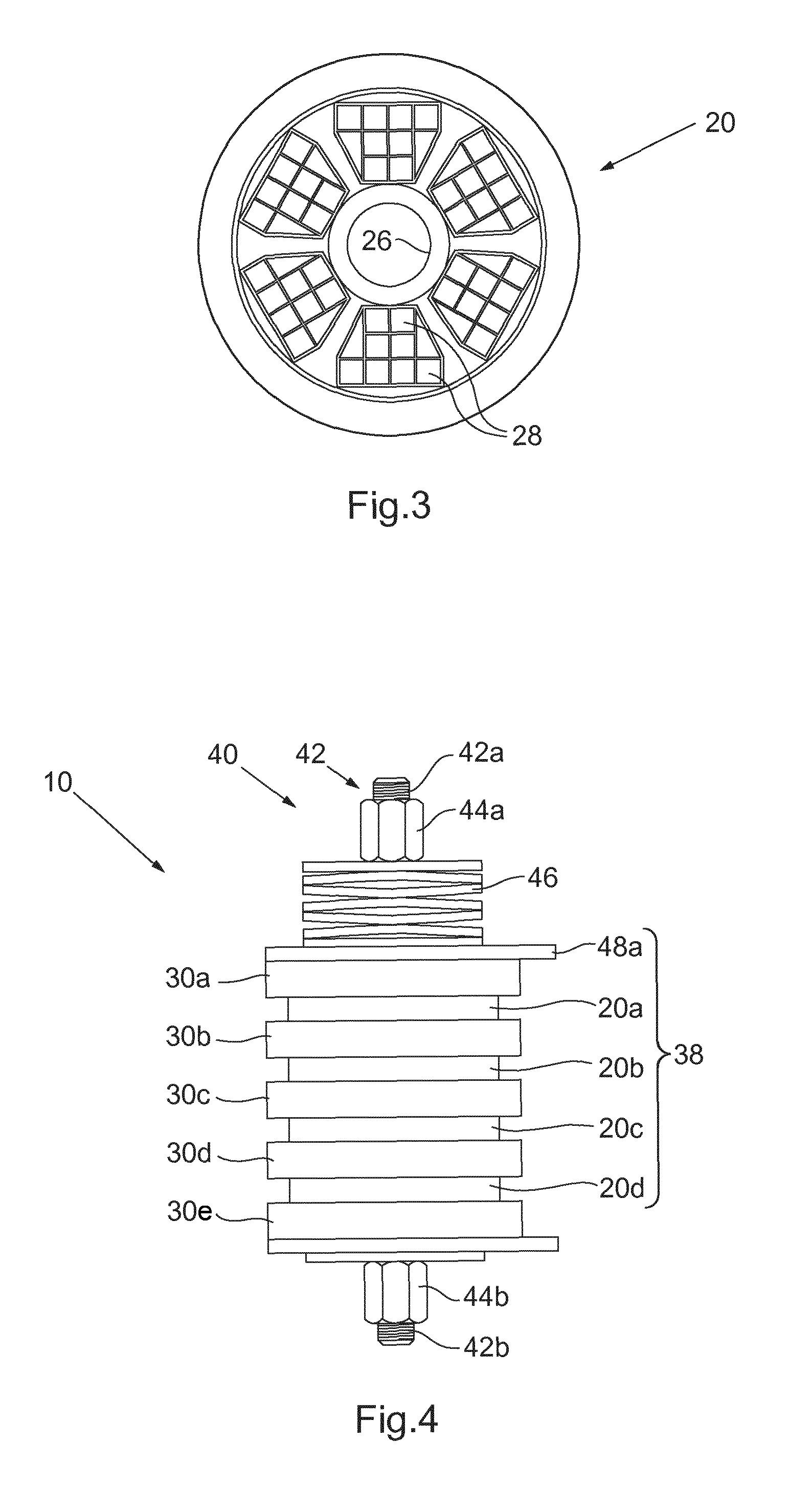

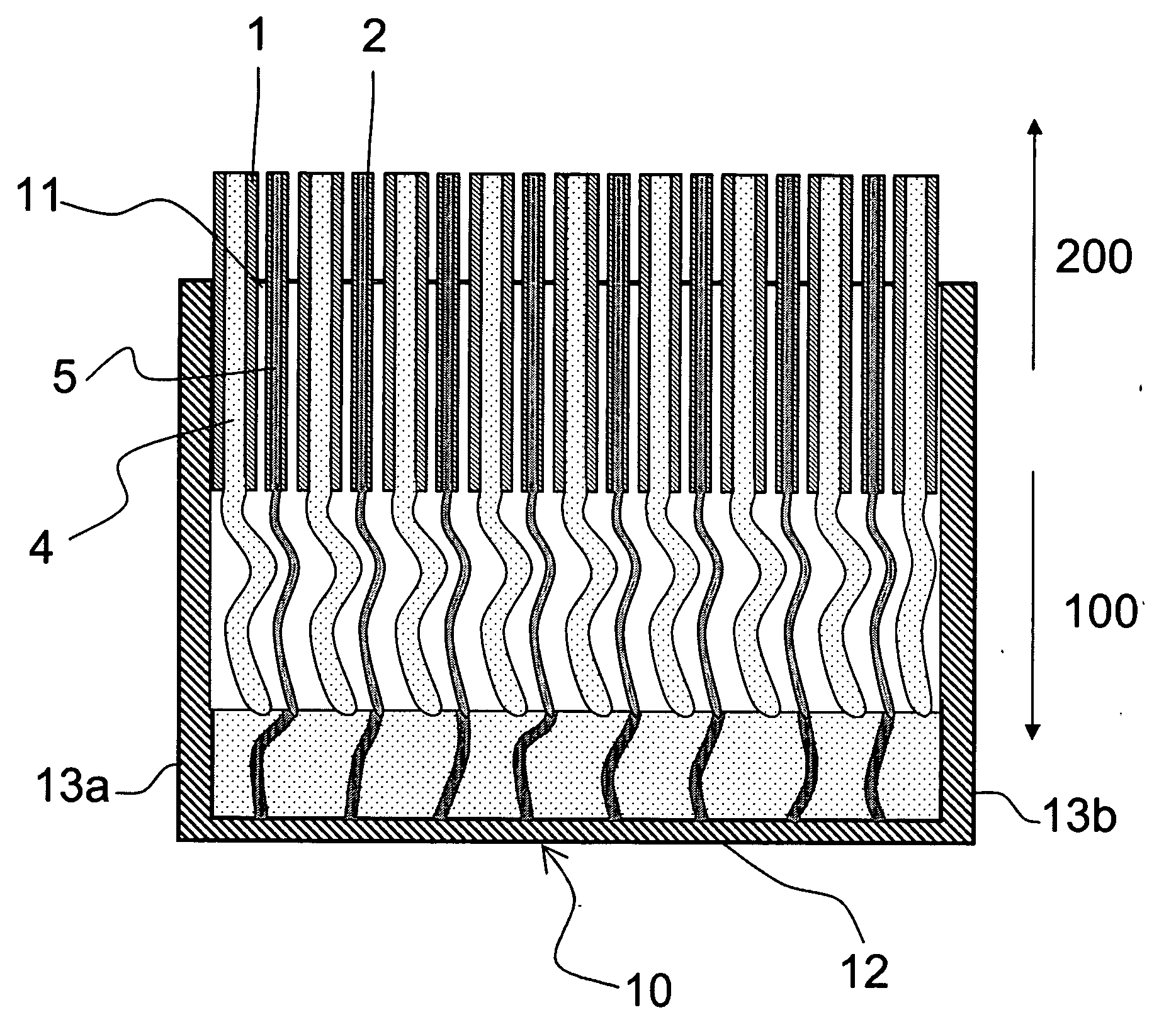

Semiconductor assembly

ActiveUS20160329264A1Simplifies mechanical designSimple designConversion constructional detailsSemiconductor/solid-state device detailsElectrically conductiveSemiconductor

A semiconductor assembly includes a stack with a semiconductor module and a cooler, wherein the semiconductor module is provided in contact with the cooler. A clamping assembly is adapted to exert a force on the two sides of the stack. The stack is provided with a through hole between the two sides thereof and a part of the clamping assembly including an electrically conductive part which extends through the through hole of the stack. Thereby, a compact mechanical arrangement is provided while obtaining improved electrical properties, such as lower inductance and more even current distribution.

Owner:HITACHI ENERGY SWITZERLAND AG

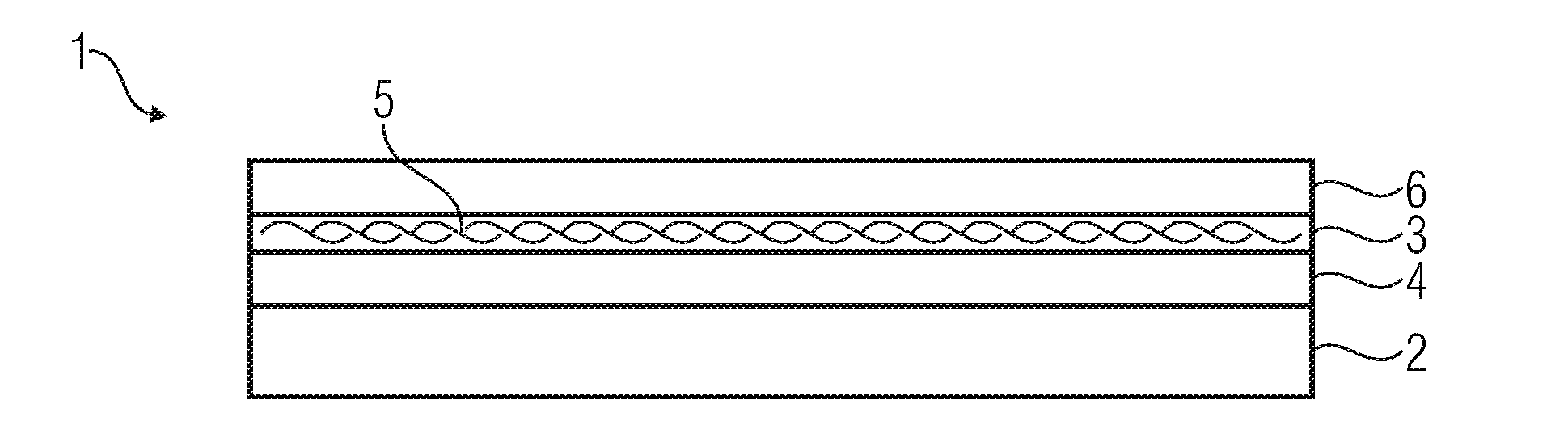

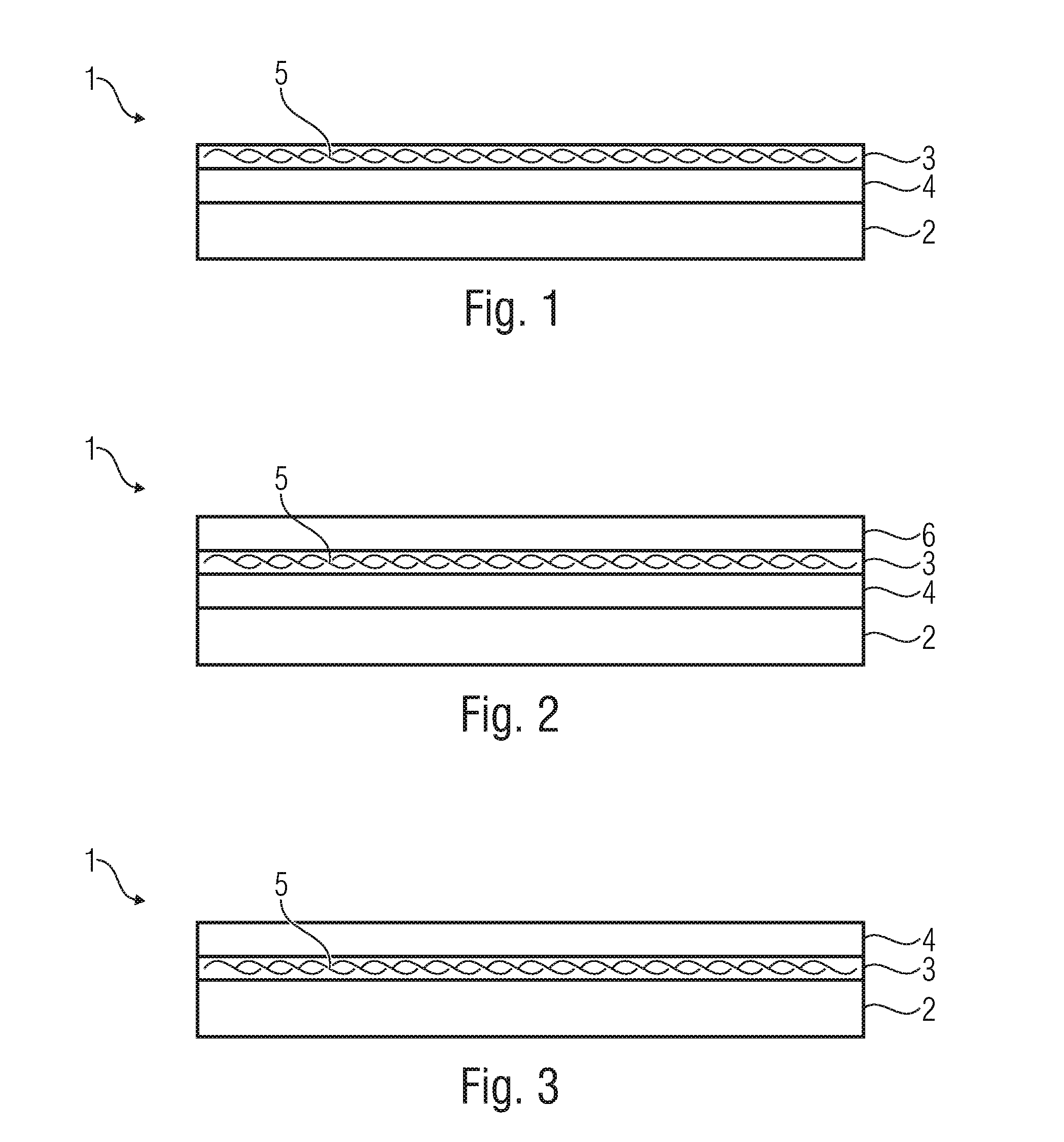

Transparent nanowire electrode comprising a functional organic layer

InactiveUS20160300637A1Improve featuresProcessing problemSolid-state devicesNon-conductive material with dispersed conductive materialOrganic layerMetal nanowires

What is presented here is a transparent electrode having: at least one carrier layer for stabilizing the electrode; at least one electrically conductive layer containing metal nanowires, which is produced by spreading a suspension of a liquid and the metal nanowires surrounded by a stabilizing layer, along the carrier layer and drying same by removing the liquid; and at least one functional organic layer formed along the carrier layer, which, while the electrically conductive layer dries, by an electrical interaction with the metal nanowires and / or with the stabilizing layers of the metal nanowires, changes an interaction between the metal nanowires and the stabilizing layers such that the result is a substance-to-substance bond between the metal nanowires.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

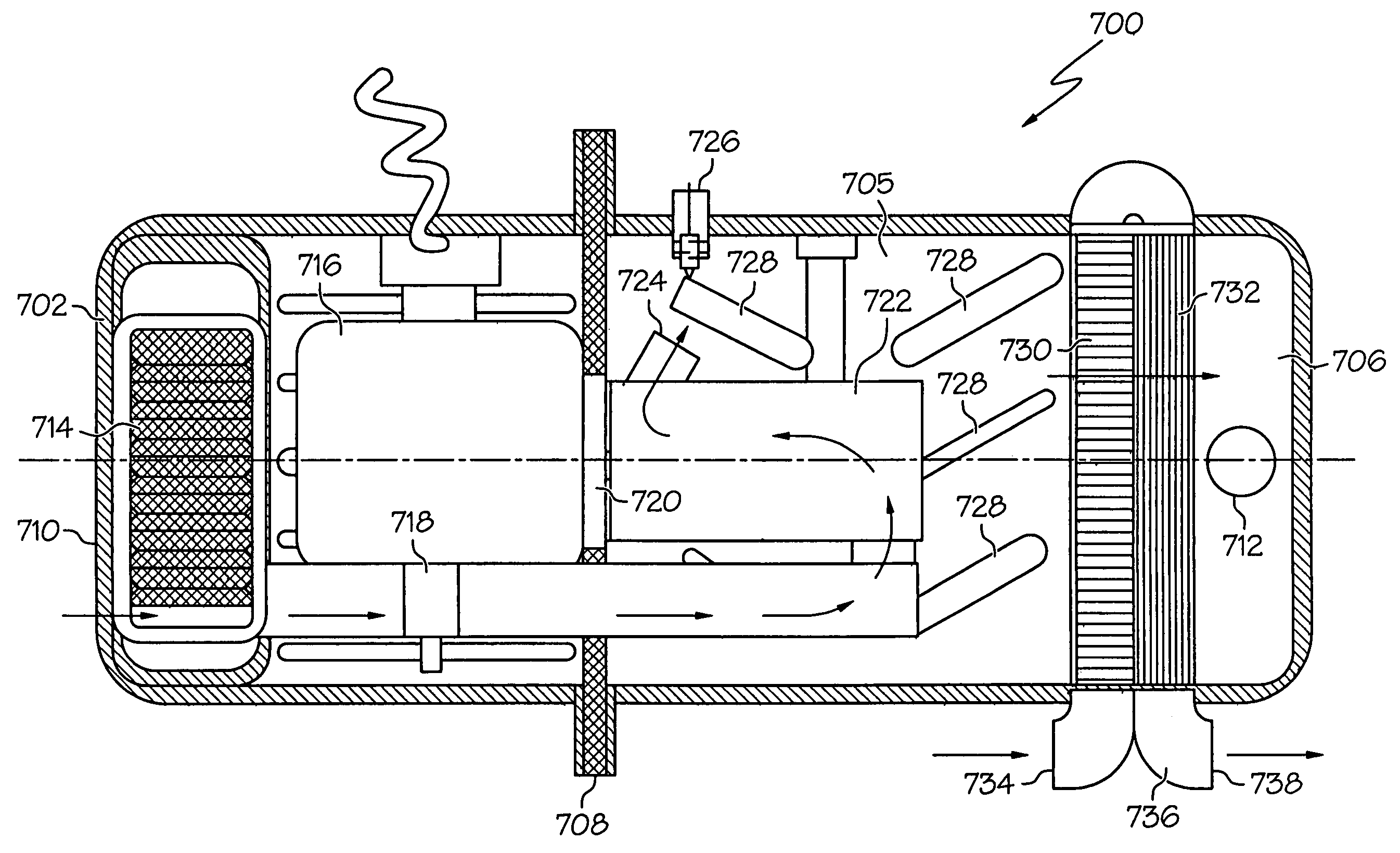

Integrated air supply with humidification control for fuel cell power systems

InactiveUS7592083B2Minimize complexityMinimize componentFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsWater vapor

A fluid delivery device for an electrochemical conversion assembly. In one embodiment, the electrochemical conversion assembly is a fuel cell system. The device includes one or more fluid-manipulating components combined into a housing to minimize weight, size and complexity. In one form, the device may include a compressor, heat exchanger and a water vapor transfer unit, at least the latter two of which are located within a chamber defined by the housing. A controller can be used to monitor and selectively vary the extent to which at least one of these components modifies properties a fluid (such as air) that can be used as a reactant in the electrochemical conversion assembly. In a particular form, the heat exchanger and water vapor transfer unit can cooperate to promote the hydration of the reactant.

Owner:GM GLOBAL TECH OPERATIONS LLC

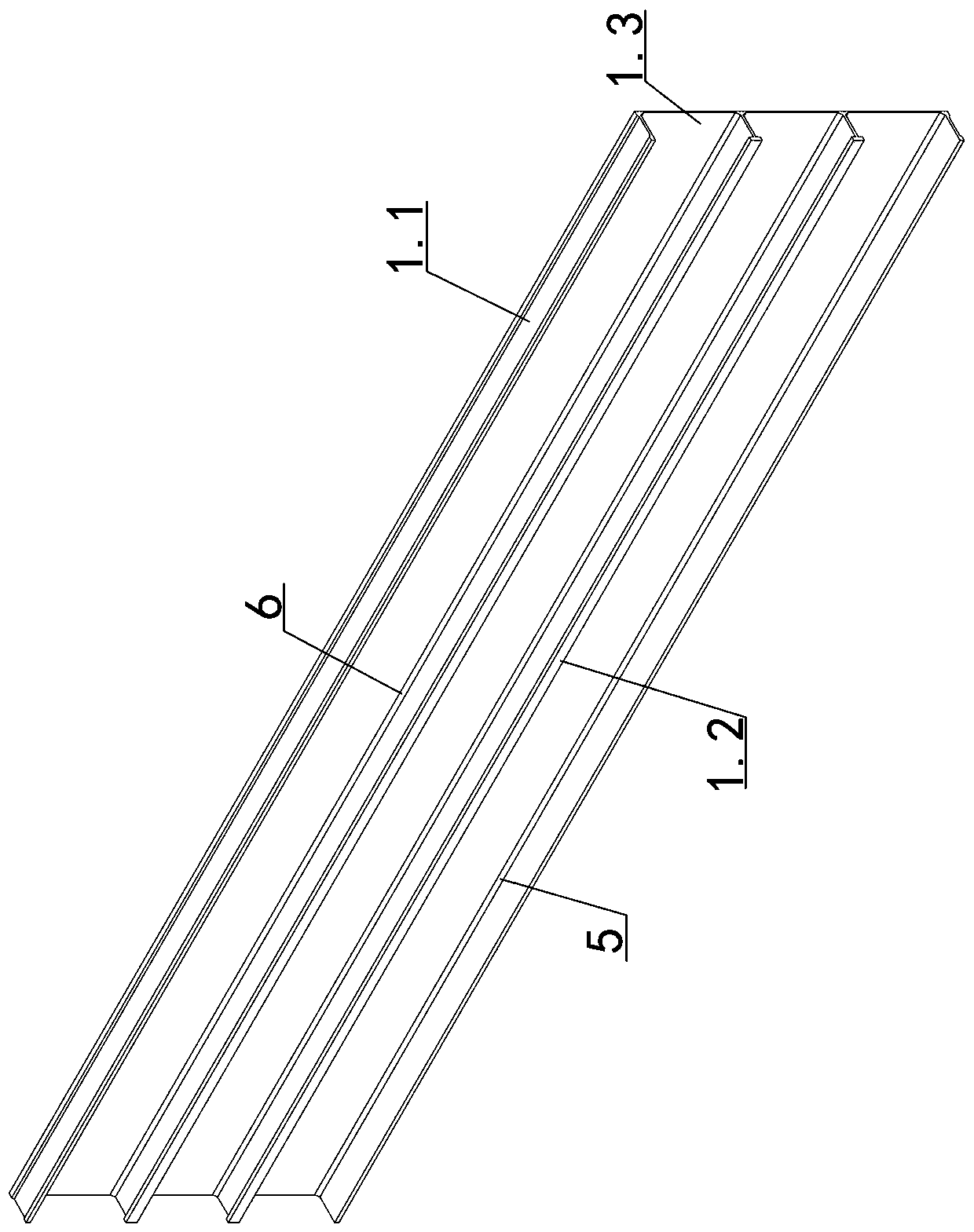

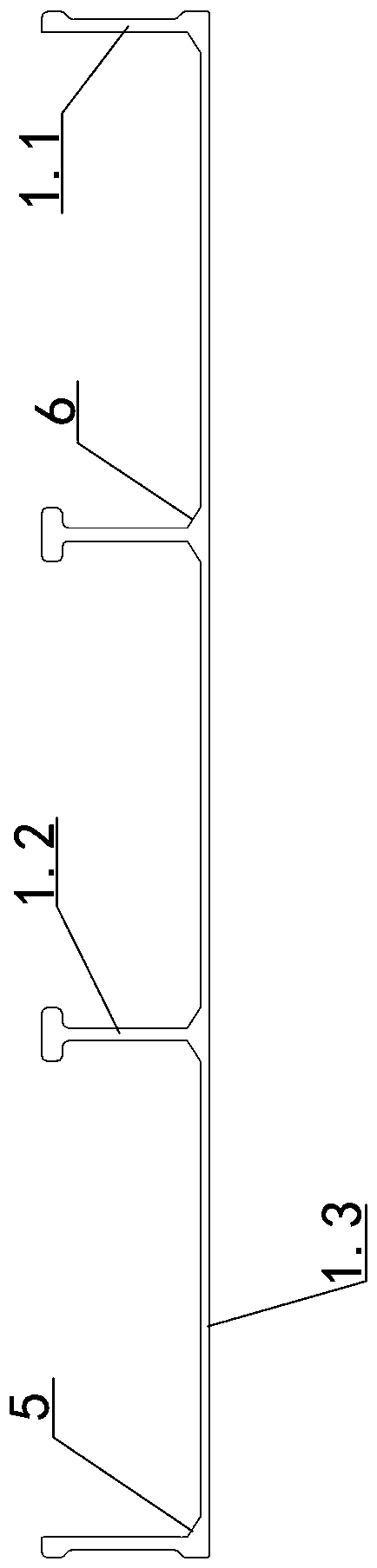

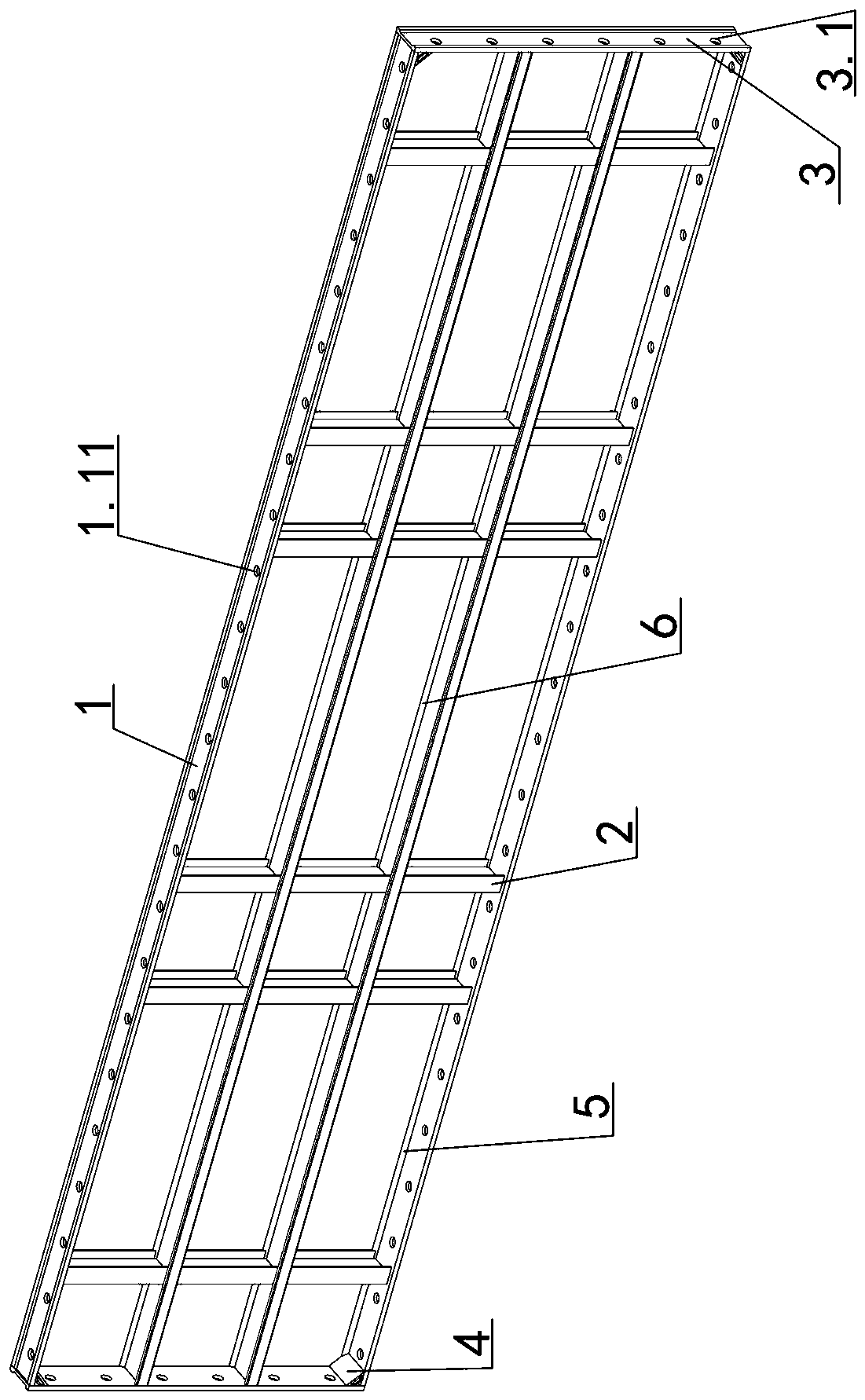

T-shaped section profile for aluminum alloy template and unit template structure of aluminum alloy template

InactiveCN105239771AReasonable section structureEasy to shapeForming/stuttering elementsStructural engineeringProcessing cost

The invention relates to a T-shaped section profile for an aluminum alloy template and a unit template structure of the aluminum alloy template. The T-shaped section profile is an integrally-molded aluminum alloy profiled plate and is composed of a groove body and a group of longitudinal reinforcing ribs, wherein the groove body is formed by a rectangular panel and two opposite longitudinal side frames on the back of the panel, and the longitudinal reinforcing ribs are uniformly distributed at the groove bottom of the groove body. The unit template structure comprises the T-shaped section profile of the aluminum alloy template, a transverse side frame, transverse reinforcing ribs and angle reinforcing blocks. The T-shaped section profile has the advantages of being definite in structure and simple in molding, little post processing of the template is required, the processing cost is reduced, and the light weight, safety in use and long service life of the template can be ensured; the construction efficiency is improved, and the standardized and systemized, industrialized production is easier; thus, the template has the advantages of being quick and convenient in disassembly and assembly, firm in mounting, high in construction efficiency and low in construction cost.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Frozen confection

InactiveUS20080317909A1Suitable viscosityEnsure even distributionLighting and heating apparatusIce productionSweet foodChemistry

The present invention relates to a frozen confection in a container having various layers of inclusion material and of confection material as well as to the production of such a frozen confection.

Owner:CONOPCO INC D B A UNILEVER

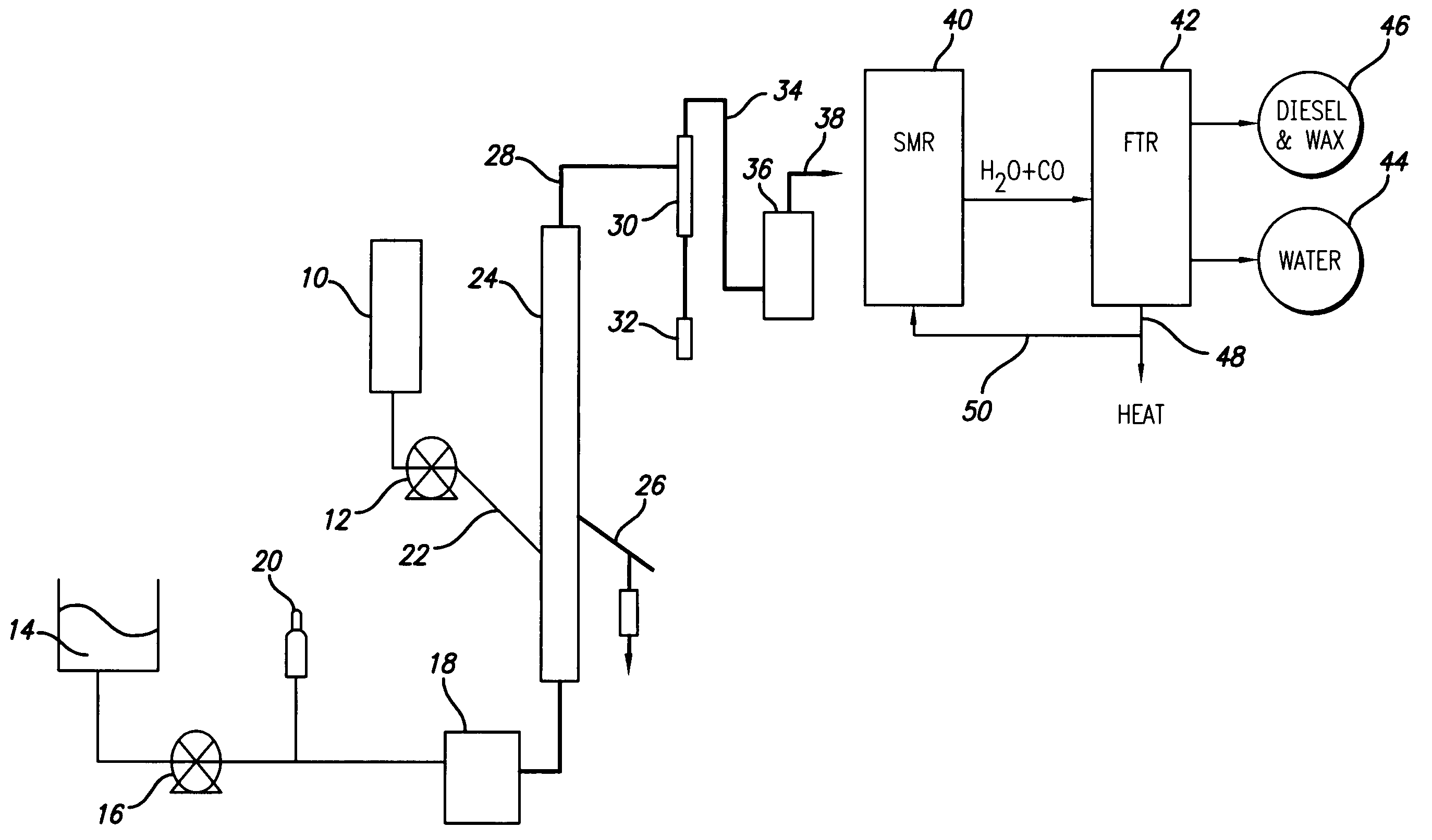

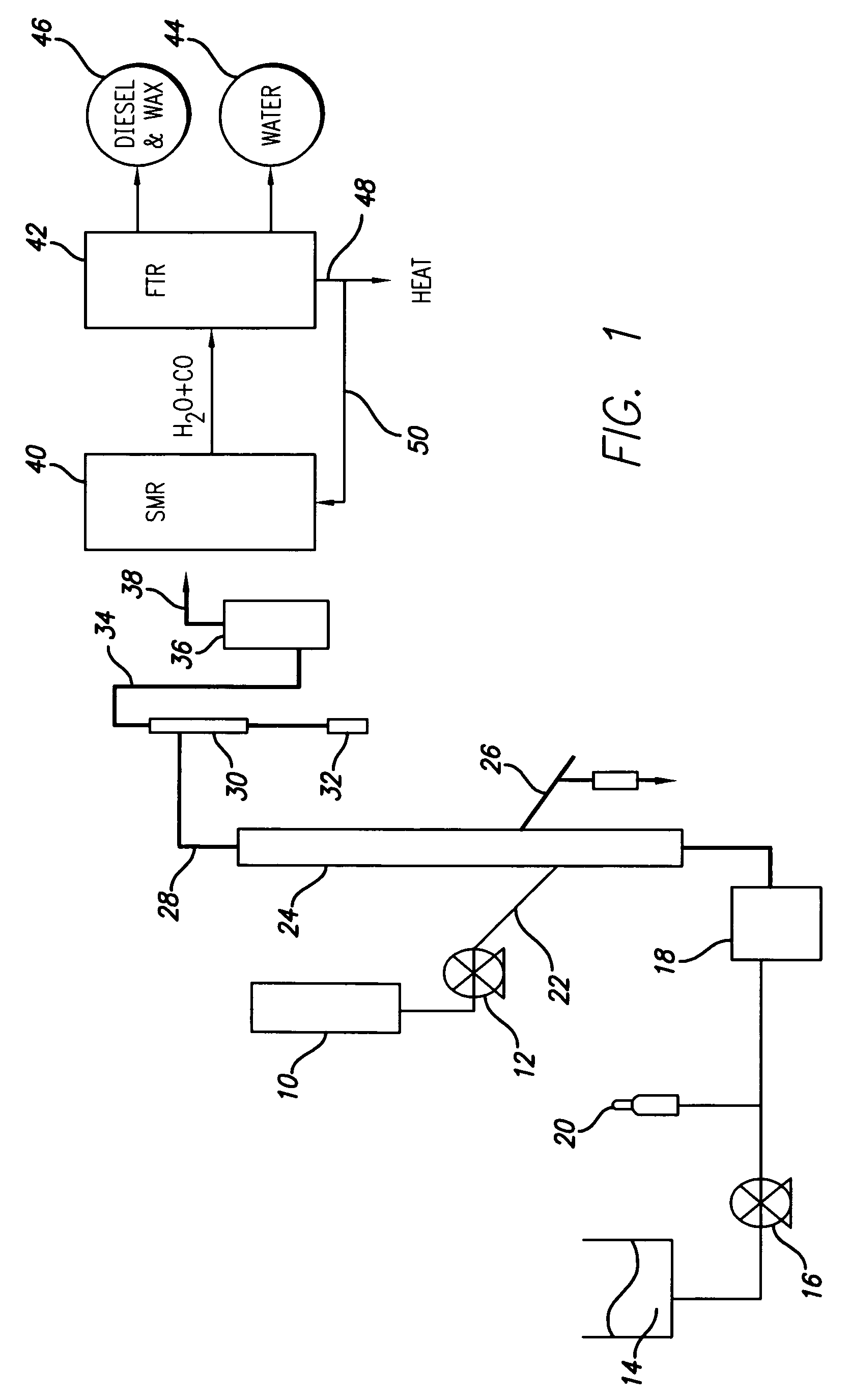

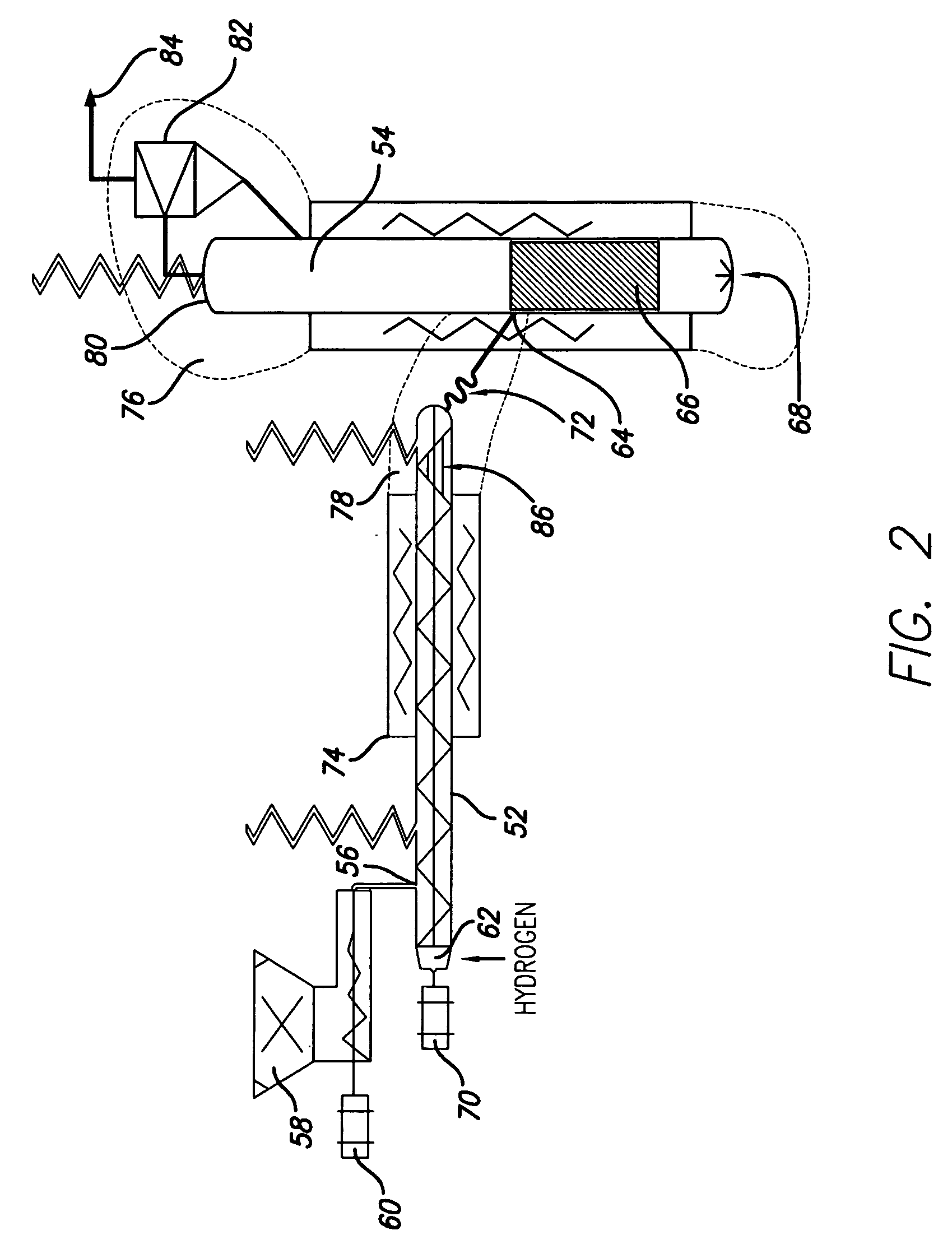

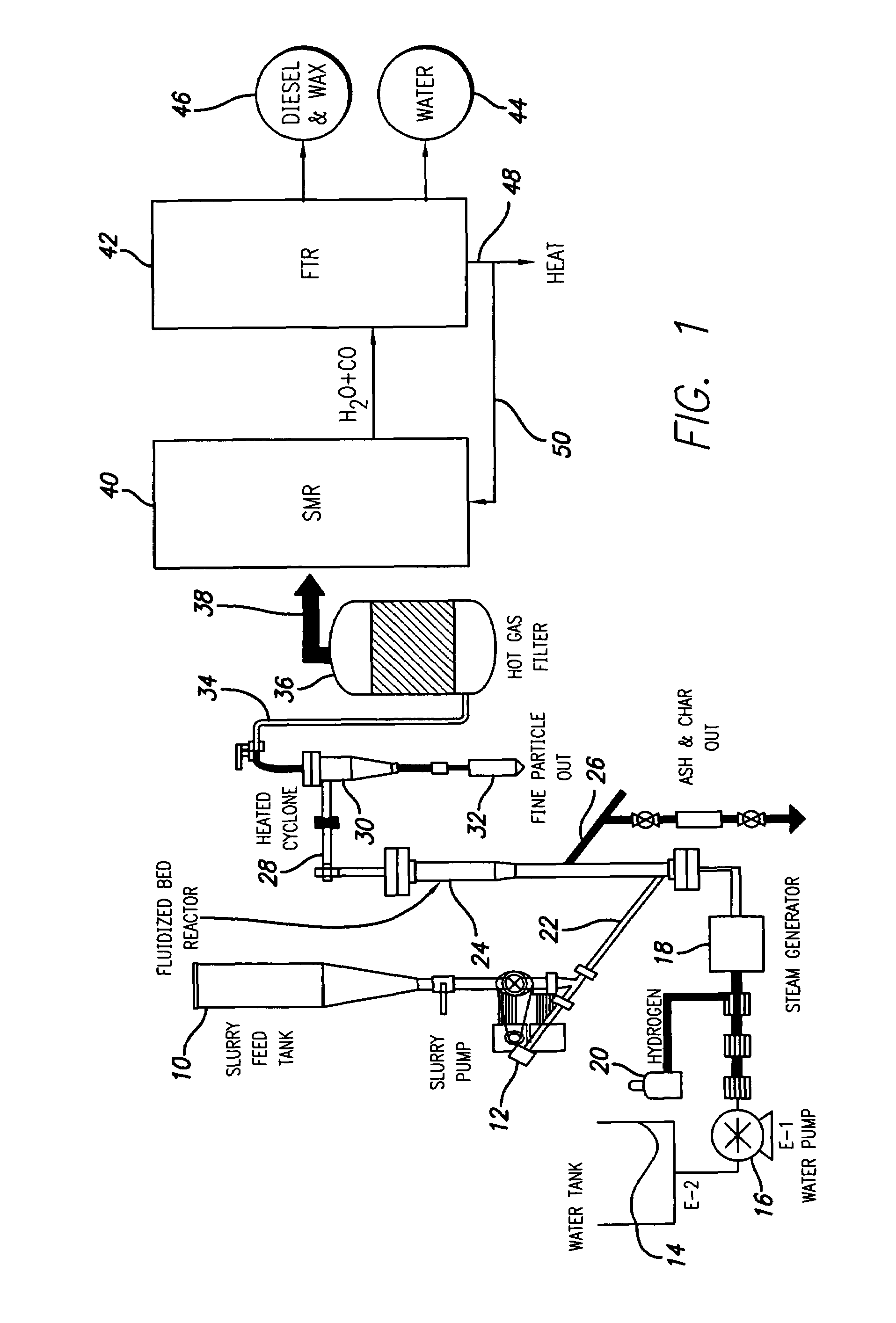

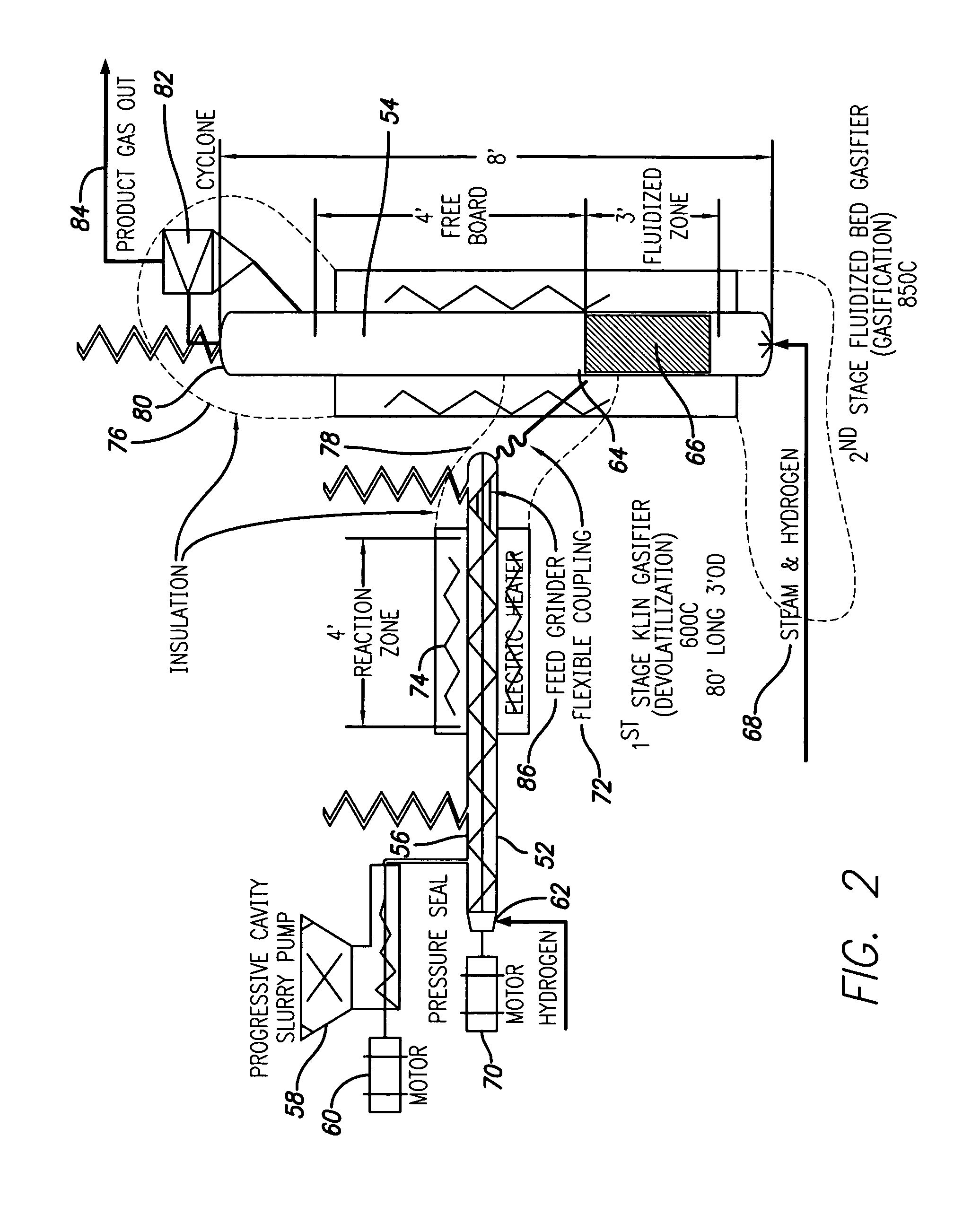

Method and apparatus for steam hydro-gasification with increased conversion times

ActiveUS20080312348A1Increase conversion timeImproved and economicalLiquid hydrocarbon mixture productionRotary drum/kiln gasifiersHydrogenFluidized bed

A method and apparatus for converting carbonaceous material to a stream of carbon rich gas, comprising heating a slurry feed containing the carbonaceous material in a hydrogasification process using hydrogen and steam, at a temperature and pressure sufficient to generate a methane and carbon monoxide rich stream in which the conversion time in the process is between 5 and 45 seconds. In particular embodiments, the slurry feed containing the carbonaceous material is fed, along with hydrogen, to a kiln type reactor before being fed to the fluidized bed reactor. Apparatus is provided comprising a kiln type reactor, a slurry pump connected to an input of the kiln type reactor, means for connecting a source of hydrogen to an input of the kiln type reactor; a fluidized bed reactor connected to receive output of the kiln type reactor for processing at a fluidizing zone, and a source of steam and a source of hydrogen connected to the fluidized bed reactor below the fluidizing zone. Optionally, a grinder can be provided in the kiln type reactor.

Owner:RGT UNIV OF CALIFORNIA

Method and apparatus for steam hydro-gasification in a fluidized bed reactor

InactiveUS7619012B2Well mixedImproved and economicalCombustible gas chemical modificationHydrogenHydrogenFluidized bed

Owner:RGT UNIV OF CALIFORNIA

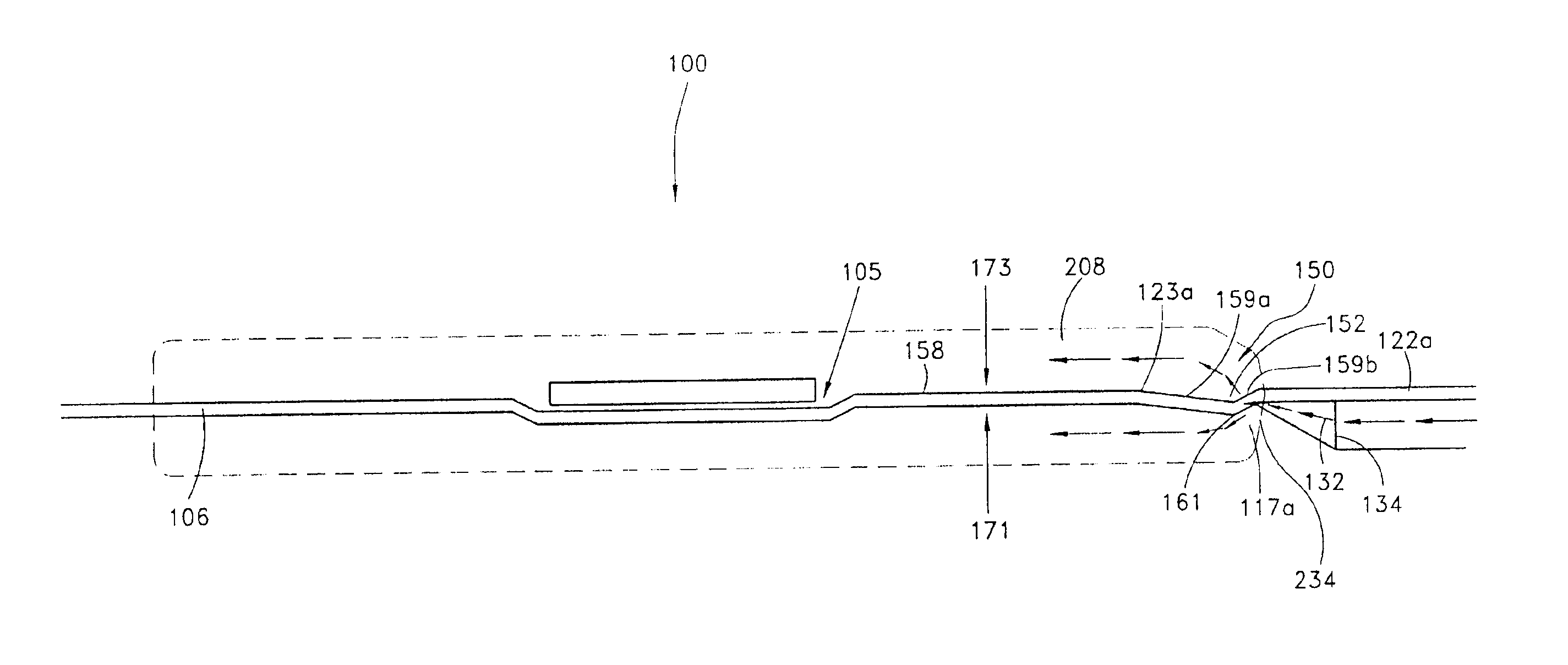

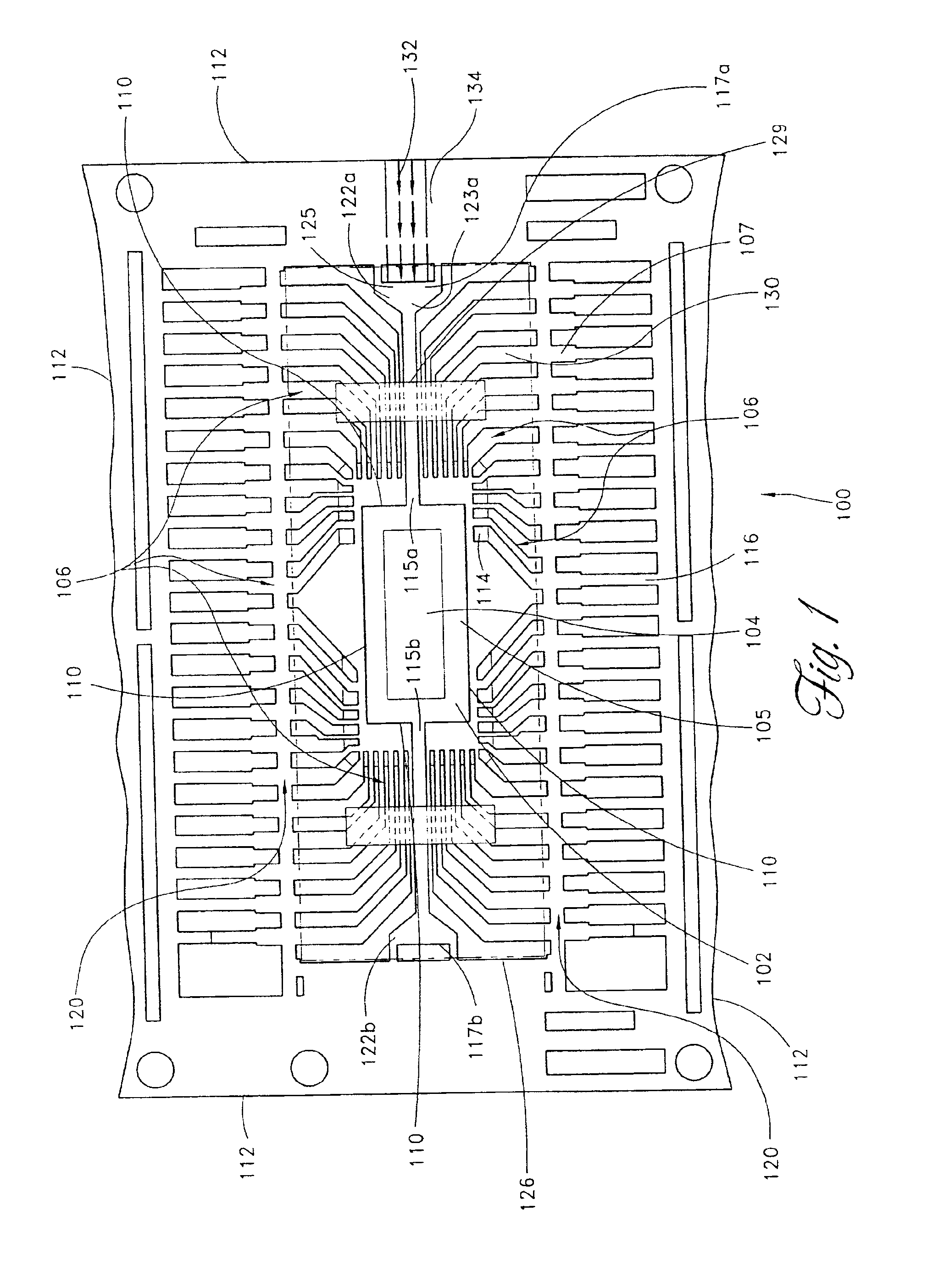

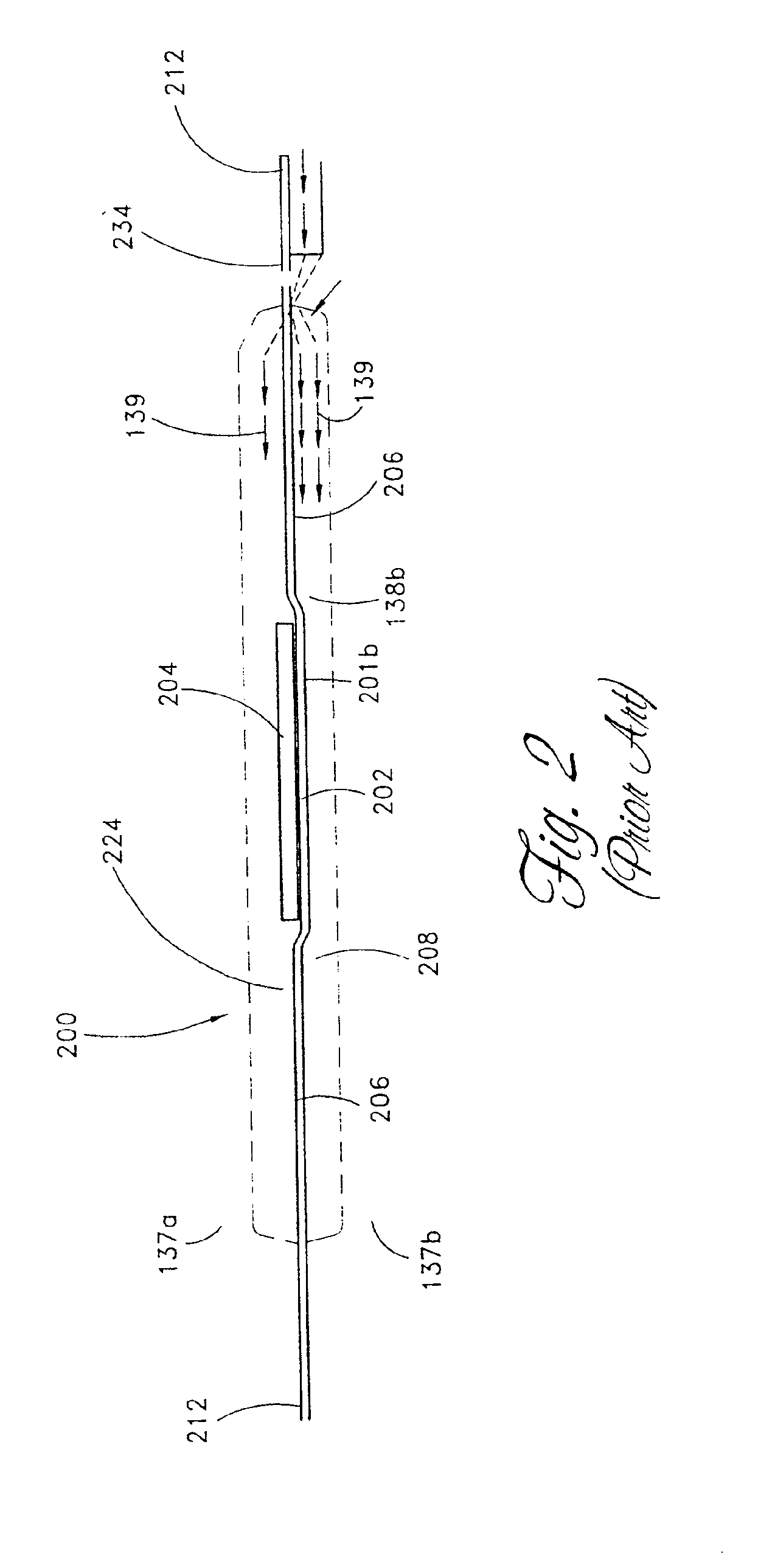

Leadframe alteration to direct compound flow into package

InactiveUS7053467B2Increase the differential pressureHigh trafficSemiconductor/solid-state device detailsSolid-state devicesBottom gateEngineering

Owner:MICRON TECH INC

Amphipathic peptide

ActiveUS9744244B2Reduce deliveryImprove localizationOrganic active ingredientsHeavy metal active ingredientsCysteine thiolateArginine

The present invention is directed to an amphipathic peptide and methods of using the amphipathic peptide for delivering small molecule agents to a cell. Ideally, the amphipathic cell penetrating peptide comprises less than approximately 50 amino acid residues with at least 6 arginine residues, at least 12 Alanine Residues, at least 6 leucine residues, optionally at least one cysteine residue, and at least two but no greater than three glutamic acids wherein the arginine residues are evenly distributed along the length of the peptide; and the peptide has a defined ratio of arginine to negatively charged amino acid residues and a defined ratio of hydrophilic amino acid residues to hydrophobic amino acid residues. The present invention is also directed to a nanoparticle and cell delivery system comprising the amphipathic cell penetrating peptide of the invention. The peptide, nanoparticle or cell delivery system of the invention may be used in therapy. For example, the peptide may be used as a therapeutic agent delivery system, in which the therapeutic agent may include nucleic acids or other small molecules.

Owner:PHION THERAPEUTICS LTD

Personal protection device

ActiveUS20170333736A1Easy to placeReduce condensationChemical protectionHeat protectionActivated carbonEngineering

The invention relates to a low pressure drop personal protection device for providing protection against a range of toxic industrial chemicals and chemical warfare agents and capable of being worn by a wide range of users. The device comprises: a flexible polymeric hood in which the polymer is selected to be impermeable to the toxic challenge molecules; a neck seal for sealing the hood about the neck;a half mask for providing connection for a canister; and a low pressure drop canister system for providing chemical protection. The canister may comprise a resiliently flexible, closed cell foam and monolithic activated carbons, the foam having holes slightly smaller than the size of the monoliths so that flow through the canister is through the monoliths. The monoliths may be the result of partially curing a phenolic resin to a solid, comminuting the partially cured resin, extruding the comminuted resin, sintering the extruded resin so as to produce a form-stable sintered product and carbonising and activating configurable the form-stable sintered product. They may be between 5 and 40 mm diameter, preferably 15 to 30 mm and 1-3 cm in length. Each monolith may have a square channel structure wherein the channel size is 100-2000μ and the wall thickness may be 100-2000 μm with an open area of between about 30 and 60%. It may have a surface area of at least 700 m2 / g, may be activated to >30 wt % weight loss and may be impregnated with materials selected from metallic additives and triethylene diamine according to the anticipated challenge.

Owner:CARBON TEX LTD

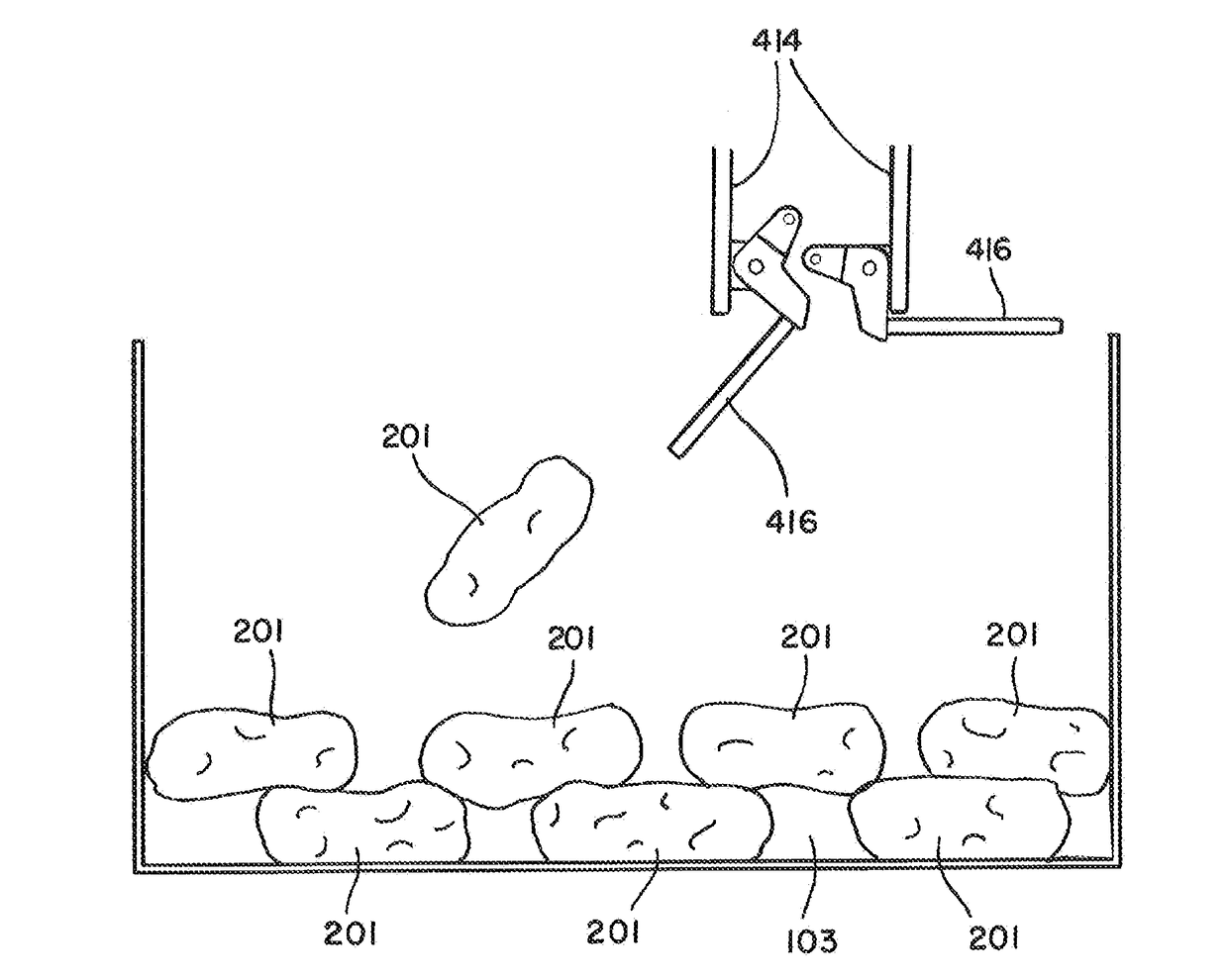

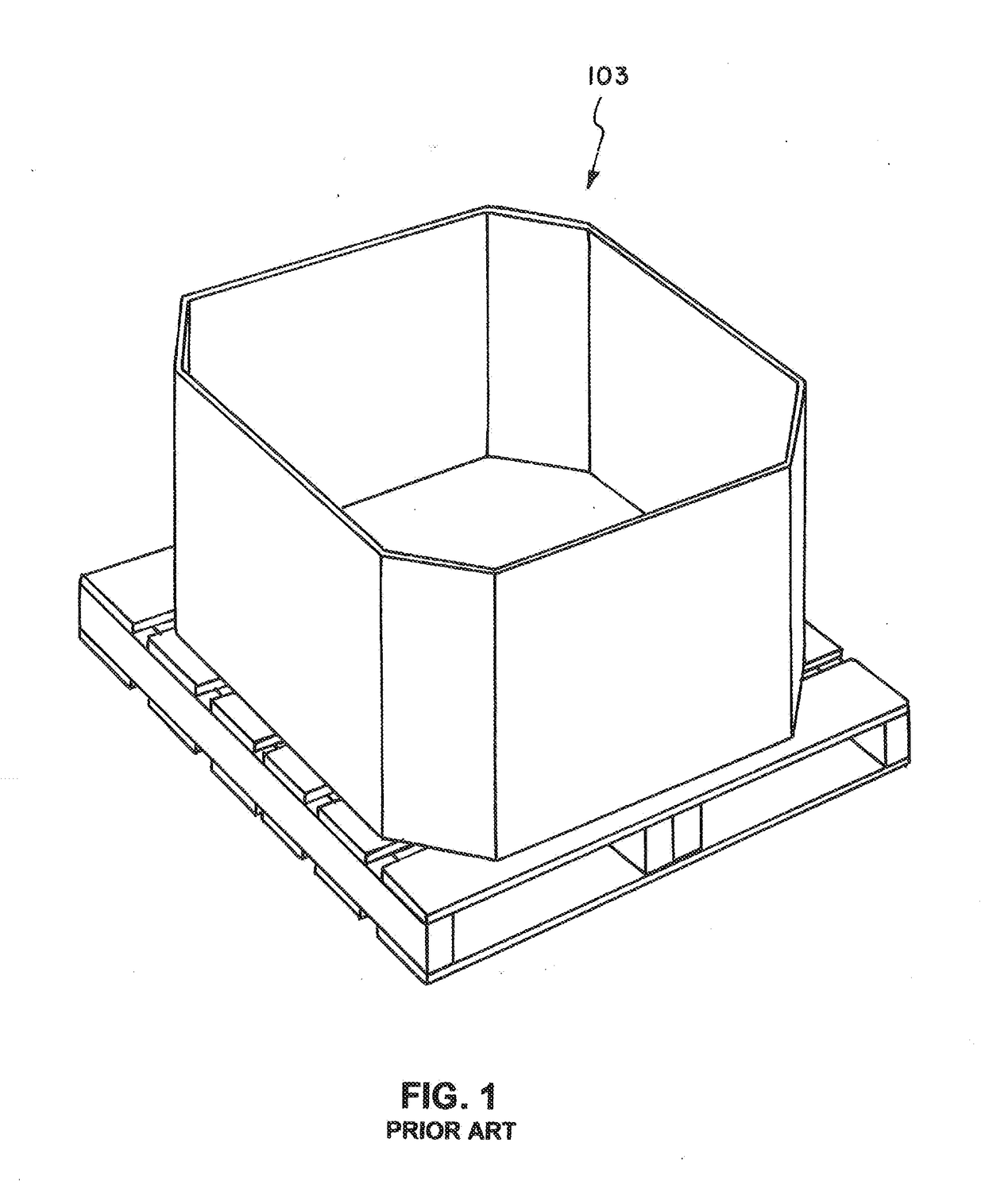

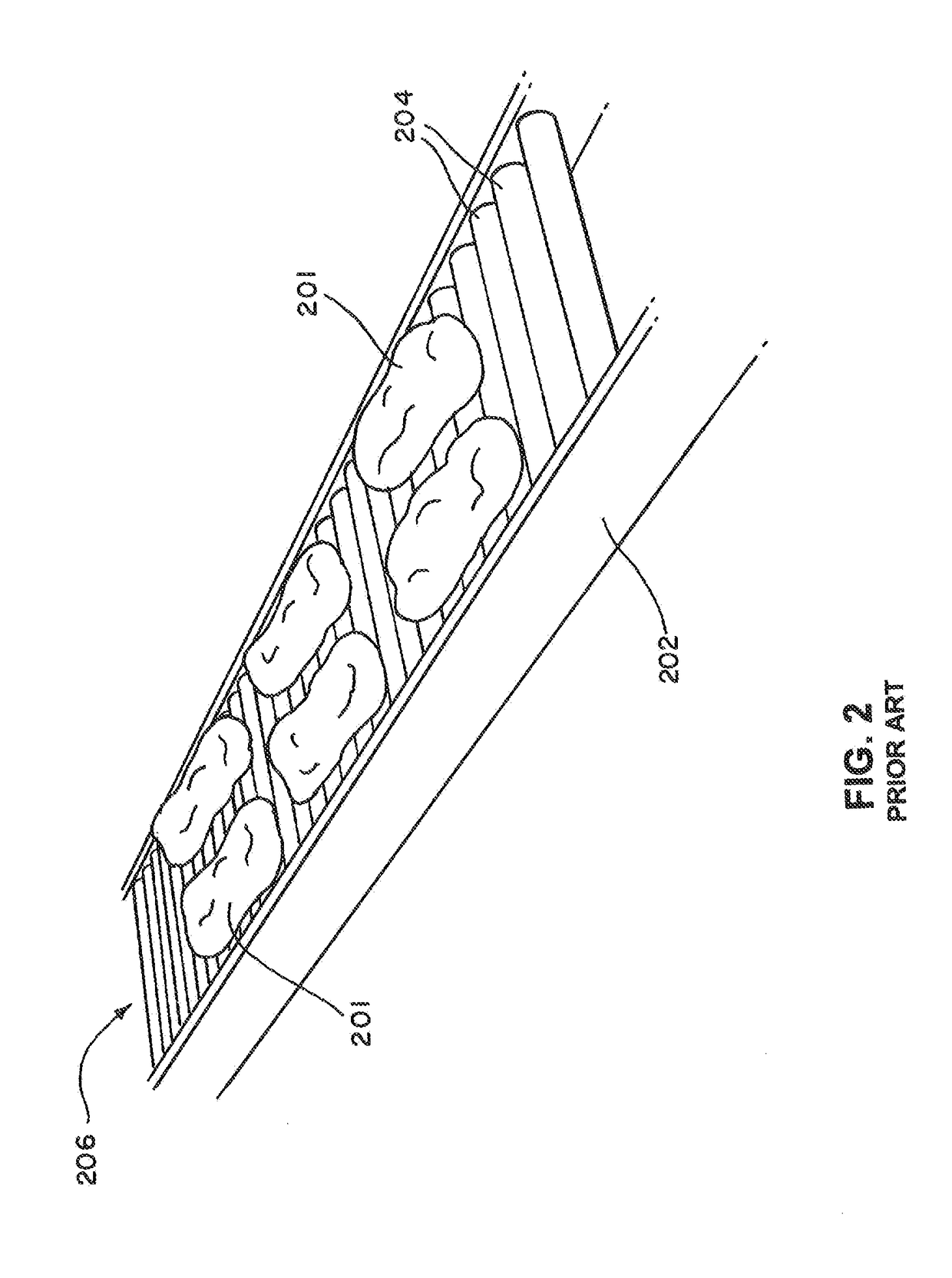

Automated bin packing tool

ActiveUS20180237235A1Efficient packagingEfficiently self-stabilizingConveyorsGripping headsCouplingProgrammable logic controller

A system automatically loads a bin with a filled deformable container such as a sack of produce being conveyed along horizontal rollers. A movable support structure has a coupling end attachable to a robotic arm, and a lifting end supporting a plurality of parallel rods. By means of the robotic arm and a programmable logic controller, the plurality of parallel rods can be positioned between and parallel to the horizontal rollers, raised when the container is conveyed to a loading position above the parallel rods, moved to a predetermined position above the bin, and rotated to allow the container to slide downward along the parallel rods and into the bin under force of gravity. The loading sequence can be repeated a number of times, changing the predetermined position each time to stack a plurality of the containers in a desired configuration such as overlapping rows of offset sacks.

Owner:SOUTHERN FIELD WELDING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com