Patents

Literature

118 results about "Cascade control system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the chemical process industries, a cascade control system is often used to reduce the effect of disturbances and upsets on the primary control objective. A cascade control loop consists of a primary loop and a secondary loop. These loops might also be referred to as the outer loop and inner loop, respectively.

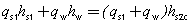

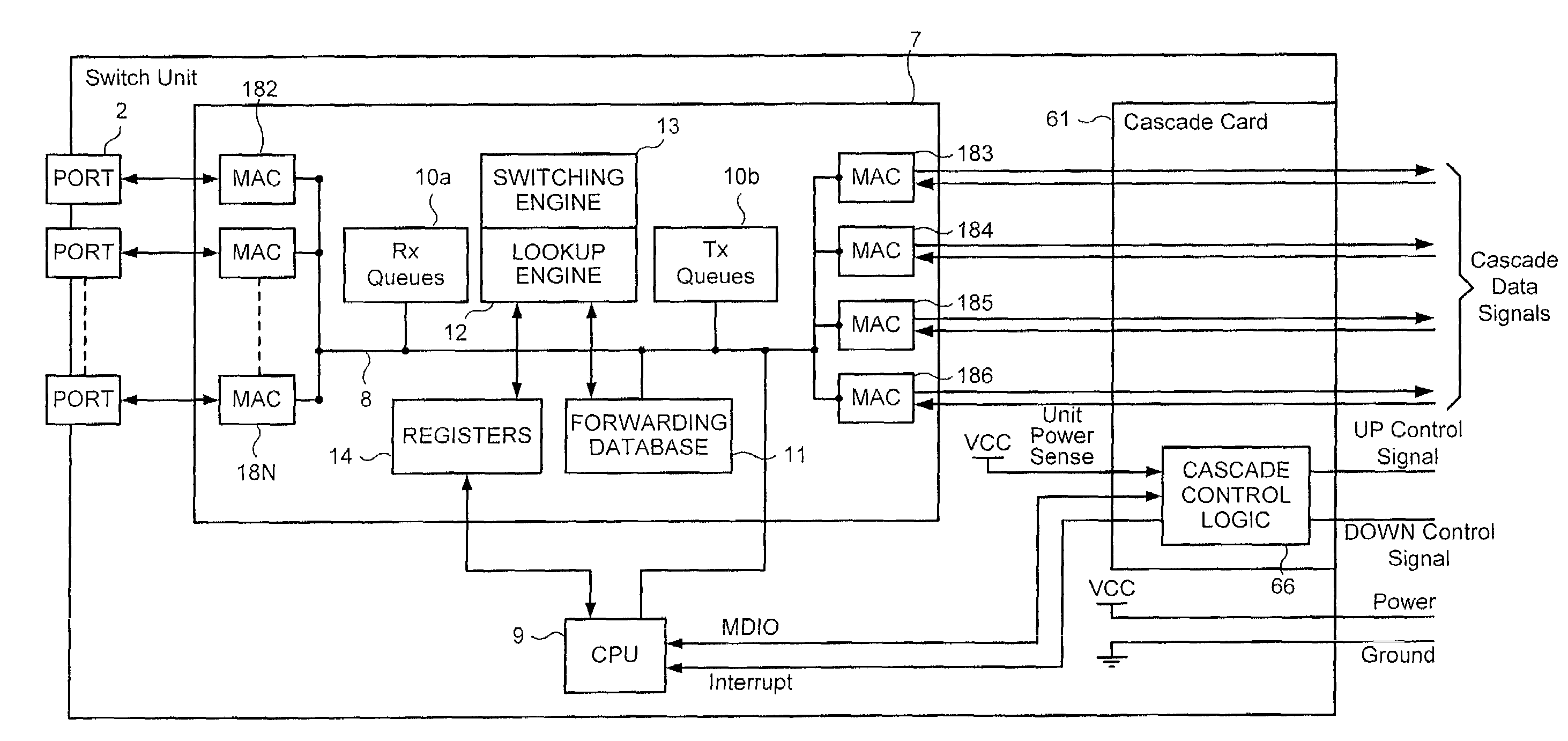

Cascade control system for network units

ActiveUS20050198373A1Digital computer detailsStore-and-forward switching systemsControl systemParallel computing

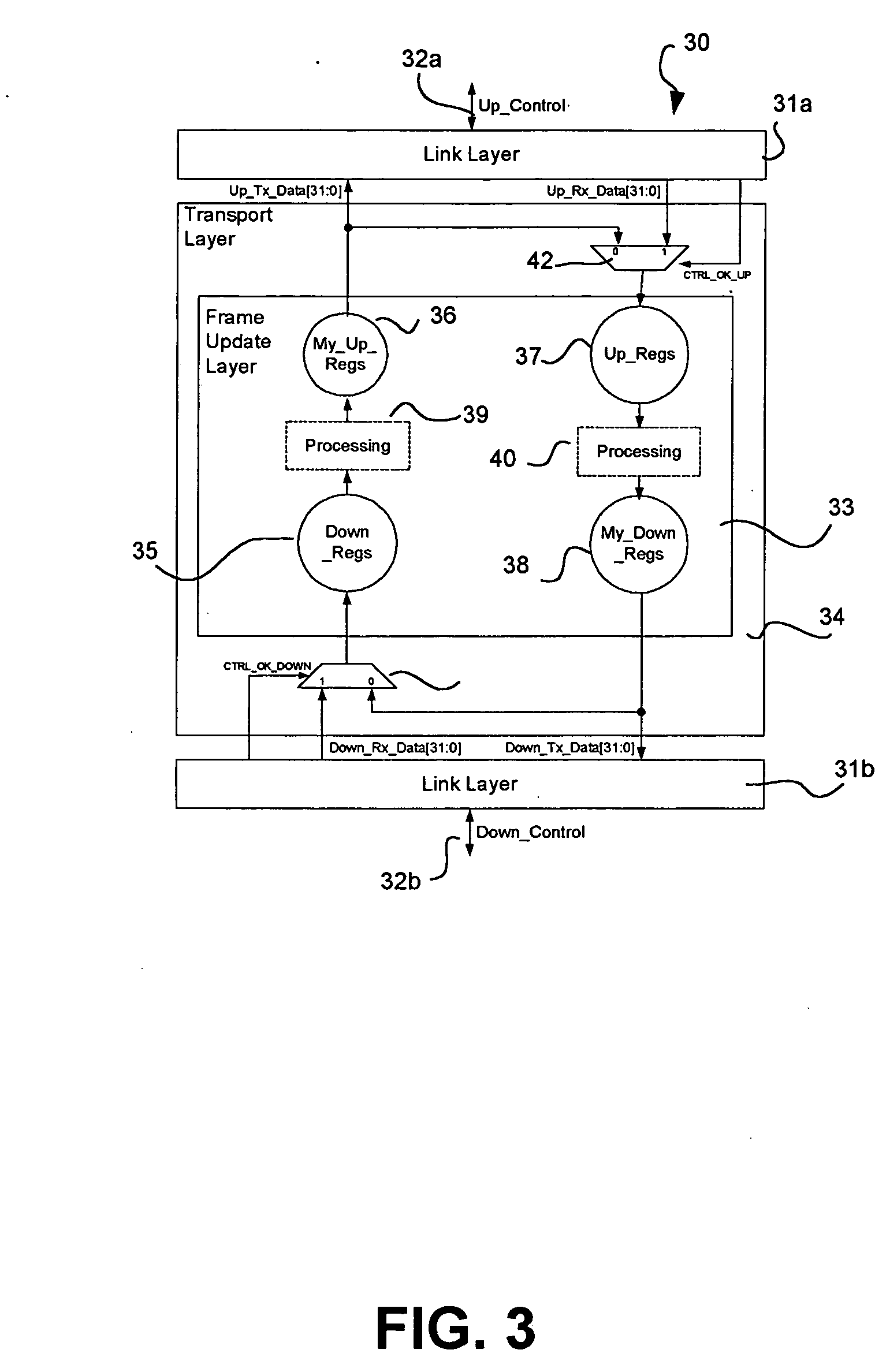

A network unit for the reception and forwarding of data packets and for use in a stack of similar units includes a data processor and cascade control logic for the exchange of control frames with others of said units in the stack. The cascade control logic is operative to cooperate by means of the control frames in an automatic process for incrementally applying stack numbers to the units in the stack. The cascade control logic can retain a stack number in storage and the data processor is operative to execute a program to apply to the network unit and the other units progressive stack numbers which accommodate previously applied and retained stack numbers. The network unit can act as a master applying the program to the other units and as a slave whereupon it receives a stack number determined by another unit in the stack. The program may determine the validity of a set of numbers applied to units in the stack by computing the aggregate of numbering gaps between numbered units and comparing the aggregate with a predetermined maximum. The program distinguishes between units which are in an automatic numbering mode and a non-automatic numbering mode and disregards units in the non-automatic numbering mode in the application of progressive stack numbers.

Owner:VALTRUS INNOVATIONS LTD +1

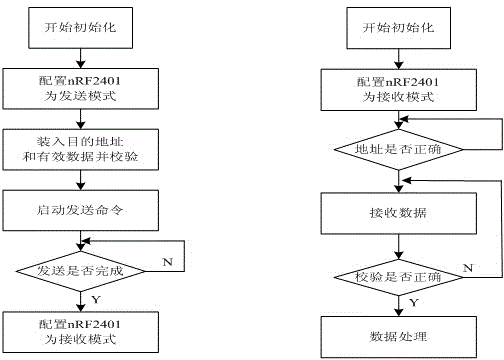

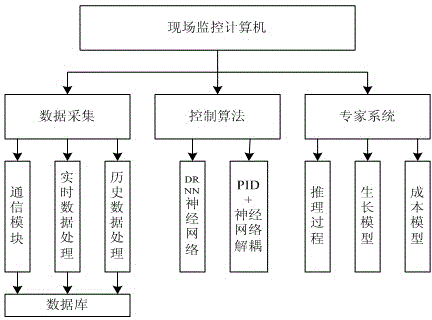

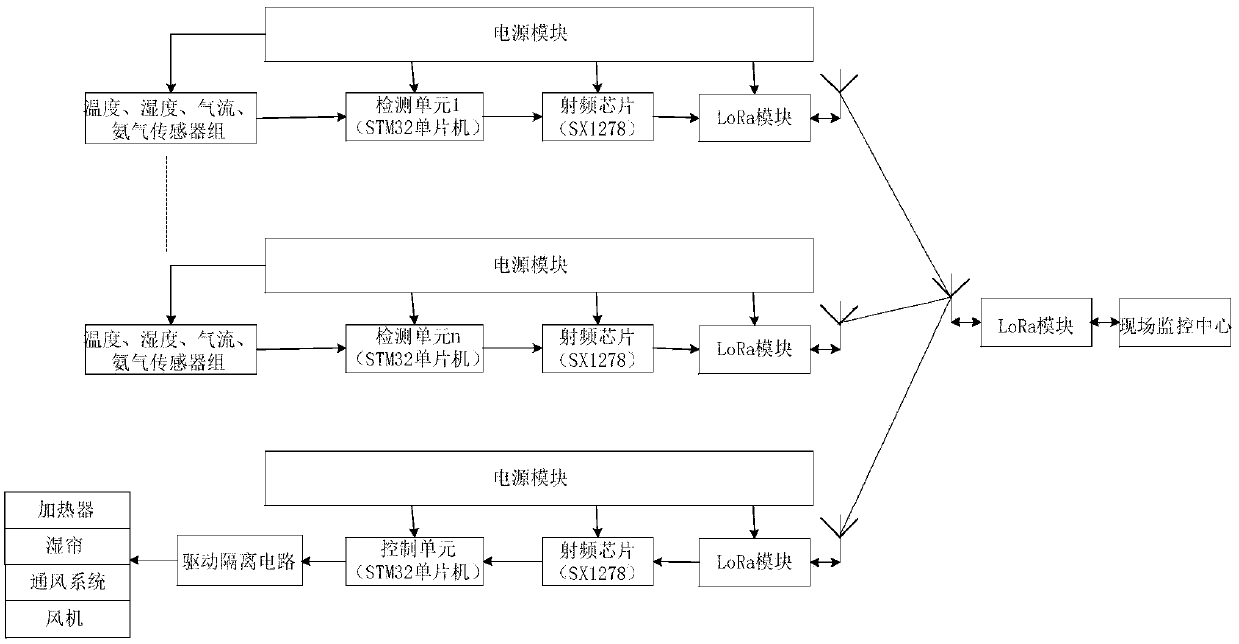

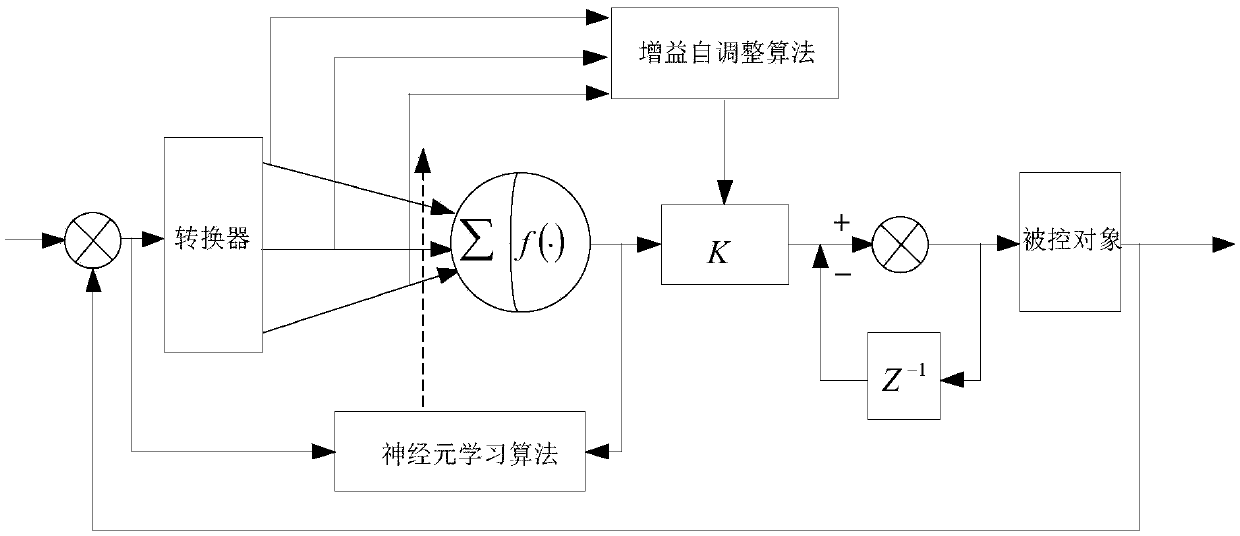

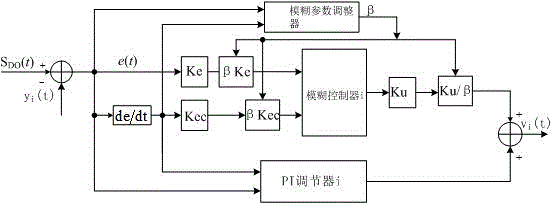

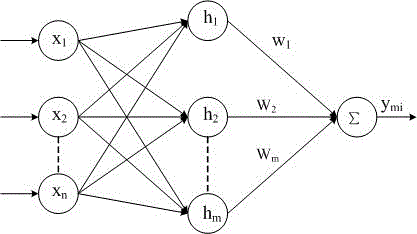

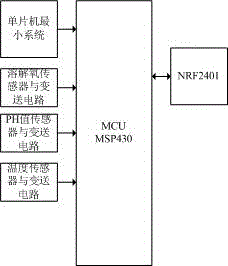

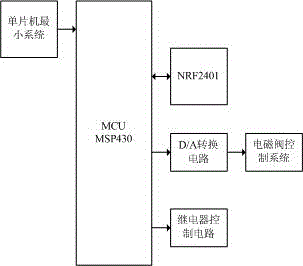

Henhouse micro climatic environment intelligent control system based on wireless sensor network

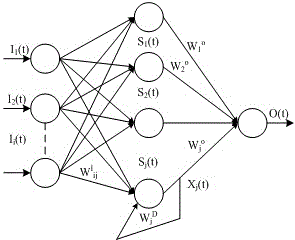

InactiveCN104155925ASmall output value change rangeEnhanced inhibitory effectData processing applicationsNetwork topologiesBiologyNeural network nn

The invention discloses a henhouse micro climatic environment intelligent control system based on a wireless sensor network. The henhouse micro climatic environment intelligent control system is characterized by comprising a henhouse micro climatic environment parameter acquisition and control platform, a henhouse micro climate farming environment cascade control system based on a DRNN PID neural network, and an expert system based on economic optimal reasoning and for setting ideal values of controlled henhouse micro climatic environment parameters. According to the invention, the henhouse micro climatic environment intelligent control system based on the wireless sensor network is designed through the characteristics of multiple parameter variables, nonlinearity, strong coupling and large inertia of conventional henhouse farming micro climatic environment.

Owner:HUAIAN COLLEGE OF INFORMATION TECH +1

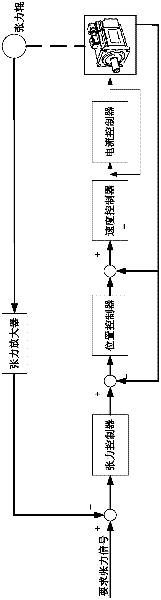

Variable-parameter drum control method in tobacco shred drying process

ActiveCN102331712AHigh control precisionImprove controlAdaptive controlTemperature controlProportion integration differentiation

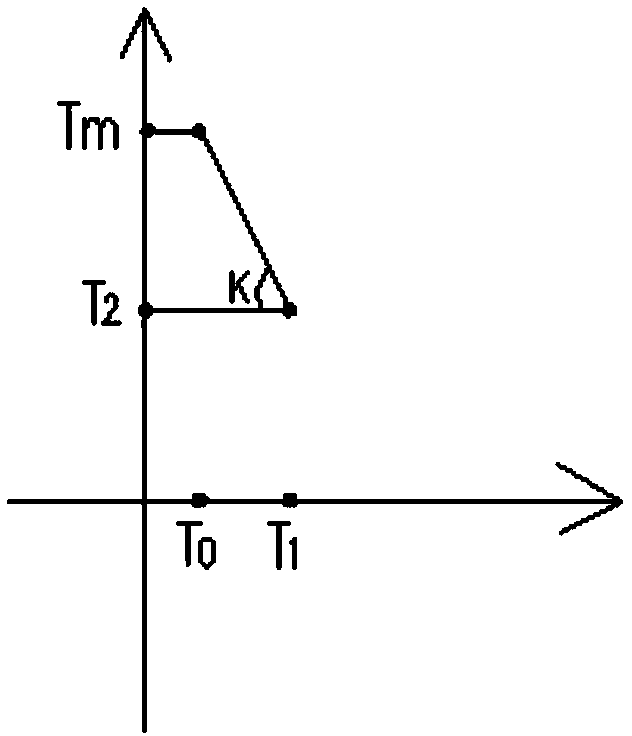

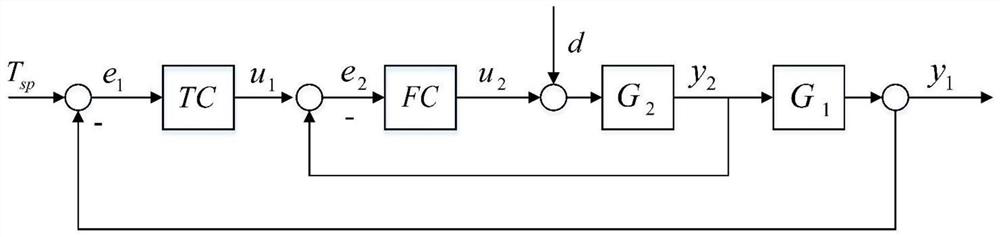

The invention discloses a variable-parameter drum control method in the tobacco shred drying process. The control method is realized by a cascade control system consisting of an outlet water ratio controller and a hot air temperature controller, wherein the hot air temperature controller is taken as a subloop or an inner loop in the control system; the outlet water ratio controller is taken as a main loop or an outer loop in the control system; the controlled output of the outlet water ratio controller is taken as a stated input of an inner loop controller; the control system is characterized in that the outlet water ratio controller adopts a variable-parameter PID (proportion integration differentiation) control way with a dead zone; when the difference between the outlet water ratio and a set water ratio is within the range of the dead zone, a PID controller does not execute the control action, so that the damage to an executing mechanism caused by frequent actions is avoided, while the difference is within a set smaller range, the proportion coefficient is reduced, the integration coefficient and the differentiation coefficient are increased, and when the difference is within a larger range, the proportion coefficient is increased, the integration coefficient and the differentiation coefficient are reduced; and therefore, the response speed is increased, the steady-state error is reduced, high stability is ensured and the integration saturation is prevented.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

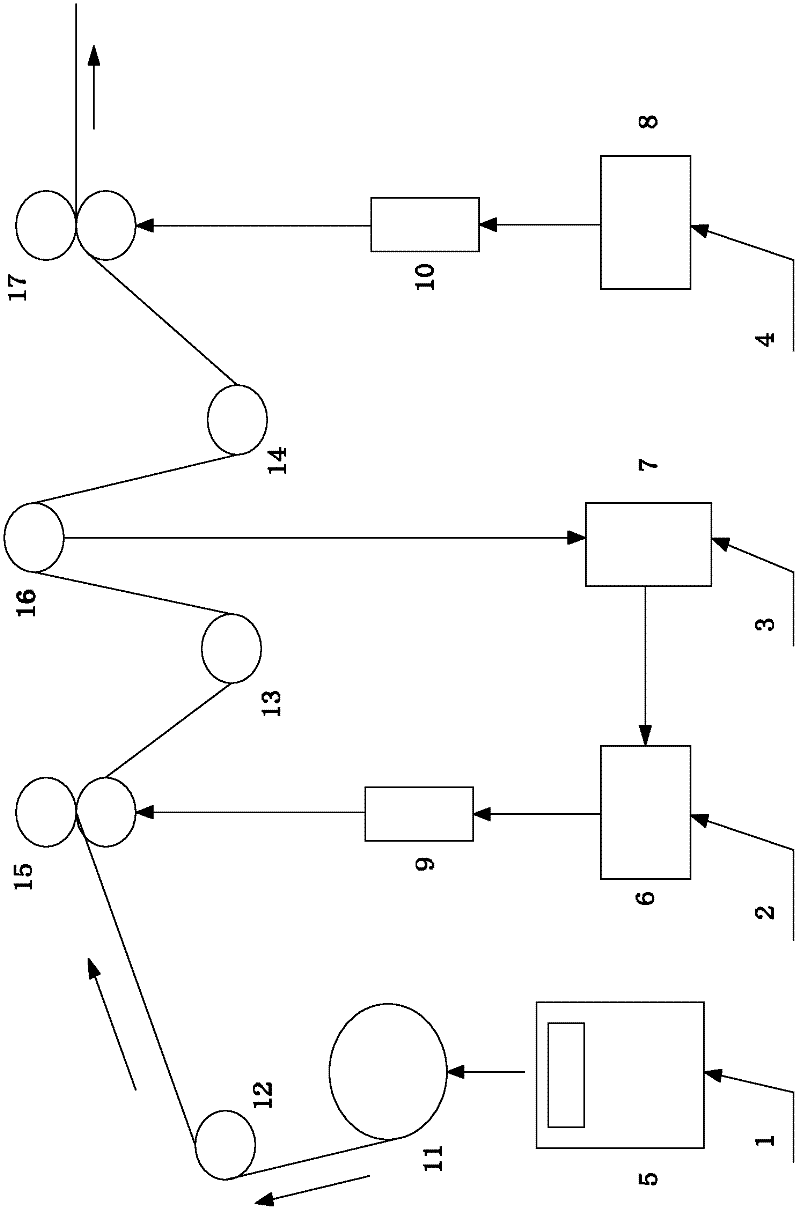

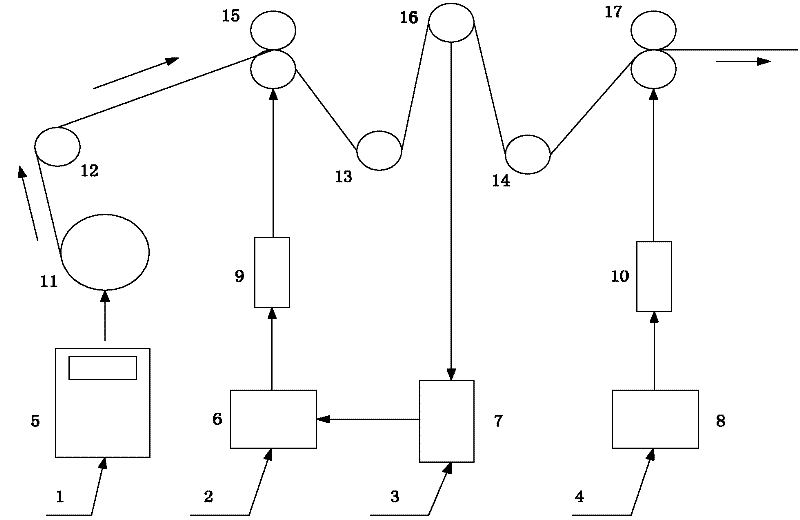

Tension stability control system for film winding conveyance

InactiveCN102530624AHigh control precisionReduce tension fluctuationsWebs handlingLoop controlControl system

The invention provides a tension stability control system for film winding conveyance, which comprises a feeding roller, paired driving rollers, paired driven rollers, a tension roller and a tension controller, wherein the feeding roller is used for uncoiling a coiled flexible film, the paired driving rollers are used for drawing the film, the paired driven rollers are used for assisting the paired driving rollers in drawing the film under control of the tension controller and are used for keeping tension stable, the tension roller is provided with a tension sensor for detecting tension during conveyance of the film, and the tension controller is used for performing tension closed-loop control according to tension acquired by the tension sensor. Output signals of closed-loop control serve as compensation of operation planning commands of a driving motor for the paired driven rollers, and further the rotation speed of the paired driven rollers is controlled to ensure stability of the tension. By the aid of a cascade control system formed by the tension roller, tension amplification filtering and driving compensation, low tension during flexible film conveyance can be effectively controlled, control precision is high, and the tension stability control system is applicable to low-tension conveyance of ultrathin and flexible hetero-structure films.

Owner:HUAZHONG UNIV OF SCI & TECH

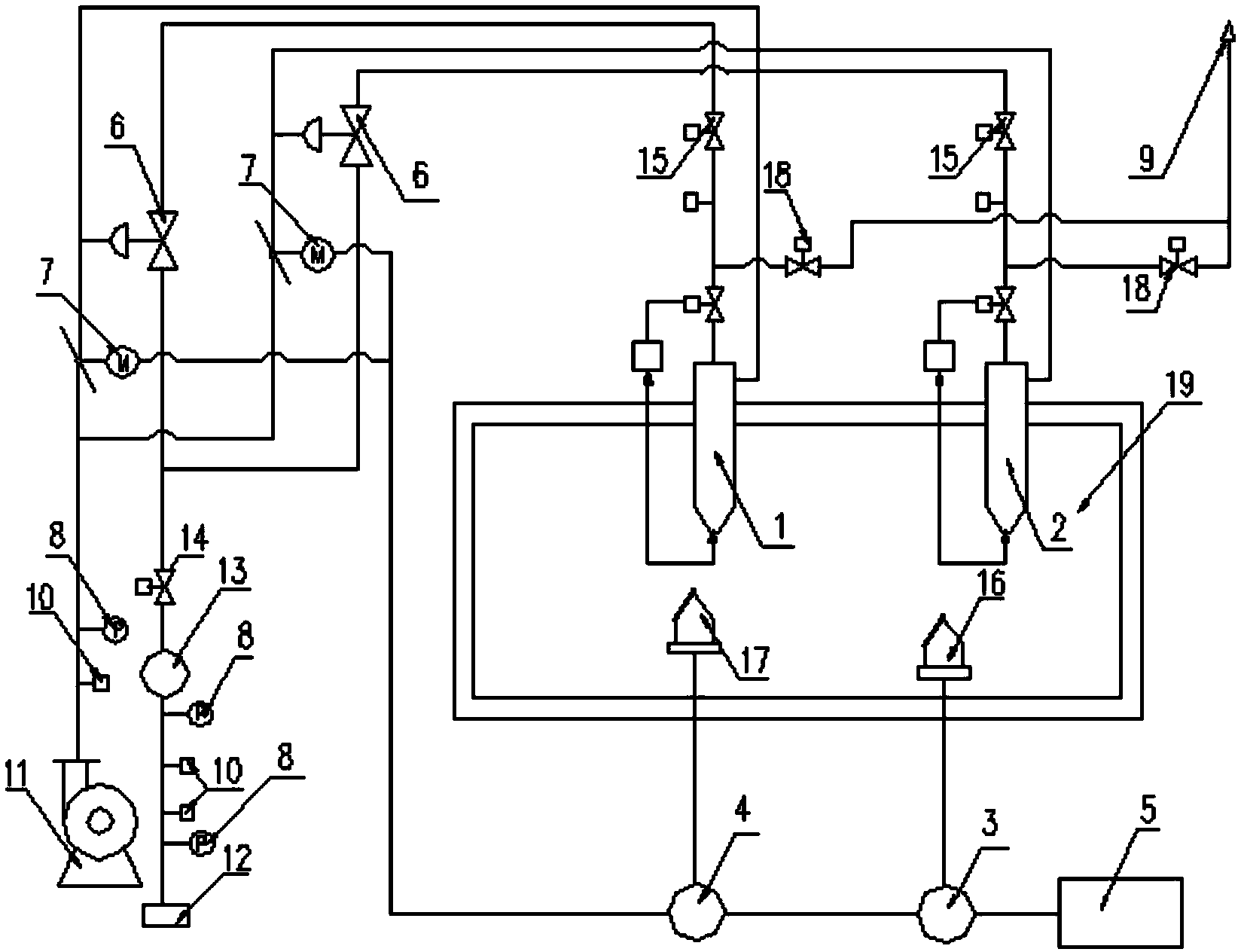

Dynamic compensation method of attemperation water impact leading steam temperature measuring point in boiler steam temperature control system

InactiveCN103343961AImprove control qualityImprove operational safetySuperheating controlPower stationCompensation effect

Provided is a dynamic compensation method of an attemperation water impact leading steam temperature measuring point in a boiler steam temperature control system. According to the method, an attemperation water impact leading steam temperature measuring point correction factor on-line computation module is arranged in the overheating and reheating steam temperature cascade control system of a power station boiler, the correction factor of the attemperation water impact leading steam temperature measuring point is computed on line through the module, the difference between a steam temperature set value and a controlled steam temperature feedback value is divided by the correction factor to compensate changing of inertia zone object gain, output of an auxiliary adjuster is multiplied by the correction factor to compensate changing of leading zone object gain, and accordingly dynamic compensation of the attemperation water impact leading steam temperature measuring point is achieved. The method achieves dynamic compensation of the attemperation water impact leading steam temperature measuring point in the steam temperature control system and has the advantages of being good in compensation effect, field conduction is convenient, control effect is good, control quality of the overheating and reheating steam temperature cascade control system of the power station boiler can be guaranteed, and safety and economy of operation of the power station boiler are improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Cascade control system for network units

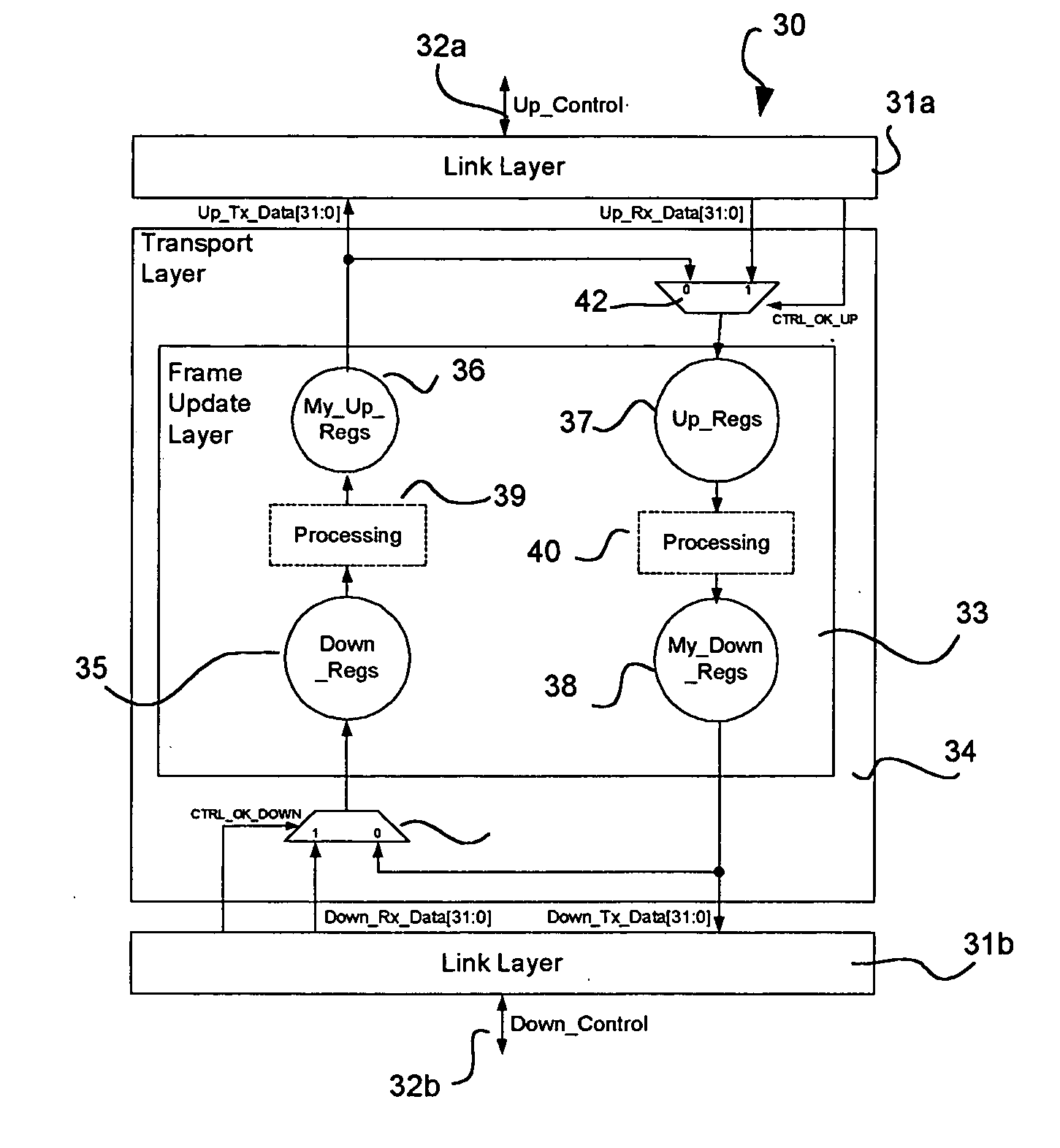

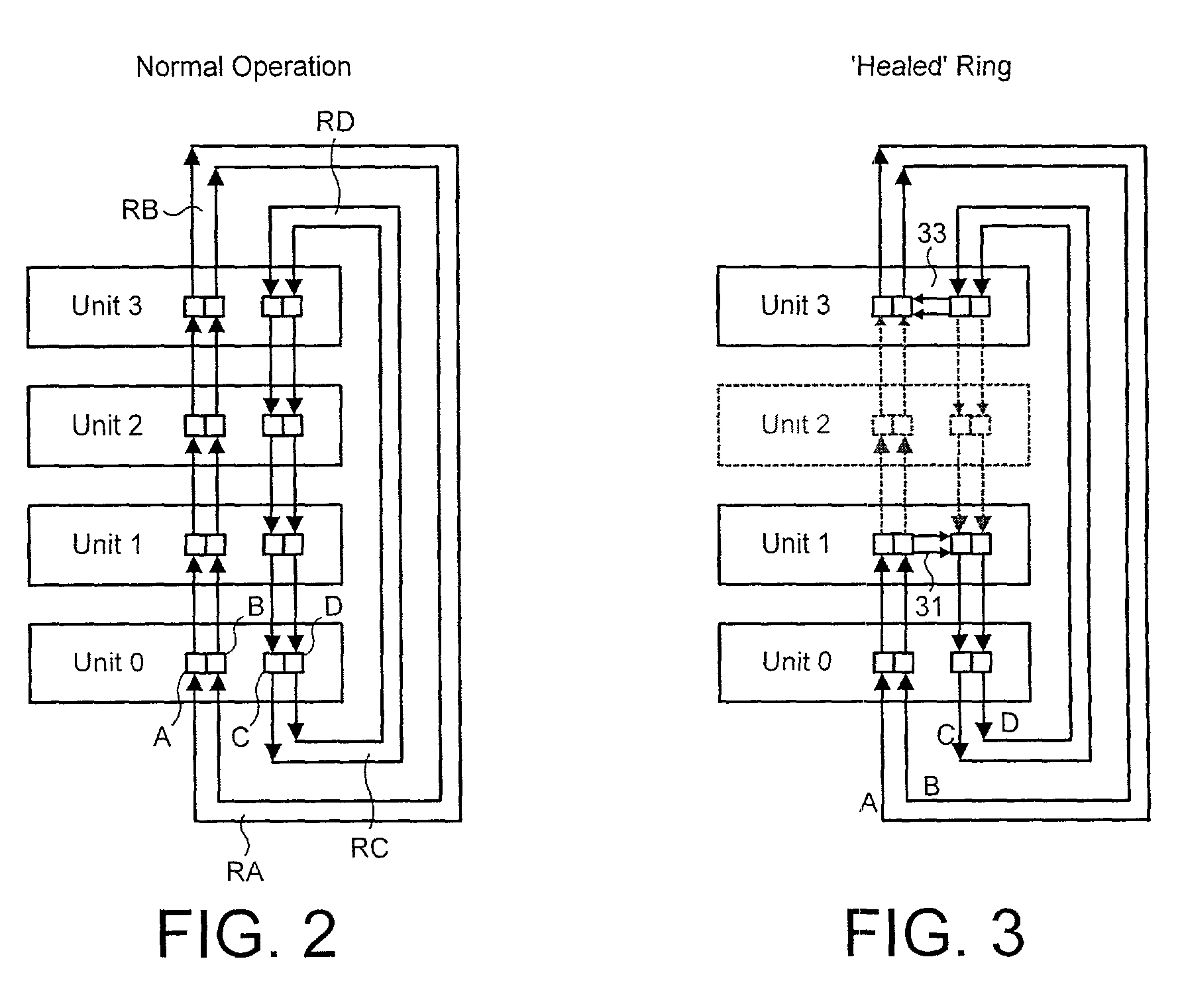

ActiveUS7167441B2Easy to controlError preventionFrequency-division multiplex detailsControl systemControl data

Cascade control logic for use in a switch or other network unit that can be used in a cascaded stack can maintain normally a point-to-point half-duplex connection for control data with each of the next preceding and next succeeding units in the cascade. Each cascade logic device is organised so that for one direction, conveniently called the up direction, a device is a master and in the other direction the device is a slave in respect of the control path. A control device will generate master control frames in the up direction and deliver slave control frames in the down direction. The control device is organised so that in the absence of reception of valid control frames on a control link control data which would otherwise be sent out on that link is looped back within the control device. In this manner the control device can maintain under normal circumstances two virtual control channels which can ‘self-heal’ notwithstanding the failure or powering-down of a unit in the cascade.Status information represented by the control frames can be used to control a switching engine to provide self healing of the data path in the cascade.

Owner:VALTRUS INNOVATIONS LTD

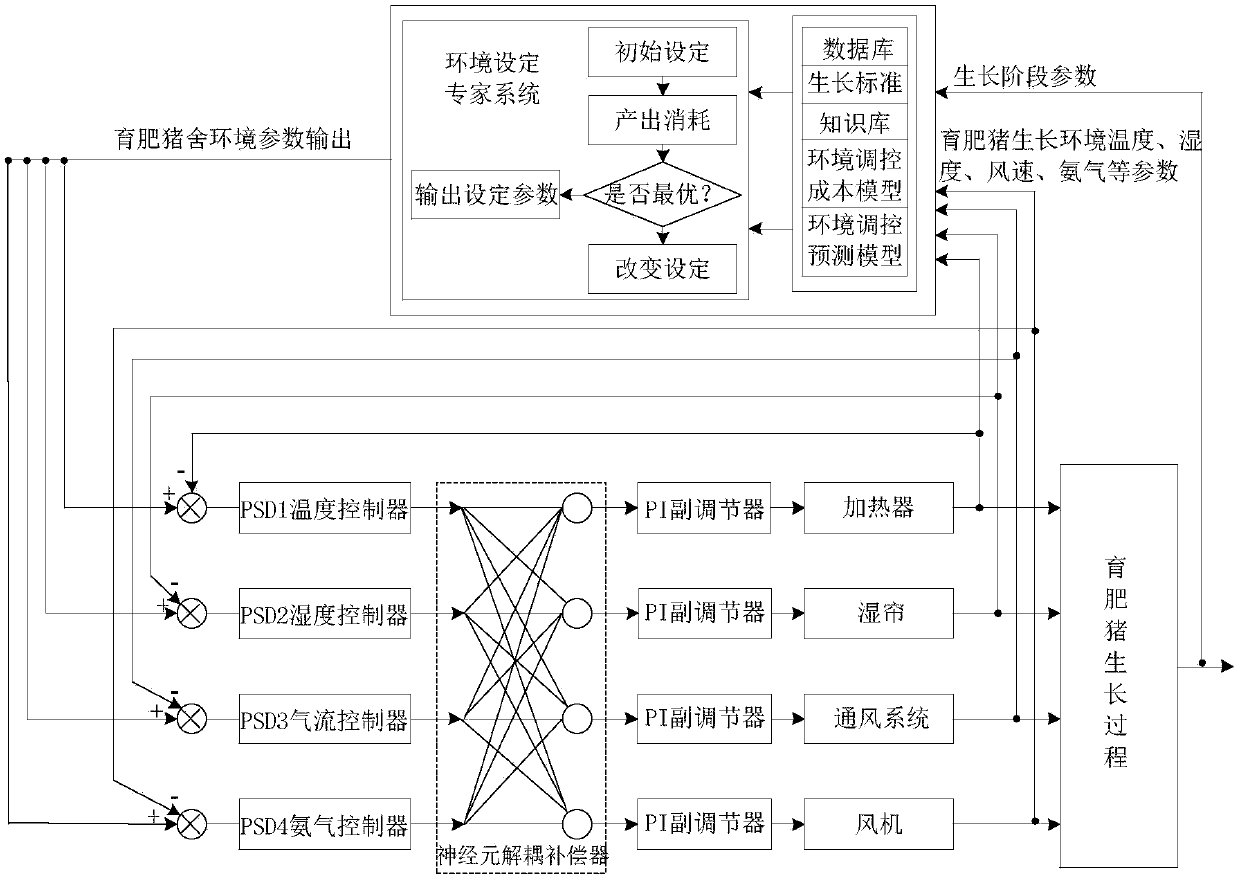

Fattening pig house environment regulation and control system and method

InactiveCN109634098AImprove control qualityInhibit bad effectsControllers with particular characteristicsControl systemEngineering

The invention discloses a fattening pig house environment regulation and control system and method. The system comprises a detection unit, a control unit and a monitoring center. The detection unit detects temperature, humidity, air flow and ammonia of a fattening pig house. The control unit controls control equipment through utilization of PI secondary regulators. The monitoring center circularlyreads temperature, humidity, air flow and ammonia parameters of a fattening pig house environment collected by the detection unit, designs a single-neuron adaptive PSD controller+ a neuron decouplingcompensator to form a fattening pig house environment master regulator for the temperature, the humidity, the air flow and the ammonia, and realizes effective control over the temperature, humidity,air flow and ammonia of the fattening pig house environment. The detection unit detects the temperature, humidity, air flow and ammonia of the fattening pig house through utilization of sensors. Inputof the PI secondary regulators of the control unit comes from output of the neuron decoupling compensator of the monitoring center, thereby forming a multi-cascade control system of the master and secondary regulators.

Owner:JIANGSU UNIV

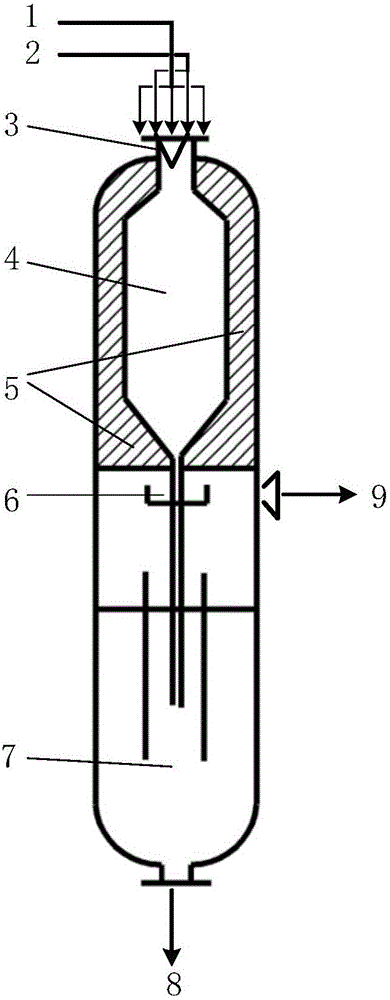

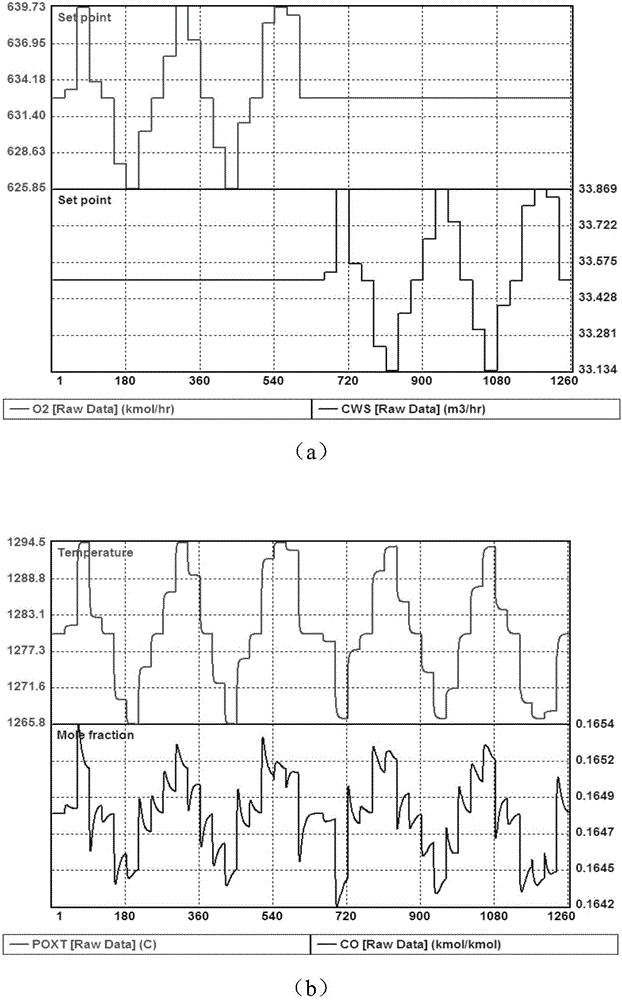

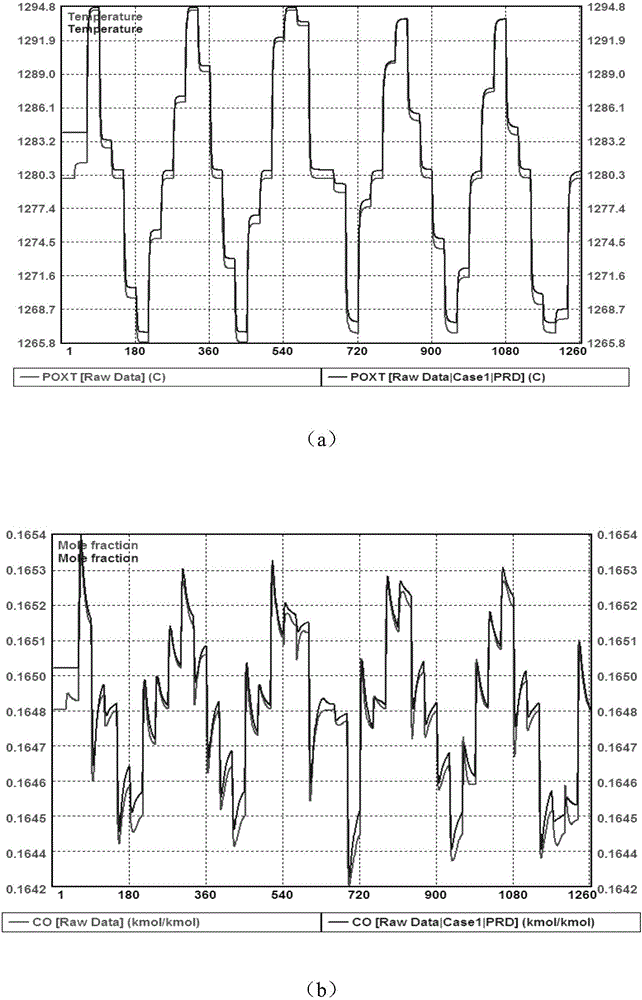

Coal water slurry gasification process DMC-PID multivariable control method

The invention relates to a coal water slurry gasification process DMC-PID multivariable control method, concretely a coal water slurry gasification process multivariable control method by employing a dynamic matrix control and proportion-integral-differential control cascade control system (hereinafter referred to as a DMC-PID control method). A coal water slurry gasification process control system is characterized in that charging flow control mainly comprises coal water slurry flow cascade control and oxygen coal ratio cascade control; the core of vaporizer control is gasifier hearth temperature control; quenching chamber control mainly comprises quenching water flow and raw gas temperature cascade control. In the adjustable range of manipulated variables, the DMC-PID control method can control coal gasification process main manipulated variables in an industrial requirement range, thereby effectively solving the problems such as multivariable coupling between a gasification temperature and a synthetic gas yield in a coal water slurry gasification process.

Owner:EAST CHINA UNIV OF SCI & TECH

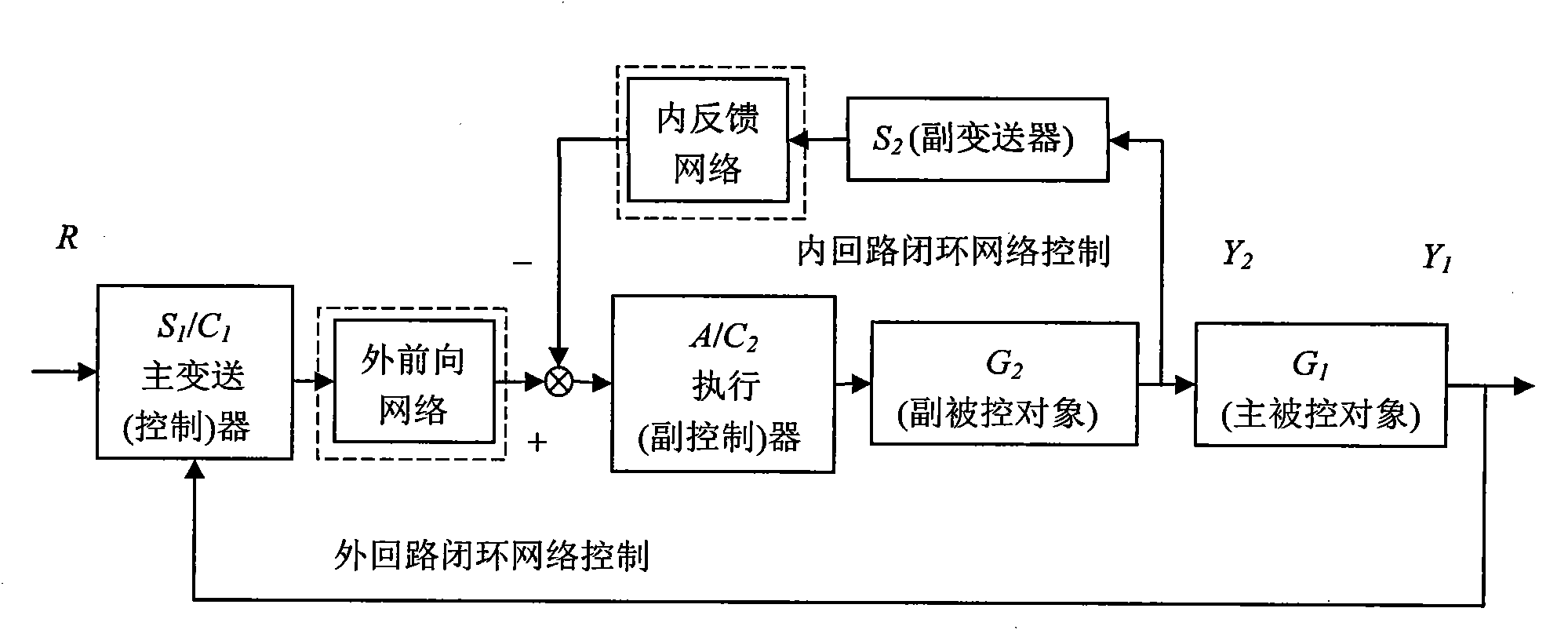

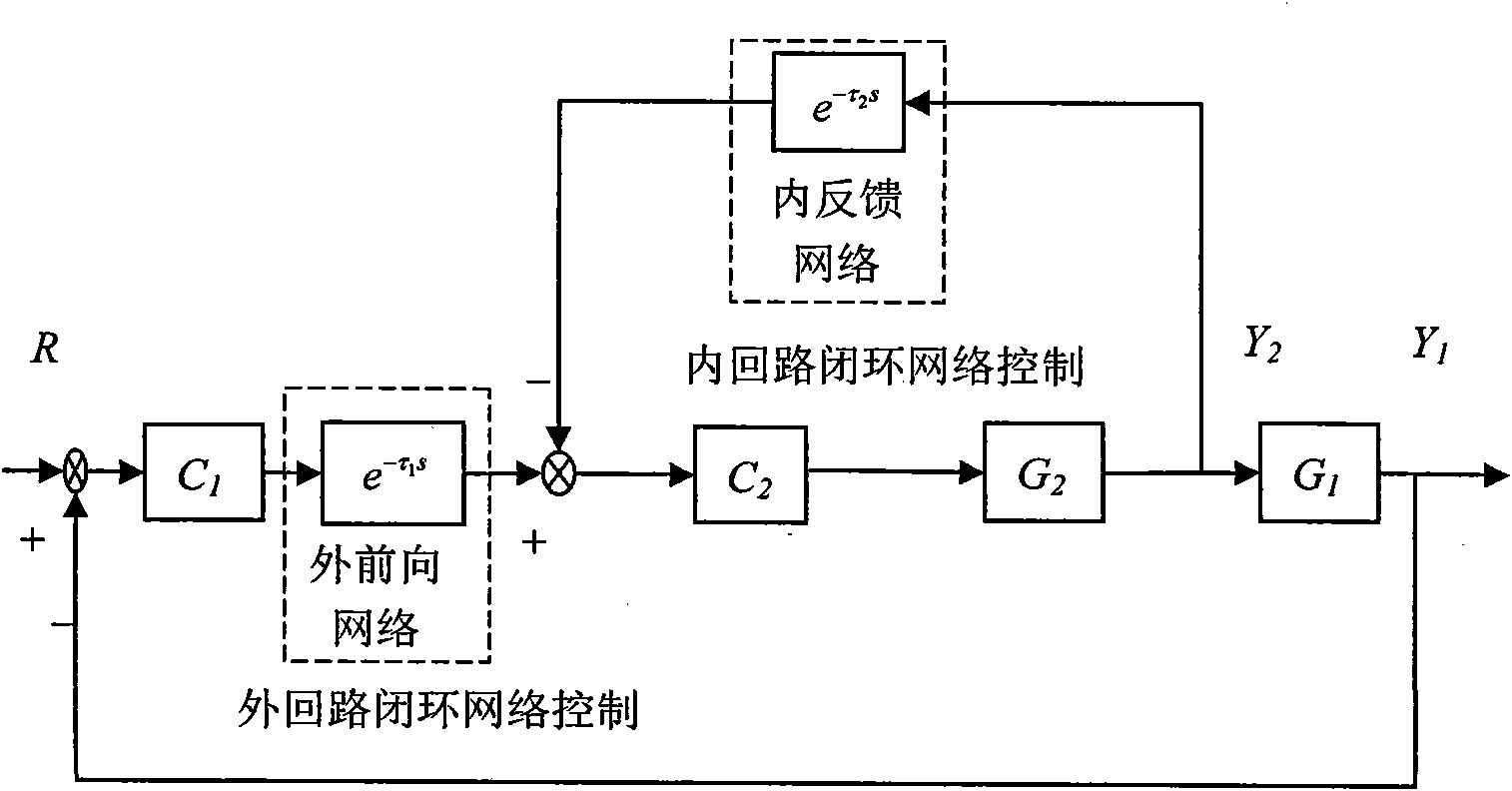

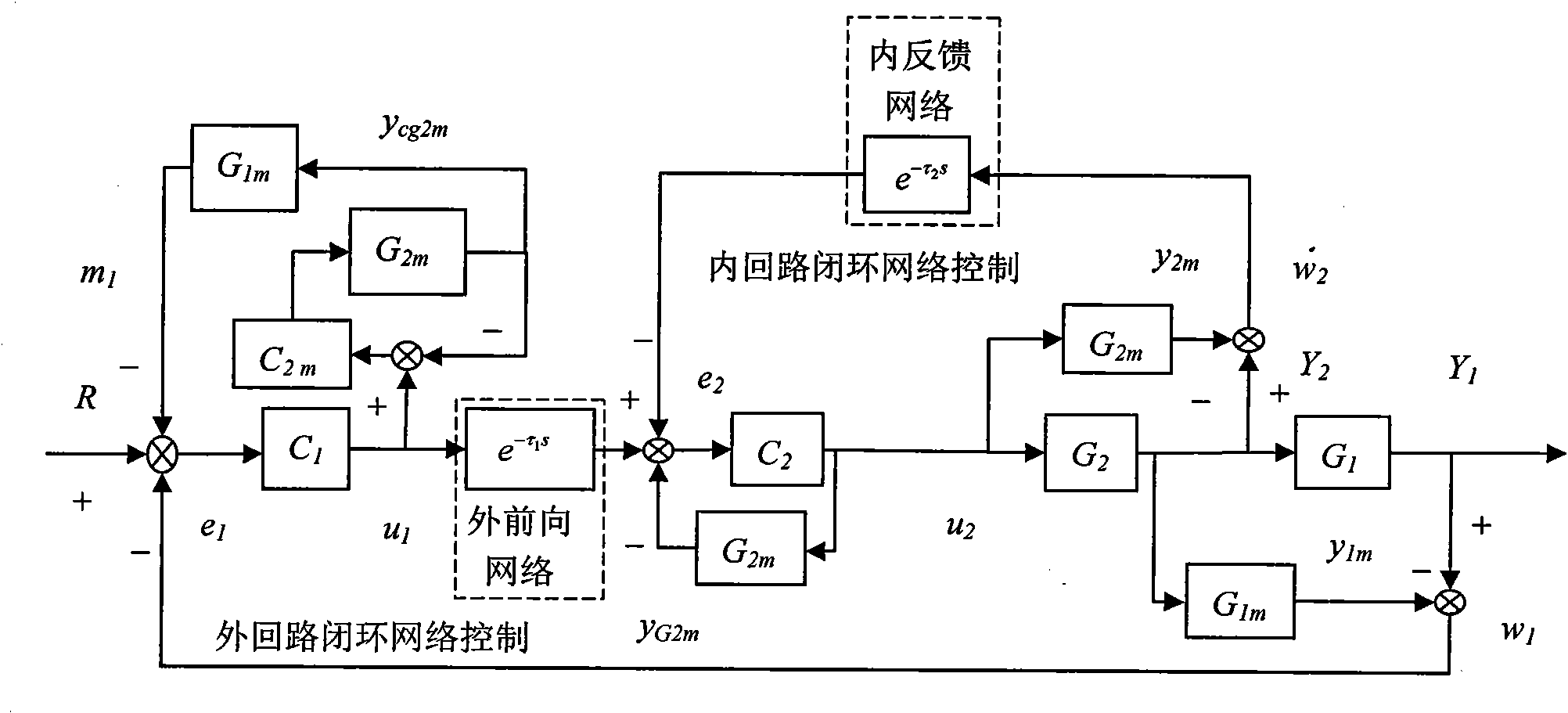

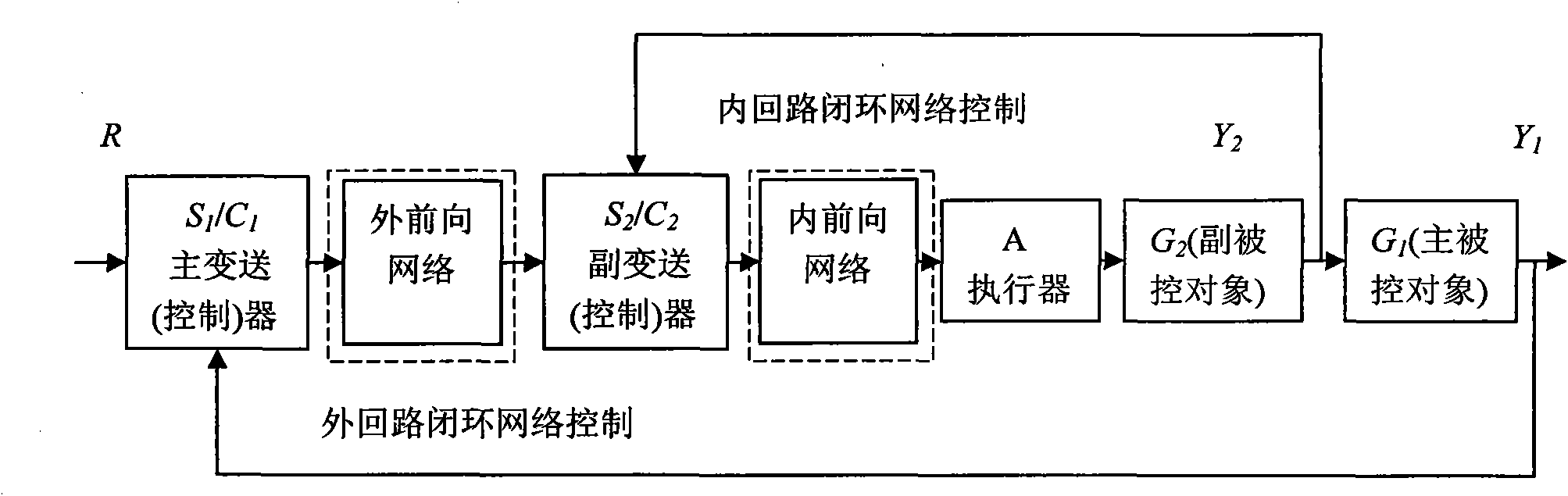

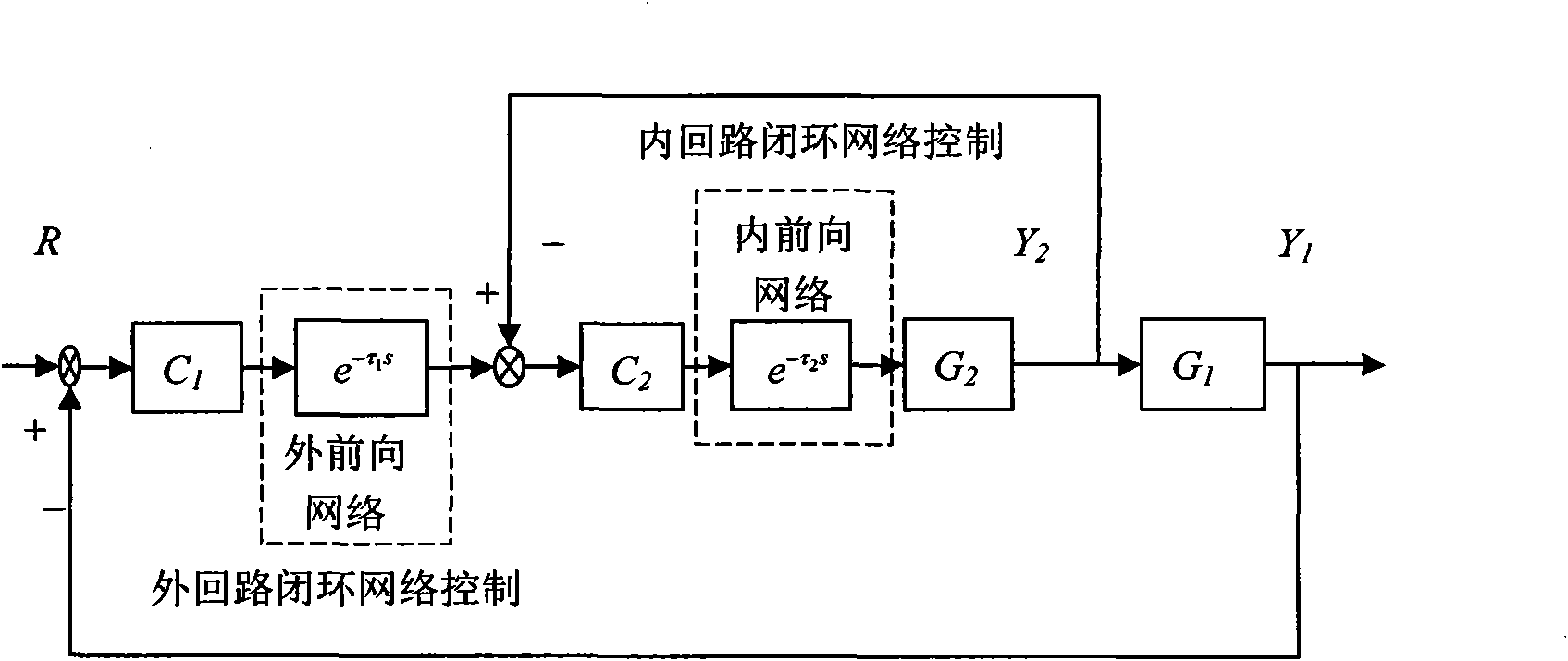

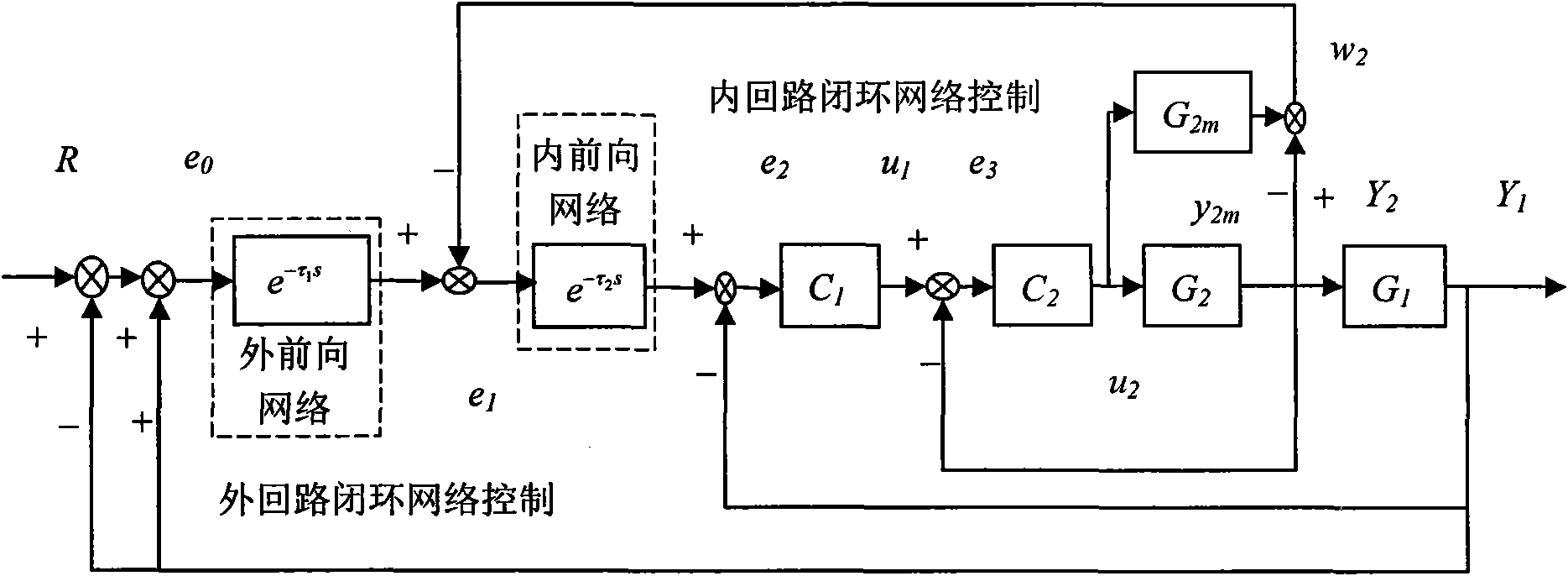

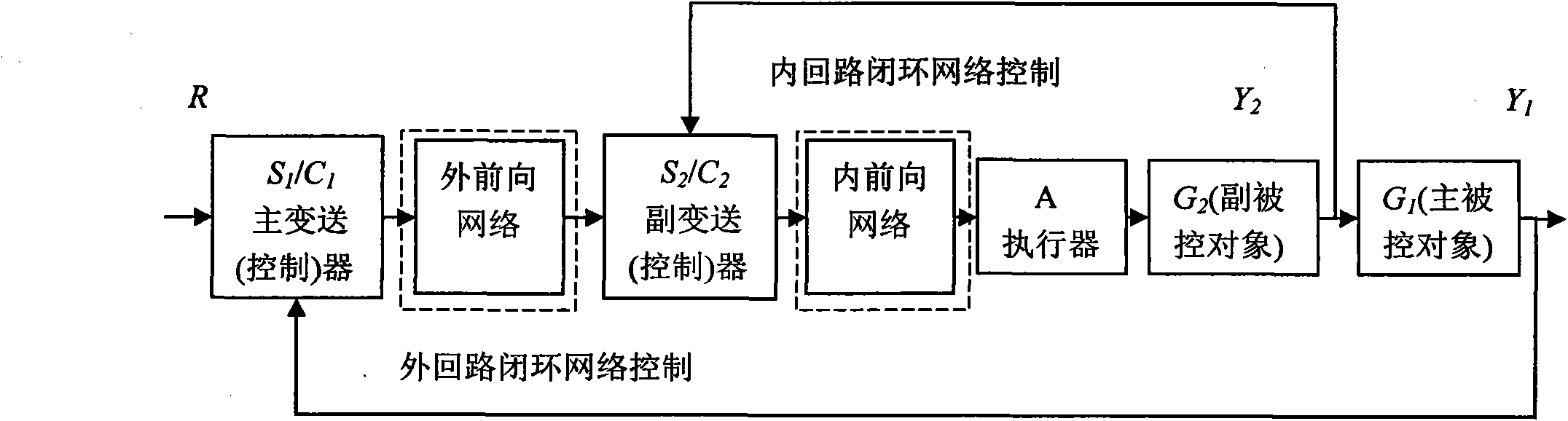

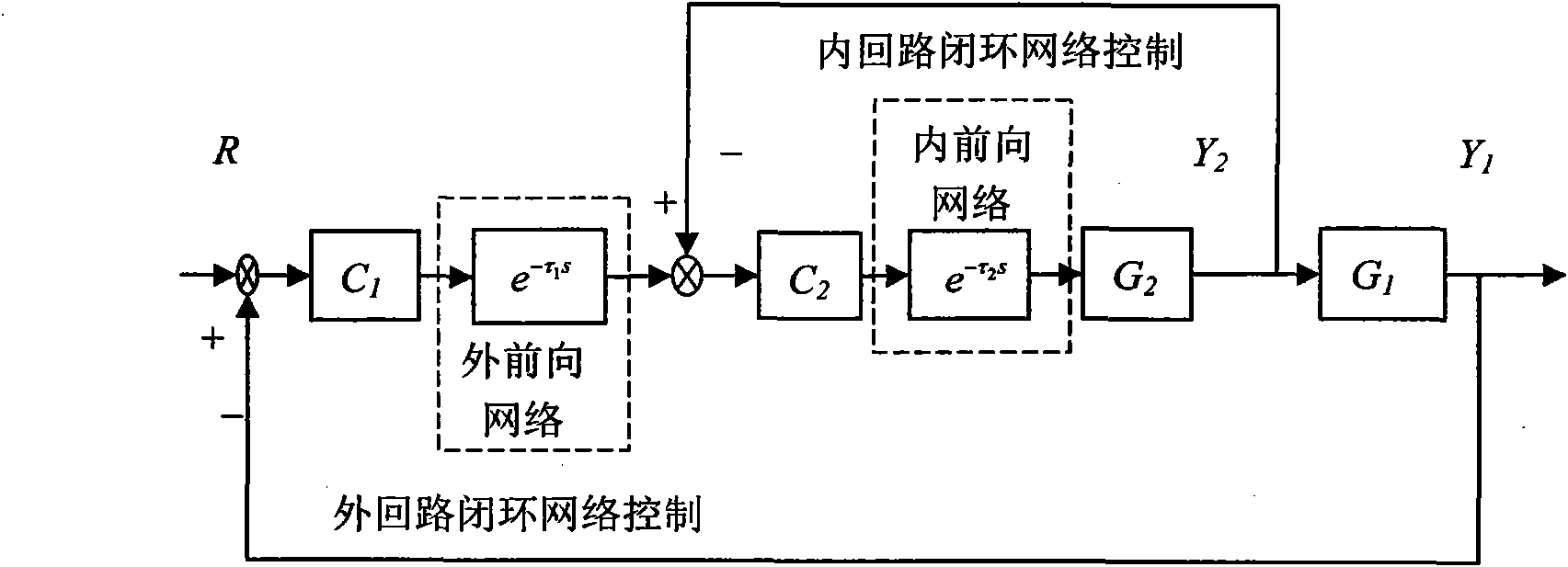

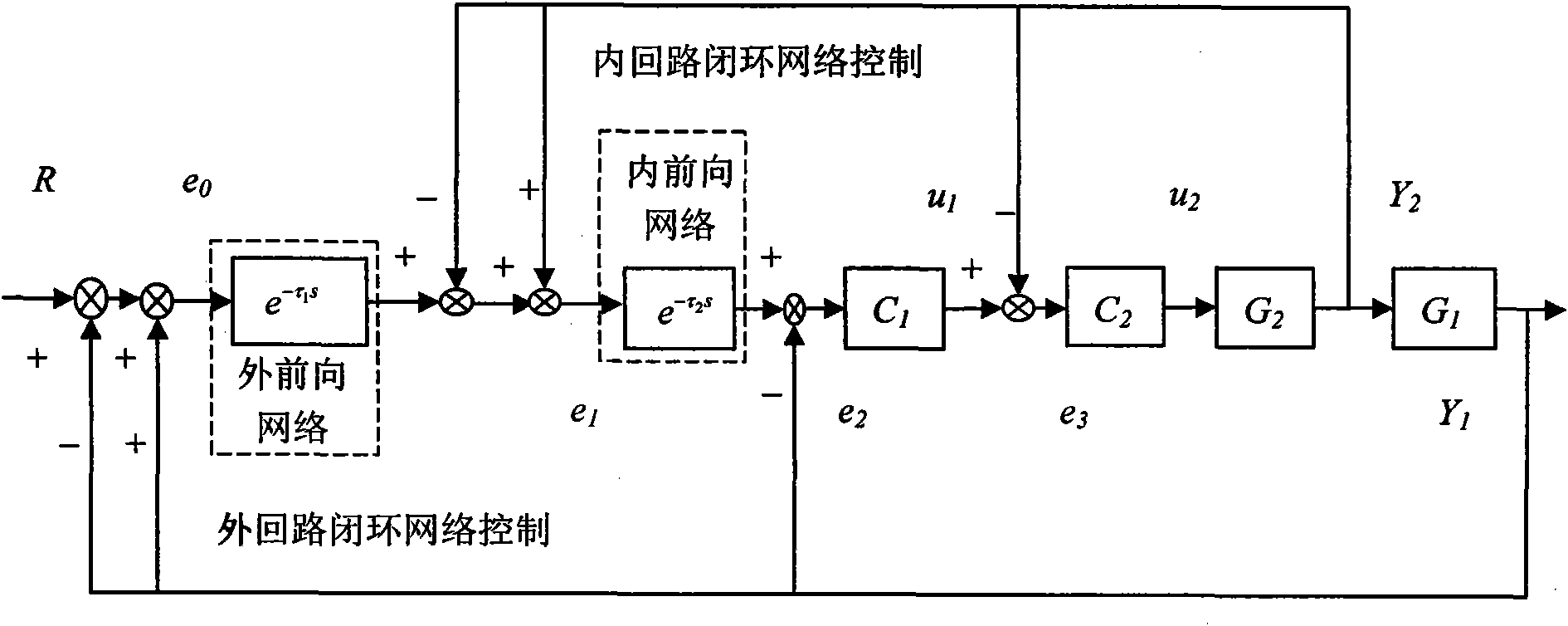

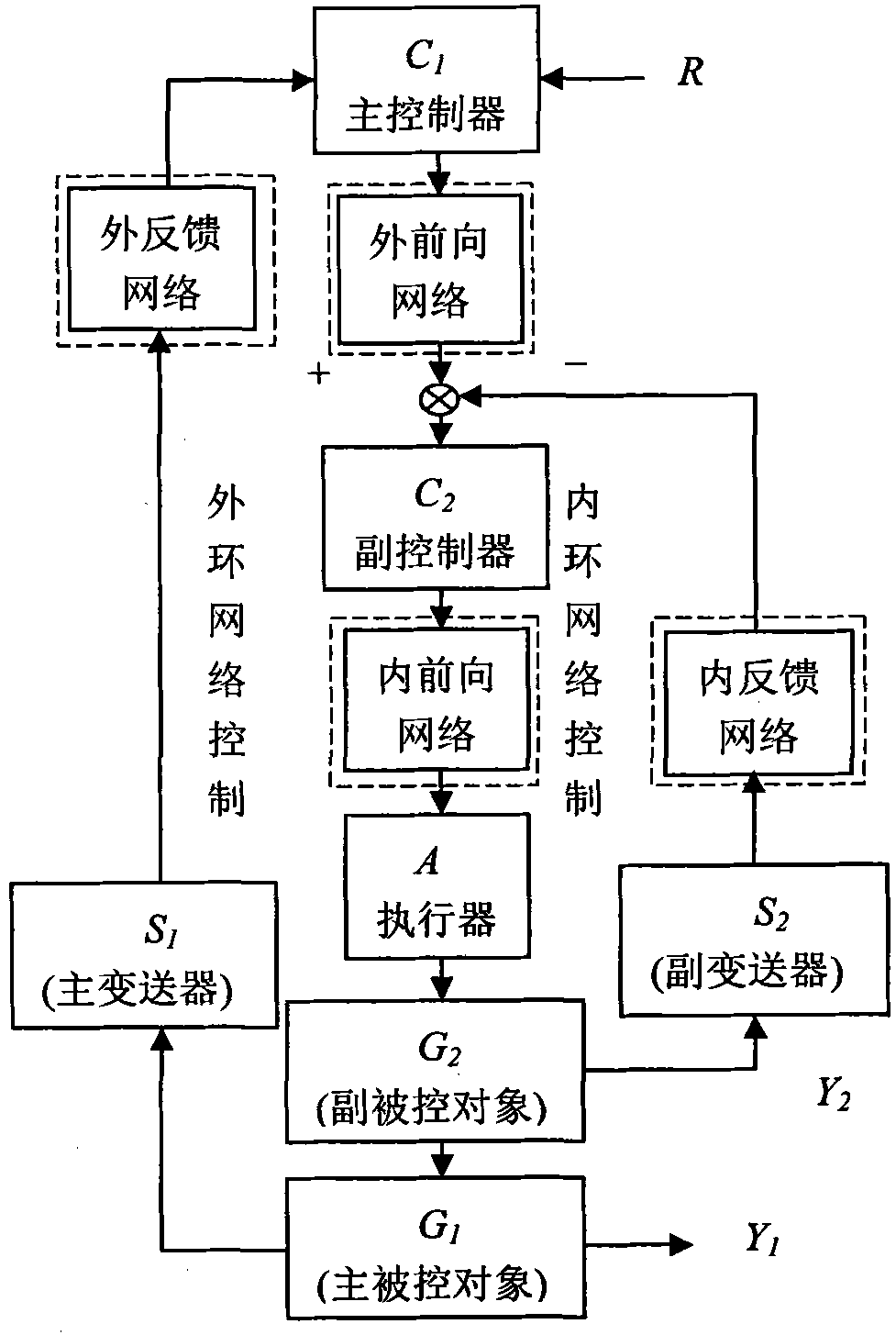

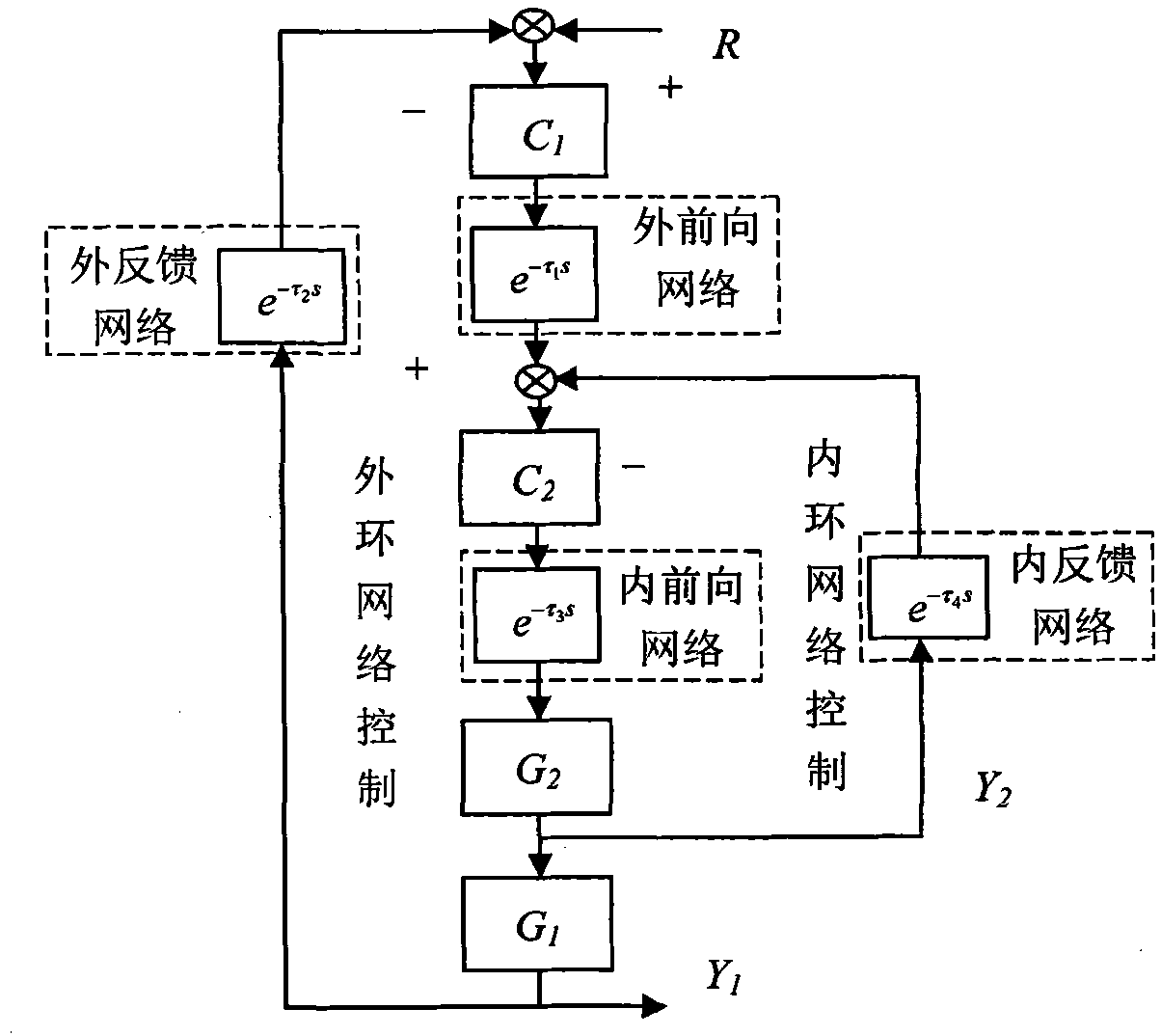

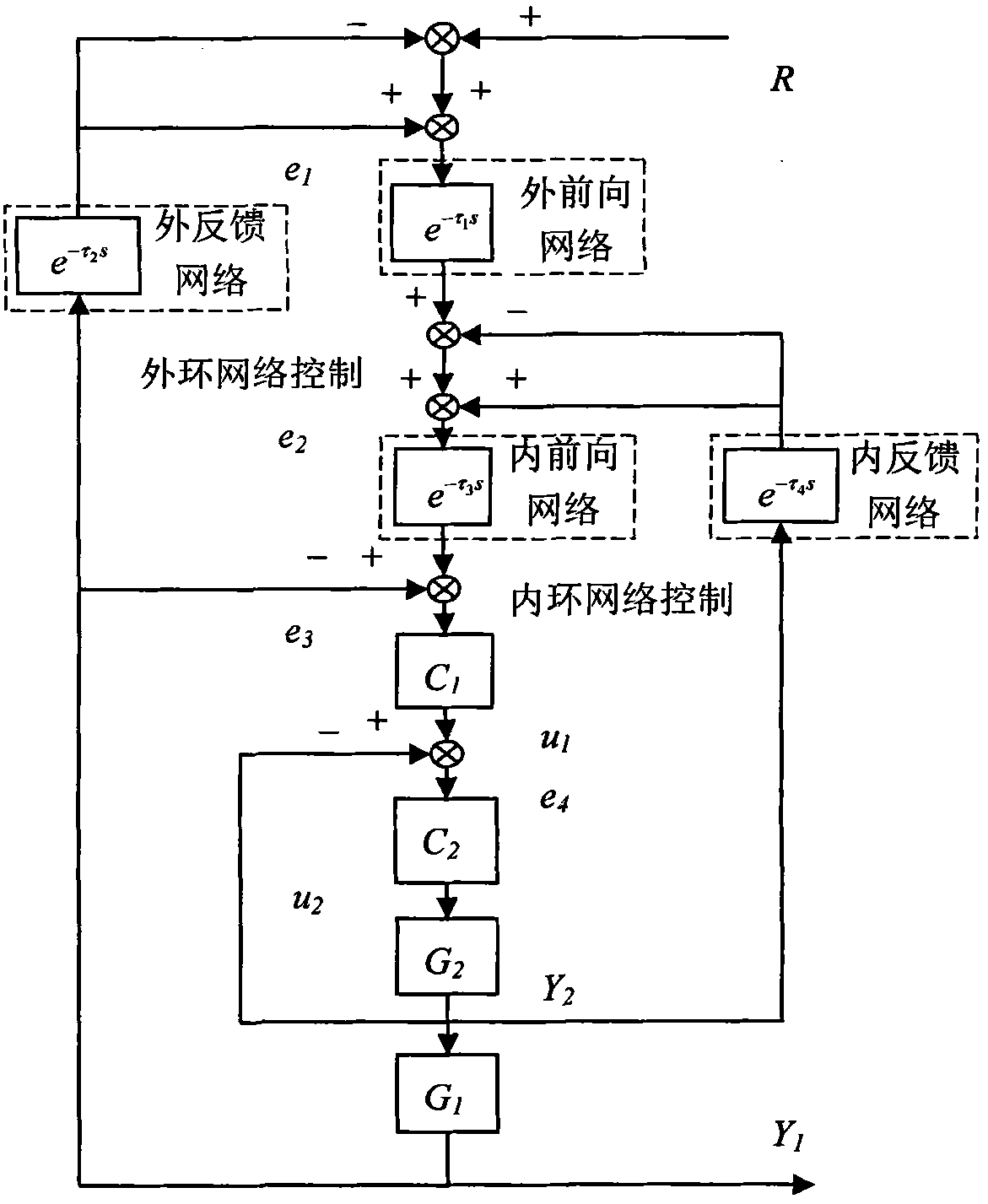

Compensation method of random time-delay of external forward and internal feedback path of network cascade control system

InactiveCN101986228AAvoid wastingAvoid estimation errorTotal factory controlSynchronising arrangementTime delaysMathematical model

The invention provides a compensation method of random time-delay of the external forward and internal feedback paths of a network cascade control system, belonging to the technical field of the network control system. The method uses the actual external forward network path nodes of the network cascade control system and adopts the network data transmission process between the internal feedback network path nodes to replace the compensation model of network time-delay between the nodes, avoid the measurement, observation, estimation or identification of the network data transmission random time-delay between the nodes and remove the synchronization requirement on the node clock signal. By adopting the method, the influence of the random network time-delay on the system stability can be reduced and the performance quality of system control can be imprved. The method of the invention is suitable for the dynamic compensation and control of random network time-delay when the mathematicalmodels of the main controlled object and auxiliary controlled object are known and the network only exists in the external forward and internal feedback paths of the cascade control system.

Owner:HAINAN UNIVERSITY

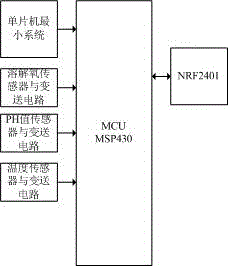

Aquaculture pond dissolved oxygen control system of wireless sensor network

InactiveCN106168813AEnhanced inhibitory effectAdaptableControlling ratio of multiple fluid flowsControl systemWireless sensor networking

By aiming at characteristics of dissolved oxygen parameters of aquaculture pond environment such as large working condition area, non-linear variety, and great inertia, and unbalance pond environment dissolved oxygen distribution, the invention discloses an aquaculture pond dissolved oxygen control system of a wireless sensor network. The aquaculture pond dissolved oxygen control system is constituted by an aquaculture pond environment dissolved oxygen acquisition and control platform, a pond dissolved oxygen cascade control system based on a composite controller, and an expert system of setting aquaculture pond environment dissolved oxygen based on economic optimal reasoning. The aquaculture pond dissolved oxygen control system is advantageous in that the control stability and the control precision of the aquaculture pond dissolved oxygen are improved, and important popularization and application values are provided for the economic benefit of the aquaculture pond.

Owner:广州穗研智能科技有限公司

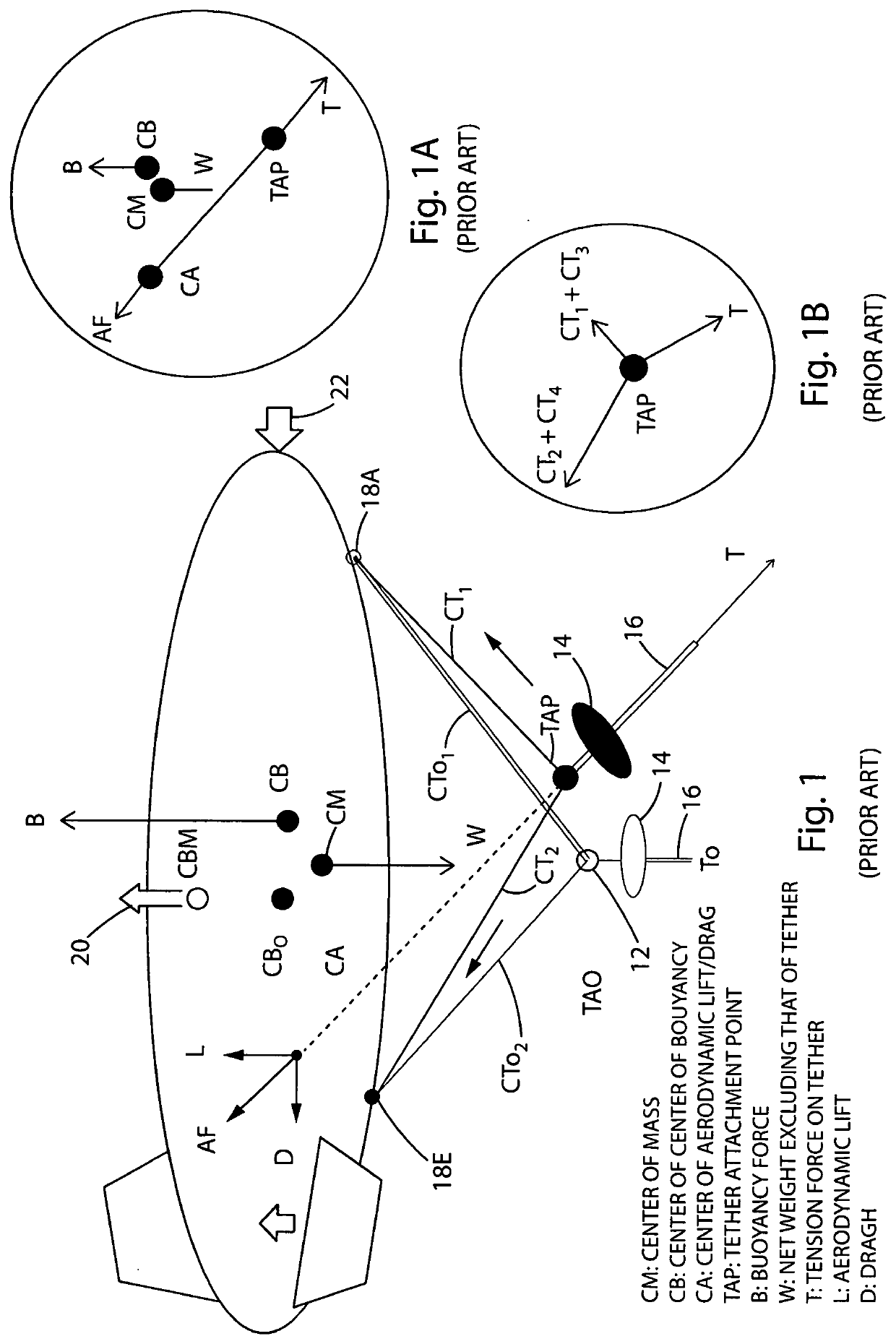

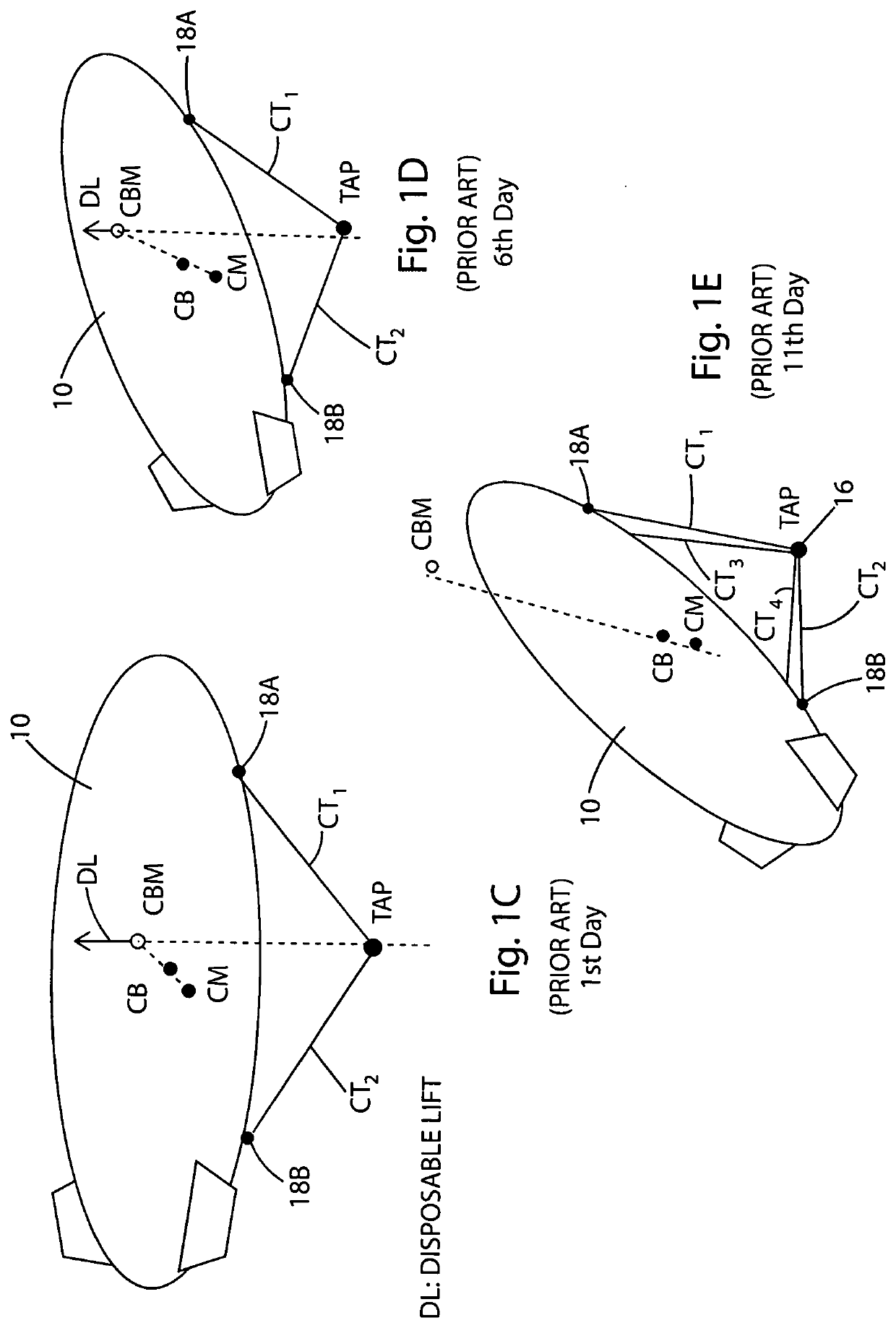

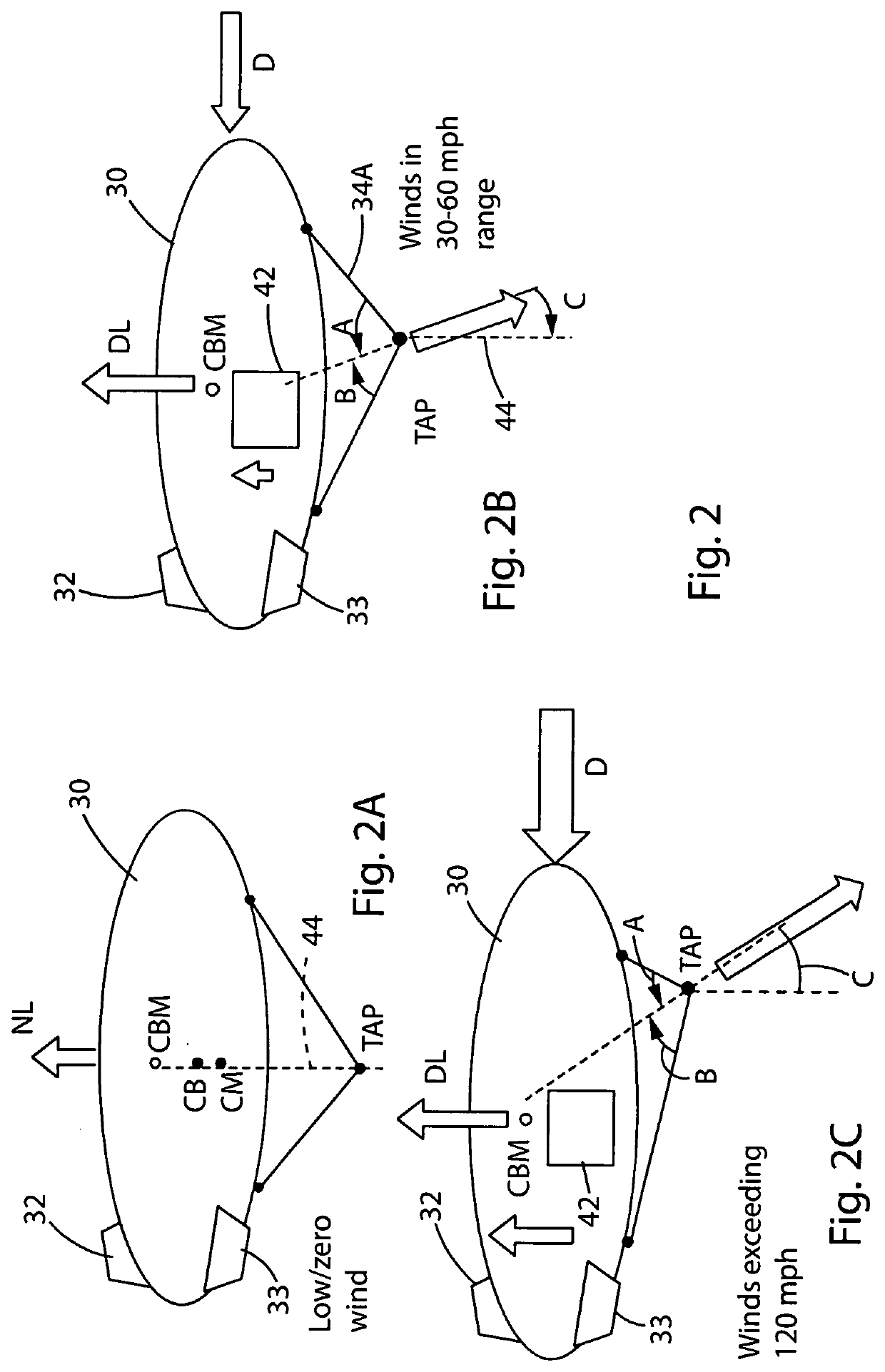

Adaptive harness to stabilize airships in high winds and method

ActiveUS20200108903A1Enhance high wind controllabilityExtend flight missionTethered aircraftNon-rigid airshipsControl systemClassical mechanics

An airship dynamic adaptive harness is provided to stabilize airships and particularly a tethered aerostat in high winds and atmospheric changes. A novel adaptive device accommodates the supply of a lift gas and simultaneously controls opposing cables in a tethered harness with a cascade control system that provides an immediate and particularly the dynamic control of roll, yaw and particularly the pitch of the aerostat in response to real time environmental flight conditions and impart stability to the airship in high winds using a stability zone geometric suspension control system and enhance the duration of in flight missions. A lifting gas replenishment system and particularly a ground based lifting gas replenishment system adds long duration deployment to the dynamic adaptability to high wind conditions for long term deployment.

Owner:ONWARD TECH LLC

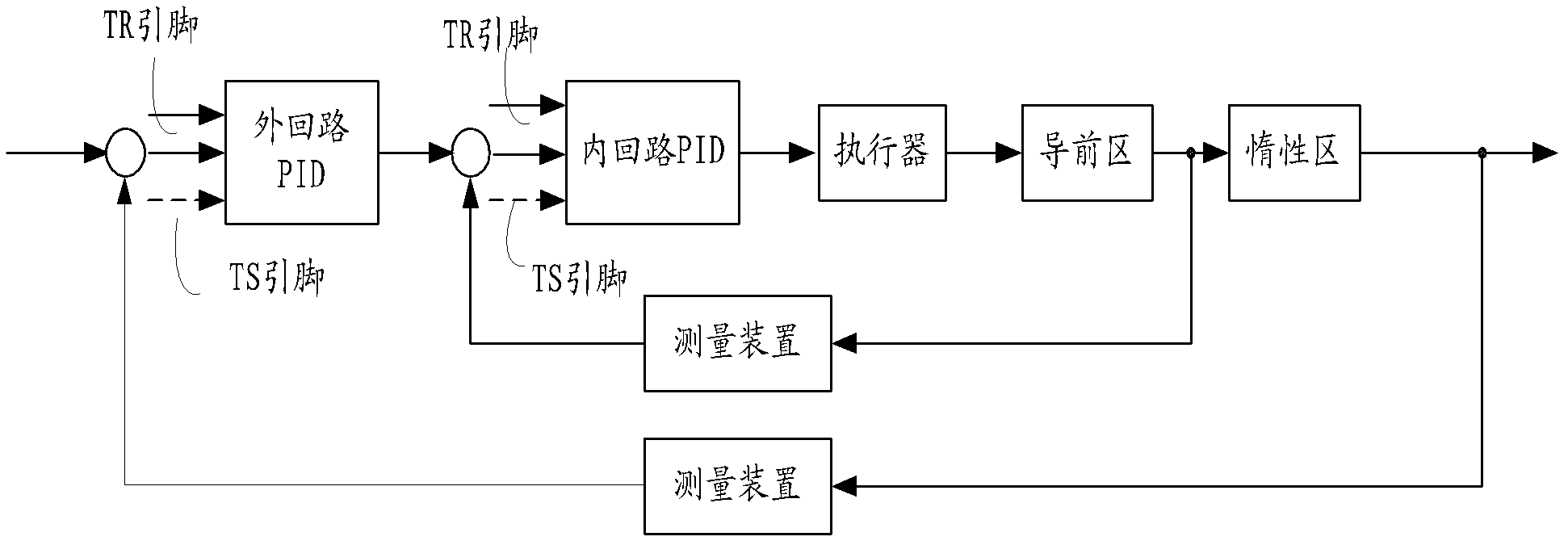

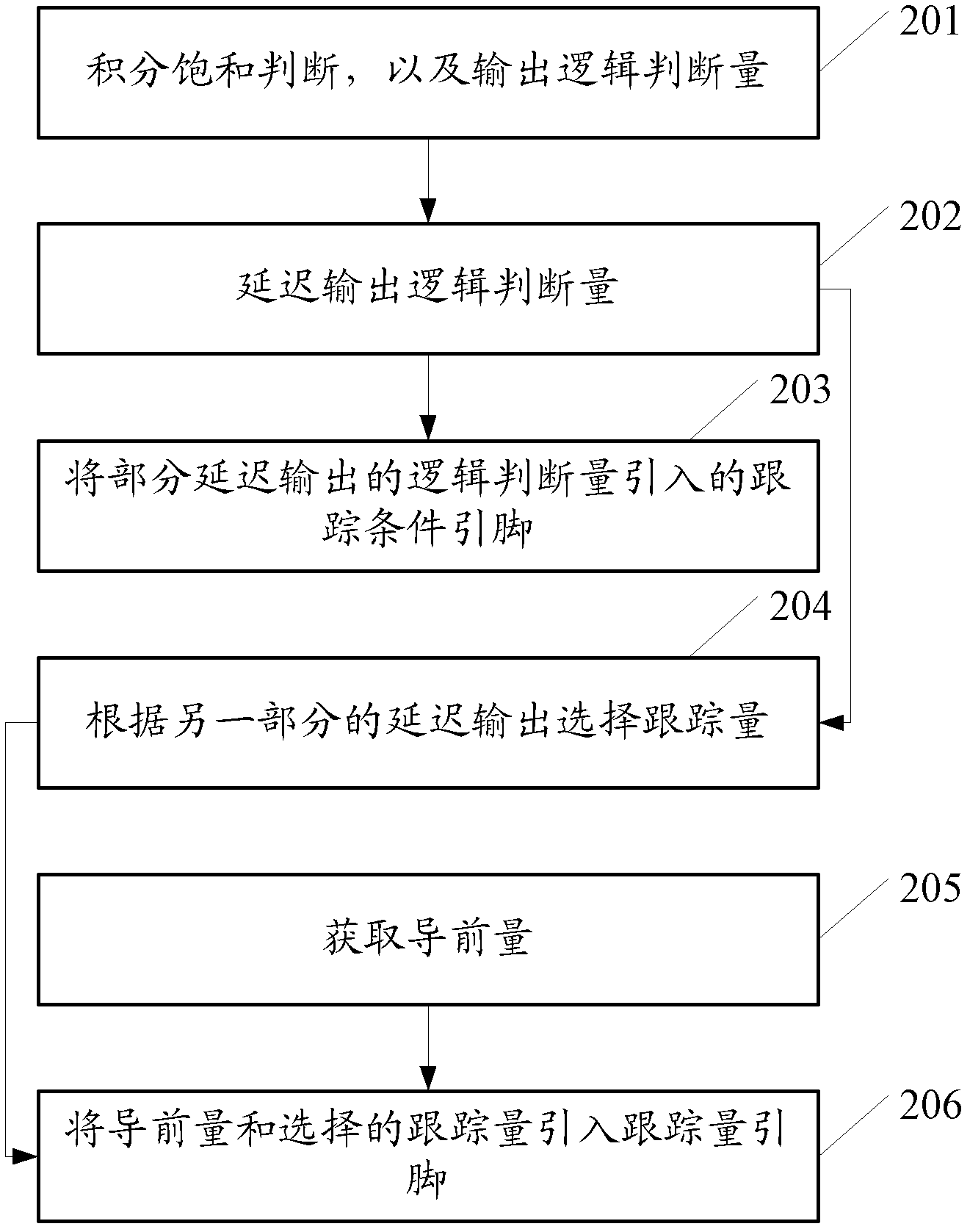

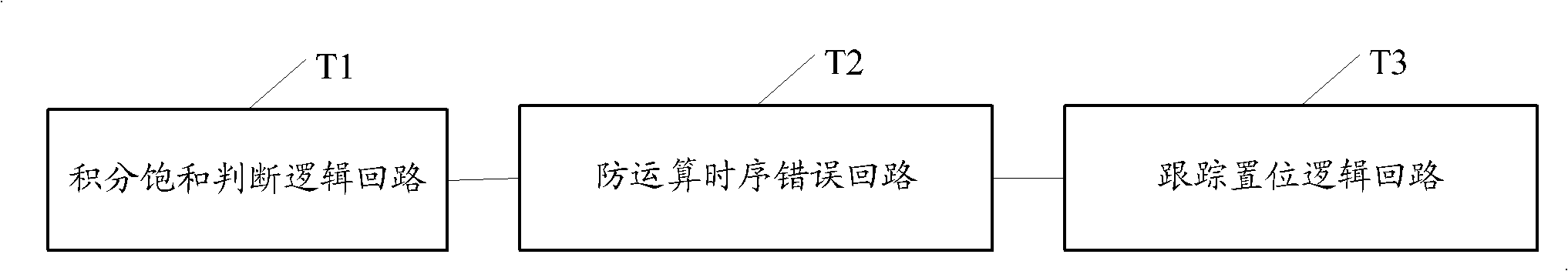

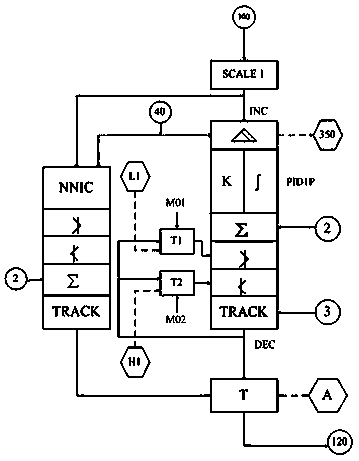

Anti-integral saturation control method and system of cascade control system

ActiveCN102426431AImprove adjustment qualityProgramme control in sequence/logic controllersControl systemCascade control system

The invention provides an anti-integral saturation control method of a cascade control system. The method comprises the following steps of: judging an anti-integral saturation direction according to input quantity and outputting logic judging quantity; delaying the output of the logic judging quantity; sending one part of the logic judging quantity output in a delayed way into a tracking condition pin of the cascade control system; selecting preset tracking quantity according to the other part of the logic judging quantity output in a delayed way; obtaining leading quantity; and sending the leading quantity and the selected tracking quantity into a tracking quantity pin of the cascade control system. The invention also provides an anti-integral saturation control system of the cascade control system; and by using the system, the integral saturation phenomenon in the industrial control process can be reduced and the adjusting quality of the industrial process control can be improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Temperature cascade control system of casting holding furnace and control method of temperature cascade control system

ActiveCN104296548ASmall temperature fluctuationsReduce oxidation burnFuel supply regulationGas emission reductionCombustionControl system

The invention discloses a temperature cascade control system of a casting holding furnace and a control method of the temperature cascade control system. The temperature cascade control system comprises the holding furnace, a furnace gas thermocouple, a metal liquid thermocouple, a combustion-supporting air adjusting valve, a wind-control air proportional valve, a combustion-supporting draught fan, a natural gas output port, a nozzle and a PLC. The nozzle is installed on the holding furnace and connected with the combustion-supporting draught fan through a pipe to form a first pipeline, and the nozzle is connected with the natural gas output port through a pipe to form a second pipeline. The wind-control air proportional valve is connected between the first pipeline and the second pipeline, and a combustion-supporting air adjusting valve is arranged between the wind-control air proportional valve and the combustion-supporting draught fan. The furnace gas thermocouple and the metal liquid thermocouple are connected with the input end of the PLC, and the output end of the PLC is connected with the combustion-supporting air adjusting valve. The temperature cascade control system is simple and reliable in control, collecting of the temperature of the furnace gas and the temperature of the metal liquid and controlling over the combustion-supporting air adjusting valve are automatically finished, the whole process is controlled in a closed-loop mode, the oxidation burning loss of the metal liquid in the furnace is effectively reduced, and the production cost is saved.

Owner:SUZHOU LONGRAY THERMAL TECH

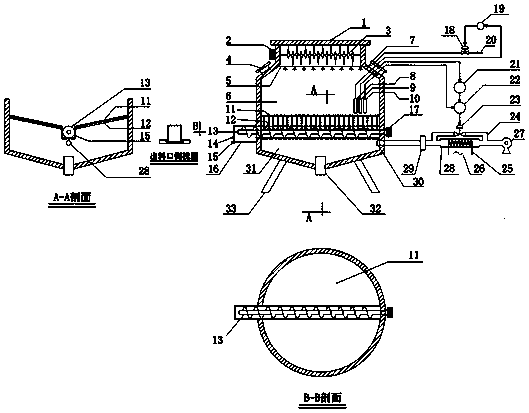

Straw type agricultural waste crushing and composting integral control device and method

InactiveCN110590423ARealize automatic controlShorten composting timeBio-organic fraction processingOrganic fertiliser preparationAutomatic controlPush pull

The invention discloses a straw type agricultural waste crushing and composting integral control device which comprises a material composting chamber, a straw crushing device, a temperature oxygen control system, a humidity control system and a discharge system, wherein a feeding hole, a measuring hole and a standby hole are formed in the material composting chamber; a groove is formed in the bottom of the material compositing chamber; the upper part of the material compositing chamber is connected with the straw crushing device; the lower part of the material compositing chamber is connectedwith a micro-pore net, a porous plate and a cold-hot air mixing chamber; the straw crushing device comprises a feeding driving motor and double mixing blades; the temperature oxygen control system comprises a temperature measurer, an oxygen measurer, a temperature oxygen cascade control system, an air blower, a hot resistance wire, an air tube, a hot air chamber, a bypass cold air valve, a rotor flowmeter and a cold-hot air mixing chamber; an air tube hole is formed beside the cold-hot air mixing chamber; a percolate discharge hole is formed in the lower part of the cold-hot air mixing chamber; the humidity control system comprises a humidity measurer, a spraying device, a straight-in single-base valve and a humidity controller; the discharge system comprises a discharge groove, a discharge driving motor, rolling wheels, a discharge hole and a push-pull type baffle plate. The invention further discloses two straw type agricultural waste crushing and composting methods of fixed value continuous control and programmed control. By adopting the device, automatic material feeding and discharge, automatic crushing and composting fermentation can be implemented in the straw type agricultural waste treatment process, automatic control on humidity, temperatures and oxygen in the composting process can be achieved, the labor and materials can be saved, meanwhile, the compositing time ofagricultural wastes can be shortened, and composting conditions can be optimized.

Owner:HARBIN UNIV OF SCI & TECH

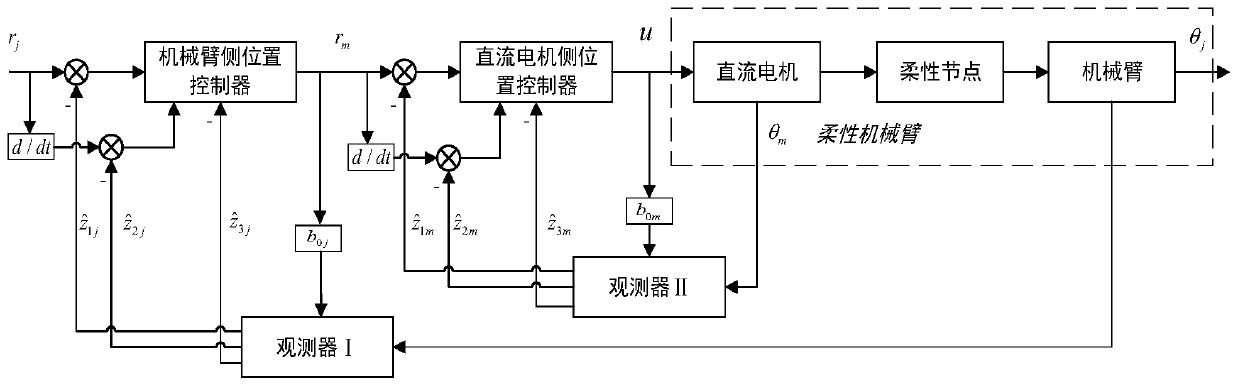

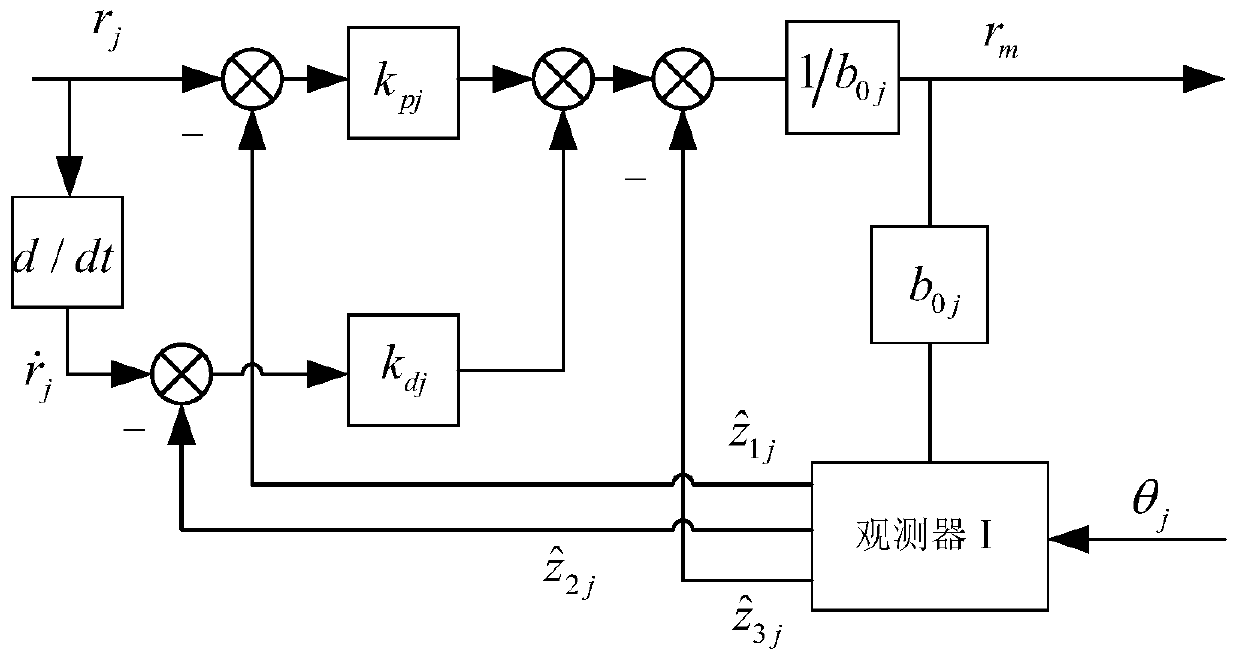

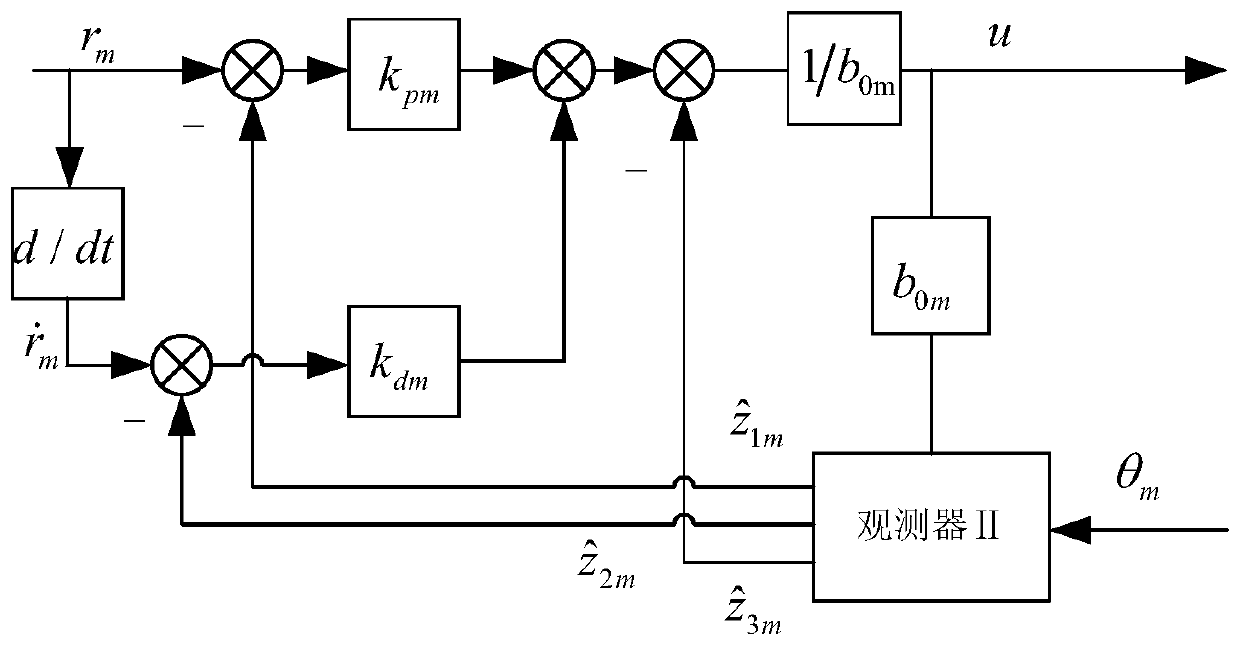

Cascade control system and method of flexible robot based on time-varying interference compensation

ActiveCN111251288ASimple control methodSimple structureProgramme-controlled manipulatorHuman–computer interactionFeedback control

The invention discloses a cascade control system and method of a flexible robot based on time-varying interference compensation. The cascade control system includes a direct current motor side position controller, an extended state observer based on a direct current motor model, a mechanical arm side position controller, an extended state observer based on a mechanical arm model, a direct currentmotor side position sensor, a mechanical arm side position sensor, a direct current motor, flexible joints and a mechanical arm. The mechanical arm side position controller comprises feedforward compensation control based on interference estimation and feedback control based on state estimation; the direct current motor side position controller includes feedforward compensation control based on interference estimation and feedback control based on state estimation. Compared with a traditional cascade proportional-differential control method, the cascade control system and a method of a flexible robot based on time-varying interference compensation are simple in design and implementation, strong in anti-interference ability, and the application requirements of a position tracking system ofa single-joint flexible mechanical arm can be meet.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

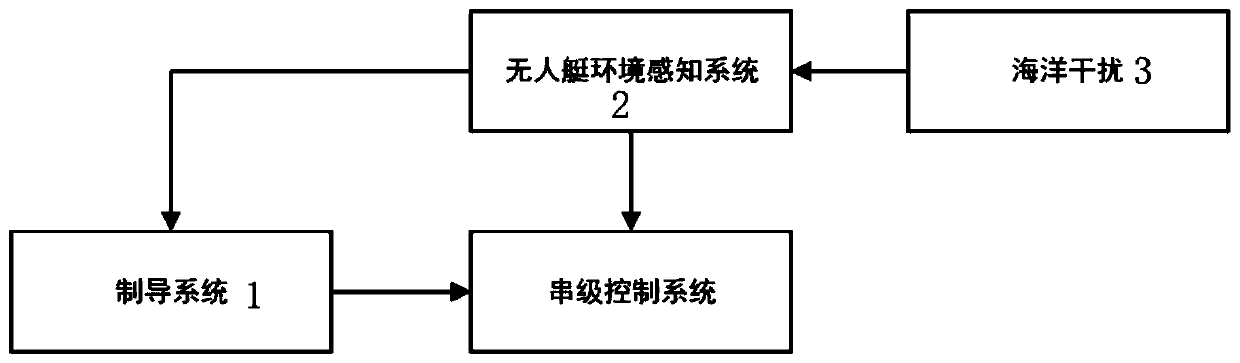

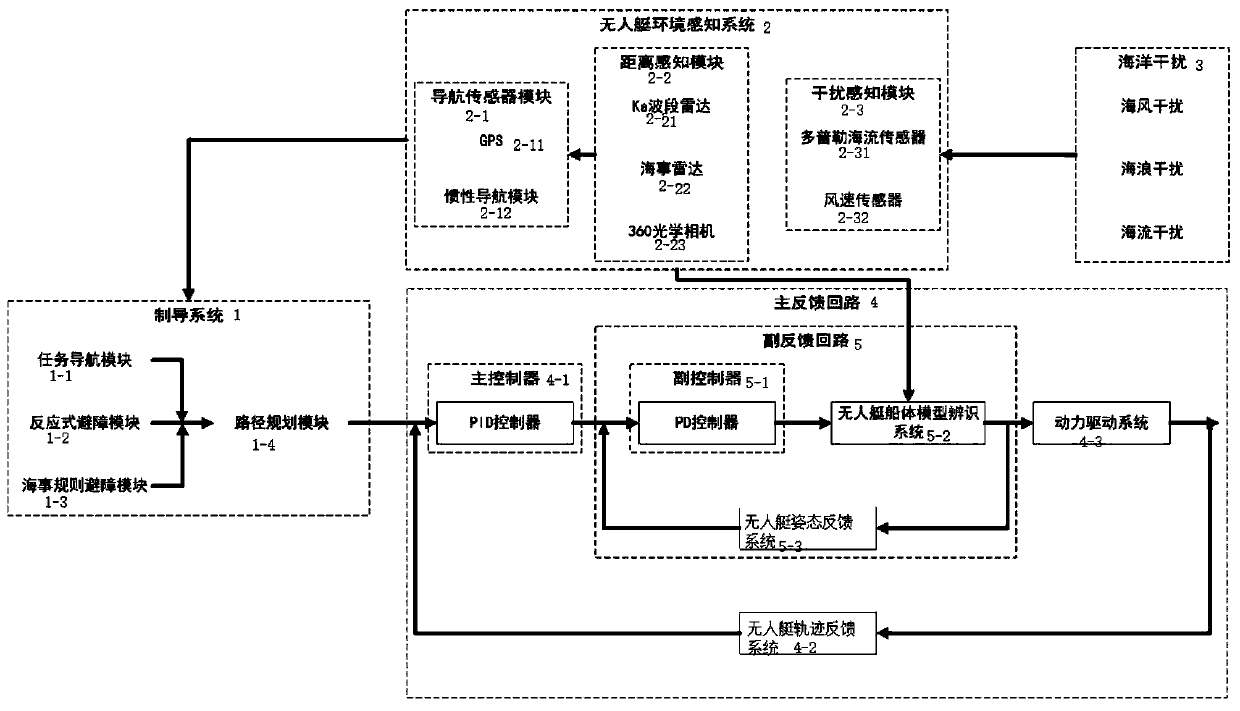

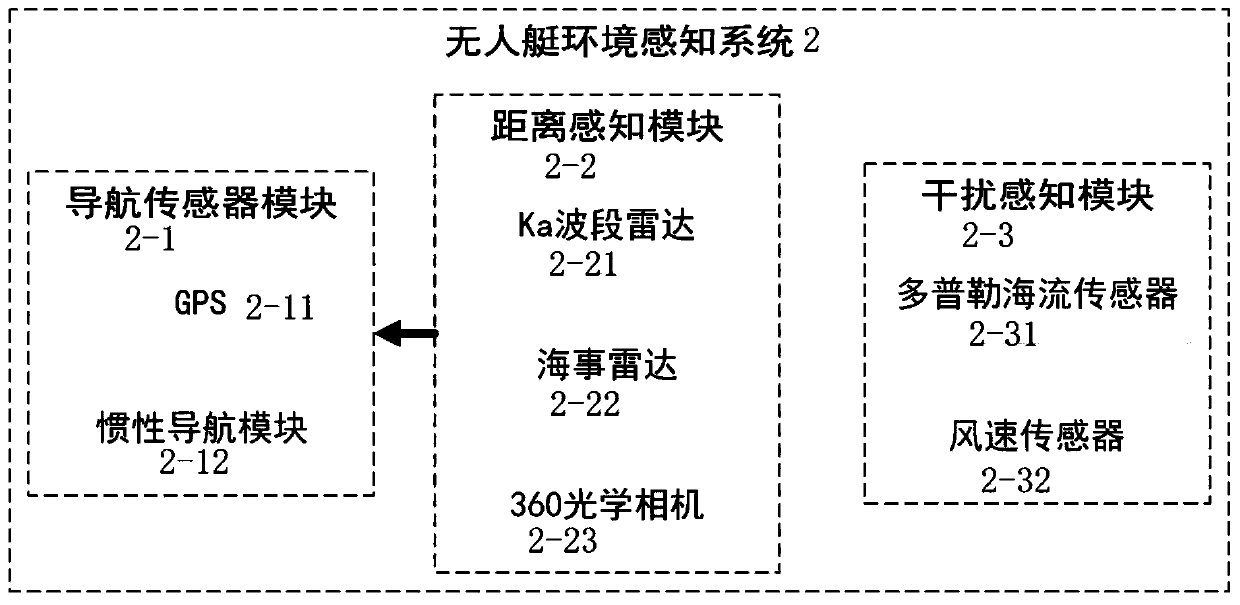

Unmanned ship navigation cascade control system

ActiveCN111208824AEnhanced inhibitory effectOvercome the effects of normal navigationPosition/course control in two dimensionsGuidance systemControl system

The invention discloses an unmanned ship navigation cascade control system and a control method thereof. The control system comprises a guidance system, a cascade control system and an unmanned ship environment sensing system. The unmanned ship environment sensing system senses navigation information and transmits the information to the guidance system and the cascade control system. The unmannedship environment sensing system comprises a navigation sensor module, a distance sensing module and an interference sensing module. The guidance system comprises a task navigation module, a reactive obstacle avoidance module, a maritime affair rule obstacle avoidance module and a path planning module. The cascade control system comprises a main feedback loop and an auxiliary feedback loop; the guidance system is connected with a main controller and an unmanned ship trajectory feedback system in the main feedback loop; the auxiliary feedback loop is arranged in the main feedback loop, the maincontroller is connected with the auxiliary controller and the unmanned ship attitude feedback system, and the auxiliary controller is connected with an unmanned ship body model identification system.According to the invention, the interference of the external environment can be inhibited such that the unmanned high-performance navigation is realized.

Owner:SHANGHAI UNIV

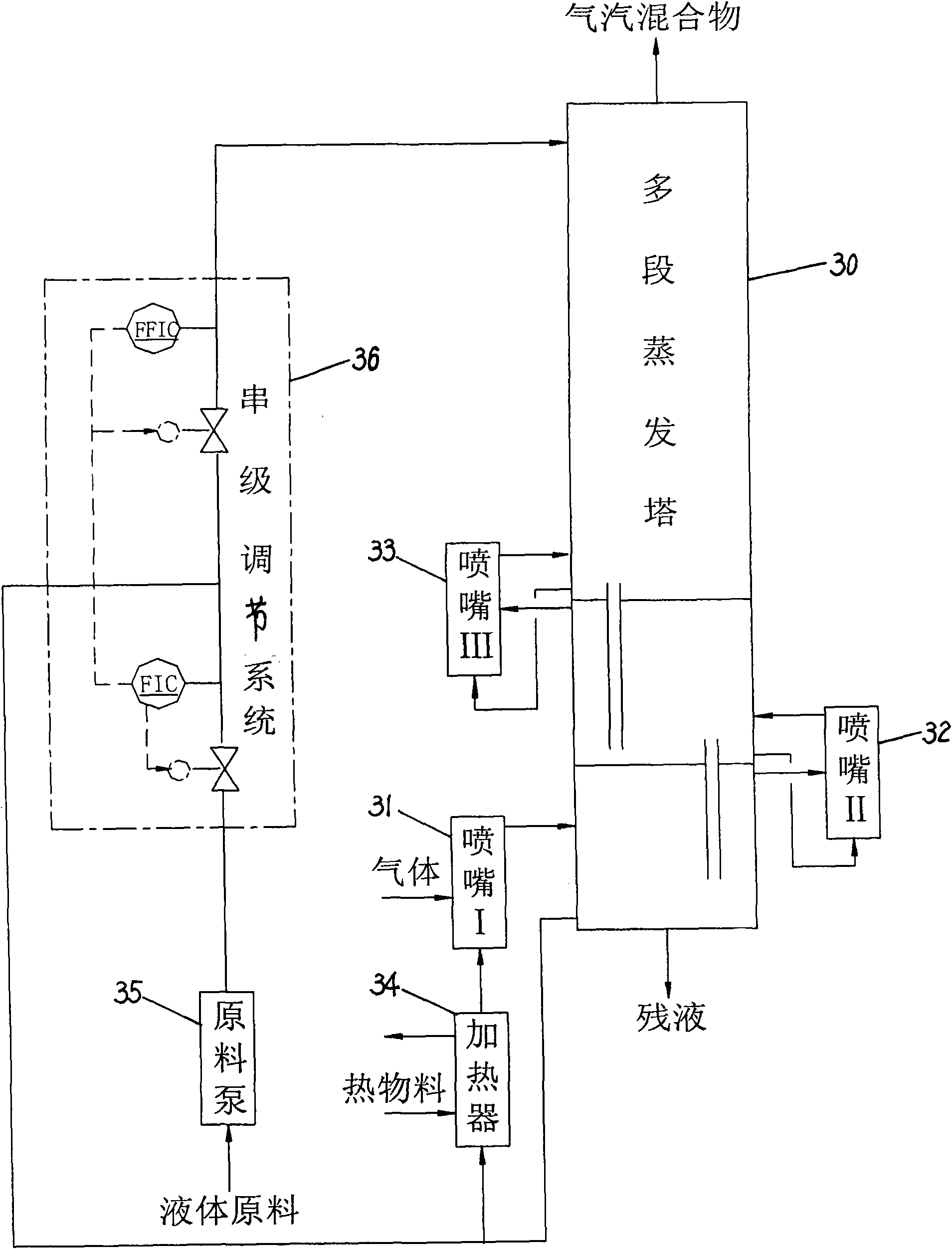

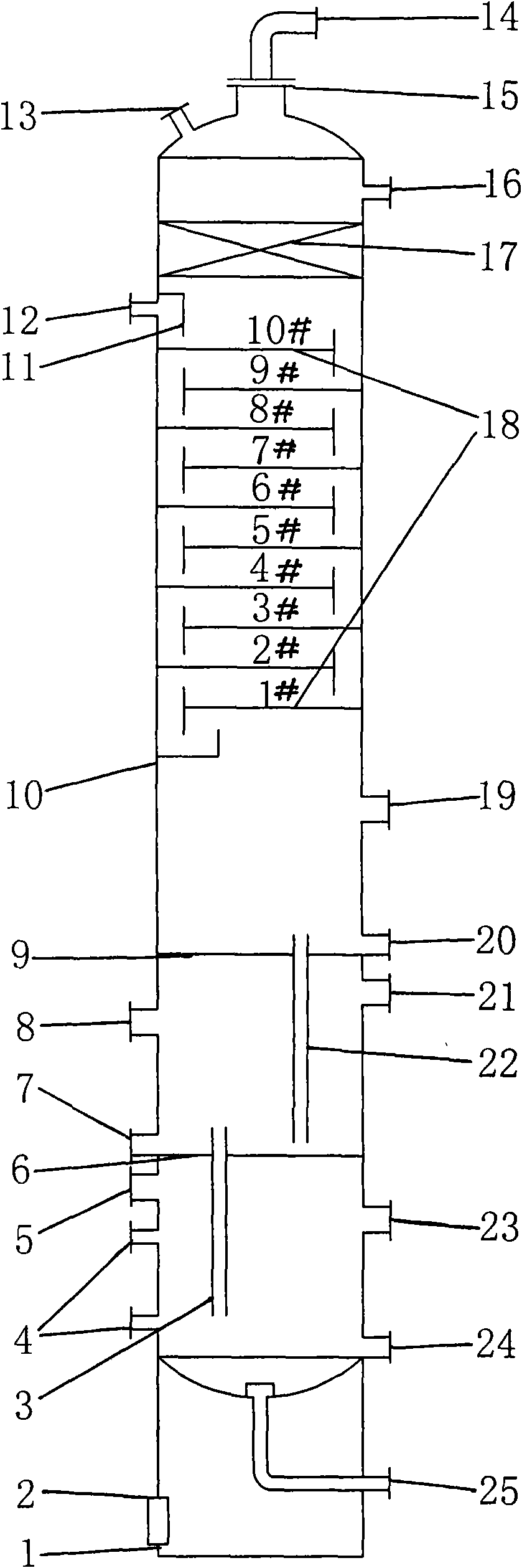

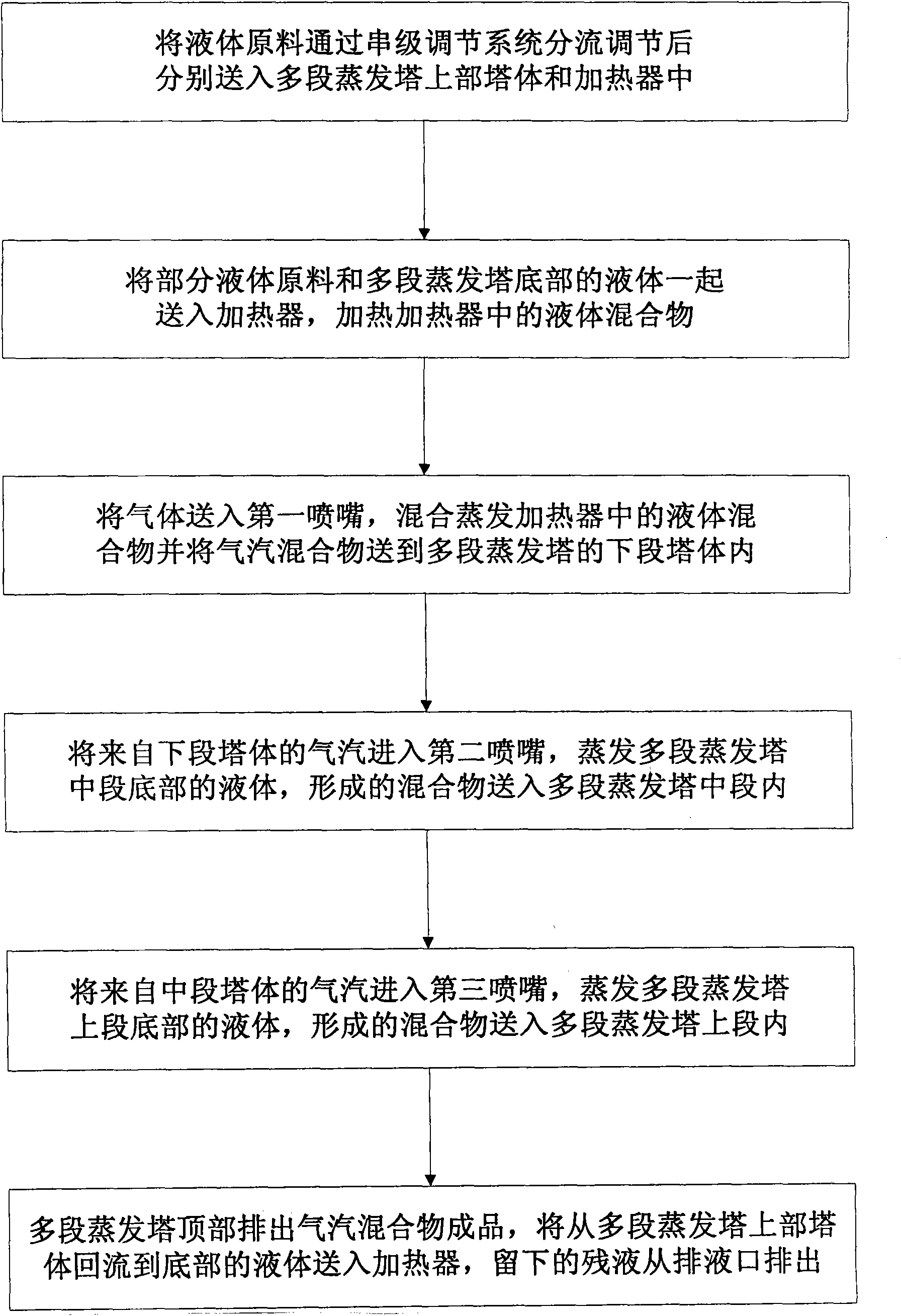

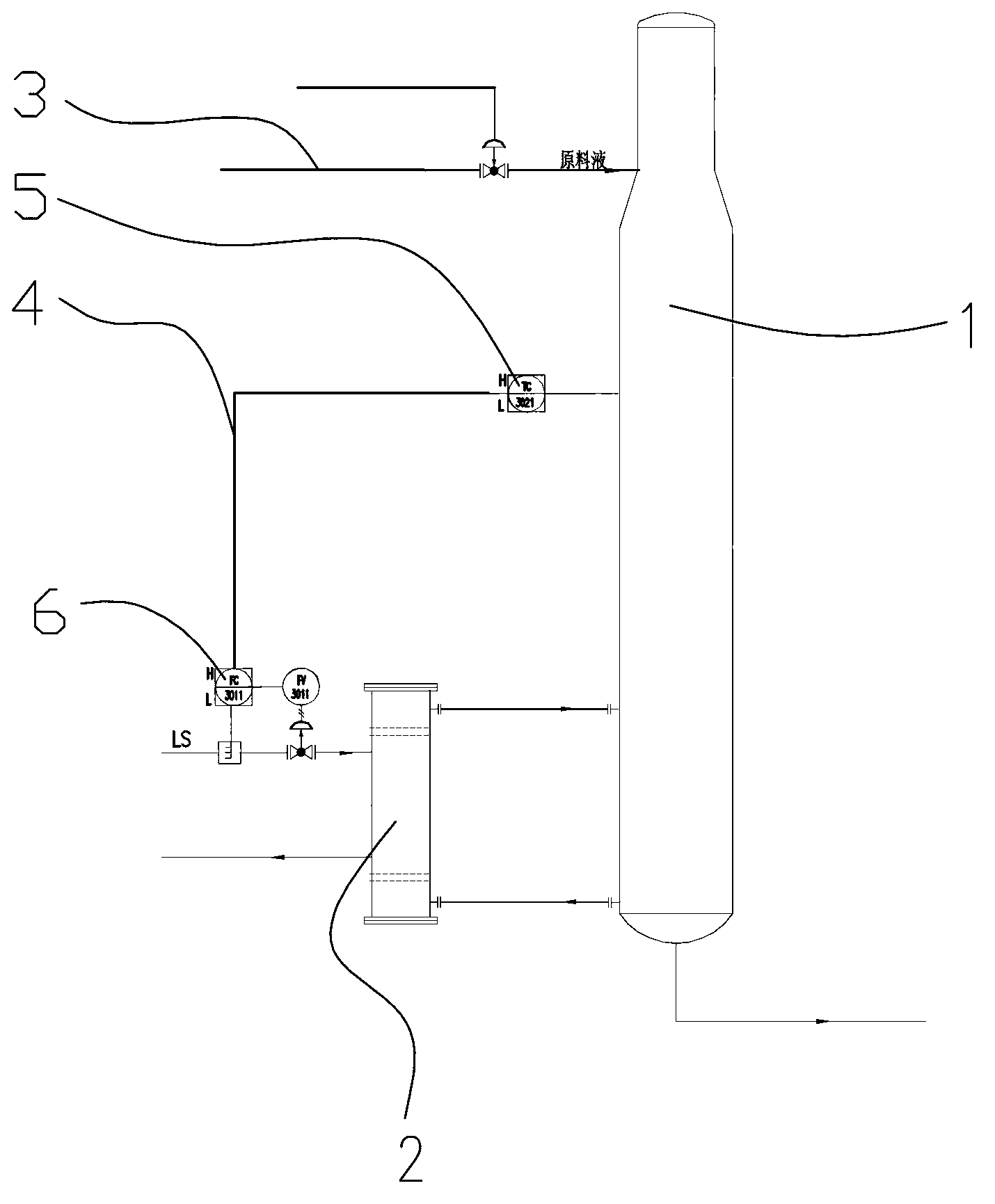

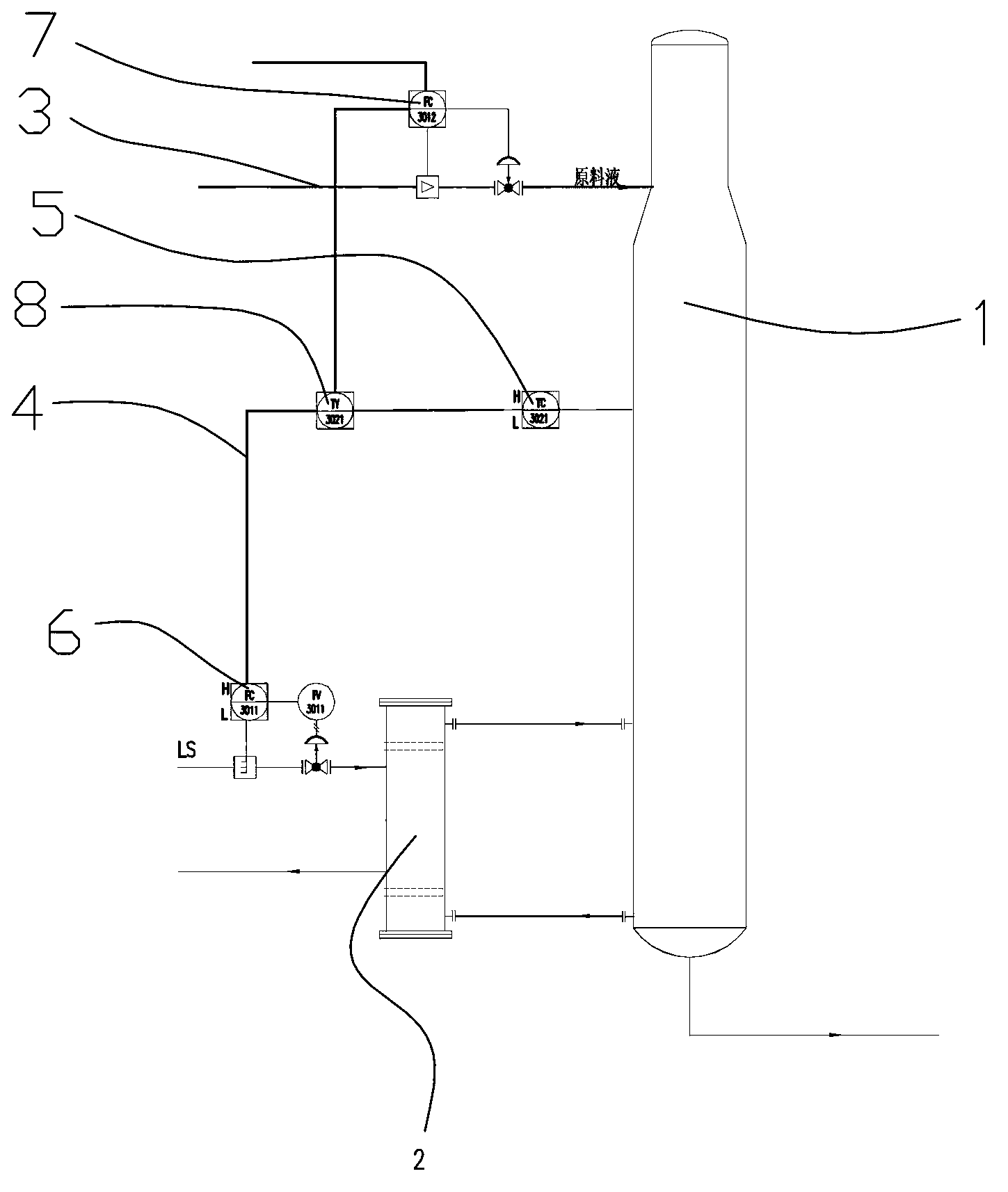

Multi-stage evaporation and air-vapour hybrid system and method thereof

InactiveCN101584943AFully evaporatedThe evaporation tower system completes the mixingMixing methodsEvaporationHybrid systemEvaporation

The invention relates to a multi-stage evaporation and air-vapour hybrid system and method thereof, comprising a multi-stage evaporation tower, a cascade control system for feeding a liquid charging stock, a heater and three nozzles. The multi-stage evaporation tower comprises a tower body and a tower base divided into three segments with two dividing tower plates. The tower body is provided with an air-vapour outlet, a feeding inlet, an air-vapour inlet, a liquid outlet and a leakage fluid drain. The method provided by the invention comprises the following steps: the liquid charging stock is shunted and regulated through the cascade control system, and then fed into an upper tower body of the multi-stage evaporation tower and the heater, and a liquid mixture is heated in the heater. The air is loaded into the nozzle, the liquid mixture is mixed and evaporated in the heater, then air-vapour mixture is fed into the multi-stage evaporation tower. The air-vapour mixture product is discharged from the top and a residual liquid is further discharged. The invention realizes multi-stage evaporation and condensation of the mixture liquid through a plurality of nozzles and multi-stage evaporation tower system, and control is simple.

Owner:BAOSTEEL ENG & TECH GRP

Time-varying network time delay compensation method of forward access of networked cascade control system (NCCS)

InactiveCN101986229AAvoid wastingAvoid estimation errorTotal factory controlSynchronising arrangementMathematical modelTime delays

The invention provides a time-varying network time delay compensation method of a forward access of a networked cascade control system (NCCS), belonging to the technical field of networked control system. In the method, a network data transmission process among forward access nodes is used instead of a network time delay compensation model among the forward access nodes so as to avoid measurement, observation, estimation or recognition of time-varying time delay when network data among the real forward access nodes are transmitted and prevent the requirements of synchronization of node clock signals. By using the method, the influence of the time-varying network time delay on the stability of a system can be reduced and the control performance quality of the system can be improved. The method is suitable for dynamic compensation and control of the time-varying network time delay when a network only exists in the forward access of the networked cascade control system under the condition that a mathematical model of a main controlled object is known or uncertainly known, a mathematical model of a vice controlled object is known, and certain interference signals exist in the system.

Owner:HAINAN UNIVERSITY

Control system and method for improving acrylonitrile production stability

ActiveCN102796028AImprove operational stabilityImprove stabilityTotal factory controlProgramme total factory controlControl systemReboiler

The invention provides a control system for improving acrylonitrile production stability. The system includes a recovery tower sensitive plate temperature controller, a recovery tower, a reboiler flow control loop, and a recovery tower feed flow control loop. The output ends of the reboiler flow control loop and the recovery tower flow control loop are connected to the input end of the recovery tower. The sensitive plate temperature controller and the reboiler flow control loop form a cascade closed loop. A temperature set value of the sensitive plate temperature controller and a measured temperature value of the recovery tower are output to a reboiler flow controller. The assemblies and the loops are controlled by automatic valves. The recovery tower flow control circuit is provided with a flow controller. The sensitive plate temperature controller and reboiler flow cascade closed loop is equipped with a calculation module. The feed amount of the recovery tower is input as a feedforward into the calculation module together with an output value of the sensitive plate temperature controller, thus forming a feedforward cascade control system. The control method is a method for realizing improvement of product acrylonitrile stability. The system and the method can improve the stability of acrylonitrile production.

Owner:CHINA PETROCHEMICAL CORP +2

Intelligent cable automatic manufacturing machine based on fuzzy support vector machine

ActiveCN107894711AImprove generalization abilityAchieve high precision controlElectronic commutation motor controlVector control systemsFuzzy support vector machineControl system

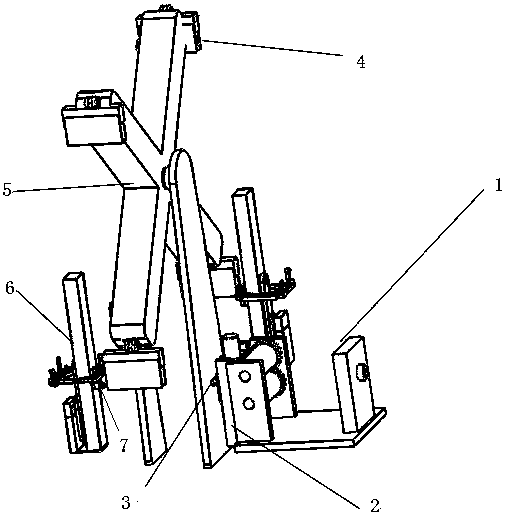

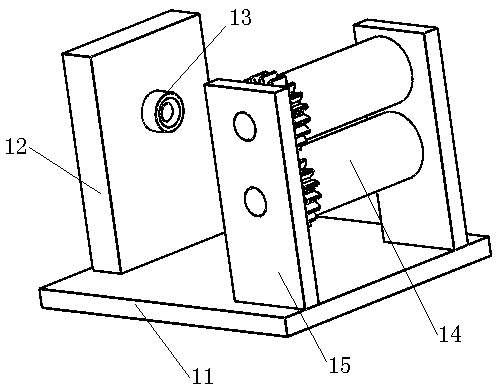

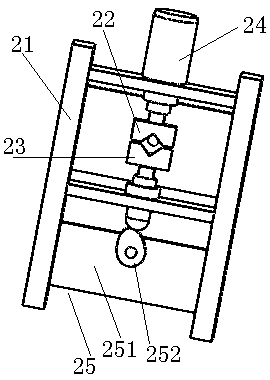

The invention discloses an intelligent cable automatic manufacturing machine based on a fuzzy support vector machine. The intelligent cable automatic manufacturing machine is characterized by comprising a wire inlet device (1), a peeling and cutting device (2), a stripping and twisting device (3), a wire clamping mechanism (4), a rotary conveying device (5), a needle pressing device (6), the wireinlet device (1), the peeling and cutting device (2), the stripping and twisting device (3), the wire clamping mechanism (4), the rotary conveying device (5), and the needle pressing device (6) construct an adjusting platform for adjustment and control through a single-chip microcomputer, a rotary drum rotating speed intelligent cascade control system based on the fuzzy support vector machine is designed in the adjusting platform to carry out the closed-loop control of the rotating speed on the pulling drum (14) of the wire inlet device (1). According to the invention, the problems that the automation degree of existing cable manufacturing equipment is not high, most procedures need manual participation, the working efficiency is low, and a certain safety accident can be caused are effectively solved, and the problem that the rotating speed precision of the pulling drum of the wire inlet device is poor is effectively solved.

Owner:深圳市精艺自动化科技有限公司

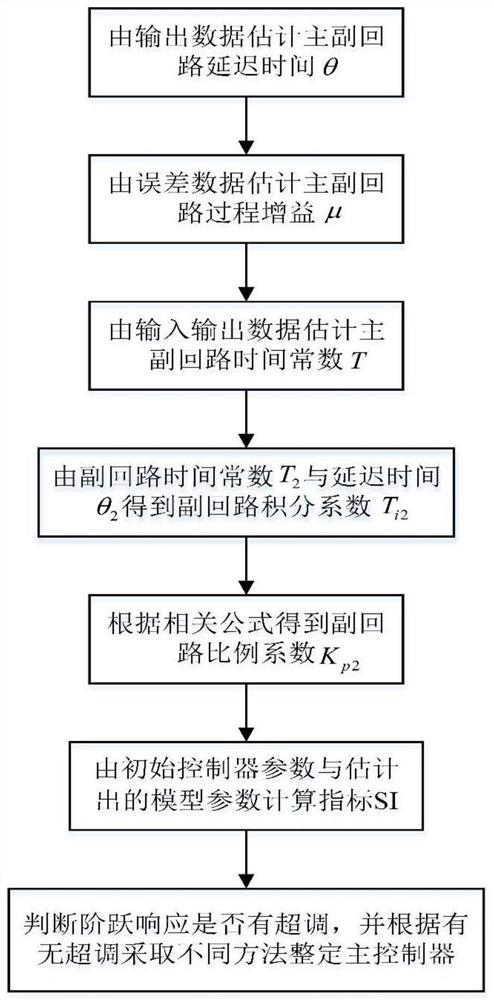

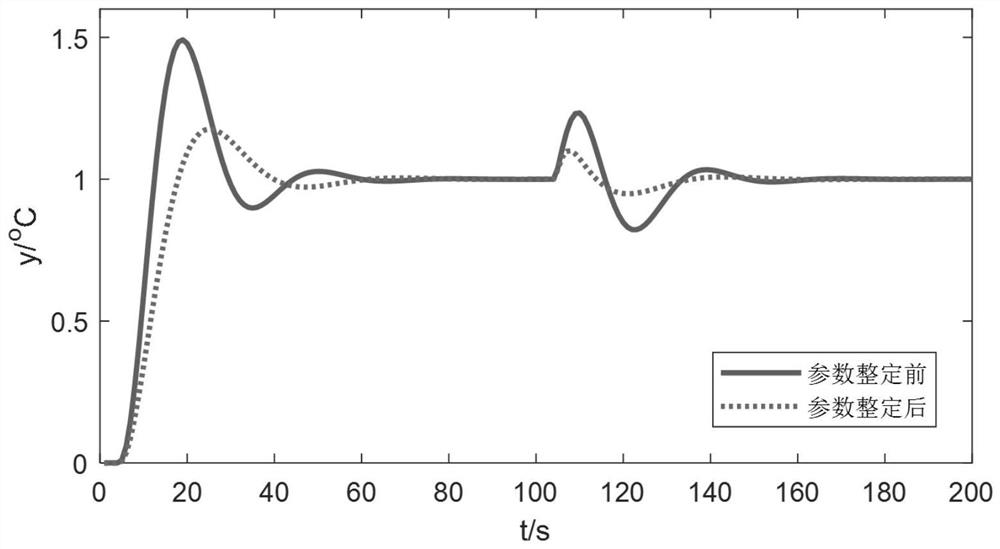

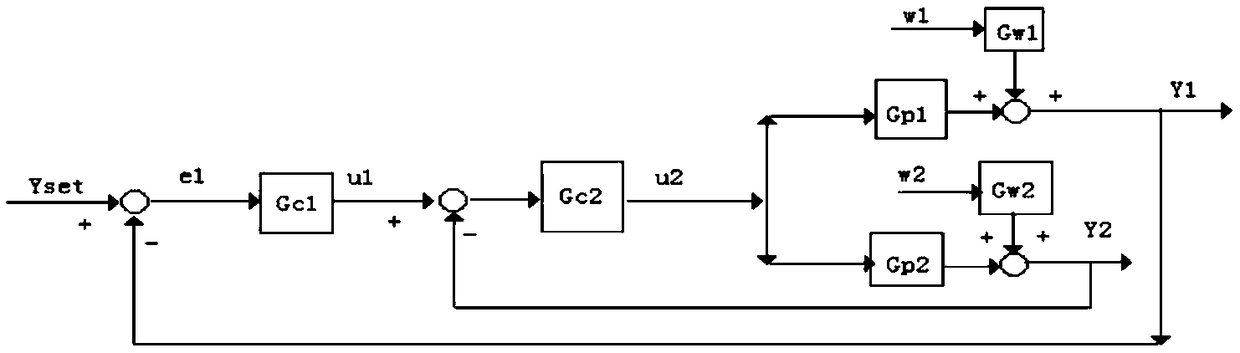

PID control parameter self-correction method based on closed-loop step response cascade loop

ActiveCN112506056AImprove anti-interference abilityImprove stabilityAdaptive controlProportion integration differentiationLoop control

The invention provides a PID (Proportion Integration Differentiation) control parameter self-correcting method based on a closed-loop step response cascade loop, and belongs to the technical field ofcascade system controller parameter setting. According to the method, closed-loop step response data of a control loop is collected, and then a series of off-line operations are carried out accordingto the closed-loop step response data to obtain a set controller parameter value, so that the condition that the normal operation of the control system needs to be interrupted when the existing controller parameter setting method corrects the controller parameters through multiple times of external excitation is avoided; and moreover, in the controller parameter derivation process, the condition that interference exists in an auxiliary loop is considered, and the parameters of an auxiliary controller are corrected by utilizing a direct analysis design principle, so that the anti-interference performance and the stability of the control loop are improved. Tests in an actual industrial application rectifying tower stripping section temperature value control system show that the method can obviously reduce the overshoot phenomenon of a cascade control system, and the fluctuation range of the control system is obviously reduced when interference is generated.

Owner:JIANGNAN UNIV

Method for compensating for unknown network time delay in forward path of network cascade control system

InactiveCN102033529AAvoid wastingAvoid estimation errorTotal factory controlSynchronising arrangementMathematical modelTime delays

The invention provides a method for compensating for an unknown network time delay in a forward path of a network cascade control system and belongs to the technical field of network control systems. A real network data transmission process between forward path nodes is adopted to substitute for a network time delay compensation model between the nodes; the measurement, the observation, the estimation or the identification of a network data transmission unknown time delay between the forward path nodes are eliminated; and the requirement on the synchronization of a node clock signal is eliminated. By the method, the influence of the unknown network time delay on the stability of the system can be reduced and the control performance quality of the system is improved. The method is applied to the dynamic compensation and control of the unknown network time delay only existing in the forward path of the network cascade control system, in which the main and secondary controlled target mathematical models are known or unknown, the network has a certain amount of packets, and the network time delay can be more than several even over ten sampling periods.

Owner:HAINAN UNIVERSITY

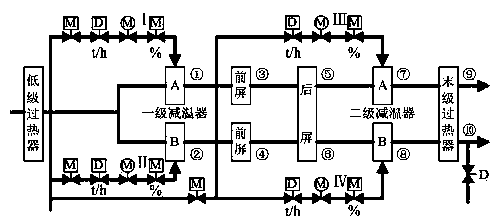

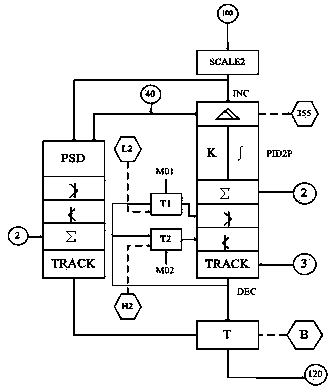

Configuration design method of switching control system

InactiveCN103453519AImprove the problem of long adjustment time and poor adaptive abilityImproved Cascade ControlSuperheating controlTemperature controlConfiguration design

The invention discloses a configuration design method of a switching control system. The configuration design method is based on a DCS (distributed control system) control platform, and includes that a secondary desuperheater is adopted for temperature control, a set value of a main control loop of primary desuperheating water spray is an inlet temperature design value of a secondary superheater, input of an auxiliary control loop is a desuperheater outlet temperature of a primary superheater, a primary desuperheater water spray regulating valve is controlled by the output, a set value of a main control loop of secondary desuperheating water spray is a main steam temperature, and an input signal of an auxiliary control loop is a post temperature of a secondary spray desuperheater; a cascade control system is adopted as a controller, an intelligent neural network controller is adopted as a main controller, a PID (proportion integration differentiation) controller is used as an auxiliary controller, and tracking modules are arranged at output ends of the main loop PID controller and the intelligent neural network controller. The method can allow operators to regulate operation timely to achieve the purposes of reliability and high efficiency, and has great transportability and dynamic expandability, and the problems of long time for conventional PID regulation and poor adaptive capability are effectively solved.

Owner:SUZHOU UNIV

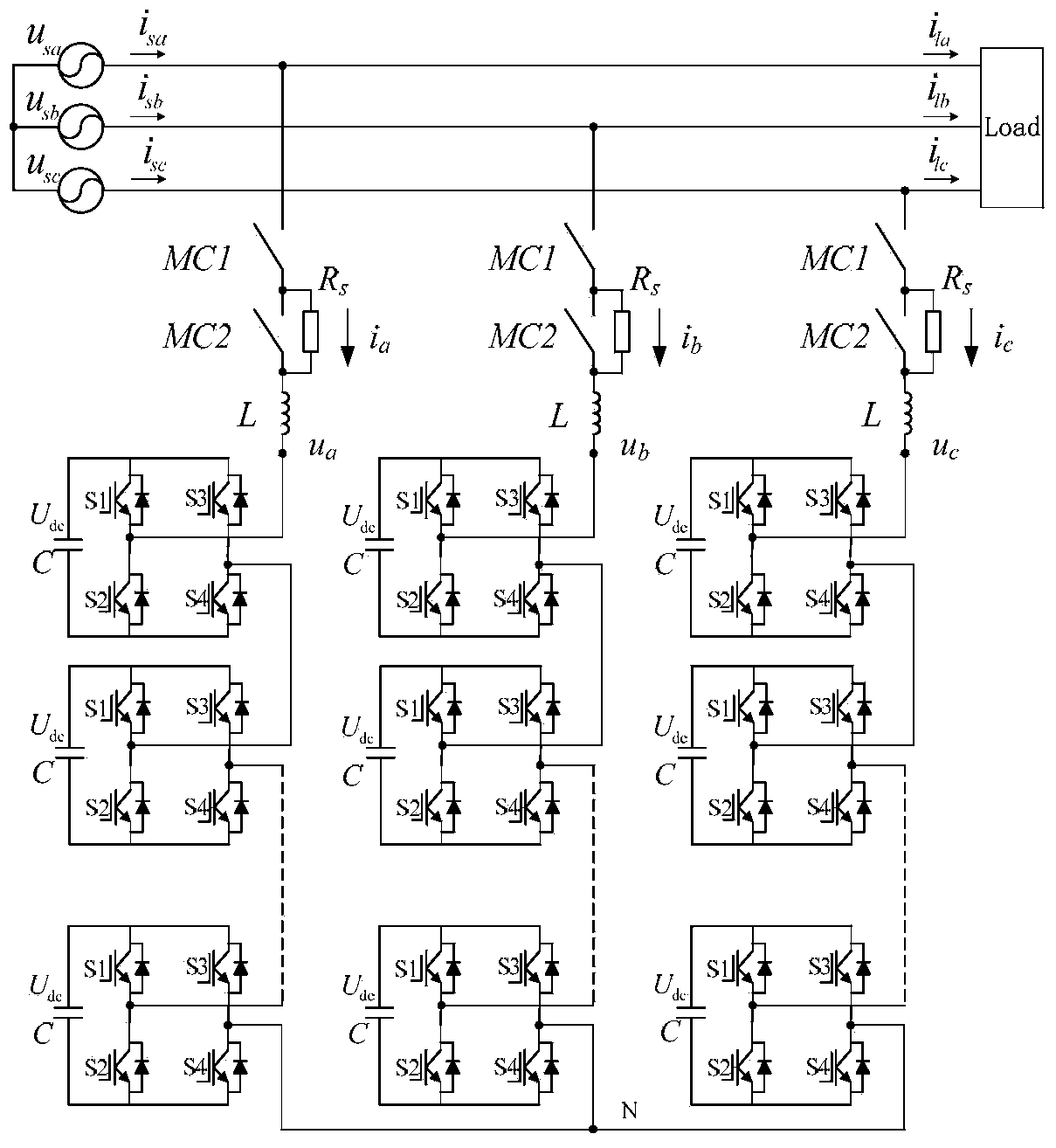

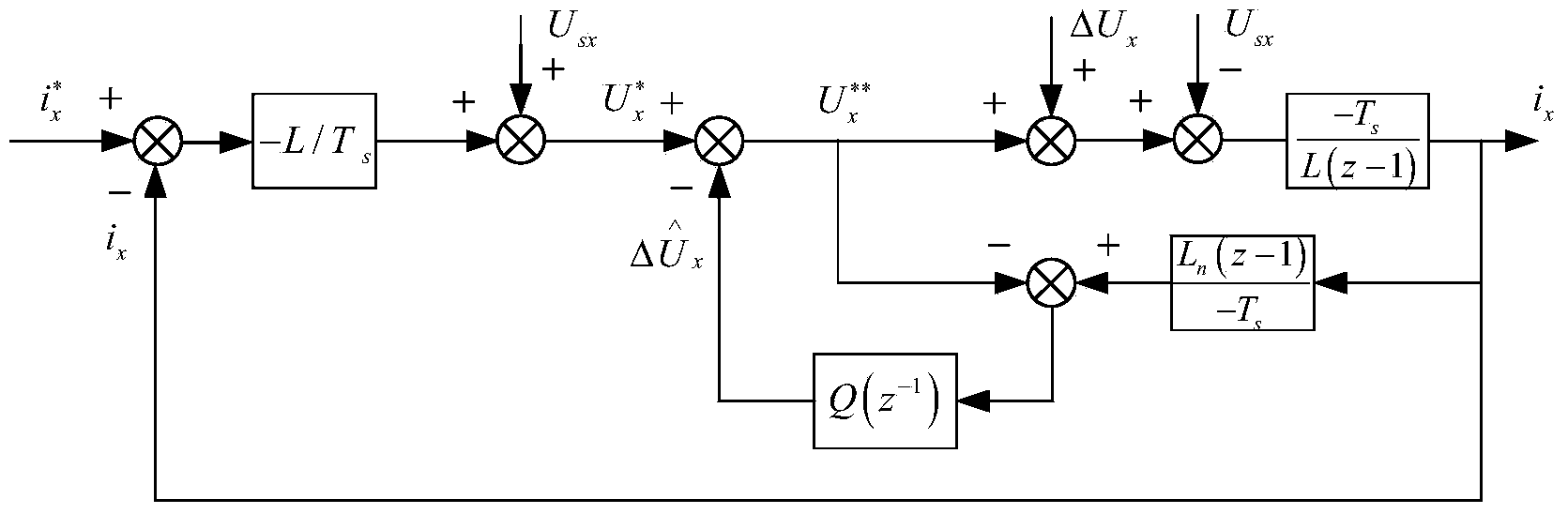

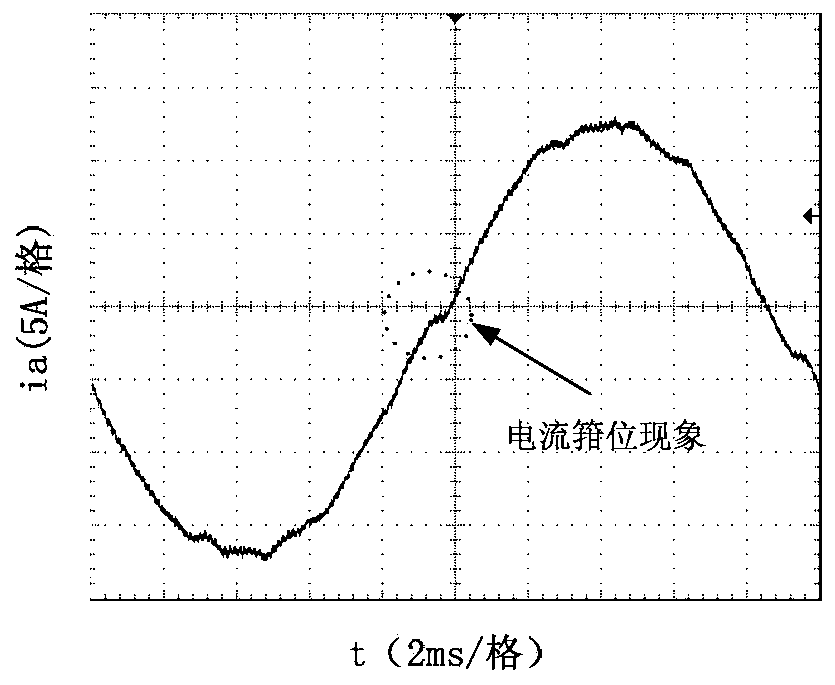

Self-adaptation dead-time compensation method for H-bridge cascade STATCOM (static synchronous compensator)

InactiveCN104037768AHarmonic reductionSmooth waveformFlexible AC transmissionHarmonic reduction arrangementControl systemDead time compensation

The invention discloses a self-adaptation dead-time compensation method for H-bridge cascade STATCOM (static synchronous compensator) and aims to solve the problem of lack of dead-time compensation directly targeting the H-bridge cascade STATCOM. According to a circuit topological structure of the H-bridge cascade STATCOM, the method includes steps of acquiring a discrete mathematic model of the H-bridge cascade STATCOM in a three-phase coordinate system; converting the discrete mathematic model into a transfer function mode in the discrete state; online monitoring difference between STATCOM output voltage and reference voltage caused by the dead-time effect by a discrete disturbance monitor in real time, utilizing the monitored difference as compensation capacity to introduce into a H-bridge cascade STATCOM control system, and self-adaptation dead-time compensation is realized.

Owner:哈尔滨同为电气股份有限公司

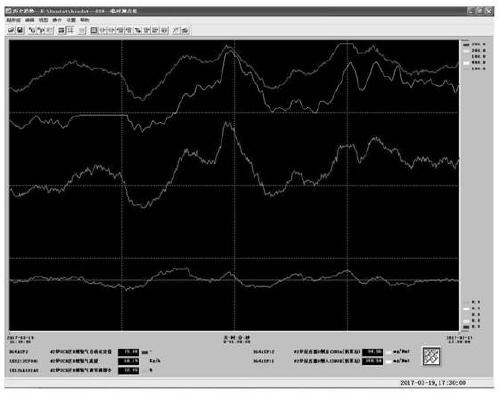

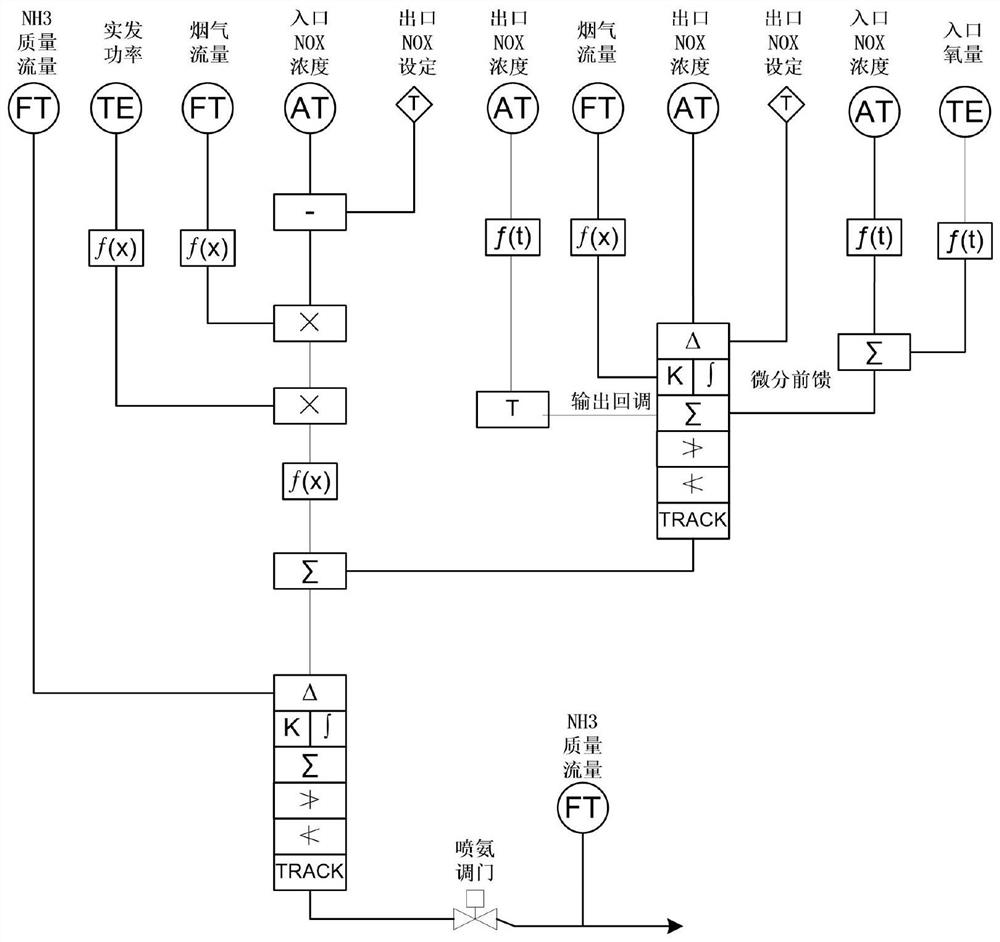

Power plant denitration ammonia injection control system

ActiveCN111644054AQuick responseEliminate static biasDispersed particle separationControllers with particular characteristicsPower stationReaction zone

The invention discloses a power plant denitration ammonia injection control system, wherein a cascade control system is adopted to improve the response speed of inlet NOX concentration disturbance andcomprises: a dynamic differential feedforward of reactor inlet NOX concentration, a denitration efficiency feedforward, a load change feedforward, PID modification parameters and a control process ofoutlet NOX deviation correction, and the denitration ammonia injection control system adopts a waveform judgment method for callback. The judgment logic of the waveform judgment method is as follows:when the outlet NOX concentration curve has a sinusoidal oscillation waveform, the ammonia injection amount is quickly called back in the second quarter period of the sinusoidal oscillation waveform.According to the cascade control system for calculating the NH3 demand quantity according to NOX at the inlet of the SCR reaction zone, the ammonia spraying response speed is increased; outlet NOx deviation correction is added in a control algorithm, so that static deviation is eliminated; and meanwhile, a waveform judgment method is adopted for callback, so that the phenomenon of output oscillation is prevented, and thereby, the problems of response lag of inlet NOx concentration disturbance and output oscillation are solved.

Owner:DATANG LUBEI POWER GENERATION

Compensation method for unknown network delay of network cascade control system

InactiveCN102004480ARealize the compensation functionReduced stabilityTotal factory controlSynchronising arrangementPacket lossMathematical model

The invention provides a compensation method for unknown network delay of a network cascade control system, belonging to the technical field of network control systems. The method adopts a network data transmission process among all forward and feedback network path nodes of the actual network cascade control system to replace a network delay compensation model thereof, avoids measurement, observation, estimate or identification for unknown delay of network data transmission among the nodes, and also avoids the synchronization requirement on node clock signals. The method can reduce the influence of unknown network delay on stability of the system and improve the control performance quality of the system. The method is suitable for dynamically compensating and controlling unknown network delay in all forward and feedback network paths of network simultaneously existing in the network cascade control system, when mathematical models of main auxiliary controlled objects are known or unknown, the system has unknown interference, and the network exists a certain amount of data packet losses.

Owner:HAINAN UNIVERSITY

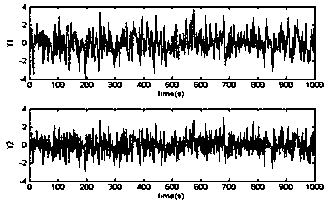

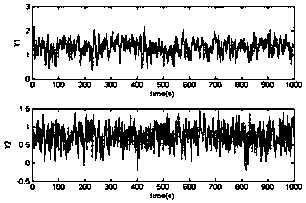

Minimum information entropy-based evaluation method of parallel cascade control system

A problem to be solved by the present invention is to provide a minimum information entropy-based evaluation method of a parallel cascade control system. The method is used for evaluating performanceof the parallel cascade control system, and the method disclosed in the present invention is invented to solve problems of a conventional evaluation method of the parallel cascade control system. Themethod disclosed in the invention is aimed at evaluating the performance of the parallel cascade control system via use of minimum information entropy reference. A minimum information entropy index can not only correctly be used for reflecting the performance of the parallel cascade control system in Gaussian perturbation, but can also be used for well reflecting the performance of the parallel cascade control system in non-Gaussian disturbance. The minimum information entropy index can be used for effectively reflecting the performance of the parallel cascade control system based on comparison with evaluation results of minimum variance and the minimum variance with forgetting factors. Shortcomings of the conventional evaluation method of the parallel cascade control system can be overcome, and limitations of the evaluation method of the parallel cascade control system can be prevented.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

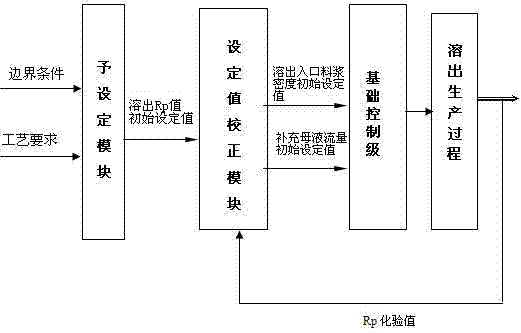

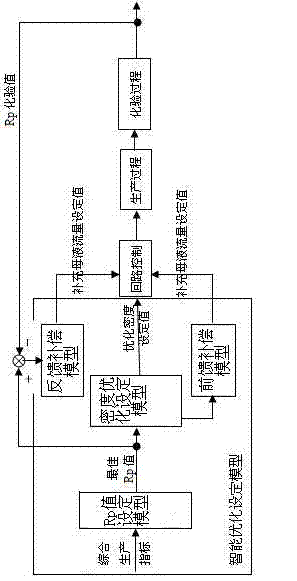

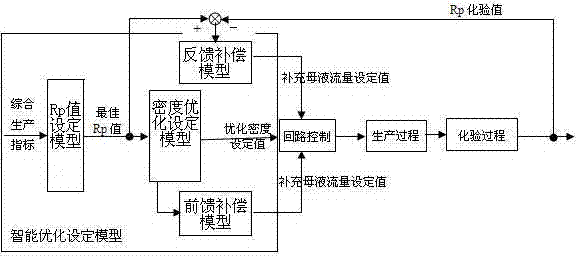

Automatic control method of Rp value of alumina digestion outlet in the Bayer process

InactiveCN102351223ALow costImprove reliabilityControlling ratio of multiple fluid flowsChemical variable controlAutomatic controlControl system

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

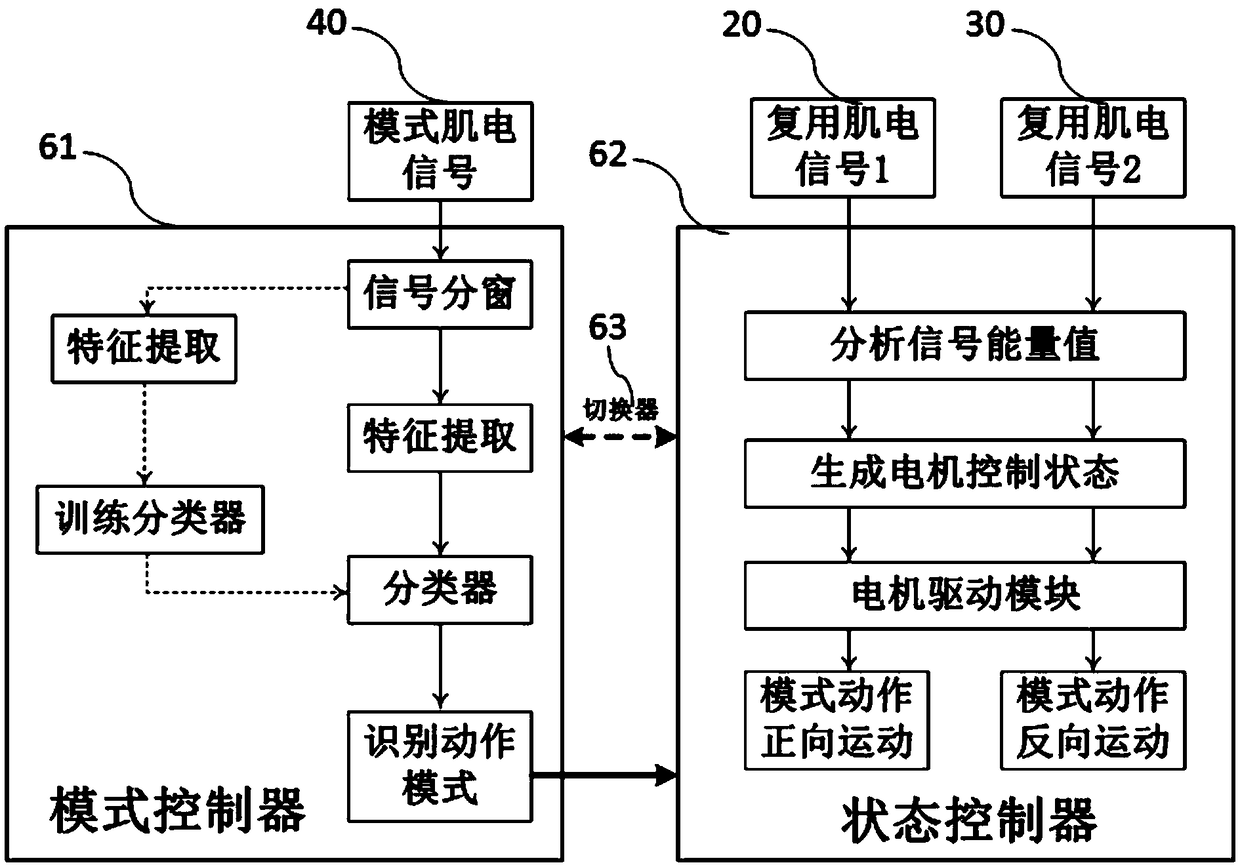

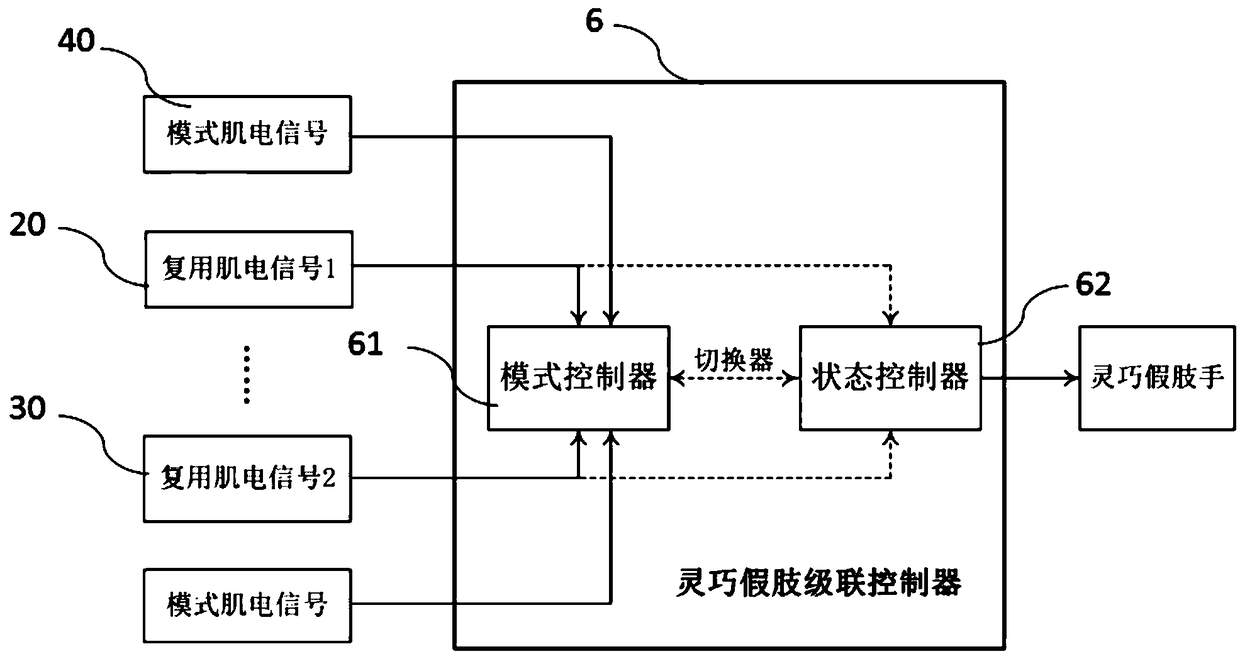

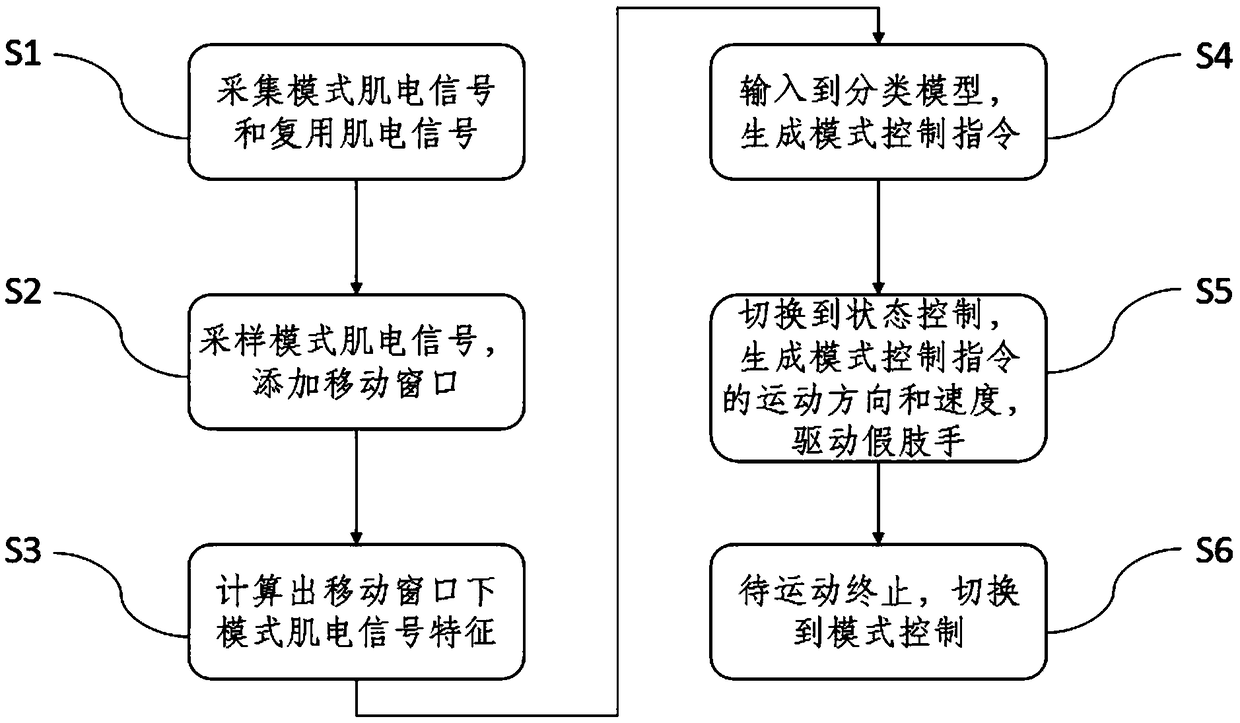

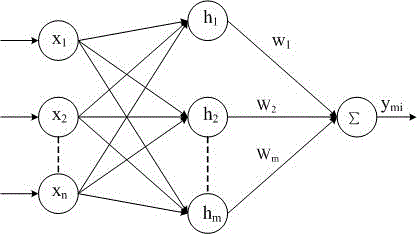

Electromyographic humanoid dexterous prosthetic hand cascade control method and system

The invention discloses an electromyographic humanoid dexterous prosthetic hand cascade control method, which comprises the following steps: under mode control, acquiring mode electromyographic signals and multiplex electromyographic signals of a user; sampling the mode electromyographic signals, adding a moving window; calculating out characteristics of the mode electromyographic signals under the moving window; inputting the characteristics of the electromyographic signals into a classifying model, and generating an action mode command; switching to state control via a swticher, in accordance with enerngy of the multiplex electromyographic sensor signals and the action mode command, generating an action mode control state and driving a humanoid dexterous prosthetic hand to move; and after the prosthetic hand is stopped in moving, switching to mode control via the switcher. The invention also relatdes to an electromyographic humanoid dexterous prosthetic hand cascade control system; and by collecting residual limb muscle change signals via a mode electromyographic sensor and a multiplex electromyographic sensor, the electromyographic humanoid dexterous prosthetic hand can be controlled to do expected actions. According to the cascade control method and the cascade control system provided by the invention, control precision and reliability of the humanoid dexterous prosthetic hand can be enhanced, and a receptance rate and a popularizing rate of the prosthetic hand can be improved.

Owner:北京通和营润智能科技发展有限公司

Aquaculture pond PH value control system with wireless sensor network

ActiveCN106200705AExpand the working areaImprove stabilityControlling ratio of multiple fluid flowsChemical variable controlWireless mesh networkControl system

The invention discloses an aquaculture pond PH value control system with a wireless sensor network. The system is composed of an aquaculture pond environment parameter collection and control platform and an aquaculture pond PH value cascade control system based on a composite controller. The aquaculture pond PH value control system with the wireless sensor network is designed according to the characteristics of the large working condition area of aquaculture pond environment PH value parameters, the nonlinearity and large lag of PH value changes, the unbalanced distribution of the pond PH value and the like. The system has huge application and popularization value in improving the stability of control over the aquaculture pond PH value and increasing the economic benefit of aquaculture.

Owner:威海晶合数字矿山技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com